Heavy-load high-accuracy lifting device with multiple sections capable of freely extending and retracting

A lifting device and large load technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems that the lifting platform is difficult to meet the load requirements, cannot meet the stability and accuracy requirements, and the volume of the lifting platform is bloated, so as to achieve high overall structural strength and compact structure , reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

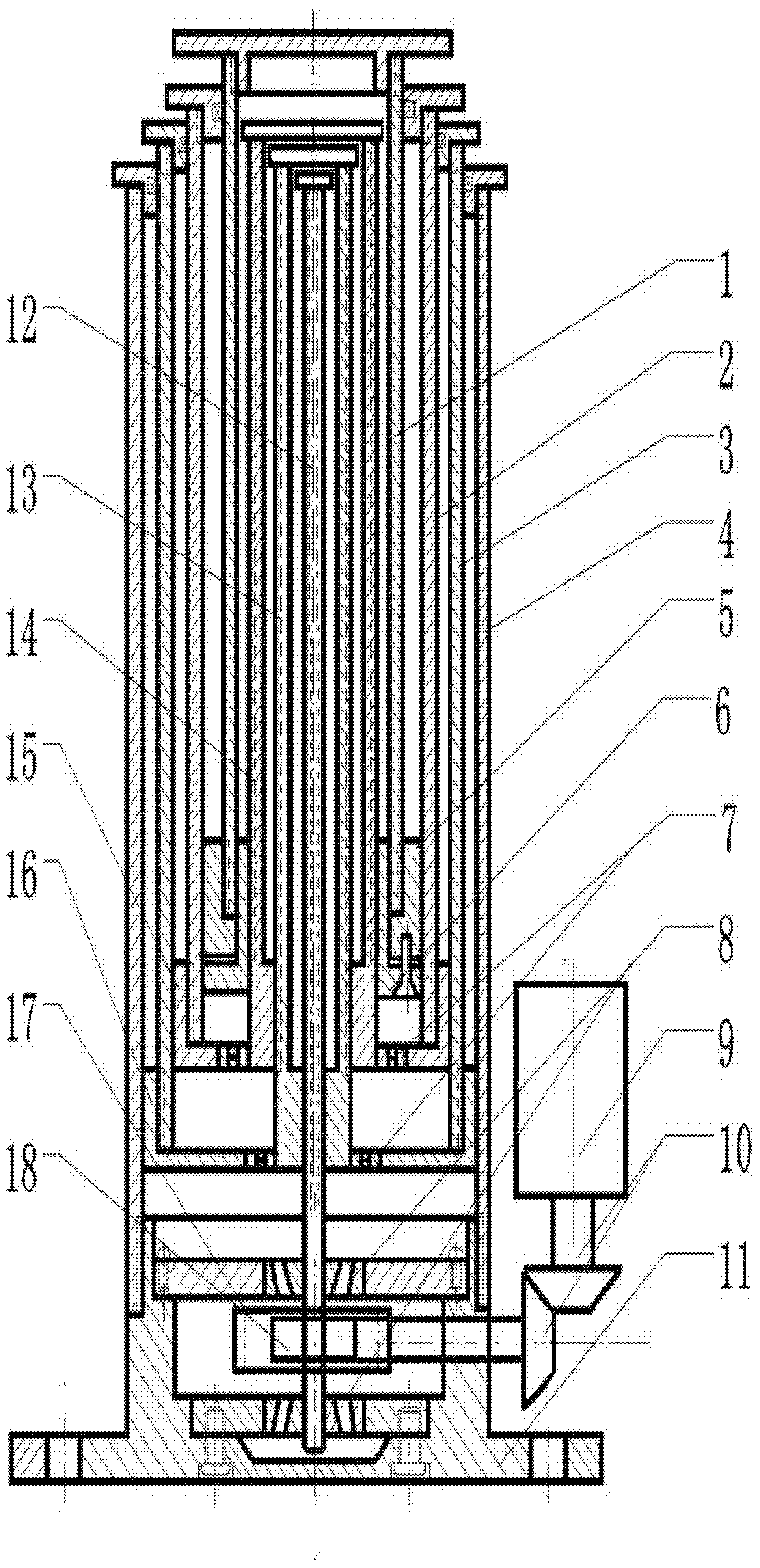

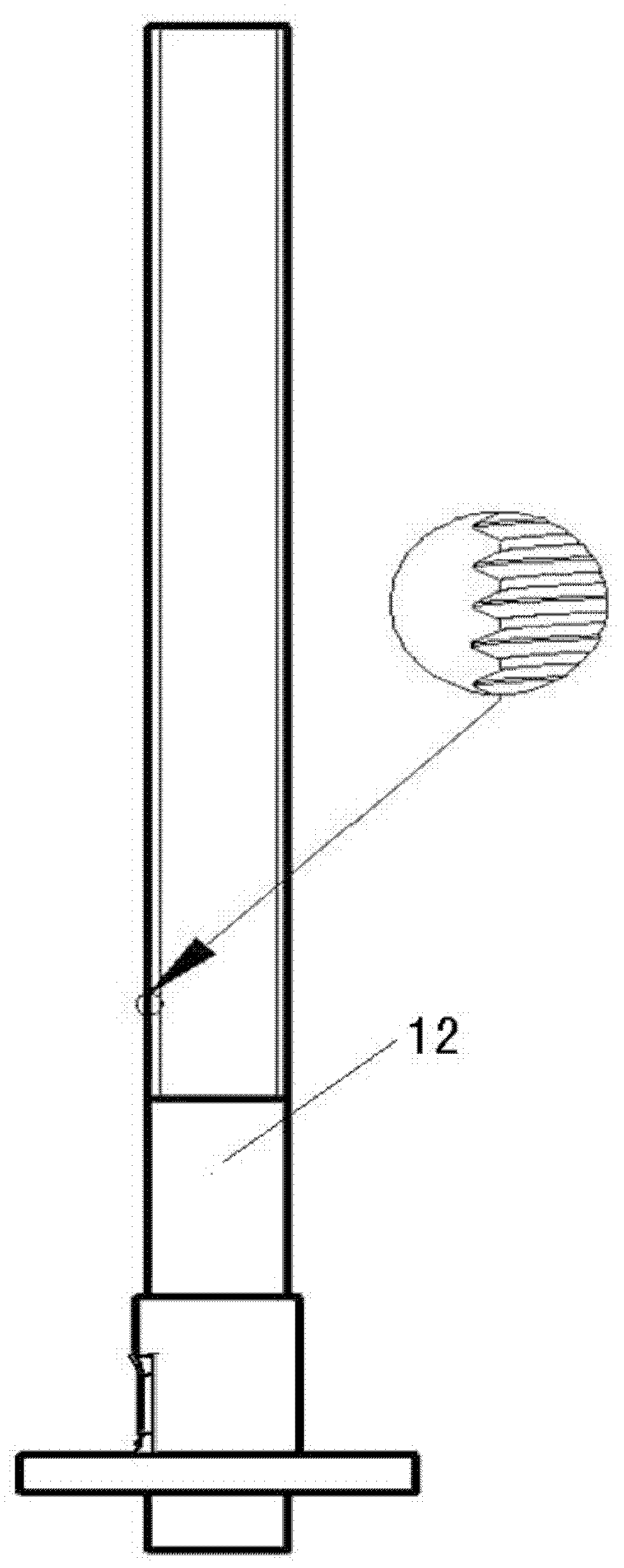

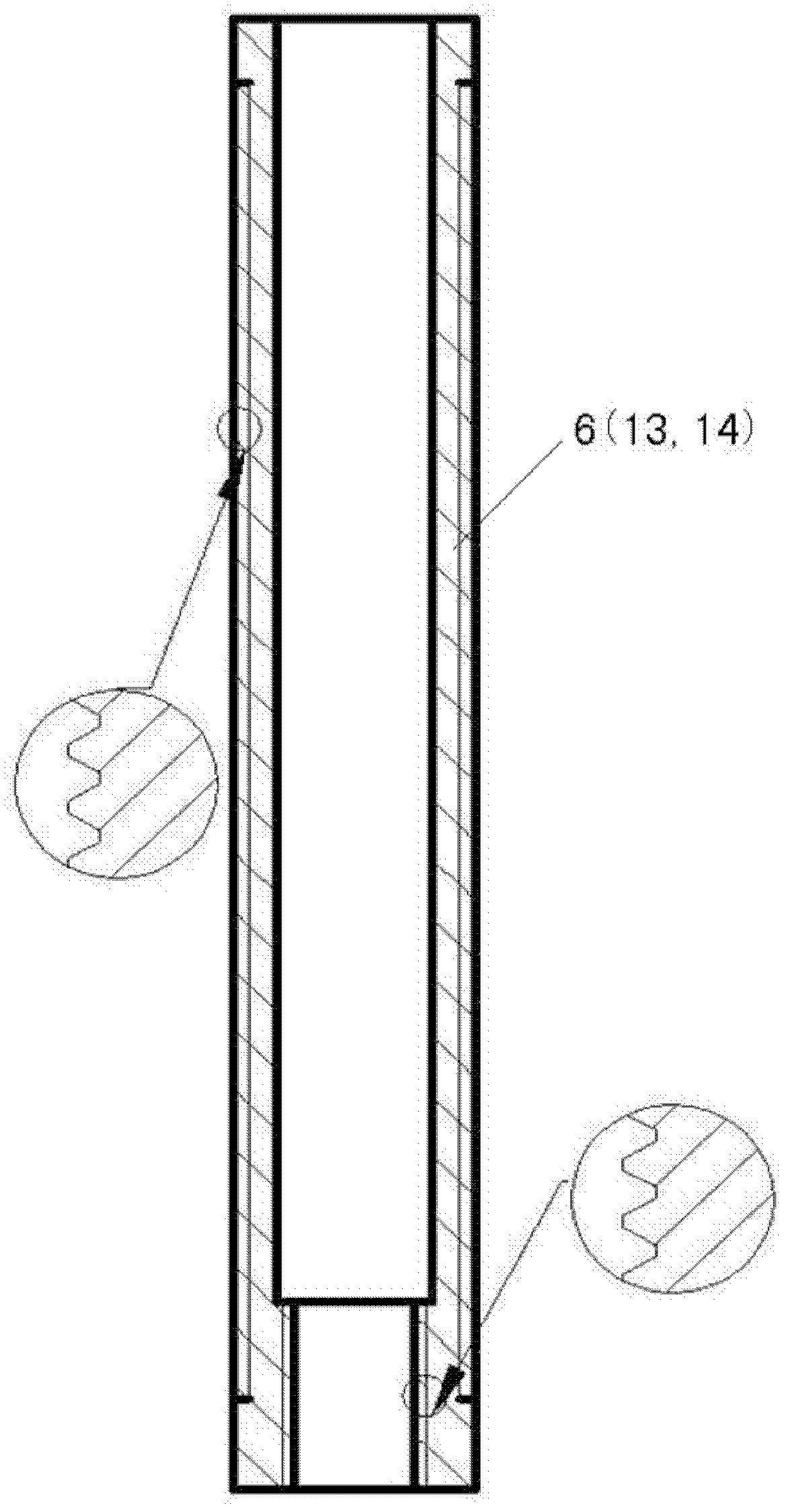

[0020] Such as figure 1 It is known that the multi-section free telescopic high-precision lifting structure device involved in the present invention includes a base module, a power module, an intermediate telescopic module A, an intermediate telescopic module B, a final telescopic module and a lifting device platform. On the base 11, the central power screw 12 of the power module is connected to the base 11 through the tapered roller bearing 8, and the power module, the intermediate telescopic module A, the intermediate telescopic module B, and the final telescopic module are arranged in sequence on the base 11. and lift platform. From the outermost layer to the innermost layer are the inner and outer screw rods Ⅰ6, Ⅱ14, and Ⅲ13, in which the inner and outer screw rods are connected with the corresponding sleeves Ⅰ1, Ⅱ2, and Ⅲ3, and the inner and outer screw rods Ⅲ13 and Ⅱ14 are installed in their horizontal sections. There are deep groove ball bearings 7 to solve the problem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com