Non-contact shuttle device for circular weaving machine

A non-contact circular loom technology, applied to circular looms, looms, textiles, etc., can solve problems such as large movement wear, large loss of wearing parts, and high noise, so as to reduce energy consumption and improve production efficiency , Equipment noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described in detail in specific embodiments below in conjunction with the accompanying drawings.

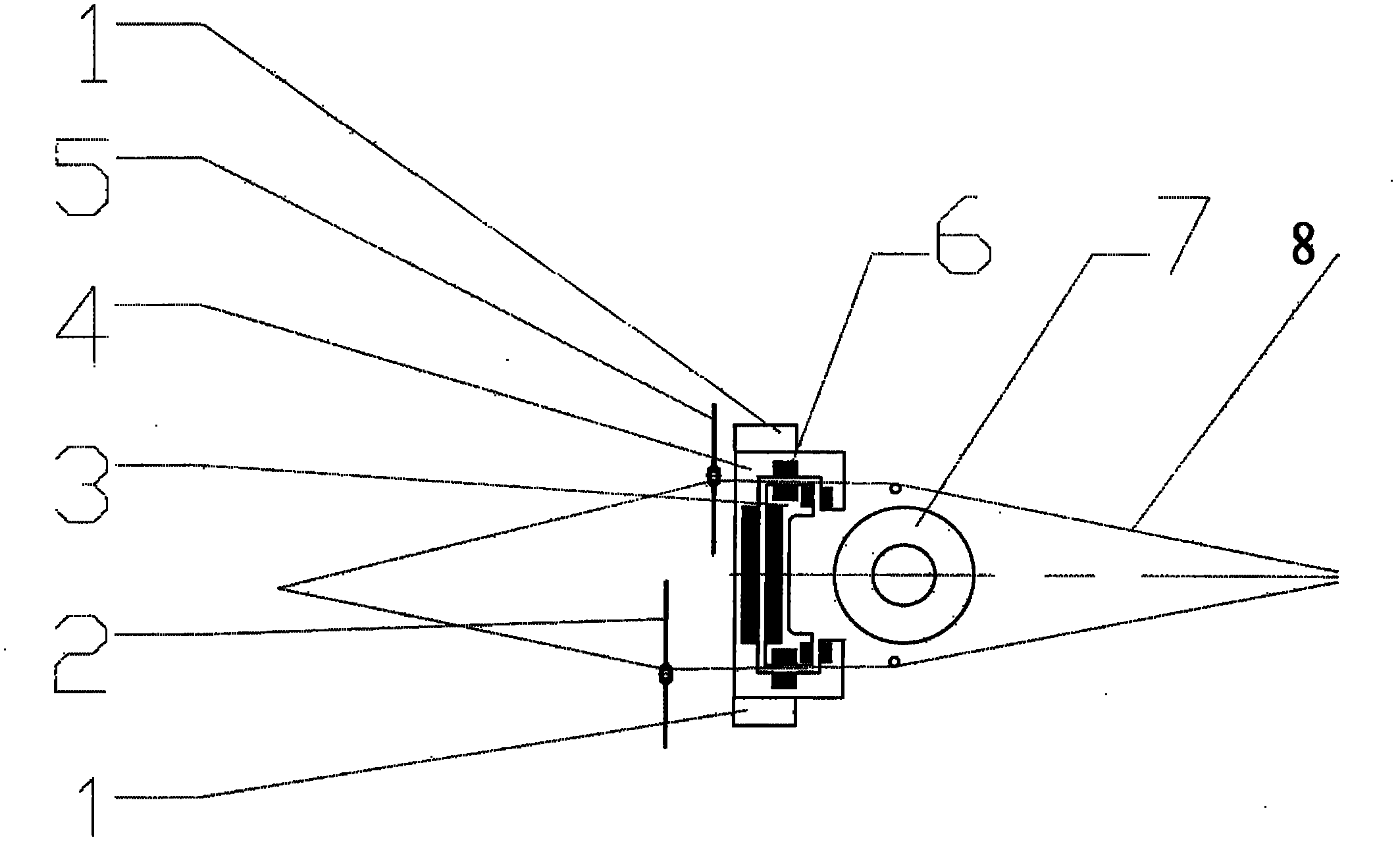

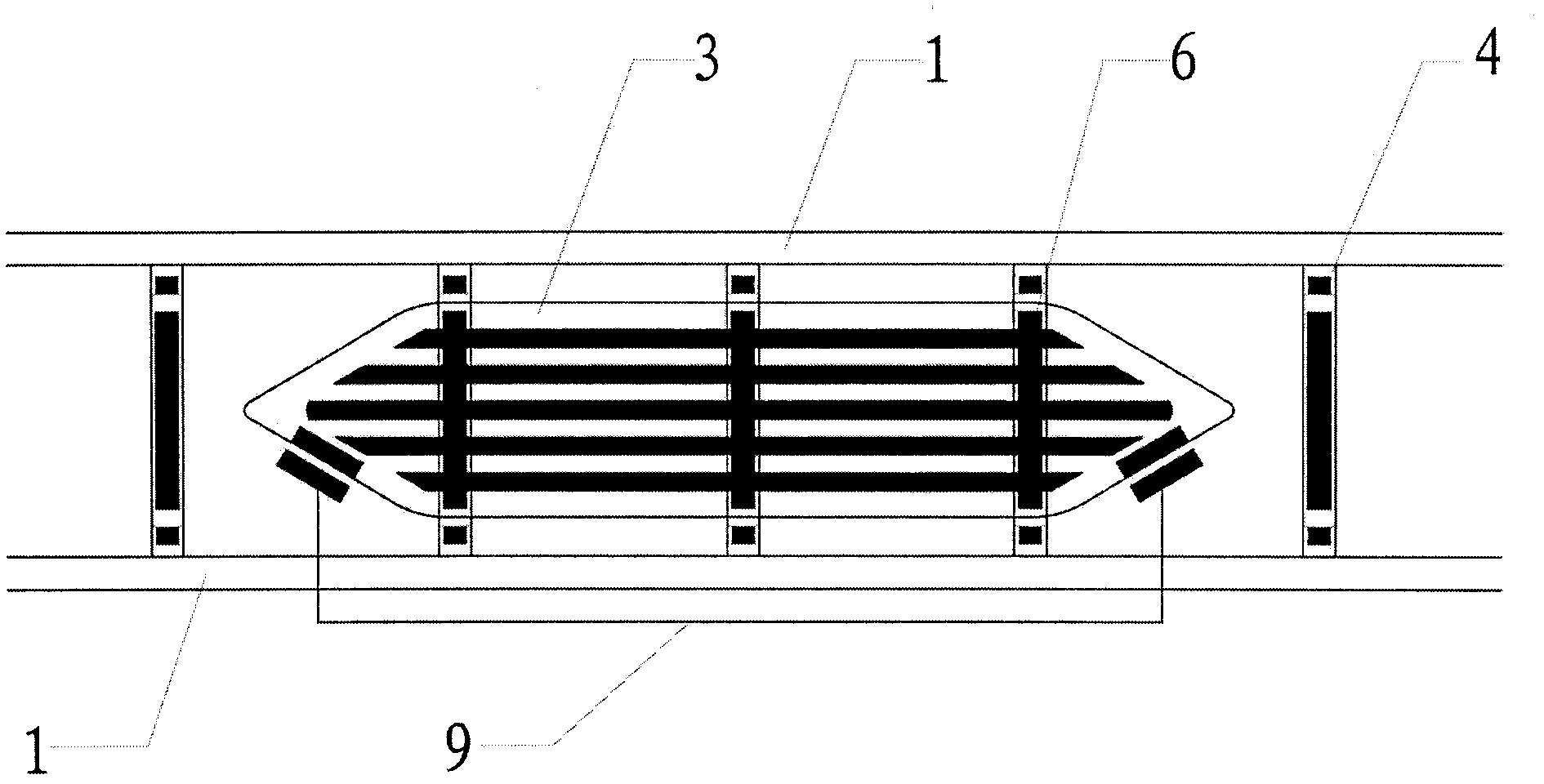

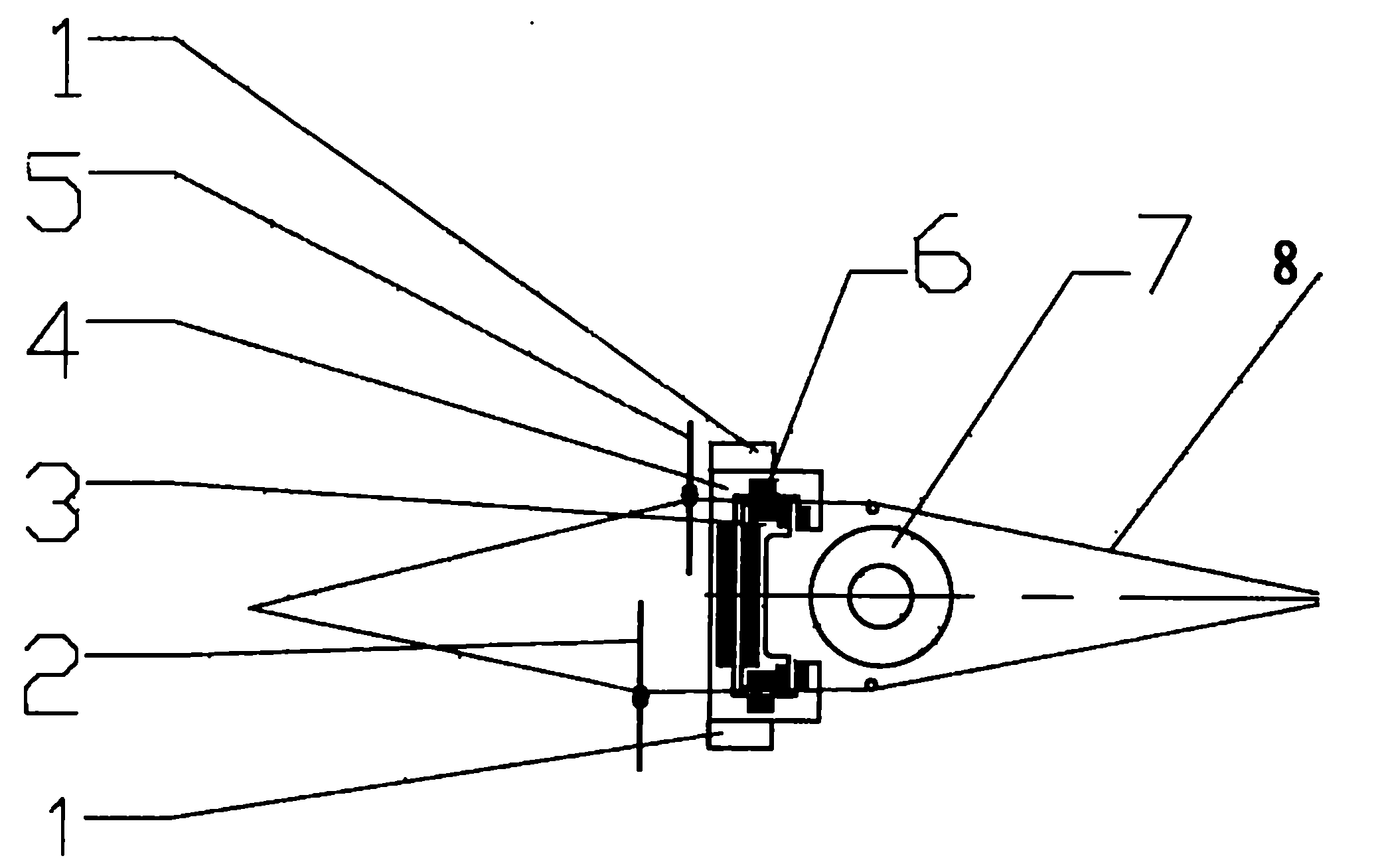

[0009] The non-contact shuttle device of the circular loom mainly includes the fixed ring 1, the outer brown wire 2, the magnetic shuttle body 3, the magnetic seat 4, the inner brown wire 5, the magnet 6, the weft wire 7, the warp wire 8, and the cage 9. It is characterized in that: at least 32 magnetic seats 4 are arranged in equal parts on the circular fixed ring 1, at least 5 magnets 6 of the same polarity are arranged on the inner plane of the magnetic seat 4, and on the magnetic shuttle body 3 and the magnetic seat 4 Set at least 5 magnets 6 with the same opposite polarity as the magnetic poles of the magnetic base 4 at the corresponding positions. The gap between the magnets 6 is: 3mm-7mm. A magnet 6 with a magnetic pole upward is respectively arranged on the left and right, and two magnets 6 with the same relative polarity are r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com