Patents

Literature

245results about "Furnace safety devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

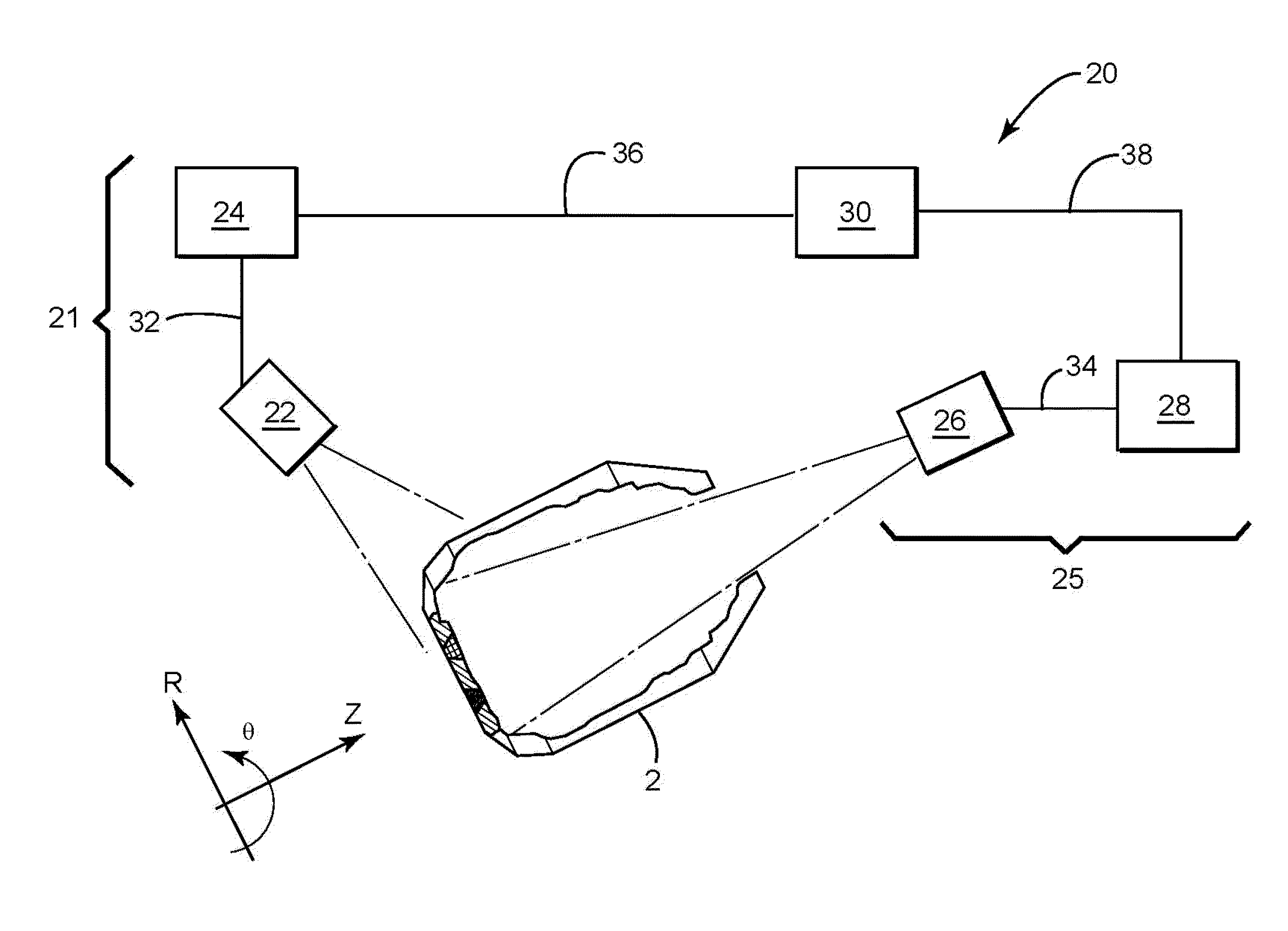

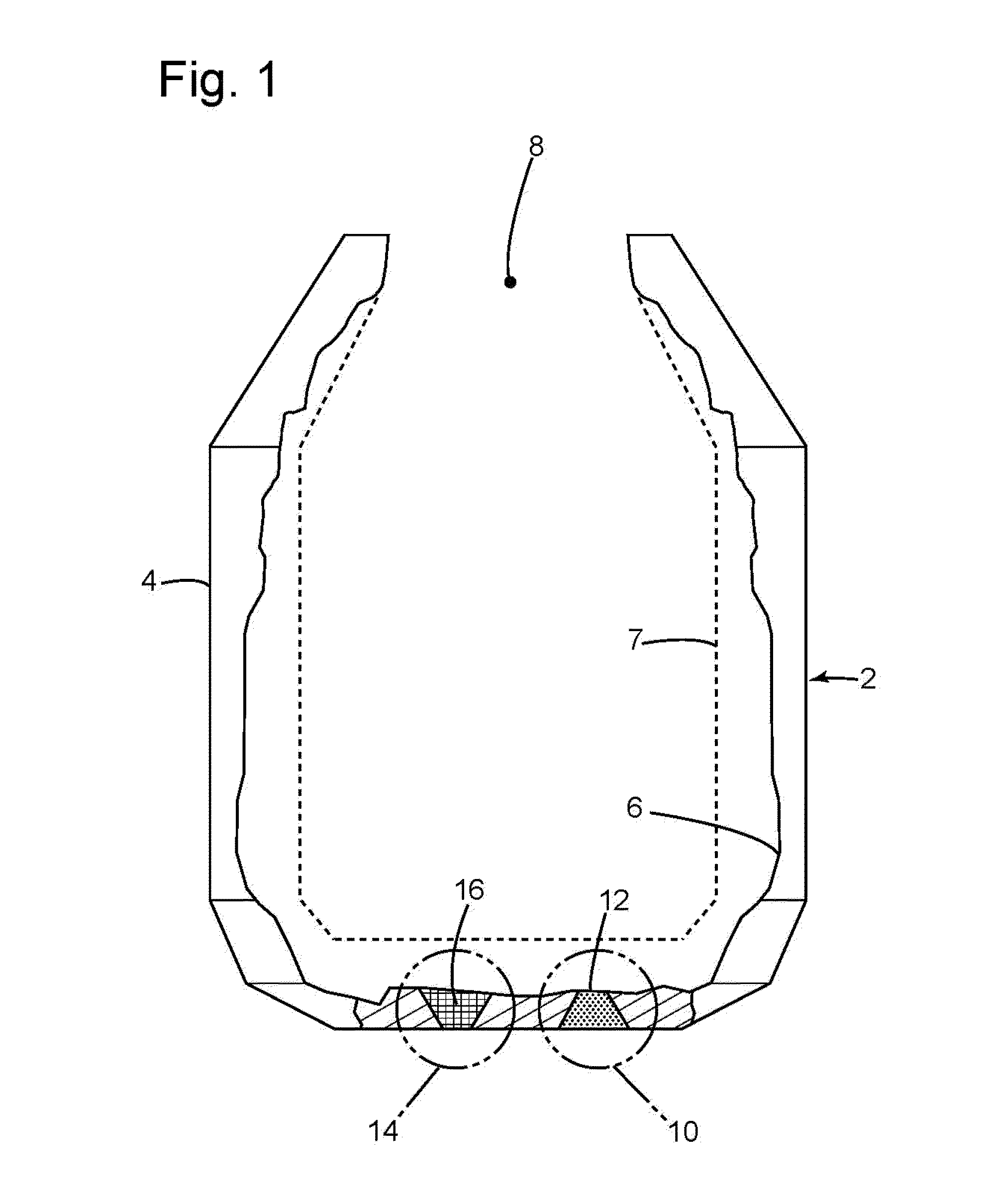

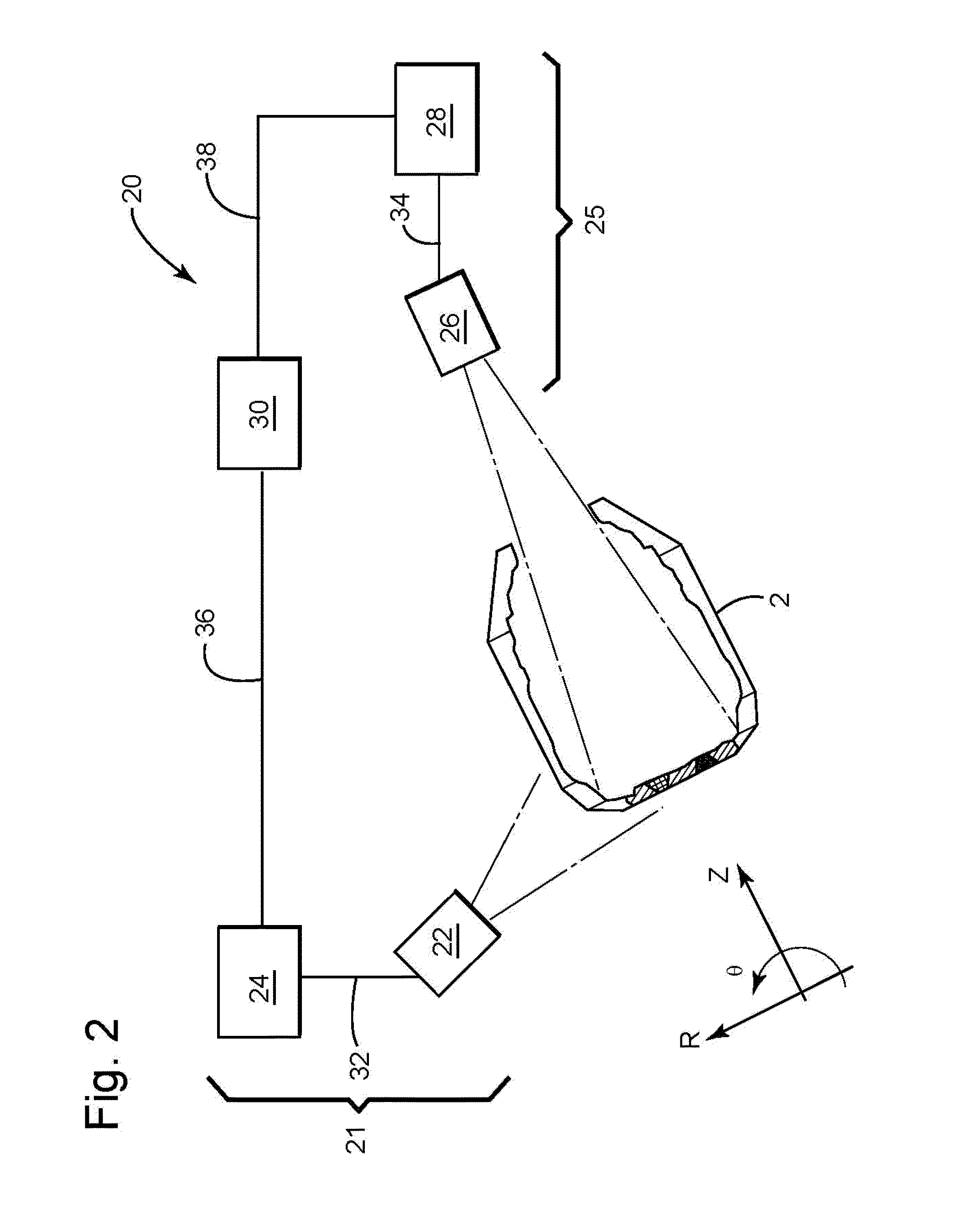

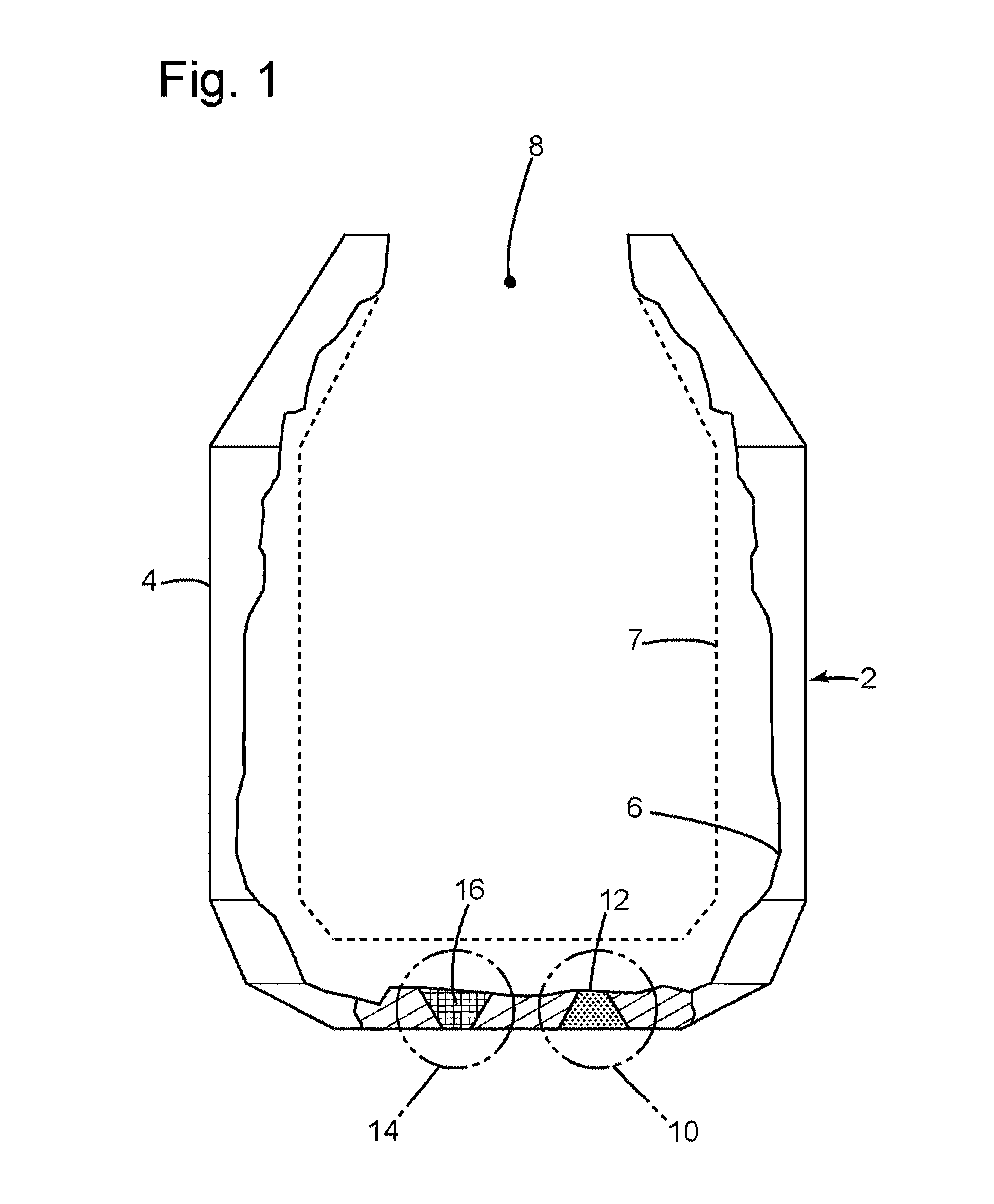

Apparatus, Process, and System for Monitoring the Integrity of Containers

Apparatuses, systems, and methods to monitor the integrity of a container protected by a refractory material are disclosed having a first radiation detector to measure an external surface temperature of the container, a first radiation source to measure a thickness of the refractory material, and a central controller configured to display to a user the measurement of the external surface temperature of the container and the measurement of the thickness of the refractory material.

Owner:PROCESS METRIX

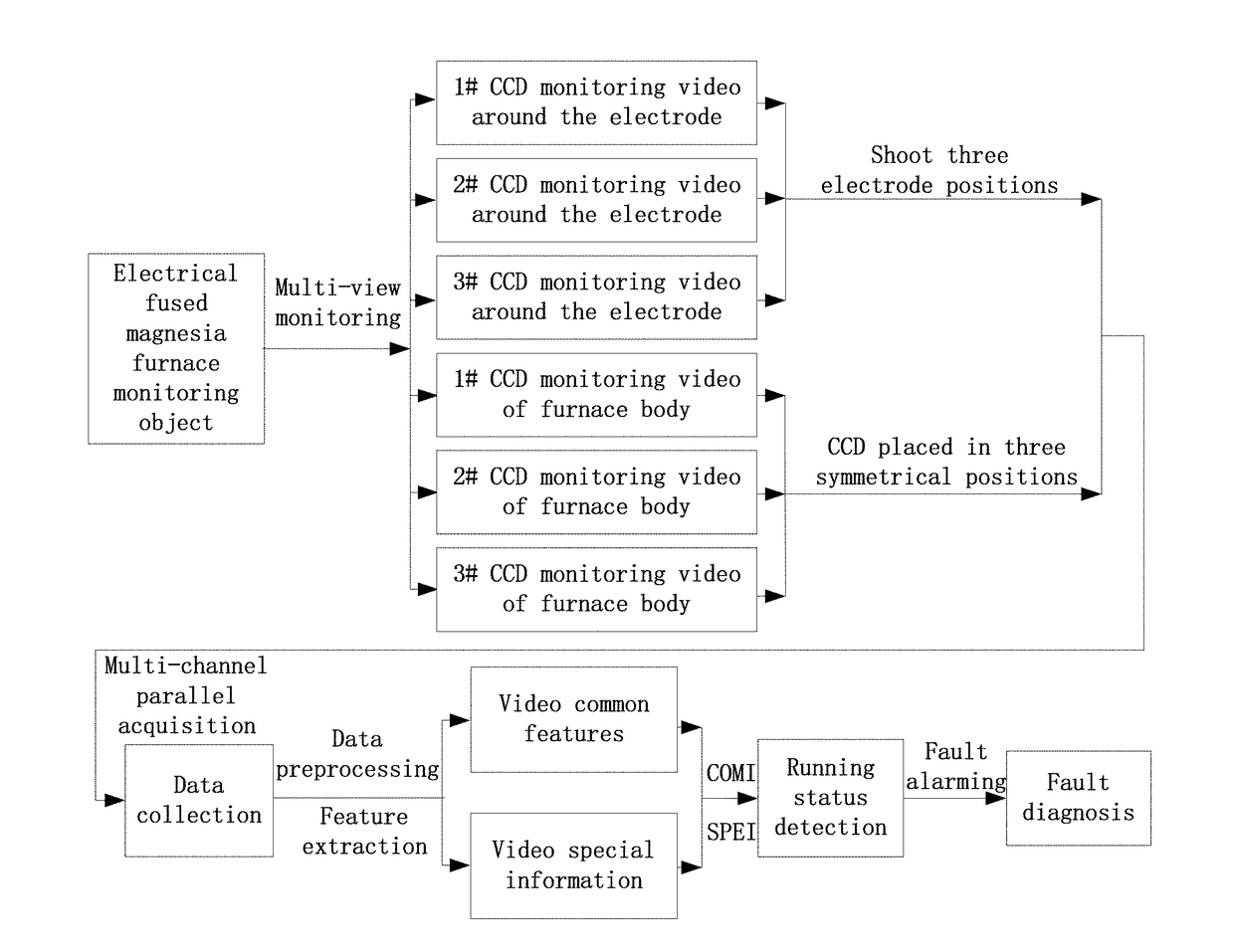

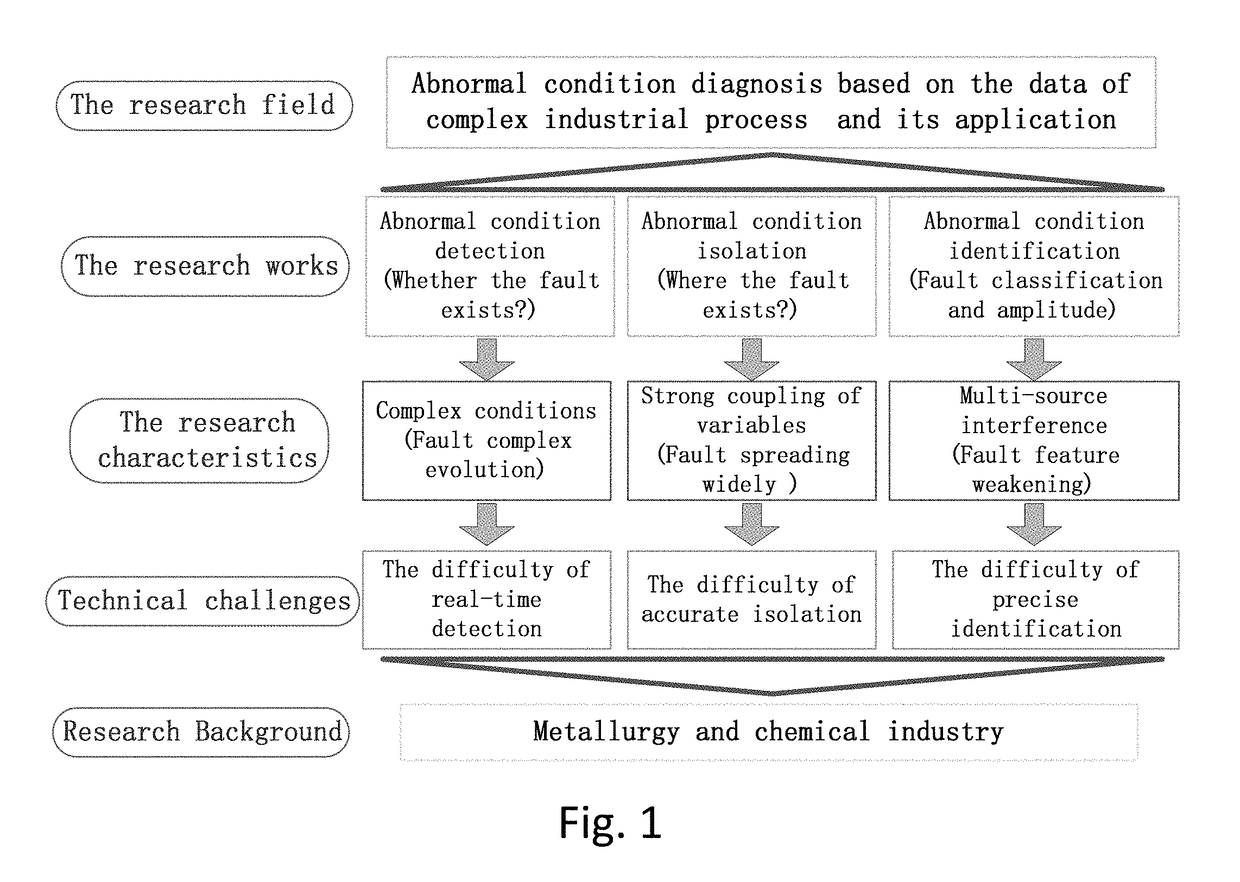

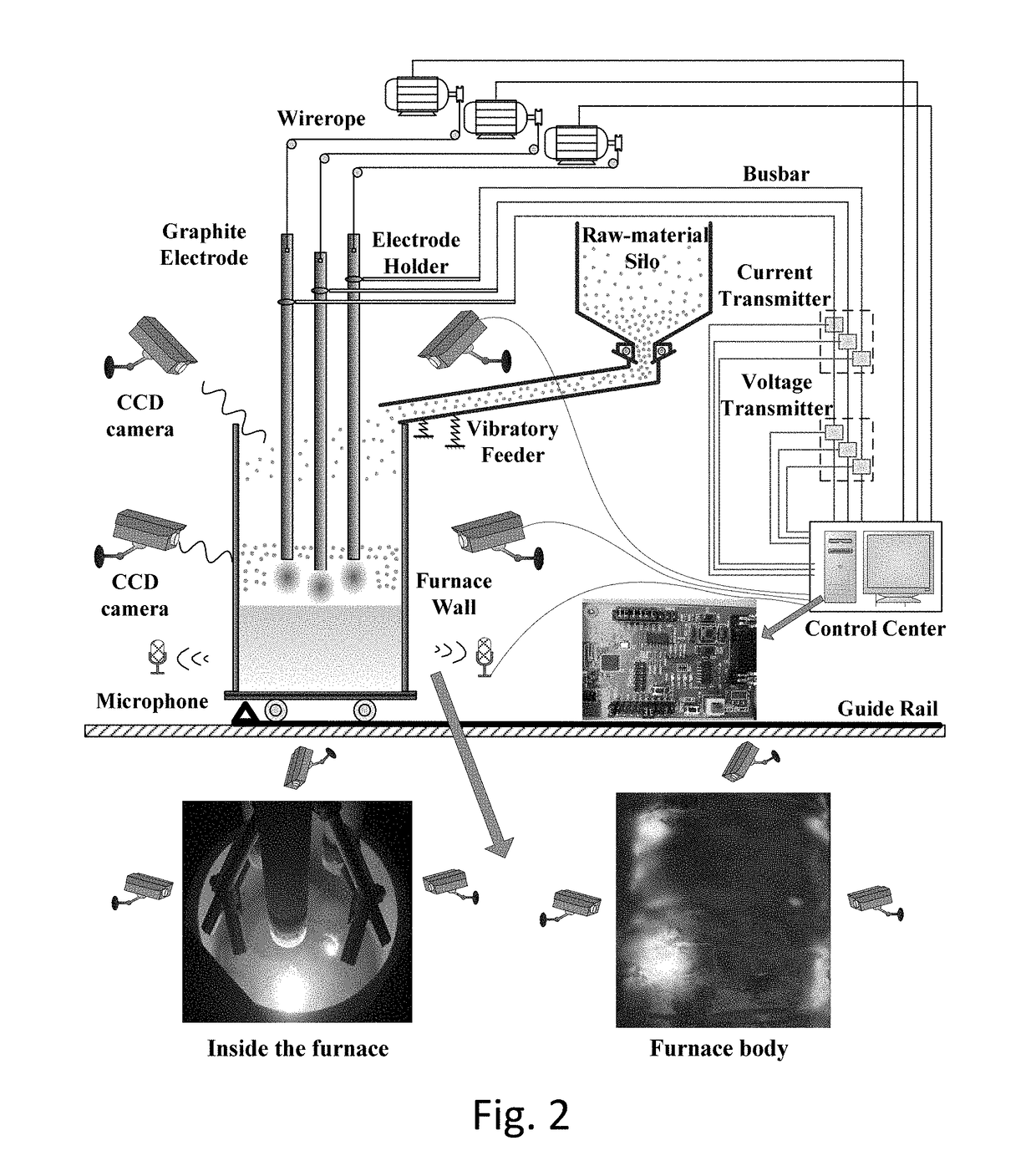

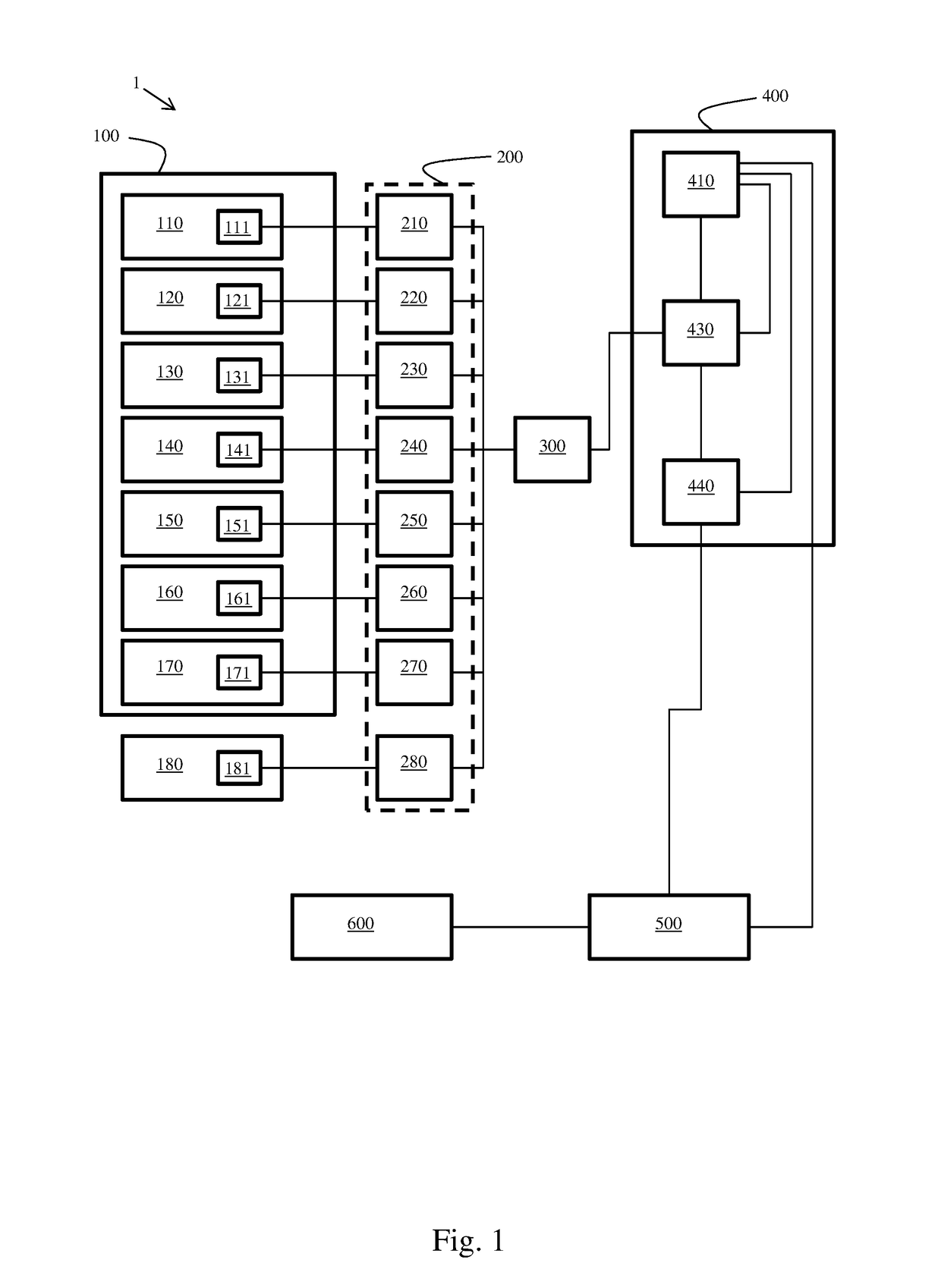

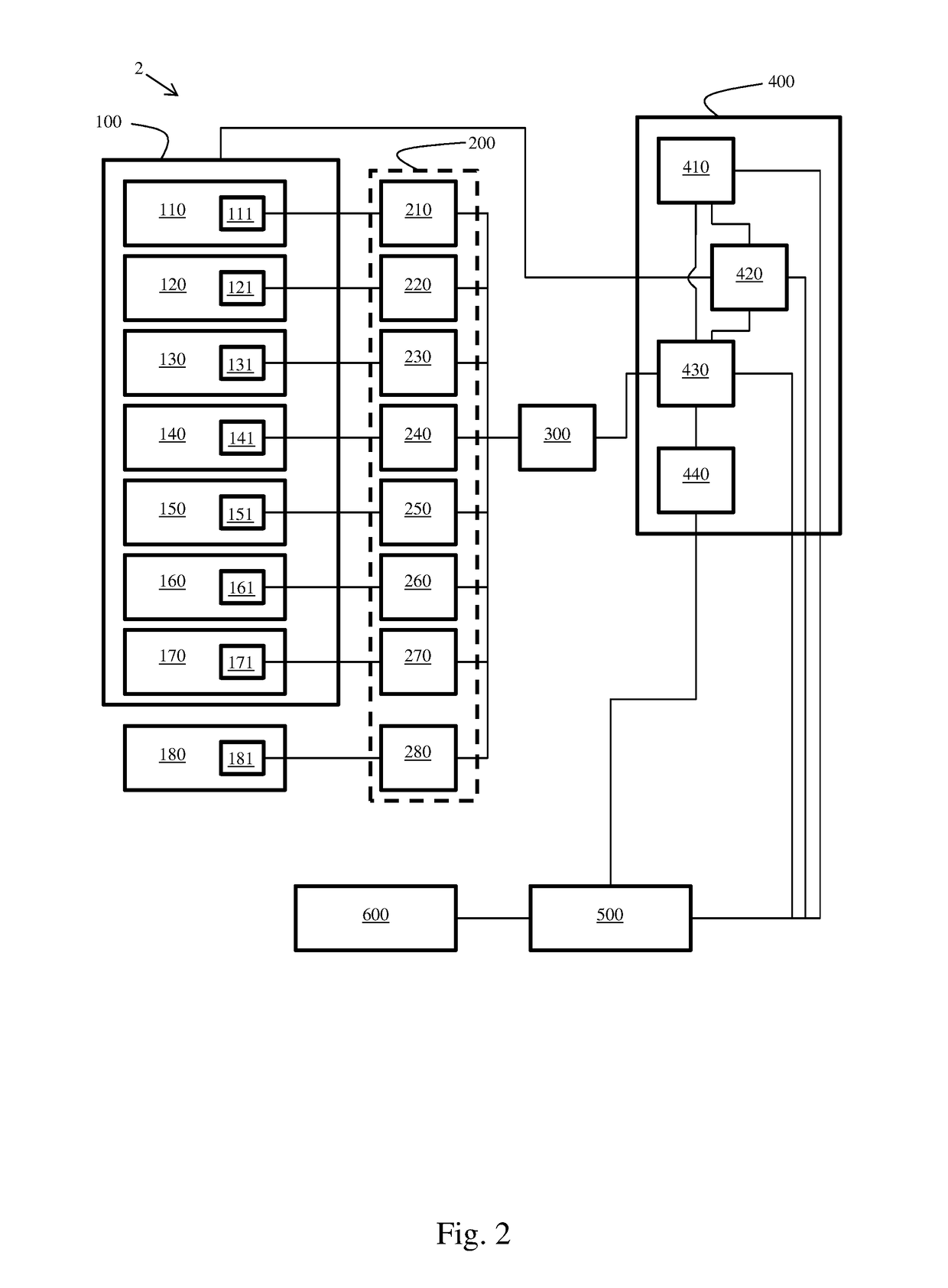

Fault diagnosis device based on common information and special information of running video information for electric-arc furnace and method thereof

ActiveUS20170261264A1Improve performanceEfficient compressionImage enhancementImage analysisElectric arc furnaceView based

A fault diagnosis method for an electrical fused magnesia furnace includes steps of: 1) arranging six cameras; 2) obtaining video information by the six cameras and sending the video information to a control center; then analyzing the video information by a chip of the control center; wherein a multi-view-based fault diagnosis method is used by the chip, comprising steps of: 2-1) comparing a difference between two consecutive frame histograms for shots segmentation; 2-2) computing a set of characteristic values for each shot obtained by the step 2-1), and then computing color, texture, and motion vector information; finally, evaluating shot importance via entropy; 2-3) clustering shots together by calculating similarity; 2-4) generating and optimizing a multi-view video summarization with a multi-objective optimization model; and 2-5) providing fault detection and diagnosis; and 3) displaying results of the fault detection and diagnosis on a host computer inter face of the control center.

Owner:NORTHEASTERN UNIV

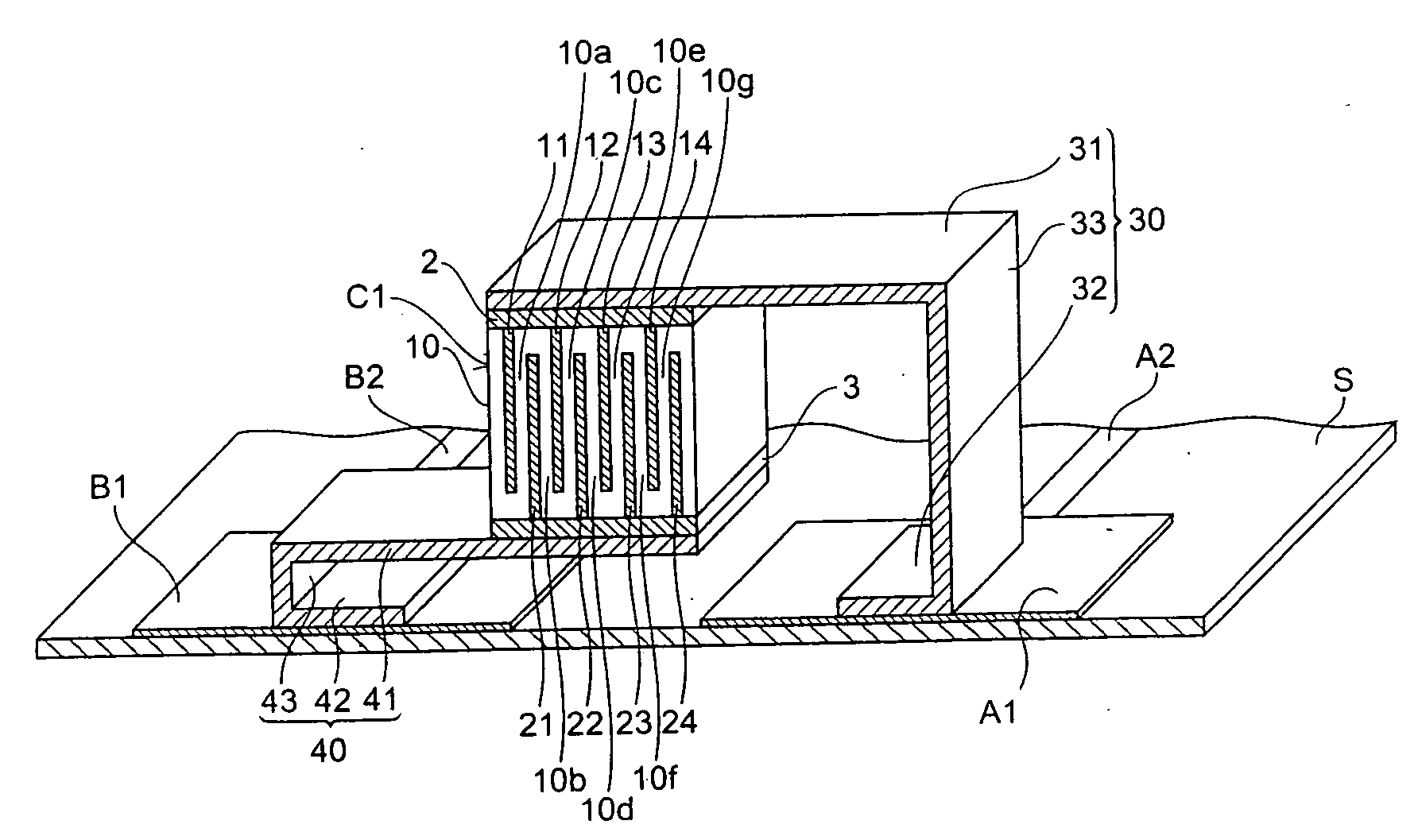

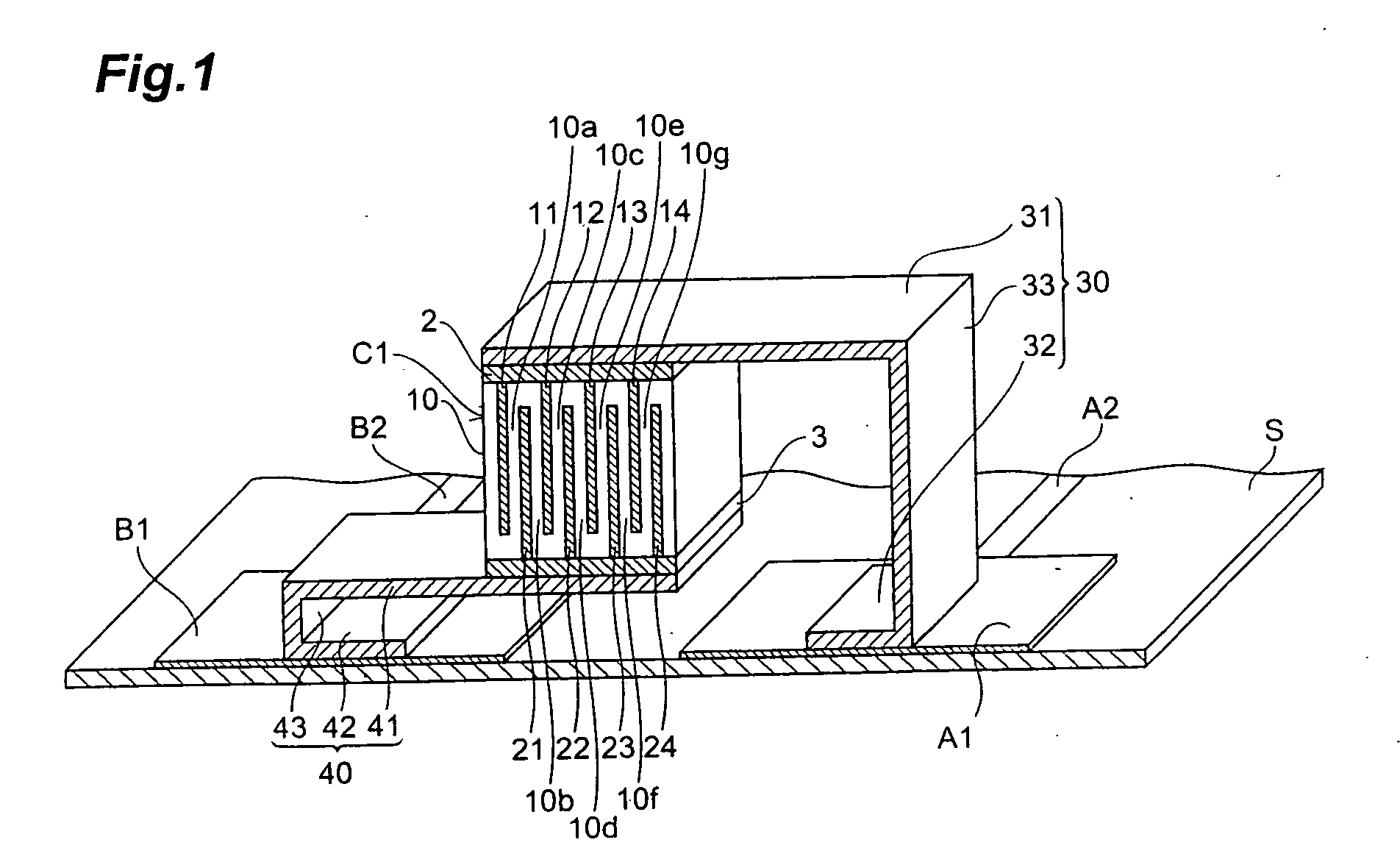

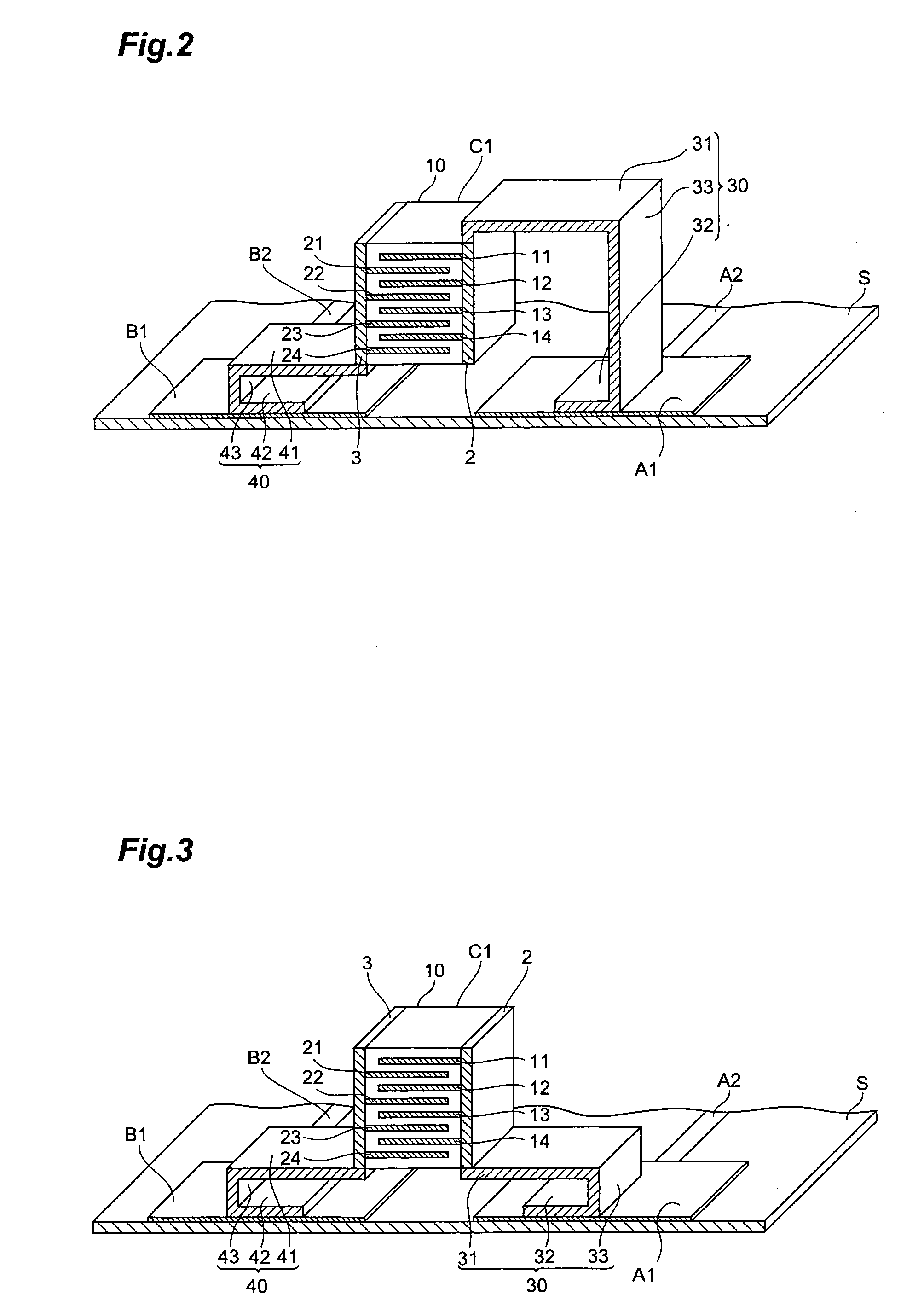

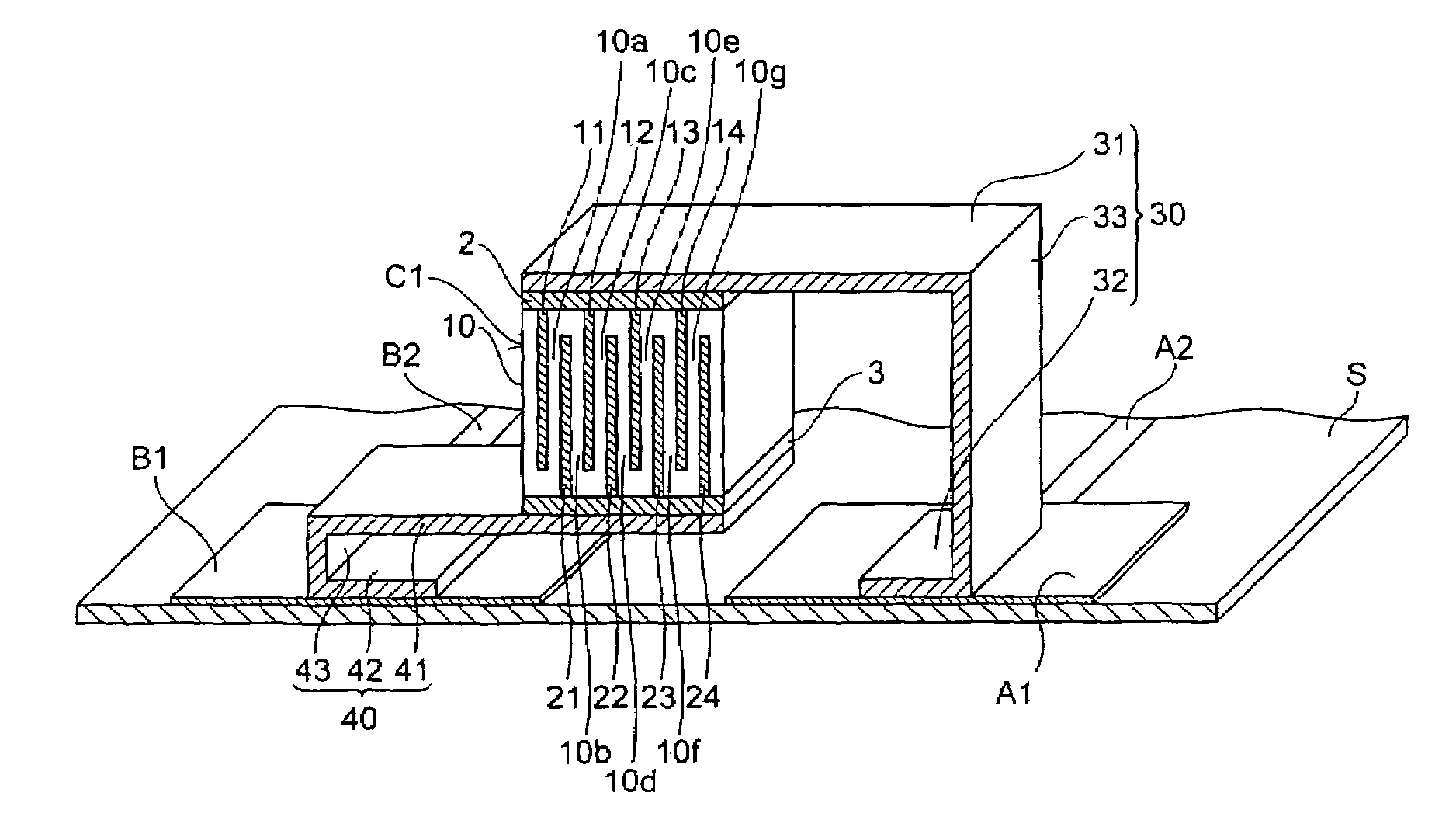

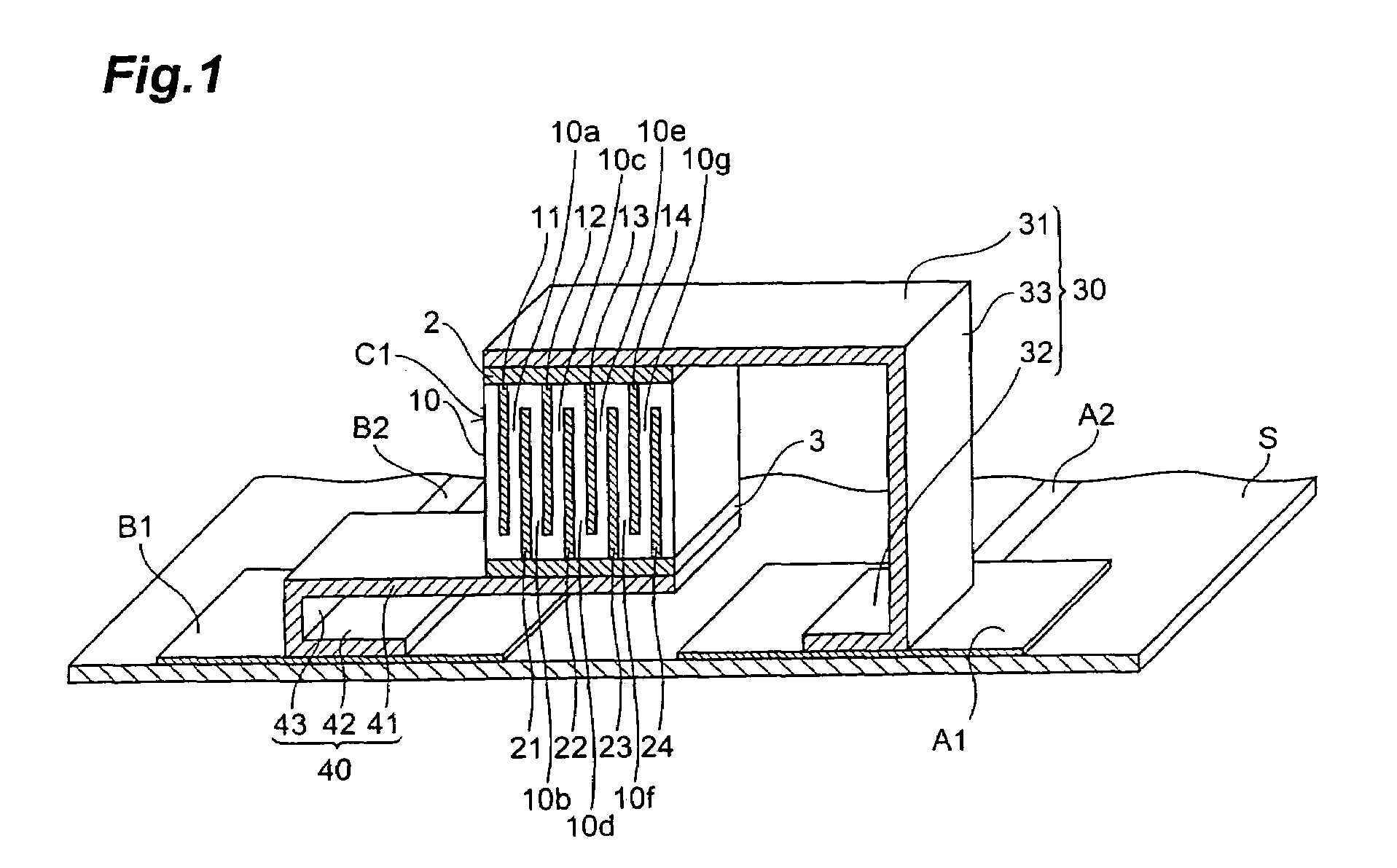

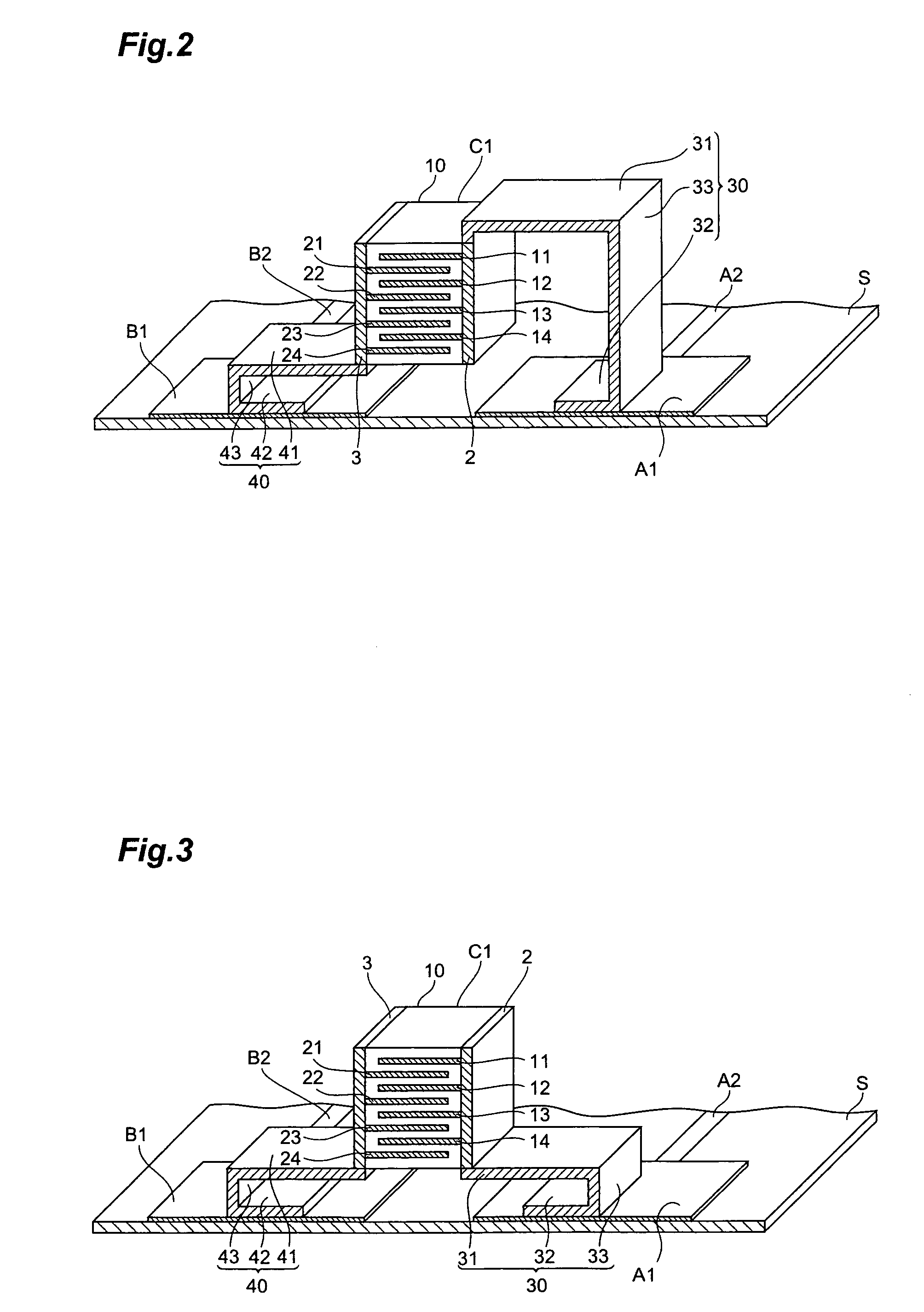

Ceramic capacitor mounting structure and ceramic capacitor

ActiveUS20070188975A1Reduce the soundAbsorb vibrationFurnace safety devicesFinal product manufactureCeramic sinteringCeramic capacitor

A ceramic capacitor comprises a ceramic sintered body, and first and second terminal electrodes formed on outer surfaces of the ceramic sintered body. The first terminal electrode is electrically connected to a land formed on a substrate through a first metal terminal. The first metal terminal has a first capacitor connecting portion mechanically connected to the first terminal electrode, a first terminal portion mechanically connected to the land, and a first intermediate portion electrically connecting the first capacitor connecting portion and the first terminal portion to each other. The first capacitor connecting portion of the first metal terminal is parallel to the substrate.

Owner:TDK CORPARATION

Continuous firing furnace and its use method

InactiveCN1346960AMake up for heat lossIncrease effective spaceFurnace safety devicesCharge manipulationEngineeringContinuous Firing

A continuous sintering furnace has an entrance-side deaerating chamber through which trays each with an material to be sintered being mounted thereon may pass, preheating, heating and cooling zones into which the trays are sequentially fed from the deaerating chamber, an exit-side deaerating chamber through which the trays having passed through the cooling zone may pass, a pusher for pushing the tray from the deaerating chamber to the preheating zone, a puller for pulling the tray from the cooling zone to the deaerating chamber, an intermediate puller for pulling the tray from the heating zone to the cooling zone, a vertically movable door between the deaerating chamber and the preheating zone, a vertically movable intermediate door adjacent to the door and arranged at an upstream end of the preheating zone in the direction of transportation of the trays, a vertically movable intermediate door between the heating and cooling zones and a vertically movable door between the cooling zone and the deaerating chamber. With the door being at a lowered position thereof for closing, heat input is suppressed to the cooling zone. Movement of the trays in the cooling zone is effected by the intermediate puller so as to decrease the number of trays needing to be pushed by the pusher.

Owner:IHI CORP

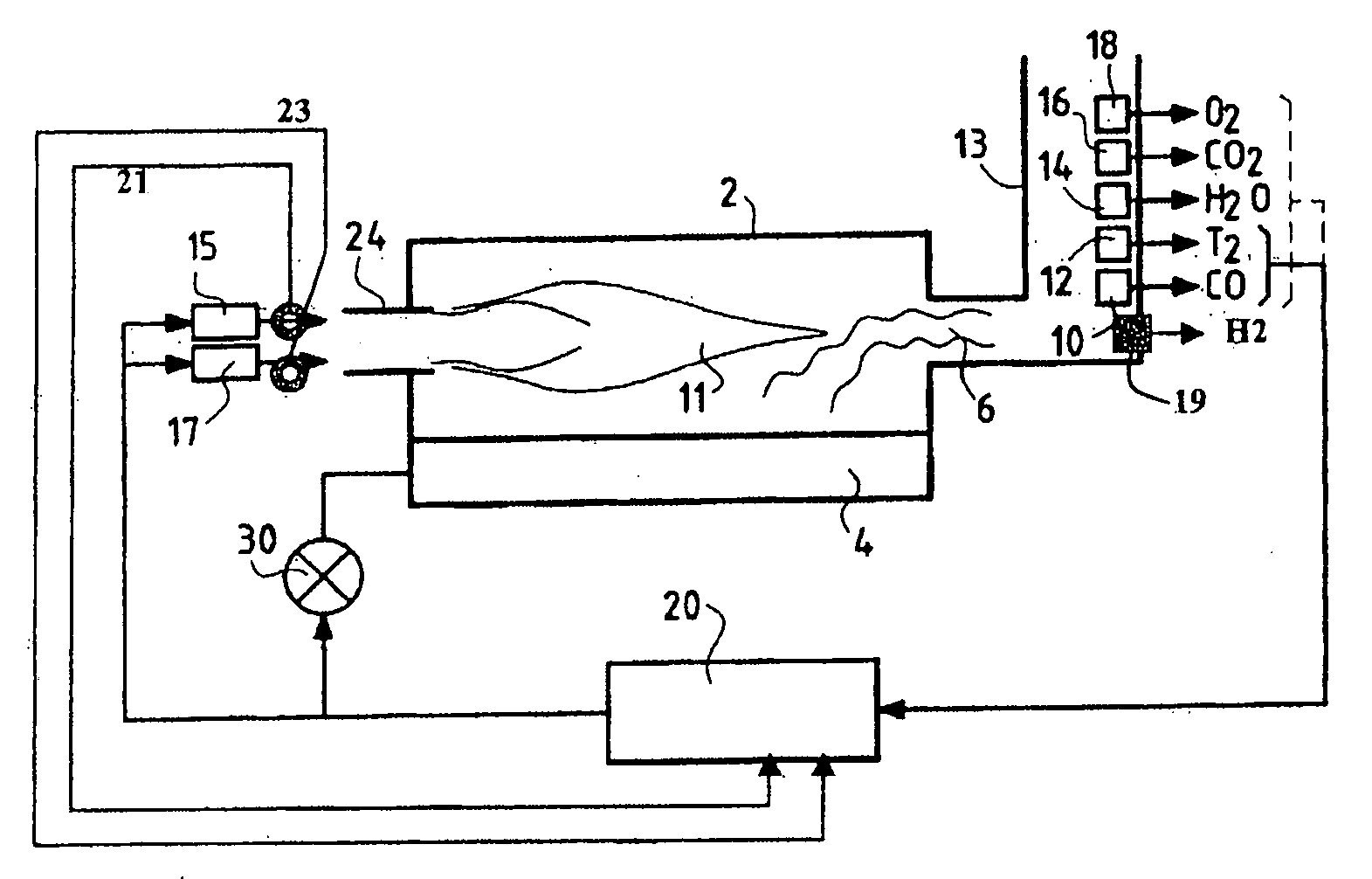

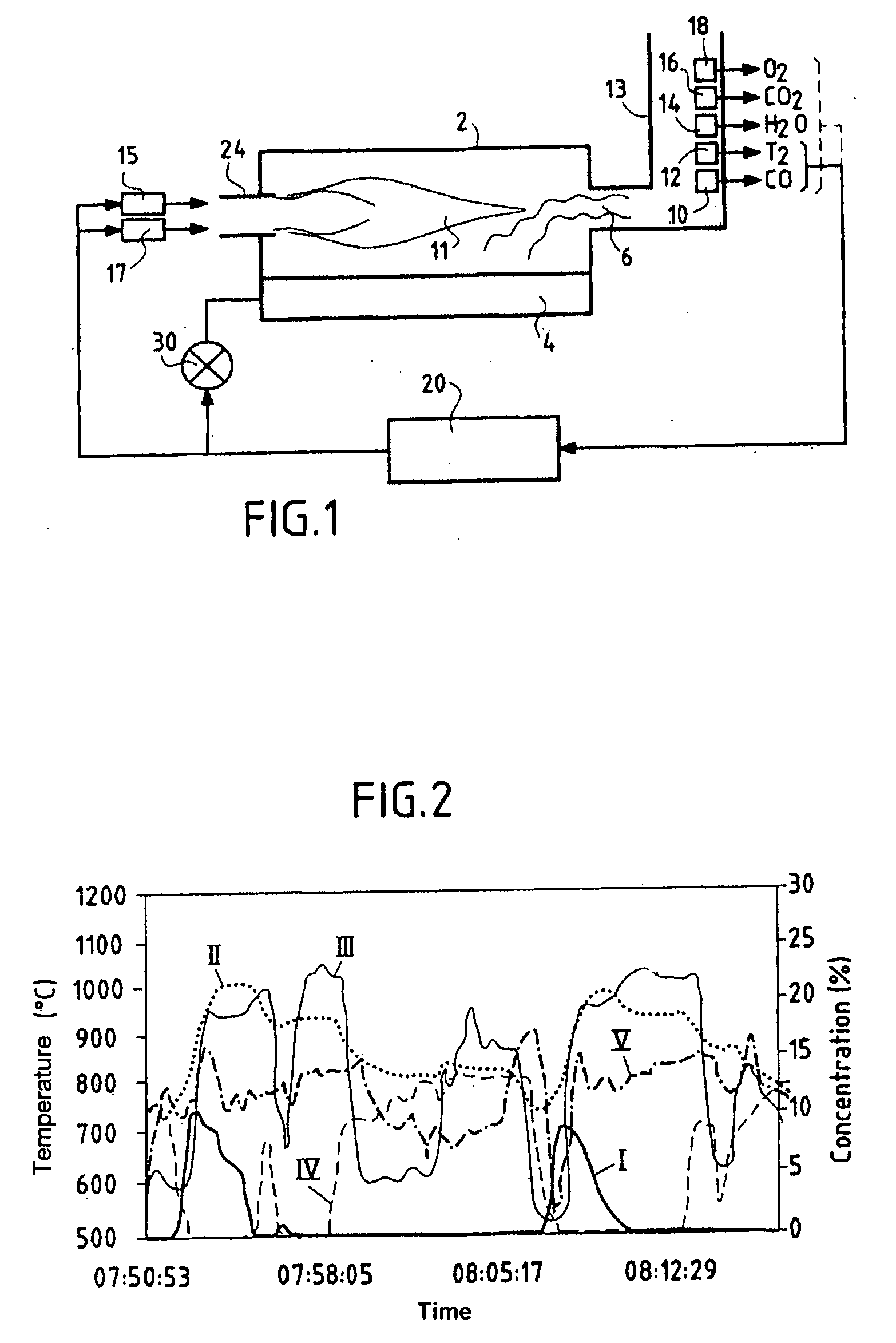

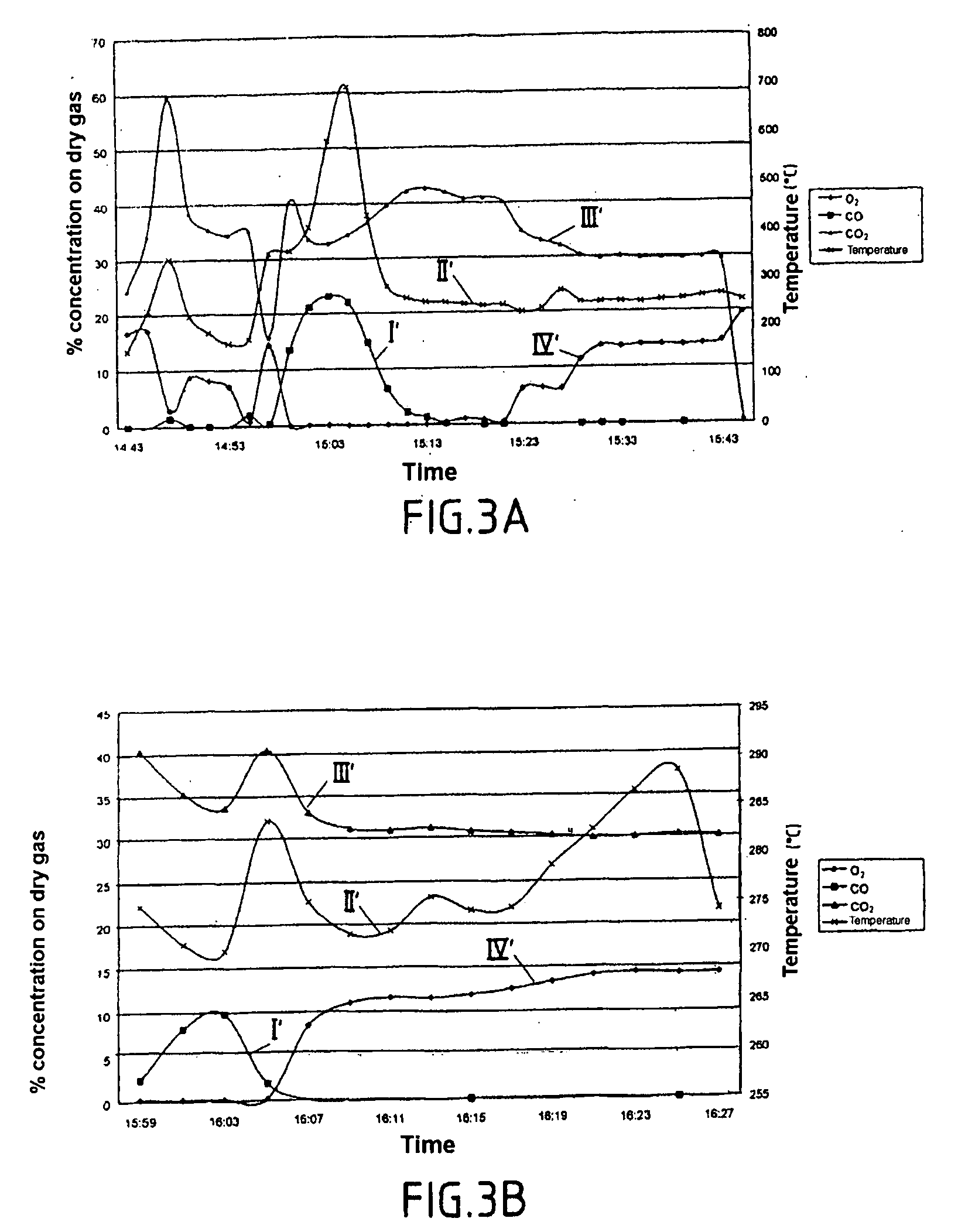

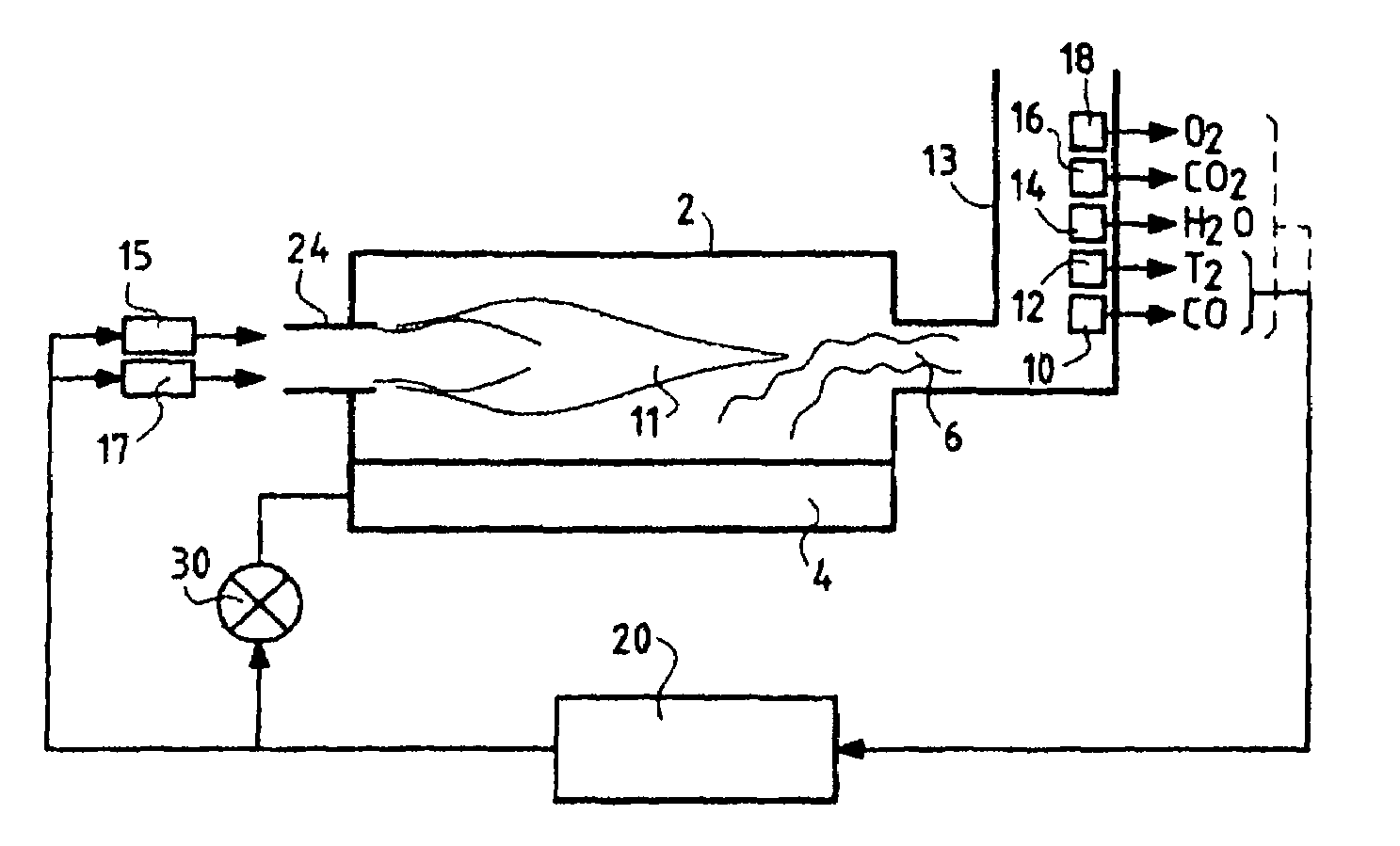

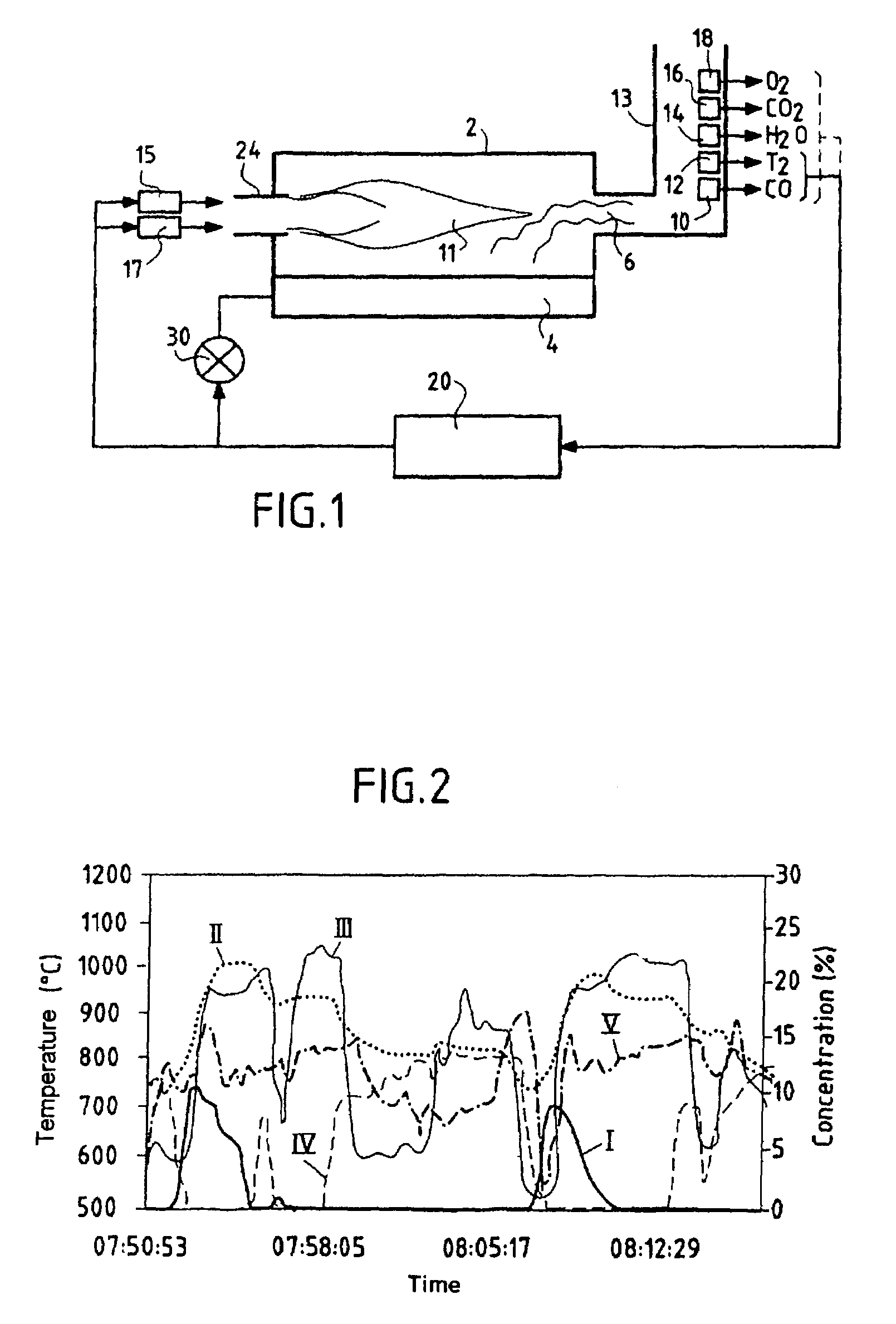

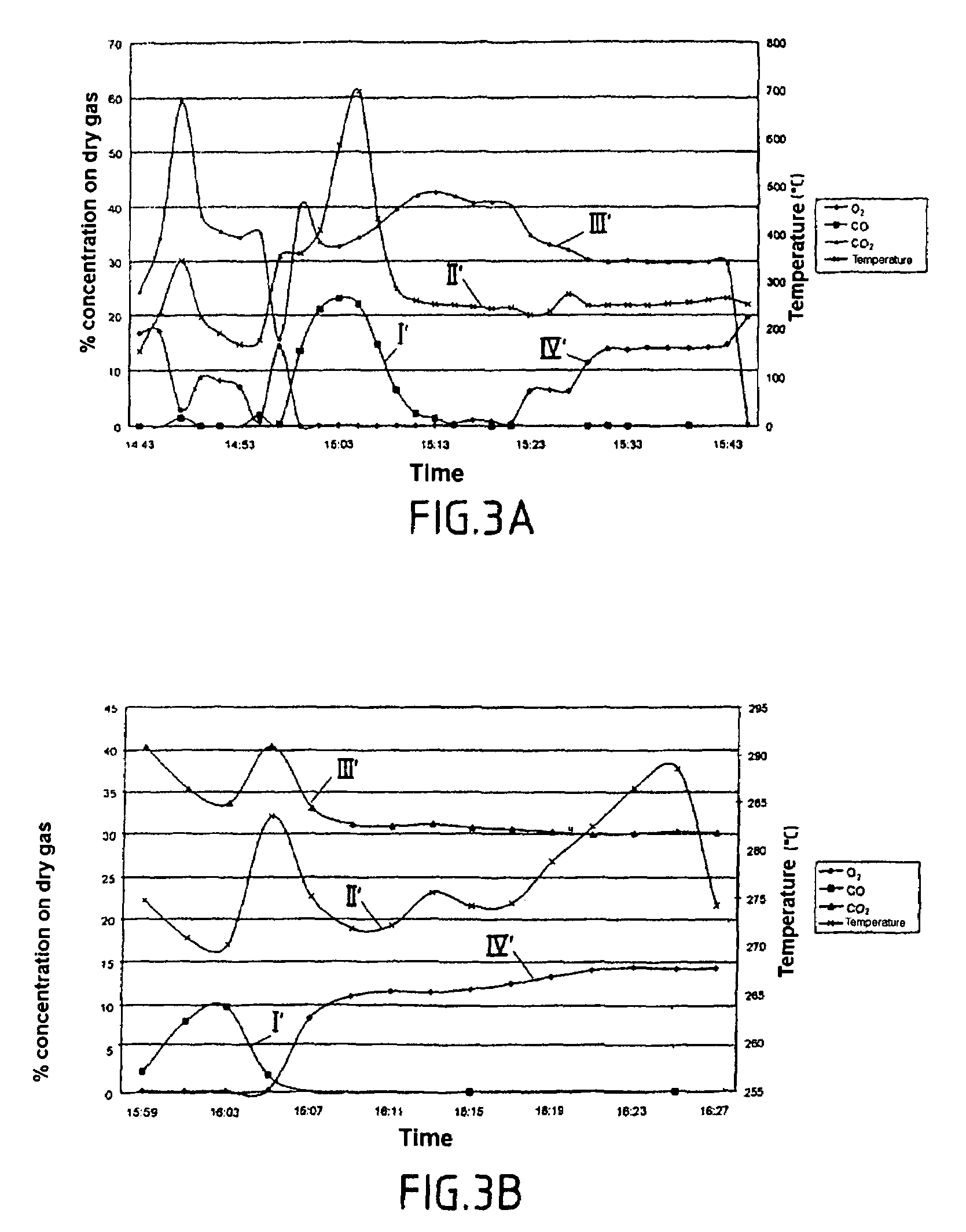

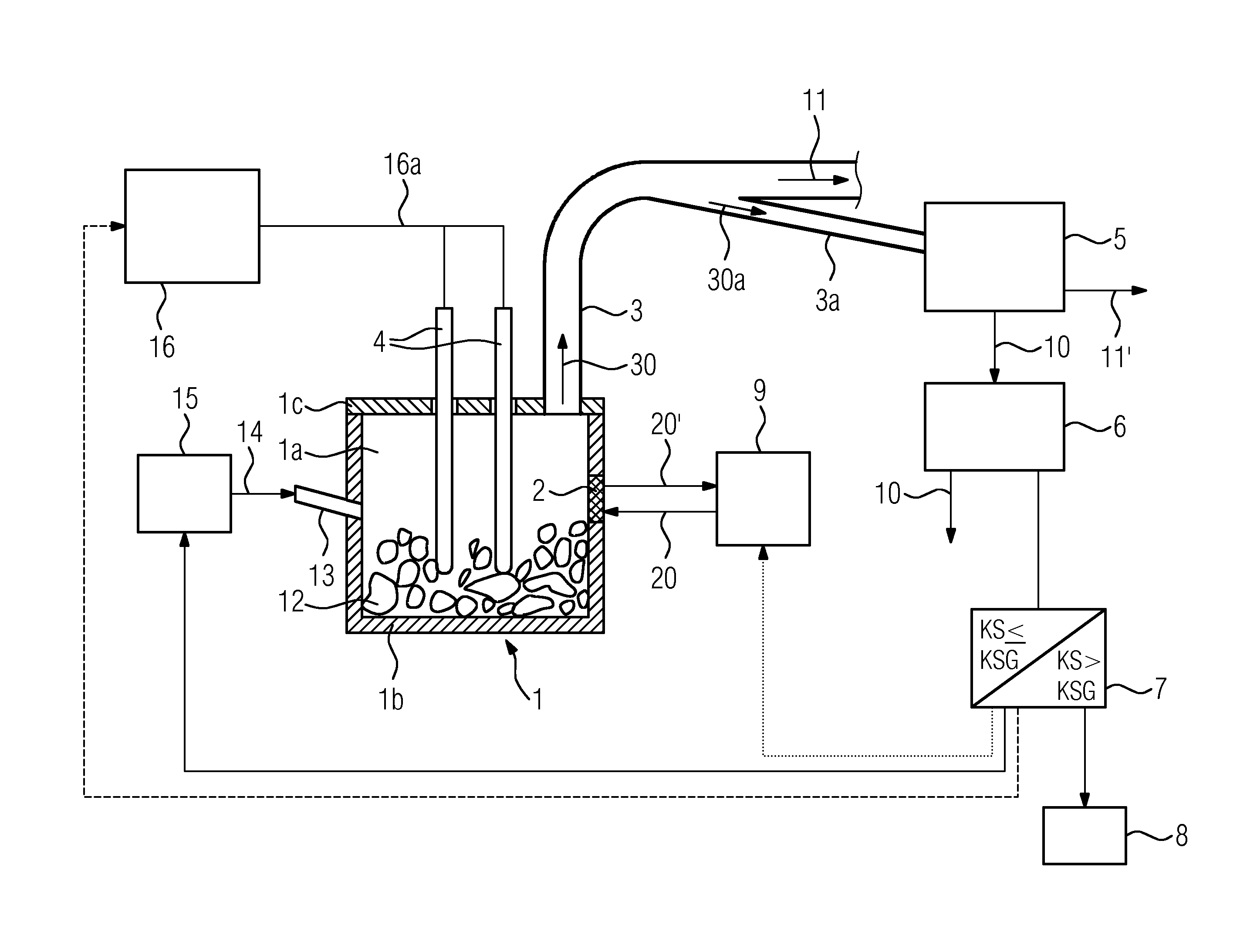

Aluminum melting method using analysis of fumes coming from the furnace

The invention concerns an alumnium melting method, which consists in introducing solid aluminium into a furnace (2), melting the aluminium to form an aluminium bath (4), detecting variations in carbon monoxide (CO) and / or hydrogen (H2) concentration and the temperature in the fumes (6) exiting from the furnace, deducing therefrom the formation of aluminium oxide at the surface of the alumnium bath (4), regulating the melting process on the basis of aluminium oxide formation. The invention also concerns a device for detecting and analyzing fumes exiting from the furnace and an aluminium melting furnace comprising said detecting device.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Aluminum melting method using analysis of fumes coming from the furnace

A process and a device for melting aluminum where solid aluminum is melted in a furnace to form aluminum melt pool. The temperature and carbon monoxide (CO) concentration of the flue gas generated in the melting process is detected and examined for variations. Using this variation information, it is determined if aluminum oxides have formed on the surface of the aluminum melt pool and if they have, the melting process is regulated accordingly.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

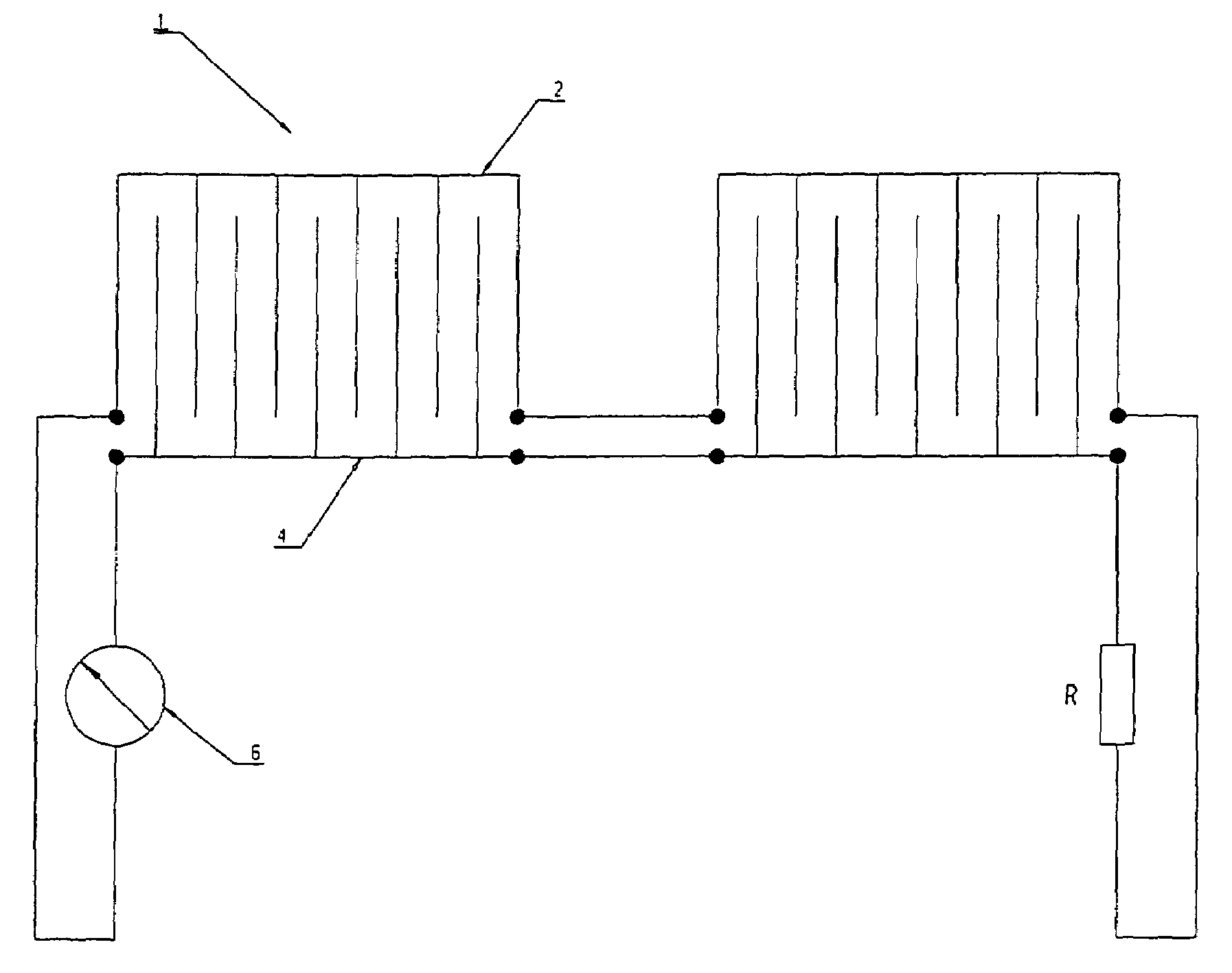

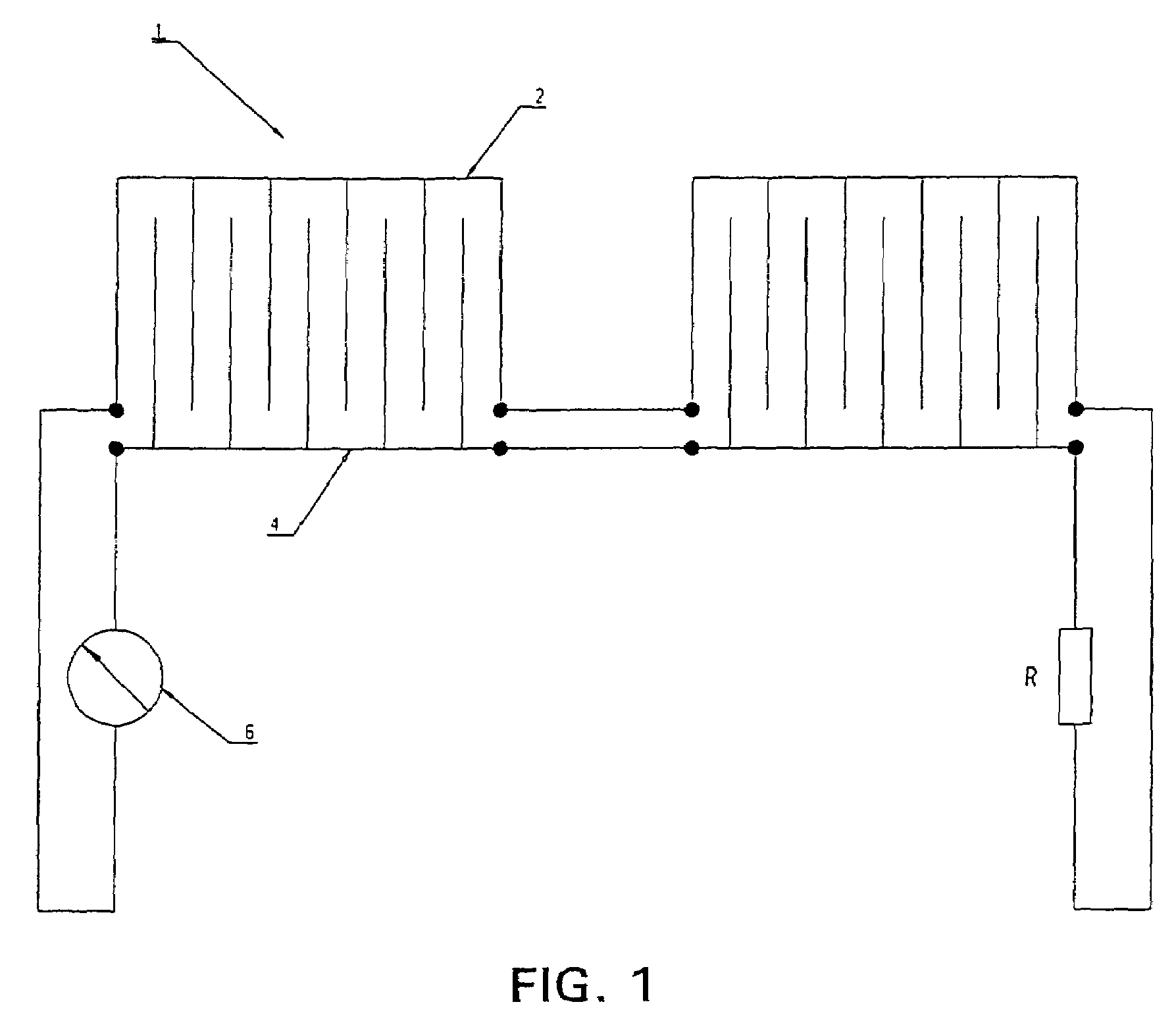

Monitoring device for melting furnaces

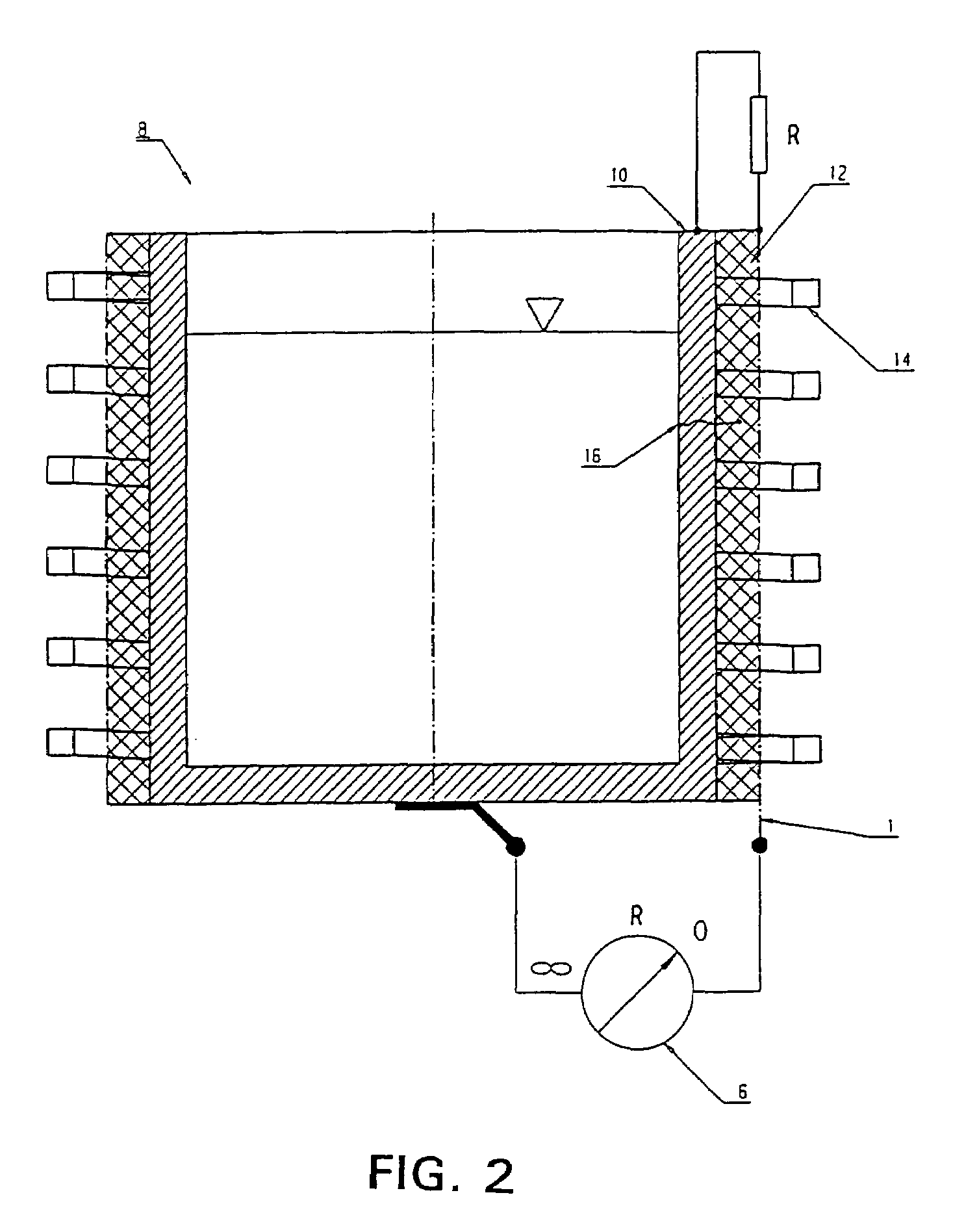

InactiveUS7090801B2Safe operation is assuredImprove electrical resistanceThermometer detailsFurnace safety devicesElectricityElectrical conductor

Cracking of a crucible can cause heavy damage to the system in melting furnaces. A reliable monitoring of threatening breaking out of the melt is therefore needed. For this purpose a monitoring device for melting furnaces is provided to monitor the breaking out of melt and includes a closed circuit consisting of several conductor sections with at least a partially conducting surface and a measuring / displaying device. A first conductor section is series connected through an ohmic resistor R to a second conductor section. The first conductor section is arranged directly adjacent, however, electrically isolatingly spaced from and with respect to the second conductor section.

Owner:WIELAND WERKE AG

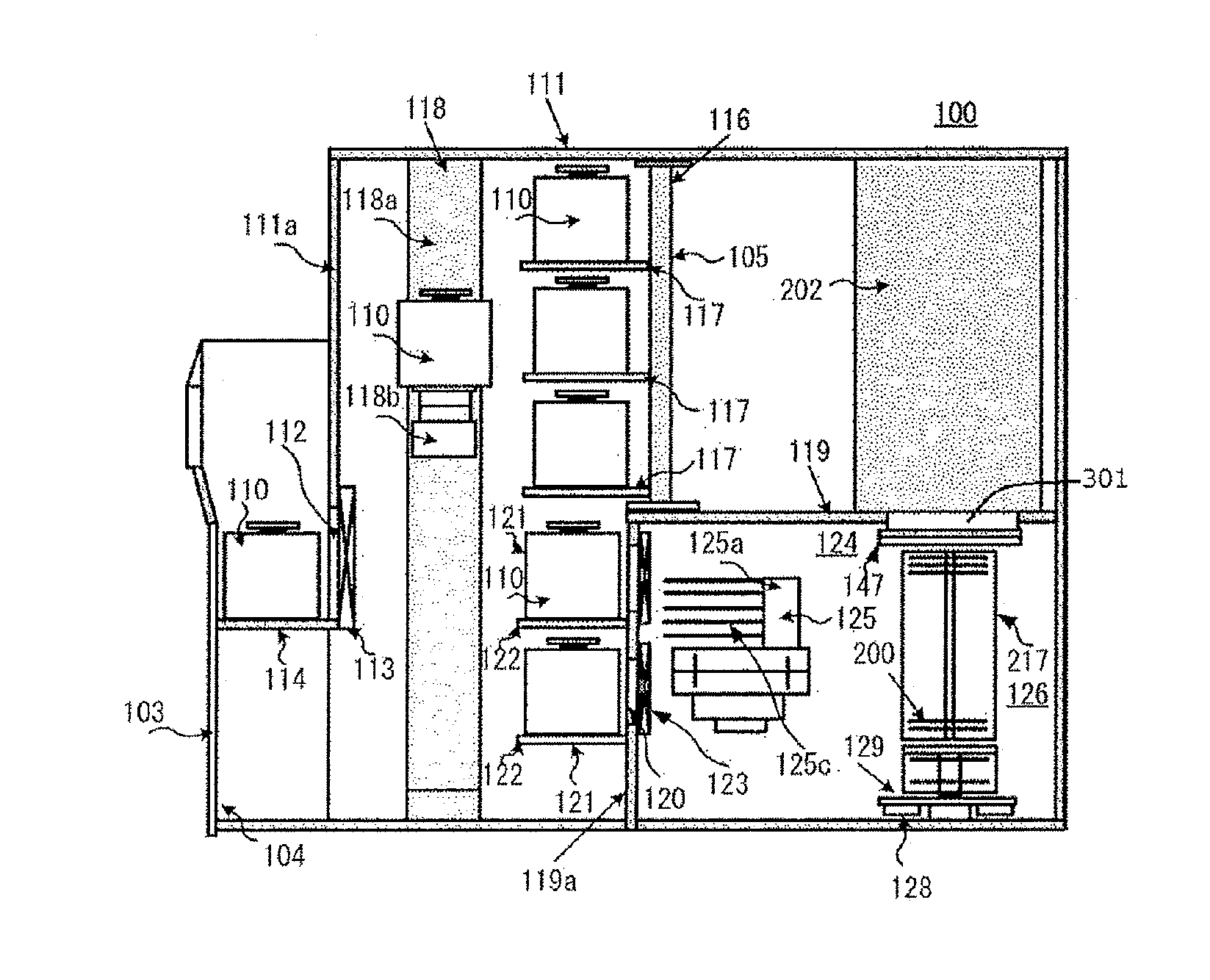

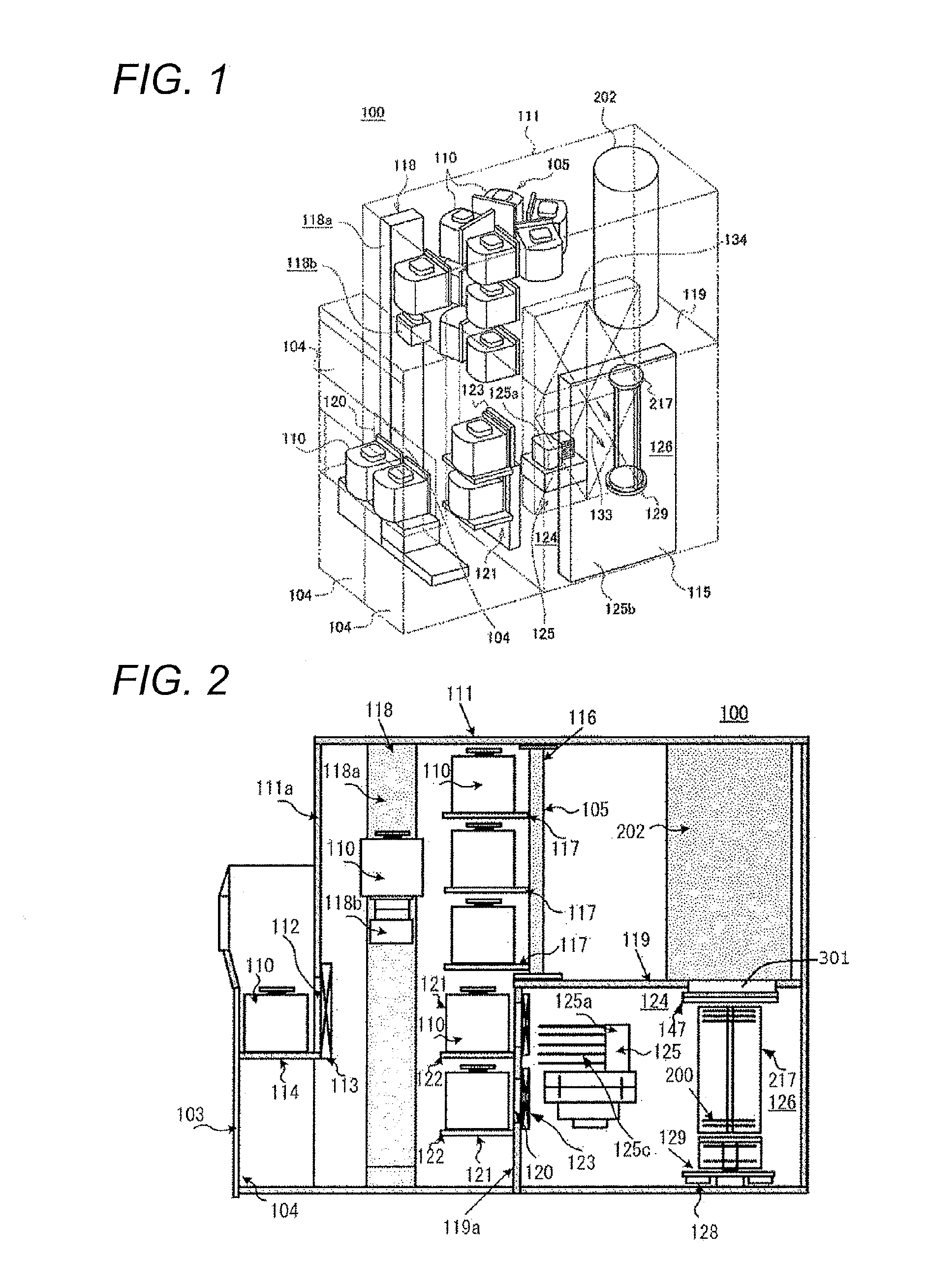

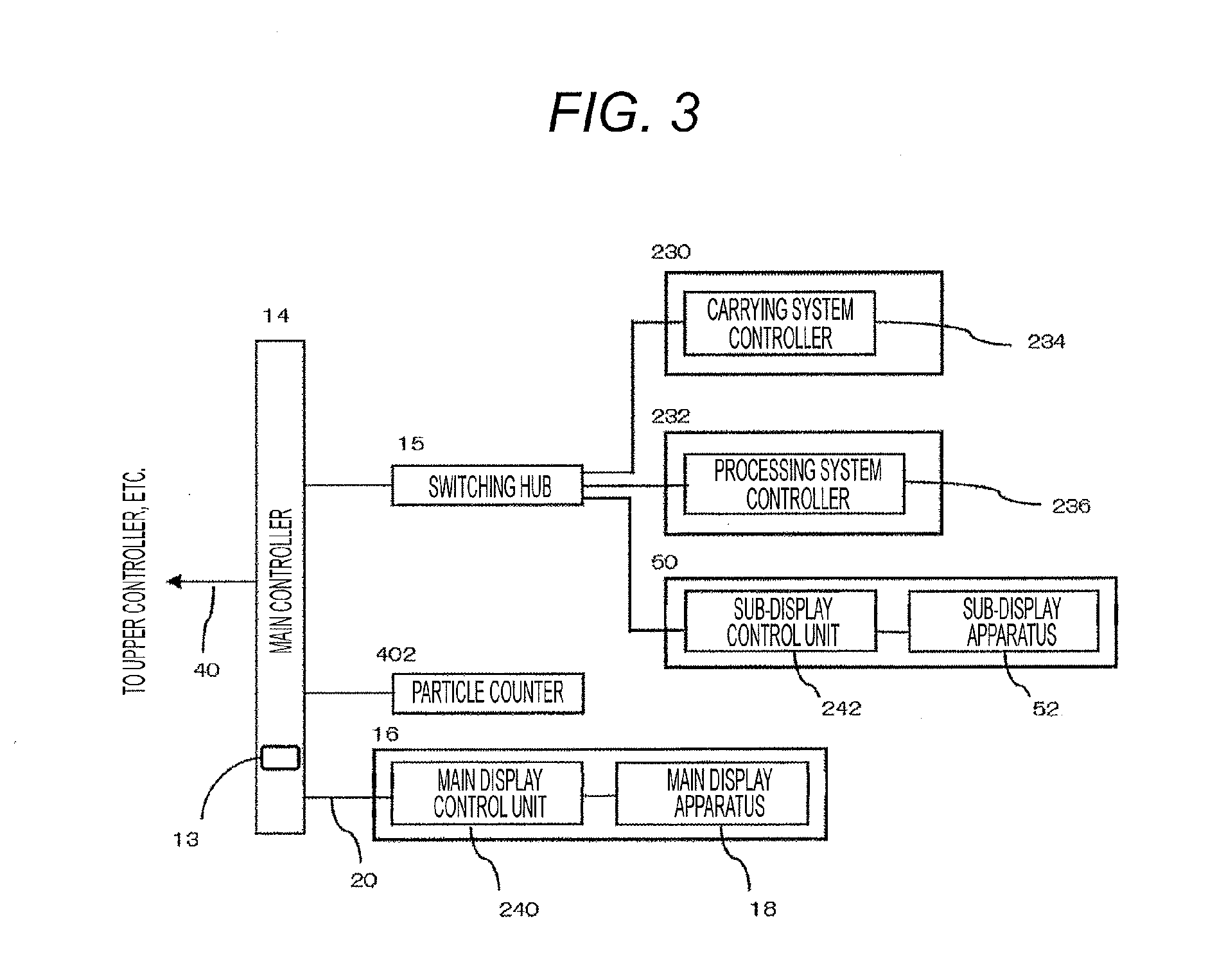

Substrate processing apparatus

InactiveUS20160365264A1Low yieldReduce yieldFurnace safety devicesSemiconductor/solid-state device manufacturingEngineeringProduct gas

The present invention provides a technique in which a reduction in yield rate caused by particles occurring in the processing furnace is suppressed. The technique includes a substrate processing apparatus comprising a transfer chamber including a gas supply mechanism on a side surface thereof and configured to transfer a substrate to a substrate holder, a processing furnace, a furnace opening, a cap having the substrate holder placed thereon and configured to close the furnace opening, a raising / lowering mechanism configured to raise and lower the cap, a measurer installed at a position facing the gas supply mechanism in the transfer chamber with the substrate holder interposed therebetween, and configured to count a number of particles at the furnace opening, and a control unit configured to control the raising / lowering mechanism and the measurer so as to start measurement of a number of particles by the measurer when the furnace opening is opened.

Owner:KOKUSA ELECTRIC CO LTD

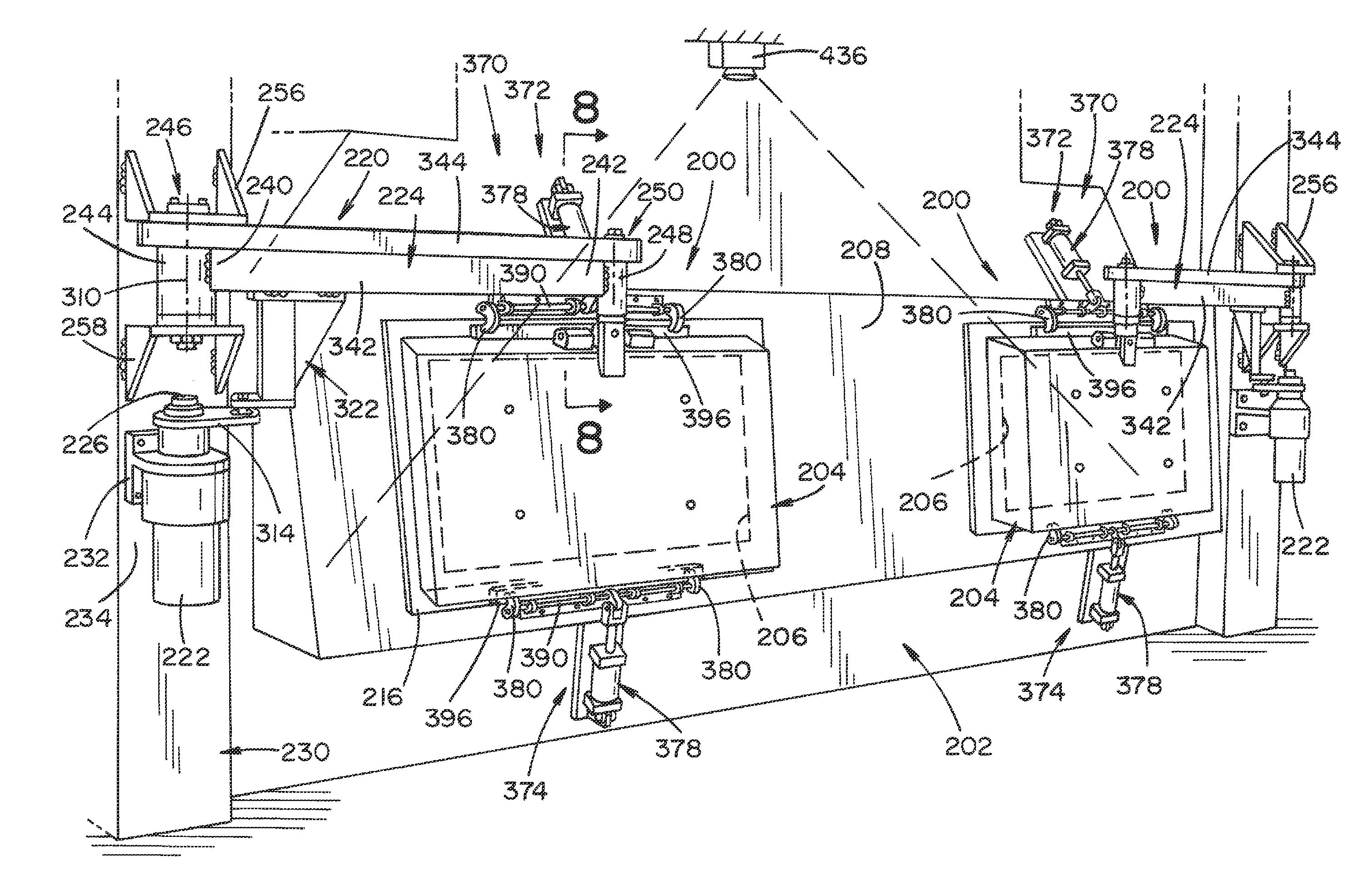

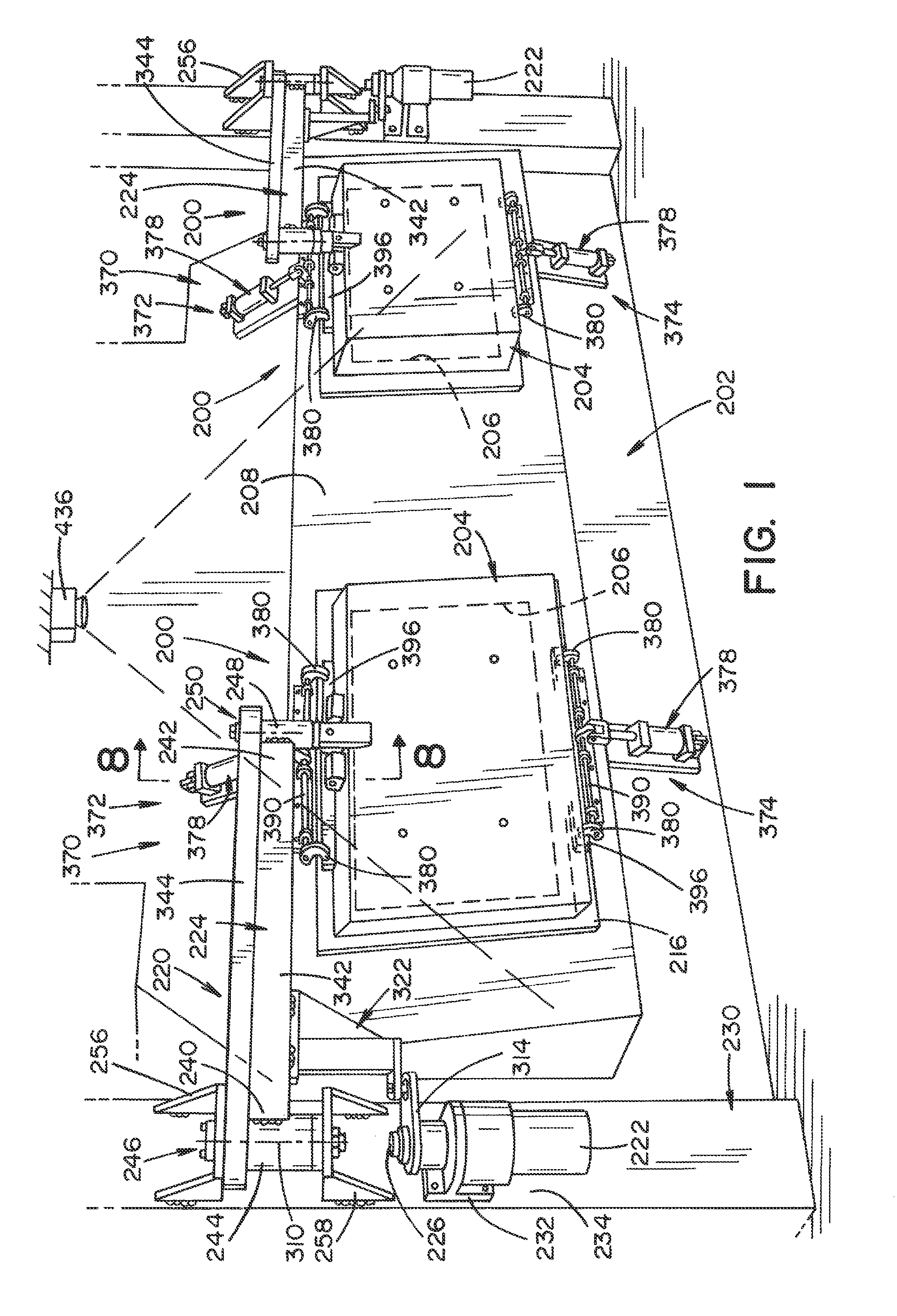

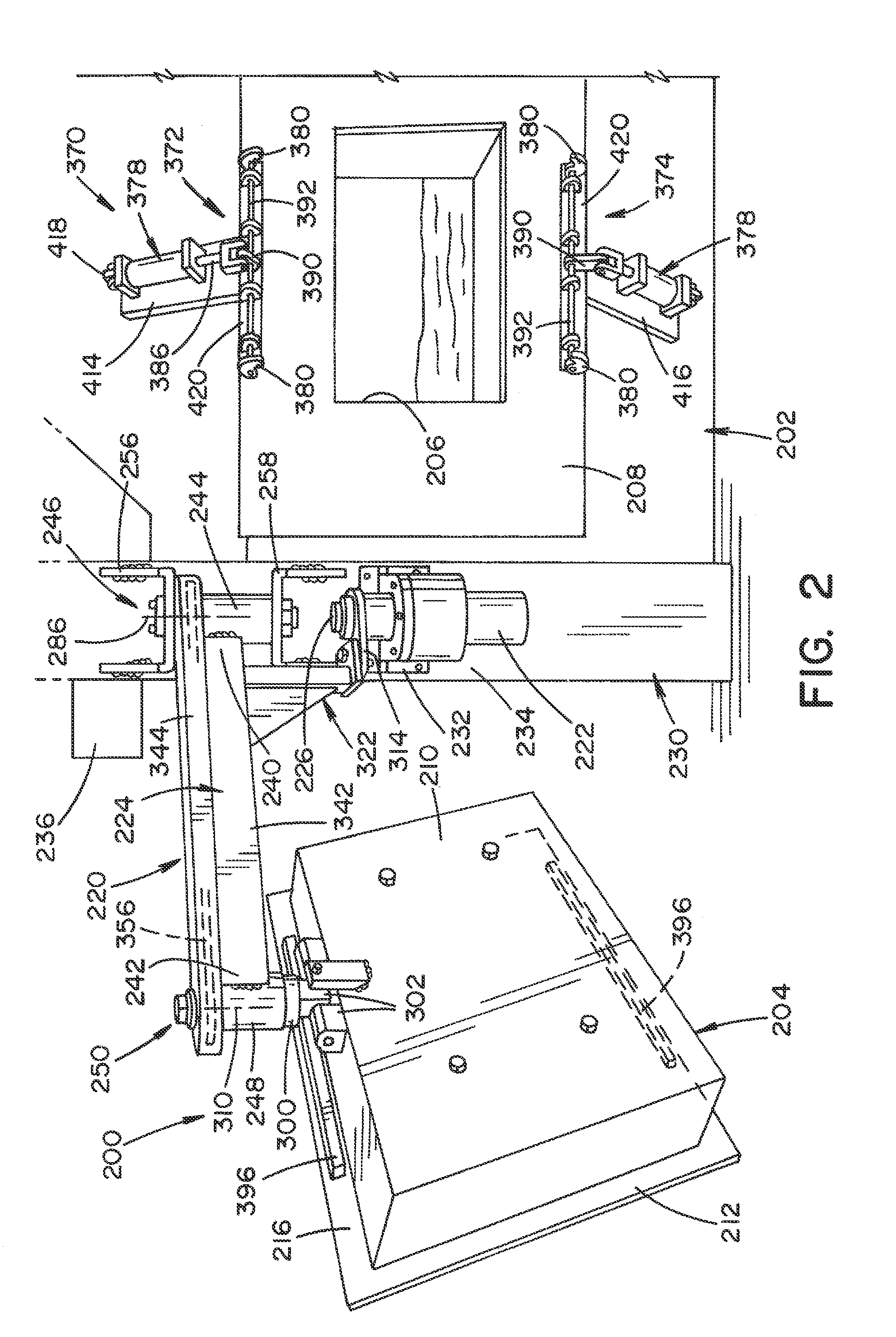

Automatic charge hearth access door assembly

An automatic charge hearth access door assembly for a melting furnace includes an access door movable between a closed position for covering a furnace opening located on a face of the furnace and an opened position for providing access to the furnace opening. A latch mechanism is configured to automatically secure the access door to the face of the furnace in the closed position. An open-and-close drive assembly includes a motor and arm operably connected to the motor. The open-and-close drive assembly is configured to automatically move the access door relative to the face of the furnace between the closed position and opened position and simultaneously move the access door relative to the arm.

Owner:HONDA MOTOR CO LTD

Ceramic capacitor mounting structure and ceramic capacitor

ActiveUS7365957B2Reduce the soundDegree of improvementFurnace safety devicesFinal product manufactureCeramic sinteringCeramic capacitor

A ceramic capacitor comprises a ceramic sintered body, and first and second terminal electrodes formed on outer surfaces of the ceramic sintered body. The first terminal electrode is electrically connected to a land formed on a substrate through a first metal terminal. The first metal terminal has a first capacitor connecting portion mechanically connected to the first terminal electrode, a first terminal portion mechanically connected to the land, and a first intermediate portion electrically connecting the first capacitor connecting portion and the first terminal portion to each other. The first capacitor connecting portion of the first metal terminal is parallel to the substrate.

Owner:TDK CORPARATION

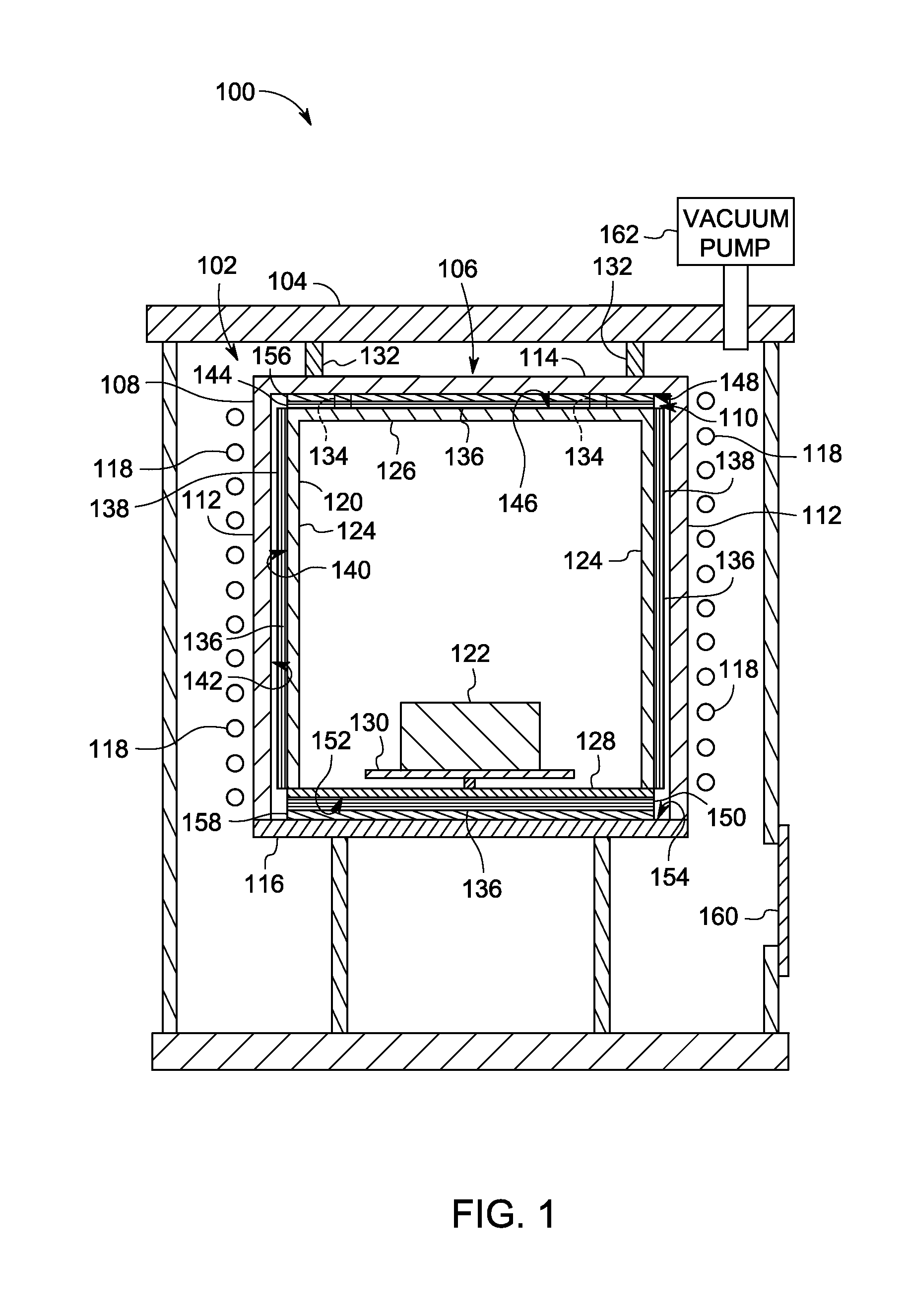

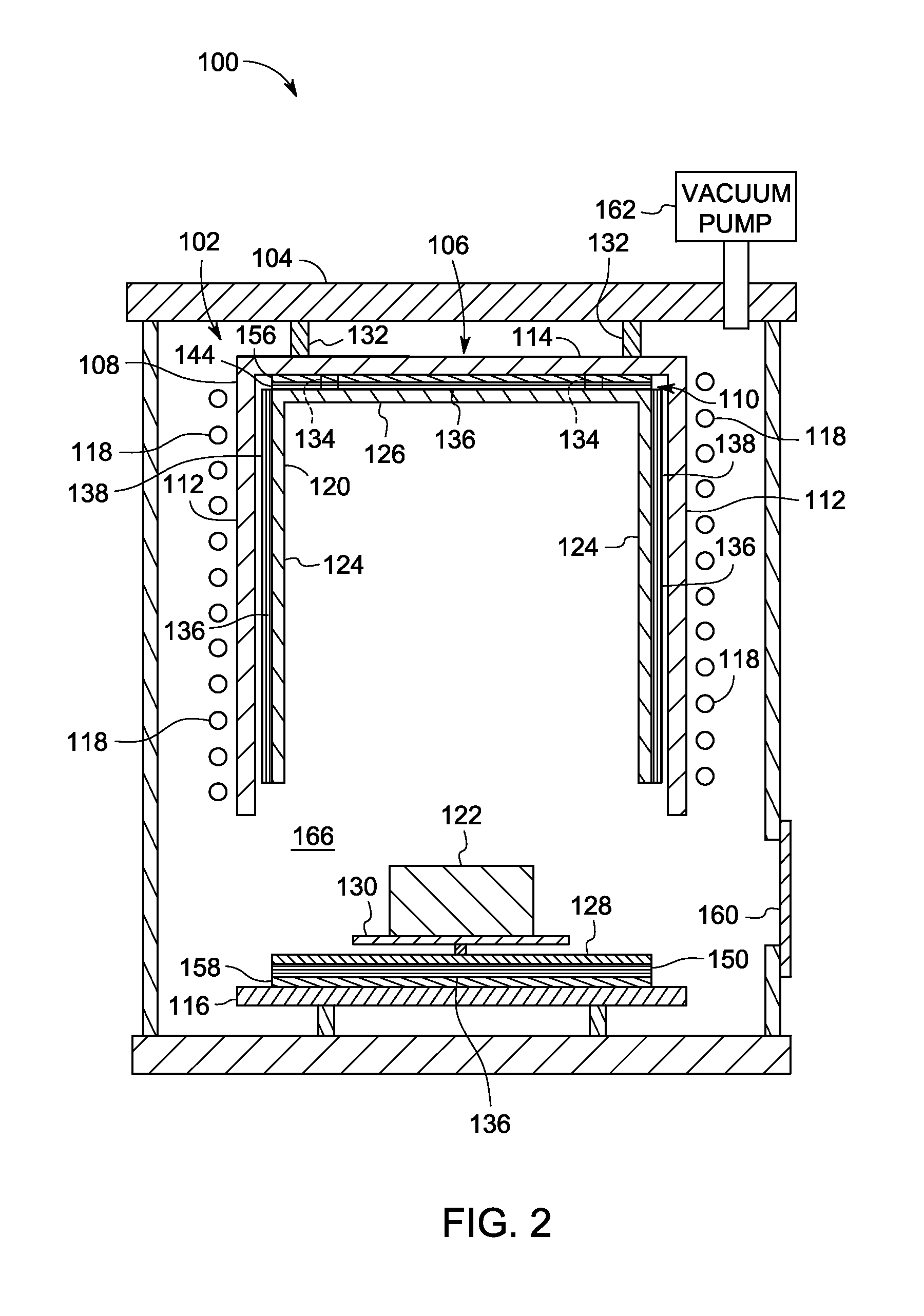

Device and method to mitigate hydrogen explosions in vacuum furnaces

A device to mitigate hydrogen explosions in a vacuum furnace includes at least one igniter, an ignition transformer, and an electrical switch. The at least one igniter includes a set of high-voltage electrodes and is connected to the ignition transformer by high-voltage wires. The electrical switch activates the ignition transformer to provide power to the at least one igniter forming a continuous electrical arc between the electrodes. The at least one igniter is located inside the vacuum furnace at an opening where air may enter the vacuum furnace, which may contain a hydrogen and steam gas mixture under accident conditions. The device consumes hydrogen by controlled combustion as flammable mixtures are formed.

Owner:STAMPS DOUGLAS WAYNE

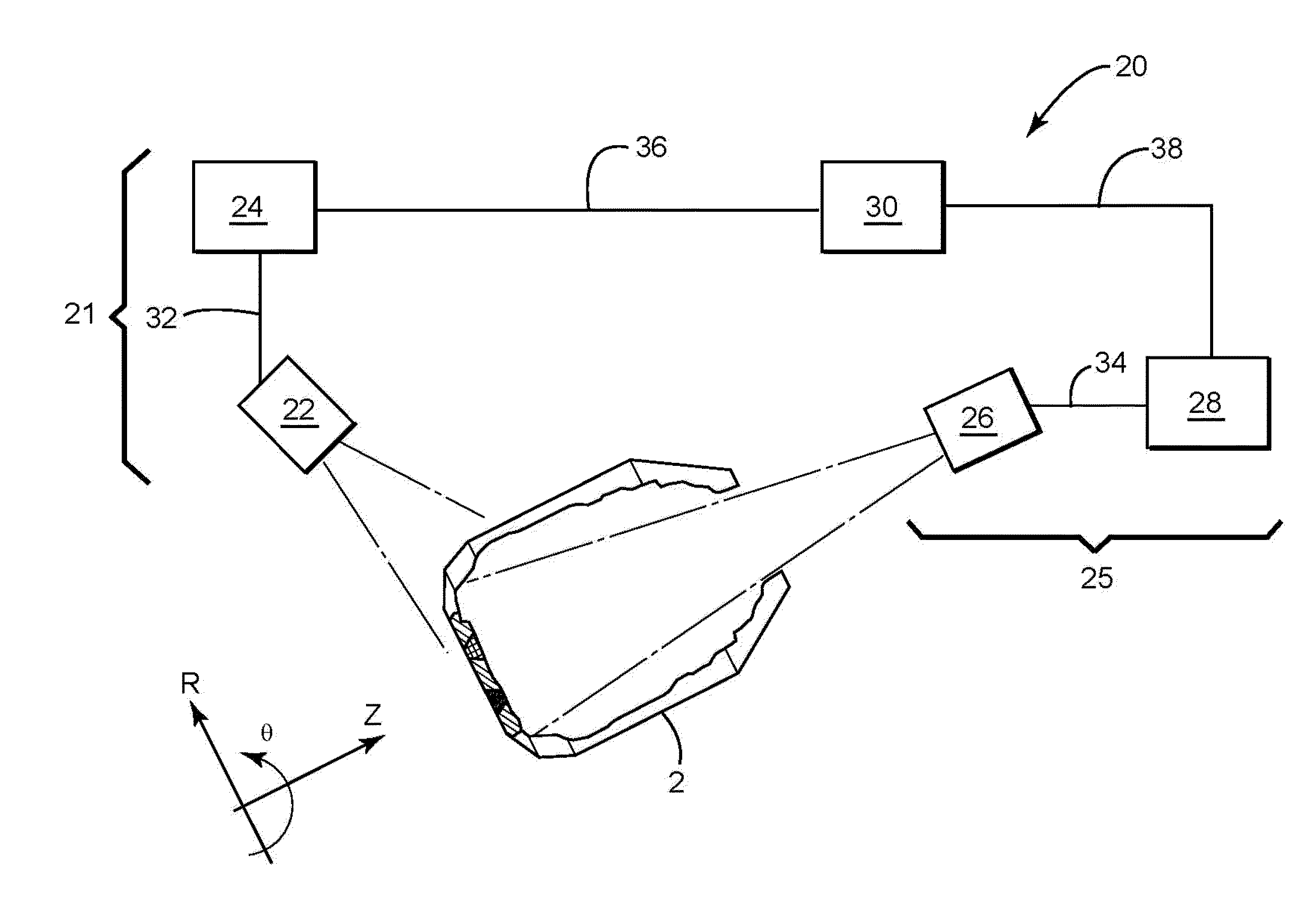

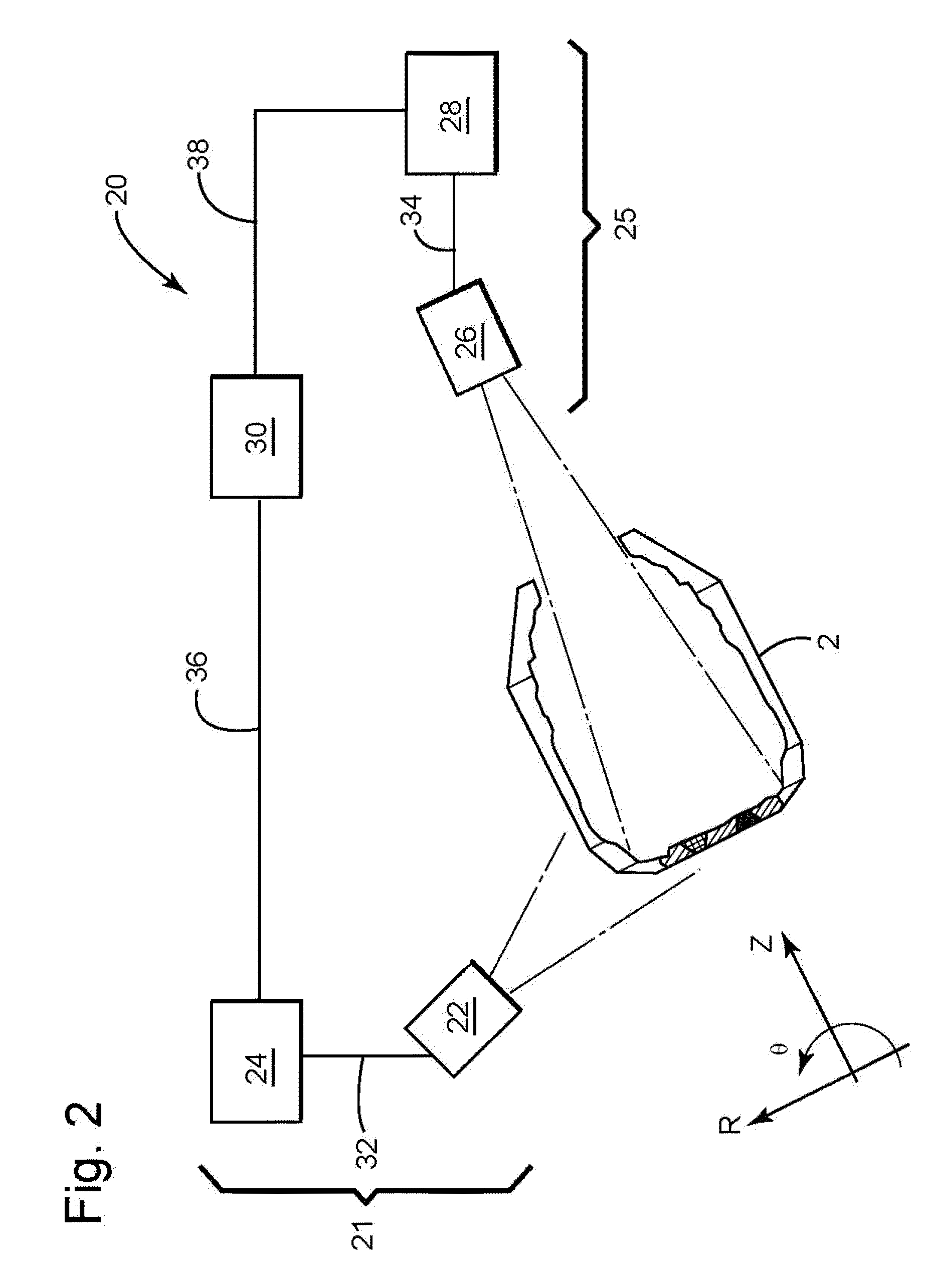

Apparatus, process, and system for monitoring the integrity of containers

Apparatuses, systems, and methods to monitor the integrity of a container protected by a refractory material are disclosed having a first radiation detector to measure an external surface temperature of the container, a first radiation source to measure a thickness of the refractory material, and a central controller configured to display to a user the measurement of the external surface temperature of the container and the measurement of the thickness of the refractory material.

Owner:PROCESS METRIX

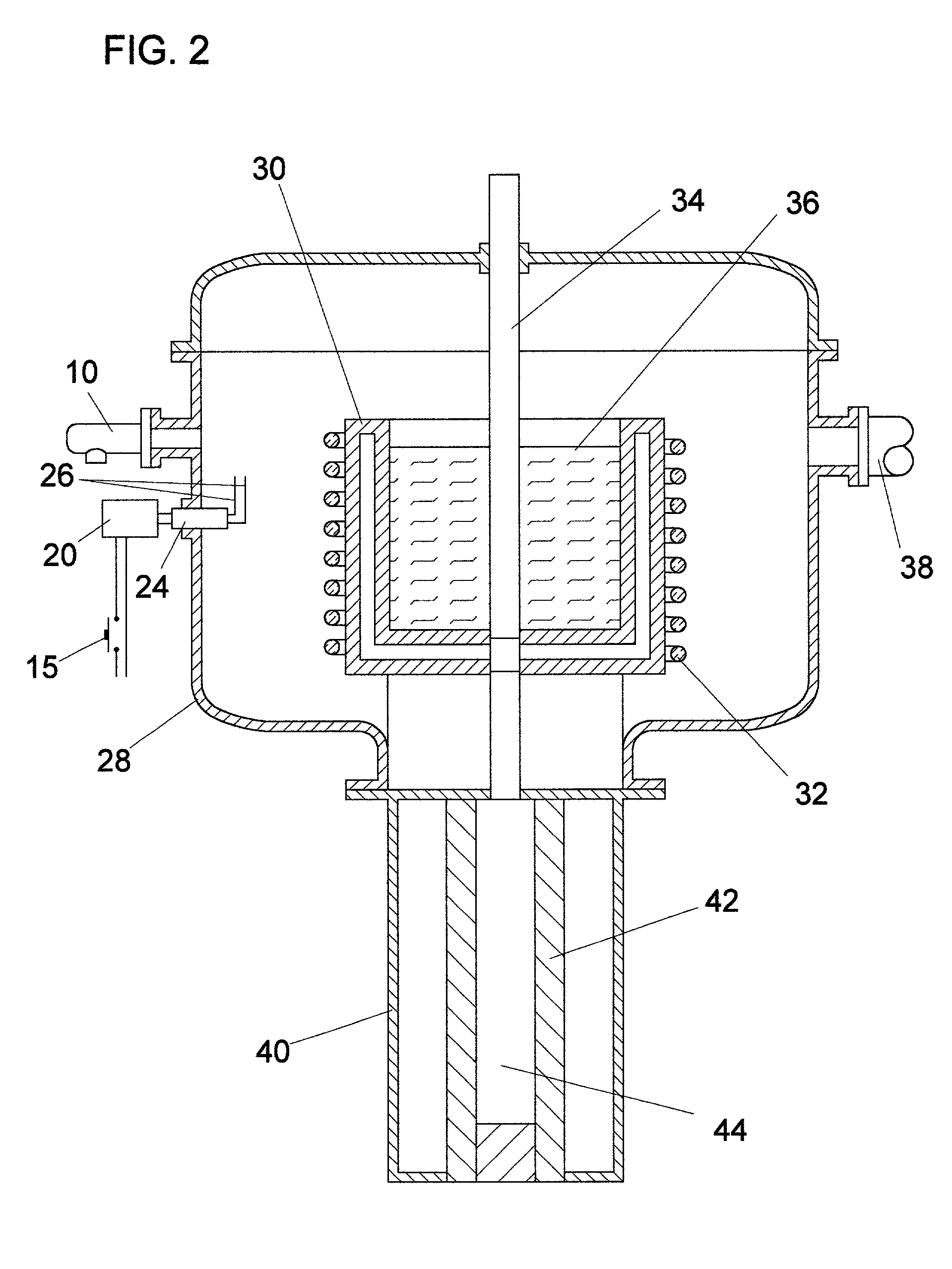

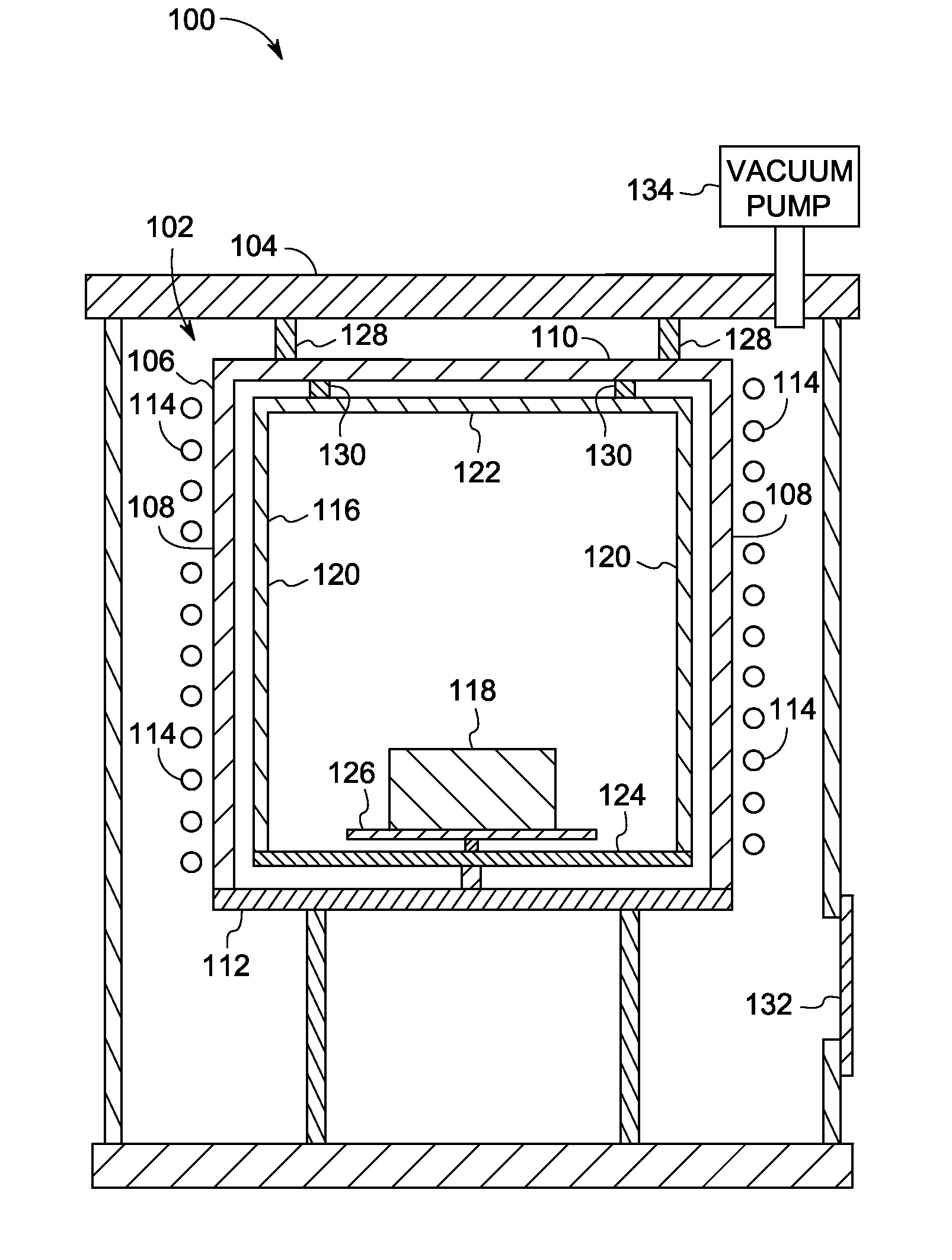

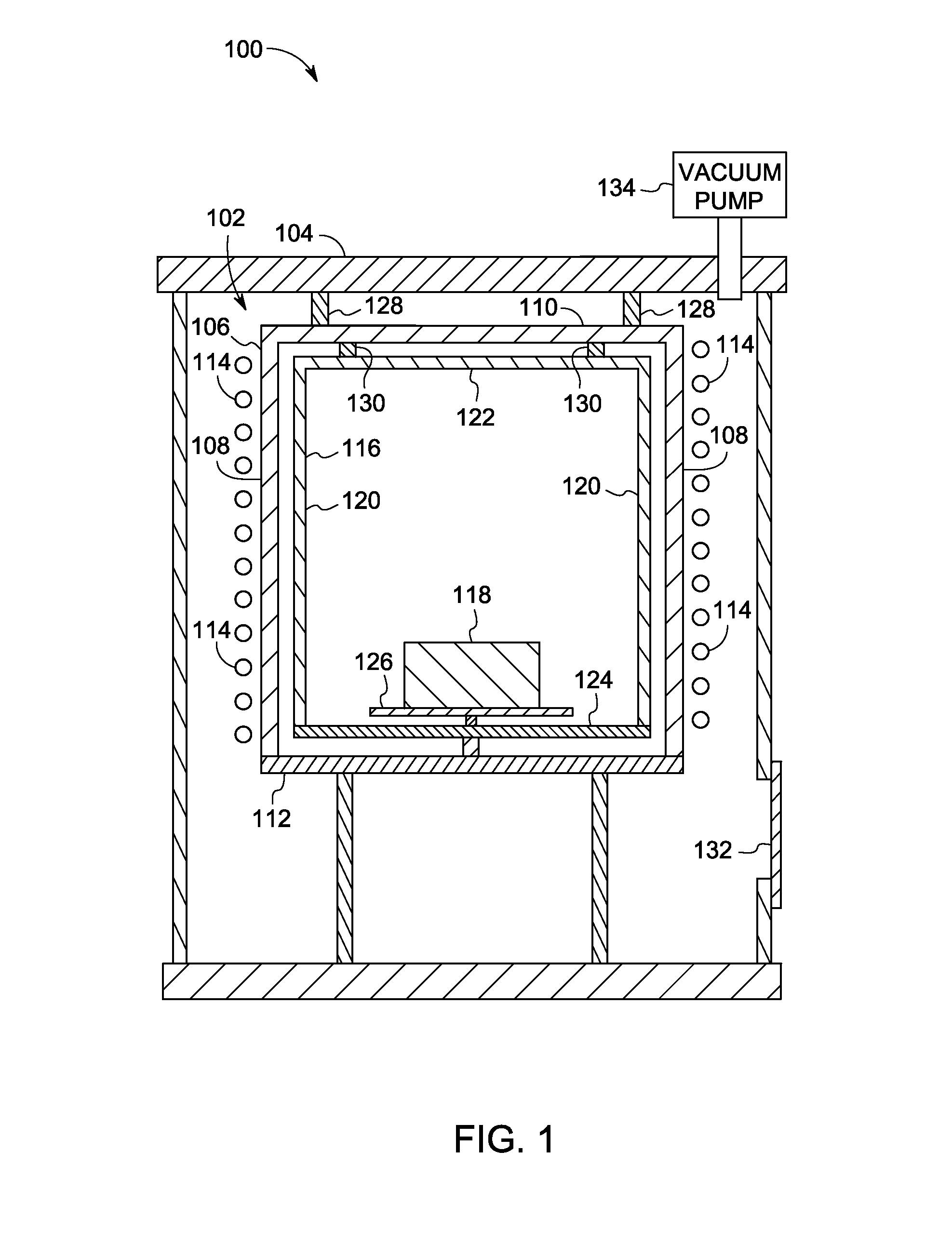

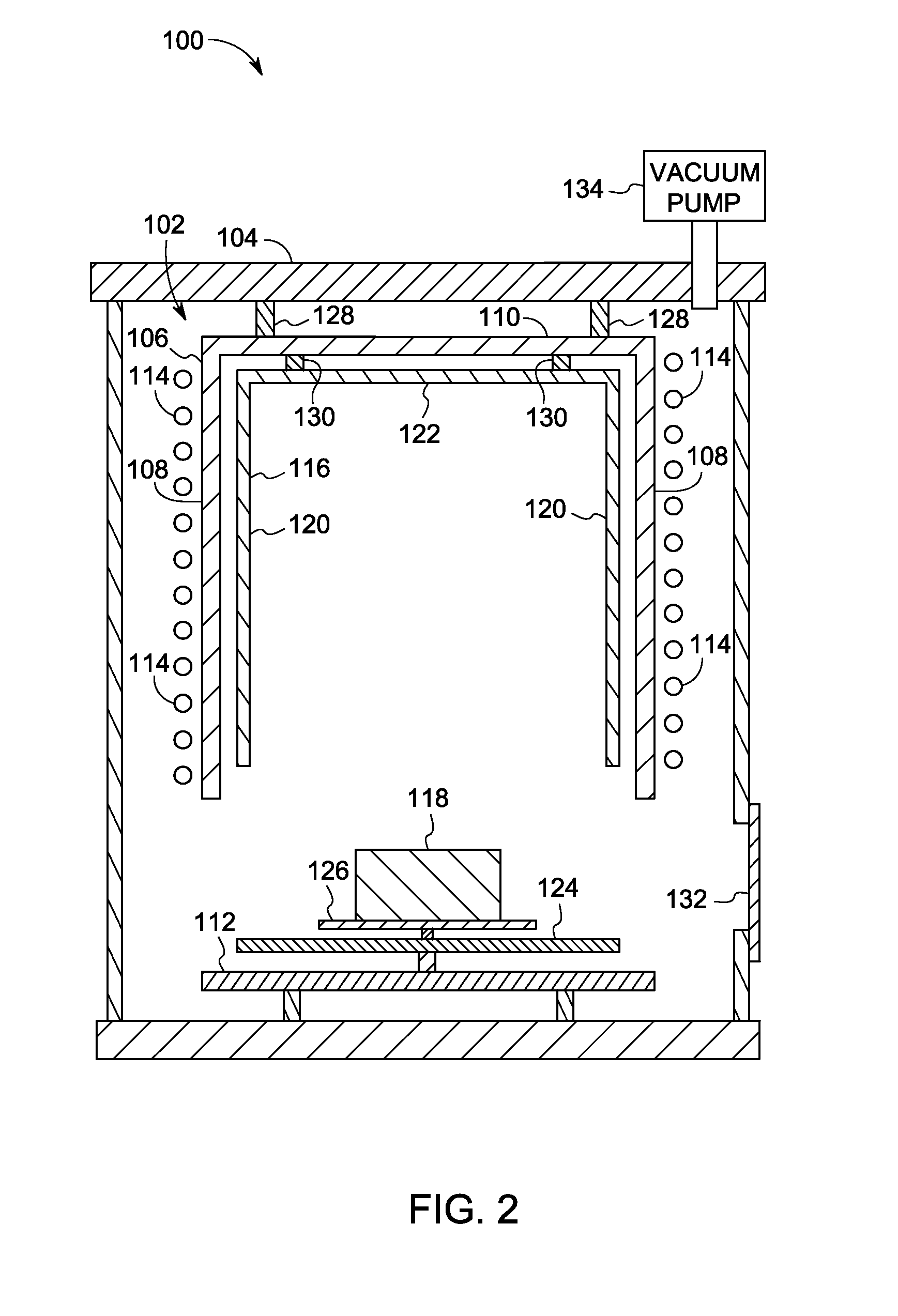

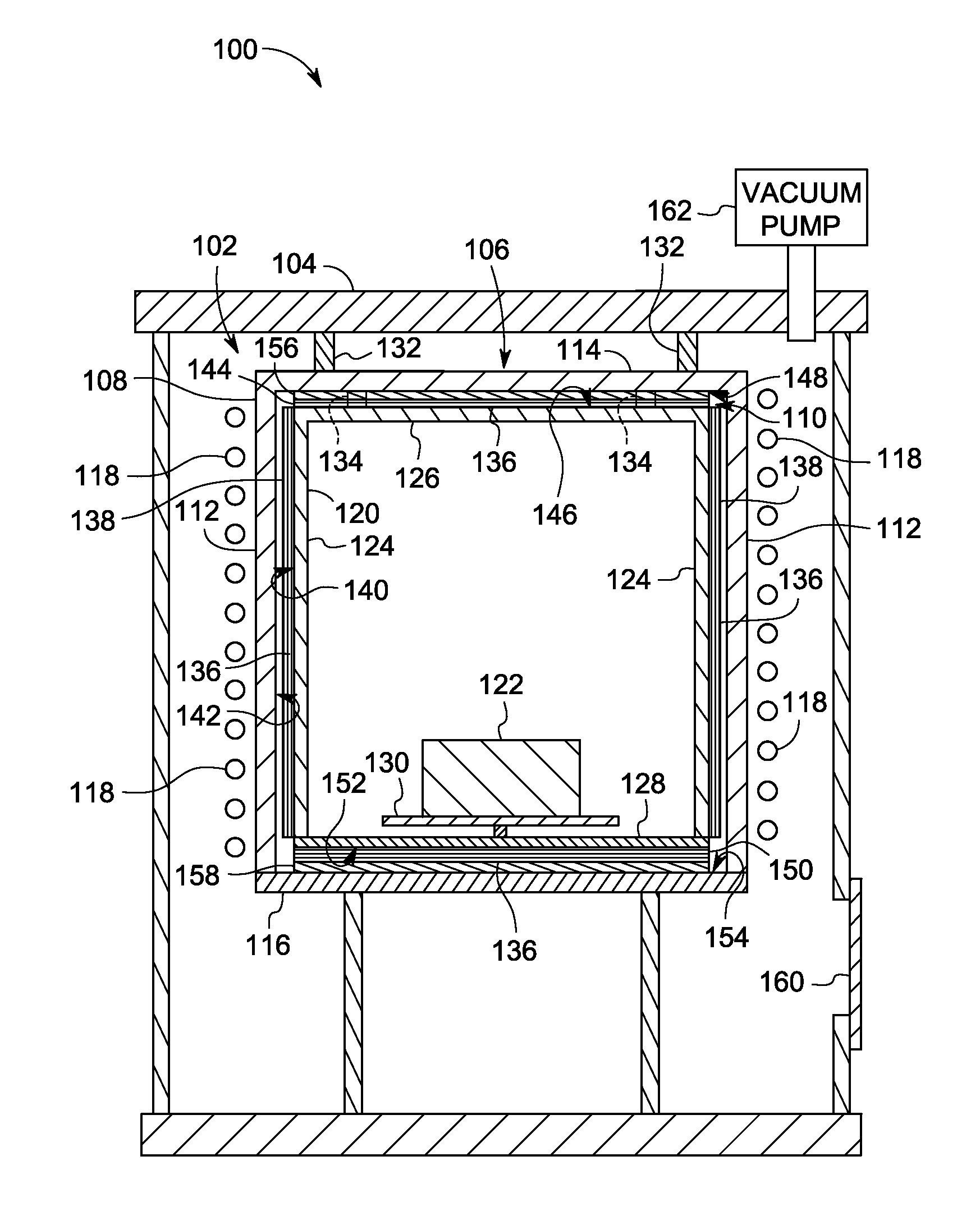

System for gas purification in an induction vacuum furnace and method of making same

InactiveUS20150226485A1Reduce CooldownReduce impurityFurnaces without endless coreMuffle furnacesProcess engineeringInduction furnace

A system and method for removing impurities in an induction furnace cooling system is disclosed. An induction furnace for heating a workpiece includes a chamber, an induction coil positioned in the chamber to provide for heating of the workpiece when a current is provided to the induction coil, and a cooling system fluidly coupled to an interior volume of the chamber, the cooling system including a heat exchanger, a blower fluidly coupled to the heat exchanger and configured to cause a gas to flow through the heat exchanger, and a filter assembly comprising a filtering device, the filter assembly fluidly coupled to the blower and configured to remove impurities from the gas flowing through the cooling system.

Owner:GENERAL ELECTRIC CO +1

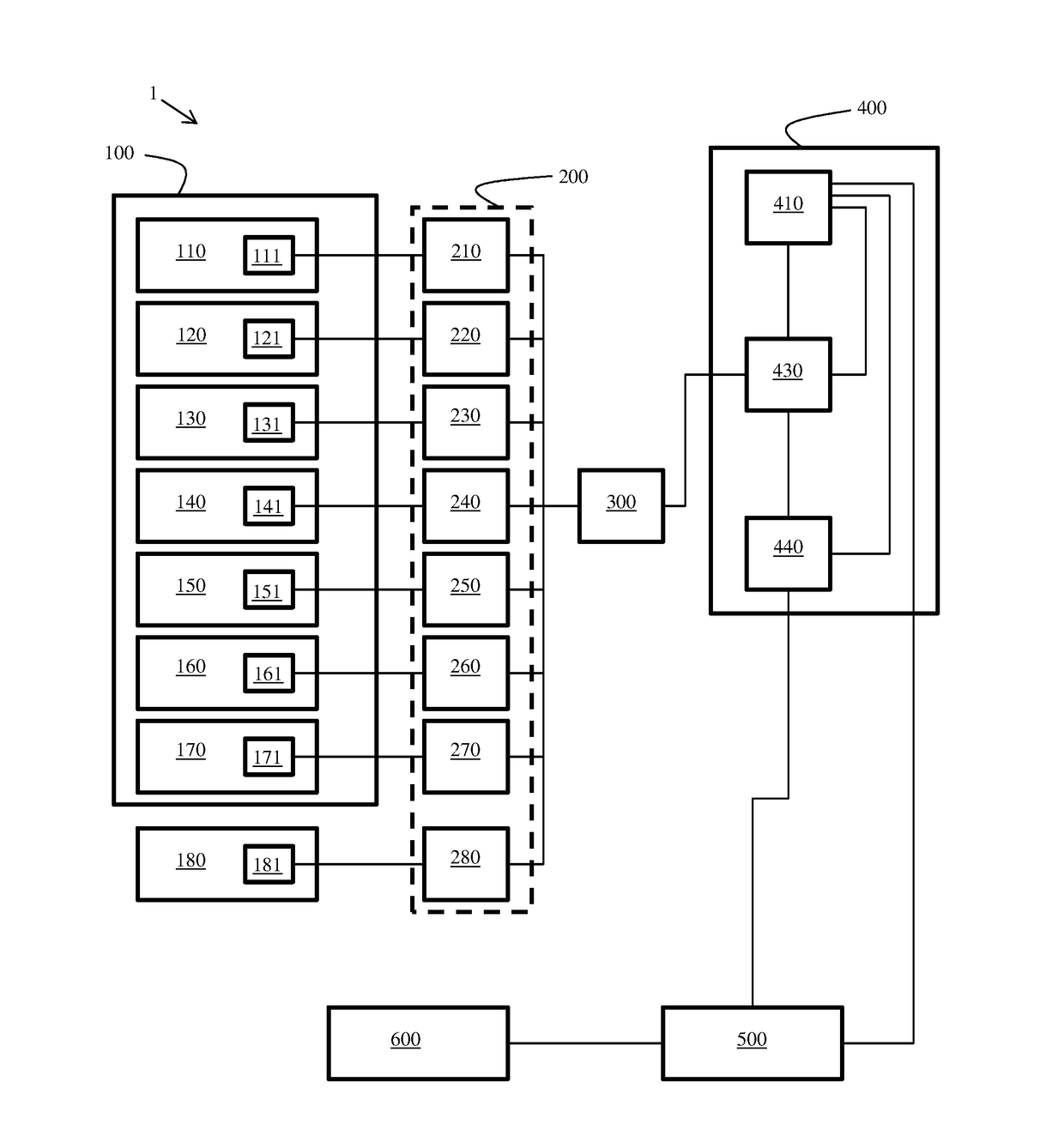

System and Method for Facilitating the Maintenance of an Industrial Furnace

InactiveUS20170074589A1Avoid failureMaintain longevityProgramme controlFurnace safety devicesEngineeringHeat treating

A system and method for facilitating the maintenance of an industrial heat treating furnace are disclosed.

Owner:IPSEN INT

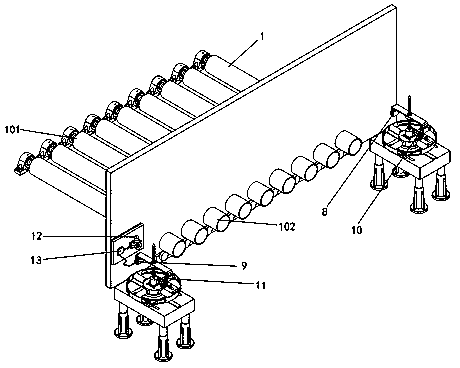

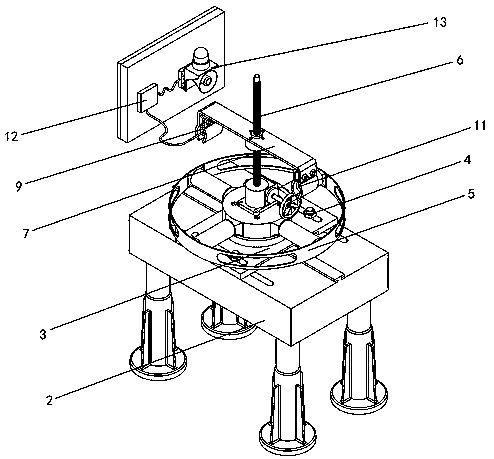

Furnace roller monitoring method and device based on infrared intrusion sensors

The invention provides an adjustable furnace roller deformation monitoring and alarming device based on infrared intrusion sensors. One end of each furnace roller is a power input end, and the other end of each furnace roller is a free end; furnace roller deformation monitoring devices are installed on two sides of the free ends of one column of furnace rollers and are infrared emitting / receivingportions separately; each emitting / receiving portion comprises a damping base, a slide board, a damping table, a lifting mechanism, an infrared emitter, an infrared receiver, a processing circuit module and an acousto-optic alarm; each infrared emitter emits a horizontal light beam to the corresponding receiver; when the furnace rollers deform or are broken, the light beam is shielded, a receivedelectric signal frequency map changes and cannot be matched with a reference signal frequency, the acousto-optic alarms give an alarm; the sliding boards and lead screw lifting mechanisms can controlthe specific positions of infrared intrusion devices, and monitoring of different deformation amounts is achieved; the damping tables can greatly reduce the longitudinal and transverse vibration transmitted to the sensors when a furnace body works, monitoring and alarming for furnace roller deformation can be carried out, and the operation safety of a furnace is guaranteed.

Owner:SOUTHEAST UNIV

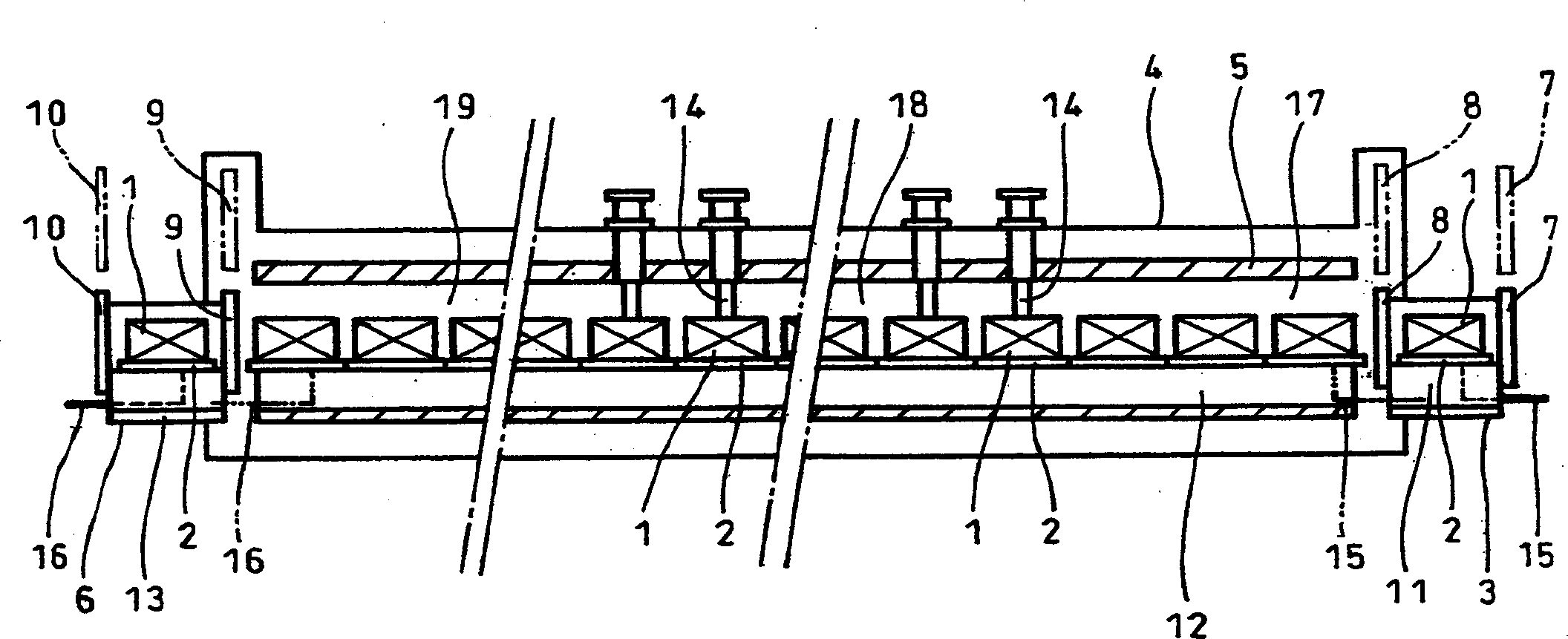

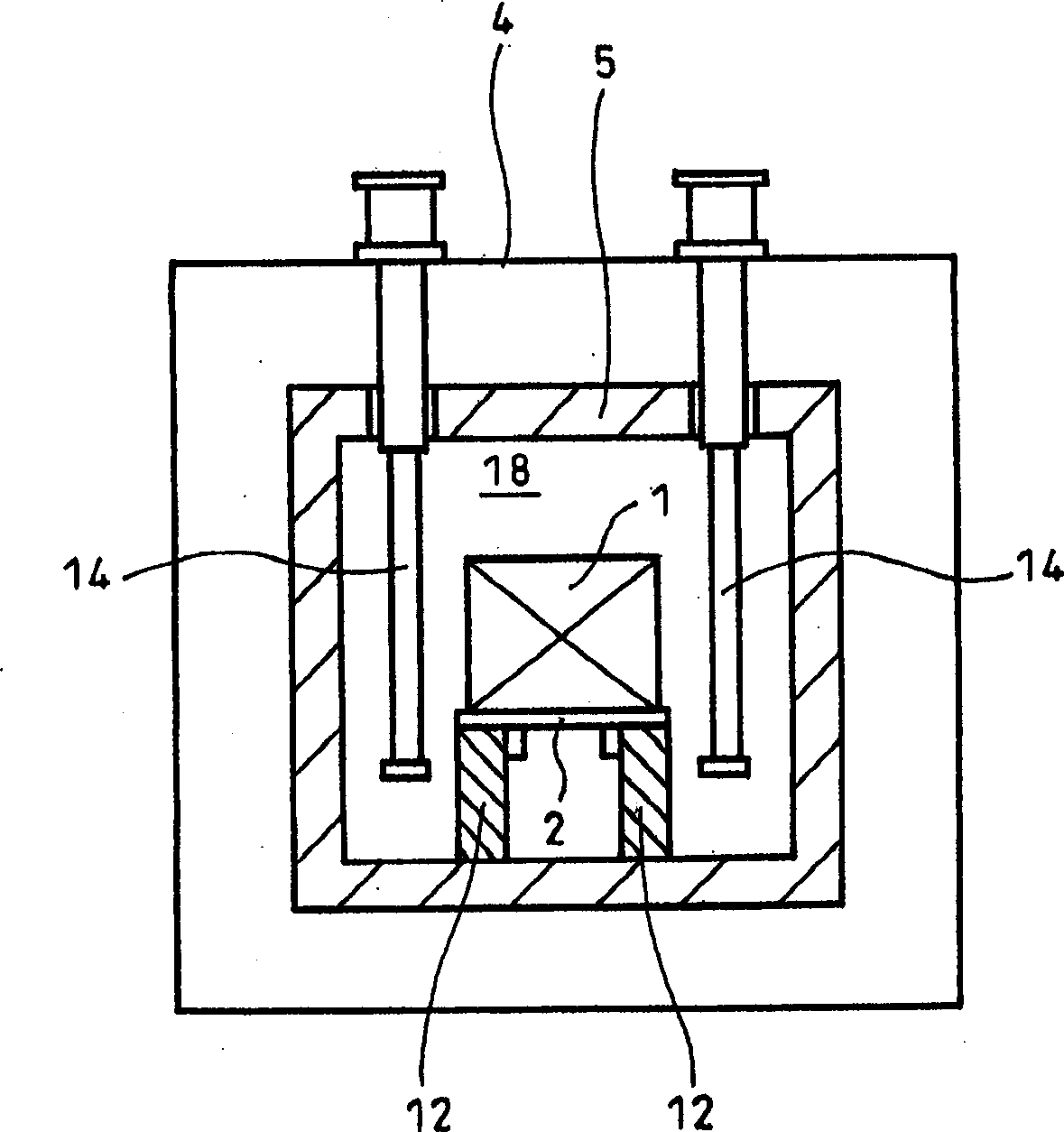

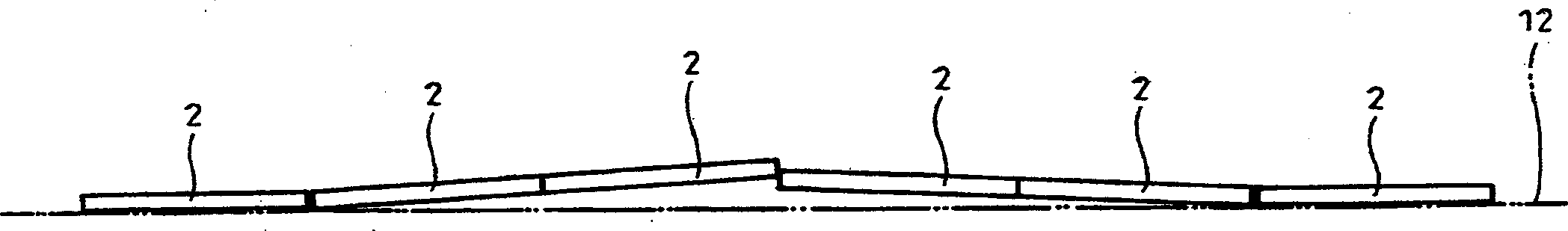

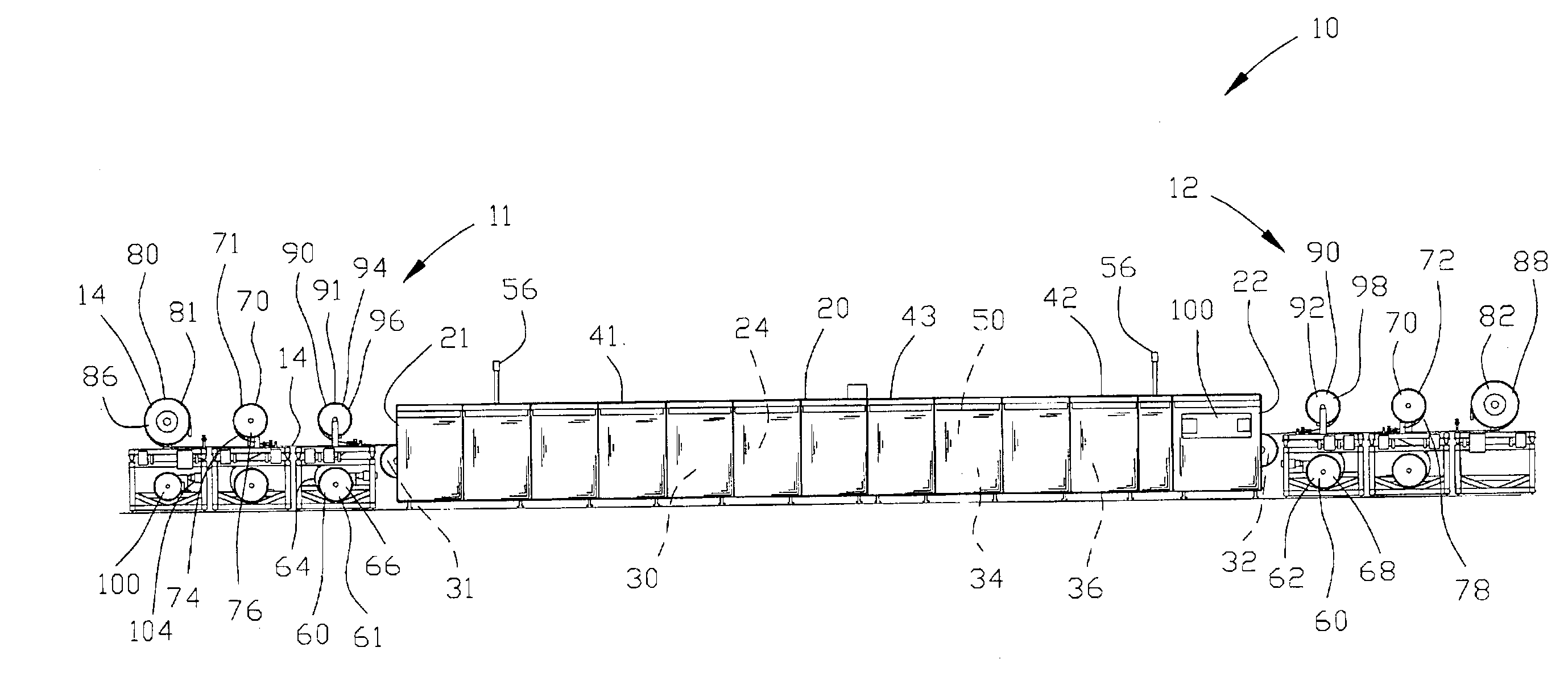

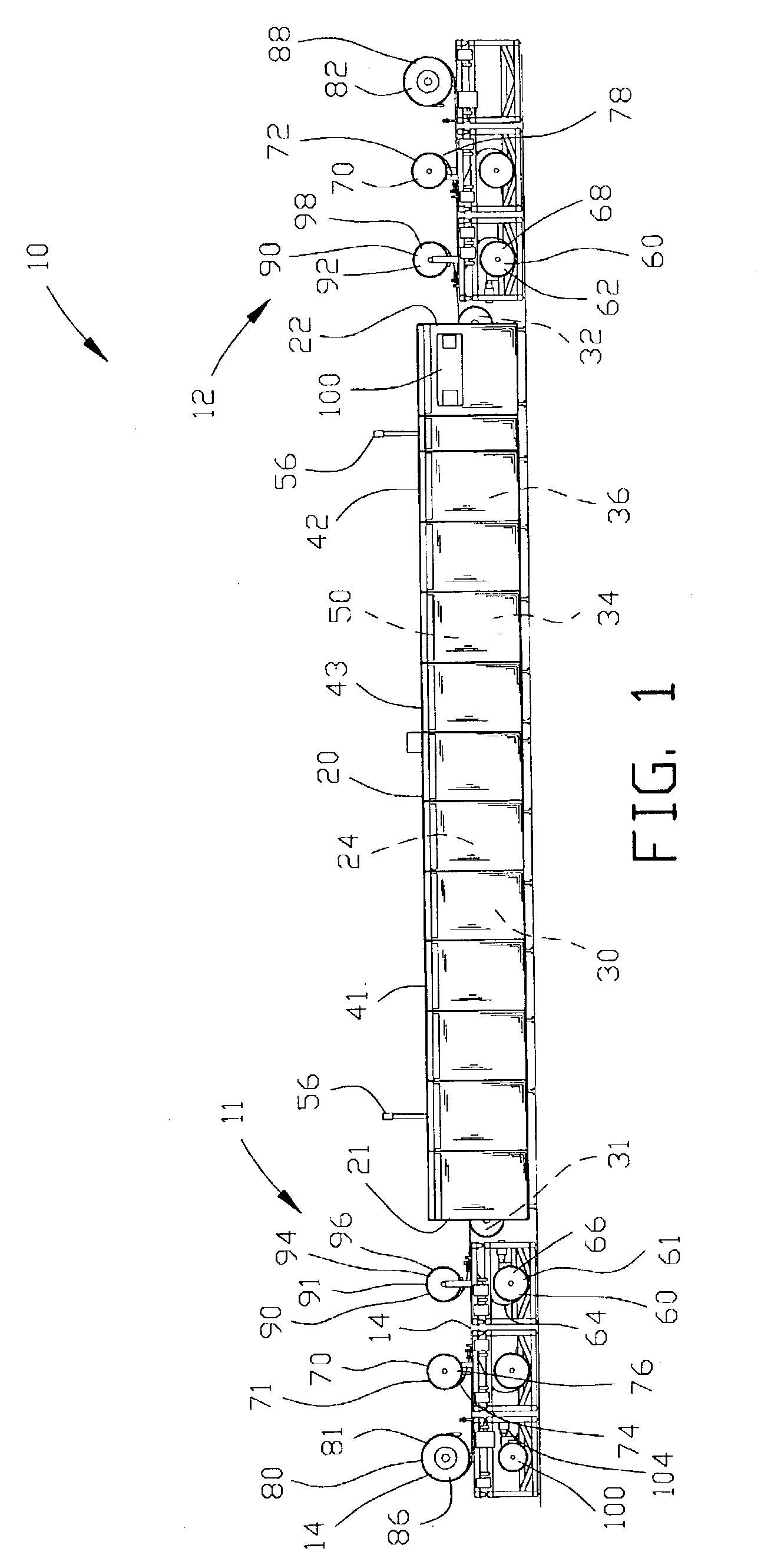

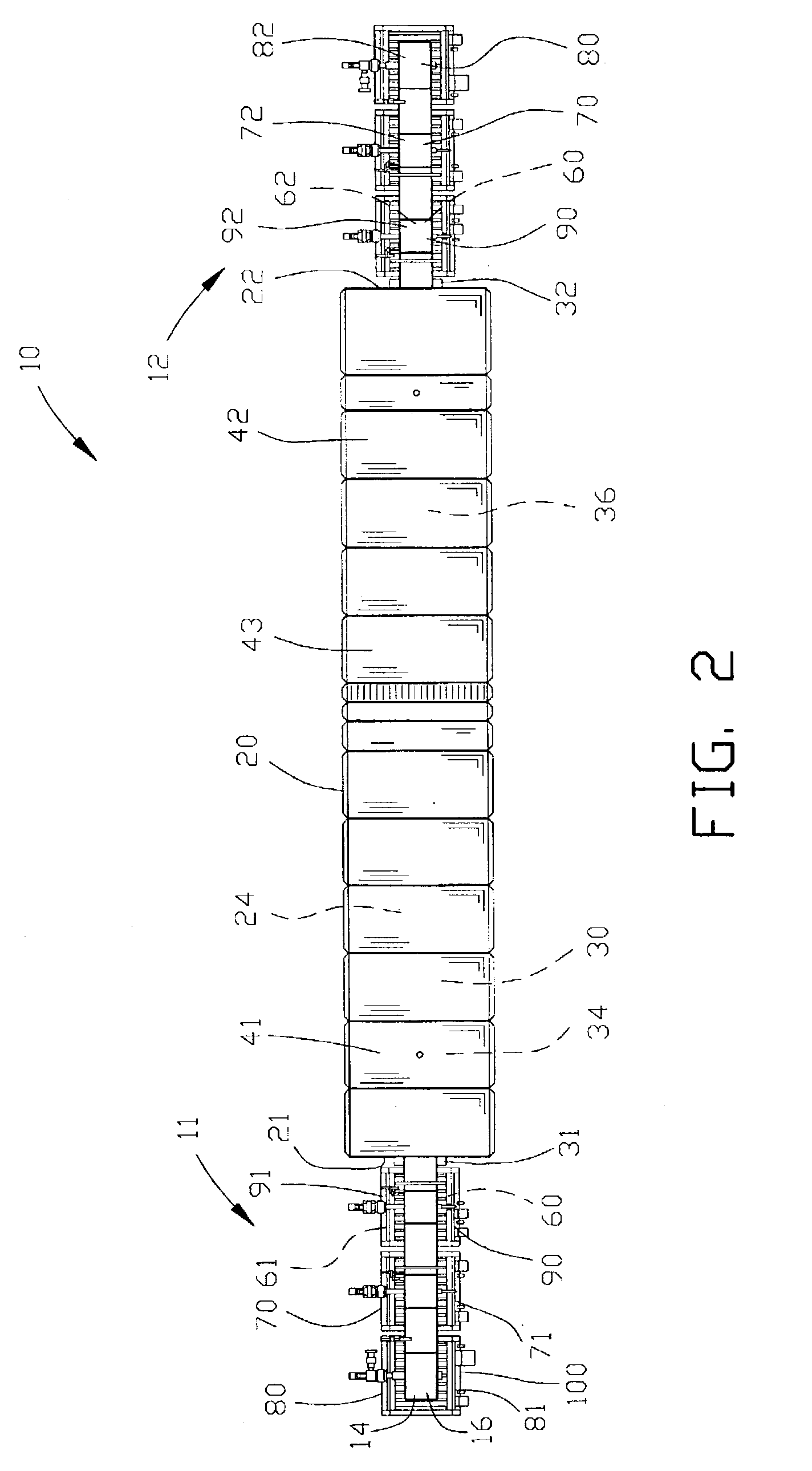

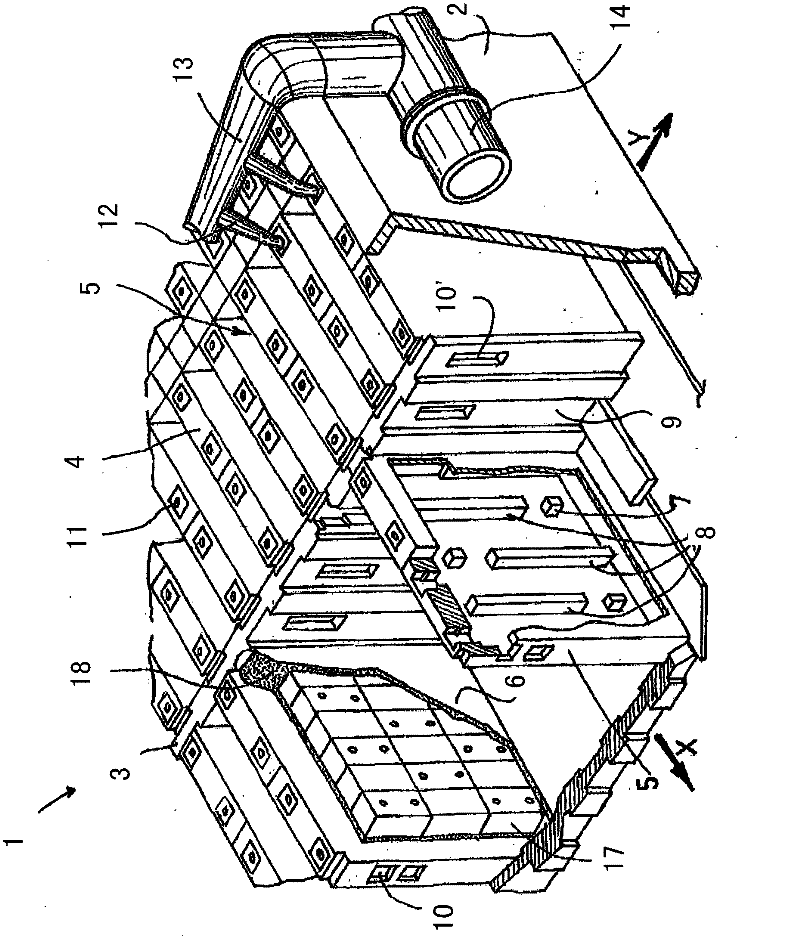

Apparatus and method of continuous sintering a web material

InactiveUS20030104332A1Meaningful and economical resultEliminate needFurnace safety devicesCharge manipulationMultiple layerRefractory

An apparatus and method is disclosed for continuously sintering a web of multiple layers of media material with a sintering furnace. In a preferred form of the invention, a plurality of web media materials are interposed between refractory materials and are simultaneously sintered in the sintering furnace. Following sintering the plurality of web media materials are separated from the refractory materials and the web media materials are independently rolled onto a plurality of output rollers. A tension device applies a tension acting upon opposed ends of the refractory materials for maintaining a constant tension therebetween for maintaining a constant force on the upper and lower surfaces of the plurality of media materials.

Owner:USF FILTRATION & SEPARATIONS GROUP

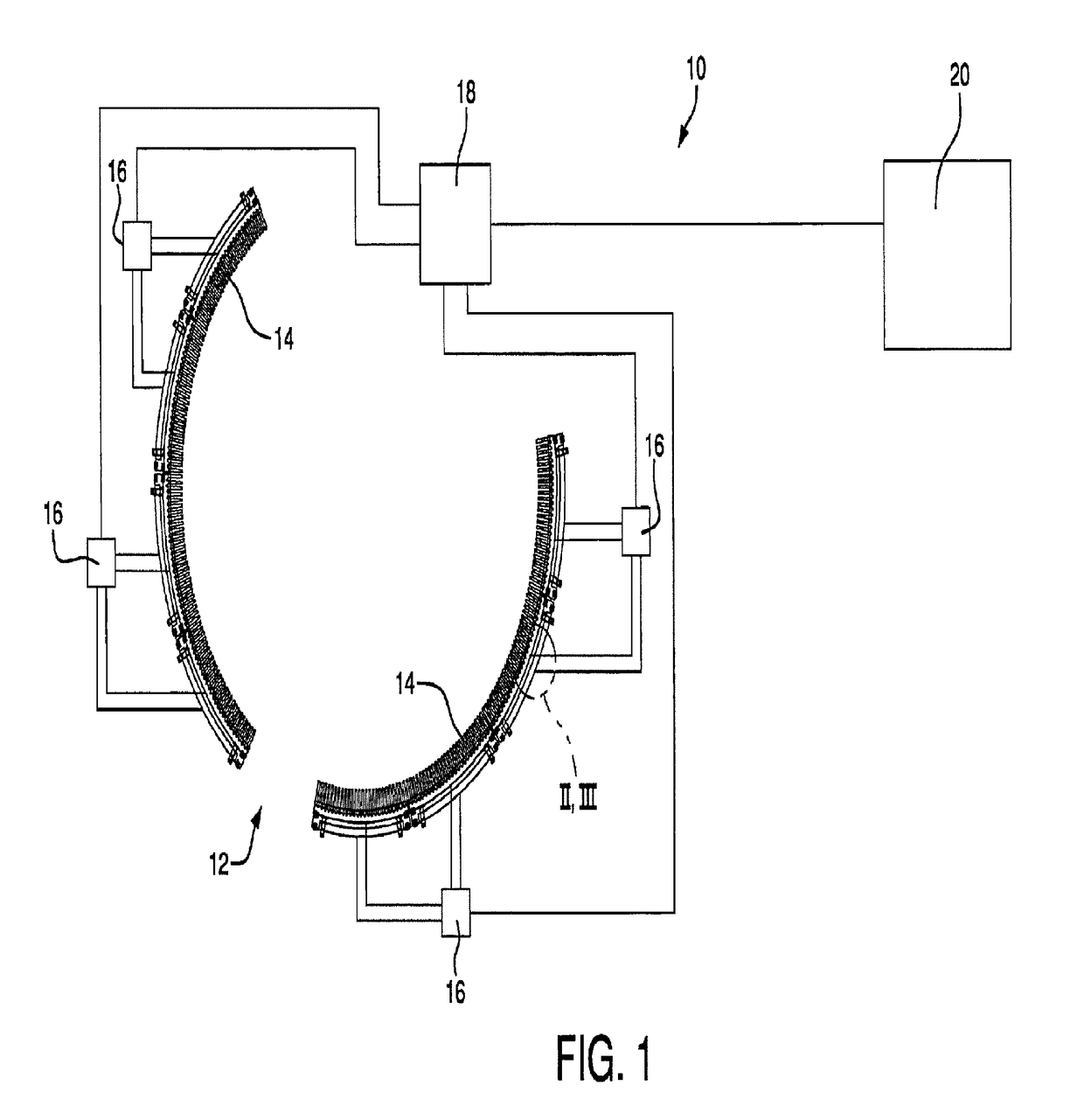

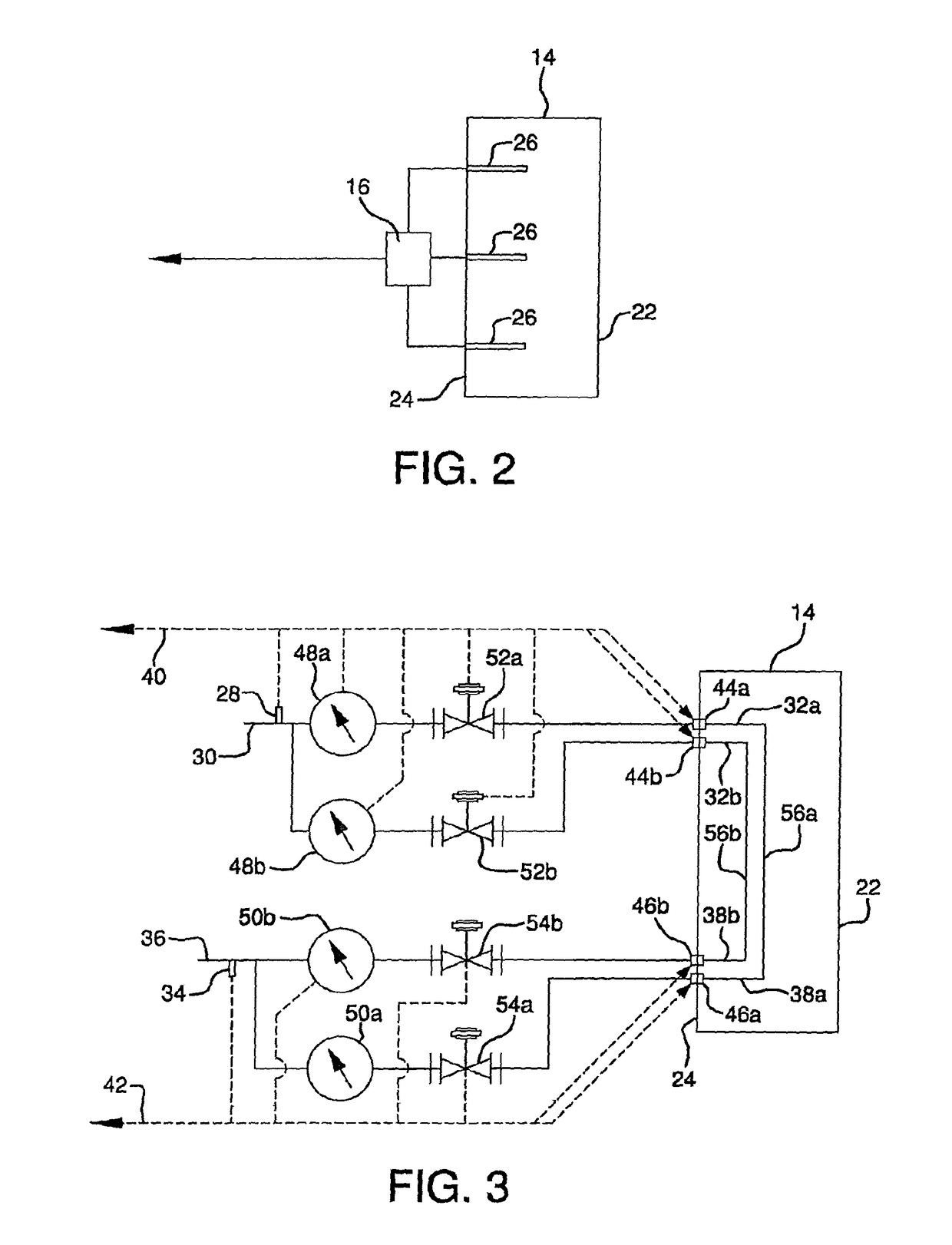

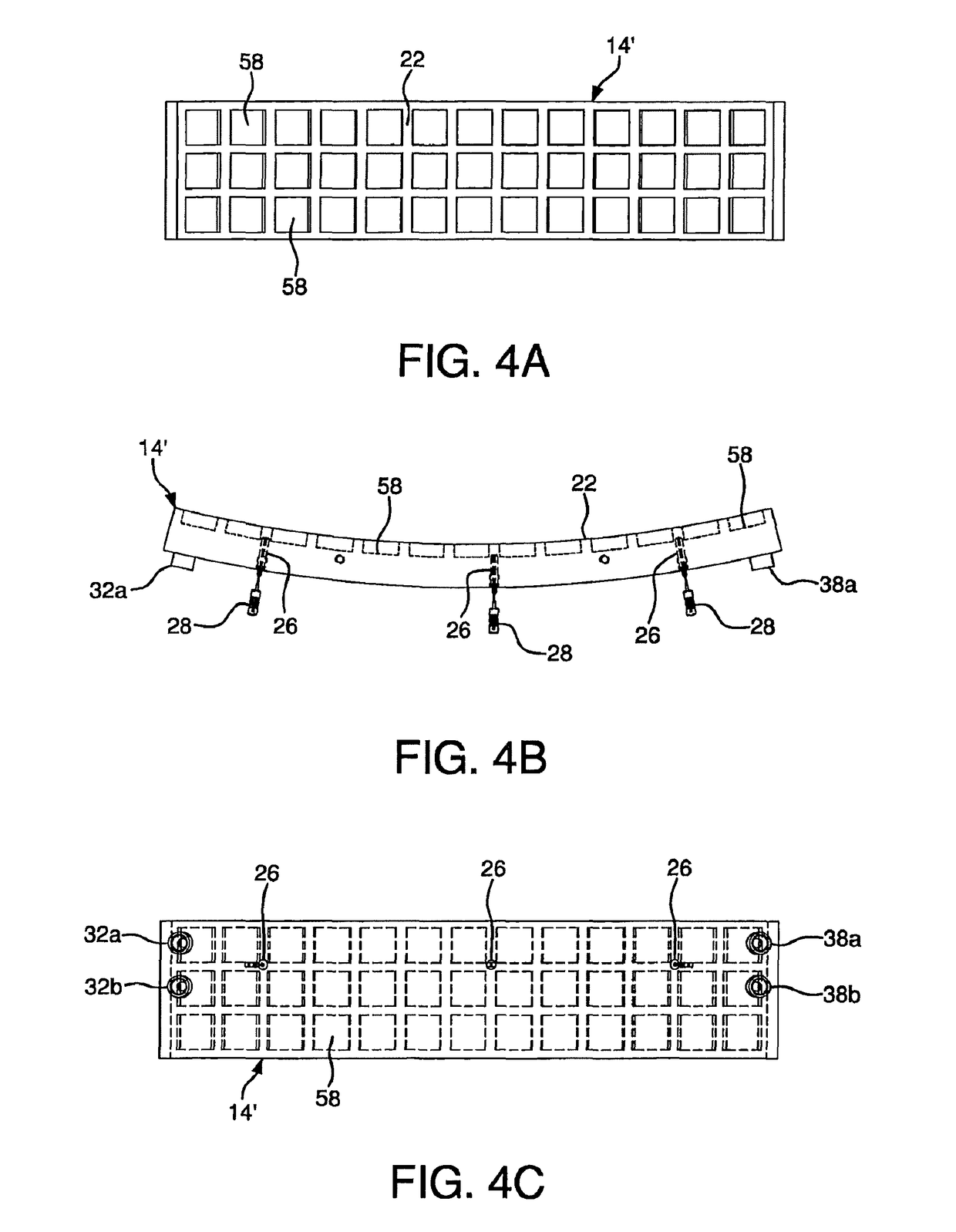

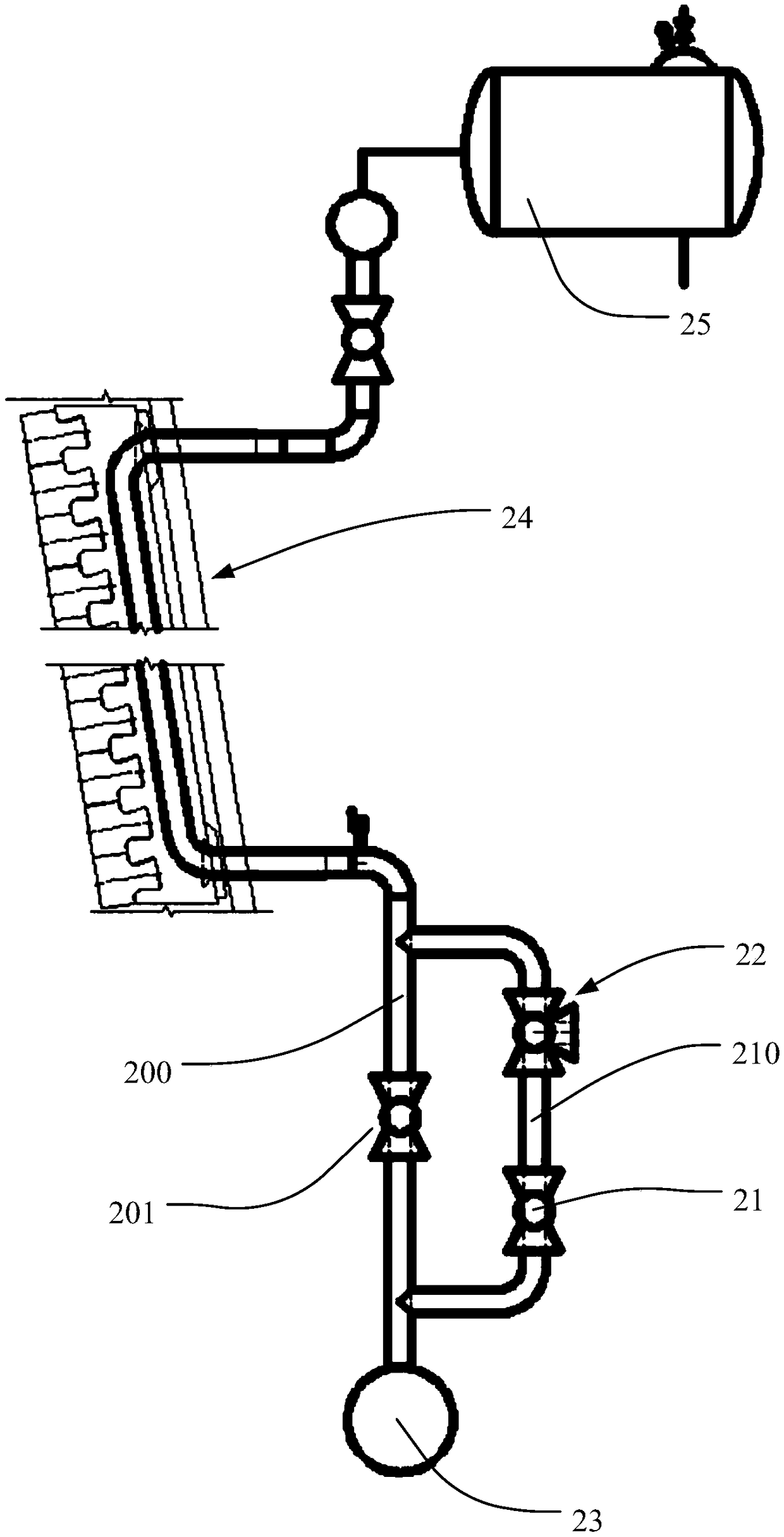

Leak detection system for furnace cooling fluid circuits

InactiveUS20180356155A1Avoid damageMeasurement of fluid loss/gain rateFurnace safety devicesCombustorEngineering

The present disclosure relates in general to a furnace apparatus and in particular to a system including a method and apparatus for detecting leaks in fluid-cooled panels, burner housings, and / or any fluid cooled component for industrial furnaces such as metal smelting furnaces, blast furnaces, electric arc furnaces (EAFs) or the like.

Owner:BERRY METAL

System for insulating an induction vacuum furnace and method of making same

InactiveUS20150230293A1Uniform heating efficiencyAvoid inductionFurnaces without endless coreMuffle furnacesSusceptorCarbide

A system and method for insulating an induction vacuum furnace is disclosed. An induction furnace for heating a workpiece includes a chamber, an insulation cylinder positioned within the chamber, and an induction coil positioned to surround at least a portion of the insulation cylinder. A susceptor is positioned within the insulation cylinder and inductively heated by the induction coil when a current is provided to the induction coil. An insulating jacket assembly including one of a carbide material and a refractory metal is positioned in a space between the insulating cylinder and the susceptor.

Owner:GH INDUCTION ATMOSPHERES +1

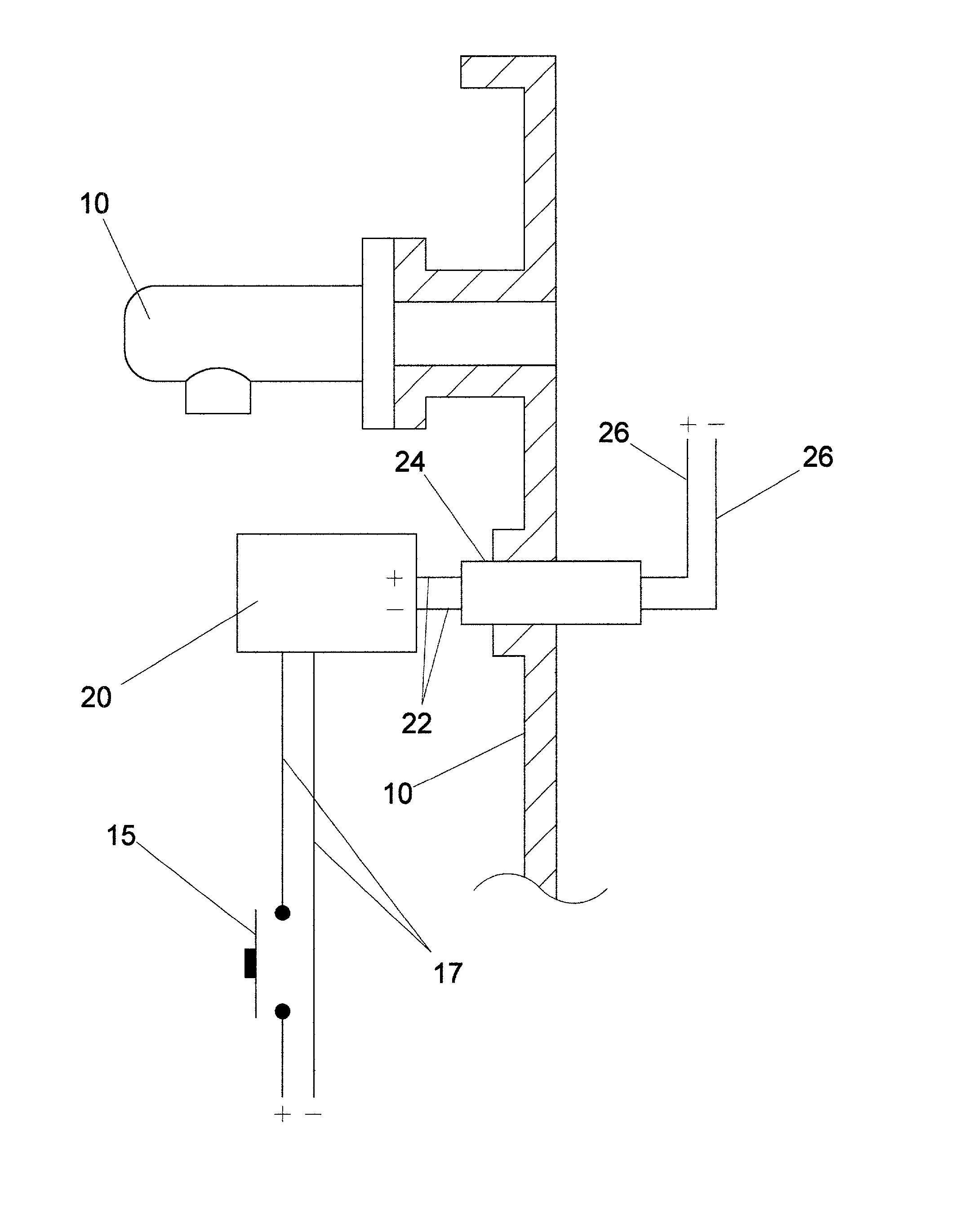

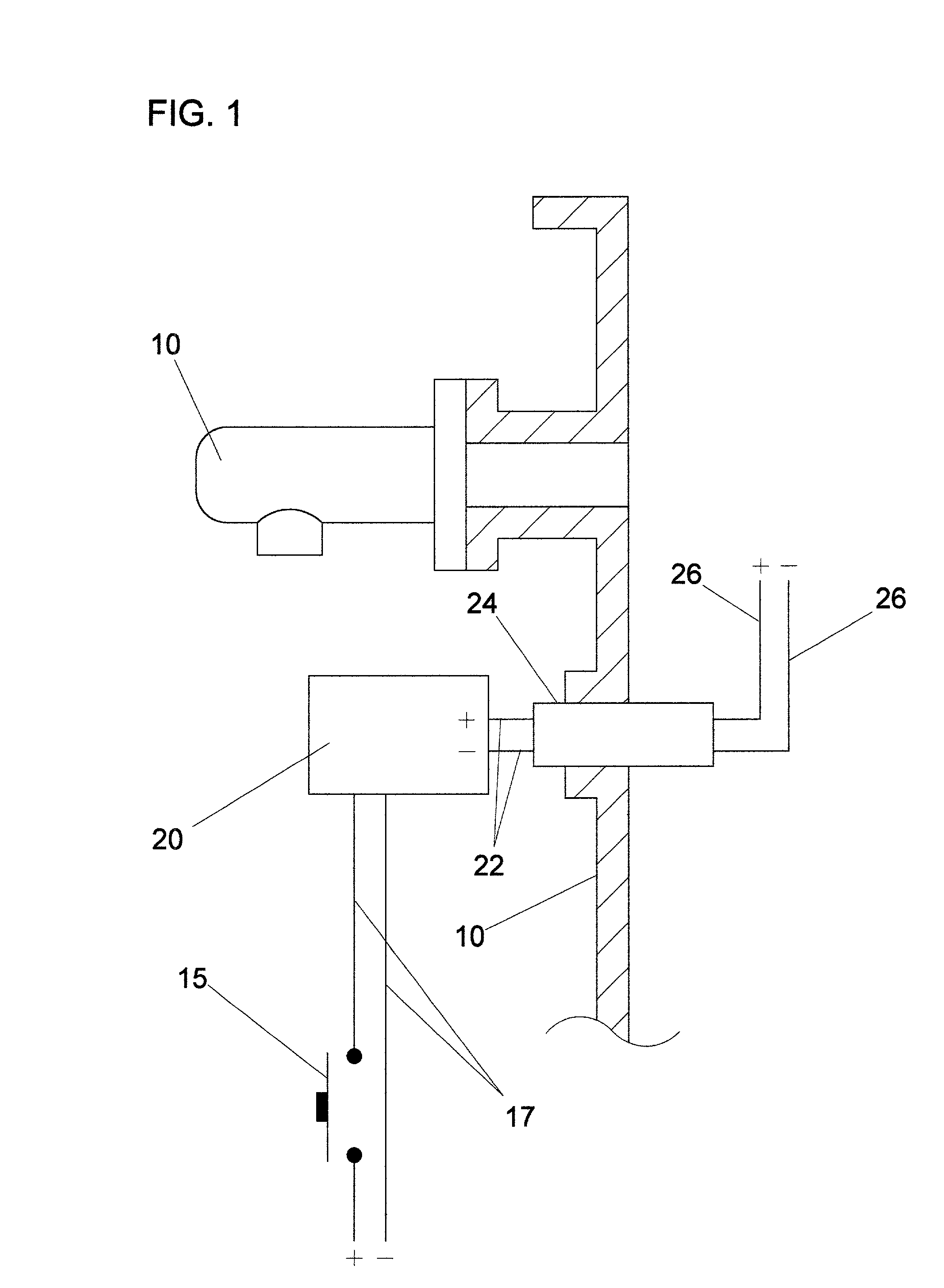

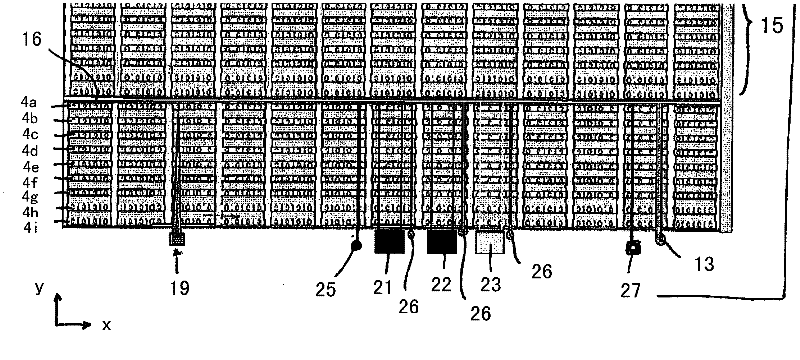

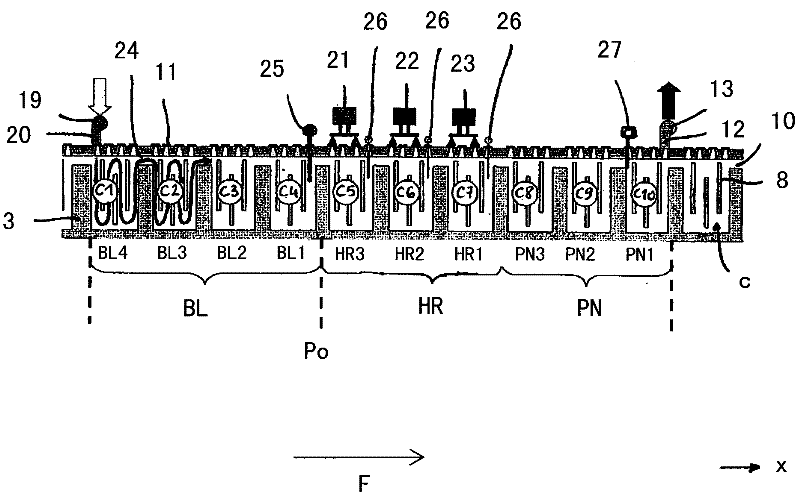

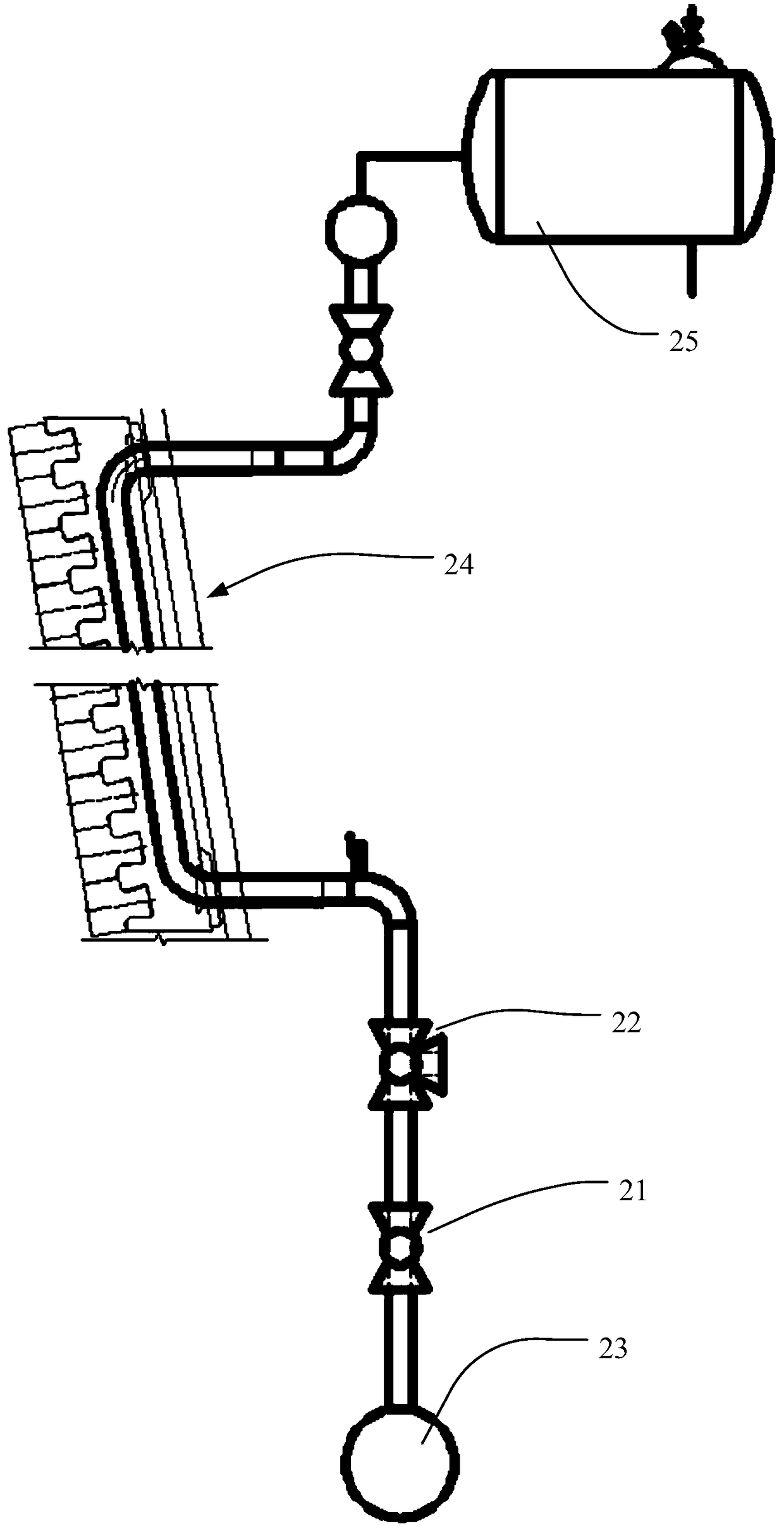

Method and system for monitoring the operation of a carbonaceous block roasting plant

The furnace equipment comprises partition walls in which hot gases from roasting carbonaceous blocks circulate, and heating ramps (21, 22, 23) with nozzles or fuel injectors rotating relative to said furnace. A gas circulation line (24) is enclosed along said partition between the air blowing arm (20) and the corresponding gas suction arm (12). In order to detect even partial partition blockages, the method comprises, continuously: a) for each gas circulation line, recording at least one of the following measured parameters: temperature, pressure, flow, oxygen concentration and carbon monoxide concentration; b) evaluating the at least one factor obtained by measuring the parameter; c) comparing the factor with a corresponding reference value; and d) signaling a fault when the comparison between said factor and said corresponding reference value does not satisfy a predetermined safety criterion.

Owner:RIOTINTO ALCAN INT LTD

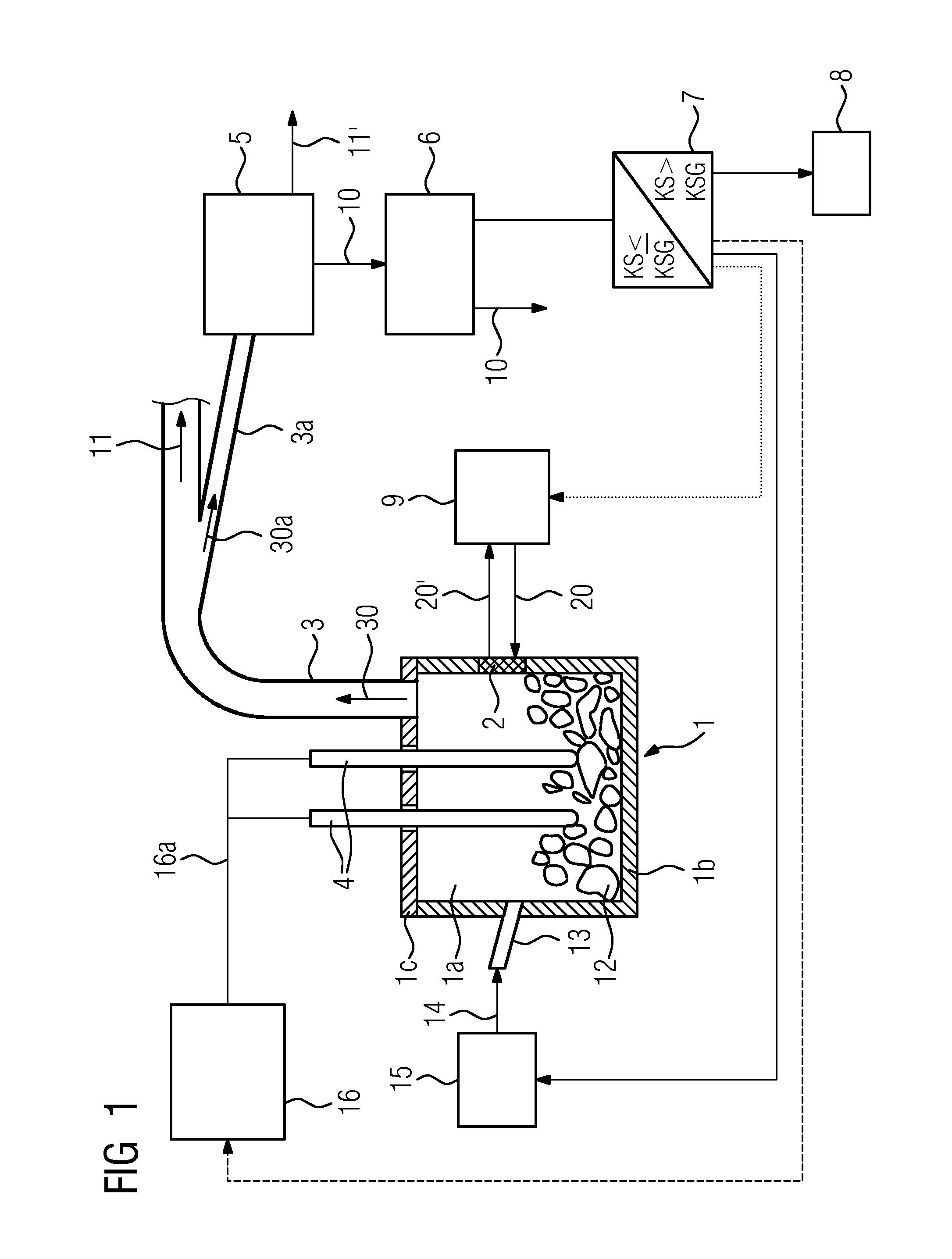

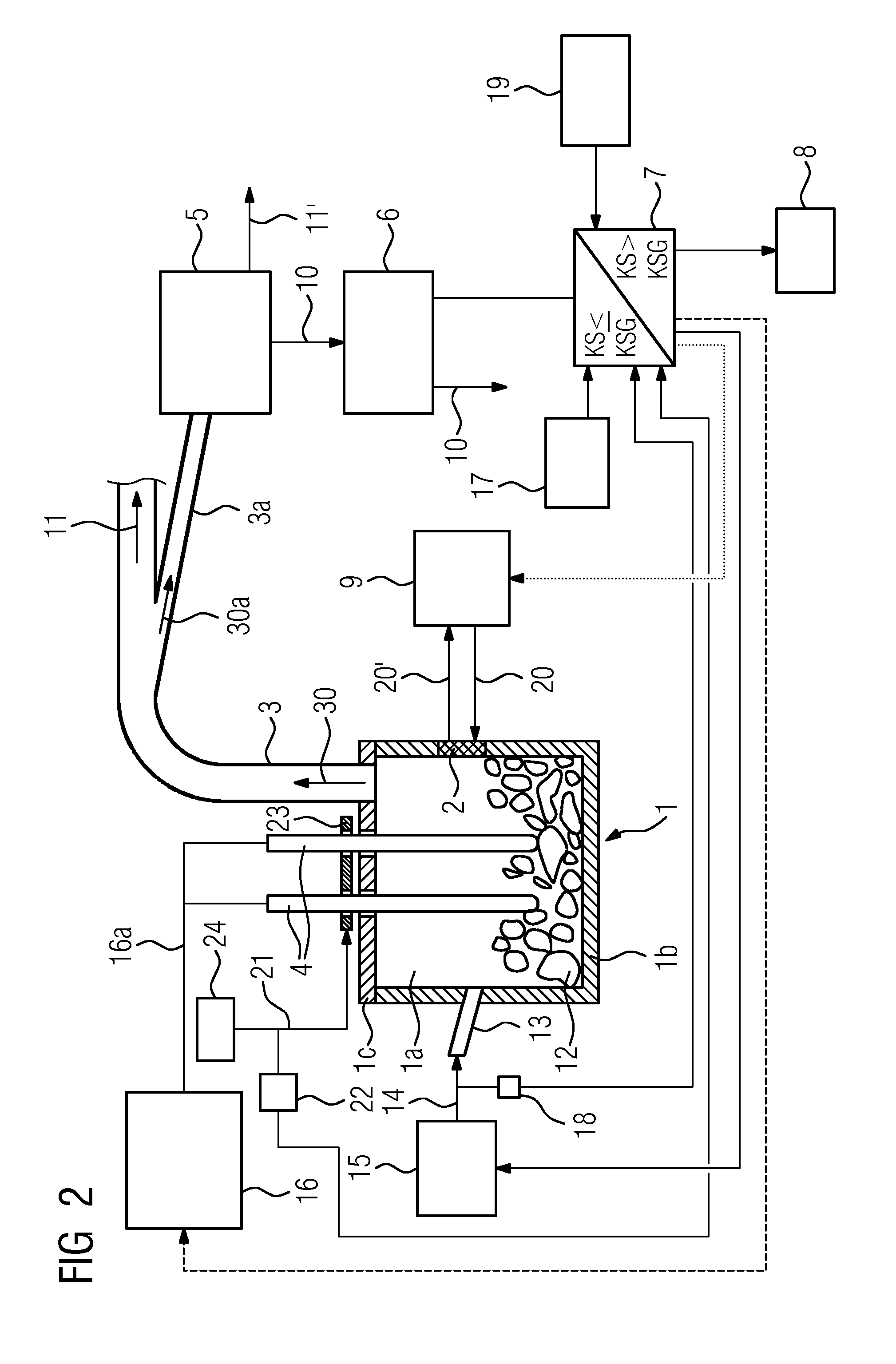

Method and device for detecting a leakage in the area of at least one cooling device of a furnace and a furnace

ActiveUS20150184943A1Rapid and reliable possibilityOperational securityDetection of fluid at leakage pointFurnace safety devicesProcess engineeringLimit value

A method for detecting a leakage in the area of at least one cooling device of a furnace, wherein, in the event of a leakage, liquid coolant gets into a furnace chamber of the furnace from the at least one cooling device, and wherein a stream of exhaust gas is continuously removed from the furnace chamber over a period of time Z. The steps include dividing off a representative partial stream from the stream of exhaust gas during the period of time Z; condensing vaporous constituents contained in the partial stream; determining a stream of condensate obtained; comparing the stream of condensate obtained with a condensate-stream limit value; and indicating a leakage if the stream of condensate exceeds the condensate-stream limit value. Also a device for carrying out the method and a furnace with such a device are disclosed.

Owner:SIEMENS VAI METALS TECH GMBH AUSTRIA +1

Anti-explosion safety industrial furnace

InactiveCN109387083AReduce pressureImprove protectionFurnace safety devicesFurnace typesEngineeringIndustrial furnace

The invention discloses an anti-explosion safety industrial furnace which comprises a working block. A combustion space is arranged in the working block. A first pipeline with the right end wall communicated with the combustion space and the left end wall communicated with the outside space is arranged in the left end wall of the combustion space. A second pipeline with the right end wall communicated with the combustion space and the left end wall communicated with the outside space is arranged in the lower end wall of the first pipeline. A buffering pipeline with the upper end wall communicated with a slide groove in the right end of a first partition plate is arranged in the lower end wall of the slide groove. A buffering groove with the upper end wall communicated with the buffering pipeline and the left end wall communicated with the outside space is formed in the lower end wall of the buffering pipeline. The anti-explosion safety industrial furnace is simple in structure and convenient to operate, can rapidly and effectively detect whether gas in the furnace can explode or not after being ignited, has a buffering effect after a small amount of gas is ignited, is quite well protected against explosion, and has quite high applicability.

Owner:新昌县恒腾科技有限公司

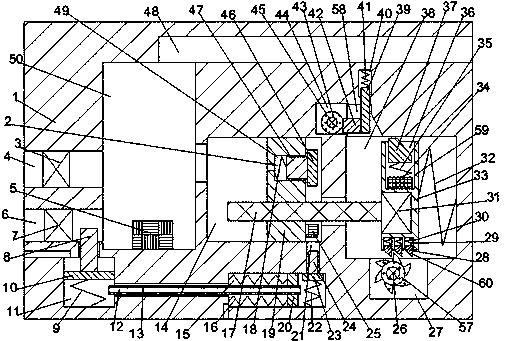

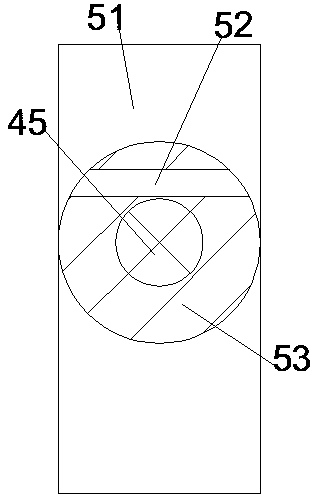

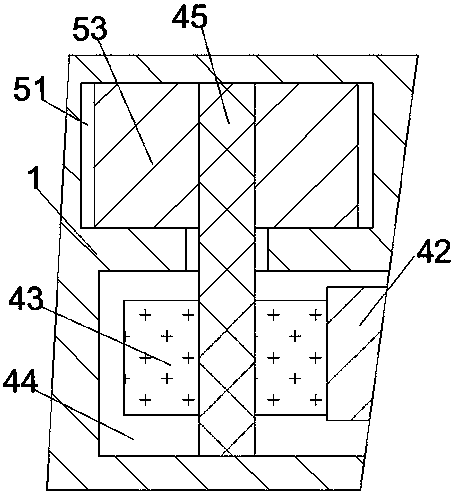

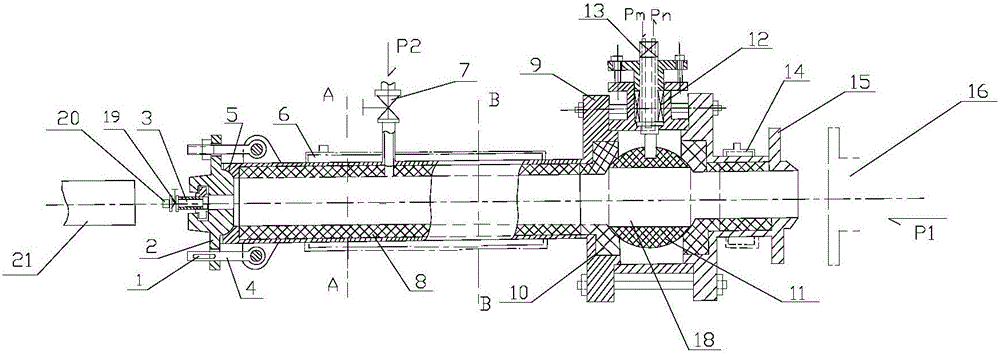

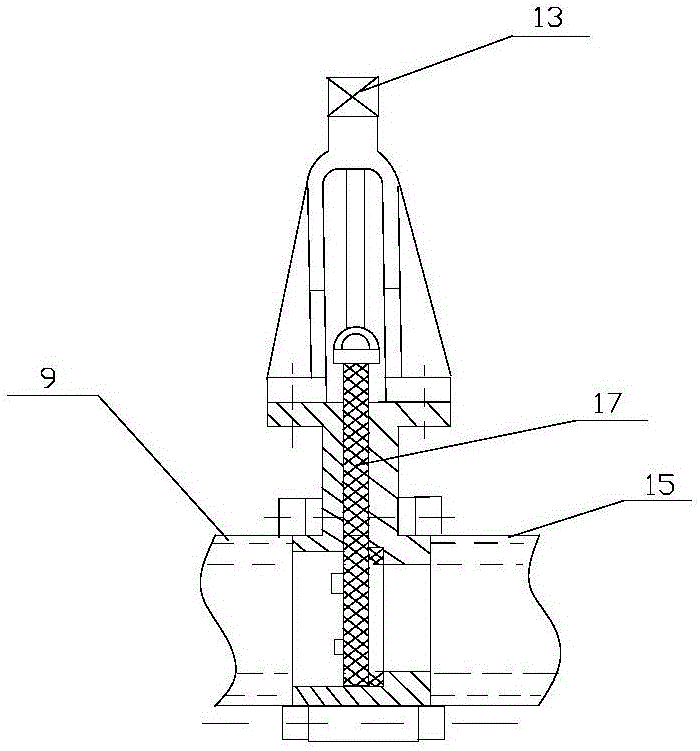

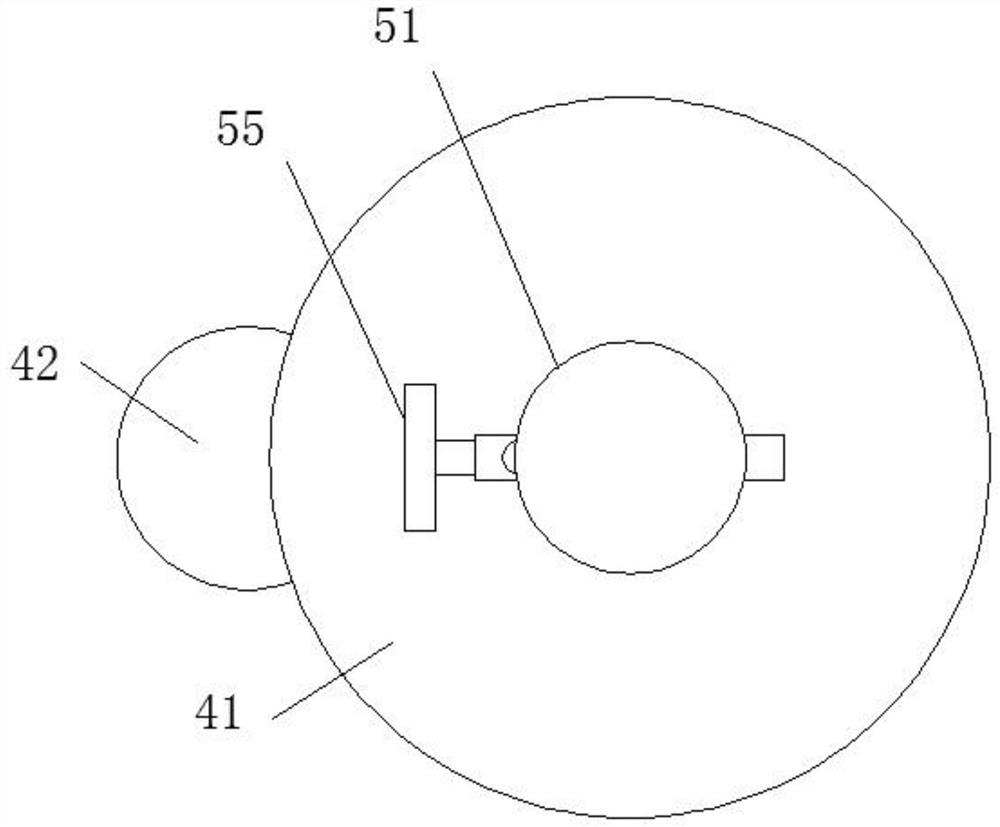

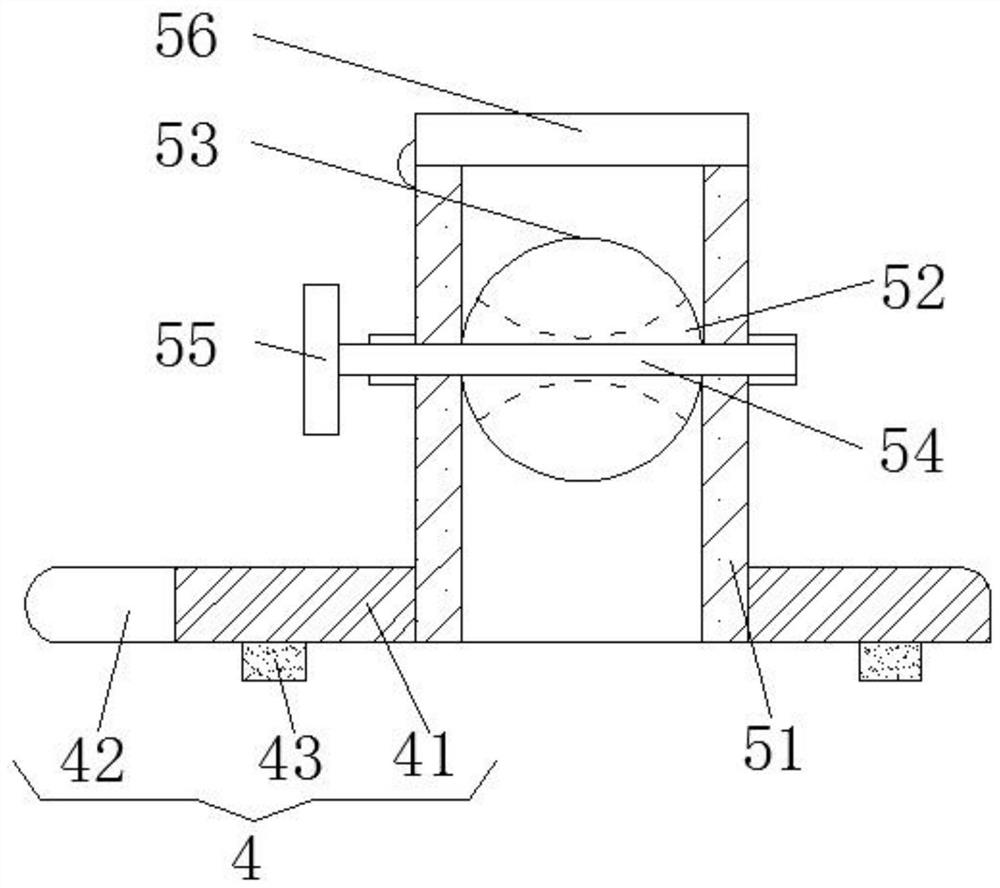

Measurement controller and measurement control method for smelter

ActiveCN106052409ASolve the security problem of measurementRealize online measurementFurnace safety devicesControl devices for furnacesMeasurement deviceMedical equipment

The invention relates to a measurement device and a measurement method for a smelter, in particular to a measurement controller and a measurement control method for the smelter, and belongs to the technical field of medical equipment. The measurement controller structurally comprises a high-temperature-resistant controller body; a measurement rod passage extending leftwards and a measurement passage extending rightwards are formed in the two ends of the controller body correspondingly; a left outer shell is arranged from the left side of the controller body to the outside of the measurement rod passage; a right outer shell is arranged from the right side of the controller body to the outside of the measurement passage; the inner walls of the left outer shell and the right outer shell are provided with linings; an end cover is arranged at the end of the measurement rod passage; and the measurement passage is connected with a to-be-measured position of the smelter. It is ensured that high-temperature and high-pressure gas in the smelter does not leak while gas and charge in the smelter are taken out during blast furnace production.

Owner:宗品禾

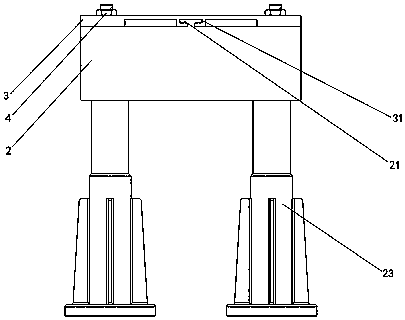

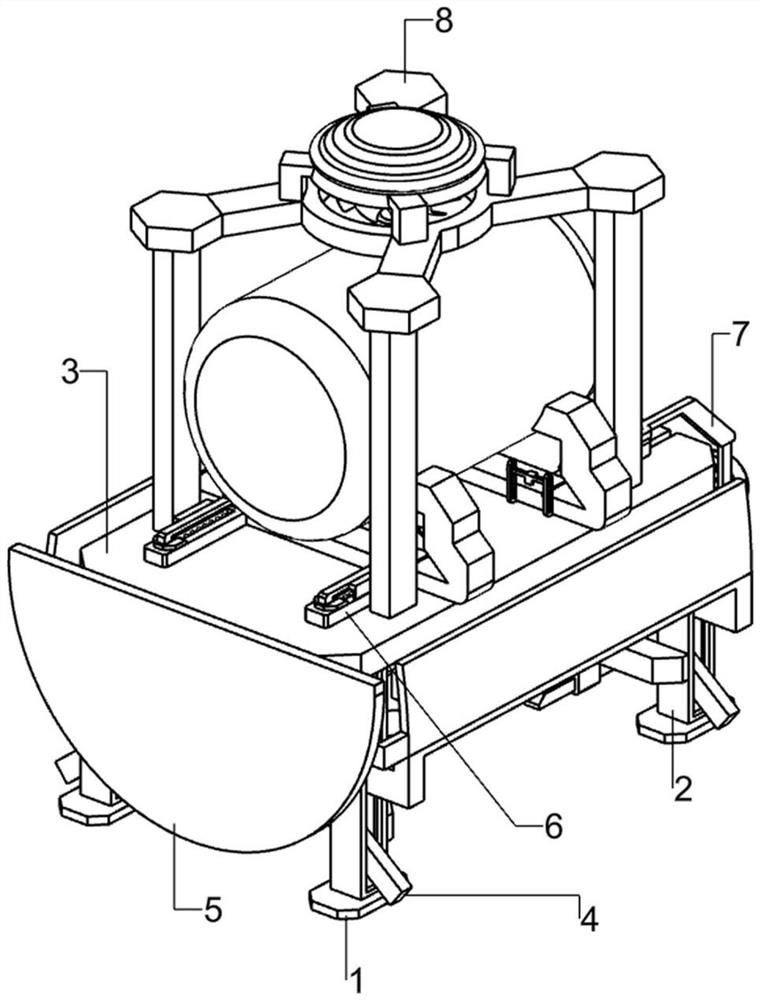

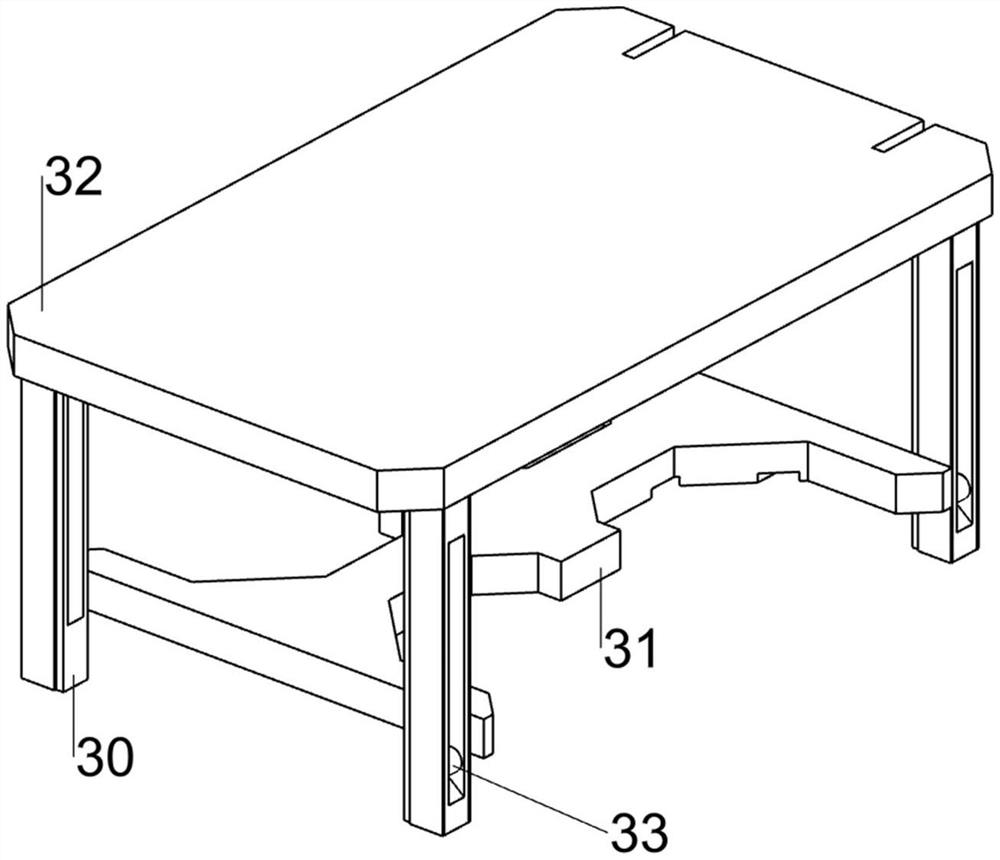

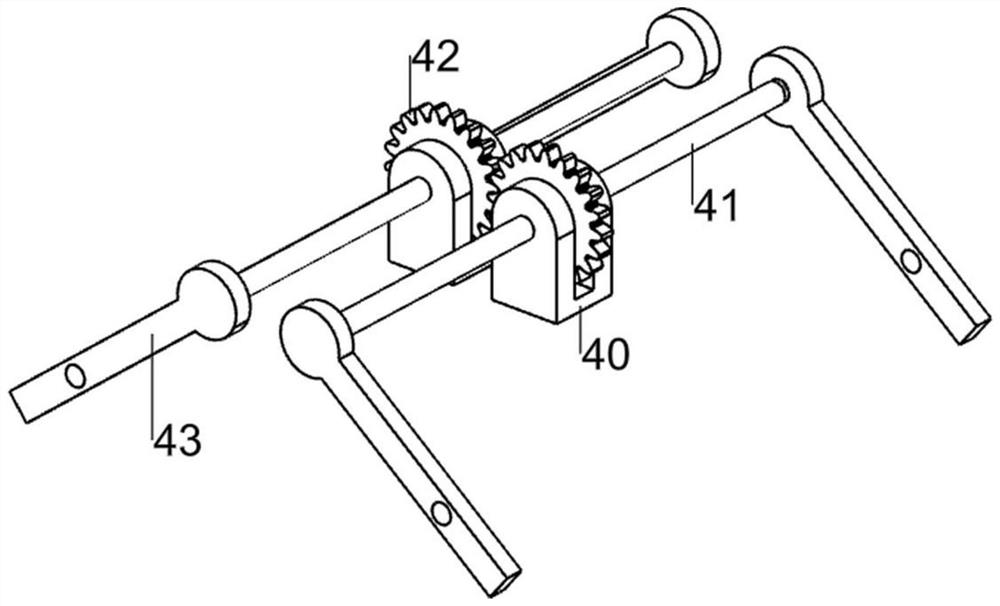

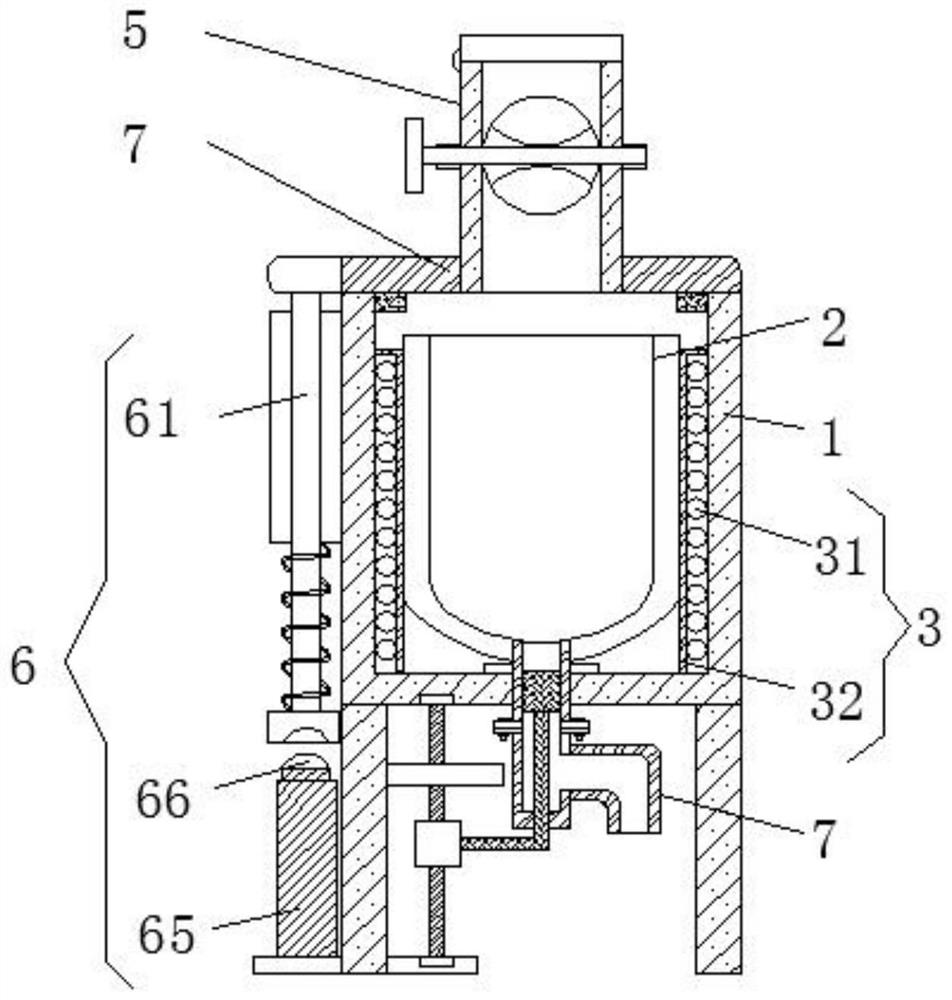

High-temperature vacuum sintering furnace lifting frame device

InactiveCN112484481AEasy to useRealize clamping and fixingMuffle furnacesFurnace safety devicesMaterials scienceHigh heat

The invention relates to a lifting frame device, in particular to a high-temperature vacuum sintering furnace lifting frame device. The high-temperature vacuum sintering furnace lifting frame device is high in safety and simple to use. According to the technical scheme, the high-temperature vacuum sintering furnace lifting frame device comprises a bottom plate and supporting frames, a placing assembly and a lifting mechanism, wherein the supporting frames are arranged on the bottom plate at equal intervals; the placing assembly is connected between the supporting frames; and the lifting mechanism is arranged on the placing assembly. Through cooperation of the placing assembly and the lifting mechanism, a vacuum sintering furnace can move up and down, and therefore people can use the vacuumsintering furnace conveniently.

Owner:江西省晶为光电科技有限公司

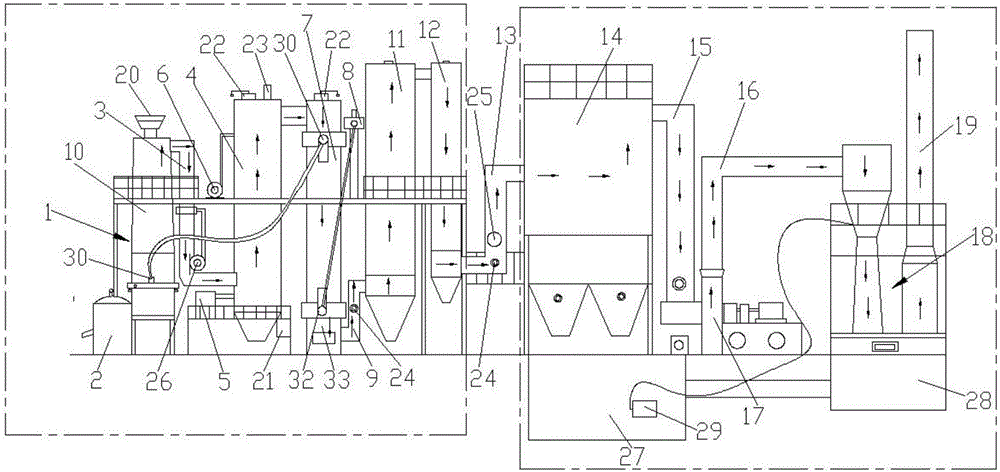

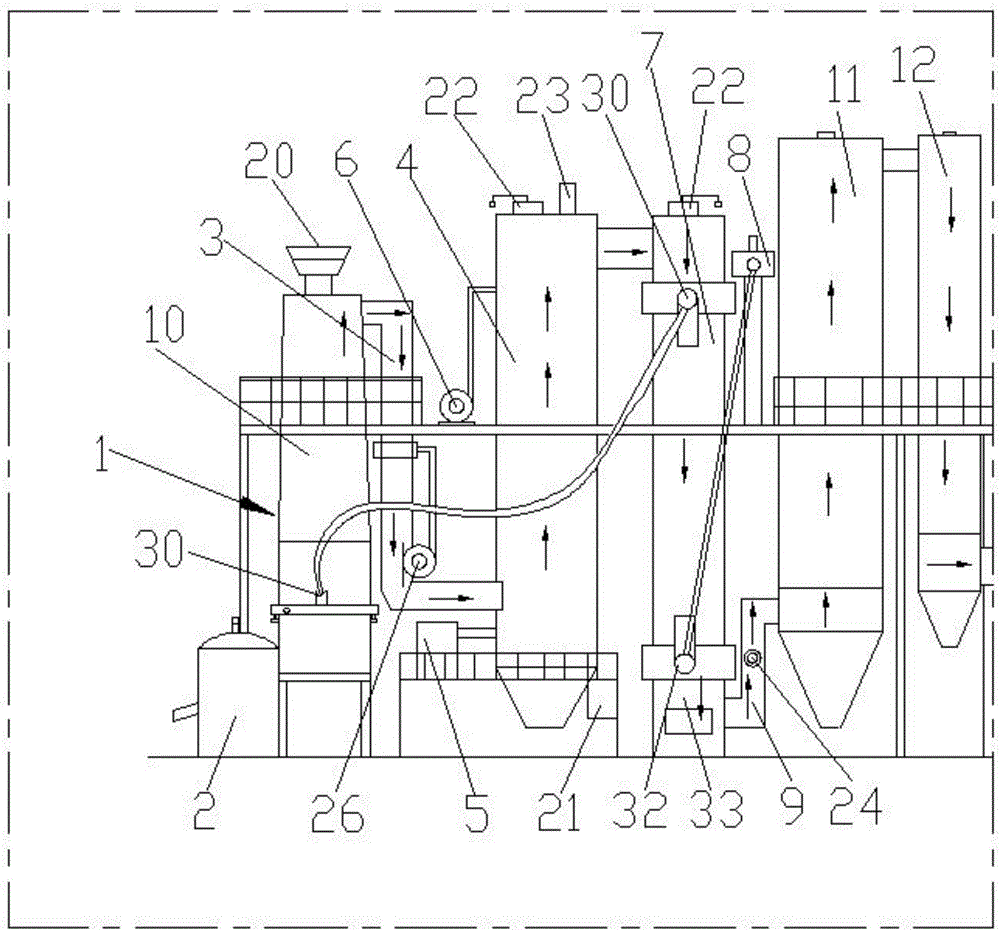

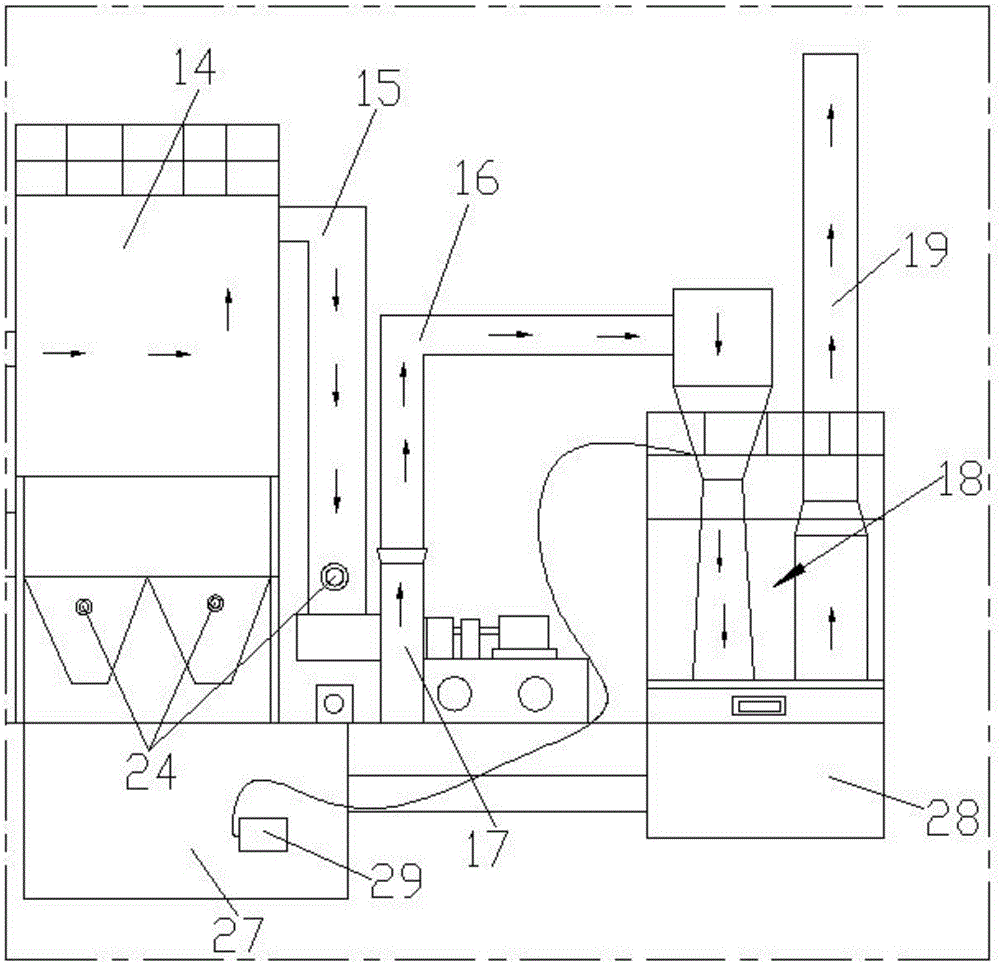

Energy-saving environment-friendly efficient hot blast cupola

InactiveCN106679402ANo pollution in the processImprove purityFurnace safety devicesCharge composition/stateCold airCombustion chamber

The invention relates to an energy-saving environment-friendly efficient hot blast cupola. The energy-saving environment-friendly efficient hot blast cupola comprises a smelting device and a waste gas treatment device which are connected. The smelting device comprises a cupola body, a front ladle, a first smoke pipe, a combustion chamber, a preheating furnace, a cold air fan, a heat exchanger, an air blower and a second smoke pipe, wherein the cupola body is provided with a hot air inlet; a feeding inlet is formed in the upper end of the cupola body, and the lower end of the cupola body communicates with the front ladle; the cupola body comprises a smoke chamber which communicates with the combustion chamber through the first smoke pipe; the preheating furnace communicating with the combustion chamber is arranged on the lower portion of the combustion chamber; the two sides of the upper portion of the combustion chamber communicate with the cold air fan and the heat exchanger correspondingly; the air blower is arranged on one side of the heat exchanger; a cold air inlet of the heat exchanger communicates with an air outlet of the air blower, and a hot air outlet of the heat exchanger communicates with the hot air inlet of the cupola body; and the lower portion of the heat exchanger communicates with the waste gas treatment device through a cooling chamber. According to the energy-saving environment-friendly efficient hot blast cupola, pig iron and scrap iron are both smelted into molten iron, the purity of the generated molten iron is high, the energy-saving and conversion efficiency is high, and meanwhile discharged waste gas is free of pollution.

Owner:苏州市润达机械制造有限公司

Casting melting device with splash-proof component

InactiveCN113154879AReduce churnStop lossFurnace safety devicesCrucible furnacesMolten stateCrucible

The invention discloses a casting melting device with a splash-proof component. The device comprises a heat-insulating furnace body, a crucible is placed in the furnace body, a heating piece is fixedly arranged on the inner wall of the furnace body, a cover plate is placed at the top of the furnace body, the splash-proof component for feeding is fixedly arranged at the middle end of the top of the cover plate, a movable assembly is arranged between the cover plate and the furnace body, the relative displacement of the cover plate and the furnace body is changed, and a discharging mechanism is arranged between the crucible and the furnace body; and the furnace body made of the heat insulation material can reduce outward loss of heat, so that the influence of the heat on the surrounding environment is reduced, in addition, the feeding safety can be improved by arranging the splash-proof component, molten metal cannot be splashed out and intercepted in the furnace body under the shielding of the splash-proof component, meanwhile, the splash-proof component has certain sealing performance, the heat loss can be prevented in a molten state, heat loss can be prevented in time under the feeding condition, and the high-temperature influence in the feeding process is reduced.

Owner:WUHU RONGCHUAN ELECTROMECHANICAL TECH

Kiln cooling wall leakage acquisition unit and device and cooling wall detecting method

PendingCN109028992ASolve the problem of inconvenient leak detectionFurnace safety devicesFurnace coolingEngineeringCooling fluid

The invention provides a kiln cooling wall leakage acquisition unit and device and a cooling wall detecting method. The acquisition unit used for acquiring environment information of a cooling wall isprovided, sudden changes of the environment information are read by acquiring the environment information of the cooling wall, and weather the cooling wall has leakage or not and the leaking positionare further judged. By means of the scheme, influences to supply of cooling liquid are small, the acquisition and detection precision is high, and the cooling wall leakage detection precision and convenience are improved.

Owner:CISDI SHANGHAI ENG CO LTD

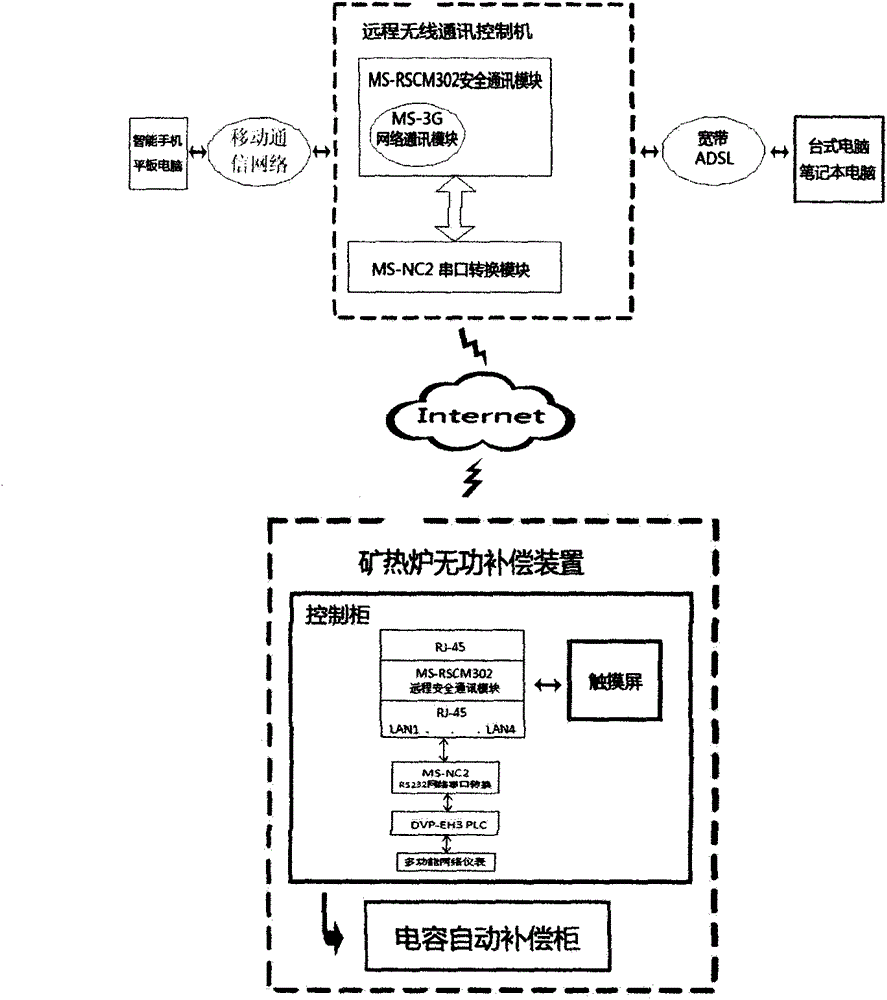

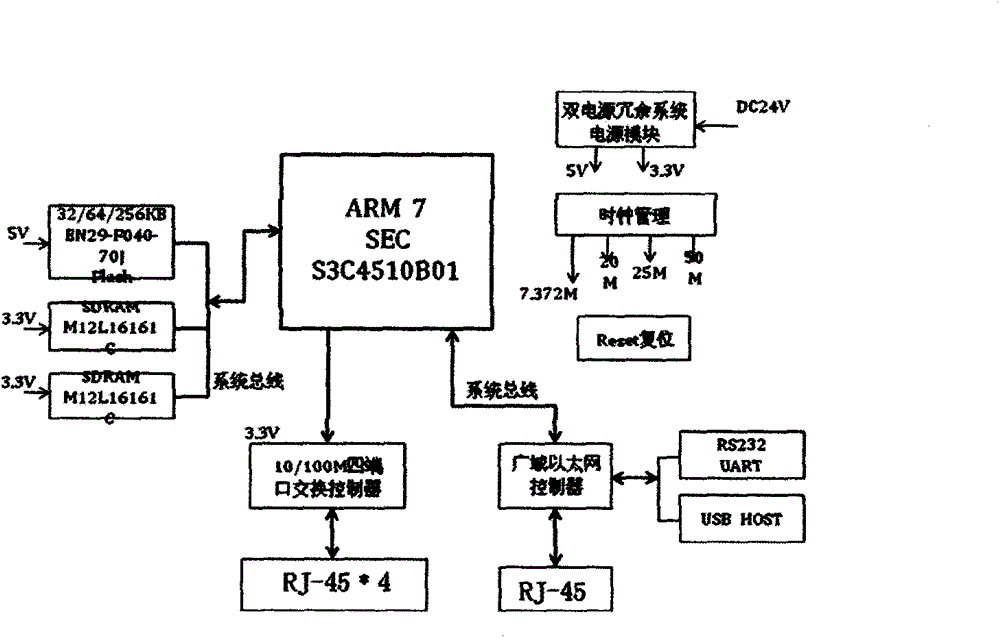

Submerged arc furnace reactive compensation remote wireless communication control system

The present invention relates to a remote wireless communication control system for submerged arc furnace reactive compensation. The system includes a remote wireless communication control machine and a submerged arc furnace reactive compensation device. The remote wireless communication control machine further includes a MS-RSCM302 security communication module integrated with a MS-3G network communication module, and a MS-NC2 serial port conversion module. The submerged arc furnace reactive compensation device includes a control cabinet and a capacitance automatic compensation cabinet. The control cabinet comprises a MS-RSCM302 security communication module, a MS-NC2 serial port conversion module, a DVPEH2 PLC controller, a programmable multi-function network instrument and a touch screen; while the capacitance automatic compensation cabinet comprises multiple compensation units. The present invention performs remote Internet communication and data collection via cable modem, wireless transmission and 3G, while remote monitoring and data reading on each site are realized through installation of customized software in the computers and smart phones, to further remotely manage the actual operation status of the submerged arc furnace reactive compensation device and to solve such maintenance burdens as tedious on-site maintenance and long maintenance time.

Owner:GUANGXI MAISHA ELECTRIC GRP

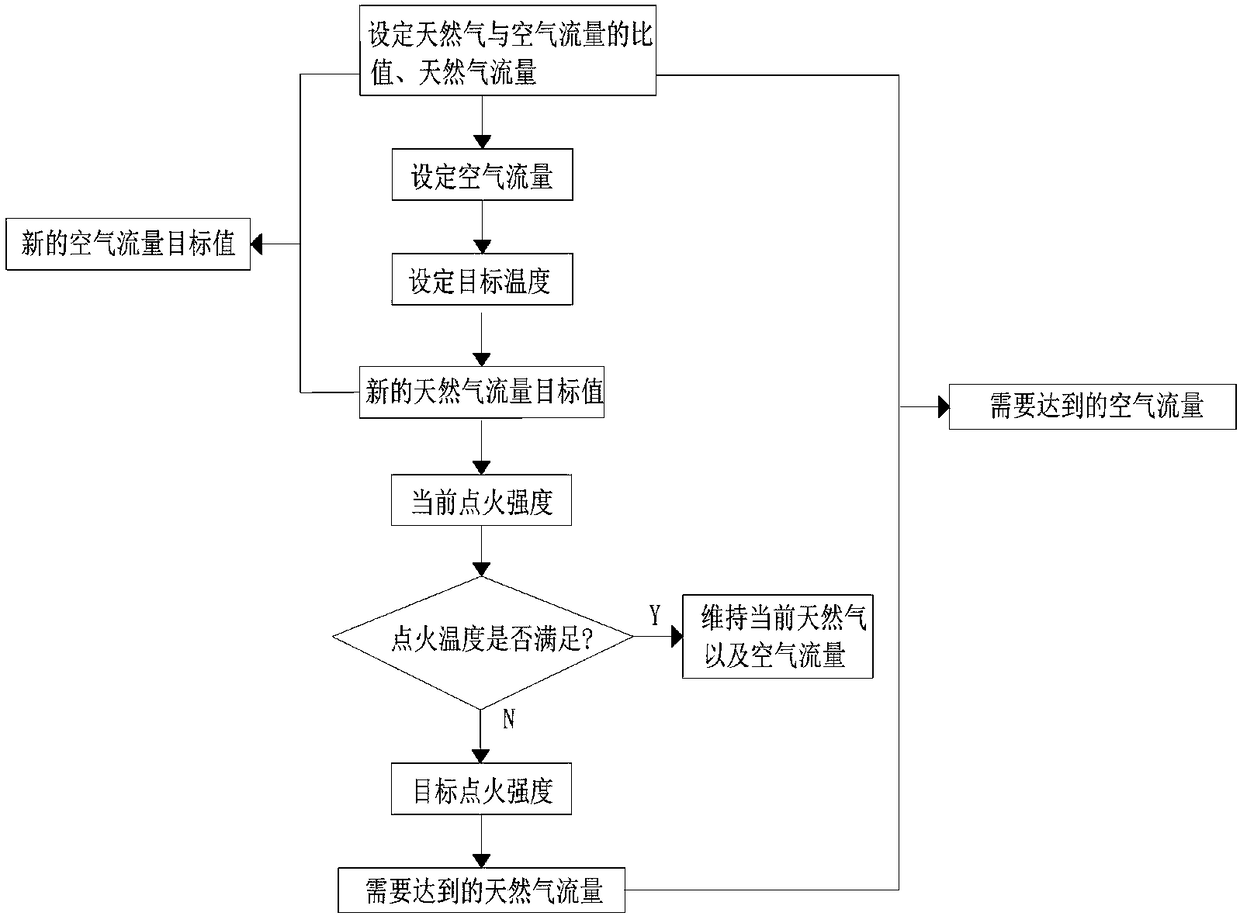

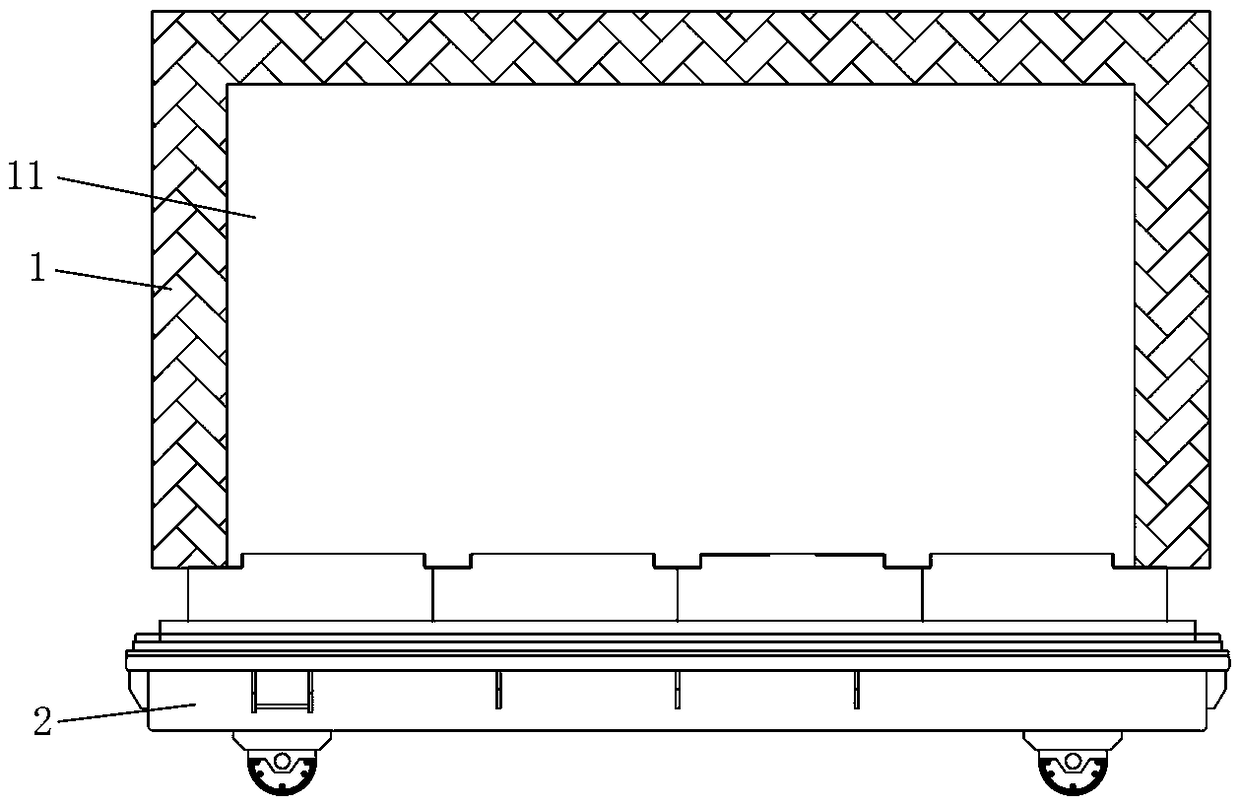

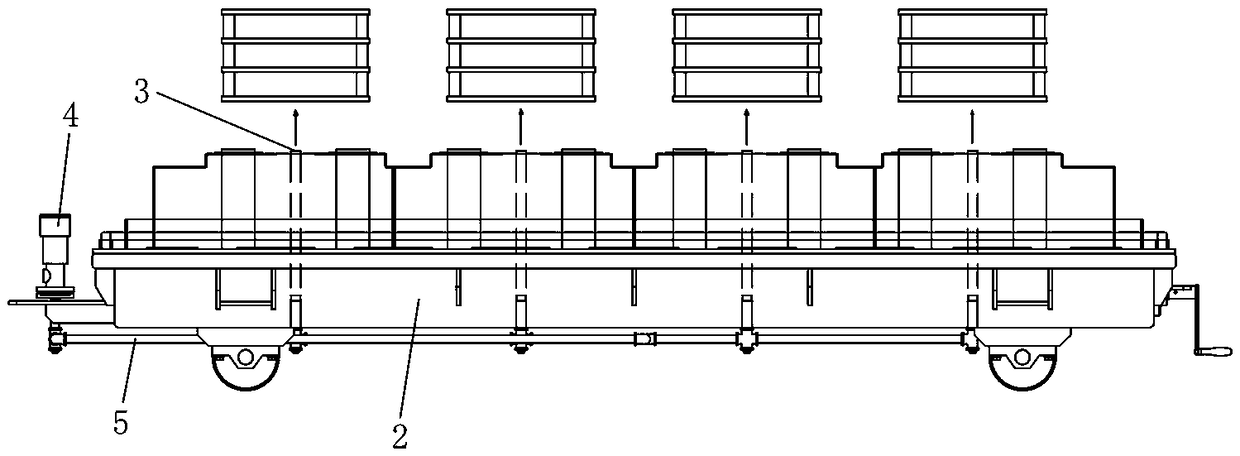

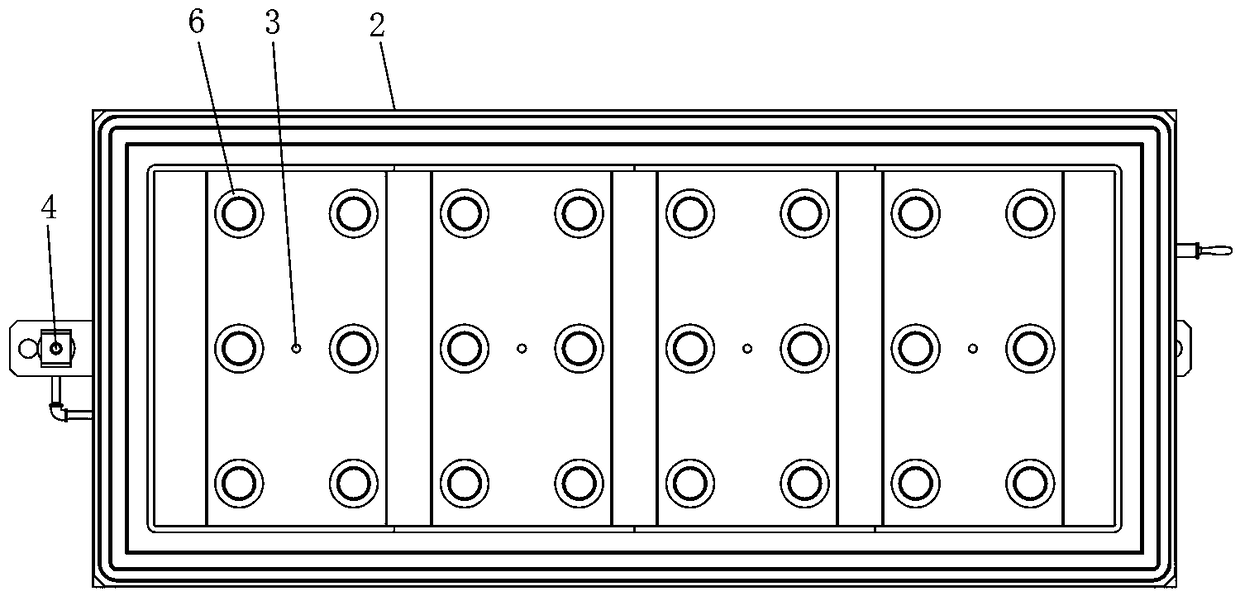

Ignition optimal control method for sintering machine

ActiveCN108507365AGuaranteed uptimeAvoid wastingFurnace safety devicesGas emission reductionOptimal controlTemperature control mode

The invention discloses an ignition optimal control method for a sintering machine. The ignition optimal control method comprises the steps that valves controlling natural gas and air flow are connected with PLC / DCS systems correspondingly, and PID closed-loop control is adopted; a flow follow-up regulation mode is used, an air-fuel ratio and natural gas flow are set, and according to the formulathat natural gas flow*air-fuel ratio=air flow, the set air flow is obtained; then an ignition temperature control mode is used, and according to the deviation of target temperature and the current temperature, a new natural gas flow target value is calculated; then an ignition strength control module is used, the current ignition strength is obtained, and then target ignition strength is given according to the current ignition strength; and then according to the target ignition strength, the natural gas flow needing to be achieved is obtained, and then air flow is obtained through the air-fuelratio. According to the ignition optimal control method, a waste or flameout phenomenon of natural gas is avoided, meanwhile stability of PID closed-loop control in the regulation process is ensured,instable burning is prevented, and thus operation of the sintering machine is safer, more reliable and more stable.

Owner:BEIJING BESTPOWER INTELCONTROL TECH CO LTD

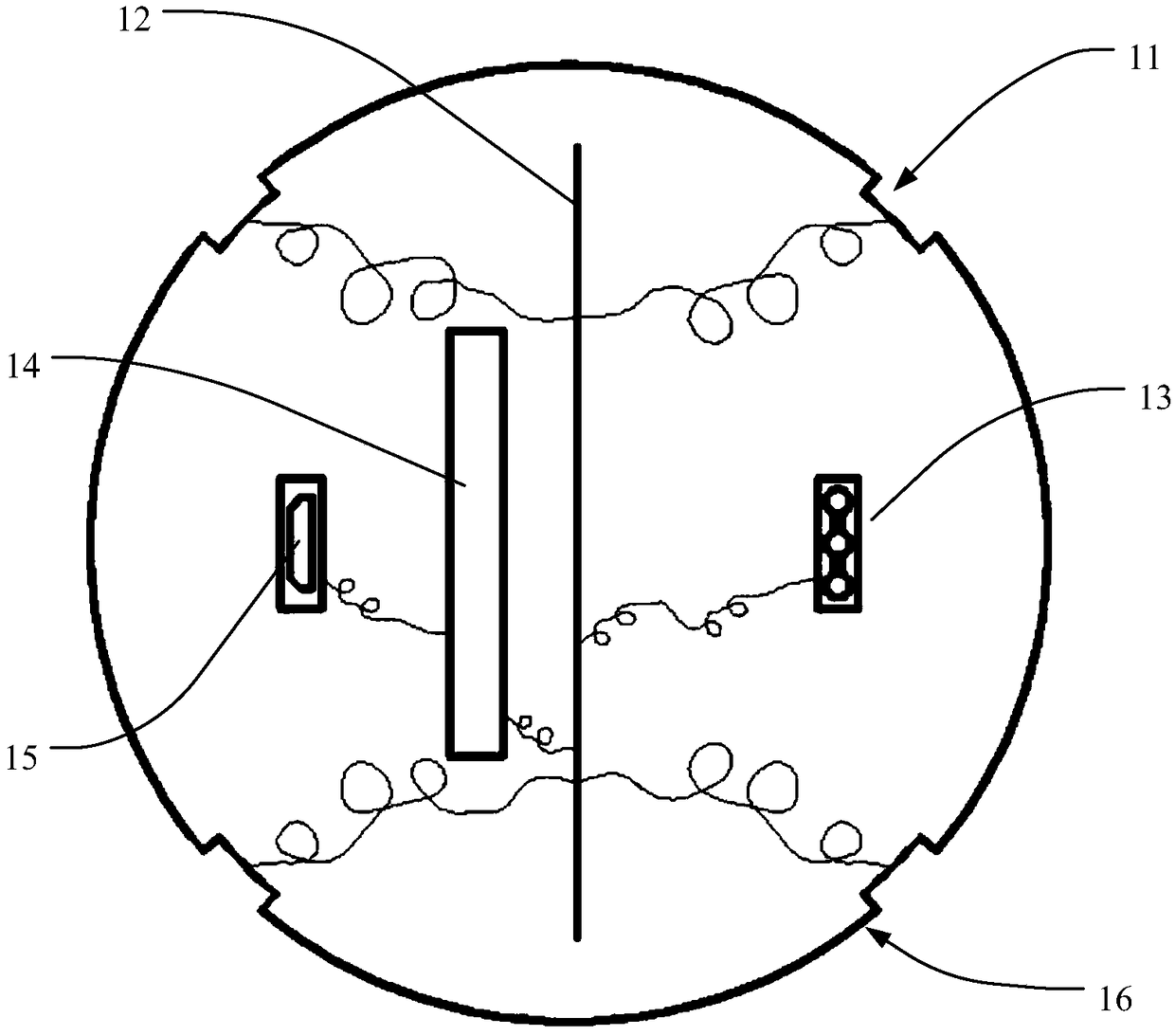

Bell-type furnace

PendingCN109237940AImprove uniformityImprove product qualityFurnace safety devicesBell type furnacesEngineering

The invention discloses a bell-type furnace which comprises a furnace body with a hearth, a movable furnace door for sealing a furnace opening of the hearth and an air inlet device for introducing protective atmosphere into the hearth. A plurality of air inlets for introducing the protective atmosphere into the hearth are formed in the movable furnace door, and all the air inlets are connected with an air source supplying the protective atmosphere. The bell-type furnace has the advantages of being simple in structure, low in cost, easy to install and maintain, good in temperature and atmosphere uniformity, capable of improving the product quality and the like.

Owner:HUNAN JINLU TECH CO LTD

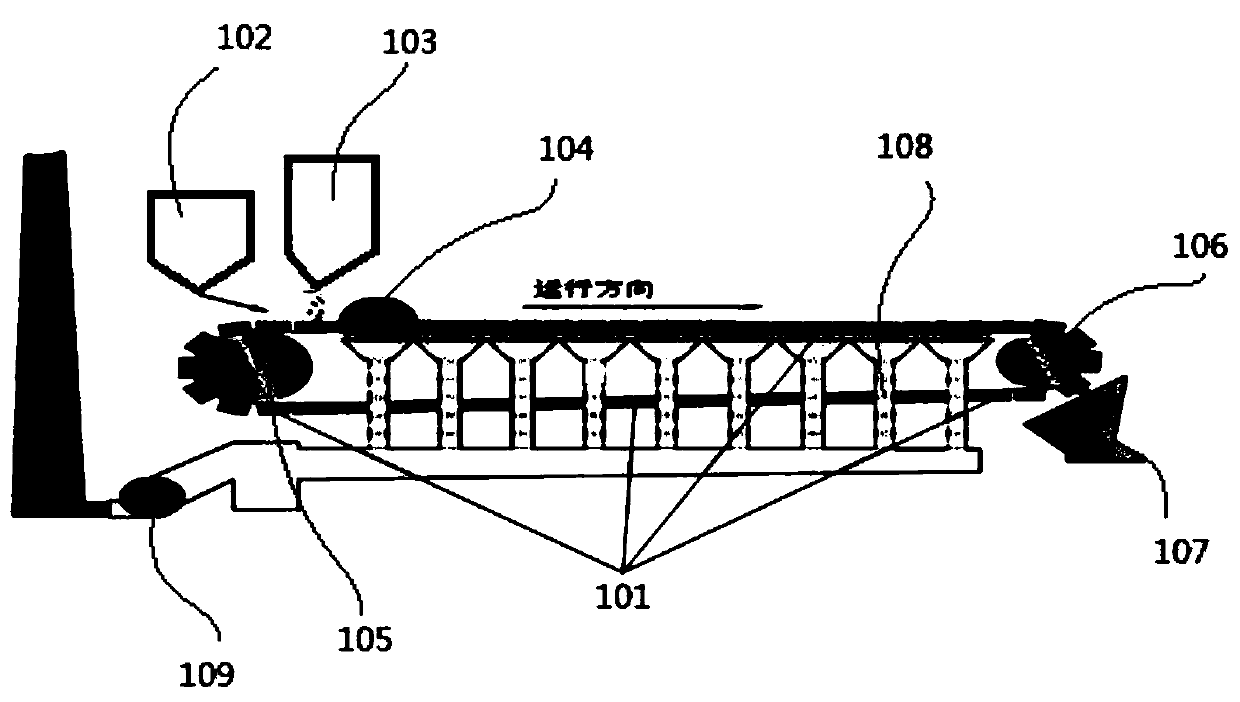

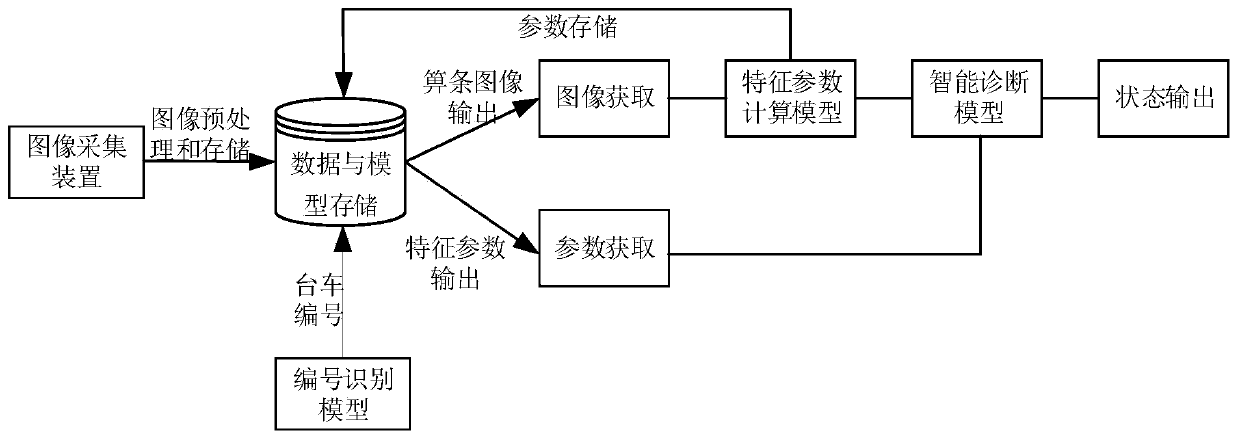

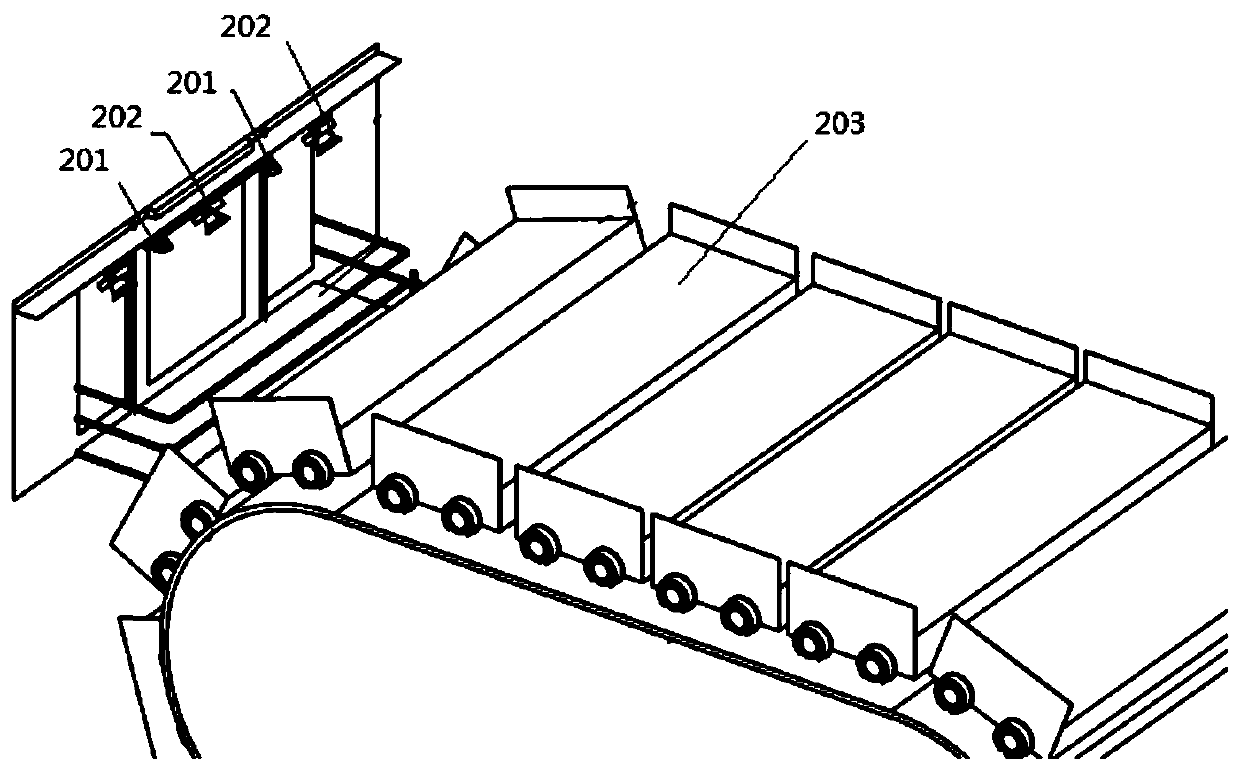

Trolley grate bar image shooting and detecting method for sintering machine

PendingCN111476712AGrasp the proportion of confusionGrasp the degree of confusionImage analysisFurnace safety devicesStructural engineeringMechanical engineering

The invention discloses a trolley grate bar image shooting and detecting method for a sintering machine, and the method can also detect the total number of grate bars very conveniently and accurately,can locate the missing positions of the grate bars, carries out the fault diagnosis and the like according to the missing conditions of the grate bars, and takes corresponding maintenance measures. And secondly, the inclination angle of the grate bar can be detected very conveniently and accurately, and the grate bar with an overlarge inclination angle can be positioned, so that fault diagnosis and the like can be carried out, and corresponding maintenance measures can be taken. And thirdly, the method can very conveniently and accurately detect the pasting and blocking proportion condition of the grate bars, and can position the missing position of the grate bars which are pasted and blocked seriously, so that fault diagnosis and the like are carried out, and corresponding maintenance measures are taken. And fourthly, the method can very conveniently and accurately detect the spacing of the grate bars, and can position the grate bars with overlarge spacing, so that fault diagnosis and the like can be carried out, and corresponding maintenance measures can be taken.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com