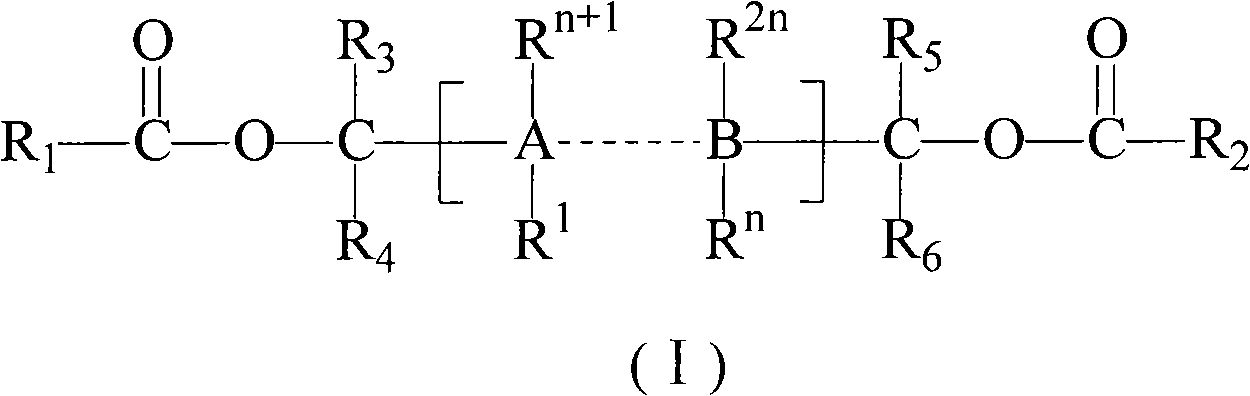

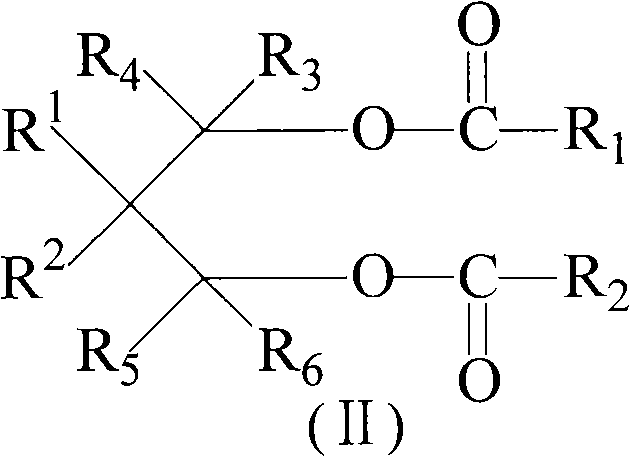

Preparation method of catalyst component for polymerization reaction of olefins and catalyst thereof

A technology for olefin polymerization and catalysts, which is applied in the preparation method of catalyst components and the field of catalysts. It can solve the problems of many polymer fine powders, difficult adjustment of particle size, and difficult control of catalyst particle shape, so as to achieve less fine powder content, Excellent stereospecificity, the effect of reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

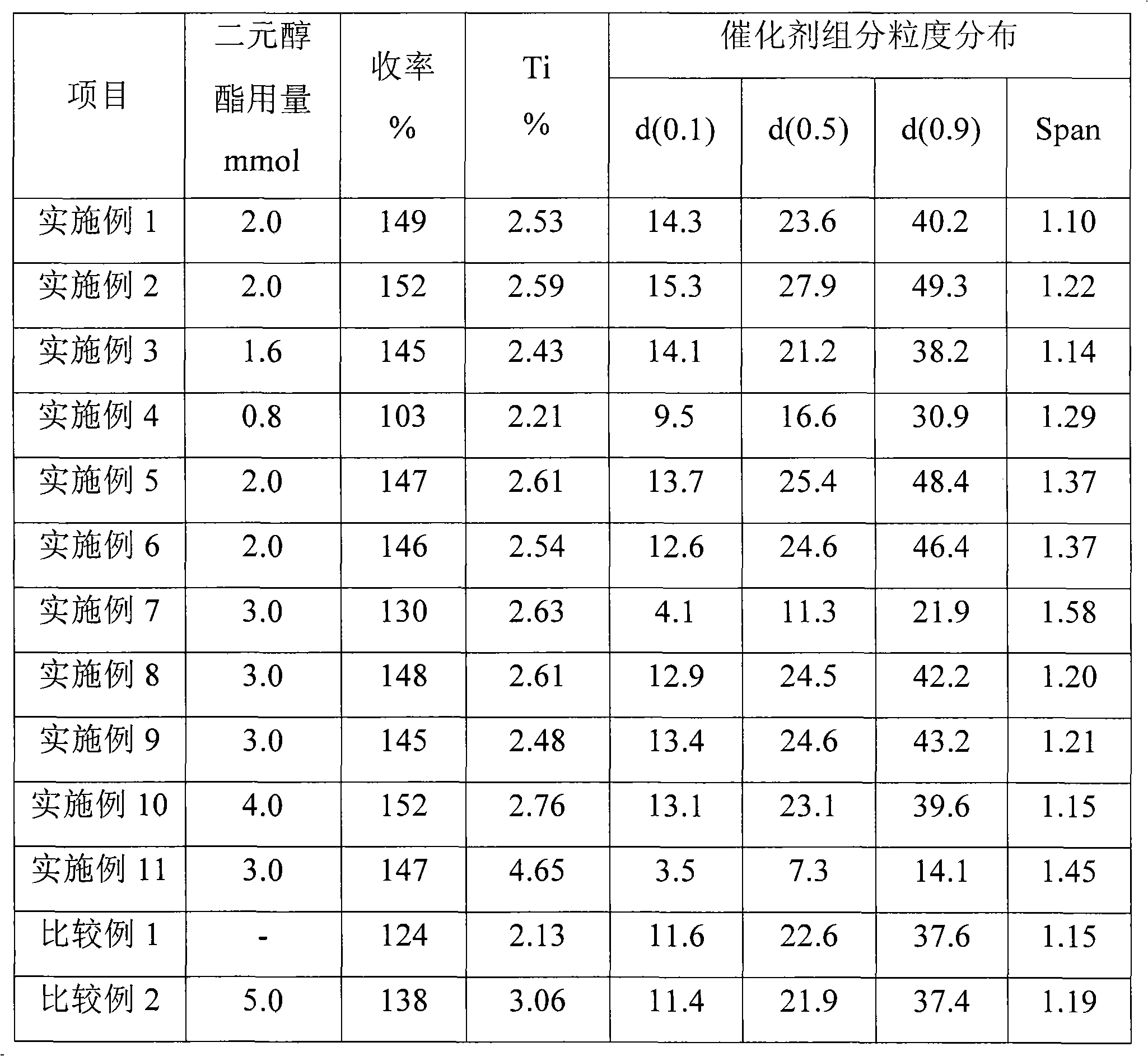

Embodiment 1

[0046] In the reaction kettle that has been repeatedly replaced by high-purity nitrogen, add 0.05 moles of anhydrous magnesium chloride, 0.75 moles of toluene, 0.1 moles of epichlorohydrin, and 0.033 moles of tributyl phosphate in sequence. , reacted for 2 hours, lowered the temperature to -28°C, added 0.51 moles of titanium tetrachloride dropwise, then added 2.0 mmoles of 4-ethyl-3,5 heptanediol dibenzoate diluted with 0.1 moles of toluene, and continued the reaction for a Hours, the temperature was gradually raised to 85°C, and solid particles were precipitated during the heating process. Add 4.0 mmoles of dibutyl phthalate to 85°C, keep the temperature for one hour, filter the mother liquor, wash and filter the liquid with inert diluent toluene several times, then add 0.44 moles of titanium tetrachloride and 0.7 moles of toluene at 110°C Keep the temperature for 2 hours, filter and repeat the treatment twice, then wash with hexane for 5 times, and vacuum dry the remaining s...

Embodiment 2

[0048] Same as Example 1, only 2.0 mmoles of 4-ethyl-3,5-heptanediol dibenzoate diluted with 0.1 moles of toluene was added, and 2.0 mmoles of 4-ethyl-3 dibenzoate diluted with 0.2 moles of toluene was added instead , 5 Heptanediol Dibenzoate.

Embodiment 3

[0050] Same as Example 1, only 2.0 mmoles of 4-ethyl-3,5-heptanediol dibenzoate diluted with 0.1 moles of toluene was added, and 1.6 mmoles of 4-ethyl-3 dibenzoate diluted with 0.1 moles of toluene was added instead , 5 Heptanediol Dibenzoate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com