Patents

Literature

665results about How to "Lower heating costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

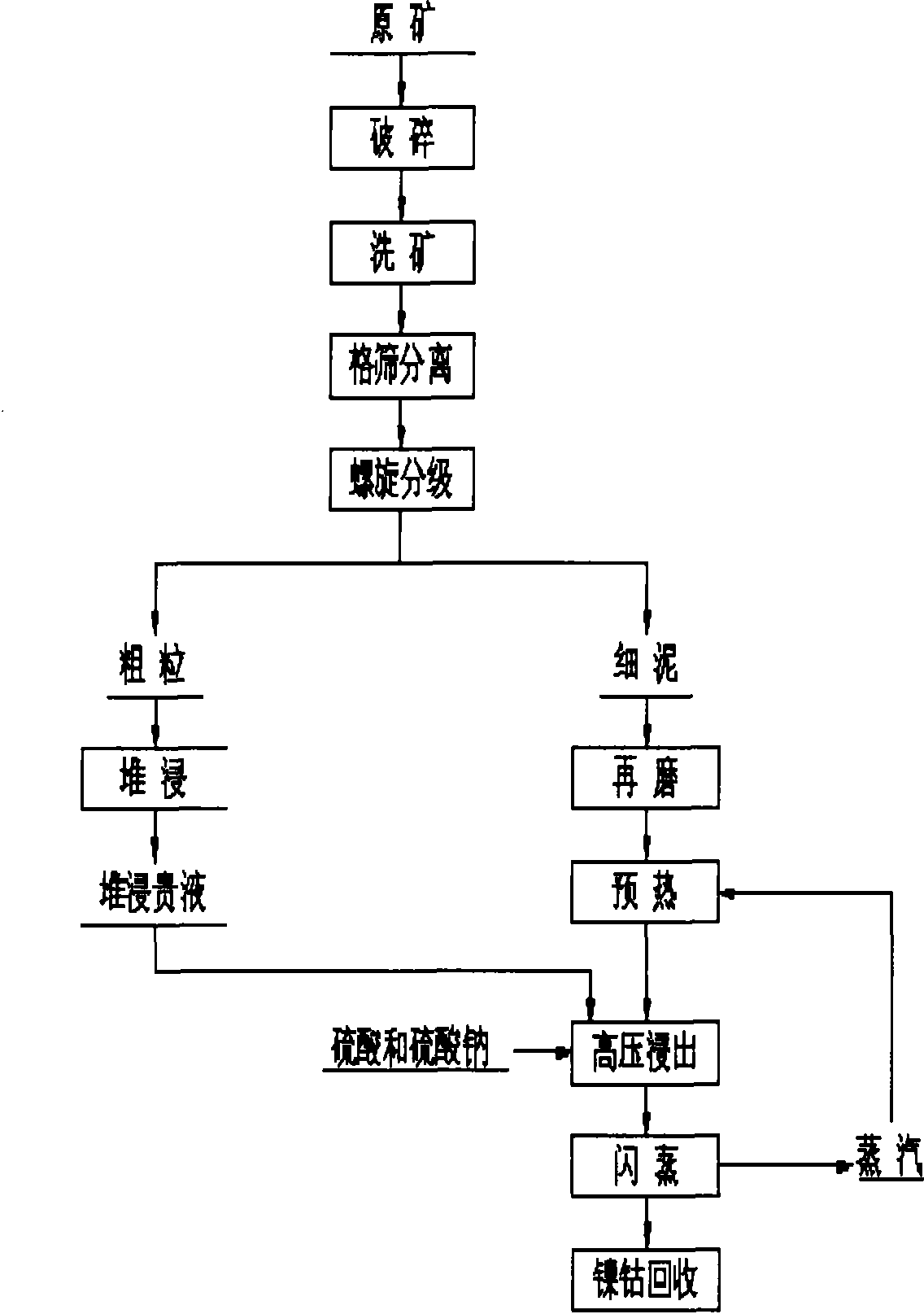

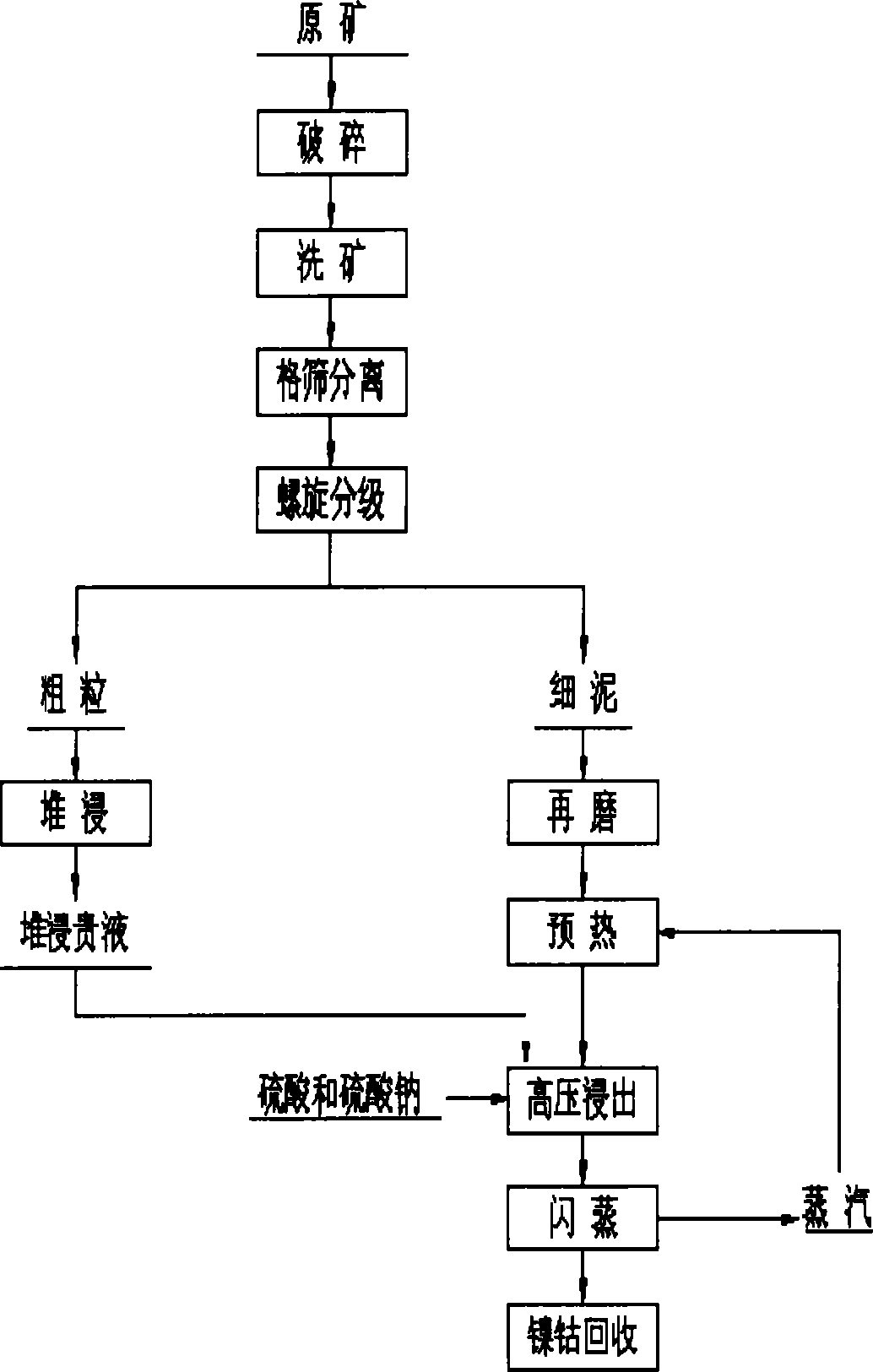

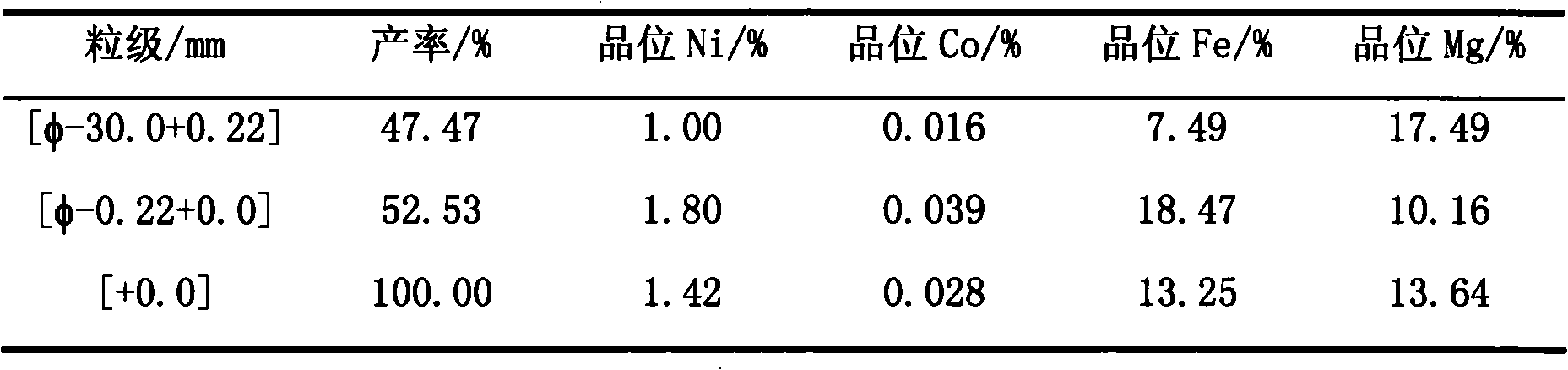

Method for reducing acid consumption during heap leaching and high-pressure leaching of nickel laterite ore

InactiveCN101768665AReduce acid consumptionReduce consumptionProcess efficiency improvementHigh pressureLaterite

The invention discloses a method for reducing acid consumption during heap leaching and high-pressure leaching of nickel laterite ore, which combines the heap leaching technology with the high-pressure leaching technology to reduce acid consumption during the treatment of nickel laterite ore; residual sulfuric acid in coarse particle immersion of limonite heap is sufficiently utilized and sodium sulfate is added during the stage of high-pressure leaching so that sulfuric acid is generated while yellow natrojarosite is formed, thereby further reducing the consumption of sulfuric acid during the stage of high-pressure leaching.

Owner:厦门紫金矿冶技术有限公司

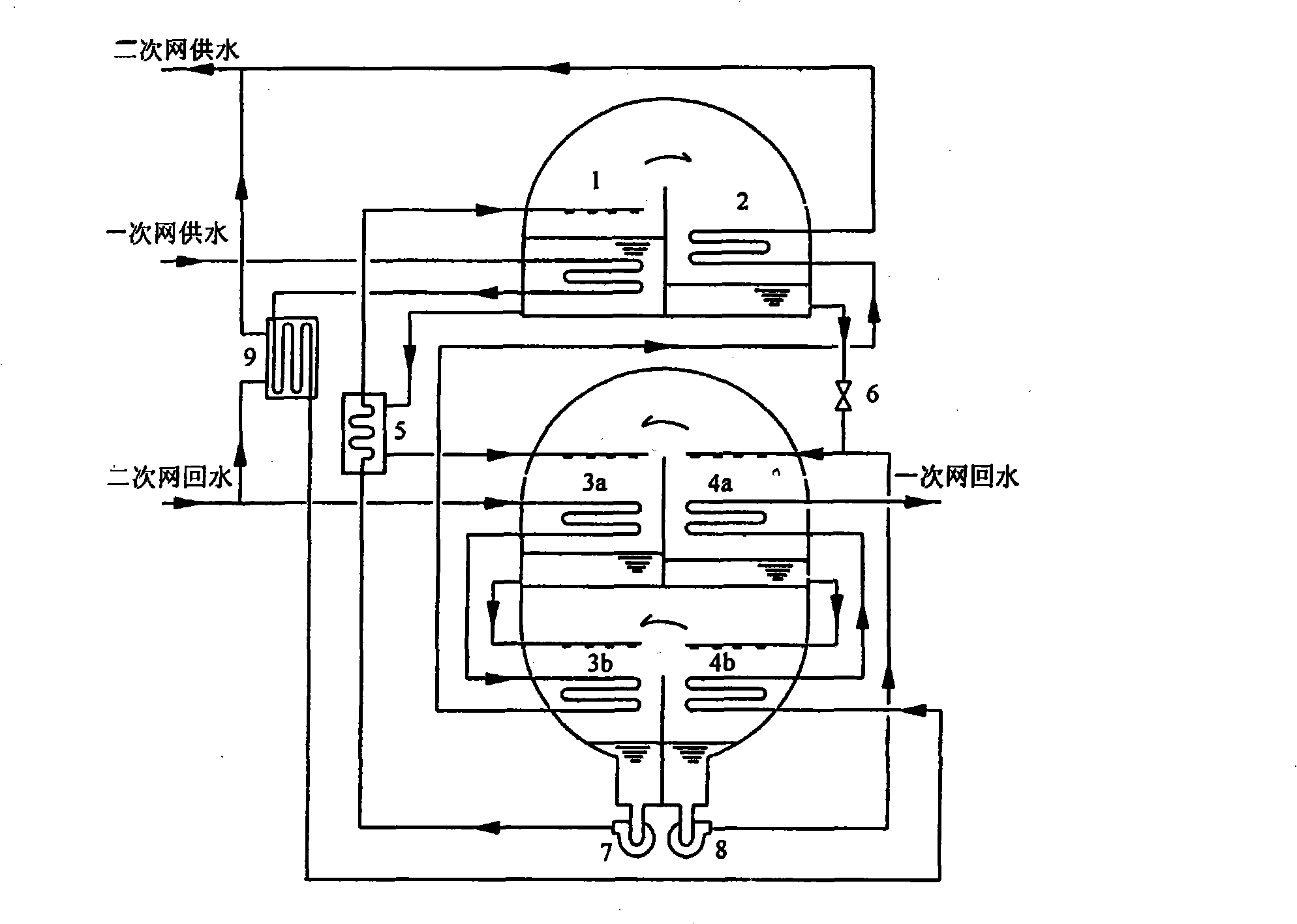

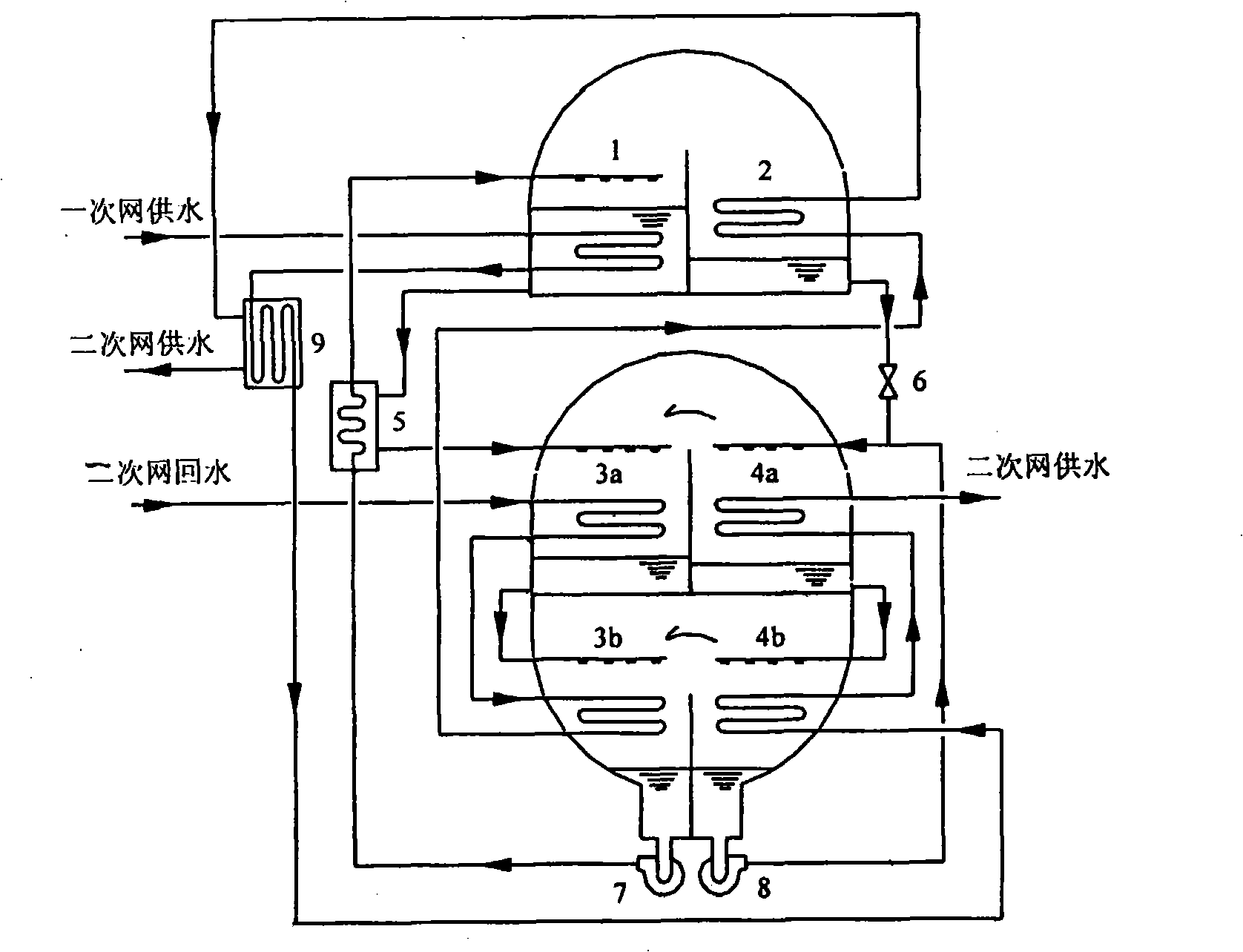

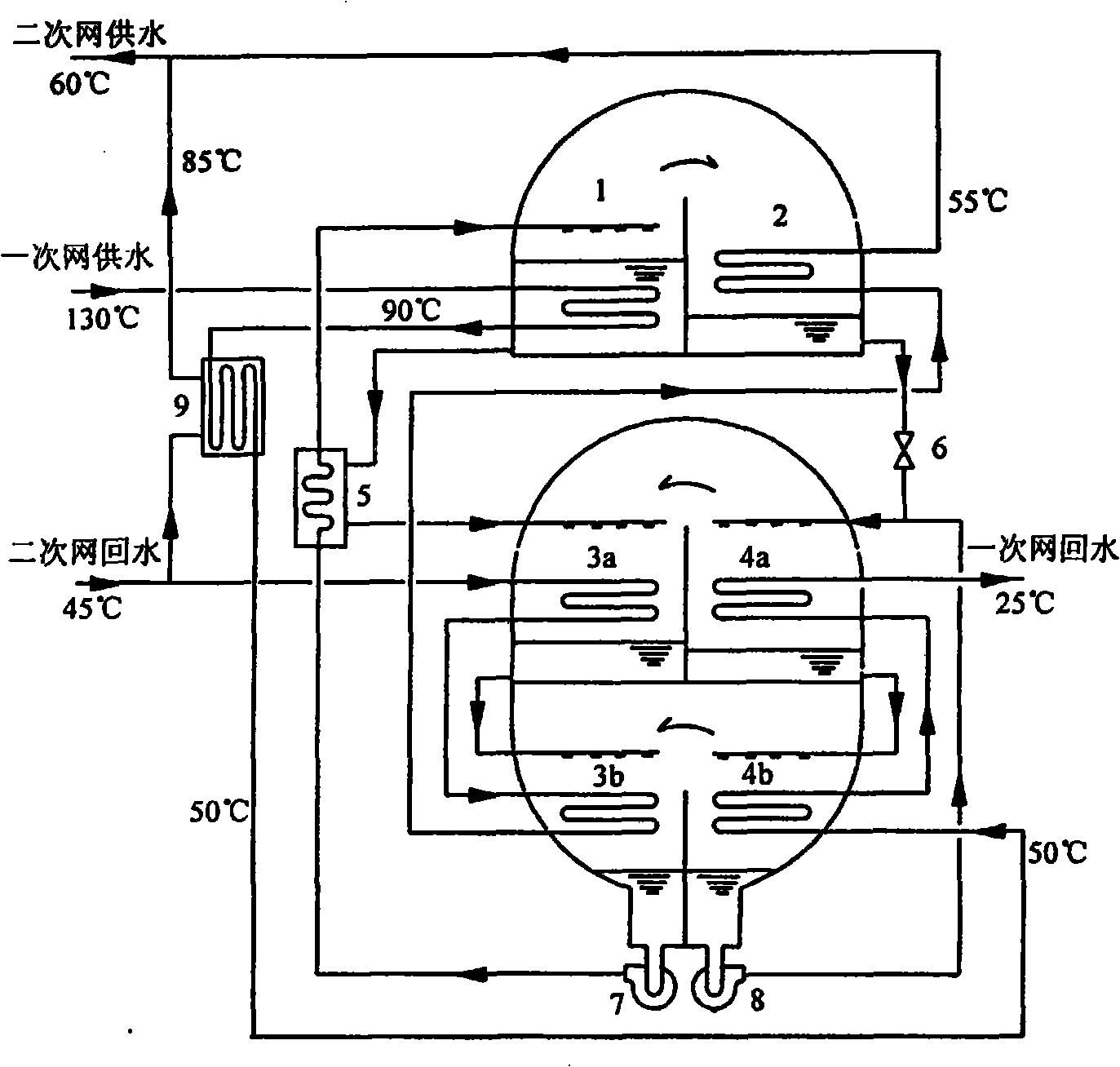

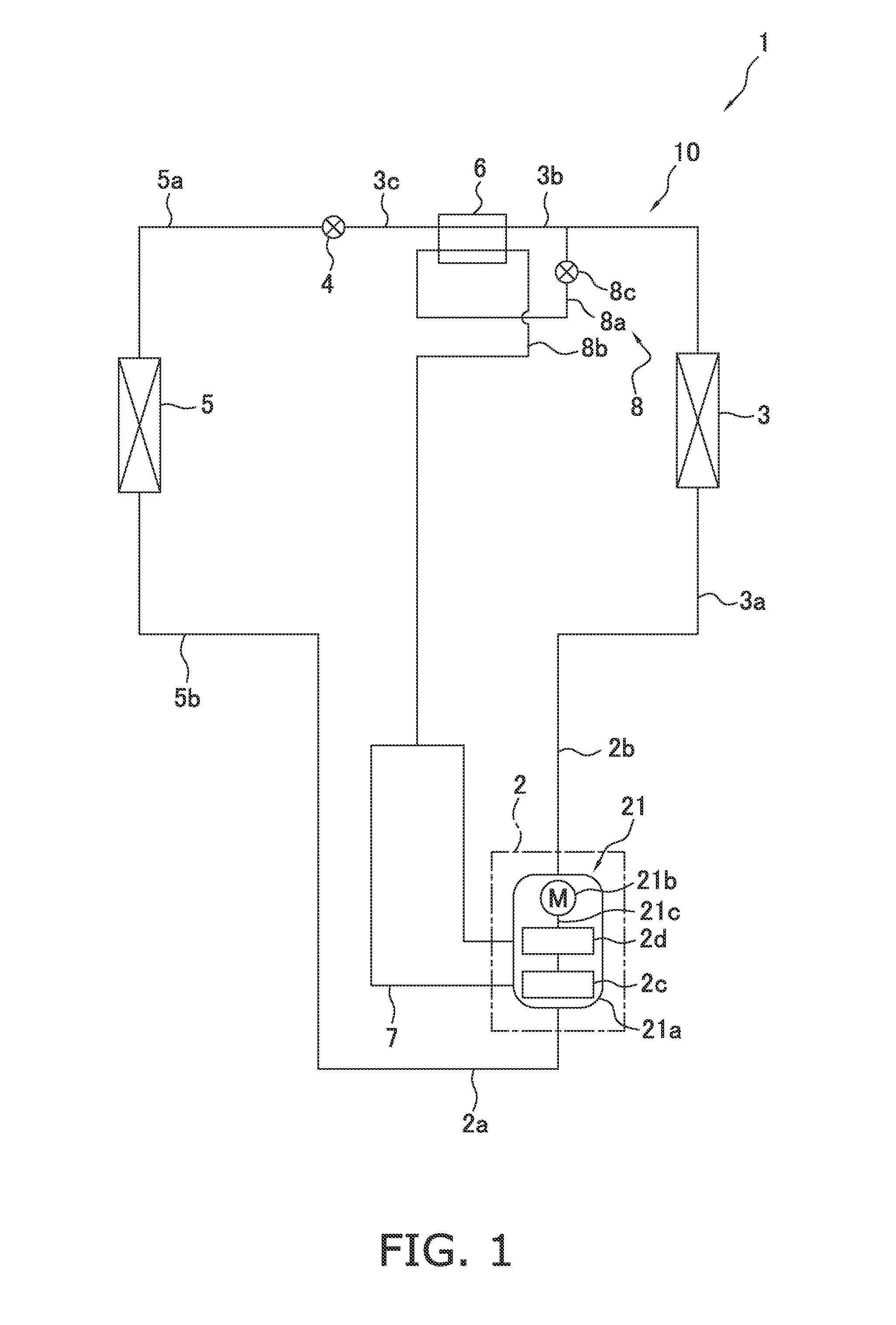

Integral type absorption type heat exchange machine unit

ActiveCN101329117ALower return water temperatureReduce initial investmentHeat pumpsClimate change adaptationThermal energyEvaporation

The invention relates to an integrated absorption heat-exchanging unit, belonging to the field of the heating and hot water supply devices and comprising a hot-water absorption heat-exchanger and a normal water-water heat exchanger which are combined, wherein, the hot-water absorption heat-exchanger adopts the means of two-level evaporation and two-level absorption. The unit comprises a generator, a condenser, a low-pressure absorber, a high-pressure absorber, a low-pressure evaporator, a high-pressure evaporator, a solution heat exchanger, a throttle device, a solution pump, a water-water heat exchanger and various connecting pipes and accessories. The invention can effectively reduce the backwater temperature of a first-time network of a collective heating system, thus greatly raising the temperature difference of between hot water supply and backwater of the first-time network, further greatly reducing the initial investment to the pipeline system and the power cost of the pump running, creating conditions for utilizing the low-quality heat energy even waste heat, etc., enhancing the comprehensive energy utilization efficiency of the system and reducing the heat supply cost.

Owner:北京华源泰盟节能设备有限公司

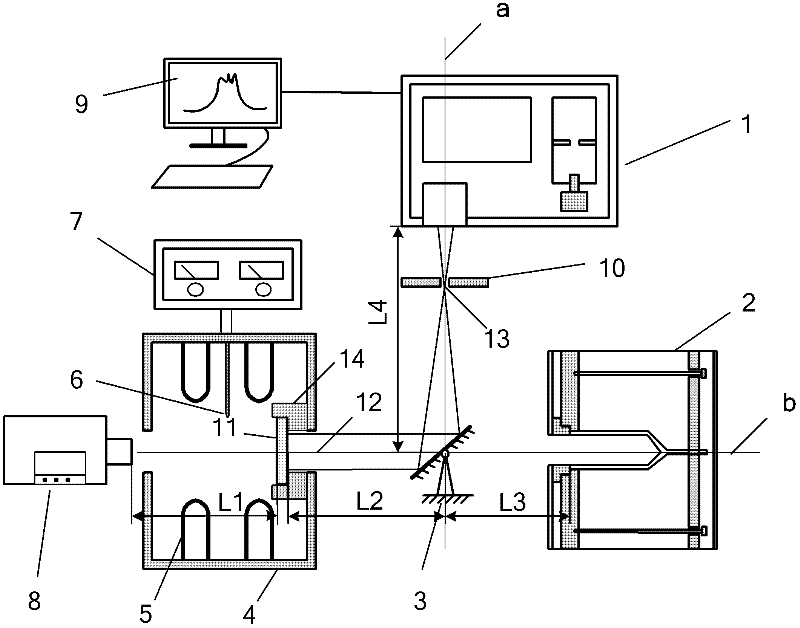

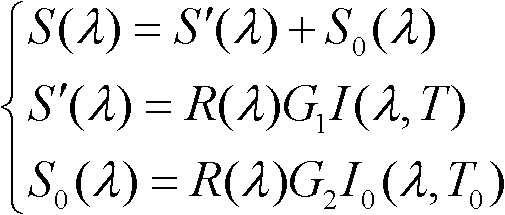

Energy method-based high-temperature radiation rate measuring device of semi-transparent material and revising method for deducting background radiation

ActiveCN102564610AAccurate calculation of high temperature spectral transmittanceEasy to measureRadiation pyrometryMaterial thermal analysisSpectrum analyzerHorizontal axis

The invention provides an energy method-based high-temperature radiation rate measuring device of a semi-transparent material and a revising method for deducting background radiation, relating to a high-temperature normal spectral radiation rate revising and testing method of the semi-transparent material and belonging to the technical field of high-temperature material physical property measurement. The energy method-based high-temperature radiation rate measuring device of the semi-transparent material and the revising method for deducting the background radiation solve the problems of high construction cost, low temperature heating upper limit and lower testing precision of the traditional test system. The high-temperature radiation rate measuring device comprises a Fourier infrared spectrum analyzer, a reference blackbody furnace, a rotatable reflection mirror, a heating furnace, a heater, a temperature collecting device, a temperature routing inspection operation instrument, an incidence light source, a data processing system, a diaphragm and a semi-transparent test piece; the heating furnace is internally provided with a light-transmitting opening, a fixing device of the semi-transparent test piece, and the temperature collecting device; the central axis of a light-emitting opening of the incidence light source, the central axis of the light-transmitting opening of the heating furnace, the mirror surface of the rotatable reflection mirror and the central axis of the light outlet opening of the reference blackbody furnace are collinear with a horizontal axis. The energy method-based high-temperature radiation rate measuring device of the semi-transparent material and the revising method for deducting the background radiation, disclosed by the invention, are used for measuring the high-temperature spectral normal radiation rate of the surface of the semi-transparent material.

Owner:HARBIN INST OF TECH

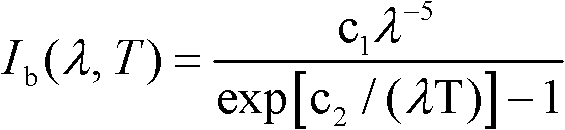

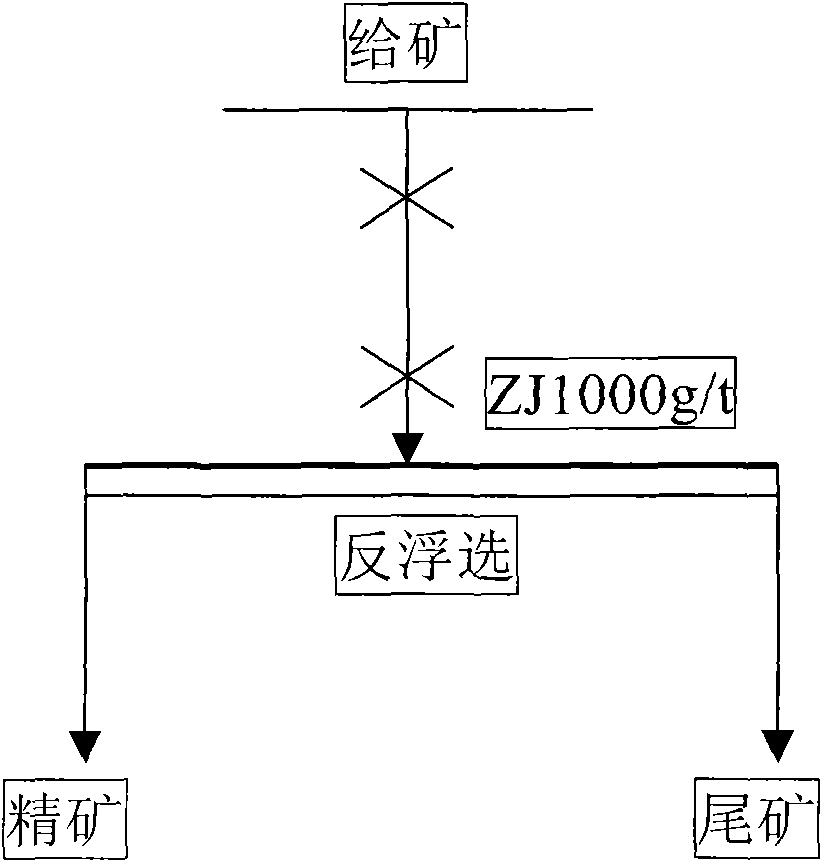

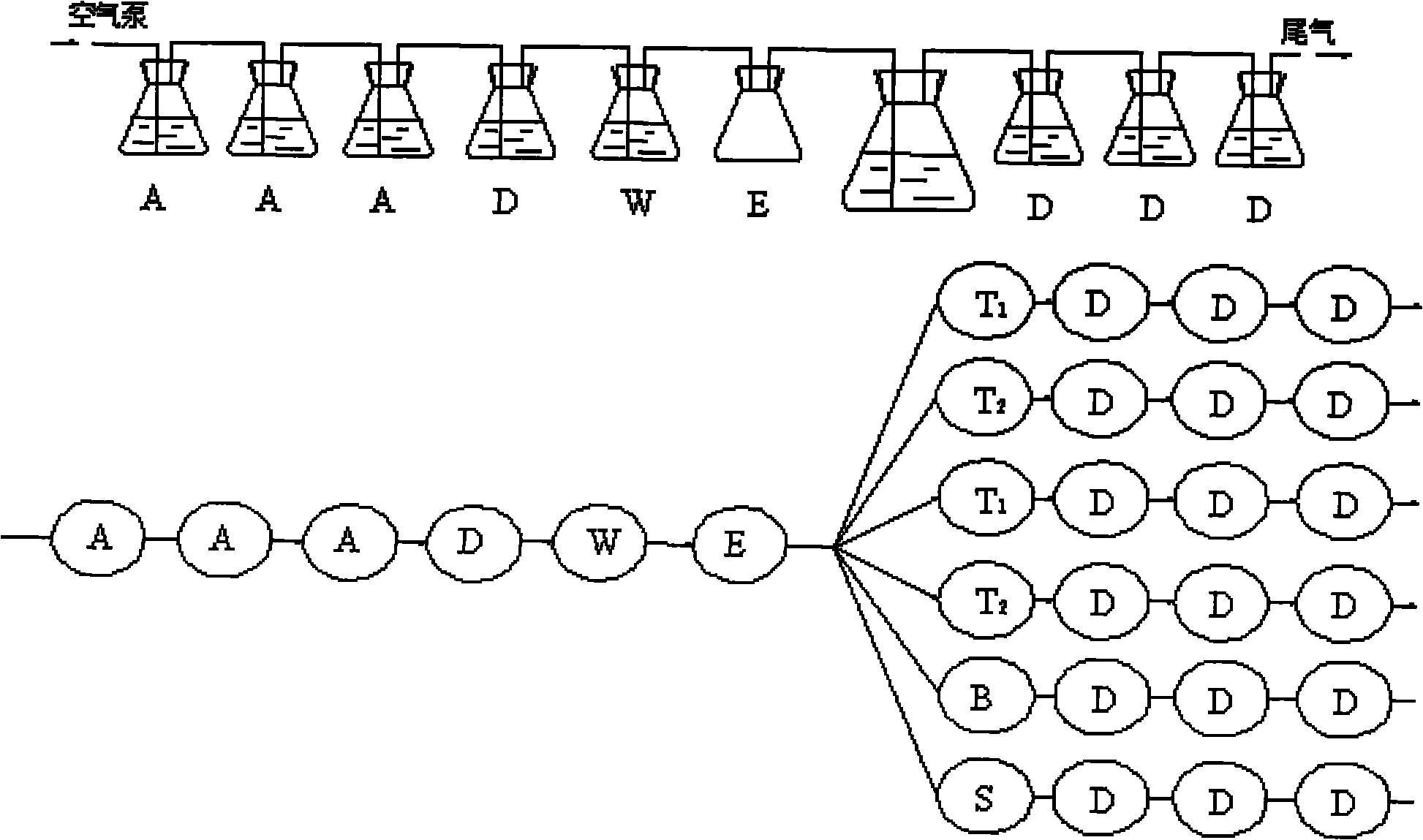

Environmentally-friendly amine cationic collector and using method thereof

InactiveCN101816981ASave on heating costsPracticalOrganic compound preparationFlotationSURFACTANT BLENDToxicity

The invention discloses an environmentally-friendly amine cationic collector and a using method thereof. The collector ZJ is ester group-containing quaternary ammonium salt cationic surfactant and has a plurality of alkyl groups, wherein an R alkyl group has 6 to 18 carbon atoms; an R1 alkyl group has 1 to 4 carbon atoms; the number of ester groups is 1 or two; and the number of the quaternary ammonium group is 1. The collector is obtained by esterification and quaternarization. As a hydrophobic chain has a carbonyl structure, the collector can hydrolyze easily into nonsurfactant fragments, and is a surfactant with high biodegradability, small toxicity and high performance. The collector is used in ore flotation for the first time and demonstrates high collecting capacity and selectivity.The collector forms fine and fragile foam that is low temperature resistant. The collector can be used under the condition that the pH value of ore pulp is 7 without corroding equipment. The preparation process of the collector is simple and easy in operation. And the collector is easy to biodegrade and is environmentally-friendly.

Owner:WUHAN UNIV OF TECH

Preparation method of soluble fish protein ammonia acid fertilizer

InactiveCN104557339AReduce lossesSimple methodBio-organic fraction processingAnimal corpse fertilisersProduct processingNutrients substances

The invention relates to a preparation method of a soluble fish protein ammonia acid fertilizer, belongs to the field of biological technical processing, and particularly belongs to the field of fertilizer additive preparation. The preparation method comprises the following steps: crushing and pulping leftovers from fishery product processing or deep-sea low-value shrimp into fish pulp, mixing with water, adding lactic acid bacillus and protease, and fermenting for 3-8 days respectively through continuous ventilation and interval ventilation at a temperature of 40-45 DEG C to obtain the soluble fish protein ammonia acid fertilizer. The preparation method disclosed by the invention is simple, and short in heating treatment time, so that the heating cost is saved and the loss of nutrient substances is reduced. The fish protein ammonia acid soluble fertilizer prepared by adopting the preparation method has a good application effect, and particularly has remarkable effect on fruits and vegetables.

Owner:ZHOUSHAN YUANFENG MARINE BIOTECH

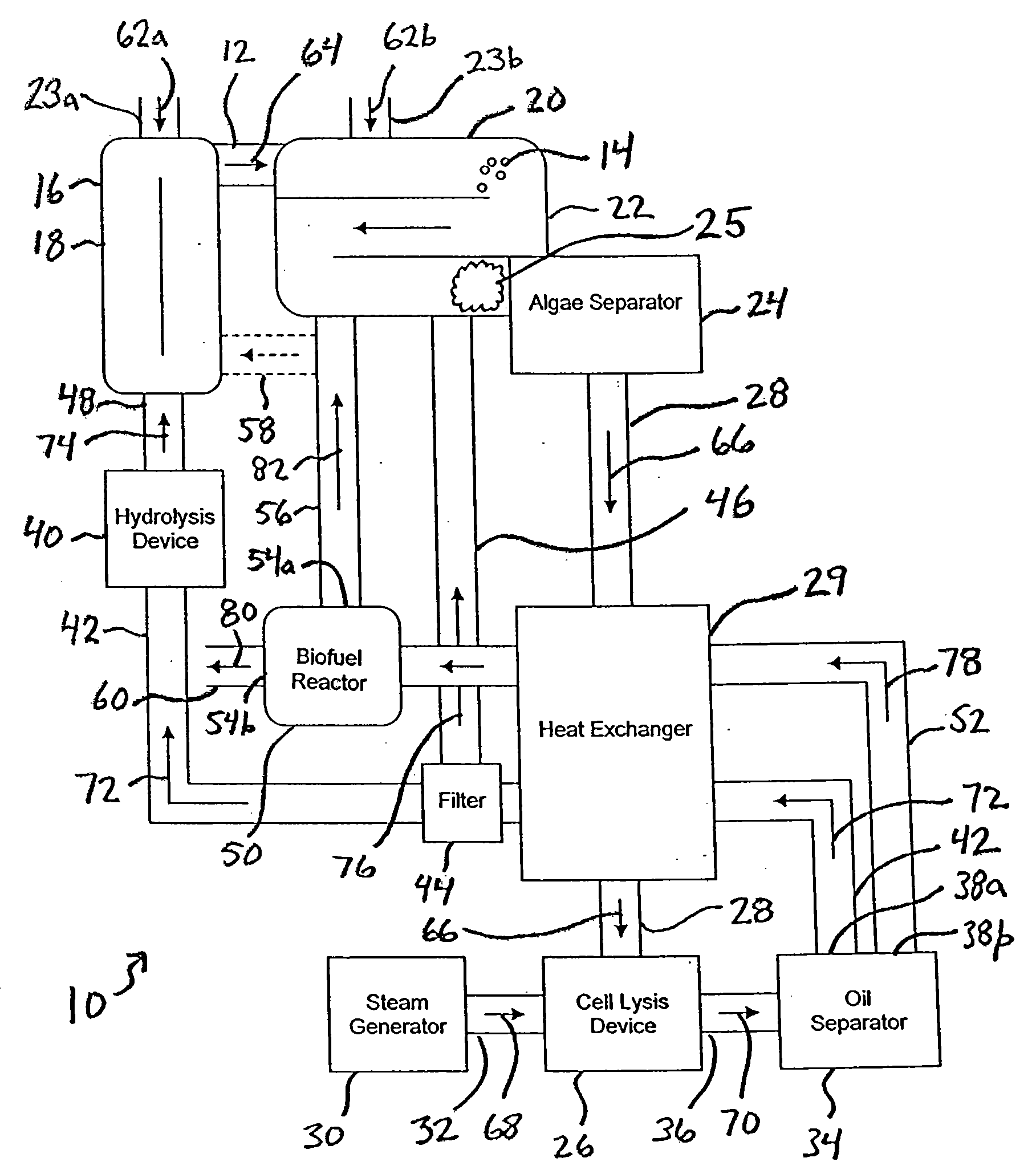

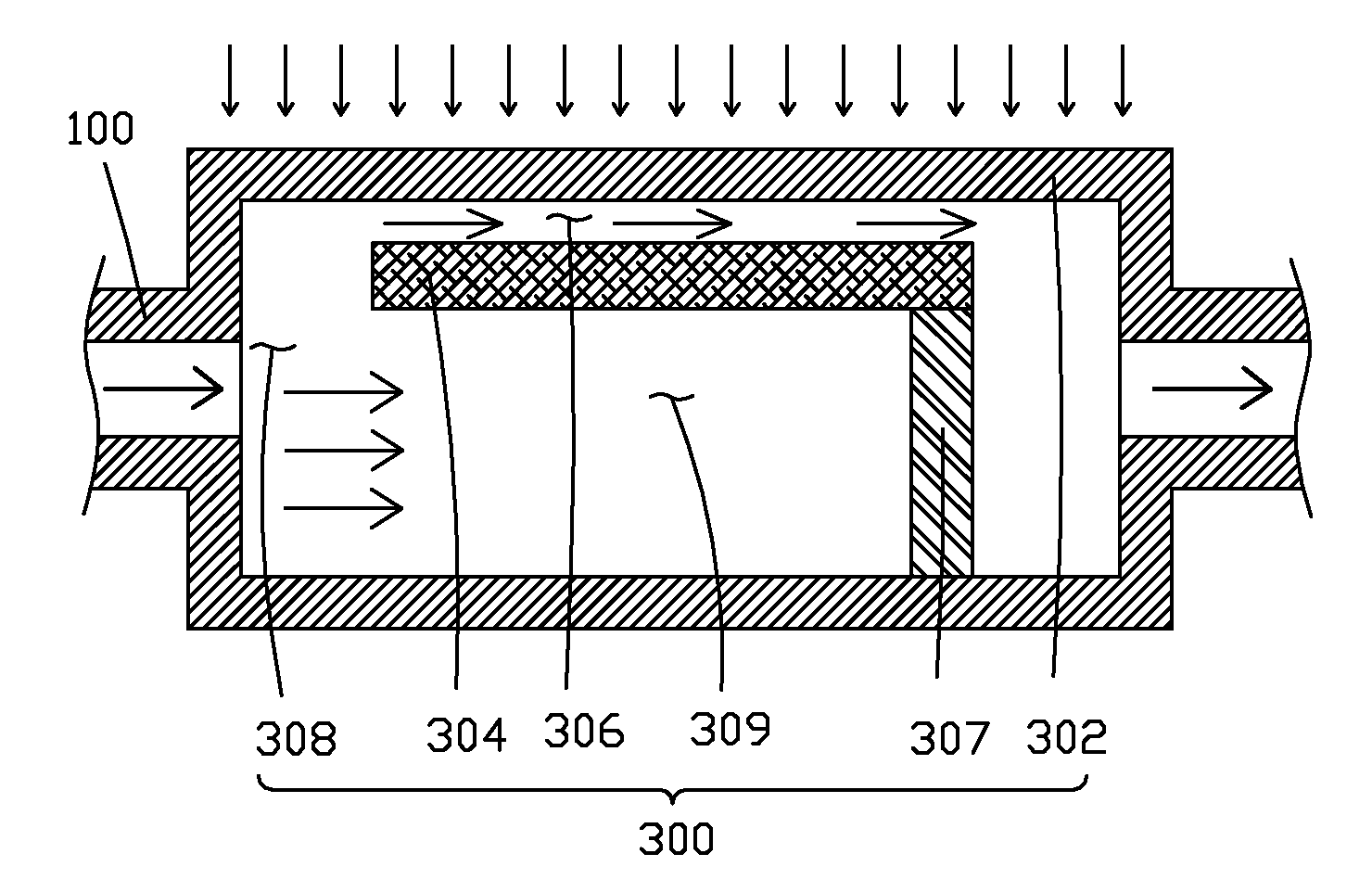

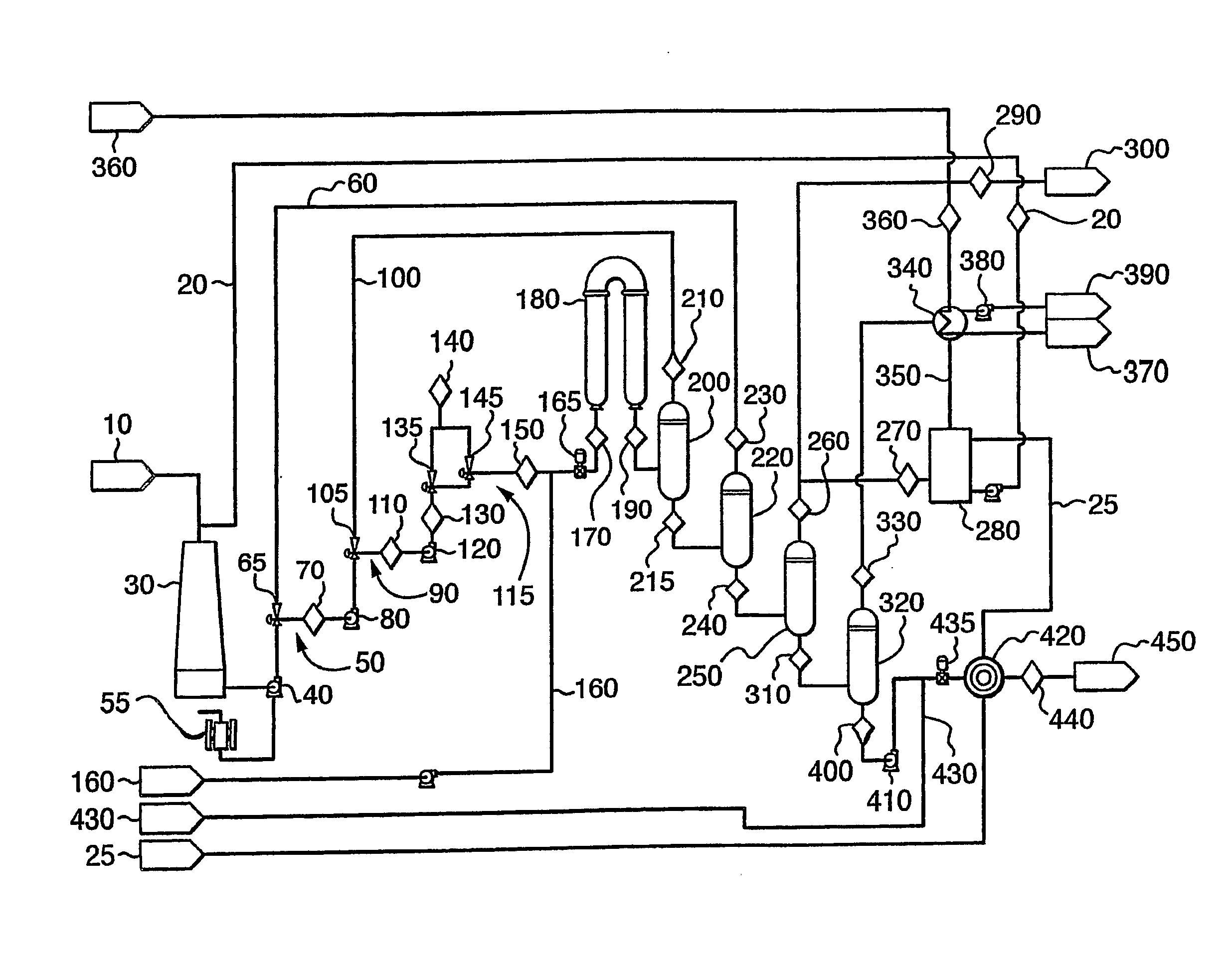

High efficiency separations to recover oil from microalgae

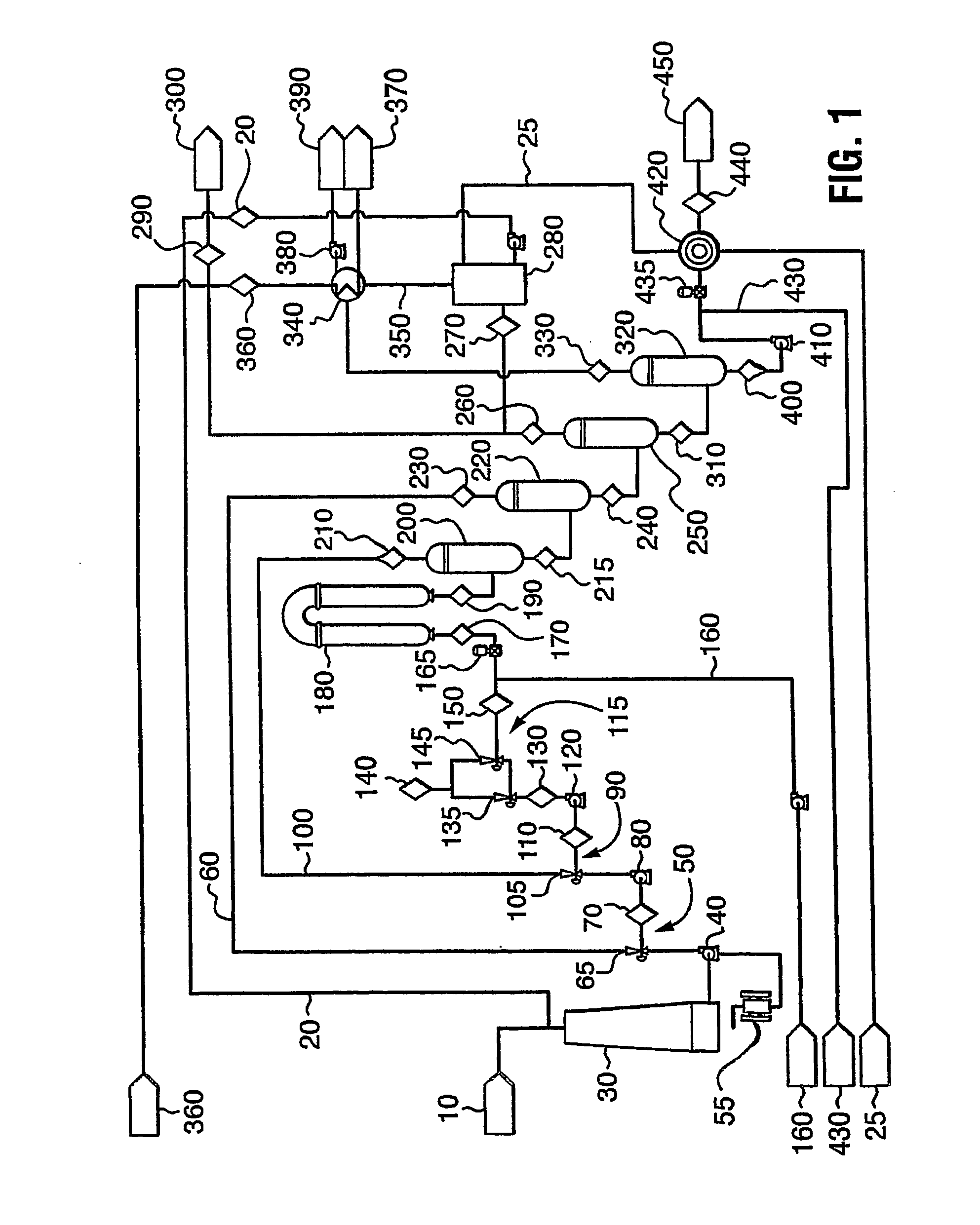

InactiveUS20090081742A1Lower heating costsIncrease ratingsBioreactor/fermenter combinationsBiological substance pretreatmentsAlgaenanBiotechnology

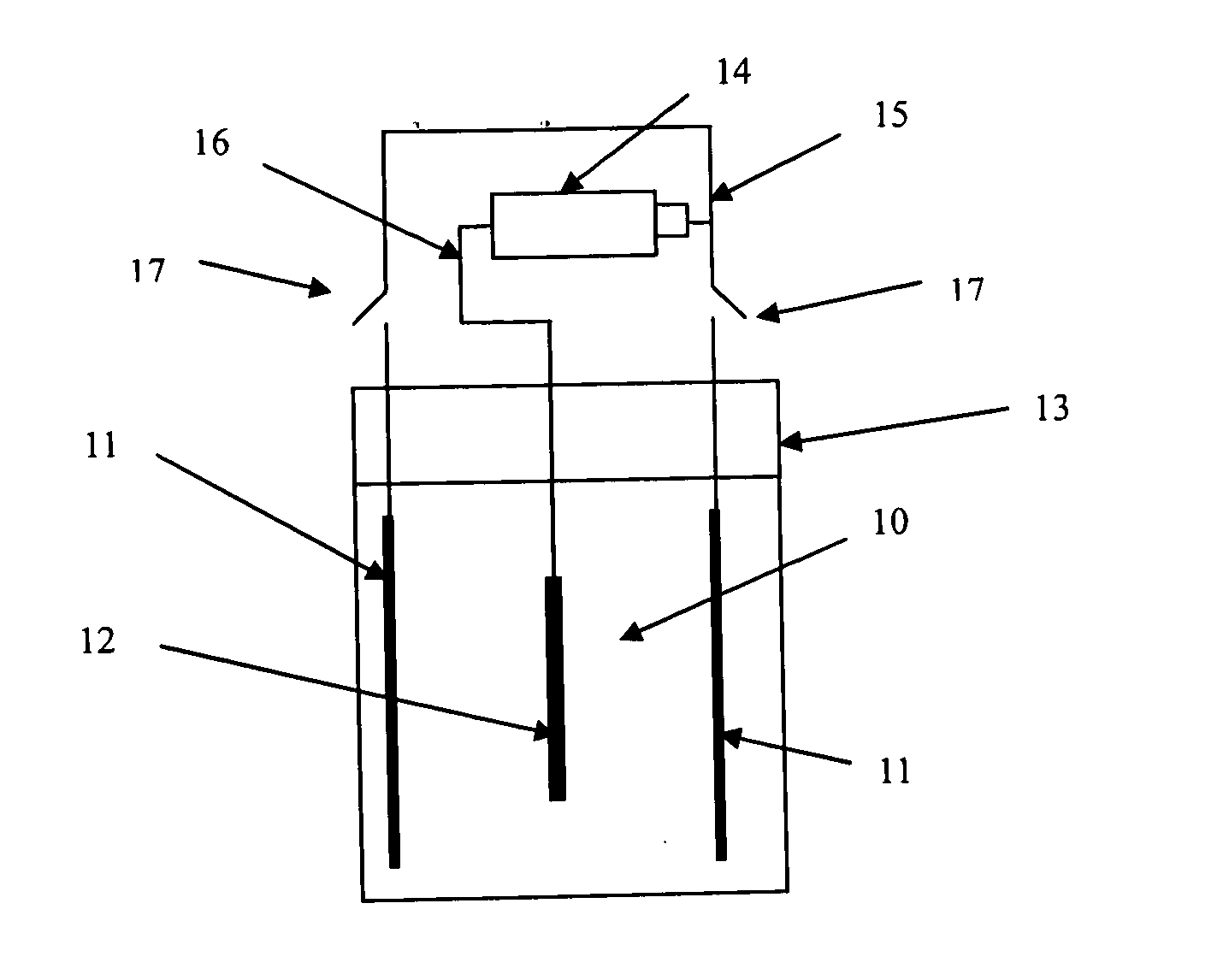

A system and method for processing algae cells to create biofuel are disclosed. Specifically, the system and method utilize steam to rupture algae cells in order to utilize intracellular oil therein. The system includes a conduit for growing algae cells and a generator for creating steam. Further, the system includes a lysing device that mixes the algae cells and the steam to rupture the algae cells. In order to maximize the efficiency of the lysing process, the system may further include a heat exchanger for preheating the algae cells with the lysed cells. In addition, the system includes a bioreactor to synthesize biofuel from the unbound oil.

Owner:GENERAL ATOMICS

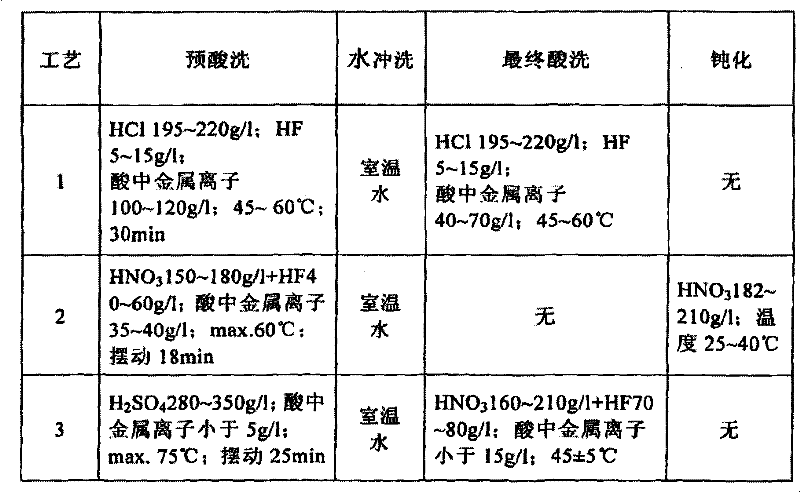

Titanium alloying milling solution and milling technique used for the same

The present invention discloses a titanium alloy chemical milling solution and its application milling process, which mainly contains nitric acid and hydrofluoric acid as the main components of mixed acid acidic corrosion solution, sodium lauryl sulfate, ethylene glycol n-butyl ether and / or or urea additives. The surface tension of the solution is maintained at a stable value by using the present invention. The adsorption of ethylene glycol n-butyl ether can reduce the interfacial tension and increase the chemical milling rate. Sodium lauryl sulfate, which improves the fluidity of the solution, can eliminate excessive corrosion of the metal at the root of the chemical milling fillet, and prevent the appearance of "grooves", "slopes" and "ripples". Sodium nitrate prevents the formation of scale of alloying elements on the surface of the chemical milling groove, improves the surface finish of the chemical milling surface and facilitates maintenance of the equipment. Urea can effectively absorb the nitrogen-containing gas produced in the chemical milling process, reduce the volatilization of acid liquid, and avoid pollution to the environment. The invention does not need heating equipment, the amount of hydrogen added is less than 9ppm, the service life of the solution is long, hydrogen embrittlement does not occur, and the process has little influence on the fatigue performance of the material.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

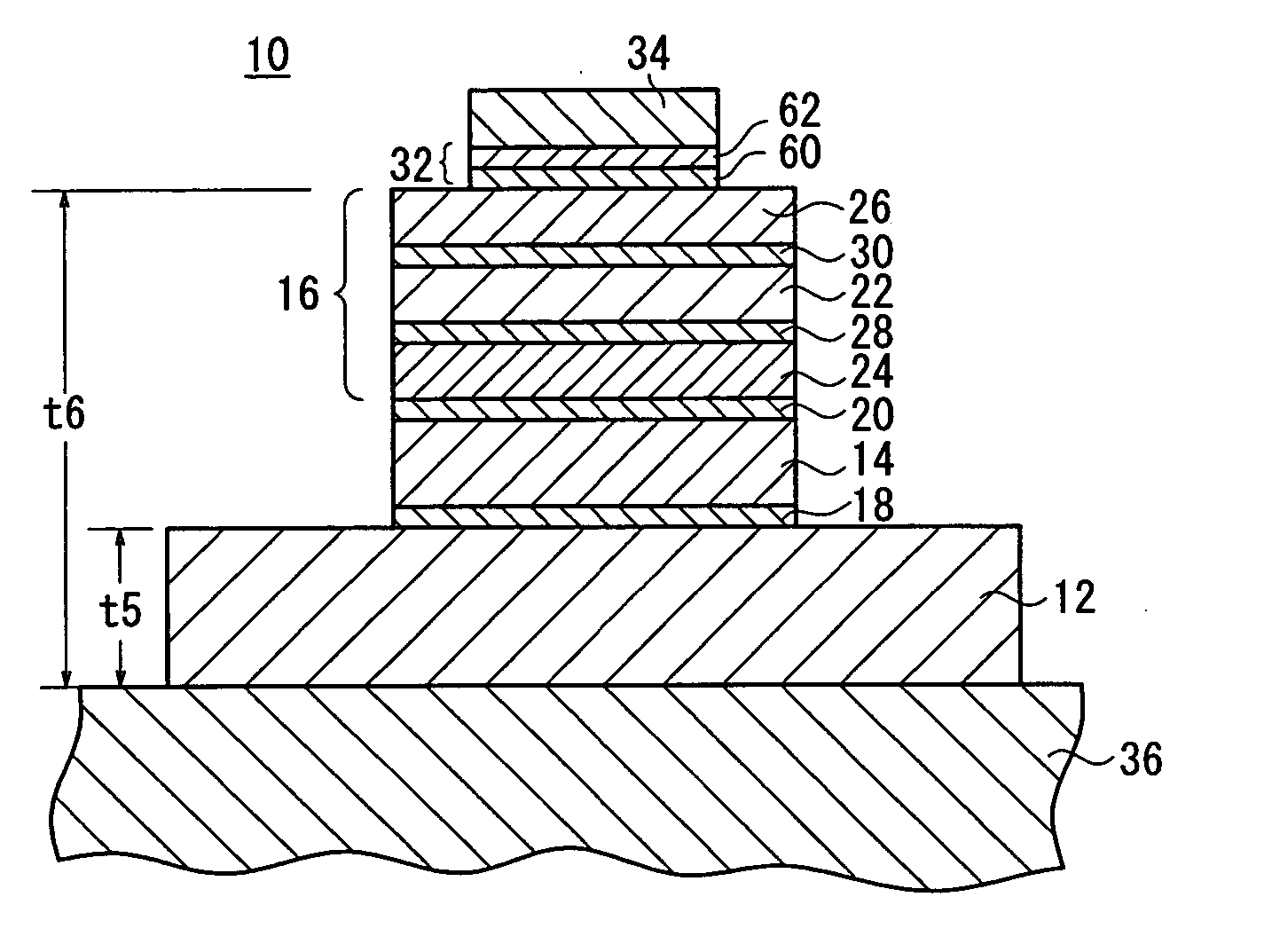

Heat spreader module and method of manufacturing same

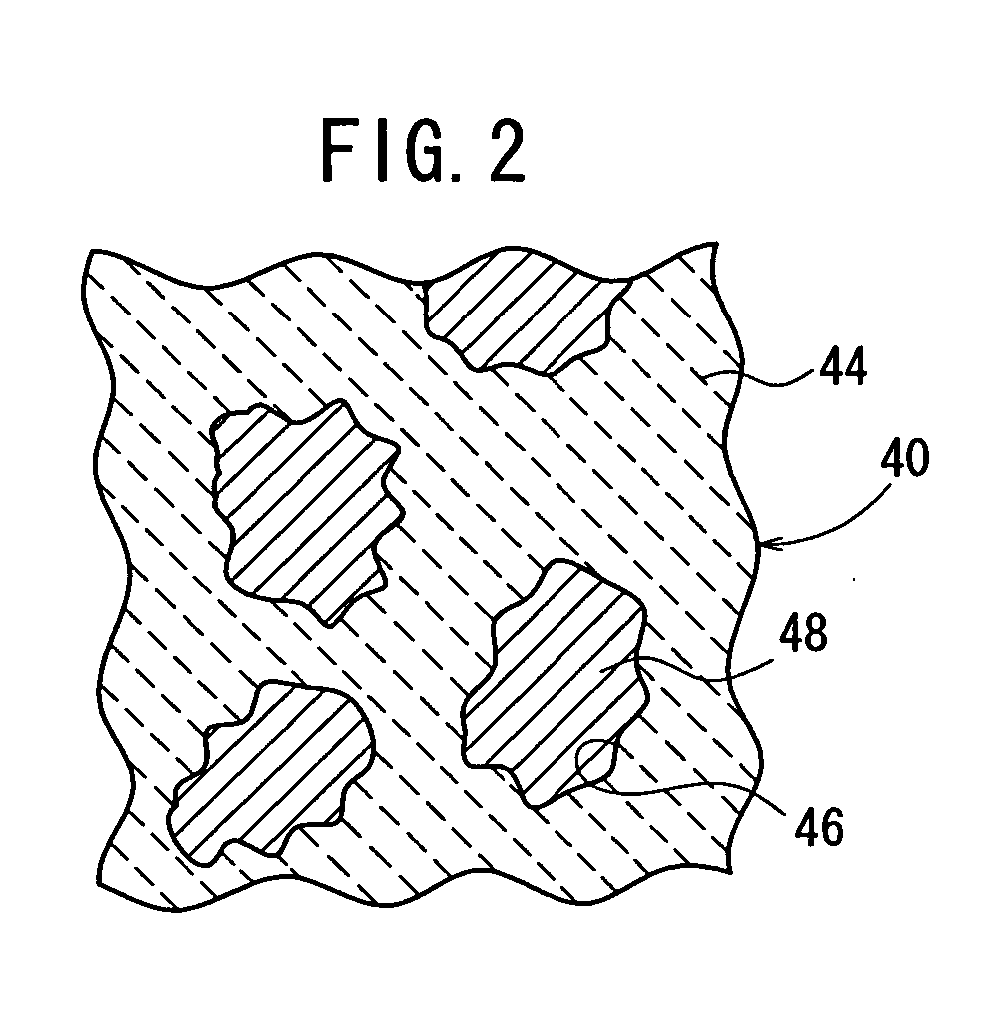

InactiveUS20040191558A1Relieve pressureAvoid heatBreathing filtersBreathing masksMaterials scienceHeat spreader

A heat spreader module has a pedestal, a heat spreader member joined to the pedestal by a first active hard brazing material, an intermediate layer joined to the heat spreader member by a second active hard brazing material, an insulating board joined to the intermediate layer by a third active hard brazing material, and a circuit board joined to the insulating board by a fourth active hard brazing material. The first through fourth active hard brazing materials are supplied such that the active hard brazing materials have a thickness ranging from 3 to 20 mum when the components of the heat spreader module are joined together under pressure, and contain an active element in an amount ranging from 400 to 1000 mug / cm<2>.

Owner:NGK INSULATORS LTD

Method and apparatus for controlling multiple games with one or more processors

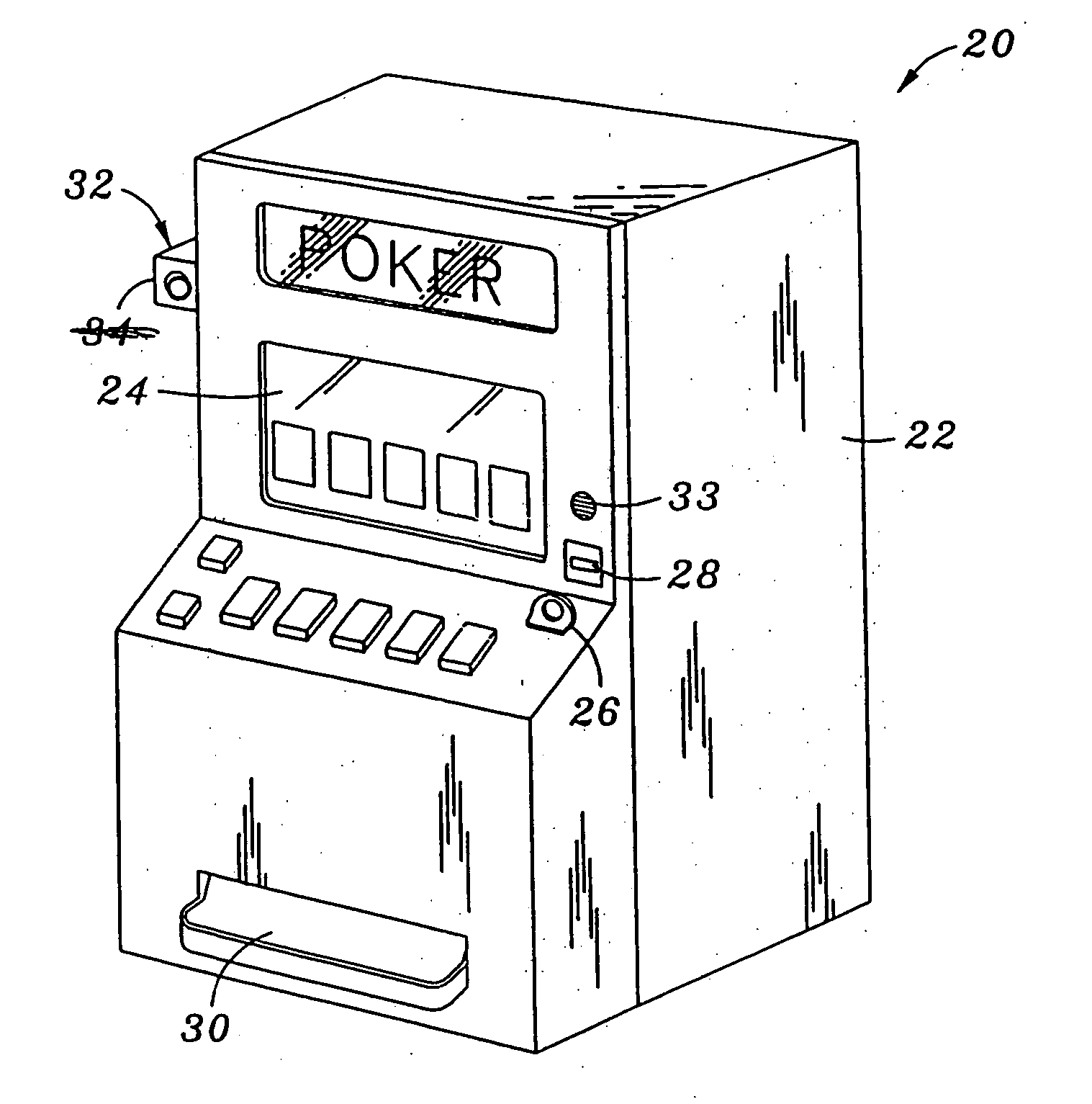

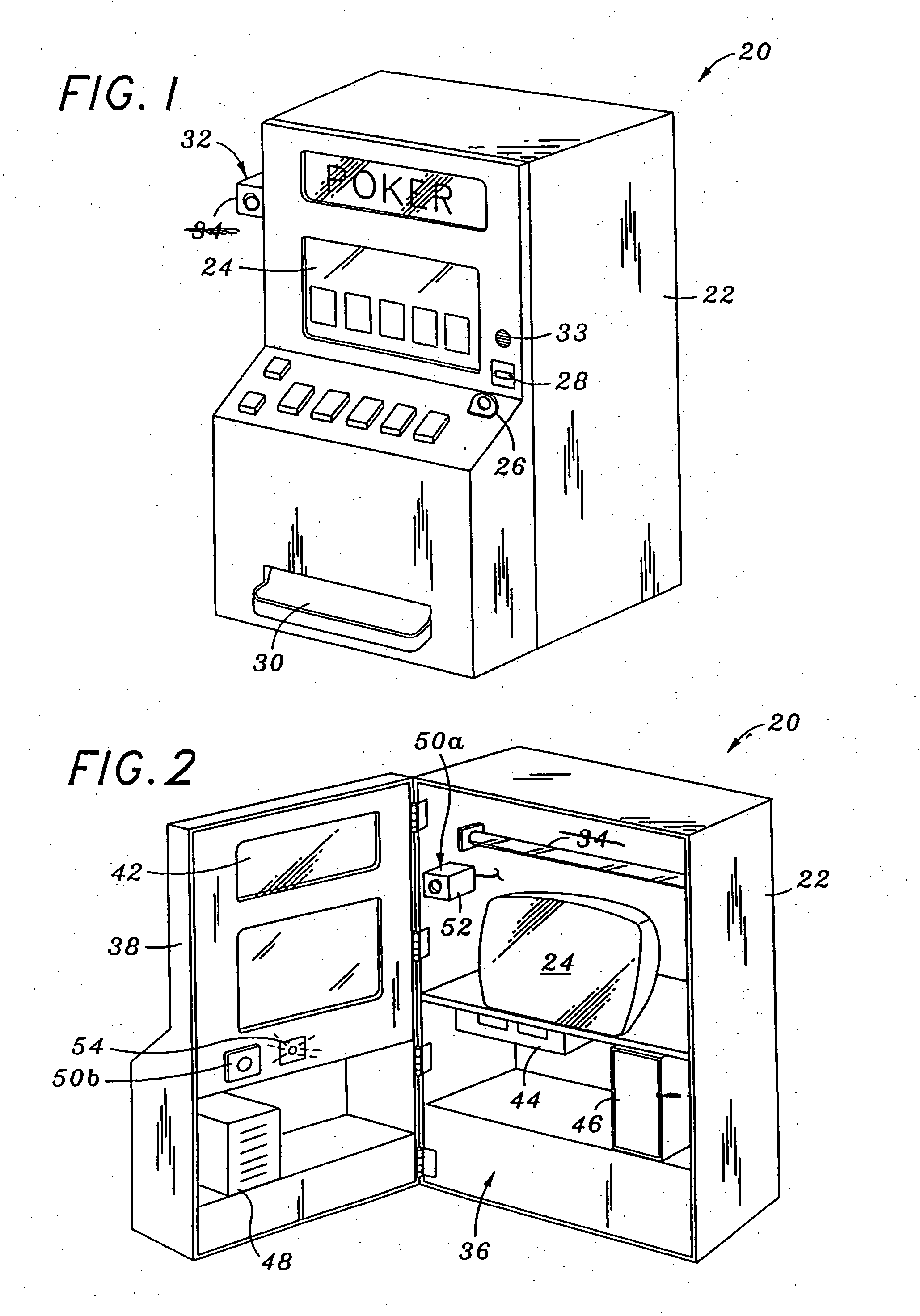

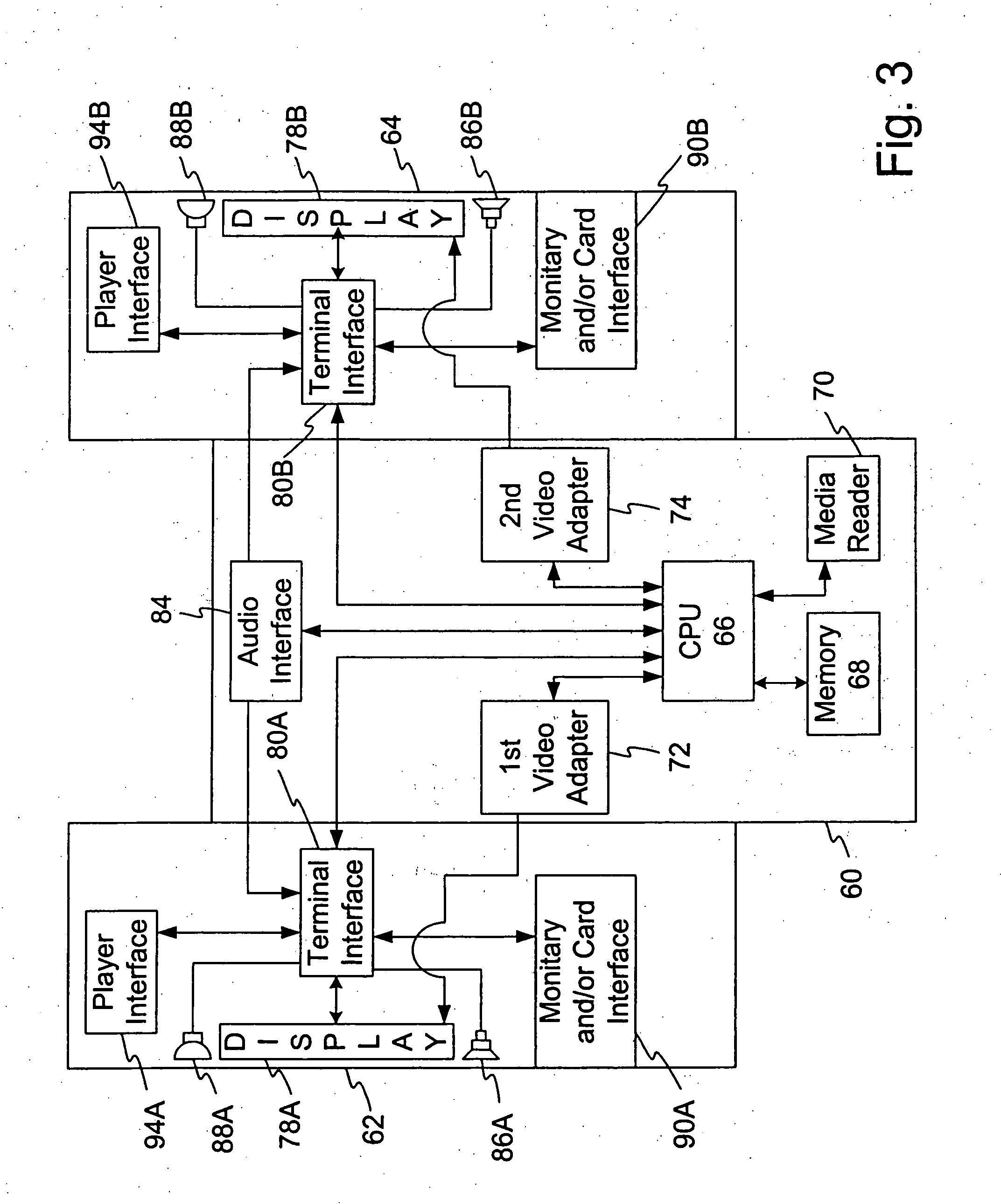

InactiveUS20050049048A1Low costLower heating costsApparatus for meter-controlled dispensingVideo gamesDisplay deviceHuman–computer interaction

A method and apparatus for providing two or more wagering events or gaming opportunities at two or more different locations to two or more different players at the same time or concurrently though multi-tasking or other shared processing arrangement of a shared control module or processor. In one embodiment a control module is configured with a processor, memory, and one or more interfaces configured to communicate with two or more game terminals. The two or more game terminals may be located remote from the control module or in close proximity. The game terminals may be configured with a display and player interfaces to receive input from a player. In one embodiment one or more video adapters are located with the control module or the game terminal. As an advantage over the prior art, controlling and enabling two or more game terminals with a shared control module or a shared processor reduces costs and the required space on a per game or per terminal basis.

Owner:IGT

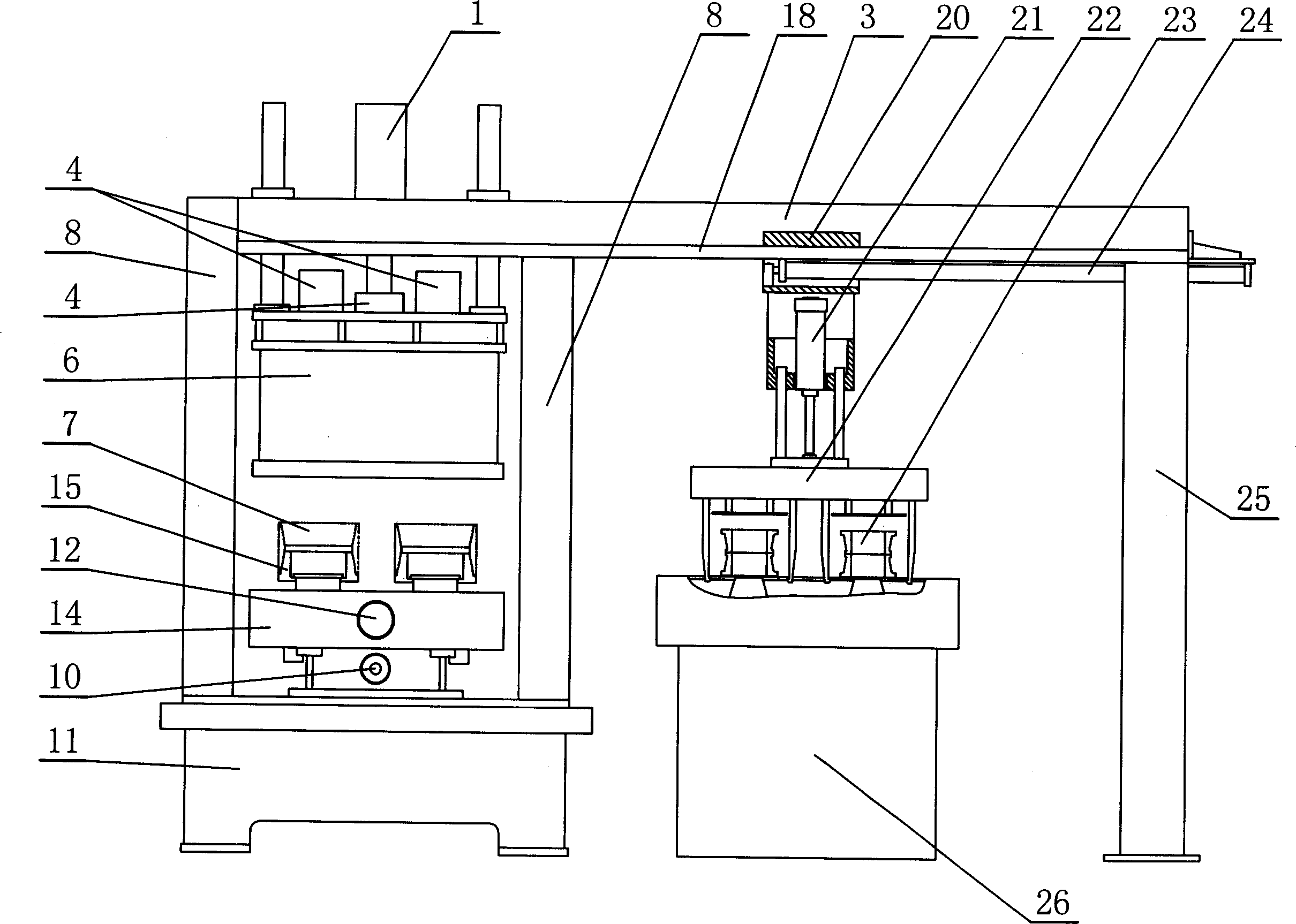

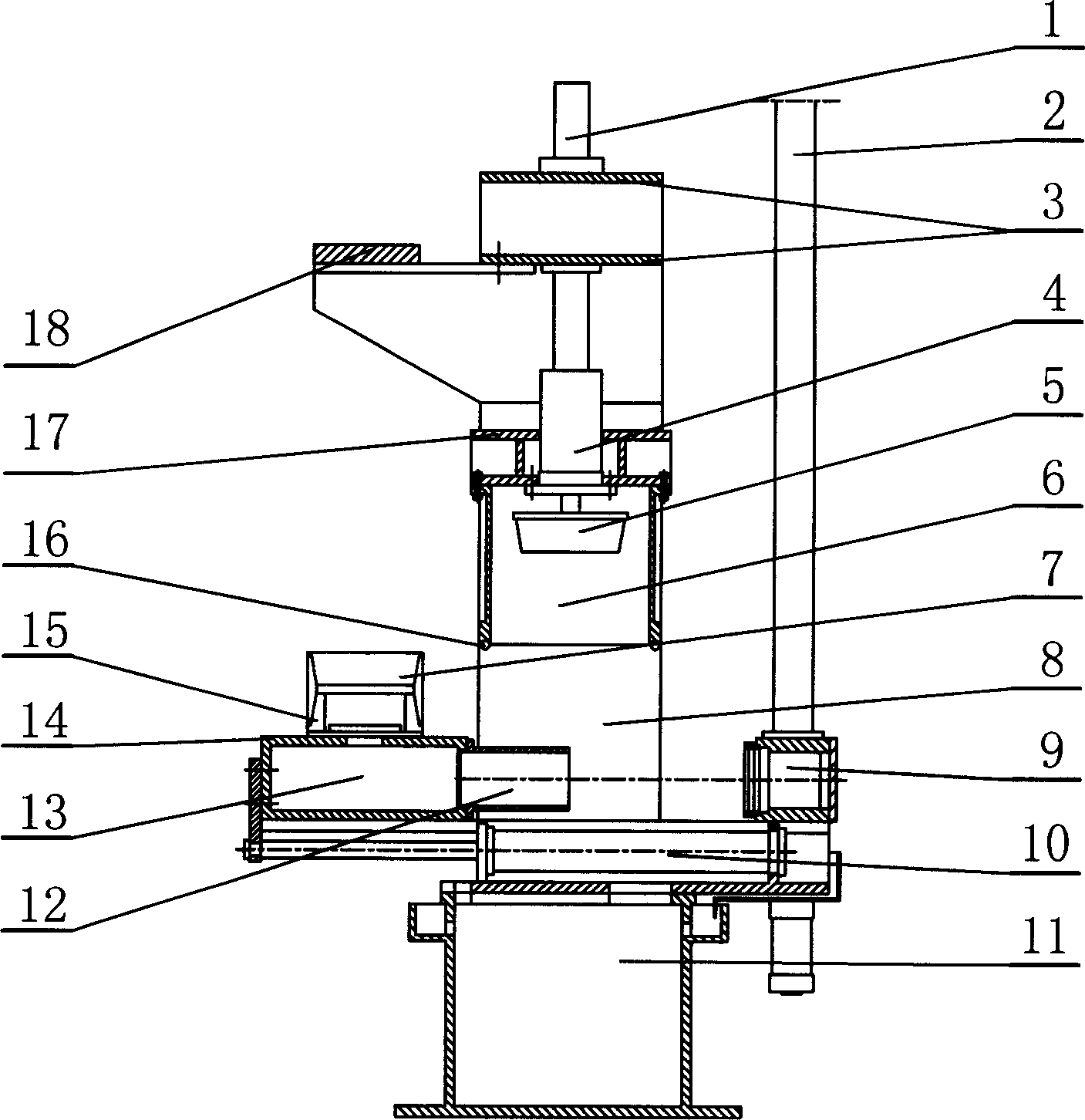

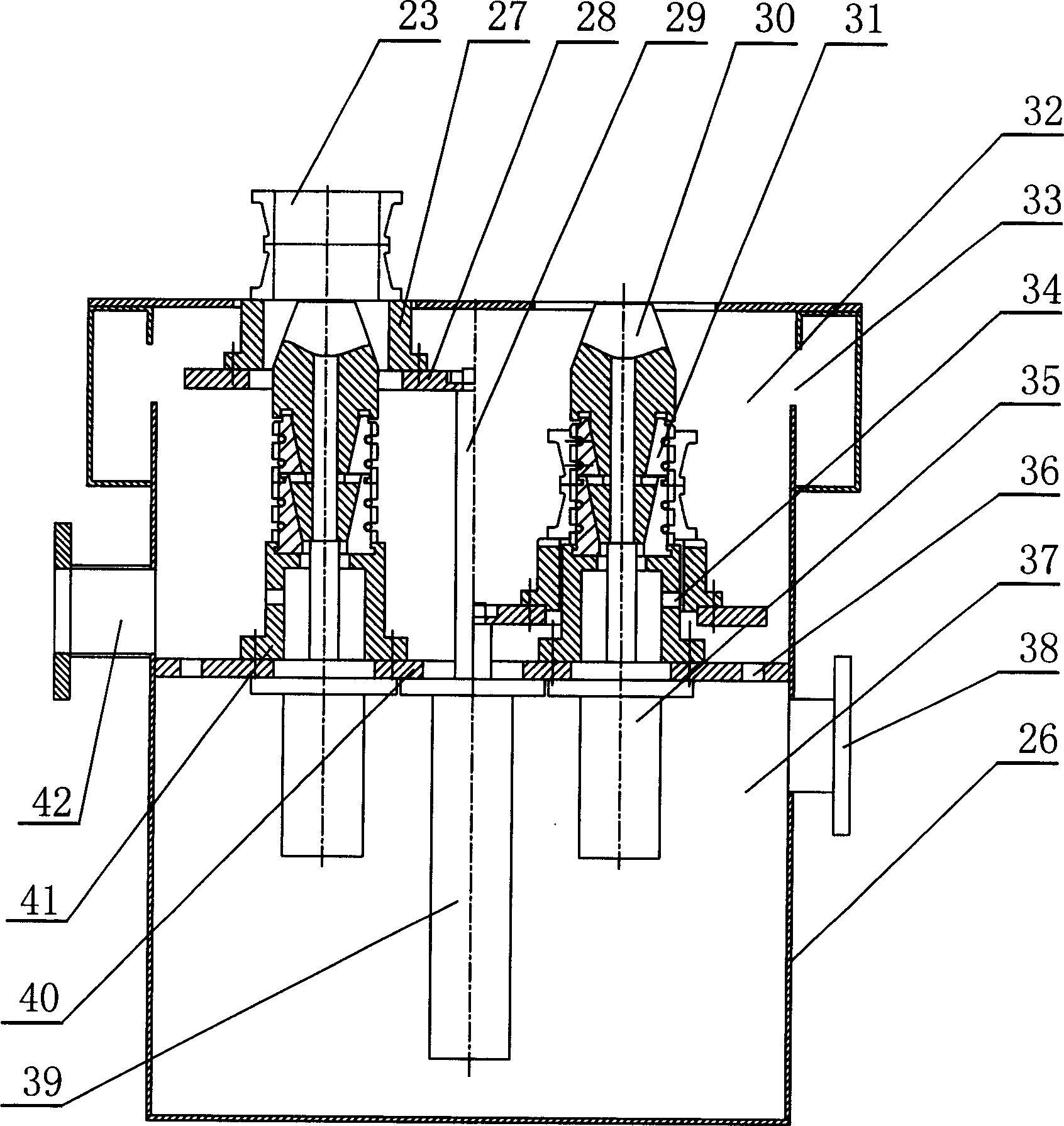

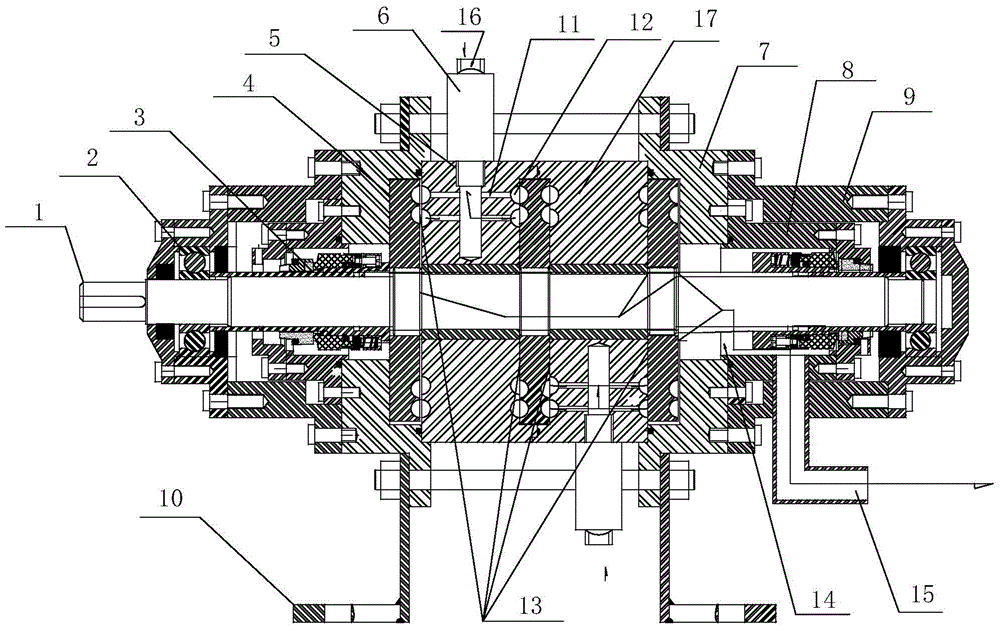

Quenching process and its quenching device for bearing internal and external rings

ActiveCN1858268ASimple structureImprove work efficiencyFurnace typesHeat treatment furnacesSmall footprintManipulator

The present invention relates to heat treatment, and is especially internal and external bearing ring quenching process and quenching press. The quenching process includes the steps of mounting and heating, feeding quenching material, simultaneous quenching of the internal bearing ring and the external bearing ring, and discharging. The special quenching apparatus includes internal bearing ring quenching apparatus, external bearing ring quenching apparatus and manipulator for grabbing the outer bearing ring. The external bearing ring quenching press is provided with fixing mold, the internal bearing ring quenching apparatus is provided with expanding mold, and the quenching process is one closed immersing process. The present invention has homogeneous quenching and is suitable for batch heat treatment.

Owner:NINGXIA MACHINERY RES INST

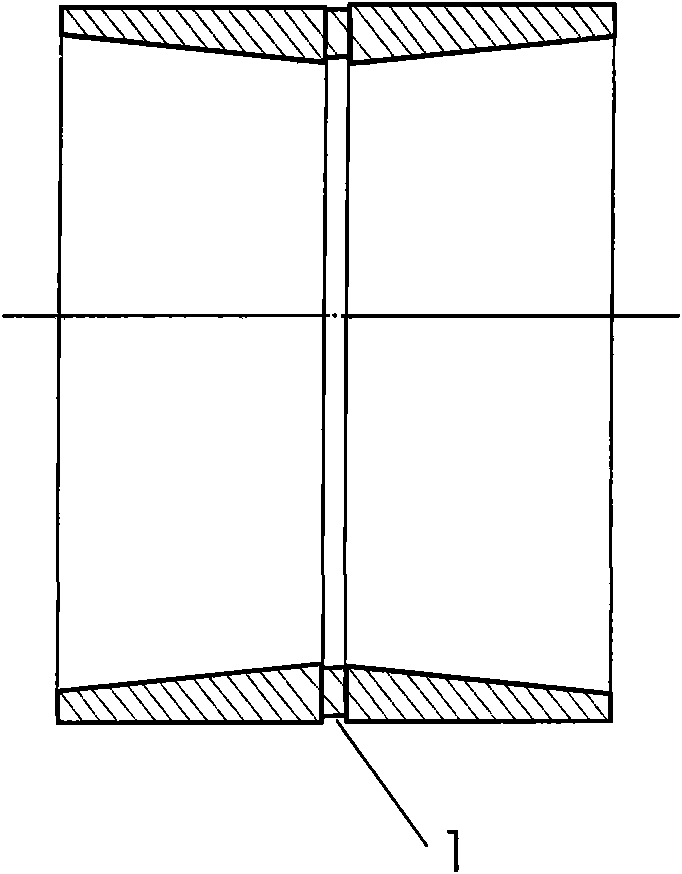

Method for manufacturing outer ring of tapered roller bearing

The invention discloses a method for manufacturing an outer ring of a tapered roller bearing, comprising the following steps of: a: taking a material: setting the quality of the finished product outer ring as M, setting the outer diameter as D, taking a bearing steel pipe with the outer diameter of D1 as the raw material, taking the bearing steel pipe with the quality of M1 and meeting the condition that one half of D is less than or equal to D1 which is less than D, and M1 is equal to 2M plus M2 plus 2M3, wherein M2 is the margin of quality by cutting, and M3 is the margin of quality of single outer ring by grinding process; b: cold rolling: rolling on the bearing steel pipe taken in the step a for obtaining a combined blank of the outer ring; c. cutting: cutting the combined blank at the connecting ring for obtaining a single blank of the two outer rings; d: thermal processing; and e: finish machining: grinding the single blank of the outer ring. The proposal leads the outer ring of the tapered roller bearing to realize the cold rolling for shaping, has the advantages of small material loss, saved energy consumption, simple process, high production efficiency and the like, and simultaneously ensures the product quality.

Owner:NINGXIA QINCHANG ROLLING BEARING MFG

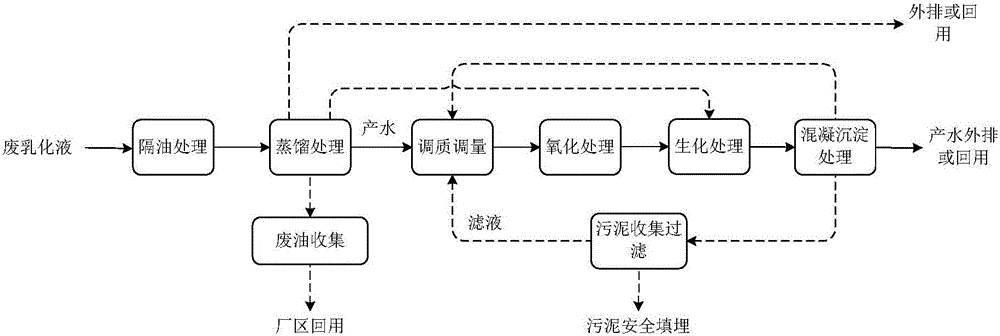

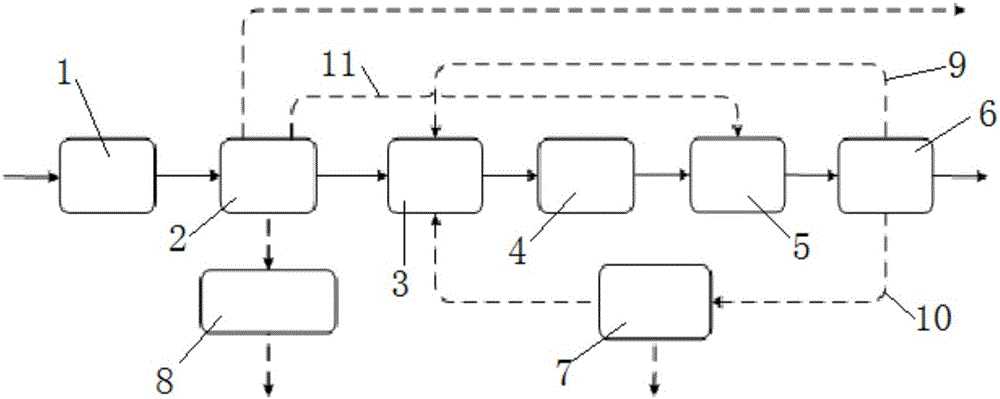

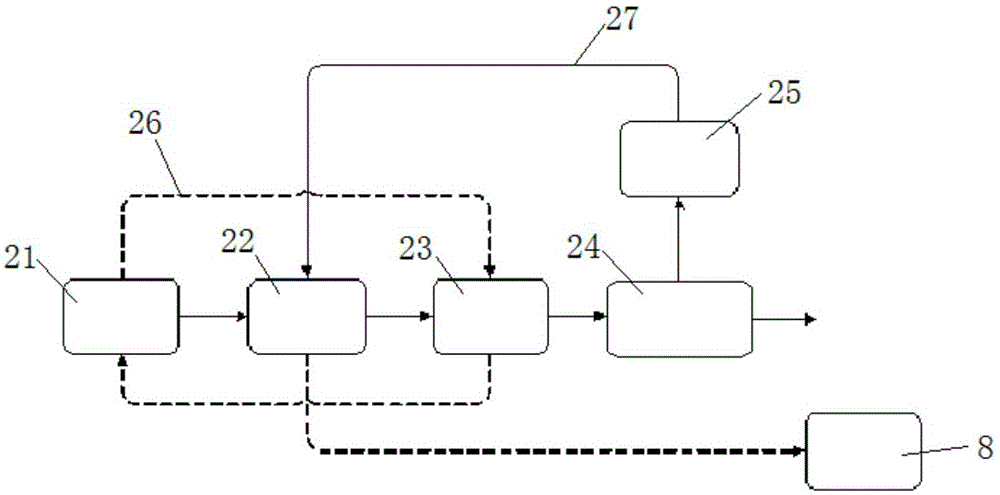

Treatment method and device for extremely-high-concentration waste emulsion

ActiveCN105731706AWill not destroy the componentsWill not destroy natureFatty/oily/floating substances removal devicesMultistage water/sewage treatmentHigh concentrationEmulsion

The invention discloses a treatment method and device for extremely-high-concentration waste emulsion. The treatment method comprises the following steps that firstly, the waste emulsion is subjected to oil separation treatment to remove floating oil on the upper layer of the waste emulsion, and the waste emulsion obtained after oil separation treatment is obtained; secondly, the waste emulsion obtained after oil separation treatment is subjected to distillation pretreatment, and waste oil and waste water are obtained. The device comprises an oil separation system and a distillation system which are connected in sequence, wherein the oil separation system is used for regulating the flow of the waste emulsion and removing the floating oil on the surface of the waste emulsion, and the distillation system is used for carrying out demulsification and achieving oil and water separation of the waste emulsion obtained after oil separation treatment. Demulsification and oil and water separation are achieved at the same time through distillation treatment, selectivity is avoided, and the method and the device can be widely applied to treatment of various kinds of waste emulsion; recycling is easy, a demulsification agent does not need to be added, the component and nature of waste oil cannot be damaged, and decrease of the utilization value of the waste oil can be avoided.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

Power rotation heater

InactiveCN104613661AFix Heating ProblemsImprove securityOther heat production devicesHeat flowCavitation

The invention relates to heating use of flammable, explosive and toxic liquid and gas and the like in the field of petroleum, chemical engineering, large machines and the like, belongs to the field of heating equipment on hot water heating occasions and the like, and relates to a power rotation heater. The power rotation heater comprises multiple liquid cavitation pipes. A drive shaft penetrates through a stator and multiple rotors coaxially. A gap is formed between the stator and the drive shaft. The rotors are at least arranged at the two ends of the stator, wherein gaps are formed between the rotors and the stator. Multiple stator liquid inlets are formed in the stator, wherein one end of each stator liquid inlet is open. Each stator liquid inlet is connected with the corresponding liquid cavitation pipe. Branch pipes are arranged in the stator. The gaps between the stator and the rotors and the stator liquid inlets are communicated through the branch pipes. Liquid with heat flows to a liquid outlet through the gaps, liquid cavitation pipe liquid inlets are connected through heating pipelines, and a circulation is formed. The purpose that the flammable, explosive and toxic liquid is not heated by naked fire and electric power is achieved, kinetic energy is converted into heat energy through a rotary power machine, immersion effluent is eliminated, and safety and reliability are improved.

Owner:丹东丹联仪表检测技术研究有限公司

Polymer modified bitumen composition to be used in asphalt binders or roofing compositions

InactiveUS20090105376A1Good storage stabilityEasy to weldIn situ pavingsBuilding insulationsCross-linkElastomer

A polymer modified bitumen composition, comprising 80 to 98.5 parts by weight of a bitumen and 20 to 1.5 parts by weight of a polymer composition, wherein the polymer composition comprises:(i) from 5 to 70% by weight of a linear styrenic block copolymer (SBC1) comprising at least two polymer blocks each substantially made of an aromatic vinyl compound and at least one polymer block substantially made of a conjugated diene compound and having an apparent molecular weight greater than 250,000 and / or a radial styrenic block copolymer (SBC2) having three or more polymer arms attached to the residue of a cross-linking agent or multifunctional compound, comprising at least two polymer blocks each substantially made of an aromatic vinyl compound and at least one polymer block substantially made of a conjugated diene compound and wherein the polymer arms have an average apparent molecular weight greater than 125,000 and(ii) from 95 to 30% by weight of an elastomer (EI) having an apparent molecular weight in the range of 120,000 to 250,000;their use as asphalt binder or as bituminous roofing composition, hot mix asphalt compositions comprising aggregate material and pavements comprising the compacted hot mix asphalt, easy welding roll roofing membranes, comprising said bitumen roofing composition, and specific block copolymers to be used in said bitumen composition.

Owner:KRATON POLYMERS US LLC

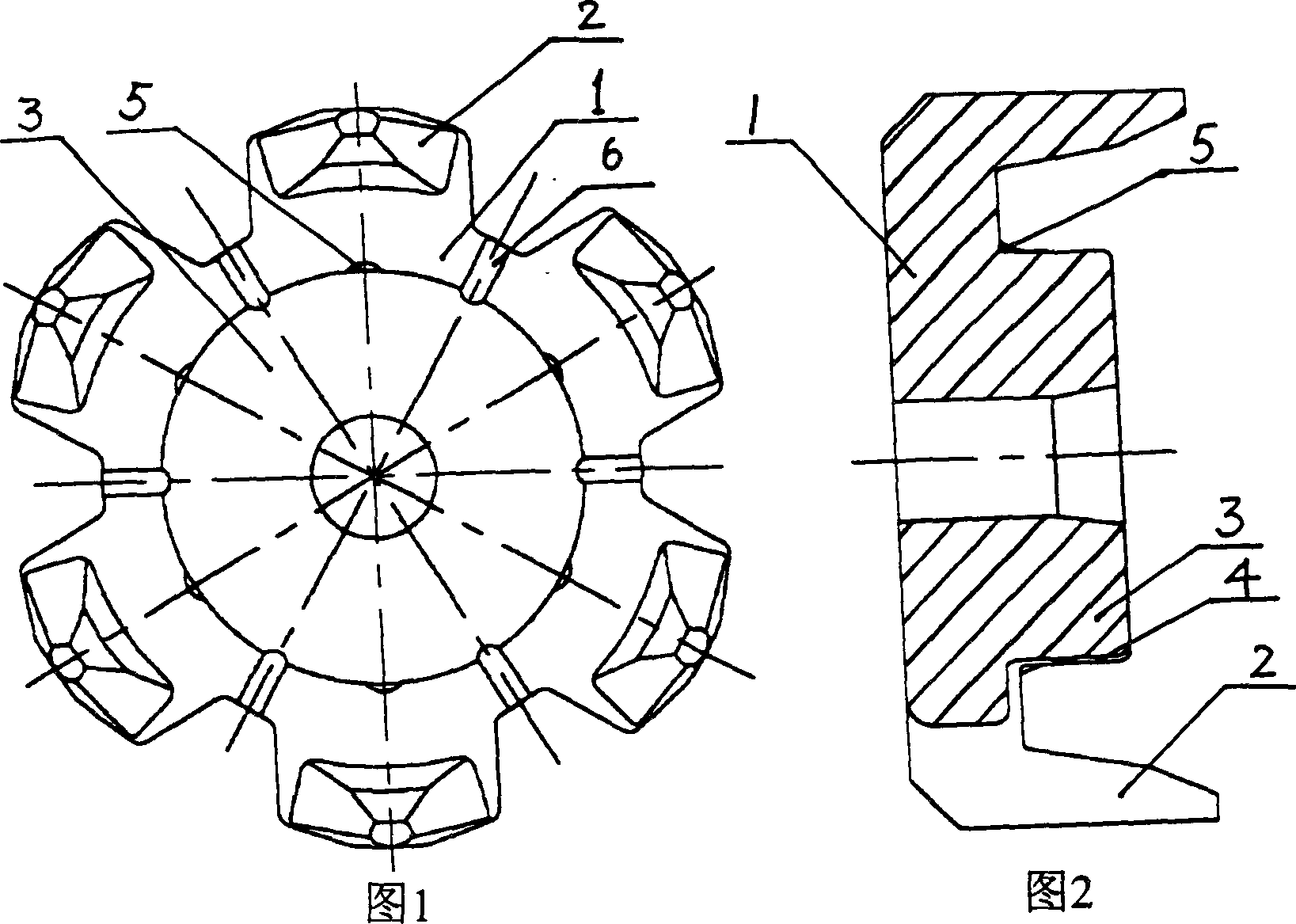

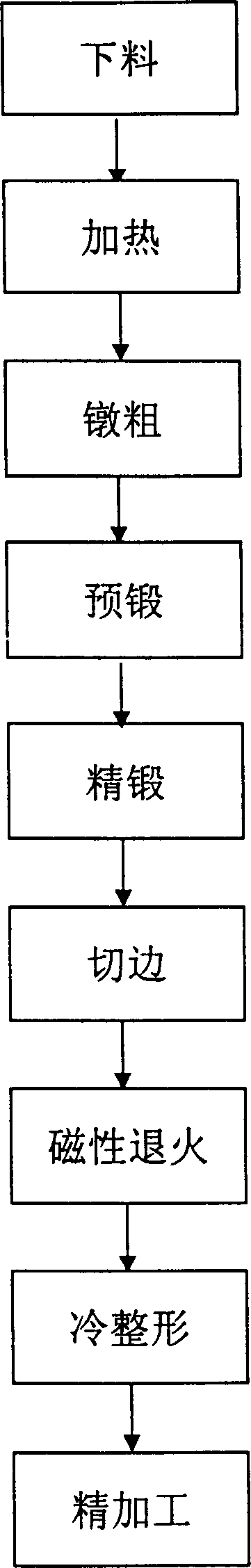

Pawl pole of automobile generator and its manufactura

ActiveCN1772413AIncrease power generationHigh dimensional accuracyManufacturing dynamo-electric machinesOther manufacturing equipments/toolsLacquerEngineering

The present invention relates to one kind of of automobile generator and its manufacture. The pawl pole has one bottom plate, one magnetic yoke on the bottom plate, six or eight insulating varnish conducting slots distributed homogeneously on the circumference of the magnetic yoke, six or eight lugs for preventing the rotation of coil, and six or eight insulated wire leading out slots in the bottom of the magnetic yoke. The manufacture of the pawl pole includes the steps of: cutting material, heating, upsetting, pre-forging, finish forging, cutting edge, magnetically annealing, cold shaping, and finishing machining. The manufacture process has low apparatus investment, low mold cost, low heating cost, high output and high product quality. The AC generator with the pawl poles of the present invention has induced electromotive force waveform of quasi-sinusoid wave and great generating power.

Owner:JIANGSU LONGCHENG PREC FORGING CO LTD

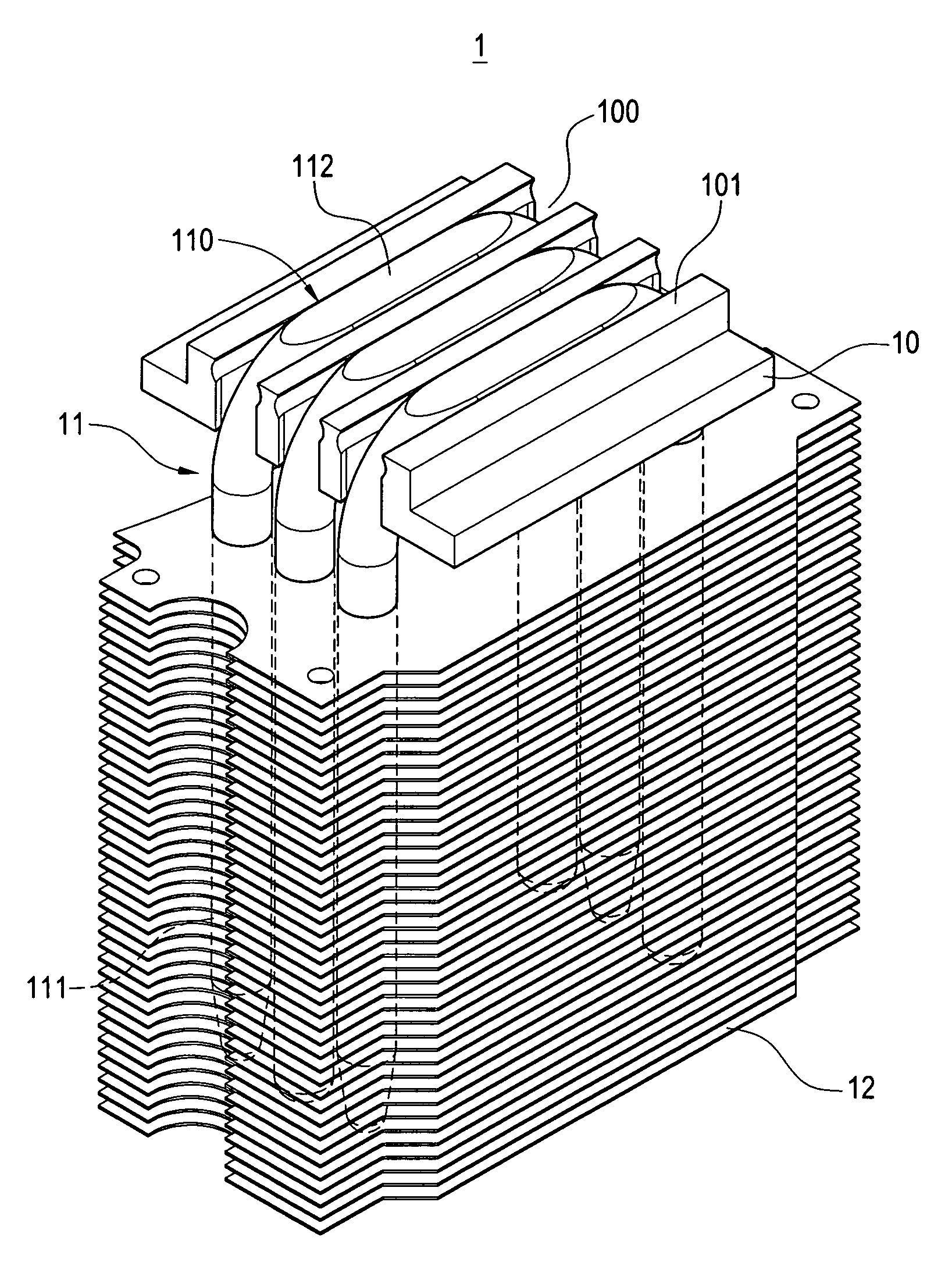

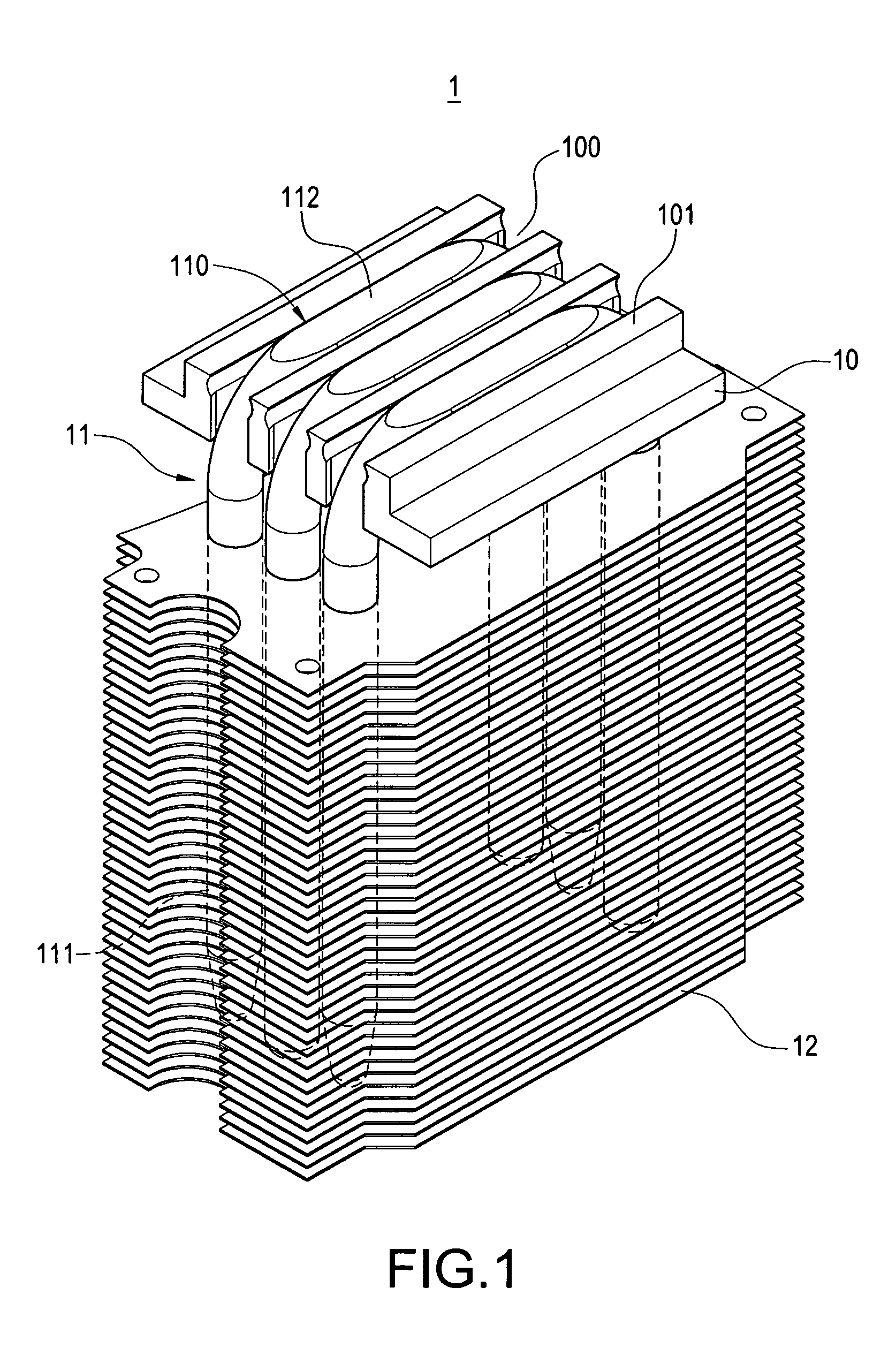

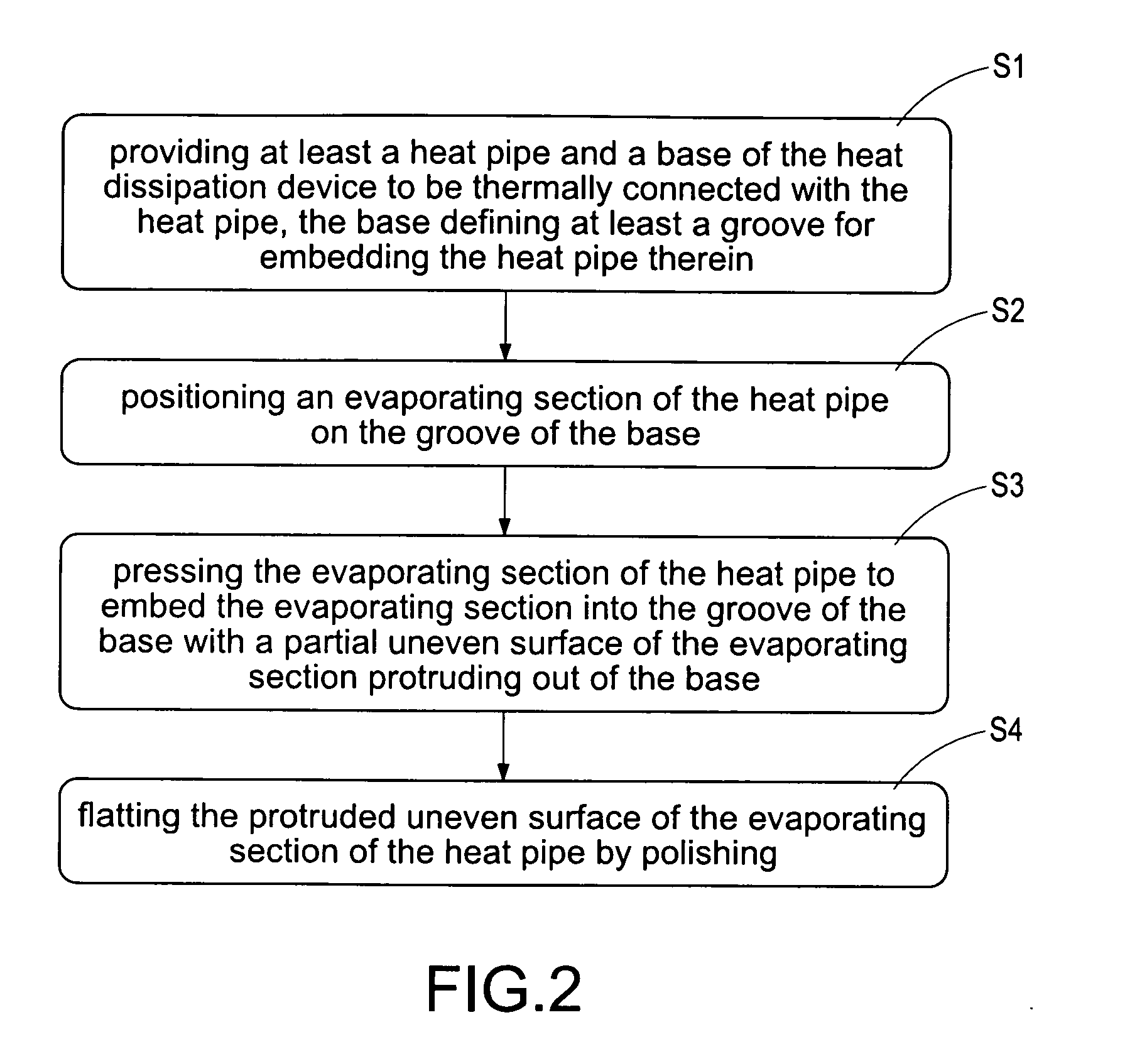

Method of flatting evaporating section of heat pipe embedded in heat dissipation device and heat dissipation device with heat pipe

InactiveUS20090266522A1High heat conductivityReduce heat transferSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat pipe

A method of flatting evaporating section of a heat pipe embedded in a heat dissipation device includes the following steps: (a) providing at least a heat pipe and a base of the heat dissipation device to be thermally connected with the heat pipe, the base defining at least a groove for embedding the heat pipe therein; (b) positioning an evaporating section of the heat pipe on the groove of the base; (c) pressing the evaporating section of the heat pipe to embed the evaporating section into the groove of the base with a partial uneven surface of the evaporating section protruding out of the base; (d) flatting the protruded uneven surface of the evaporating section by polishing.

Owner:GOLDEN SUN NEWS TECHN +1

Pipeline cleaning agent

InactiveCN103740489AEfficient removalKeep clean for a long timeInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsBetaineActive agent

The invention relates to a pipeline cleaning agent which comprises the following components by weight: 15-28 parts of organic acid, 20-35 parts of an asurface active agent, 18-30 parts of a penetrating agent and 0.5-3 parts of an acorrosion inhibitor, wherein the surface active agent comprises one or more ofpolyether, butyl cellosolve, coconut oil fatty acid diethanol amide and fatty alcohol-polyoxyethylene ether sulfate sodium; the penetrating agent comprises one or more of alcohol, sodium dodecyl sulfate, sodium dioctyl sulfosuccinate,dodecyl dimethyl betaine, sodium oleoyl methylamine ethanesulfonate and calcium chloride; the corrosion inhibitor comprises one or more of imidazolinequaternary ammonium salts or imidazoline amides. The pipeline cleaning agent can effectively remove grease and dirt in a pipeline to keep the pipeline unblocked, is safe and non-toxic, cannot corrode equipment, is harmless tohuman skin and conforms to emission standards.

Owner:BEIJING DAISI SCI & TECH

Air energy, solar energy and ground source heat pump marsh gas tank

InactiveCN101775352AGuaranteed uptimeImprove filtration efficiencyGas production bioreactorsWaste based fuelCold airControl system

The invention relates to a heat pump marsh gas tank, in particular to an air energy, solar energy and ground source heat pump marsh gas tank, which belongs to environment engineering equipment. The heat pump marsh gas tank consists of an anaerobic digestion system, a heat insulation and thermal preservation system, a solar energy hot water system, an air energy heat pump system, a ground source heat pump system and a control system, wherein the tail end heat exchange equipment of the ground source heat pump system, solar energy hot water pipelines and the air energy heat pump system are connected with the heat insulation and thermal preservation system and the anaerobic digestion system through hot water circulation pipes, a hot water transit box arranged in the thermal preservation system is used for regulating and balancing the hot water of heat resource systems, hot water heats the anaerobic digestion tank through circulation pipes for promoting the anaerobic digestion, and the hot water circulation pipes can be arranged inside the anaerobic digestion tank and can also be arranged outside the anaerobic digestion tank. The marsh gas tank can also provide hot water and cold air at the same time of producing marsh gas, and the invention can solve the problems of high production cost, great energy consumption and the like of winter production of the marsh gas engineering, and can be popularized easily.

Owner:刘军林

Novel stainless steel acid-washing passivation liquid

ActiveCN102653868AReduce pollutionLow running costMetallic material coating processesHydrofluoric acidAcid washing

The invention relates to a novel stainless steel acid-washing passivation liquid which comprises inorganic acid, penetrant, oxidant and corrosion inhibitor. The stainless steel acid-washing passivation liquid does not generate violent pungent odor or yellow acid mist in the application process, thereby avoiding hurting the skin, reducing the air pollution and lowering the cost. The stainless steel acid-washing passivation liquid is easy to use: the stainless steel acid-washing passivation liquid is poured into a tank, and soaks the stainless steel at normal temperature without heating; and the washing speed is about 50% higher than those of the acid-washing passivation liquid (paste) in the existing market and the acid-washing passivation liquid containing nitric acid and hydrofluoric acid, and the washing quantity is as 3.2 times or so as the like products in the market. The novel stainless steel acid-washing passivation liquid can complete oil removal, derusting, descaling and acid-washing passivation at one time. The residual liquid after use can be treated by a conventional treatment method, and can also be used for treating dyeing waste water; and the treated dyeing waste water is clear and transparent and achieves the reclamation standard. Thus, the stainless steel acid-washing passivation liquid has the advantages of environment protection and water resource saving, and can recycle water.

Owner:王福平

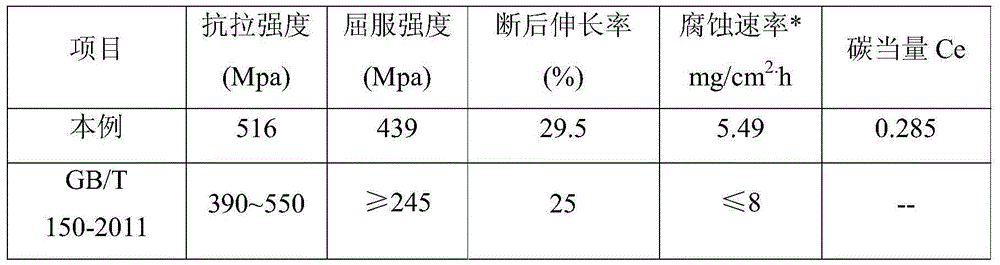

Production technology of low-carbon weather-resistant steel

The invention discloses a production technology of low-carbon weather-resistant steel, belongs to the field of rolled steel preparation, and particularly relates to a method for controlling the surface quality of a rolled product of the low-carbon weather-resistant steel containing copper and stibium. Through design of liquid steel components, optimization of a continuous casting process and cooling control after a casting blank is discharged from a withdrawal and straightening machine, the surface quality of the casting blank is improved; enrichment and precipitation of low-melting point elements Cu and Sb on the crystal boundary in the casting blank cooling process are effectively inhibited; a hot charging process is adopted; the tapping interval is improved; the heating cost is reduced; the heating time in a furnace is shortened; the heating temperature is controlled; by virtue of high-temperature quick calcination, secondary enrichment of the low-melting point elements Cu and Sb along the austenite crystal boundary in the heating process is relieved; through the measures, the surface quality problem of the rolled product caused by corner cracks and crystal boundary cracks on the casting blank surface is greatly improved; and the barreling attrition rate of the rolled product is effectively reduced.

Owner:ZENITH STEEL GROUP CORP +1

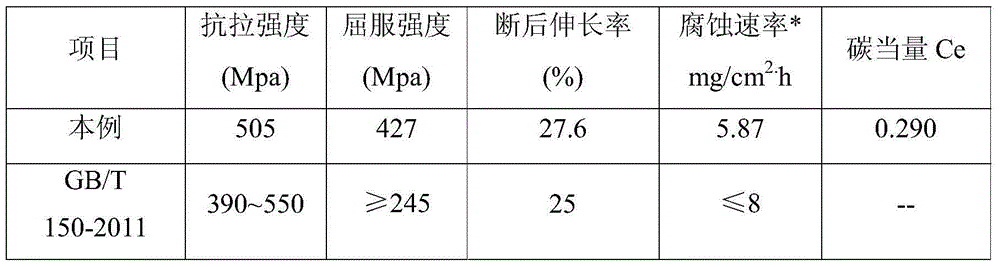

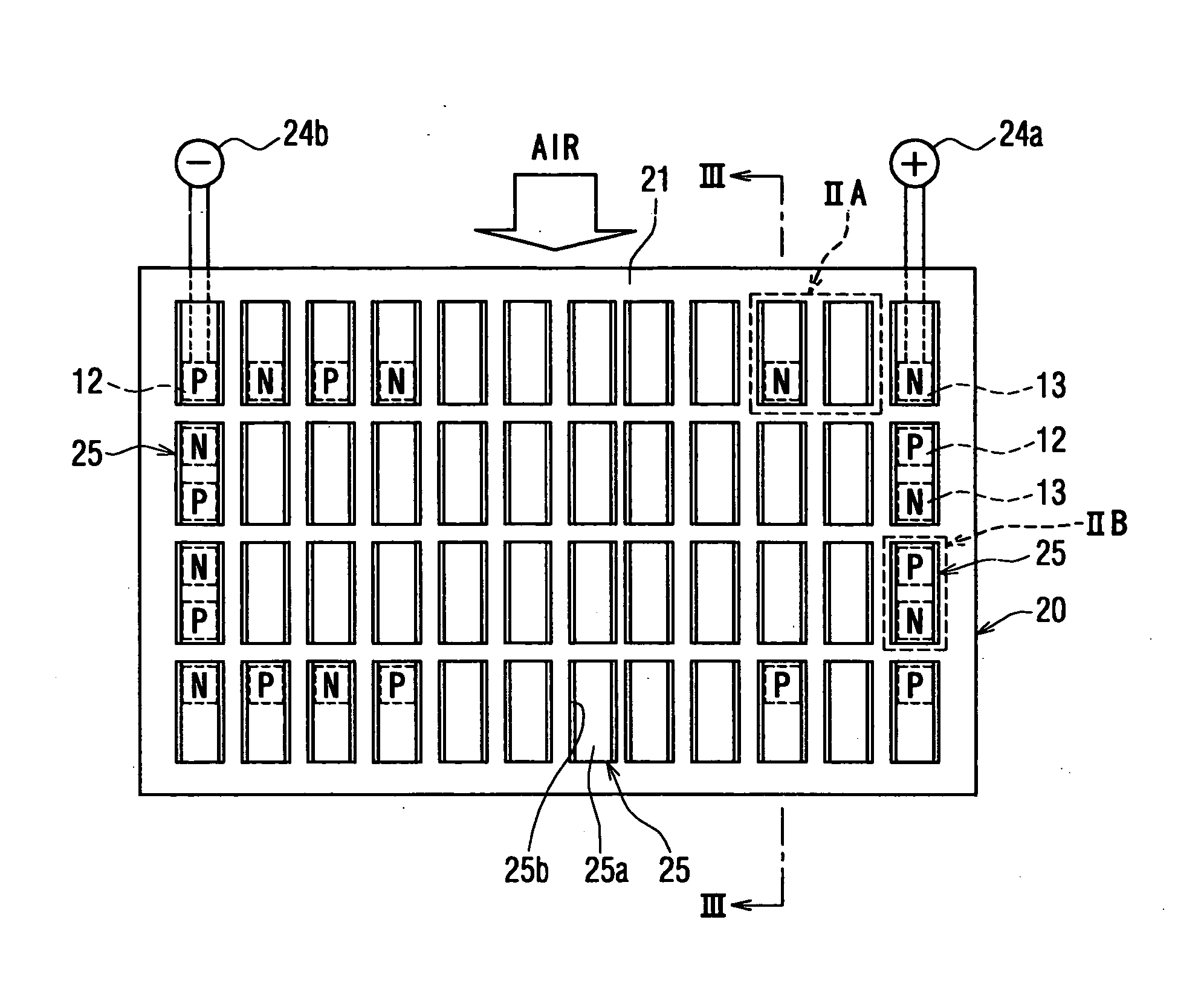

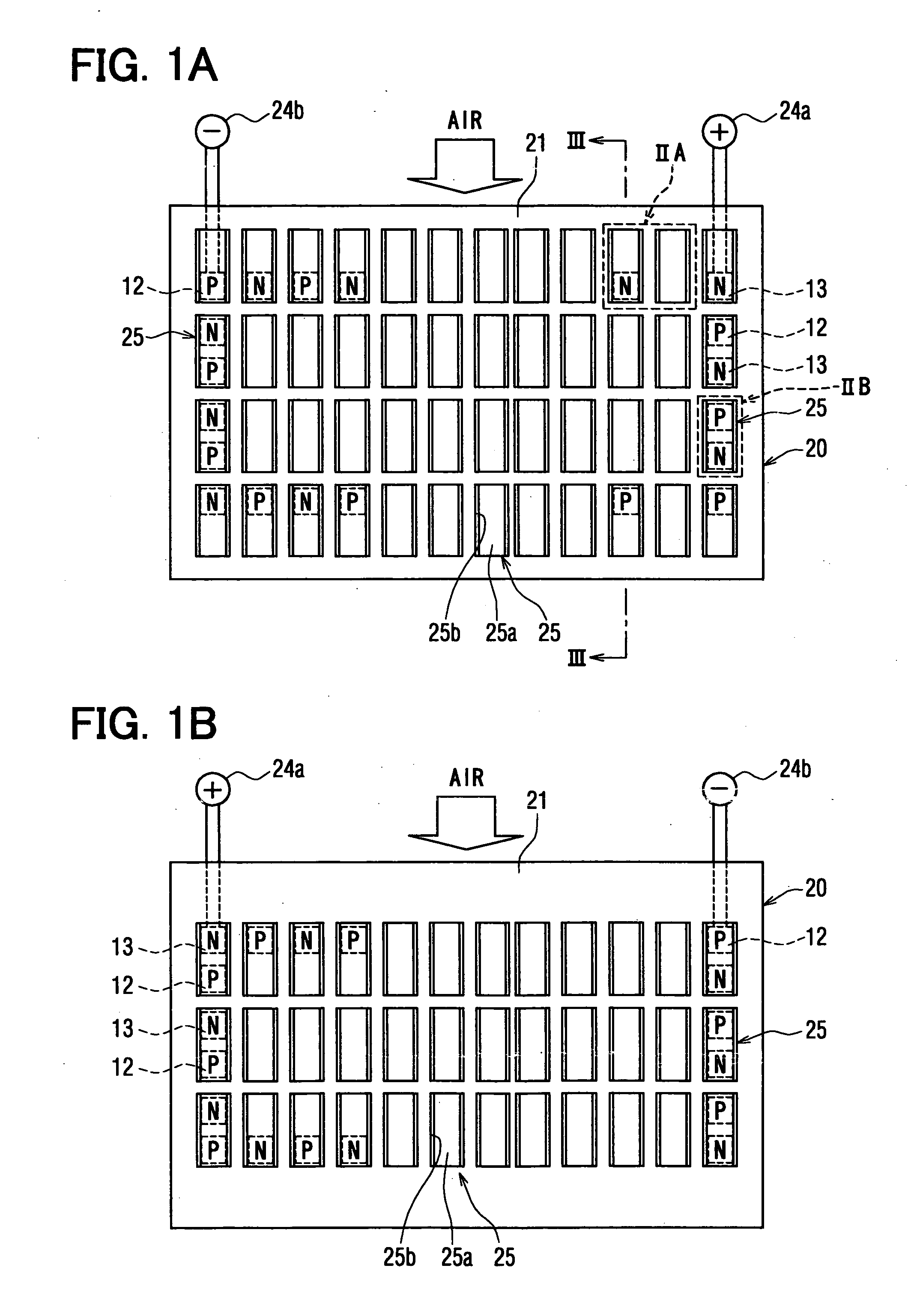

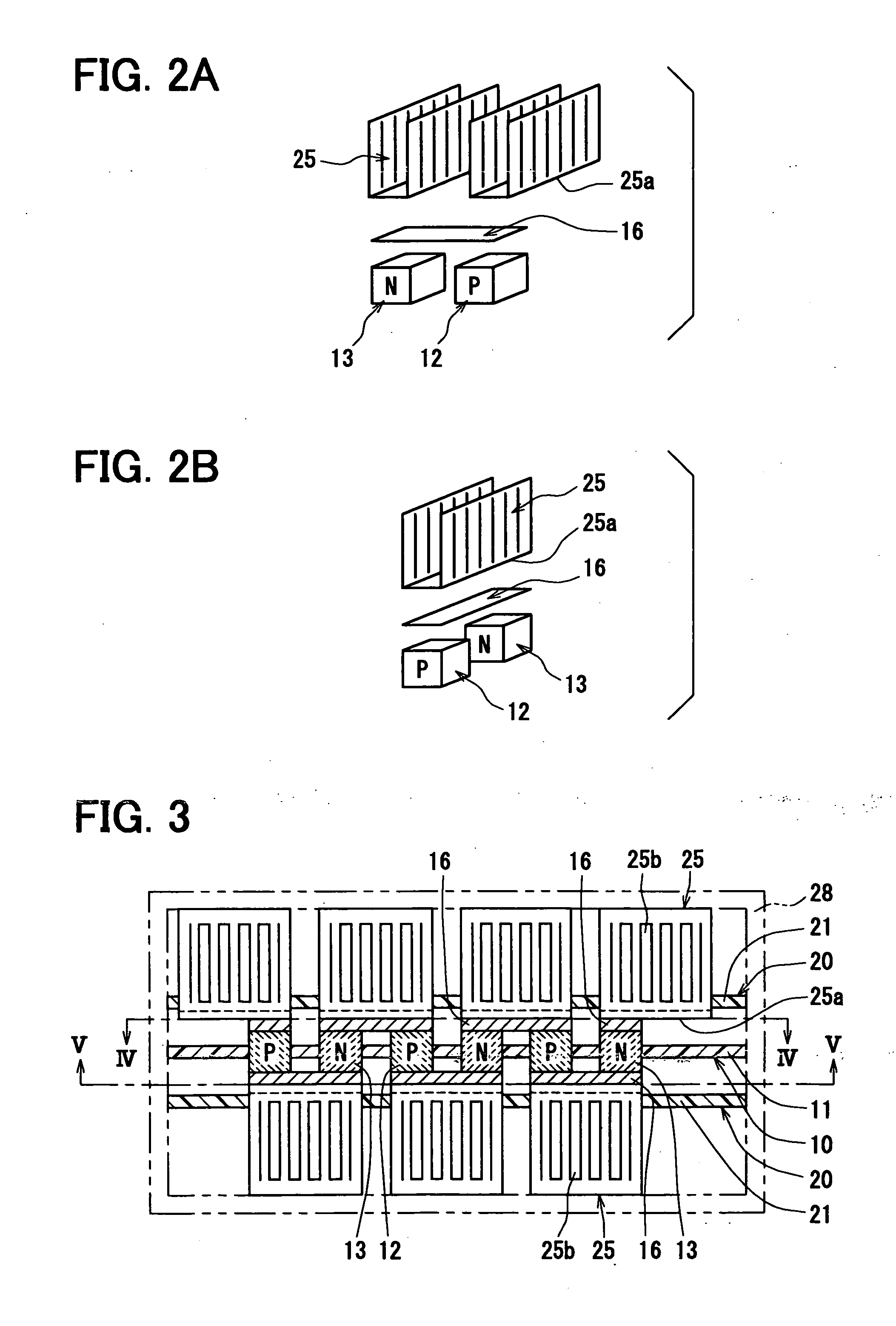

Thermoelectric transducer

InactiveUS20060219281A1Easy to manufactureImprove efficiencyThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentTransducerElectrode

In a thermoelectric transducer, a plurality of P-type thermoelectric devices and N-type thermoelectric devices are alternately arranged on an insulating board, and each of a plurality of electrode members is connected to two end portions of adjacent N-type and P-type thermoelectric devices for electrically connecting the adjacent N-type and P-type thermoelectric devices. Furthermore, a plurality of heat exchanging members each of which includes an electrode portion connectable to the electrode member and a heat exchanging portion for exchanging heat transmitted from the electrode portion are located at two sides of a thermoelectric device substrate to form a heat absorbing part and a heat radiating part partitioned from each other. The electrode portions and the heat exchanging portions have, respectively, the same shapes, and the electrode portions and the heat exchanging portions are arranged in the same direction in all the heat exchanging members of each heat absorbing or radiating part.

Owner:DENSO CORP

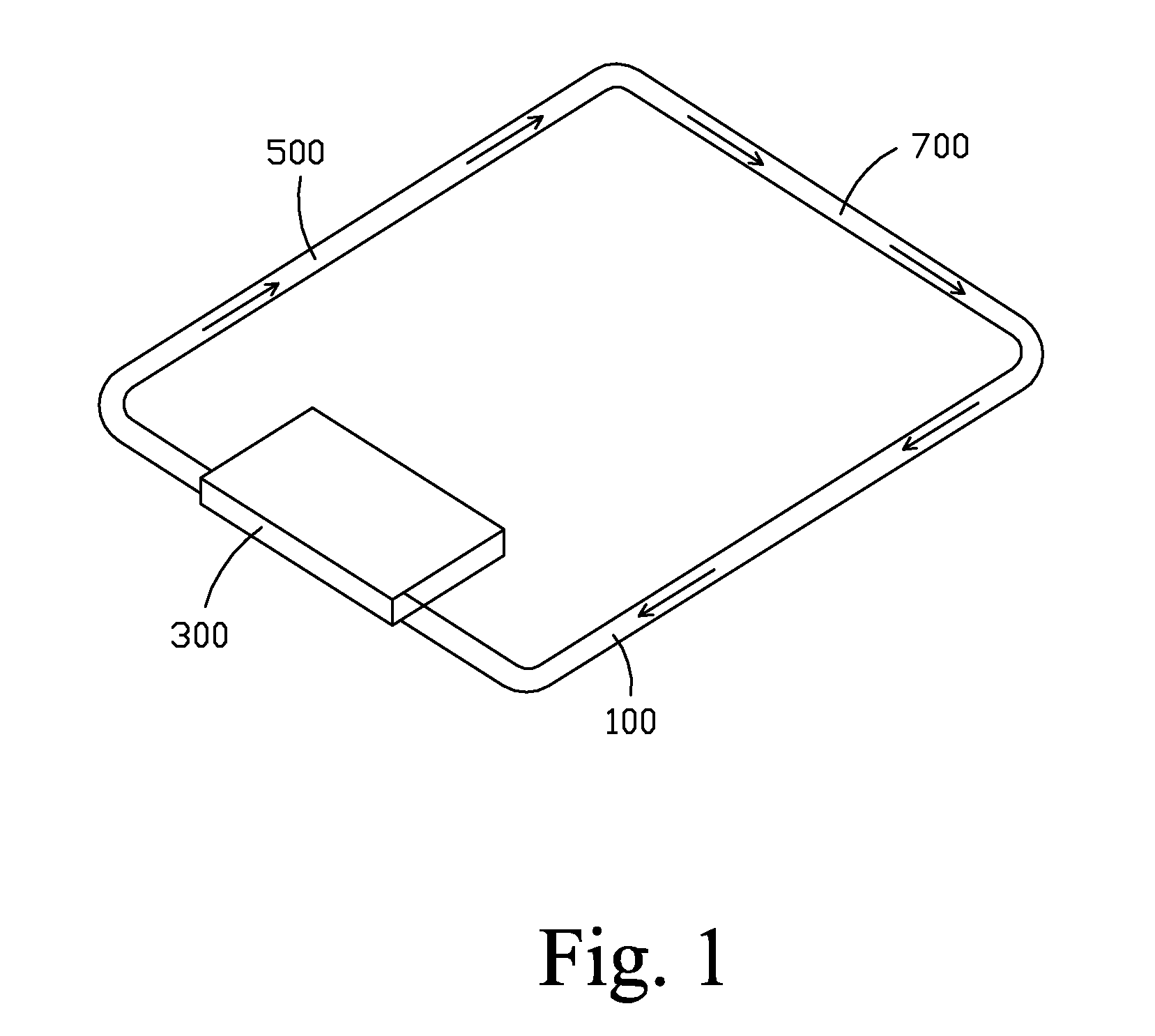

Heat dissipation pipe loop and backlight module using same

ActiveUS20150305199A1Simple structureLow costMechanical apparatusSemiconductor/solid-state device detailsEngineeringPipe

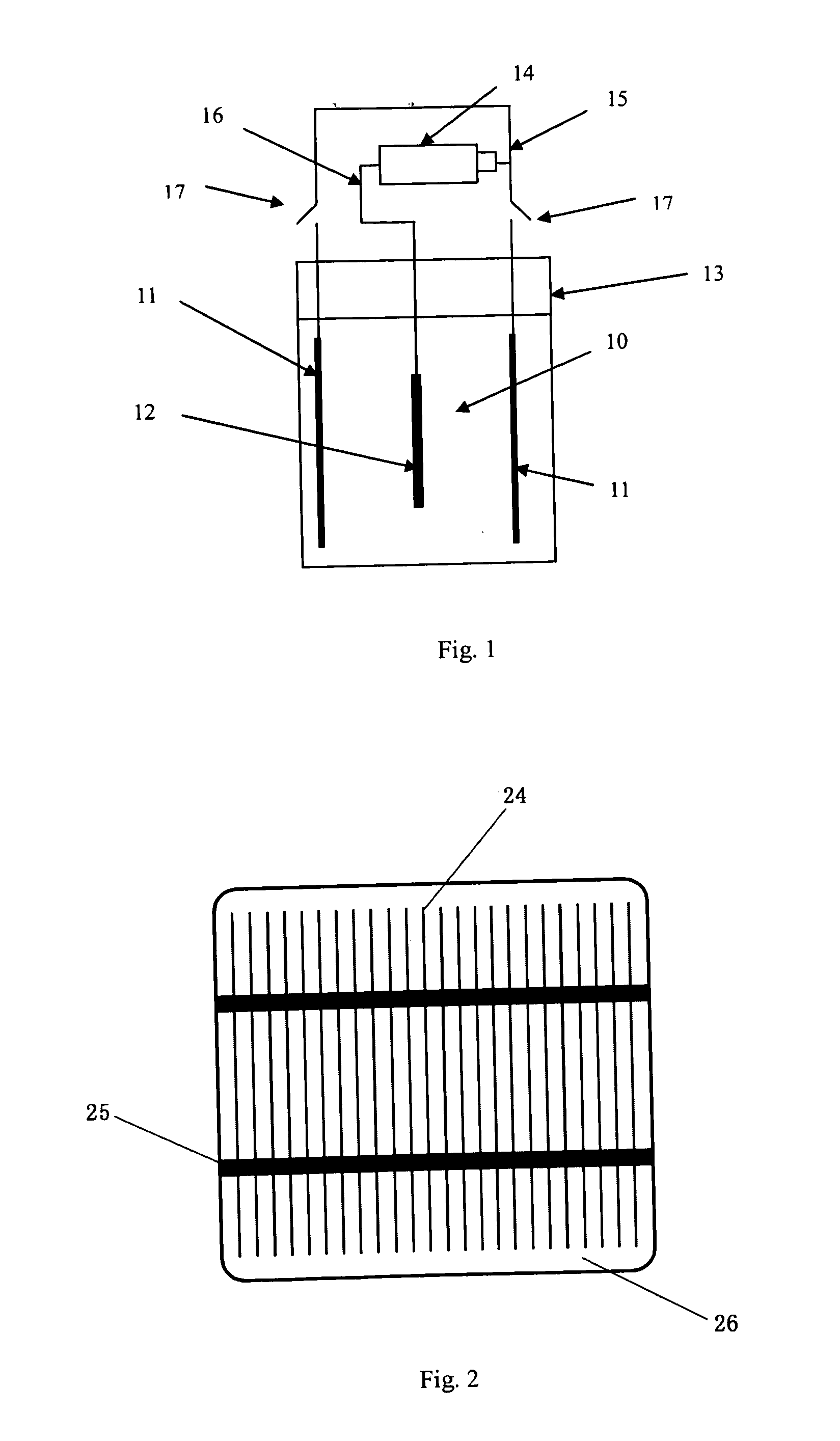

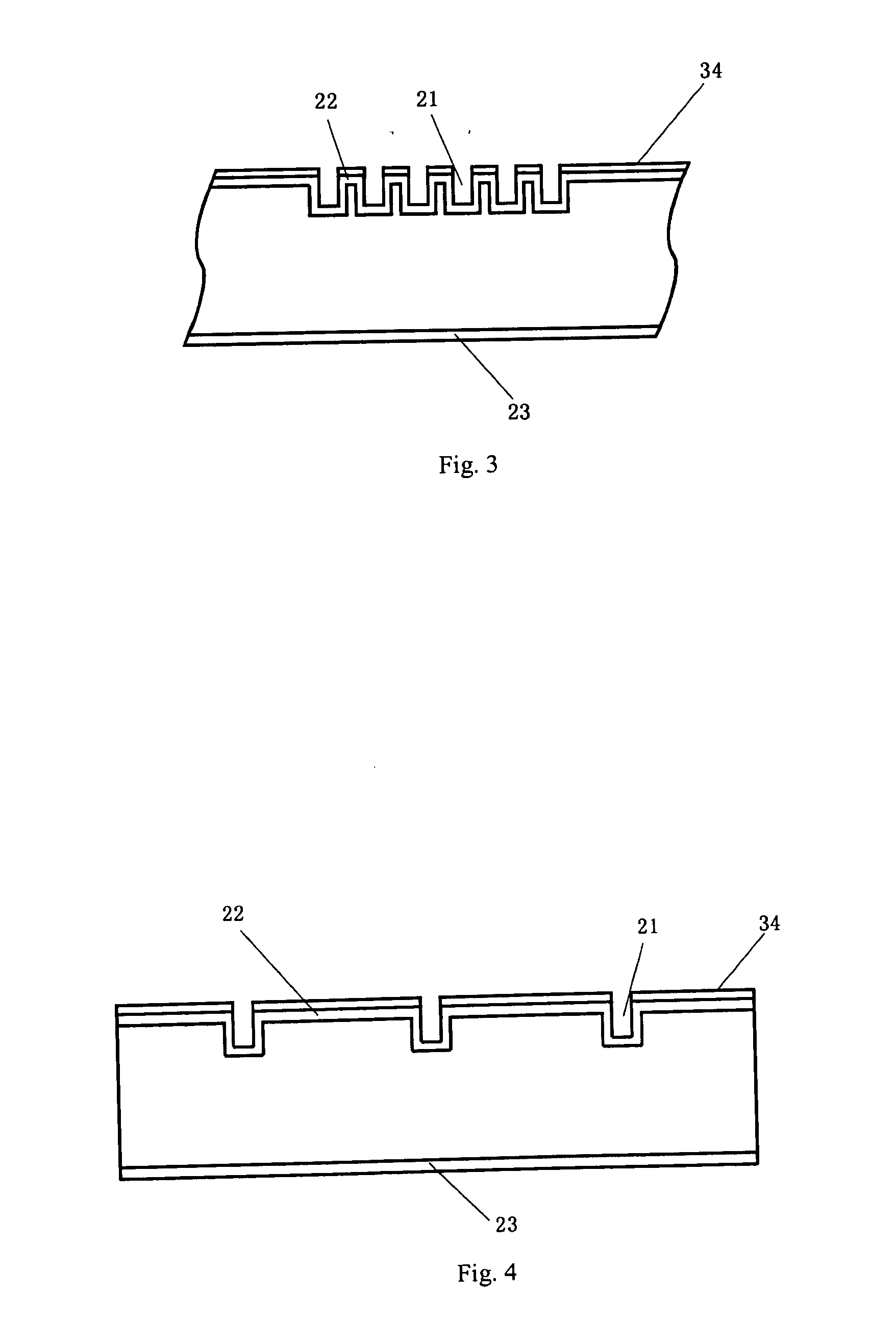

The present invention provides a heat dissipation pipe loop and a backlight module using the dissipation pipe loop. The heat dissipation pipe loop includes: an evaporator section (2), a liquid pipe (4) connected to an end of the evaporator section (2), a condenser pipe (6) connected to an end of the liquid pipe (4) distant from the evaporator section (2), and a gas pipe (8) having an end connected to the condenser pipe (6) and an opposite end connected to the evaporator section (2). The evaporator section (2) includes an enclosure (22) and a separation board (24) received in the enclosure (22). The enclosure (22) defines therein a receiving space (246) and the separation board (24) is mounted in the receiving space (246) to divide the receiving space (246) into a liquid chamber (262) and a gas chamber (264). The liquid pipe (4) is in communication with the liquid chamber (262) and the gas pipe (8) is in communication with the gas chamber (264). The separation board (24) separates gas and liquid from each other.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

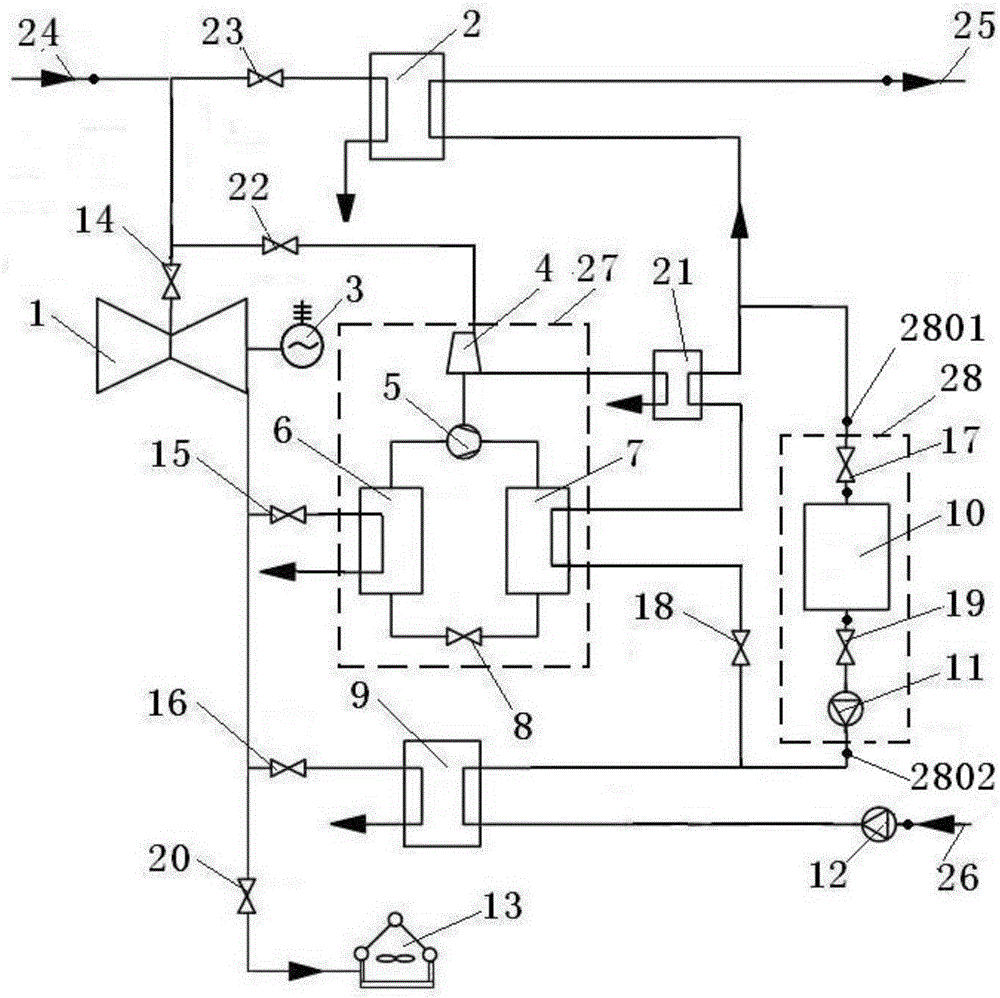

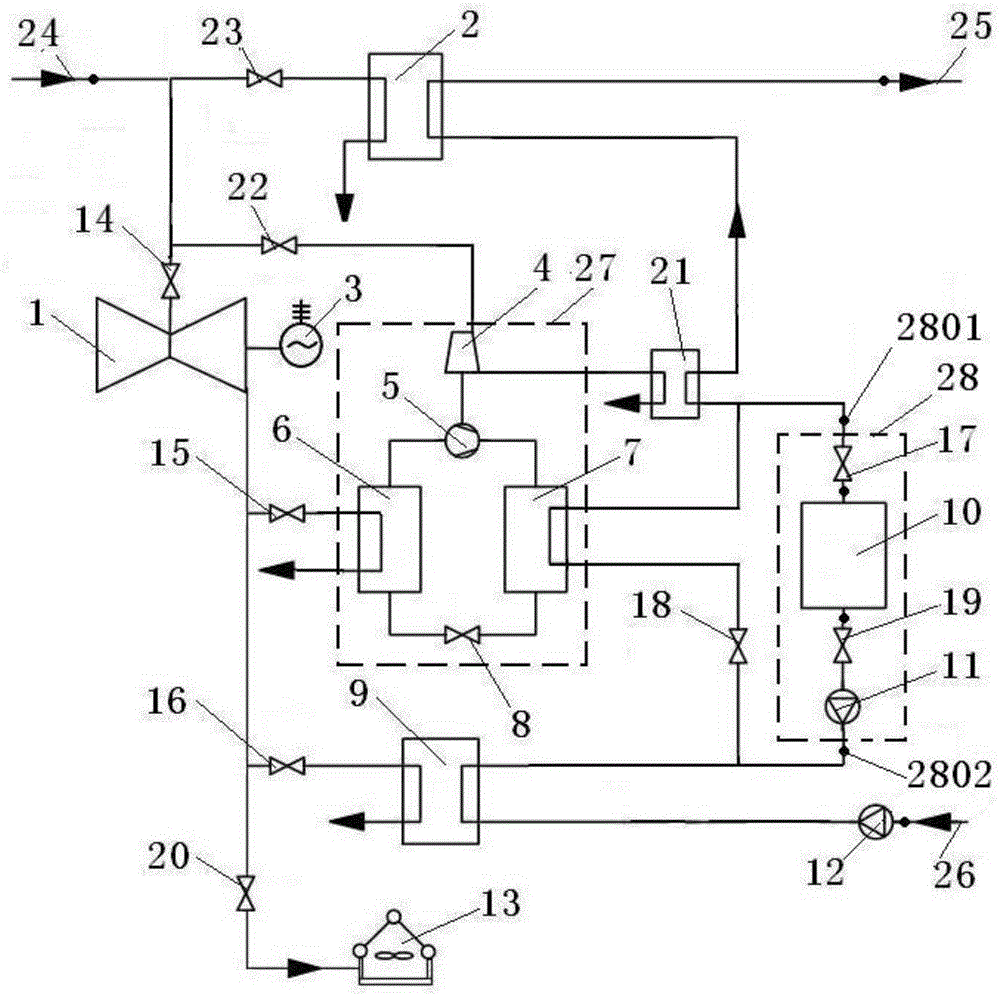

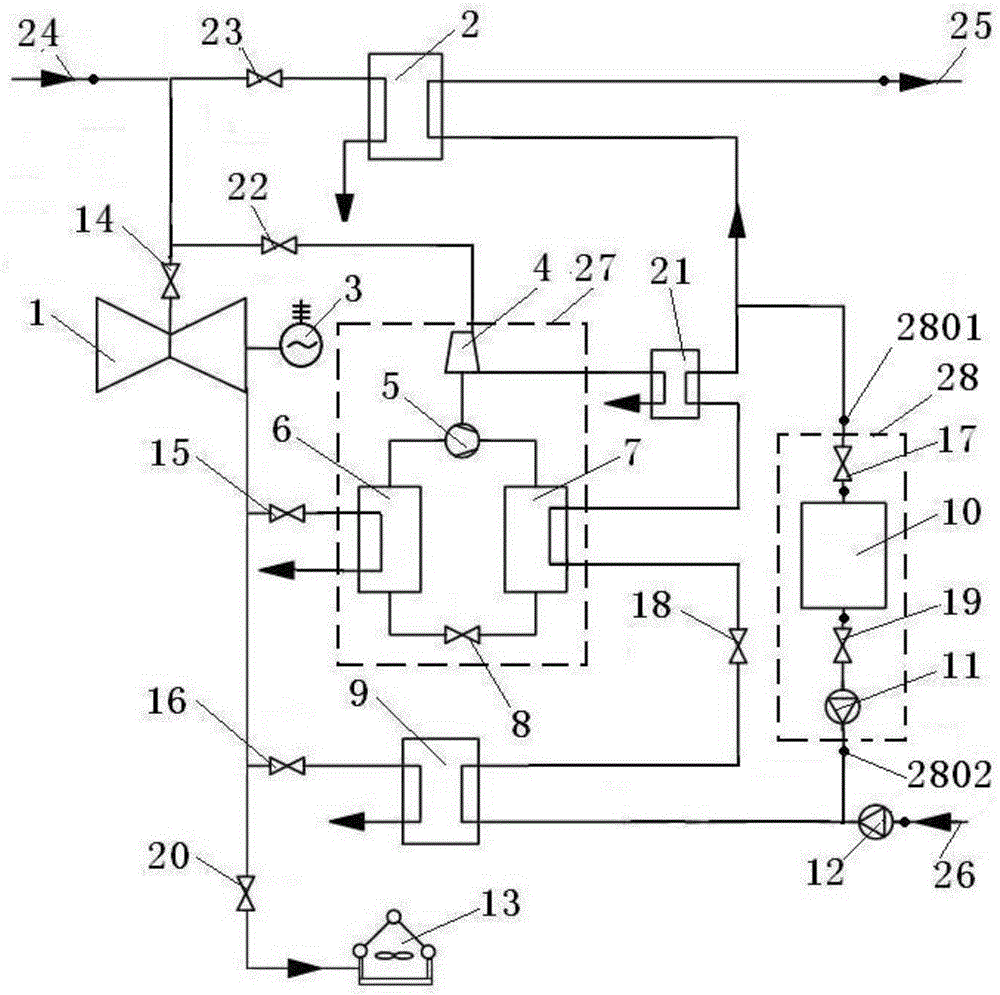

Cogeneration set for combining steam-driven heat pump with heat storage device and peak regulation method for cogeneration set

ActiveCN106196697AChange the grid power generationLower heating costsEnergy industryMachines/enginesCogenerationEngineering

The invention belongs to the technical field of thermoelectricity, and relates to a cogeneration set for combining a steam-driven heat pump with a heat storage device and a peak regulation method for the cogeneration set. The cogeneration set comprises a steam turbine, the steam-driven heat pump and the heat storage device basically, and is used for peak load regulation. By combining the steam-driven heat pump with the heat storage device, switching between a heat storage mode and a heat release mode is conducted according to the requirement on power generation dispatching of a thermal power plant, and the purpose that the grid power generation of the thermal power plant is changed when heat supply is ensured is achieved; and the steam exhaust heat is recovered through a condenser and an evaporator of the steam-driven heat pump, so that the heat supply cost of the thermal power plant is reduced. According to the cogeneration set, the peak load regulation range of the thermal power plant is expanded, the power regulation range of the power grid is further expanded, more grid power generation time is provided for renewable energy sources, such as wind power, and the problems such as wind curtailment are finally solved; and the external heating capacity of the thermal power plant of which the heating capacity is limited can be improved with the recovered steam exhaust heat. The cogeneration set is suitable for participating in peak load regulation.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

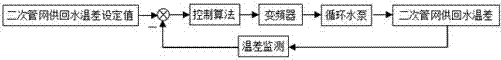

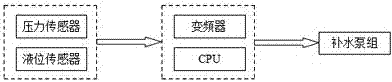

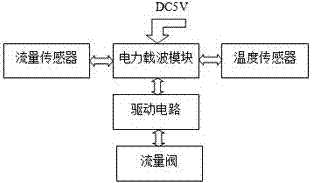

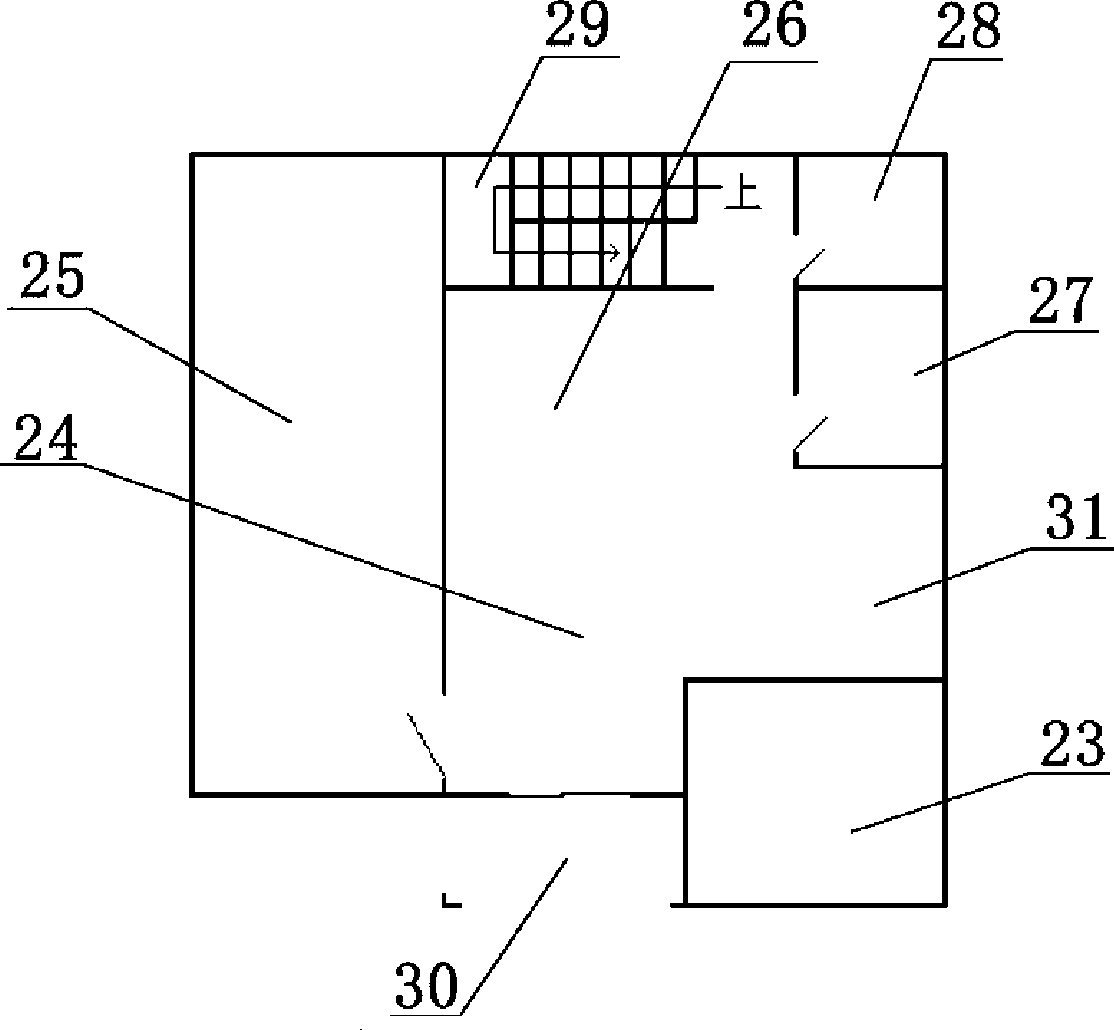

Smart urban heat supply energy consumption management and control technical platform

InactiveCN107274303AOvercome uneven heating and coolingOvercoming Water Hammer EffectData processing applicationsLighting and heating apparatusTaking temperaturesCarrier signal

A smart urban heat supply energy consumption management and control technical platform takes temperature regulation and control as a goal and the regulation and control of heating equipment of the whole pipe network as the core to establish a software and hardware platform for heat users, heat exchange stations and heating management and command center. For a heat user portion software and hardware for smart regulating valves, smart temperature controller and wall embedded terminals are designed. For the heat exchange station portion, the temperature, pressure and flow of primary and secondary pipe network are monitored, and the heat exchangers and circulating water pumps are controlled. For the heating management and command center portion, system management and support are provided to workers through intuitive interfaces, and heating cost query and other service are provided to users. A temperature controller in each room provides temperature control service for the room, and the acquired data of the room are gathered at a household end wall embedded terminal through electric carrier technology to provide temperature control service for the entire house. The gathered data is transmitted to a building data gathering terminal through electric carrier, and then gathered to the heating management and command center through GPRS modules via the heat exchange stations.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

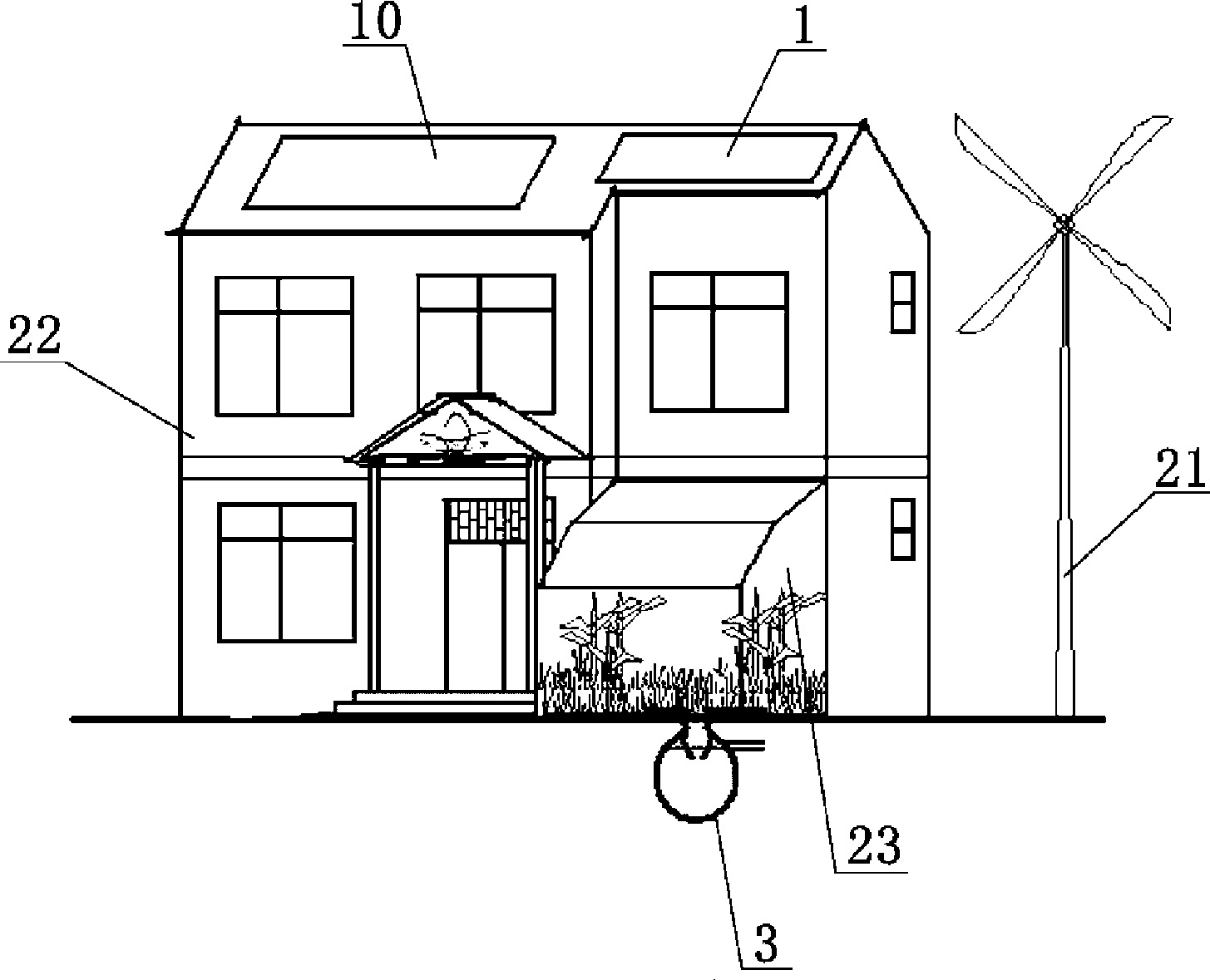

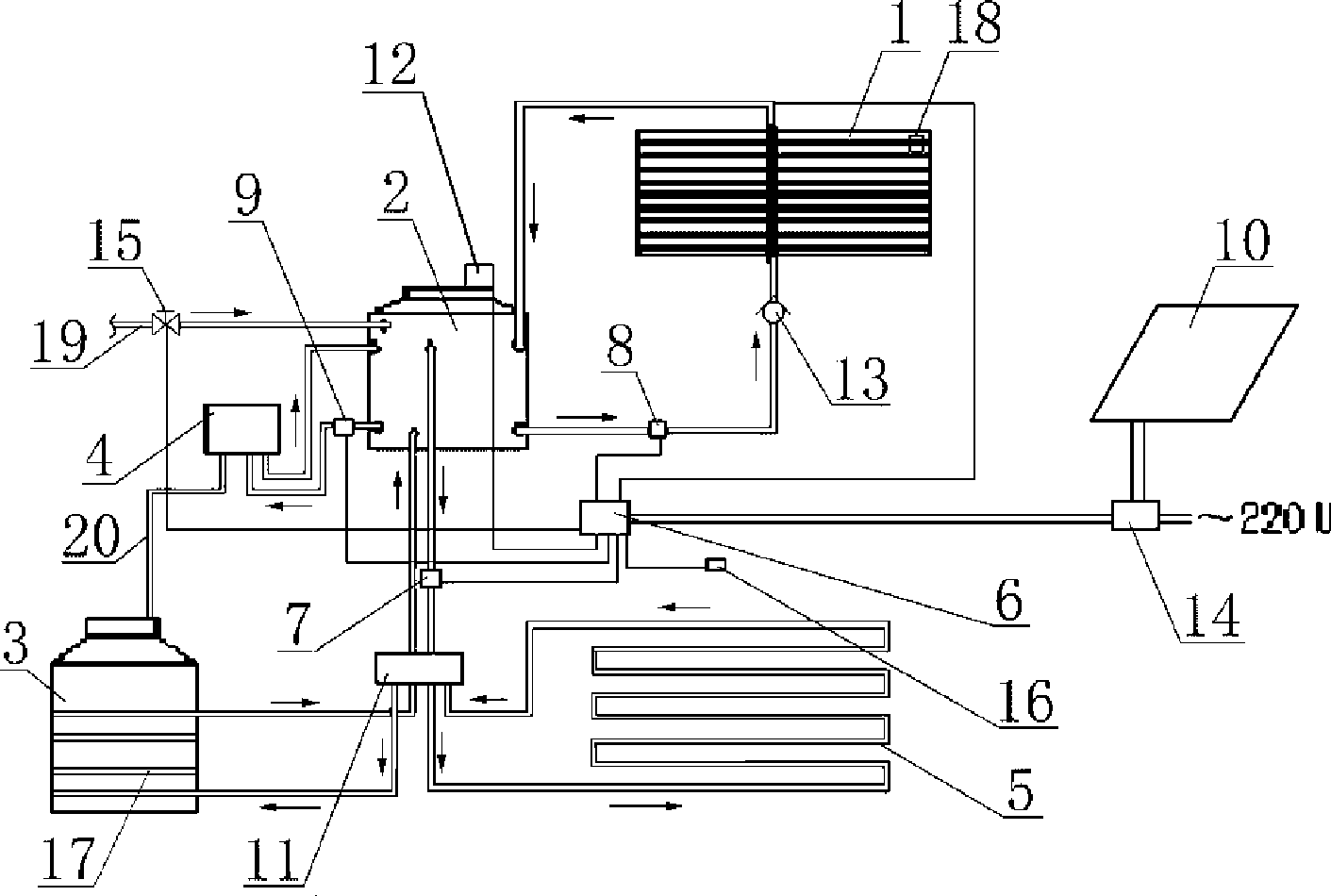

Green ecological zero energy consumption integration house

InactiveCN101457594AIncrease heatIncrease gas productionWallsSolar heat devicesLiving roomCollector device

The invention relates to a green ecological zero energy integrated building, a first floor of the building is provided with a living room, a bedroom, a dinning room, a kitchen, a toilet; a second floor of the building is provided with a bedroom and a toilet; a heat supply system is arranged inside the room, the building is connected with a heliogreenhouse on the ground and is connected with a methane tank under the ground. A solar thermal collector arranged at the top of the building is communicated with a temperature-holder box arranged inside the rooms of the building by a circulating pipe of the first line, the temperature-holder box is communicated with a water heating pipe of a gas-fuel heater by the circulating pipe, a gas line of the gas-fuel heater is communicated with the methane tank by a methane pipe. A hot water outlet of the temperature-holder box is respectively communicated with a PE-RT pipe and a heating pipe of the methane tank which is buried near the methane tank. A water tank temperature sensor, a room temperature sensor and a collector temperature sensor are connected with an intelligent controller. With the solar energy, bioenergy and wind energy complementing each other, the building has the characteristics of comfort, environmental protection, energy saving and zero-pollution.

Owner:赵民忠

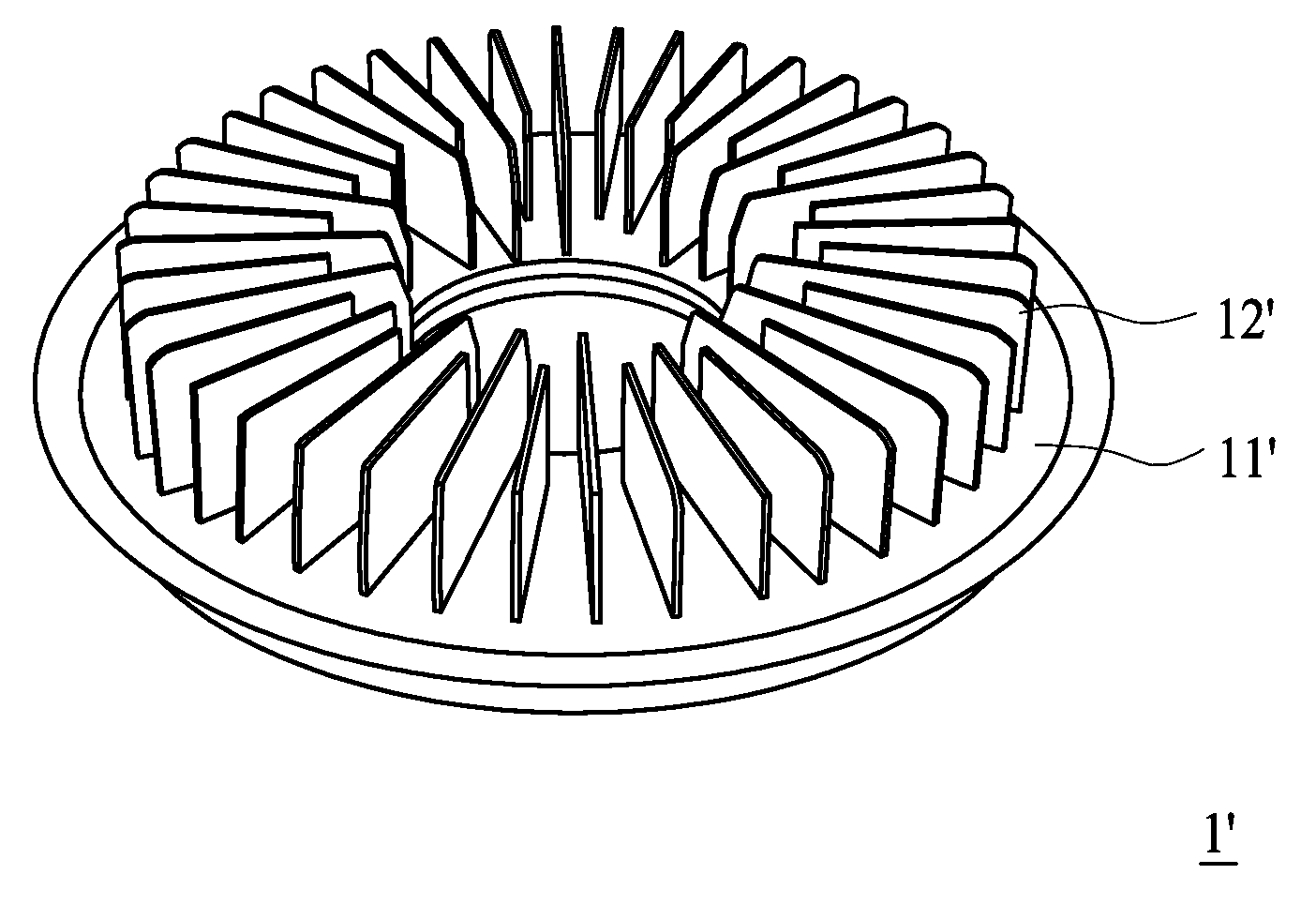

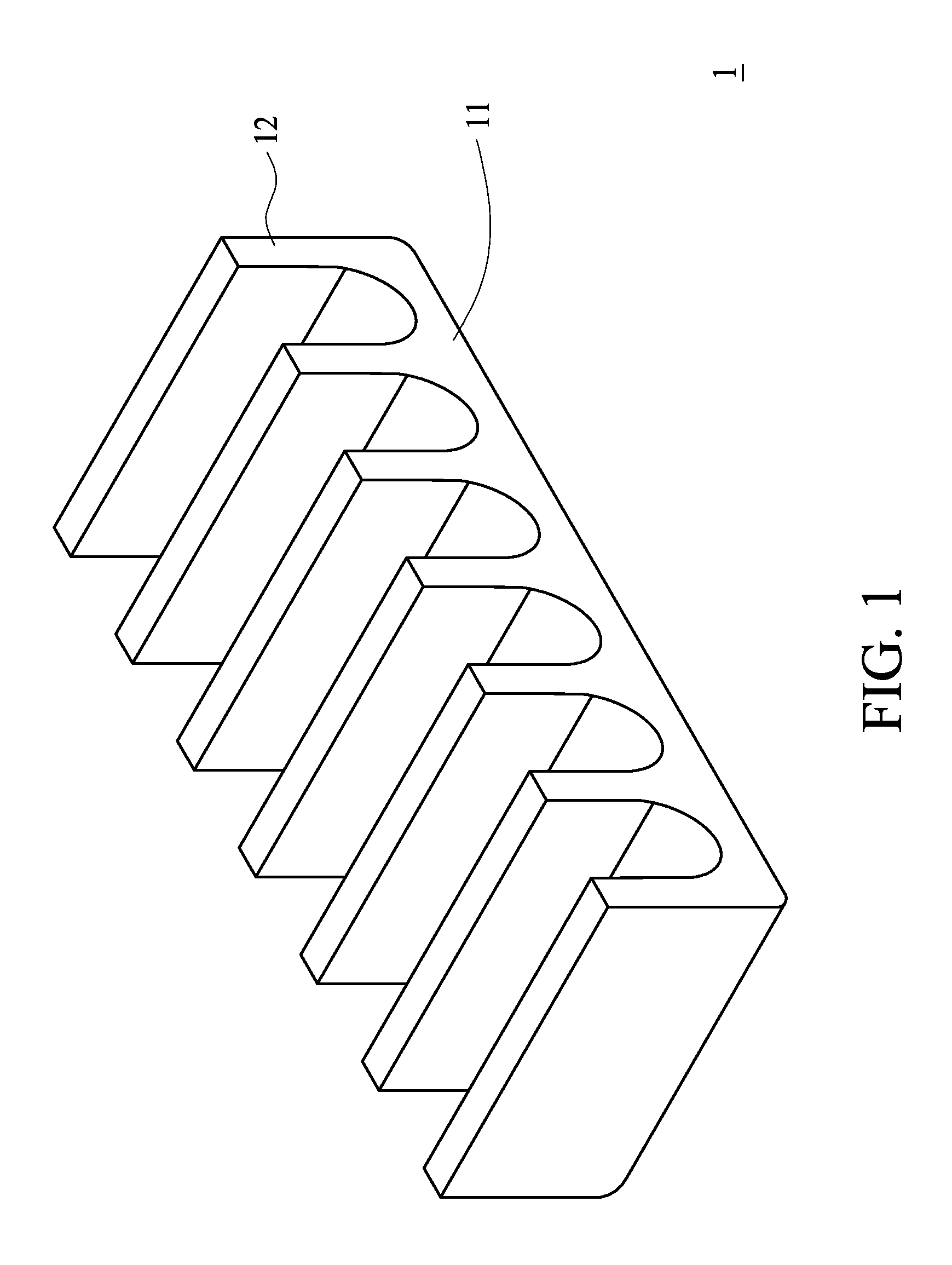

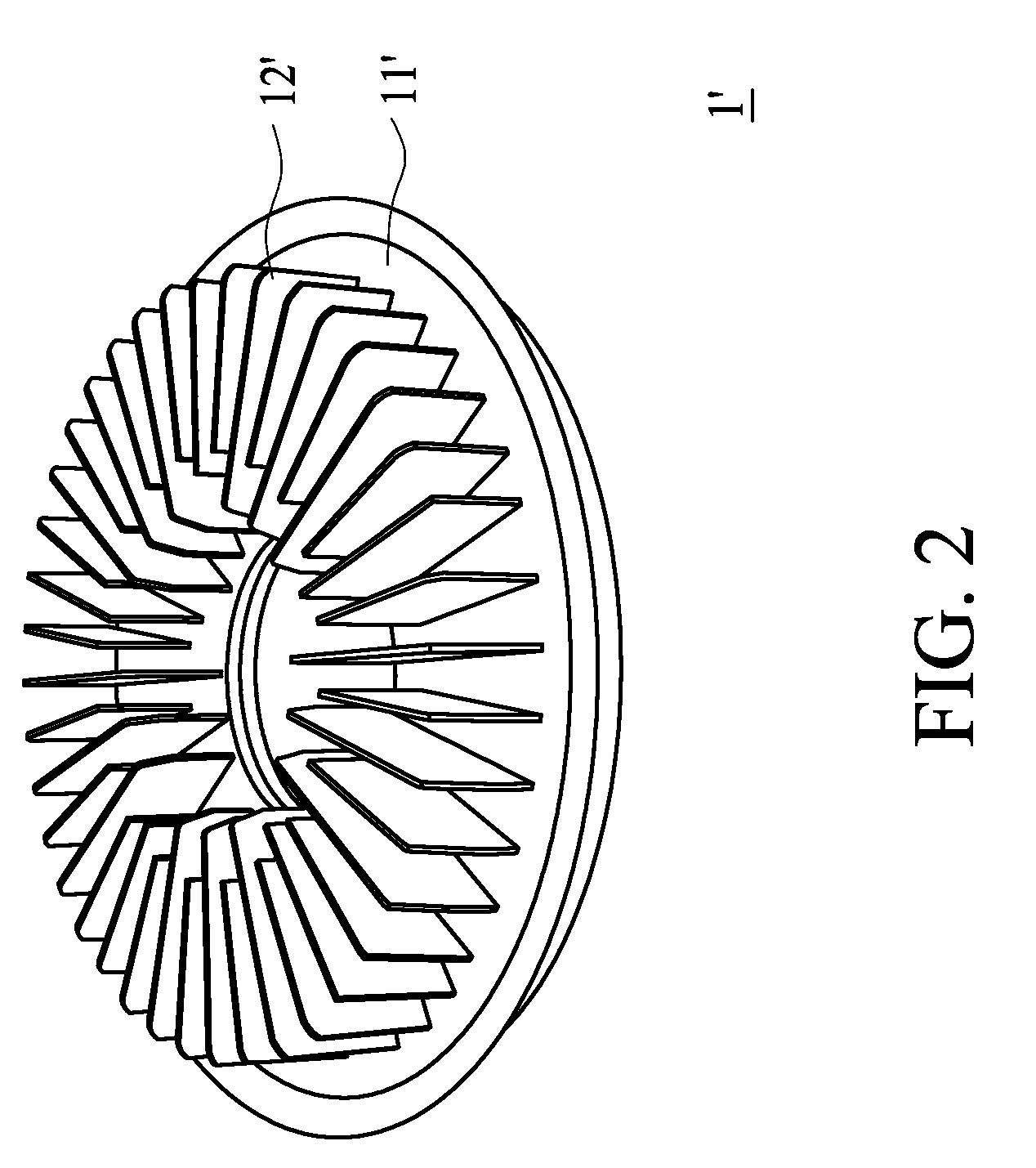

Passive heat sink and light emitting diode lighting device using the same

ActiveUS20100020553A1Lower heating costsReduce manufacturing costPoint-like light sourceSemiconductor/solid-state device detailsEffect lightEngineering

A light emitting diode (LED) lighting device is provided. The LED lighting device includes an LED light bar and a passive heat sink. The passive heat sink includes a base and a plurality of heat sink fins. The LED light bar is placed on one side of the base, and the heat sink fins are placed on the other side of the base. The fins are fixed on the base by soldering.

Owner:ADVANCED OPTOELECTRONICS TECH

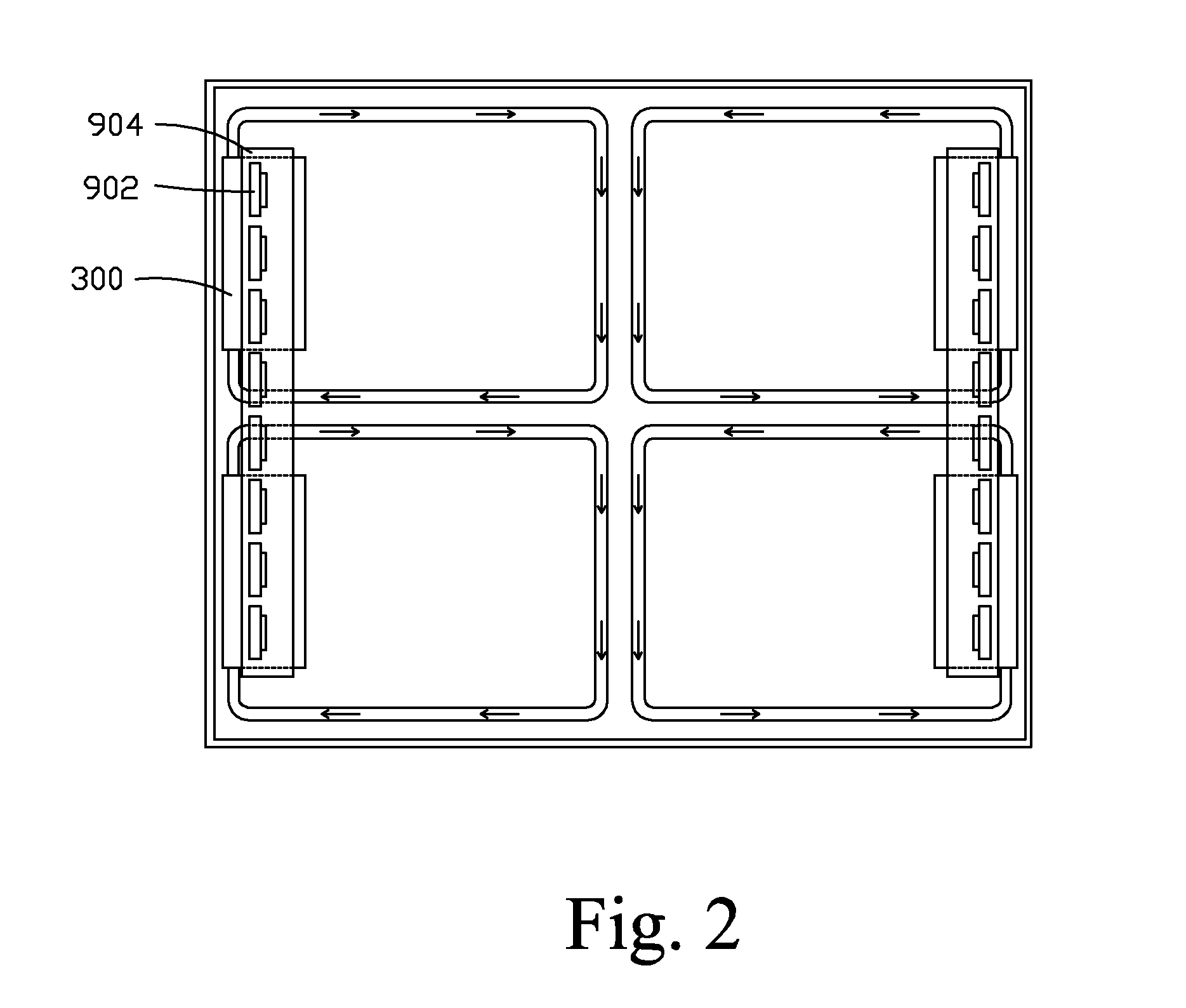

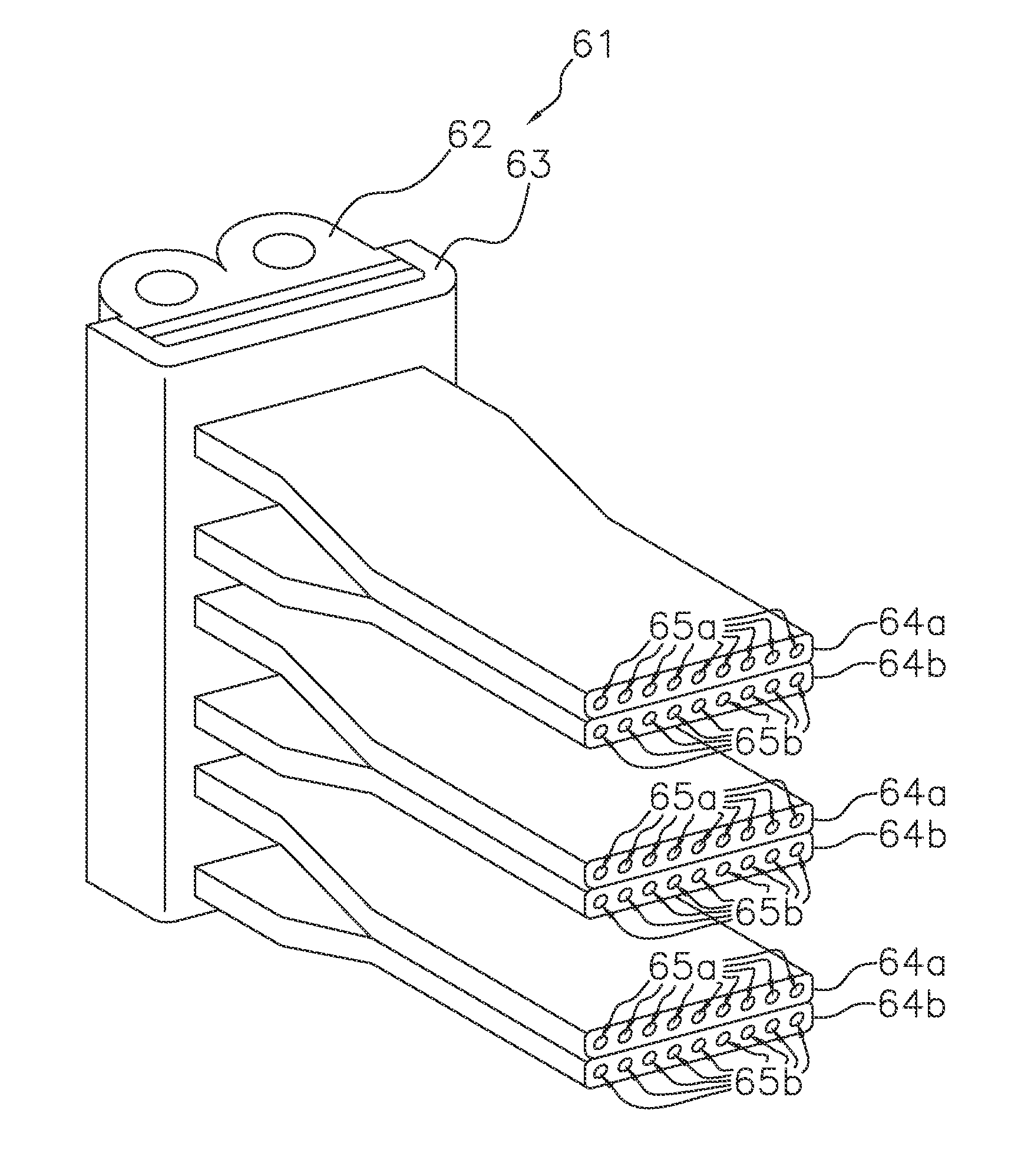

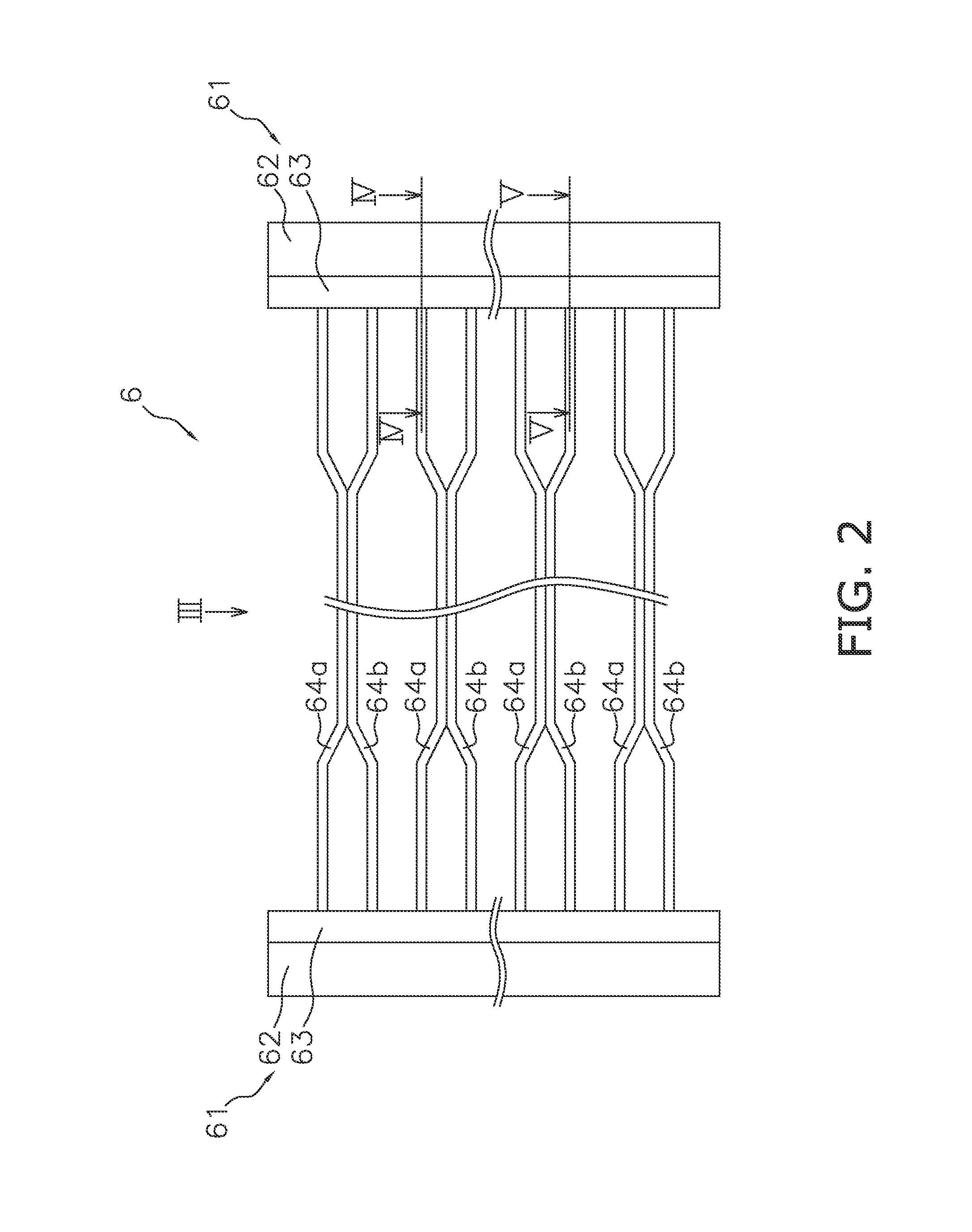

Heat exchanger

InactiveUS20140174703A1Lower heating costsReduce manufacturing costCompression machines with non-reversible cycleStationary conduit assembliesRefrigerantPrimary channel

A heat exchanger includes a header, a first flat porous tube, and a second flat porous tube. The header has first and second primary channels, with first and second refrigerants flowing through the first and second primary channels. The first flat porous tube has a plurality of first refrigerant-channel holes through which the first refrigerant flows. The second flat porous tube has a plurality of second refrigerant-channel holes through which the second refrigerant flows. The header has sub-channel-forming member that forms a first sub-channel and a second sub-channel. The first sub-channel allows the first primary channel to be communicated with the first refrigerant-channel holes. The second sub-channel allows the second primary channel to be communicated with the second refrigerant-channel holes. The first flat porous tube and the second flat porous tube are in close contact to allow heat exchange between the first refrigerant and the second refrigerant.

Owner:DAIKIN IND LTD

Continuous Flowing Pre-Treatment System with Steam Recovery

InactiveUS20080064906A1Avoid spendingMinimize contactSolid waste disposalDigestersSufficient timeCellulase

The present invention is directed to a continuous process for pretreating a lignocellulosic feedstock. A feedstock slurry is provided, which has a solids concentration of 10% to 33% by weight. The feedstock slurry is pumped through a heating train of at least two stages, each stage including a pump to increase stage pressure and a direct steam injection to heat the feedstock slurry. Acid is also added to the feedstock slurry prior to the heating train, during a heating stage, or after leaving the heating train; the acid is added at a concentration of 0% to 12% weight of acid on weight of initial feedstock. A heated, acidified feedstock slurry is thus produced. The heated, acidified feedstock slurry is flowed through a pre-treatment reactor at a temperature of 160° C. to 280° C. for a time sufficient to increase efficiency of conversion of cellulose in the feedstock to glucose using cellulase enzymes. After the slurry exits the pre-treatment reactor, it is cooled using two, or more than two flashing stages at successively lower pressures, without intermittent increases in pressure. The steam energy, at or near its flash temperature, from two or more than two of the flashing stages is used to heat the feedstock slurry in the heating train.

Owner:IOGEN ENERGY CORP

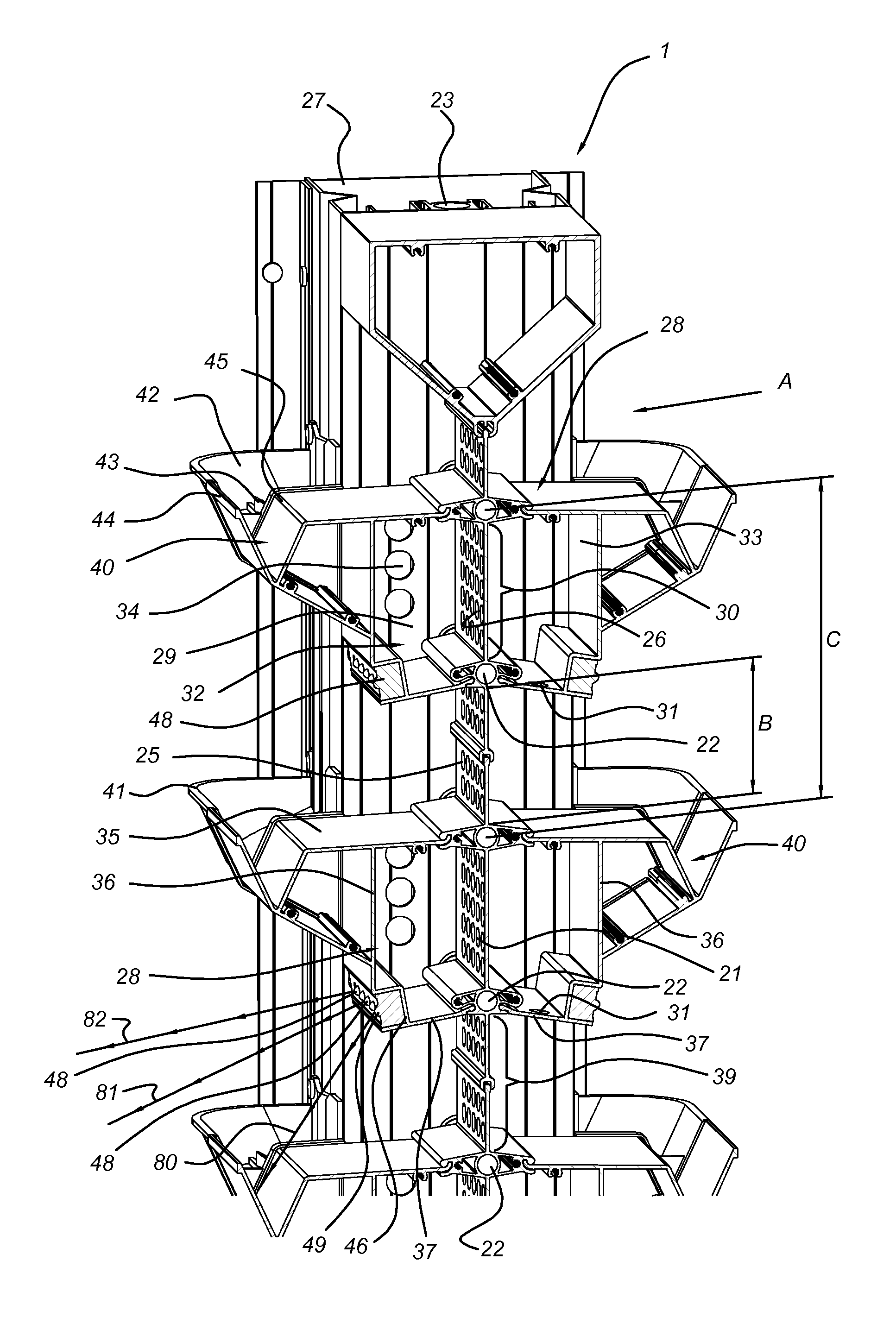

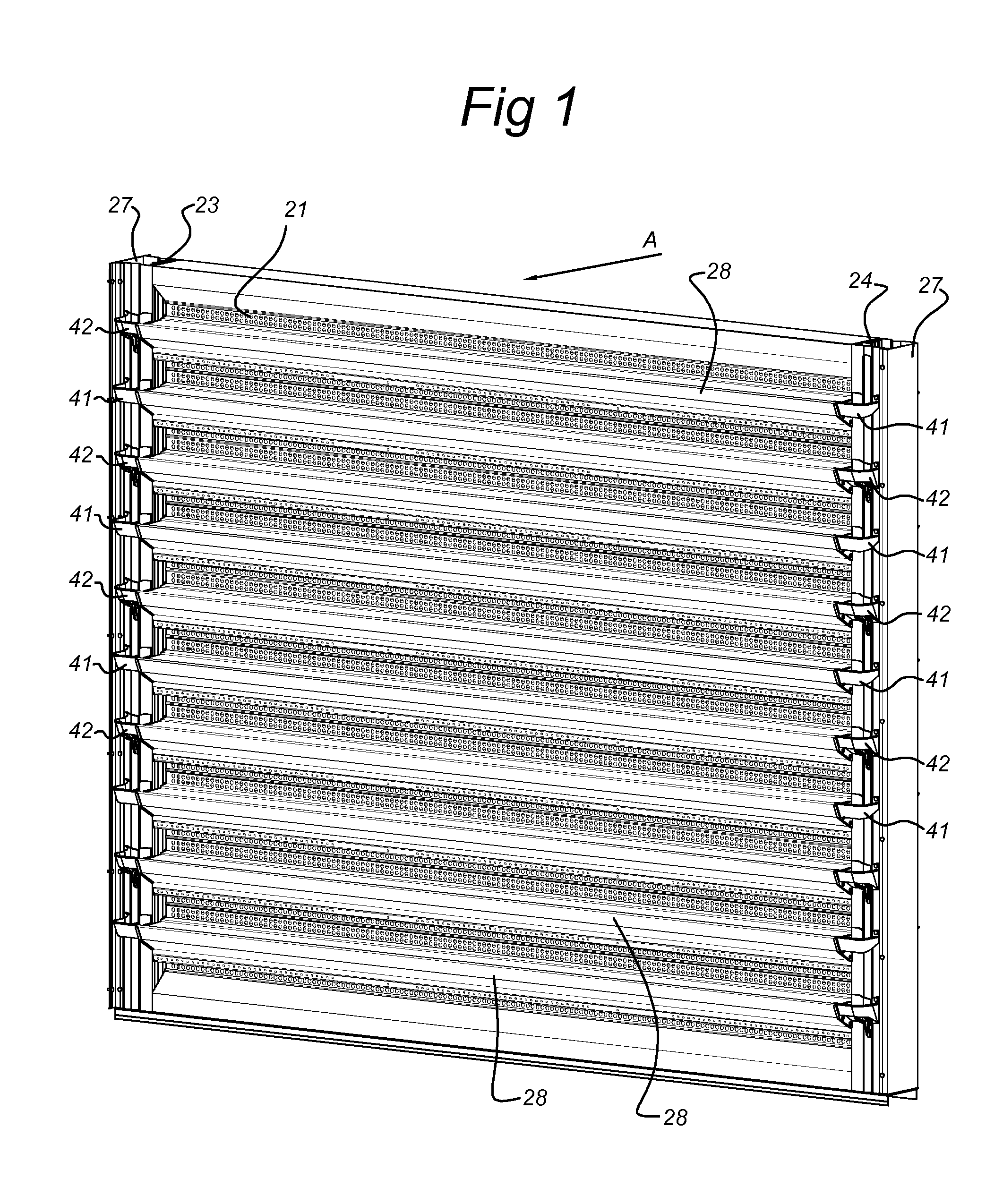

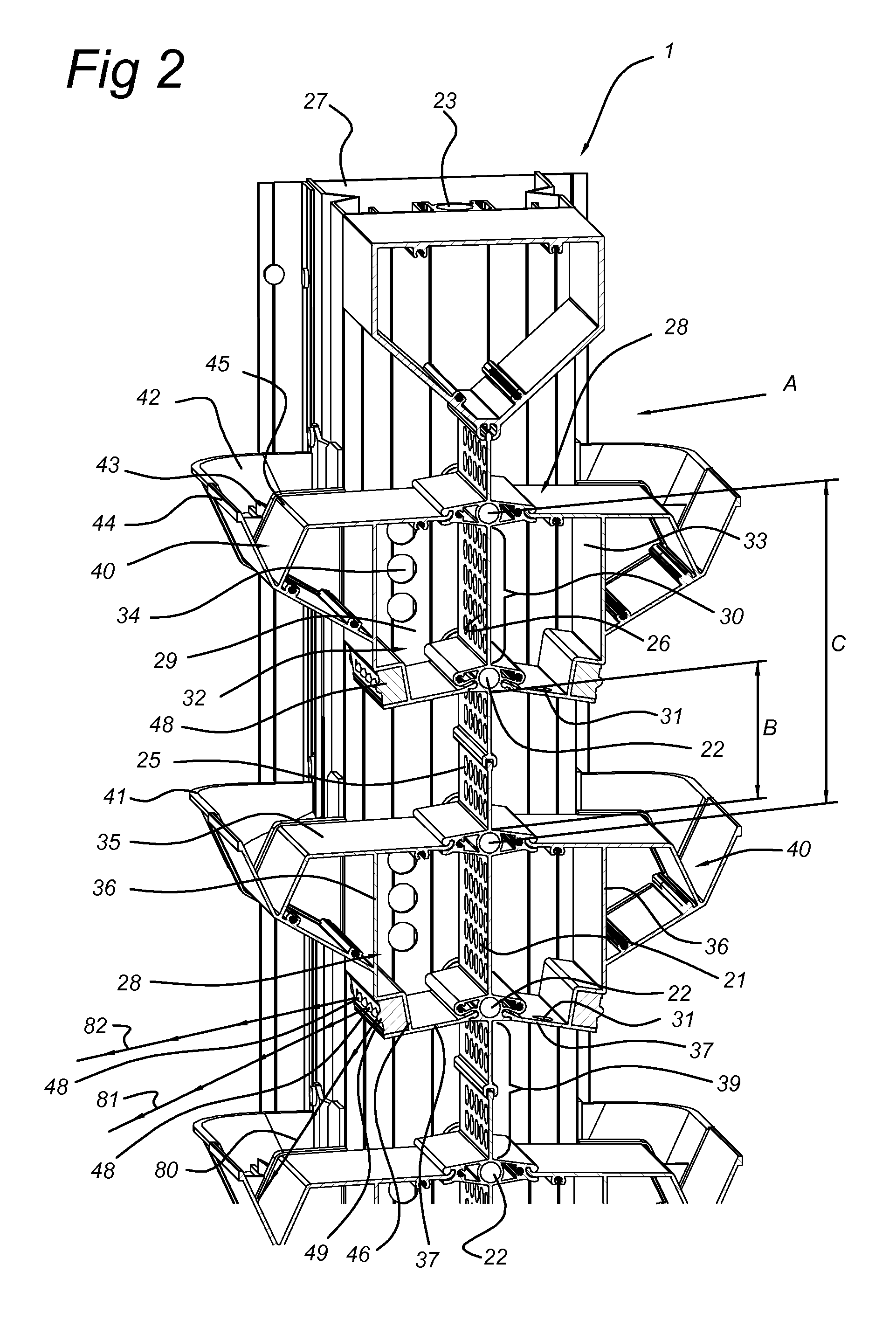

Method for brooding or growing poultry

The invention relates to a method for brooding or growing poultry, wherein eggs of the first 3-5 layings of young animals, preferably hens younger than 29 weeks, usually starting from about 26 weeks, are collected and are hatched together, directly after hatching the hatched chicks are provided in crates with about 10-500 animals arranged in stacks in an incubator chamber, in which incubator chamber food and drinking are provided to each crate and the temperature, humidity, CO2 level and flow rate of air are controlled.

Owner:HATCHTECH GRP

Method for manufacturing electrodes of solar cell and electrochemical depositing apparatus

InactiveUS20110045631A1Shorten molding timeFaster rateCellsSemiconductor/solid-state device manufacturingMetal alloyElectrochemistry

A method for manufacturing electrodes of solar cell and electrochemical depositing apparatus are disclosed. The method for manufacturing electrodes of solar cell is a method using the process of electrochemical depositing metal or metal alloy to form electrodes of solar cell. The method of the present invention can improve photoelectric conversion efficiency and reduce the production cost. The reaction time of the method is short and industrial waste liquid is treated easily.

Owner:WUXI SUNTECH POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com