Patents

Literature

2456results about How to "Reduce the amount added" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

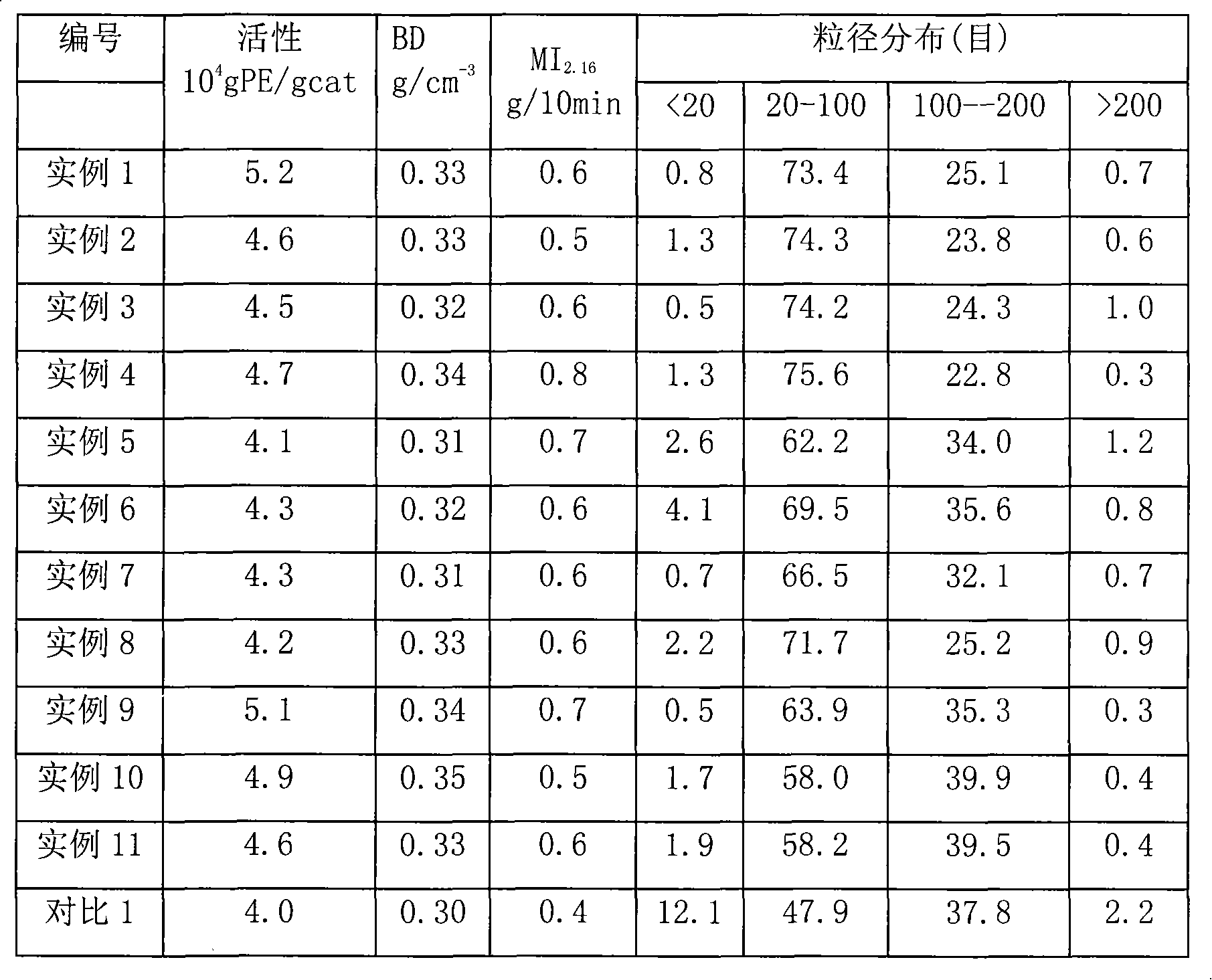

Catalyst components in use for polymerizing ethylene, and catalyst

This invention relates to a method for preparing catalyst for ethylene homopolymerization or copolymerization with other alpha-olefins. The catalyst comprises at least one Mg composite, at least one Ti compound, at least one organic alcohol compound, and at least one Si compound. The general formula of the Si compound is R1xR2ySi (OR3) z, where R1 and R2 are alkyl or halogen; R3 is alkyl; x is 0-2; y is 0-2; z is 0-4; x + y + z = 4. The catalyst has such advantages as high catalytic activity, high hydrogen sensitivity and narrow particle size distribution of polymer. The catalyst is suitable for slurry polymerization of ethylene, and combined polymerization process where catalyst with high activity is needed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Halogen-free flame-retardant type injection molding-class polyolefin wood plastic composite material and preparation method thereof

The invention discloses a halogen-free flame-retardant type injection molding-class polyolefin wood plastic composite material and a preparation method thereof. The composite material consists of the following components in percentage by mass: 25 to 80 percent of polyolefin resin, 5 to 60 percent of plant fiber, 0.5 to 20 percent of compatilizer, 0 to 30 percent of flexibilizer, 0.5 to 8 percent of dispersant, 5 to 40 percent of flame retardant and flame retardance synergist and 0 to 1 percent of antioxidant. Compared with the conventional wood plastic composite material, the halogen-free flame-retardant type injection molding-class polyolefin wood plastic composite material has the characteristics of simple production flow, little using amount of the flame retardant, good halogen-free flame retardant effect, wide range of molding modes and the like and is applicable to various injection molding products, such as electric appliance shells, automobile parts, furniture, buildings and other parts.

Owner:GUANGDONG KINGFA TECH CO LTD

Fire-proof adhesive and application thereof

ActiveCN104099028AReduce total calorific valueImprove thermal conductivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesCombustionAdhesive

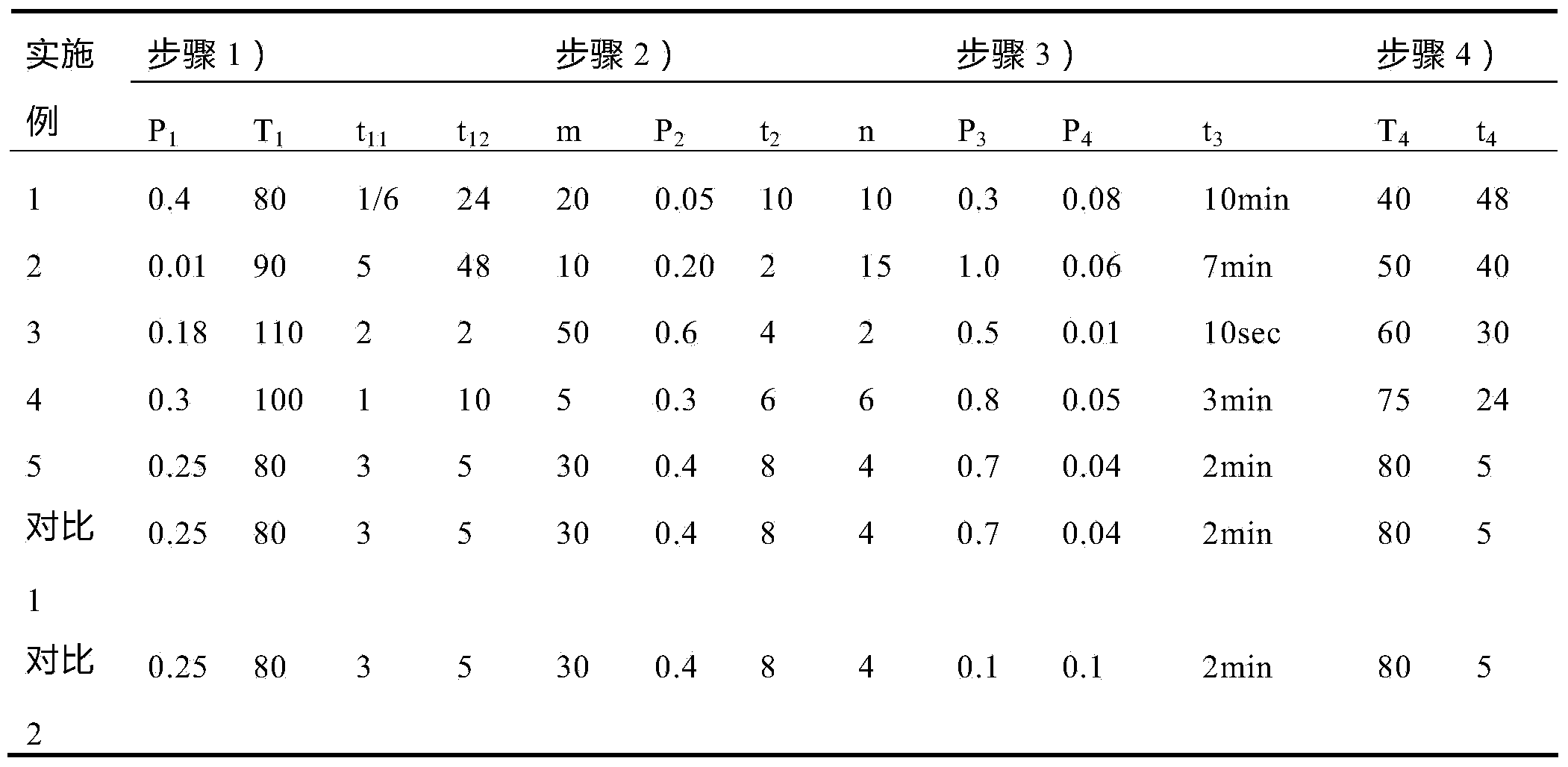

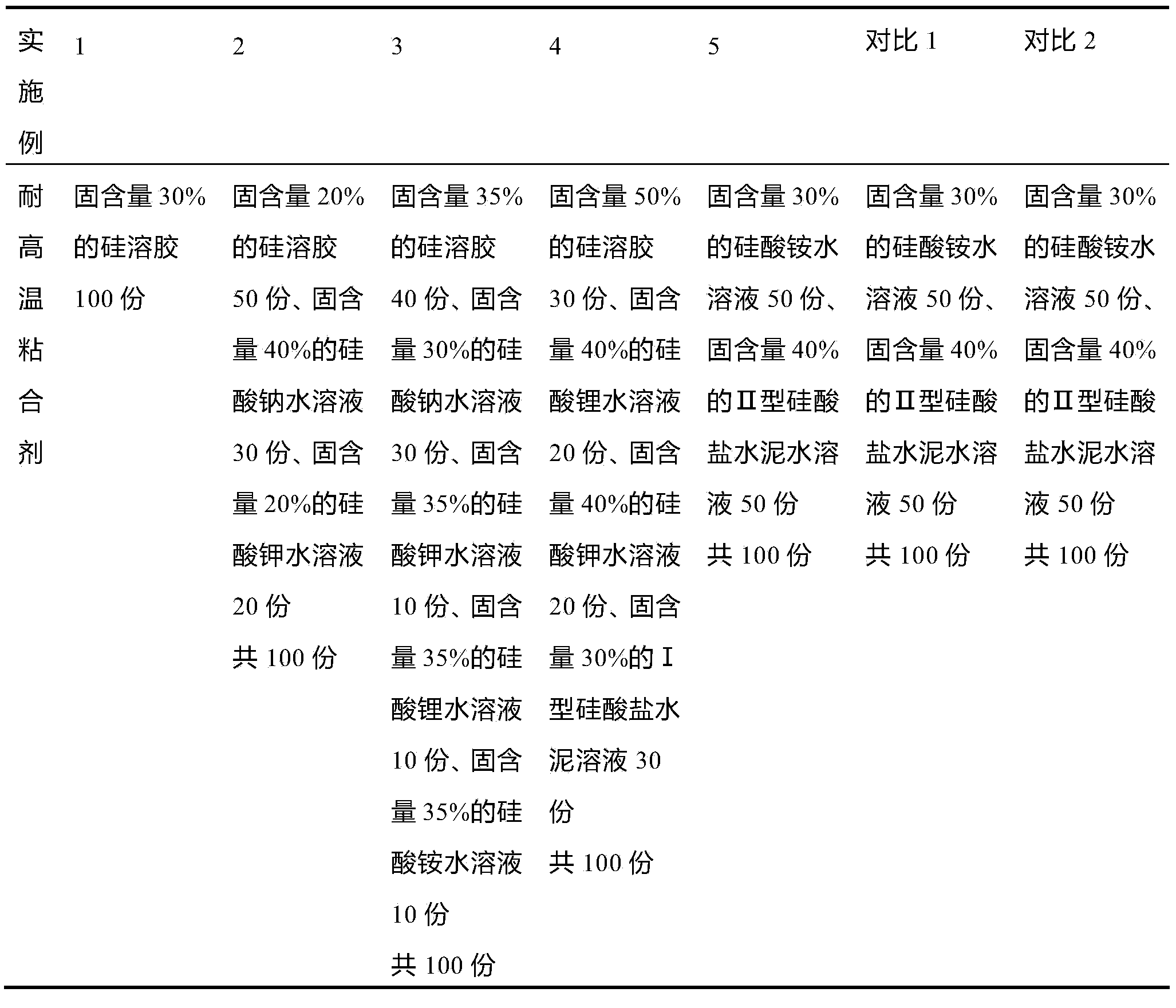

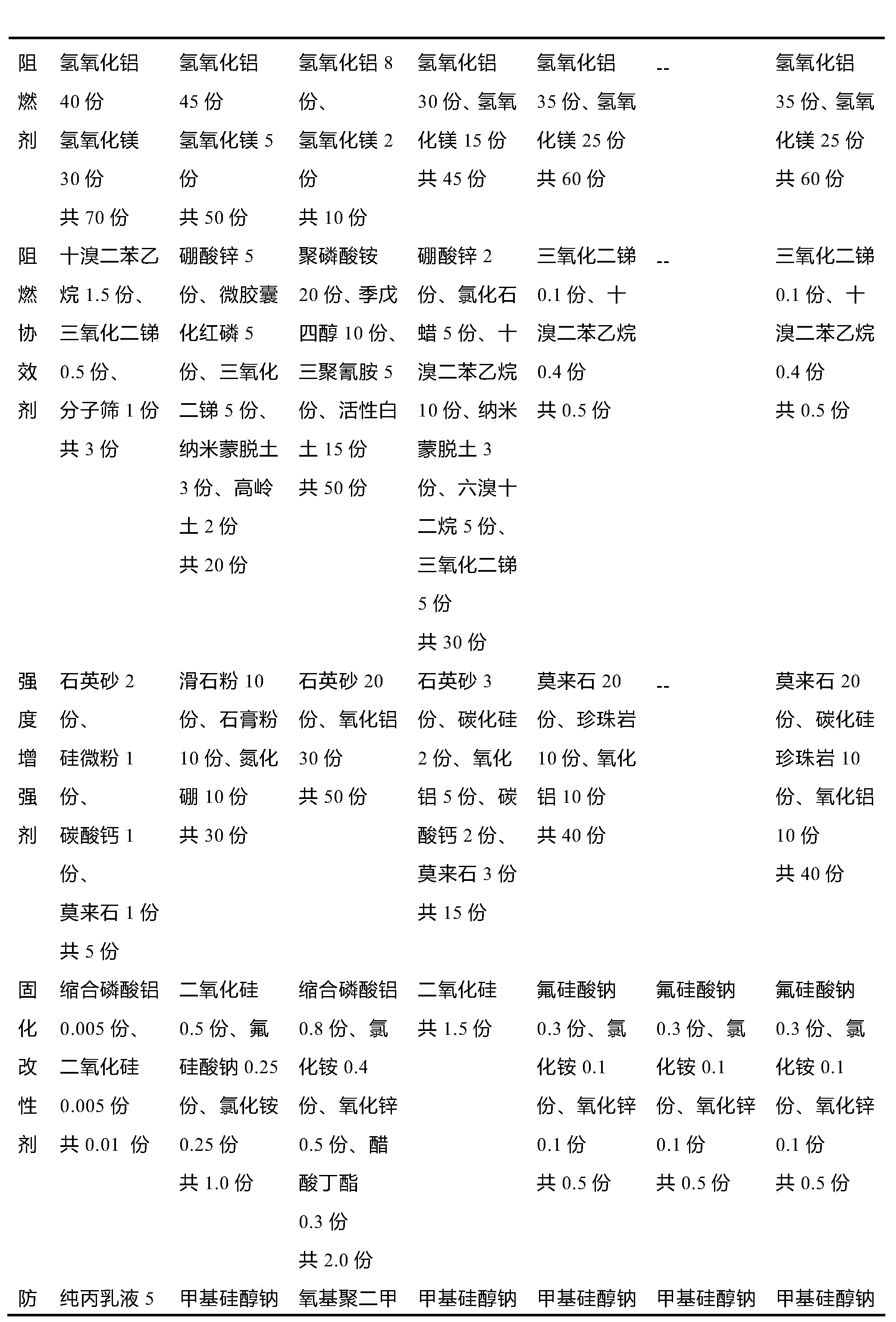

The invention discloses a fire-proof adhesive and application thereof. The fire-proof adhesive comprises the following components by parts: 100 parts of high-temperature bonding agent, 10-70 parts of fire retardant, 0.5-50 parts of flame retardant synergist, 5-50 parts of strength enhancer, 0.05-20.0 parts of water-proof modifying agent and 0.01-2.0 parts of curing modifying agent. By adopting the fire-proof adhesive and a preparation method of a fire-retardant EPS (Expandable Polystyrene) foam heat-insulating plate, the combustion performance and physicochemical performance of the fire-retardant EPS foam heat-insulating plate can be improved remarkably. For example, the heat-conducting coefficient can be lowered below 0.055w / m.k, the specific gravity can be lower than 150Kg / M<3>, the compressive strength is higher than 150KPa, and the heat value is less than 3MJ / kg.

Owner:应急管理部四川消防研究所

High-boron low-alloy high-speed steel roll and preparation method thereof

ActiveCN101831590AReduce the amount addedReduce manufacturing costRollsElectric furnaceHardnessHigh-speed steel

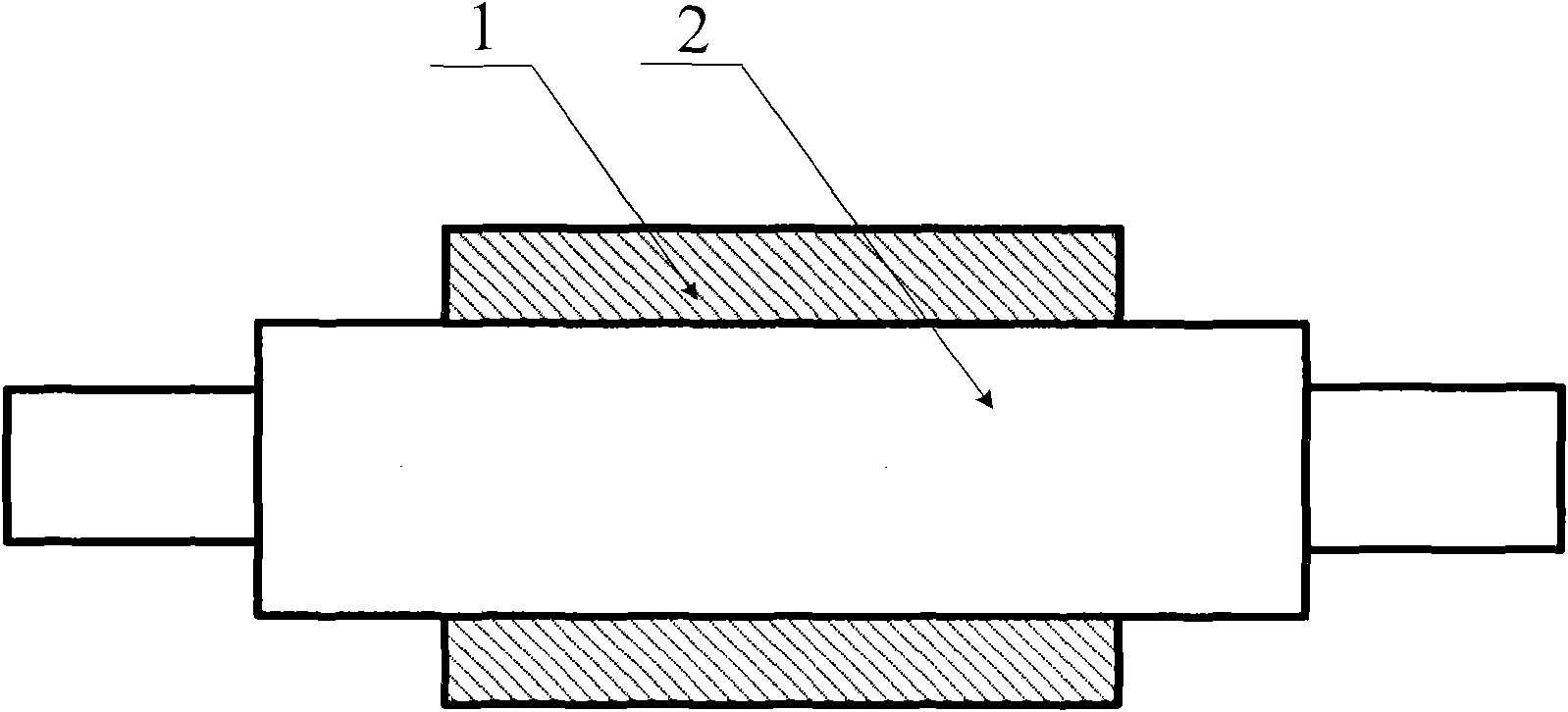

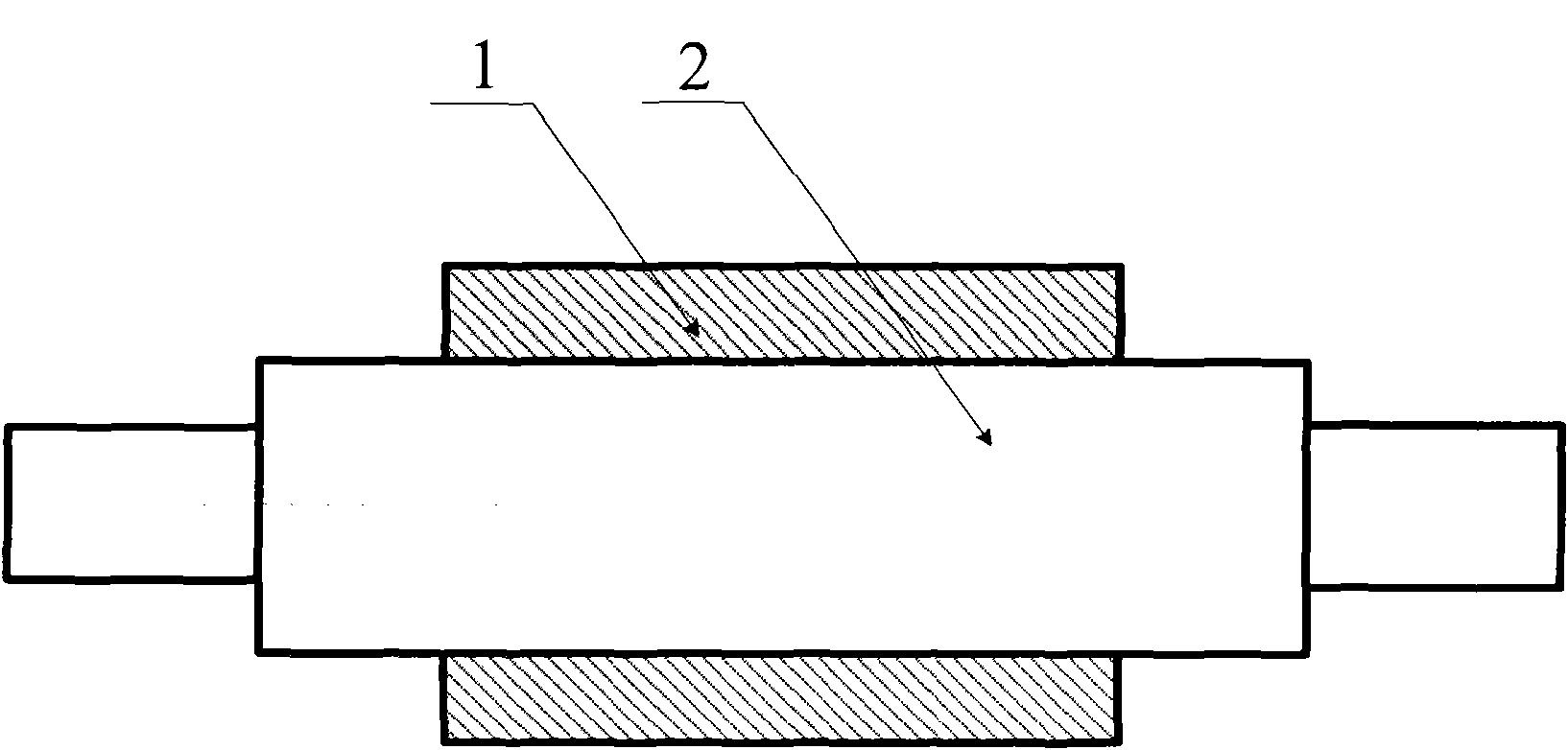

The invention relates to high-boron low-alloy high-speed steel roll and a preparation method thereof. The roll comprises two parts, namely a roll barrel (1) and a roll core (2), wherein the roll barrel comprises the following chemical components by weight percent: 0.32-0.55% of C, 1.42-2.13% of B, 5.2-6.5% of Cr, 2.5-4.5% of W, 1.6-1.8% of V, 0.5-1.0% of Nb, 0.3-1.0% of Si, 0.3-1.0% of Mn, 0.10-0.20% of Ti, 0.05-0.12% of N, 0.04-0.12% of Y, 0.08-0.15% of Mg, less than 0.04% of P, less than 0.04% of S and the balance Fe. The roll prepared by the method of the invention is characterized by high hardness, deep quenched depth and good wear resistance and thermal fatigue resistance, and has good use effect in the production of hot rolled steel.

Owner:JIANGSU DONGYE ROLL

Electroplating wastewater zero-discharge or low-discharge handling method

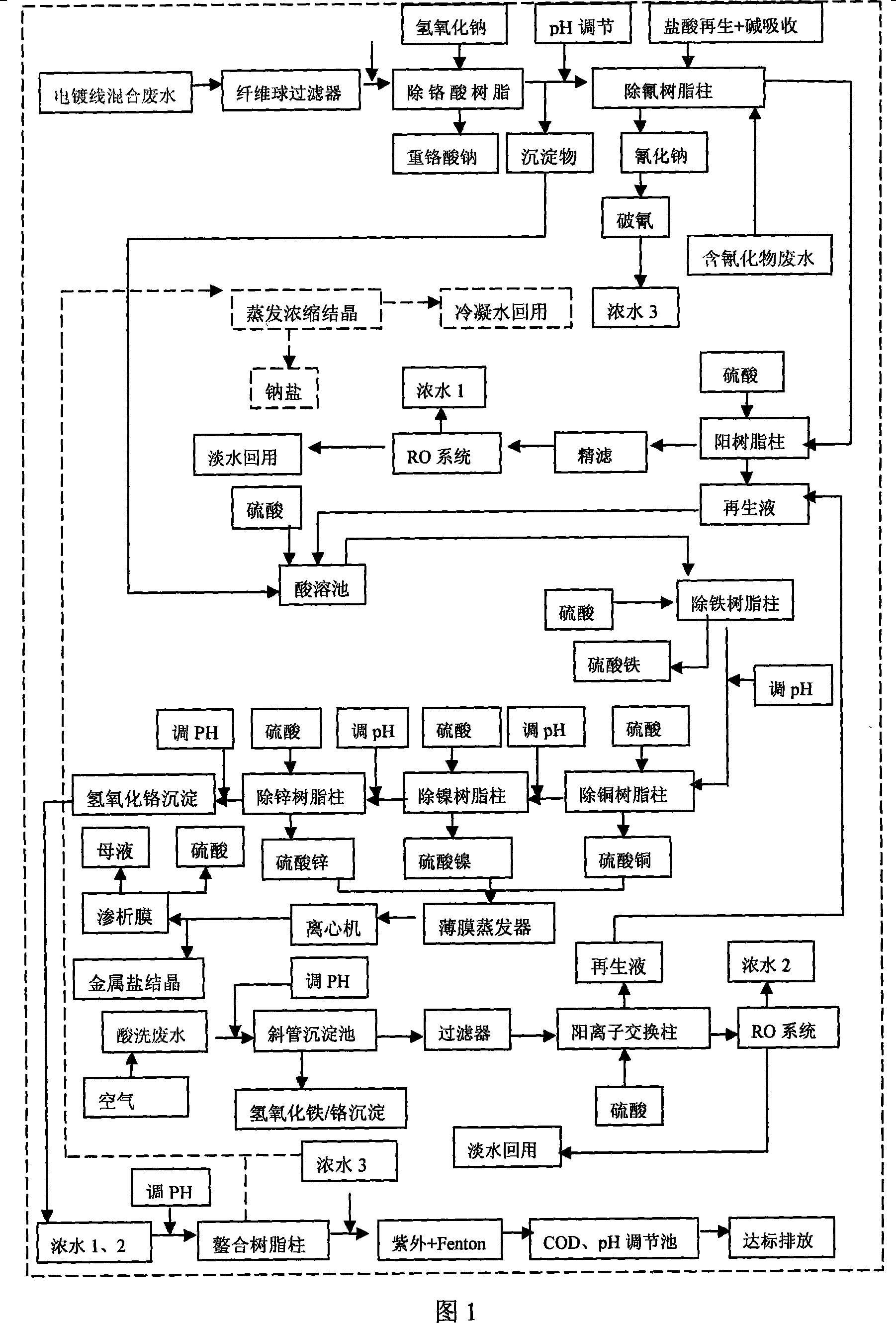

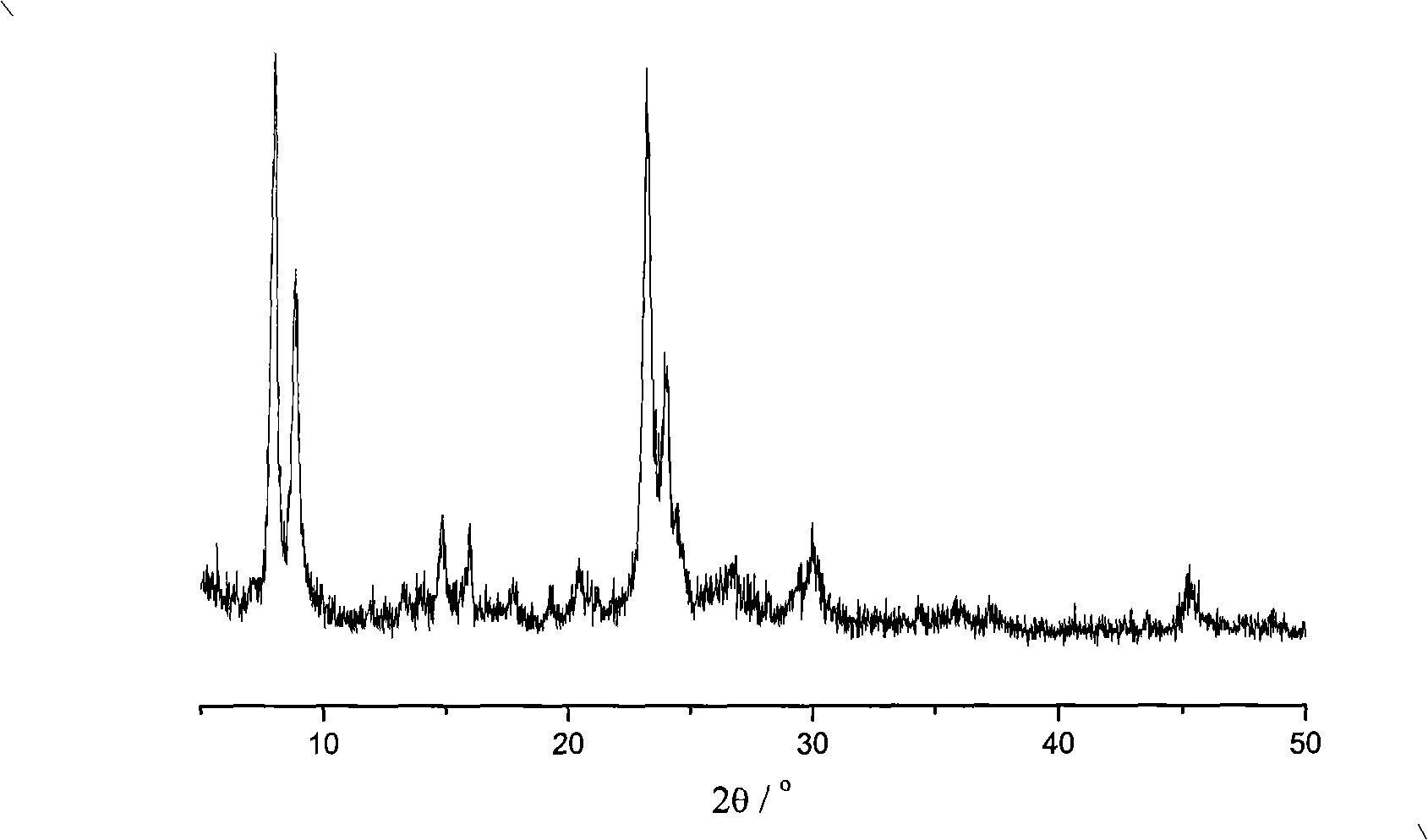

InactiveCN101157509ASolve pollutionReduce processing costsFatty/oily/floating substances removal devicesWater/sewage treatment by irradiationIonAutomatic control

The invention provides a processing method for zero draining or low draining of electroplating wastewater. The method adopts an integrative technique, such as barrier concentration, barrier separation, ion exchange, and ultraviolet light catalytic oxidation, etc. The following steps are adopted: the pretreatment of the electroplating wastewater; the treatment for the three types of wastewater including pickling wastewater, wastewater containing cyanide and passivating and electroplating rinsing composite wastewater; and the treatment for the wastewater in an acid-soluble pool. Compared with the wastewater in an integrative electroplating plant with universal generic multi-plating species, only the prior water separation method with no need to control the troubled water strictly can realize : first, zero draining of the electroplating wastewater is performed; second, when operating in the low energy consumption way, 65 to 85 percent of water recovery is realized, the left wastewater which can not be recovered is discharged when reaching the primary discharge standard of National Standard; third, the processing cost is reduced; fourth, the metallic ion in the wastewater can be effectively recovered and utilized, at the same time, the benefit disinvestment cost is produced; fifth, the amount for causing solid waste is reduced; sixth, the invention is advantageous to realize the automatic control and the operation.

Owner:SURFACE & INTERFACE CHEM ENG TECH RES CENT NANJING UNIV +1

Styrene series non-halogen flame retardant injection-grade wood plastic composite and preparation method thereof

The invention discloses a styrene series non-halogen flame retardant injection-grade wood plastic composite and a preparation method thereof. The styrene series non-halogen flame retardant injection-grade wood plastic composite is prepared from the following components in percentage by mass: 25-60 percent of styrene series resin, 5-60 percent of plant fiber, 0.5-20 percent of compatilizer, 0-30 percent of flexibilizer, 0.5-8 percent of dispersing agent, 5-40 percent of fire retardant and synergetic fire retardant and 0-1 percent of antioxidant. Compared with the traditional wood plastic composite, the styrene series non-halogen flame retardant injection-grade wood plastic composite prepared by the invention has the characteristics of simple production flow, less consumption amount of fireretardant, good non-halogen flame retardant effect, wide range of moulding ways, and the like, and is suitable for various injection moulded parts such as shells of electric appliances, parts for vehicles, and parts for furniture and buildings, and the like.

Owner:GUANGDONG KINGFA TECH CO LTD

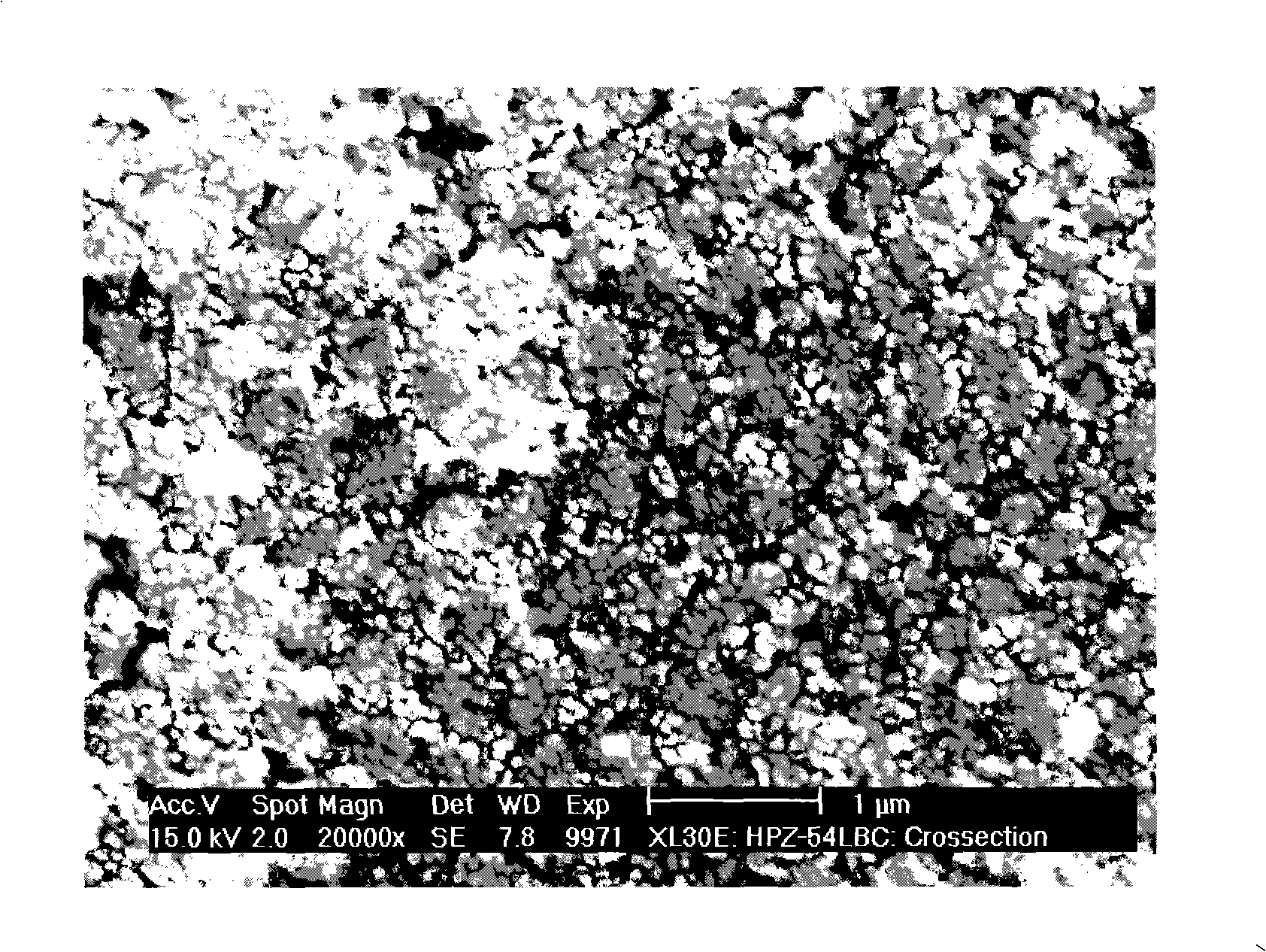

Preparation of binderless ZSM-11 zeolite

The invention relates to a method for preparing no-binding agent ZSM-11 zeolite, which mainly aims at overcoming the defects of difficult recovery, easy deactivation and easy aggregation existing in the practical application of the zeolite powder and the problems of small effective surface area and limited diffusion due to the addition of the binding agent in the forming process. In the invention, at least one of diatomaceous earth, carbon white, silicasol or water glass is taken as a silicon source, at least one of aluminum oxide, aluminum salt or aluminate is taken as an aluminum source, and proper quantity of necessary crystal seed guiding agents are added and subjected to pugging, extrusion and forming so as to obtain a precursor mixture with the mass ratio of XNa2O:YAl2O3:100SiO2, wherein x is between 0.5 and 14, and y is between 0 and 6, and the precursor mixture is subjected to hydrothermal crystallization treatment in the water solution containing tetrabutyl ammonium positive ions and converted to the no-binding agent ZSM-11 zeolite. The technical proposal of the invention better resolves the problems, and can be applied to the industrial preparation of the ZSM-11 zeolite molecular sieve catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Carbon nanotube/polypropylene composite materials and process for preparing same

InactiveCN1654528ANo thermal decompositionImprove heat resistancePolypropylene compositesCarbon nanotube

The present invention provides one kind of composite antistatic carbon nanotube / polypropylene material and its preparation process. The composite antistatic carbon nanotube / polypropylene material has carbon nanotube as main antistatic modifying material and polypropylene as main modified target. The composite antistatic carbon nanotube / polypropylene material has both excellent antistatic performance and excellent mechanical performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment method for inferior heavy oil and residual oil

ActiveCN1766059ABroaden sources of raw materialsReduce production operating costsTreatment with hydrotreatment processesSolventChemistry

The invention discloses a process for treating inferior heavy oil and residual oil comprising the following steps: loading heavy oil and petroleum residue into a solvent extraction apparatus, charging the obtained deasphalted oil into a fixed bed for hydrotreatment, entering the obtained tail oil into a catalytic cracking device, loading part or total slurry oil and de-oiled asphalt into a floating bed hydrogenation unit, separating the outcome yield to obtain lightweight fraction and untransformed tail oil, which is circulated to the solvent extraction device.

Owner:CHINA PETROLEUM & CHEM CORP +1

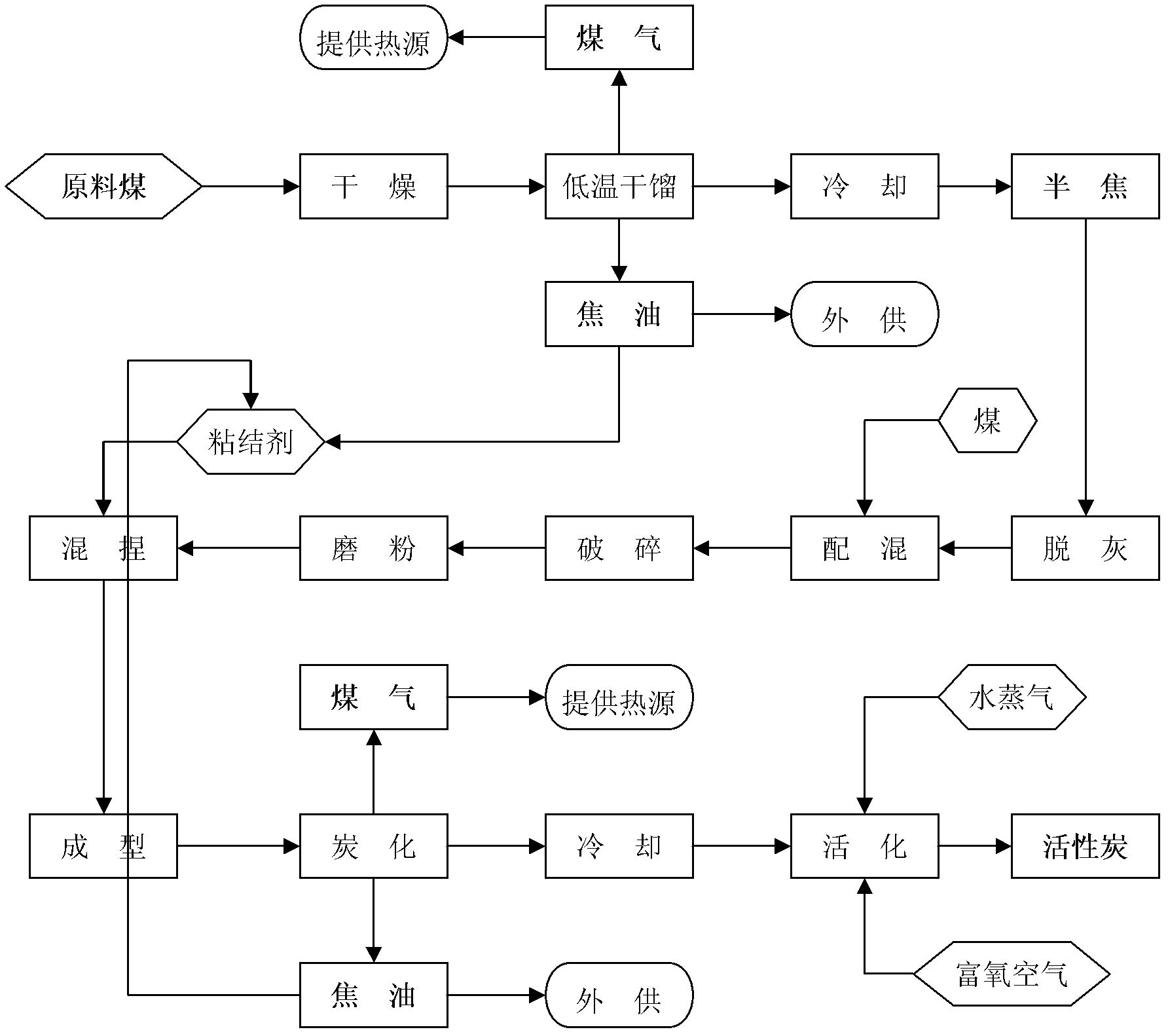

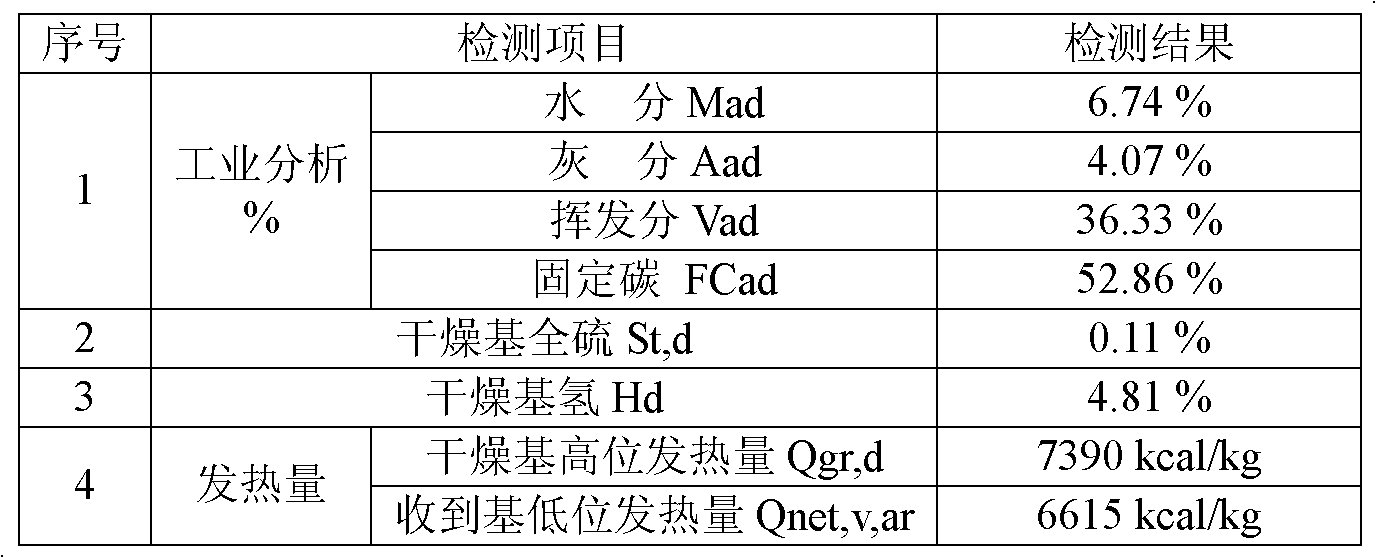

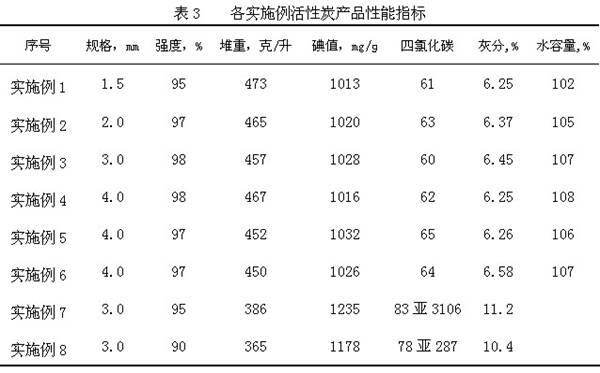

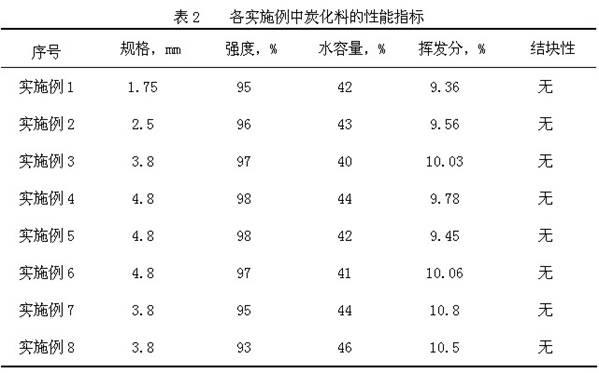

Method for preparing active carbon by using coal

The invention provides a method for preparing active carbon by using coal. The method comprises the following steps: after feed coal is dried, dry-distilled at low temperature and cooled, semicoke is obtained; deashing is carried out on the semicoke in which the ash content can not meet the production requirement of the active carbon; coal is mixed with certain viscosity into the semicoke which can not meet the strength of the active carbon according to the characteristics; after mixed with the coal, the raw materials are mixed fully by crushing and grinding; after a certain amount of binding agent is added, the powder is mixed and kneaded, and is pressed into a forming material with a special shape in forming equipment; the forming material enters a carbonization furnace by a conveying device, carrying out heat treatment, dry-distillation, heat cracking and condensation reaction at different temperature sections to prepare carbonized materials; the carbonized materials are conveyed to a cooling furnace for cooling by the conveying device; and the cooled carbonized materials are conveyed to an activating furnace, and is activated by utilizing an activating agent. The method has the advantages that the industrial chain for comprehensive utilization of subcannel coal is extended, the utilization bottleneck of the semicoke is broken, products with increasing market demand are produced, the strategic resources short in China can be effectively recovered, and large economic and social benefits can be created.

Owner:西安三瑞实业有限公司

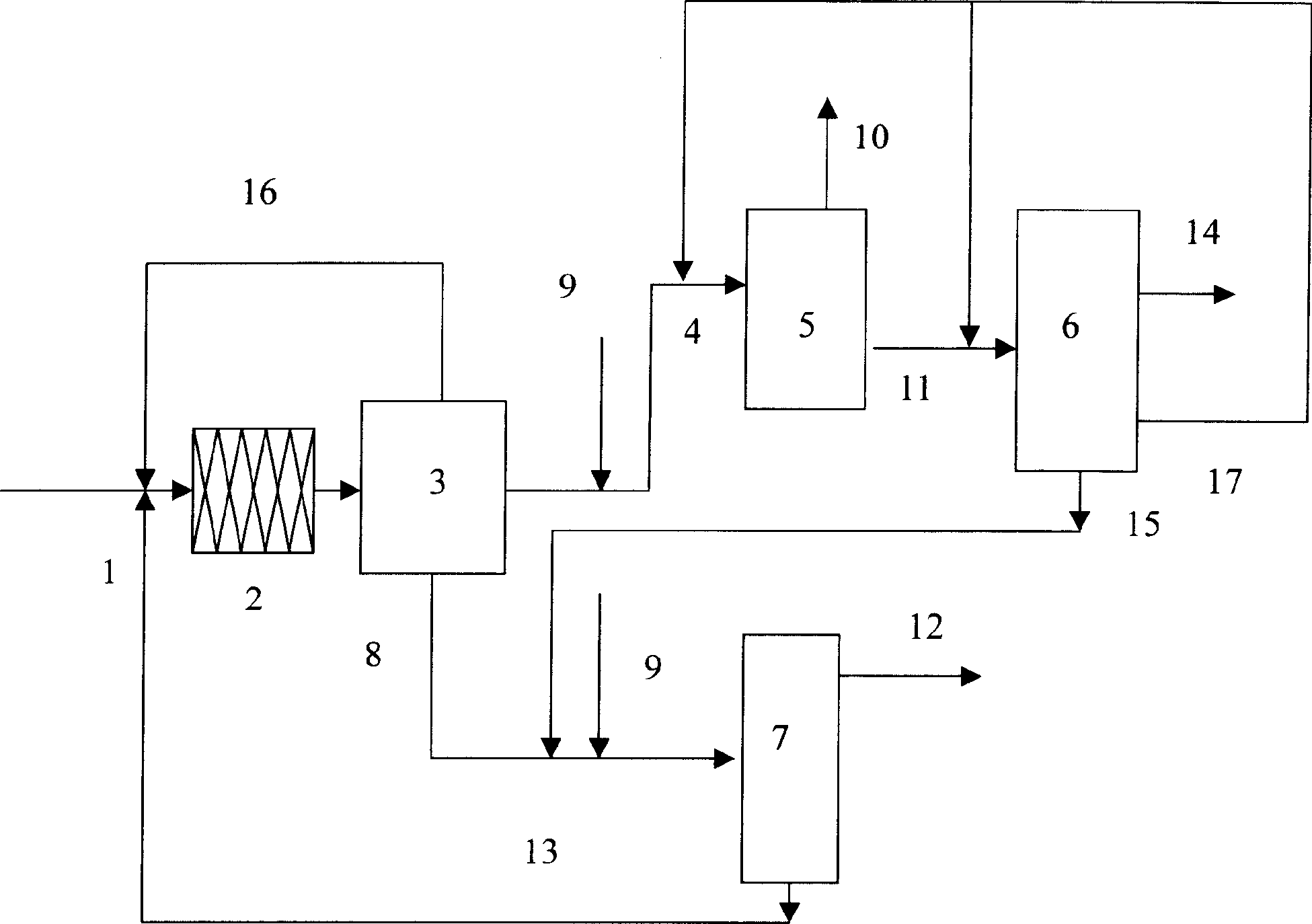

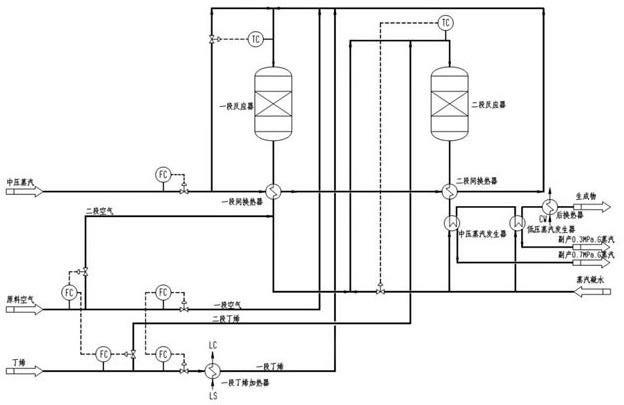

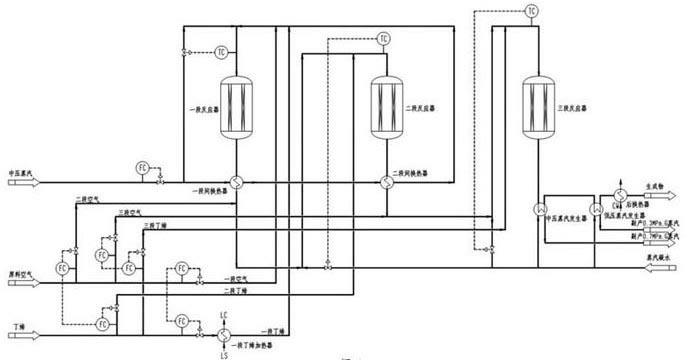

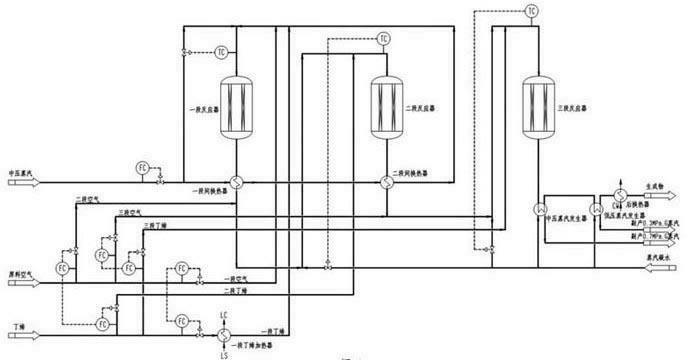

Process for preparing butadiene through oxidative dehydrogenation of butene

InactiveCN102675027ARunner shortReduce resistanceChemical industryHydrocarbonsProcess equipmentWater vapor

The invention relates to a process for preparing butadiene through the oxidative dehydrogenation of butene on an adiabatic radial fixed bed. The process comprises the step of performing oxidative dehydrogenation reaction of butene, air and water vapor in an adiabatic radial fixed bed reactor to obtain the butadiene. The radial fixed bed reactor is divided into three sections (or three stages); and process equipment sequentially comprises a first-section reactor, a first-section recuperative heat exchanger, a second-section reactor, a second-section recuperative heat exchanger, a third-section reactor, a medium-pressure steam generator, a low-pressure steam generator, a rear heat exchanger and the like. The preparation process is technically characterized in that the yield of the butadiene is high, the selectivity is high, the production device has high production capacity, the unit consumption of steam is low, and the heat energy is reasonably utilized; and the yield of wastewater, the pretreatment capacity of internal wastewater and the discharge amount of sewage can also be effectively reduced.

Owner:HUNAN BAILI ENGINEERING SCIENCE AND TECHNOLOGY CO LTD

Iron-base catalyst for Fischer-Tropsch synthesis and its preparation method

ActiveCN1597105AReduce manufacturing costLow priceHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsIron sulfatePotassium silicate

A Fe-based catalyst for the Fischer-Tropsch synthesis contains Re2O3, Fe3O4, La2O3, CuO, K2O and SiO2. It is prepared through using oxidant to oxidize partially the ferrous sulfate to obtain the mixed solution of iron sulfate and ferrous sulfate, mixing with the mixed solution of lanthanum nitrate and copper salt, fast depositing by alkaline compound, washing the deposited slurry, adding potassium silicate-water glass solution, and spray drying.

Owner:SYNFUELS CHINA TECH CO LTD

Method of recovery copper, nickel and noble metal in waste water and slag by combined technology of wet method and fire method

A process for recovering the copper, Ni and noble metals from the sewage and dregs by the combination of wet method and fire method includes the wet process including extracting, Cu-Ni separation, removing Fe, extracting, and refining nickel carbonate, and the fire process including sintering and smelting to produce nickel matte and black copper. Its advantages are high recovery rate of Ni, Cu, Au, Ag and Pd, and no secondary pollution.

Owner:孙涛 +1

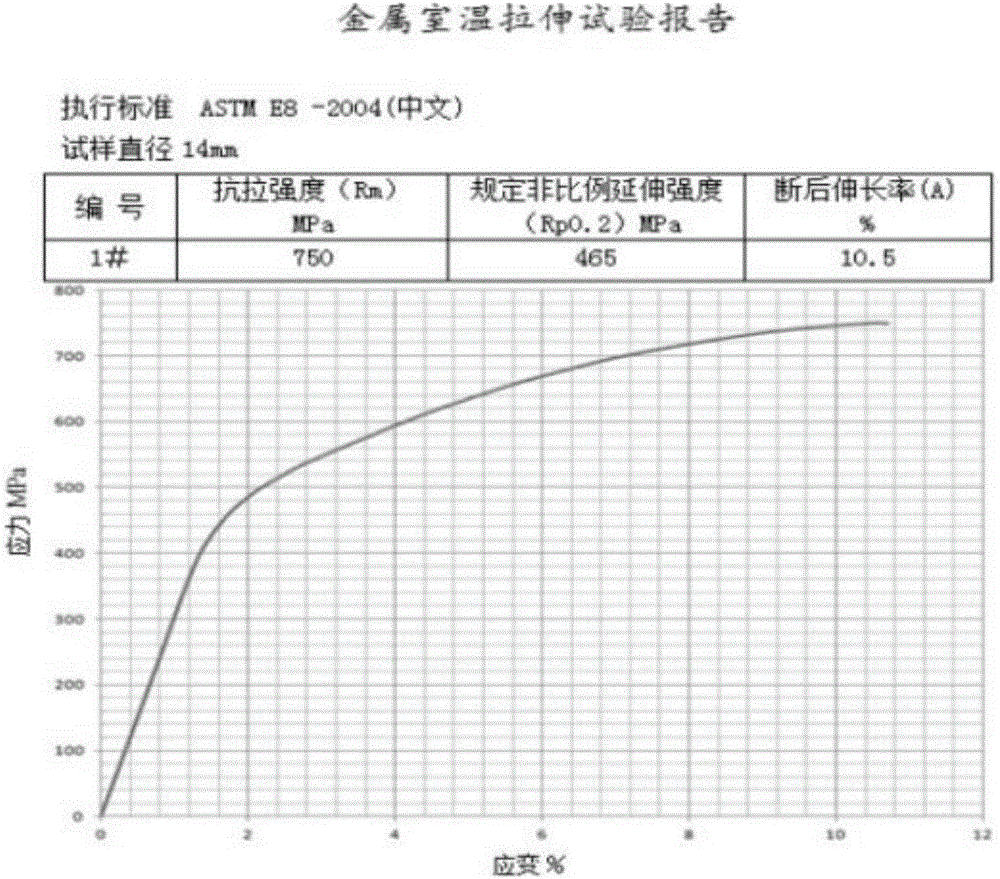

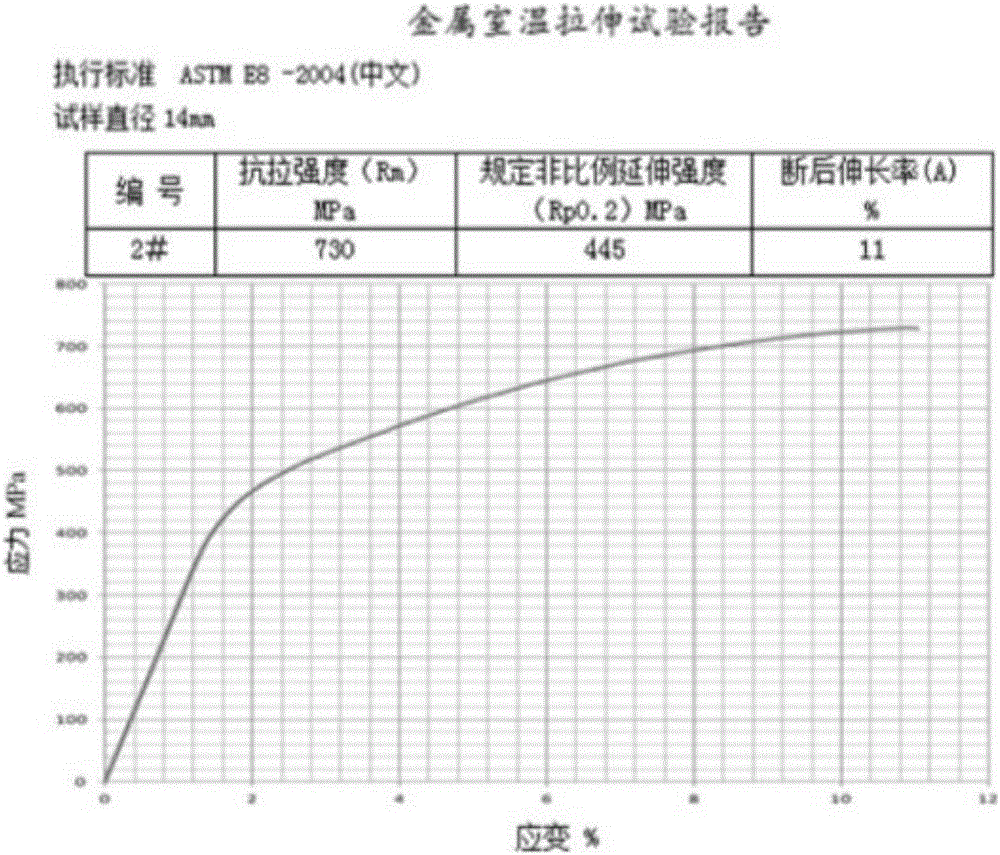

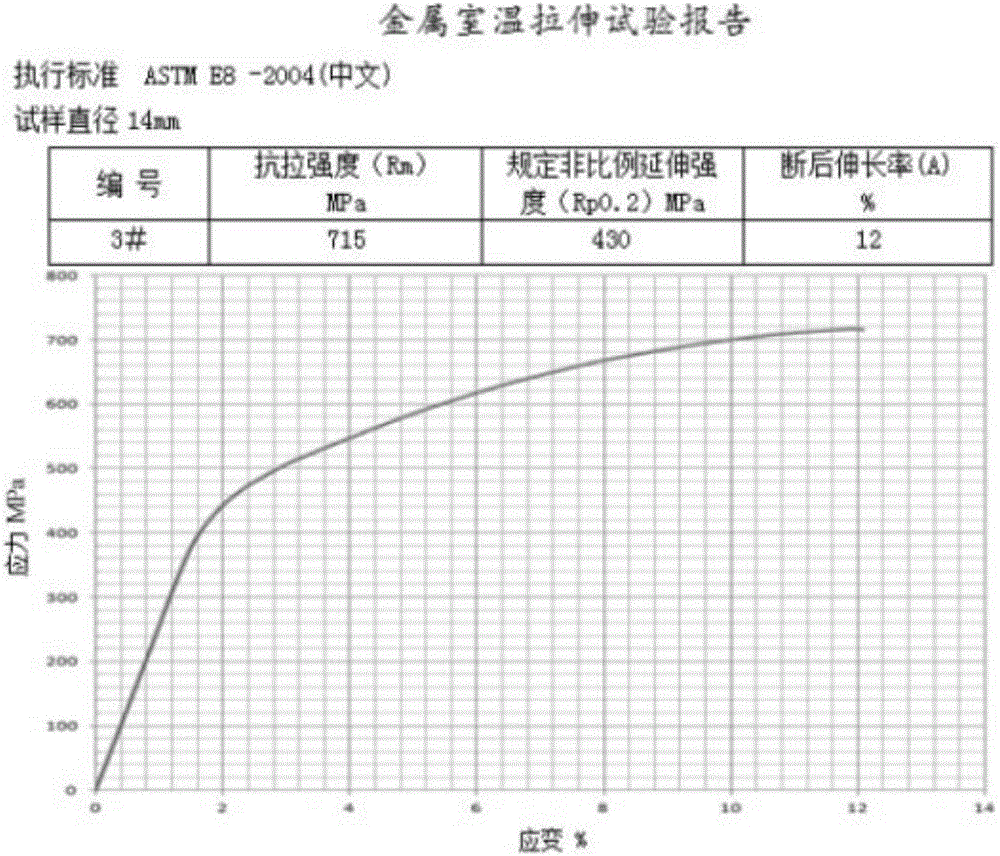

High-strength high-tenacity cast-state QT700-10 and production method thereof

ActiveCN106811676AIncrease the number ofReduce oxidation burnProcess efficiency improvementHigh intensityDuctile iron

The invention belongs to the field of casting technologies and new materials and particularly relates to a high-strength high-tenacity cast-state QT700-10 and a production method thereof. Compared with ductile iron produced in the prior art, the high-strength high-tenacity cast-state QT700-10 has high strength and a high elongation rate, heat treatment is not needed, heavy metal, such as, Ni and Mo are not added in production, the tensile strength Rm in the cast state is larger than or equal to 700 MPa, the elongation rate A is larger than or equal to 10%, compared with the standard brand QT 450-10, the lowest tensile strength is improved by 55% under the same elongation rate; and compared with the standard brand QT 700-2, the lowest elongation rate is improved by four times under the same tensile strength. The high-strength high-tenacity cast-state QT700-10 can meet requirements of automobile ductile iron castings with high requirements for safety and comprehensive mechanical properties.

Owner:山东汇金股份有限公司

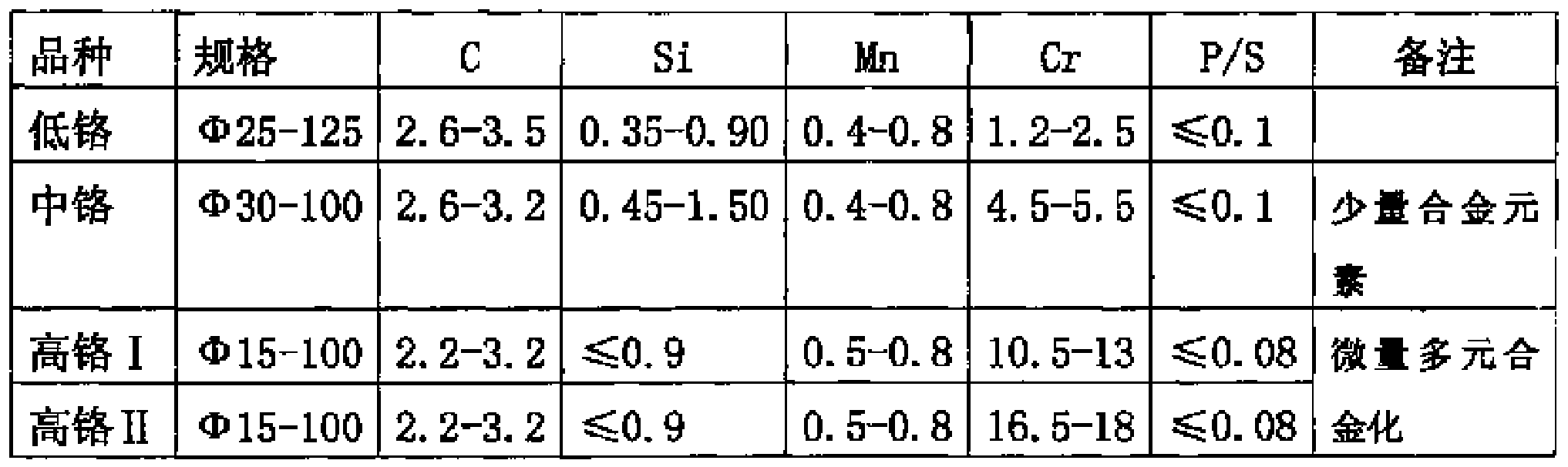

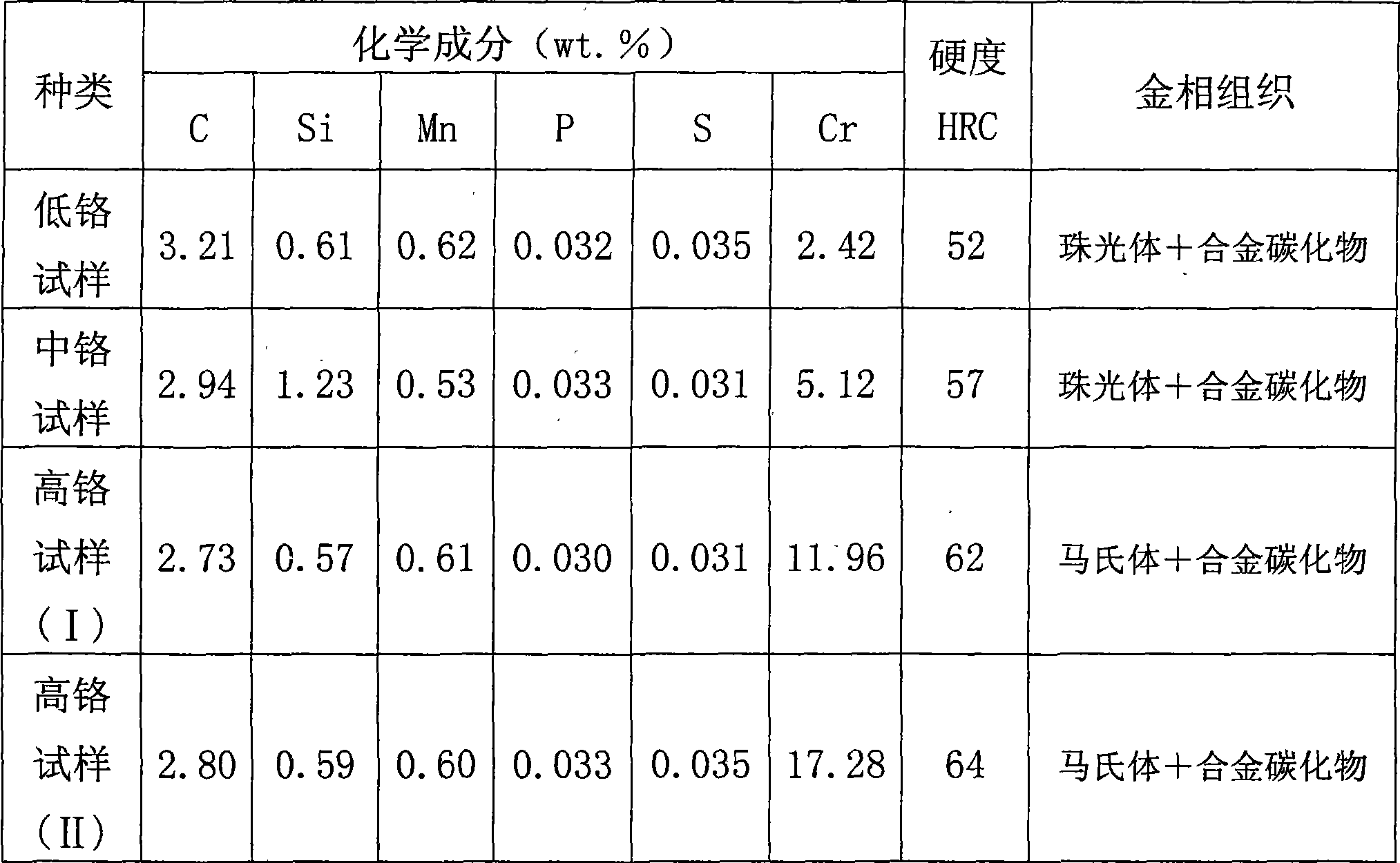

High abrasion proof re-synthesizing cast iron grinding ball and production method thereof

InactiveCN101445889AHigh hardnessImprove toughnessEdge grinding machinesPolishing machinesIntermediate frequencyCarbide

The invention relates to a high abrasion proof resynthesizing cast iron grinding ball for a ball grinding mill and a preparation method thereof. The method reduces the content of carbon in material on the premise that carbide is formed in materials, thereby reducing the contents of chrome and molybdenum in the material and simultaneously controlling the content of other elements, so that the obtained material of the grinding ball has good overall mechanical property and service performance. Compared with a No. 45 steel forging ball, the abrasion proof property of the grinding ball is improved by 3 to 10 times, so that both the consumption of steel products and the recourses are saved. In the method, cast iron is melted and synthesized by using an intermediate frequency electric furnace and a large amount of scrap steel, steel scraps and other renewable resources are utilized, so that not only the quality of synthetic cast iron products is improved and the performance is stabler, but also the pollution to environment is reduced.

Owner:MAANSHAN YIFENG INDAL GROUP

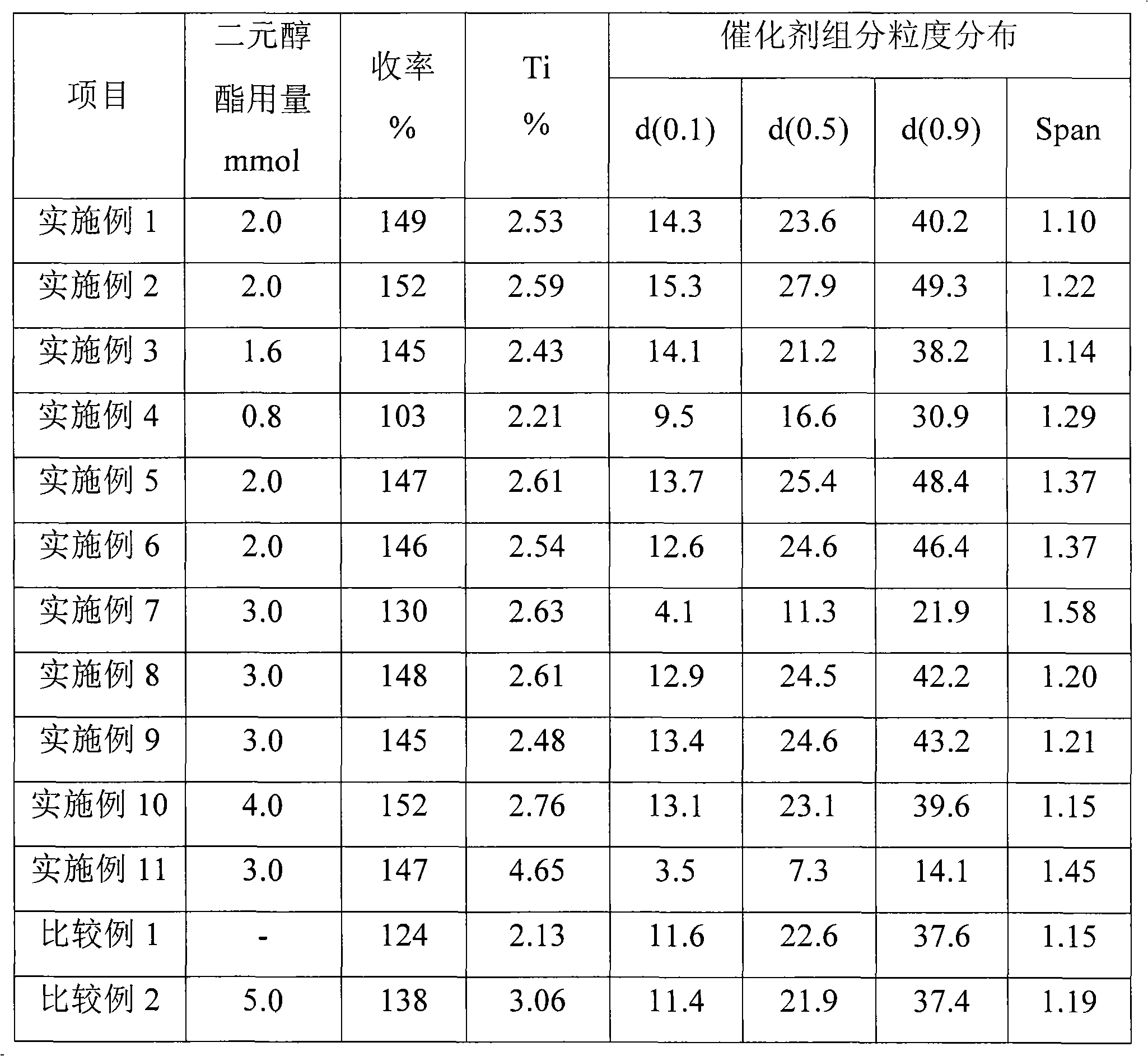

Preparation method of catalyst component for polymerization reaction of olefins and catalyst thereof

The invention provides a method for preparing a catalyst component for the polymerization reaction of olefins, which comprises the following steps: (1) dissolving magnesium halide in a solvent system comprised of an organic epoxy compound, an organic phosphorus compound and an inert diluent to form uniform solution; (2) mixing a titanium compound with the uniform solution formed by the step (1) and adding a precipitant to form a mixture, or adding the precipitant into the uniform solution formed by the step (1) first and mixing the uniform solution with the titanium compound to form a mixture; and (3) heating the mixture obtained by the step (2), adding any selected electronic donor compound during heating or after heating, and washing the resulting product with an inert diluent to obtain a magnesium / titanium-containing solid material, wherein the precipitant is a glycol ester compound. The catalyst component has high polymerization activity and stereoselectivity and causes little polymer fine powder when used in the polymerization reaction of olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

Master batch with light scattering function, and preparation method and application thereof

The invention discloses a master batch with a light scattering function, and a preparation method and application thereof. The master batch with a light scattering function comprises 20-99.5% of transparent thermoplastic resin, 0.1-40% of small-particle-size light scattering agent, 0.1-10% of large-particle-size light scattering agent, 0.01-10% of antioxidant and 0.01-20% of light stabilizer. By compounding the light scattering agents with two particle sizes, the optical properties of the light scattering material can be obviously enhanced. Under the condition of the same content of light scattering agent, since the light scattering agents with two particle sizes are compounded, the light scattering material not only can achieve the same light scattering effect, but also has better light transmittance. The light scattering agents, antioxidant, light stabilizer and other functional assistants are mixed with the matrix resin to prepare the functional master batch, so that the concentration of the assistants in the master batch is increased; and the functional master batch is blended with the matrix resin to prepare the light scattering material. The invention has the advantages of low consumption of light scattering agents, uniform distribution, excellent optical properties, fewer surface defects, lower cost and the like. The master batch with a light scattering function is suitable for producing high-quality optical components, lamp shells, diffuser plates in backlight modules, advertisement signboards, display windows and the like.

Owner:KINGFA SCI & TECH CO LTD +1

Columnar activated carbon based on coal pitch binders and preparation method of columnar activated carbon

InactiveCN102674341AImprove initial strengthEquivalent mechanical strengthCarbon compoundsActivated carbonUltimate tensile strength

The invention discloses columnar activated carbon based on coal pitch binders. The columnar activated carbon with grain size range of 1.0-10mm is prepared through a preparation method which comprises the steps of: using 100 parts by weight of carbonaceous materials as basic raw materials and 6-30 parts by weight of coal pitch as binders, respectively pulverizing the carbonaceous materials and the coal pitch, mixing the pulverized carbonaceous materials with the pulverized coal pitch, adding 20-50 parts by weight of temporary binders, kneading, molding, drying, carbonizing in a rotary carbonizing furnace and activating in a Slapple activating furnace. Since the temporary binders are used for endowing the molded materials with primary strength and the coal pitch and the pulverized carbon are co-carbonized and solidified and endow the carbonized materials with final mechanical strength, the traditional long-lasting mode of columnar activated carbon coal tar molding production is broken through and the goal of preparing columnar activated carbon by using coal pitch as binders to replace coal tar is realized.

Owner:李钱胜

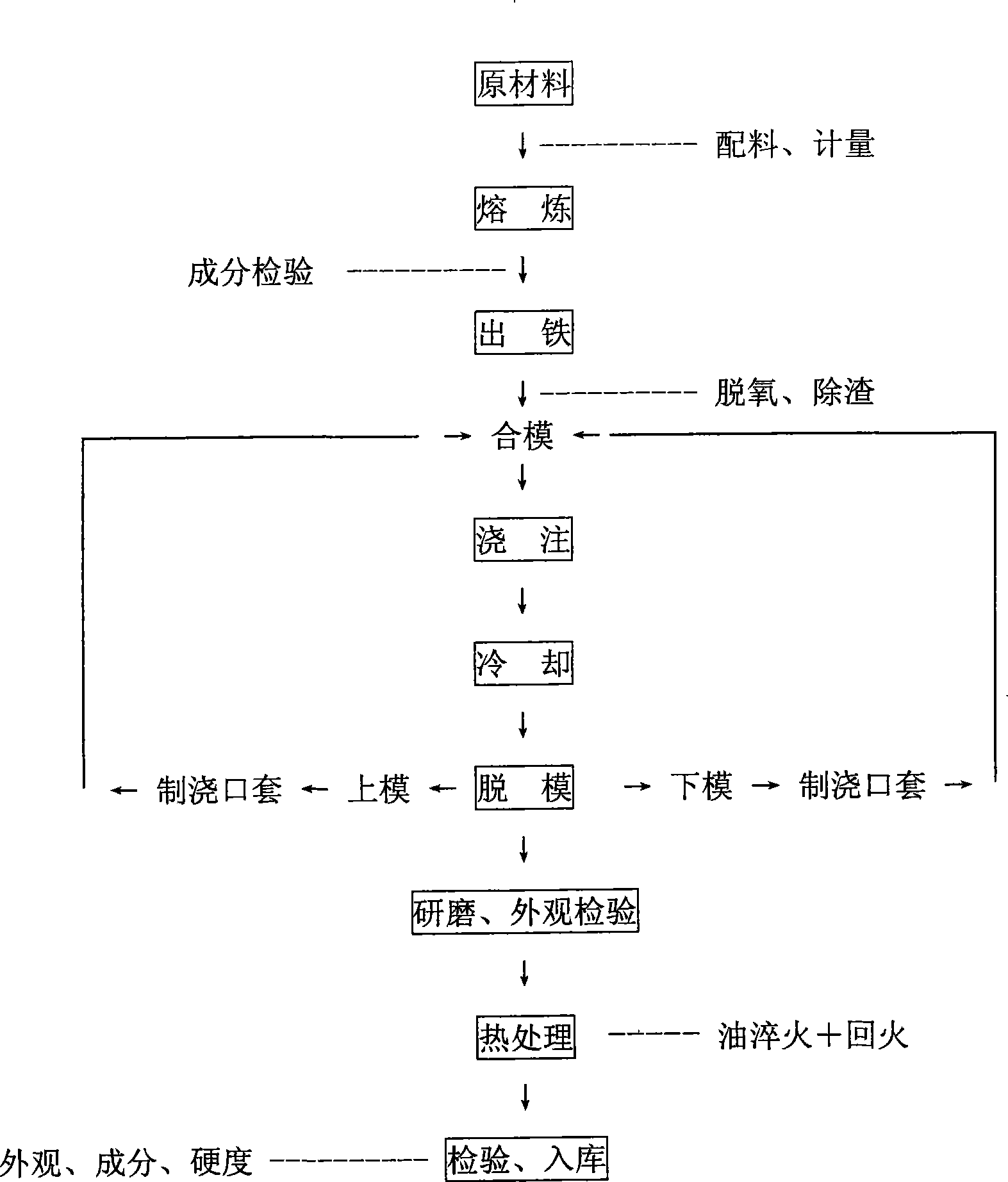

Preparation method for high-toughness nodular cast iron

The invention provides a preparation method for high-toughness nodular cast iron, which is a method for producing high-toughness nodular cast iron by utilizing a medium-frequency electric furnace and selecting materials such as cast iron which is low in sulfur, phosphor and manganese content, waste steel, and the like. The preparation method mainly comprises chemical component design, furnace burden selection, medium-frequency furnace smelting, a nodulizing agent selection and nodulizing treatment method, a nucleating agent selection and nucleating treatment method, and the like. The method disclosed by the invention does not need thermal treatment and desulfuration treatment, is less in processes, adopts a wet type sand production line to manufacture QT600-10 casting pieces, has casting efficiency higher than that of sand-lined iron type, and is low in cost. The produced nodular cast iron is high in strength, good in plasticity and toughness, can be used for components such as a transmission shaft, a rear axle shell, a differential mechanism shell, a bracket, and the like for a car and a tractor chassis.

Owner:HENAN POLYTECHNIC UNIV

Composite conductive printing ink

ActiveCN103436099AReduce the amount addedPlay the role of conductive connectionInksOrganic solventGraphite

The invention provides composite conductive printing ink which comprises the following components in parts by weight: 5.0-30.0 parts of film-forming resin, 20-40 parts of a mixture of silver flakes and nano silver powder or silver flakes, 0.1-5.0 parts of a mixture of graphene and nano-graphite sheets or graphene, 1.5-11.0 parts of an additive and the balance of an organic solvent. The composite conductive printing ink provided by the invention is lower in silver content and further has a good conductive effect at the same time.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

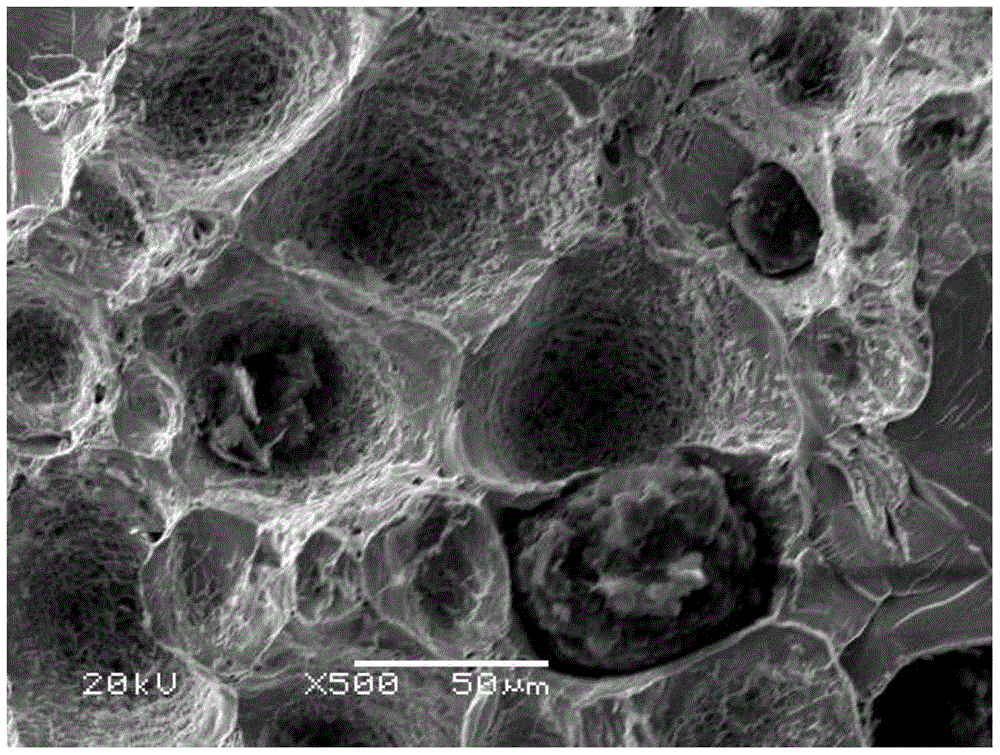

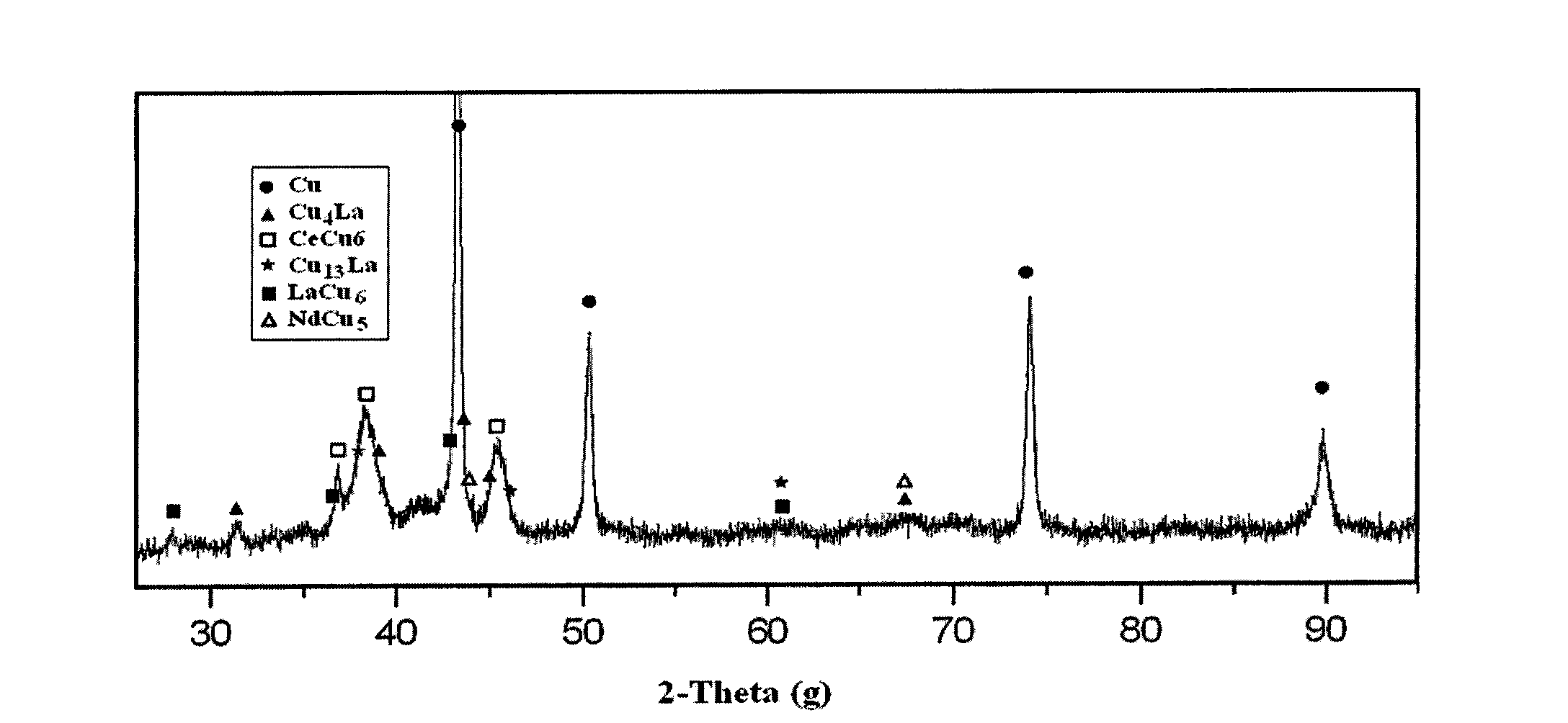

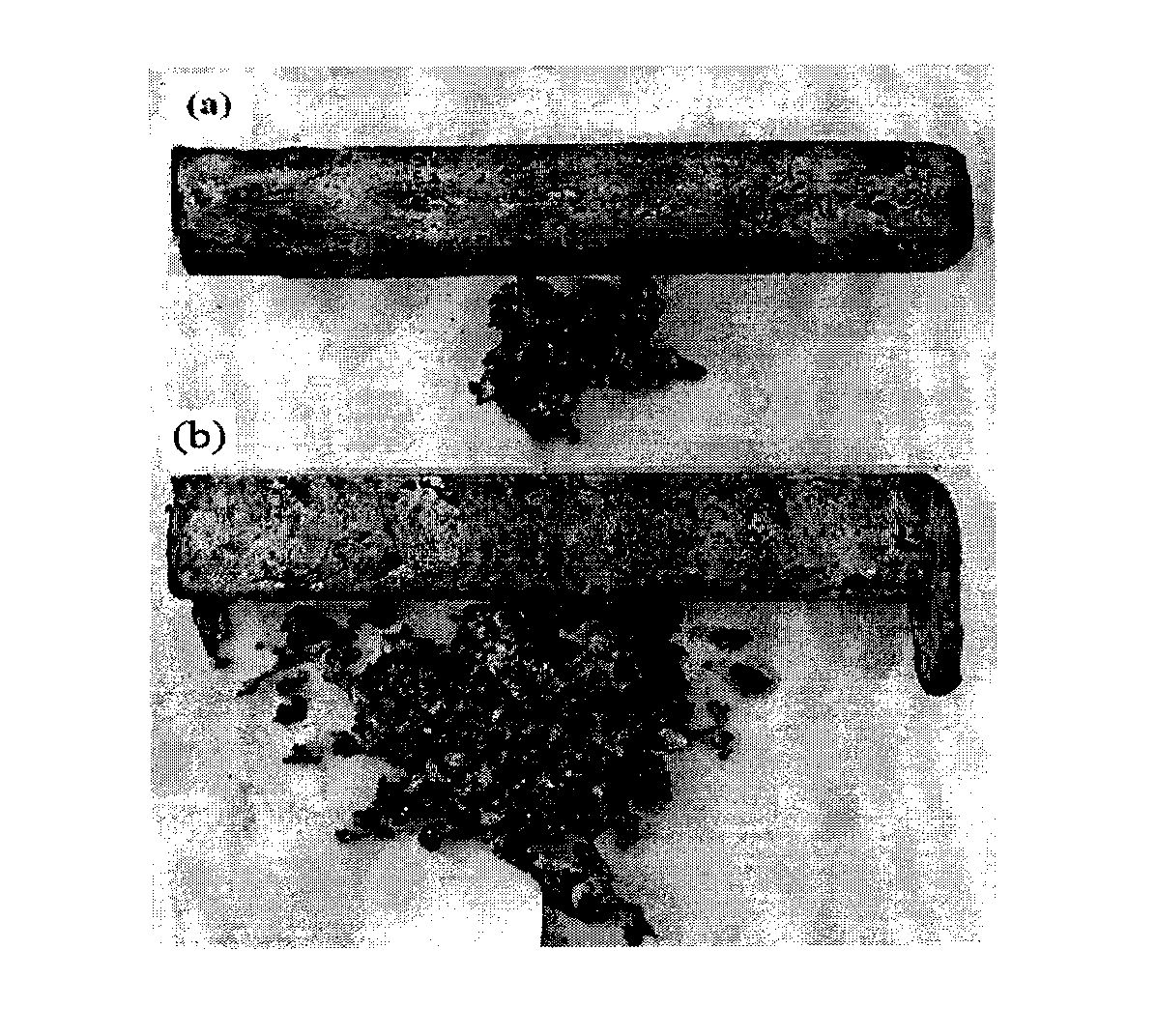

High Cu-RE interalloy refining agent for refining scrap copper and preparation and application thereof

The invention relates to a high Cu-RE refining agent which has high efficiency and low burning loss rate and can be used for copper and copper alloy, applied to mass refining of the copper and the copper alloy, especially applied to refining and modification of red impure copper and white impure copper. The Cu-RE interalloy refining agent is prepared by a vacuum melting method, wherein, rare earth content is up to 30-65%; and only 2-6g / kg refining agent is added while the Cu-RE interalloy refining agent is applied to remelting refining of scrap copper. The Cu-RE refining agent enhances slagging and deslagging of copper fused mass, reduces deleterious substances in the fused mass of the scrap copper, and improves texture and performance of the copper and the copper alloy, therefore, products prepared from the red impure copper as a raw material reach or exceed the quality of the products prepared from electrolytic copper as a raw material, and the white copper process waste can be used for directly producing high-quality products after remelting refined, thus promoting recycle and reutilization of the scrap copper, saving energy and resource, reducing environmental pollution and generating significant economic and social benefits.

Owner:CENT SOUTH UNIV

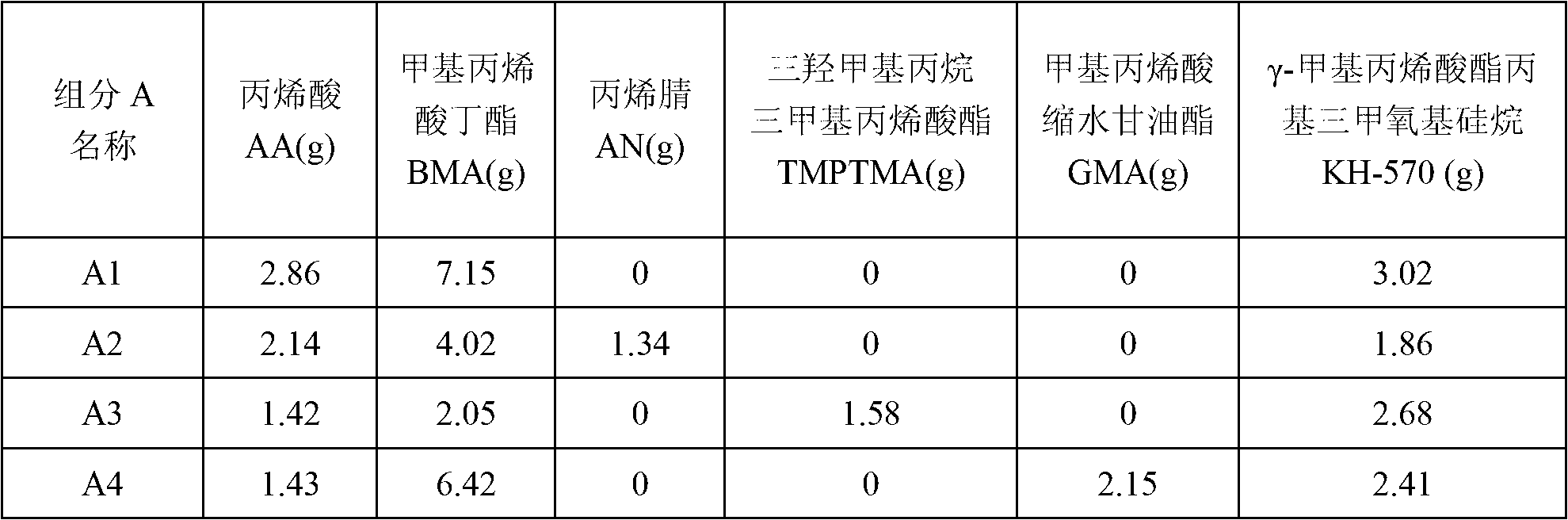

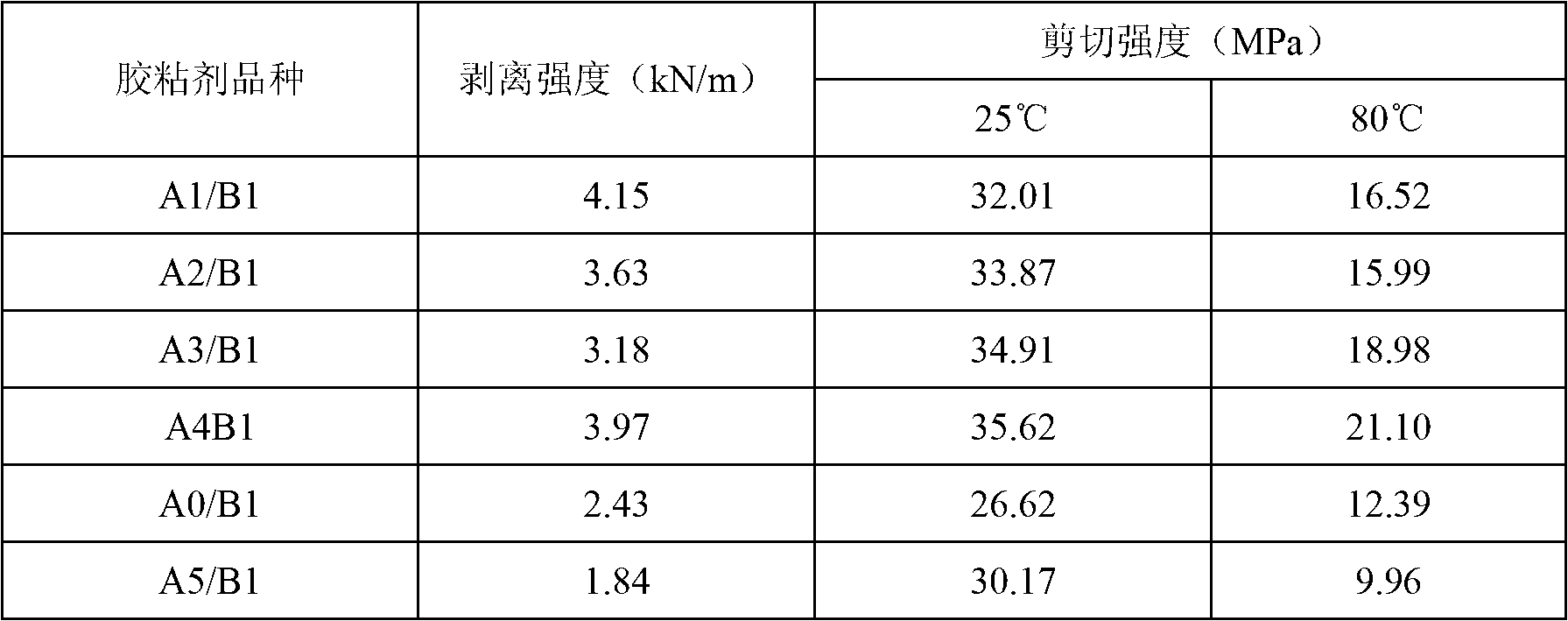

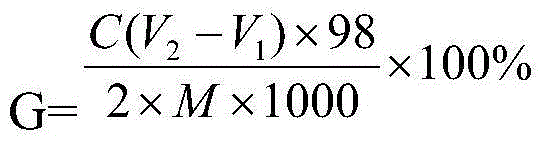

Preparation method of nano silicon dioxide/polyacrylate modified epoxy resin adhesive

InactiveCN102703009AHigh peel strengthGood adhesionNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyNanoparticle

The invention relates to a preparation method of an epoxy resin adhesive, particularly a preparation method of a nano silicon dioxide / polyacrylate modified epoxy resin adhesive. The invention solves the problems of unsatisfactory high-temperature properties and peel strength in the existing nano silicon dioxide modified epoxy resin adhesive. The method comprises the following steps: 1. preparing polyacrylate-modified nano silicon dioxide compound particles; 2. preparing the nano silicon dioxide / polyacrylate modified epoxy resin; and 3. preparing the nano silicon dioxide / polyacrylate modified epoxy resin adhesive. The invention has the characteristics of smaller addition amount of modified nanoparticles, obvious toughening effect and high high-temperature strength; and the peel strength and the shear strength of the nano silicon dioxide / polyacrylate modified epoxy resin adhesive are obviously enhanced.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

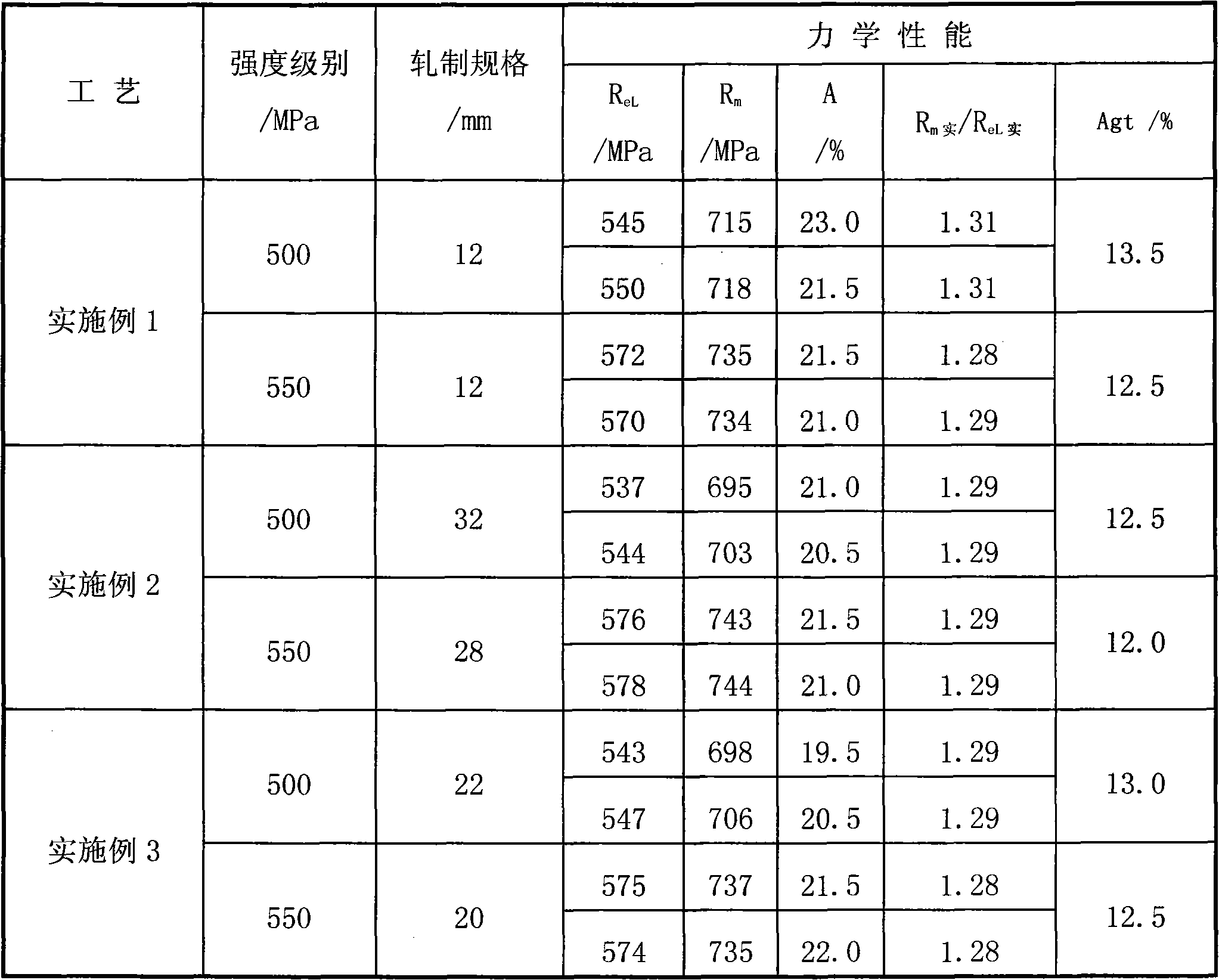

Nitrogenous niobium vanadium microalloying 500MPa and 550MPa high-intensity aseismic reinforcing steel bar and melting method

ActiveCN102071357AIncrease supersaturationIncrease the number ofManufacturing convertersNiobiumAdditive ingredient

The invention provides a nitrogenous niobium vanadium microalloying 500MPa and 550MPa high-intensity aseismic reinforcing steel bar and a melting method. The high-intensity aseismic reinforcing steel bar comprises the following ingredients in percentage by mass: 0.20 to 0.25 wt percent of C, 0.35 to 0.55 wt percent of Si, 1.35 to 1.58 wt percent of Mn, 0.013 to 0.025 wt percent of V, 0.019 to 0.032 wt percent of Nb, 0.065 to 0.085 wt percent of N, at most 0.040 wt percent of S, at most 0.040 wt percent of P and the balance Fe and unavoidable impurities. The reinforcement effect of microalloy V and Nb is sufficiently exerted through increasing the N and decreasing the V and the Nb, the addition of the ferrocolumbium and vanadium nitrogen alloy is reduced, and the addition of noble alloy issaved. Compared with the traditional vanadium nitrogen alloy microalloying 500MPa high-intensity reinforcing steel bar , the nitrogenous niobium vanadium microalloying 500MPa and 550MPa high-intensity aseismic reinforcing steel bar provided by the invention has the advantages that the alloying cost of the process is reduced by 65 to 75 Yuan / t steel over the same periods, the economic benefit is obvious, the process production cost is low, the applicability and the controllability are high, the produced 500MPa and 550MPa high-intensity reinforcing steel bar is widely applicable to highrise andlarge-scale constructional engineering, and the aseismic performance and the welding performance of the reinforcing steel bar are good.

Owner:WUKUN STEEL

Adhesive for casting mold, manufacturing core and method of manufacturing the same

InactiveCN101108407AReduce the amount addedHigh strengthFoundry mouldsFoundry coresPentaerythritolPolyethylene glycol

A cohesion agent for casting module and making core is provided, which is characterized in that: the mass per centage ration of the main chemical component of the cohesion agent is SiO2, 23 to 31, K2O 0.5 to 28, Na2O 1 to 21, modifying agent 0.5 to 21 and excess water. Wherein, the modifying agent chooses one or two in sorbierite, xylitol, mannite, maltitol, glycol, propanediol, glycerol, pentaerythritol, diglycol, propylene glycol, carbowax, PPG and polyglycerol, the adding volume is 0.5 to 21 per cent. When using the cohesion agent to prepare sand mole core, the dosage is little, the old sand can be recycled and the prepared core has good collapse performance.

Owner:SHENYANG HYATON FOUNDRY MATERIAL

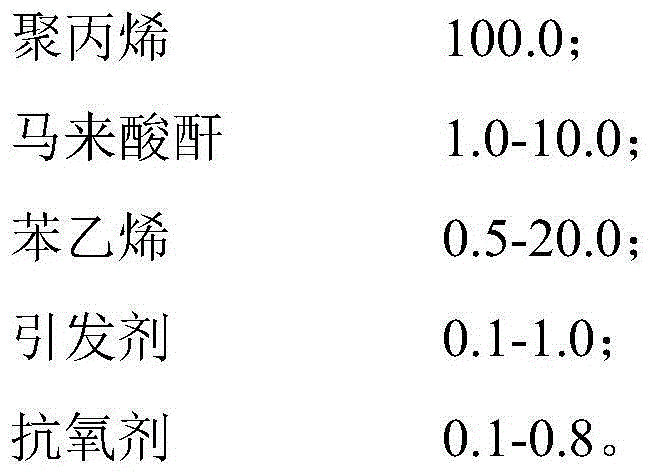

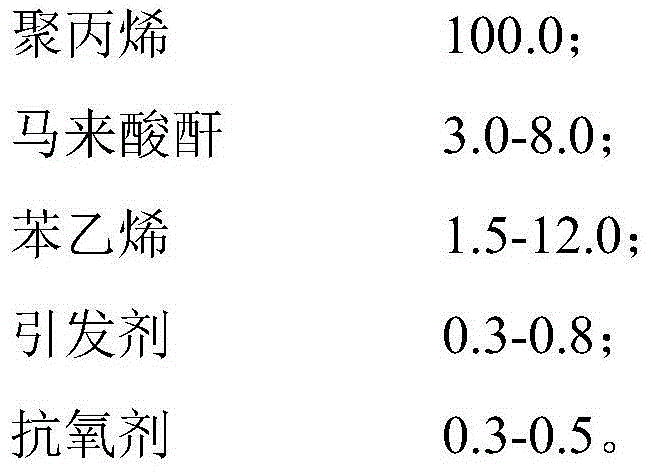

Preparation method of maleic anhydride grafted polypropylene

The invention provides a preparation method of maleic anhydride grafted polypropylene. According to the method, maleic anhydride is grafted to a polypropylene molecular chain through melting free radical grafting reaction. In the melting grafting reaction initiated by a peroxide initiator, the initiator and auxiliary monomer styrene are prepared into a solution, and the solution is continuously metered and input to a plurality of positions of different screw barrel sections of a double-screw extruder. The adopted extruder is the double-screw extruder of which the draw ratio is greater than or equal to 48: 1 or a double-order double-screw extruder. The usage of the maleic anhydride in raw materials is 1.0-10.0 weight percent of that of polypropylene. According to the preparation method, the functional maleic anhydride grafted polypropylene which is high in grafting rate can be obtained, and the molecular weight of the functional maleic anhydride grafted polypropylene is not obviously reduced compared with the molecular weight of the polypropylene in the raw materials.

Owner:EAST CHINA UNIV OF SCI & TECH

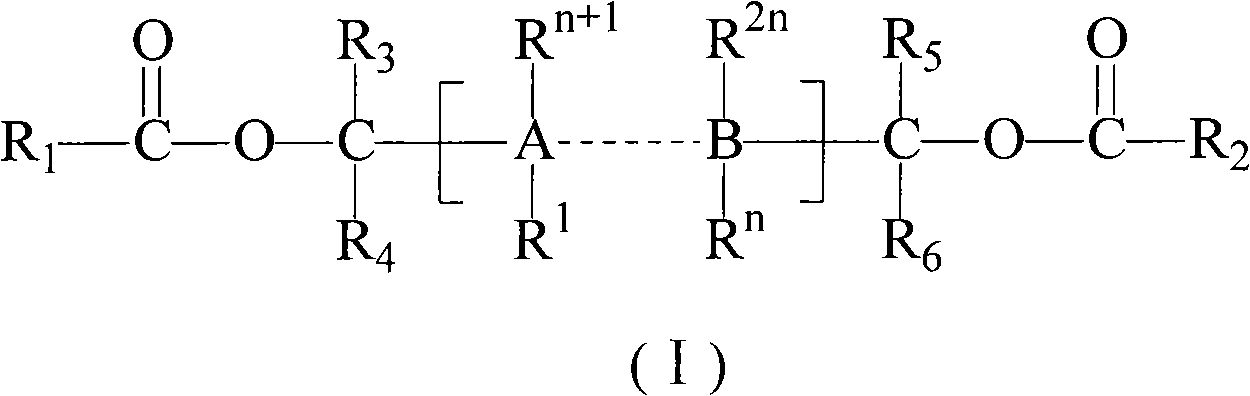

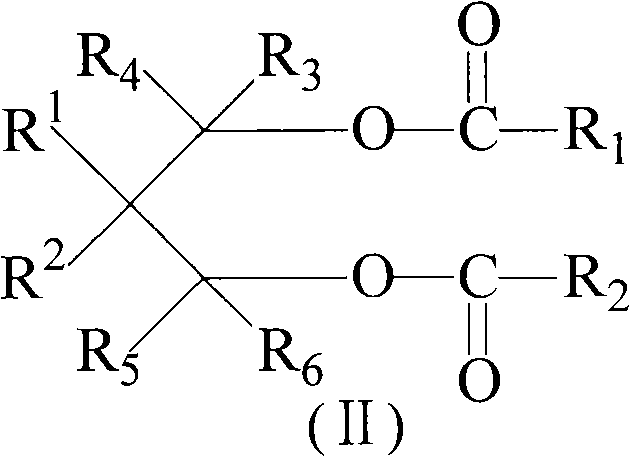

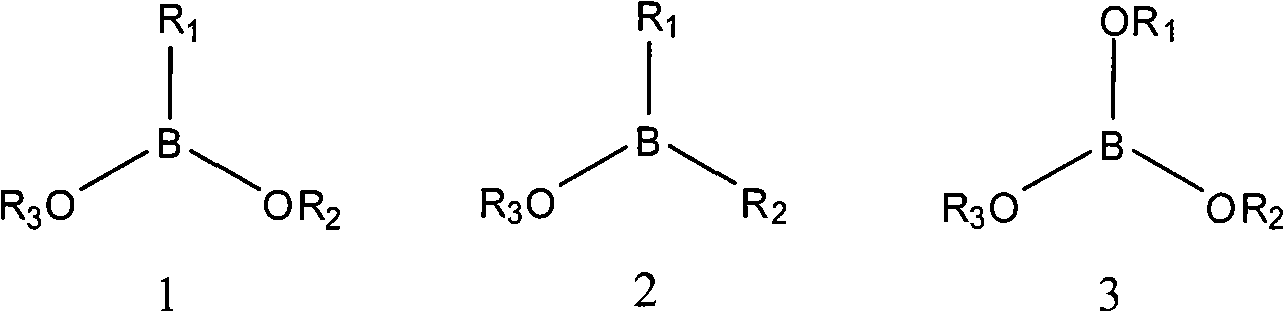

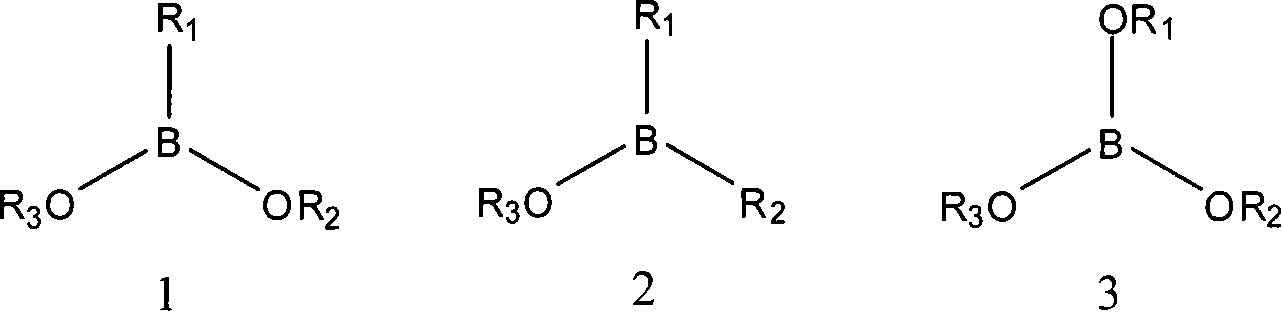

Catalyst component used for ethylene polymerization reaction and catalyst thereof

The invention relates to a catalyst component used for ethylene polymerization reaction and a catalyst thereof. The catalyst component contains magnesium composite, titanium compound, organic alcoholic compound and boron compound. The organic boron compound is selected from at least one of structural formula 1, structural formula 2 and structural formula 3. The catalyst of the invention is quite applicable for a slurry polymerization process of ethylene, and the catalyst has better hydrogen regulation sensitivity and higher catalytic activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

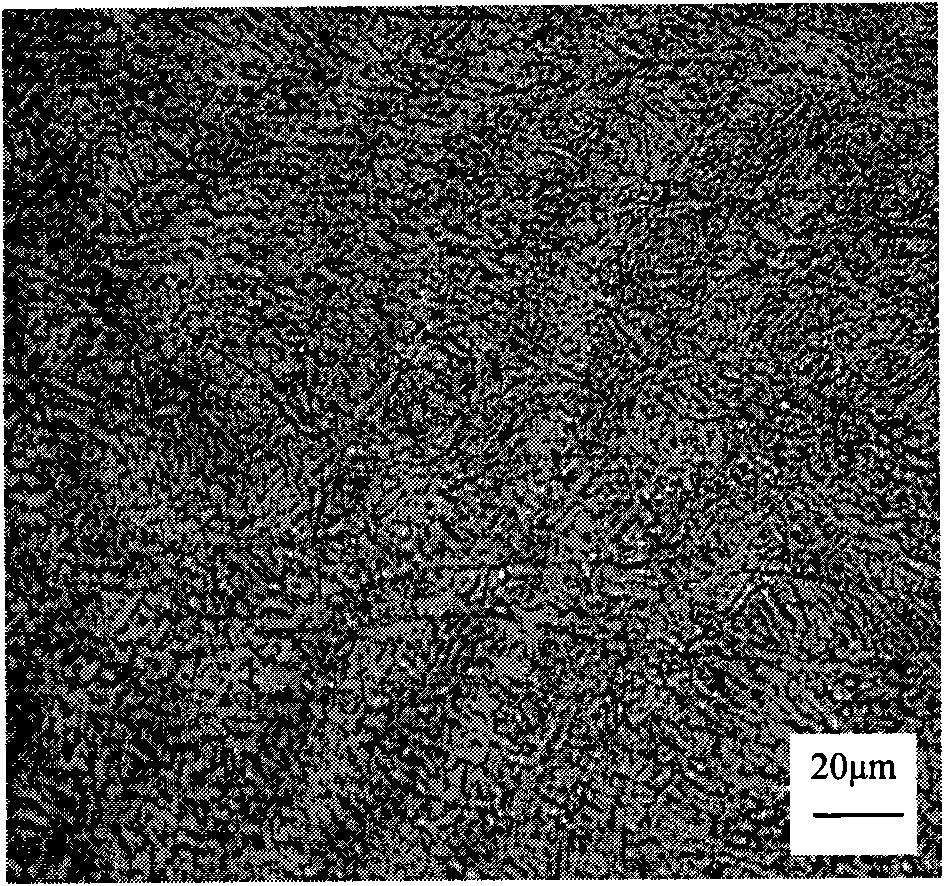

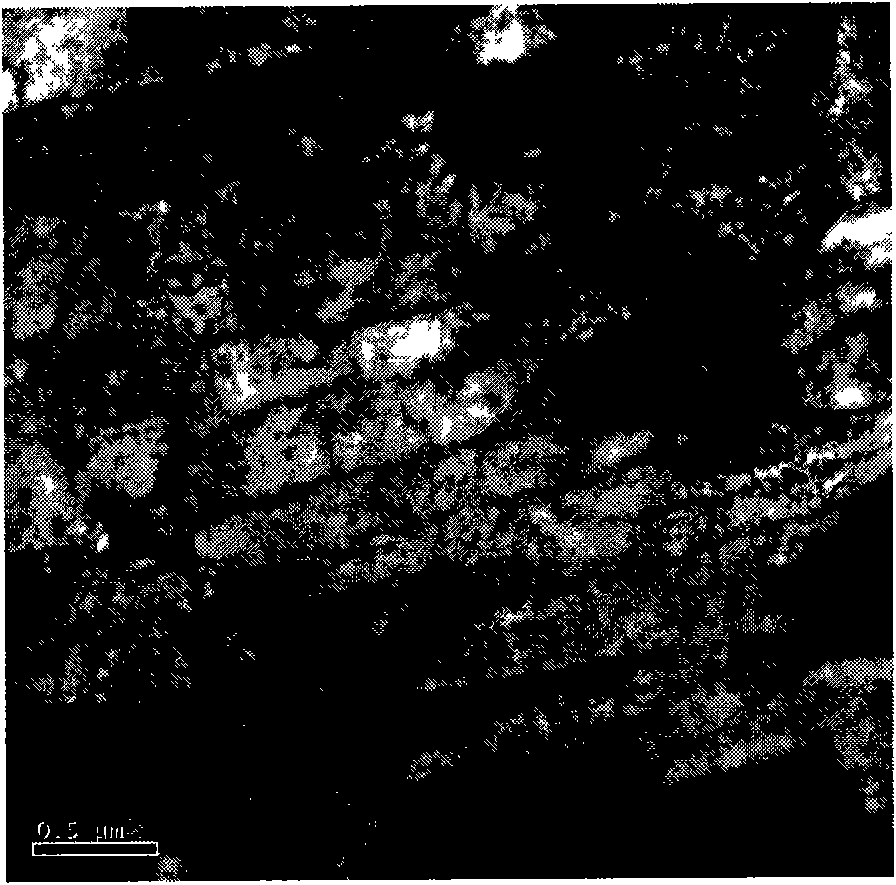

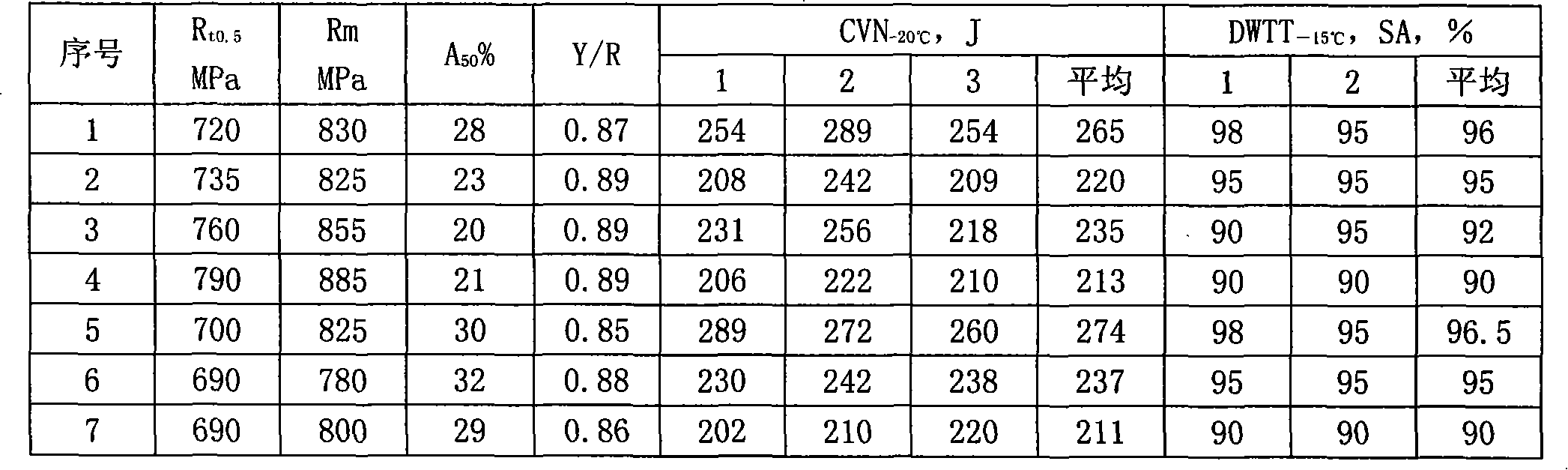

High-strength X100 pipe line steel hot rolling flat plate and method for manufacturing same

InactiveCN101619416AReduce alloy costLow carbon equivalentTemperature control deviceCooling temperatureHigh intensity

The invention discloses a high-strength X100 pipe line steel hot rolling flat plate and a method for manufacturing the same. The steel comprises the following chemical components in percentage by weight: 0.02 to 0.08 percent of C, 0.10 to 0.35 percent of Si, 1.65 to 2.20 percent of Mn, 0.005 to 0.020 percent of P, less than or equal to 0.003 percent of S, 0.04 to 0.11 percent of Nb, 0.008 to 0.030 percent of Ti, 0.02 to 0.045 percent of Als, one or more of less than or equal to 0.60 percent of Ni, less than or equal to 0.30 percent of Mo and less than or equal to 0.30 percent of Cu, and the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps that: the heating temperature of a plate blank is between 1,160 and 1,280 DEG C, the rough rolling temperature is between 1,070 and 1,150 DEG C, the finish rolling temperature is between 830 and 950 DEG C, the finish cooling temperature is between 300 and 550 DEG C, and the controlled cooling speed is between 15 and 30 DEG C / S. By using the method, a complex phase structure mainly comprising the following bainites can be obtained. By adopting the complex phase structure, the yield strength of the pipe line steel hot rolling flat plate reaches 690 to 825MPa, the tensile strength reaches over 780MPa, the impact energy at a temperature of 20 DEG C below zero is more than or equal to 200J, and the shearing area of DWTT at a temperature of 15 DEG C below zero is more than or equal to 90 percent; and the rolling resistance and the straightening resistance are reduced, and the operating rates of the rolling machine and the straightening machine are improved.

Owner:ANGANG STEEL CO LTD

High-boron high-speed steel roller material and smelting process thereof

ActiveCN102994692AHigh yieldEasy to useProcess efficiency improvementElectric furnaceMetallic aluminumSilicon alloy

The invention provides a high-boron high-speed steel roller material and a smelting process thereof. The smelting process of the high-boron high-speed steel roller material comprises the following steps: firstly, adopting Q235 waste steel, ferrotungsten, ferromolybdenum, ferrovanadium, high carbon ferro-chrome, metal copper, metal aluminum, calcium-silicon alloy, rare earth ferrosilicon magnesium alloy, ferrocolumbium, ferroboron, ferrosilicon, vanadium-nitrogen alloy, zirconium ferrosilicon and ferrotitanium as materials for smelting low-alloy high-speed molten steel in an electric furnace; then, adding the ferrovanadium and part of ferroboron to carry out alloying in a discharging process; finally, adding part of ferroboron and composite modificator in a casting ladle, adding the vanadium-nitrogen alloy, the zirconium ferrosilicon, the ferrosilicon and part of ferroboron in the casting process. The obtained casting piece has a little alloy elements, excellent abrasive resistance and good thermal fatigue resistance. When the high-boron high-speed steel roller material is used as a roller, the service life is prolonged by more than six times relative to a high nickel-chrome infinite cast-iron roller, and prolonged by 20% relative to a high-vanadium high-speed steel roller. Moreover, the roller is safe to use and reliable.

Owner:YUNNAN HEAVY EQUIP MFG GRP

Fe-Cr-B cast abrasion-resistant alloy and manufacturing method thereof

The invention discloses Fe-Cr-B cast abrasion-resistant alloy and a manufacturing method thereof, the alloy comprises the following chemical compositions by mass percent: 0.22-0.45% of C, 12.0-18.0% of Cr, 0-8-1.5% of Si, 0-6-1.5% of Mn, 0-9-1.2% of B, 0.30-0.45% of Ni, 0.02-0.04% of Mg, 0.03-0.05% of Ce, 0.04-0.08% of Ti, 0.008-0.015% of N, 0.06-0.09% of Zn, less than 0.04% of S, less than 0.04% of P and the balance of Fe. After melting, casting and hot-processing, the hardness and toughness of the Fe-Cr-B cast abrasion-resistant alloy can be adjusted in a wide range so as to meet the requirements of different abrasion working conditions. The invention uses low-cost chromium and boron as the main alloying elements, does not contain expensive alloying elements such as tungsten, molybdenum, vanadium, niobium and the like, has the characteristics of high hardness, good toughness and the like, and has low cost, and has good economic benefit when being popularized.

Owner:BEIJING UNIV OF TECH

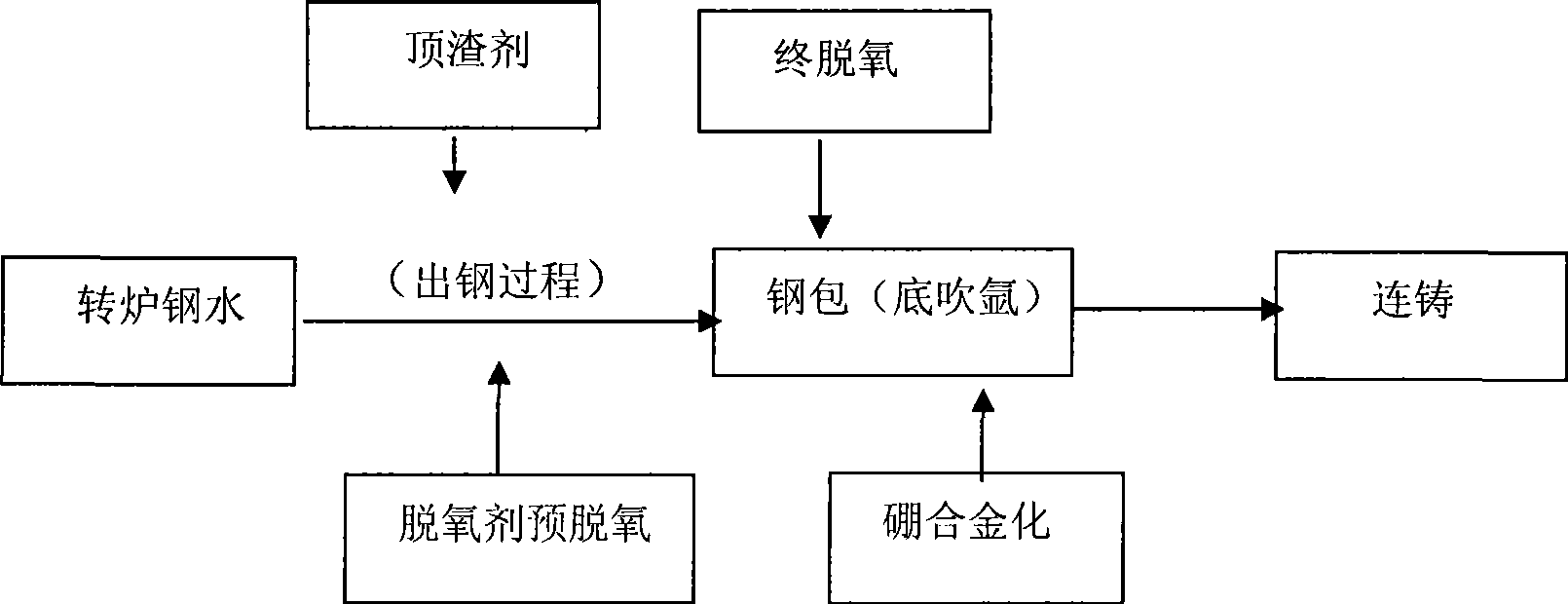

Method for producing boron steel by converter

InactiveCN101503746AAvoid stickinessAvoid water-prone mouthsManufacturing convertersAlloyMolten steel

The invention provides a method for producing boron steel in a converter, which is characterized in that argon subaeration is performed on a ladle in the whole process; a deoxidizer and alloys required by steel grades are begun to be added into the ladle for preliminary deoxidation and alloying under the condition of 1 / 4 tapping, and simultaneously a desulfurizer is added for desulfurization treatment; aluminum is added into the ladle in an argon blowing station for final deoxidation, and ferroboron is added into the ladle when the [O] is controlled to be between 0.0020 and 0.0040 percent; and the ferroboron is coated by an aluminum sheet and added into molten steel. The method has the advantages that: firstly, the method saves the refining procedure of an LF furnace and a vacuum furnace and has low production cost, short production procedure and high production efficiency; secondly, the pourability of the molten steel is good; thirdly, no requirement is put forward as for acid-soluble aluminum in the steel, so that the method solves the problems of pastiness of the molten steel, easy bonding of water gaps, reduction of the steel quality and the like caused by the increase of Al2O3 inclusion due to high acid-soluble aluminum; and fourthly, the recovery rate of boron can reach 60 to 75 percent and the wave range of the yield is small. Moreover, the method has good application prospect.

Owner:新余钢铁股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com