Continuous firing furnace and its use method

A technology for firing furnaces and sintering materials, applied in furnaces, furnace cooling, furnace types, etc., can solve the problems of equipment cost, operation cost increase, thermal efficiency reduction, etc., to achieve the effect of compensating for heat loss and increasing effective space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The continuous firing furnace of the present invention is preferably used when the sintering temperature is above 1600°C and below 2500°C, and its structure is described in detail below.

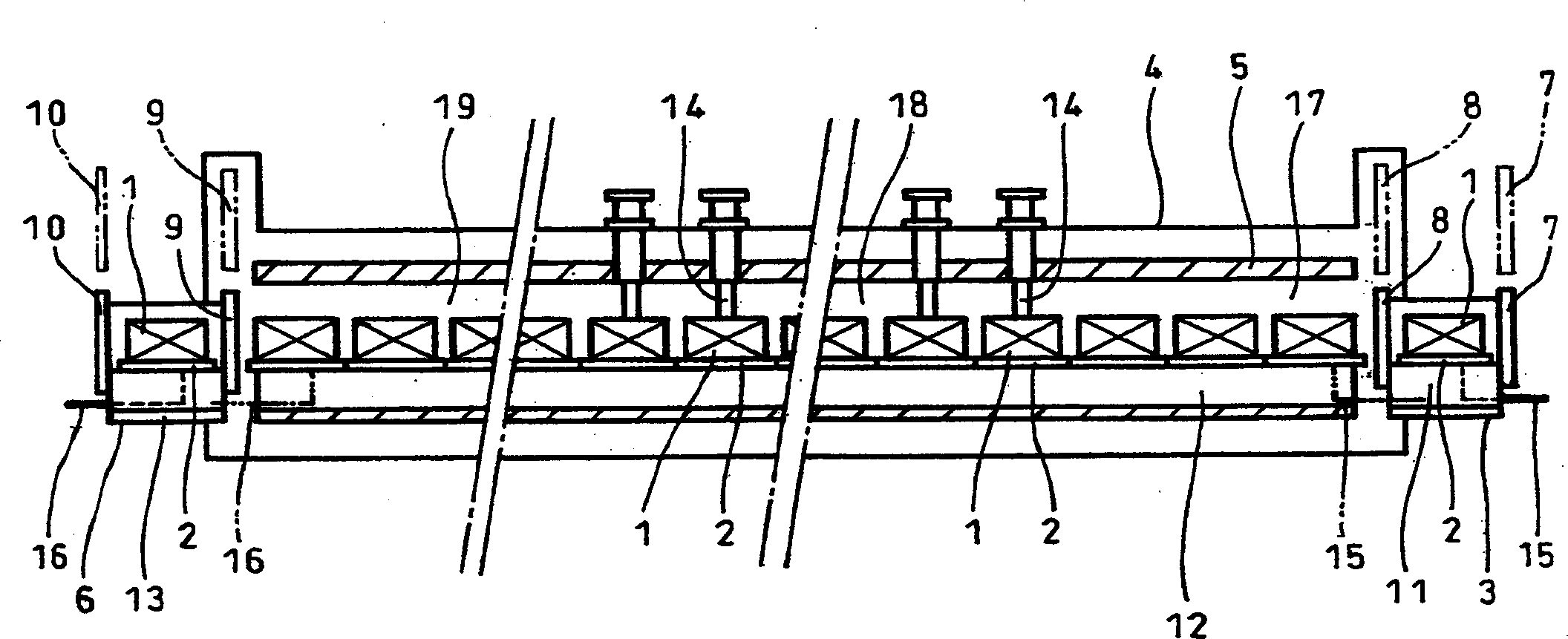

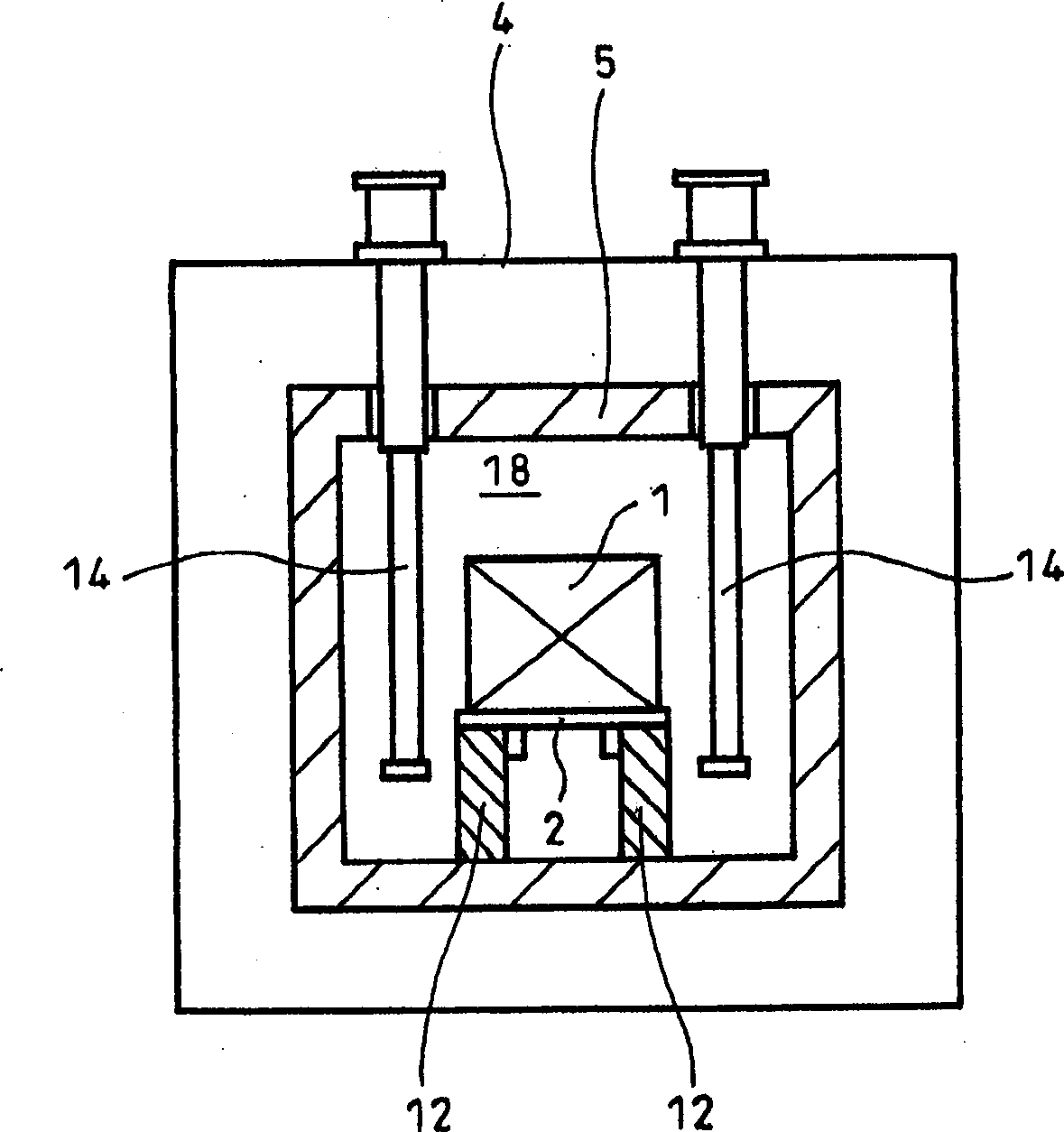

[0067] Figure 4-Figure 9 It is a figure showing embodiment 1 of the continuous firing furnace of the present invention, and is marked with and figure 1 and figure 2 Parts with the same symbols represent the same thing.

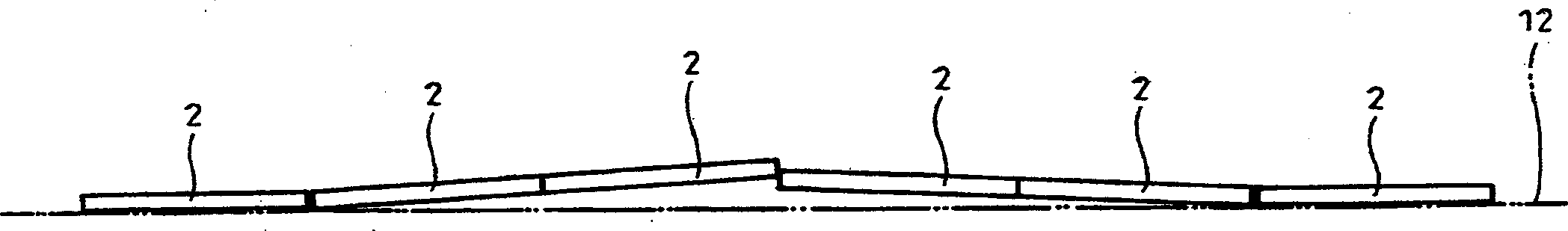

[0068] The continuous sintering furnace comprises: an input side degassing chamber 23 through which a pallet 22 of materials to be sintered 1 can pass; a chamber 24 connected to the input side degassing chamber 23; The firing furnace main body 25 that a plurality of trays 22 that are arranged in a row are sent into successively from input side degassing chamber 23; Air chamber 26; a plurality of free rollers pivotally supported in contact with the lower surface of the tray 22 on substantially the entire length of the firing furnace main body 25 and the downstream...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com