Patents

Literature

277 results about "Froth flotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Froth flotation is a process for selectively separating hydrophobic materials from hydrophilic. This is used in mineral processing, paper recycling and waste-water treatment industries. Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th century. It has been described as "the single most important operation used for the recovery and upgrading of sulfide ores". The development of froth flotation has improved the recovery of valuable minerals, such as copper- and lead-bearing minerals. Along with mechanized mining, it has allowed the economic recovery of valuable metals from much lower grade ore than previously.

Materials and process for enhancing selective separations

Use of a Maillard reaction product as an adjuvant in a variety of applications including solid-liquid separations, corrosion inhibition, emulsification, dust suppression, slow release fertilization, viscosity modification and others and especially as a depressant or collector in separation processes, including the selective separation of solids and / or ionic species from aqueous media, such as in the process of froth flotation.

Owner:GEORGIA PACIFIC CHEM LLC

Modified amine-aldehyde resins and uses thereof in separation processes

InactiveUS20070000839A1Easy to disassembleHighly selective bindingTransportation and packagingSolid sorbent liquid separationParticulatesSolid particle

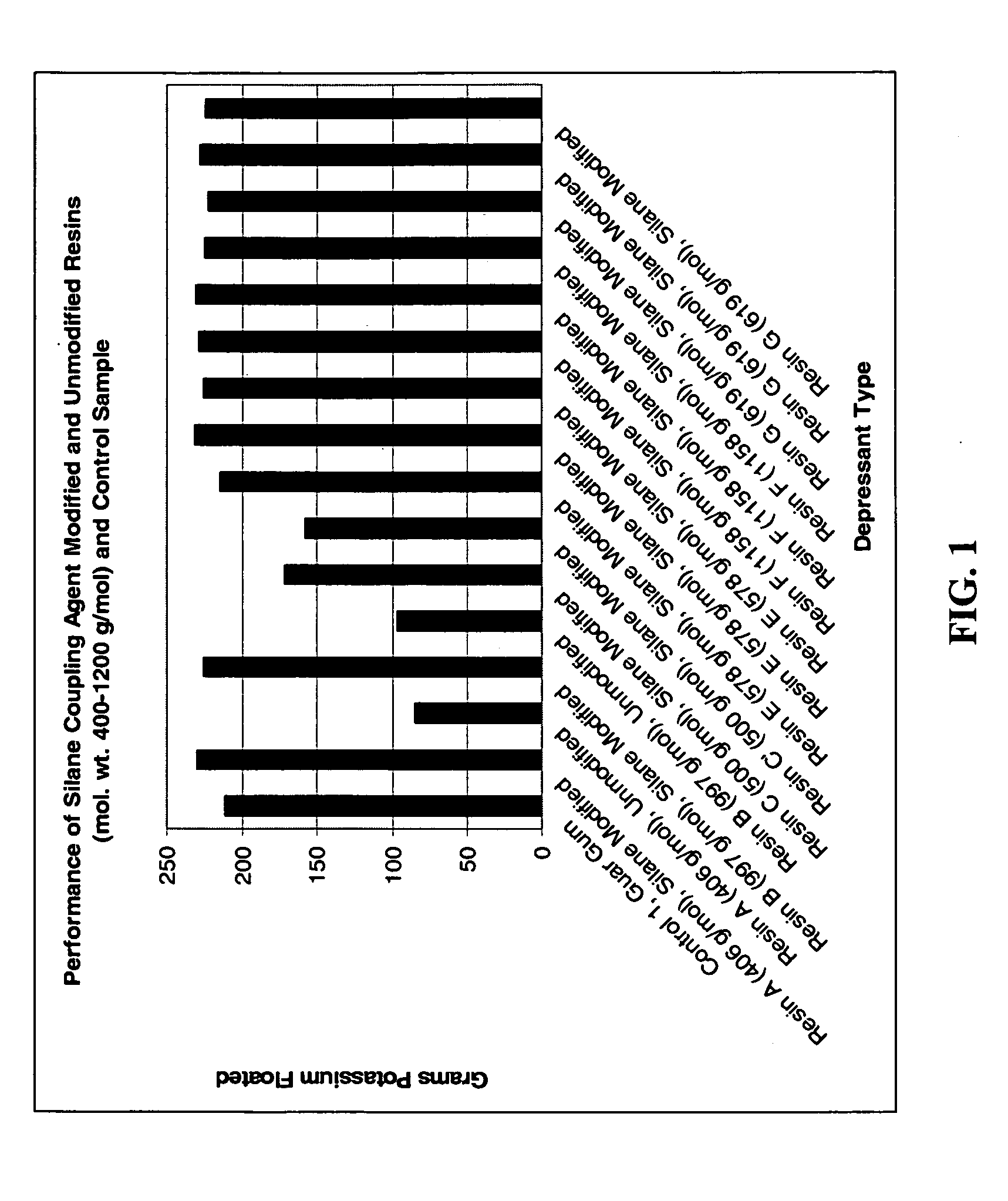

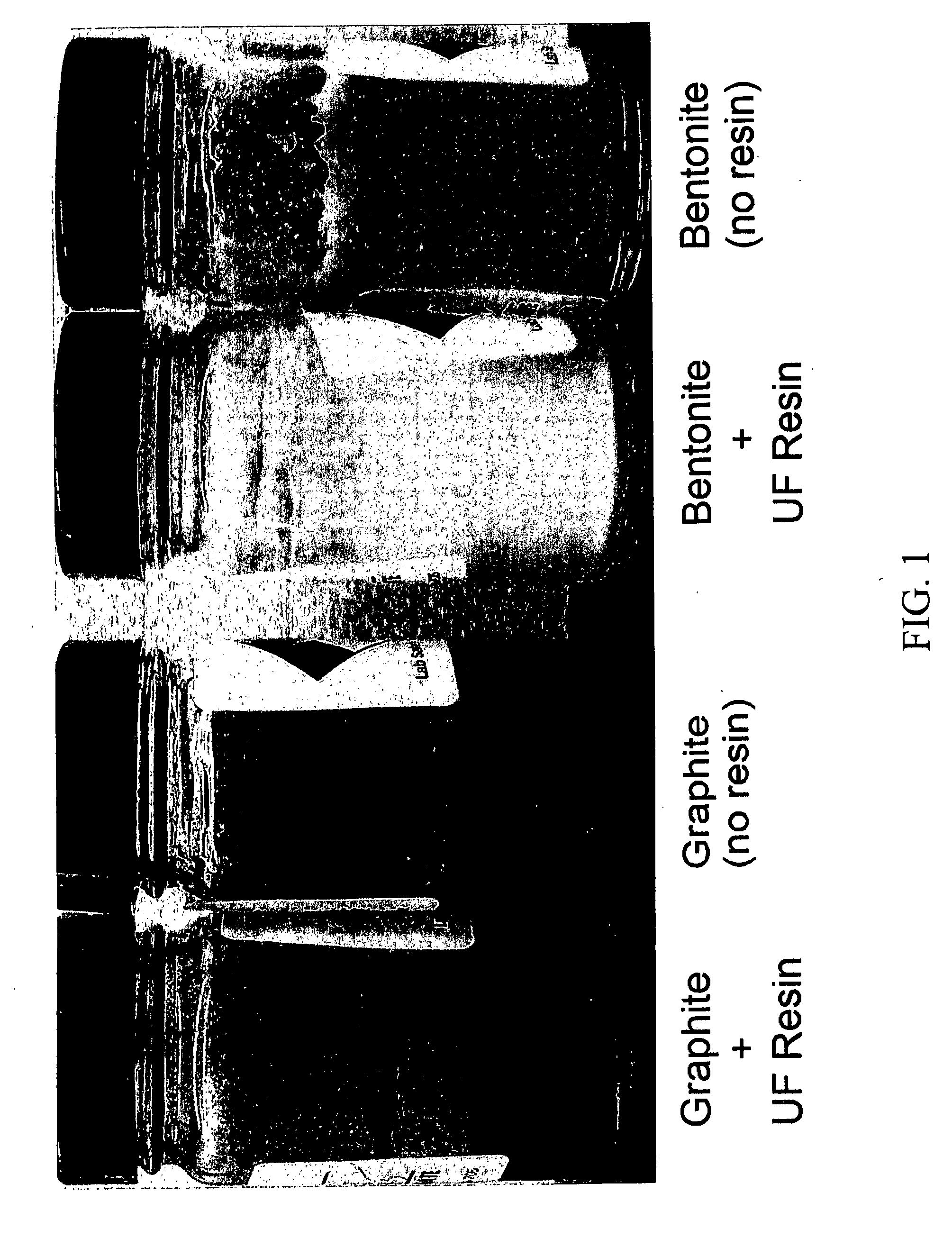

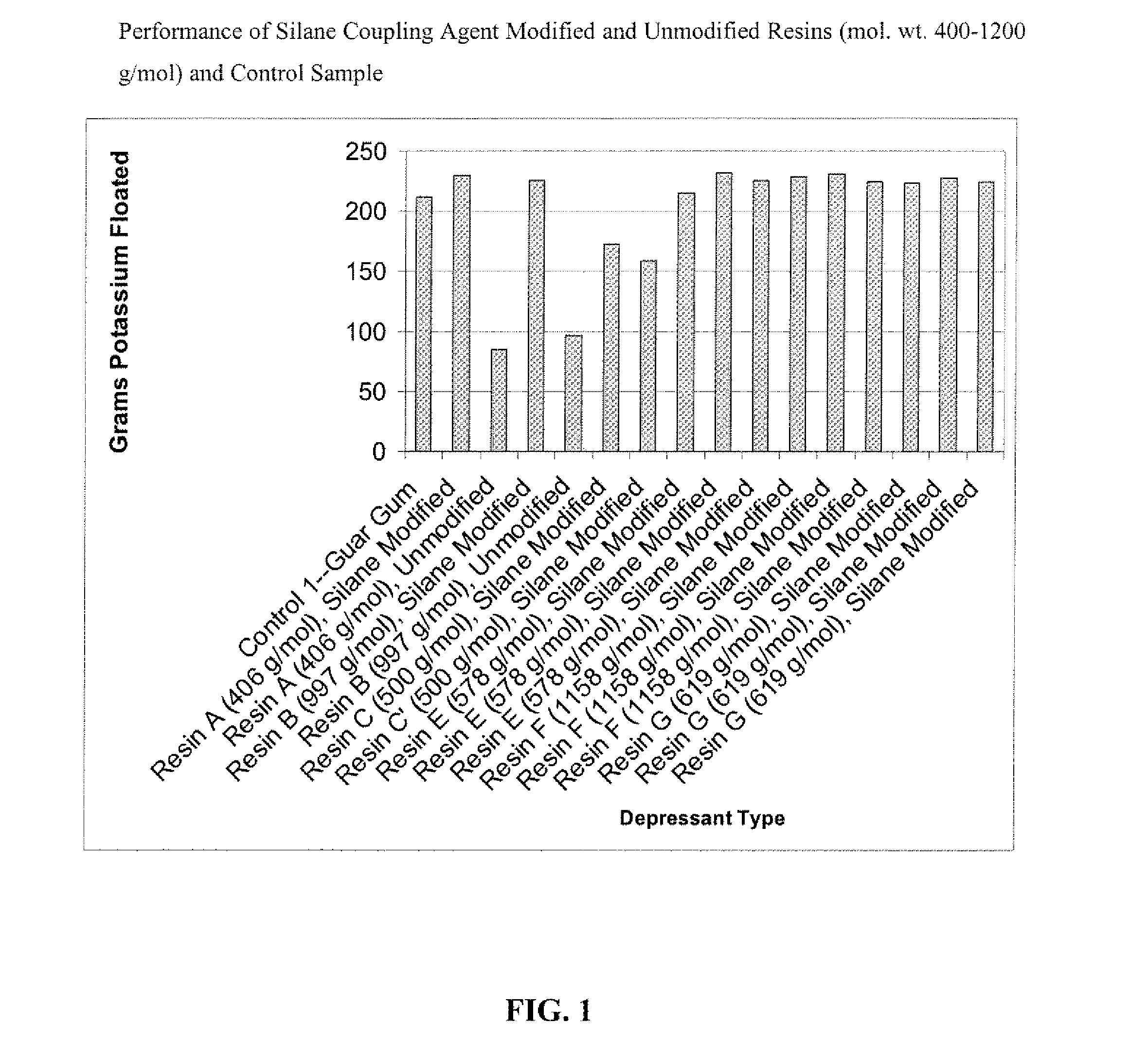

Modified resins are disclosed for removing a wide variety of solids and / or ionic species from the liquids in which they are suspended and / or dissolved. These modified resins are especially useful as froth flotation depressants in the beneficiation of many types of materials (e.g., mineral and metal ores), including the beneficiation of impure coal comprising clay impurities, as well as in the separation of valuable bitumen from solid contaminants such as sand. The modified resins are also useful for treating aqueous liquid suspensions to facilitate the removal of solid particulates, as well as the removal of metallic ions in the purification of water. The modified resins comprise a base resin that is modified with a coupling agent, which is highly selective for binding to solid contaminants and especially siliceous materials such as sand or clay.

Owner:INGEVITY SOUTH CAROLINA

Amine-aldehyde resins and uses thereof in separation processes

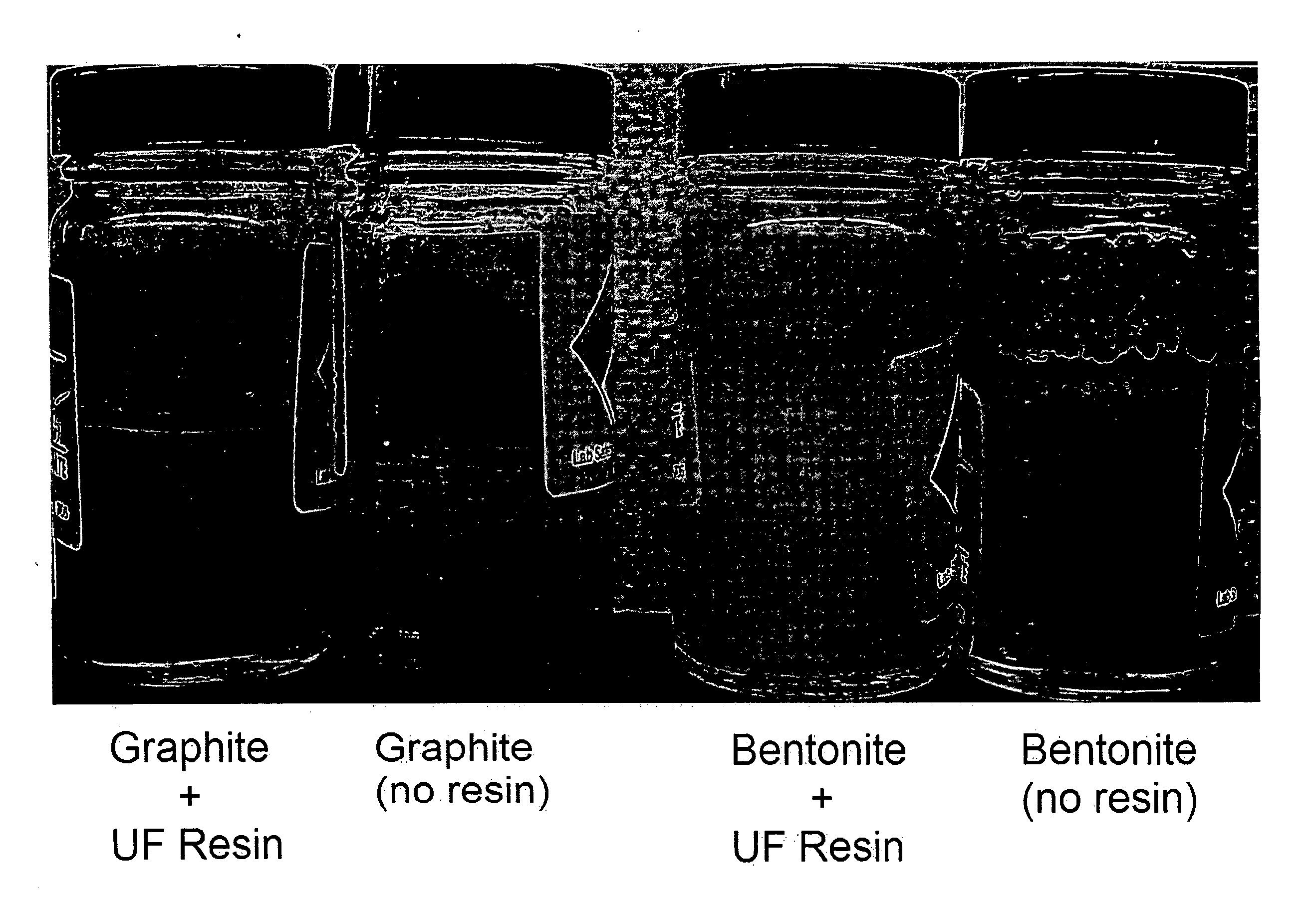

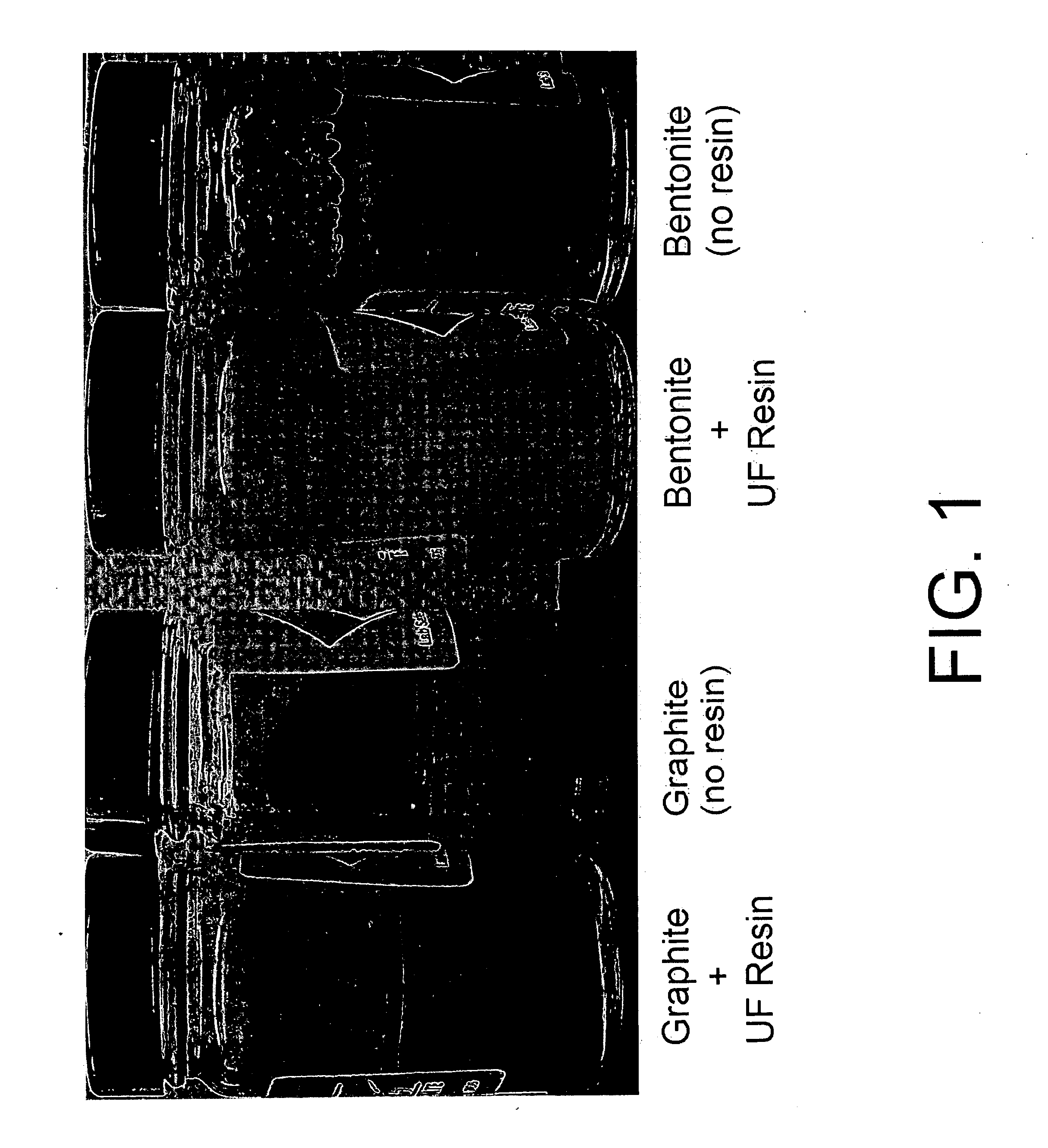

InactiveUS20060151397A1Highly versatileEffective isolationWaste water treatment from quariesWaste water treatment from ceramic industriesParticulatesKaolin clay

Amine-aldehyde resins are disclosed for removing a wide variety of solids and / or ionic species from the liquids in which they are suspended and / or dissolved. These resins are especially useful as froth flotation depressants in the separation of bitumen from sand and / or clay or in the beneficiation of clay (e.g., kaolin clay) from an impure clay-containing ore. The resins are also useful for treating aqueous liquid suspensions to remove solid particulates, as well as for removing metallic ions in the purification of water.

Owner:INGEVITY SOUTH CAROLINA

Amine-aldehyde resins and uses thereof in separation processes

InactiveUS20080029460A1Highly versatileHigh selectivitySpecific water treatment objectivesWater contaminantsParticulatesKaolin clay

Amine-aldehyde resins are disclosed for removing a wide variety of solids and / or ionic species from the liquids in which they are suspended and / or dissolved. These resins are especially useful as froth flotation depressants, for example in the beneficiation of value materials (e.g., bitumen, coal, or kaolin clay) to remove impurities such as sand. The resins are also useful for treating aqueous liquid suspensions to remove solid particulates, as well as for removing metallic ions in the purification of water.

Owner:INGEVITY SOUTH CAROLINA

Modified amine-aldehyde resins and uses thereof in separation processes

ActiveUS20080017552A1Easy to disassembleHighly selective bindingWater contaminantsSedimentation separationParticulatesSolid particle

Modified resins are disclosed for removing a wide variety of solids and / or ionic species from the liquids in which they are suspended and / or dissolved. These modified resins are especially useful as froth flotation depressants in the beneficiation of many types of materials (e.g., mineral and metal ores), including the beneficiation of impure coal comprising clay impurities, as well as in the separation of valuable bitumen from solid contaminants such as sand. The modified resins are also useful for treating aqueous liquid suspensions to facilitate the removal of solid particulates, as well as the removal of metallic ions in the purification of water. The modified resins comprise a base resin that is modified with a coupling agent, which is highly selective for binding to solid contaminants and especially siliceous materials such as sand or clay.

Owner:INGEVITY SOUTH CAROLINA

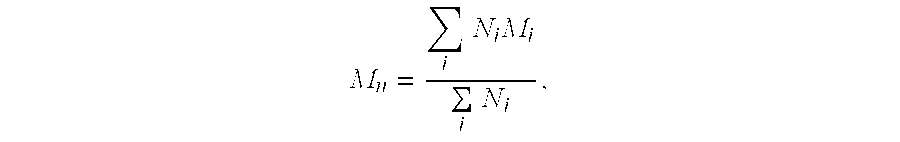

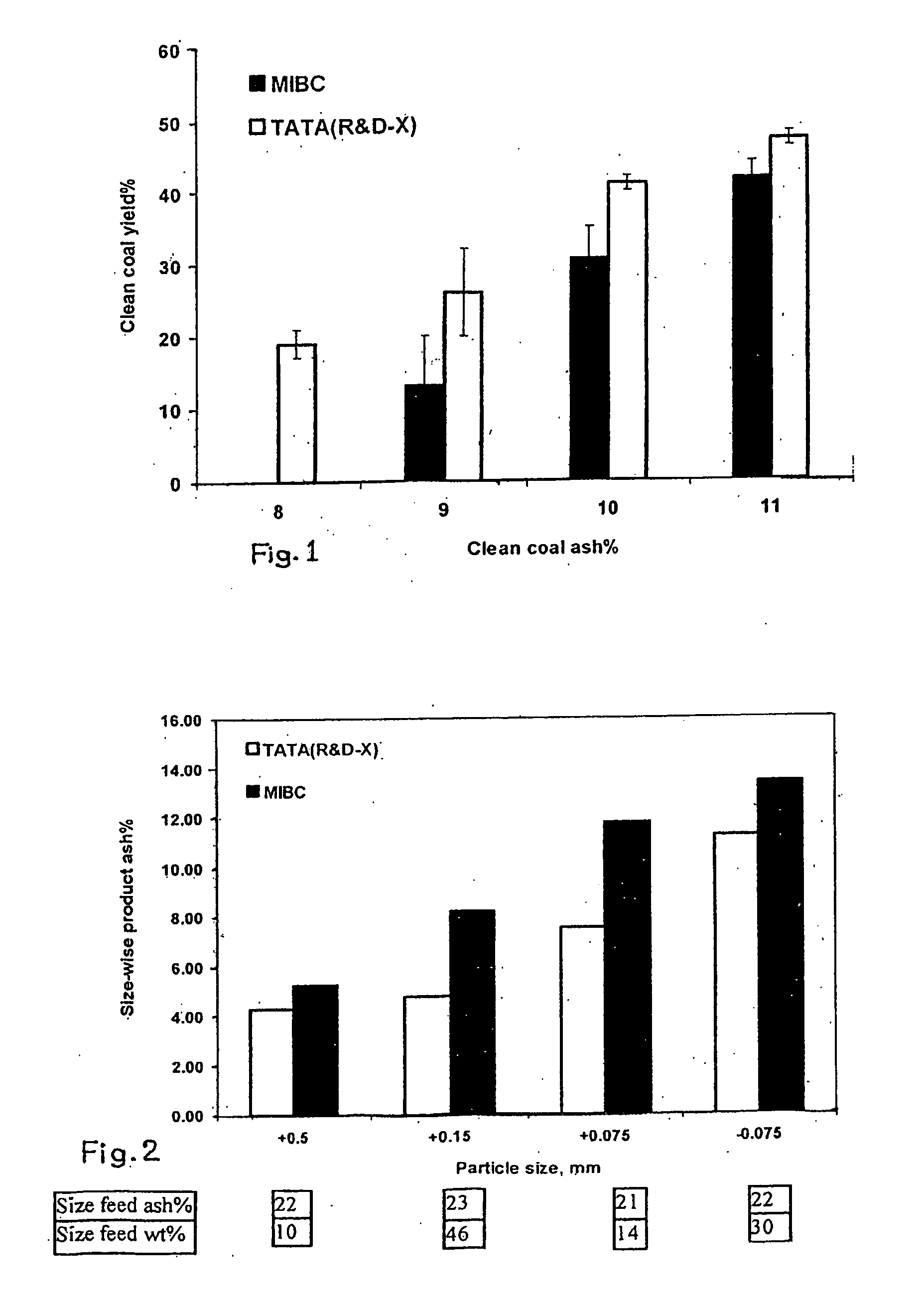

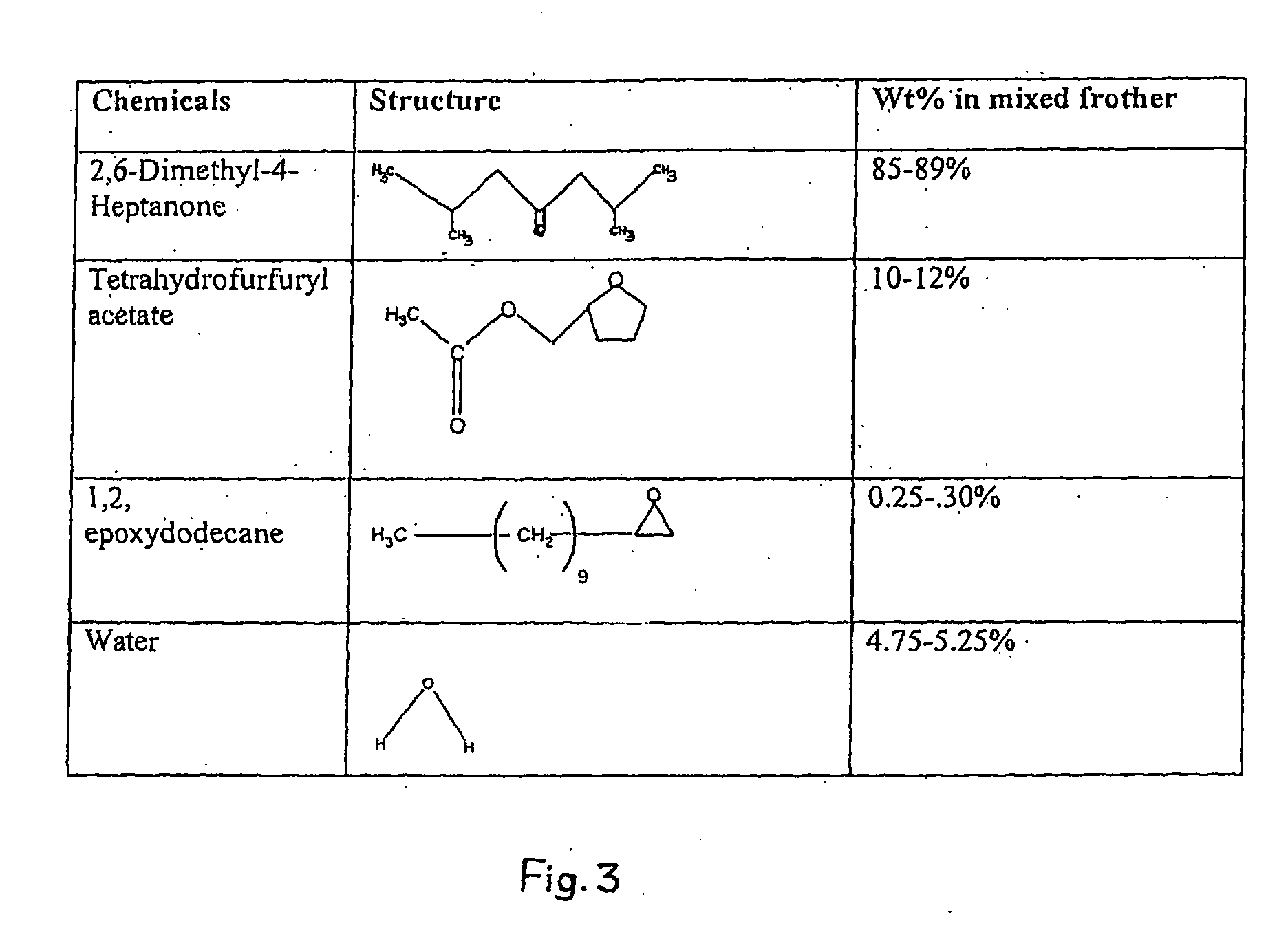

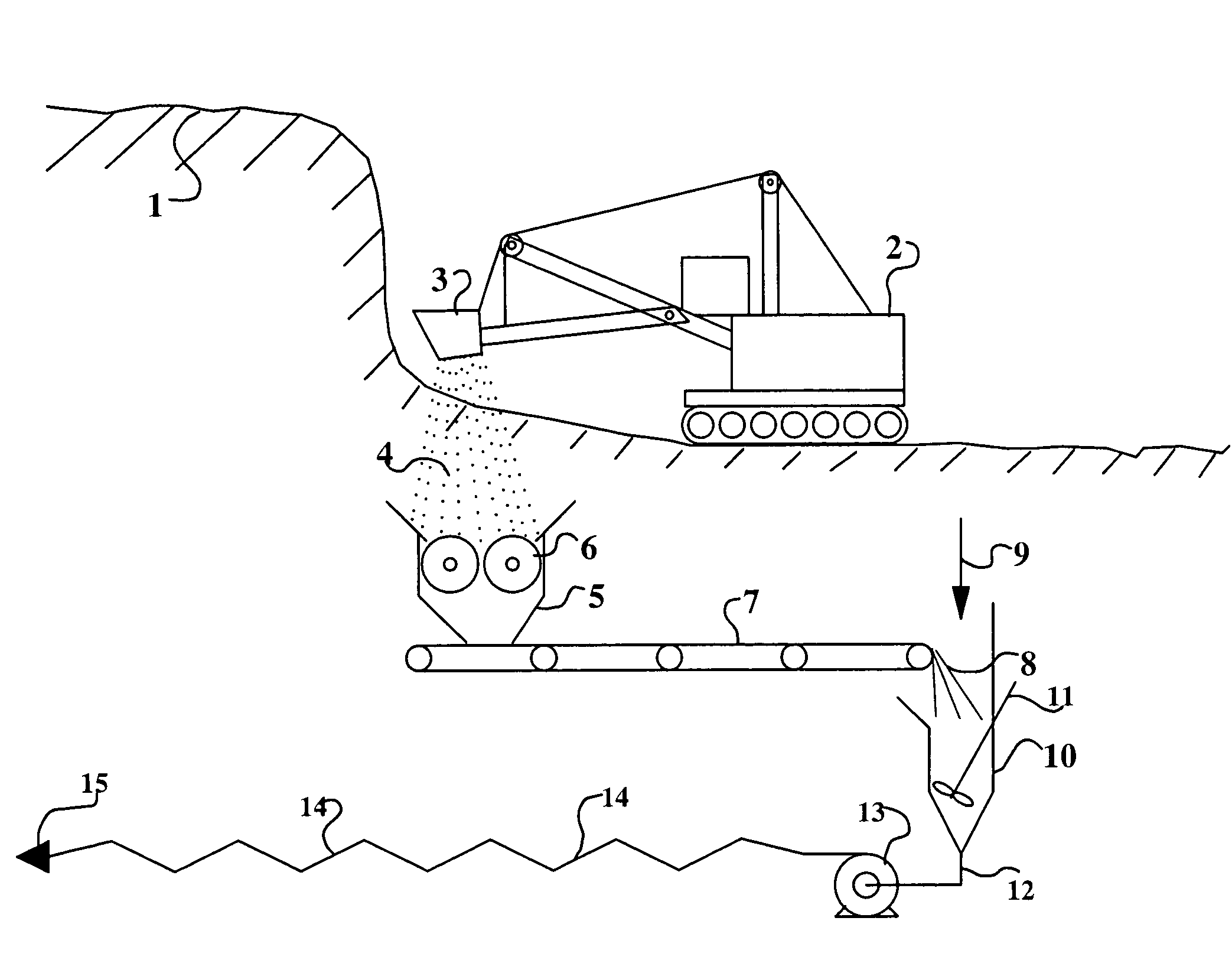

Blended frother for producing low ash content clean coal through flotation

An improved frothing agent adaptable to froth flotation process to enhance coal selectivity for separation and efficiency of the forth flotation process comprises:-A blended mixture ofKetone (2,6 Dimethl-4-Heptanone)85-89%(Wr %)Ester molecule(Tetrahydrofurfuryl acetate)10-12%(Wt %)Epoxide conditioner (1,2-Epoxydodecane)0.25-0.30%(Wt %)Water4.75-5.25%(Wt %)

Owner:TATA STEEL

Phosphate beneficiation process using methyl or ethyl esters as float oils

ActiveUS20050269248A1Fatty/oily/floating substances removal devicesSewerage structuresPhosphoriteEthyl ester

A process for use in a phosphate ore beneficiation process to minimize the long-term environmental impact of the use of petroleum based hydrocarbon materials mixed with fatty acid based primary floatation reagents for froth flotation in the flotation of phosphate ores, wherein the process comprises substituting the petroleum based hydrocarbon materials with methyl and / or ethyl esters of fatty acids.

Owner:ARRMAZ PROD INC

Isoelectric separation of oil sands

InactiveUS20090139906A1Reduced effectivenessReduce recoveryWater/sewage treatmentLiquid hydrocarbon mixture productionSlurryFroth flotation

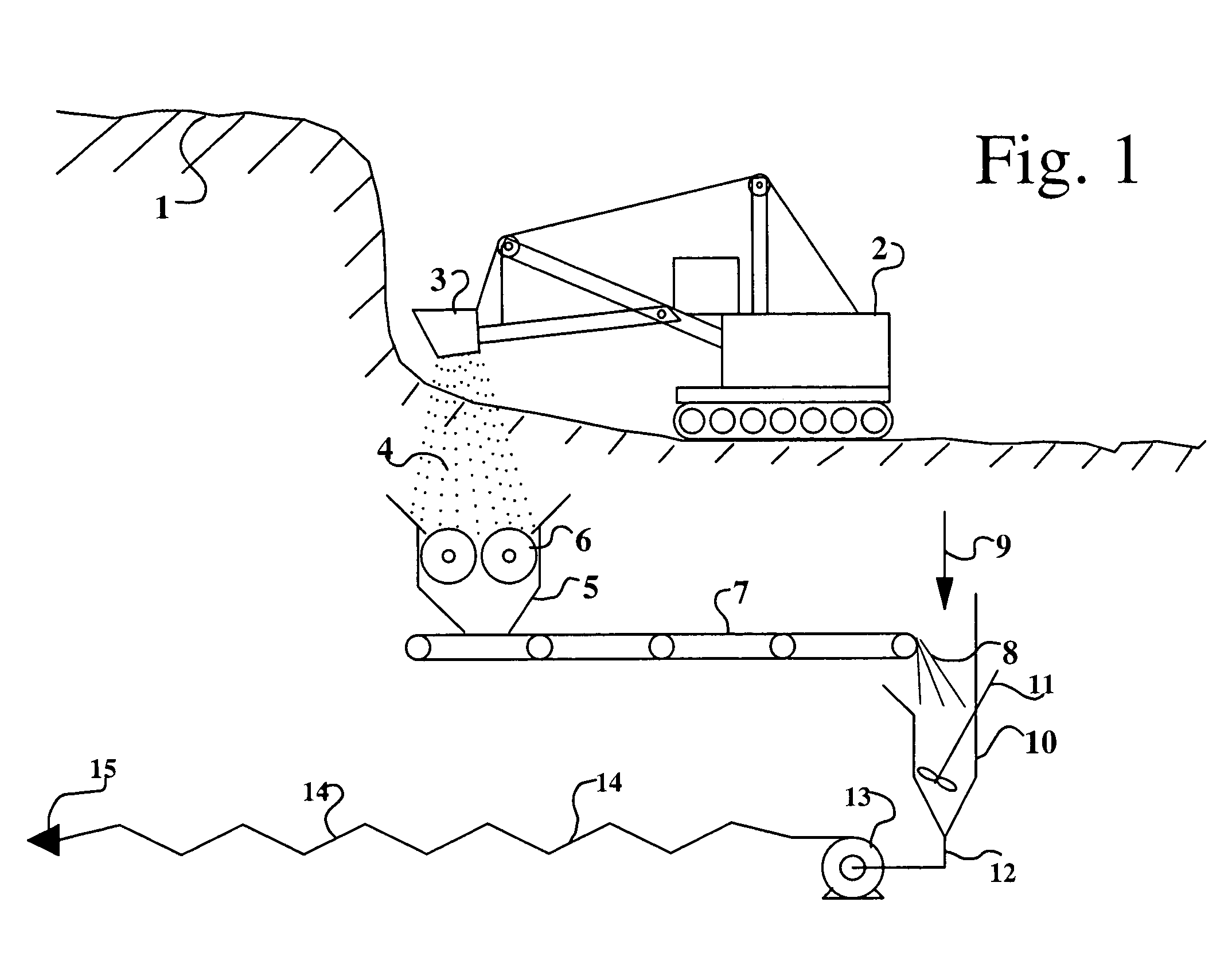

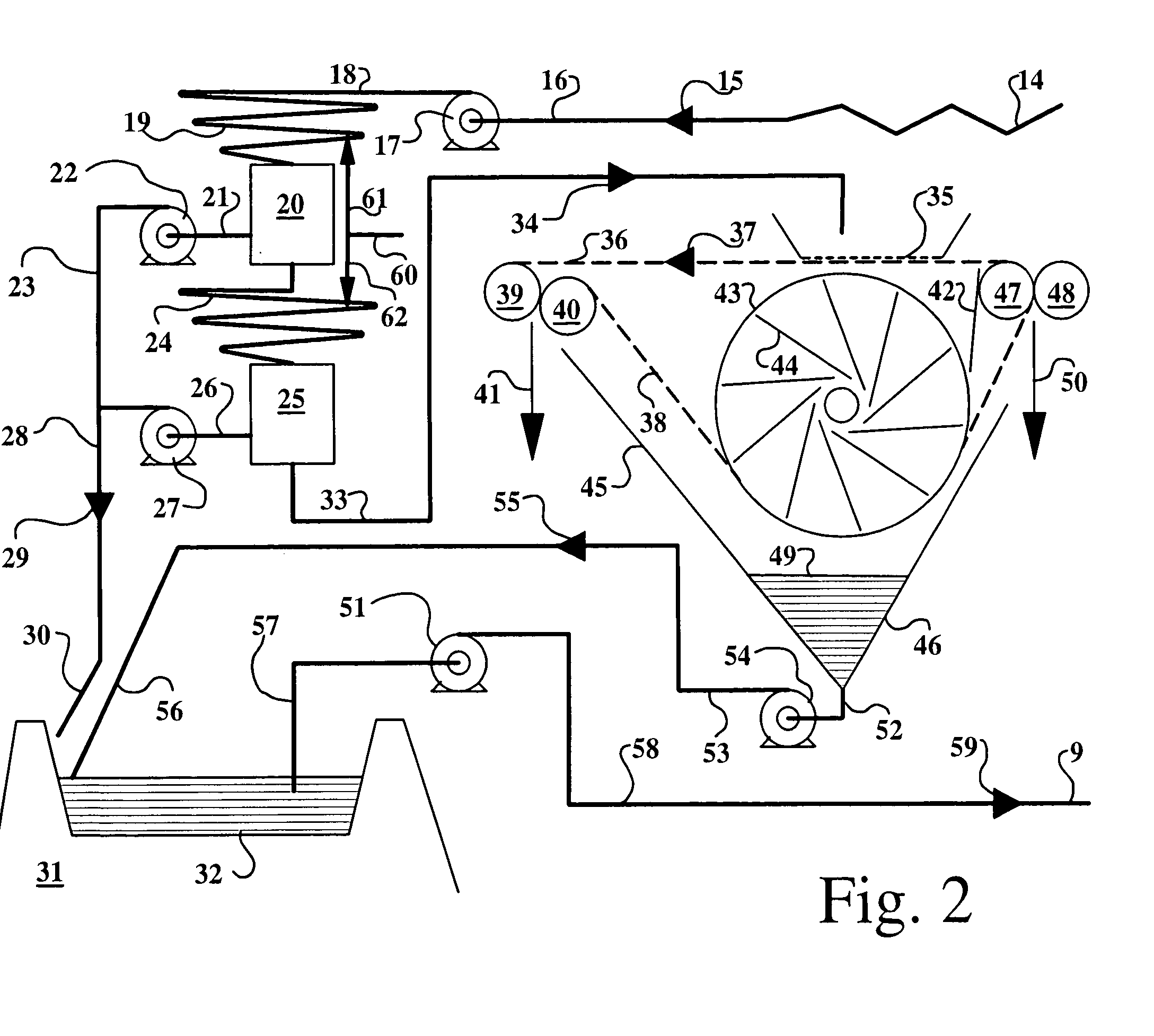

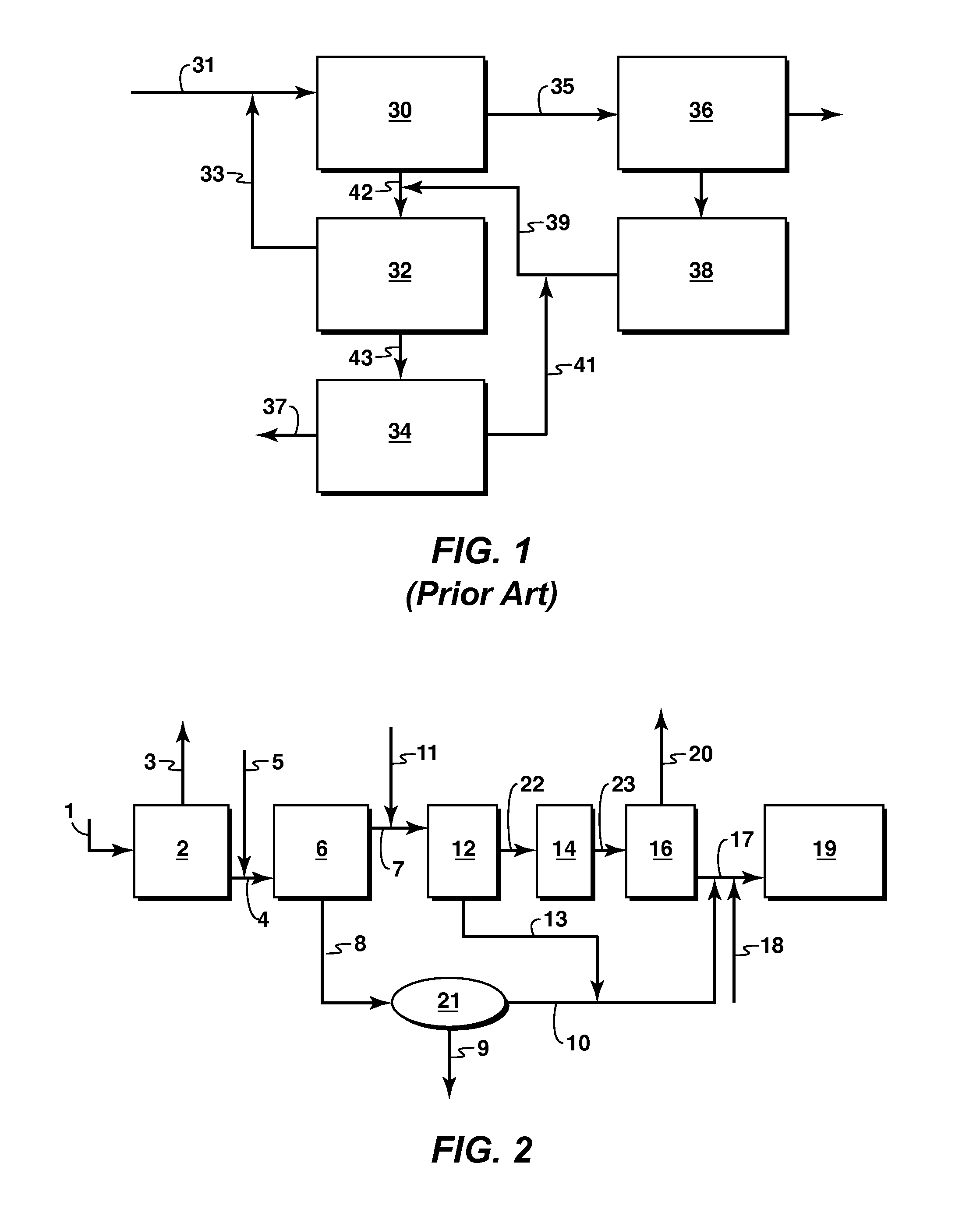

A process and system for substantially isoelectric separation of an oil sand slurry is disclosed and described. The process can include mining oil sand, crushing the oil sands, forming a slurry of the oil sands, and transporting the oil sands slurry to a sinusoidal pipe. The sinusoidal pipe acts to digest the slurry from which bitumen can be separated using a hydrocyclone. Overflow from the hydrocyclone can be further treated using a revolving oleophilic device from which bitumen is recovered. Various optional further treatments can be used to dewater and / or further treat the bitumen and other process streams. The use of caustic soda, long-term tailing ponds, and froth flotation can be avoided resulting in an effective production of oil using less water than currently conventional processes.

Owner:KRUYER JAN

Flyash treatment method for waste incineration

InactiveCN101797575AReduce follow-up processing costsEfficient separationSolid waste disposalLiquid wasteCombustion chamber

The invention discloses a flyash treatment method for waste incineration, comprising the following steps: (1) mixing flyash produced in waste incineration with water to prepare into mortar, and adding acid extractant, collecting agent and foaming agent in the mortar to blend into grout; (2) performing foam flotation treament on the grout, and separating to obtain refined flyash and residual grout; (3) feeding the fined flyash in a secondary combustion chamber of a waste incinerator for supporting combustion, wherein carbon components enriched in the refined flyash are utilized in a combusted manner and dioxin in the refined flyash is decomposed at high temperature; (4) filtering the residual grout, separating to obtain tail flyash and filtrate, feeding the tail flyash in a domestic garbage landfill site for dumping; and (5) adding heavy metal precipitator in the filtrate, filtering once again, separating to obtain heavy metal precipitator salt and waste liquor, and discharging the waste liquor after sewage treament. The invention can effectively separate and recovery carbon components in high carbon and high chlorine waste incineration flyash, chloridion, dioxin and heavy metal at the same time.

Owner:TIANJIN URBAN CONSTR COLLEGE

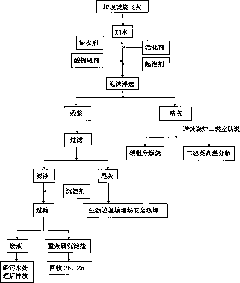

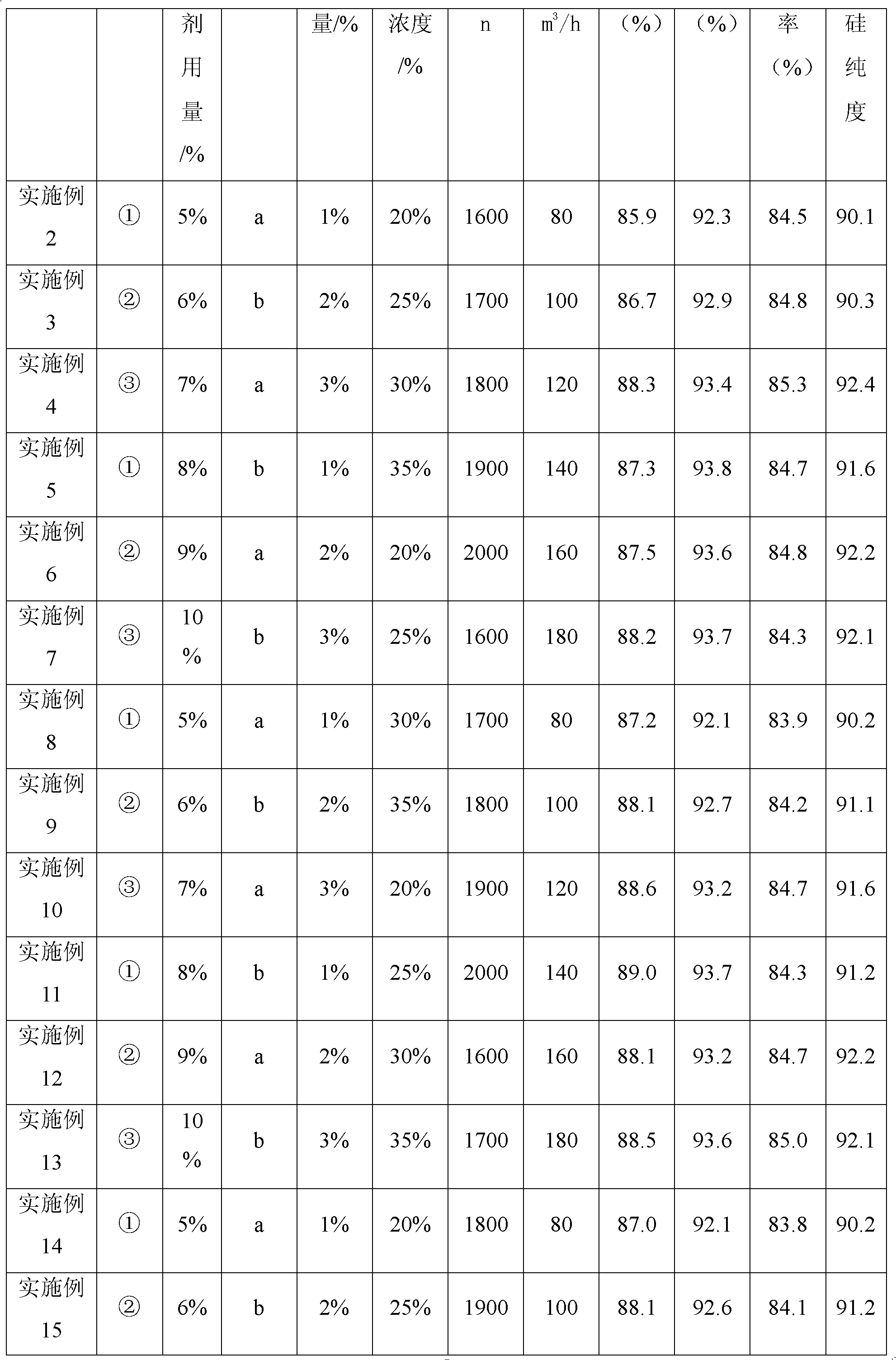

Foam flotation method for separating silicon powder from silicon carbide powder

The invention discloses a foam flotation method for separating silicon powder from silicon carbide powder. The foam flotation method includes the steps: 1) using powder generated in cutting of a solar cell as raw materials and obtaining raw materials after acid treatment; 2) adding water into collecting agents, foaming agents and the raw materials after acid treatment to prepare water solution, filling the water solution into a flotation tank for flotation, collecting spilling foam and reserving solid-liquid mixture in the flotation tank; 3) performing flotation again after the foam collected in the step 2 naturally disappears and changes into liquid, and drying the finally obtained foam after suction filtration to obtain silicon; and 4) performing flotation for the solid-liquid mixture reserved in the flotation tank in the step 2 again, and filtering and then drying the solid-liquid mixture finally reserved in the flotation tank to obtain silicon carbide.

Owner:CHINA CONSTR IND & ENERGY ENG GRP CO LTD +1

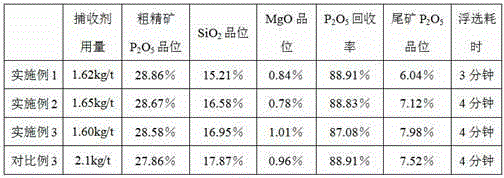

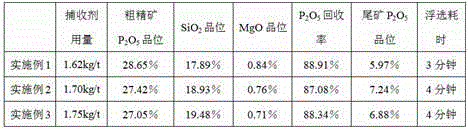

Phosphorite low-temperature foam flotation collector and preparation method thereof

ActiveCN101791591AStrong harvesting abilityHigh selectivityFlotationSesquioxideTemperature resistance

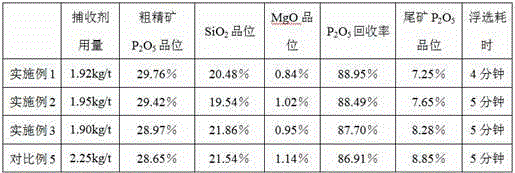

The invention relates to a phosphorite low-temperature foam flotation collector and a preparation method thereof. The collector consists of the following substances in part by weight: 0.7 to 0.9 part of cottonseed acidic oil, 0.1 to 0.3 part of fatty acid methyl ester, 0.01 to 0.05 part of sodium dodecyl benzene sulfonate, and 0.01 to 0.05 part of foaming agent. The preparation method comprises the following steps: mixing the 0.7 to 0.9 part of cottonseed acidic oil and the 0.1 to 0.3 part of fatty acid methyl ester; heating the mixture to the temperature of between 100 and 120 DEG C; adding alkali liquor into the mixture, stirring the mixture for saponification; controlling pH to be between 8 and 10; and adding the 0.01 to 0.05 part of sodium dodecyl benzene sulfonate and the 0.01 to 0.05 part of foaming agent into the mixture by using the saponified semi-finished product as a reference part to prepare the phosphorite low-temperature foam flotation collector. When the collector can be used in 'Haizhou type' phosphorite low-temperature direct flotation, the produced product still can achieve low sesquioxide concentrate and has higher recovery rate. Compared with the conventional 'Haizhou type' phsophorite low-temperature direct flotation collector, the collector has the characteristics of high collection capability, high selectivity, small using amount, low-temperature resistance, low mineral separation cost and the like.

Owner:HUBEI FORBON NEW MATERIAL CO LTD

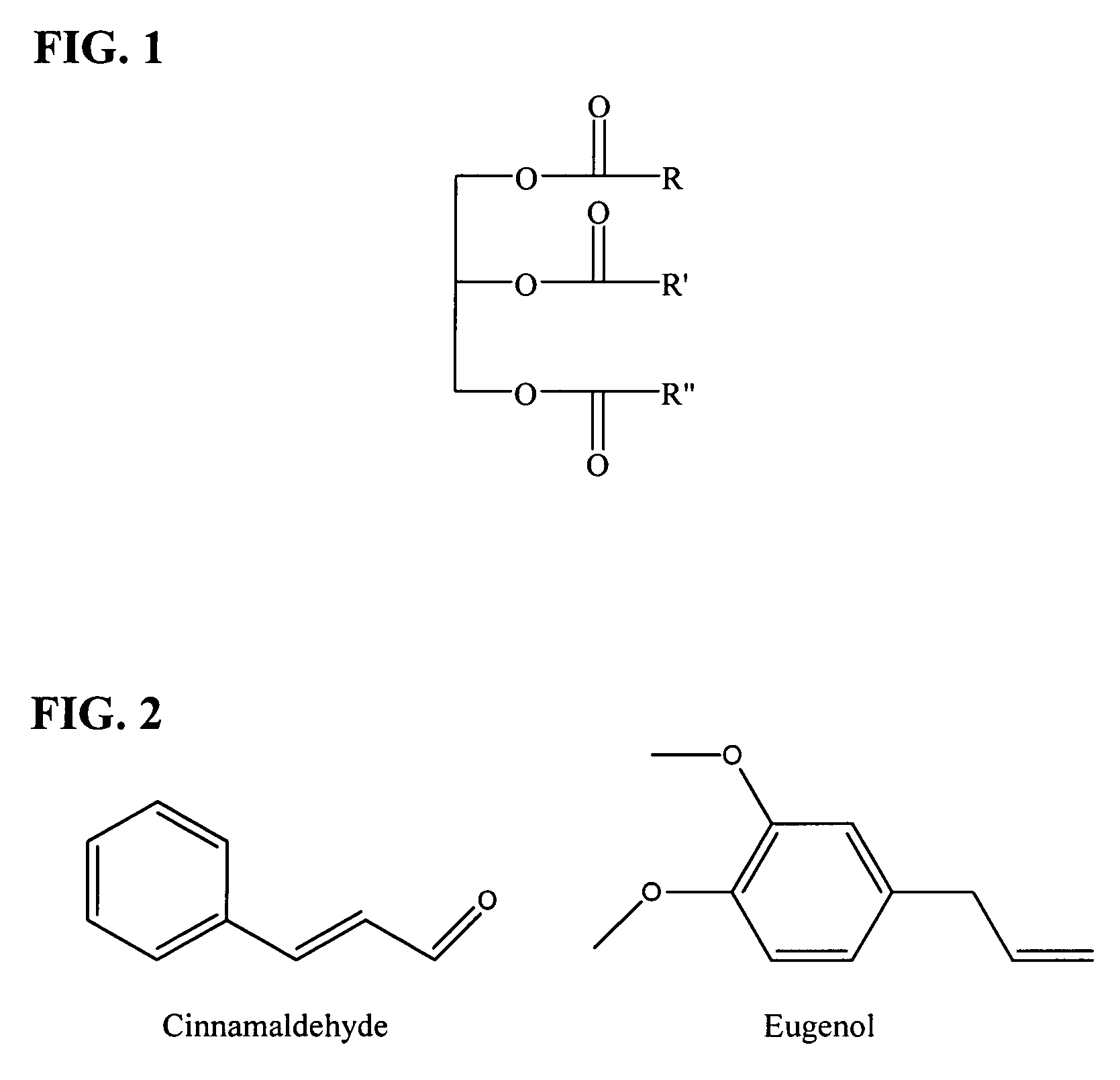

Method for the froth flotation of coal

The present invention relates to the beneficiation of coal by the process of froth flotation and specifically relates to a process for the froth flotation of coal using a collector consisting essentially of a fatty acid monoester of a polyol, a fatty acid diester of a polyol, or a mixture thereof.

Owner:INGEVITY SOUTH CAROLINA

Separation of minerals

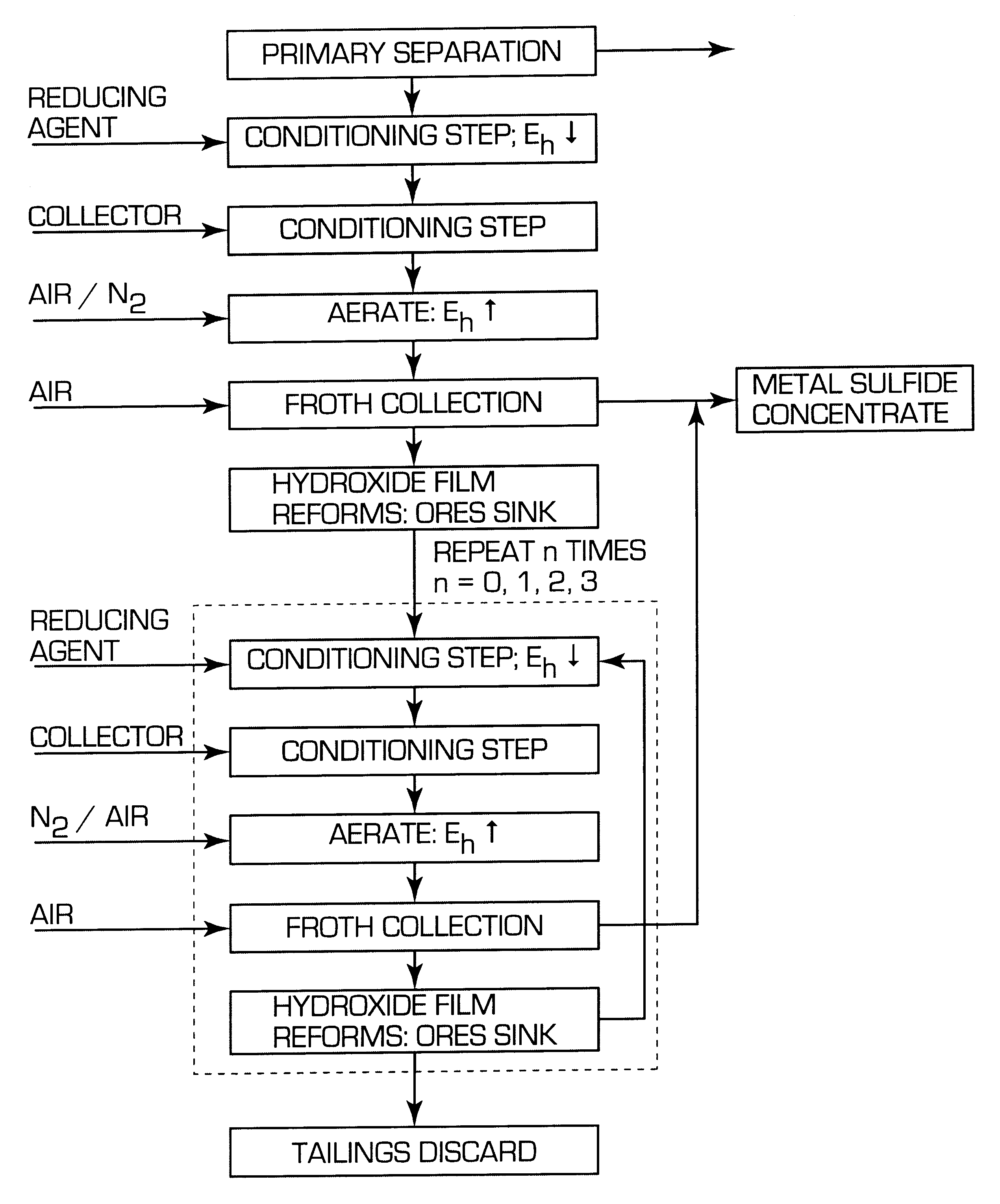

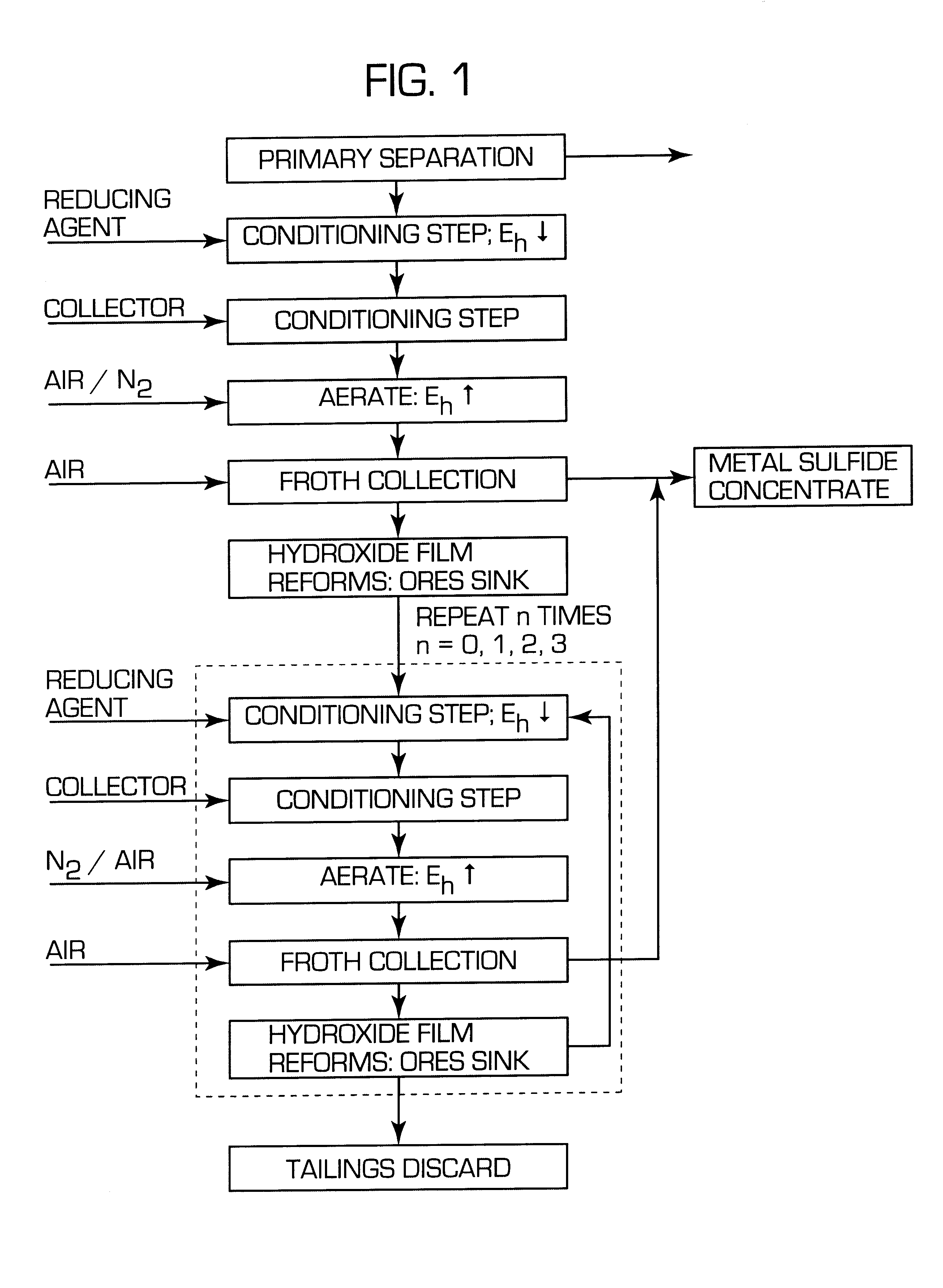

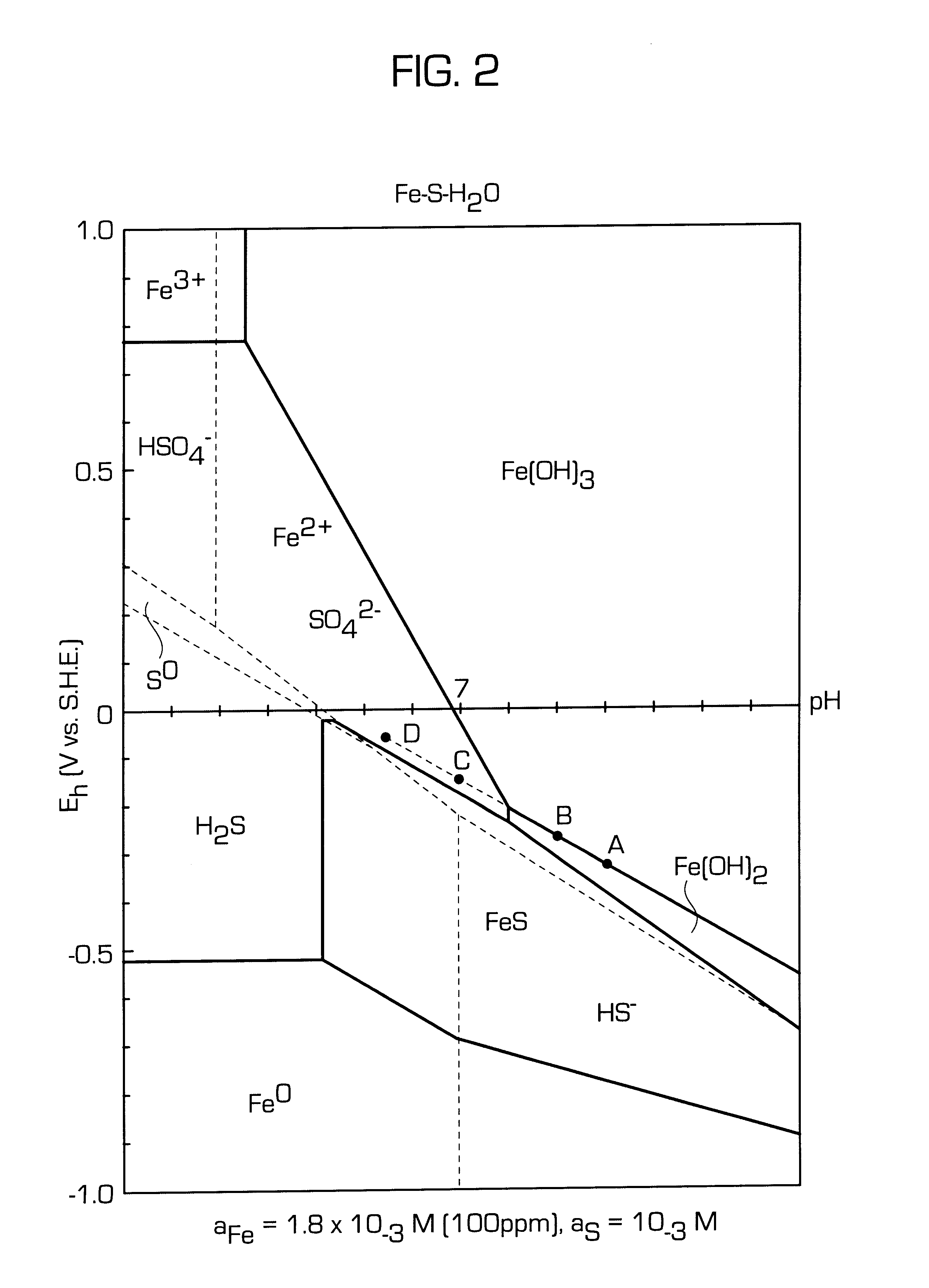

A process for floating fine particles containing metal values of an iron-bearing sulphide mineral ore including the steps of conditioning the aqueous pulp of ore at a pH of between about 7 and about 10 with a reducing agent which is preferably oxy-sulphur compound which dissociates to form oxy-sulphur ions having the general formula:where n is greater than 1; y is greater than 2; and z is the valance of the ion.A suitable collector is then added to the conditioned aqueous pulp to further condition the pulp and the pulp potential of the pulp raised to a sufficient level for the collector to adsorb onto the sulphide mineral ore. Gas is then bubbled through the aqueous pulp to subject the pulp to froth flotation. The froth from the flotation process is recovered to produce a concentrate of fine sulphide mineral and other metal values.By conditioning the aqueous pulp at a pulp potential which dissolves the iron hydroxide film from the surface of the metal sulphide inclusions in the ore and subjecting the ore to froth flotation at a suitable pulp potential before the iron hydroxide can reform, the recovery of metal values in the fine ores can be greatly enhanced.

Owner:COMMONWEALTH SCI & IND RES ORG

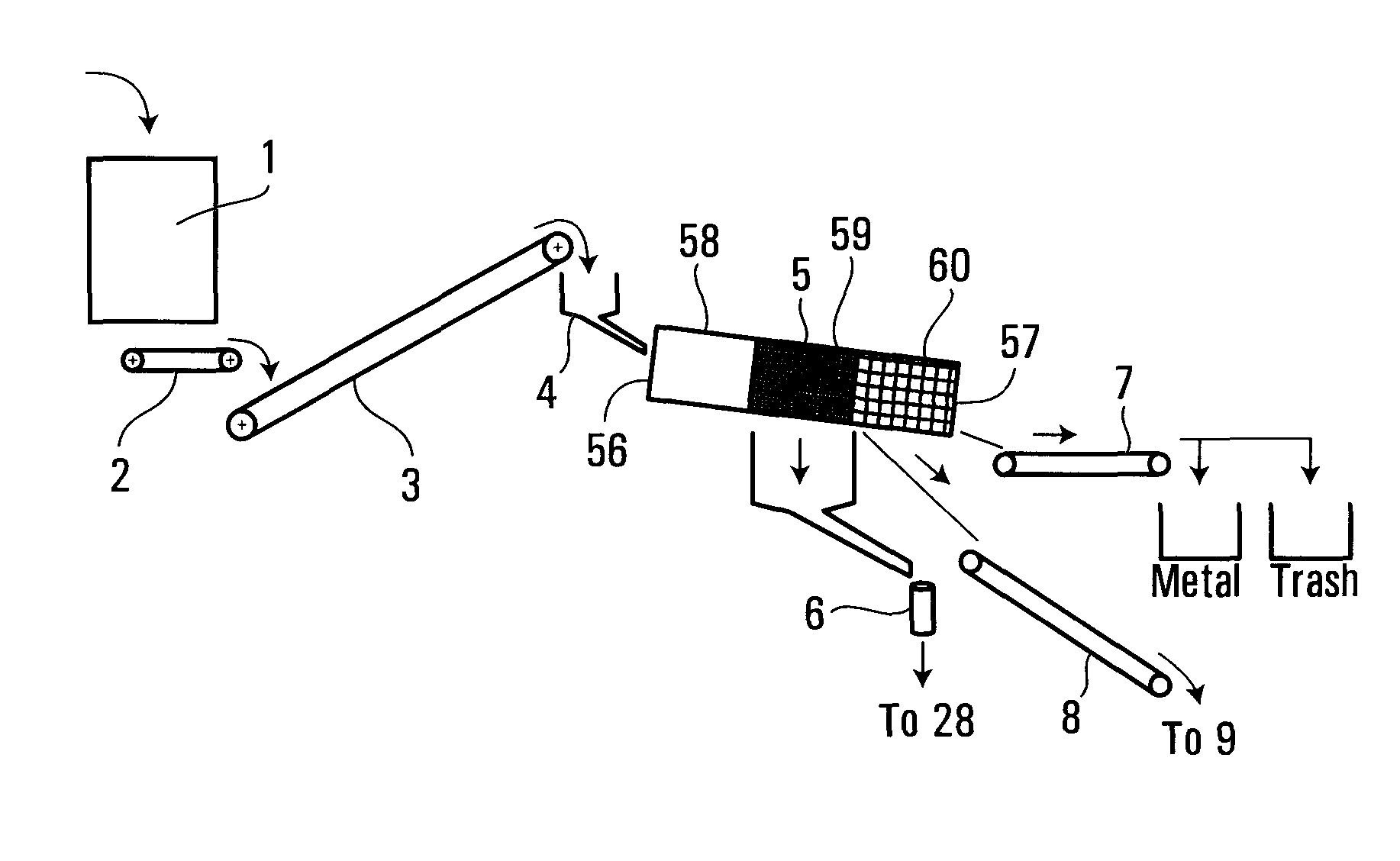

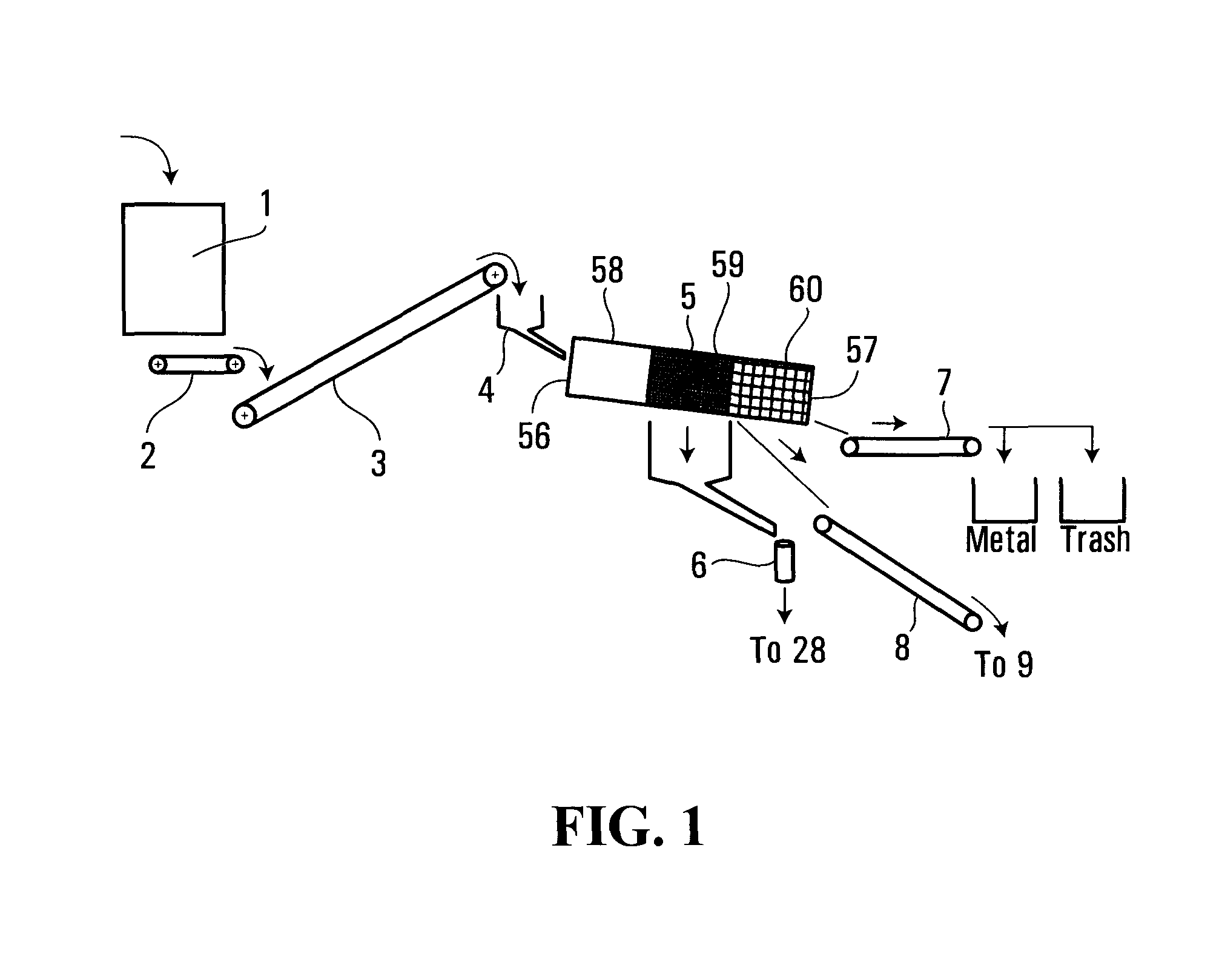

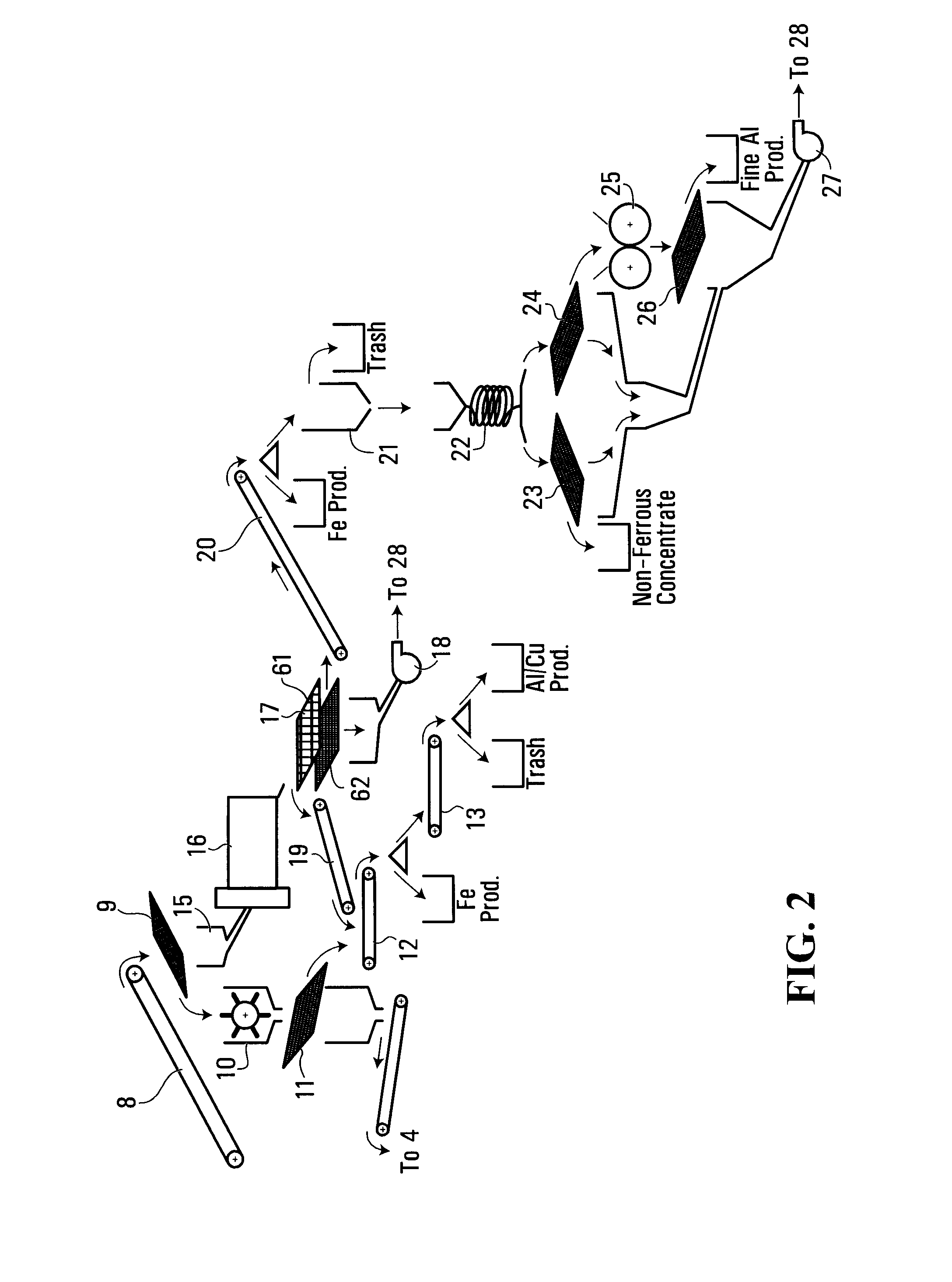

Methods of and systems for treating incinerated waste

One method of treating incinerated waste comprises: size separating at least some of the incinerated waste into a first undersize fraction comprising particles smaller than the first separation size and into a first oversize fraction comprising particles larger than the first separation size; size reducing at least some of the first oversize fraction; size separating at least some of the size-reduced first oversize fraction into a second undersize fraction comprising particles smaller than the second separation size and into a second oversize fraction comprising particles larger than the second separation size; combining at least some of the first undersize fraction and at least some of the second undersize fraction into a fine fraction; and extracting metal from at least some of the fine fraction. Another method of treating incinerated waste comprises extracting metal by froth flotation from at least some of the incinerated waste. Systems are also disclosed.

Owner:BLUE SKY MINES

Foam flotation method capable of separating silicon powder and carbon silicon powder

InactiveCN101491888AEasy to combineGuaranteed separation effectFlotationGrinding/polishing safety devicesLiquid layerSeparation technology

The invention relates to technology for the powder separation of silicon and carborundum in mortar produced in a silicon chip wire sawing process in the field of solar photovoltaic, in particular to a foam flotation method for separating silicon from carborundum. The foam flotation method for separting silicon power and carborundum powder comprises the following steps of: adding a finishing agent into mortar produced in a silicon chip wire sawing process according to a principle of 100 to 1,000 weight portions of mortar and 100 to 1,000 weight portions of finishing agent; and stirring the mortar and the finishing agent uniformly, allowing the mixture to settle in three layers, and collecting the upper layer of carborundum and the lower layer of silicon power respectively, wherein the middle layer is a liquid layer. The finishing agent is prepared by mixing a solvent and surface modifier according to a principle of 99 to 70 percent of solvent and 1 to 30 percent of surface modifier. The content of the residual carborundum of the collected silicon powder is less than 0.5 volume percent and the content of the residual silicon in the mortar is less than 10 volume percent.

Owner:NANCHANG UNIV

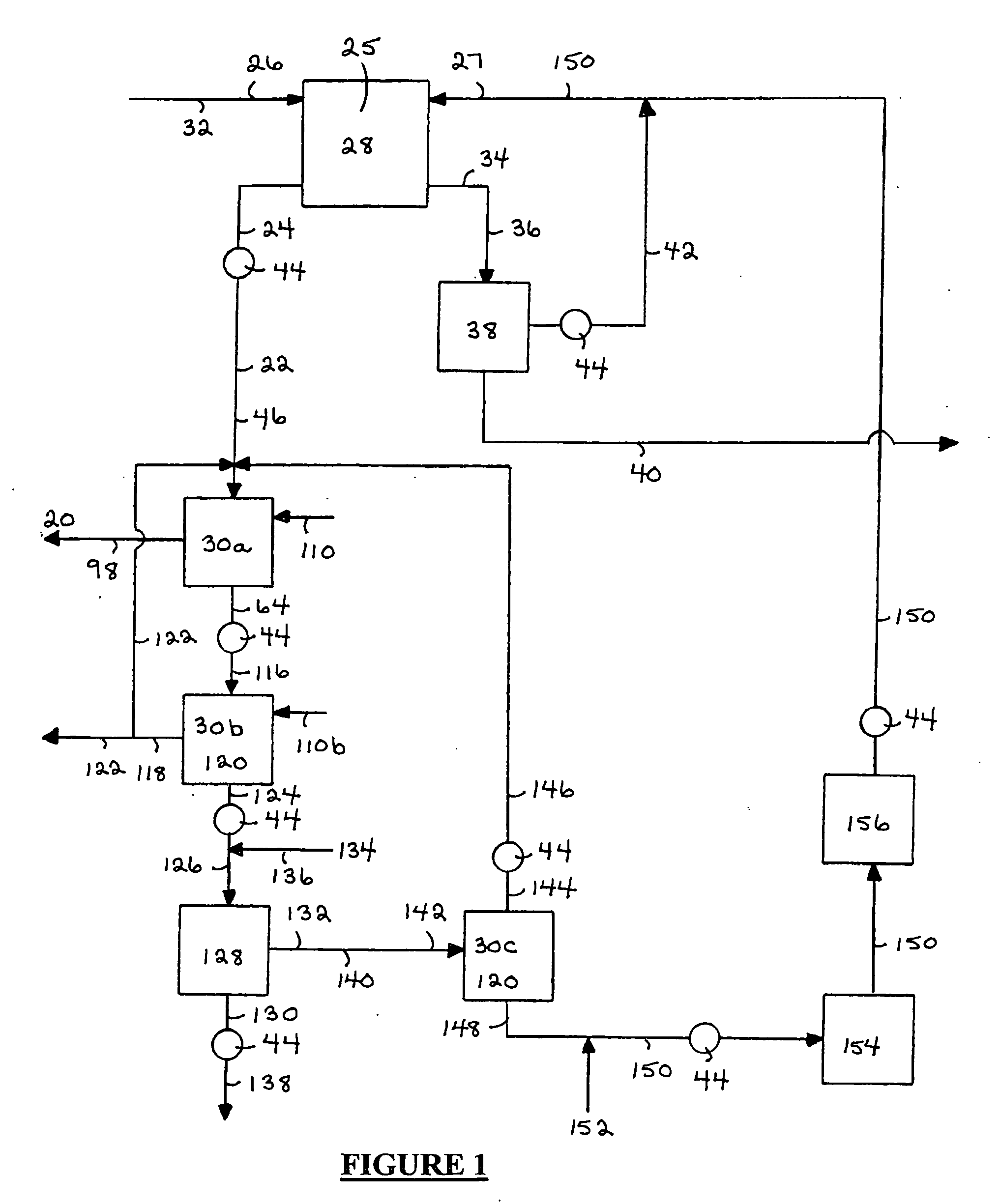

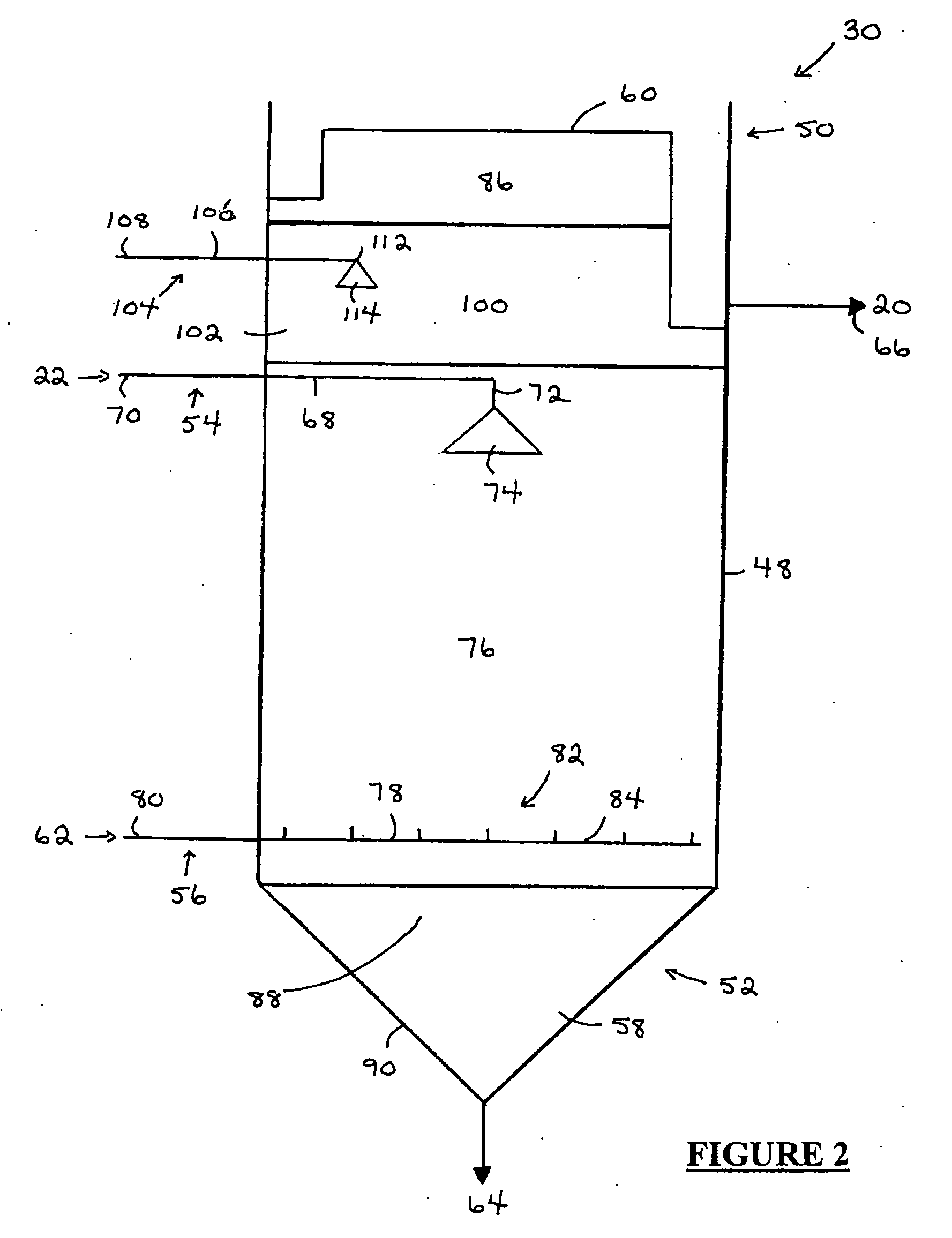

Bitumen recovery process for oil sand

ActiveUS20070090025A1Aid in recovery of bitumenGood choiceFloating sedimentation devicesLiquid hydrocarbon mixture productionProcess engineeringSlurry

A bitumen recovery process is provided which includes the step of providing a bitumen froth or a component derived from the bitumen froth as a feed material, wherein the bitumen froth is produced in a primary separation process from a slurry comprising oil sand and water. Further, the process includes the step of subjecting the feed material to froth flotation in a column flotation cell in order to recover a bitumen product from the feed material. Preferably, the froth flotation cell includes an underwash zone, wherein a bitumen-rich fraction of the feed material is passed through the underwash zone as the bitumen-rich fraction rises within the column flotation cell.

Owner:BITMIN RESOURCES

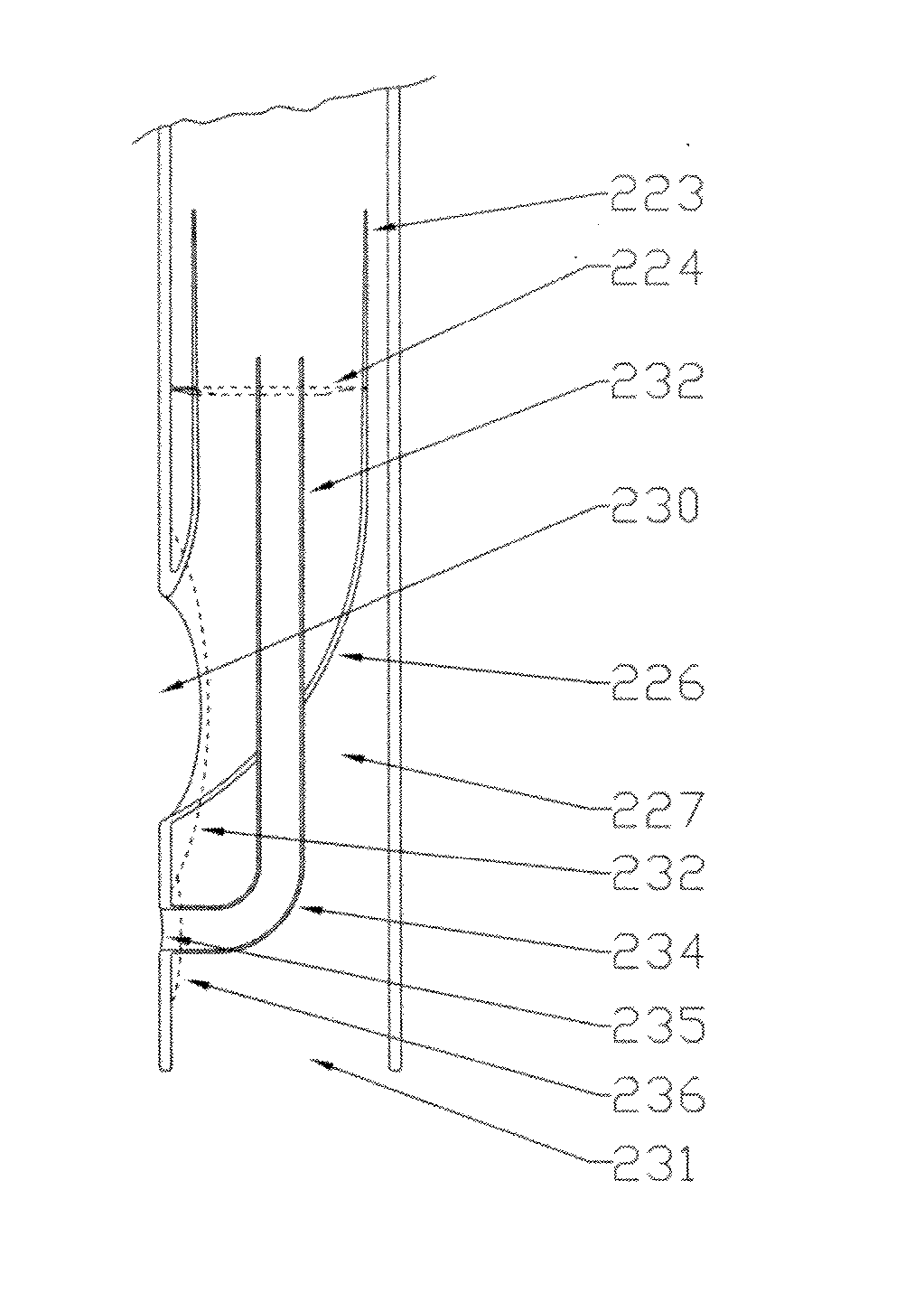

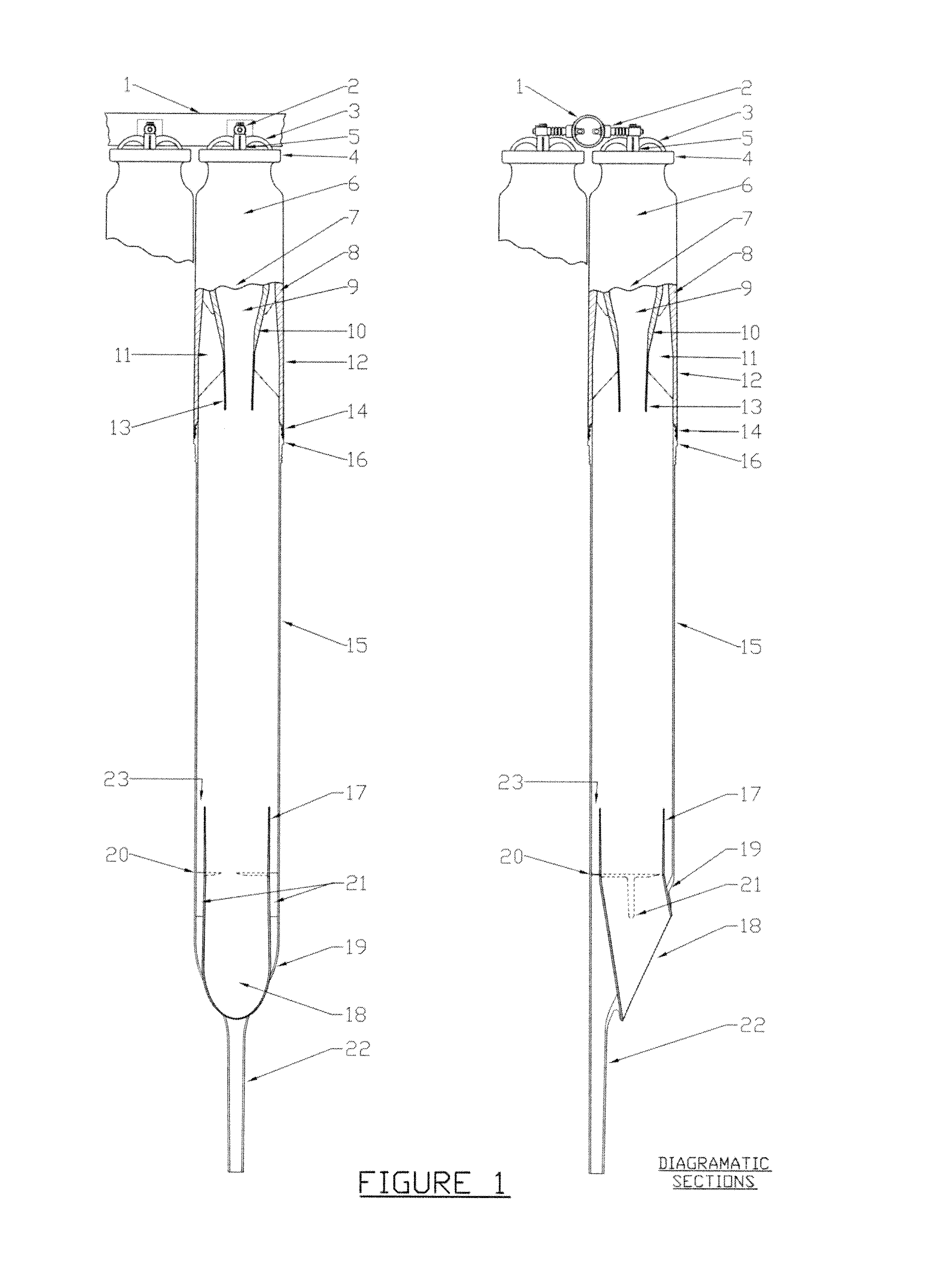

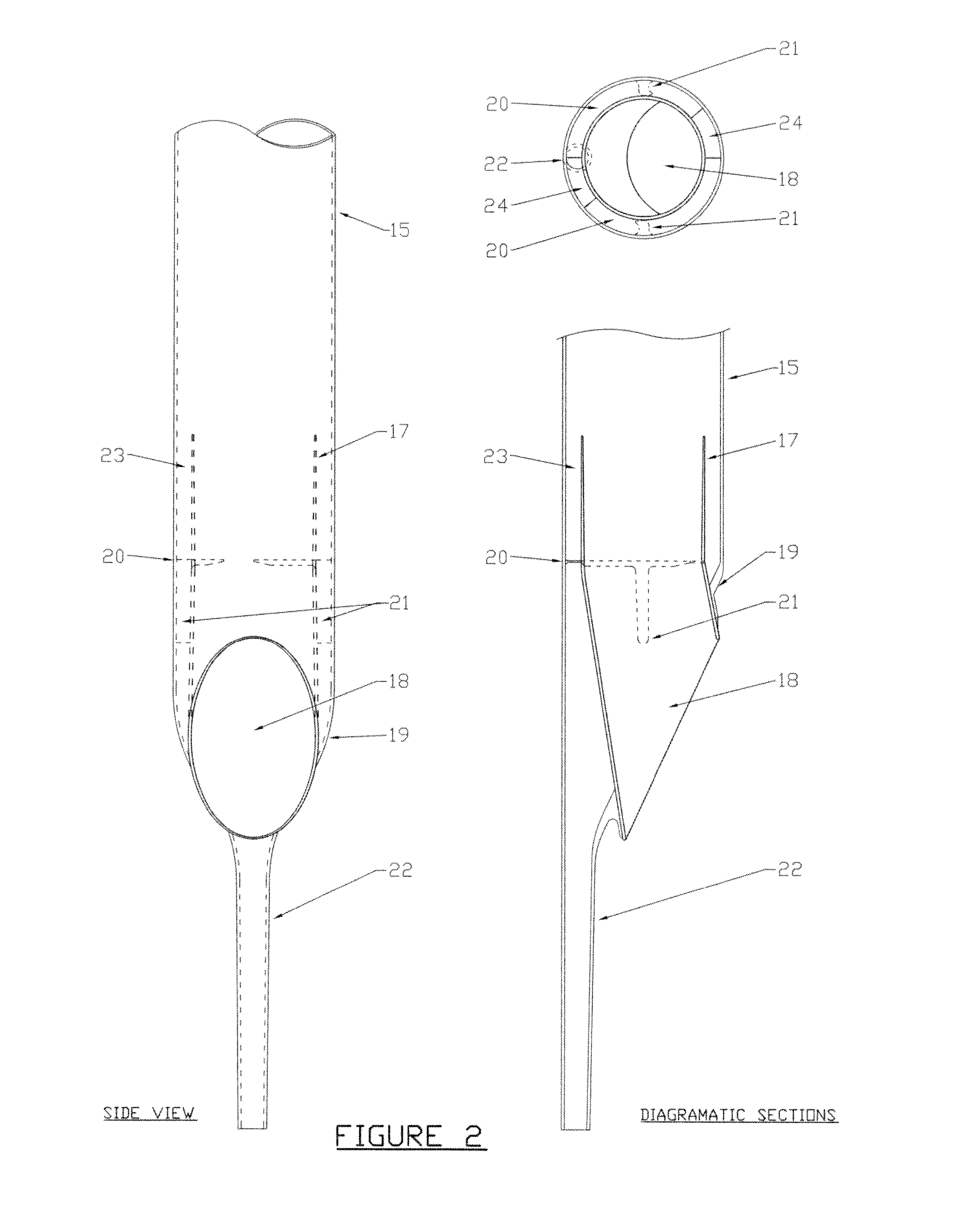

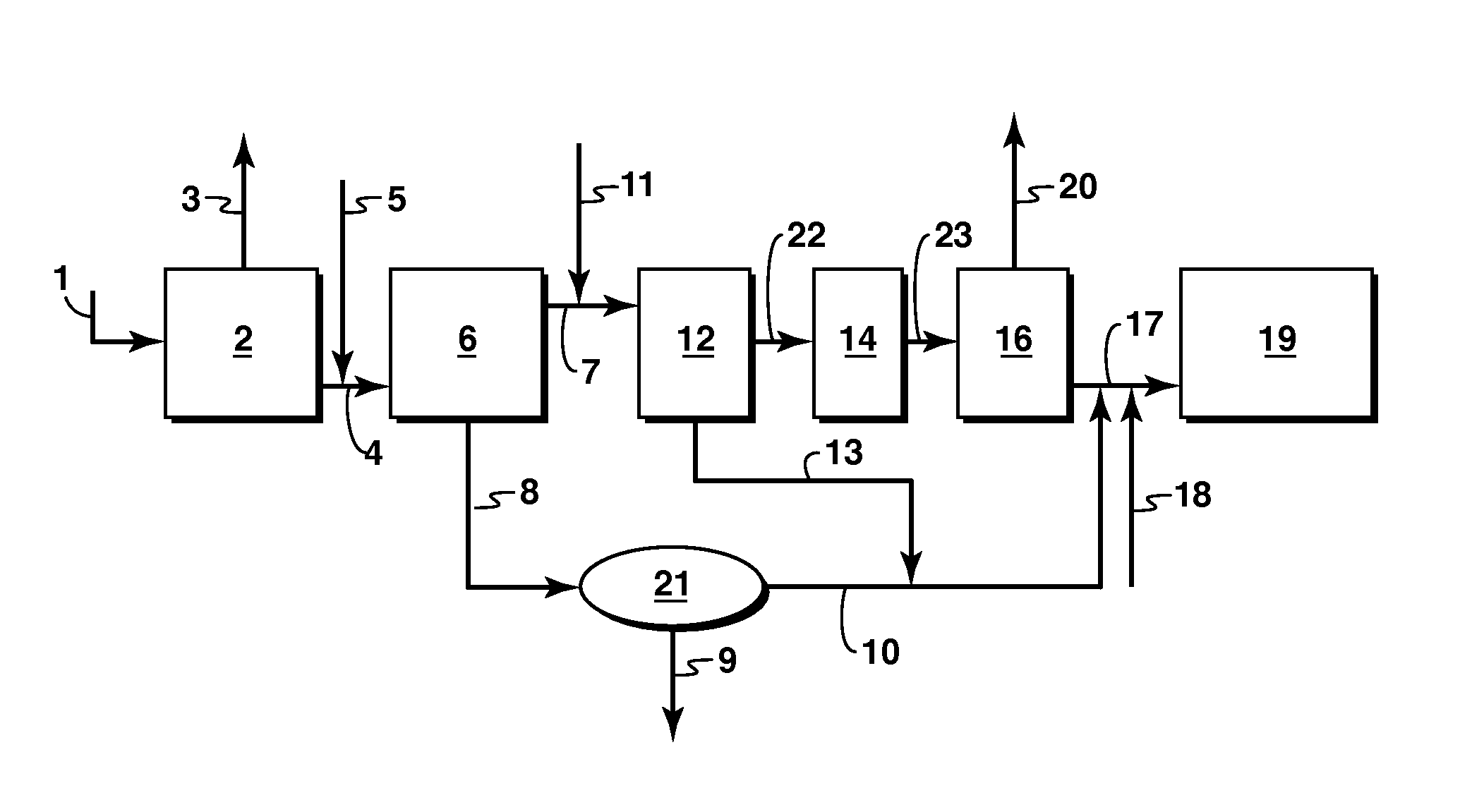

Apparatus for separation and processing of materials

ActiveUS20140225286A1Effectively frictionlessFineness is limitedLiquid degasificationReversed direction vortexCyclonic separationEngineering

This invention relates to a tubular cyclonic separation device the style of which was presented in PCT / ZA2003 / 000160 and which enables all of the inlet and outlet connections to be completely contained within a tubular profile, the diameter of which is that of the body of the cyclonic section. This disclosure adds further novel and inventive developments to the cyclonic device which enable it to be used as a separating device for systems involving all three phases (gas, liquid and solid) and where two, three or more different product streams may be separated, all within the same cylindrical profile. These further inventive developments also relate to the use of externally supplied gas and / or additional liquid phases which are injected through the walls of the cyclonic body using specifically located slots and / or holes in combination with specifically located stepped edges. These further novel and inventive developments enable the concepts of froth floatation (FF) and Dispersed Air Floatation (DAF) to be exploited within an enhanced gravitational field together with the options for washing the separated froth and / or the separated heavier fractions, all within the same cyclonic unit. As part of the novel and inventive introduction of the stepped edges, means are provided whereby gas bubbles smaller than 30 microns can be created on a large scale and with a reduced energy input relative to typical conventional equipment. Also the size of the gas bubbles may be controlled together with the intensity of any particle on particle interactions that may be created. This latter has many potential applications within FF and / or DAF processes, including applications within oil and tar separation from solid surfaces and within many ore preparation and ore leaching processes. The tubular profile enables processing and separation to be achieved “within the pipe line” or for very closely packed arrangements to be assembled within carrier vessels.

Owner:CYDAF TECH

6-aryl amido hexyl hydroximic acid collecting agent and preparation and application methods thereof

ActiveCN103301953AStrong harvesting abilityImprove flotation recoveryFlotationPotassium hydroxideSodium hydroxide

The invention discloses a 6-aryl amido hexyl hydroximic acid collecting agent and preparation and application methods thereof. 6-aryl amido hexyl hydroximic acid represented by a formula (I) is taken as a collecting agent and utilized in flotation of tungsten ore, tombarthite ore, tin ore or bauxite, wherein R represents H or C1-8 alkyl. 6-aryl amido hexyl hydroximic acid and sodium hydroxide, potassium hydroxide or ammonium hydroxide are put into water to prepare an aqueous solution of 6-aryl amido hexyl hydroxyoximate; a flotation reagent is added for size mixing during an ore grinding and / or flotation process, the added reagent at least contains the aqueous solution of 6-aryl amido hexyl hydroxyoximate, and the dosage of 6-aryl amido hexyl hydroximic acid ranges from 100g / t to 3,500g / t; and useful metallic minerals are floated out through a froth flotation method, and the flotation recovery rate can be increased by 2%-5%.

Owner:CENT SOUTH UNIV

Method for flotation after acid etching pretreatment of high-calcium fluorite

The invention discloses a method for flotation after acid etching pretreatment of high-calcium fluorite. Acid is added into high-calcium fluorite pulp before flotation, inhibitors are added while the acid is added, and acid etching pretreatment is carried out; pH regulators and collecting agents are sequentially added after pretreatment is completed, and then air agitation pulp mixing is carried out; foam flotation is carried out after pulp mixing is completed, and rough concentrate is obtained; and the rough concentrate is further subjected to concentration to obtain high-quality fluorite concentrate. The method is clean, environmentally friendly, efficient and low in cost, and the obtained fluorite concentrate is high in grade and recovery rate.

Owner:CENT SOUTH UNIV

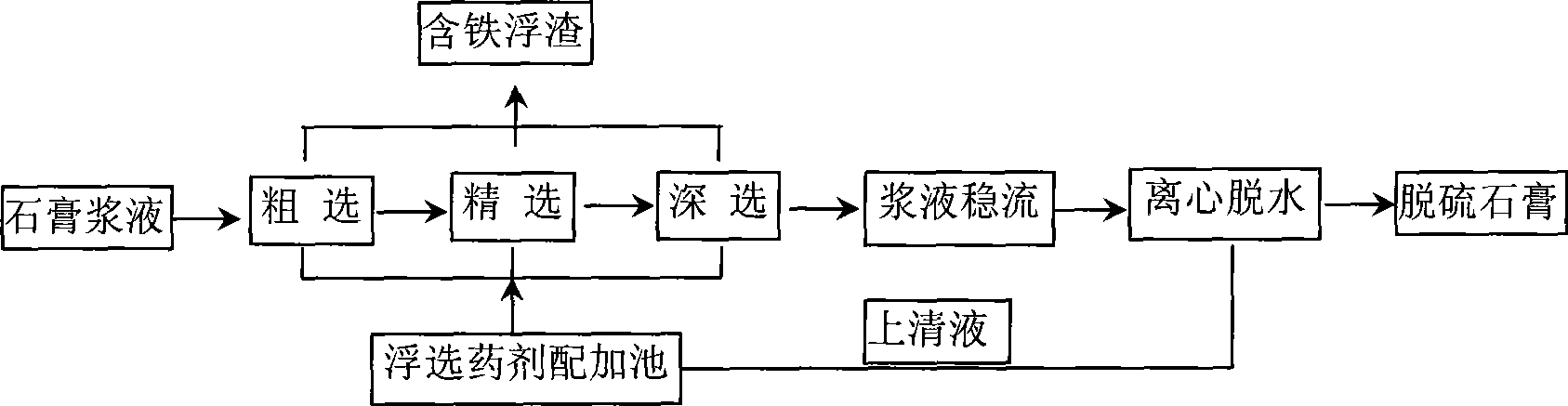

Purification method of sintered flue gas desulfurization gypsum

ActiveCN101397148ARealize impurity removal and separationAvoid the disadvantages of poor separation effectCalcium/strontium/barium sulfatesPurification methodsSlurry

The invention discloses a method for purifying sintering flue gas desulfurized gypsum and is characterized in that the following steps are included: (1) the reverse flotation technology: one or the combination of no less than two of rough flotation, selectiveness flotation and deep flotation; (2) steady flow, the steady flow is carried out on the serious fluid after reverse flotation by adopting a steady flow device; (3) centrifugal dehydration, solid-liquid separation is carried out on the serious fluid after steady flow by adopting a centrifugal dehydration device. The method can overcome the shortcomings that the dehydration performance of the serious fluid of desulfurized gypsum is not good, the color of the by-product gypsum is deep and the content of impurities is high in the prior art, and the desulfurized gypsum with high quality and high whiteness is obtained, meanwhile, the scum containing iron obtained in the by-product can be returned to the sintering process for re-utilization. Moreover, the device of the process is compact and occupies small area, investment is small, and operation is steady.

Owner:BAOSHAN IRON & STEEL CO LTD

Method and system for reclaiming waste hydrocarbon from tailings using solvent sequencing

InactiveUS8454821B2Working-up pitch/asphalt/bitumen by selective extractionLiquid hydrocarbon mixture productionParaffin waxEmulsion

Owner:EXXONMOBIL UPSTREAM RES CO

Collophanite froth flotation collecting agent and preparation method thereof

The invention provides a collophanite froth flotation collecting agent and a preparation method of the collophanite froth flotation collecting agent. The collophanite froth flotation collecting agent comprises, by mass, 0.3-0.75 part of stearic acid, 0.2-0.5 part of oleic acid and 0.05-0.2 part of citric acid. The stearic acid and the oleic acid are uniformly mixed, a sodium hydroxide solution is added for a saponification reaction, the citric acid is added and uniformly mixed, sodium chloride is added for salting out, a surface active agent is added, a primary substance is obtained after uniform stirring is conducted, diesel oil is added and uniformly stirred, and the collophanite froth flotation collecting agent can be obtained. The obtained collophanite froth flotation collecting agent is good in selectivity, high in collecting capacity, high in flotation speed and small in material consumption. Only 1.0 kg-2 kg / t of the collecting agent is consumed for each ton of ore, 20%-40% of the collophanite froth flotation collecting agent is reduced compared with a conventional collecting agent, and 2.5 yuan of agent cost is saved for each ton of raw ore. The collecting agent is used for positive floatation roughing, only three minutes are consumed for flotation, and 4-6 minutes needs to be consumed for the conventional collecting agent.

Owner:YUNNAN COPPER IND SUNWARD CHEM

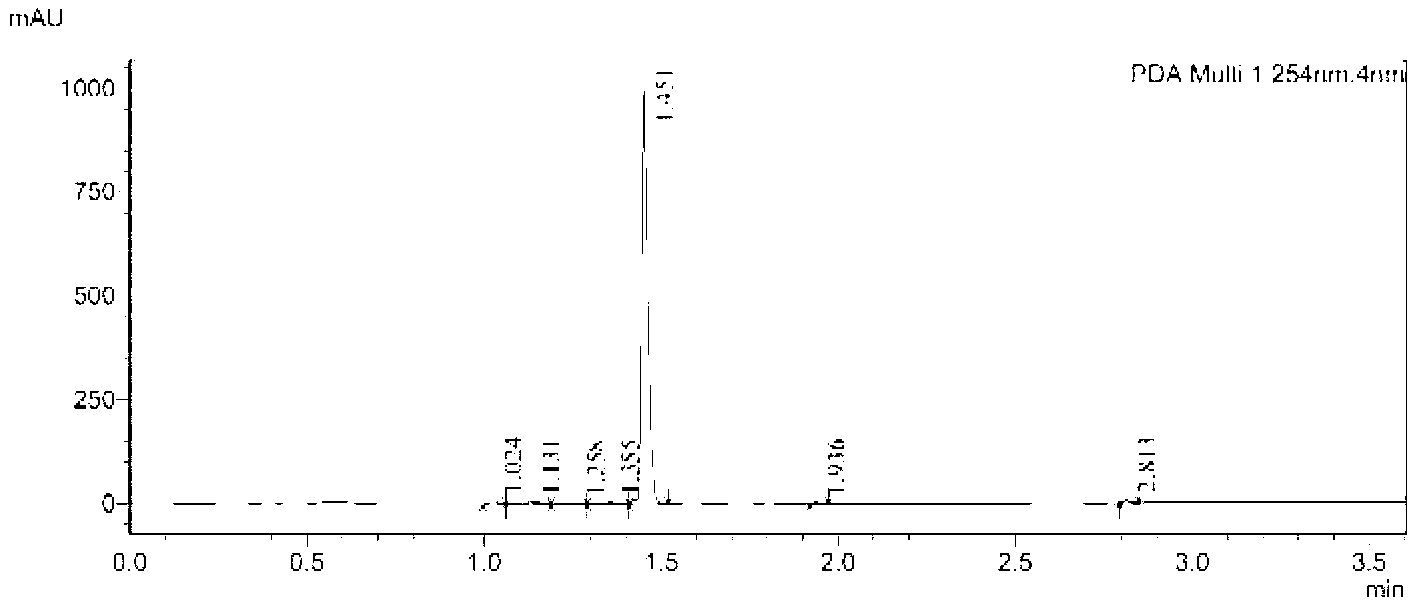

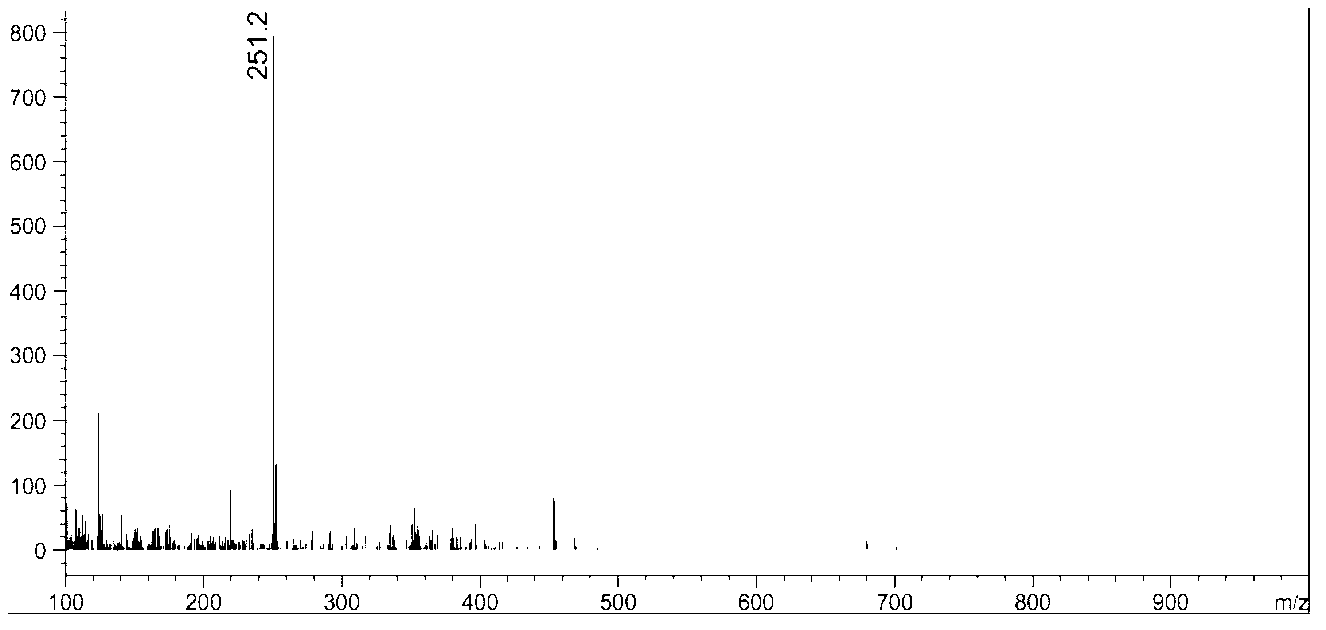

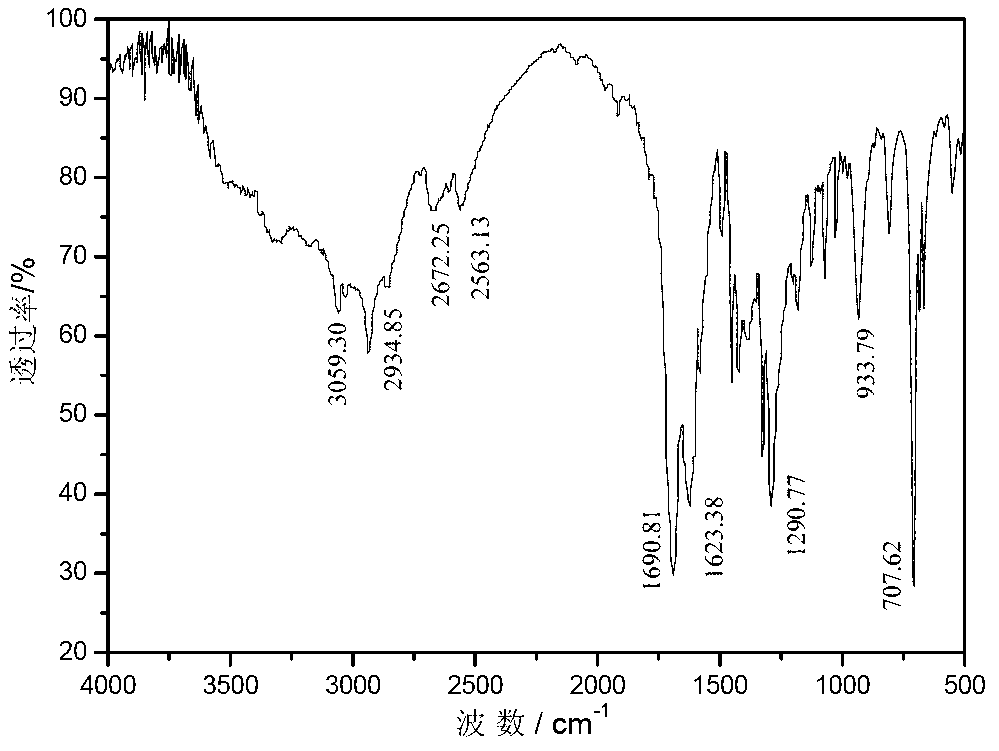

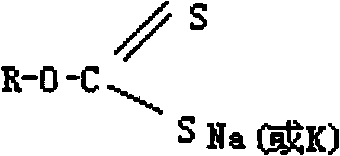

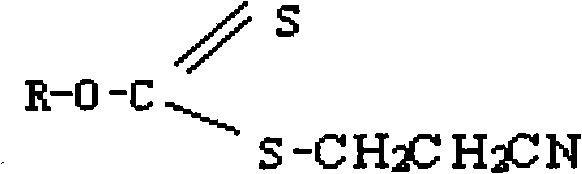

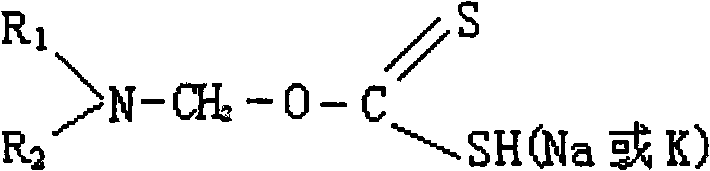

Amino methyl xanthogenic acid cyanogen ethyl ester compound and preparation method as well as collector thereof

InactiveCN102464599ALight weightReduce solubilityOrganic chemistryFlotationSolubilityMineral flotation

The invention relates to an amino methyl xanthogenic acid cyanogen ethyl ester compound and a preparation method thereof; and the compound can serve as a metallic mineral flotation collector to be used for recycling sulphide ore or oxidized ore containing metals in foam flotation. The aim of the invention is to provide the amino methyl xanthogenic acid cyanogen ethyl ester compound and the preparation method thereof. The other aim of the invention is to provide the amino methyl xanthogenic acid cyanogen ethyl ester to serve as a new sulfide mineral or oxidized mineral flotation collector and an application method of the flotation collector so as to enrich the variety of the xanthogenic acid cyanogen methyl ester collector and enlarge the range of selection of a flotation agent. The amino mthyl xanthogenic acid cyanogen ethyl ester compound synthesized by the method is generally of oily liquid, has special smell and little solubility and is slightly lower than water in specific gravity; the product is not needed to be purified and separated; and the mixed product containing impurities has better ore dressing and collecting performance for the metallic minerals. The preparation process is simple, efficient and economic; and the crude product can be used as the flotation collector; and the conversion yield of the crude product is in the range of 65%-100%.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

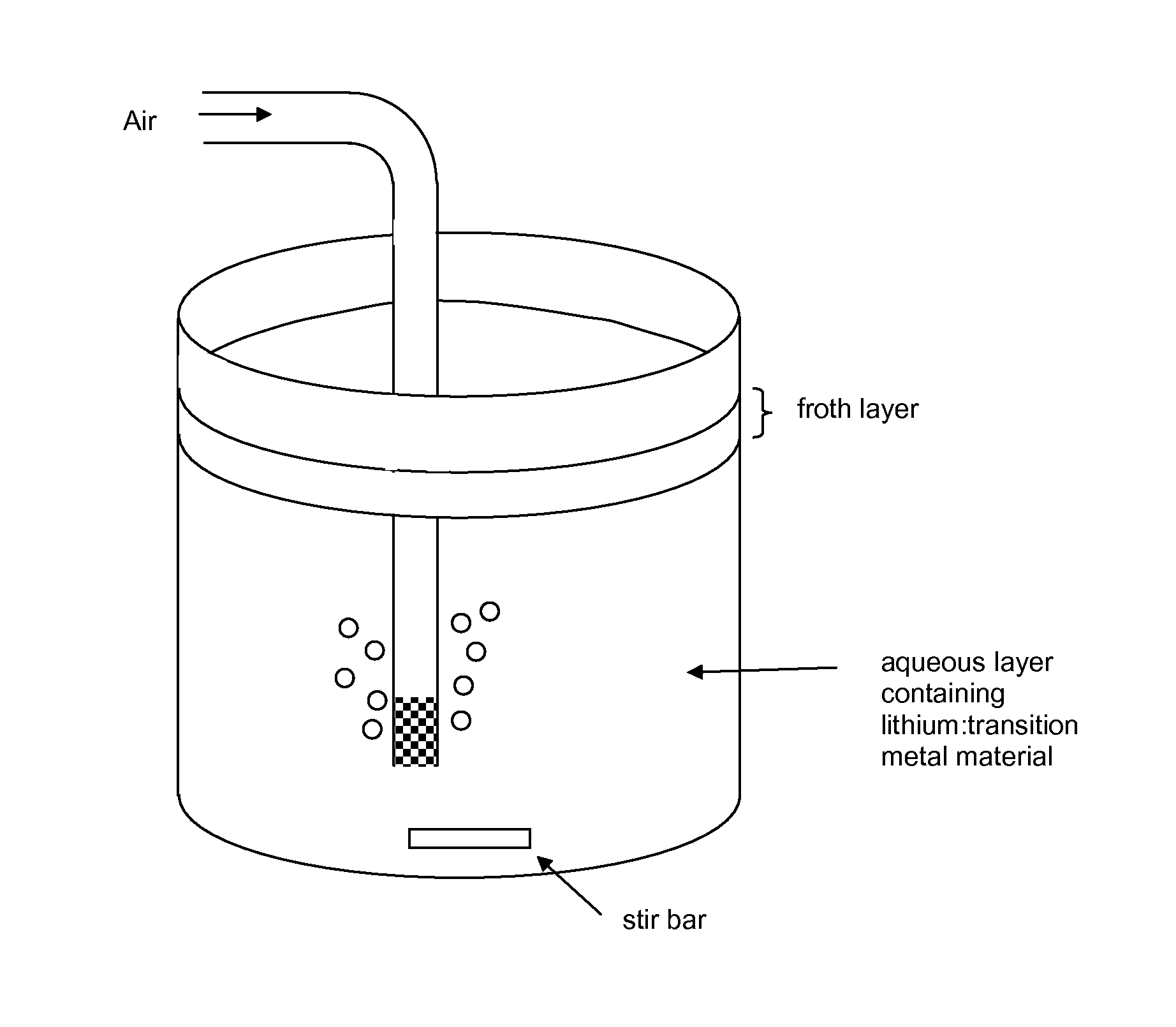

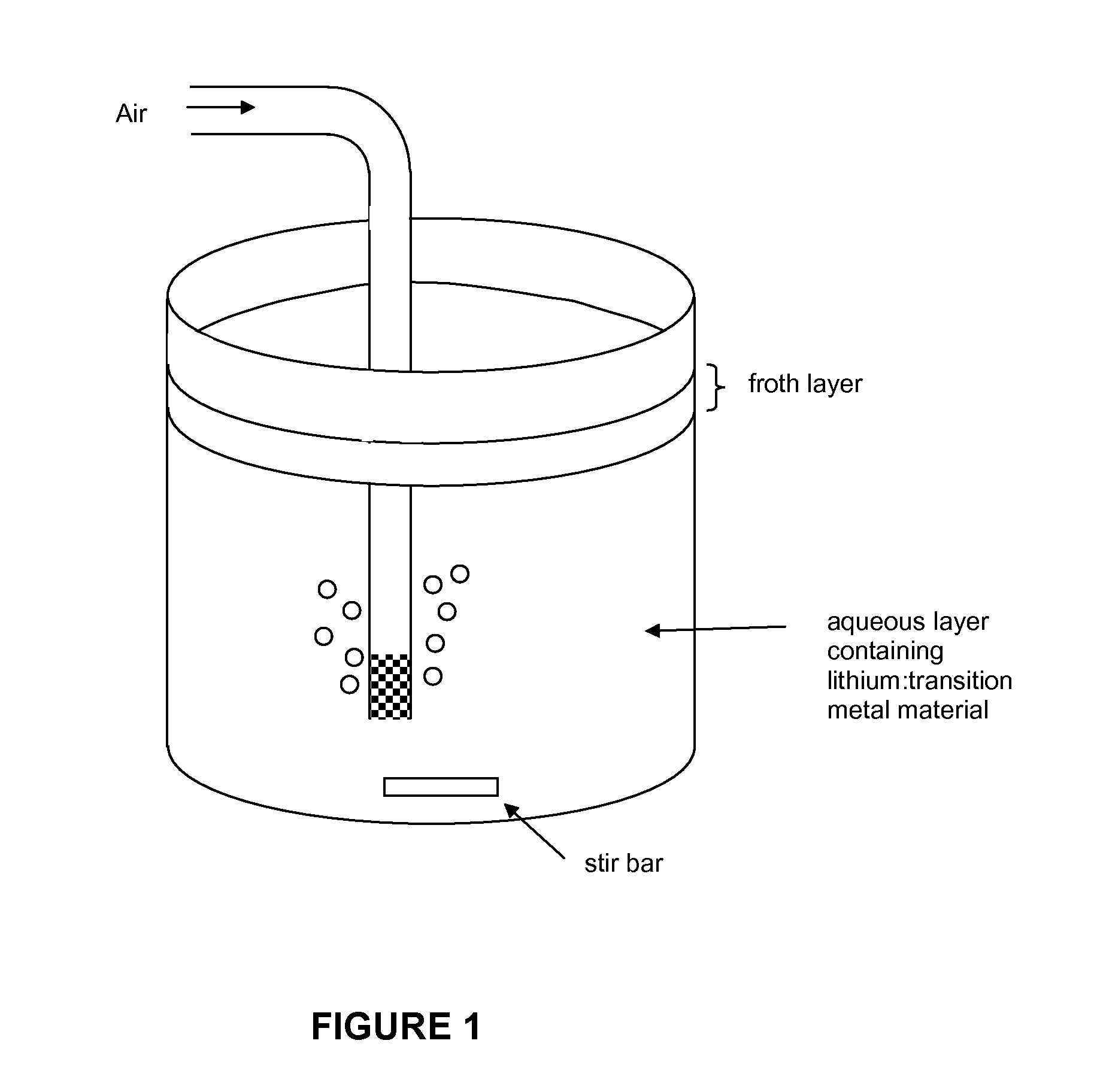

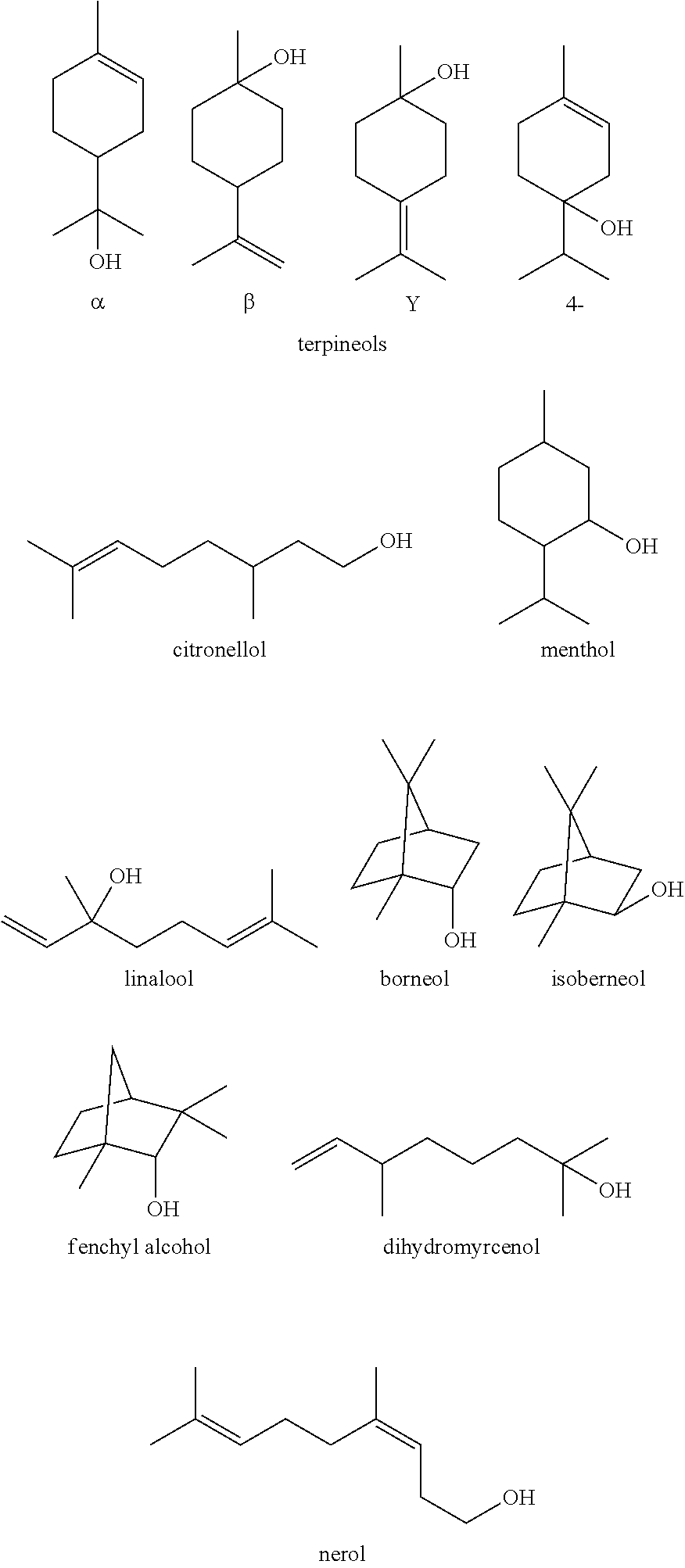

Method for the recovery of lithium cobalt oxide from lithium ion batteries

A method of recovering lithium cobalt oxide from spent lithium ion batteries, wherein said method is more environmentally friendly than the methods presently known in the art. The method includes a froth flotation step using renewable and biodegradable solvents such as terpenes and formally hydrated terpenes. The method can also include a relithiation step to return the Li:Co ratio back to about 1:1 for use in second-life applications.

Owner:WARNER BABCOCK INST FOR GREEN CHEM

Water-soluble weathering phosphorite mineral foam flotation collecting agent

The invention relates to a water-soluble weathering phosphorite mineral foam flotation collecting agent which comprises the following substances in part by weight: 40-50 parts of cotton oleic acid, 0-10 part of vegetable oleic acid and 50 parts of foaming agent. The preparation method comprises the following steps of: mixing the 40-50 parts of cotton oleic acid, 0-10 part of vegetable oleic acid and 50 parts of foaming agent, heating to 80 DEG C, and stirring until the substances are mixed uniformly. The collecting agent provided by the invention can be applied to foam floatation of phosphorite minerals similar to severe Vietnam weathering argillization, and has the characteristics of high selectivity, less using amount, simple production manufacturing technology, low mineral selection cost and high recycling ratio compared with the traditional positive flotation collecting agent of weathering phosphorite minerals.

Owner:HUBEI FORBON TECH

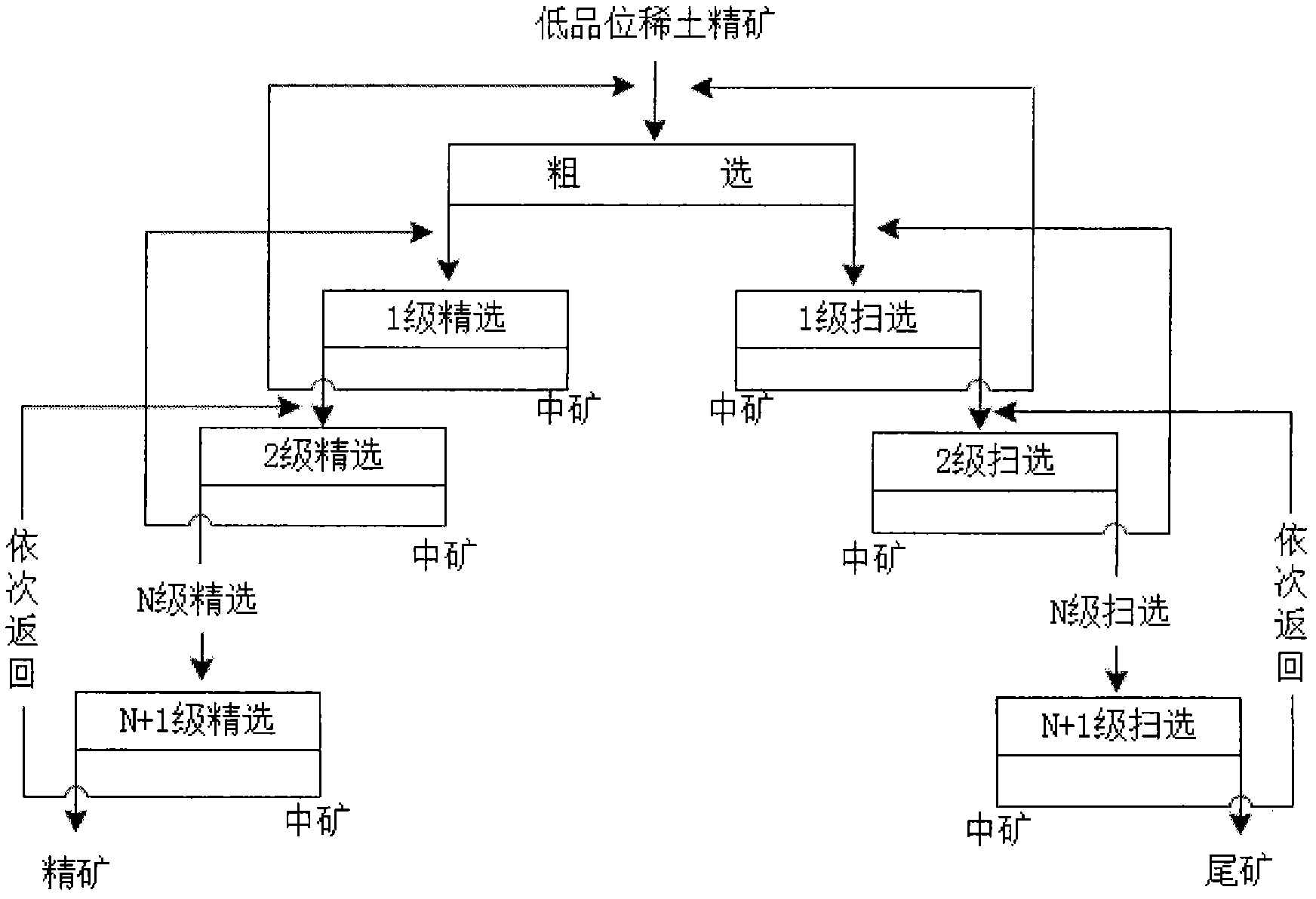

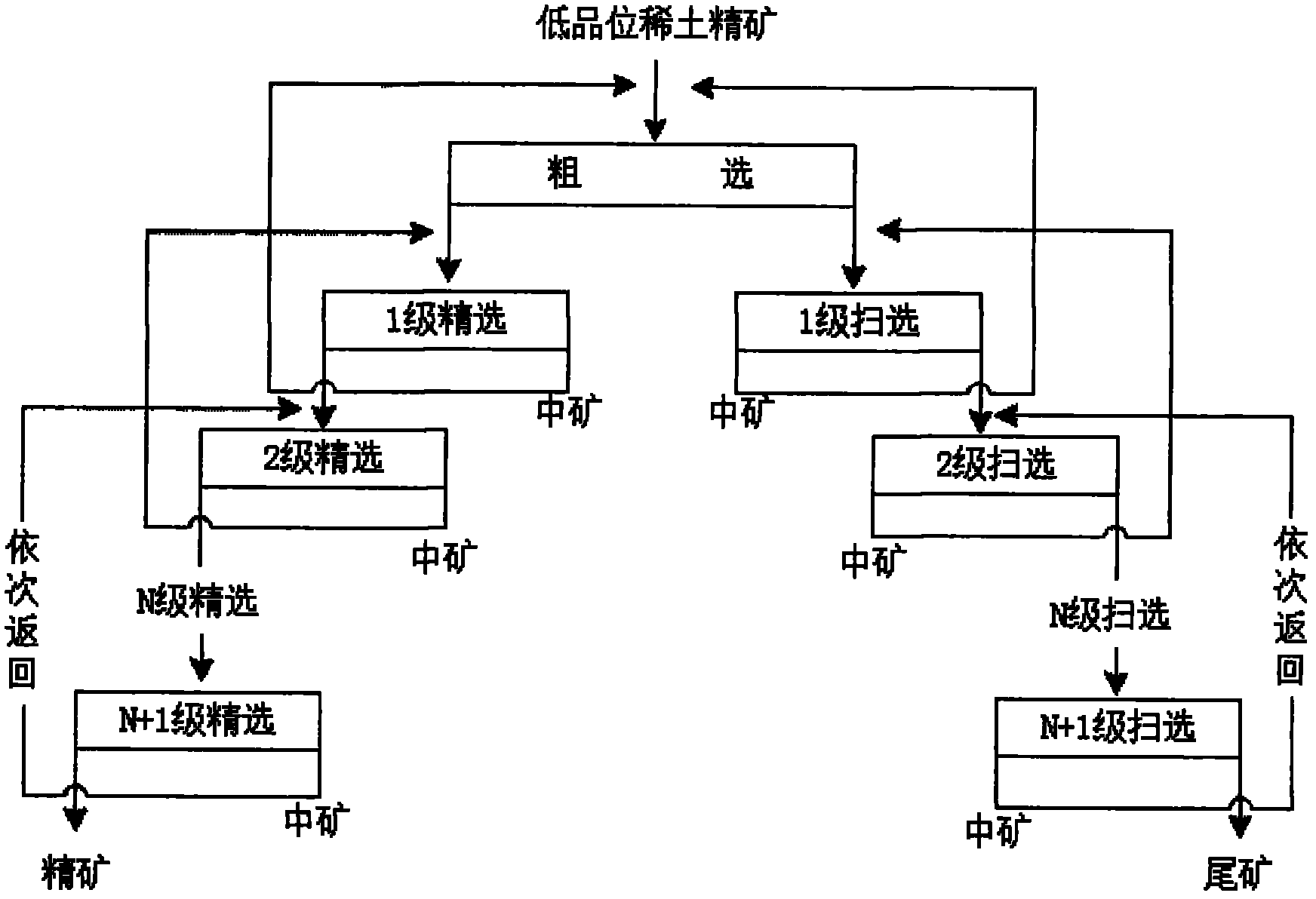

Method for improving rare earth grade of rare earth ore

The invention relates to a method for improving rare earth grade of rare earth ore, and belongs to the technical field of beneficiation technologies. The method is characterized in that: Baotou mixed rare earth ore of which the rare earth ore (REO) grade is between 30 and 60 percent and over 98 percent of which has the grain size of -200 meshes is used as a raw material and subjected to flotation, wherein the flotation comprises three continuous steps of rough flotation, fine flotation and scavenging; a beneficiation technology of closed cycle is adopted in the whole process; produced middling ore is sequentially returned for previous-stage flotation; and high-grade mixed rare earth ore concentrates and tailings with extremely low rare earth grade are only produced. By the method, high-grade rare earth ore concentrate of which the REO grade is more than or equal to 65 percent and the recovery rate is more than or equal to 88 percent can be continuously and stably produced; and the method is simple, effective and high in rare earth recovery rate, does not cause pollution, and effectively solves the awkward situation which cannot be thoroughly improved and caused by raw material problems in the traditional mixed rare earth smelting technology.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

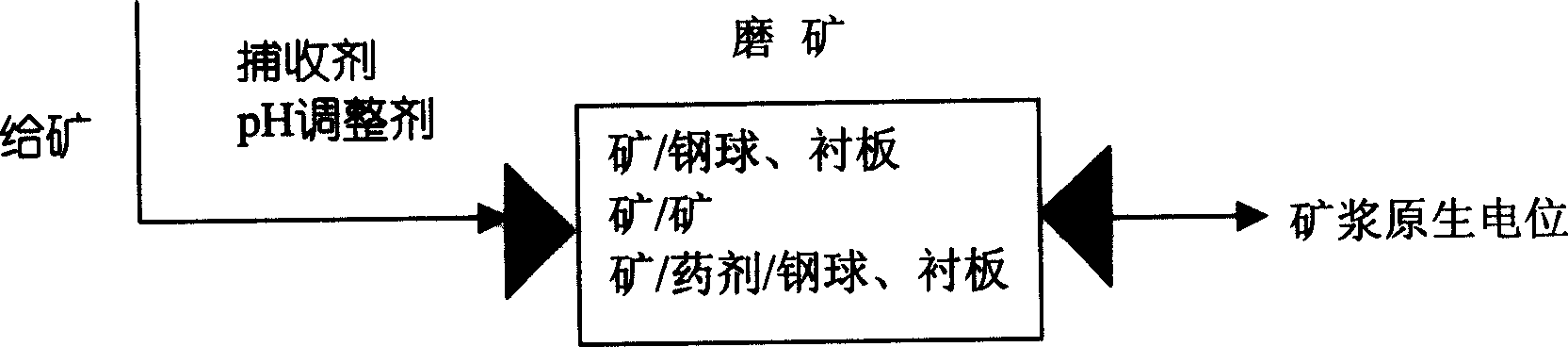

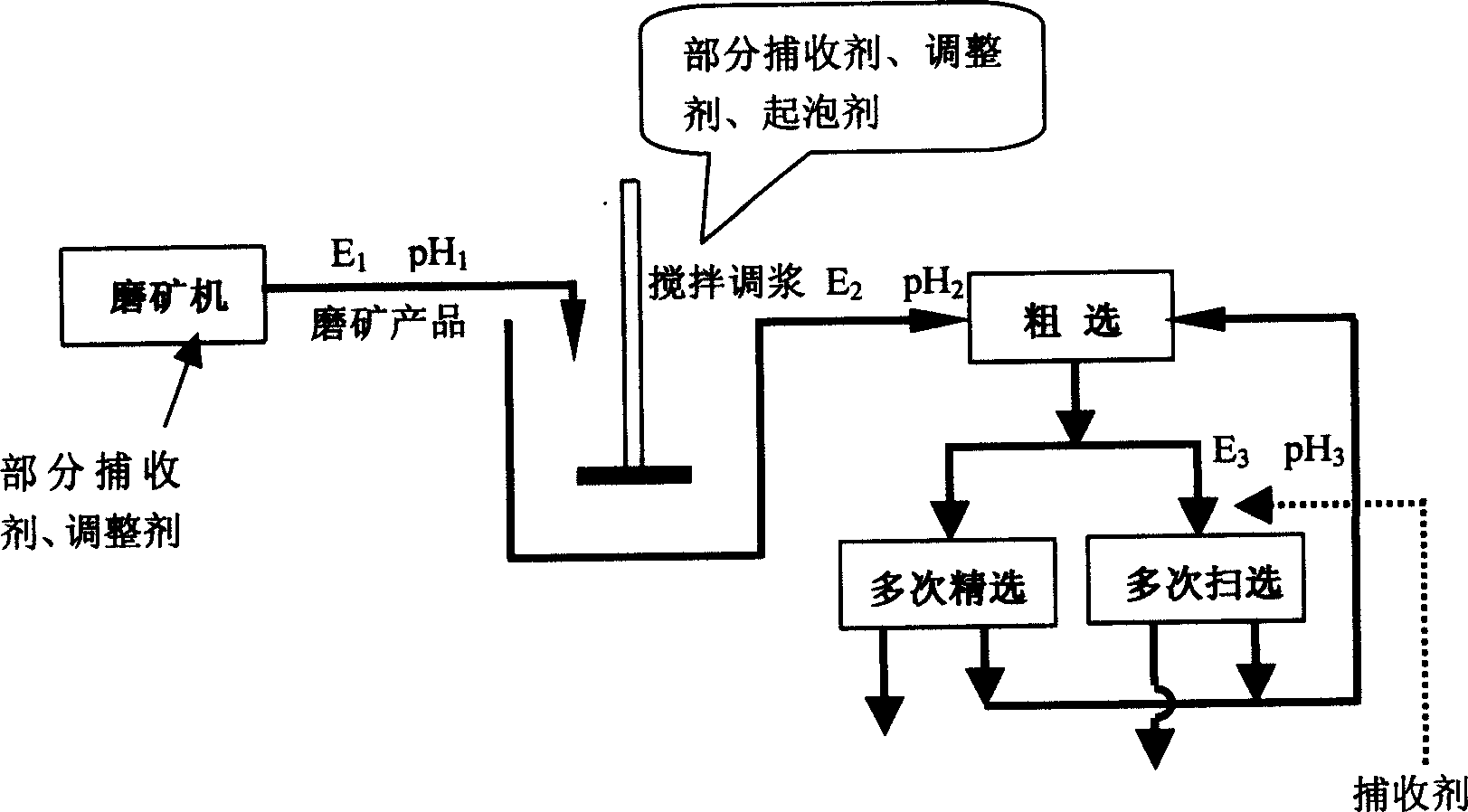

Lead and zinc sulfide ore in situ electric potential flotation process

The invention is protogenesis potential flotation technology for lead and zinc sulfide. The invention uses the ore pulp protogenesis potential formed in each complex electrochemical reaction as the ore pulp potential criterion of sulfide selectivity floatation separation, the invention uses electrochemical action namely oxide-reduction reaction in ore milling-floatation ore pulp, through adjusting and controlling the ore pulp pH value, capturing agent and floatation time and so on traditional operation parameter, thus adjusts and control the ore pulp potential. The invention can upgrades the separation selectivity of ore; the metal reclaiming rate can reach over 5%; the system processing ability is upgraded to 30%.

Owner:CENT SOUTH UNIV

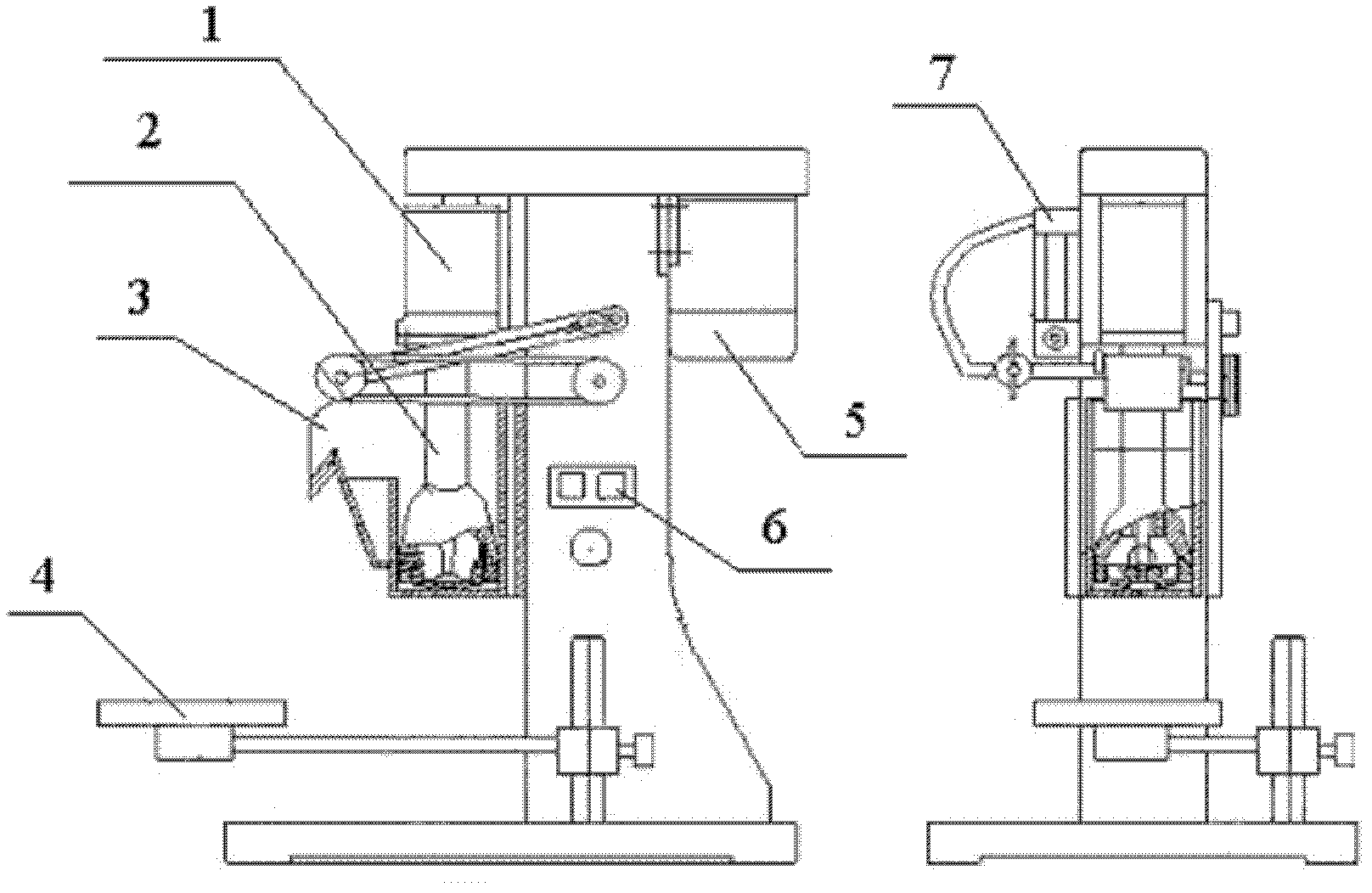

Method for recovering and separating silicone and silicon carbide powder through foam flotation in silicon wafer cutting effluent

The invention relates to the technology for recovering and recycling solid in silicon wafer cutting effluent in the new energy silicone industry, in particular to a method for recovering and separating silicone and silicon carbide powder through foam flotation in the silicon wafer cutting effluent. The method includes the following steps: performing solid-liquid separation on the cutting effluent by using a separating agent to separate the solid and the liquid; washing the solid into neutral through distilled water, and centrifugally drying the solid for spare; mixing the prepared solid and a flotation agent to form turbid liquid, regulating the pH value to a required value and then stirring; adding the turbid liquid into a flotation machine, stirring with certain rotating speed, and simultaneously feeding gas with the required flow from the lower portion for a flotation test; and filtering to recover foam and precipitate particles, and washing and drying to obtain the silicone and silicon carbide powder. By means of the method, the silicone and silicon carbide powder in the cutting effluent produced by the silicon wafer cutting technology can be effectively recovered and separated, silicone wafer processing cost is remarkably reduced, recycling of resources is achieved, and the method makes contributions for environment protection and is the practical technology in solving the problem of shortage in resources.

Owner:铁生年

Flotation of sulfide mineral species with oils

This invention is directed to the use of non-sulfur containing compounds as collectors in the froth flotation of certain mineral sulfide and metallic compounds. These non-sulfur-containing compounds may be from natural sources, such as vegetable oils, or synthesized commercial sources. These non-sulfide collectors can be used singularly, in combinations, and in mixtures with known commercial sulfur containing collectors. These non-sulfur-containing collectors are compatible with common frothers.

Owner:ECOLAB USA INC

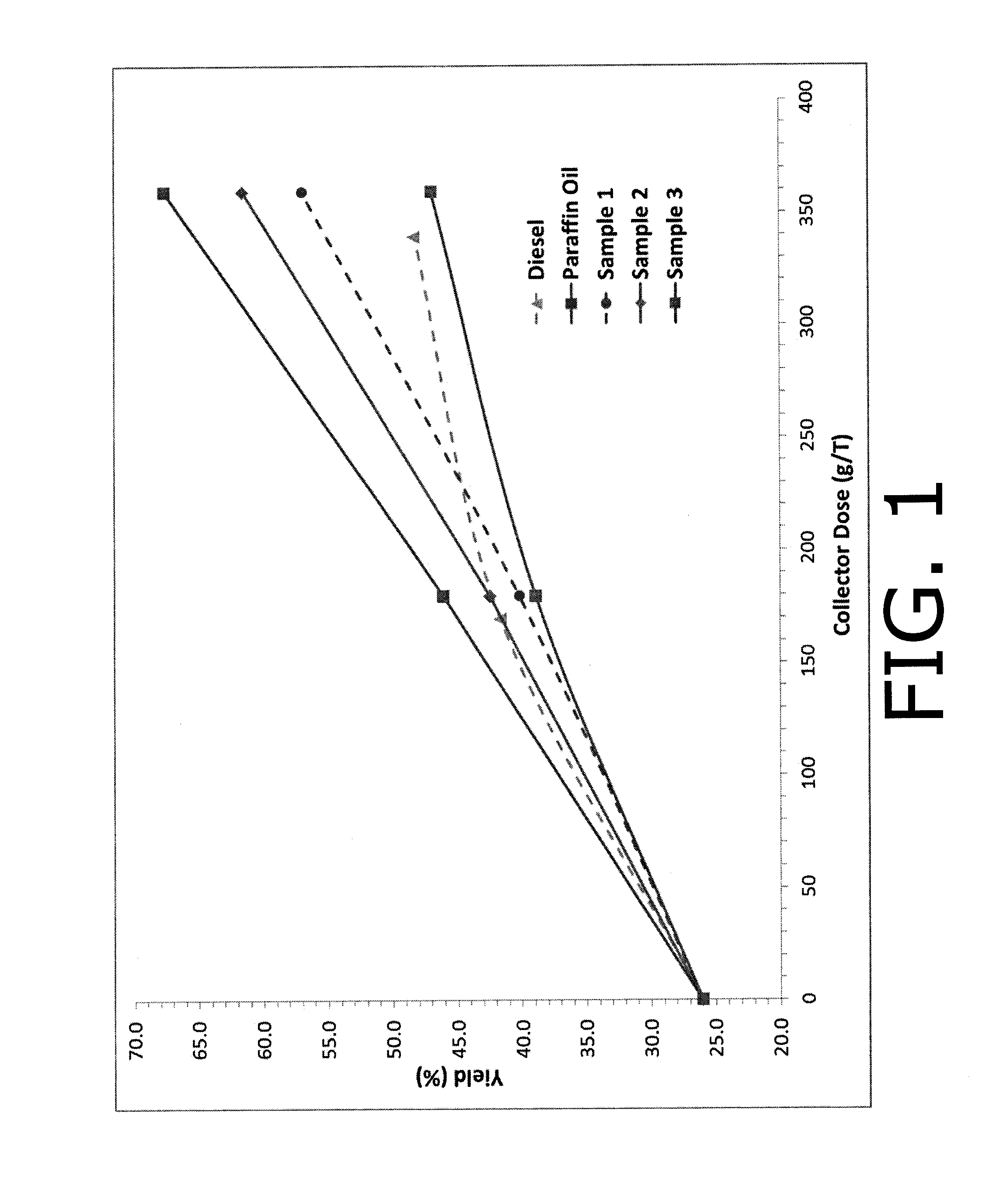

Collectors for mineral flotation

The invention provides methods and compositions for improving a froth flotation type separation. The method uses a microemulsion to improve the effectiveness of a collector. The improvement allows for low dosages of collector to work as well as much greater amounts of non-microemulsified collector.

Owner:ECOLAB USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com