Clamp for eccentric machining

An eccentric and fixture technology, applied in the direction of expanding the mandrel, etc., can solve the problems of bumps and scratches, affecting the processing quality of the tensioner, and affecting the smoothness treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

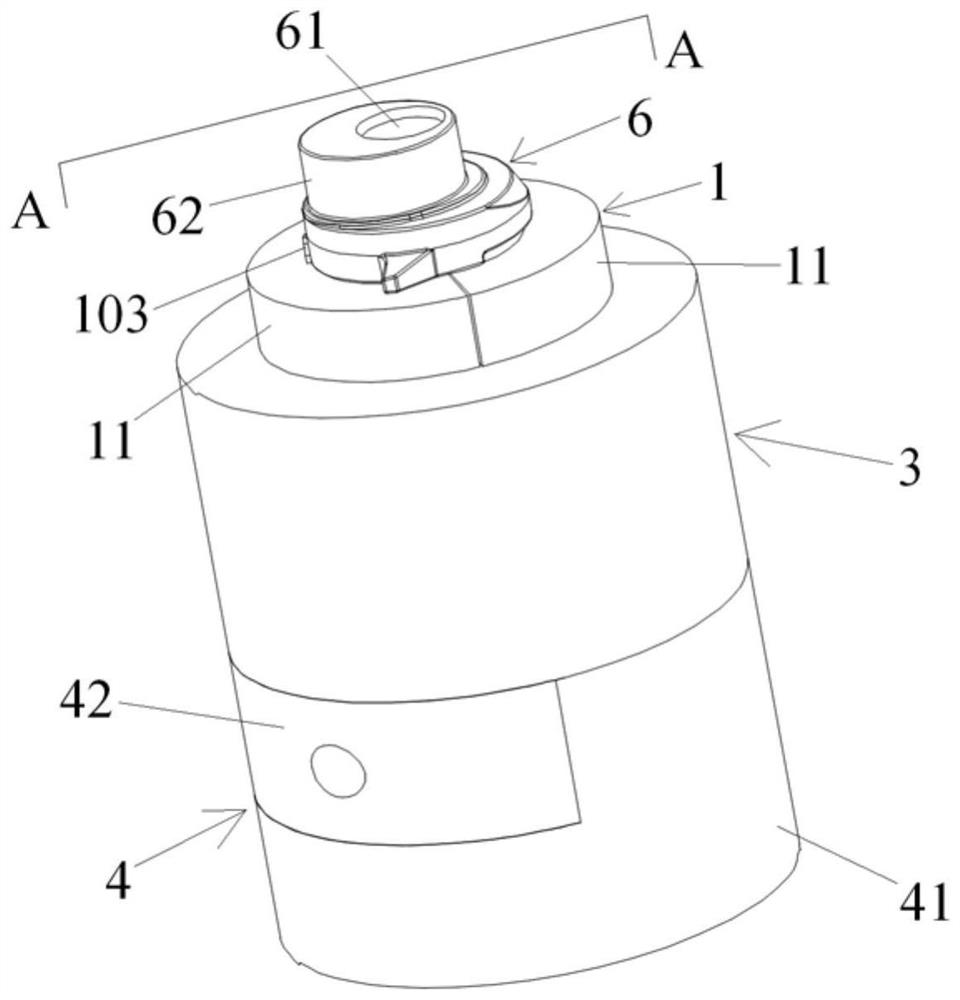

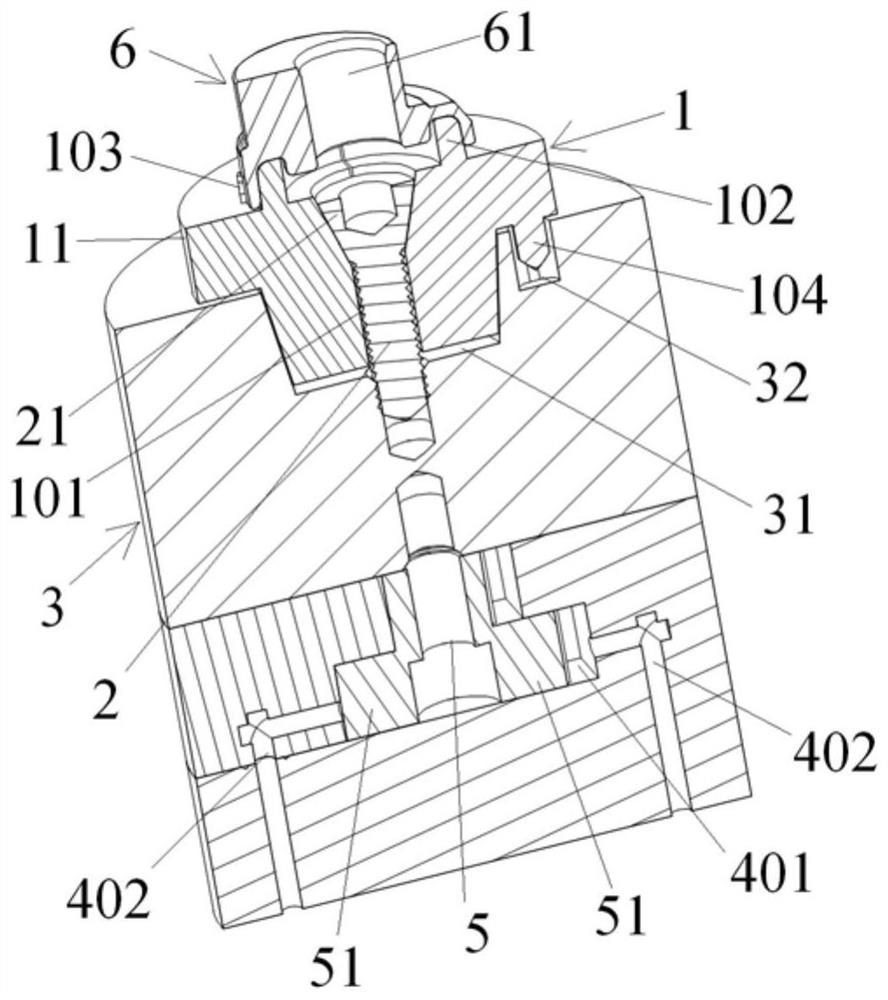

[0018] Below, combine Figure 1-5 The jig for eccentric machining of the present invention will be described in detail.

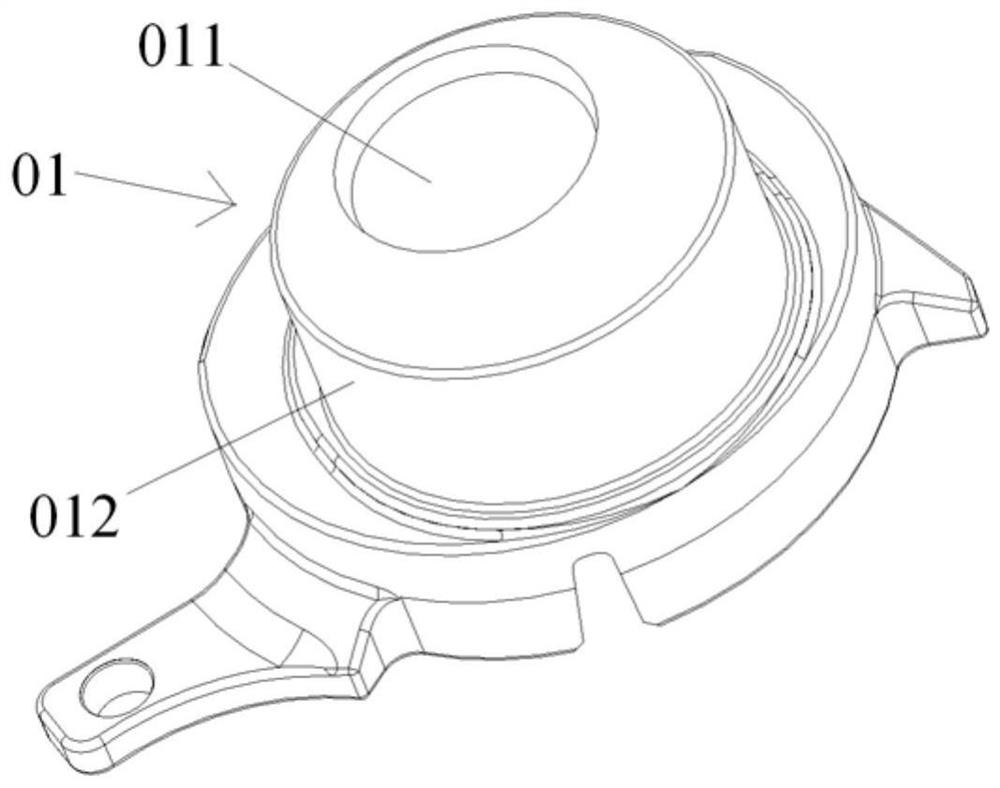

[0019] Such as Figure 1-5 As shown, the jig for eccentric processing of the present invention includes a jig for eccentric processing including an inner support clip 1 , an inner support screw 2 , a connecting piece 3 , a limiting piece 4 and an eccentric piece 5 . Wherein, the middle part of the inner support clip 1 is provided with a connection through hole 101, and the top of the inner support clip 1 is provided with an inner support convex ring 102 and a positioning key 103, the inner support convex ring 12 is concentric with the connection through hole 101, and the positioning key 103 is located inside On the outer side of the supporting ring 102 , the lower part of the inner supporting clip 1 is provided with a limiting protrusion 104 . The inner support clip 1 is installed in the receiving groove 31 on the top of the connecting piece 3, the limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com