Patents

Literature

33results about How to "Not prone to wire breakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

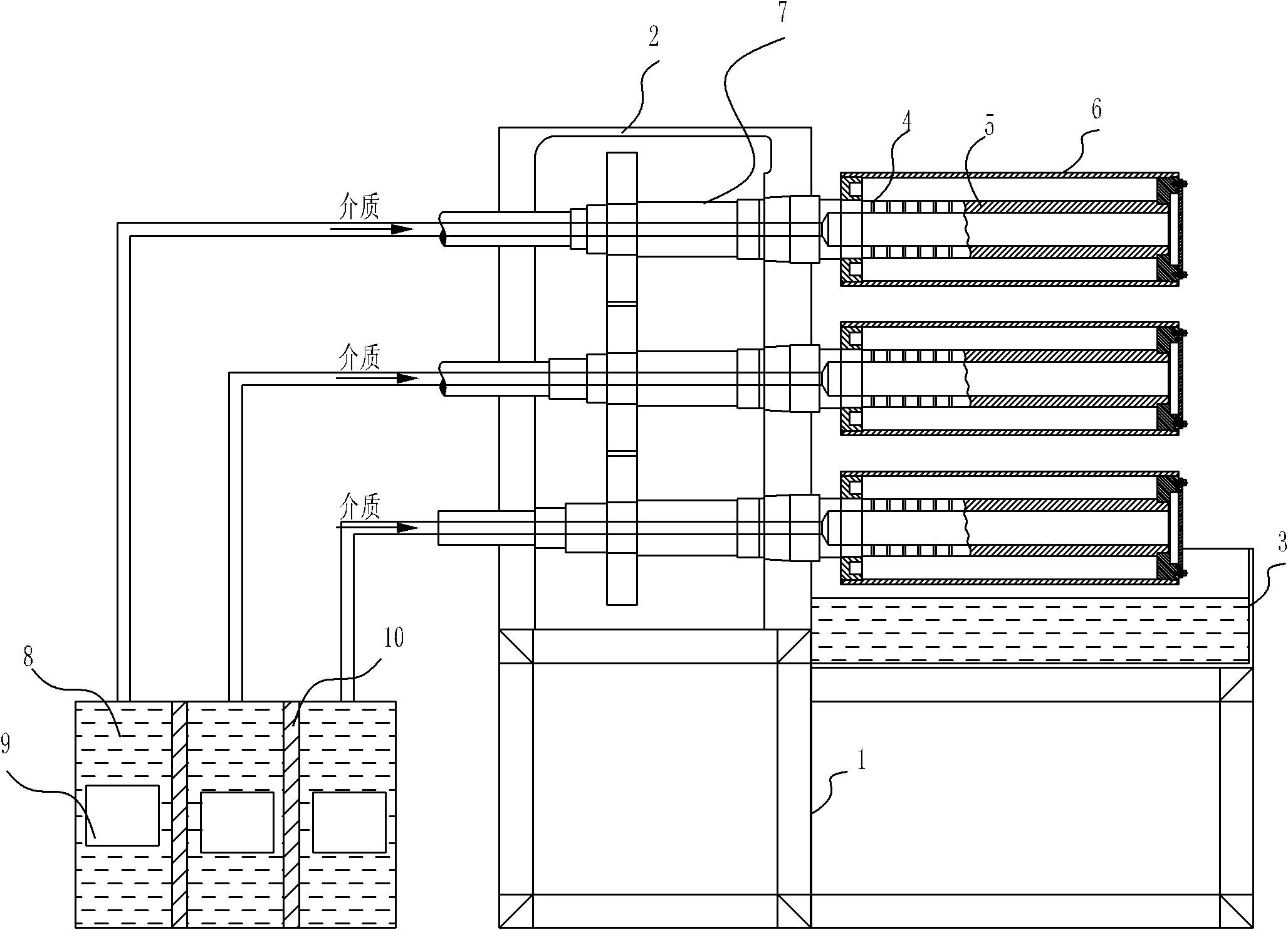

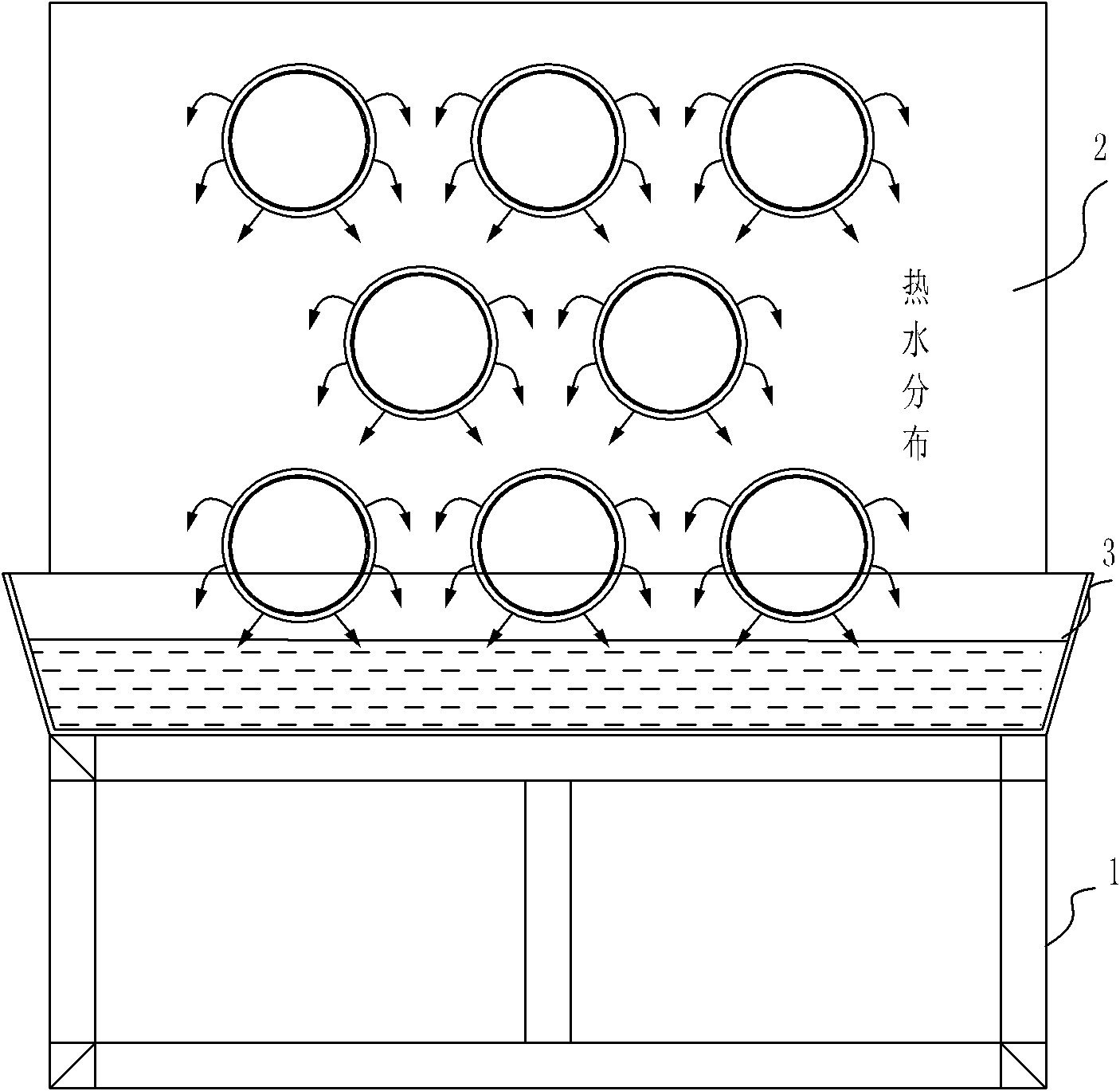

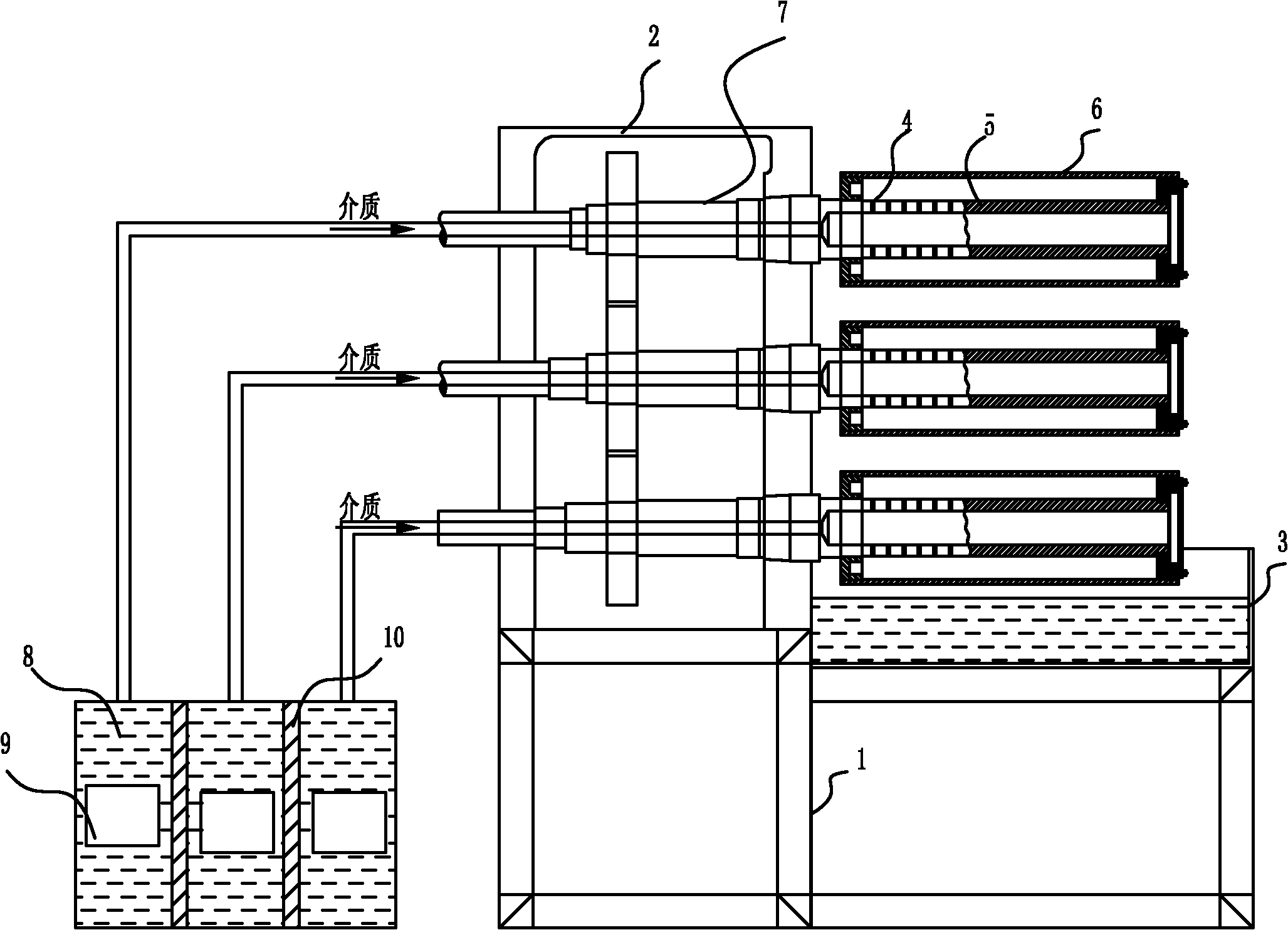

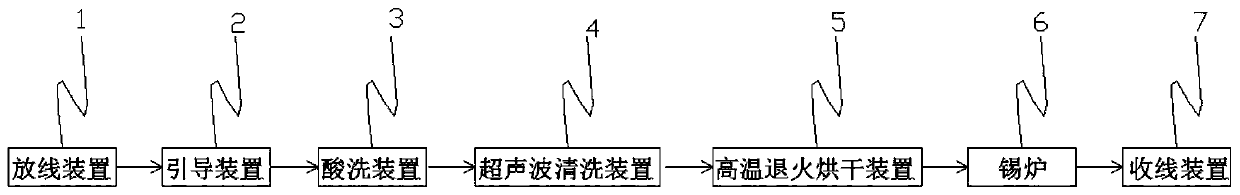

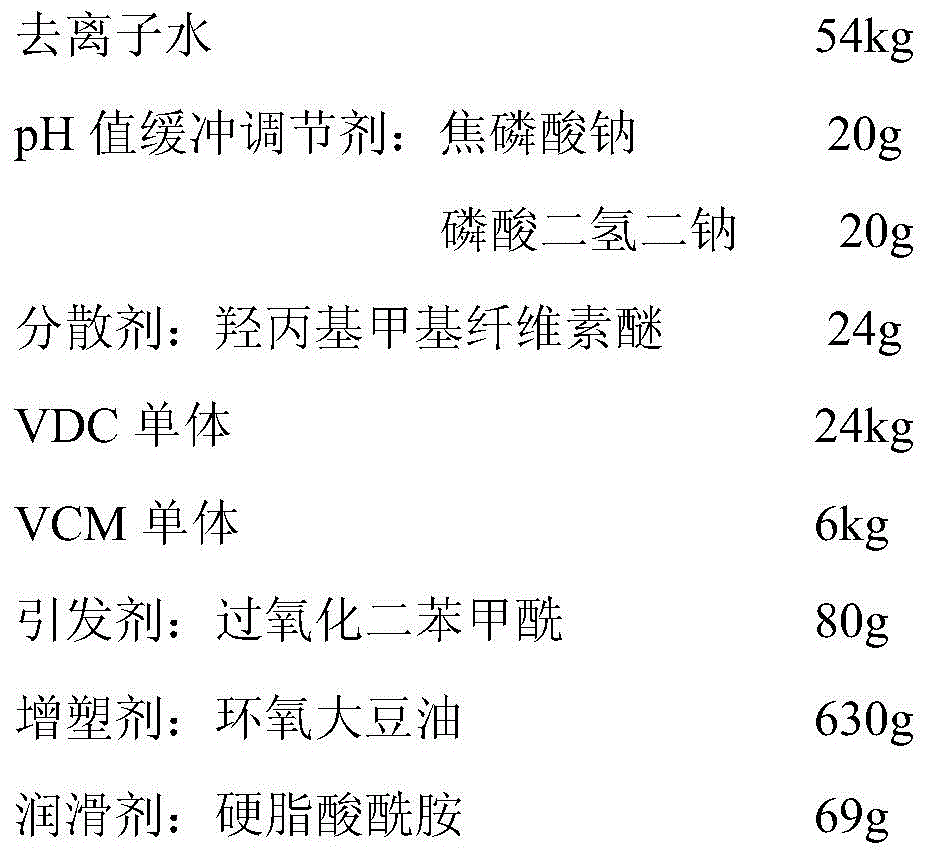

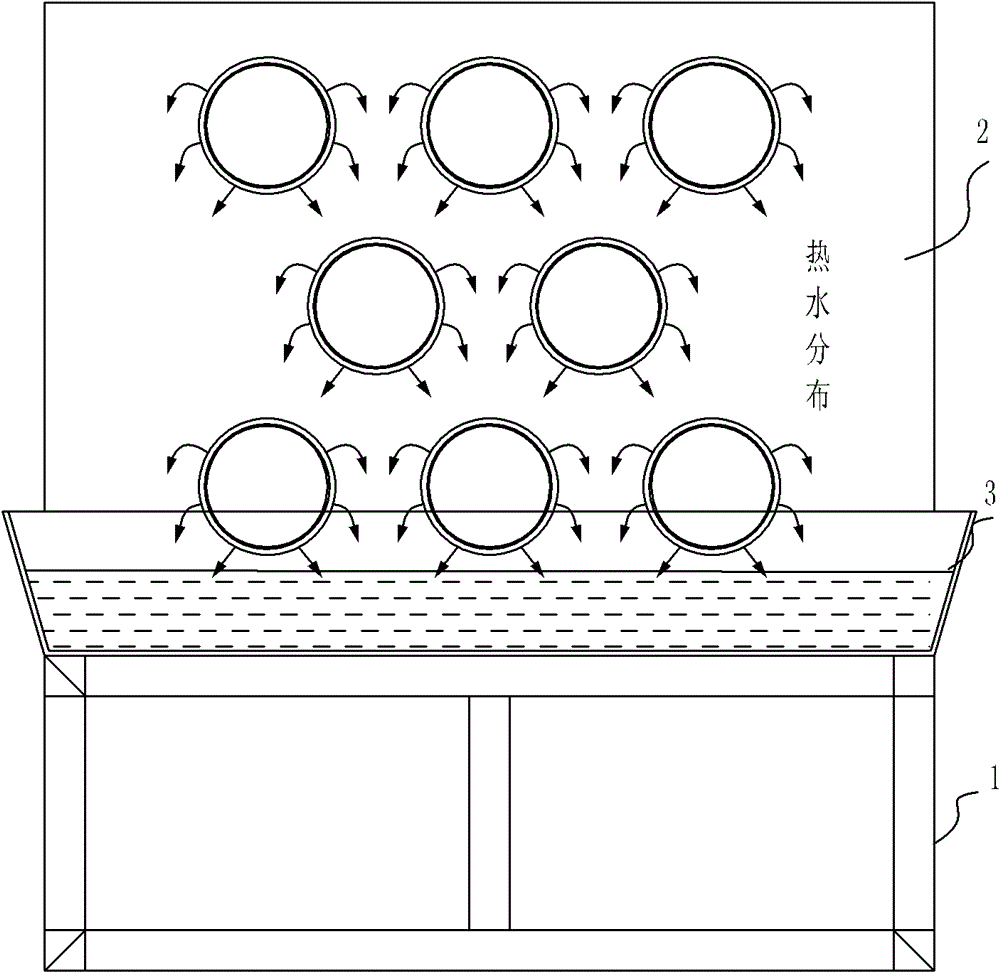

Rinsing and hot drawing device for fibre tow spinning

InactiveCN102011202AHigh strengthGood for intensive washingArtificial filament washing/dryingTextile/flexible product manufactureFiberCarbon fibers

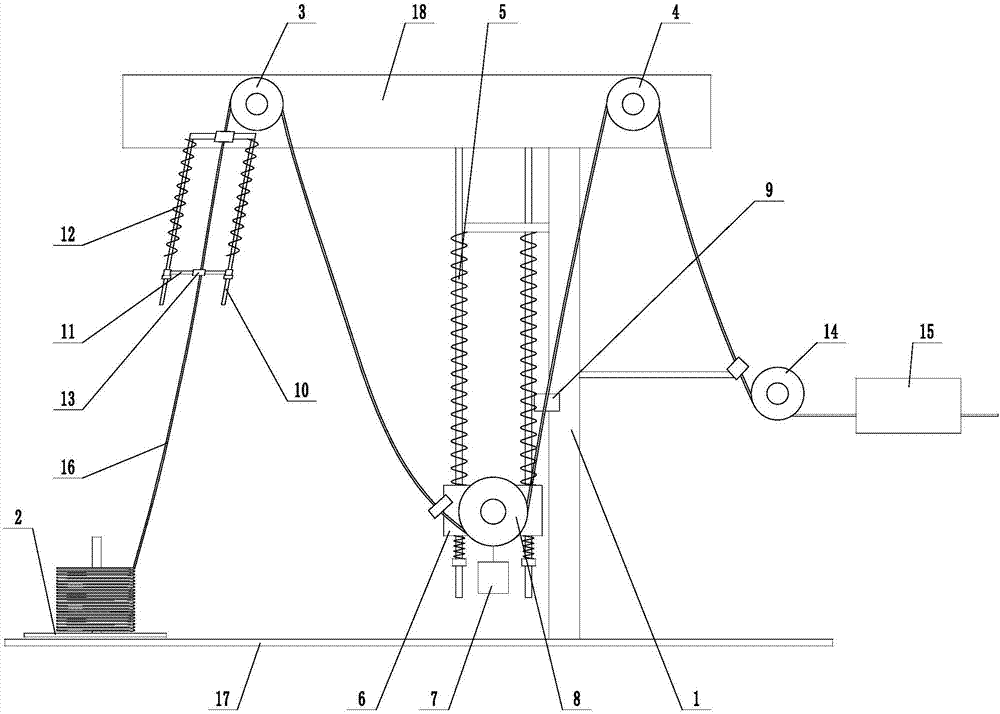

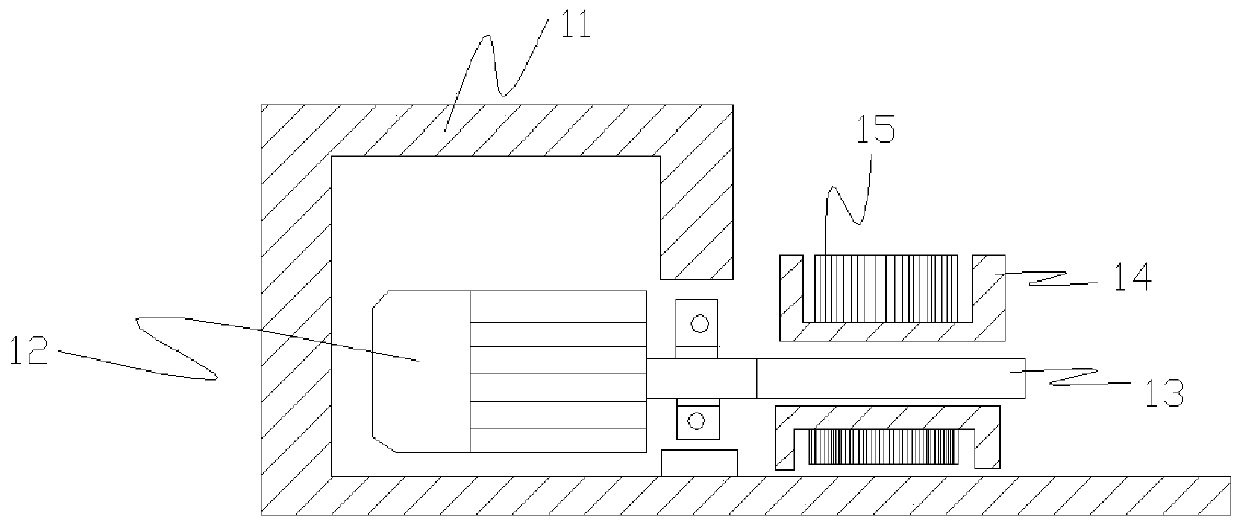

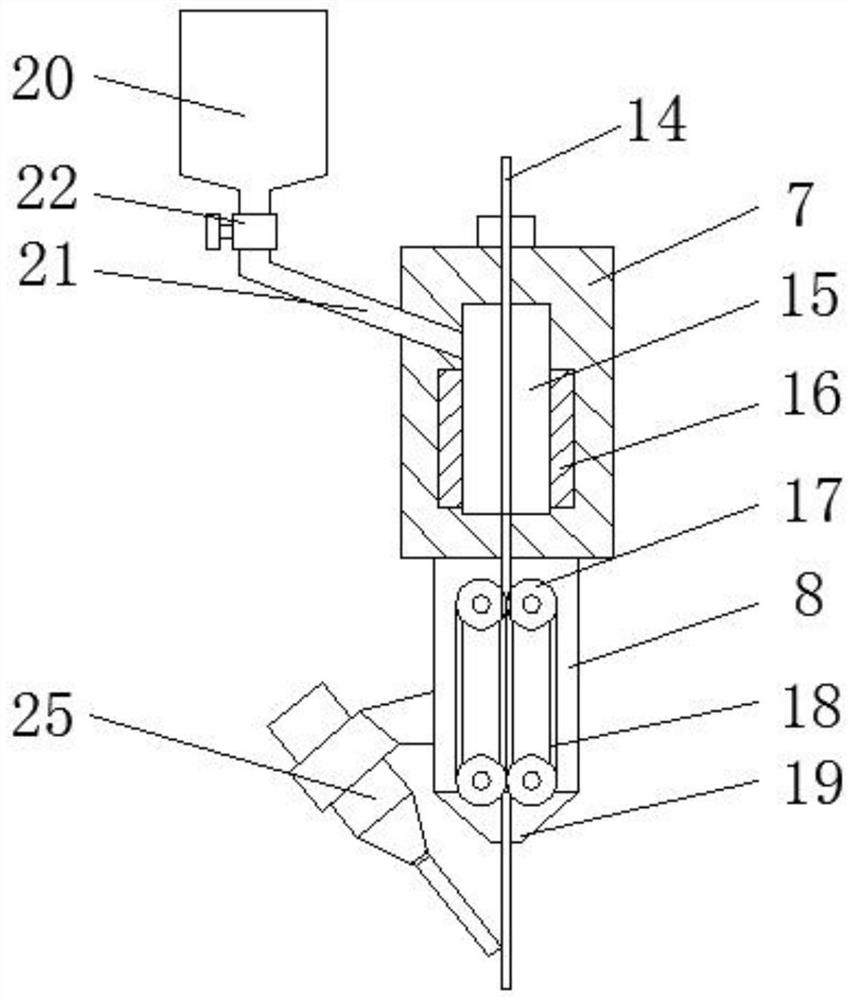

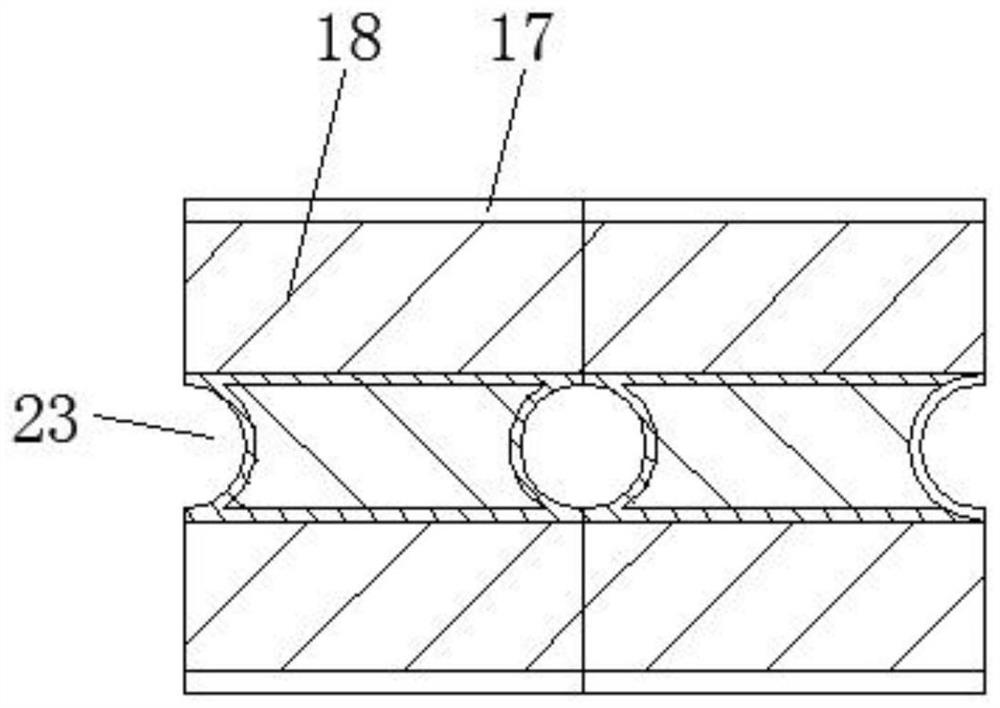

The invention relates to a rinsing and hot drawing device for fibre tow spinning. The device comprises a box body, a heat source supply device arranged outside the box body, a plurality of transmission devices which are fixed on the box body and arranged in the box body and a waste heat collecting device arranged on the top of the box body, wherein each transmission device contains a transmission shaft and a transmission roller sleeved on the transmission shaft; the transmission roller is prepared from a porous material; the transmission shaft is of a hollow structure; a plurality of liquid outlet holes are uniformly distributed on the side wall of the transmission shaft; and the heat source supply device is communicated with a plurality of transmission shafts respectively. By adopting the rinsing and hot drawing device, the technical problems that the existing rinsing and hot drawing device for fibre tow spinning damages the fibre tow and has low drawing efficiency can be solved. The invention provides the rinsing and hot drawing device for fibre tow spinning which can realize that the high strength of the carbon fibre precursor tow can be ensured and the filaments can not be broken easily under a large drafting force.

Owner:西安航科等离子体科技有限公司

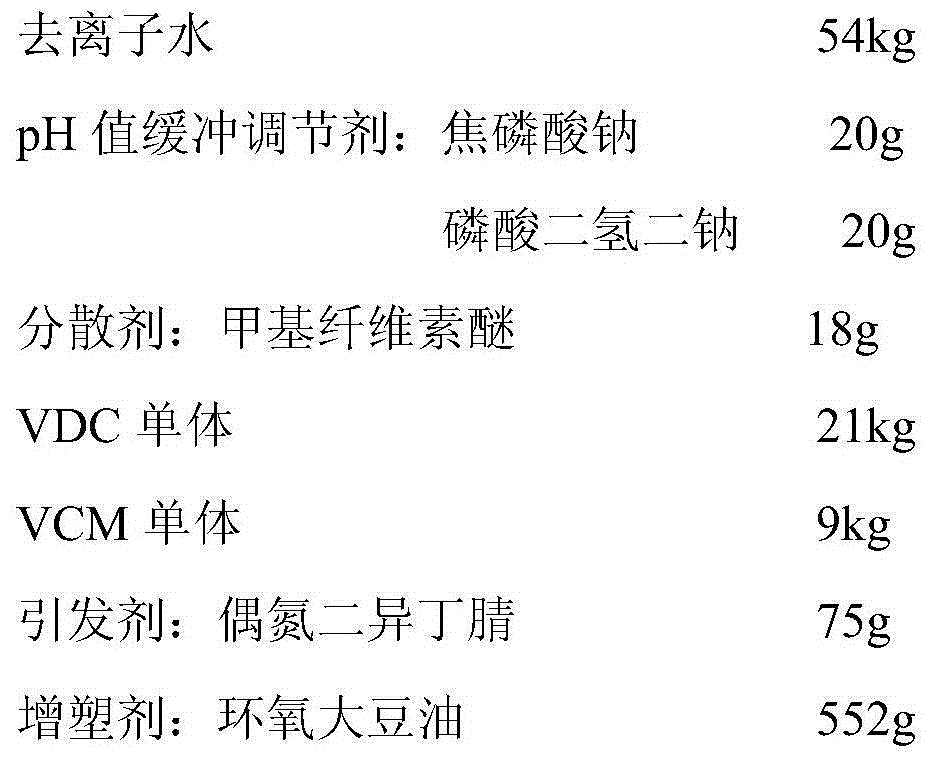

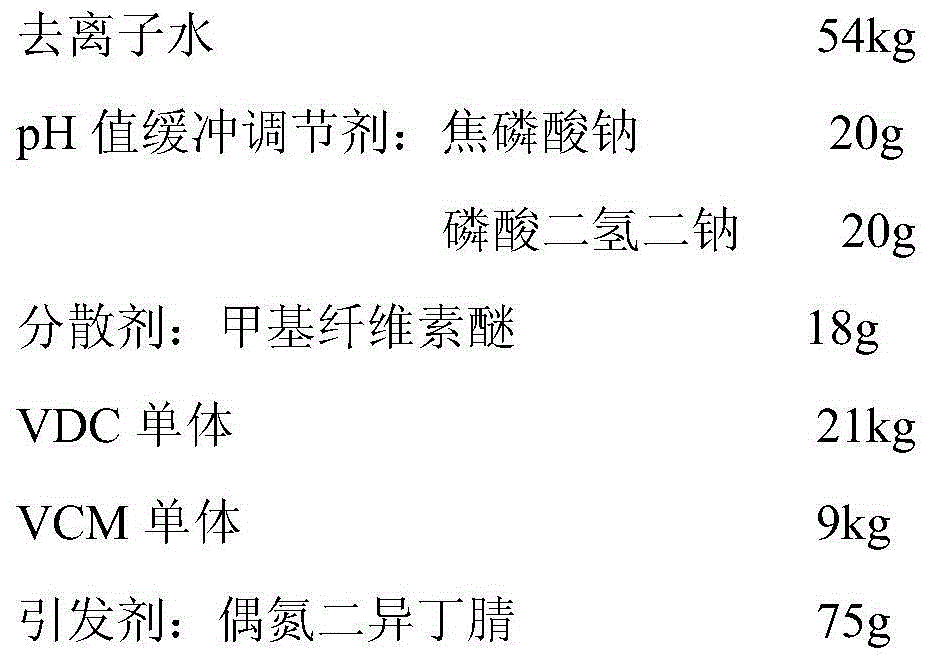

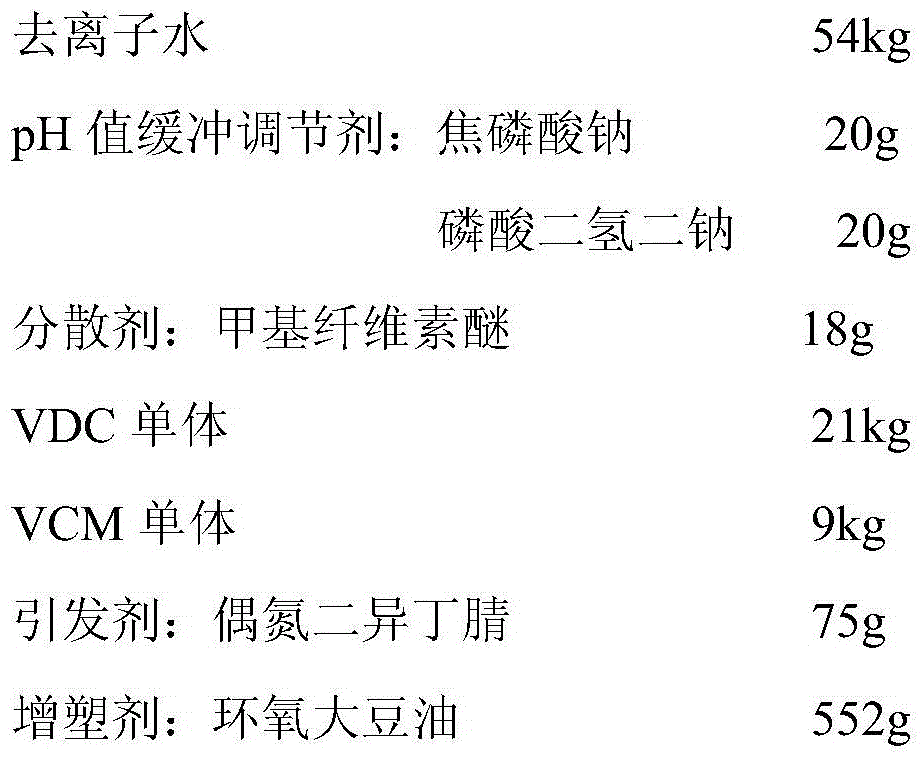

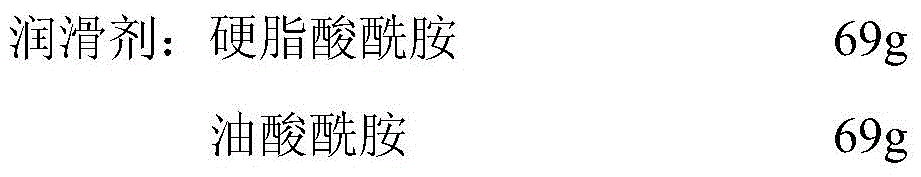

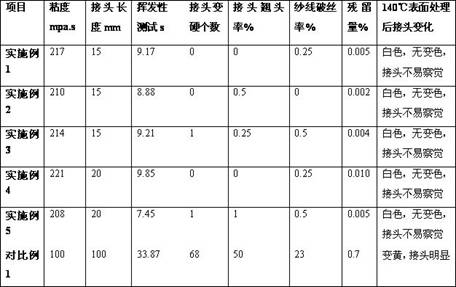

Preparation method of PVDC (polyvinyl dichloride) composition for spinning

ActiveCN104927253AImprove thermal stabilityEasy to processMonocomponent halogenated hydrocarbon artificial filamentArtifical filament manufactureHydrogenPlasticizer

The invention discloses a preparation method of a PVDC (polyvinyl dichloride) composition for spinning. The preparation method of the PVDC composition for the spinning comprises the following steps of carrying out a polymerization reaction on the following raw materials in parts by weight: 49 to 60 parts of deionized water, 20 to 30 parts of vinylidene chloride monomers, 3 to 9 parts of vinyl chloride monomers, 0.06 to 0.3 parts of initiator, 0.02 to 0.04 part of pH (potential of hydrogen) value buffer conditioning agent and 0.01 to 0.05 part of dispersing agent, after the reaction is carried out for 25 hours to 35 hours, terminating the polymerization reaction, separating out residual monomers in a vacuum manner, and cooling, discharging, centrifuging and drying an obtained material; adding 0.5 to 0.8 part of plasticizer and 0.05 to 0.2 part of lubricating agent into the dried material, and mixing and curing an obtained mixture, so as to obtain a PVDC composition product for the spinning. The PVDC composition prepared by the preparation method of the PVDC composition for the spinning has favorable heat stability and spinning processing performance.

Owner:ZHEJIANG QUZHOU JUSU CHEM IND CO LTD +1

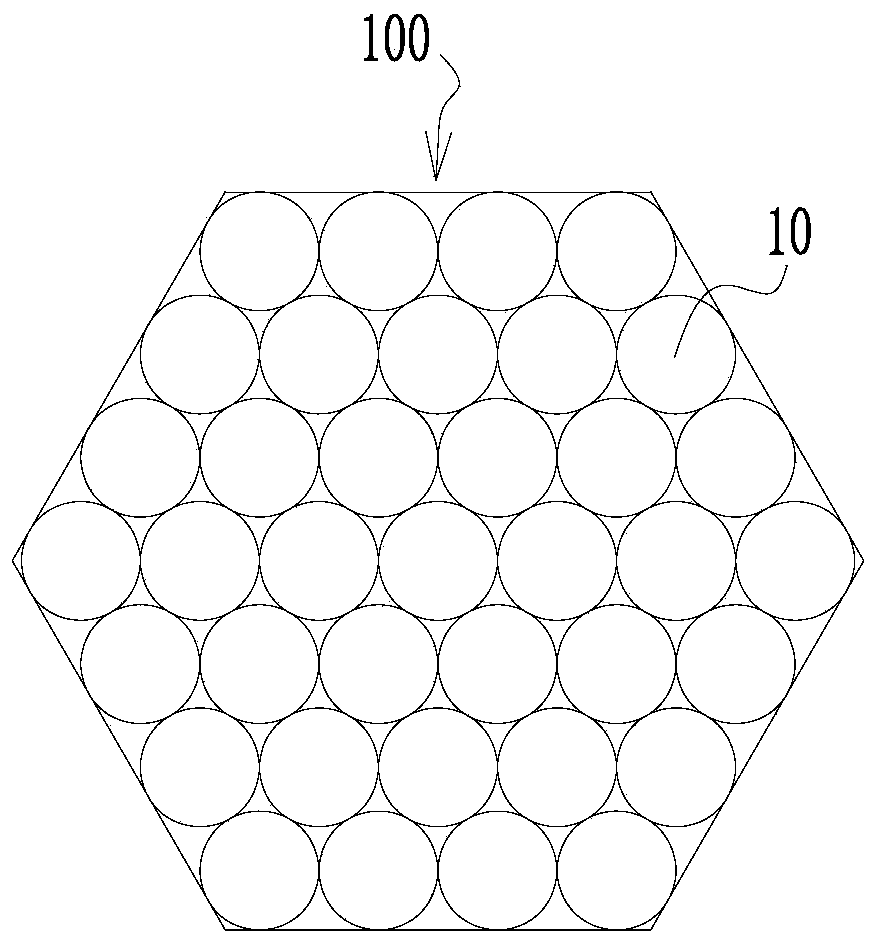

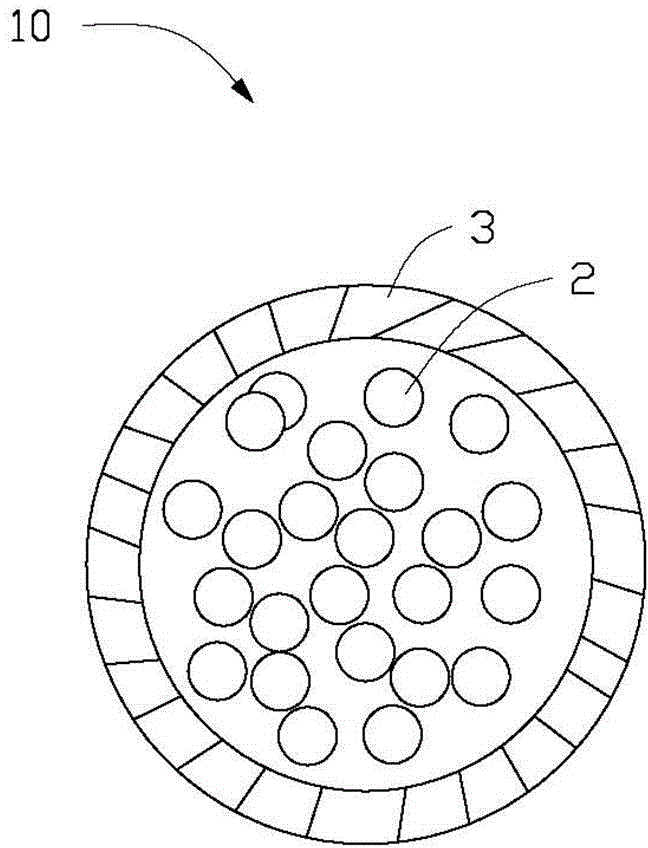

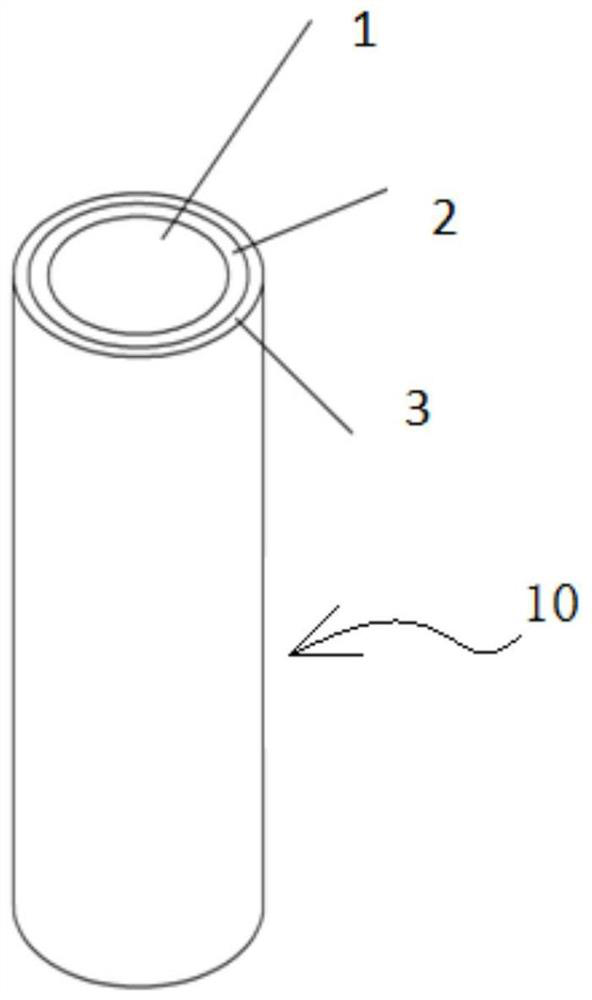

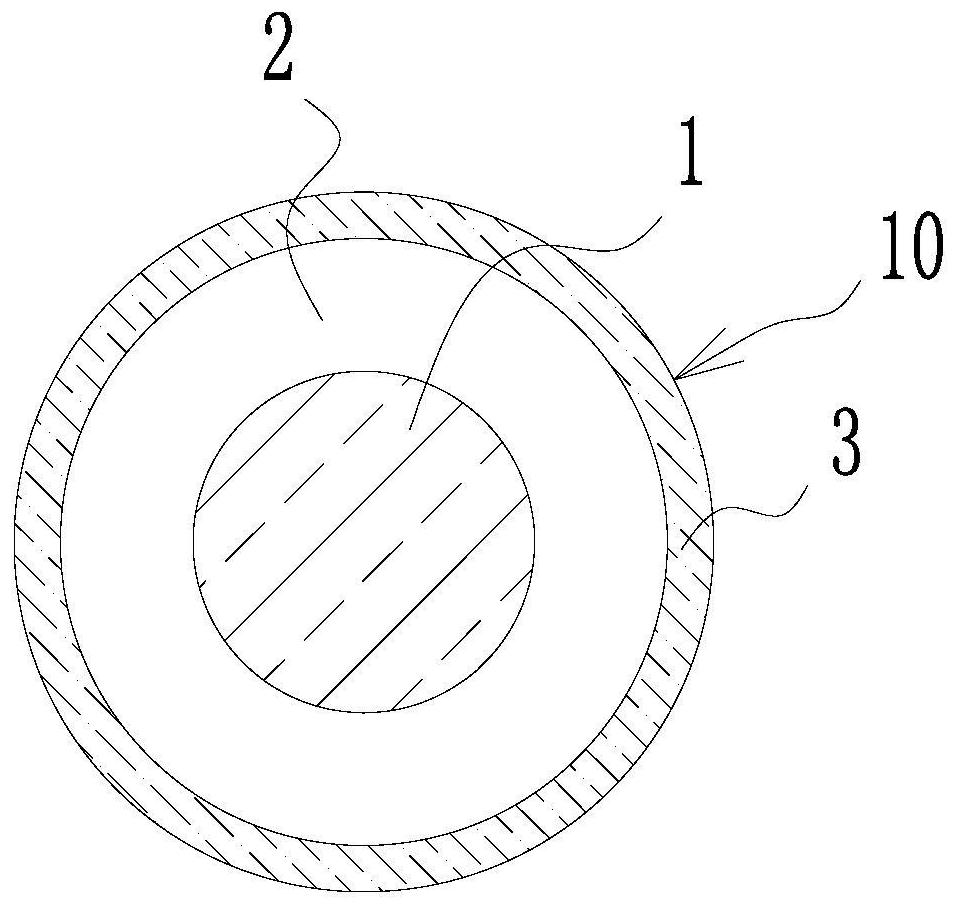

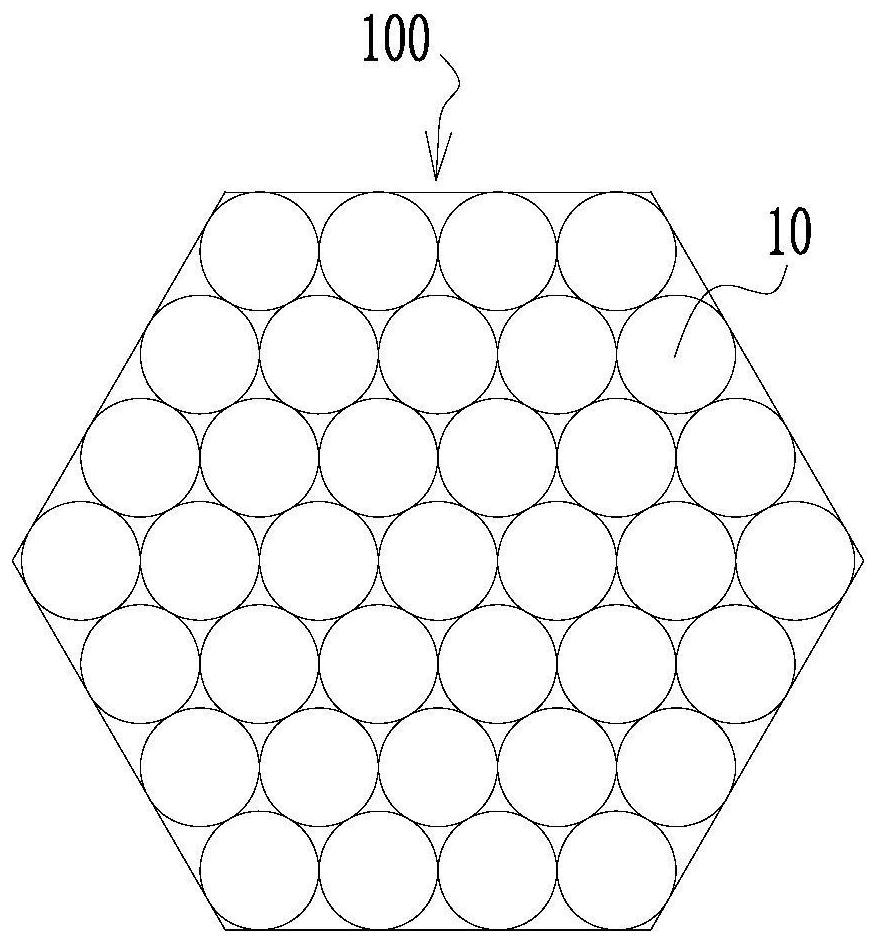

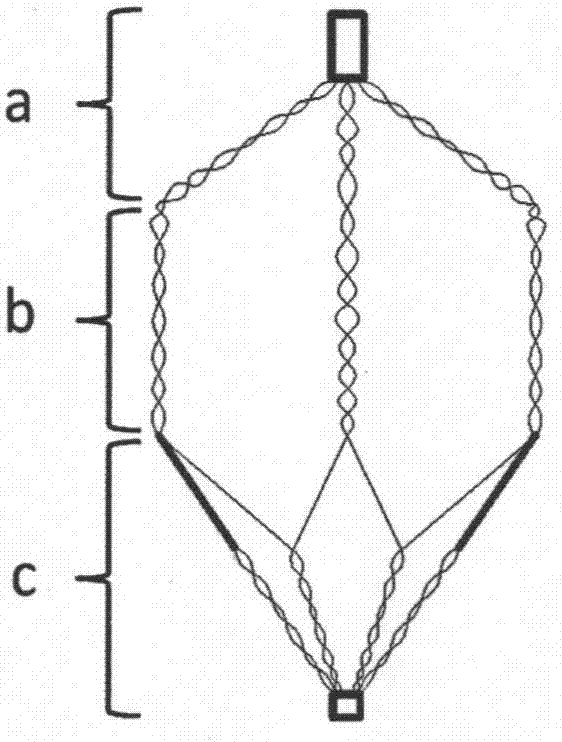

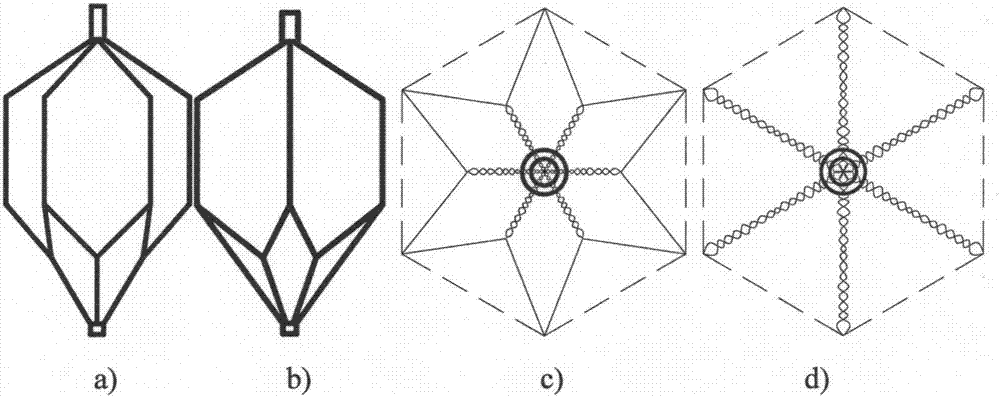

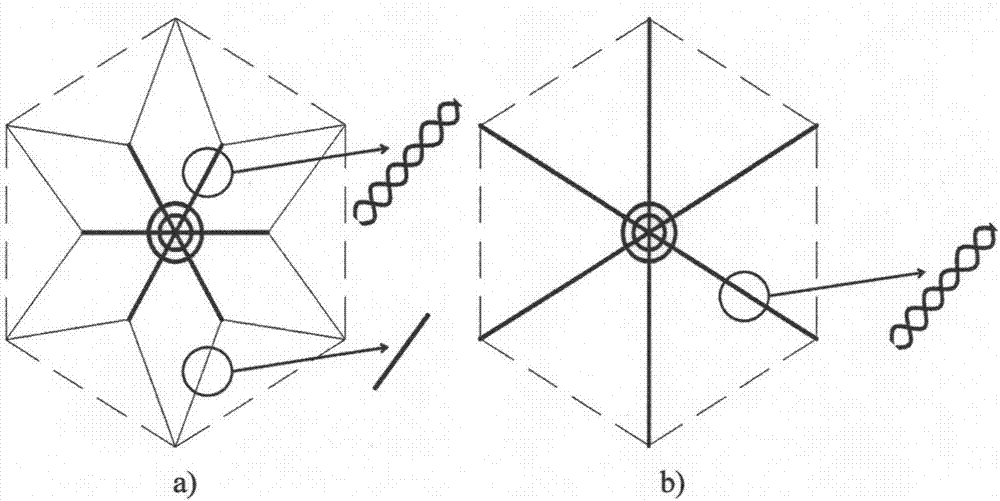

Method for manufacturing large-section high-resolution flexible optical fiber image transmission bundle

ActiveCN111190251ANot easy to breakGuaranteed monofilament strengthGlass making apparatusBundled fibre light guideImage resolutionAcid dissolution

The invention discloses a manufacturing method of a large-section high-resolution flexible optical fiber image transmission bundle. An optical fiber monofilament with two claddings is drawn by a three-crucible or rod-tube method; the optical fiber monofilament is drawn into a hard optical fiber image transmission unit body with a regular polygon-shaped cross section through primary filament arrangement and primary multifilament drawing. Secondary filament arrangement is carried out on the unit body to obtain a large-section hard optical fiber image transmission bundle, end part hot melting iscarried out on the hard optical fiber image transmission bundle, a middle part of the hard optical fiber image transmission bundle into an acid solution, and acid dissolution is carried out to removean acid dissolution layer to obtain a flexible optical fiber image transmission bundle. By using the manufacturing method provided by the invention, the large-section high-resolution flexible opticalfiber image transmission bundle with a circular section or a regular polygon section can be manufactured, the size of the regular hexagon section is 8.8 mm, the size of the square section is more than5mm, the length can reach 6m, and the highest resolution can reach 191lp / mm.

Owner:NANJING CHUNHUI SCI & TECH IND

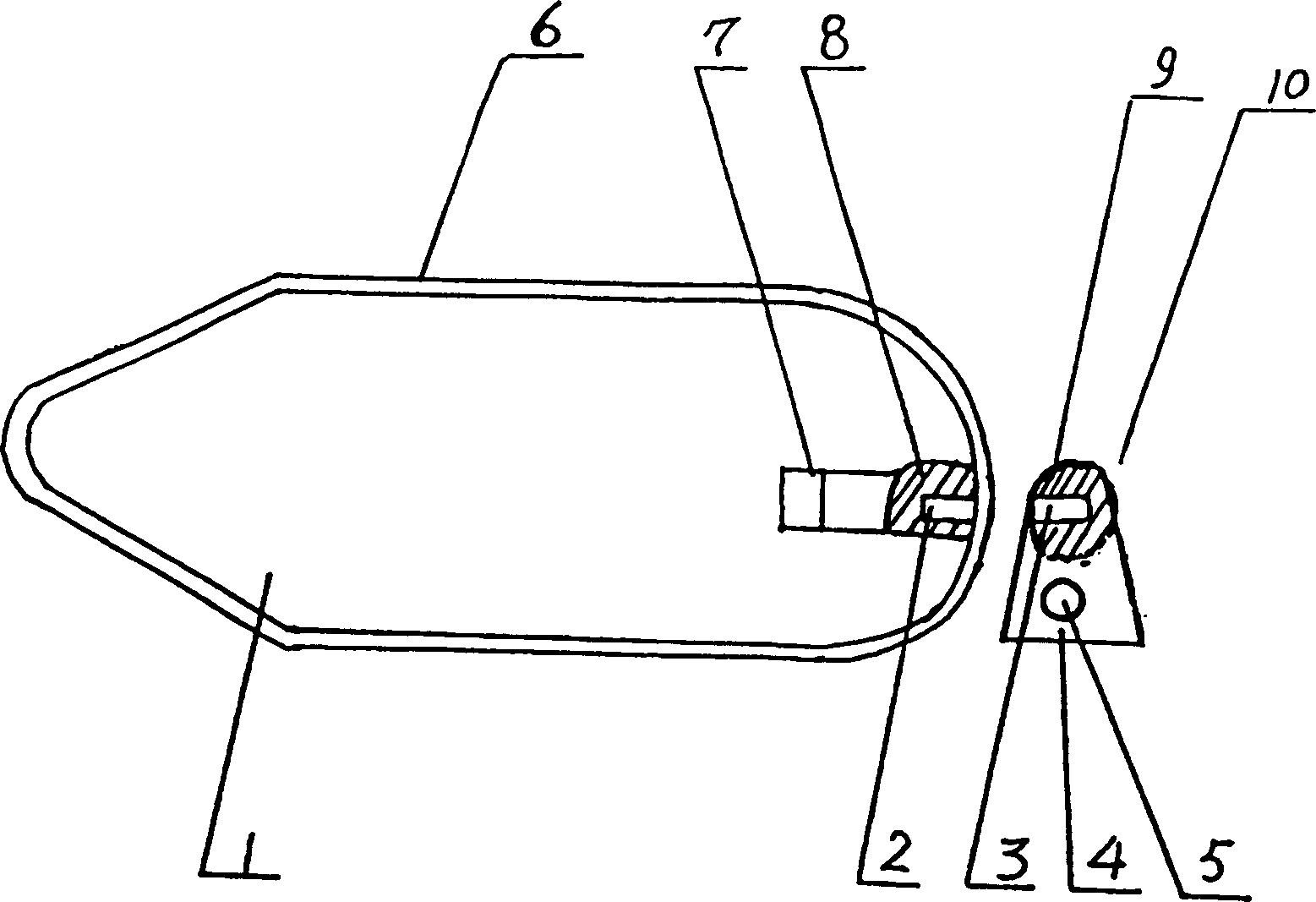

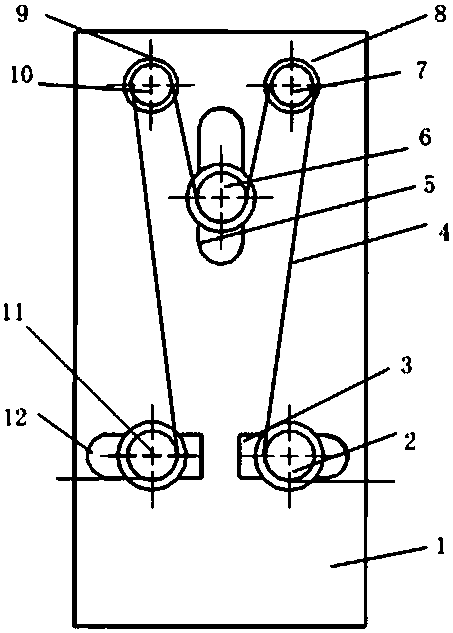

Magnetic shuttle movement aid unit of circular weaving machine

InactiveCN1789519AImprove work performanceNot prone to wire breakageCircular loomsEngineeringNon magnetic

The invention provides circular loom magnetic shuttle power assistance unit, comprising the following solving scheme: the shuttle is settled in the orbit of a circle; the pushing bodies is connected with principal axis through handspikes; in the rump of the shuttle there are permanent-magnets which are fixed in the pushing bodies and the two poles of the permanent-magnets nearby are of the same homonymy; there is a nonmagnetic lead-thread frame is equipped outside of the shuttles and in the rump of the shuttle there is an aluminium alloy back bracket, and upon the back bracket there is a eccentric fixed wheel. The invention is simple in the structure, convenient to use, hard to see the phenomenon of silk breaking, improves the efficiency of loom, and suits for any type of looms.

Owner:唐欢利

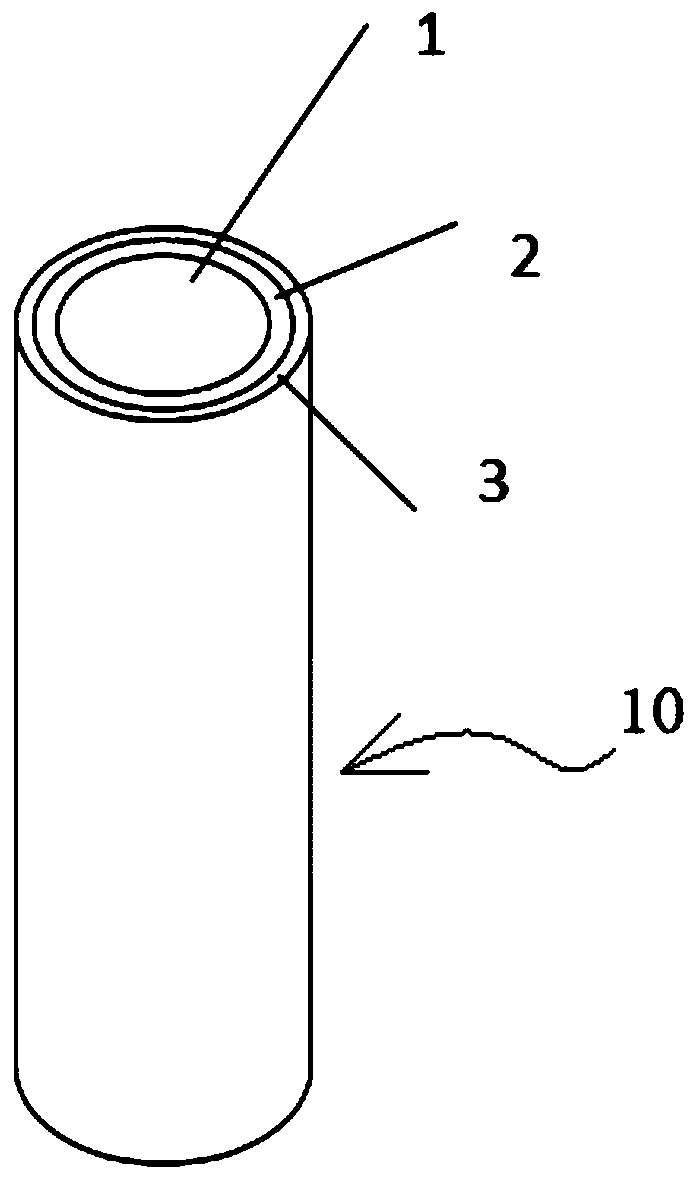

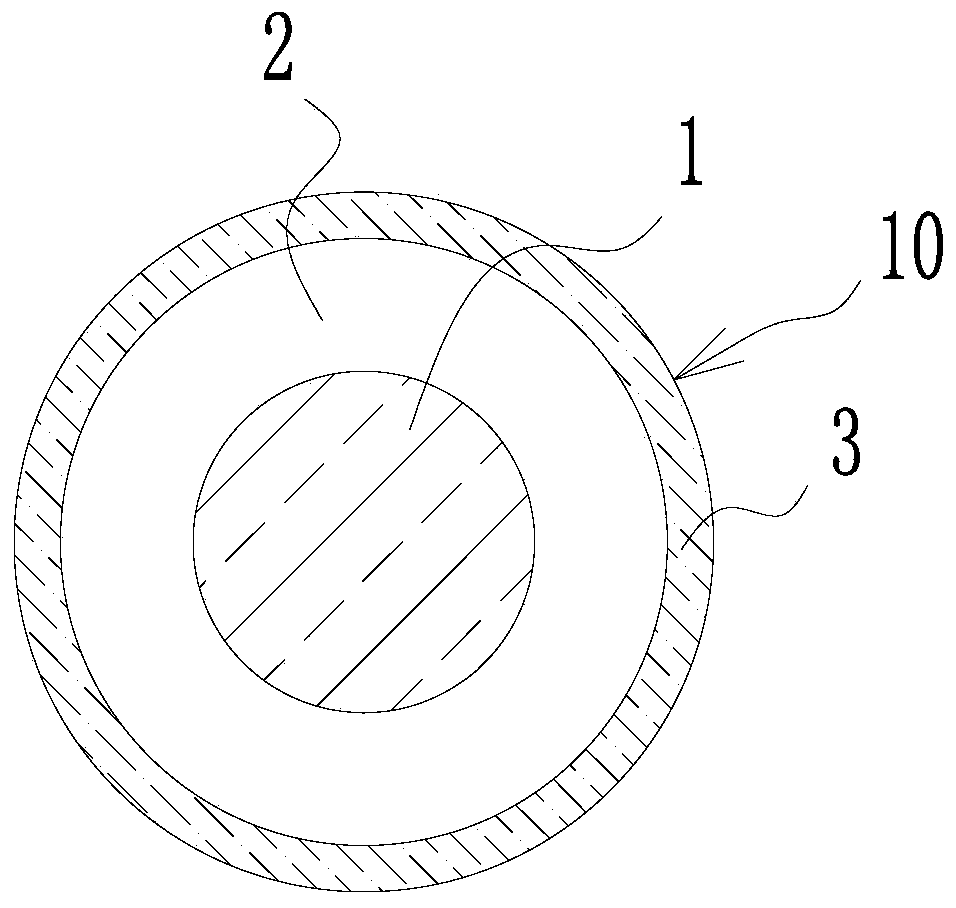

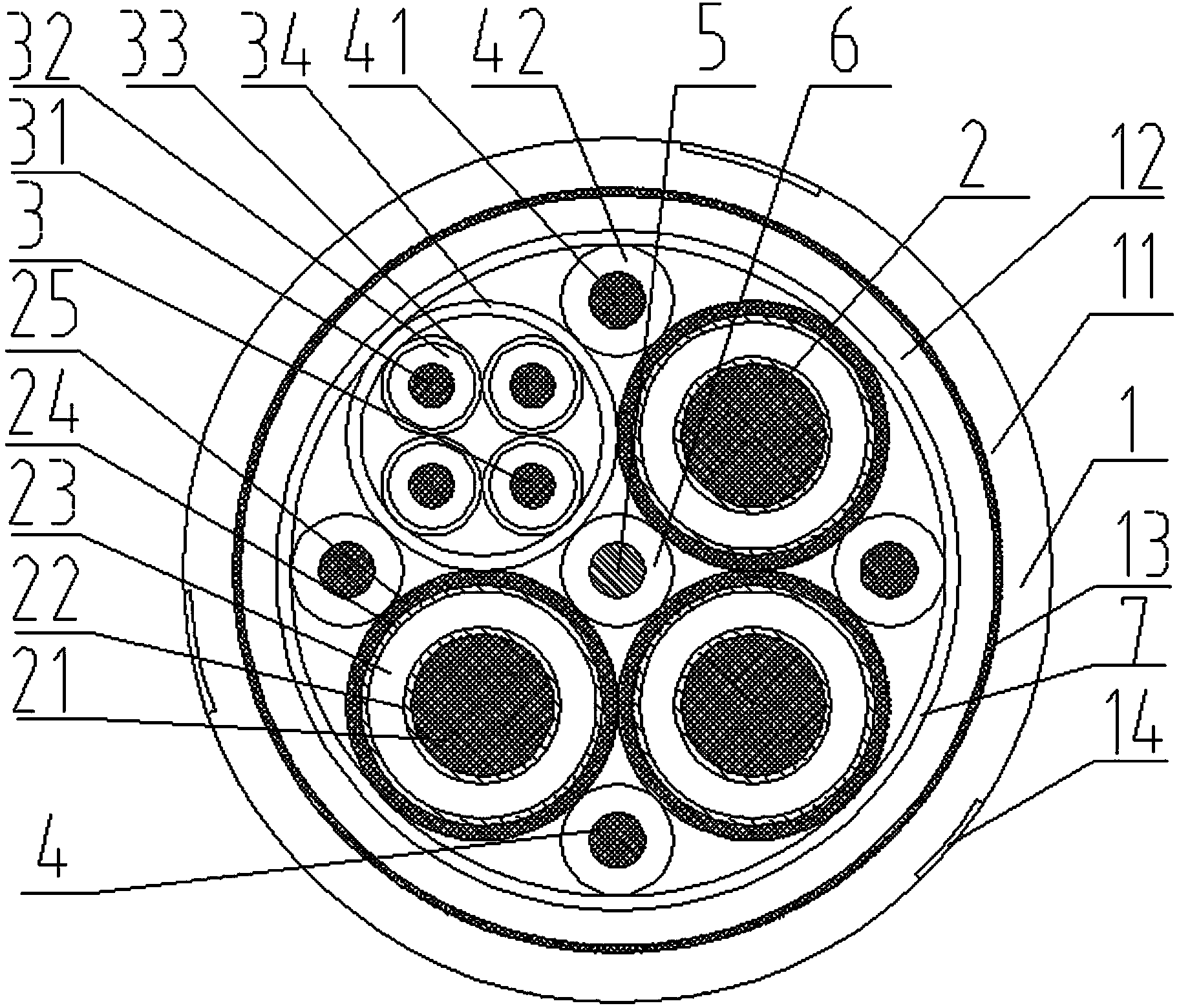

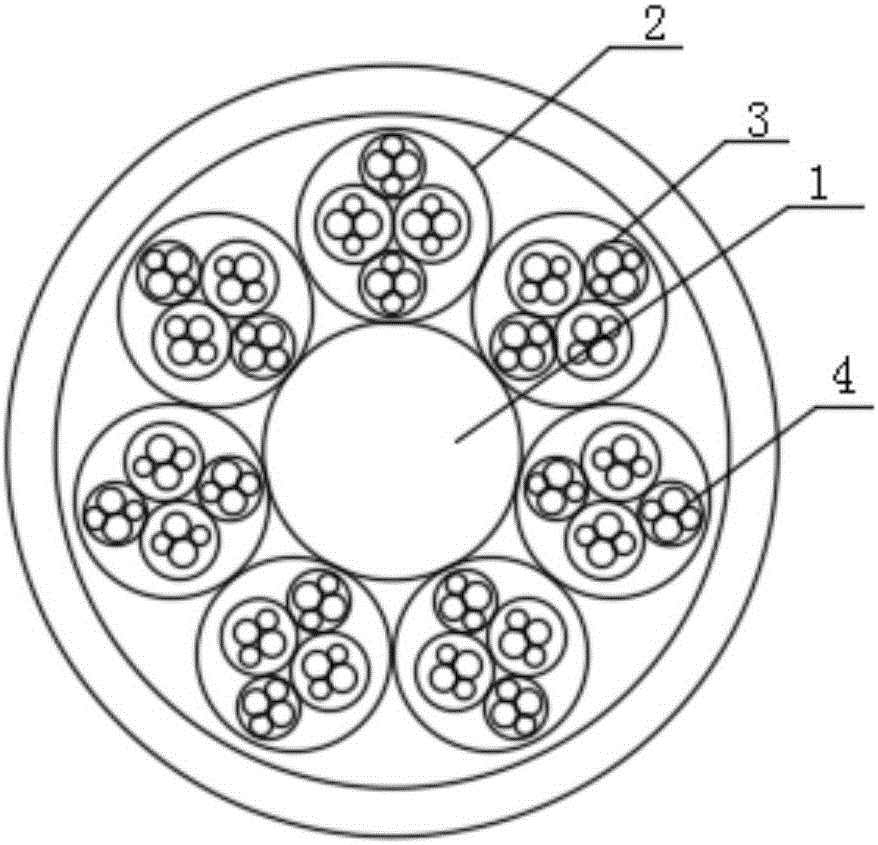

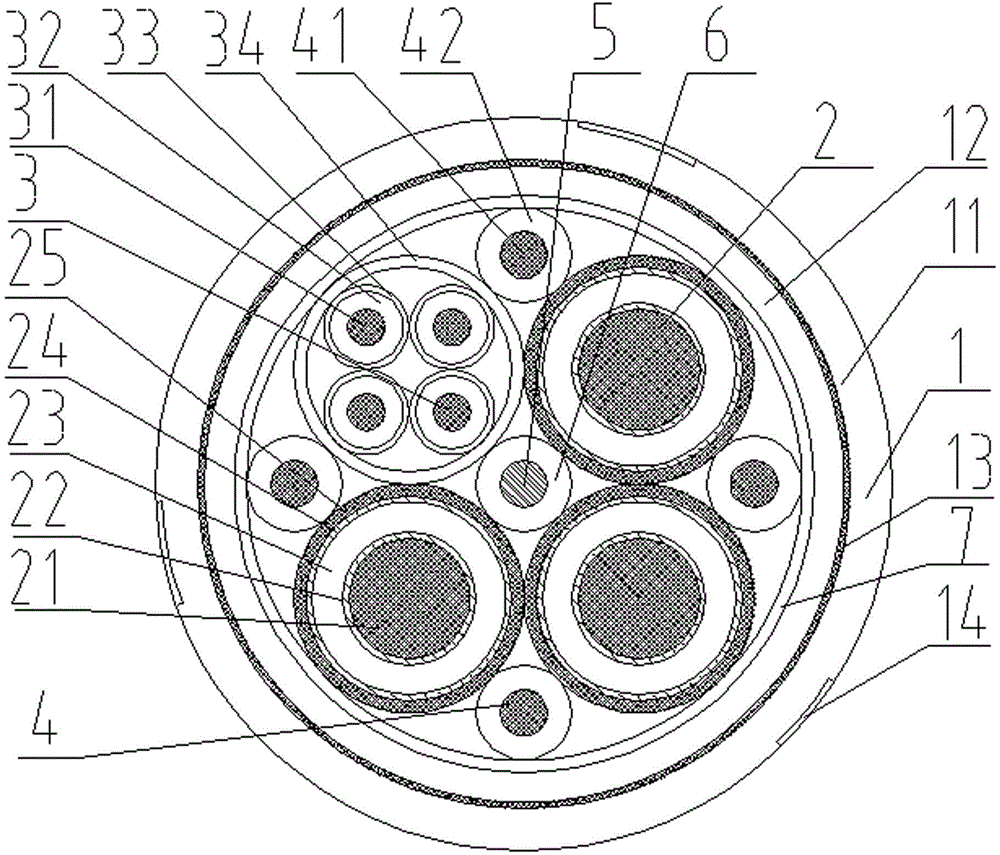

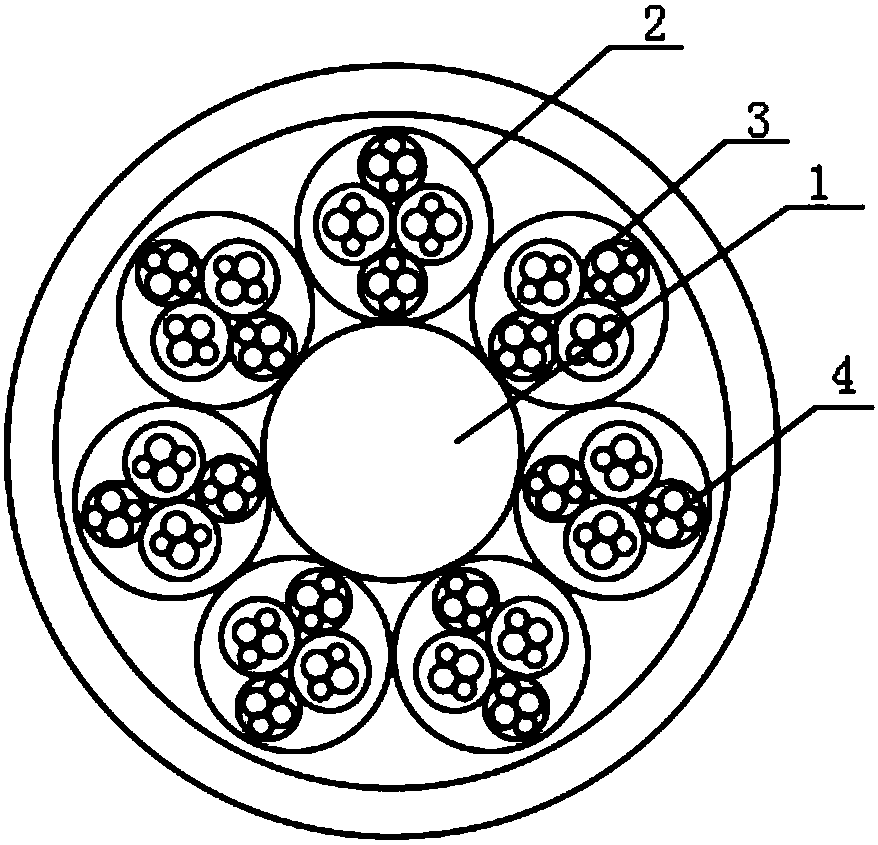

Dragging twist-resistant metallic shield flexible cable for mining equipment

ActiveCN103400644AGood flexibilityExcellent torsion resistance and bending resistancePower cables with screens/conductive layersFlexible cablesFiberElectrical conductor

The invention discloses a dragging twist-resistant metallic shield flexible cable for mining equipment. The flexible cable comprises a protective sleeve, a plurality of power wire cores and a plurality of ground wire cores, high-strength fibers and control wire cores, wherein each control wire core comprises a conductor, a high-elasticity rubber insulation layer and a heat-resisting thin slip band layer; the conductor is wrapped with the high-elasticity rubber insulation layer and the heat-resisting thin slip band layer; the high-elasticity rubber insulation layer is located between the conductor and the heat-resisting thin slip band layer; each power wire core comprises a conductor which is wrapped with a heat-resisting semiconductor nylon shield strip layer, an insulation layer and a heat-resisting semiconductor nylon shield strip, metal and fiber fixing weaving layer sequentially from inside to outside; each ground wire core comprises a conductor and a semiconductive elastic rubber layer, and the conductor is wrapped with the semiconductive elastic rubber layer; and outer sides of the plurality of the power wire cores and the plurality of the ground wire cores, the high-strength fibers and the control wire cores are wrapped with the protective sleeve, so that a whole is formed. The dragging twist-resistant metallic shield flexible cable is good in flexibility, tensile resistance and twist resistance and longer in service life.

Owner:湖南华菱线缆股份有限公司

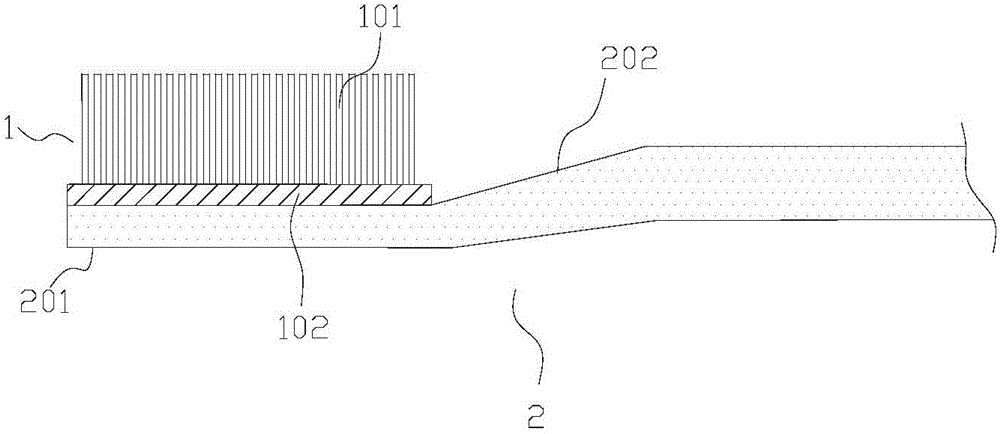

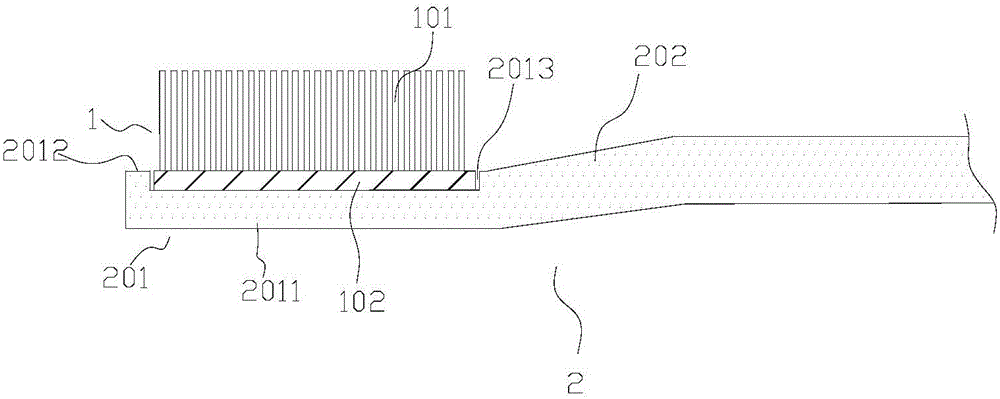

Toothbrush and preparation method thereof

InactiveCN105768520ALarge cleaning areaSimple preparation processBrush bodiesBristle carriersOral diseaseEngineering

The invention discloses a toothbrush and a preparation method thereof. The toothbrush comprise a brush handle and a cleaning part, wherein the brush handle comprises a handheld part and a brush head part, the handheld part is connected with the brush head part, and the cleaning part is fixedly connected with the brush head part; the cleaning part comprises a plurality of brush hairs and a hair plate, the hair plate is formed through integral fusion of the bottom of the plurality of brush hairs, and the hair plate and the brush head part are fixedly connected. The toothbrush has the beneficial effects that the plurality of brush hairs are tightly arranged and the bottom of the brush hairs is fused as the hair plate, the unfused part stands erectly on the hair plate, the integral adhesion force of the brush hairs is enhanced, the direct cleaning area of the brush hairs and the teeth is increased at the same time, and the toothbrush is in favor of the cleaning of the teeth; furthermore. The toothbrush has soft brush hairs, can bring comfort feeling for the user while being used for cleaning the teeth, and is more in favor of the children, pregnant, and oral disease patient with gingiva easy to blood after friction. Furthermore, the toothbrush is simple in preparation process and low in cost.

Owner:PESITRO HEALTHCARE PROD CO LTD

Method for preparing spandex fibers with low breaking rate

ActiveCN110791835AIncrease the speed of diffusionImprove broken wire problemMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberPolymer science

The invention relates to a method for preparing spandex fibers with low breaking rate, in particular to a method for manufacturing spandex by introducing a blend solution of an abrasion-resistant agent and a flow promoter into a polyurethane urea spinning solution; the method includes: 1) blending and dissolving the abrasion-resistant agent and the flow promoter in an organic solvent to obtain a blend solution A; 2) adding the blend solution A into the polyurethane urea spinning solution B to prepare a spinning dope C, and performing spinning and winding with the spinning stock solution C. Themethod herein is simple and convenient to implement and can be widely applied to spandex fibers of different varieties, and the breaking condition of the prepared spandex fibers is obviously alleviated.

Owner:ZHEJIANG HUAFENG SPANDEX

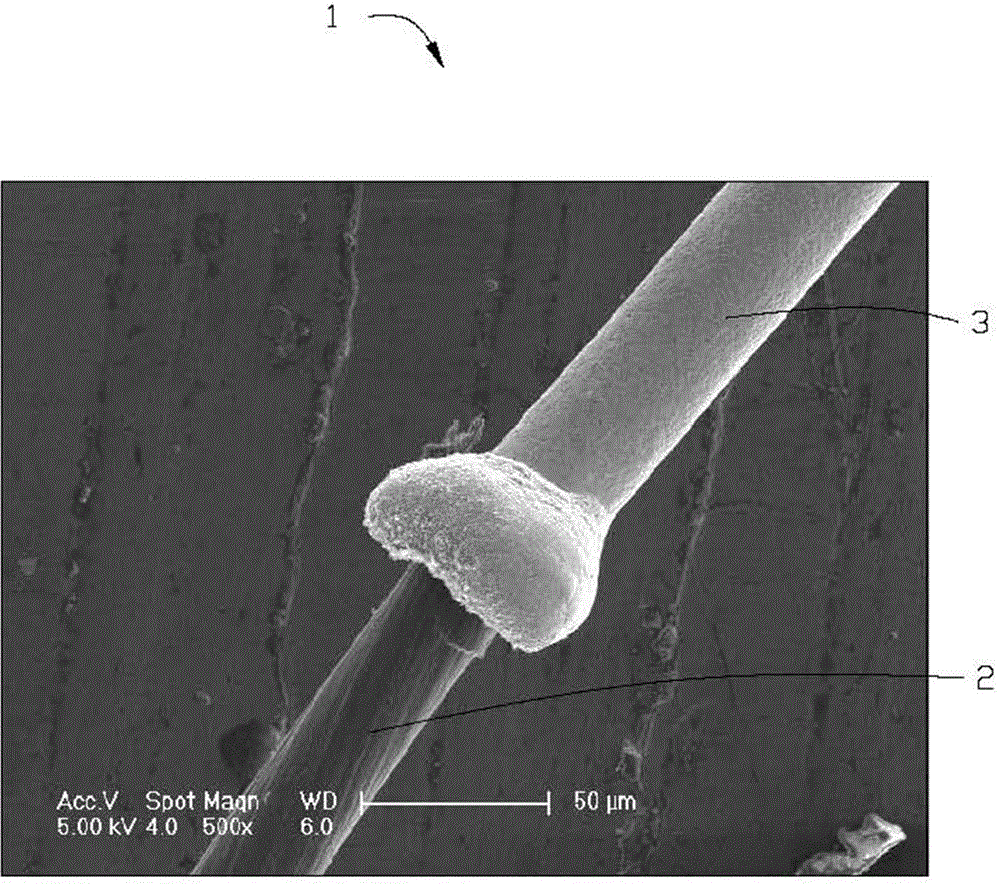

Linear-cutting electrode wire and linear-cutting device

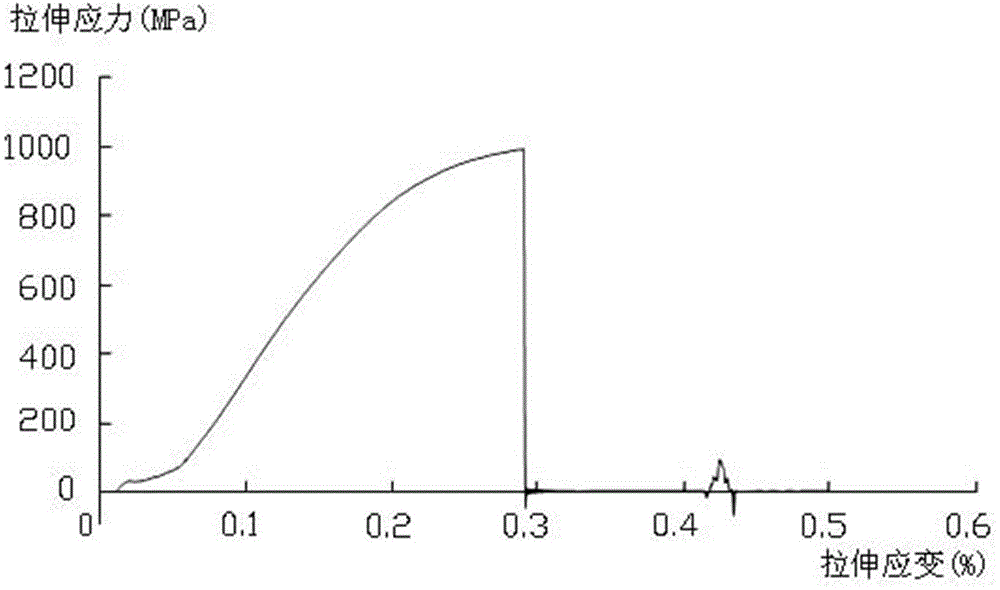

ActiveCN105081490AImprove mechanical propertiesImprove tensile propertiesElectrical-based machining electrodesTensile strainWire cutting

A wire cutting electrode which includes a carbon nanotube composite wire, a tensile strain rate of the carbon nanotube composite wire being less than or equal to 3%. The carbon nanotube composite wire includes a carbon nanotube wire and a metal layer. The carbon nanotube wire consists of a plurality of carbon nanotubes oriented around a longitudinal axis of the carbon nanotube composite wire. A twist of the carbon nanotube wire ranges from 10r / cm to 300r / cm. A diameter of the carbon nanotube wire ranges from 1 micron to 30 microns. The metal layer is coated on an outer surface of the carbon nanotube wire, and a thickness of the metal layer ranges from 1 micron to 5 microns. A wire cutting device using the wire cutting electrode is also provided.

Owner:BEIJING FUNATE INNOVATION TECH

Flat waste wire recycling and drawing process and wire-drawing pay-off mechanism

The invention discloses a waste flat wire recycling and drawing process and a wire drawing and releasing mechanism, aiming at solving the problems of low product quality, high energy consumption and potential safety hazards of waste wire recycling. The invention comprises the following steps: a. Butt welding the recovered waste wire into a linear shape; b. Pressing the waste wire, putting the butt-welded waste wire on a press to press it into waste flat wire; c. Waste flat wire Rough drawing, the waste flat wire is drawn through the wire drawing machine for the first time; d, take-up, the waste flat wire is roughly drawn and wound on the pay-off reel; e, annealed and softened, the waste flat wire is placed Put the wire reel into the annealing furnace for annealing and softening; f, take out the pay-off reel in the annealing furnace, and air-cool the waste flat wire; g, pay off the wire reel to discharge the waste flat wire, and the waste flat wire will pass through the shelling wheel after being discharged Remove the surface oxide layer; h. Fine drawing of the waste flat wire, sending the waste flat wire into the wire drawing machine for fine cold drawing, and winding it on the take-up reel for take-up after the wire drawing is completed.

Owner:杭州富阳飞润五金有限公司

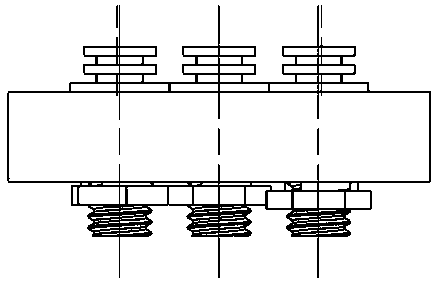

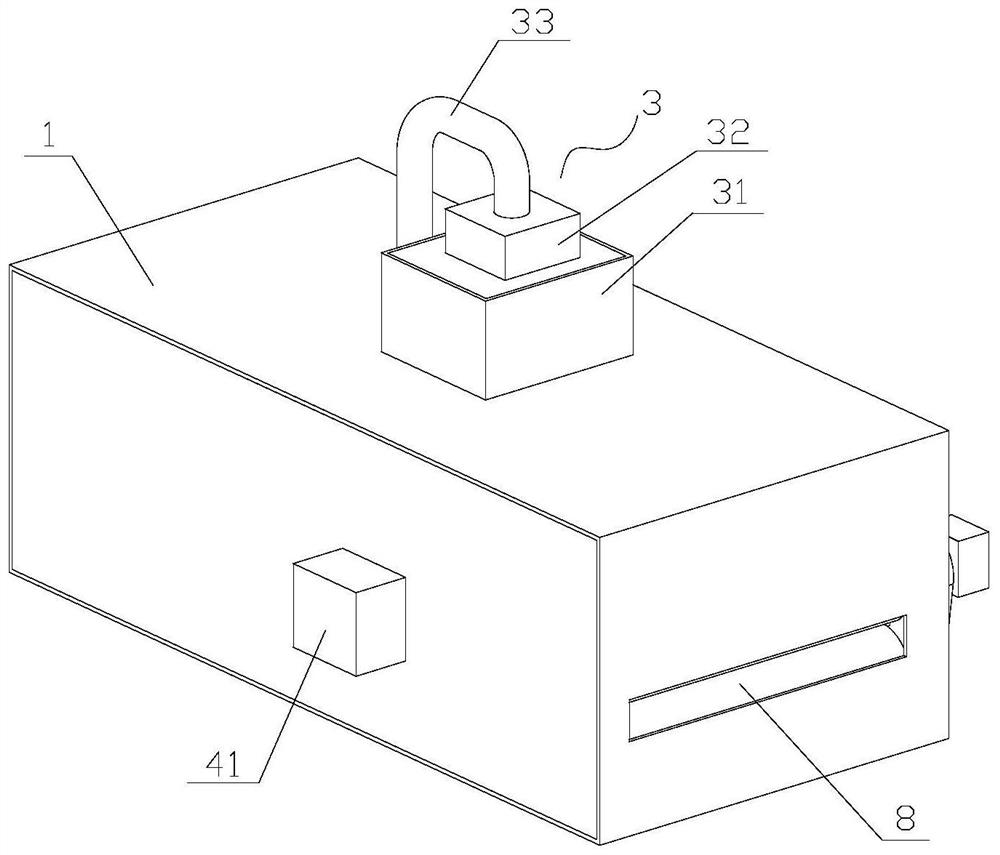

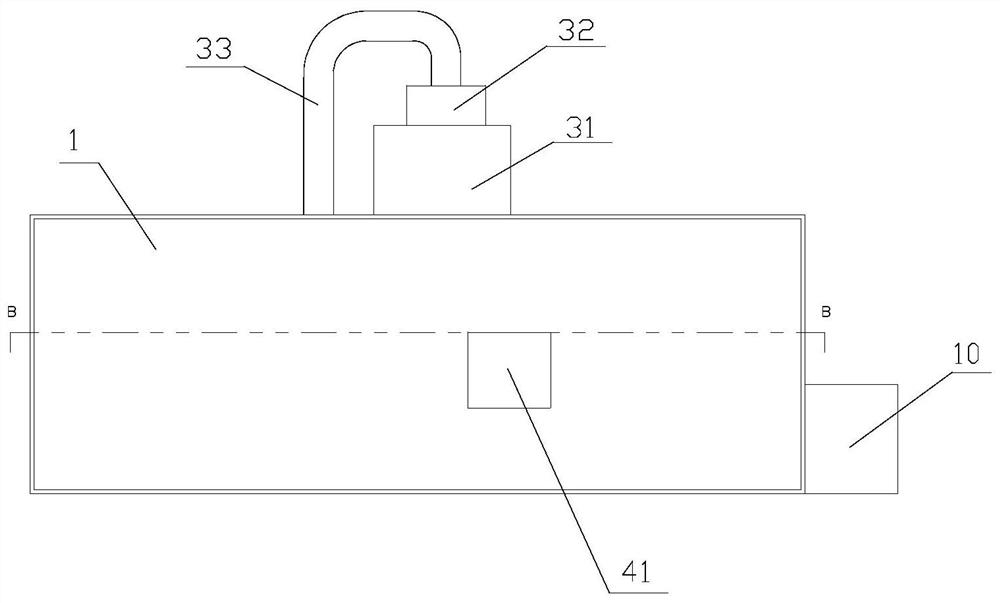

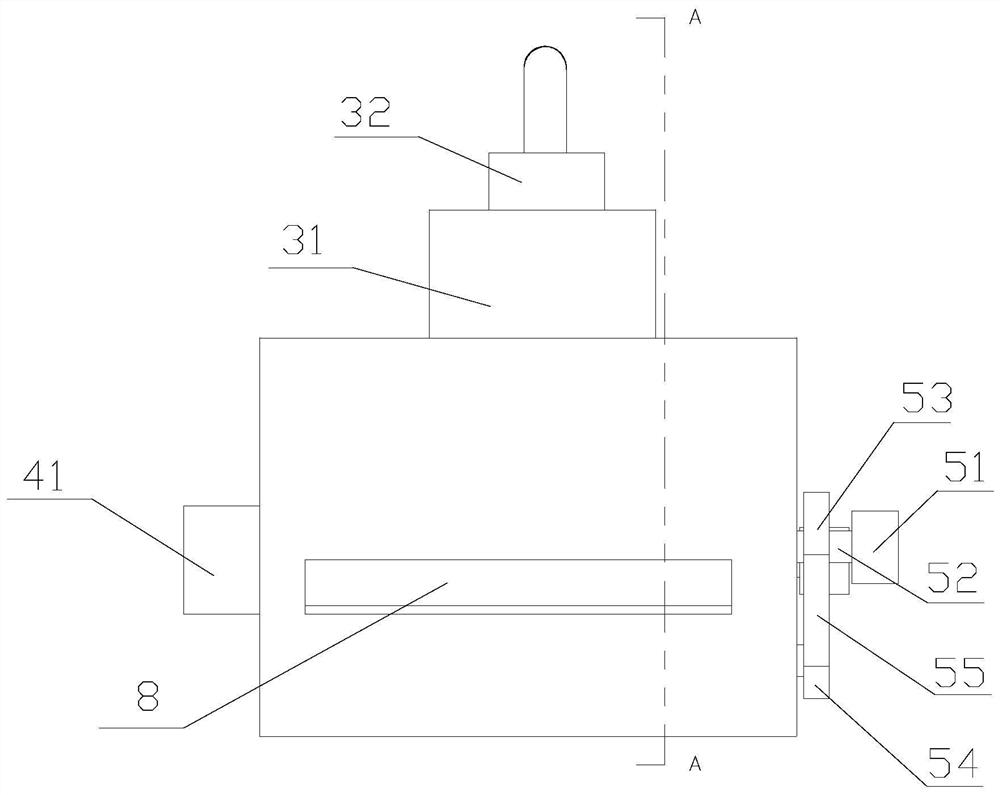

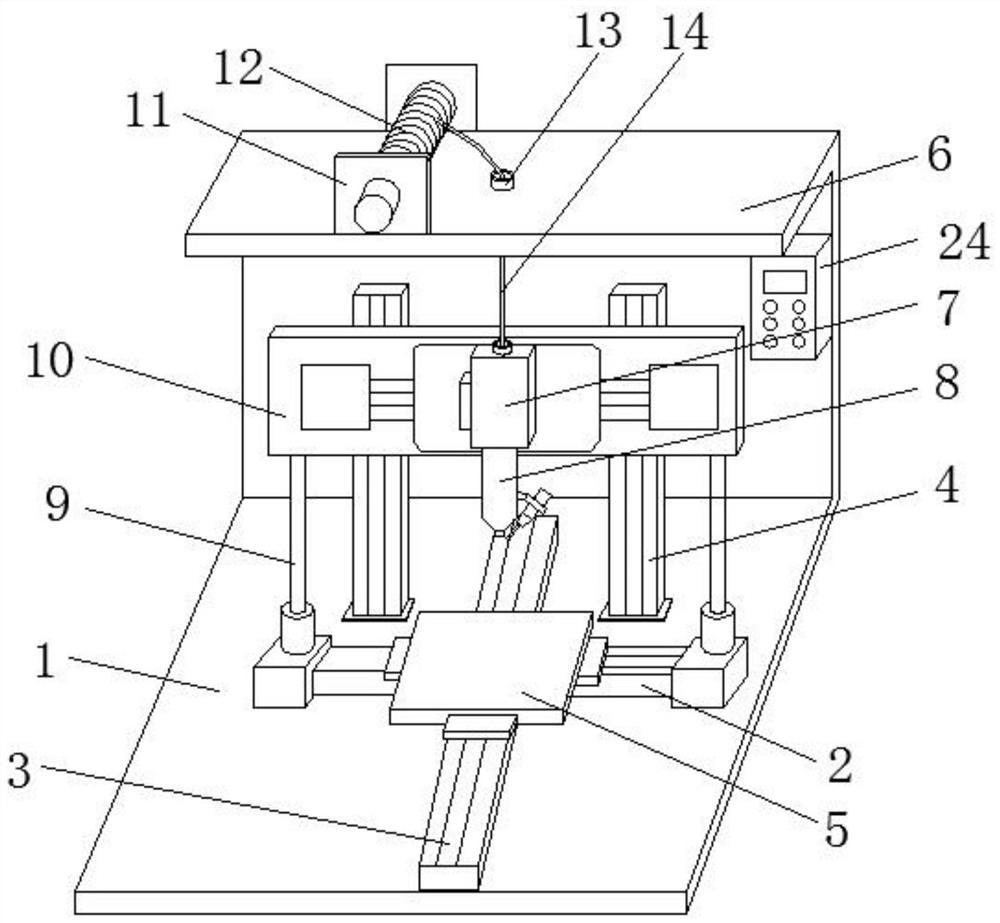

Wire guiding device for electric spark linear cutting machine tool

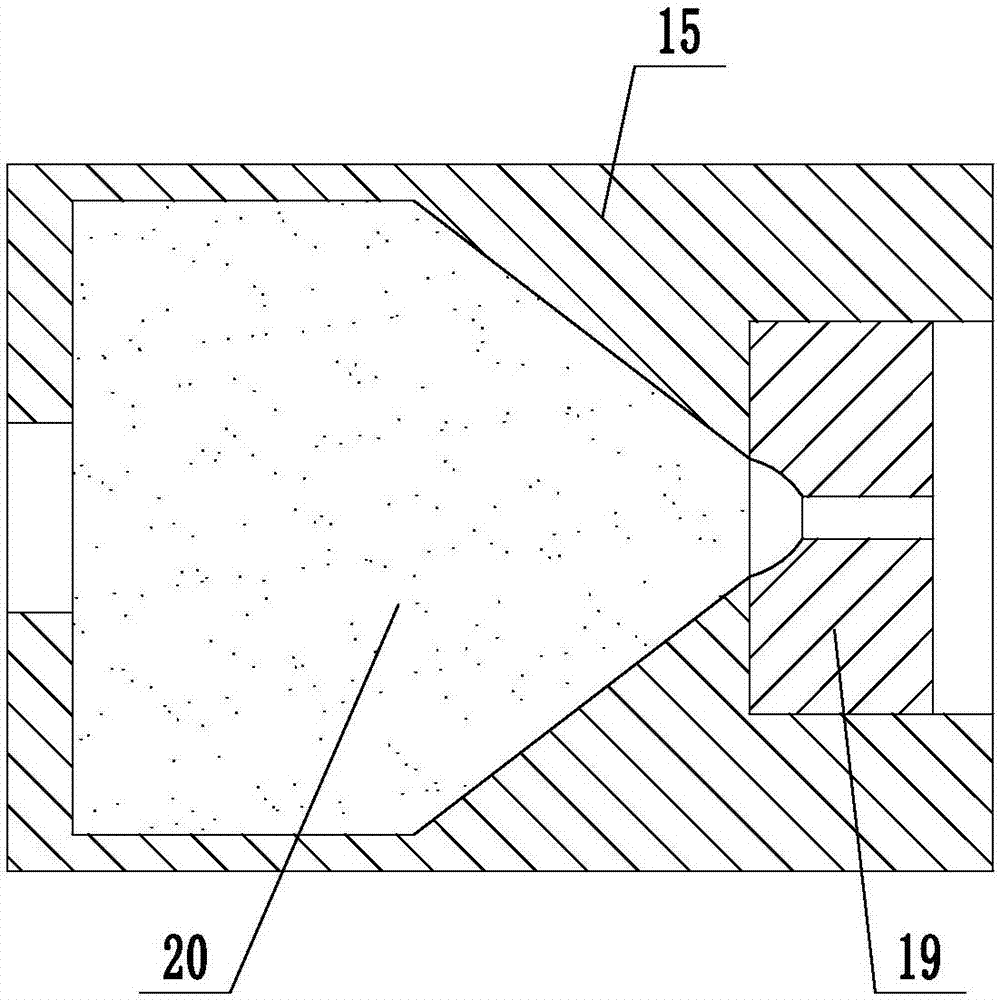

InactiveCN108406023ANot prone to wire breakageSimple structureElectrical-based machining electrodesEngineeringMachine tool

The invention discloses a wire guiding device for an electric spark linear cutting machine tool. The wire guiding device comprises a fixed base, a left sliding block, a right sliding block, a middle sliding block, an upper right fixed sliding block, an upper left fixed sliding block and sliding block fixing nuts. The fixed base is provided with a left sliding groove, a right sliding groove, a middle sliding groove, an upper right hole and an upper left hole. The left sliding block is in sliding connection with the left sliding groove and fixed to the appropriate position of the left sliding groove through the corresponding sliding block fixing nut, the right sliding block is in sliding connection with the right sliding groove and fixed to the appropriate position of the right sliding groove through the corresponding sliding block fixing nut, and the middle sliding block is in sliding connection with the middle sliding groove and fixed to the appropriate position of the middle sliding groove through the corresponding sliding block fixing nut. The upper right fixed sliding block and the upper left fixed sliding block are in clearance fit with the upper right hole and the upper left hole correspondingly, and fixed to the fixed base through the corresponding sliding block fixing nuts. The wire guiding device can be adjusted in different directions to tension an electrode wire, andis simple in structure, low in cost and high in practicability.

Owner:HARBIN UNIV OF SCI & TECH

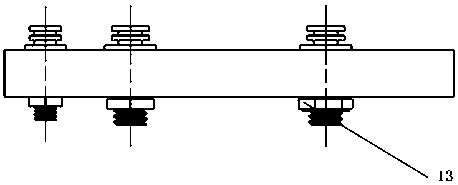

High-speed environmental-friendly tinning machine and smooth-transition method

InactiveCN109943795AReduce resistanceIncrease production speedHot-dipping/immersion processesTinningCopper wire

The invention discloses a high-speed environmental-friendly tinning machine and a smooth-transition method. The high-speed environmental-friendly tinning machine comprises an emptying device, a guiding device, an acid pickling device, an ultrasonic cleaning device, a high-temperature annealing and drying device, a tin furnace and a winding device connected sequentially, wherein the guiding deviceis provided with a first wire passing area; the acid pickling device is provided with a second wire passing area; the ultrasonic cleaning device is provided with a third wire passing area; the high-temperature annealing and drying device is provided with a fourth wire passing area; the tin furnace is provided with a fifth wire passing area; and the first, the second wire passing area, the third wire passing area, the fourth wire passing area and the fifth wire passing area coexist on one horizontal plane and are matched to form a linear wire passing area. According to the smooth-transition method, a copper wire moves smoothly, and a tin liquid level is improved. According to the high-speed environmental-friendly tinning machine and the smooth-transition method provided by the invention, the production speed can be improved, the cost is reduced, the phenomenon of wire fracture cannot occur easily, the production quality is stable, the service life is long, the method is simple, and theresistance to copper wire movement can be greatly reduced.

Owner:珠海蓉胜电子材料研究院有限公司

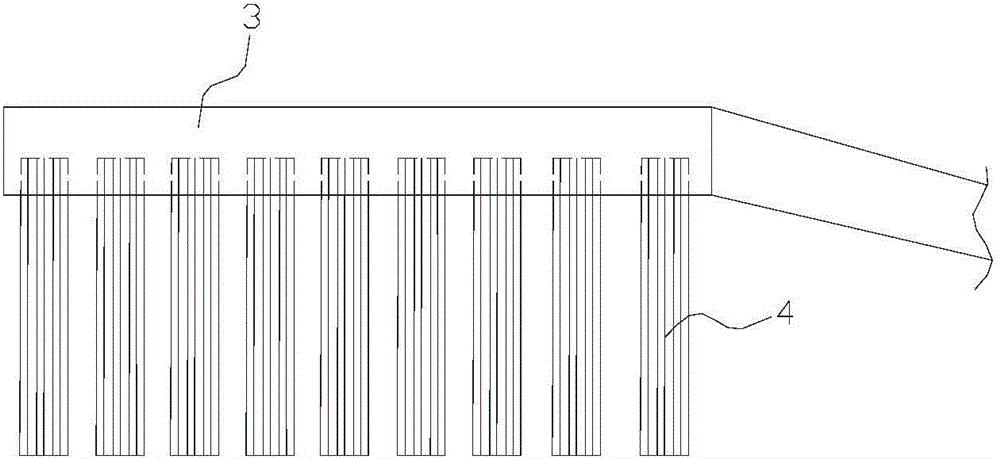

Production method and preparation device of anti-explosion line paperboard

InactiveCN113355946AHigh folding resistanceNot prone to wire breakageMechanical working/deformationPhysical paper treatmentWater storage tankPaperboard

The invention relates to the technical field of anti-explosion line paperboards, in particular to a production method and a preparation device of an anti-explosion line paperboard. A paperboard is put into the conveying box through the inlet, and the conveying belt is started after the paperboard is put above the conveying belt; the conveying belt conveys the paperboard to the atomization assembly, a water pump of the atomization assembly is started, the water pump injects water flow in a water storage tank into a water distribution plate, and the paperboard is atomized through an atomization nozzle; after the paperboards are atomized, the conveying belt conveys the paperboards to the cutting assembly for cutting treatment; then, the conveying belt conveys the cut paperboard to the line pressing assembly, and the line pressing assembly conducts line pressing treatment on the paperboard; and after the line pressing assembly completes line pressing on the paperboards, the conveying belt conveys the paperboards to the collecting box at the outlet of the rear end face of the conveying box to be collected, and the situation of line explosion of the paperboards is not prone to occurring.

Owner:安徽意达包装有限公司

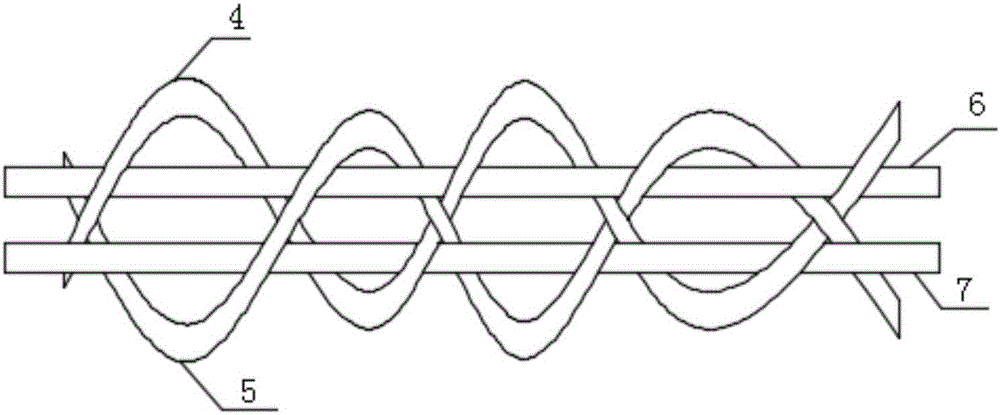

Cable solder wire for CMT welding system and CMT welding system

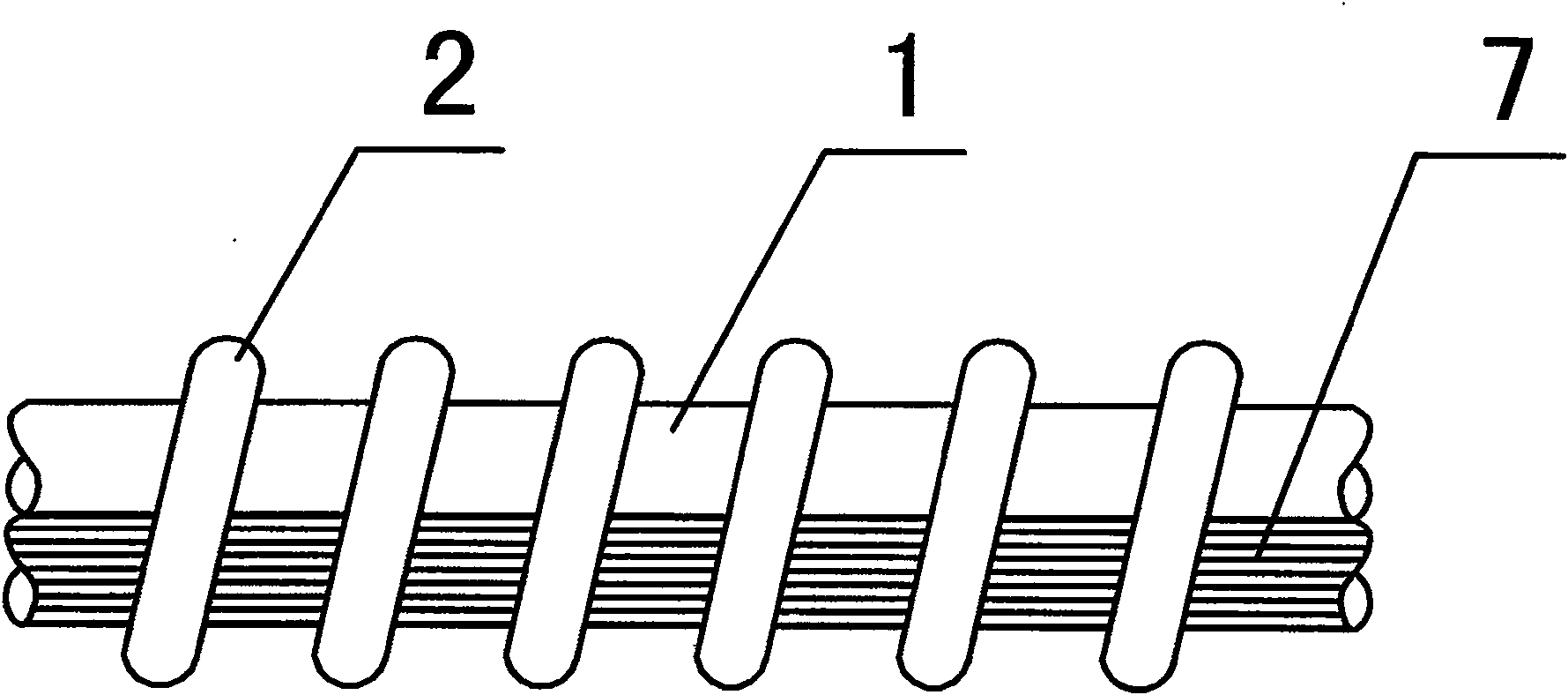

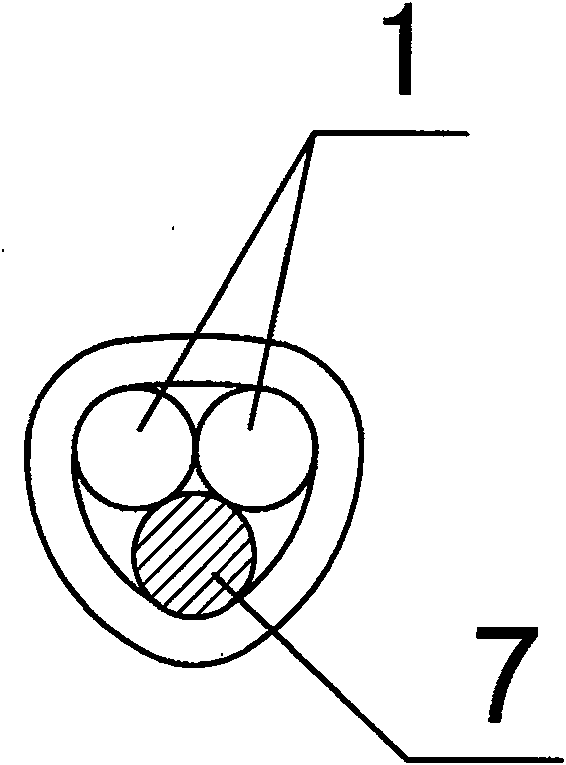

ActiveCN106363314AImprove welding effectReduce the number of weld layersArc welding apparatusWelding/cutting media/materialsTight bindingEngineering

The invention discloses a cable solder wire for a CMT welding system. The solder wire comprises a central solder wire. The outer side of the central solder wire is provided with a spiral solder wire which is twined tightly around the central solder wire in a spiral manner. The outer side of the spiral solder wire is provided with a protection ring. The inside of the spiral solder wire is provided evenly with 4 subordinate solder wire groups. The subordinate solder wire groups are tangentially arranged. The inside of each subordinate solder wire group is provided with a first solder wire, a second solder wire, a third solder wire and a fourth solder wire. The fusion depth in the welding operation is deep. This structure can reduce the quantity of overlapping welding seams layers and can fundamentally increase the welding efficiency, reduce the production costs with negligible splashes. The high mechanical property of the welding seam and the tight binding structure of the solder wire stabilize the solder wire feeding process, enhances the welding property of the cable solder wire and makes the CMT welding system to render a better soldering effects.

Owner:QINGDAO BRANCH CO., LTD. OF MECHANICAL SCIENCE RESEARCH INSTITUTE

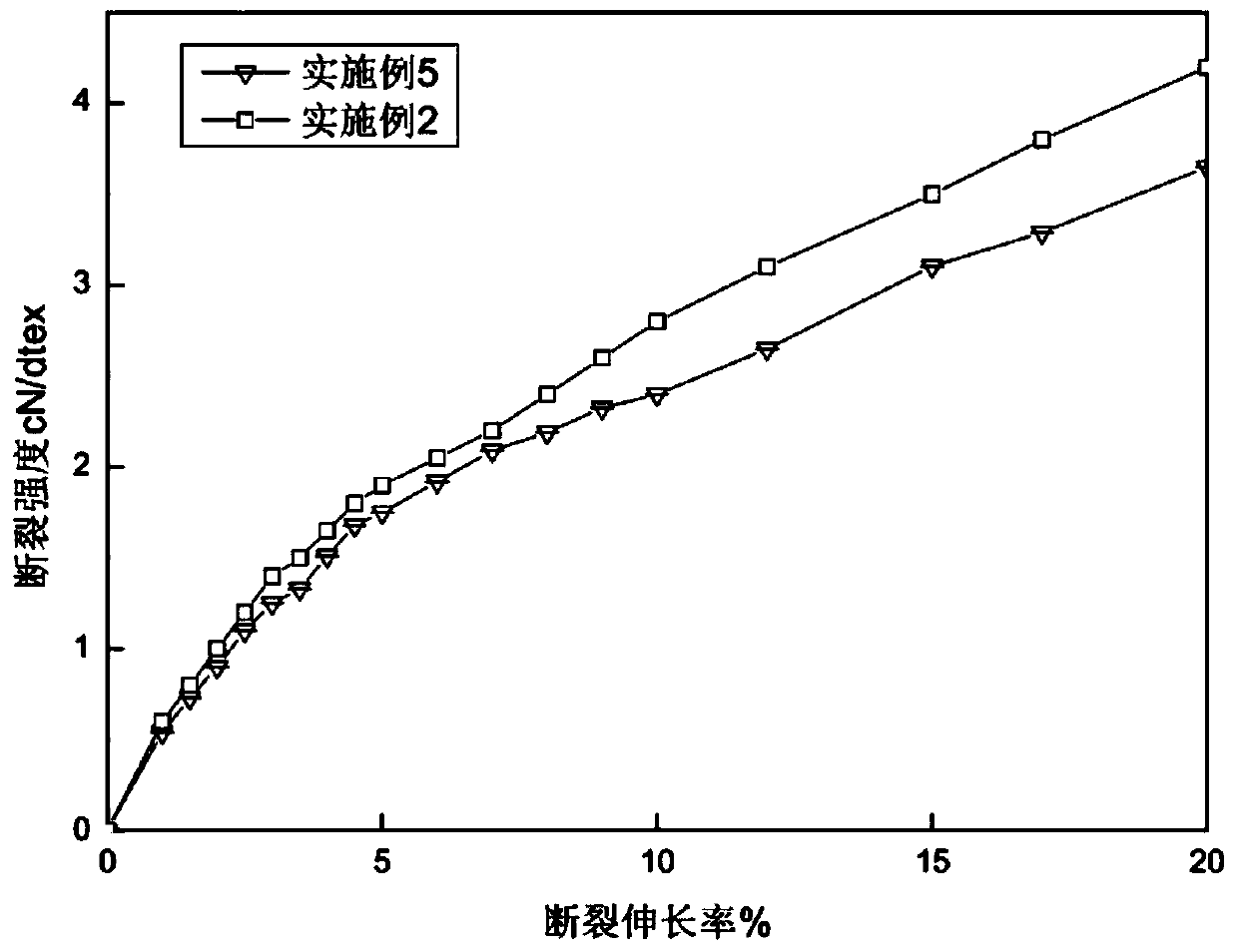

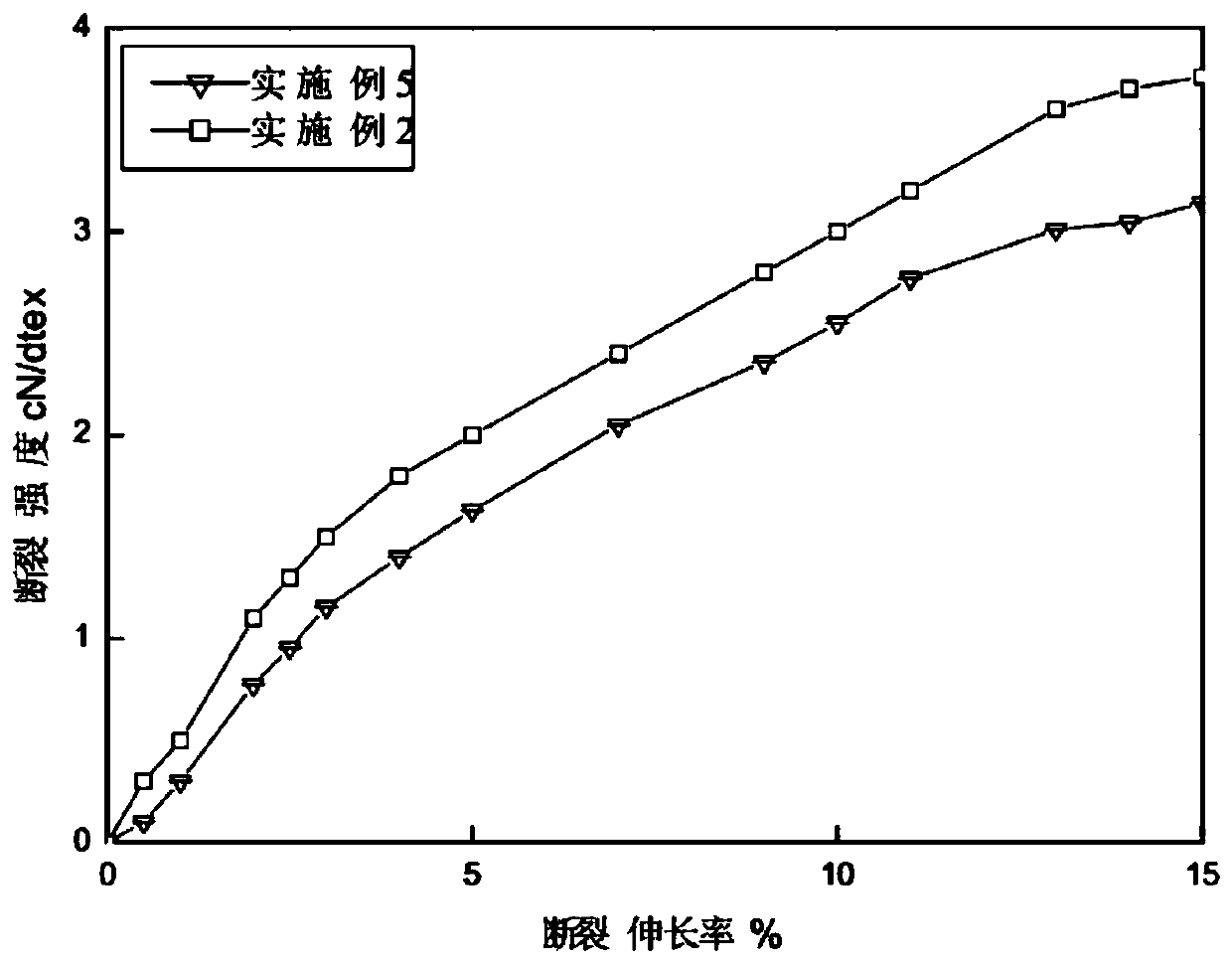

Antistatic bamboo charcoal fiber for underwear

InactiveCN110219066AHigh breaking strengthImprove spinnabilityElectroconductive/antistatic filament manufactureArtificial filaments from cellulose solutionsCarbonizationUltimate tensile strength

The invention provides an antistatic bamboo charcoal fiber for underwear, and belongs to the field of textiles. A preparation method of the fiber includes a carbonization process for high temperaturecarbonization of moso bamboos, a homogenization process for bamboo charcoal obtained after carbonization, a preparation process of a spinning solution, and a spinning process. The bamboo charcoal fiber obtained by the spinning process has dry tensile strength of 2.0-4.5 cN / dtex and wet tensile strength of 1.8-3.8 cN / dtex. The bamboo charcoal fiber can prevent surface charge accumulation, and has enhanced antistatic effect and antistatic endurance, excellent shaping durability and shape retention, reinforced heat and washing resistance, and improved wearing comfort; the preparation method can improve the tensile strength of the fiber, especially the wet tensile strength, breakage and blockage can be prevented during spinning, damage to the fabric due to exposure to the blazing sun can be alleviated, and the fiber can be resistant to scrubbing and twisting and does not deform, so that the spinnability of the fiber and the quality of fiber products are improved.

Owner:HAIYAN SHUOCHUANG CLOTHING RES INST

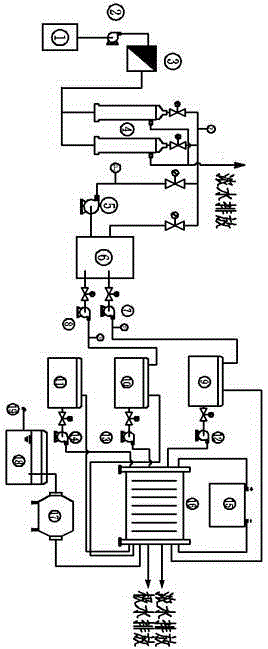

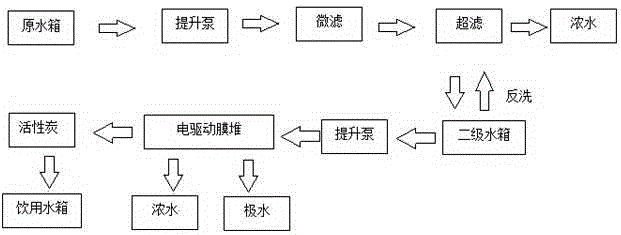

Multi-membrane-method sea water desalination integrated device

InactiveCN105174545AIncrease water fluxHigh breaking strengthSeawater treatmentMultistage water/sewage treatmentWater desalinationWater quality

The invention provides a multi-membrane-method sea water desalination integrated device. According to the multi-membrane-method sea water desalination integrated device, a novel multi-membrane-method sea water desalination integrated technology is created by coupling microfiltration, ultrafiltration, frequent electrodialysis reversal and active carbon optimizing, and aims at solving the problems of membrane pollution and the like in the sea water desalination process; an ultrafiltration membrane with high pollution resistance is adopted for a pre-treatment system, and the ultrafiltration membrane and an electric-driving homogeneous membrane form a double-membrane system, so that the system is more stable in running, the service life of the system is prolonged, and it is guaranteed that the quality of yielded water meets a tap water standard; the sea water desalination integrated technology is a novel sea water desalination technology.

Owner:江苏省科建成套设备有限公司

PET color master batch for water-based superfine fibers and preparation method thereof

InactiveCN110903617ALow costGood coloring effectPigment addition to spinning solutionMonocomponent polyesters artificial filamentNonwoven fabricAnoxomer

The invention discloses a PET color master batch for water-based superfine fibers. The PET color master batch comprises the following raw materials in percentage by mass: 30-80% of a carrier, 10-50% of a coloring agent, 3-15% of a dispersing agent, 3-15% of a compatibilizer, 3-10% of a slip agent, 3-20% of an antistatic agent, 0.5-20% of modified inorganic filler and 0.1-1% of an antioxidant. By adopting the PET color master batch for water-based superfine fibers, the performances of superfine fiber spinning, non-woven fabric processing and the like are guaranteed, and the problems of coloringand color migration of a final product are solved. The PET color master batch for water-based superfine fibers is low in cost, strong in coloring agent and carrier effect, good in coloring effect, simple in production and preparation process, small in environmental pollution, good in compatibility and liquidity in the spinning process and not prone to yarn breakage, and the final product is stable in hue and free of color migration.

Owner:明新梅诺卡(江苏)新材料有限公司

A 3D printer for printing carbon fiber

ActiveCN108943719BNot easy to slipIncrease frictionAdditive manufacturing apparatus3D object support structuresFiberCarbon fibers

The invention relates to the technical field of 3D printers, in particular to a 3D printer for printing carbon fibers, including a frame body, a printing platform, a mixing box, a discharge end, a lifting platform, an electric heating layer, a conveyor belt, and a resin liquid storage box And the control cabinet, the X-axis guide rail, the Y-axis guide rail and the Z-axis guide rail are installed on the frame body, the X-axis guide rail and the Y-axis guide rail are vertically intersected on the horizontal plane, and the printing platform is located on the plane where the X-axis guide rail and the Y-axis guide rail are located, and The printing platform can reciprocate along the X-axis guide rail and the Y-axis guide rail. The lifting platform is located on the Z-axis guide rail, and the lifting platform can reciprocate along the Z-axis guide rail. A mixing box is installed on one side of the middle part. In the present invention, a conveying trough is provided in the middle part of the conveyor belt, and the carbon fiber filaments can be clamped in the conveying trough for conveying, which is convenient for continuous feeding and is not prone to broken wires.

Owner:丹阳创华电子有限公司

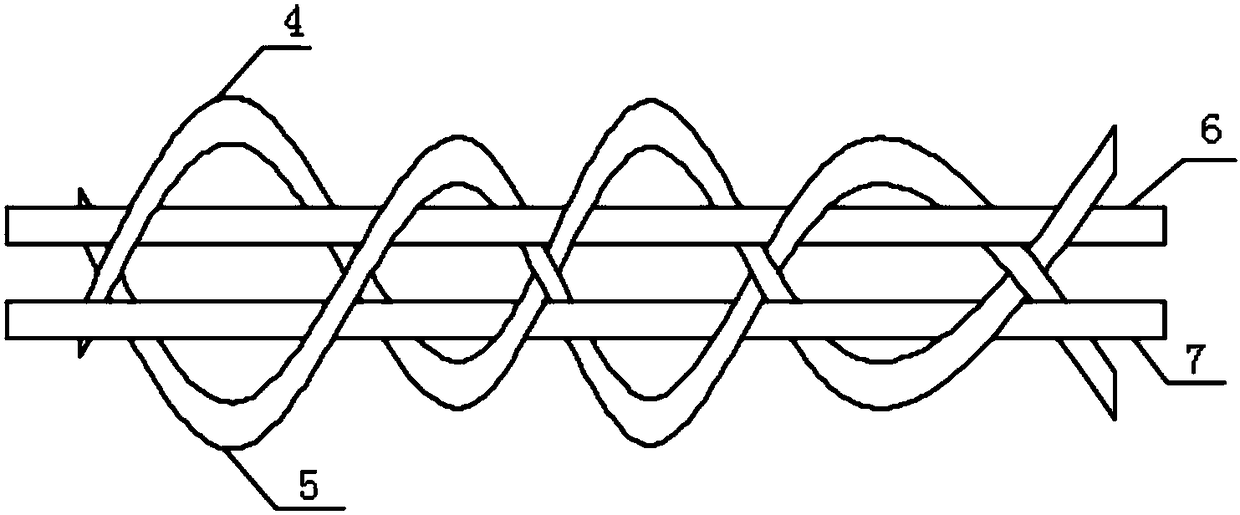

Double main thread master-slave type three-helix energy-saving lamp filament and manufacturing method thereof

InactiveCN100557758CExtended service lifeShorten warm-up timeGas discharge lampsCold cathode manufactureYarnEngineering

Owner:湖州太箭照明有限公司

Lifting rope for crane

The invention discloses a lifting rope for a crane. The lifting rope for the crane comprises, by weight, 40-80 parts of iron, 5-10 parts of silver, 1-3 parts of zinc, 0.005-0.02 part of gold, 4-9 parts of sodium, 20-25 parts of copper, 1-5 parts of chromium, 0.5-1.5 parts of graphite, 5-15 parts of zinc oxide, 0.2-0.4 part of manganese bioxide, and 0.2-0.6 part of silicon dioxide. Break and fracture of wire are not liable to occur, abrasion resistance is achieved and the service life is long.

Owner:安徽骏达起重机械有限公司

A method for manufacturing a large-section high-resolution flexible optical fiber image transmission bundle

ActiveCN111190251BGuaranteed StrengthReduce the number of timesGlass making apparatusBundled fibre light guideImage resolutionEngineering

The invention discloses a method for manufacturing a large cross-section and high-resolution flexible optical fiber image transmission bundle. An optical fiber monofilament with two claddings is drawn by a three-crucible or rod-tube method. The rigid optical fiber image transmission unit body with a regular polygonal cross-section is drawn by wire drawing, and the hard optical fiber image transmission bundle with a large cross-section is obtained after the second wire arrangement of the unit body, and the hard optical fiber image transmission bundle is thermally fused at the end Afterwards, the middle part is placed in an acid solution to dissolve the acid-soluble layer to obtain a flexible optical fiber image transmission bundle. Using the manufacturing method of the present invention can produce a circular section or a regular polygonal section, the size of the regular hexagonal section is 8.8 mm, the size of the square section is more than 5 mm, the length can reach 6 meters, and the resolution can reach up to 191 lp / mm. High resolution flexible fiber optic imaging bundle.

Owner:NANJING CHUNHUI SCI & TECH IND

A kind of production technology of copper braided wire

ActiveCN107622831BNot prone to wire breakageBraided wire conductorsCable/conductor manufactureBobbinDrive wheel

The invention discloses a production technology of a copper braided wire. The production technology comprises the step of arranging a pay-off stand: bobbin copper wires are fixed on the pay-off stand,the bobbin is released and the copper wire connector penetrates through a sliding wheel; the step of wire scutching: the copper wires are pulled out of the pay-off stand to be wound on a spindle for3-4 circles in a clockwise way, all the copper wires are adjusted to be on the same plane and consistent in degree of tightness and wire scutching is performed; the step of arranging the spindle: thespindle after processing of the step of wire scutching is arranged on a braiding machine, the copper wires penetrate through the middle of the spindle to be pulled to a driving wheel and then compressed by a rolling wheel in the middle of the driving wheel; the step of gear adjustment: the power is disconnected and the size and the tooth space of the gear are adjusted; the step of braiding: the braiding machine is started to perform braiding, and the thickness, the uniformity and the appearance of the braided wire are inspected; and the step of wire leading: the braided copper braided wire isled to a rubber roller to perform coiling. With application of the production technology of the copper braided wire, the phenomenon of wire fracturing is not liable to occur in the production process,and the copper braided wire obtained through braiding is uniform without the situation of burrs or wire fracturing.

Owner:广州光为照明科技有限公司

A kind of braided vena cava filter and braiding method

ActiveCN105726158BGuarantee unimpededLong-term unimpededBlood vessel filtersVeinPulmonary vein embolism

The invention provides a woven type venae cava filter. The woven type venae cava filter is characterized by comprising a filter part, a fixing part and connecting parts, wherein the filter part, the fixing part and the connecting part are woven together and distributed in sequence from a heart near end to a heart far end; the filter part comprises N1 Y-type woven structures distributed in the circumferential direction; the fixing part comprises N1 ridges distributed in the circumferential direction; the connecting parts are of conical woven structures which are formed by extending directly the N1 ridges of the fixing part and ligating by second steel bushings or conical woven structures which are formed by extending the N1 ridges of the fixing part, then weaving, and then ligating by the second steel bushings. Another technical scheme of the invention provides a weaving method of the woven type venae cava filter. The venae cava filter, provided by the invention, can intercept larger size internal clots in the pulmonary embolism dangerous period, prevents venae pulmonales embolism, keeps smooth for a long term by shear force, can be taken out by an interventional operation after passing the pulmonary embolism dangerous period, and also can remain in a patient's body for a long term.

Owner:SHANGHAI SHAPE MEMORY ALLOY

A towed twist-resistant metal shielded flexible cable for mining equipment

ActiveCN103400644BGood flexibilityExcellent torsion resistance and bending resistancePower cables with screens/conductive layersFlexible cablesFiberElectrical conductor

The invention discloses a dragging twist-resistant metallic shield flexible cable for mining equipment. The flexible cable comprises a protective sleeve, a plurality of power wire cores and a plurality of ground wire cores, high-strength fibers and control wire cores, wherein each control wire core comprises a conductor, a high-elasticity rubber insulation layer and a heat-resisting thin slip band layer; the conductor is wrapped with the high-elasticity rubber insulation layer and the heat-resisting thin slip band layer; the high-elasticity rubber insulation layer is located between the conductor and the heat-resisting thin slip band layer; each power wire core comprises a conductor which is wrapped with a heat-resisting semiconductor nylon shield strip layer, an insulation layer and a heat-resisting semiconductor nylon shield strip, metal and fiber fixing weaving layer sequentially from inside to outside; each ground wire core comprises a conductor and a semiconductive elastic rubber layer, and the conductor is wrapped with the semiconductive elastic rubber layer; and outer sides of the plurality of the power wire cores and the plurality of the ground wire cores, the high-strength fibers and the control wire cores are wrapped with the protective sleeve, so that a whole is formed. The dragging twist-resistant metallic shield flexible cable is good in flexibility, tensile resistance and twist resistance and longer in service life.

Owner:湖南华菱线缆股份有限公司

A cable type welding wire applied to cmt welding system and cmt welding system

ActiveCN106363314BImprove welding effectReduce the number of weld layersArc welding apparatusWelding/cutting media/materialsWeld seamEngineering

The invention discloses a cable solder wire for a CMT welding system. The solder wire comprises a central solder wire. The outer side of the central solder wire is provided with a spiral solder wire which is twined tightly around the central solder wire in a spiral manner. The outer side of the spiral solder wire is provided with a protection ring. The inside of the spiral solder wire is provided evenly with 4 subordinate solder wire groups. The subordinate solder wire groups are tangentially arranged. The inside of each subordinate solder wire group is provided with a first solder wire, a second solder wire, a third solder wire and a fourth solder wire. The fusion depth in the welding operation is deep. This structure can reduce the quantity of overlapping welding seams layers and can fundamentally increase the welding efficiency, reduce the production costs with negligible splashes. The high mechanical property of the welding seam and the tight binding structure of the solder wire stabilize the solder wire feeding process, enhances the welding property of the cable solder wire and makes the CMT welding system to render a better soldering effects.

Owner:QINGDAO BRANCH CO., LTD. OF MECHANICAL SCIENCE RESEARCH INSTITUTE

A kind of preparation method of spandex fiber with low broken filament rate

ActiveCN110791835BIncrease the speed of diffusionImprove broken wire problemMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberPolymer science

The present invention relates to a method for preparing spandex fiber with a low breakage rate, and more particularly, to a method for manufacturing spandex by introducing a blended solution of an anti-wear agent and a flow promoter into a polyurethaneurea spinning solution, 1) By blending and dissolving the anti-wear agent and the flow promoter in an organic solvent, a blended solution A is prepared; 2) the above-mentioned blended solution A is added to the polyurethaneurea spinning solution B to prepare a spinning dope C, Spinning and winding of the above-mentioned spinning dope C were carried out. The manufacturing method has a simple and convenient implementation process, and can be widely applied to different varieties of spandex fibers, and the situation of the prepared spandex fibers being broken is obviously reduced.

Owner:ZHEJIANG HUAFENG SPANDEX

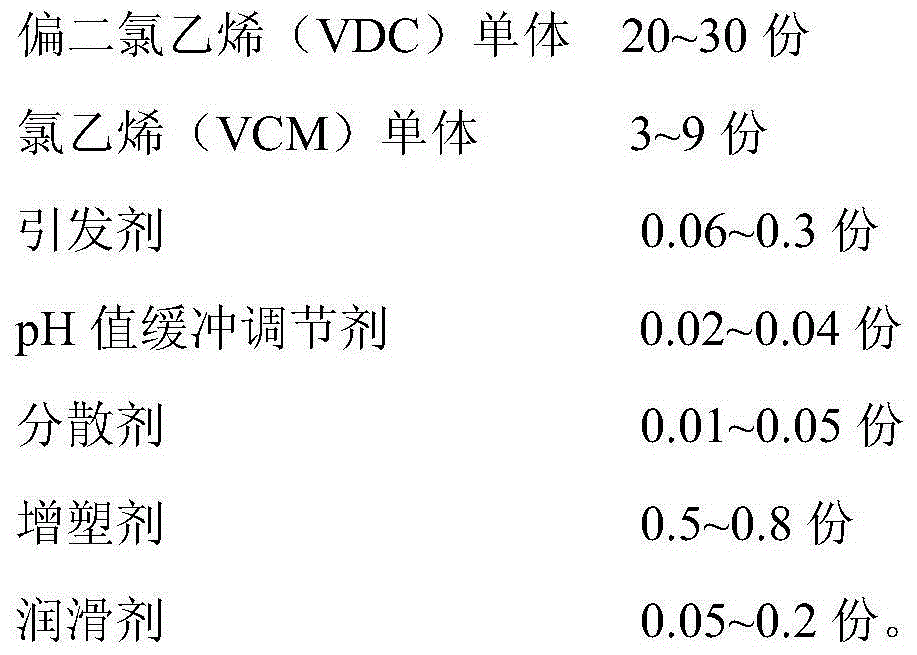

PVDC (polyvinyl dichloride) composition for spinning

InactiveCN104926978AImproved thermal stability and processabilityGood spinning performance and processing thermal stabilityMonocomponent halogenated hydrocarbon artificial filamentChemistryPlasticizer

The invention discloses a PVDC (polyvinyl dichloride) composition for spinning. The PVDC composition for the spinning comprises the following components in parts by weight: 20 to 30 parts of vinylidene chloride monomers, 3 to 9 parts of vinyl chloride monomers, 0.06 to 0.3 parts of initiator, 0.02 to 0.04 part of pH (potential of hydrogen) value buffer conditioning agent, 0.01 to 0.05 part of dispersing agent, 0.5 to 0.8 part of plasticizer, and 0.05 to 0.2 part of lubricating agent. The PVDC composition provided by the invention has favorable heat stability and spinning processing performance.

Owner:ZHEJIANG QUZHOU JUSU CHEM IND CO LTD +1

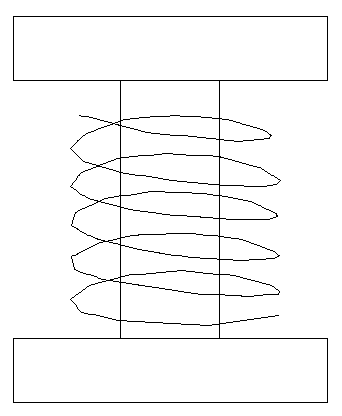

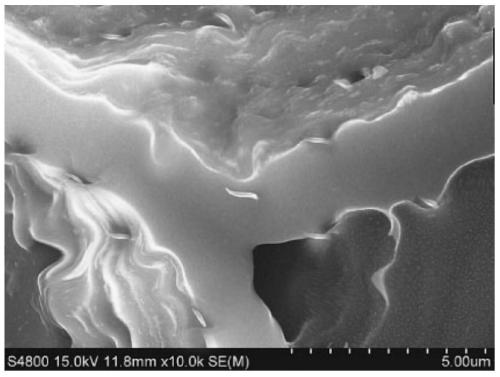

Preparation method of bundled hollow fiber membrane

InactiveCN110605032APure water flux dropImprove throughputSemi-permeable membranesHollow fibre membraneFiber

The invention relates to the technical field of preparation of hollow fiber membranes, in particular to a preparation method of a bundled hollow fiber membrane. The pure water flux of the bundled hollow fiber membrane prepared by the method is reduced compared with that of a single-core membrane, but the tensile stress of the same is increased by more than one time compared with that of the single-core membrane. In the actual application process, the bundled hollow fiber membrane is not liable to being flattened under high pressure, can hold relatively large flux and is not liable to wire breakage, so that the application field and the application range of the bundled hollow fiber membrane are greatly improved; meanwhile, the maintenance and replacement cost of products can be reduced, andthe service life of the products can be prolonged. Besides, the preparation method of the bundled hollow fiber membrane is simple in process, the mechanical strength of the hollow fiber membrane is improved, the loss of raw materials is reduced, the production efficiency of the hollow fiber membrane is improved, the cost is reduced, and the hollow fiber membrane is good in water permeability andsuitable for popularization and application.

Owner:苏州五颗星特种超滤膜科技有限公司

A kind of preparation method of PVDC composition for spinning

ActiveCN104927253BImprove thermal stabilityEasy to processMonocomponent halogenated hydrocarbon artificial filamentArtifical filament manufactureHydrogenPlasticizer

The invention discloses a preparation method of a PVDC (polyvinyl dichloride) composition for spinning. The preparation method of the PVDC composition for the spinning comprises the following steps of carrying out a polymerization reaction on the following raw materials in parts by weight: 49 to 60 parts of deionized water, 20 to 30 parts of vinylidene chloride monomers, 3 to 9 parts of vinyl chloride monomers, 0.06 to 0.3 parts of initiator, 0.02 to 0.04 part of pH (potential of hydrogen) value buffer conditioning agent and 0.01 to 0.05 part of dispersing agent, after the reaction is carried out for 25 hours to 35 hours, terminating the polymerization reaction, separating out residual monomers in a vacuum manner, and cooling, discharging, centrifuging and drying an obtained material; adding 0.5 to 0.8 part of plasticizer and 0.05 to 0.2 part of lubricating agent into the dried material, and mixing and curing an obtained mixture, so as to obtain a PVDC composition product for the spinning. The PVDC composition prepared by the preparation method of the PVDC composition for the spinning has favorable heat stability and spinning processing performance.

Owner:ZHEJIANG QUZHOU JUSU CHEM IND CO LTD +1

Water washing and hot drawing device for fiber tow spinning

InactiveCN102011202BHigh strengthGood for intensive washingArtificial filament washing/dryingTextile/flexible product manufactureFiberCarbon fibers

Owner:西安航科等离子体科技有限公司

Adhesive for electronic grade glass fiber yarn and preparation method thereof

ActiveCN111548757BGood adhesionHigh viscosityNon-macromolecular adhesive additivesCellulose adhesivesCelluloseYarn

An adhesive used for electronic grade glass fiber yarn and a preparation method thereof belong to the technical field of electronic grade glass fiber. The following raw materials are included in parts by weight: 1-2 parts of ethyl cellulose, 6-8 parts of ethanol aqueous solution, 2-3 parts of sodium carboxymethyl cellulose, and 0.5-1.0 parts of dibutyl phthalate. The preparation method comprises the following steps: 1) mixing and stirring ethanol and ethyl cellulose to obtain an ethyl cellulose solution; 2) mixing and stirring ethanol and sodium carboxymethyl cellulose to obtain a sodium carboxymethyl cellulose solution; 3) ) Pour the sodium carboxymethyl cellulose solution into the ethyl cellulose solution, and stir for 2 to 3 hours to obtain a mixed solution; 4) Add dibutyl phthalate to the mixed solution in parts by weight, and stir evenly to obtain an adhesive agent. The adhesive used for the electronic grade glass fiber yarn of the present invention has strong adhesive force and high temperature resistance, and the joint is not easy to harden after bonding, and is not easy to change color and remain.

Owner:山东兴国大成电子材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com