Patents

Literature

144results about How to "Minimize turbulence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

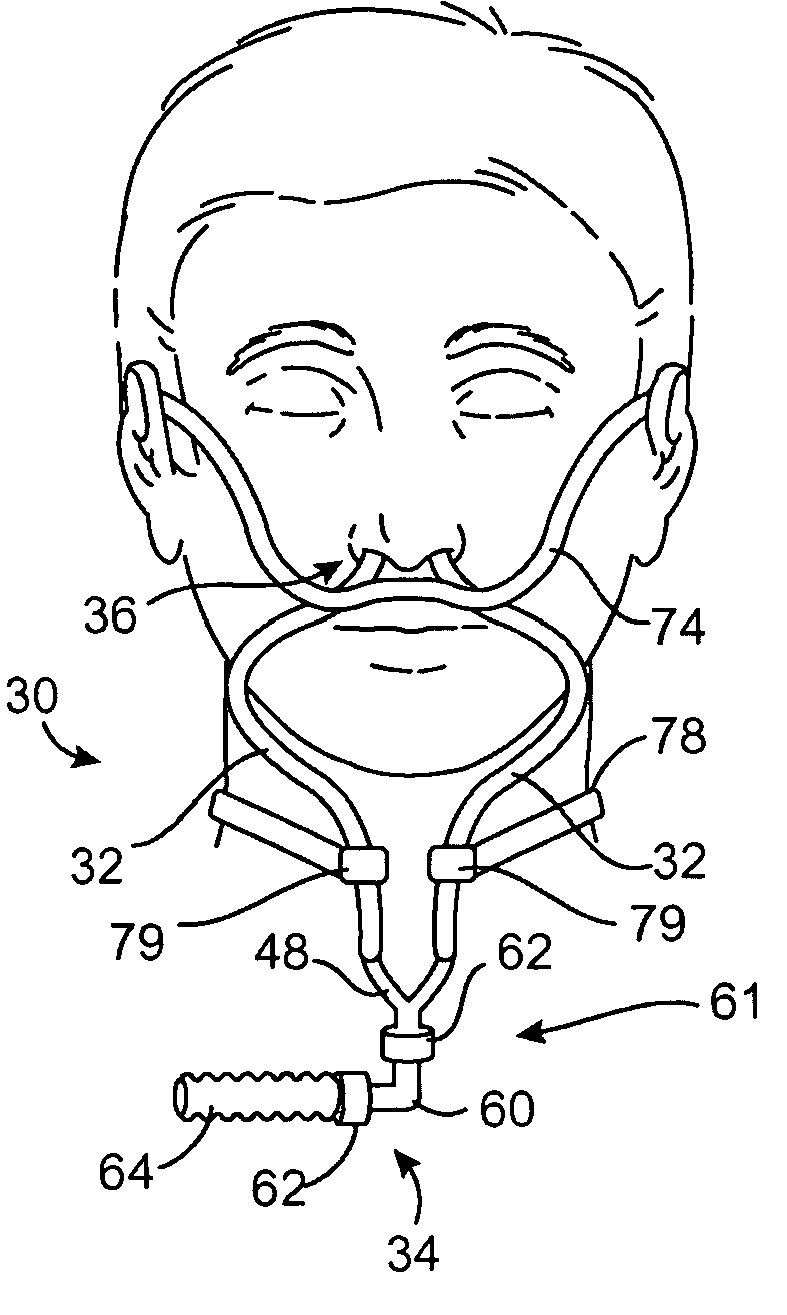

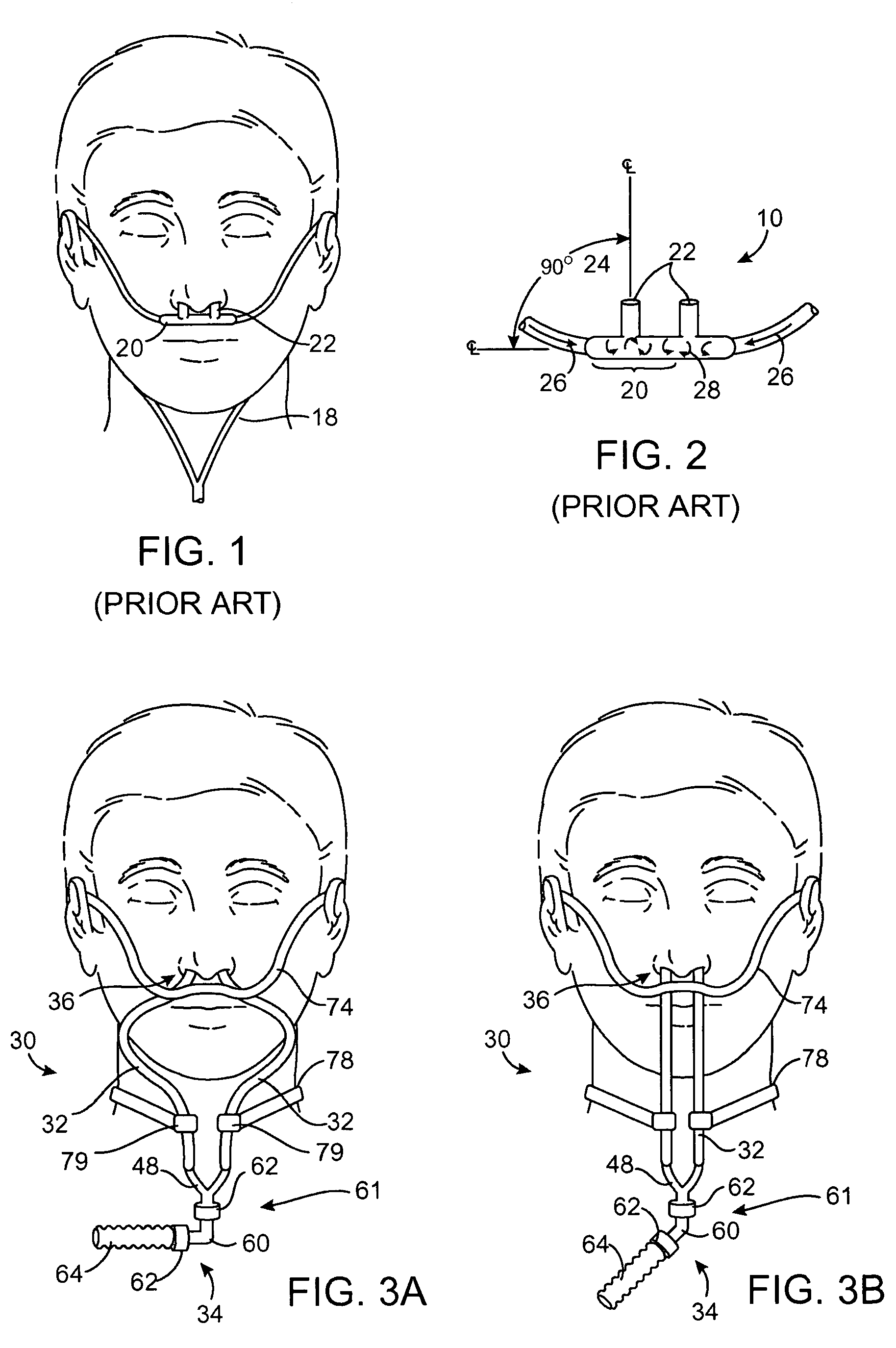

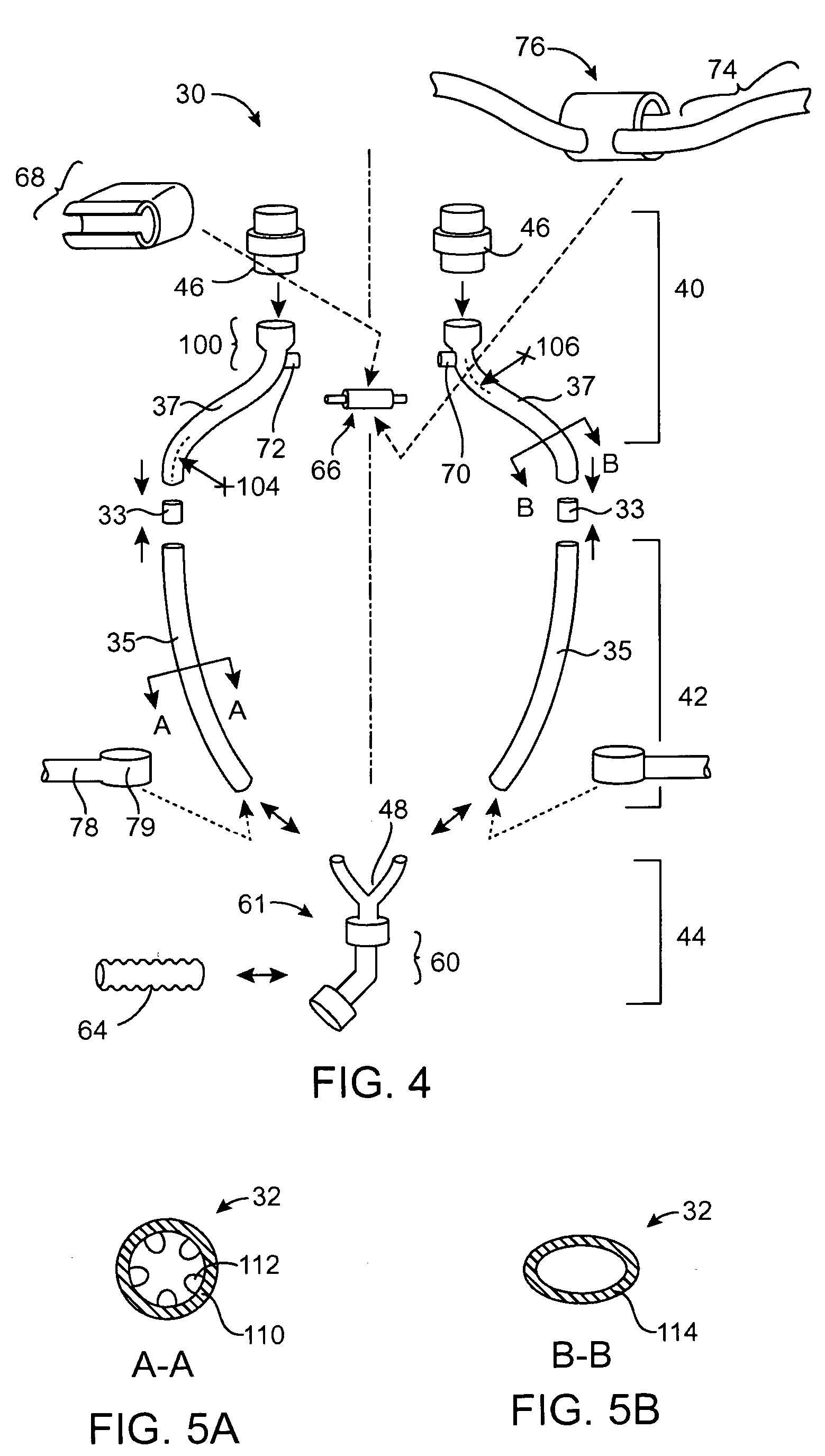

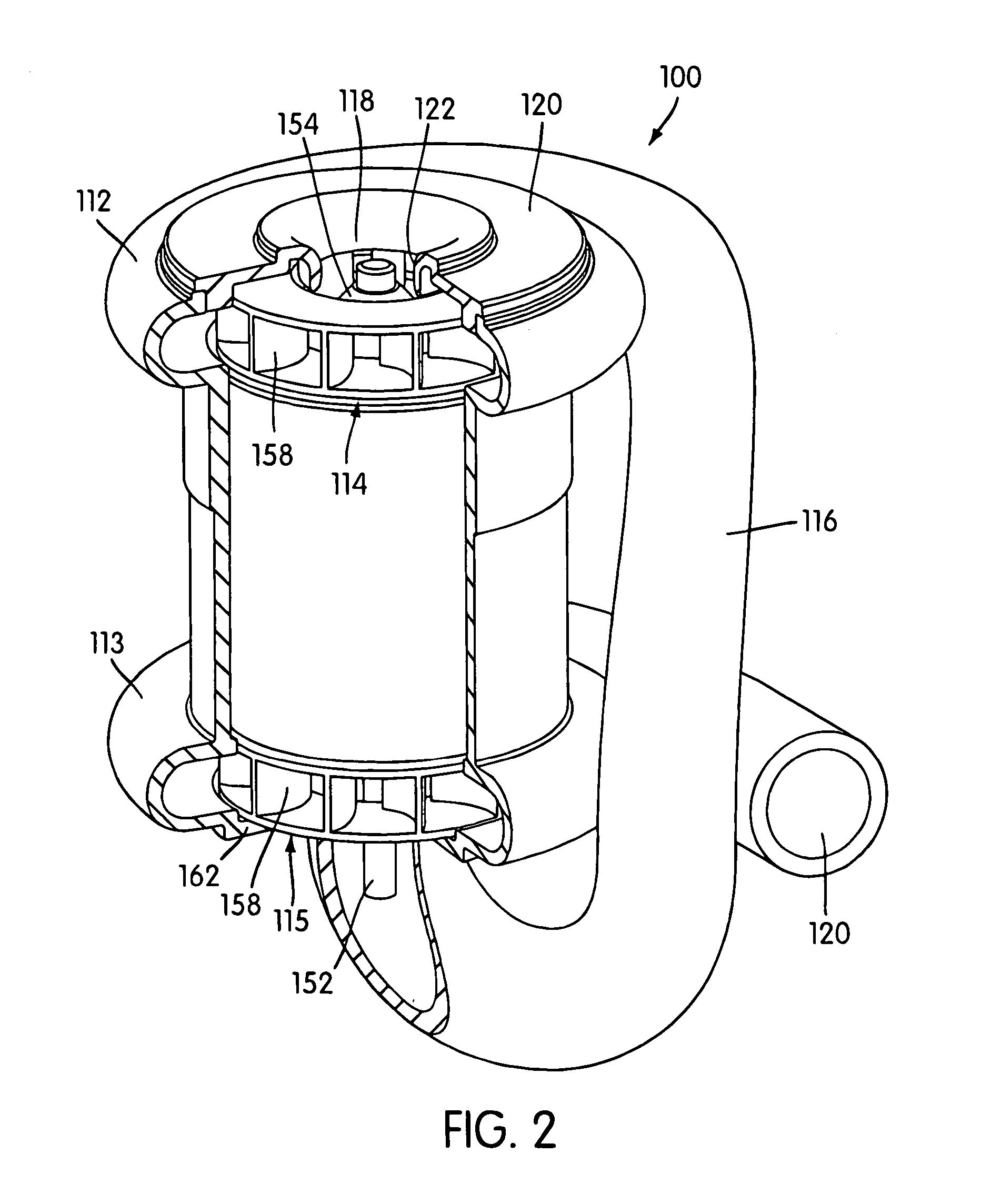

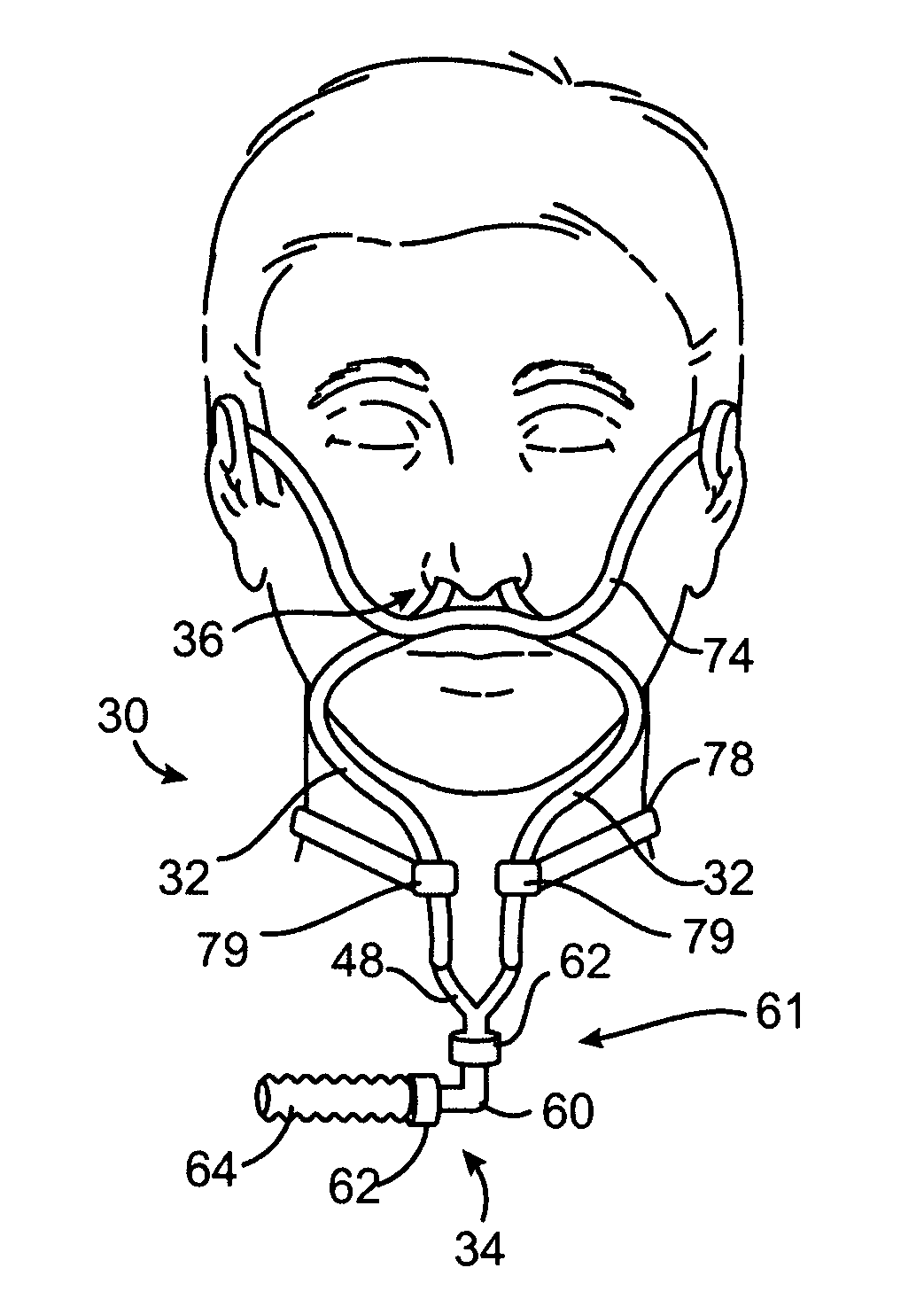

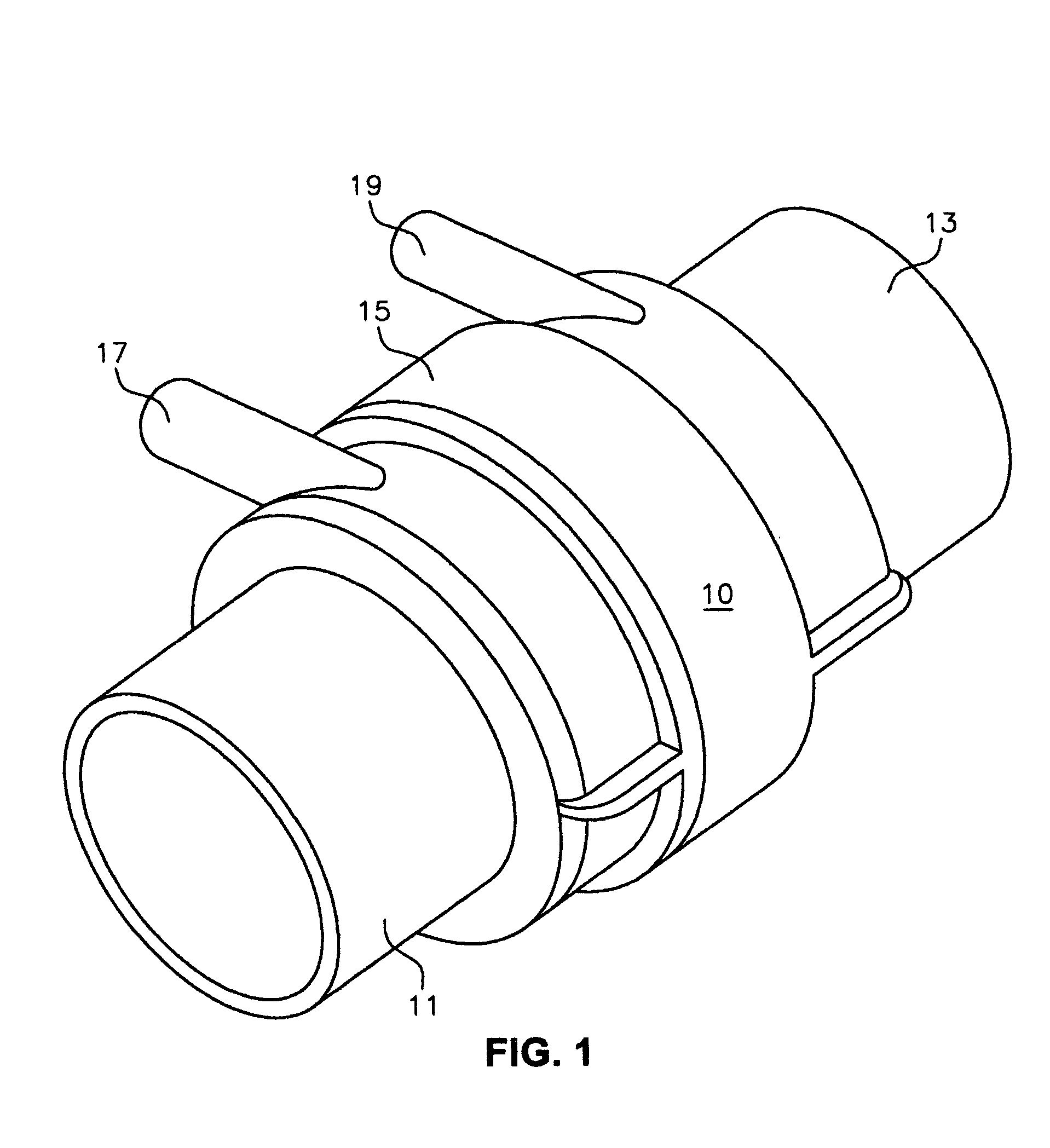

Method and device for non-invasive ventilation with nasal interface

ActiveUS20050066976A1Noise minimizationMinimize resistancePhysical therapyBreathing filtersNasal cavityNostril

A nasal ventilation interface including a pair of tubes configured to deliver a ventilation gas. The tubes are attachable at a first end to a ventilation gas supply hose and engageable at a second end with a person's nostril. A coupler is configured to align the pair of tubes with the person's nostrils, wherein each tube has an absence of pneumatic interconnection with the other tube.

Owner:MENLOLIFE

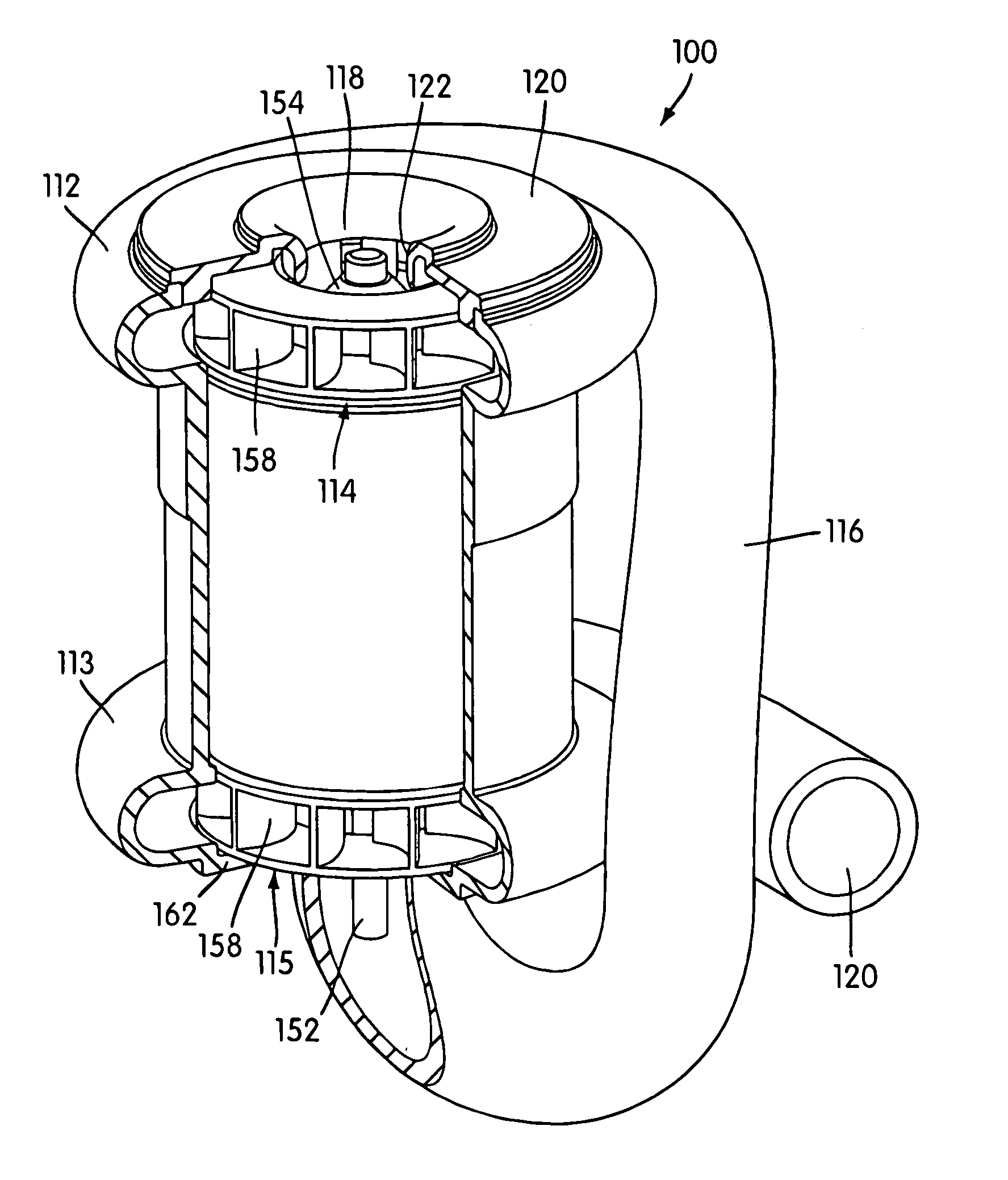

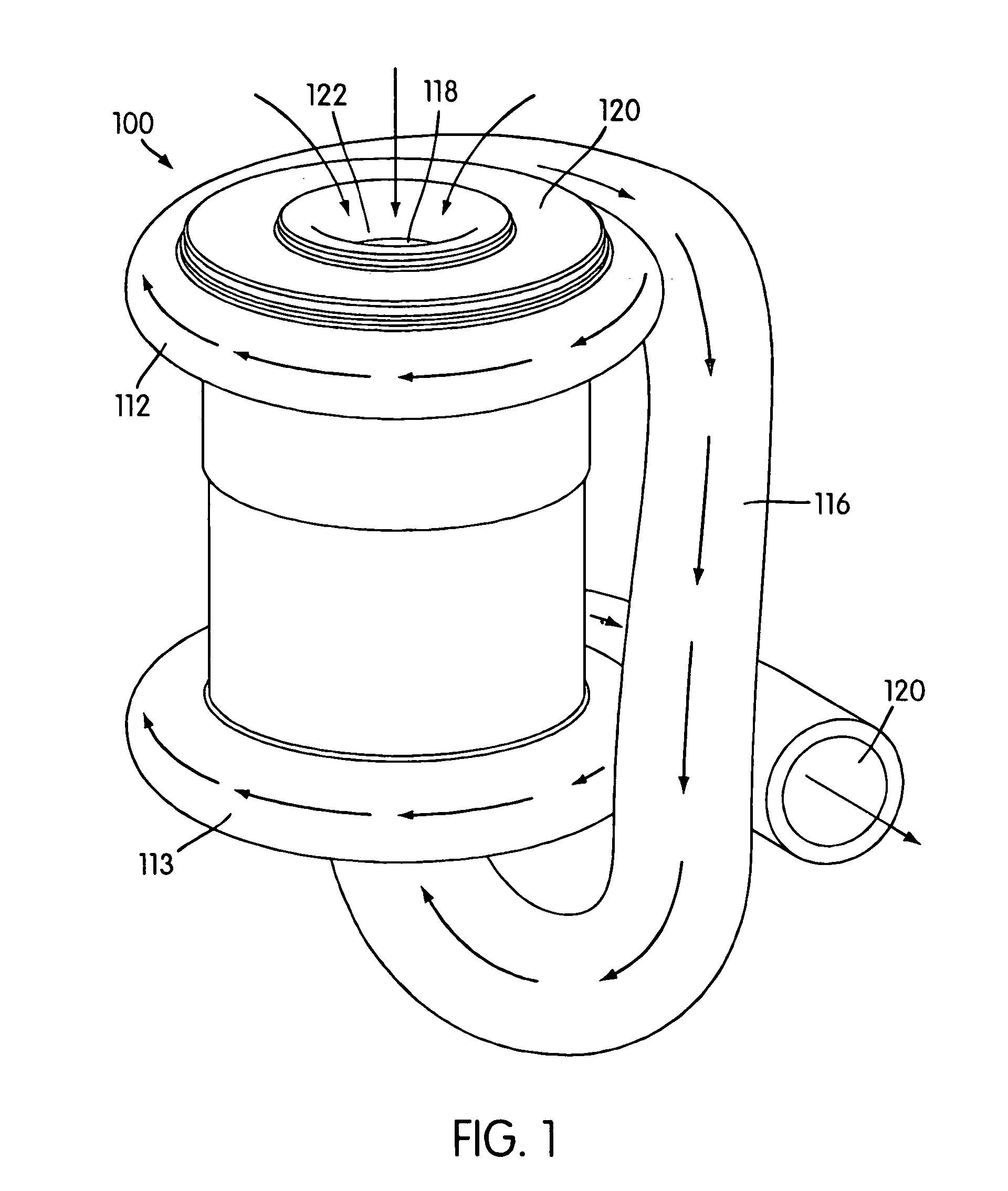

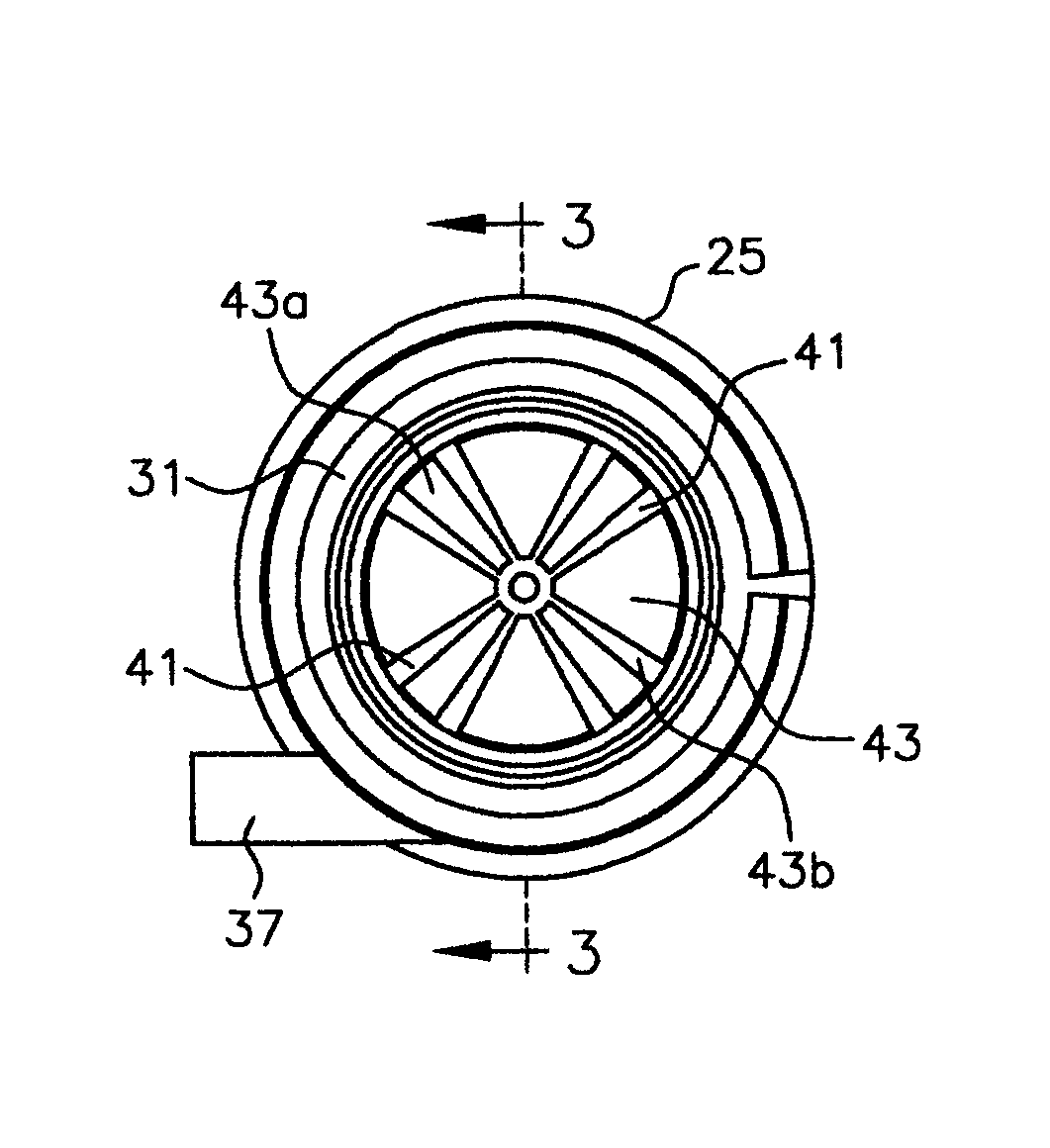

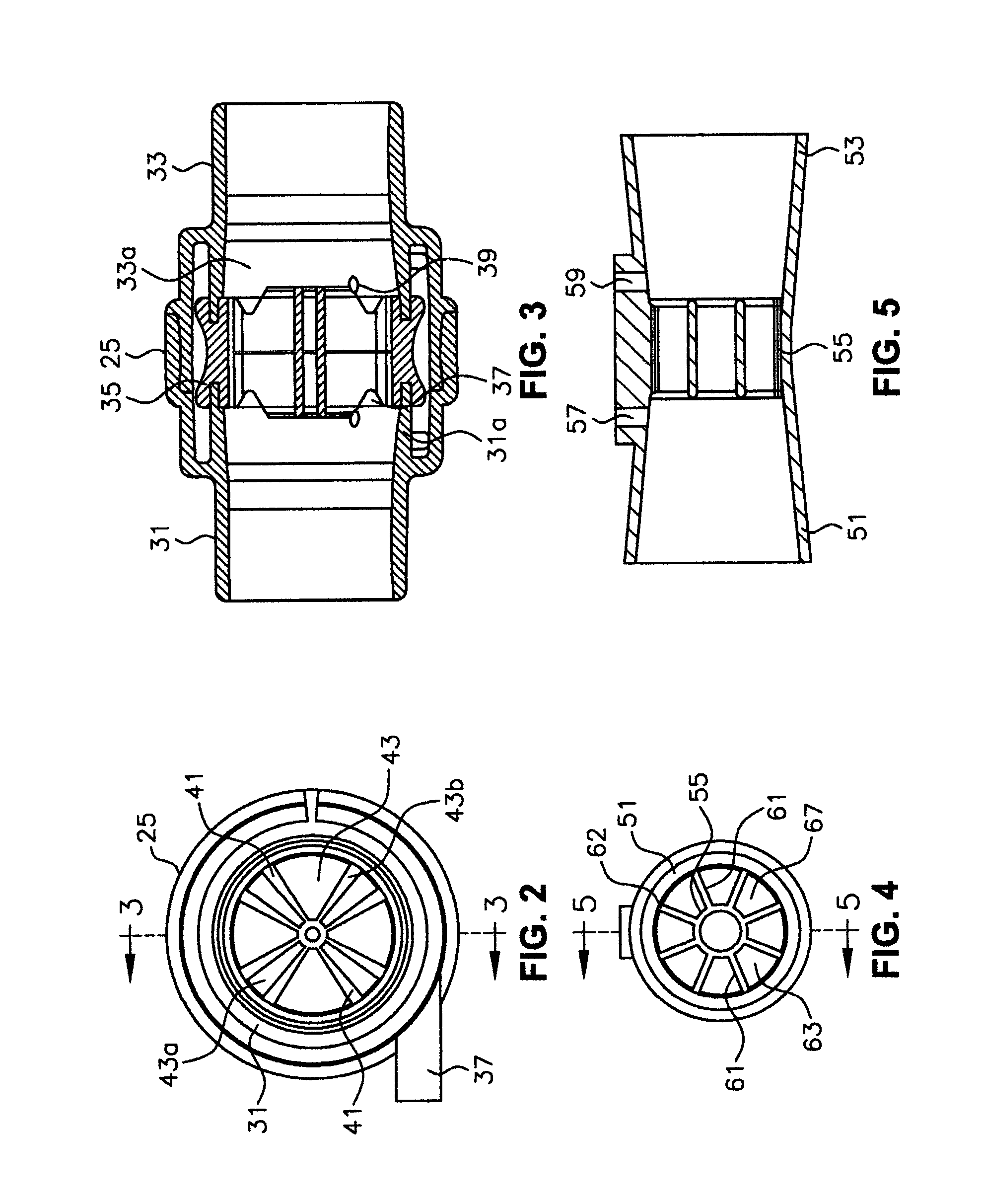

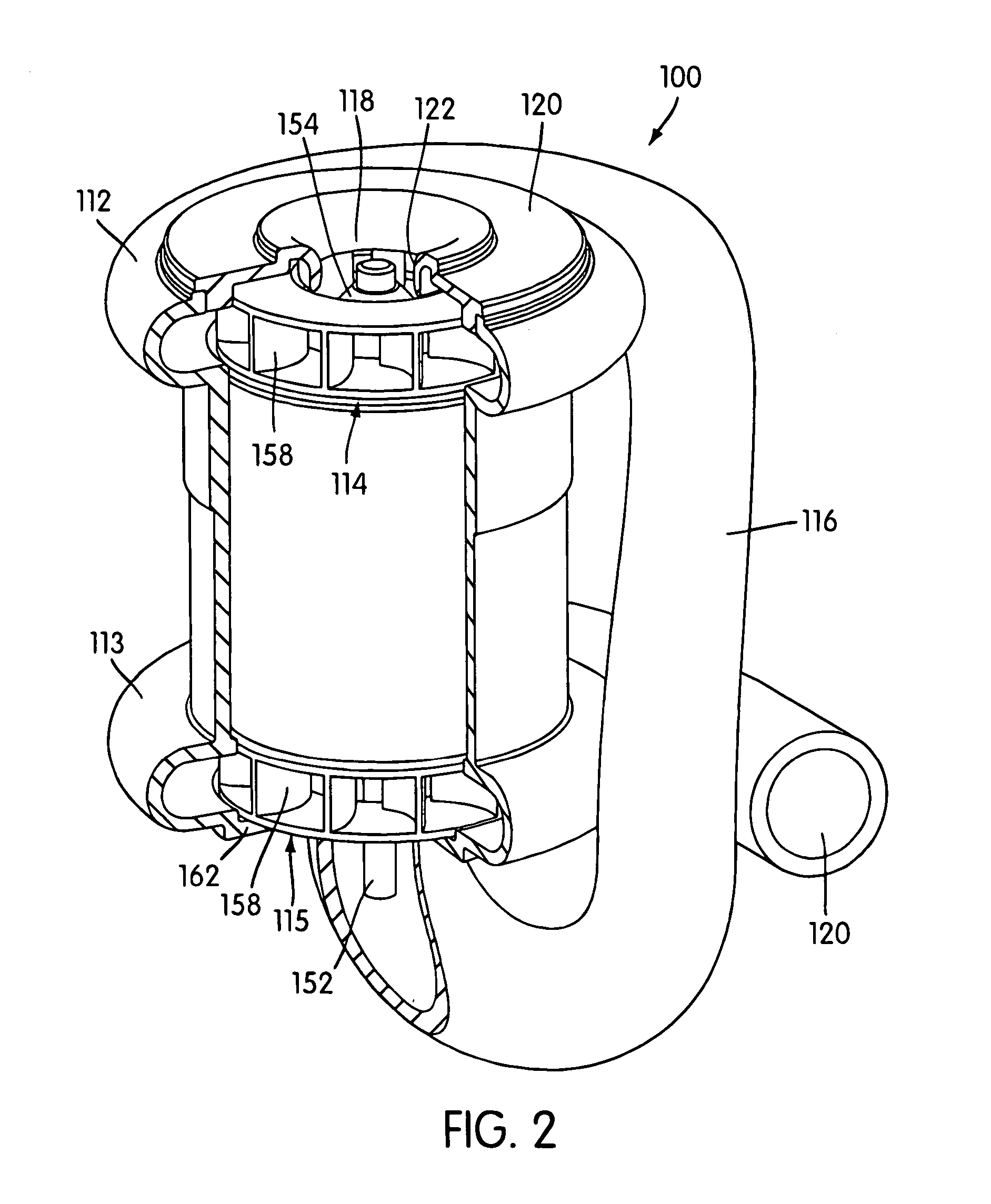

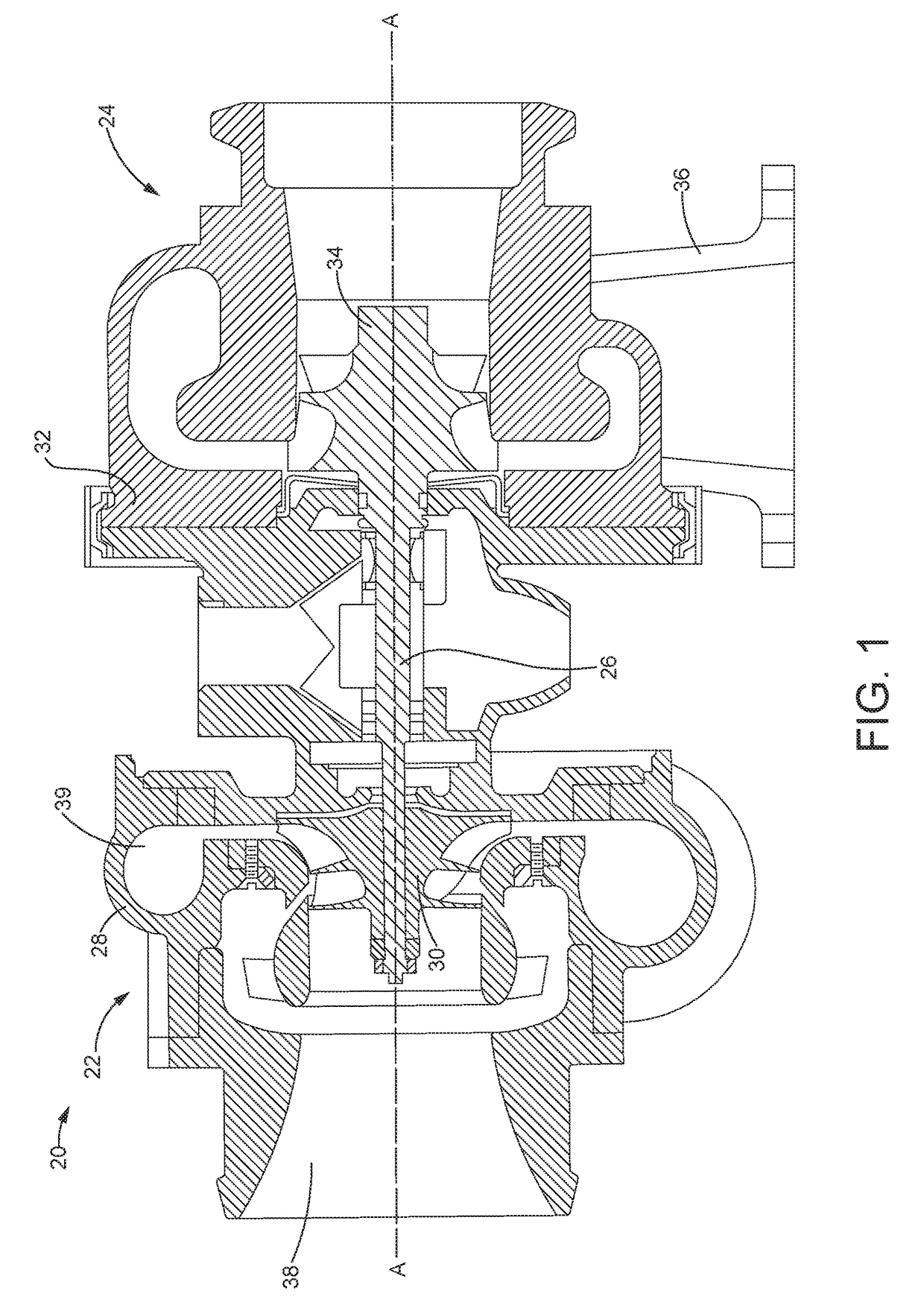

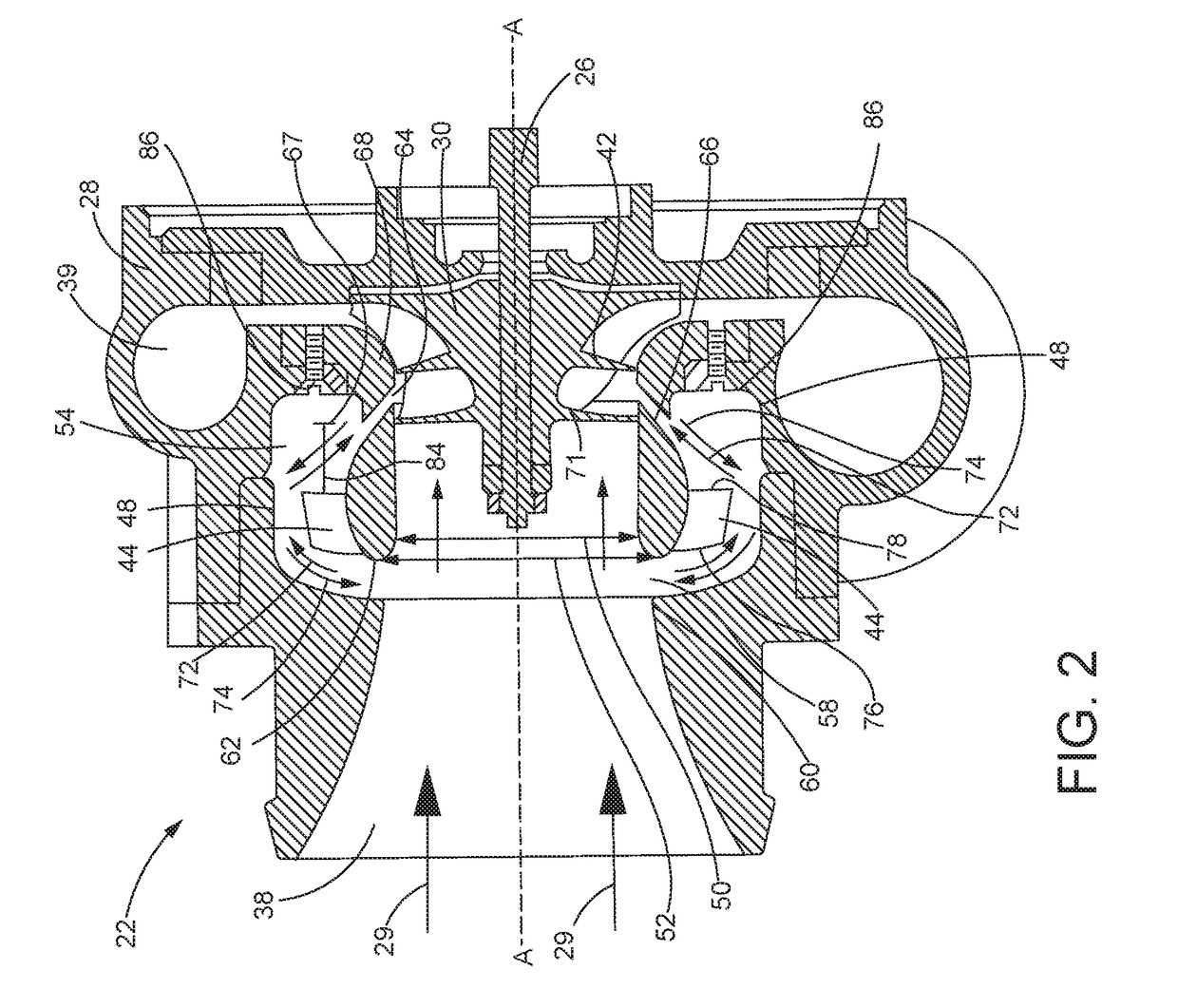

Multiple stage blowers and volutes therefor

ActiveUS20050103339A1Faster pressure rise timeImprove reliabilityPump componentsMedical devicesImpellerMotor speed

A multiple stage variable speed blower for Continuous Positive Airway Pressure (CPAP) ventilation of patients includes two impellers in the gas flow path that cooperatively pressurize gas to desired pressure and flow characteristics. Thus, the multiple stage blower can provide faster pressure response and desired flow characteristics over a narrower range of motor speeds, resulting in greater reliability and less acoustic noise.

Owner:RESMED LTD

Method and device for non-invasive ventilation with nasal interface

ActiveUS7406966B2Retain comfortNoise minimizationPhysical therapyBreathing filtersNasal cavityNostril

A nasal ventilation interface including a pair of tubes configured to deliver a ventilation gas. The tubes are attachable at a first end to a ventilation gas supply hose and engageable at a second end with a person's nostril. A coupler is configured to align the pair of tubes with the person's nostrils, wherein each tube has an absence of pneumatic interconnection with the other tube.

Owner:MENLOLIFE

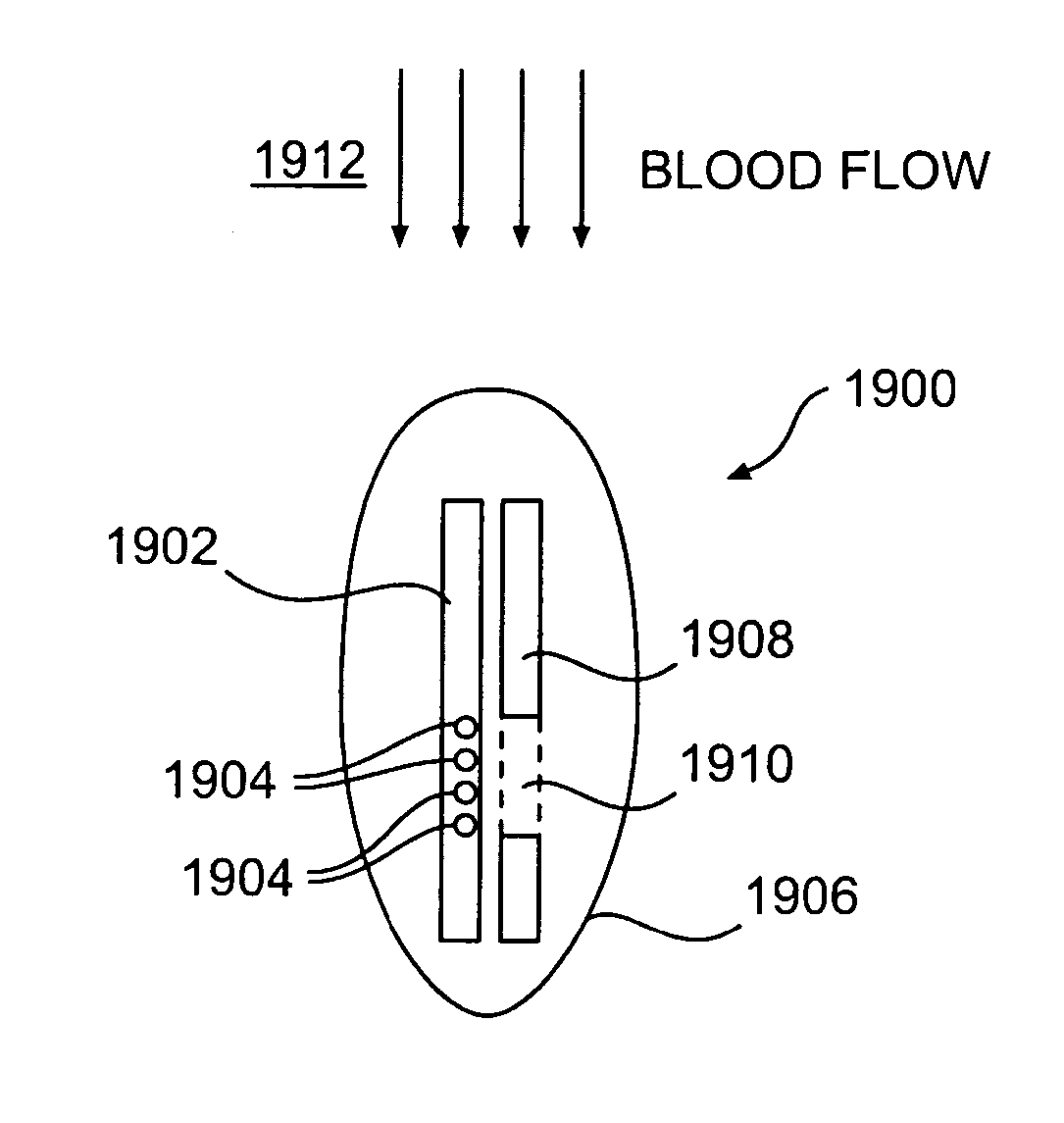

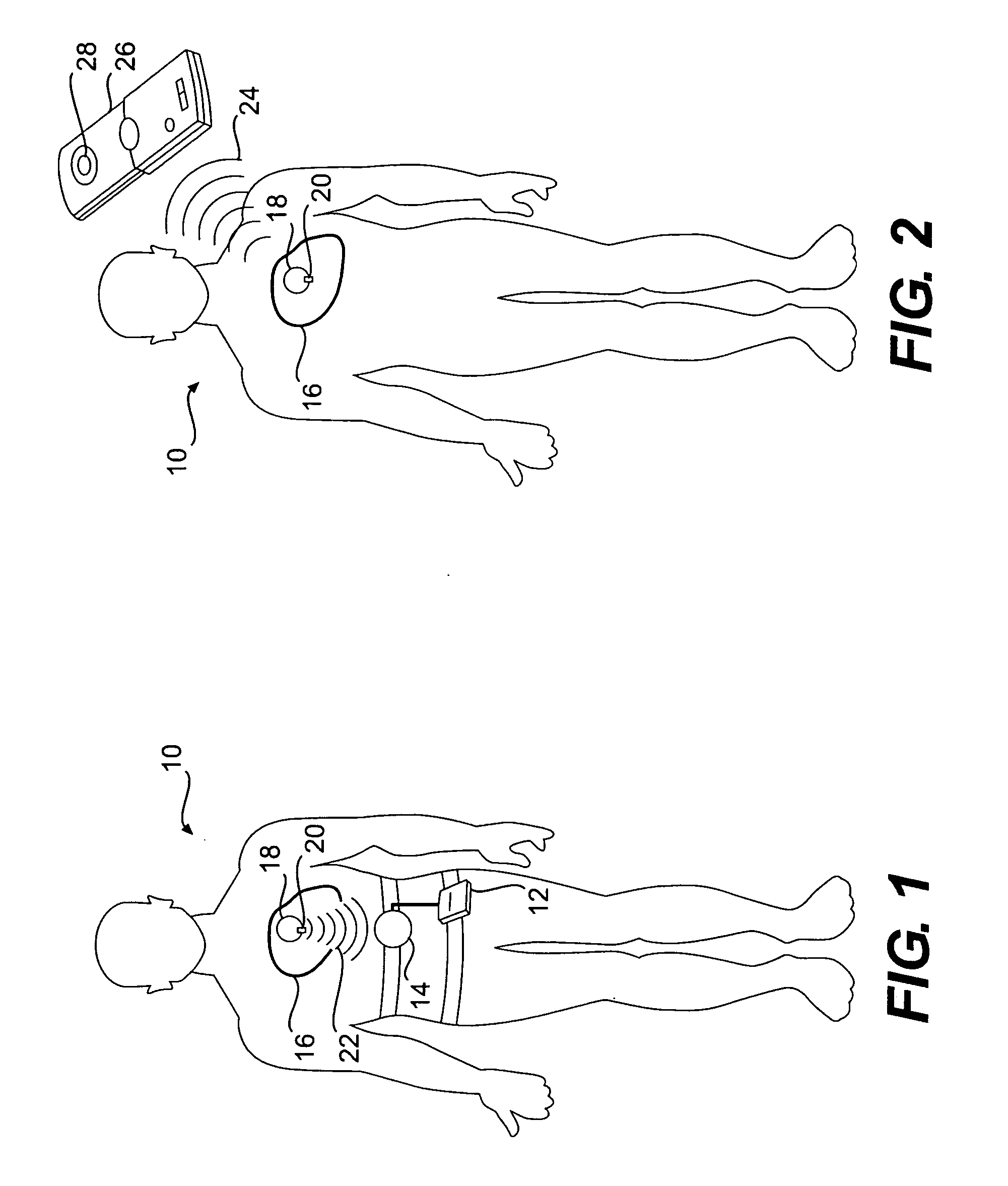

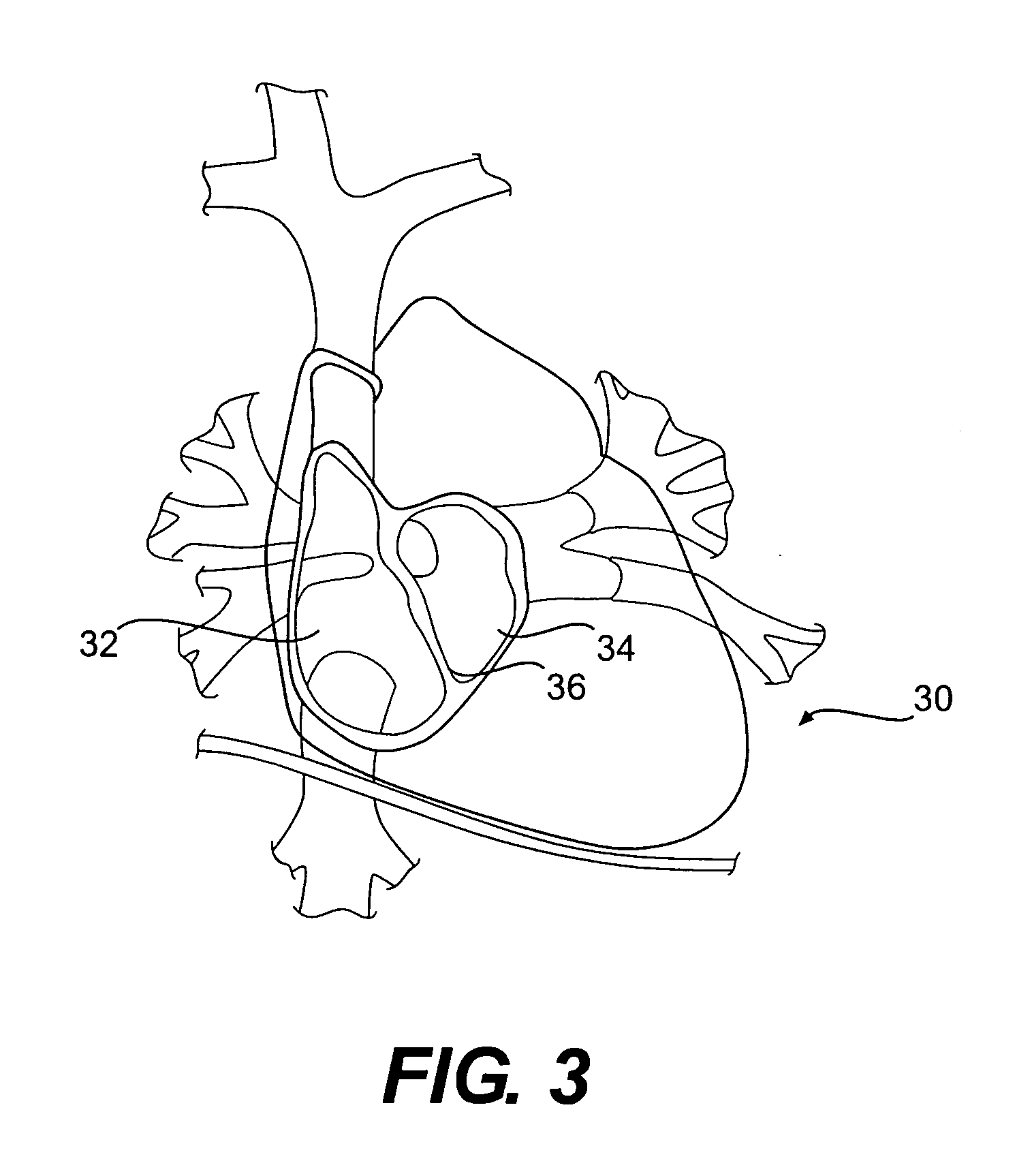

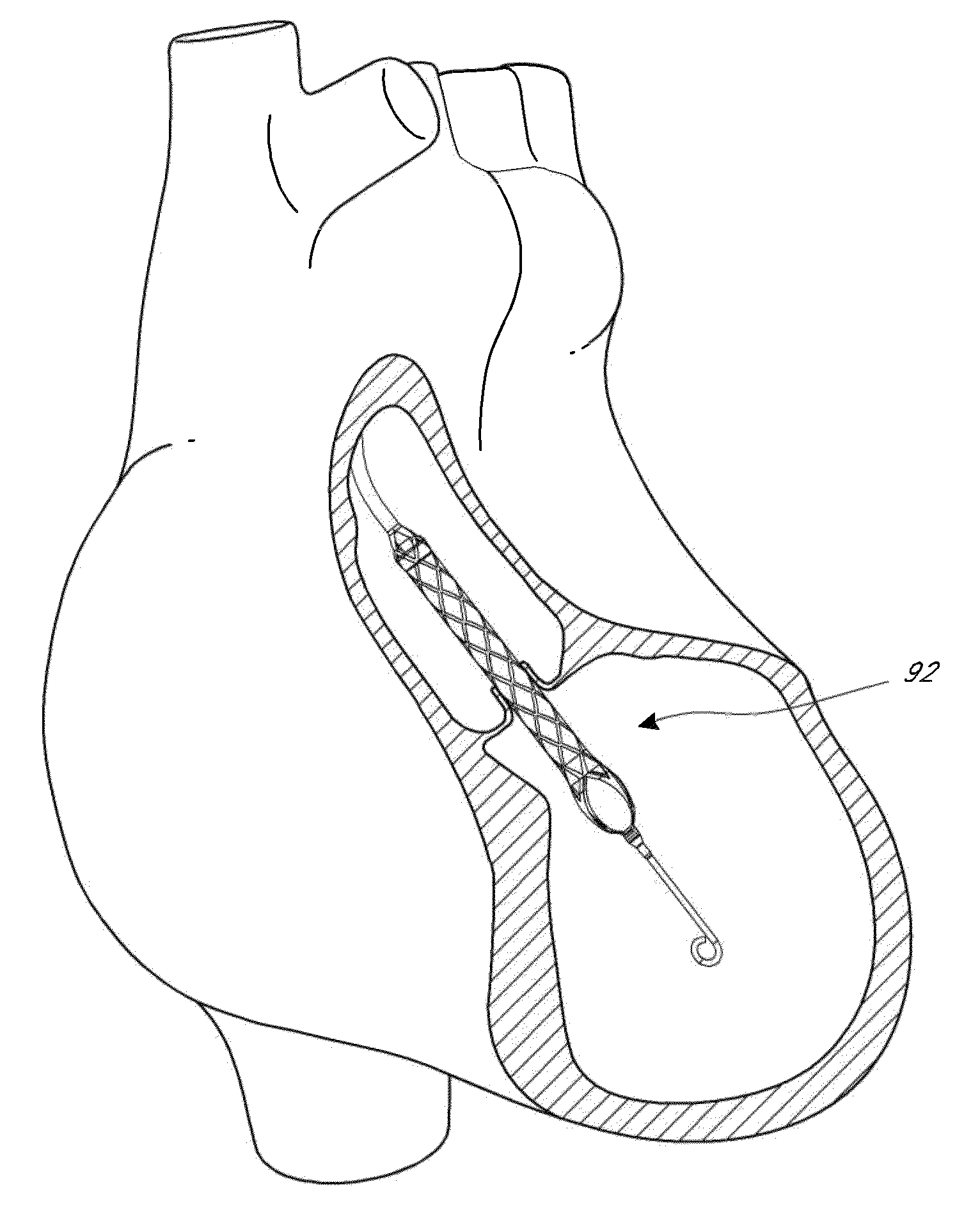

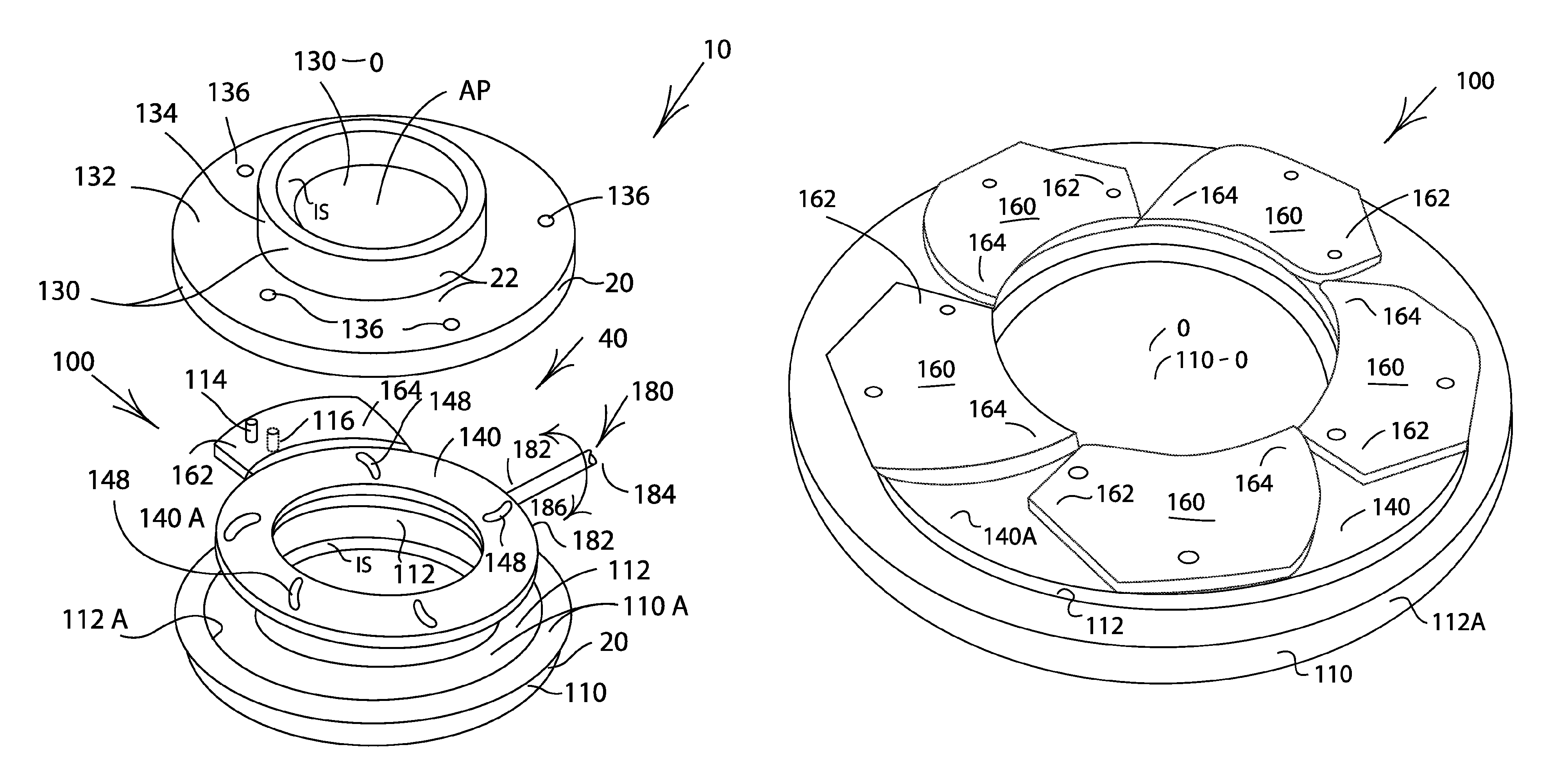

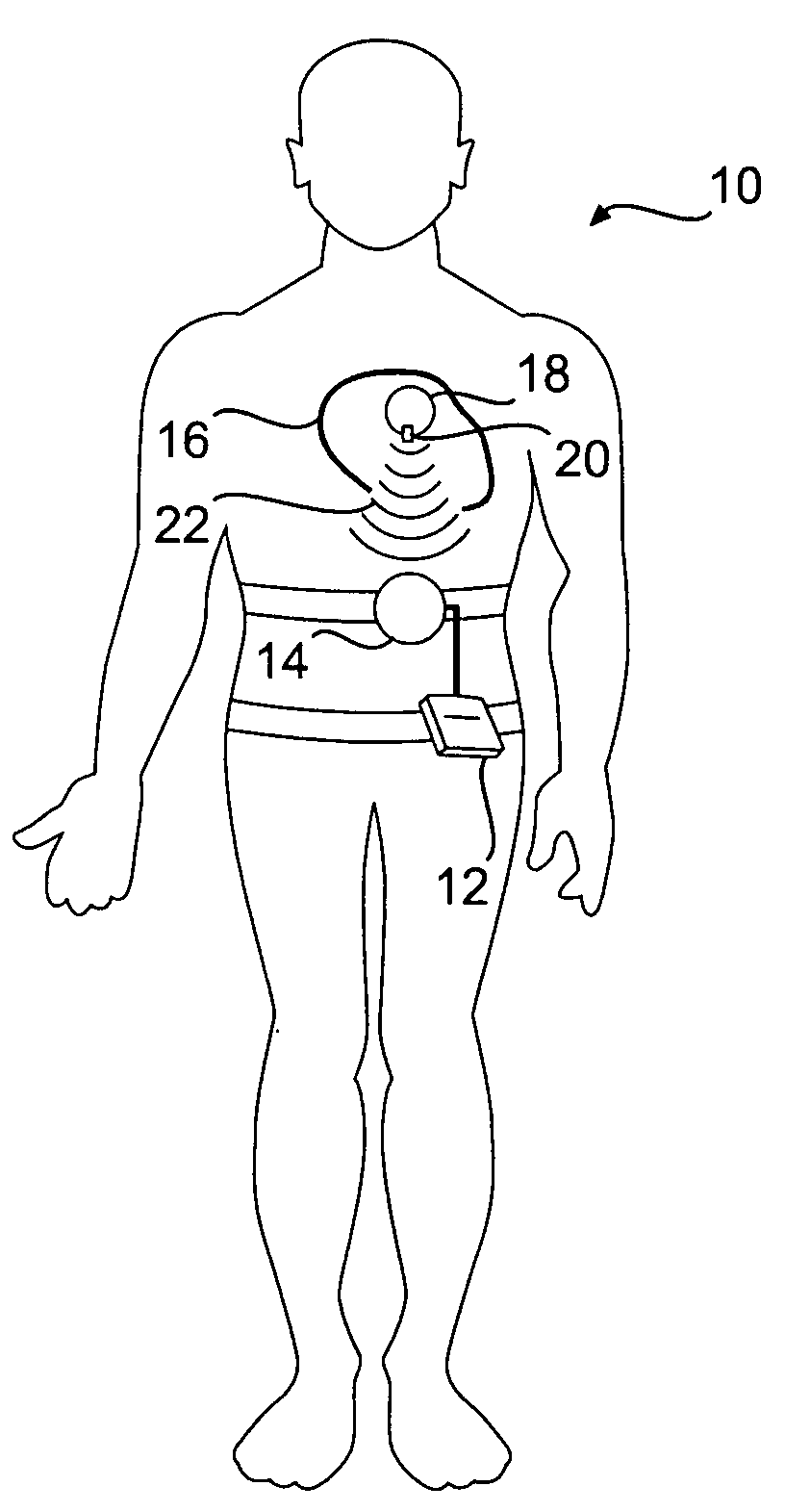

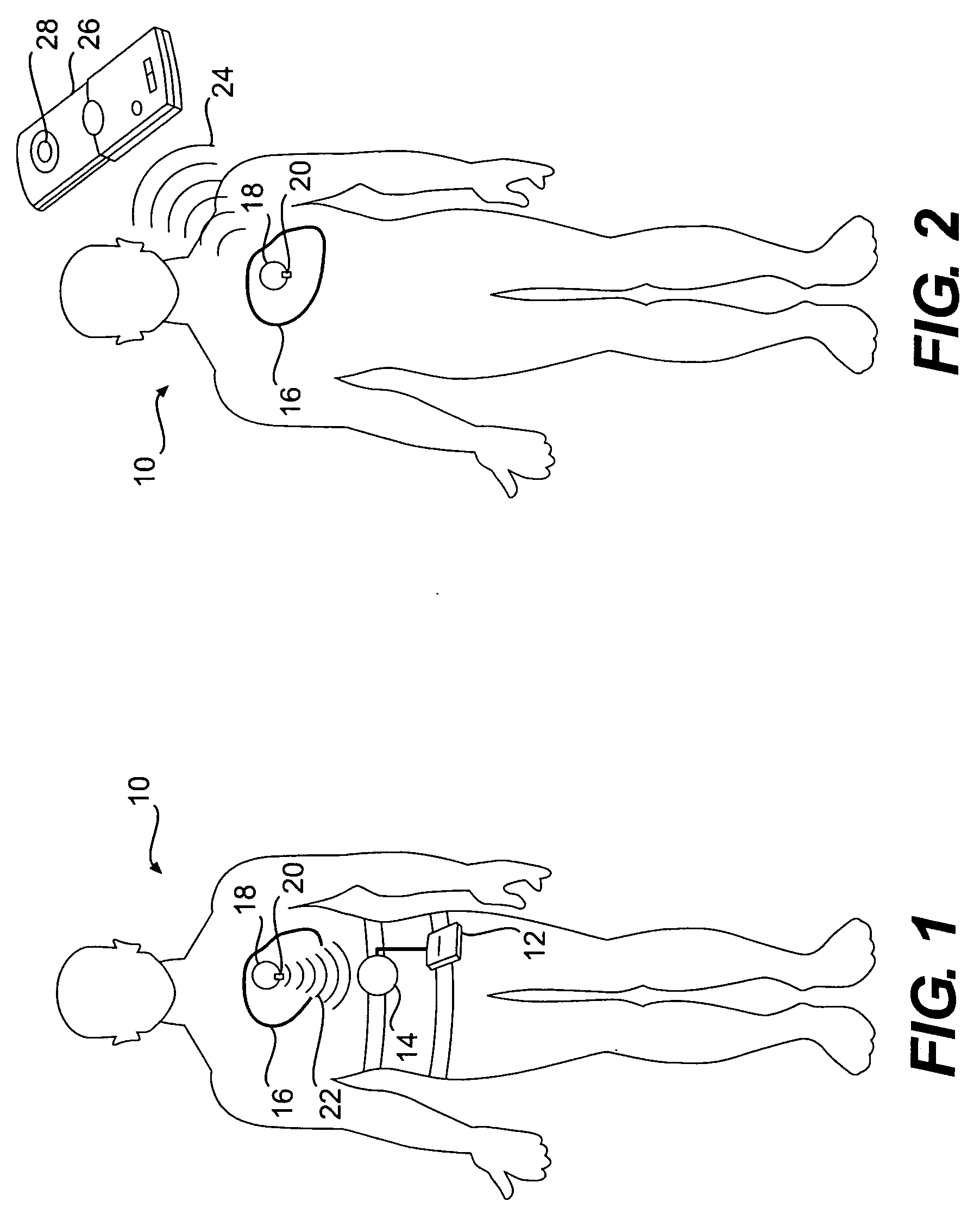

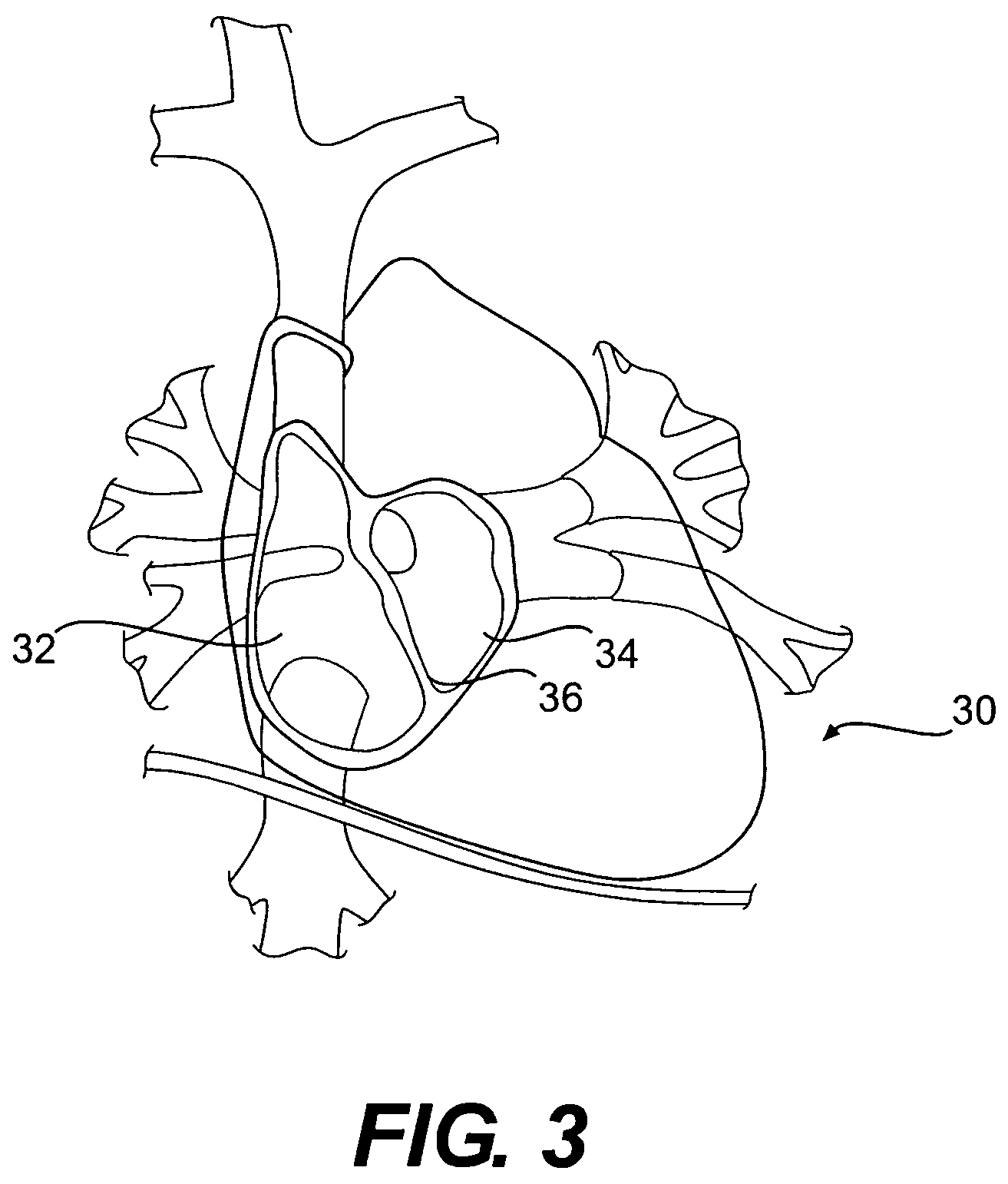

Implantable device for telemetric measurement of blood pressure/temperature within the heart

ActiveUS20070118039A1Interference to data transmissionIncreased durabilityCatheterAngiographyCapacitive pressure sensorMinimally invasive procedures

A system and method for the intra corporal, telemetric measuring of blood pressure, particularly within the heart or a great vessel, includes a substantially rigid sensor chip mounted in a holder and an antenna. The holder is anchored within an appropriate location in the cardiovascular system, such as in the cardiac septum, via a catheter or other minimally-invasive procedure to position at least one capacitive pressure sensor on the chip in the blood flow to be sensed. Measured values are transmitted telemetrically from the chip to an extra corporal monitoring device.

Owner:ENDOTRONIX

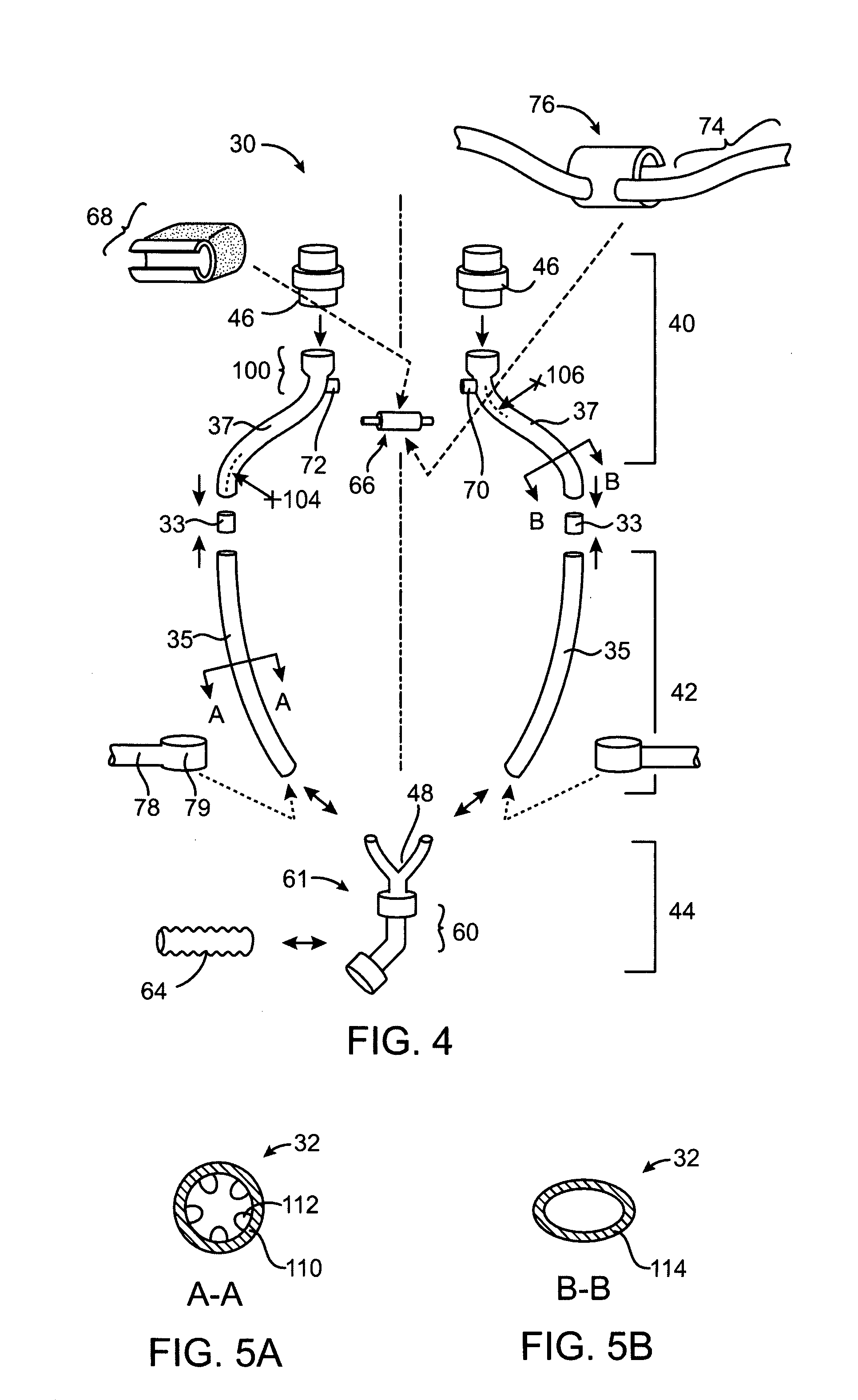

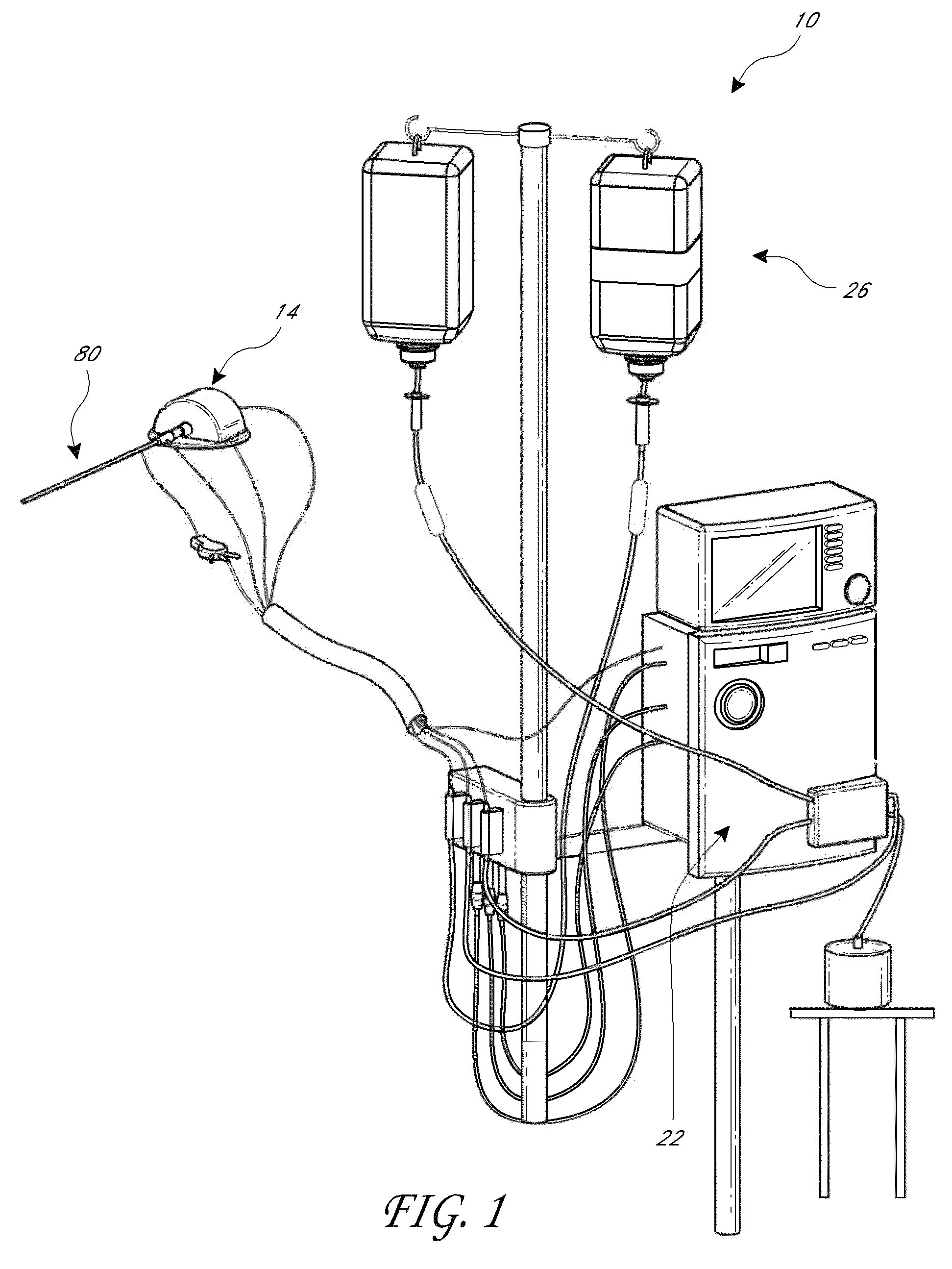

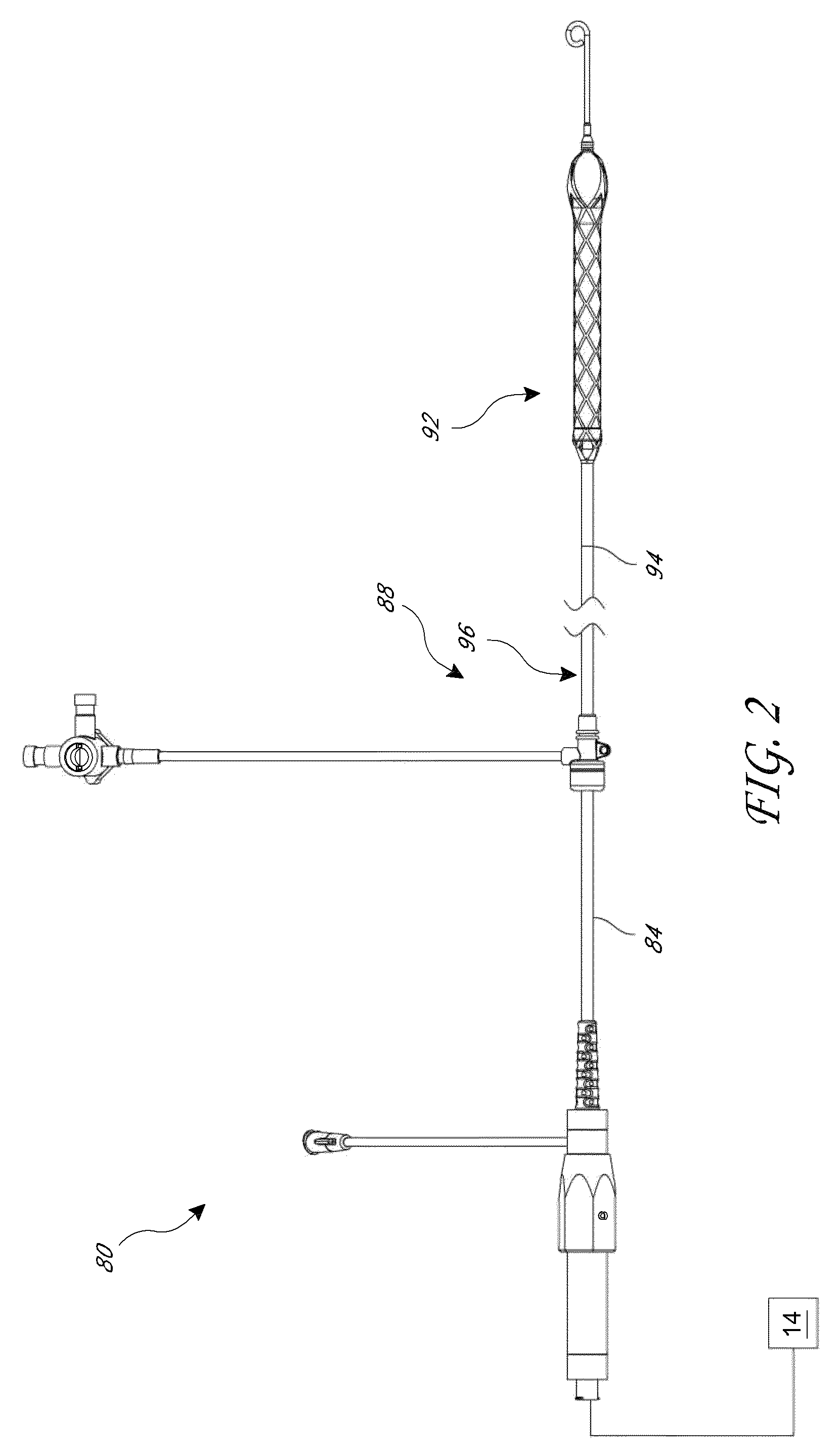

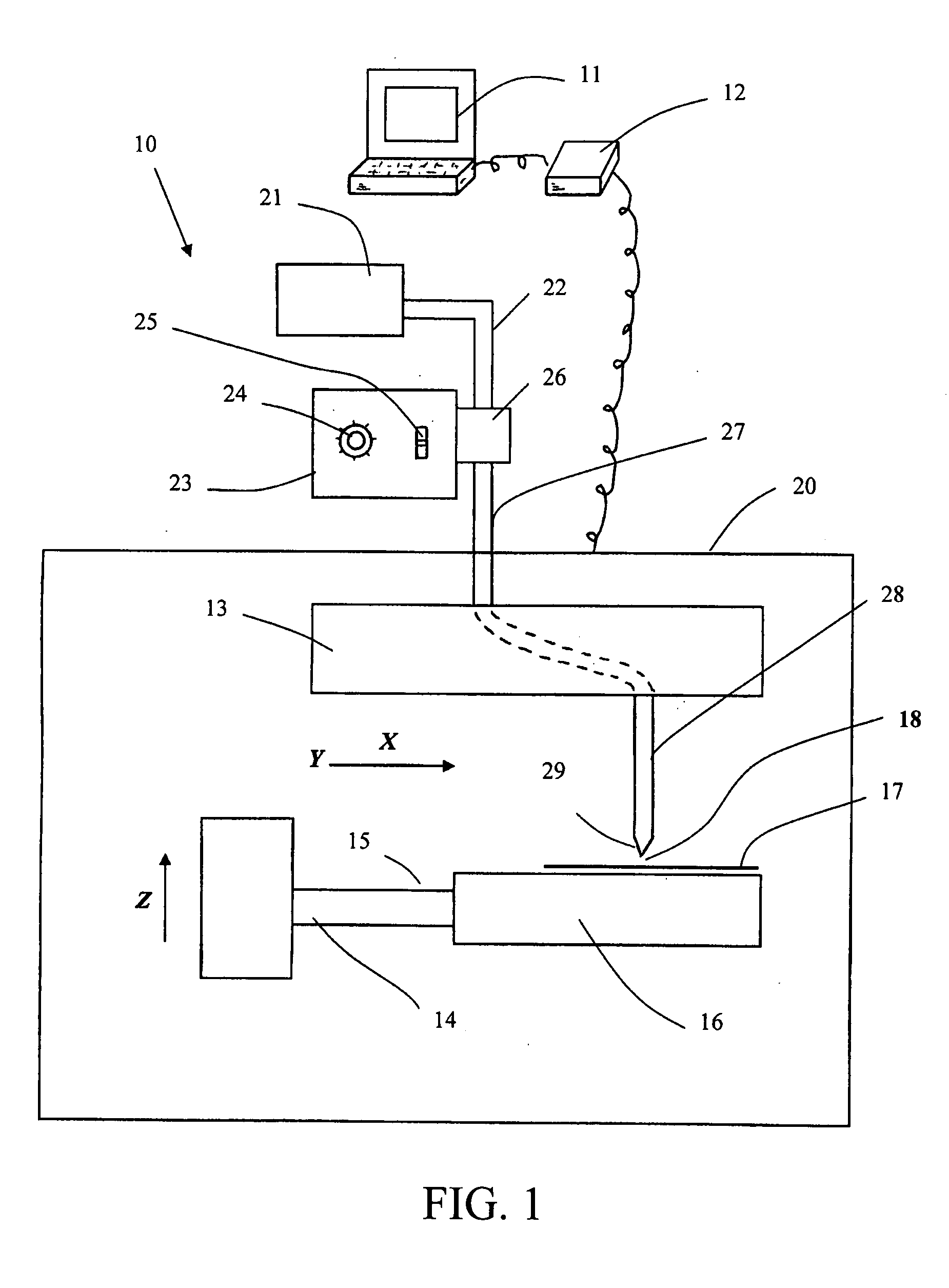

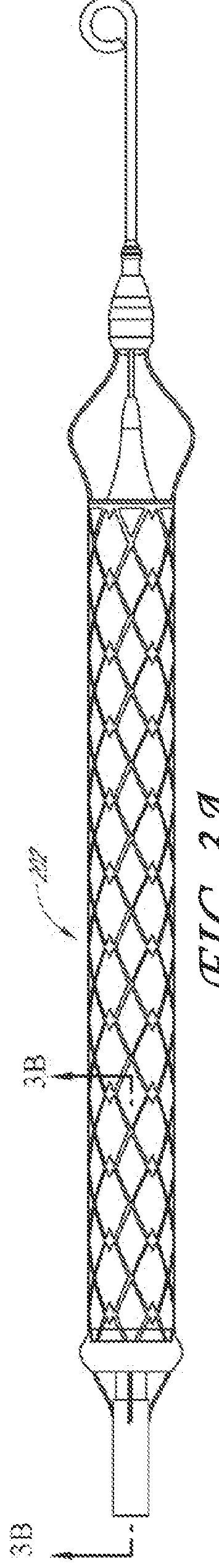

Catheter pump assembly including a stator

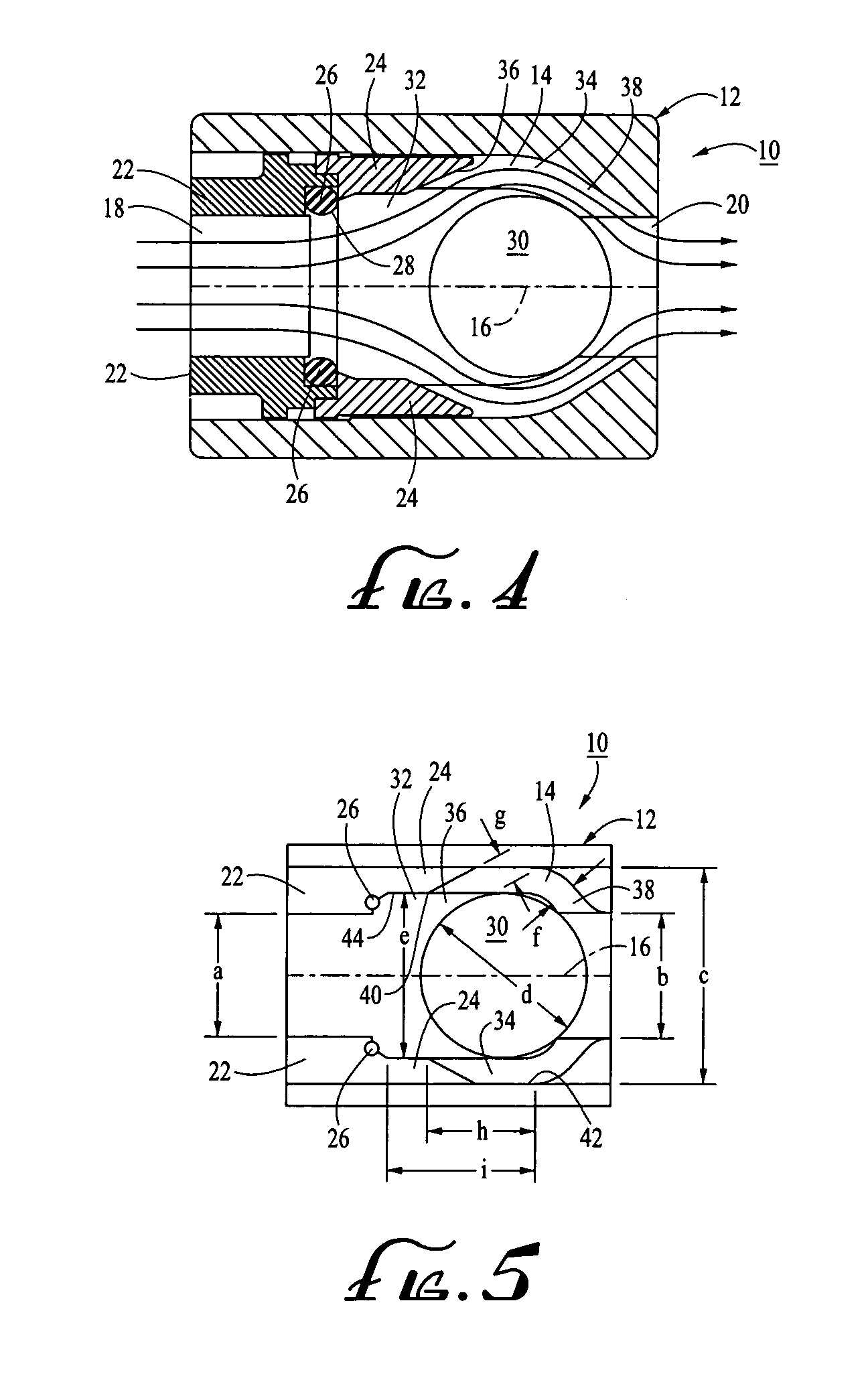

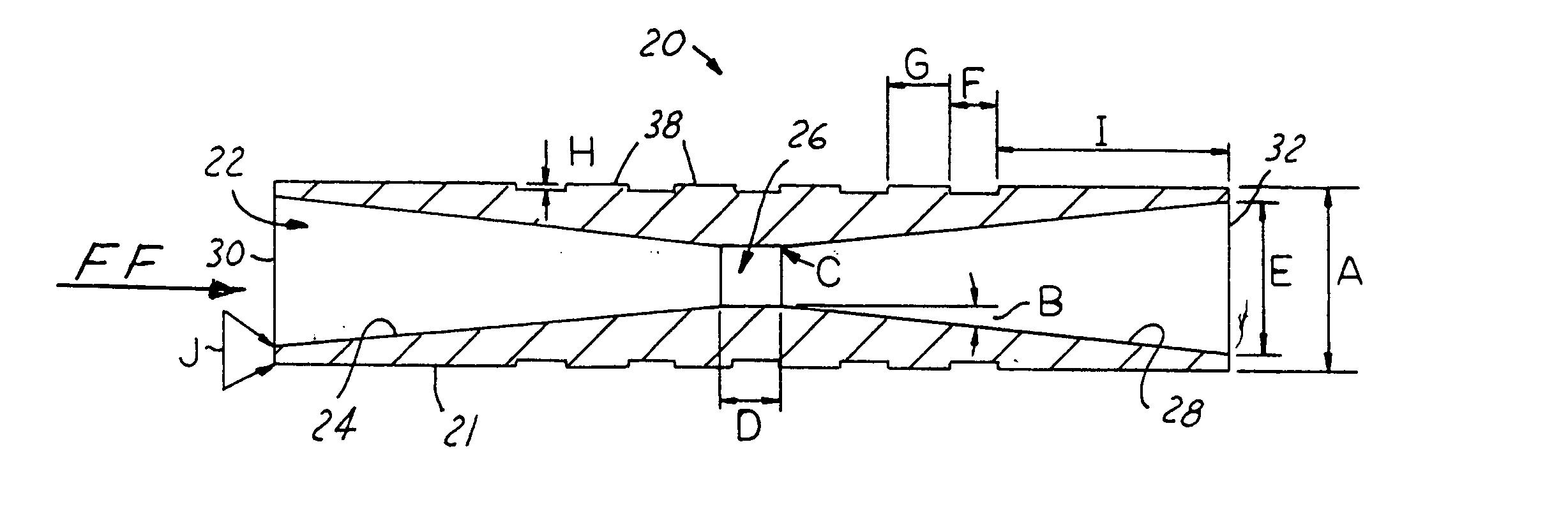

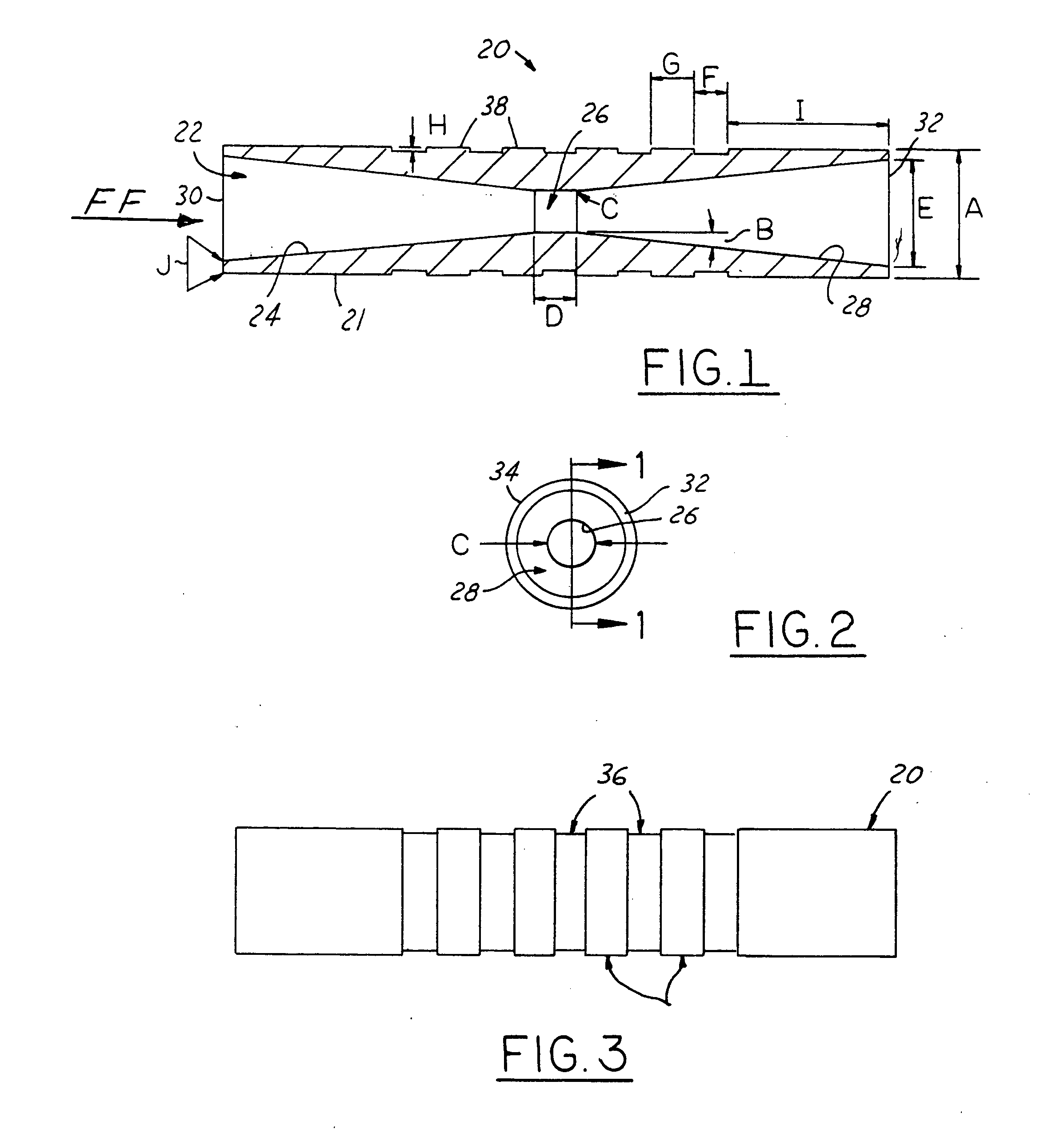

ActiveUS9308302B2Reduce lossesMinimize turbulenceOther blood circulation devicesBlood pumpsImpellerLeading edge

Owner:TC1 LLC

Flow sensor with integrated delta P flow restrictor

A high mass flow sensor device having a flow restrictor formed by a body having a generally cylindrical shape with an upstream end and a downstream end separated by a center portion having pressure taps proximate the junction of the ends with the center portion. Flow passes from upstream to downstream. The upstream end has a decreasing tapering inner surface for contact with the flow and the downstream end having an increasing tapering inner surface for contact with the flow. A center portion has radial and axial restrictor elements positioned forming axial openings in the path of flow through the center portion. The restrictor elements having tapered leading edges. One opening is formed by a central tube having a predetermined diameter and the remaining openings are radially extending members supporting the central tube, each of the radially extending members having substantially the same cross-sectional area as the central tube.

Owner:RESPIRONICS

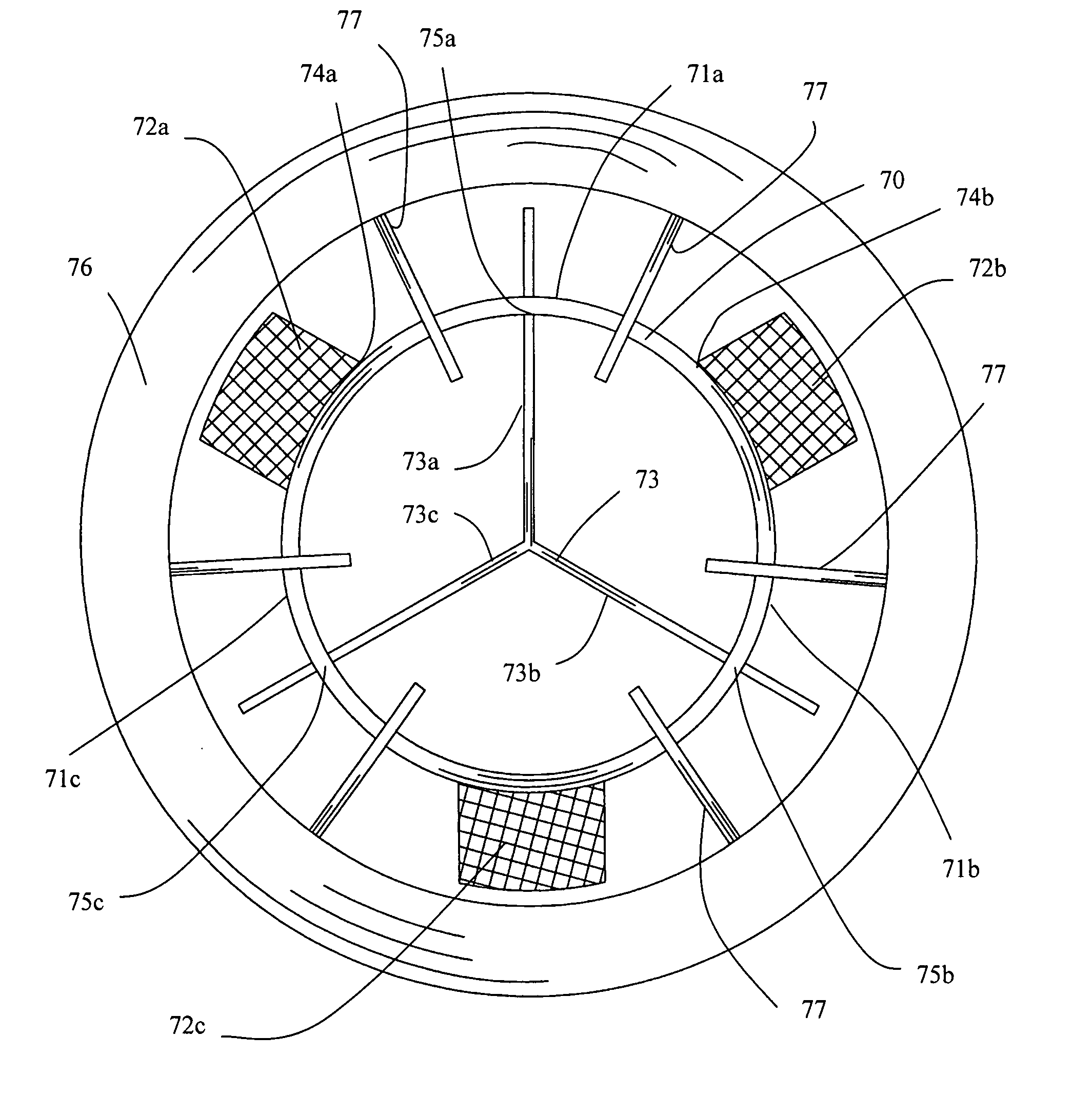

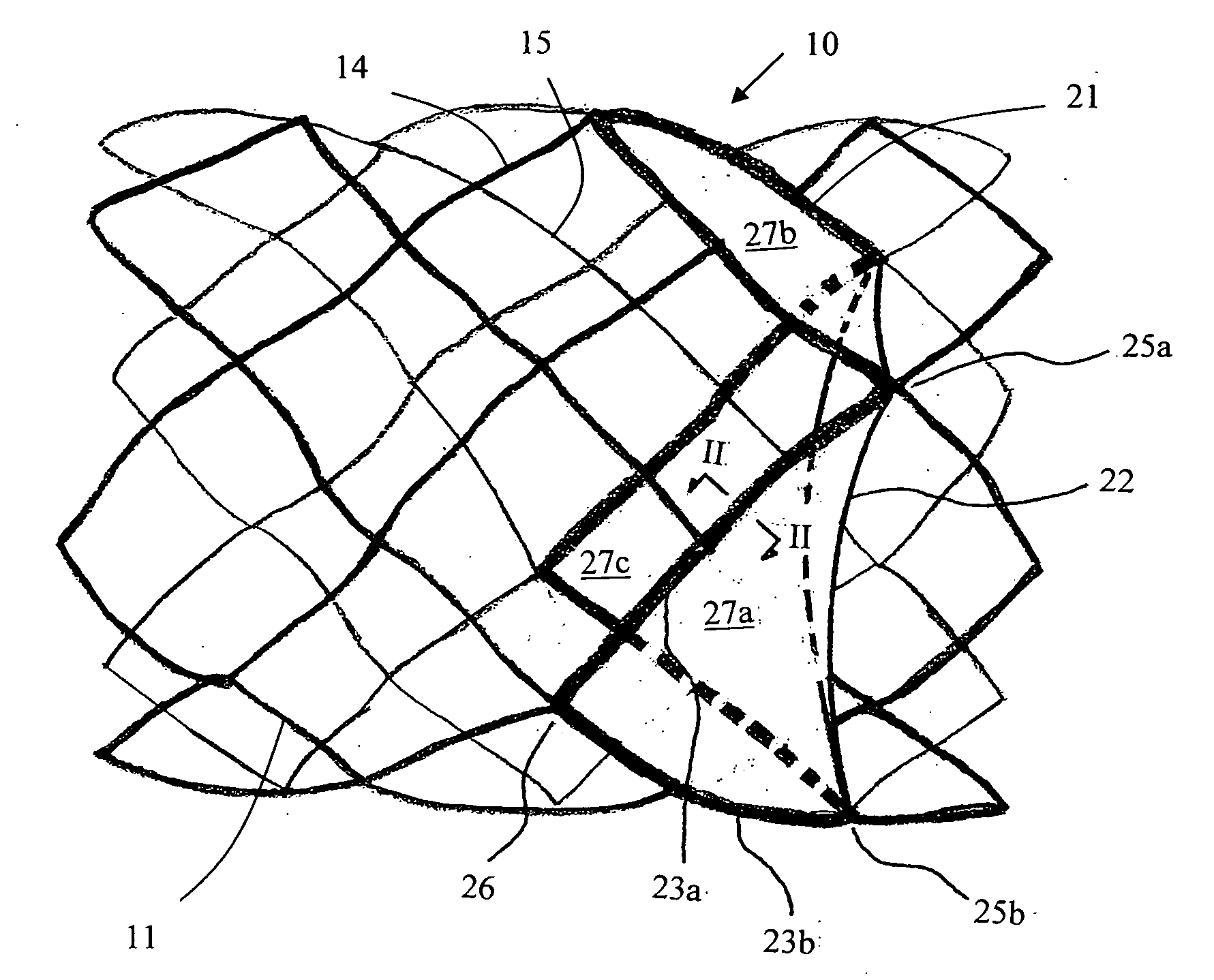

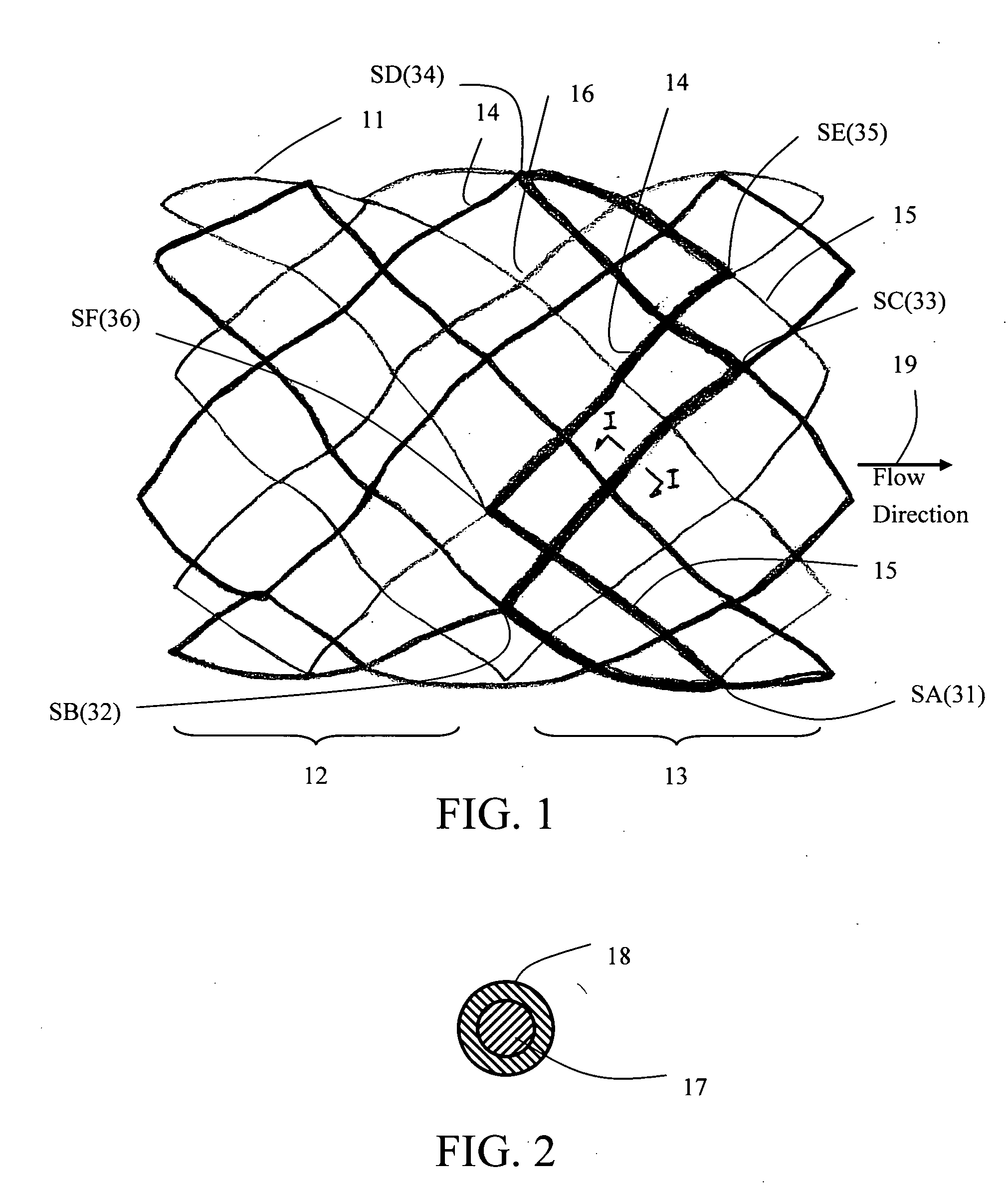

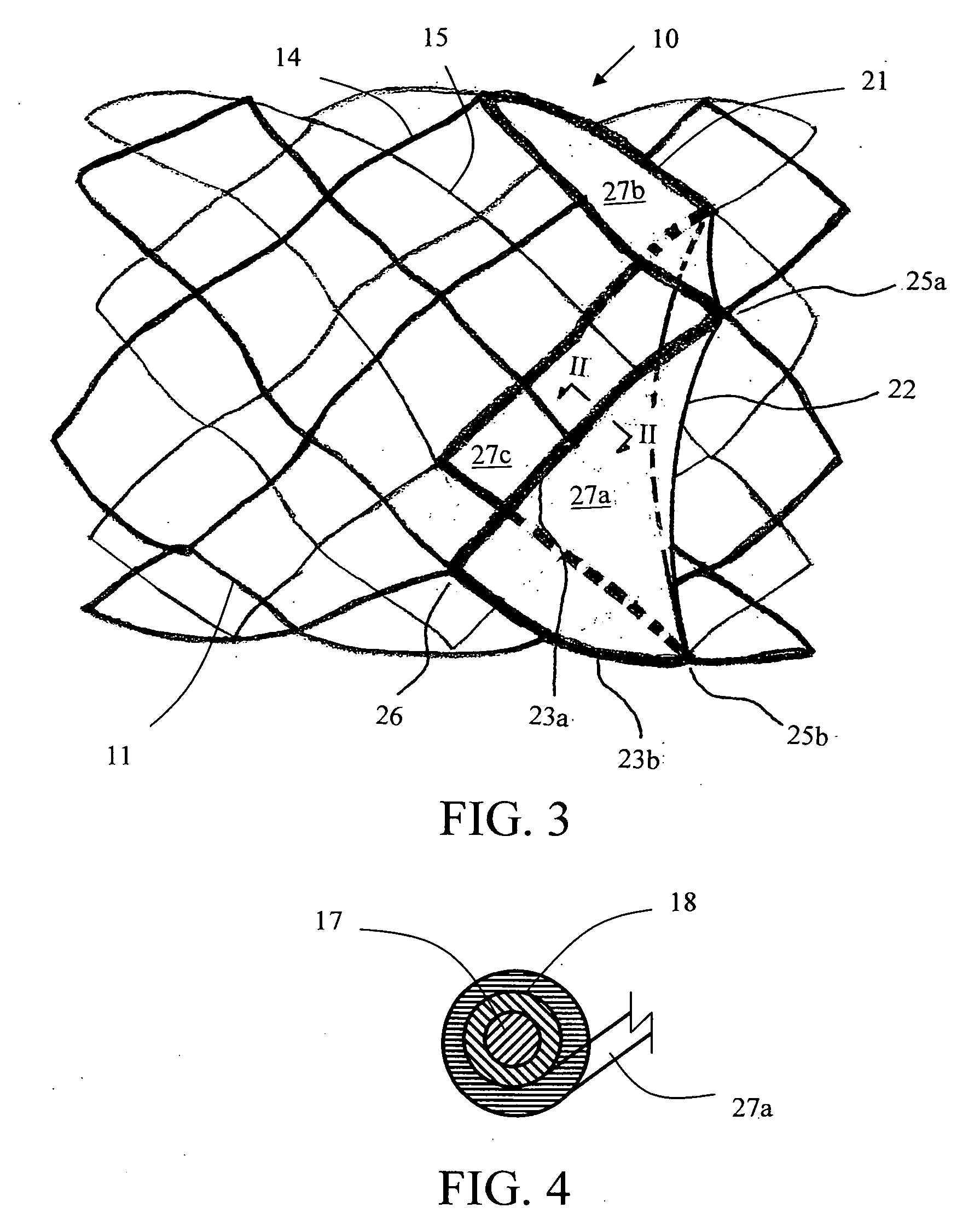

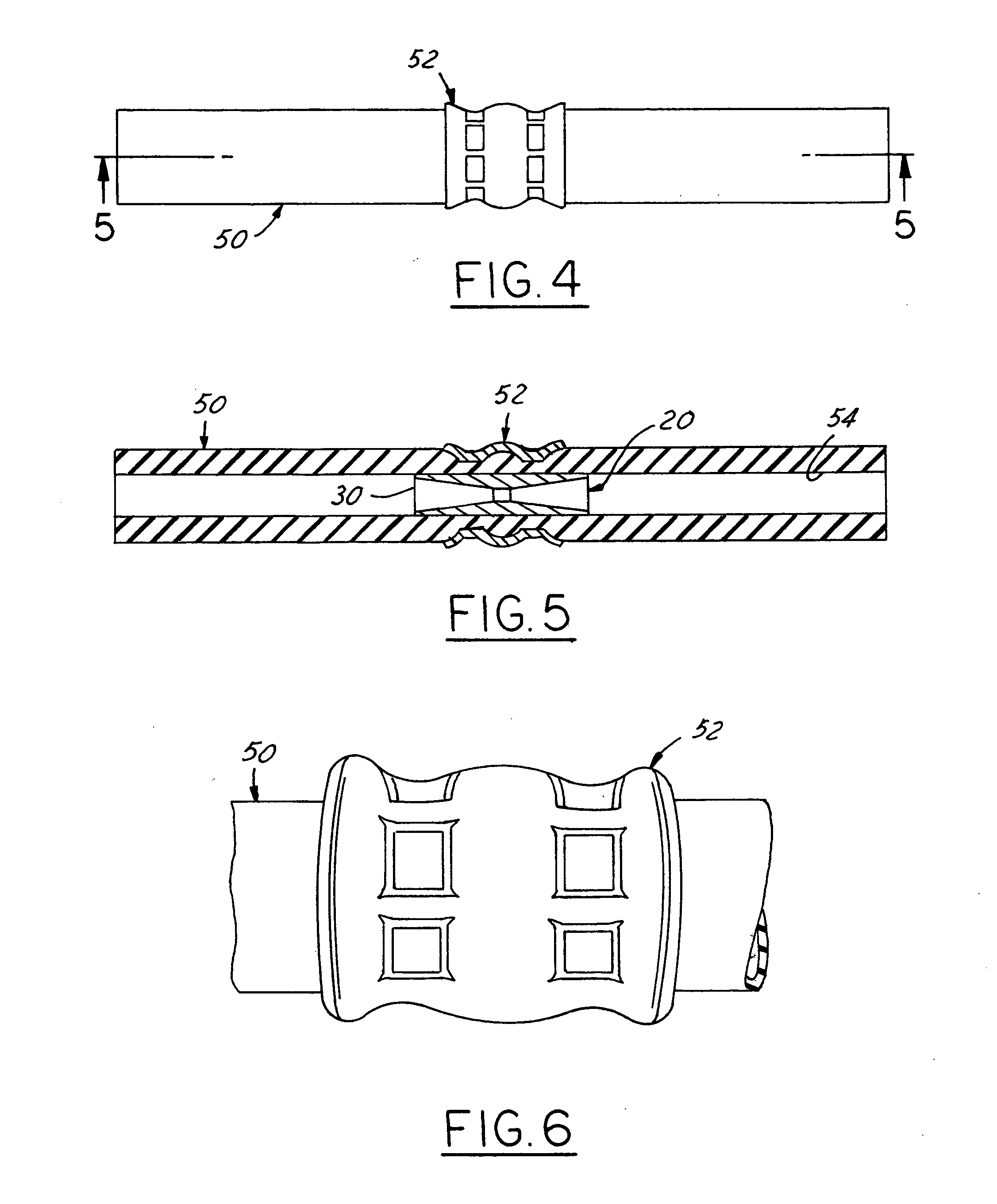

Self-expanding valve for the venous system

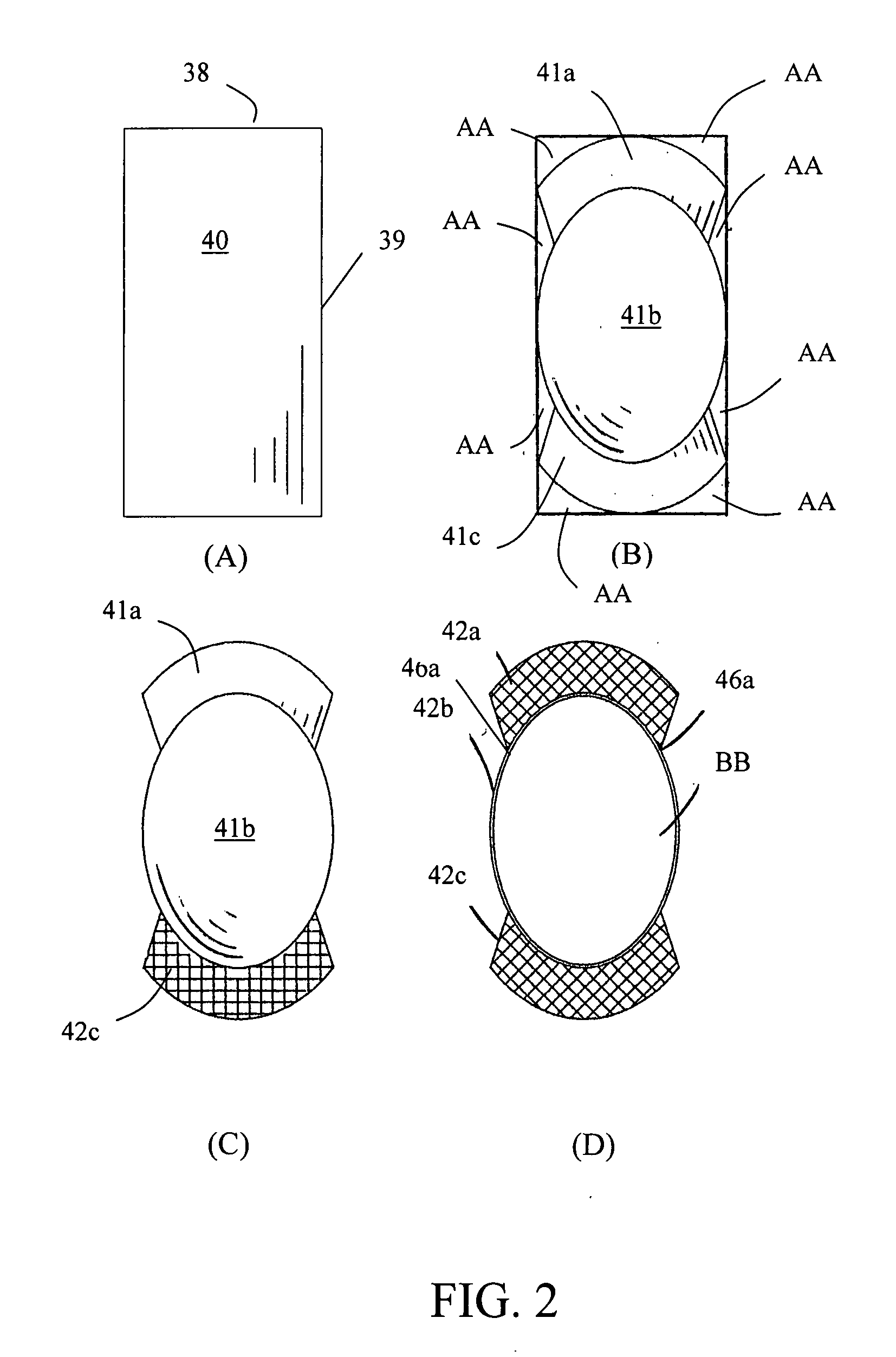

InactiveUS20090062907A1Minimize turbulenceAcceptable cytotoxicityVenous valvesBlood vesselsVenous ValvesVenous vessel

A venous valve device and method of formation are described to provide antegrade blood flow in the deep venous vessels of the leg or in other venous vessels of the body having incompetent or irreversibly dysfunctional valves. The venous valve device is made of a sheet of biocompatible material, comprising a longitudinal wire-frame structure that is a continuous seamless wire loop and plural anchoring mesh-lattice wing members spaced apart and connected to the base of the wire-frame structure.

Owner:QUIJANO RODOLFO C +1

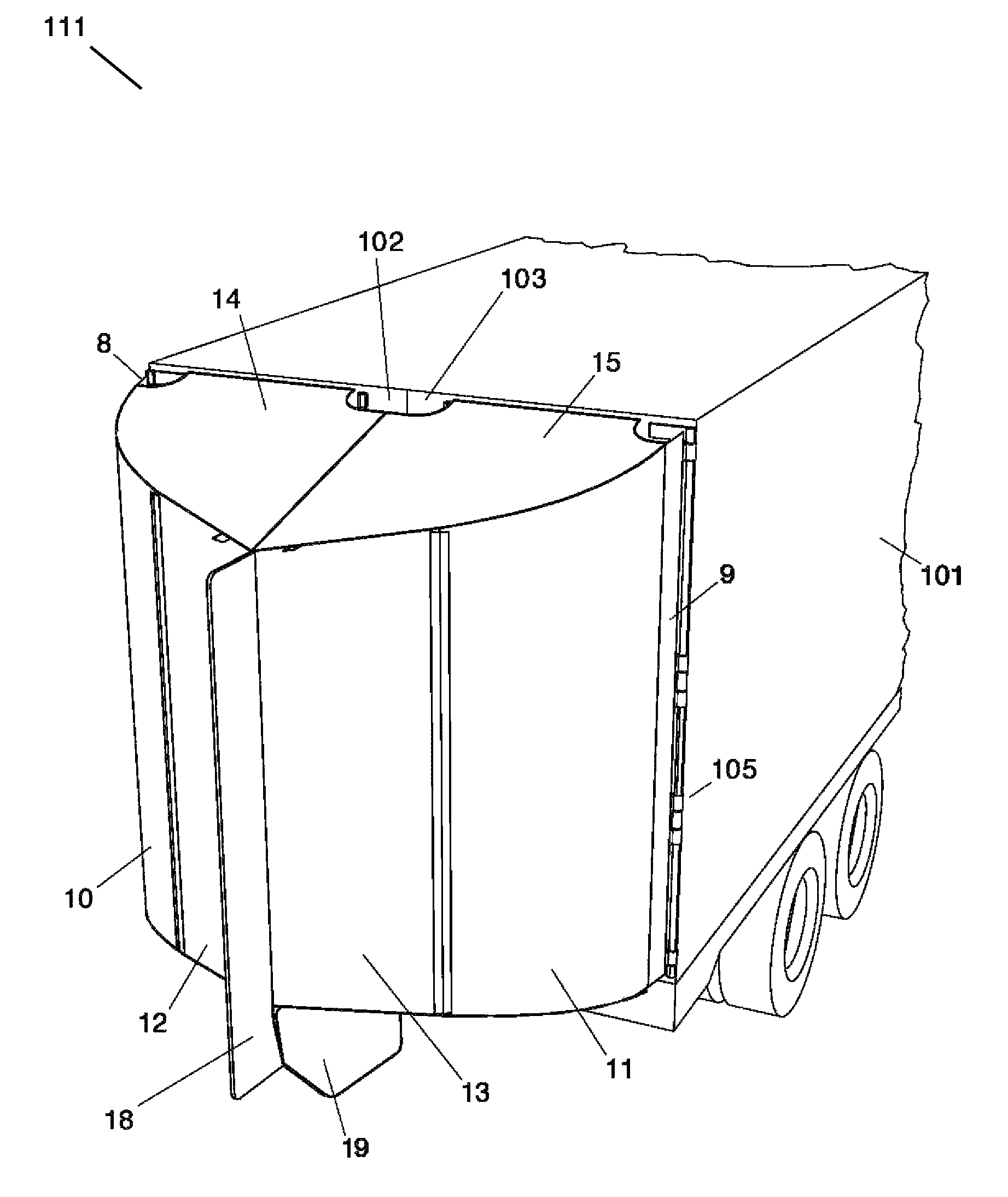

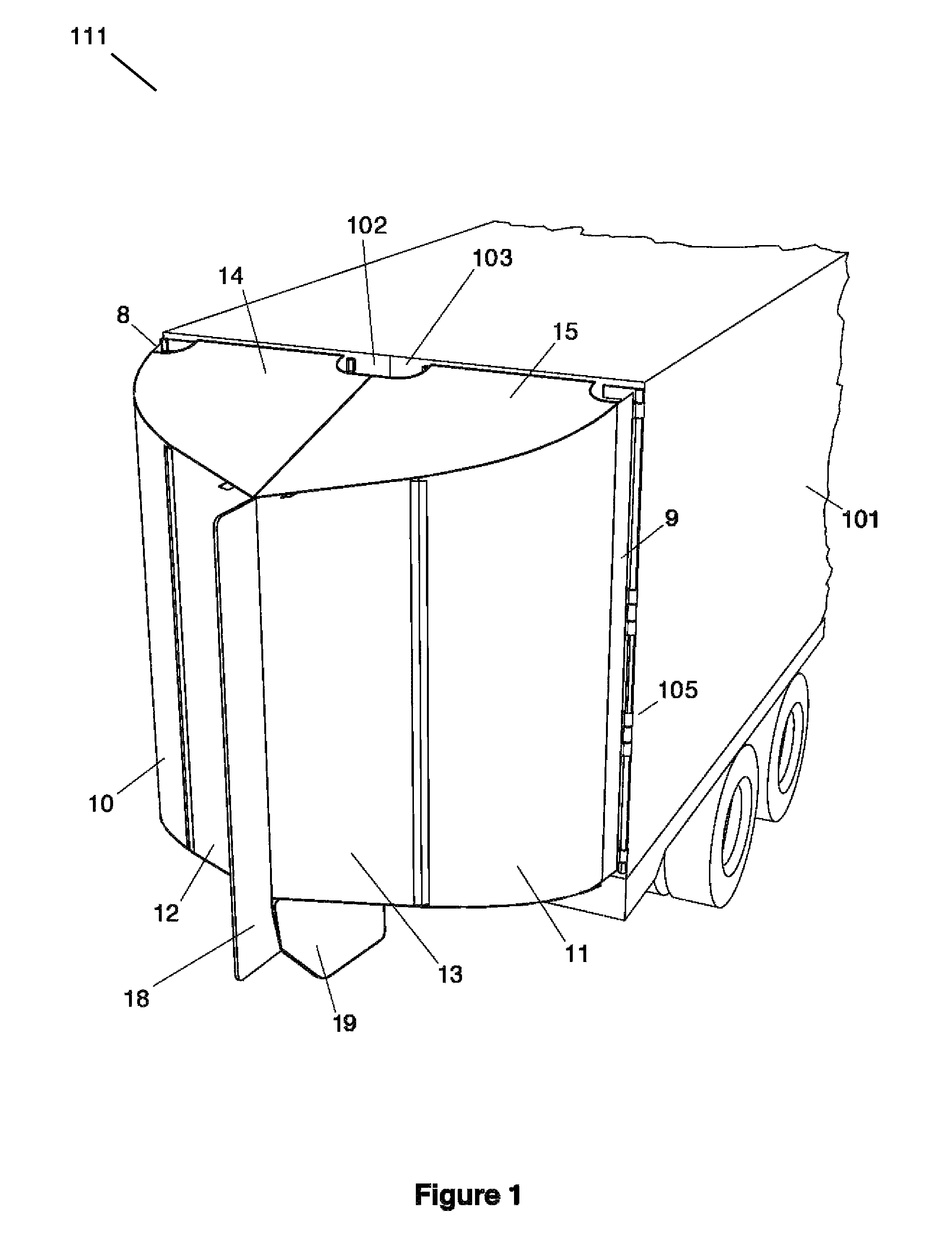

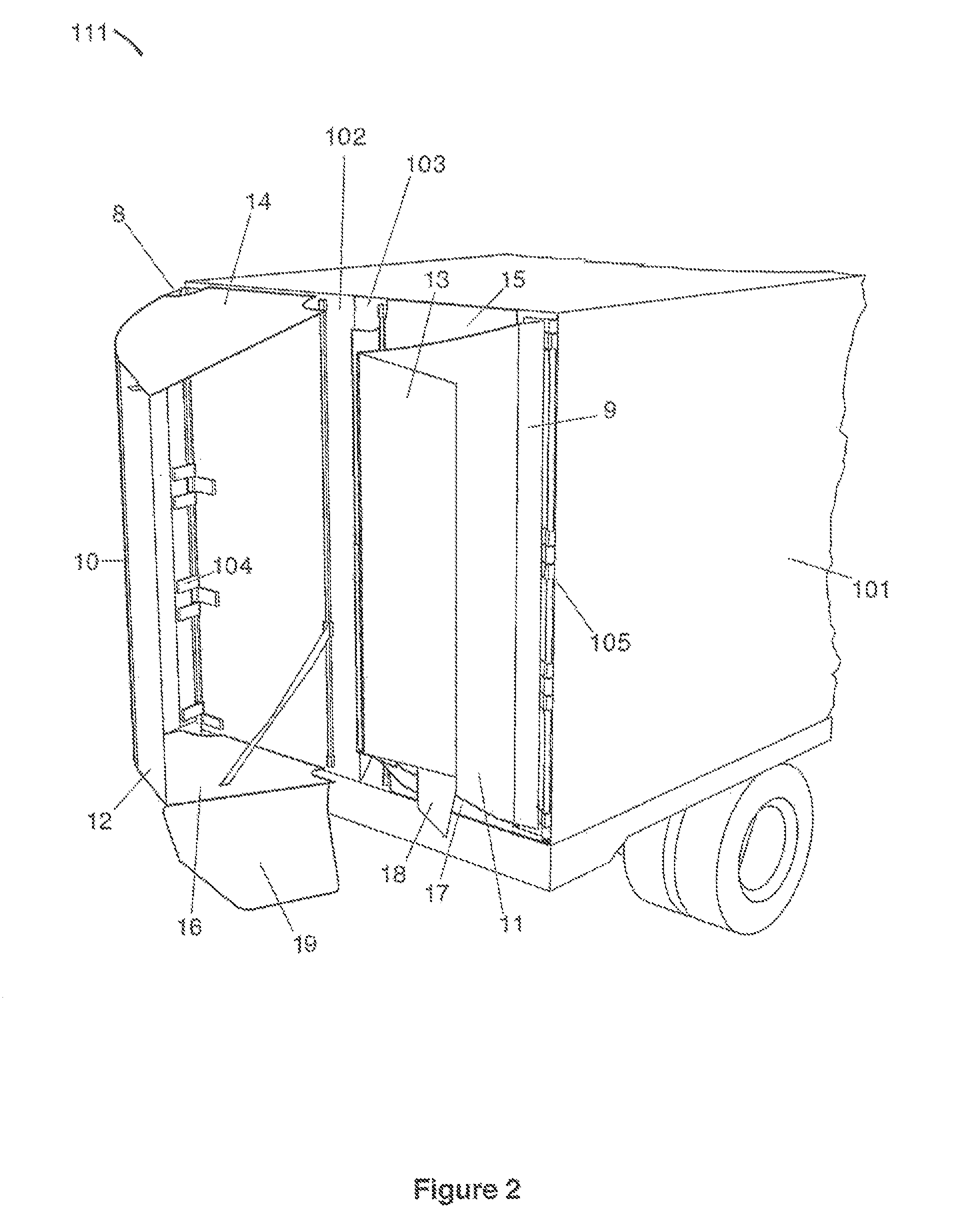

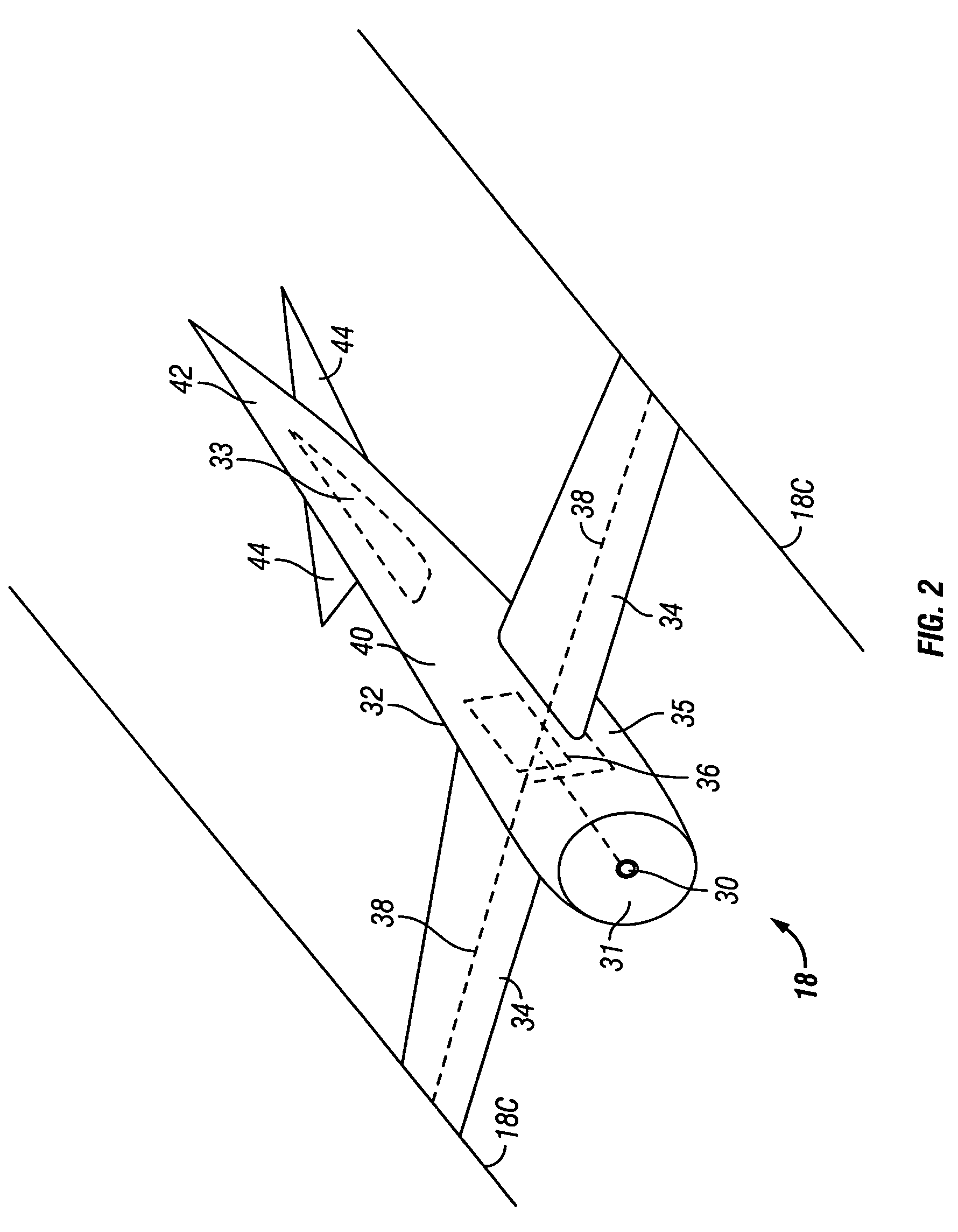

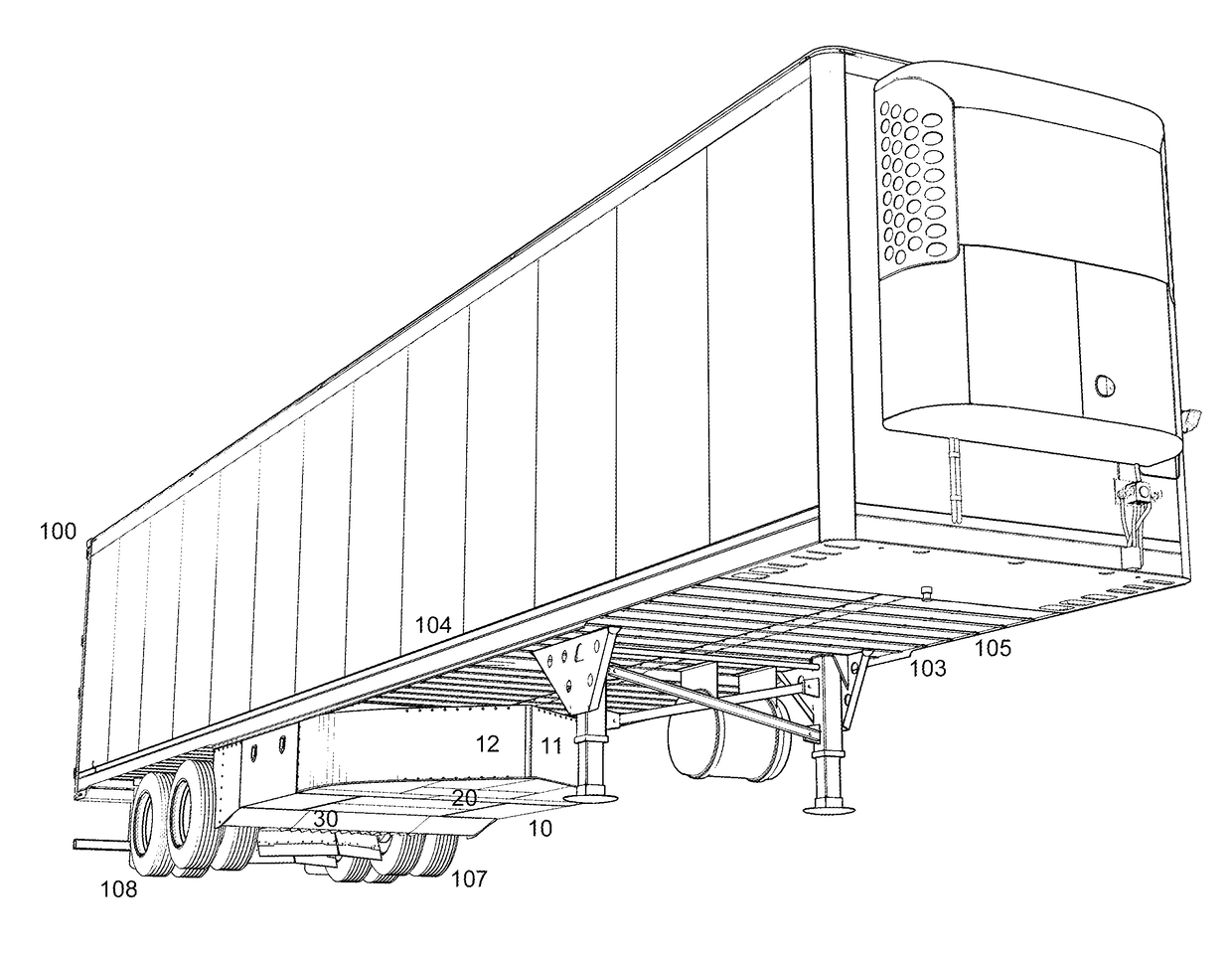

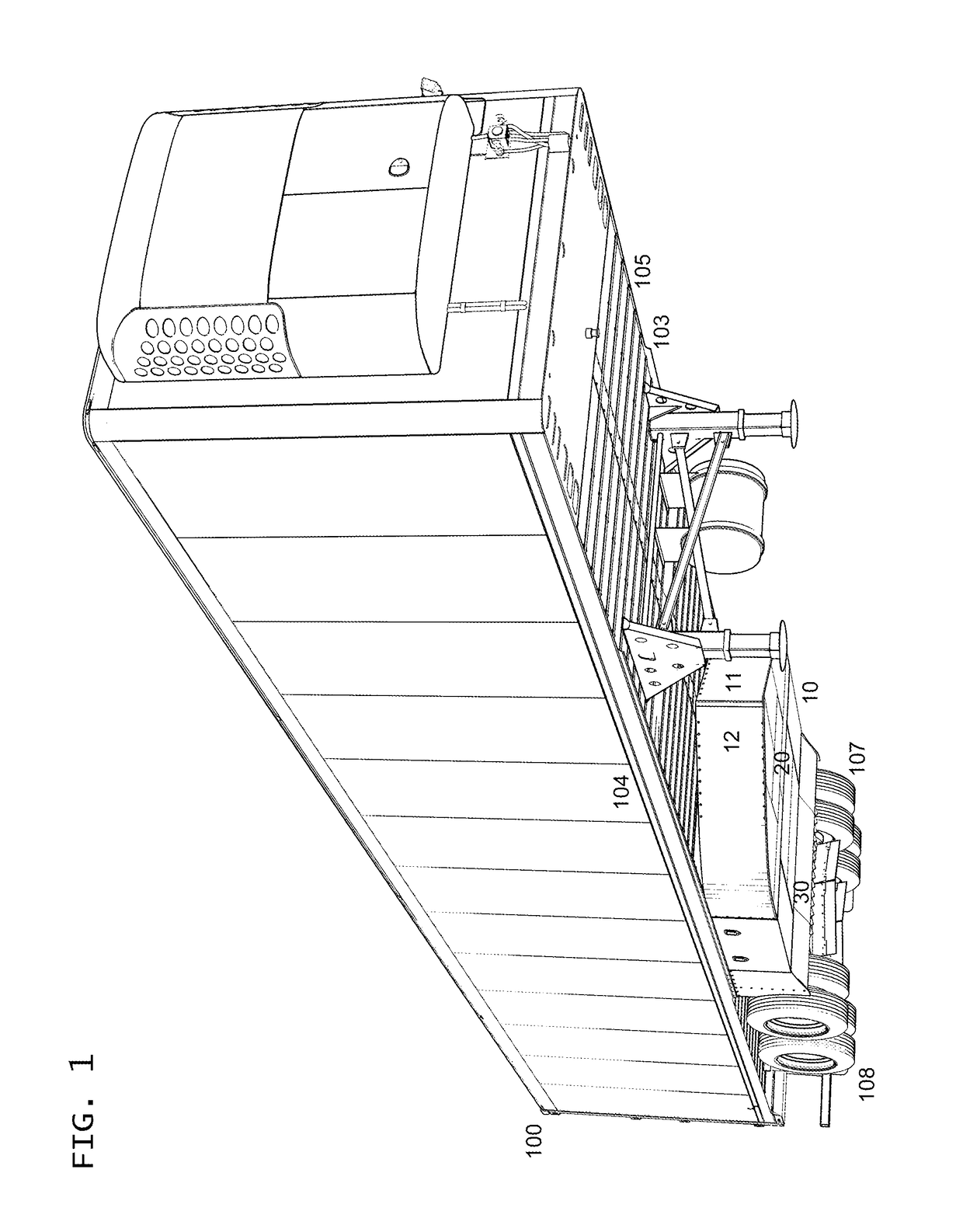

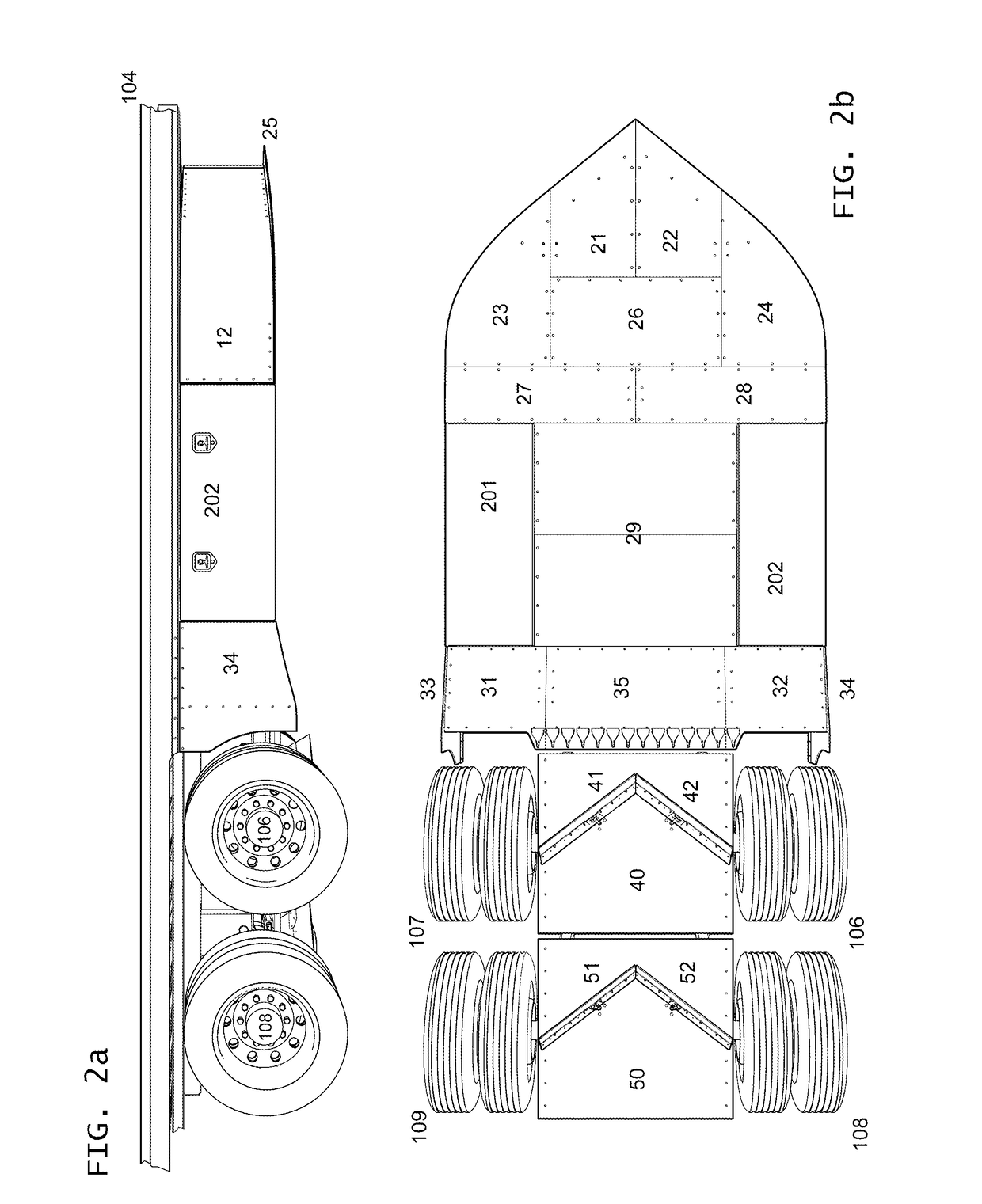

Collapsible airfoil for trucks and trailers

InactiveUS8025329B1Drag minimizationMinimize turbulenceVehicle seatsWindowsTrailing edgeSemi-trailer

The purpose of the device is to minimize drag and turbulence otherwise occurring at the rear of a semi trailer, in order to reduced the consumption of fuel by a semi tractor. This is accomplished using directionally flexible sheets of composite material, which create contours that taper towards a terminating edge to form a teardrop shape, as established by panels attached to the top and bottom of either door. Along the trailing edge of the main body, another vertical panel known as a wake separator maintains separation between confliction columns of air. An additional wake separator attached to the bottom of the device performs a similar function, and will facilitate collapse in the event of a collision.

Owner:KRON STEVEN TODD

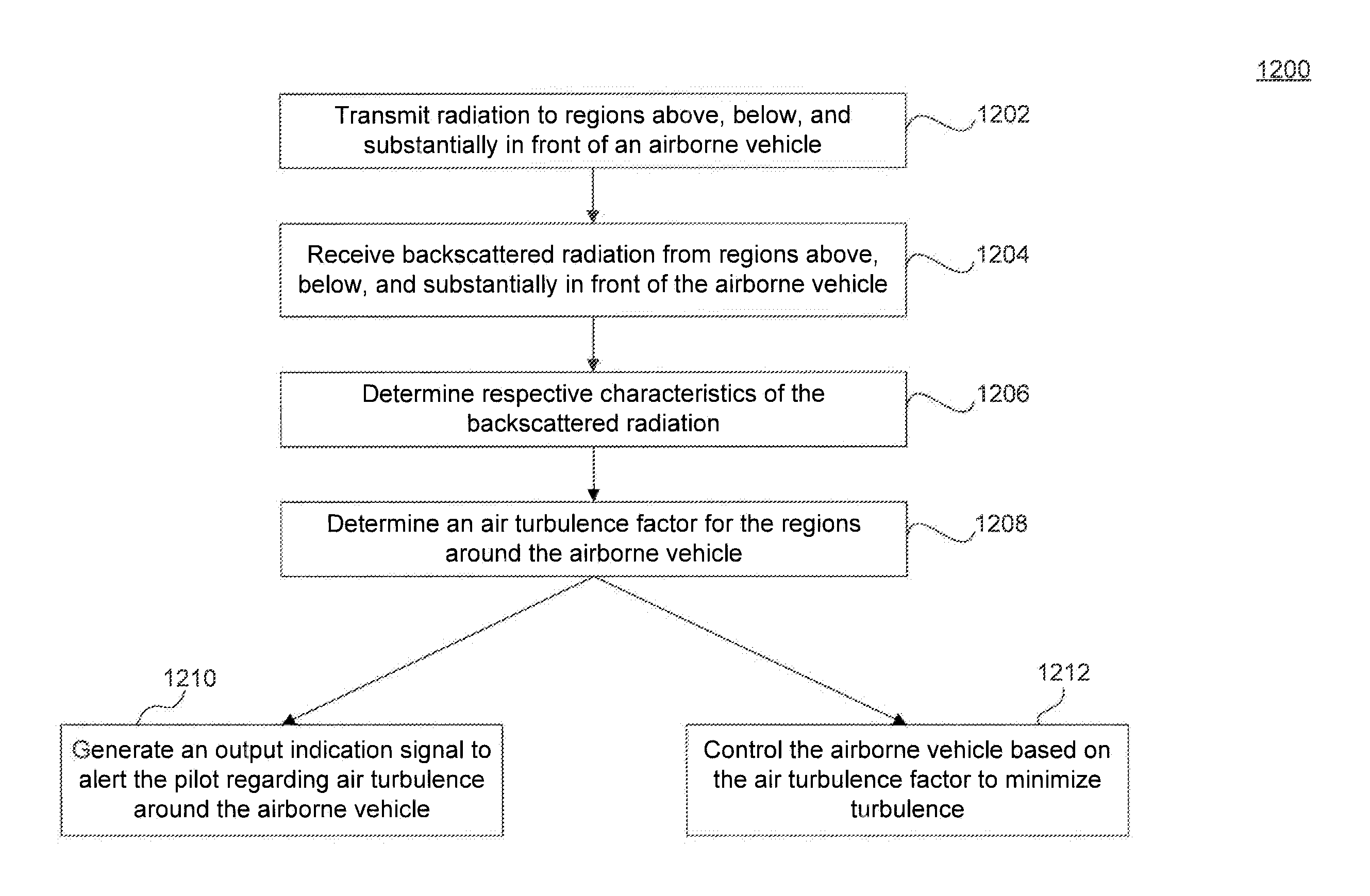

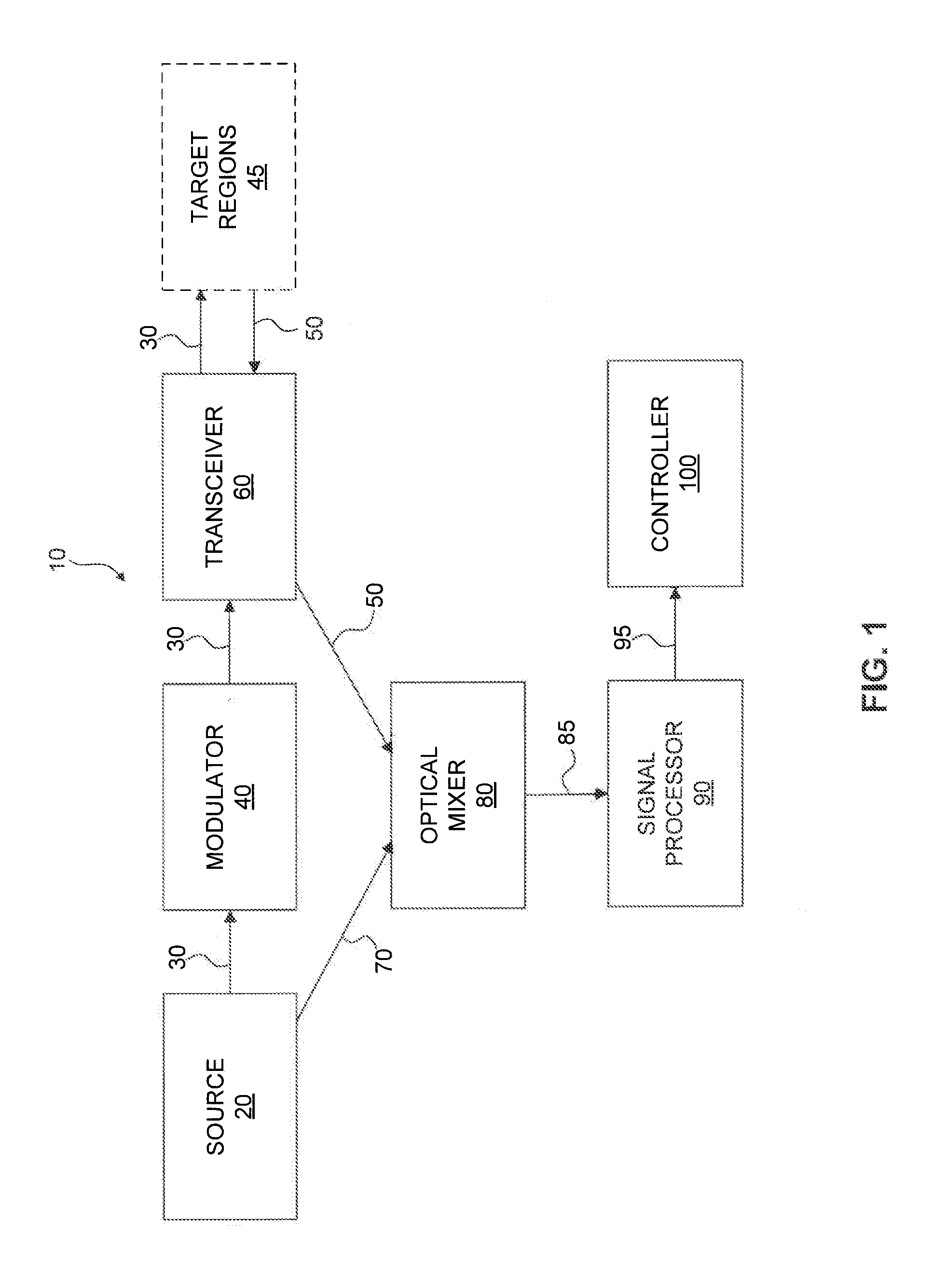

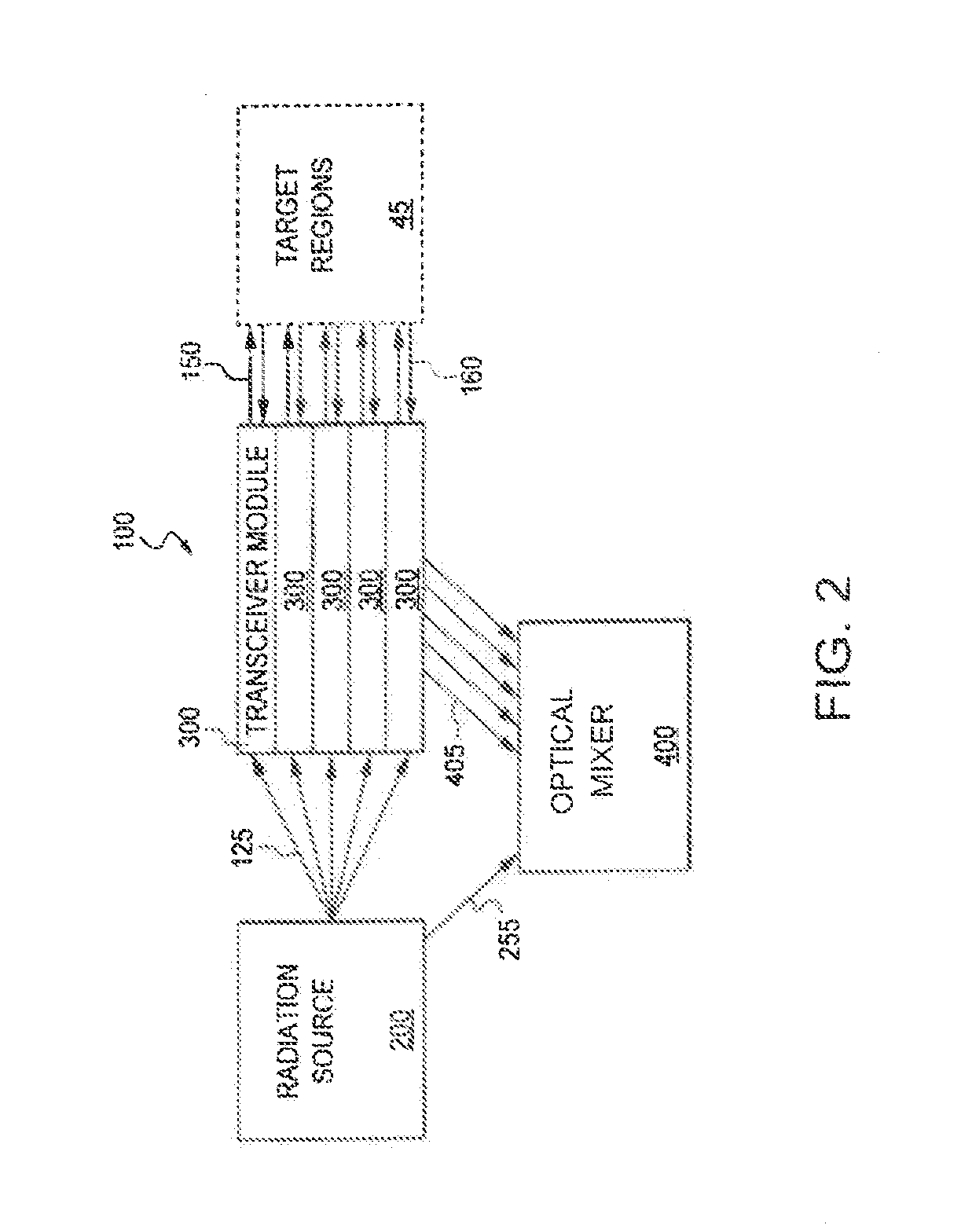

LDV System for Measuring Wind at High Altitude

ActiveUS20130166113A1Reduce turbulenceAvoid collisionOptical rangefindersDigital data processing detailsCarbon footprintAtmospheric sciences

A method of using LIDAR on an airborne vehicle is described. A beam of radiation is transmitted to target areas at least one of above, below, and in front of the airborne vehicle, the target areas including particles or objects. Scattered radiation is received from the target areas. Respective characteristics of the scattered radiation are determined. Air turbulence factor or characteristics are determined from the respective characteristics. The airborne vehicle is controlled based on the air turbulence factor, such that turbulence experienced by the airborne vehicle is minimized. Alternatively, the airborne vehicle is controlled based on the characteristics to avoid colliding with the one or more objects. In another example, the airborne vehicle is controlled based on the characteristics to reduce headwind or increase tailwind, and substantially reduce a carbon footprint of the aircraft.

Owner:RD2 LLC

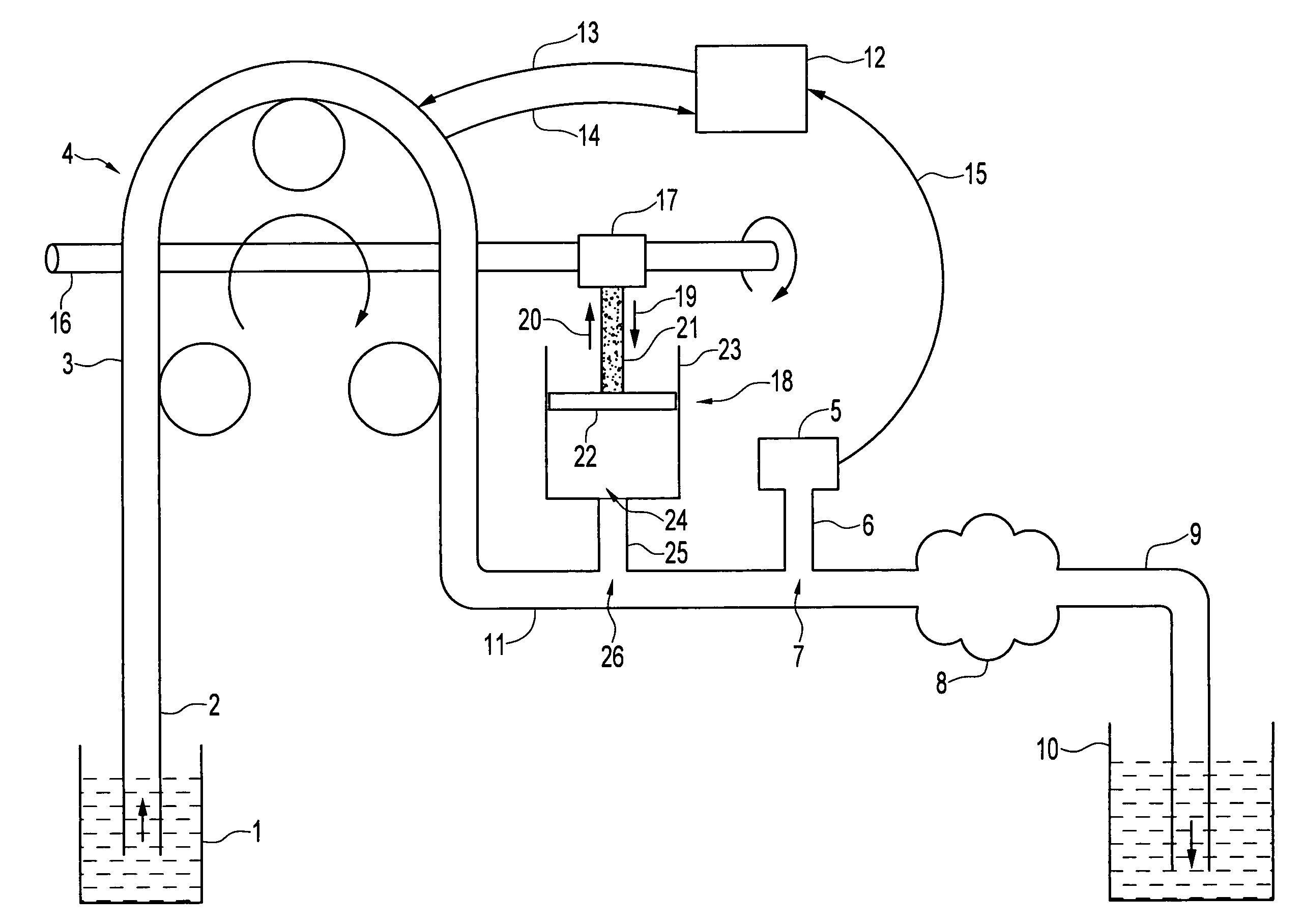

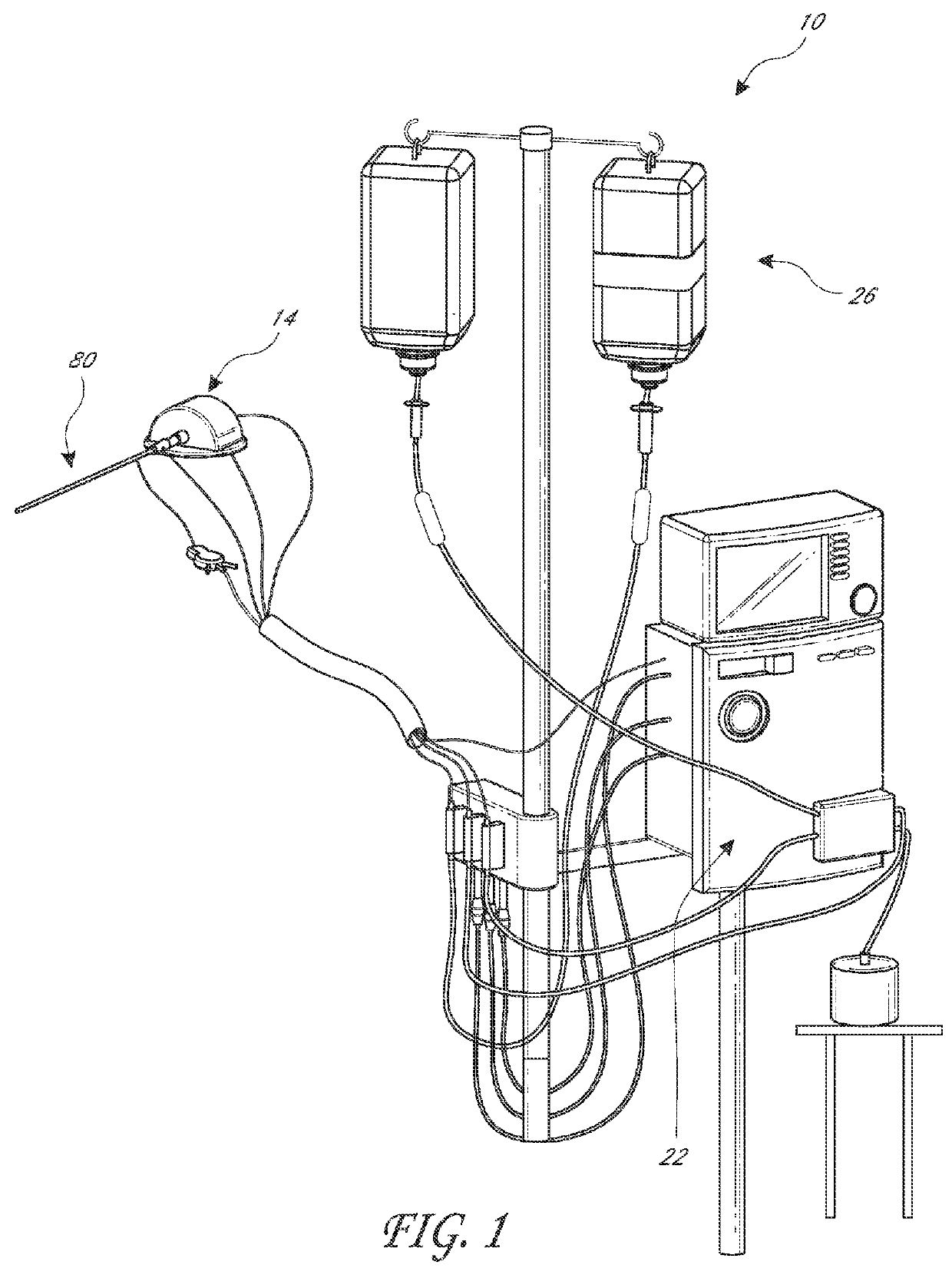

System of dampening pressure pulsations caused by a positive displacement pump in endoscopic surgery

ActiveUS7678070B2Minimizing amplitudeMinimize frequencyMedical syringesSuction devicesEndoscopic ProcedureContinuous flow

A system for distending body tissue cavities of subjects by continuous flow irrigation during endoscopic procedures, the system including: a fluid source reservoir containing a non viscous physiologic fluid meant for cavity distension; a fluid supply conduit tube connecting the fluid source reservoir to an inlet port of a variable speed positive displacement inflow pump and an outlet port of the said inflow pump being connectable to an inflow port of an endoscope instrument through an inflow tube for pumping the fluid at a controlled flow rate into the cavity, the flow rate of the said inflow pump being termed as the inflow rate; an inflow pressure transducer being located anywhere in the inflow tube between the outlet port of the inflow pump and the inflow port of the endoscope; an outflow port of the endoscope being connectable to a waste fluid collecting container via a waste fluid carrying tube, and characterized in that an active inflow pressure pulsation dampening means is connected to the inflow tube for dampening the pressure pulsations inside the cavity created by the positive displacement inflow pump.

Owner:KUMAR BV

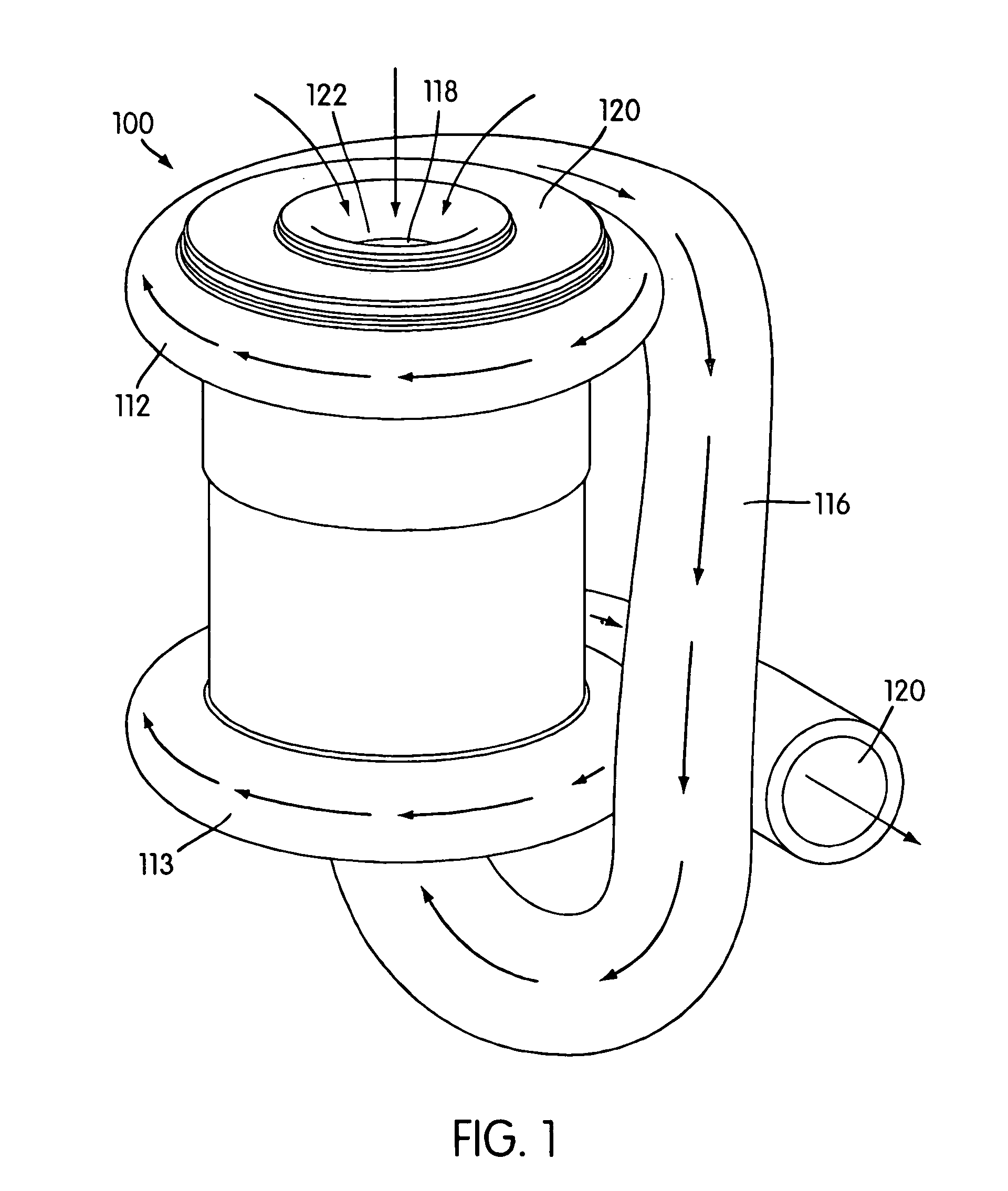

Multiple stage blowers and volutes therefor

ActiveUS8517012B2Faster pressure rise timeImprove reliabilityPump componentsMedical devicesNarrow rangeMotor speed

A multiple stage variable speed blower for Continuous Positive Airway Pressure (CPAP) ventilation of patients includes two impellers in the gas flow path that cooperatively pressurize gas to desired pressure and flow characteristics. Thus, the multiple stage blower can provide faster pressure response and desired flow characteristics over a narrower range of motor speeds, resulting in greater reliability and less acoustic noise.

Owner:RESMED LTD

Valved stent for chronic venous insufficiency

InactiveUS20090254175A1Minimize turbulenceReduce molecular weightVenous valvesBlood vesselsChemical treatmentCoupling

The invention discloses a valved stent and process of manufacture for treating chronic venous insufficiency having the geometry of the supporting frame and its coupling to the membrane of a specific geometry that provides the valvular mechanism for optimal function. The membrane may comprise a decellularized pericardial tissue via chemical treatment with cholic acid or bile salts and crosslinked.

Owner:QUIJANO RODOLFO C +1

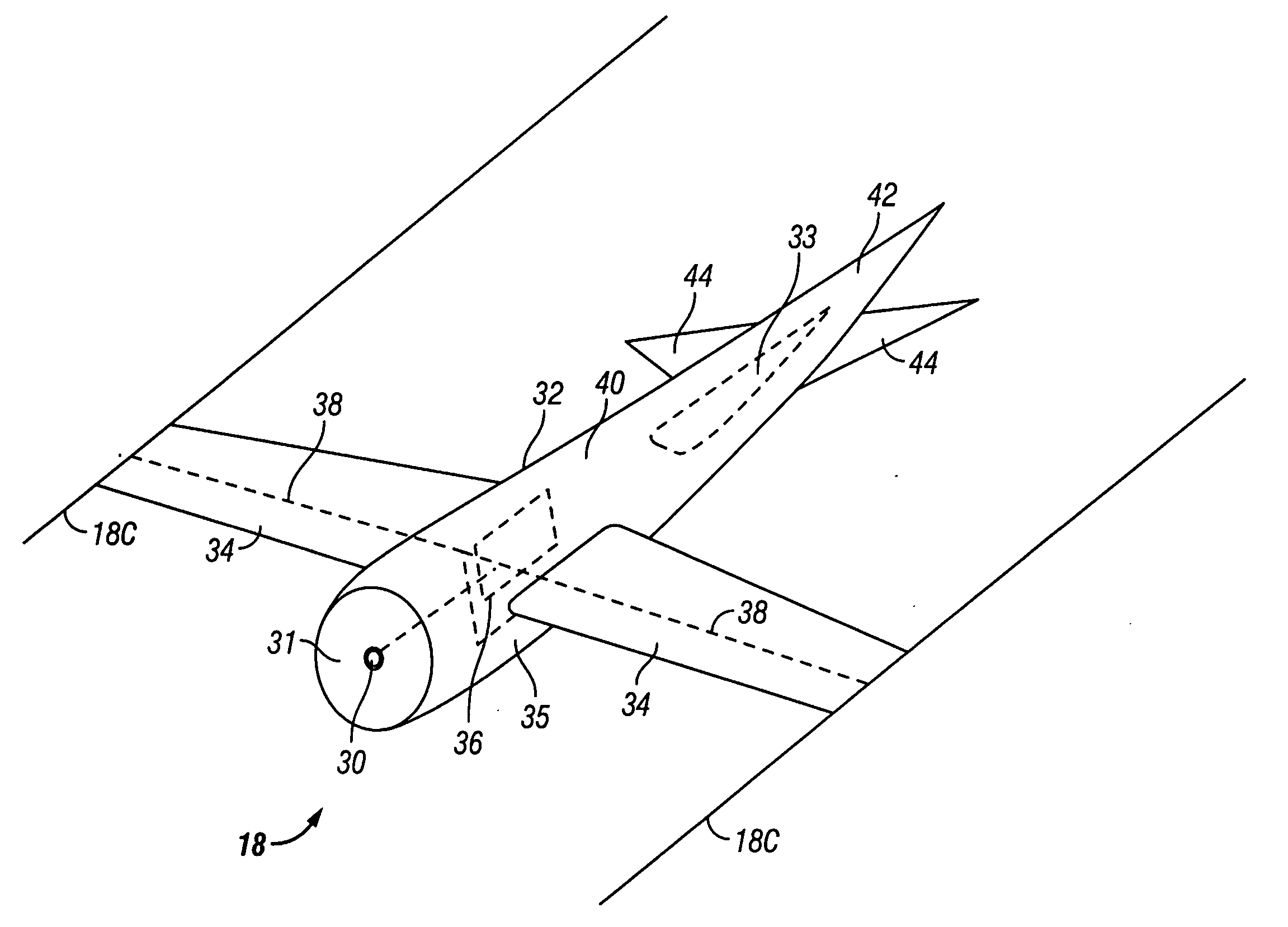

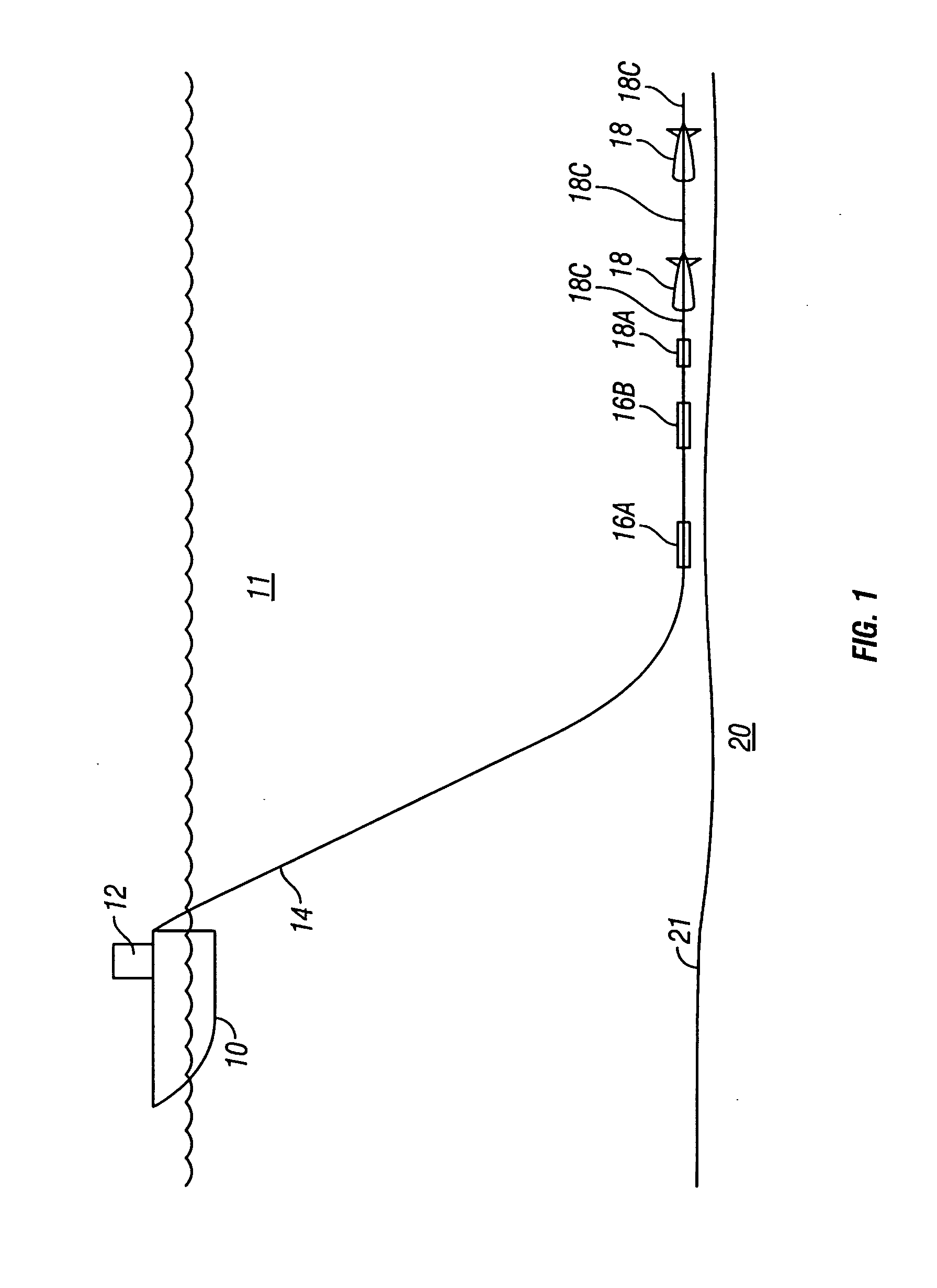

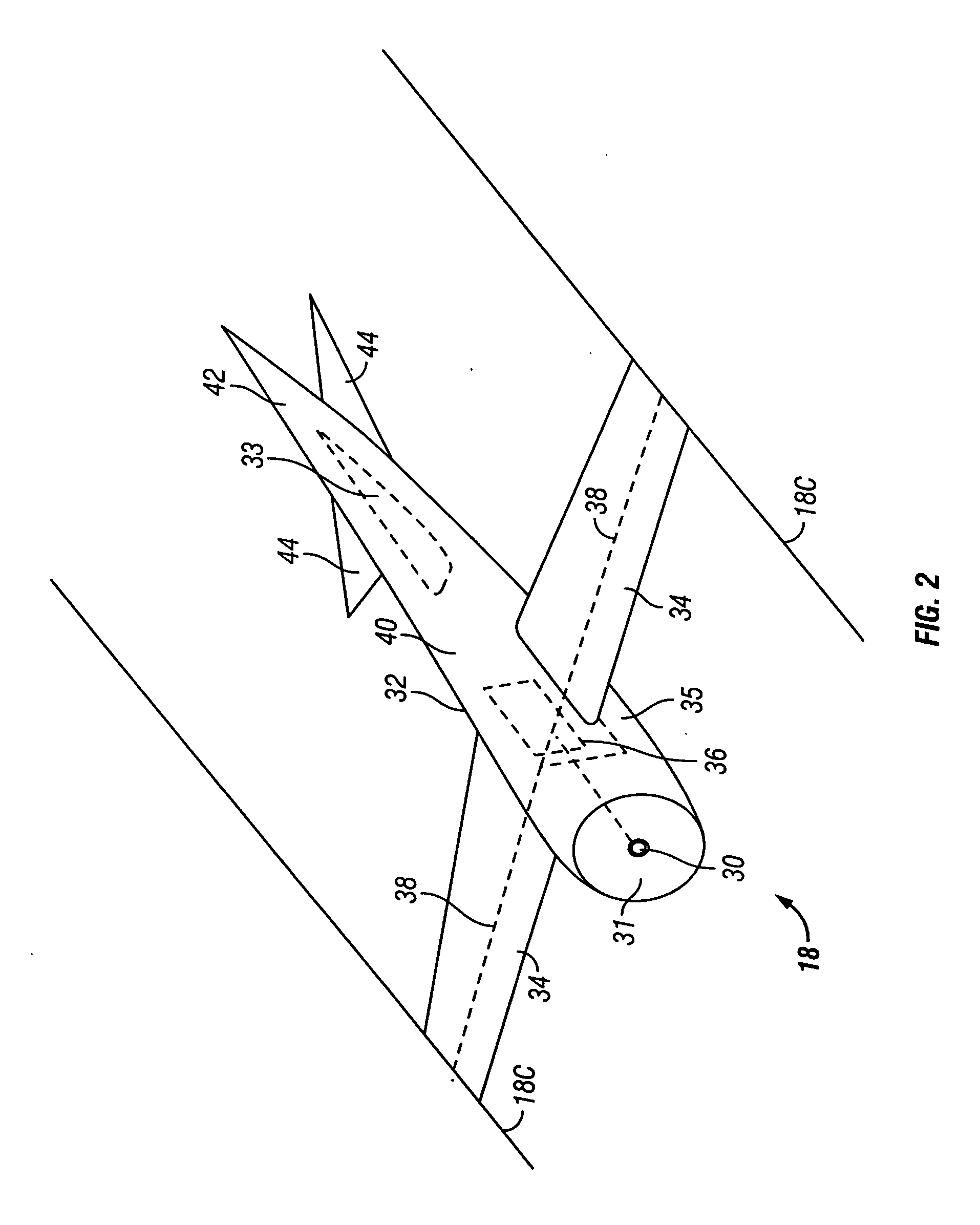

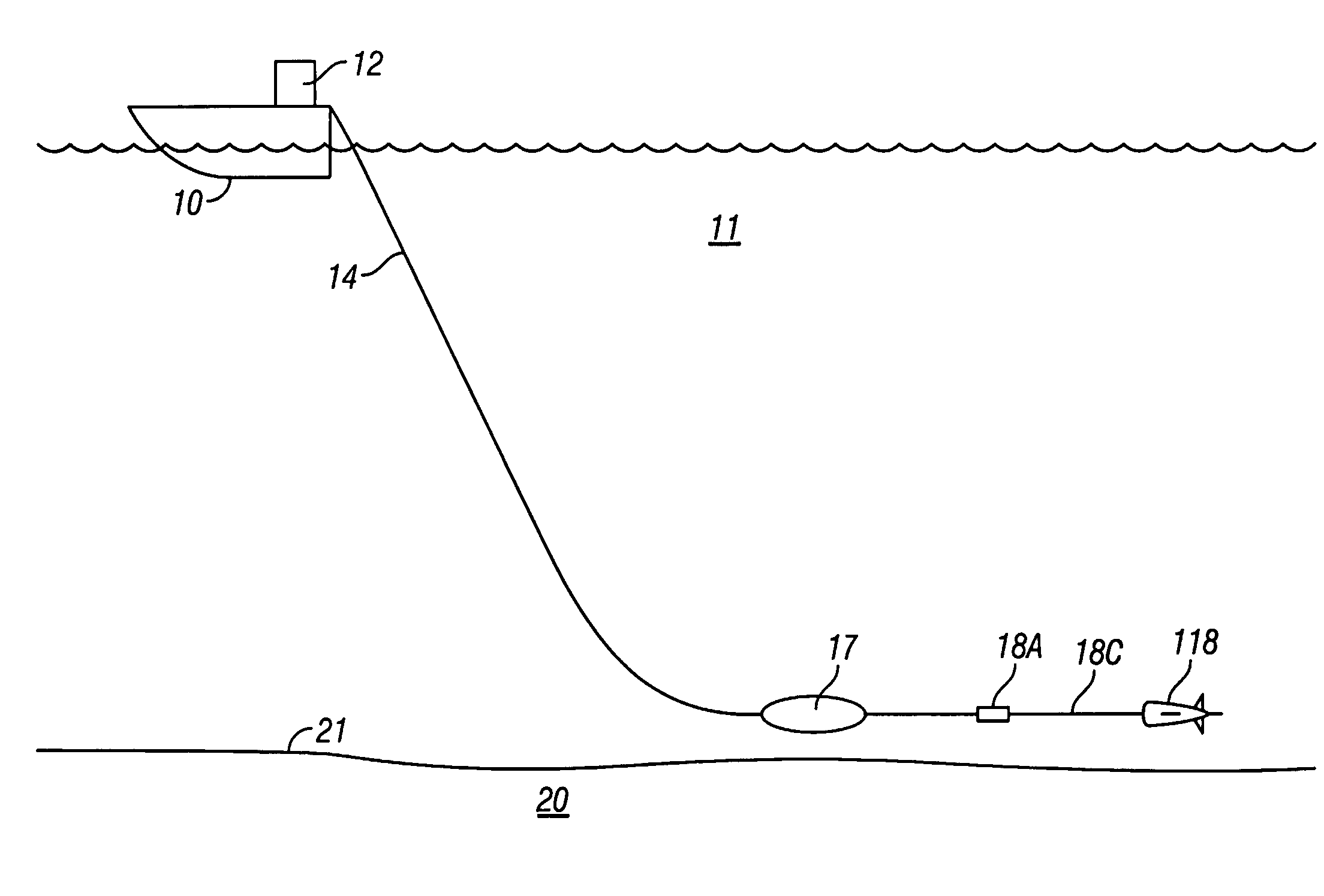

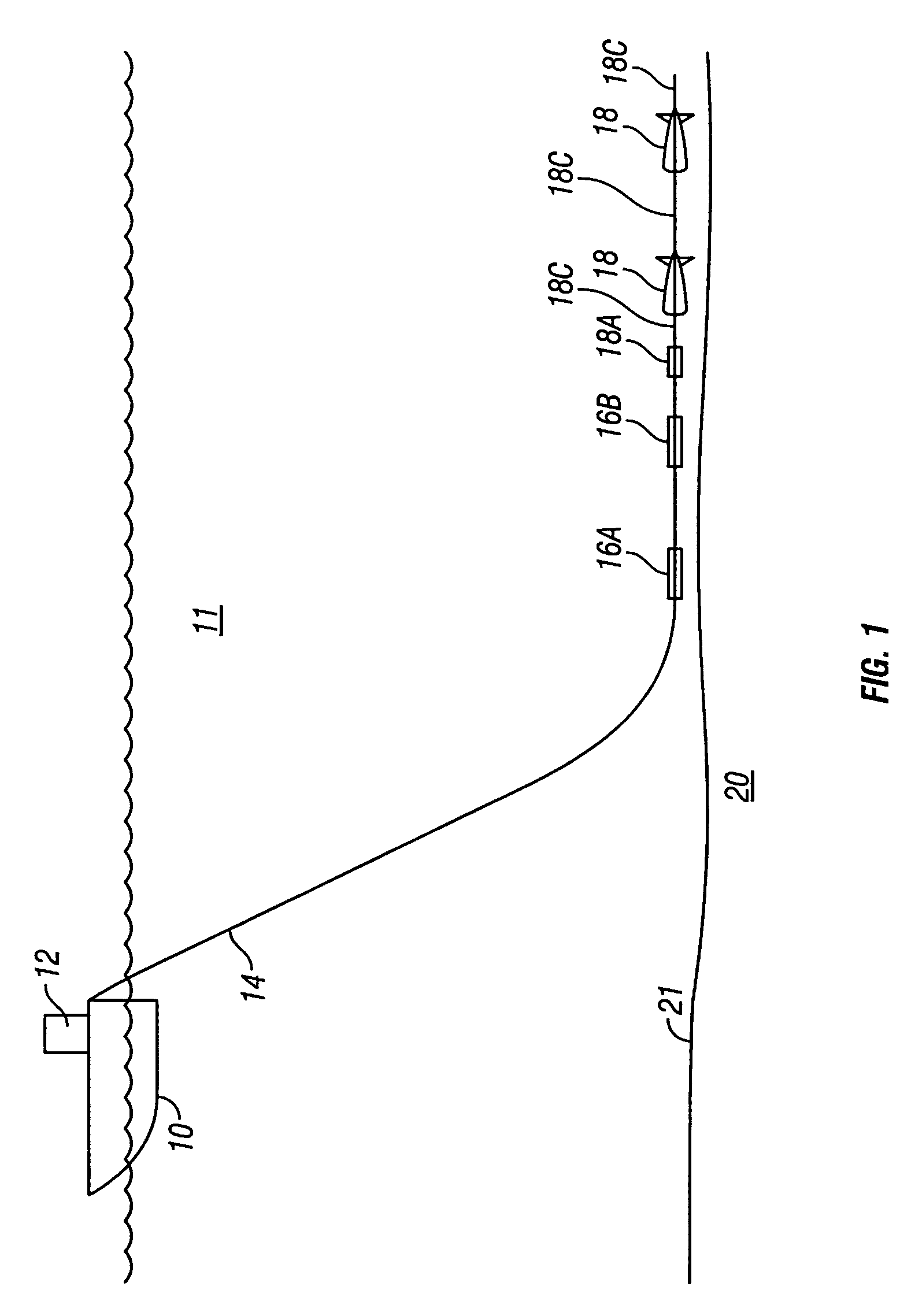

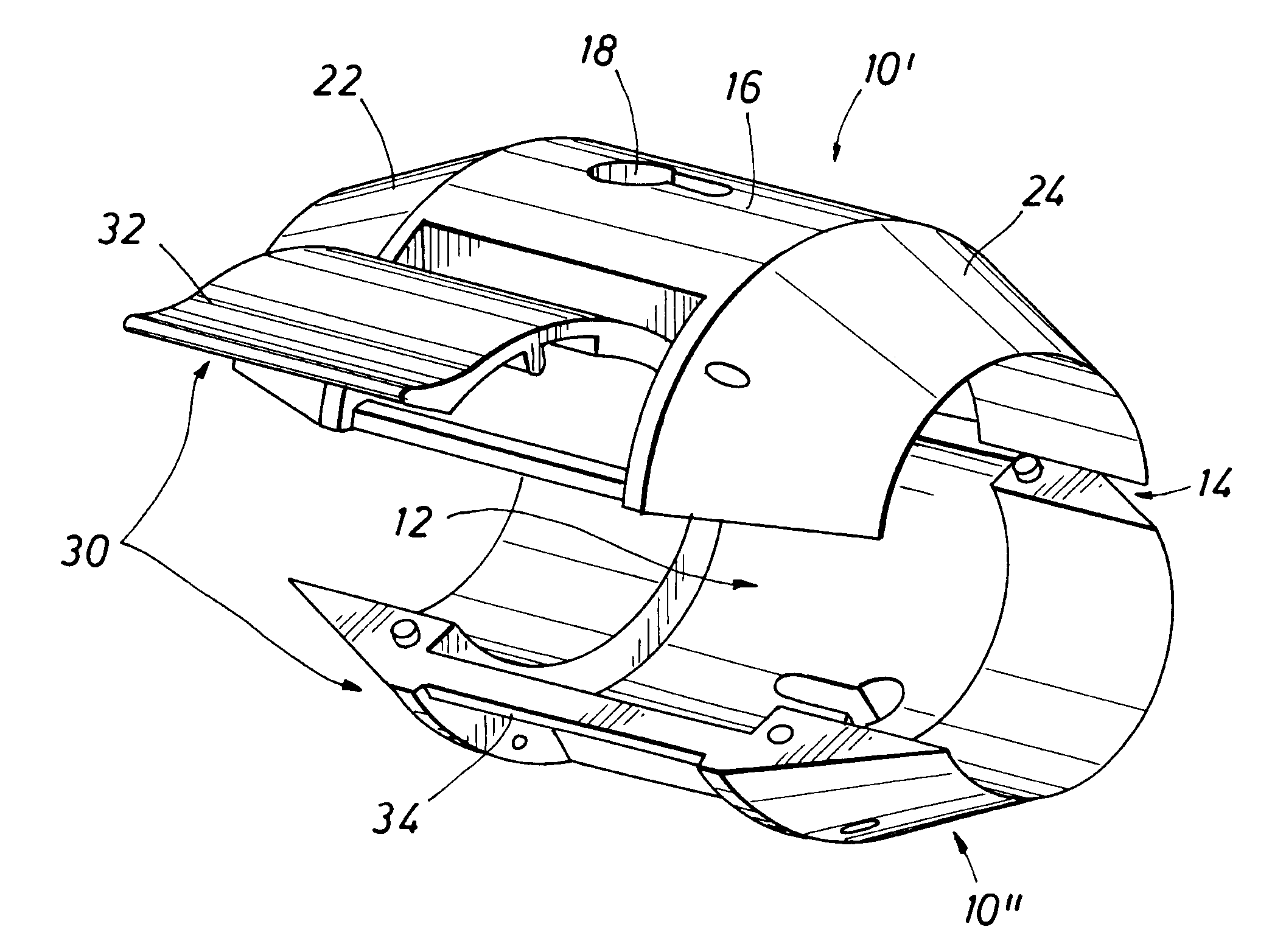

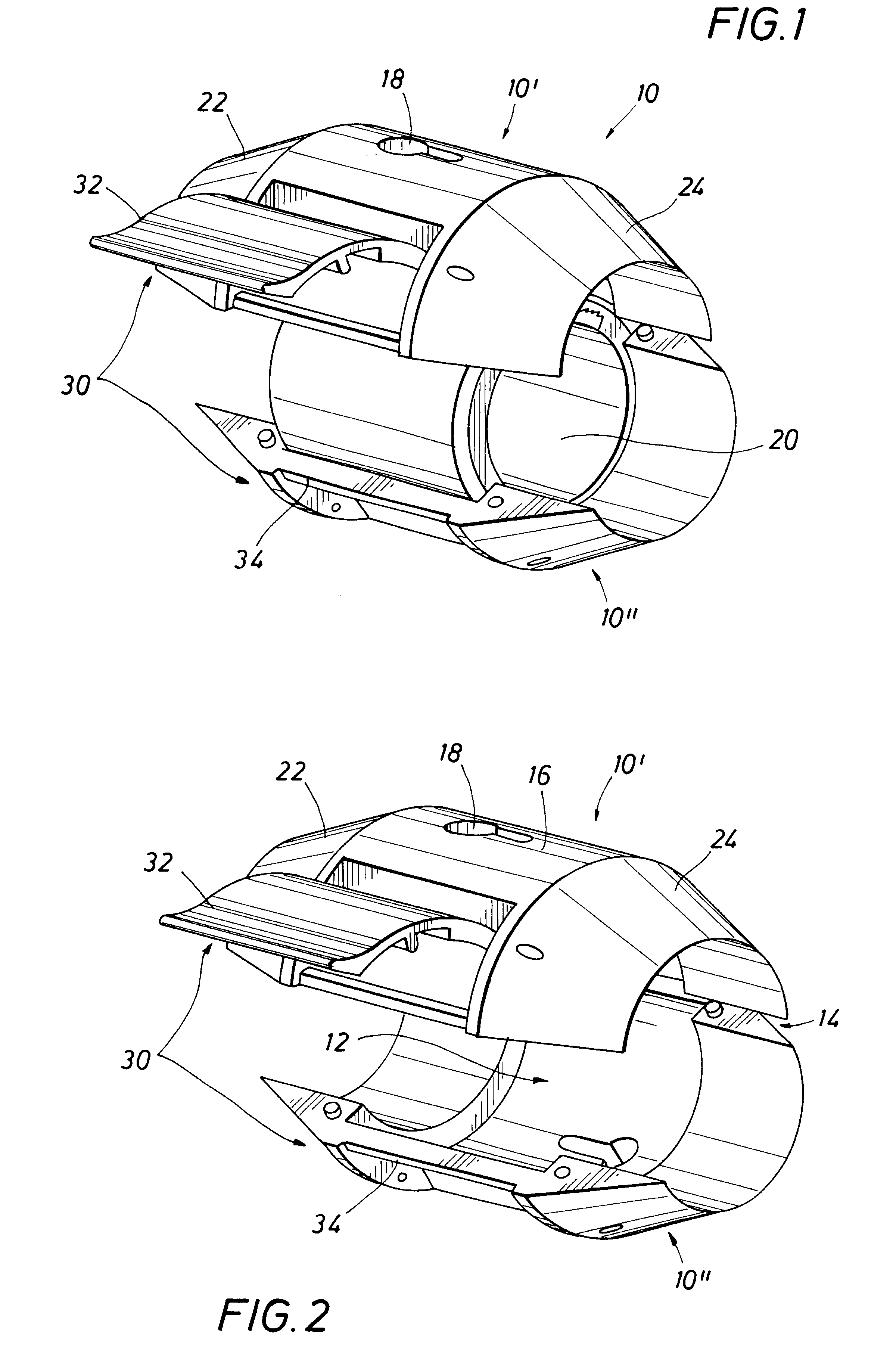

Low noise, towed electromagnetic system for subsurface exploration

ActiveUS20070229083A1Minimize turbulenceMiniaturization exerciseWater resource assessmentDetection using electromagnetic wavesLow noiseEngineering

A detector for a marine electromagnetic survey system includes a housing arranged to minimize turbulence when the housing is towed through a body of water, and to minimize motion of the housing in any direction other than the tow direction. The housing includes at least one of an electric field and a magnetic field sensing element associated therewith.

Owner:PGS GEOPHYSICAL AS

Throttle providing unobstructed air flow path when fully open and vortex generating configuration when partly open

InactiveUS8316820B1Increase the diameterIncrease or decrease areaPlug valvesEngine controllersDiaphragm valveControl theory

A throttle includes a throttle body having a generally tubular throttle body side wall with a throttle body side wall interior surface defining a throttle body interior for containing an air flow path for delivering air into at least one cylinder of an engine; and a flow regulating mechanism including an diaphragm valve secured to the throttle body and extending diametrically across the throttle body interior for progressively reducing and progressively increasing the diameter of an air flow passing valve opening defined within the diaphragm valve, and thereby regulating air flow through the throttle body.

Owner:CAMMARATA EDWARD

Low noise, towed electromagnetic system for subsurface exploration

ActiveUS7737698B2Minimize turbulenceMiniaturization exerciseWater resource assessmentDetection using electromagnetic wavesLow noiseEngineering

A detector for a marine electromagnetic survey system includes a housing arranged to minimize turbulence when the housing is towed through a body of water, and to minimize motion of the housing in any direction other than the tow direction. The housing includes at least one of an electric field and a magnetic field sensing element associated therewith.

Owner:PGS GEOPHYSICAL AS

Moving lens for immersion optical lithography

InactiveUS7088422B2Reduce turbulenceMinimize disruptionMaterial analysis using wave/particle radiationPhotometryImage resolutionRelative motion

An apparatus for immersion optical lithography having a lens capable of relative movement in synchrony with a horizontal motion of a semiconductor wafer in a liquid environment where the synchronous motion of the lens apparatus and semiconductor wafer advantageously reduces the turbulence and air bubbles associated with a liquid environment. The relative motions of the lens and semiconductor wafer are substantially the same as the scanning process occurs resulting in optimal image resolution with minimal air bubbles, turbulence, and disruption of the liquid environment.

Owner:INT BUSINESS MASCH CORP

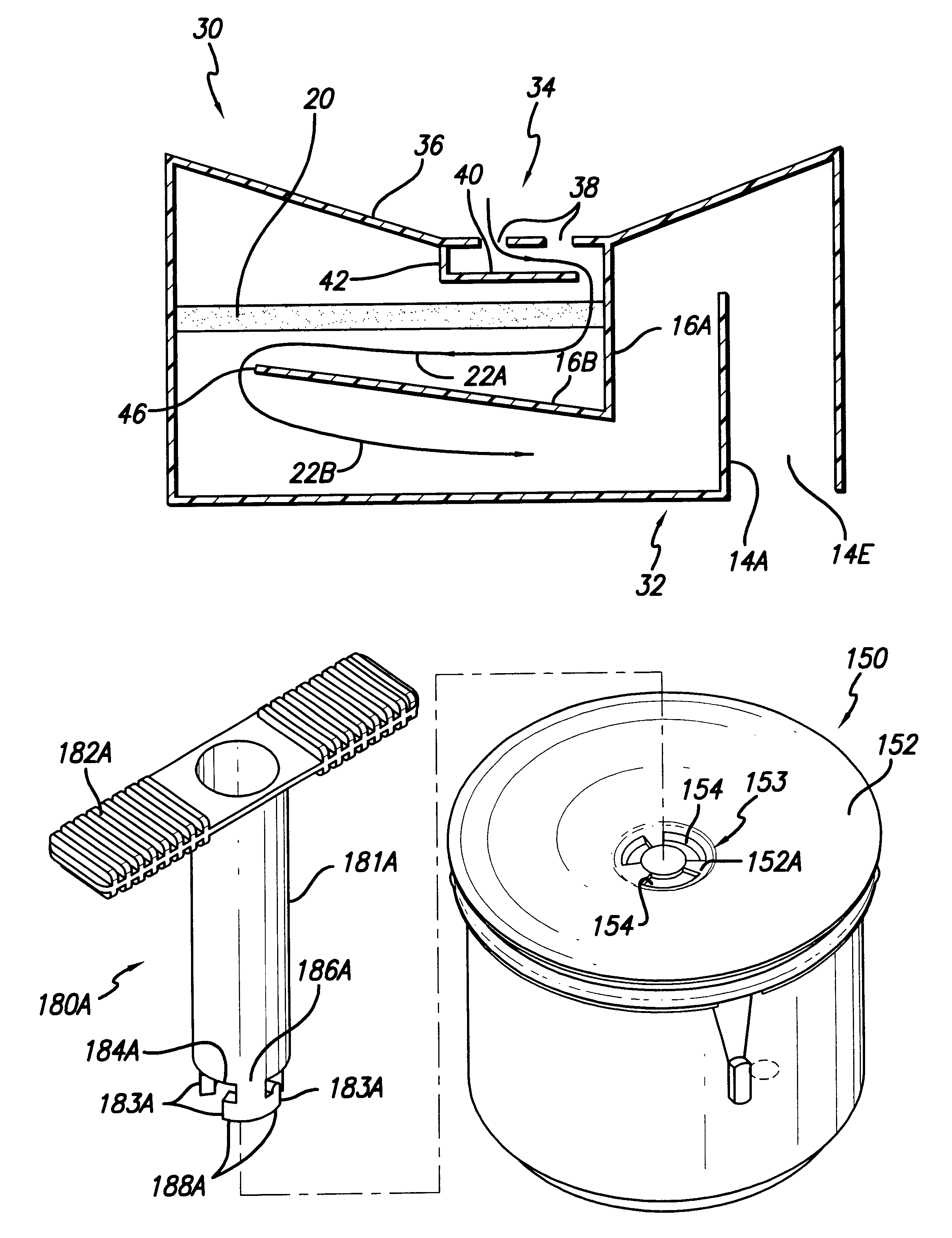

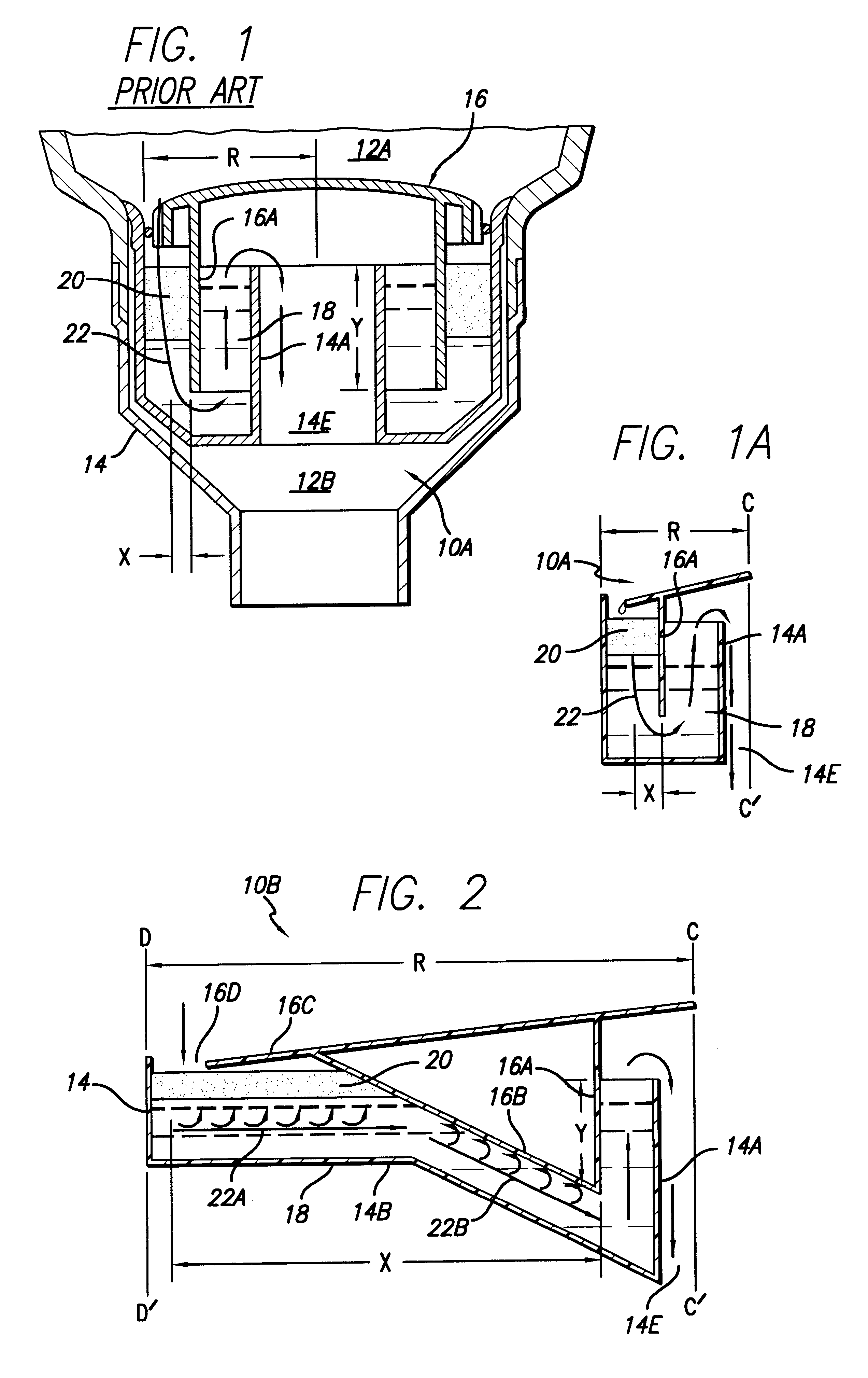

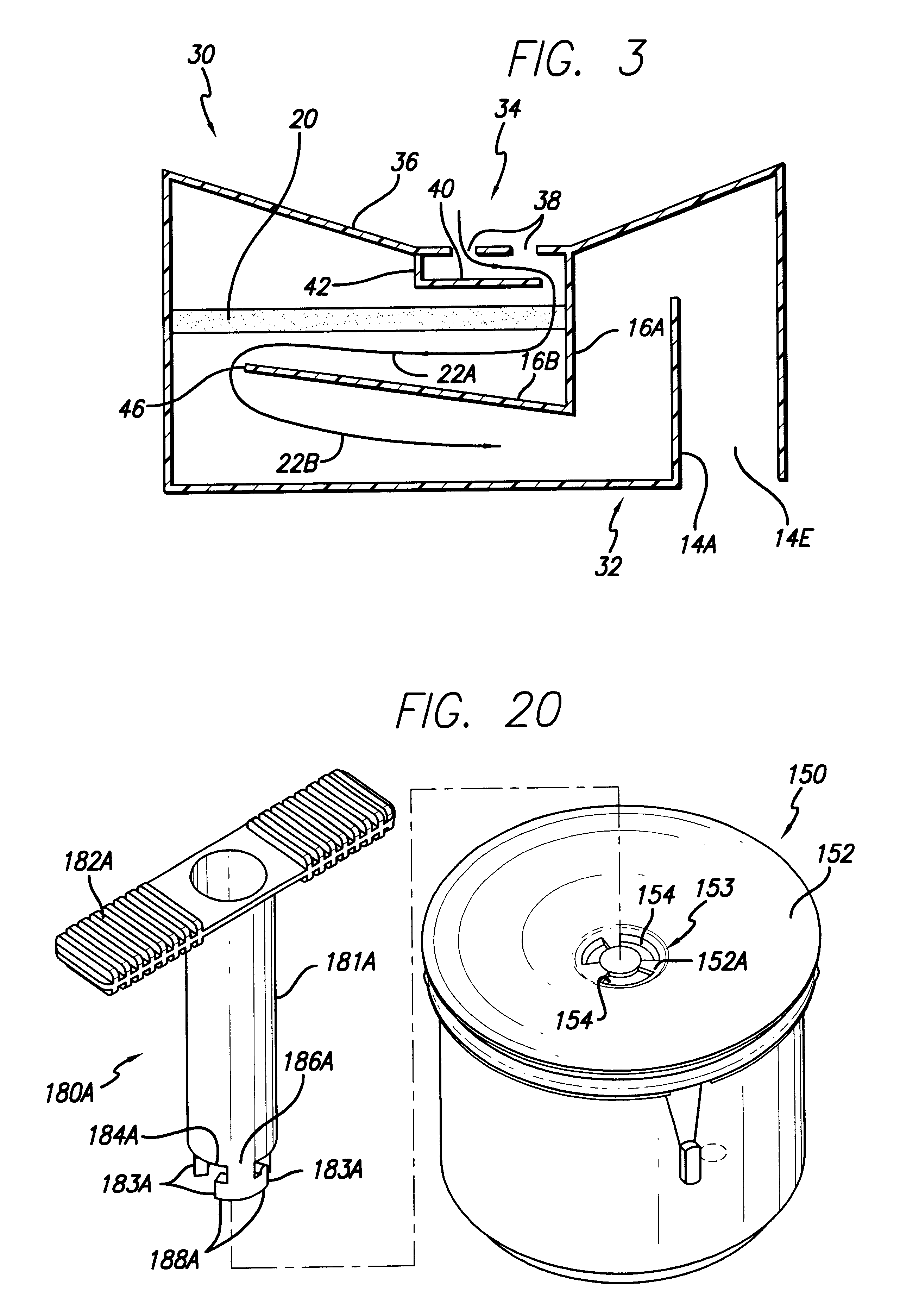

Oil sealant-preserving drain odor trap

InactiveUS6959723B2Minimal turbulenceEscaping of sealant down the drain is largely preventedUrinalsValve arrangementsDraining tubeWaste product

Improvements in retention of the oily liquid sealant (20) in a oil-sealed odor trap (10B-10M), for drain applications such as a waterless urinal or anti-evaporation floor drain, are accomplished by minimizing turbulence in the oil sealant, such as by making the liquid flow path (22A, 22B) substantially horizontal as a departure from conventional practice of substantially vertical flow and by positioning a barrier (40) above the oil sealant to prevent direct impingement of urine or other waste products onto the sealant. The trap is thus structured to realize the substantially horizontal liquid flow path and to locate the flow path immediately beneath the sealant layer or beneath a baffle portion (16B). The baffle portion may be sloped such that stray sealant droplets are encouraged to migrate upwardly to the upper surface of the flow path due to their buoyancy and, therefore, the stray droplets will be recaptured and returned to the main sealant layer. To accomplish substantially horizontal flow, the entry compartment can be made to have entry and exit openings (16D, 14E) substantially offset from each other. The baffle between the entry compartment and the discharge compartment, which has traditionally been made entirely vertical, is made to have a non-vertical portion that is preferably sloped for sealant recovery. A sealant sheltering region (T) with an air vent (16F) can be provided in the vicinity of the entry region to prevent catastrophic loss of sealant in the event of high pressure water flushing. When the trap is embodied as a replaceable cartridge, a tool with hook-shaped projections, such as L-shaped or T-shaped projections (183, 183A), engageable with openings (154) in an upper wall (152) of the cartridge is used to help removal and replacement of the cartridge.

Owner:FALCON WATERLESS TECH INC

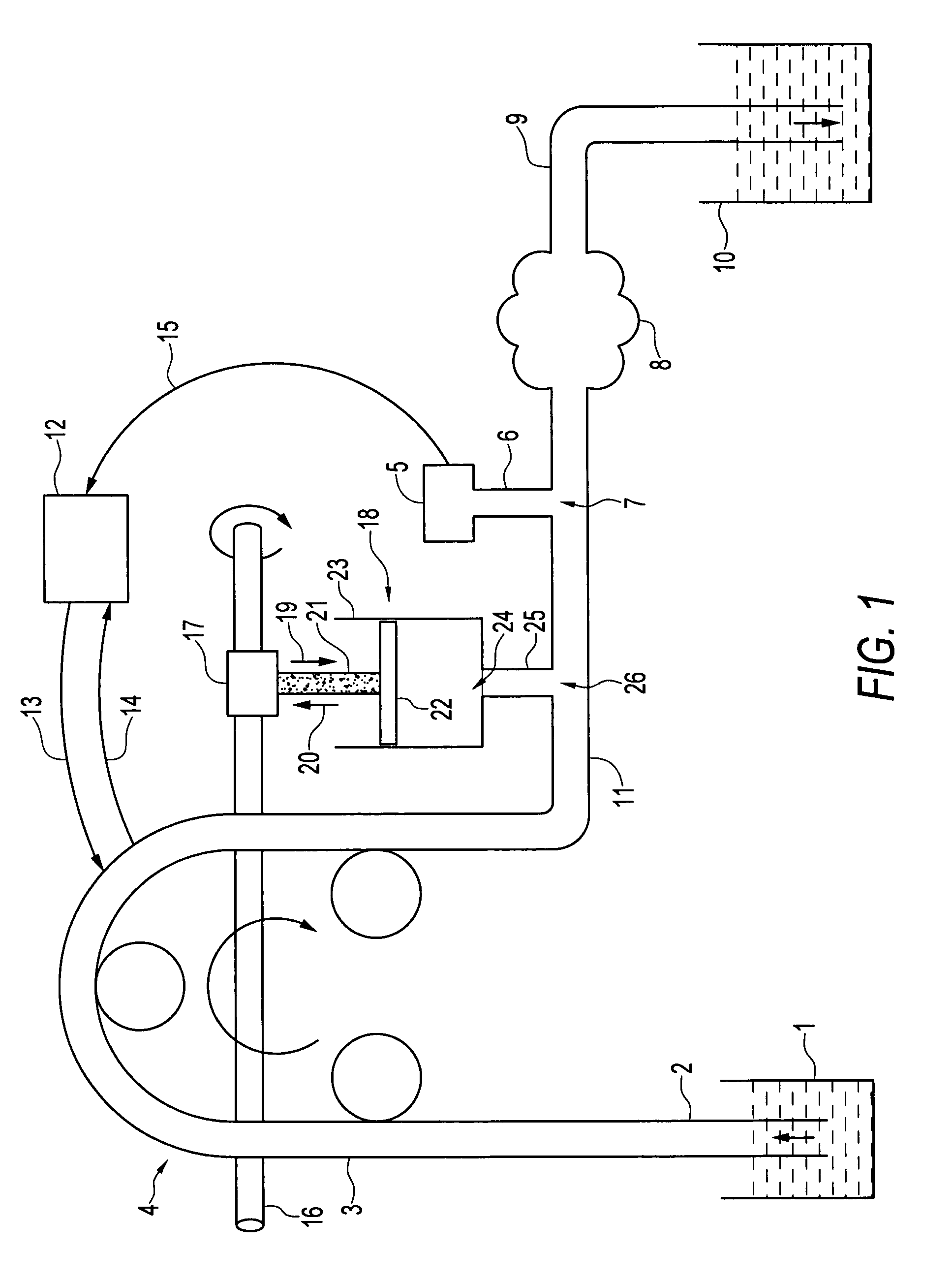

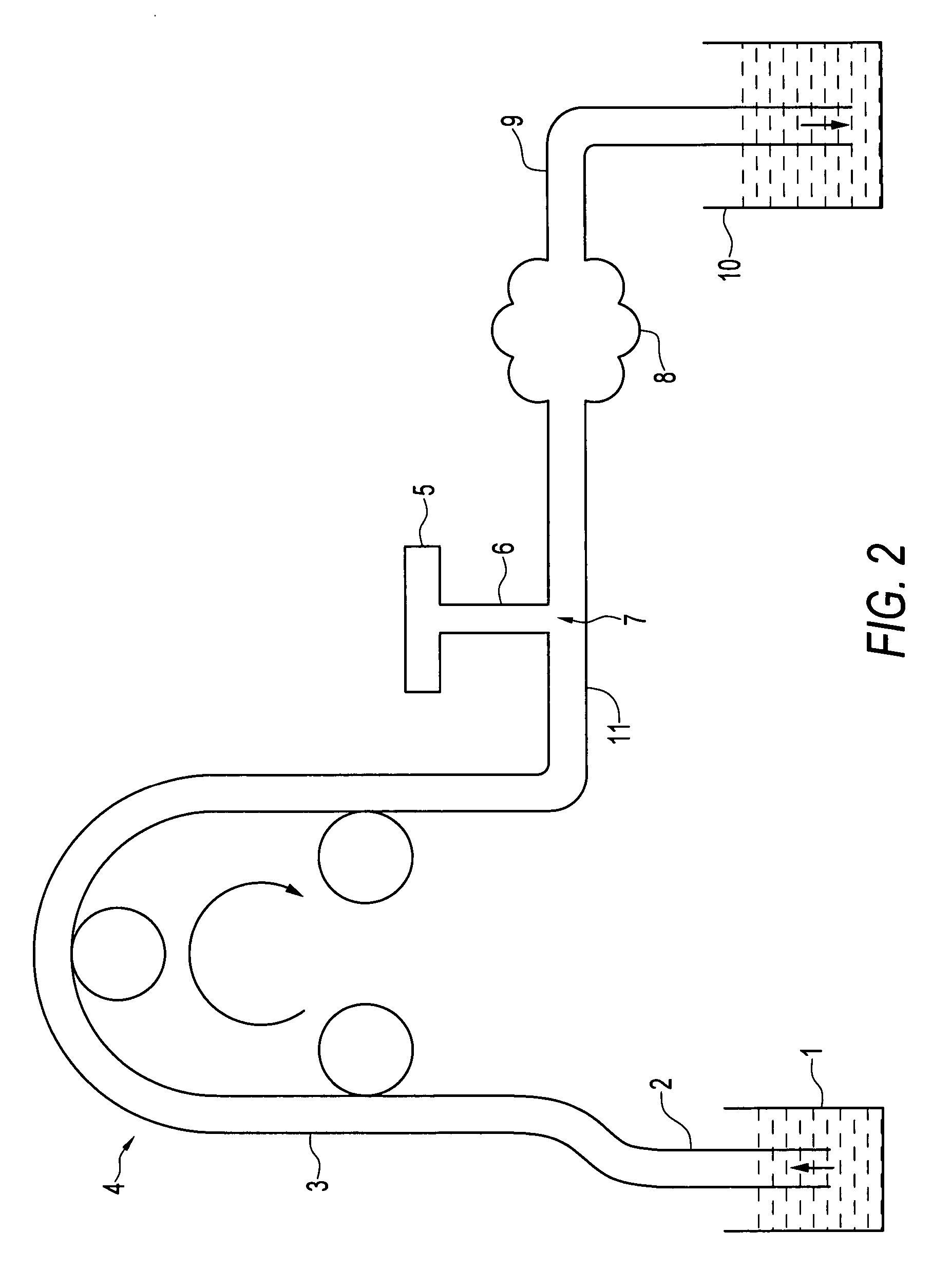

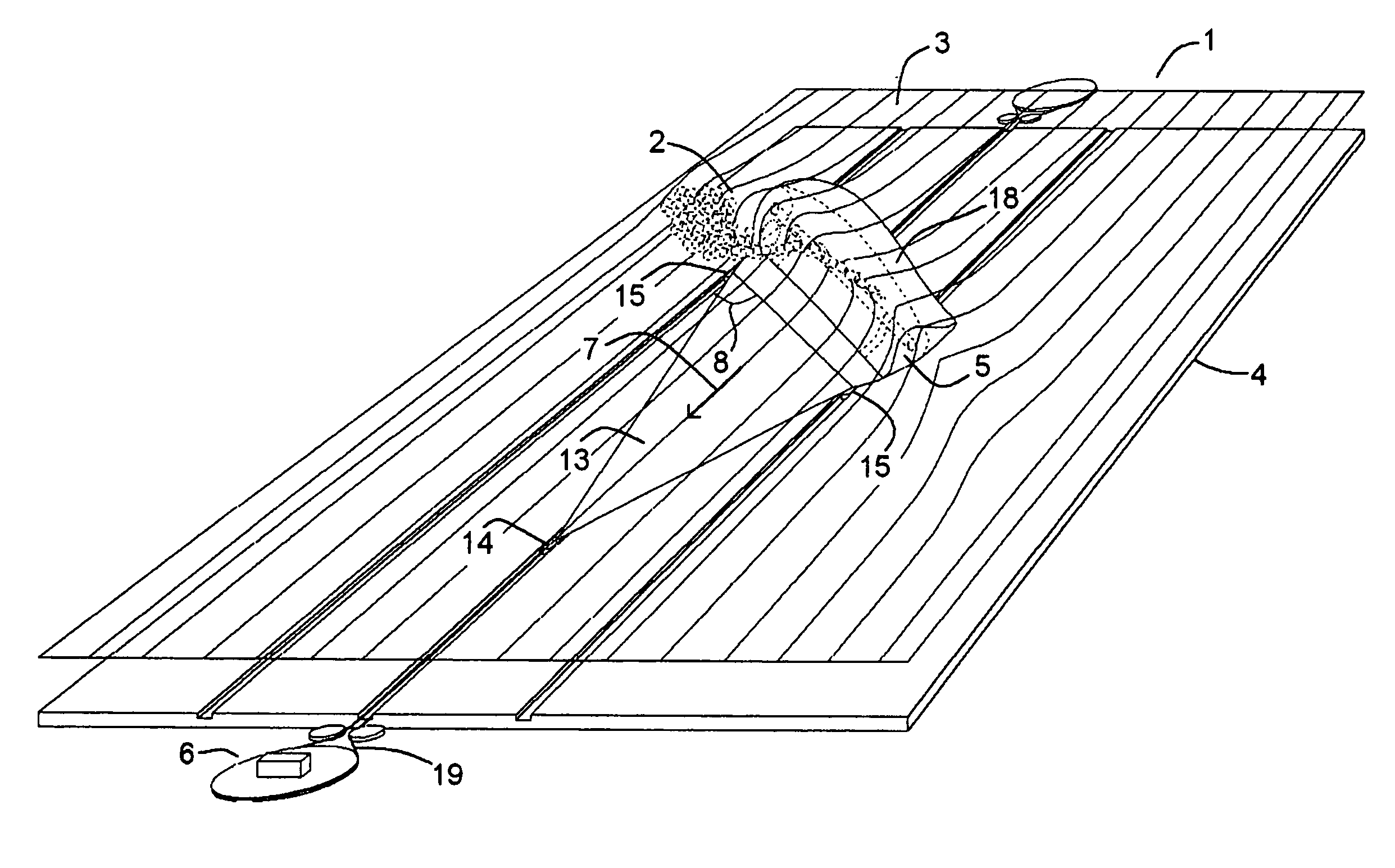

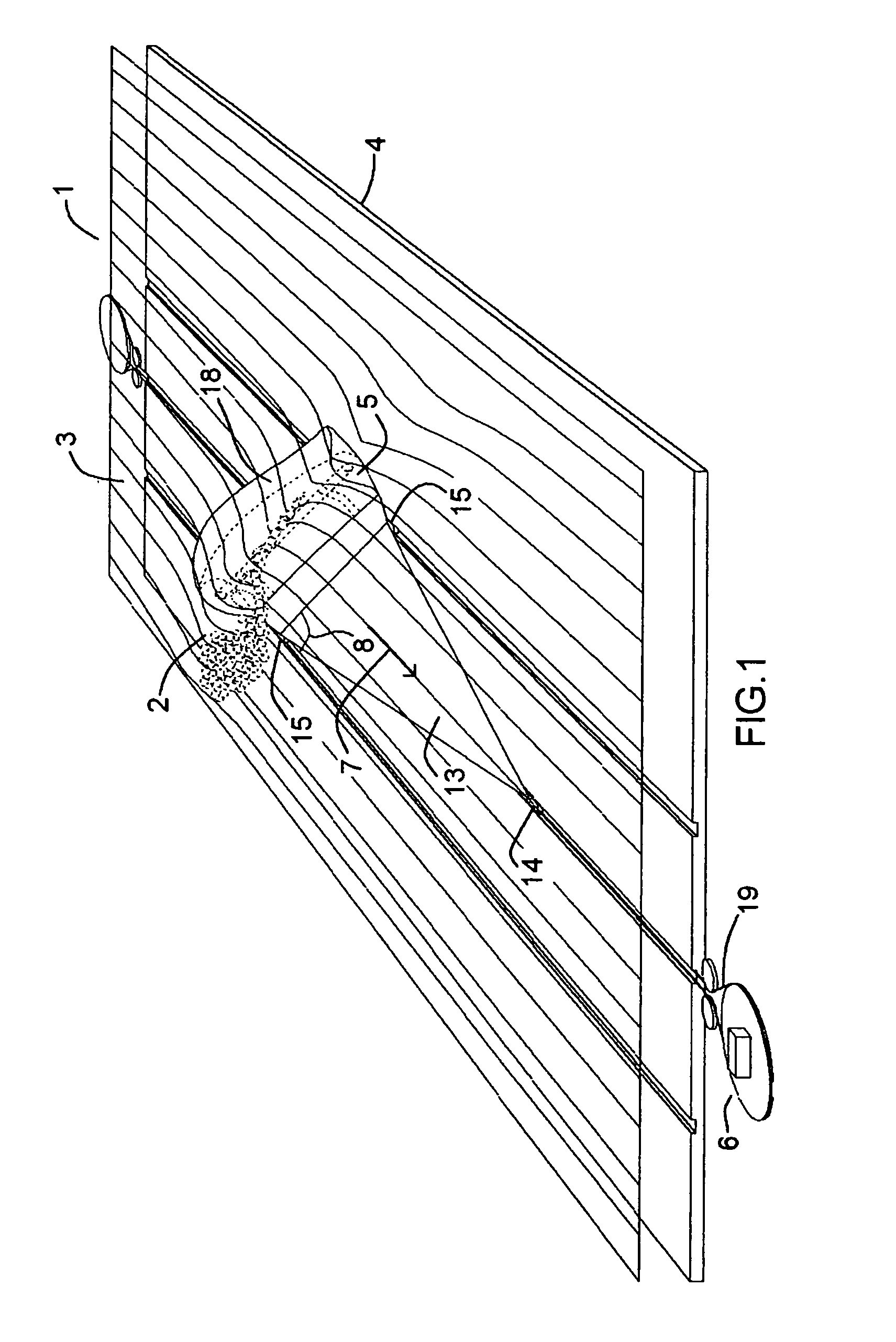

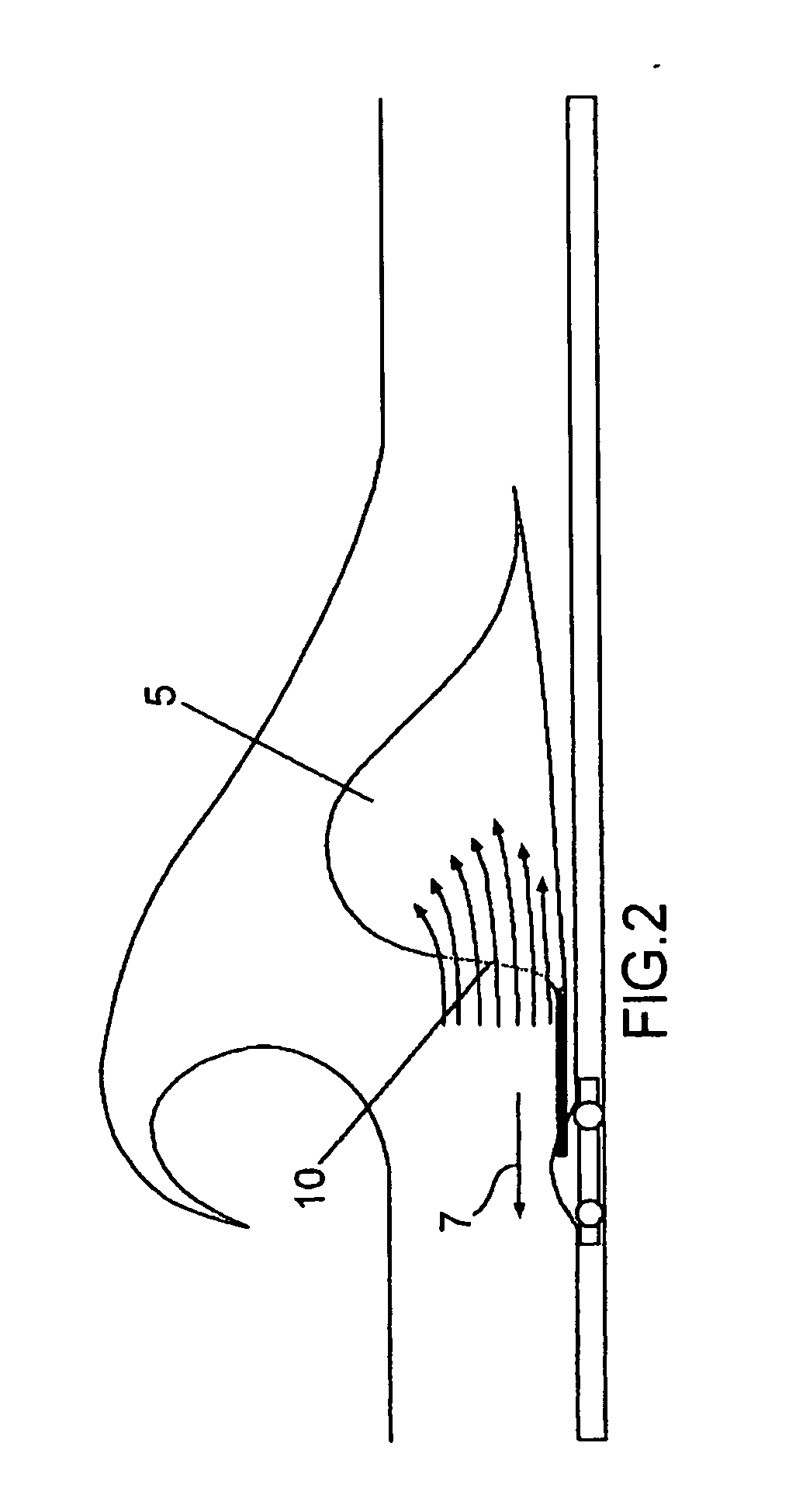

Wave-generating apparatus

Wave-generating apparatus (1) that is installed in an aquatic environment (3) and which comprises, as its main elements, at least one elongated profile (5) that moves tangentially in relation in relation to a uniformly-deep floor (4) by the action of a drive mechanism (6). As a result, a wave (2) forms on the profile (5) and moves along with the profile (2). The profile (5) is disposed to form an angle (8) other than 90° with the direction of displacement (7), the purpose being to generate a wave (2) with an escape area and which can therefore be surfed. Some parameters of the apparatus (1) may be adjusted for the purpose of changing the degree of difficulty of the wave (2) that is generated.

Owner:INSTANT SPORT

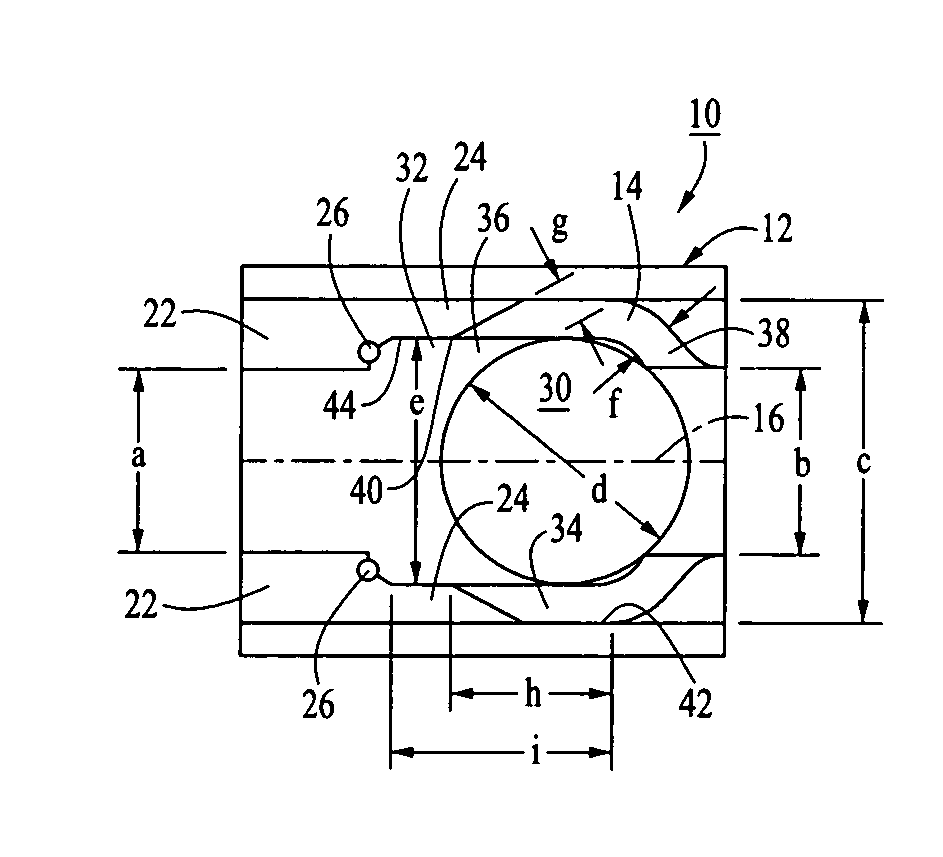

Non-vibrating ball check valve

InactiveUS6899127B1Energy lossMinimizes rattlingCheck valvesEqualizing valvesCheck valveSpherical form

A ball check valve comprises a valve body chamber which includes an inlet opening, an outlet opening, and a ball that is free to travel within the valve body chamber. A valve seat is adapted for receiving the ball. A body clearance section is located downstream of the inlet opening. A bore section is located downstream of the body clearance section. Fluid flow is allowed to flow through the valve body from the inlet opening through the outlet opening, but fluid flow through the valve body from the outlet opening through the inlet opening is prohibited by the interaction of the ball and the valve seat. The inlet opening is smoothly contoured to urge fluid flow between the inlet opening and the outlet opening to be laminar in nature.

Owner:SPEARS MFG

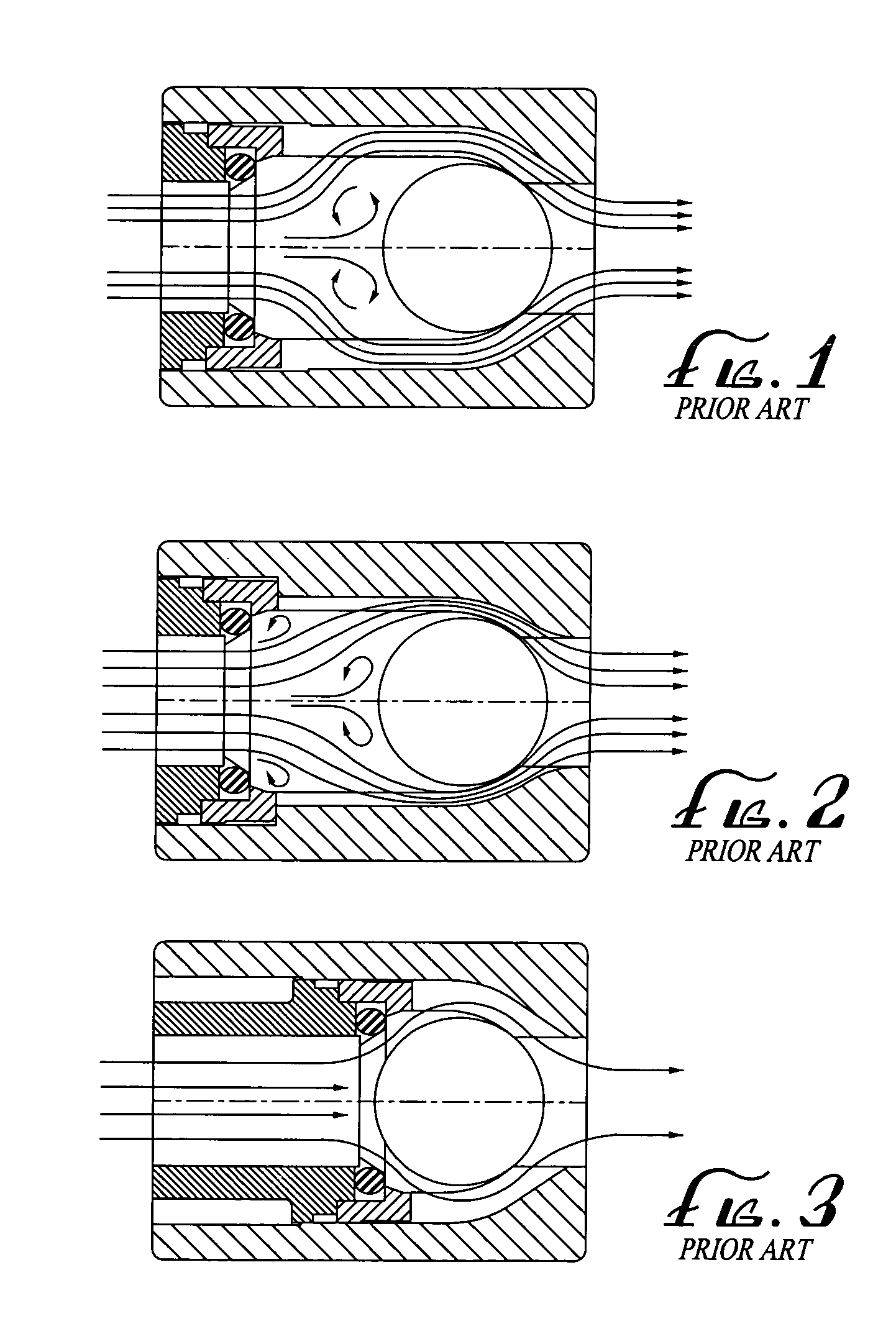

Method and apparatus for reduction of fluid-borne noise in hydraulic systems

InactiveUS20050045239A1Minimize and eliminate noiseMinimize turbulenceFluid dynamicsPipe elementsVolumetric Mass DensitySystem parameters

Method and apparatus for eliminating turbulence-induced noise in a pulsation-absorbing flexible hose, as in a hydraulic power steering system containing a pressure fluid-feeding pump and a steering gear operated by the pressure fluid discharged from the pump. The hose has a restrictor positioned in the hose bore, and the restrictor has a flow-through bore of smaller diameter than that of the adjacent wall of the hose bore. The flow-through bore has a venturi tube cross section. The restrictor venturi inlet, throat and outlet are designed so as to efficiently conduct fluid therethrough by matching the characteristics of the fluid, the operational pressures, fluid density and other system parameters such that the venturi operates below the lower critical value of the Reynolds number of fluid flow through the restrictor to thereby minimize or eliminate fluid turbulence in the restrictor outlet and / or immediately downstream thereof.

Owner:COUPLED PRODS

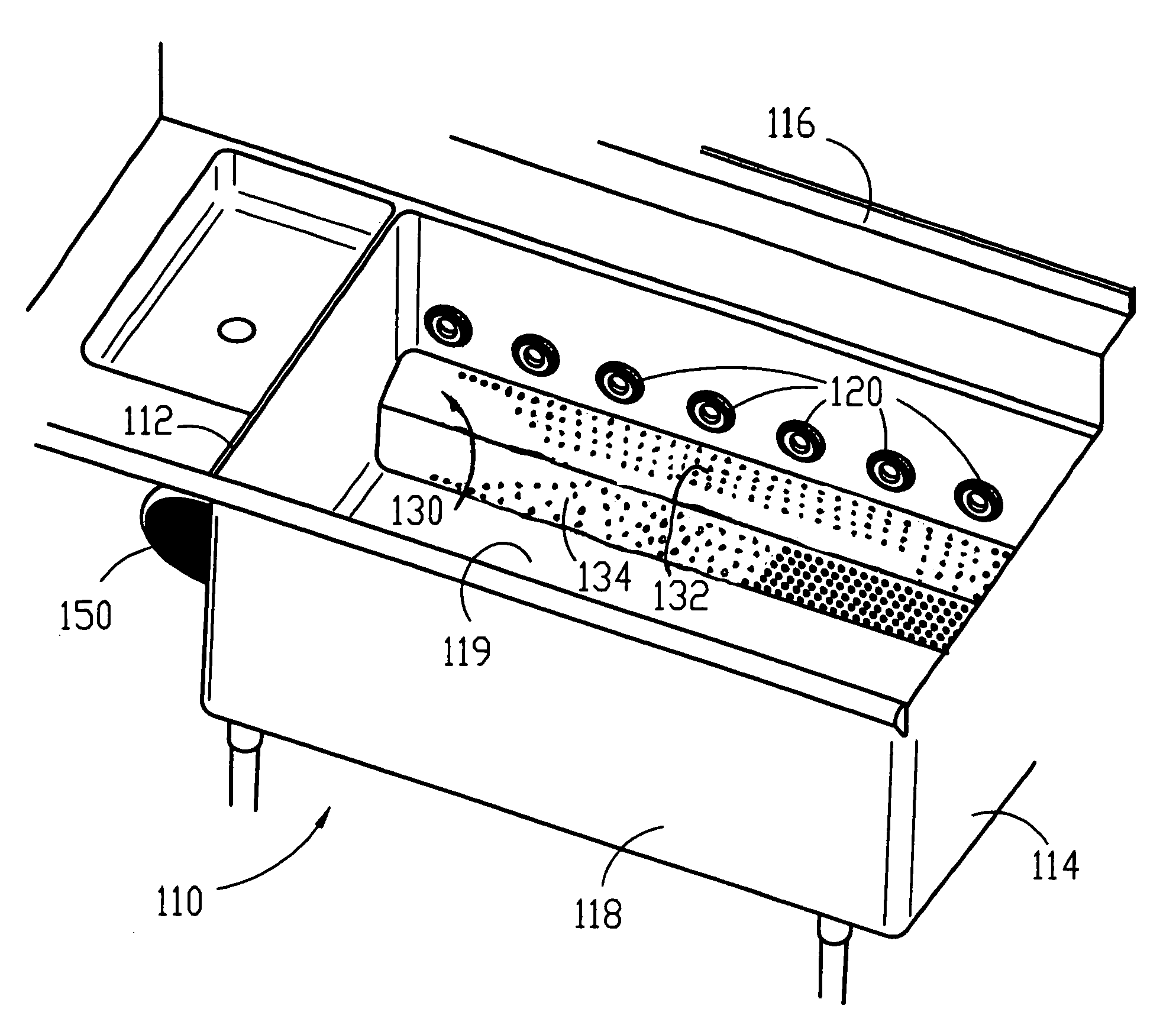

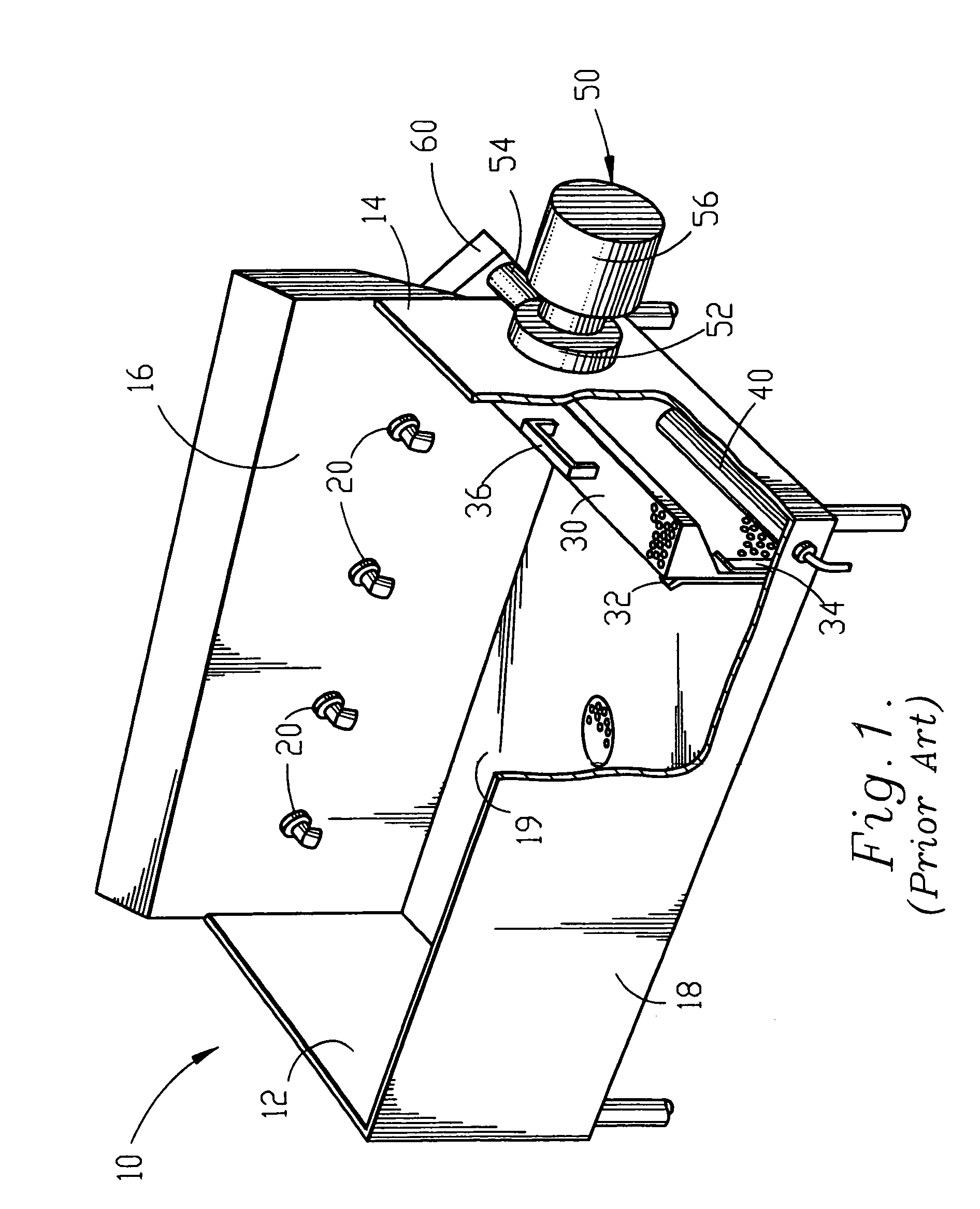

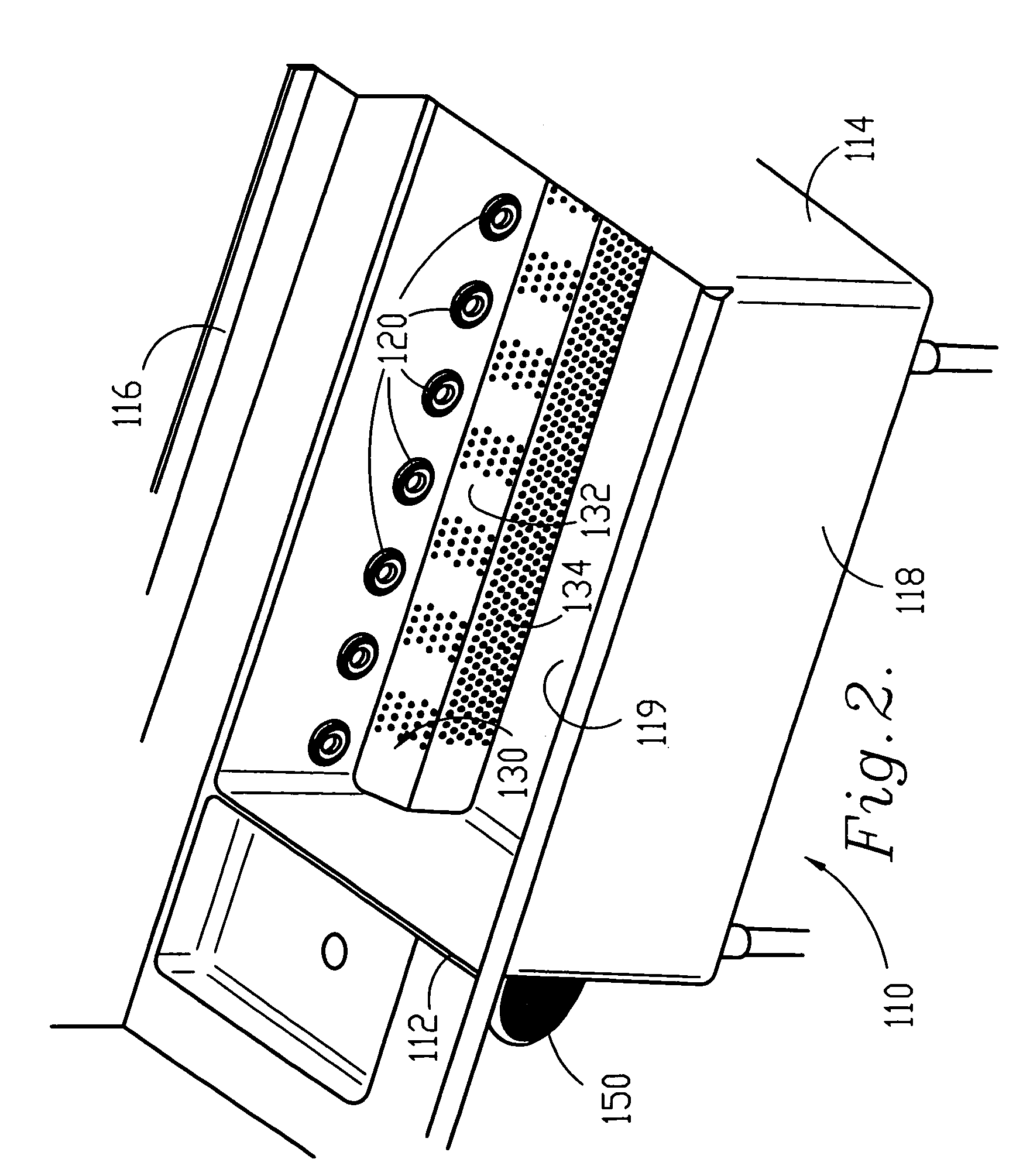

Pot and pan washing machine, components, and methods of washing items

InactiveUS7246624B2Eliminates potentialLess turbulenceTableware washing/rinsing machine detailsPump componentsBiomedical engineeringInlet manifold

An improved pot and pan washing machine is provided including a low suction intake manifold and a partition for capturing a substantial portion of the wash action of the washing machine within a segregated area. The intake manifold of the instant invention includes a plurality of voids having a void concentration that increases as the distance from the source of suction (such as a pump or intake inlet) increases. The partition (or divider) of the instant invention can be removed and repositioned within the wash tank through the use of channels along the walls of the wash tank that receive the partition.

Owner:UNIFIED BRANDS

Vehicle Fairing with Brake Cooling System

InactiveUS20170240220A1Cool them quickly and efficientlyLower the volumeVehicle sub-unit featuresFluid dynamicsTruckAirflow

The primary purpose of this device is to reduce the fuel consumption of heavy trucks by improving airflow along the underside of a trailer, by way of a fairing mounted forward of the axles. This fairing is a teardrop shaped wedge with a flat bottom surface, which directs air towards the sides of the vehicle, while allowing a smaller volume to flow beneath the fairing such that it will clear the axles. Each axle is also covered by a flat panel, such that air will continue to travel smoothly beneath them. Attached to each panel is a brake cooling system, which consists of a pair of panels protruding downward, with their surfaces parallel to the direction of airflow. When the brakes are engaged, these panels rotate towards the center in an angled configuration, which redirects air towards the drums during and after braking, cooling them quickly and efficiently.

Owner:KRON STEVEN +1

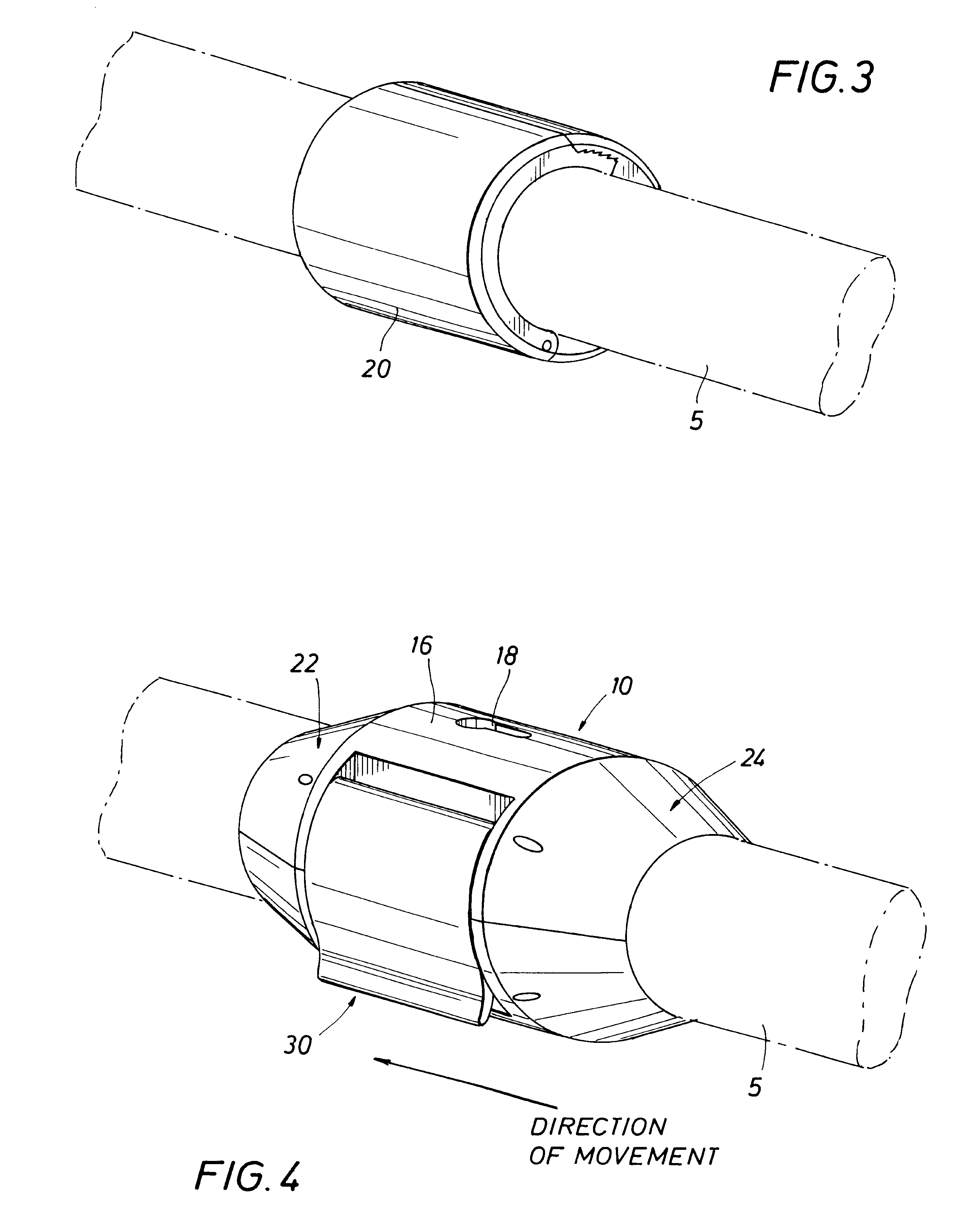

Streamer cable connector

InactiveUS6758157B2Reduces self-generated noiseMinimal damageDefensive equipmentTowing/pushing equipmentEngineeringElectric cables

A streamer cable connector including a cylindrical inner race and an outer race with a cavity formed therein to capture the inner race. The outer race has leading and trailing fairings to minimize abrupt structural changes along the longitudinal length of the connector in order to minimize self-generated noise as the streamer cable is pulled through the water. The fairings are fabricated of compliant material so that the connector can be wound around a reel while under tension to inhibit damage to the inner race or to the cable itself.

Owner:CONCORD TECH

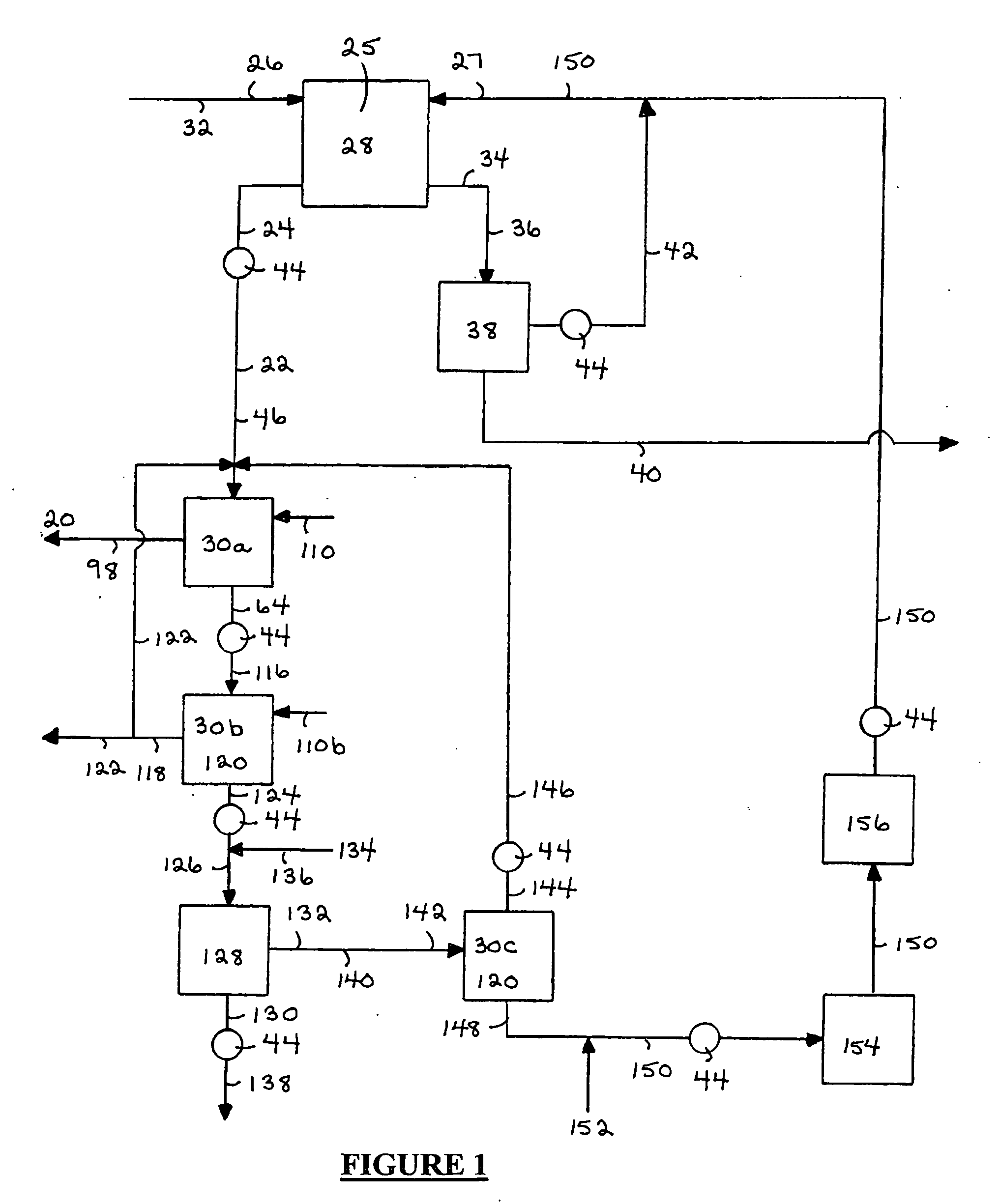

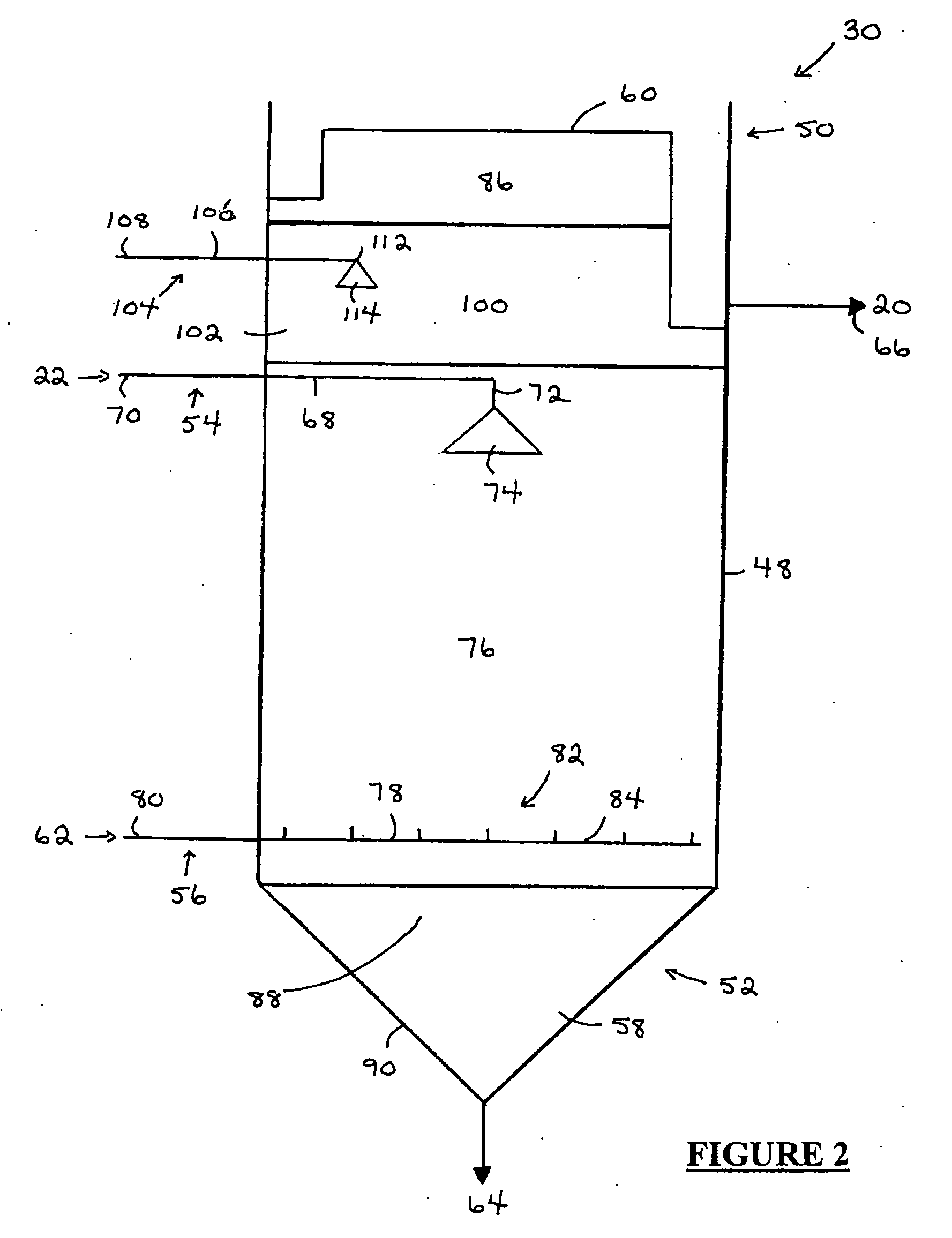

Bitumen recovery process for oil sand

ActiveUS20070090025A1Aid in recovery of bitumenGood choiceFloating sedimentation devicesLiquid hydrocarbon mixture productionProcess engineeringSlurry

A bitumen recovery process is provided which includes the step of providing a bitumen froth or a component derived from the bitumen froth as a feed material, wherein the bitumen froth is produced in a primary separation process from a slurry comprising oil sand and water. Further, the process includes the step of subjecting the feed material to froth flotation in a column flotation cell in order to recover a bitumen product from the feed material. Preferably, the froth flotation cell includes an underwash zone, wherein a bitumen-rich fraction of the feed material is passed through the underwash zone as the bitumen-rich fraction rises within the column flotation cell.

Owner:BITMIN RESOURCES

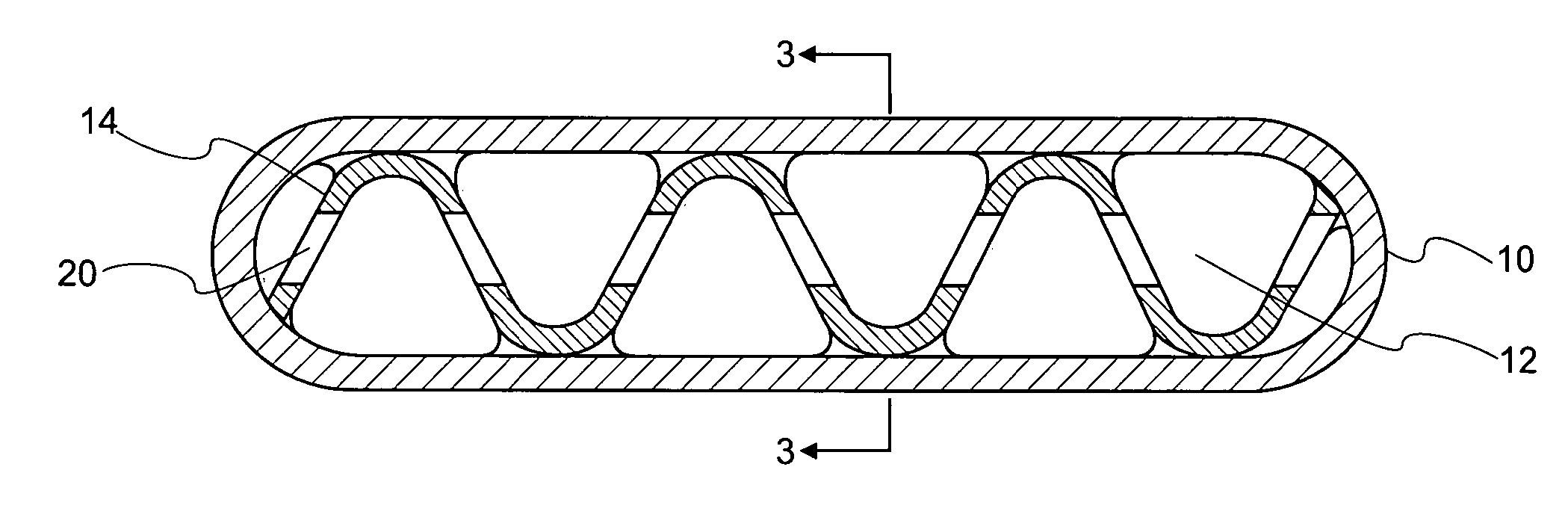

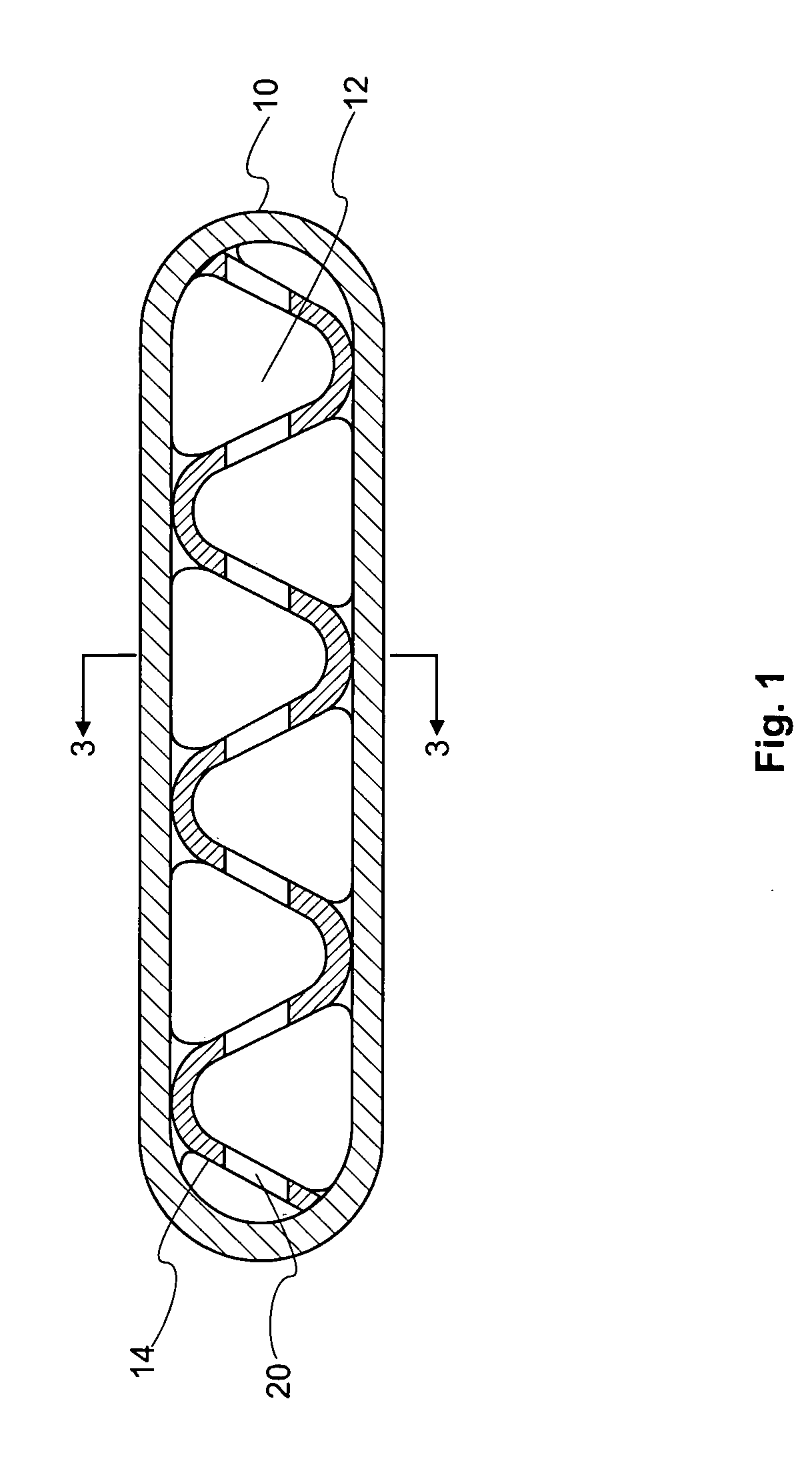

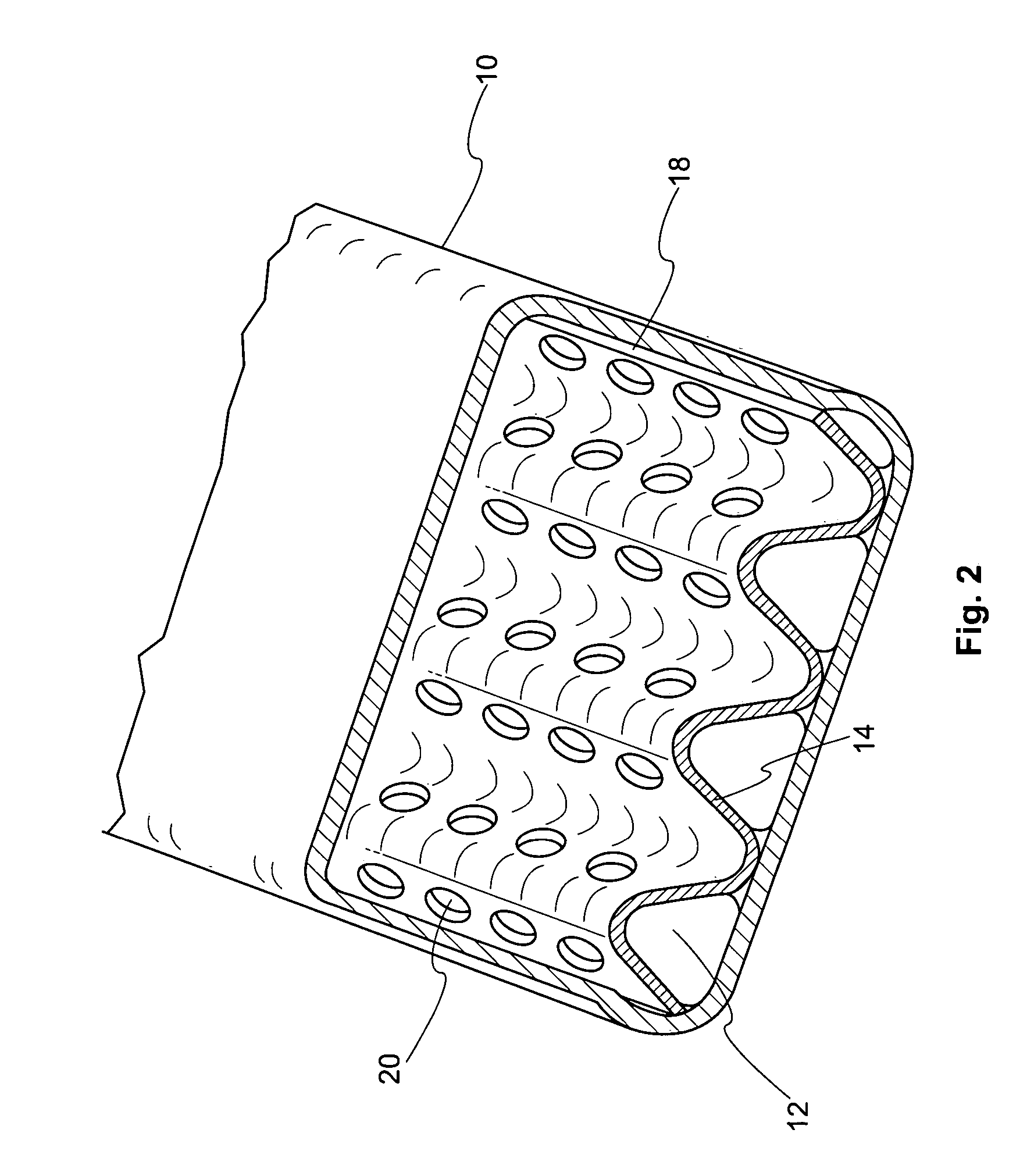

Interconnected microchannel tube

InactiveUS20050241816A1Improve heat transfer performanceMinimize turbulenceLaminated elementsTubular elementsGas phaseEngineering

The invention relates to a microchannel tube for use in a heat transfer system. The microchannels have openings in the partitions that separate them from each other, thereby creating many short interconnected passages through which a heat transfer medium will flow in a laminar manner. This permits the liquid and vapor phases of the medium to mix, thereby increasing the efficiency of the system.

Owner:OUTOKUMPU OY

Ported shroud geometry to reduce blade-pass noise

ActiveUS9951793B2Minimize turbulenceReduce noiseInternal combustion piston enginesPump componentsImpellerAxial distance

A compressor housing may include a shroud portion which is axially spaced from an inlet portion and configured to at least partially surround the compressor wheel. The compressor housing may be further configured to include a recirculation cavity which is formed between an exterior surface of the shroud portion and an interior surface of the compressor housing. Furthermore, a recirculation slot may define an airflow pathway between the recirculation cavity and the compressor wheel. Additionally, the compressor housing may include an angled shroud support extending radially through the recirculation cavity from the exterior surface of the shroud portion to the interior surface of the compressor housing. The angled shroud support may be spaced an axial distance away from the recirculation slot to reduce turbulence in the airflow as the airflow moves from the recirculation cavity to the compressor wheel.

Owner:BORGWARNER INC

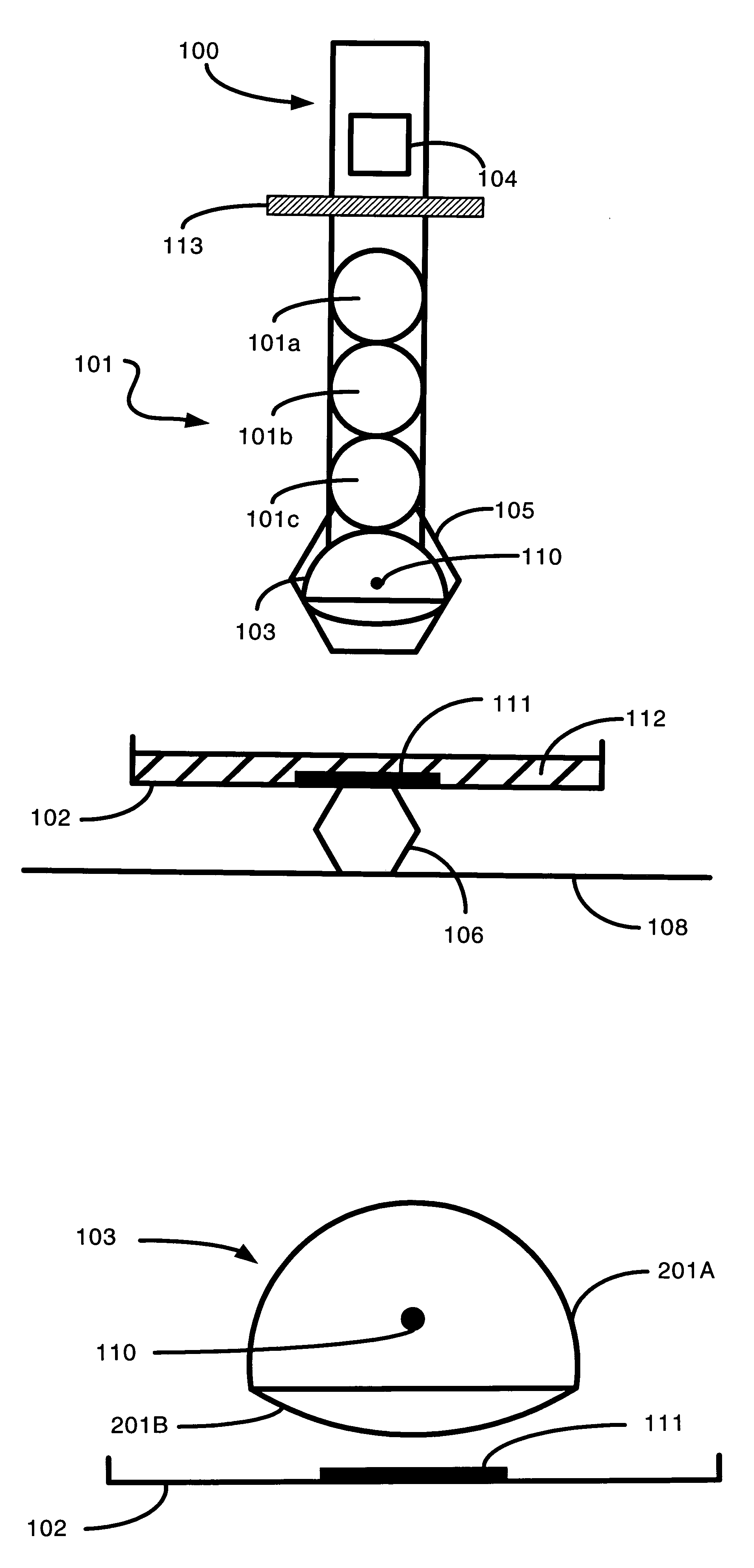

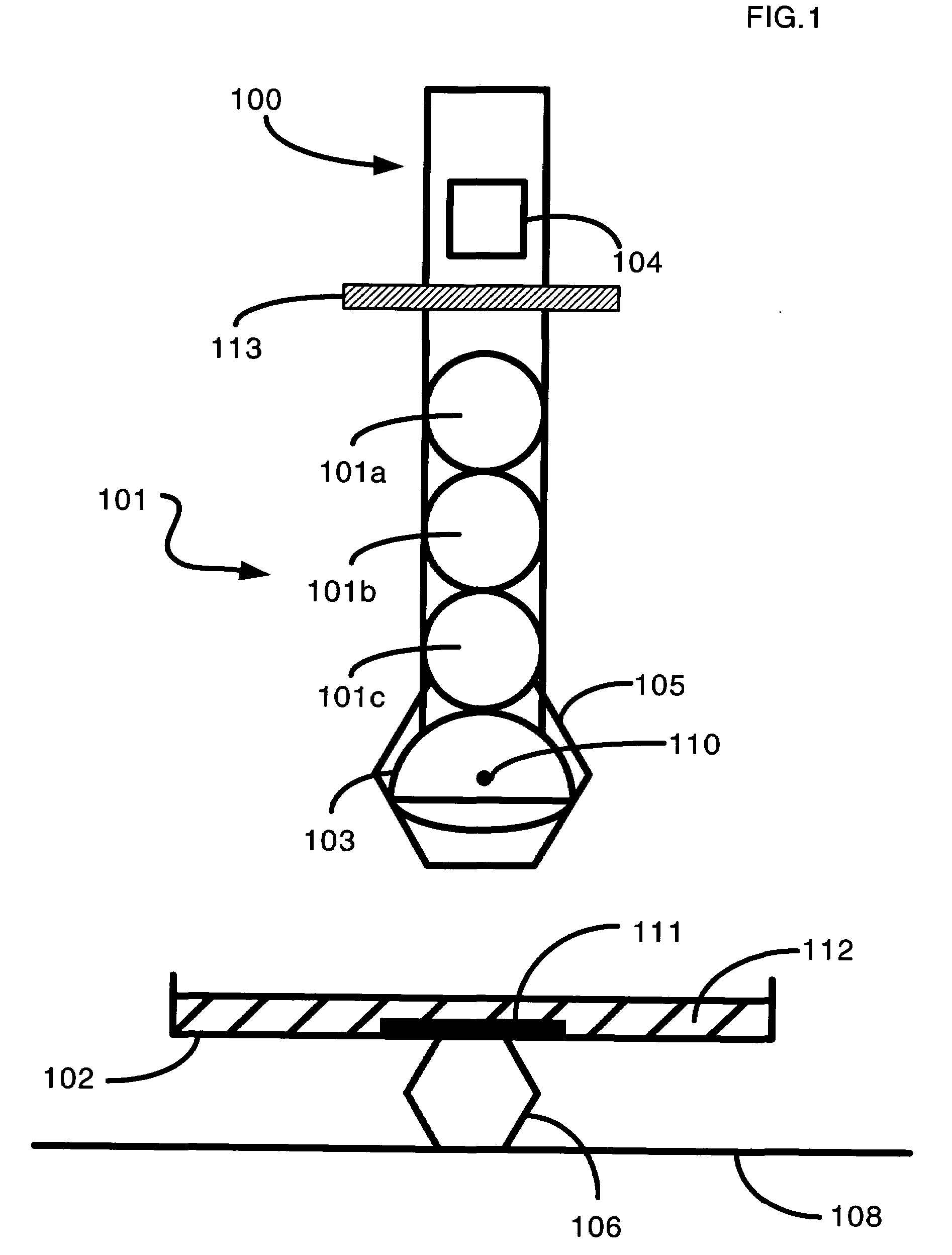

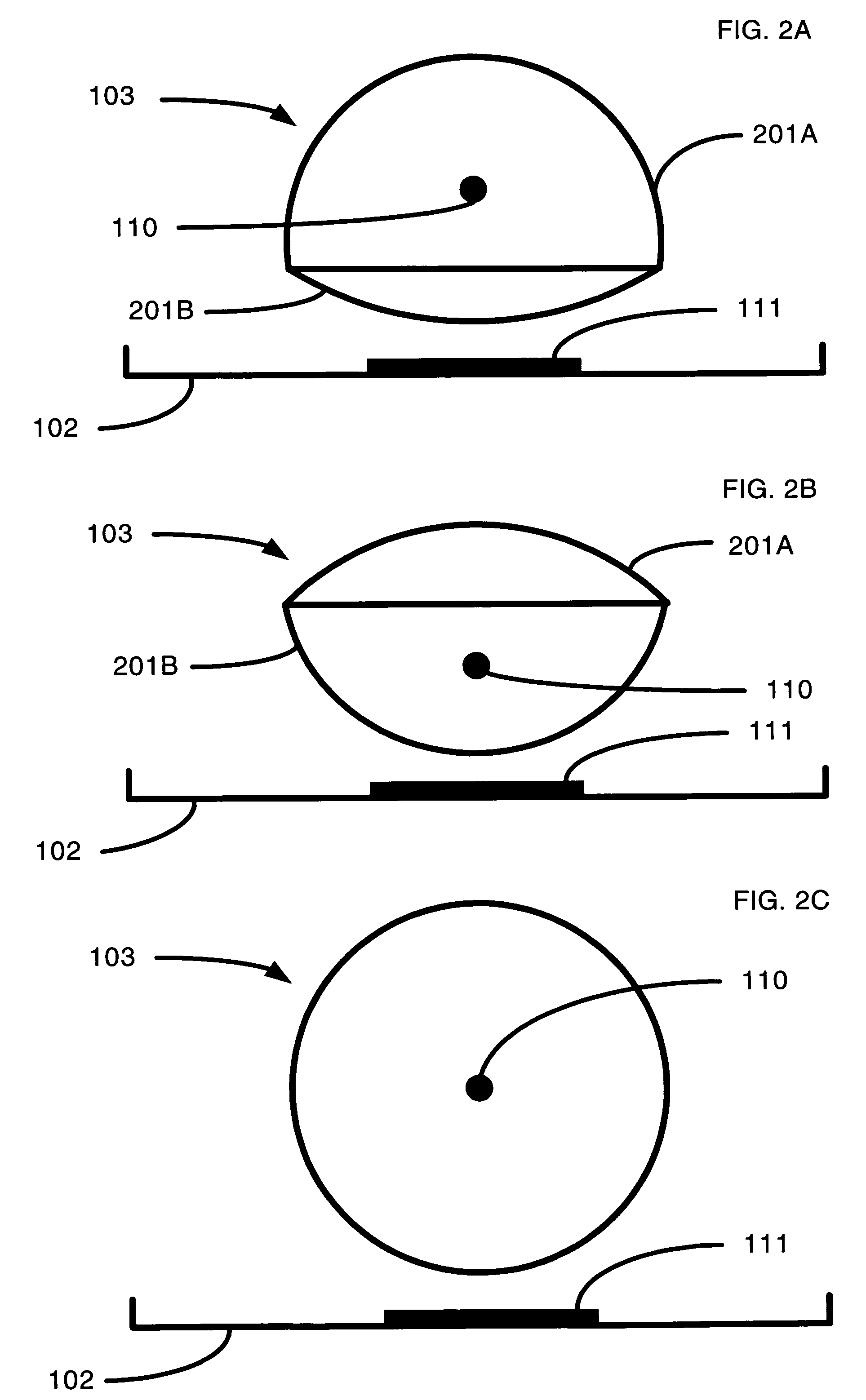

Implantable pressure monitor

ActiveUS7682313B2Reduce and eliminate data transmission interferenceMinimize turbulenceCatheterAngiographyCapacitive pressure sensorMinimally invasive procedures

A system and method for the intra corporal, telemetric measuring of blood pressure, particularly within the heart or a great vessel, includes a substantially rigid sensor chip mounted in a holder and an antenna. The holder is anchored within an appropriate location in the cardiovascular system, such as in the cardiac septum, via a catheter or other minimally-invasive procedure to position at least one capacitive pressure sensor on the chip in the blood flow to be sensed. Measured values are transmitted telemetrically from the chip to an extra corporal monitoring device.

Owner:ENDOTRONIX

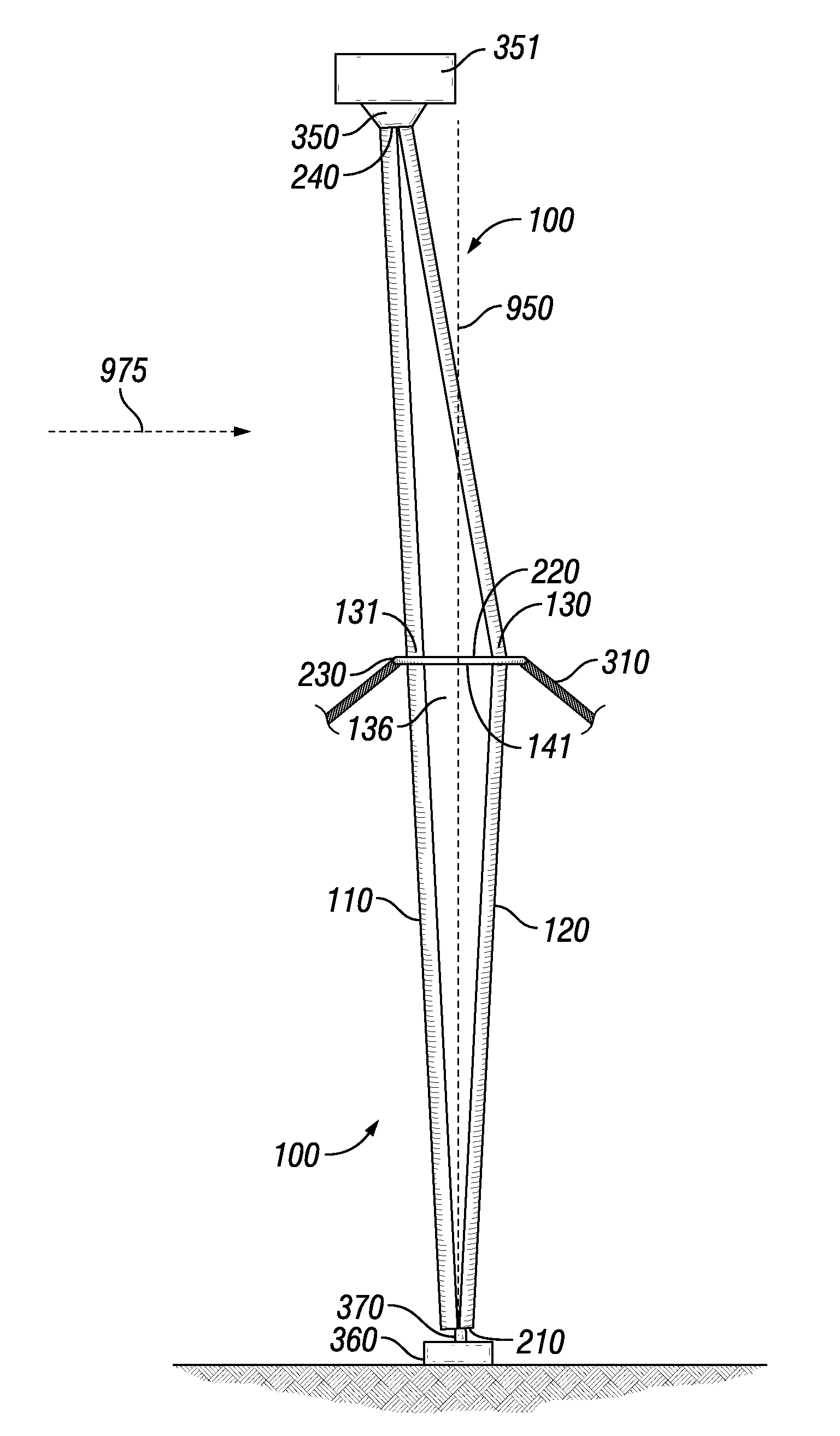

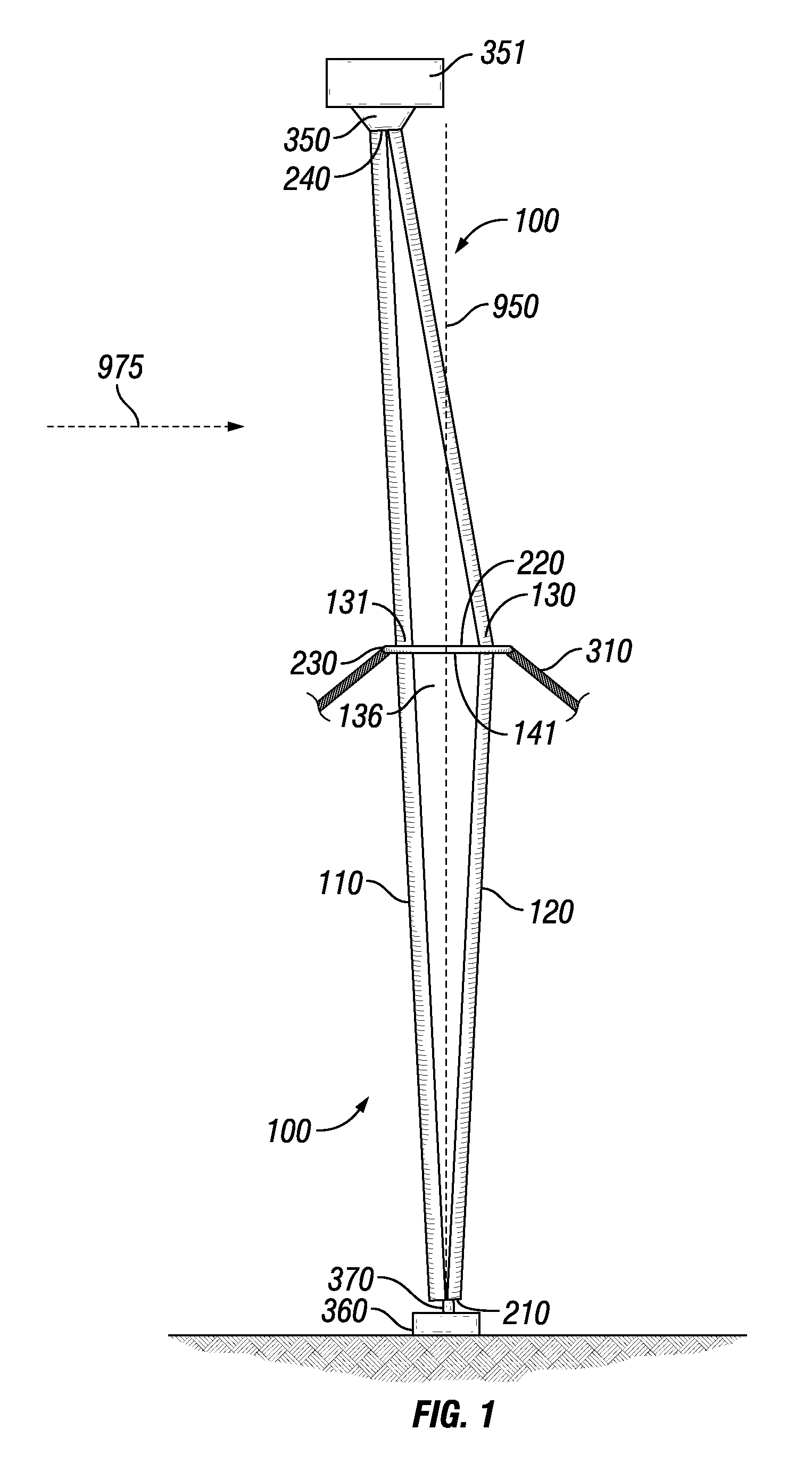

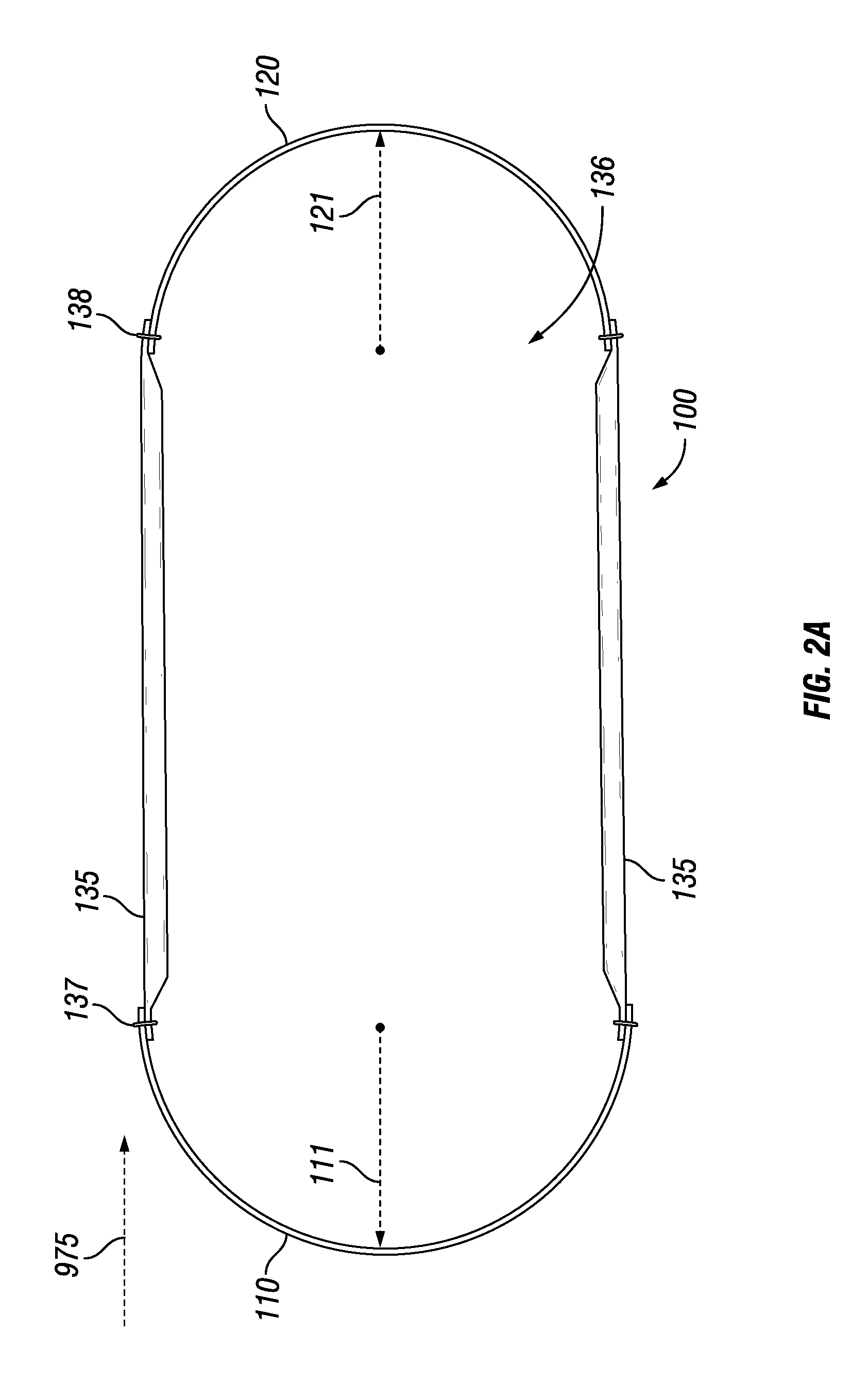

Hybrid multi-element tapered rotating tower

InactiveUS7891939B1Increased energy productionMinimize turbulencePropellersPump componentsLeading edgeEdge structure

The specification discloses a rotating turbine tower. The tower rotates to maintain the turbine facing into the wind. This allows structural optimization. The tower structure is comprised of a leading edge and a trailing edge, with joining panels between the edge structures. The tower edges are the main structural components of the tower. The separation of the edges tapers to follow the thrust bending moment on the tower, reducing the need to taper material thickness. The tapering shape of the tower structure matches the primary edgewise moment distribution. The tower can be assembled on site from components, thereby facilitating transportation to the tower site. The material properties and shape can be selected based upon the tower maintaining a near constant orientation with the wind. This can save weight and costs. The tower architecture can be of differing shapes such as a triangle or a structure tapering at each end.

Owner:ZUTECK MICHAEL D

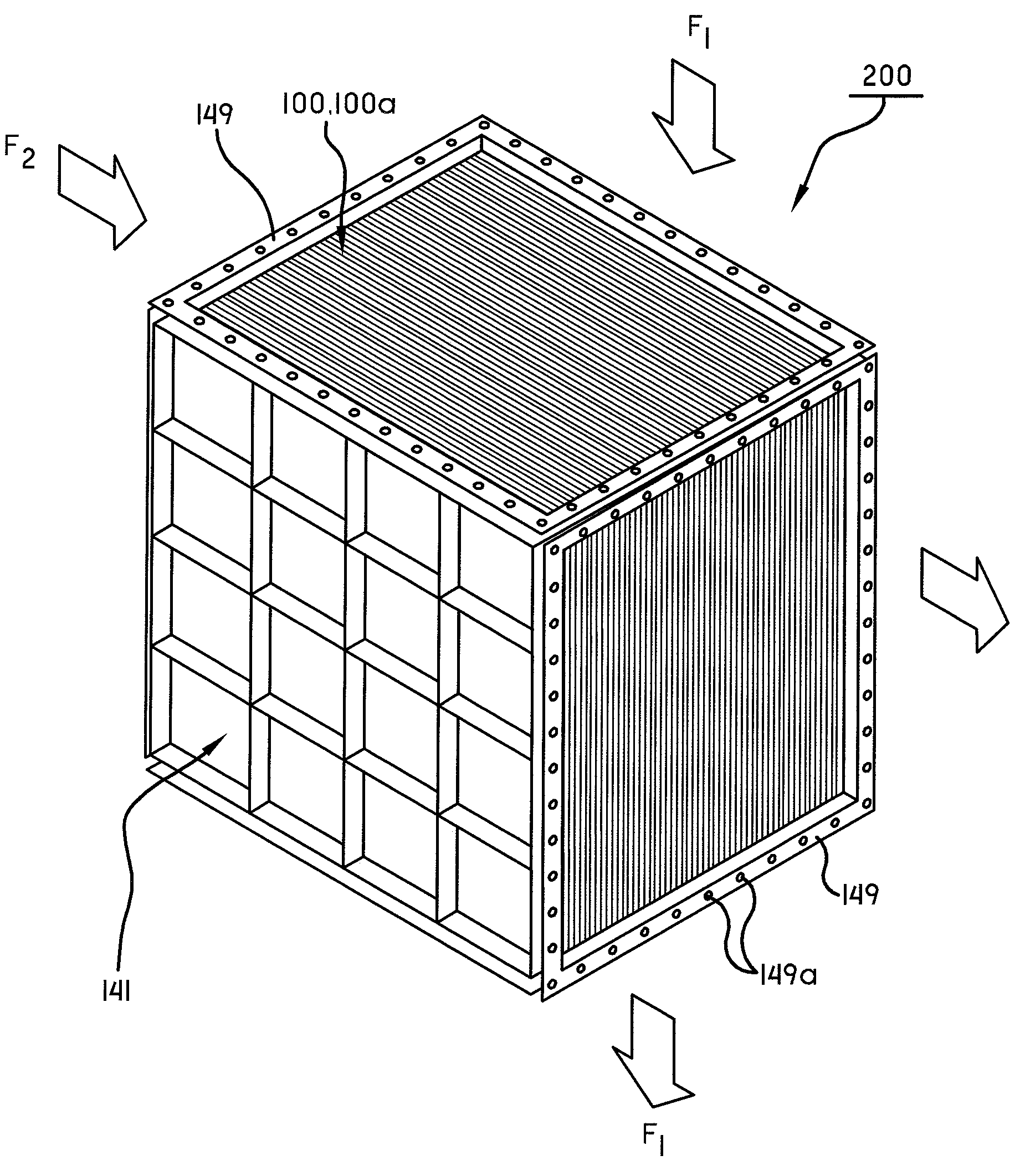

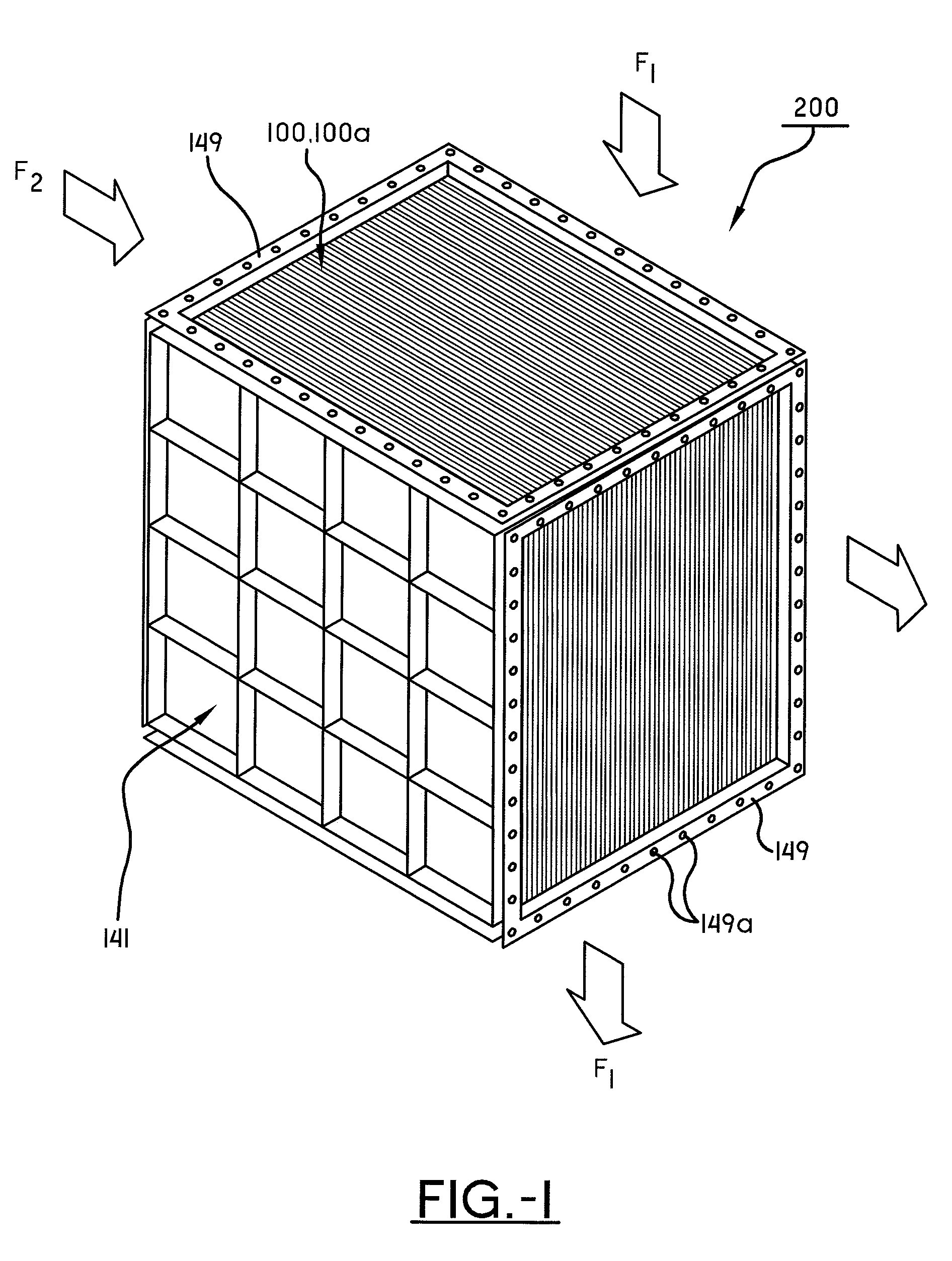

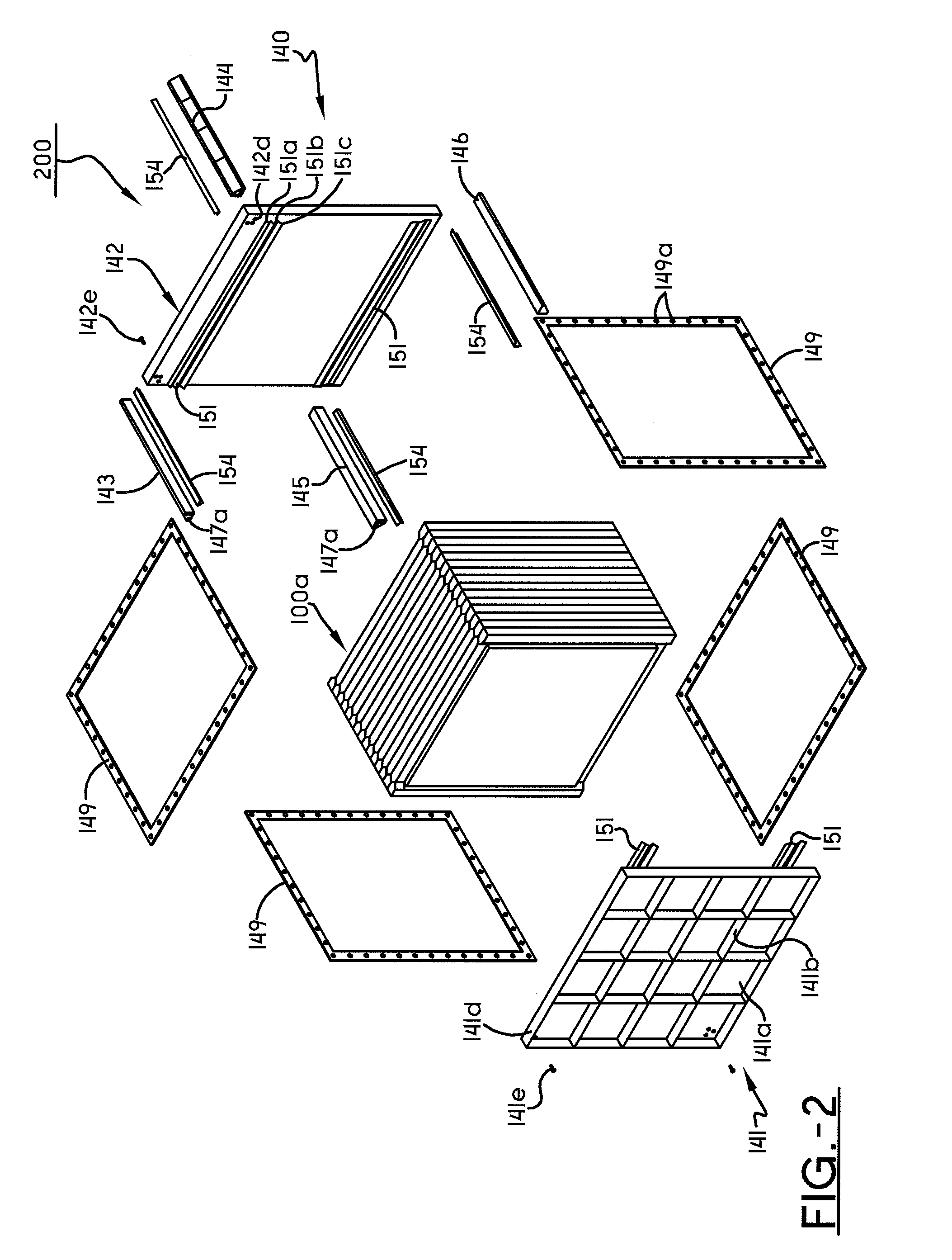

Plate type heat exchanger

InactiveUS20110017436A1Simply and rapidly fabricatingAvoid defectsSpacing meansSafety devices for heat exchange apparatusPlate heat exchangerThermal expansion

A plate type heat exchanger includes a heat transfer assembly having a plurality of heat transfer cells stacked in multiple layers, first fluid passages, and second fluid passages between the heat transfer cells so as to intersect with the first fluid passage at a right angle and to exchange heat with the first fluid passages, a framework having a plurality of support beams connected between a pair of sealing panels facing opposite outer faces of the heat transfer assembly, and an elastic support having first elastic members installed between the sealing panels and the heat transfer assembly and second elastic members installed between the support beams and the heat transfer assembly, absorbing thermal expansion of the heat transfer assembly, and preventing fluids from leaking out.

Owner:SHINHAN APEX CORP

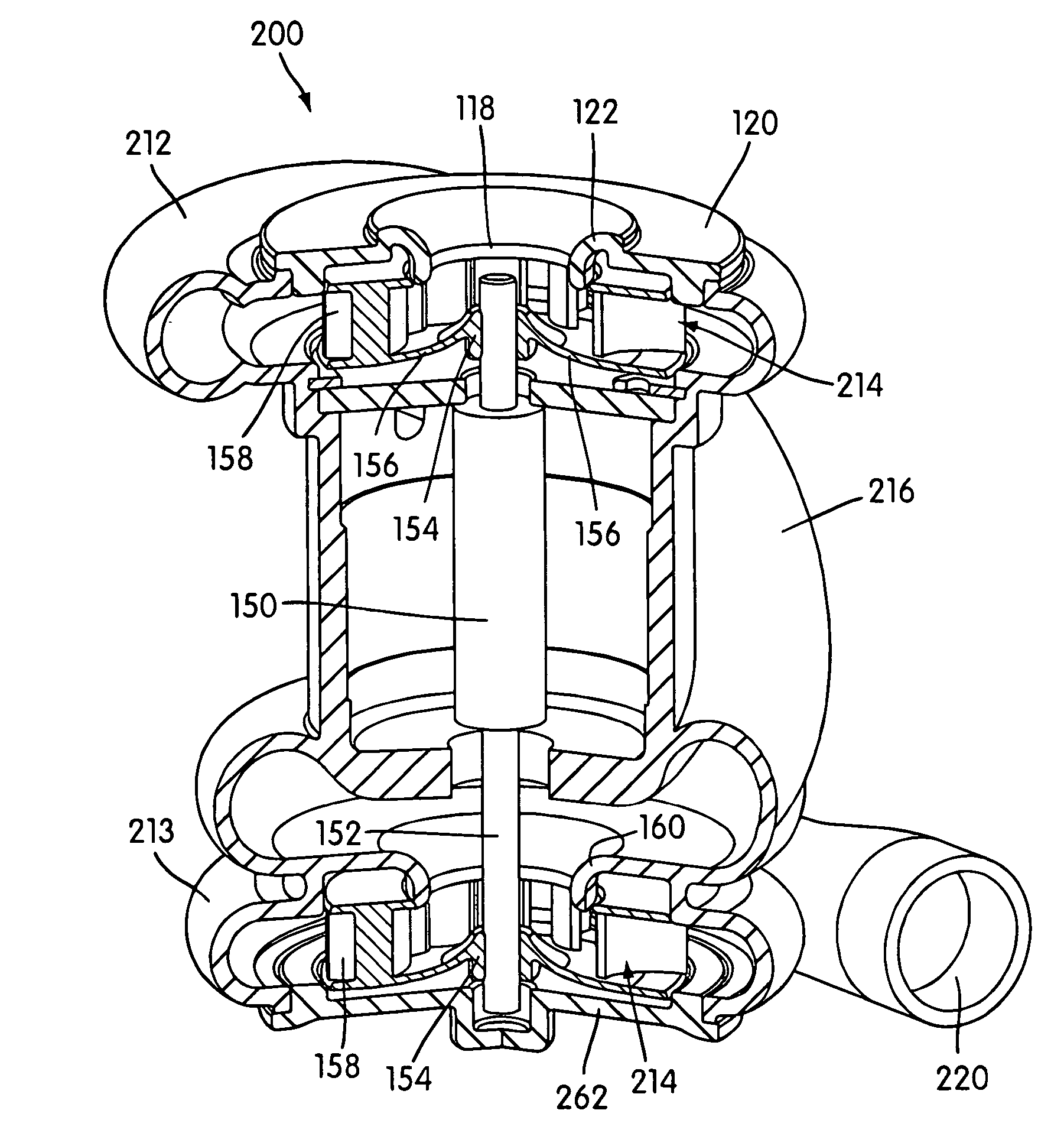

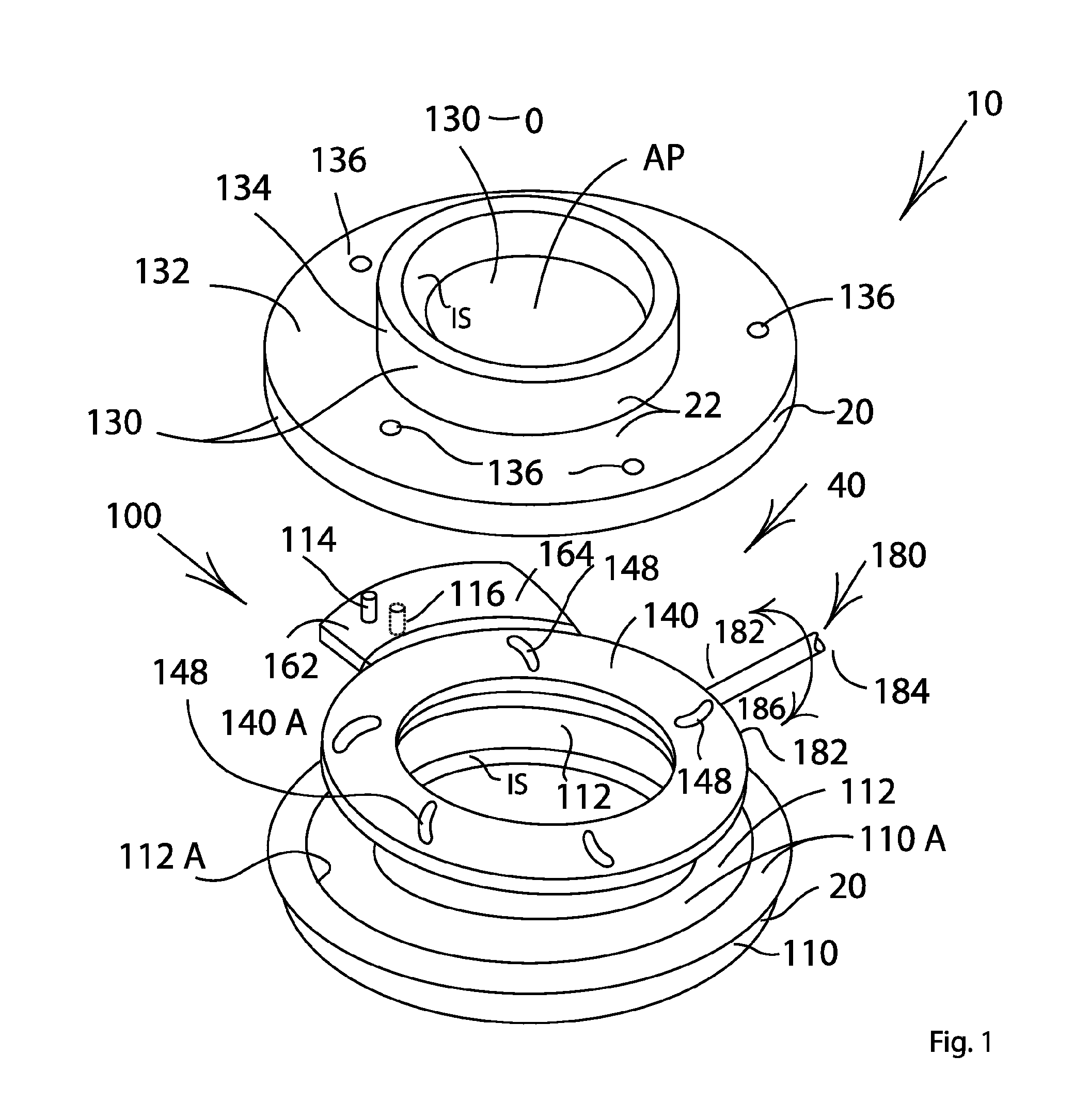

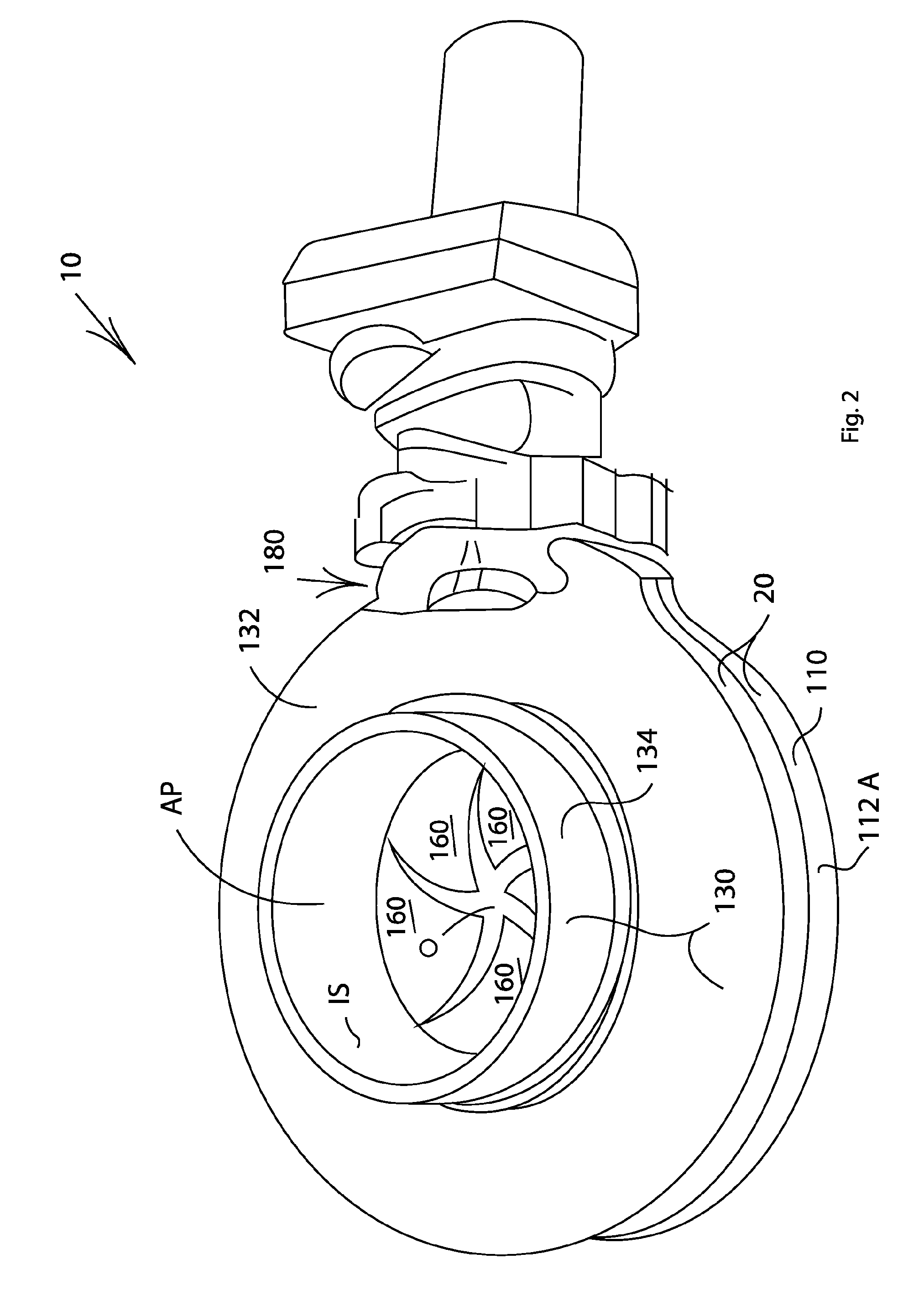

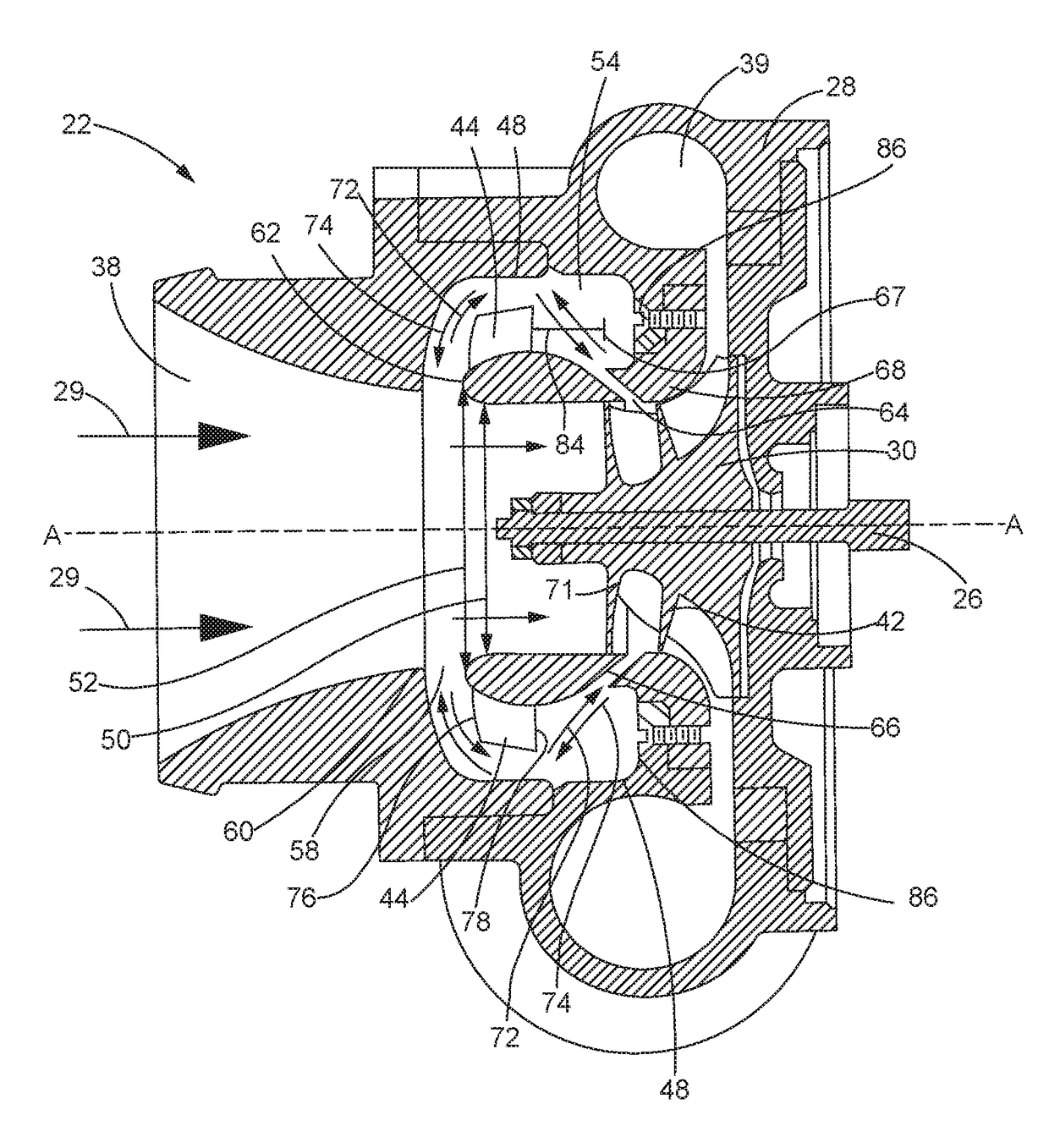

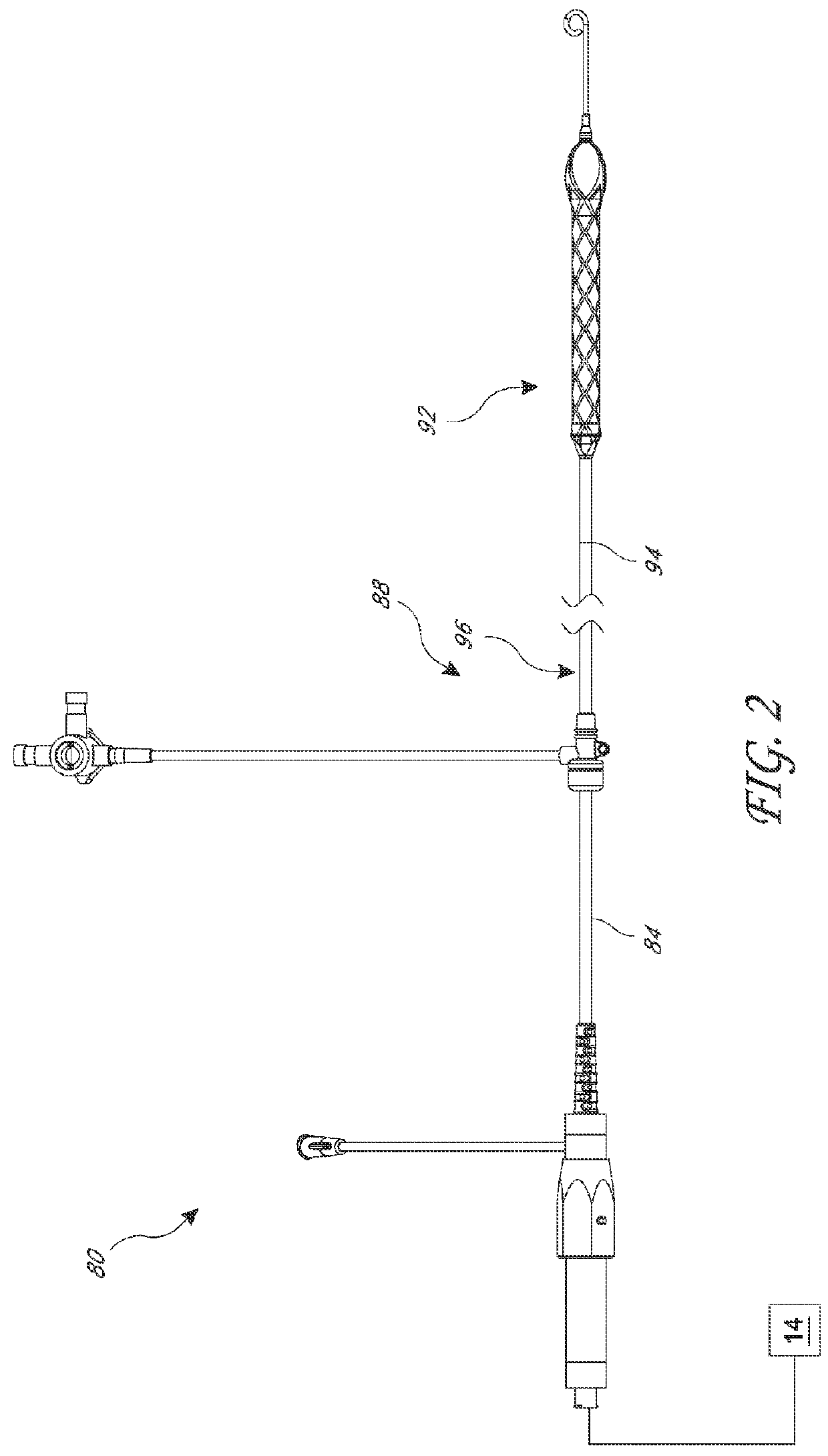

Catheter pump assembly including a stator

InactiveUS20160030649A1Reduce lossesMinimize turbulenceBlood pumpsMedical devicesImpellerLeading edge

A catheter pump assembly is provided that includes a proximal a distal portion, a catheter body, an impeller, and a flow modifying structure. The catheter body has a lumen that extends along a longitudinal axis between the proximal and distal portions. The impeller is disposed at the distal portion. The impeller includes a blade with a trailing edge. The flow modifying structure is disposed downstream of the impeller. The flow modifying structure has a plurality of blades having a leading edge substantially parallel to and in close proximity to the trailing edge of the blade of the impeller and an expanse extending downstream from the leading edge. In some embodiments, the expanse has a first region with higher curvature and a second region with lower curvature. The first region is between the leading edge and the second region.

Owner:TC1 LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com