Patents

Literature

2010 results about "Tapered roller bearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

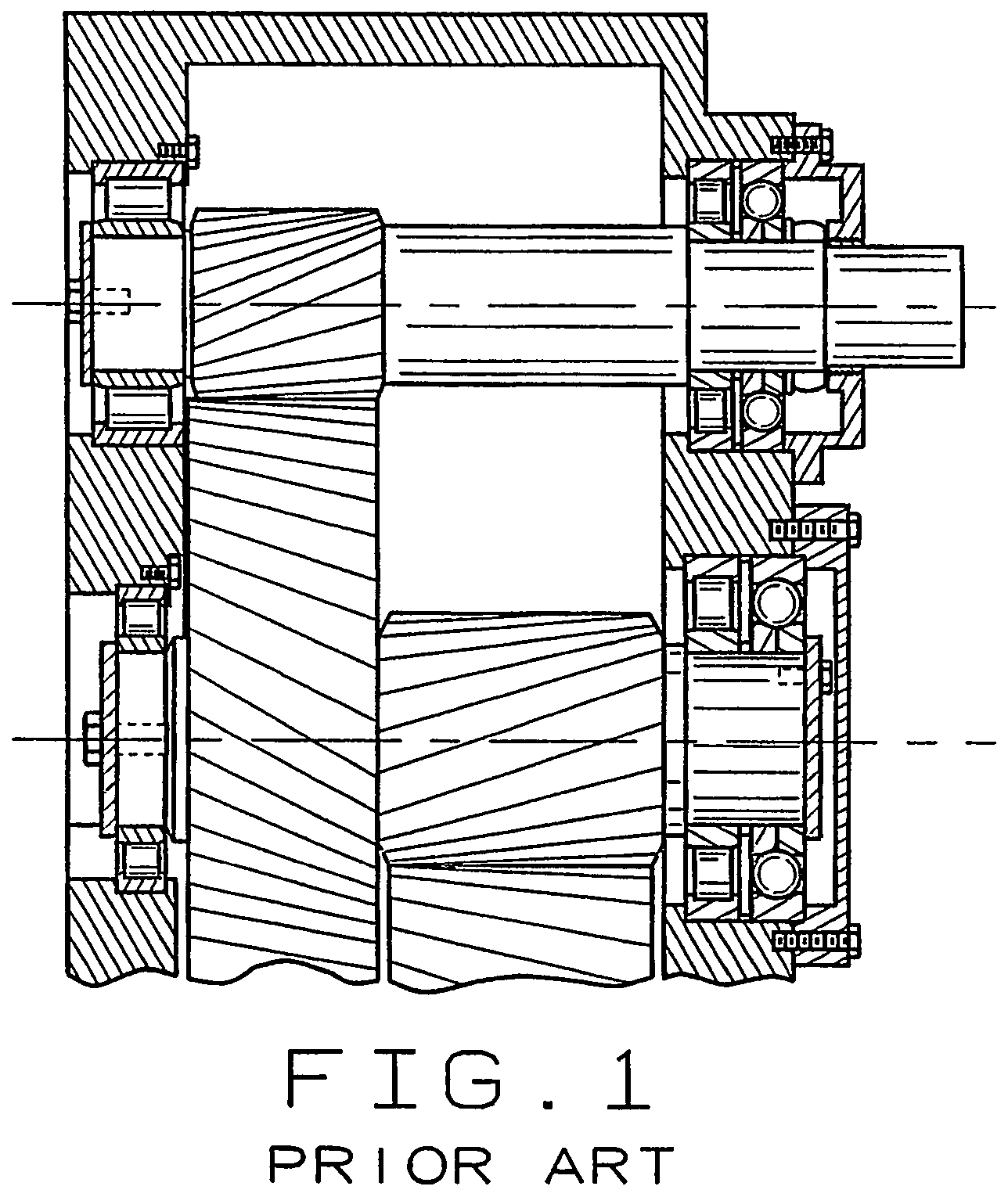

Tapered roller bearings are rolling element bearings that can support axial forces (i.e., they are good thrust bearings) as well as radial forces.

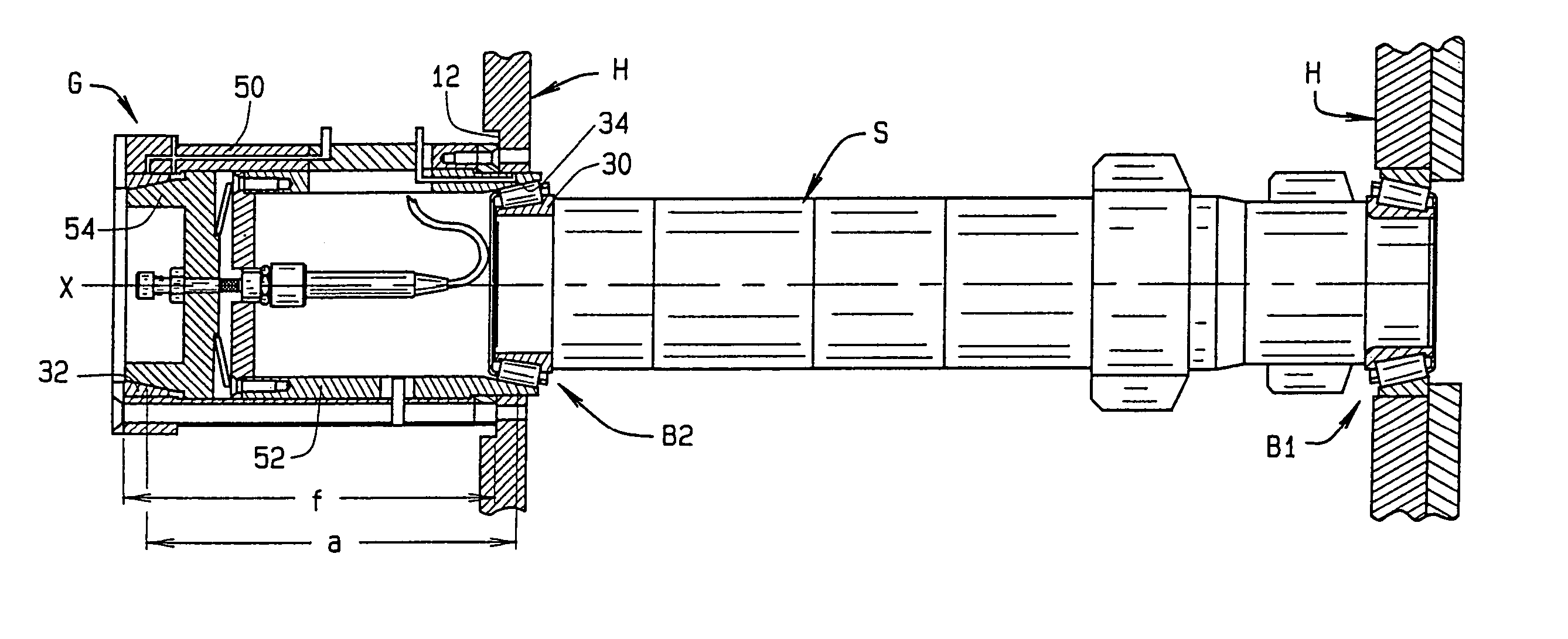

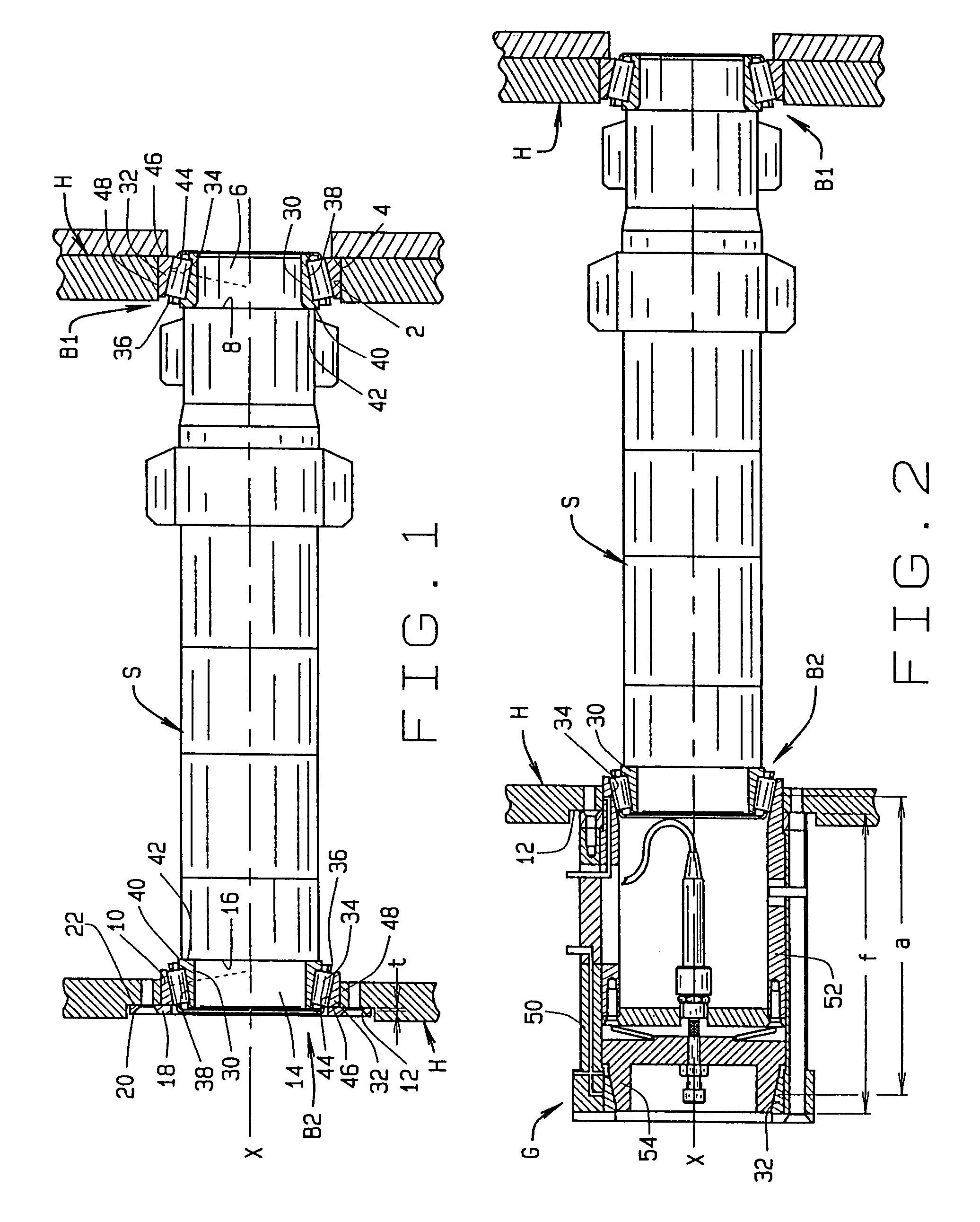

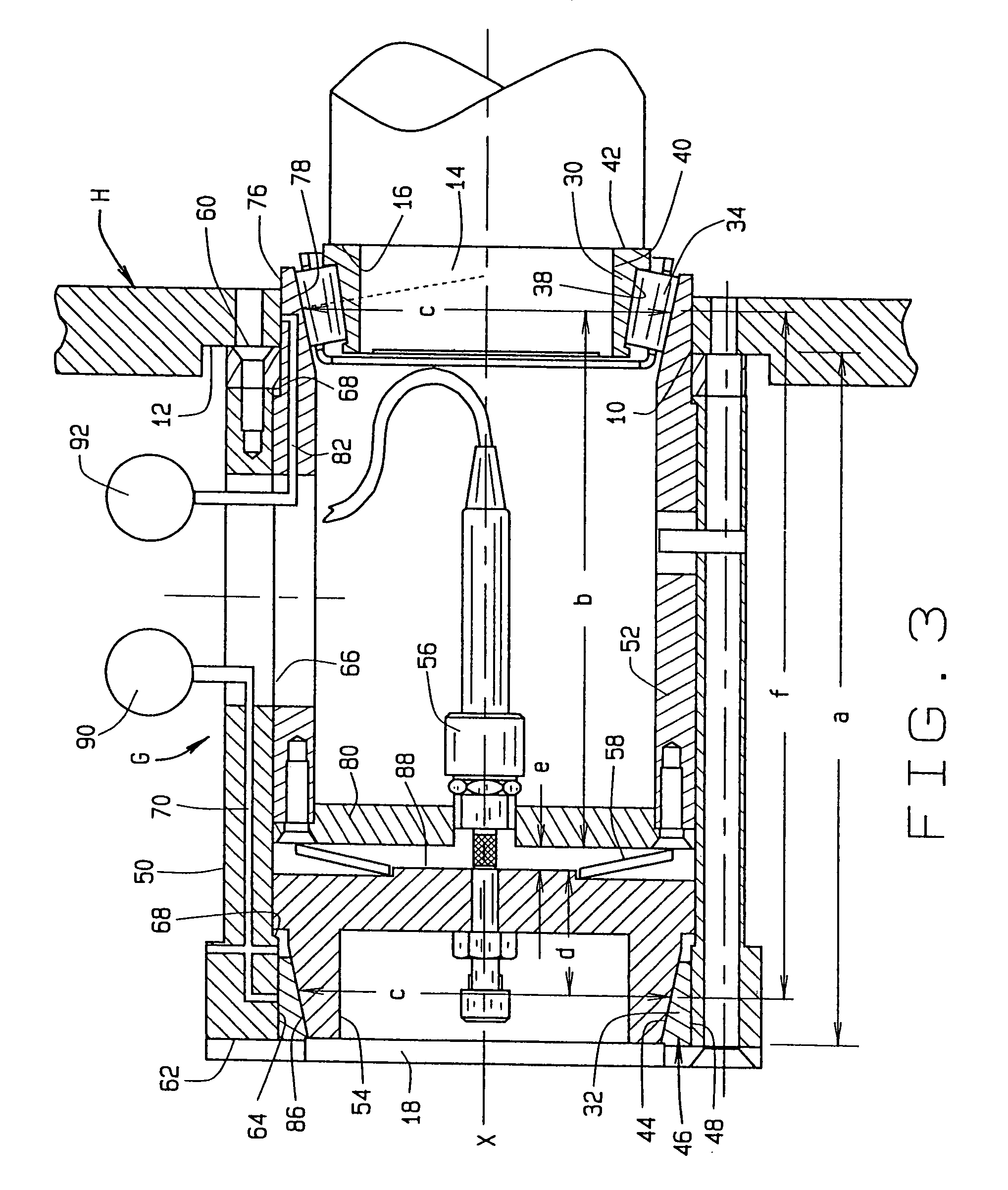

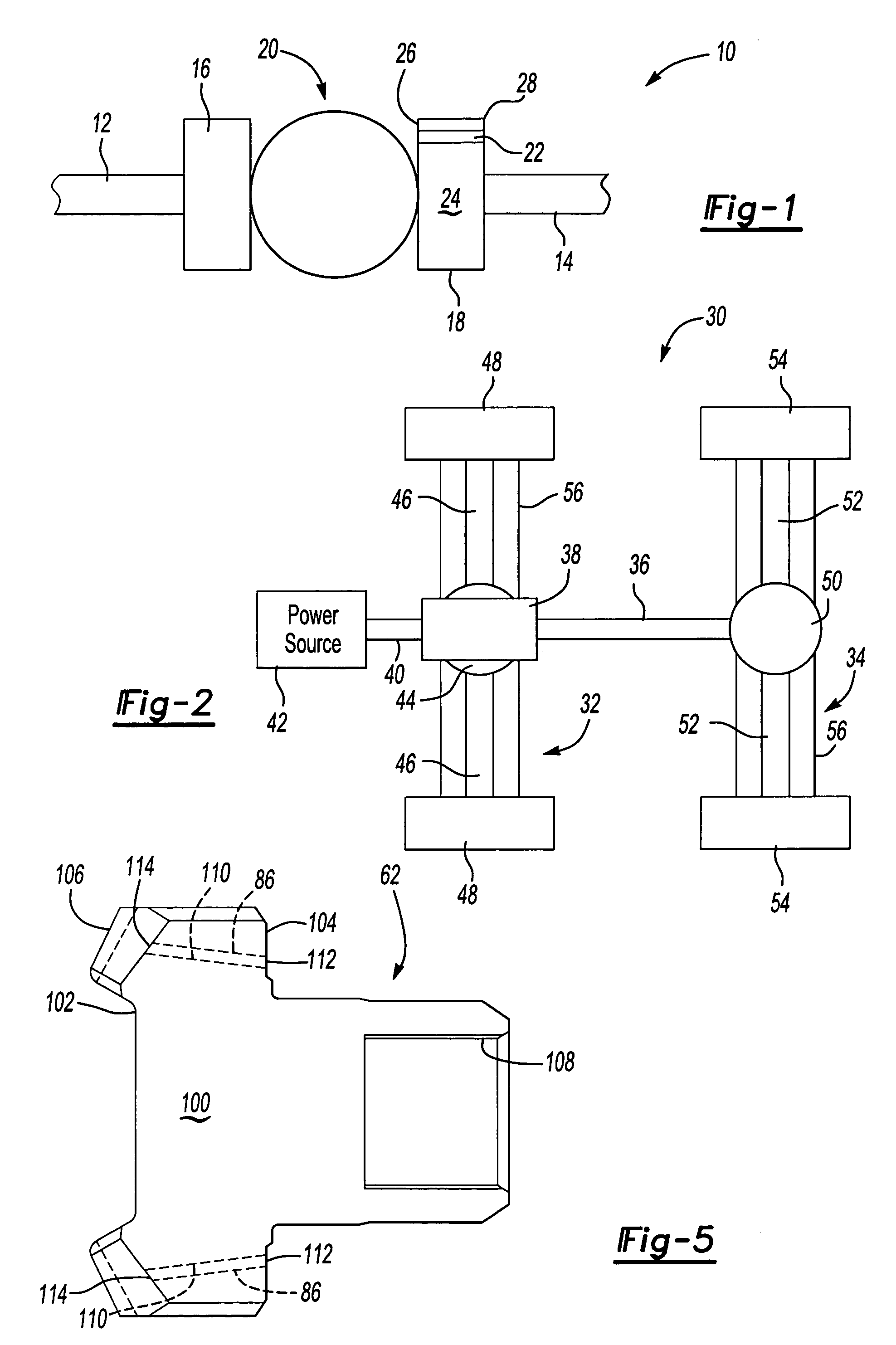

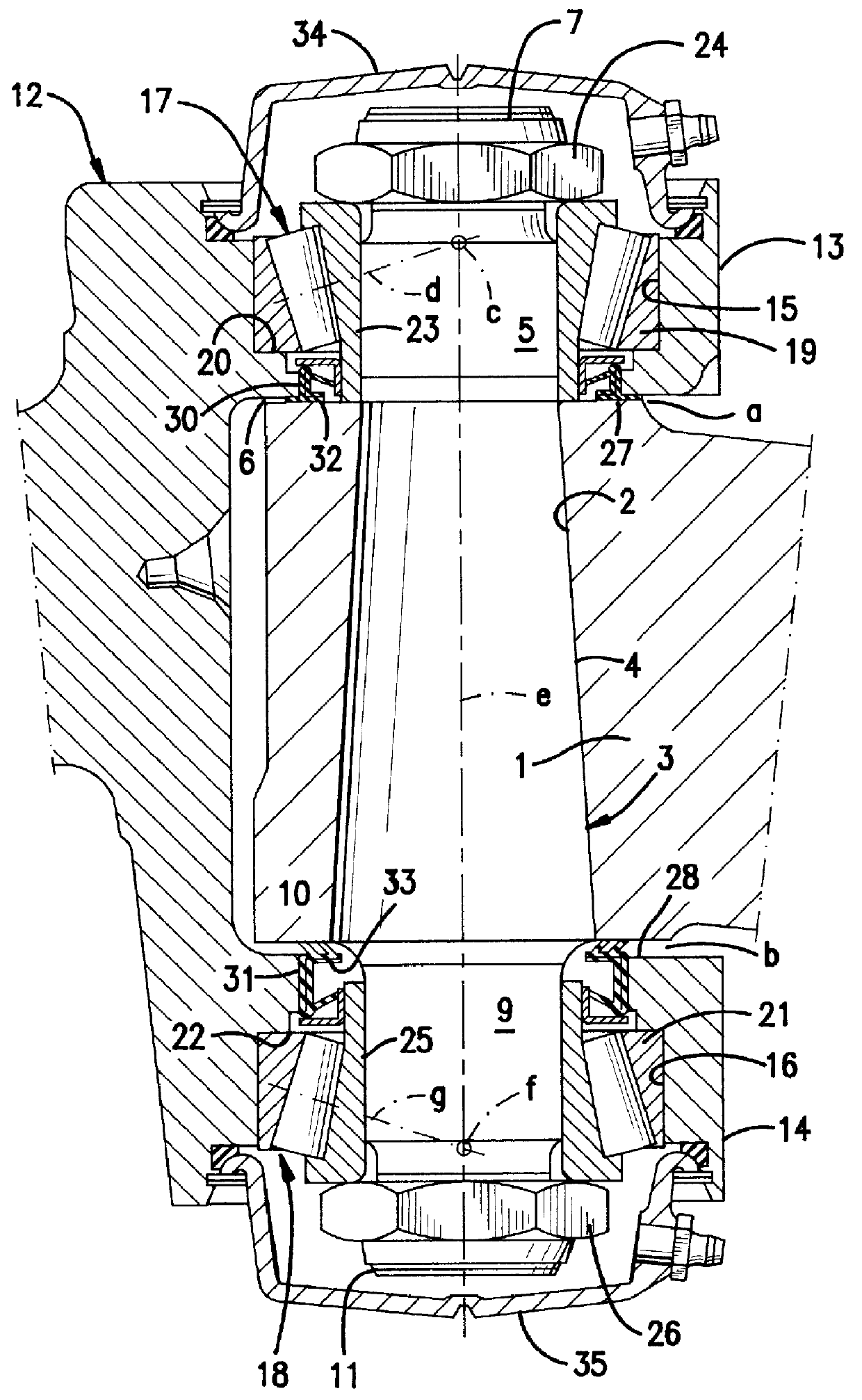

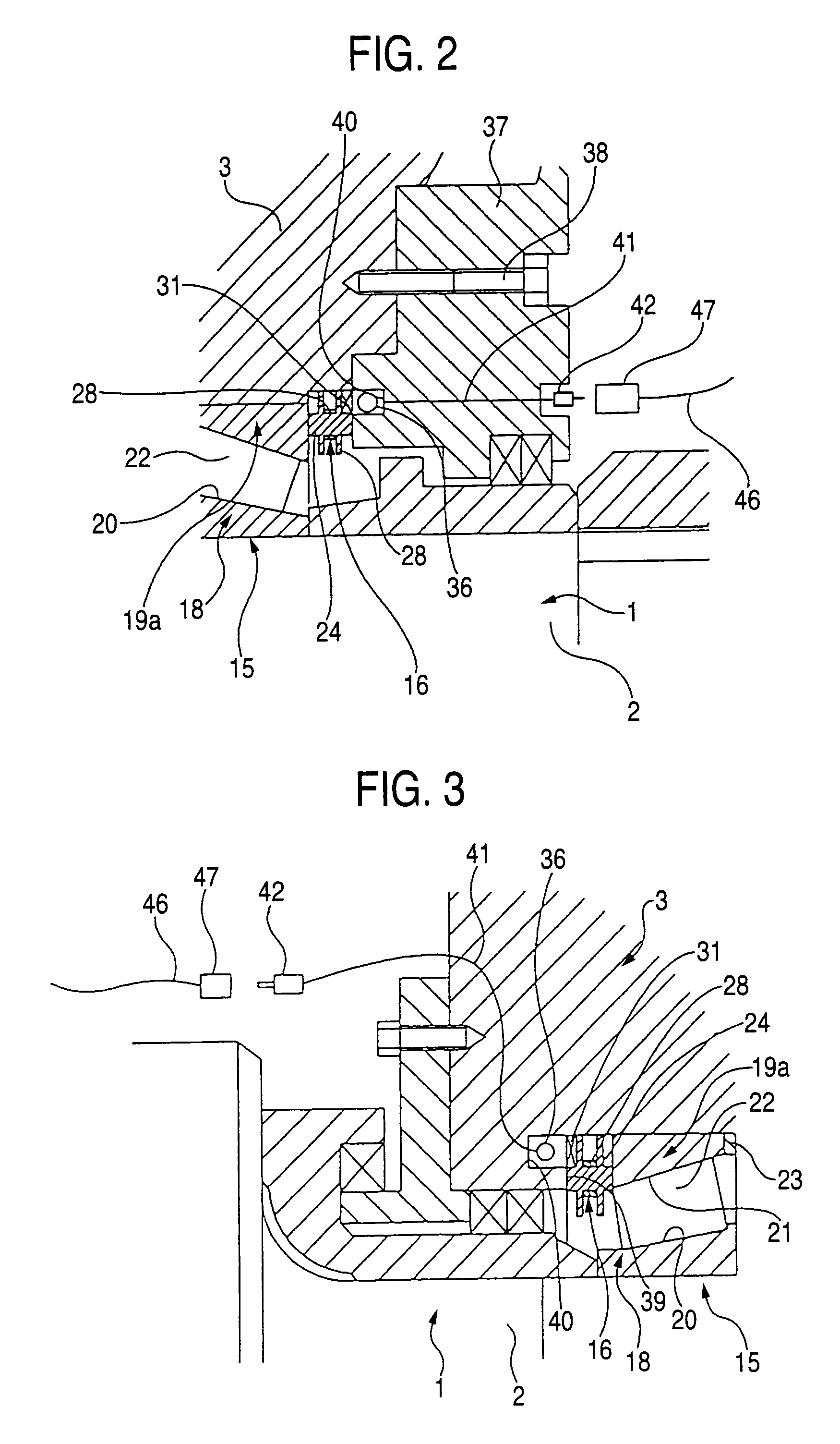

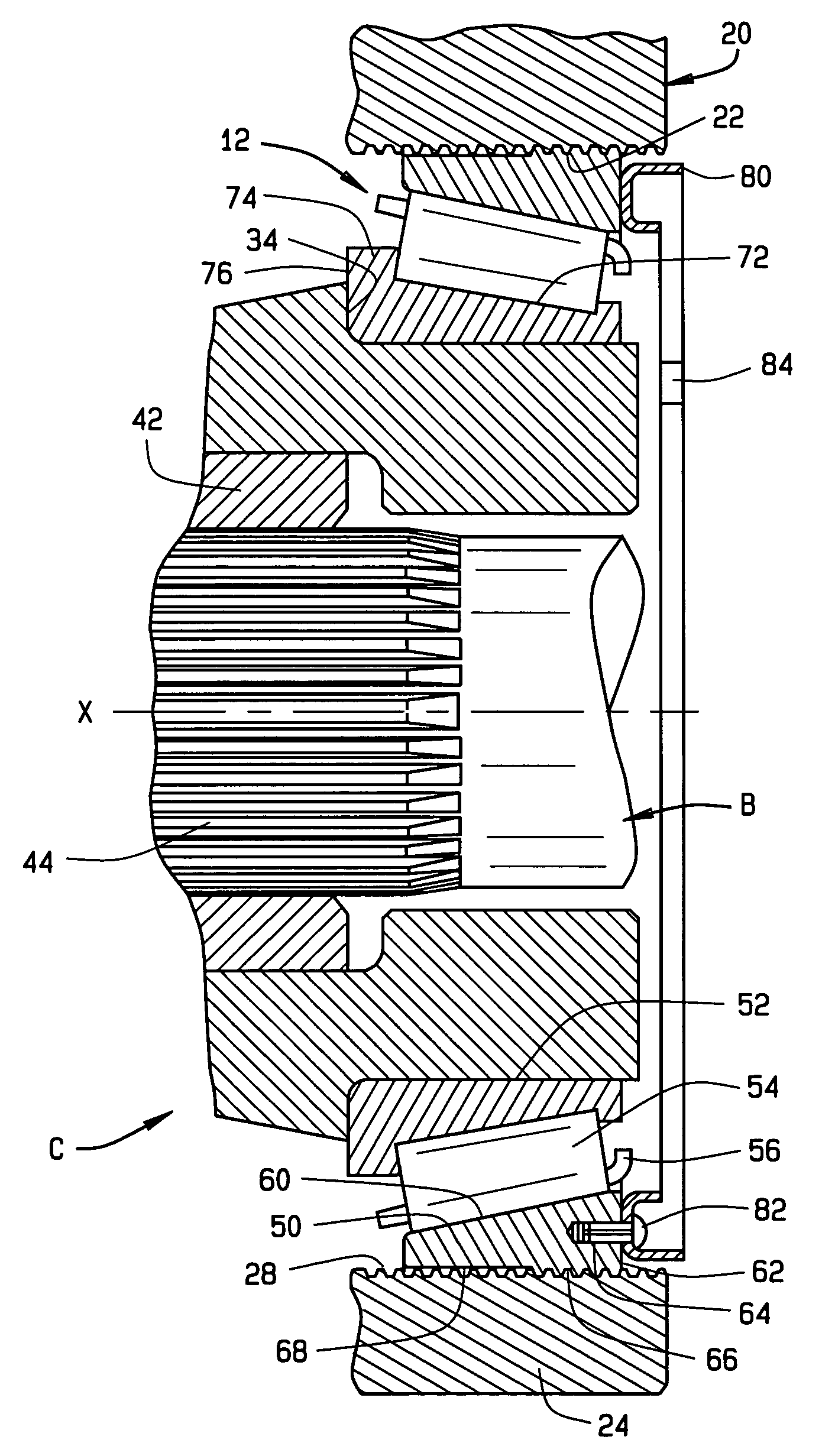

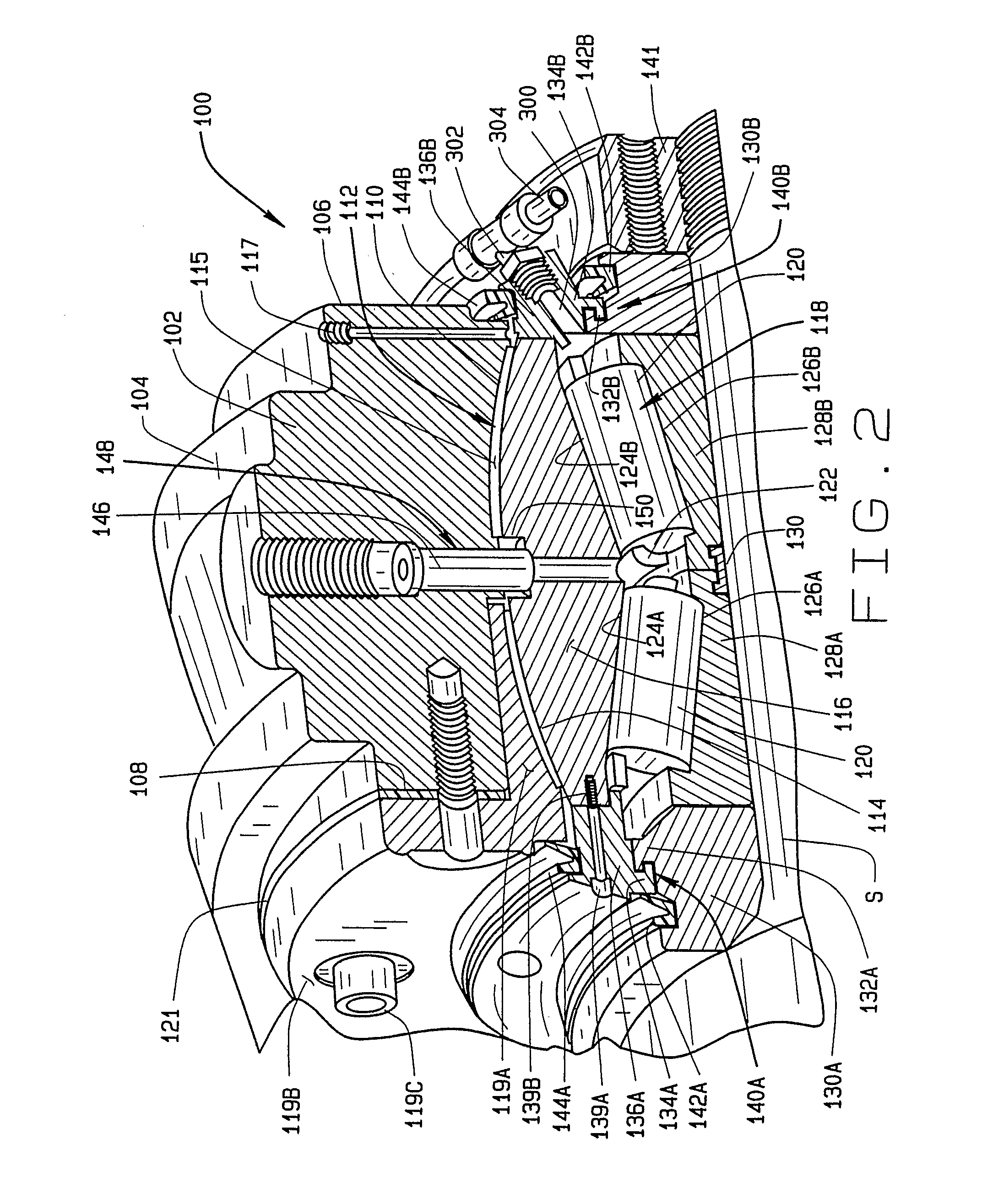

Gauge and process for adjusting bearings

A setting gauge (G) determines the thickness of a spacer (22) which gives the correct setting for a pair of tapered roller bearings (B1, B2) that are mounted in opposition to accommodate relative rotation between machine components (S, H). The gauge has a base (50) which at one end fits against a surface (12) to which the spacer is to be applied, and at its other end holds one of the races (32) of the bearing (B2) remote from the other race (30) which remains in its operating position. In addition, the gauge has a pair of gauge elements (52, 54), one of which fits against a conical envelope along the remote race and the other of which fits against an identical conical envelope on the race which remains in its operating position, in effect, projecting the conical envelope defined by the in-place race out of the bearing to a remote location so that measurements may be taken from the bearing. The race which is remote during the measurements has a cylindrical surface (48) which is configured to fit another cylindrical surface (10) on one of the machine components (H) with an interference fit, and the gauge also measures the diameters of the two cylindrical surfaces so that the magnitude of the interference fit may be ascertained and its effect on the bearing compensated.

Owner:THE TIMKEN CO

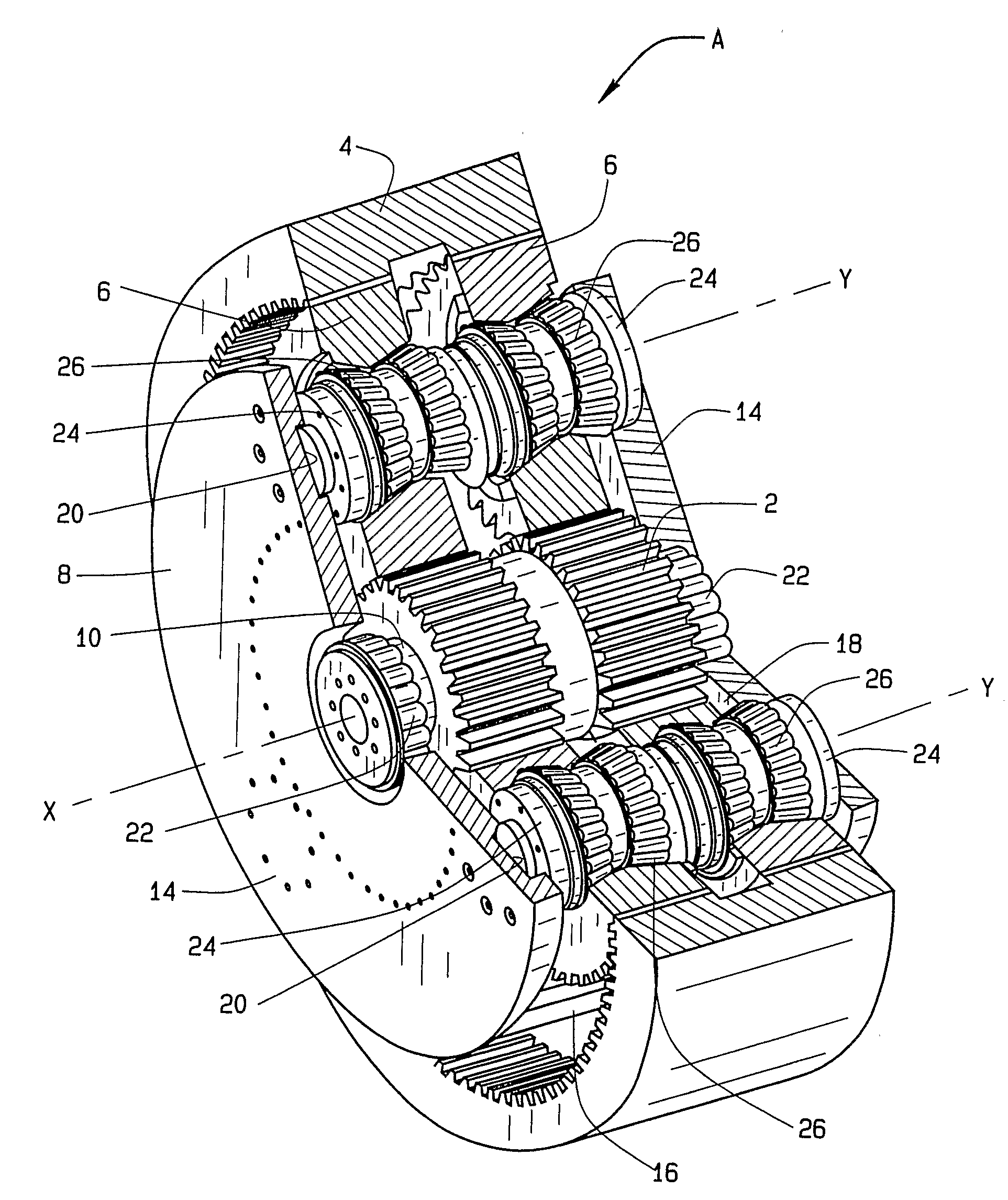

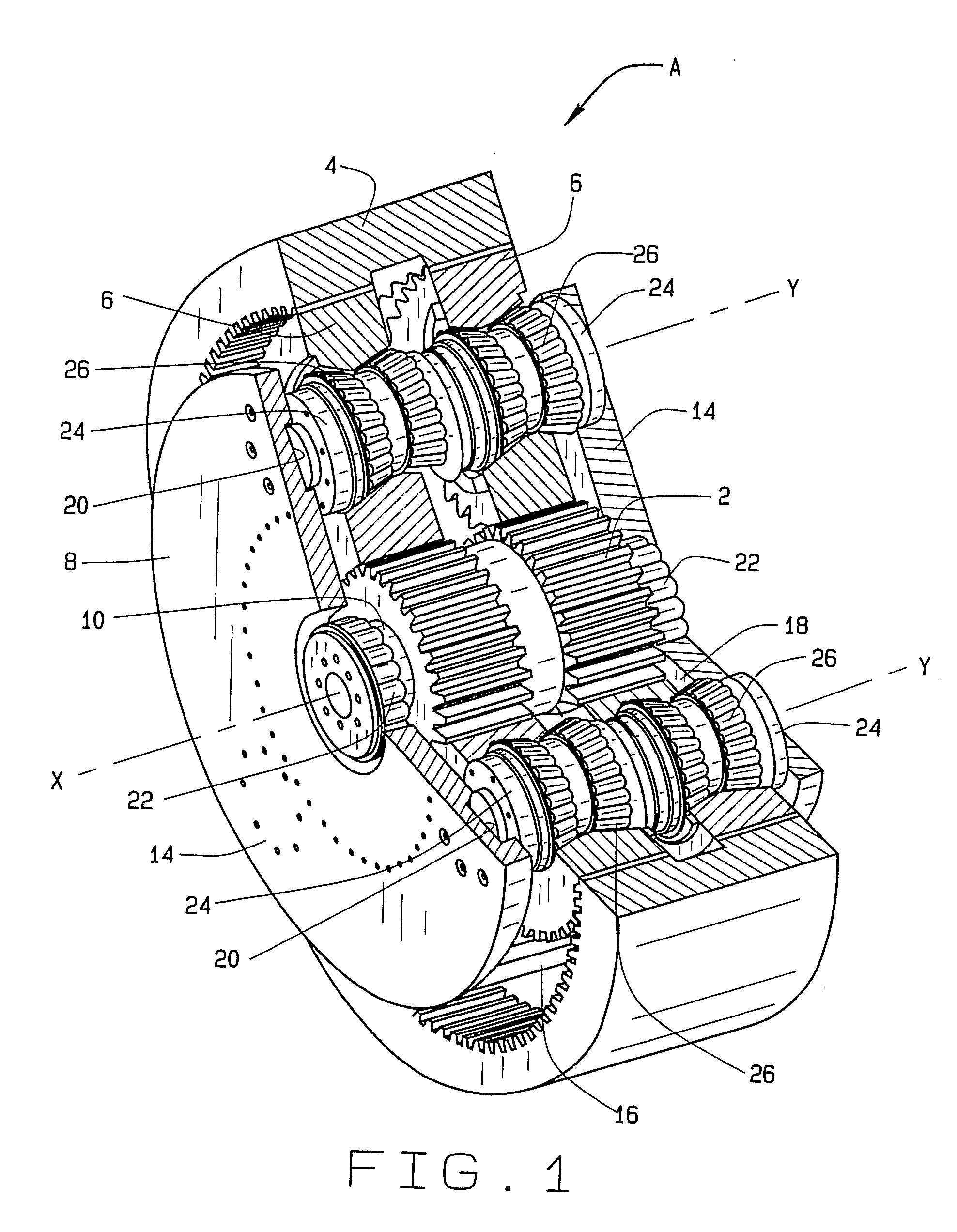

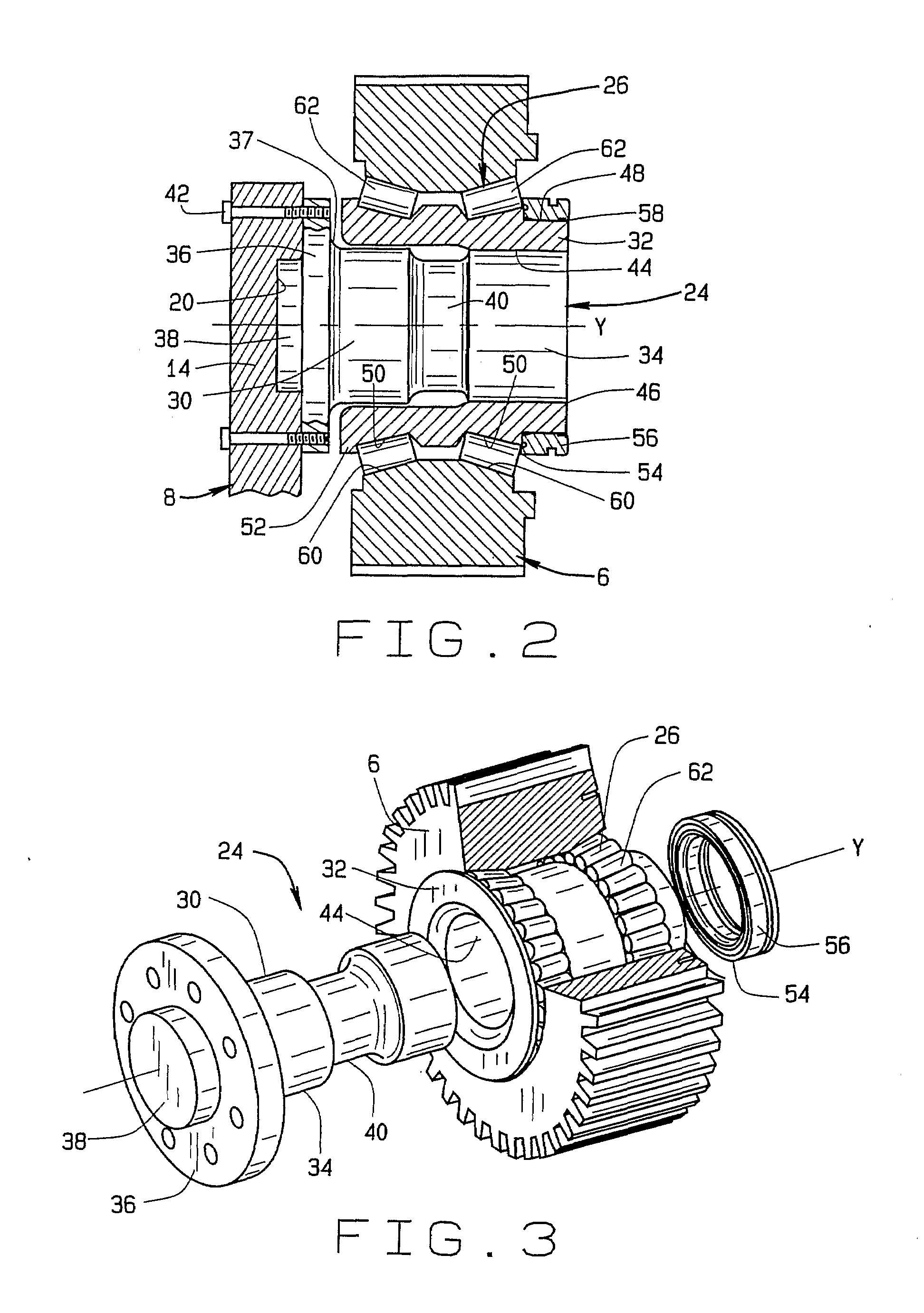

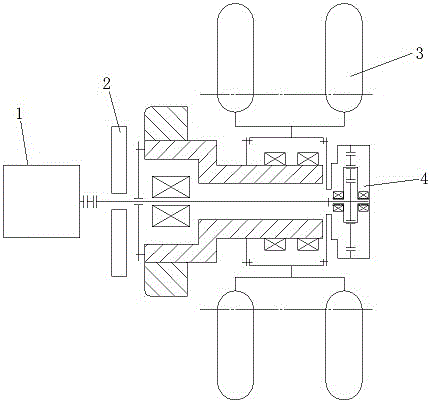

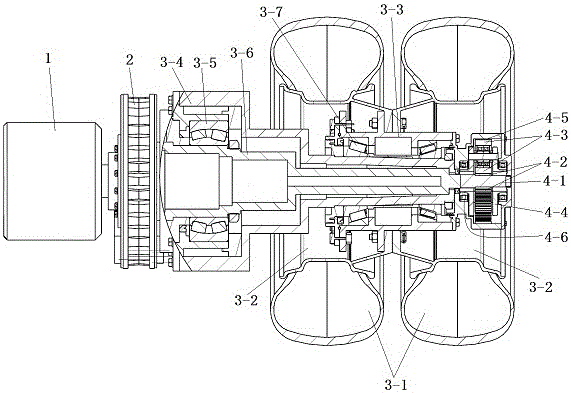

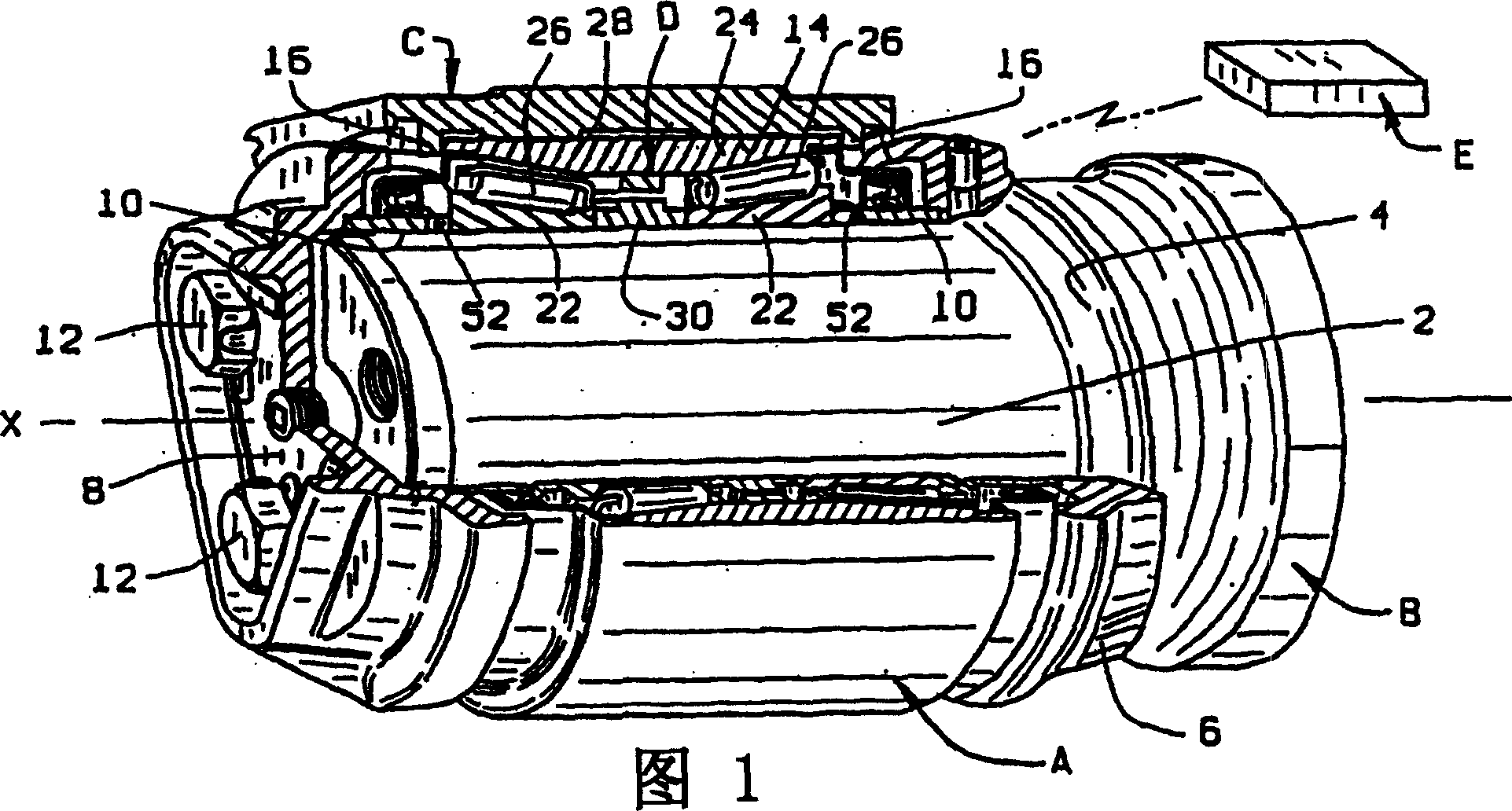

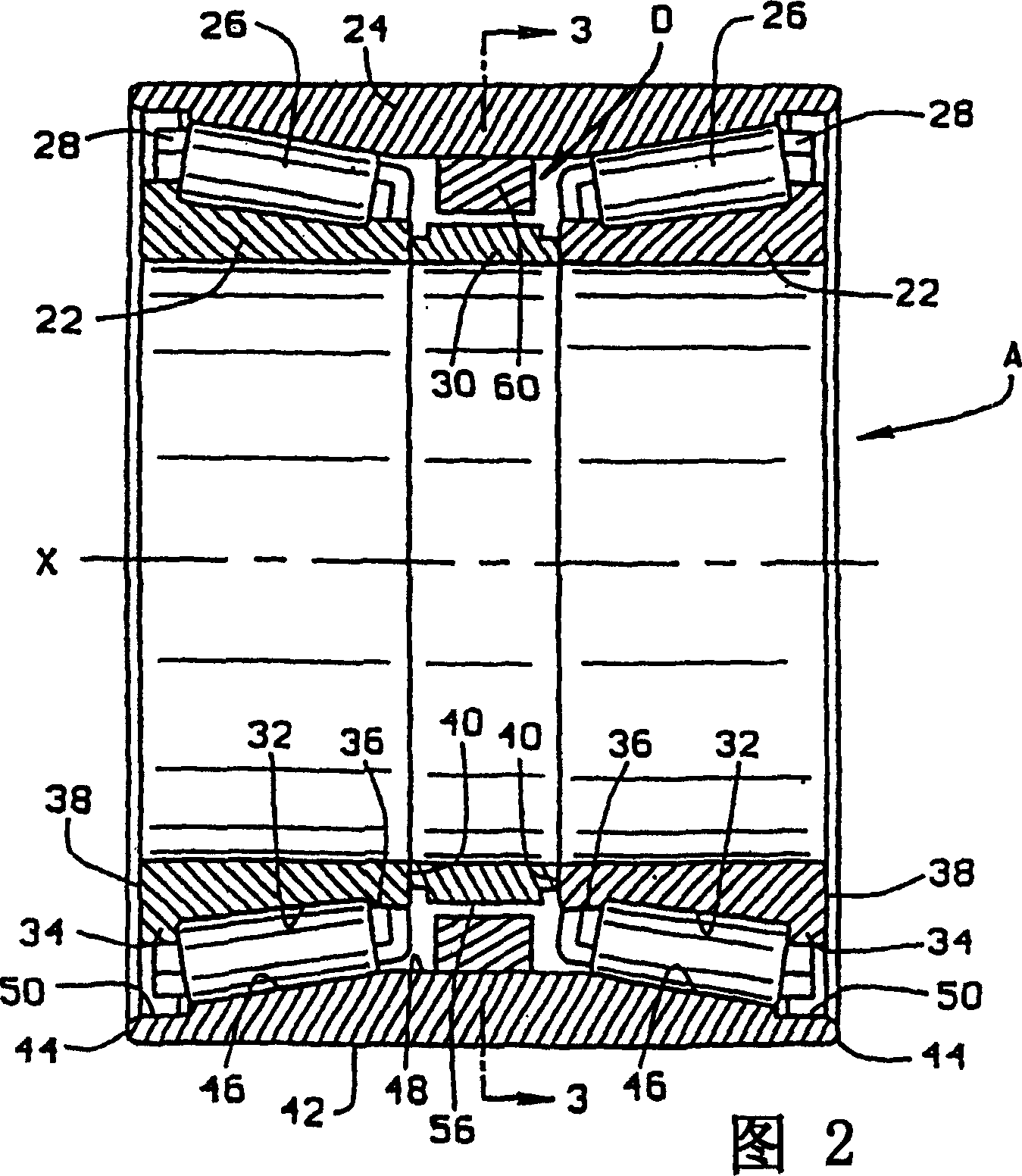

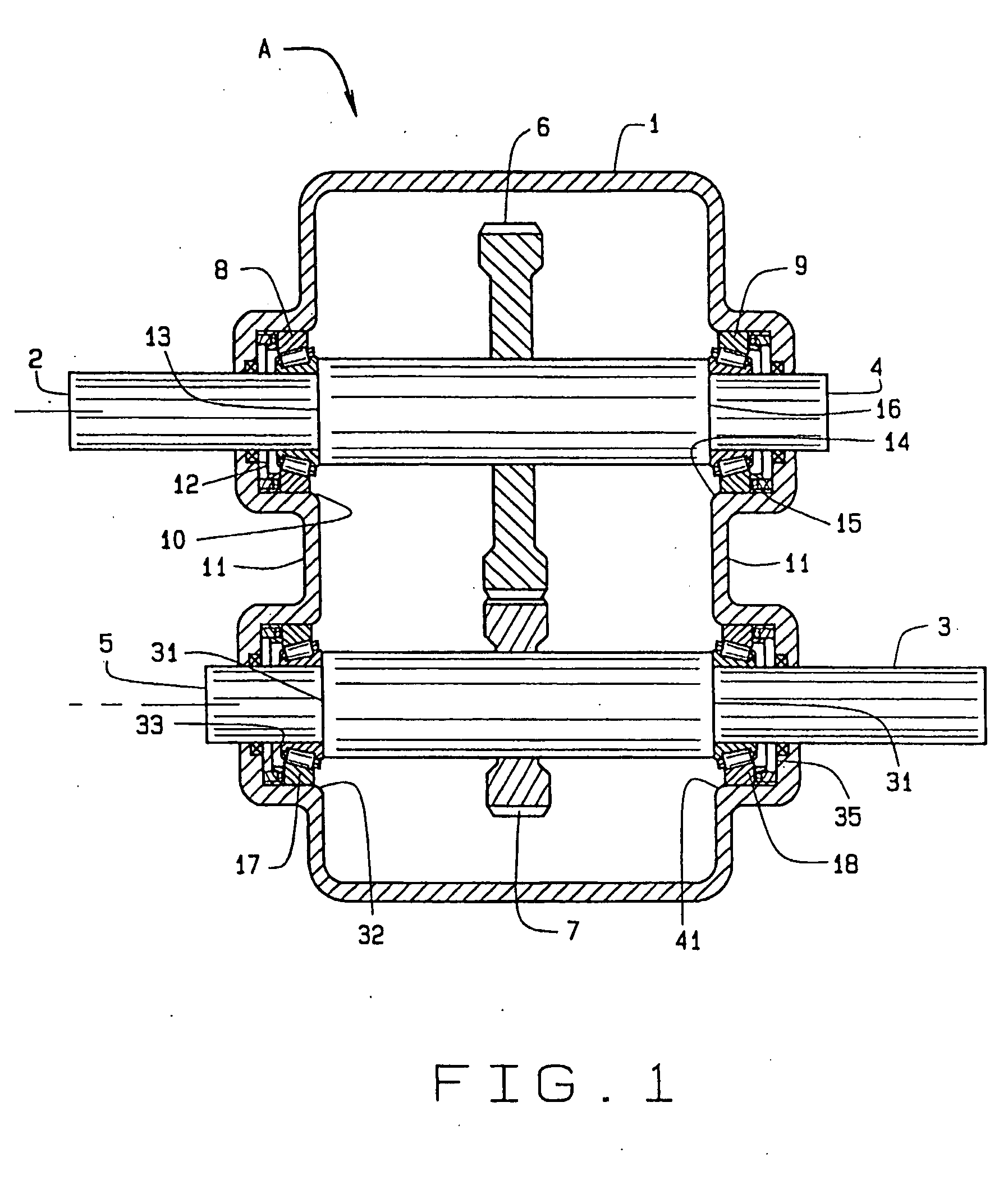

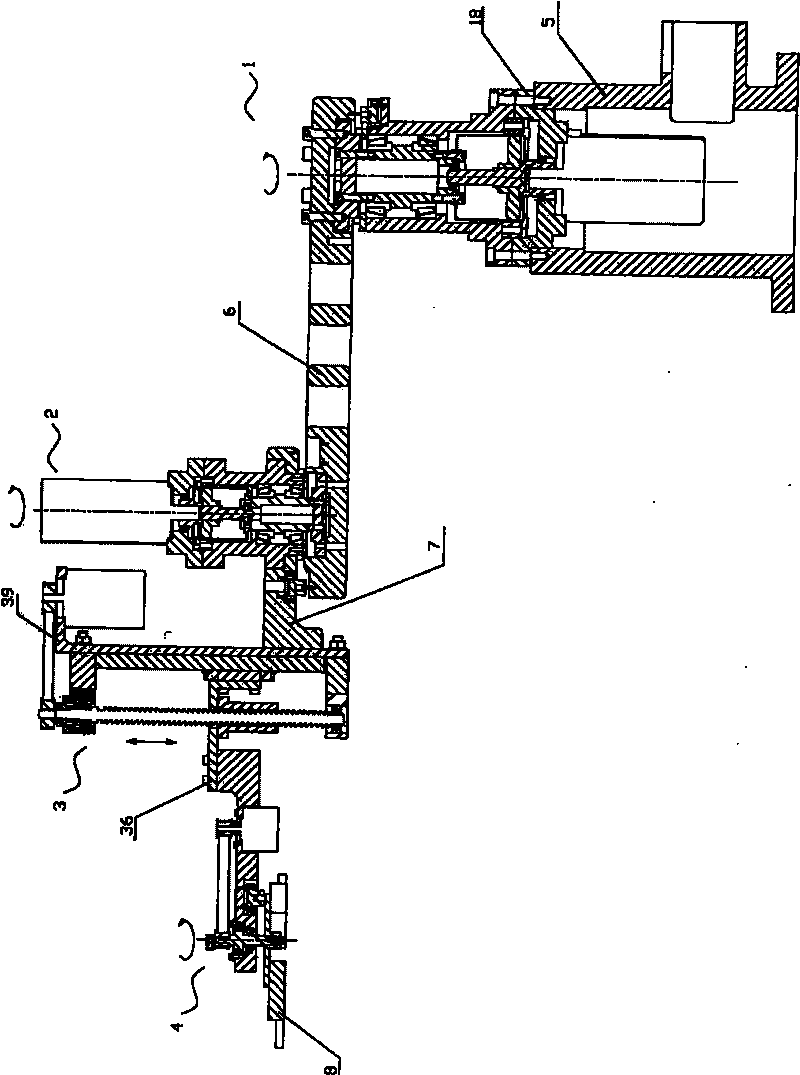

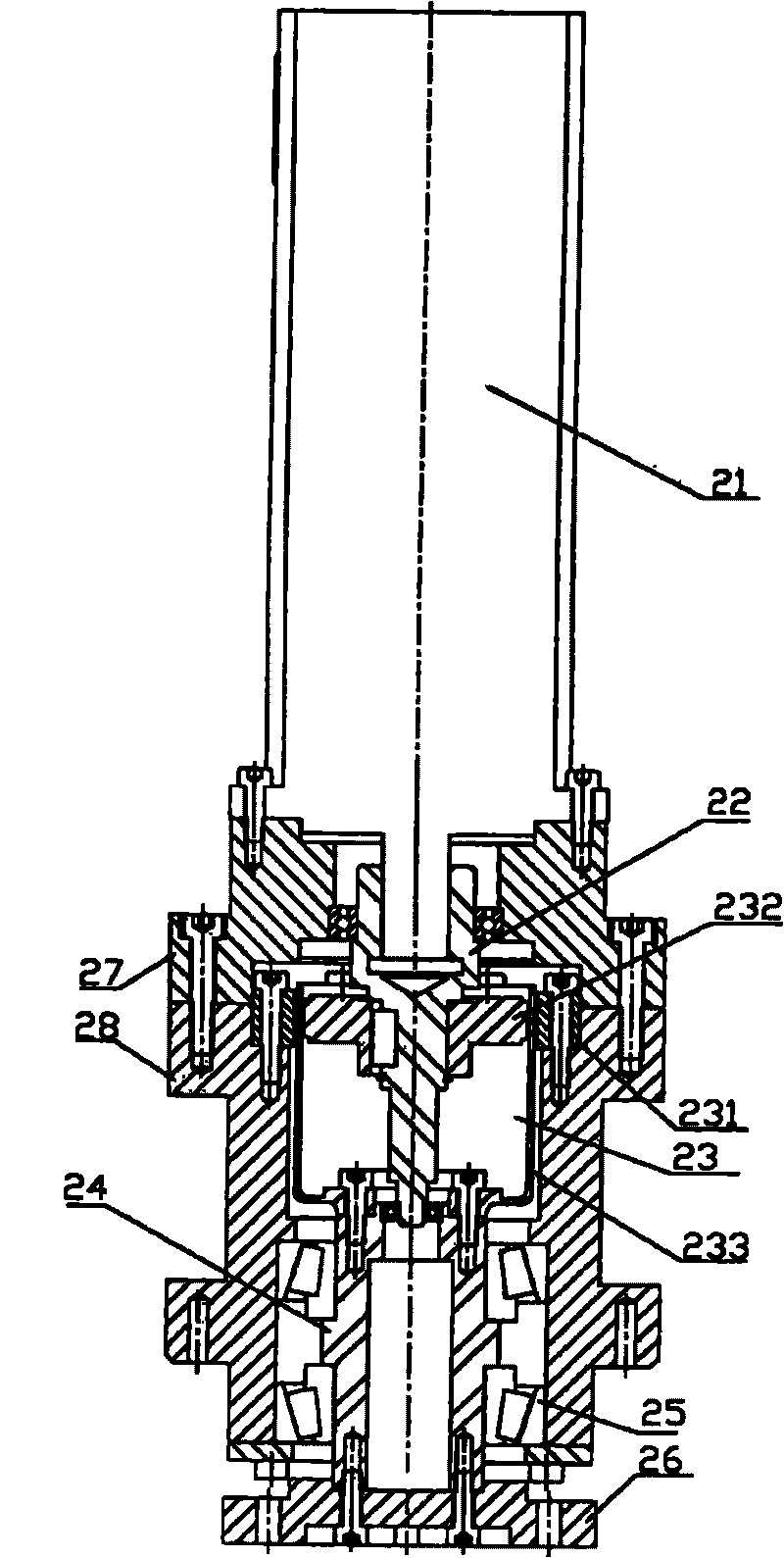

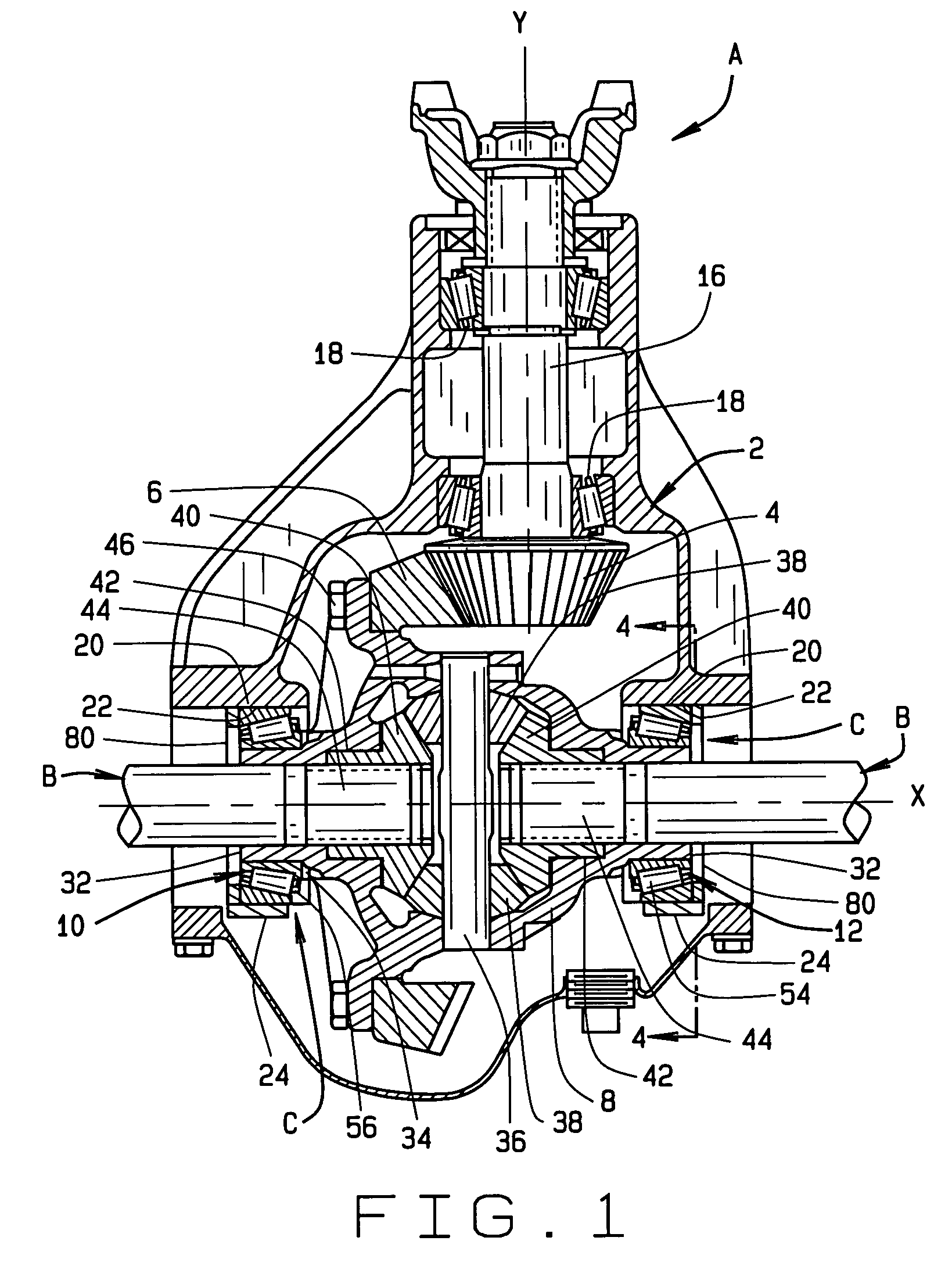

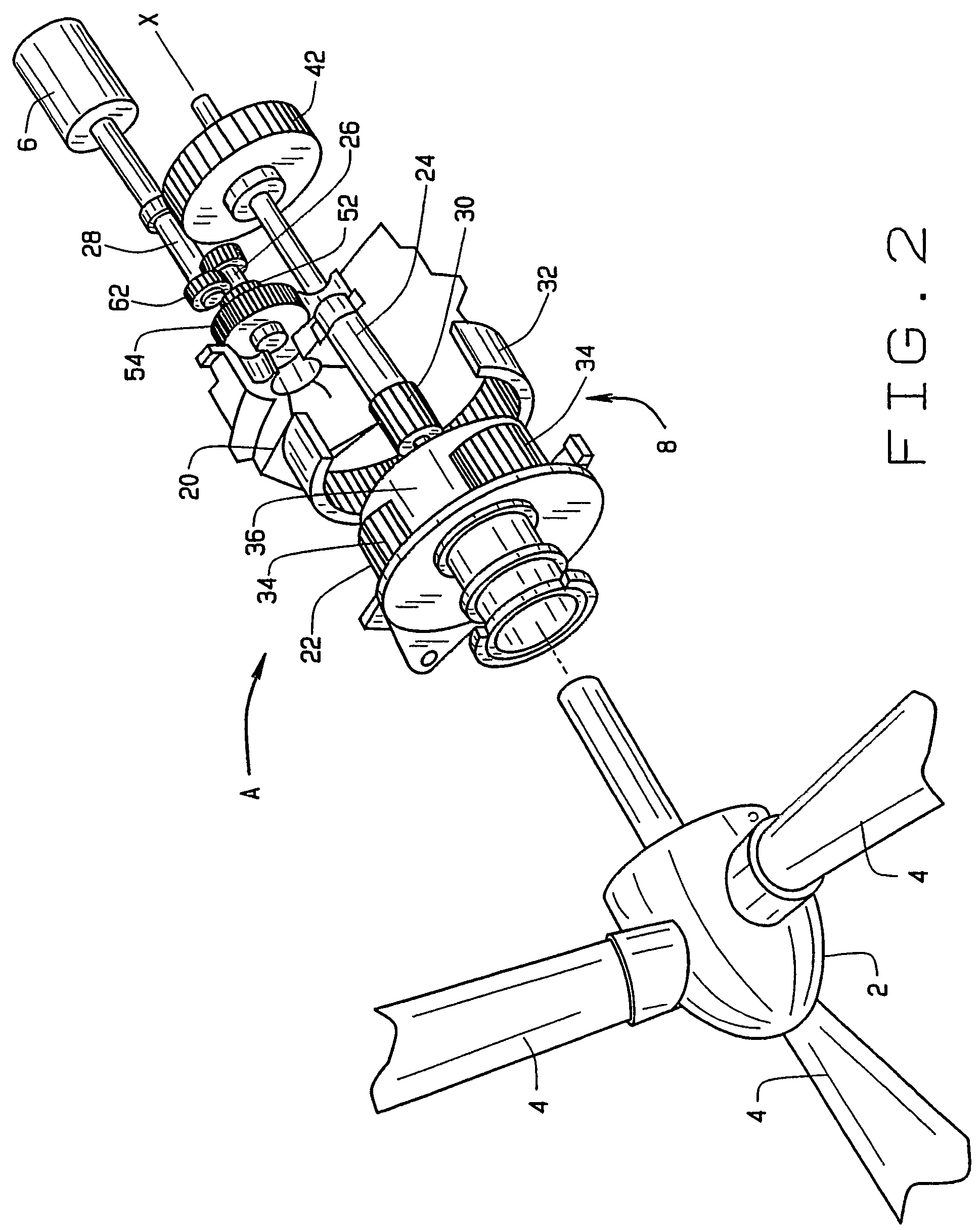

Epicyclic Gear System with Flexpins

An epicyclic gear system (A) includes a sun gear (2), a ring gear (4) located around the sun gear, planet gears (6) organized in two arrays between the sun and ring gears, and a carrier (8) having walls (14) located beyond the planet gears and flexpins (24) that project from the walls into the planet gears. Each flexpin includes an inner pin (30) provided with a flange 36 that is secured to the wall from which the inner pin projects, thus cantilevering the inner pin from the wall, and a sleeve (32) that is cantilevered from the opposite end of the inner pin and extends back over the inner pin, thus providing a double cantilever. Between the sleeve of the flexpin and the planet gear for that flexpin is a double row tapered roller bearing (26). The planet gears on the one array may be offset angularly with respect to the planet gears of the other array.

Owner:THE TIMKEN CO

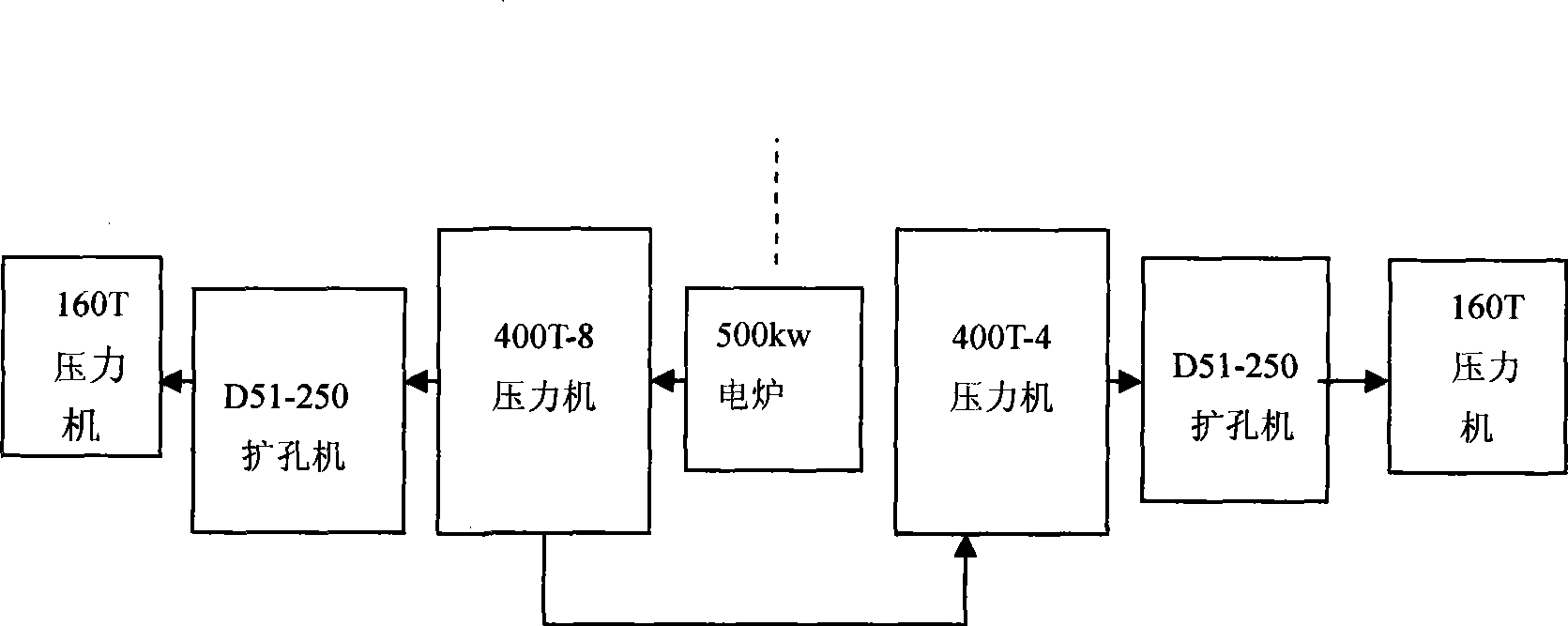

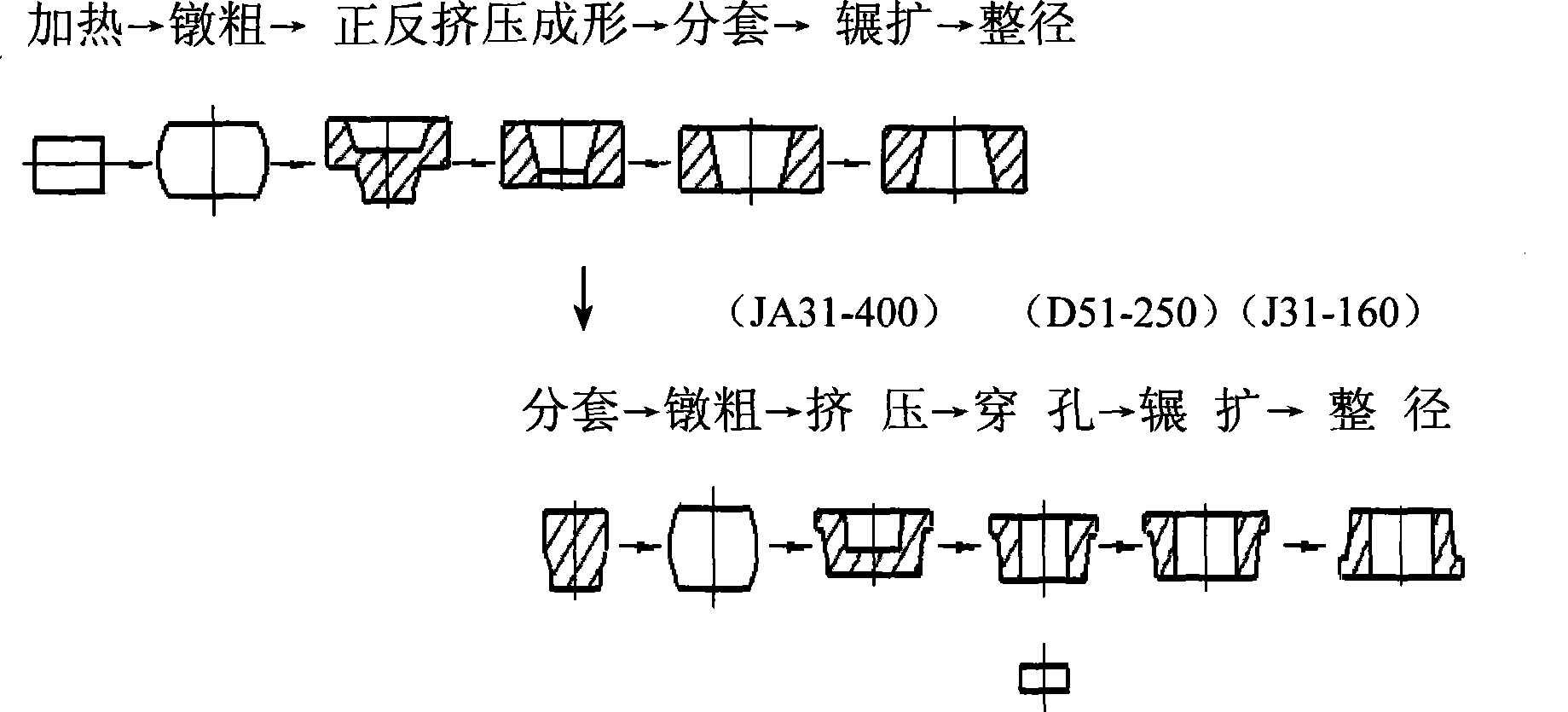

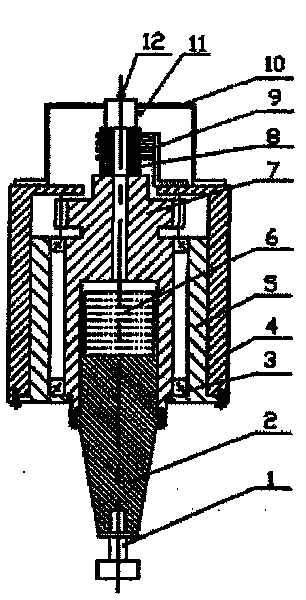

Tapered roller bearing ring double extension-sleeve forging technique

ActiveCN101417379AReduce labor intensityIncrease profitMetal rollingHigh volume manufacturingDouble diffusion

The invention relates to a double diffusion intussusception forge technique of a bearing ring of a tapered roller, belongs to the technical field of forging of the bearing ring of the tapered roller and mainly aims at solving the problems that the existing ring forging technique is not suitable for various bearing rings of the large and medium size tapered rollers. The technique is mainly characterized in that: (1) a GCr15 steel material section is heated to 1050 DEG C on a medium frequency induction furnace, then upset on a press, extruded backward and forward, formed, sheathed respectively and is separated into an outer sleeve and an inner sleeve or a small outer sleeve blank; (2) the outer sleeve blank is ring-rolled on a ring rolling machine, then reeled on the press and cooled into an outer sleeve forged parts of a bearing; and (3) the inner sleeve or the small outer sleeve blank is placed on the press, upset again, extruded and punched and then a ring part is obtained which is ring-rolled on the ring rolling machine, then an inner sleeve hot forged part after being ring-rolled is reeled on the press and then cooled to obtain the inner sleeve forged part of the bearing. The technique is mainly used for manufacturing the inner and outer ring forged parts of the bearing of the large and medium size tapered roller with various types, small batch or large batch.

Owner:XIANGYANG AUTOMOBILE BEARING CO LTD

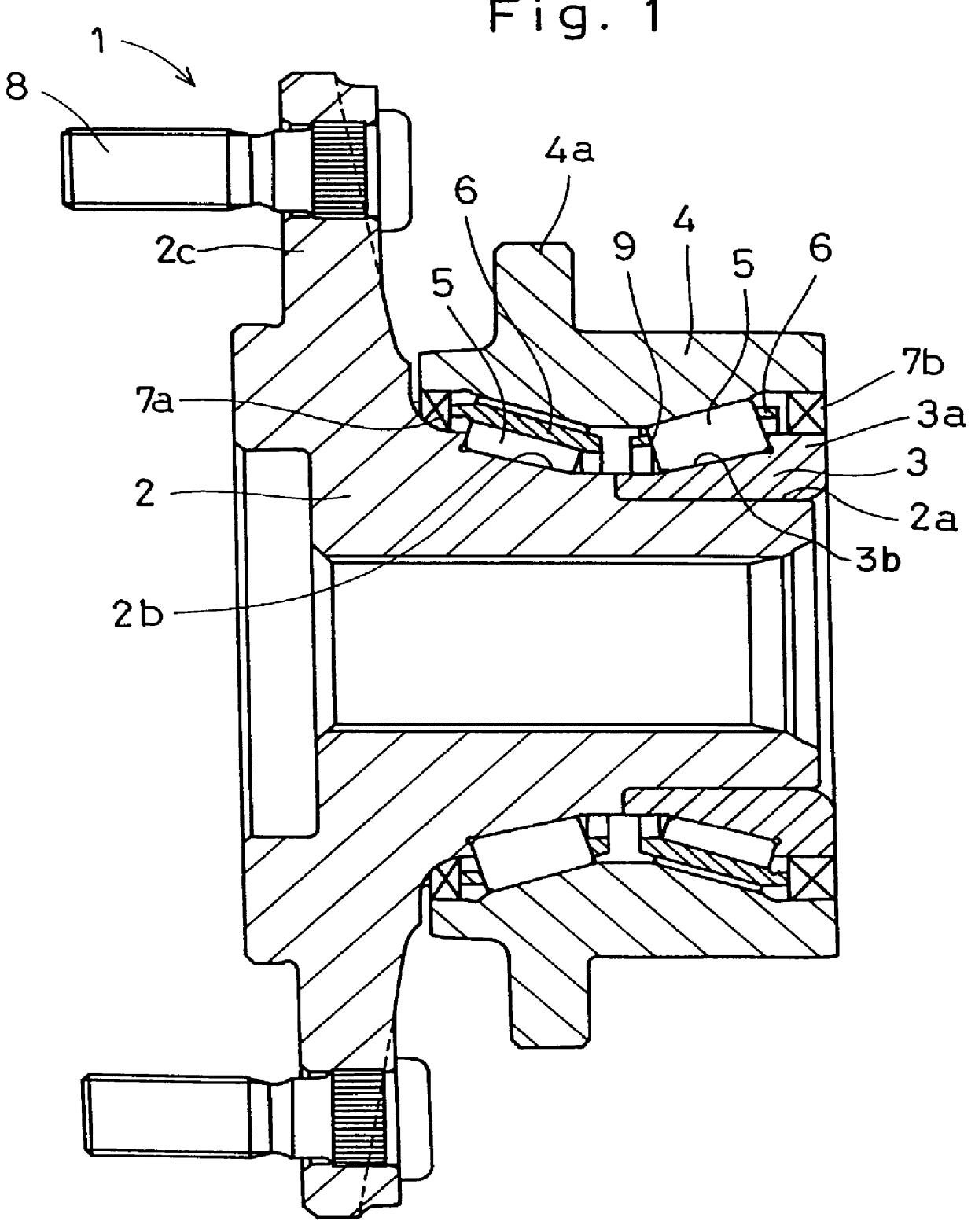

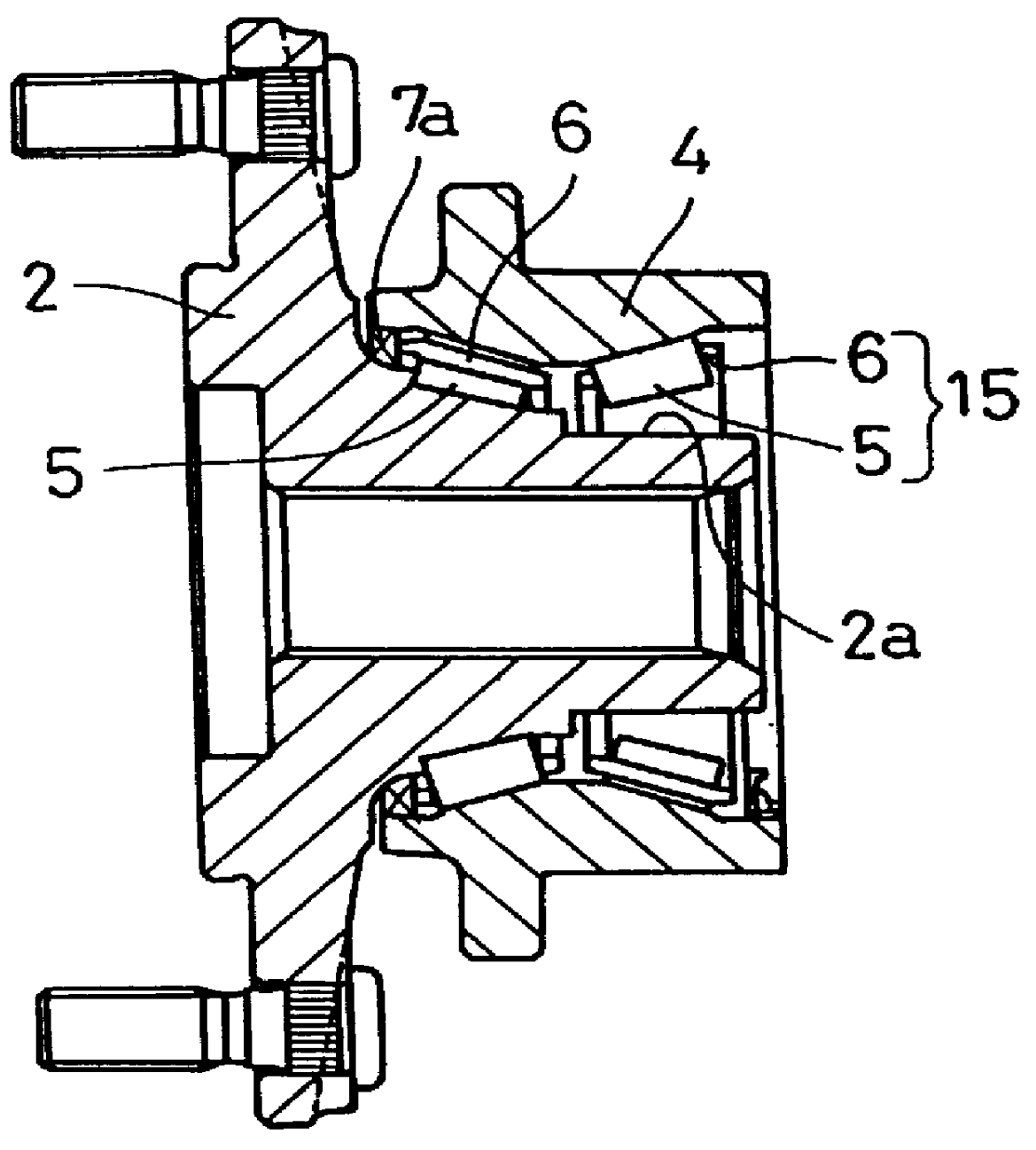

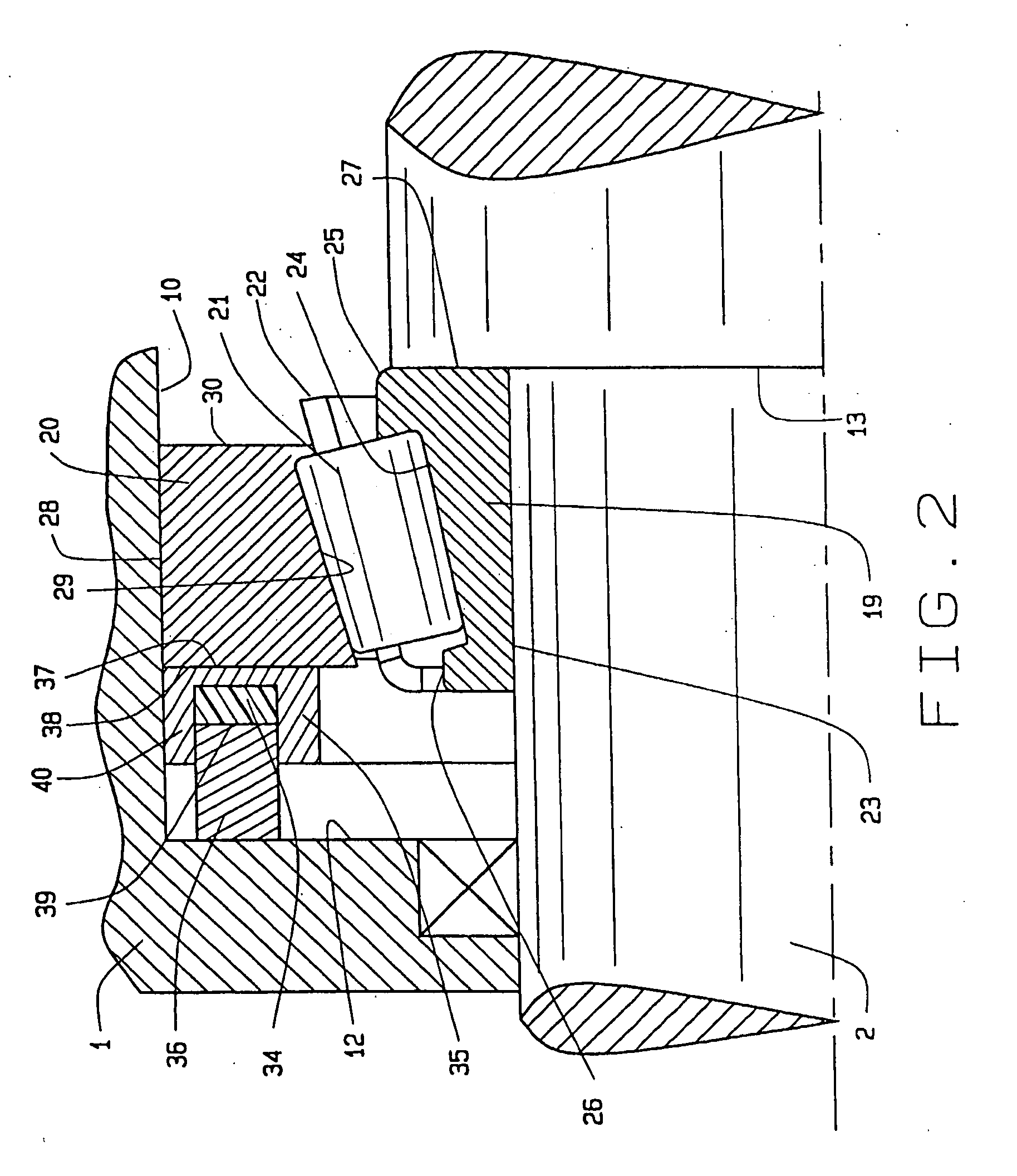

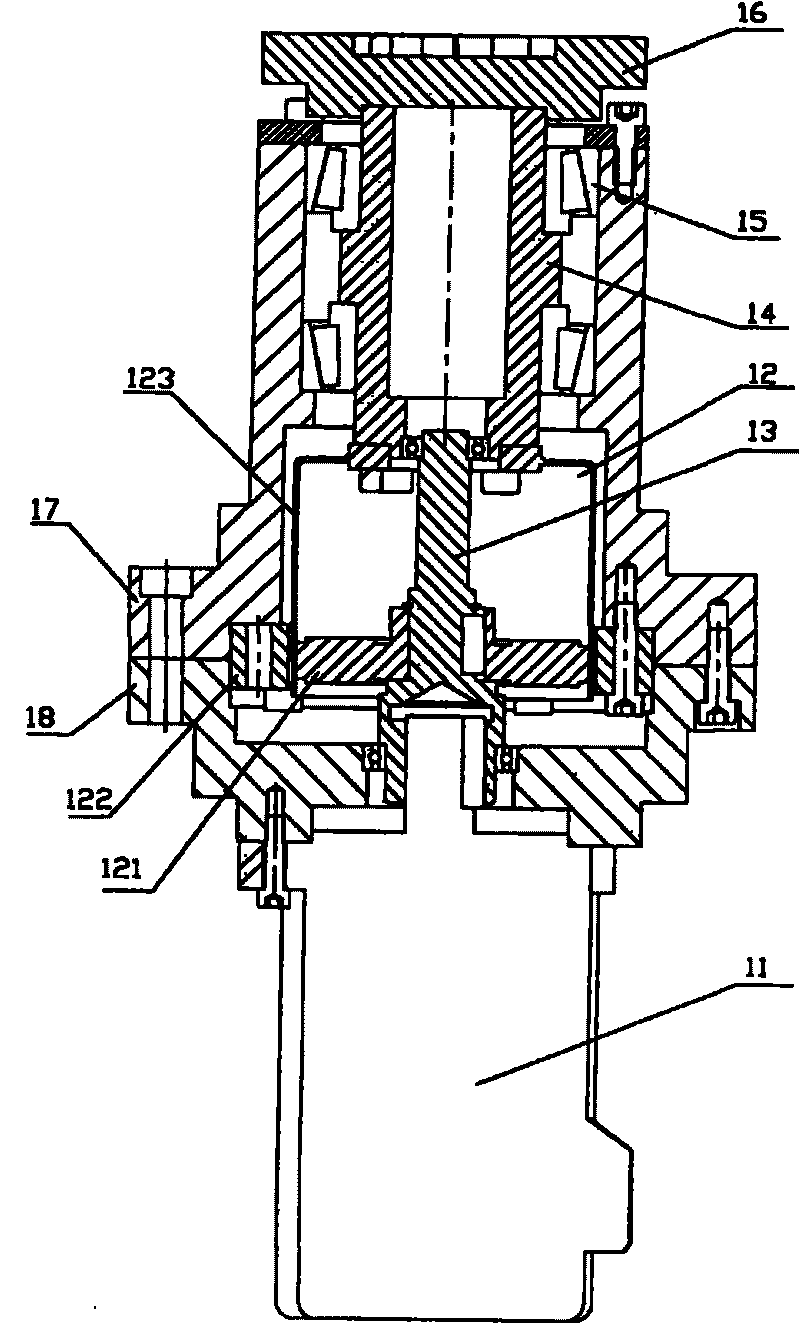

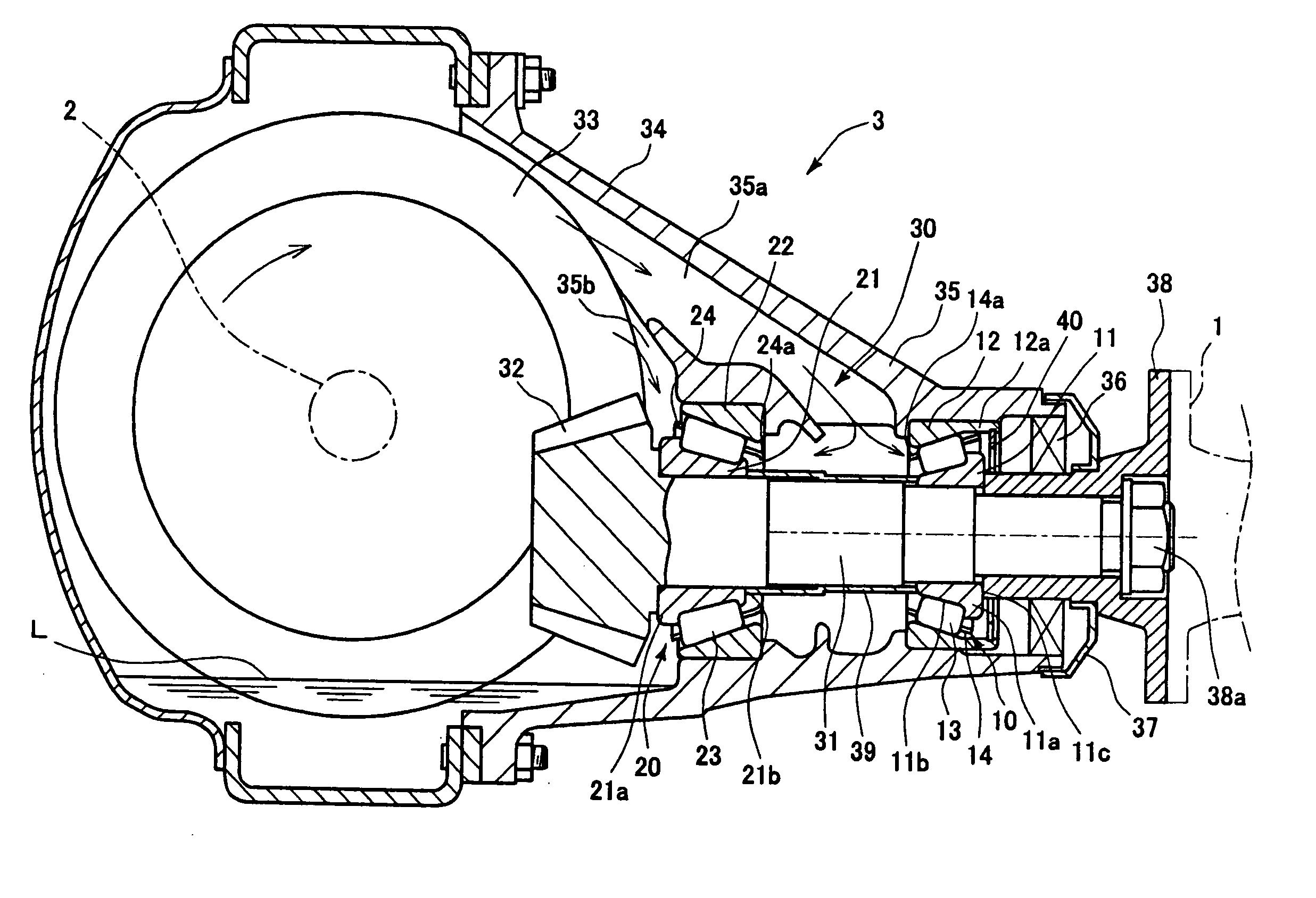

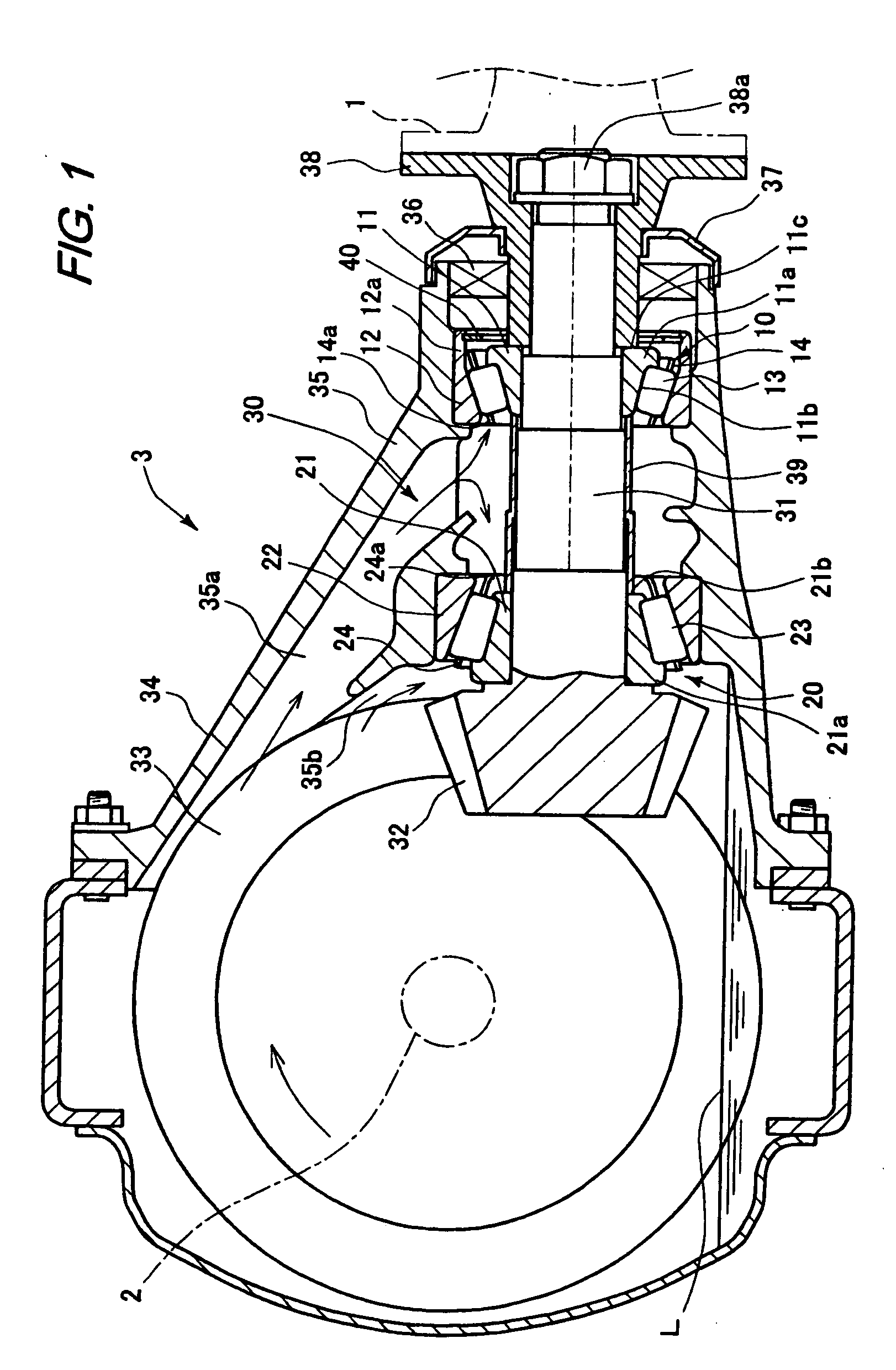

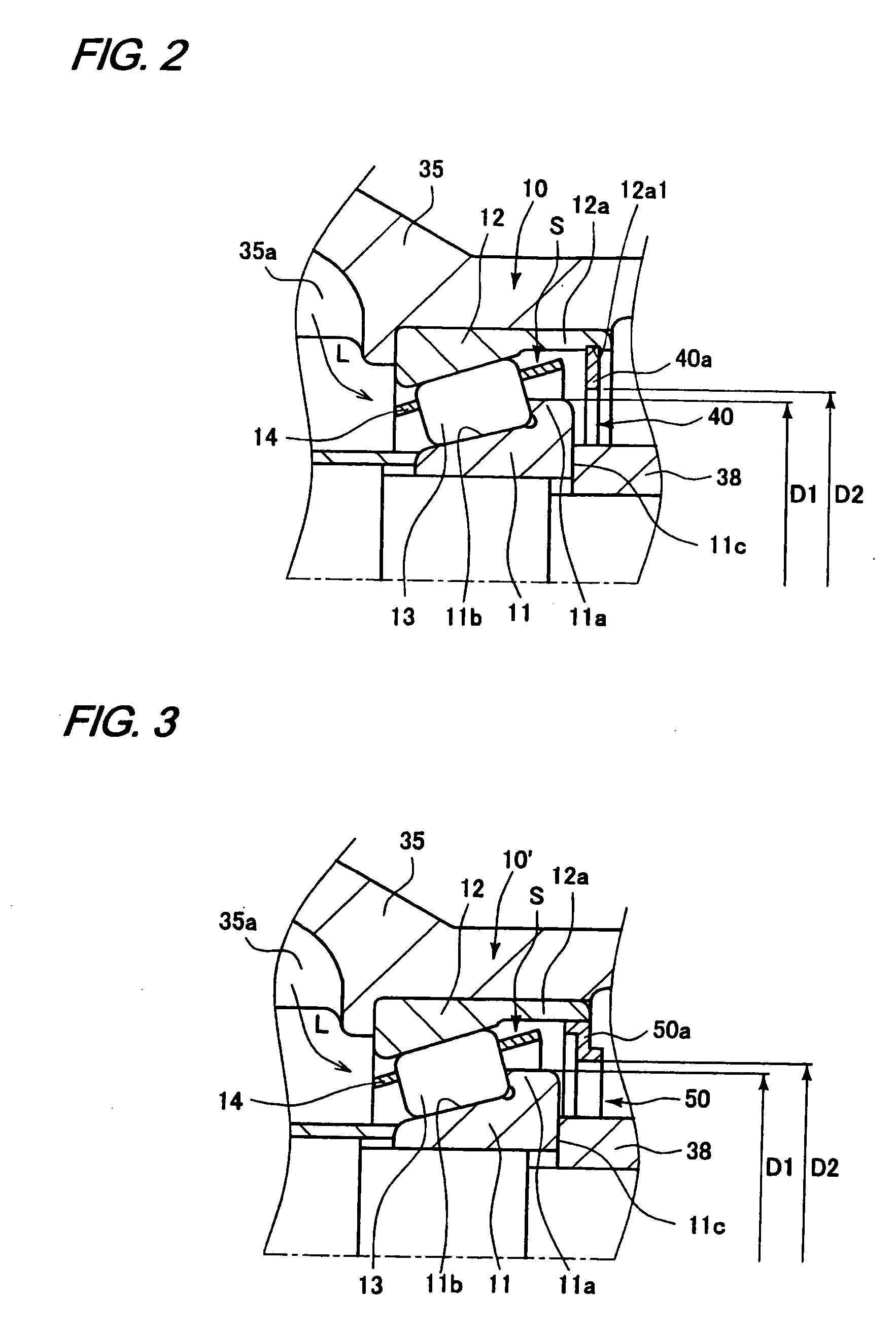

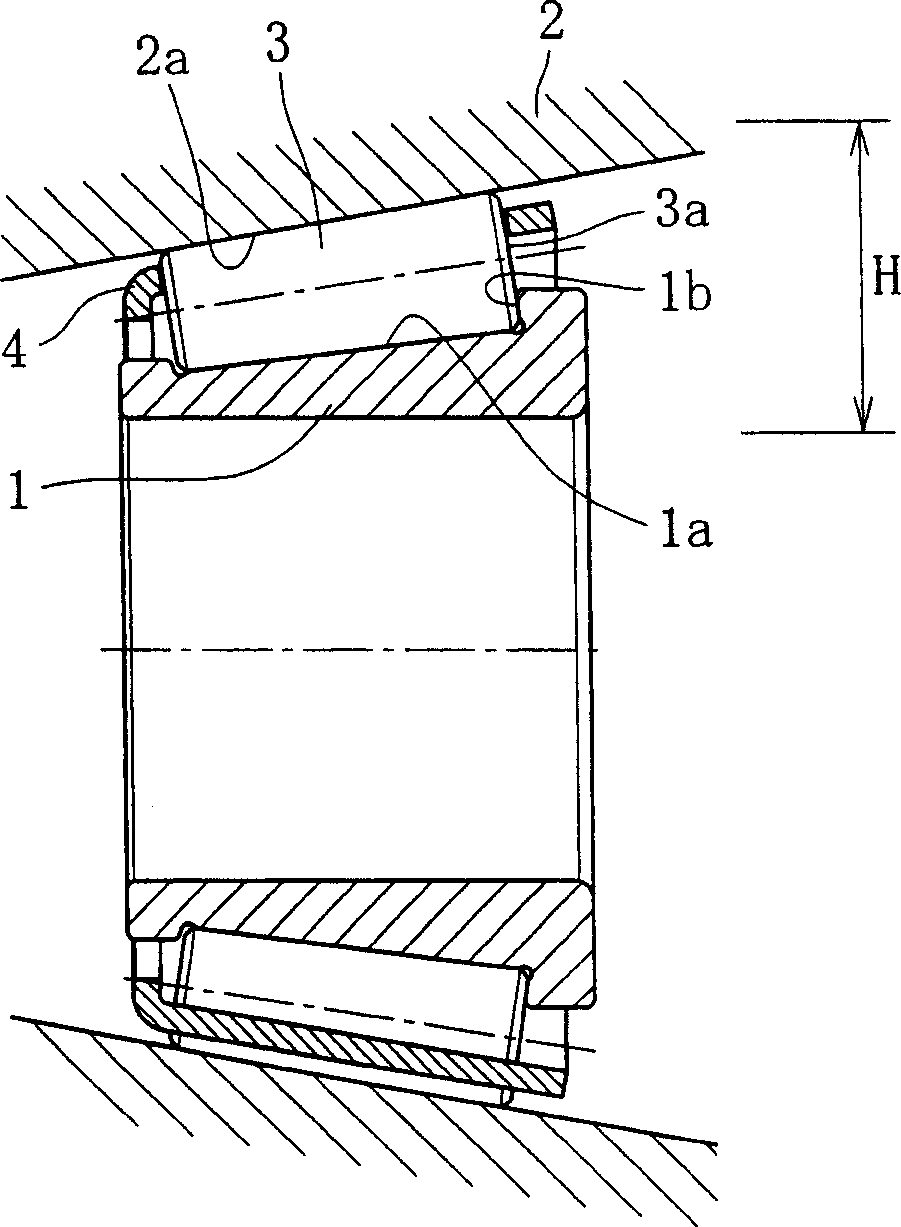

Hub unit bearing assembly and a method of making the same

InactiveUS6135643AEasy to assembleIncrease freedomRoller bearingsHubsEngineeringMechanical engineering

A hub unit bearing assembly includes a tapered roller bearing including an inner race (3), an outer race (4) having a fixture (4a) defined therein so as to extend radially outwardly therefrom, and a multiplicity of rollers (5) retained in a circumferential row by a cage (6) and rollingly positioned between the inner race (3) and the outer race (4). A hub (2) including the inner race (3) on a portion of an outer periphery of said hub (2). The inner race (3) is a member either integral with the hub (2) or separated from the hub (2). The cage (6) rotatably accommodates the respective rollers (5) in the form as retained thereby prior to assemblage of the cage (6) with the rollers (5) into the roller bearing. The cage (6) and the rollers (5) are, after the rollers have been mounted in the cage (6), inserted in between the inner race (3) and the outer race (4).

Owner:NTN CORP

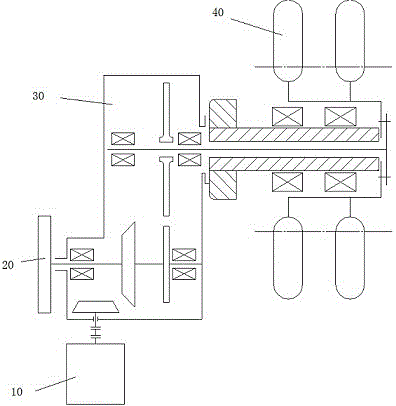

Single axle bogie transmission of straddle-type single rail vehicle

InactiveCN105905120ACompact structureEasy to disassembleElectric motor propulsion transmissionBogieReduction drive

The invention discloses a single axle bogie transmission of a straddle-type single rail vehicle. The transmission is arranged on a bogie frame and used for realizing that walking wheels are driven to walk through the torque of a motor. The transmission comprises the motor, a brake disc, a walking wheel assembly and a reducer. The motor and the brake disc are transversely arranged on the fixed end of an axle, and the walking wheel assembly and the wheel reducer are transversely arranged on the cantilever end of the axle; a walking wheel support shaft is unidirectionally fixed by adopting double fulcrums, one end of the support shaft is fixed on the bogie frame, the other end of the support shaft is suspended, the fixed end of the support shaft is supported by a self-aligning roller bearing, and the cantilever end of the support shaft is supported by a group of tapered roller bearings installed in an axle box in the reverse direction. Longitudinal symmetric planes of the walking wheels are coincided with longitudinal symmetric planes of track beams. The single axle bogie transmission of the straddle-type single rail vehicle has the technical beneficial effects that the bogie is compact in structure, tires are disassembled and assembled easily, and the curve passing performance of the cantilever beam straddle-type single rail vehicle is met.

Owner:SOUTHWEST JIAOTONG UNIV

Method and apparatus for lubricating a differential gear assembly

An inter-axle differential gear assembly includes a first side gear driven by an input shaft, a plurality of inter-axle differential pinion gears in meshing engagement with the first side gear, and a second side gear in meshing engagement with the inter-axle differential pinion gears. The second side gear includes a gear body having a front face and a rear face positioned opposite of the front face. At least one channel, formed within the gear body, extends between the front and rear faces. Lubricating fluid is pumped through the channel to lubricate the inter-axle differential gear assembly. A tapered roller bearing is positioned adjacent the rear face of the second side gear. A seal, positioned between the tapered roller bearing and the rear face of the second side gear, forms a sealed fluid cavity. Rotation of the tapered roller bearing generates a pumping action that pumps the lubricating fluid through the tapered roller bearing, into the sealed fluid cavity, and into the channel.

Owner:ARVINMERITOR TECH

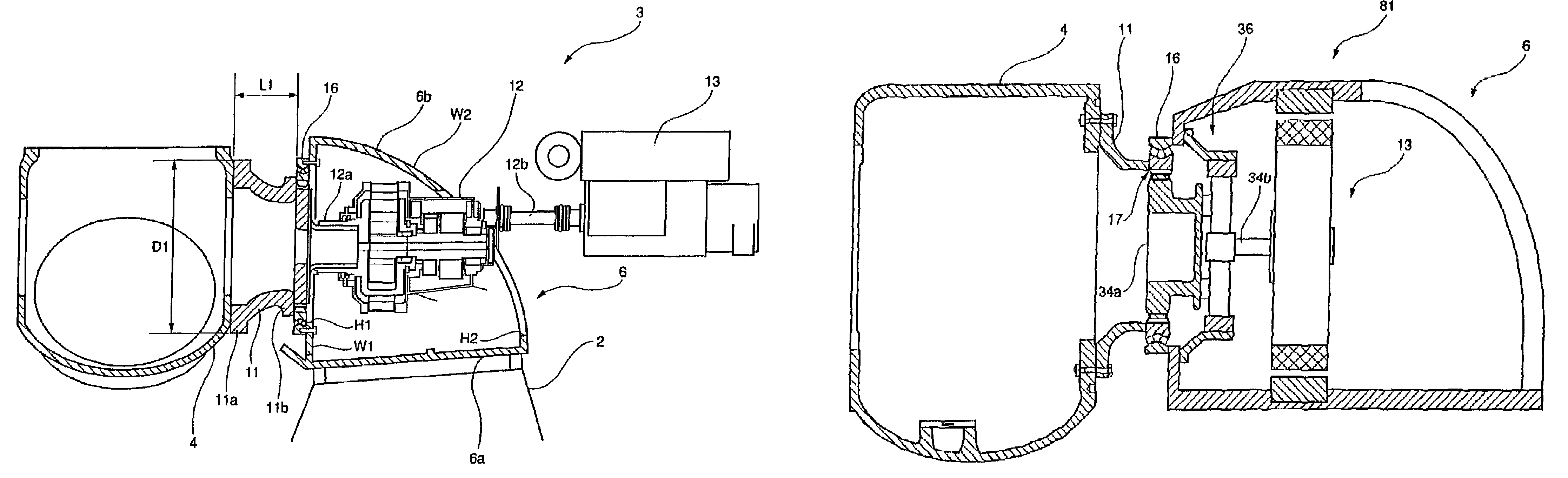

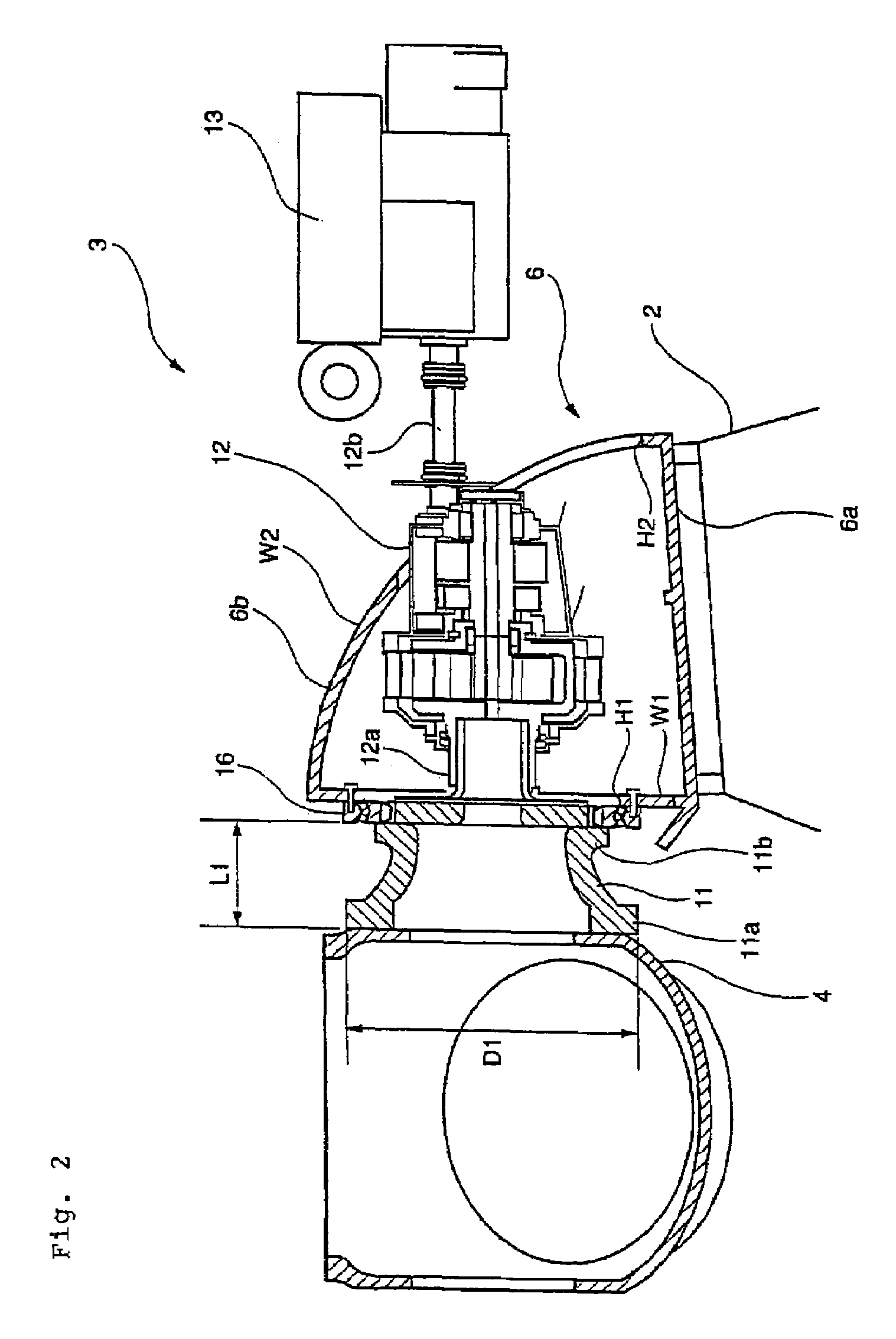

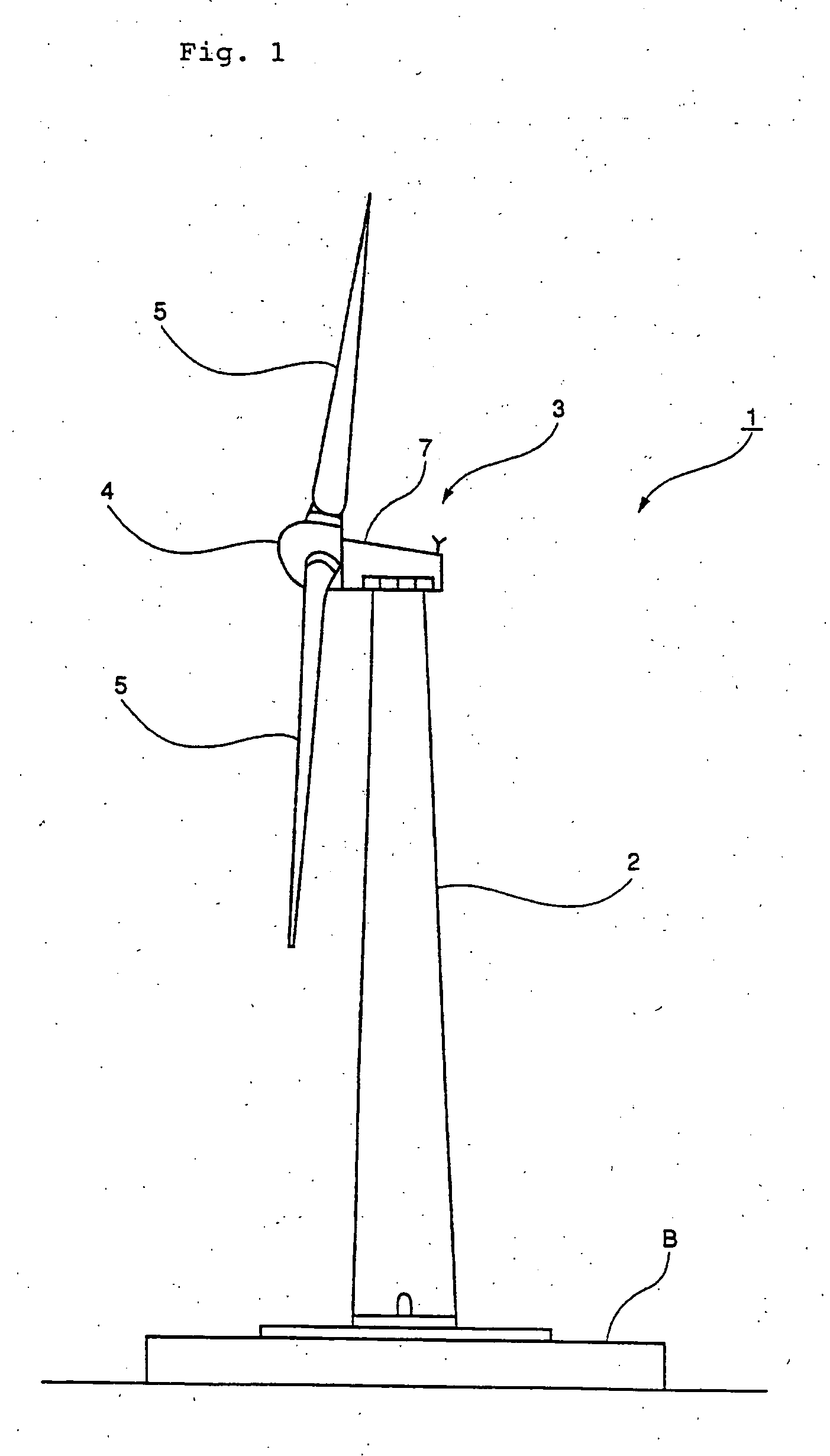

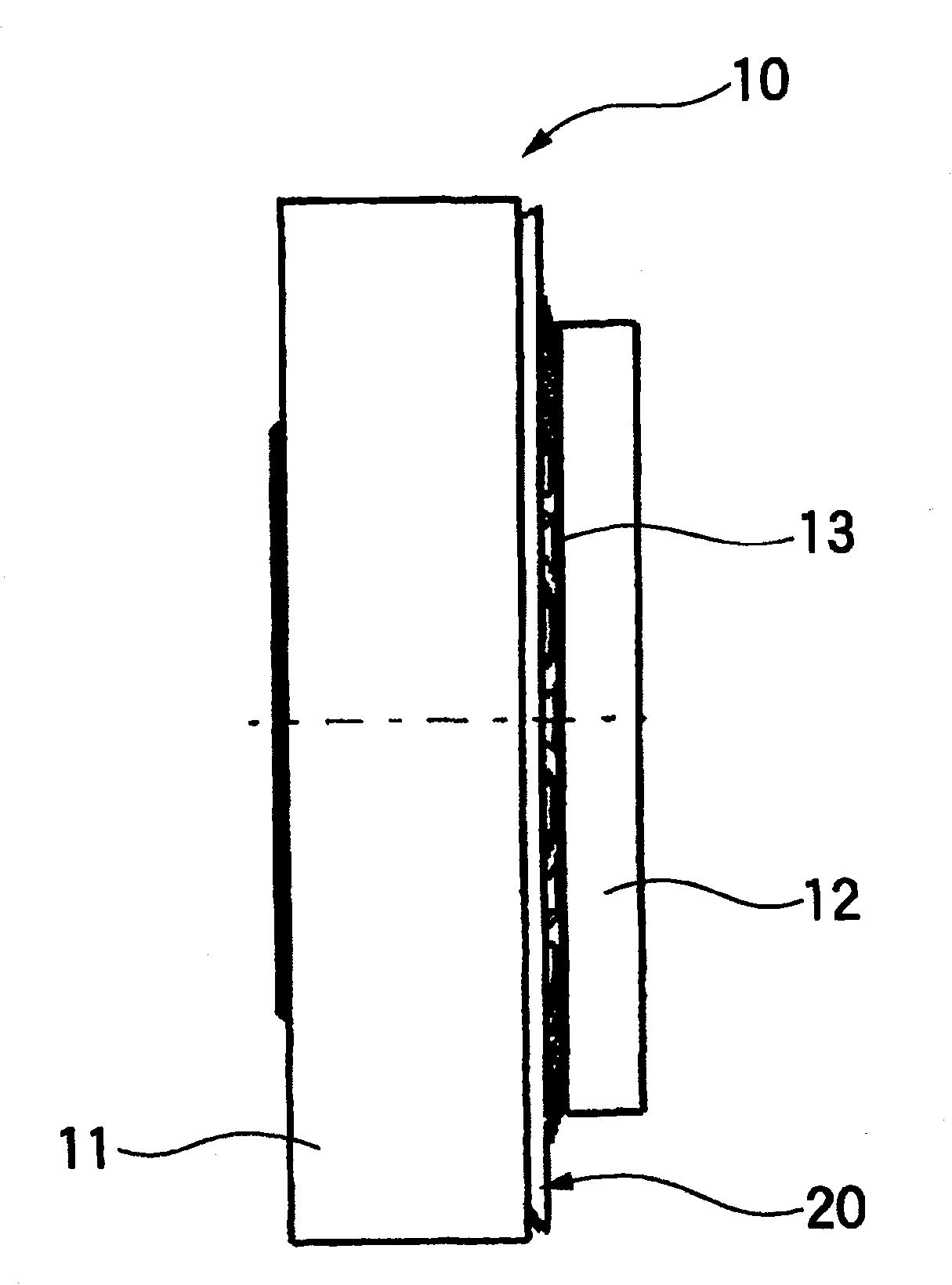

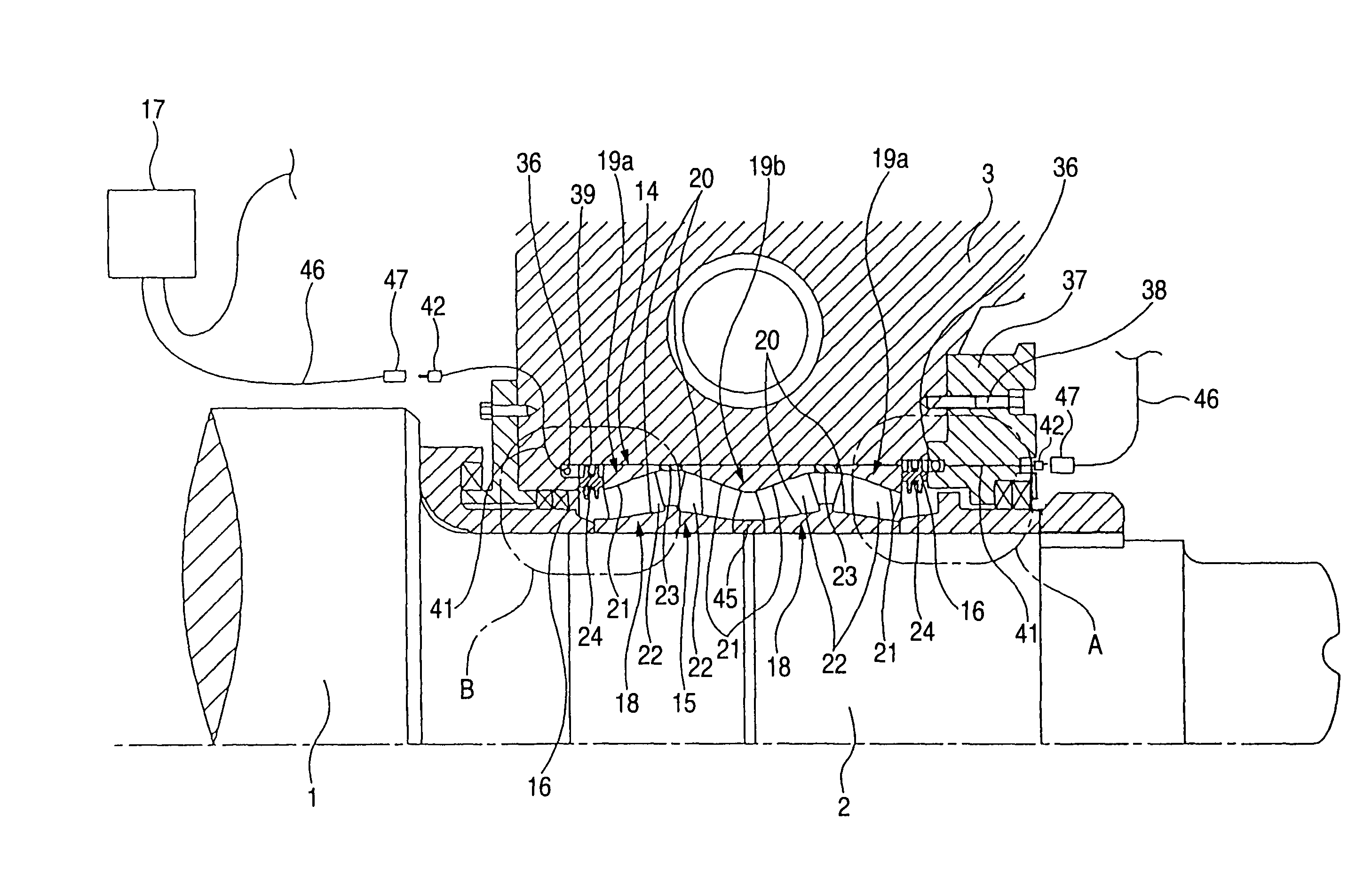

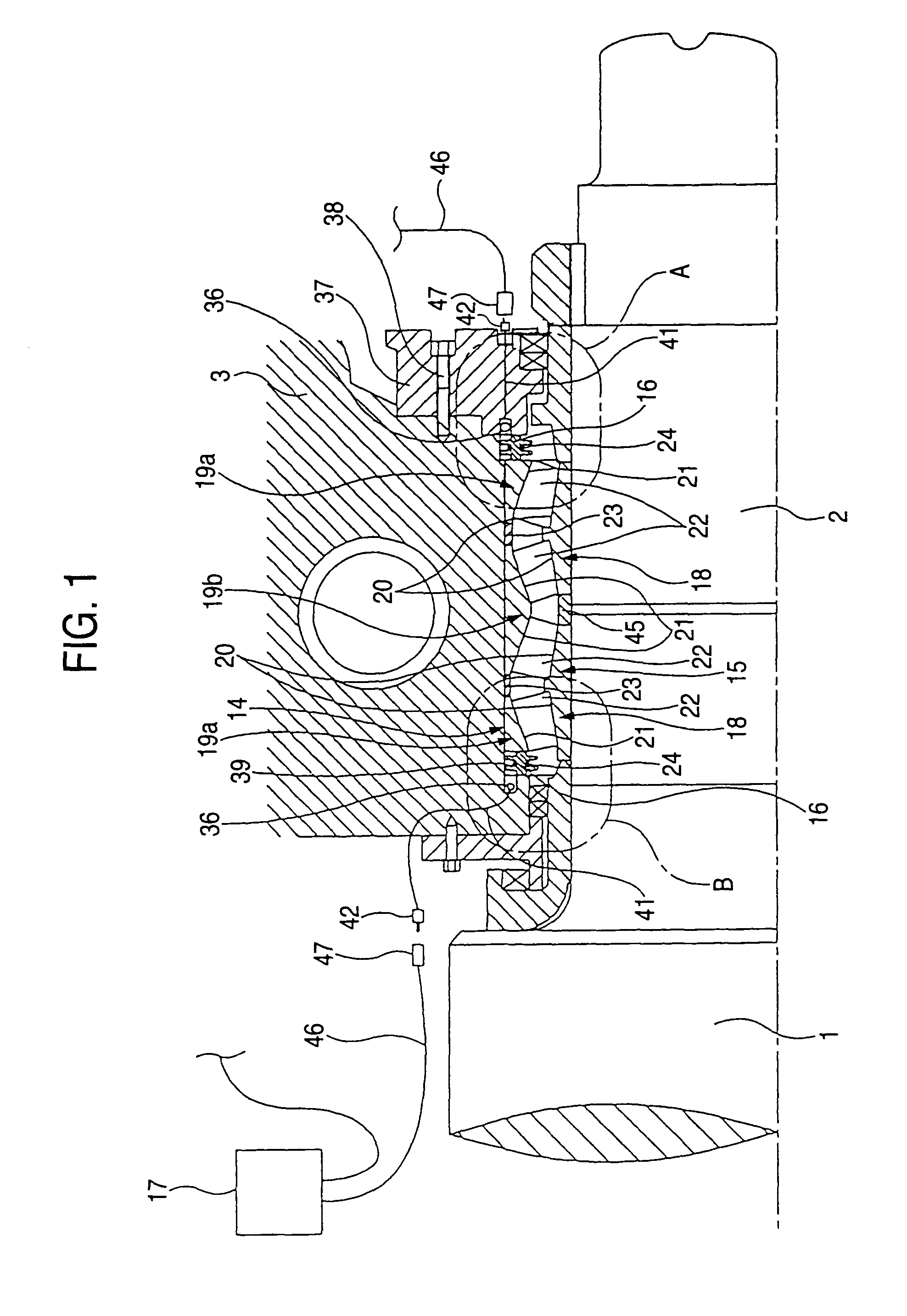

Power generating wind turbine

A power generating wind turbine includes parts and components installed in or on a nacelle which are made smaller and lighter, thus facilitating maintenance. A main shaft 11, a gear-box for speeding up rotation of the main shaft 11 and a generator 13 driven by an output of the gear-box 11 are provided on a nacelle bed plate 6. The main shaft 11 is connected to an input shaft 12a end of the gear-box 12 via a double-row tapered roller bearing 16. The main shaft 11 is supported to a wall portion W1 of the nacelle bed plate 6 with the double-row tapered roller bearing 16 being interposed therebetween. The main shaft 11 is formed in an annular shape having its outer diameter D1 larger than its axial directional length L1.

Owner:MITSUBISHI HEAVY IND LTD

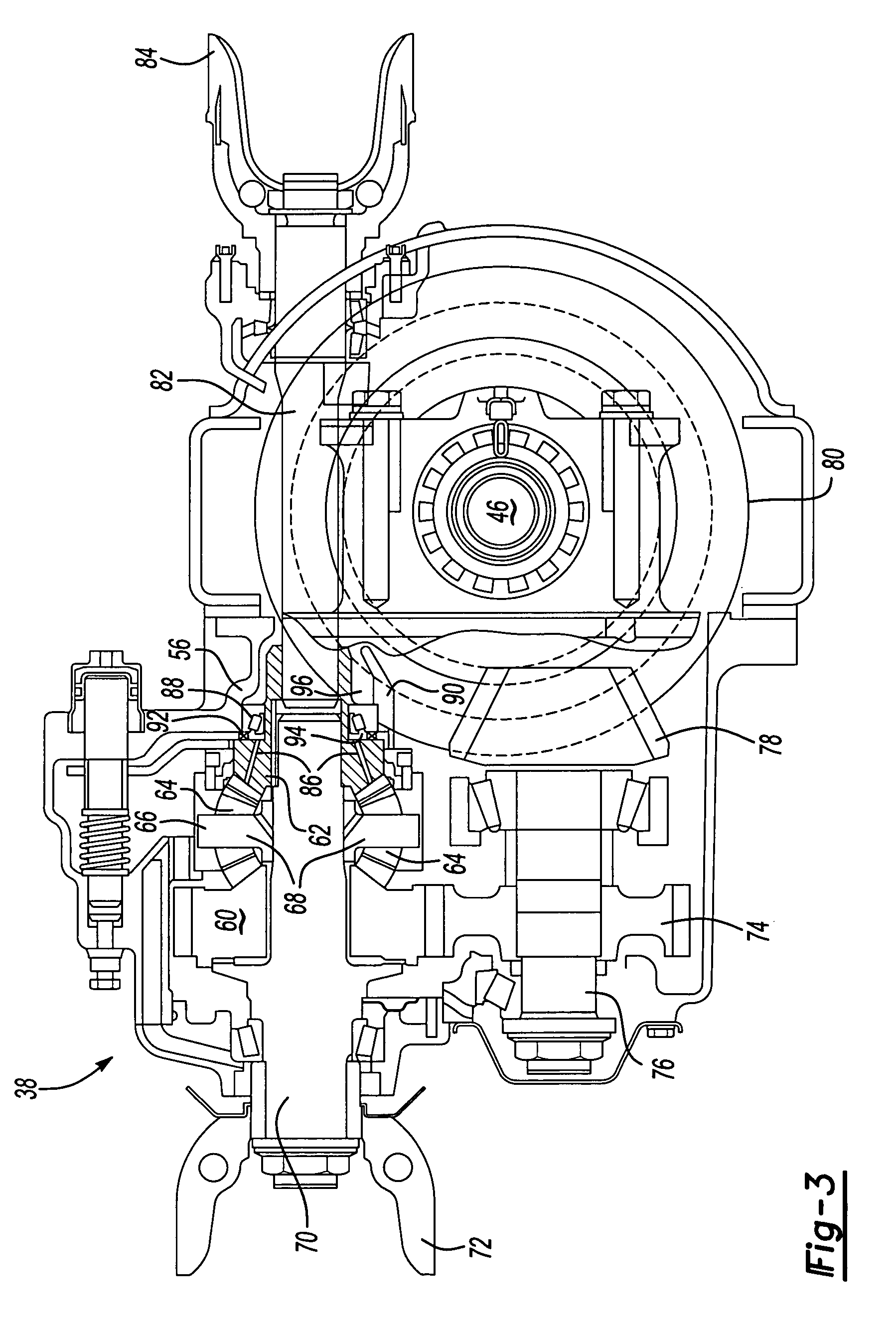

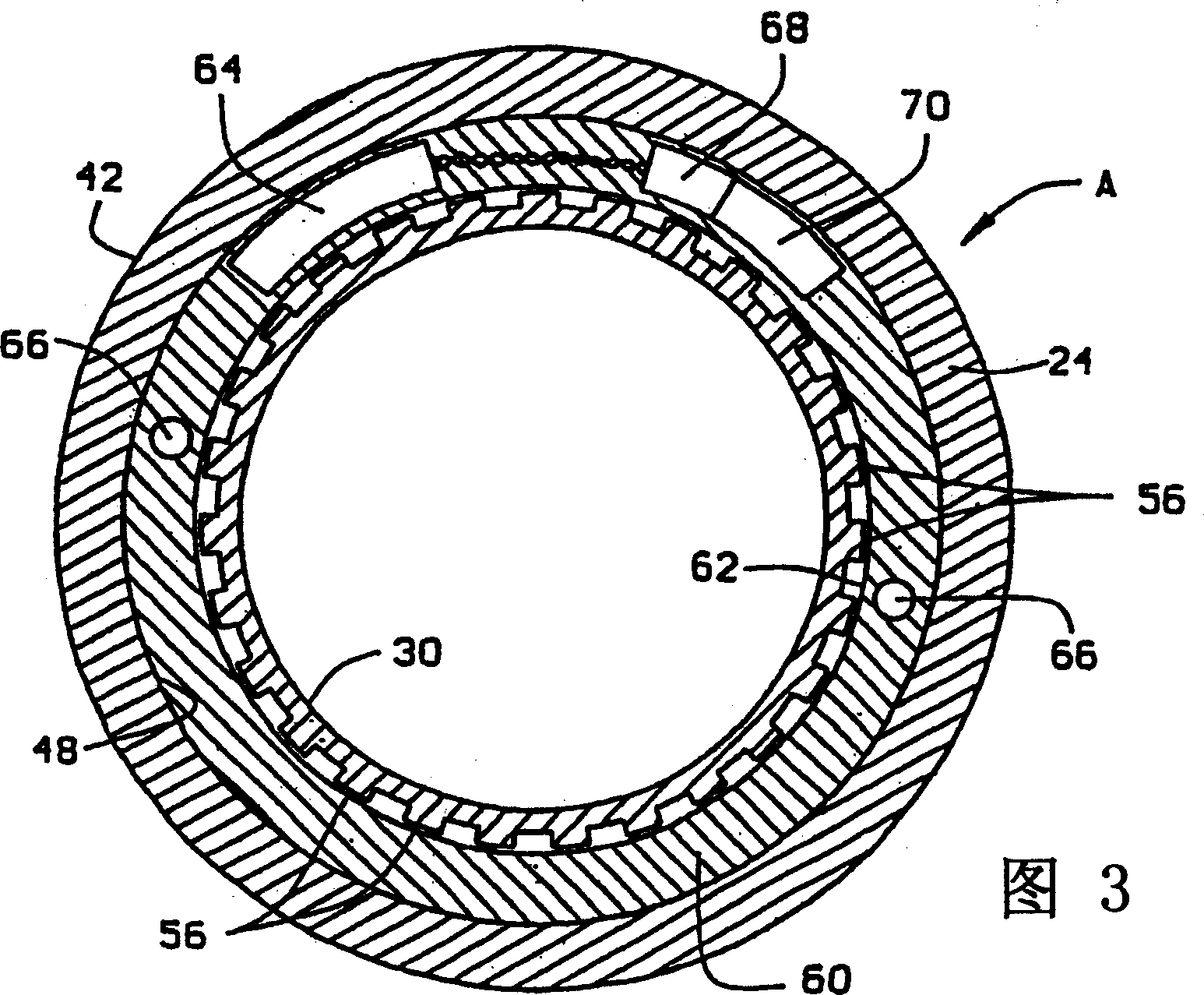

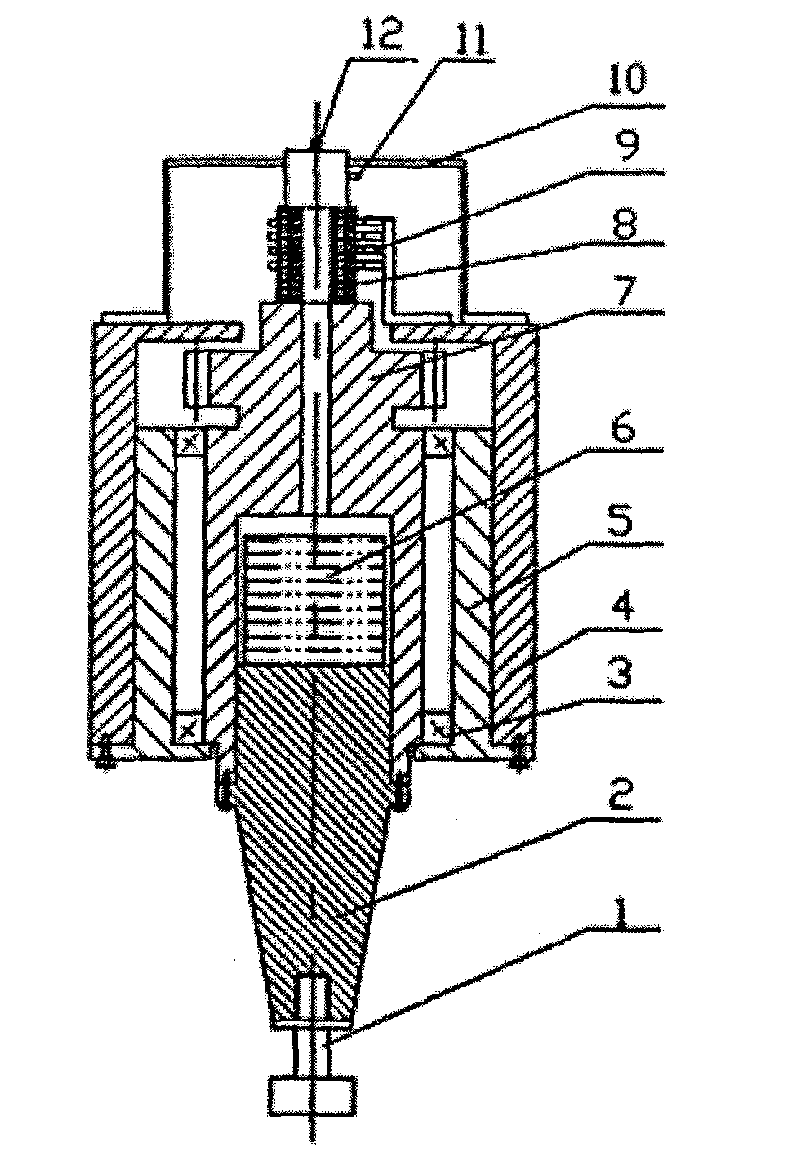

Bearing with wireless self-powered sensor unit

A tapered roller bearing having its rollers arranged in two rows within an outer race and around an inner race contains a sensing device that radiates signals which reflect conditions within the bearing. In one embodiment, the outer race is unitary and the sensing device is wireless and self-powered and includes a mounting ring that is fitted to the outer race between the raceways along which the rollers roll. The ring has embedded within it several sensors for monitoring bearing conditions such as temperature and vibrations. The ring also contains a radio transmitter, a microprocessor to which the sensors are connected, and a power supply for producing the electrical energy required to operate the processor and the transmitter. The electric power is generated by means of electromechanical energy conversion using permanent magnets, armature winding and a target wheel that is captured between and rotates with the two cones. The transmitter converts conditions registered by the sensors and processed by the processor into radio signals which are received externally from the bearing. In another embodiment the unitary outer race has a groove which opens inwardly between the two rows of rollers, and the sensors, radio transmitter, processor, and power supply are located within the groove. In other embodiments the inner race is unitary and the sensors, radio transmitter, processor and power supply are carried by the inner race.

Owner:THE TIMKEN CO

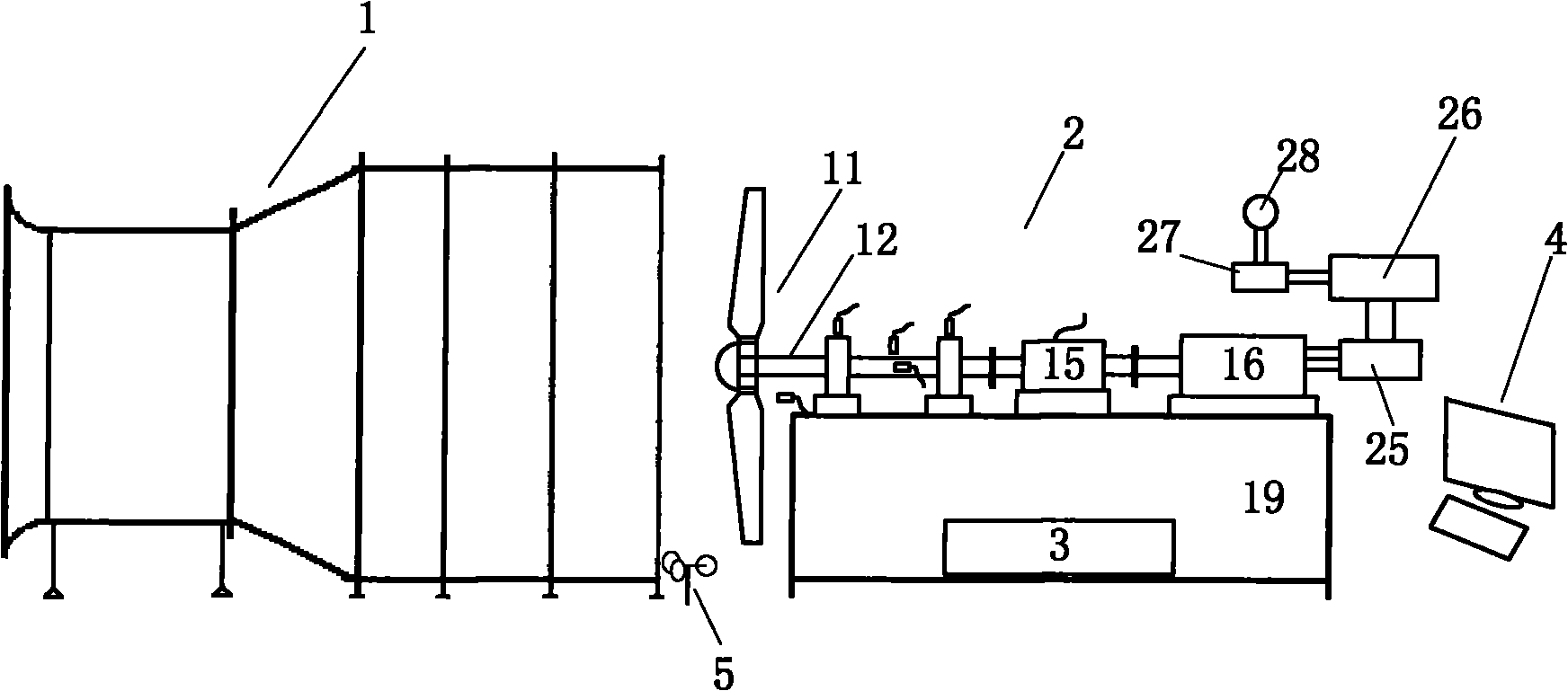

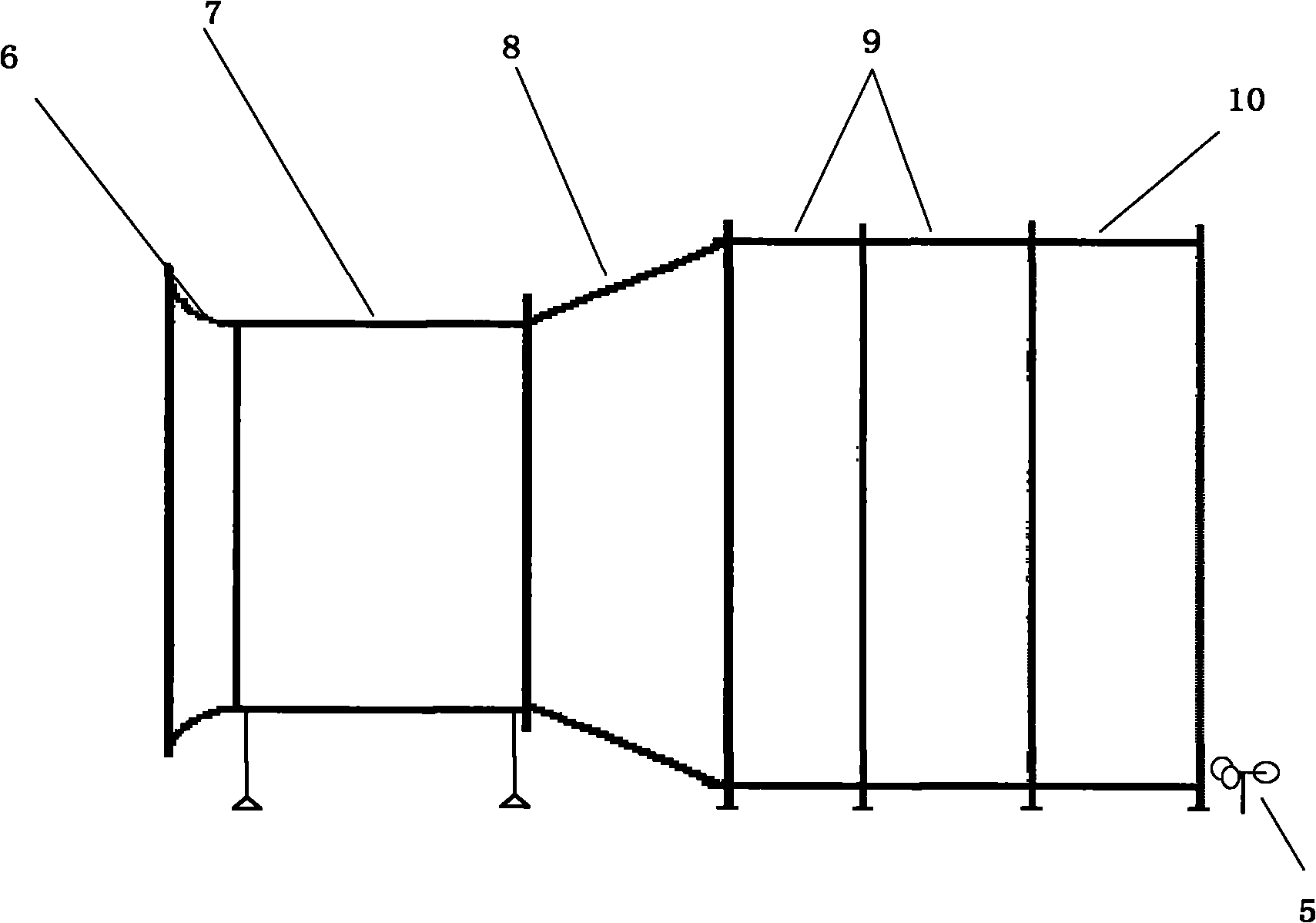

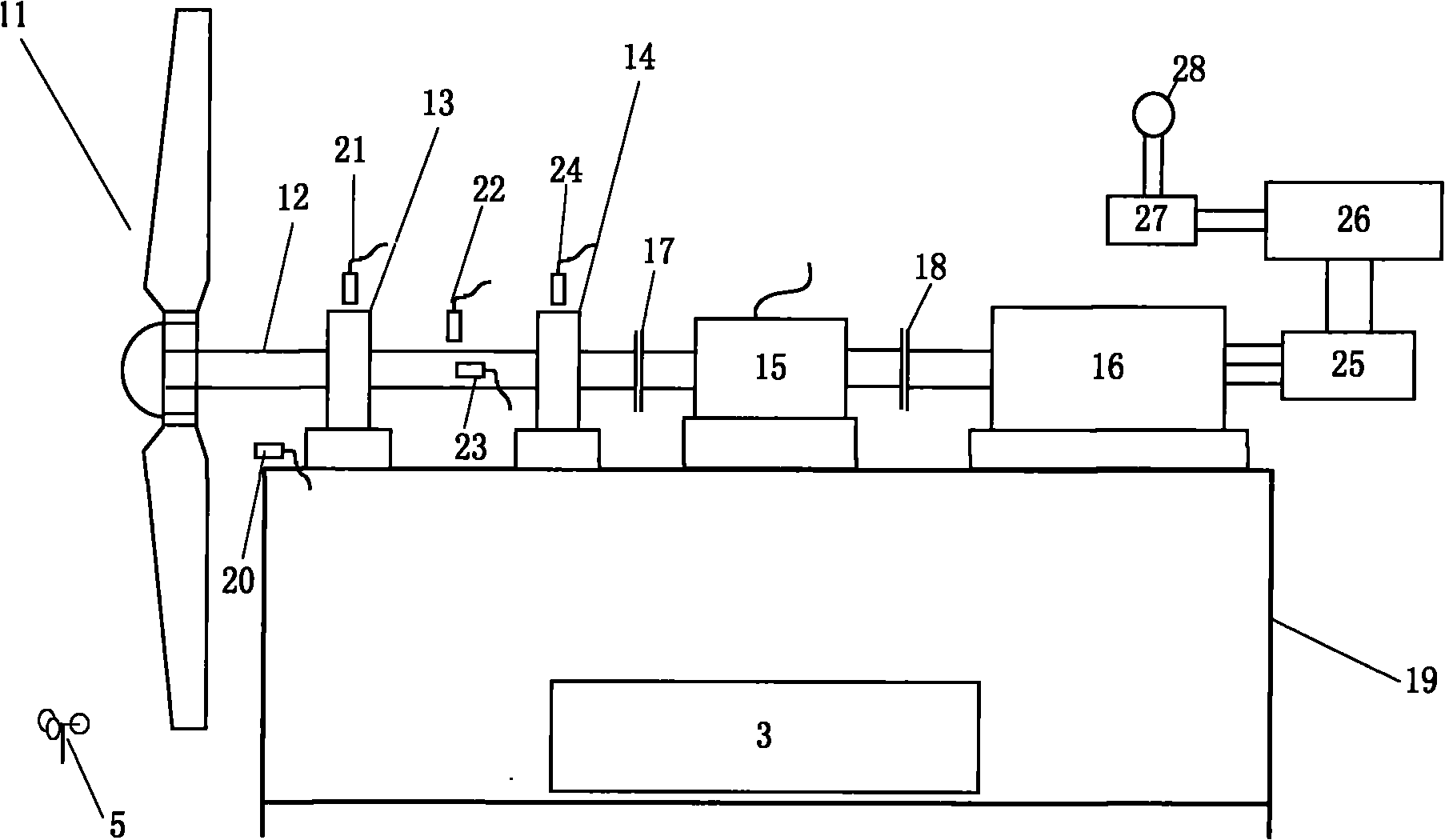

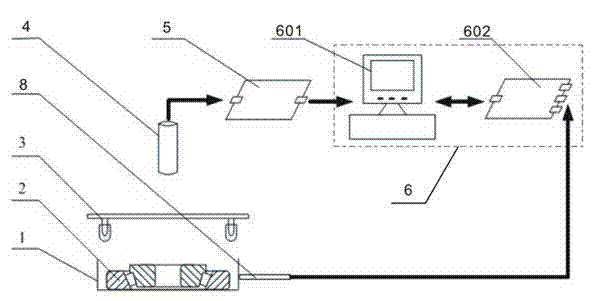

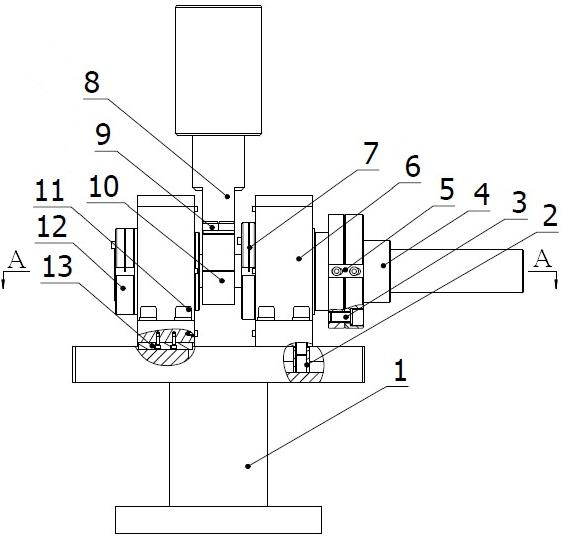

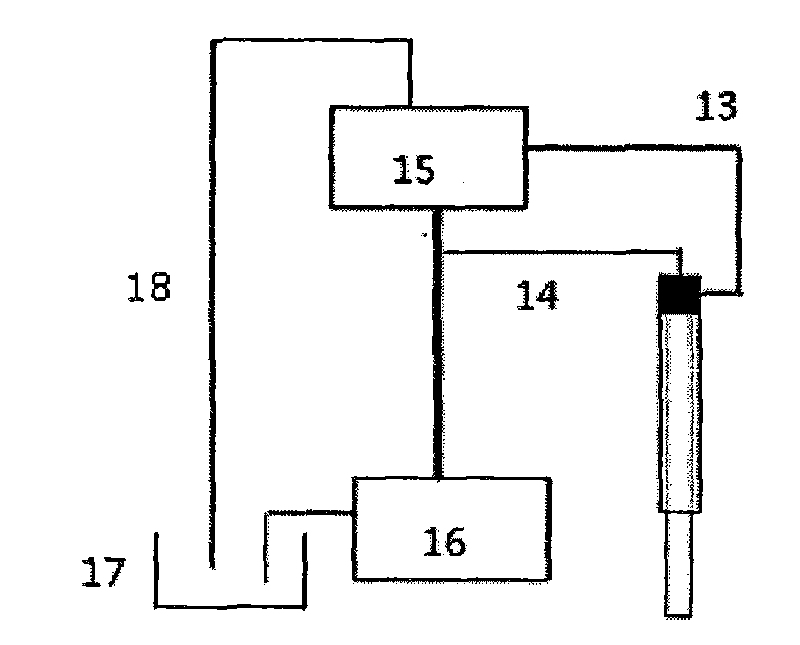

Performance analysis and fault simulation experiment system of wind machine

ActiveCN101871844ASimulation is accurateIncrease opennessAerodynamic testingEngine testingWinding machineReal time analysis

The invention relates to a performance analysis and fault simulation experiment system of a wind machine, belonging to the technical field of wind machine experiment devices. The system comprises a wind tunnel, a wind machine experiment device and a data analysis and processing system, wherein the wind machine experiment device comprises a rack, a wind wheel, a spindle, a generator, a controller and a sensor of torques, wind speed, speed and displacement. The system can be used for researching the influences of different airfoil profiles, wind speeds, wind wheel faults and mechanical faults on the aerodynamic performance of the wind machine, the vibration characteristics and the output force of a shaft system, and the like, and various faults such as unbalanced wind wheel mass, unbalanced pneumatic power, yawing, no shaft system centering, supporting seat loosening, bearing damages, and the like of the wind machine are simulated and analyzed in real time. Through selecting and assembling different types of bearings such as a self-aligning roller bearing, a cylinder roller bearing, a tapered roller bearing, and the like, the performances of the wind machine in different supporting forms can be compared. The system has good openness, dismantlability and expansibility and is mainly suitable for the fields of scientific researches and teaching of the wind machine.

Owner:TSINGHUA UNIV

Steering knuckle

InactiveUS6029986AGreat lateral forceEasy to processRoller bearingsSteering linkagesEngineeringMechanical engineering

PCT No. PCT / SE96 / 01285 Sec. 371 Date Apr. 6, 1998 Sec. 102(e) Date Apr. 6, 1998 PCT Filed Oct. 9, 1996 PCT Pub. No. WO97 / 13674 PCT Pub. Date Apr. 17, 1997Steering axle arrangement for non-driven steerable vehicle wheel, comprising a kingpin (3), on which a steering knuckle (12) is mounted in upper and lower taper roller bearings (17,18). The bearings are preloaded against bearing seats (20, 22) in the steering knuckle yoke arms (13, 14) by means of upper and lower nuts screwed onto the kingpin ends. The nuts press against the inner rings (23,25) of the bearings.

Owner:AB VOLVO

Wind wheel for wind power generation

ActiveUS20060220389A1Small sizeLight weightRoller bearingsWind motor supports/mountsNacelleWind force

Provided is a power generating wind turbine in which parts and compoments installed in or on a nacelle are made smaller and lighter and maintenance is facilitated. A main shaft 11, a gear-box speeding up rotation of the main shaft 11 and a generator 13 driven by output of the gear-box 11 are provided on a nacelle bed plate 6. The main shaft 11 is connected to an input shaft 12a end of the gear-box 12 via a double-row tapered roller bearing 16. The main shaft 11 is supported to be fitted to a wall portion W1 of the nacelle bed plate 6 with the double-row tapered roller bearing 16 being interposed therebetween. The main shaft 11 is formed in an annular shape having its outer diameter D1 made larger than its axial directional length L1.

Owner:MITSUBISHI HEAVY IND LTD

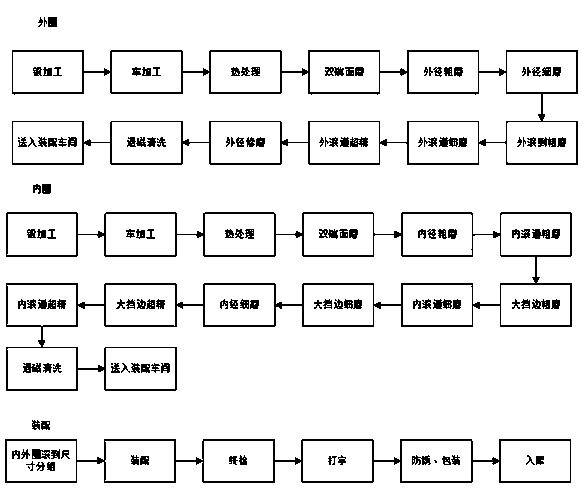

Production process for conical roller bearing

InactiveCN104191170ASimplify complex processing processesImprove processing qualityEngineeringThermal treatment

The invention discloses a production process for a conical roller bearing. The production process includes the following steps of the production technological process of an outer ring, the production technological process of an inner ring and the step that after the inner ring and the outer ring are sent to an assembly workshop, the sizes of an inner ring roller path and an outer ring roller path are grouped, assembling, final inspecting, typewriting, rust protecting and packaging are conducted, and then the conical roller bearing is put in storage. The production technological process of the outer ring includes the steps of forging, lathing, thermal treatment, double end face grinding, outer diameter part coarse grinding, outer diameter part fine grinding, outer roller path coarse grinding, outer roller path fine grinding, outer roller path super-finishing, outer diameter coping and demagnetization cleaning and the step of sending the outer ring to an assembly workshop. The production technological process of the inner ring includes the steps of forging, lathing, thermal treatment, double end face grinding, inner diameter coarse grinding, inner roller path coarse grinding, large flange coarse grinding, inner roller path fine grinding, large flange fine grinding, inner diameter fine grinding, large flange super-finishing, inner roller path super-finishing and demagnetization cleaning and the step of sending the inner ring to the assembly workshop. The production process has the advantages that the complex machining procedures of an ordinary process are simplified, bearing machining quality is improved, production efficiency is greatly improved, and production cost is saved.

Owner:ZHEJIANG HUANYU BEARING

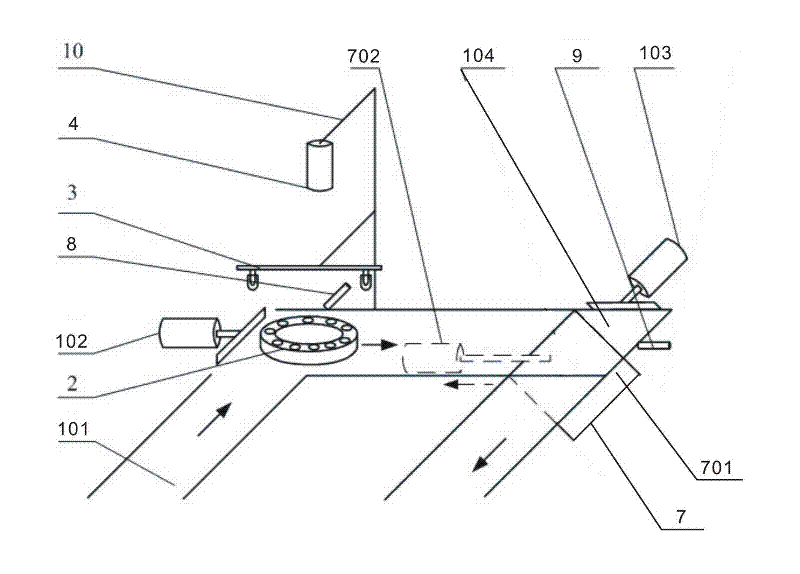

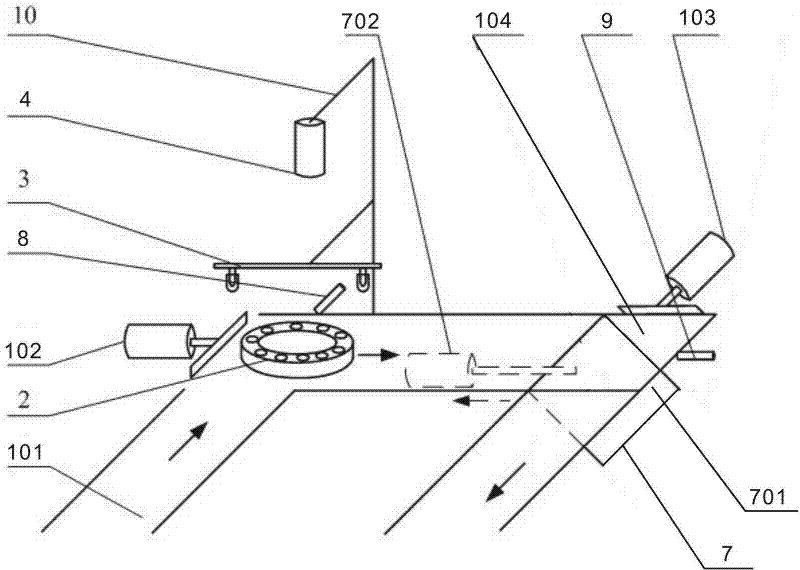

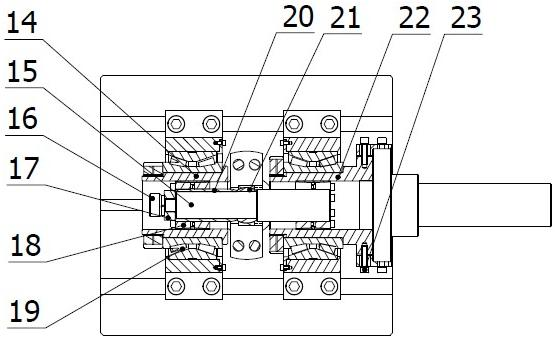

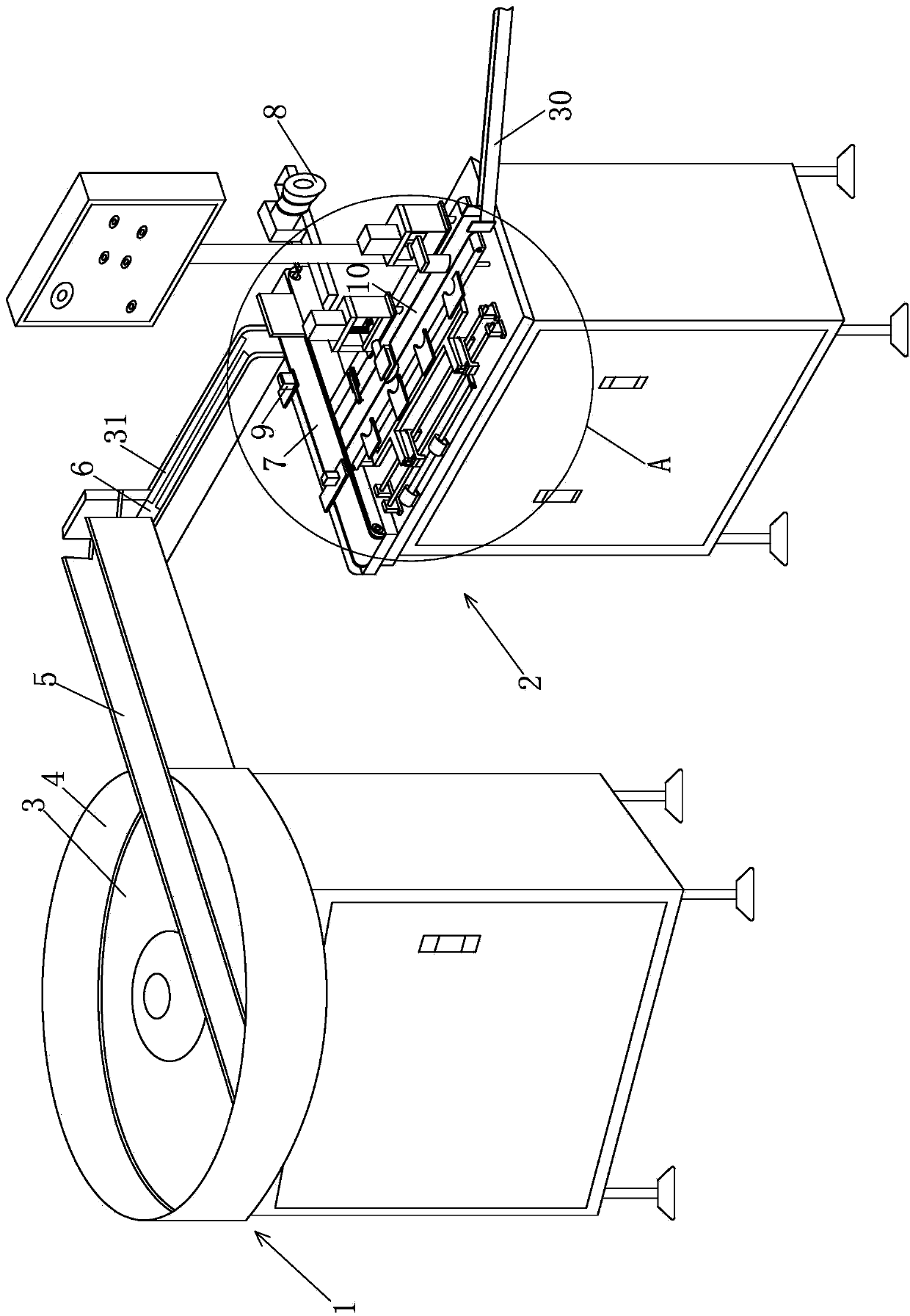

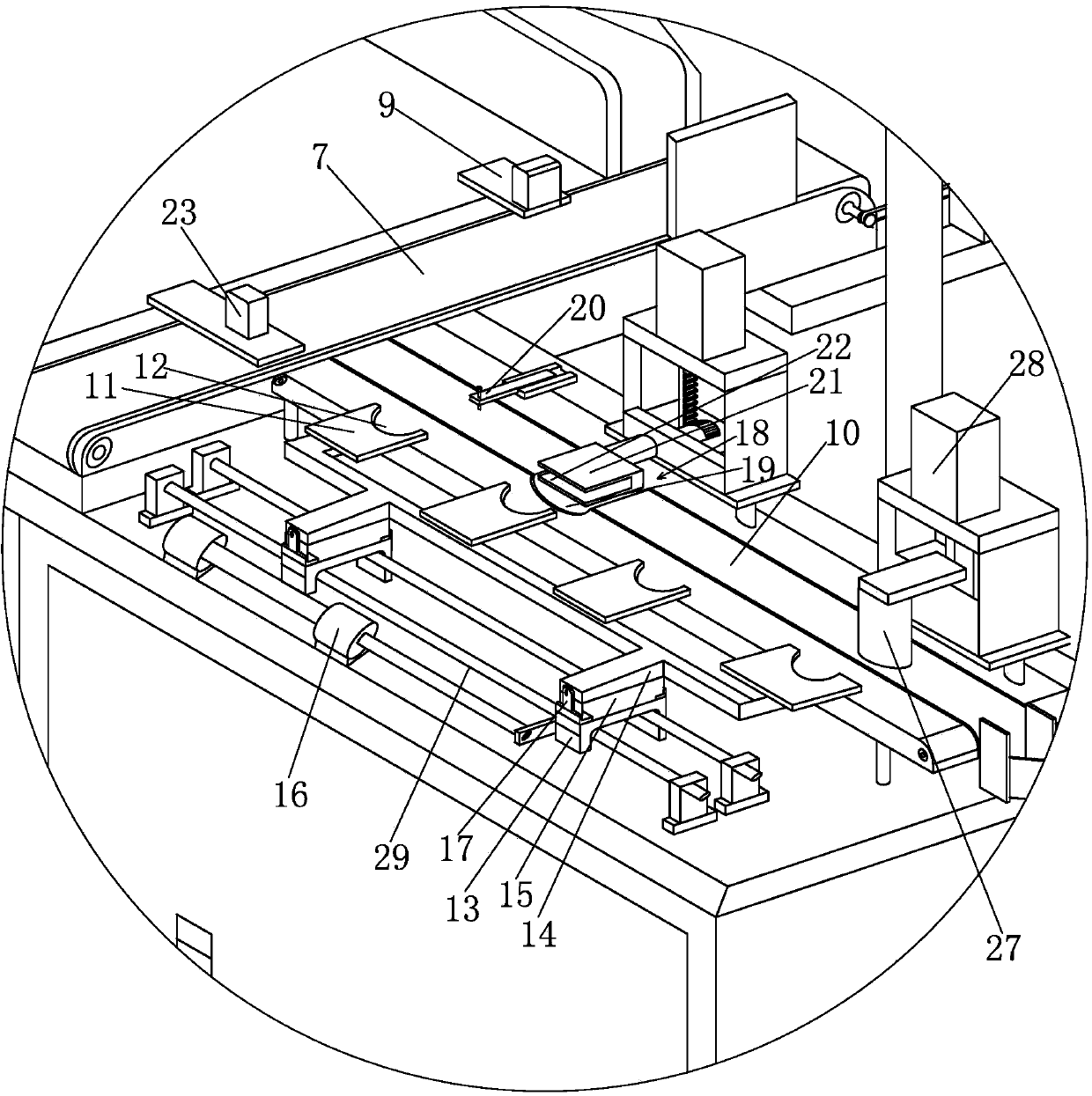

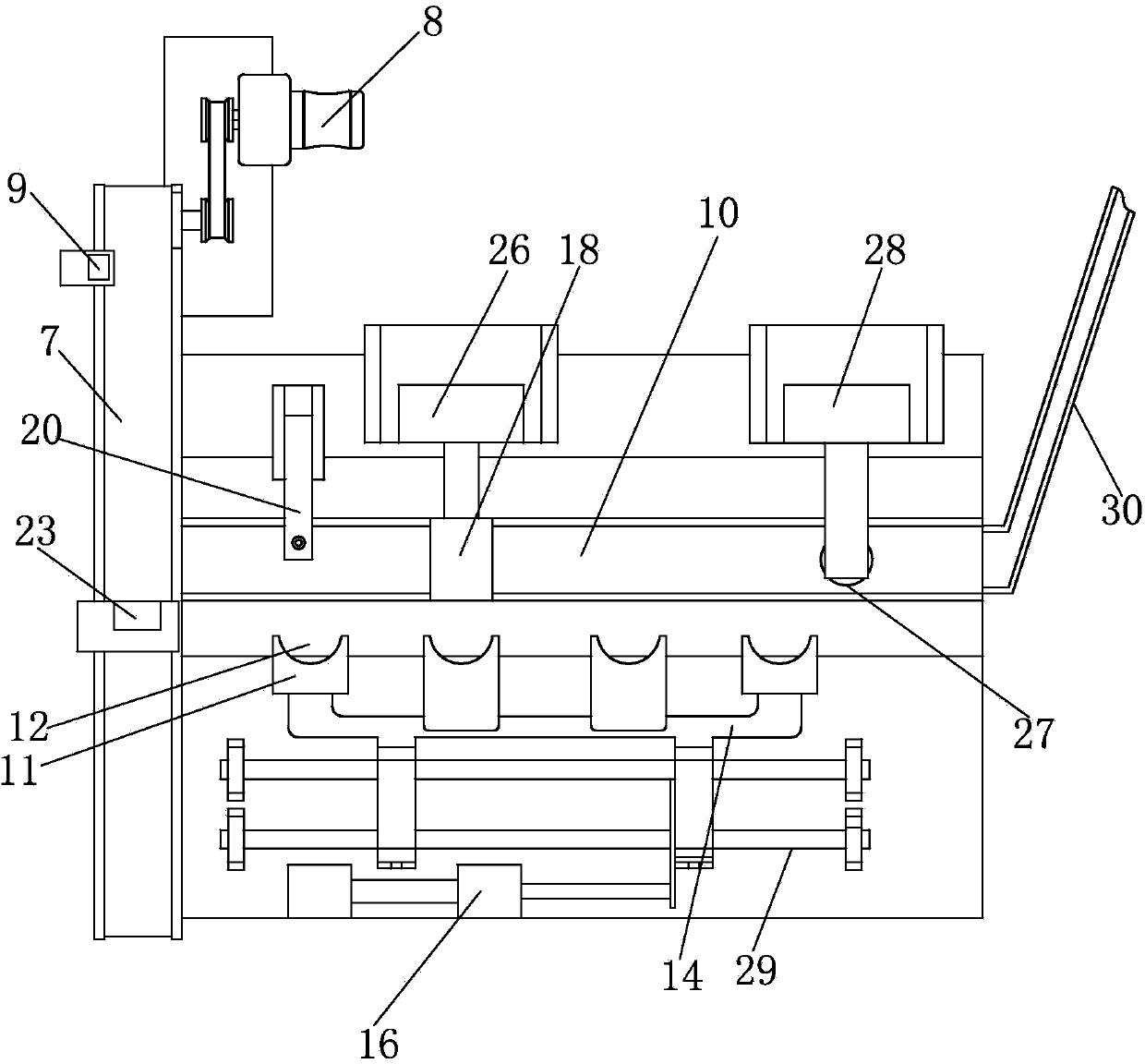

Apparatus and method for detecting tapered roller bearing rolling element upside-down mounting and missing mounting

InactiveCN102226739AQuality improvementEasy to operateMachine bearings testingSortingLocation detectionComputer module

Owner:HENAN UNIV OF SCI & TECH

Test detection device for joint bearing

ActiveCN102221462ANovel structureImprove reliabilityMachine bearings testingInterference fitThrust bearing

The invention relates to a test detection device for a joint bearing, belonging to the technical field of engineering machine test equipment. The joint bearing and a connecting shaft are arranged in an inner hole of a loading bracket in an interference fit way; two ends of the connecting shaft are fixed inside a following shaft sleeve and a rotary sleeve by using an expansion sleeve; the following shaft sleeve and the rotary sleeve are arranged in inner holes of double-row conical roller bearings; the double-row conical roller bearings are arranged on bearing seats at the two ends; and the bearing seats at the two ends are fixed on a base through guide blocks. The test detection device has the advantages of novel structure, high reliability, convenience for repeated assembly and disassembly, suitability for testing bearings of different specifications and capability of detecting the friction coefficient and the service life of the joint bearing and measuring the temperature change of the joint bearing under repeated load.

Owner:中机试验装备股份有限公司 +1

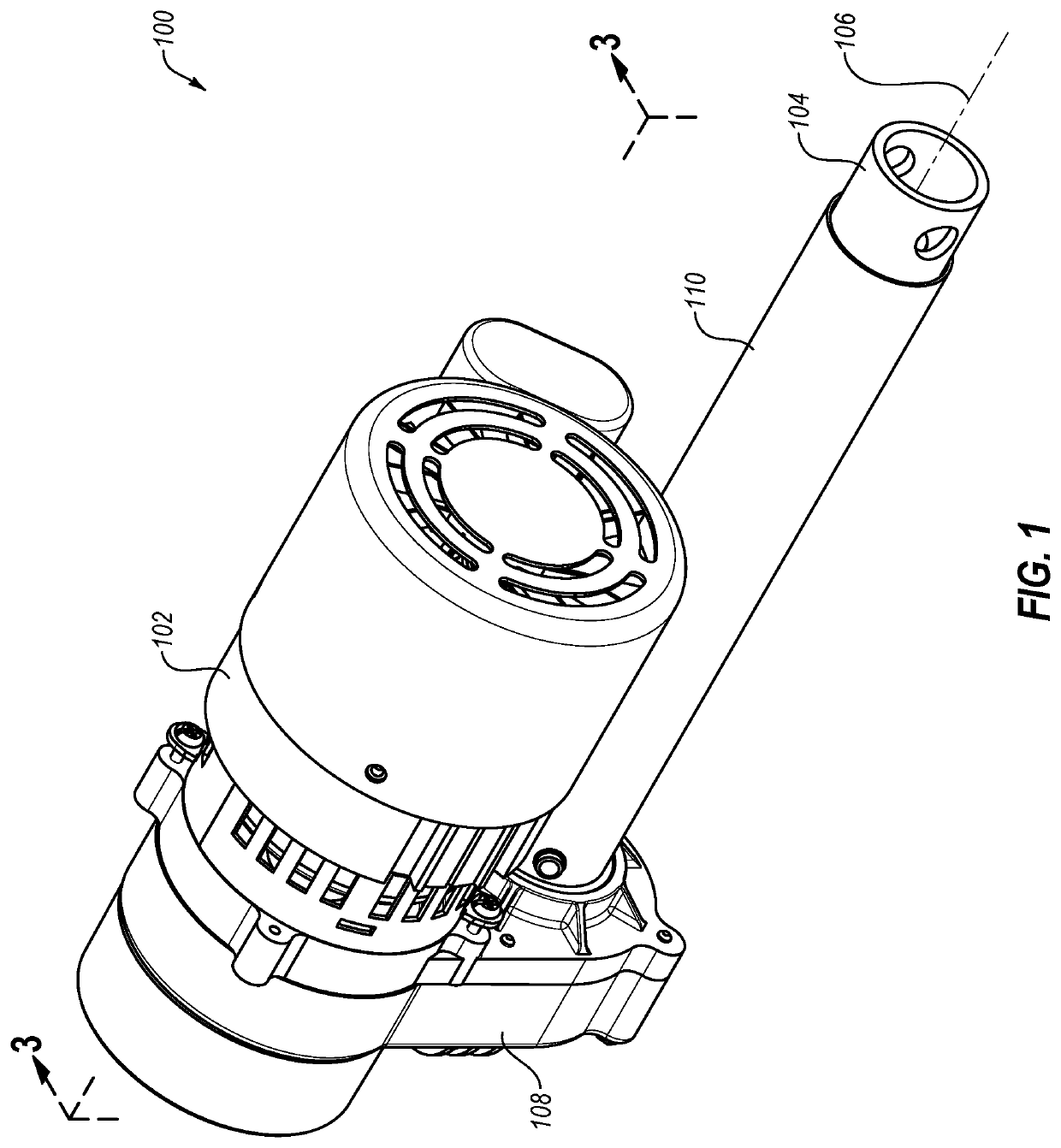

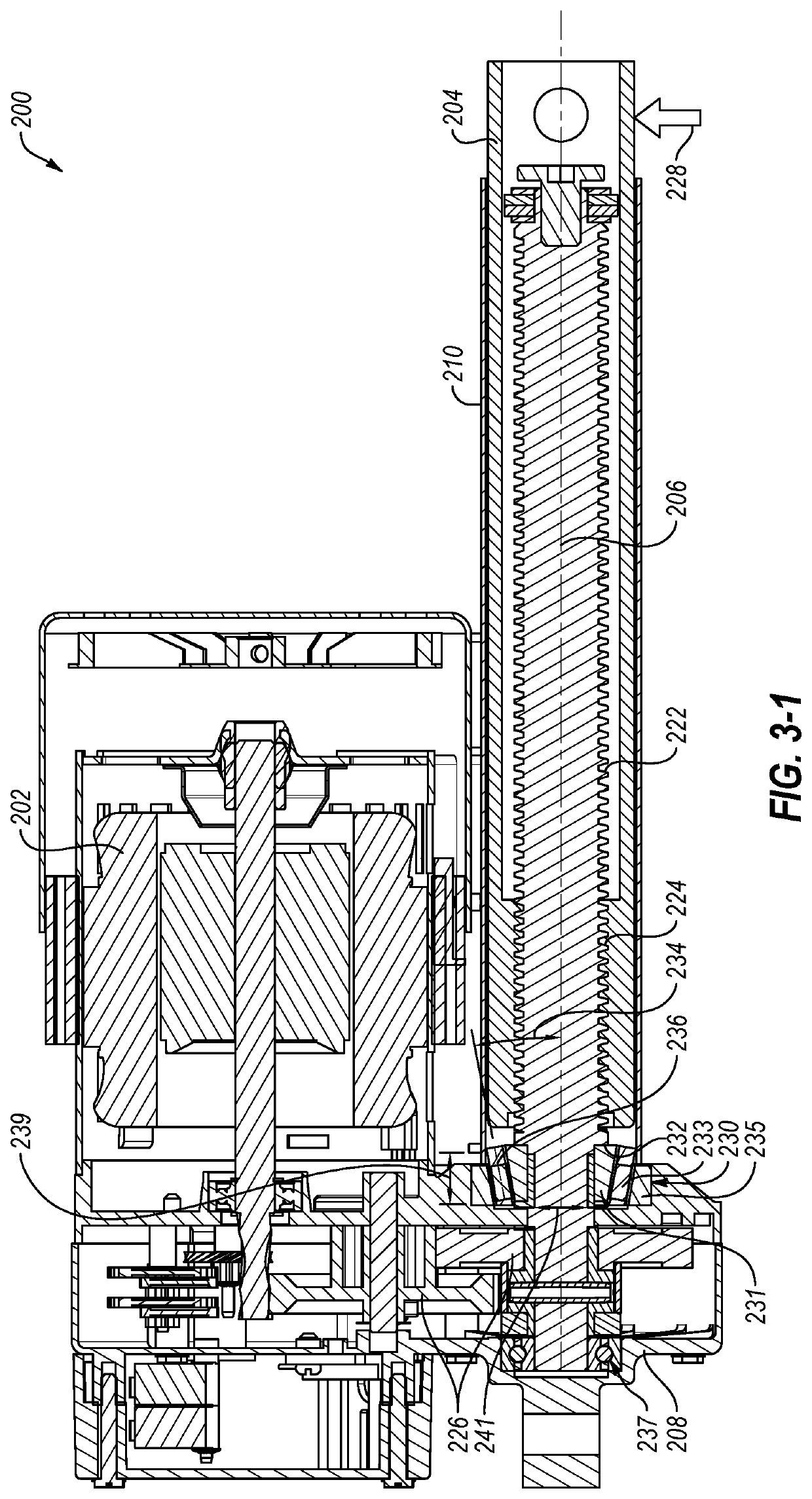

Increased durability linear actuator

ActiveUS20190376585A1Well formedGearingMovement coordination devicesLinear actuatorTapered roller bearing

A linear actuator includes a motor, a shaft, and a casing. The shaft has a longitudinal axis, and the shaft is moveable along the longitudinal axis by the motor. The casing supports the motor and the shaft with a tapered roller bearing positioned between at least a portion of the shaft and a portion of the casing.

Owner:IFIT INC

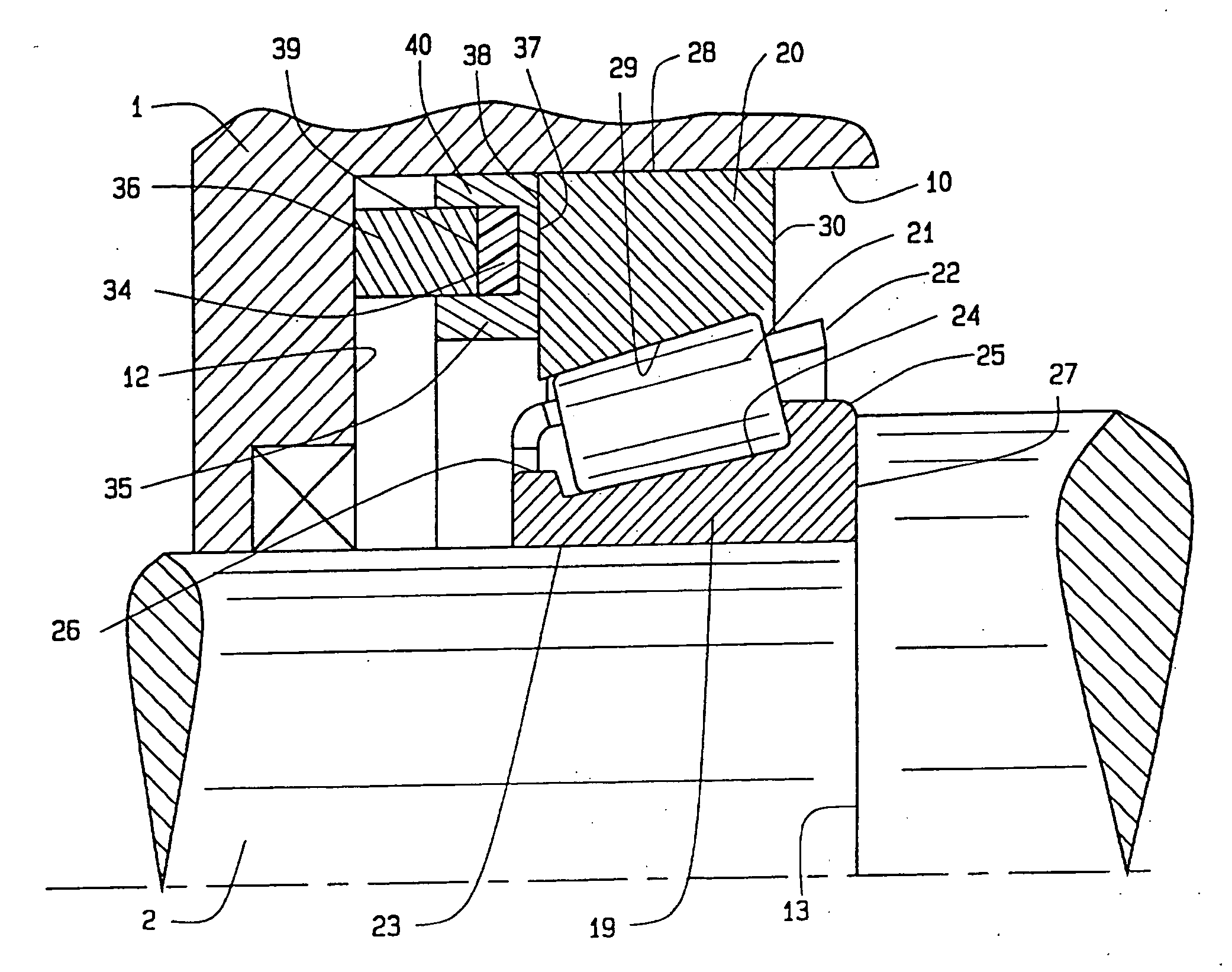

Bearing having thermal compensating capability

InactiveUS20090080824A1Low costLess complex to assembleRoller bearingsGearboxesThermal expansionAlloy

A roller bearing for use in transmission cases (1) made from aluminum alloy or other lightweight materials where the transmission contains a steel shaft (2) which is supported in the case on two directly mounted tapered roller bearings (8,9) so that the two bearings (8,9) confine the shaft (2) both radially and axially. To compensate for the differences in expansion and contraction between the case and the steel shaft (2) as the transmission or transaxle experiences variations in temperature, a race (20) of at least one of the bearings is fitted with a compensating ring (34) having a coefficient of thermal expansion greater than that of the case (1) or shaft (2). As a consequence, the bearings operate at a generally uniform setting over a wide range of temperature variations.

Owner:THE TIMKEN CO

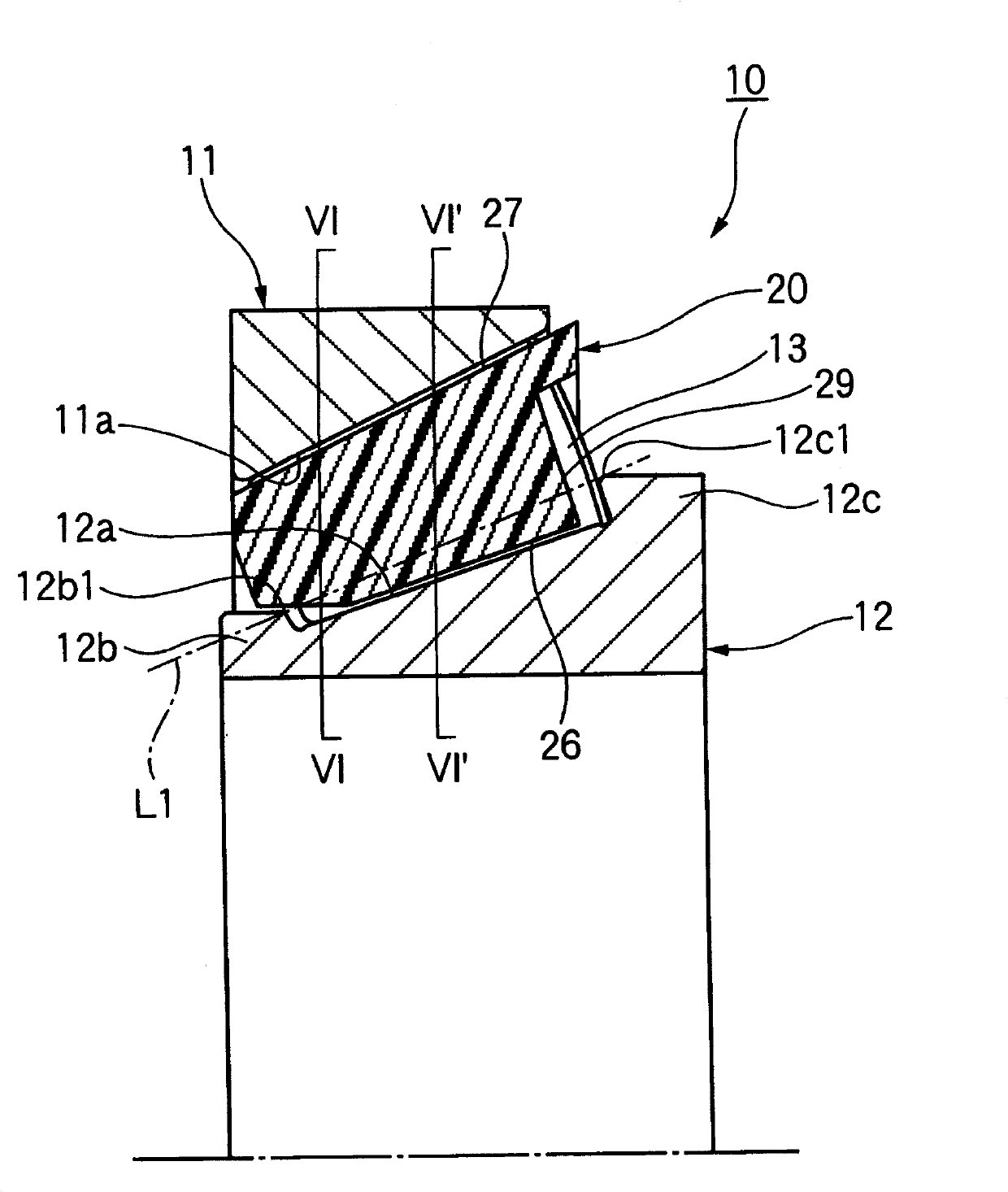

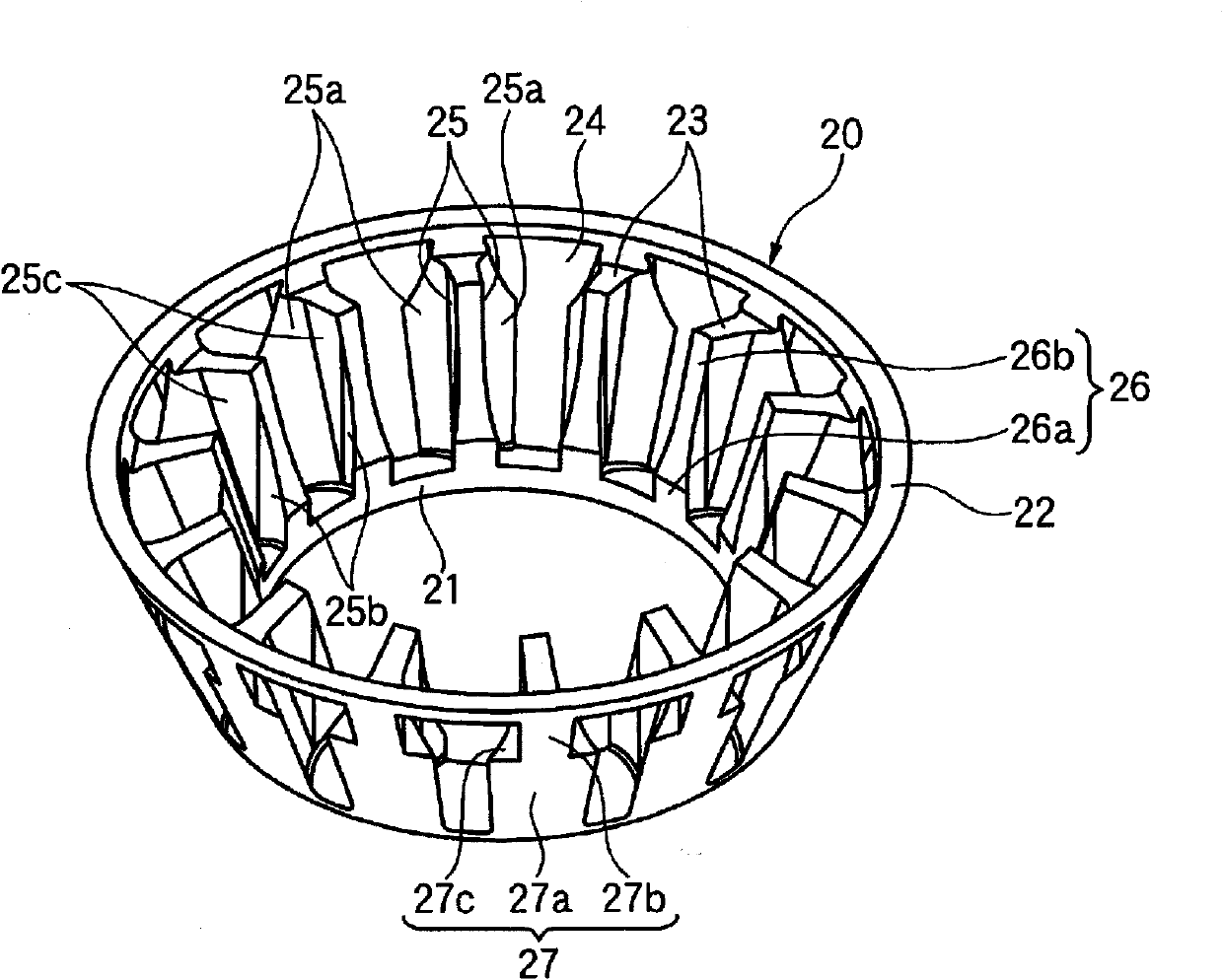

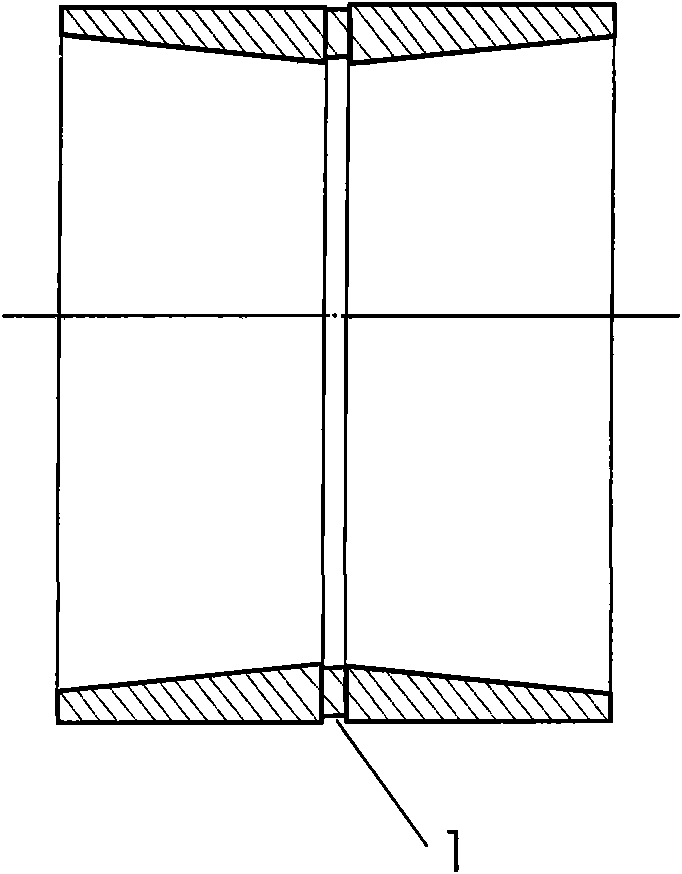

Resin retainer for tapered roller bearing, and tapered roller bearing

ActiveCN102089541AReduce stirring resistanceImproves ease of installationRoller bearingsShaftsEngineeringMechanical engineering

A resin retainer for a tapered roller bearing and the tapered roller bearing which are configured such that a space in the tapered roller bearing is reduced, stir resistance of lubricating oil contained in the bearing is reduced, and easiness of mounting of tapered rollers into the bearing is enhanced. A resin retainer (20) for a tapered roller bearing is provided with a small-diameter annular section (21), a large-diameter annular section (22), and struts (23) for interconnecting both the annular sections (21, 22). The struts (23) are each provided with a pair of circumferential side surfaces (25) respectively having roller guide surfaces (27), and also each provided with an inner peripheral surface (26) having a circumferential width smaller on the large-diameter annular section (22) side than on the small-diameter annular section (21) side. Between adjacent struts (23) is provided a retaining region (Ar) having, between the opposed circumferential side surfaces (25) of the adjacent struts (23), an outer-diameter-side pocket width (W1) and an inner-diameter-side pocket width (W2) which are set less than a diameter (D) of the tapered rollers.

Owner:NSK LTD

Charging and blanking robot of punch press

InactiveCN101758497AEasy to adjustImprove work efficiencyProgramme-controlled manipulatorMetal-working feeding devicesPunch pressReduction drive

The invention discloses a charging and blanking robot of a punch press, comprising four joints, a base, two arms and an end effector, wherein the first joint, the second joint and the fourth joint have the degree of freedom of rotation, and the third joint has the degree of freedom of up and down translation; one end of the first joint is connected with the base by an input end shell; the other end of the first joint is connected with one end of the first arm by a first joint output flange; the other end of the first arm is connected with a second joint output flange of the second joint; a third joint connecting plate is connected with the joint rack of the fourth joint; and a fourth joint output rotary table is provided with the end effector. A harmonic transmission mode is adopted by a first joint transmission device and a second joint transmission device of the robot. Aiming at the characteristic that a harmonic speed reducer only can bear torque but can not bear bending moment, a pair of tapered roller bearings is arranged on an output shaft and is used for bearing overturning bending moment. The transmission mode has compact structure, high transmission efficiency, small return difference and high transmission accuracy.

Owner:ZHEJIANG UNIV

Rolling bearing unit

InactiveUS6971799B2Prolong lifeReduce signalingElectric signal transmission systemsRoller bearingsRolling-element bearingDistortion

A four-row tapered roller bearing is incorporated in the clearance between the inner surface of a housing and the outer surface of a rolling roller. A pair of supporting members supporting sensor devices are fitted in and supported by a part of the inner surface of the housing in such a manner that they are opposed to the ends of outer rings of the four-row tapered roller bearing disposed close to the both axial ends thereof. The sensor devices each comprise a distortion gauge as a detecting portion and a first coil for transmitting as a wireless signal a signal obtained by processing an output signal outputted from the distortion gauge. A second coil for receiving the wireless signal transmitted by the first coil is retained on a part of a member other than the supporting members.

Owner:NSK LTD

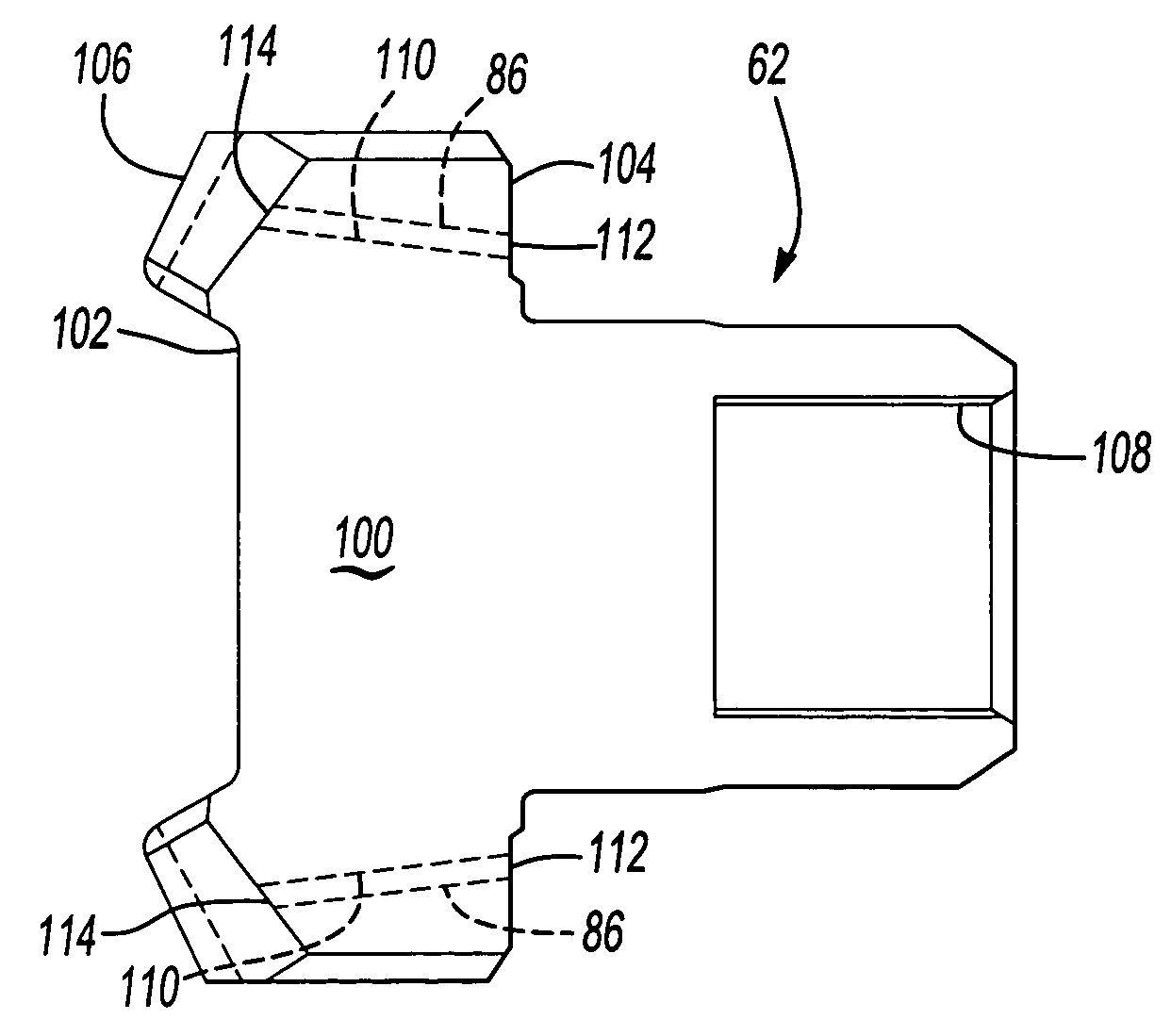

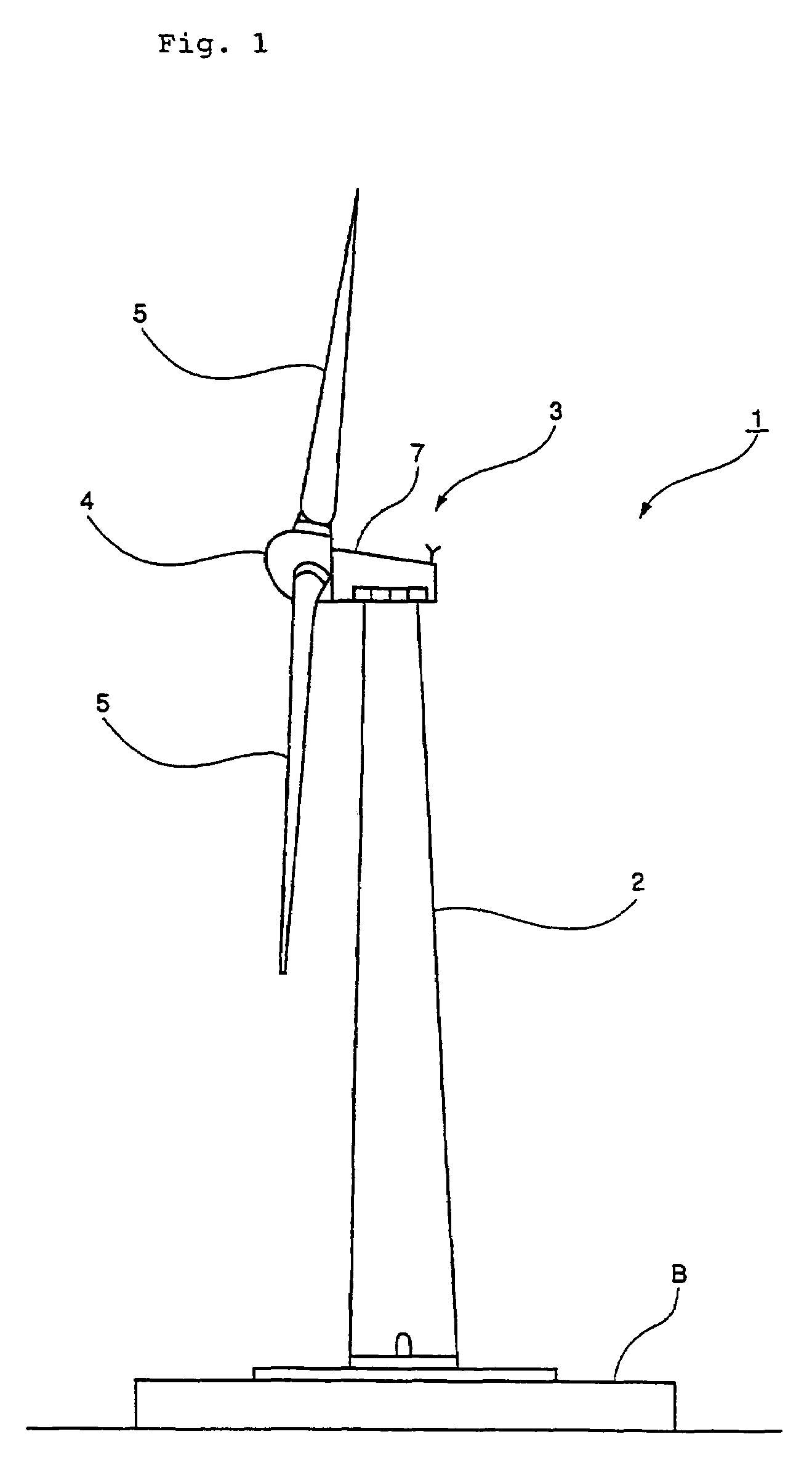

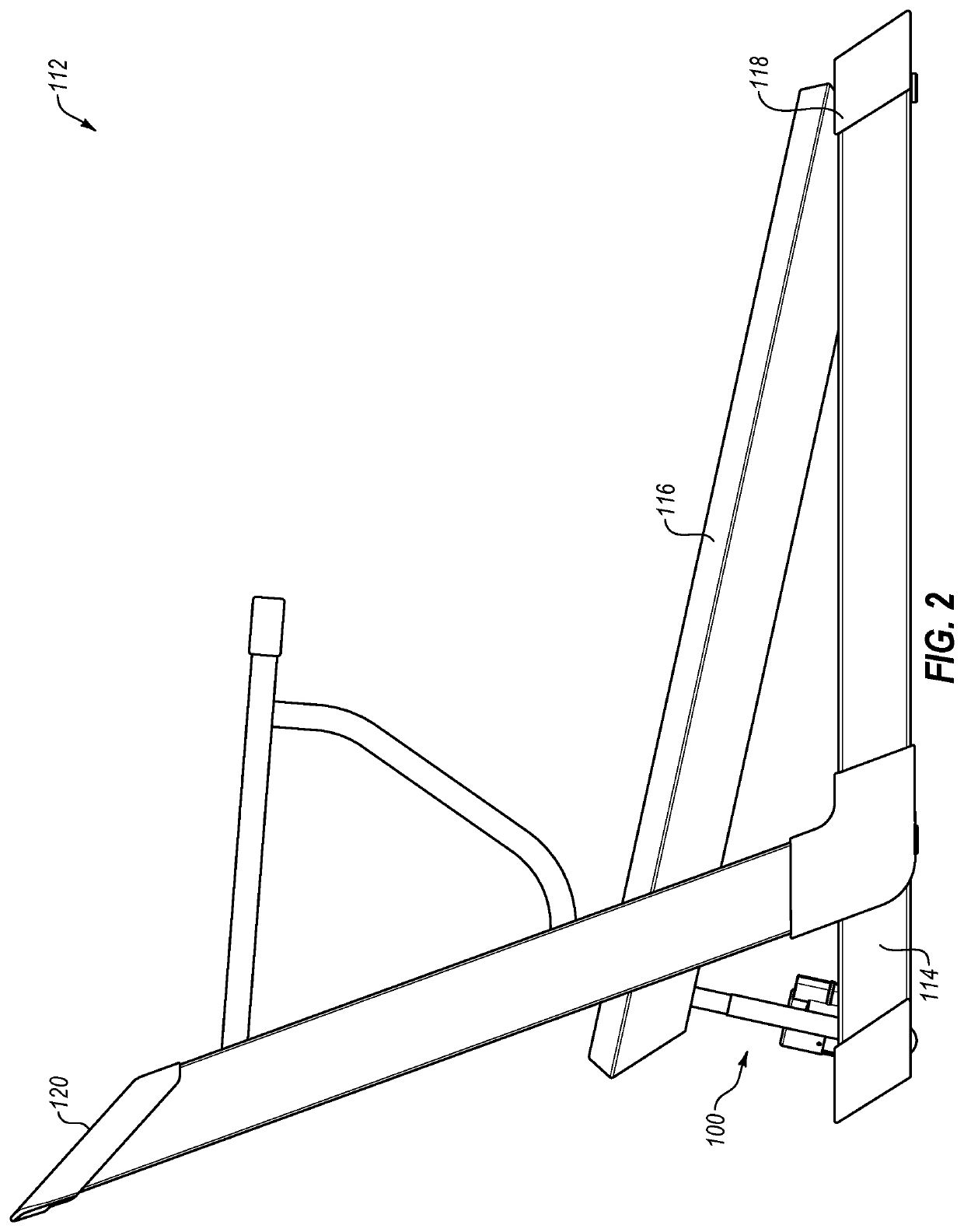

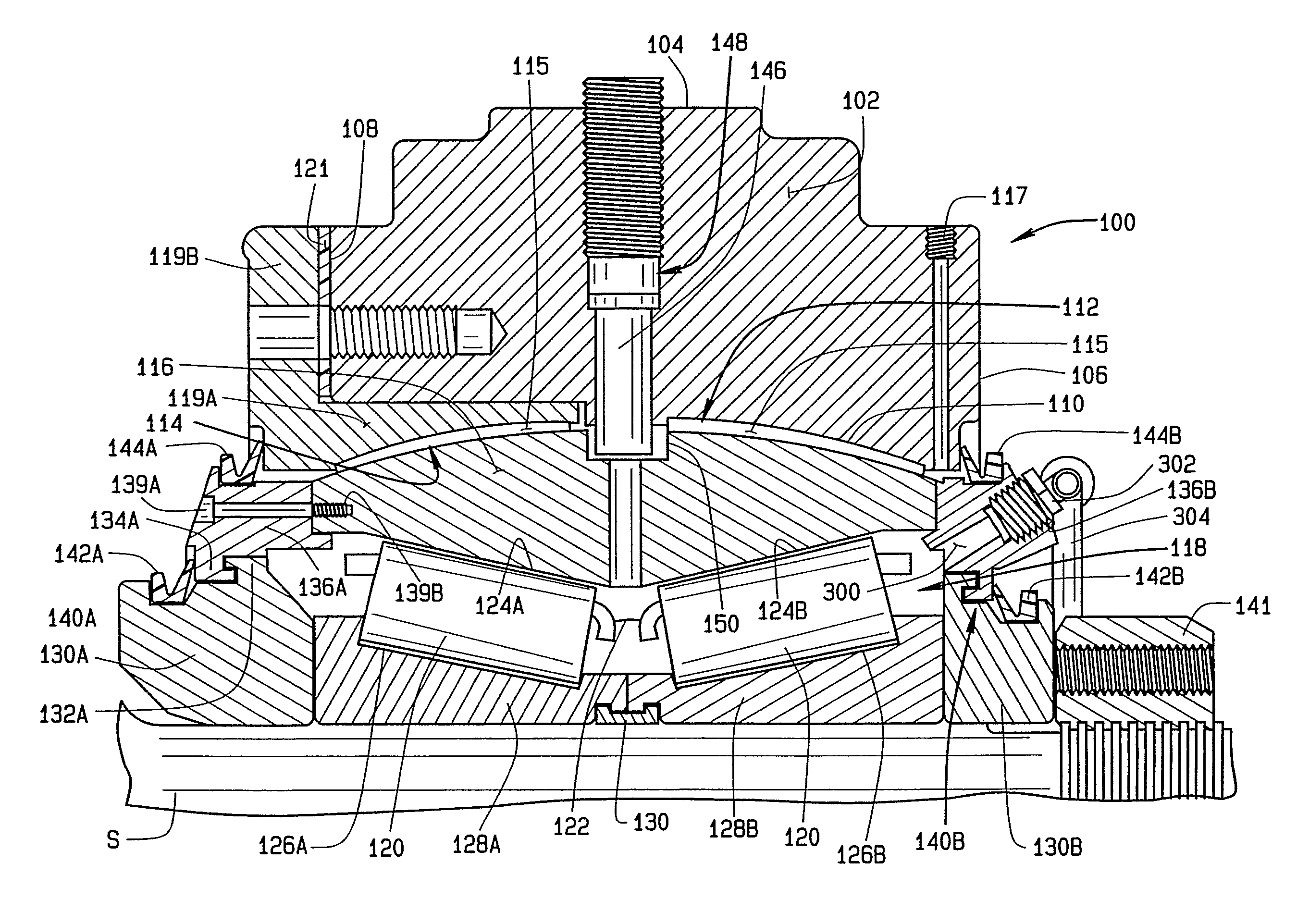

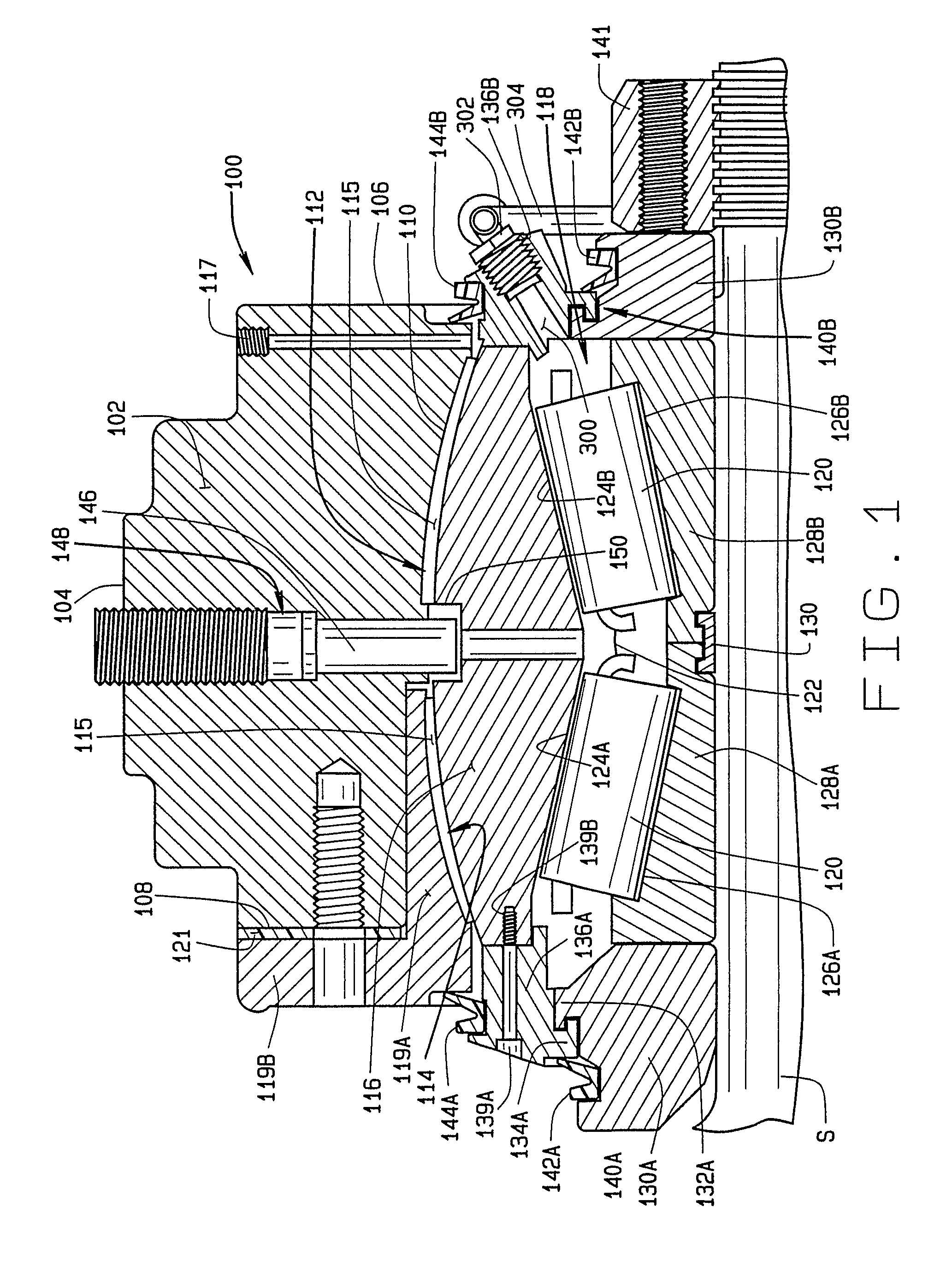

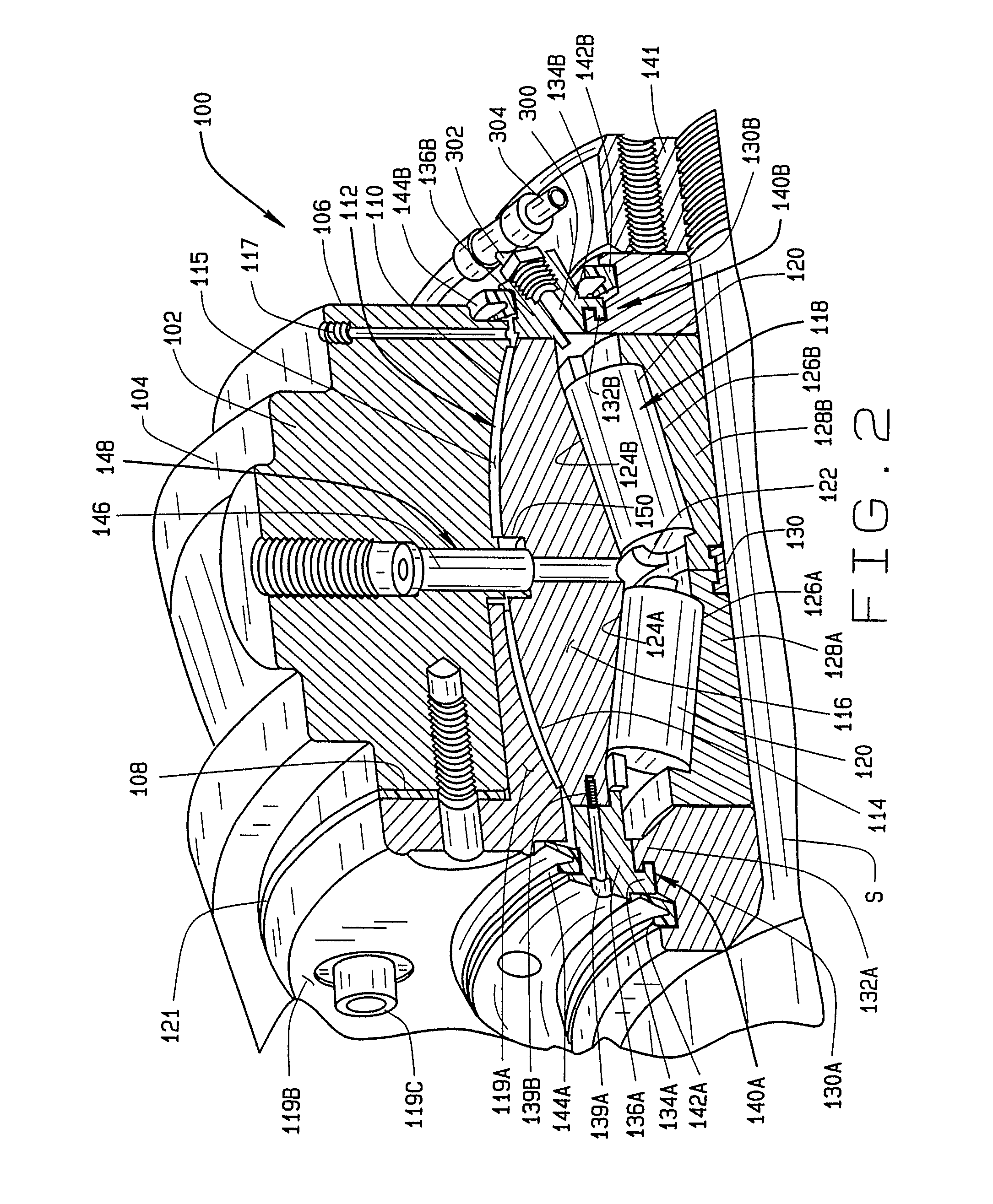

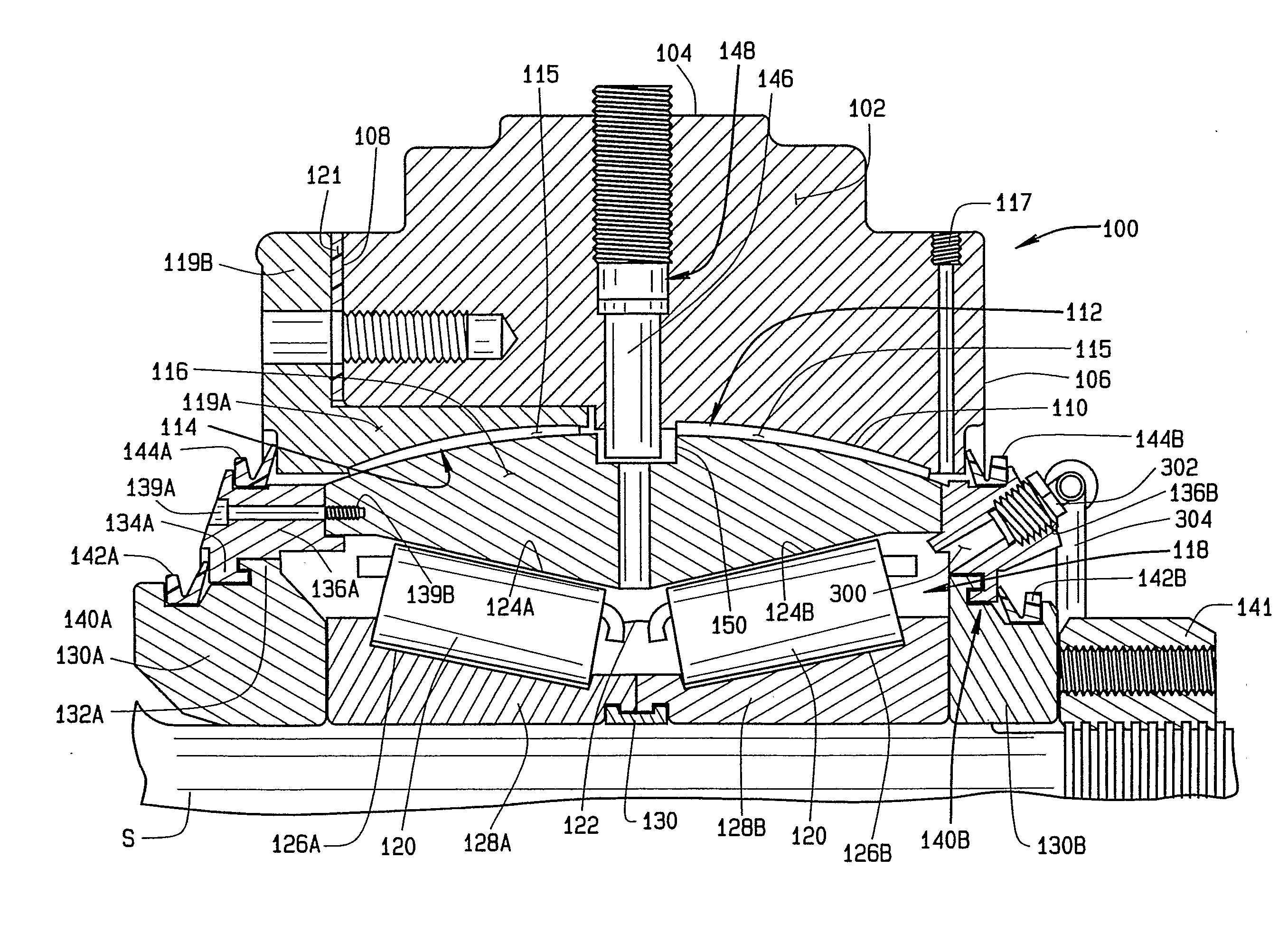

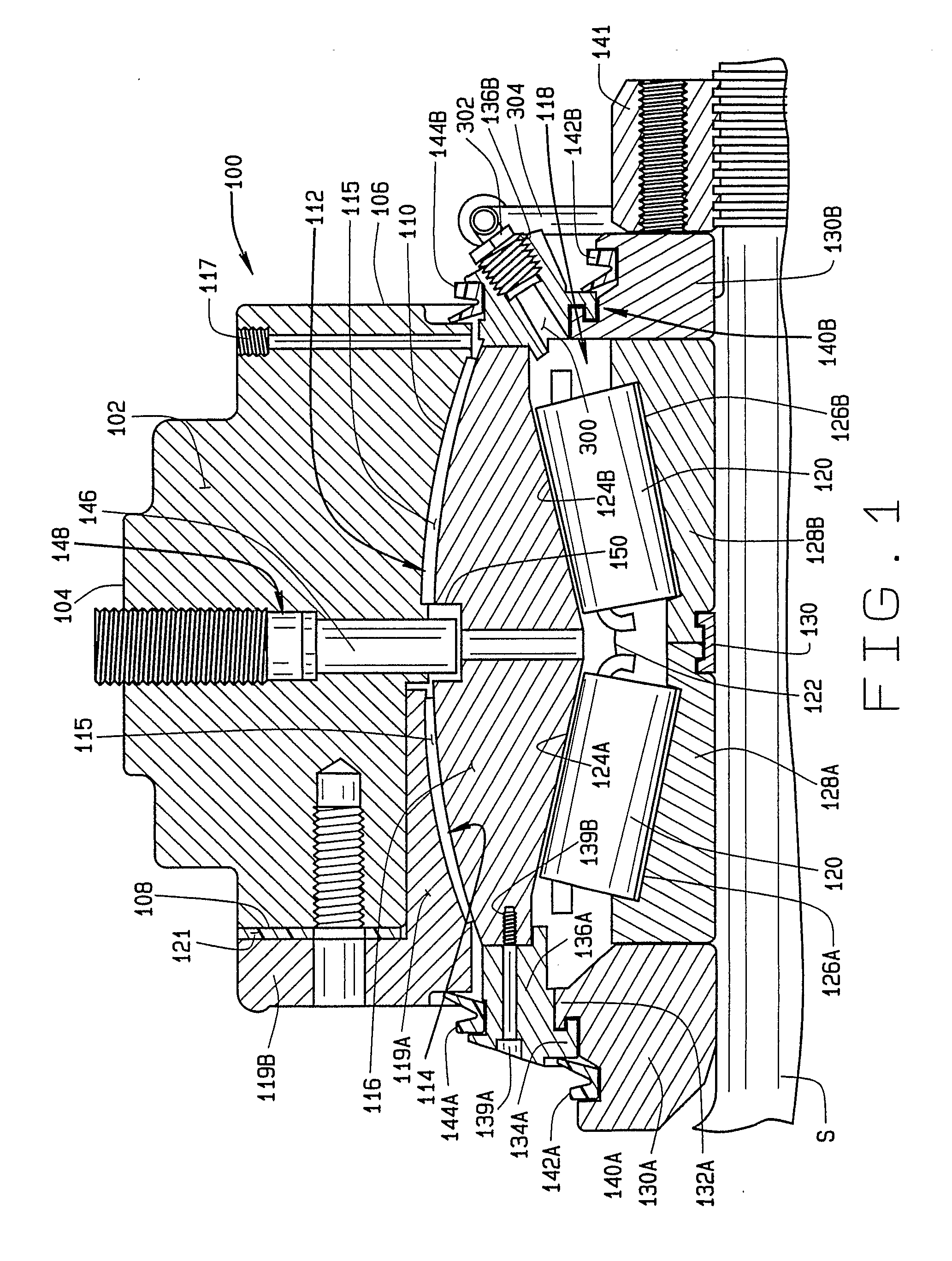

Pillow block housing with tapered roller bearings

ActiveUS8075196B2Reduce exerciseReduced responseEngine sealsRolling contact bearingsPillow block bearingTurbine

A spherical outer diameter tapered roller bearing pillow block system (100) for supporting the rotating main shaft of a wind turbine. The bearing system is configured with a unitized construction and factory set preload bearing settings to facilitate installation and setup. A spherical outer diameter surface (114) is formed on the outer race (116) of a tapered roller bearing assembly disposed about the rotating main shaft of the wind turbine. The bearing assembly is secured to a stationary support structure of the wind turbine through a pillow block housing assembly (102) providing a matching spherical housing seat (112) to form a ball and socket interface between the tapered roller bearing assembly (118) and the pillow block housing assembly (102). The ball and socket interface accommodates static and dynamic misalignments between the wind turbine main shaft and the supporting structure, while the bearing assembly (118) accommodates radial and axial loads.

Owner:THE TIMKEN CO

Tapered roller bearing and differential gear apparatus

InactiveUS20080096715A1Reduce fuel consumptionIncreased durabilityRoller bearingsGearboxesEngineeringLarge ribs

An outer peripheral surface of an inner ring extends straight along outer peripheral surfaces of tapered rollers, and is open at a front side of a tapered roller bearing which is a lubricating oil supply side. A smaller-diameter end portion of a cage is cut in a radial direction to be open. A hole retaining ring is disposed at aback face side of the inner ring which is a lubricating oil discharge side, and is fixed at its outer peripheral portion to an inner peripheral portion of an extension portion of an outer ring. An inner diameter of the hole retaining ring is larger than an outer diameter of a larger rib portion of the inner ring.

Owner:JTEKT CORP

Conical roller bearing automatic feed and face recognizing machine

The invention discloses a conical roller bearing automatic feed and face recognizing machine. The conical roller bearing automatic feed and face recognizing machine comprises a feed device and a face recognizing system. The feed device comprises a circular feed rotary plate which is obliquely disposed relative to the horizontal face. A feed groove is formed at the bottommost end of the plate face of the circular feed rotary plate. The circular feed rotary plate continuously rotates to feed bearings into the feed groove. A guide groove is formed below the feed groove. A movable conveying belt is disposed below the guide groove. The face recognizing system comprises a face recognizing workbench, a pushing device, a recognizing device and face turning device, wherein the pushing device is used for pushing the bearing on the conveying belt into the face recognizing workbench and continuously pushing the same to move forwards, the recognizing device is used for recognizing the size of the upper end faces of the bearings, and the face turning device is used for turning the bearings into required states. The conical roller bearing automatic feed and face recognizing machine has the advantages that automatic feed and detection can be achieved, when the placing states of the bearings do not accord to preset states, the bearings can be turned automatically, state consistency of the bearings before grinding can be guaranteed, and automatic face reorganization is achieved.

Owner:慈溪市伊纳轴承有限公司

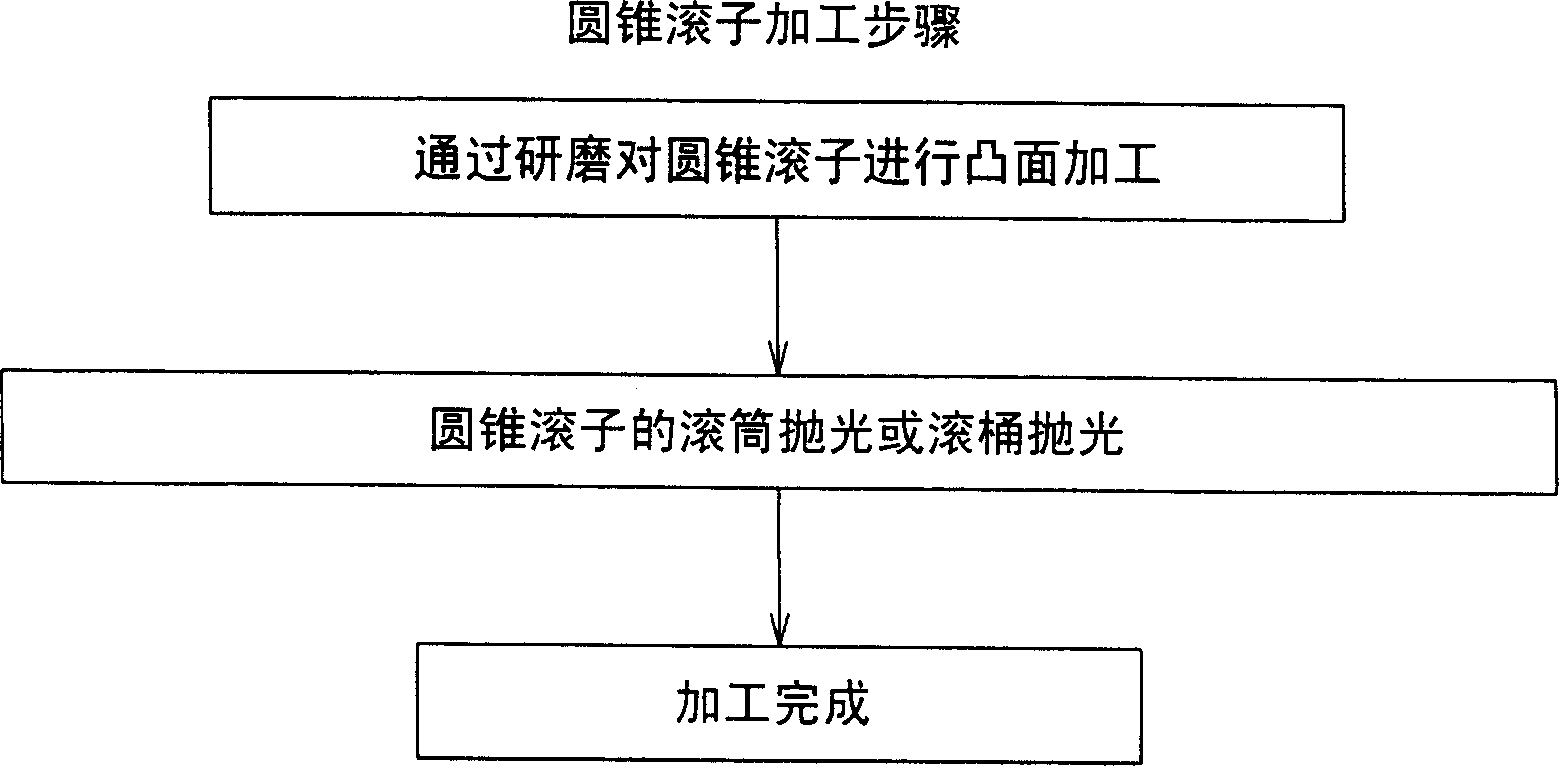

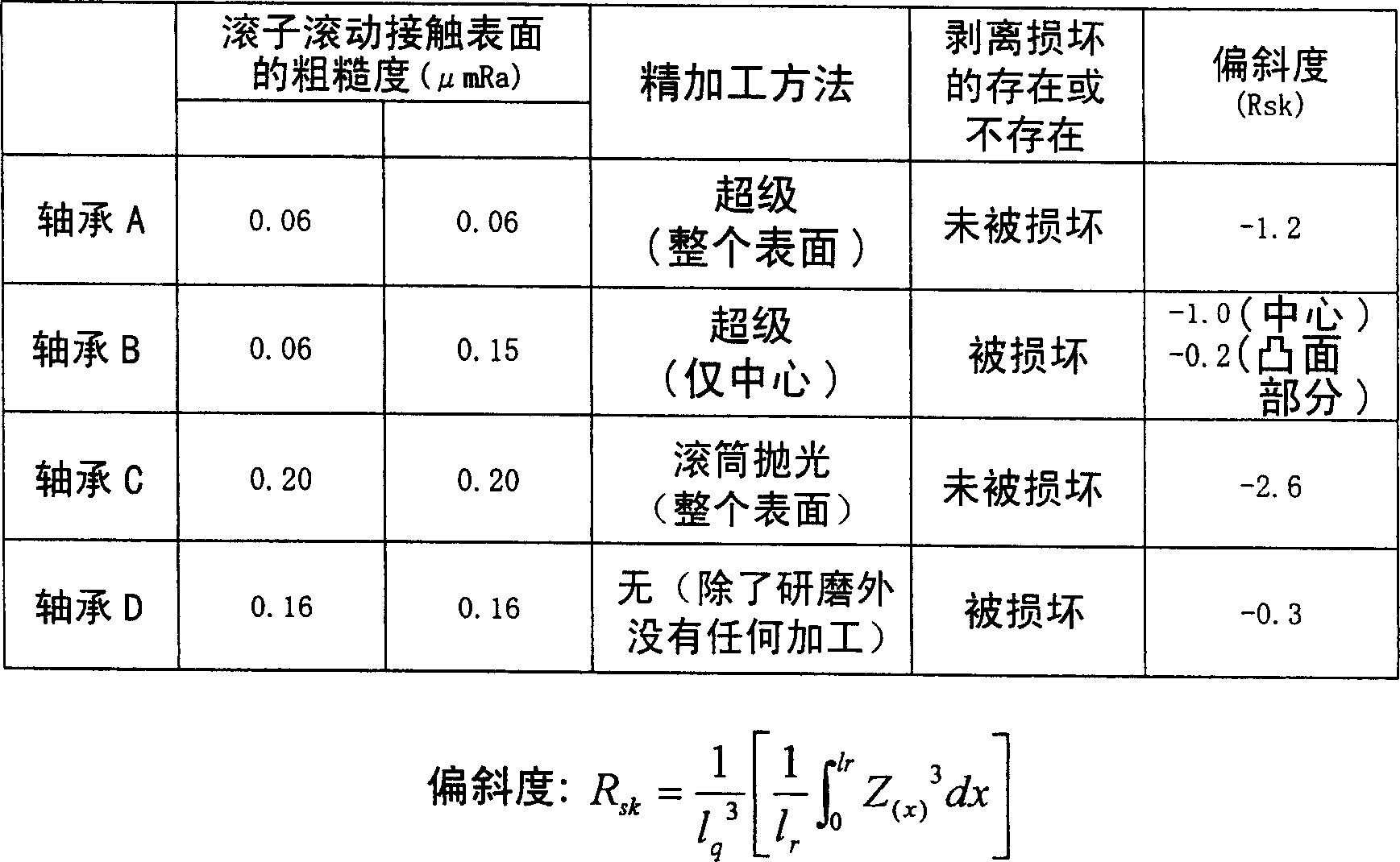

Tapered roller bearing and method of machining tapered roller

The invention discloses a method for machining the tapered roller of a tapered roller bearing, which is characterized in that a roller is subjected to crowning machining by grinding and then is subjected to fine machining by barrel polishing or tumbler polishing so as to remove grinding marks. Due to the adoption of the method, each tapered roller is crowning-processed by grinding and finished by barrel polishing or tumbler polishing so as to be provided with a large crowning, while the tapered roller is low in cost and deflection-resistant. Meanwhile, the super-processing operation, which causes peeling damage on the raceway surface and shortens the service life of the roller, is no longer adopted.

Owner:NTN CORP

Method for manufacturing outer ring of tapered roller bearing

The invention discloses a method for manufacturing an outer ring of a tapered roller bearing, comprising the following steps of: a: taking a material: setting the quality of the finished product outer ring as M, setting the outer diameter as D, taking a bearing steel pipe with the outer diameter of D1 as the raw material, taking the bearing steel pipe with the quality of M1 and meeting the condition that one half of D is less than or equal to D1 which is less than D, and M1 is equal to 2M plus M2 plus 2M3, wherein M2 is the margin of quality by cutting, and M3 is the margin of quality of single outer ring by grinding process; b: cold rolling: rolling on the bearing steel pipe taken in the step a for obtaining a combined blank of the outer ring; c. cutting: cutting the combined blank at the connecting ring for obtaining a single blank of the two outer rings; d: thermal processing; and e: finish machining: grinding the single blank of the outer ring. The proposal leads the outer ring of the tapered roller bearing to realize the cold rolling for shaping, has the advantages of small material loss, saved energy consumption, simple process, high production efficiency and the like, and simultaneously ensures the product quality.

Owner:NINGXIA QINCHANG ROLLING BEARING MFG

Bearing arrangement for a vehicle differential

A vehicle differential includes a housing having bearing seats and a carrier provided with stub shafts which project into the bearing seats. The carrier is supported in the housing on two single row tapered roller bearings which allow the carrier to rotate, but confine it radially and axially. The housing also contains a beveled pinion which meshes with a beveled ring gear that is attached to the carrier. The two bearings are mounted in opposition and each includes a cup that is located in the bearing seat for that bearing, a cone that fits around the stub axle that projects into that bearing seat, and tapered rollers located between the cup and cone. Each bearing seat contains an internal thread and the bearing cup which fits into the seat has an external thread that engages the internal thread. Each cup also carries a locking ring which is engaged by an adjustment tool to turn the cup, but is later deformed into the housing to secure the cup against rotation. By rotating the cups in their bearing seats, one can adjust the setting of the bearings and the mesh setting of the pinion and ring gear.

Owner:THE TIMKEN CO

Pillow block housing with tapered roller bearings

A spherical outer diameter tapered roller bearing pillow block system (100) for supporting the rotating main shaft of a wind turbine. The bearing system is configured with a unitized construction and factory set preload bearing settings to facilitate installation and setup. A spherical outer diameter surface (114) is formed on the Outer race (116) of a tapered roller bearing assembly disposed about the rotating main shaft of the wind turbine. The bearing assembly is secured to a stationary support structure of the wind turbine through a pillow block housing assembly (102) providing a matching spherical housing scat (112) to form a ball and socket interface between the tapered roller bearing assembly (118) and the pillow block housing assembly (102). The ball and socket interface accommodates static and dynamic misalignments between the wind turbine main shaft and the supporting structure, while the bearing assembly (118) accommodates radial and axial loads.

Owner:THE TIMKEN CO

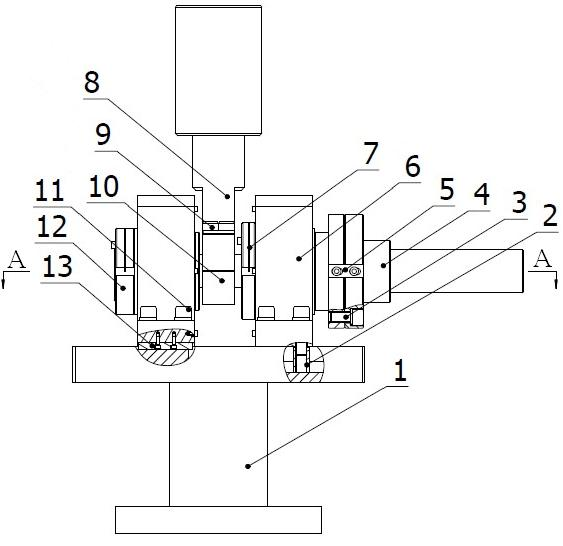

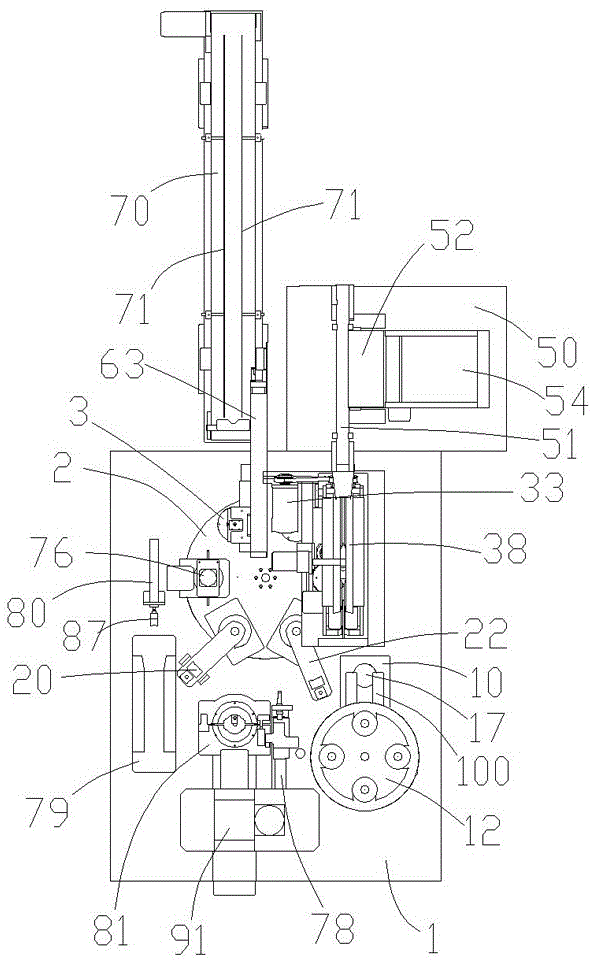

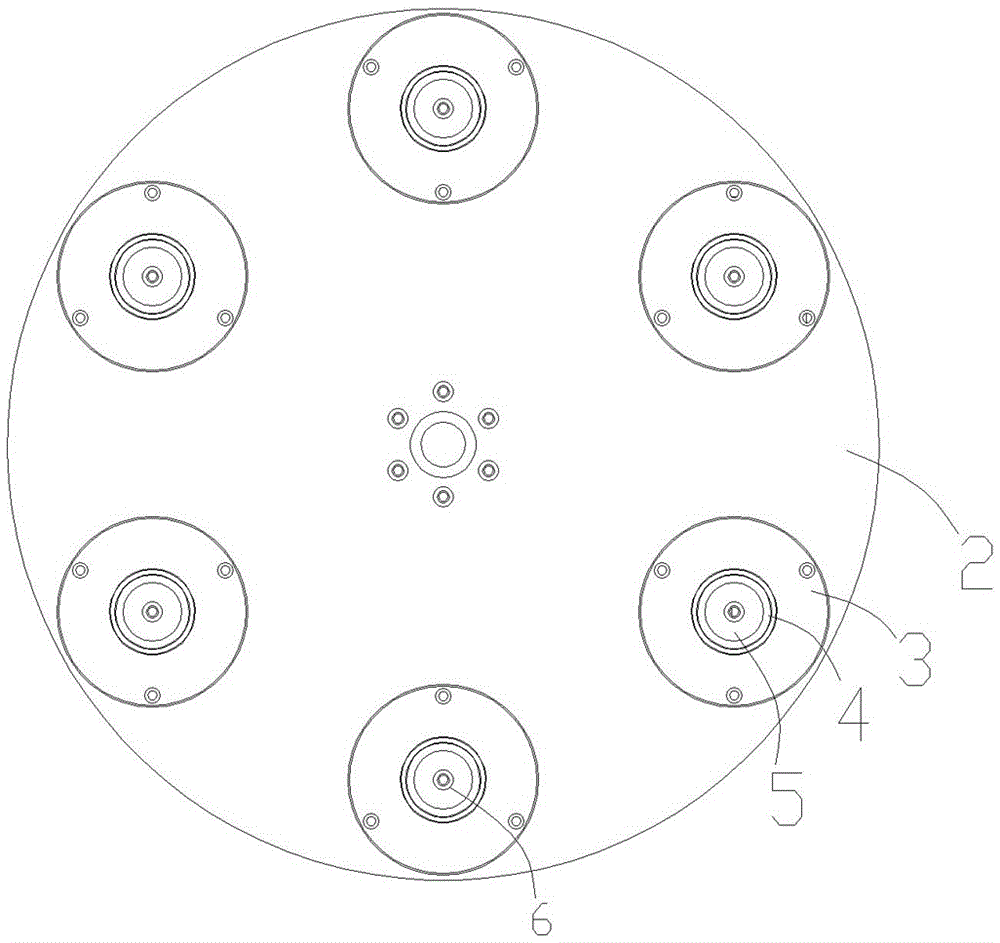

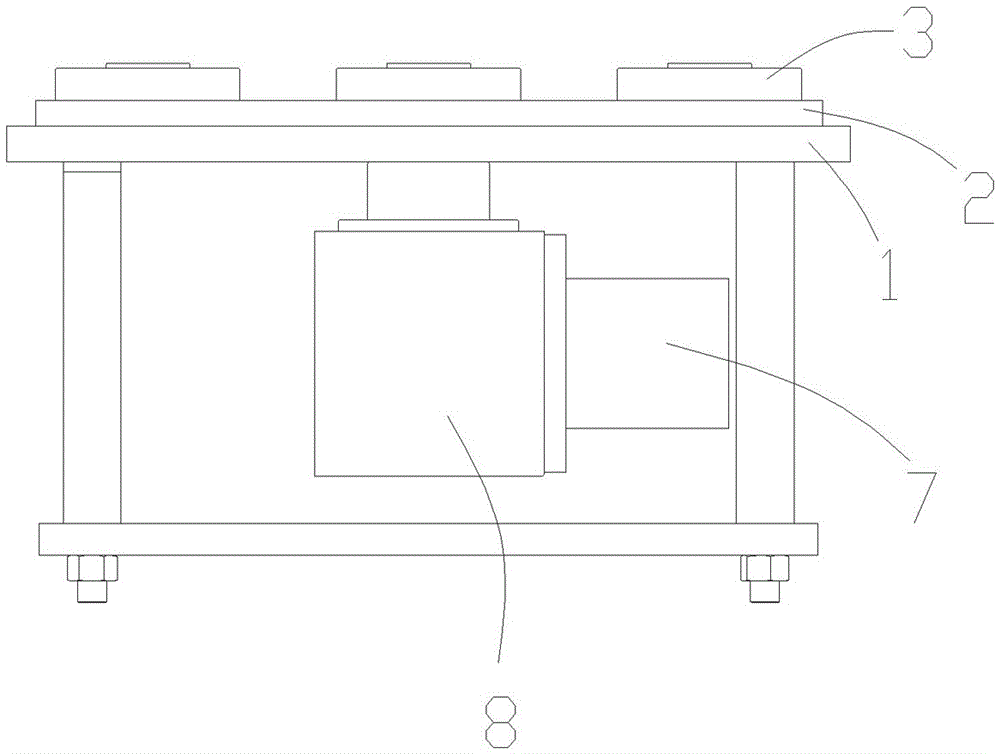

Full-automatic assembling machine for tapered roller bearing inner components

ActiveCN106523536AReduce labor intensityReduce the failure rateBearing assemblyShaft assemblyEngineeringRejection rate

The invention discloses a full-automatic assembling machine for tapered roller bearing inner components. The full-automatic assembling machine for the tapered roller bearing inner components comprises a workbench. A turnplate and a drive mechanism used for driving the turnplate to rotate are arranged on the workbench. A plurality of assembling stations are evenly distributed on the turnplate. A retainer feeding mechanism, a roller feeding mechanism, an inner ring feeding mechanism, a sorting mechanism and a pressing mechanism are distributed anticlockwise in sequence on the peripheries of the multiple assembling stations. Through the assembling machine, automatic assembling of the tapered roller bearing inner components is achieved, the labor intensity is relieved, the rejection rate is decreased, the production efficiency is greatly improved, and the production effectiveness can be improved.

Owner:宁波致泰自动化装备有限公司

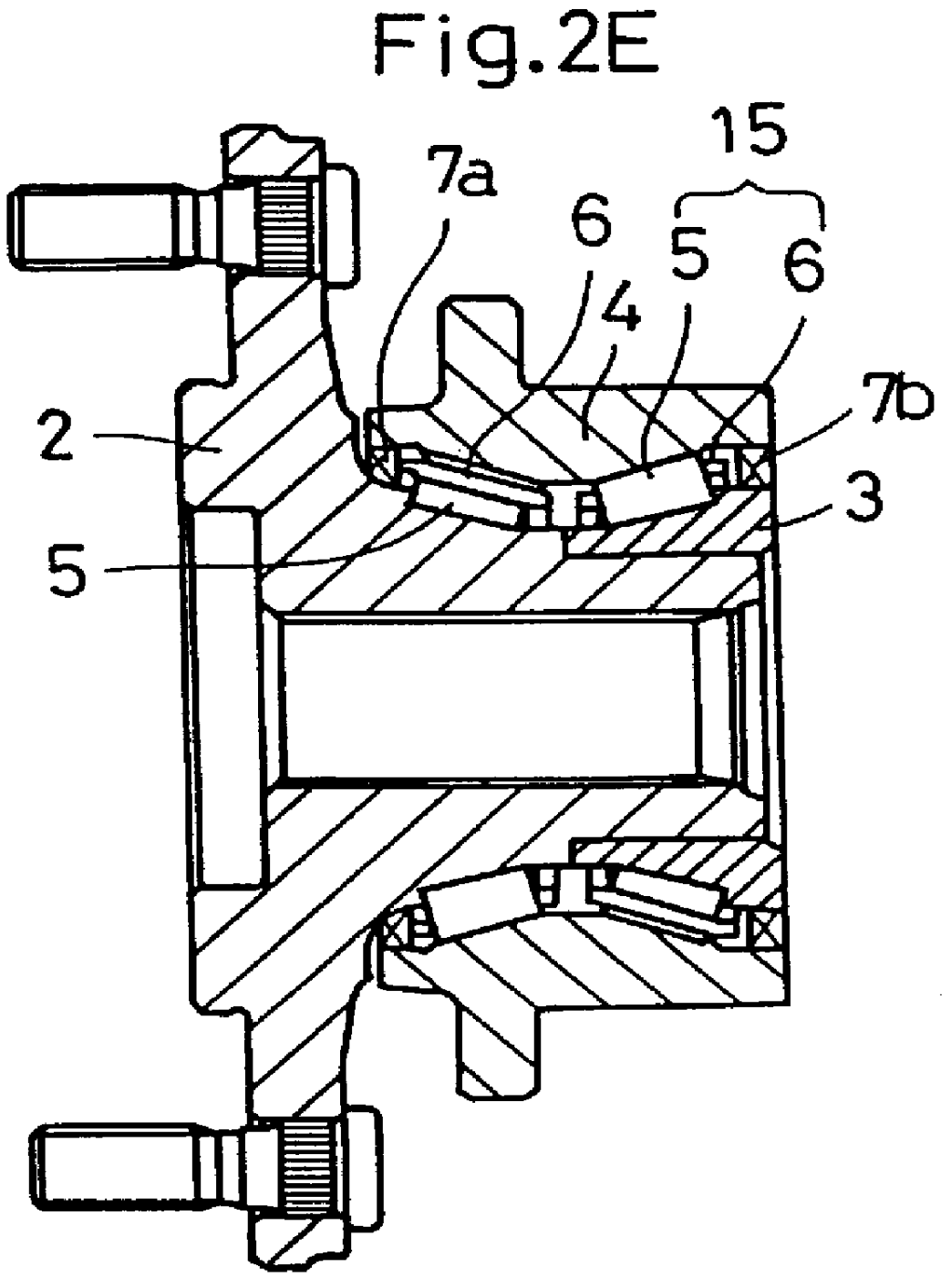

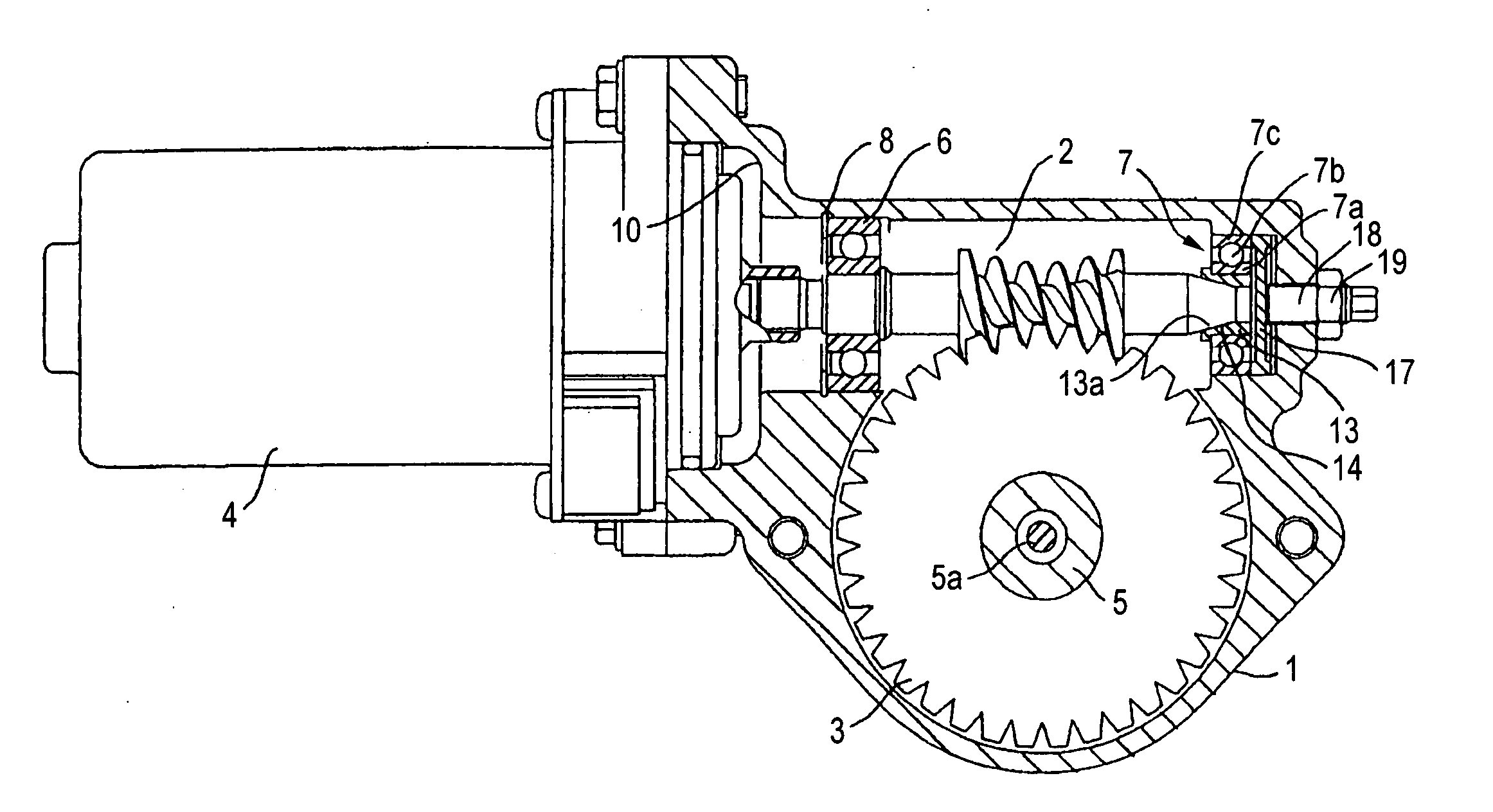

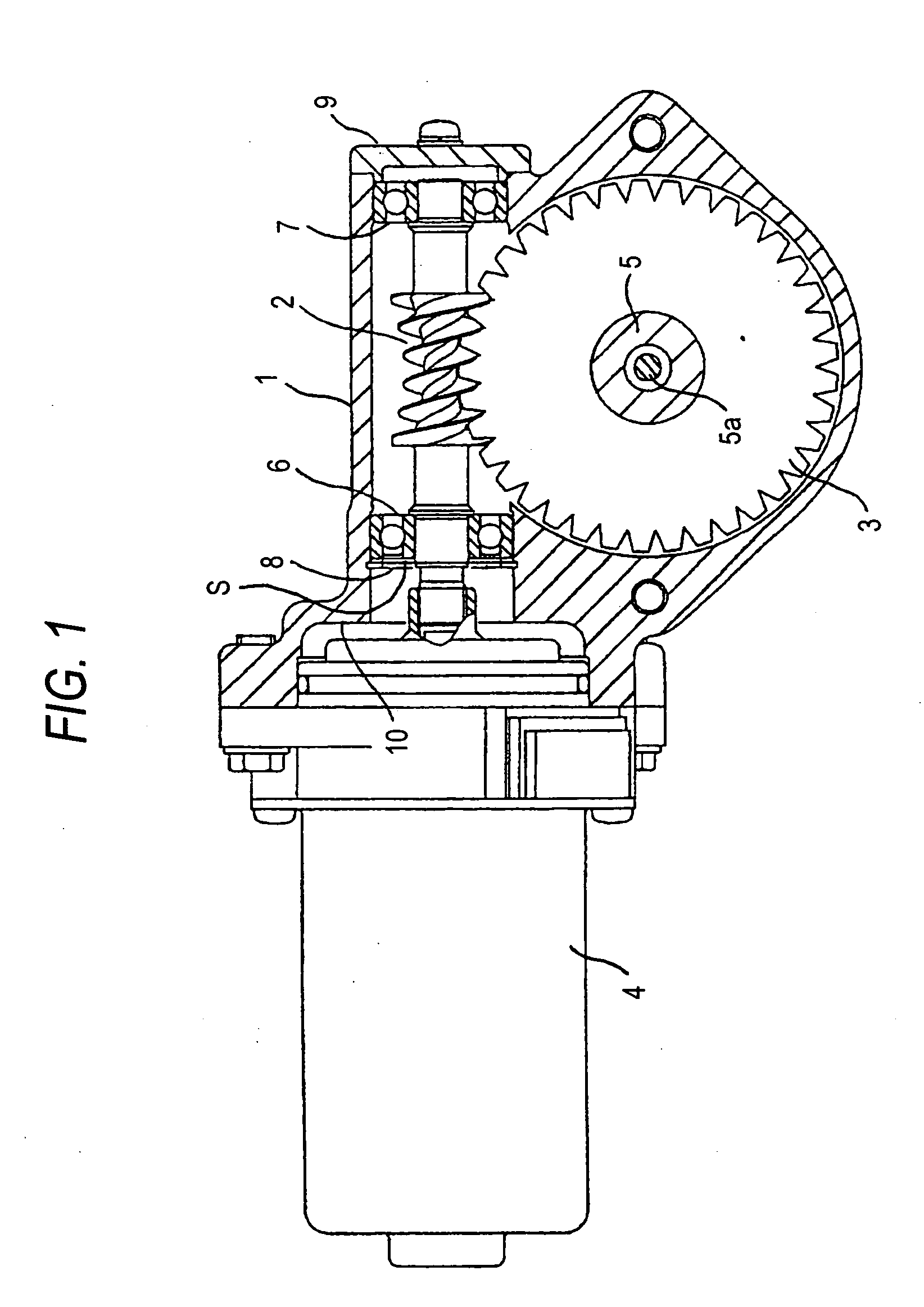

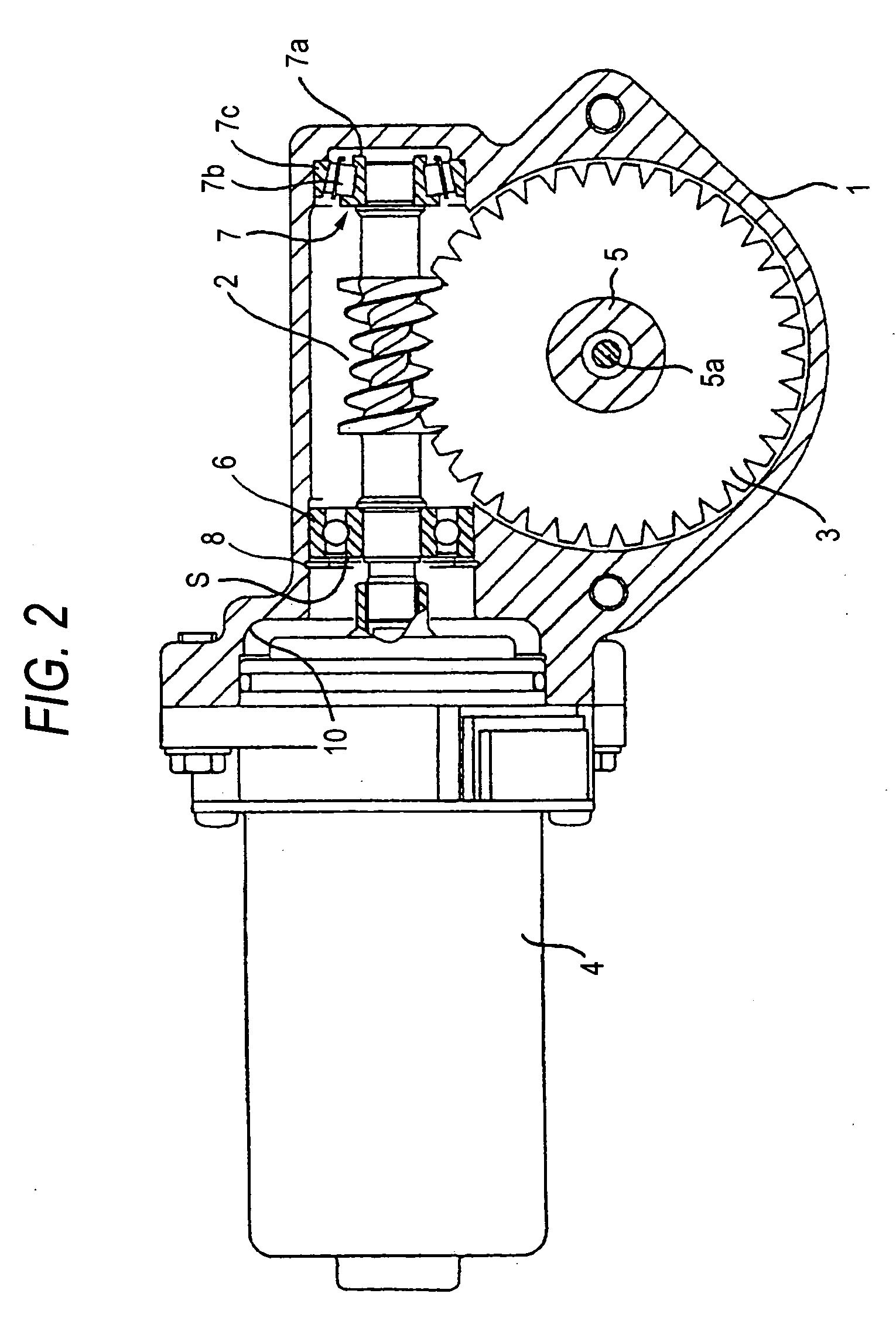

Electric power steering device

InactiveUS20060191736A1Increase contact rateIncrease productionToothed gearingsElectrical steeringElectric power steeringGear system

A subject of the present invention is to provide an electric power steering capable of improving a contact ratio by using an hourglass worm to attain a higher output, and also performing a correction of a misalignment easily by simplifying remarkably a fitting operation of the hourglass worm. A worm gear system causes a hourglass worm 2 driven by an electric motor 4 to mesh with a worm wheel 3 provided to an output shaft 5, and a bearing 7 on the shaft end side, which bears rotatably the hourglass worm 2 is composed of a tapered roller bearing an outer ring of which can be separated. In a fitting operation, an inner ring 7a and rolling elements 7b are fitted into the hourglass worm 2 and also an outer ring 7c is fitted in advance in a gear housing 1. Then, the tapered roller bearing 7 is assembled in the gear housing 1 by moving the hourglass worm 2 obliquely to a rotating shaft line of the hourglass worm 2 in the gear housing 1 along a raceway of the outer ring 7c.

Owner:NSK LTD

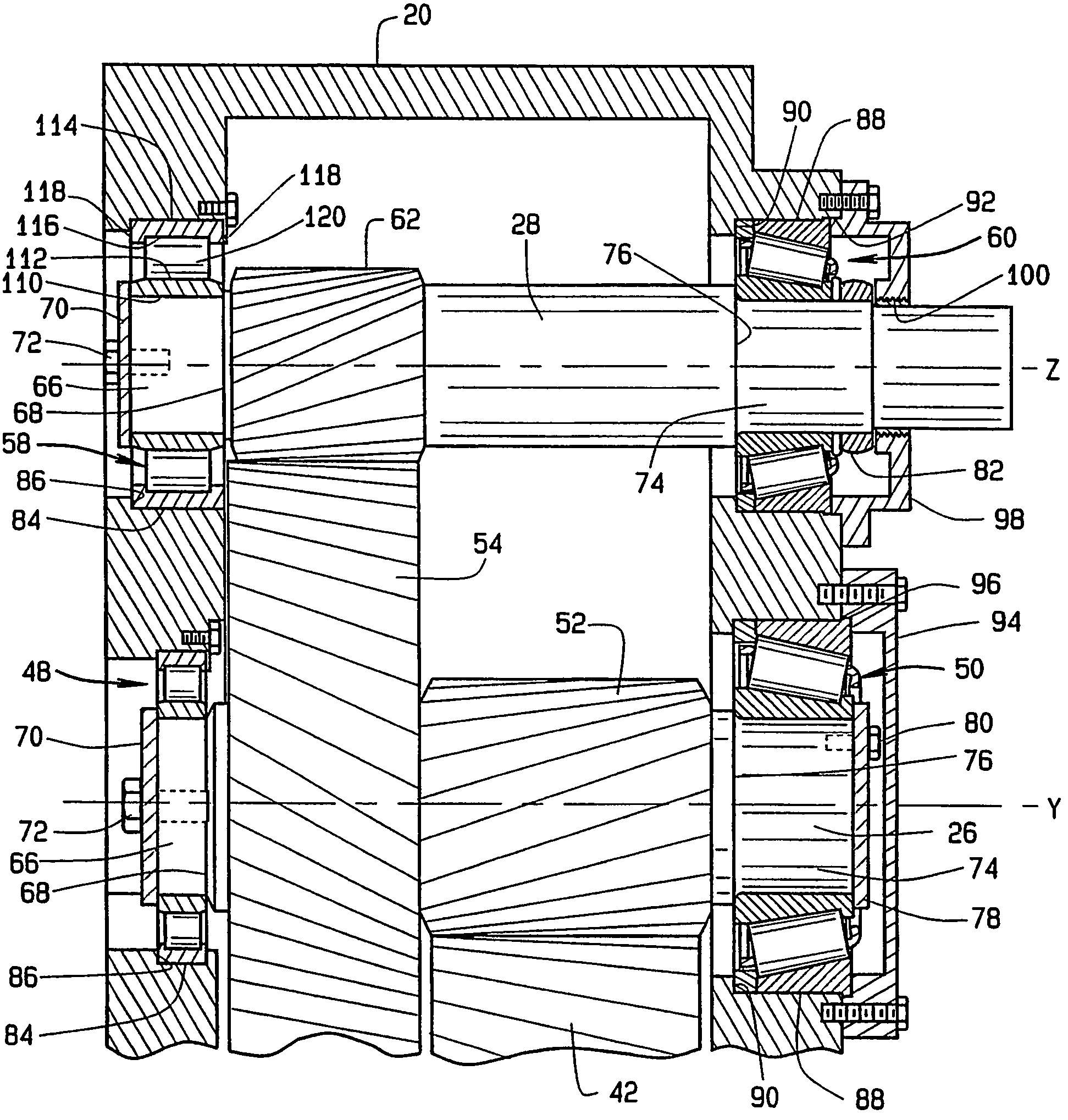

Transmission containing helical gearing and bearing arrangement therefor

A transmission for a wind turbine includes a housing (20) in which two shafts (26, 28) rotate, each being supported on a locating bearing (50, 60) which transmits thrust loads to the housing as well as radial loads and on a nonlocating bearing (48, 58) which transmits only radial loads to the housing. The shafts carry helical gears (52, 52, 62) which induce thrust loads in the shafts when the shafts transmit torque. The locating bearings are unitized single row tapered roller bearings which are oriented to transmit thrust loads in the primary direction through their raceways (132, 138) and in the secondary direction through ribs (134, 144) at the ends of their rollers (146). The nonlocating bearings take the form of a single row cylindrical roller bearings which accommodate differential thermal expansion and contraction between the shafts and housing.

Owner:THE TIMKEN CO

Combined machining spindle unit of supersonic vibration assistant grinding-impulse discharge

InactiveCN101733492AEfficient, stable and reliable composite processingRealize the combinationElectrical-based auxillary apparatusEngineeringUltrasonic vibration

The invention discloses a combined machining spindle unit of supersonic vibration assistant grinding-impulse discharge, which has the advantages of simple structure, convenient use and realization of efficient, stable and reliable combined machining, and the like. The structure of the combined machining spindle unit is as follows: the unit comprises a shell, a spindle penetrates through the shell and is connected with a supersonic vibration machining device and a transmission pulley. The supersonic vibration machining device is provided with an electric spark pulse discharge machining and grinding device. A correction support sleeve is further arranged on the inner wall of the shell, and a tapered roller bearing is mounted on the inner side of the shell.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com