High-temperature vacuum sintering furnace lifting frame device

A high-temperature vacuum and sintering furnace technology, which is applied in the direction of furnace safety devices, furnaces, muffle furnaces, etc., can solve the problems of easy damage, no protective measures, etc., and achieve the effect of avoiding movement and dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

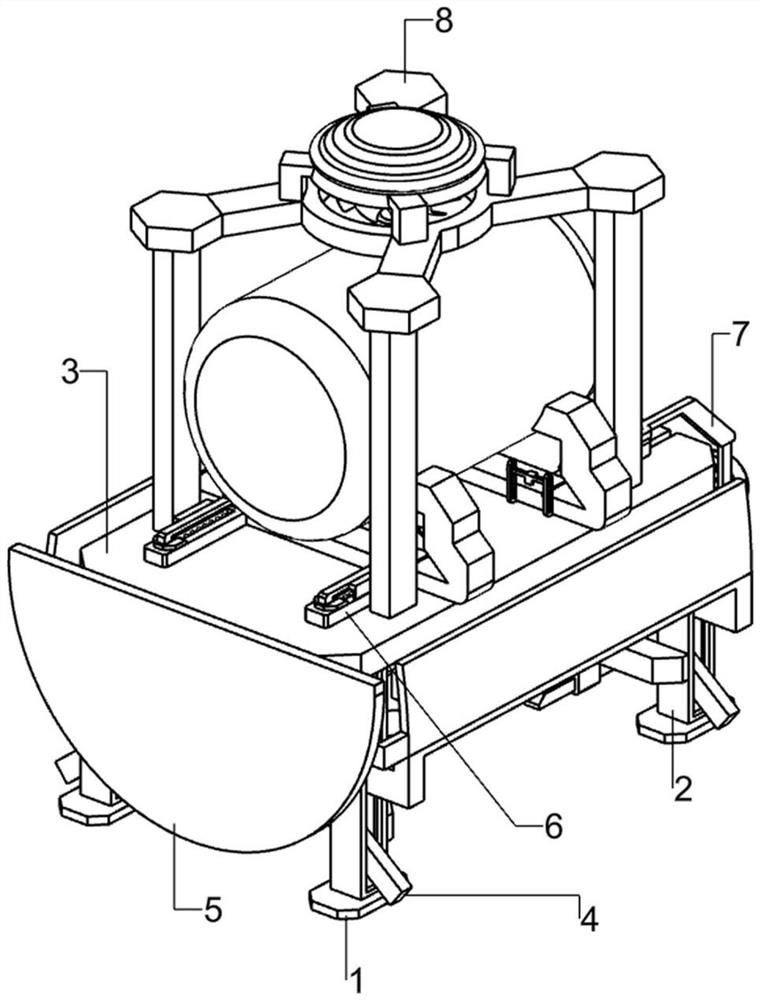

[0058] A high-temperature vacuum sintering furnace lifting frame device, such as Figure 1-3 As shown, it includes a bottom plate 1, a support frame 2, a placement component 3 and a lifting mechanism 4. The bottom plate 1 is provided with a support frame 2, and a placement component 3 is connected between the support frames 2, and a lifting mechanism 4 is provided on the placement component 3. .

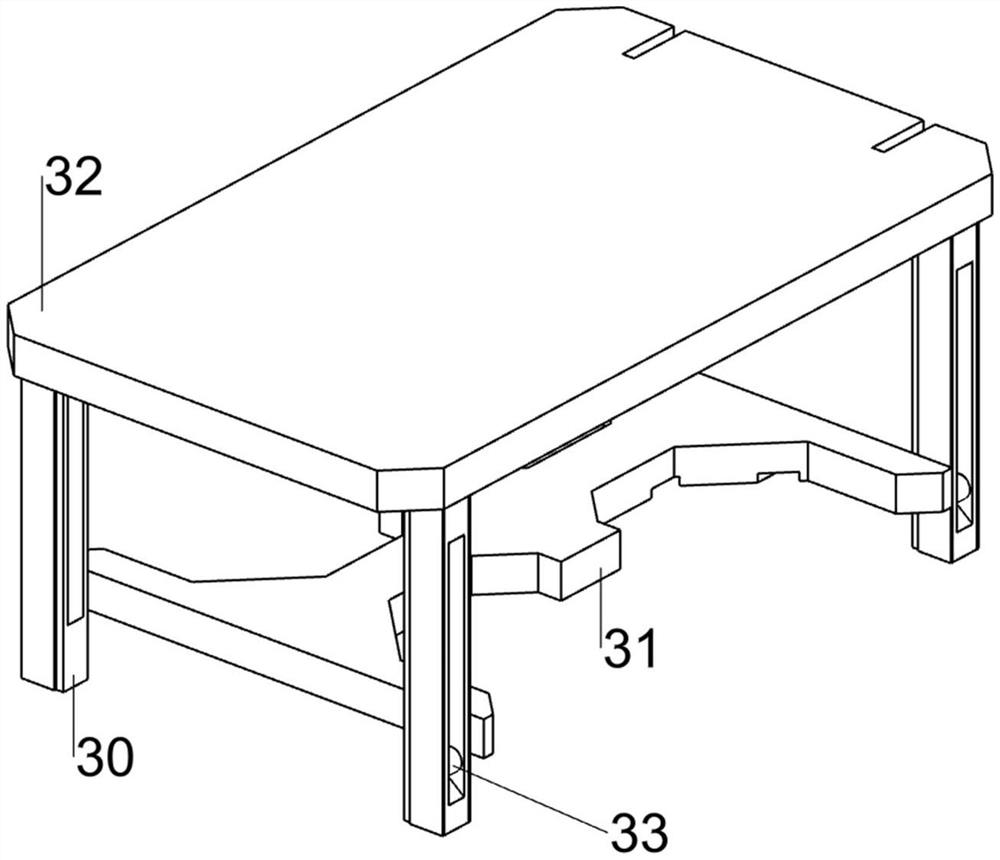

[0059] The placement assembly 3 includes a mounting plate 30, a connecting plate 31, a lifting plate 32 and a fixed rod 33. The mounting plate 30 is slidably connected in the support frame 2, and the lifting plate 32 is connected between the tops of the mounting plate 30. Connecting plates 31 are connected between them, and fixing rods 33 are arranged in the mounting plates 30 .

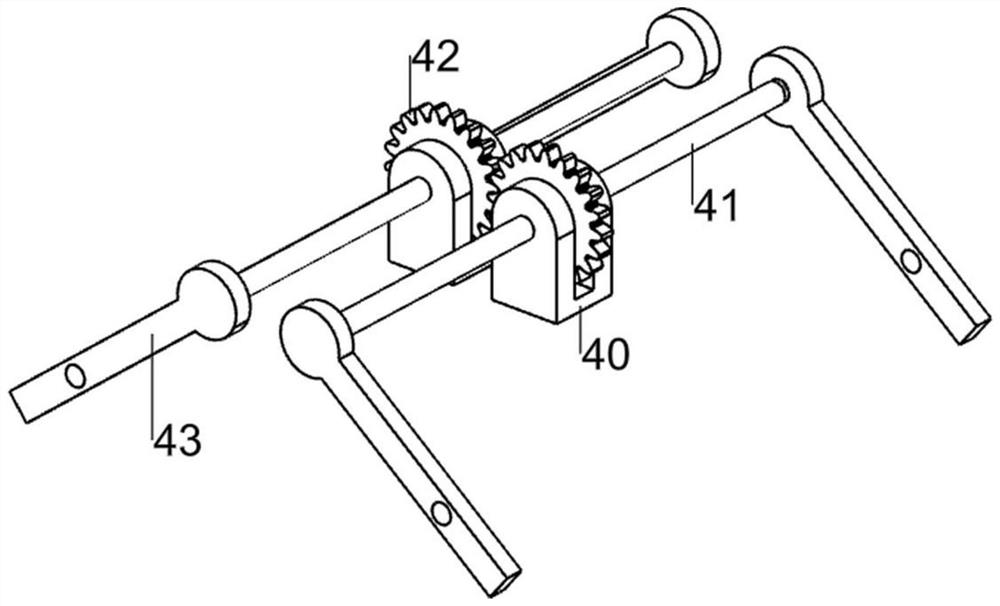

[0060] Lifting mechanism 4 comprises bearing seat 40, rotating shaft 41, gear 42 and crank 43, and connecting plate 31 top front and rear sides are all connected with bearing seat 40, and the bearing seat ...

Embodiment 2

[0063] On the basis of Example 1, such as Figure 4-8 As shown, a baffle 5 is also included, and the baffle 5 includes a rising block 50, a side protection plate 51 and a front protection plate 52, and a rising block 50 is arranged between the horizontal mounting plates 30, and a rising block 50 is provided on the top of the rising block 50. There are side shields 51, and a front shield 52 is connected between the left sides of the side shields 51.

[0064] The upward movement of the mounting plate 30 drives the rising block 50, the side protection plate 51 and the front portion protection plate 52 to move upwards, which plays a protective role for people, and the downward movement of the mounting plate 30 drives the rising block 50, the side protection plate 51 and the front portion protection plate 52 Move down to reset.

[0065]Also includes clamping mechanism 6, clamping mechanism 6 includes first slide rail 60, first spring 61, hook slider 62, anti-skid clamp 63, second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com