Linear-cutting electrode wire and linear-cutting device

An electrode wire, wire cutting technology, used in electrode manufacturing, electric processing equipment, metal processing equipment, etc., can solve the problems of reduced tensile strength, poor durability, etc., to achieve high mechanical strength, excellent mechanical properties, and avoid short circuits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The wire-cut electrode wire provided by the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

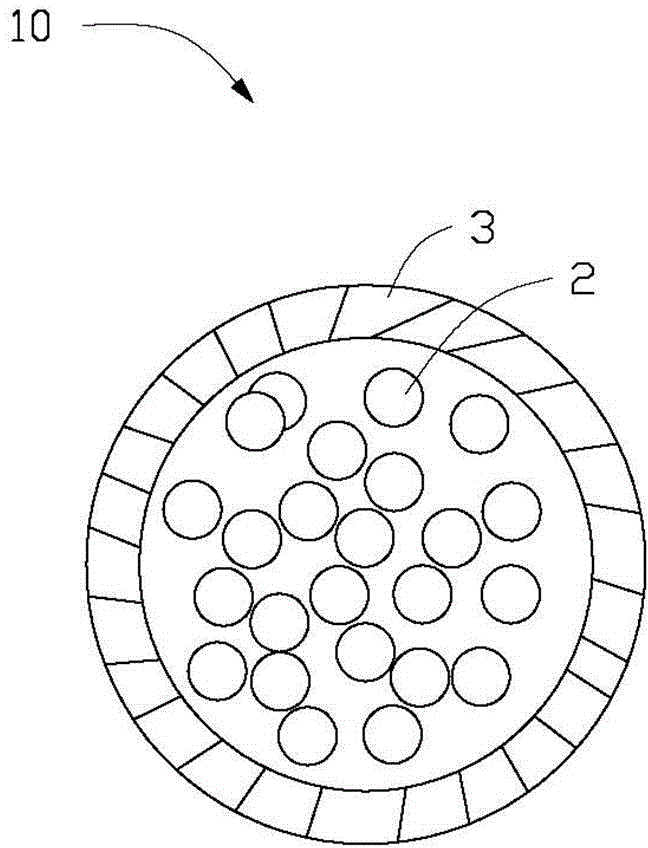

[0016] see figure 1 , The first embodiment of the present invention provides a wire cutting electrode wire 10 for wire electric discharge cutting. The wire cutting electrode wire 10 includes a carbon nanotube composite wire 1 .

[0017] The wire-cutting electrode wire 10 can be formed by one carbon nanotube composite wire 1 , or can be a stranded wire composed of multiple carbon nanotube composite wires 1 . The diameter of the wire-cut electrode wire 10 ranges from 2 to 35 microns.

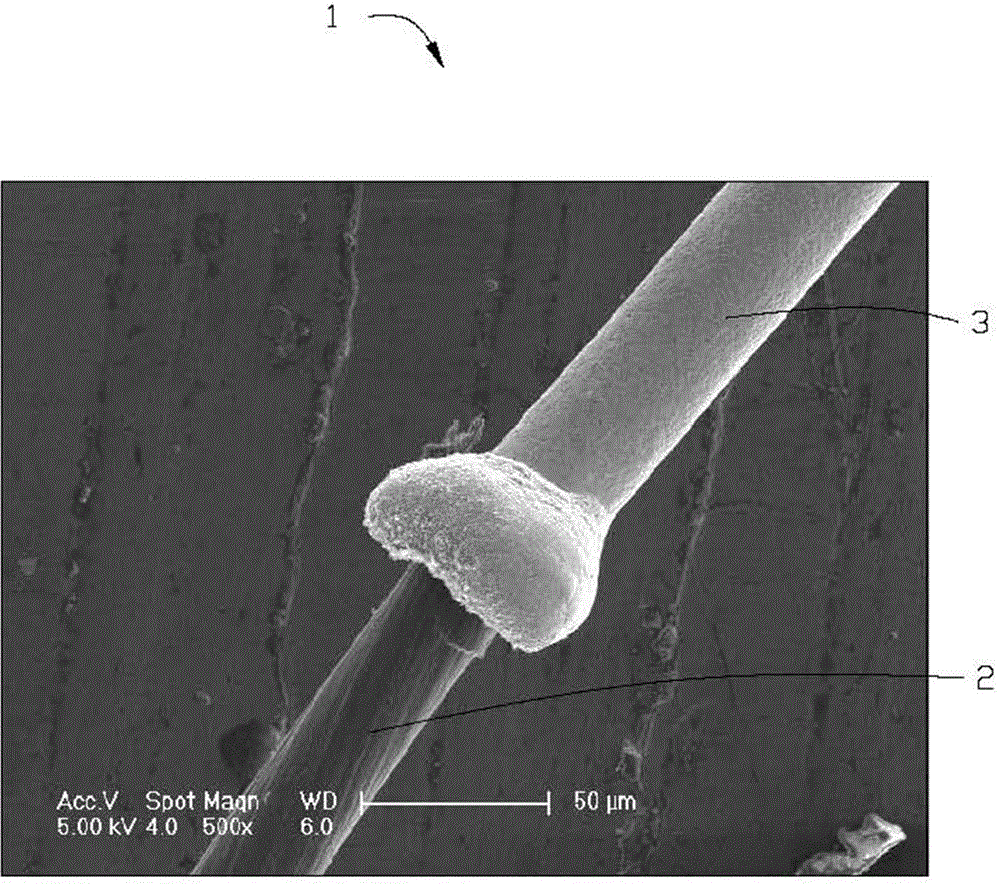

[0018] Specifically, the carbon nanotube composite wire 1 is composed of a carbon nanotube single yarn 2 and a metal layer 3 covering the outer surface of the carbon nanotube single yarn. The carbon nanotube single yarn 2 is composed of a plurality of carbon nanotubes rotated and twisted along the axial direction of the carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com