Patents

Literature

100 results about "Continuous Firing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

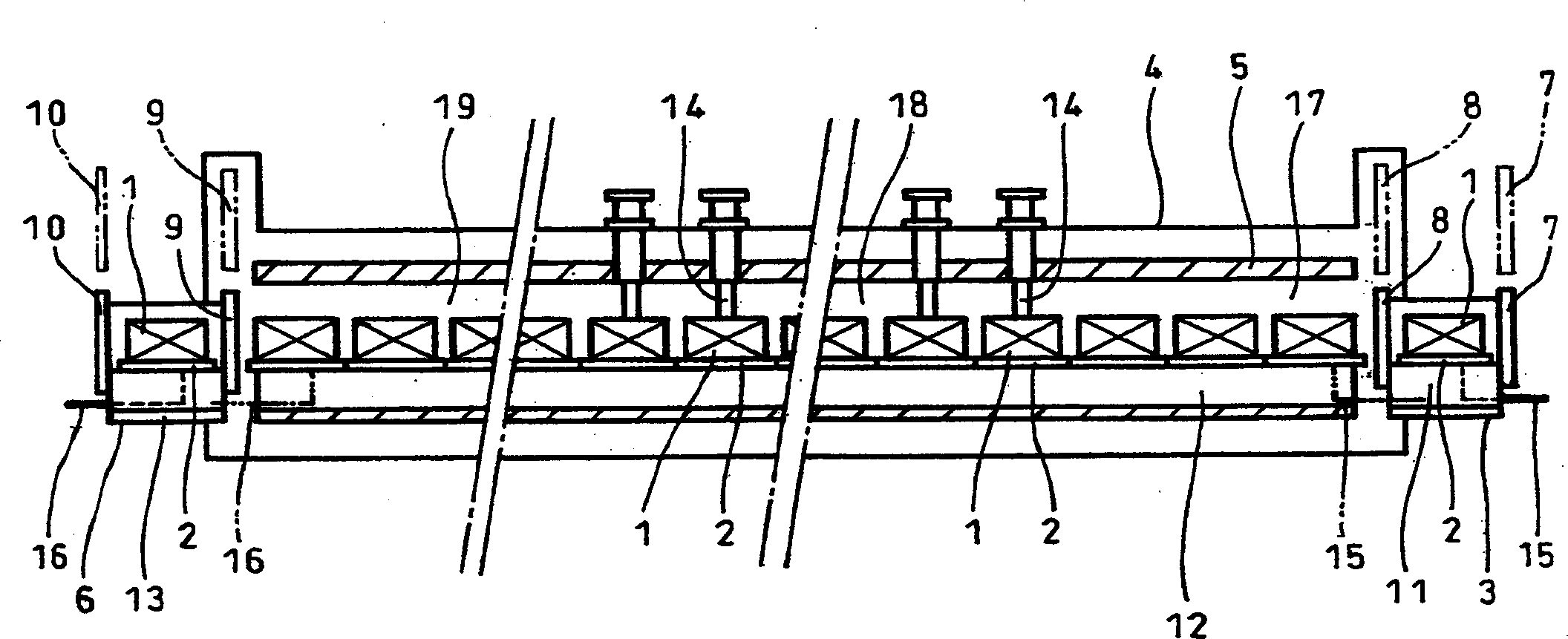

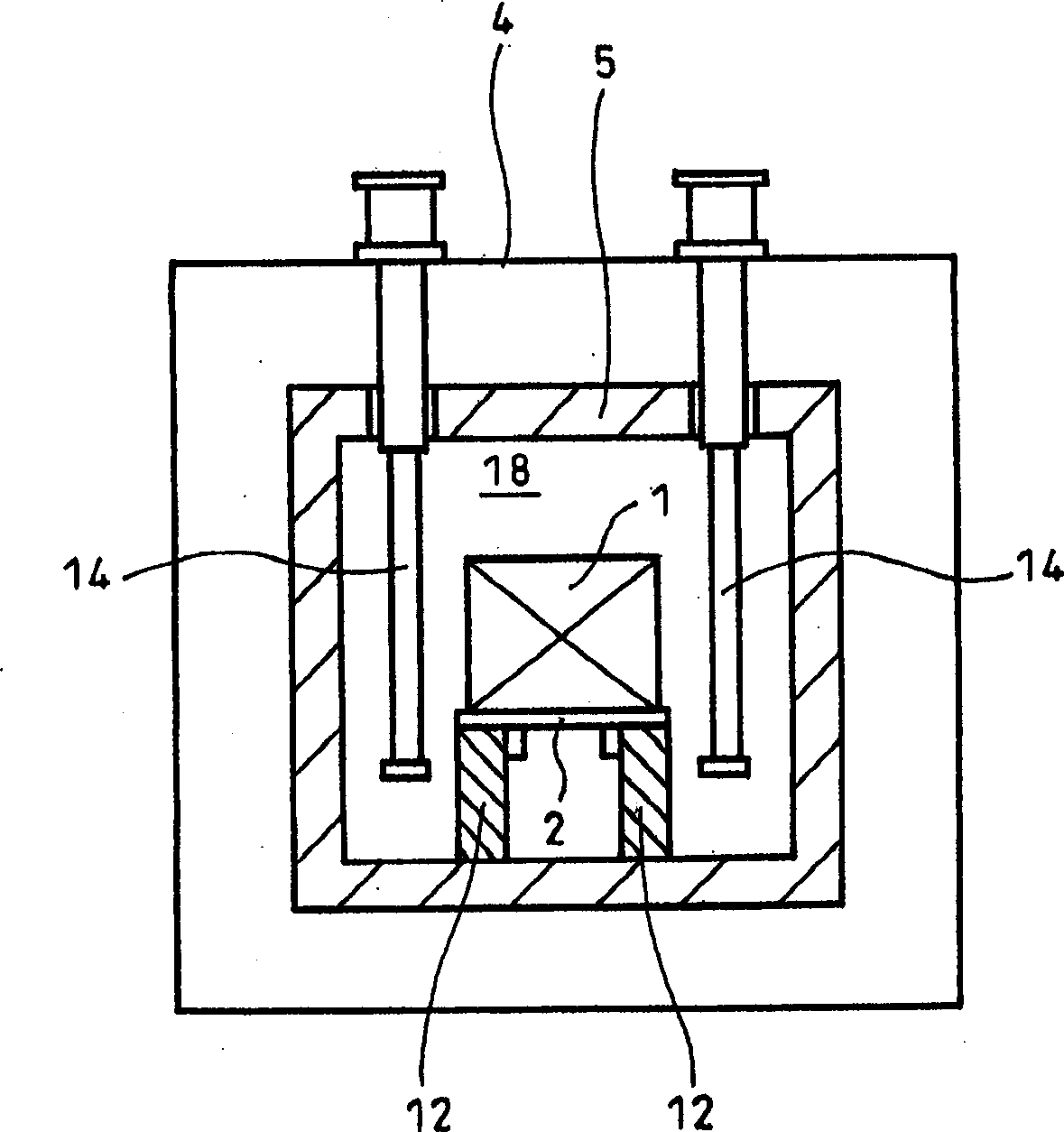

Continuous firing furnace, manufacturing method of porous ceramic member using the same, porous ceramic member, and ceramic honeycomb filter

InactiveUS20060029897A1Ensuring spaceMaintainance of heating chambersCharge manipulationMetallurgyPorous ceramics

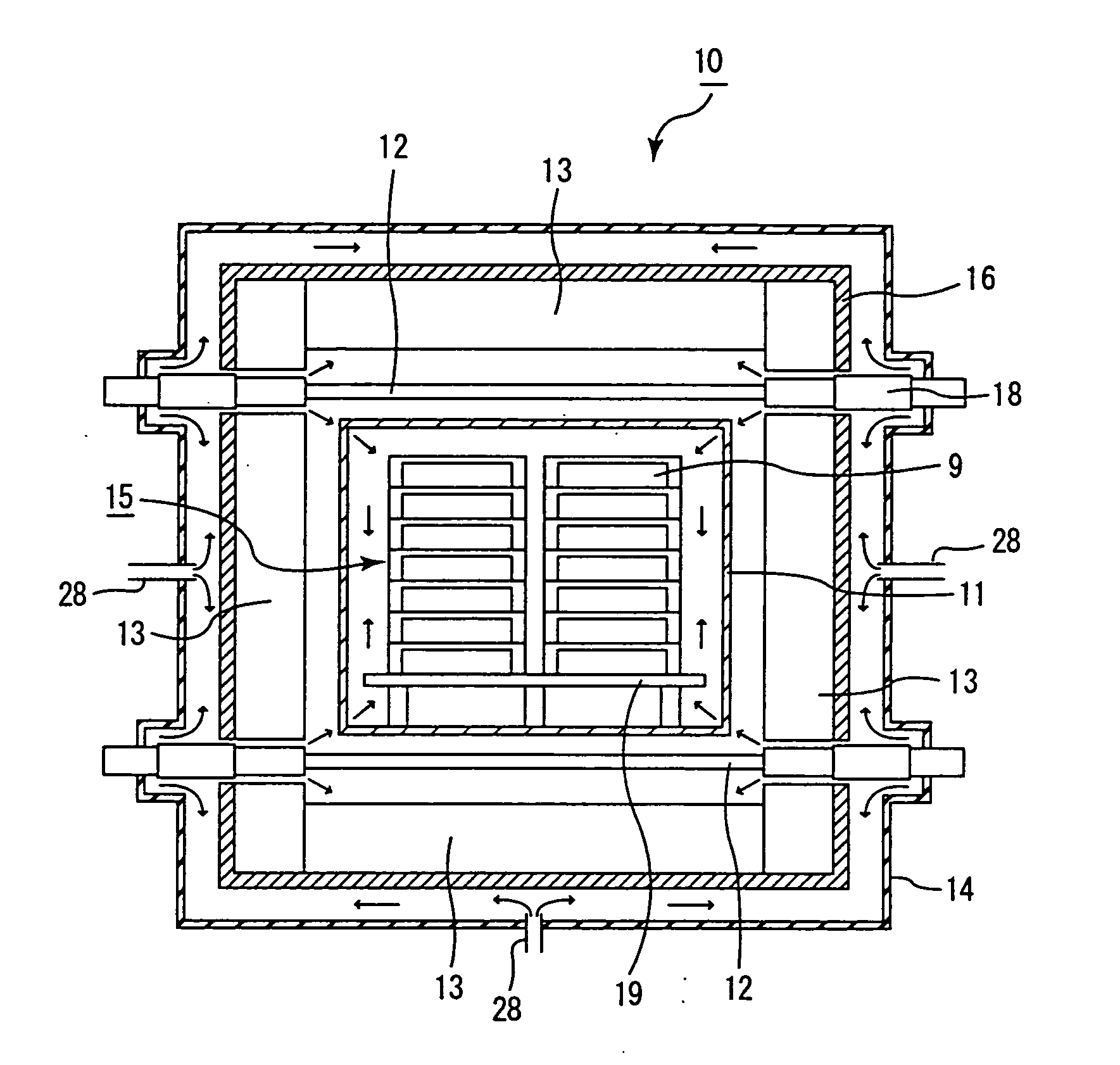

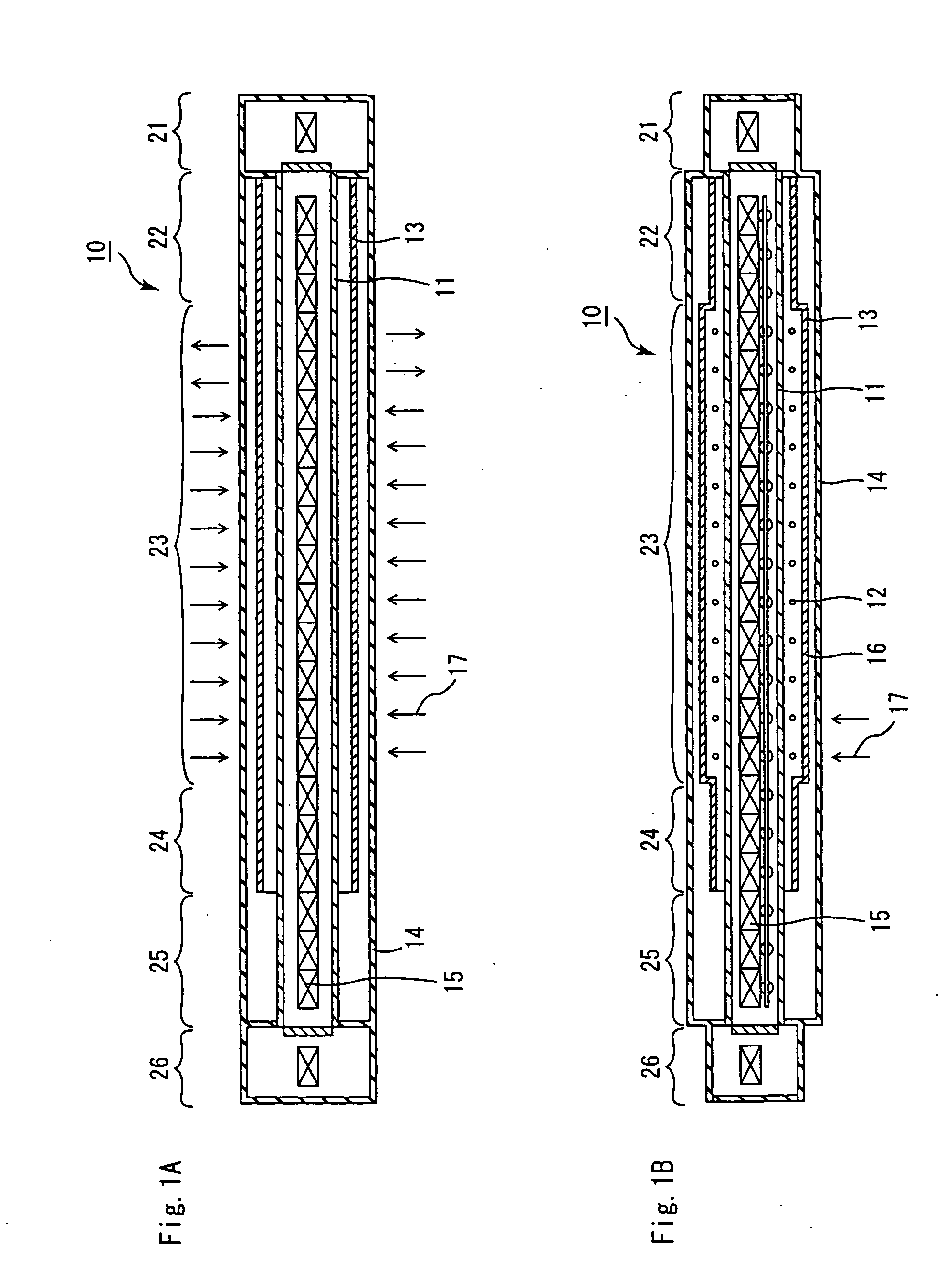

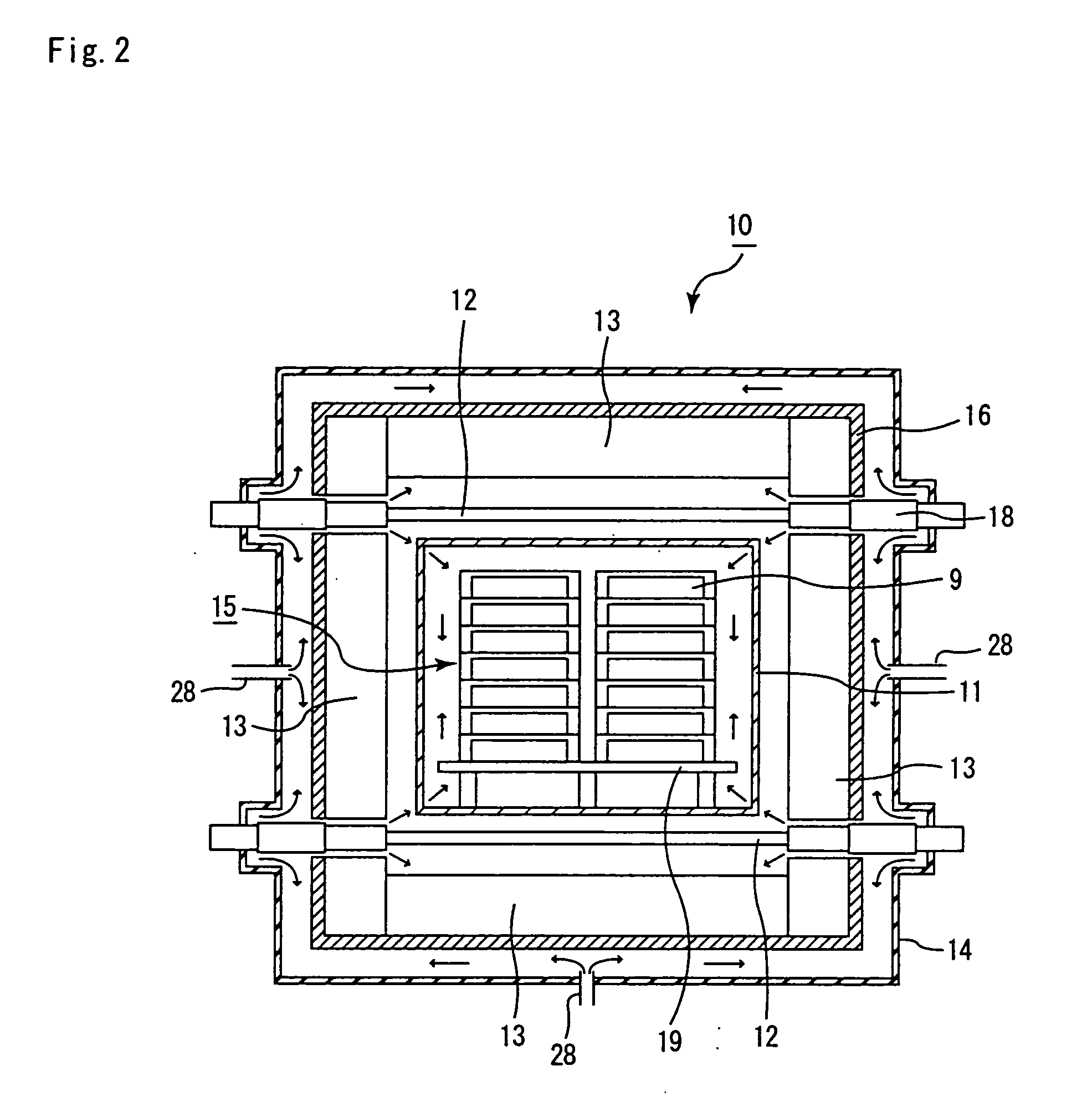

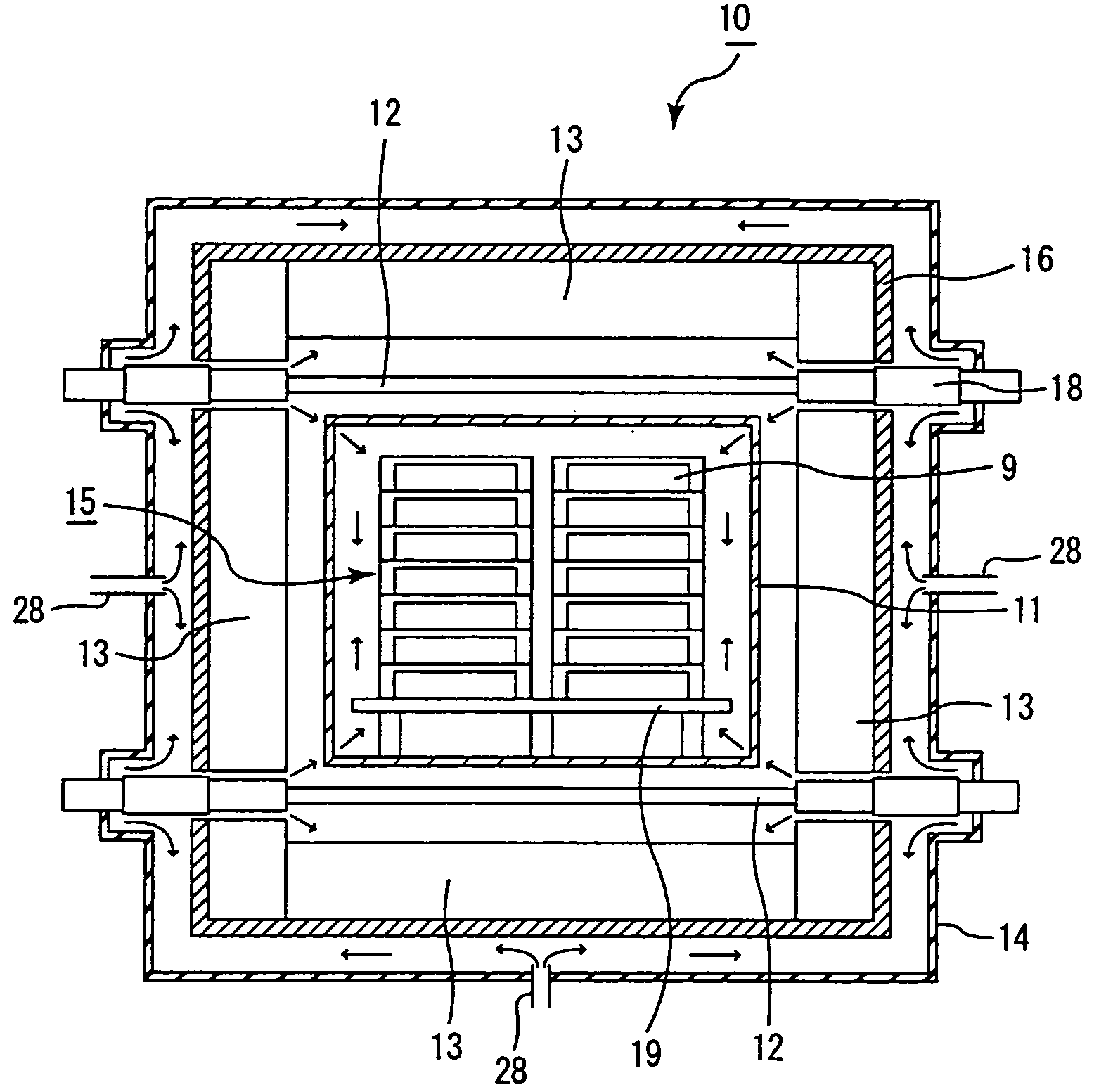

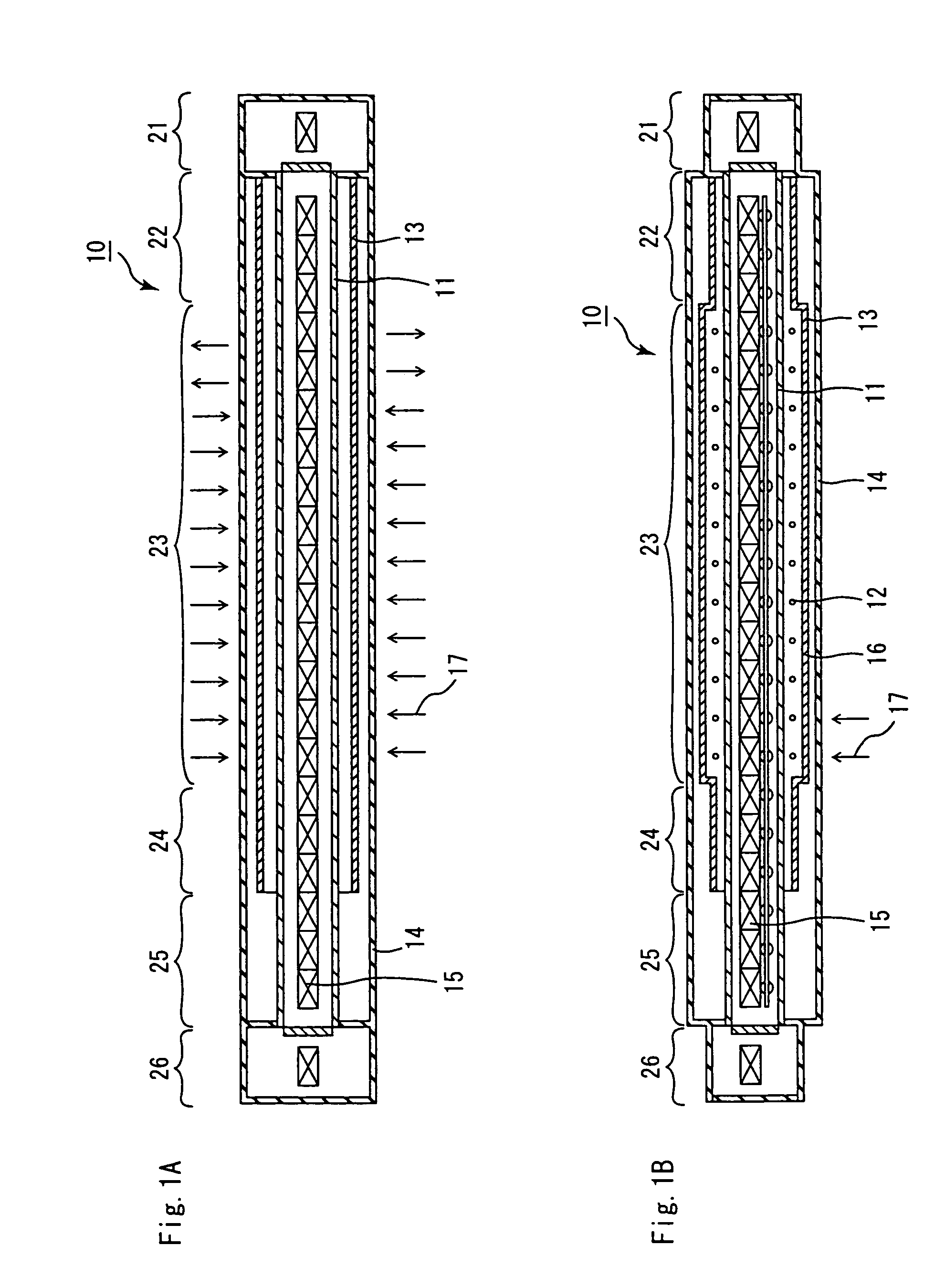

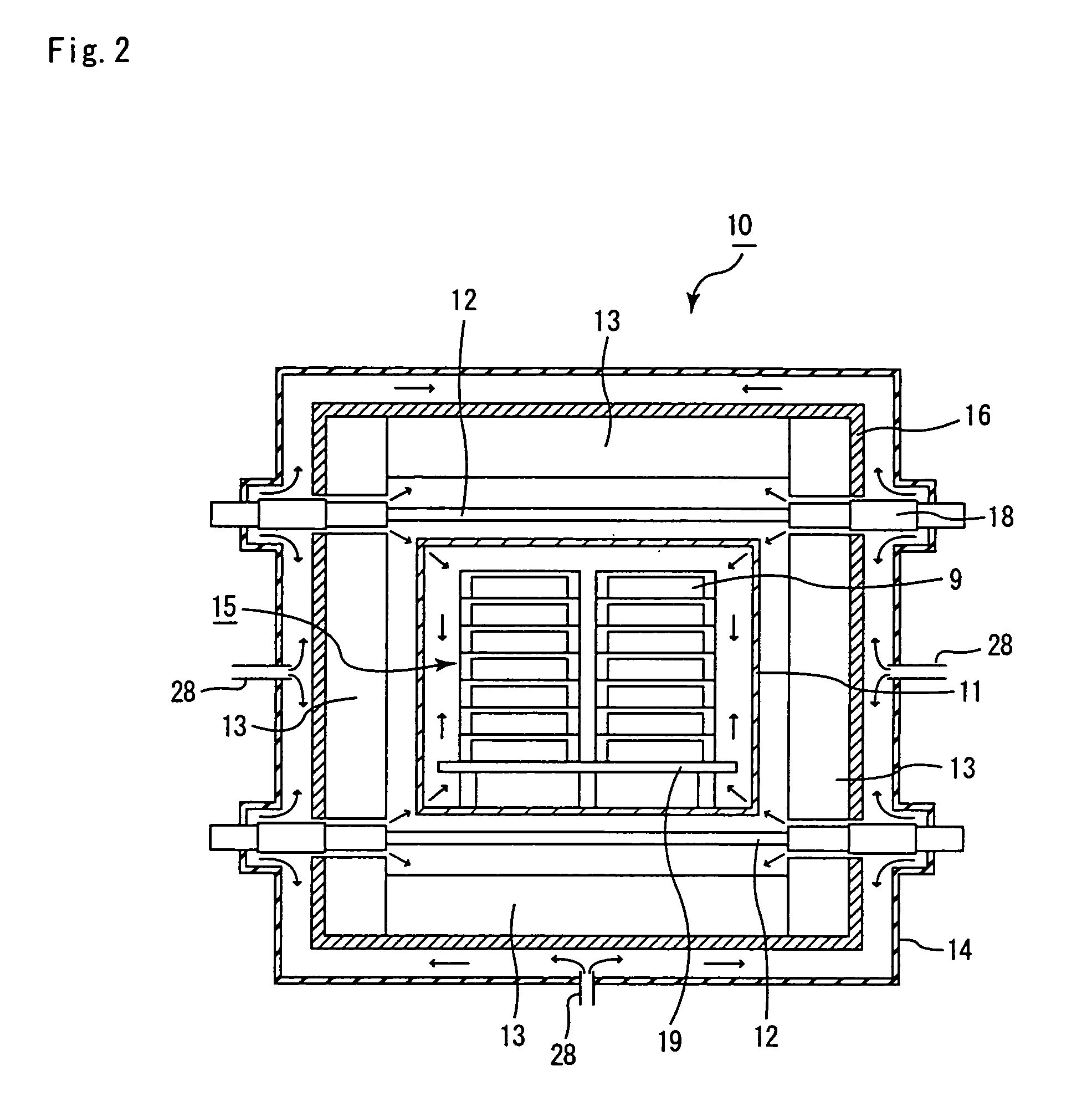

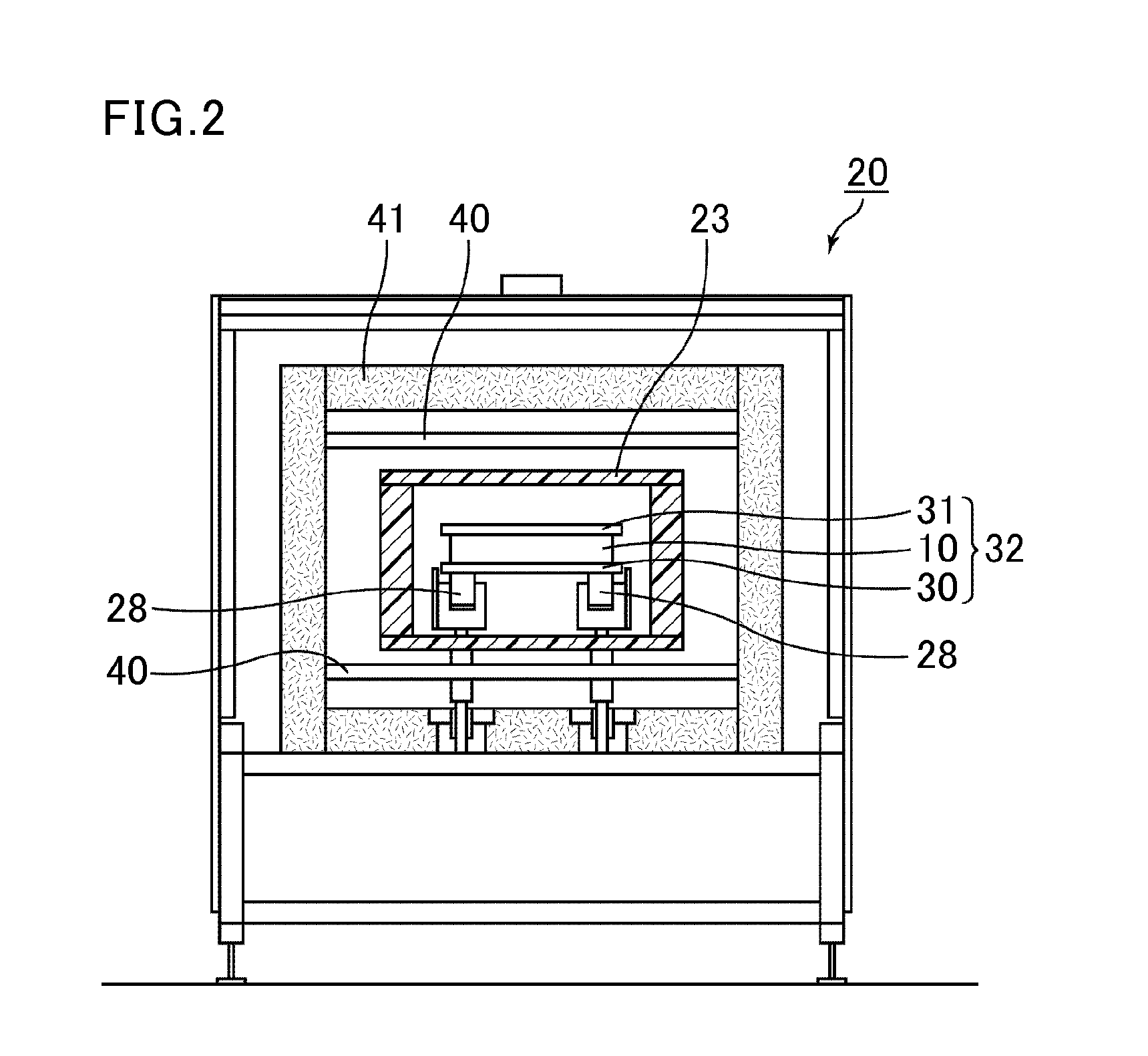

A continuous firing furnace of the present invention comprises: a muffle formed into a cylindrical shape so as to ensure a predetermined space; a plurality of heat generators placed at the peripheral direction from the muffle; and a heat insulating layer formed in a manner so as to enclose said muffle and said heat generators therein, said continuous firing furnace being configured such that a formed body to be fired, which is transported from an inlet side, passes through the inside of said muffle at a predetermined speed in an inert gas atmosphere and, then, is discharged from an outlet so that said formed body is fired, wherein said inert gas flows through: a space between said muffle and said heat insulating layer; and a space inside the muffle, in sequence.

Owner:IBIDEN CO LTD

Continuous firing furnace, manufacturing method of porous ceramic member using the same, porous ceramic member, and ceramic honeycomb filter

A continuous firing furnace of the present invention comprises: a muffle formed into a cylindrical shape so as to ensure a predetermined space; a plurality of heat generators placed at the peripheral direction from the muffle; and a heat insulating layer formed in a manner so as to enclose said muffle and said heat generators therein, said continuous firing furnace being configured such that a formed body to be fired, which is transported from an inlet side, passes through the inside of said muffle at a predetermined speed in an inert gas atmosphere and, then, is discharged from an outlet so that said formed body is fired, wherein said inert gas flows through: a space between said muffle and said heat insulating layer; and a space inside the muffle, in sequence.

Owner:IBIDEN CO LTD

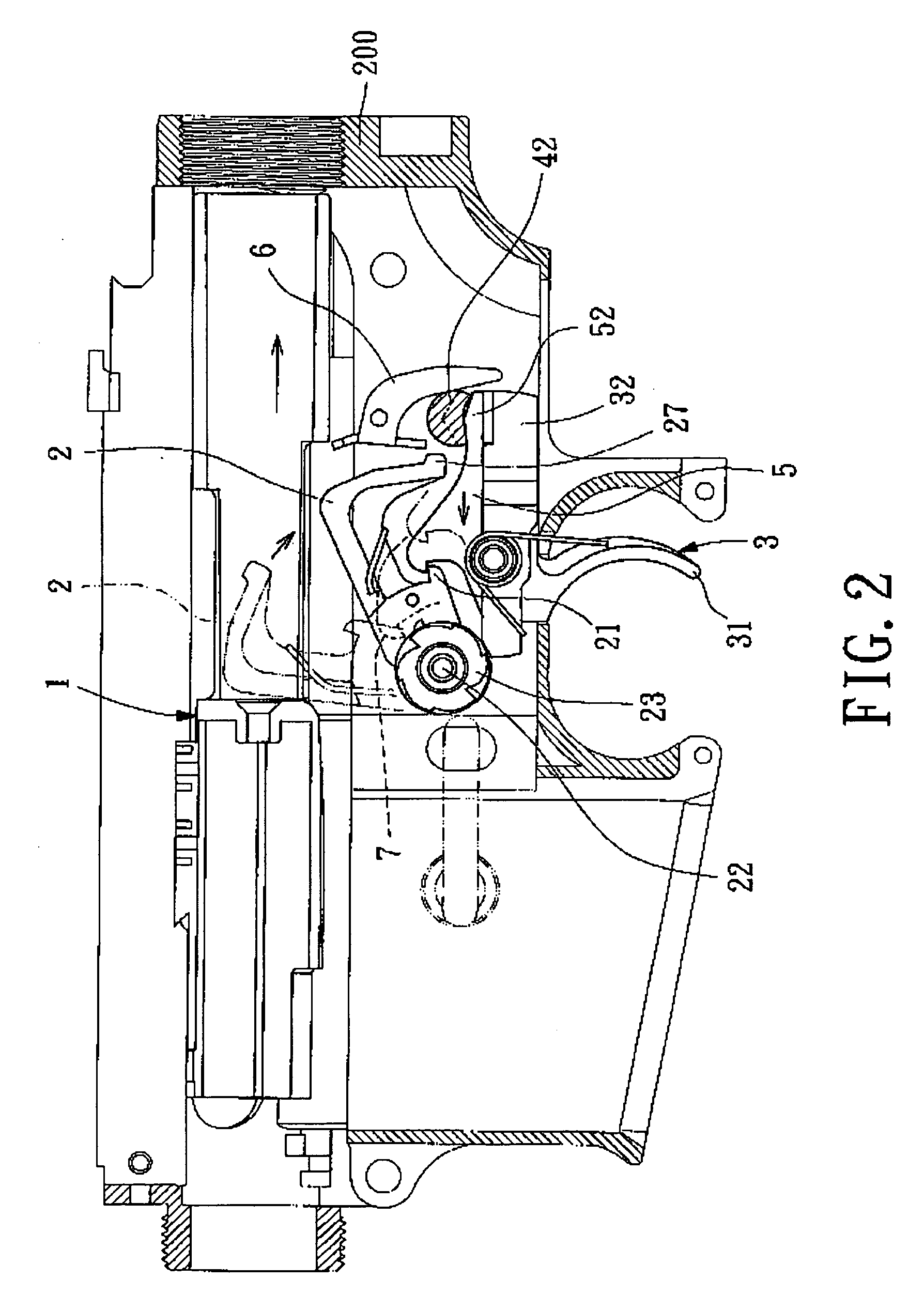

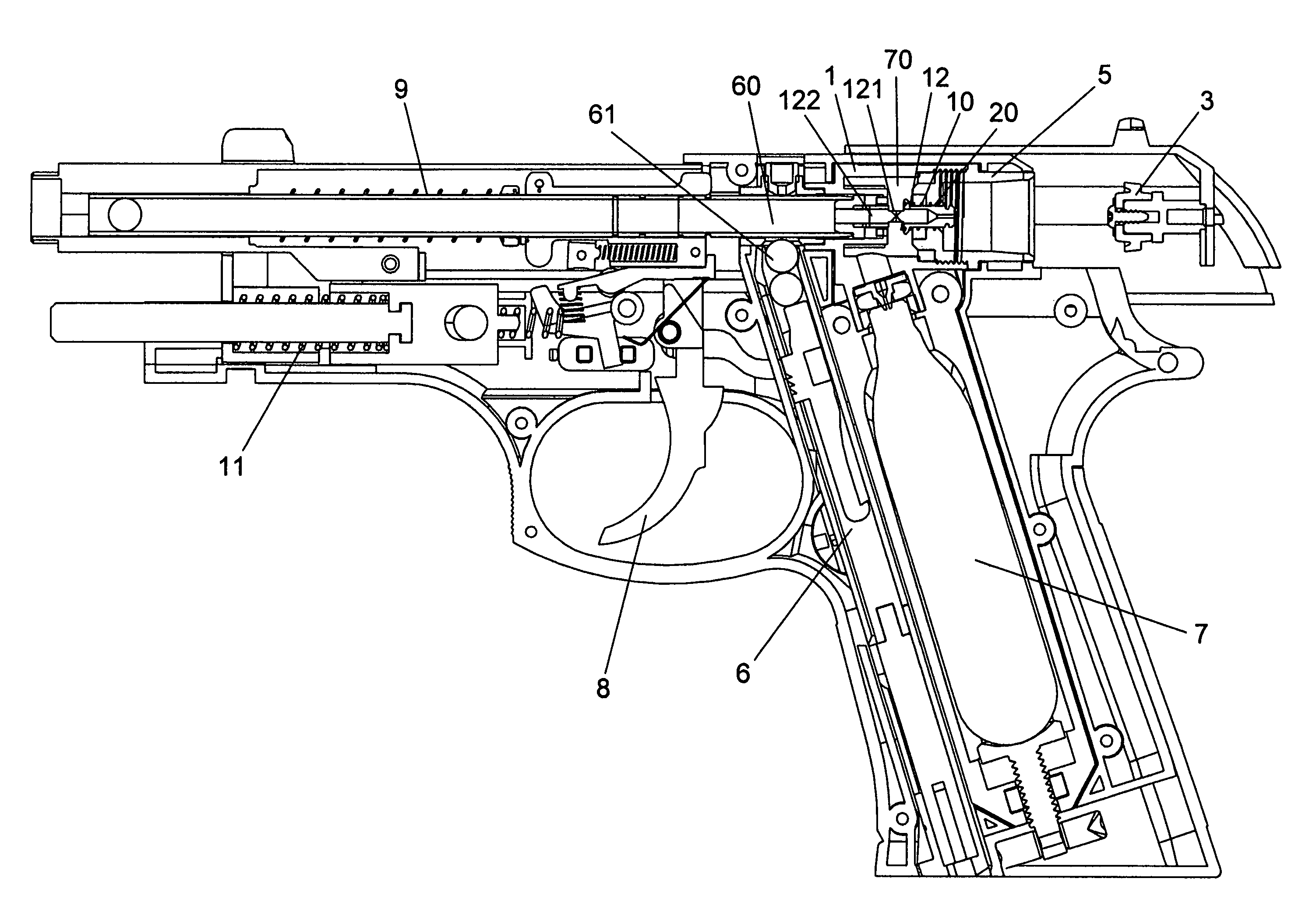

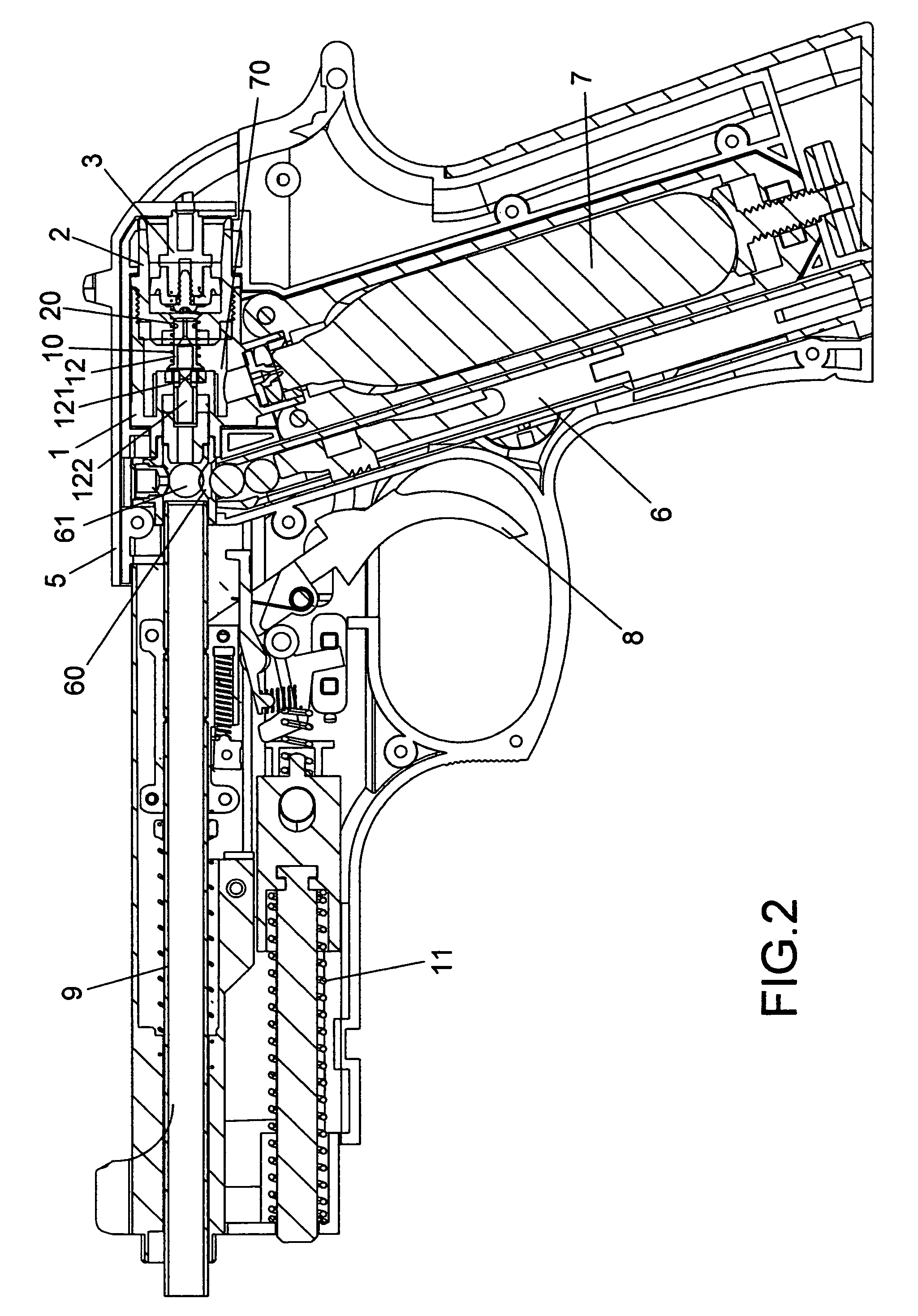

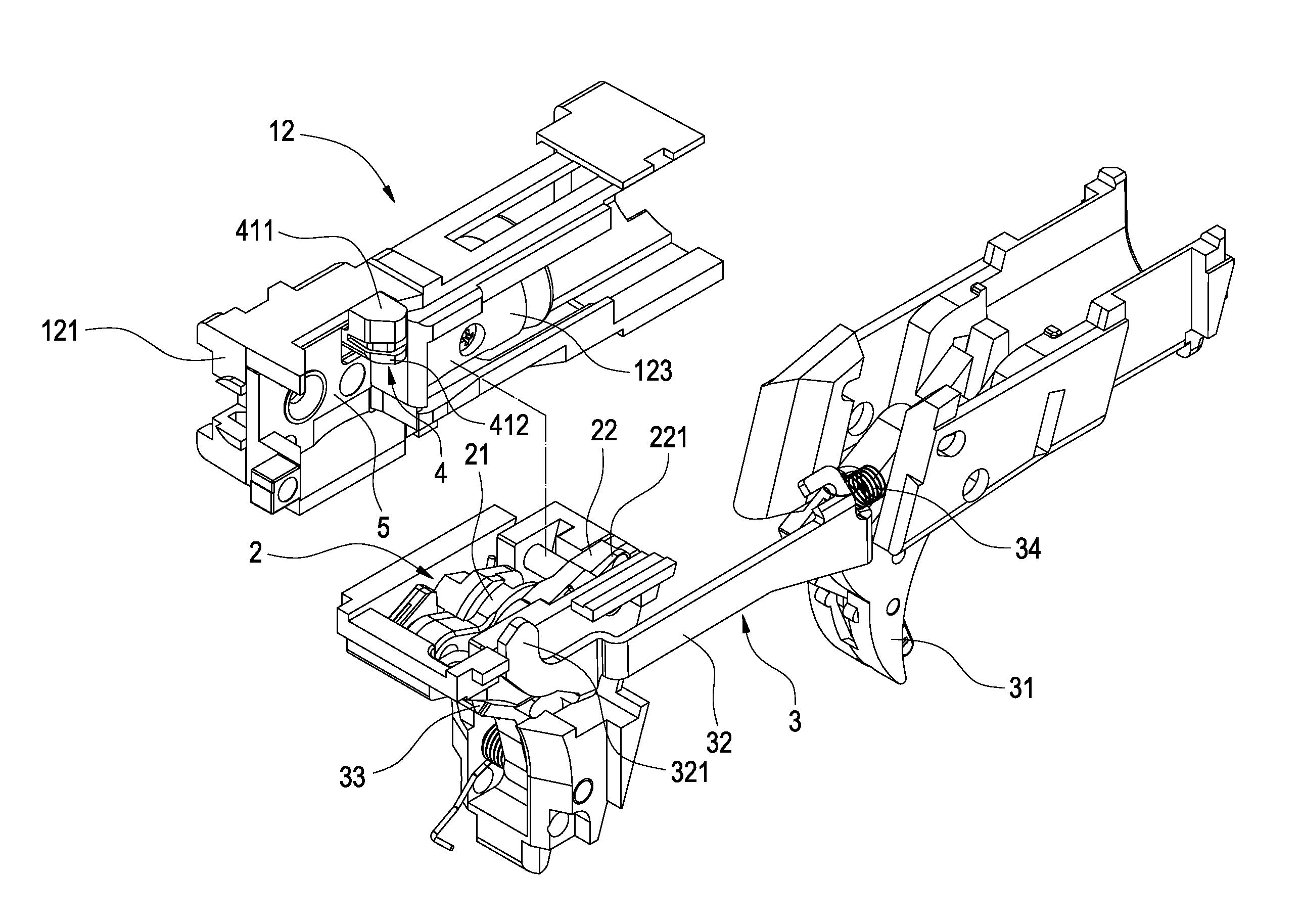

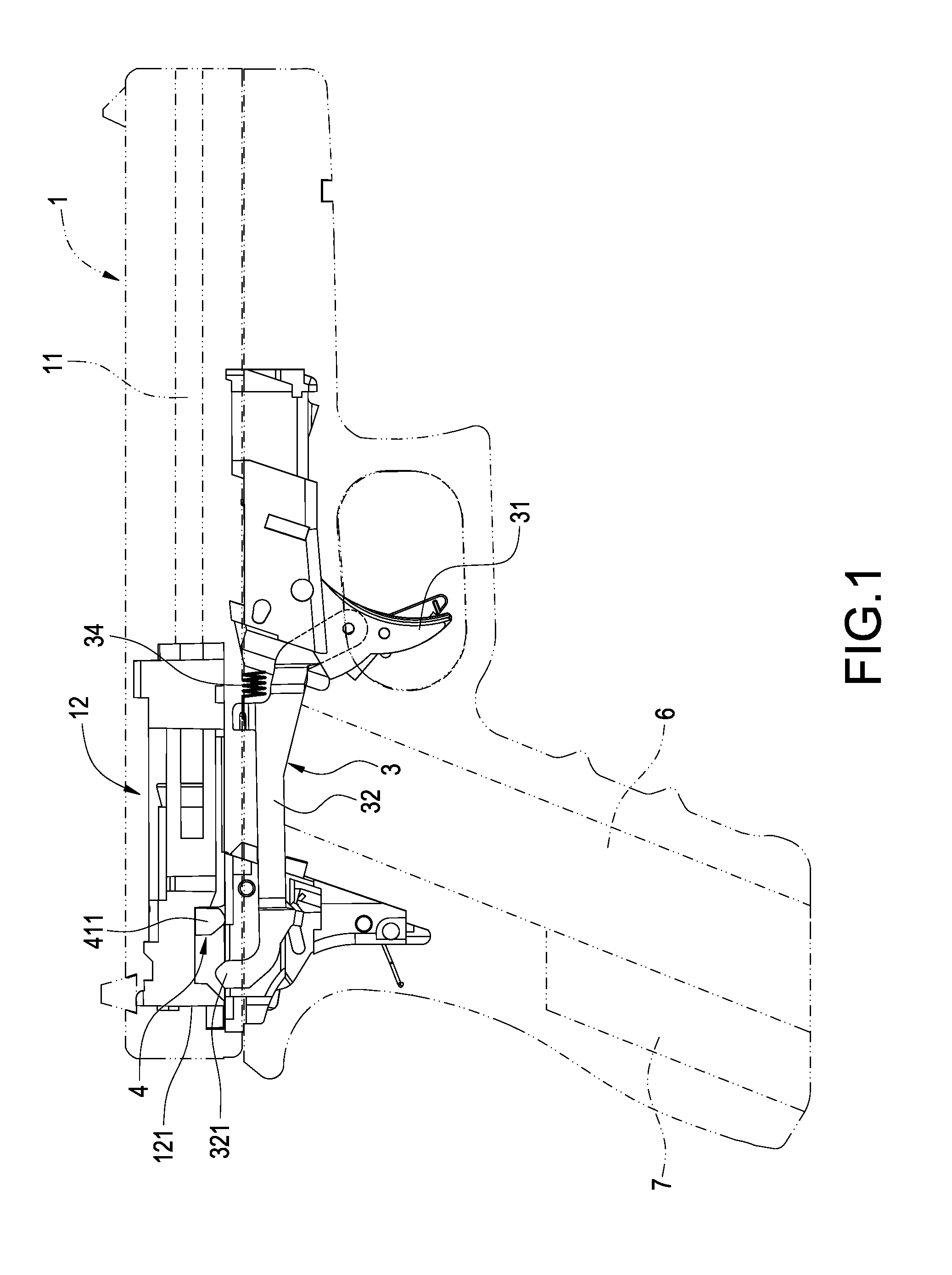

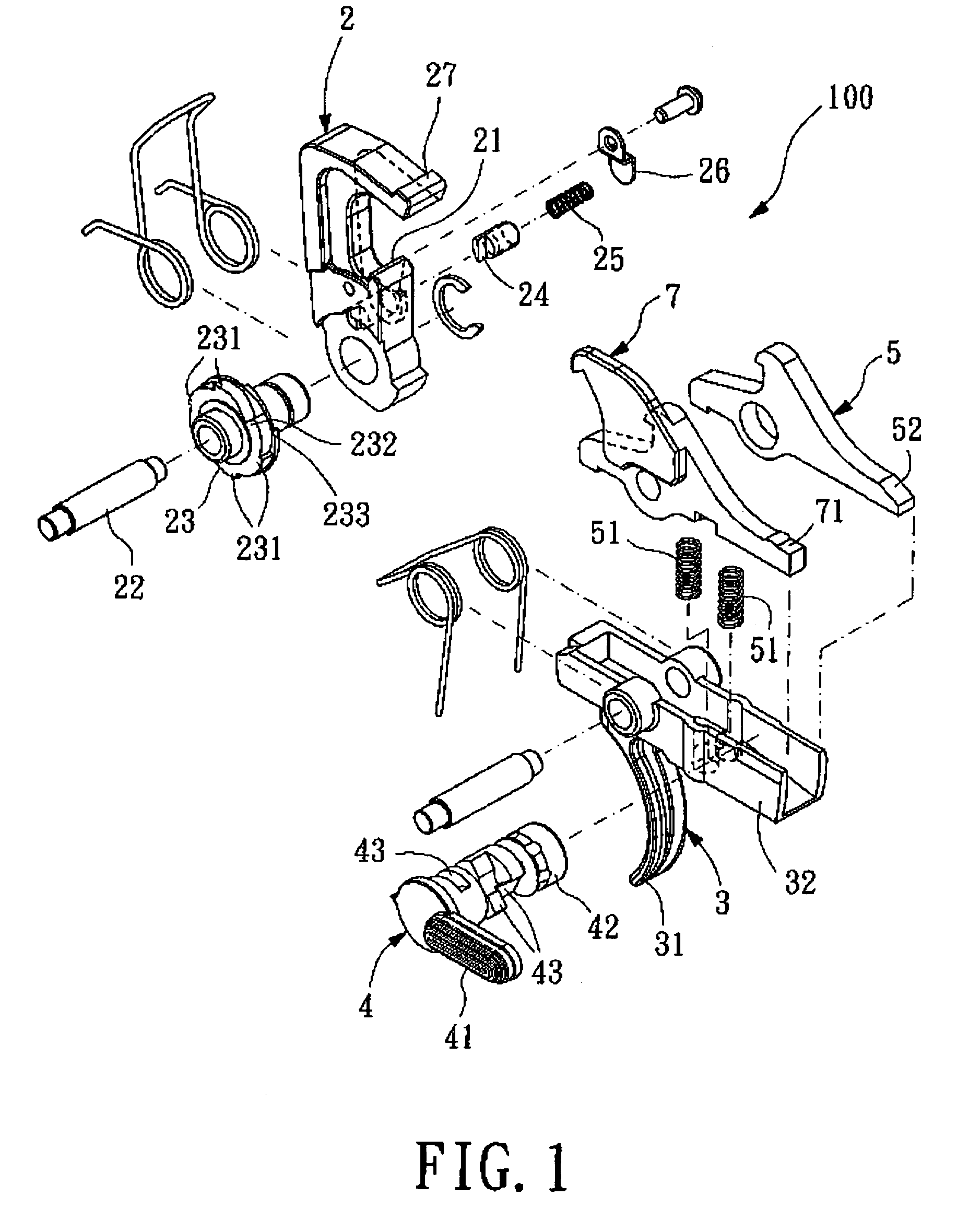

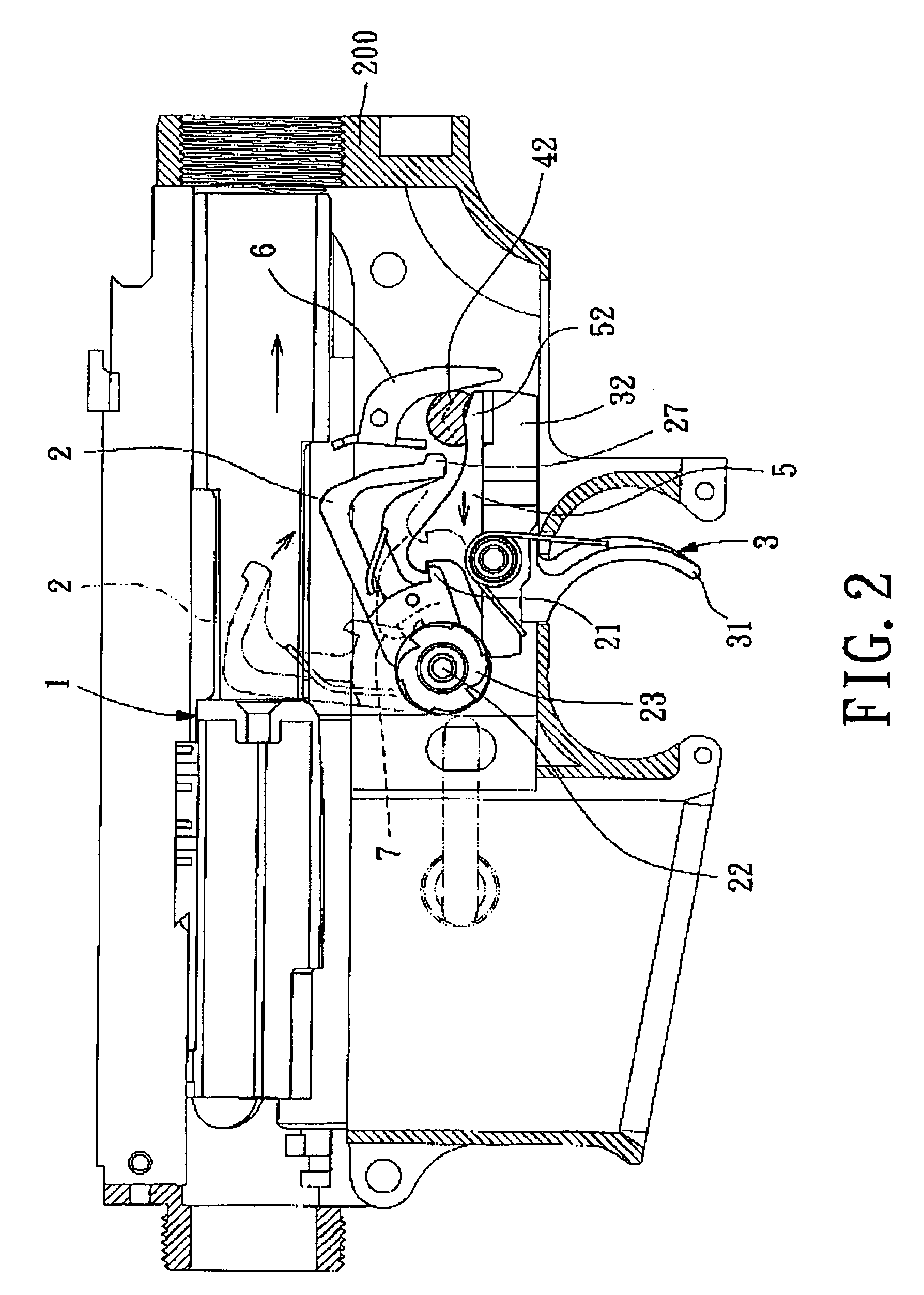

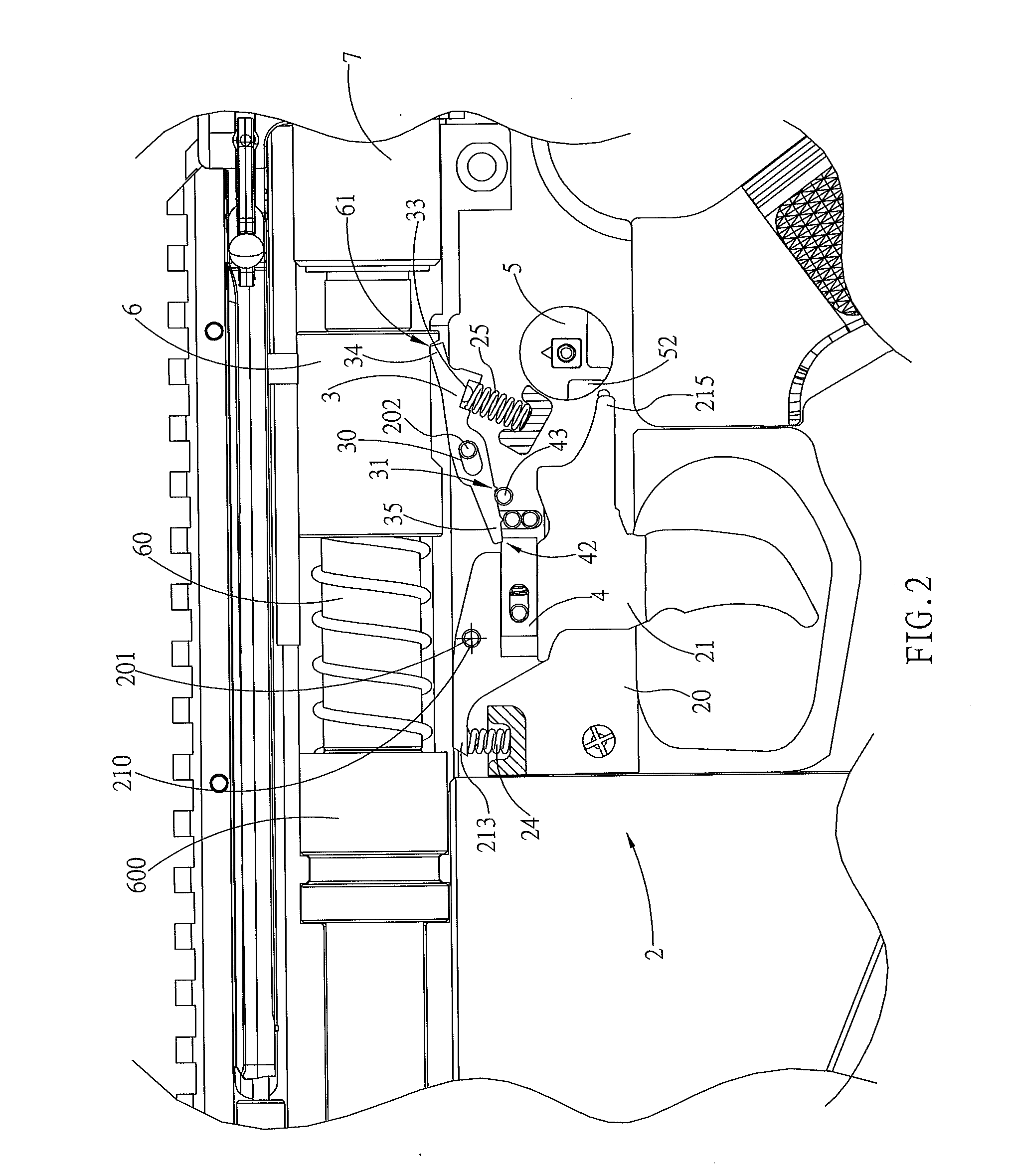

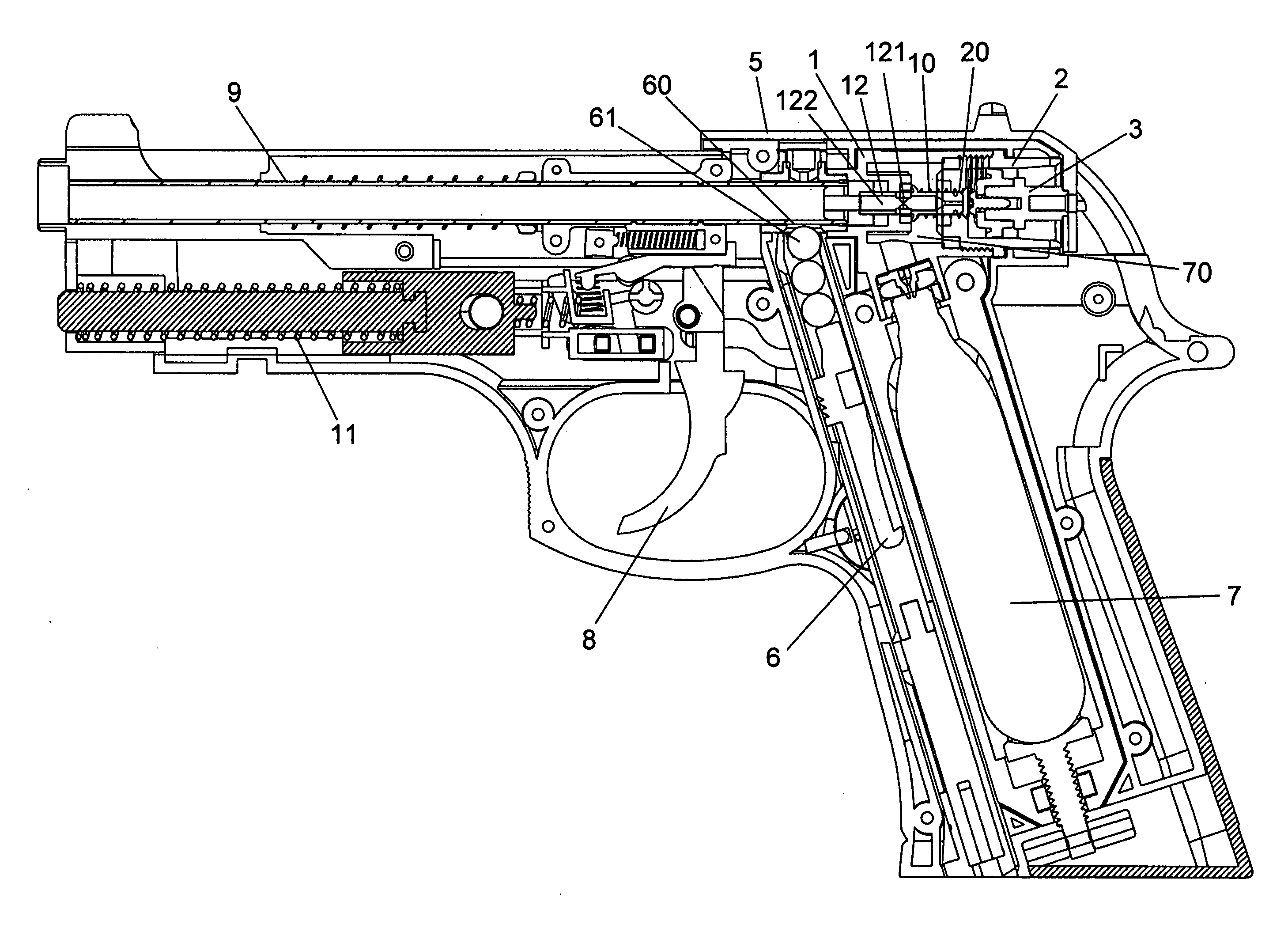

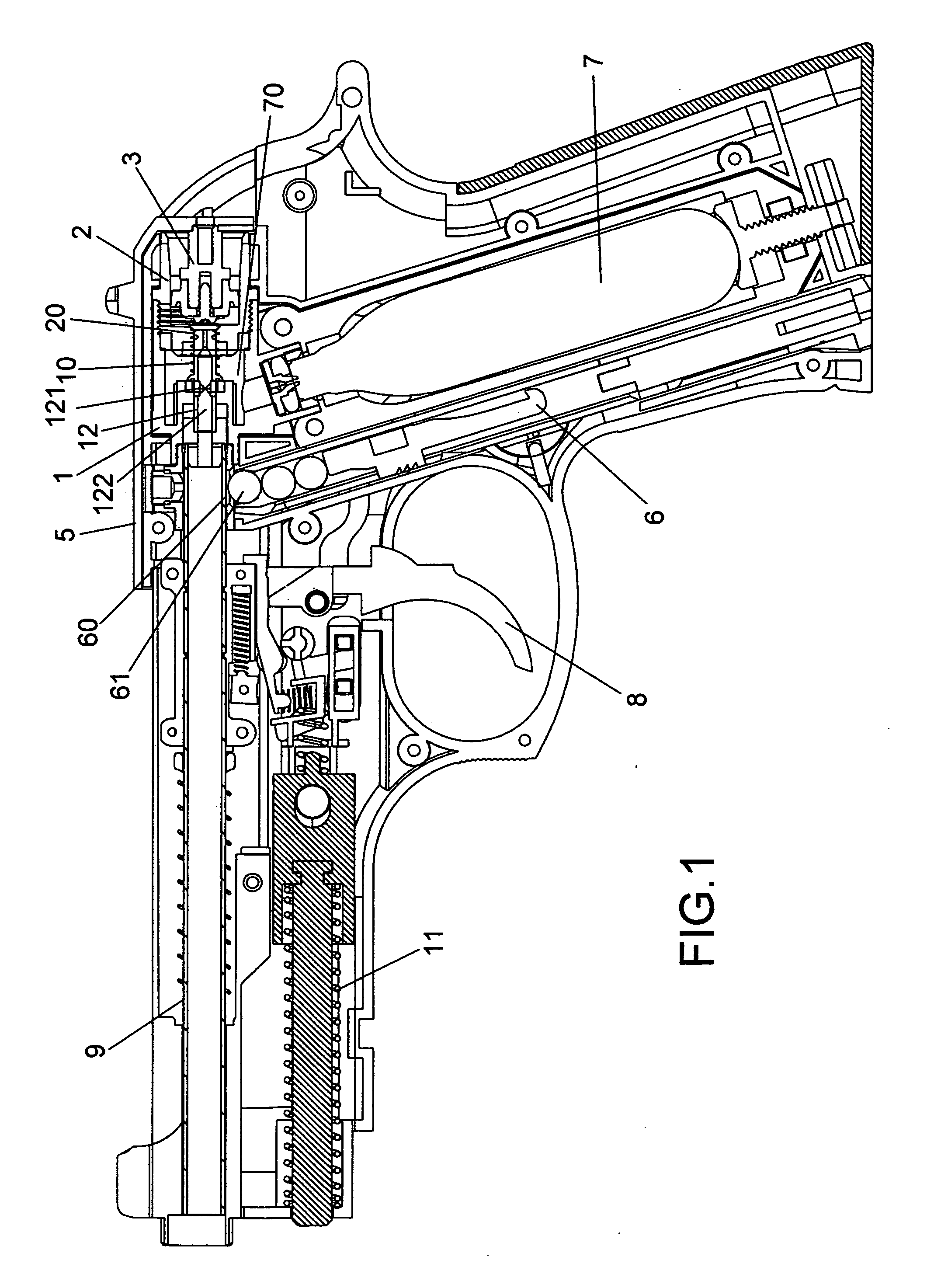

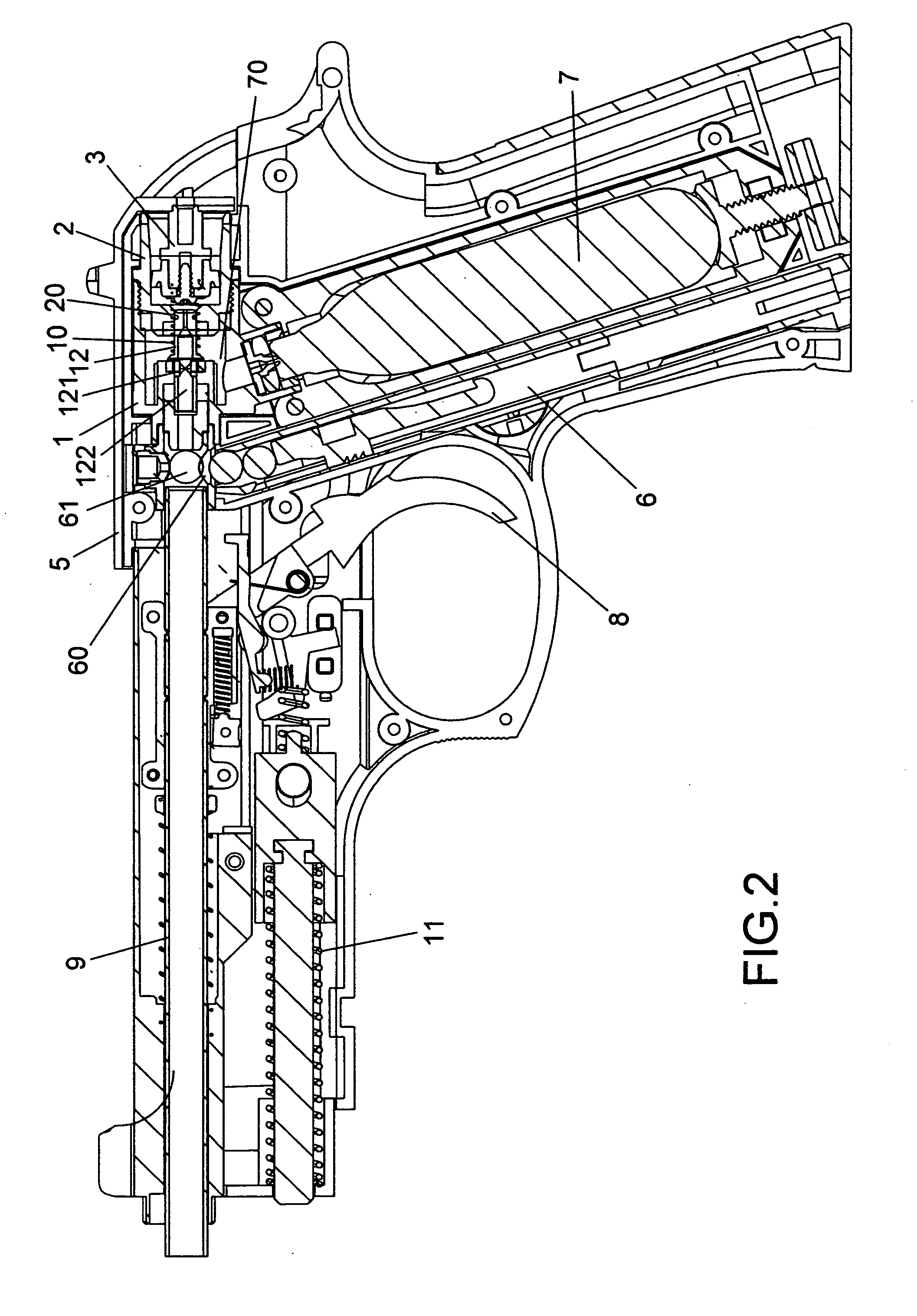

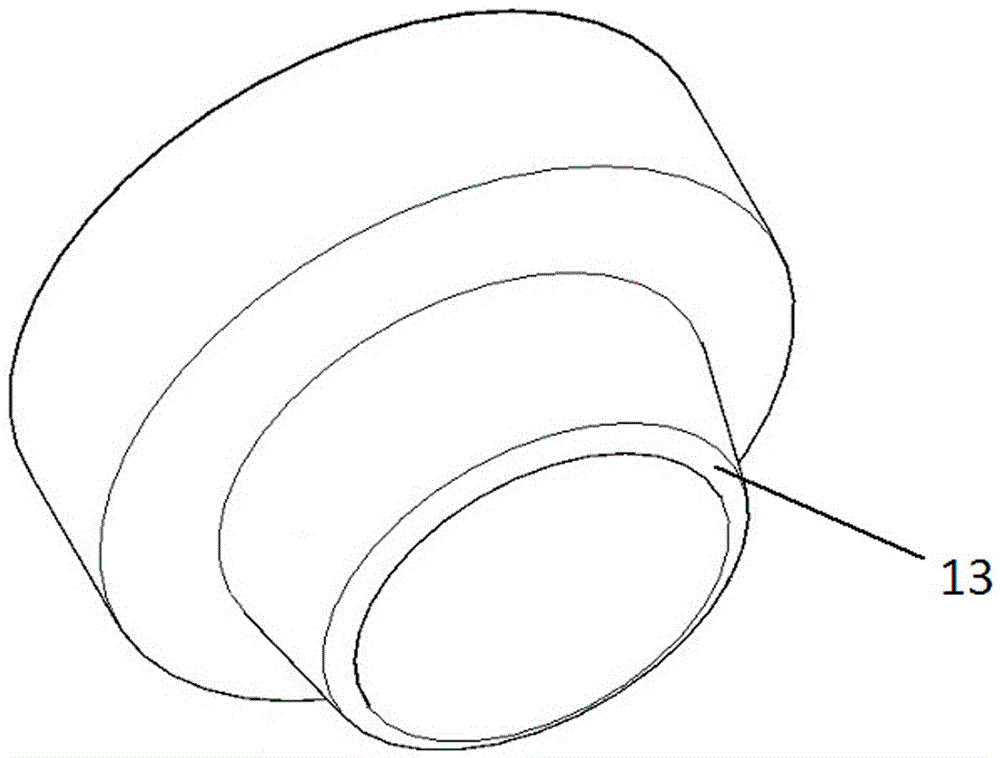

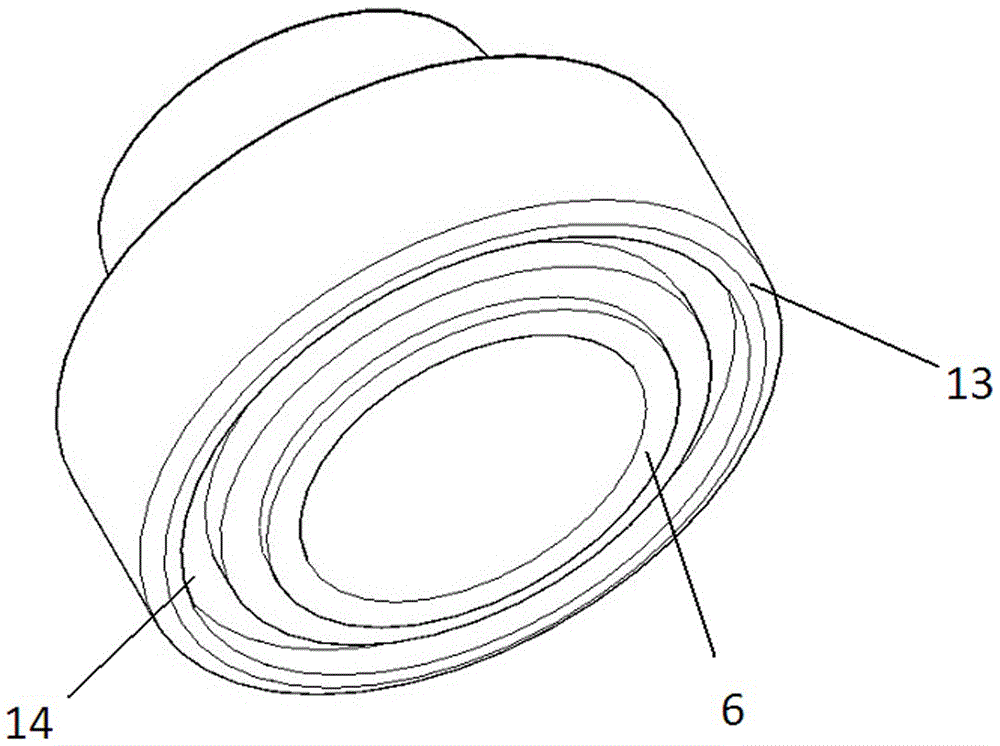

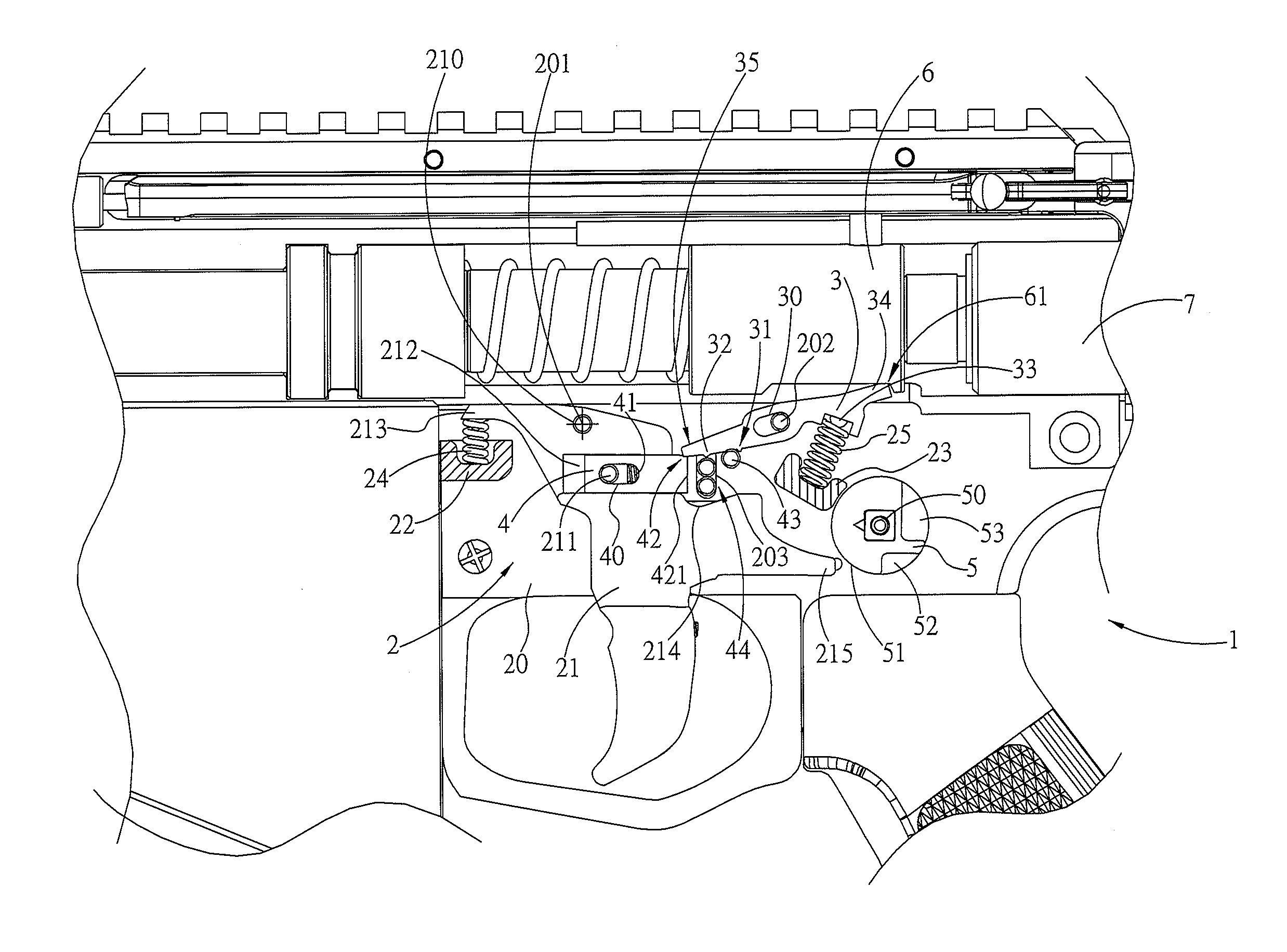

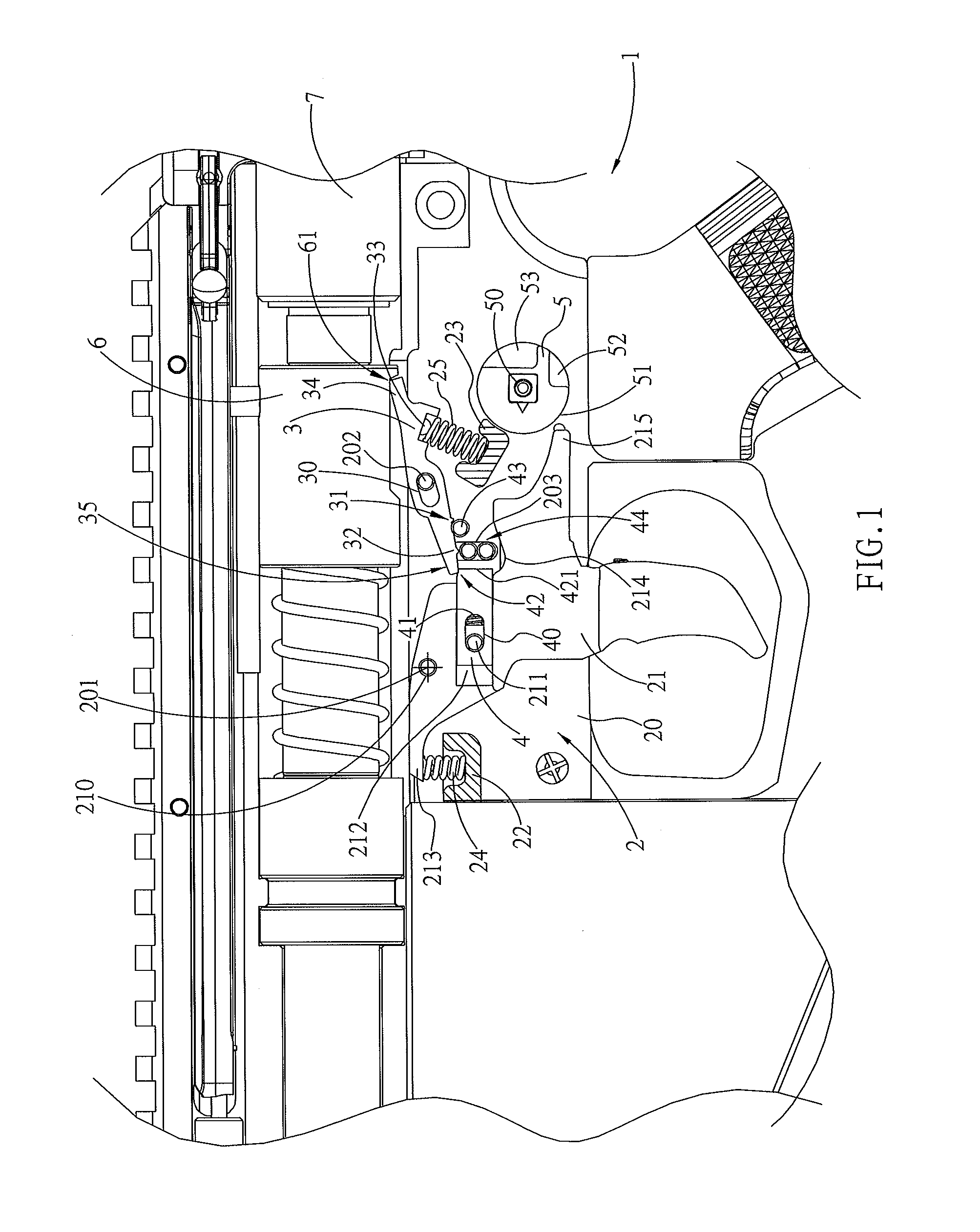

Firing control mechanism for toy gun

ActiveUS20100229843A1Reverse rotationFiring/trigger mechanismsCompressed gas gunsFire controlRotary switch

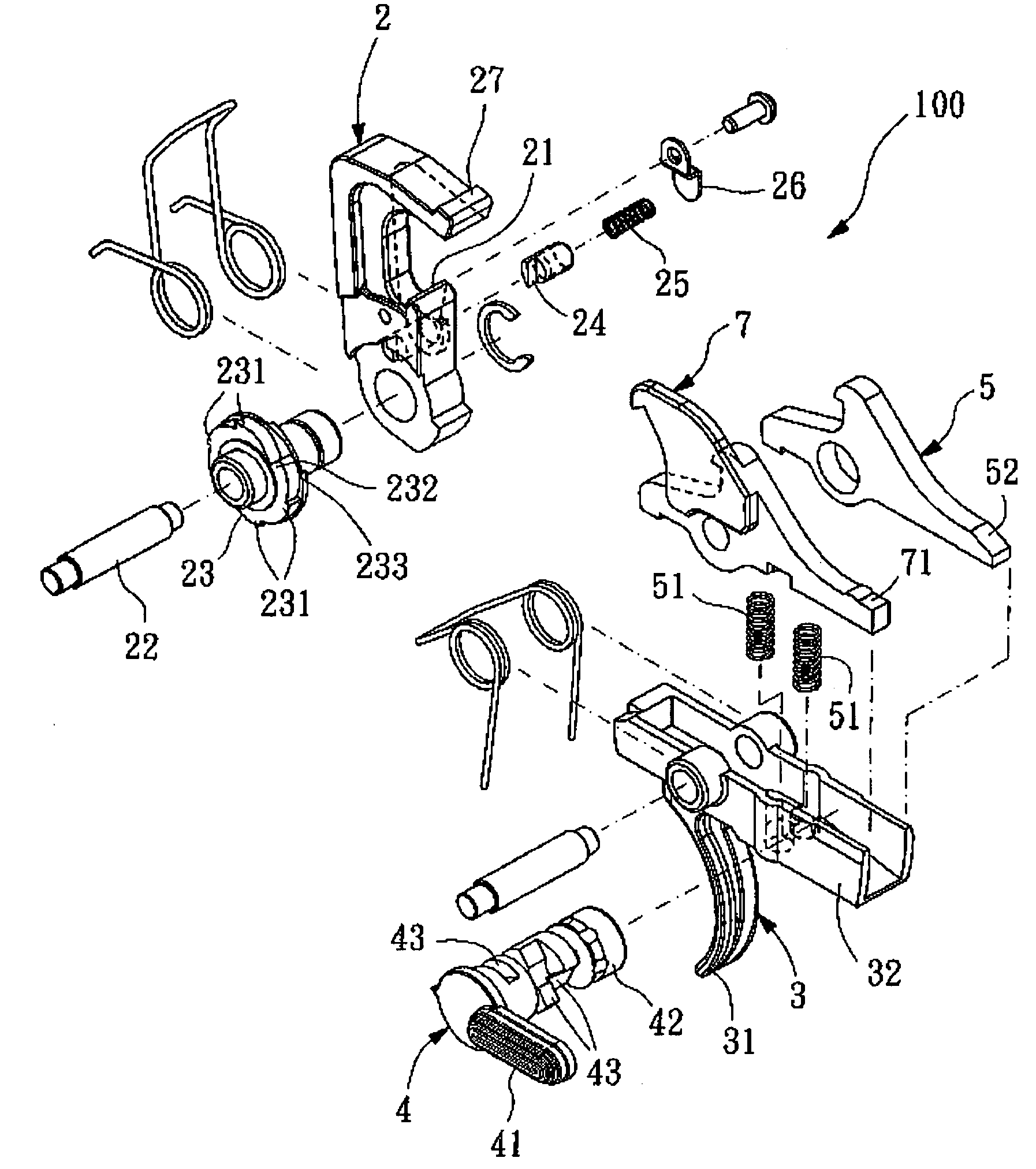

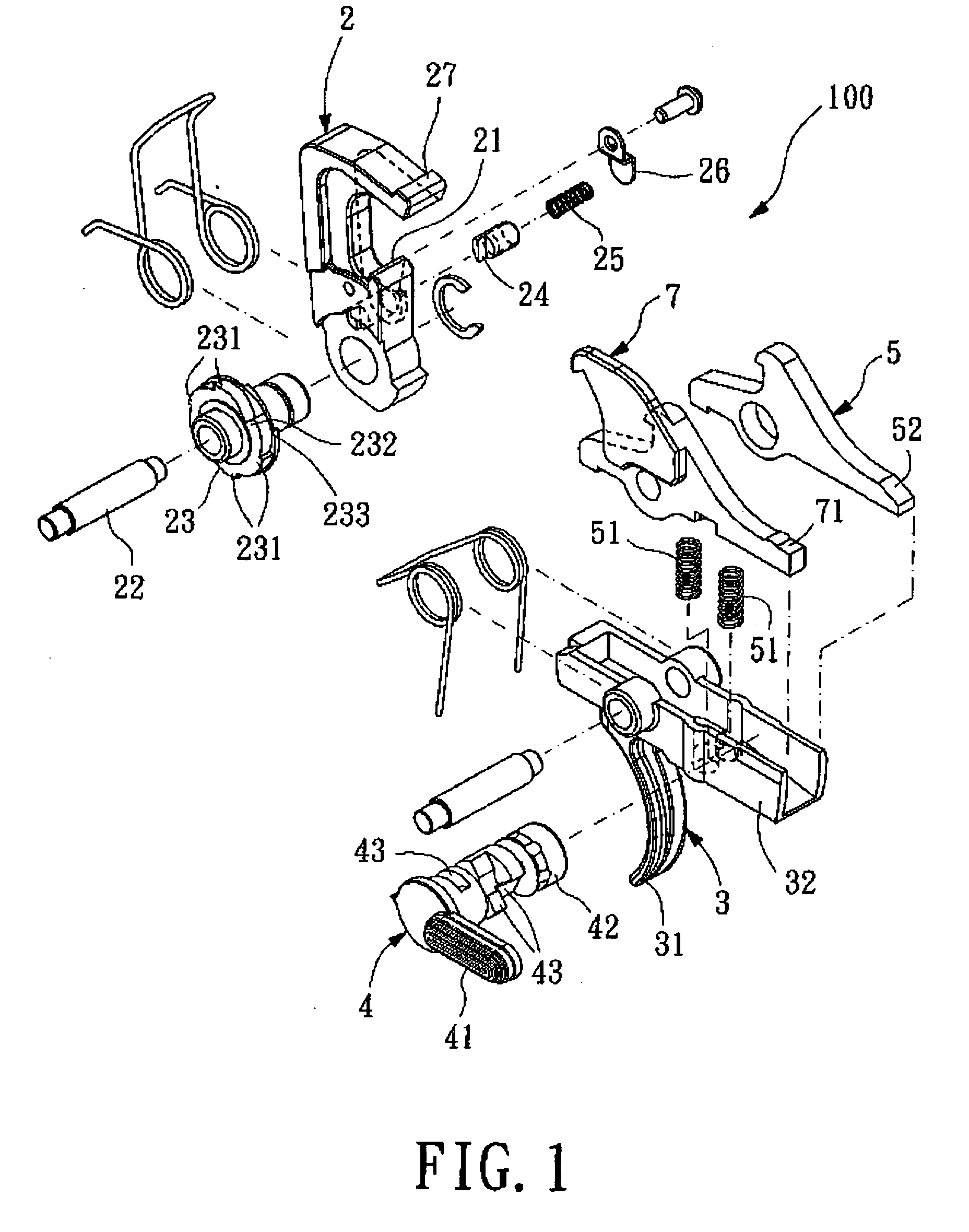

A firing control mechanism for an air-soft toy gun is disclosed for enabling a user to rotate a switch in selecting a single shot, 3-shot continuous firing, multi-shot continuous firing or safety lock mode, having a ratchet wheel pivotally mounted on an axle of the hammer thereof, which ratchet having two shadow teeth and one deep tooth arranged in a series around the periphery at one side and sloping teeth arranged around the periphery at an opposite side. The hammer has a stop rod meshed with one sloping tooth of the ratchet wheel. During a continuous 3-shot firing action, the ratchet wheel is rotated following down stroke of the hammer, and a pawl is meshed with one shadow tooth or the deep tooth, and the stop rod of the hammer is shifted into mesh with a next sloping tooth of the ratchet wheel to prohibit reverse rotation of the ratchet wheel when the hammer is returned after a firing action.

Owner:HU SHIH CHE

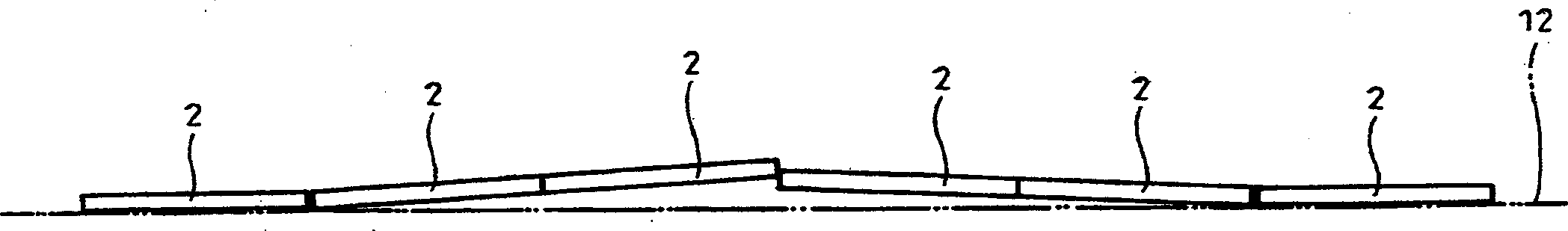

Continuous firing furnace and its use method

InactiveCN1346960AMake up for heat lossIncrease effective spaceFurnace safety devicesCharge manipulationEngineeringContinuous Firing

A continuous sintering furnace has an entrance-side deaerating chamber through which trays each with an material to be sintered being mounted thereon may pass, preheating, heating and cooling zones into which the trays are sequentially fed from the deaerating chamber, an exit-side deaerating chamber through which the trays having passed through the cooling zone may pass, a pusher for pushing the tray from the deaerating chamber to the preheating zone, a puller for pulling the tray from the cooling zone to the deaerating chamber, an intermediate puller for pulling the tray from the heating zone to the cooling zone, a vertically movable door between the deaerating chamber and the preheating zone, a vertically movable intermediate door adjacent to the door and arranged at an upstream end of the preheating zone in the direction of transportation of the trays, a vertically movable intermediate door between the heating and cooling zones and a vertically movable door between the cooling zone and the deaerating chamber. With the door being at a lowered position thereof for closing, heat input is suppressed to the cooling zone. Movement of the trays in the cooling zone is effected by the intermediate puller so as to decrease the number of trays needing to be pushed by the pusher.

Owner:IHI CORP

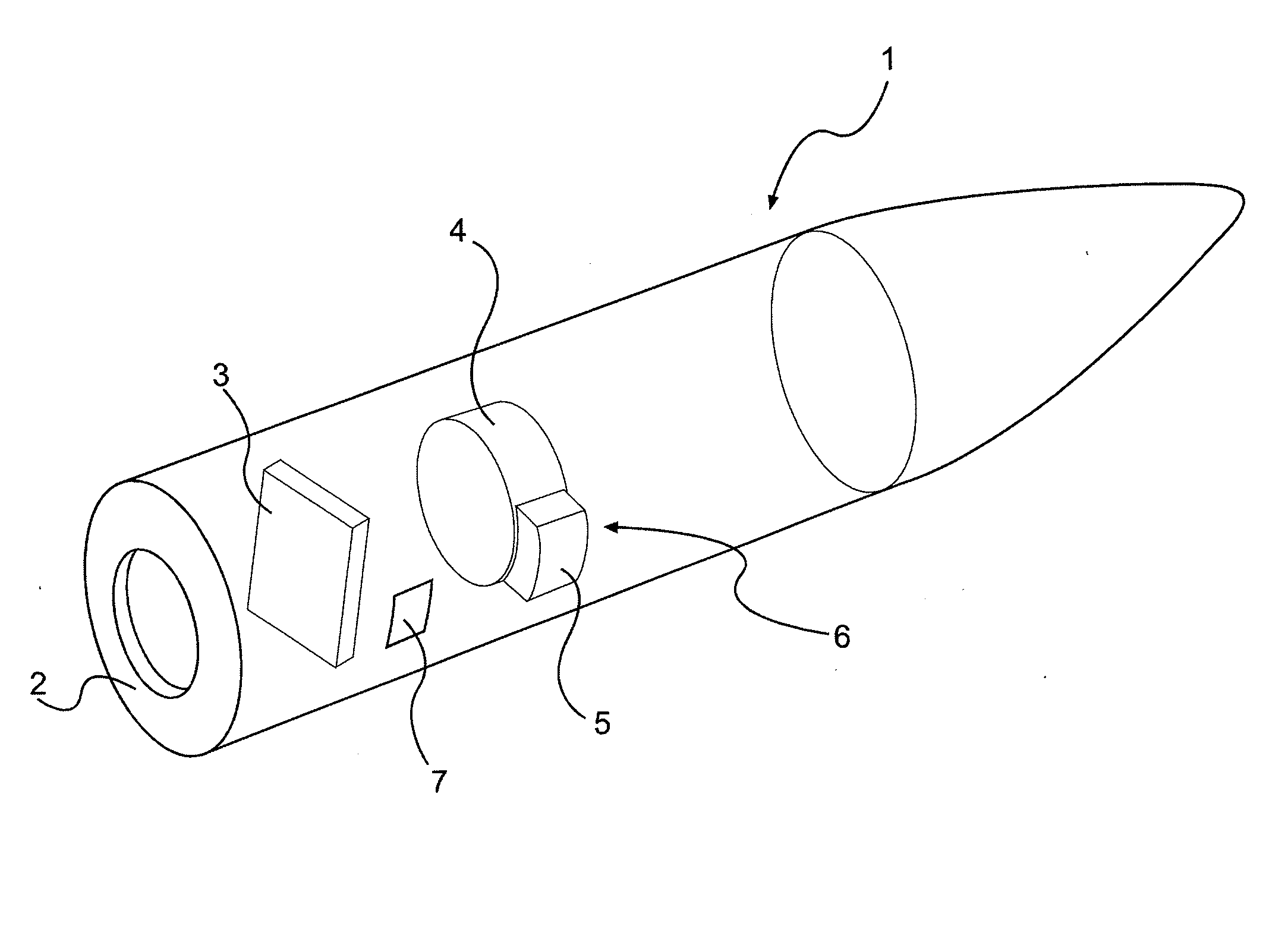

Method for correcting the trajectory of terminally guided ammunition

InactiveUS20100308152A1Easy to useBetter engagementDirection controllersVehicle position/course/altitude controlHigh probabilityEngineering

A method for correcting a trajectory of terminally guided ammunition is provided. In order to achieve a high probability of hits, in particular when firing in bursts (continuous fire, rapid single shot fire), it is provided that every individual ammunition is addressed separately. The “imprinting” is performed based on the beam rider guidance principle of terminally guided ammunition. Every individual ammunition reads only the guidance beam identified for this ammunition and can, using additional information, determine its absolute roll attitude in space in order to achieve the proper triggering of the correcting propulsion unit.

Owner:OERLIKON CONTRAVES BESCHRAENKTER HAFTUNG

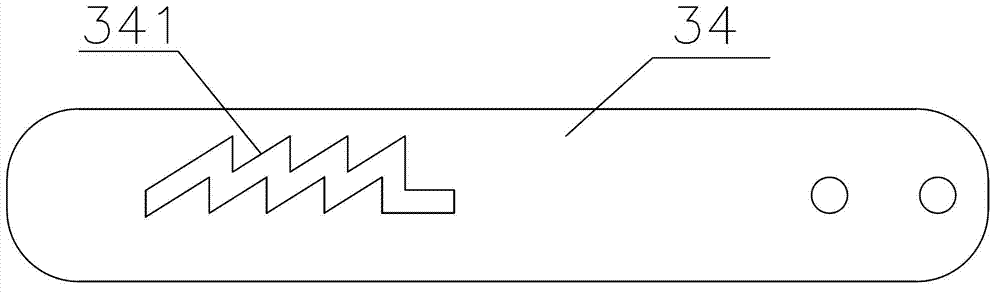

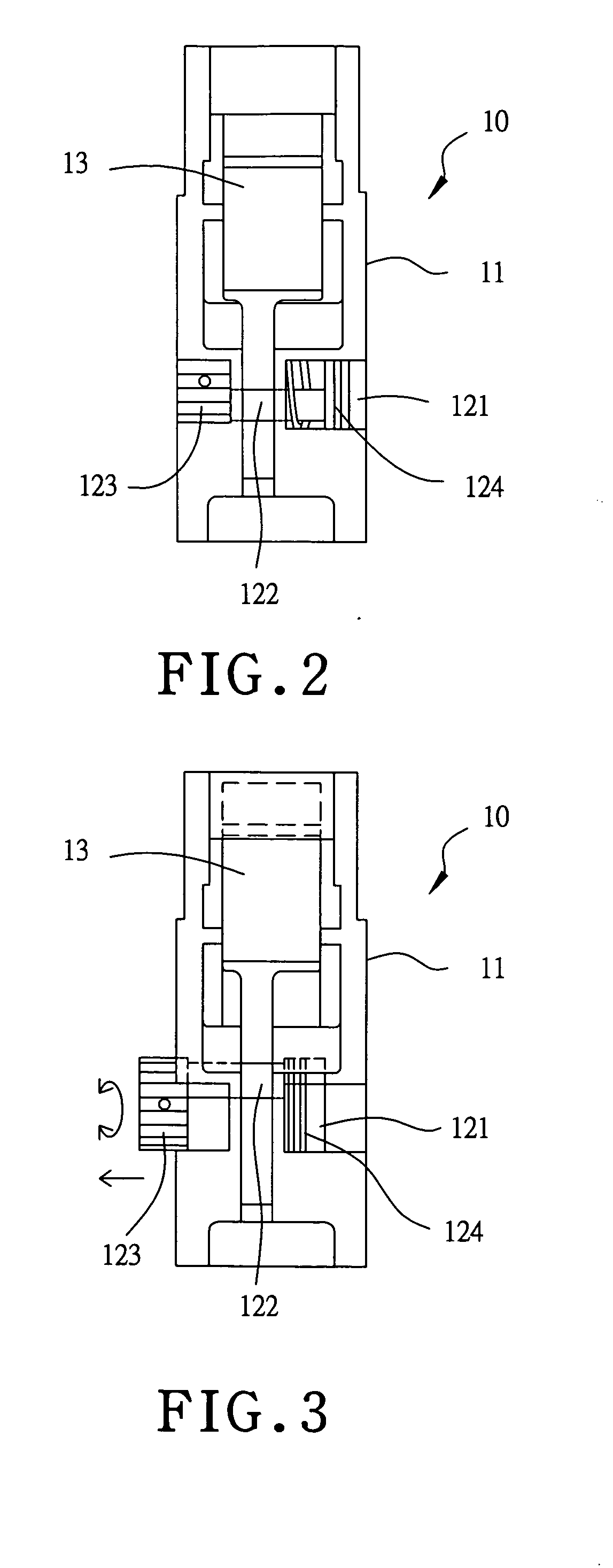

Continuous firing type trigger structure for toy gun

A continuous firing type trigger structure of a toy gun (air soft gun / BB-gun) includes a valve body disposed behind the output port of a magazine clip in air communication with the gas outlet of a high-pressure gas can, an enclosed socket connected to the rear side of the valve body, a valve tube inserted through the valve body, a spring that pushes the valve tube forwards to keep the air inlet of the valve tube not in communication with the inside space of the valve body, and a piston inserted into the enclosed socket and fixedly connected to a sliding shell on the outside of the toy gun such that the valve tube is moved with the piston forwards (or backwards) to let a high pressure gas be discharged out of the high-pressure gas can into the valve tube to drive an airsoft gun out of the toy gun and to force the piston and the sliding shell backwards after triggering of the trigger of the toy gun, for enabling the piston and the sliding shell to be immediately returned by a return spring for a next firing operation. A hammer is pivoted to the toy gun and releasably secured in place by a spring-supported sear for firing one single airsoft bullet per each hammering action.

Owner:WEI WILSON

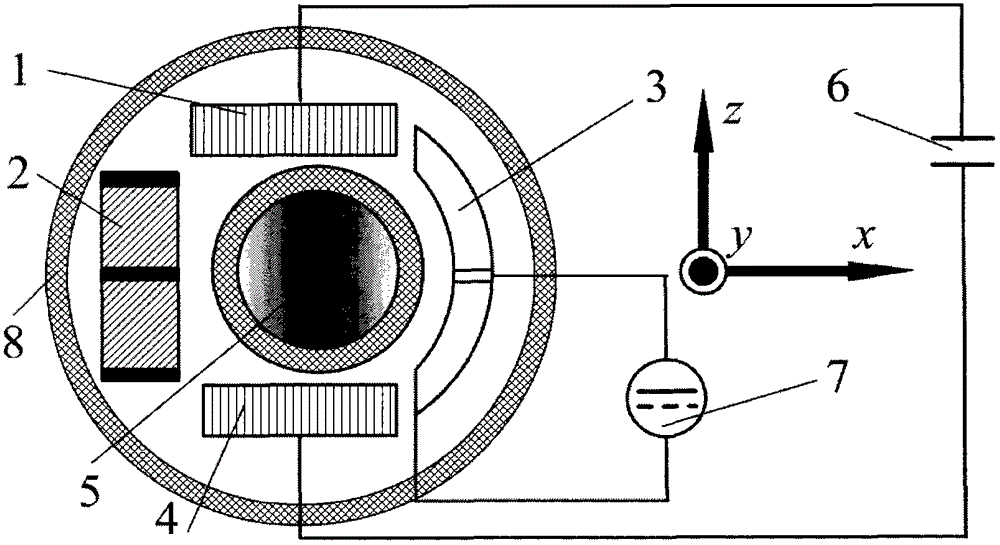

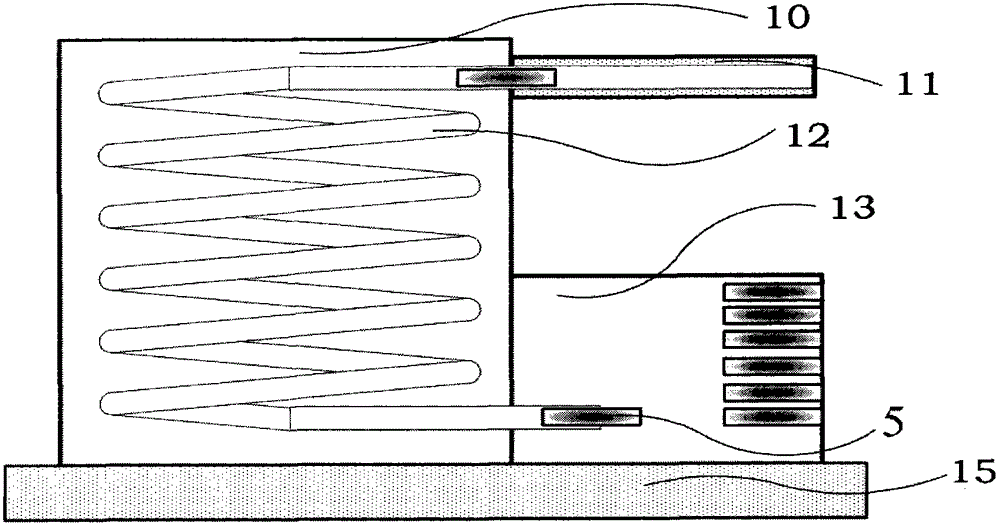

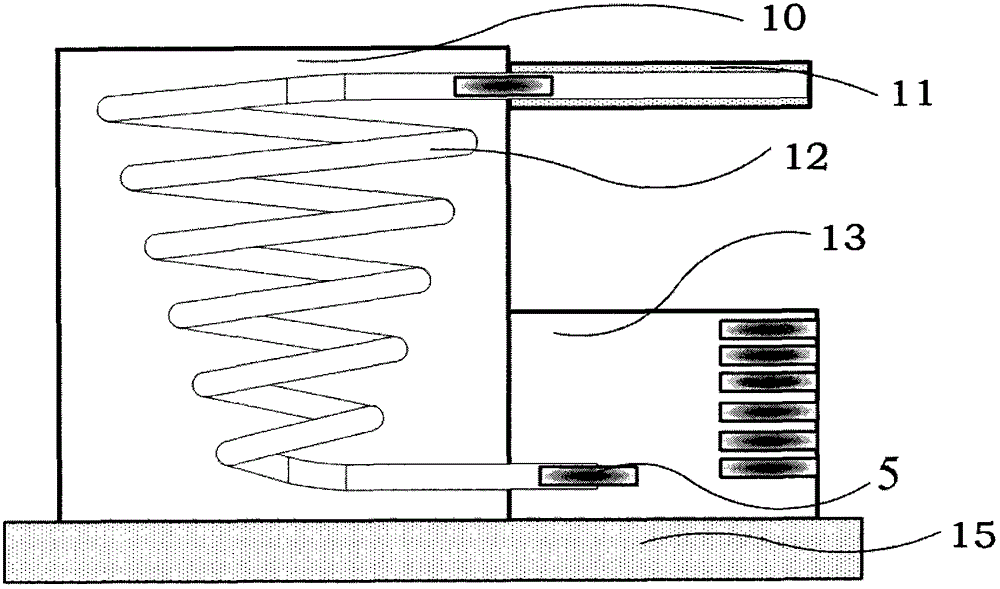

Spiral acceleration-type electromagnetic gun system and obtaining method thereof

ActiveCN104019697AExtended acceleration distanceLess stringent requirementsElectromagnetic launchersEngineeringGun barrel

The invention discloses a spiral acceleration-type electromagnetic gun system and an obtaining method of the spiral acceleration-type electromagnetic gun system. The spiral acceleration-type electromagnetic gun system comprises a spiral-type superconductive electromagnetic boosting subsystem, a high-temperature superconductive magnetic suspension subsystem and a superconductive magnetic confinement subsystem. An electromagnetic gun boosting process is carried out in a spiral acceleration mode through the spiral-type superconductive electromagnetic boosting subsystem and the requirement for impulse power of a boosting system is lowered; a superconductive magnetic suspension technology is adopted in the high-temperature superconductive magnetic suspension subsystem for eliminating mechanical friction, so that ablation of a projectile body and a gun barrel is avoided; high centrifugal force generated because the spiral radius is small in the acceleration process of the projectile body is overcome by the superconductive magnetic confinement subsystem according to a superconductive magnetic confinement technology; heat-dissipation-free design of the gun barrel is achieved by the electromagnetic gun system according to the electrical-resistance-free characteristic of a superconductive material, and therefore the high-firing-speed continuous firing capacity is achieved. According to the spiral acceleration-type electromagnetic gun system, the spiral gun barrel and the spiral acceleration mode of the projectile body are adopted, so that high outlet speed is easy to achieve; no mechanical friction and ablation influence on the gun barrel exists in the whole firing process and the gun barrel can be used for a long time; active control over a boosting coil is not needed and the problem that a traditional halved joint electromagnetic gun is difficult to control is solved; forced cooling and heat-dissipating waiting do not needed to be conducted on the gun barrel in the process of continuous firing and the continuous firing capacity of the spiral acceleration-type electromagnetic gun system is far higher than that of the traditional electromagnetic gun.

Owner:BEIJING AEROSPACE CENTURY SUPERCONDUCTING TECH

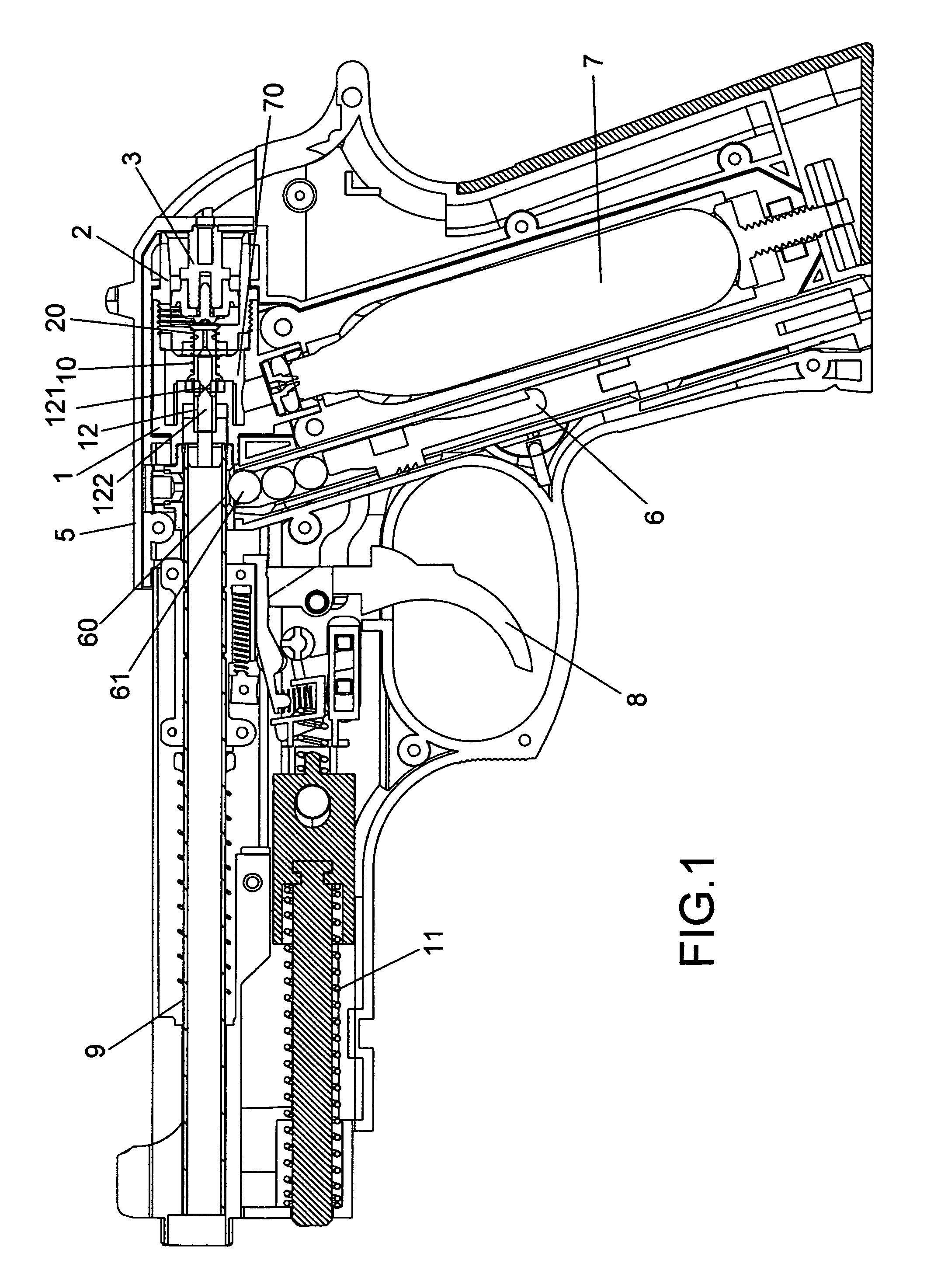

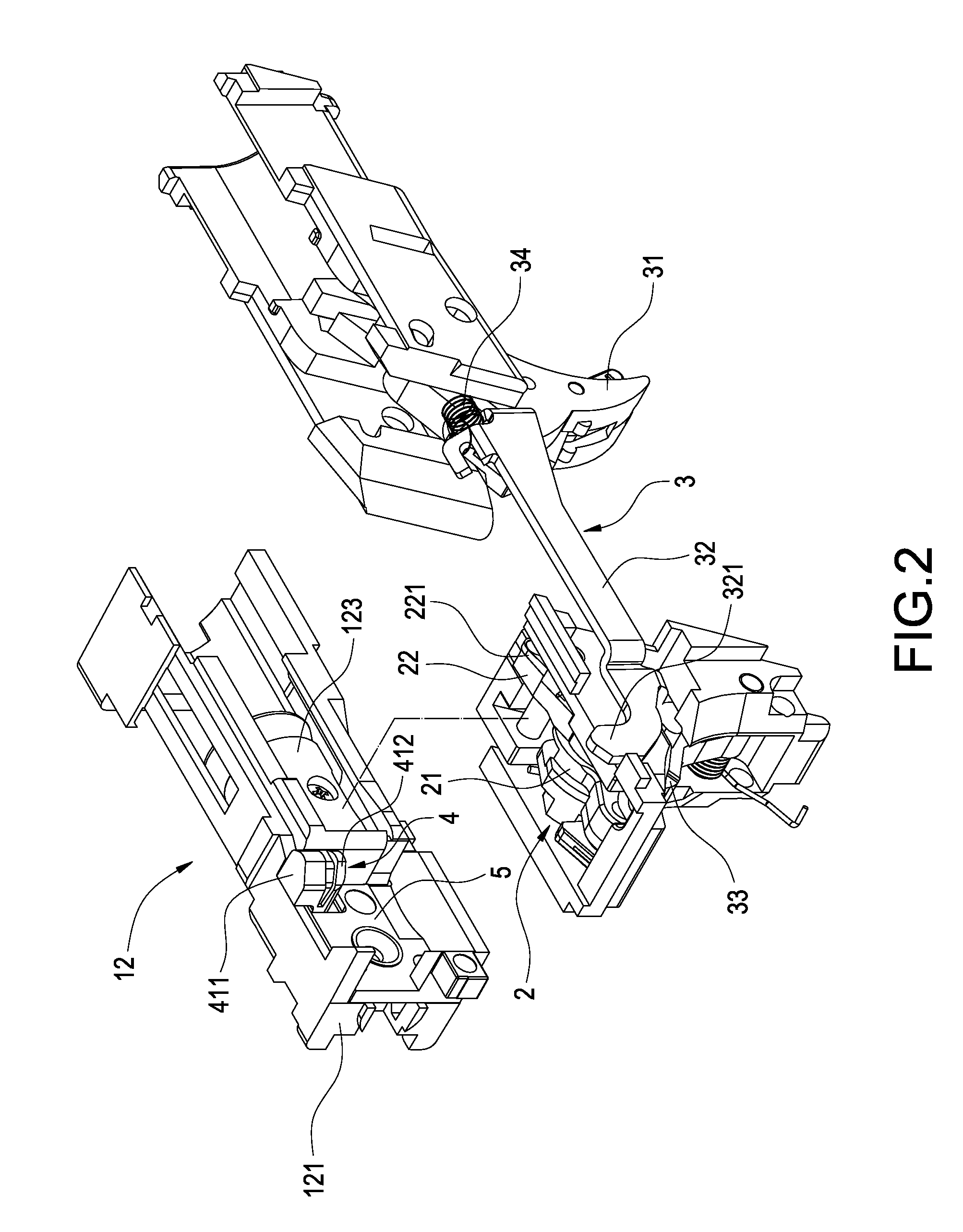

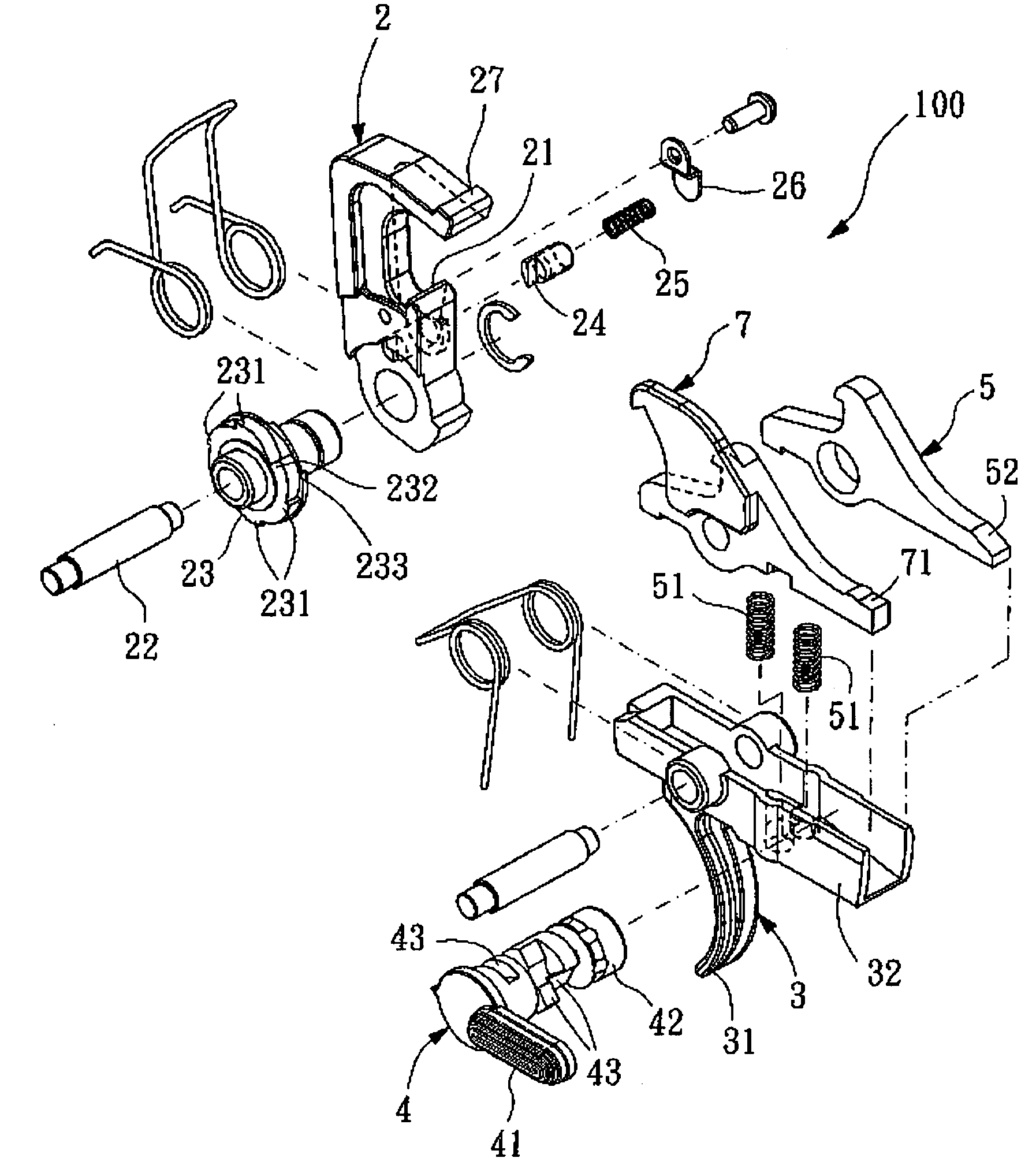

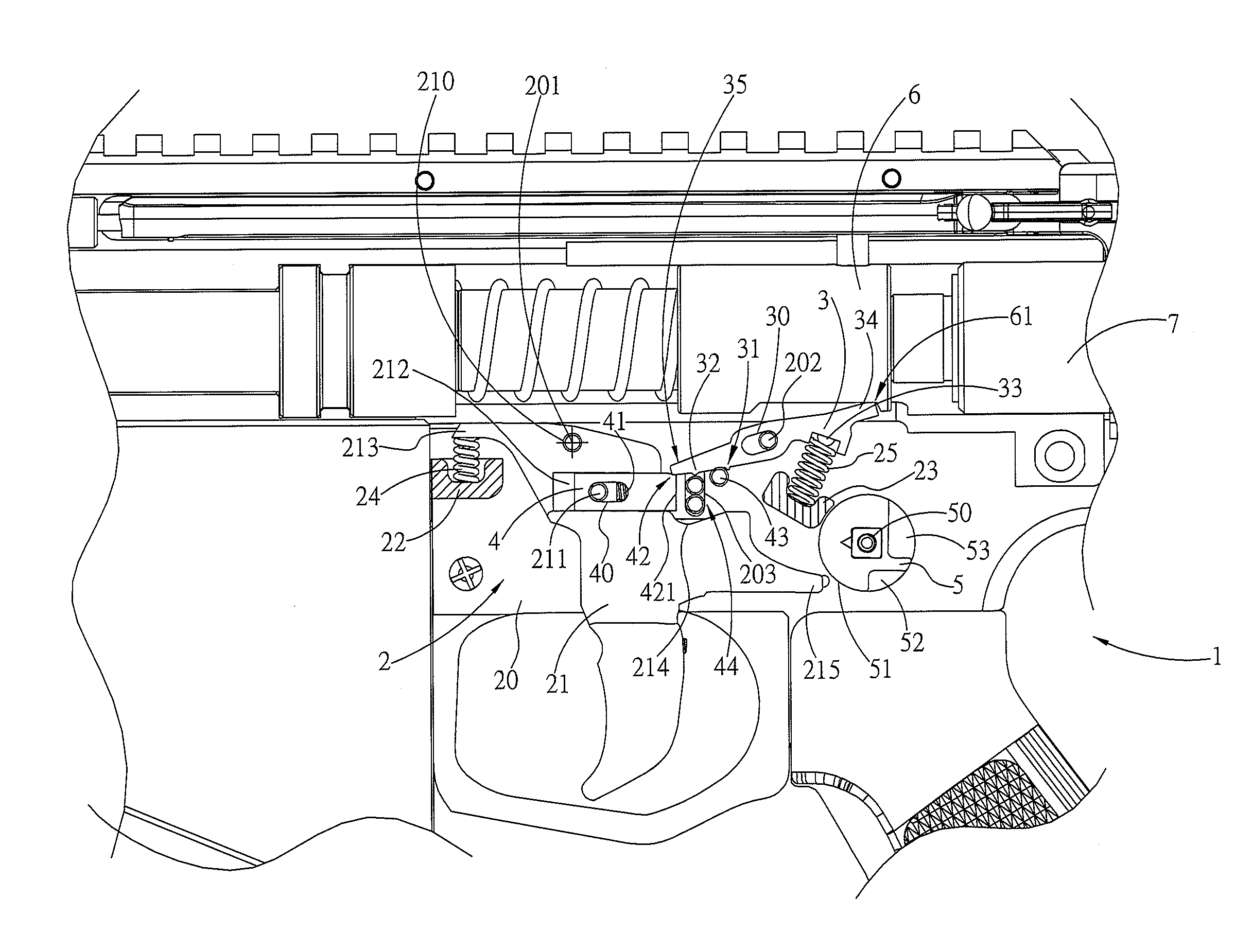

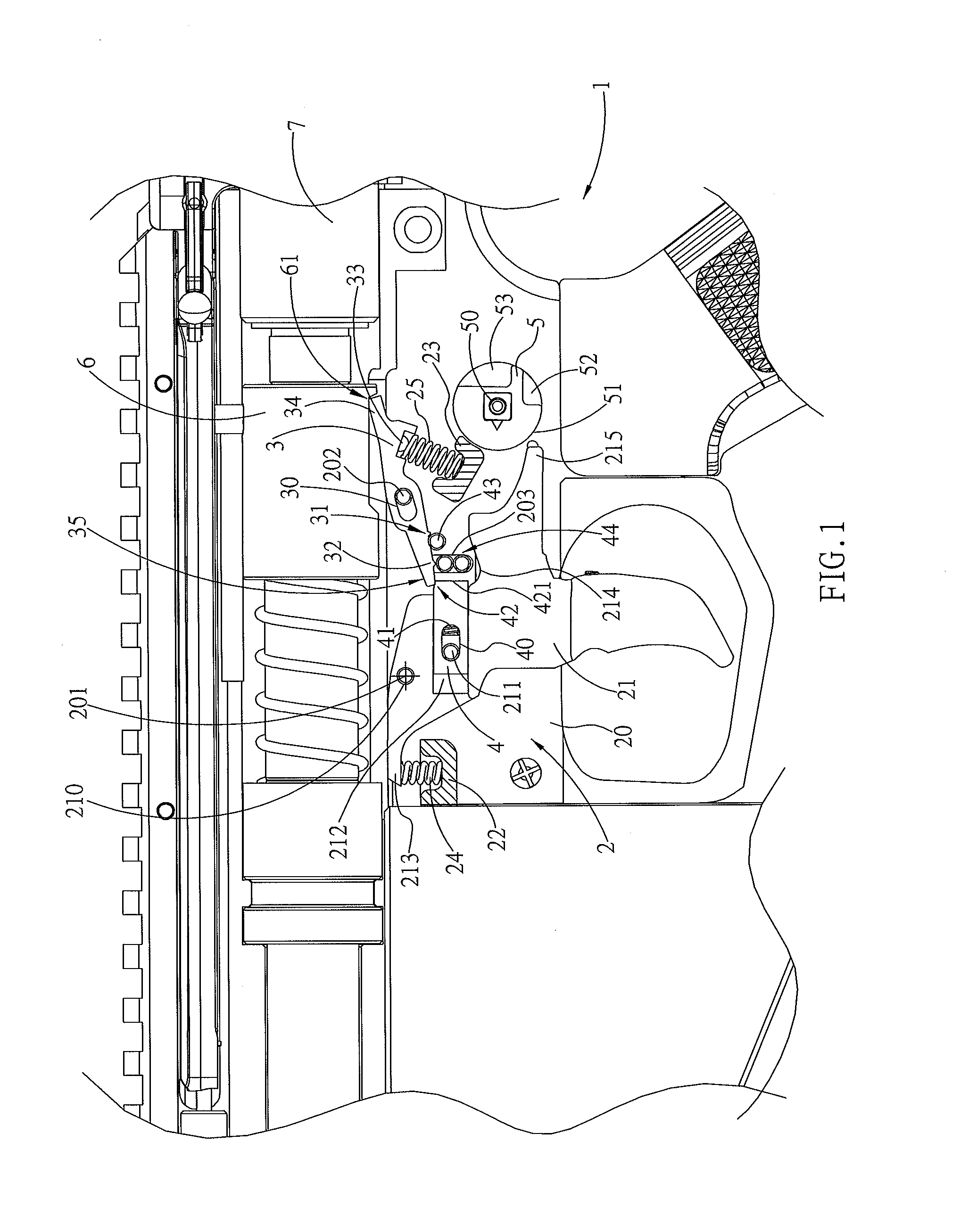

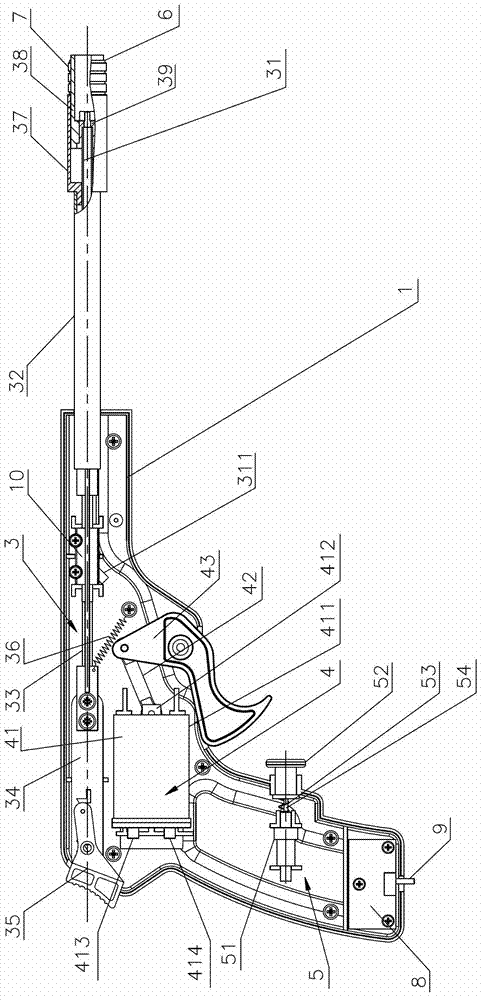

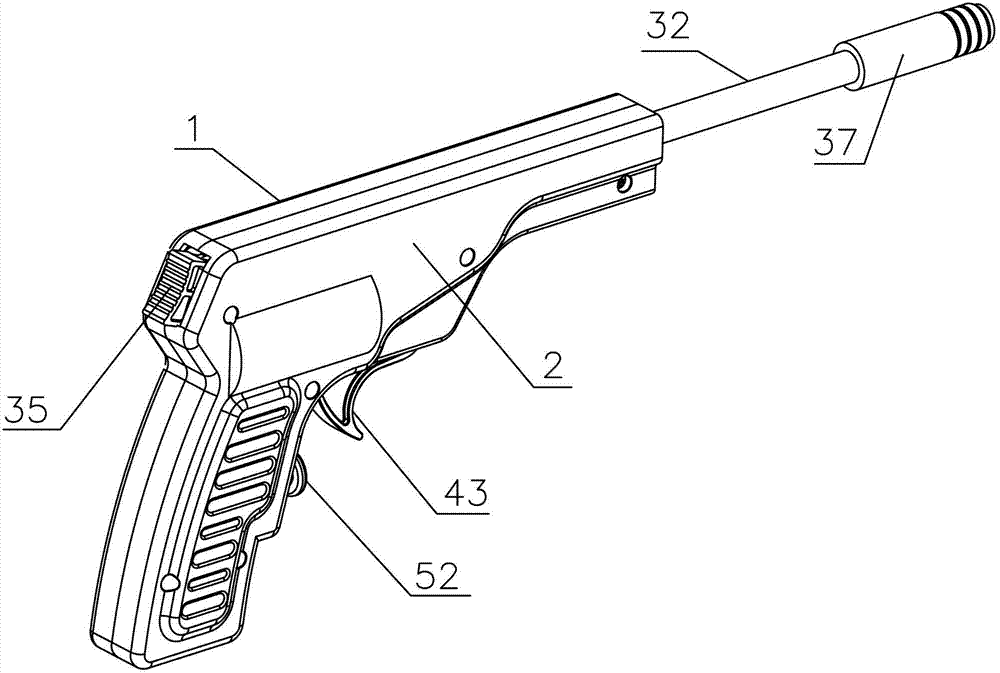

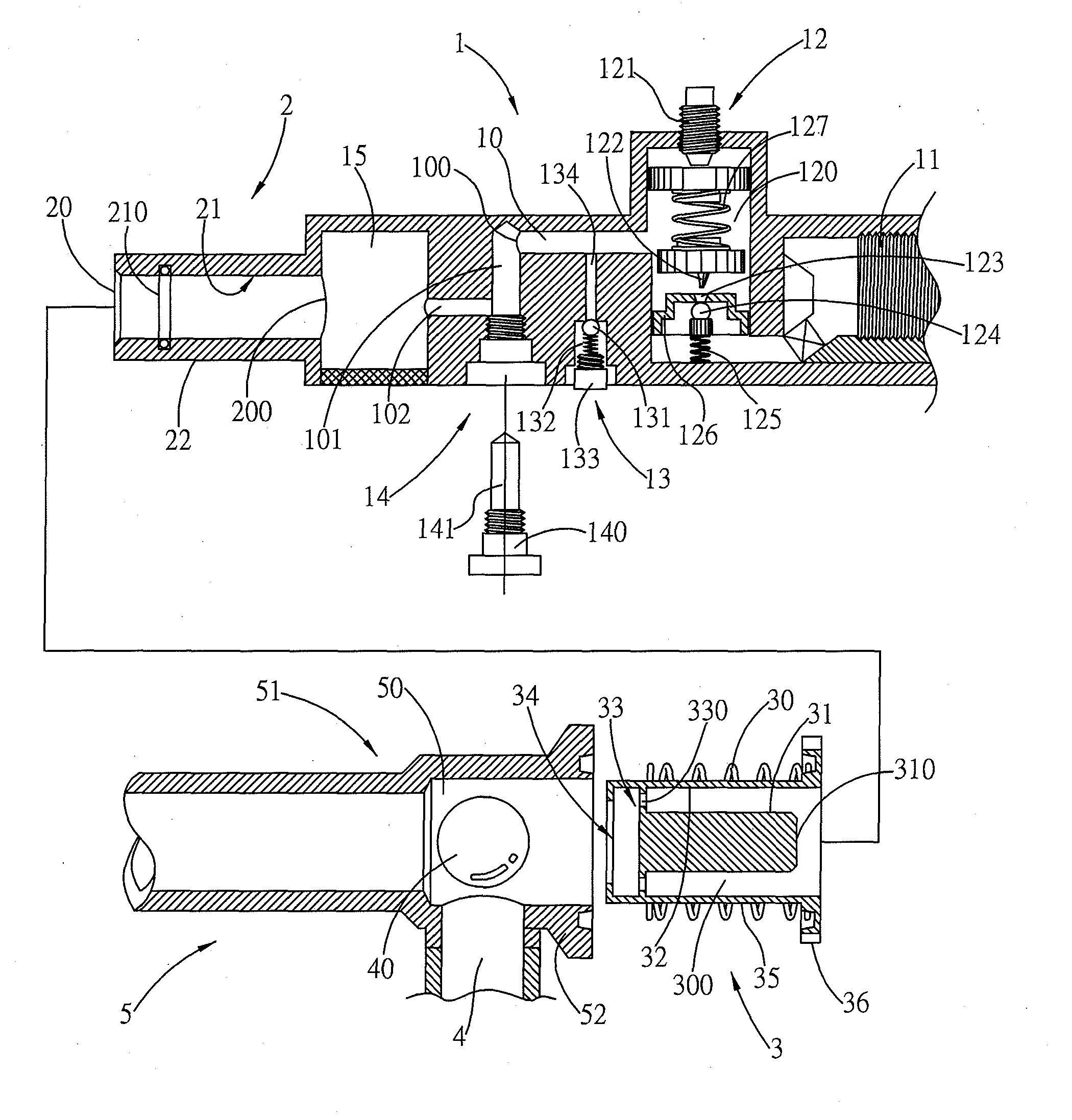

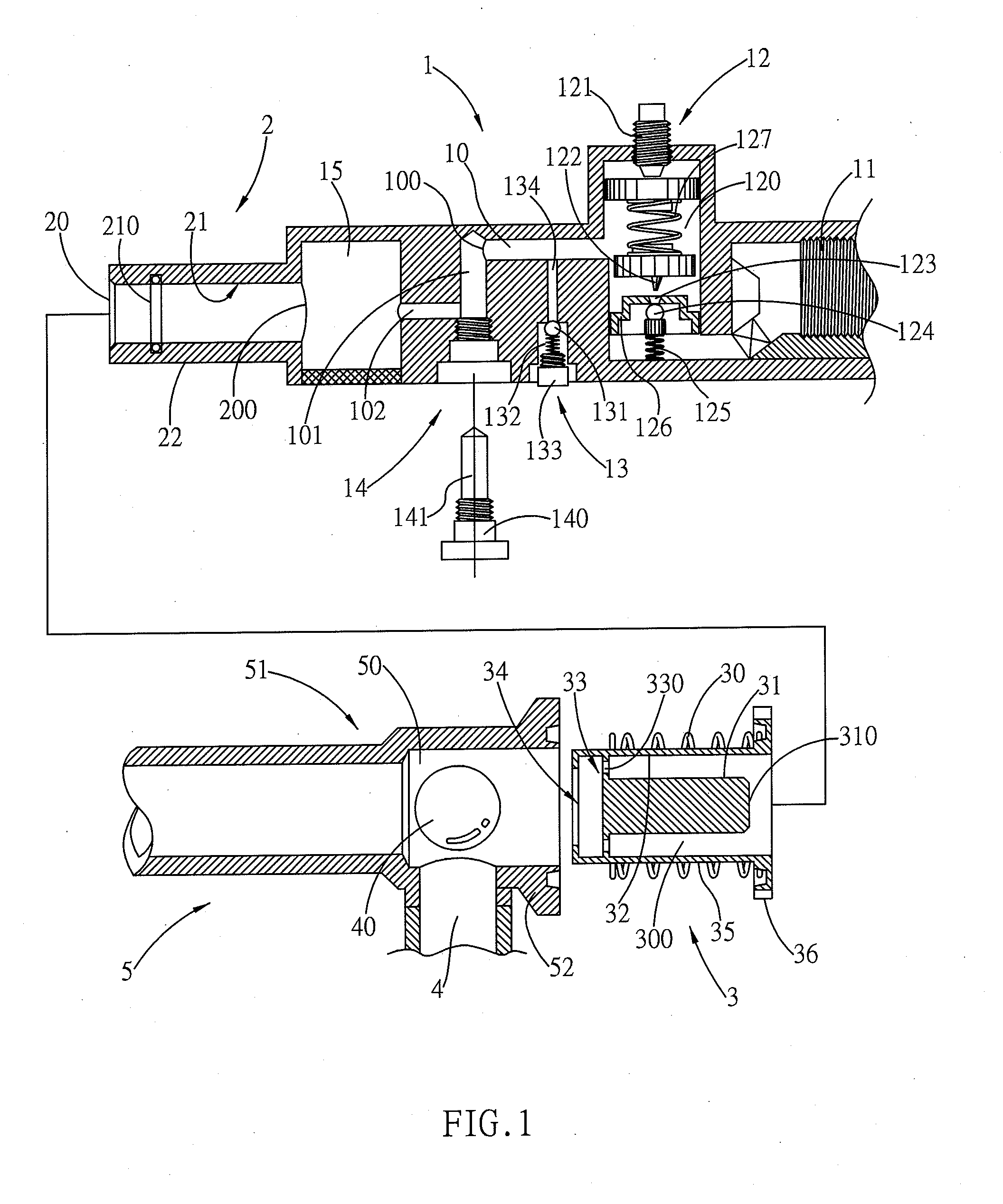

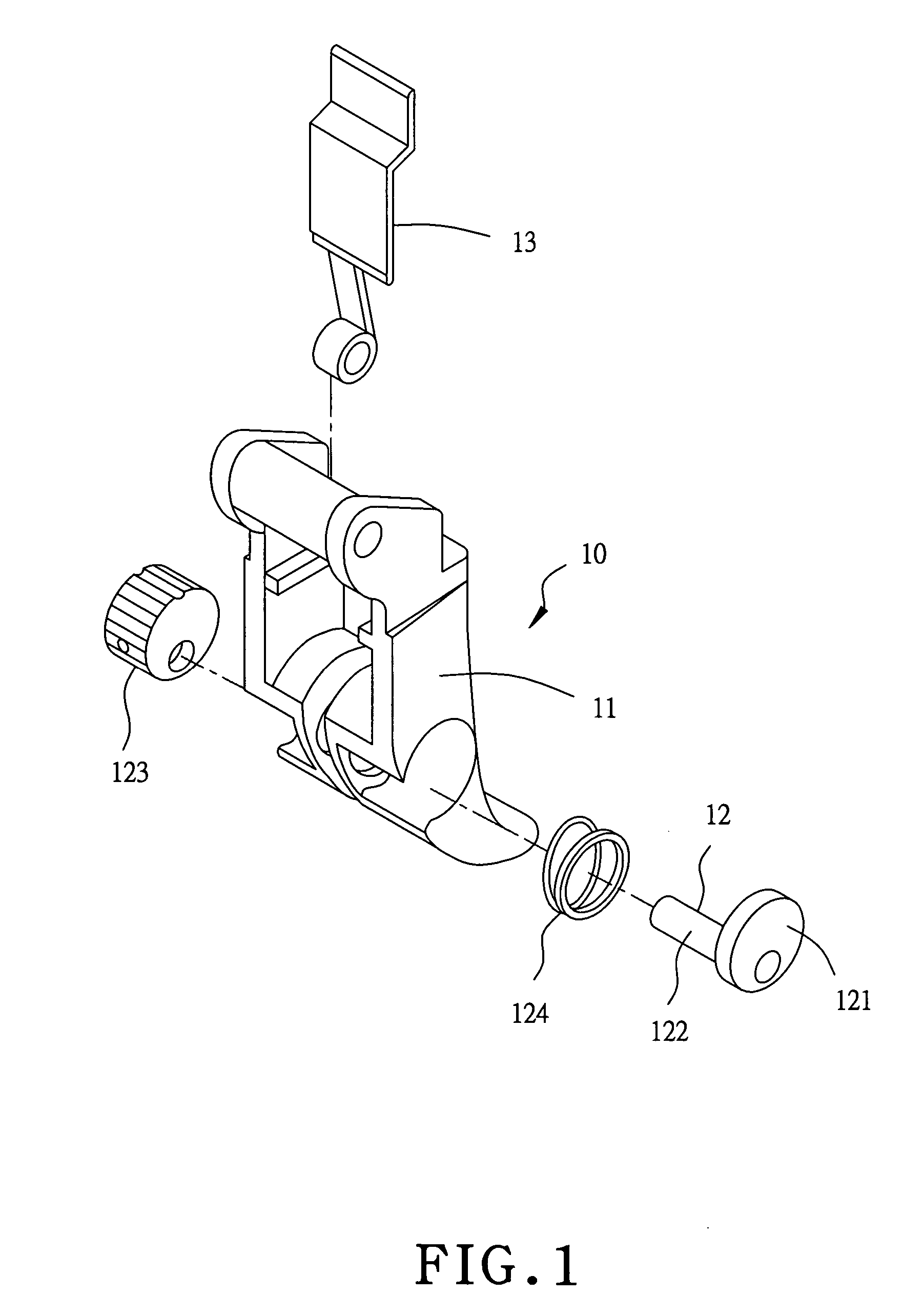

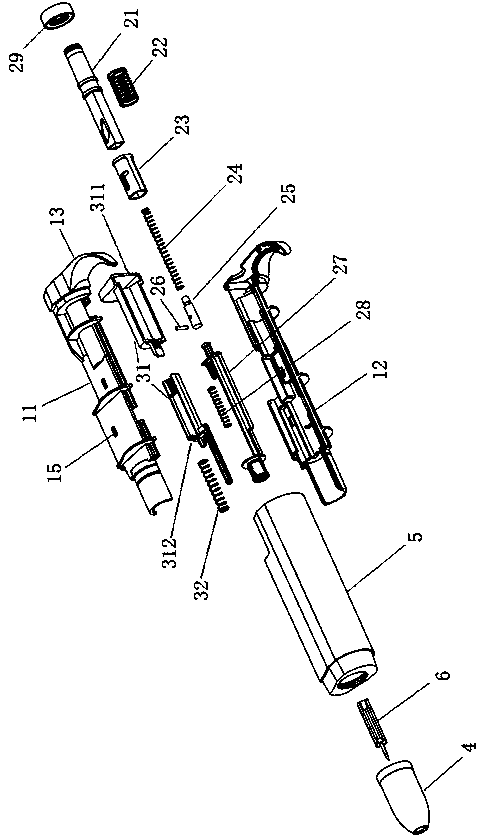

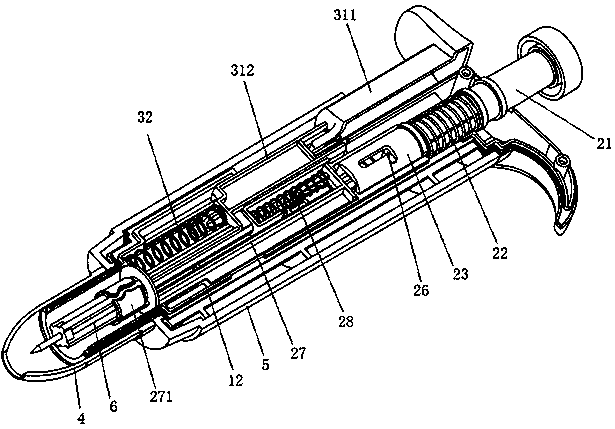

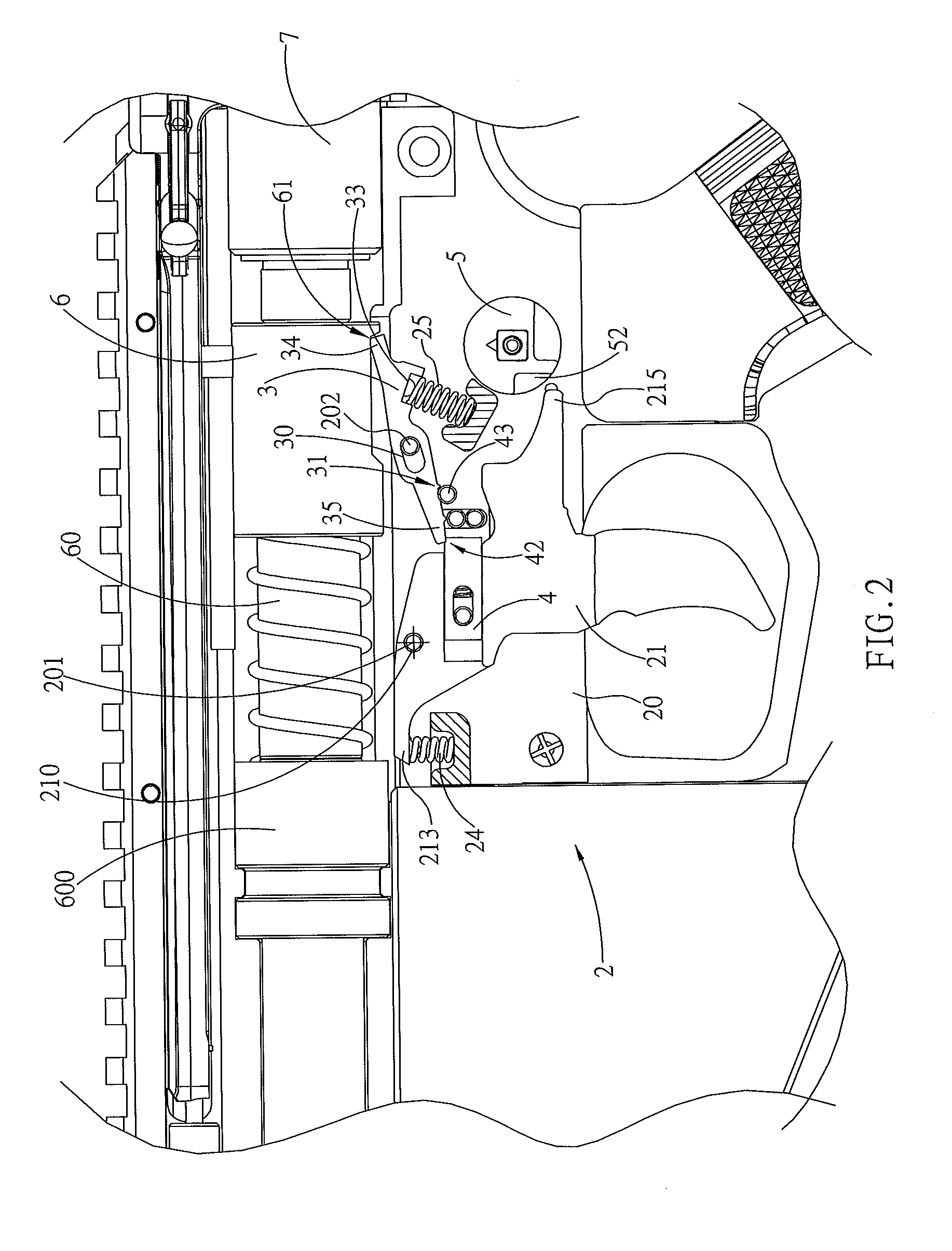

Single/continuous firing air soft gun and firing switch thereof

ActiveUS20140000578A1Low production costEasy to assembleFiring/trigger mechanismsCompressed gas gunsGun barrelPiston

In a single / continuous firing air soft gun and a firing switch thereof, the air soft gun includes a gun body and a barrel fixed in the gun body, and the firing switch includes a piston seat and a firing switch device, wherein the piston seat is disposed in the gun body and capable of reciprocally moving in horizontal with respect to the barrel; and the firing switch device is installed on the piston seat, and includes a stop piece and a toggle piece connected with the stop piece, and the stop piece is disposed corresponding to the trigger assembly.

Owner:VEGA FORCE INT CORP

Firing process of Nixing pottery products

The invention discloses a firing process of Nixing pottery products. The process comprises the steps that: (1) blank moisture eliminating is carried out, wherein blanks processed through a drying treatment are placed in a kiln, a temperature is gradually increased to 40-60 DEG C with a heating speed of 20-30 DEG C per hour, and continuous firing is carried out for 10-12h under the temperature; (2) after the moisture eliminating treatment, the temperature is increased to 1050-1100 DEG C with a heating speed of 50-100 DEG C per hour; and (3) heating is stopped, and the blanks are fetched from the kiln after cooling, such that blank firing is finished. According to the invention, moisture eliminating is carried out upon the blanks first, water content in the blanks are slowly discharged by firing under a low-temperature environment. Blank moisture eliminating is uniform, and blank cracking due to breakage caused by large amounts of bubbles produced in the blanks is avoided. With the process, a firing success rate is higher than 95%. Also, during the subsequent high-temperature firing process, blank shrinkage is reduced, and blank cracking rate is reduced, such that firing success rate is further improved.

Owner:钦州市奇圣古坭斋坭兴陶有限公司

Firing control mechanism for toy gun

ActiveUS7878106B2Reverse rotationFiring/trigger mechanismsCompressed gas gunsFire controlEngineering

A firing control mechanism for an air-soft toy gun is disclosed for enabling a user to rotate a switch in selecting a single shot, 3-shot continuous firing, multi-shot continuous firing or safety lock mode, having a ratchet wheel pivotally mounted on an axle of the hammer thereof, which ratchet having two shadow teeth and one deep tooth arranged in a series around the periphery at one side and sloping teeth arranged around the periphery at an opposite side. The hammer has a stop rod meshed with one sloping tooth of the ratchet wheel. During a continuous 3-shot firing action, the ratchet wheel is rotated following down stroke of the hammer, and a pawl is meshed with one shadow tooth or the deep tooth, and the stop rod of the hammer is shifted into mesh with a next sloping tooth of the ratchet wheel to prohibit reverse rotation of the ratchet wheel when the hammer is returned after a firing action.

Owner:HU SHIH CHE

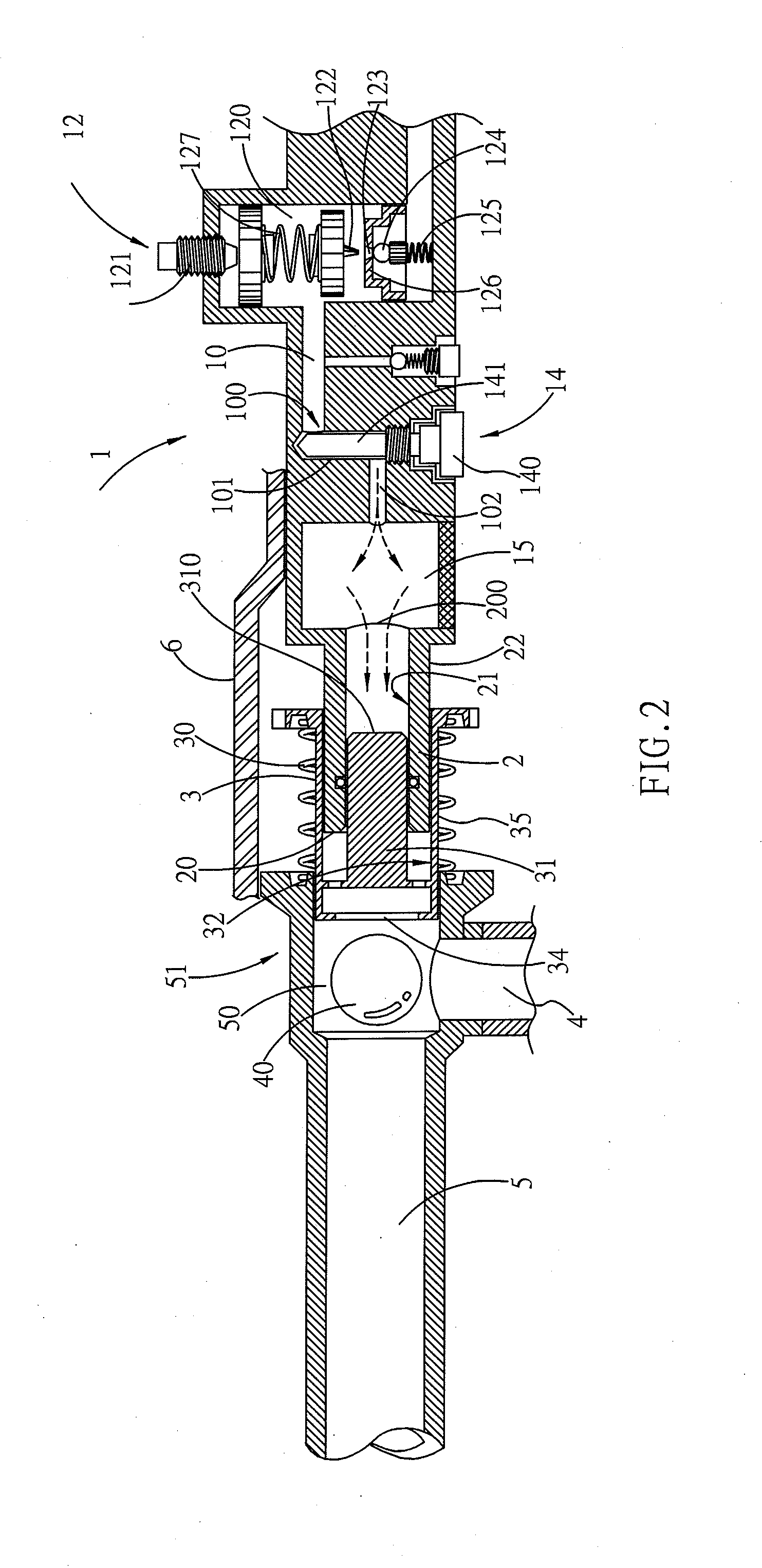

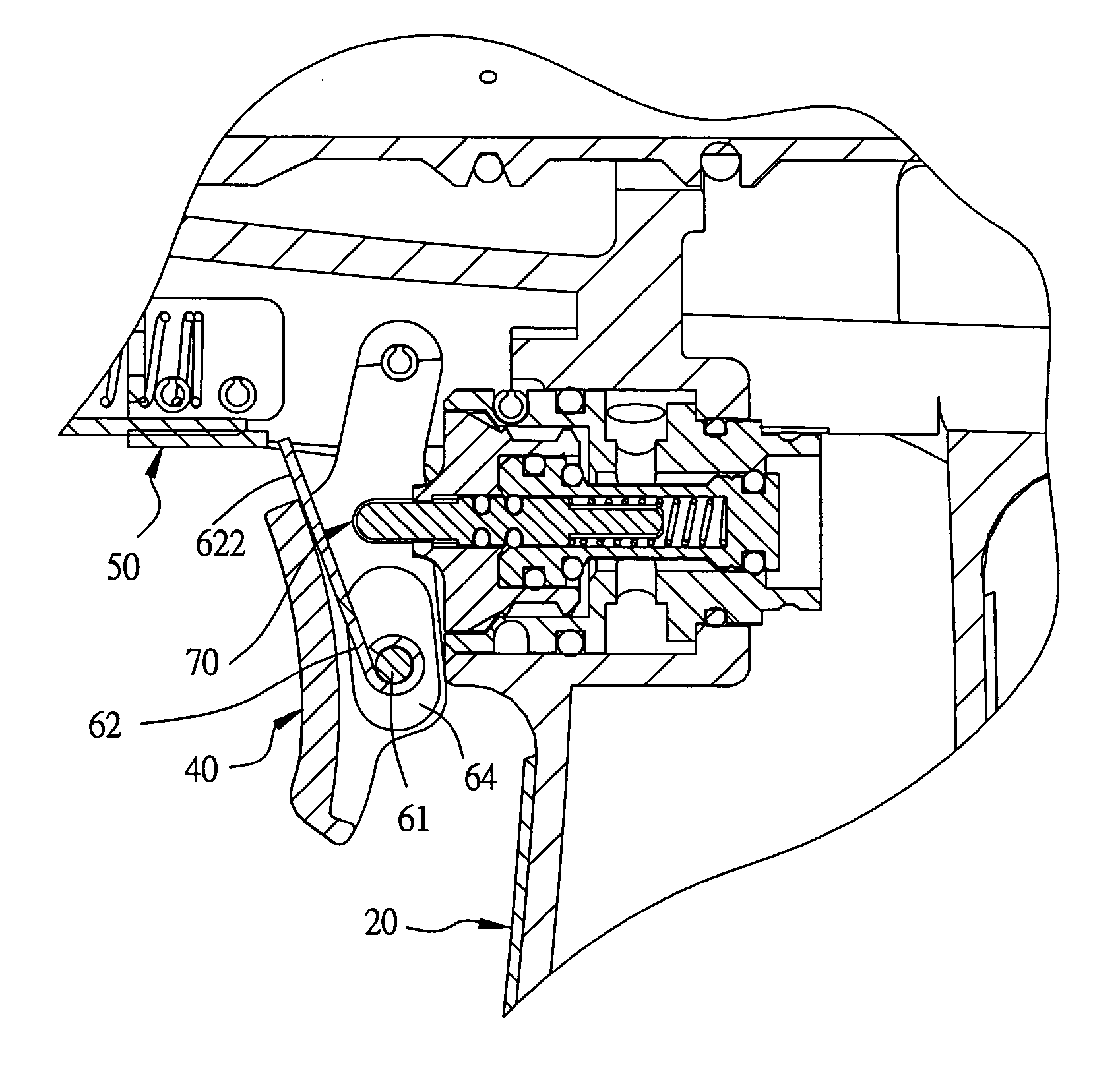

Air gun firing control device

ActiveUS20150308784A1Improve fitEasy to assembleFiring/trigger mechanismsCompressed gas gunsFire controlBottle

The present invention uses pressurized air from an air pressure bottle to create the firing motive force for game firearms. After accumulating sufficient pressure, the pressurized air is channeled to the gun chamber to achieve a firing objective.Using an application system for single firing, the present invention primarily includes a purely mechanical firing control device that is formed as an integral body to achieve single firing and continuous firing, and which is simply fitted with an auxiliary component to assist in achieving continuous firing. The auxiliary component is located in the swinging path of a cocking a trigger. The select continuous firing clasp is pushed upward by the trigger and supports a jumping bar, which causes the jumping bar to lose its clasping retaining capacity on a firing tube to achieve a continuous firing operation.

Owner:CHO CHAO HSIUNG

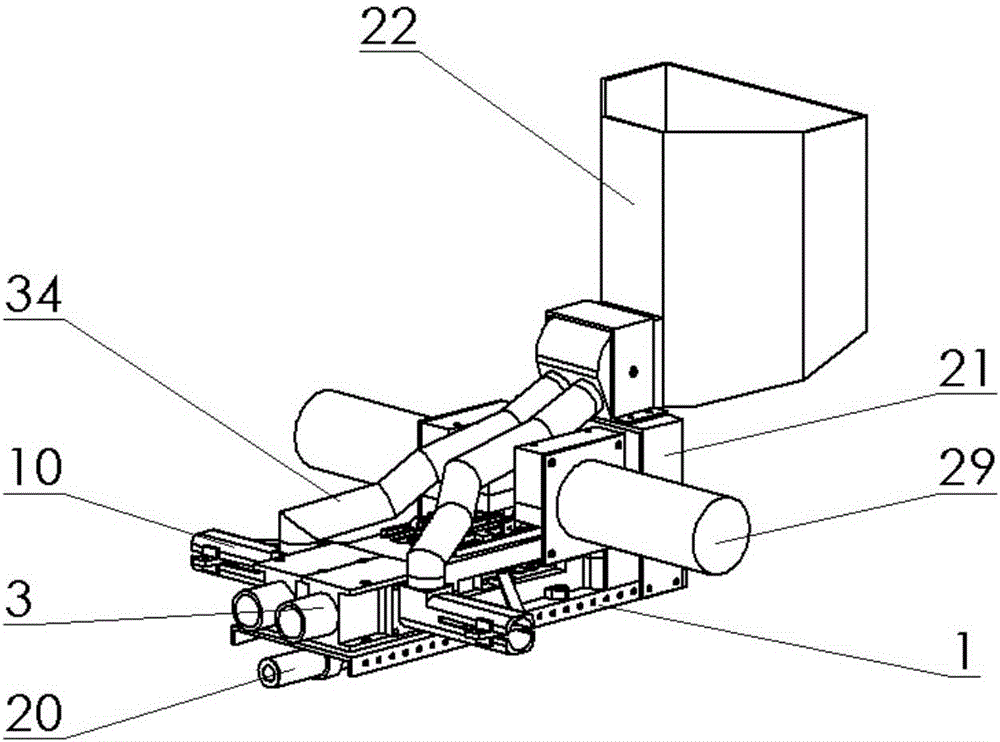

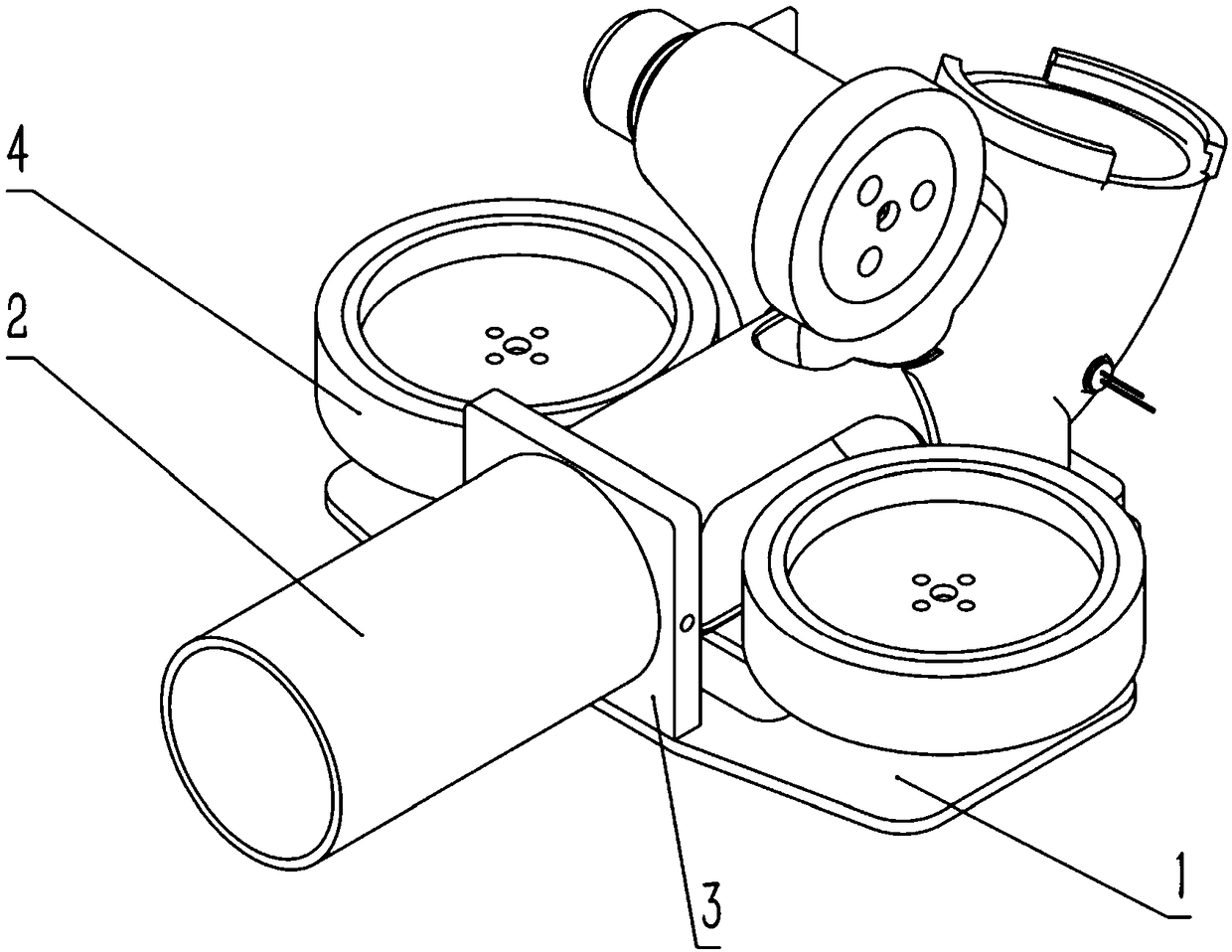

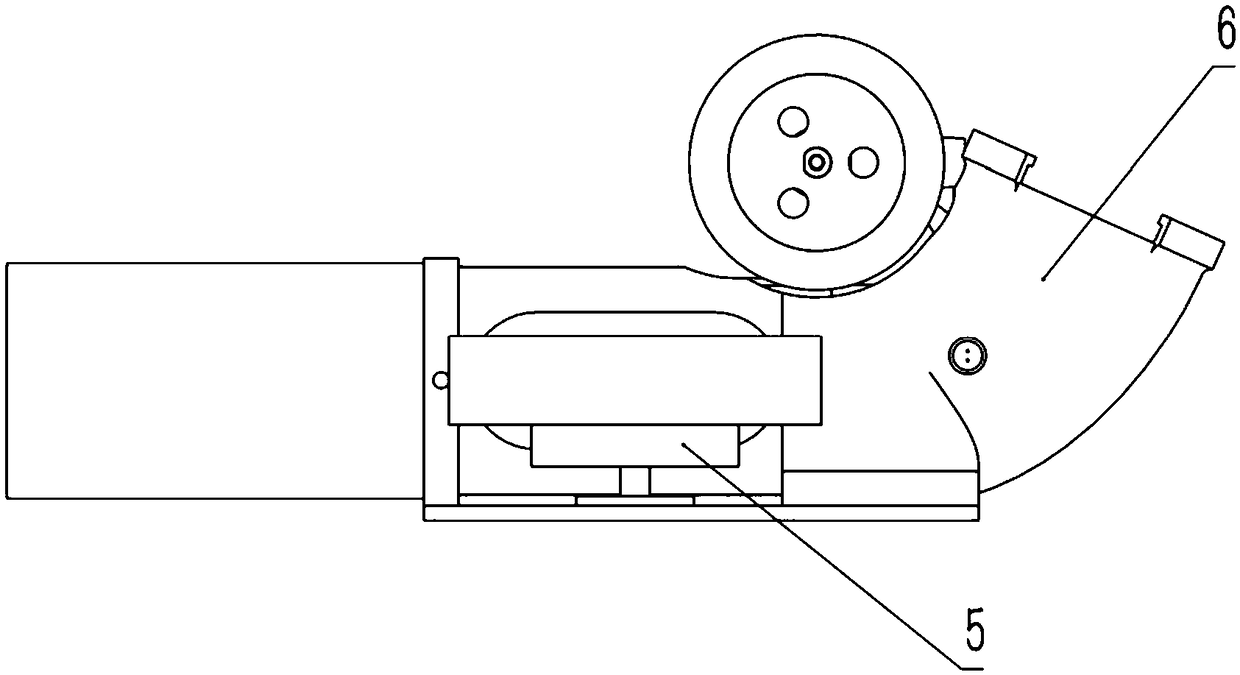

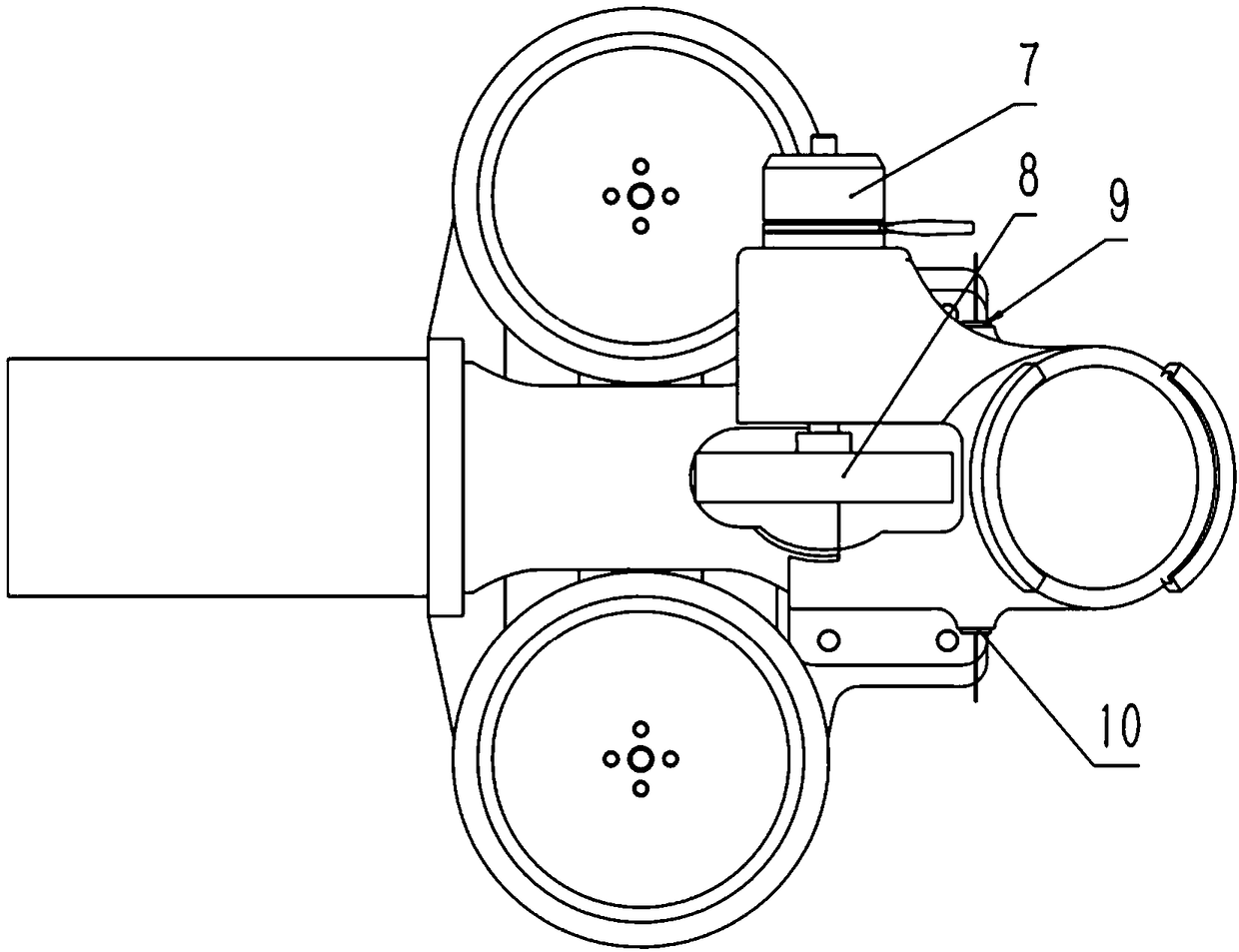

Two-barrel BB firing mechanism achieving continuous firing

InactiveCN106123682AAchieve continuous launchImprove operational efficiencySpring gunsSighting devicesSpring forceTorque motor

The invention discloses a two-barrel BB firing mechanism achieving continuous firing. The two-barrel BB firing mechanism achieving continuous firing comprises a bullet box, a fixing frame, a laser head, a base plate and two single-barrel BB firing sub-mechanisms identical in structure. The fixing frame is fixed to the top face of one end of the base plate. The laser head is fixed to the bottom surface of the other end of the base plate. The bullet box is fixed into the fixing frame. The two single-barrel BB firing sub-mechanisms are arranged side by side. One end of each single-barrel BB firing sub-mechanism is connected with the bullet box, and the other end of each single-barrel BB firing sub-mechanism is fixed to the base plate. According to the two-barrel BB firing mechanism achieving continuous firing, stir wheels and bullet supply hoses are used for supplying bullets, torque motors are used as power sources of the mechanism, seamless continuous operation of bullet supplying, spring force accumulation and bullet firing is achieved through cranks, firing pin connecting rod mechanisms and bullet pushing connecting rod mechanisms, and finally continuous firing of two barrels is achieved; and therefore, the operation efficiency of the two-barrel BB firing mechanism is improved.

Owner:NANJING UNIV OF SCI & TECH

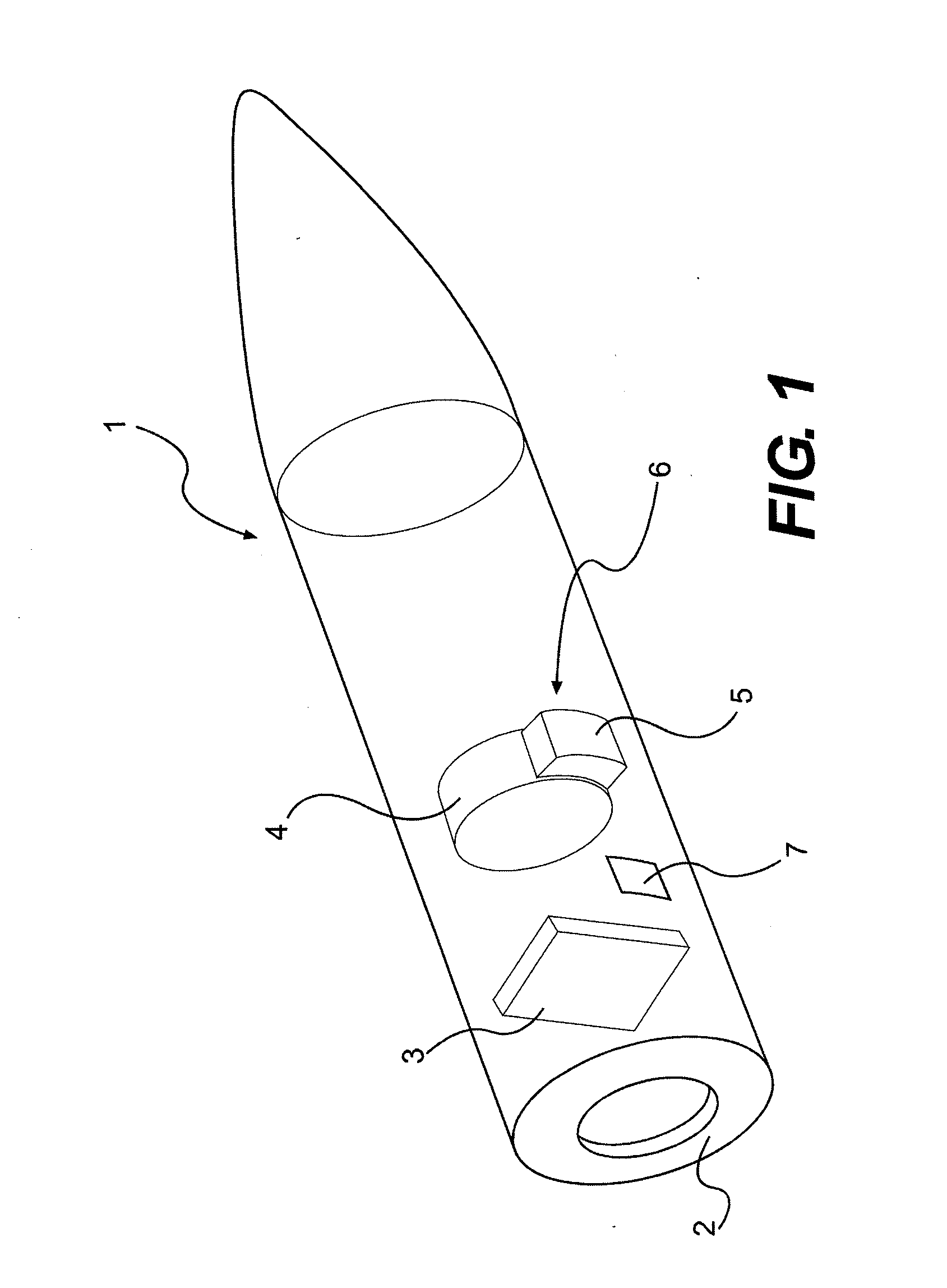

Gun firing method for dispersion of projectiles in a pattern

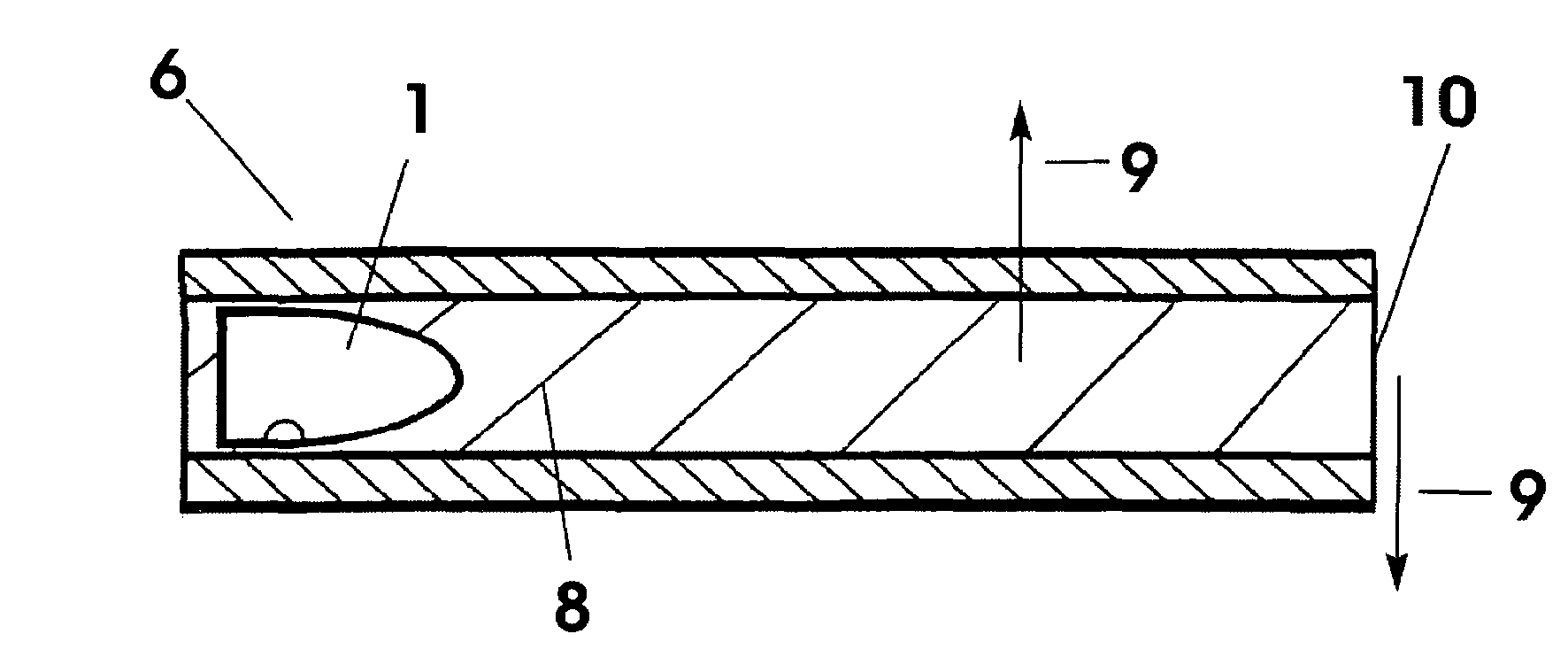

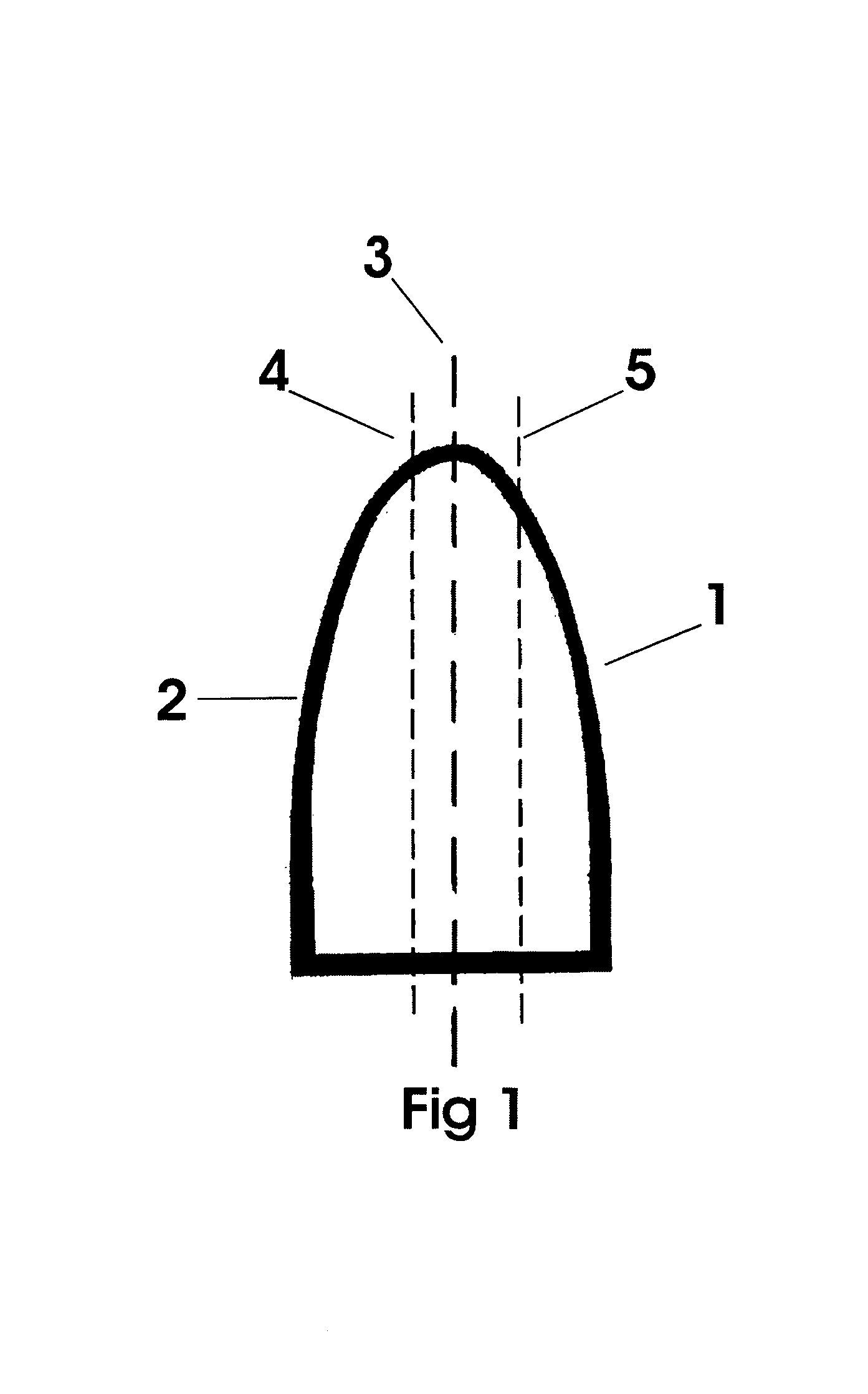

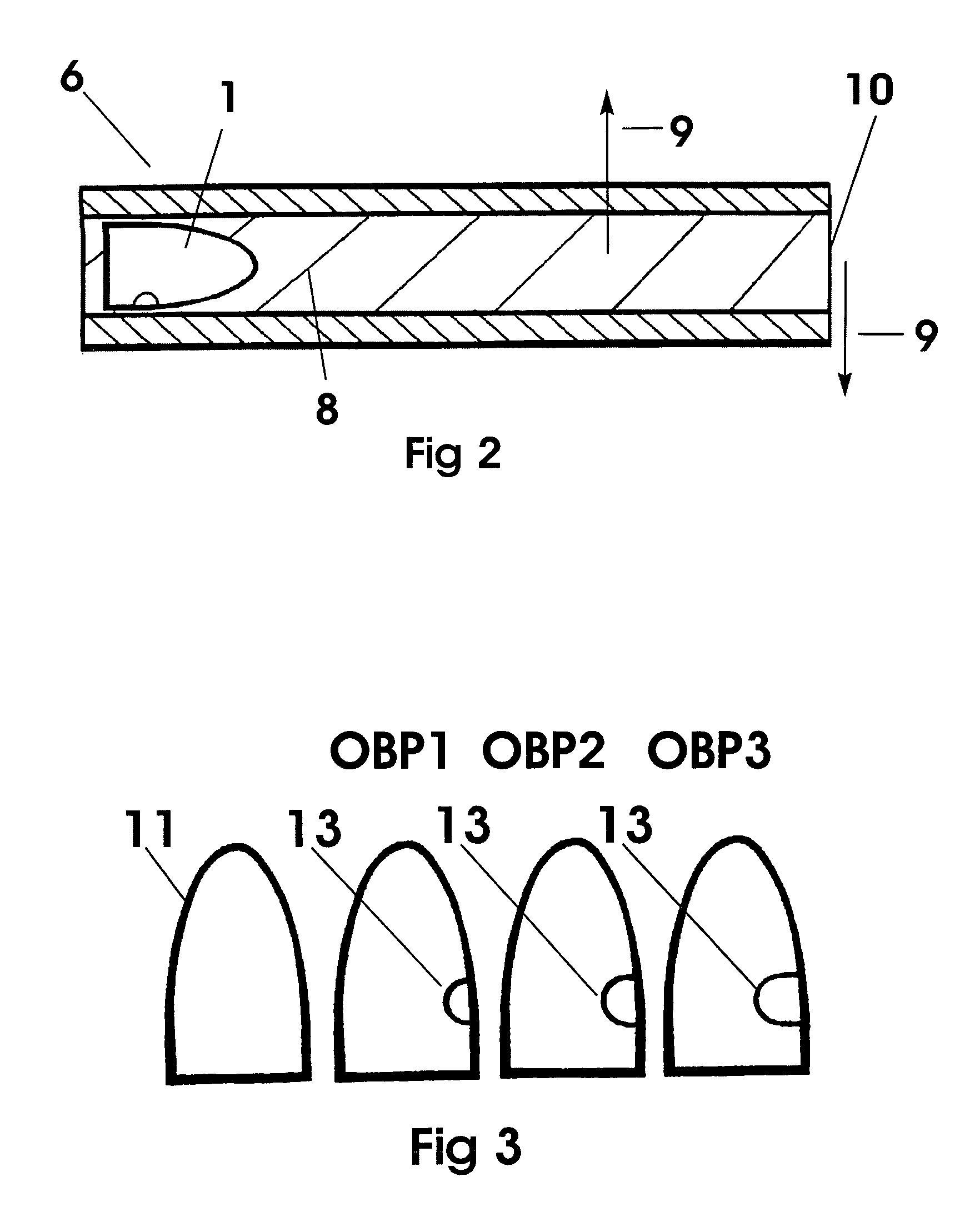

InactiveUS7017495B2Correction for dispersionAmmunition projectilesTraining ammunitionEngineeringRifling

A method for the dispersion of projectiles from guns capable of firing multiple projectiles in rapid succession whereby some of the projectiles are modified by moving the center of mass of the projectile away from it's central axis and oriented prior to firing. This, in combination with bring fired from a rifled gun barrel, imparts velocity to the projectile upon exiting the gun barrel at right angles to the barrel. This velocity along with the higher muzzle velocity will cause the modified projectile to diverge away from the trajectory of a standard projectile. The magnitude of the divergence will vary with the distance the projectile's center of mass is away from its central axis, and the placement of the modified projectile strikes around the bull's-eye will be determined by the loading orientation of the modified projectile. Firing a multiplicity of standard and modified projectiles in rapid succession will produce an accurate dispersion pattern on a target, increasing the hit probability on that target.

Owner:SEXTON RICHARD

Loop ligature device for minimally invasive treatment of haemorrhoids

The invention relates to a loop ligature device for minimally invasive treatment of haemorrhoids. The loop ligature device is mainly gun-shaped, and comprises a left cover plate, a right cover plate, a continuous firing mechanism for continuously looping and ligaturing a focus tissue, a negative-pressure mechanism for providing continuous negative pressure for the continuous firing mechanism and a pressure release mechanism for releasing the pressure of the continuous firing mechanism, wherein the left cover plate and the right cover plate are assembled to form a gun housing, the continuous firing mechanism is arranged in a gun pipe, the negative-pressure mechanism is arranged in the barrel of a gun, the pressure release mechanism is arranged in a handle of the gun, and the pressure release mechanism and the negative-pressure mechanism are respectively communicated with the continuous firing mechanism by air pipes. According to the loop ligature device, the multiple looping and ligaturing can be realized on the larger diseased tissue, the continuity can be improved, the time can be saved, and the patient pain can be reduced.

Owner:PRECISION CHANGZHOU MEDICAL INSTR

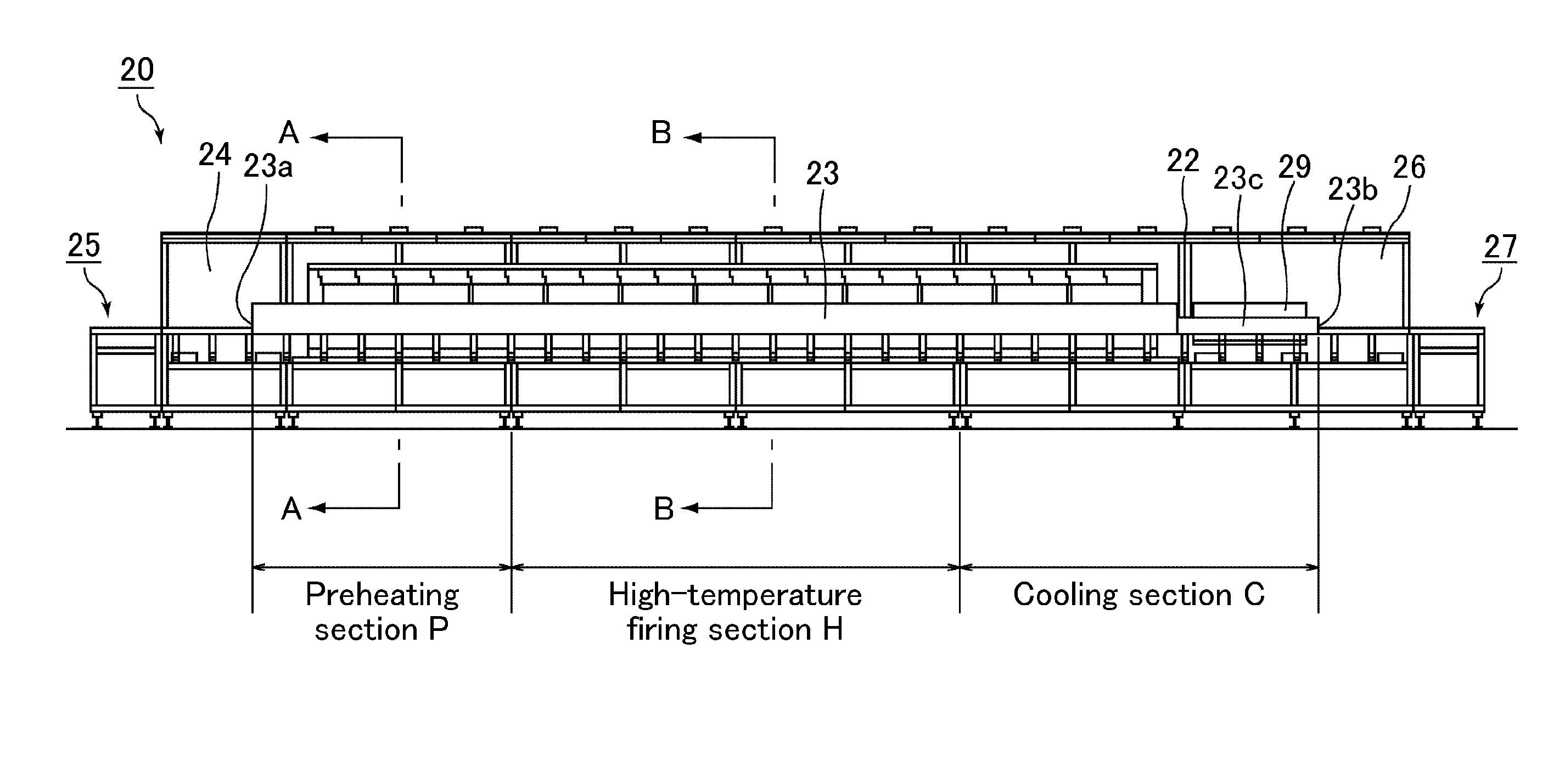

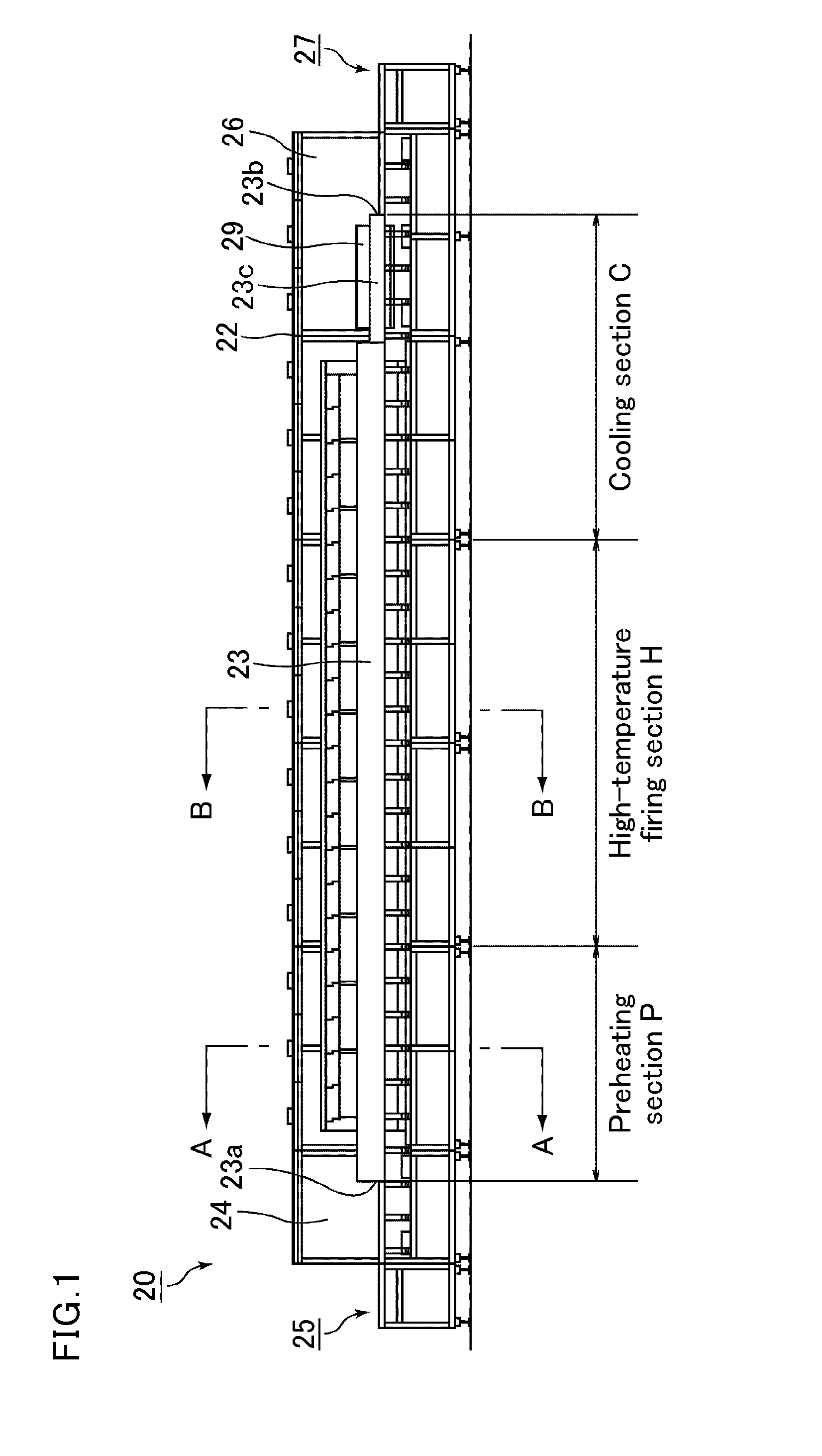

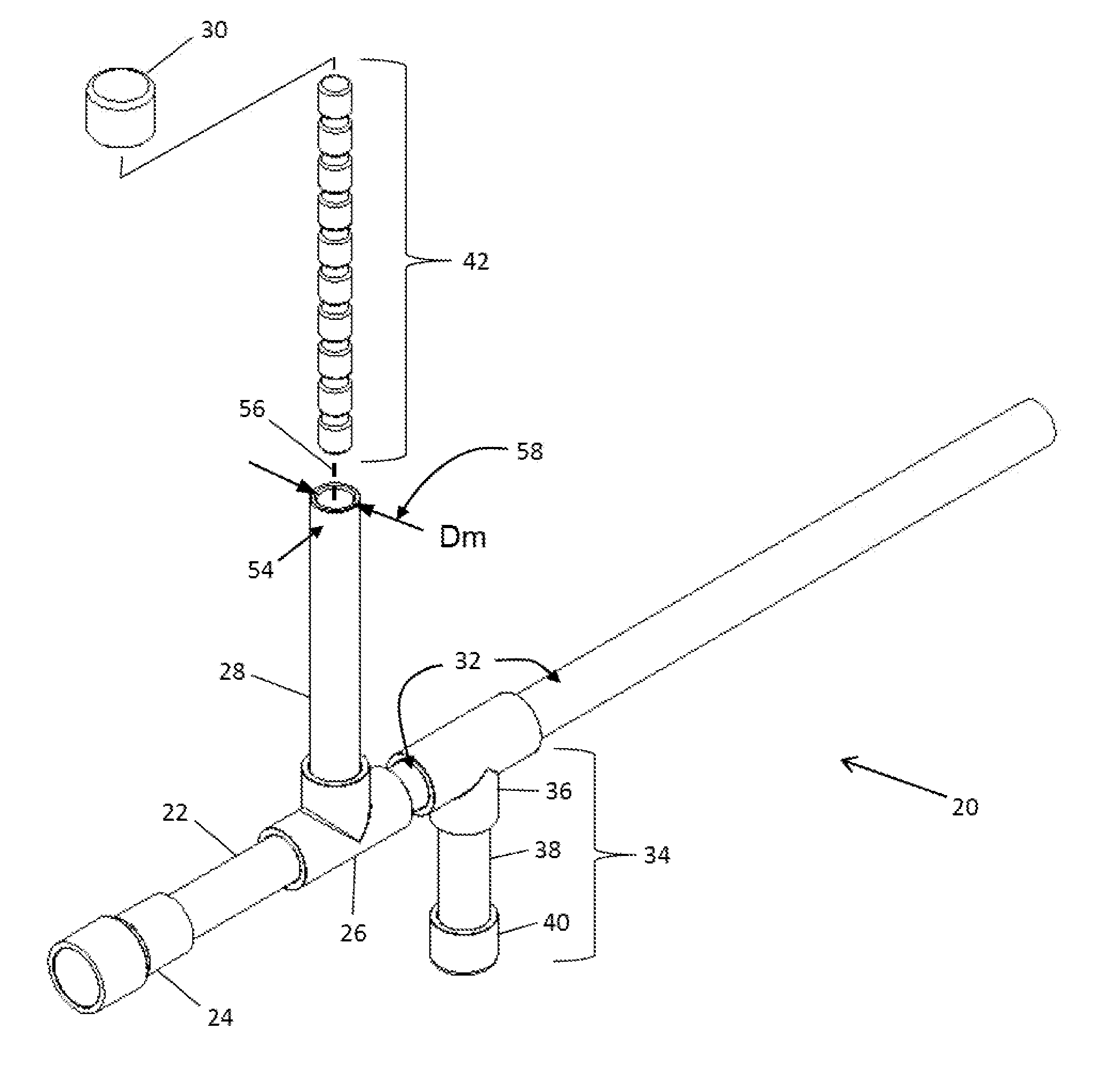

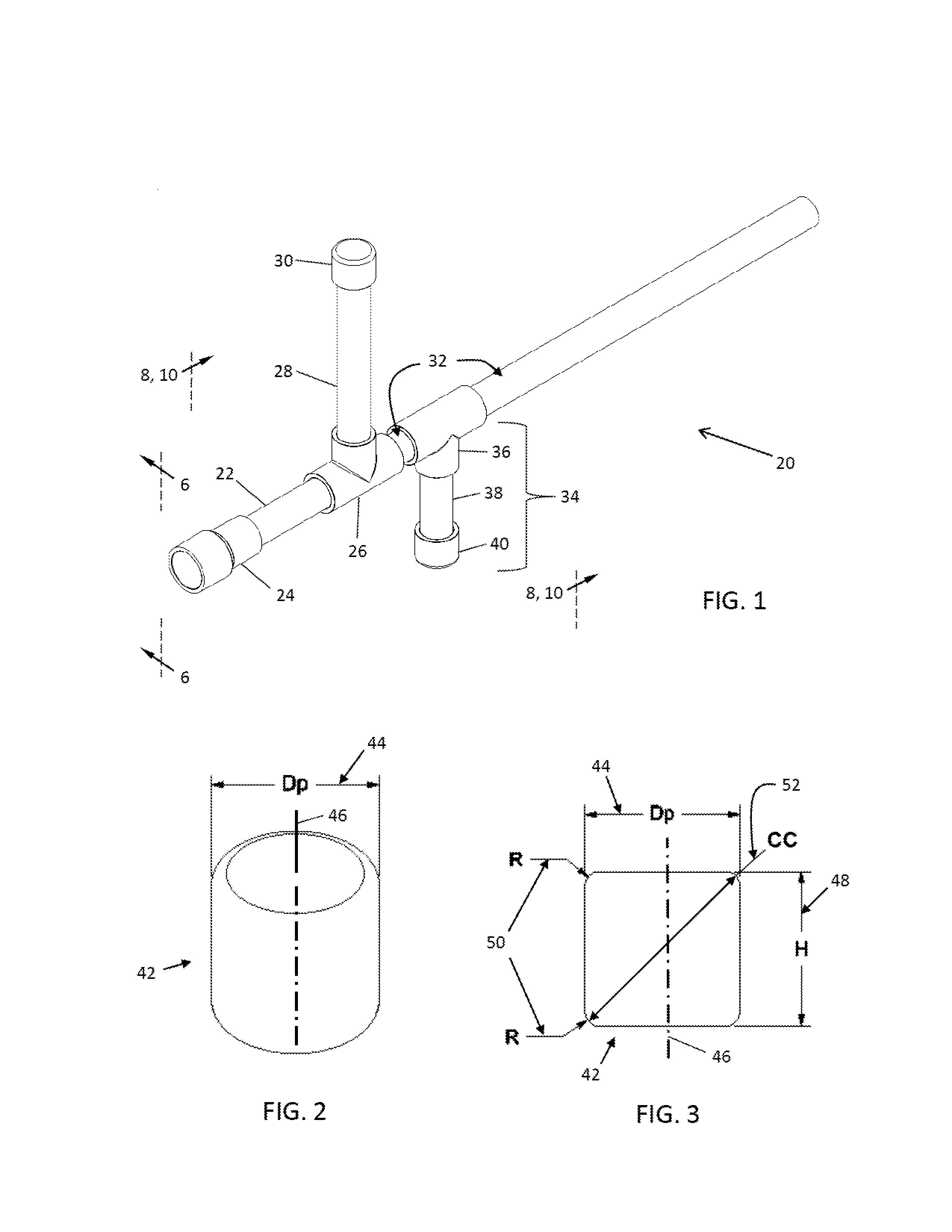

Method for manufacturing ceramic fired body and method for manufacturing honeycomb structured body

A method for manufacturing a ceramic fired body includes molding and degreasing a ceramic raw material to manufacture a ceramic degreased body. The ceramic degreased body is fired in a continuous firing furnace. The firing step includes preheating the ceramic degreased body up to a preheating temperature of at least about 1500° C. and at most about 2000° C. by resistance heating with a resistance heating mechanism. High-temperature firing includes heating the ceramic degreased body from the preheating temperature to a firing temperature of at least about 2000° C. and at most about 2300° C. by both the resistance heating with the resistance heating mechanism and direct energizing heating in which the ceramic degreased body is energized and heated. The temperature of the ceramic degreased body is held at the firing temperature.

Owner:IBIDEN CO LTD

Continuous firing type trigger structure for toy gun

A continuous firing type trigger structure of a toy gun (air soft gun / BB-gun) includes a valve body disposed behind the output port of a magazine clip in air communication with the gas outlet of a high-pressure gas can, an enclosed socket connected to the rear side of the valve body, a valve tube inserted through the valve body, a spring that pushes the valve tube forwards to keep the air inlet of the valve tube not in communication with the inside space of the valve body, and a piston inserted into the enclosed socket and fixedly connected to a sliding shell on the outside of the toy gun such that the valve tube is moved with the piston forwards (or backwards) to let a high pressure gas be discharged out of the high-pressure gas can into the valve tube to drive an airsoft gun out of the toy gun and to force the piston and the sliding shell backwards after triggering of the trigger of the toy gun, for enabling the piston and the sliding shell to be immediately returned by a return spring for a next firing operation. A hammer is pivoted to the toy gun and releasably secured in place by a spring-supported sear for firing one single airsoft bullet per each hammering action.

Owner:WEI WILSON

Air gun firing operating system

The present invention provides an air gun firing operating system that uses compressed air to eject bullets by purely mechanical means, and enables single firing or high-speed continuous firing. During the firing operation, the system uses a sliding shuttle tube that is able to slide back and forth in a linear displacement on a central axis between a bullet chamber and a cylinder. The sliding shuttle tube uses differential pressure variation in a pressure buffer chamber to achieve a stroke state that can be continuously changed, thereby achieving high-speed back and forth motion and continuous firing of bullets. The relevant driving position of a trigger device is provided with a sliding retainer, which is able to effect transient retaining of the sliding shuttle tube, thereby restricting the system for single firing, or discontinuing the retention to enable the system to be in a continuous firing operation state.

Owner:CHO CHAO HSIUNG +3

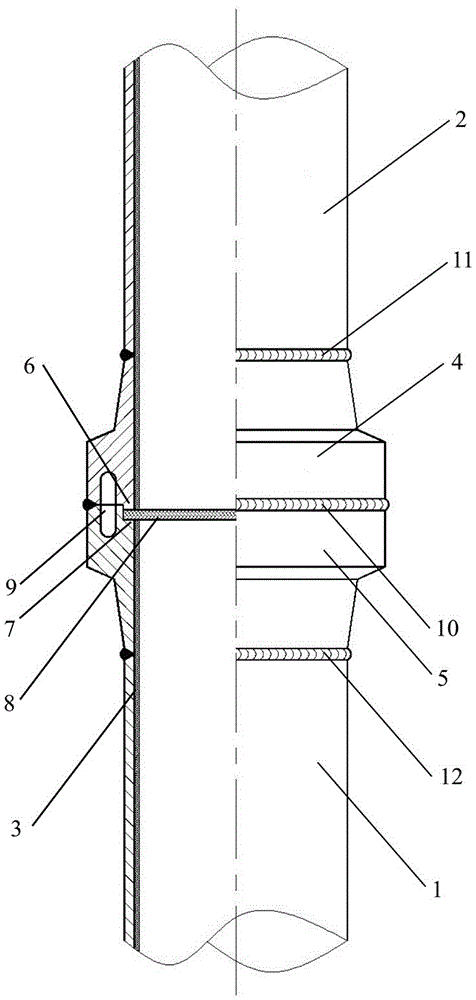

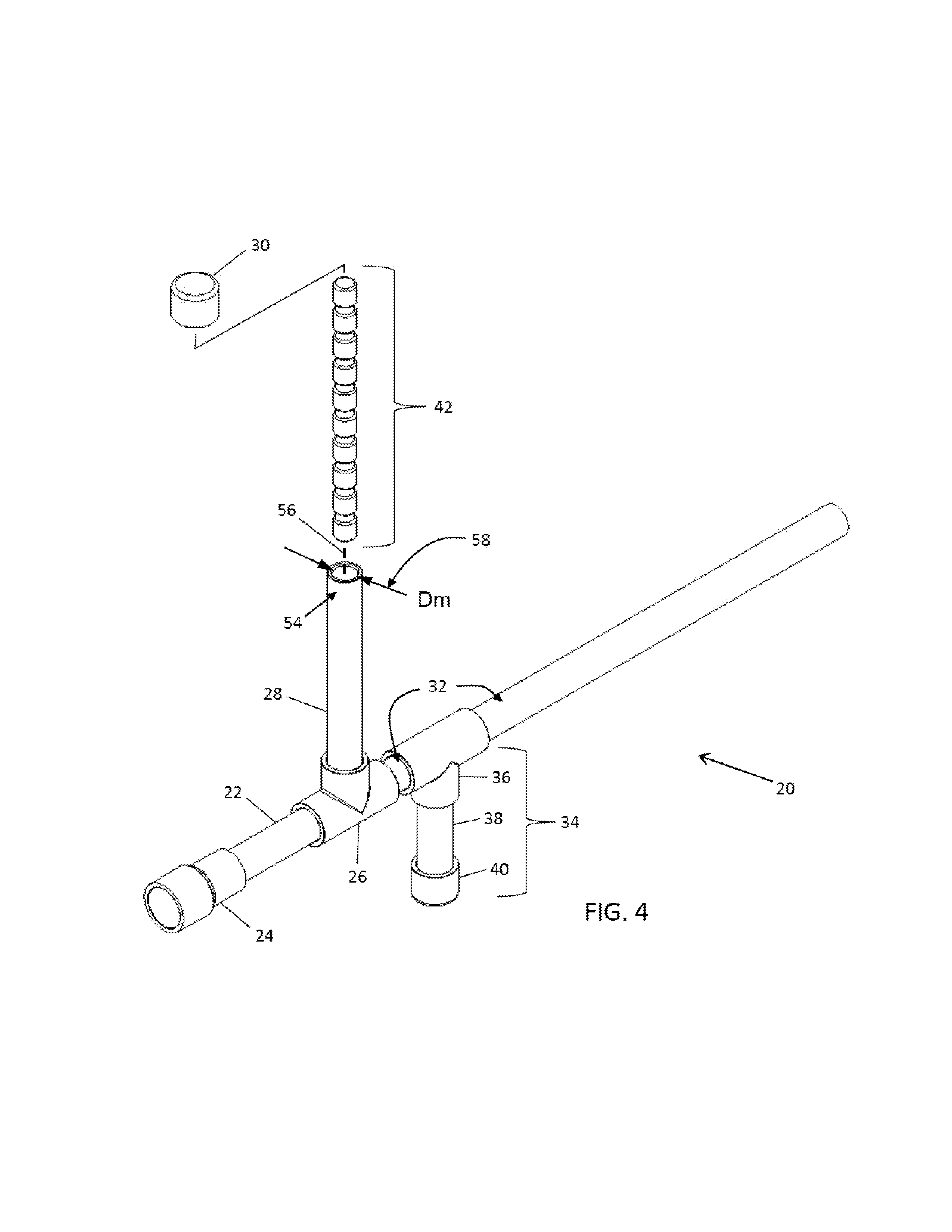

Corrosion-resisting enamel composite pipeline and manufacturing method thereof

ActiveCN106122613AEliminate scale burst defectsGuaranteed continuityThermal insulationCorrosion preventionButt weldingLarge size

The invention discloses a corrosion-resisting enamel composite pipeline and a manufacturing method thereof. Due to adoption of glaze components, it can be guaranteed that an enamel anti-corrosion layer on the inner wall of a hot rolled steel pipe is free of fish-scaling defects. The achievement of the large-size steel pipe inner wall enamel technology and efficient large-scale manufacturing can be guaranteed through an accumulation chain transmission system, a tunnel type continuous firing furnace and other equipment related to the technical scheme. Continuity and integrity of an anti-corrosion structure can be guaranteed through an enamel anti-corrosion layer, a teflon gasket and related structures, all of which are integrally prefabricated. Effective sealing and continuity of the anti-corrosion layer can be conveniently achieved through a butt welding pipe flange with a limiting boss structure and a butt welding pipe flange with a sealing groove structure, and field construction is facilitated. The enamel anti-corrosion layer and a sealing structure cannot be excessively affected by the high welding temperature through an annular heat isolation cavity, and the failure of the anti-corrosion system is avoided.

Owner:洪德胜

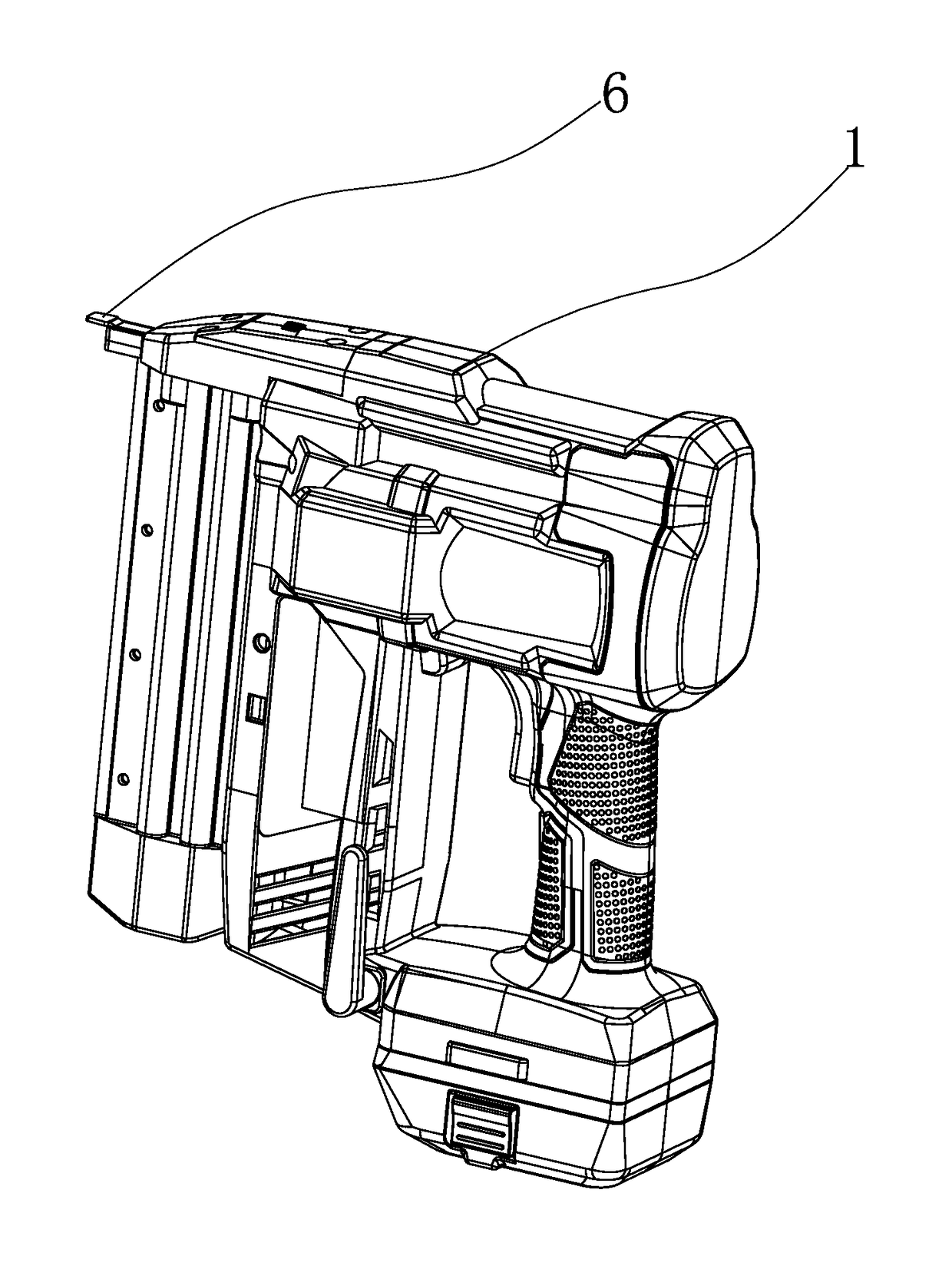

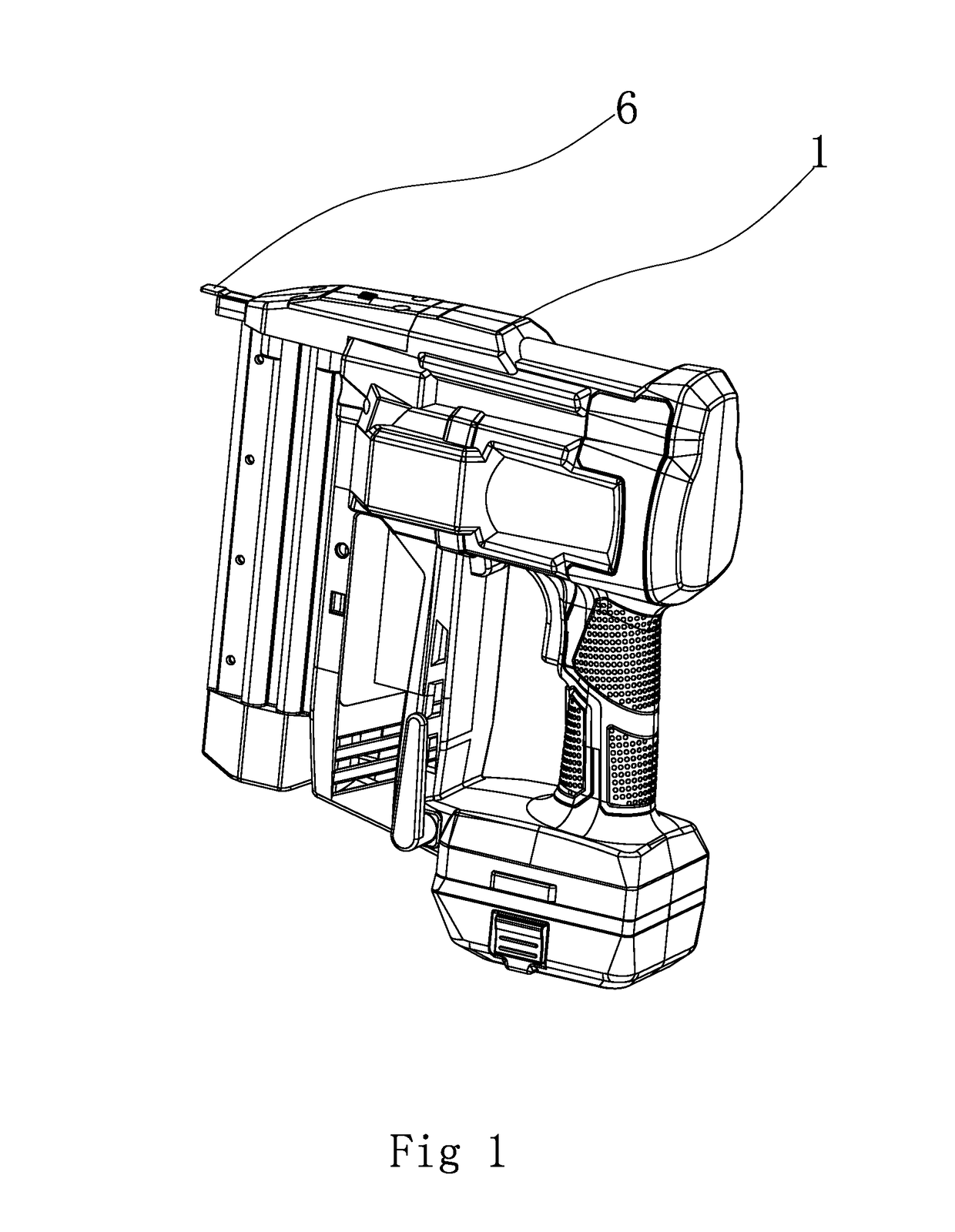

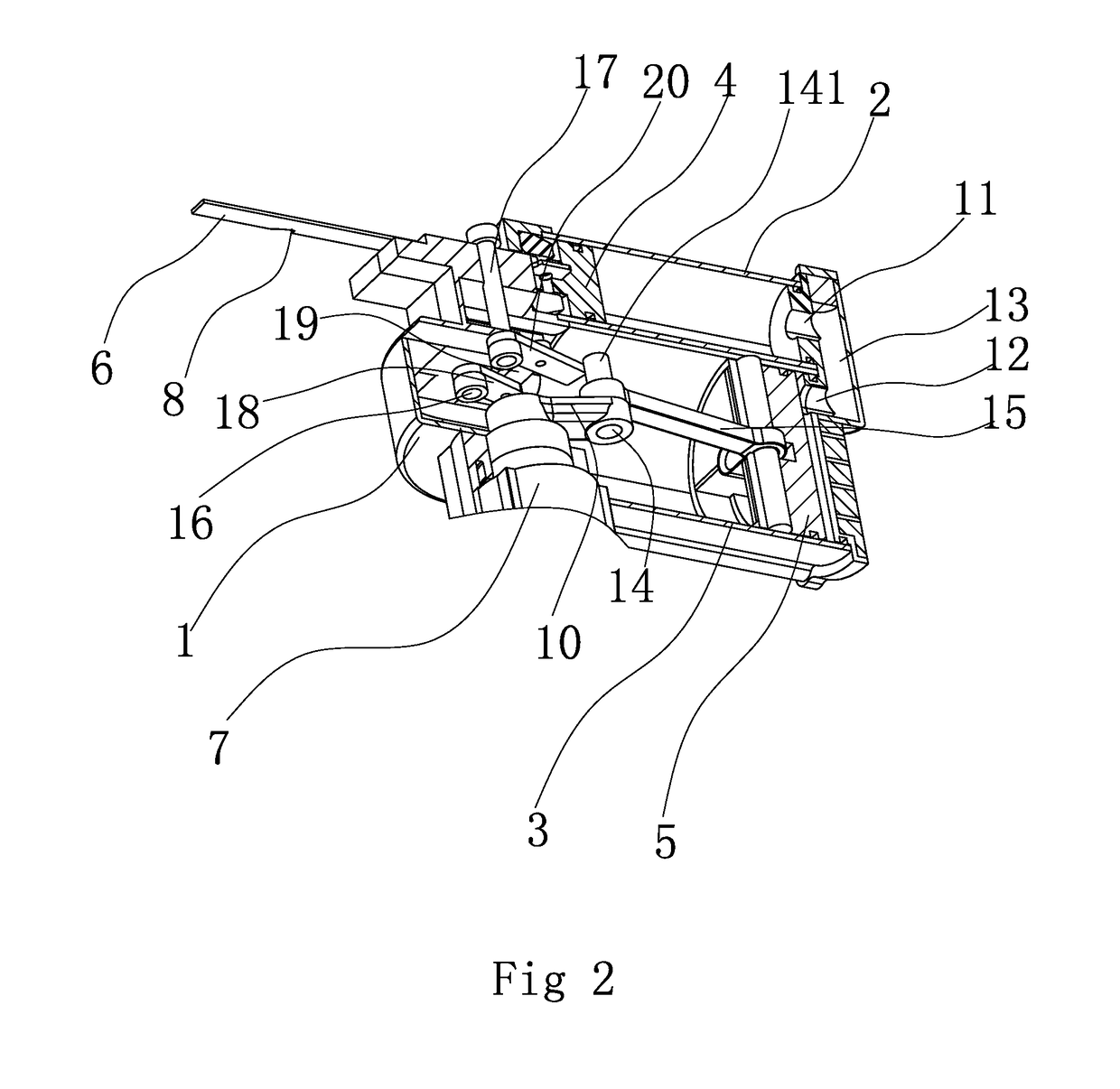

Single-and-continual shot changeover device for a nailing gun

InactiveUS20060144379A1Easy transferHandling the changeover device is very stable and accurateElectromagnetic launchersOperating means/releasing devices for valvesEngineeringSingle shot

A single-and-continual shot changeover device for a nailing gun includes a trigger shaft positioned in an interior of a trigger body, a trigger inner member pivotally connected with an intermediate fitting stage of the trigger shaft, which also has two slide shaft stages at two sides of the fitting stage for two springs and two press buttons to fitting around respectively. The two press buttons are elastically pushed to shift outward to engage one of two—an upper and a lower—grooves of the two sidewalls of the trigger body. When the two press buttons are pressed inward, the trigger inner member can be shifted up and down to let the press buttons secured at either of the two limit grooves by means of the trigger shaft. Then the trigger inner member is controlled to separate or not from the safety connect rod for changing firing a single shot or continual shot.

Owner:BENTLEY FASTENING TOOLS

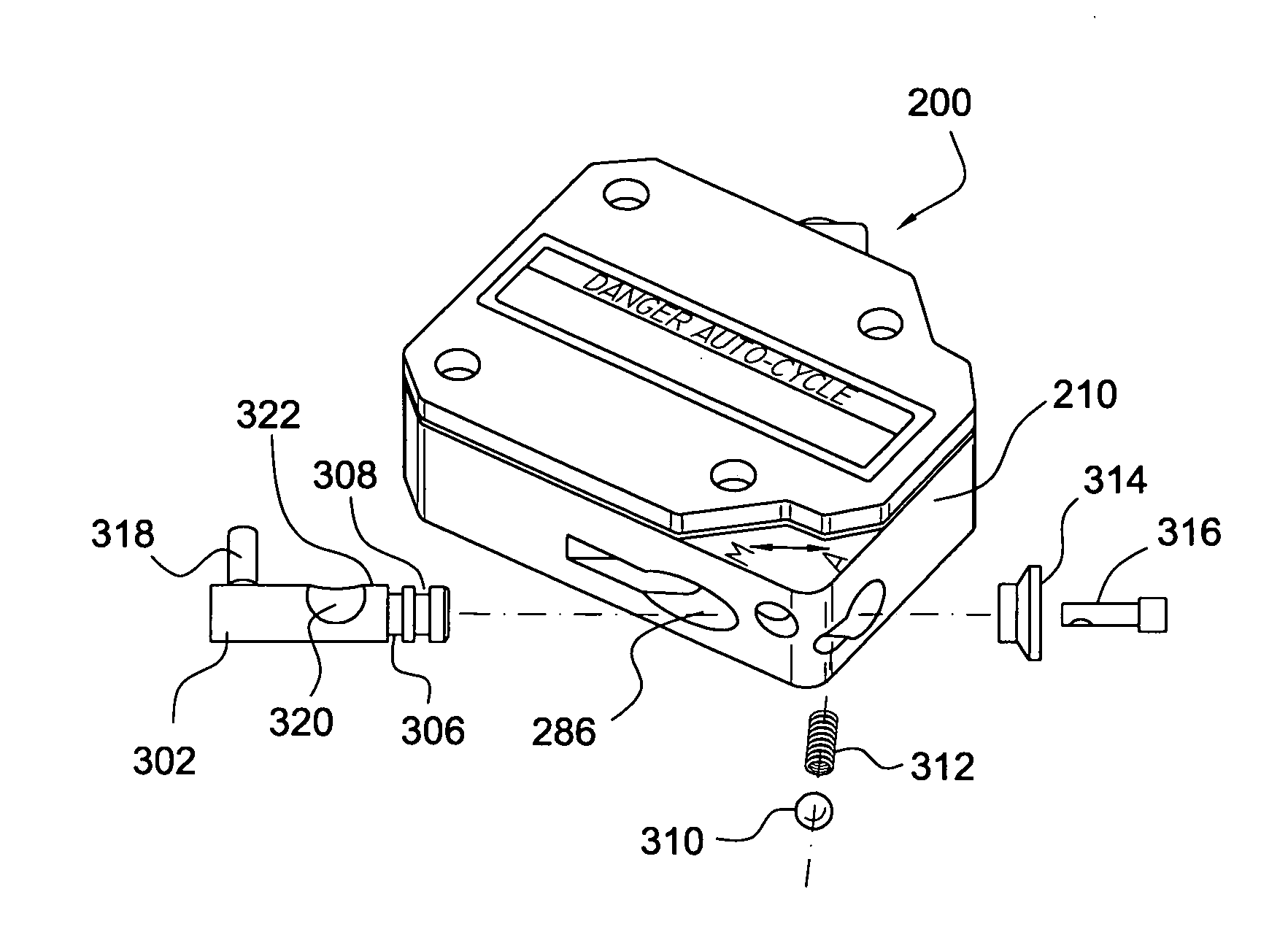

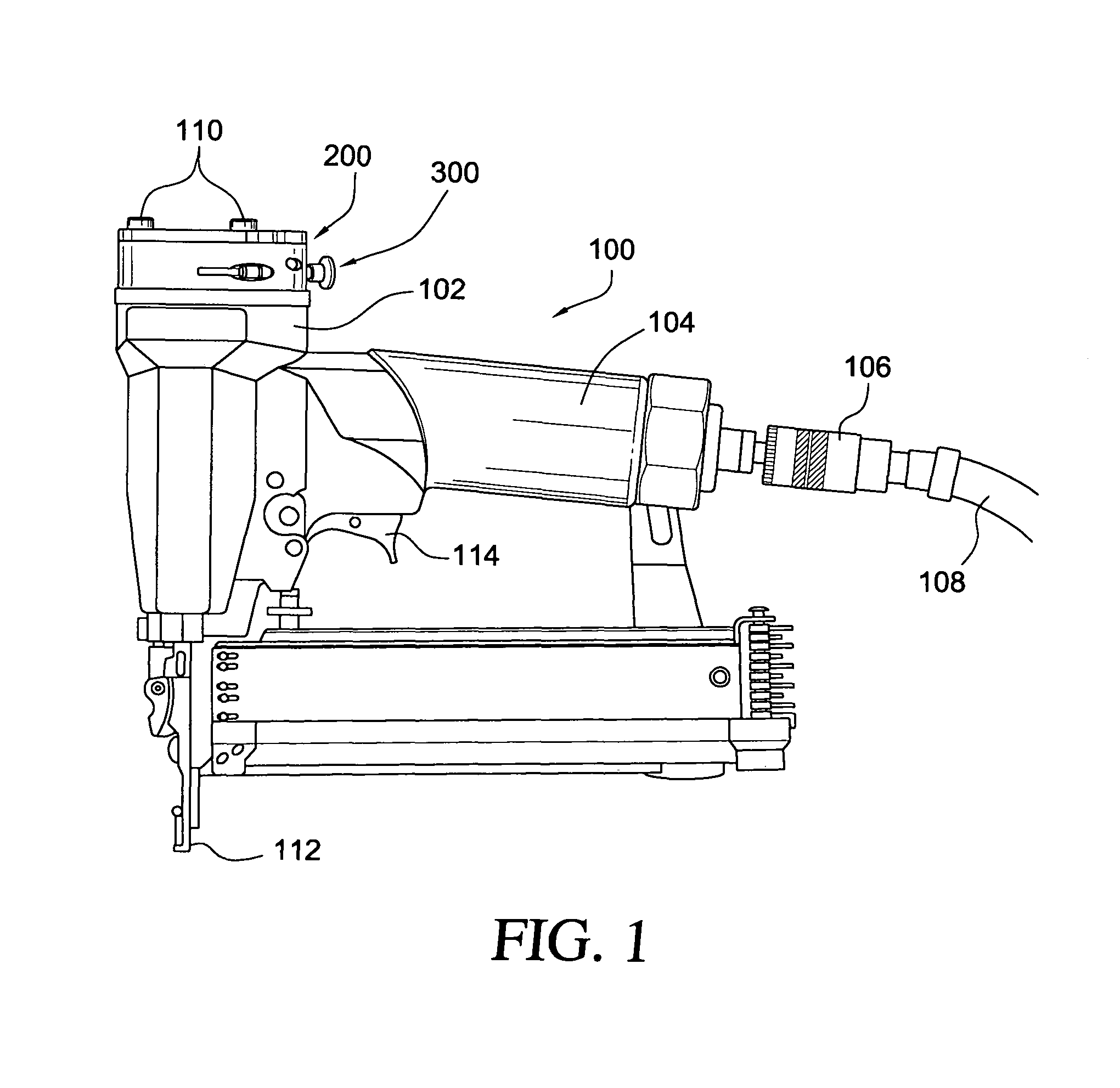

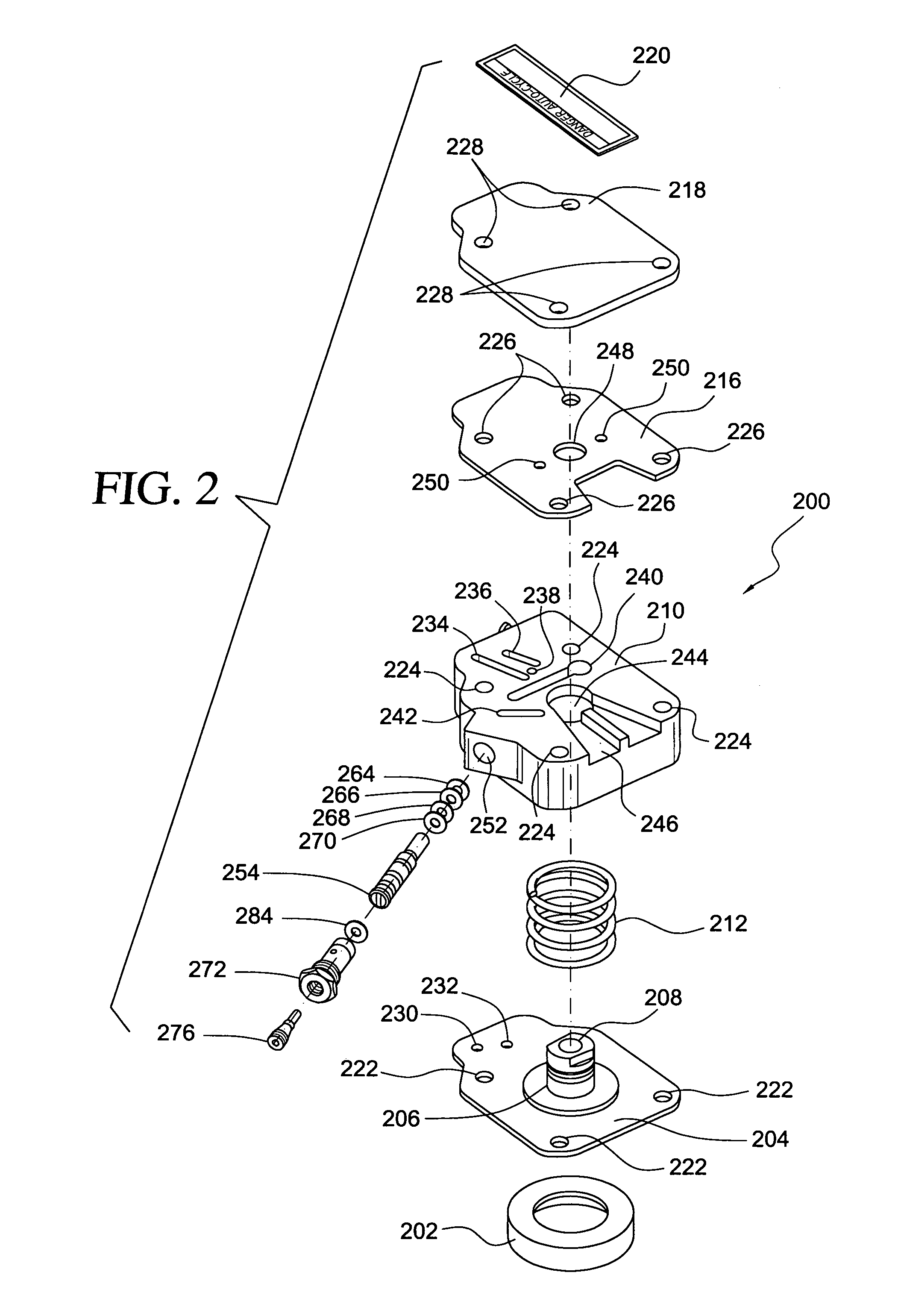

Cap assembly of a fastener-driving tool having switch mechanism incorporated therein for switching modes of operation of the fastener-driving tool

A fastener-driving tool is provided with a cap assembly which includes a switch mechanism that permits the tool to be operated in one of two firing modes of operation. The switch mechanism comprises a two-position switch mechanism such that when the switch mechanism is disposed at a first one of its two positions, the tool will be able to operate in a fully automatic continuous firing mode of operation so as to continuously fire fasteners into a substrate as long as the workpiece contact element and the trigger mechanism are disposed at their depressed positions, or alternatively, when the switch mechanism is disposed at the second one of the two positions, the tool can be operated in a one-shot firing mode such that the tool can only fire a single fastener, either in accordance with, for example, a sequential-firing mode of operation or a bump-firing mode of operation, until the trigger mechanism is released and again depressed.

Owner:ILLINOIS TOOL WORKS INC

A Nailing Machine

The nailing machine includes a closed first cylinder and a closed second cylinder, a working chamber of the first cylinder and a working chamber of the second cylinder are communicated with each other. A first piston inside a first cylinder is fixedly connected with a striker that has a locking part. The locking part could be locked by a pawl. The second cylinder is provided with a second piston reciprocated by a motor between a first position and a second position. When the second piston is in the first position, after the first piston moves inward, the pawl snaps at the locking part of the striker. When the second piston is in the second position, the motor drives the pawl to disengage from the locking part. The motor drives the second piston to compress air, and triggers the pawl, achieving the rapid and continuous firing of strip nails.

Owner:ZHANG HUADING

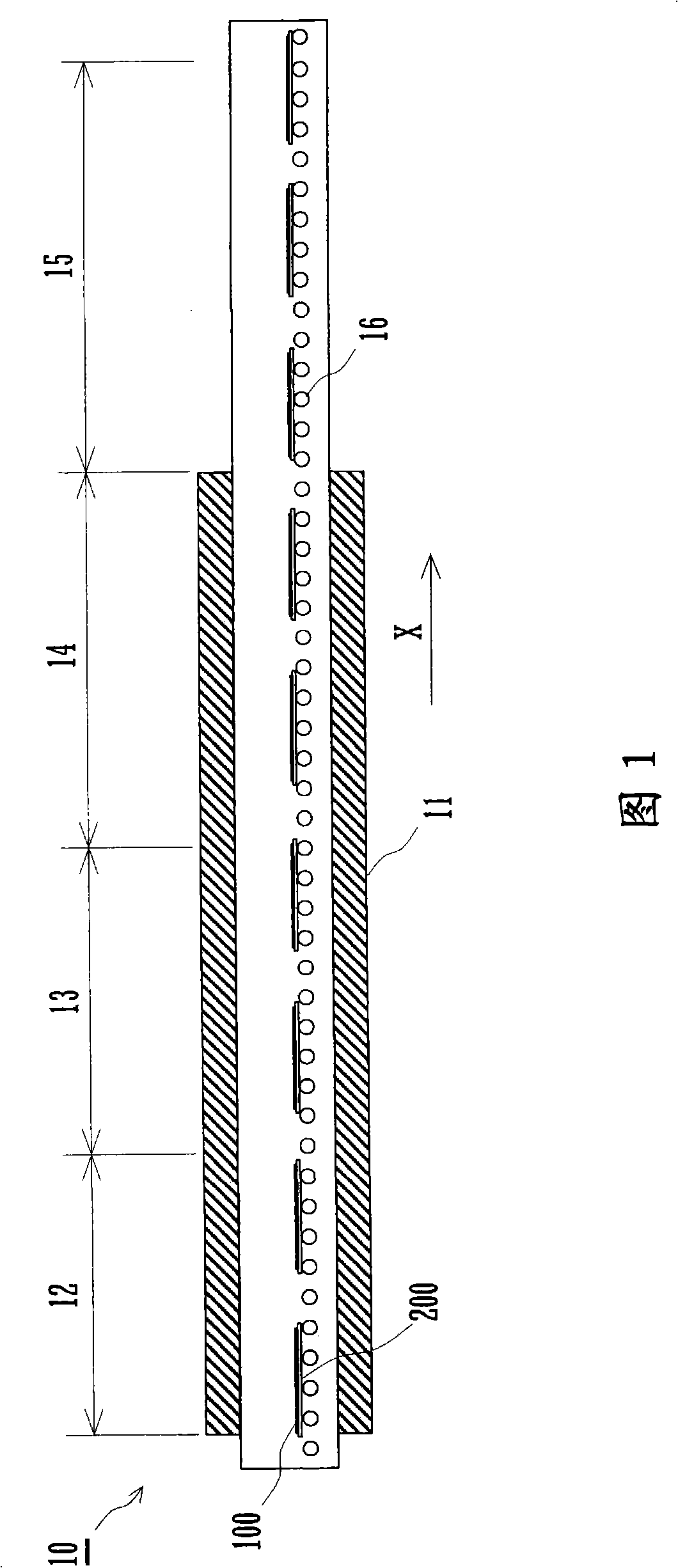

Continuous burning furnace

ActiveCN101265021AEven contactUniform treatmentGas discharge electrodesMaintainance of heating chambersCooling chamberEngineering

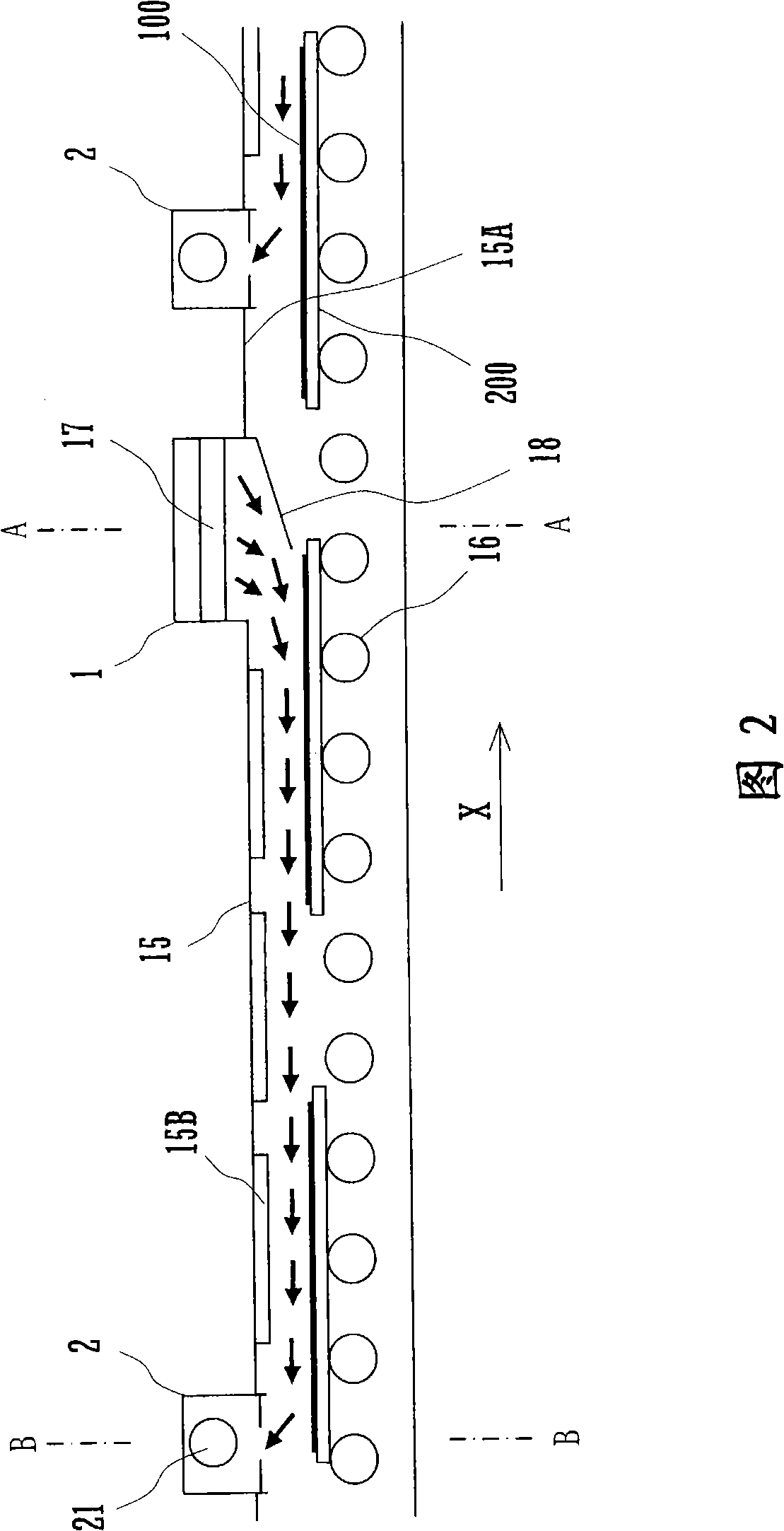

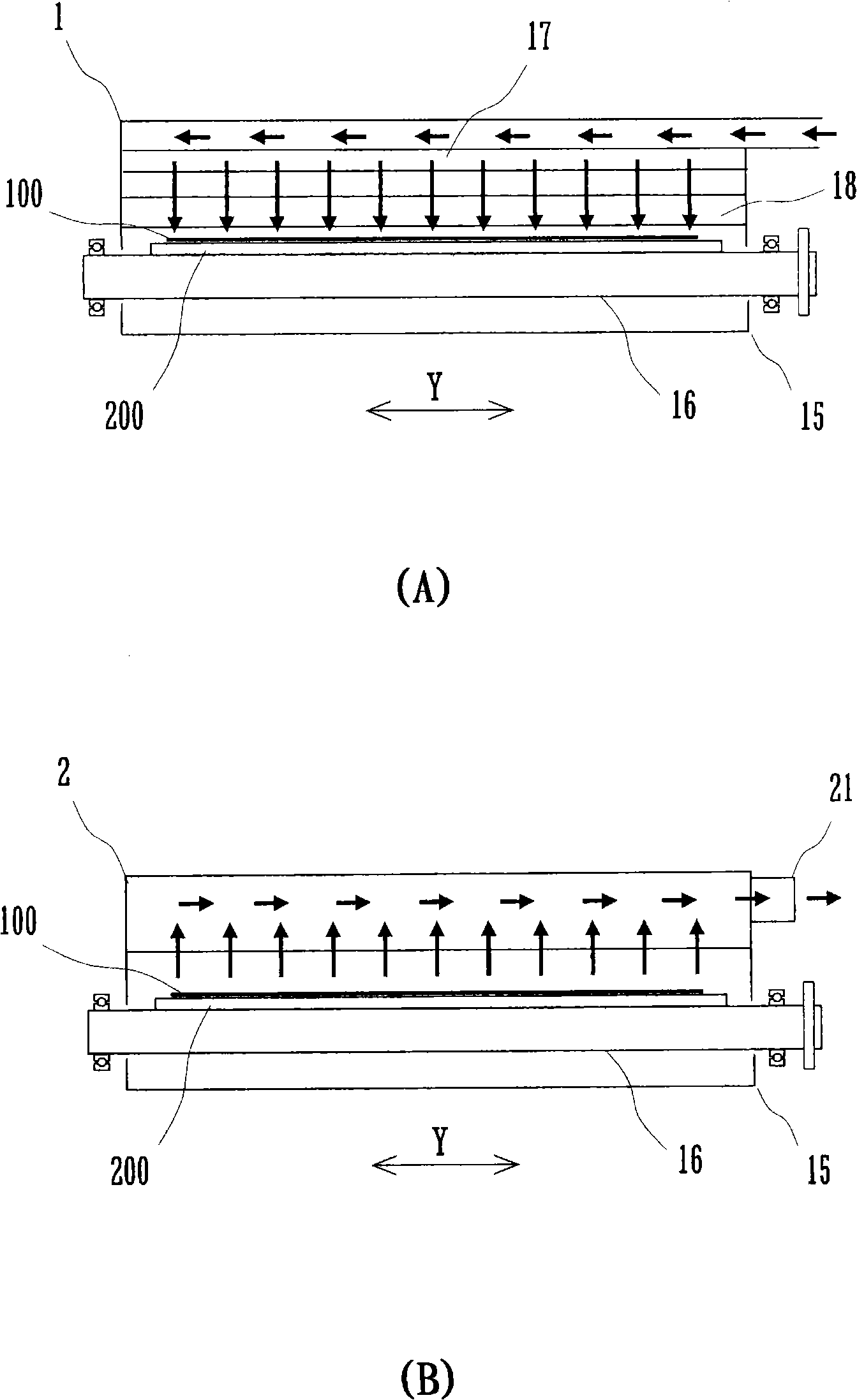

The present invention provides a continuous firing furnace. The continuous firing furnace is able to effectively cool the whole outer surface of the processing objects such as glass substrate etc., does not generate partial warpage or deformation on the processing object and reduces the cooling processing time. The cooling chamber (15) of the continuous firing furnace (10) is installed with guiding passage (1) and exhaust passage (2). The guiding passage and exhaust passage open at the almost whole area in the furnace-width direction (Y) on the inner furnace wall (15A) at the upper side of the cooling chamber. The guiding passage ejects the air by the mode of facing to the upper reach side of the moving direction (X). The exhaust passage exhausts the air of the cooling chamber at the upper reach along the moving direction (X) of the guiding passage. On the upper part of the processing object moved on the roller (16), the flow path with cooled external gas is uniformly formed in the almost whole area on the furnace-width direction (Y). The whole upper surface of the processing object is uniformly contacted with the air.

Owner:KOYO THERMO SYST CO LTD

Firing process of Nixing pottery products

Owner:钦州市奇圣古坭斋坭兴陶有限公司

Multiple soft projectile blow gun

InactiveUS20130180513A1Rapid continuous firingEliminating a choking hazard for the userBlow gunsBatonsSingle breathGun barrel

A blow gun assembly allows the rapid continuous firing of multiple soft, cylindrical projectiles using a single breath. The assembly includes at least one soft cylindrical projectile with a height generally equal to or slightly greater than its diameter, and a centrally-located breech in fluid communication with a mouthpiece, a vertical magazine, and a barrel. Projectiles loaded into the magazine enter a breech chamber by gravity. Upon receiving a charge of air through the mouthpiece, the projectiles travel successively through the breech chamber and out through the barrel in rapid fashion. Sizing of the magazine, breech chamber, and barrel, relative to the projectile, causes the projectiles to flow through the blow gun in continuous succession without jamming, with projectiles being rotated within the breech chamber to properly align with the barrel.

Owner:FOELLER MARK R

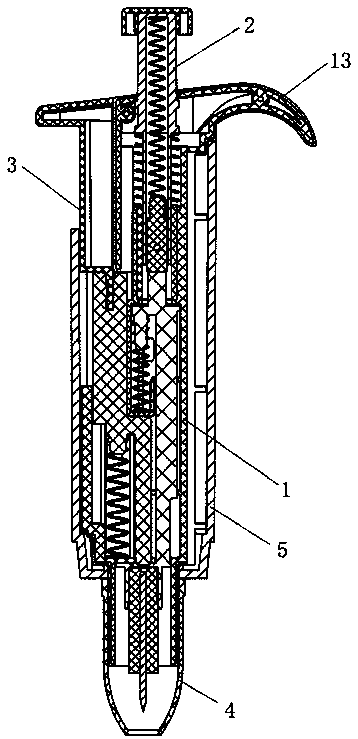

Puncturing appliance capable of performing continuous firing and needle lifting by single hand

PendingCN110801235AReduce work fatigueImprove ease of useDiagnostic recording/measuringSensorsBiomedical engineeringContinuous Firing

The invention discloses a puncturing appliance capable of performing continuous firing and needle lifting by a single hand. The puncturing appliance comprises a housing, a trigger striking assembly, aneedle lifting assembly and a pen cap, wherein the housing is combined by the butting of an upper housing and a lower housing; an accommodating cavity is formed in the housing; two parallel through openings are formed in the rear end of the housing; the trigger striking assembly and the needle lifting assembly are mounted in the accommodating cavity in parallel, and the rear ends of the trigger striking assembly and the needle lifting assembly extend from the two through openings, and are arranged at the rear ends of the housing in parallel; the pen cap is connected to a contracting part of the front end of the housing in a sleeving manner; and an opening allowing an adapted blood taking needle to pass and penetrate is formed in the opening in the front end of the pen cap. The puncturingappliance disclosed by the invention is grasped by the single hand, the operations of firing, puncturing and lifting needle can be realized through position exchanging and pressing by a thumb; after akey is loosened, the puncturing appliance is automatically returned to prepare for the next operation; when a needle lifting key is pressed, the blood taking needle is directly removed from the frontend of the pen cap, during assembling a needle, the blood taking needle is directly assembled at the front end of the pen cap, and the pen cap does not need to be removed, so that the effect of performing continuous firing and needle lifting by the single hand is realized, and the using convenience is greatly improved.

Owner:HUAIAN EFAST INNOVATION TECH CO LTD

Air gun firing control device

ActiveUS9372047B2Improve fitEasy to assembleFiring/trigger mechanismsCompressed gas gunsFire controlBottle

Pressurized air from an air pressure bottle creates the firing motive force for game firearms. After accumulating sufficient pressure, the pressurized air is channeled to the gun chamber to achieve a firing objective. Using an application system for single firing, a purely mechanical firing control device is formed as an integral body to achieve single firing and continuous firing, and which is simply fitted with an auxiliary component to assist in achieving continuous firing. The auxiliary component is located in the swinging path of a cocking trigger. The select continuous firing clasp is pushed upward by the trigger and supports a jumping bar, which causes the jumping bar to lose its clasping retaining capacity on a firing tube to achieve a continuous firing operation.

Owner:CHO CHAO HSIUNG

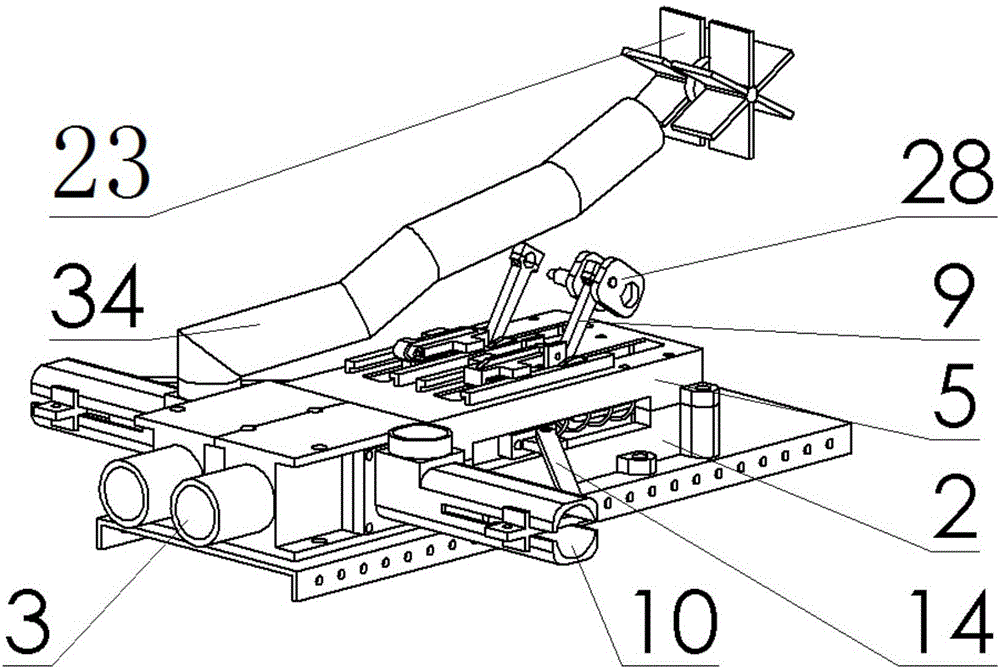

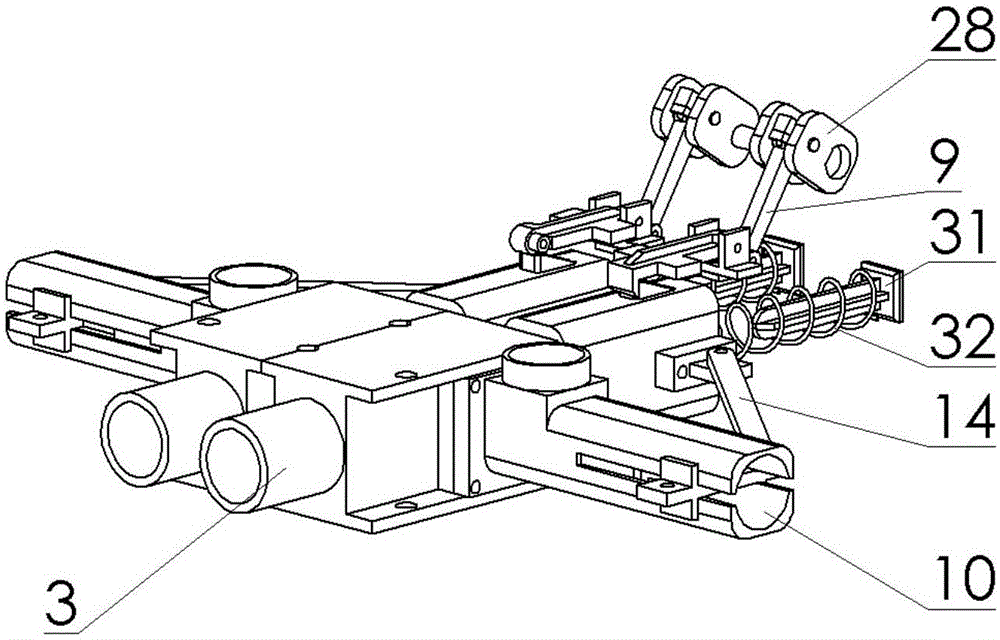

A launching mechanism and a method for controllable continuous firing

The invention discloses a controllable continuous firing mechanism and a method thereof. The firing mechanism comprises a bearing base plate, a firing pipe, a firing friction wheel, a first motor, a bomb feeding pipe and a bomb plucking device. The firing pipe, the first motor and the bomb feeding pipe are installed on the bearing bottom plate; Hollow at the end of the launching pipe; The firing friction wheel is sleeved on the first electric machine and symmetrically arranged on both sides of the firing pipe end, and the distance between the outer sides of the two firing friction wheels is smaller than the diameter of the projectile; The bomb feeding pipe is connected with the launching pipe; The cartridge plucking device realizes squeezing and plucking out single or multiple projectilesby controlling the rotation angle of the cartridge. The launching mechanism can not only launch a single projectile at high speed, but also realize the continuous firing of multiple projectiles. The whole launching mechanism is small in size, simple and reliable in control.

Owner:SOUTH CHINA UNIV OF TECH

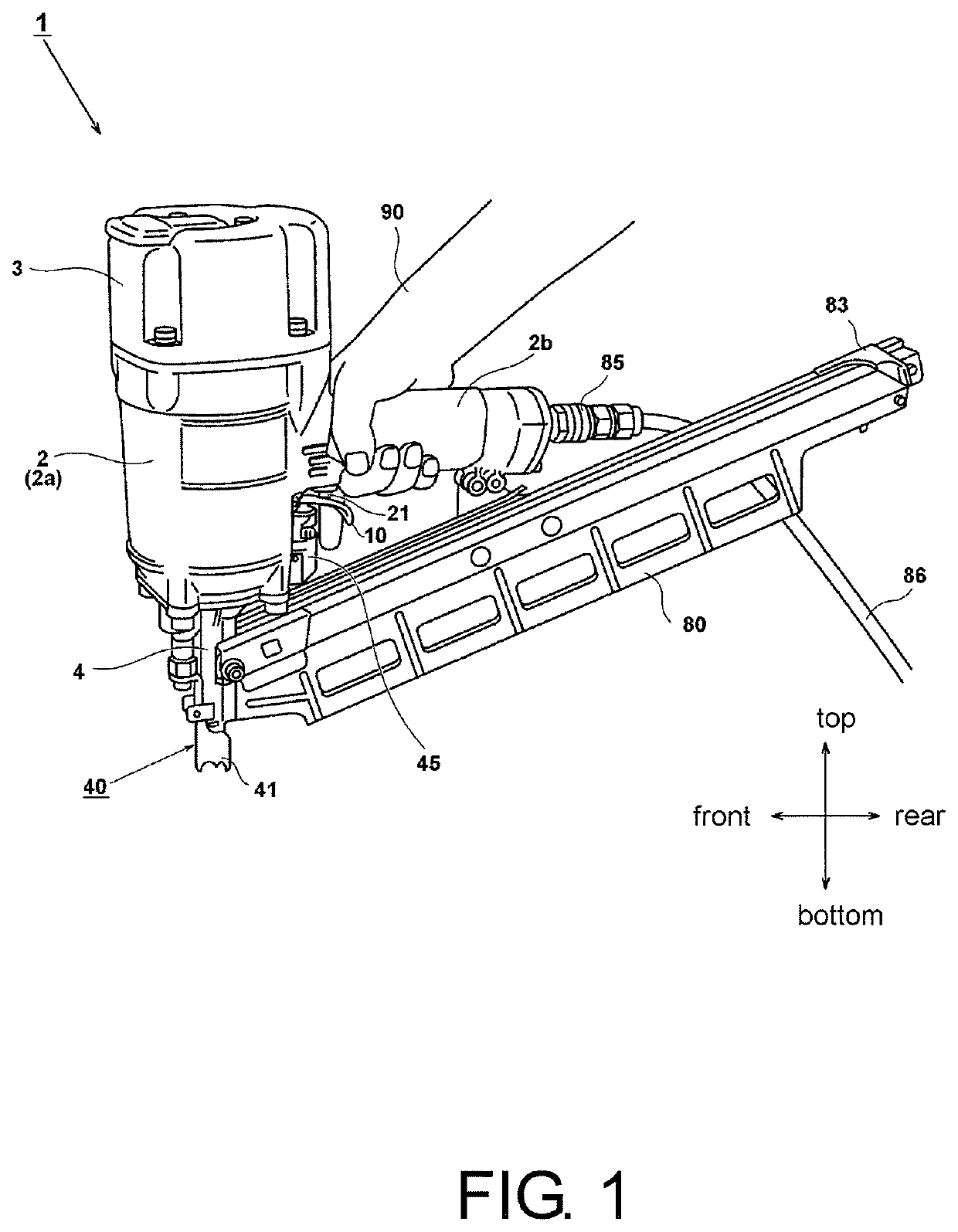

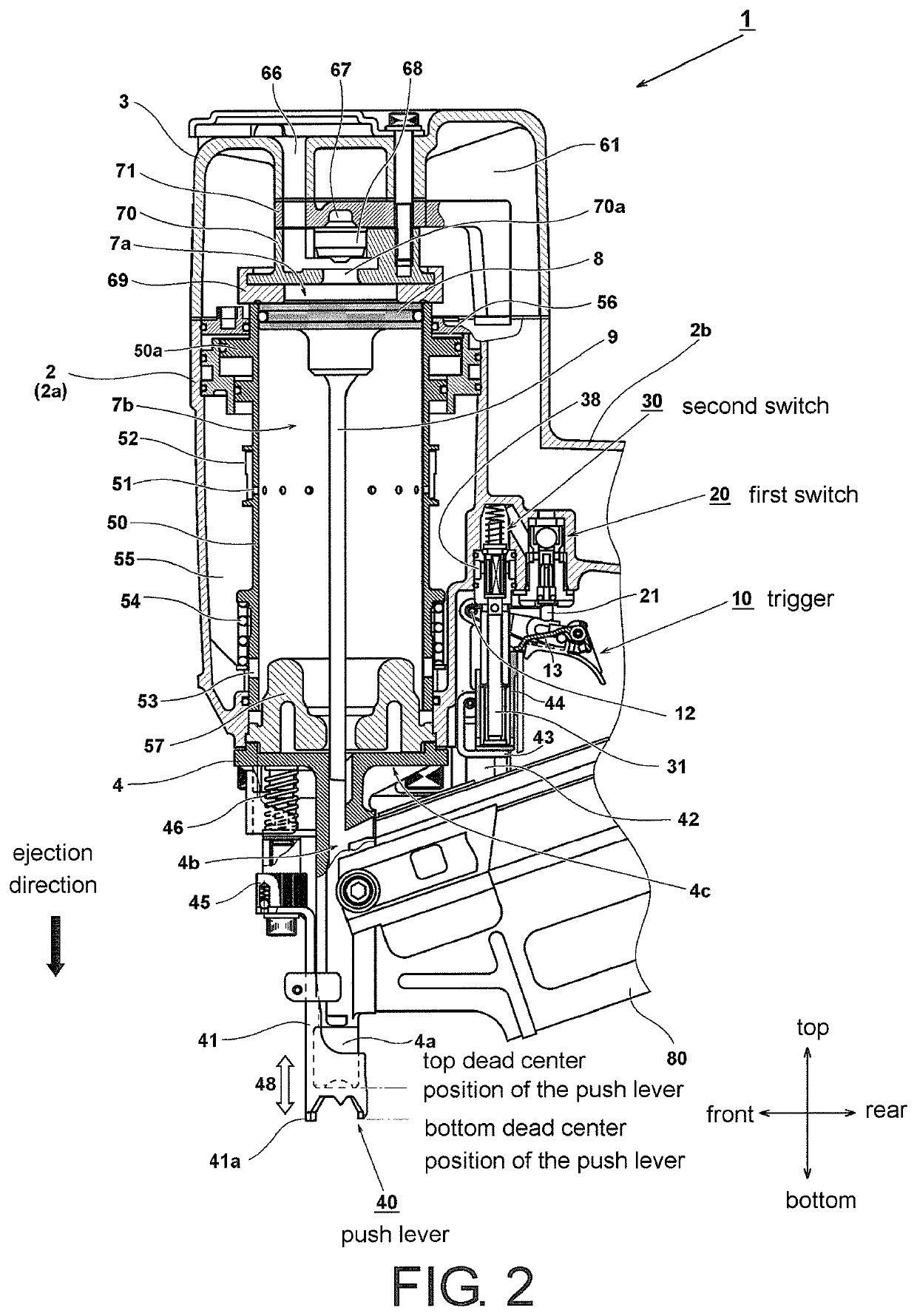

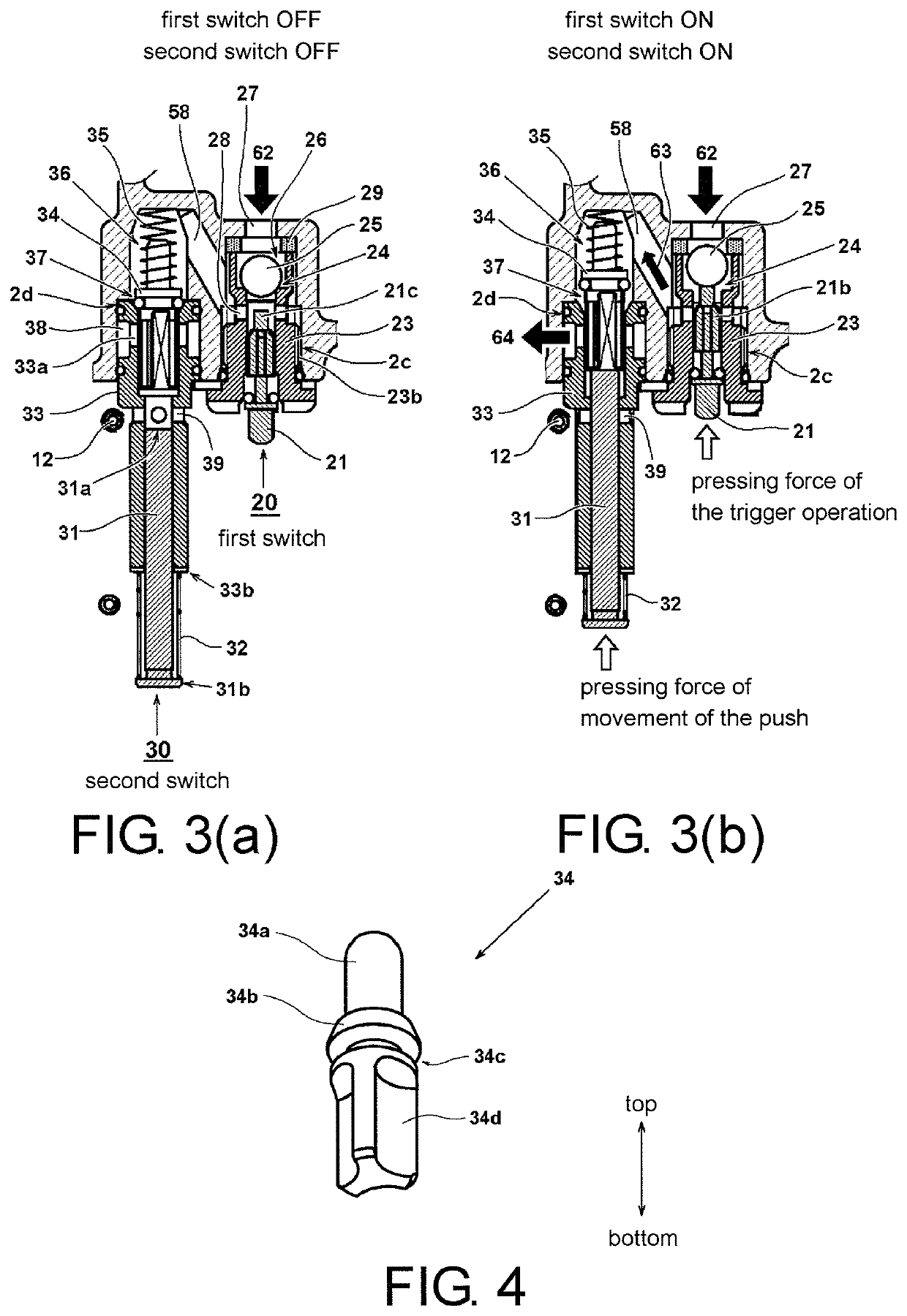

Driving machine

The disclosure discloses a driving machine includes a trigger, a first switch turned on or off by an operation of the trigger, a push lever that moves in response to an operation of pressing an ejection port of a fastener against a driven material, and a second switch turned on or off by movement of the push lever. The driving machine drives the fastener when the first switch and the second switch are both in the ON state. The trigger includes a switching mechanism to switch between a single-shot driving mode and a continuous-shot driving mode.

Owner:KOKI HLDG CO LTD

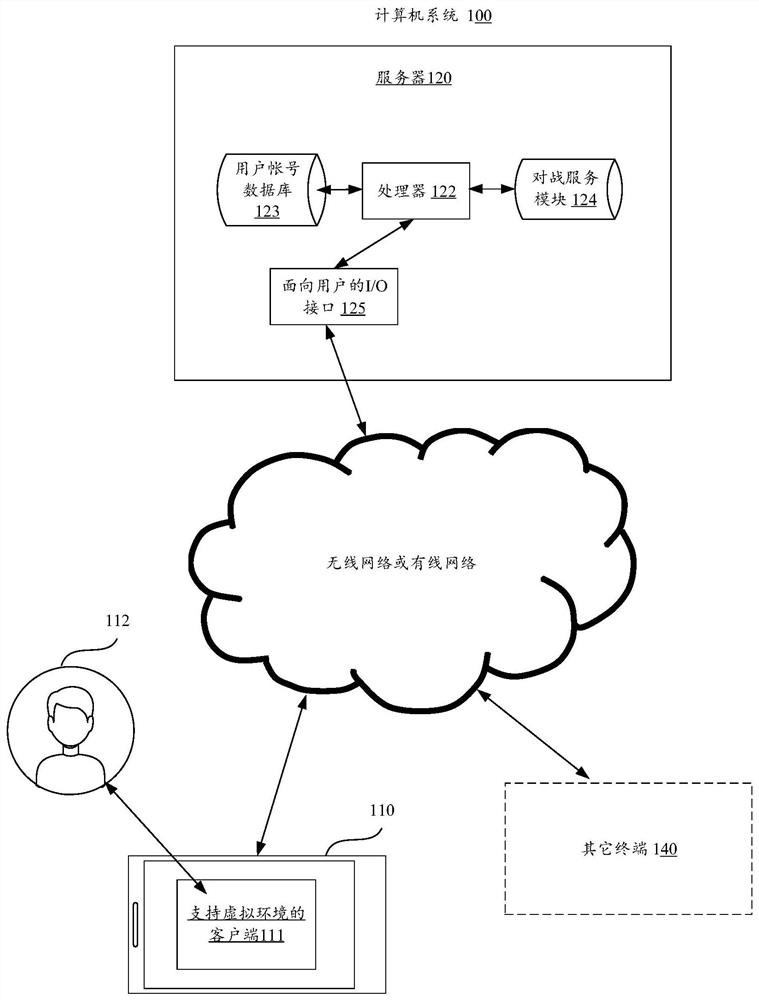

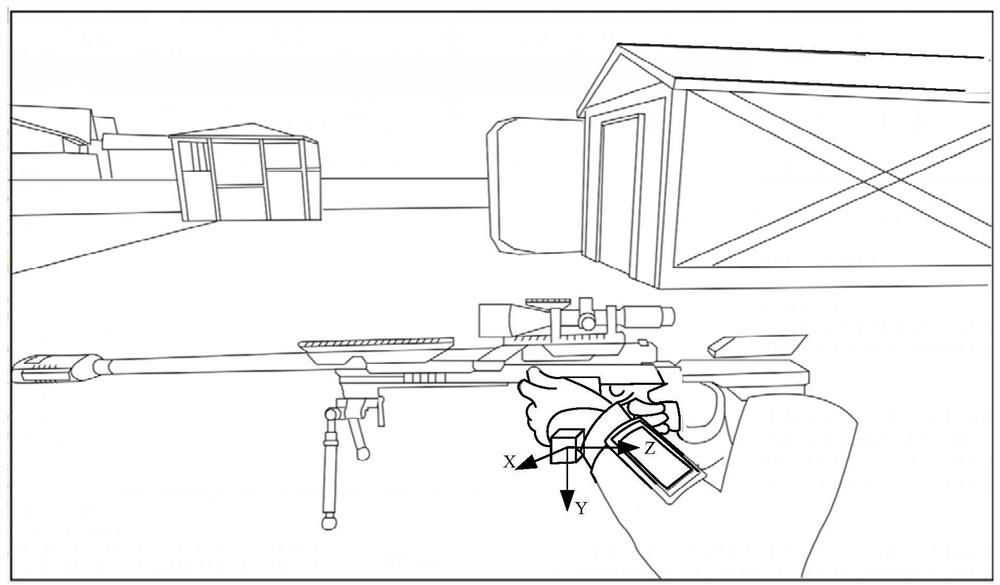

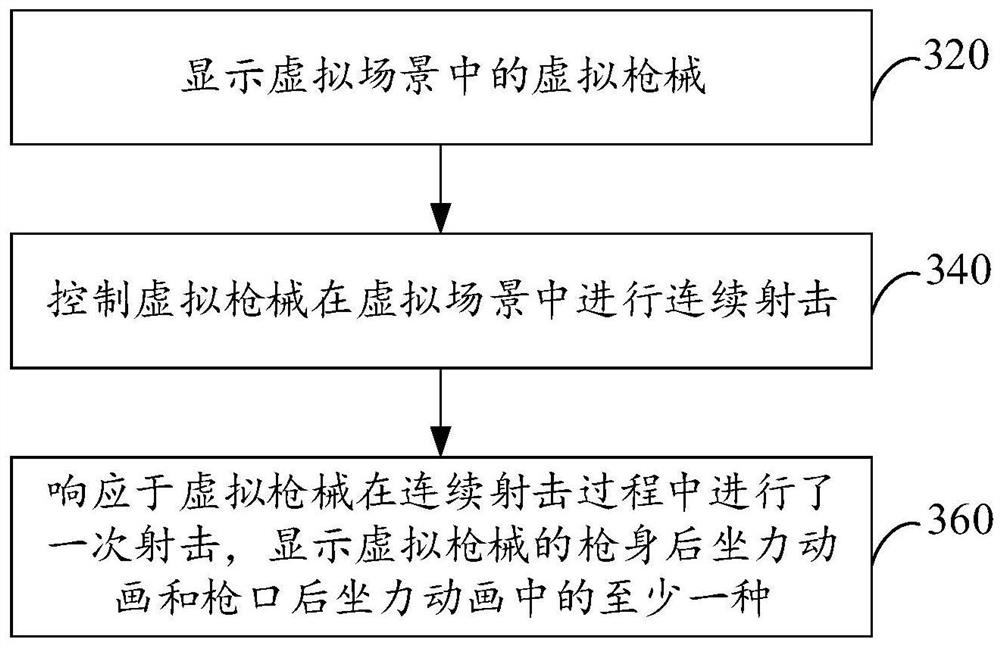

Shooting display method and device of virtual gun, computer equipment and storage medium

The invention discloses a shooting display method and device of a virtual gun, computer equipment and a storage medium, and relates to the technical field of virtual scenes. The method comprises the following steps: displaying a virtual gun in a virtual scene; controlling the virtual gun to continuously shoot in the virtual scene; and displaying at least one of a gun body recoil animation and a muzzle recoil animation of the virtual gun in response to once shooting of the virtual gun in the continuous shooting process, wherein the gun body recoil animation is an animation that a gun body of the virtual gun fluctuates in at least one direction of an X axis and a Y axis according to a fluctuation curve, the muzzle recoil animation is an animation that a muzzle of the virtual gun fluctuates by taking a root node of the virtual gun as a center according to the fluctuation curve, the X axis is used for indicating a horizontal recoil direction of the virtual gun, and the Y axis is used for indicating the vertical recoil force direction of the virtual gun. According to the method and the device, a user can obtain the percussion feeling of real shooting in the process of shooting by using the virtual gun.

Owner:TENCENT TECH (SHENZHEN) CO LTD

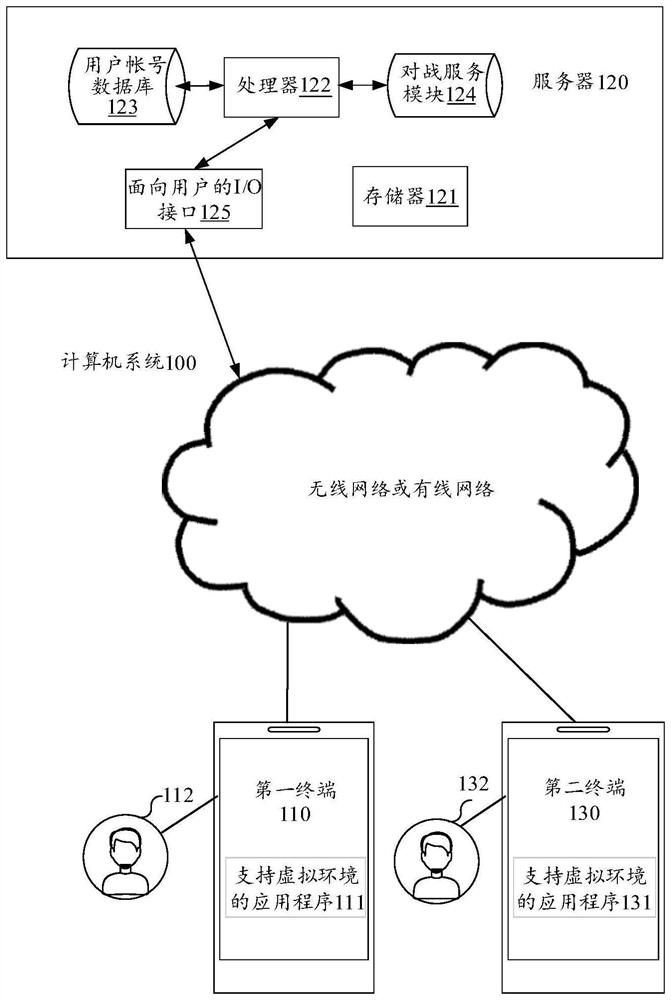

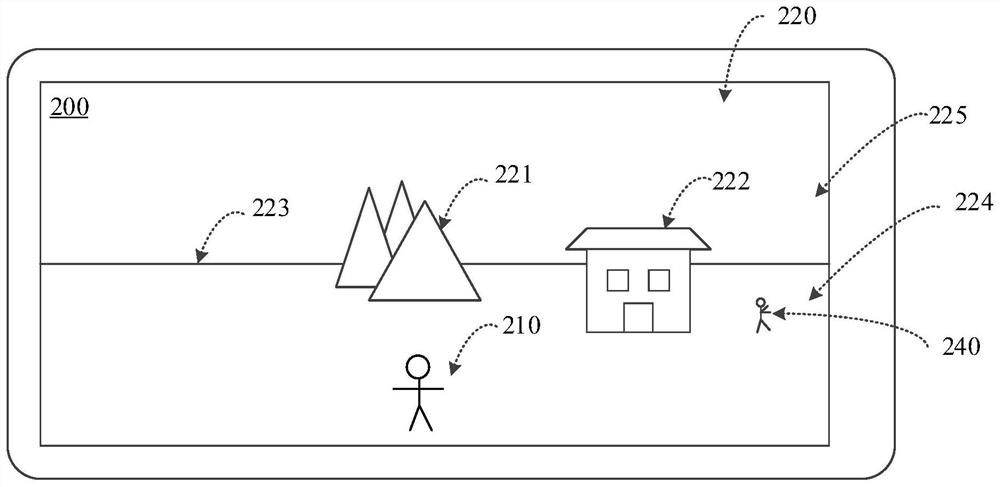

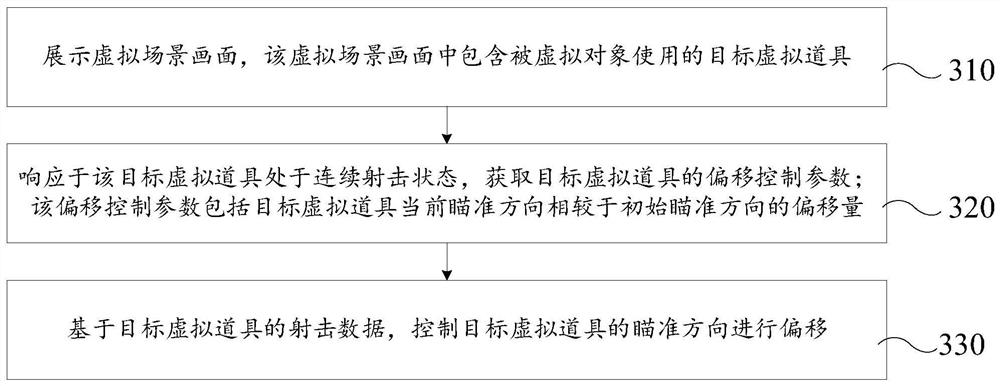

Virtual prop control method and device, computer equipment and storage medium

The embodiment of the invention discloses a virtual prop control method and device, computer equipment and a storage medium, and belongs to the technical field of virtual scenes. The method comprisesthe following steps: displaying a virtual scene picture containing a target virtual prop used by a virtual object; in response to the fact that the target virtual prop is in the continuous shooting state, acquiring an offset control parameter of the target virtual prop including the offset of the current aiming direction of the target virtual prop relative to the initial aiming direction; and controlling the aiming direction of the target virtual prop to deviate based on the deviation control parameter of the target virtual prop. By means of the method, in the control process of the virtual prop, the accumulated offset in the aiming direction influences the subsequent offset process, the aiming direction of the target virtual prop can be conveniently controlled to be kept relatively stablein the continuous shooting process, the man-machine interaction effect in a virtual scene is improved, therefore, the duration of a single battle can be reduced, and the electric quantity and the data flow consumed by the terminal are saved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com