Patents

Literature

830results about How to "High precision requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

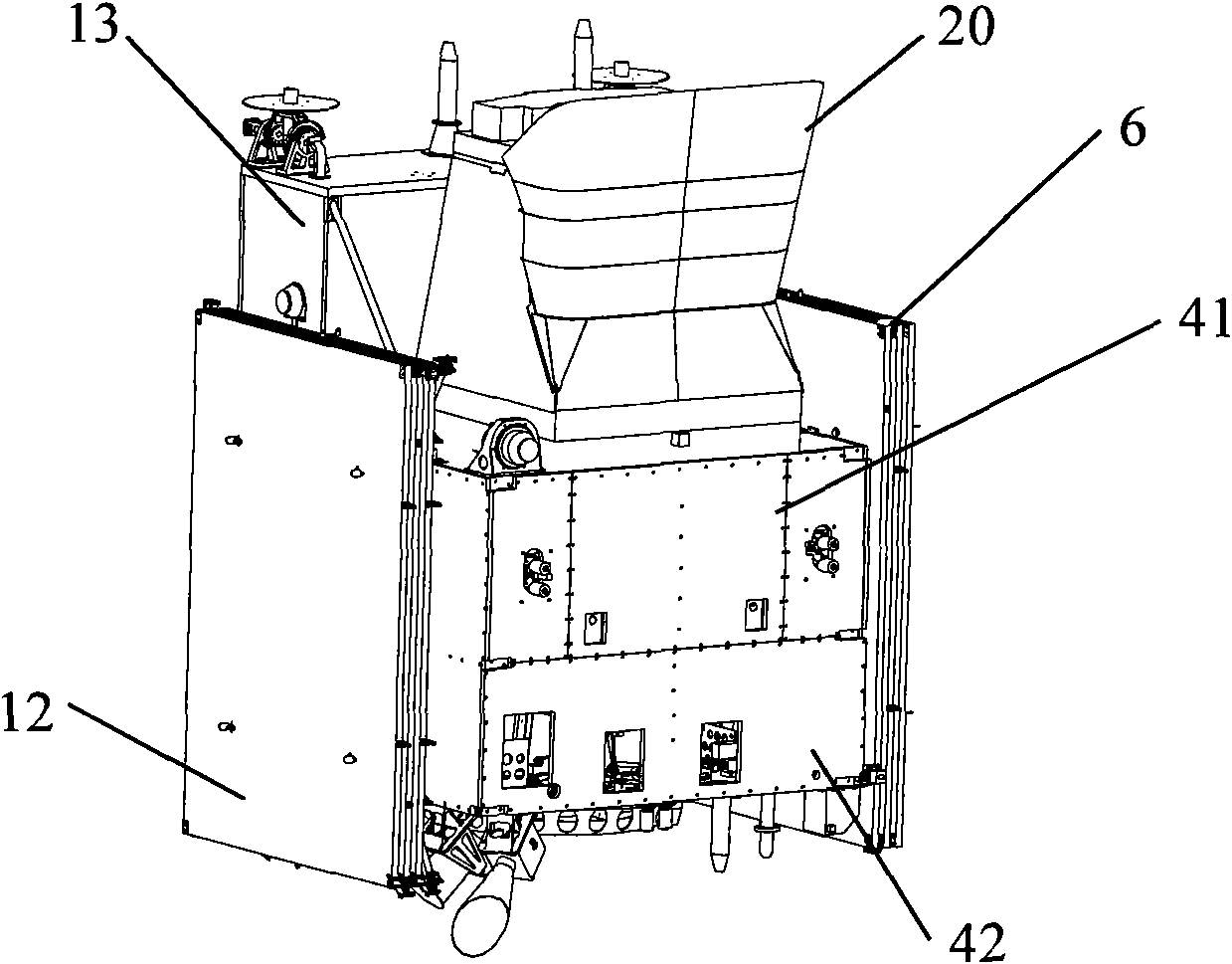

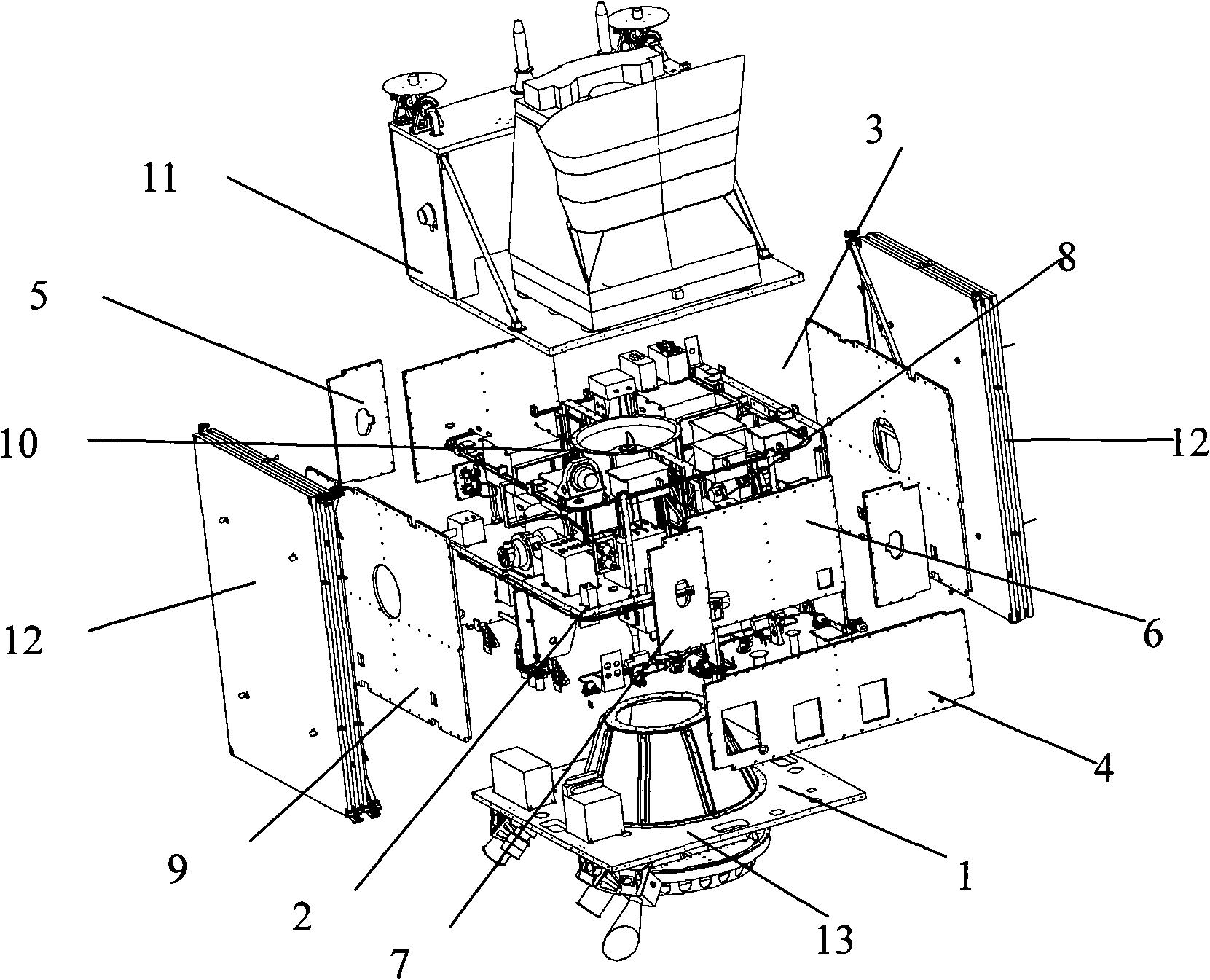

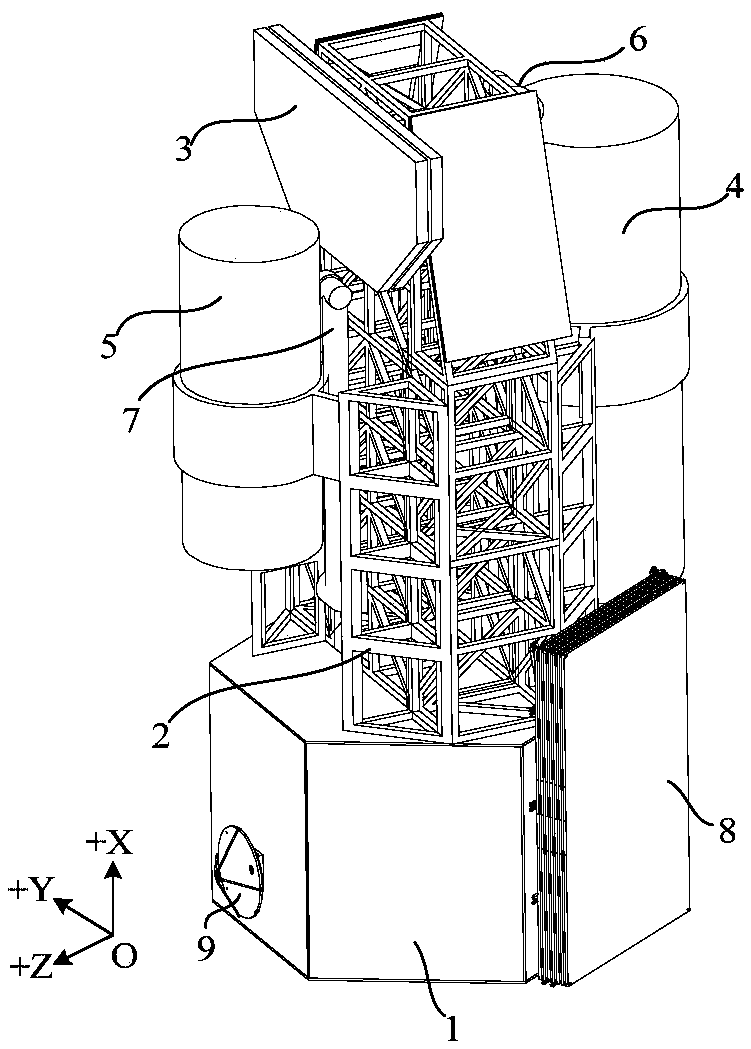

Configuration for low-earth-orbit remote sensing satellite and mounting method thereof

InactiveCN102372092AStable structureHigh precision requirementsArtificial satellitesCentral forceLow earth orbit

The invention provides a configuration for a low-earth-orbit remote sensing satellite, which comprises a base plate, a middle plate, a top plate, a plurality of transverse lateral plates and upright lateral plates, wherein the base plate, the middle plate and the top plate are enclosed into a sealed space by the transverse lateral plates and the upright lateral plates; a central force-bearing cylinder is arranged in the sealed space; corresponding solar cell arrays are arranged on the two sides of the sealed space; a supporting rod is connected between the base plate and the middle plate; four isolating plates are uniformly distributed and are arranged between the middle plate and the top plate; a payload bay is connected above the top plate; and an overskirt is connected to the bottom of the base plate. The configuration for the low-earth-orbit remote sensing satellite has a stable structure, is capable of carrying a large-size and large-mass load, and is high in adaptability for the characteristics of large volume, heavy weight, high precision demand and difficulty in mounting of the present payload.

Owner:SHANGHAI SATELLITE ENG INST

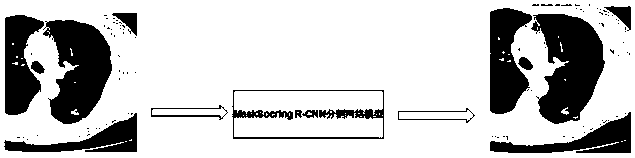

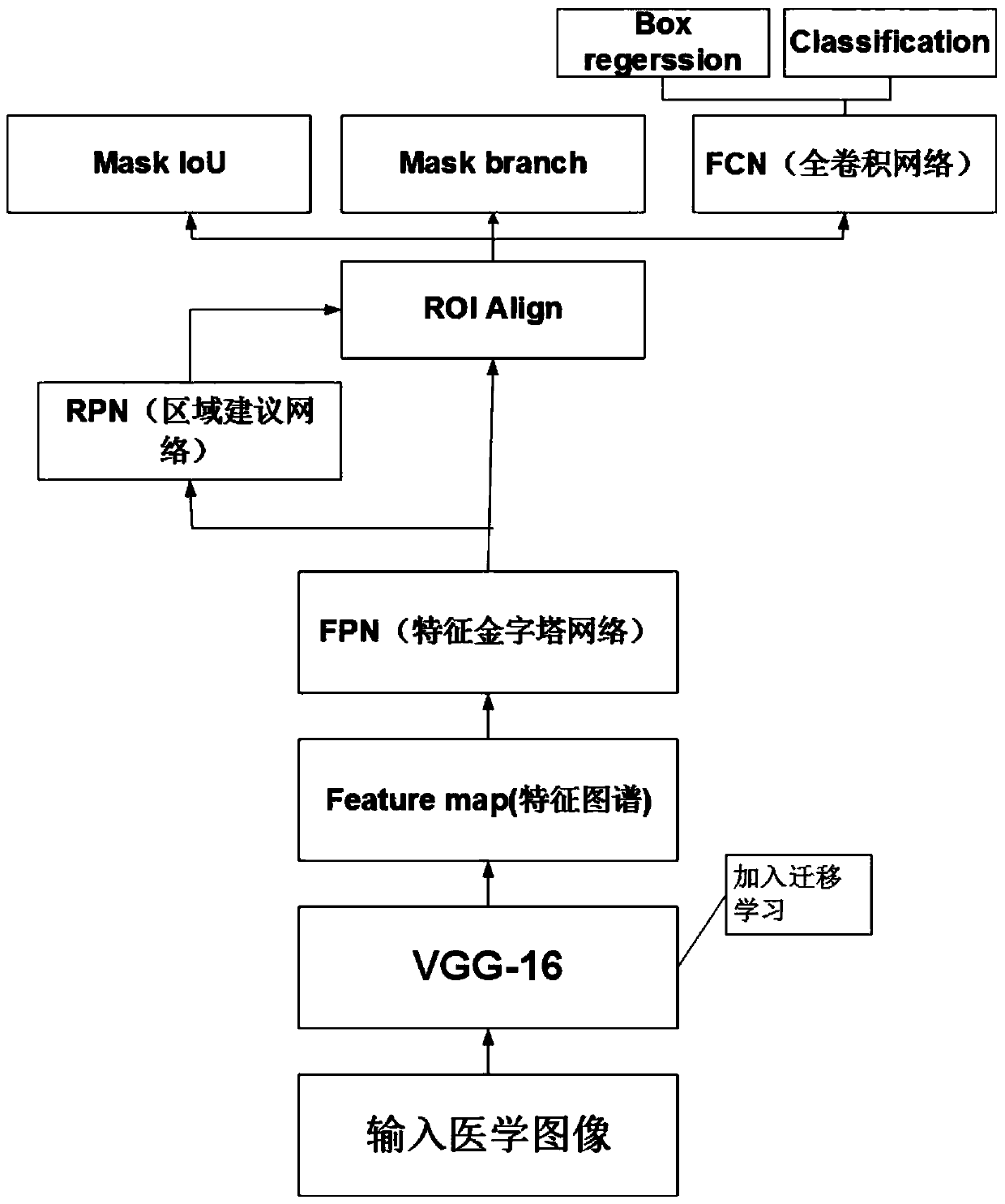

Migration learning lung lesion tissue detection system based on MaskScoring R-CNN network

ActiveCN110599448AMeet high precisionStrong generalizationImage enhancementImage analysisNetwork modelLung cancer

A migration learning lung lesion tissue detection system based on an MaskScoring R-CNN network comprises a storage module for storing four lung diseases including lung cancer, pneumonia, pulmonary tuberculosis and emphysema and further comprises a diagnosis module, and the diagnosis module is in communication connection with the storage module and comprises the following steps of 1) preprocessinga medical image; 2) constructing the MaskScoring R-CNN network model, wherein the step 2) specially comprises 1, constructing a shared convolutional neural network backbone (for feature extraction); 2, carrying out transfer learning on a shared convolutional neural network; 3, constructing an FPN network; 4, constructing an RPN network; 5, constructing an ROIAlign layer; 6, adding the MaskIoU head; and 3) identifying the lung medical image lesion tissue, inputting a to-be-detected lung CT image into the constructed MaskScoring R-CNN network, outputting and obtaining an identified image by thenetwork, framing out and masking the identified lesion tissues, and marking the lesion categories. According to the method, the requirement for high precision of medical image segmentation is met, andthe network can have the good generalization.

Owner:ZHEJIANG UNIV OF TECH

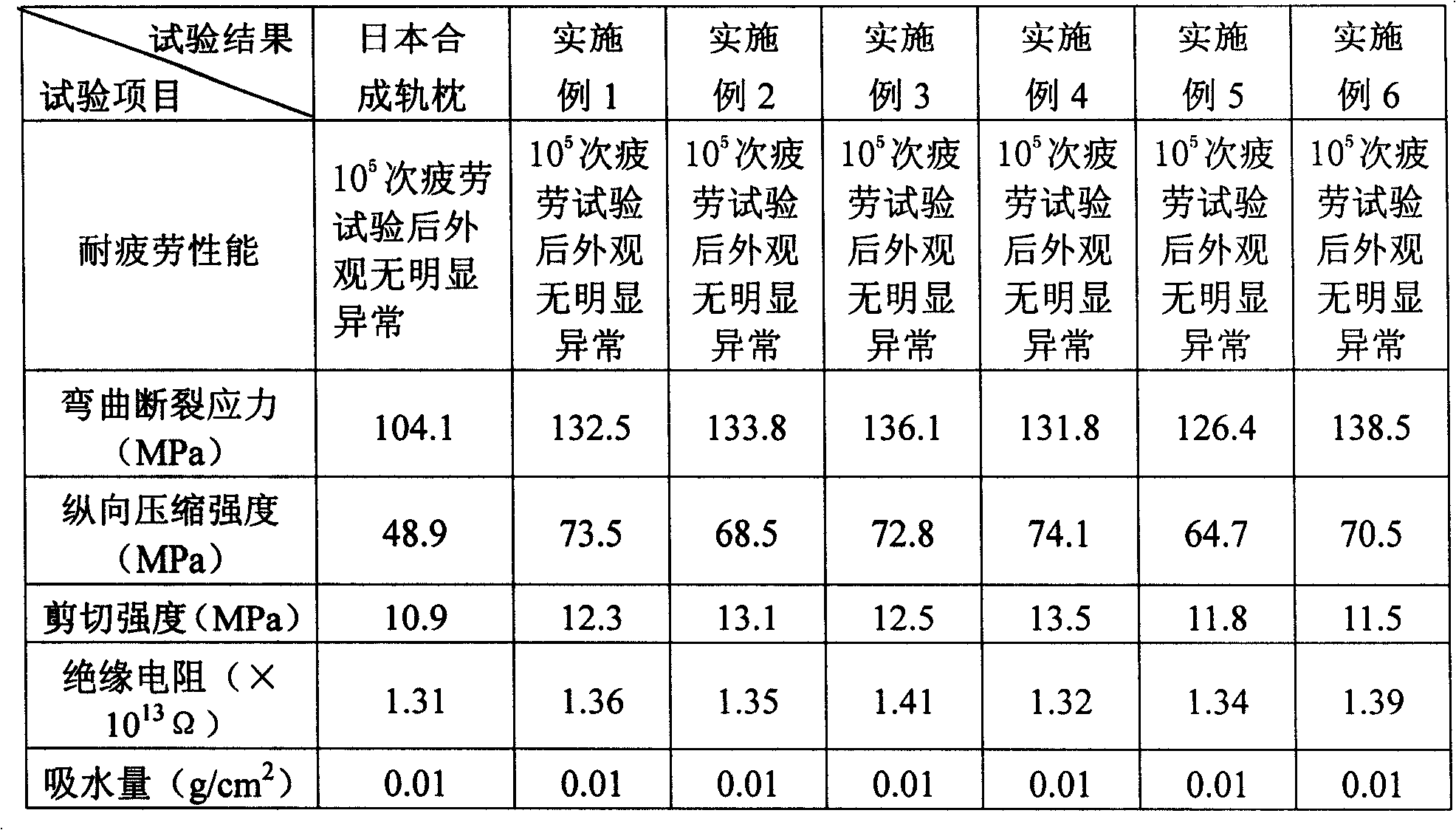

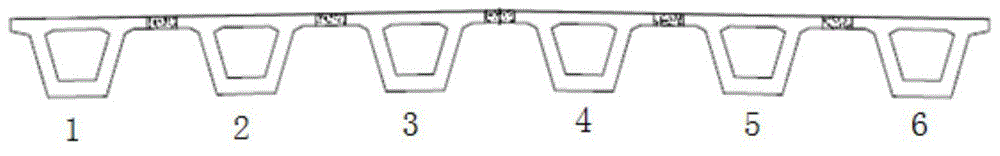

Long glass fiber reinforced hard polyurethane synthetic material sleeper and method for preparing the same

The invention discloses a sleeper made of hard polyurethane synthesized material intensified by long glass fiber and a preparation method thereof; the sleeper has low densityííand long service life and is easy to be processed and installed, and the preparation method thereof is also simple. The sleeper made of hard polyurethane synthesized material intensified by long glass fiber is made from the following materials by weight proportion: 100 portions of composite material of polyurethane raw liquor and 30 portions to 50 portions of long glass fiber; wherein the composite material of polyurethane raw liquor consists of polyol component I and isocyanate component II, and the weight ratio of the component I to the component II is 1: 1 to 1: 1.25.

Owner:NANJING FORESTRY UNIV

Method and device for cleaning space debris

InactiveCN103434658AEasy accessEfficient removalCosmonautic partsArtificial satellitesAtmospheric layerEngineering

The invention discloses a method and device for cleaning space debris. According to the method, electromagnetic force is applied to the space debris running on an original orbit; the speed and / or direction of the space debris are / is changed under the action of the electromagnetic force; the space debris of which the speed is changed is changed to run on a new orbit under the action of gravity; at least the height of the perigee of the space debris on the new orbit is smaller than the height of the perigee of the space debris on the original orbit; the space debris running on the new orbit finally falls into the atmosphere of the earth under the action of atmosphere resistance. The device comprises a satellite bearing platform which is provided with an electric field device cleaning the space debris or a magnetic field device cleaning the space debris or a combination of the electric field device and the magnetic field device. The method and device for cleaning the space debris do not have high requirements for the accuracy of position detection of the space debris, micro space debris can be effectively cleaned, solar energy can be fully utilized for power generation, and self-carried energy is saved. The device for cleaning the space debris has the advantages of being simple in structure, low in manufacturing cost, and better in pulse action effect.

Owner:李怡勇 +3

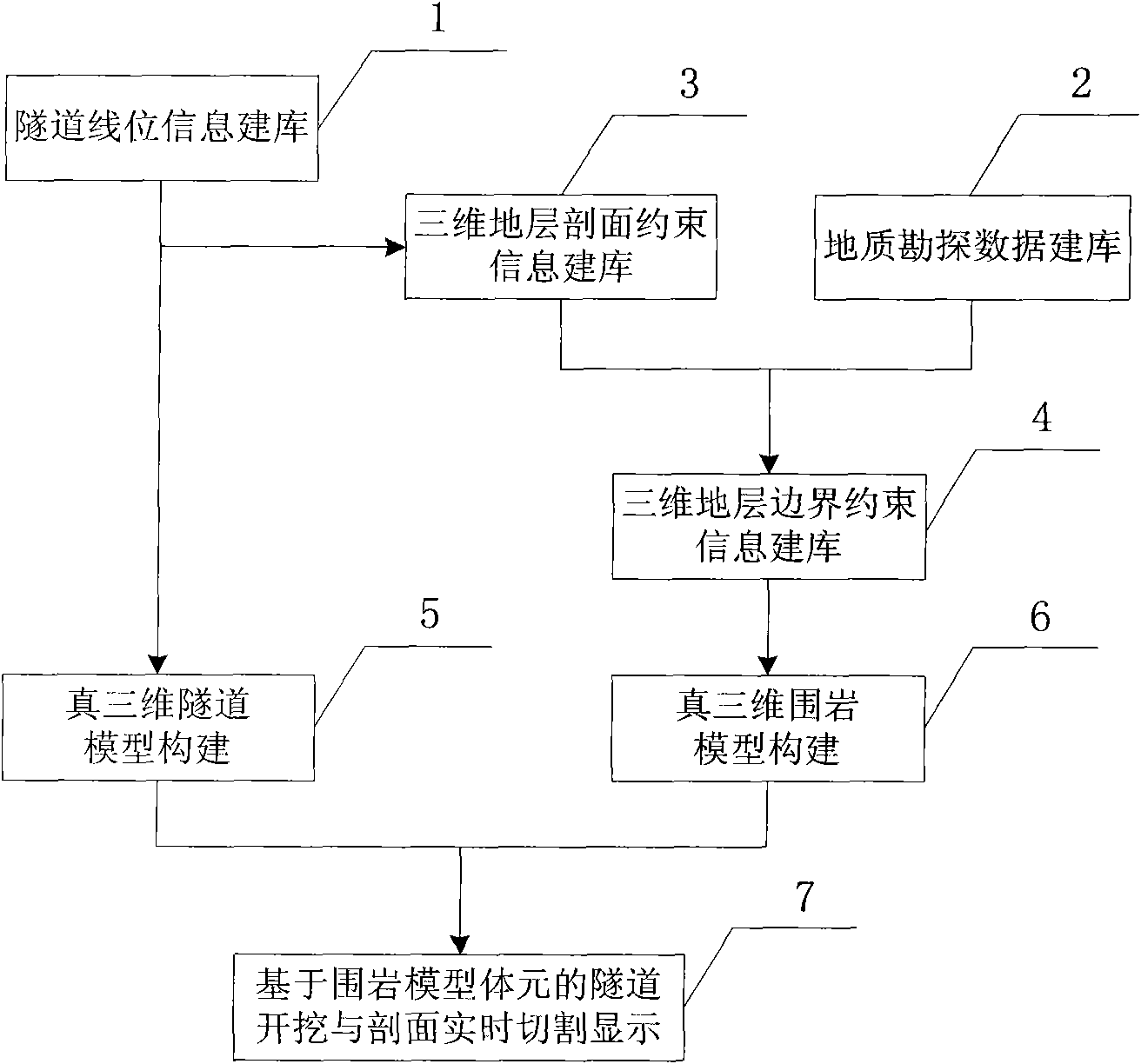

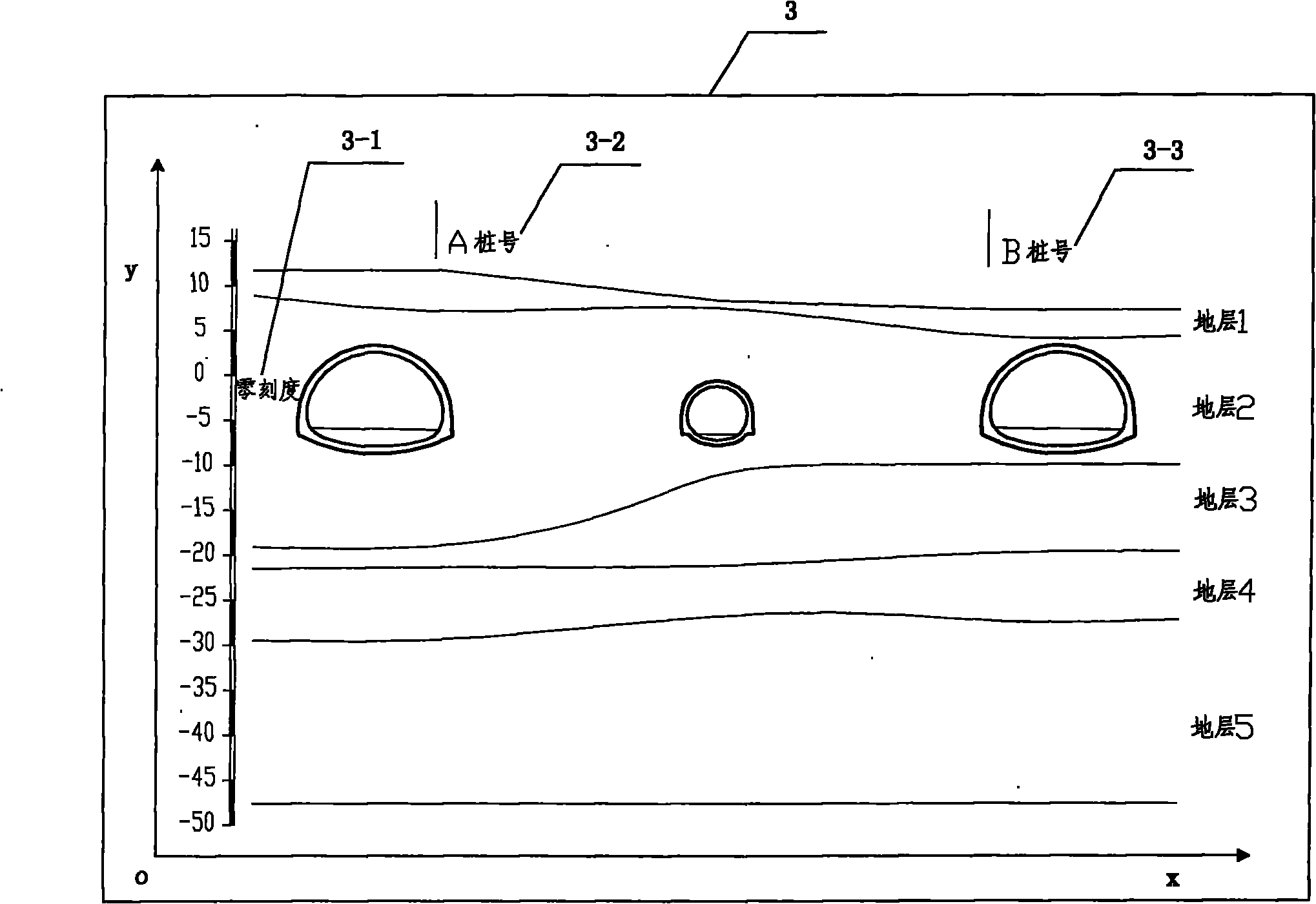

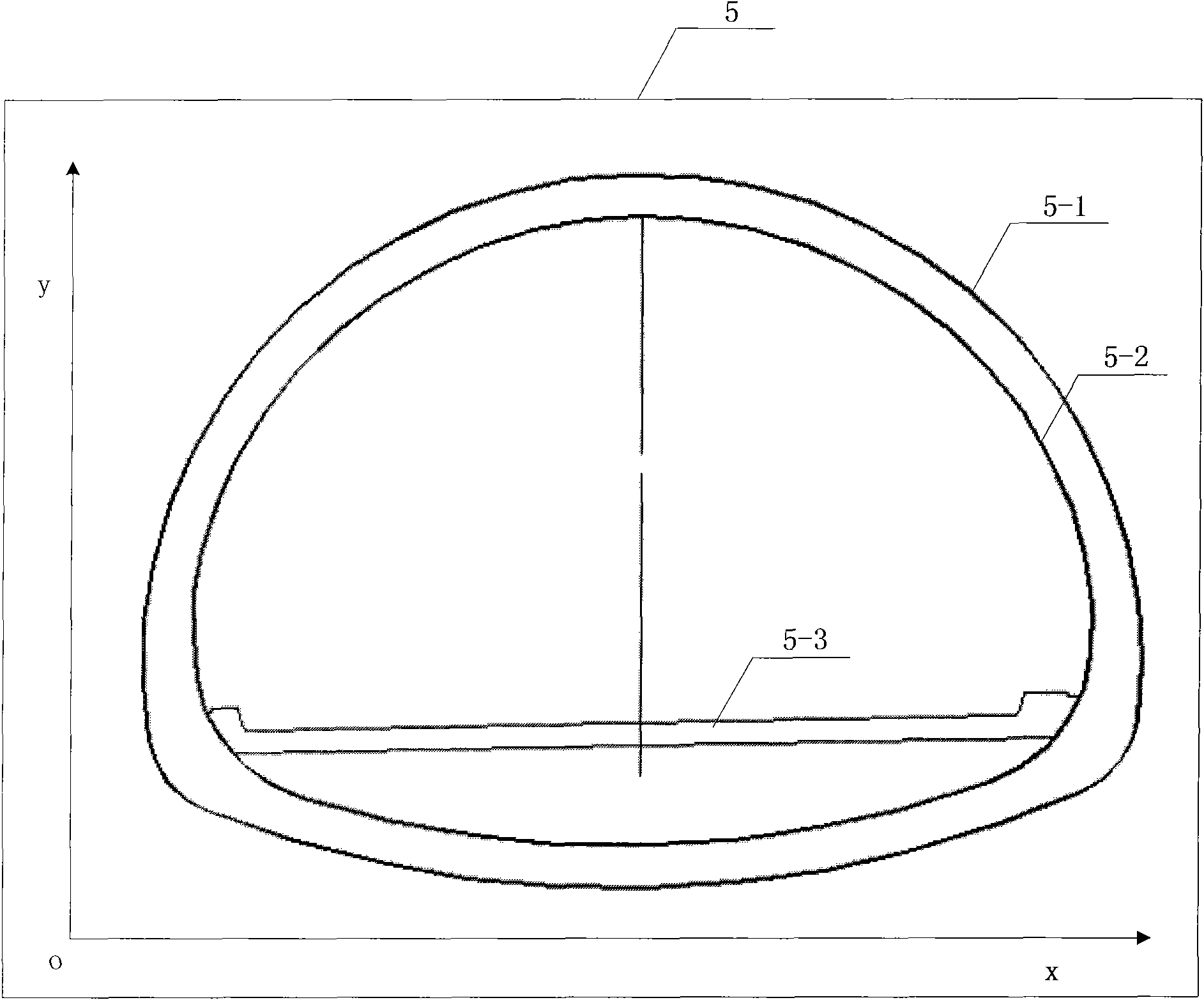

Method for fast establishing interactive tunnel and wall rock body three-dimensional models

ActiveCN101882171AFast refactoringOvercome time-consuming remodelingTunnelsSpecial data processing applicationsInformation repositoryClassical mechanics

The invention discloses a method for fast establishing interactive tunnel and wall rock body three-dimensional models, which comprises the following steps: A. tunnel line position information base establishment: collecting tunnel line position information and establishing a line position information base; B. geological exploration base establishment: carrying out standardized processing on hole drilling data obtained through geological exploration; C. three-dimensional stratigraphical profile constraint information base establishment: collecting three-dimensional stratigraphical profile constraint information; D. three-dimensional stratigraphical boundary constraint information base establishment: collecting self defined model establishing boundary; E. real three-dimensional tunnel model establishment: precisely establishing a tunnel three-dimensional model according to the information of tunnel line positions, the tunnel hole body outer cross section and the inner cross section; F. real three-dimensional wall rock model establishment: establishing a wall rock model according to the hole drilling and stratigraphical information; and G. tunnel digging and profile real-time cutting display based on the wall rack model body unit. The model establishing efficiency and precision of the tunnel simulation and digitalized design can be improved, the real-time cutting display of the tunnel passing through the wall rock and any vertical profile can be realized, and the fast reestablishment of the model can be realized.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

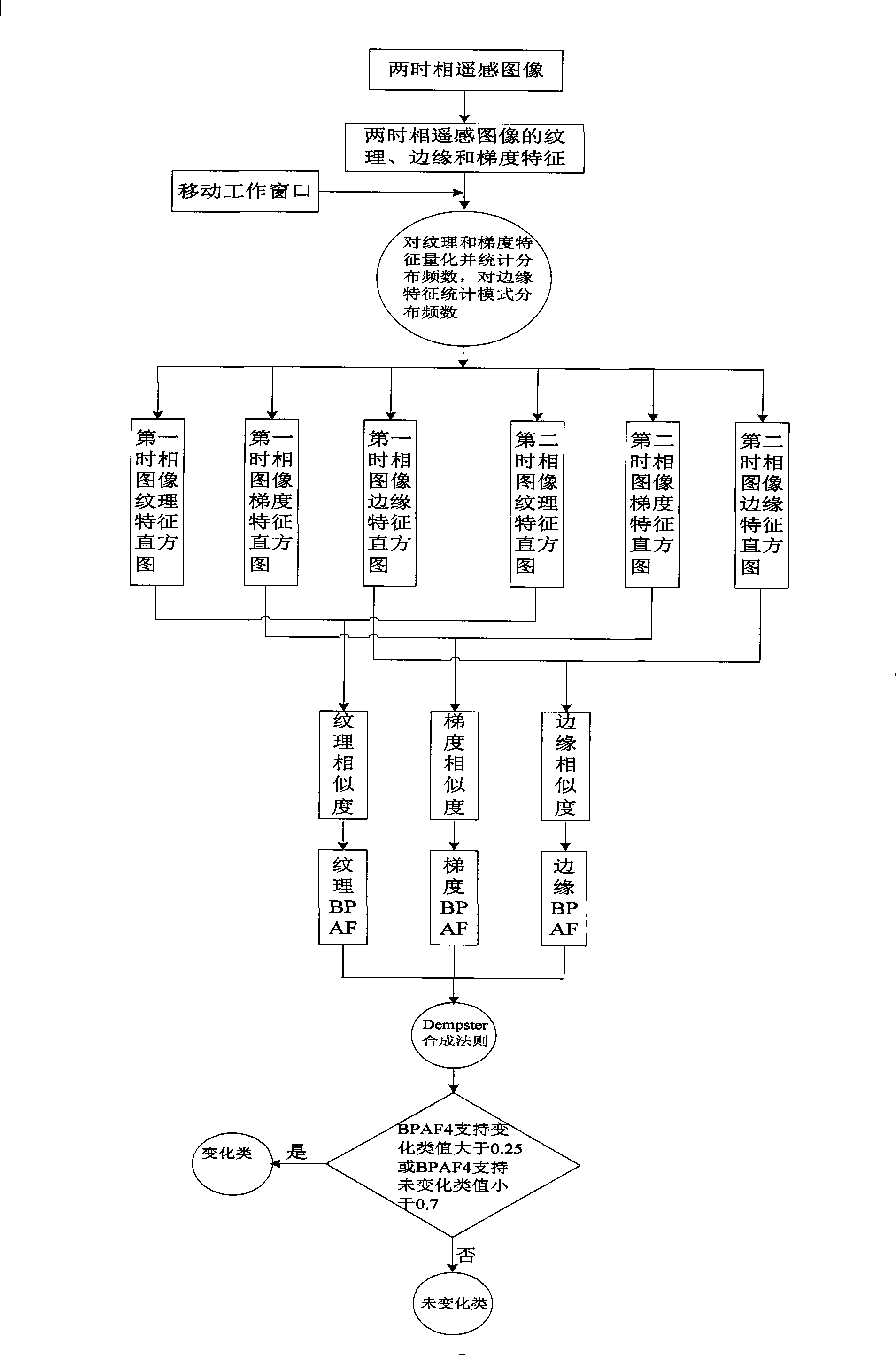

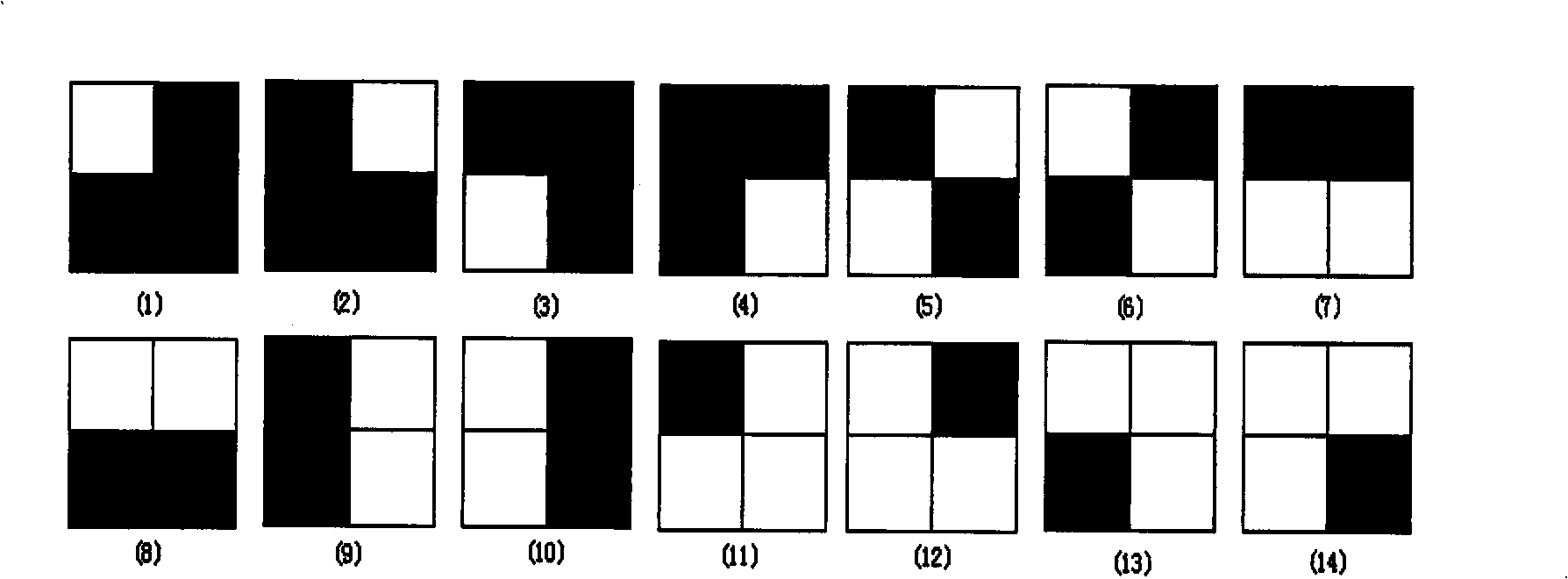

Remote sensing image change detection method based on multi-feature evidence integration and structure similarity

InactiveCN101539629AImprove immunityImprove robustnessElectromagnetic wave reradiationFeature extractionEdge structure

The invention discloses a remote sensing image change detection method based on multi-feature proof integration and structure similarity, comprising the following steps: A. data preparation: selecting remote sensing images to be carried out with change detection in different time phase and in the same spatial scope; B. feature extraction: respectively extracting features of textures, grads and edges of images in two time phases; C. structure similarity calculation: calculating the texture structure similarity, grads structure similarity and edge structure similarity of the remote sensing images in two time phases in a working window; D. basic probability assignment function determination: building basic probability assignment function (BPAF) of evidence theory based on texture structure similarity, the grads structure similarity and edge structure similarity; and E. forming evidence and obtaining change areas to realize change detection. The method carries out change detection based on the area statistic features of edges, texture sand grads of images and can effectively avoid detection miss and false detection caused by the change detection using single feature; and the algorithm has robustness.

Owner:NANJING NORMAL UNIVERSITY

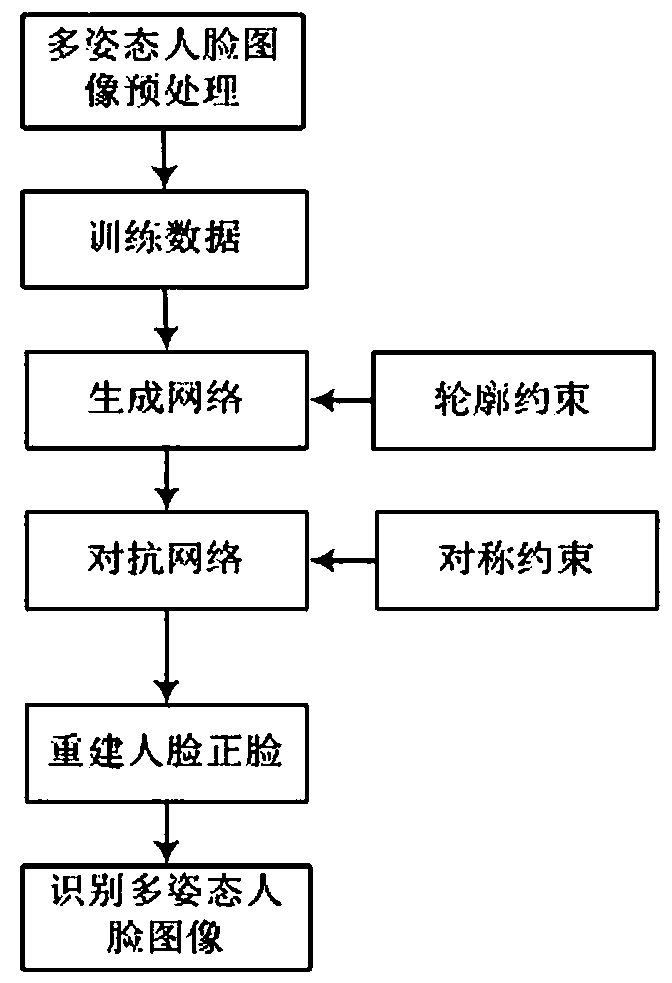

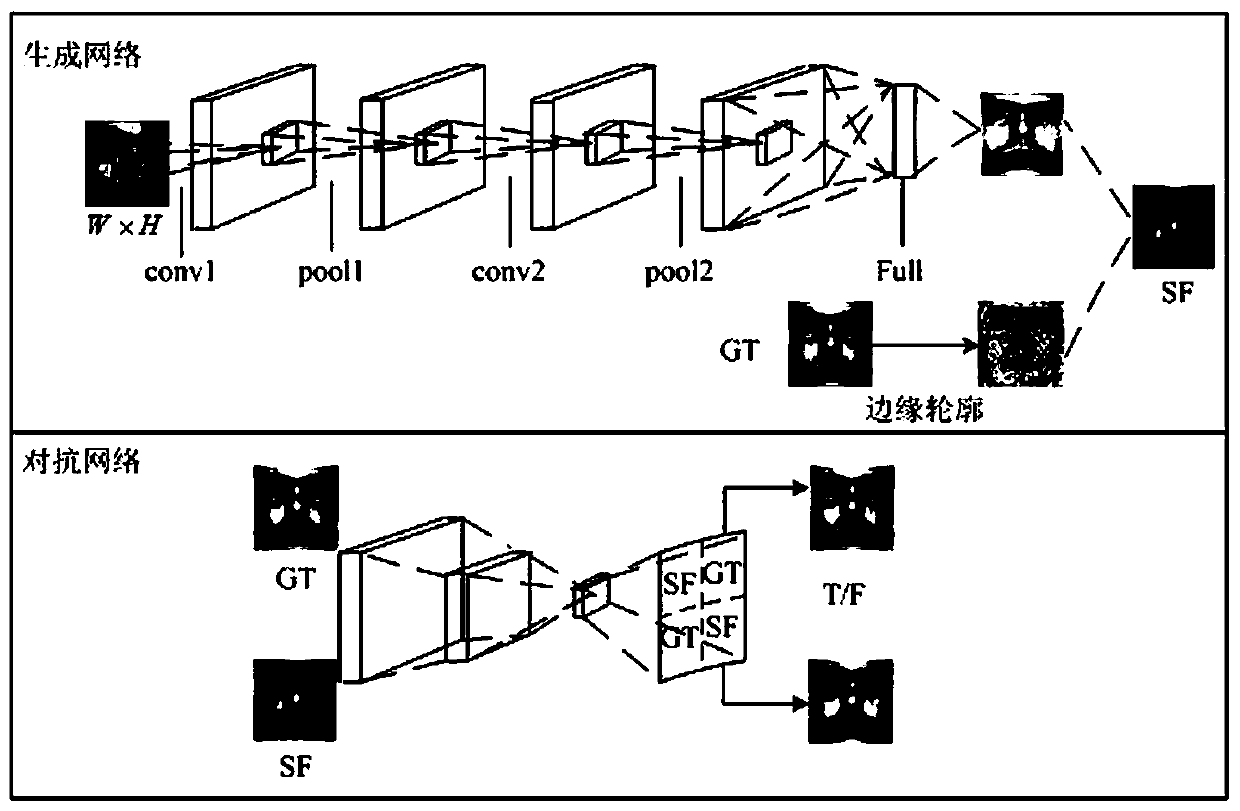

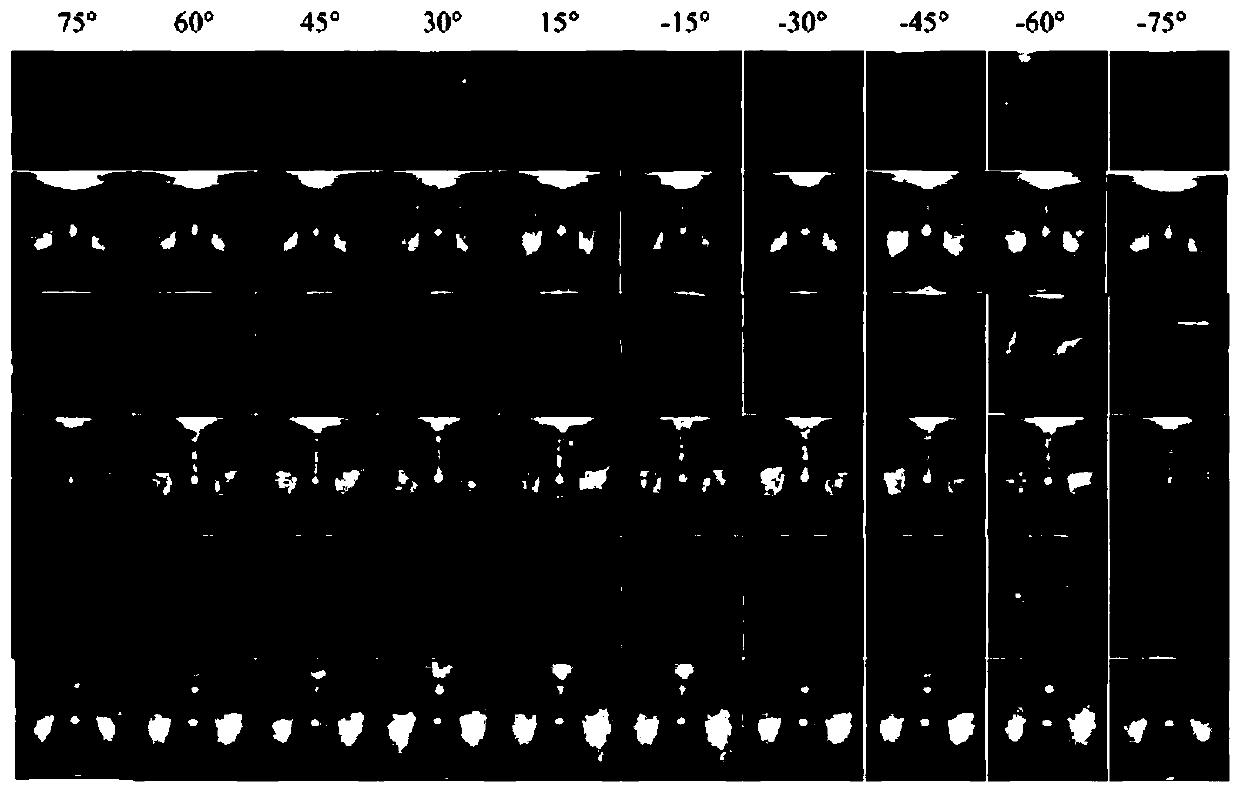

Contour symmetry constraint generative adversarial network-based multi-pose face recognition method

ActiveCN108334816AMeet high precision requirementsSolve the influence of attitude angle deflectionCharacter and pattern recognitionComputer visionGenerative adversarial network

The invention discloses a contour symmetry constraint generative adversarial network-based multi-pose face recognition method. The method is characterized by comprising the following steps of 1) performing data preprocessing; 2) creating a contour constraint generative network; 3) creating a symmetry constraint adversarial network; 4) training and balancing the networks; and 5) performing reconstruction and recognition. According to the method, the pose angle deflection influence of a face image can be effectively eliminated; a characteristic that a face is robuster under multiple poses is extracted; especially global quality and local details are mutually constrained under large-angle pose reconstruction; contour characteristic information of the front face is kept; and the high-precisiondemand on the multi-pose face recognition in actual application can be met.

Owner:GUILIN UNIV OF ELECTRONIC TECH

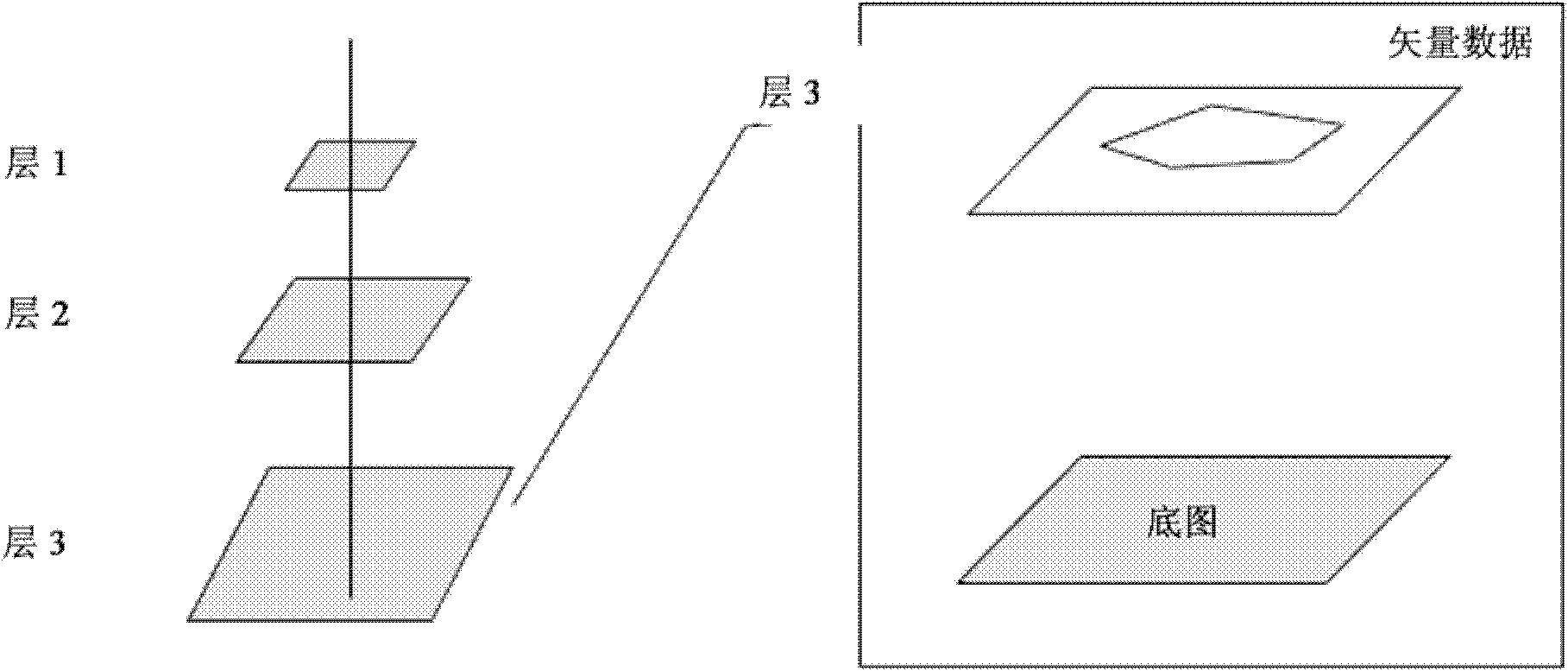

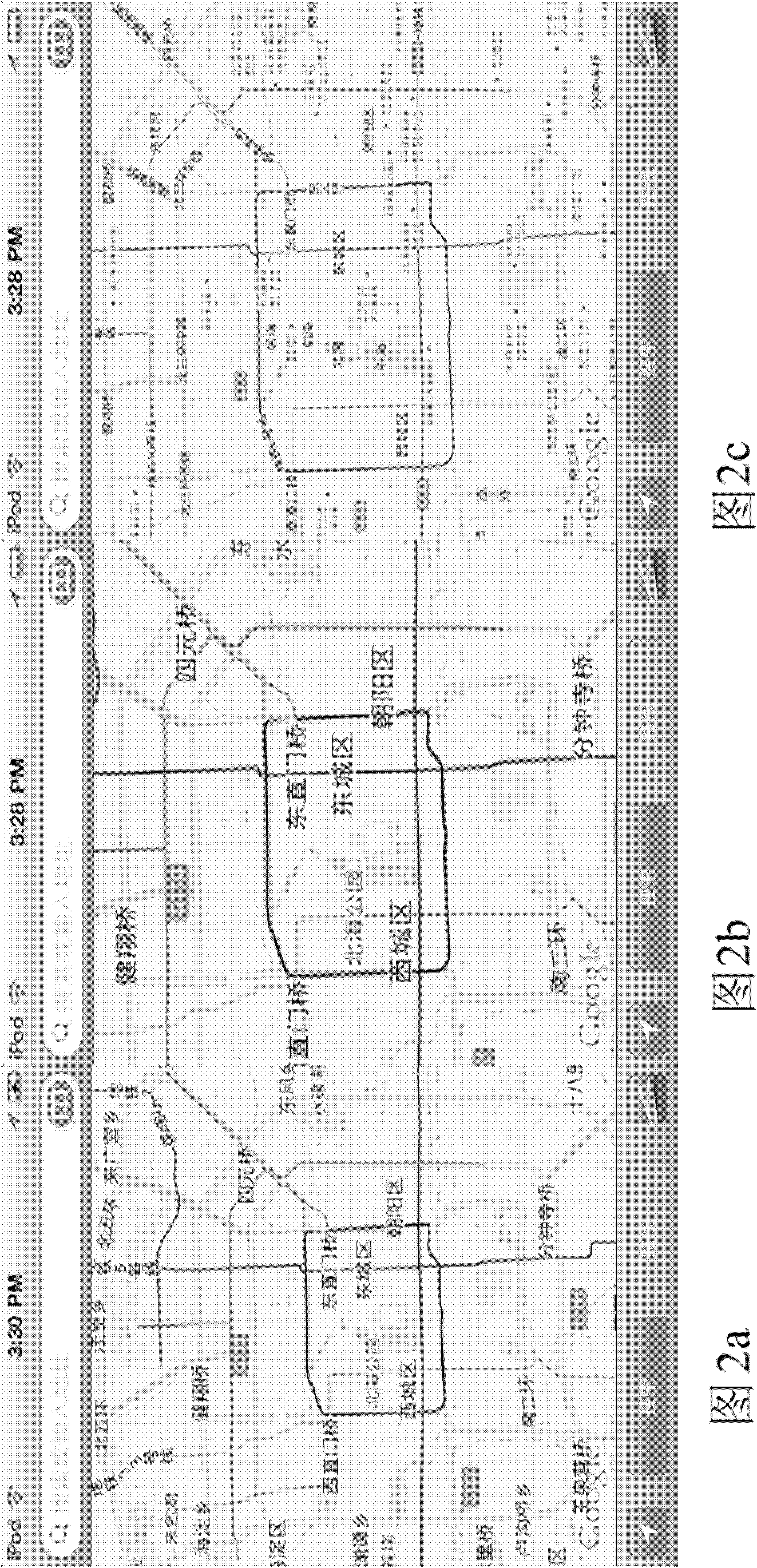

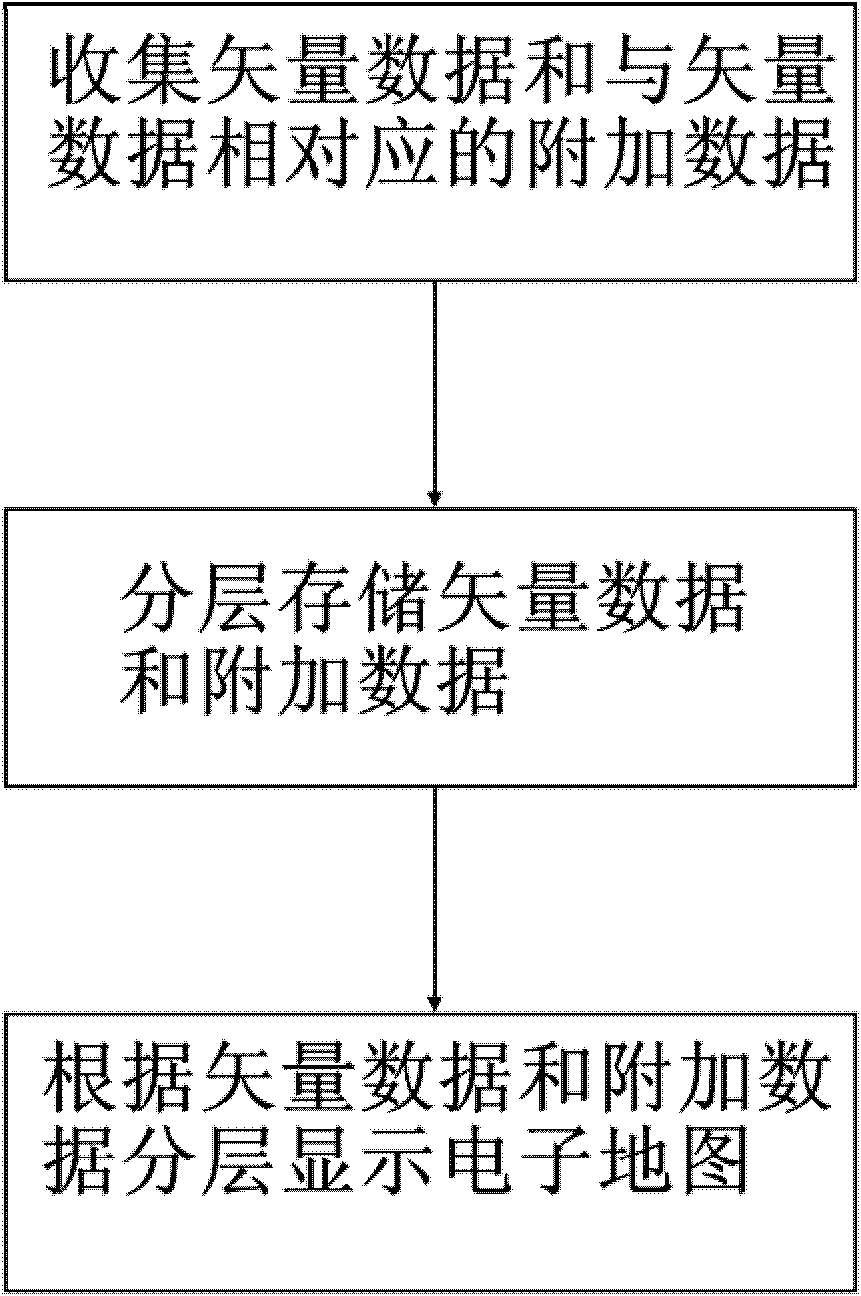

Method for generating electronic map

InactiveCN103187002AShortcut displayClear logicMaps/plans/chartsGeographical information databasesElectronic mapCollections data

The invention provides a method for generating an electronic map. The method includes a data collecting procedure, a data storage procedure and an electronic map displaying procedure, wherein the data collecting procedure includes a step of collecting vector data and additional data corresponding to the vector data; the data storage procedure includes the steps of storing the collected vector data and the collected additional data in a server database, enabling the vector data corresponding to different types of main body elements to be stored in a plurality of layers, and enabling the vector data of each type of main body elements to be stored in one layer; the electronic map displaying procedure includes the steps that an electronic map displaying end obtains the vector data and the additional data from a server, draws vector diagrams corresponding to each layer of vector data layer by layer according to the vector data in each layer, and adds the additional data related to main body element identification data (ID) in the layer of vector data, and consequently the electronic map is generated in a displaying device.

Owner:北京点道互联科技有限公司

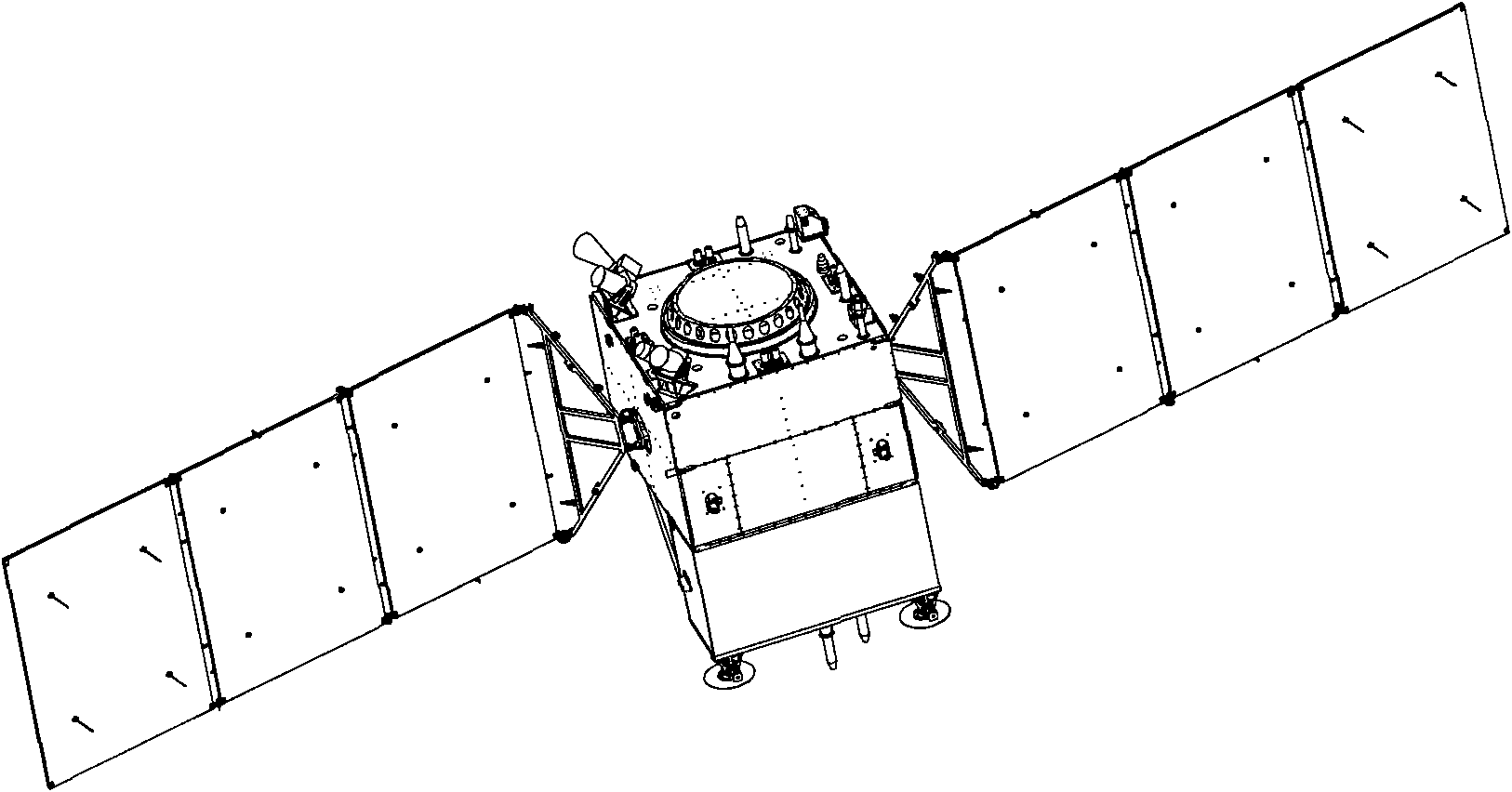

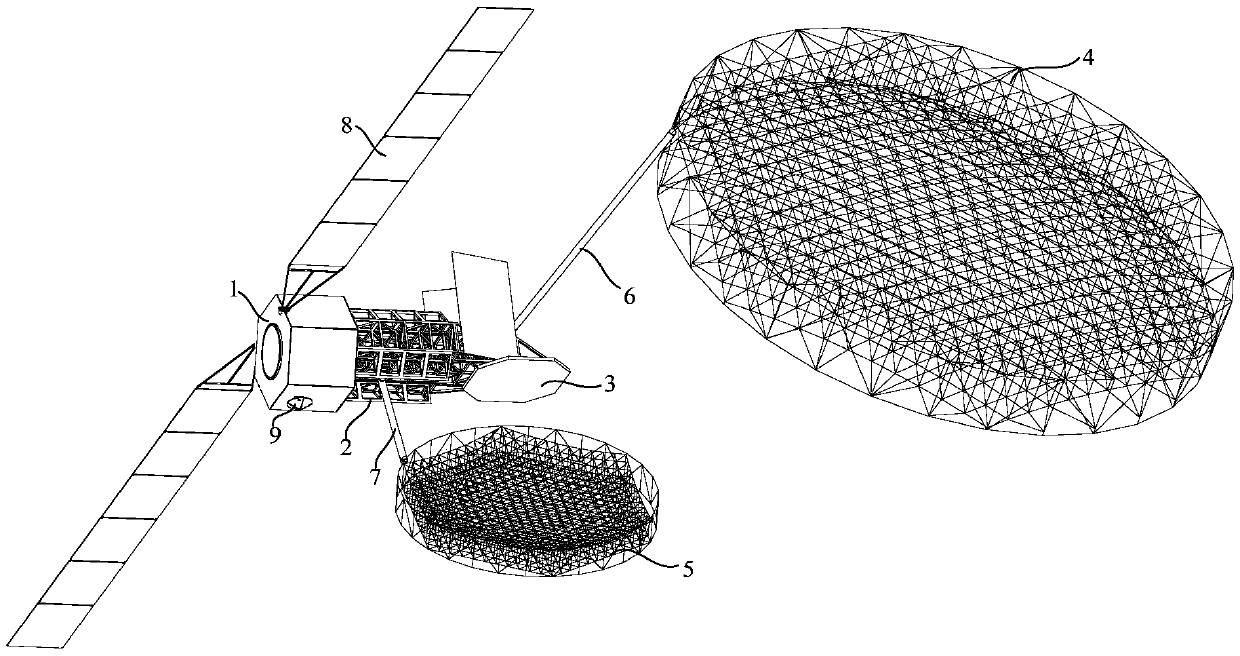

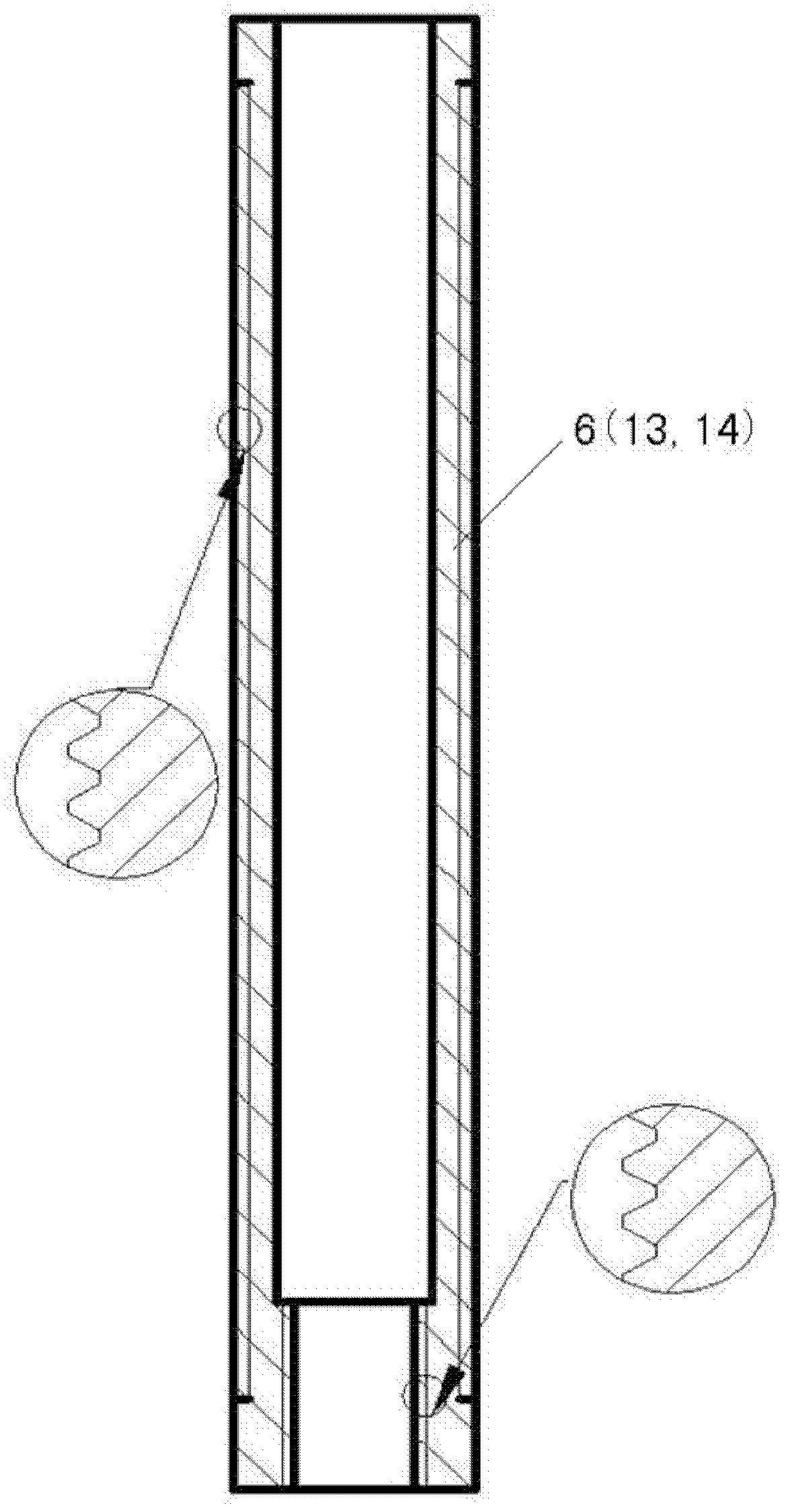

Configuration of satellite loaded with large deployable antenna with double reflecting surfaces

ActiveCN105501471AStable structureHigh precision requirementsCosmonautic vehiclesCosmonautic partsSolar cellRocket

The invention provides configuration of a satellite loaded with a large deployable antenna with double reflecting surfaces. The relative position relation of a feed source array, a main reflecting surface and an auxiliary reflecting surface in an in-orbit flight state is guaranteed, main force transfer path design is optimized through design of a payload capsule in a truss structure style and reasonable layout and placement while the constraint conditions about enveloping of a fairing of a carrier rocket and correct deployment of the large deployable antenna are met, compactness and reasonableness of structure space of the large deployable antenna in a folded state can be guaranteed, meanwhile, the deploy path requirement of the large deployable antenna is met, and the area of a satellite solar cell array is guaranteed by fully using the enveloping space provided by the carrier rocket.

Owner:SHANGHAI SATELLITE ENG INST

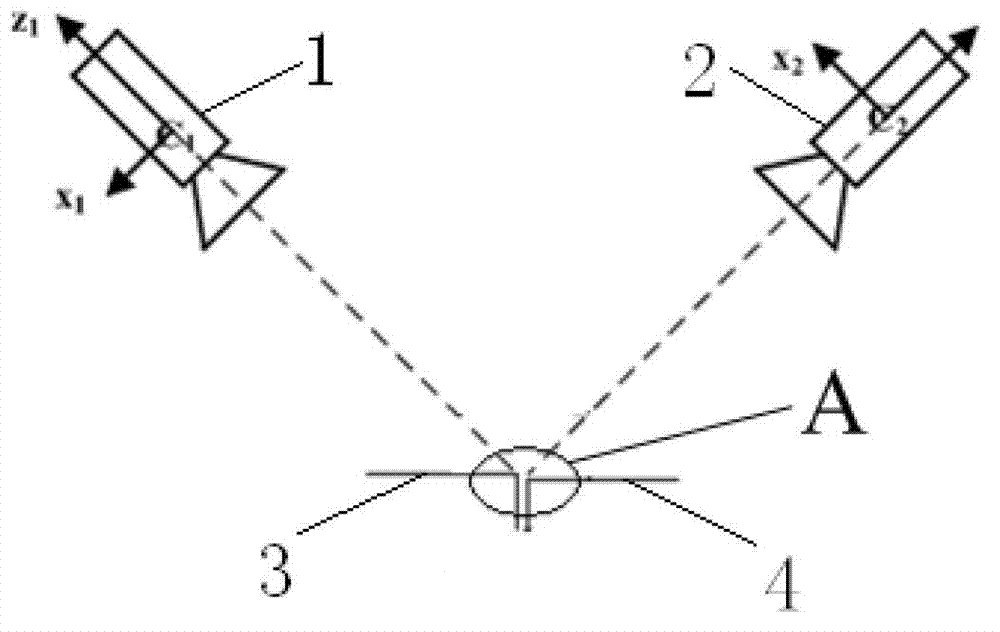

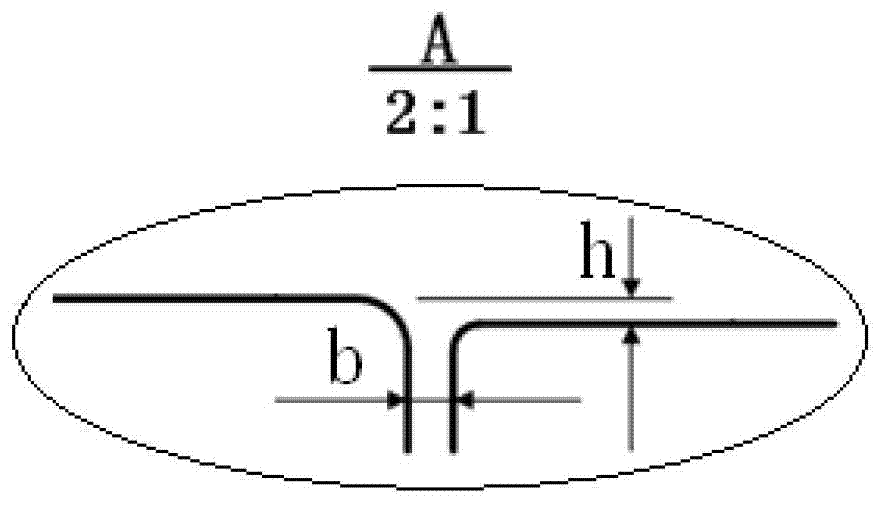

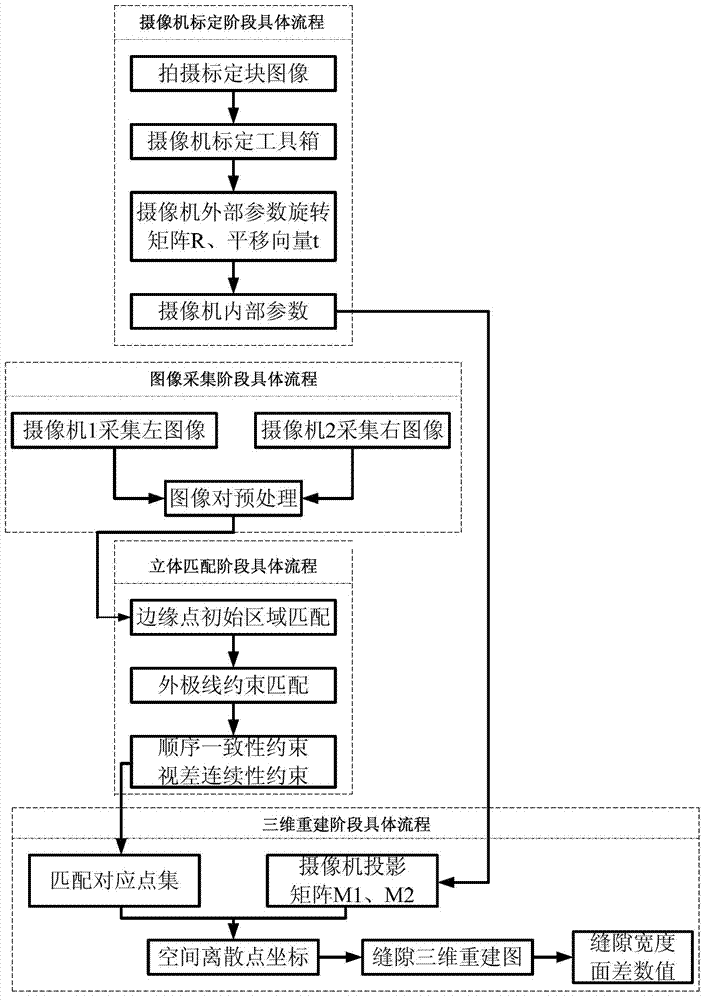

Non-contact online inspection method for automobile body gap size

InactiveCN103075973AEasy to operateSmall amount of calculationImage enhancementUsing optical meansIn planeCalibration result

The invention discloses a non-contact online inspection method for automobile body gap size, aiming at overcoming the problems that the size of equipment is large, the equipment is inconvenient to carry, influences are apt to cause by external factors due to contact-type measurement, and online measurement and large-size covering part gap measurement cannot be realized in the prior art. The non-contact online inspection method comprises the following steps of: 1. camera calibration; 2. image acquisition: placing a gap part of an automobile body covering part in the view field of a camera to take images; 3. stereoscopic matching; and 4. three-dimensional reconstruction, which comprises the steps of: 1) according to a calibration result of a binocular stereoscopic visual system, determining three-dimensional space coordinates of gap edge points of the covering part according to stereoscopic matching points; 2) reconstructing an automobile body gap three-dimensional curve according to the determined three-dimensional space coordinate points; 3) spatially rotating the reconstructed three-dimensional curve according to included angles and directions between the curve and an x-axis, y-axis and a z-axis; and 4) respectively projecting gap curves in planes after rotation to determine the width value and the plane difference value of the gap.

Owner:JILIN UNIV

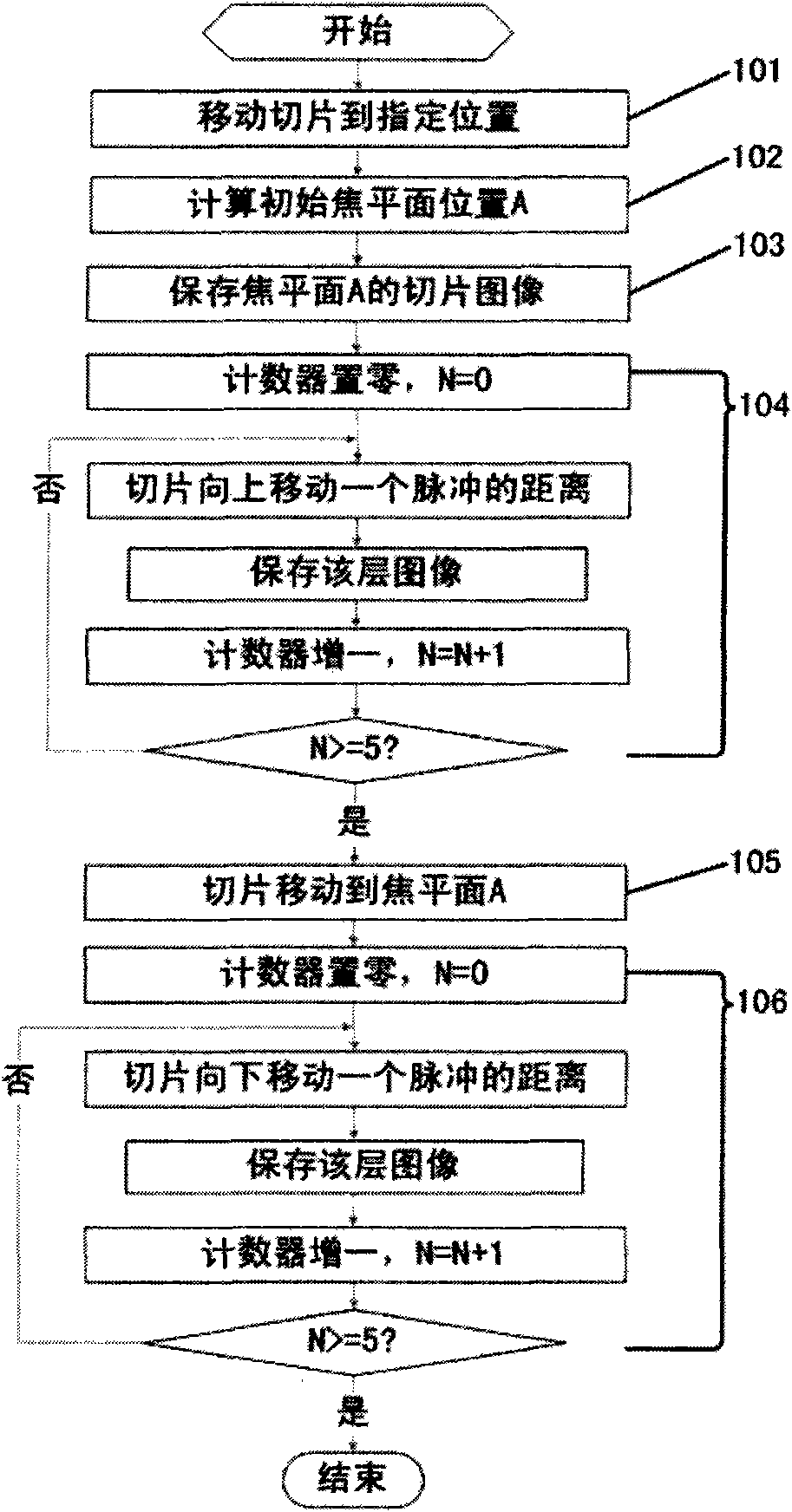

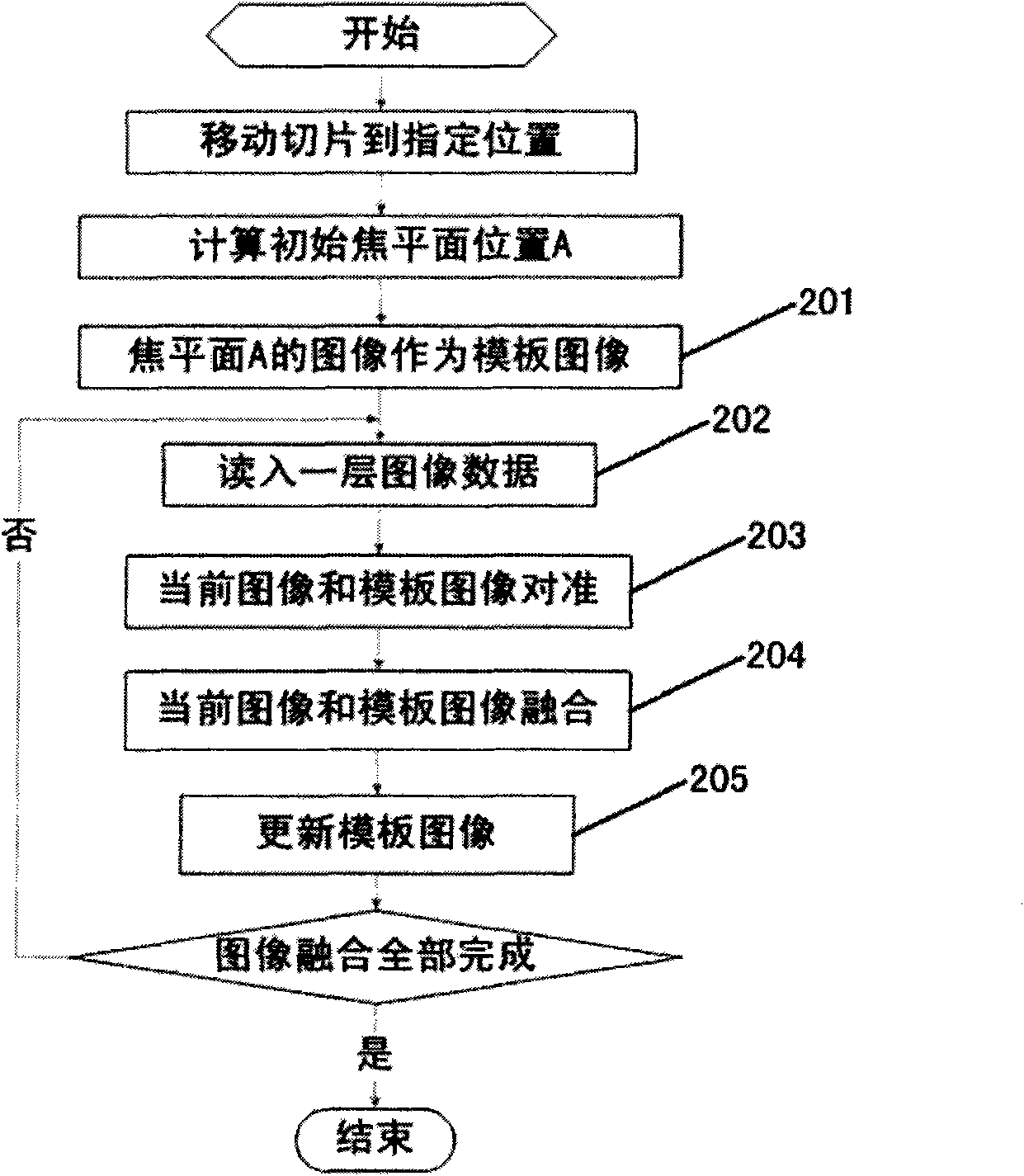

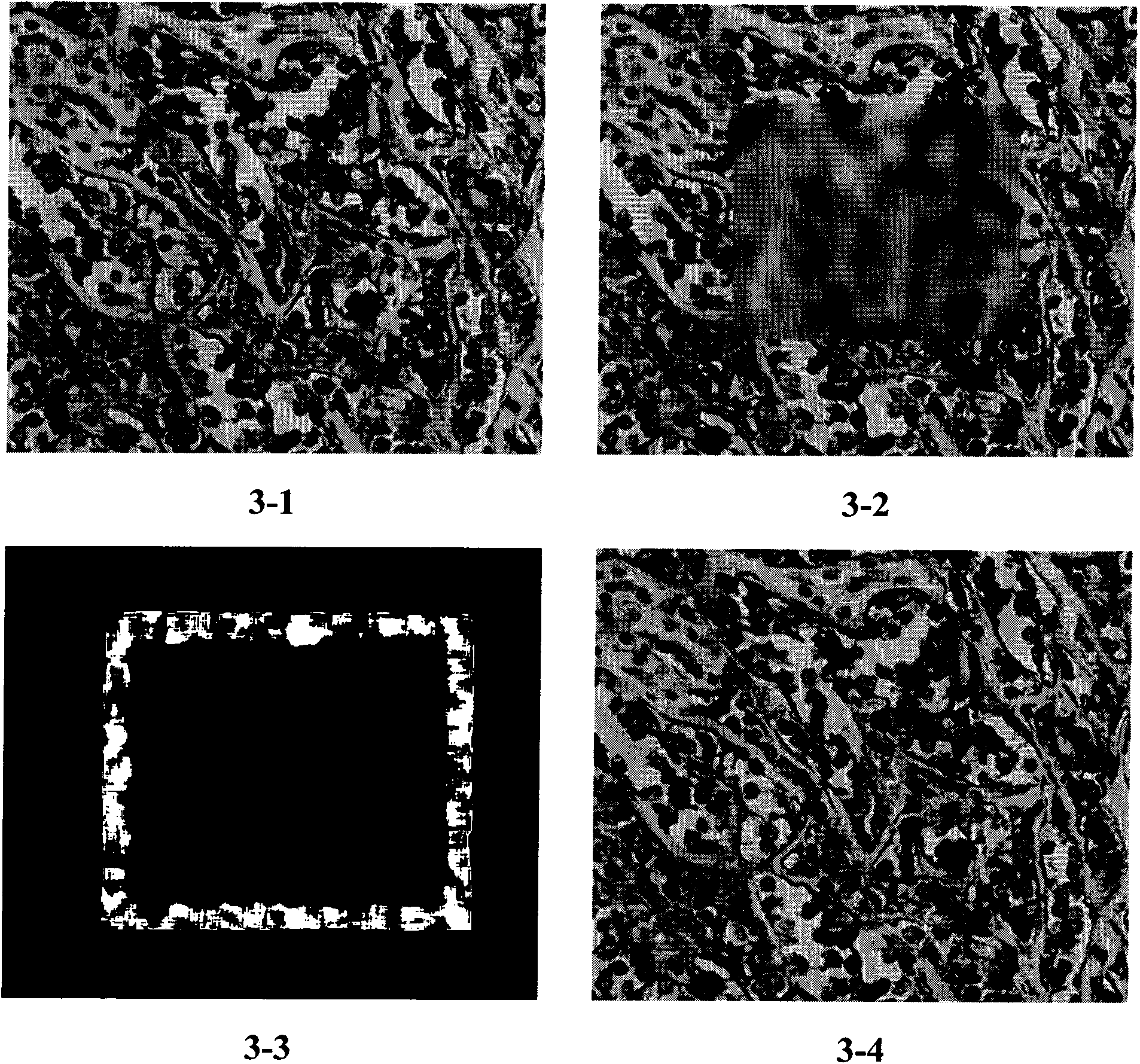

Three-dimensional acquisition of biopsy tissues and fusion method of multilayer images

ActiveCN101615289AHigh precision requirementsReduce omissionsImage enhancementSurface/boundary effectSlice thicknessTissue characterization

The invention discloses three-dimensional acquisition of biopsy tissues and a fusion method of multilayer images after acquisition. During three-dimensional acquisition of the biopsy tissues, the position of the initial focalplane is taken as the center, multilayer image acquisition is carried out on the update positions within the range of biopsy thickness and simultaneously the biopsy image on each layer is stored. The multilayer images of the invention adopt a partitioned area fusion method; based on the definition of the pixels in the images, the areas with relatively high definition in the images to be fused are selected and the template images are updated to finally achieve the purpose of optimizing the definition of the image of the whole biopsy. At the same time, a method of assignment weight is adopted to smoothen the pixel points in the boundary areas, thereby effectively inhibiting false edges. Being adopted, the method of the invention improves the reproduction accuracy of the digital images towards the characteristics of the biopsy tissues. The invention effectively alleviates the workload of the doctors and provides a basis for remote diagnosis.

Owner:苏州优纳医疗器械有限公司

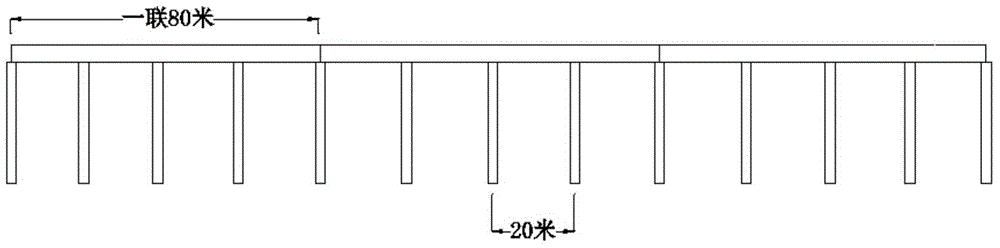

Bridge finite element model modifying method

InactiveCN104133959AImprove correction efficiencyAvoid the drawbacks of repeated iterative calculations that take too longSpecial data processing applicationsTest designUniform design

The invention discloses a bridge finite element model modifying method, which comprises the following steps that: 1, an entity finite element model of a whole bridge is built by universal finite element calculation software ANSYS; and 2, the entity finite element model of the whole bridge is subjected to primary modification by a uniform design method. The bridge finite element model modifying method has the following advantages that the uniform design method is used as a test optimization design method with obvious superiority, and the application of the uniform design method to the bridge structure finite element model modification is feasible; on the basis of the uniform design method, a more correct result can be found in a very short time by the uniform design method in the efficiency aspect, and the bridge large-scale finite element model modification efficiency is improved; a response surface method is used as a test design and mathematical statistics combined mathematical analysis method, and the application of the response surface method to the finite element model modification of a large-scale complicated bridge structure is feasible; and higher modification efficiency and higher modification precision can be ensured at the same time.

Owner:NORTHEASTERN UNIV LIAONING

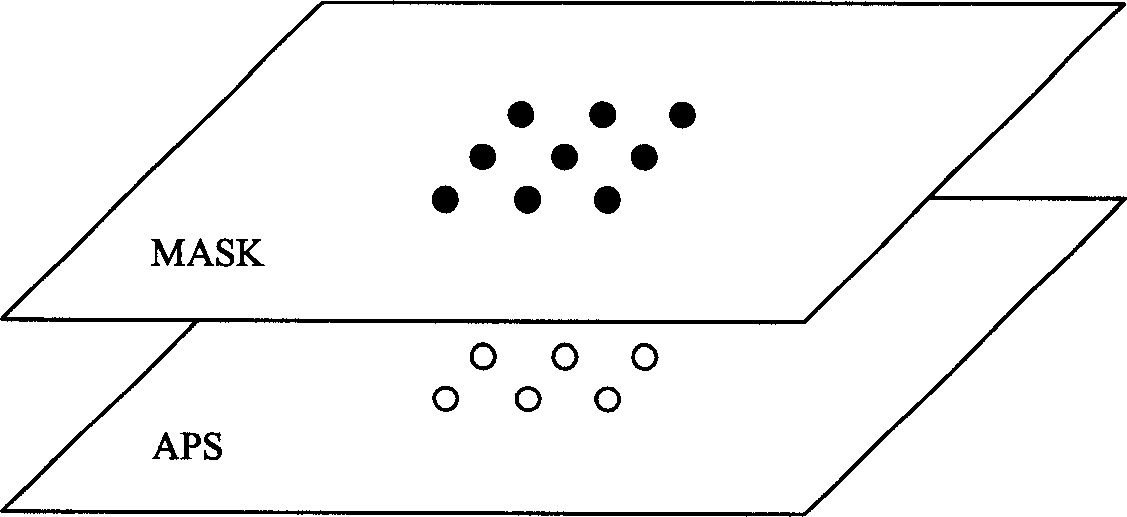

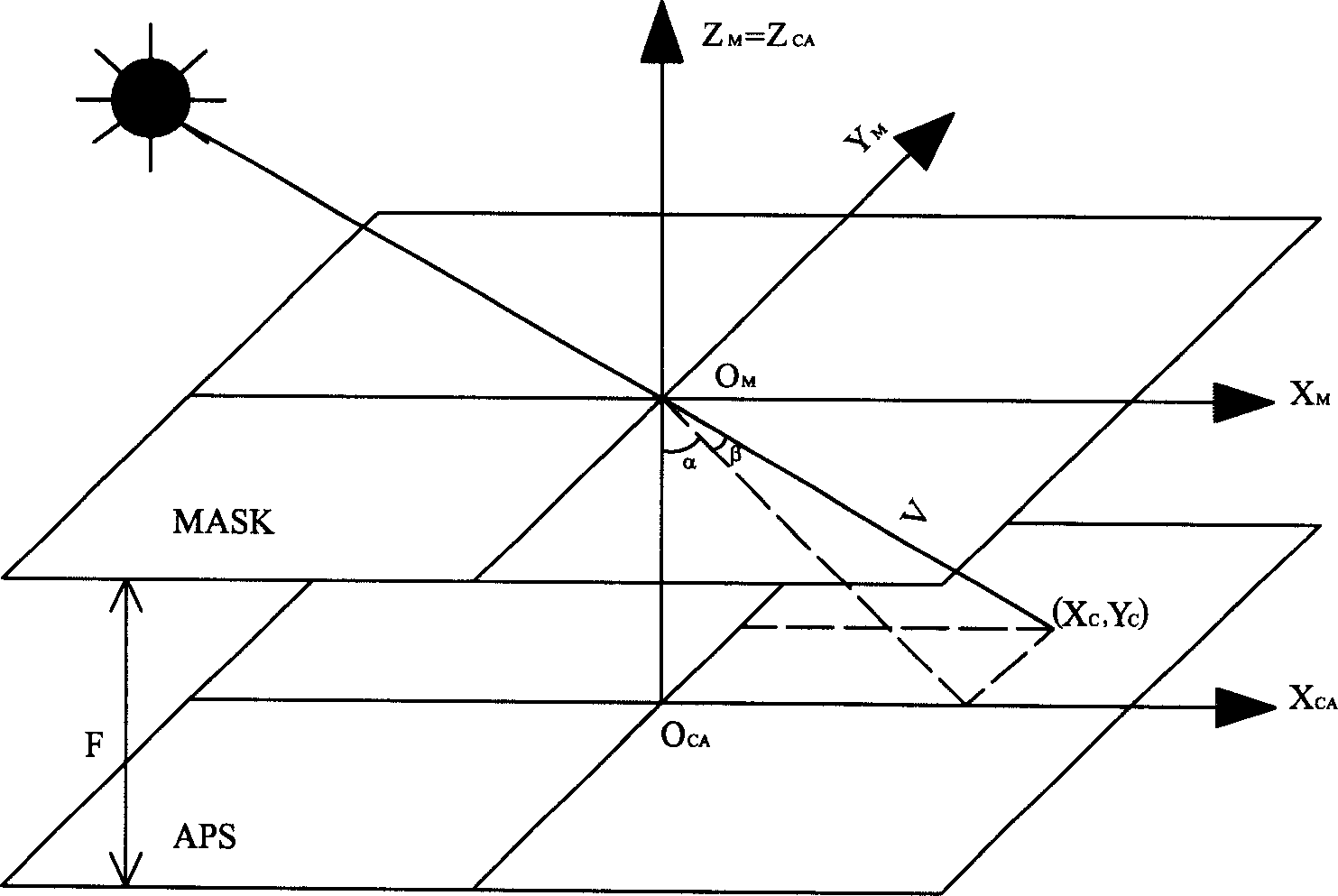

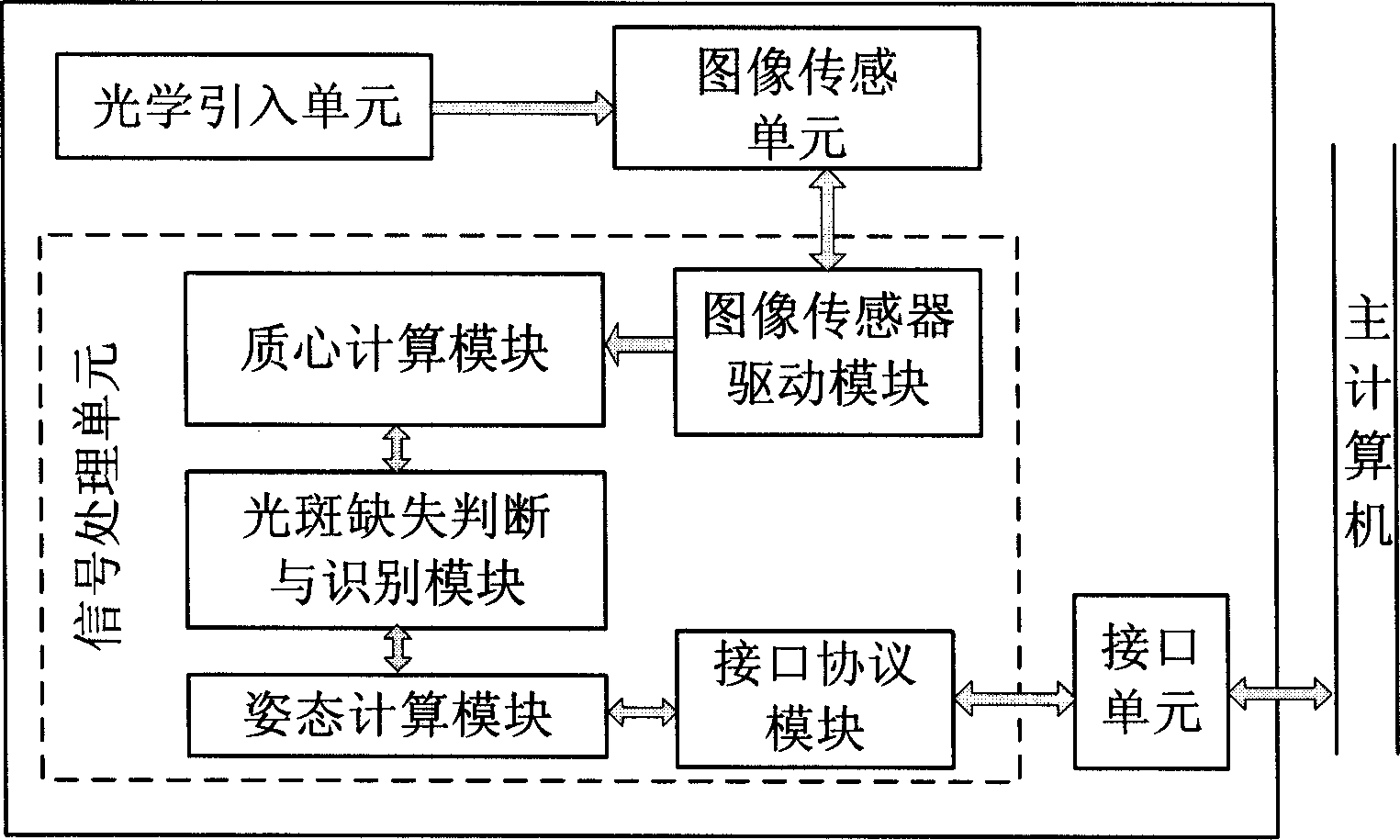

High precision APS sun sensor

InactiveCN1907809AAchieve integrationRealize miniaturization designCosmonautic vehiclesCosmonautic partsComputer hardwareMiniaturization

The invention relates to a high-accuracy APS sun sensor, which comprises: a light lead unit, a picture sensor, a signal processing unit and an interface unit, wherein said light lead unit is connected to the picture sensor; the signal processing unit is connected to the picture sensor and the interface unit; said interface unit is connected to the main computer; the light lead unit is used to generate the speckle array picture; the picture sensor is used to output the pixel gray valve of speckle array picture; the signal processing unit, based on said gray valve, tests the state angle; the interface unit is used to transmit the state angle to the main computer. The invention has high speed, small volume, large view angle, high accuracy and low power consumption.

Owner:BEIHANG UNIV

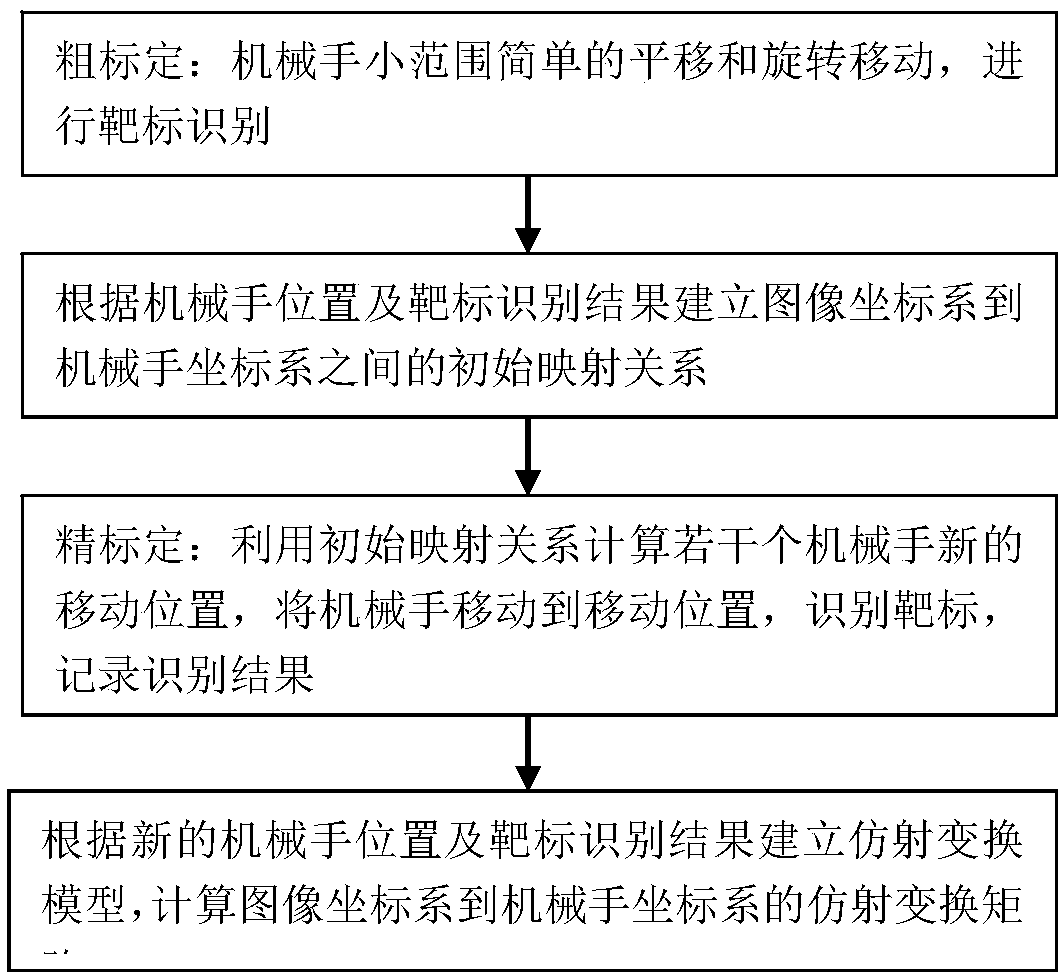

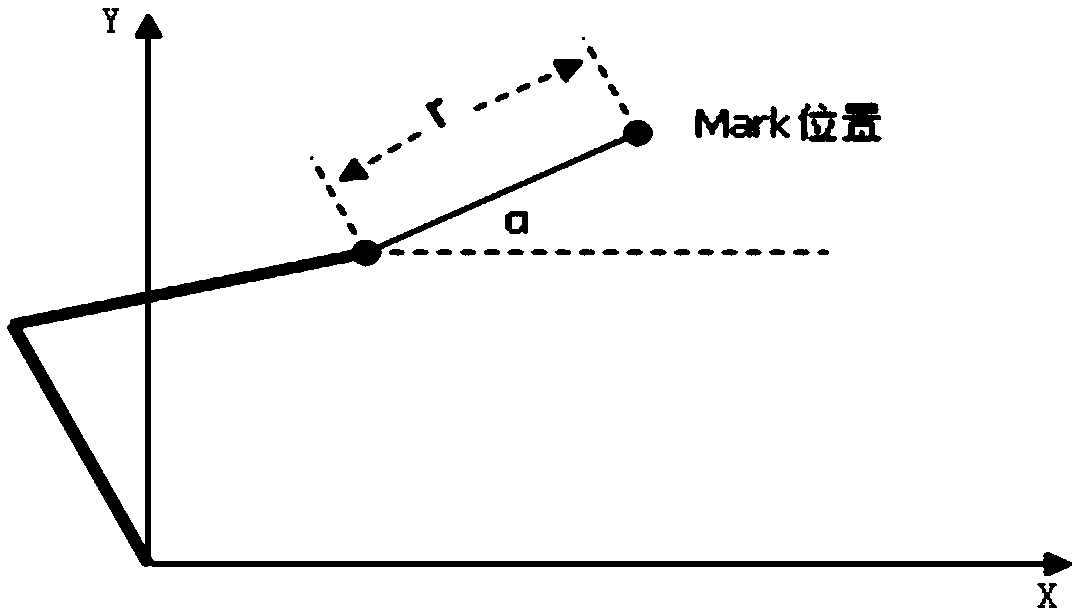

High-precision method for hand-eye calibration of fixed camera vision system of SCARA mechanical arm

ActiveCN109159114AImprove calibration accuracyHigh precisionProgramme-controlled manipulatorHand eye calibrationComputer vision

The invention provides a high-precision method for hand-eye calibration of a fixed camera vision system of an SCARA mechanical arm. The high-precision method comprises the following steps that a target is adhered to one end of a strip-shaped tool, the other end of the strip-shaped tool is fixed to the end of the mechanical arm, a camera is fixed at a fixed position of the working range of the mechanical arm, and the camera shooting surface and the target are parallel to the working plane; rough calibration is carried out, wherein the mechanical arm drives the target to move and rotate within apreset small range, and an initial mapping relation between an image coordinate system and a mechanical arm coordinate system is established according to the position of the mechanical arm and the identification result of the target at each position; and fine calibration is carried out, wherein a plurality of target image positions are preset in the image coordinate system, the moving position corresponding to the mechanical arm is calculated on the basis of the initial mapping relation, the corresponding target images are automatically recognized, affine transformation models are constructed, an affine transformation model is converted into the optimal solution problem, and the affine transformation matrix of the image coordinate system to the mechanical arm coordinate system is obtained. The method is high in calibration precision, simple and convenient to operate and capable of realizing one-key calibration.

Owner:ZHENGZHOU UNIV

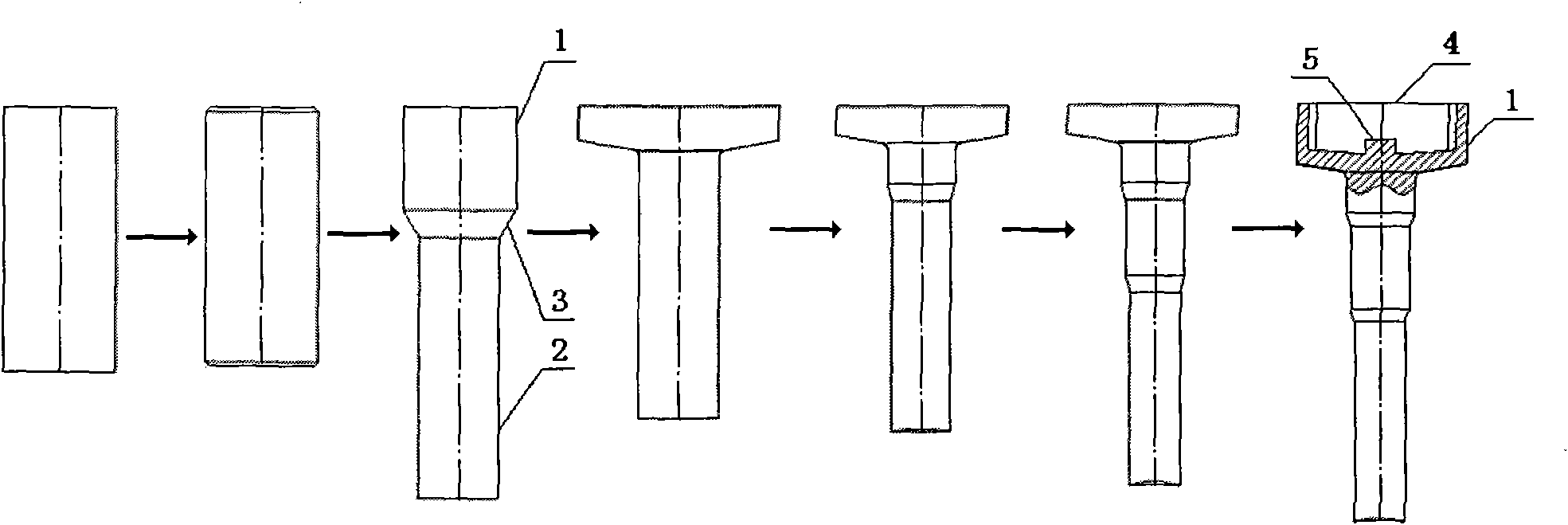

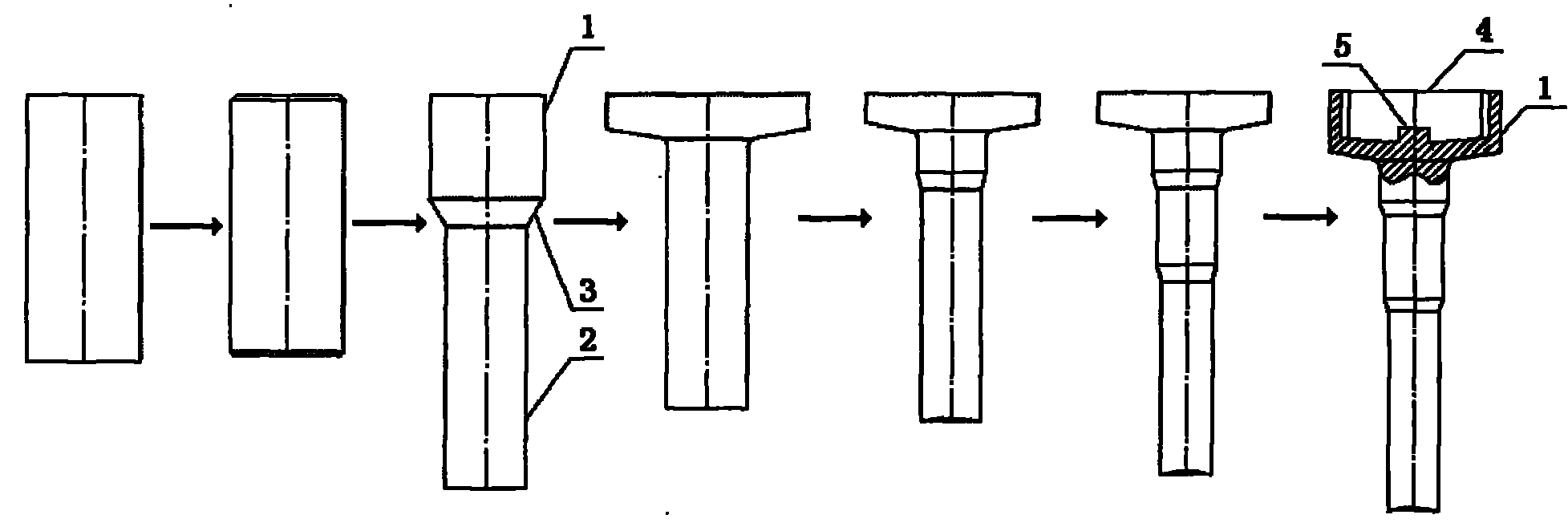

Cold forging precise forming process for mechanical transmission gear shaft

InactiveCN102463320AMeet the precision requirementsHigh strengthEngine componentsHigh volume manufacturingGear wheel

The invention discloses a cold forging precise forming process for a mechanical transmission gear shaft. The process comprises the following steps of: blanking, annealing, performing shot blasting, phosphatizing, saponifying, performing reducing extrusion, performing upsetting extrusion, performing small-end reducing extrusion, and reversely extruding an inner bore. By the process, blanks are processed by a cold forging precise forming mold and are machined to form finished products, so that the process has a simple production process flow, toothed holes in the wall of the inner bore at a large end have high intensity and high consistency, an outer wall is convenient to hob after a small end is subjected to reducing extrusion, and the process is suitable for mass production.

Owner:江苏威鹰机械有限公司

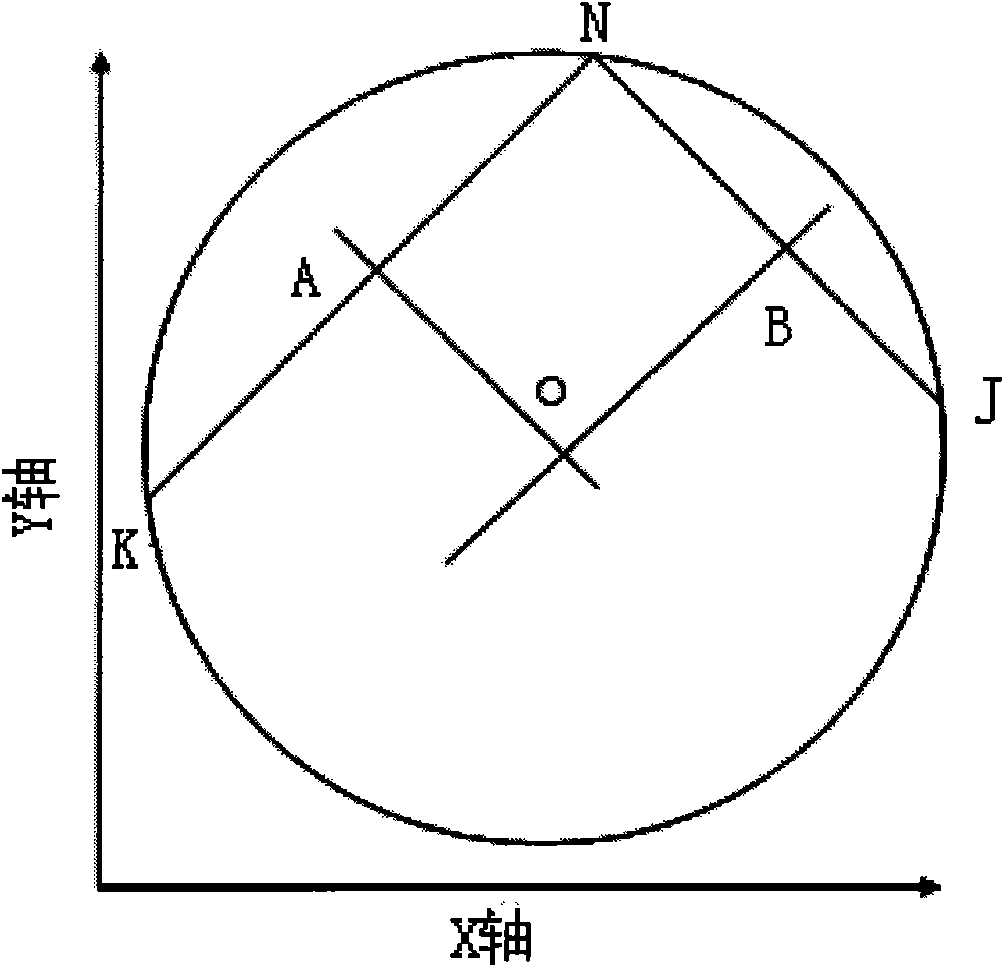

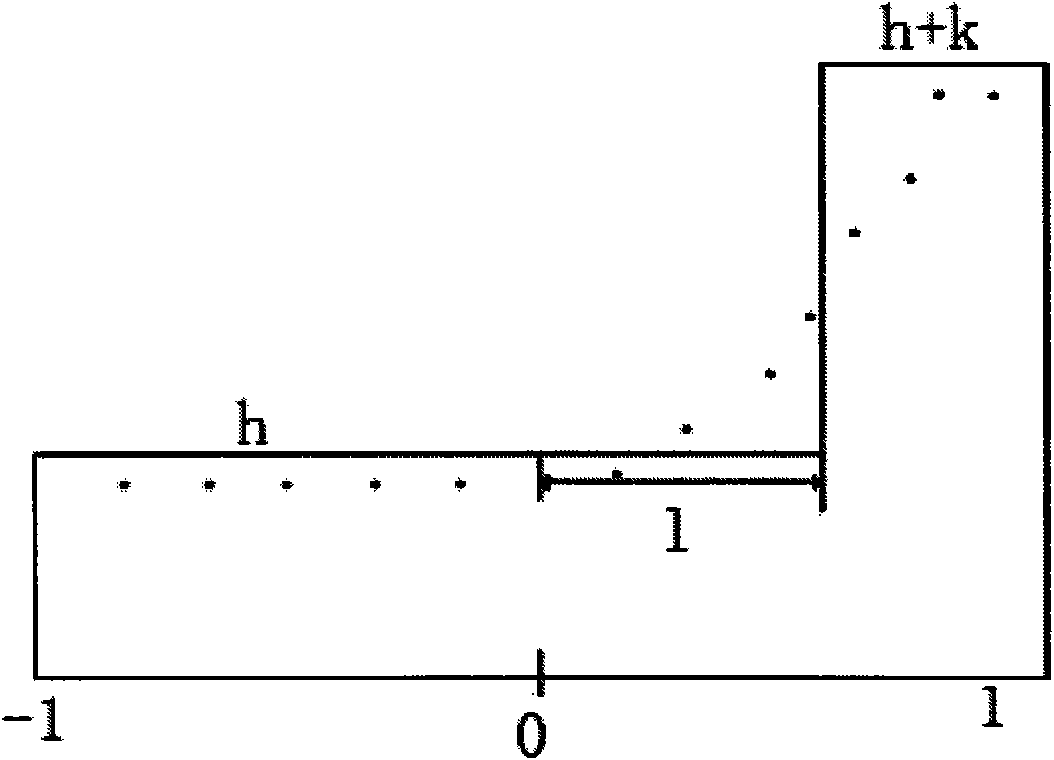

Method for quickly positioning circular mark in PCB visual detection

ActiveCN102034101AFast operationHigh precision requirementsCharacter and pattern recognitionHough transformErrors and residuals

The invention discloses a round sub-pixel detection algorithm based on point Hough transform and Legendre moments, and provides a method for quickly positioning a circular mark in polymerase chain reaction (PCR) visual detection. The method comprises the following steps of: performing edge detection and Hough transform to acquire a circular mark pixel-level reference value by using a Canny arithmetic operator; filtering off noise points in edge points by using the circular mark pixel-level reference value; analyzing a sub-pixel edge positioning method based on Legendre orthogonal moments, and an error; evaluating sub-pixels of the edge points from which the noise points are filtered off by using the Legendre orthogonal moments and an error method; and finally fitting the edge points by a fast least square method to acquire accurate circle center positioning parameter and radius parameter of a round. By the method, the characteristic of high speed of point Hough transform operation is kept; and the method has the characteristics of high positioning accuracy, high noise resistance, accuracy, high speed and robustness and meets the requirements of high accuracy and real-time property in the PCB visual detection.

Owner:GUANGDONG UNIV OF TECH

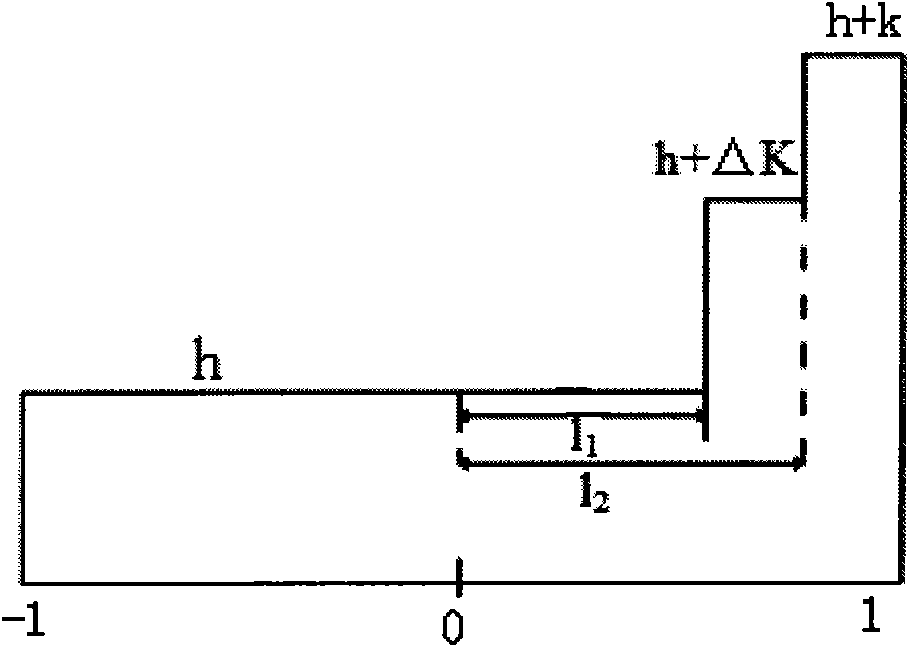

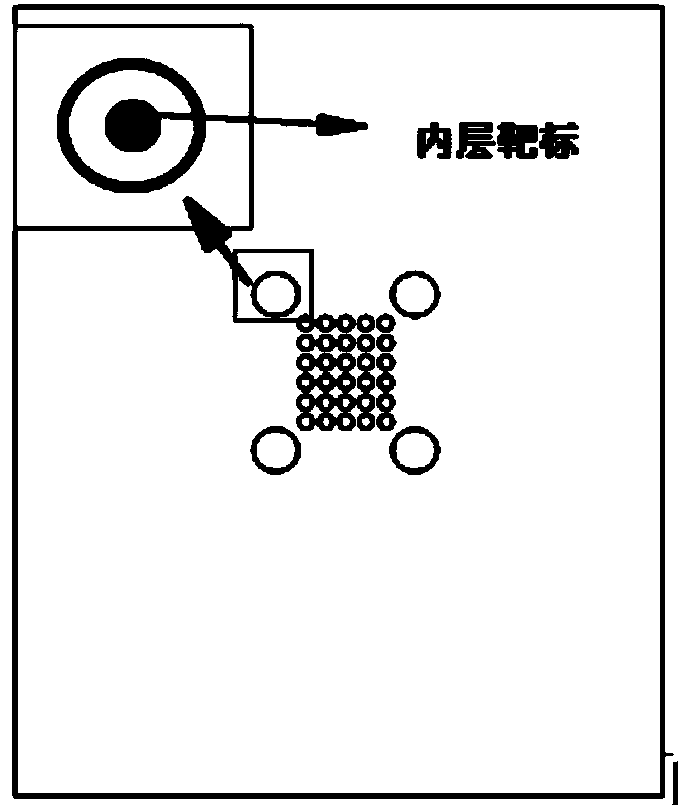

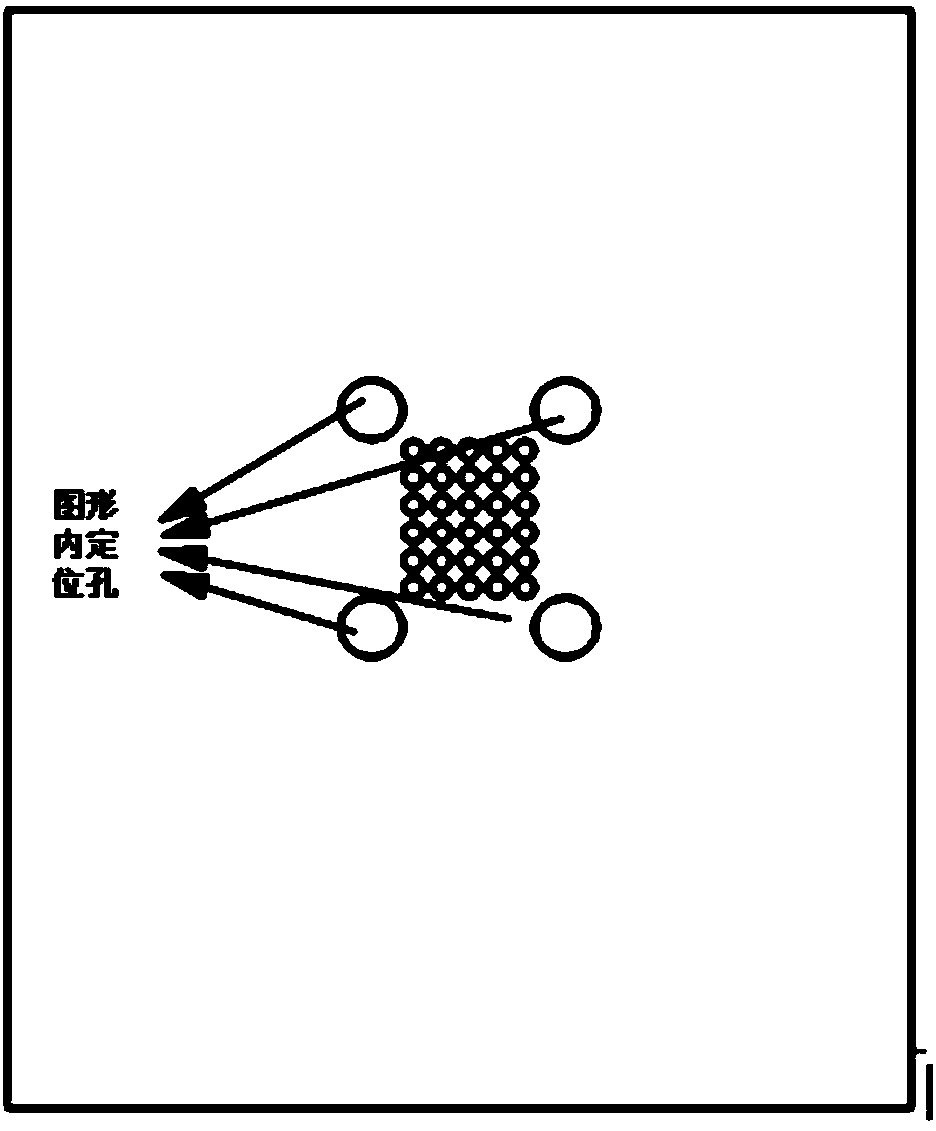

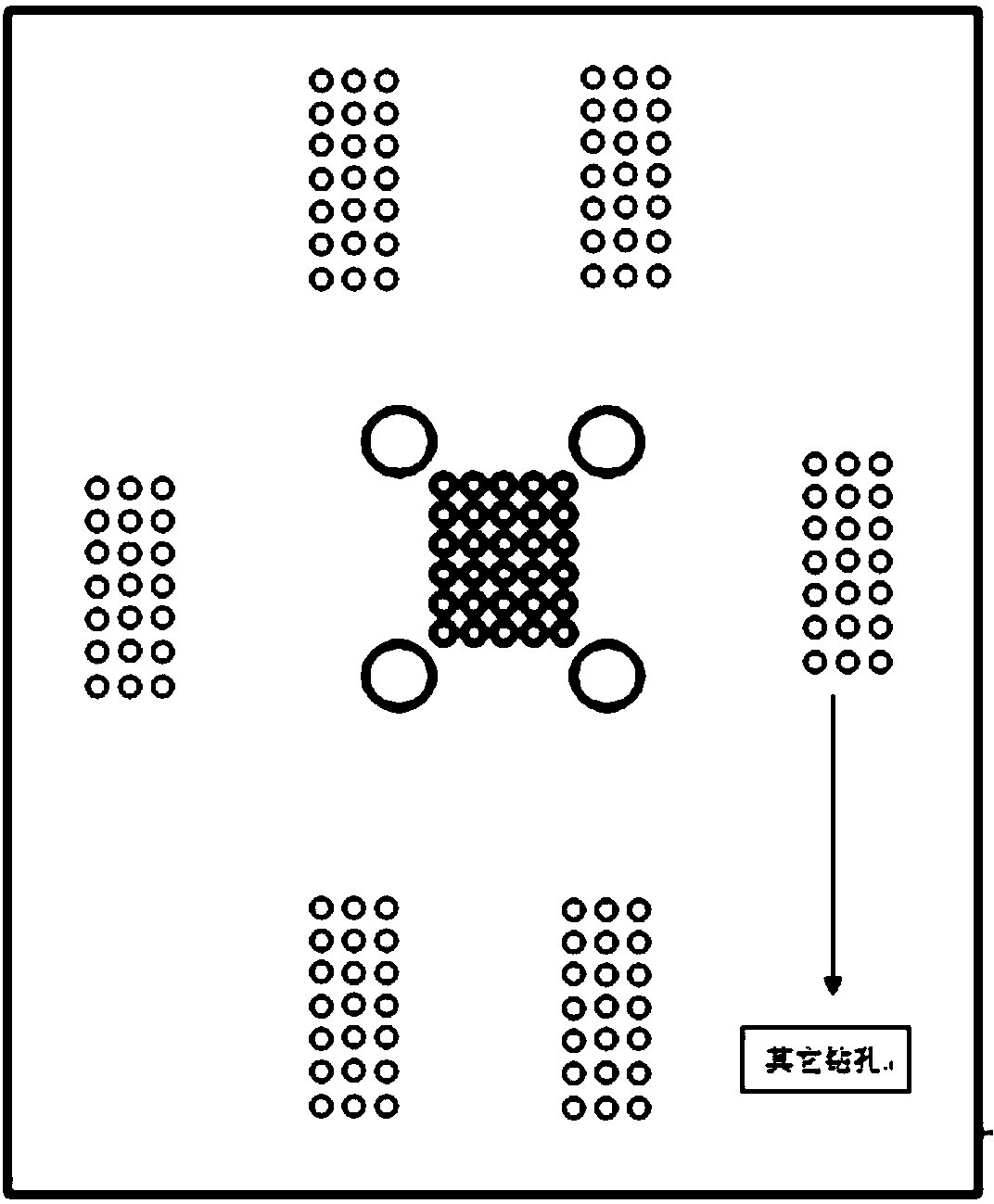

Local high-precision printed circuit board and manufacturing method thereof

ActiveCN104270889AImprove drilling alignment accuracyReduce the scrap rate of drilling deviationPCB positioning during processingElectrical connection printed elementsEngineeringPrinted circuit board

The invention discloses a local high-precision printed circuit board and a manufacturing method thereof. The whole printed circuit board is divided into a high-precision graphic area and a common graphic area. The manufacturing method comprises the steps of inner-layer graph manufacturing, press-fitting, drilling, outer-layer film drying and follow-up procedures. According to the press-fitting step, the Pin-Lam technology is adopted for conducting manufacturing; after the press-fitting step is executed, a graphic inner positioning hole is punched, so that a local expansion coefficient of the high-precision graphic area is calculated. According to the drilling step, a local drilling file is set according to the local expansion coefficient, meanwhile, an LDI datum hole is formed, drilling is carried out on the high-precision graphic area, and the datum hole is drilled; then drilling is carried out on the common graphic area through the whole board expansion coefficient. According to the outer-layer film drying step, the LDI technology is adopted. According to the manufacturing method, the drilling alignment precision of the local high-precision printed circuit board can be effectively improved, highly-difficult drilling can be carried out, the drilling misregistration scrap rate is greatly reduced, and the process is simple.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

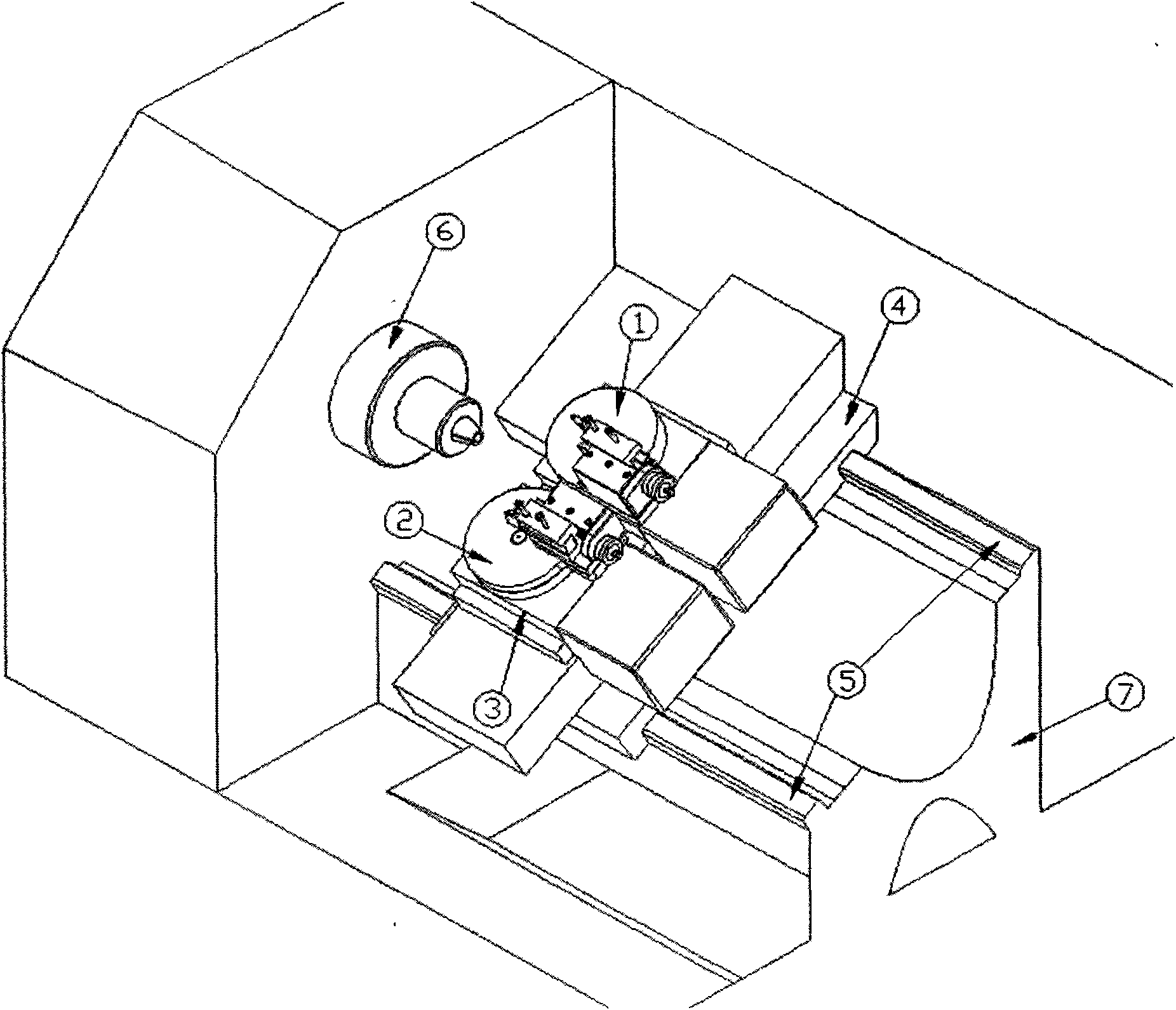

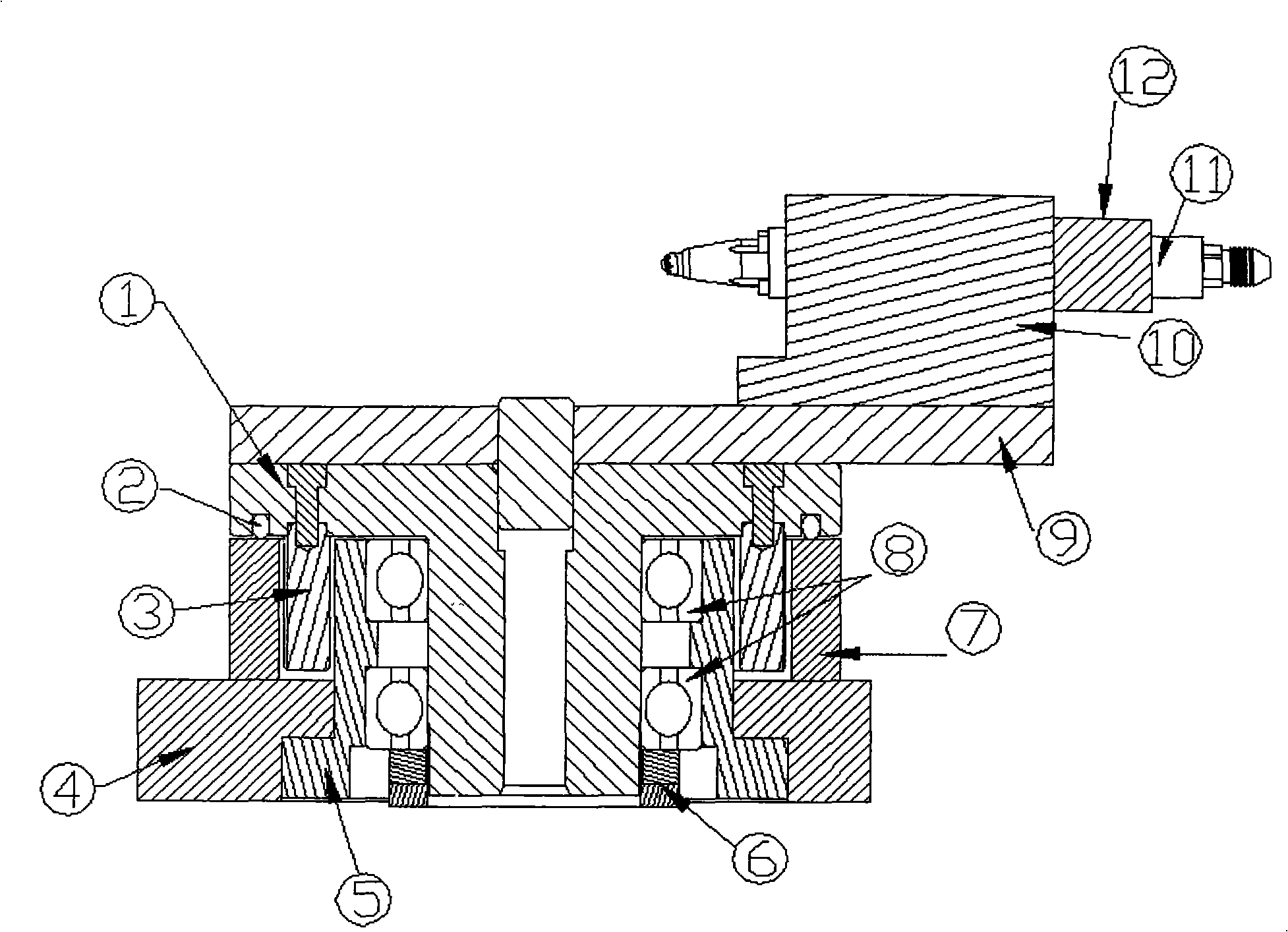

Spherical (spherical surface) mirror surface rolling lathe

ActiveCN101628378ASimple organizationLower center of gravityOther manufacturing equipments/toolsLarge fixed membersQuenchingEngineering

The invention relates to a spherical (spherical surface) mirror surface rolling lathe. A disk revolving tool holder (1) and a disk revolving tool holder (2) which can do circular movement are arranged in the lathe; the disk revolving tool holders are in transmission connection with a servomotor through synchronous belts and synchronous wheels; and a large-diameter thrust bearing (pressure bearing) is used as a tool holder revolving guide rail. The disk revolving tool holder (1) and the disk revolving tool holder (2) are connected with a middle carriage through a disk sealing seat (3), the middle carriage is connected with a large carriage (4) through the guide rail, the large carriage (4) is connected with a guide rail (5), the guide rail (5) is connected with a lathe body (7), and a main shaft (6) is connected with the lathe body (7). One of the tool holders is provided with a special and dismountable cutter system or tool system which is processed by a spherical part surface in a rolling way. The lathe can be used for cutting and processing axisymmetric spherical or externally-forming parabolic parts, and can be used for finely processing the spherical part surface (mirror surface) under the condition that the roughness Ra is smaller than or equal to 0.1 mum. Corresponding devices can be also held on the disk revolving tool holders to develop and upgrade the technologies of drilling, milling, grinding, polishing, quenching and the like, thereby adapting to the processing requirements of spherical (spherical surface) parts in many industries.

Owner:宁波市精恒凯翔机械有限公司

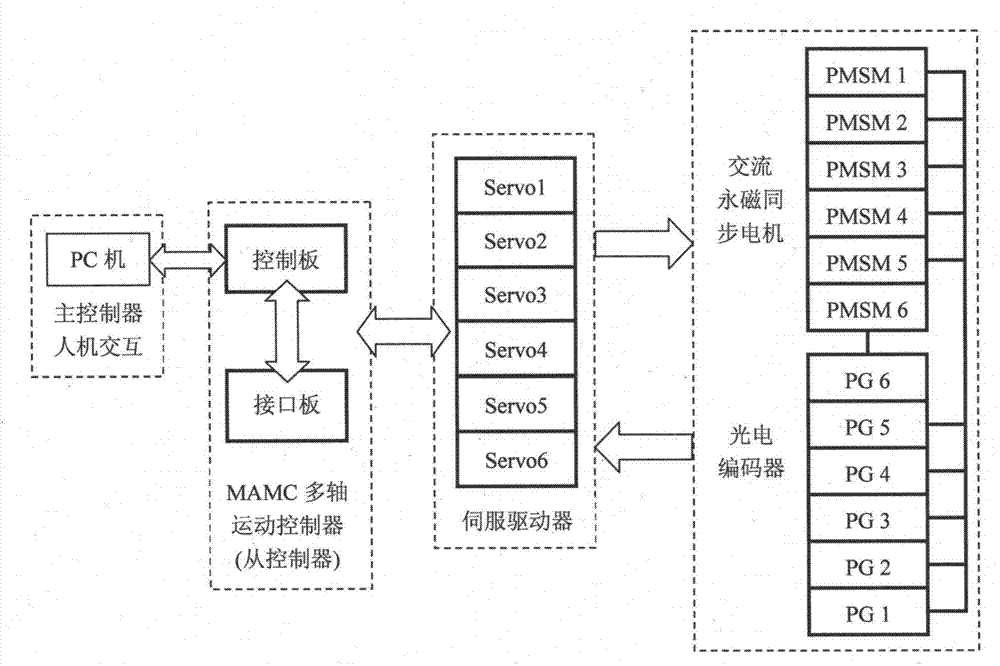

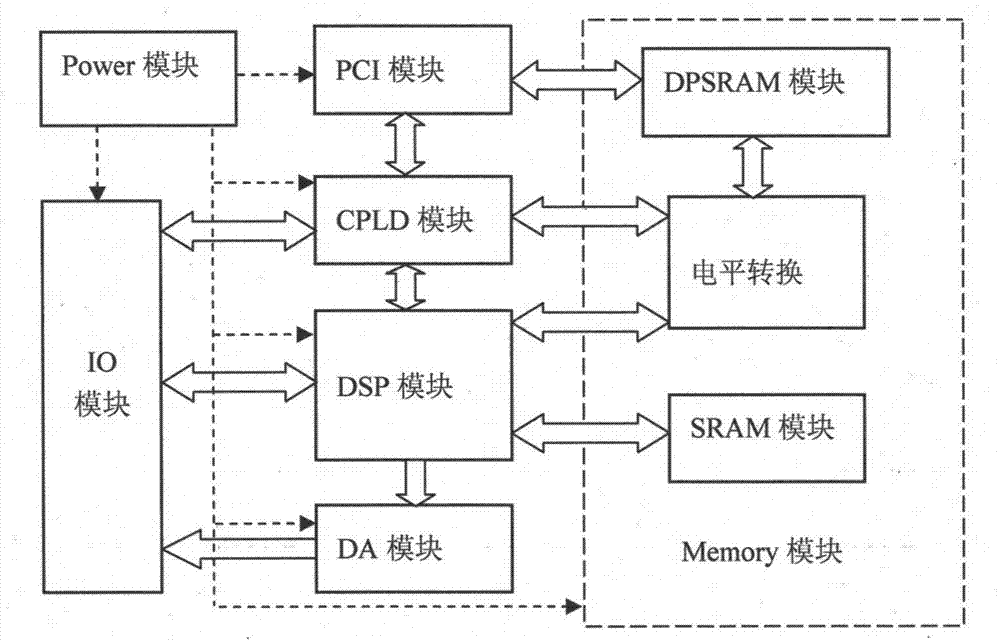

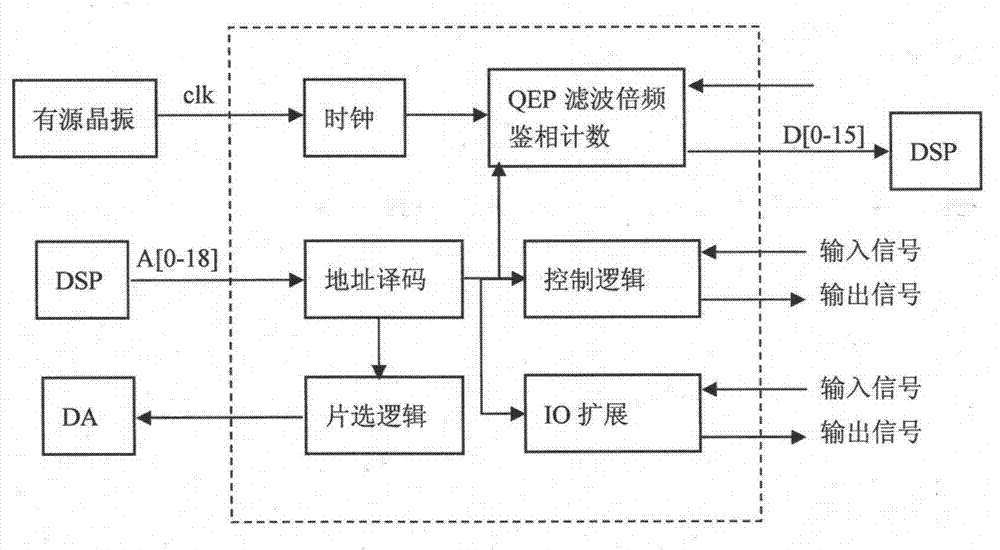

Multi-axis motion control system

InactiveCN103576614AMeet real-time requirementsHigh precision requirementsNumerical controlElectricityControl system

The invention provides a multi-axis motion control system comprising a master-slave mode open type hardware system. The master-slave mode open type hardware system is composed of a PC and a multi-axis motion controller, wherein the PC serves as a master controller, and the multi-axis motion controller serves as a slave controller. The multi-axis motion controller controls an alternating current permanent magnet synchronous motor through a servo driver. The alternating current permanent magnet synchronous motor is connected with an optical-electricity encoder. The optical-electricity encoder detects operation states of the alternating current permanent magnet synchronous motor and transmits the operation states serving as a feedback signal to the multi-axis motion controller through the servo driver. The multi-axis motion control system overcomes the defects in the prior art, takes the advantages of abundant software resources of the PC and high-speed hardware of the multi-axis motion controller to the maximum extent, meets the requirements for real-time performance and high accuracy of the controller, and has universality.

Owner:DONGHUA UNIV

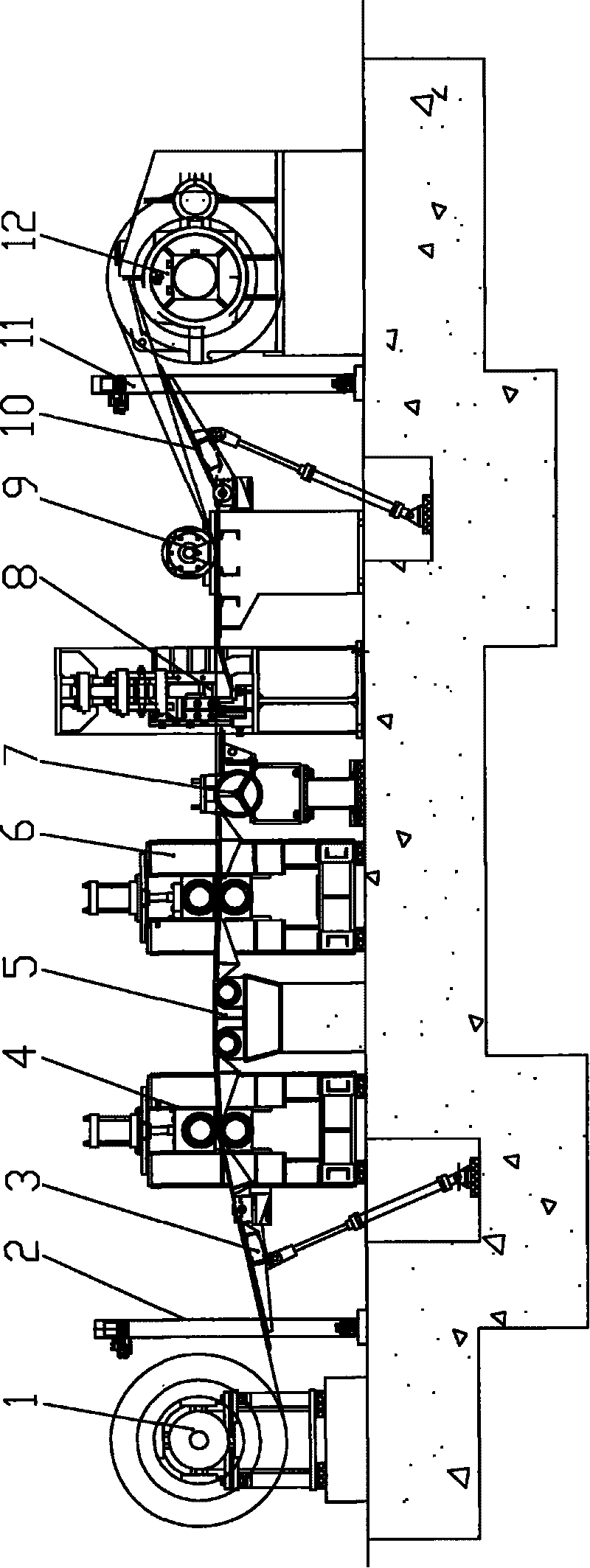

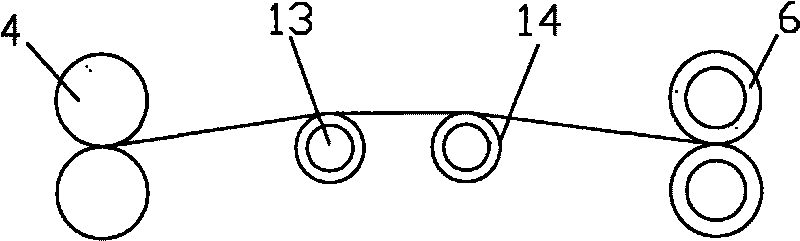

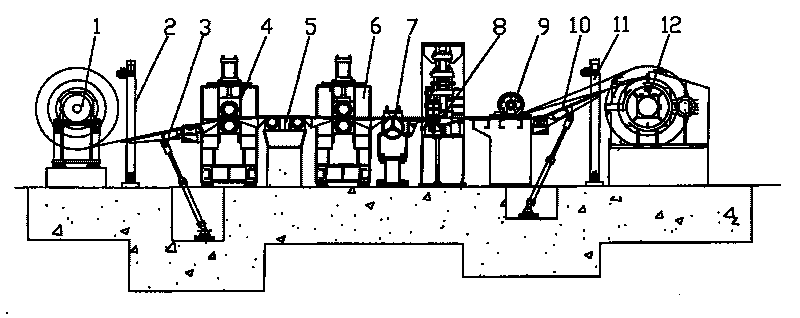

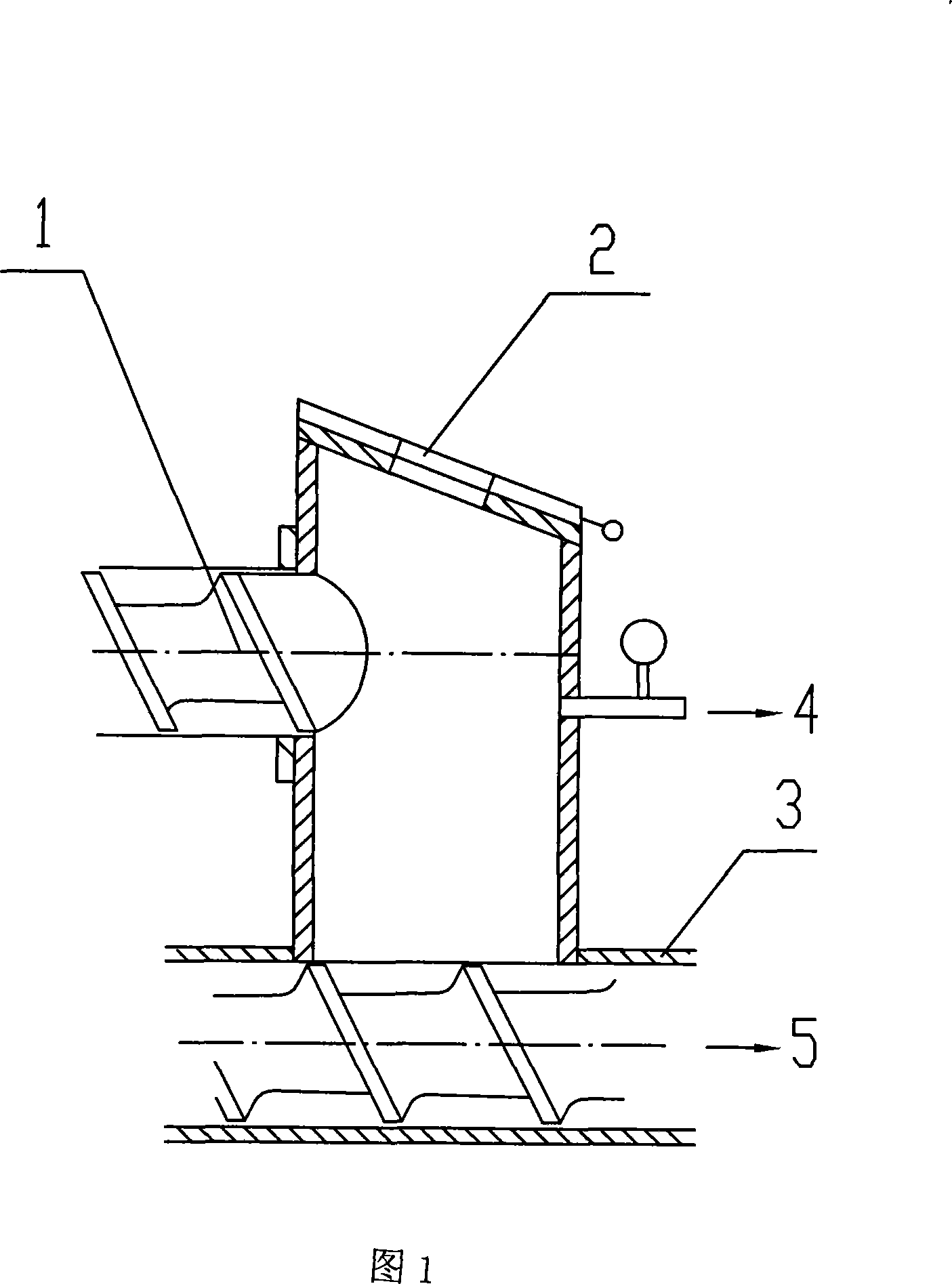

Device and method for maintaining stable operation of strip steel for cold-rolled strip steel production unit

ActiveCN101722195AImprove productivityEliminates wobble and chatterTension/compression control deviceMetal rolling arrangementsTension controlMaterials science

The invention relates to a device and a method for maintaining stable operation of strip steel for a cold-rolled strip steel production unit. The method guarantees the stable operation of the strip steel by tension control, prevents the strip steel from torsion and shake by tension of the strip steel, and prevents the strip steel from deviation by adopting an automatic deviation-rectifying control device for the strip steel. The device comprises a decoiler (1) and a coiler (2) which are respectively arranged at the head and the tail of the unit. A high-precision coder is arranged on the decoiler and the coiler. A tension roll (5) is arranged in the unit, and comprises a left roll and a right roll with the same height. The elevation of the left roll and the right roll is respectively higher than that of an inlet pinch roll (4) and an outlet pinch roll (6). A wrap angle is respectively formed at the inlet and the outlet of the tension roll, so that the strip steel is tensioned. An automatic centering and edge-aligning deviation-rectifying control device for the strip steel is respectively arranged on the rear of the decoiler and in front of the coiler. The device and the method can eliminate the problem that the production efficiency is not high due to the torsion, shake and deviation during the operation of the strip steel, and meet the requirements of high stability and high precision of the strip steel on a laser scoring machine unit.

Owner:WISDRI ENG & RES INC LTD

Polyetheretherketone steel bar and preparation method and uses thereof

The invention discloses a novel polyether-ether-ketone (peek) bar which is designed for solving the problems of slow crystallization speed caused by too large viscosity during processing and being too difficult to be processed caused by good metal cohesiveness after the forming by processing existing in a present PEEK bar. The invention comprises the following components according to weight proportion: 55.5 parts to 100 parts of peek resin, 2 parts to 4 parts of lubricant, 0.05 part to 0.5 part of nucleating agent and 0.05 part to 43 parts of filler. The invention also discloses the preparation method and use of the bar and has the advantages of fast molding, good processing performance and wide use.

Owner:南京金紫鑫工程塑料有限公司

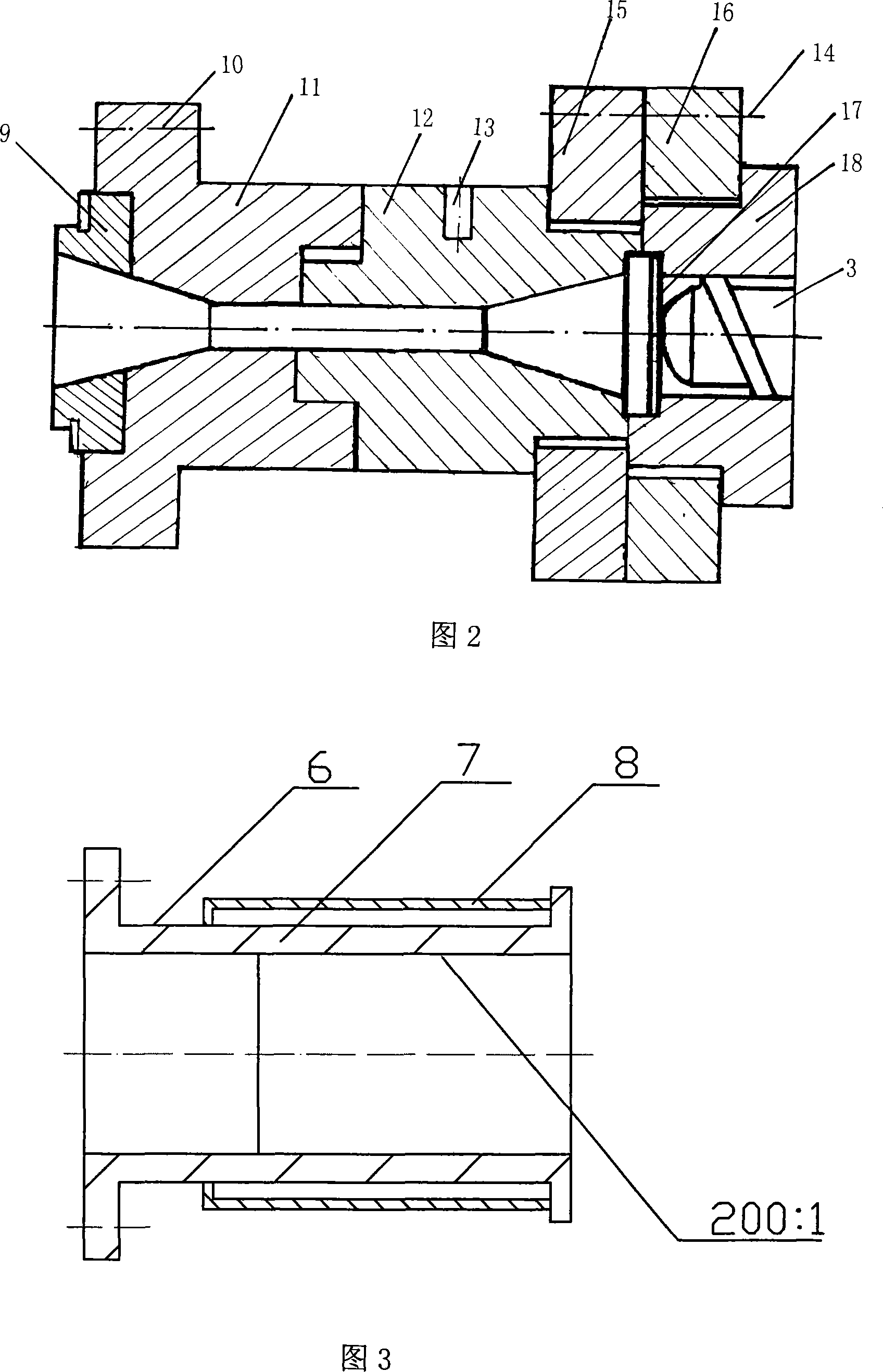

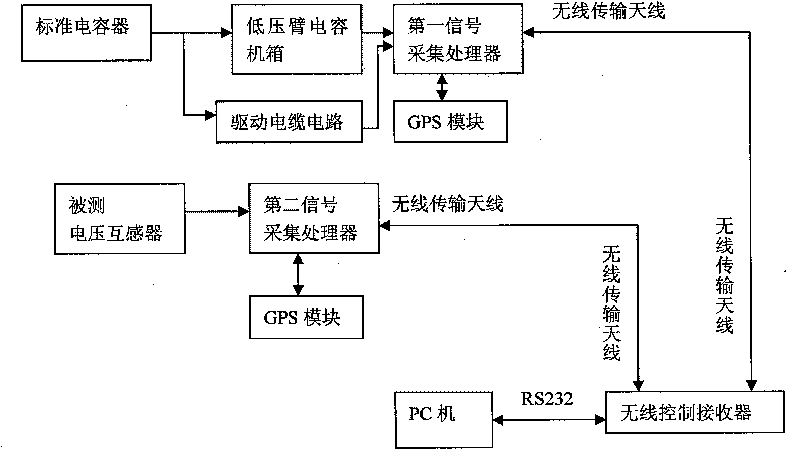

Method and system for online detection of voltage transformer precision

ActiveCN101762799AFlexible online assessmentEasy on-site connectionElectrical measurementsCapacitanceData processing system

The invention discloses a method and a system for online detection of voltage transformer precision. The invention is characterized in that the system comprises a capacitive voltage dividing loop, a signal acquisition processor and a data processing system, the output end of the capacitive voltage dividing loop is connected with the input end of a first signal acquisition processor, the output end of the voltage transformer to be detected is connected with the input end of a second signal acquisition device, the output end of the first signal acquisition processor and the output end of a second signal acquisition processor are connected with the data processing system, voltage signal on a power transmission line and voltage signal of the voltage transformer to be detected are acquired, calculated and processed respectively by the signal acquisition processing system of the power transmission line and the signal acquisition processing system of the voltage transformer to be detected, and the error condition of the voltage transformer to be detected is obtained. Tens of hours of uninterrupted measurement can be conducted to the voltage transformer to be detected under the charged operation condition and no influence is caused to the grid during accessing and quitting, so the assessment of the voltage transformer under different operation conditions and environmental characteristics can be realized and the online evaluation of the voltage transformer precision is flexibly realized.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

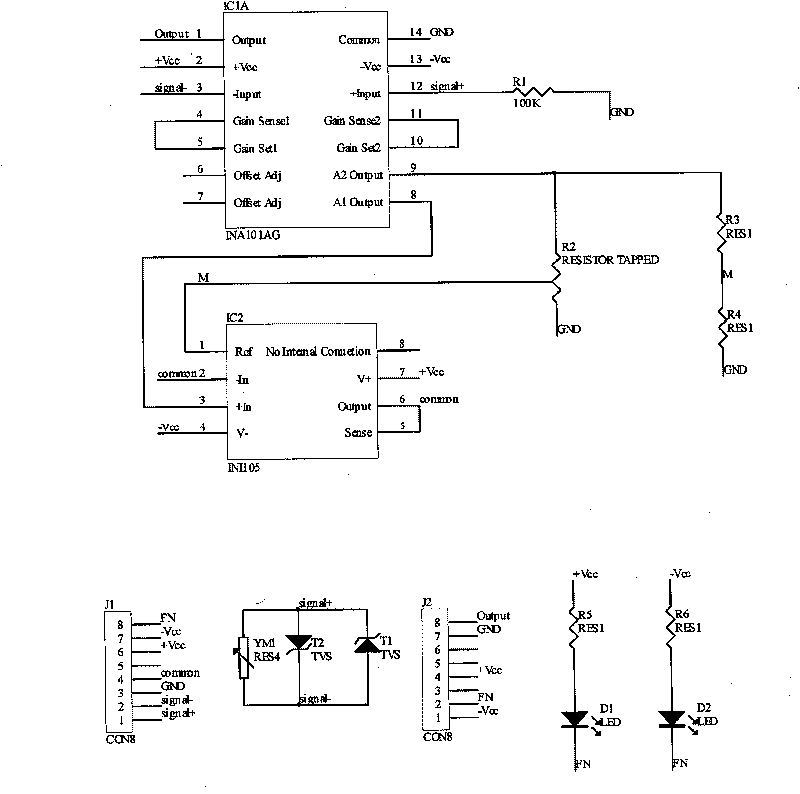

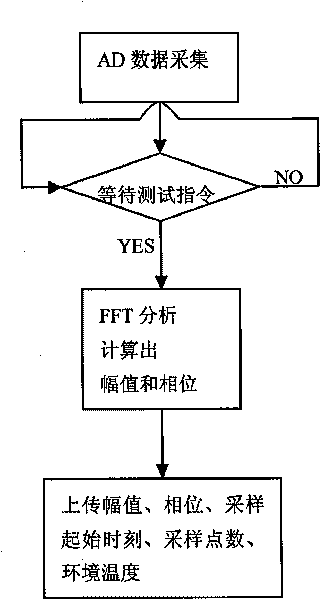

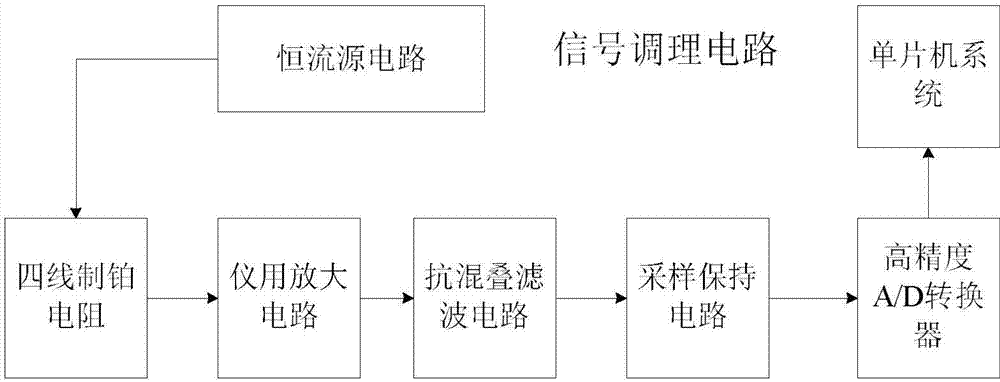

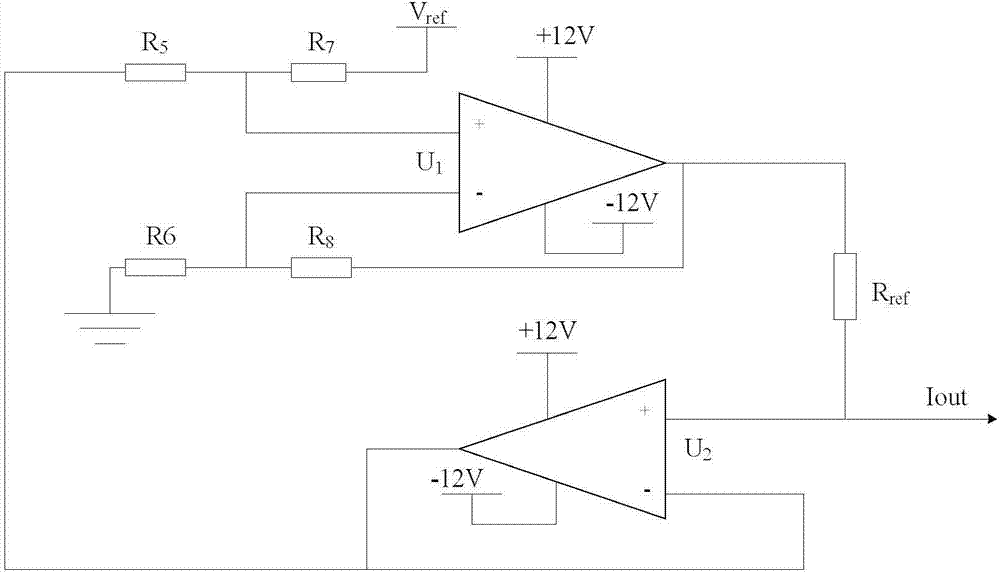

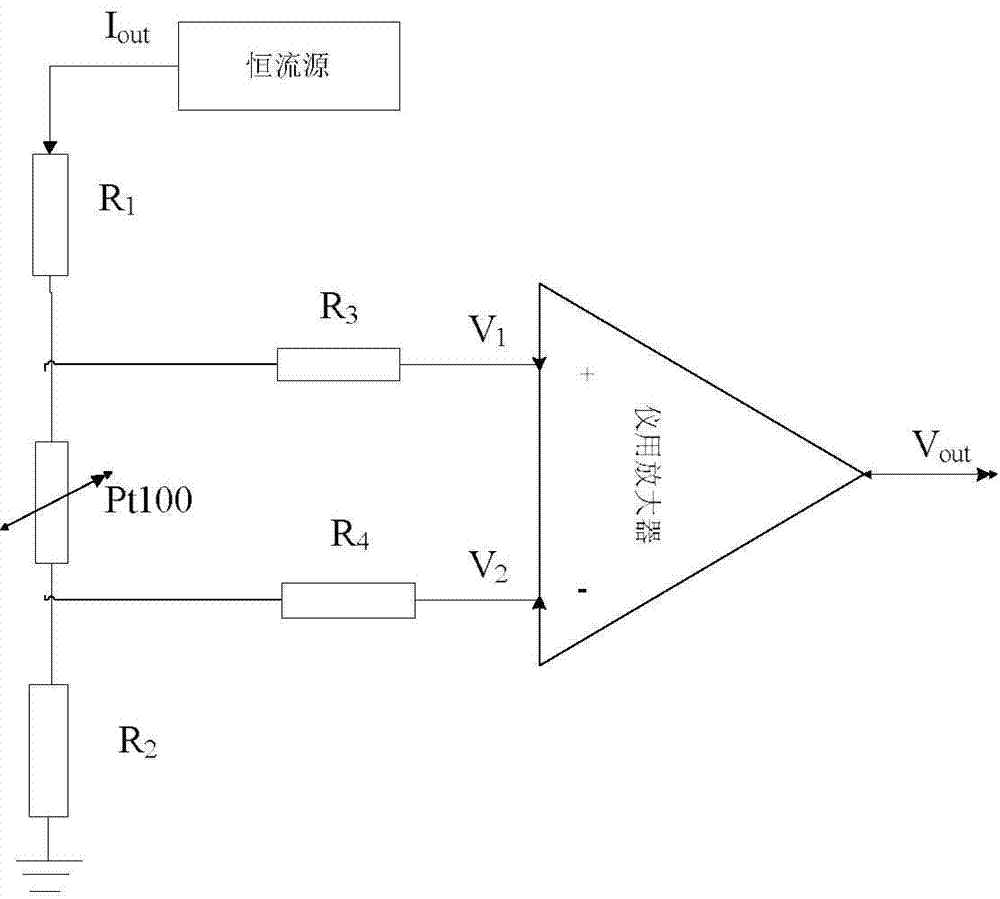

Method and device for precisely measuring temperatures of platinum resistors

InactiveCN104236742AReduce mistakesReduce self-heating effectThermometers using electric/magnetic elementsUsing electrical meansMicrocomputer systemLow-pass filter

The invention discloses a method and a device for precisely measuring temperatures of platinum resistors. The scheme for measuring the temperatures of the micro-current-drive four-wired Pt100 platinum resistors includes that the device for precisely measuring the temperatures of the platinum resistors comprises a constant-current source drive circuit, a four-wired platinum resistor interface circuit, an instrument amplifier circuit, an anti-aliasing filter circuit, a sampling hold circuit, an A / D (analog / digital) sampling circuit and a single chip microcomputer system. A constant-current source comprises two low-noise and low-offset bipolar operational amplifiers OP07CD with high open-loop gain; the four-wired platinum resistor interface circuit is divided into a constant-current source power lead and a voltage drive lead; the instrument amplifier circuit comprises a double-stage differential amplifier circuit; the anti-aliasing filter circuit is an RC low-pass filter circuit; an A / D converter is a 24-bit high-resolution A / D converter CS5550. The method and the device have the advantage that the measurement precision is high, calibrated temperature measurement errors are smaller than + / -0.03 DEG C, and requirements of industrial production procedures on high temperature measurement precision can be met.

Owner:JIANGNAN UNIV

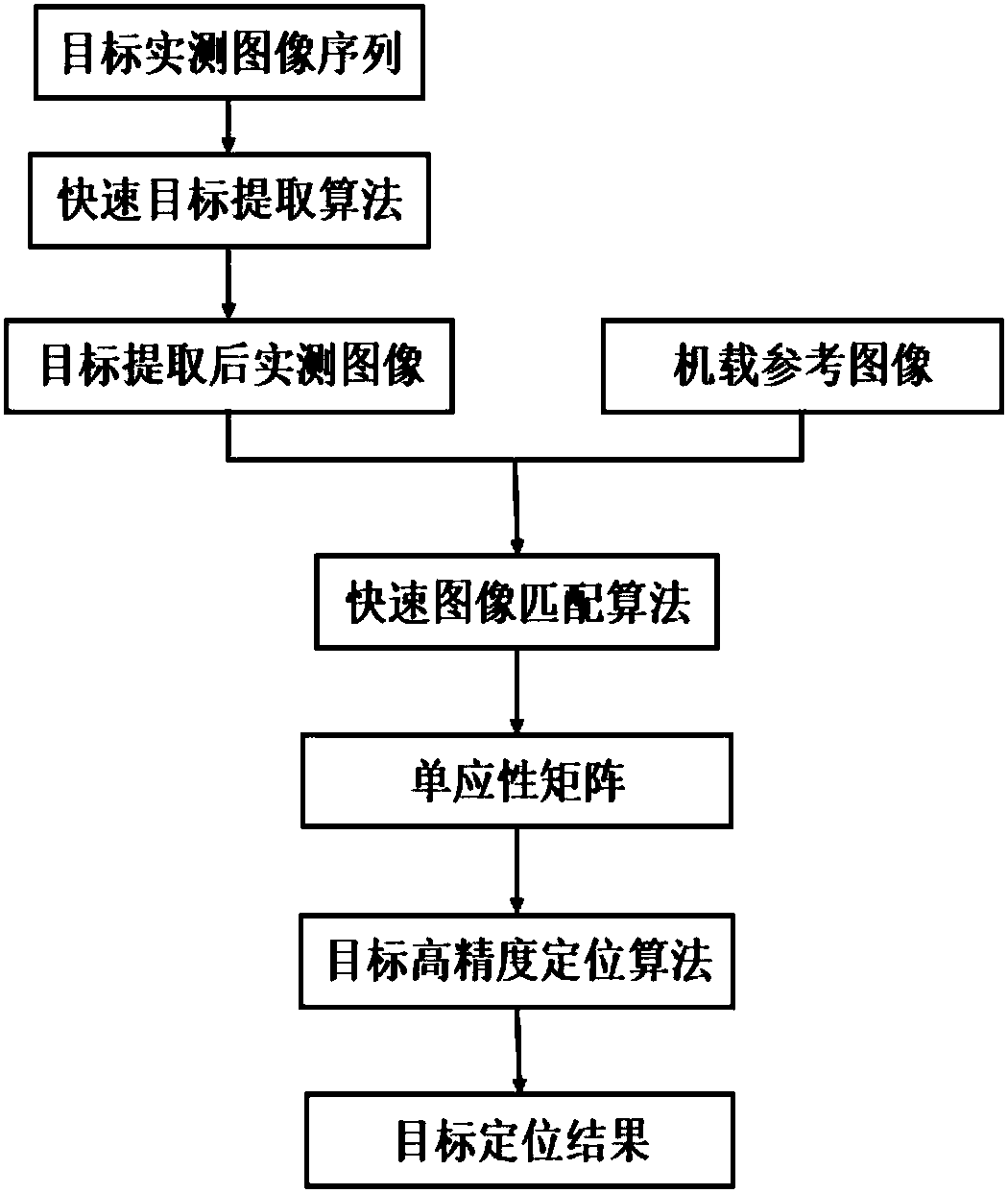

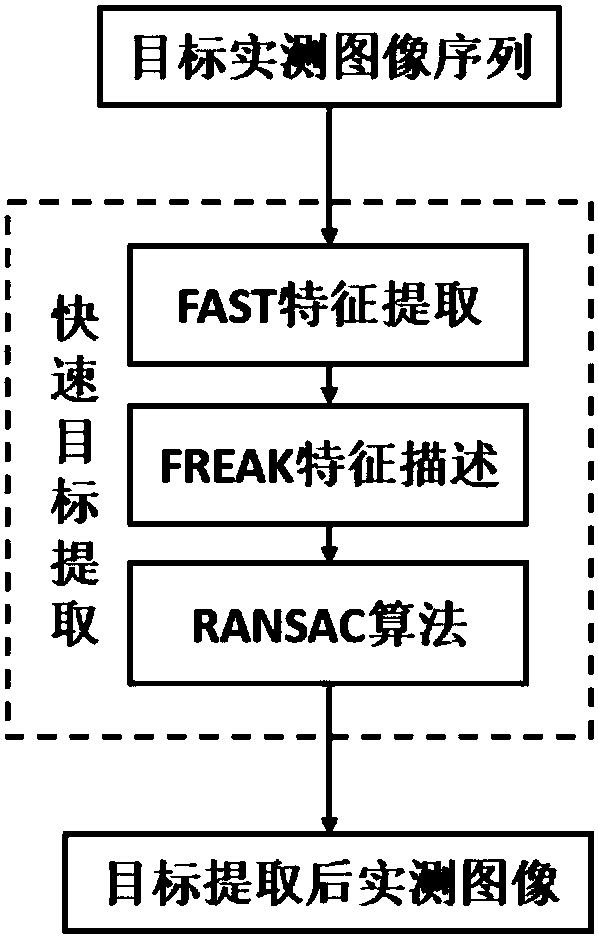

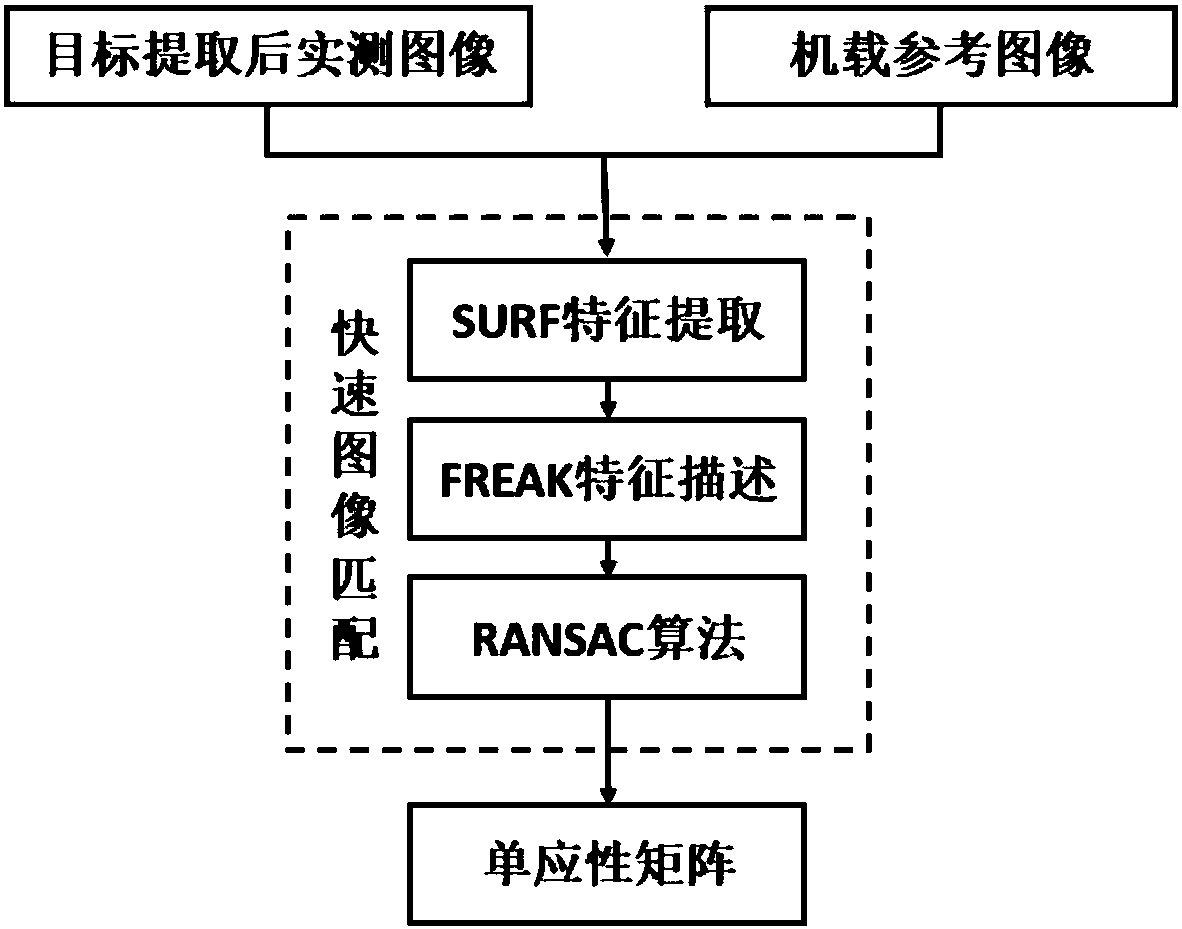

Image matching based quick and accurate target positioning method

ActiveCN107067415AQuick matchEffective Error RejectionImage enhancementImage analysisReference imageImage matching

The invention discloses an image matching based quick and accurate target positioning method. First, a quick target extracting algorithm is utilized for processing a target actual measurement image sequence and to-be-positioned target effective pixels are extracted from the target actual measurement image sequence. A quick image matching algorithm is utilized for matching an actual measurement image subjected to target extraction and an onboard reference image. Finally, a target high accuracy positioning algorithm is utilized for processing a quick image matching result so as to obtain target position information. Compared with a prior target positioning method, the method provided by the invention has substantially improved real time performance and accuracy in target positioning.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

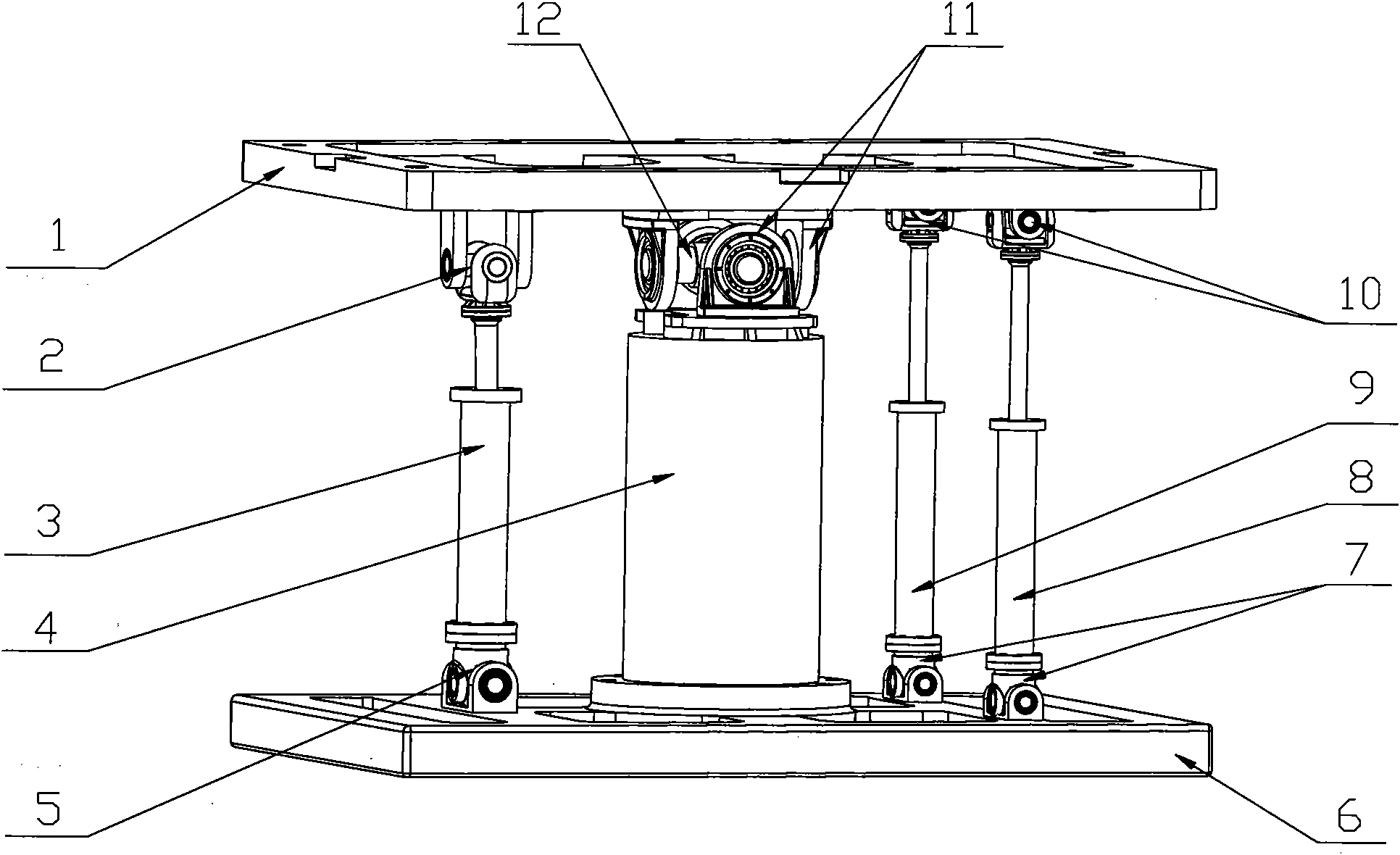

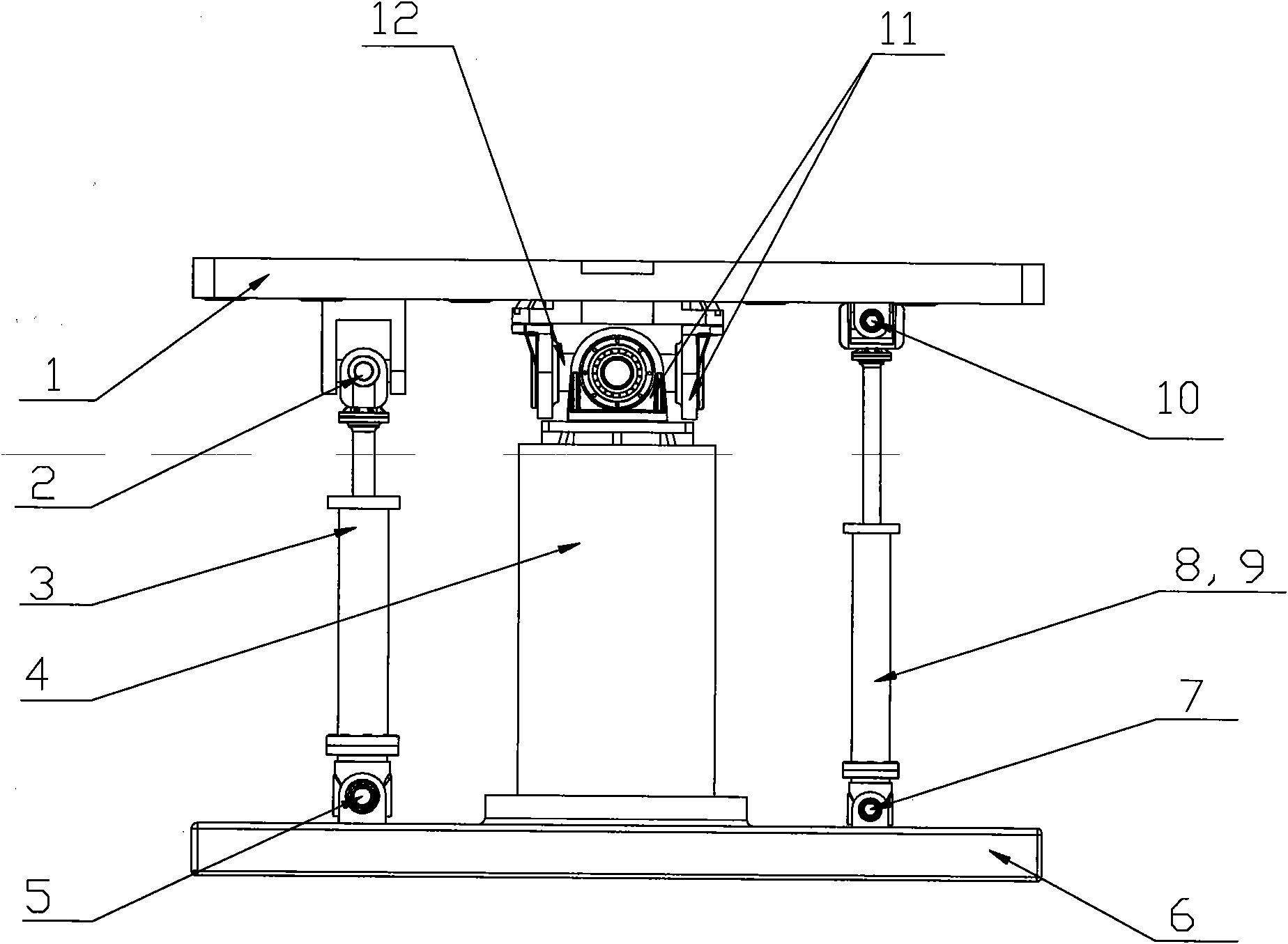

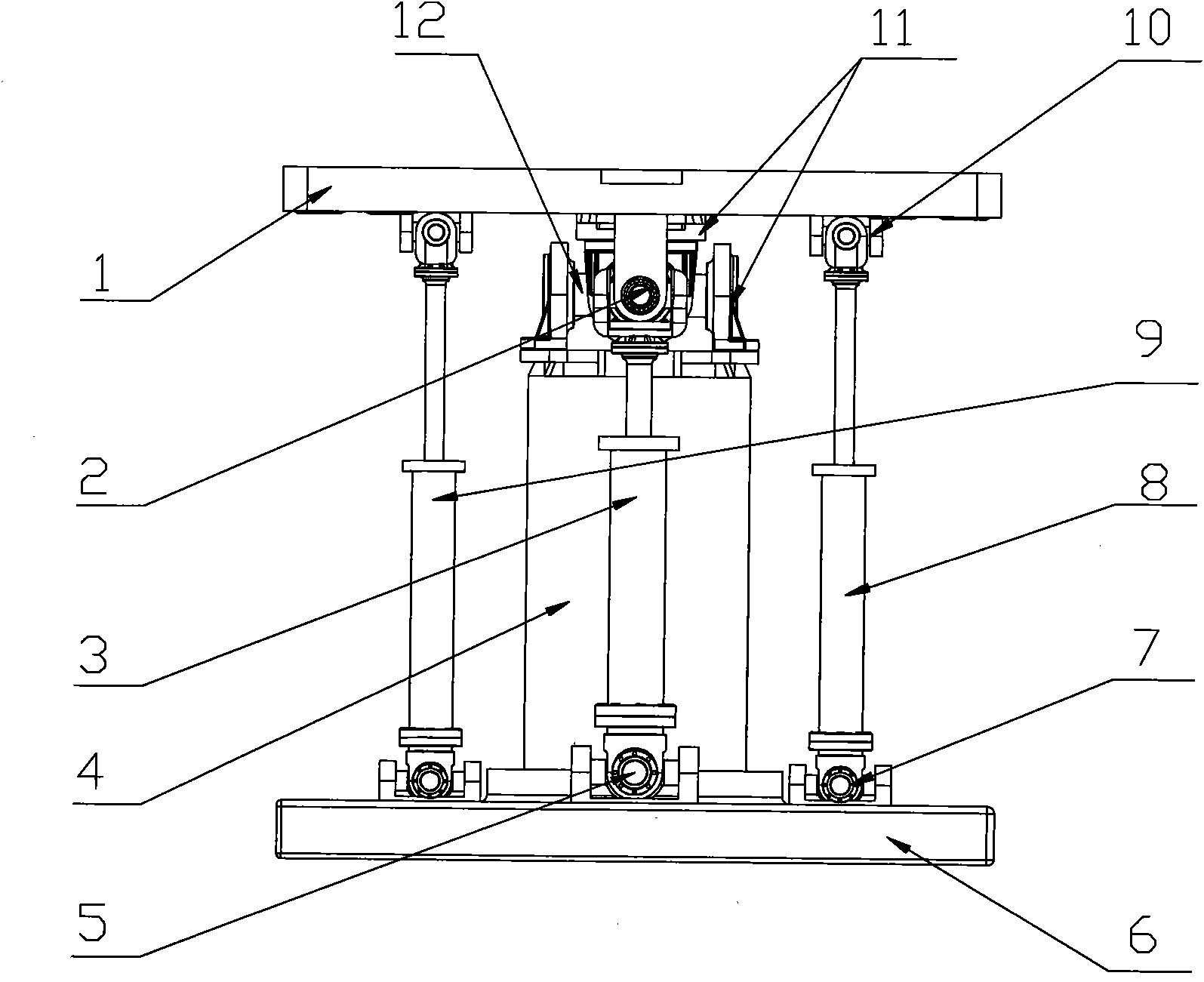

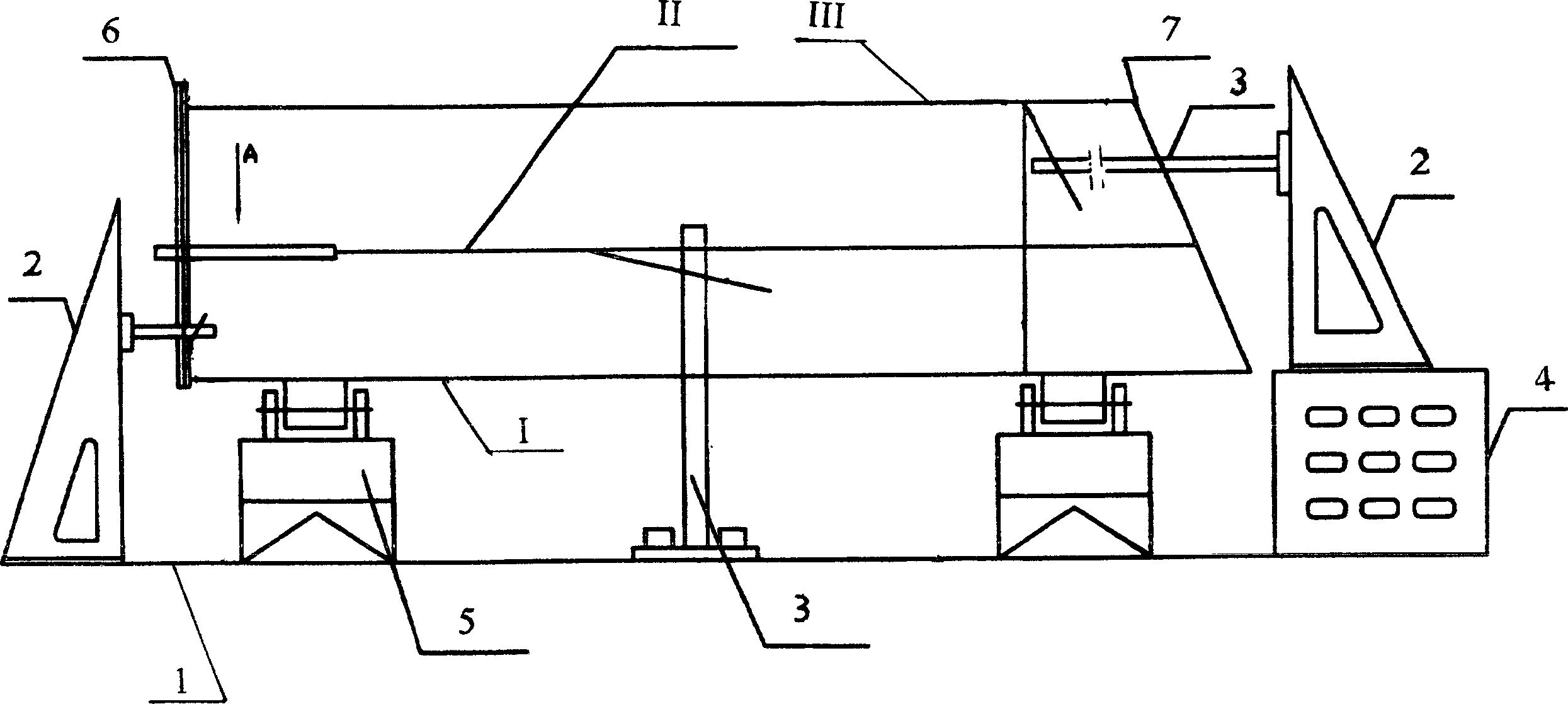

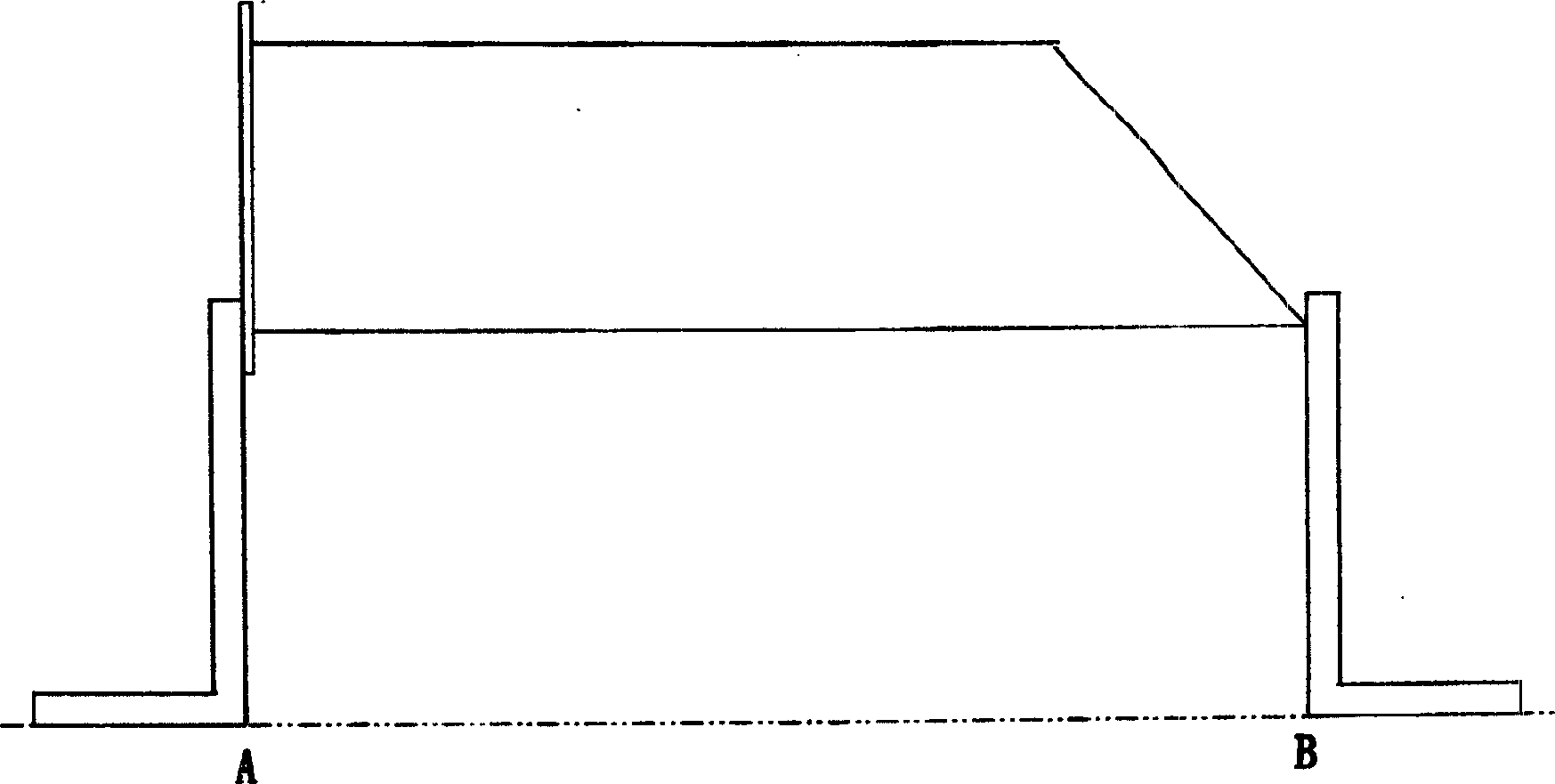

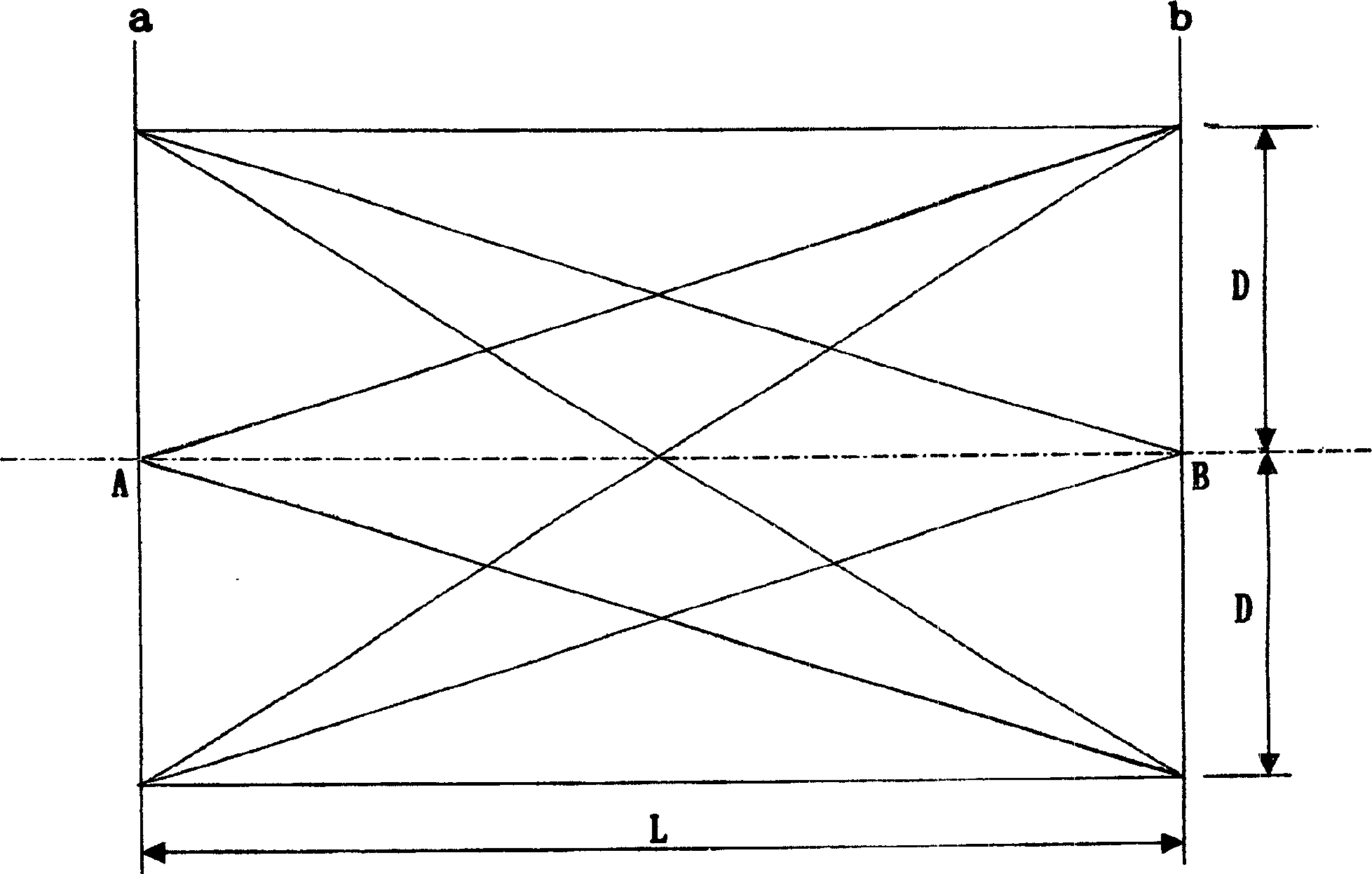

Spatial redundant drive swinging experiment table with two degrees of freedom

The invention discloses a spatial redundant drive swinging experiment table with two degrees of freedom, which comprises a static platform at the bottom, wherein an upright post is fixed at the center of the static platform; the upright post is connected with a movable platform through a first Hooke joint; two second Hooke joints are arranged at one end below the movable platform in symmetrical positions and are respectively connected with a first drive hydraulic cylinder; the lower end of each first drive hydraulic cylinder is connected with the static platform through a third Hooke joint; the center line of the other end below the movable platform is connected with a second drive hydraulic cylinder through a fourth Hooke joint; the distance between the center of the fourth Hooke joint and the movable platform is equal to the distance between the center of the first Hooke joint and the movable platform; the lower surface of the second drive hydraulic cylinder is connected with the static platform through a fifth Hooke joint; each first drive hydraulic cylinder drives the swinging experiment table to swing transversely and longitudinally; and the second drive hydraulic cylinder cooperates with each first drive hydraulic cylinder to drive the swinging experiment table to swing transversely and longitudinally. By innovation of a mechanism and a drive method, the invention can meet the requirements of heavy load and high accuracy for the swinging experiment table in a ship simulation process and has the advantages of simple mechanism and convenient operation.

Owner:TIANJIN UNIV

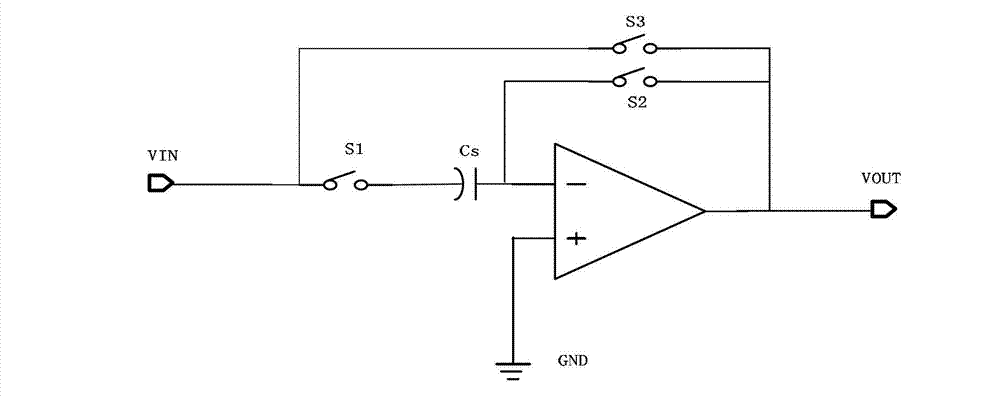

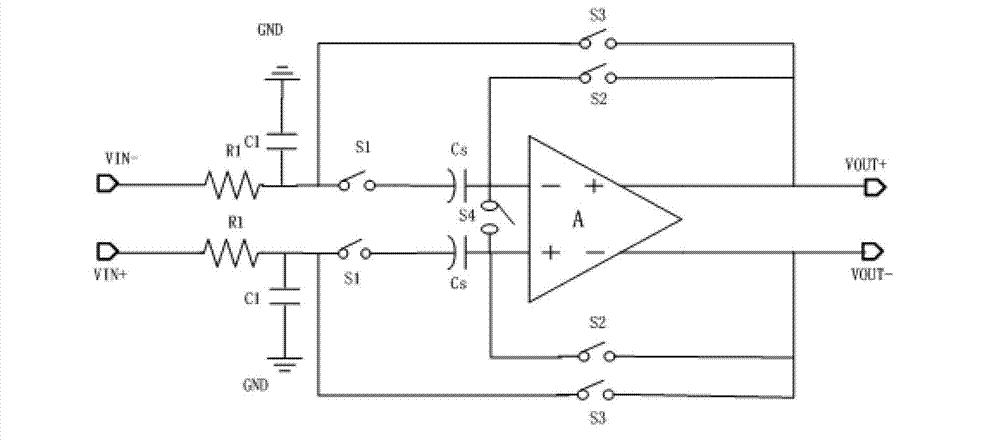

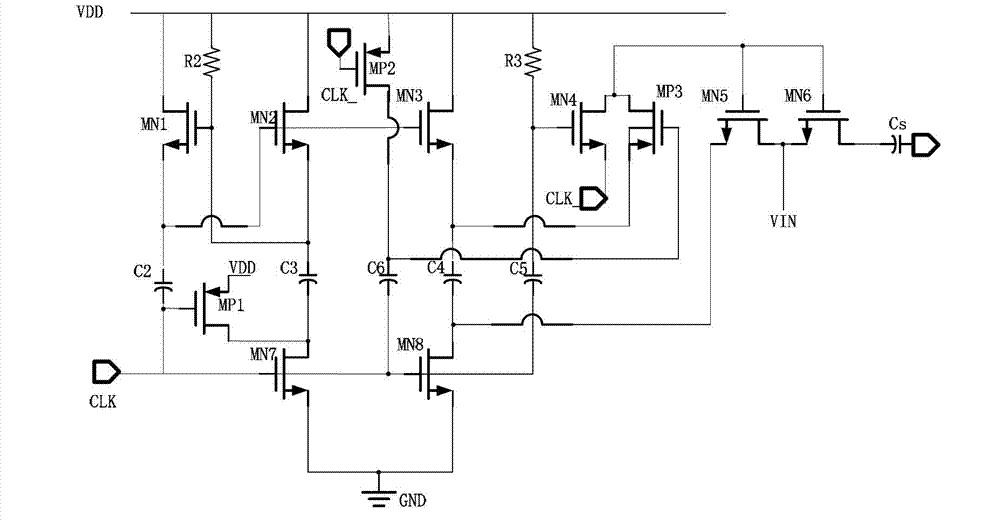

Sampling holding circuit applied to high-speed high-precision circuit

ActiveCN103095302AHigh precisionReject common mode signalsAnalogue/digital conversionElectric signal transmission systemsLower poleOperational amplifier

The invention discloses a sampling holding circuit applied to a high-speed high-precision circuit. The sampling holding circuit comprises a full-differential type operational amplifier, two sampling capacitors Cs, two sampling switches S1 and five selective switches and a low-pass filter circuit formed by a resistor R1 and a capacitor C1. The full-differential type operational amplifier is a gain enhancement folding cascade full-differential type operational amplifier, a sampling switch S1 is a grid voltage bootstrap switch, connected structures of the positive end and the negative end of the full-differential type operational amplifier are completely same, and a signal input end passes through the low-pass filter circuit to be connected with a lower pole plate of the sampling capacitors Cs through the sampling switches S1. A selective switch S3 is connected with the lower pole plate of the sampling capacitors Cs and the output end of the full-differential type operational amplifier. An upper pole plate of the sampling capacitors Cs is connected with the input end of the full-differential type operational amplifier, a selective switch S4 is connected with upper pole plates of the two sampling capacitors Cs, and a selective switch S2 is connected with the input end and the output end of the full-differential type operational amplifier. The sampling holding circuit can achieve sampling holding of the input signals in the high-speed high-precision circuit.

Owner:TIANJIN UNIV

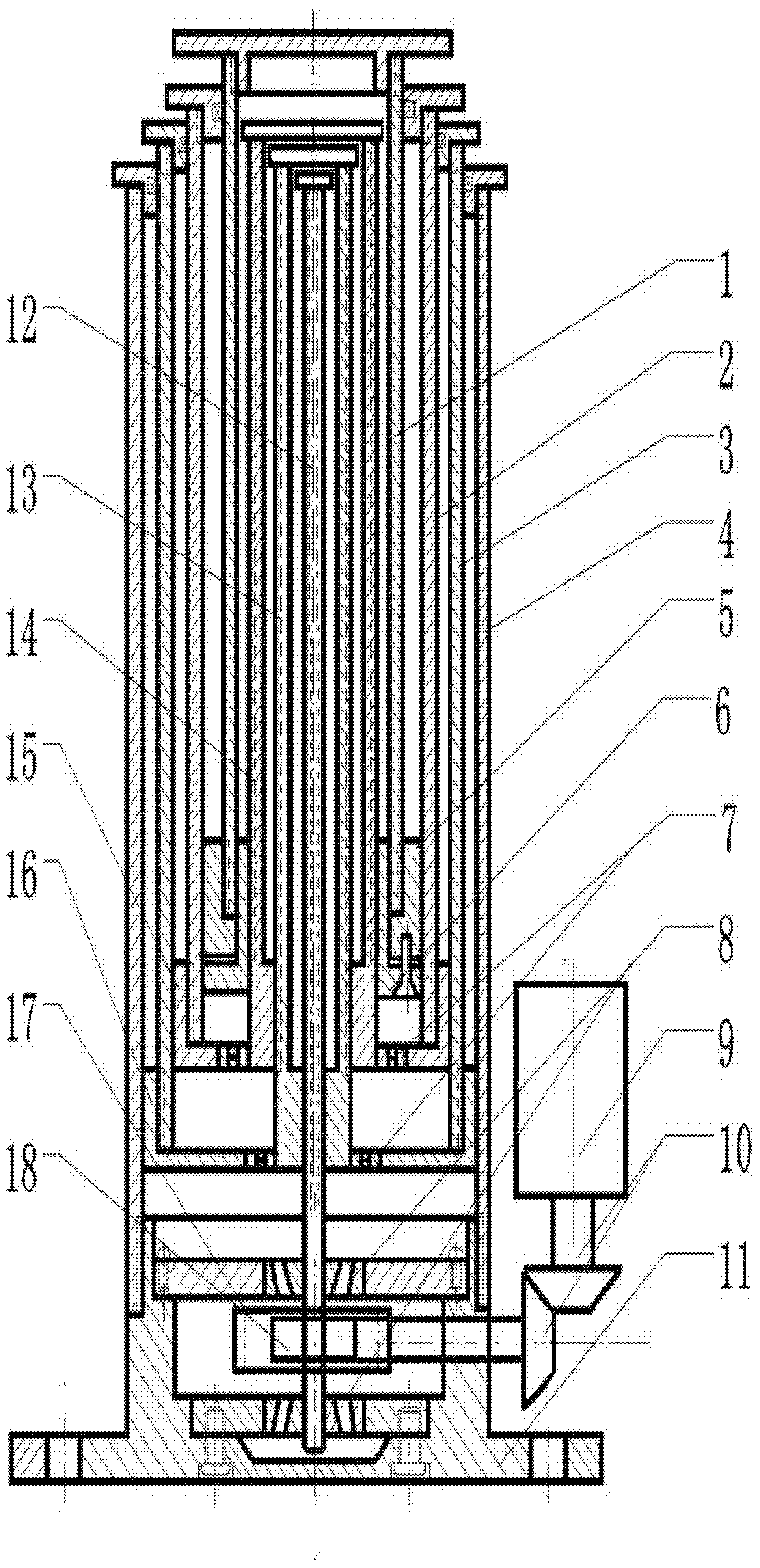

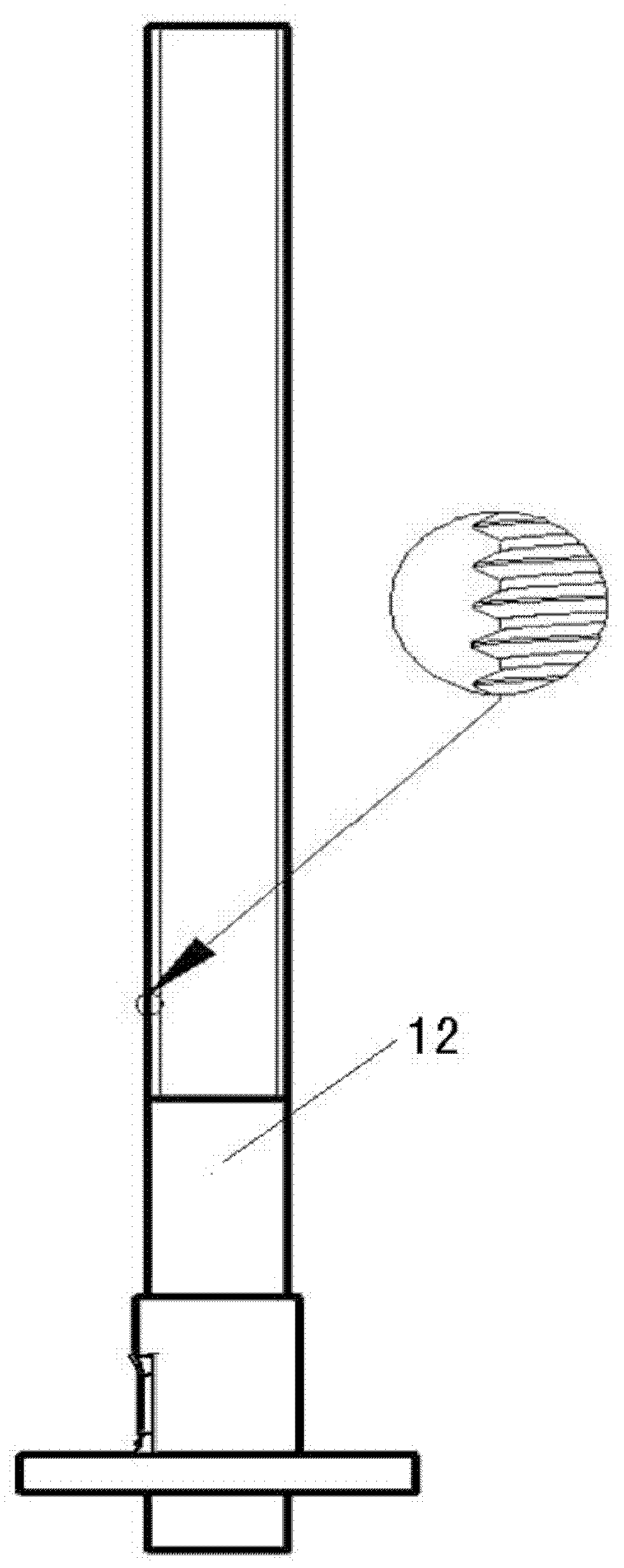

Heavy-load high-accuracy lifting device with multiple sections capable of freely extending and retracting

The invention relates to a heavy-load high-accuracy lifting device with multiple sections capable of freely extending and retracting, which comprises a base module, a power module, an intermediate extension and retraction module A, an intermediate extension and retraction module B, a final extension and retraction module and a lifting device platform, wherein the base module is arranged on a base. The heavy-load high-accuracy lifting device is characterized in that the power module transmits power to a central power lead screw (12) and the central power lead screw (12) helically transmits the power to the intermediate extension and retraction module A to drive the internal male-thread lead screw III (13) of the intermediate extension and retraction module A to extend and retract; the internal male-thread lead screw III (13) helically transmits the power to an internal male-thread lead screw II (14) to drive the intermediate extension and retraction module B to extend and retract; and the internal male-thread lead screw II (14) helically transmits the power to the internal male-thread lead screw I (6) of the final extension and retraction module to drive the internal male-thread lead screw I (6) to extend or retract. The heavy-load high-accuracy lifting device has the advantages that the device can be stopped and self-locked at any position under heavy-load complex working conditions, the device is convenient to install, the fitting is close, the device is modularized and the performance is reliable.

Owner:JIANGSU UNIV OF SCI & TECH

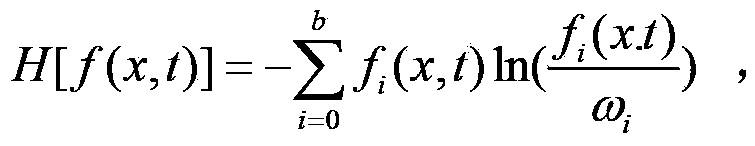

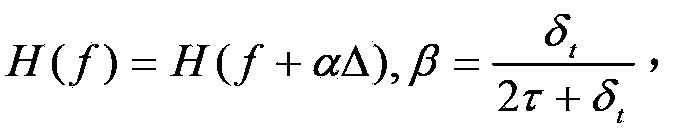

Implement method of parallel fluid calculation based on entropy lattice Boltzmann model

ActiveCN103425833AReduced simulation timeShorten the timeSpecial data processing applicationsPerformance indexIterative method

The invention discloses an implement method of parallel fluid calculation based on an entropy lattice Boltzmann model, and provides a parallel implement mode of the entropy lattice Boltzmann model based on the GPU of a mainstream video card nVIDIA in current general calculation territory. The fact that ELBM simulated time is shortened by one third than the simulated time on a CPU is achieved by measuring the speed-up ratio of fluid parallel calculation and comparing the performance index of lattice number updated per second, and applying the CUDA on the GPU of the nVIDIA video card. A method of directly approximately solving a parameter alpha is more effective than an iterative method, namely, and time can be reduced by 31.7% averagely. The implement method of the parallel fluid calculation based on the entropy lattice Boltzmann model can use hardware resources of the system fully, and verifies the parallel calculation mode of the entropy lattice Boltzmann model from the actual operation level, and therefore efficiency of the whole parallel fluid calculation is improved obviously.

Owner:HUNAN UNIV

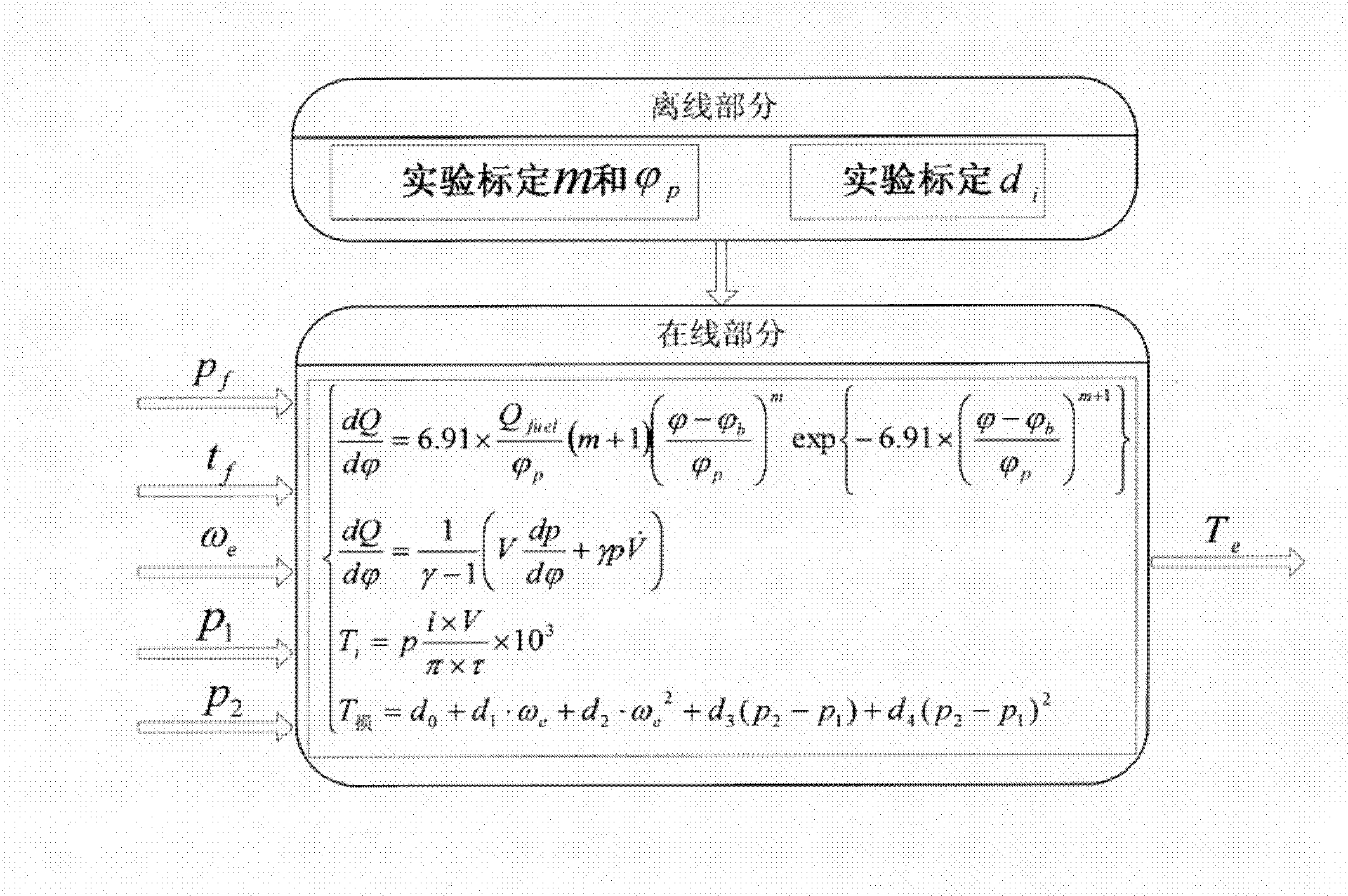

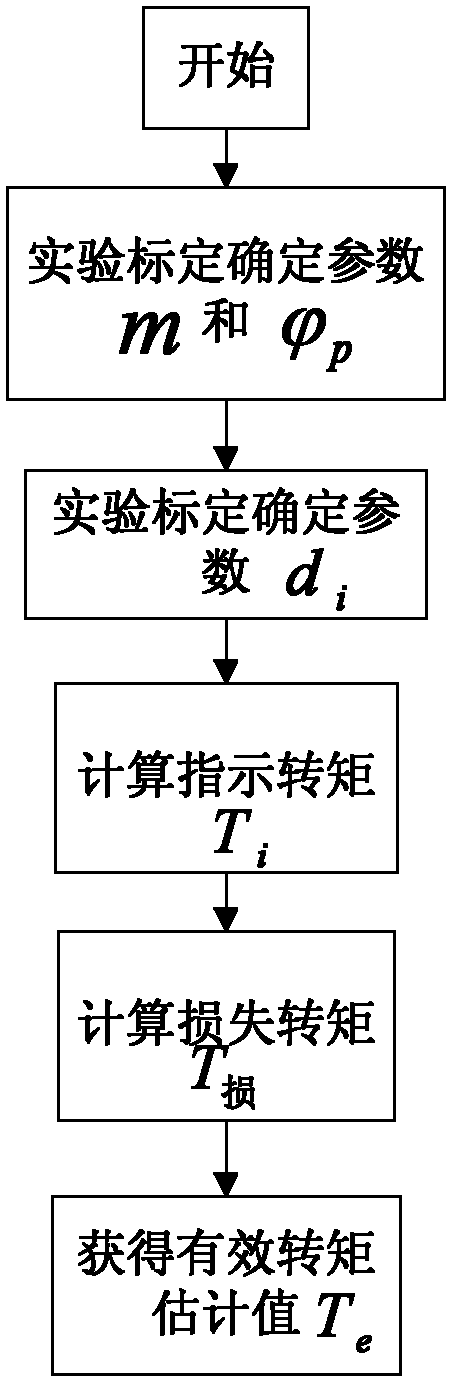

Torque estimation method for vehicle engine

InactiveCN102518521ALow costEstimated torque valueEngine controllersMachines/enginesStable stateTransient state

The invention discloses a torque estimation method for a vehicle engine, which comprises the following steps: first calibrating a parameter in the rate of heat release and a coefficient in torque loss in an off-line mode; and then estimating torque on line, first determining indication torque Ti of the engine, then determining loss torque T of the engine, and obtaining the difference between the indication torque and the loss torque of the engine, namely an effective torque estimation value of the engine. The torque estimation method for the vehicle engine can calculate pressure in a cylinder according to the rate of heat release without a pressure sensor and a torque sensor in the cylinder, reduces cost, and overcomes the shortcomings of installation difficulties of sensors and short effective service life. The torque estimation method for the vehicle engine not only can estimate the torque value of the engine under a stable state according to the rate of heat release, but also can estimate the torque value of the engine under a transient state, and simultaneously can meet higher requirement accuracy under the condition of satisfying real time performance.

Owner:DALIAN UNIV OF TECH

Large tubular structure piece platform scribing method

InactiveCN1586824AHigh precision requirementsReduce construction difficultyOther workshop equipmentScriberEngineering

The platform scribing method for large tubular structure member includes fixed point lining method, ground sampling method, back measuring method and four point coplane method. The fixed point lining method for scribing in internal wall includes pointing long scriber held in scribing block to the inner wall of large tubular structure member, scribing with small scriber several points and lining these points. The ground sampling method is used to solve the problem of measuring overall size of large tubular member. The back measuring method and the four point coplane method are used in detecting and regulating the lines of the ground sampling method to obtain even high scribing precision. The present invention is used in scribing large tubular member in high precision and may be used in petroleum, metallurgy, ship making, military industry and other industry.

Owner:中国船舶集团渤海造船有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com