Oxygen-enriched combustion domestic ceramic roller kiln waste-heat utilization hot-air preheating system

A technology of oxygen-enriched combustion and ceramic rollers, which is applied in the directions of preheating, ceramic material production, waste heat treatment, etc., and can solve the problems of uneven temperature distribution in the section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

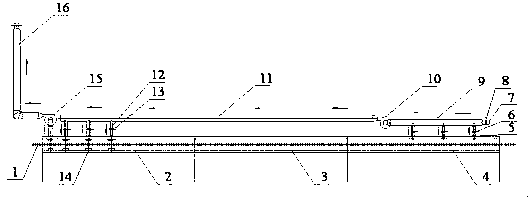

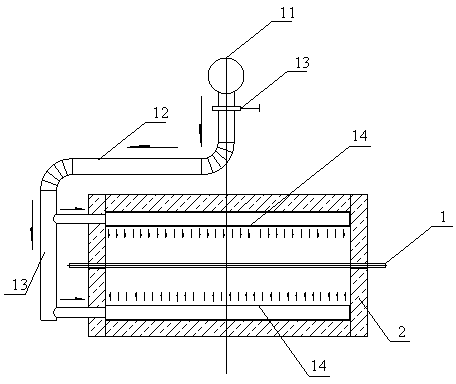

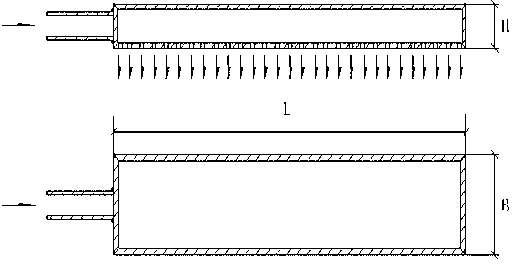

[0023] figure 1 Schematic diagram of the waste heat utilization hot air preheating system of the oxygen-enriched combustion daily-use ceramic roller kiln. The technical embodiment of the invention is: the daily-use ceramics placed on the backing plate pass through the transmission of the ceramic roller rod 1, and then pass through the preheating zone 2, the firing zone 3 and the cooling zone 4 in the roller kiln in sequence; the ceramic green body Firing is carried out in the firing zone according to its predetermined firing system, and the hot flue gas in the firing zone 3 flows from the firing zone 3 to the pre-tropical zone 2 under the action of the kiln head smoke exhaust fan 15, and the ceramic green body Form the reverse movement; after the firing of the ceramic green body, it enters the cooling zone 4 through the rapid cooling air curtain between the firing zone 3 and the cooling zone 4; the product is rapidly cooled in the cooling zone 4 according to the cooling proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com