Method for manufacturing outer ring of tapered roller bearing

A technology of tapered roller bearing and manufacturing method, applied in bearing components, shafts and bearings, mechanical equipment and other directions, can solve the problems of high energy consumption, complex process, large material loss, etc., to extend the life of the core roller, the process is simple, The effect of low material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

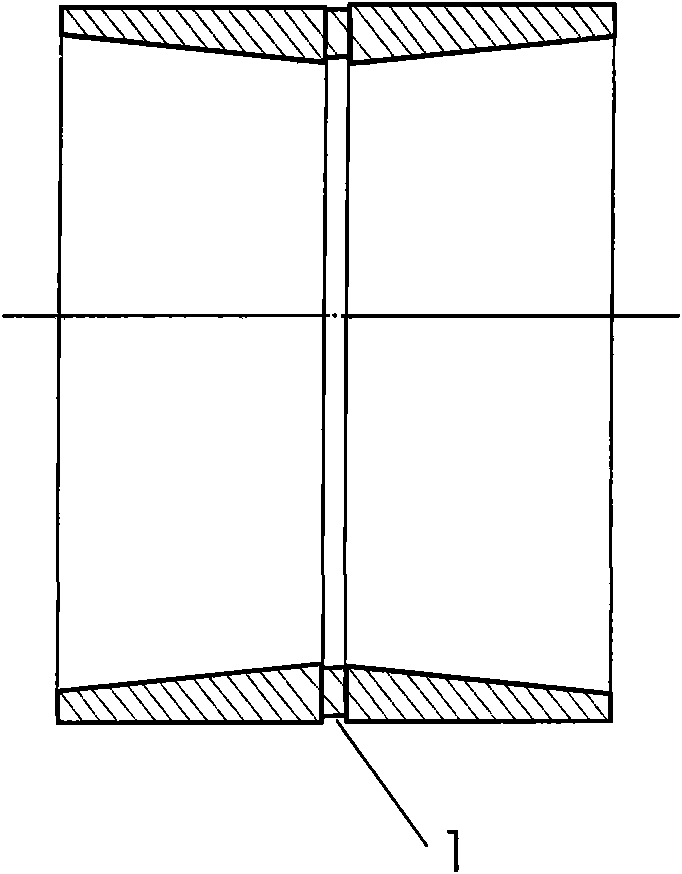

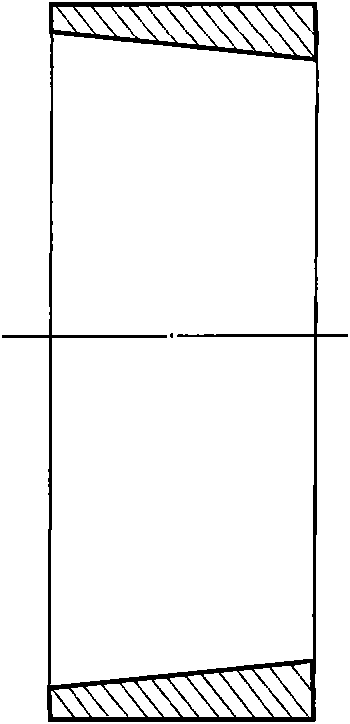

[0028] Taking the manufacture of the 30209 type tapered roller bearing shell as an example, the specific manufacturing method of the present invention is explained:

[0029] Type 30209 tapered roller bearing shell mass M = 0.161 kg, its outer diameter D = 85 mm, the inner diameter of the large radius end is 70 mm, the inner diameter taper is 15 ° 6'34 ", and the axial height of the outer shell is 16 mm.

[0030] Set the mass allowance M for cutting 2 is 0.046 kg, and the grinding mass allowance of the outer ring of a single bearing is M 3 is 0.001 kg.

[0031] 1) The outer diameter of the reclaimed material is D 1 = Bearing steel pipe with an inner diameter of 62 mm and an inner diameter of 42 mm is the raw material, take M 1 = 0.37 kg of this kind of bearing steel pipe, its length is 29.4 mm.

[0032] What needs to be explained here is the outer diameter D of the raw material of the bearing steel pipe used. 1 Just satisfy: 1 / 2D≤D 1 <D is sufficient, and has a correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com