Purification method of sintered flue gas desulfurization gypsum

A technology of desulfurization gypsum and purification method, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems of poor dehydration performance, high impurity content, dark color of by-product gypsum, etc., to avoid poor separation effect and improve gypsum Quality, small investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

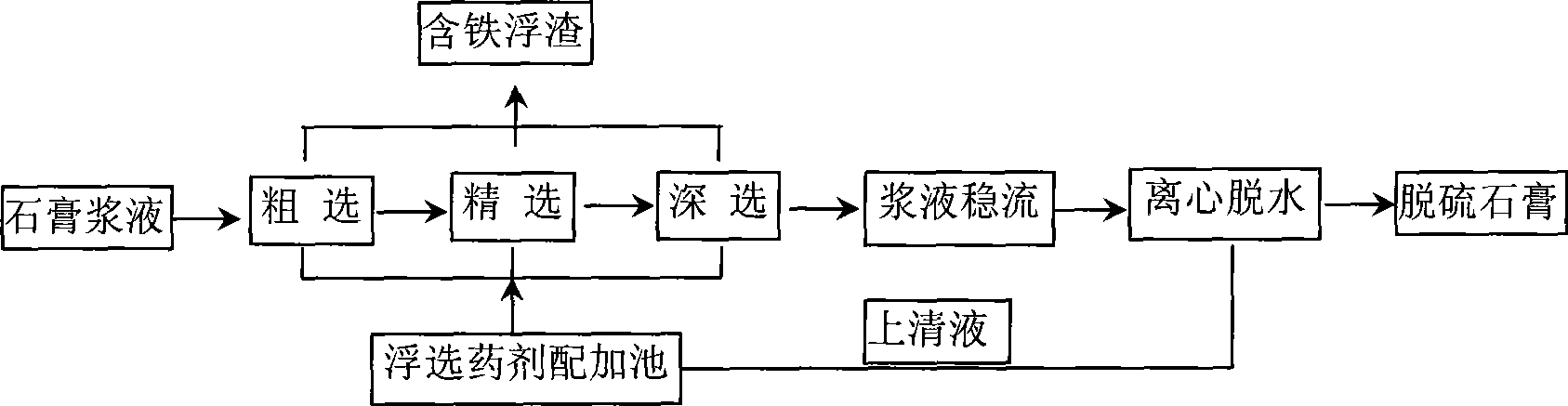

[0032] Such as figure 1 As shown, the self-flue gas treatment capacity is 57000Nm 3 In the desulfurization absorption tower of the sintering flue gas desulfurization industrial test device of / h, the sintering flue gas desulfurization gypsum slurry with a concentration of 20% is drawn out, and the gypsum slurry purification test of three-stage reverse flotation is carried out.

[0033]The operating conditions of the primary roughing reverse flotation cell are: the pH value of the slurry is 4.0, the slurry temperature is 40°C, the residence time of the flotation cell is 5min, the collector is tall oil (500g / t), and the inhibitor is sulfuric acid Ammonium (400g / t), pH adjuster is sulfuric acid (250g / t), dispersant is water glass (200g / t), carrier is limestone powder (100g / t).

[0034] The operating conditions of the secondary selective reverse flotation cell are: the pH value of the slurry is 8.0, the temperature of the slurry is 30°C, the residence time of the flotation cell i...

Embodiment 2

[0043] Such as figure 1 As shown, the self-flue gas treatment capacity is 90000m 3 / h sintering flue gas desulfurization industrial test device desulfurization absorption tower, leading the concentration of 12% sintering flue gas desulfurization gypsum slurry, three-stage reverse flotation gypsum slurry purification test.

[0044] The operating conditions of the primary roughing reverse flotation cell are: the pH value of the slurry is 5.2, the slurry temperature is 55°C, the residence time of the flotation cell is 15min, the collector is tall oil (1000g / t), and the inhibitor is sulfuric acid Ammonium (500g / t), pH adjuster is sulfuric acid (200g / t), dispersant is water glass (400g / t), carrier is limestone powder (100g / t).

[0045] The operating conditions of the secondary selective reverse flotation cell are: the pH value of the slurry is 9.5, the temperature of the slurry is 45°C, the residence time of the flotation cell is 25min, the collector is dodecylamine (300g / t), and ...

Embodiment 3

[0054] The self-flue gas treatment capacity is 60000m 3 In the desulfurization absorption tower of the sintering flue gas desulfurization industrial test device of / h, the sintering flue gas desulfurization gypsum slurry with a concentration of 11% is drawn out, and the gypsum slurry purification test of three-stage reverse flotation is carried out.

[0055] The operating conditions of the primary roughing reverse flotation cell are: the pH value of the slurry is 6.0, the slurry temperature is 60°C, the residence time of the flotation cell is 15min, the collector is oleic acid (1000g / t), and the inhibitor is ammonium sulfate (1000g / t), the pH adjuster is sulfuric acid (500g / t), the dispersant is water glass (900g / t), and the carrier is limestone powder (450g / t).

[0056] The operating conditions of the secondary selective reverse flotation cell are: the pH value of the slurry is 10.0, the temperature of the slurry is 40°C, the residence time of the flotation cell is 30min, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com