Electrode core drying device and method

A drying device and drying method technology, applied in the direction of drying gas arrangement, drying solid materials, non-progressive dryers, etc., can solve the problems of electrode material structure damage, large temperature difference, increased production costs, etc., to reduce drying temperature, Improve product quality and avoid secondary water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

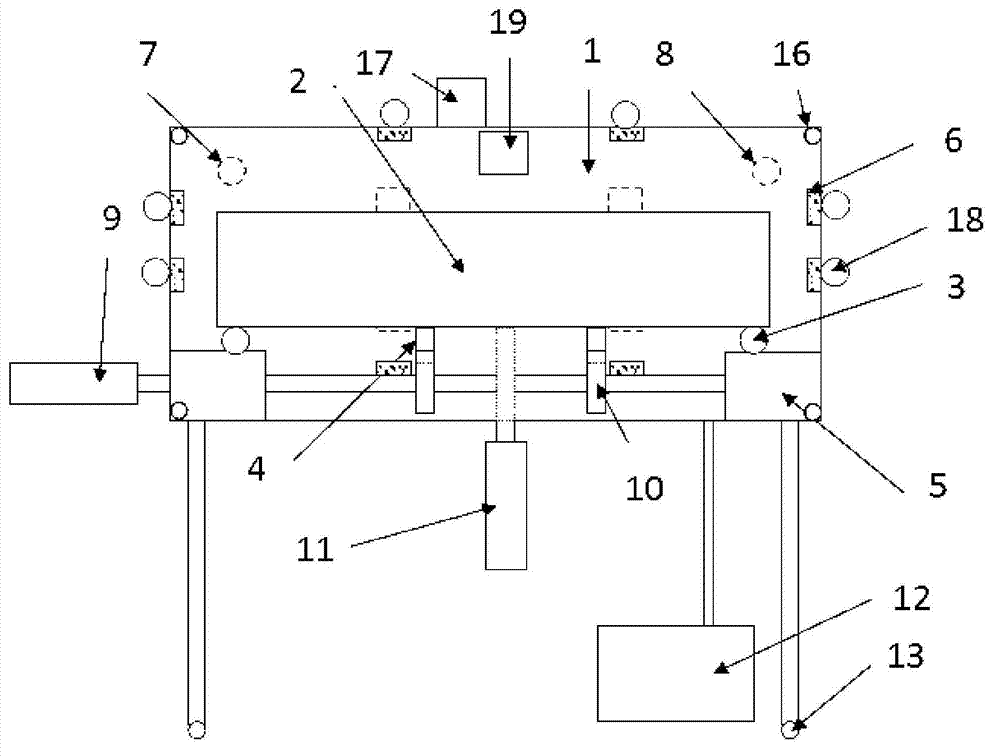

[0073] Put 60 supercapacitor electrode cores into the tray, press the button, the horizontal drive motor 9 drives the tray into the vacuum oven, and then close the oven door to start.

[0074] (1) Vacuum until the pressure inside the oven is 50Pa;

[0075] (2) Fill inert gas until the pressure in the oven reaches 0.2MPa;

[0076] (3) Extend the drive shaft of the motor in the vertical direction, insert it into the bottom groove of the tray and prop up the tray, start to rotate at a speed of 5r / min, and the built-in fan starts to rotate at the same time;

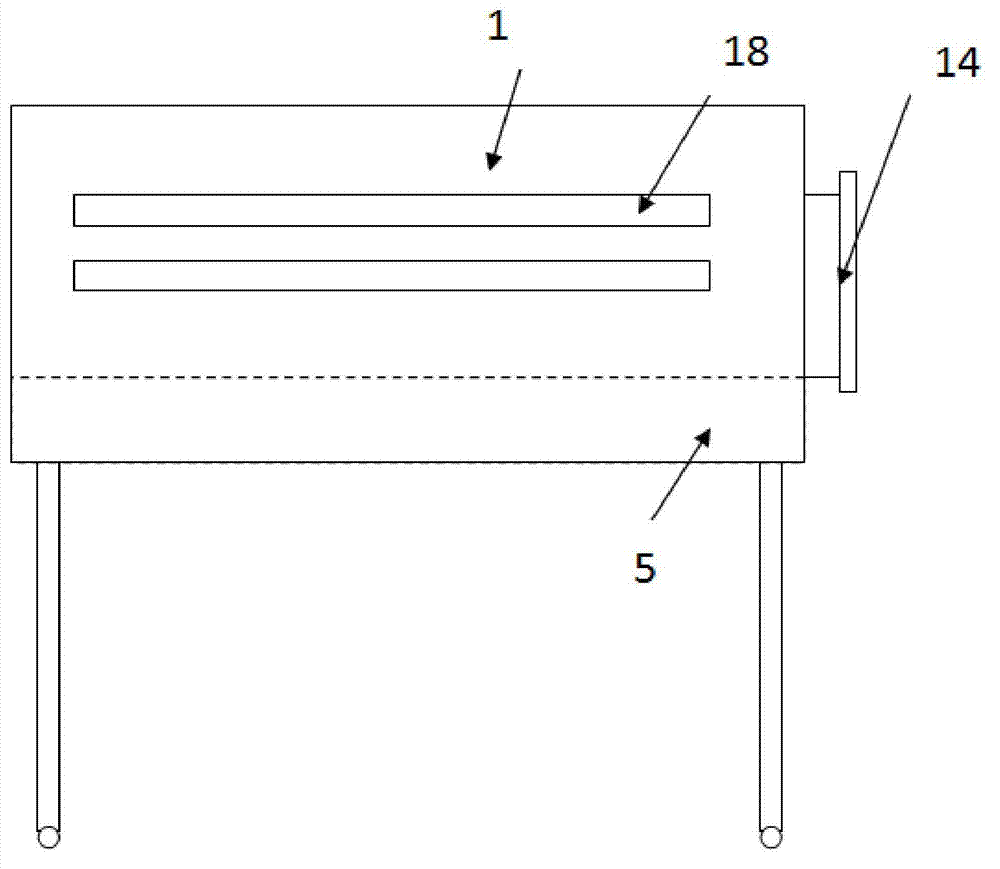

[0077] (4) The oven starts to heat, and the heating is performed by the parallel heating plates on the left, right and three panels on the rear panel. The 9 temperature probes are distributed in the 8 corners of the oven and the center of the rear panel;

[0078] (5) When the temperature in the oven reaches 150°C, the vacuum pump is automatically turned on and the fan is turned off, and the oven continues to heat at this tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com