Patents

Literature

957results about "Preheating charges" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

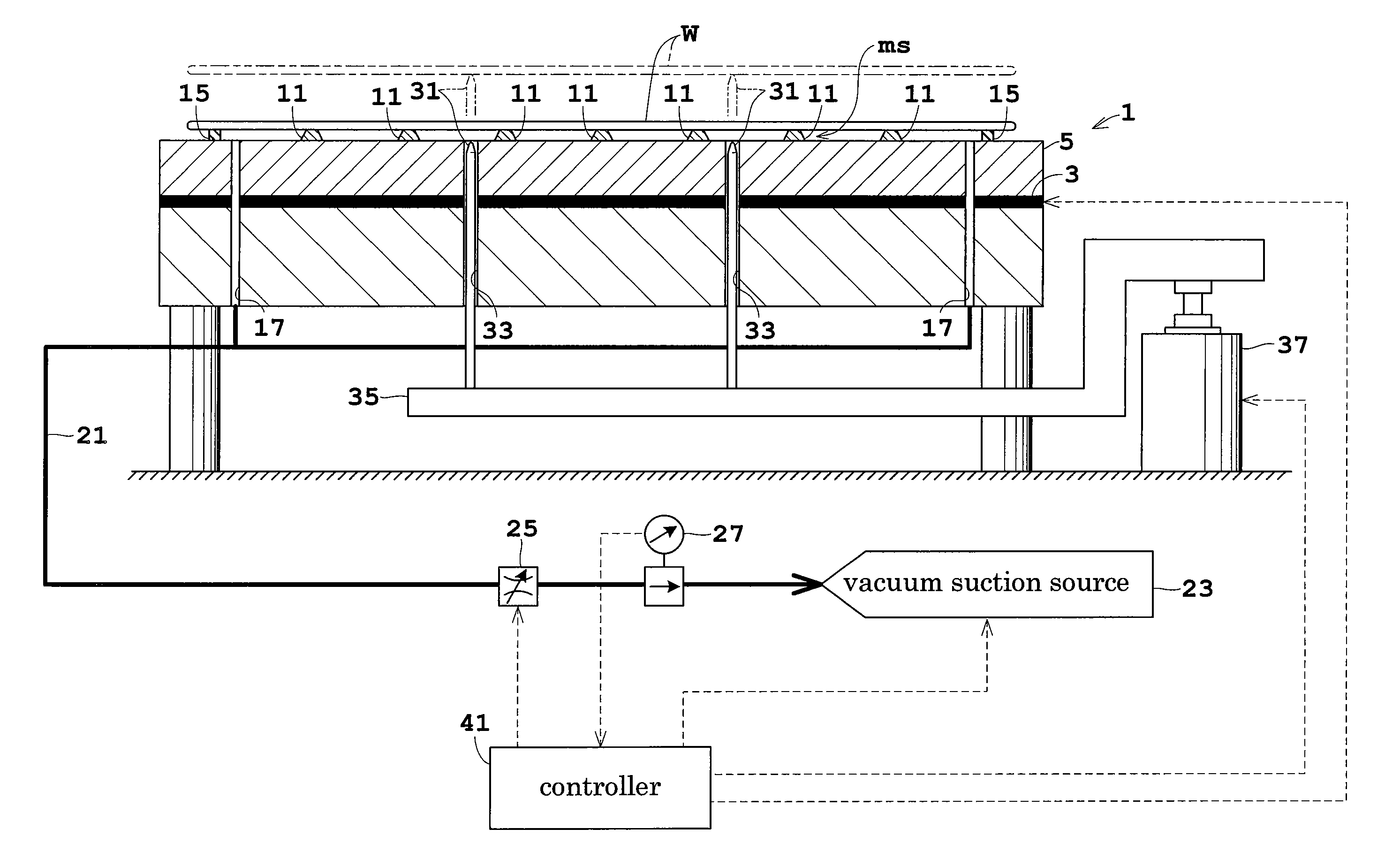

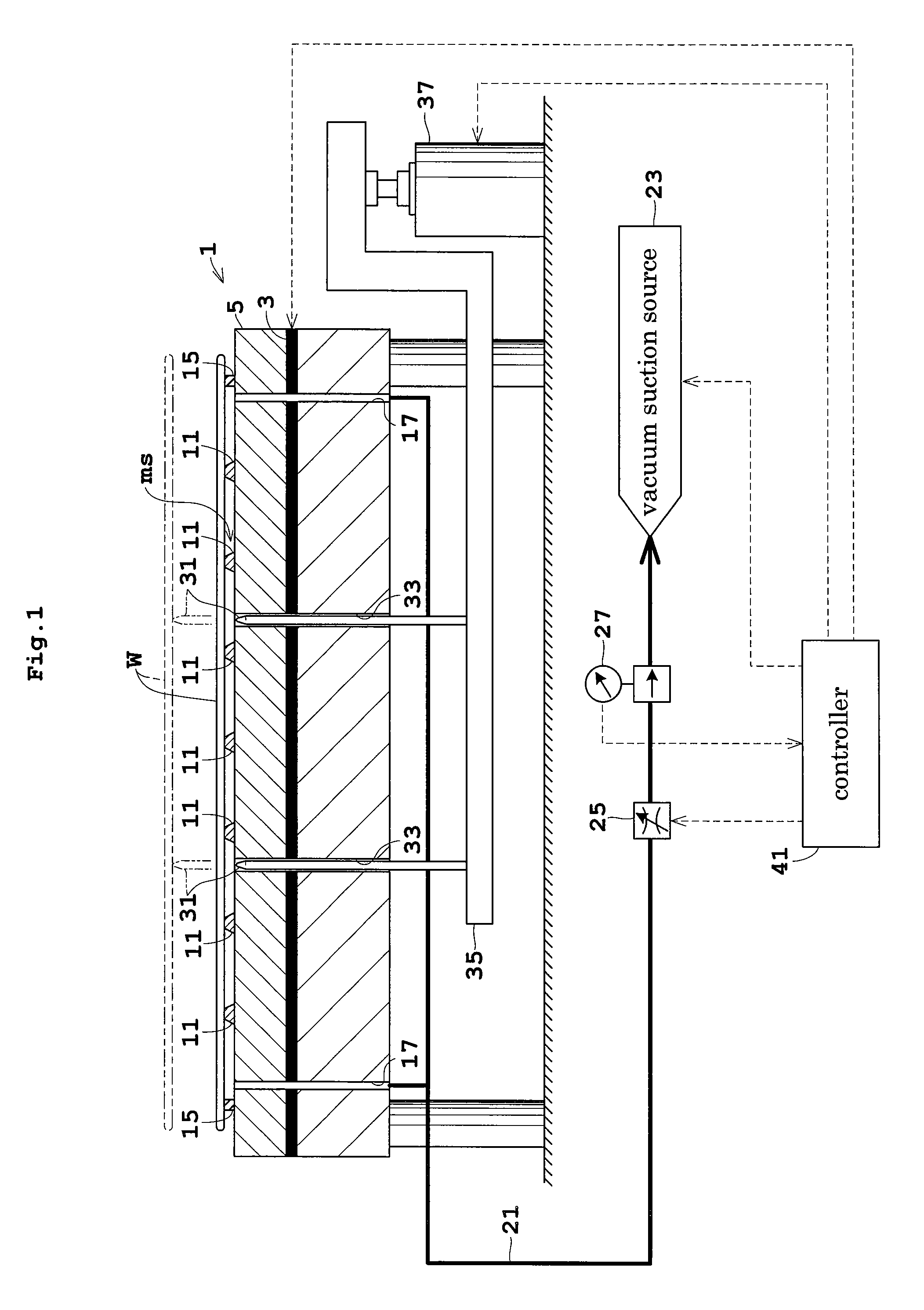

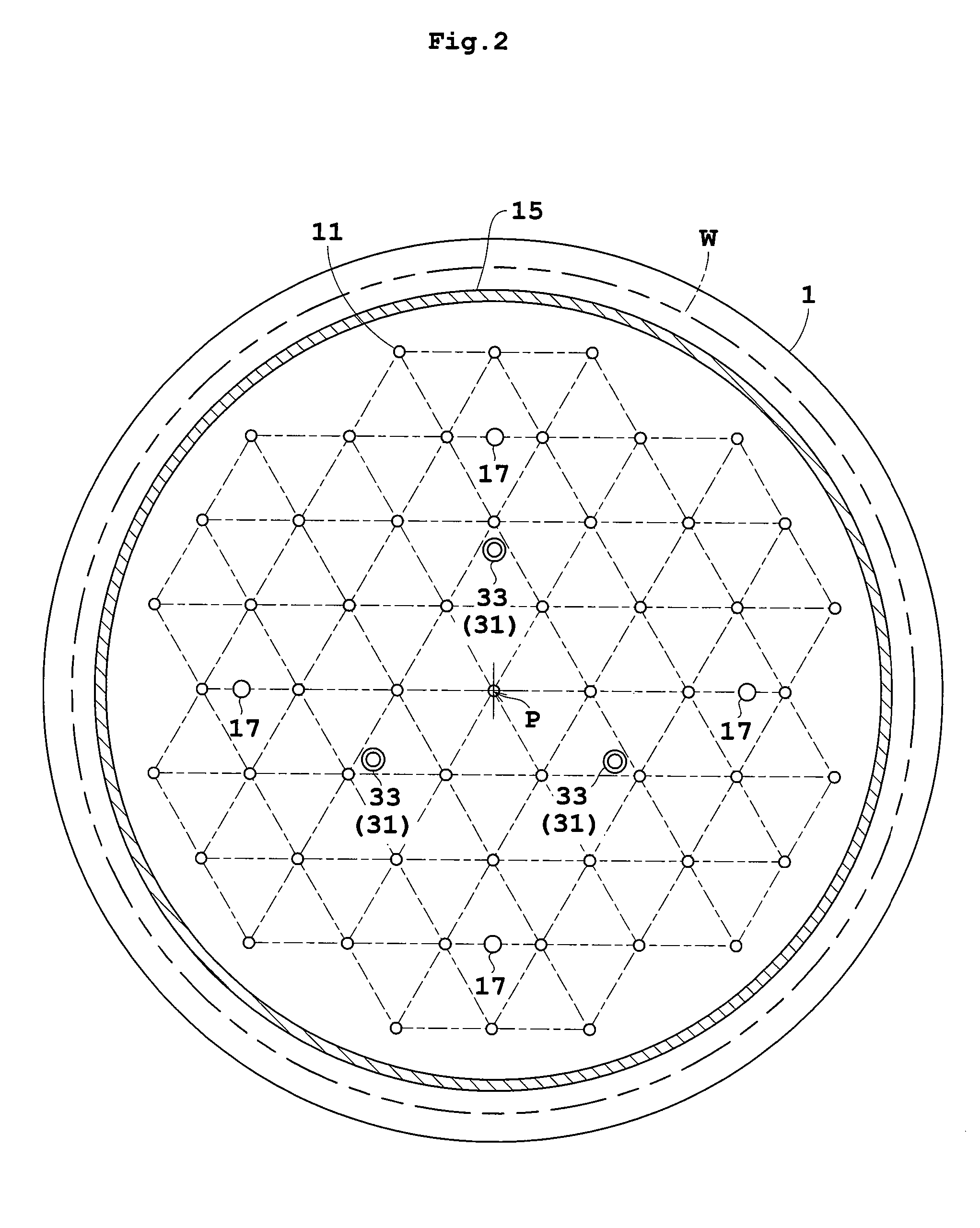

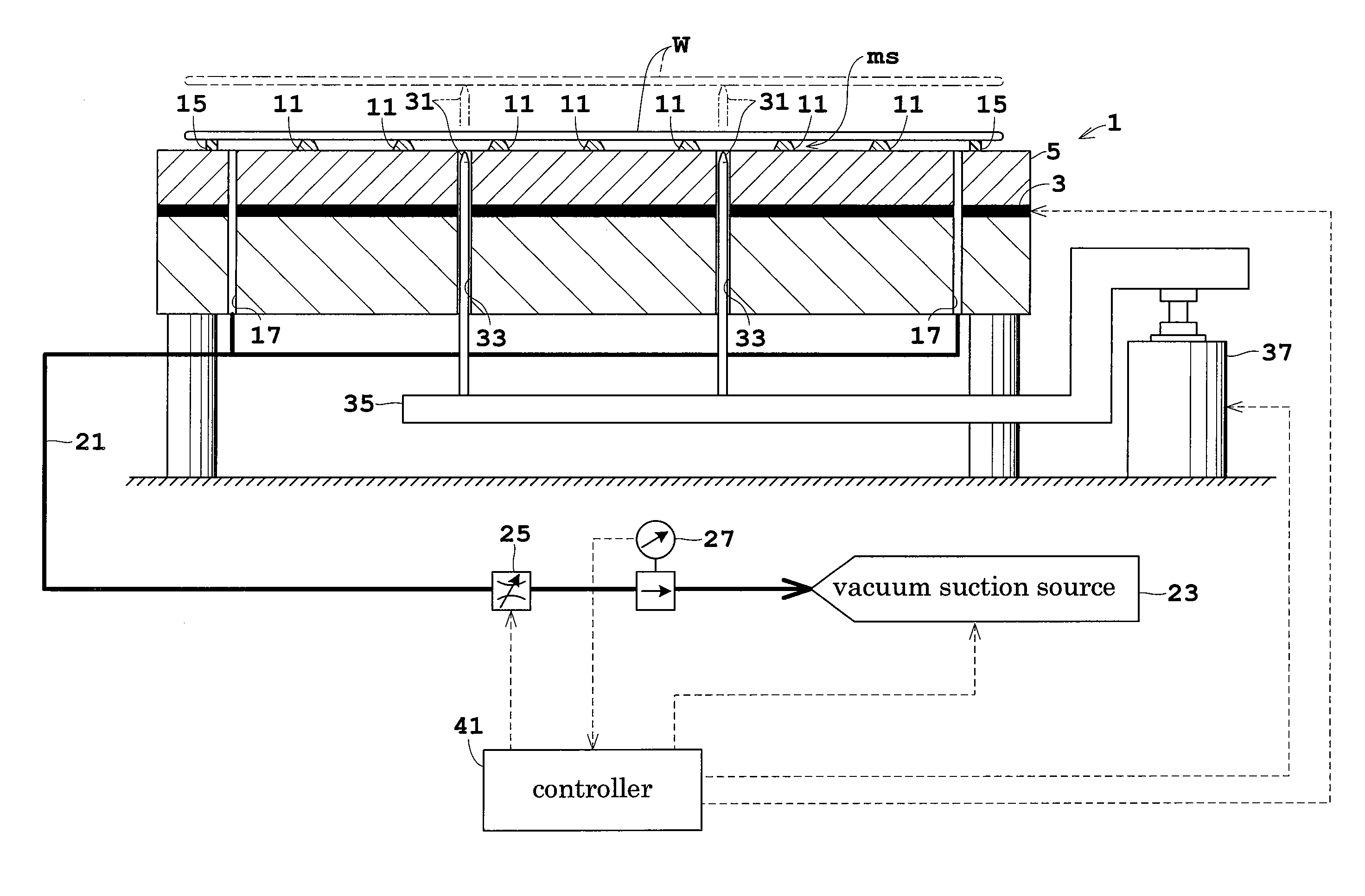

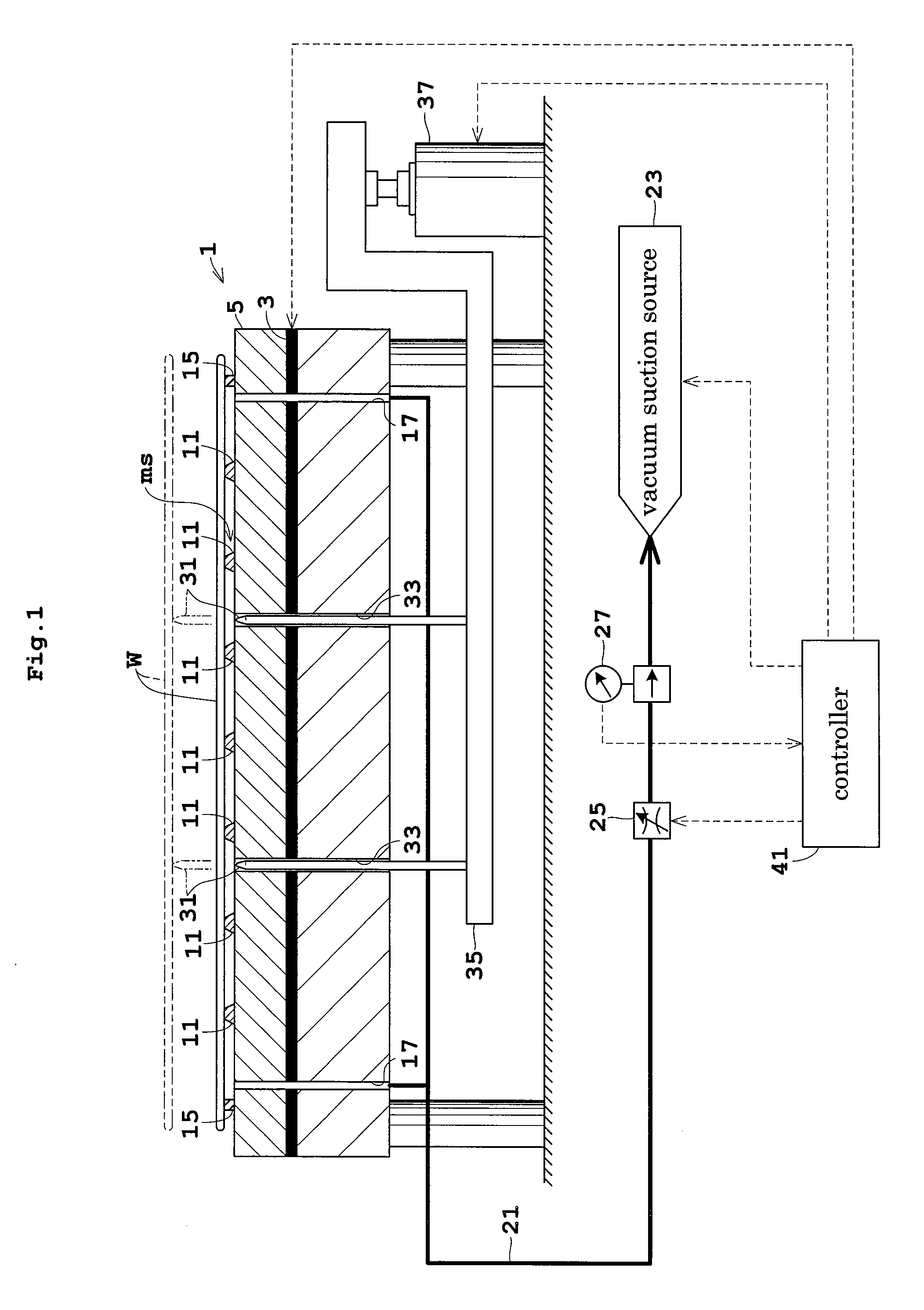

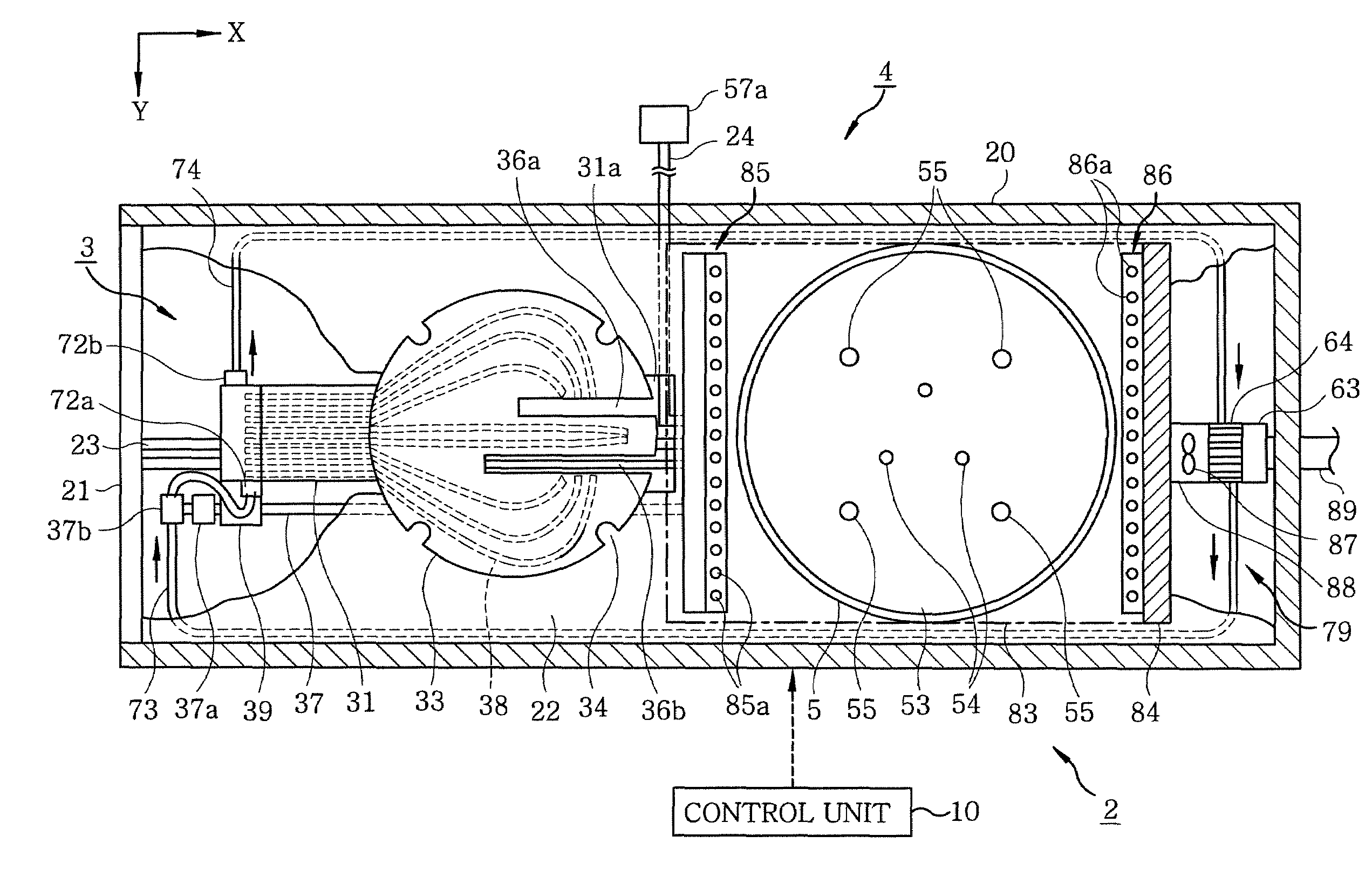

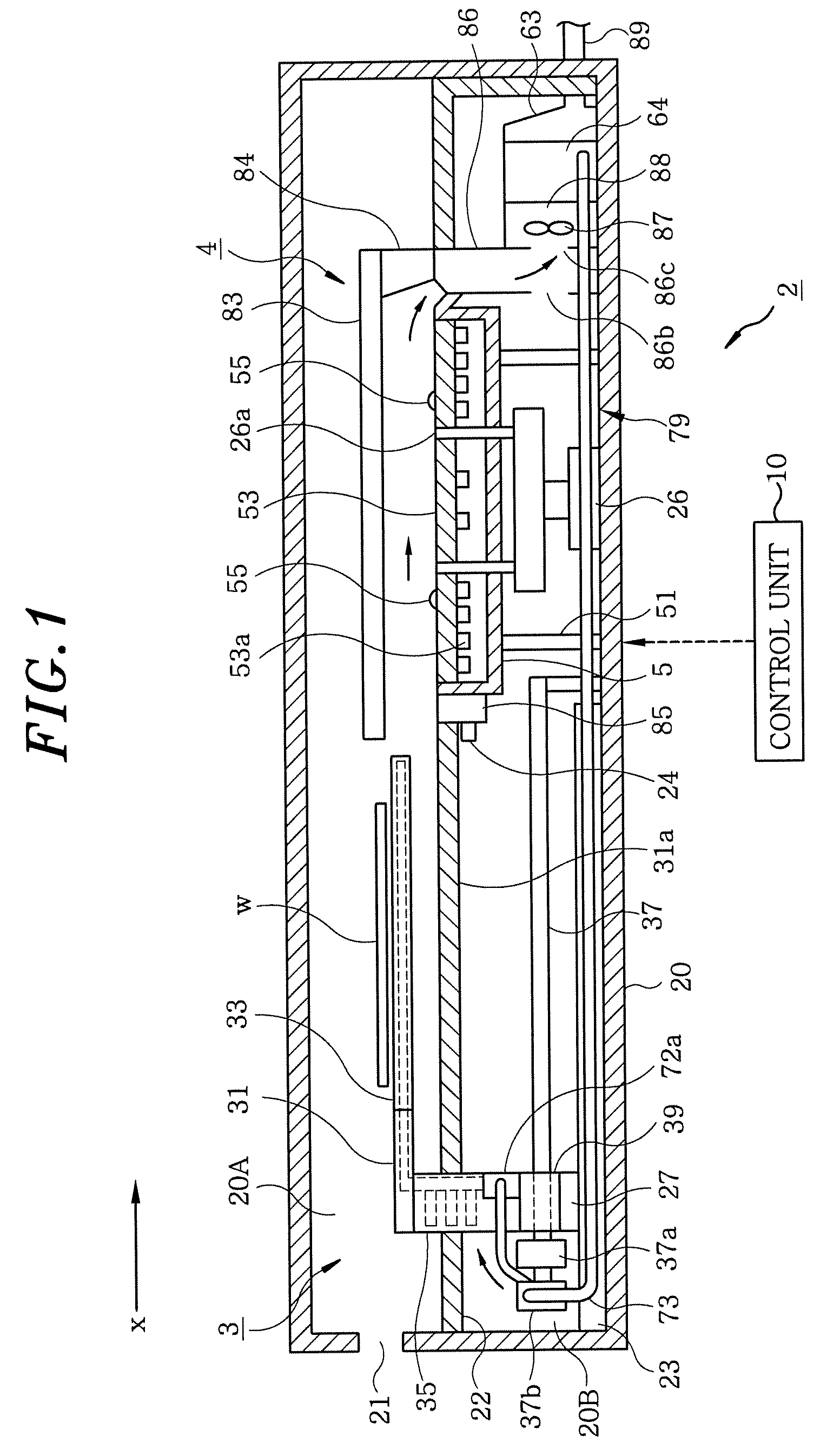

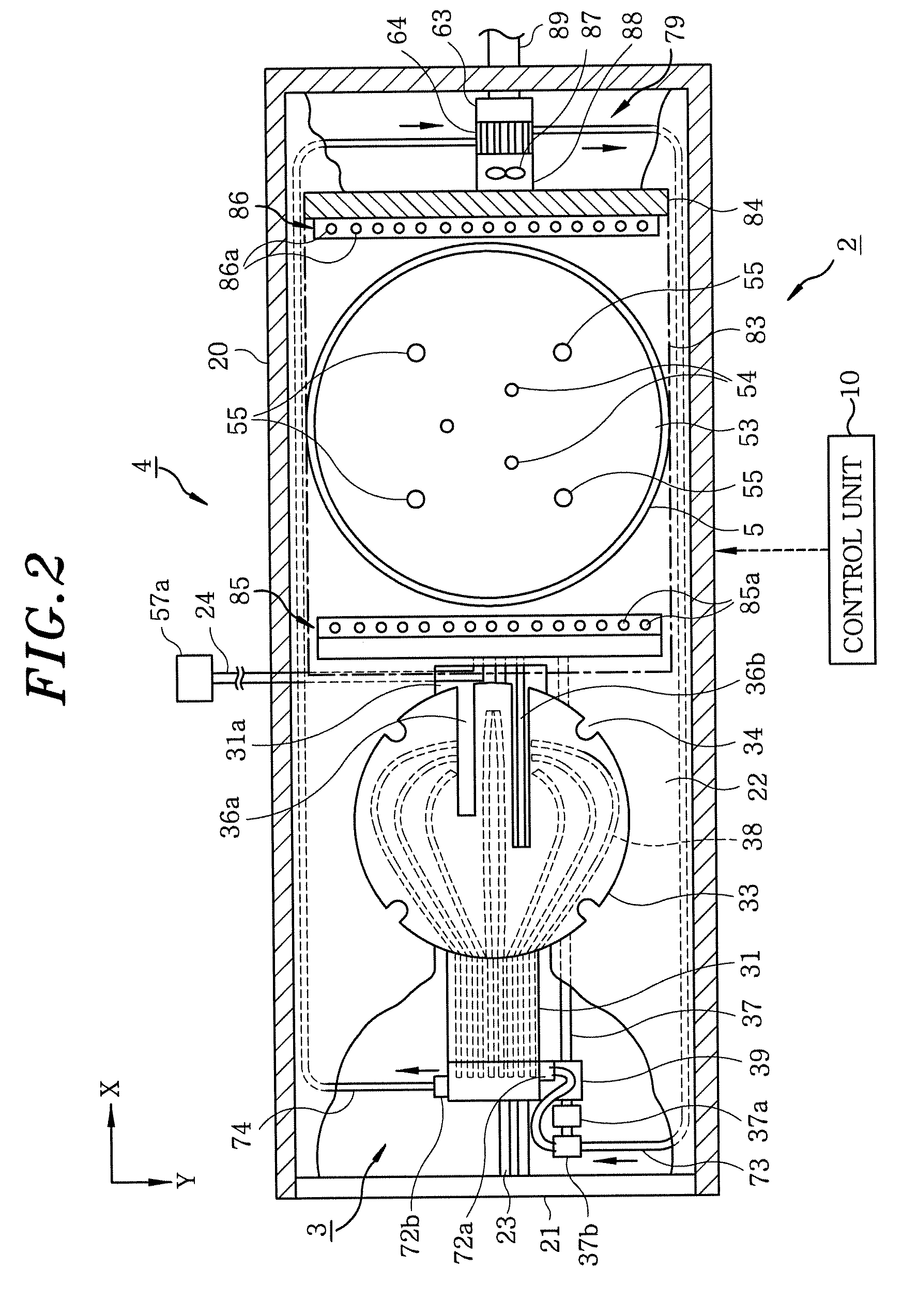

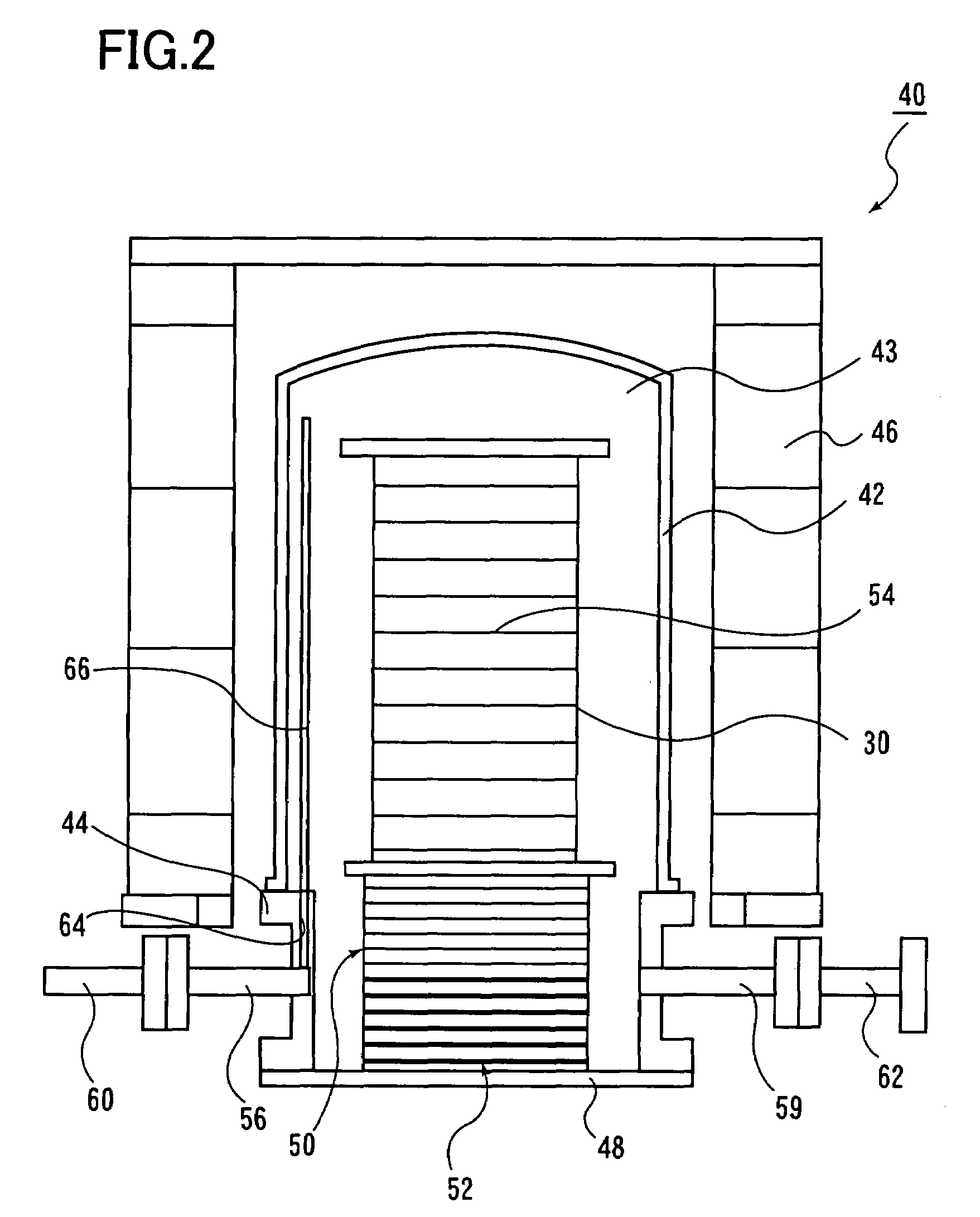

Substrate heat treatment apparatus

A substrate heat treatment apparatus includes a heat-treating plate having a flat upper surface, support devices formed of a heat-resistant resin for contacting and supporting a substrate, a seal device disposed annularly for rendering gastight a space formed between the substrate and heat-treating plate, and exhaust bores for exhausting gas from the space. The support devices are formed of resin, and the upper surface of the heat-treating plate is made flat, whereby a reduced difference in the rate of heat transfer occurs between contact parts and non-contact parts on the surface of the substrate. Consequently, the substrate is heat-treated effectively while suppressing variations in heat history over the surface of the substrate.

Owner:DAINIPPON SCREEN MTG CO LTD

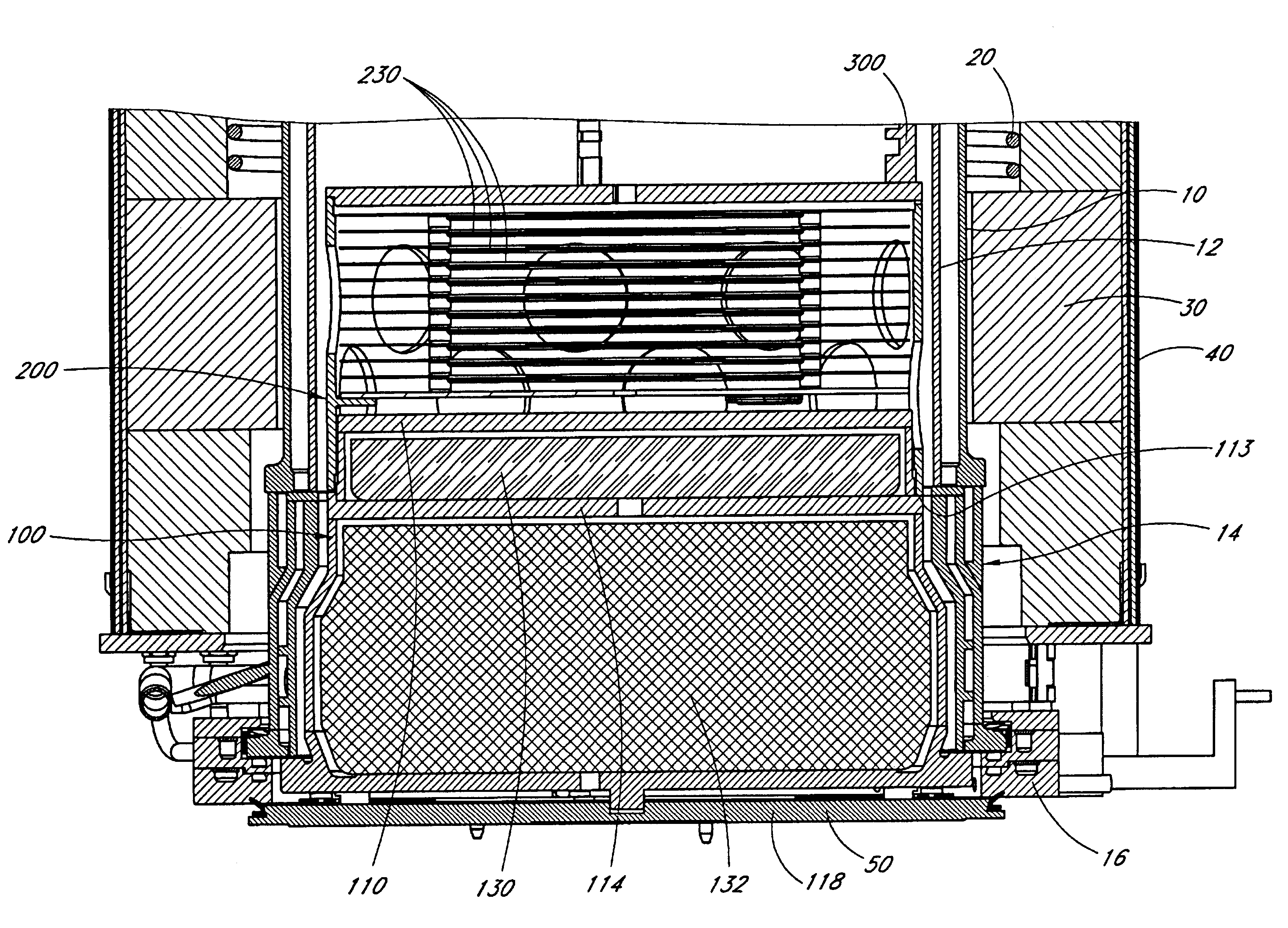

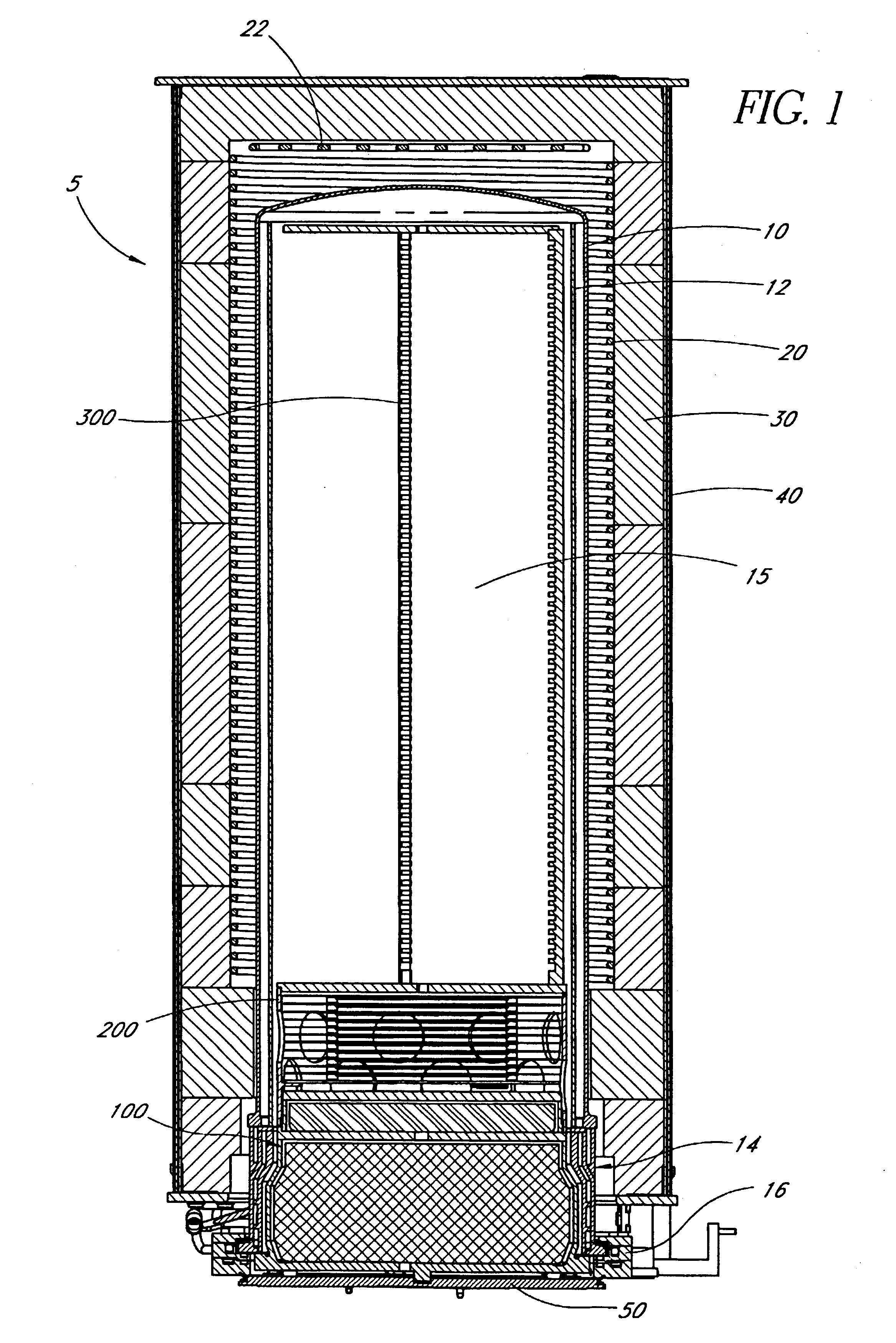

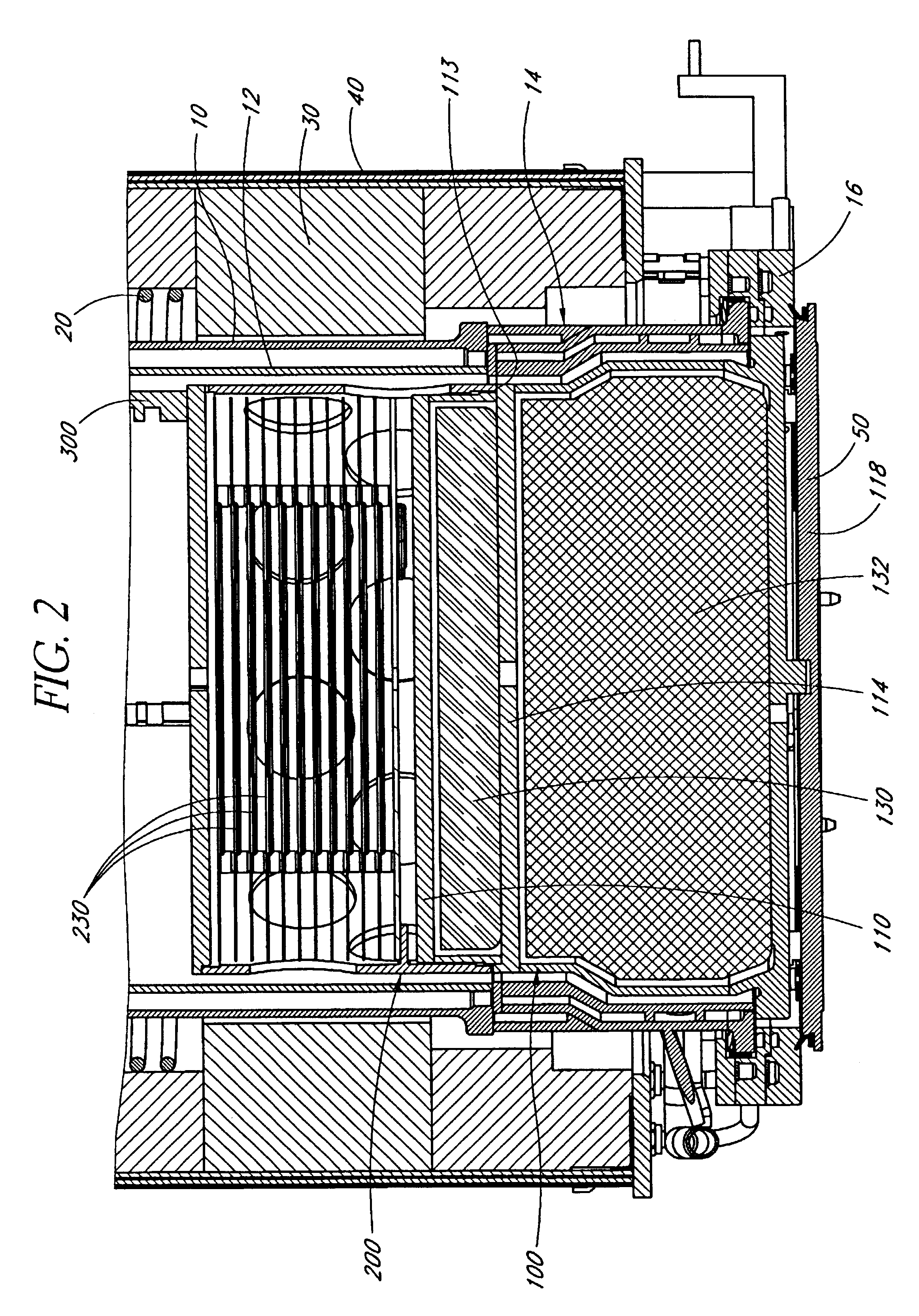

Multilevel pedestal for furnace

A pedestal for use in a high temperature vertical furnace for the processing of semiconductor wafers provides a closure and heat insulation for the lower end of the furnace and is a wafer boat support. The pedestal, comprising quartz-enveloped insulation material, supports a wafer boat at a boat support level and is provided with an upper section disposed above the boat support level. The upper section comprises enveloped insulating material. The envelope of the upper section is also formed of quartz and the insulating material in the upper section has a lower thermal conductance than the insulating material in a lower quartz enveloped section.

Owner:ASM INTERNATIONAL

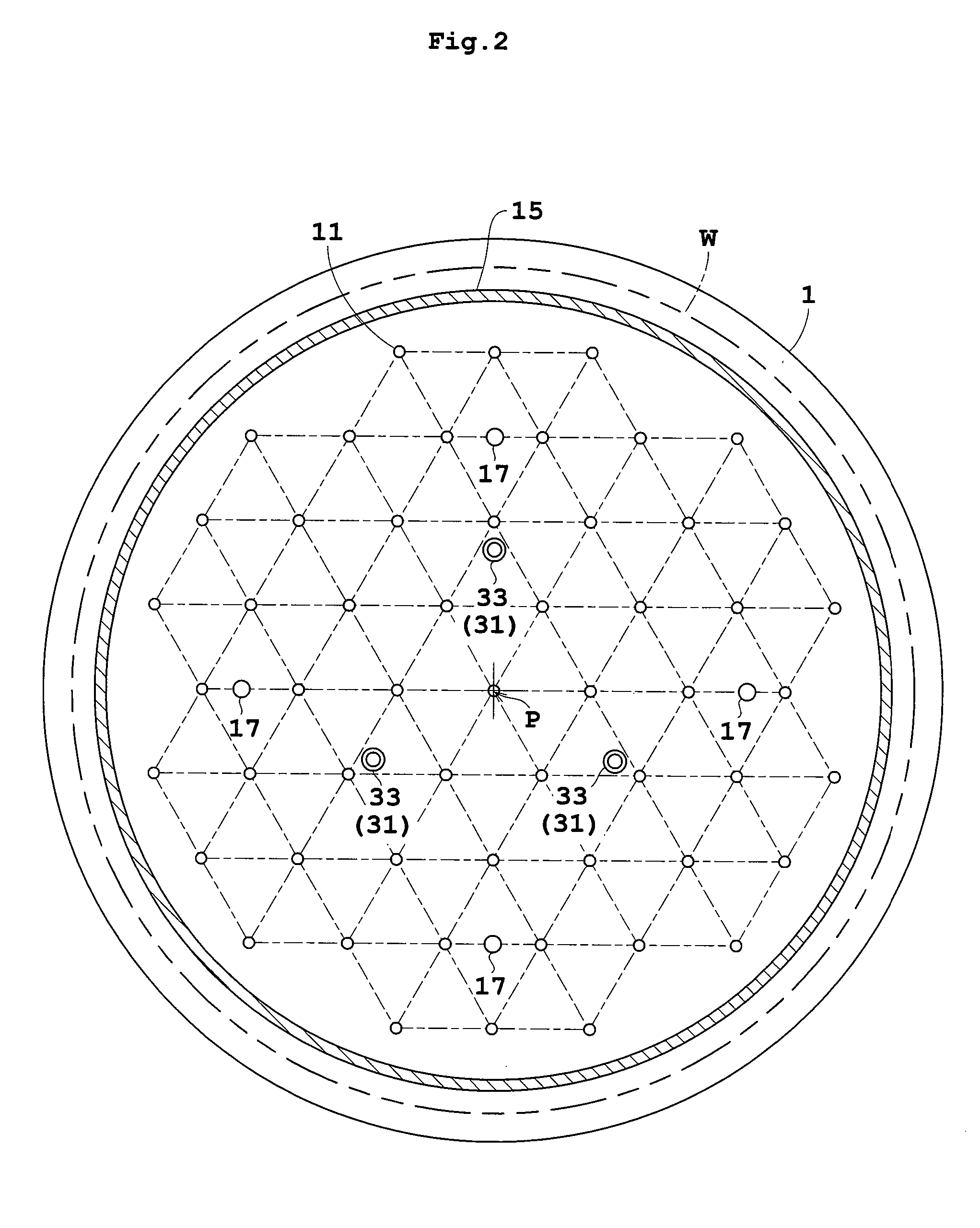

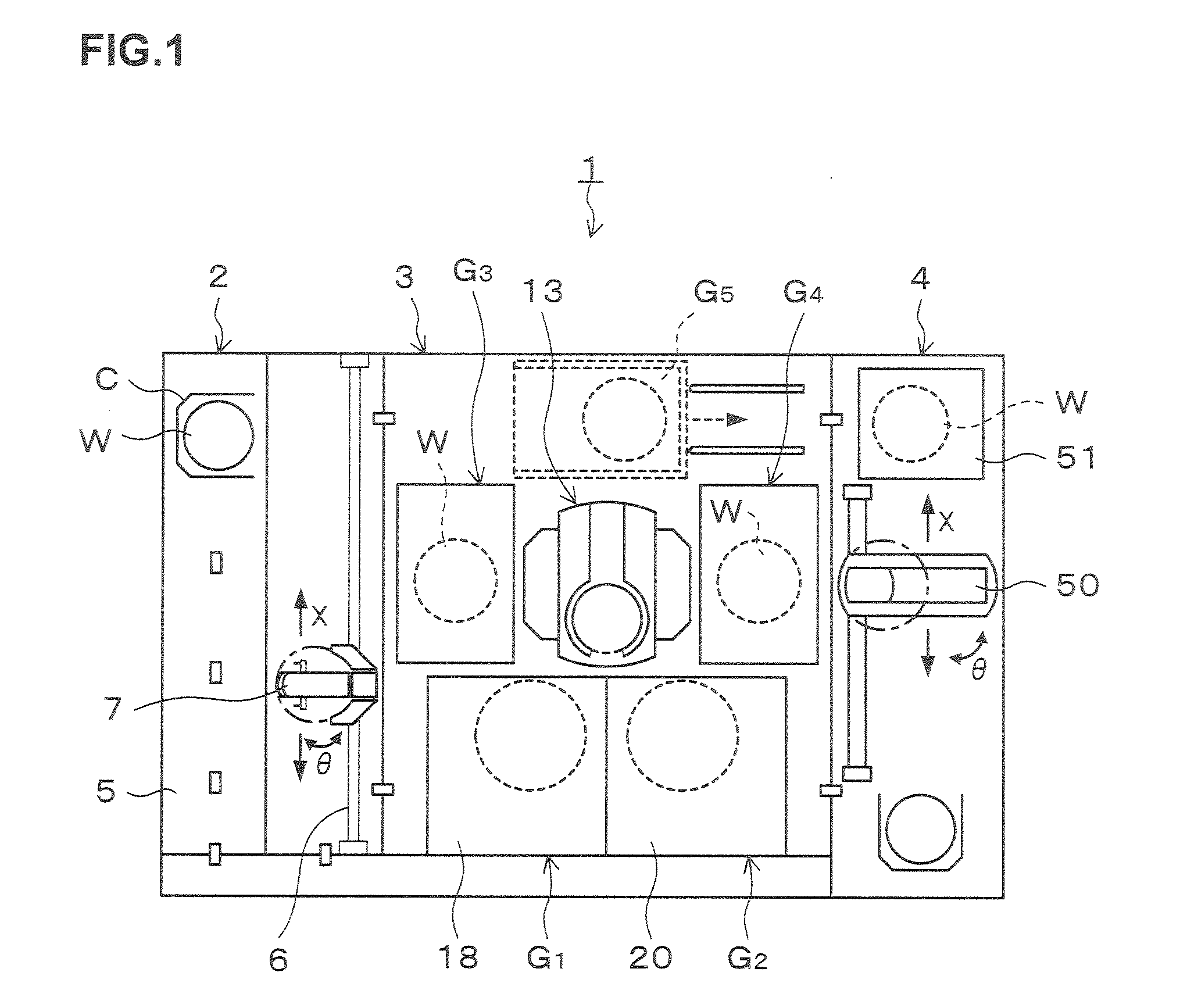

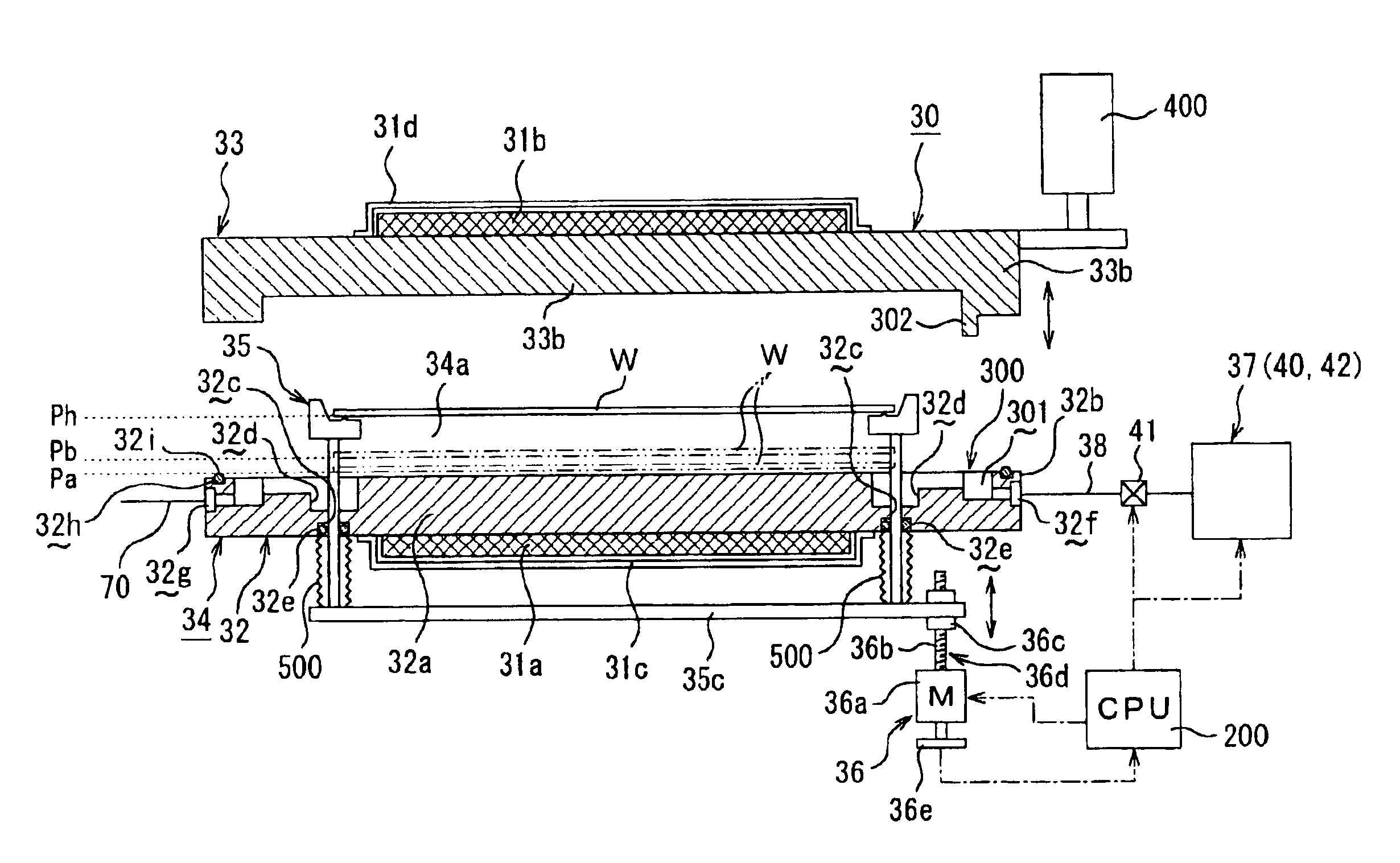

Substrate heat treatment apparatus

ActiveUS20070128570A1Stable separationEfficiently suckedCharge supportsSemiconductor/solid-state device manufacturingDevice formHeat treated

A substrate heat treatment apparatus includes a heat-treating plate having a flat upper surface, support devices formed of a heat-resistant resin for contacting and supporting a substrate, a seal device disposed annularly for rendering gastight a space formed between the substrate and heat-treating plate, and exhaust bores for exhausting gas from the space. The support devices are formed of resin, and the upper surface of the heat-treating plate is made flat, whereby a reduced difference in the rate of heat transfer occurs between contact parts and non-contact parts on the surface of the substrate. Consequently, the substrate is heat-treated effectively while suppressing variations in heat history over the surface of the substrate.

Owner:DAINIPPON SCREEN MTG CO LTD

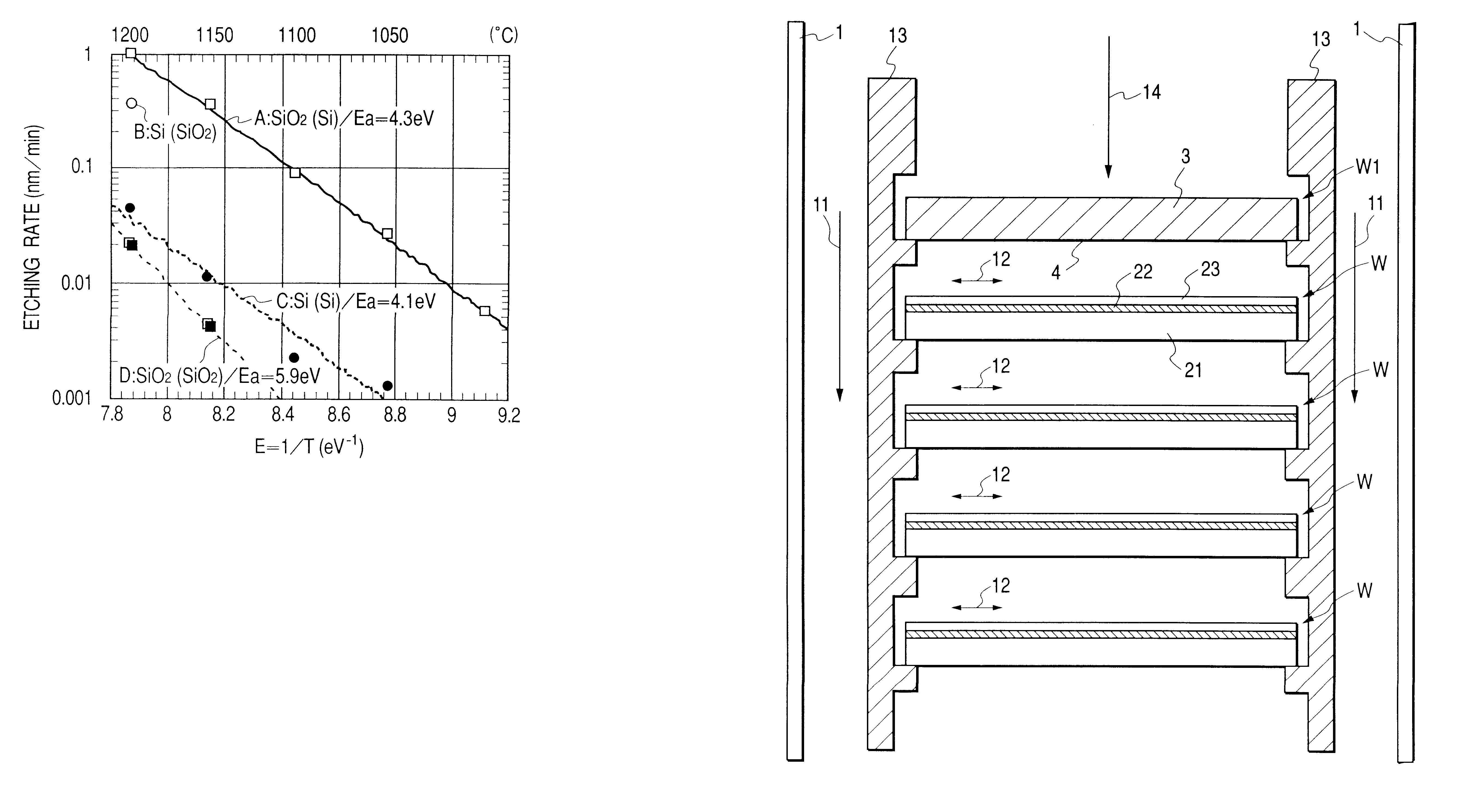

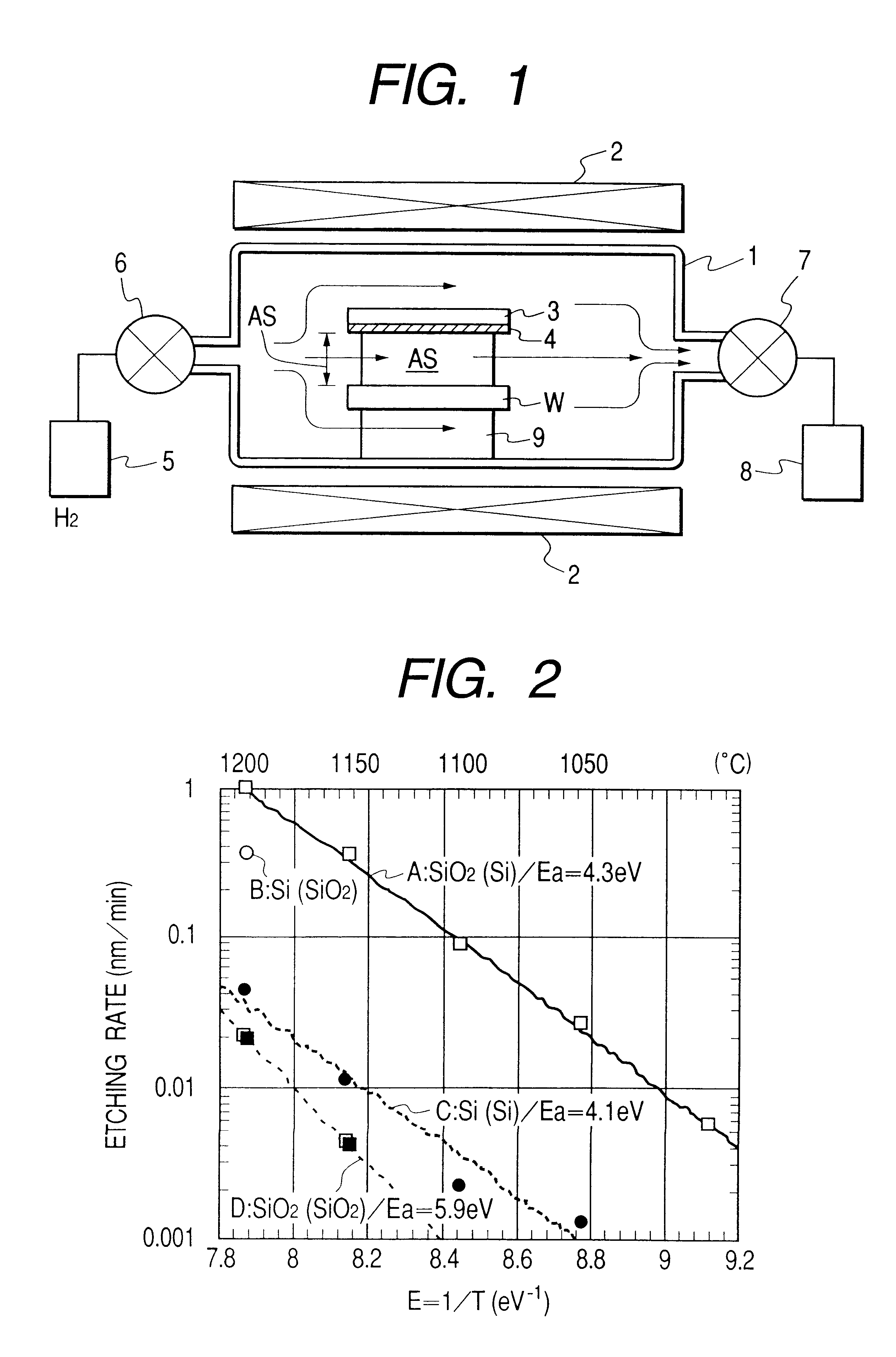

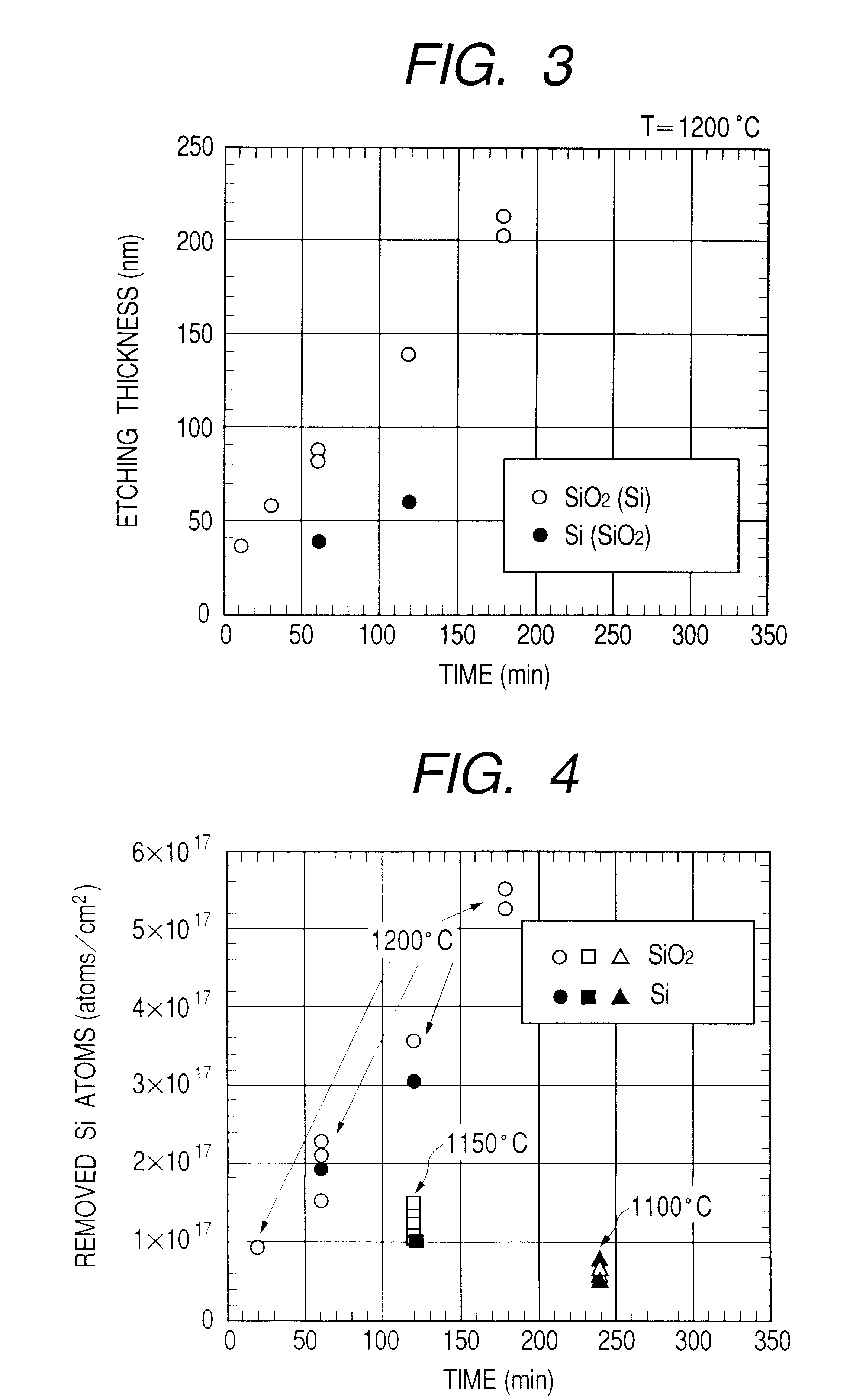

Method and apparatus for heat-treating an SOI substrate and method of preparing an SOI substrate by using the same

InactiveUS6171982B1Reduce the presence of impuritiesMaintain consistencyMuffle furnacesSolid-state devicesWaferingHydrogen

An SOI substrate having on the surface thereof a single crystal silicon film formed on an insulator is heat-treated in a hydrogen-containing reducing atmosphere in order to smooth the surface and reduce the boron concentration without damaging the film thickness uniformity in a single wafer and among different wafers. The method is characterized in that the single crystal silicon film is arranged opposite to a member of non-oxidized silicon for heat treatment.

Owner:CANON KK

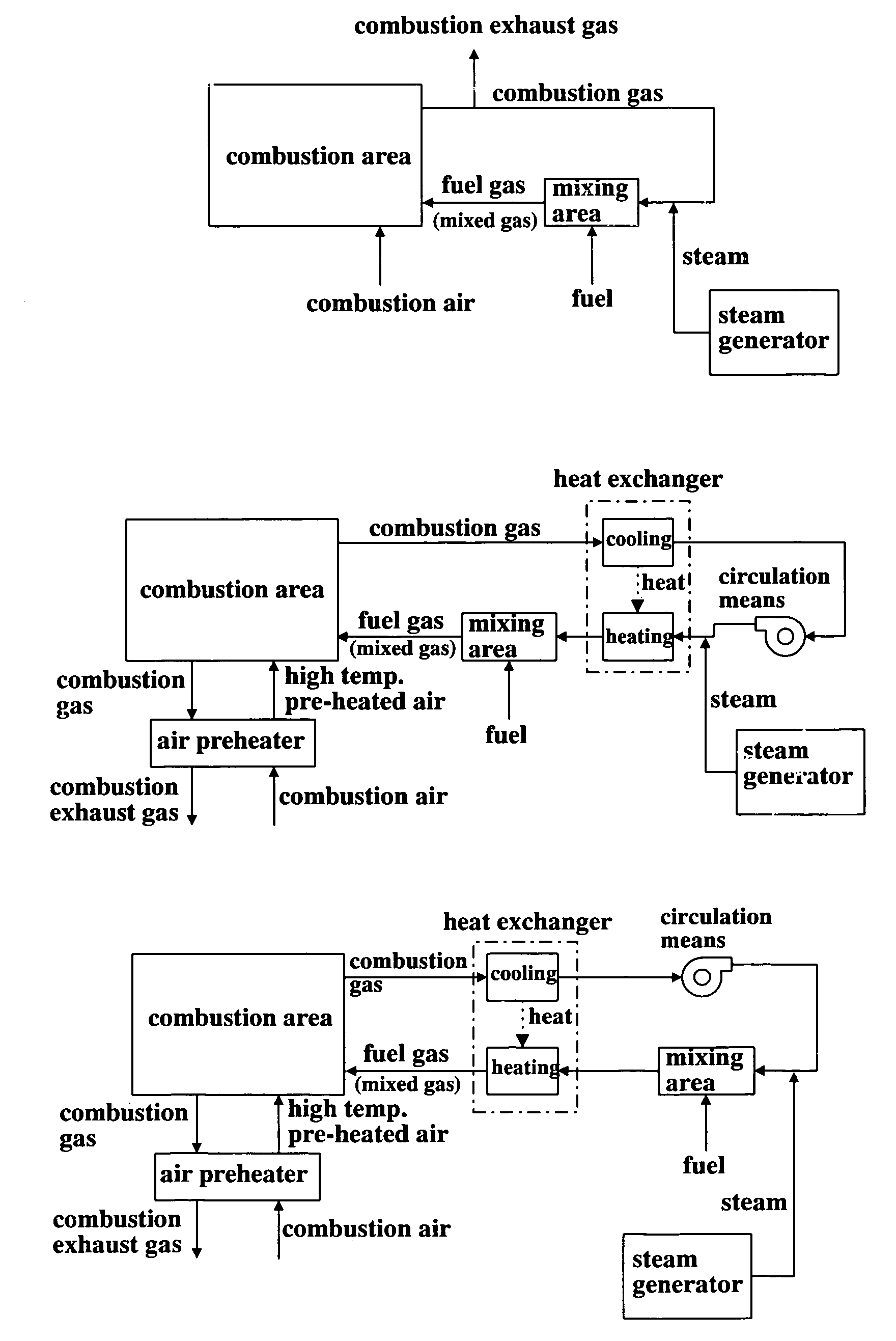

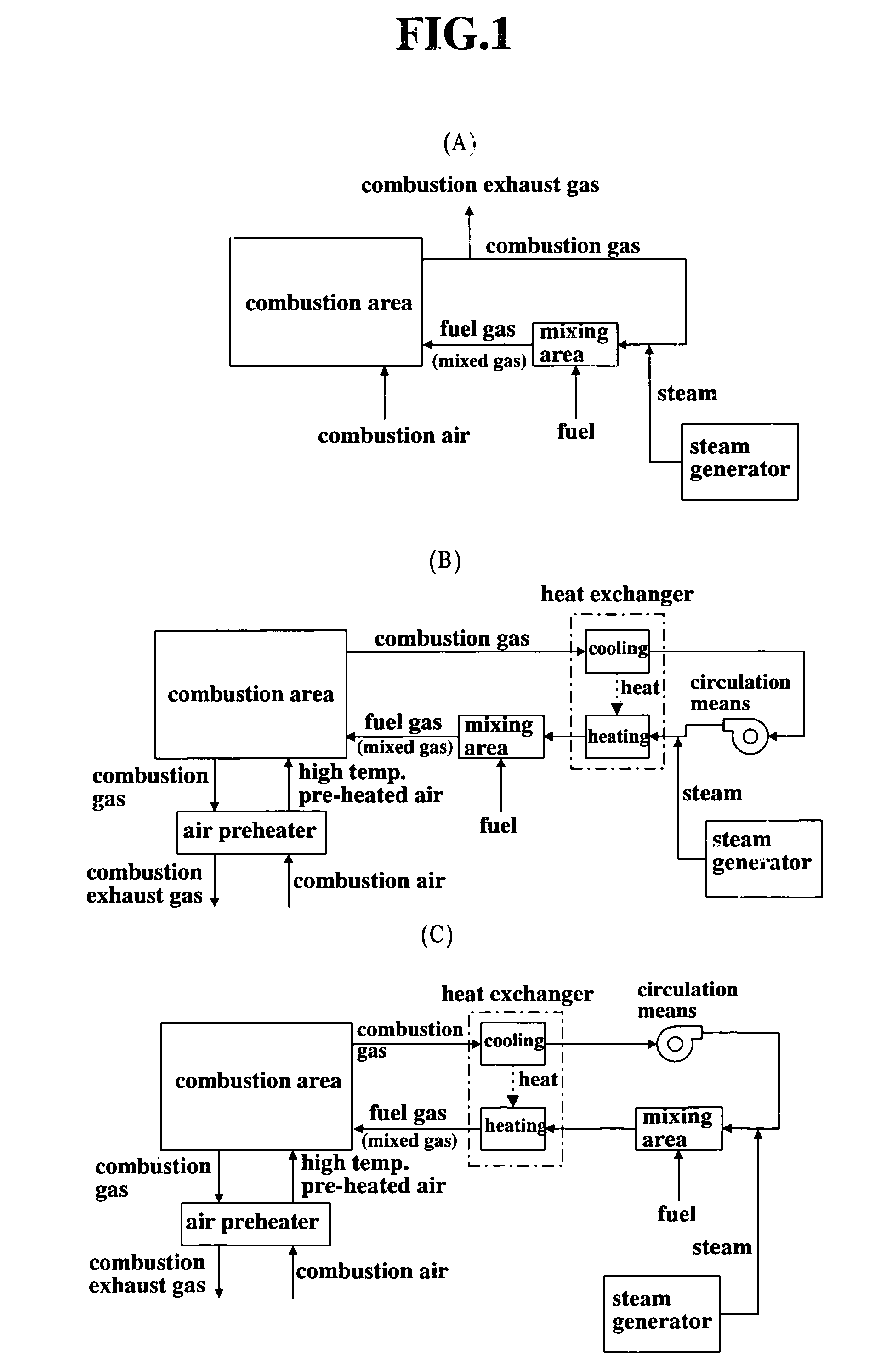

Device and method for feeding fuel

InactiveUS7104784B1Control of combustionReduced flexibilityGaseous fuel pretreatmentCombustion using multiple fuelsCombustion systemProduct gas

The present invention provides a fuel feeding apparatus and method for improving the controllability of mixing process and mixing ratio of fuel and combustion air, and a combustion system and method for effecting new combustion properties. The fuel feeding apparatus of the combustion system has fuel feeding means, combustion gas extraction means, steam supply means, mixing means and fuel gas introduction means. The combustion gas extraction means extracts combustion gas of a combustion area therefrom. The mixing means mixes the fuel of fuel feeding means with at least one of combustion gas extracted from the furnace and steam of a steam generator. The fuel gas introduction means introduces a mixed fluid of combustion gas, steam and fuel to the combustion area as a fuel gas, and allows the fuel gas to be mixed with the combustion air. A step of mixing the fuel with the combustion gas after extracted from the furnace and a step of mixing the fuel gas with the combustion air are stepwisely carried out, so that the controllability of mixing process and ratio of the air and fuel is improved. Such a control of fuel gas flow enables control of characteristics of flame and production of flame with new properties in the combustion area.

Owner:NFK HLDG

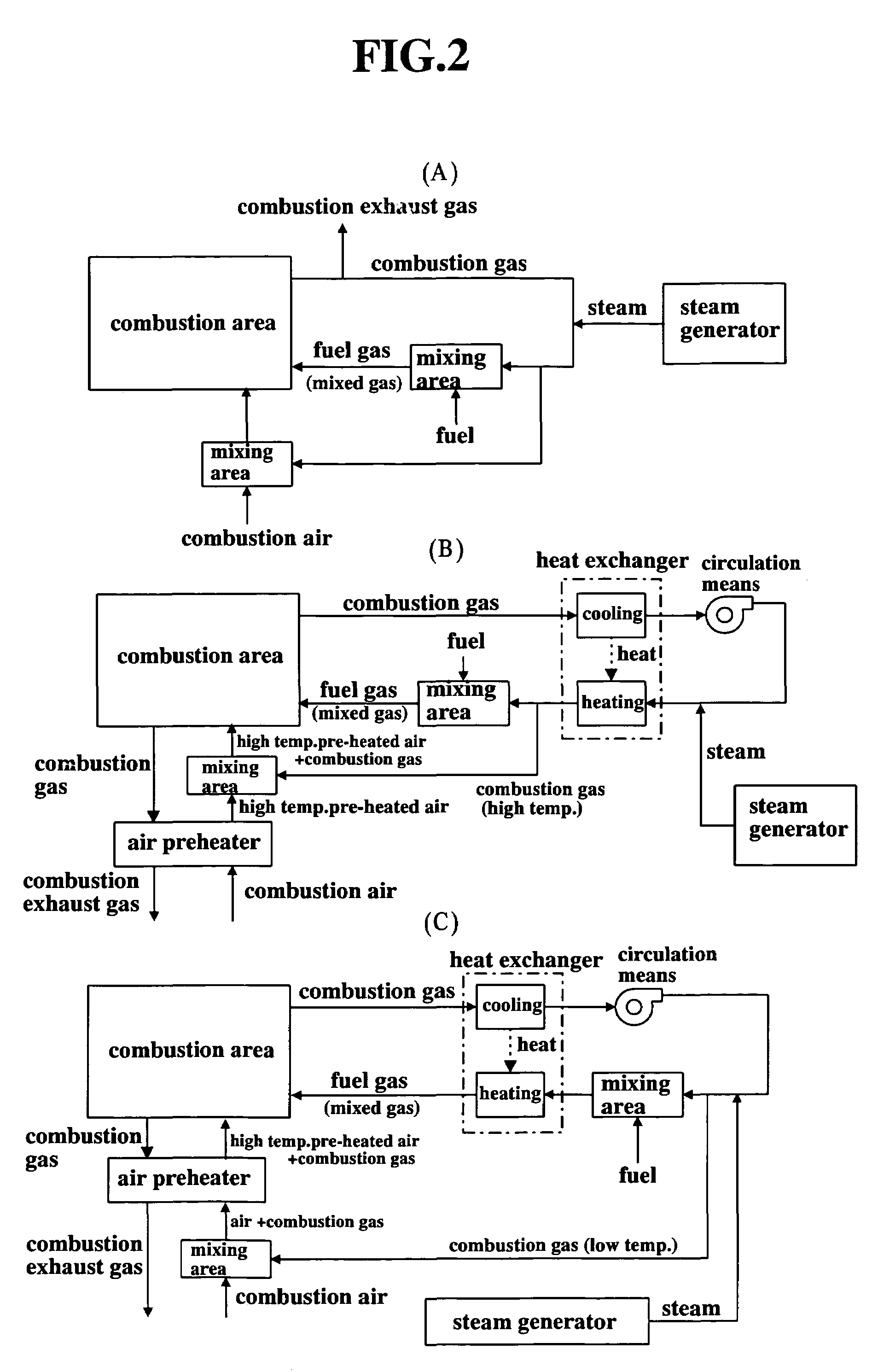

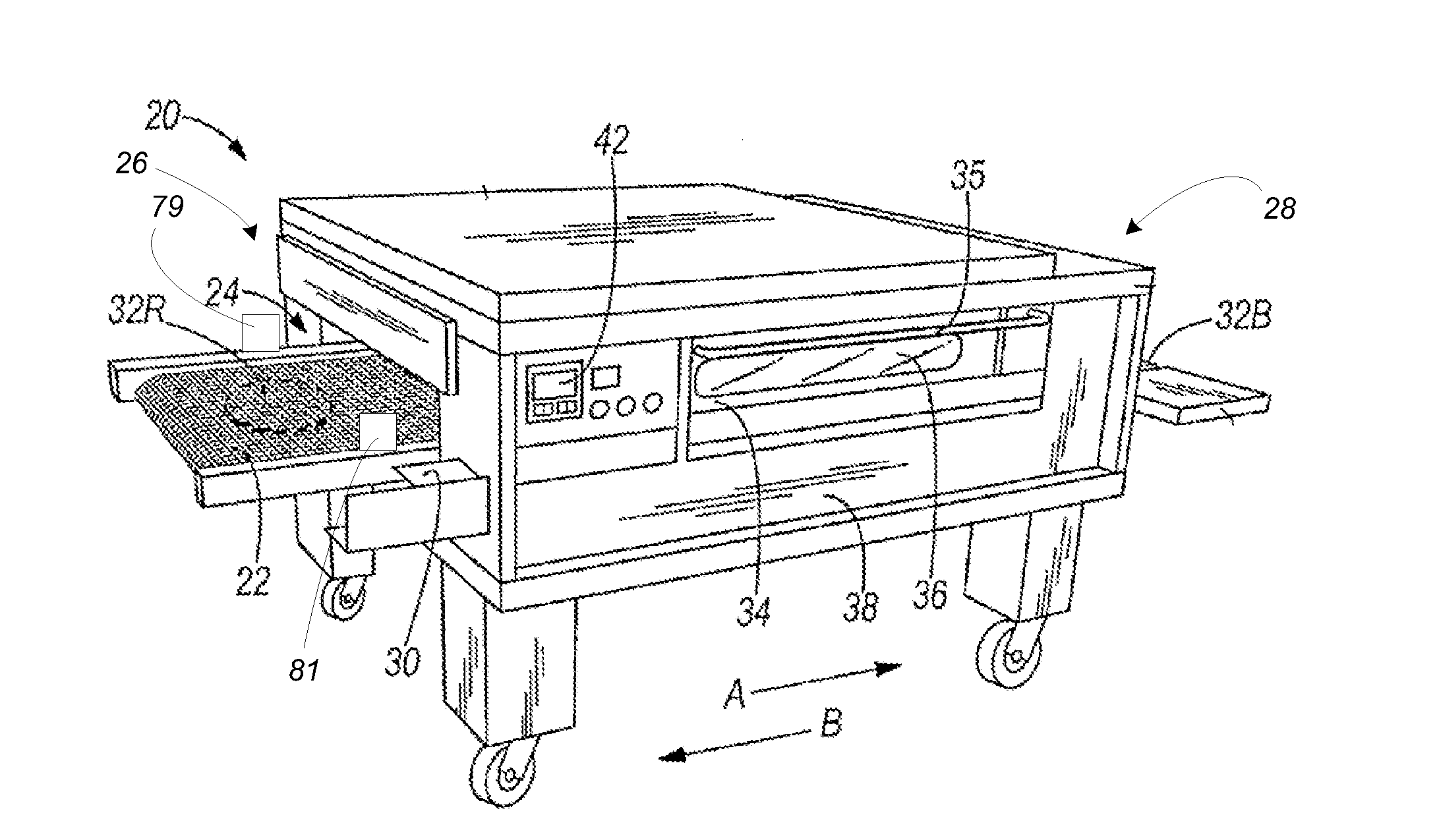

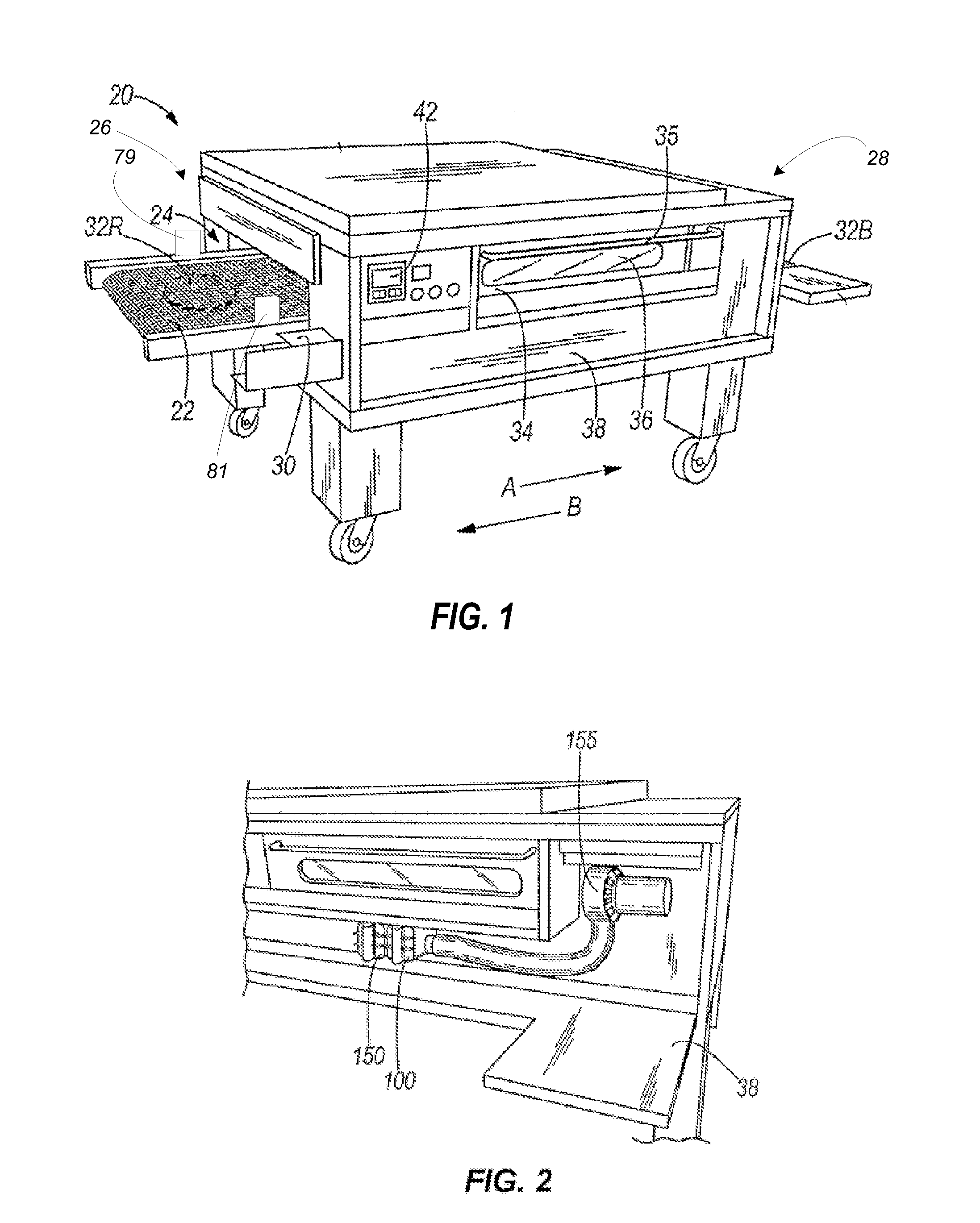

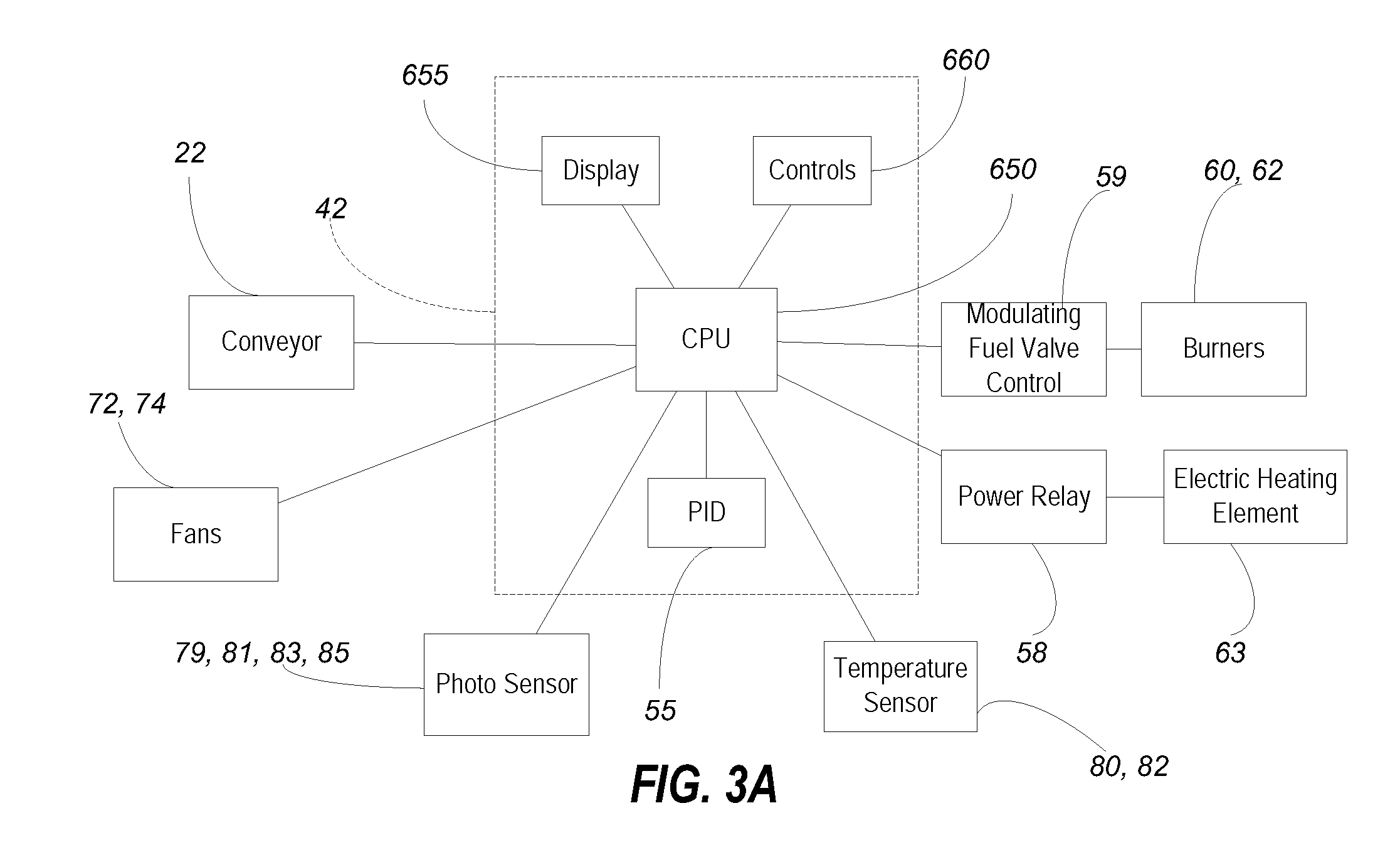

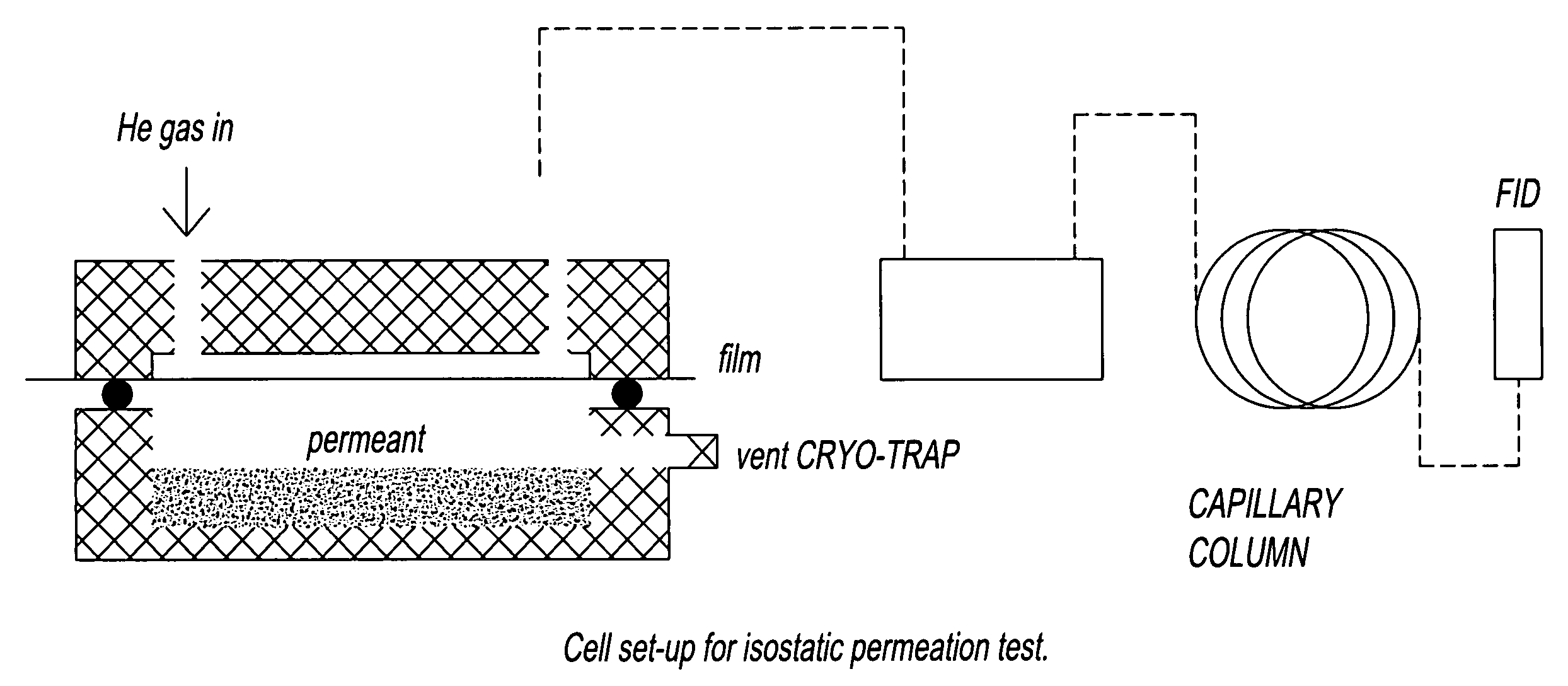

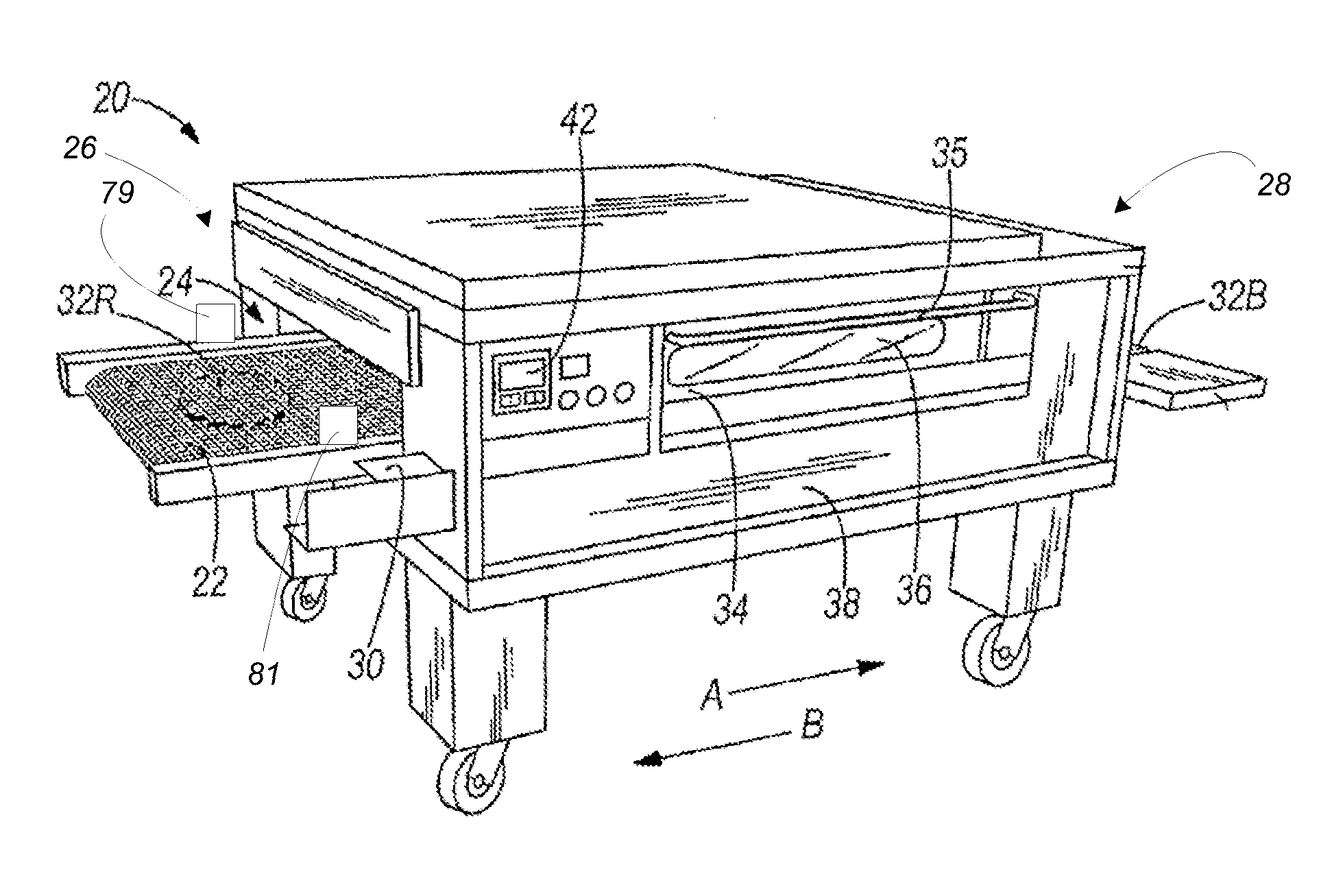

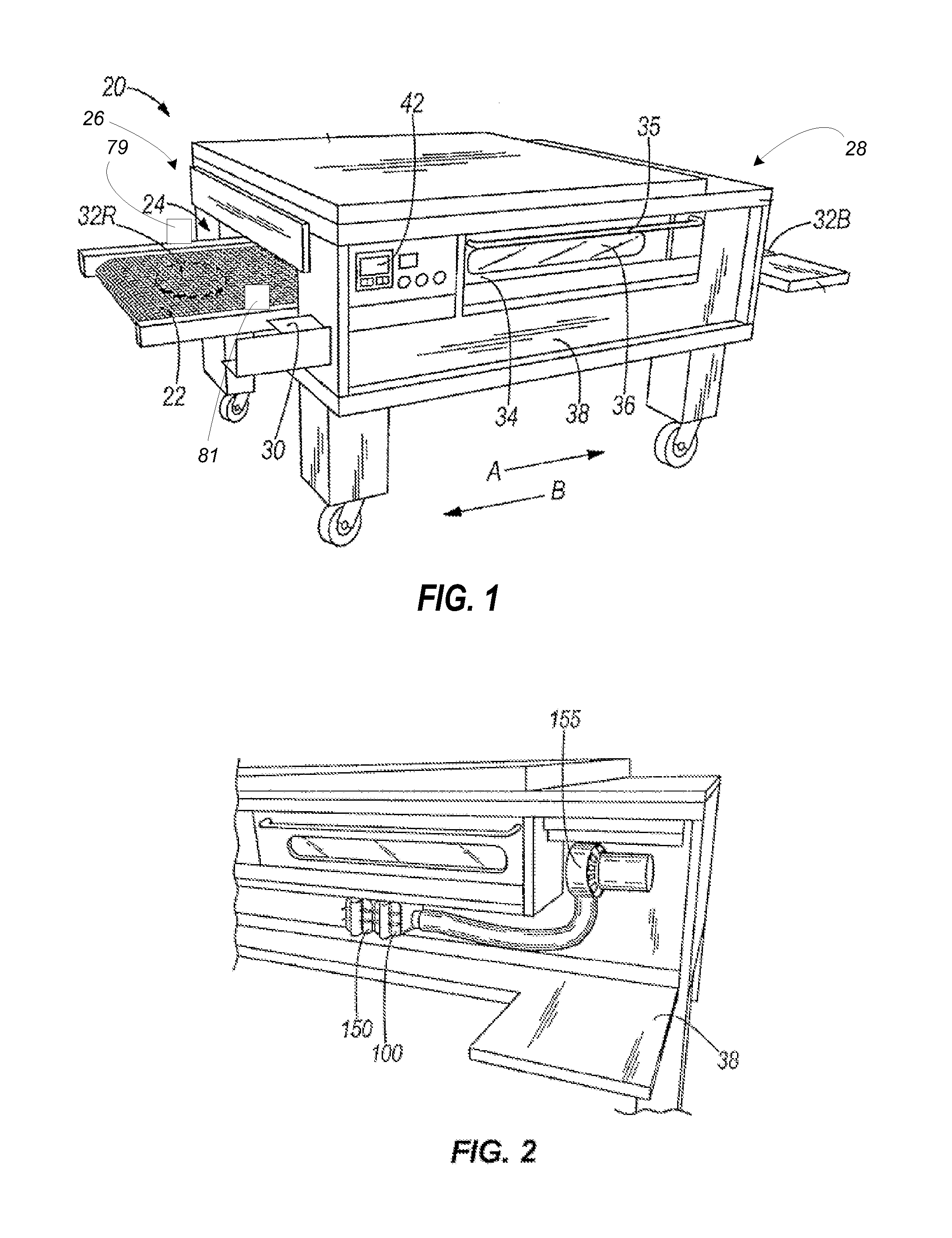

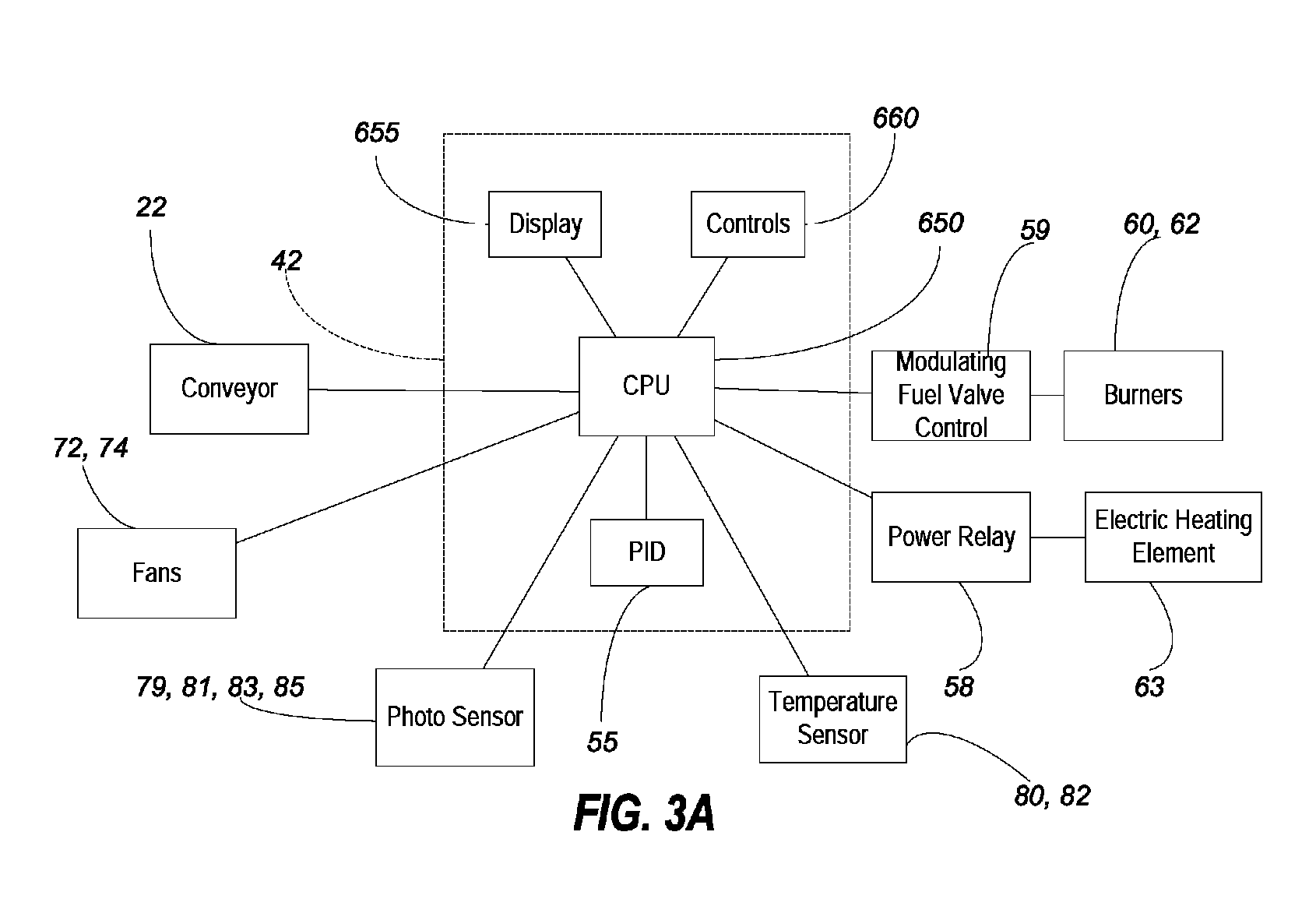

Conveyor oven apparatus and method

ActiveUS20110269085A1Increase productionReduce internal temperatureStoves/ranges foundationsDomestic stoves or rangesEngineeringInternal temperature

An oven with a sensor positioned to detect an event that will cause a decrease in the internal temperature of a tunnel. The oven includes a controller configured to increase the thermal output of a heating element in anticipation of the upcoming decrease in the internal temperature. In some embodiments, the oven is a conveyor over and the sensor is positioned to detect a food item approach the tunnel on a conveyor. In some embodiments, the amount of current provided to an electric heating element is increased by increasing the target temperature. In some embodiments, the amount of current provided to the electric heating element is increased by a predetermined offset.

Owner:MIDDLEBY CORPORATION

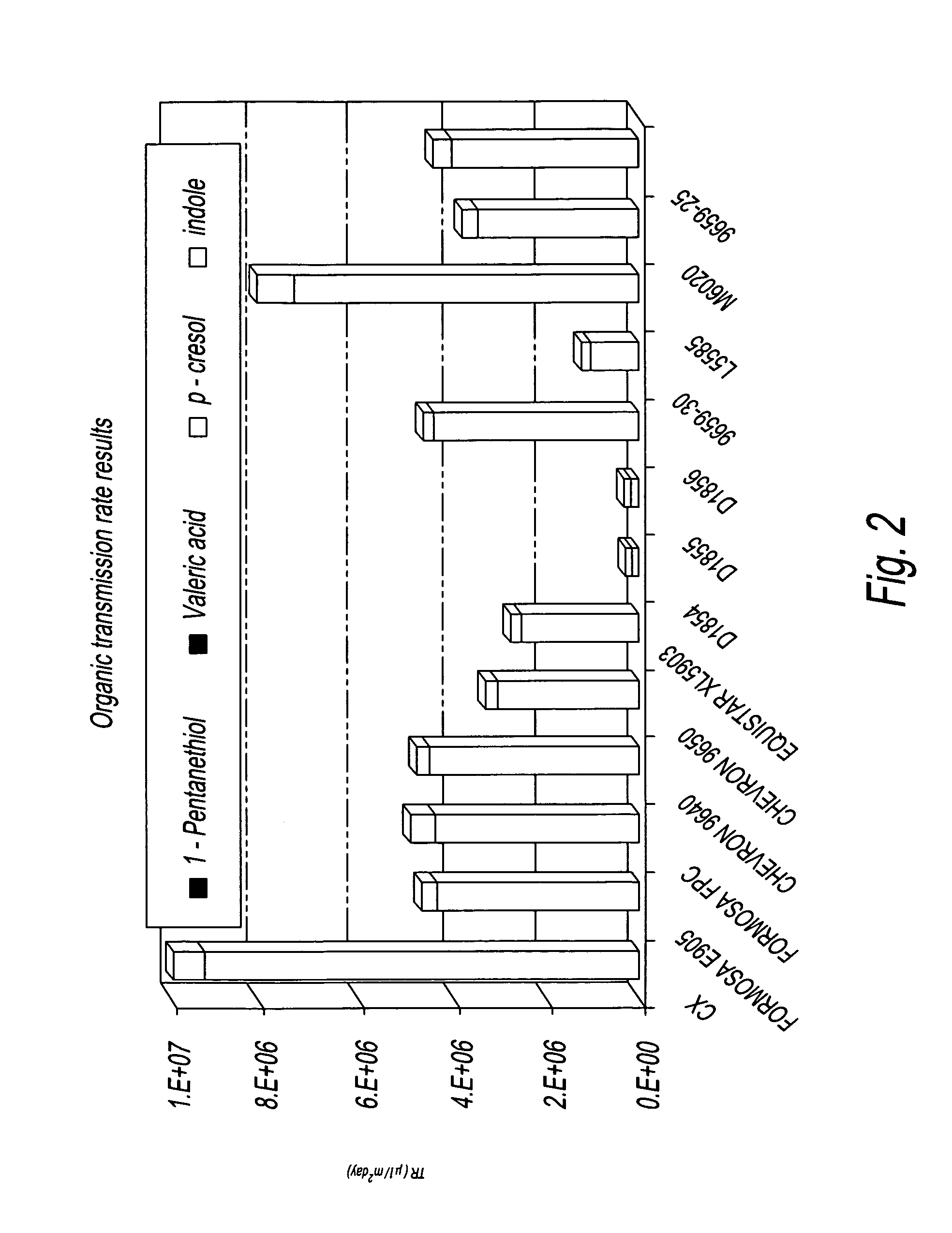

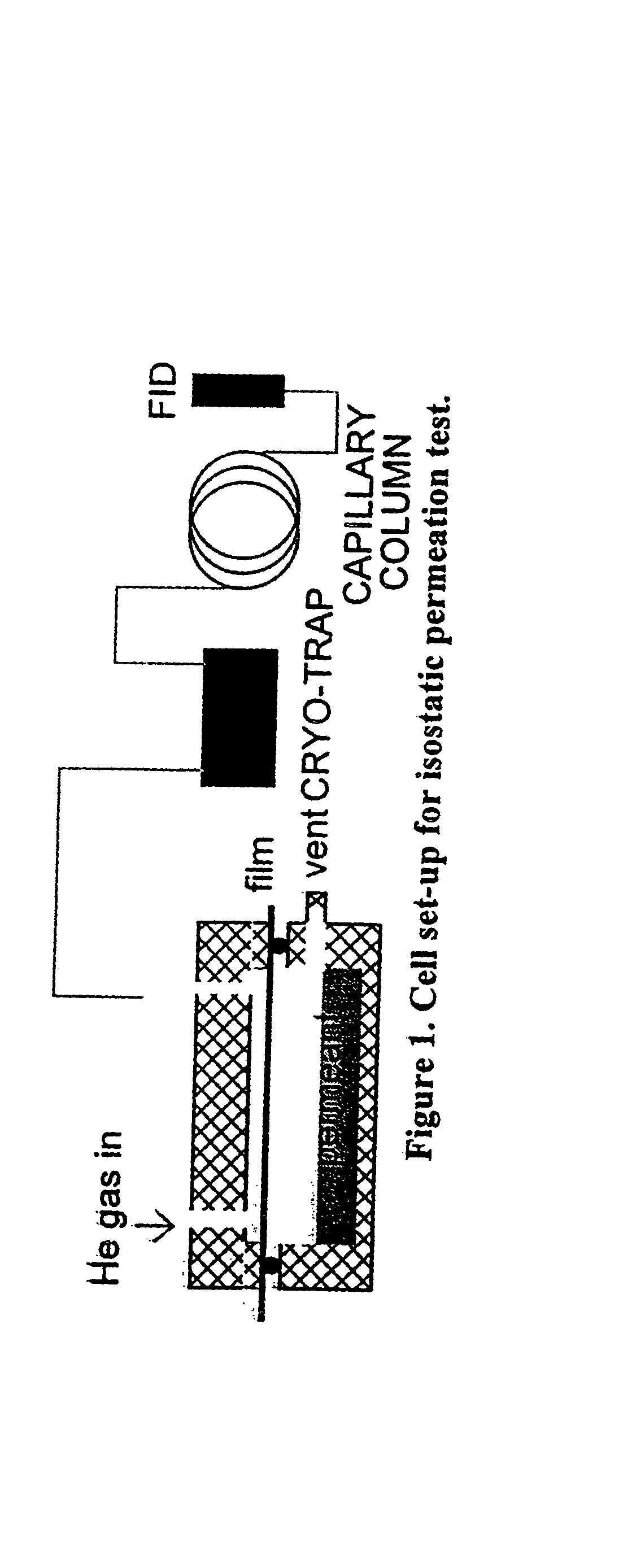

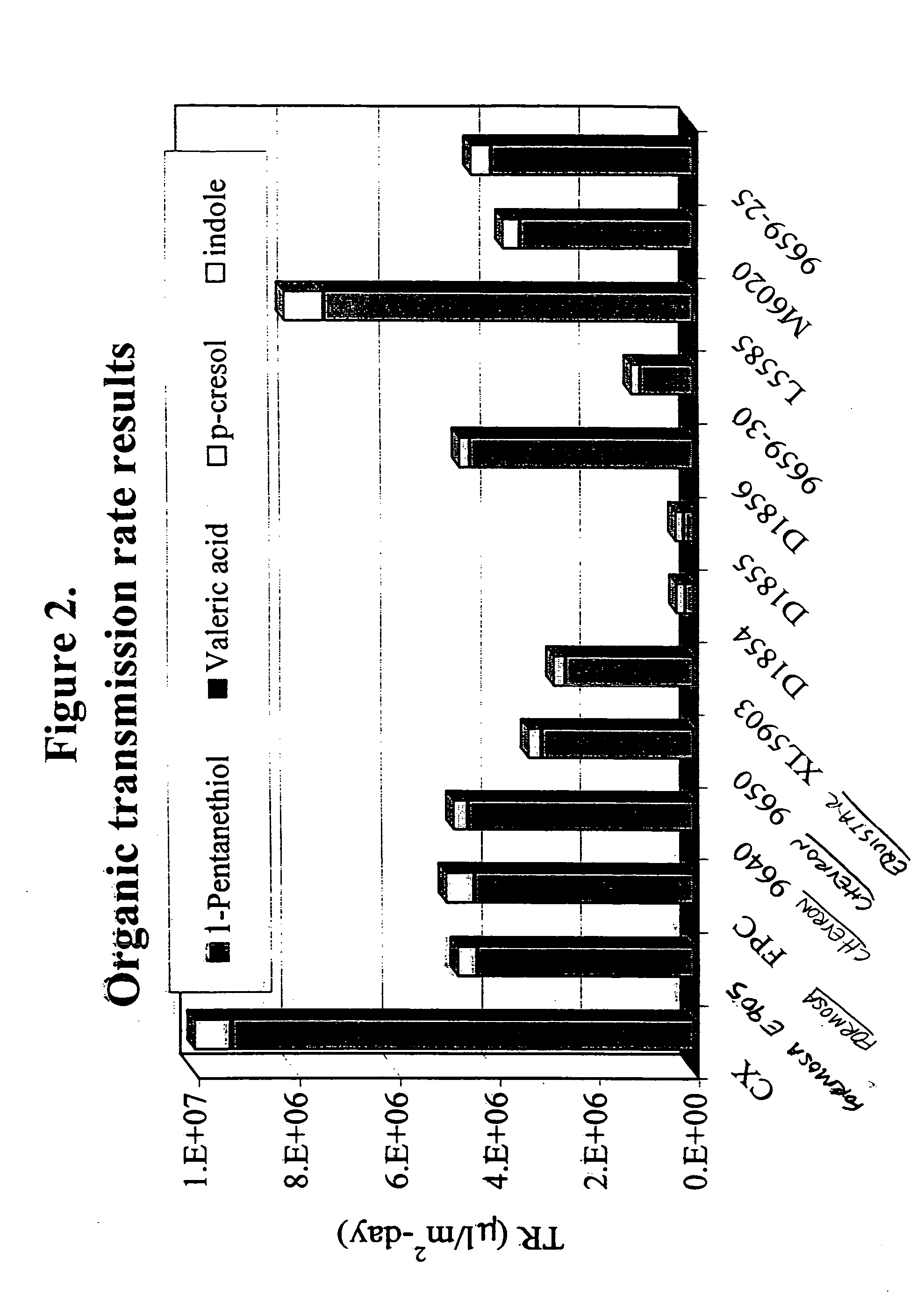

Odor control cassette

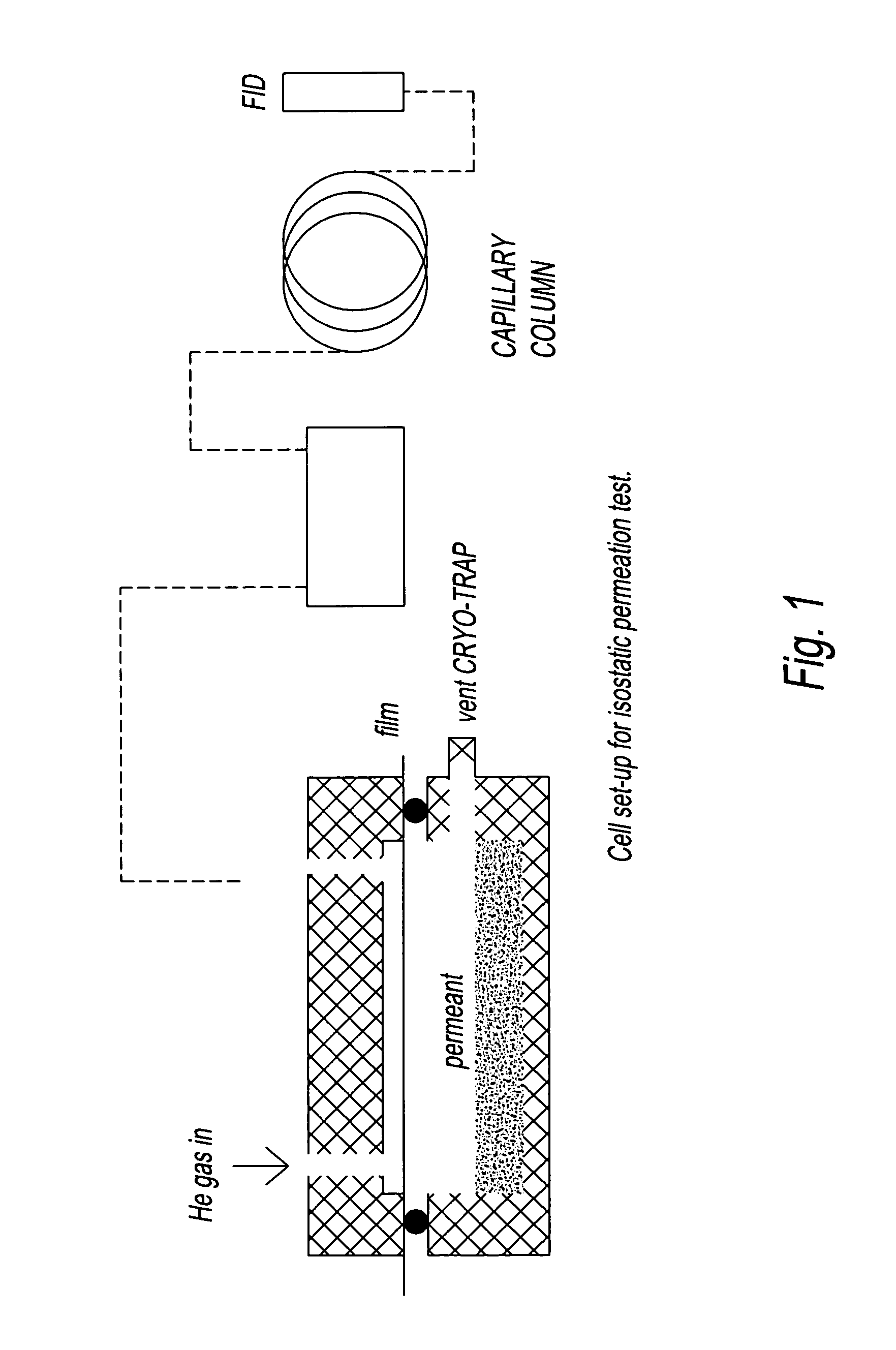

InactiveUS7073311B2Reduce odorInexpensive and easy to manufactureLayered productsCharge supportsHigh densityMagnetic tape

A film is provided for use in a cassette. Preferably, the cassette is used in a waste disposal system. The film is a high density polyethylene film resin having both a low melt index and a high density, thereby providing improved odor control capabilities and enhanced tear strength and assembly strength.

Owner:WELLS FARGO BANK NAT ASSOC

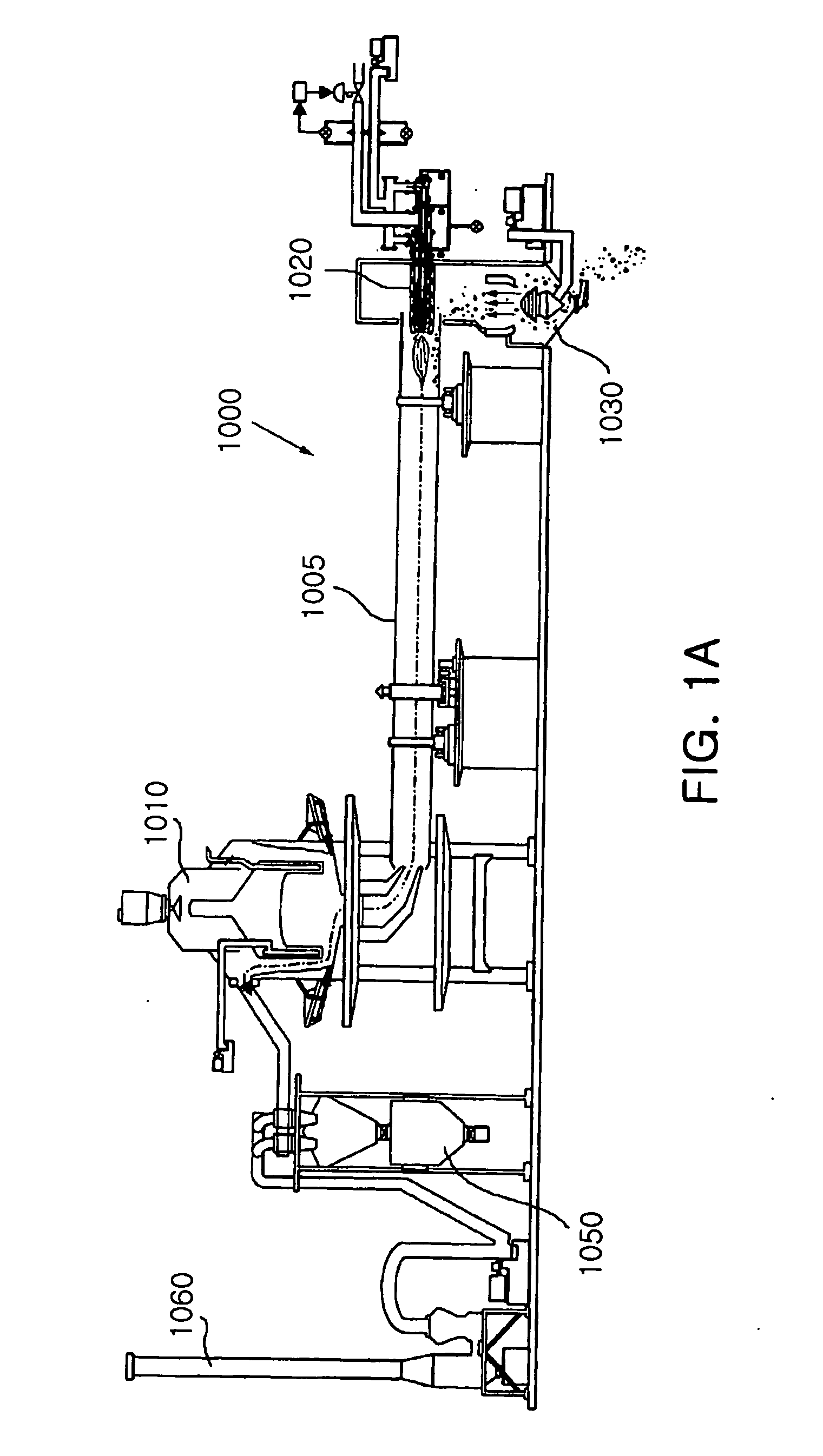

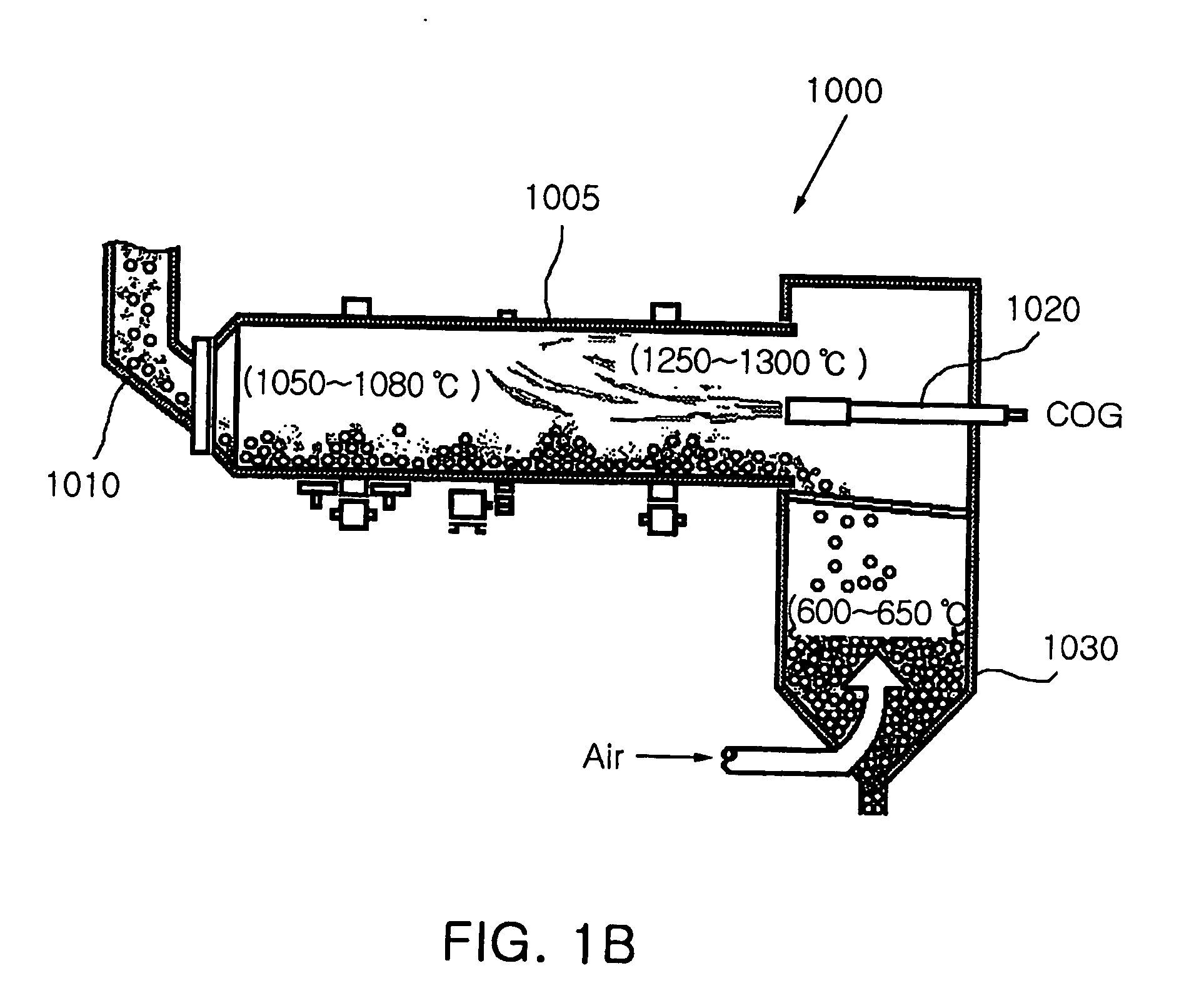

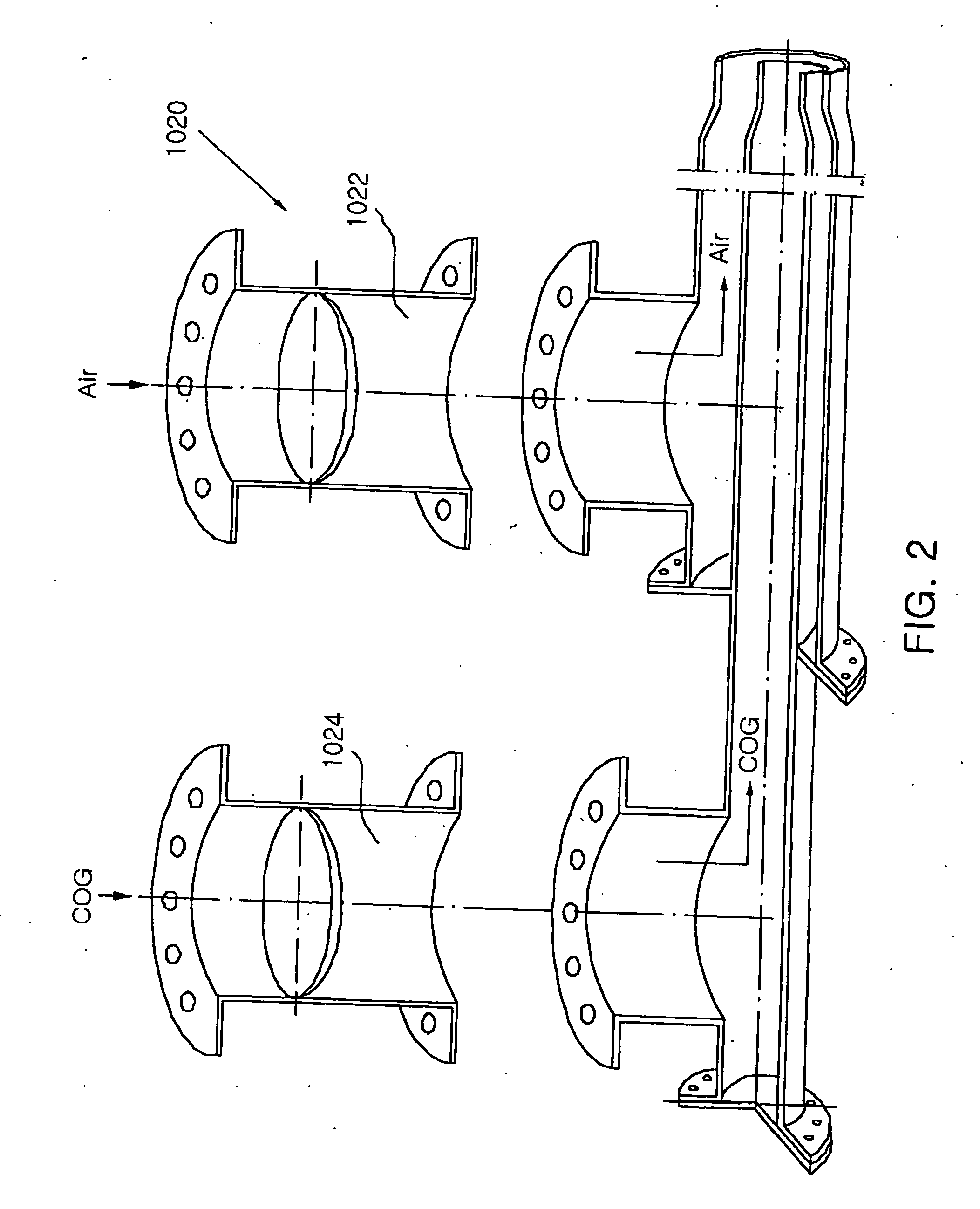

Method and burner apparatus for injecting a pulverized coal into rotary kilns, method and apparatus for producing cao using them

InactiveUS20060169181A1Reduce concentrationMinimize diameter variationPigmenting treatmentSolid fuel pretreatmentCombustorEngineering

The invention relates to a method and burner for injecting pulverized coal into a rotary kiln that uses pulverized coal as fuel in order to produce quick lime of excellent hydration level. The invention calcines lime stone charged into the rotary kiln, and uses pulverized coal as fuel of a heat source applied to the lime stone charged in the rotary kiln. The invention also provides a method and apparatus for producing quick lime by using the pulverized coal. The invention can use pulverized fossil fuel (hereinafter will be referred to as pulverized coal), which is created during coke manufacturing and cooling processes and collected by a dust collector, in order to produce quick lime of excellent hydration level while decreasing SOx (sulfide) and NOx (nitride) generation.

Owner:POHANG IRON & STEEL CO LTD

Method for the heat treatment of substrates

A substrate undergoes a semiconductor fabrication process at different temperatures in a reactor without changing the temperature of the reactor. The substrate is held suspended by flowing gas between two heated surfaces of the reactor. Moving the two heated surfaces in close proximity with the substrate for a particular time duration heats the substrate to a desired temperature. The desired temperature is then maintained by distancing the heated surfaces from the substrate and holding the heated surface at the increased distance to minimize further substrate heating.

Owner:ASM INTERNATIONAL

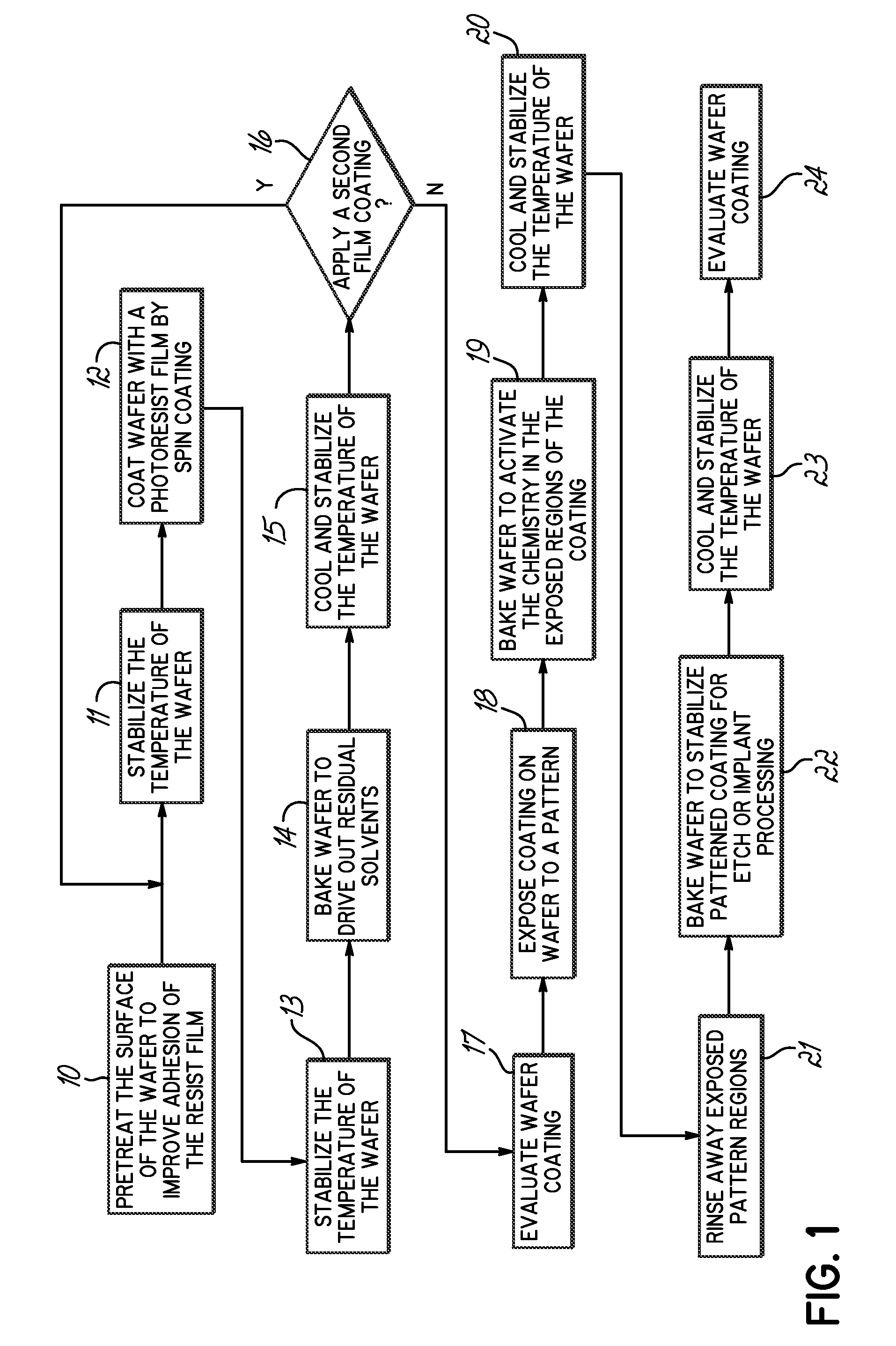

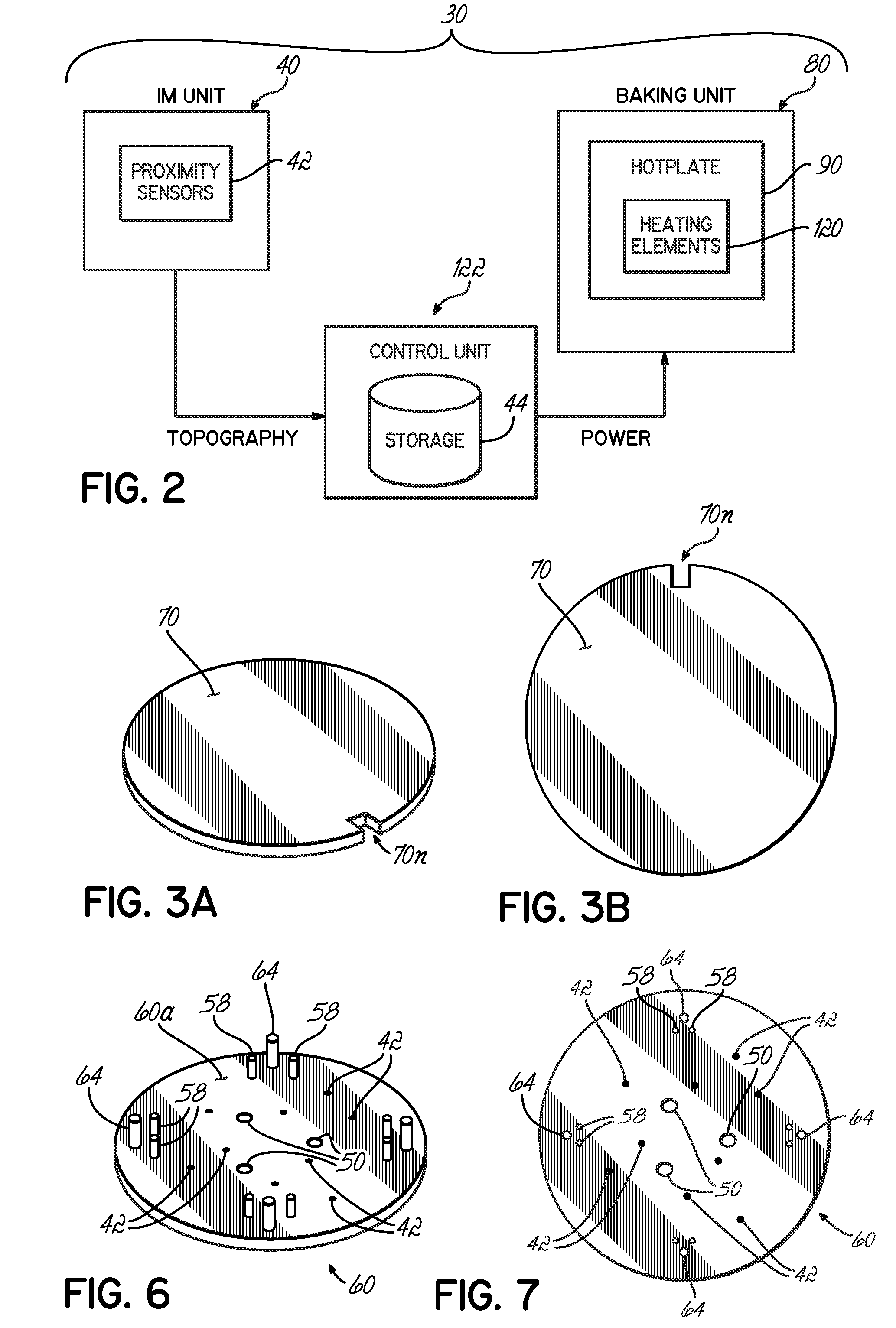

Apparatus and method for predictive temperature correction during thermal processing

InactiveUS20080241778A1No loss in productionIncrease speedCharge supportsSemiconductor/solid-state device manufacturingEngineeringHeat processing

A thermal processing apparatus and method with predictive temperature correction. Distances are measured from a backside of the wafer relative to a reference plane. Heat is transferred to the backside of the substrate in relation to the measured distances. This allows a baking unit to uniformly heat the substrate to compensate for irregularities or warpage.

Owner:TOKYO ELECTRON LTD

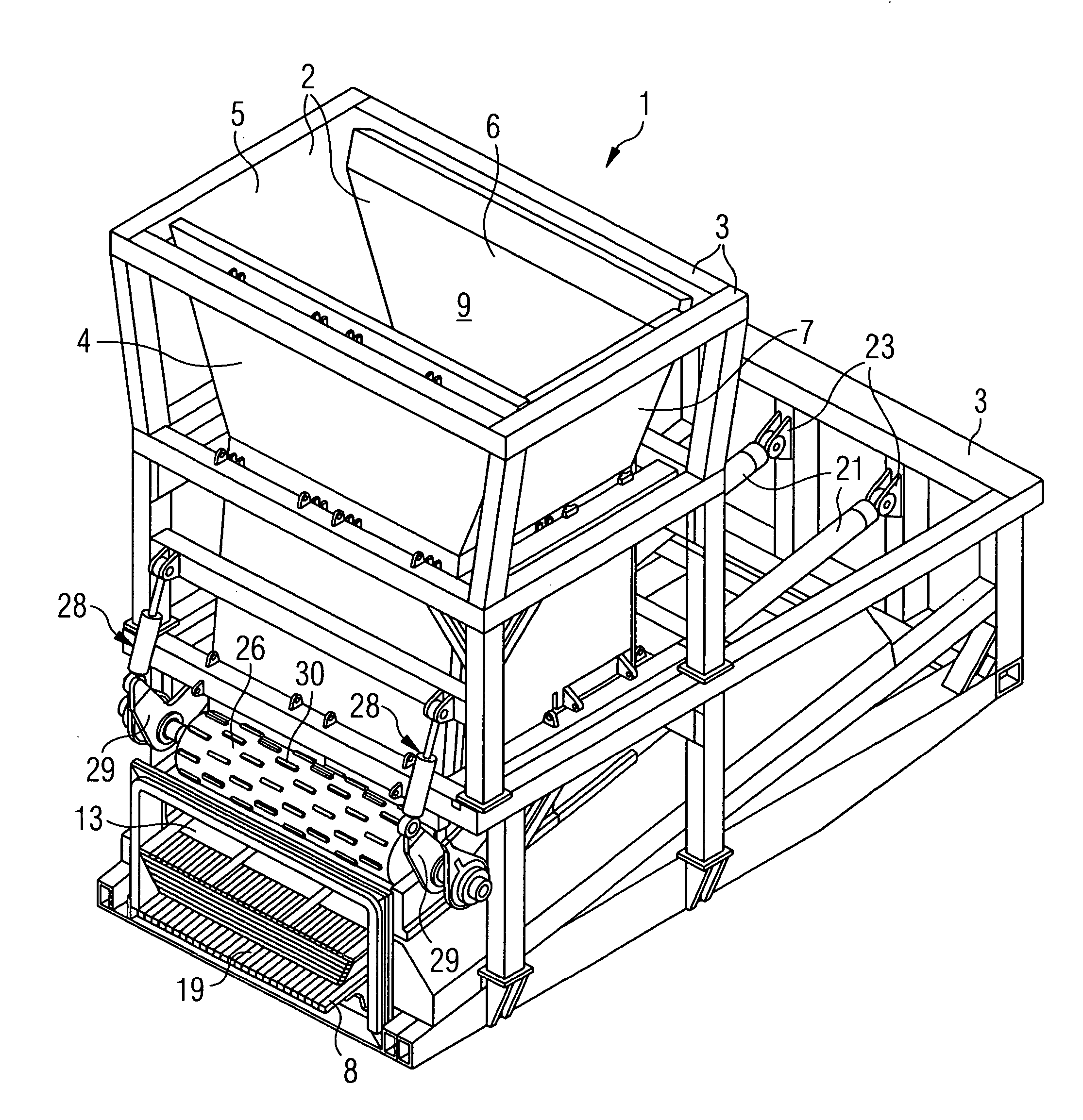

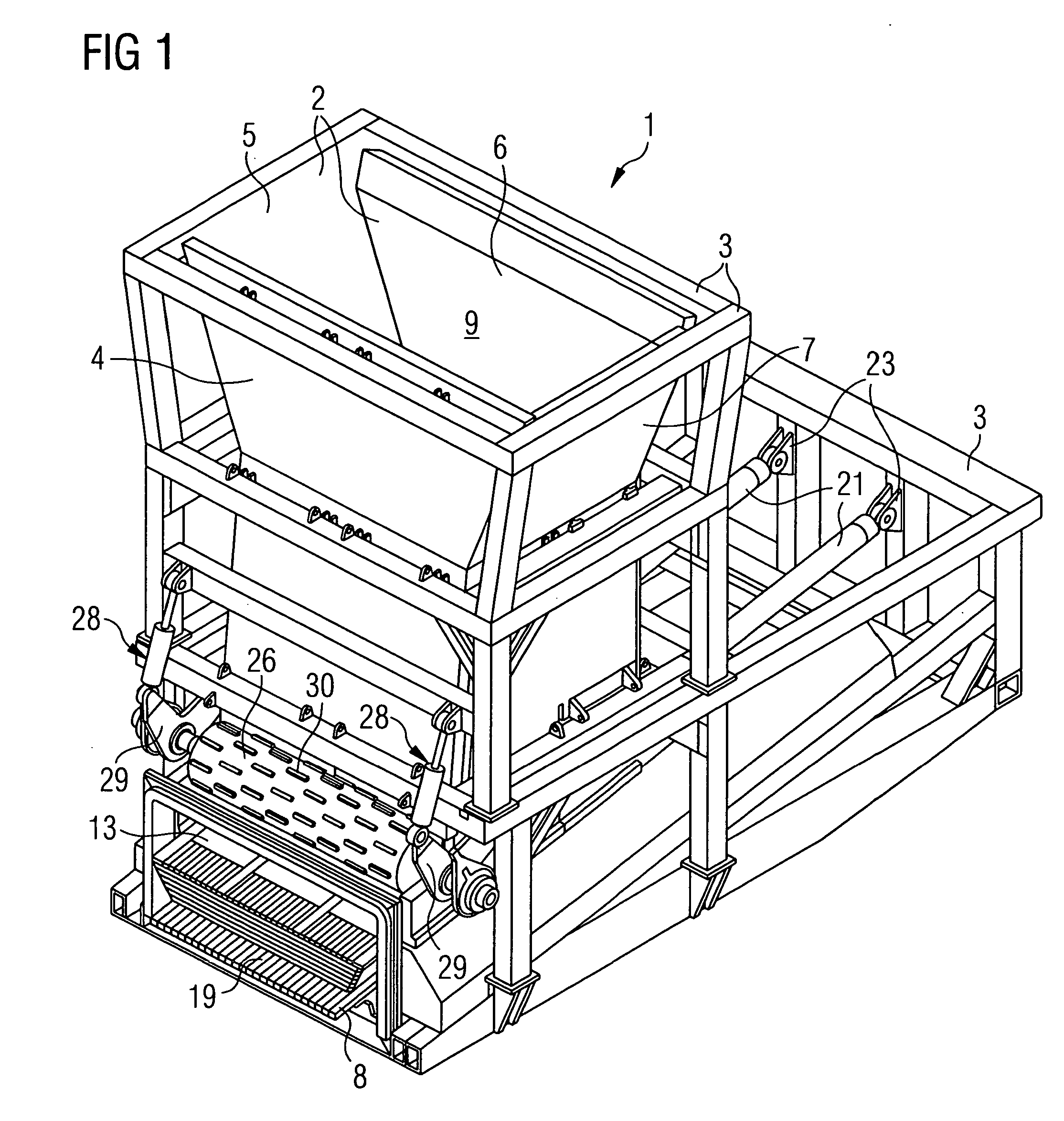

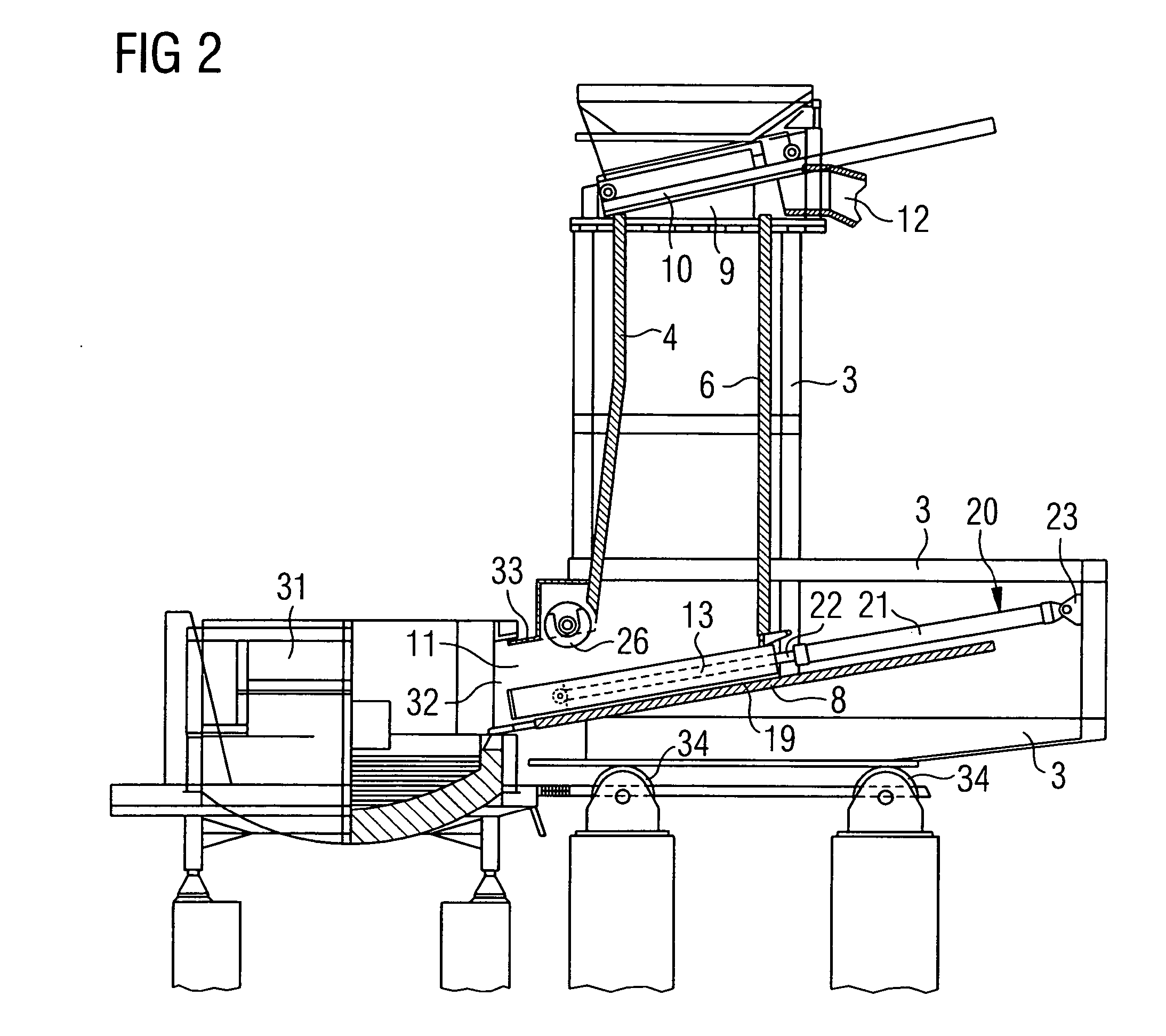

Charging device, especially charging stock preheater

InactiveUS20070013112A1Raise the discharge heightIncrease heightBagsSacksShaped chargeHorizontal axis

To facilitate a trouble-free charging of scrap metal having differing constitutions, such as light and heavy scrap metal, from a lower discharge opening of a shaft-shaped charging device or a charging stock preheater (1) into a melting vessel by a pusher (13), the lateral surfaces of the pusher (13) are formed so as to converge from the upper side to the lower side and the actuating device (2) of the pusher (13) is pivotably supported in a frame structure (3) about a horizontal axis. In addition, the upper boundary of the discharge opening for the charging stock from the shaft (2) is preferably formed by a horizontal, rotatably supported roller (26), more preferably with engaging elements (30) distributed around the circumferential surface. Sections of the charging device that are severely mechanically stressed are preferably formed by steel billet sections connected to form a structural unit.

Owner:FUCHS TECH

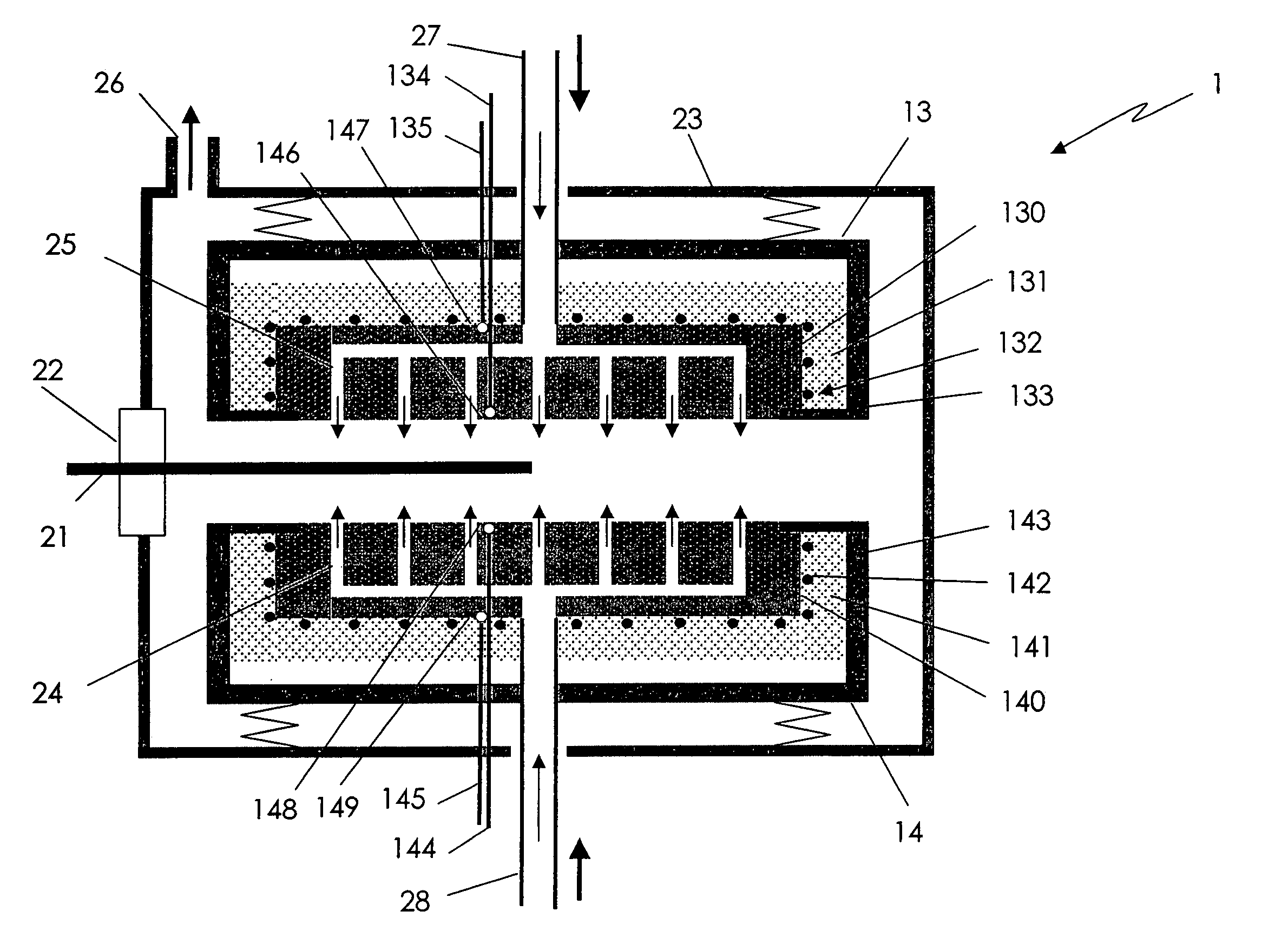

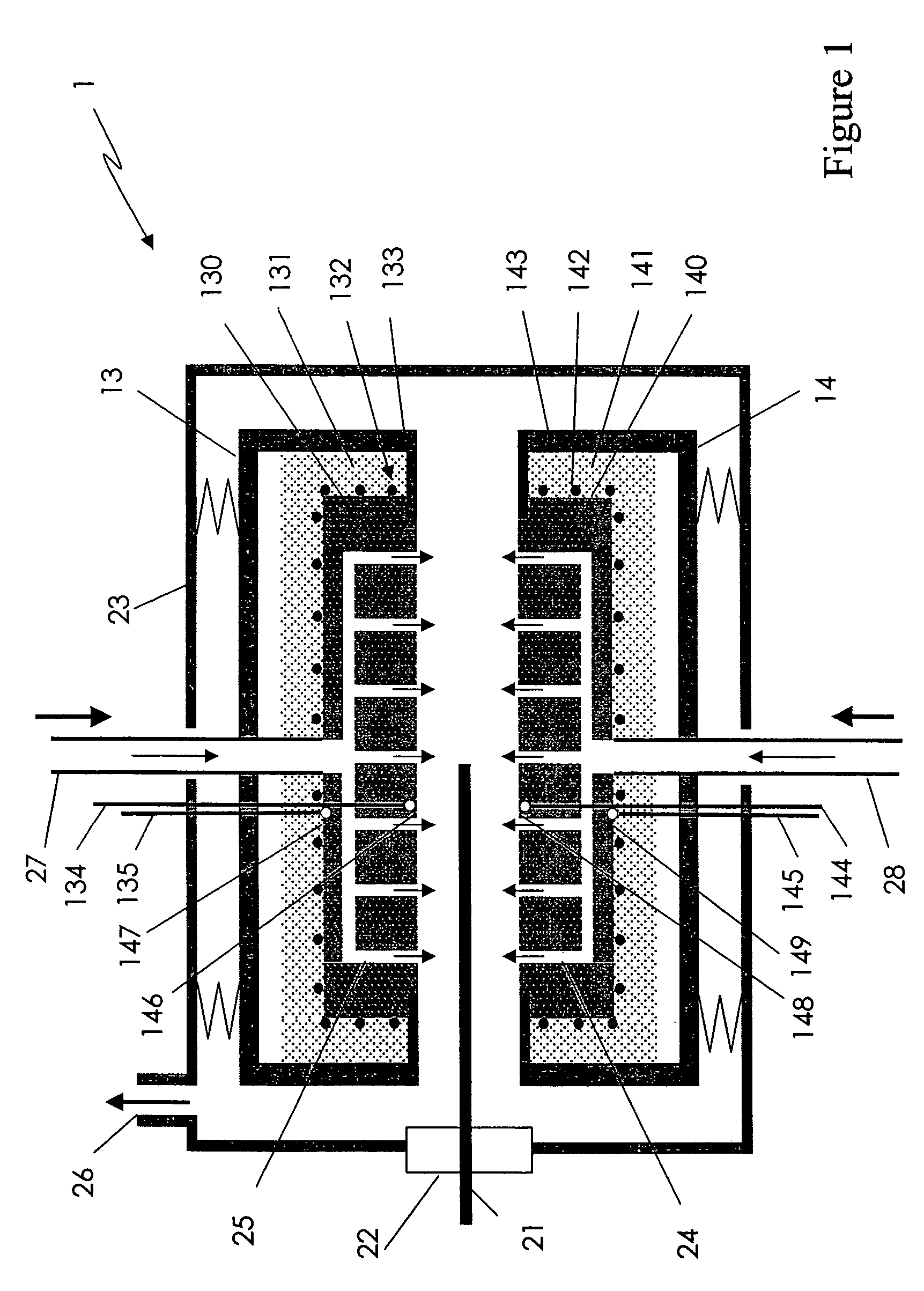

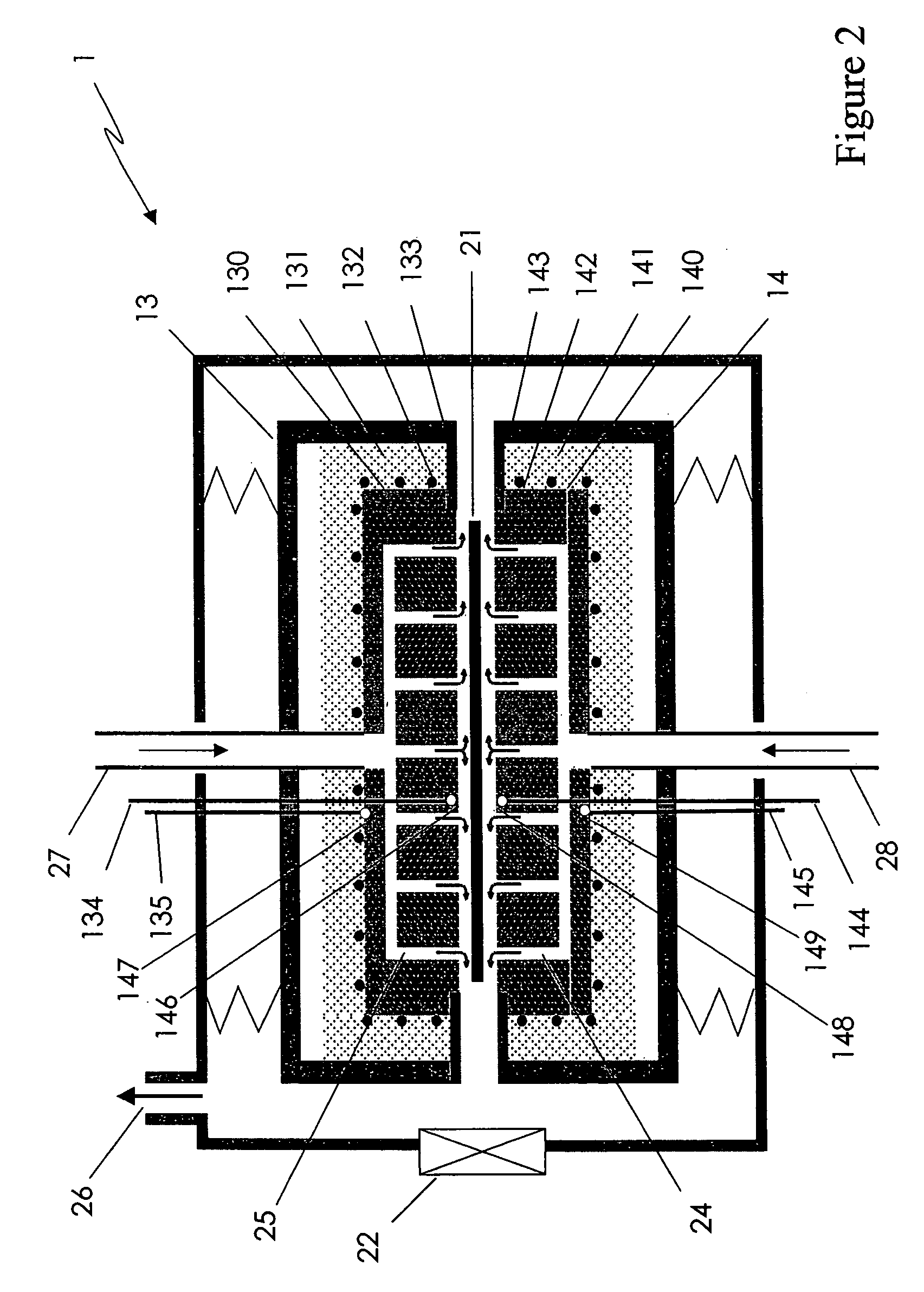

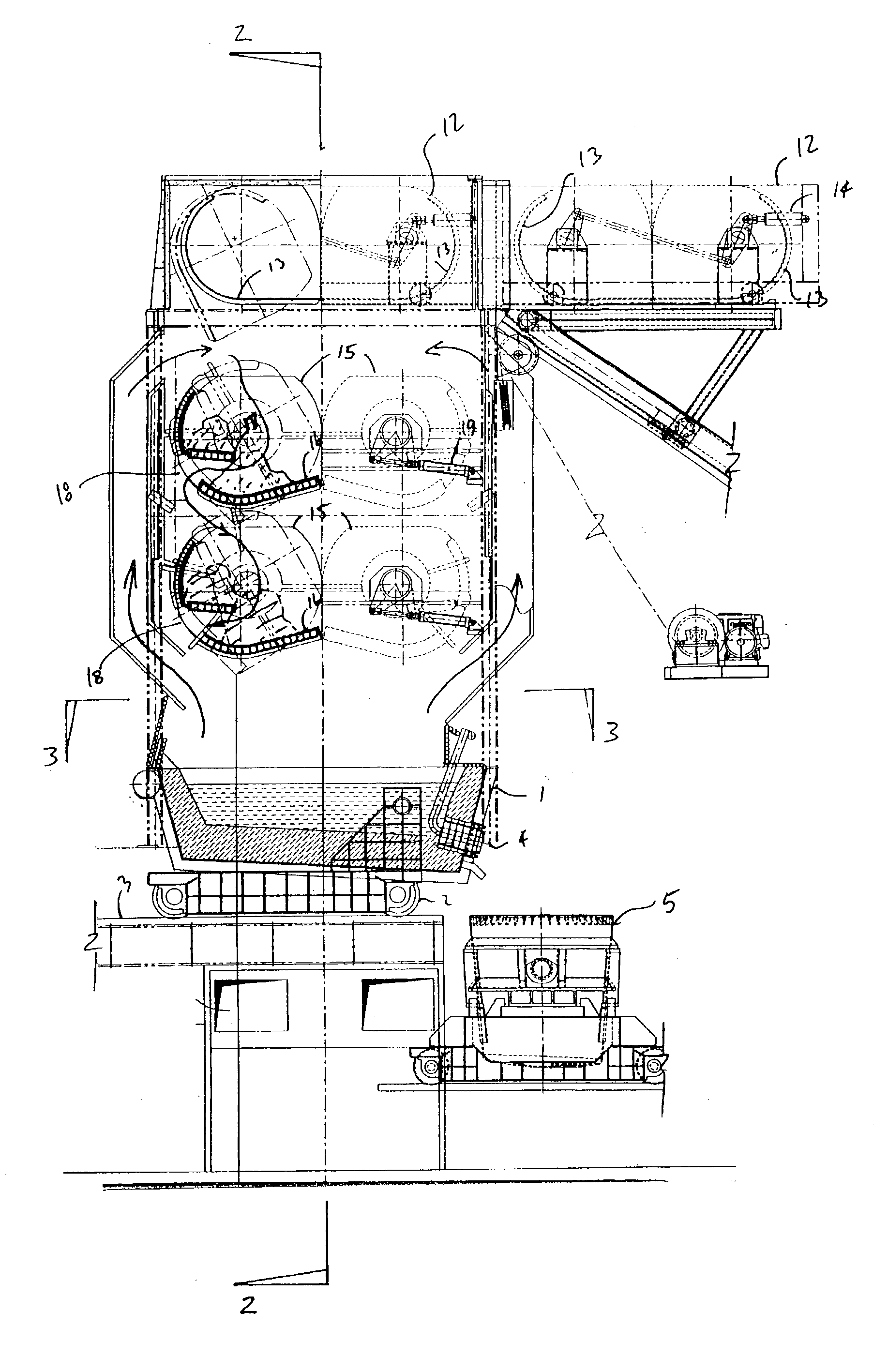

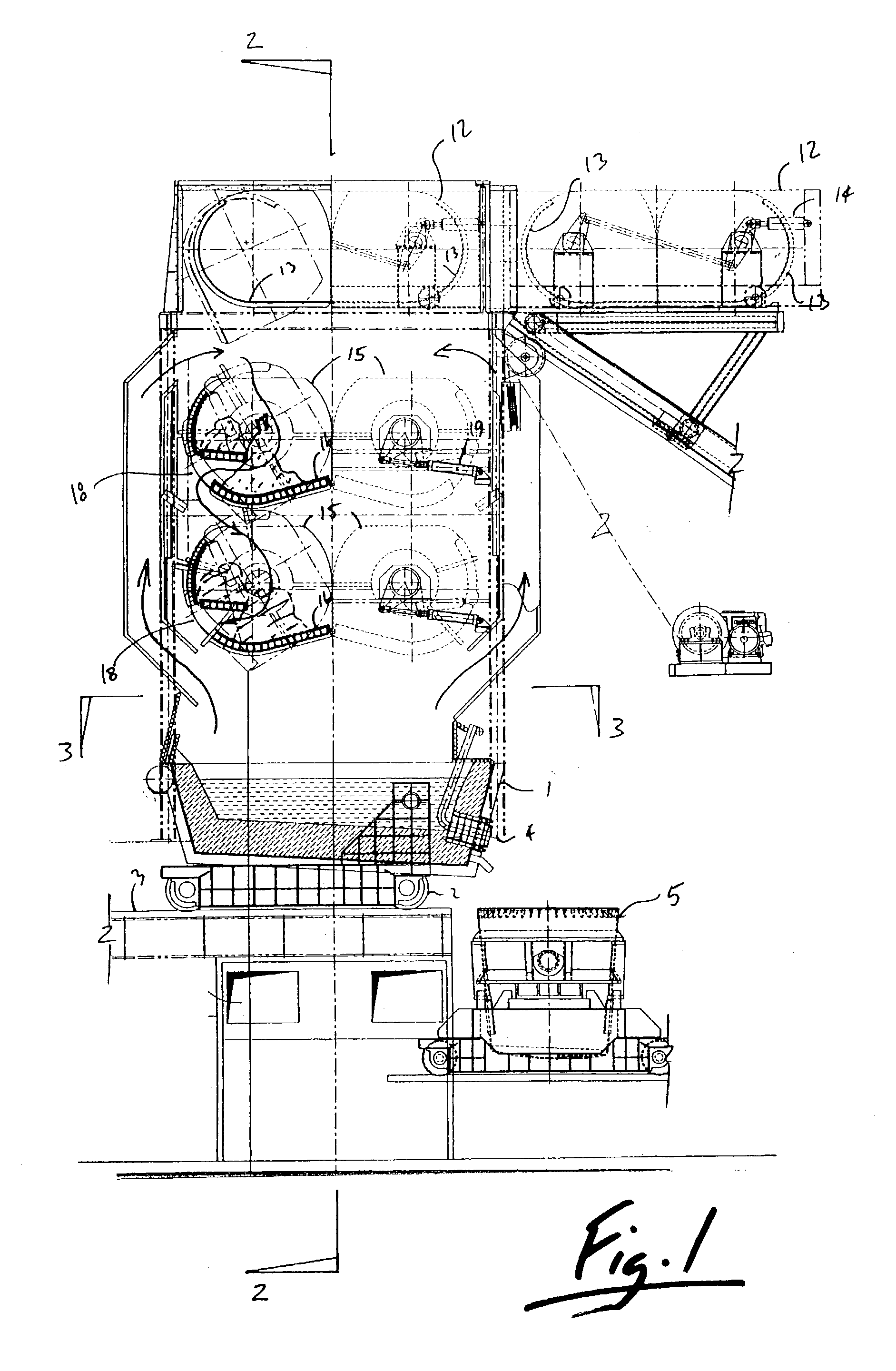

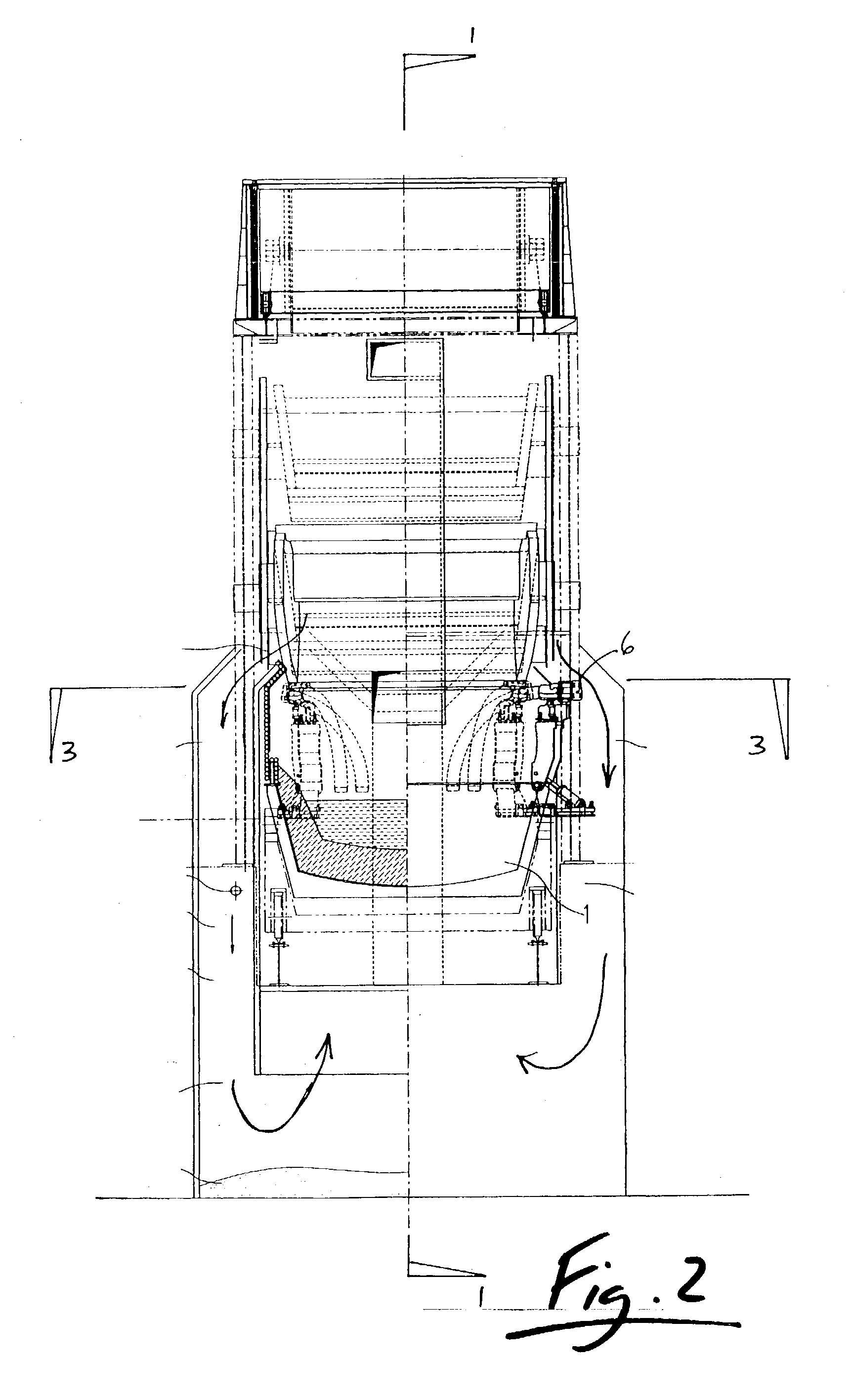

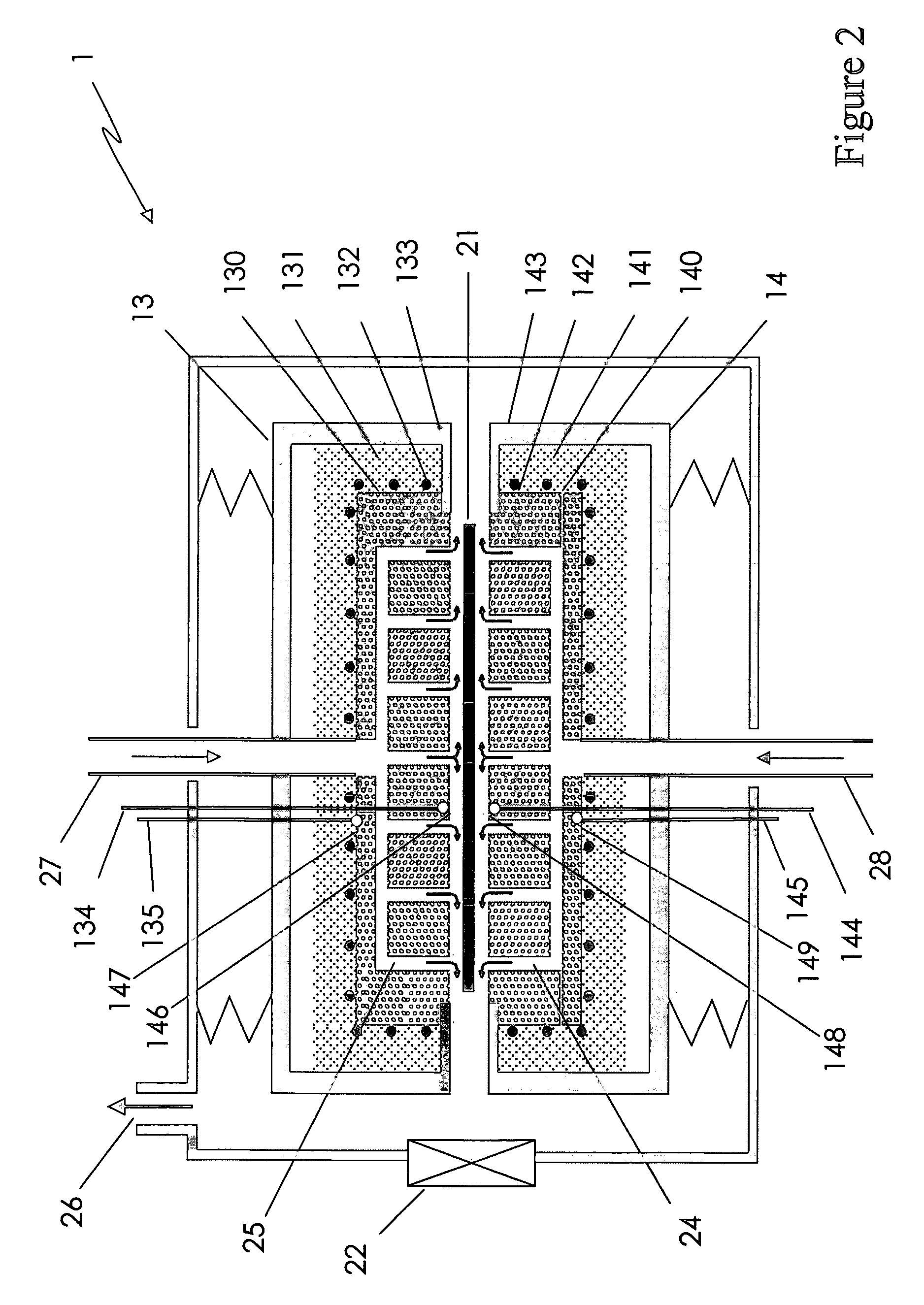

Metallurgical furnace with scrap metal preheater and dispenser

InactiveUS20030122290A1Reduce oxidationSimple and compact designBlast furnace componentsCharge supportsThermal energyProcess systems

A Preheater-Steelmaking Furnace and closed loop Process System for semi-continuous melting of integrally preheated recycled or virgin ferrous charge, by using highly energy efficient combustion process of natural gas combusted by oxygen as the main heat source, after preheating of the cold charge, by fully exploiting thermal energies of the melting process off-gases, in a gas tight, low noise, ecologically friendly PSF with scant CO and drastically reduced CO2 in exhaust gases for semi-continuous, batch self-charging, sealed pairs of eccentrically rotating quasi cylindrical, permeable half drums hoppers creating separate preheating chambers.

Owner:EMPCO (CANADA) LTD

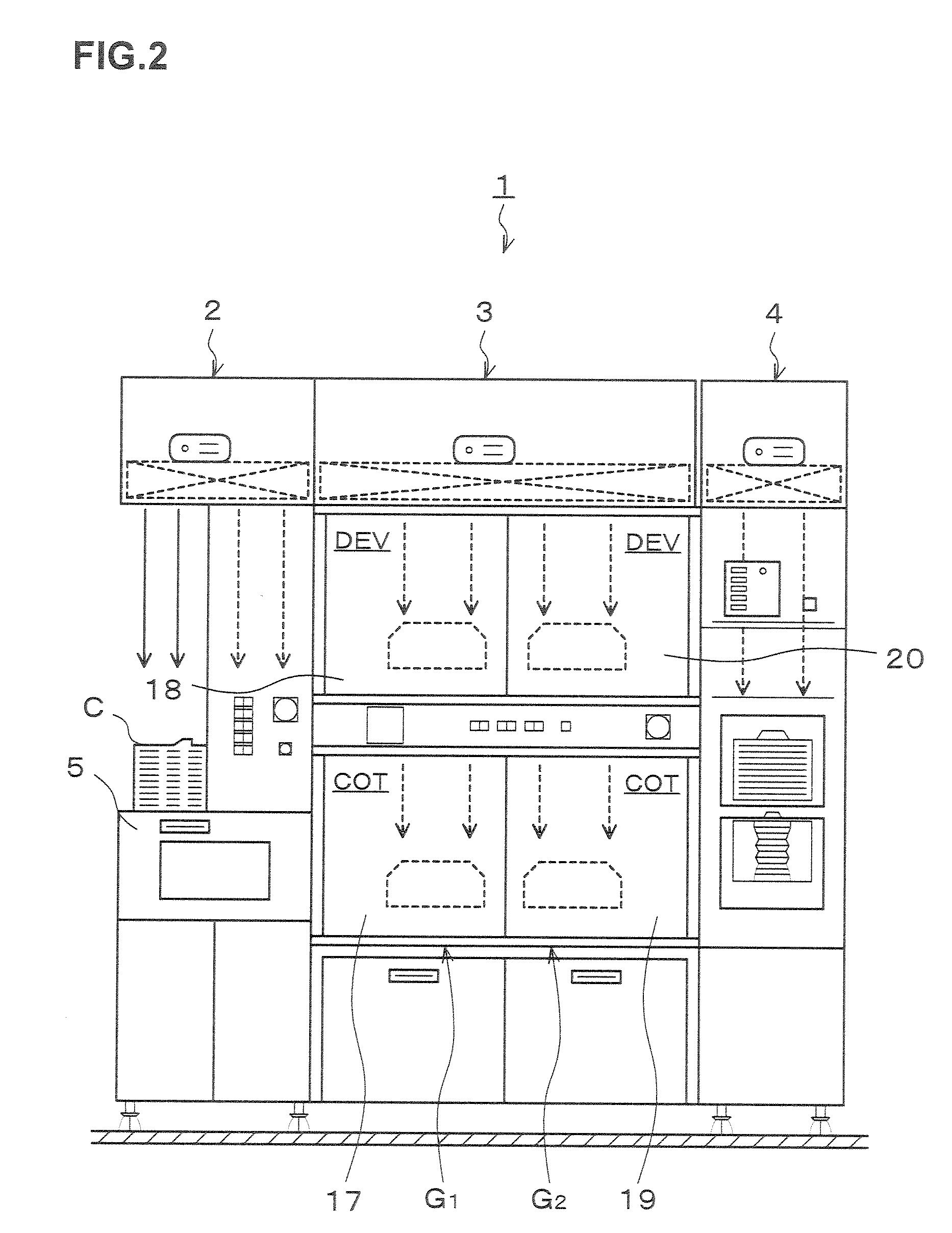

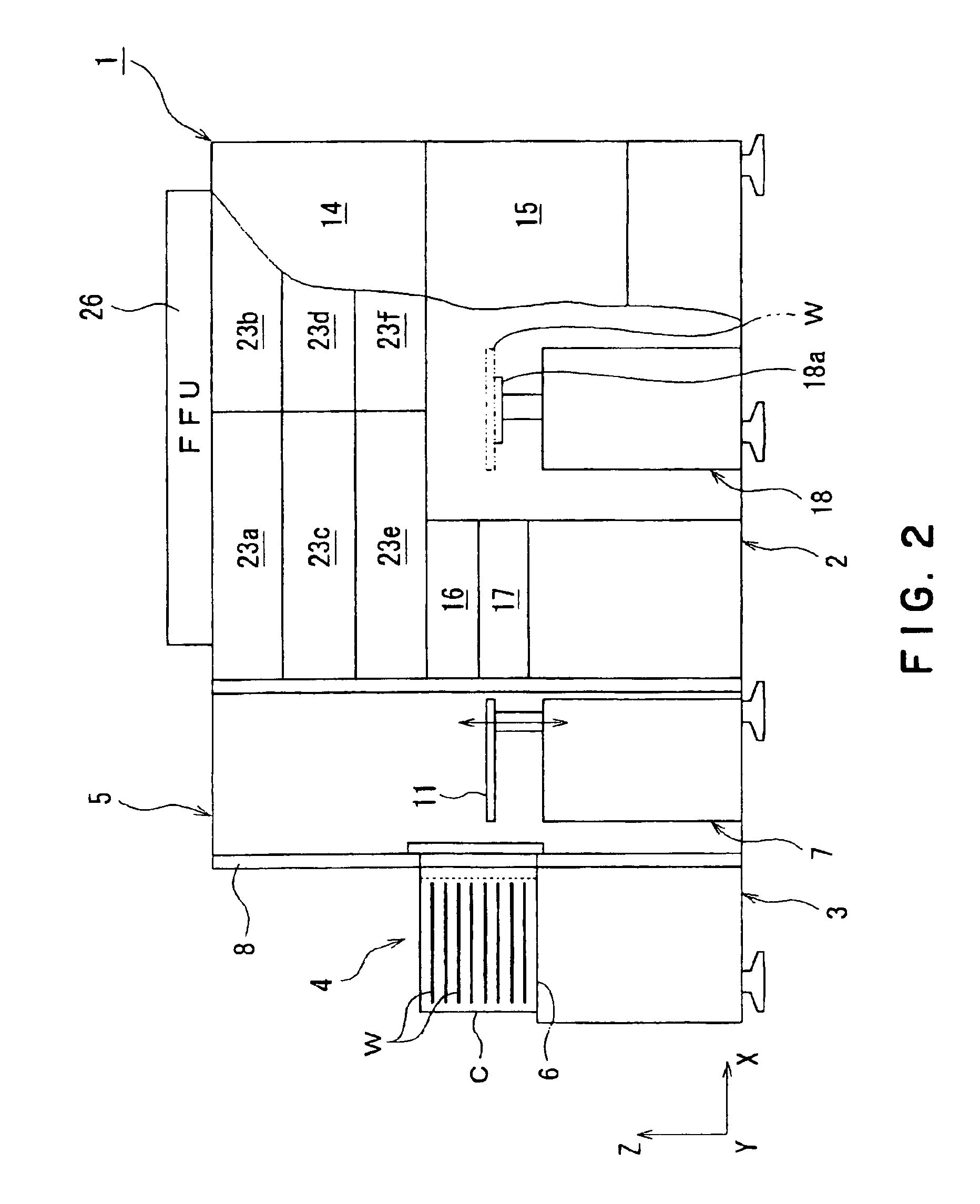

Heat treating apparatus, heat treating method, and storage medium

InactiveUS20070218706A1Promote exchangeEasy maintenanceMuffle furnacesElectric heatingCooling chamberEngineering

A heat treating apparatus includes a heating plate for heating a substrate coated with a coating liquid, a cooling plate for cooling the substrate and a heat pipe provided in the cooling plate, a cooling chamber being moved together with the cooling plate by the drive mechanism and accommodating a cooling liquid for cooling one end side of the heat pipe. The apparatus further includes a circulation passage provided in the heat treating apparatus to circulate the cooling liquid in the cooling chamber, a circulation pump for circulating the cooling liquid in the circulation passage; and a heat radiating member provided on the circulation passage to radiate the heat received by the cooling chamber to the outside of the heat treating apparatus.

Owner:TOKYO ELECTRON LTD

Tobacco processing

InactiveUS20050022832A1Lower Level RequirementsInhibition formationTobacco preparationTobacco treatmentTobacco-specific nitrosaminesEngineering

Tobaccos are cured in a manner so as to provide tobaccos having extremely low tobacco specific nitrosamine (TSNA) contents. Harvested Virginia tobacco is subjected to flue-curing so as to provide flue-cured tobacco. During the curing processing steps, contact of the tobacco with nitric oxide gases, such as those produced as combustion products of propane burning heating units, is avoided. Tobacco in curing barns is not subjected to direct-fire curing techniques, but rather, heat for tobacco curing can be provided by heat exchange or electrical heating methods.

Owner:R J REYNOLDS TOBACCO COMPANY

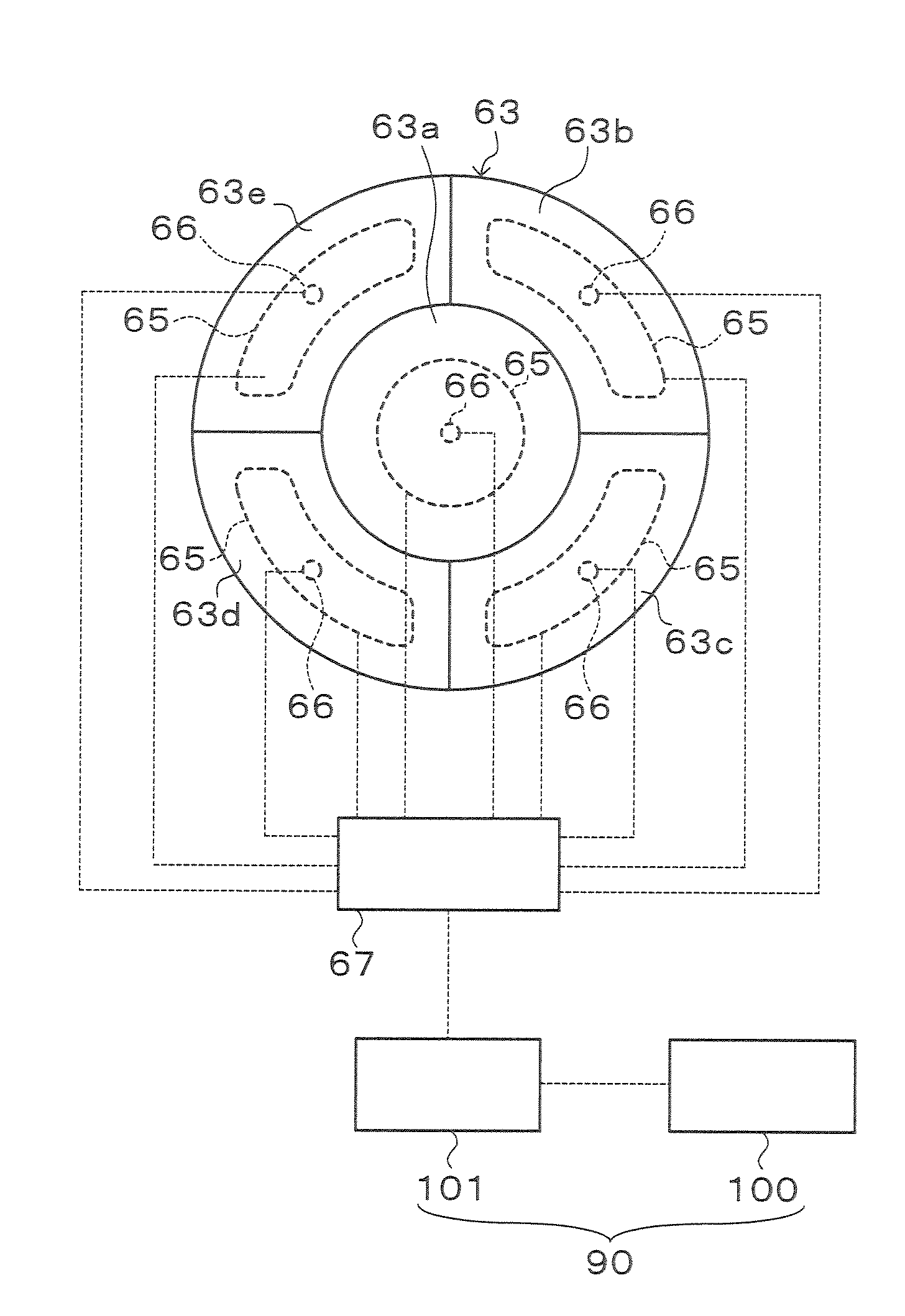

Temperature setting method of heat processing plate, temperature setting apparatus of heat processing plate, program, and computer-readable recording medium recording program thereon

ActiveUS20090254226A1Increase productionUnified performanceCombustible gas coke oven heatingSpace heating and ventilationEngineeringHeat treated

An object of the present invention is to perform temperature setting of a heating plate so that a wafer is uniformly heated in an actual heat processing time. The temperature of a wafer is measured during a heat processing period from immediately after a temperature measuring wafer is mounted on the heating plate to the time when the actual heat processing time elapses. Whether the uniformity in temperature within the wafer is allowable or not is determined from the temperature of the wafer in the heat processing period, and if the determination result is negative, a correction value for a temperature setting parameter of the heating plate is calculated using a correction value calculation model from the measurement result, and the temperature setting parameter is changed.

Owner:TOKYO ELECTRON LTD

High temperature energy-saving tunnel kiln for physical thermal circulation application

The invention relates to a high temperature energy-saving tunnel kiln for physical thermal circulation application. A metal tube type air preheater is arranged in a medium temperature section furnace cavity in a tunnel kiln cooling zone; a silicon carbide air preheater made from non-metallic material is arranged in a high temperature section furnace cavity in the tunnel kiln cooling zone; wherein, one end of the metal tube type air preheater is connected with a blower and the other end thereof is connected with the silicon carbide air preheater; the other end of the silicon carbide air preheater is connected with a high temperature airpipe; then preheated combustion-supporting air is connected to a high temperature combustor by a high temperature airpipe air valve through the high temperature airpipe air; a group of forced cooling blowers are arranged at the low temperature section of the cooling zone to blow wind to the high temperature zone and high temperature blowers are arranged at the medium temperature section of the cooling zone to pump hot air to a gas pipe mounting groove to heat coal gas, excess heat in the gas pipe mounting groove is connected to a blank drying room and a blank drying shed by a pipeline; wherein, the blower arranged at a preheating zone pumps excess heat and waste gas from the cooling zone and a burning zone, which enters the blank drying shed by the pipeline.

Owner:岳阳市安达耐火材料有限公司

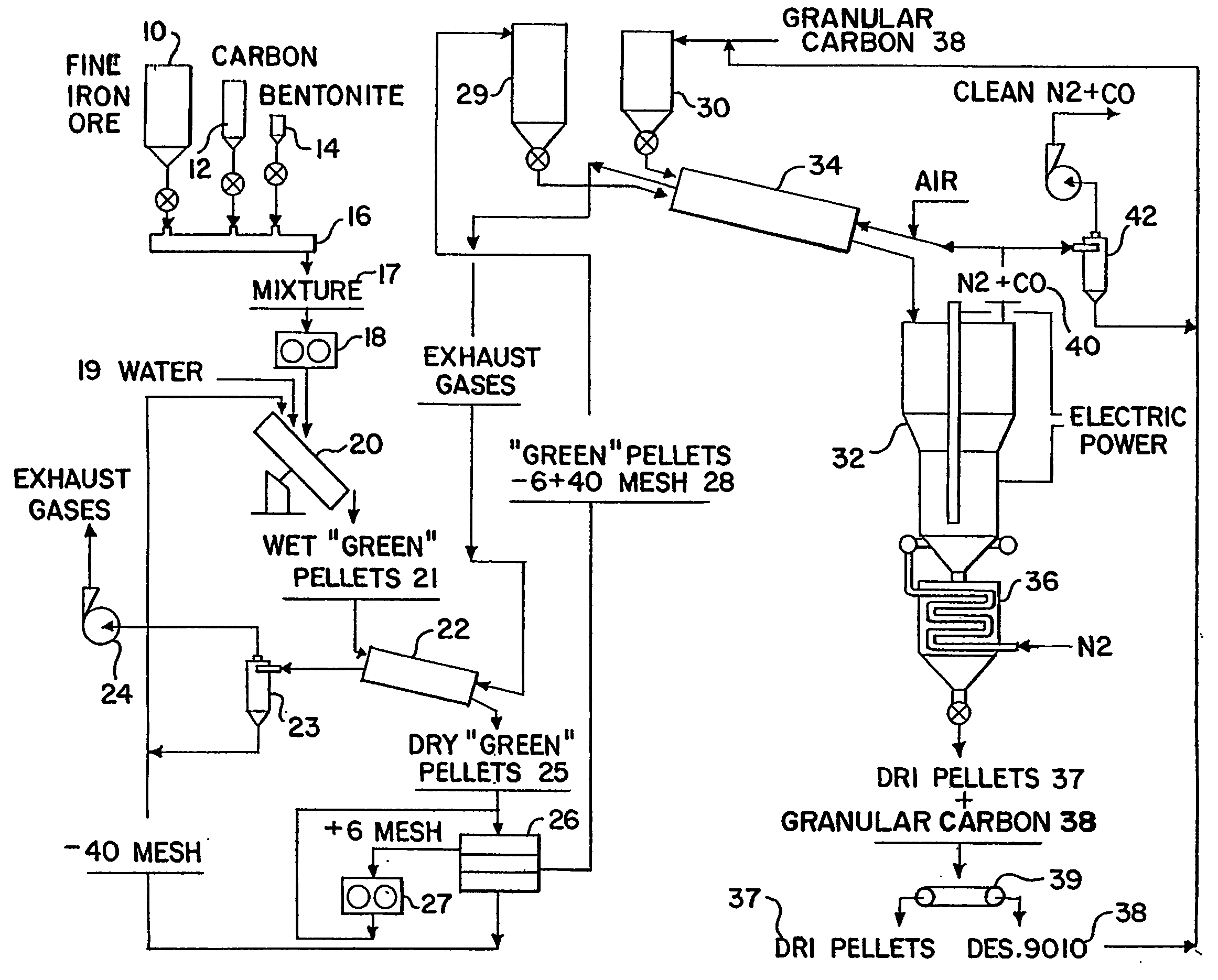

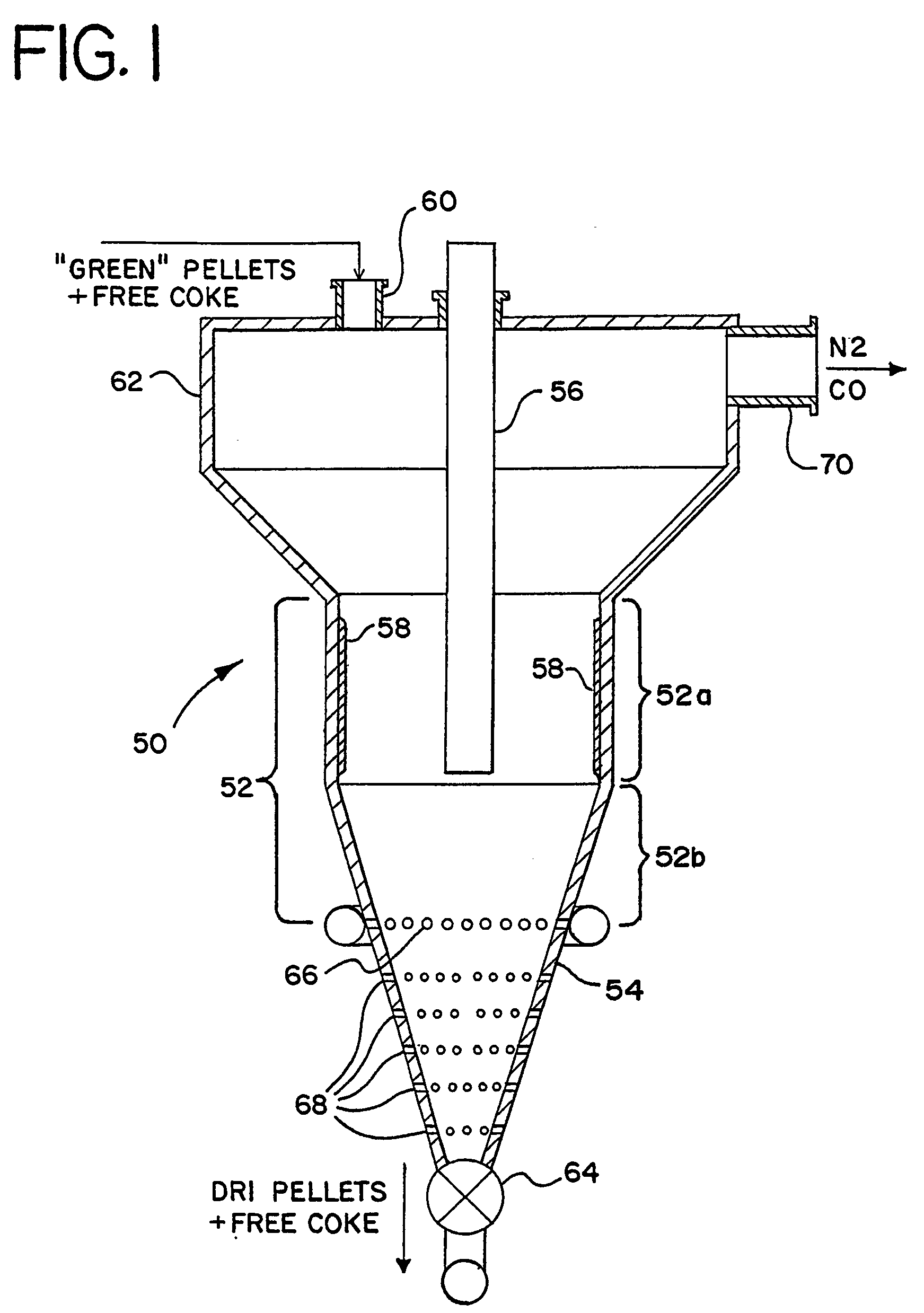

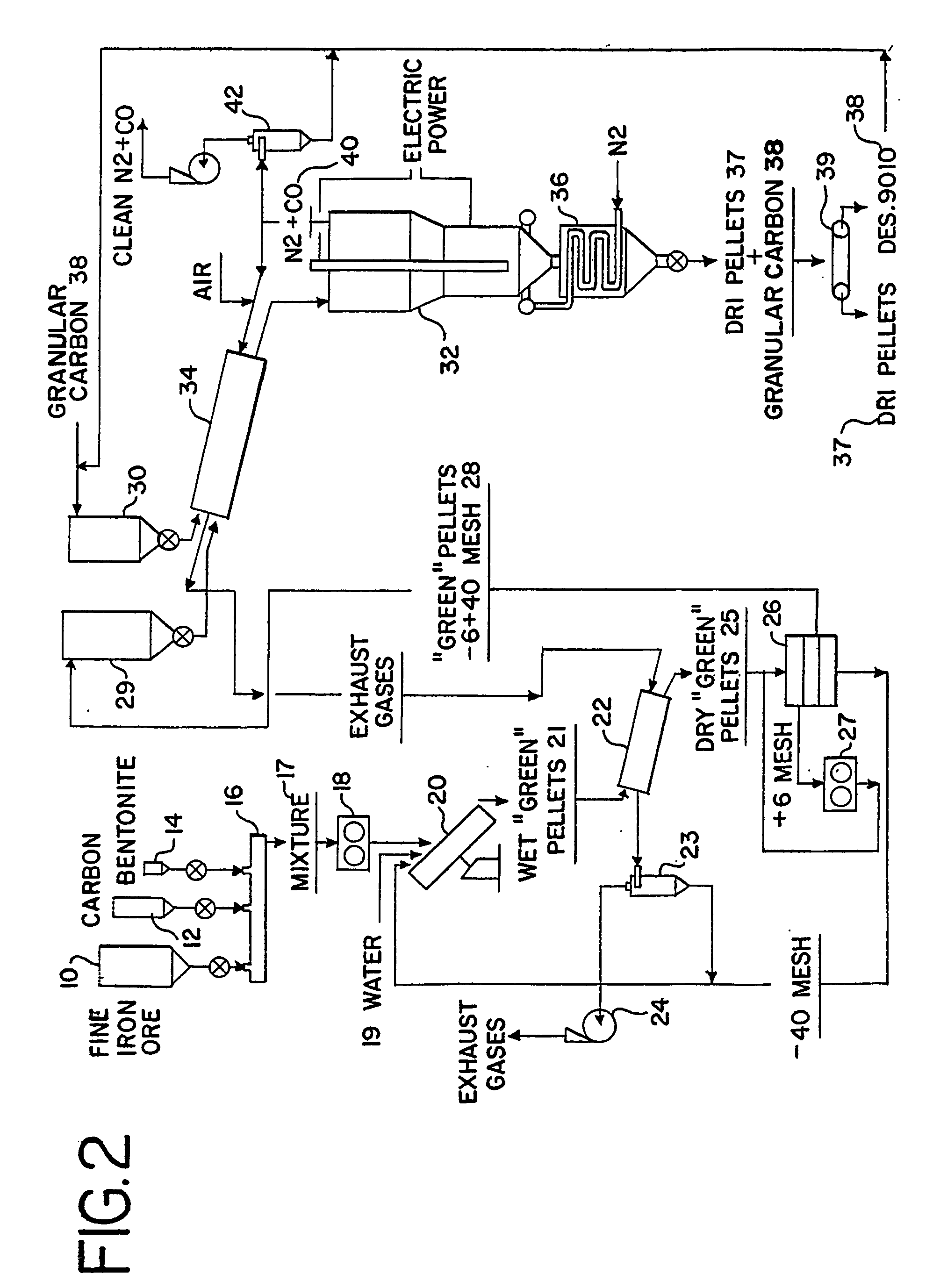

Process and apparatus for the direct reduction of iron oxides in an electrothermal fluidized bed and resultant product

InactiveUS20050092130A1Avoid particle agglomerationInhibits the formation of depositsMaintainance of heating chambersCharge manipulationVolatilesFluidized bed

A method and an apparatus (50) for producing direct reduced iron (37) from dry pellets (25) composed of iron oxide and carbonaceous material. A mixture of pellets (25) and free coke particles (38) with weight relation from 3:1 to 5:1 is fed into the top of an electrothermal fluidized bed (32) that is fluidized by nitrogen. By exposing pellets (25) in the electrothermal fluidized bed (32) to temperatures of between approximately 850-1,100° C. for an average period of between approximately 15-60 minutes, the volatiles are removed and the pellets (25) metallized. Reduced pellets (37) mixed with free coke (38) are discharged from the bottom of fluidized bed (32) and cooled. The reduced iron pellets (37) are physically separated from any free coke (38) and the free coke (38) is recycled back into the fluidized bed (32).

Owner:GOLBERGER WILLIAM M +1

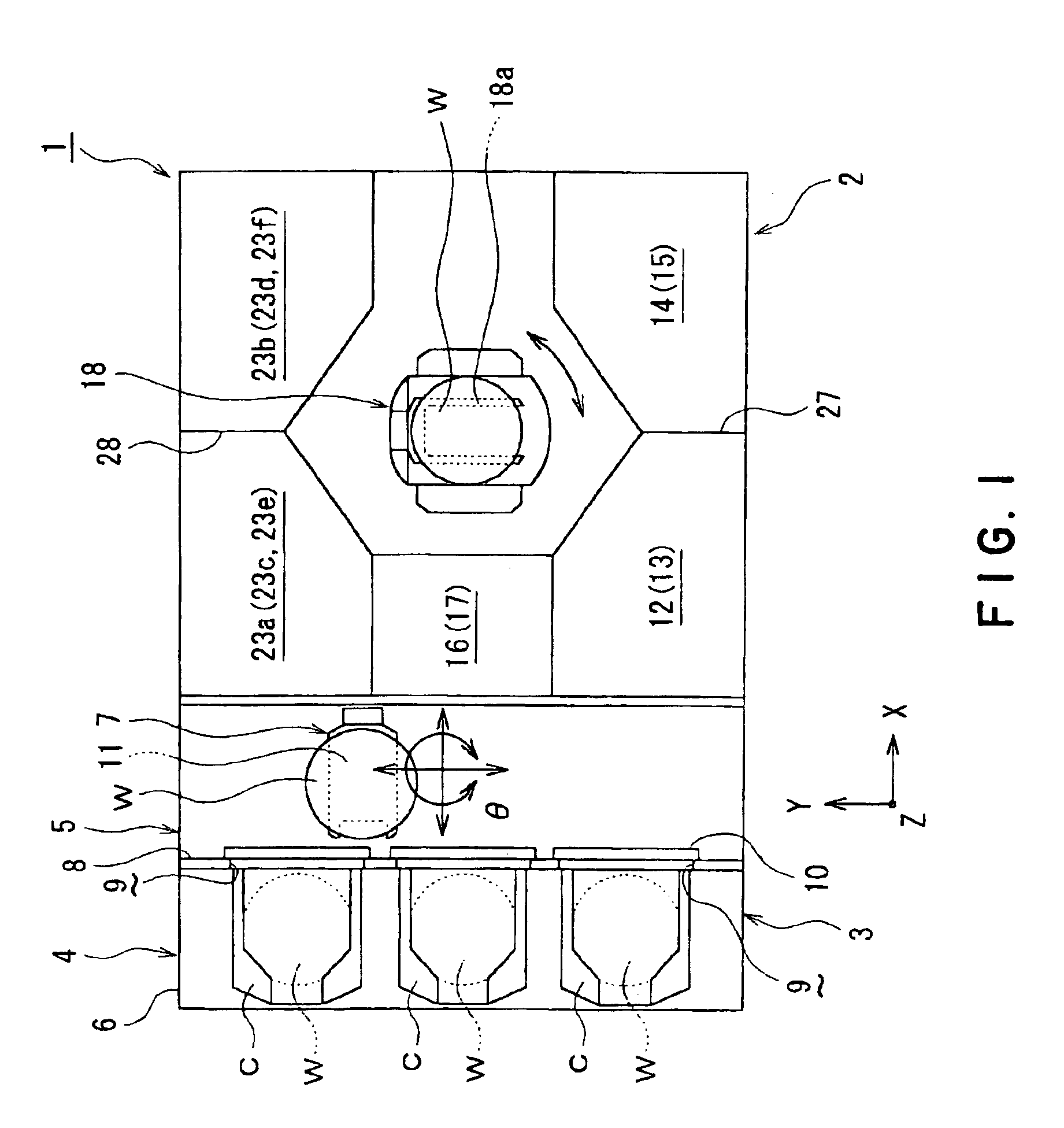

Substrate processing method and apparatus

ActiveUS6954585B2Uniform processingUniform supplyDrying solid materials with heatMuffle furnacesEngineering

A method for heating a wafer to a predetermined temperature, the wafer being held by a holding unit and being accommodated in a processing container equipped with a heater. The wafer is heated to a processing temperature while positioning the wafer at an adjacent position that results form making the wafer approach the heating surface of the heater. After heating the wafer to the predetermined temperature, the wafer is separated from the flat bottom surface of the container body to a processing position. In this state, a processing chamber of the processing container is supplied with a processing fluid, while the holding unit and the heater are relatively moved close to and apart from each other intermittently or continuously. Accordingly, it is possible to quickly heat the substrate to a processing temperature while supplying the substrate with the processing fluid uniformly. This improves throughout and the homogenization in processing.

Owner:TOKYO ELECTRON LTD

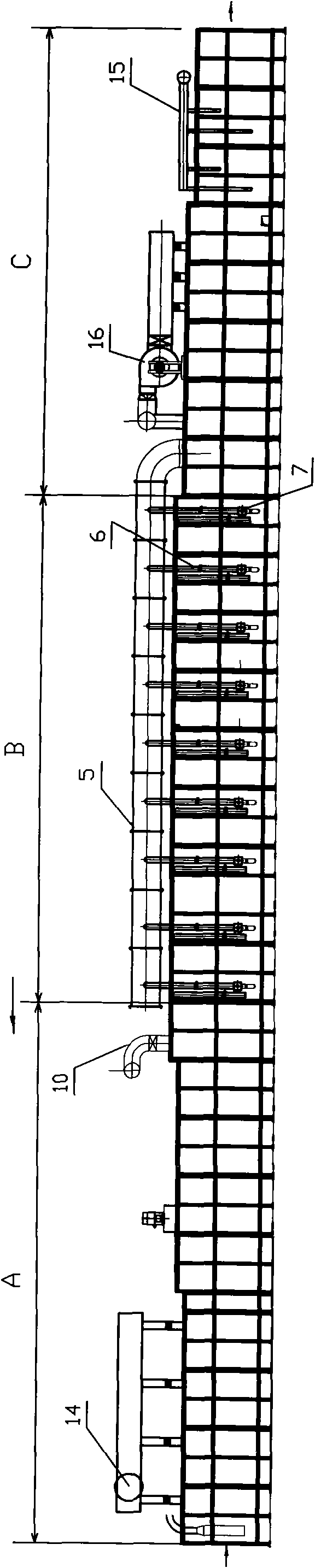

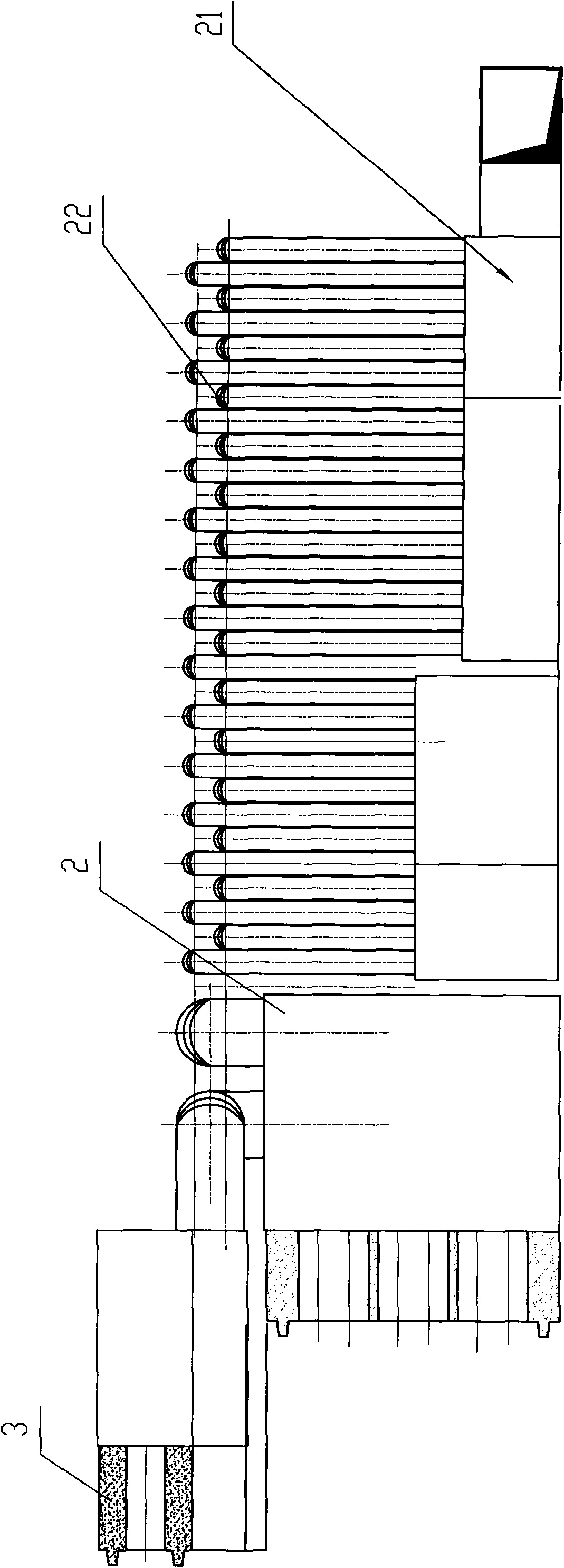

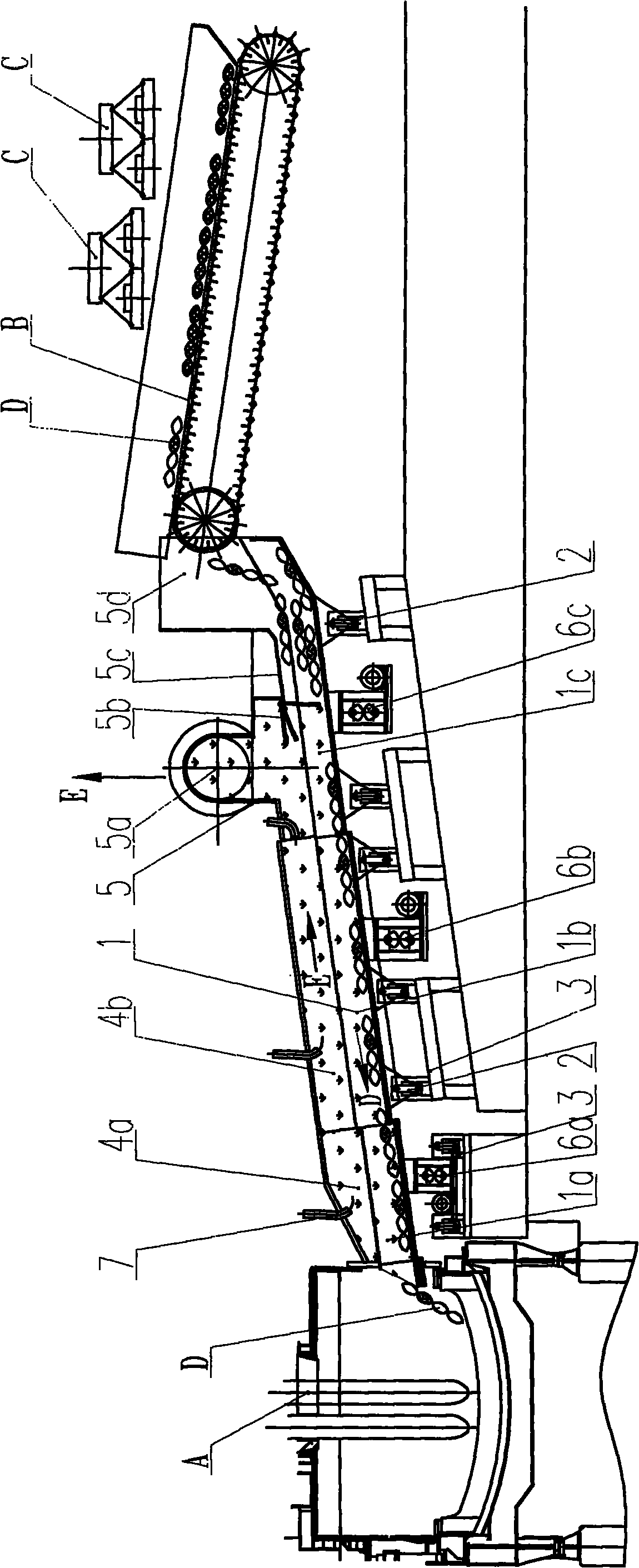

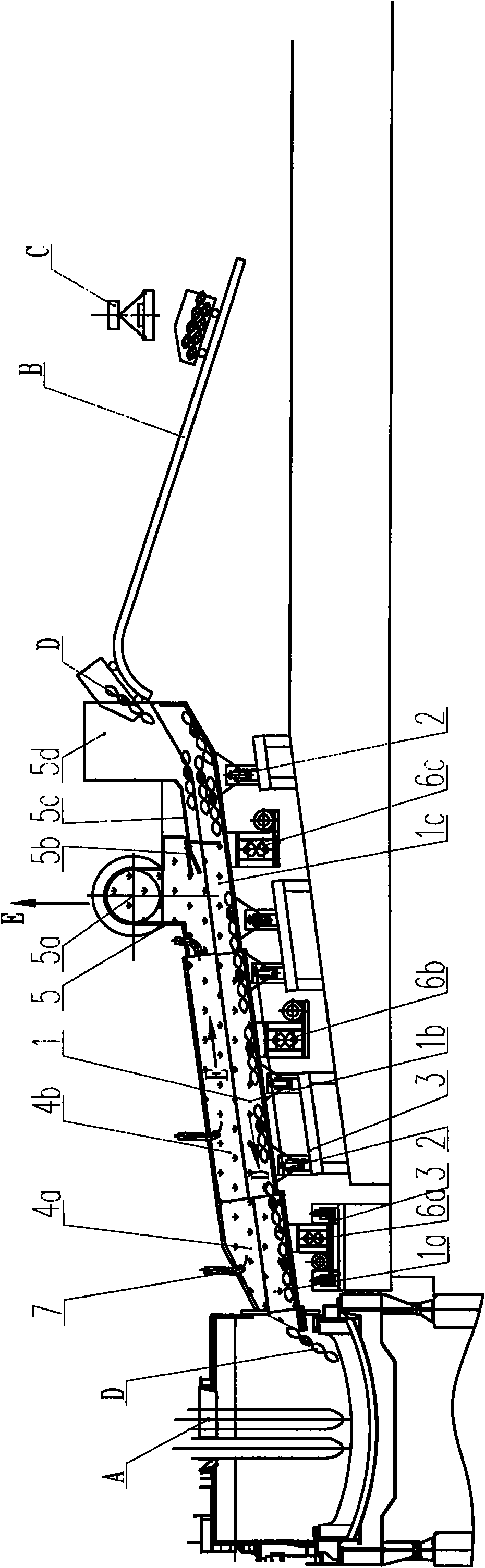

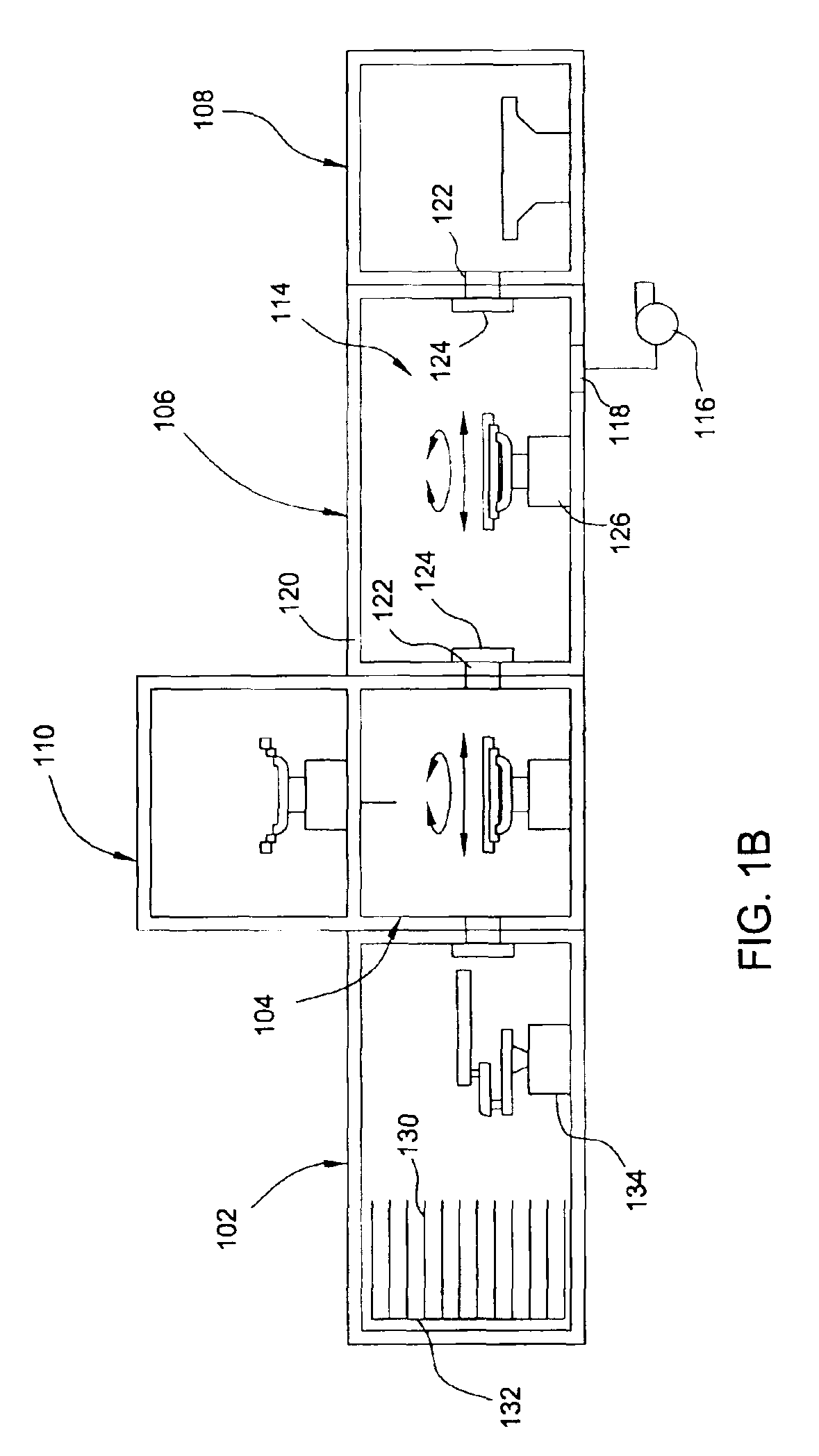

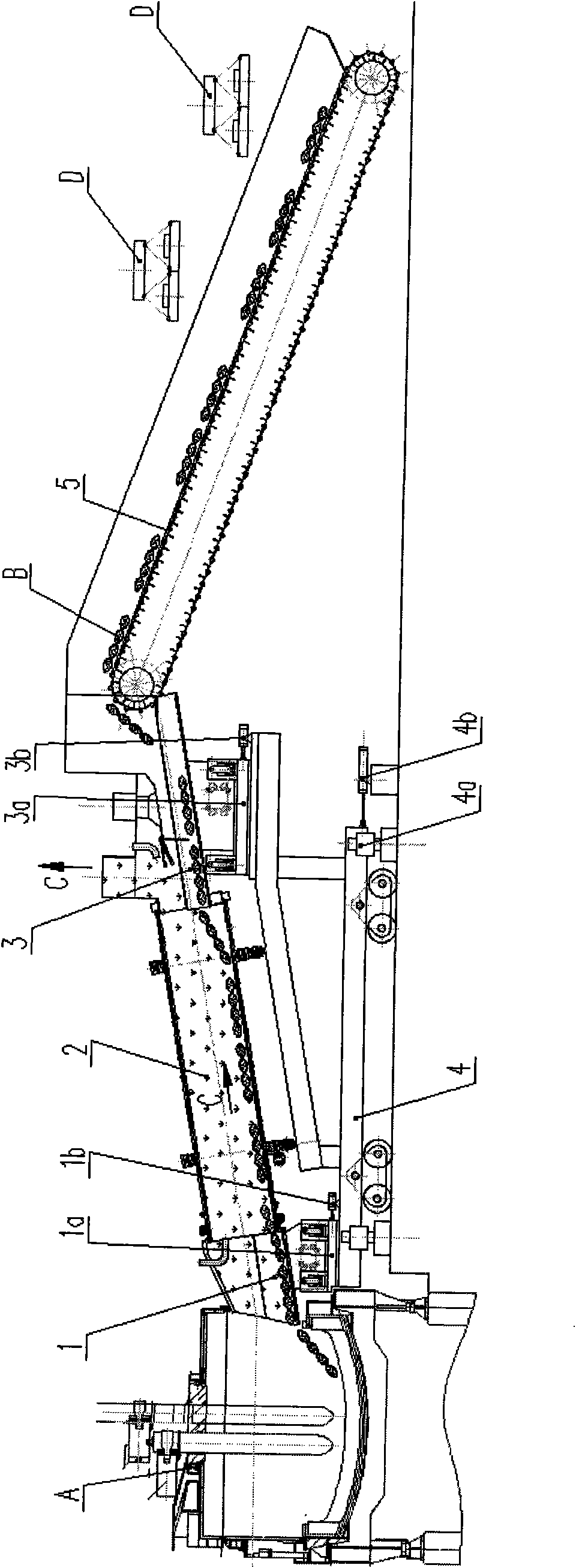

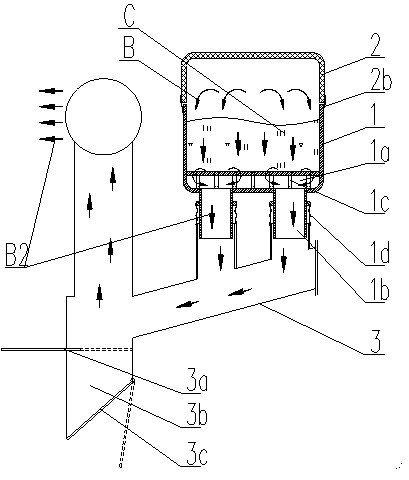

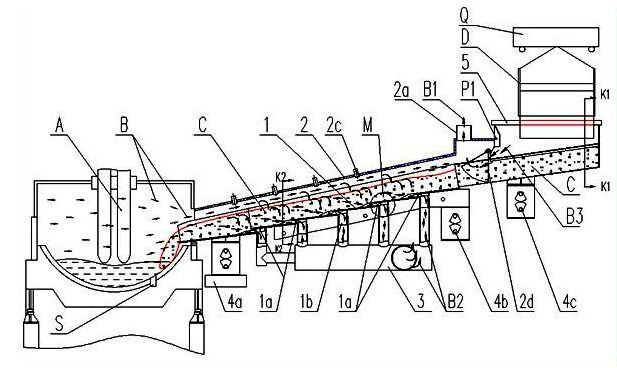

Device for preheating and conveying scrap steel

InactiveCN101825396AExtend your lifeReduce wearCharge manipulationPreheating chargesSmelting processNew energy

The invention discloses a device for preheating and conveying scrap steel, which comprises a conveying groove (1) obliquely formed relatively to the horizontal plane. A fume guide hood (2) is arranged on the conveying groove (1); the lower end of the conveying groove (1) extends into an electric furnace (A) through an opening on a side wall of the electric furnace (A); a bottom-open long distributing groove (D) is formed above the other end of the conveying groove (1) and is installed above a material receiving section of the conveying groove (1) through a lifting device (Q); the bottom-open long distributing groove (D) is in a top view projection of the material receiving section of the conveying groove (1) along a longitudinal direction; the scrap steel is longitudinally arranged at the groove bottom of the material receiving section of the conveying groove (1) in the form of strips; and the scrap steel (C) is fed into the electric furnace (A) through the conveying groove (1). The device has small length, high heat exchanging efficiency, low lifting operation rate, small wear and maintenance, energy conservation and environment friendliness, lowers investment and operation costs and uses new energy-saving and environment-friendly technology with popularization value on smelting processes, such as the electric furnace and the like.

Owner:CISDI ENG CO LTD

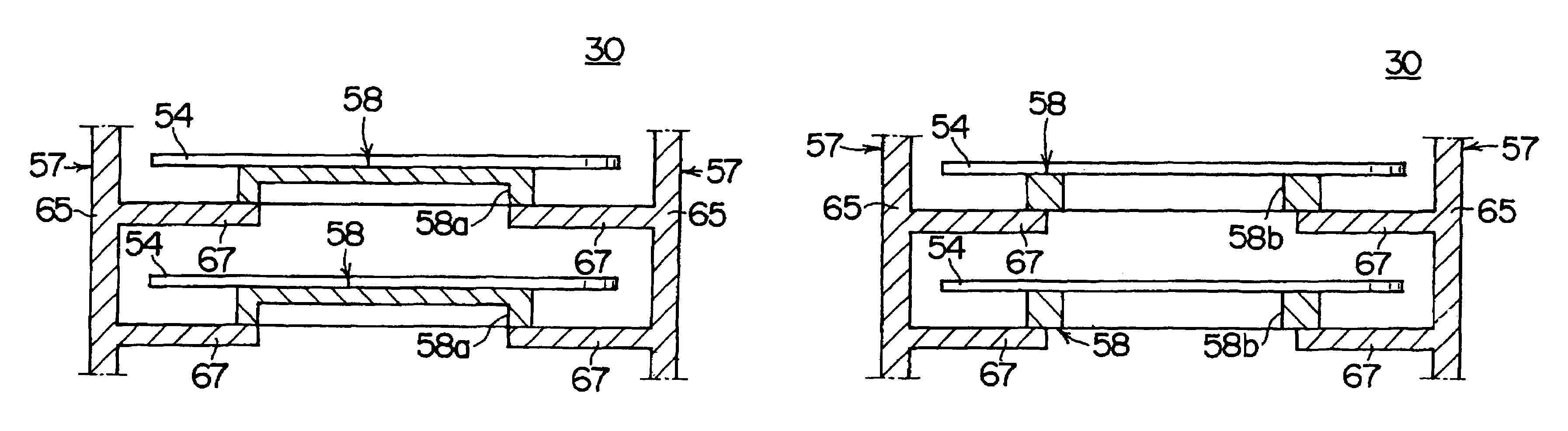

Heat treatment apparatus and method of manufacturing substrates

InactiveUS7625205B2Charge supportsSemiconductor/solid-state device manufacturingMechanical engineeringHeat treated

Owner:KOKUSA ELECTRIC CO LTD

Odor control cassette

InactiveUS20050064123A1Reduce odorInexpensive and easy to manufactureLayered productsCharge supportsHigh densityMagnetic tape

A film is provided for use in a cassette. Preferably, the cassette is used in a waste disposal system. The film is a high density polyethylene film resin having both a low melt index and a high density, thereby providing improved odor control capabilities and enhanced tear strength and assembly strength.

Owner:WELLS FARGO BANK NAT ASSOC

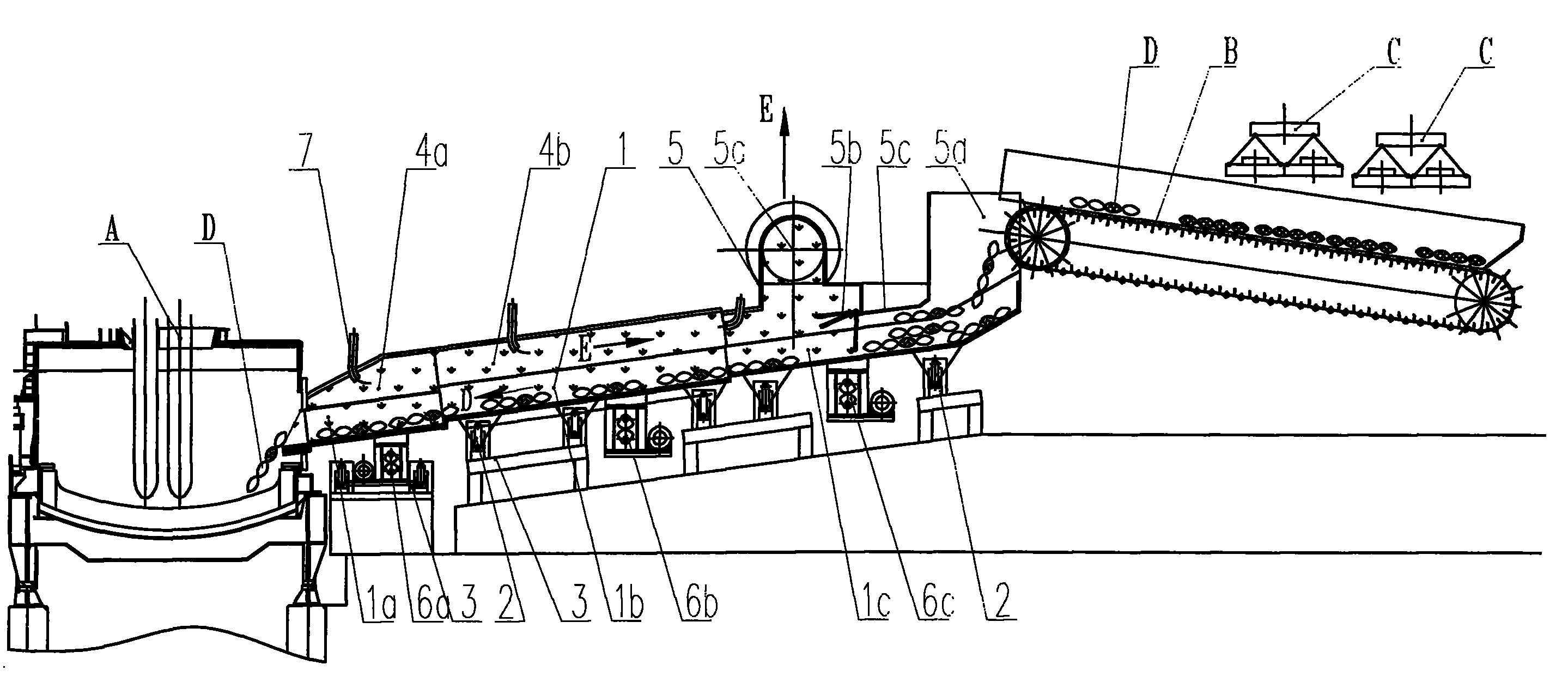

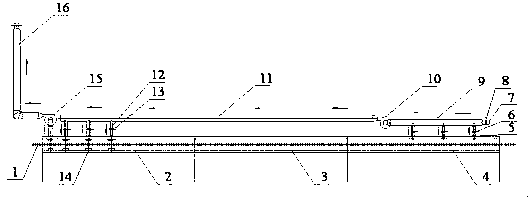

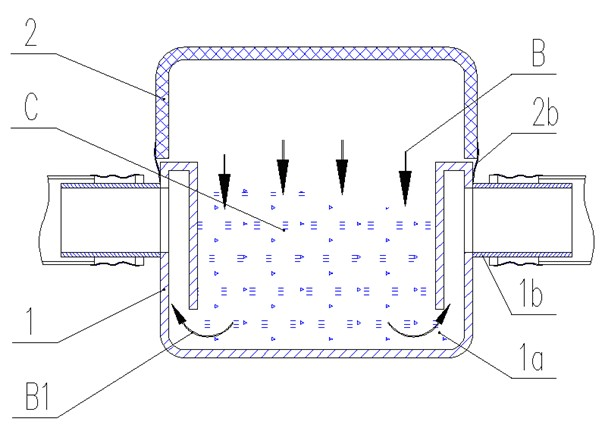

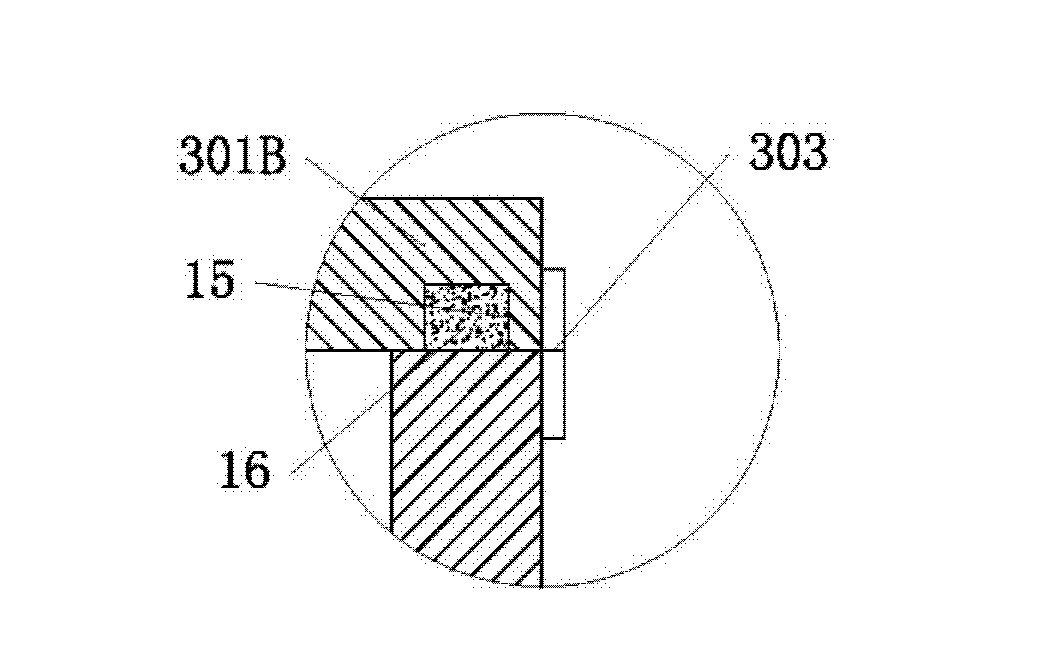

Electric furnace charging and preheating device

InactiveCN101776395ASolve the space height problemImprove transmission efficiencyCharge manipulationPreheating chargesElectric arc furnaceNew energy

The invention belongs to the technical field of metallurgy, and discloses an electric furnace charging and preheating device, comprising a steel scrap conveying chute (1) which is arranged aslant with the horizontal plane; the high end of the steel scrap conveying chute (1) is provided with an inclined pull-type material receiving conveyor (B), and the low end of the steel scrap conveying chute (1) extends into an electric furnace (A) from a pore on the side wall of the electric furnace (A); the upper part of the steel scrap conveying chute (1) is provided with a seal cover which forms a steel scrap and smoke path with the steel scrap conveying chute (1). The electric furnace charging and preheating device of the invention has the advantages of small electric energy consumption, small equipment abrasion, large steel scrap conveying amount and small total length of equipment and is a new energy-saving and environment-protection technology with promotional value in electric furnaces or other production processes.

Owner:CISDI ENG CO LTD

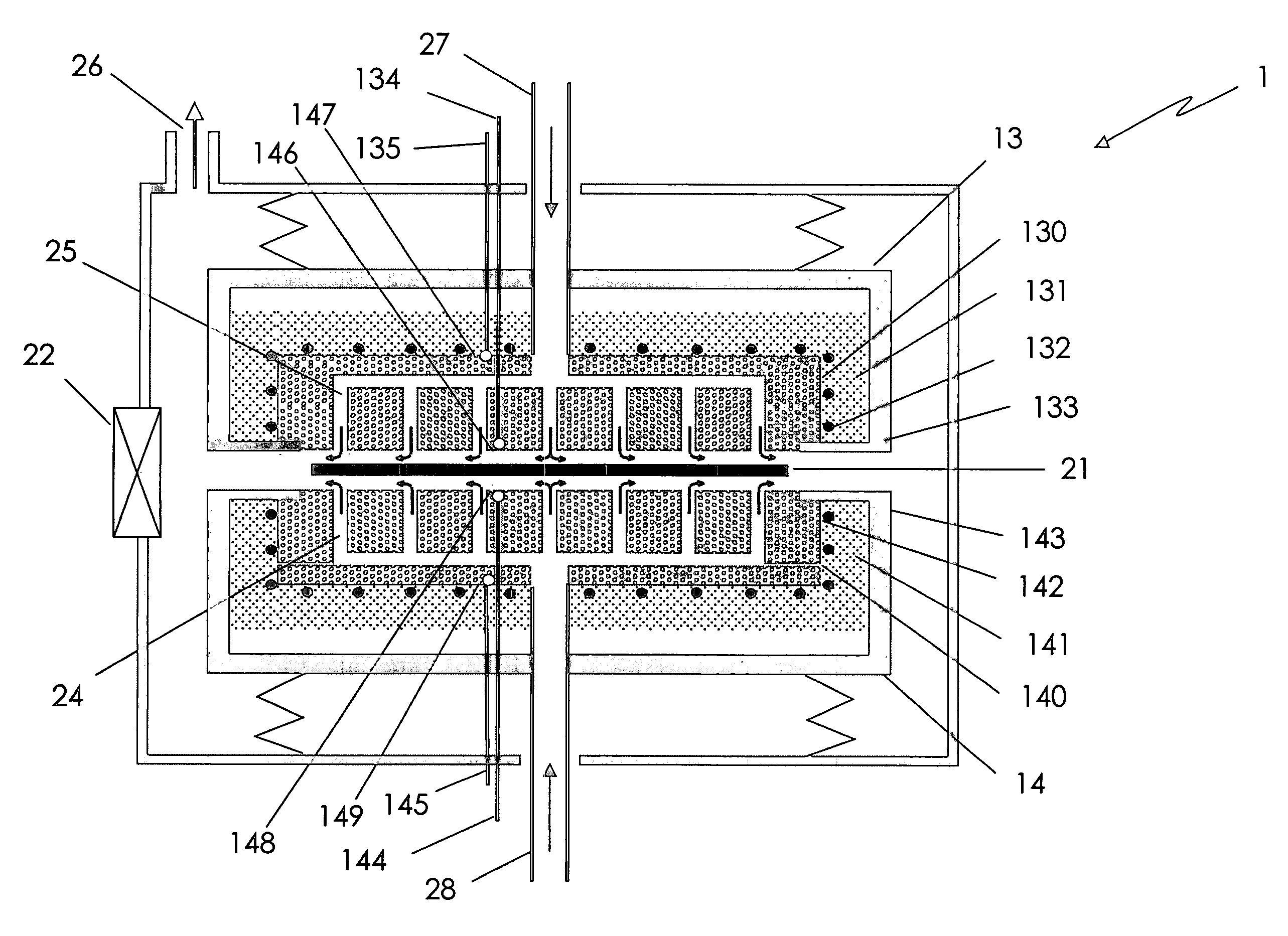

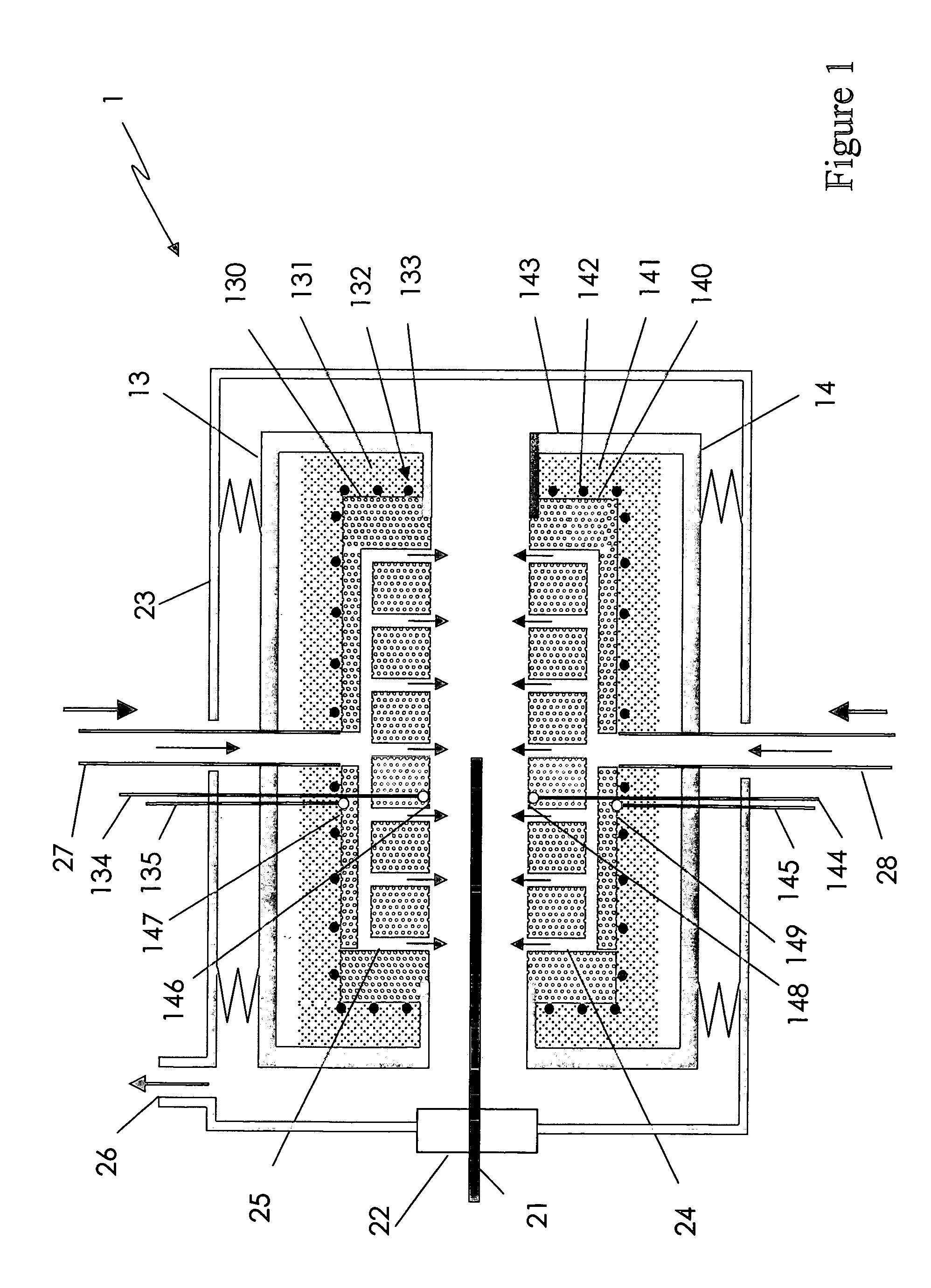

Heat treatment apparatus with temperature control system

A floating substrate reactor allows heat treatment of a series of semiconductor substrates, one by one. The heat treatment occurs while flowing gas suspends a substrate between two heated surfaces of the reactor. The two heated surfaces each have multiple heating zones. The heating zones are heated to desired temperature(s) and a substrate is then loaded into the reactor for heat treatment. Upon loading, the relatively cold substrate absorbs heat and cools the process chamber. A heat spike, which can be varied, is applied to the heating zones to heat the reactor to the desired temperature again. The substrate, however, is unloaded from the reactor before the temperatures of the heating zones have reached the desired temperature. After the heating zones have reached the desired temperature, the next substrate in the series of substrates is loaded into the reactor for heat treatment. The heating rate of each heating zone is independently controlled by two nested control loops in a cascade temperature control configuration, permitting differences in the heating rates of the heating zone to be accounted for, thus allowing a uniform temperature or predetermined gradient to be established across all the heating zones. The intensity of the heat spike is recalculated after the introduction of each substrate, using the heating behavior of the previous heat spike as a calculation input, to more accurately heat the heating zones to the desired temperature. The variability of the heat spike intensity from substrate to substrate also allows the throughput of the heat treatment apparatus to be varied.

Owner:ASM INTERNATIONAL

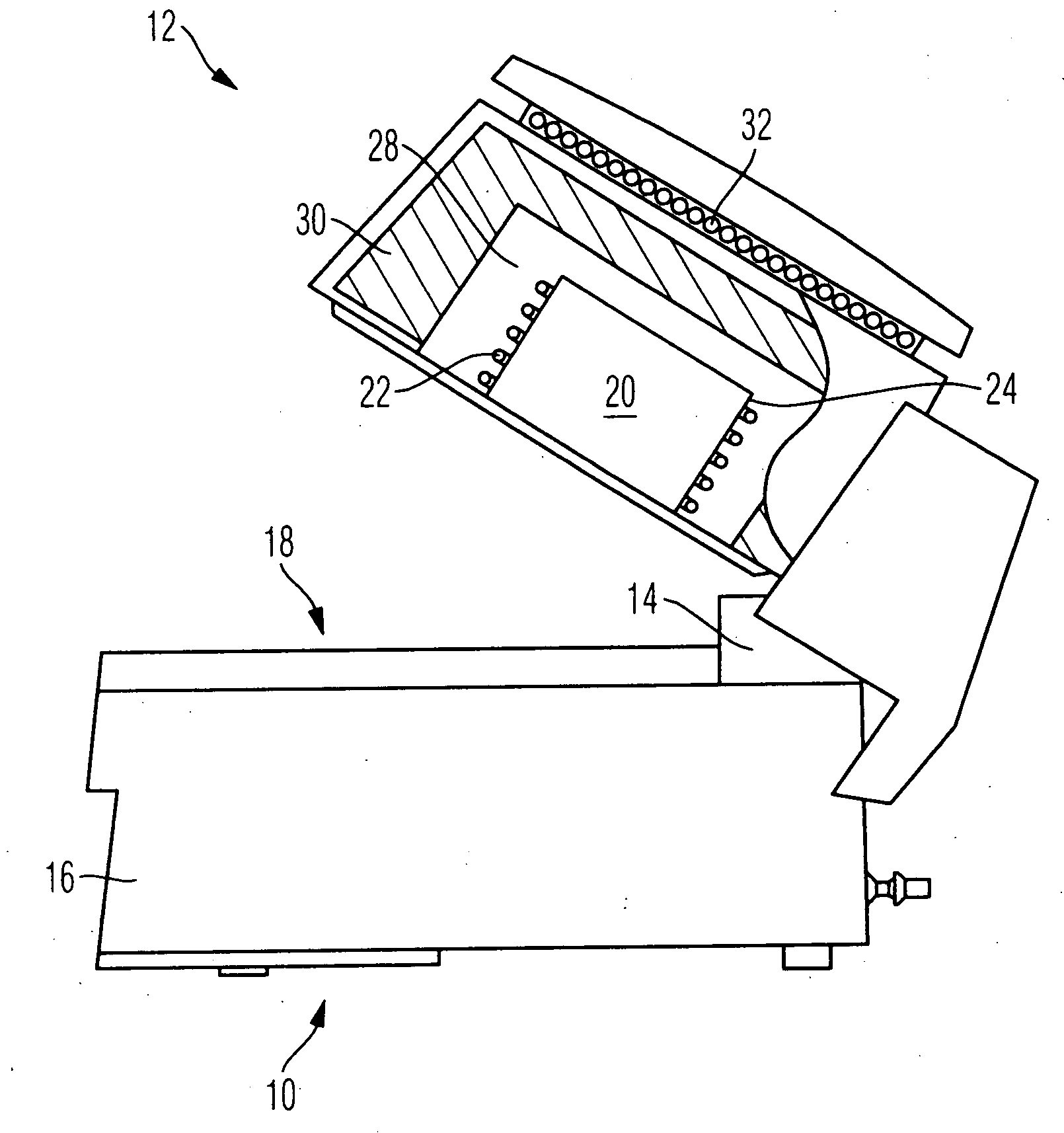

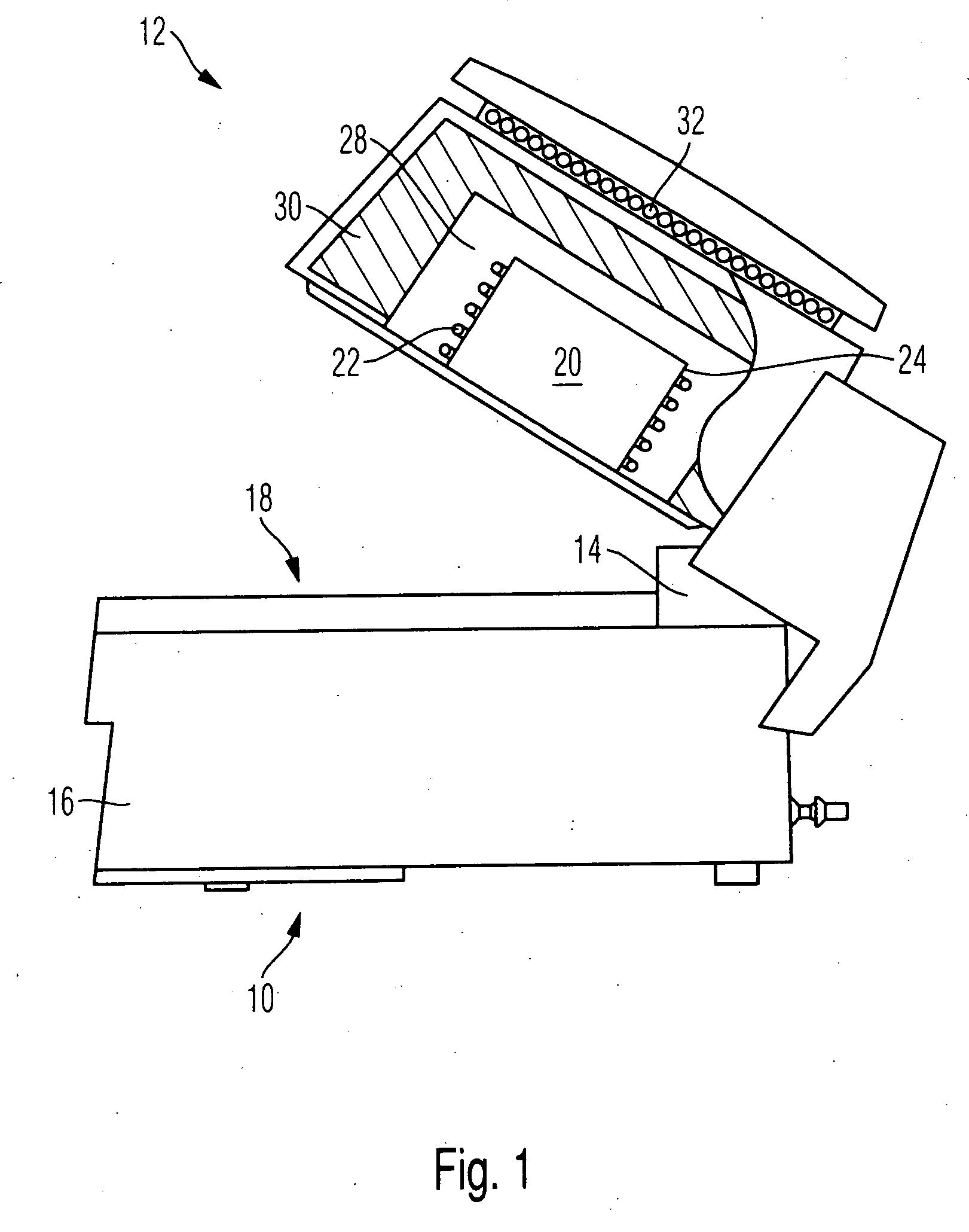

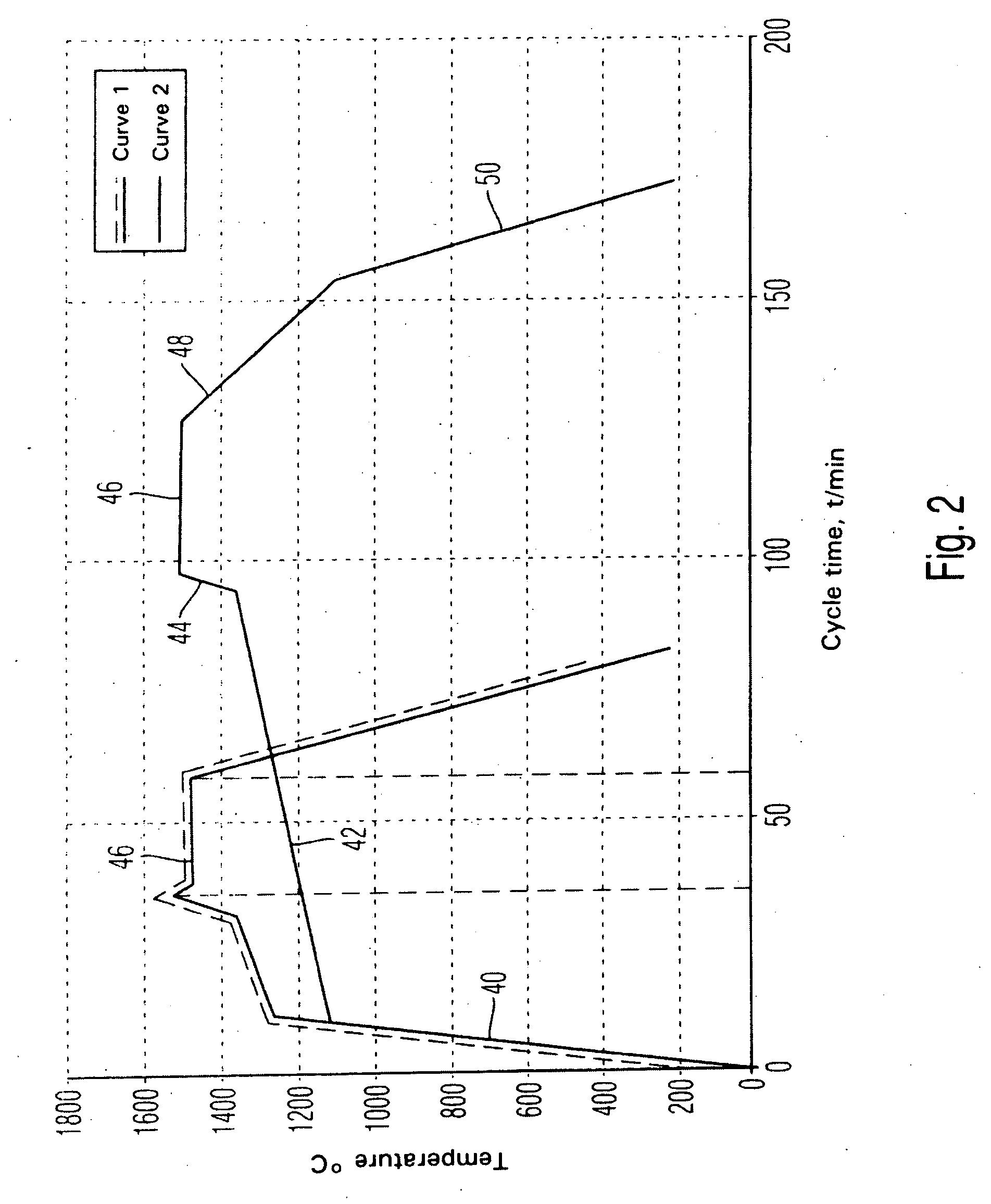

Dental furnace

ActiveUS20090226855A1Reduce heating capacityReduce thermal massMaintainance of heating chambersFurnace typesFurnace temperature

The invention relates to a dental furnace wherein a firing chamber is heated up in a first heating-up period at a first heating-up rate of more than 50° K / min, in particular more than 100° K / min, which heats the furnace to at least 1000° C., in particular to 1100-1250° C. The first heating-up period is followed by an intermediate heating period, which is at least five minutes long, in particular at least ten minutes long, the gradient or heating-up rate of which is adapted to the material to be sintered in the dental furnace (10), and wherein this is followed by an end heating-up period (44) during which heating up is effected at a heating-up rate of more than 30° K / min, in particular approximately 50° K / min, and wherein during this the furnace temperature is held for at least five minutes, in particular for at least 25 minutes, above the temperature toward the end of the first heating-up period, and wherein forced cooling of the furnace (10) is performed after this.

Owner:IVOCLAR VIVADENT AG

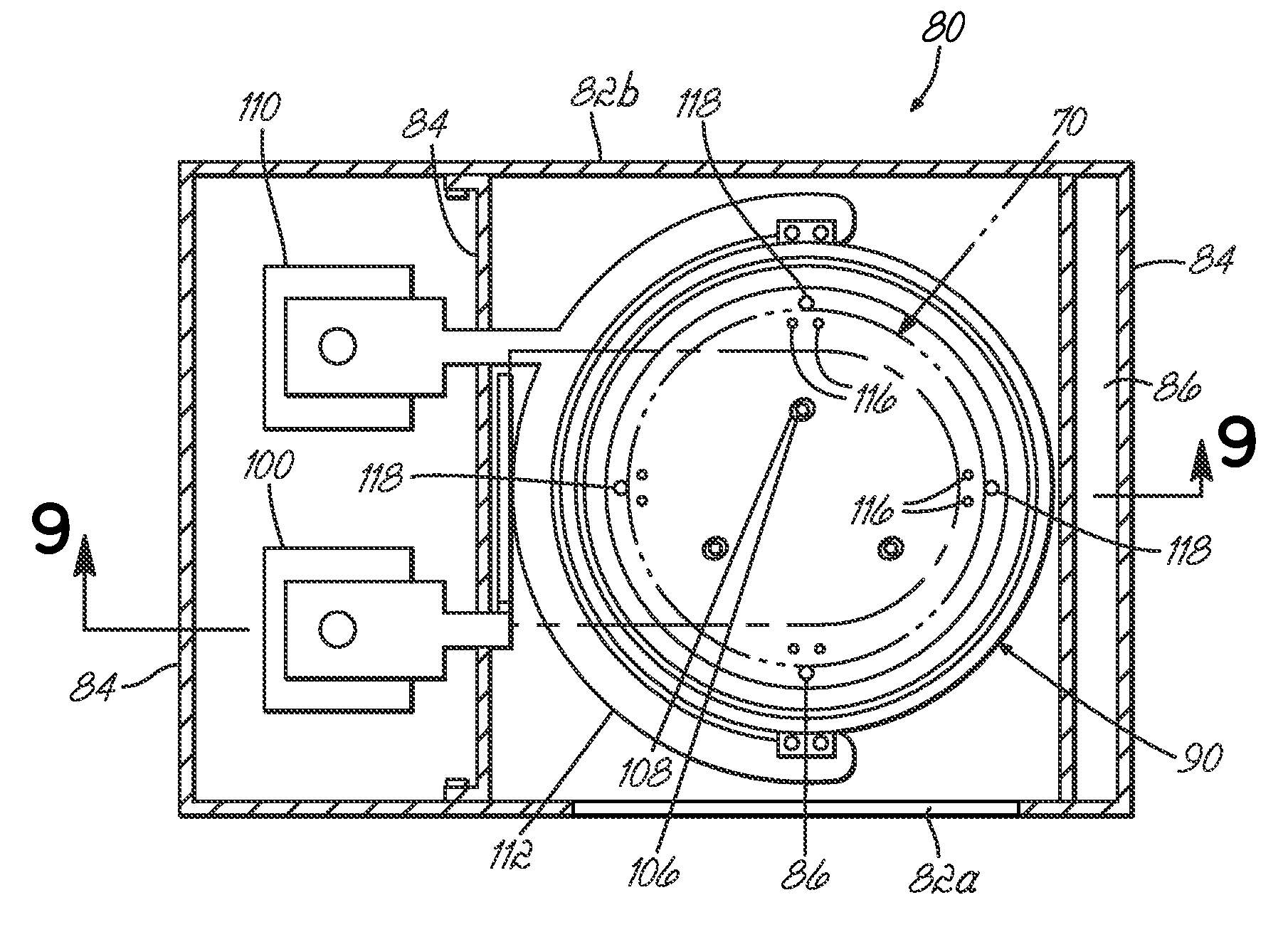

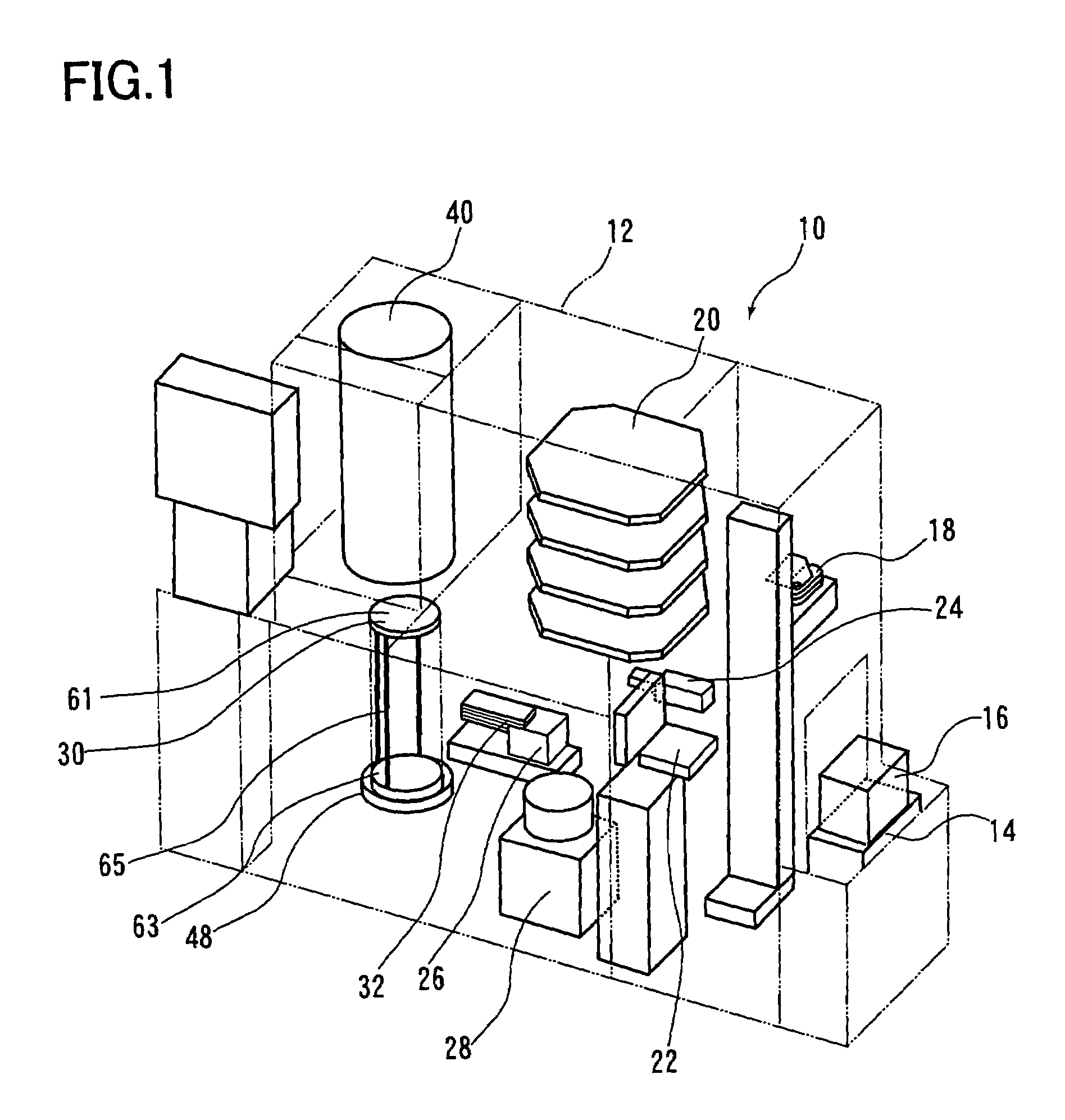

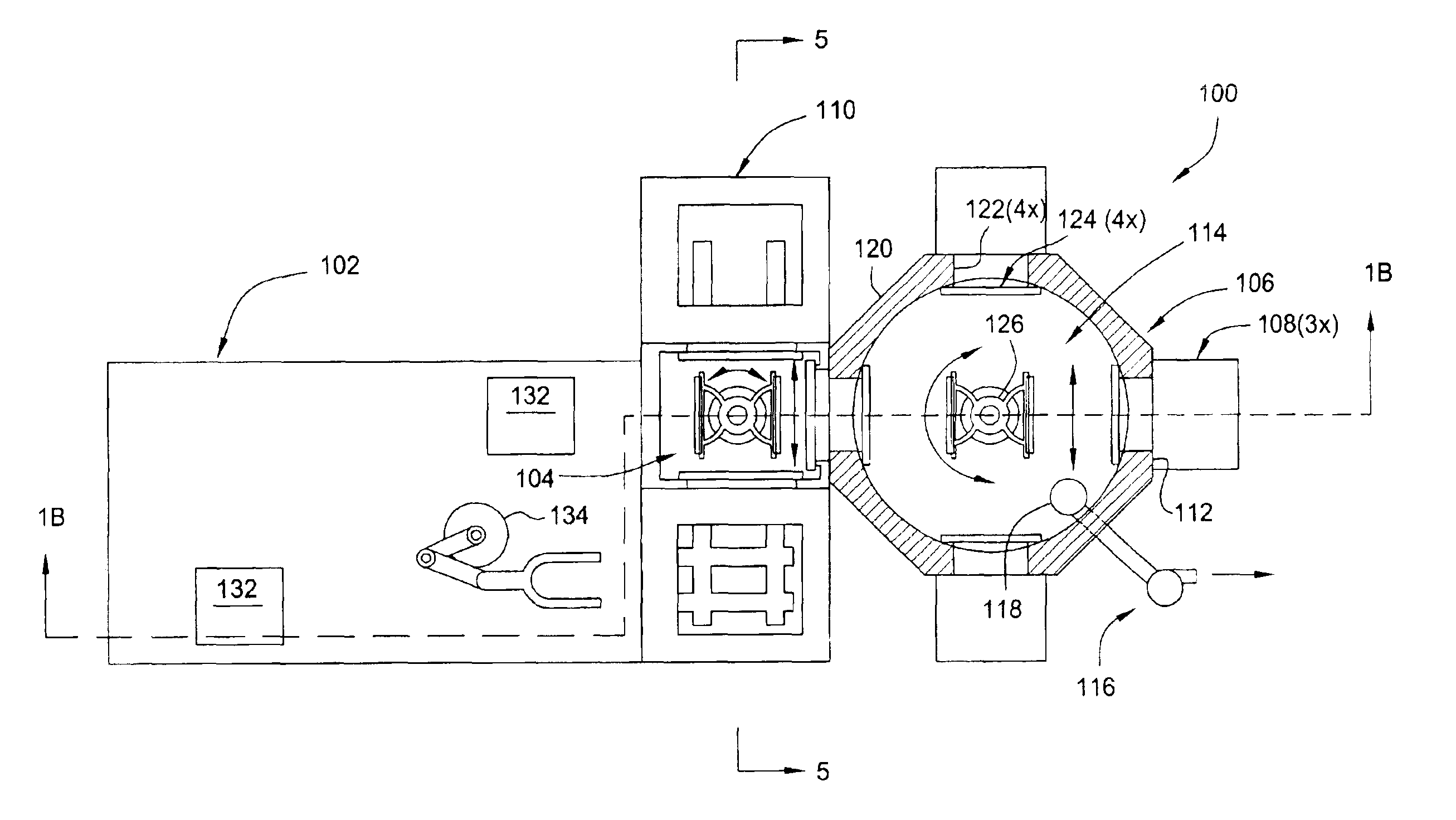

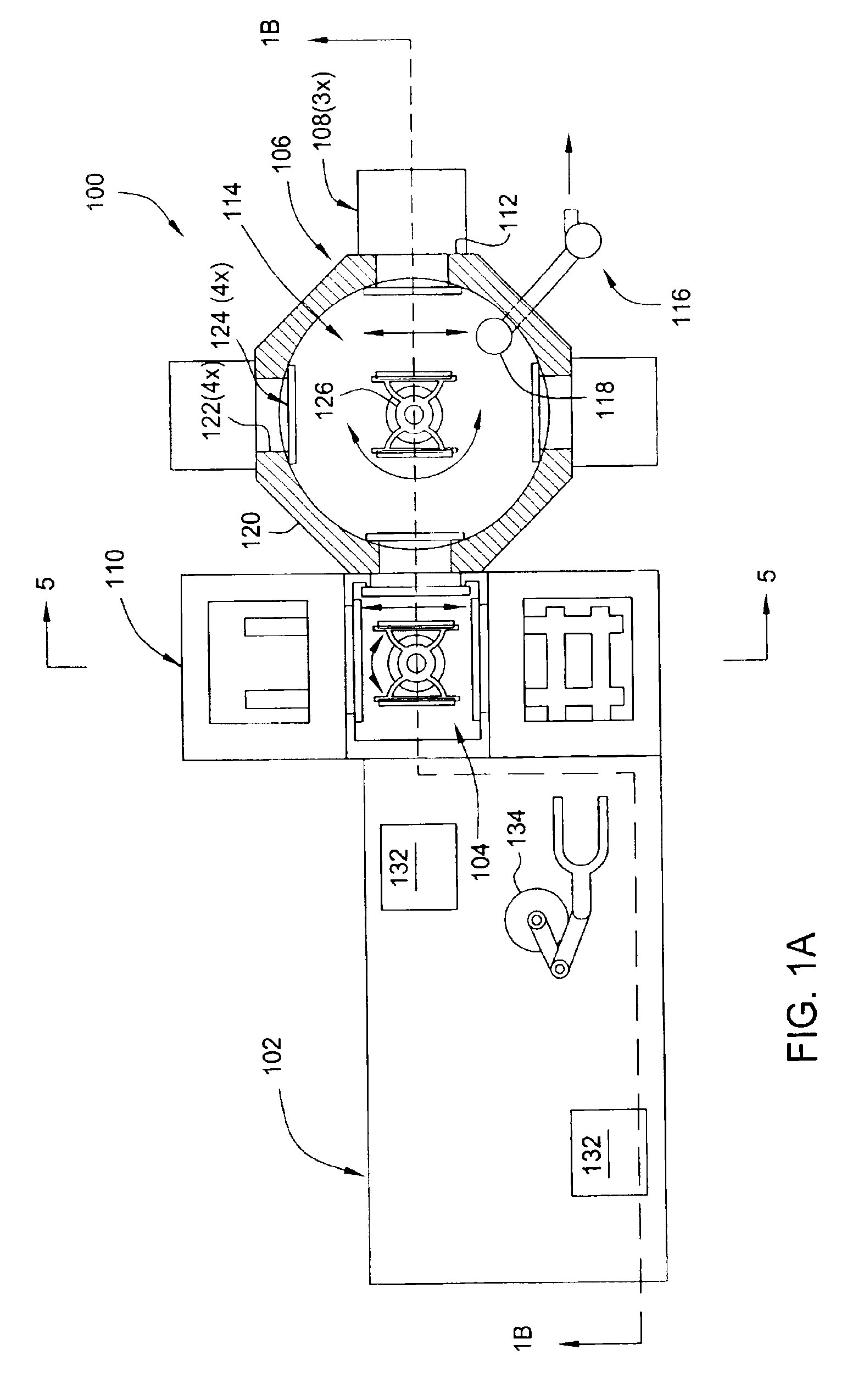

Large area substrate processing system

InactiveUS6896513B2Easy transferCharge supportsSemiconductor/solid-state device manufacturingHandling systemHeat treating

A system and method for processing large area substrates is provided. In one embodiment, a processing system includes a transfer chamber having at least one processing chamber and a substrate staging system coupled thereto. The staging system includes a load lock chamber having a first port coupled to the transfer chamber and a heat treating station coupled to a second port of the load lock chamber. A load lock robot is disposed in the load lock chamber to facilitate transfer between the heat treating station and the load lock chamber.

Owner:APPLIED MATERIALS INC

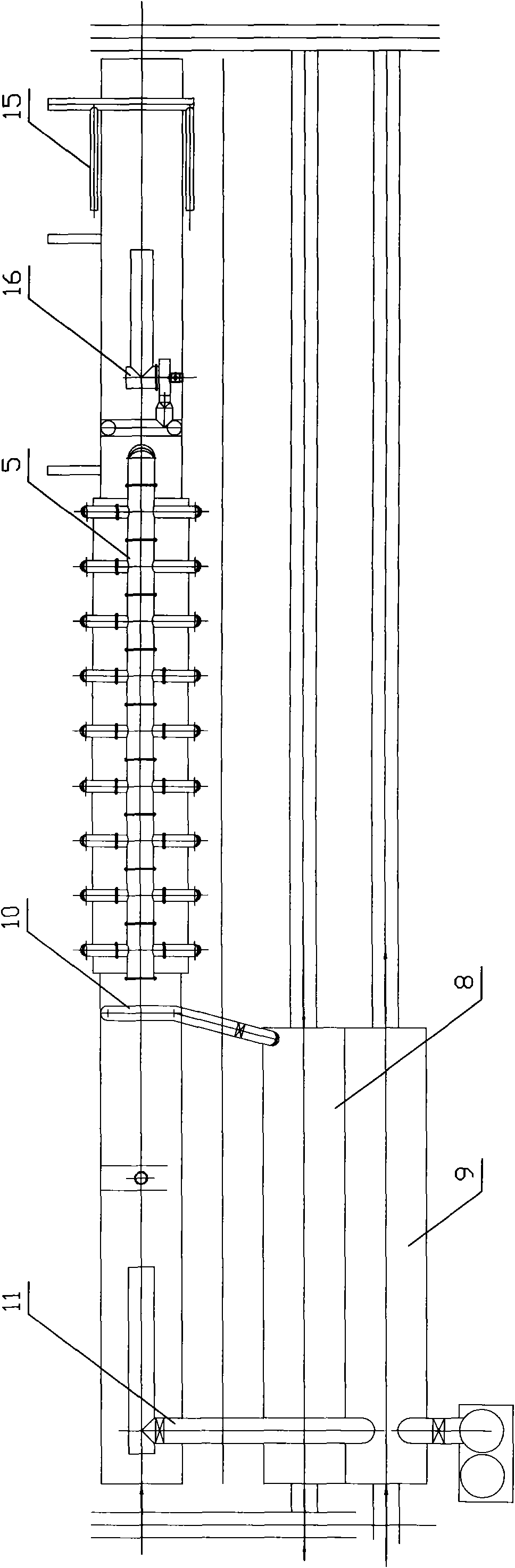

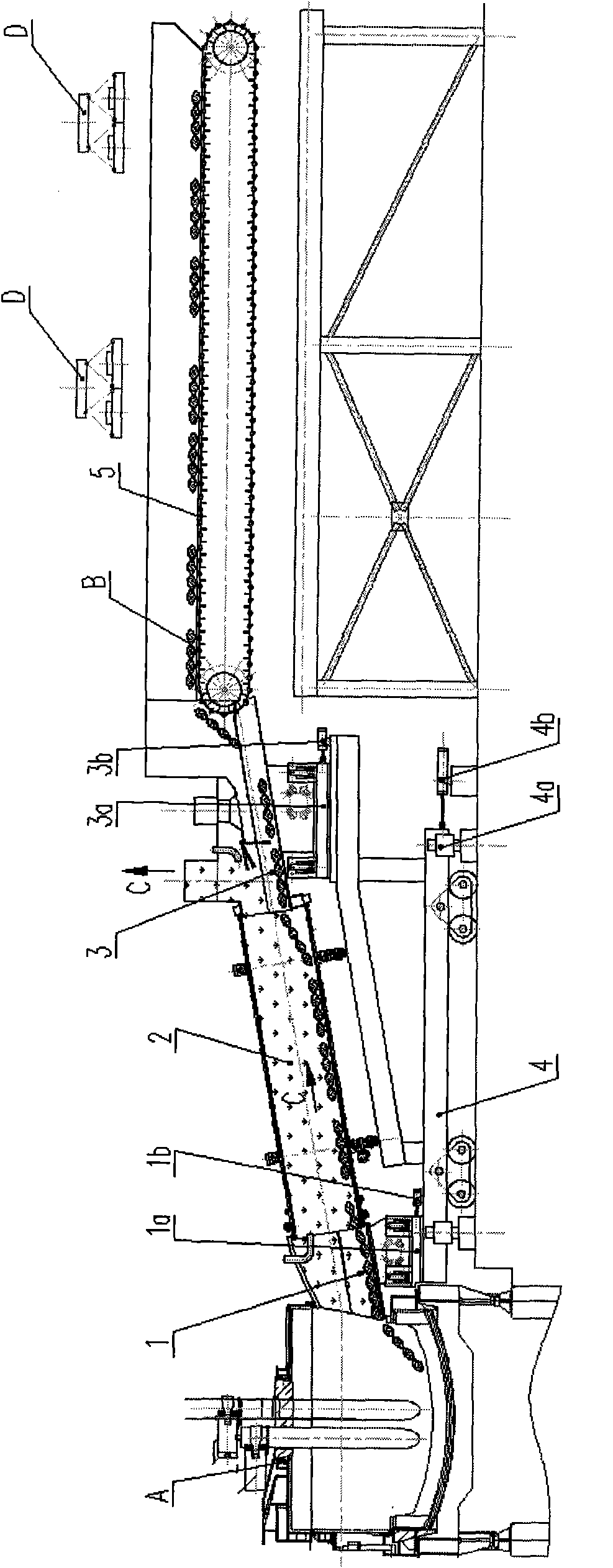

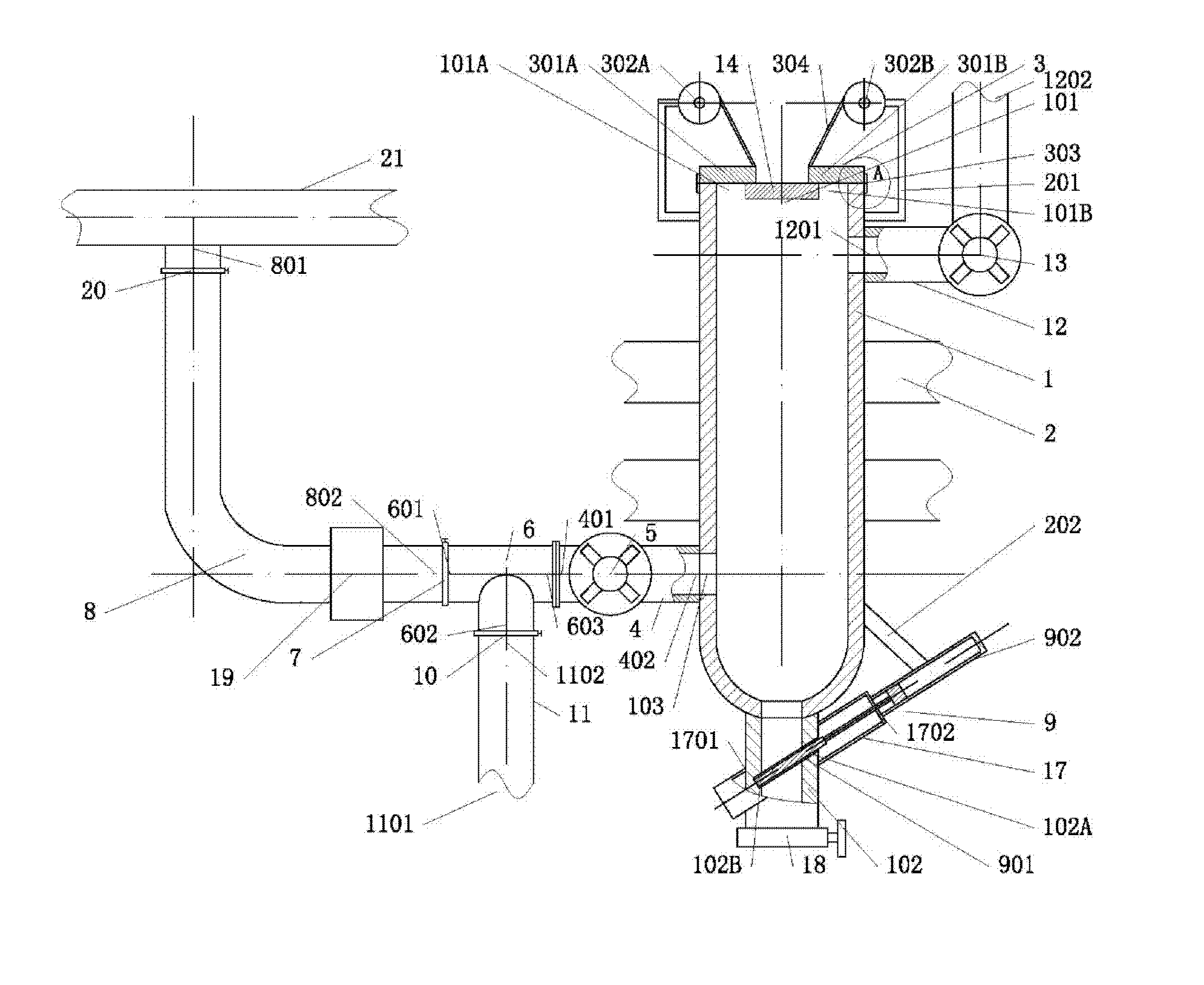

Electric stove metal bulk cargo continuous feeding and preheating device and method

InactiveCN101644539AReduce manufacturing costSave energyCharge manipulationPreheating chargesBulk cargoShortest distance

The invention belongs to the metallurgy technical field and discloses an electric stove metal bulk cargo continuous feeding and preheating device and method. The metal charge roller preheating grooveof the device is inclined with the horizontal plane, the lower end of the metal charge roller preheating groove is inserted into the inlet of a stove entering vibratory conveyor to be sheathed in short distance fit, the stove entering vibratory conveyor is connected with open pore A of the electric stove, the position of approach end is lower, the higher end of the metal charge roller preheating groove is sheathed and combined with a groove entering vibratory conveying and air sealing device, and the two are sheathed in short distance fit. The method is characterized in that metal charge is fed into the metal charge roller preheating groove to be preheated. The preheated metal charge is fed into the electric stove, and smoke of the electric stove is exhausted by the stove entering vibratory conveyor, the metal charge preheating groove and the groove entering vibratory conveying and air sealing device. The invention has the advantages of less electrical energy consumption, steady operation, high scrap preheating efficiency, high operational throughput and short total device length and is a new energy-saving and environmentally friendly technology with promotional value on electric stove or other production technologies.

Owner:CISDI ENG CO LTD

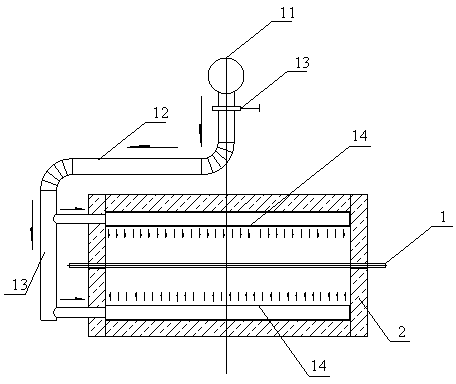

Oxygen-enriched combustion domestic ceramic roller kiln waste-heat utilization hot-air preheating system

The invention discloses an oxygen-enriched combustion domestic ceramic roller kiln waste-heat utilization hot-air preheating system. The oxygen-enriched combustion domestic ceramic roller kiln waste-heat utilization hot-air preheating system comprises hot air acquisition pipelines, a first conveying pipeline, an induced draft fan, a second conveying pipeline, a branch conveying pipeline, and a hot air distributor which is arranged in a roller kiln preheating zone; multiple hot air acquisition pipelines are arranged at a plurality of positions in a cooling zone kiln body of the roller kiln; the hot air acquisition pipelines are communicated with the first conveying pipeline; an inlet / outlet of the induced draft fan is communicated with the first conveying pipeline and the second conveying pipeline respectively; an outlet end of the second conveying pipeline is communicated with the hot air distributor which is arranged in the roller kiln preheating zone through the branch conveying pipeline; the hot air distributor is arranged at the upper and lower ends of a rod in the kiln; and flow regulation gates are arranged on the hot air acquisition pipelines and the branch conveying pipeline. The hot air in the cooling zone is exhausted and is uniformly conveyed to a preheating zone in the kiln through the air distributor, so that the temperature distribution on the section of the kiln is uniform, the overall heat efficiency is improved by 5-25 percent, and the fuel is saved by 5-15 percent.

Owner:WUHAN UNIV OF TECH

Conveyor oven apparatus and method

ActiveUS9585400B2Increase productionReduce internal temperatureDomestic stoves or rangesOven air-treatment devicesEngineeringInternal temperature

An oven with a sensor positioned to detect an event that will cause a decrease in the internal temperature of a tunnel. The oven includes a controller configured to increase the thermal output of a heating element in anticipation of the upcoming decrease in the internal temperature. In some embodiments, the oven is a conveyor over and the sensor is positioned to detect a food item approach the tunnel on a conveyor. In some embodiments, the amount of current provided to an electric heating element is increased by increasing the target temperature. In some embodiments, the amount of current provided to the electric heating element is increased by a predetermined offset.

Owner:MIDDLEBY CORPORATION

Scrap steel pre-heating conveyor with short process

InactiveCN101907401AExtend your lifeReduce wearCharge manipulationPreheating chargesNew energyEngineering

The invention discloses a scrap steel pre-heating conveyor with a short process, comprising a conveying trough (1) which is provided with a fume guiding hood (2) and is inclined relative to the horizontal plane. The lower end of the conveying trough (1) extends into an electric furnace (A) via an opening on the sidewall of the electric furnace (A); a bottom-opened long distributing trough (D) is arranged above the other end of the conveying trough (1), is arranged above a material receiving section of the conveying trough (1) by a swing device (Q), and is arranged in the downward projection of the material receiving section of the conveying trough (1) longitudinally; and scrap steels (C) are longitudinally arranged at the bottom of the material receiving section of the conveying trough (1) in a strip shape, and then the conveying trough (1) conveys the scrap steels (C) into the electric furnace (A). The scrap steel pre-heating conveyor with a short process is short, has high heat exchange efficiency, low operation rate of a crane, small abrasion, less maintenance, energy conservation, environment protection and reduces investment and operation cost, thus the invention is a new energy-saving and environment-friendly technology with promotional value in smelting technique, such as electric furnaces and the like.

Owner:CISDI ENG CO LTD

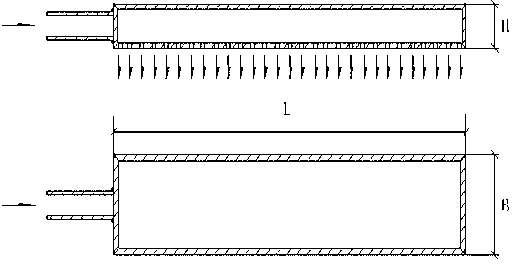

System and method utilizing flue duct waste gas of hot air furnace to bake and preheat charging of blast furnace

ActiveCN102538491AAvoid furnaceQuality assuranceBlast furnace componentsBlast furnace detailsInlet channelControl valves

The invention discloses a system and a method utilizing flue duct waste gas of a hot air furnace to bake and preheat charging of a blast furnace. The system includes a storage bin, wherein a feed opening of the storage bin is provided with a sealing cover device; an air inlet of the storage bin is sealed and communicated with an outlet end of an air inlet channel; an induced draft fan is arranged on the air inlet channel; an exhaust opening of the storage bin is sealed and communicated with an inlet end of an air exhaust channel; and an exhaust fan is arranged on the air exhaust channel. The method includes the steps as follows: A), loading the storage bin with the charging, and closing the sealing cover at the feed opening and an air supplementing control valve; B), opening an induced draft control valve, starting the induced draft fan and the exhaust fan, introducing flue duct waste gas in the hot air furnace into the storage bin through an induced draft pipeline, and directly baking the charging; C), closing the induced draft control valve and opening the air supplementing control valve, enabling air to enter the storage bin through an air supplementing pipeline, and further quickly discharging residual waste gas in the storage bin through the air exhaust channel; and D), stopping the induced draft fan and the exhaust fan, and discharging the charging in the storage bin. The system and the method provided by the invention are mainly used for baking and preheating the charging in the blast furnace through the flue duct waste gas of the hot air furnace.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com