Polyetheretherketone steel bar and preparation method and uses thereof

A technology of polyether ether ketone and polyetherether ketone resin, which is applied in the field of rod-shaped special high-temperature-resistant thermoplastic engineering plastics and its preparation, can solve the problems of high melt viscosity, slow crystallization speed, and difficult processing, and overcome noise big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

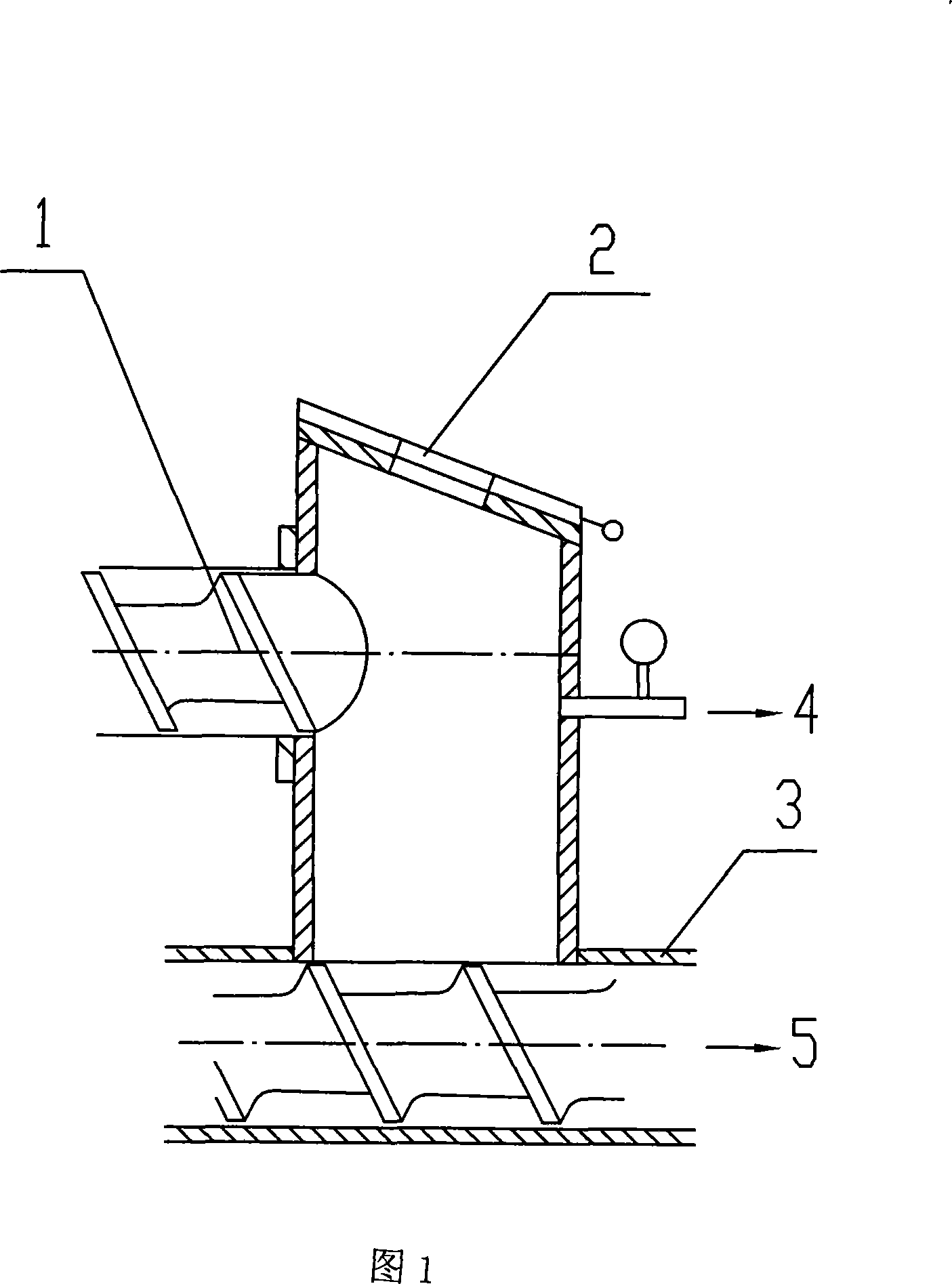

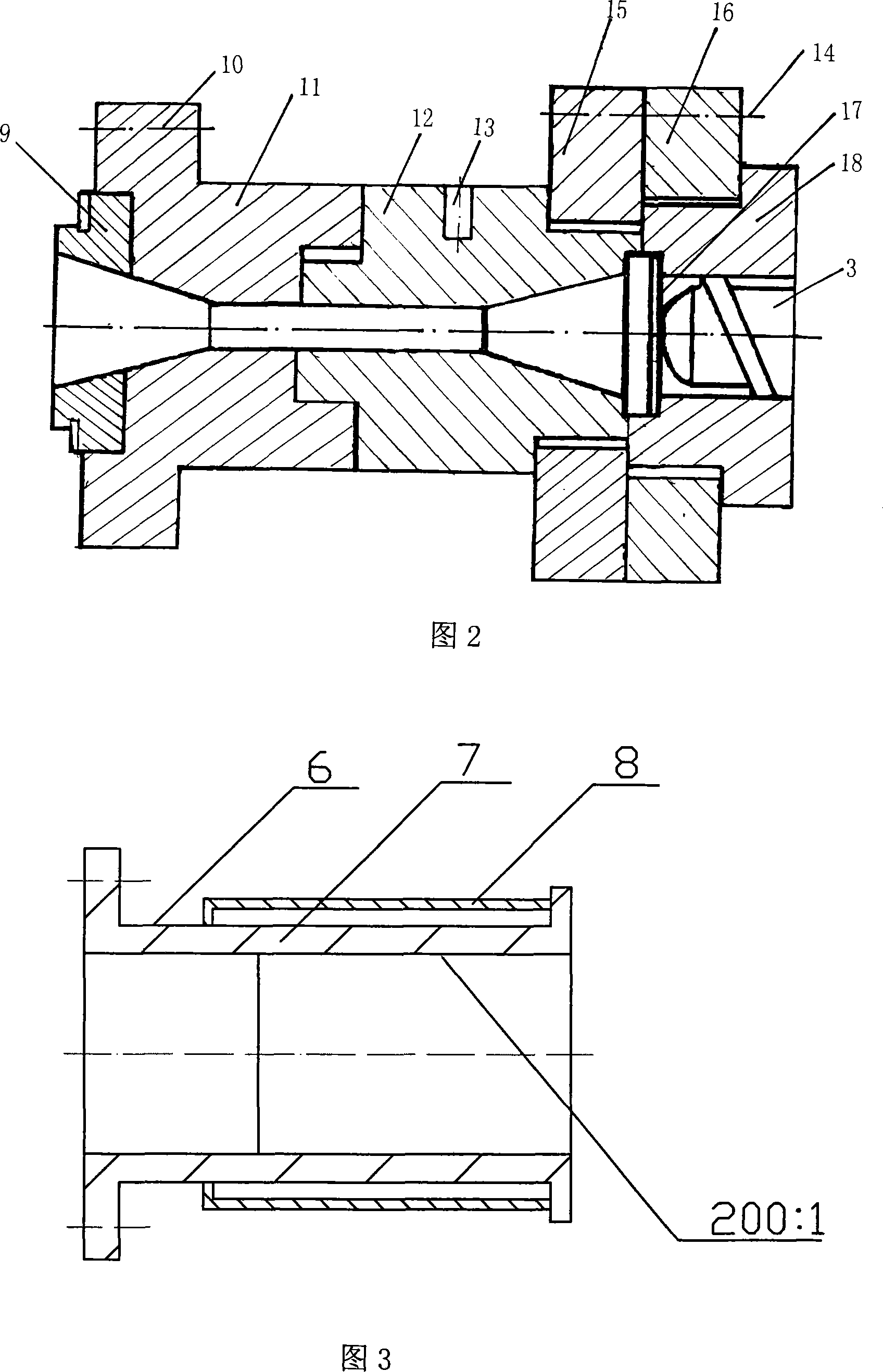

[0039]First will get PEEK resin 2940g, lubricant graphite 60g, nucleating agent-kaolin 3g and filler silicon carbide whisker 3g join in the two-stage vacuum exhaust single-screw extruder (as shown in Figure 1), control described The extrusion temperature of the double-stage vacuum-exhausted single-screw extruder is 350-380°C, so that they are first plasticized in the upper-stage screw to obtain molten materials. After vacuum exhaust, they are sent to the lower-stage screw. Extrude through the extruder head (see Figure 2) under a working pressure of 8 Pa, and then undergo final shaping, cooling, and solidification (as shown in Figure 3) to obtain polyether ether ketone rods with a diameter of 20-80 mm. The bar can be used to make engine inner covers, automotive bearings, gaskets, seals, clutches, gear ring parts, pump bodies or valve parts.

Embodiment 2

[0041] First will get PEEK resin 2025g, lubricant molybdenum disulfide 60g, nucleating agent silicon dioxide 15g, filler glass fiber 900g join in the two-stage vacuum exhaust single-screw extruder (as shown in Figure 1), control described The extrusion temperature of the double-stage vacuum exhaust single-screw extruder is 350-380°C, so that they are first plasticized in the upper-stage screw to obtain molten materials, and then sent to the lower-stage screw after vacuum exhaust. Extrude through the extruder head (as shown in Figure 2) under a working pressure of 9 Pa, and then finalize, cool and solidify (as shown in Figure 3) to obtain polyether ether ketone rods with a diameter of 20-80 mm. The bar can be used to make engine inner covers, automotive bearings, gaskets, seals, clutches, gear ring parts, pump bodies or valve parts.

Embodiment 3

[0043] First will get PEEK resin 1725g, lubricant graphite 60g, nucleating agent kaolin 15g, filler carbon fiber 1200g, join in the two-stage vacuum exhaust single-screw extruder (as shown in Figure 1), control described two-stage vacuum The extrusion temperature of the vented single-screw extruder is 350-380°C, so that they are firstly plasticized in the upper-stage screw to obtain molten materials. After being vacuum-exhausted, they are sent to the lower-stage screw. After being extruded through the extrusion head (as shown in Figure 2), it is finally shaped, cooled and solidified (as shown in Figure 3) to obtain a polyether ether ketone rod with a diameter of 20-80 mm. The bar can be used to make engine inner covers, automotive bearings, gaskets, seals, clutches, gear ring parts, pump bodies or valve parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com