Tapered roller bearing and method of machining tapered roller

A tapered roller bearing, tapered roller technology, applied in the direction of roller bearings, rolling contact bearings, bearings, etc., can solve problems such as cost increase, uneven contact surface roughness, and roller damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

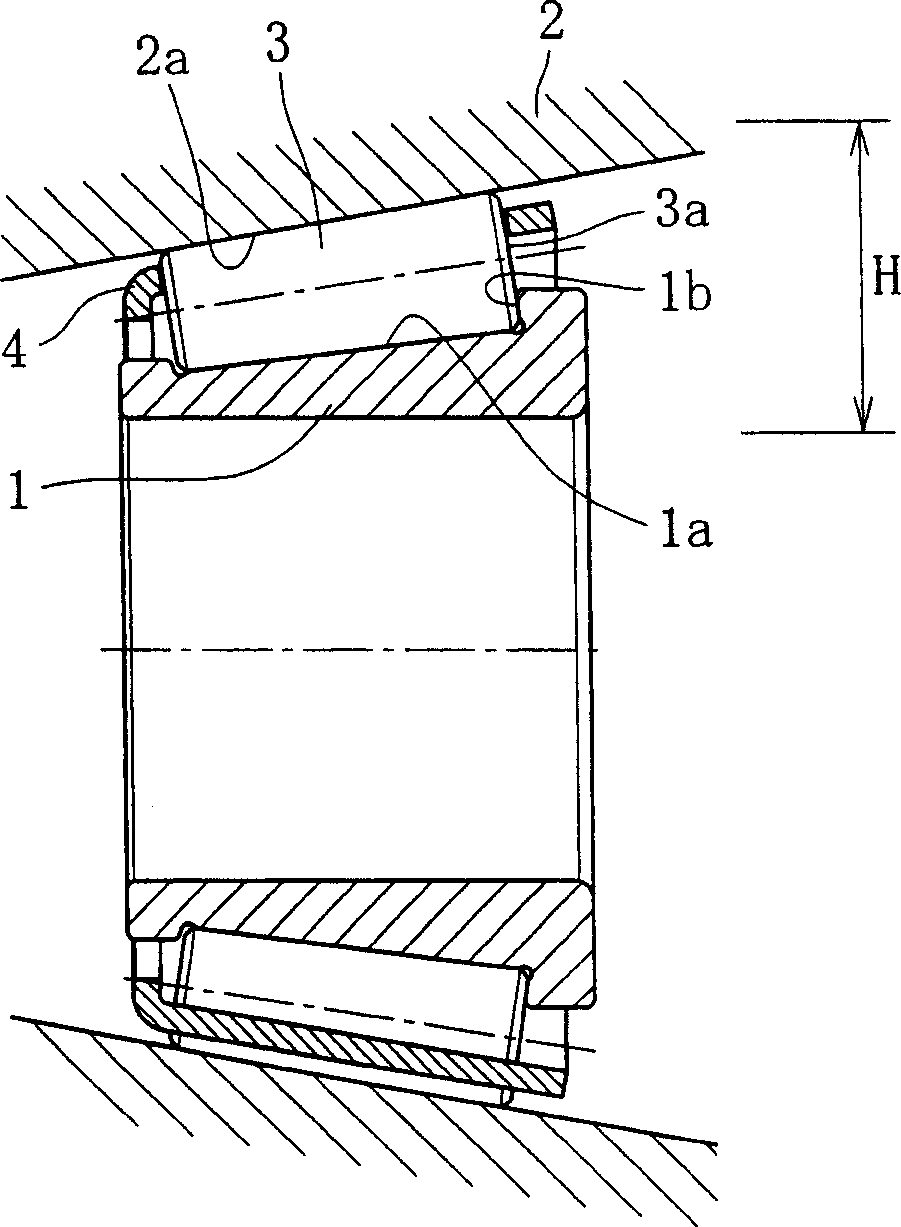

[0024] Embodiments of the present invention will be described below with reference to the drawings.

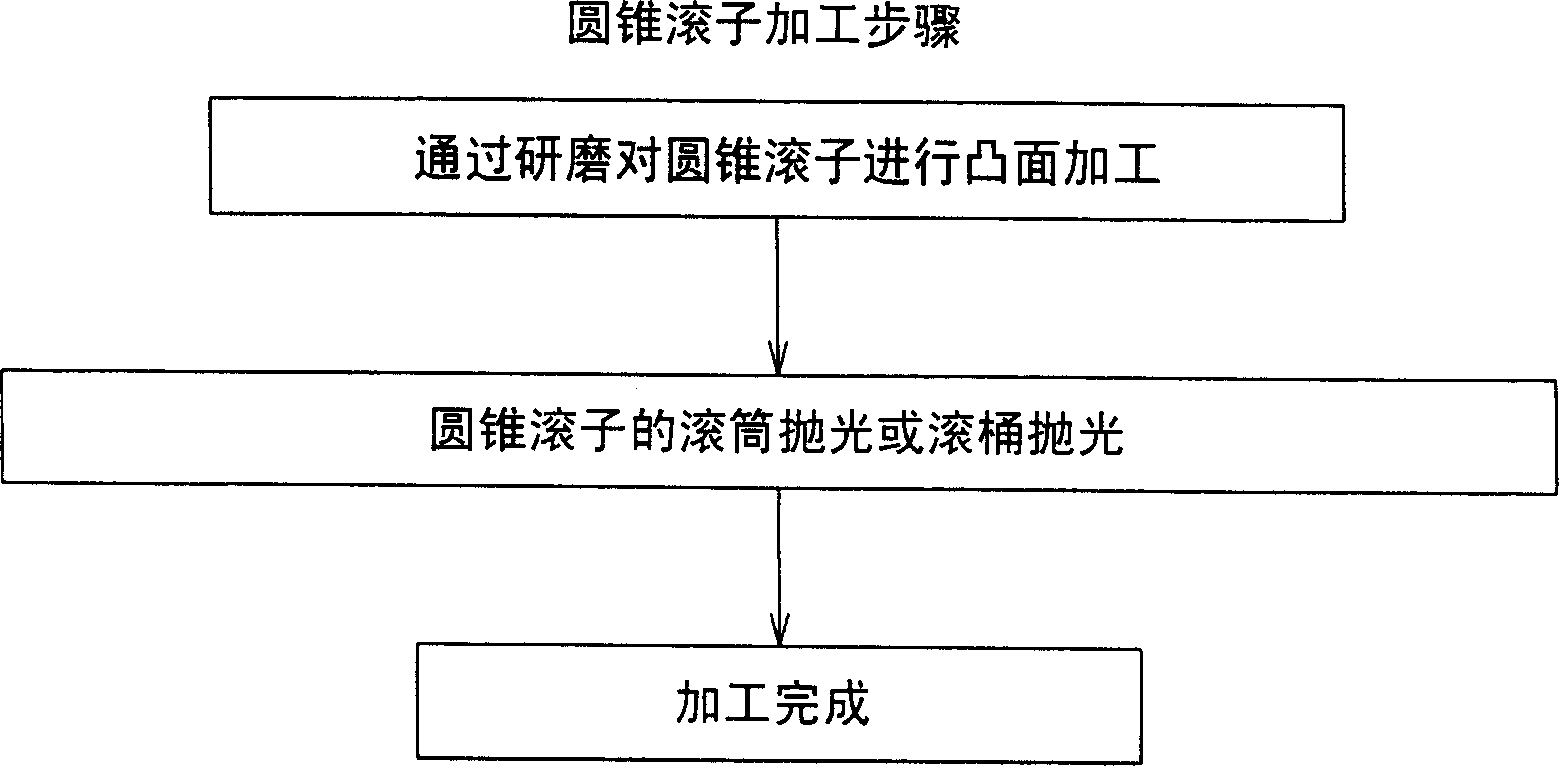

[0025] figure 1 A method for machining the rollers in the tapered roller bearing of the invention is shown. First, the tapered rollers are crowned by grinding. Next, barrel polishing or barrel polishing is continued on the crowned tapered roller surface until the grinding streaks disappear.

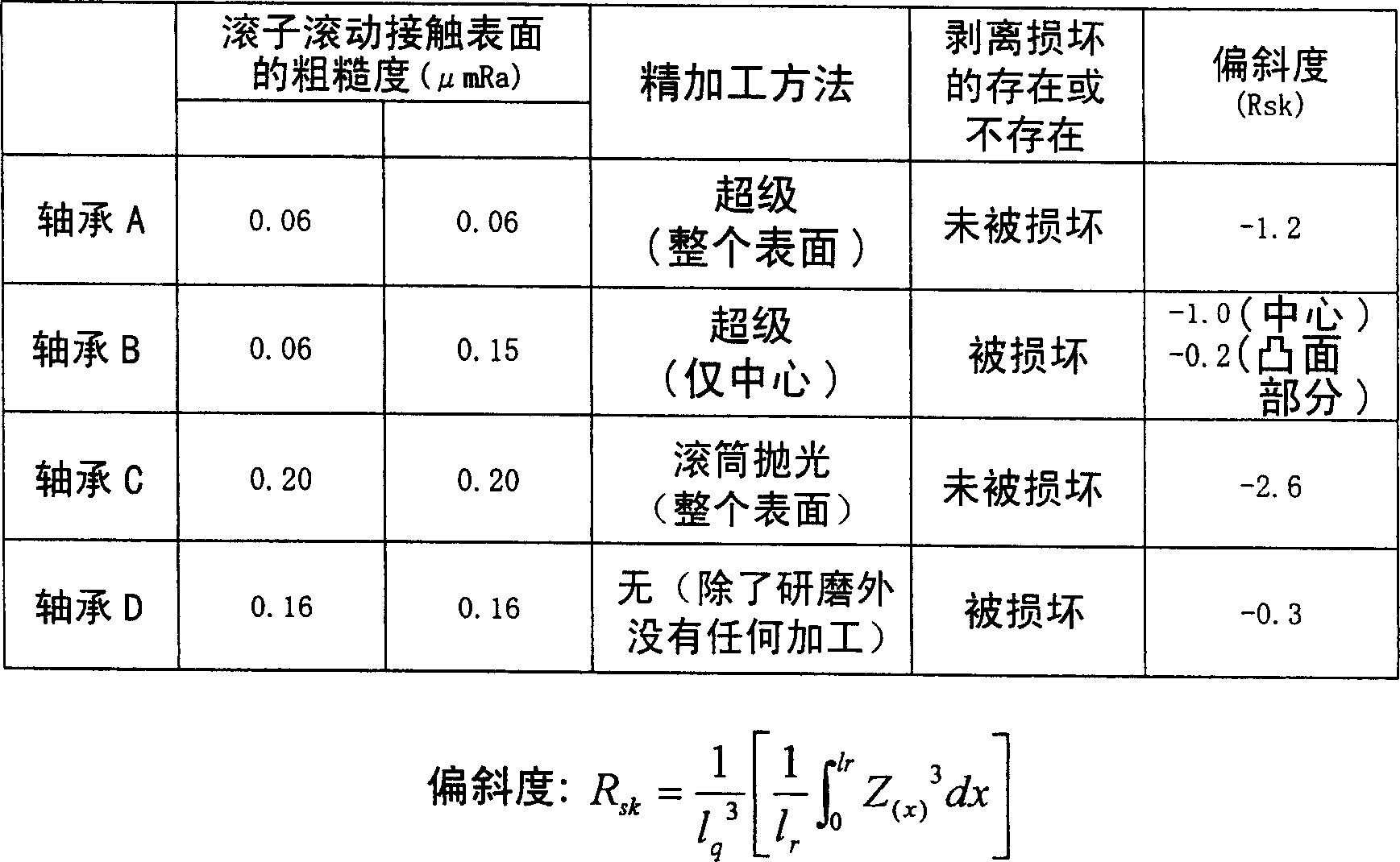

[0026] Tapered roller bearings were assembled using the above machined rollers, and the bearings were tested for peel damage. figure 2 Shown are the results of an experiment comparing bearing C related to the present invention with bearings A, B, and D tested as comparative examples under the same conditions. Each roller of bearings A to D has the same crown formed by grinding.

[0027] Bearing A has a roller with the entire convex surface finished by super machining. The roughness of the entire surface thereof is good, but high cost is required to process the bearing. In bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com