System for gas purification in an induction vacuum furnace and method of making same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

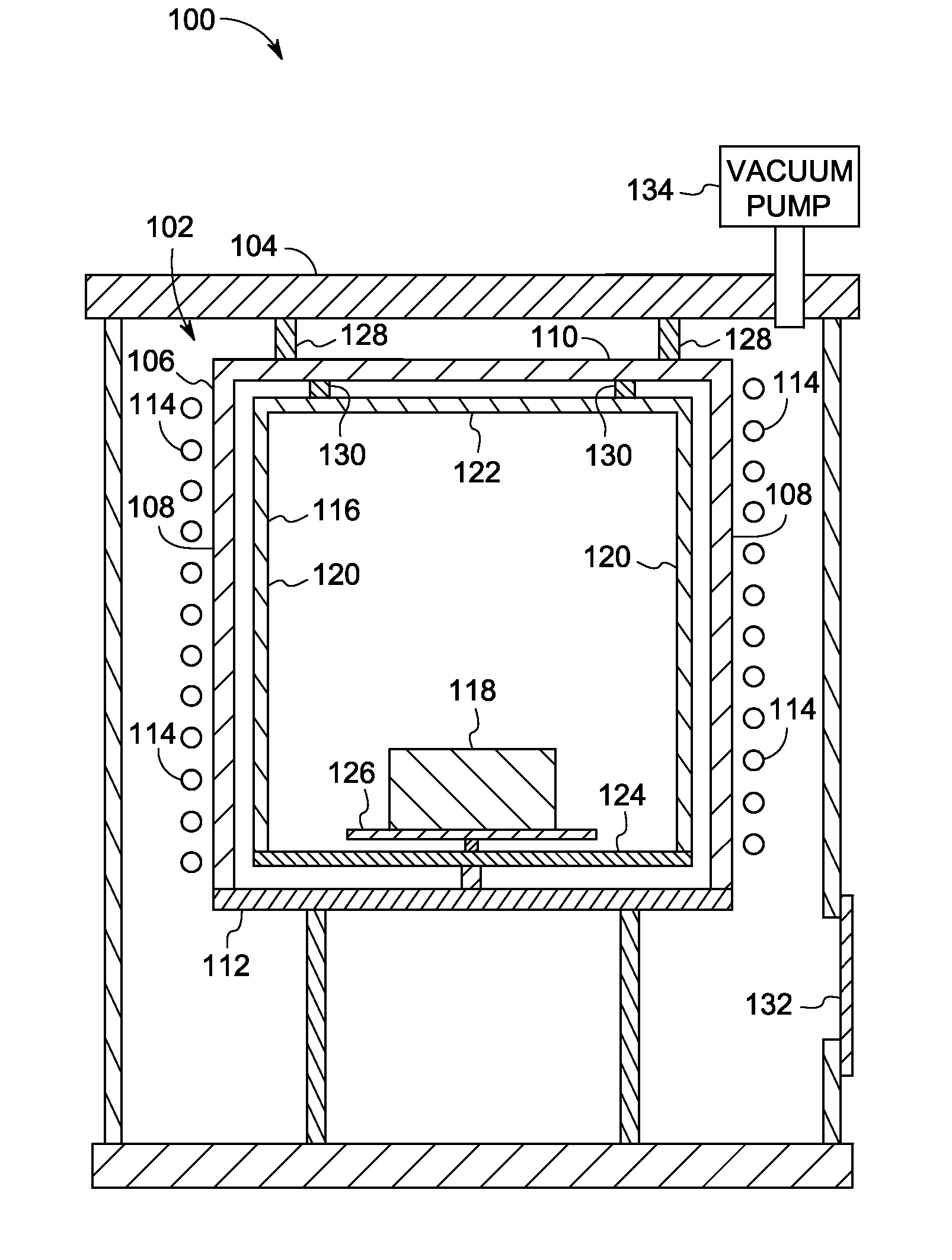

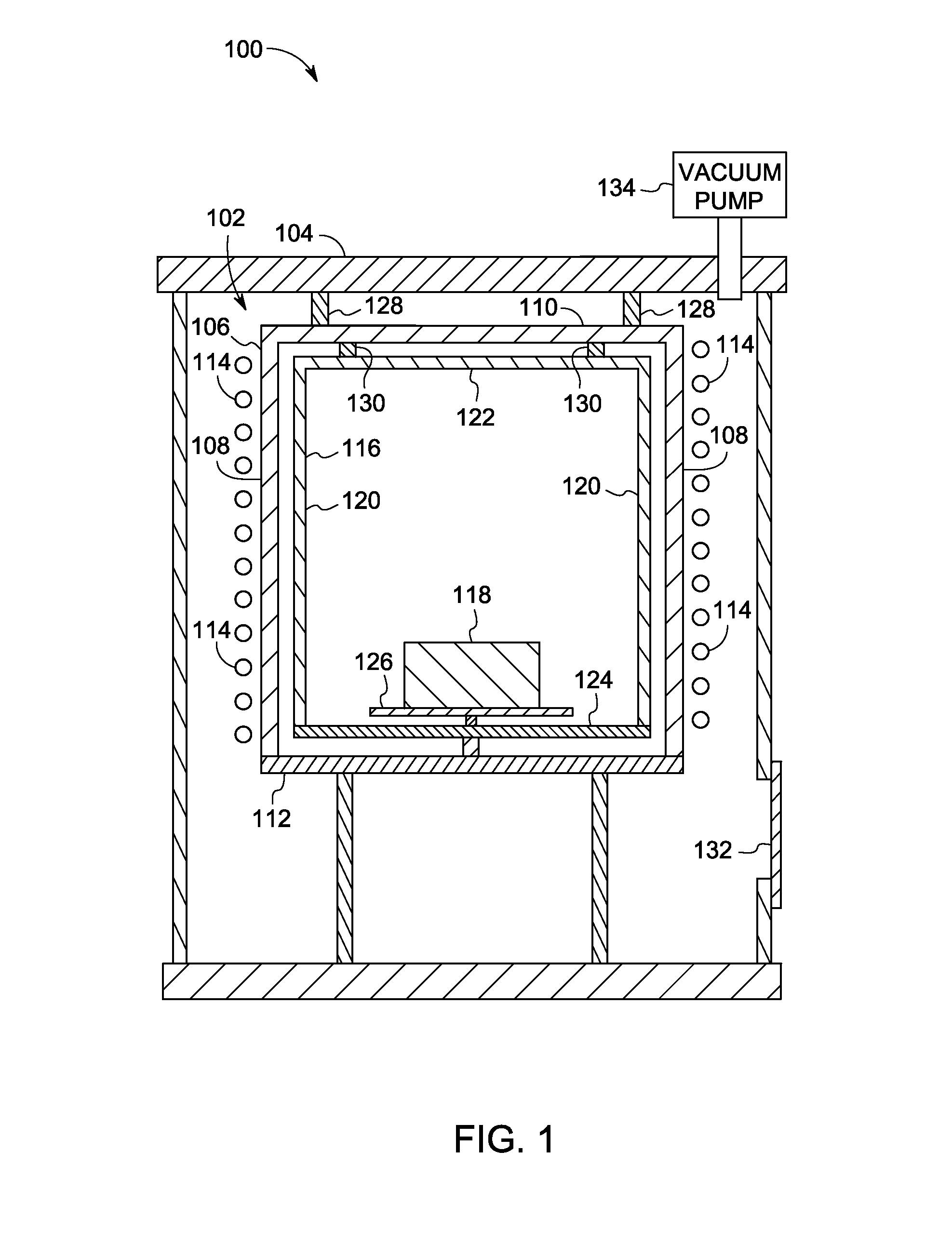

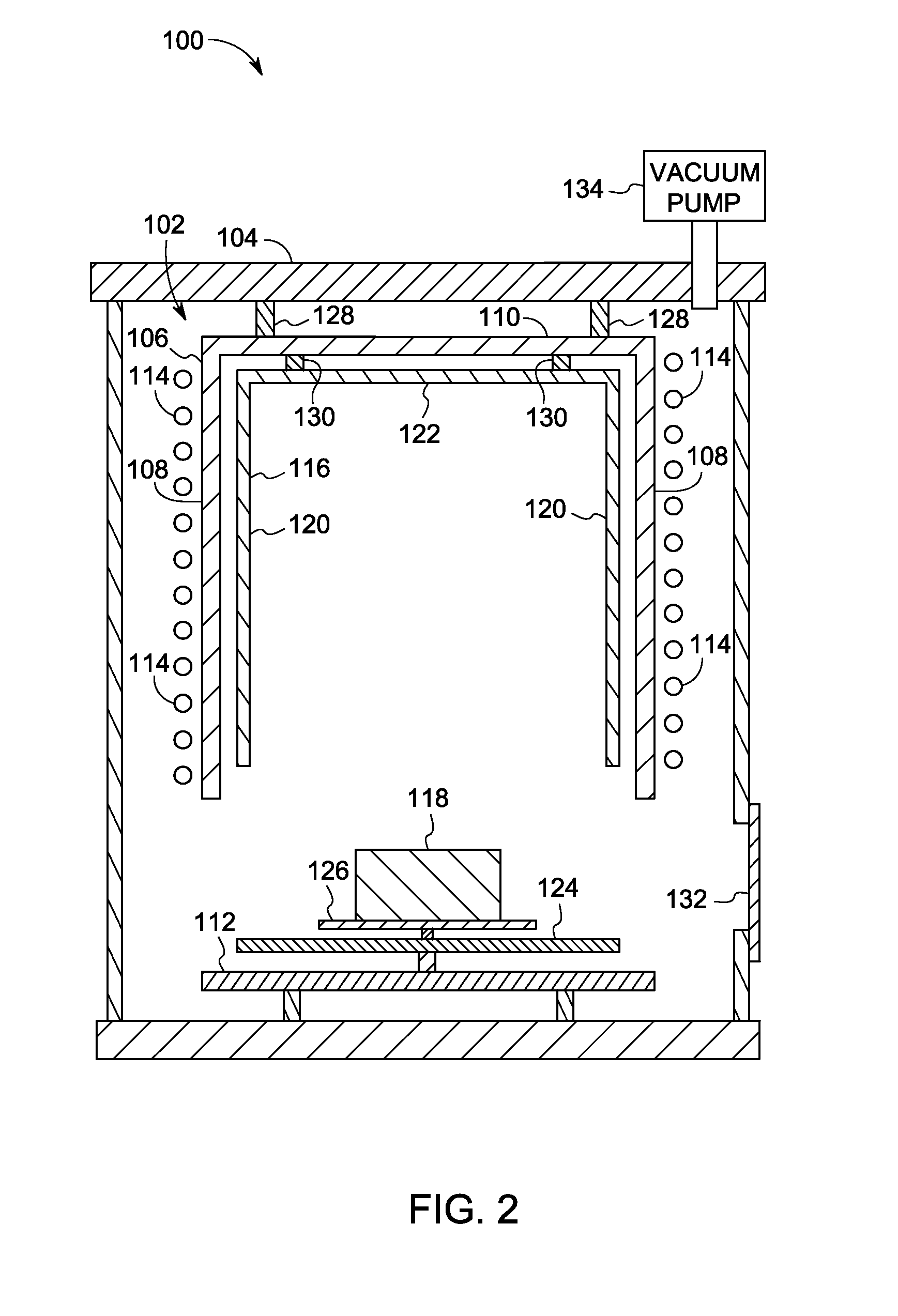

[0020]Referring to FIGS. 1 and 2, the major components of an induction furnace 100 are shown. Induction furnace 100 includes an induction heating system 102 inside a chamber 104. Induction heating system 102 includes an insulation cylinder 106 having a side wall 108, a top or first cover 110 for sealing one end of cylinder 106, and a base or second cover 112 for sealing the second end of cylinder 106. Induction heating system 102 includes a coil 114 and a power supply (not shown) that provides an alternating current that flows through coil 114 during a heating cycle. Coil 114 is wound to form a helical shape within chamber 104 about insulation cylinder 106 as shown in FIG. 1.

[0021]Contained within insulation cylinder 106 is a susceptor 116 that is susceptible to induction heating. That is, when an alternating current flows through coil 114, an alternating magnetic field is generated that induces eddy currents and other effects in susceptor 116 that cause the susceptor 116 to heat. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Vacuum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com