Patents

Literature

362results about "Circular looms" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

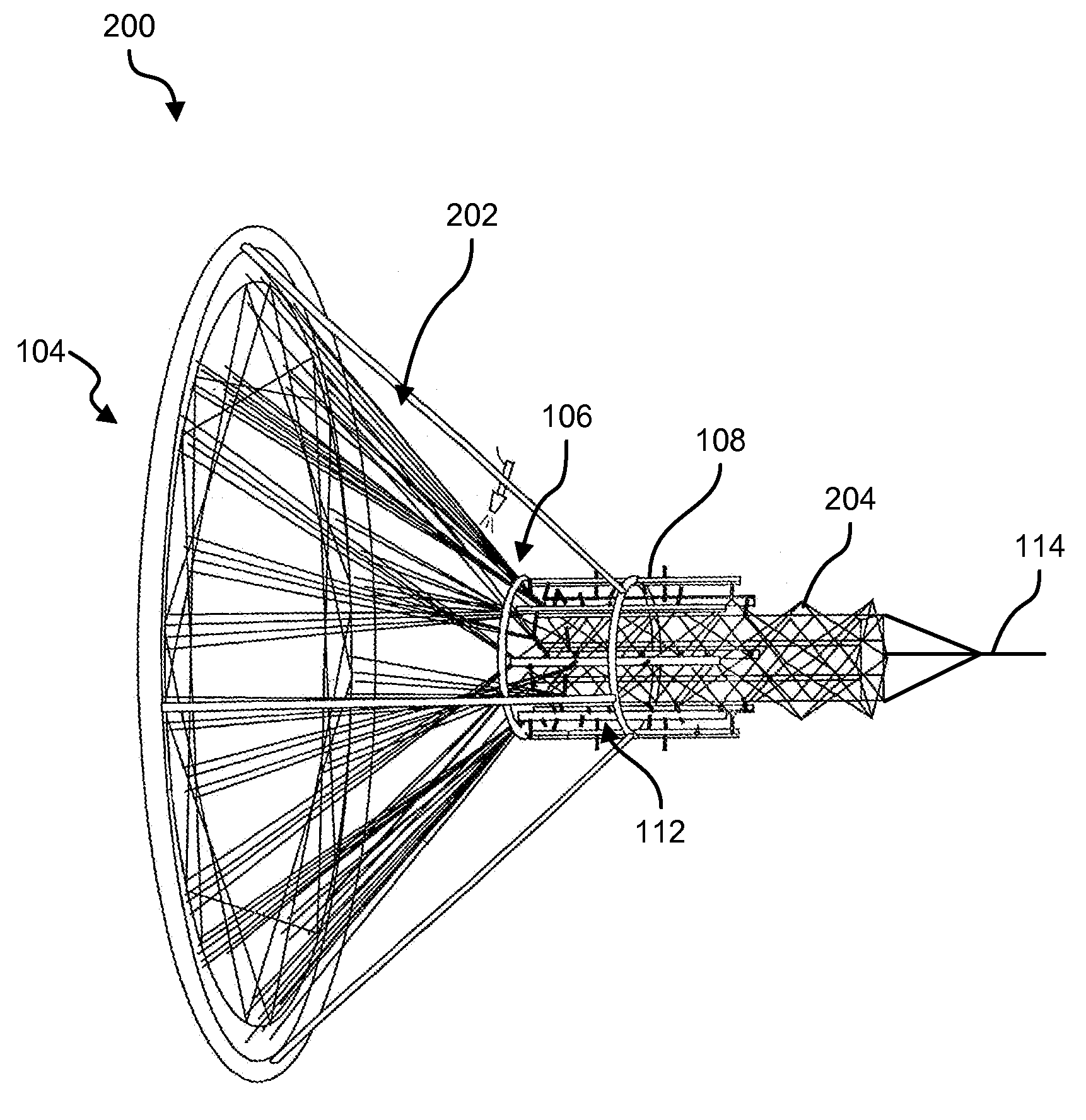

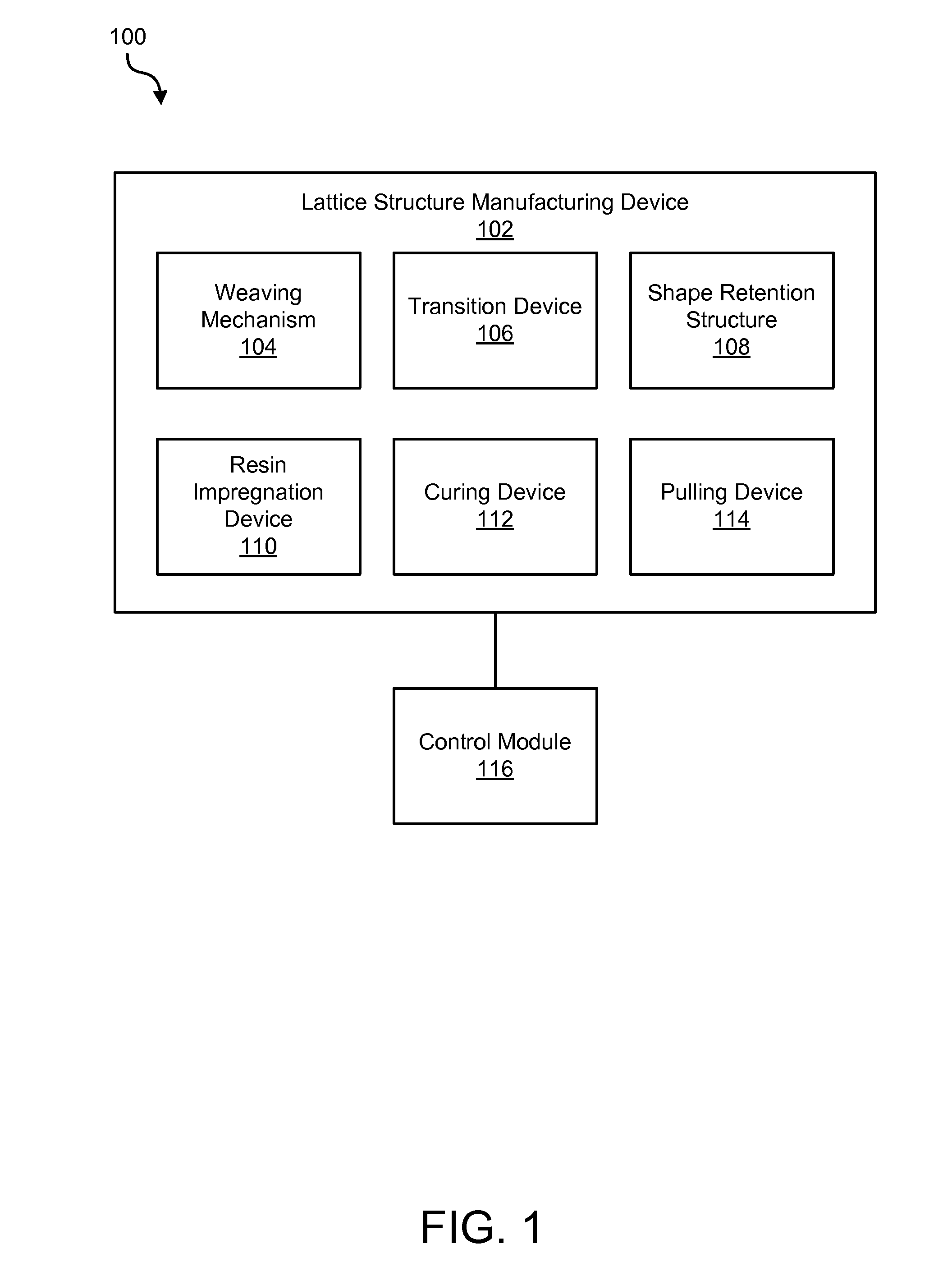

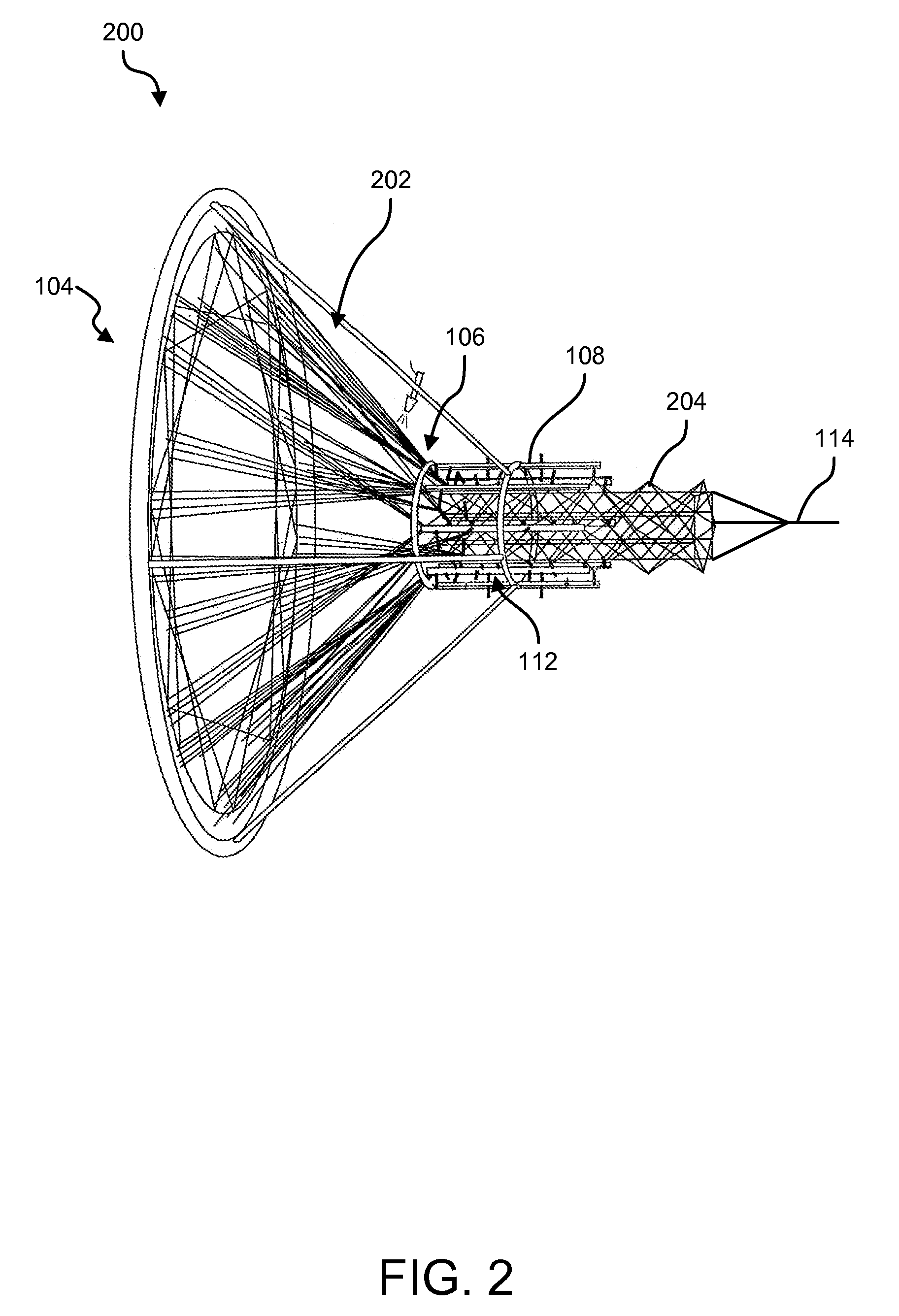

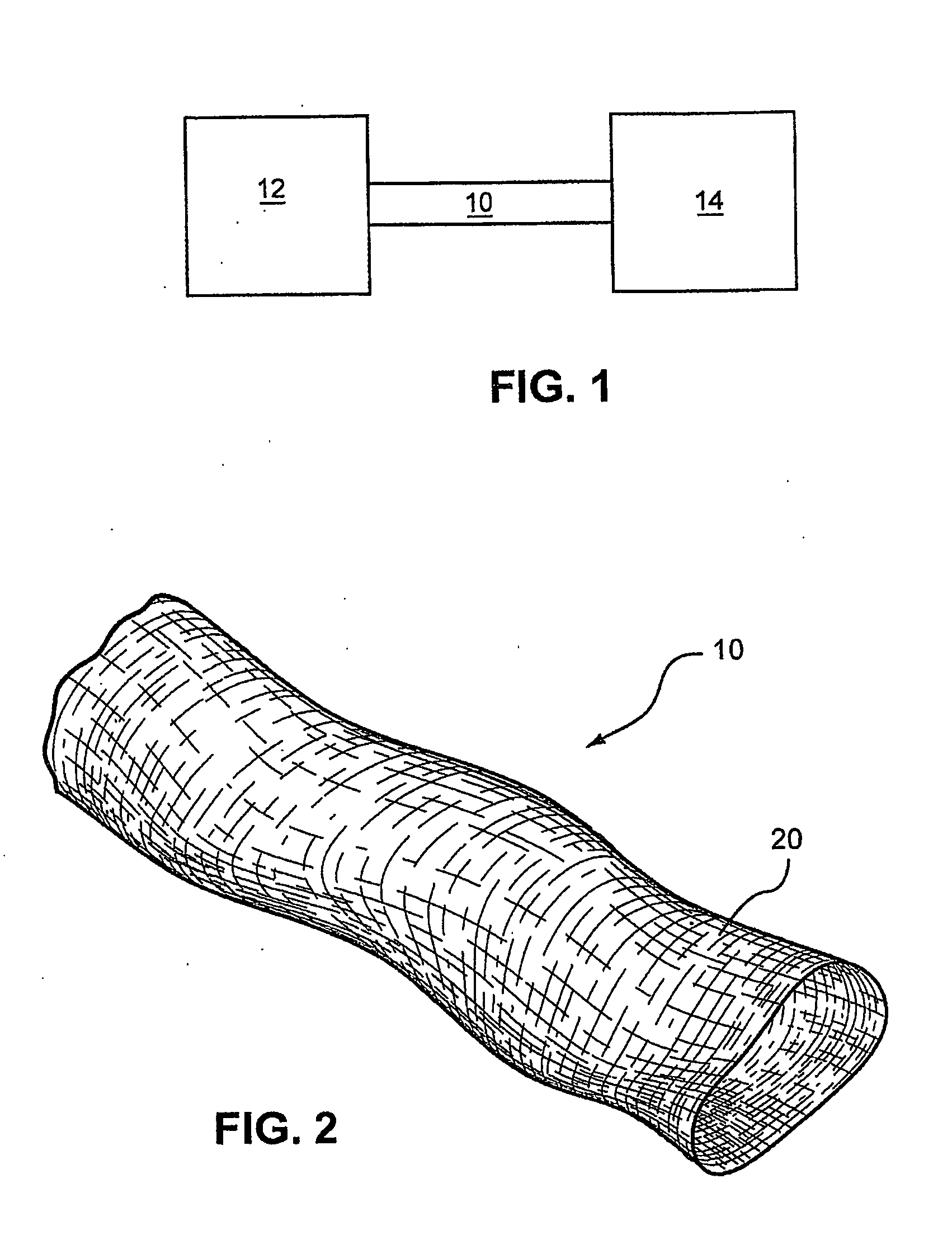

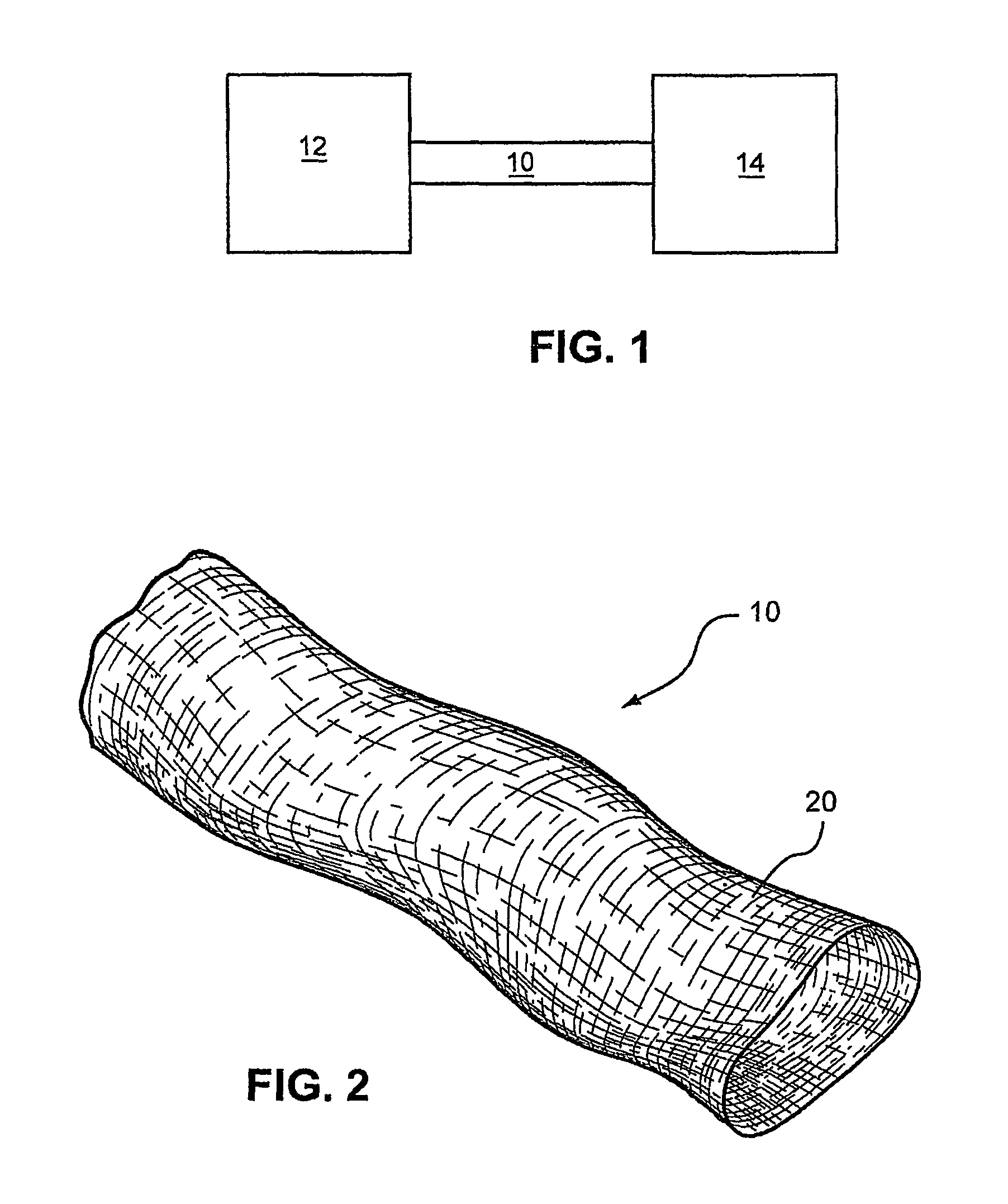

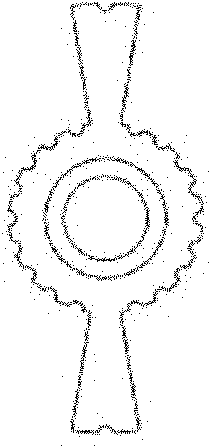

Apparatus, System, and Method for Filamentary Composite Lattice Structure Manufacturing

An apparatus, system, and method are disclosed for the manufacture of composite lattice structures comprising a weaving mechanism 104 configured to position fibers in a lattice structure, the weaving mechanism 104 comprising one or more bobbins 304, each one or more bobbin 304 configured to carry fiber and a plurality of horn gears 302 configured to move the one or more bobbins 304 across the face of the weaving mechanism 104 to control the position of the fiber carried by the one or more bobbins 304 in the lattice structure, and a shape retention structure 108 configured to hold the fibers in lattice structure. Beneficially, such an apparatus, system, and method would automate the process of manufacturing composite lattice structures and reduce the costs associated with the existing methods for manufacturing such structures.

Owner:BRIGHAM YOUNG UNIV

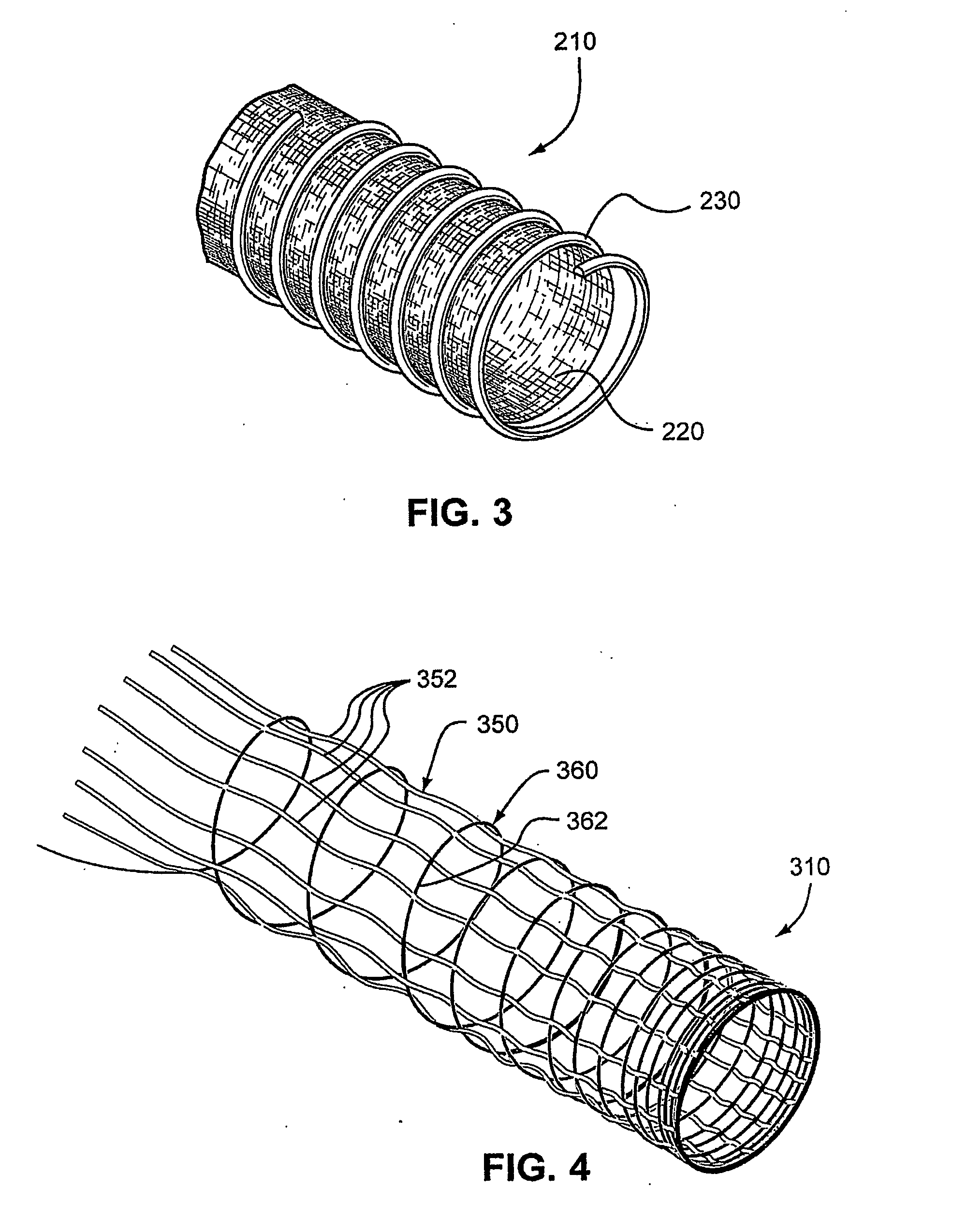

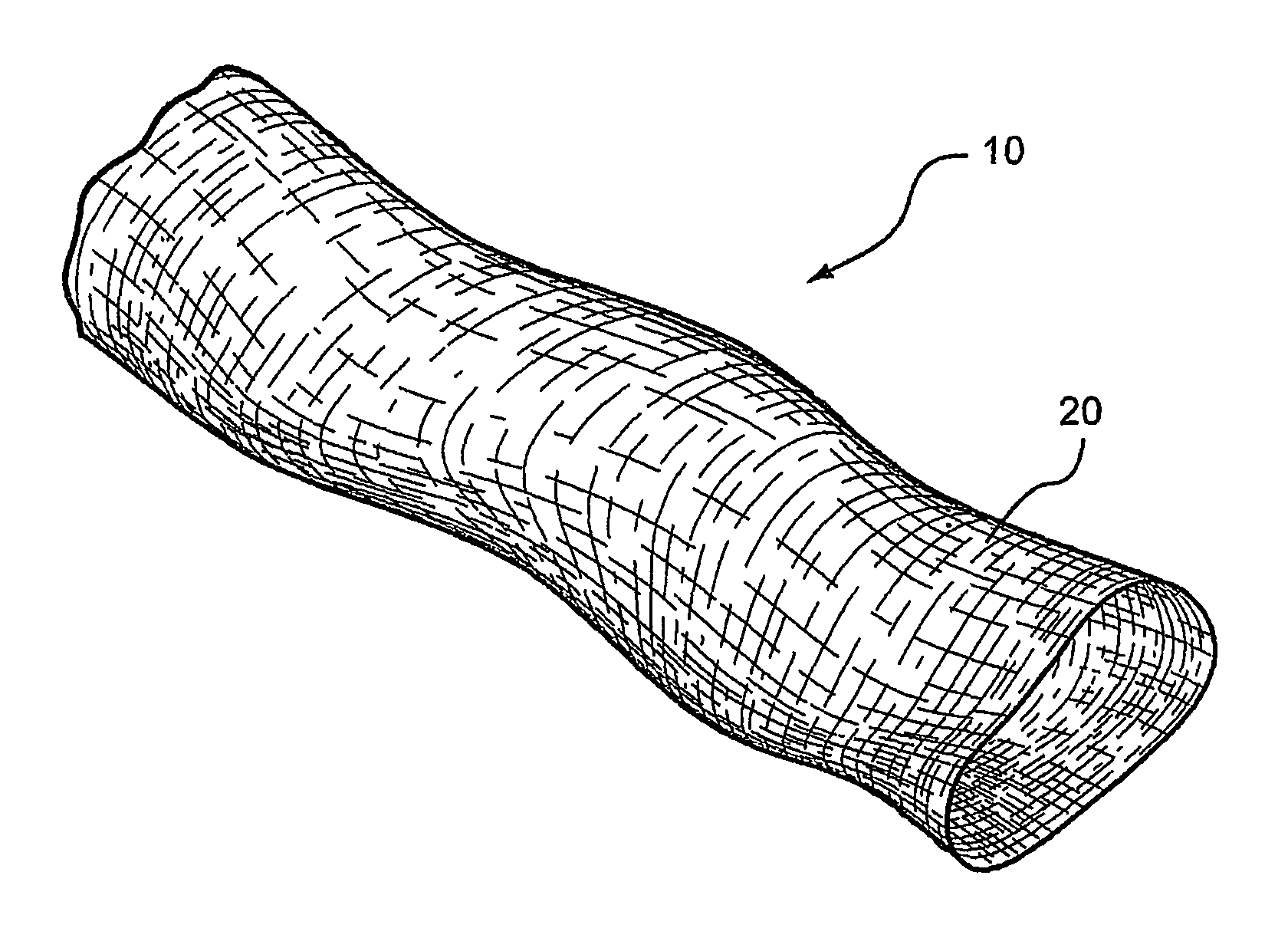

Air Delivery Conduit

ActiveUS20100224195A1Prevent kinking and collapsing of wall structureImprove insulation performanceCircular loomsRespiratory masksPositive airway pressure deviceEngineering

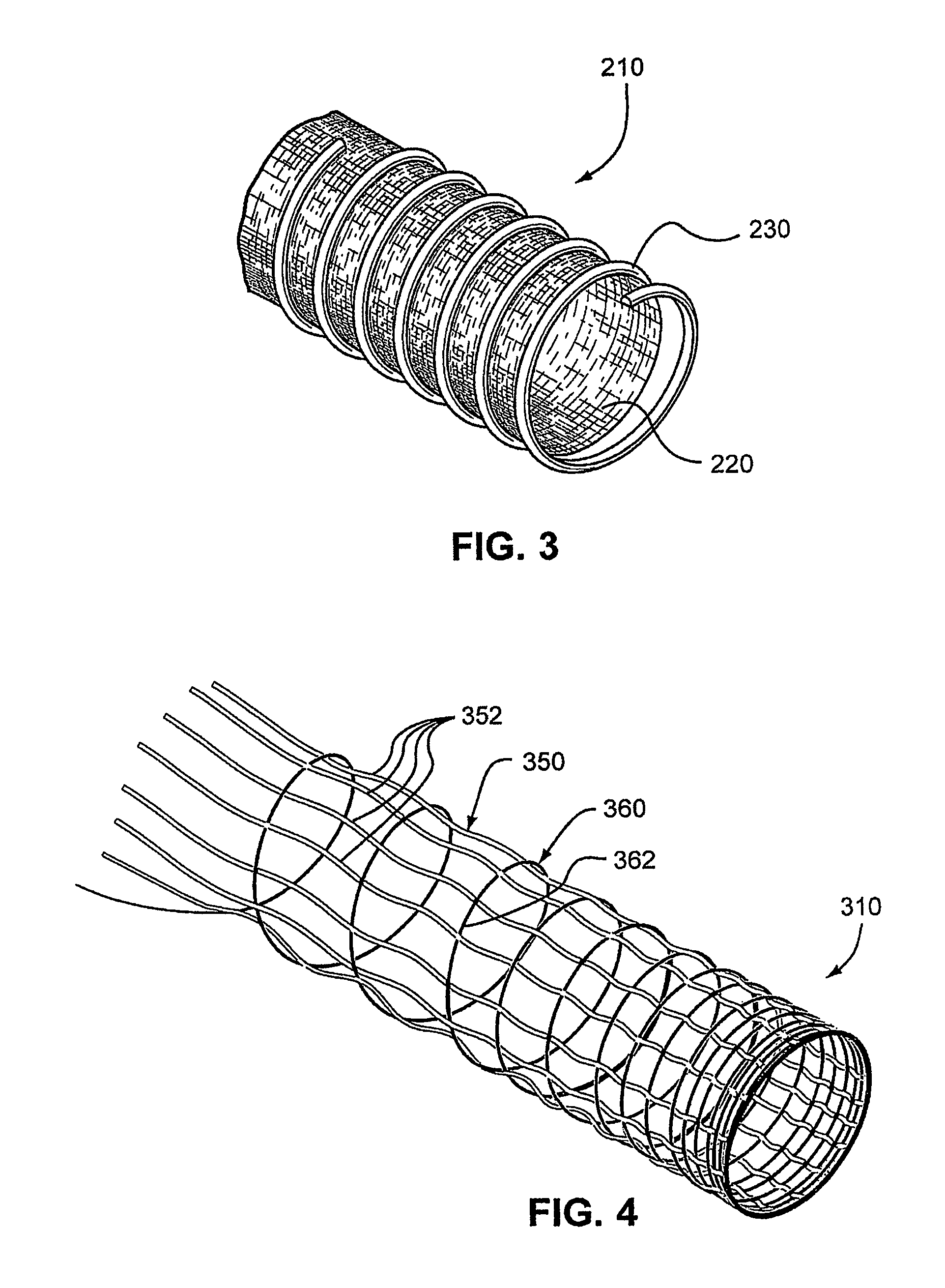

An air delivery conduit for conveying breathable gas from a positive airway pressure device to a patient interface includes a tubular wall structure constructed from a textile material. A reinforcing structure may be provided to the wall structure that is structured to prevent kinking or collapsing of the wall structure. The wall structure may include a warp having a plurality of lengthwise textile warp threads arranged in a circle and a weft having a textile weft thread that is woven through the warp threads.

Owner:RESMED LTD +2

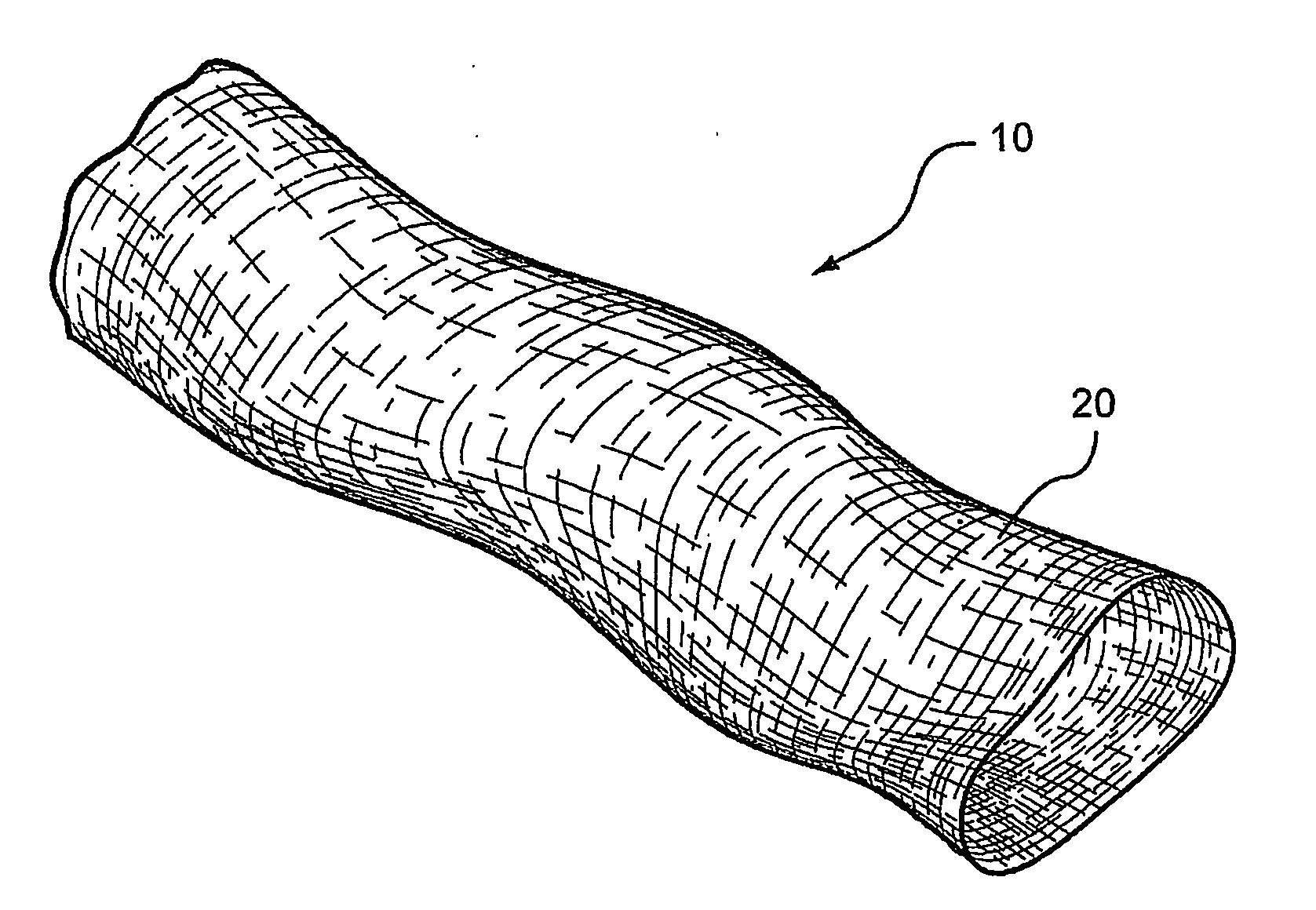

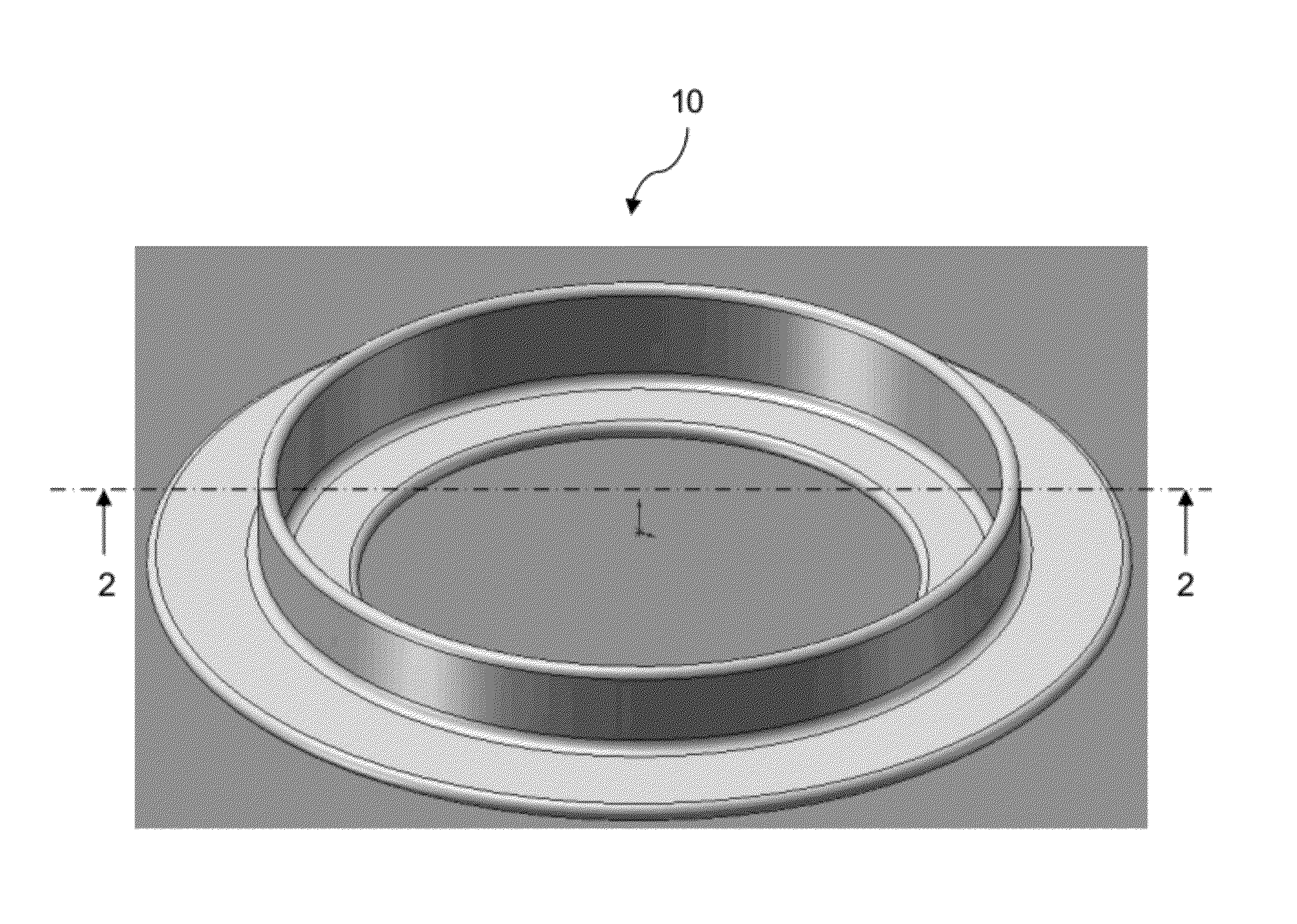

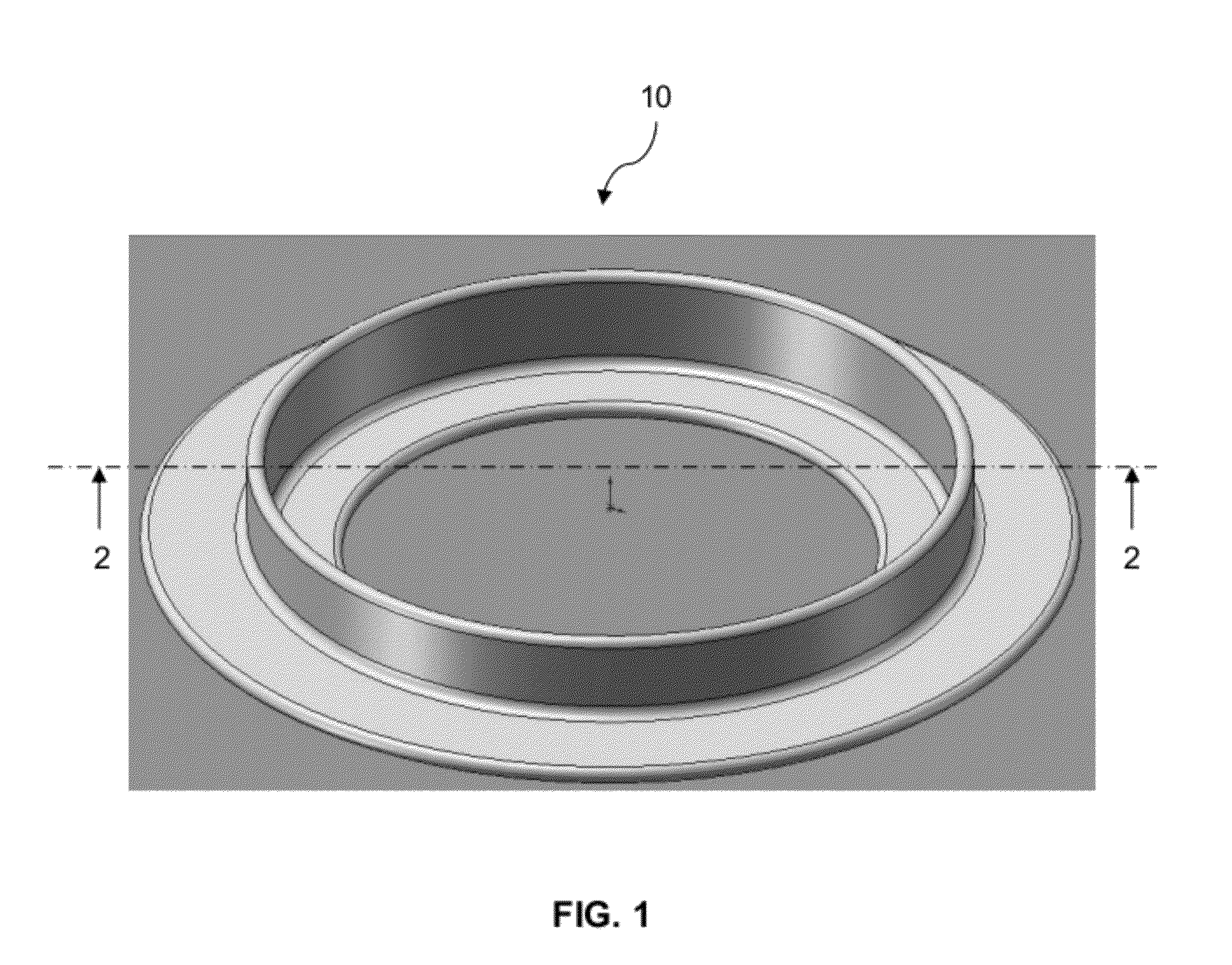

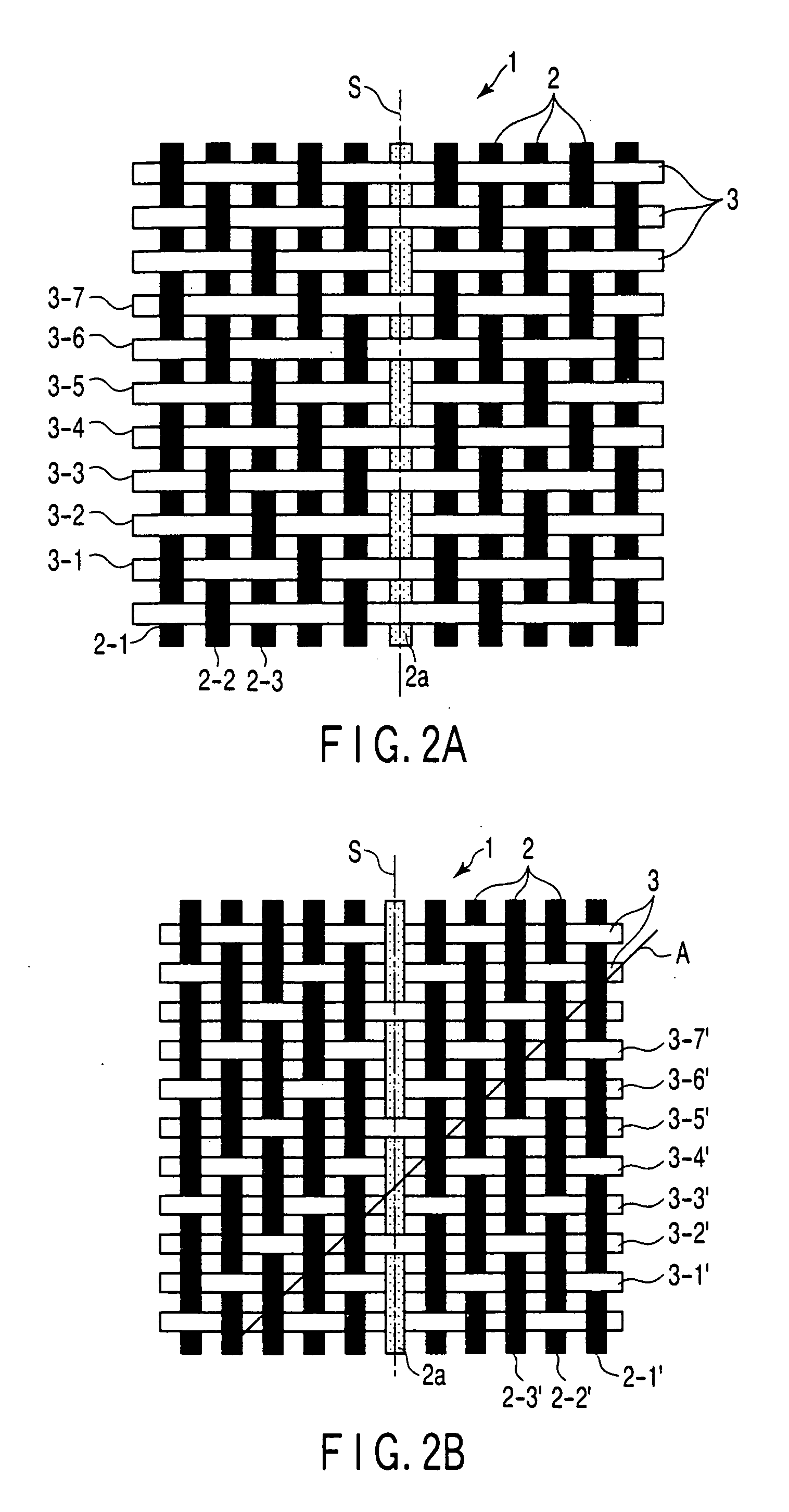

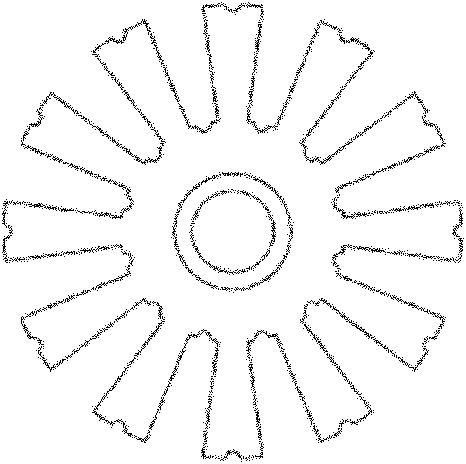

Woven preforms, fiber reinforced composites, and methods of making thereof

Preforms for use in fiber-reinforced composites, fiber-reinforced composites, and methods for making thereof are disclosed. One method includes interweaving a plurality of warp yarns with a single weft yarn so as to form a tubular woven structure with a central axis. The preform can be woven using an endless or tubular weaving technique, and can be woven so as to have two or more diameters along a length thereof. The preform can include one or more layers of a fabric formed on or attached to one or both surfaces of the tubular woven structure. The end structure can be a part of a window frame, a wheel rim, or a combustor in a jet engine.

Owner:ALBANY ENGINEERED COMPOSITES

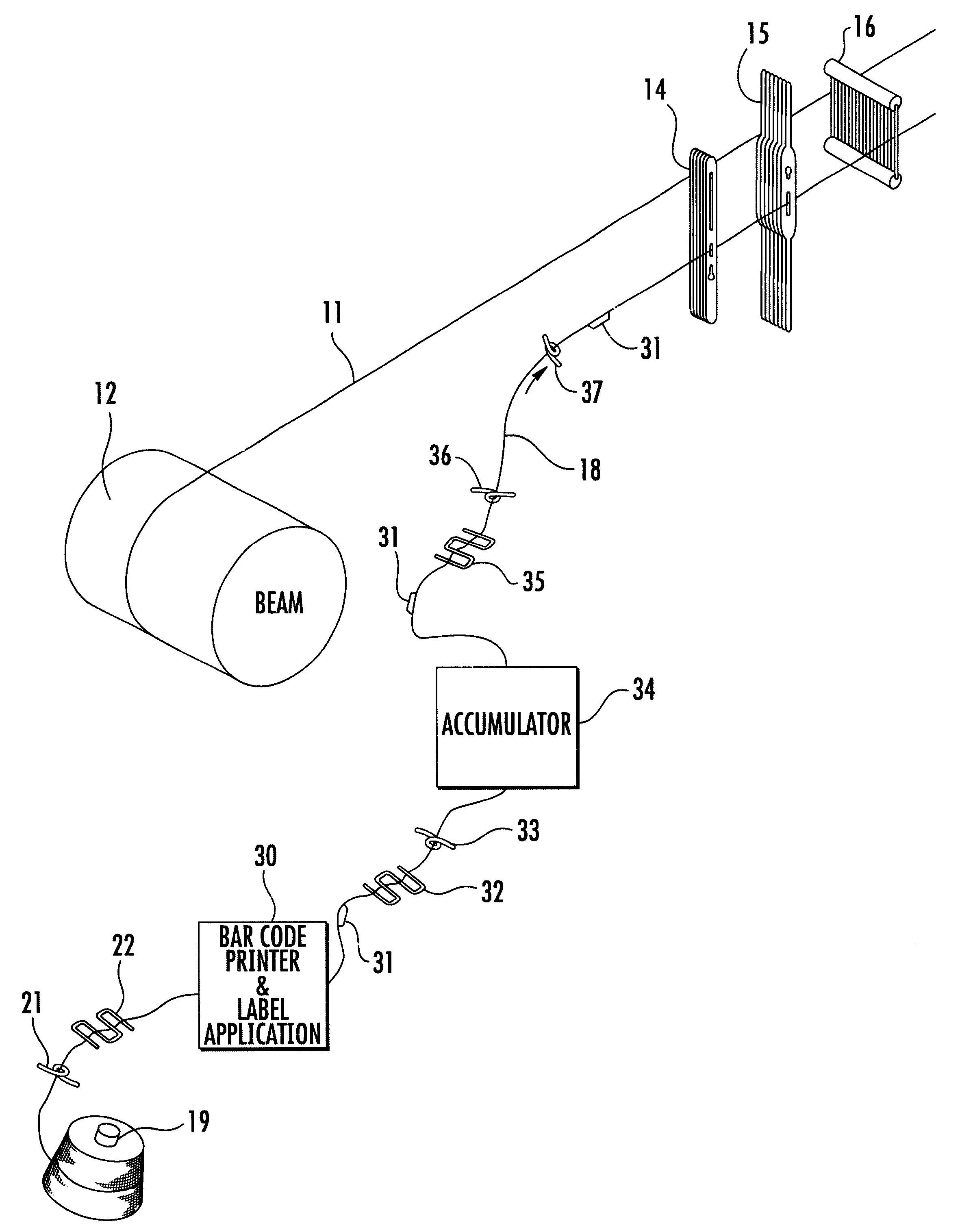

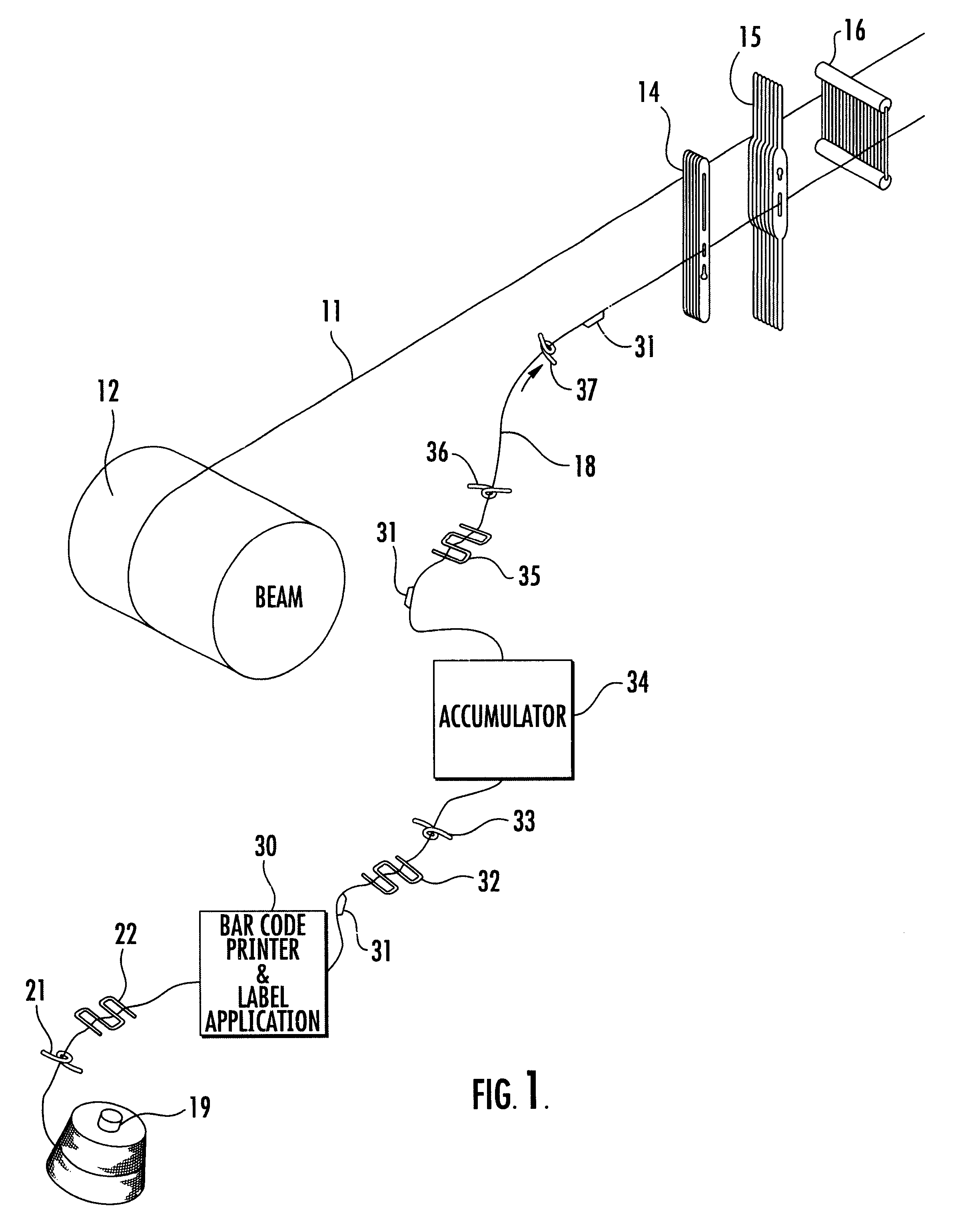

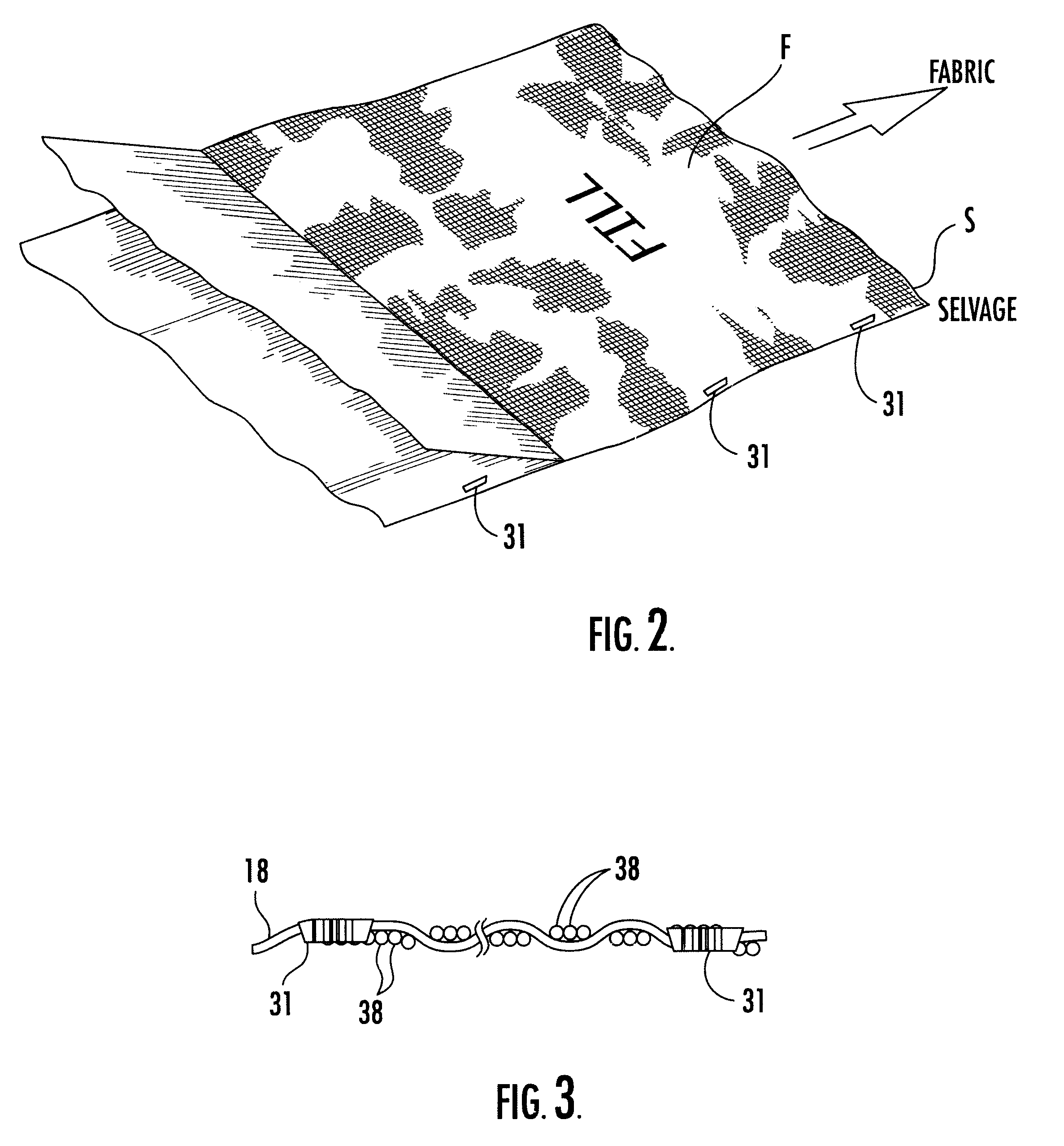

ID labeled fabric and method of applying an ID label to fabric at its point of manufacture

InactiveUS6494362B1Readily and accurately identifiedReadily and accuratelyCircular loomsCharacter and pattern recognitionYarnEngineering

A fabric is formed of interlacing yarns, and is labeled for ready and accurate identification by a manufacturer. The fabric includes a label carrier yarn selected from at least one end of the interlacing yarns. A fabric identifying label is attached to the label carrier yarn prior to incorporation of the label carrier yarn into the fabric. The label encircles the label carrier yarn in closely spaced relation such that the label avoids interfering with subsequent formation of the fabric.

Owner:HARMON CHRISTOPHER M

Method and apparatus of forming integrated multilayer fabrics

ActiveUS20110014403A1Eliminate needSimple tension controlEnvelopes/bags making machineryCircular loomsYarnEngineering

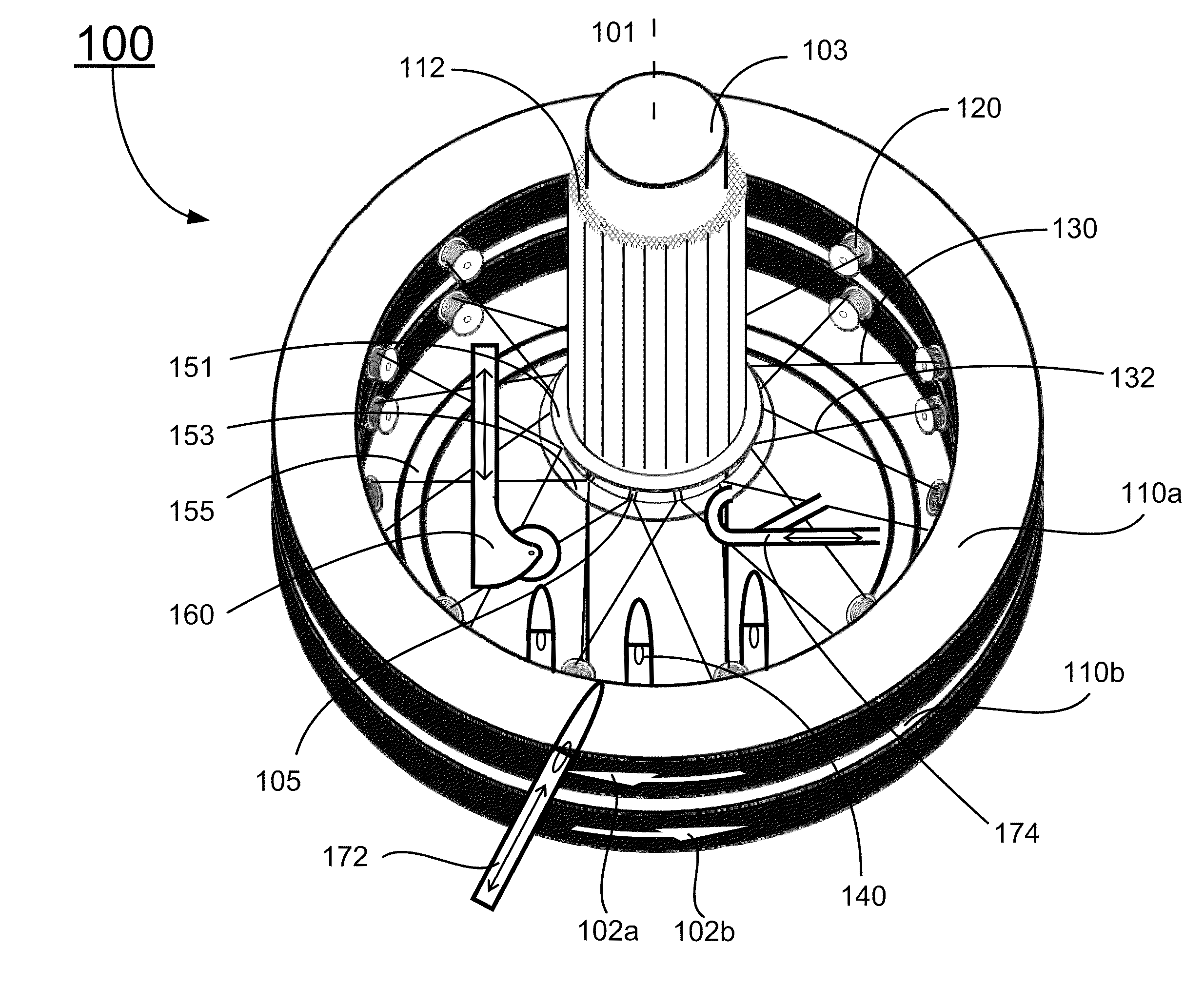

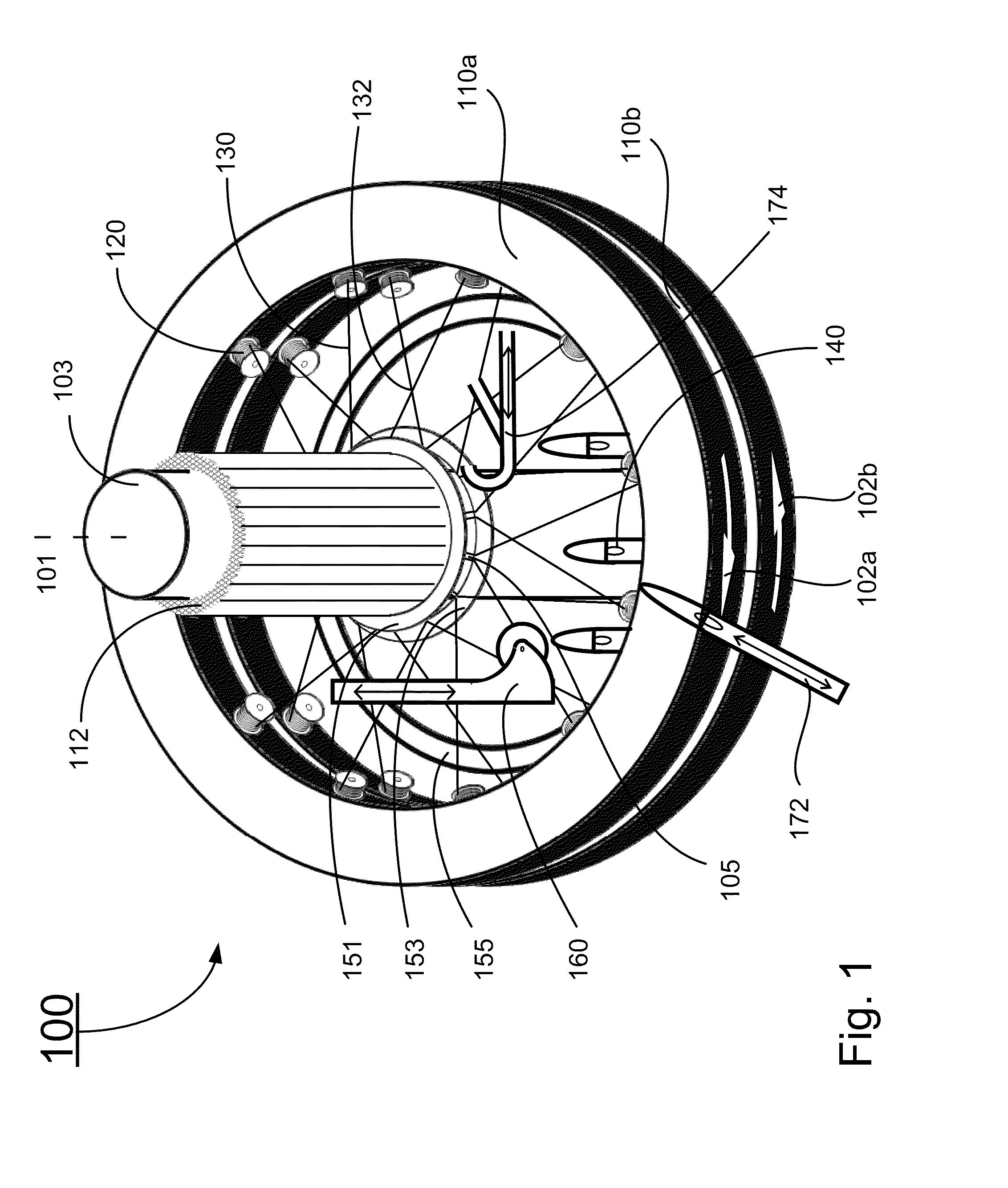

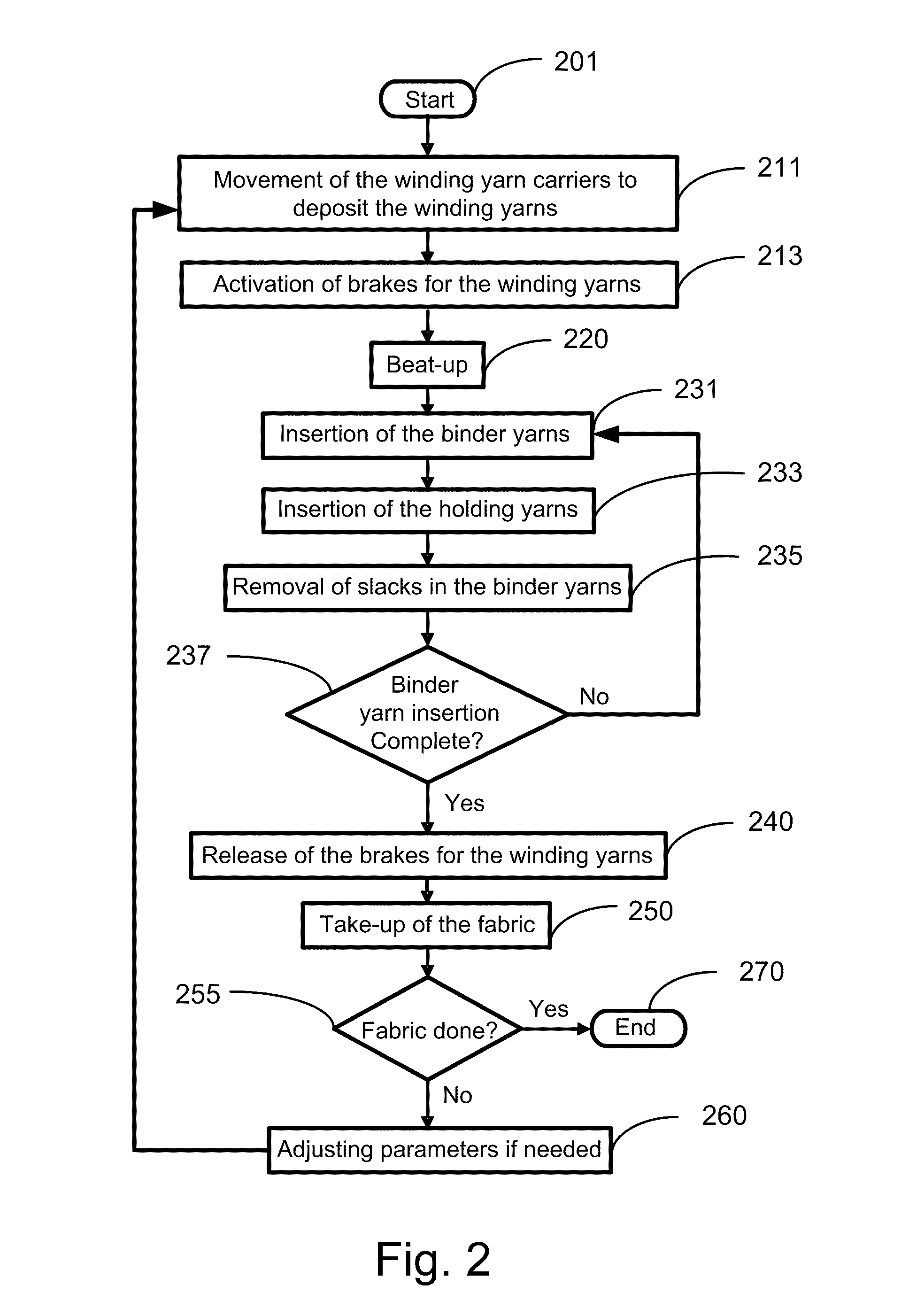

A method for fabricating multilayer fabrics having a prescribed integration pattern and an apparatus of implementing same. In one embodiment, the method include the steps of providing a plurality of winding yarn carriers arranged in a multilayer structure along a first direction and configured such that each winding yarn carrier is operably movable with respect to one another along a second direction that is perpendicular to the first direction, forming a plurality of crossover points of the winding yarns by moving at least one winding yarn carrier along the second direction according to the integration pattern, transporting the binder yarns through the plurality of winding yarn layers at predetermined locations along the first direction, and locking the binder yarns in place, pushing the binder yarns toward the fell of the multilayer fabrics, and taking up the formed multilayer fabrics.

Owner:STONEFERRY TECH +1

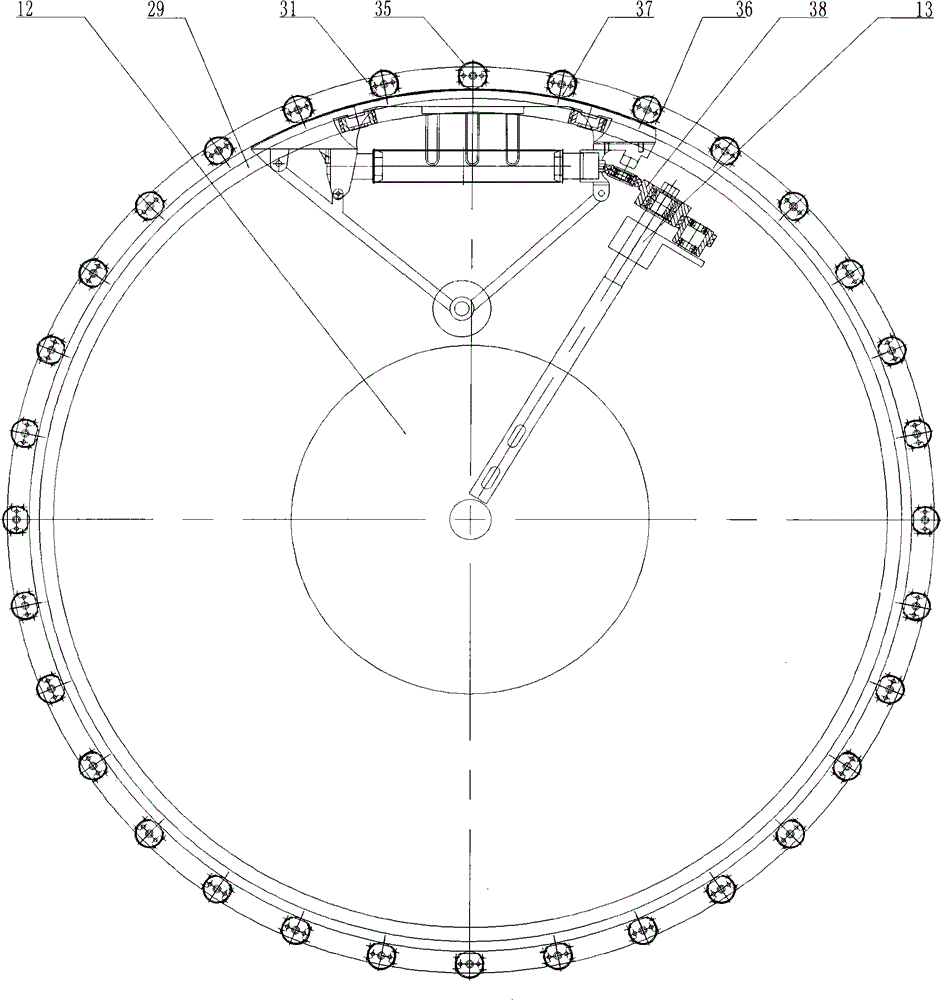

Plastic circular weaving machine with rolling track and without shuttle wheel

InactiveCN1600925AAvoid defectsOvercoming the defects of rolled warp yarnCircular loomsEngineeringPulley

A plastic circular loom has shuttle boat formed by shuttle body, shuttle base plate, shuttle boat guide and silk guide band. The shuttle is run along rolling rail formed by 30-288 pieces of drums in between top and bottom door coils and 60-576 pieces of tin pulleys on top and bottom door coils for realizing high speed runing of shuttle without shuttle wheel on rolling rail of top and bottom door coil.

Owner:黄美昌

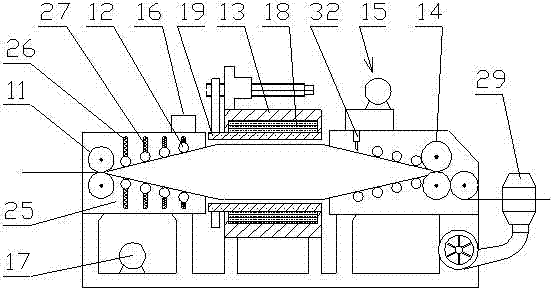

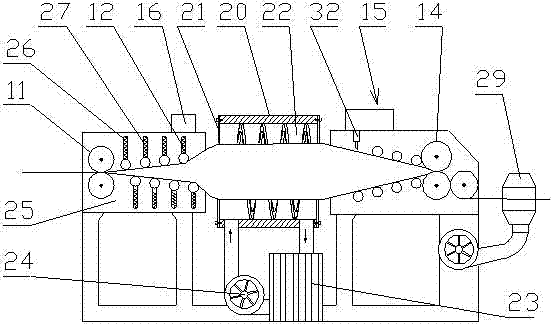

Plastic woven bag circular weaving machine with automatically adhered lining film

The invention discloses a plastic woven bag circular weaving machine with an automatically adhered lining film; and the plastic woven bag circular weaving machine comprises a plastic woven bag circular weaving machine host, a bobbin cradle and a winding device. A spindle of the host is provided with a film-passing tube, one side of the host is provided with a film-laying rack, and a dual-layer plastic film on the film-laying rack penetrates in a bobbin cloth at the upper part of the host through a roller and the membrane-passing tube; the bobbin cradle is provided with a guide rail on which alining film adhering device and a traveling mechanism are arranged; the lining film adhering device is provided with an automatic air-supplying device which comprises a boost roller position detection switch and an inflating needle driven by a plugging mechanism; the host, the lining film adhering device and the traveling mechanism are all connected with a control system. The plastic woven bag circular weaving machine with automatically adhered lining film can continuously and automatically composite the plastic woven bag and the lining film, is small in volume, high in production efficiency,and is an update product of the existing apparatus.

Owner:陈上利

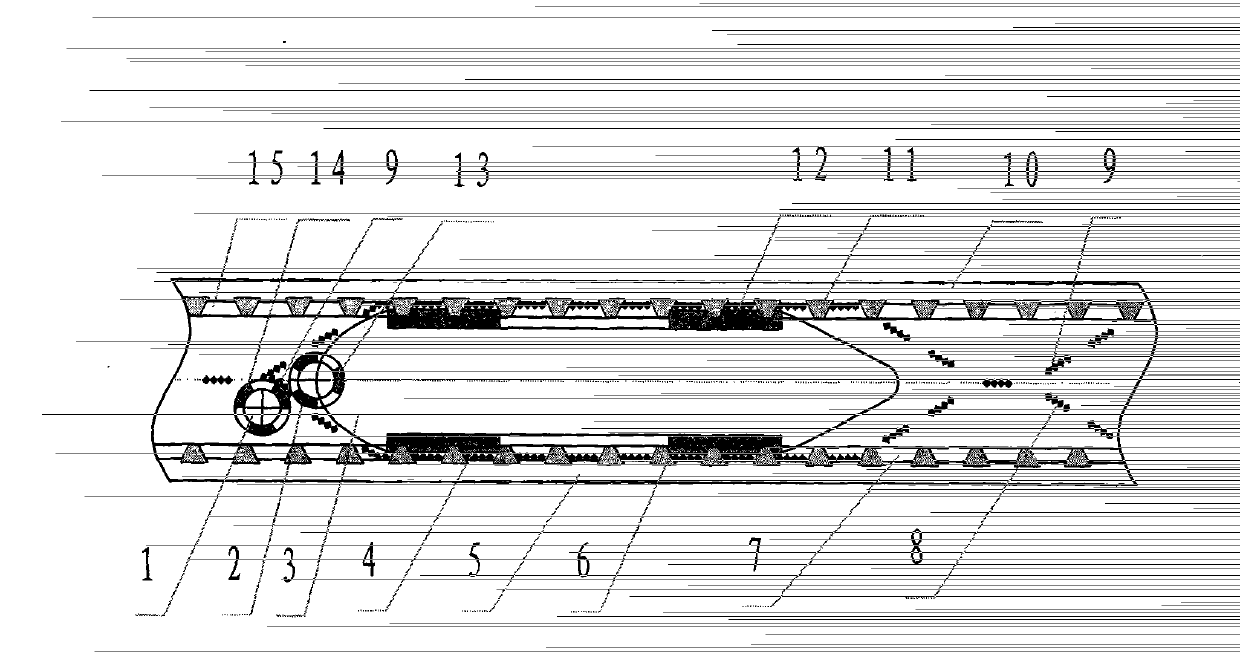

Rolling type shuttle wheel-free double xiaoliu shuttle plastic circular loom

InactiveCN101116981AImprove work efficiencyCircular loomsCane mechanical workingPolypropyleneMechanical engineering

The invention relates to a manufacturing device of polypropylene (PP) knitted bags, in particular to a tumbling-type double-six-small-shuttle plastic round loom without shuttle wheels. The main technical characteristics of the invention are that six shuttles without shuttle wheels are arranged at the upper and lower levels respectively between the upper door ring and the lower door ring on the basis of the prior sliding-rail plastic round loom without shuttle wheels. Meanwhile, 30-72 pillars are respectively distributed between the upper and lower door rings. Rails for movement are arranged in two layers for the upper shuttle and the lower shuttle. The PP knitted bags made by the upper shuttle are coiled up by the first coiling machine through the upper size ring, upper width widening machine and upper traction and likewise the bags made by the lower shuttle are coiled up by the second coiling machine through the lower size ring, lower width widening machine and lower traction. A plastic round loom can produce two bags simultaneously, the efficiency of which triples the traditional four-shuttle round loom and doubles the small six-shuttle round loom.

Owner:黄美昌

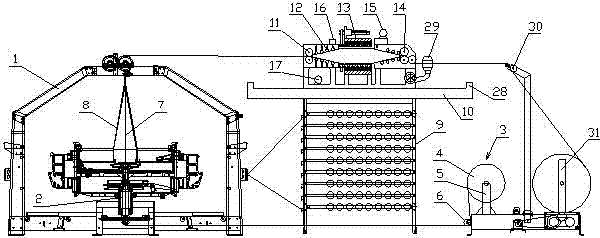

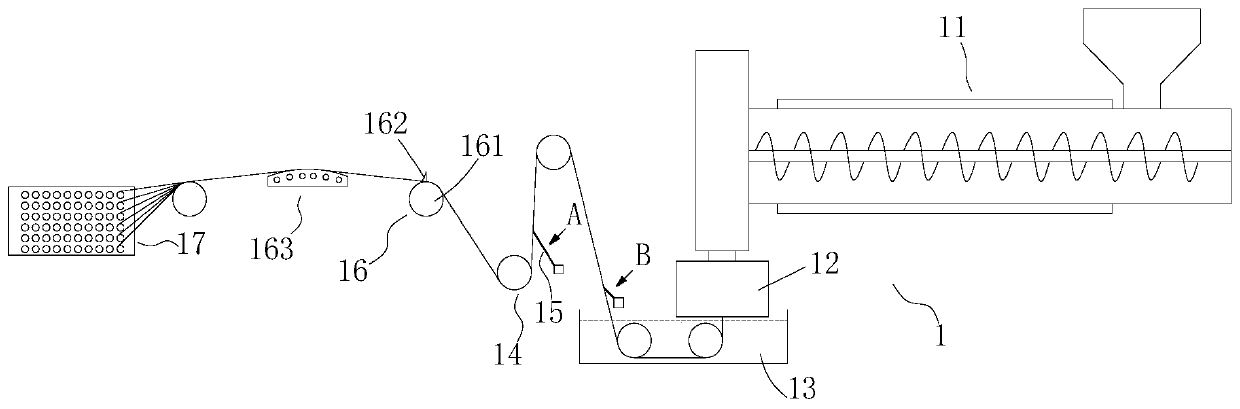

Production assembly line for woven bags

ActiveCN110552076AAvoid stickingAvoid tilting your headPaper article packagingCircular loomsAssembly lineAutomation

The invention relates to the field of production of woven bags, in particular to a production assembly line for woven bags. The production assembly line comprises a ribbonfil production device, a circular weaving device, a roll printing device, a cutting sewing device and a packaging device. Raw materials are heated, melted, extruded and formed into ribbonfil through the ribbonfil production device, the circular weaving device weaves the continuous cylindrical woven bags through the ribbonfil, the woven bags are printed with patterns and characters through the roll printing device, and the printed woven bags are cut off and sewn through the cutting sewing device, then discharged from the cutting sewing device and automatically packaged through the packaging device finally. The production assembly line for the woven bags has the advantages that the production assembly line for the woven bags can achieve production of the woven bags, the overall production efficiency and automation degree are high, the product quality is good, and the production assembly line is suitable for large-scale popularization.

Owner:泗县鸿盛塑业股份有限公司

A high-speed plastic circular weaving machine

The invention provides a high-speed plastic circular weaving machine. Shuttle bodies are ship-shaped shuttle bodies. More than two tapered location shuttle wheels are arranged on each of the upper portion and the lower portion of the inner side of each shuttle body; the tapered location shuttle wheels are tapered at such an angle that the tapered location shuttle wheels are in rolling contact with inclined steps on inner circumferential planes of upper and lower door rings; the back of each shuttle body is provided with an arc-shaped part. More than twenty-four roller shafts are arranged on the outer planes of the upper and lower door rings; each roller shaft is provided with more than two track rollers to form a roller set; more than one bearing is arranged in each roller; a roller sheath or protection pillar is arranged outside each roller and is a certain distance away from each roller; the vertical side of the outer circumference of each sheath is provided with a C-shaped opening to expose one side of the circumference of the corresponding roller; the more than twenty-four sets of rollers are uniformly distributed between the upper door ring and the lower door ring with a main shaft as the axis to form a rolling track; the rollers in each set move independently and are in rolling contact with the arc-shaped steel plates independently. Therefore, the operation is stable, the temperature rise is low, and the operation speed is increased so that the objective of high speed is achieved.

Owner:PINGYANG DAYU PLASTIC MACHINERY

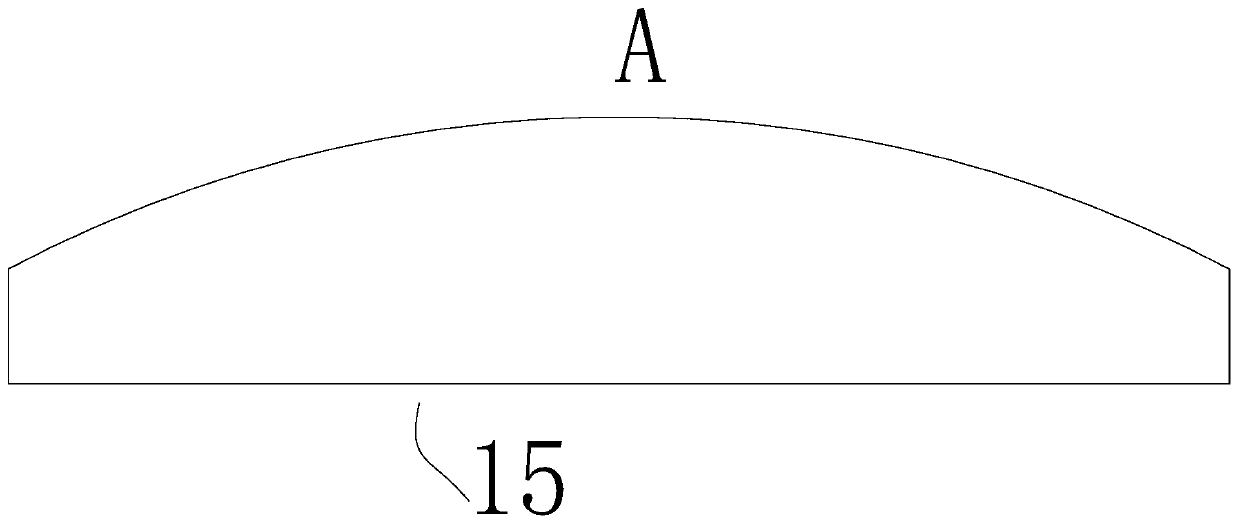

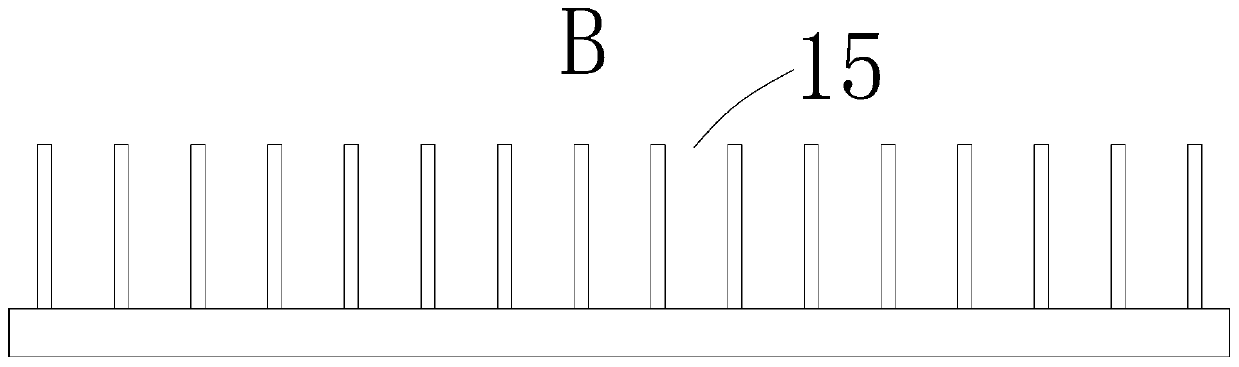

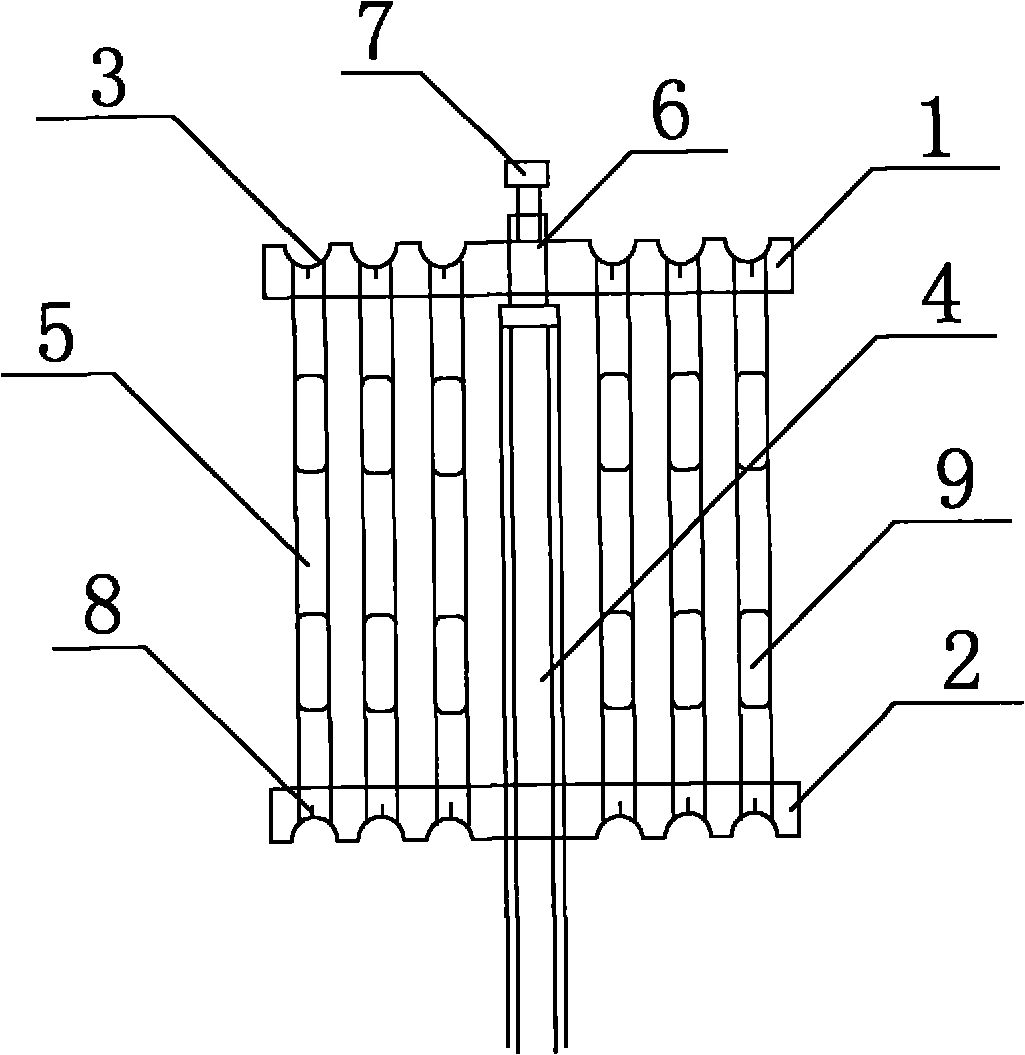

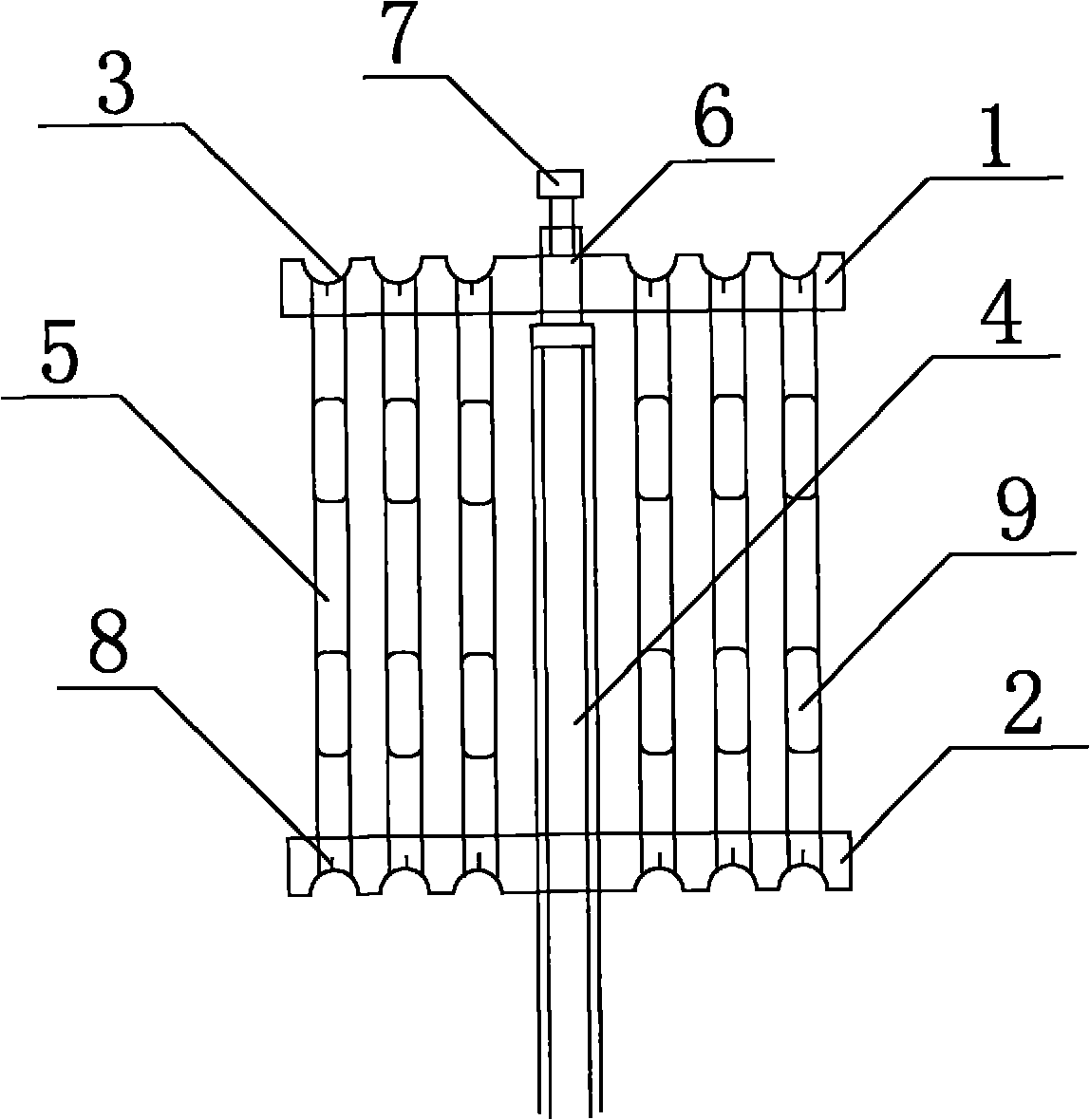

Heald frame of circular loom

The invention relates to the technical field of heald frames, in particular to a heald frame of a circuit loom, which comprises an upper beam, a lower beam, grooves, a heald bar and a heald wire, wherein the upper and lower beams have the grooves and are fixedly connected by the heald bar; the heald wire is fixedly connected with the upper and lower beams through the grooves; a threaded hole is formed in the middle of the upper beam; the upper beam is fixedly connected with the heald bar through the screw in the threaded hole; the grooves are semispherical; slots are formed at the bottom of the grooves; and the heald wire has two thread holes. In the circular loom, the grooves and slots are formed on the upper and lower beams, so that the heald wire is in a tightened state constantly in operation, the wear of machine parts is relieved, noises are reduced, the service life of the heald frame is prolonged, and working environment is improved; meanwhile, the heald wire has the two thread holes for two yarns to pass through, so the working efficiency is improved and working time is saved.

Owner:吴国平

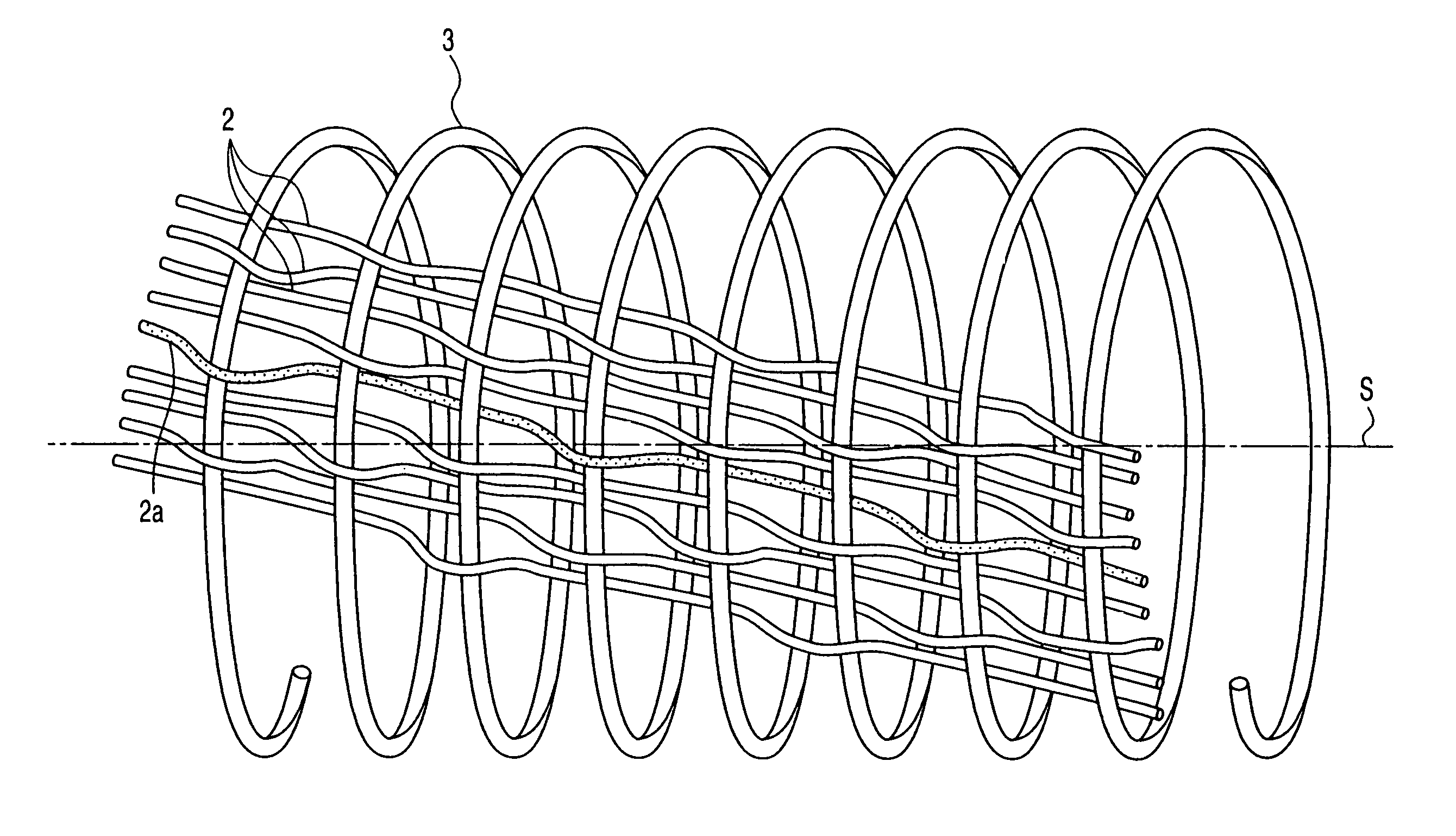

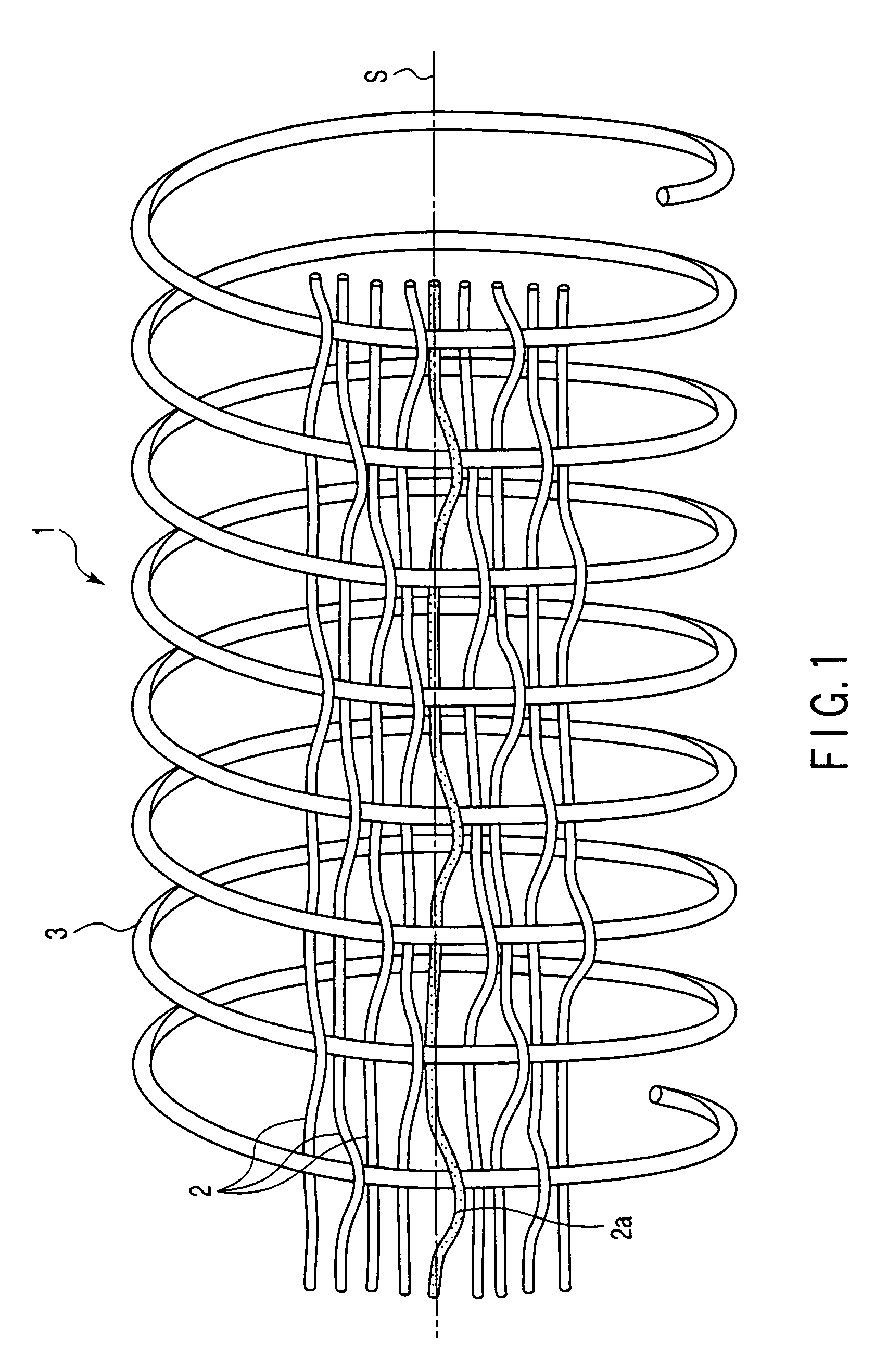

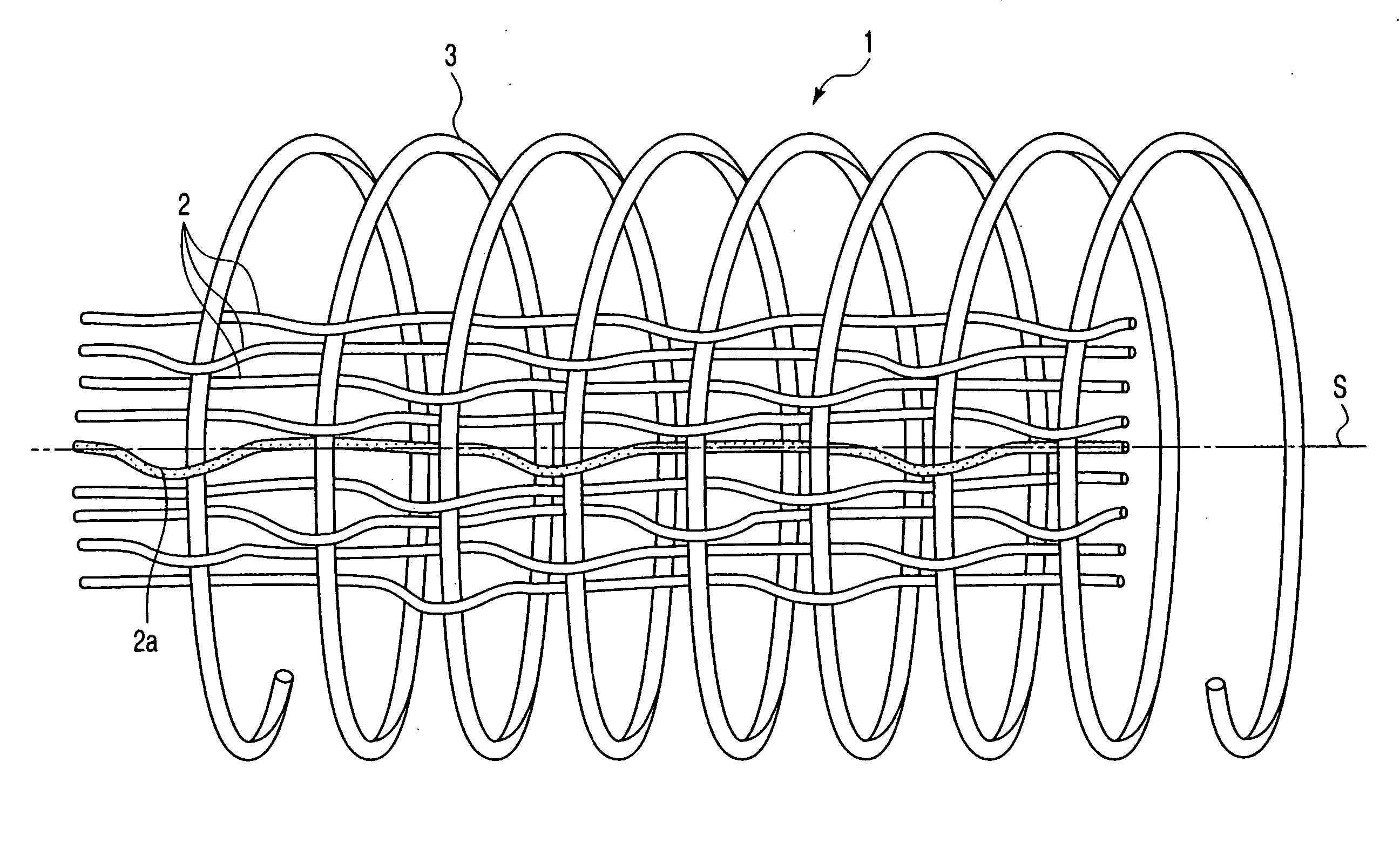

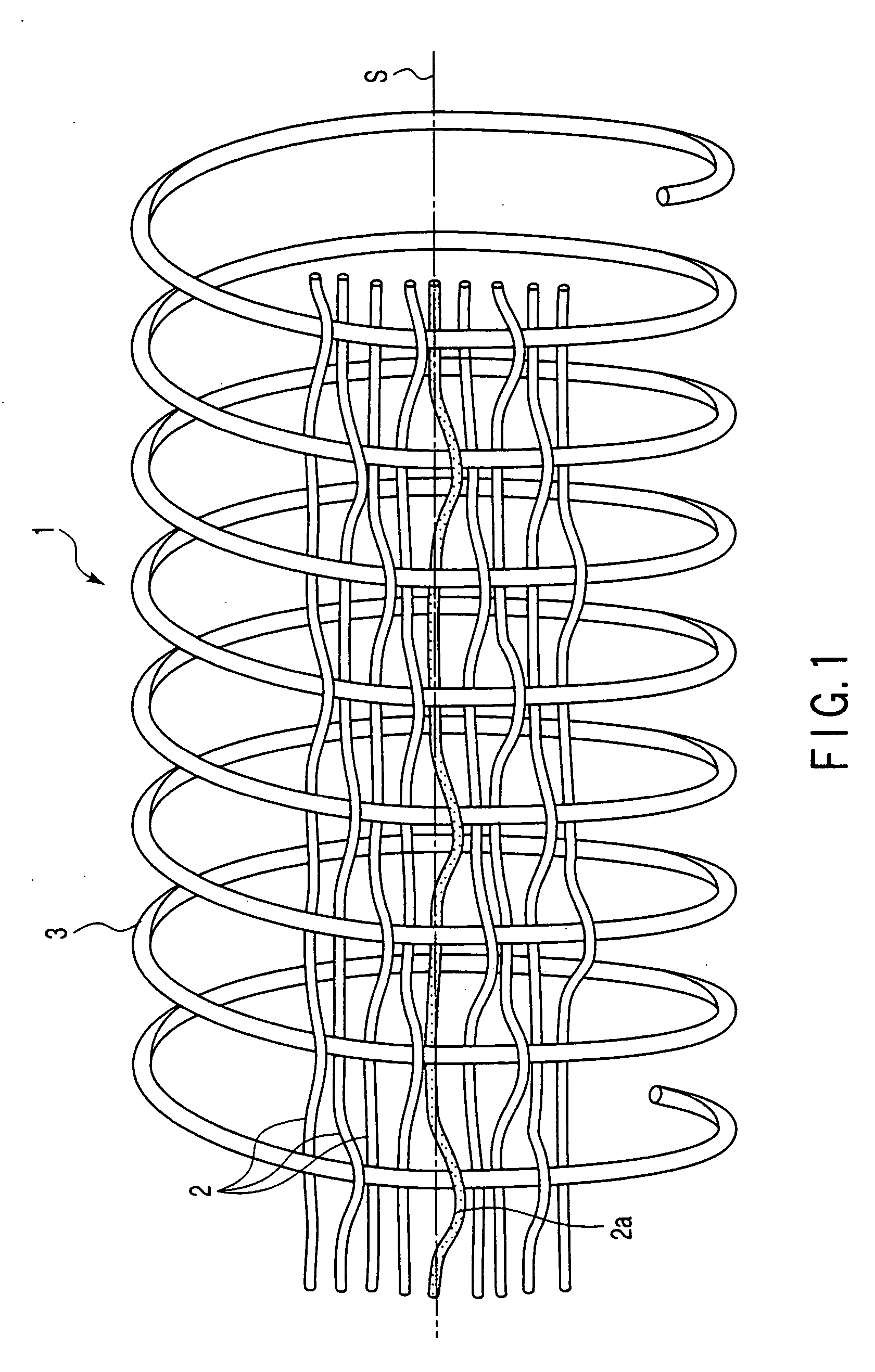

Cylindrical jacket, jacket hose, suction hose, and cylindrical jacket manufacturing apparatus

InactiveUS7926517B2Small pressure lossEven twistCircular loomsFlexible pipesMarine engineeringManufactured apparatus

Owner:SAKURA GOMME KK

Energy-saving circular weaving machine

The invention provides an energy-saving circular loom which has optimum structural design, increases motor rotational speed and reduces motor power, thereby reduces power consumption, which improves the shortcoming that the existing circular loom has large energy consumption, convenient maintain and the like. The invention mainly comprises a circular guideway, a shuttle guiding frame, a wallboard, a shuttle-race, a bearing support of the shuttle-race, a central seat, a main drive nylon large gear, a drive gear wheel, a beveled wheel, a button box, an electric motor and a large chassis, wherein the shuttle-race is fixed on the bearing seat of the shuttle-race, the lower end of the bearing seat of the shuttle-race is connected with the central seat, the central seat is fixed on the large chassis, the drive gear wheel is connected with the main drive nylon large gear, and the inner lateral of the circular guideway is provided with a line breaking alarm indicator light. The invention is characterized in that the electric motor is horizontally arranged and horizontally connected with a reversing decelerator through a shaft coupling, the drive gear wheel is sleeved on the vertical output end of the reversing decelerator and engaged with the main drive nylon large gear which is fixed on the lower end of the bearing seat of the shuttle-race, and both the electric motor and the reversing decelerator are mounted on the surface of the large chassis.

Owner:NANTONG BECA MACHINERY TECH

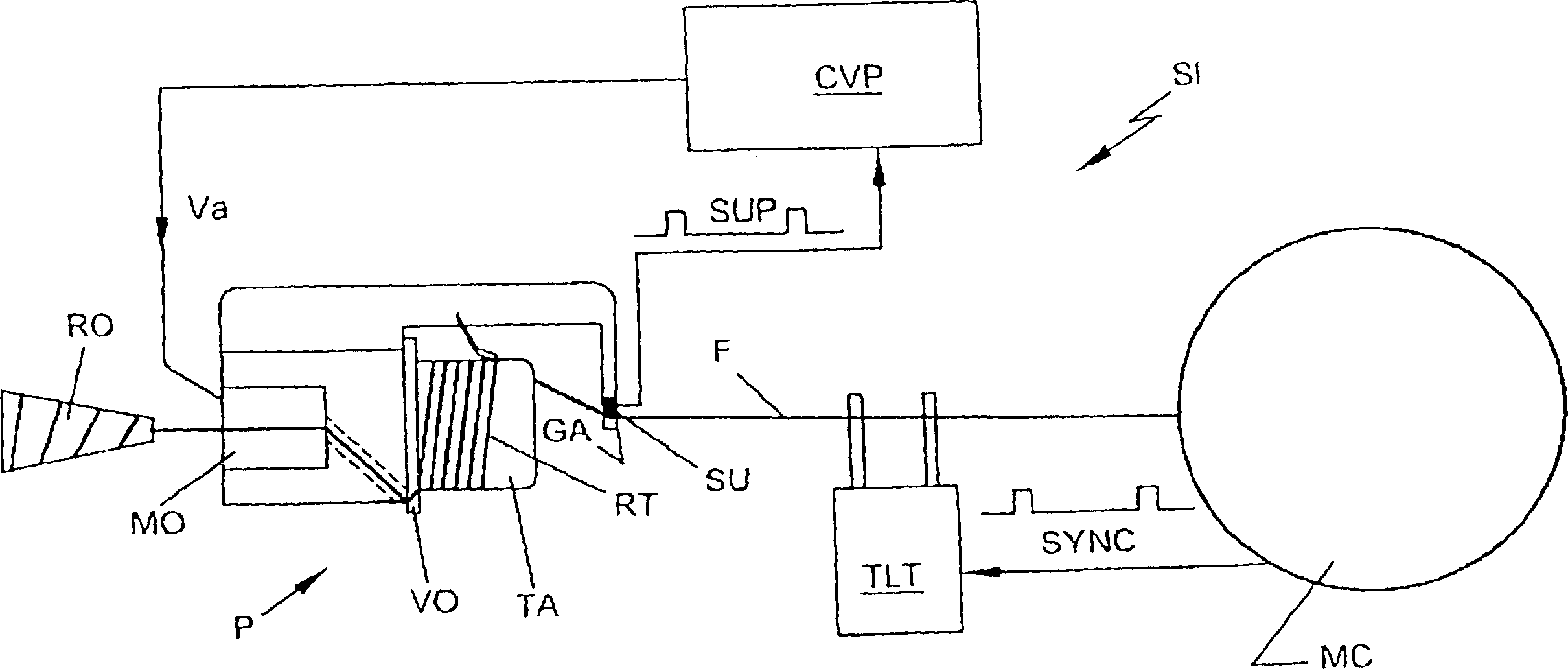

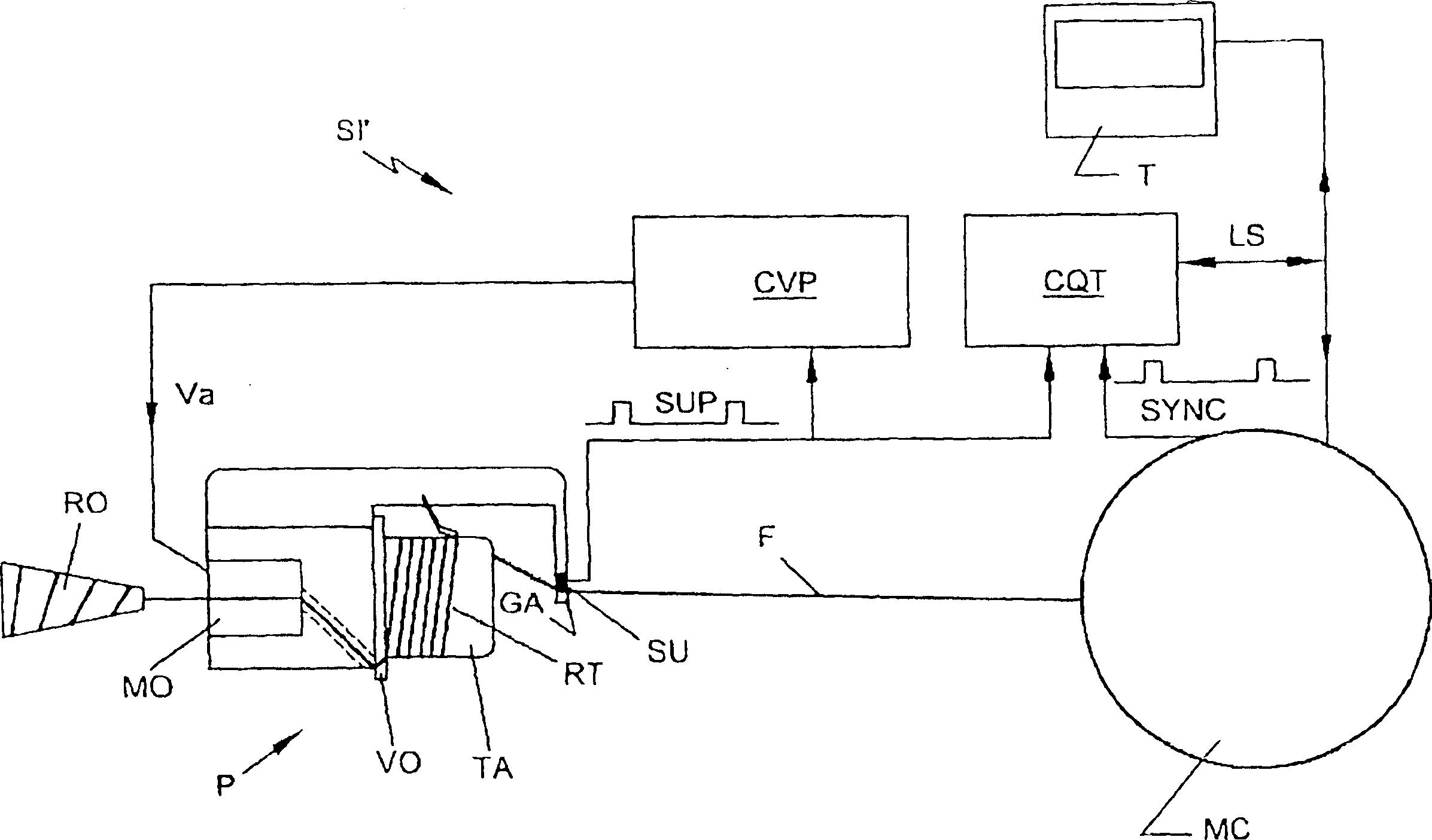

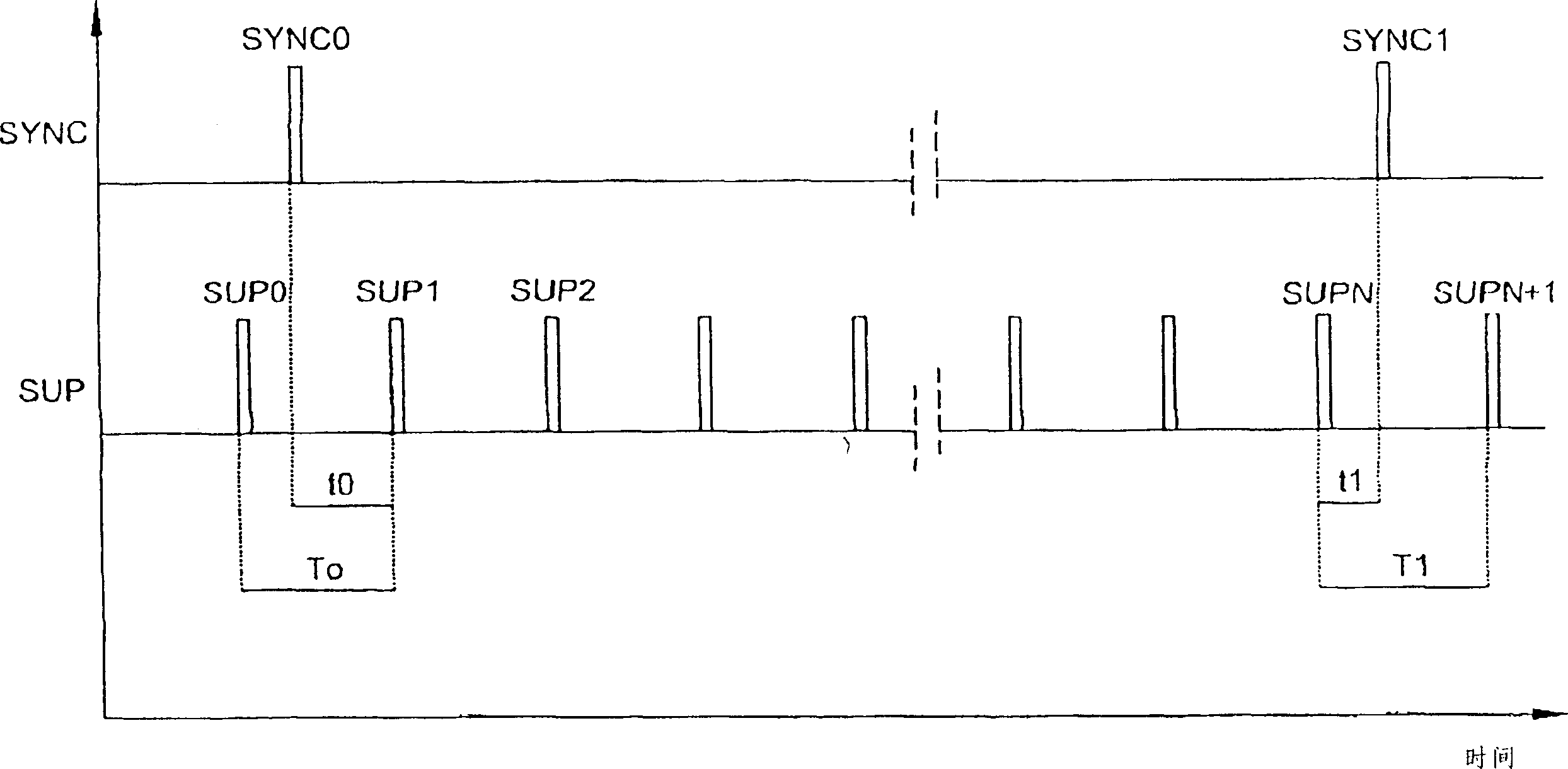

Method and apparatus specially adapted for measuring weft yarn in circular loom

A method for measuring the use of weft thread (F) inserted in textile machines by means of weft feeders (P), especially electronic circular knitting machines (MC), which consists in using the output sensor (SU) of the weft feeder (P), by sending its pulses (SUP) to a functional logic block (CQT), which also receives synchronization signals (SYNC) generated by the textile machine (MC). The logic block (CQT) is programmed to calculate the quantity (Qt) of weft used between two successive synchronization signals (SYNC0-SYNC1) by taking into account the circumference (C) of the drum (TA) of the feeder (P), the number (N) of pulses (SUP) emitted by the output sensor (SU) of the feeder (P) between one synchronization signal and the next, and a time correction factor.

Owner:L G L ELECTRONICS

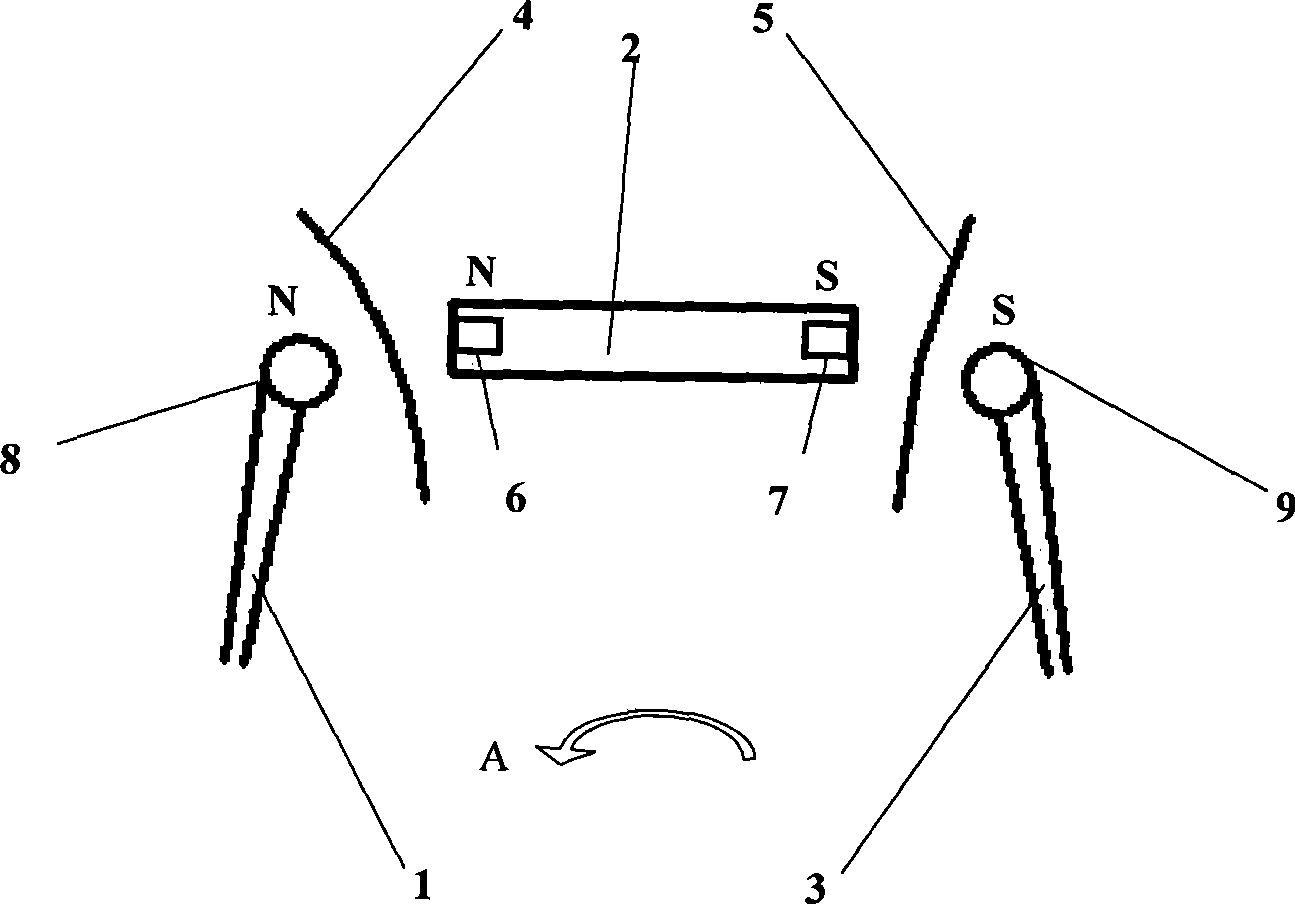

Magnetic shuttle movement aid unit of circular weaving machine

InactiveCN1789519AImprove work performanceNot prone to wire breakageCircular loomsEngineeringNon magnetic

The invention provides circular loom magnetic shuttle power assistance unit, comprising the following solving scheme: the shuttle is settled in the orbit of a circle; the pushing bodies is connected with principal axis through handspikes; in the rump of the shuttle there are permanent-magnets which are fixed in the pushing bodies and the two poles of the permanent-magnets nearby are of the same homonymy; there is a nonmagnetic lead-thread frame is equipped outside of the shuttles and in the rump of the shuttle there is an aluminium alloy back bracket, and upon the back bracket there is a eccentric fixed wheel. The invention is simple in the structure, convenient to use, hard to see the phenomenon of silk breaking, improves the efficiency of loom, and suits for any type of looms.

Owner:唐欢利

Three-shuttle circular weaving machine for high pressure resistant large-caliber hose fabric

The invention discloses a three-shuttle circular weaving machine for a high pressure resistant large-caliber hose fabric. The three-shuttle circular weaving machine is characterized by comprising a machine body supporting device, a transmission device, a weaving device and a motor, wherein the transmission device and the weaving device are fixed on the machine body supporting device; the machine body supporting device comprises a rack, a large base plate, a central seat, seat rings, pressure ring sleeves and cylinder port seats; the large base plate is arranged on the rack; the central seat is arranged on the large base seat; the pressure ring sleeves are arranged on two sides of the upper end of the central seat; cylinder port seats are arranged on the pressure ring sleeve; and the seat rings are arranged on two sides of the cylinder port seats. The three-shuttle circular weaving machine has the advantages that the machine is high in reliability, simple in structure and convenient to maintain, more warp positions are provided, the weavable density is high, a large-caliber hose strip with a larger size can be produced, a traction device is fixed on the rack, the height of the central seats is shortened, the traction distance is increased effectively, the traction uniformity is kept, the machine height is controlled at the same time, the operation stability is improved, and the machine is easy to assemble and maintain and simple in structure.

Owner:蔡宝祥 +2

High-speed plastic circular weaving machine capable of preventing all strands of warp yarn from being ground

A high-speed plastic circular weaving machine capable of preventing all strands of warp yarn from being ground comprises an upper door ring, a lower door ring, a shuttle, a shuttle push wheel and a shuttle rear wheel. The peripheral surface of the shuttle rear wheel and the peripheral surface of the shuttle push wheel are provided with magnets with the same polarity, the lower edge of the upper door ring and the upper edge of the lower door ring are respectively provided with magnets which form an inner circle and an outer circle and are arrayed in a V-shaped mode, meanwhile, the lower edge of the upper door ring and the upper edge of the lower door ring are respectively provided with a plurality of warp yarn passing grooves, and the two side edges of the shuttle are respectively provided with one or more magnets. The warp yarn passes through a gap between the magnets of the two wheels and the warp yarn passing grooves of the upper door ring and the lower door ring without being damaged. The high-speed plastic circular weaving machine has the advantages that the warp yarn is prevented from being ground and damaged when plastic woven bags or plastic mesh bags are woven through the circular weaving machine, the failures such as yarn breakage and shuttle flying are effectively avoided, the running speed of the circular weaving machine can be improved by more than 30%, and energy is saved by more than 30%.

Owner:黄美昌

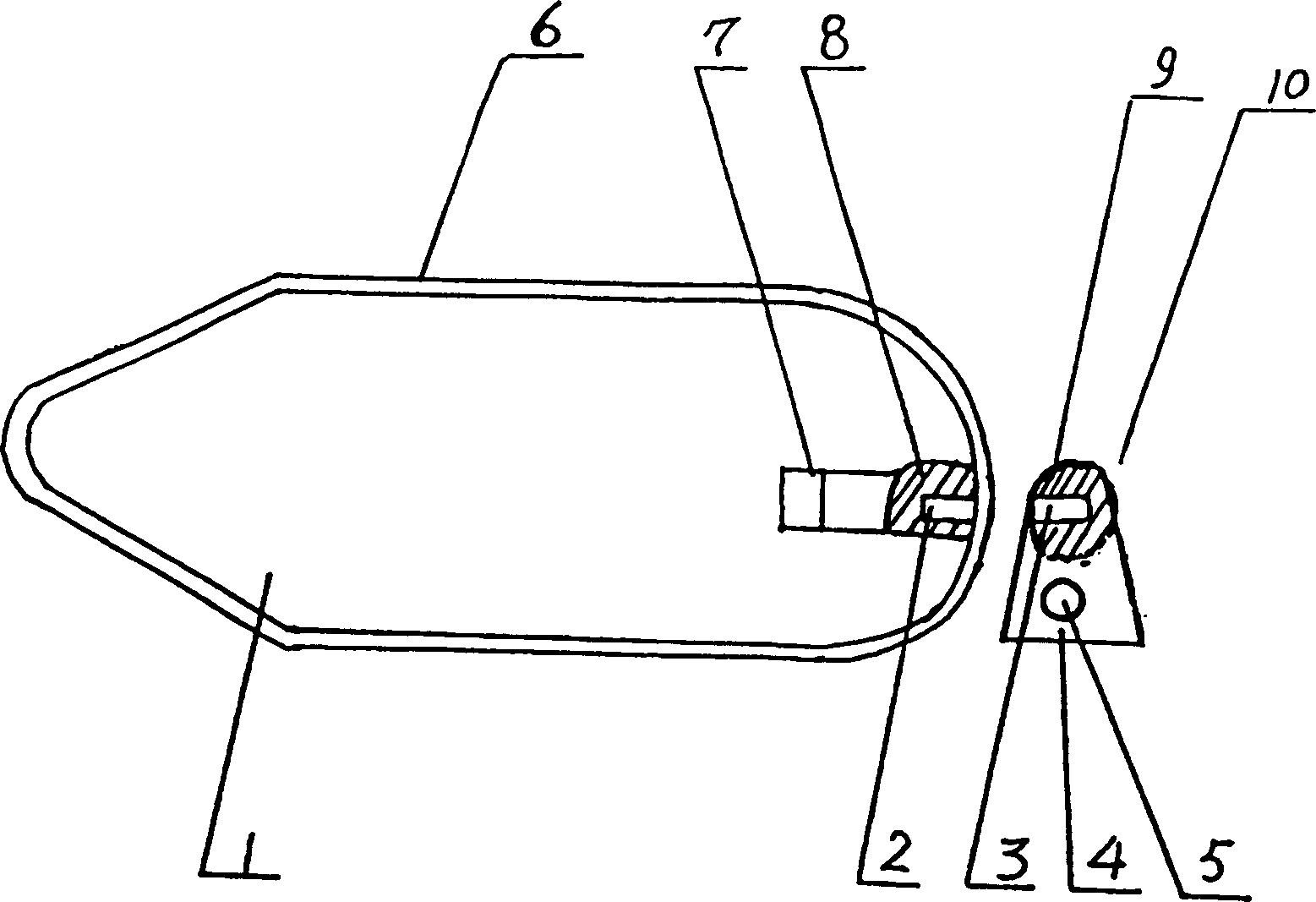

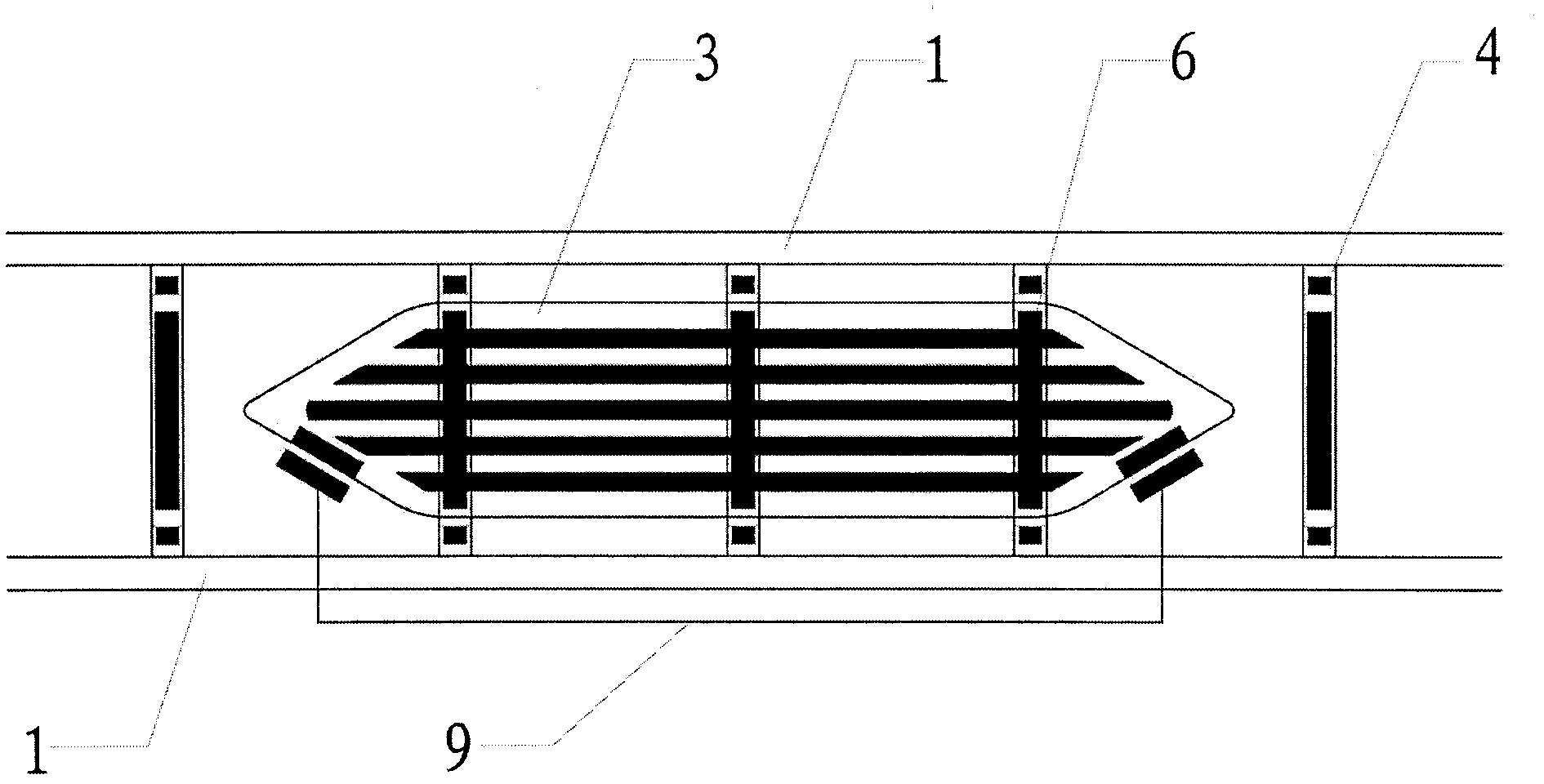

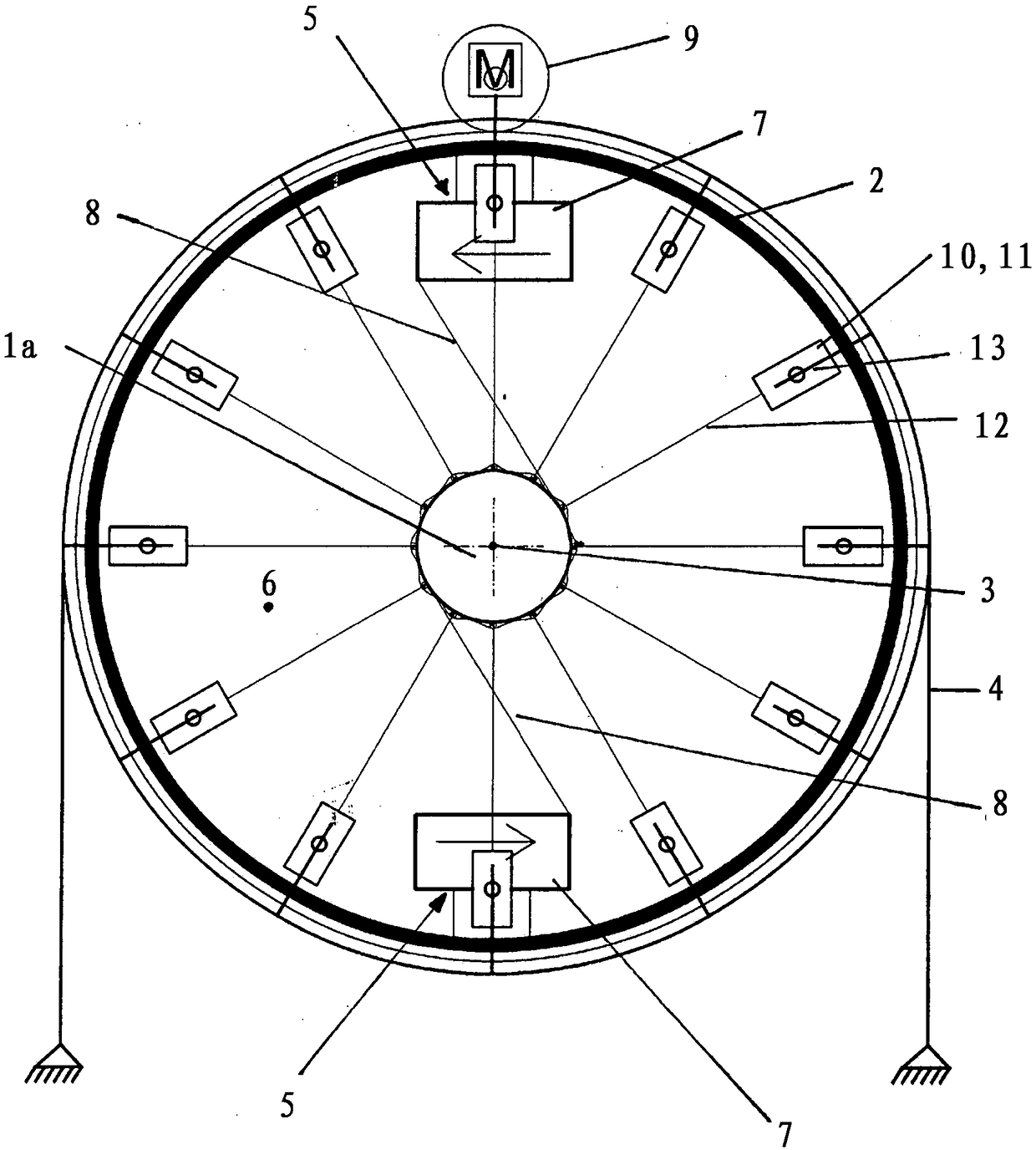

Non-contact shuttle device for circular weaving machine

The invention discloses a non-contact shuttle device for a circular weaving machine, which mainly comprises a fixing ring (1), outer palm fiber (2), a magnetic shuttle body (3), magnetic seats (4), inner palm fiber (5), magnets (6), weft yarns (7), warp yarns (8) and maintaining frames (9), wherein at least 32 magnetic seats (4) are uniformly arranged on the round fixing ring (1), at least five homopolar magnets (6) are arranged on the inner plane of the magnetic seat (4), at least five magnets (6) which have the magnetic poles opposite to magnetic poles of the magnetic seat (4) and have the same polarity are arranged in positions on the magnetic shuttle body (3) corresponding to the magnetic seat (4), at least four maintaining frames (9) are arranged in the fixed ring, and a magnet (6) with the upward magnetic poles is respectively arranged at the left side and the right side of the maintaining frame (9). The non-contact shuttle device has the beneficial effects that the energy source consumption is reduced by more than 40 percent, the equipment noise is greatly reduced, the consumption of wearing parts is mostly avoided, and the nearly once production efficiency is improved.

Owner:胡圣桃 +1

Circular weaving machine and method for producing a hollow profile-like fabric

Owner:INNOTEC LIGHTWEIGHT ENG & POLYMER TECH

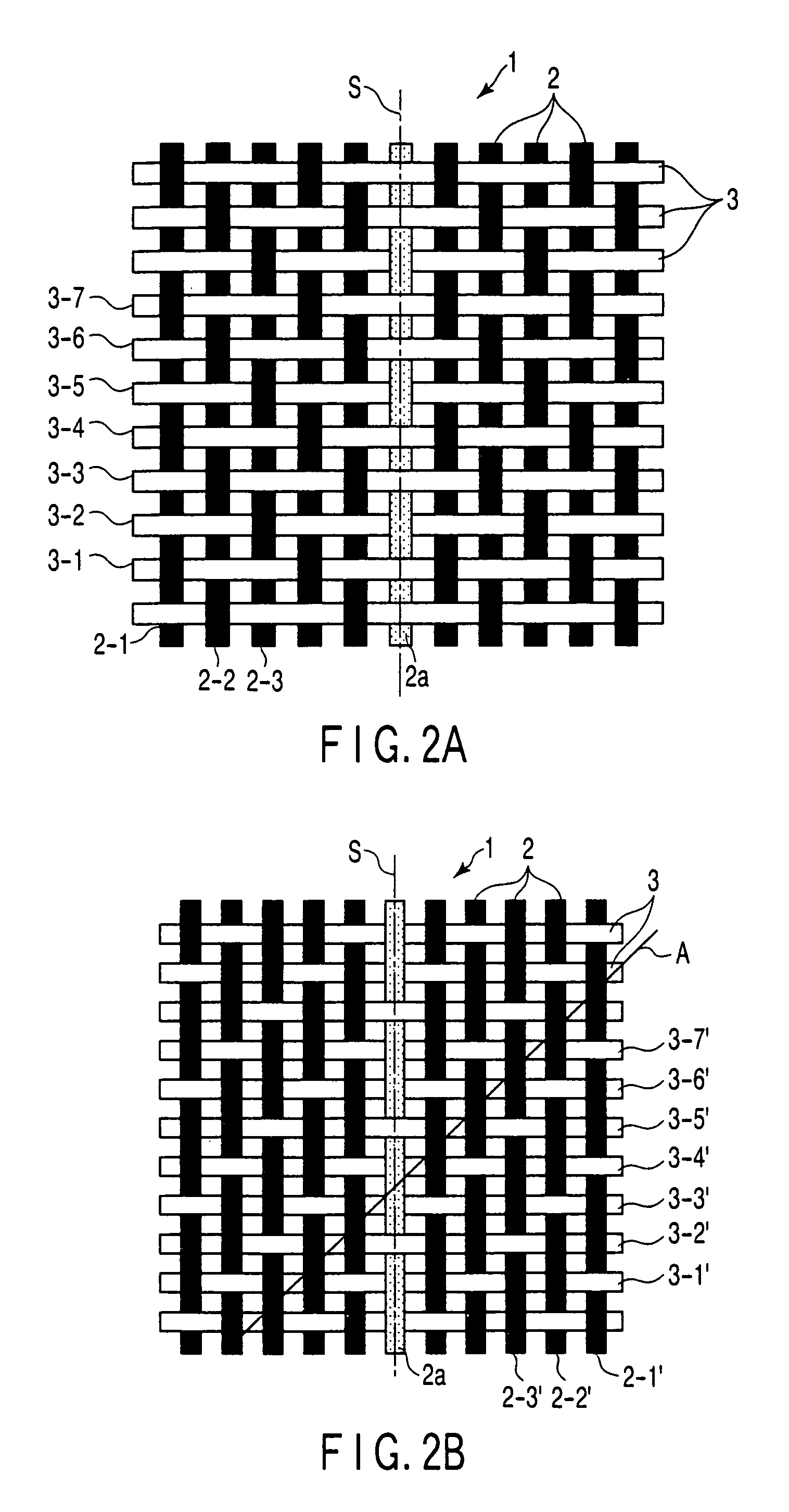

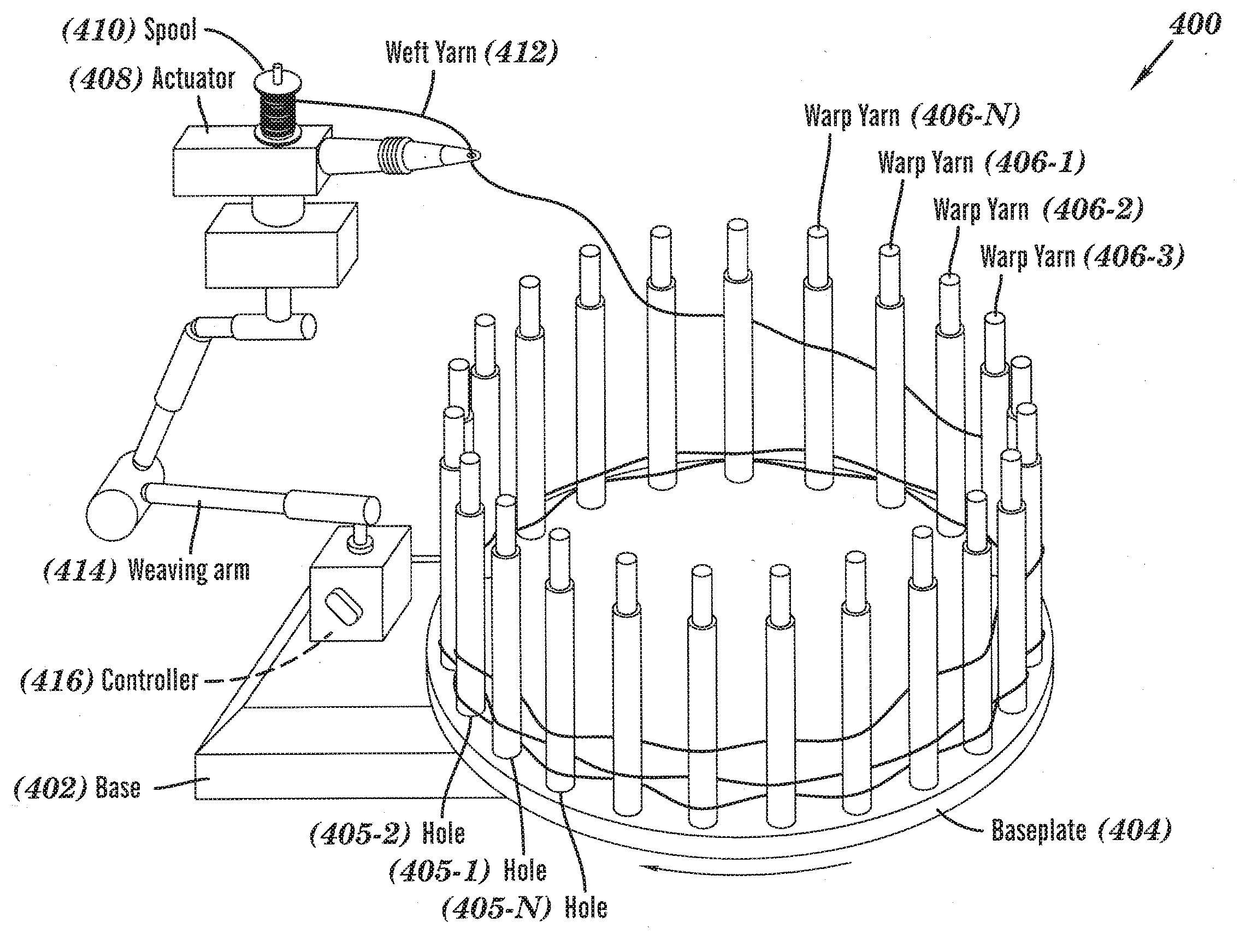

Systems and methods for creating three-dimensional woven textile products

Described herein are techniques for creating a three-dimensional woven textile products. A method includes rotating strands of warp yarns, where each strand of warp yarn is in a direction away from a surface, in a circular motion while moving a strand of weft yarn forwards and backwards in a direction parallel to the surface so as to cause the strand of weft yarn to alternately weave in and out of the strands of warp yarn. The method includes moving the strand of weft yarn in a direction away from the surface so as to cause the strand of weft yarn to alternately weave in and out of the strands of warp yarn at a different height to create a three-dimensional woven textile product. The method includes supplying at least one of the strand of warp yarn or the strand of weft yarn with a yarn generator.

Owner:UNSPUN INC

Magnetic weft insertion method of circular knitting machine

The invention relates to a magnetic weft inserting method of a round braider. A group of magnets are respectively arranged at the front and the rear sides of a weft shuttle, namely, the contact part of a shuttle pushing device and a shuttle blocking rod, by utilizing the principle of homosexual repulsion, to keep a certain distance between the weft shuttle and the shuttle pushing device and between the weft shuttle and the shuttle blocking rod so as to prevent the direct contact, extrusion and abrasion of warp yarns, thereby being capable of widening the choosing scope of the yarn types of the round braider, improving the mechanical performance of a fabric and developing the application field of the fabric.

Owner:JIANGNAN UNIV

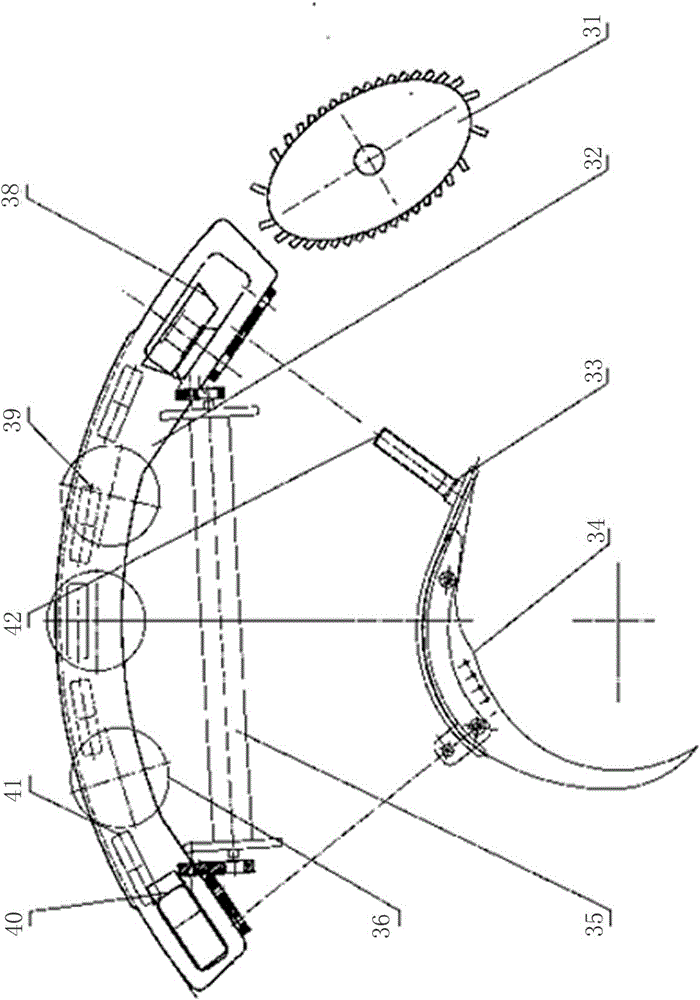

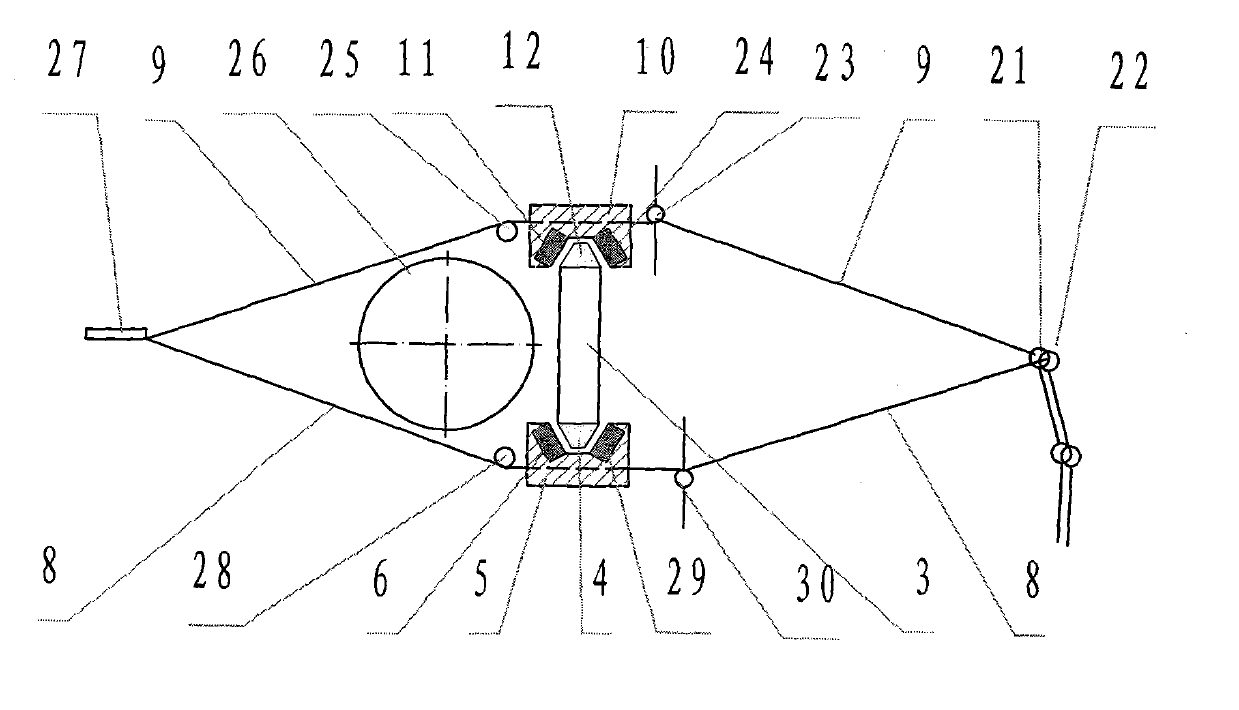

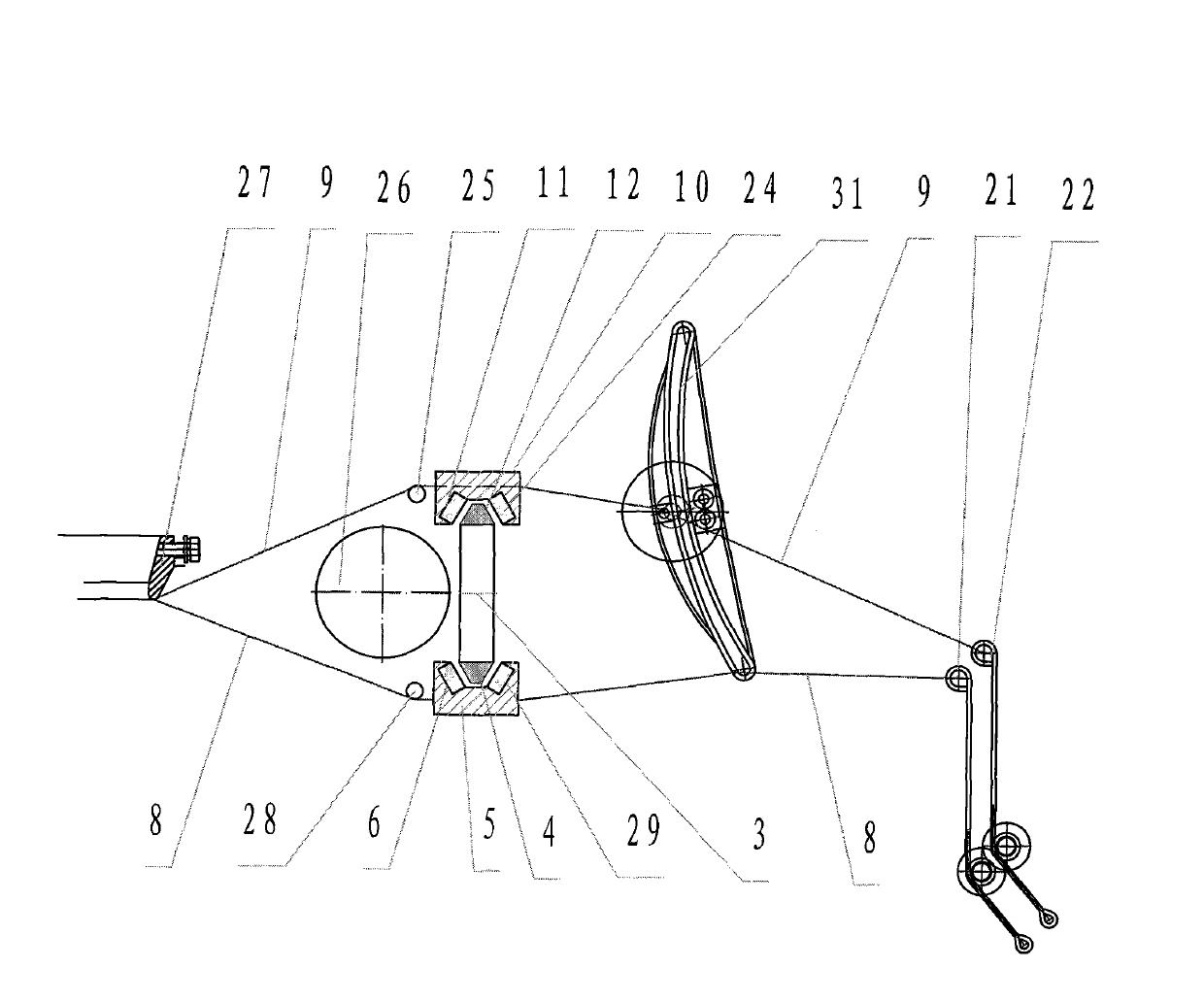

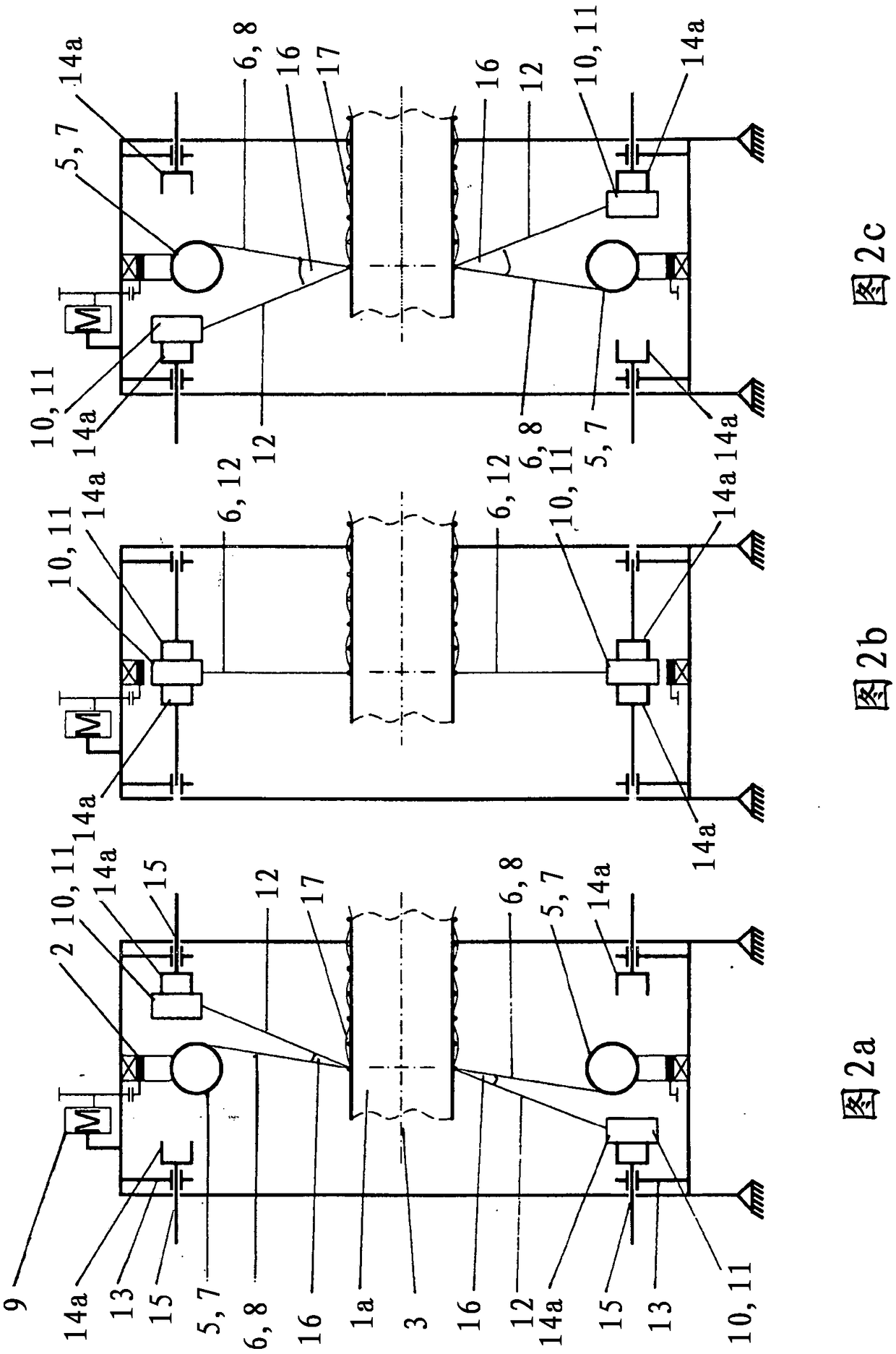

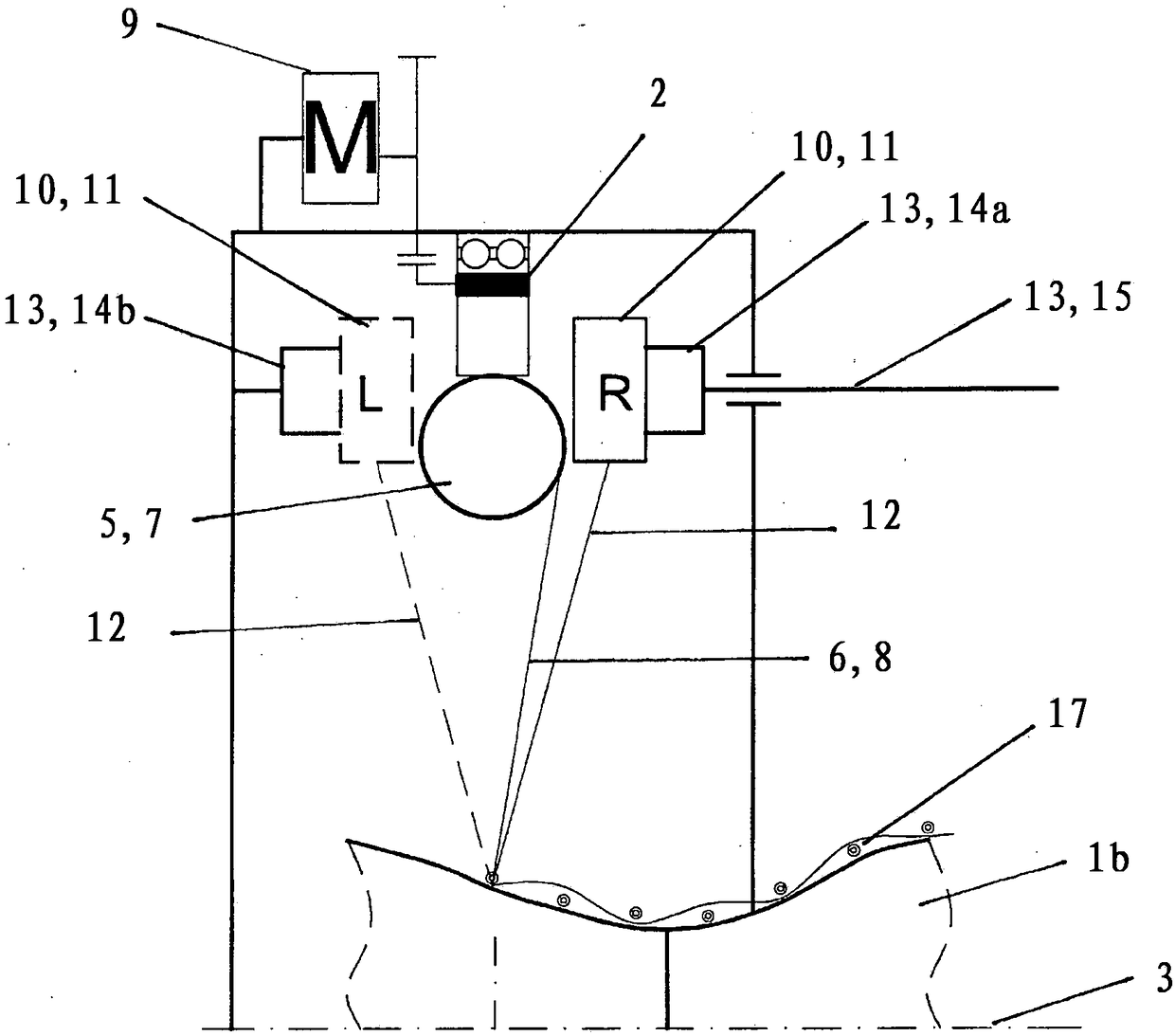

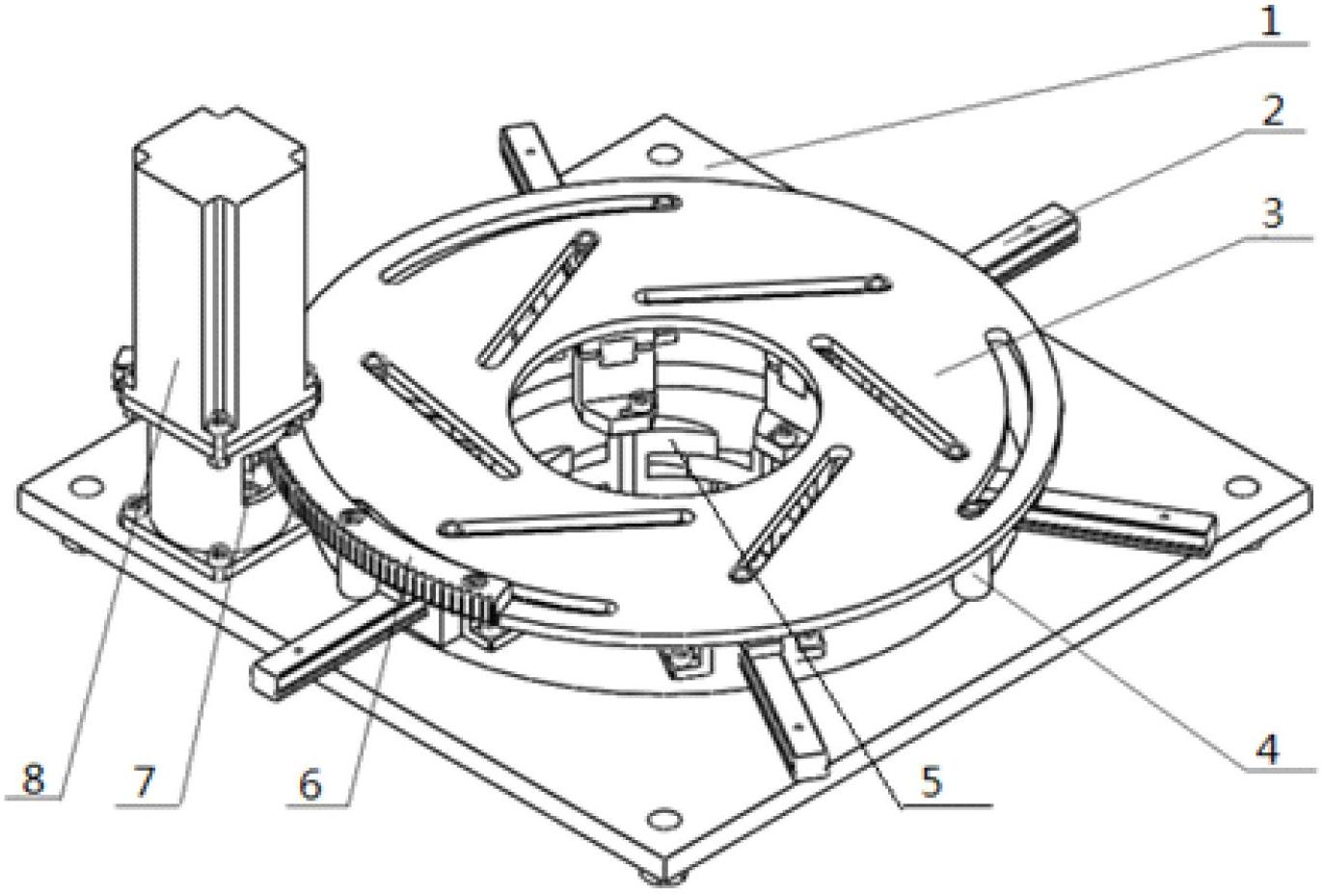

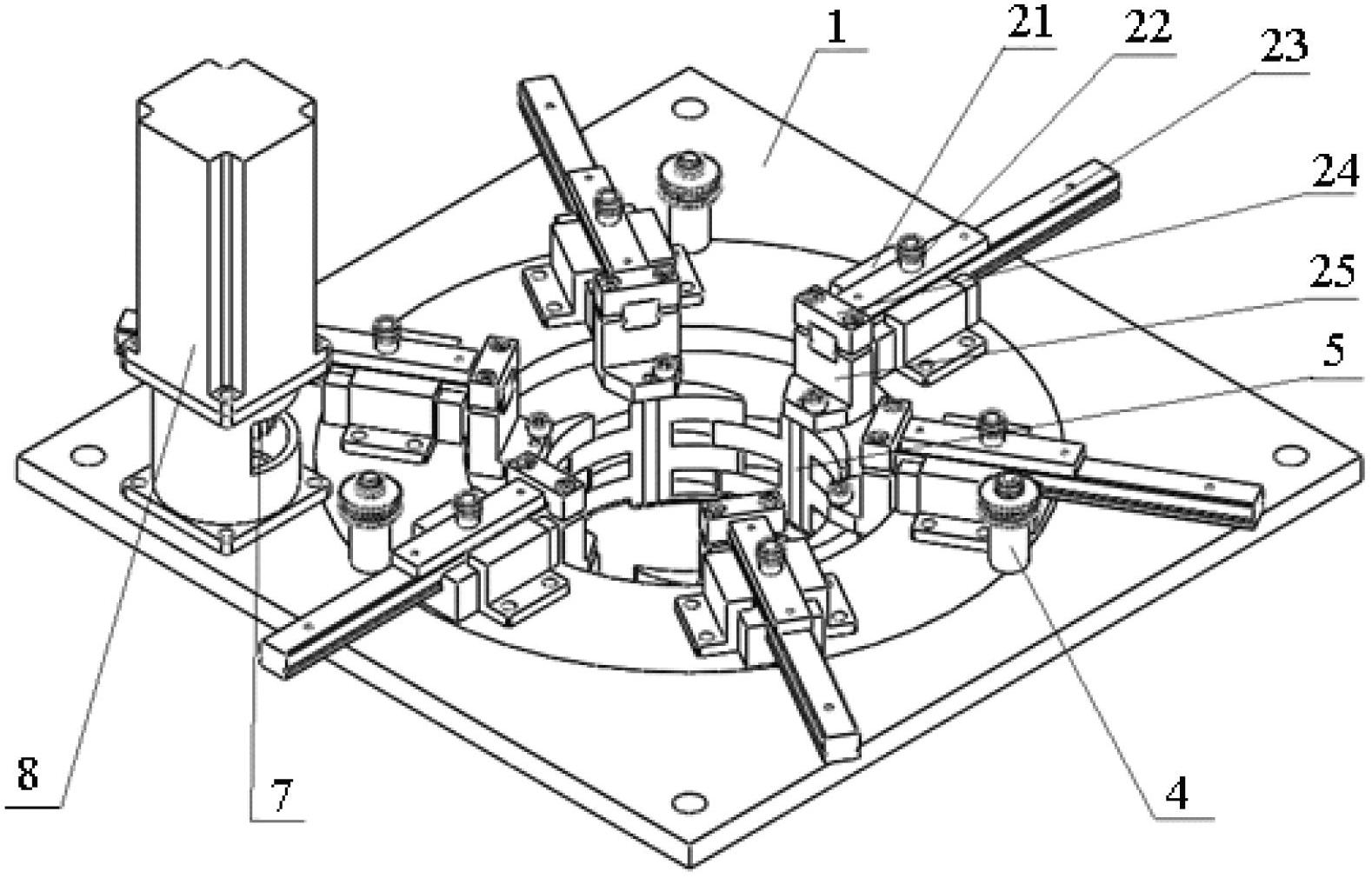

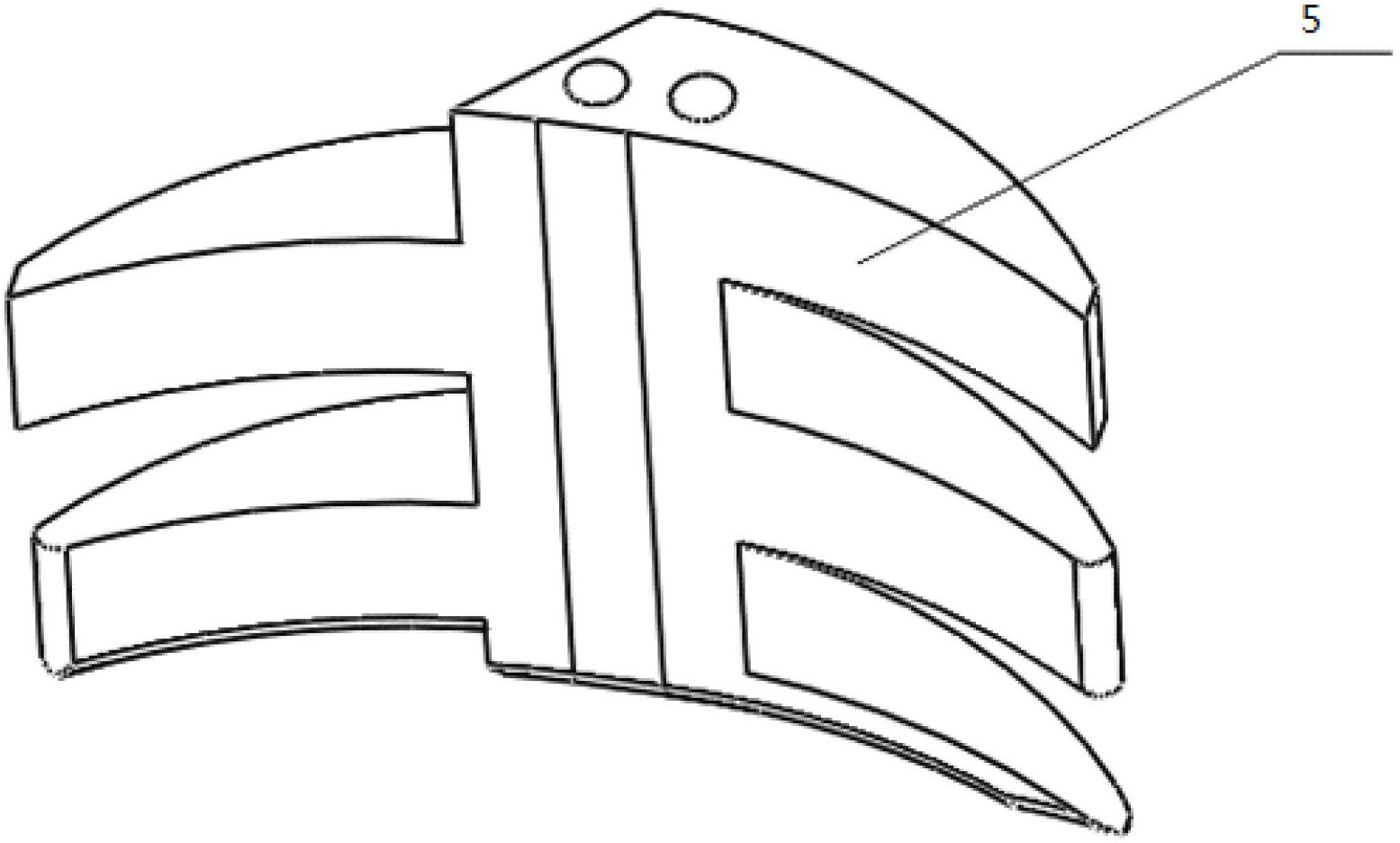

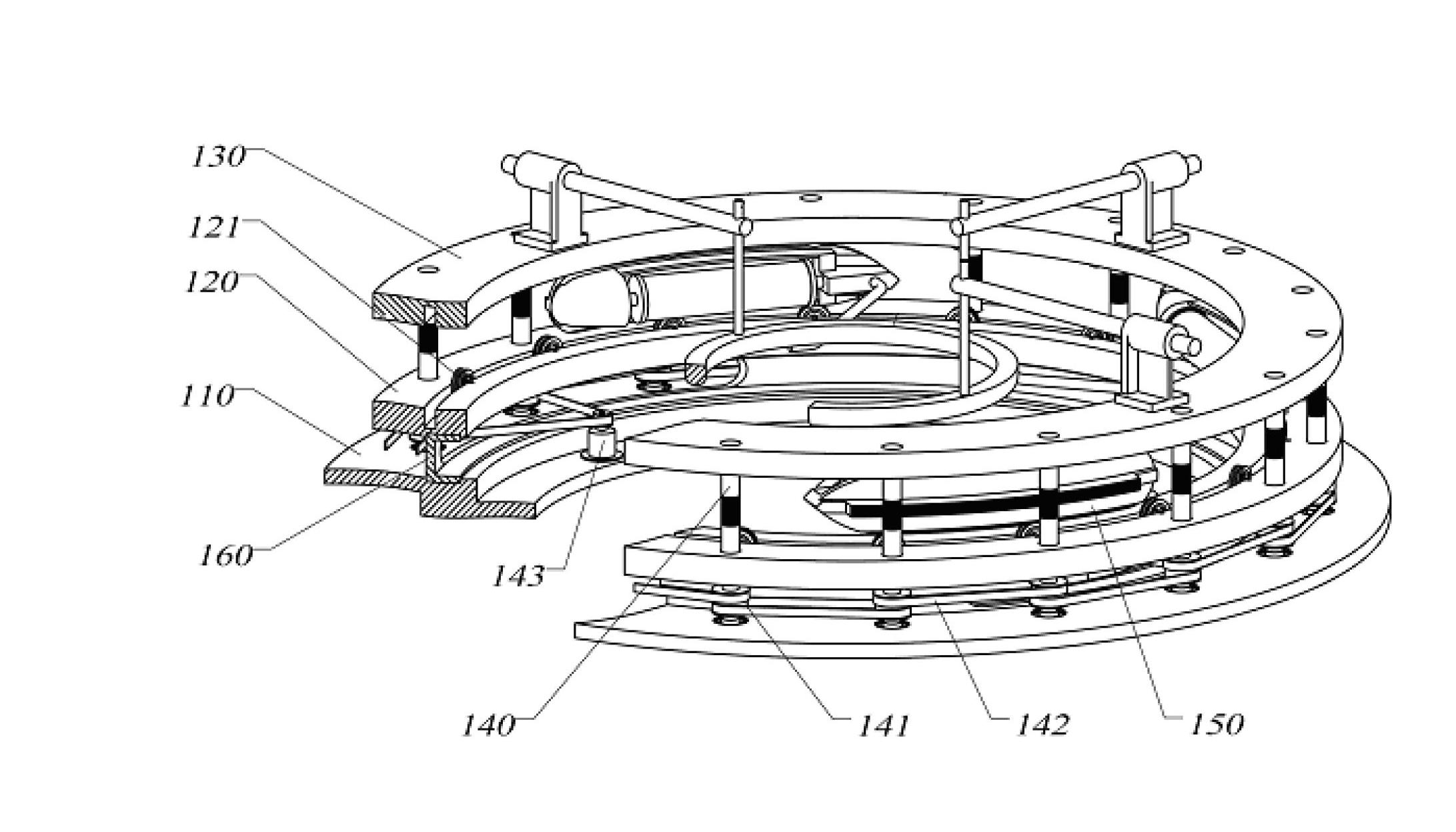

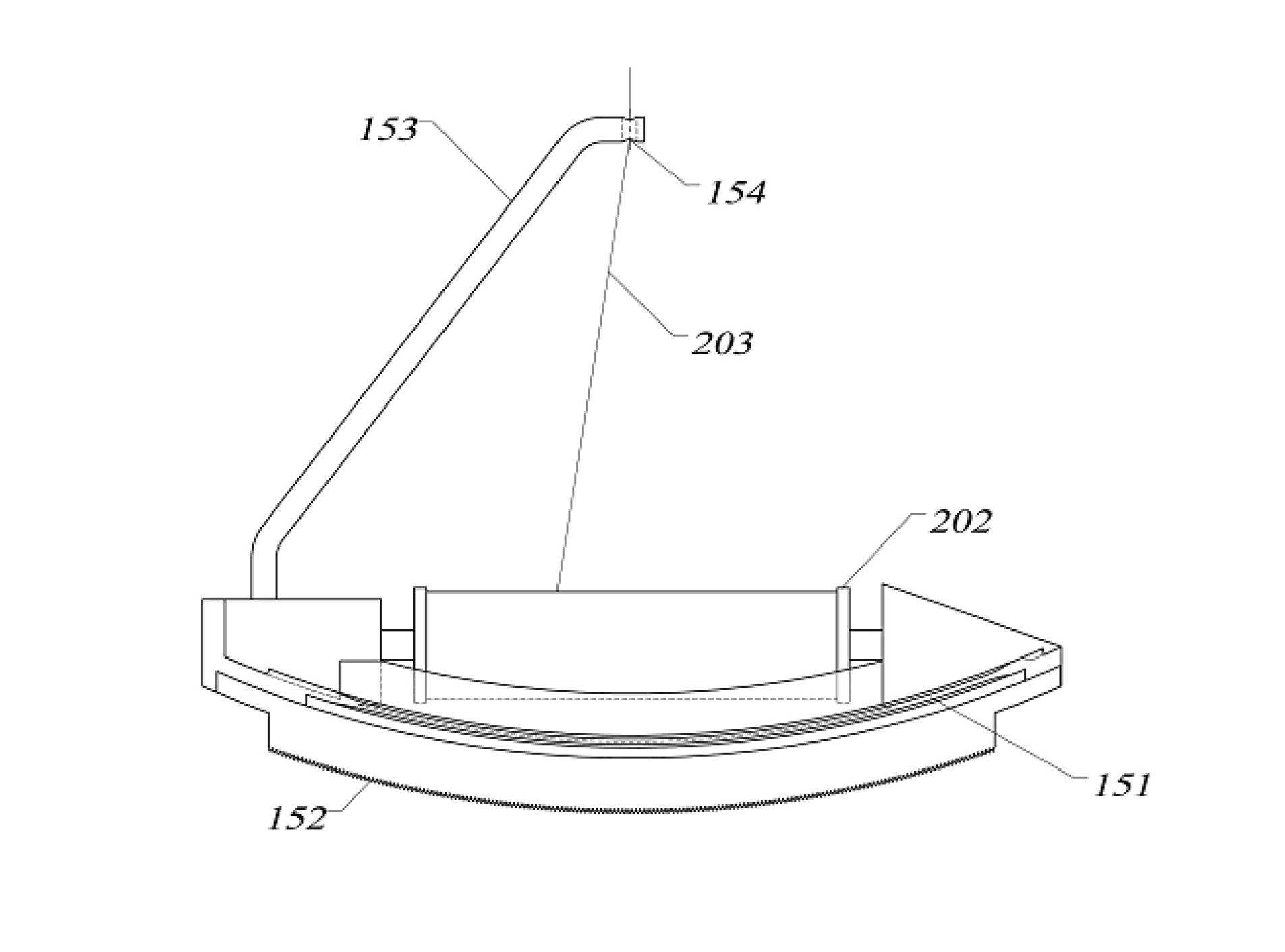

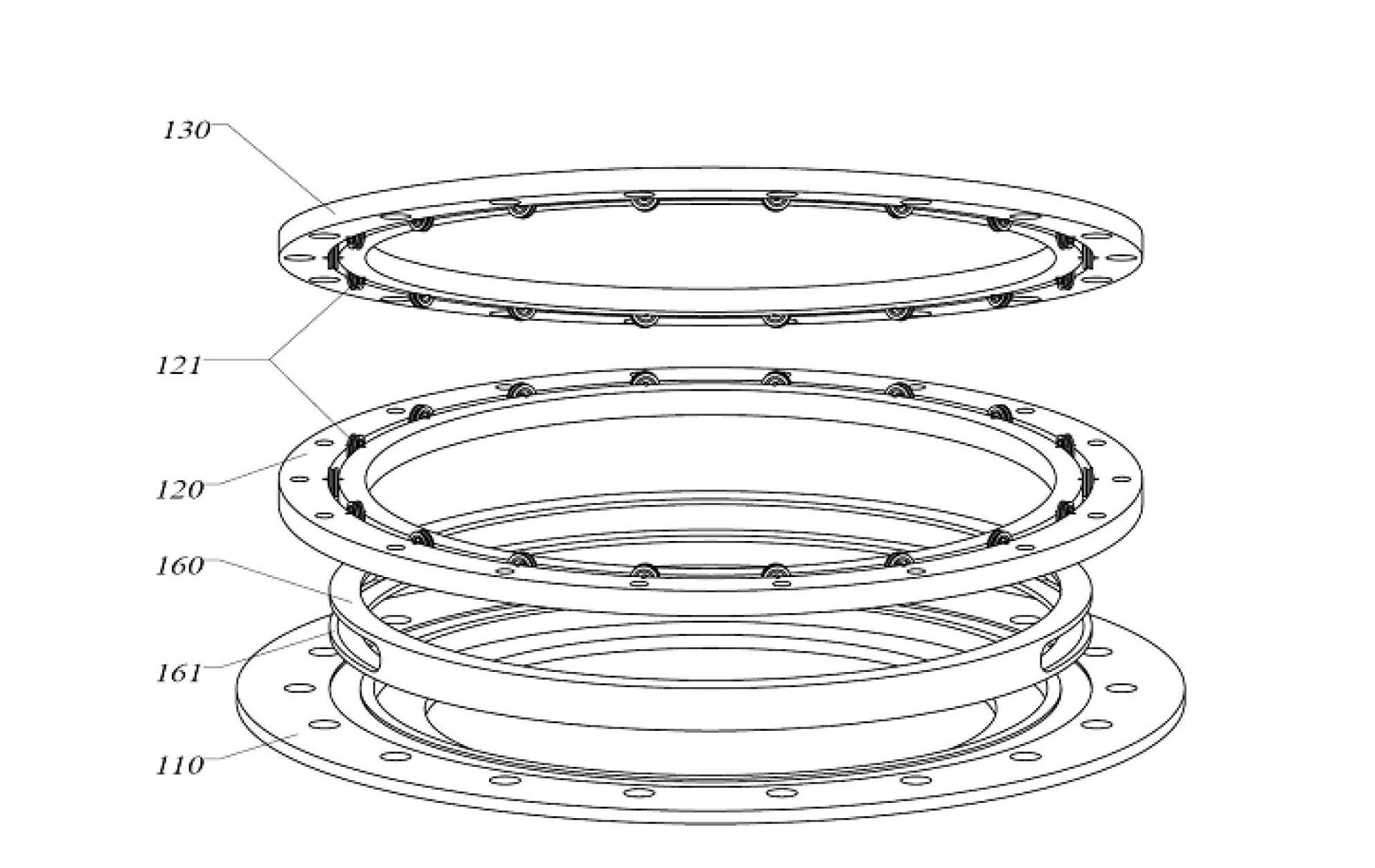

Reducing control mechanism of loom

InactiveCN102677376ARealize dynamic controlSimple structureCircular loomsBraidGear wheelElectric machinery

The invention relates to a reducing control mechanism of a loom, comprising a base, wherein the base is provided with a plurality of linear guide rail assemblies, the linear guide rail assemblies are uniformly distributed by taking an opening at the center of the base as the center of a circle; the end part of each linear guide rail assembly is provided with a size ring; the size rings penetrate through the opening at the center of the base to be combined into a closed region below the base; a disk grooved cam provided with the opening at the center is erected on each linear guide rail assembly; the disk grooved cams are respectively provided with line grooves which are in one-to-one correspondence with the linear guide rail assemblies; pin shafts of the linear guide rail assemblies are arranged in the line grooves and can slide along the line grooves; incomplete gears are arranged on the circumference of each disk grooved cam; rotation centers of the incomplete gears are coincided with the rotation centers of the disk grooved cams, and the incomplete gears are driven to rotate along axis of the disk grooved cams by virtue of a motor. By adopting the reducing control mechanism of the loom disclosed by the invention, dynamic control on the calibre of a fabric on a circular weaving machine can be realized.

Owner:DONGHUA UNIV +1

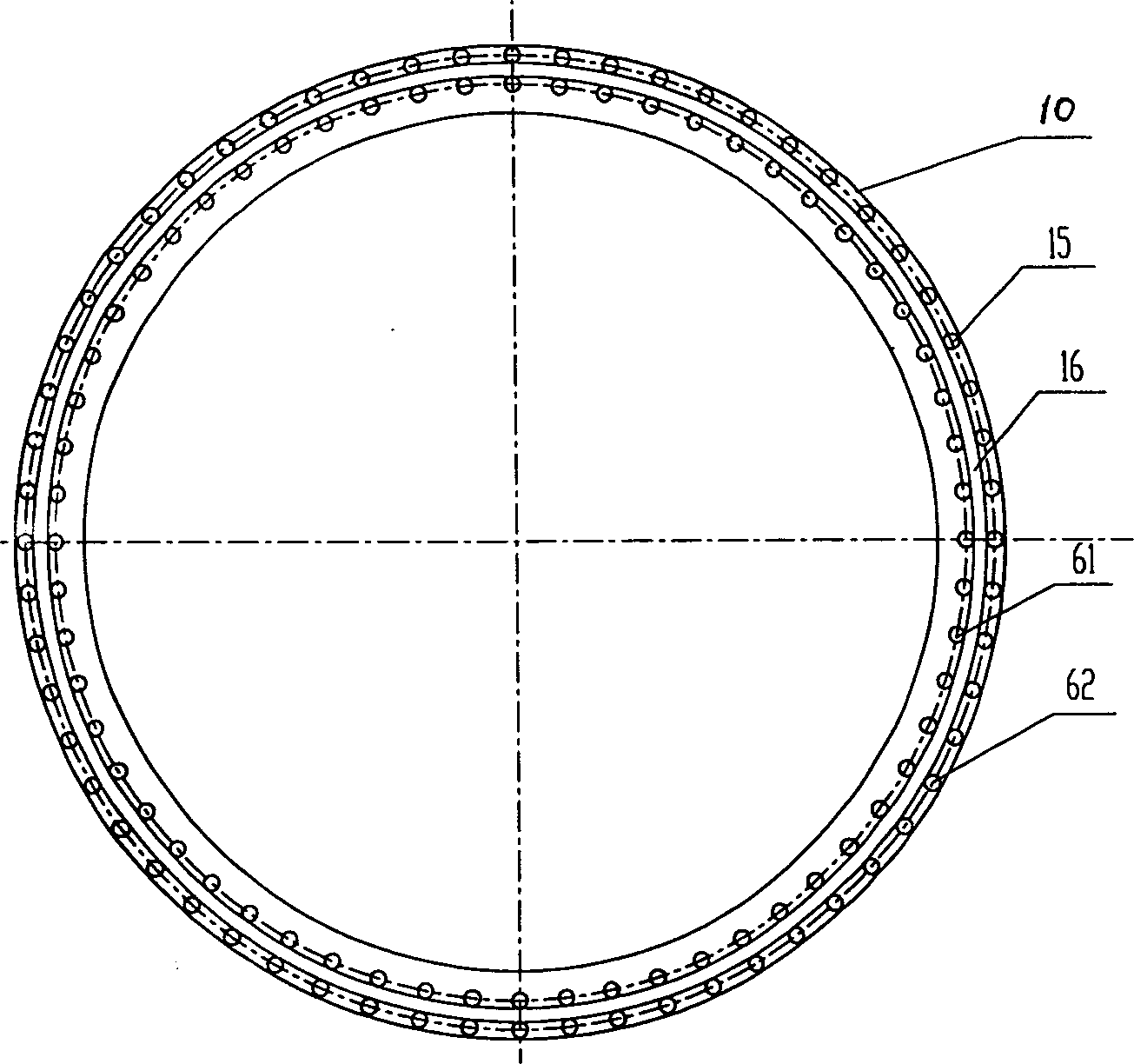

Plastic circular weaving machine

The invention discloses a plastic circular weaving machine and belongs to the field of plastic weaving machines. The problem that rollers are inconvenient to change in the prior art is solved. According to the technical scheme for solving the problem, the plastic circular weaving machine mainly comprises a mainframe, wherein the mainframe comprises a door ring assembly and a shuttle, the door ring assembly comprises an upper door ring and a lower door ring, multiple rollers are arranged between the upper door ring and the lower door ring and are connected with the door ring assembly through axles, the rollers are distributed in the peripheral direction of the door ring assembly and form a rolling track for the shuttle to operate, the shuttle is provided with an upper limiting wheel and a lower limiting wheel, the lower surface of the upper door ring is provided with an upper track surface for the upper limiting wheel to roll, the upper surface of the lower door ring is provided with a lower track surface for the lower limiting wheel to roll, a supporting part for retaining the separation distance between the upper door ring and the lower door ring is arranged between the upper door ring and the lower door ring, and supporting parts are located on the outer sides of the rollers to protect the rollers in the radial direction of the door ring assembly. The plastic circular weaving machine is mainly used for weaving plastic woven bags.

Owner:陈耀武

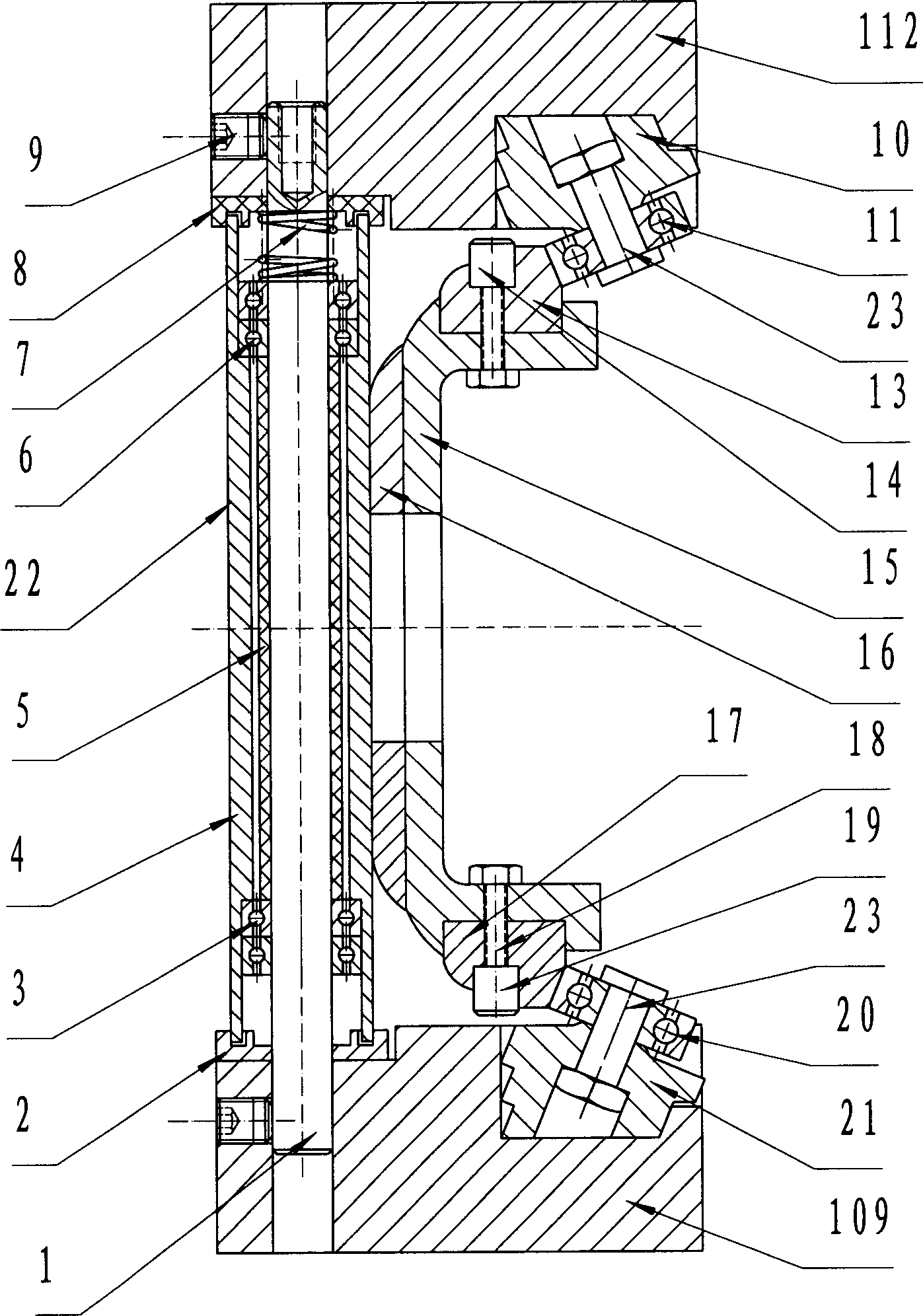

Circular shuttle guide raceway device

The invention relates to a circular shuttle guide raceway device. The device is provided with guide wheels on track surfaces of upper and lower door rings; shuttle guide columns with gears are arranged between the upper and lower door rings; guide strips are arranged at the upper and lower sides of shuttles and capable of being moved in V-shaped grooves of the guide wheels; arched racks are arranged on the back of the shuttles and capable of being meshed with the gears on the shuttle guide columns; when the device is working, a shuttle guide motor drives synchronous belt wheels at lower end of the shuttle guide columns through synchronous teeth-shaped belts to enable the shuttle guide columns to be rotated; and the meshing action between the gears on the shuttle guide columns and the arched racks on the back of the shuttles drive the shuttles to move forward on the guide wheels. According to the circular shuttle guide raceway device, the power of the shuttles is provided by the shuttle guide columns, so that the whole machine needs no shuttle pusher component; the scraping between organzine and shuttle pushers is avoided; therefore, the requirements of the device on intensity and durability of organzine are lowered; and the circular shuttle guide raceway device is suitable for weaving various silk threads with different intensities or low durability and capable of guaranteeing quality of products.

Owner:DONGHUA UNIV +1

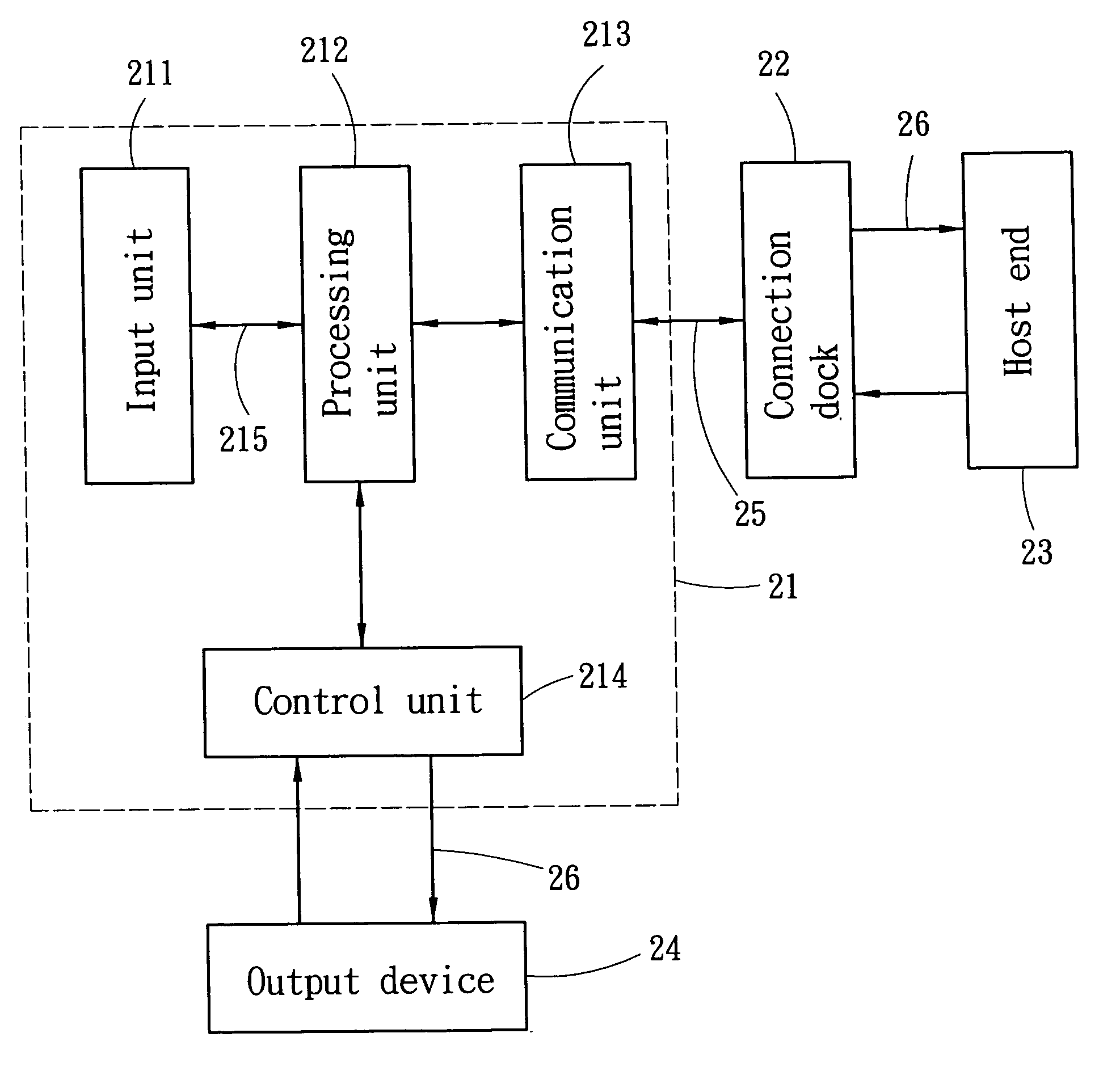

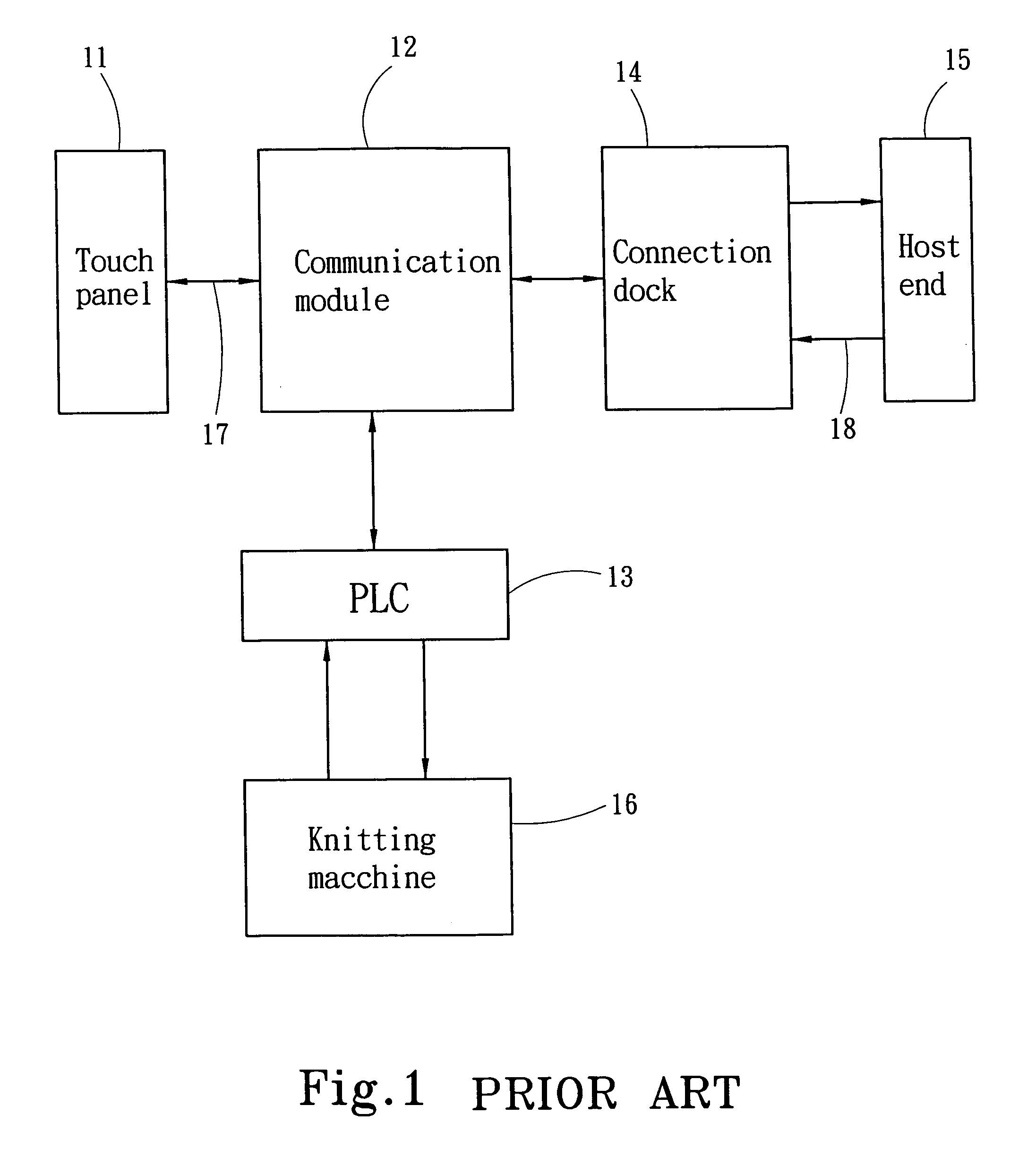

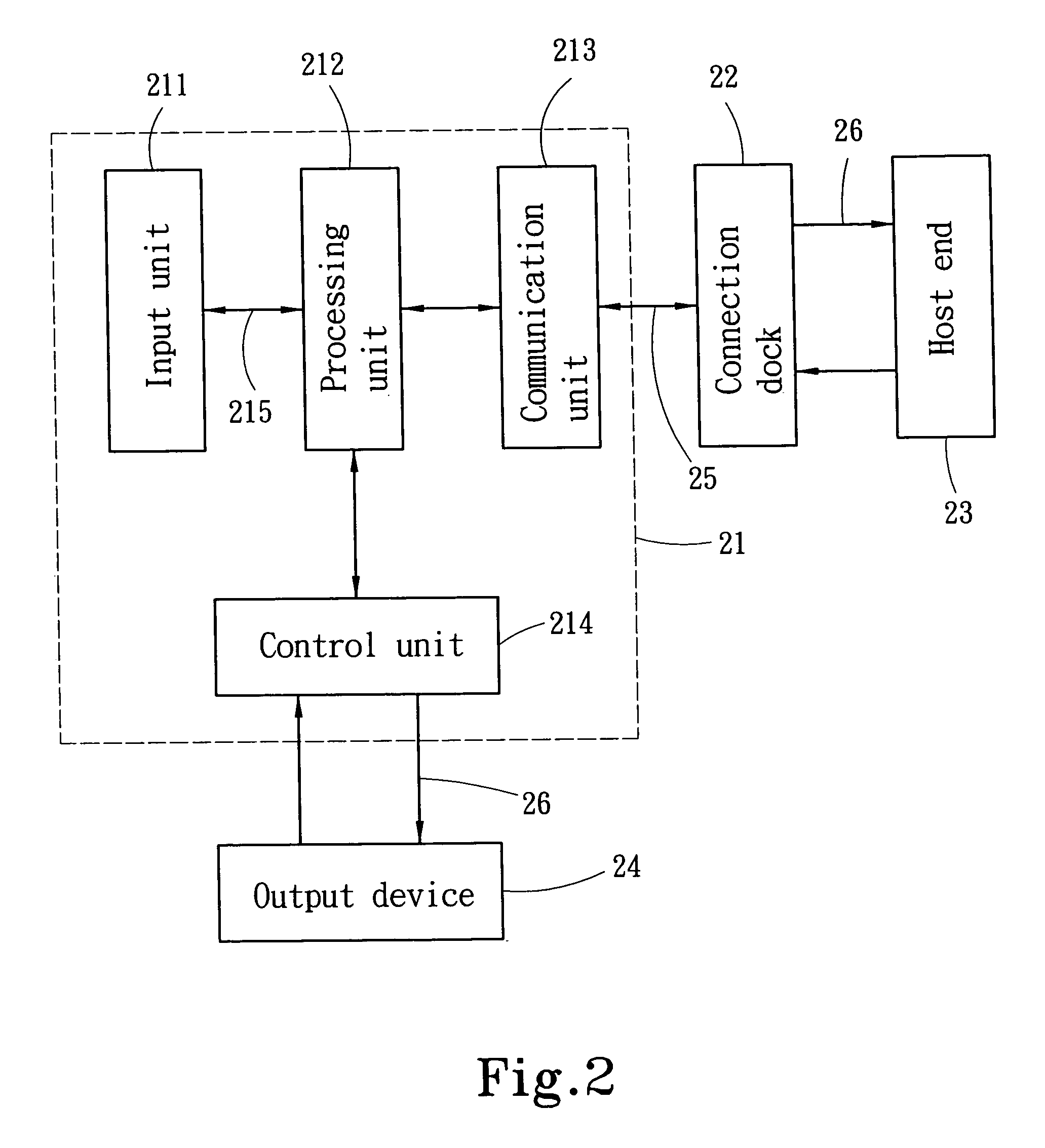

Micro-control apparatus for circular knitting machines

ActiveUS6931299B2Increase speedExtension of timeCircular loomsWeft knittingMicrocontrollerCommunication interface

Owner:PAI LUNG MACHINERY MILL CO LTD

Cylindrical jacket, jacket hose, suction hose, and cylindrical jacket manufacturing apparatus

InactiveUS20060162954A1Small pressure lossEven twistCircular loomsFlexible pipesEngineeringMechanical engineering

Owner:SAKURA GOMME KK

Air delivery conduit

ActiveUS9566408B2Prevent kinking and collapsing of wall structureImprove insulation performanceRespiratorsCircular loomsPositive airway pressure deviceCatheter

An air delivery conduit for conveying breathable gas from a positive airway pressure device to a patient interface includes a tubular wall structure constructed from a textile material. A reinforcing structure may be provided to the wall structure that is structured to prevent kinking or collapsing of the wall structure. The wall structure may include a warp having a plurality of lengthwise textile warp threads arranged in a circle and a weft having a textile weft thread that is woven through the warp threads.

Owner:RESMED LTD +2

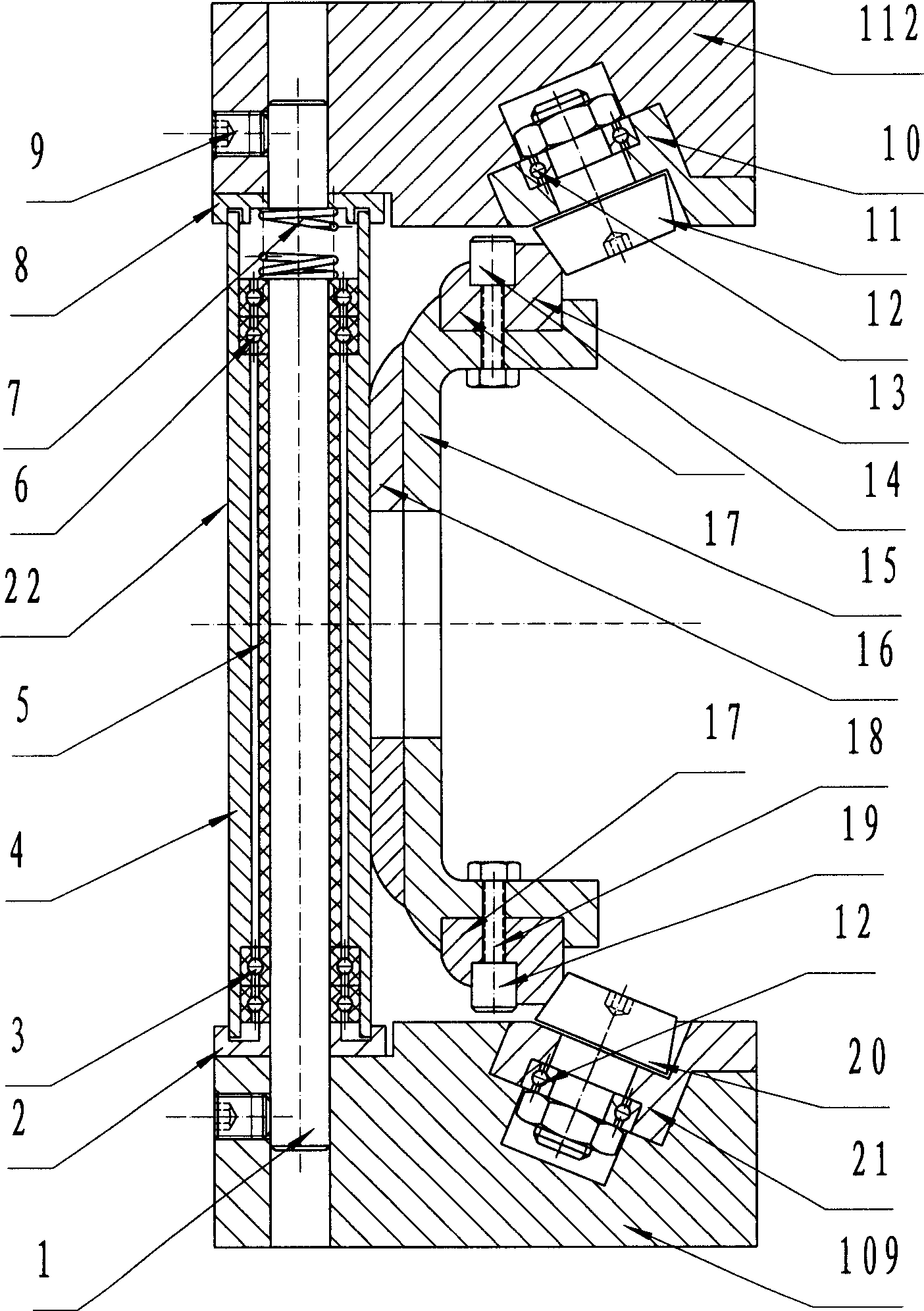

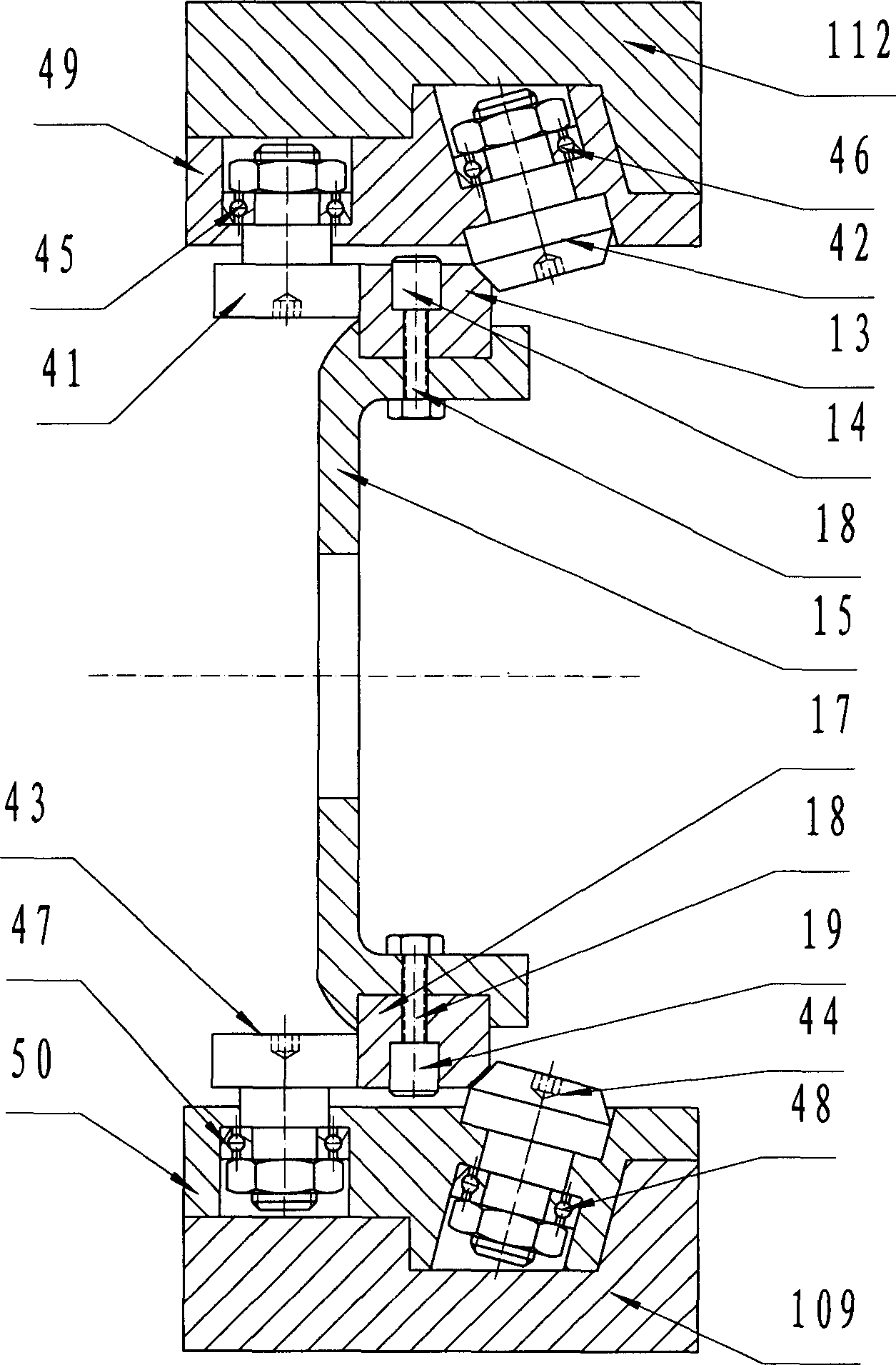

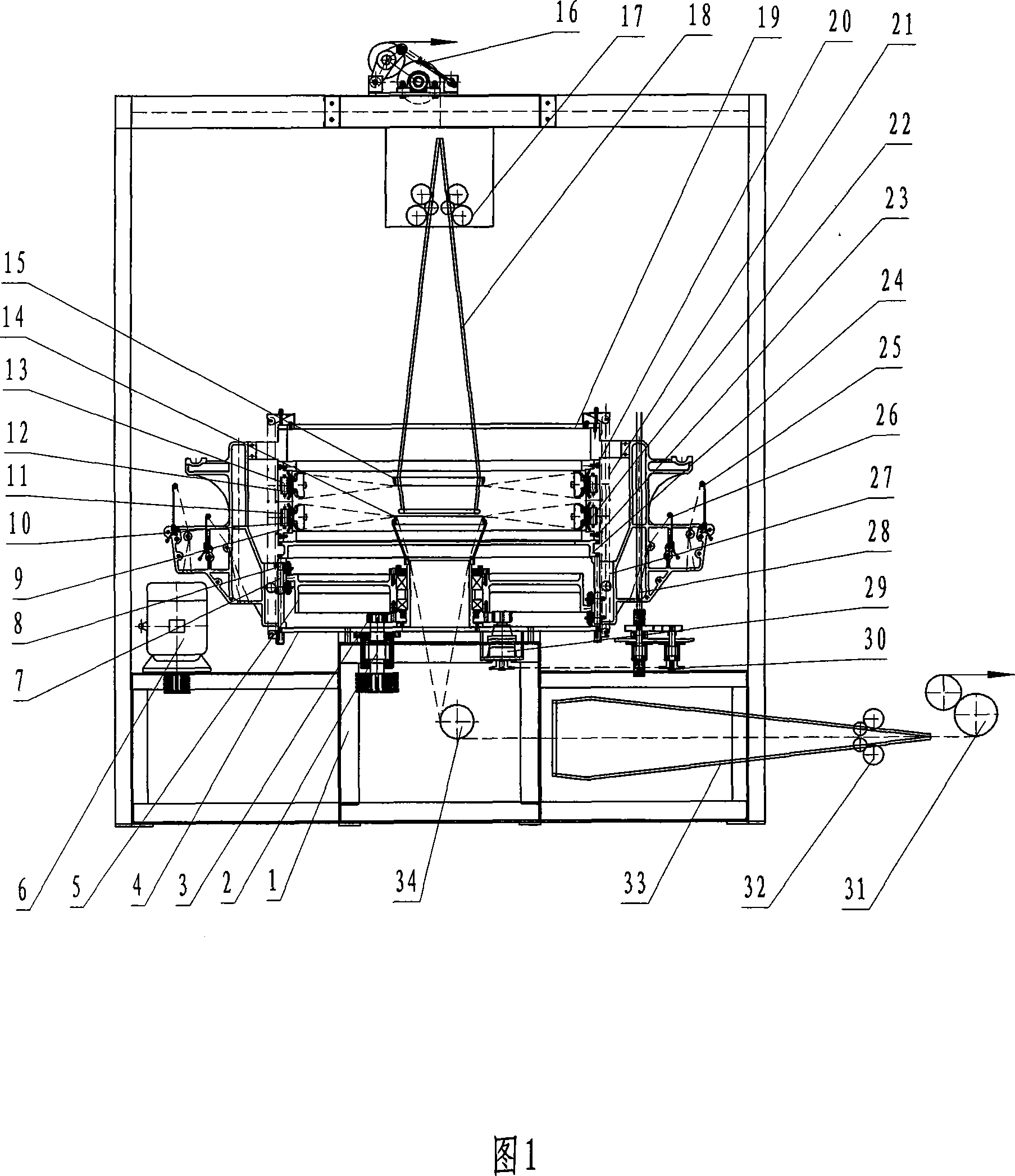

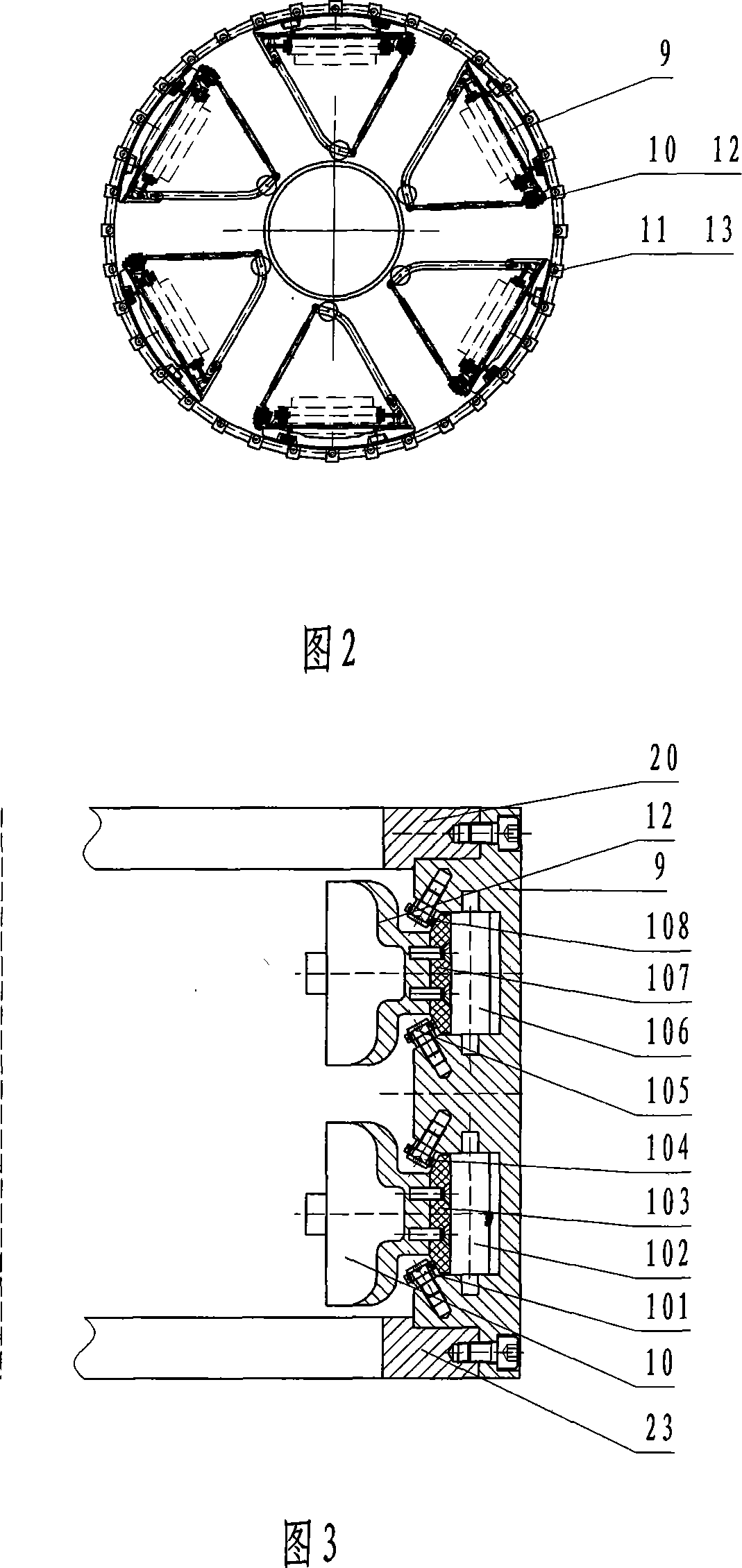

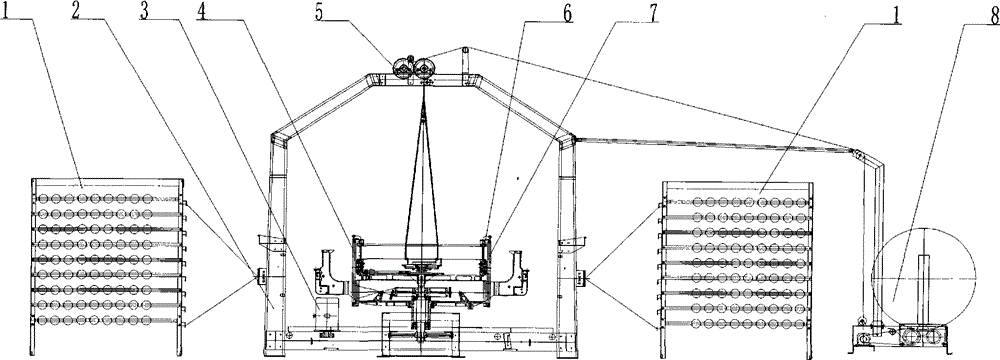

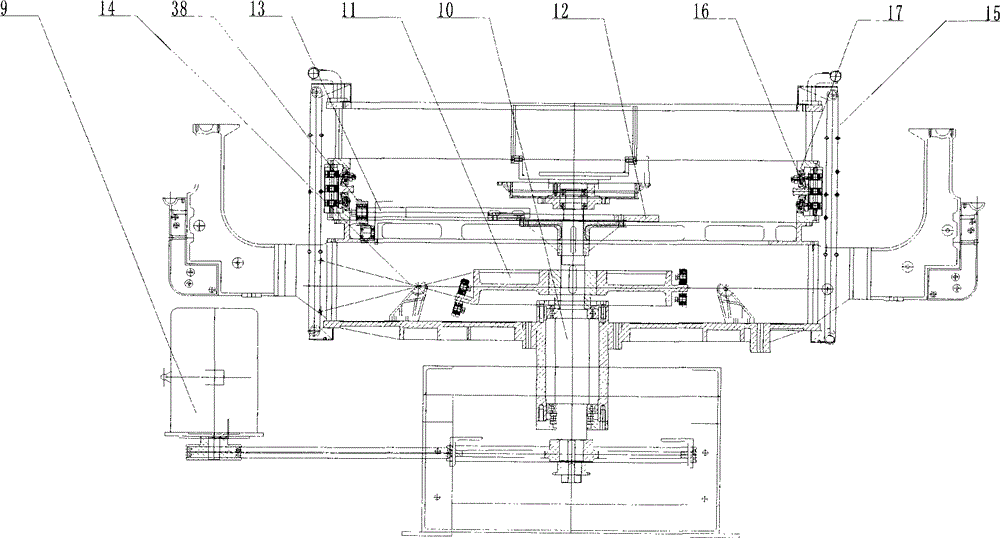

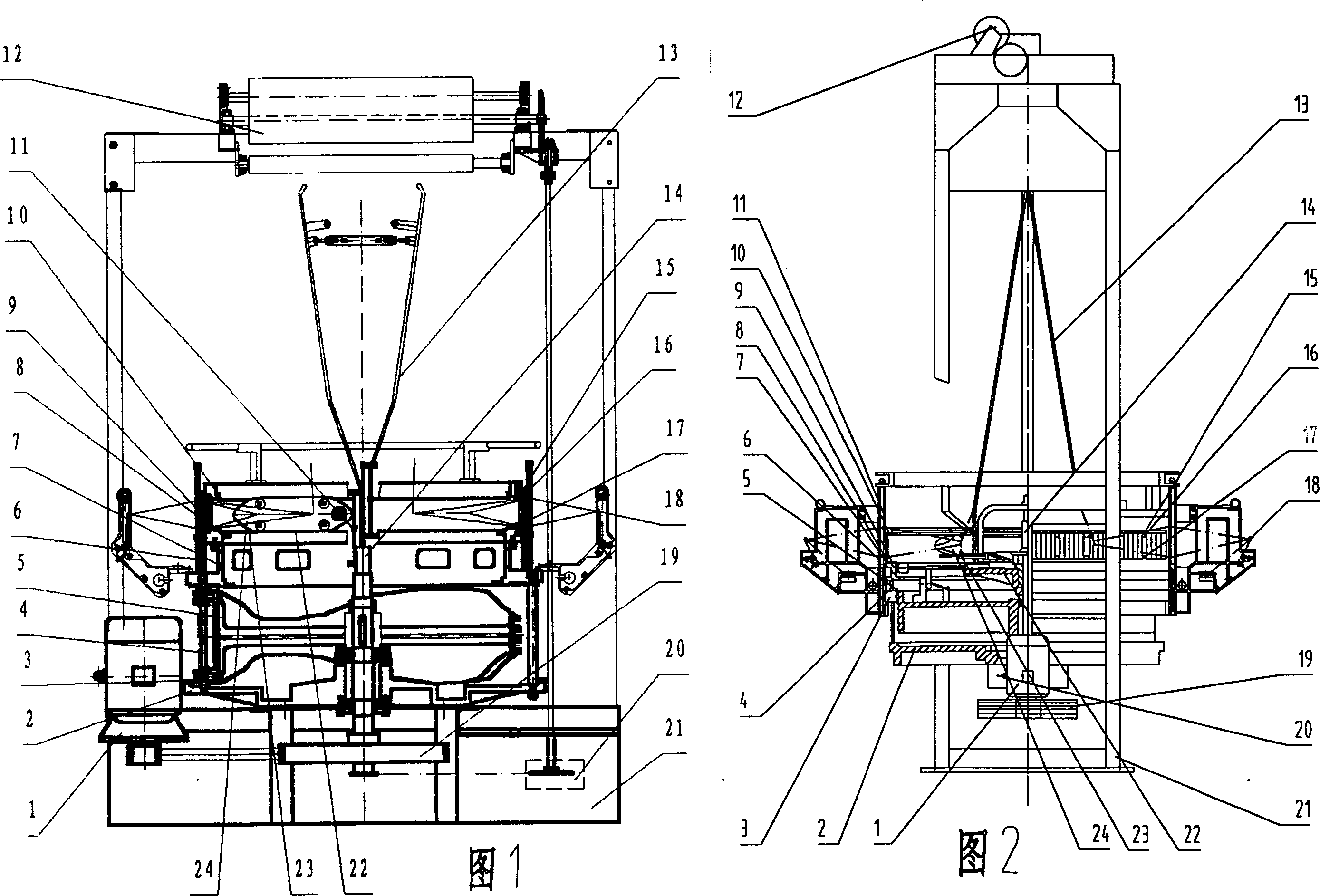

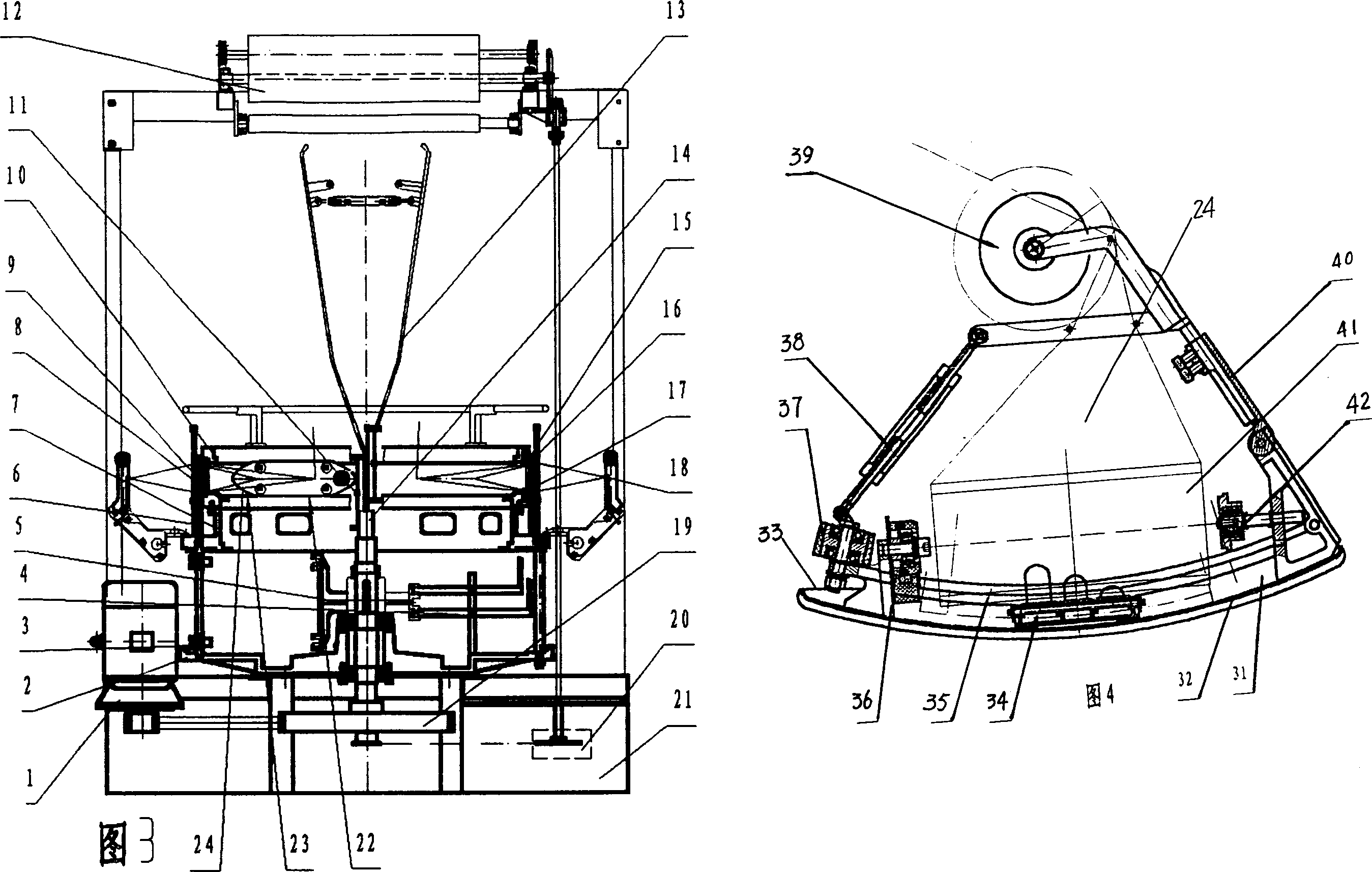

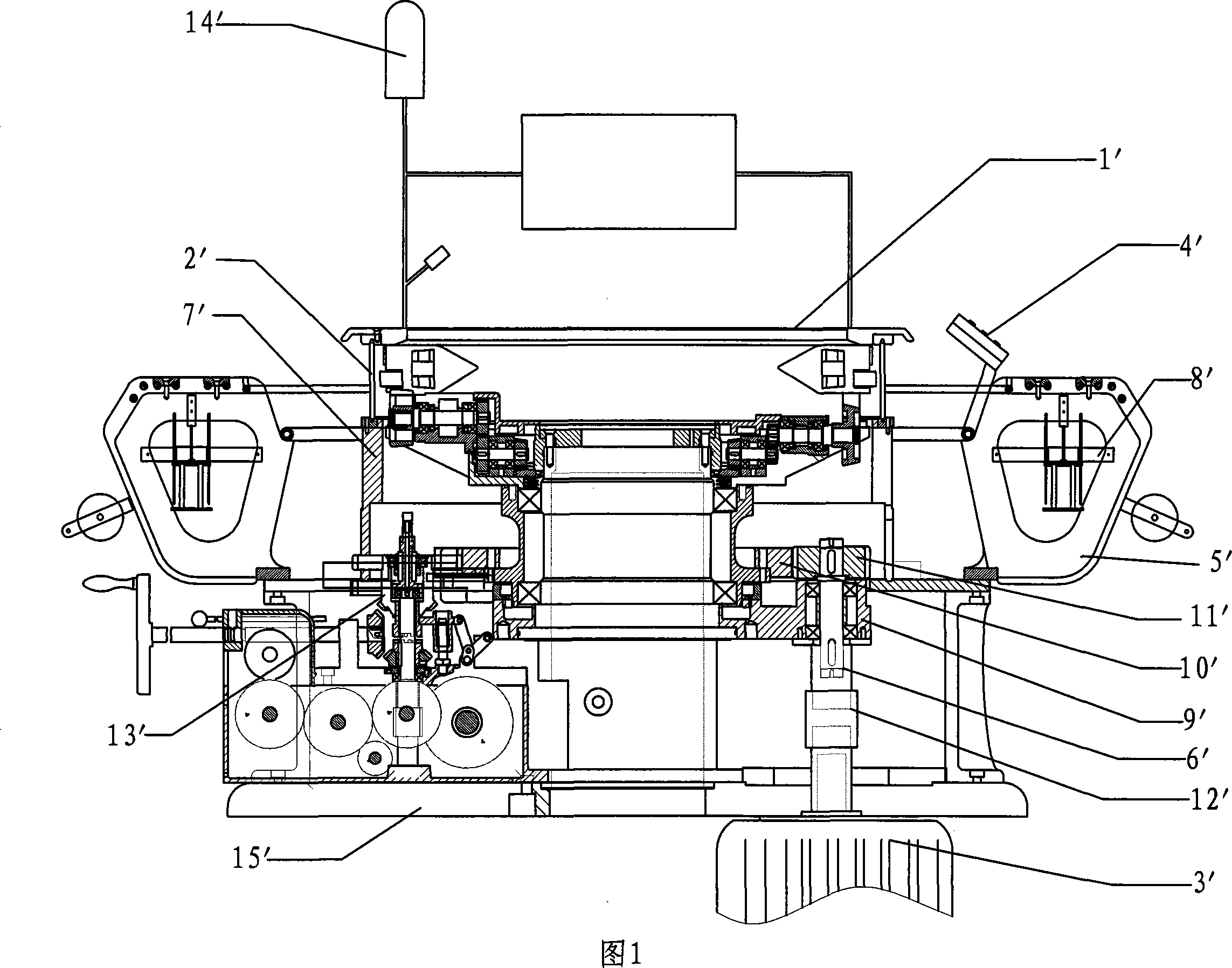

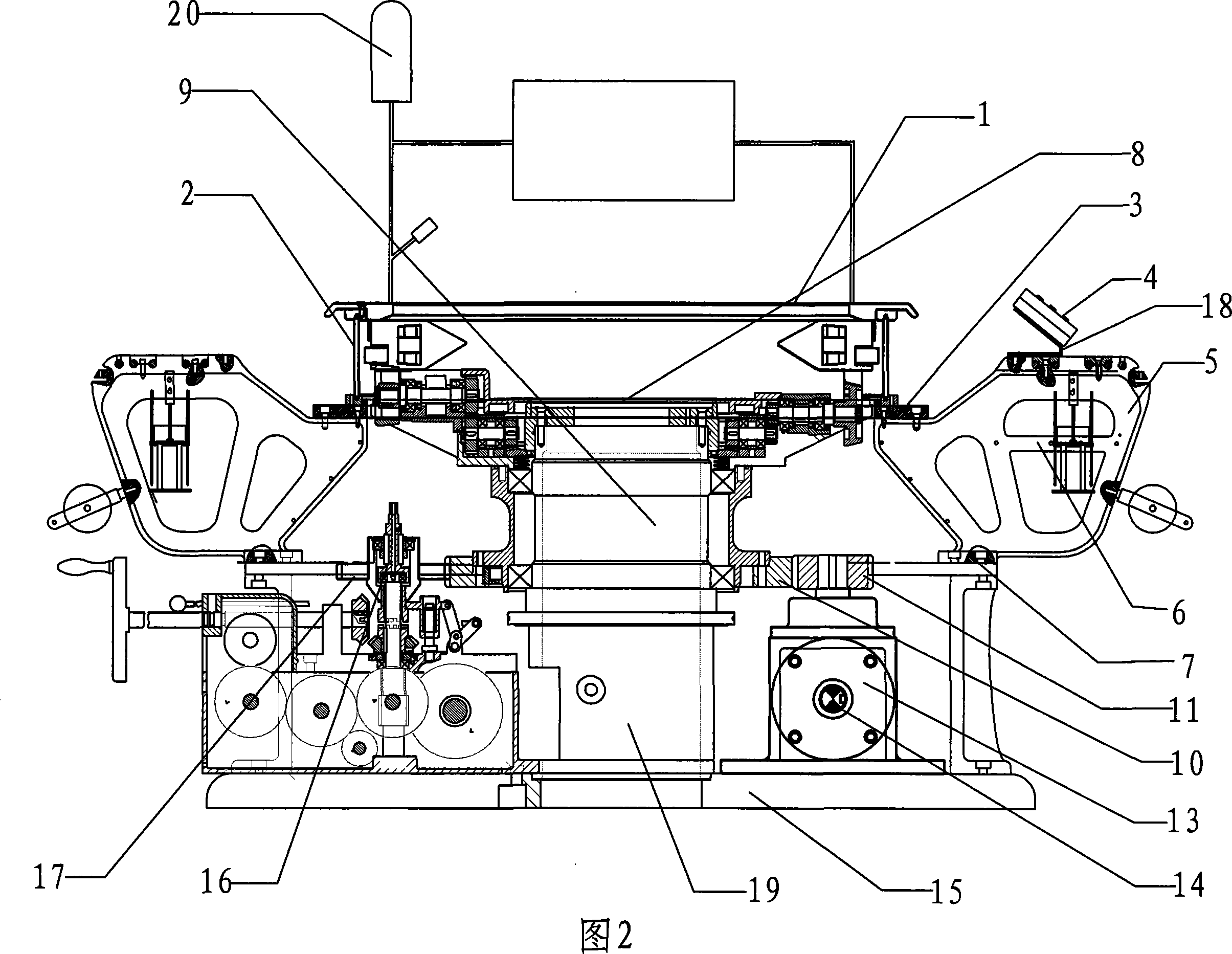

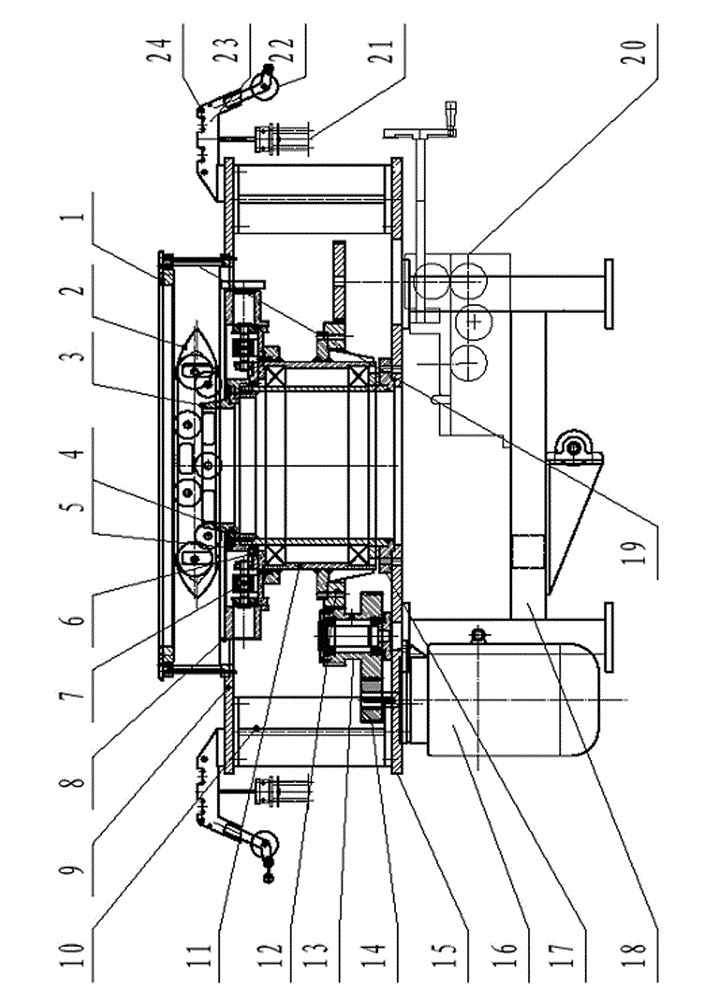

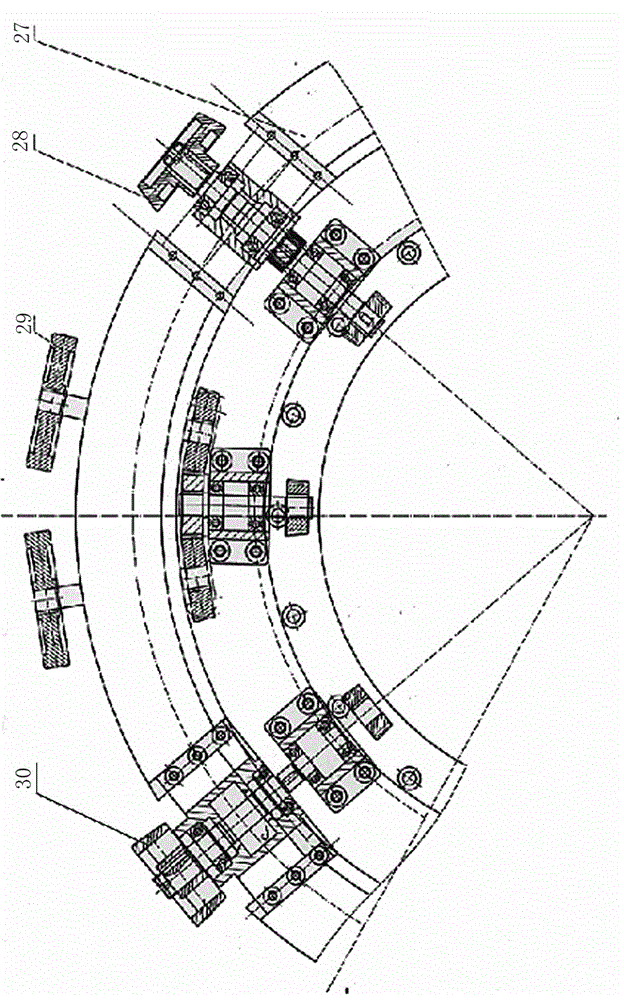

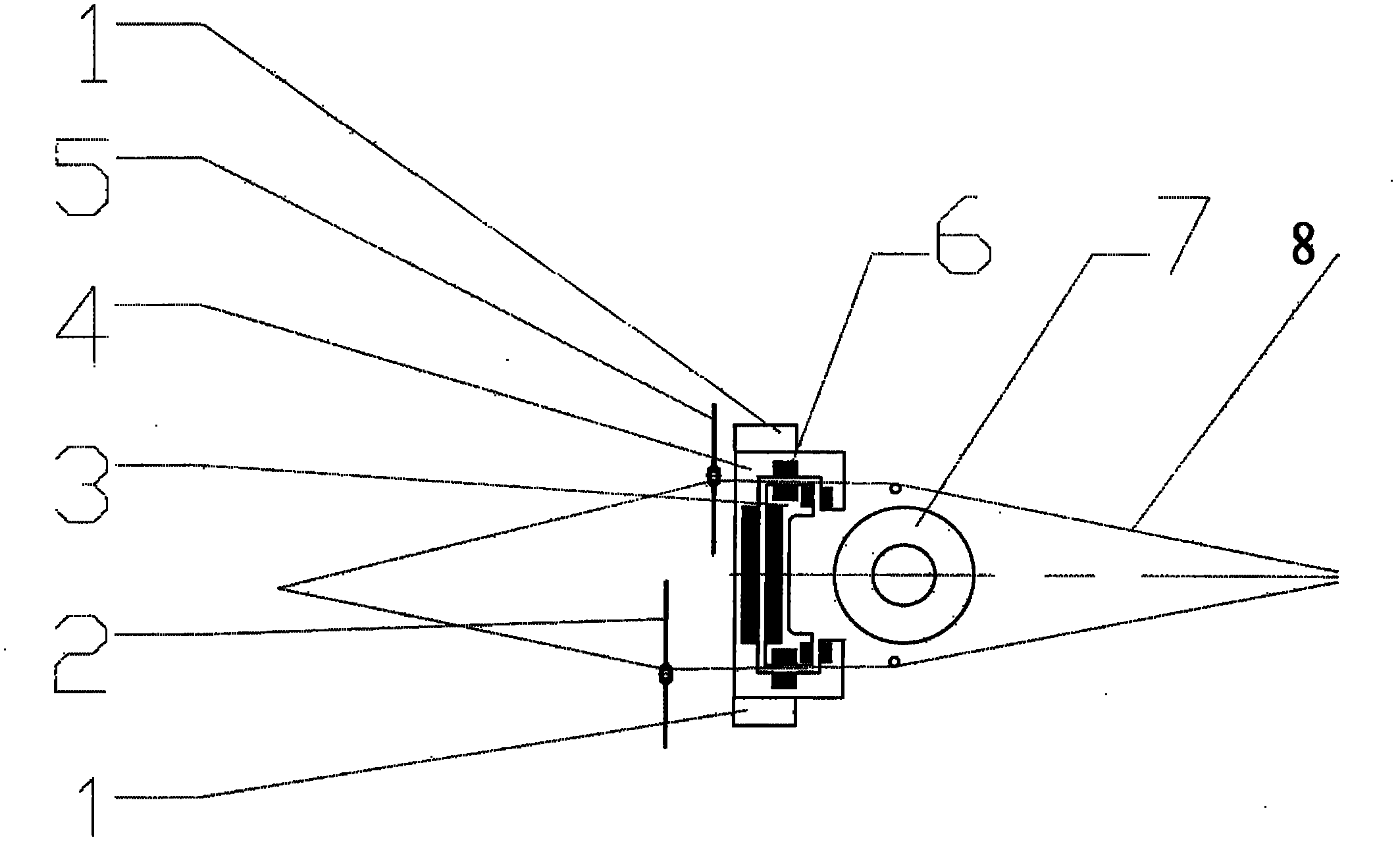

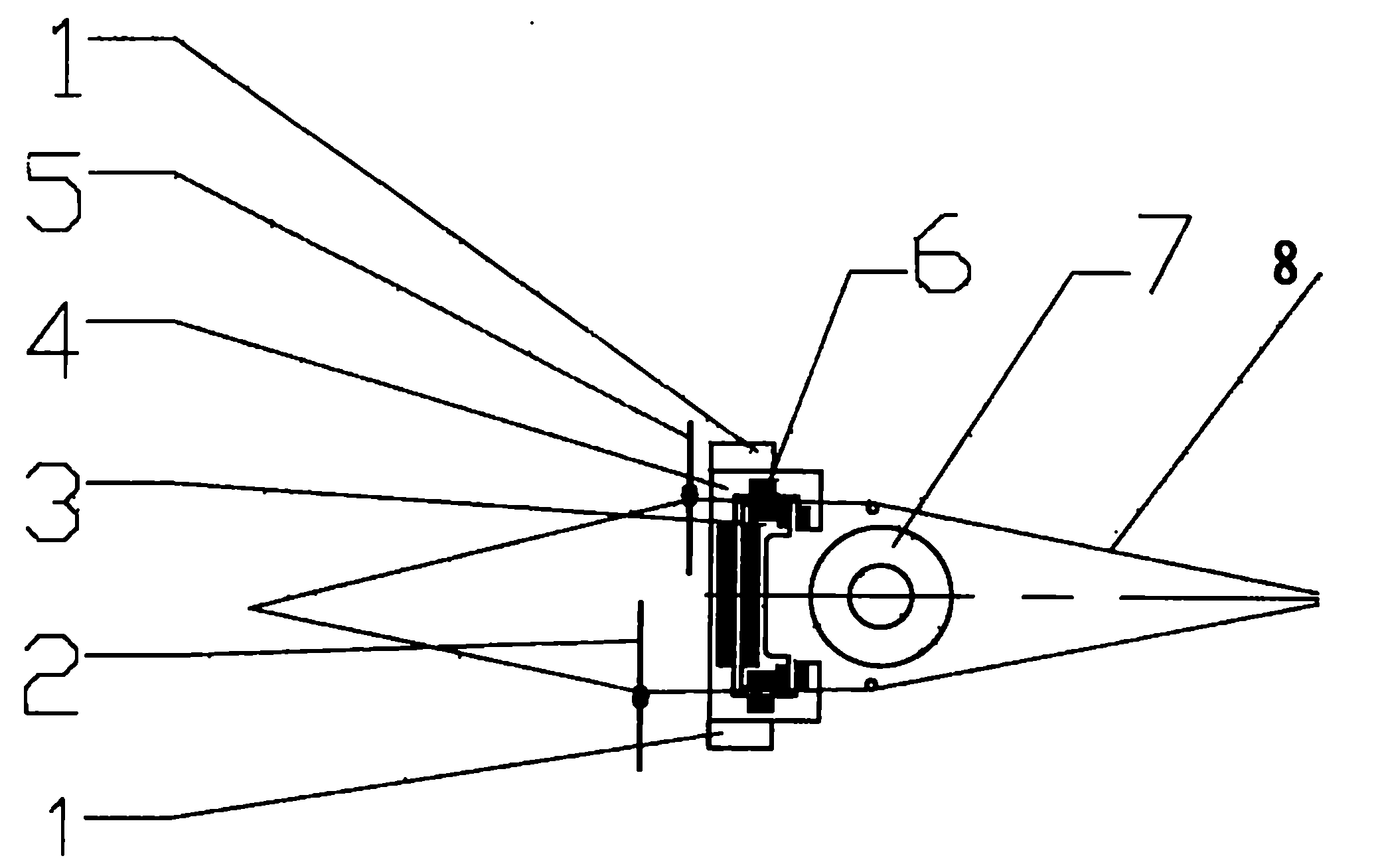

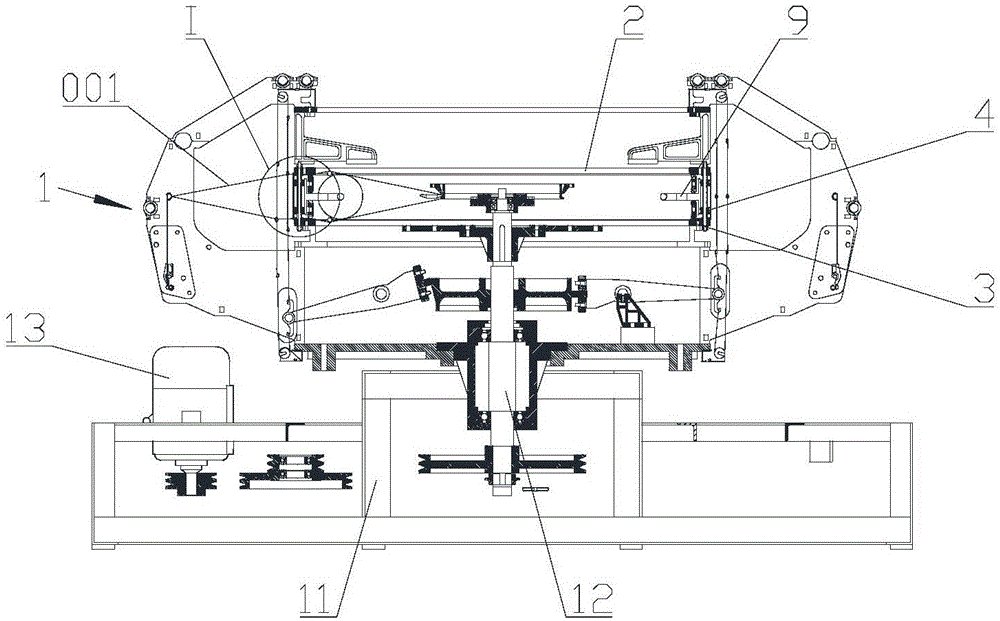

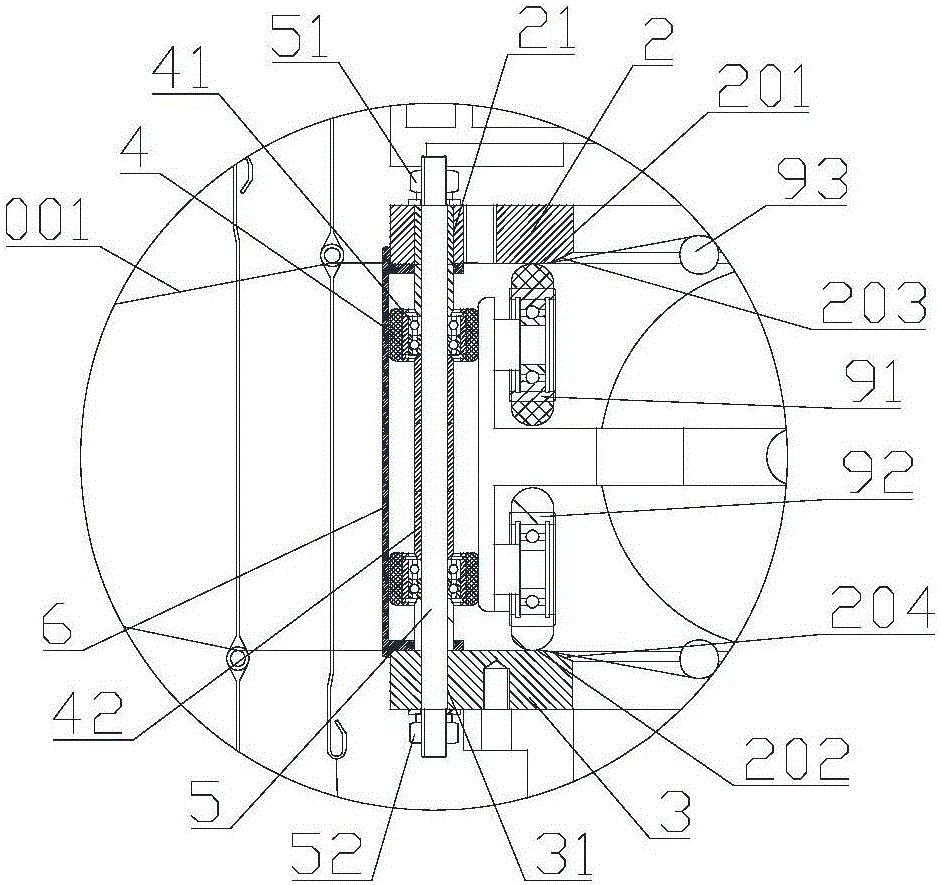

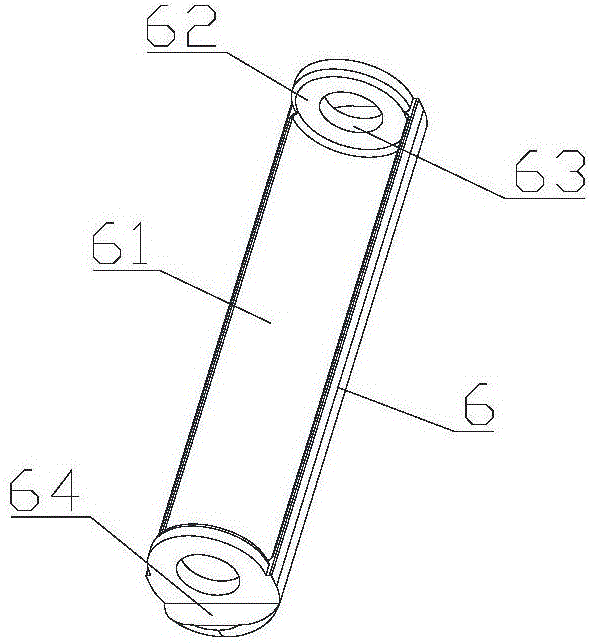

Spinning moulding device of composite material stereo tubular structural component and method thereof

The invention relates to a spinning moulding device of a composite material stereo tubular structural component. A line distributing board, a yarn guiding plate and a pushing-shuttling device are arranged on a main rotating disc; the line distributing board is provided with a bottom groove, a top groove, a mounting boss and a mounting hole; an upper runway, a lower runway and reeding plates form a shuttle track; the lower runway is arranged at the main rotating disc; a shuttle is arranged in the shuttle track, and provided with a pushing-shuttling wheel which is contacted with the pushing-shuttling device; the reeding plates are vertically and uniformly arranged in the shuttle track; and a reeding groove is arranged between every two reeding plates. Wraps form a shuttle port under the action of the bottom groove and the top groove on the line distributing board; the shuttle and the wraps are interweaved from the shuttle port through completing the introduction of wefts and vertical yarns so as to acquire a tubular structure orthogonal weaving tissue. The invention can solve the problems of higher cost, slower production speed and worse production continuity of the traditional production method of stereo tubular fabrics.

Owner:DONGHUA UNIV

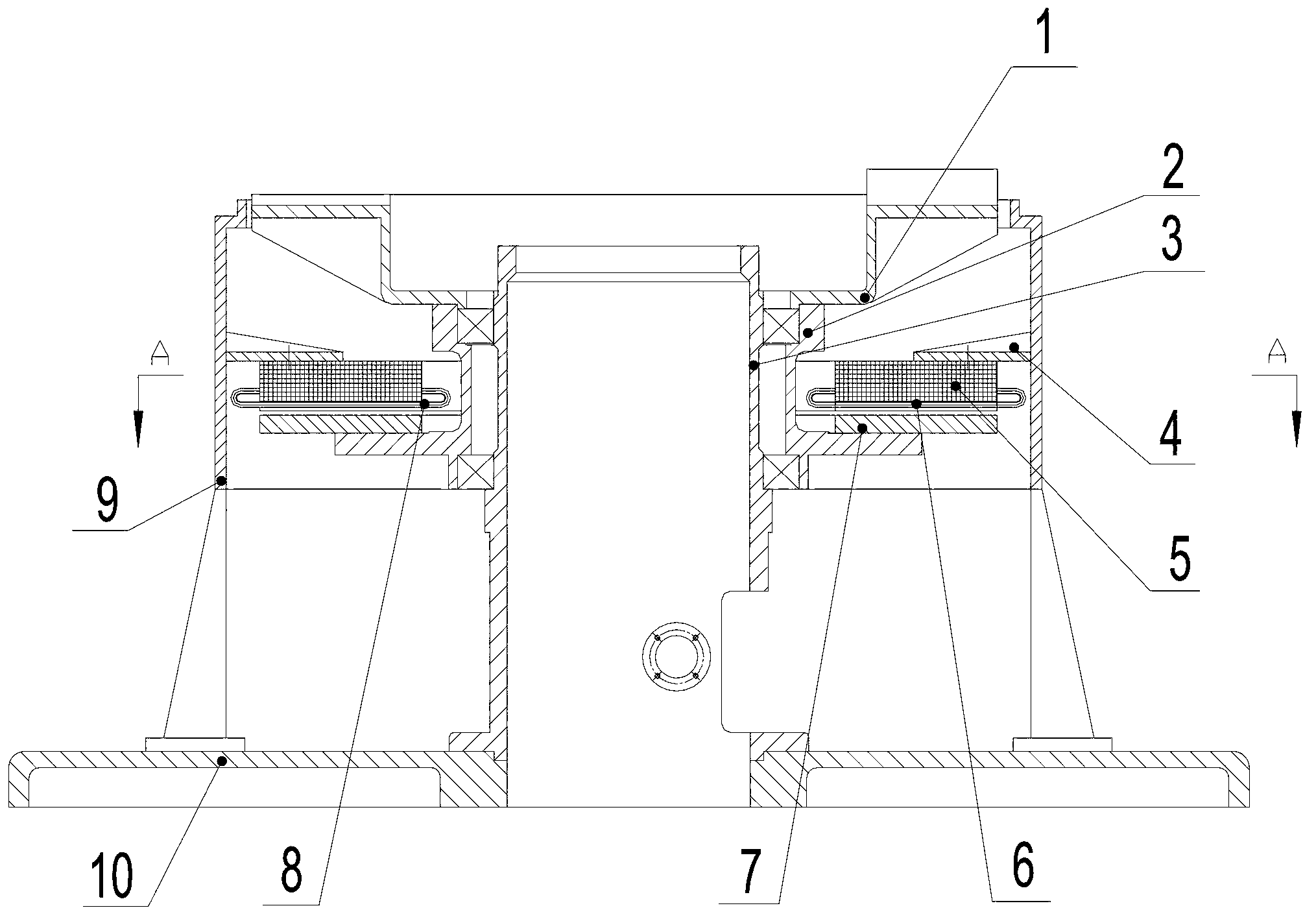

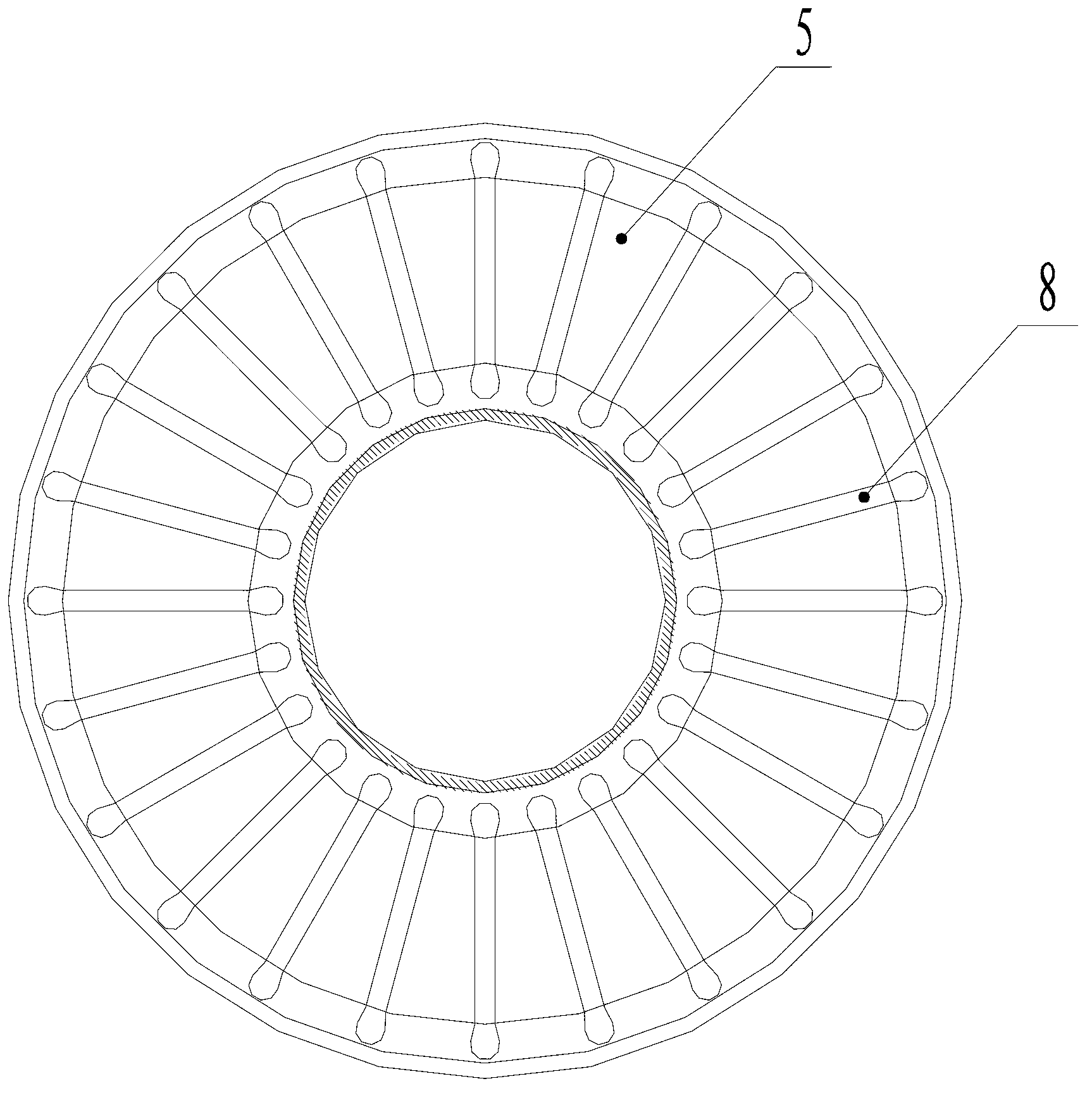

Non-contact circular weaving machine directly driven through electromagnetism

The invention relates to a non-contact circular weaving machine directly driven through electromagnetism. The non-contact circular weaving machine comprises a chassis, a central column, a loop sleeve and a shuttle carrier. The shuttle carrier is connected with the central column through a bearing seat. A planar motor is arranged below the shuttle carrier. The planar motor is formed by a stator and a rotor. The stator is fixed with the loop sleeve through a mounting support. The rotor is fixed with the shuttle carrier through the bearing seat. The stator is provided with a plurality of wire slots, and a coil is arranged in the wire slots in an embedded mode. The rotor is made of pure iron or a permanent magnet. When the rotor coil is powered on, the rotor rotates under the action of electromagnetic force and drives the shuttle carrier to rotate around the central column. The stator is arranged above the rotor. The distance between the stator and the rotor is 1-5 millimeters. According to the non-contact circular weaving machine, the planar motor is adopted to directly drive the shuttle carrier to rotate, so moving parts are decreased. When the motor works, the stator arranged above the rotor acts on the shuttle carrier through the electromagnetic force, so that the gravity which the shuttle carrier acts on a bearing is decreased and even is completely balanced out. Consequently, the bearing rotates in a relatively suspending state, friction resistance is small, and energy consumption is reduced.

Owner:TAIZHOU CITY JIANGYAN DISTRICT XINHUILAI TEXTILE MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com