Patents

Literature

51results about How to "Avoid movement misalignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

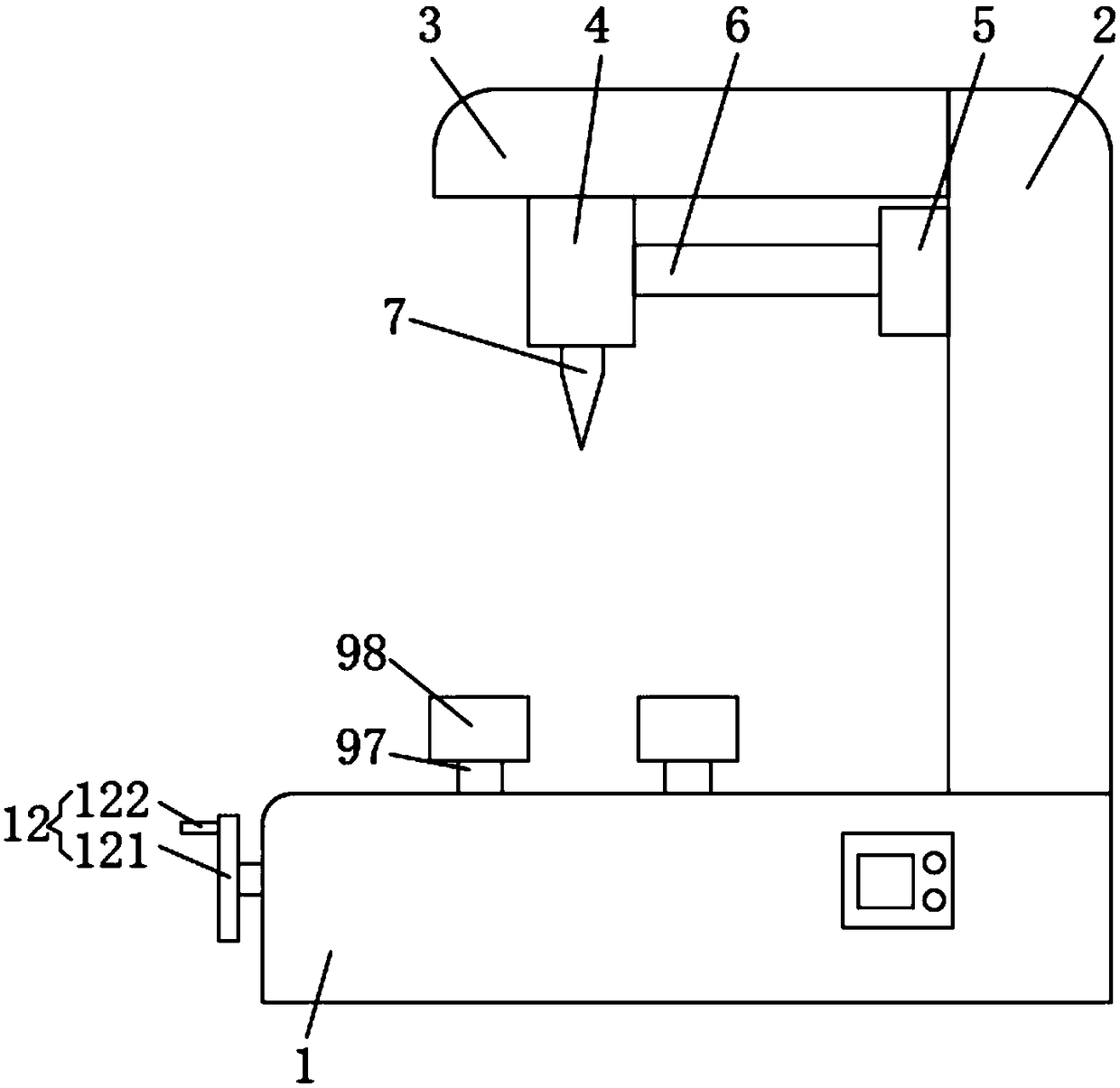

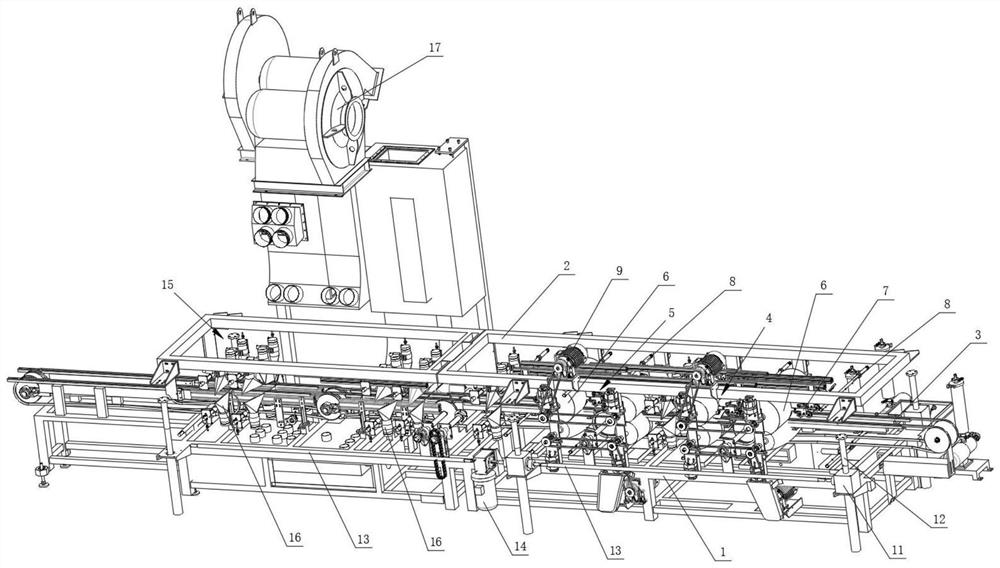

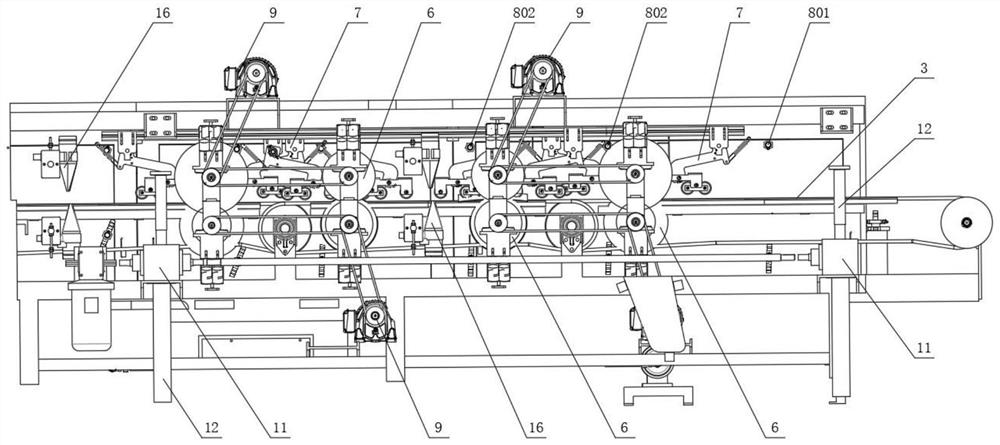

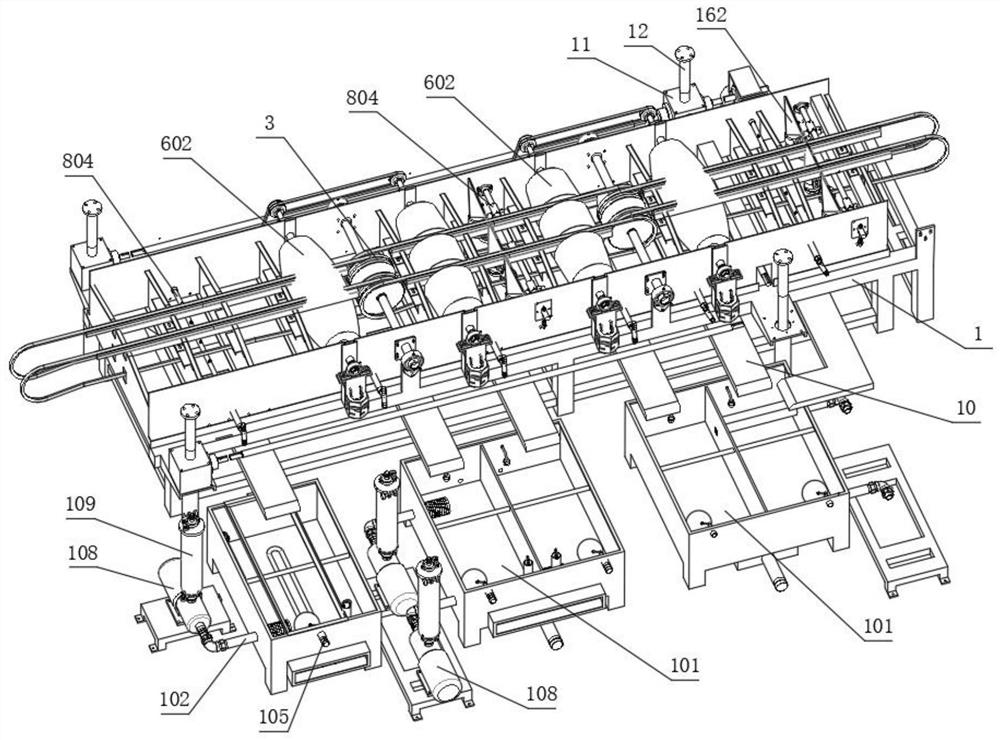

Production assembly line for woven bags

ActiveCN110552076AAvoid stickingAvoid tilting your headPaper article packagingCircular loomsAssembly lineAutomation

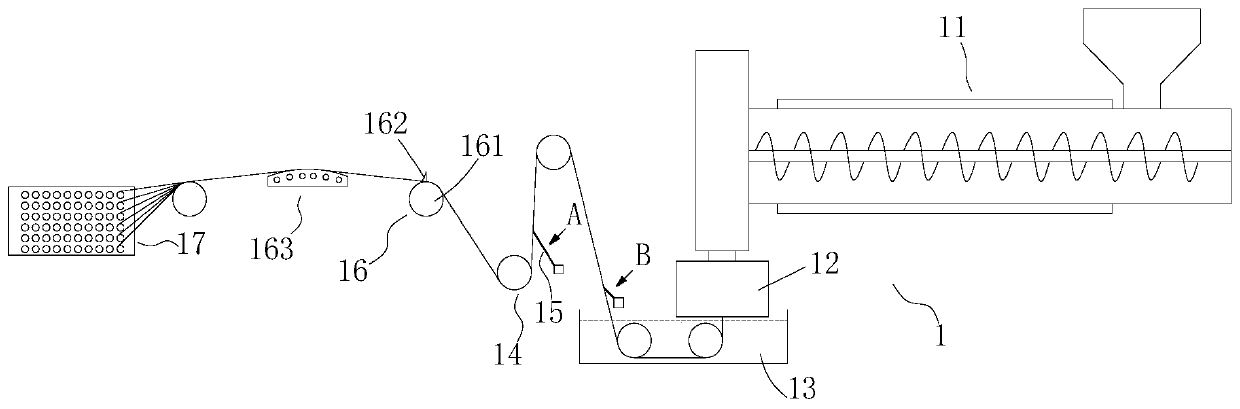

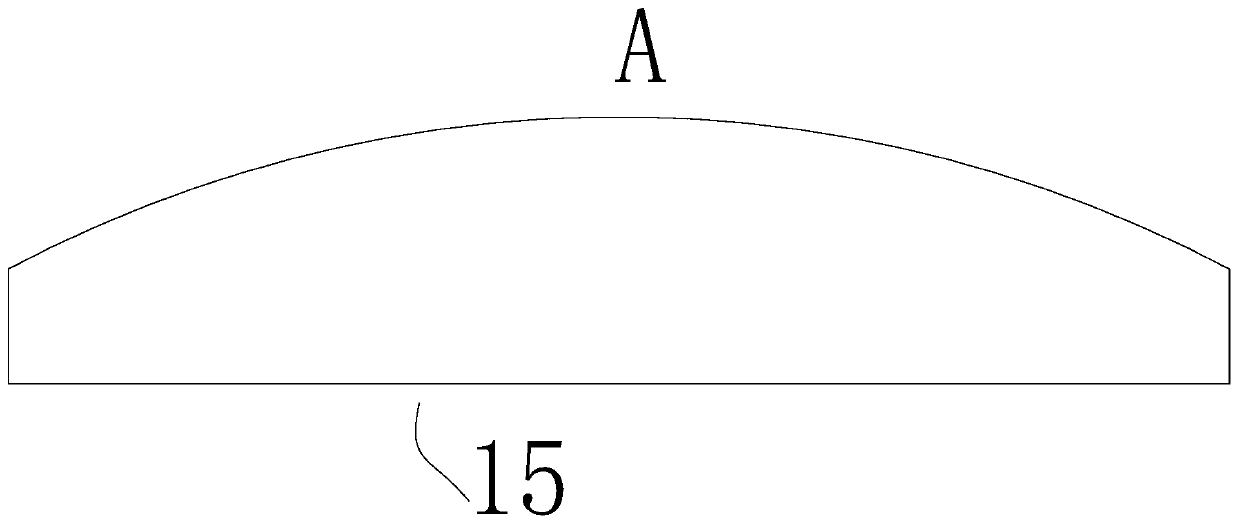

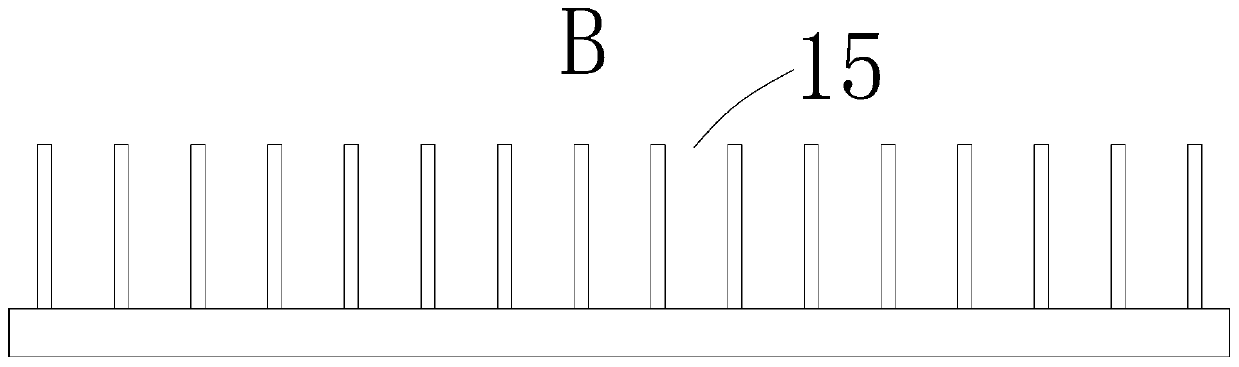

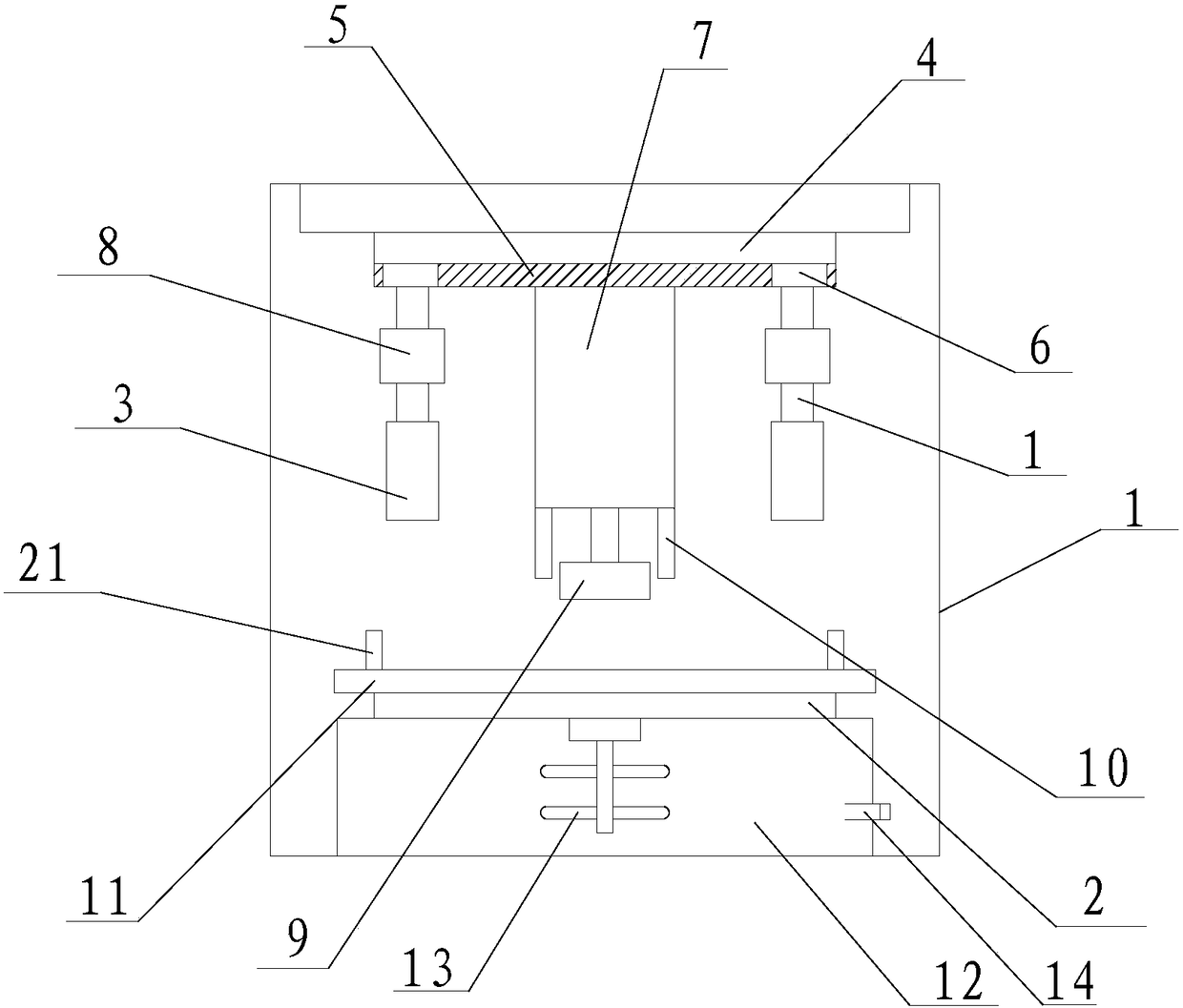

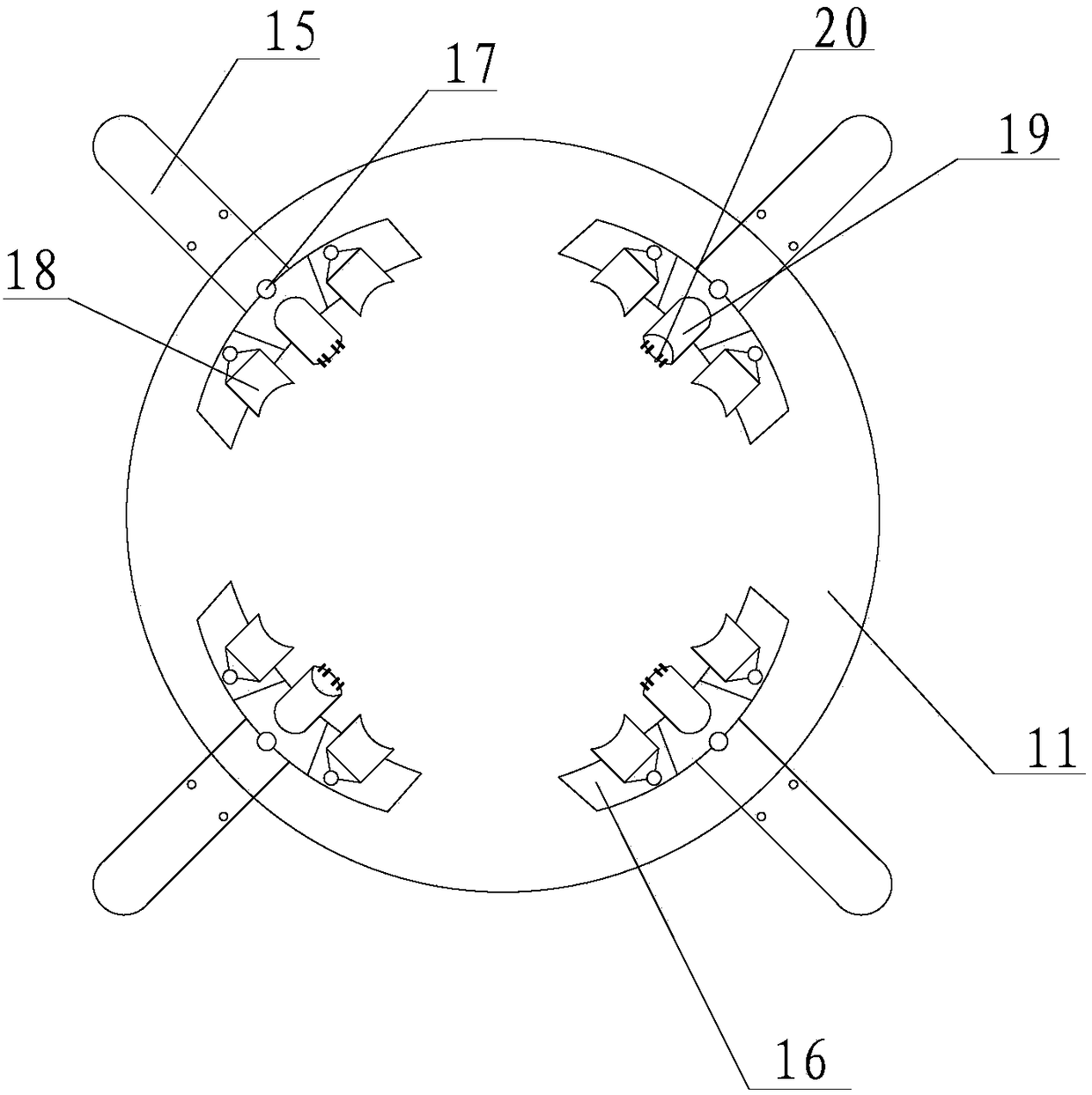

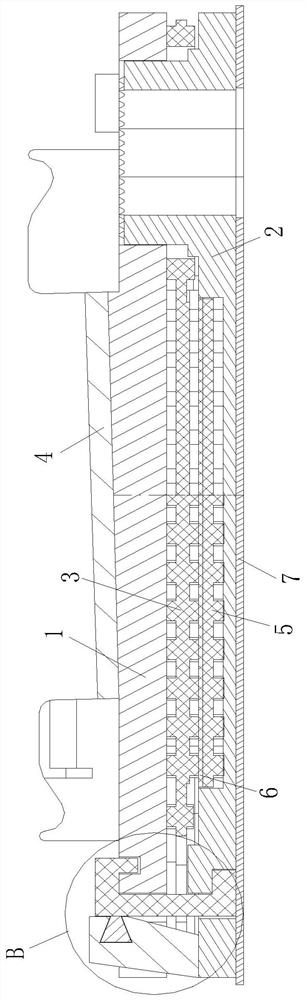

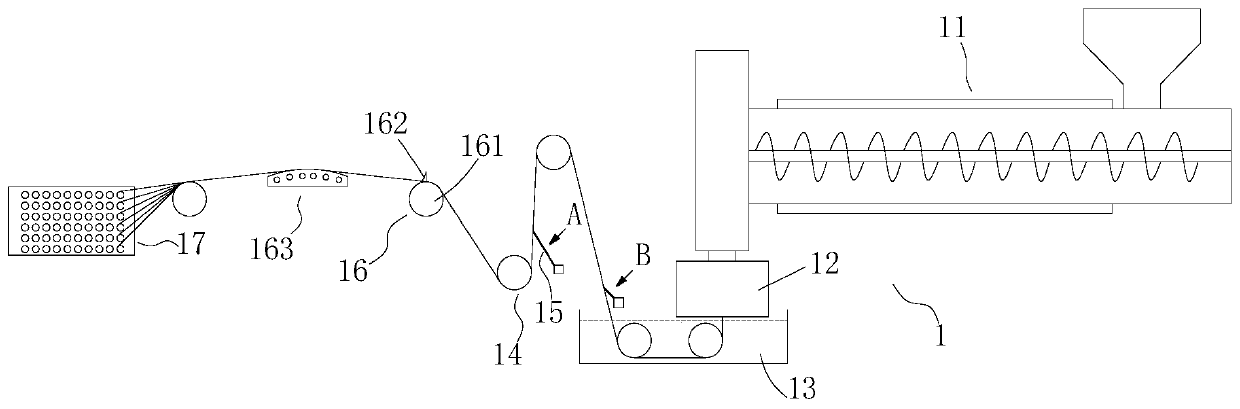

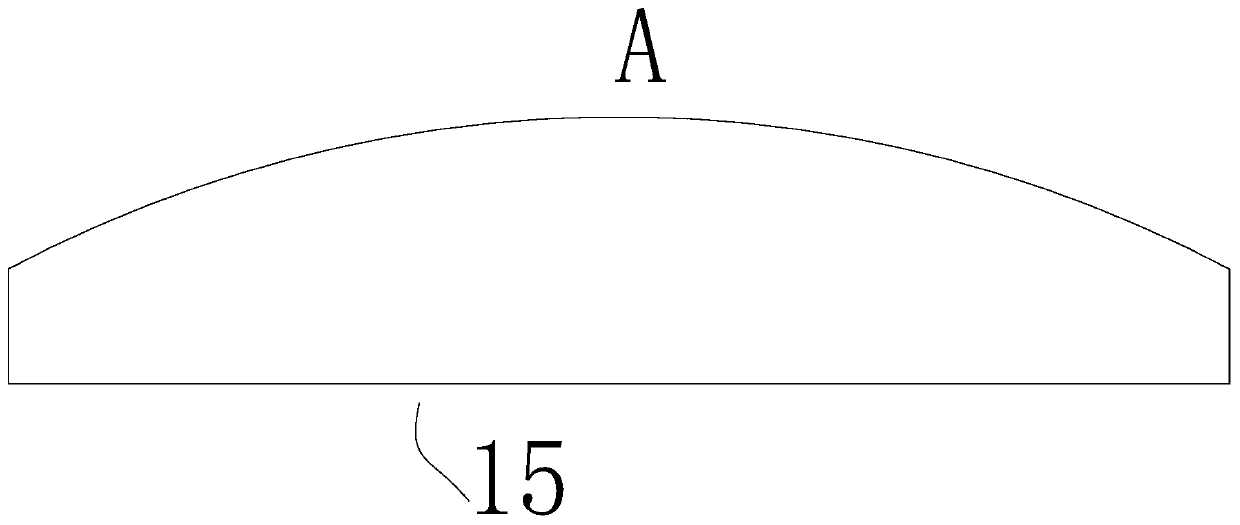

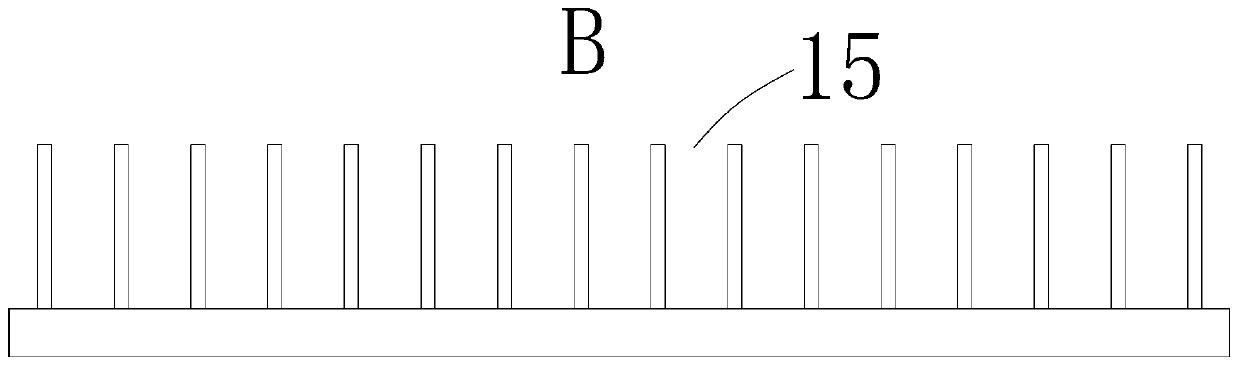

The invention relates to the field of production of woven bags, in particular to a production assembly line for woven bags. The production assembly line comprises a ribbonfil production device, a circular weaving device, a roll printing device, a cutting sewing device and a packaging device. Raw materials are heated, melted, extruded and formed into ribbonfil through the ribbonfil production device, the circular weaving device weaves the continuous cylindrical woven bags through the ribbonfil, the woven bags are printed with patterns and characters through the roll printing device, and the printed woven bags are cut off and sewn through the cutting sewing device, then discharged from the cutting sewing device and automatically packaged through the packaging device finally. The production assembly line for the woven bags has the advantages that the production assembly line for the woven bags can achieve production of the woven bags, the overall production efficiency and automation degree are high, the product quality is good, and the production assembly line is suitable for large-scale popularization.

Owner:泗县鸿盛塑业股份有限公司

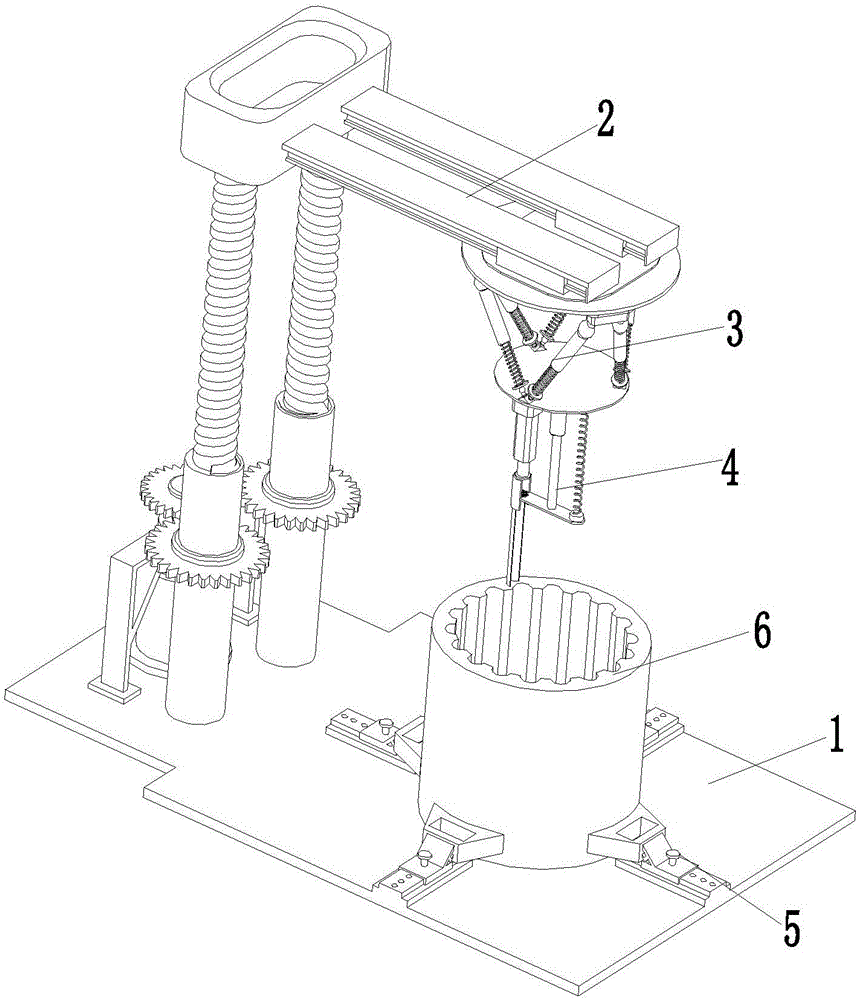

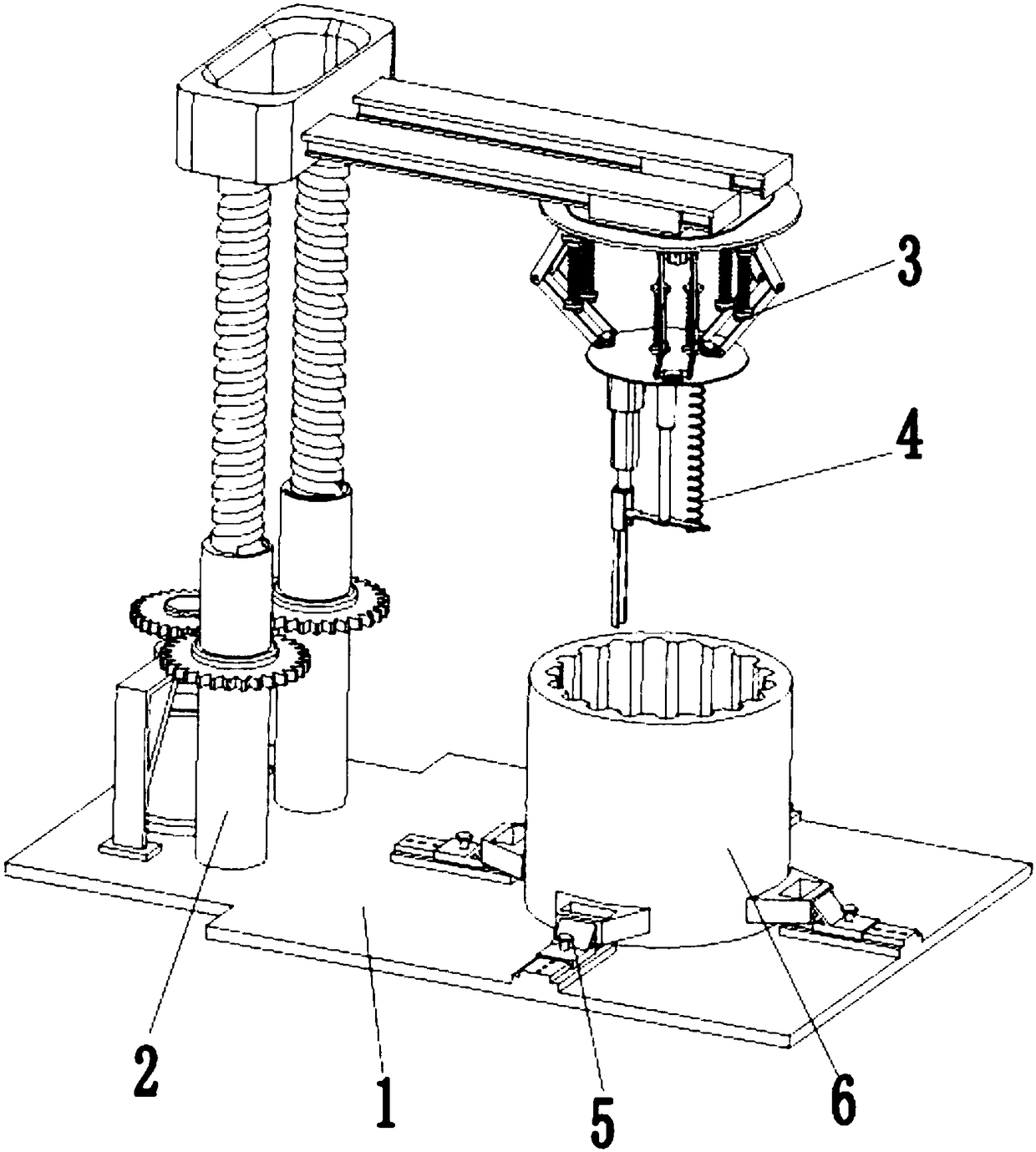

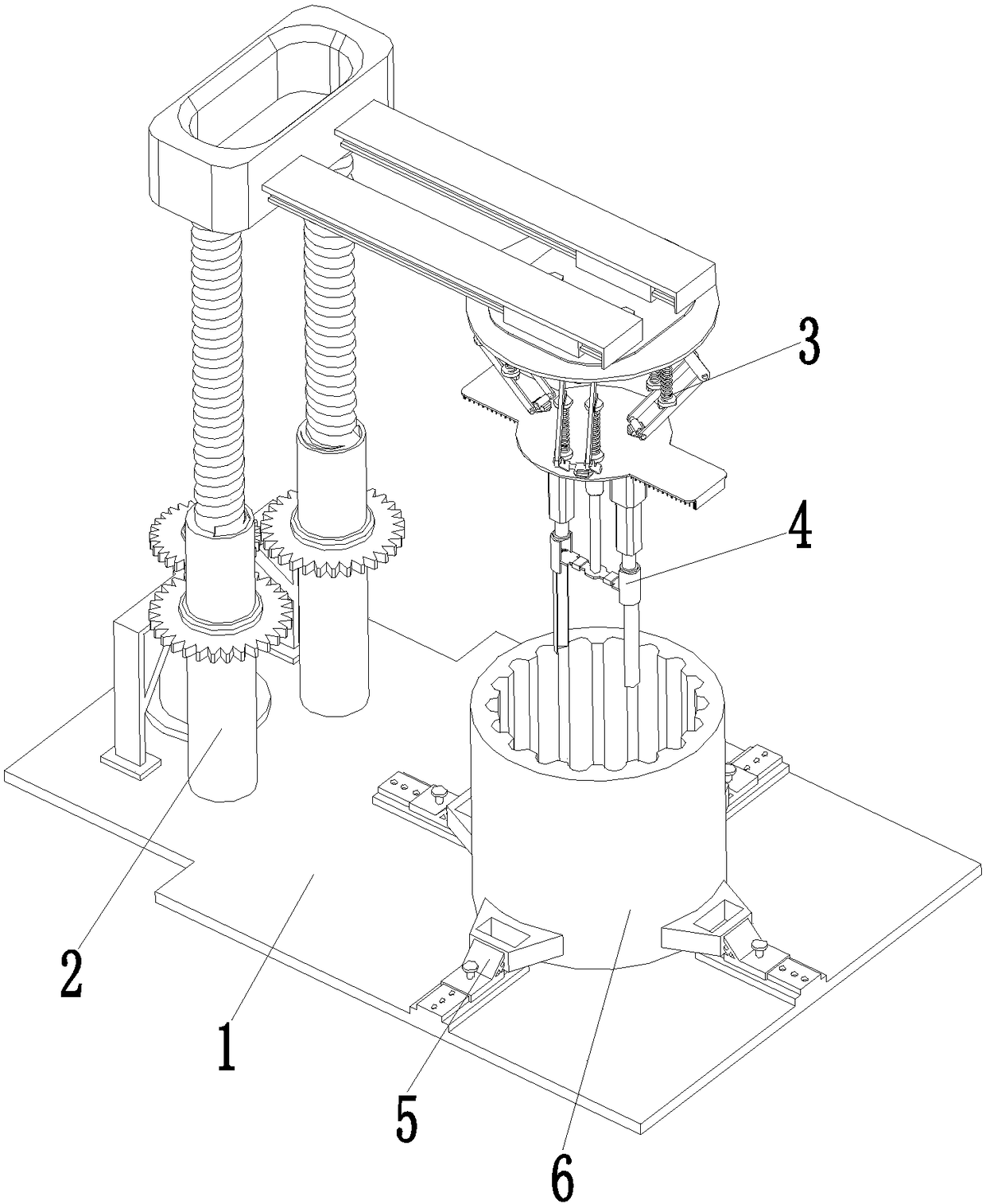

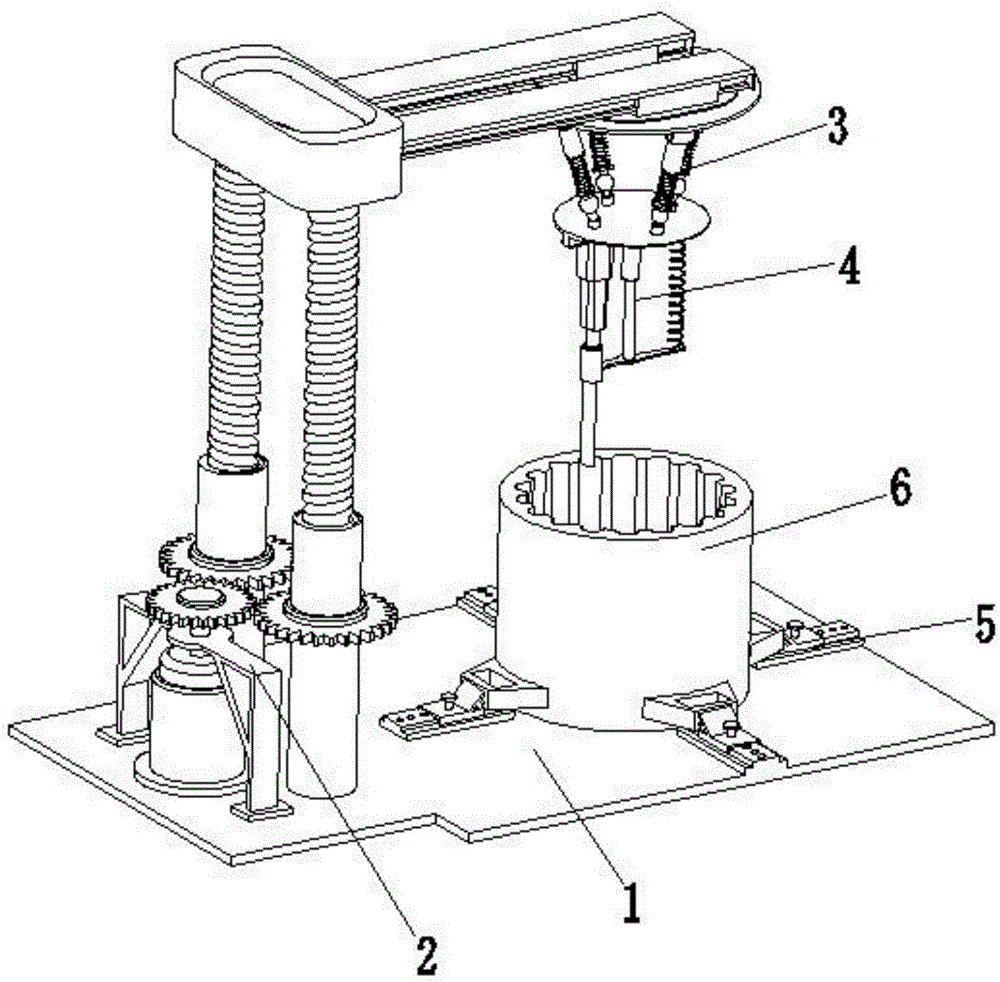

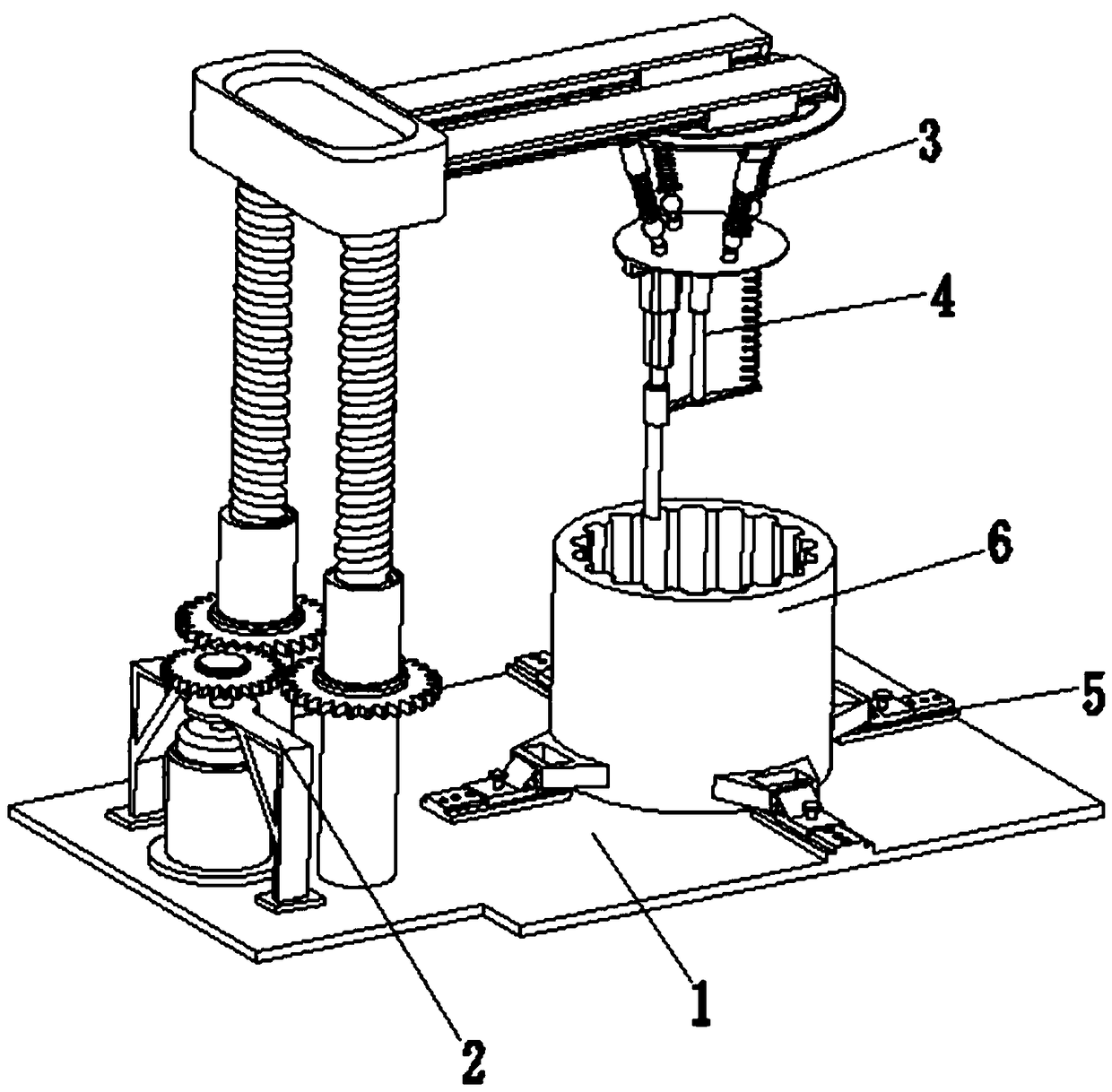

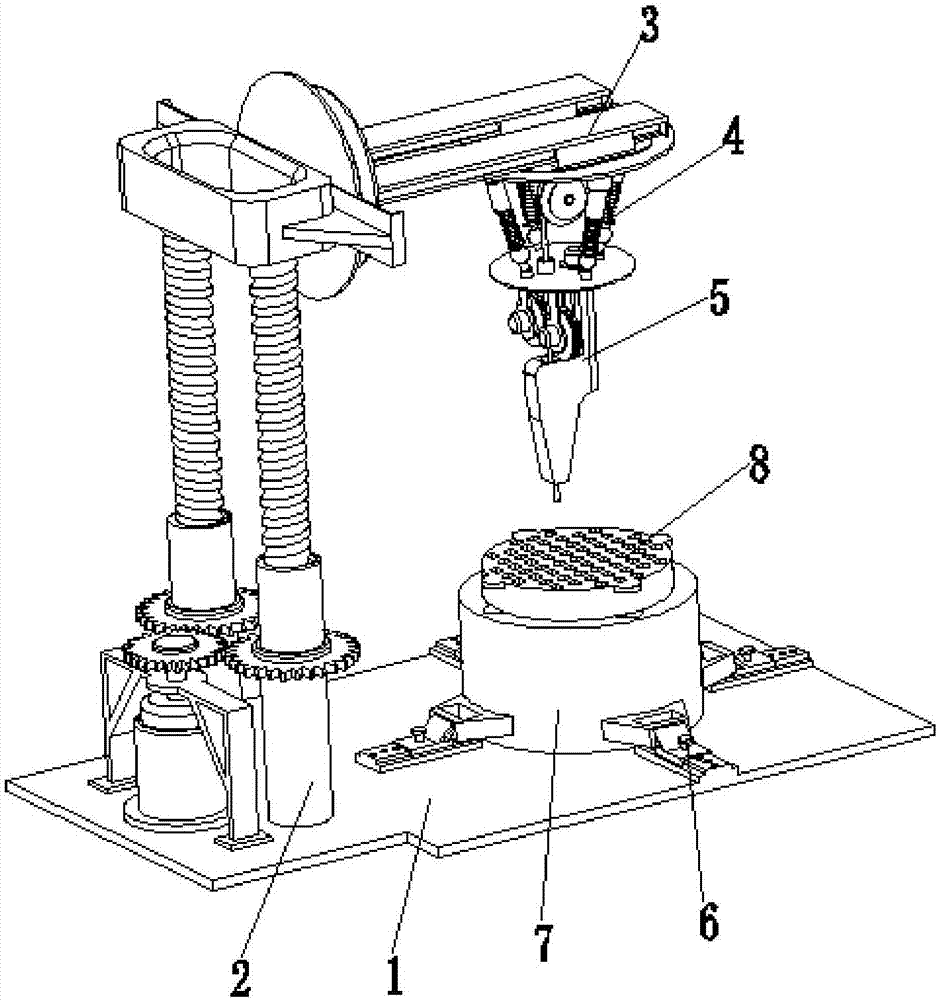

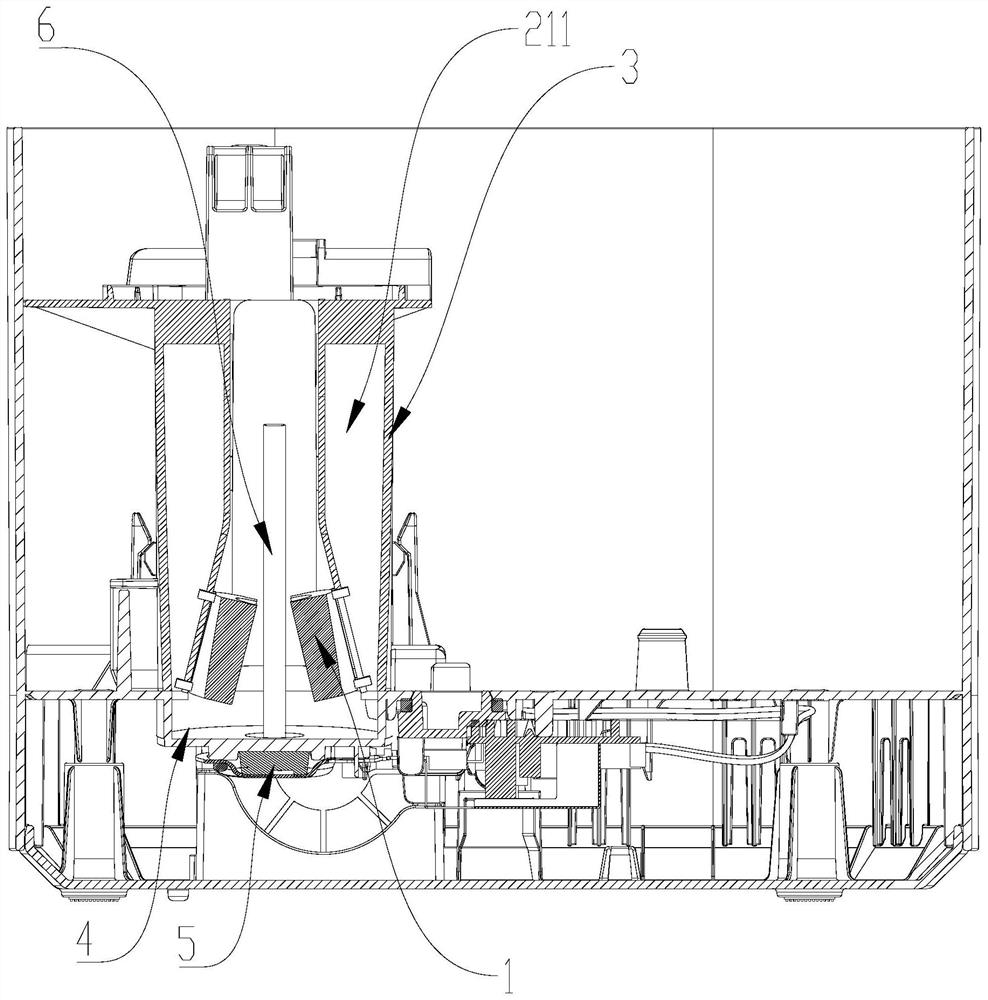

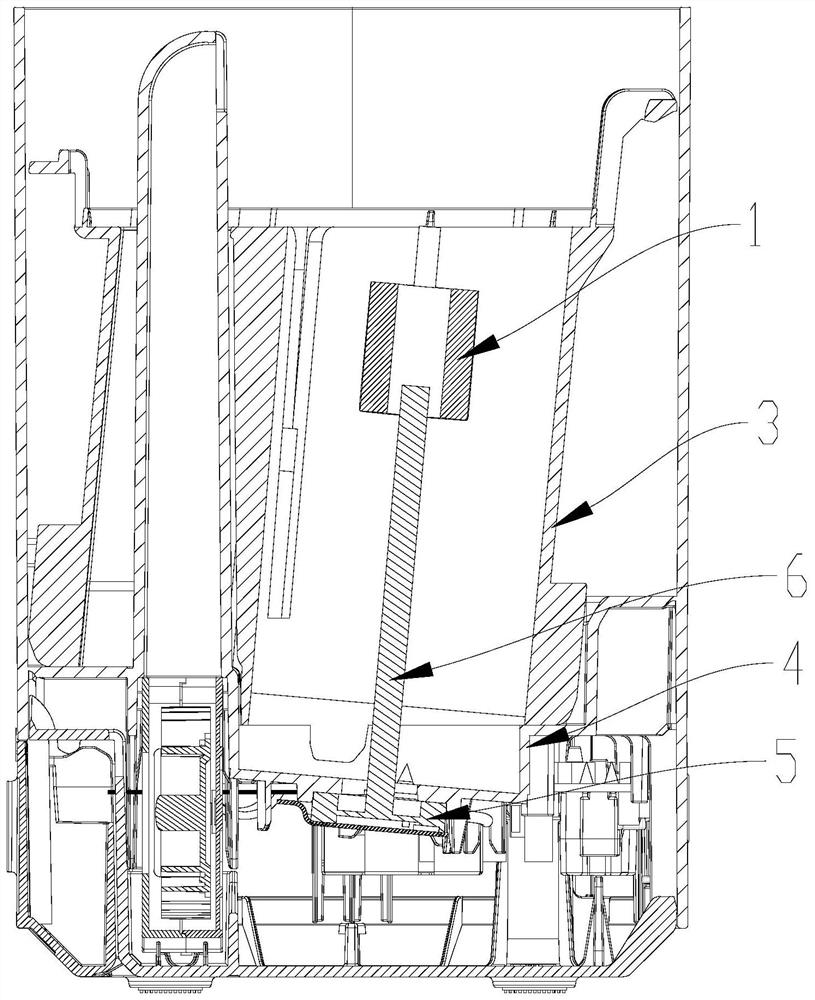

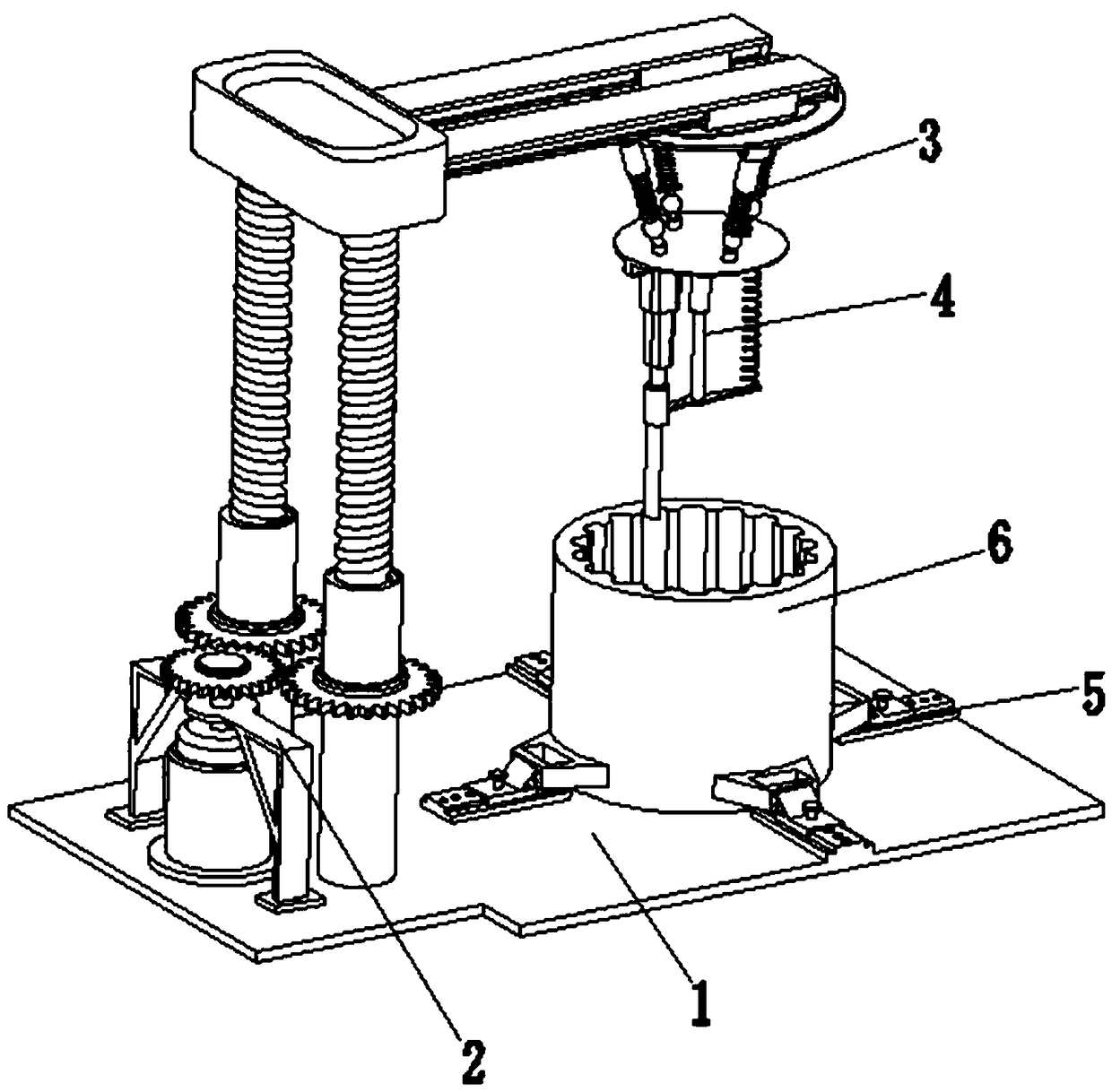

Paper inserting robot for stator of electric power motor

InactiveCN106041886ALow costQuality improvementProgramme-controlled manipulatorGripping headsInsertion depthPulp and paper industry

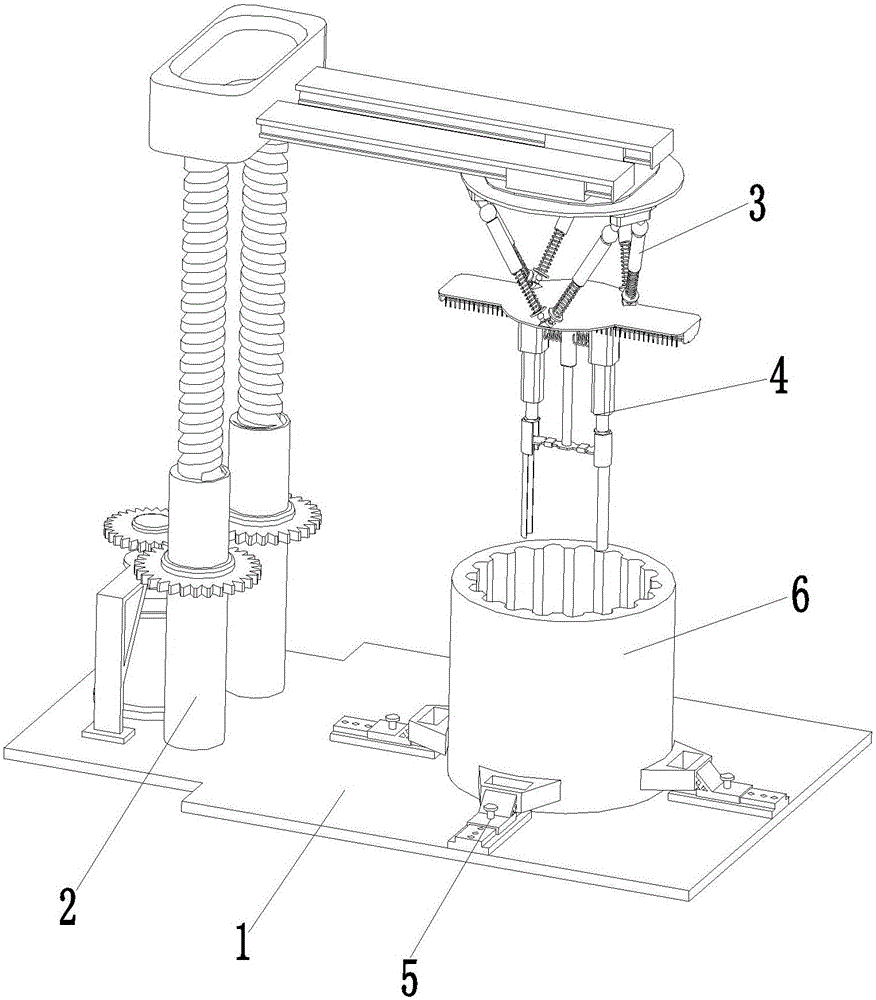

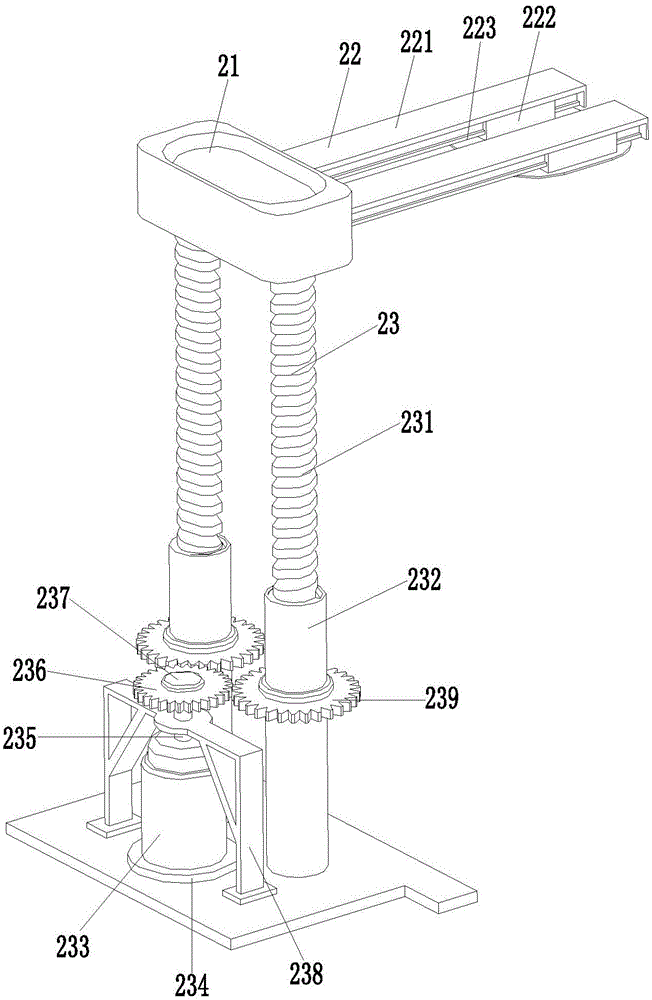

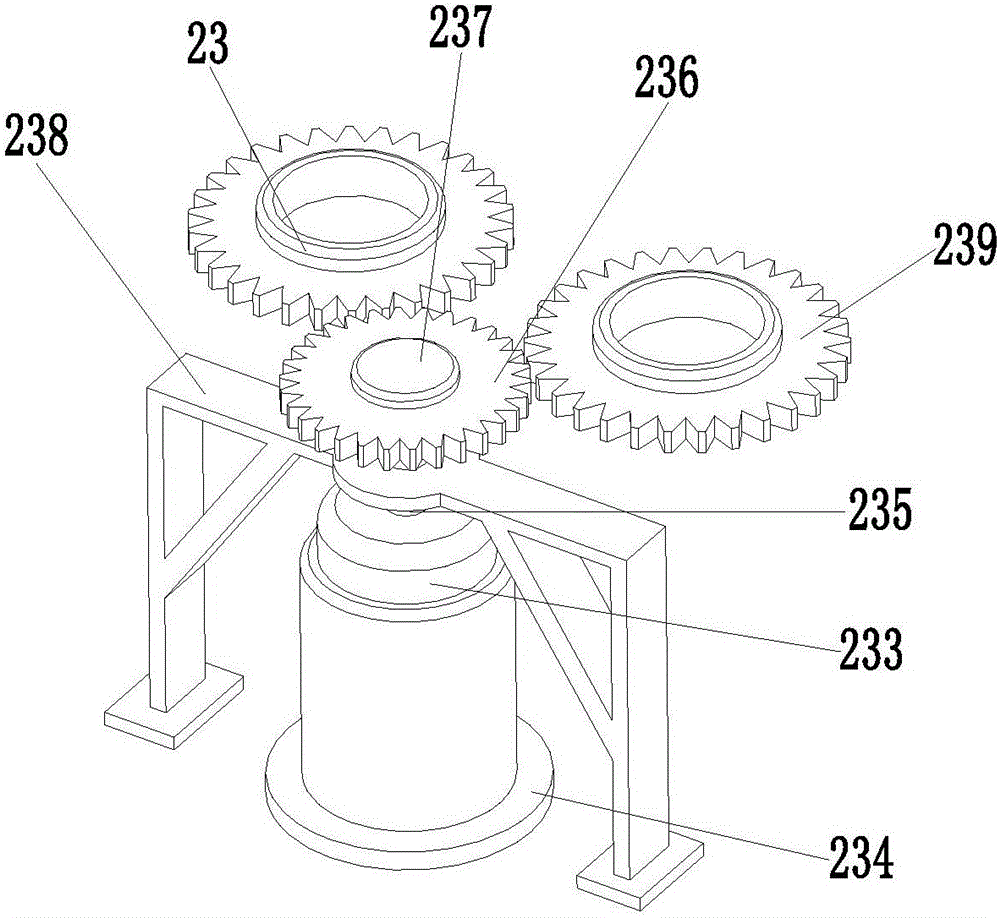

The invention relates to a paper inserting robot for a stator of an electric power motor. The paper inserting robot comprises a base, a supporting device, a Stewart parallel mechanism, a paper inserting device and four fixing devices. The base adopts a T-shaped plate structure. The supporting device is located at the rear side end of the base, and is fixedly connected with the base. The Stewart parallel mechanism is mounted at the front end of the supporting device. The paper inserting device is located under the Stewart parallel mechanism. The fixing devices are respectively and symmetrically arranged on the upper end surface of the base, and are fixedly connected with the base. Insulation paper can be inserted in the stator of the electric power motor, the whole paper insertion process is mechanical and automatic, paper insertion is quick and convenient, the safety is high, the paper insertion depth consistency is high, the labor investment is reduced, the production cost of the motor is reduced, and the production quality of the motor is improved to a certain degree.

Owner:JIANHU YONGJIA MACHINERY

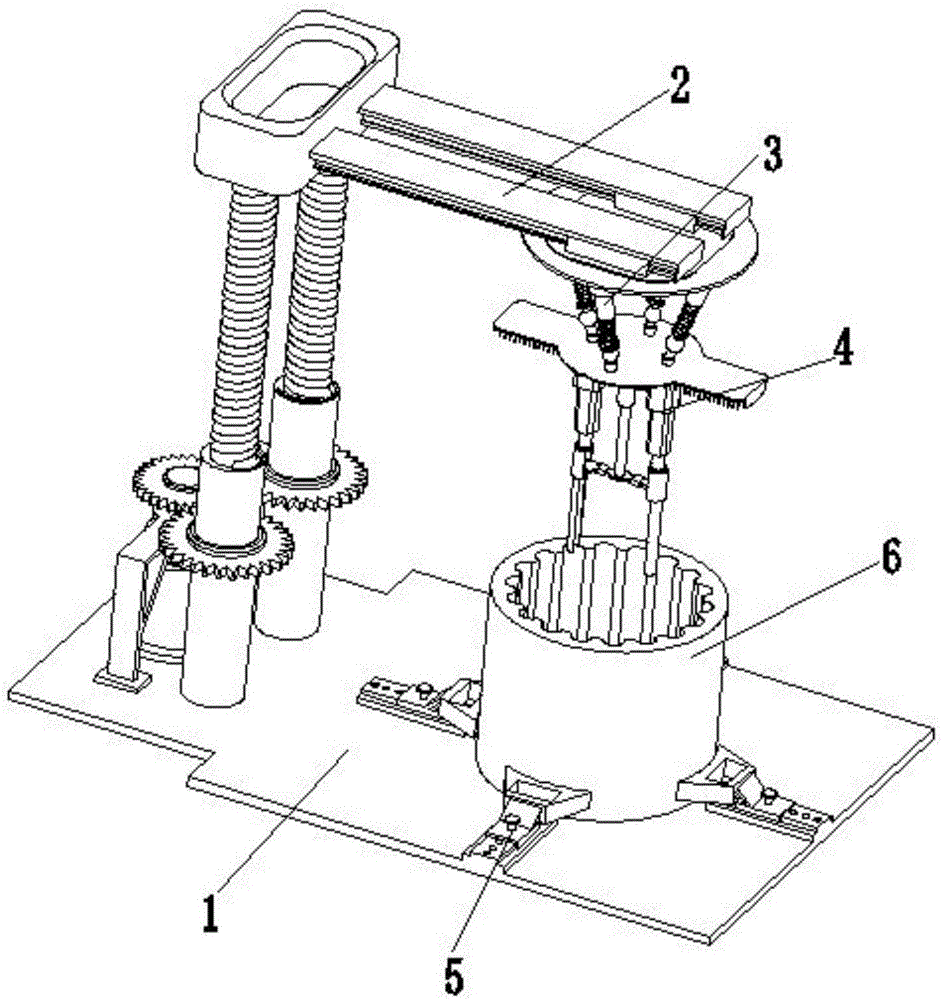

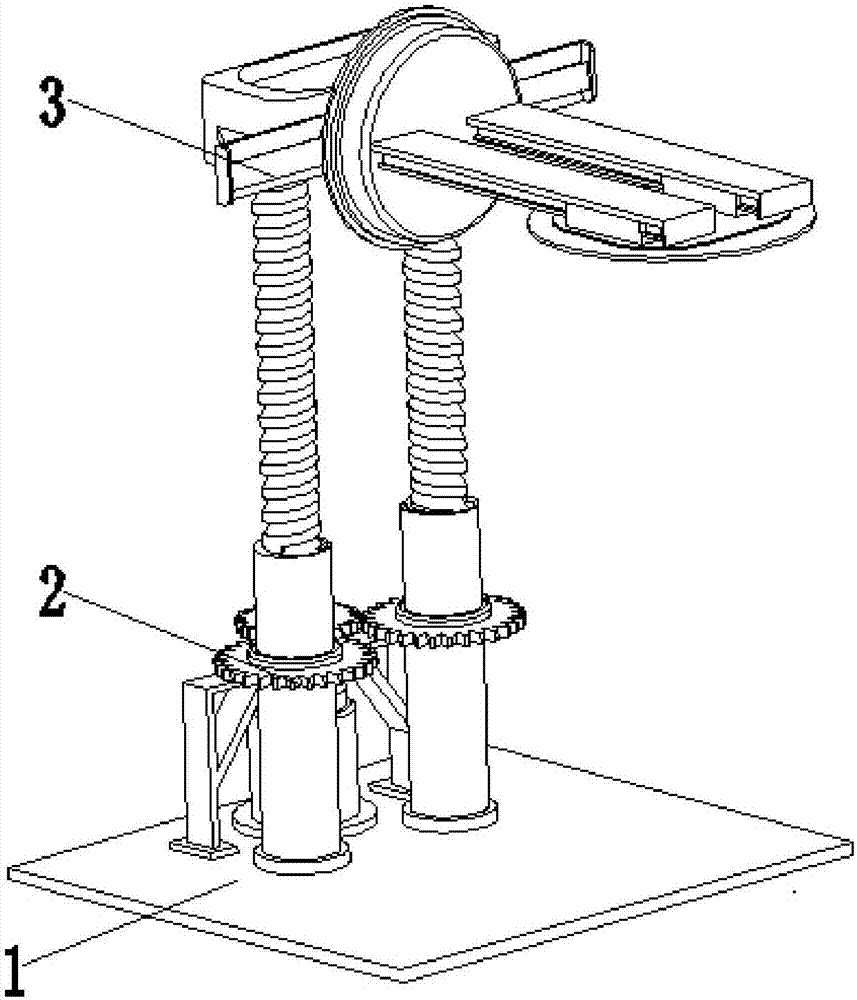

Multi-freedom-degree environment-friendly welding industrial robot for sewage treatment pipeline and drain grating plate

ActiveCN105880892AAccurate movement size and orientationGood welding position adjustmentWelding/cutting auxillary devicesAuxillary welding devicesSewage treatmentIndustrial engineering

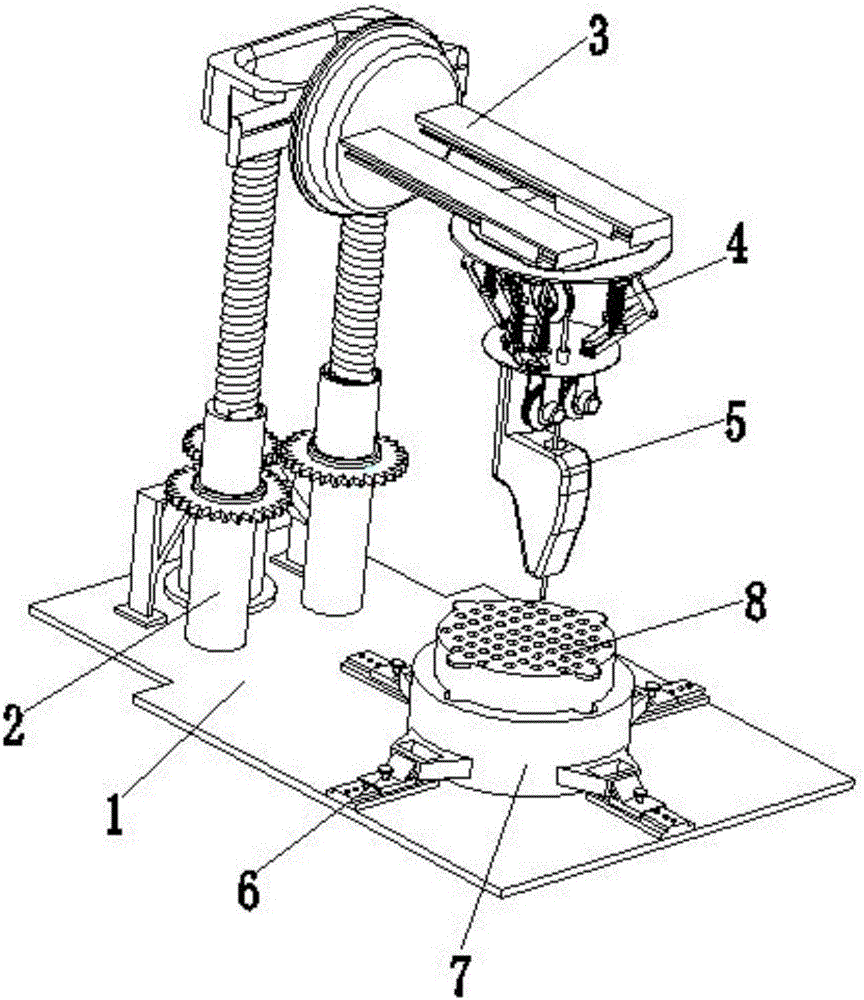

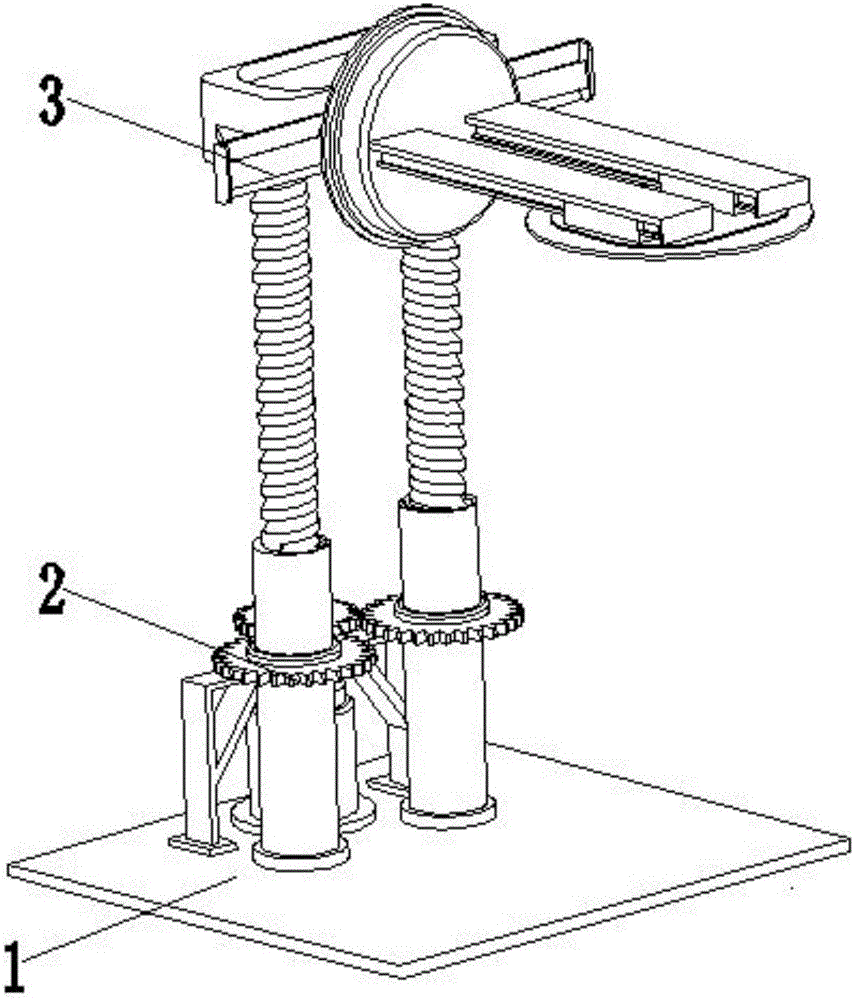

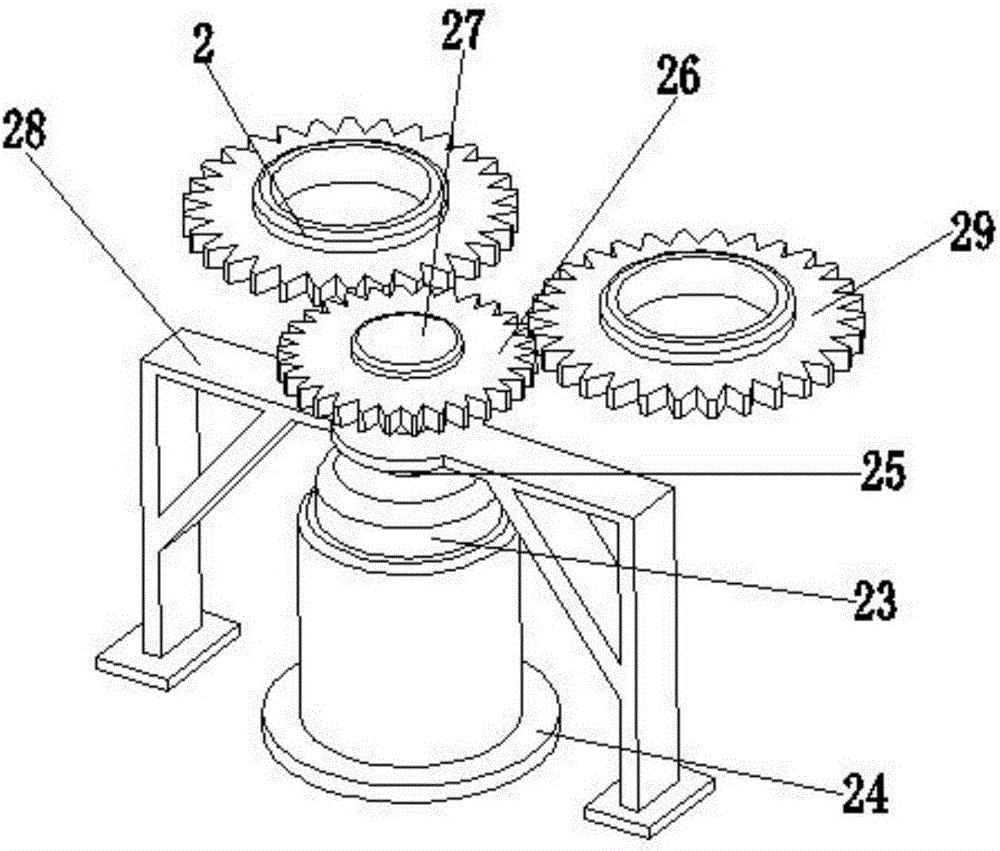

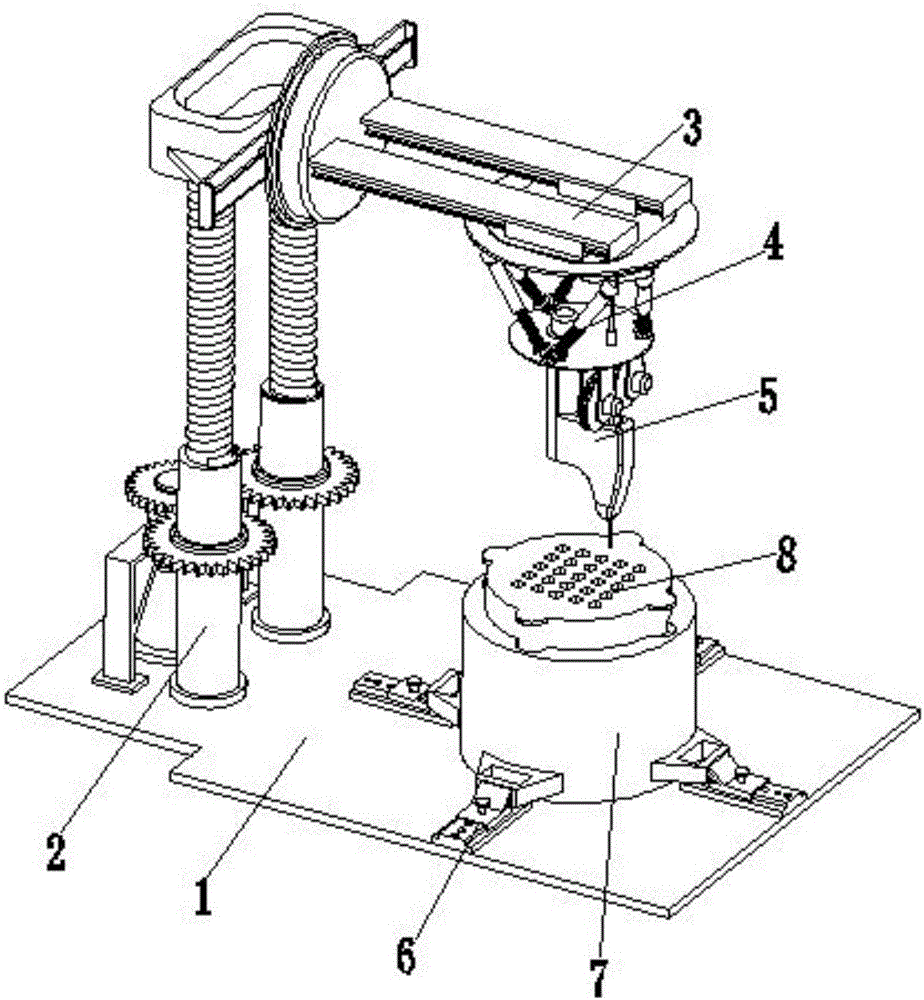

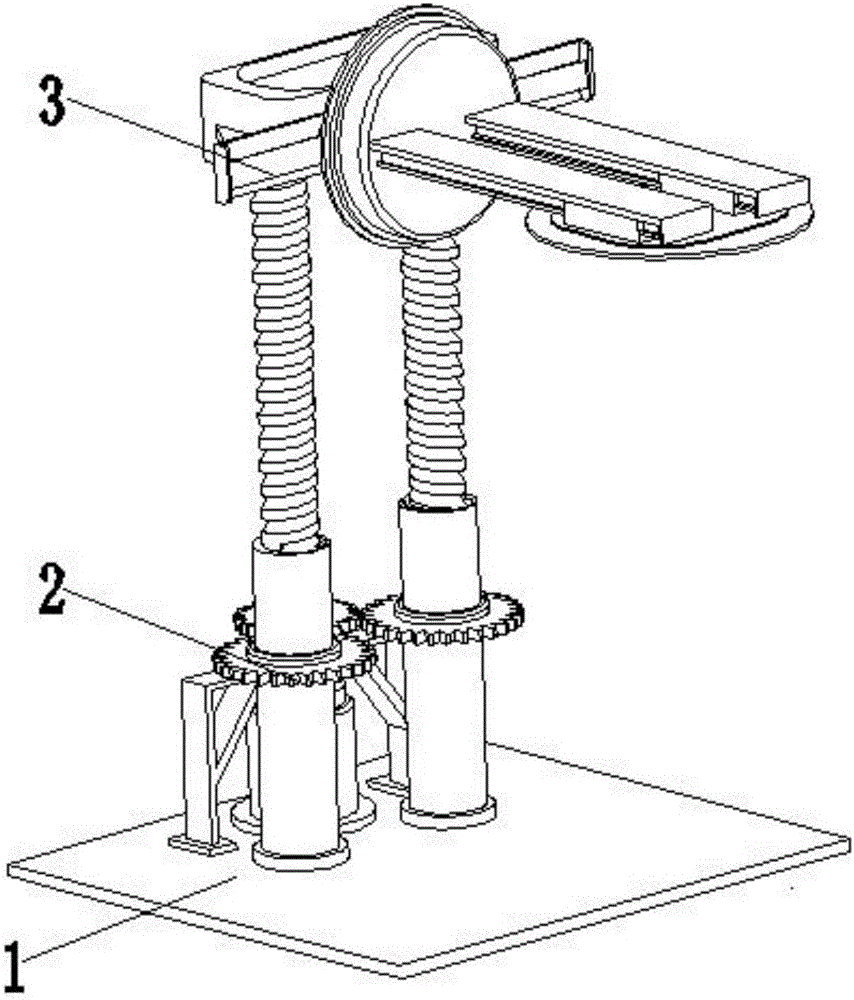

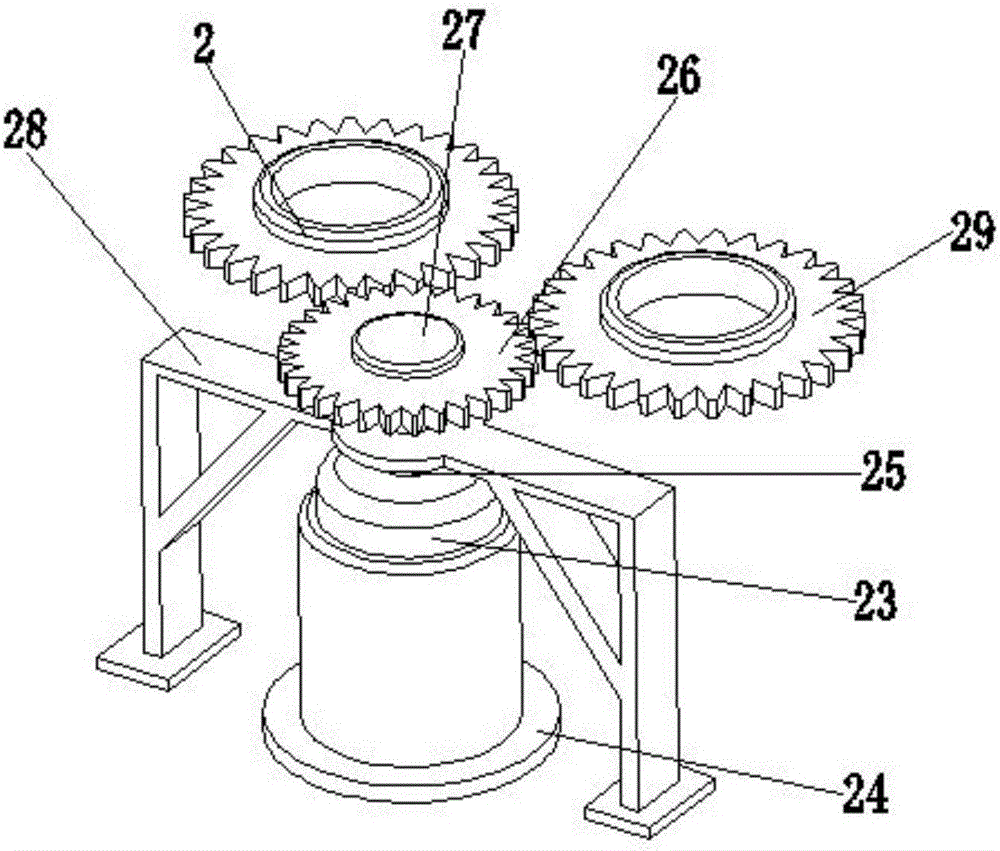

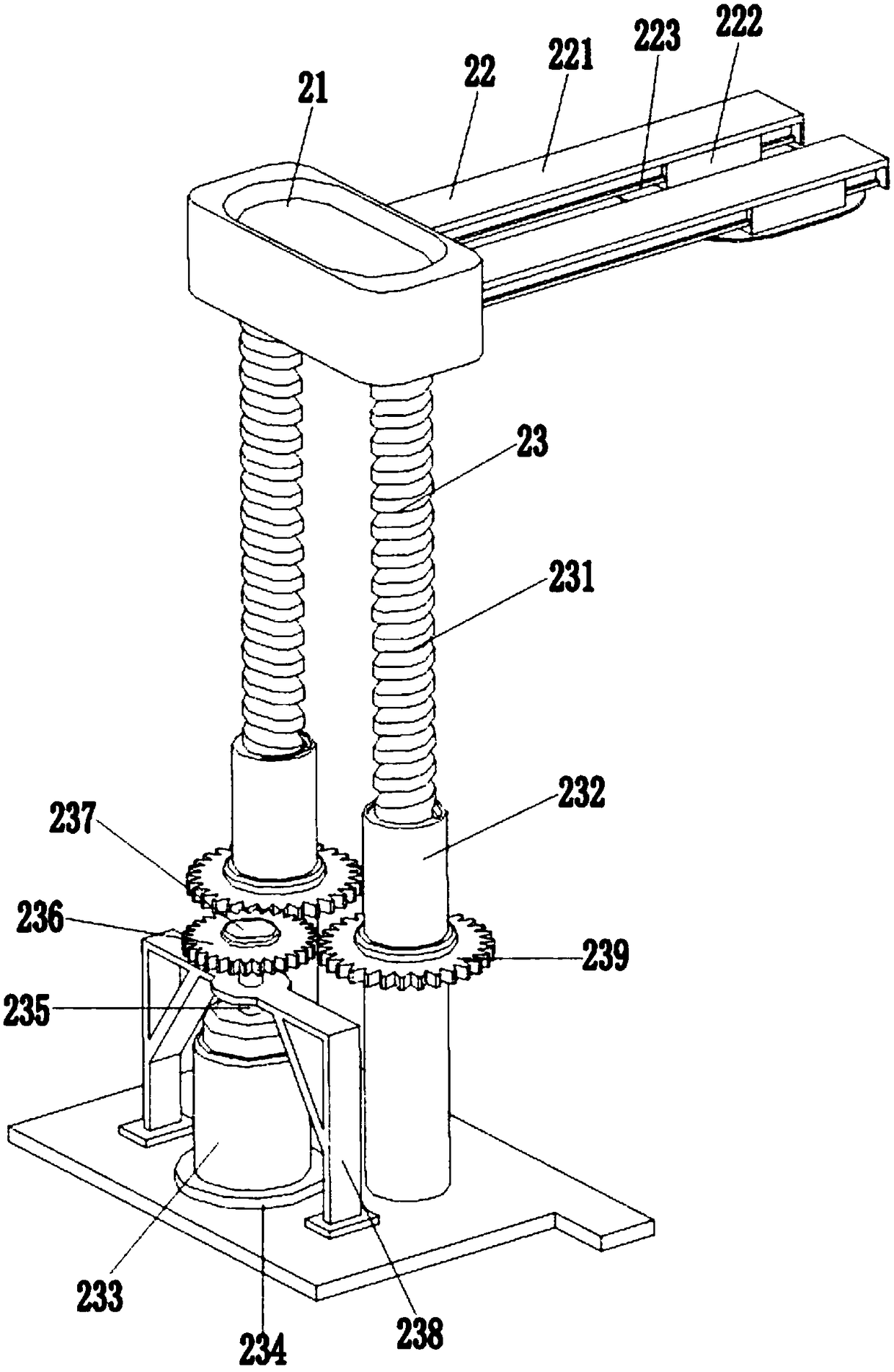

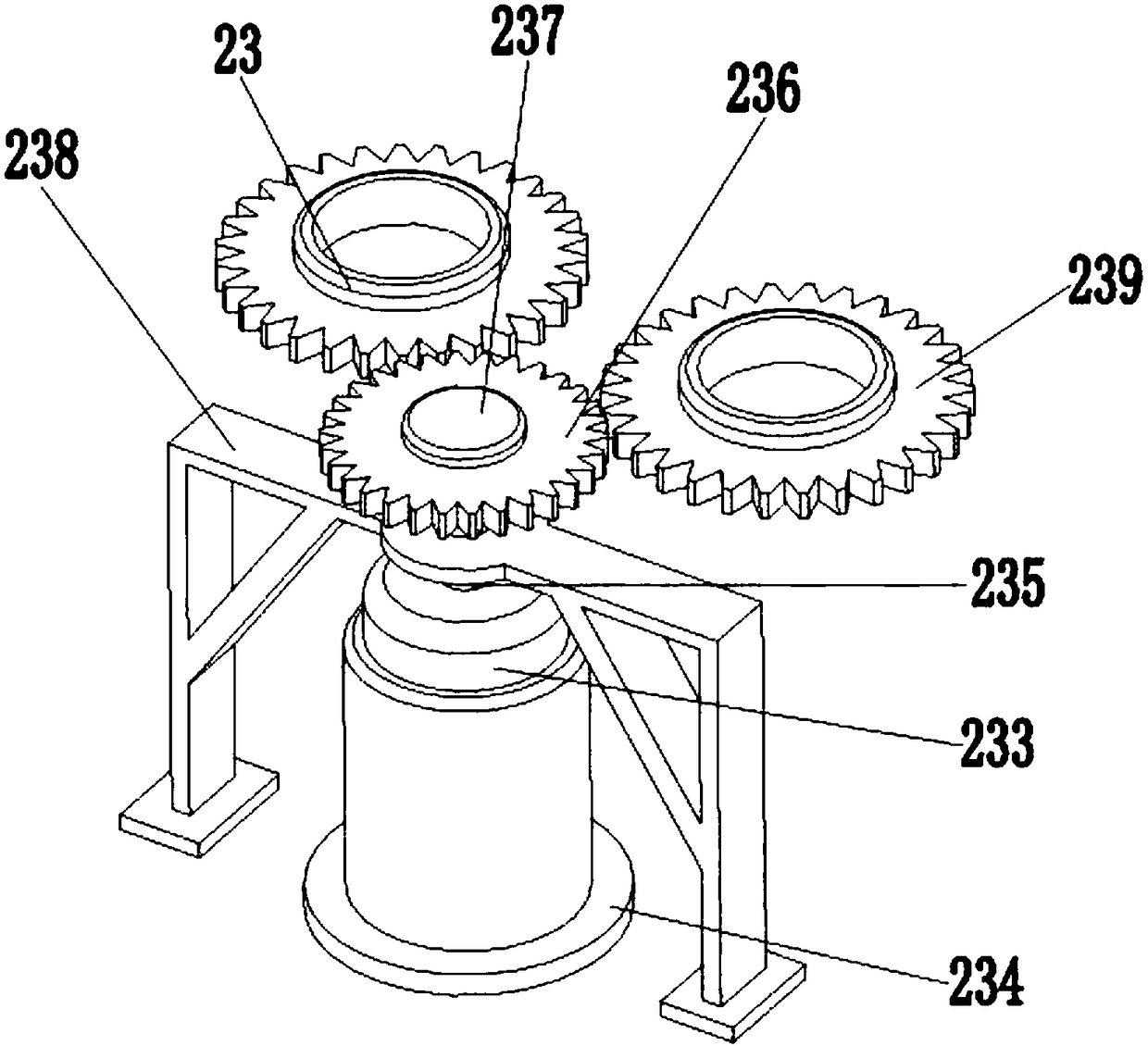

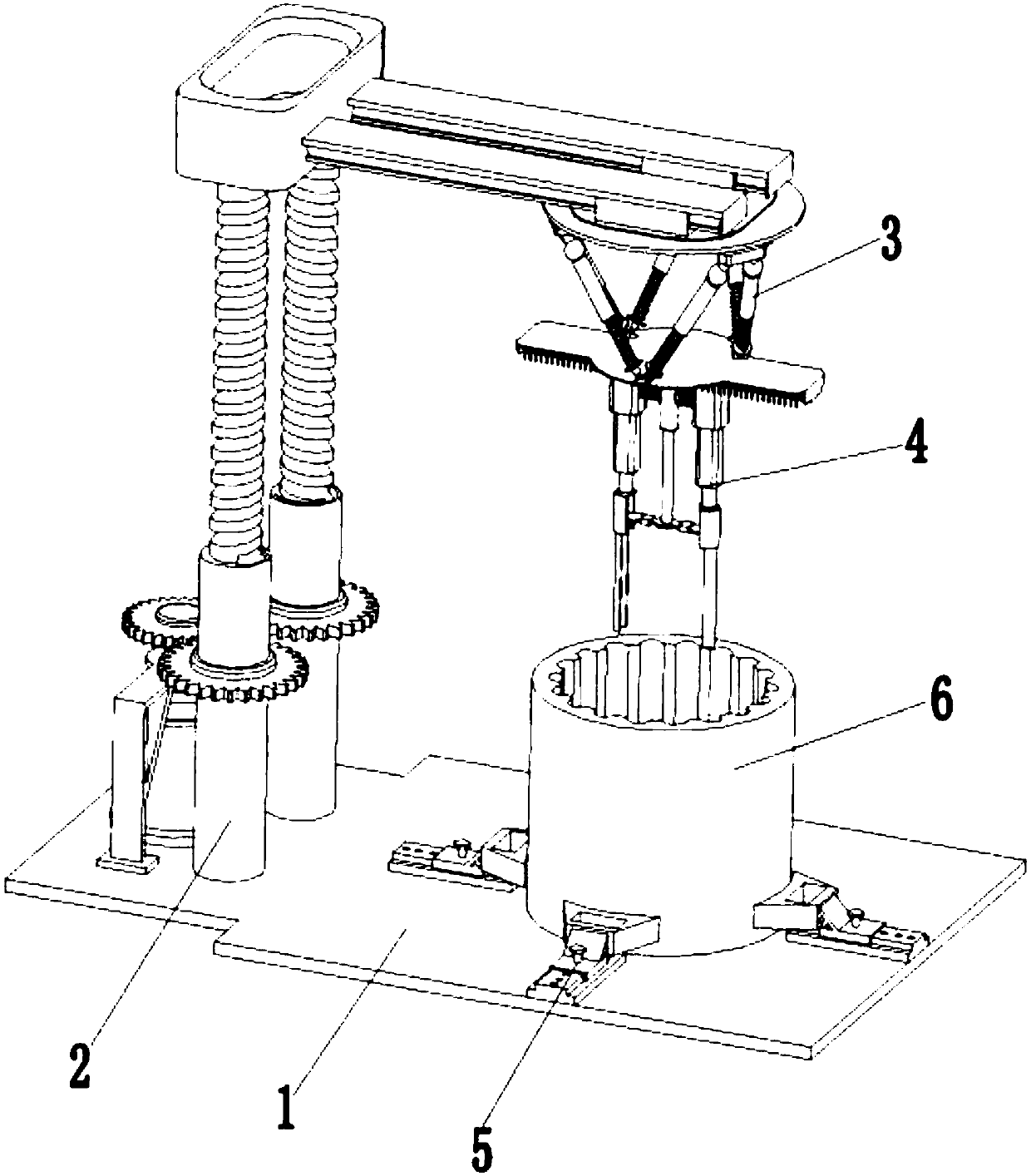

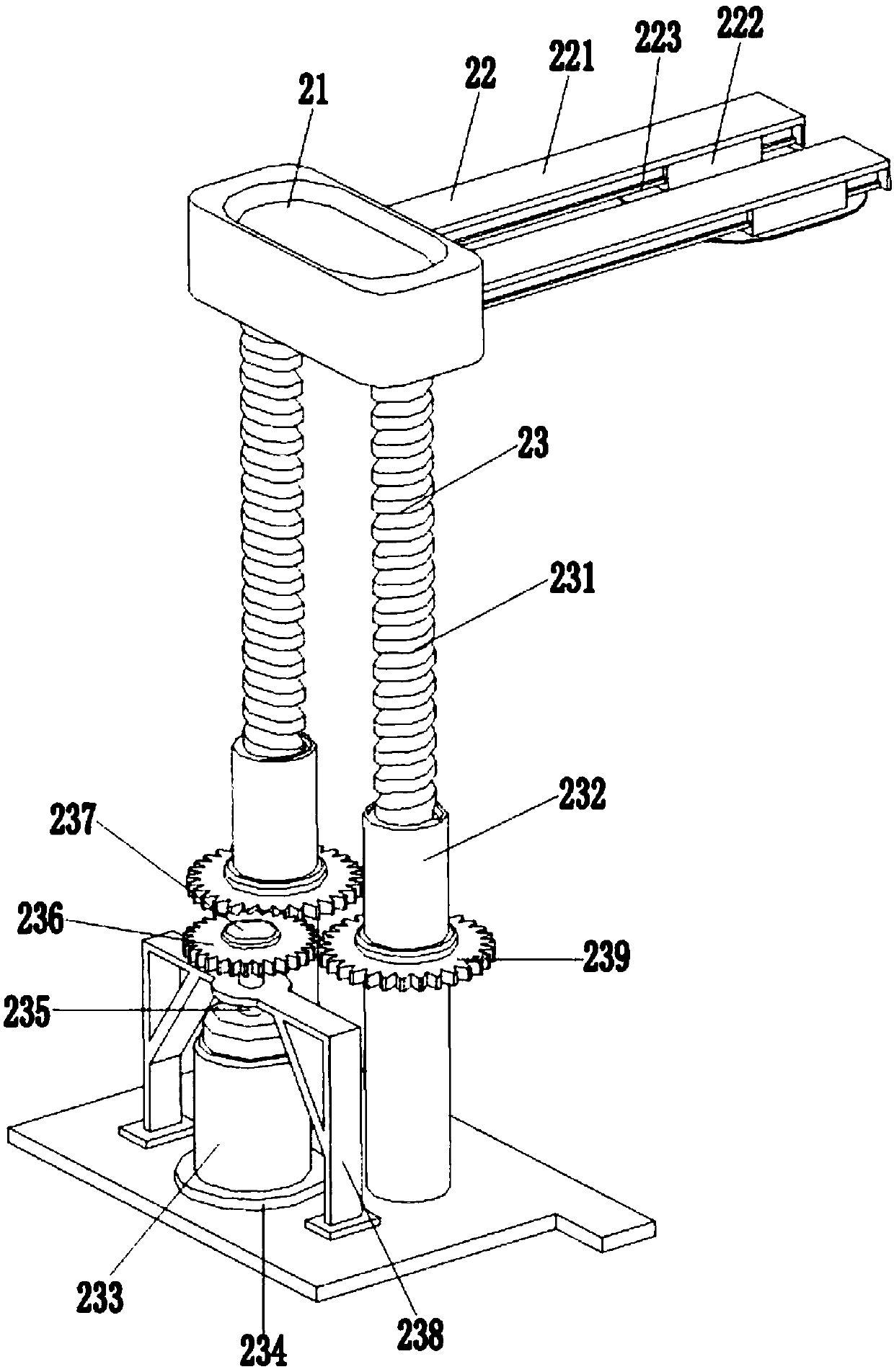

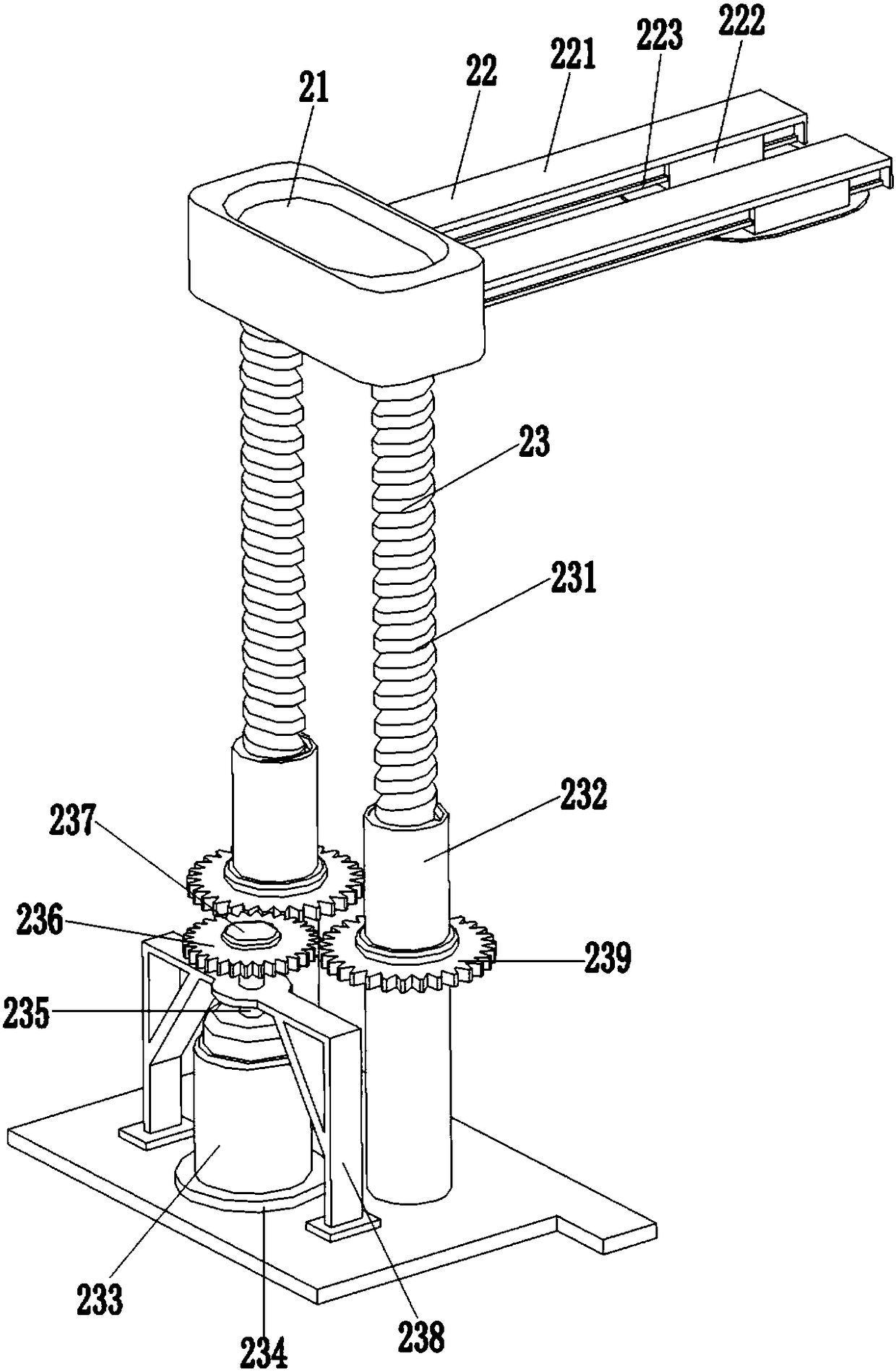

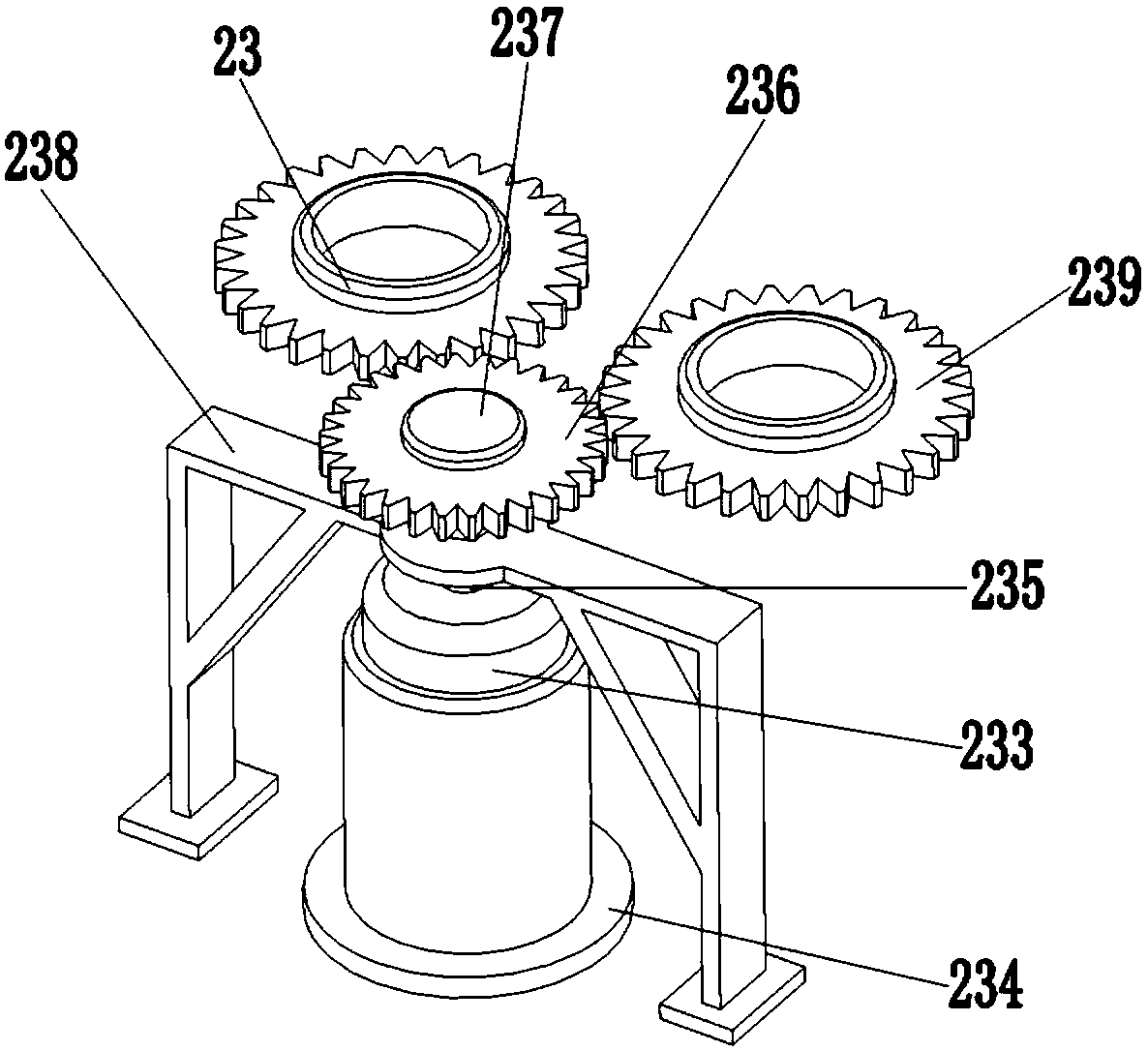

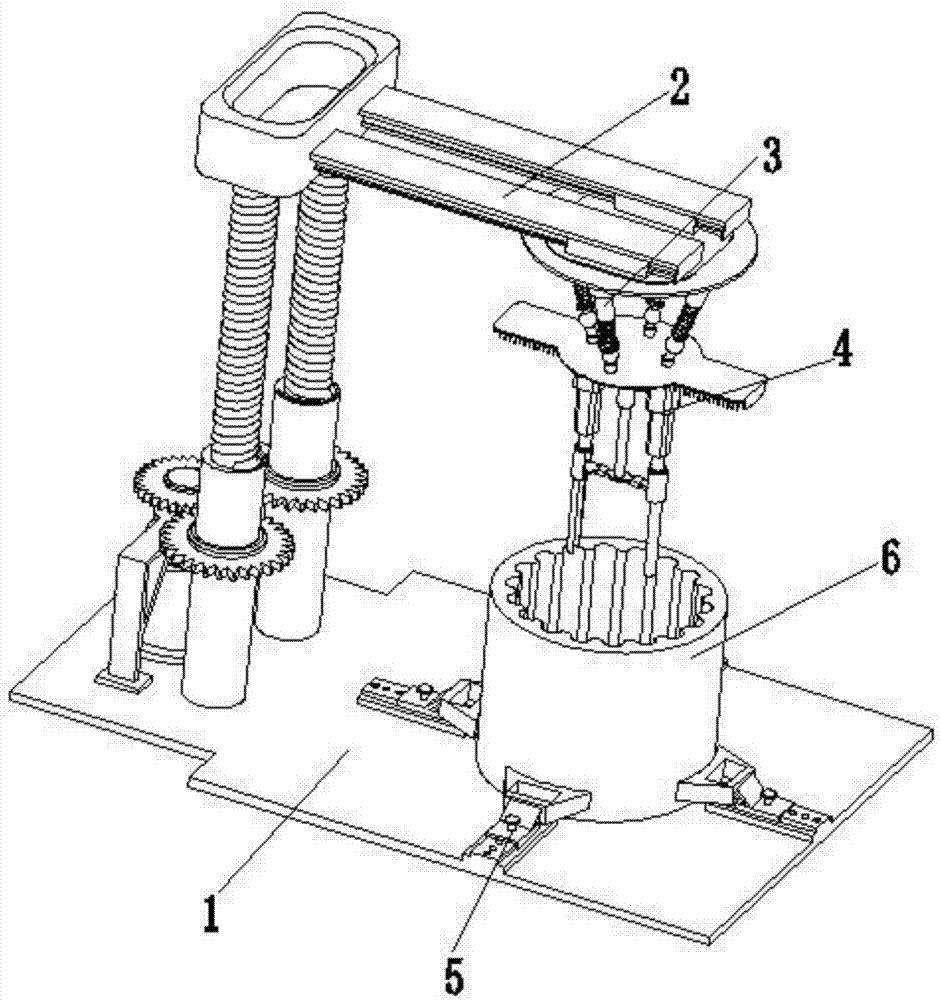

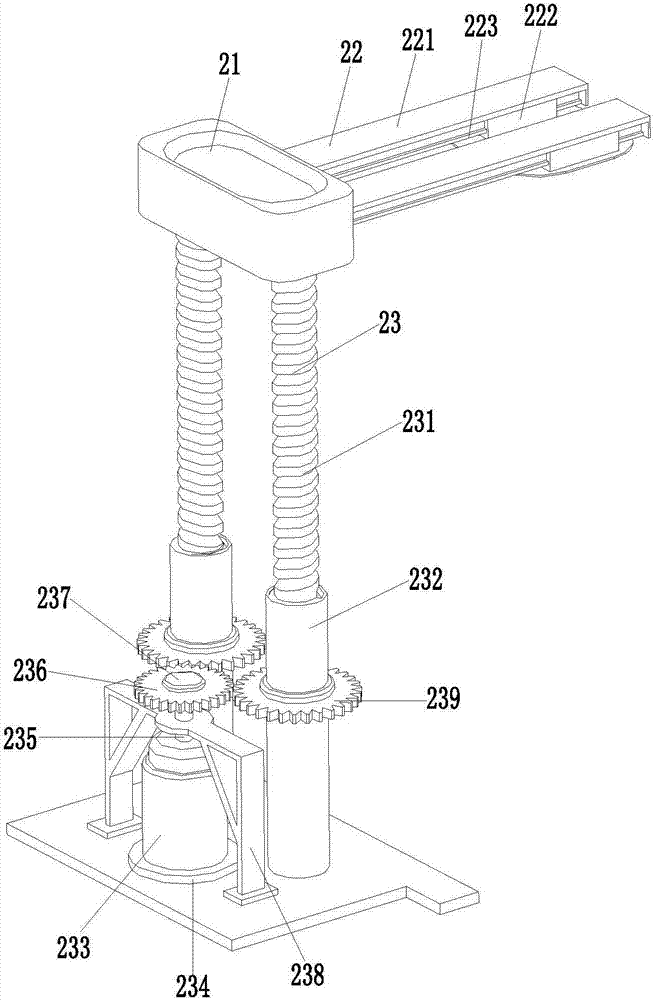

The invention relates to a multi-freedom-degree environment-friendly welding industrial robot for a sewage treatment pipeline and a drain grating plate. The multi-freedom-degree environment-friendly welding industrial robot comprises a base, a lifting device, a rotation drive device, a delta parallel mechanism, a welding execution device and fixing devices. The lifting device is located at the rear side end of the base. The rotation drive device is located over the lifting device. The delta parallel mechanism is located below the front end of the rotation drive device. The welding execution device is located under the delta parallel mechanism. The welding execution device is fixedly connected with the delta parallel mechanism. The number of the fixing devices is four. The fixing devices are symmetrically arranged on the upper end face of the base. The fixing devices are fixedly connected with the base. The multi-freedom-degree environment-friendly welding industrial robot can conduct the full-automatic intelligent welding operation on the portion between the sewage treatment pipeline and the drain grating plate, the overall position can be adjusted during welding, local positions can flexibly move, and stability is high; meanwhile, the function that welding is conducted during welding wire feeding can be achieved; and the welding efficiency is high, and the welding quality is good.

Owner:玉环呈祥科技有限公司

Environment-friendly sewage treatment pipe and dirt baffle plate welding robot

ActiveCN105817798AAdjustable positionFlexible movementWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSewage treatment

The invention relates to an environment-friendly sewage treatment pipe and dirt baffle plate welding robot. The robot comprises a base, a lifting device, a rotary driving device, a six-degree-of-freedom parallel mechanism, a welding actuation device and fixing devices; the lifting device is positioned at the back side end of the base, and is fixedly connected with the base; the rotary driving device is positioned rightly above the lifting device, and is fixedly connected with the lifting device; the six-degree-of-freedom parallel mechanism is positioned below the front end of the rotary driving device; the welding actuation device is positioned rightly below the six-degree-of-freedom parallel mechanism, and is fixedly connected with the six-degree-of-freedom parallel mechanism; and the fixing devices are symmetrically arranged on the upper end surface of the base, and are fixedly connected with the base. The robot can perform full-automatic intelligent welding operation between a sewage treatment pipe and a dirt baffle plate, is adjustable in whole position during welding, flexible in motion in local positions and high in stability, can realize the function of feeding welding wires while welding, and is high in welding efficiency and excellent in welding quality.

Owner:郑州严格智能科技有限公司

High-temperature vacuum sintering furnace lifting frame device

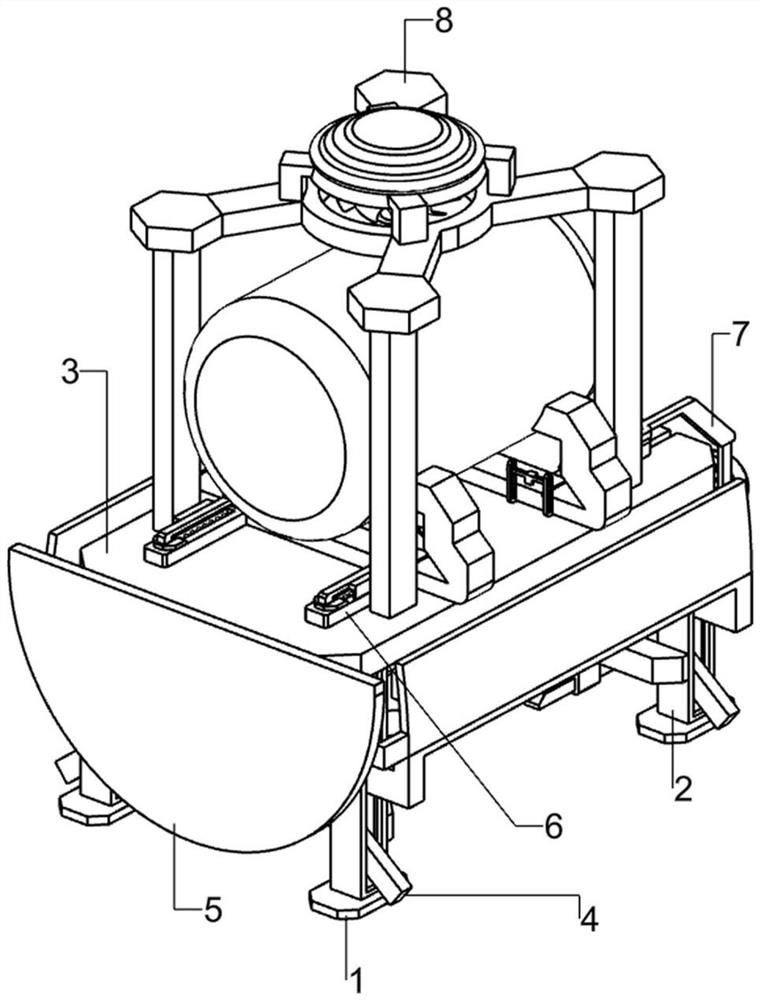

InactiveCN112484481AEasy to useRealize clamping and fixingMuffle furnacesFurnace safety devicesMaterials scienceHigh heat

The invention relates to a lifting frame device, in particular to a high-temperature vacuum sintering furnace lifting frame device. The high-temperature vacuum sintering furnace lifting frame device is high in safety and simple to use. According to the technical scheme, the high-temperature vacuum sintering furnace lifting frame device comprises a bottom plate and supporting frames, a placing assembly and a lifting mechanism, wherein the supporting frames are arranged on the bottom plate at equal intervals; the placing assembly is connected between the supporting frames; and the lifting mechanism is arranged on the placing assembly. Through cooperation of the placing assembly and the lifting mechanism, a vacuum sintering furnace can move up and down, and therefore people can use the vacuumsintering furnace conveniently.

Owner:江西省晶为光电科技有限公司

Novel motor paper inserting industrial robot

ActiveCN106002942ALow costQuality improvementProgramme-controlled manipulatorGripping headsPulp and paper industryPaper sheet

The invention relates to a novel motor paper inserting industrial robot. The novel motor paper inserting industrial robot comprises a base, a supporting device, a redundant parallel mechanism, a paper inserting device and fixing devices. The supporting device is located at the rear side end of the base and is fixedly connected with the base. The redundant parallel mechanism is mounted at the front end of the supporting device. The paper inserting device is located under the redundant parallel mechanism. The four fixing devices are symmetrically arranged on the upper end face of the base correspondingly and are fixedly connected with the base. The novel motor paper inserting industrial robot can conduct insulation paper inserting operation on motor stators, the whole paper inserting process is operated in a mechanical automation mode, paper inserting is rapid, convenient and high in safety, the uniformity of the paper inserting depth is high, and input of labor force is reduced; and production cost of motors is reduced, folded insulation paper can be sucked through the suction principle, compared with one-way paper inserting, the paper inserting efficiency is improved by one time, operation is rapid and easy, the paper inserting efficiency is high, and the production efficiency and quality of the motors are improved.

Owner:叶青

Novel machine part polishing device

InactiveCN108067986AFast and Smart CoolingImprove yieldEdge grinding machinesGrinding work supportsEngineeringMaterial storage

The invention provides a novel machine part polishing device. The front end of a fixing device is provided with a fixing end, the two sides of the fixing end are provided with dust collectors, a polishing platform is arranged under a polishing mechanism, and the upper end of the polishing platform is provided with a clamping disk. The polishing platform is internally provided with a material storage cavity, and the material storage cavity is internally provided with stirring paddles. One side of the polishing platform is provided with a discharge pipe. The edge of the clamping disk is providedwith fixing arms which are distributed in an annular array manner. The fixing arms and a rotating block are connected through a rotating shaft. The rotating block is provided with a clamping jaw anda cooling device. The front end of the cooling device is provided with a plurality of spray heads. The clamping disk is provided with a temperature sensor, and the cooling device is connected with thetemperature sensor and the spray heads through wires. The novel machine part polishing device has the beneficial effects that residue is rapidly sucked, under the action of the clamping disk, a partis fixed, clamped and positioned, and the phenomenon that the part moves and is dislocated is avoided; and during machining, cooling liquid is sprayed around the part according to the temperature, thetemperature is rapidly and intelligently reduced, the working efficiency is improved, and the machining cost is reduced.

Owner:TIANJIN HAOHANG COMPOSITE PIPE

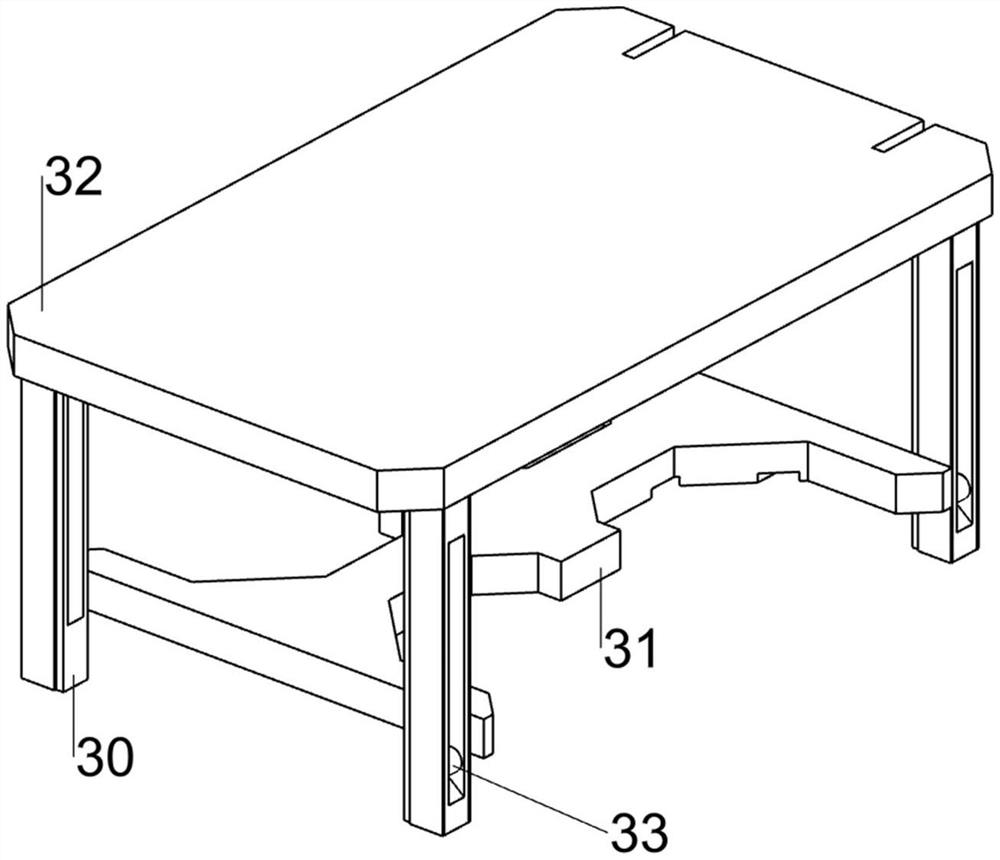

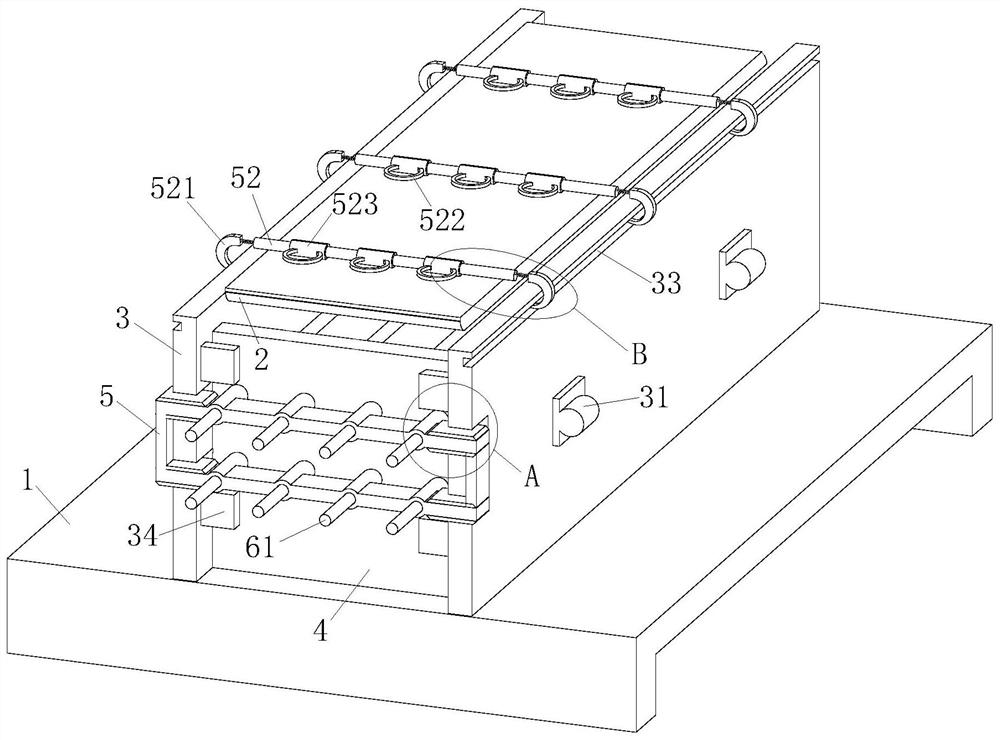

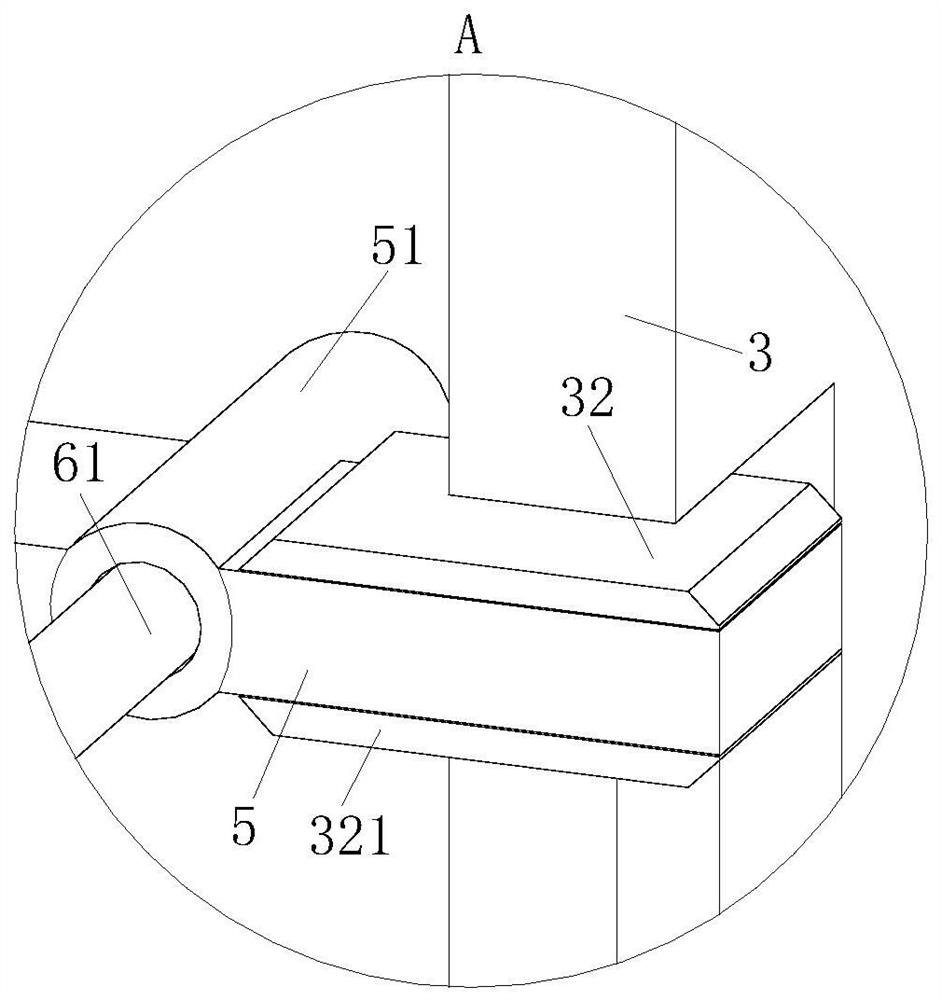

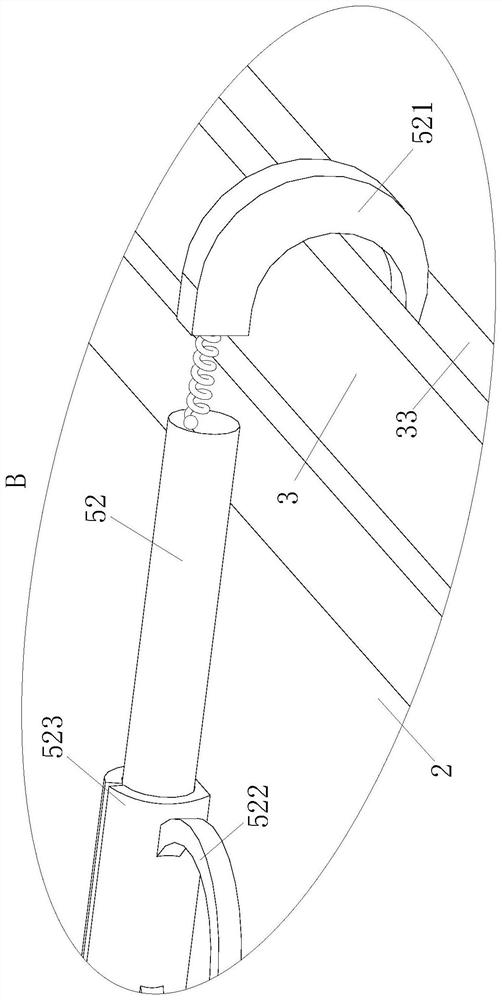

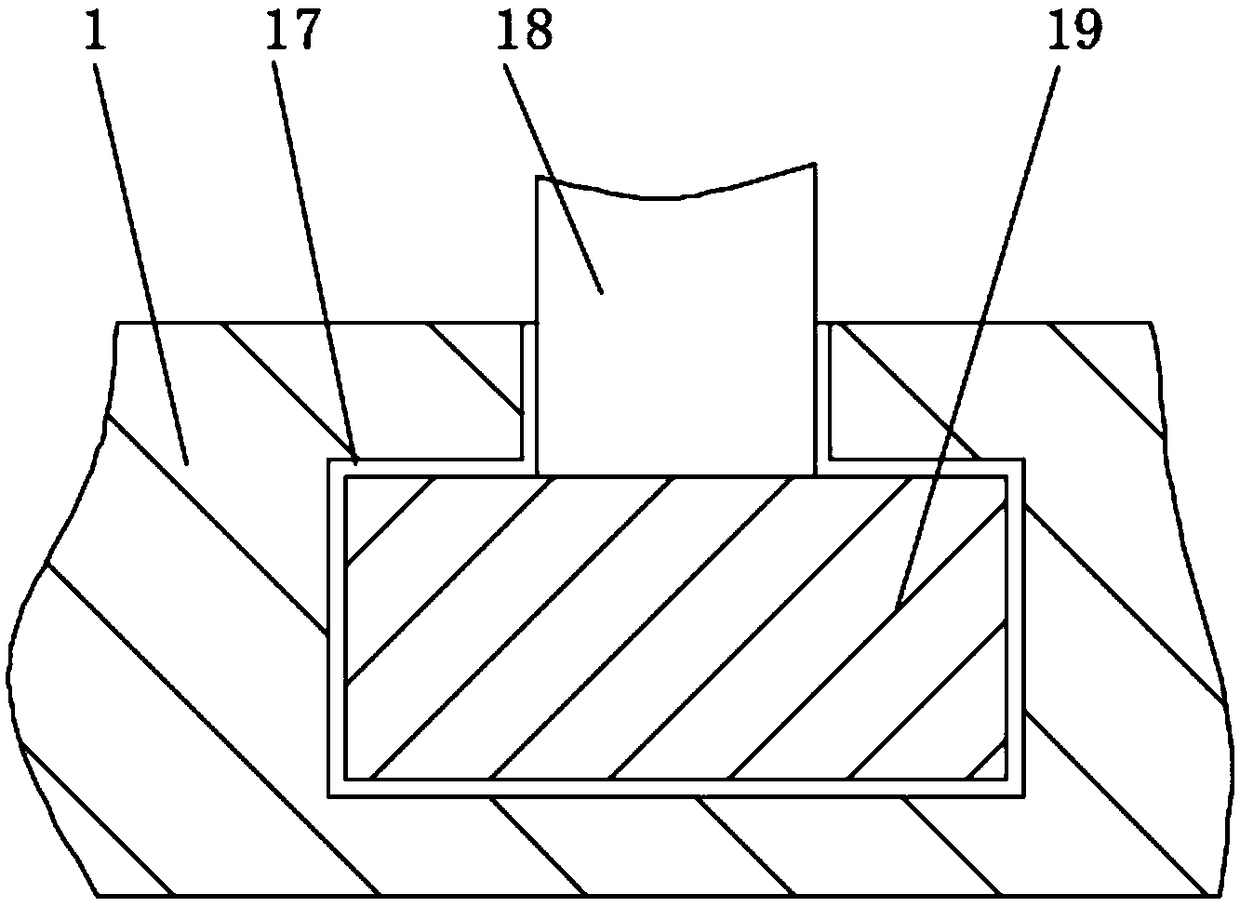

Forming die for prefabricated reinforced concrete

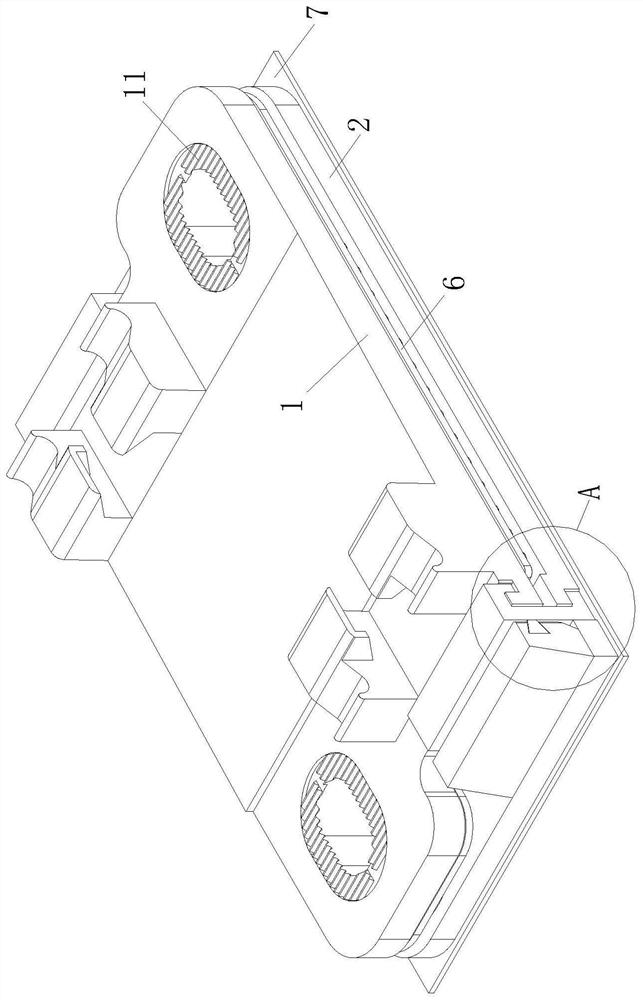

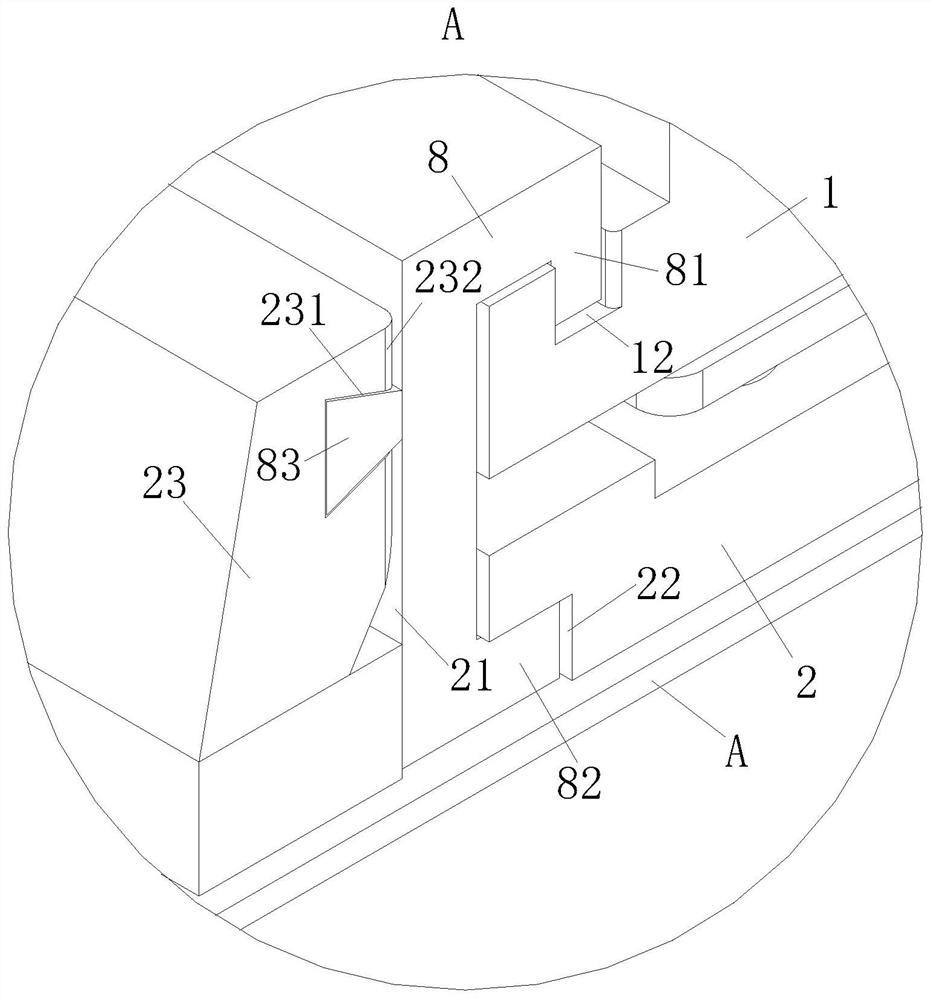

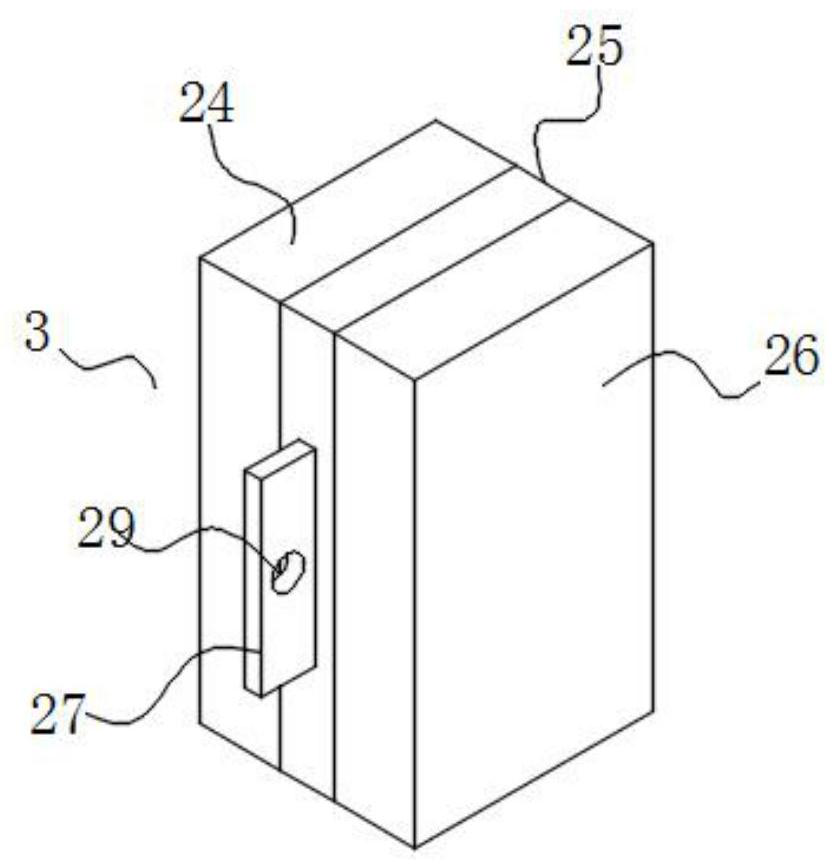

ActiveCN113263586AAvoid movement misalignmentAvoid uneven distributionMouldsMould auxillary partsReinforced concreteArchitectural engineering

The invention belongs to the technical field of concrete prefabrication forming, and particularly relates to a forming mold for prefabricated reinforced concrete. The forming mold comprises a bottom mold plate, an upper mold plate, side mold plates, end mold plates and a fixing frame, wherein the side mold plates are symmetrically arranged on the upper surface of the bottom mold plate, the end mold plates are symmetrically arranged on the portion, located between the side mold plates, of the upper surface of the bottom mold plate; and an area surrounded by the side mold plates and the end mold plates is a pouring cavity. The fixing frames are arranged at the end parts of steel bars, and in addition, a fixing sleeve is arranged on the fixing frame, so that in the pouring process of concrete, the moving misplacing of evenly arranged steel bars under the impact effect of concrete flowing under pressure is avoided, and the flexural capacity and the structural strength of the concrete prefabricated part are enabled not to be affected.

Owner:河南绿筑集成科技有限公司

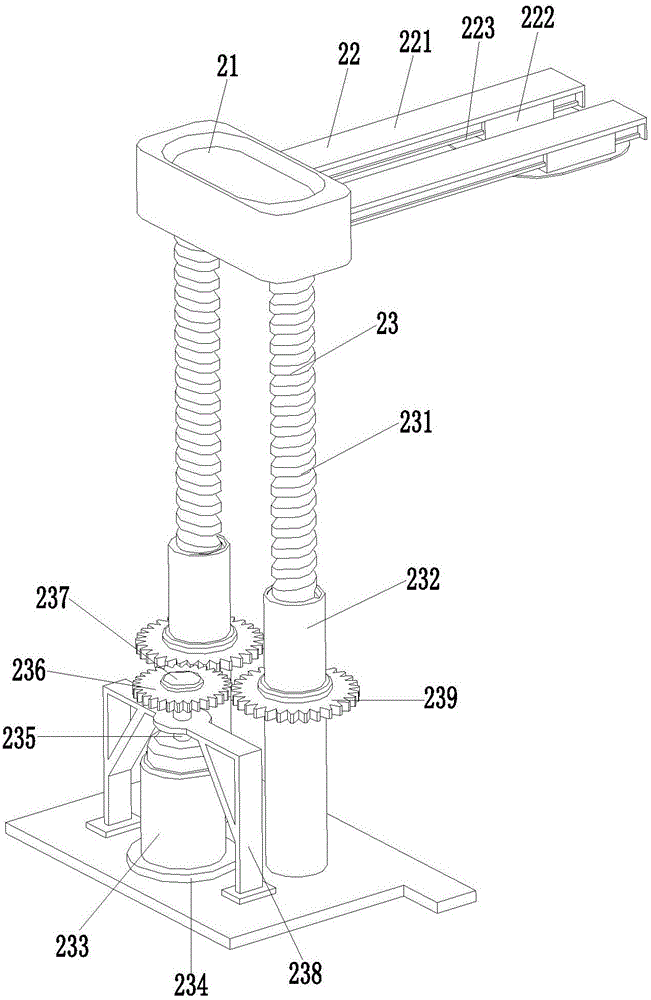

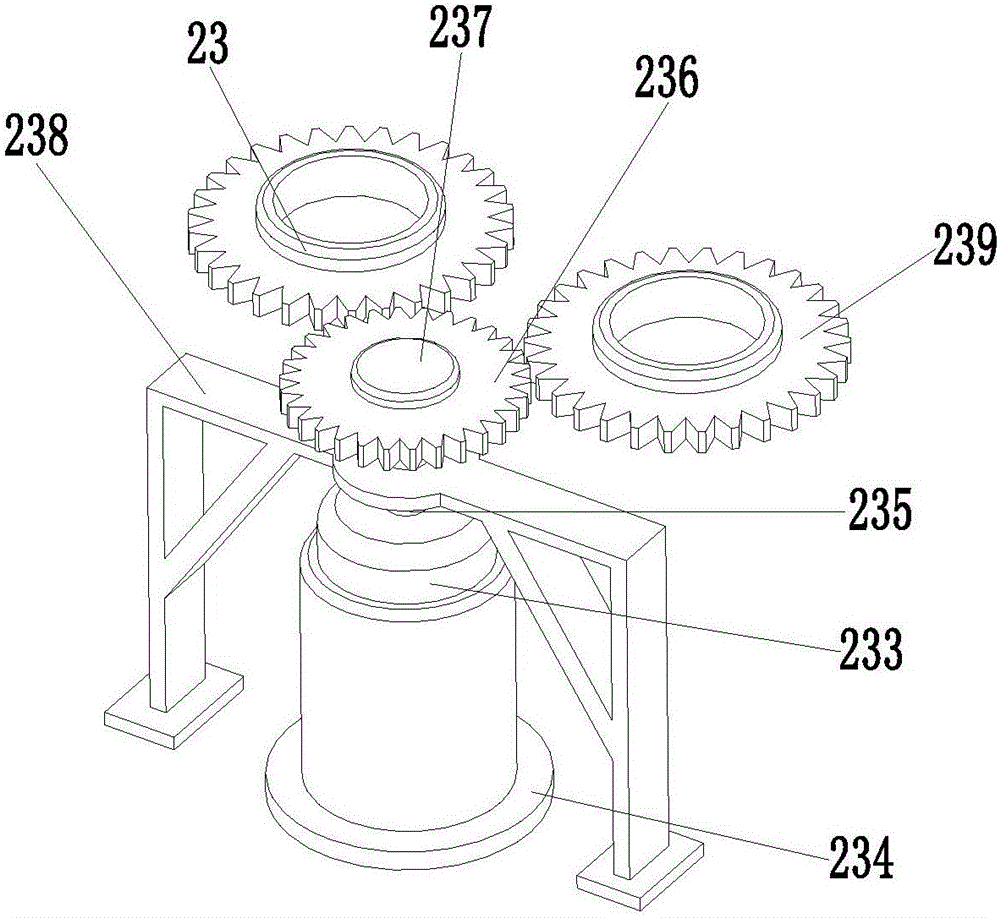

Industrial Robot for Carrying Out Insulating Paper Inserting Operation on Motor Stator and Working Method Thereof

InactiveCN108115656AReduce investmentLow costProgramme-controlled manipulatorGripping headsPulp and paper industryIndustrial robot

The invention relates to an industrial robot for carrying out insulating paper inserting operation on motor stator and working method thereof, which includes a base, a supporting device, a delta parallel mechanism, a paper inserting device and a fixing device; the base has a T-shape plate structure. The support device is arranged at the rear side end of the base, the supporting device is fixedly connected with the base, the delta parallel mechanism is arranged at the front end of the supporting device, the paper inserting device is positioned right below the delta parallel mechanism, and the number of the fixing devices is four, the fixing devices are symmetrically arranged on the upper end surface of the base, and the fixing devices are fixedly connected with the base. According to the invention, the insulating paper inserting operation can be carried out on the motor stator, the whole paper inserting process is a mechanical automatic operation, the paper inserting process is fast andconvenient, the safety is high, the consistency of the paper inserting depth is high, the investment of the labor force is reduced, the production cost of the motor is reduced, and the quality of themotor production is improved to a certain extent.

Owner:吴小再

Electric motor bidirectional synchronous paper inserting robot and working method thereof

InactiveCN108054888ALow costQuality improvementProgramme-controlled manipulatorGripping headsPulp and paper industryWorking set

The invention relates to an electric motor bidirectional synchronous paper inserting robot and a working method thereof. The robot comprises a base, a supporting device, a Stewart parallel mechanism,a paper inserting device and fixing devices; the base is of a T-shaped platelike structure, the supporting device is arranged at the rear side end of the base, the supporting device is fixedly connected with the base, the Stewart parallel mechanism is installed at the front end of the supporting device, the paper inserting device is located below the Stewart parallel mechanism, the robot is provided with four fixing devices, the fixing devices are symmetrically arranged on the upper end face of the base respectively, and the fixing devices are fixedly connected with the base. According to therobot, bidirectional synchronous insulation paper inserting operation can be conducted on a stator of a motor, and the whole paper inserting process is a mechanical automation operation; paper inserting is fast and convenient, and has high safety and high paper inserting depth uniformity, input of the labor force and the production cost of the motor are reduced, and production quality of the motoris improved to an extent.

Owner:蔡留凤

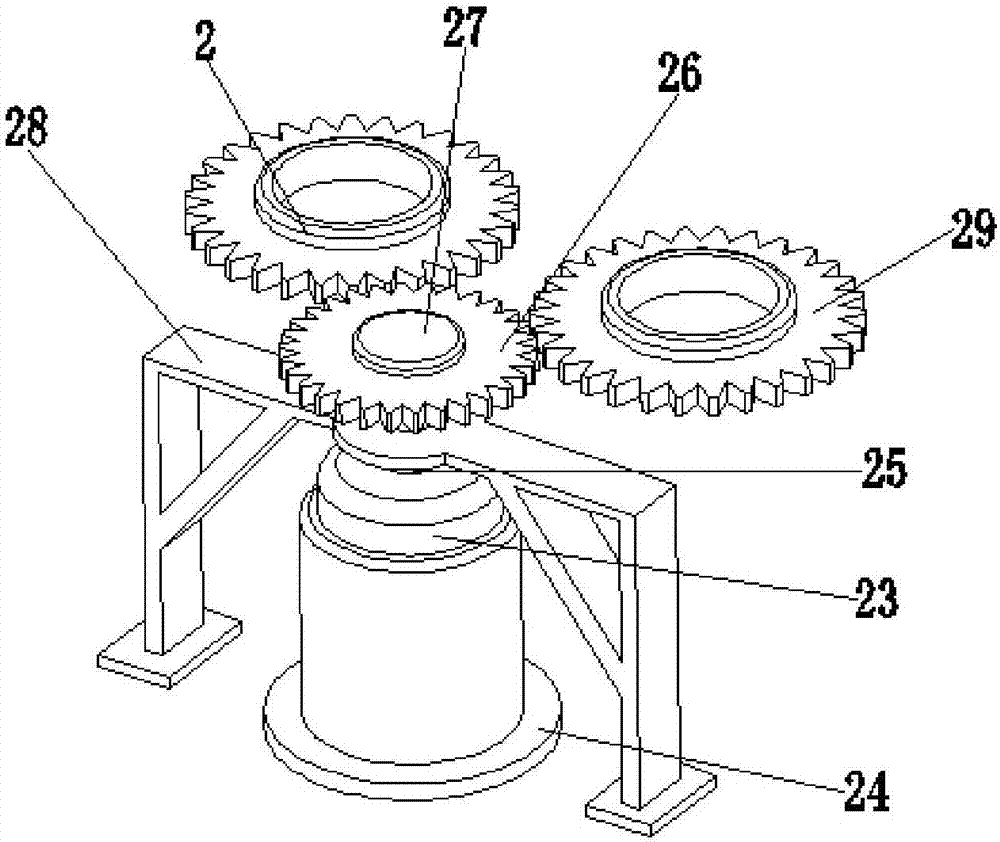

A multi-degree-of-freedom intelligent insulating paper inserting machine

ActiveCN105978262BLow costQuality improvementApplying solid insulationMulti degree of freedomPulp and paper industry

The invention relates to a multi-degree-of-freedom novel intelligent insulation paper inserting machine, which comprises a base, a support device, a delta parallel mechanism, a paper inserting device and fixing devices, wherein the support device is located at the rear side end of the base; the delta parallel mechanism is arranged at the front end of the support device; the paper inserting device is located below the delta parallel mechanism; the fixing devices are symmetrically arranged on the upper end surface of the base separately; and the fixing devices are fixedly connected with the base. Insulation paper inserting operation can be carried out on a motor stator; the overall paper inserting process is mechanical automation operation; paper insertion is fast and convenient and the safety is high; and the paper inserting depth consistency is high. Furthermore, the paper inserting device can absorb folded insulation paper through the suction principle and then the absorbed insulation paper is bi-directionally and synchronously inserted into an insulating slot of the motor stator through the pressure principle. Compared with unidirectional paper insertion, the multi-degree-of-freedom novel intelligent insulation paper inserting machine has the advantages that the paper inserting efficiency is fully doubled; the operation is fast and simple; the paper inserting efficiency is high; and the production efficiency and quality of a motor are improved.

Owner:盐城翼飞航空工业有限公司

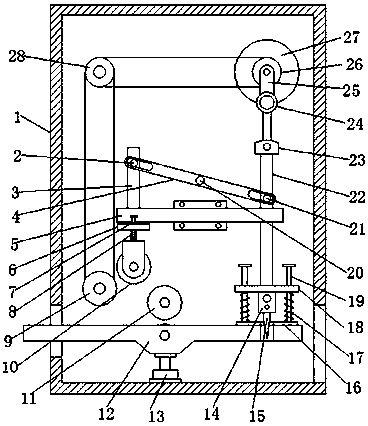

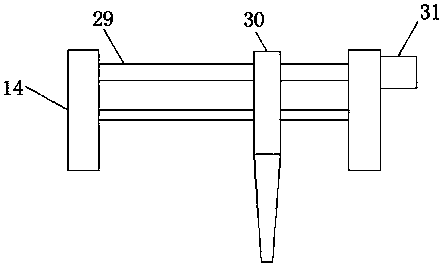

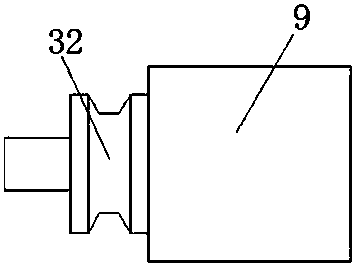

Cutting device for synthetic leather production and machining

InactiveCN108436994AImprove shear efficiencyAvoid movement misalignmentMetal working apparatusWebs handlingMachiningScrew thread

The invention discloses a cutting device for synthetic leather production and machining. The cutting device comprises a shell body, wherein a supporting plate is fixedly mounted on the inner wall of one side of the shell body through a bolt; a driven rod and a driving rod which are vertically arranged movably penetrate through the supporting plate; a mounting plate is welded with one end of the driving rod; two mounting blocks are fixedly mounted at the bottom end of the mounting plate; a two-way screw rod is rotationally mounted between the mounting blocks through a bearing; a first guiding rod is also fixedly mounted between the mounting blocks; a moving block is movably mounted on the two-way screw rod through a screw thread; the first guiding rod is positioned below the two-way screw rod and penetrates through the moving block; a cutter blade is fixedly mounted at the bottom end of the moving block; four second guiding rods movably penetrate through the mounting plate; a pressing plate is fixedly mounted at one end of all the second guiding rods jointly; and first springs sleeve rod bodies of all the second guiding rods. The cutting device disclosed by the invention is reasonable in design and structure, simple to operate, and convenient to use; the feeding operation and the cutting operation can be performed integrally; and furthermore, the working procedures are centralized and the practicability is high.

Owner:安徽耀博皮革制品制造有限公司

Automatic C-shaped insulation paper inserting robot for motor

The invention relates to an automatic C-shaped insulation paper inserting robot for a motor. The automatic C-shaped insulation paper inserting robot comprises a base, a support device, a redundant parallel mechanism, a paper inserting device and four fixing devices, wherein the base is of a T-shaped plate-type structure; the support device is located at the rear side end of the base; the support device is fixedly connected with the base; the redundant parallel mechanism is arranged at the front end of the support device; the paper inserting device is located below the redundant parallel mechanism; the four fixing devices are symmetrically arranged on the upper end surface of the base separately; and the fixing devices are fixedly connected with the base. Insulation paper inserting operation can be carried out on a motor stator; the overall paper inserting process is mechanical automation operation; paper insertion is fast and convenient and the safety is high; the paper inserting depth consistency is high; input of the labor force is reduced; the production cost of the motor is reduced; and the production quality of the motor is improved to a certain extent.

Owner:广东省肇庆电机有限公司

Vibration reduction fastener system

The invention belongs to the technical field of urban rail transit, and particularly relates to a vibration reduction fastener system which comprises an upper iron base plate, a lower bottom plate, a middle vibration reduction pad, an under-rail vibration reduction pad, an under-plate vibration reduction pad, a middle vibration isolation plate, an insulating coupling plate and a self-locking limiting structure. The insulating coupling plate is laid on the ground, and the lower bottom plate is mounted above the insulating coupling plate; a self-locking buckle is arranged and embedded into the mounting groove, so that the lower bottom plate and the upper iron base plate are limited, it is guaranteed that the lower bottom plate, the upper iron base plate and components in the gap between the lower bottom plate and the upper iron base plate are kept stable, and the phenomenon that the vibration reduction fastener moves and is staggered under the vibration effect of passing of a train is avoided; and through the series connection effect of the middle anti-vibration pad, the under-rail anti-vibration pad and the under-plate anti-vibration pad, the overall rigidity of the fastener is effectively reduced, meanwhile, excessive deformation of the anti-vibration pads is prevented, and therefore it is guaranteed that the fastener system can normally play a vibration reduction role.

Owner:河北中烁轨道科技有限公司

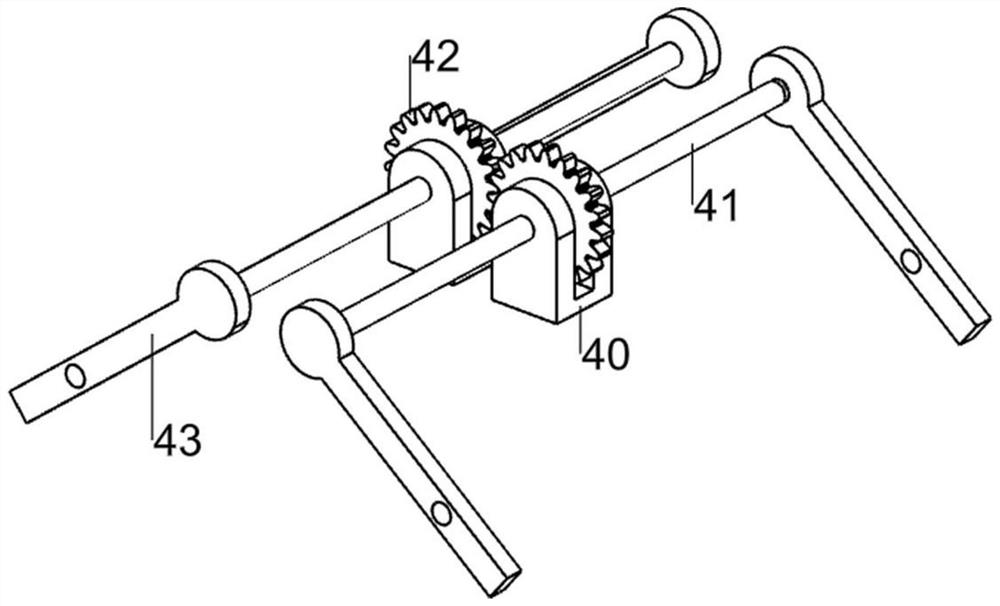

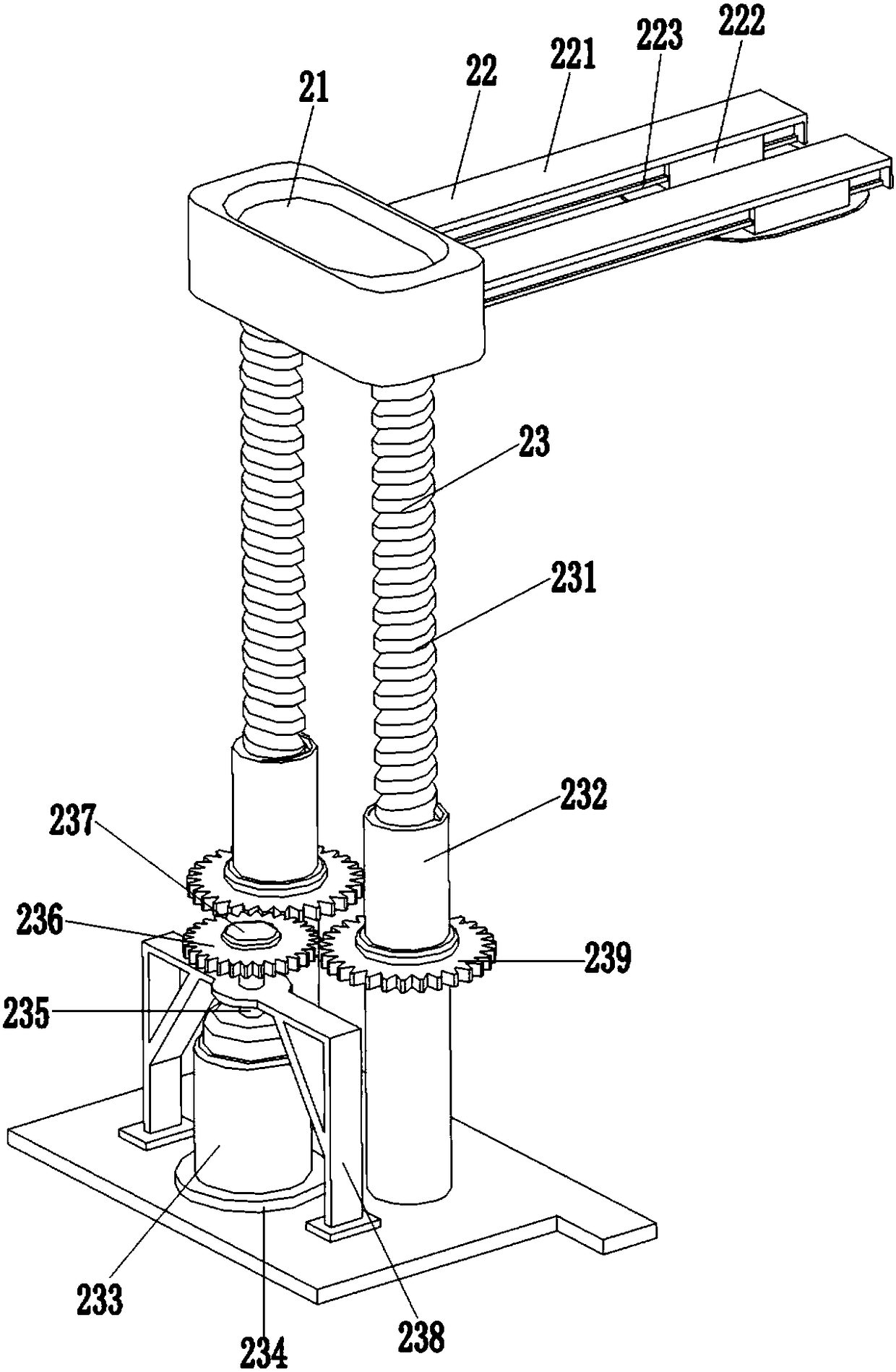

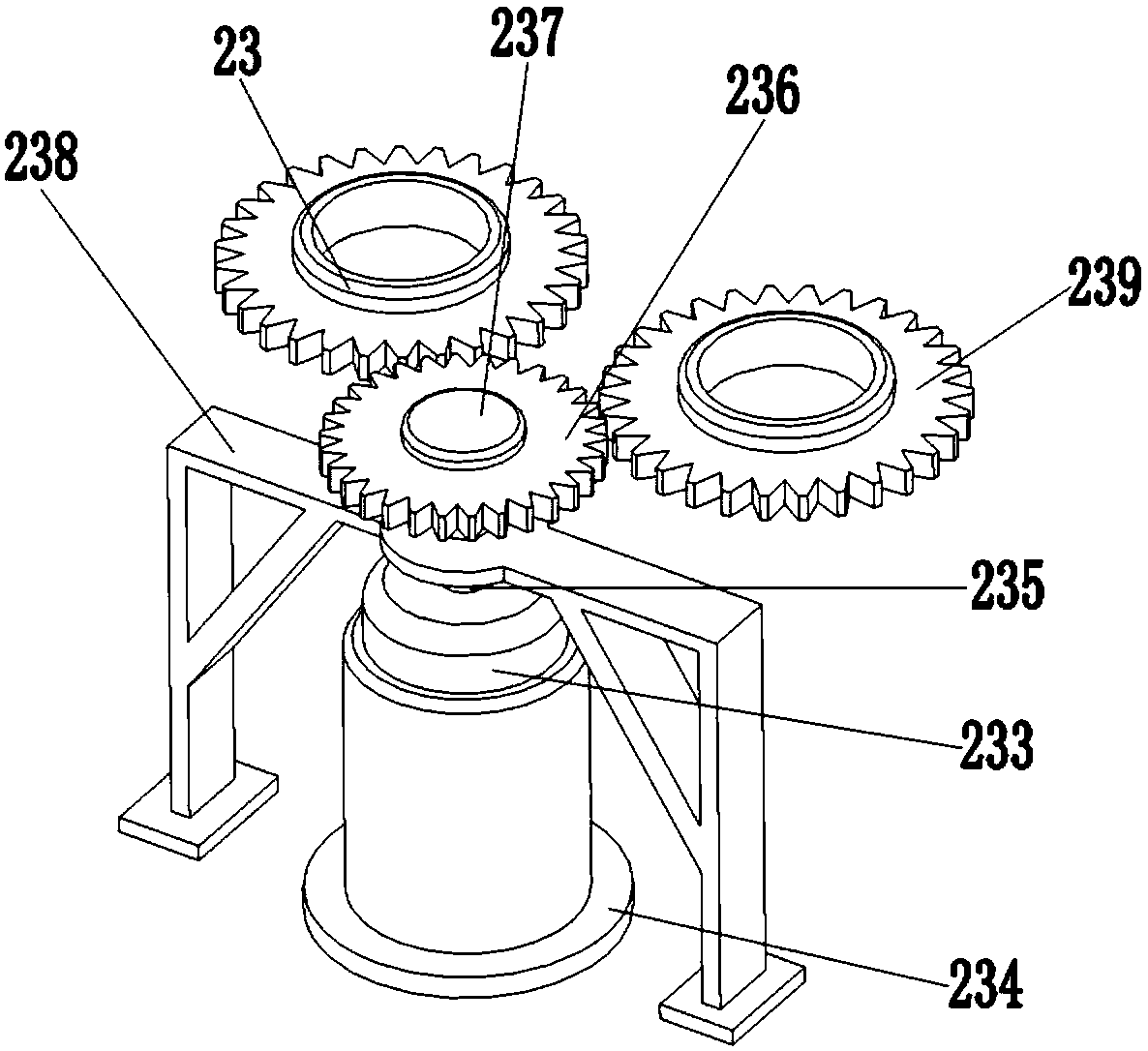

Hot press for quickly forming multilayer building template and use method

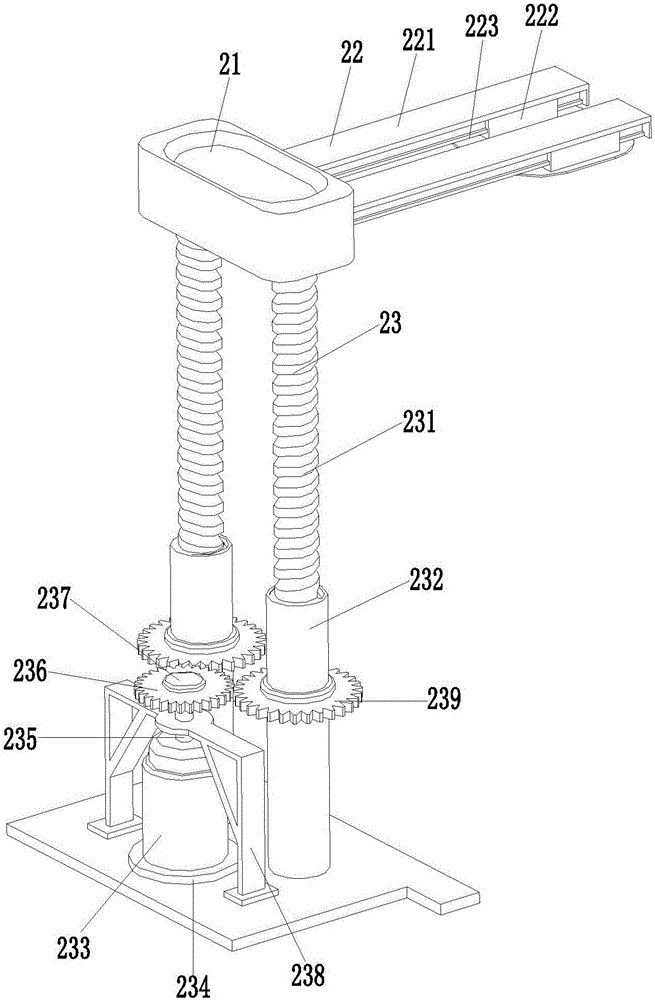

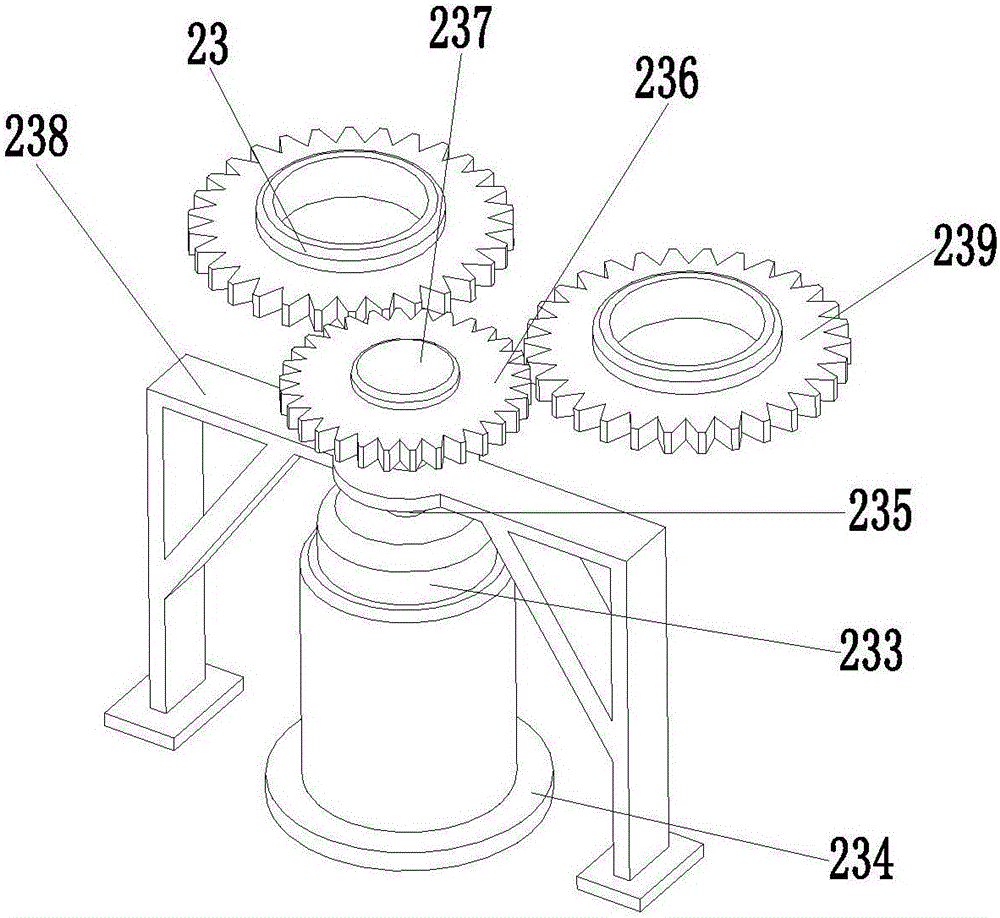

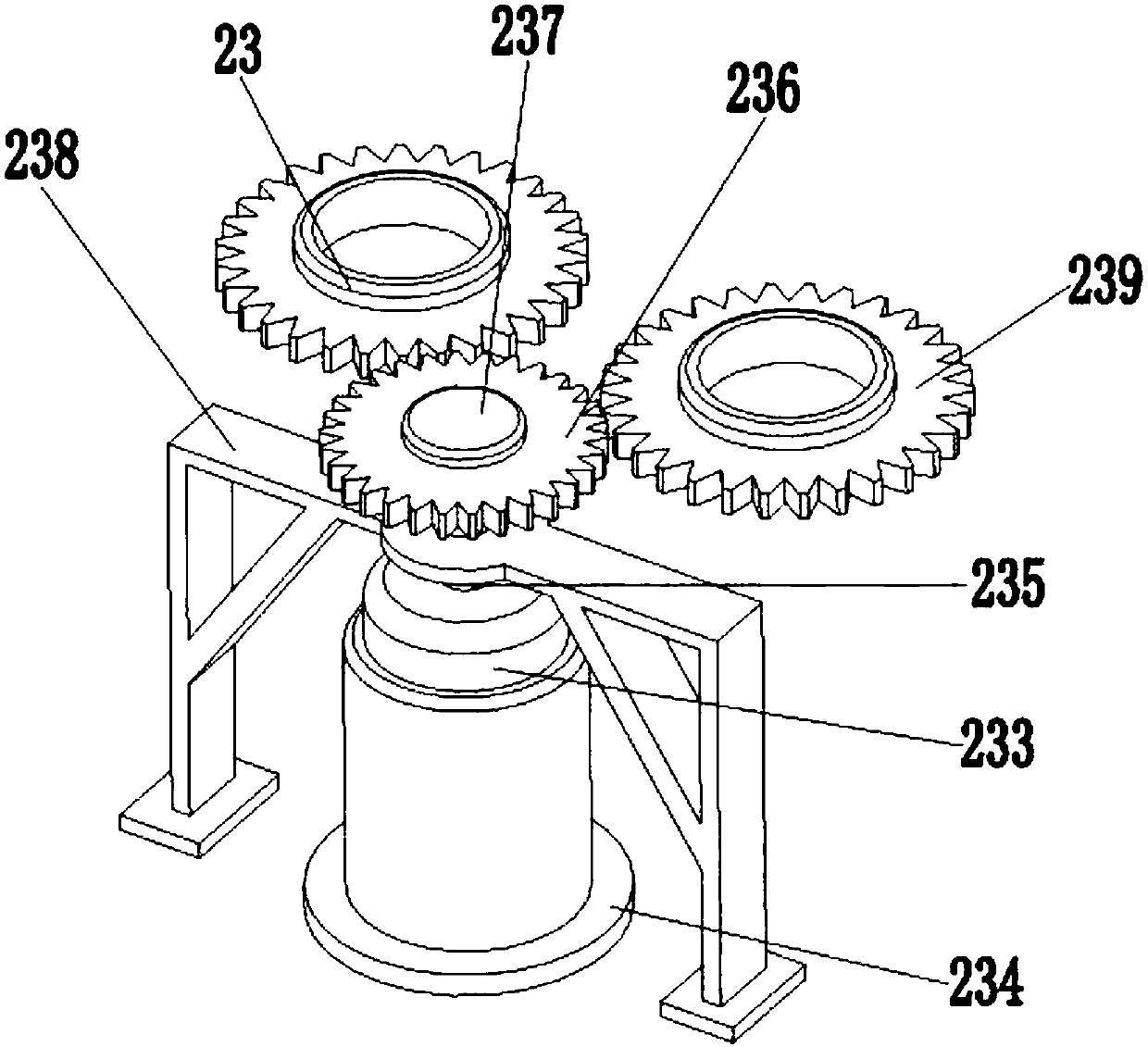

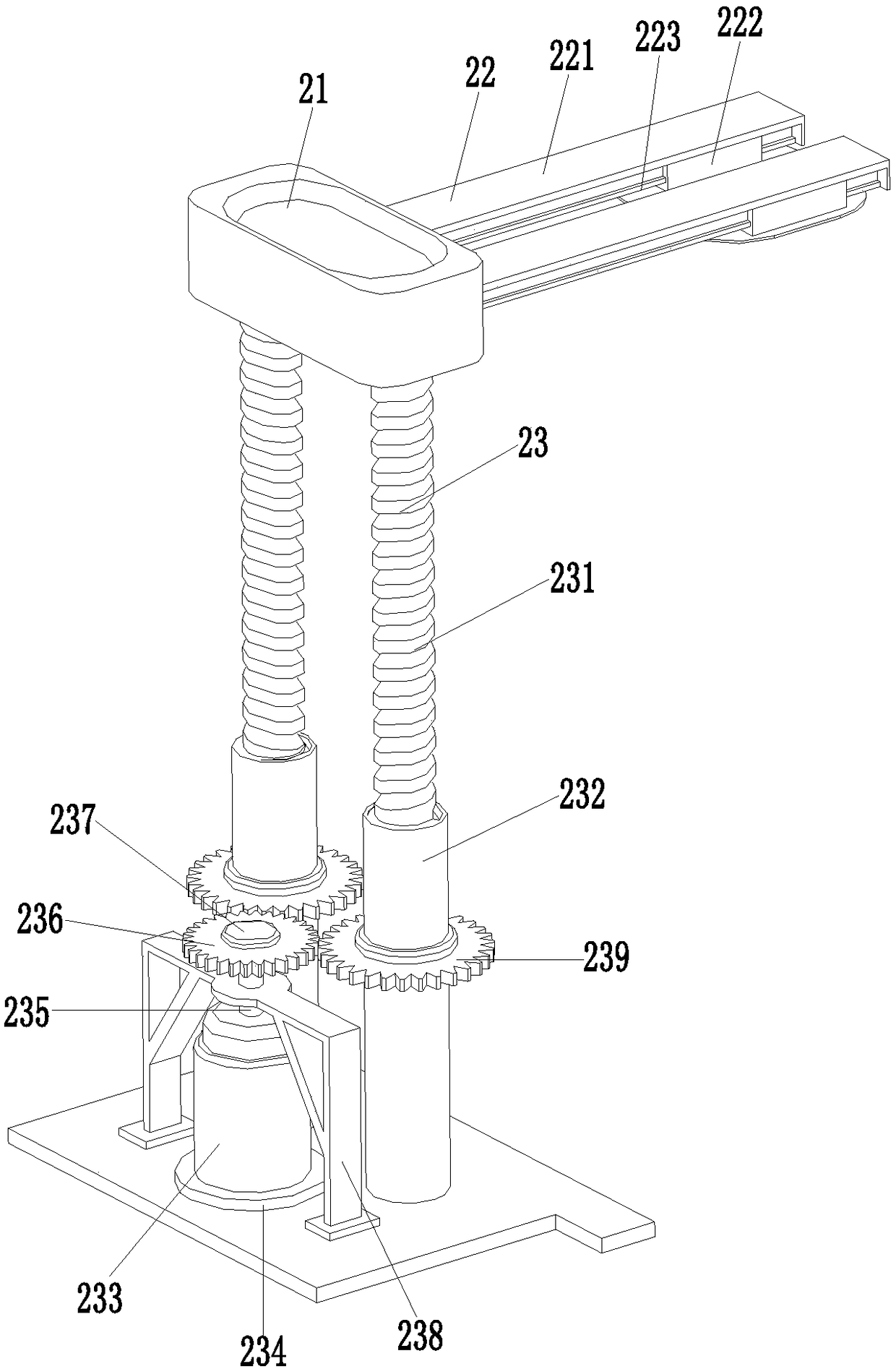

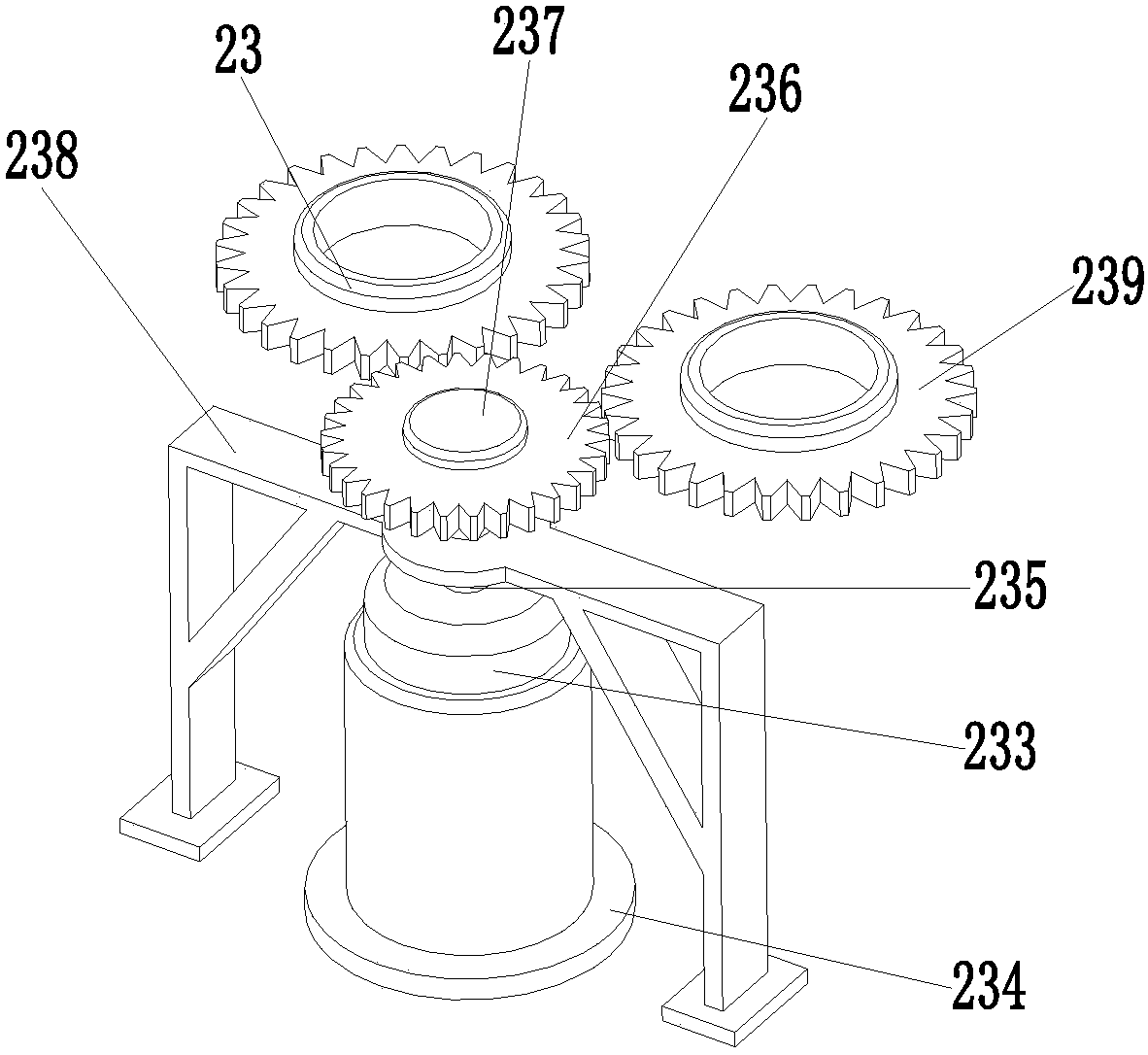

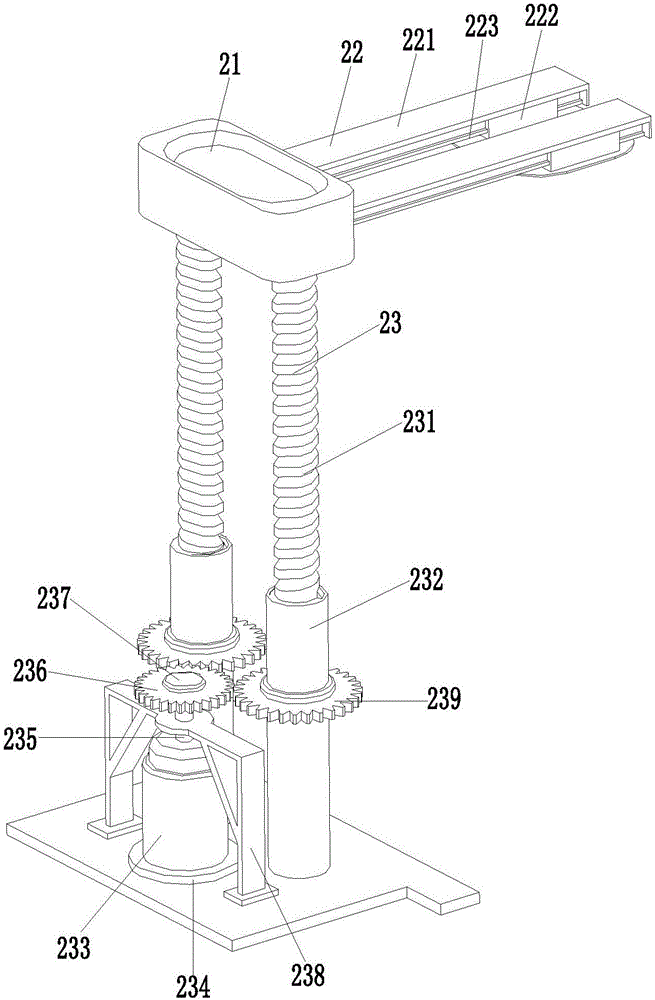

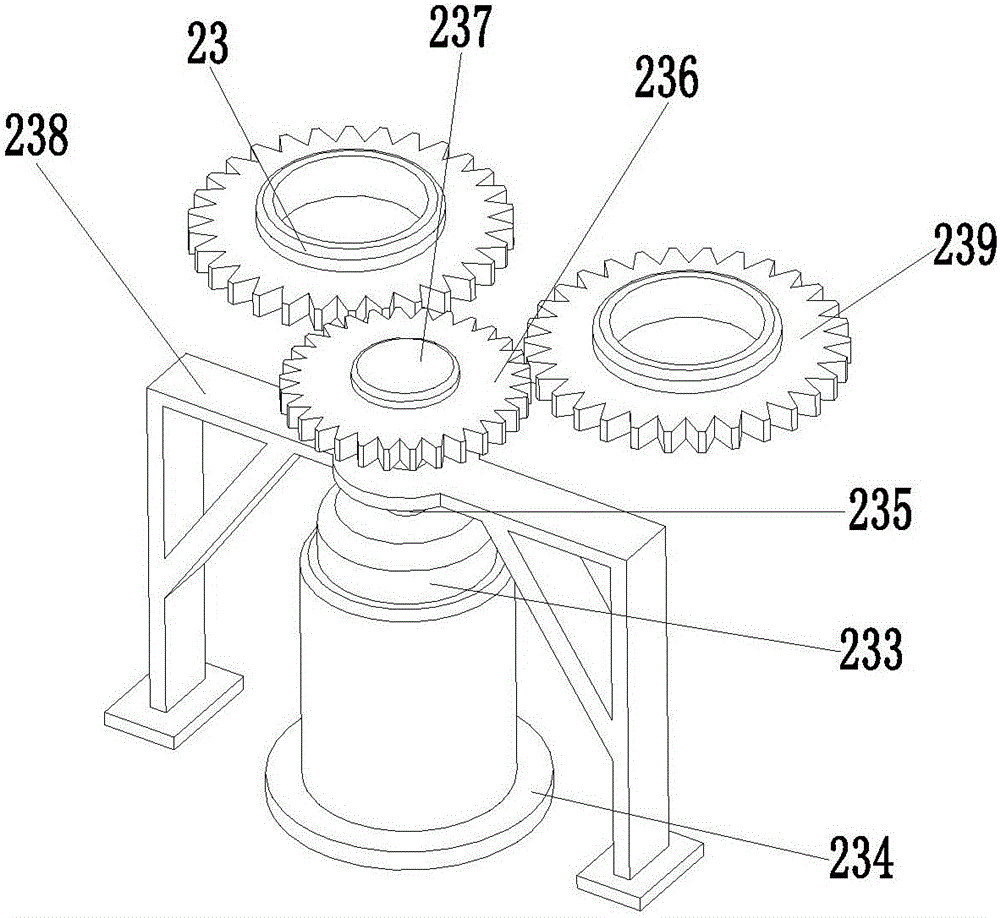

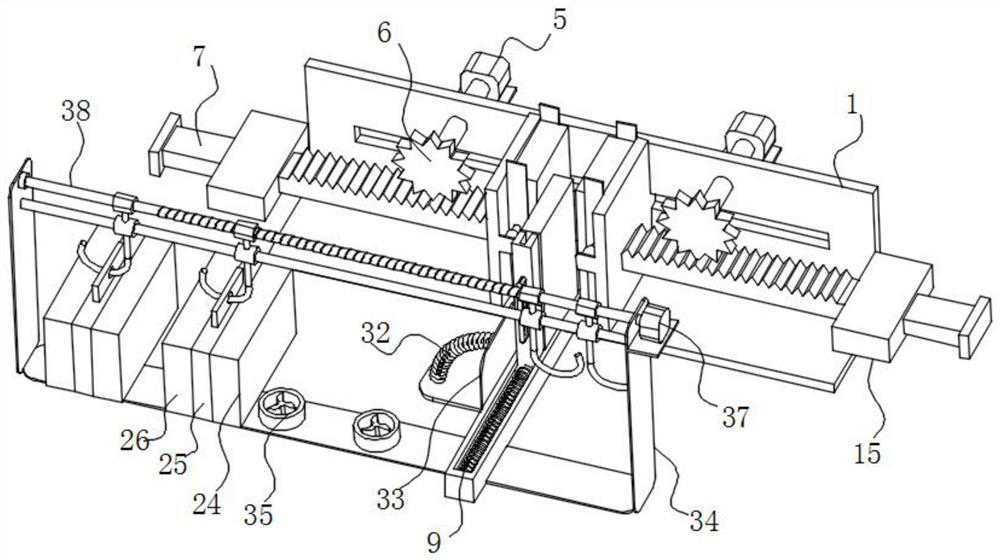

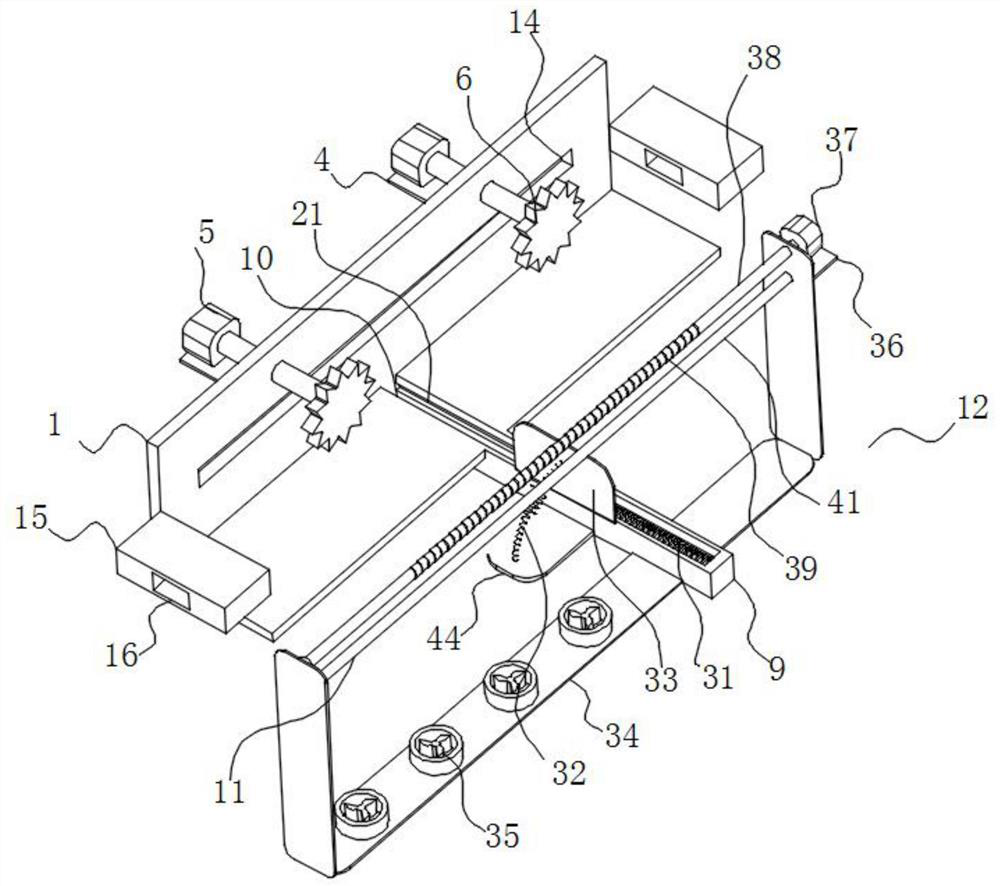

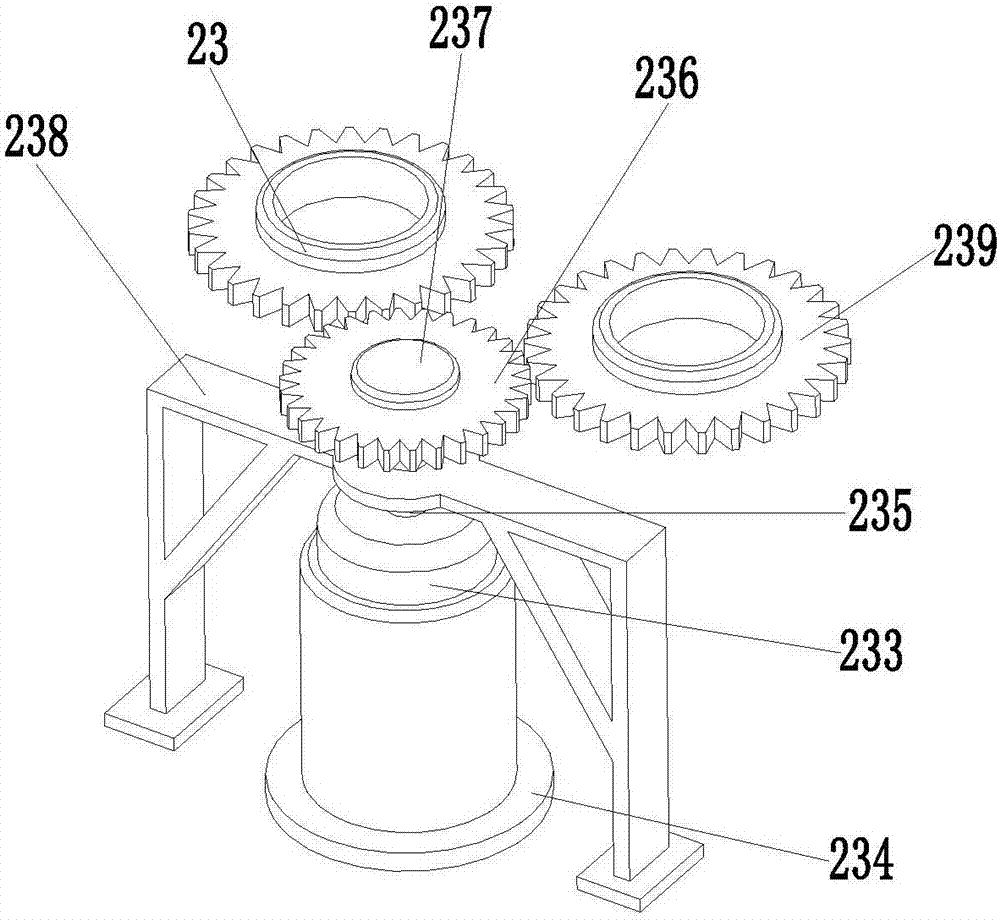

InactiveCN113245424AAvoid movement misalignmentAvoid the problem of lamination seamShaping toolsMetal-working feeding devicesElectric machineGear wheel

The invention discloses a hot press for quickly forming a multilayer building template and a use method, and relates to the technical field of hot presses. The hot press comprises an angle steel mounting plate, a hot press assembly and a building template; the hot press assembly is in sliding fit with the angle steel mounting plate; the surface of a first motor mounting plate is fixedly connected with a synchronous driving motor; one end of a gear rack is fixedly connected with a hot press body; the gear rack is meshed and matched with a rotating gear; the building template is clamped and matched with an L-shaped fixed plate; a conveying frame is fixedly connected to the bottom of a connecting plate; and a conveying frame is in sliding fit with a hanging assembly. An electric telescopic rod is started to drive a second clamping plate to move, so that outer templates are fixedly clamped, and a core plate with the two side surfaces coated with glue is clamped to the L-shaped fixed plate and fixedly inserted through an inserting rod; the core plate is conveyed to the position between the two outer templates under the acting force of an extrusion spring, and two synchronous driving motors are started to drive two gear racks to move reversely and synchronously, so that quick hot-press molding of the building template is realized.

Owner:王泽平

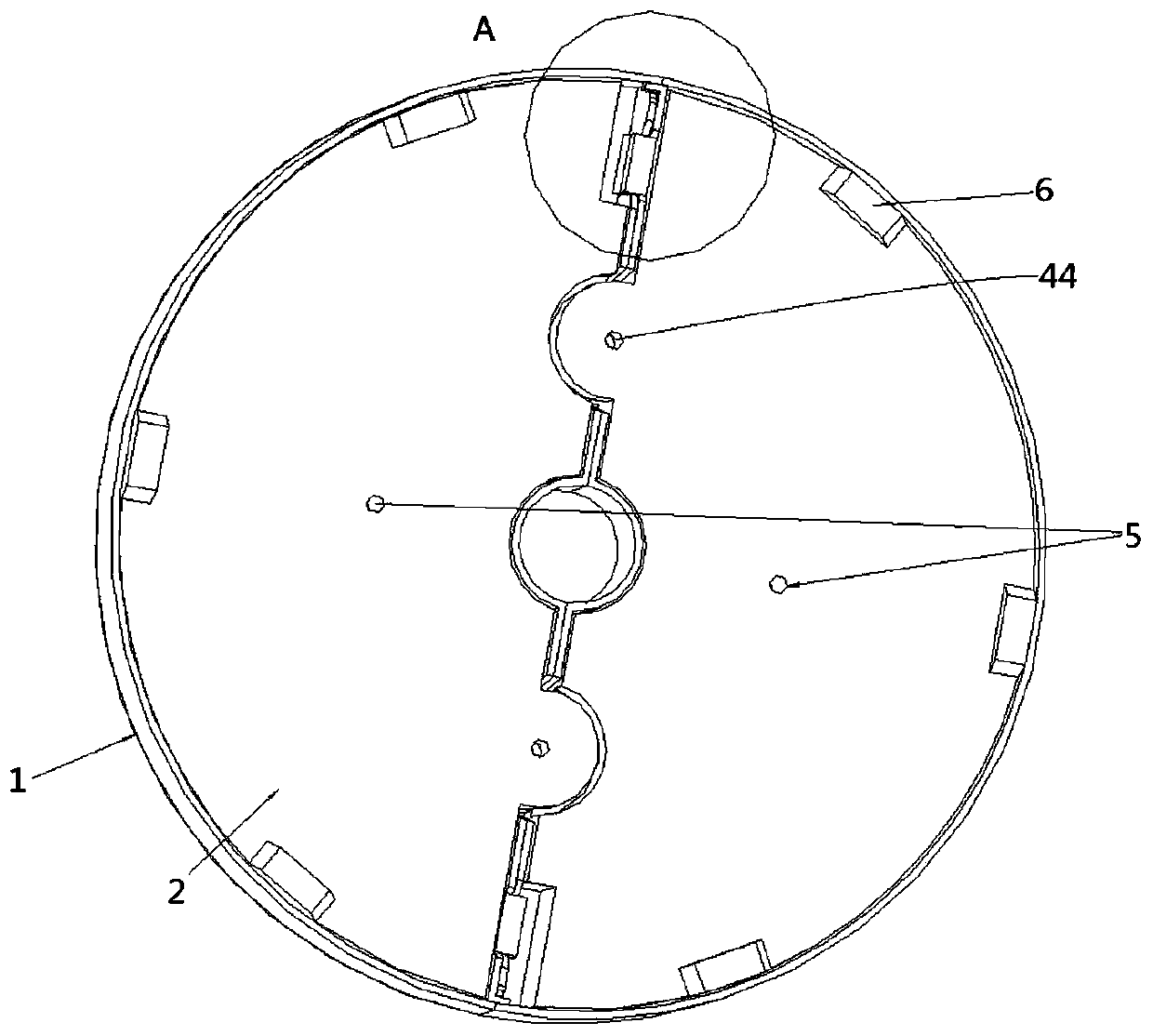

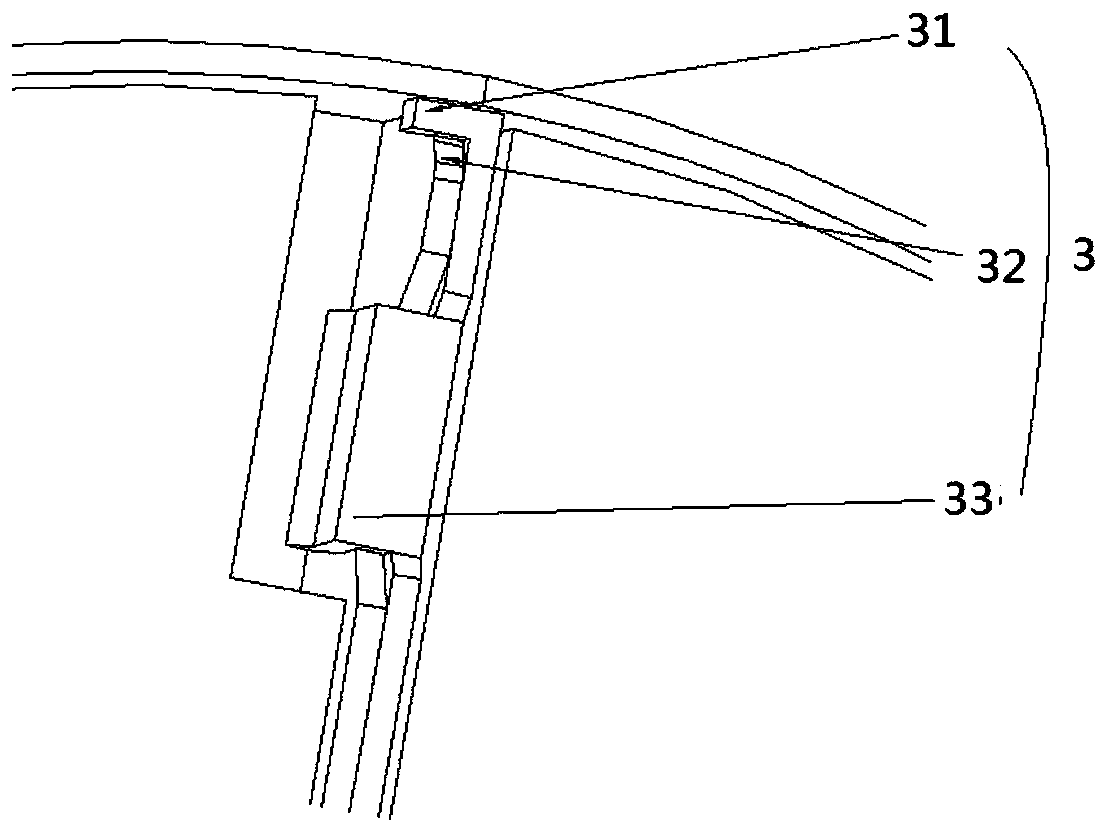

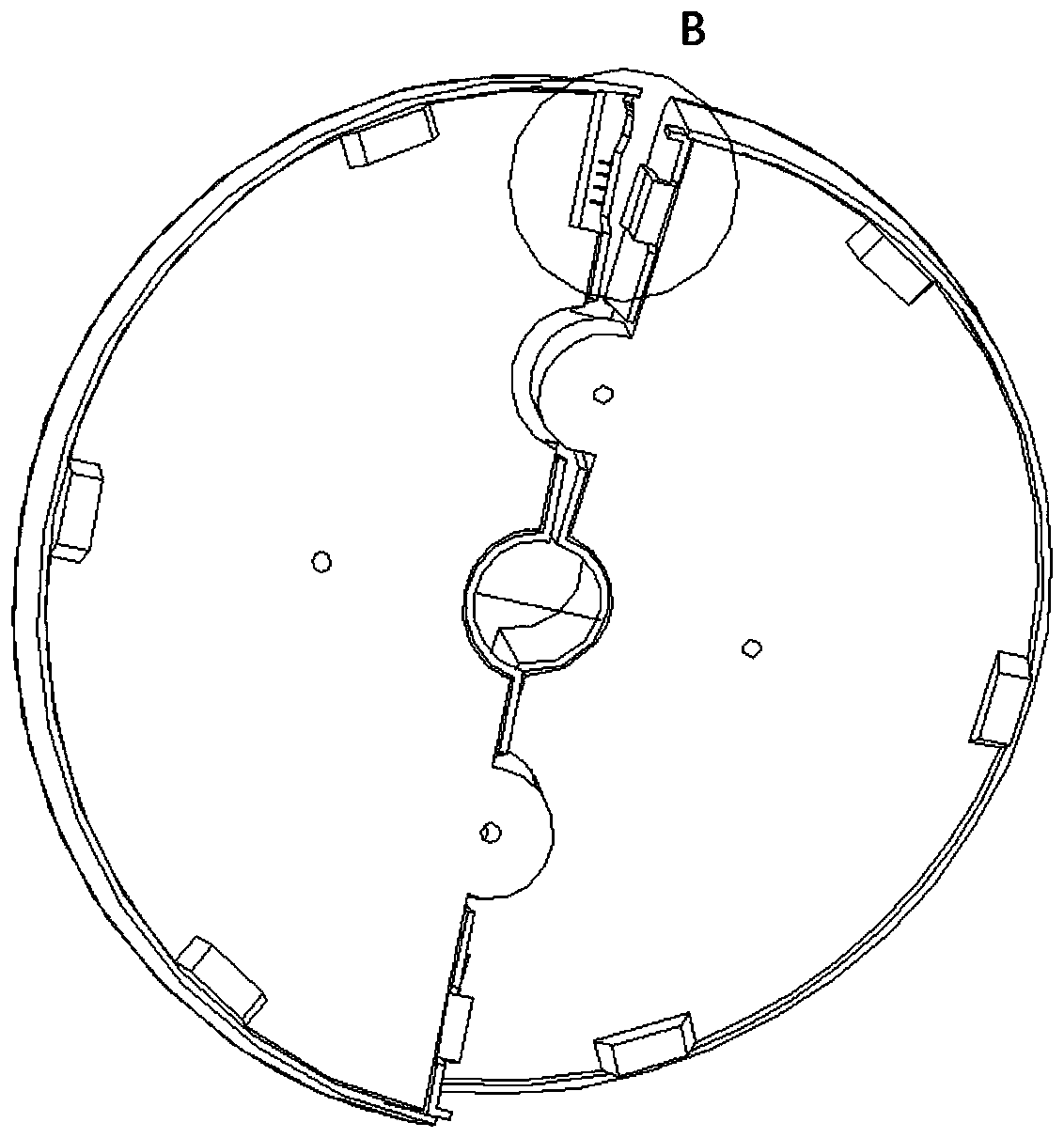

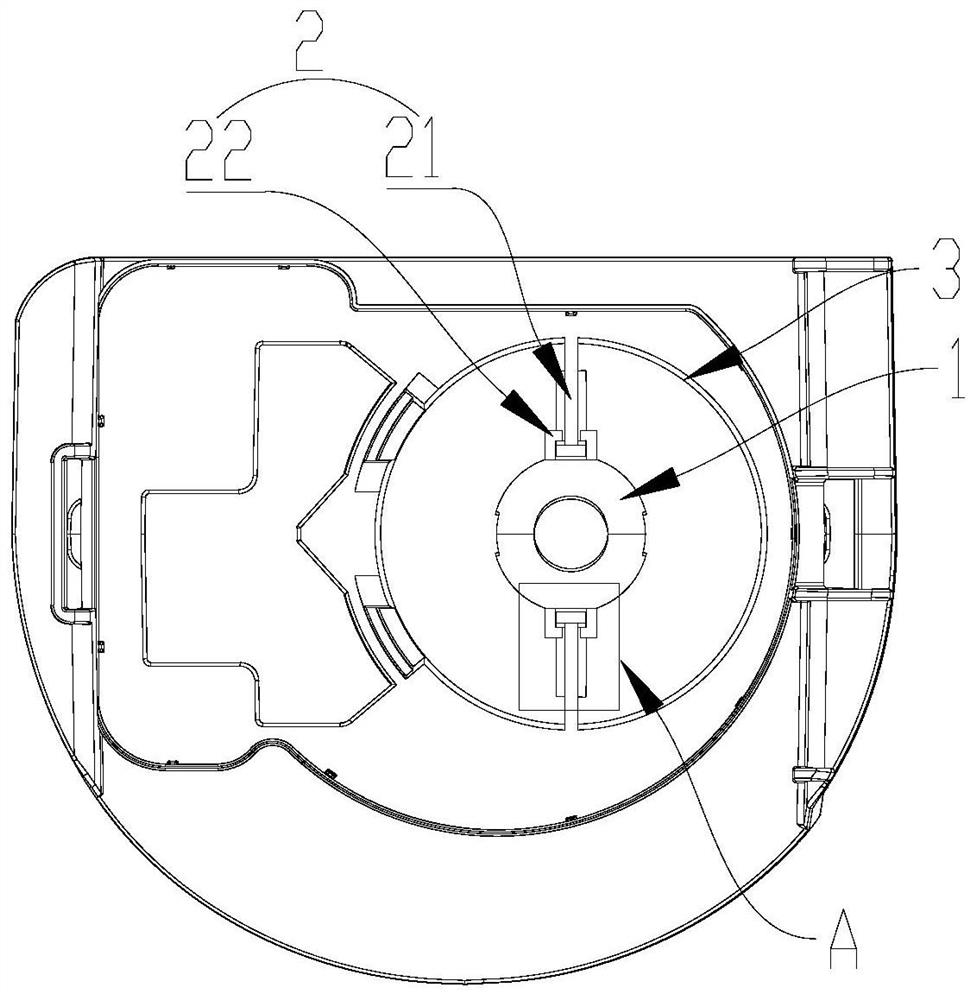

Assembled chassis and fan

PendingCN110701093AReduce volumeTake up less packaging spacePump componentsLighting and heating apparatusRolling chassisAutomotive engineering

The invention provides an assembled chassis and a fan. The assembled chassis comprises sub chassis provided with accommodating tanks, first connecting parts arranged on the sub chassis, counterweightpieces arranged in the accommodating tanks, and second connecting parts arranged on the counterweight pieces, wherein the multiple same sub chassis are assembled as a whole by the first connecting parts; and the multiple same counterweight pieces are assembled as a whole by the second connecting parts. The assembled chassis is low in cost, less in occupied space and high in strength of connectingstructures.

Owner:GREE ELECTRIC APPLIANCES INC

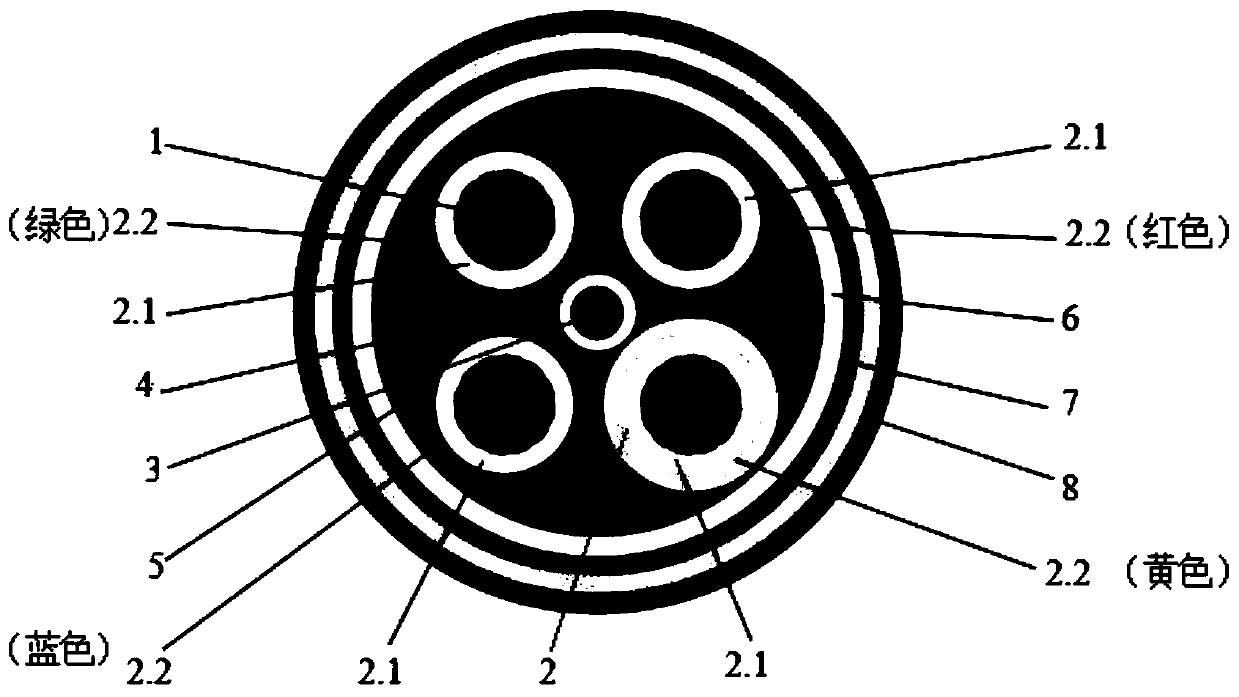

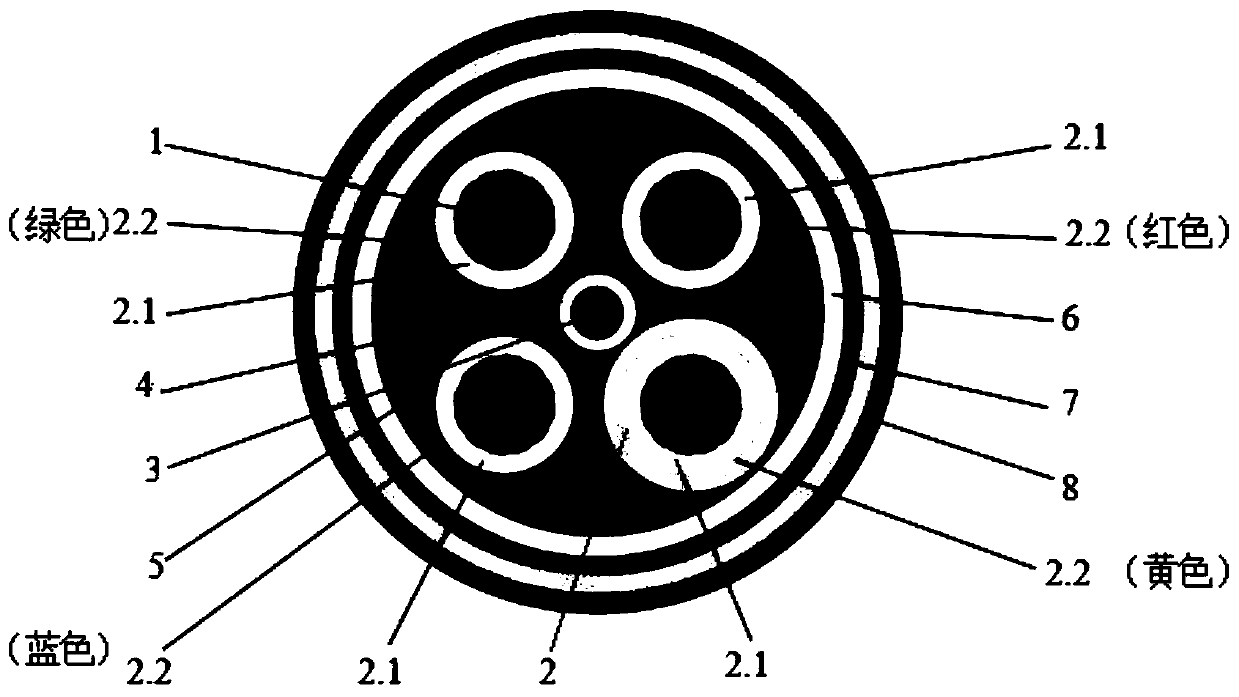

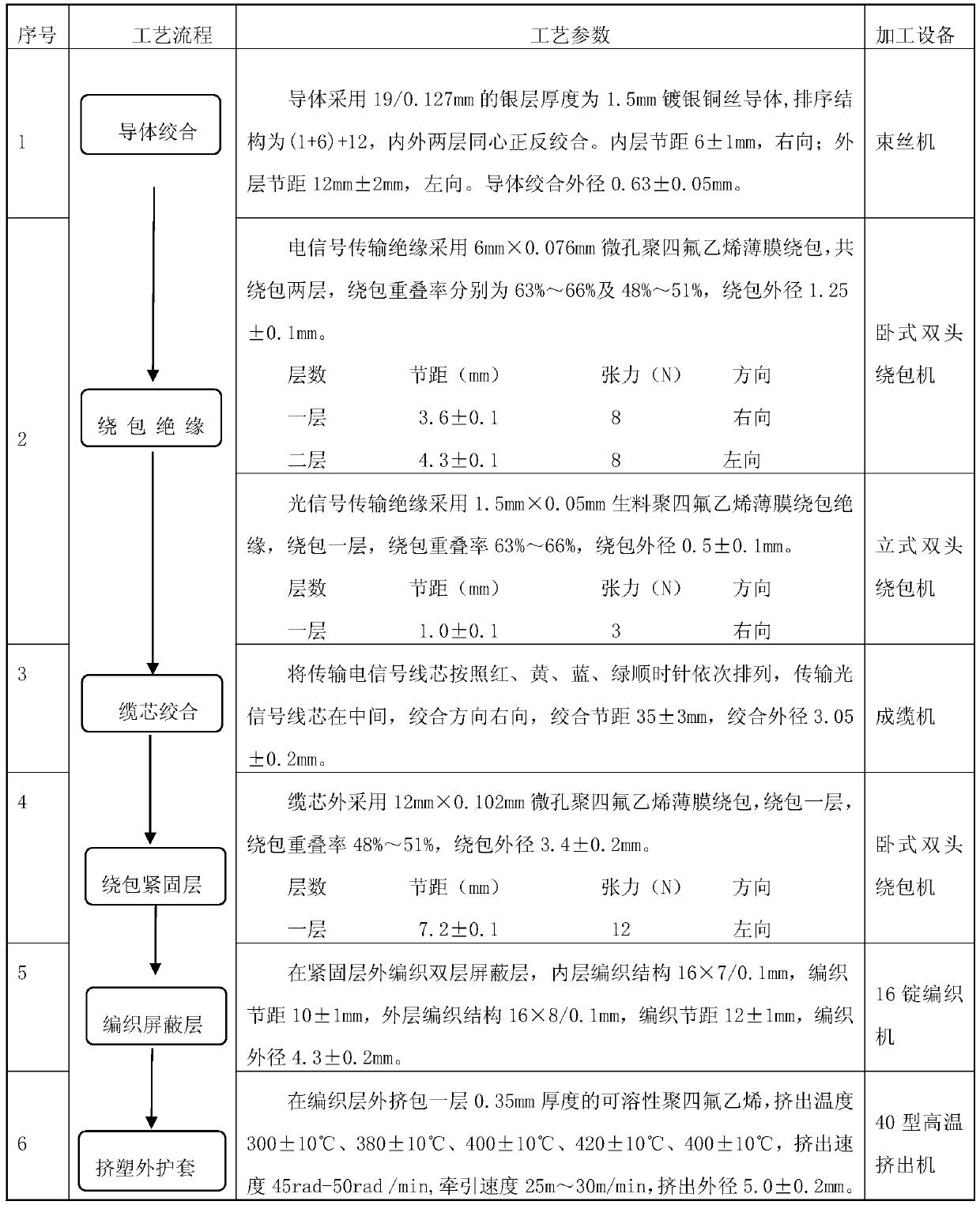

Photoelectric composite data bus and preparation method thereof

PendingCN111145957AGood photoelectric transmission performanceSolve the problem of not being able to transmit at the same timePlastic/resin/waxes insulatorsConductive materialElectrical conductorCopper wire

The invention discloses a photoelectric composite data bus and a preparation method thereof. The photoelectric composite data bus comprises at least three silver-plated copper wire stranded conductorsand a single-mode optical fiber transmission carrier; the silver-plated copper wire stranded conductors are wrapped with a first insulating layer; the single-mode optical fiber transmission carrier is wrapped by a second insulating layer; the silver-plated copper wire stranded conductors are stranded in the peripheral direction of the single-mode optical fiber transmission carrier to form a photoelectric composite cable core; a fastening layer is disposed outside the photoelectric composite cable core in a wrapping manner; a shielding layer is arranged outside the fastening layer; an outer sheath is extruded outside the shielding layer, and the photoelectric composite data bus is obtained through the method of twisting the conductors, wrapping the insulating layer, forming the electric composite cable core, wrapping the fastening layer and the shielding layer, and extruding the outer sheath. According to the invention, the problems that photoelectric signals cannot be transmitted at the same time and are not resistant to high temperature and low temperature are solved, and the technical effects that the bus can transmit the photoelectric signals at the same time, can resist high and low temperatures of-65 DEG C to + 200 DEG C, and can meet the requirement for transmitting photoelectric multi-path signals in aerospace craft tasks and control systems are achieved.

Owner:西安飞机工业(集团)亨通航空电子有限公司

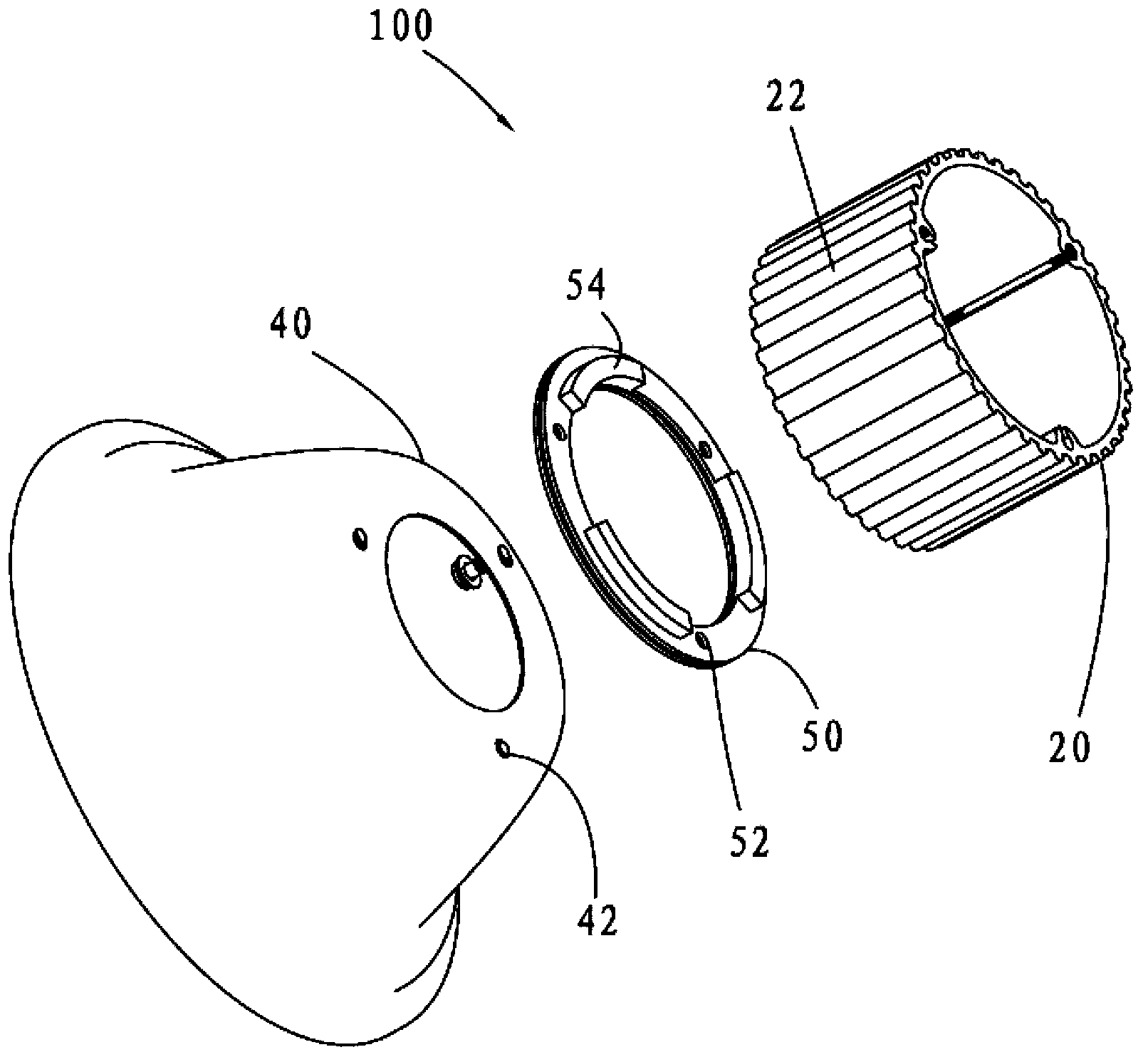

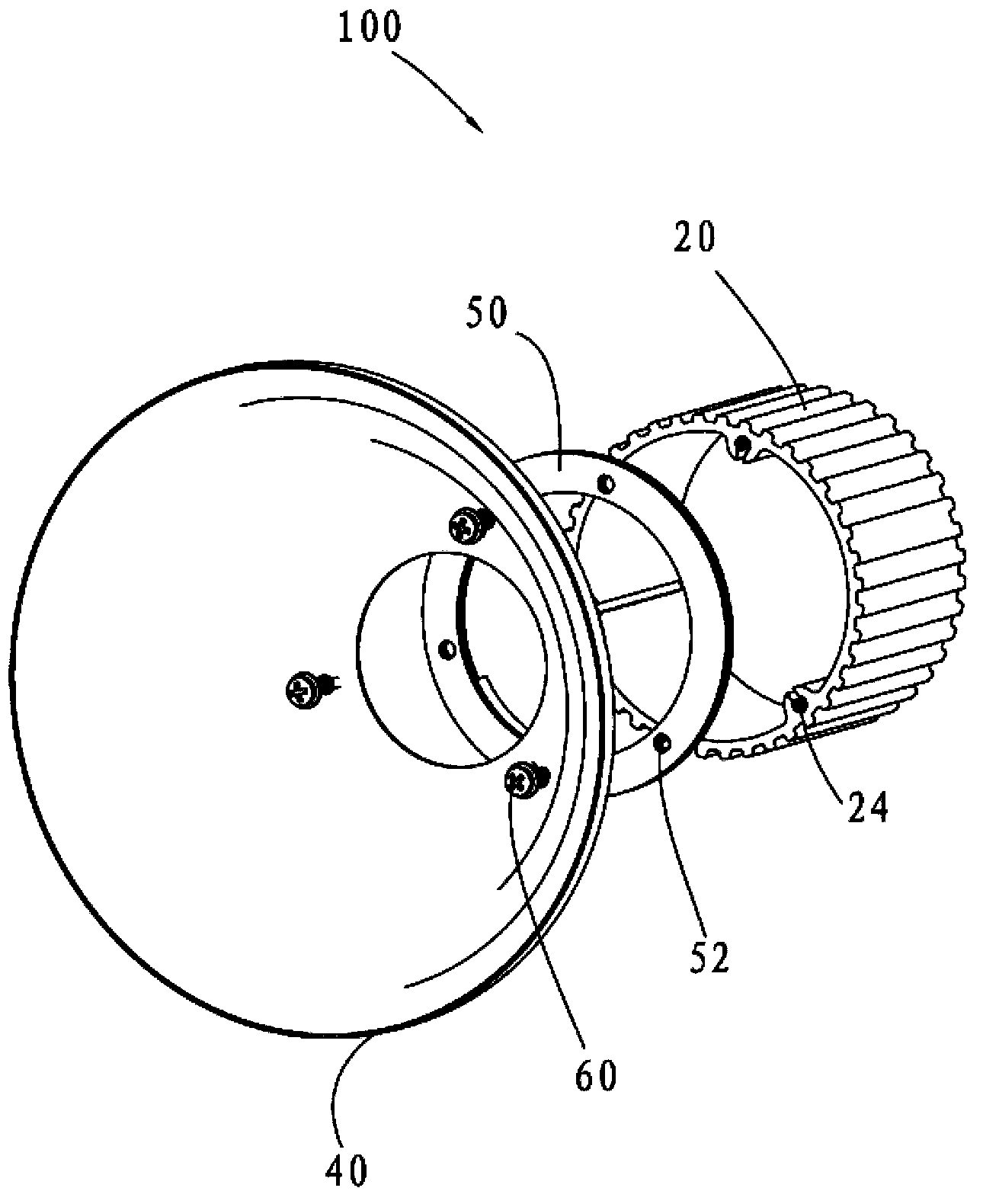

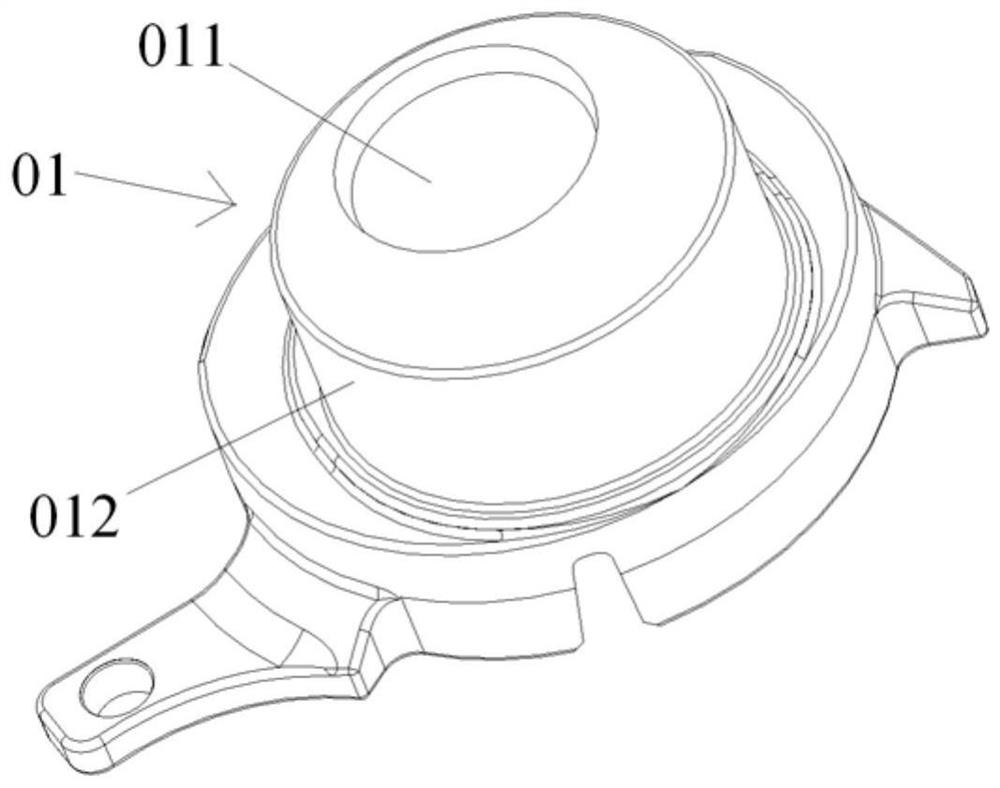

Lamp structure

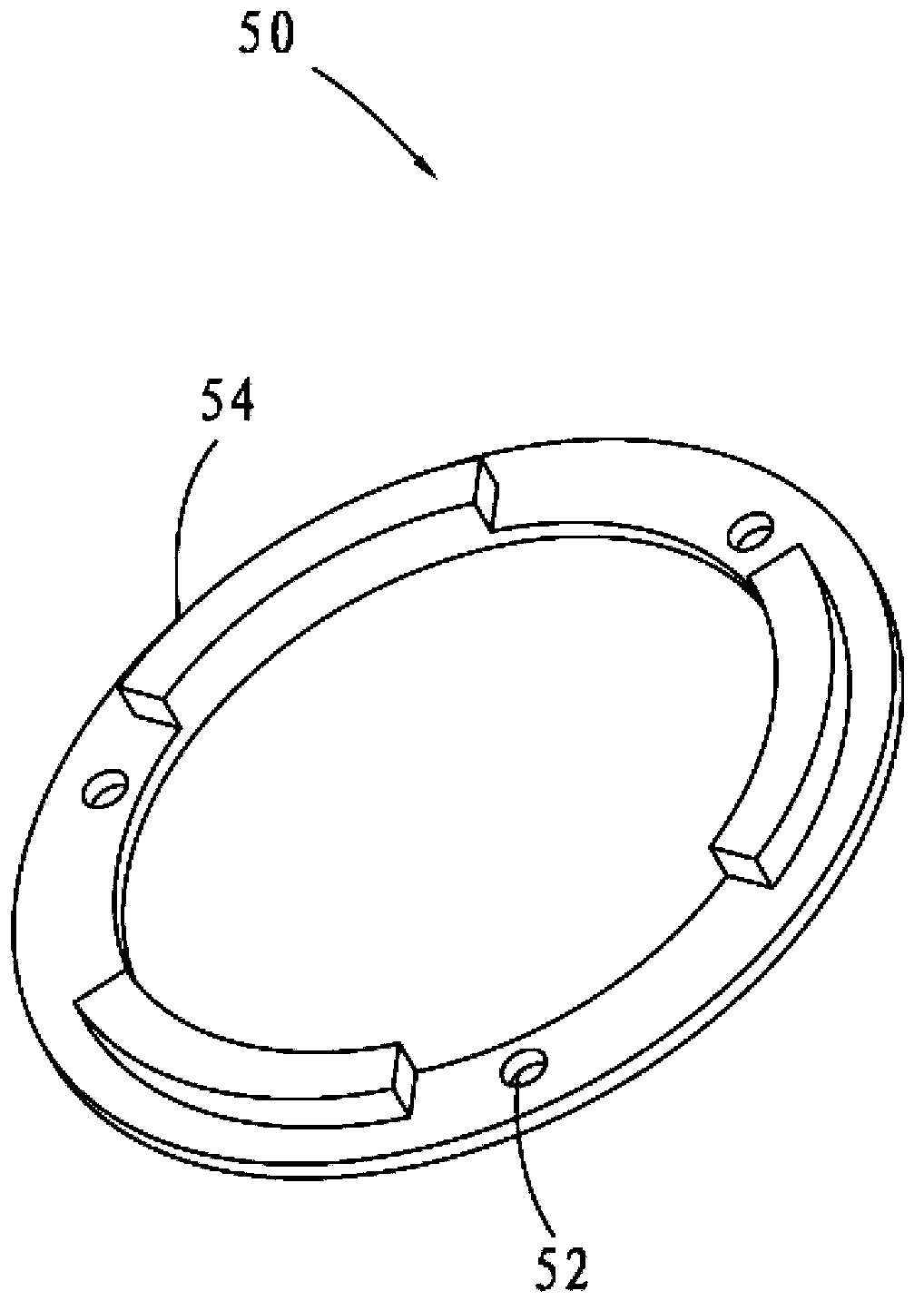

InactiveCN104048184AGuaranteed sealing reliabilityFit tightlyElectric lightingGas-tight/water-tight arrangementsOptoelectronicsRadiation

The invention provides a lamp structure, which comprises a heat radiation device, a reflecting device and a sealing ring structure, wherein the reflecting device is connected with the heat radiation device, the sealing ring structure is positioned between the heat radiation device and the reflecting device and comprises a plurality of positioning elements, and the positioning elements are convexly arranged on the surface, corresponding to the heat radiation device, of the sealing ring structure, are accommodated in the heat radiation structure and are butted against the inner wall of the heat radiation device. When the sealing ring structure is arranged between the heat radiation device and the reflecting device, the positioning elements are butted against the inner wall of the heat radiation device for positioning the position of the sealing ring structure on the heat radiation device, and in addition, the sealing ring structure can be prevented from moving between the heat radiation device and the reflecting device during the assembling operation. Therefore the lamp structure can be conveniently assembled, in addition, the pasting of the sealing ring structure with the heat radiation device in the assembling process is tight, the position deviation cannot be generated, in addition, the compression quantity of the sealing ring structure is uniform, and the sealing reliability of the lamp structure is ensured.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

Electric motor bidirectional synchronous paper inserting robot

ActiveCN106002943ALow costQuality improvementProgramme-controlled manipulatorGripping headsPulp and paper industryProduction quality

The invention relates to an electric motor bidirectional synchronous paper inserting robot. The electric motor bidirectional synchronous paper inserting robot comprises a base, a supporting device, a Stewart parallel mechanism, a paper inserting device and fixing devices. The base is of a T-shaped plate structure. The supporting device is located at the rear side end of the base and fixedly connected with the base. The Stewart parallel mechanism is mounted at the front end of the supporting device. The paper inserting device is located under the Stewart parallel mechanism. The four fixing devices are symmetrically arranged on the upper end face of the base correspondingly and are fixedly connected with the base. The electric motor bidirectional synchronous paper inserting robot can conduct bidirectional synchronous insulation paper inserting operation on motor stators, the whole paper inserting process is operated in a mechanical automation mode, paper inserting is rapid, convenient and high in safety, the uniformity of the paper inserting depth is high, input of labor force is reduced, production cost of motors is reduced, and the production quality of the motors is improved to a certain extent.

Owner:MAANSHAN LANXIN ENVIRONMENTAL PROTECTION TECH CO LTD

Intelligent production cutting device capable of automatically clamping

ActiveCN108972683ASolve the problem of poor automatic clamping effectImprove clamping effectMetal working apparatusShearing machine accessoriesDrive shaftArchitectural engineering

The invention discloses an intelligent production cutting device capable of automatically clamping. The intelligent production cutting device comprises a clamping box, wherein the right side of the top of the clamping box is fixedly connected with a supporting base; the left side of the top of the supporting base is fixedly connected with a transverse plate; the left side of the bottom of the transverse plate is fixedly connected with a protective cover; the left side of the top of the supporting base is fixedly connected with a drive motor; the output shaft of the drive motor is fixedly connected with a drive shaft through a shaft coupler; the left side of the surface of the drive shaft is in sleeve connection with a cutting blade; the right side of the bottom of the inner wall of the clamping box is fixedly connected with a fixed base; the top of the fixed base is fixedly connected with a clamping mechanism; the left side of the inner wall of the clamping box is fixedly connected with a fixed column; the left side of the top of the fixed base is fixedly connected with a supporting plate; the top of the supporting plate is fixedly connected with the top of the inner wall of the clamping box; the left side of the clamping box is equipped with a manual clamping mechanism; and the right side of the fixed column and the left side of the supporting plate are each fixedly connectedwith an anti-collision mechanism. The intelligent production cutting device capable of automatically clamping disclosed by the invention improves clamping precision and processing efficiency.

Owner:湖南明珠集团有限公司

Method for automatically inserting insulation paper into motor stator insulated slot

InactiveCN108347143AReduce investmentLow costApplying solid insulationAir pumpPulp and paper industry

The present invention discloses a method for automatically inserting insulation paper into a motor stator insulated slot. The method comprises the steps of: (1) vertically putting a motor stator at amiddle portion of four fixing devices, moving the motor stator on a linear guide rail through a moving slide block, and when a front end of a fixing clamp is in contact with the outer side wall of themotor stator, fixing the moving slide block onto the linear guide rail through a locking bolt to achieve an effect on fixing of the motor stator; (2) aligning the lower end of the insulation paper toan insulated groove at the inner side wall of the motor stator through a redundant parallel mechanism; and (3) starting a paper insertion electric push rod, and when the pressure of a pressure plateis larger than suction generated by a mini-type air pump, allowing the insulation paper to vertically move downwards along the inner side wall of a C-shaped annular tube and to be vertically insertedinto the insulated groove at the inner side wall of the motor stator, and when the insulation paper is completely inserted into the motor stator insulated groove, driving the vertical upward movementof the pressure plate through contraction movement of the paper insertion electric push rod. The method for automatically inserting insulation paper into a motor stator insulated slot is rapid and convenient to insert paper and reduces the input of labor.

Owner:张雪梅

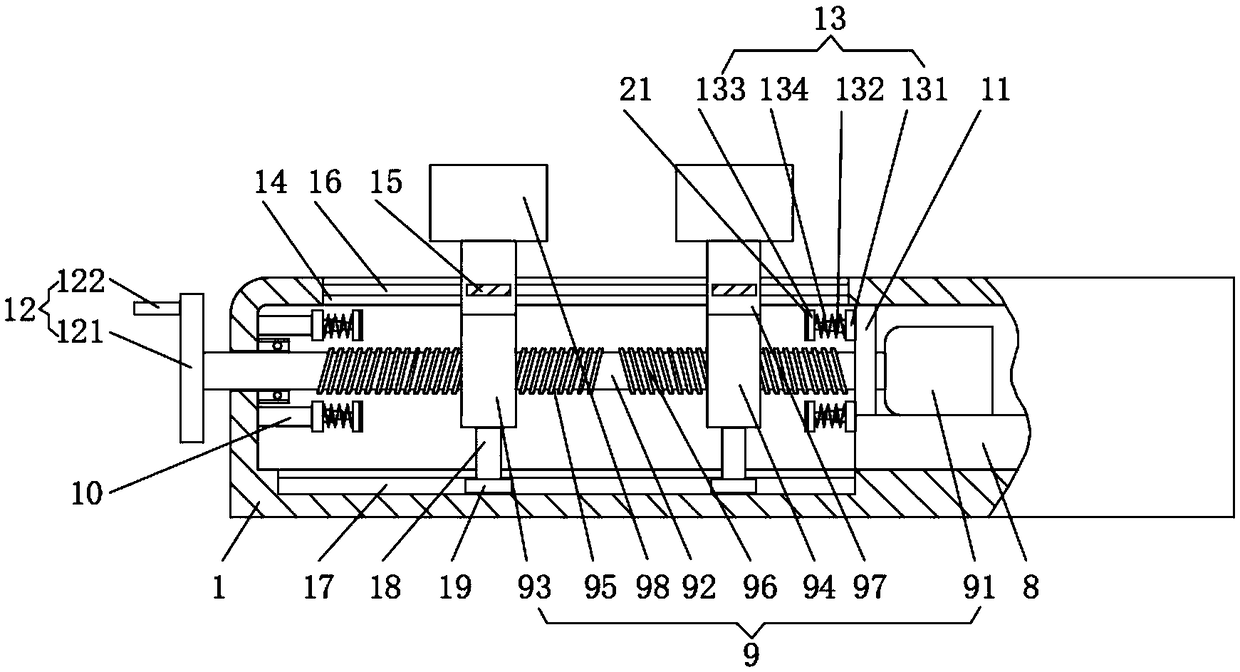

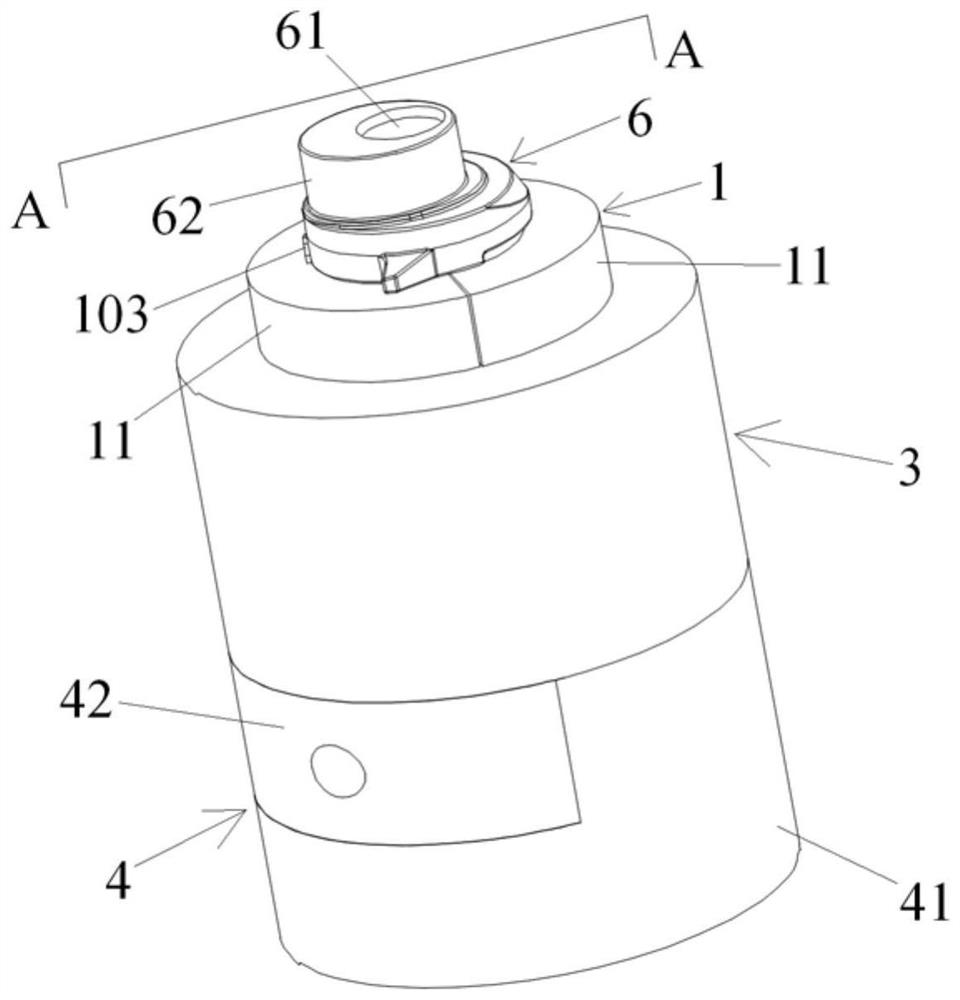

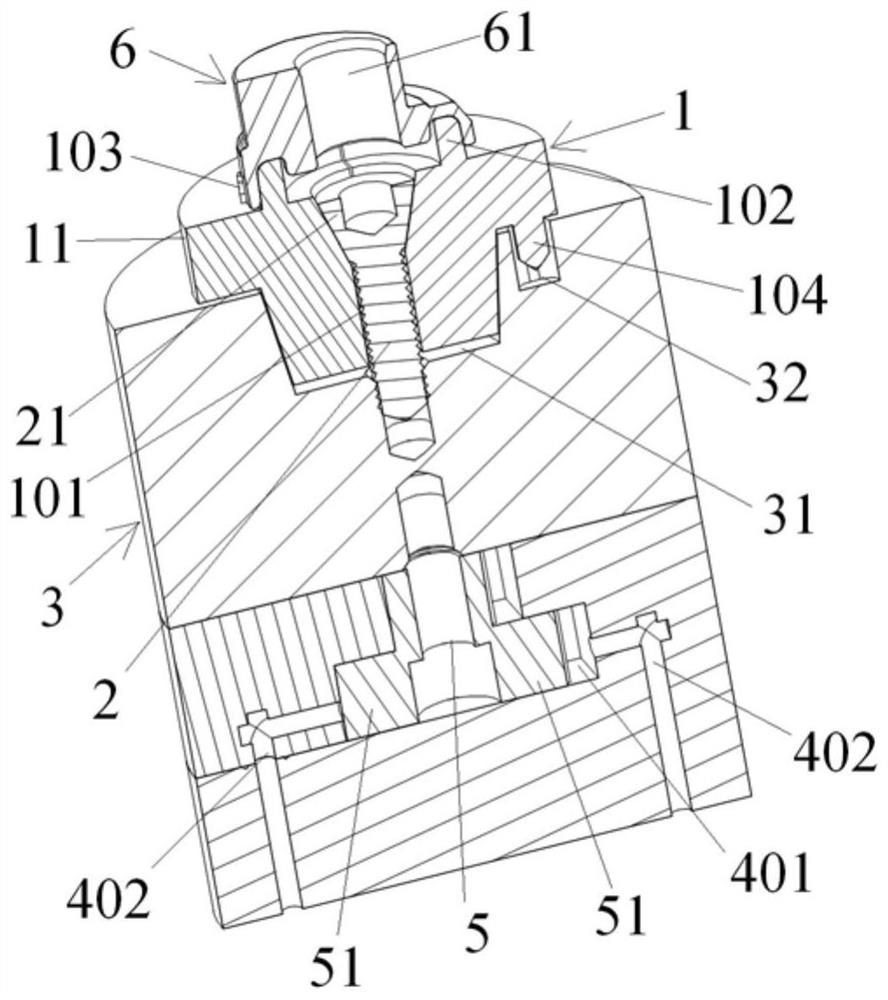

Clamp for eccentric machining

PendingCN111730084AAvoid movement misalignmentGuaranteed eccentricity accuracyExpansion mandrelsScrew threadMachining

The invention relates to the technical field of eccentric part machining, and particularly relates to a clamp for eccentric machining. The invention provides the clamp for eccentric machining in orderto improve the machining precision, the machining quality and the production efficiency of a tensioning wheel and reduce the production cost, wherein a connecting through hole is formed in the middleof an inner supporting clamp, an inner supporting convex ring and a positioning key are arranged at the top of the inner supporting clamp, and a limiting protrusion is arranged on the lower portion of the inner supporting clamp; the inner supporting clamp is installed in a containing groove in the top of a connecting piece, the limiting protrusion is clamped in a limiting groove in the connectingpiece, and an inner supporting screw is inserted into the connecting through hole and a screw hole in the bottom of the containing groove to be in threaded connection with the connecting piece; an eccentric part is fixedly installed at the bottom of the connecting piece, and two eccentric protruding blocks are arranged at the bottom end of the eccentric part and inserted into eccentric clamping grooves; and eccentric flow channels communicating with the eccentric clamping grooves are arranged at the two ends of the eccentric clamping grooves respectively. The clamp for the eccentric machiningis adopted for auxiliary machining, precision is high, efficiency is high, quality is high, and production cost is low.

Owner:SHANGHAI PRECISE IND

A four-degree-of-freedom industrial robot for welding waste-retaining plates of sewage treatment pipelines

ActiveCN105798502BAdjustable positionFlexible movementWelding/cutting auxillary devicesAuxillary welding devicesWastewaterSewage

The invention relates to a four-freedom-degree industrial welding robot for a sewage treatment pipeline and a feculence-blocking plate. The four-freedom-degree industrial welding robot comprises a base, a lifting device, a rotary drive device, a redundant parallel mechanism, a welding execution device and a fixing device. The lifting device is located at the rear side end of the base, the rotary drive device is located over the lifting device, the redundant parallel mechanism is located below the front end of the rotary drive device, the welding execution device is located under the redundant parallel mechanism, and the welding execution device is fixedly connected with the redundant parallel mechanism. The fixing device is symmetrically arranged on the upper end face of the base and is fixedly connected with the base. According to the industrial welding robot, the sewage treatment pipeline and the feculence-blocking plate can be subject to full-automatic intelligent welding work, during welding, the whole position is adjustable, the local position is flexible in motion, stability is high, meanwhile the function that welding wire feeding is achieved while welding is carried out is achieved, the welding efficiency is high, and the welding quality is good.

Owner:CHINA UNION ENG

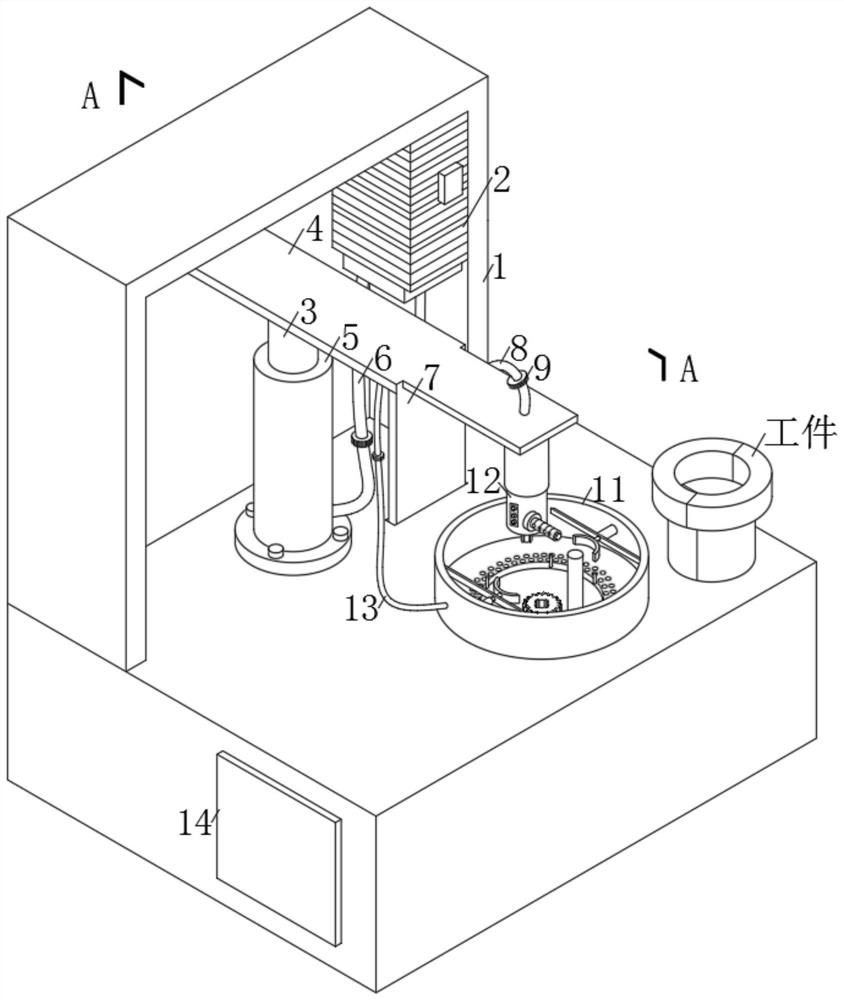

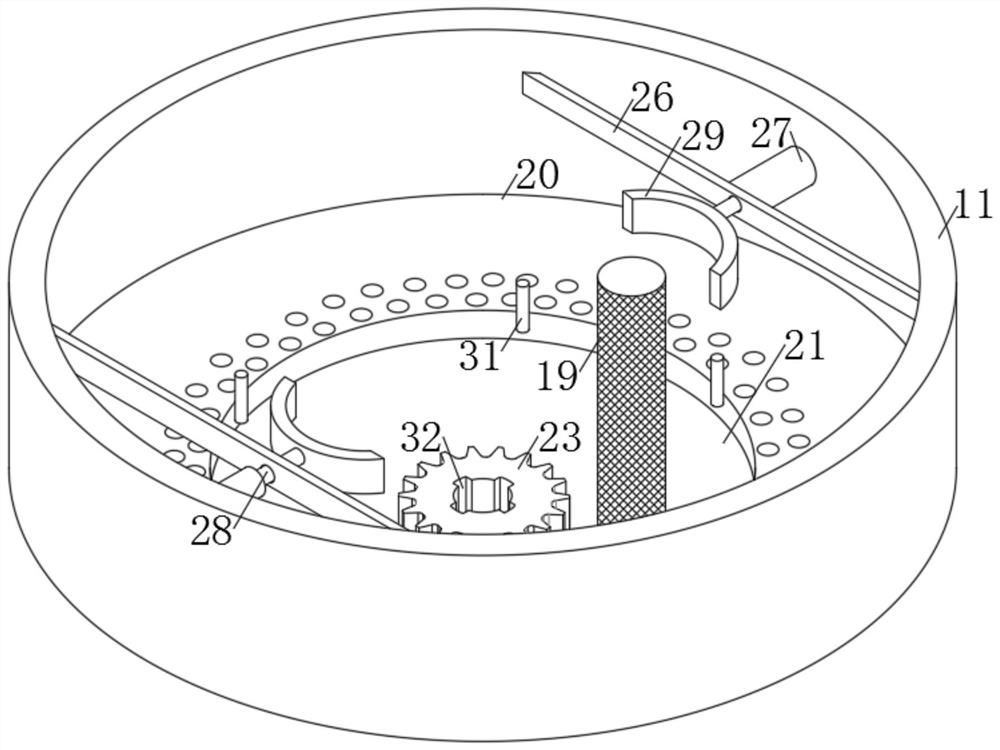

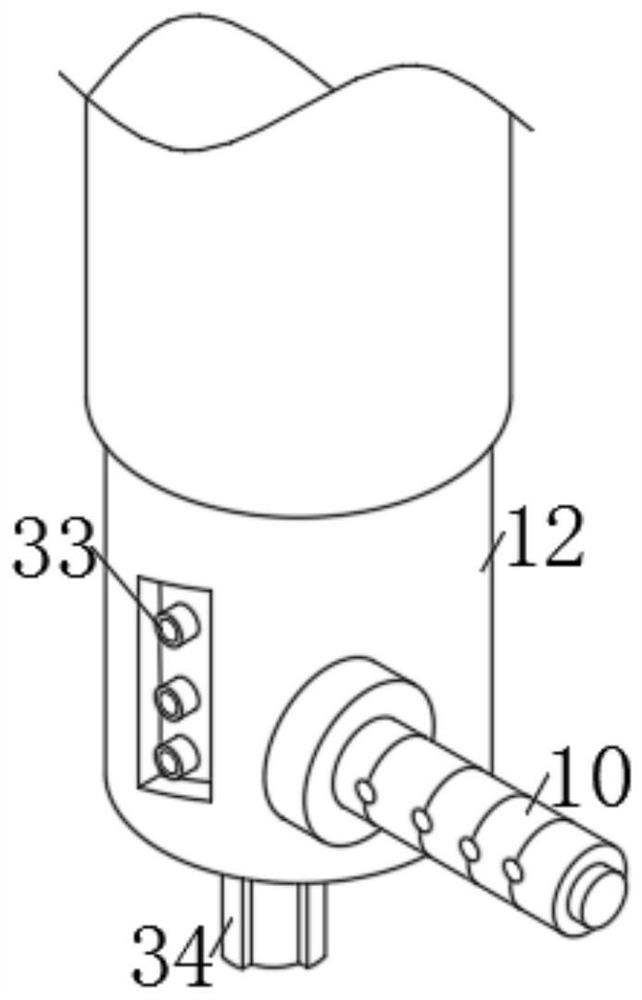

Processing device for household metal fittings and processing method thereof

InactiveCN114714088AAvoid movement misalignmentRealize multi-position welding workEdge grinding machinesGrinding drivesDevice PlateGear wheel

The invention discloses a household metal fitting machining device and a machining method thereof, and relates to the field of metal fitting machining, the household metal fitting machining device comprises a device base, a placing frame and a welding head, the placing frame is rotatably mounted on the upper side of the device base, the welding head is located over the circle center of the placing frame, and a rotating part comprises a first rotating mechanism and a second rotating mechanism; the driving gear is connected with a power source which drives the driving gear to rotate along the axis, the power source is a motor, the driving gear rotates and polishes a workpiece through meshing of the rotating gear and the inner gear, the second rotating mechanism comprises a connecting groove and a connecting shaft, and the driving gear enables rotation transposition of the welding head through meshing of the connecting groove and the connecting shaft. The first air cylinder enables the device plate to drive the welding head to vertically move through the first air rod, the second moving mechanism comprises a moving plate, the moving plate drives the polisher to vertically move under the action of the device plate, multi-position welding is achieved, synchronous polishing of the interior of a workpiece is achieved, machining procedures are reduced, and working efficiency is improved.

Owner:江苏百欧货架有限公司

Automatic glass cleaning machine for manufacturing curved glass of automobile side window

ActiveCN113894127AEasy to debugSimple height adjustmentDrying gas arrangementsFlexible article cleaningEngineeringMechanical engineering

The invention relates to an automatic glass cleaning machine for manufacturing curved glass of an automobile side window. The automatic glass cleaning machine comprises a cleaning device and an air drying device which are arranged front and back, the cleaning device comprises a lower frame and an upper frame which can be adjusted up and down relative to the lower frame, and a conveying mechanism is arranged in the middle of the lower frame; a primary cleaning unit and a secondary cleaning unit are sequentially arranged in the conveying direction of the conveying mechanism, the primary cleaning unit and the secondary cleaning unit are each provided with a plurality of brush mechanisms at intervals in the conveying direction, the two sides of the brush mechanisms are provided with pressing wheel type pressing mechanisms respectively, and the pressing mechanisms are connected to the middle of the upper frame in a swinging mode; the air drying device is arranged at the outlet end of the secondary cleaning unit; and a constant-temperature spraying system is arranged in the conveying direction of the conveying mechanism. According to the cleaning machine, the gap between the brush mechanisms can be adjusted according to the appearance of to-be-cleaned glass, the adjusting mode is simple and reliable, the swing type pressing mechanisms are matched, the glass can be stably conveyed and cleaned, and a good cleaning effect is achieved.

Owner:福州新富创智能科技有限公司

Atomization energy-gathering device and humidifier

PendingCN113803821AAvoid movement misalignmentLarge amount of fogLighting and heating apparatusSpace heating and ventilation detailsPhysicsEngineering

The invention relates to the technical field of humidifiers, in particular to an atomization energy gathering device and a humidifier. The humidifier comprises energy gathering parts and a sliding structure, the number of the energy gathering parts is at least two, the energy gathering parts are arranged in a sleeve of the humidifier, and the at least two energy gathering parts have an energy gathering state in which the energy gathering parts float upwards and are mutually closed inwards to form an energy gathering ring and an opening state in which the energy gathering parts move downwards and are mutually opened outwards; the number of sliding structures is at least two, each energy gathering part is matched with one sliding structure, each sliding structure comprises a first sliding assembly and a second sliding assembly which are connected in a sliding mode, and the first sliding assemblies are arranged on the inner wall of the sleeve; and the second sliding assembly is arranged on the side, facing the inner wall of the sleeve, of the energy gathering part. According to the atomization energy gathering device, the mist outlet amount is increased when the water level is high, and the mist outlet amount cannot be reduced when the water level is low.

Owner:GREE ELECTRIC APPLIANCES INC

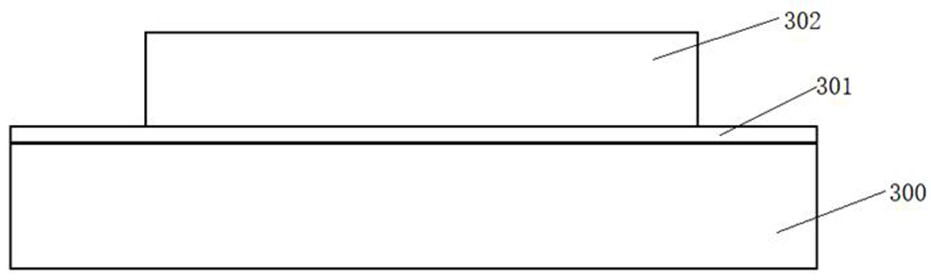

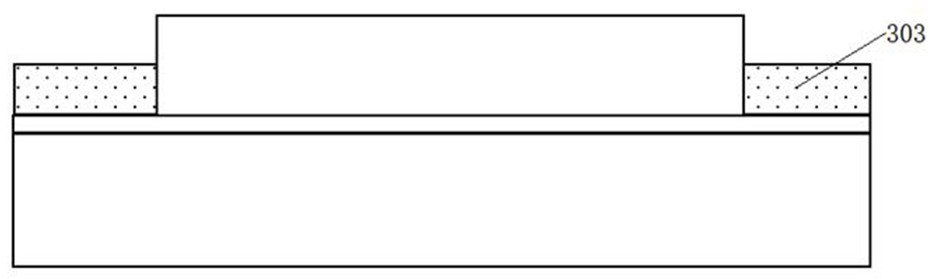

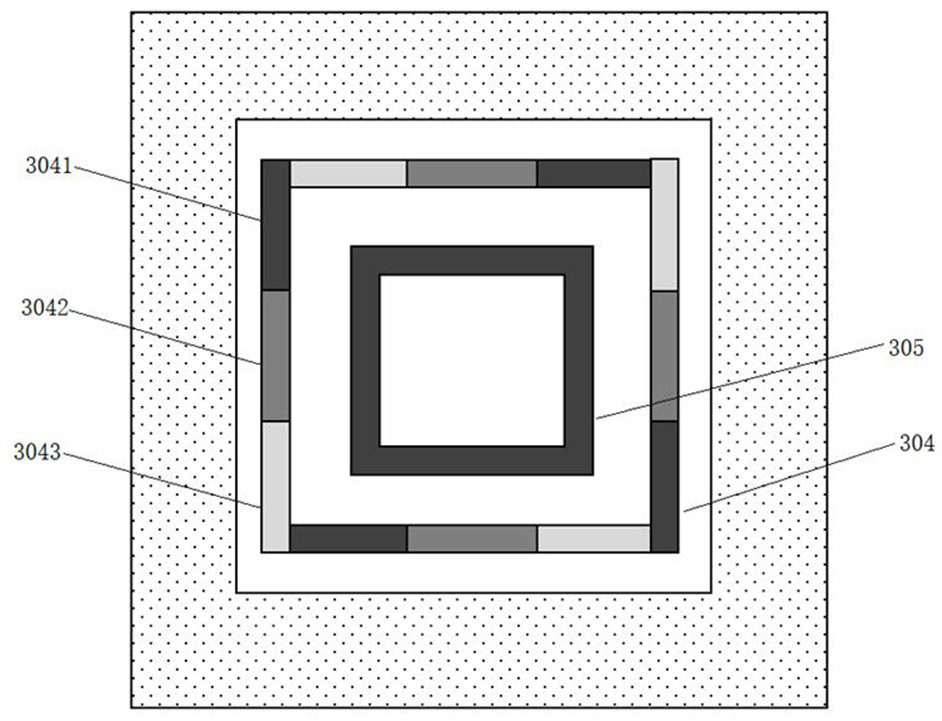

A chip stack and its preparation method

ActiveCN113506749BAvoid glue overflowHigh bonding strengthSemiconductor/solid-state device detailsSolid-state devicesMechanical engineeringChip stacking

The present invention relates to a chip stack and a preparation method thereof. By forming a first annular protrusion and a second annular protrusion on the top surface of the first semiconductor element, the first annular protrusion surrounds the second annular protrusion, the first annular protrusion includes a plurality of a first sub-bump region, a plurality of second sub-bump regions and a plurality of third sub-bump regions, and the top surface of the second semiconductor element is etched to A first annular groove, a second annular groove, and a plurality of third grooves connecting the first annular groove and the second annular groove are formed on the top surface of the first annular groove, and the first annular groove surrounds the A second annular groove, followed by embedding a first annular protrusion into the first annular groove by using an adhesive material, and embedding the second annular protrusion into the second annular groove.

Owner:NANTONG HUIFENG ELECTRONICS TECH

A woven bag production line

ActiveCN110552076BPrevent penetrationEnsure equal sharePaper article packagingCircular loomsProduction lineAssembly line

The invention relates to the field of production of woven bags, in particular to a production assembly line for woven bags. The production assembly line comprises a ribbonfil production device, a circular weaving device, a roll printing device, a cutting sewing device and a packaging device. Raw materials are heated, melted, extruded and formed into ribbonfil through the ribbonfil production device, the circular weaving device weaves the continuous cylindrical woven bags through the ribbonfil, the woven bags are printed with patterns and characters through the roll printing device, and the printed woven bags are cut off and sewn through the cutting sewing device, then discharged from the cutting sewing device and automatically packaged through the packaging device finally. The production assembly line for the woven bags has the advantages that the production assembly line for the woven bags can achieve production of the woven bags, the overall production efficiency and automation degree are high, the product quality is good, and the production assembly line is suitable for large-scale popularization.

Owner:温州平塑包装有限公司

Motor insulation paper inserting machine with high paper insertion efficiency

InactiveCN108377072AReduce investmentLow costApplying solid insulationMotor insulationPulp and paper industry

The invention discloses a motor insulation paper inserting machine with high paper insertion efficiency. The motor insulation paper inserting machine comprises a supporting device, a redundant parallel mechanism and a paper insertion device; the redundant parallel mechanism is installed at the front end of the supporting device; the paper insertion device is located just below the redundant parallel mechanism; the supporting device comprises a lifting block, a horizontal moving device and a vertical lifting device; the redundant parallel mechanism comprises a fixed platform, a moving platform,a first branch chain and a second branch chain; and the paper insertion device comprises a micro air pump, a suction nozzle , a C-shaped bushing, a pressing plate, a paper insertion electric push rod, a reset spring, a mounting post and insulation paper. With the motor insulation paper inserting machine of the invention adopted, insulation paper insertion operation can be performed on a motor stator. The motor insulation paper inserting machine has the advantages of quick and simple operation and high paper insertion efficiency.

Owner:张雪梅

A paper-inserting industrial robot with a motor

ActiveCN106002942BLow costQuality improvementProgramme-controlled manipulatorGripping headsPulp and paper industryAutomation

The invention relates to a novel motor paper inserting industrial robot. The novel motor paper inserting industrial robot comprises a base, a supporting device, a redundant parallel mechanism, a paper inserting device and fixing devices. The supporting device is located at the rear side end of the base and is fixedly connected with the base. The redundant parallel mechanism is mounted at the front end of the supporting device. The paper inserting device is located under the redundant parallel mechanism. The four fixing devices are symmetrically arranged on the upper end face of the base correspondingly and are fixedly connected with the base. The novel motor paper inserting industrial robot can conduct insulation paper inserting operation on motor stators, the whole paper inserting process is operated in a mechanical automation mode, paper inserting is rapid, convenient and high in safety, the uniformity of the paper inserting depth is high, and input of labor force is reduced; and production cost of motors is reduced, folded insulation paper can be sucked through the suction principle, compared with one-way paper inserting, the paper inserting efficiency is improved by one time, operation is rapid and easy, the paper inserting efficiency is high, and the production efficiency and quality of the motors are improved.

Owner:叶青

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com