Amino methyl xanthogenic acid cyanogen ethyl ester compound and preparation method as well as collector thereof

A technology of aminomethyl cyanoethyl xanthate and n-propyl aminomethyl xanthate cyanoethyl ester is applied in the field of aminomethyl cyanoethyl xanthate compound and its preparation, and achieves good metal mineral beneficiation The effect of collection performance, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

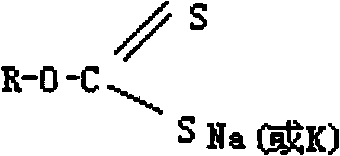

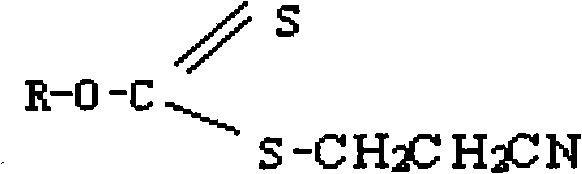

Image

Examples

Embodiment 1

[0047] Embodiment 1: A kind of cyanoethyl diethylaminomethyl xanthate and preparation method thereof

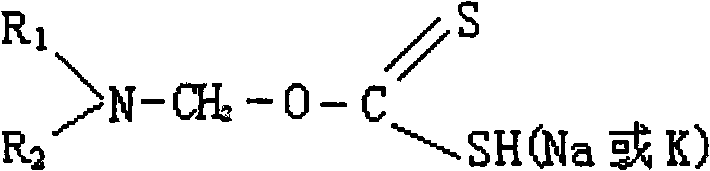

[0048] The structural formula of diethylaminomethyl xanthate cyanoethyl ester compound is:

[0049]

[0050] The raw materials used in the preparation method and their weights are: 73g of diethylamine, 75g of 40% formaldehyde solution, 76g of carbon disulfide and 54g of acrylonitrile. It consists of the following two steps:

[0051] (1) To prepare diethylaminomethanol, the method is to put 73g of diethylamine into a reaction bottle, start stirring, add 75g of 40% formaldehyde solution dropwise, drop it for about 0.5h, react at room temperature for 1h, and then heat up to 45 ~65°C, continue to react for 2.5h, then add 1.5g of fine-grained sodium chloride salt, stir and dissolve for salting out, cool down to below 20°C and let stand for stratification, separate the water in the lower layer, and the light yellow product in the upper layer is diethylamine Altogether 117 g we...

Embodiment 2

[0053] Embodiment 2: A kind of diethylaminomethyl xanthate cyanoethyl ester and preparation method thereof

[0054] The raw materials used in its preparation method and their weight are: 73g of diethylamine, 75g of 40% formaldehyde aqueous solution, 76g of carbon disulfide, 133g of 30% aqueous sodium hydroxide solution, and 89.5g of β-chloropropionitrile, including the following three steps:

[0055] (1) Take 73g of diethylamine and put it into a reaction bottle, start stirring, add 75g of 40% formaldehyde solution dropwise, and finish dropping in about 0.5h. Ethylaminomethanol, the product does not need to be separated, and the next reaction can be continued after cooling down to below 20°C.

[0056] (2) Take 76g of carbon disulfide and add it to the above-mentioned reaction flask. The temperature of the water bath is below 20°C. Start stirring, add 133g of 30% sodium hydroxide aqueous solution dropwise, and finish adding dropwise within about 1 hour. Control the reaction tem...

Embodiment 3~43

[0058] Embodiment 3-43: A kind of cyanoethyl aminoxanthate and its preparation method

[0059] Raw materials used and proportioning ratio are as shown in Table 1, and the preparation method of each embodiment is identical with example 1 or example 2.

[0060] Table 1

[0061]

[0062]

[0063]

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com