Production technology of low-carbon weather-resistant steel

A technology of weathering steel and continuous casting process, which is applied in the field of surface quality control during the preparation of copper-containing and antimony low-carbon weathering steel rolled products, which can solve the problems of limited applicability, increase steel inclusions, increase corrosion resistance, etc., and achieve improvement Surface quality problems of rolled products, reducing the loss rate of rolling and grinding, and improving the effect of tapping rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

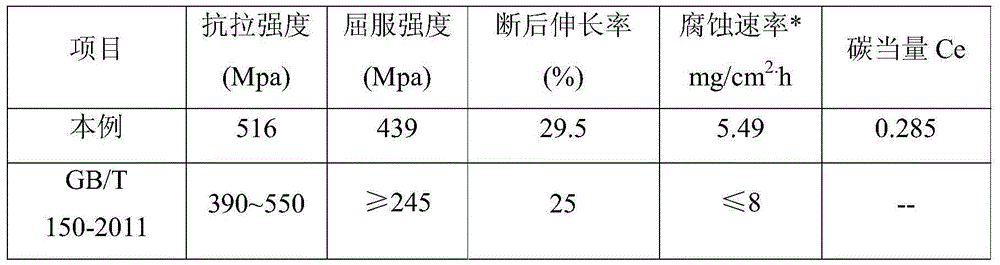

Embodiment 1

[0027] The process route of EAF-CONVERTER electric converter smelting→LF furnace refining→VD vacuum treatment→CCM continuous casting→hot delivery→hot rolling is used to produce low-carbon weathering steel containing copper and antimony.

[0028] Smelting product composition control: C: 0.07%, Si: 0.39%, Mn: 0.52%, Cr: 0.95%, Cu: 0.37%, Sb: 0.09%, Ni: 0.12%, Ti: 0.017%, P: 0.020%, S: 0.003%, the rest is Fe.

[0029] The superheat of continuous casting is 22℃, and the flow rate of primary cold water is 102m 3 / h, the inlet water temperature is 31°C, the temperature difference of the primary cooling water is 7.6°C, the specific water volume of the secondary cooling is 0.25L / kg, the casting speed is 0.95m / min, special mold slag for peritectic steel is used, and the temperature of the slab entering the drawing and leveling machine is 952-978 ℃, cancel the slab insulation cover on the slab discharge roller table after the stretching and leveling machine, increase the cooling rate of...

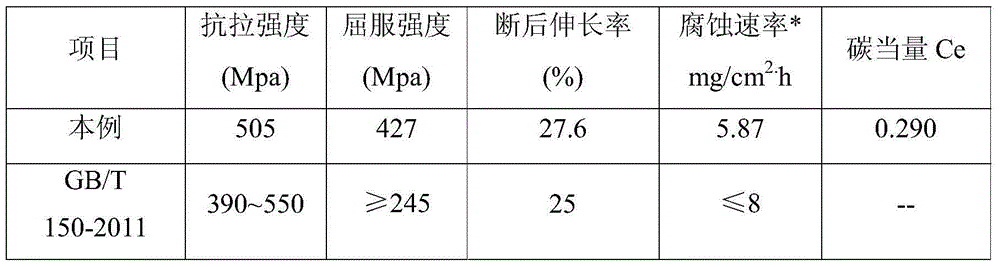

Embodiment 2

[0033] The process route of EAF-CONVERTER electric converter smelting→LF furnace refining→VD vacuum treatment→CCM continuous casting→hot delivery→hot rolling is used to produce low-carbon weathering steel containing copper and antimony.

[0034] Smelting finished product composition control: C: 0.07%, Si: 0.41%, Mn: 0.51%, Cr: 0.93%, Cu: 0.36%, Sb: 0.08%, Ni: 0.13%, Ti: 0.015%, P: 0.018%, S: 0.002%, the rest is Fe.

[0035] The superheat of continuous casting is 24°C, and the flow rate of primary cold water is 100m 3 / h, the inlet water temperature is 29℃, the temperature difference of the primary cooling water is 8.1℃, the specific water volume of the secondary cooling is 0.25L / kg, the casting speed is 0.98m / min, the special mold powder for peritectic steel is used, and the temperature of the slab entering the drawing straightening machine is 961~982 ℃, cancel the slab insulation cover on the slab discharge roller table after the stretching and leveling machine, increase the...

Embodiment 3

[0039] The process route of EAF-CONVERTER electric converter smelting→LF furnace refining→VD vacuum treatment→CCM continuous casting→hot delivery→hot rolling is used to produce low-carbon weathering steel containing copper and antimony.

[0040] Smelting finished product composition control: C: 0.08%, Si: 0.40%, Mn: 0.54%, Cr: 0.92%, Cu: 0.39%, Sb: 0.09%, Ni: 0.14%, Ti: 0.017%, P: 0.021%, S: 0.002%, the rest is Fe.

[0041] The superheat of continuous casting is 20℃, and the flow rate of primary cold water is 105m 3 / h, the inlet water temperature is 32°C, the temperature difference of the primary cooling water is 7.7°C, the specific water volume of the secondary cooling is 0.25L / kg, the casting speed is 0.92m / min, special mold slag for peritectic steel is used, and the temperature of the slab entering the drawing and leveling machine is 951-971 ℃, cancel the slab insulation cover on the slab discharge roller table after the stretching and leveling machine, increase the cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com