Heat exchanger

a heat exchanger and heat exchanger technology, applied in the field of heat exchangers, can solve the problem that the device is not readily made more compact, and achieve the effect of compactness and limited manufacturing costs of the heat exchanger according to the fourth through sixth aspect of the present invention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

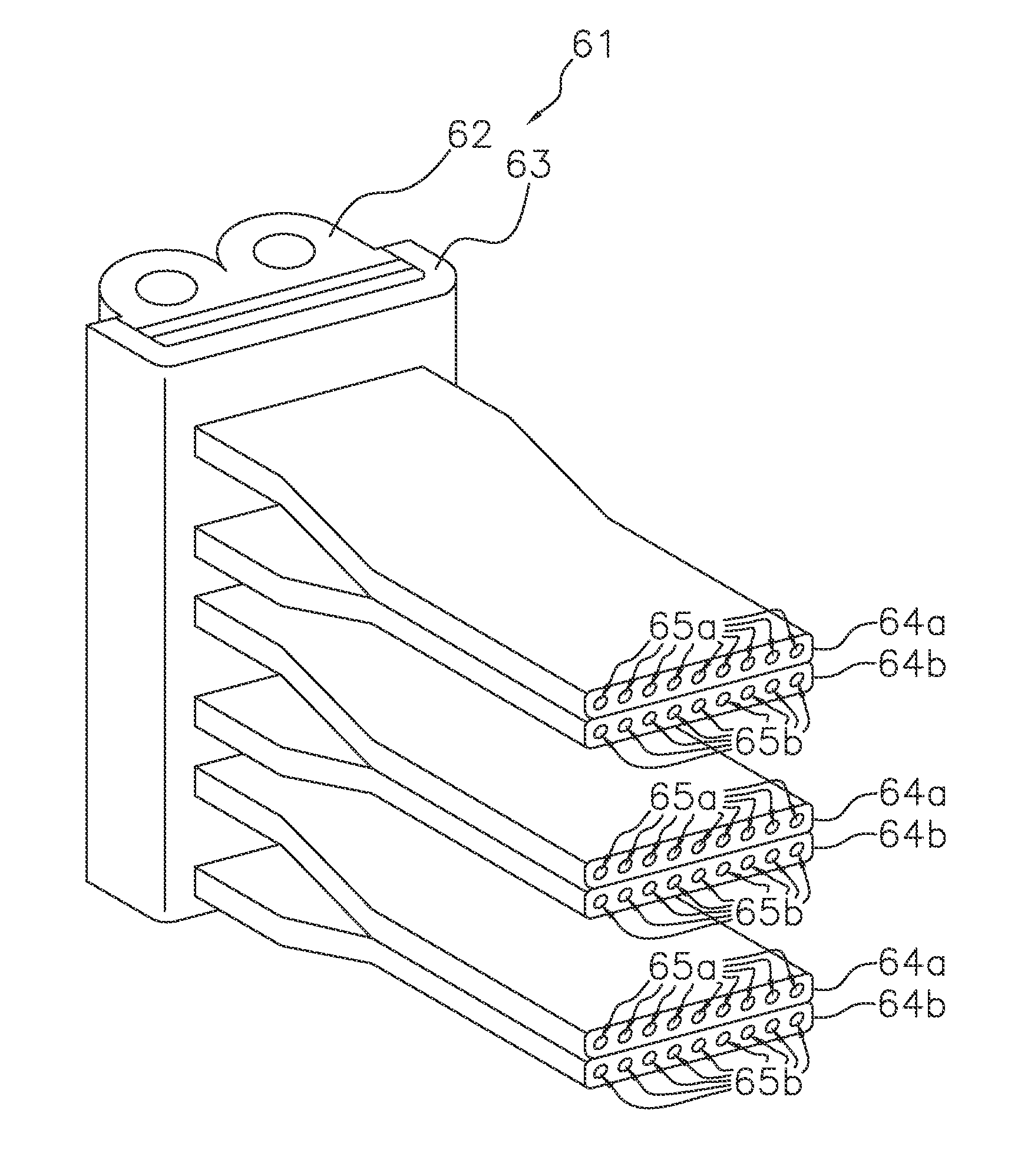

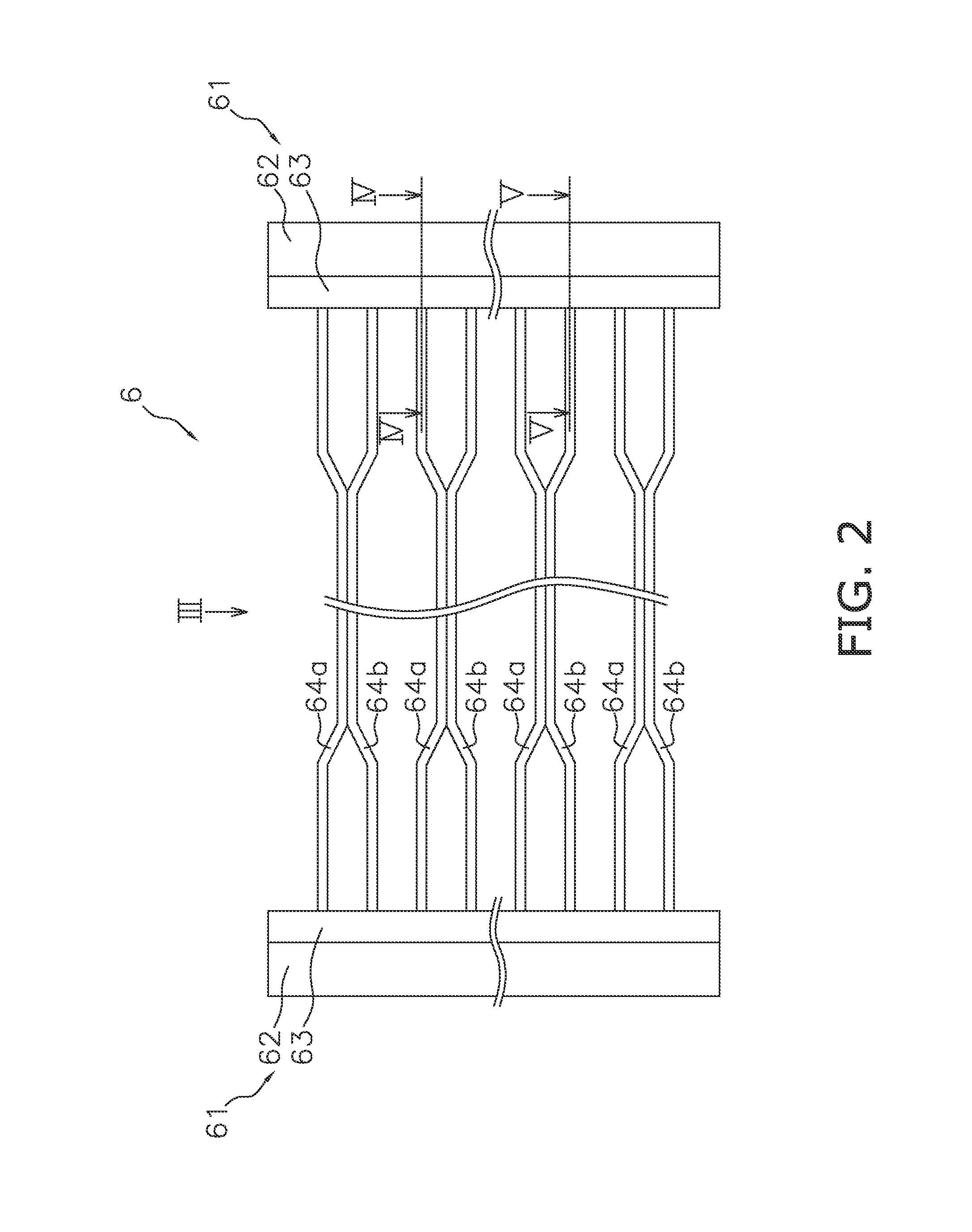

[0030]An embodiment of a heat exchanger according to the present invention will be described below on the basis of the drawings. The embodiment of the heat exchanger according to the present invention is a specific example of the present invention and does not limit the technical scope of the present invention.

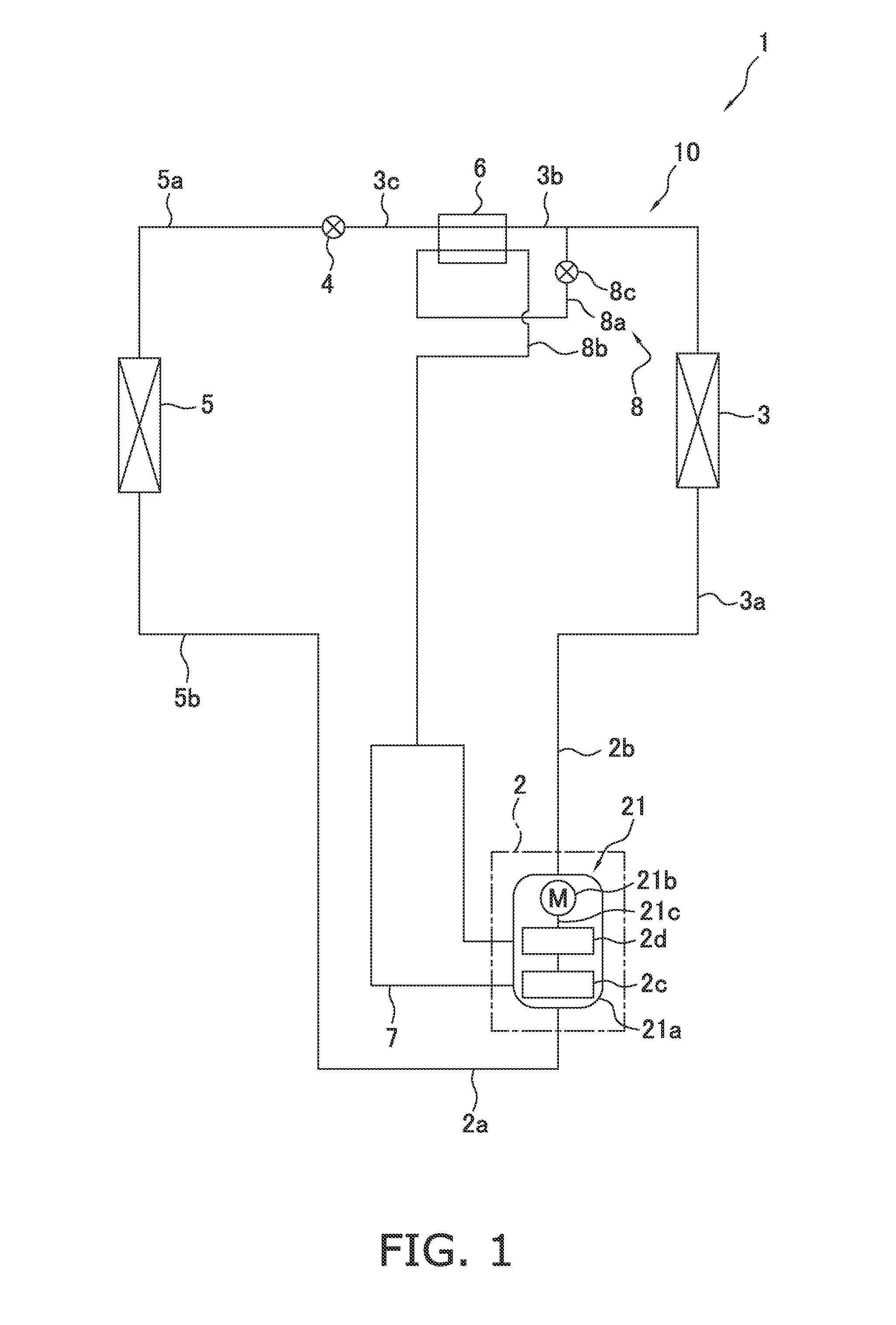

[0031](1) Configuration of Air-Conditioning Device

[0032]FIG. 1 is a schematic diagram of an air-conditioning device 1 that serves as an example of a refrigerating device provided with a heat exchanger according to the present invention. The air-conditioning device 1 has a refrigerant circuit 10 configured so as to allow air-cooling operations, uses carbon dioxide or another refrigerant active in the supercritical region, and performs a two-stage compression refrigeration cycle. The refrigerant circuit 10 primarily has a compression mechanism 2, a heat-source-side heat exchanger 3, an expansion mechanism 4, a usage-side heat exchanger 5, and an economizer heat exchanger 6. Thes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com