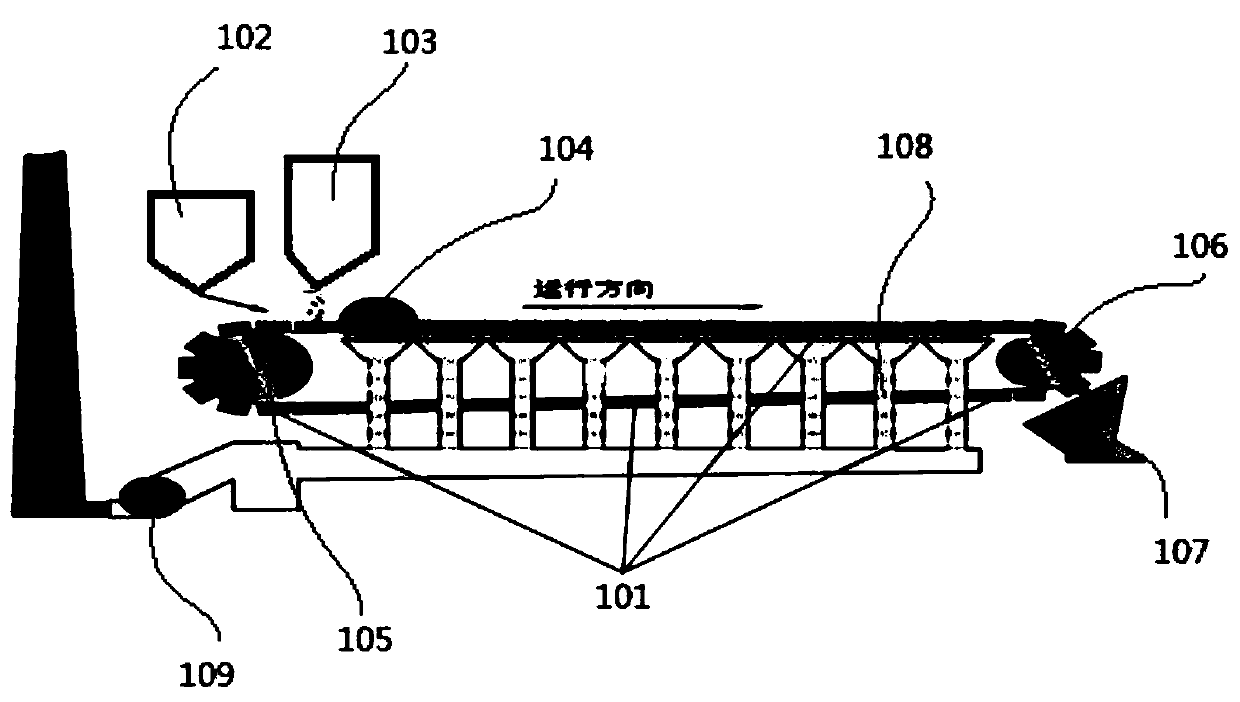

Trolley grate bar image shooting and detecting method for sintering machine

A detection method and technology of a sintering machine, which are applied in image analysis, image data processing, graphic image conversion, etc., can solve the problems of poor air permeability, falling off, and affecting the quality of sintered ore during sintering reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

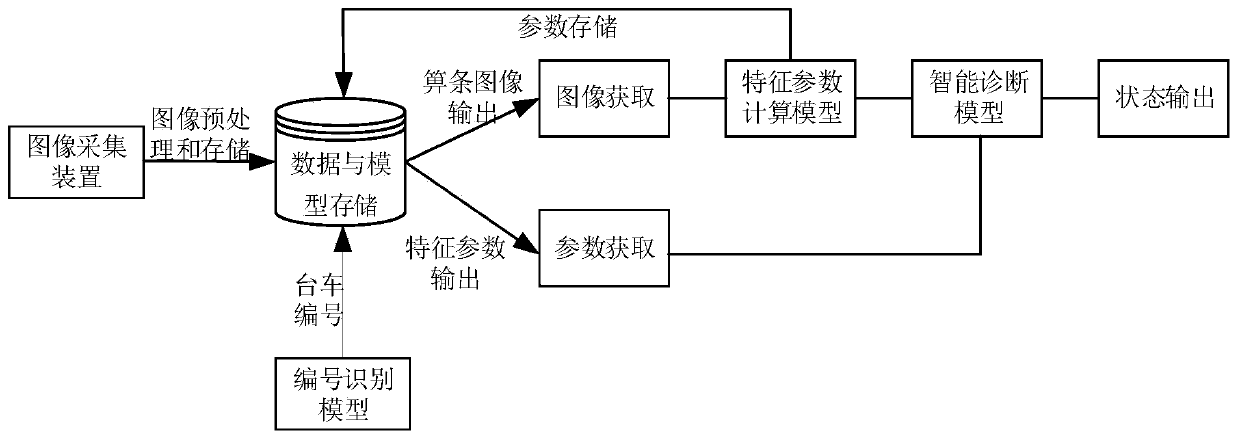

[0134] For the system function structure of this application, please refer to figure 2 , figure 2 It is a functional block diagram of a trolley grate image capture and detection method of a sintering machine in an embodiment of the present application.

[0135] Such as figure 2 As mentioned above, the functional modules include image acquisition device, data and model storage, image acquisition, parameter output, characteristic parameter calculation, intelligent diagnosis model, status output and so on. Wherein, the image acquisition device preprocesses the acquired images and stores them in the data and model storage module. Data and model storage outputs grate images to the image acquisition module, and outputs feature parameters to the parameter acquisition module. The parameters in the feature parameter calculation model are also stored in the data and model storage module. In addition, there is a trolley identification model, and the trolley number is input into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com