Patents

Literature

575 results about "Warming process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The formation of condensation is a warming process because it releases energy into the atmosphere that causes its temperature to increase. When condensations forms, water vapor condenses from a gas into a liquid.

Calcification vanadium slag sintering method

InactiveCN101161831AEasy temperature controlShorten roasting timeProcess efficiency improvementSlagCalcification

The invention discloses a method of vanadium slag direct entering high temperature roasting furnace calcify roasting, that is, high calcium vanadium slag or ordinary vanadium slag and lime or limestone are mixed uniformly without the gradual heating up process from low temperature to high temperature, the mixture enters into the roasting furnace of more than 600 DEG C for calcified roasting., the vanadium of the vanadium slag is changed into vanadium acid calcium, vanadium of the roasting clinker is dissolved into the solution under the leaching function of sulphuric acid solution, vanadium oxide and the like vanadium products are further made. The invention needs no gradual heating up process from low temperature to high temperature of the prior sodium treatment roasting, thereby reducing roasting time, improving productivity of unit and reducing production cost.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

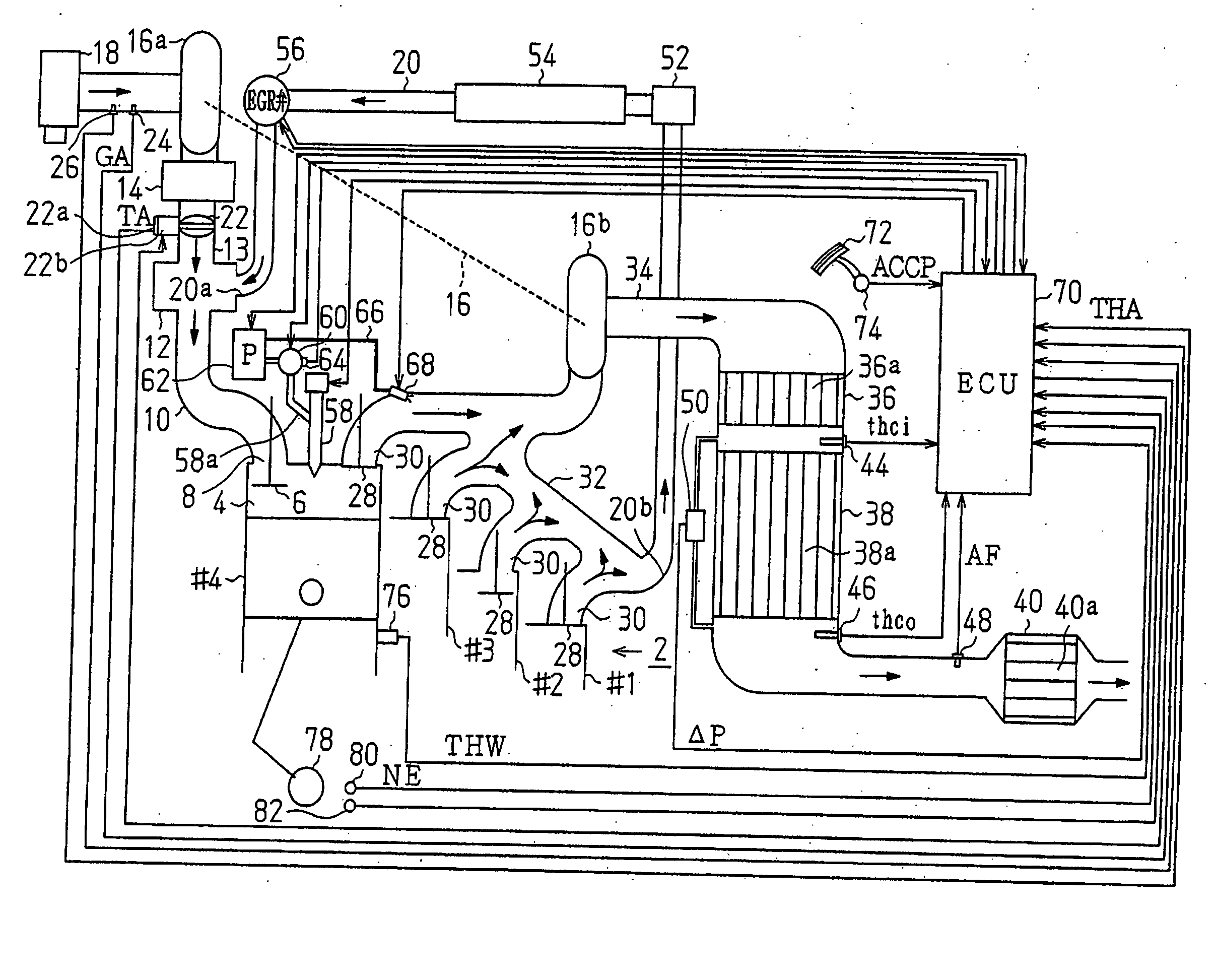

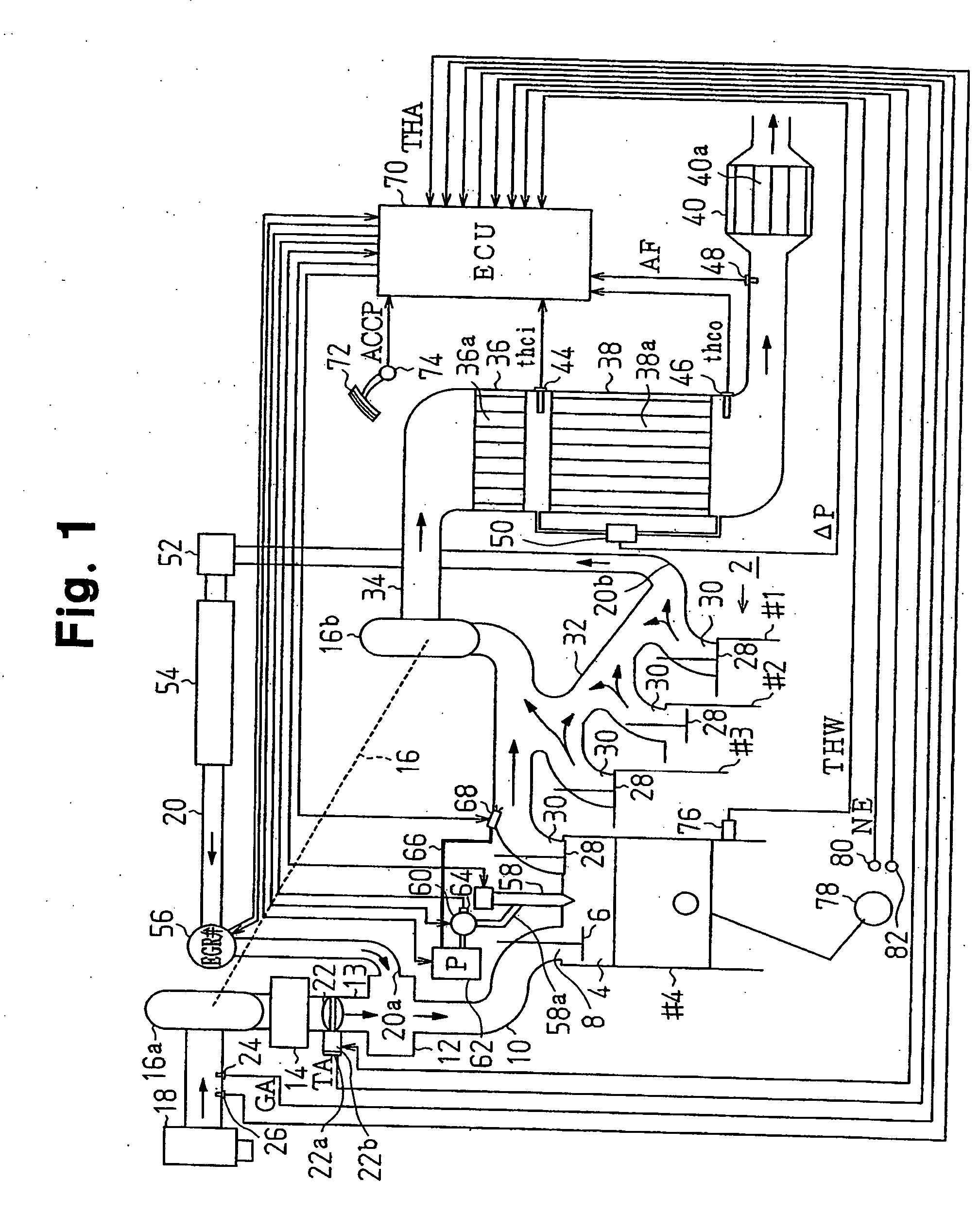

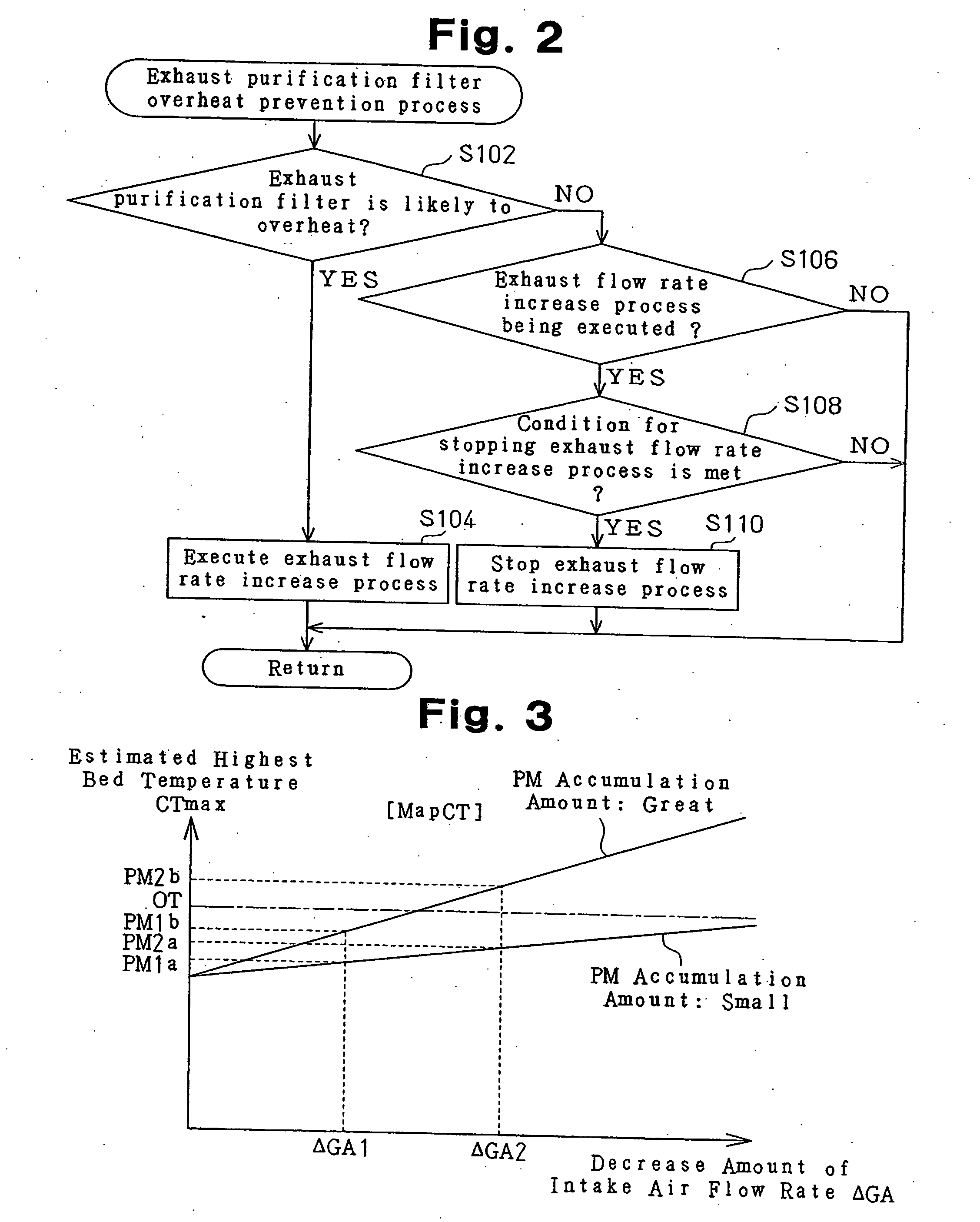

Apparatus and method for preventing overheating of exhaust purification filter

InactiveUS20060016180A1Avoid purificationReduce degradation rateElectrical controlNon-fuel substance addition to fuelParticulatesExhaust fumes

An apparatus for preventing a filter for purifying exhaust gas emitted by a vehicle diesel engine from overheating is provided. The filter filters particulate matter in exhaust gas. Particulate matter that is accumulated in the filter through filtering is burned and purified by executing a temperature increase process in which the filter is heated. The apparatus includes an electronic control unit as overheat prevention means. During the temperature increase process, the overheat prevention means executes an increase process for increasing the flow rate of exhaust gas when the filter is likely to overheat. As a result, the filter is effectively prevented from overheating.

Owner:TOYOTA JIDOSHA KK

Active carbon prepared from waste plant-based biomass, and preparation method thereof

The invention discloses an active carbon prepared from waste plant-based biomass, and a preparation method thereof. The method comprises the following steps: crushing 100 parts of plant-based biomass, uniformly mixing and dipping the crushed plant-based biomass, 0-200 parts of a chemical activator and 1-200 parts of one or more of nitrogen-containing phosphates, and carrying out heating carbon-forming activation to obtain the active carbon; or crushing 100 parts of plant-based biomass, uniformly mixing the crushed plant-based biomass with one or more of 1-200 parts of nitrogen-containing phosphates, forming carbon, mixing and dipping the obtained carbon and 0-200 parts of the chemical activator, and heating and activating to obtain the active carbon; or crushing 100 parts of plant-based biomass, uniformly mixing the crushed plant-based biomass with one or more of 1-200 parts of nitrogen-containing phosphates, forming carbon, and physically activating the obtained carbon in the heating process to obtain the active carbon, wherein the above heating mode comprise temperature programmed mode, uniform heating re or rapid heating, and the stay time is 30min ~ 4h. The method has the advantages of low raw material cost, simple operation and high active carbon yield, and the active carbon has a nitrogen-containing functional group and an excellent adsorption performance.

Owner:SICHUAN UNIV

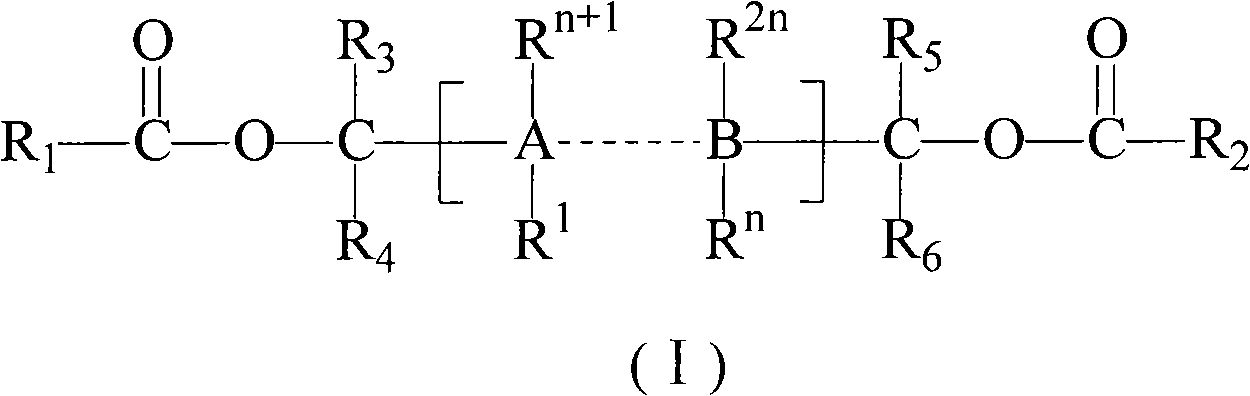

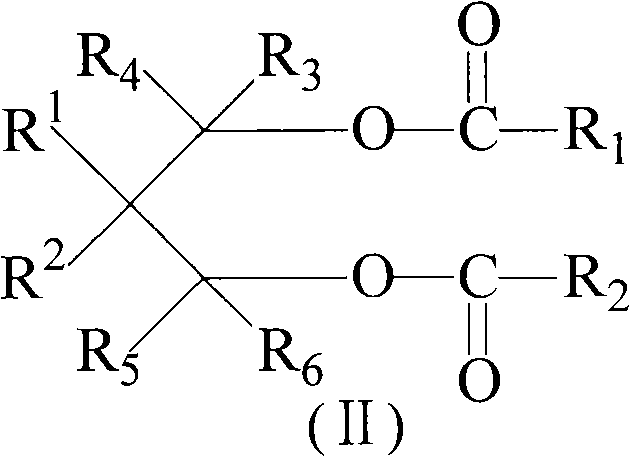

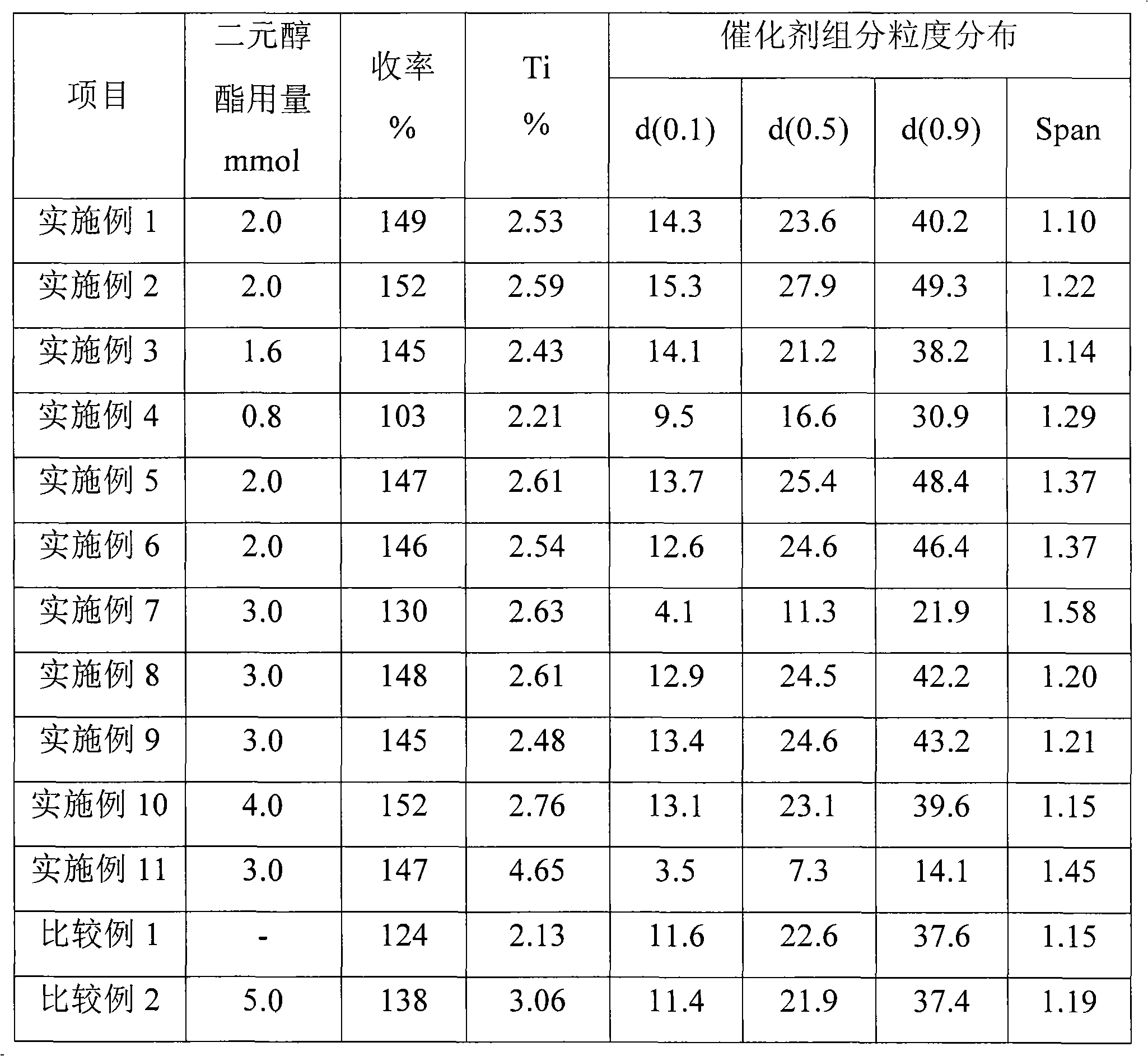

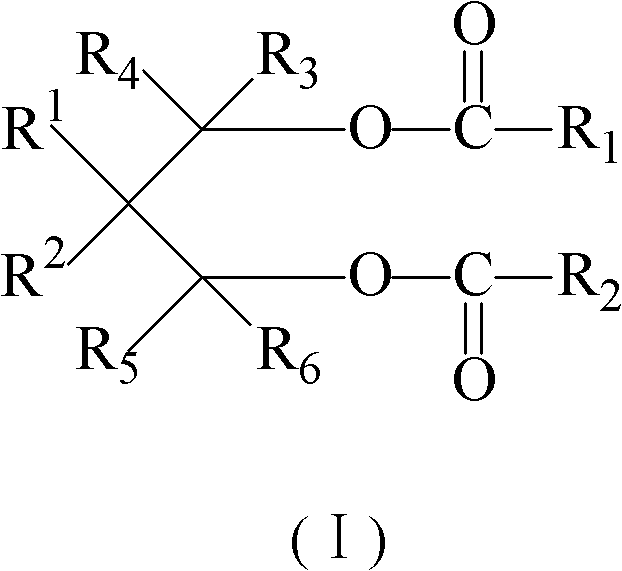

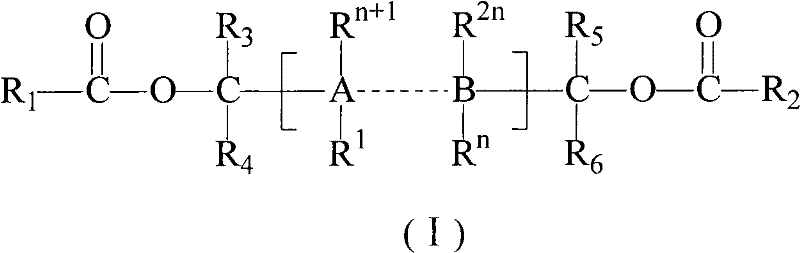

Preparation method of catalyst component for polymerization reaction of olefins and catalyst thereof

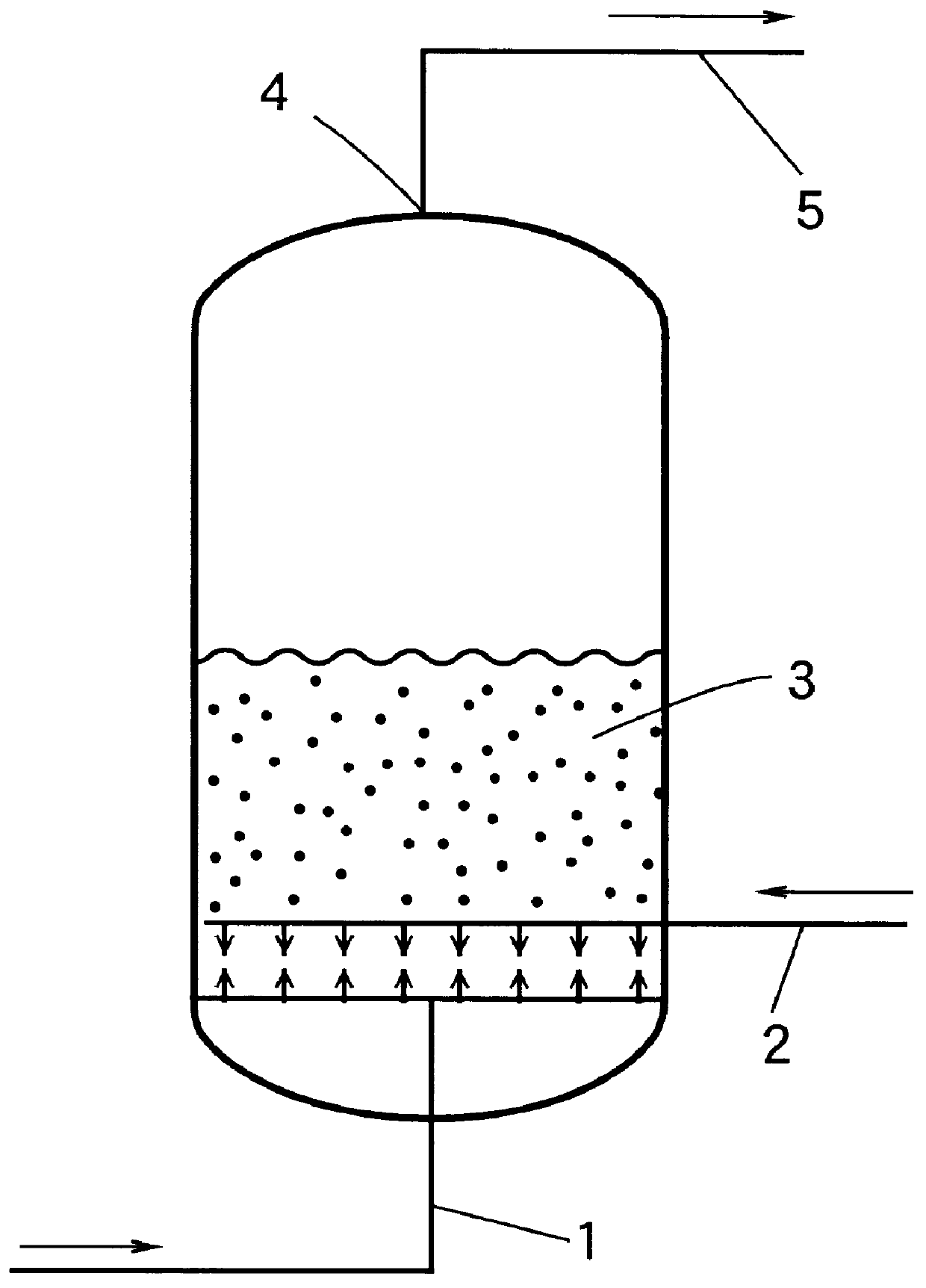

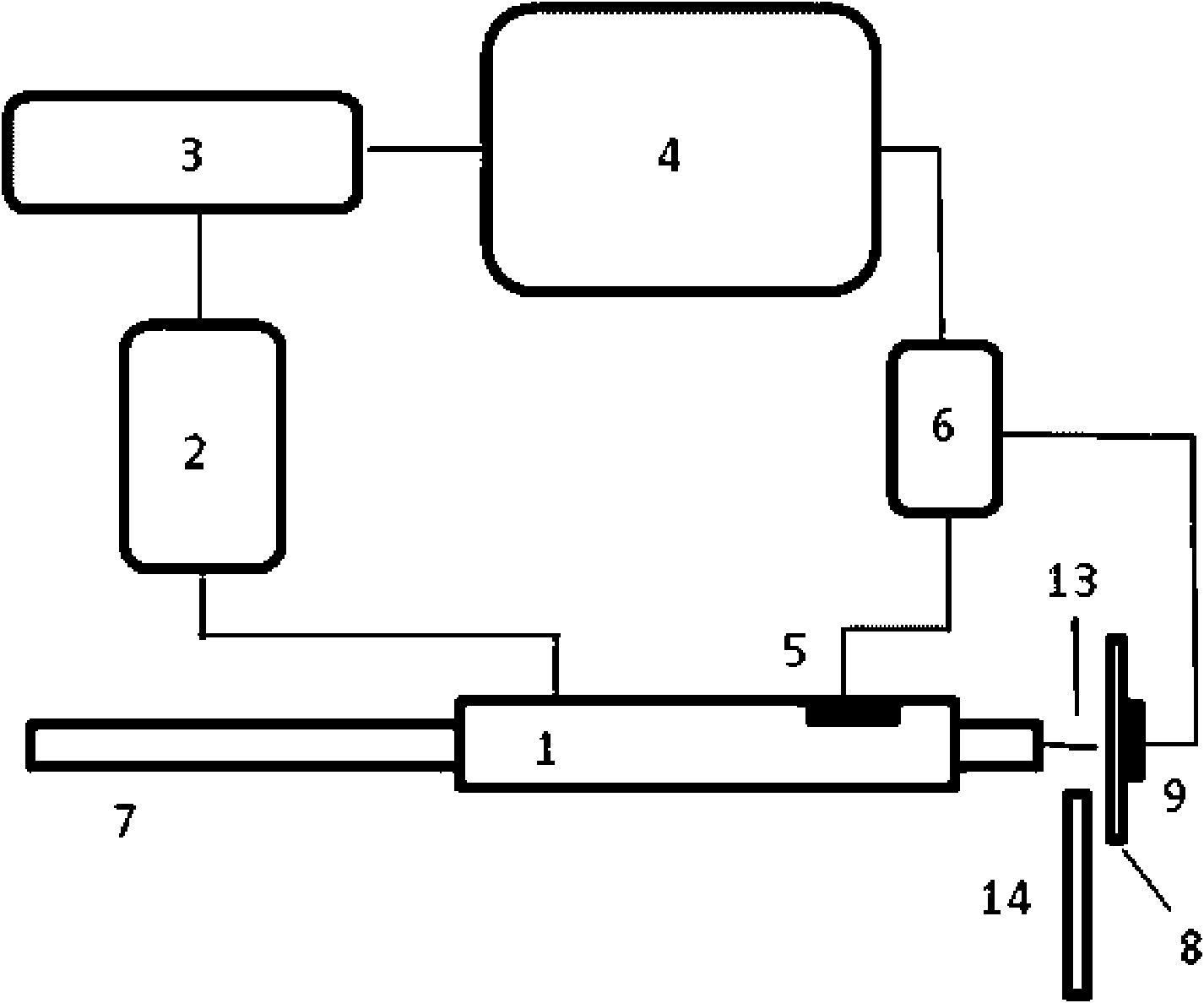

The invention provides a method for preparing a catalyst component for the polymerization reaction of olefins, which comprises the following steps: (1) dissolving magnesium halide in a solvent system comprised of an organic epoxy compound, an organic phosphorus compound and an inert diluent to form uniform solution; (2) mixing a titanium compound with the uniform solution formed by the step (1) and adding a precipitant to form a mixture, or adding the precipitant into the uniform solution formed by the step (1) first and mixing the uniform solution with the titanium compound to form a mixture; and (3) heating the mixture obtained by the step (2), adding any selected electronic donor compound during heating or after heating, and washing the resulting product with an inert diluent to obtain a magnesium / titanium-containing solid material, wherein the precipitant is a glycol ester compound. The catalyst component has high polymerization activity and stereoselectivity and causes little polymer fine powder when used in the polymerization reaction of olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing acrylonitrile or methacrylonitrile from propane or isobutane by ammoxidation

Owner:ASAHI KASEI KK

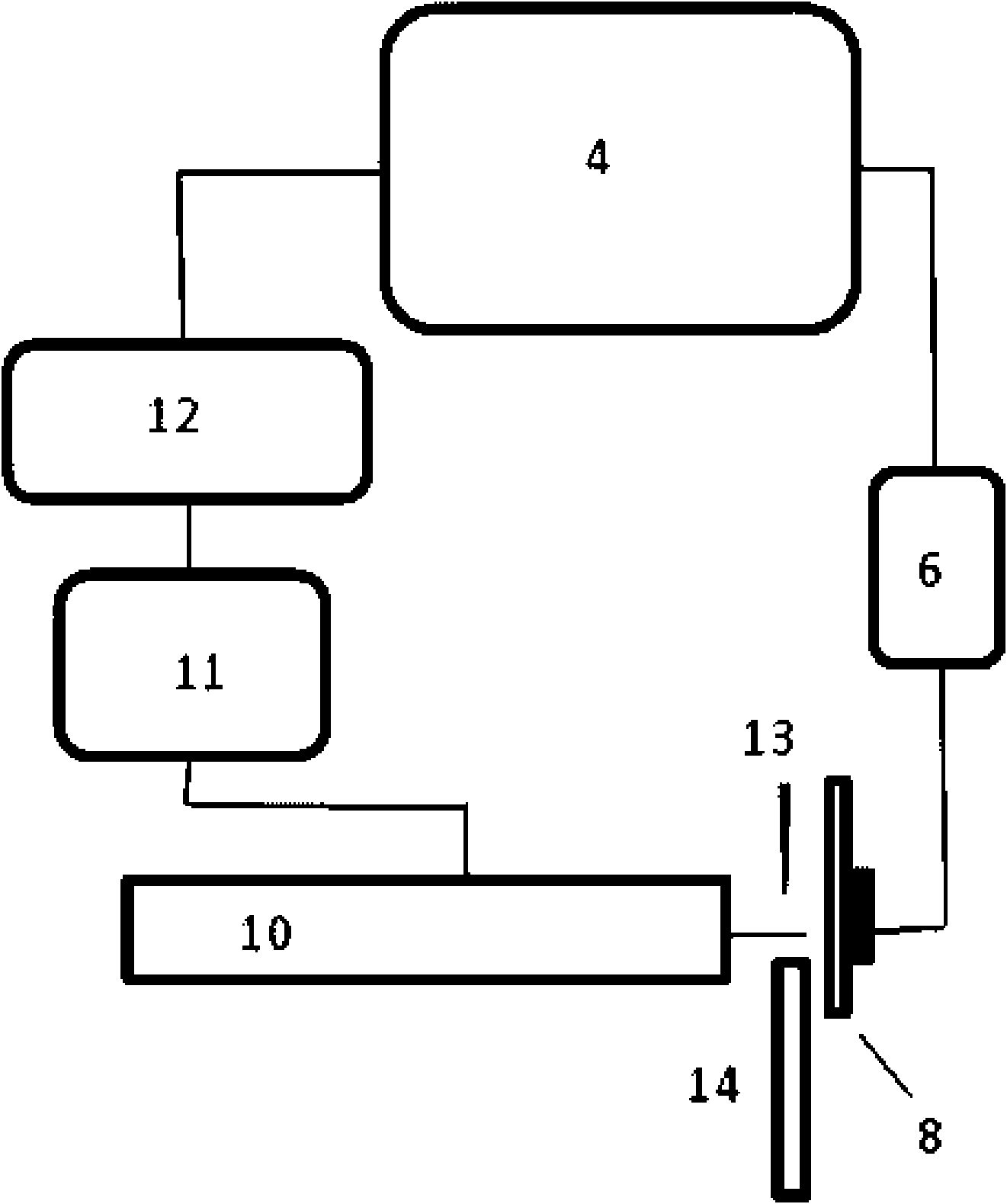

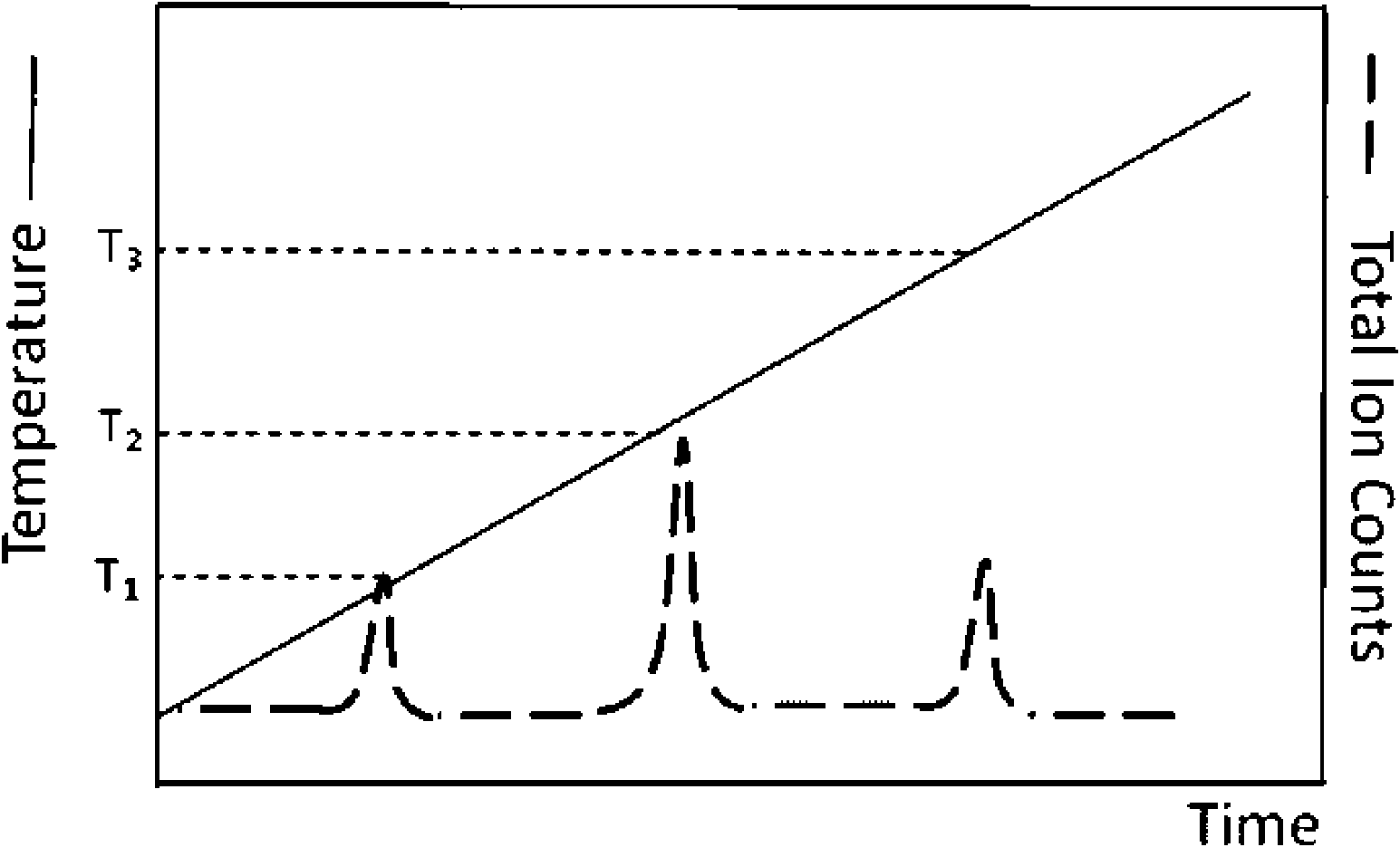

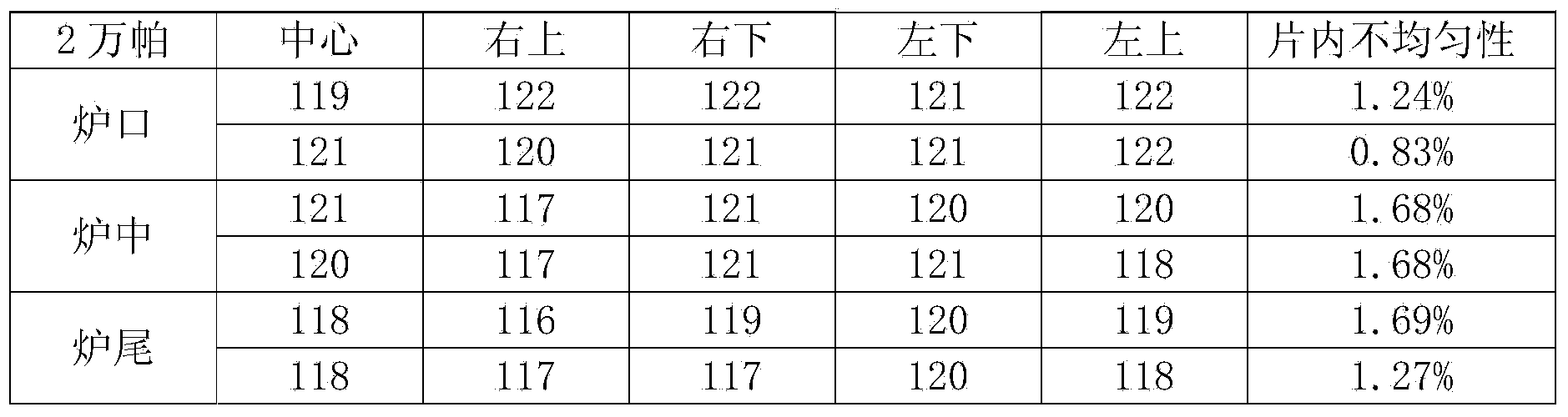

Method and device thereof for desorption ionization

InactiveCN101871914AReduce difficultyImprove detection efficiencySamples introduction/extractionMaterial analysis by electric/magnetic meansBoiling pointData acquisition

The invention relates to a method and a device thereof, which adopt a mode of rising the temperature gradually under normal pressure to carry out desorption ionization in sequence on mixed objects to be tested on the solid surface and carry out continuous and multiple data acquisition in the process of desorption ionization gradually. The invention leads the objects to be tested with different thermal desorption capabilities to be desorbed out of the surface of the solid object to be tested by rising the temperature of at least one part of samples gradually, thus providing a means for pre-separating mixed samples so as to reduce the difficulty for subsequent mass spectrometric detection. Simultaneously, the invention acquires mass spectrometric data for multiple times for objects to be tested with various boiling points in the process of rising temperature so as to lead the objects to be tested with low boiling point not to be consumed completely quickly due to high temperature, thus improving the detection efficiency of the objects to be tested with lower boiling points.

Owner:SHIMADZU RES LAB SHANGHAI

Ultrahigh temperature heat treatment method of wood

The invention provides a wood ultra-high temperature heat treatment method for improving wood dimensional stability and durability. The heating-up process of the treatment method includes: the first heating-up stage, using only water vapor as isolating oxygen protect media; the subsequent second heating-up stage, introducing nitrogen and using the mixture gas of nitrogen and water vapor as isolating oxygen protect media to reject degradation of wood main component cellulose then prevent the decline of wood strength. The products treated by the invention have good dimensional stability and durability, while strength decline is small; Moreover, the needed processing time of the treatment method is short, production efficiency is high and cost is low.

Owner:王益新 +1

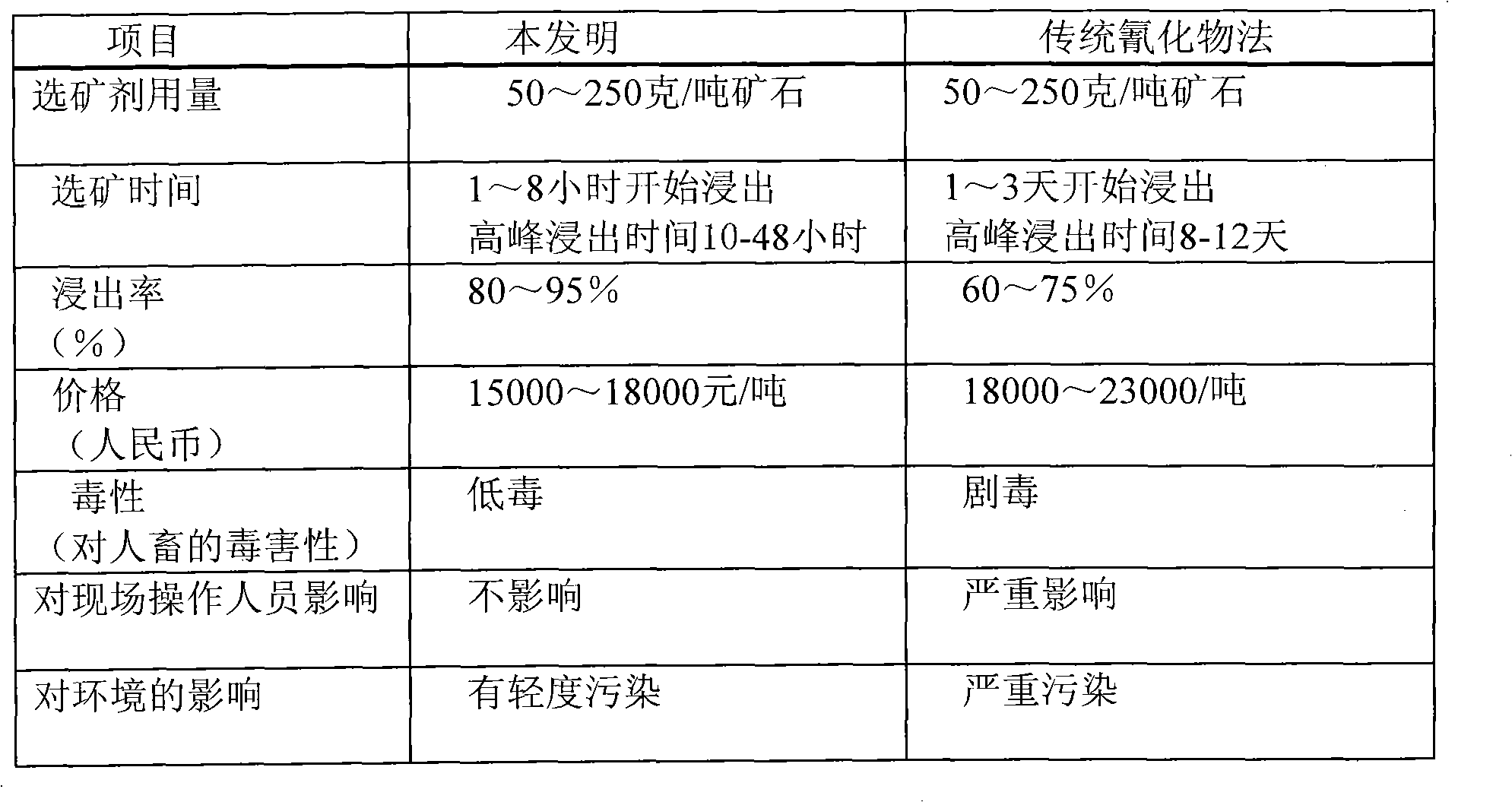

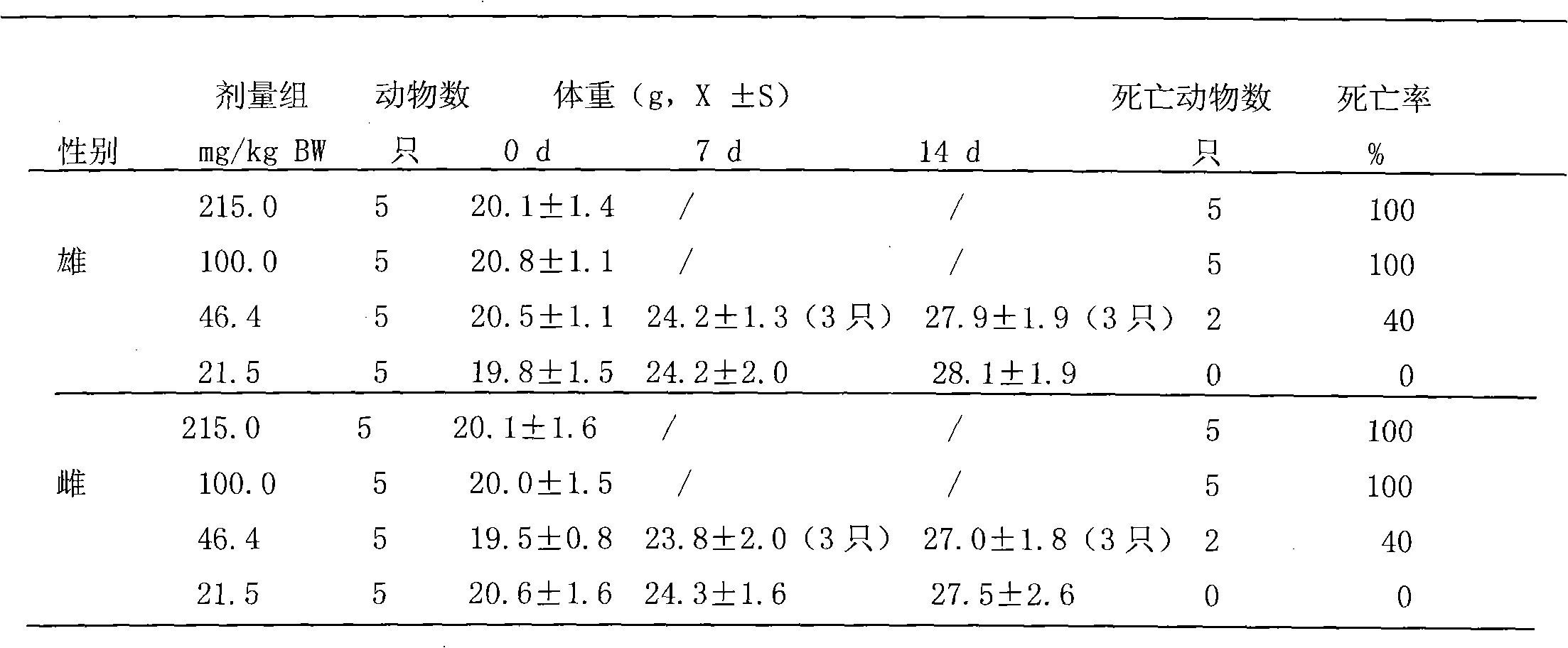

Production and using method of environmentally-friendly noble metal mineral processing reagent

ActiveCN102321807AEasy to produceAccurate ingredientsProcess efficiency improvementMolten stateCopper oxide

The invention discloses the production method of an environmentally-friendly noble metal mineral processing reagent. The method comprises the following steps: putting potassium ferrocyanide and urea after being mixed into a reactor; adding a pH regulator during the slow temperature rise process; heating to the molten state; taking a small amount of molten material detection samples, cooling and dissolving into water; measuring the pH value, enabling the molten material pH value to be 8-14; keeping the molten temperature for 5-60 minutes; and cooling to the normal temperature, thus the environmentally-friendly noble metal mineral processing reagent is obtained. The product obtained from the invention can be widely applied to the production of noble metal mine, such as the soaking, core spray of gold oxide ores, silver oxide ores and copper oxide ores, also can be used in industrial production industries such as electroplating, and used as medicaments for replacing toxic Cymag; and compared with all the other non-toxic or low-toxicity mineral processing reagents, the noble metal mineral processing reagent has the advantages of good effect, stable drug property, environmentally-friendly product, simple production method, low cost and the like.

Owner:广西地生金矿业科技有限公司 +2

Production process of 5-acetyl acetamino benzimidazolone

The invention relates to a technology for producing 5-acetyl amido benzimidazolone. The condensation process is as follows: o-phenylendiamine, carbamide, water and concentrated sulfuric acid are added into a condensation reaction kettle step by step, the pH value is controlled to between 6 and 7, and benzimidazolone is obtained by drying the mixture; the nitration process is as follows: the benzimidazolone, chlorinated benzene and concentrated sulfuric acid are added into a nitration reaction kettle, the chlorinated benzene is reclaimed and purified by reduced pressure distillation and water boiling, and 5-nitryl benzimidazolone is obtained by drying the mixture; the reduction process is as follows: the 5-nitryl benzimidazolone, iron powder, hydrochloric acid and water are added into a reduction reaction kettle, the mixture is subject to suction filtering, cooling, crystallization and drying after the reaction for producing the 5-amino benzimidazolone; and the acetylization process is as follows: the 5- amino benzimidazolone, Diketene, phosphoric acid, caustic soda liquid and water are added into an acetylization kettle, the pressure inside the kettle is discharged in the temperature rising process, and the mixture is subject to suction filtering and drying to produce the 5-acetyl amido benzimidazolone. The process has the total yield coefficient up to 75 percent, purity quotient more than 99 percent and the product quality which meets the international standards of the same products at home and abroad.

Owner:DONGYING TIANZHENG CHEM

Decompression diffusion technology for manufacturing high-square-resistance battery pieces

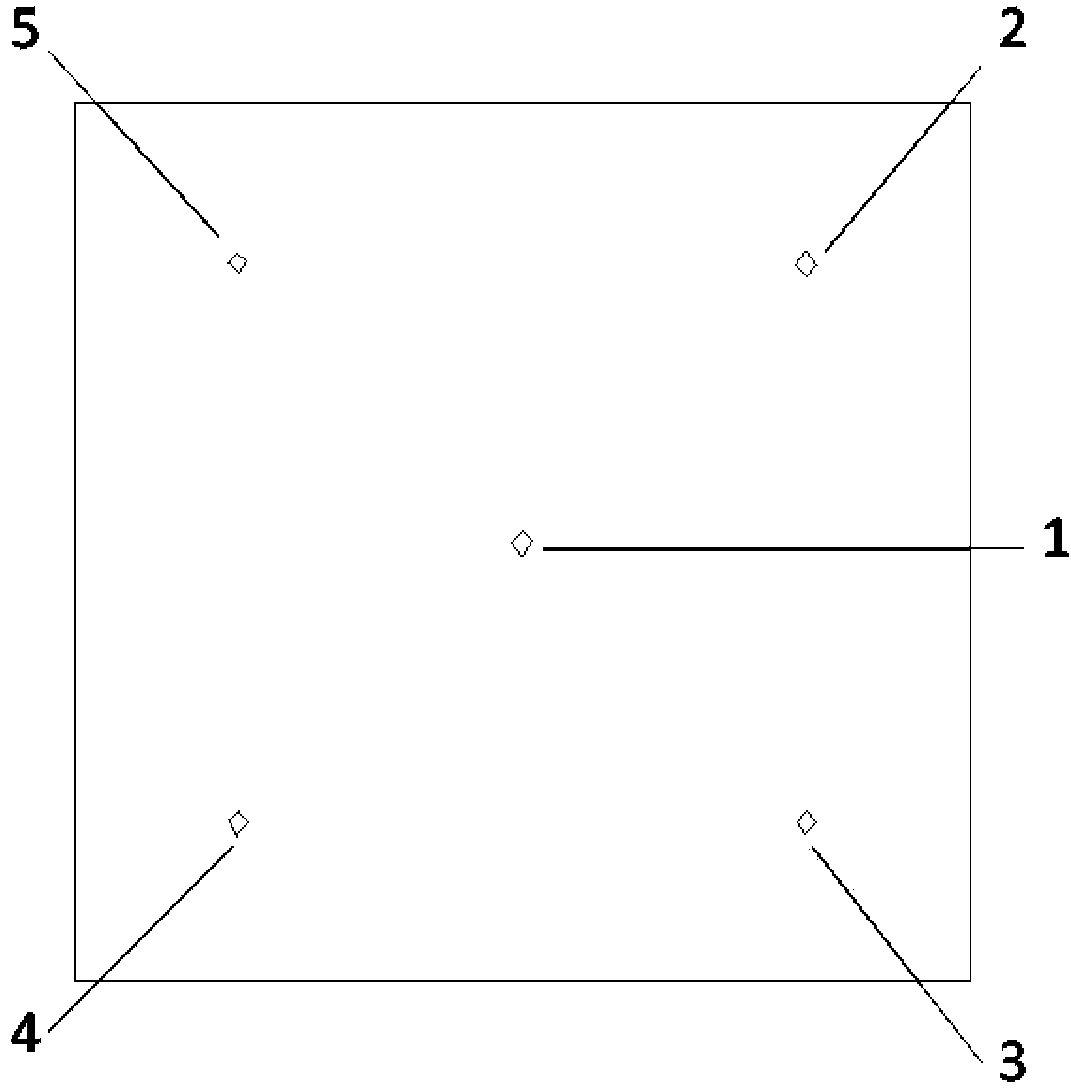

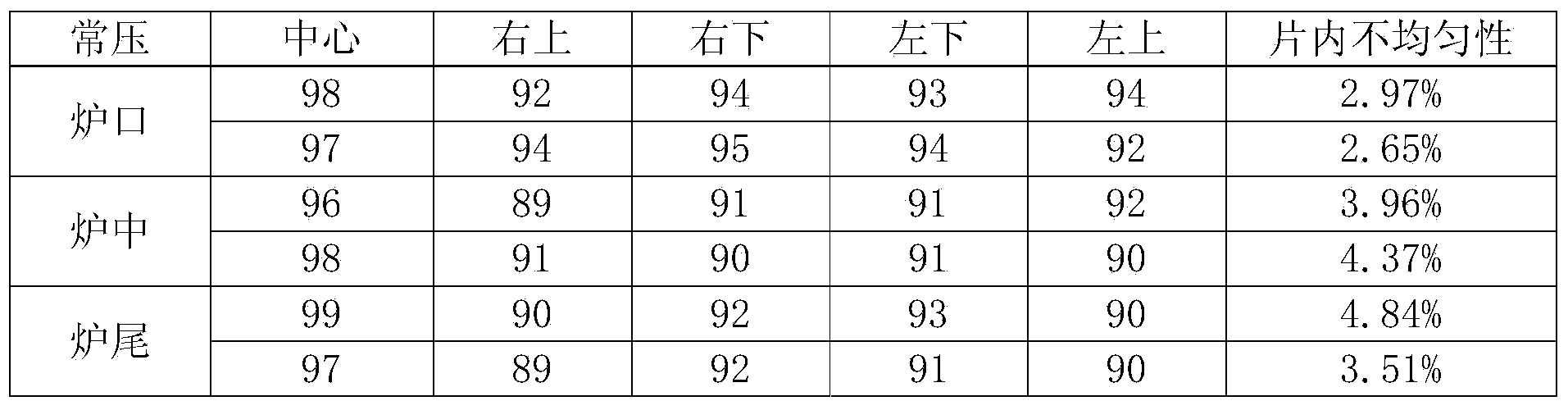

ActiveCN104269459ARelieve pressureReduce unevennessFinal product manufactureSemiconductor/solid-state device manufacturingElectrical resistance and conductancePressure rise

The invention discloses a decompression diffusion technology for manufacturing high-square-resistance battery pieces. The technology comprises a constant-temperature decompression process, a pre-oxidation process, a temperature rise process, a deep diffusion process, a phosphorus propulsion process, a post-oxidation treatment process and a temperature drop and pressure rise process. Compared with a constant-pressure diffusion technology, the variable of pressure in the diffusion process is introduced into the decompression diffusion technology, the pressure in a diffusion furnace tube is reduced, meanwhile temperature, time and airflow are adjusted so that the uniformity of the diffusion square resistance can be better, and the photovoltaic conversion efficiency of the manufactured battery pieces can be higher; besides, the yield in unit time of equipment can be increased, and the usage amount of diffusion phosphorus sources is reduced.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

Temperature control system-based evaporation temperature control method for OLED (Organic Light Emitting Diode) organic layer

InactiveCN103305803AIncrease profitImprove uniformityVacuum evaporation coatingSolid-state devicesTemperature controlControl system

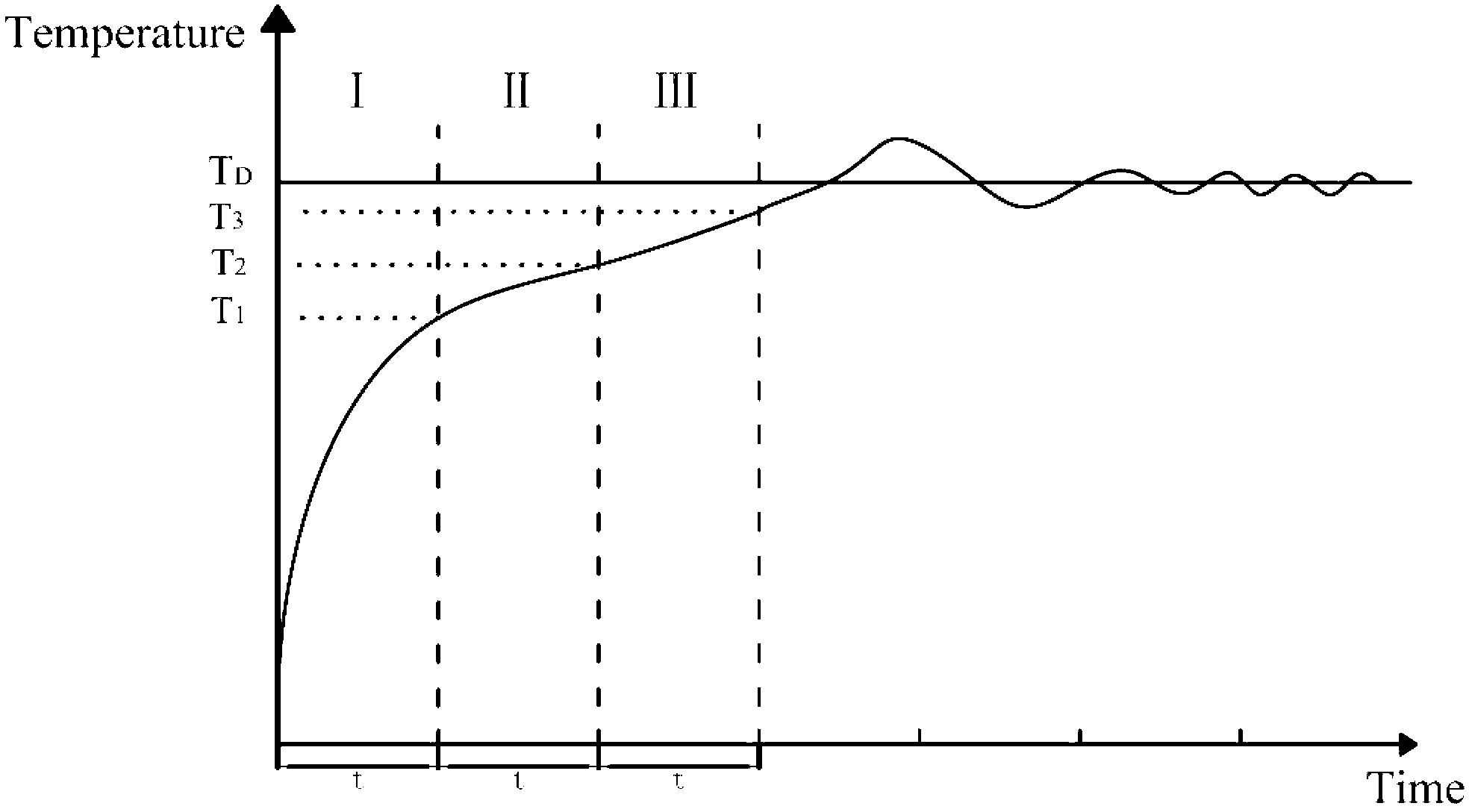

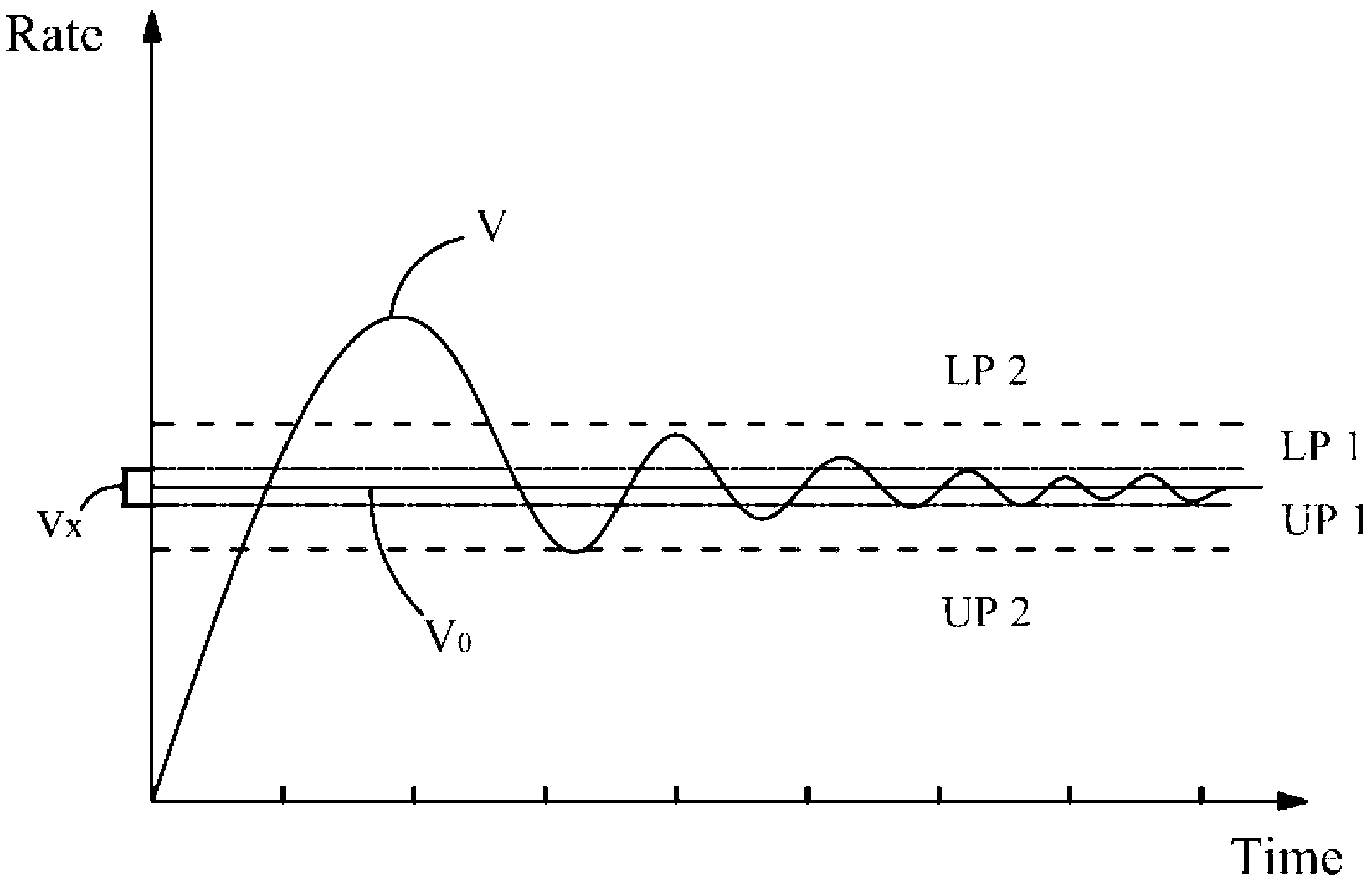

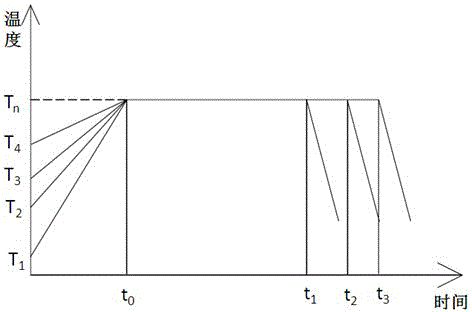

The invention discloses a temperature control system-based evaporation temperature control method for an OLED (Organic Light Emitting Diode) organic layer. The evaporation temperature control method comprises a preheating process and an evaporation process, wherein the preheating process is divided into three temperature-rise processes with temperature gradients; the evaporation process comprises a step of controlling the temperature of an evaporation source by controlling the power of an evaporation power supply on the basis of an actually-measured deposition rate curve. According to the temperature control system-based evaporation temperature control method for the OLED organic layer, the stabilization time of the temperature of the evaporation source and the deposition rate is shortened, the use ratios of the organic materials of the evaporation source are improved, meanwhile, the degradation, the degeneration and the like of the organic materials caused when the temperature rise is too fast or the risen temperature is too high are avoided, and the production cost is lowered; by utilizing a characteristic that the evaporation rate is changed by 20-30% when the evaporation temperature is changed by 1%, the accuracy of the temperature control is improved, the stability of evaporation temperature is maintained, and the uniformity of evaporated films is improved.

Owner:SICHUAN CCO DISPLAY TECH

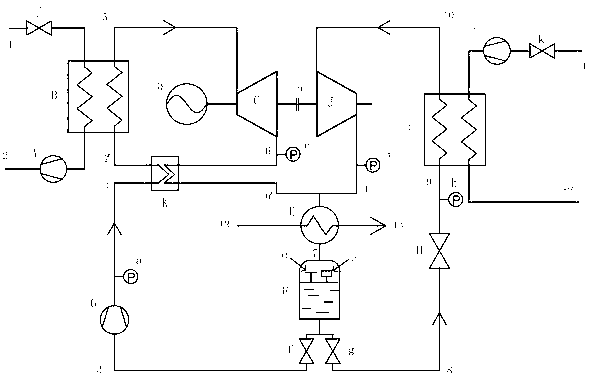

Combined cooling power generation composite system based on supercritical organic Rankine cycle

InactiveCN103195526AGuaranteed uptimeGuaranteed safe operationCompression machines with non-reversible cycleSteam useElectricityOrganic Rankine cycle

The invention provides a combined cooling power generation composite system based on a supercritical organic Rankine cycle and belongs to the field of industrial energy conservation. An expansion machine, a power generator and a steam compressing cold cycling compressor of the Rankine cycle are connected coaxially, same organic working medium is used to be simultaneously cooled in a condenser, and a steam compressing refrigerating cycle is coupled effectively on the basis of basic organic Rankine cycle. In addition, supercritical pressure is used to allow heat rising of organic working medium in a heat absorber to be well matched with temperature changing curve of a heat source, system irreversible loss is further lowered, and waste heat recycling rate is improved. Industrial smoke water heat or other water heat sources are used as driving force, combined cooling power generation is performed by taking refrigerating as priority, refrigerating is not performed by using smoke waste heat for power generation and using power for refrigerating, and accordingly loss caused by energy conversion is reduced. Cooling amount and power output amount can be flexibly adjusted according to cooling amount requirements.

Owner:CHONGQING UNIV

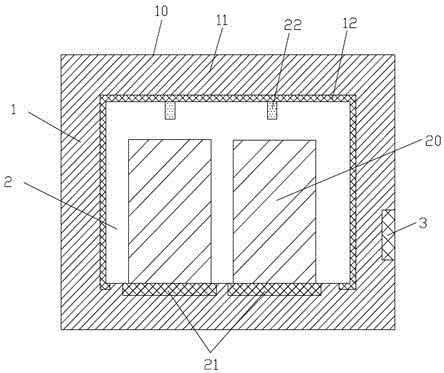

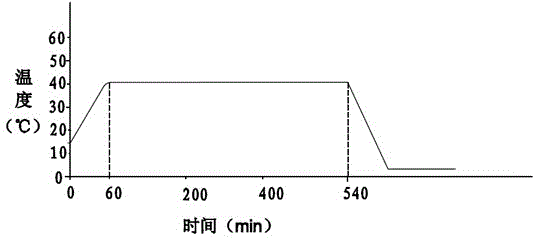

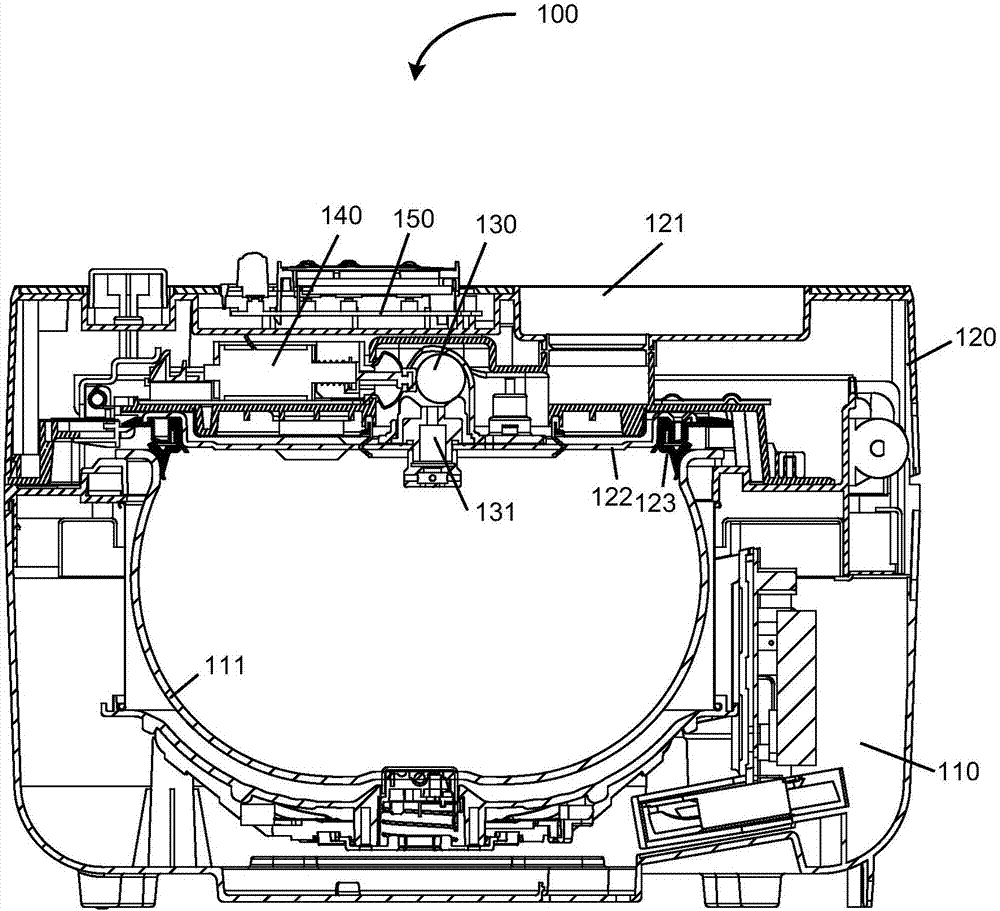

Yoghourt fermenting apparatus, refrigerator and yoghourt fermenting method

ActiveCN105076395AControllable heating processImprove qualityMilk preparationDomestic cooling apparatusEngineeringWarming process

A provided yoghourt fermenting apparatus comprises a housing, a fermentation chamber enclosed by the housing, and a heating device; the fermentation chamber is inside provided with a temperature sensor and a yoghourt cup for holding a substance; the bottom of the yoghourt cup is provided with a mass sensor measuring the mass of the substance in the yoghourt cup; and the fermenting apparatus also comprises a controller for adjusting the heating device and enabling the device to reach a preset fermentation temperature at preset time and keep the fermentation temperature. The yoghourt fermenting method employing the yoghourt fermenting apparatus comprises utilizing the temperature sensor and the mass sensor to measure the temperature and the mass of fresh milk, and controlling the heating device via a temperature signal and a mass signal through the controller, so as to enable fresh milk with any mass and temperature to be able to reach a preset fermentation temperature at preset time. By using the method, the heating process before fermentation is controllable, the temperature of fresh milk is capable of rapidly rising to the fermentation temperature, growth of harmful bacteria during heating is limited, and therefore the yoghourt quality can be improved.

Owner:HAIER SMART HOME CO LTD

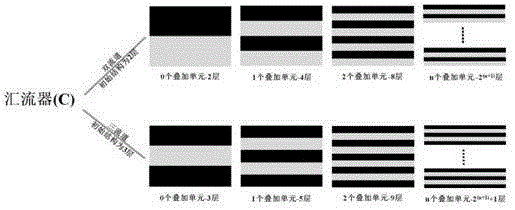

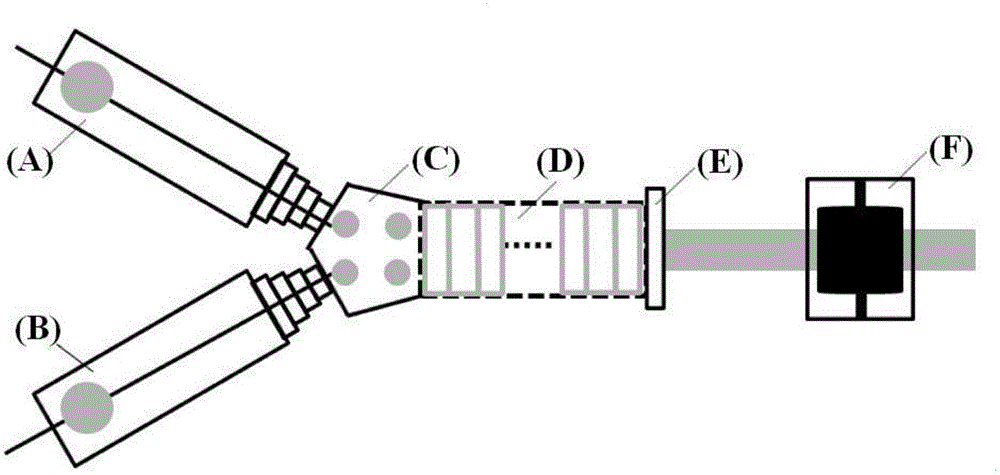

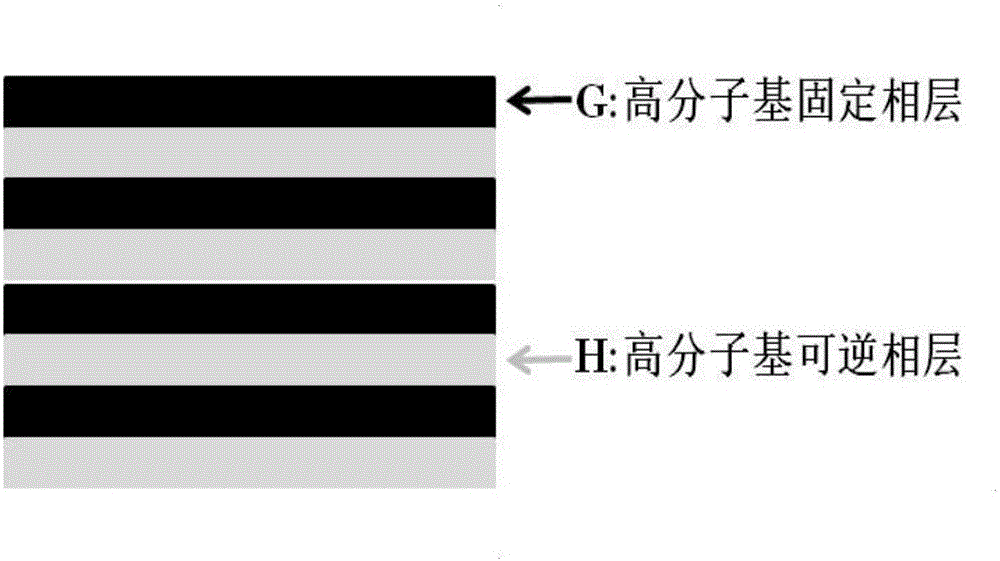

Preparation method of novel polymer-based multilayer shape memory material

ActiveCN106379011AExcellent shape memory performanceEasy to fixSynthetic resin layered productsRubber layered productsPolymer scienceRubber elasticity

The invention discloses a preparation method of a novel polymer-based multilayer shape memory material. The multilayer shape memory material prepared through the preparation method is formed by a polymer-based fixed phase layer and a polymer-based revertible phase layer, and has a two phase alternate multilayer bicontinuous structure, wherein the polymer-based fixed phase layer is a polymer having rubber elasticity at room temperature, and the polymer-based revertible phase layer is a polymer having obvious melt transition or glass transition in the heating process. The multilayer material deforms at a melting point or a glass transition temperature or above, then is cooled to room temperature in order to obtain a temporary shape, and then is heated to the melting point or the glass transition temperature or above in order to recover to an initial shape. The polymer-based multilayer shape memory material prepared through the preparation method has the advantages of controllable layer quantity, layer thickness and layer structure, adjustable raw material formula, excellent shape memory performance, commercial raw materials, and low production cost; and the preparation method has the advantages of simplicity, high production efficiency, and realization of continuous batch production.

Owner:SICHUAN UNIV

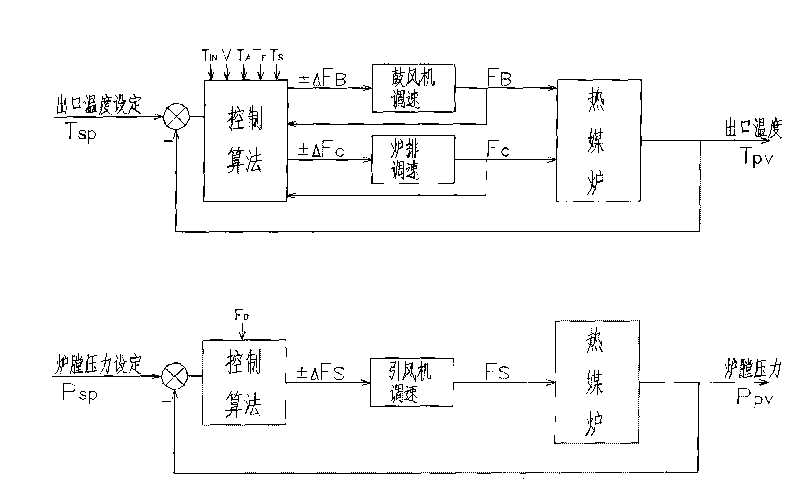

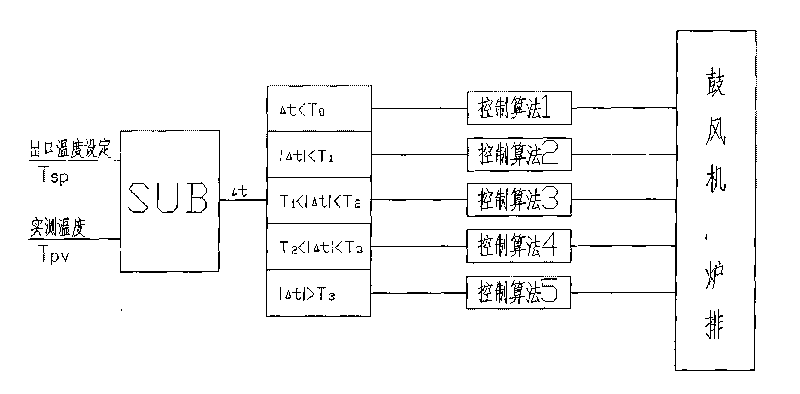

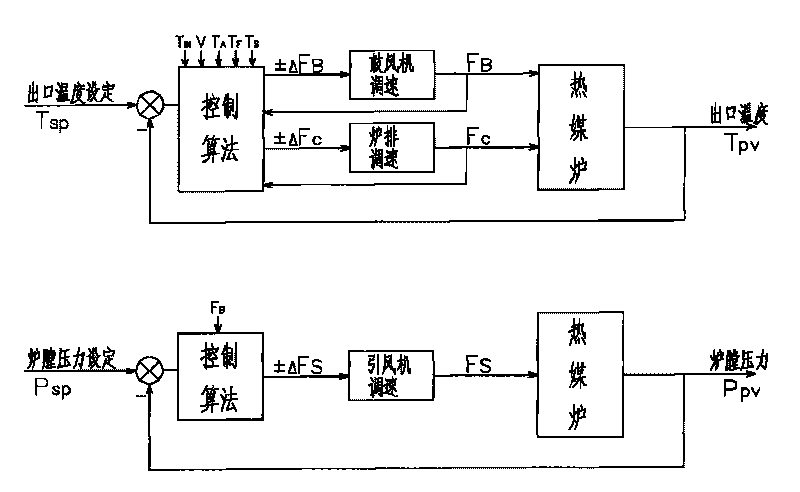

Coal burning heat medium furnace high-precision temperature regulation and combustion control method

ActiveCN101749730AHelp with troubleshootingImprove combustion efficiencyFuel supply regulationAutomatic controlEngineering

The invention provides a coal burning heat medium furnace high-precision temperature regulation and combustion control method and relates to the technical field of DCS industrial control systems, in particular to large-scale chain coal bed burning heat medium furnace (heat medium furnace for short) high-precision temperature regulation and combustion control. As is generally known, the temperature control of the coal burning heat medium furnace depends on the combustion control of the coal burning heat medium furnace. Therefore, a suitable sensor and a suitable transmitter are used to obtain parameters which influence the combustion and the heat medium outlet temperature in the burning process; the factors which influence the combustion and the heat medium outlet temperature are treated differentially and destroyed by adopting multi-circuit regulation when grasping main problems, thus avoiding interaction among the steps; the control algorithm adopts sectional control, feed-forward control and self-adaptive control on the basis of normal PID. According to the scheme, the influence of nonlinearity, much interference, large lag and the like can be overcome, thus realizing automatic control in the heating process and automatic regulation in normal heating, and the actual control precision of the heat medium outlet temperature can achieve plus or minus 0.7DEG C.

Owner:CHINA SHIPPING NETWORK TECH

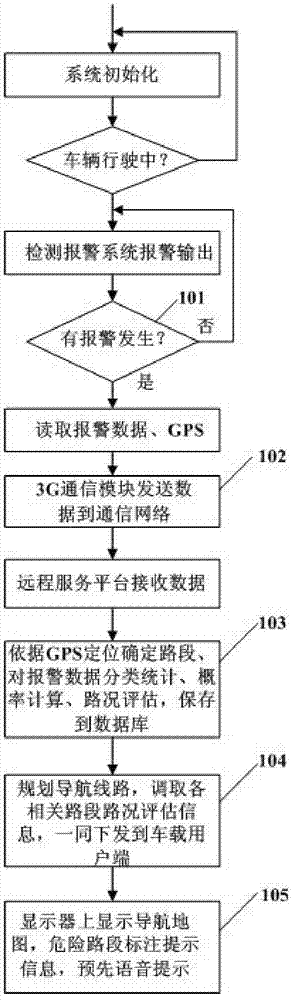

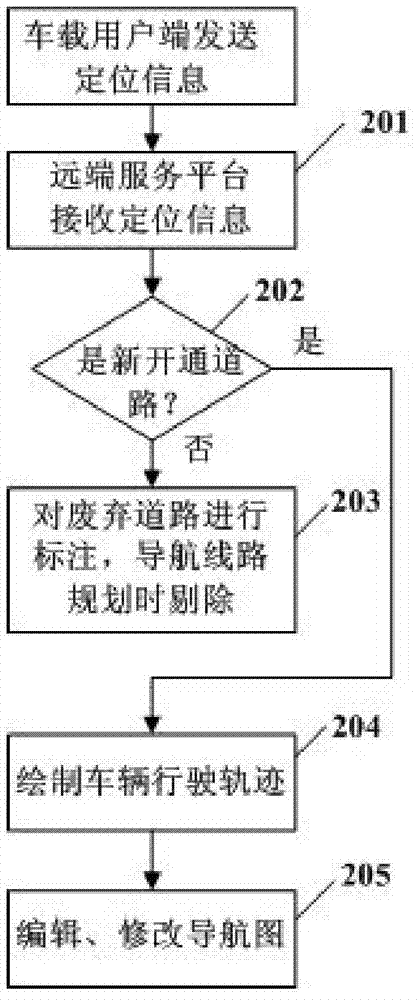

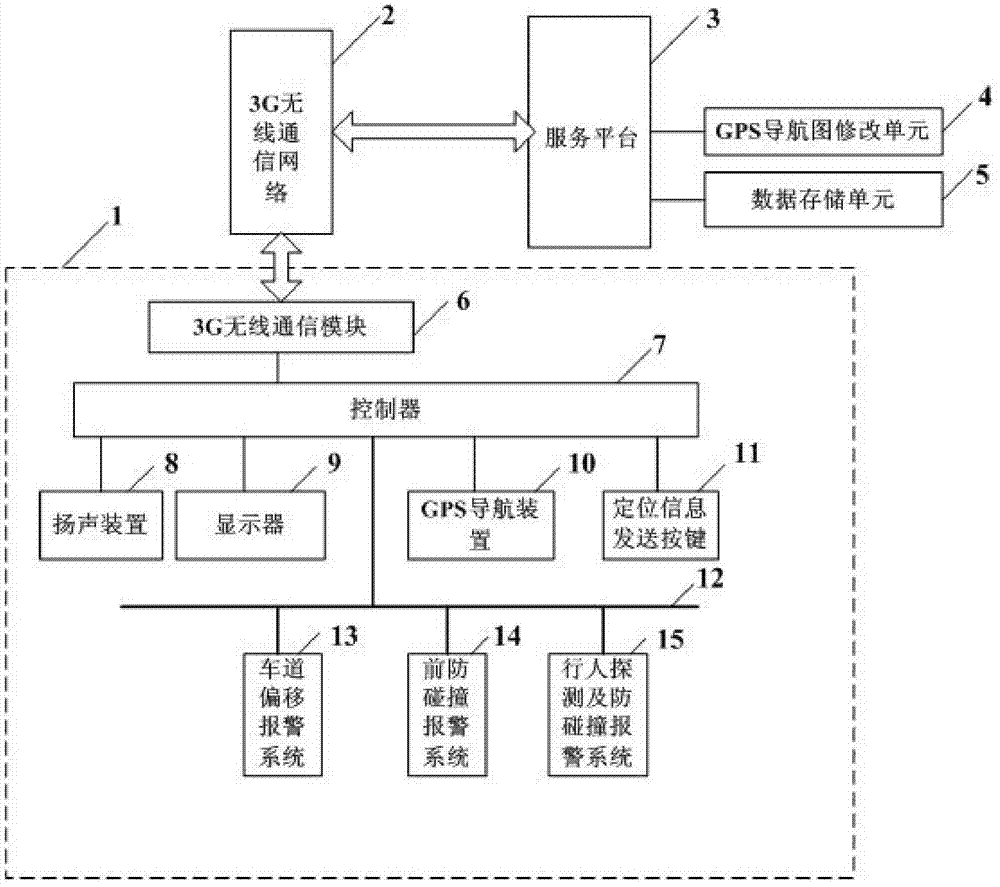

Active safety information collecting method and information service system for automobile

ActiveCN102881179AImprove securityImprove practicalityAnti-collision systemsWireless commuication servicesLane departure warning systemActive safety

The invention discloses an active safety information collecting method and an information service system for an automobile. The information service system for the automobile has functions of prompting the active safety information to prevent an accident from occurring, and modifying and updating a GPS (global position system) navigation chart. The active safety information collecting method comprises the steps that the automobile provided with a lane departure warning system, a front anti-collision warning system and a pedestrian detection and anti-collision warning system sends warning information, and the speed of the automobile and GPS positioning information in the warming process to a remote service platform through a wireless communication network; and the remote service platform conducts data processing, stores a calculated result and road section information in a database, downloads a planned route and occurrence probabilities of warning accidents in all road sections to an on-board client through the wireless communication network, and prompts safety driving before the automobile enters the road sections.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

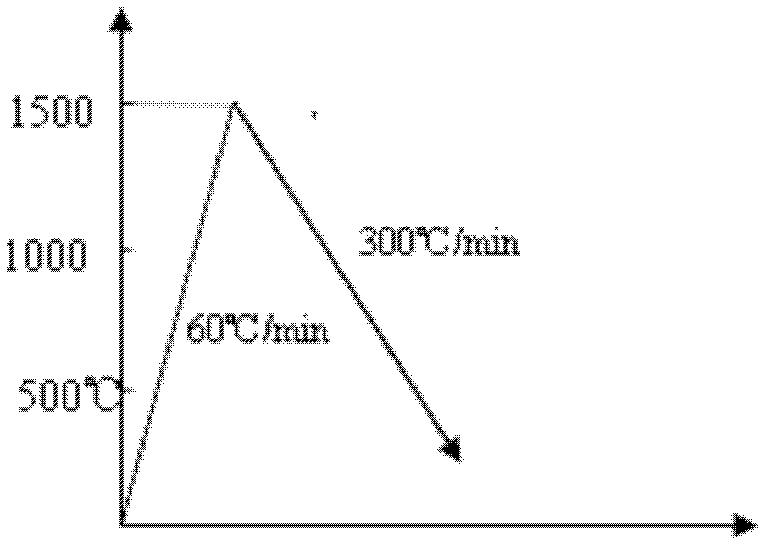

Production method of polycrystalline ceramic body

InactiveUS7470390B2High densityPiezoelectric/electrostrictive device manufacture/assemblyCeramic shaping apparatusWarming processCoarse particle

To provide a production method of a polycrystalline ceramic body with excellent density, a preparation step, a mixing step, a forming step and a heat-treating step are performed. In the preparation step, a coarse particle ceramic powder, and a fine particle powder having an average particle diameter of ⅓ or less of the average particle diameter of the coarse particle ceramic powder are prepared. In the mixing step, the coarse particle ceramic powder and the fine particle powder are mixed to produce a raw material mixture. In the forming step, the raw material mixture is formed to a shaped body. In the heat-treating step, the shaped body is heated and thereby sintered to produce a polycrystalline ceramic body. In the heat-treating step, a temperature elevating process and a first holding process are performed and at the same time, a second holding process and / or a cooling process are performed. In the temperature elevating process, heating is started to elevate the temperature and in the first holding process, the shaped body is held at a temperature T1° C. In the second holding process, the shaped body is held at a temperature T2° C. lower than the temperature T1° C. In the cooling process, the shaped body is cooled at a temperature dropping rate of 60° C. / h or less from the temperature T1° C.

Owner:DENSO CORP

Vitrification frozen stock solution

InactiveCN101253856AInhibit growthInhibition of recrystallizationDead animal preservationVitrificationPolyvinyl alcohol

The invention discloses a vitrification frozen stock solution. Each 100 milliliters of the solution contains 0.1-5g of polyvinyl alcohol, 1-30g of dimethyl sulfoxide, 1-30g of 1, 2-propylene glycol and water for the rest. The inventive frozen stock solution contains a penetrability and a non-penetrability cryoprotective protective agents, particularly the polyvinyl alcohol which is taken as the non-penetrability frozen stock solution component, has obvious effects of preventing the ice crystal growth and restraining the recrystallization and is capable of effectively forming the vitrification frozen stock at low temperature. Given the factors including the toxicity of the protective agent and the penetrability, the vitrification property and stability as well as the speeds of warming and cooling, etc. the inventive frozen stock solution is subject to the vitrification state in the cooling process and further guarantees the stability of the vitrification solution in the warming process. The inventive frozen stock solution has simple and all-purpose effects and is applicable to the vitrification frozen stock of various cells, tissues and organs.

Owner:SUN YAT SEN UNIV

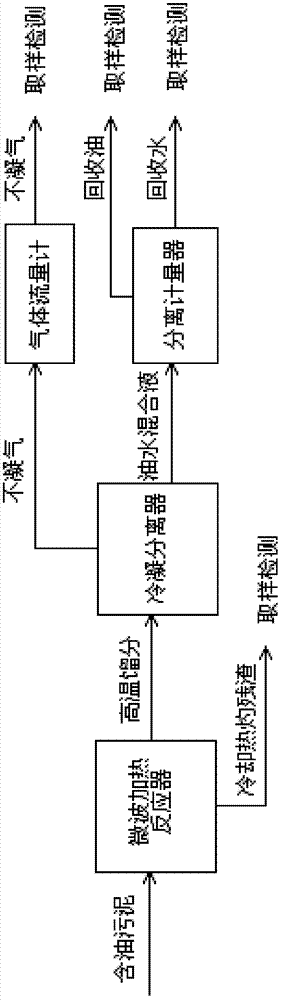

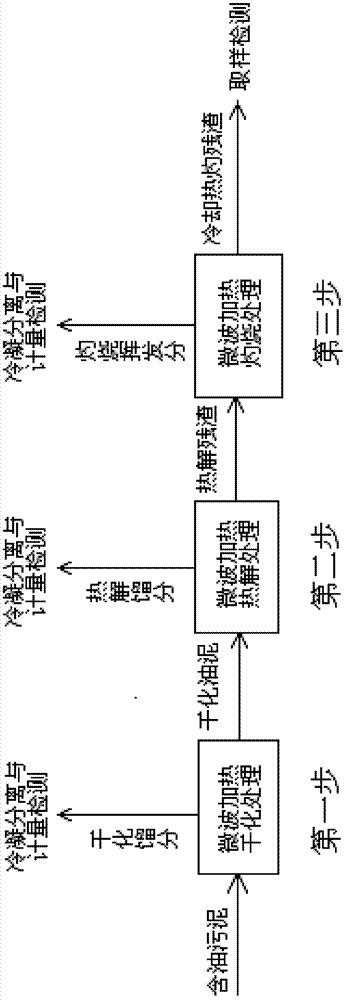

Experimental method of oil-containing sludge heat treatment

ActiveCN102849905AImplement resourcesReduce pollutionSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisResource utilizationEvaporation

An experimental method of oil-containing sludge heat treatment is applicable to research of oil-containing sludge heat treatment effect and characteristics. The programmed heating process comprises the following steps of: firstly, desiccation treatment, wherein an oil-containing sludge sample is heated from room temperature to 200-250 DEG C to realize complete moisture evaporation, and the composition of non-condensable gas and recovered oil is analyzed; secondly, pyrolysis treatment, wherein the desiccated oil sludge is heated to 600-700 DEG C to realize complete pyrolysis of organic substances such as heavy oil, asphaltene and the like in the oil sludge by high-temperature heating, and the composition of recovered oil and non-condensable gas is analyzed; thirdly, calcination treatment, wherein the oil-containing sludge pyrolytic residues are heated to 800-900 DEG C, and the content of pollutants such as petroleum and the like is analyzed. The method is convenient and rapid for the obtaining of the yield and composition data of heat treatment products of the oil-containing sludge at different heating temperature phases, and for the research and mastering of the heat treatment effect and characteristics of oil-containing sludge, and can realize the purpose of harmless and resource utilization of oil-containing sludge.

Owner:PETROCHINA CO LTD +1

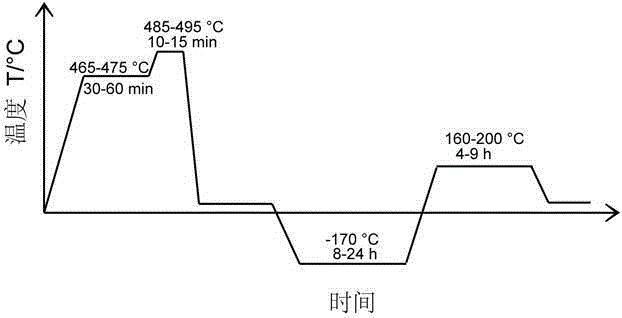

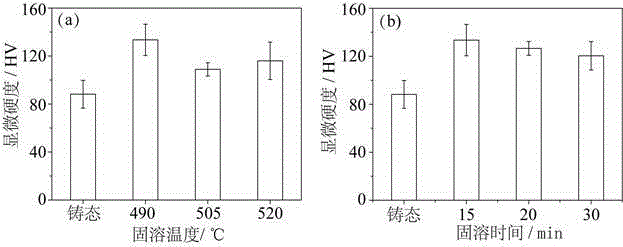

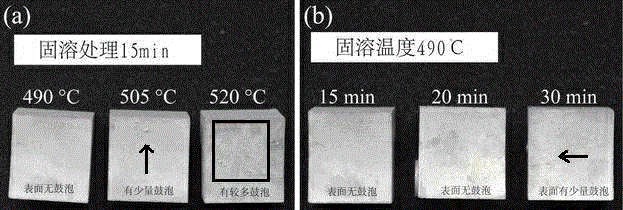

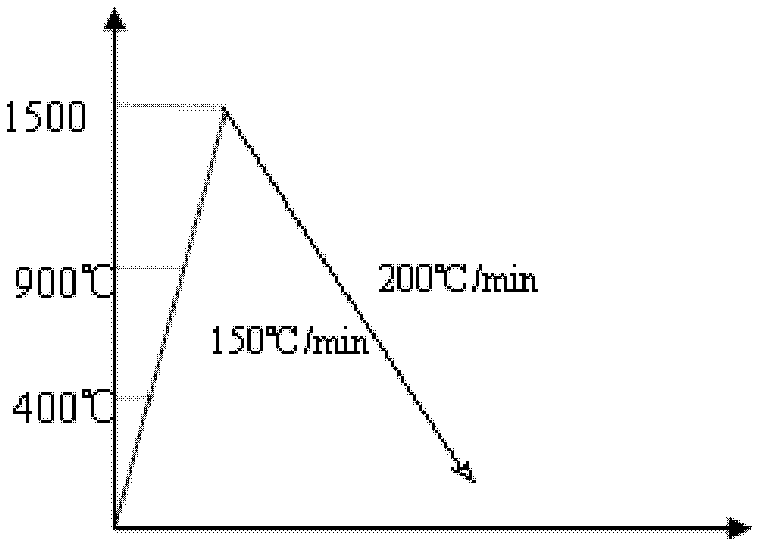

Heat treatment method for vacuum high-pressure die-cast aluminum alloy casting

The invention provides a heat treatment method for a vacuum high-pressure die-cast aluminum alloy casting. According to the heat treatment method, gradient temperature rising type high-temperature transient solution treatment conducted on the high-pressure die-cast aluminum alloy casting is achieved, then liquid-nitrogen subzero treatment is conducted, and thus the later aging treatment effect is improved. During operation, a gradient temperature rising process is adopted so that dissolving can be conducted on a low-melting-point phase at a relative low temperature firstly, eutectic silicon in the alloy is fully granulated after the temperature is increased again, and in this way, the situation that cracks appear in the structure and the performance is reduced due to overburning is avoided; subzero treatment is adopted firstly after solution treatment and quenching and before manual aging treatment so that the casting can contract to generate great contraction stress, a large amount of dislocation is introduced into the structure, a large number of nucleation mass points are provided for second-phase dispersed precipitation during aging, and aging strengthening is enhanced.

Owner:ZHONGBEI UNIV +1

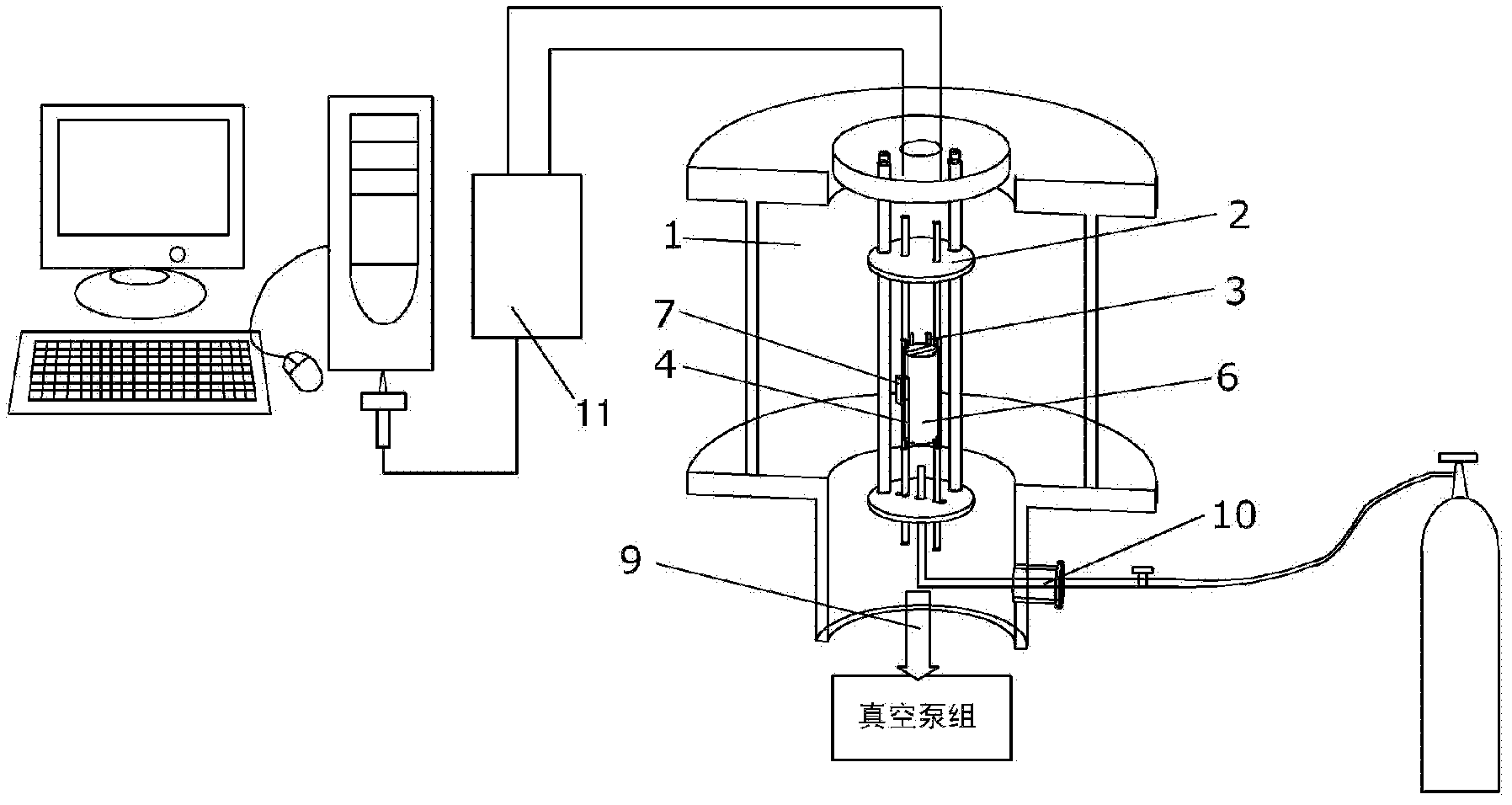

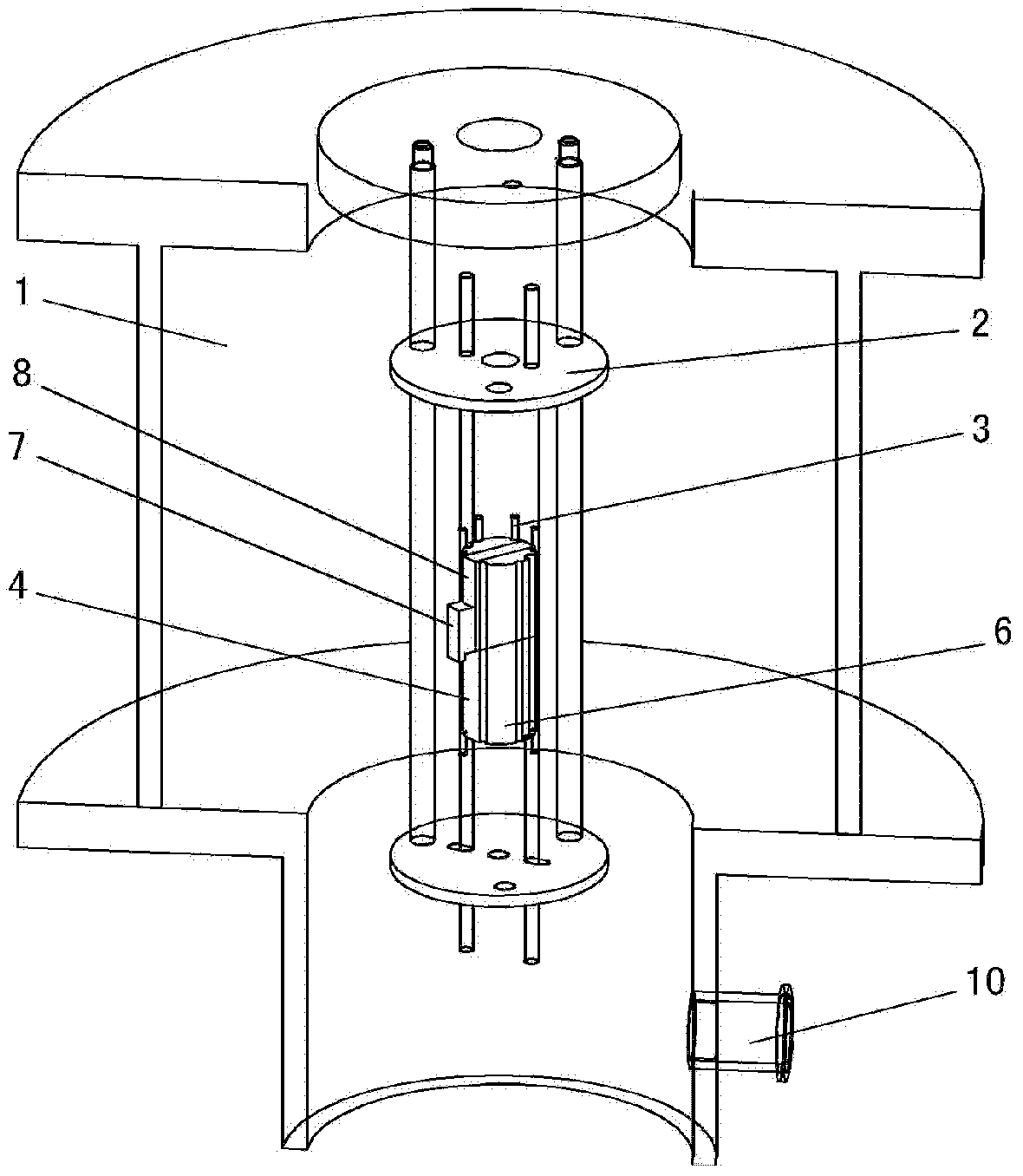

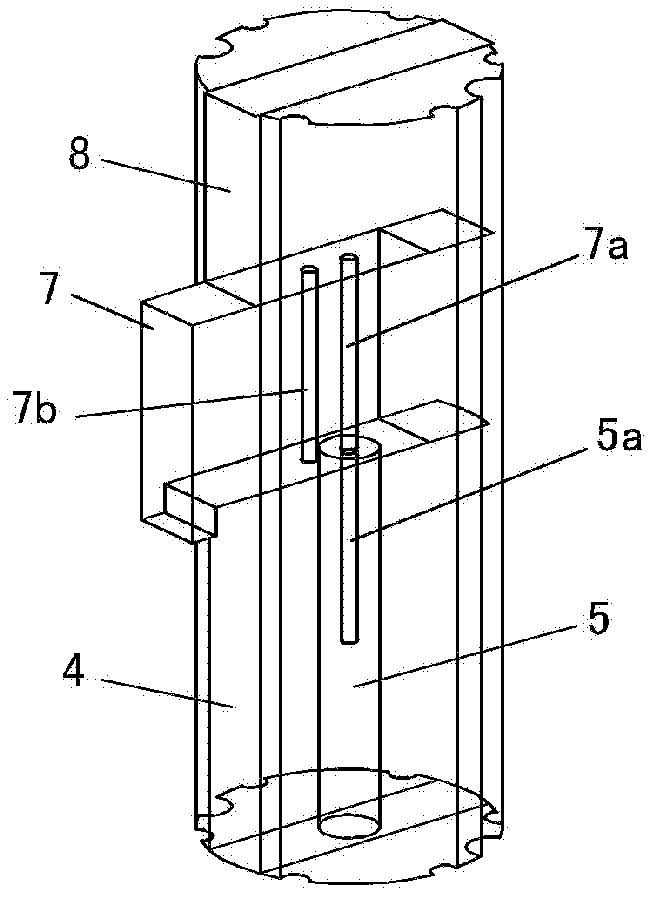

Preparation method of metal melt diffusion sample

ActiveCN102620970AAccurate and reasonable diffusion coefficient measurementReduce residual temperature diffusion timePreparing sample for investigationSurface/boundary effectDiffusionGraphite

The invention discloses a preparation method of a metal melt diffusion sample. The preparation method is characterized in that a vacuum cavity is internally provided with a framework, wherein a diffusion platform made from graphite is fixed in the framework; the diffusion platform is a cylinder body vertically fixed; a heating device is arranged on the periphery of the diffusion platform; the diffusion platform is an assembly and comprises a fixed base, a slide block and a top plate; and a vacuum port and a cooling gas introducing port for introducing cooling gas are respectively arranged on the side wall of the vacuum cavity. According to the preparation method of the metal melt diffusion sample, disclosed by the invention, the cutting of a metal liquid in a sample cylinder cavity is realized by two different work stations between the slide block and the fixed base; and oxidized skin generated by slight oxidization of the surface of the material is removed by cutting; meanwhile, the system error of the diffusion phenomenon in a temperature-rising process is further removed and the residual temperature diffusion time is greatly reduced in a temperature-reducing process, so that the subsequent measurement of diffusion coefficient of the diffusion sample is more precise and more reasonable.

Owner:HEFEI UNIV OF TECH

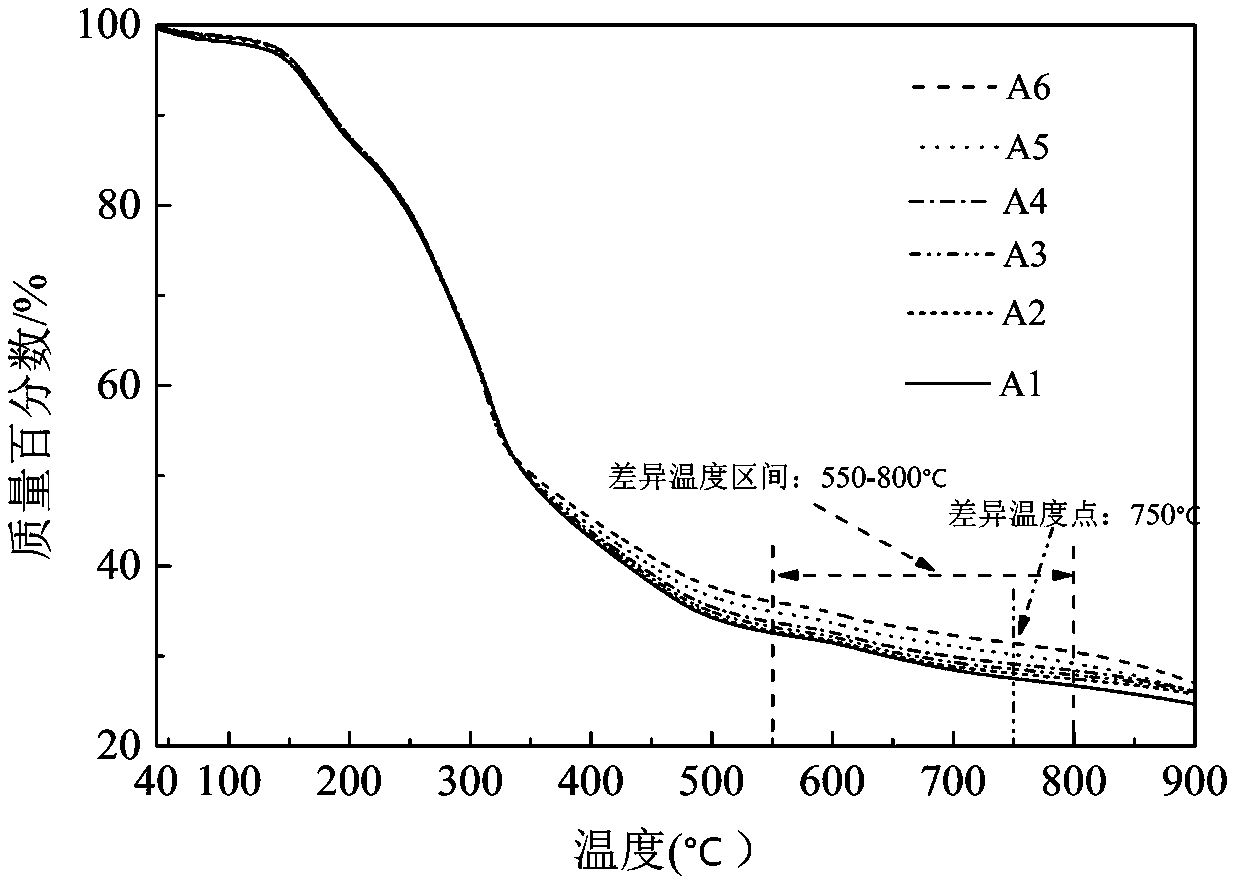

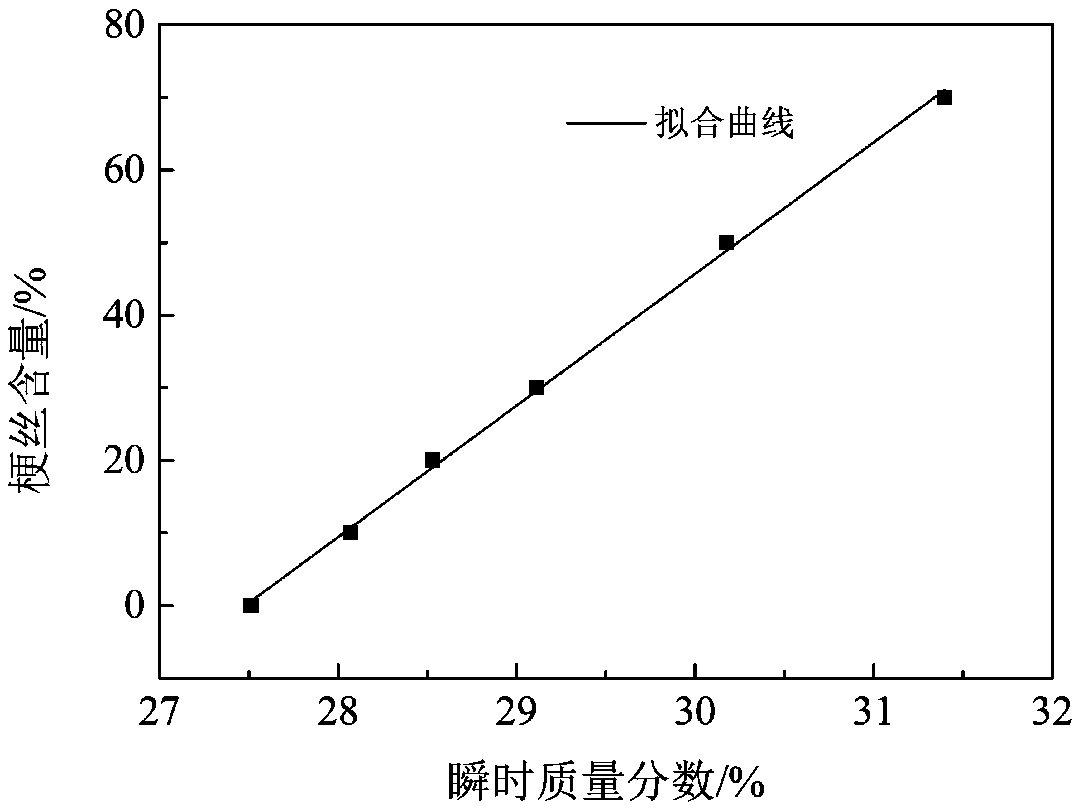

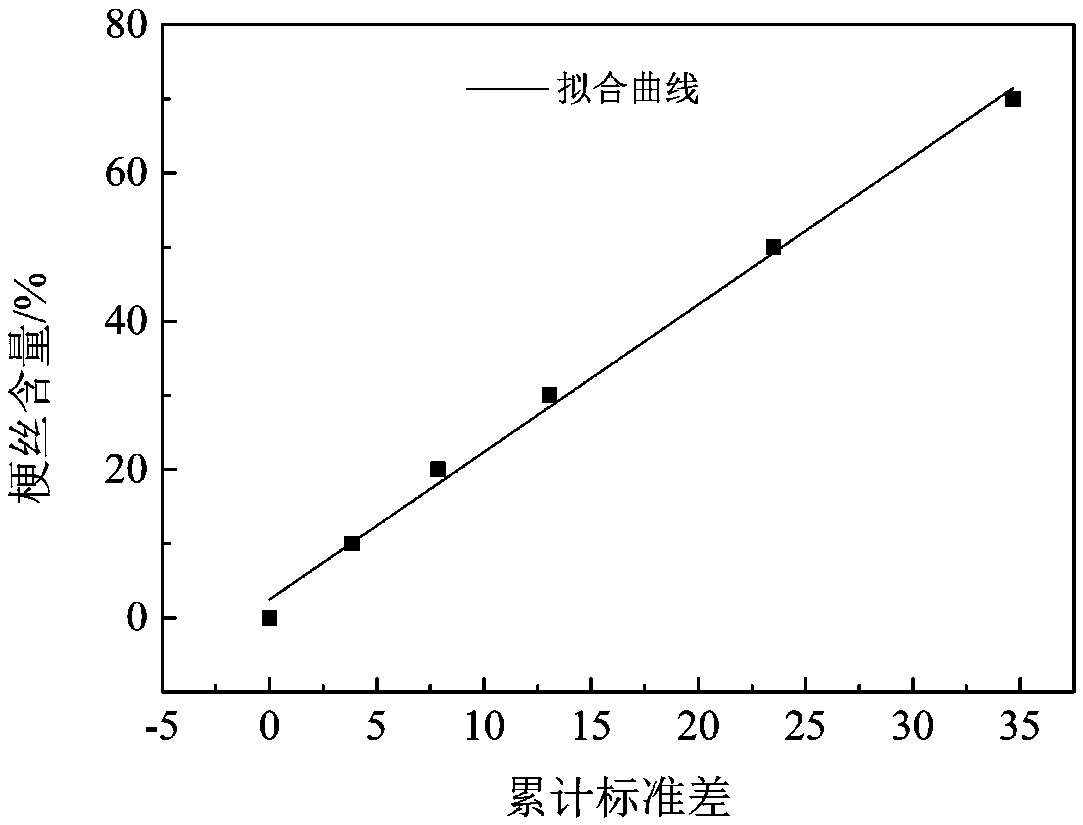

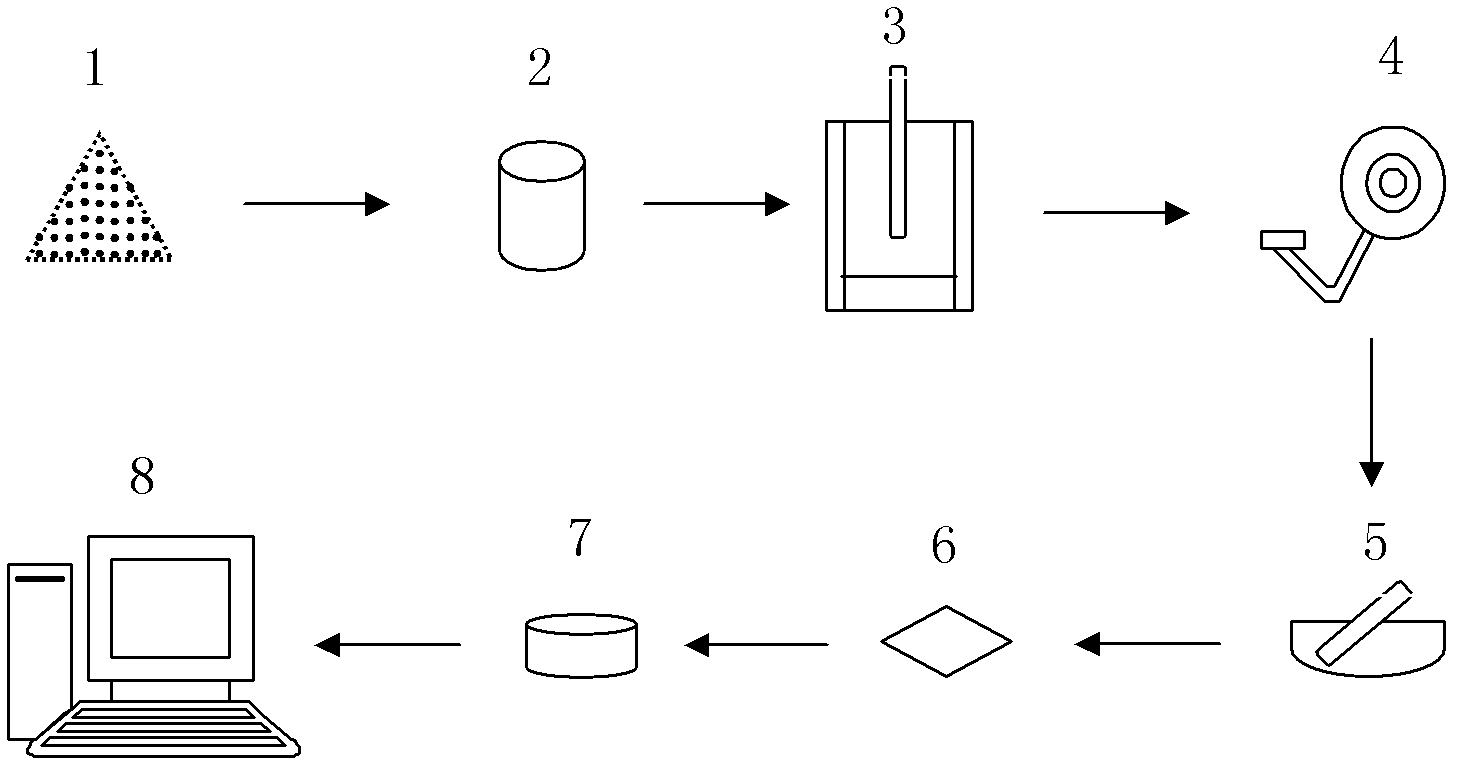

Method for determining content of cut stem in cut tobacco based on thermal analysis technique

The invention discloses a method for determining content of cut stem in cut tobacco based on a thermal analysis technique. The method comprises selecting pyrolysis conditions in a thermogravimetric analyzer, acquiring a weight change curve of multiple cut tobacco samples having known cut stem contents in the temperature programming process, analyzing a sample pyrolysis curve to find an instantaneous mass fraction value having obvious difference of the sample at a certain temperature or a temperature range having large sample pyrolysis curve difference, carrying out corresponding data processing and linear fitting to obtain a cut stem content standard curve equation, testing an unknown sample, and substituting the data into the equation to realize determination of the cut stem content in a cut tobacco sample. Because of the difference of chemical composition and properties of cut stem and cut tobacco, pyrolysis behaviors have difference so that the thermogravimetric analyzer can acquire mass change curves of different samples in the temperature programming process. Through difference analysis of the pyrolysis curve, the cut stem content of the cut tobacco is obtained.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +3

Method for determining melting behavior and melting point of slag-like material

ActiveCN102495096AThe test result is accurateDynamic and intuitive testing processInvestigating phase/state changeMetallurgical slagTemperature testing

The invention relates to a method for determining a melting behavior and a melting point of a slag-like material, belonging to the technical field of detection of metallurgical slag-like material. The process comprises slag sample preparation, slag sample formation, high-temperature laser sample filling, experimental parameter setting, melting process observation and data and image processing. The method provided by the invention has the advantages that the defect of low accuracy of the slag column deformation method, i.e. the hemisphere point temperature testing method, in the traditional melting point testing can be overcome, and the limitations of difficulties in control of the stability of testing conditions and high testing costs in the method of slag melting in liquid steel can be eliminated. The initial melting temperature of the slag sample from the solid phase to the liquid phase and the melting temperature of the slag sample to the full liquid phase can be captured promptly so as to accurately determine the melting point of the slag sample; and the liquid phase nucleation, growth and other melting changes and behaviors of the slag sample in the heating process can also be analyzed, the direct theoretical basis and technical support can be provided for the curing of liquid slag and the control of metallurgical reaction in the steel-making and iron-making process, and different characteristics of different slag samples in the melting process can be used as an important means for evaluation of high-temperature properties of different slag samples.

Owner:SHOUGANG CORPORATION

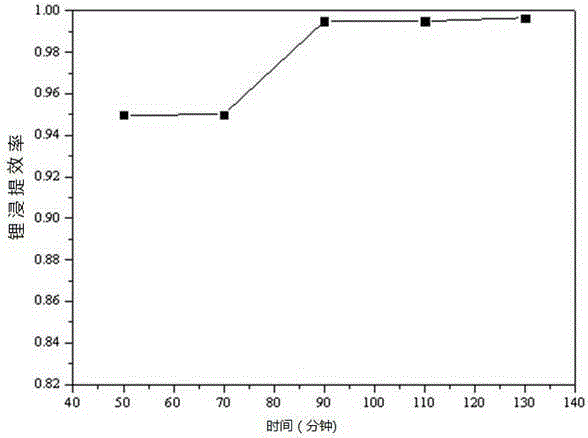

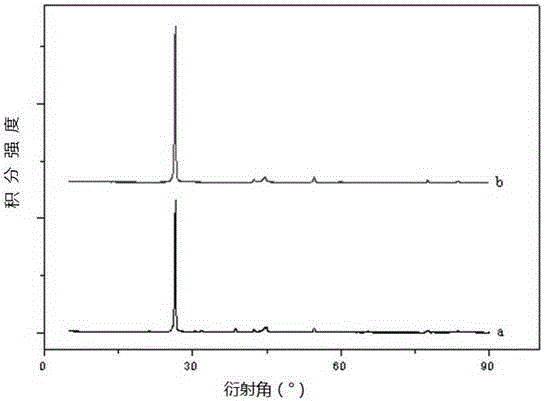

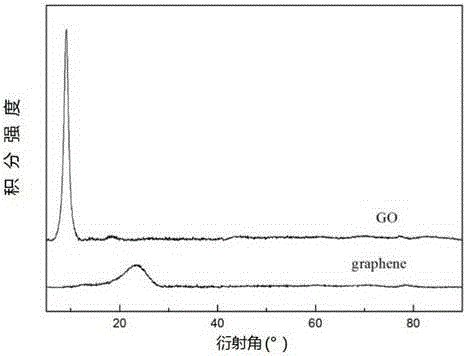

Method for separating lithium and graphite from negative electrode material of waste lithium battery and resource utilization

InactiveCN105355996ANo structural damageWaste accumulators reclaimingBattery recyclingResource utilizationMixed materials

The invention relates to a method for separating lithium and graphite from a negative electrode material of a waste lithium battery and resource utilization. The method comprises the steps of pre-treatment on a negative electrode graphite material, separation and leaching of lithium ions in a waste lithium battery mixed material and preparation of graphene, wherein pre-treatment mainly comprises lithium battery disassembly, graphite material stripping, organic impurity removal and the like; the separation and leaching of the lithium ions in the waste lithium battery mixed material comprises control on indexes such as acid concentration, solid-liquid ratio, time, temperature and acid / oxidizing agent volume, and finally, the lithium ion recycle is realized by methods of low-temperature stirring and filtering; and the graphene preparation comprises graphite oxidization and reduction, oxidization mainly comprises control and regulation on the oxidizing agent and process parameters of the temperature rise process and the like, and reduction mainly comprises adjustment on parameters such as pH, the ratio of hydrazine hydrate to graphite oxide and the like. According to the method, a lithium-rich leaching liquid and the graphene are finally obtained through the application of a series of combined processes.

Owner:TONGJI UNIV

Preparation method of catalyst component for polymerization reaction of olefins and catalyst thereof

The invention provides a method for preparing a catalyst component for the polymerization reaction of olefins, which comprises the following steps: (1) dissolving magnesium halide in a solvent system comprised of an organic epoxy compound, an organic phosphorus compound and an inert diluent to form uniform solution; (2) mixing a titanium compound with the uniform solution formed by the step (1) and adding a precipitant to form a mixture, or adding the precipitant into the uniform solution formed by the step (1) first and mixing the uniform solution with the titanium compound to form a mixture; and (3) heating the mixture obtained by the step (2), adding any selected electronic donor compound during heating or after heating, and washing the resulting product with an inert diluent to obtaina magnesium / titanium-containing solid material, wherein the precipitant is a glycol ester compound. The catalyst component has high polymerization activity and stereoselectivity and causes little polymer fine powder when used in the polymerization reaction of olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production method of polyoxazolidone laminated board

InactiveCN101695880AImprove toughnessReduce polarityLamination ancillary operationsLaminationVitrificationEpoxy

The invention provides a production method of a polyoxazolidone laminated board, comprising the following steps: reacting diisocyanate with epoxide resin by taking imidazole compounds as catalyst for producing polyoxazolidon resin during the gradual rise of temperature; and then producing the polyoxazolidone laminated board by using the polyoxazolidon resin. The polyoxazolidone laminated board the end of which is sealed with isocyanate has better mechanical strength, favorable heat resistance and high glass transition temperature above 155 DEG C; and when in use at 180 DEG C or 200 DEG C, the mechanical property and electrical propertye of the polyoxazolidone laminated board are over 70 percent.

Owner:HUNAN HENGYUAN NEW MATERIAL TECH CO LTD

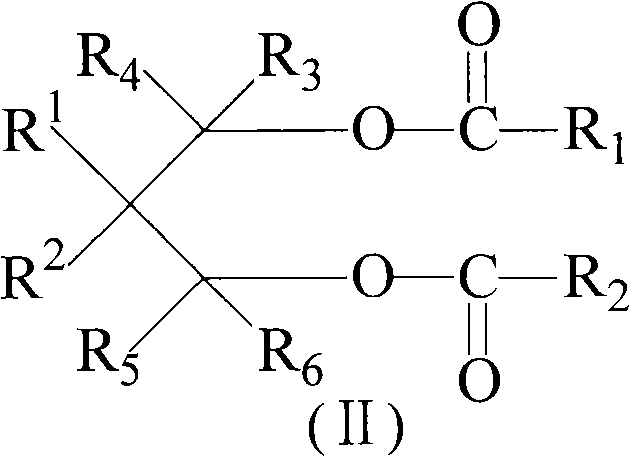

Method for controlling igniter burner of powdered coal pressurized gasifier

ActiveCN104449867AImprove ignition success rateImprove securityGasification processes detailsCombined combustion mitigationWarming processProcess engineering

The invention discloses a method for controlling an igniter burner of a powered coal pressurized gasifier and provides a method for logic control of an igniter burner of a multi-nozzle counter-position type powdered coal pressurized gasifier. According to the technical scheme, the method comprises the following steps: 1, 'initializing' the igniter burner; 2, 'resetting' the igniter burner in the following way: (1) performing nitrogen sweeping, (2) establishing emptying flows of fuel gas and factory air, and (3) switching on inlet fuel gas and inlet oxygen flow adjusting valves according to a preset valve opening and flow relationship; 3, 'igniting' by the igniter burner in the following way: (1) introducing ignition fuel gas and ignition factory air into the gasifier in sequence and discharging by the igniter, wherein the igniter successfully ignites when a flame detector of the igniter detects a flame signal; (2) introducing heating fuel gas and oxygen into the gasifier in sequence, wherein the ignition of the gasifier is successful when the flame detector detects a flame signal and the hearth temperature of the gasifier is of a rising trend; (3) exiting the igniter and introducing protective nitrogen gas, and (4) switching the fuel gas and oxygen during a heating process; 4 'exiting' the igniter burner; and 5, introducing steam to protect the igniter burner. By adopting the method disclosed by the invention, a logic control scheme and a detection manner are reasonably optimized according to technological requirements of a powdered coal gasification production device, the ignition success rate and security of a water cooled wall gasifier are improved, and the driving time and cost are saved.

Owner:水煤浆气化及煤化工国家工程研究中心

Method for preparing porous titanium coating on surface of titanium alloy

InactiveCN103266319ALow impurity contentReduce oxygen contentMetallic material coating processesDehydrogenationWarming process

The invention provides a method for preparing a porous titanium coating on the surface of titanium alloy. The method comprises the following steps of: adding a forming additive to TiH2 powder selected as a raw material, mixing to obtain a coating material, then obtaining a product green body through a warm-pressing or injection forming method, and finally carrying degreasing, dehydrogenation and sintering integrated treatment to obtain the product. The method can be used for realizing the preparation of the porous titanium coating with high interface bonding strength, and the interface bonding strength of the porous titanium coating exceeds 400MPa; and the impurity content in the coating is substantially reduced through an integrated treatment technology in the heating process, and the oxygen content in the coating is less than 0.35wt%. The method can be used for coating the surface of titanium alloy with the coating with the controlled porosity, size and thickness, and is particularly suitable for preparing the porous titanium coating. The method is simple and practical in a preparation technology; and the prepared product has excellent performance and is suitable for industrial production.

Owner:李建久

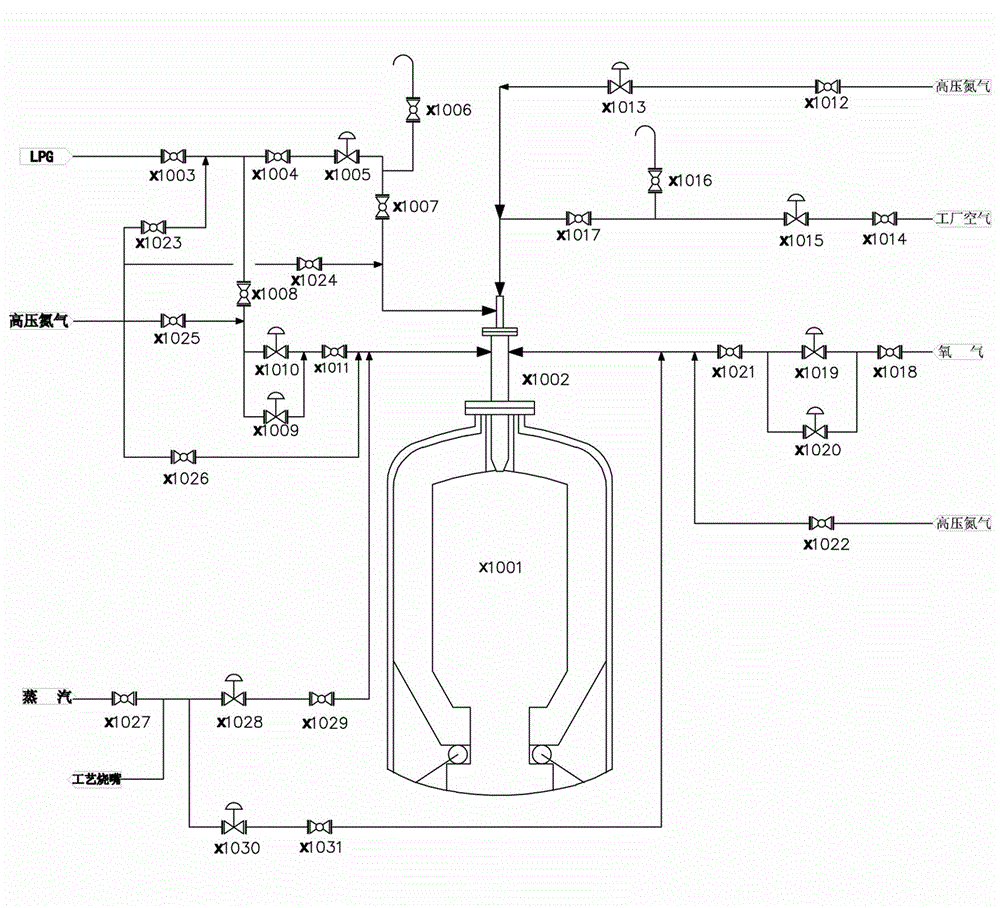

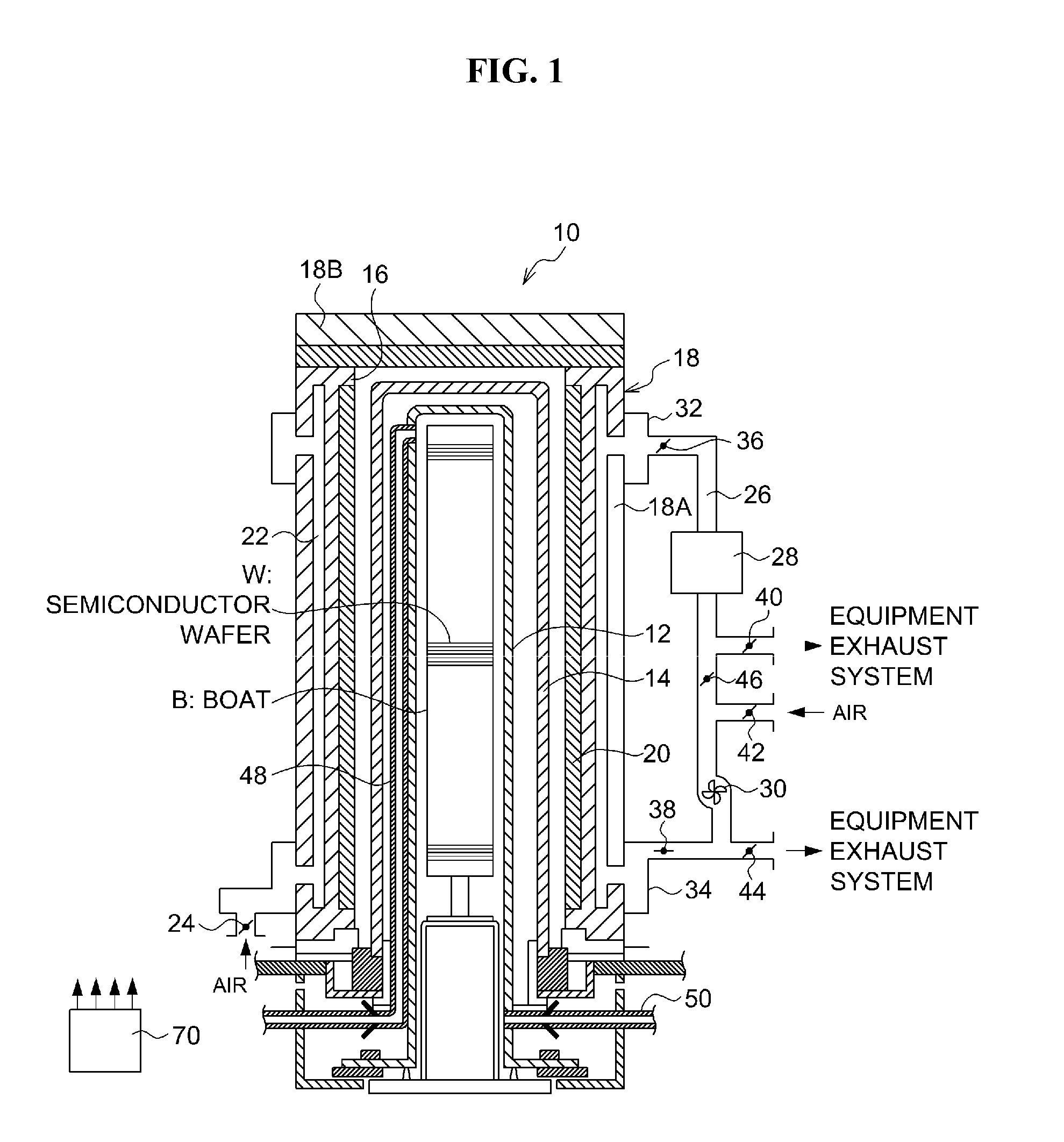

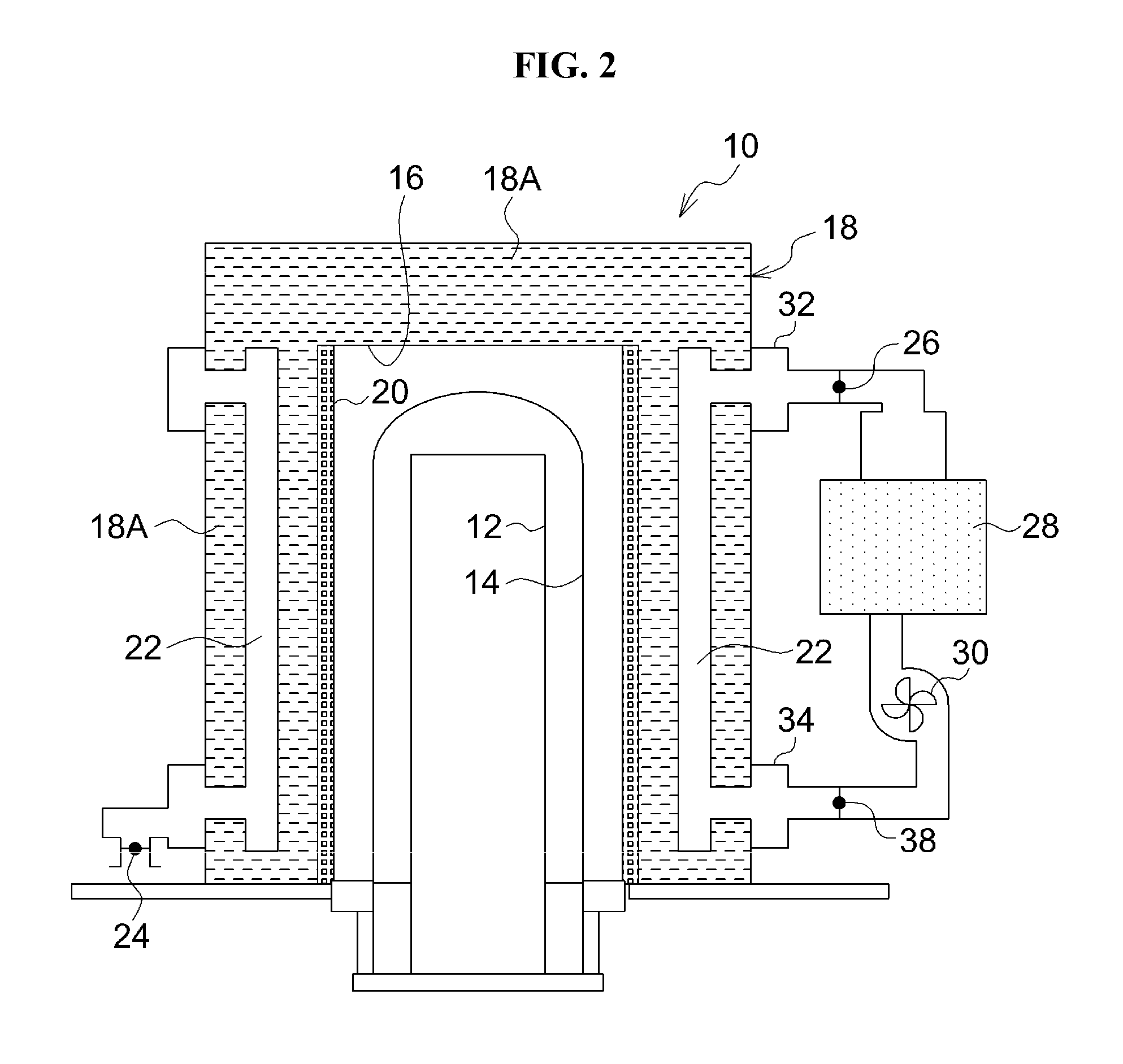

Substrate Processing Apparatus, Method of Manufacturing Semiconductor Device and Method of Processing Substrate

ActiveUS20150093909A1Improve insulation performanceRapid coolingLiquid surface applicatorsSemiconductor/solid-state device manufacturingAir cycleExhaust valve

A substrate processing apparatus including a vertical reaction container; an insulating wall formed of an insulating material and including a reaction container accommodation chamber for accommodating the reaction container therein; a heater installed in an inner wall of the reception container reception chamber on the insulating wall; an air circulation channel installed vertically in a sidewall of the insulating wall; a blower for distributing air upward or downward in the air circulation channel; intake valves for communicating the air circulation channel with the air; and exhaust valves for communicating the air circulation channel with an equipment exhaust system. In a temperature elevating process and a temperature lowering process, the intake valves and the exhaust valves are switched.

Owner:KOKUSA ELECTRIC CO LTD

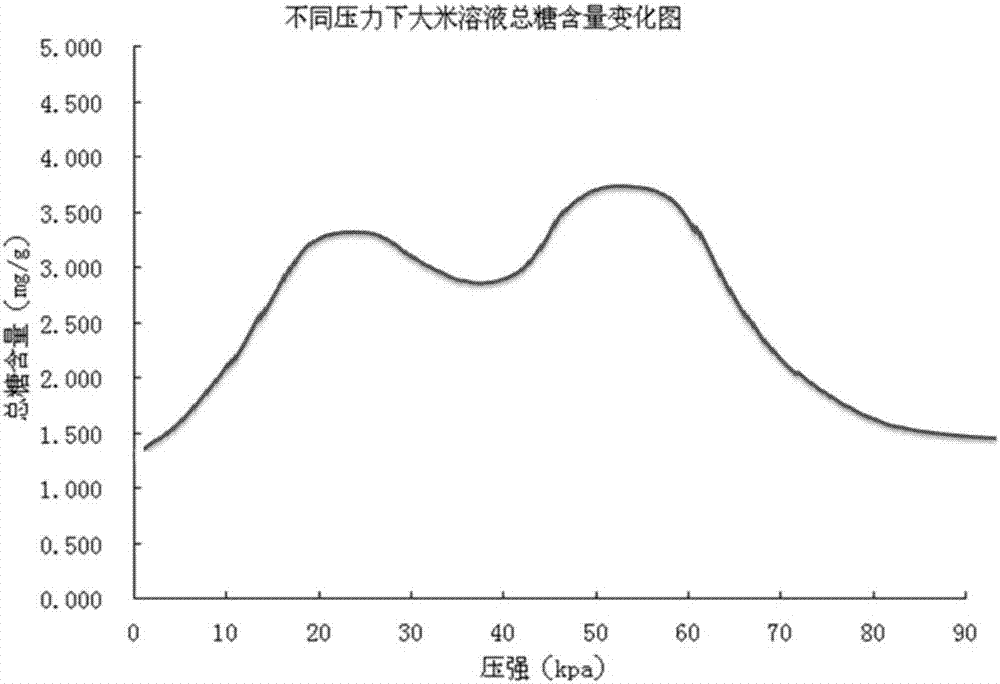

Pressure cooking utensil and heating control method for pressure cooking utensil

The invention discloses a pressure cooking utensil and a heating control method for the pressure cooking utensil. The pressure cooking utensil comprises a pot body, an inner pot, a cover body, a temperature sensor, a pressure valve, a pressure valve switching mechanism and a control device; the control device controls an inner pot heating device and the pressure valve switching mechanism to conduct cooking process, the cooling process comprises a water absorption process, a warming process, a boiling process and a cooked rice process in sequence, the control device controls the pressure valve switching mechanism, so that in the later period of the boiling process or the earlier stage of the cooked rice process, a steam discharge hole is in an off state, the pressure in the cooking space is kept within the range of the first pressure, and through the configuration of the control device, the time that the pressure in the cooking space is kept within the range of the first pressure is first preset time. According to the pressure cooking utensil, cooked rice is better in taste.

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com