Submerged arc furnace reactive compensation remote wireless communication control system

A remote wireless, control system technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of wasting manpower and material resources, consuming technical personnel, and long working hours, and achieves the effect of solving cumbersome maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

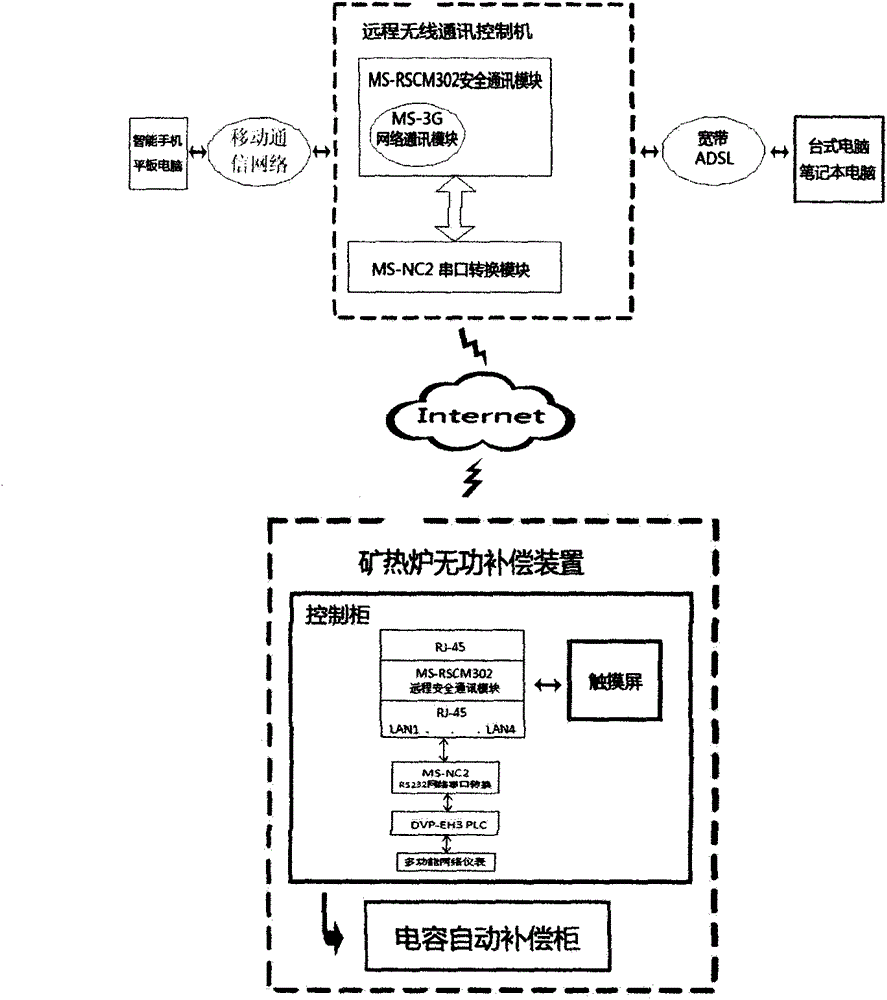

[0016] figure 1 It is a structural schematic diagram of the reactive power compensation remote wireless communication control system of the submerged arc furnace of the present invention. Through the wired or wireless connection between the remote wireless communication control machine and the desktop computer, notebook computer or smart phone terminal, apply the customized professional program on the desktop computer, notebook computer or smart phone terminal, and use the Internet network remote wireless communication to control the reactive power compensation device of the submerged arc furnace , carry out real-time monitoring, data collection, automatic control, data analysis and processing, and system operation diagnosis, online detection and automatic adjustment, and automatically generate the best control plan for the operator to refer to and choo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com