Patents

Literature

50results about How to "Avoid Purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

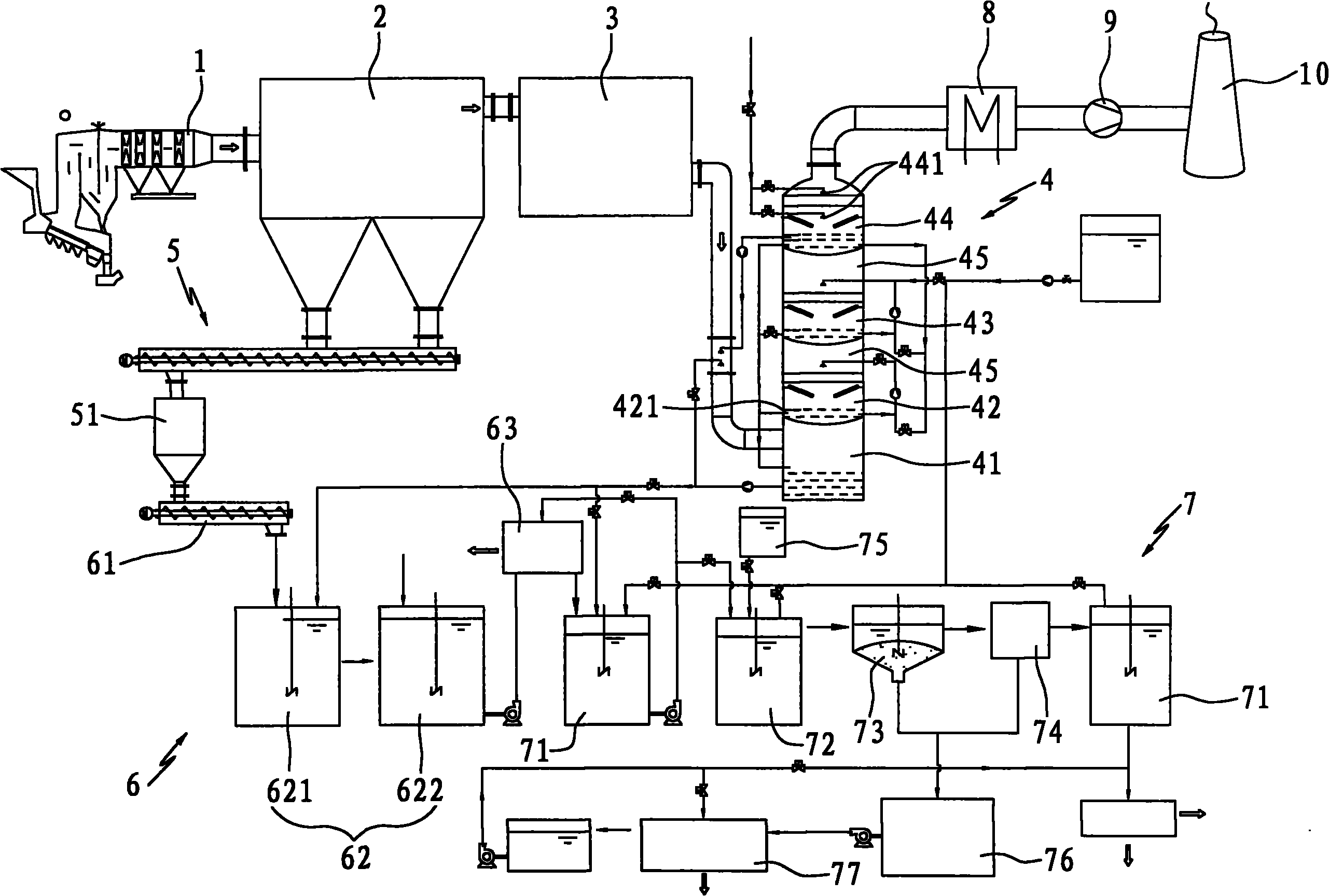

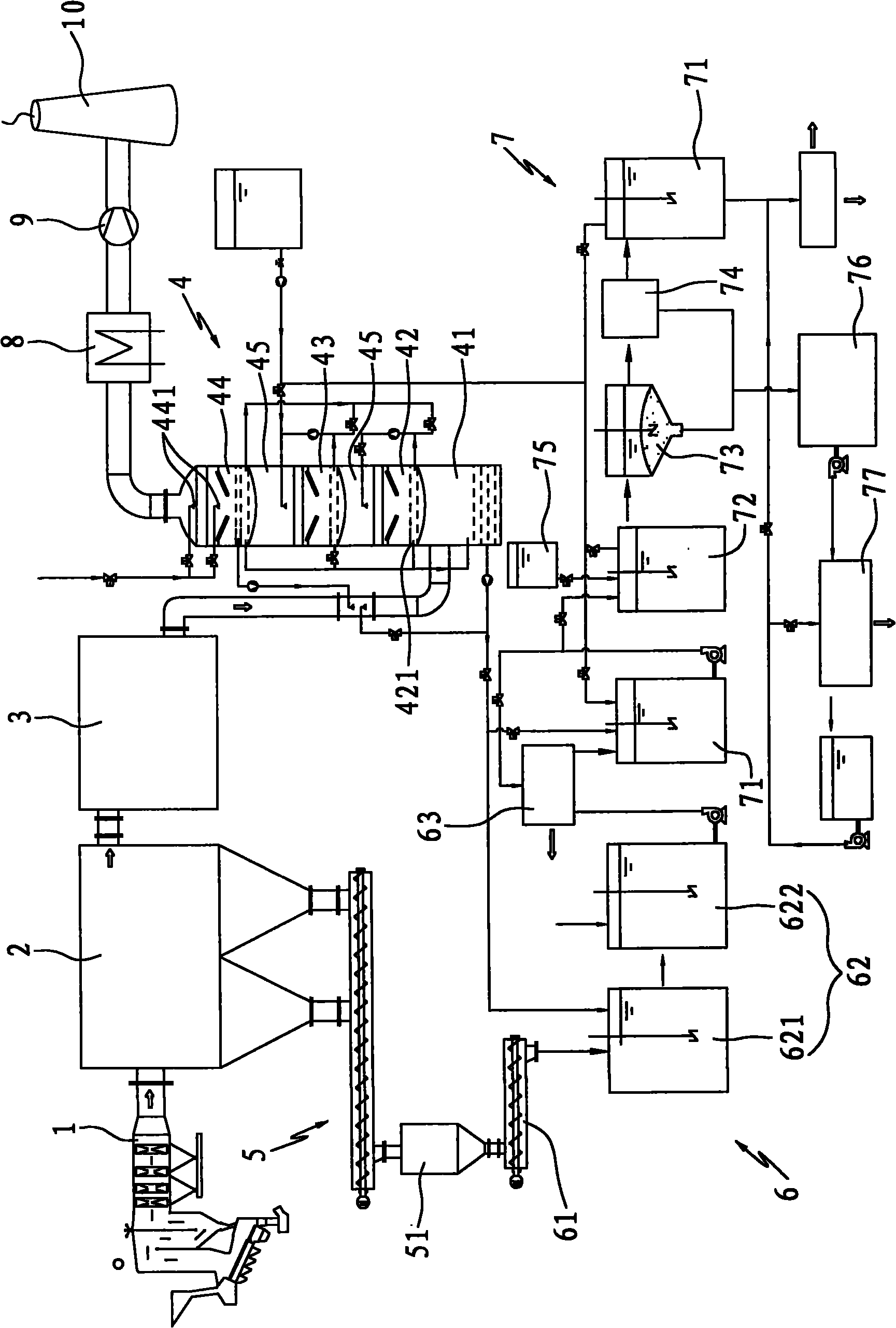

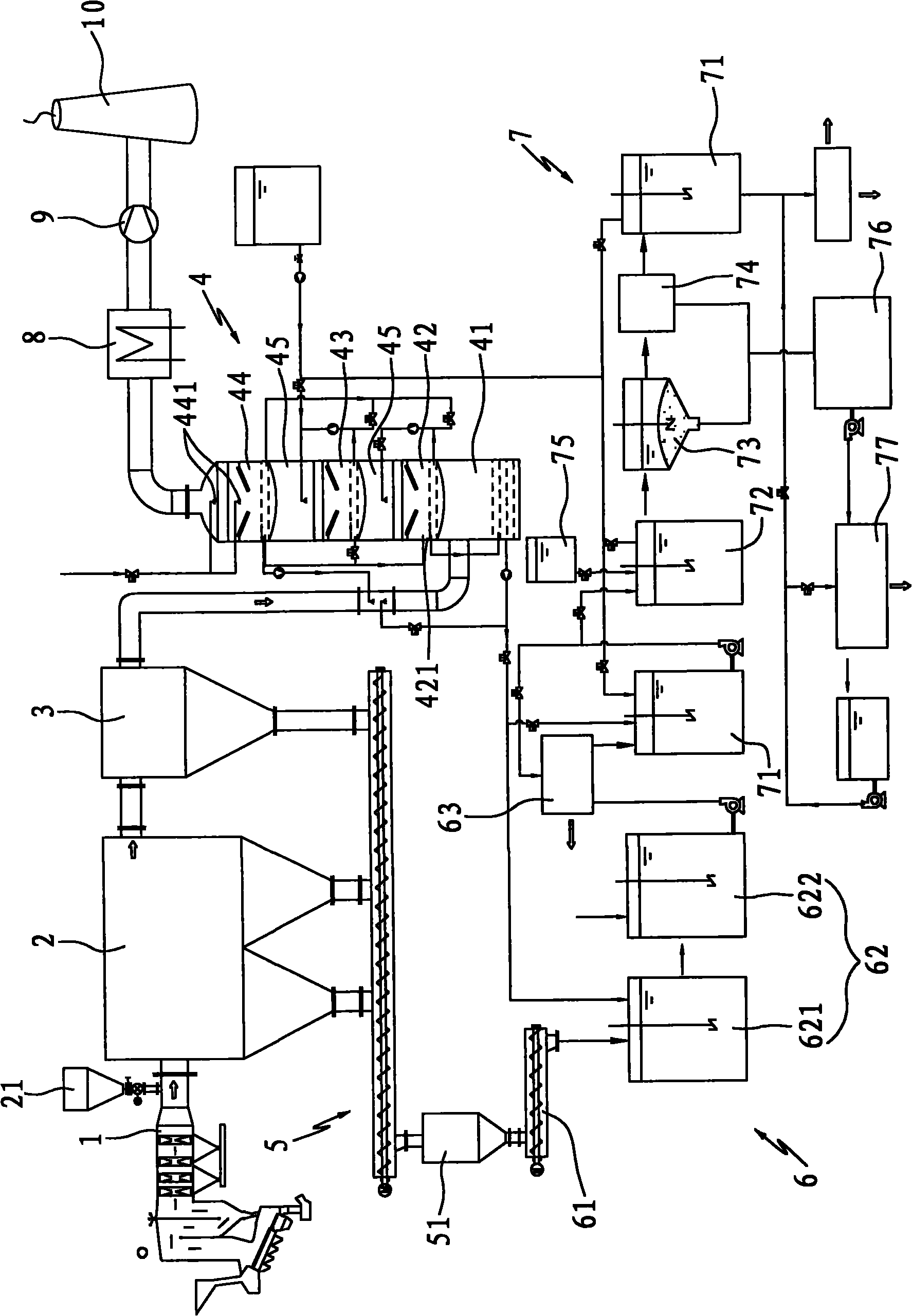

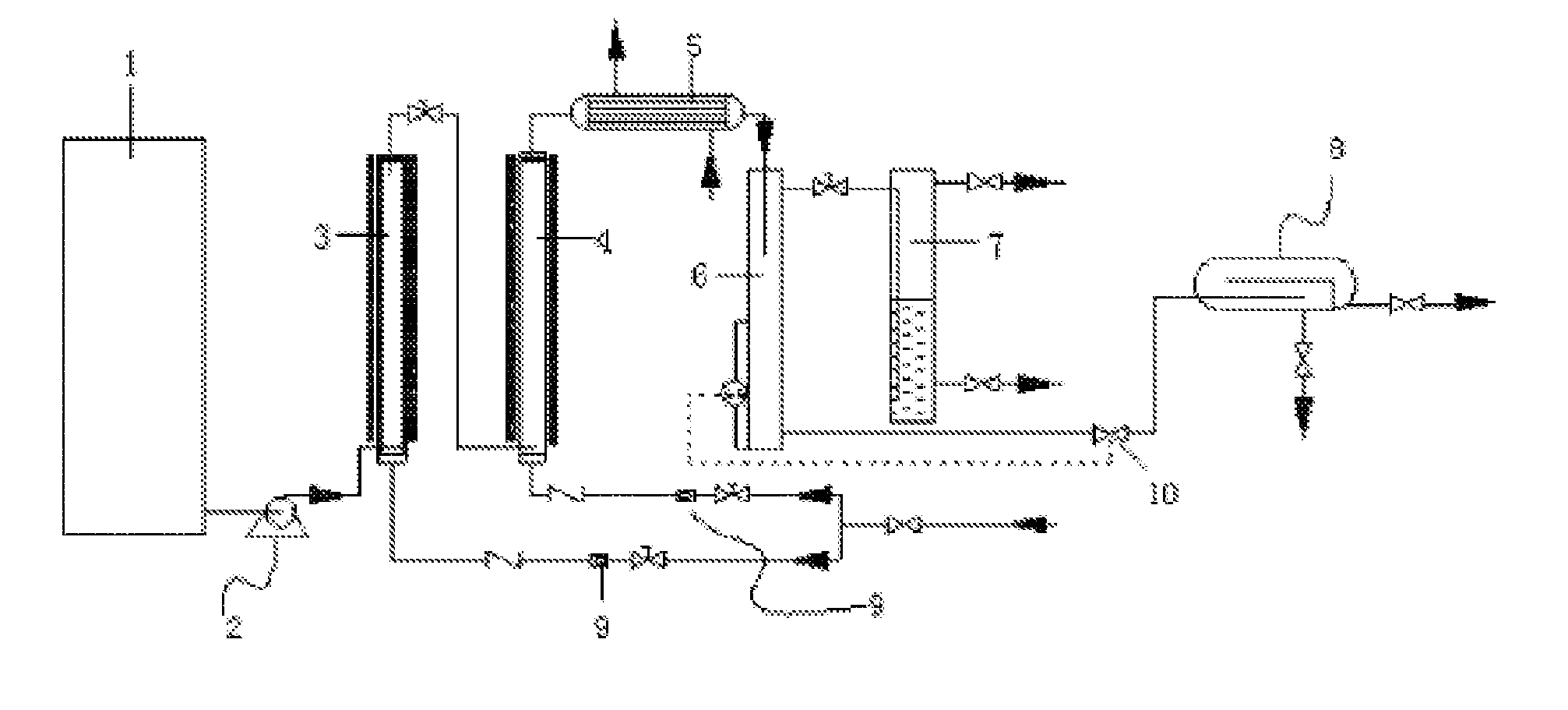

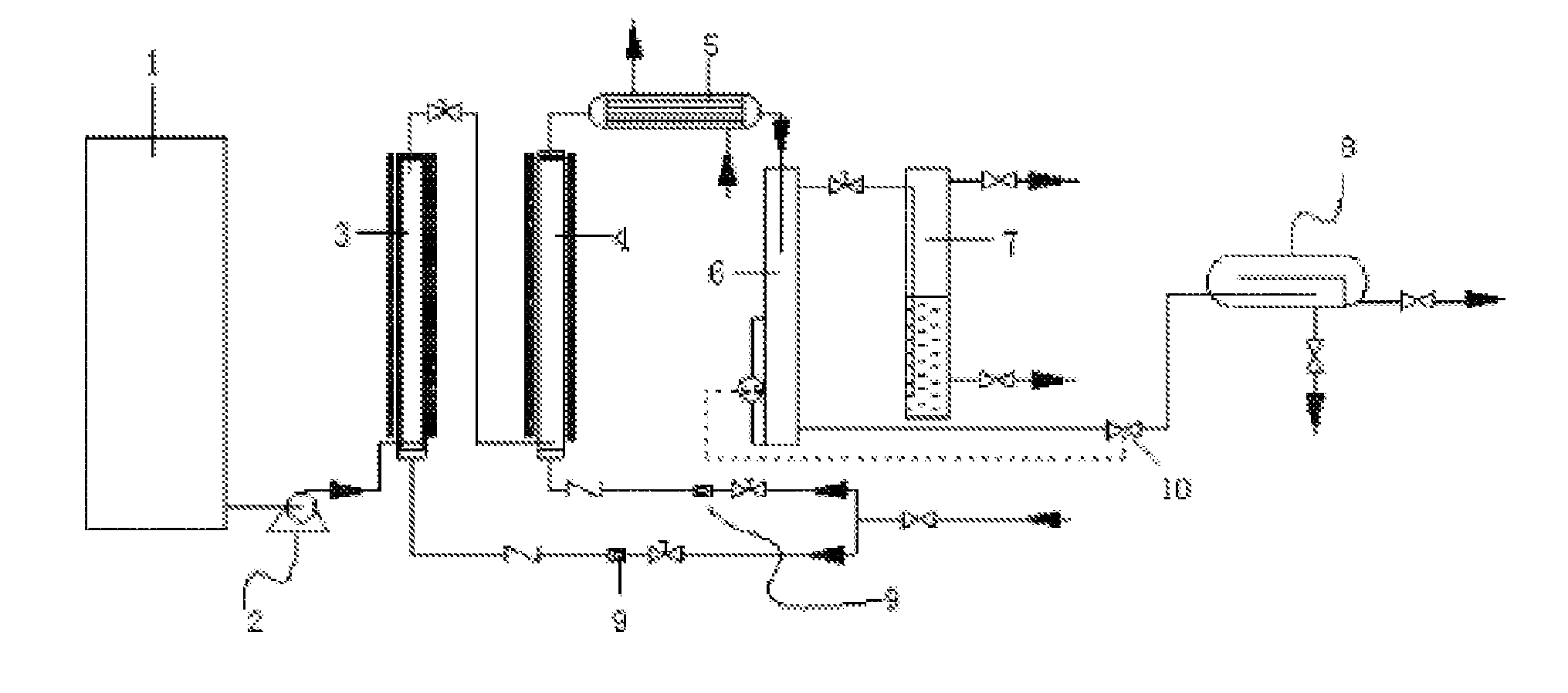

Purification system for flue gas generated by burning wastes and purification process thereof

InactiveCN101810992ASimple purification processEfficient purification processCombination devicesFlue gasSewage

The invention discloses a purification system for flue gas generated by burning wastes and a purification process thereof. The purification system comprises a flue of a refuge incinerator, a dust remover, a device for decomposing and removing dioxins, a flue gas washing tower, a fly ash collecting device, a fly ash washing and dehydrating system, a sewage treatment system, a flue gas heating device and a draught fan; one side of an inlet of the dust remover is connected with the flue, and the other side of the inlet of the dust remover is connected with the device for decomposing and removing dioxins; the fly ash collecting device is connected under the dust remover and the fly ash washing and dehydrating system; the device for decomposing and removing dioxins is connected with the lower part of the flue gas washing tower through a pipeline; an outlet of the flue gas washing tower is connected with the flue gas heating device; meanwhile, a water drain of the flue gas heating device is respectively connected with the fly ash washing and dehydrating system and the sewage treatment system; and purified flue gas is exhausted through the draught fan by using the flue gas heating device. The flue gas can meet the stricter exhaust standard by the purification treatment processes of removing dust, decomposing the dioxins, absorbing and neutralizing acid gases, removing heavy metals, deeply removing dust and the like.

Owner:瀚蓝(厦门)固废处理有限公司 +2

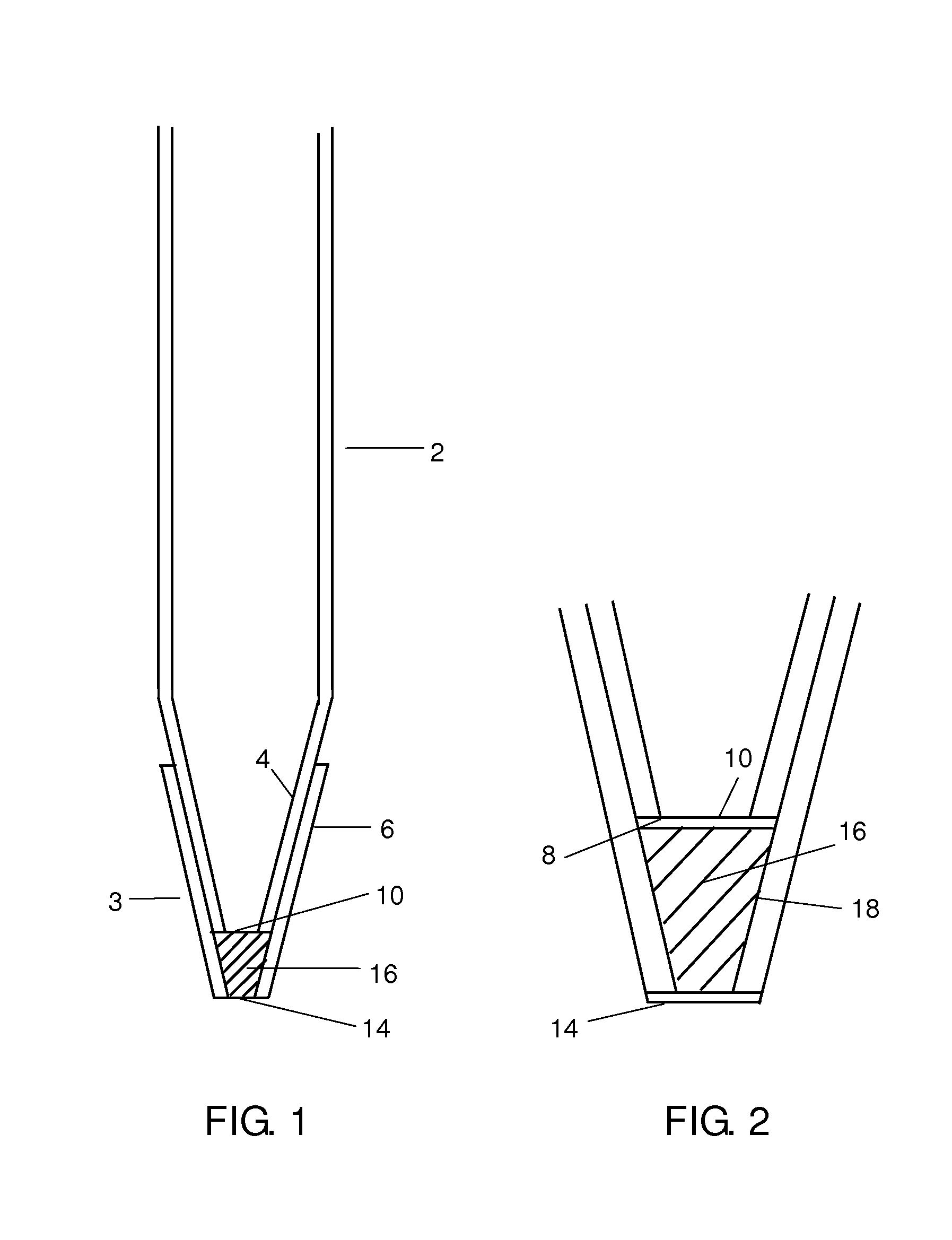

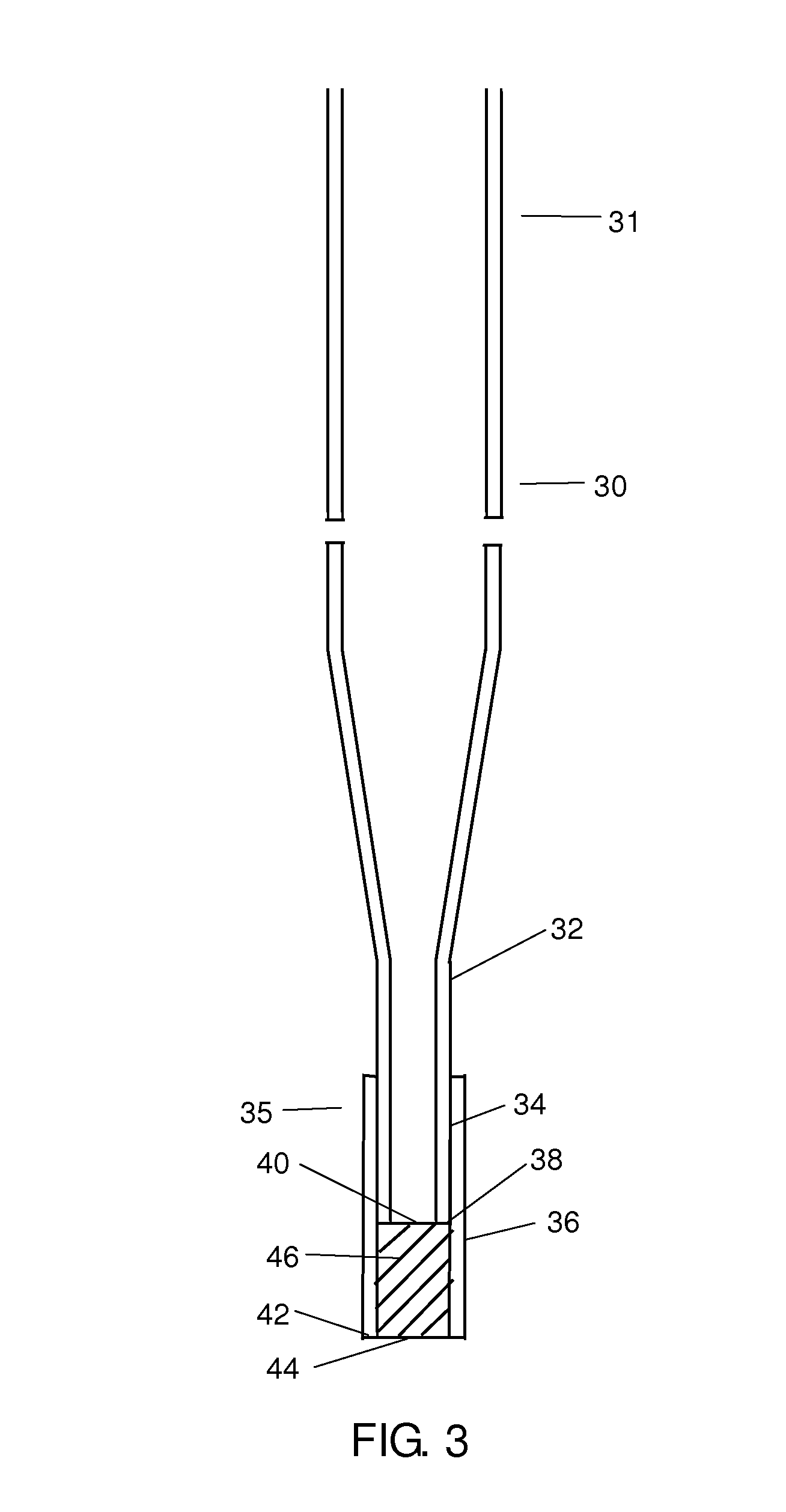

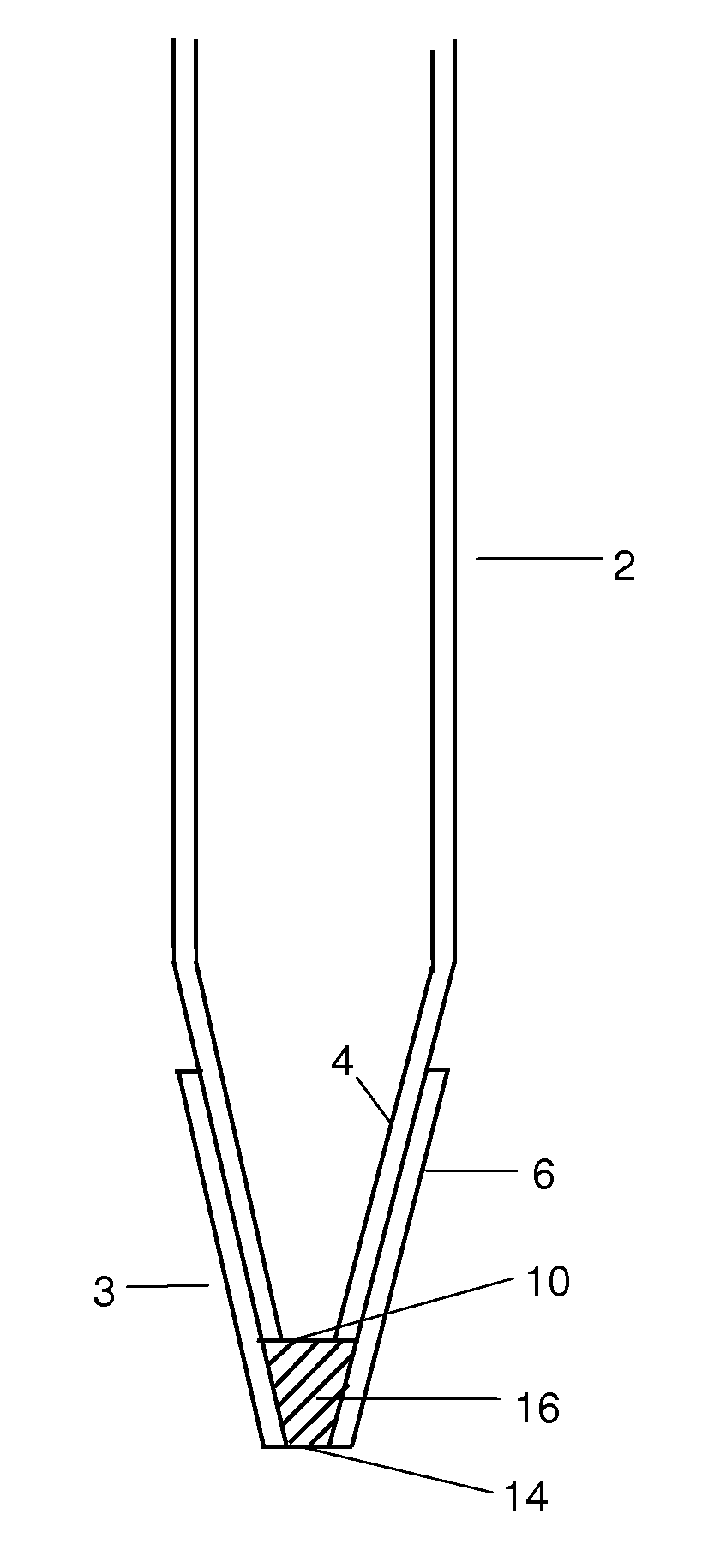

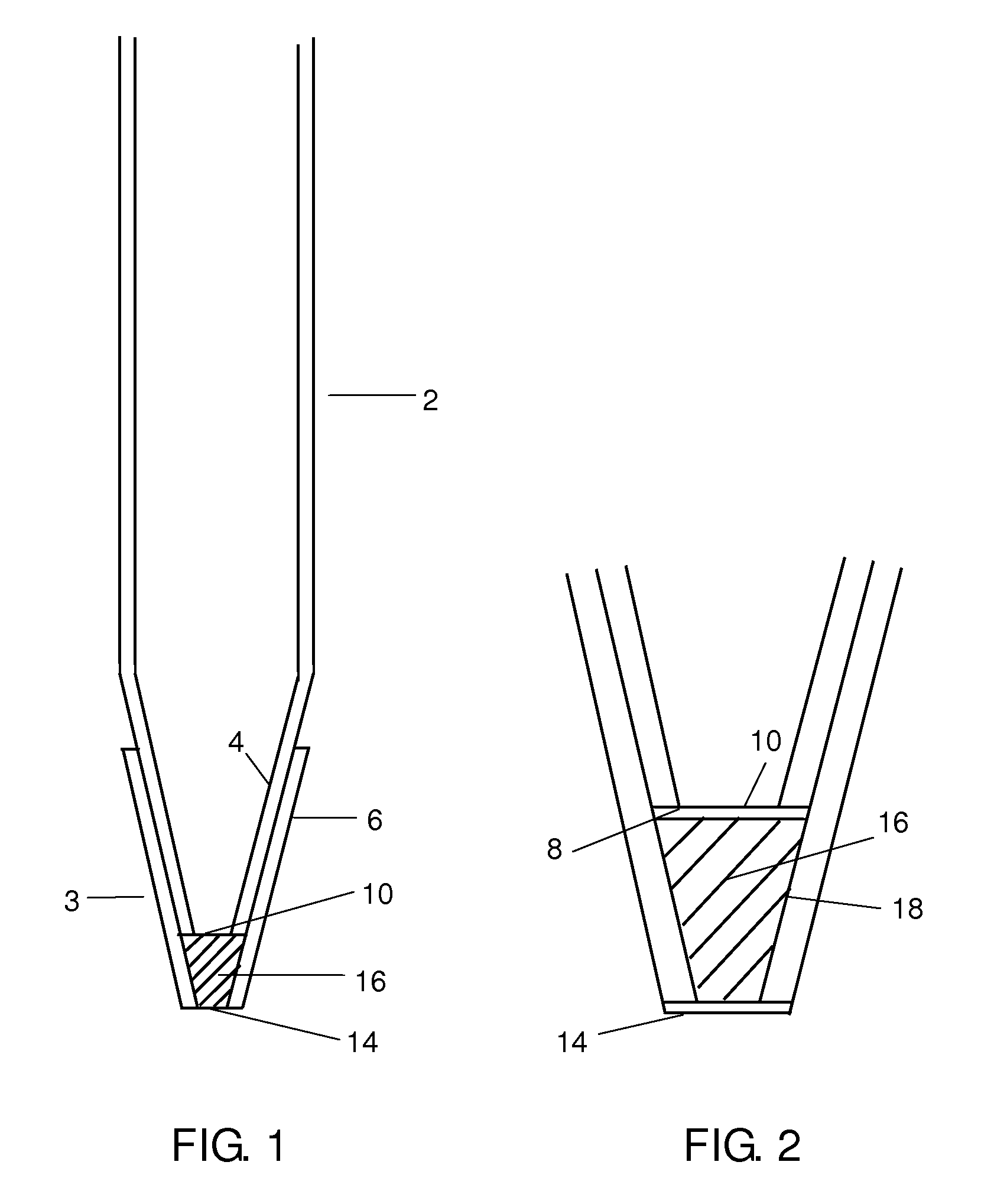

Method and device for sample preparation

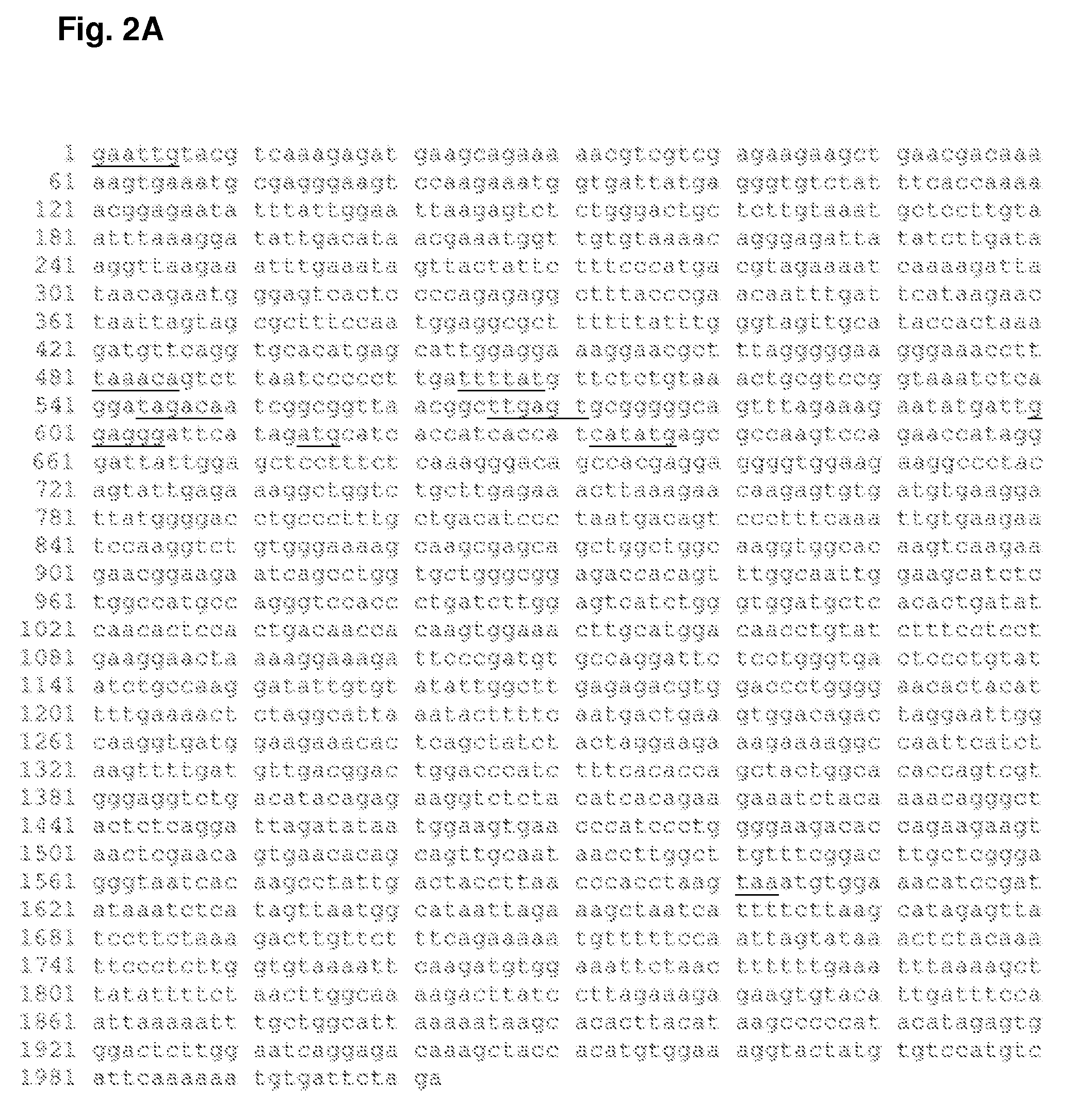

InactiveUS20100200509A1Easily plug columnAvoid purificationMaterial nanotechnologyComponent separationPipetteFrit

The invention provides pipette tip extraction columns for the purification of a DNA vector from un-clarified cell lysate containing cell debris as well as methods for making and using such columns. The columns typically include a bed of extraction media positioned in the pipette tip column, above a bottom frit and with an optional top frit.

Owner:PHYNEXUS

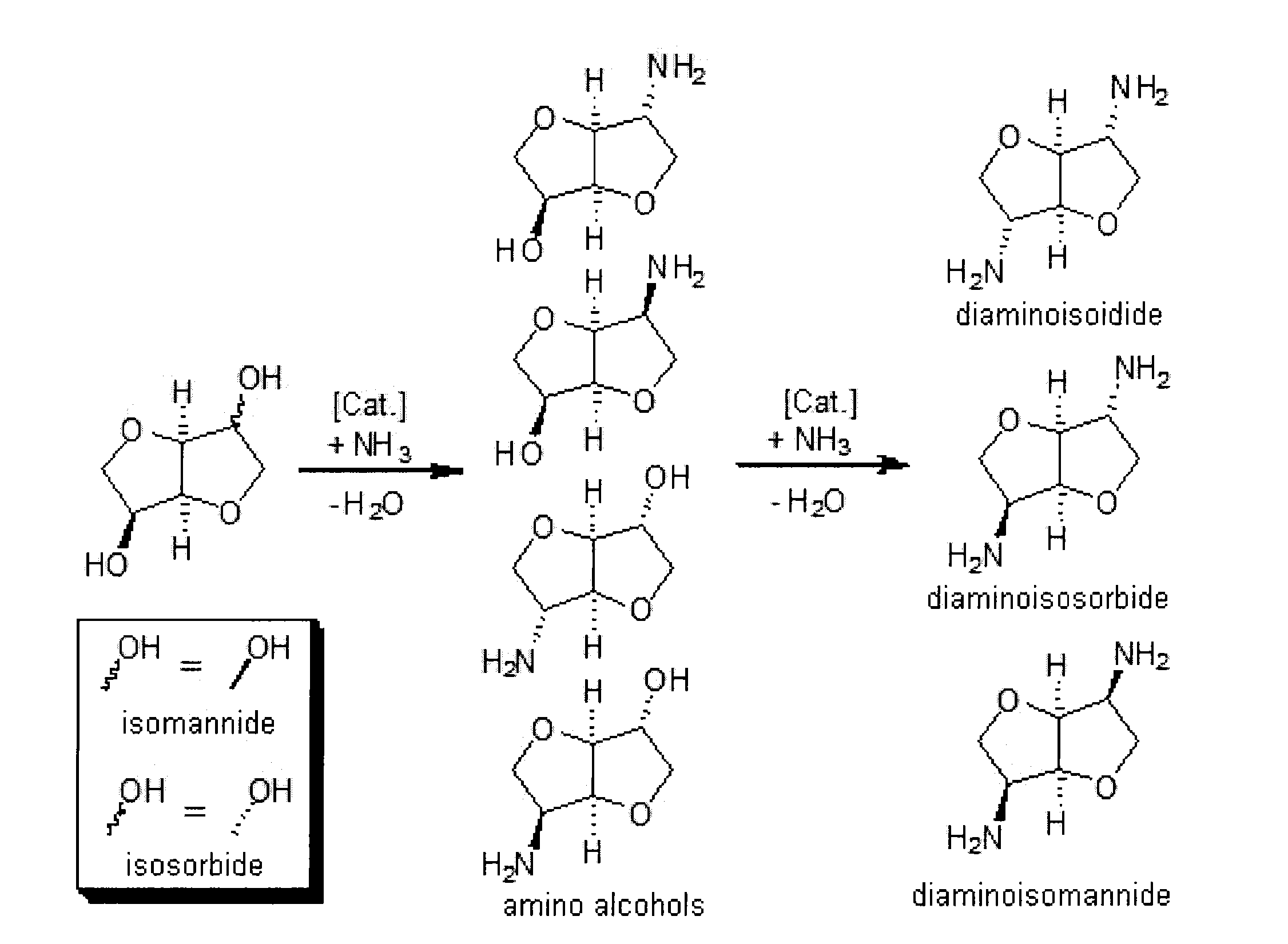

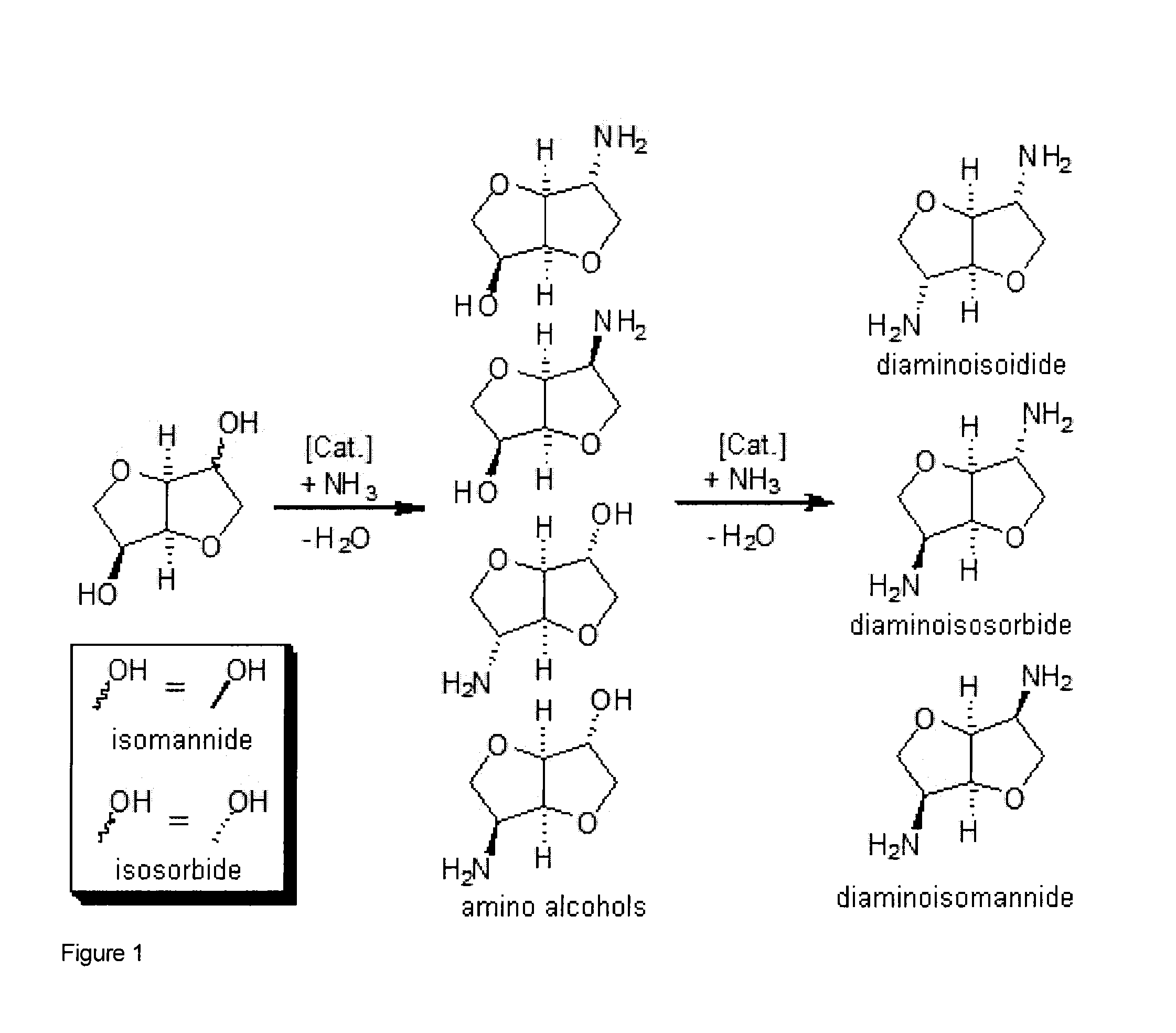

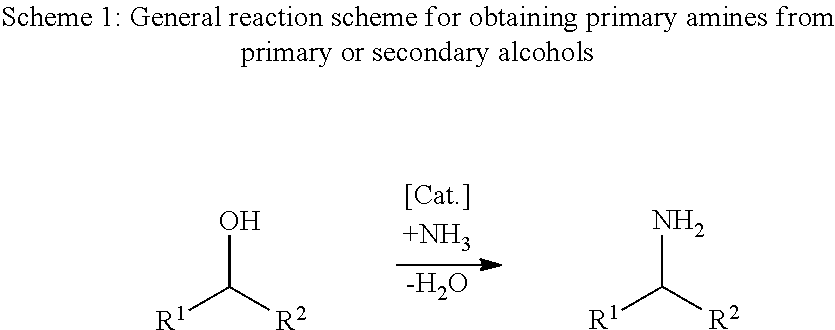

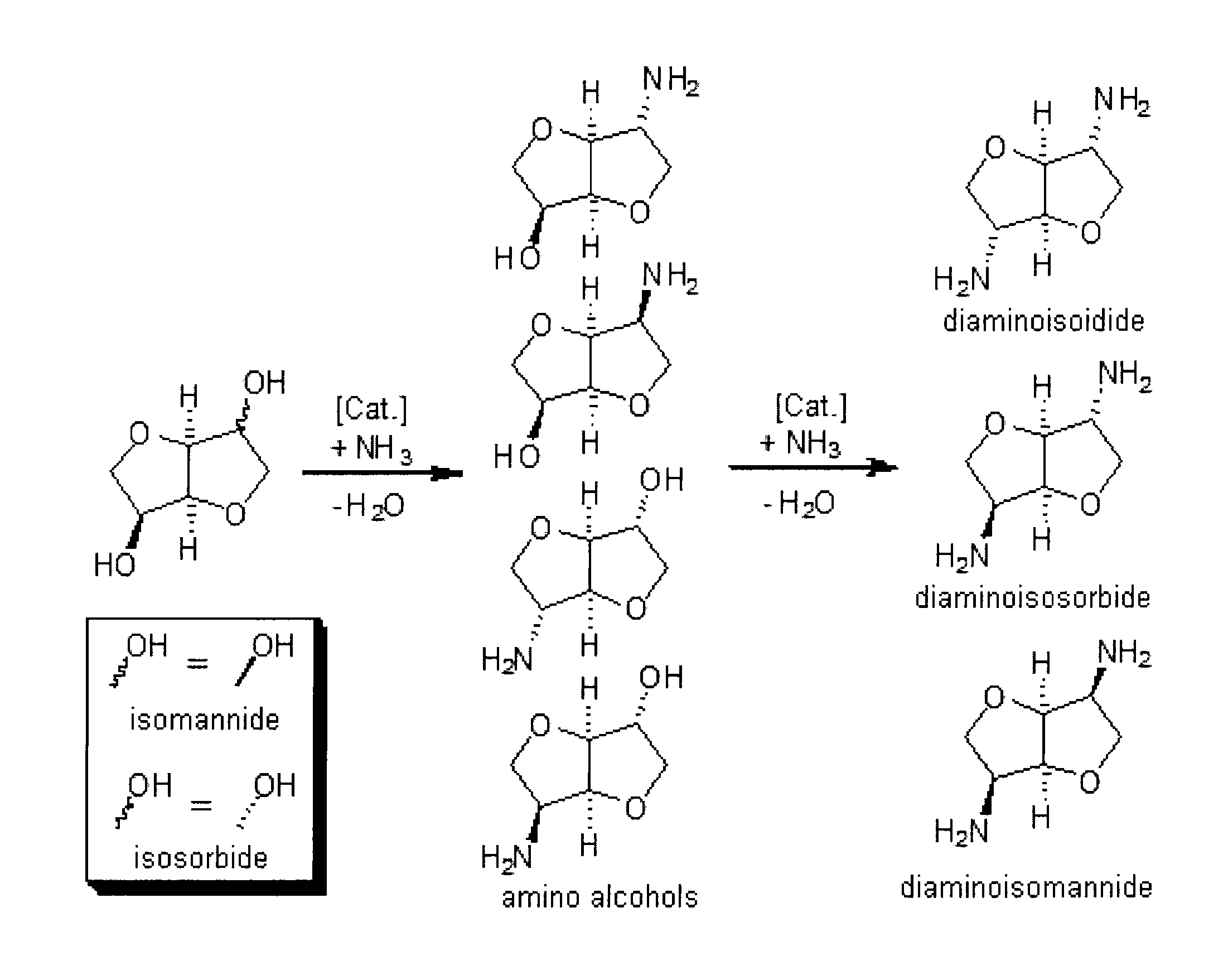

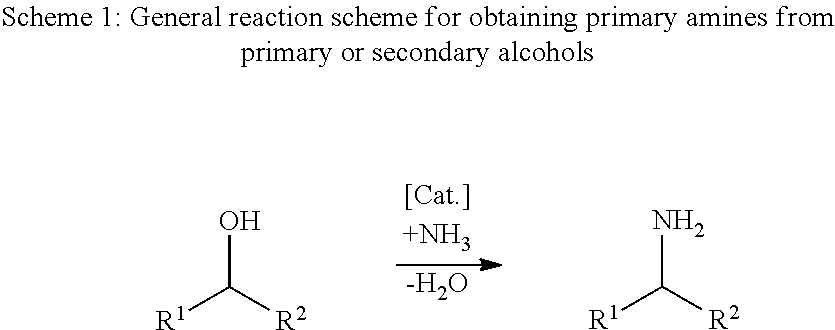

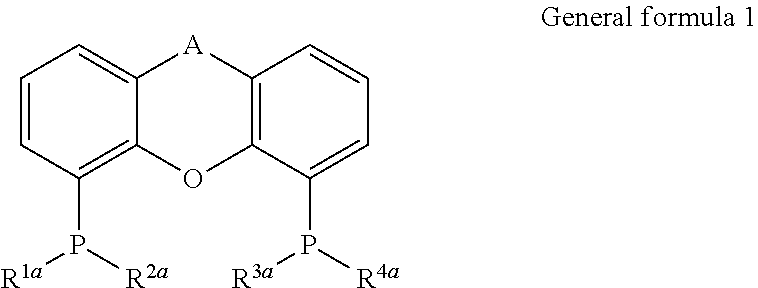

Process for the direct amination of secondary alcohols with ammonia to give primary amines

InactiveUS20130165672A1Isolation and purification of intermediatesAvoid isolationOrganic compound preparationAmino compound preparationAlcoholGas phase

The invention relates to a process for preparing primary amines which comprises the process stepsA) provision of a solution of a secondary alcohol in a fluid, nongaseous phase,B) contacting of the phase with free ammonia and / or at least one ammonia-releasing compound and a homogeneous catalyst and optionallyC) isolation of the primary amine formed in process step B),characterized in that the volume ratio of the volume of the liquid phase to the volume of the gas phase in process step B is greater than or equal to 0.25, and / or in that the ammonia is used in process step B) in a molar ratio based on the hydroxyl groups in the secondary alcohol of at least 5:1.

Owner:EVONIK DEGUSSA GMBH

Method and device for sample preparation

InactiveUS8377715B2Easily plug columnsAvoid purificationMaterial nanotechnologyComponent separationFritPipette

The invention provides pipette tip extraction columns for the purification of a DNA vector from un-clarified cell lysate containing cell debris as well as methods for making and using such columns. The columns typically include a bed of extraction media positioned in the pipette tip column, above a bottom frit and with an optional top frit.

Owner:PHYNEXUS

Novel method for producing balsampear polypeptide protein extract at low temperature in whole course, balsampear polypeptide protein extract and application thereof

InactiveCN107468744AReduce energy consumptionIncrease productivityHydrolysed protein ingredientsMetabolism disorderSlagUltrafiltration

The invention provides a novel method for producing balsampear polypeptide protein extract at a low temperature in the whole course, the balsampear polypeptide protein extract and application thereof, and relates to the technical field of food deep processing. The method comprises the following steps: washing a balsampear raw material, pulping and grinding, putting into a temperature-controllable ultrasonic-assistant extraction tank, adding a neutral buffer solution for extracting, and centrifugally removing slag to obtain centrifugate; filtering the centrifugate through a microfiltration membrane system to obtain microfiltration membrane permeate; filtering the permeate through two roll-to-roll ultrafiltration membrane purification systems having different molecular weights to obtain ultrafiltration membrane trapped fluid; concentrating the trapped fluid with a roll-to-roll high-pressure reverse osmosis permeable membrane to obtain a concentrate having a solid content of more than or equal to 30 percent; and drying the concentrate. The method is operated at normal temperature, and natural activity and more than 20 percent of content of the balsampear polypeptide protein can be effectively guaranteed; the produced balsampear extract has the function of regulating blood glucose, and can be applied to special dietary foods, health foods or medicines for treating or preventing diabetes mellitus.

Owner:李玉保 +2

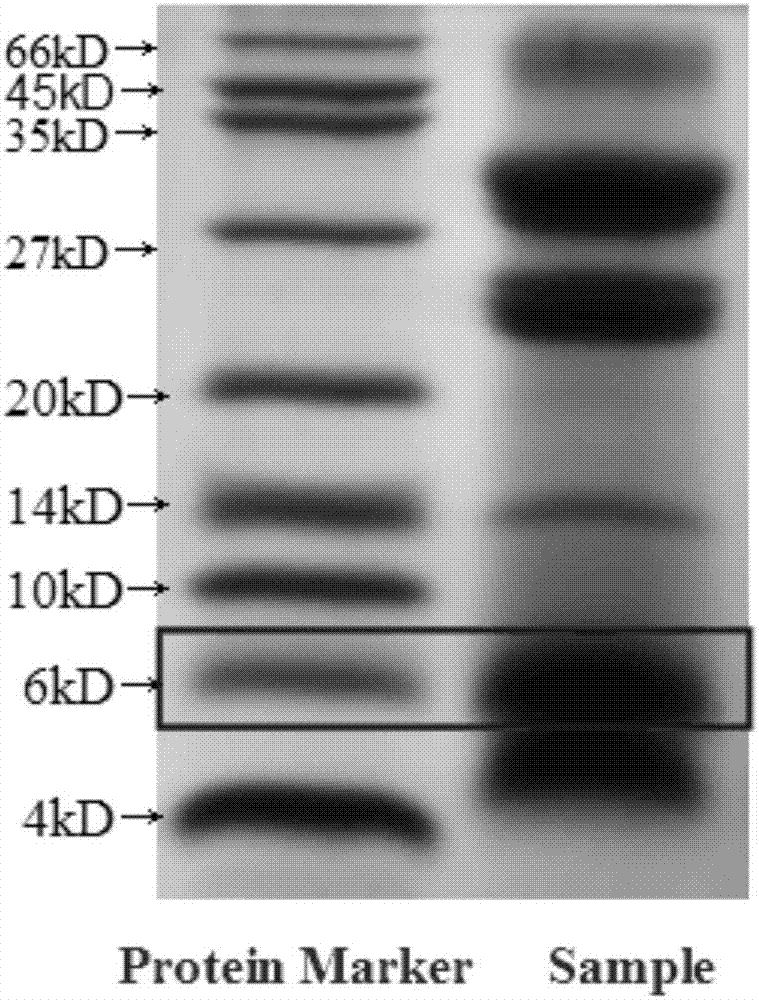

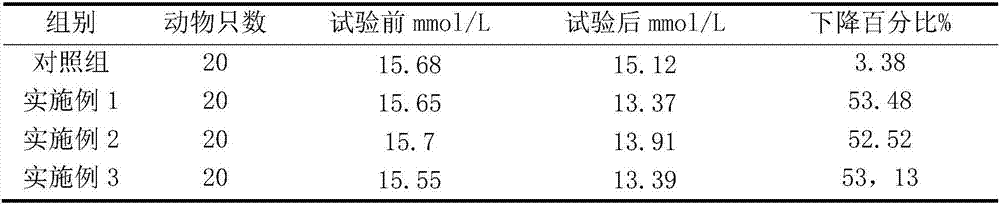

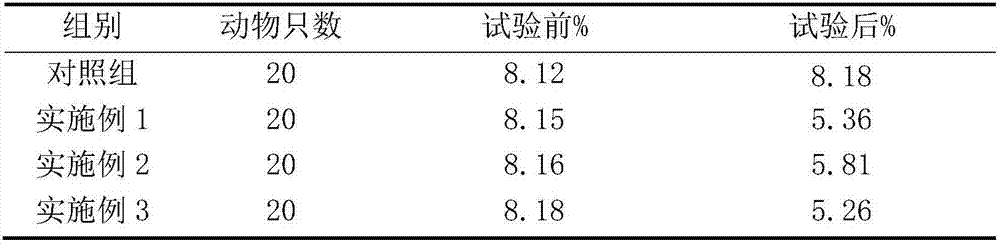

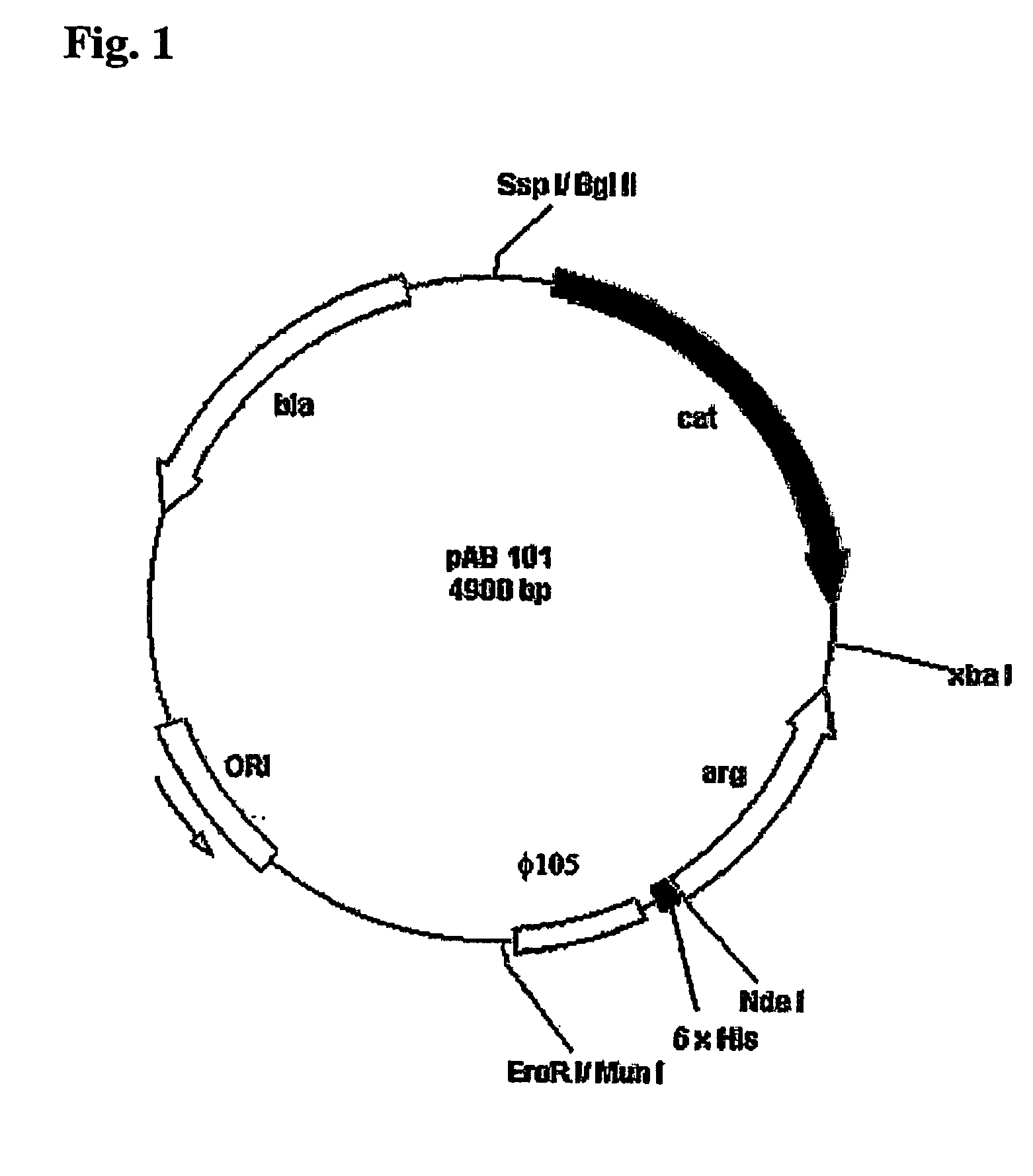

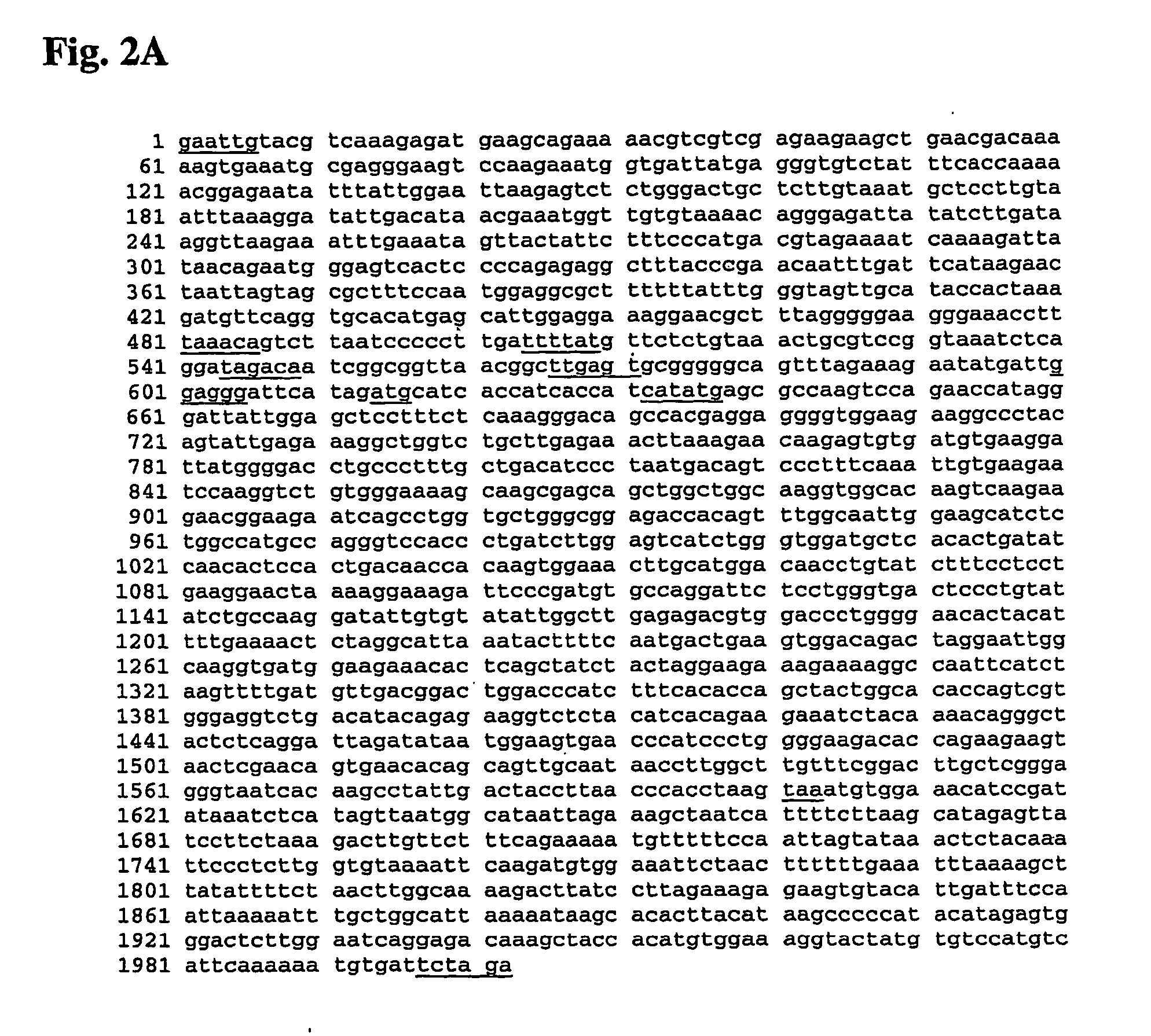

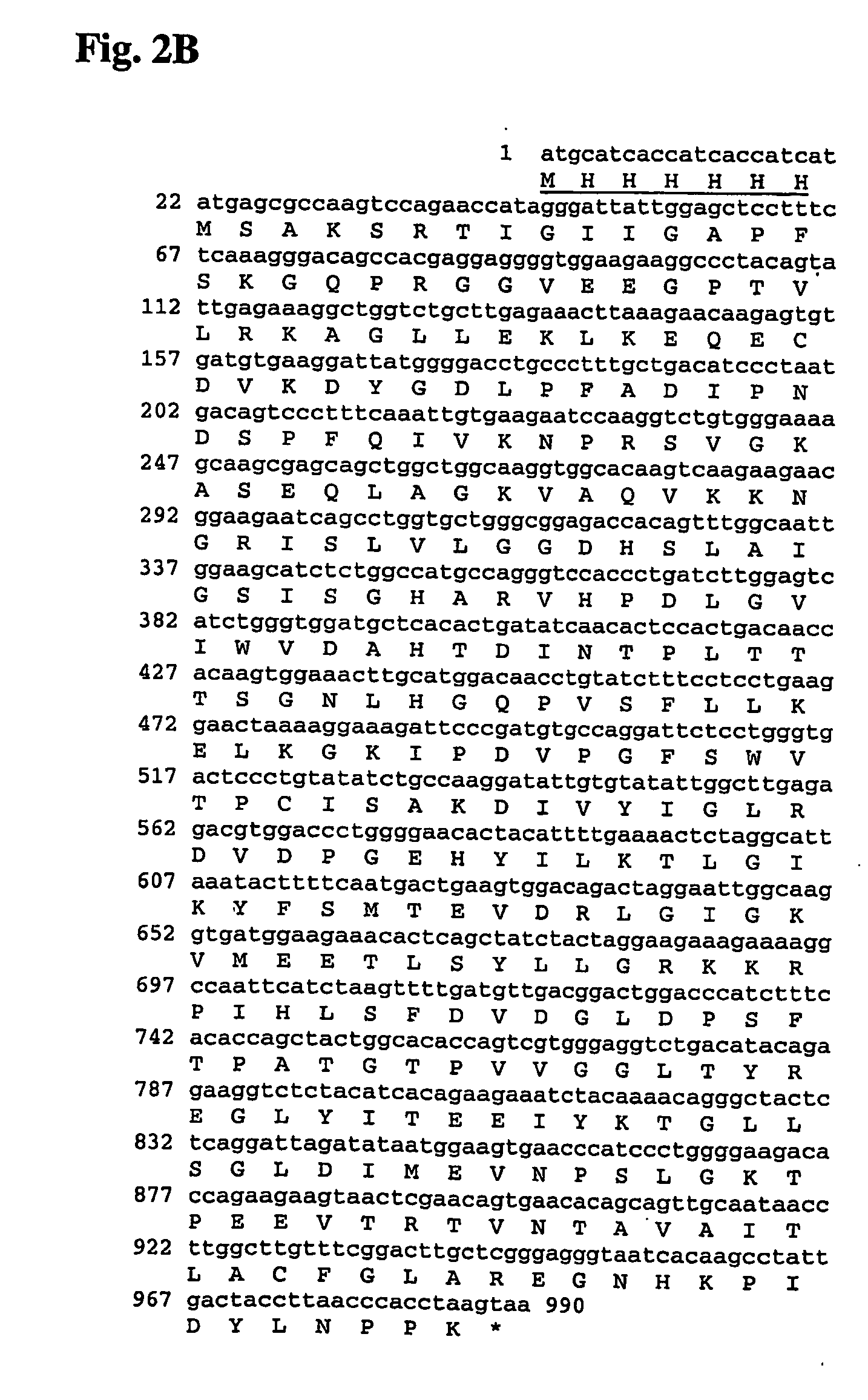

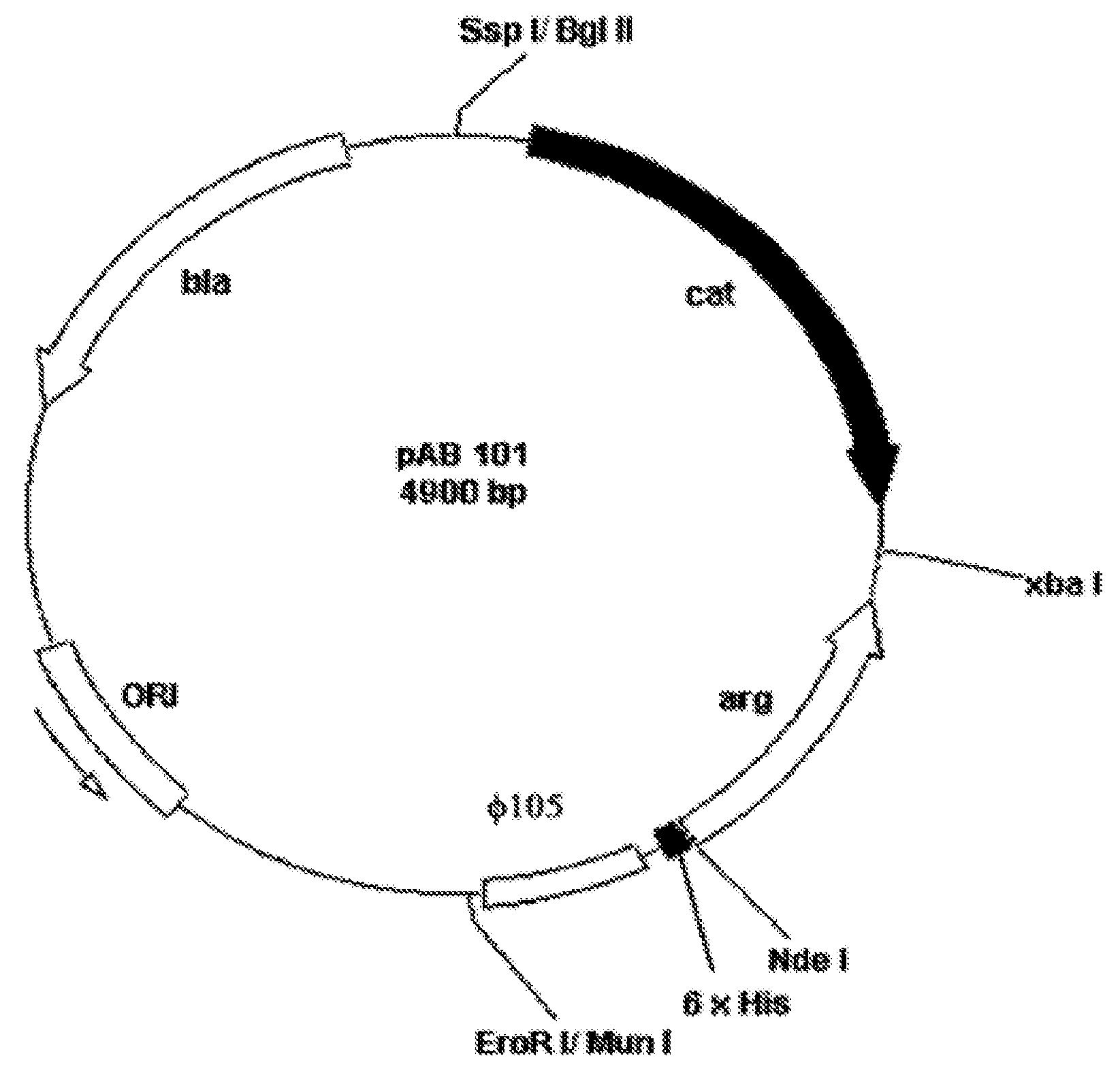

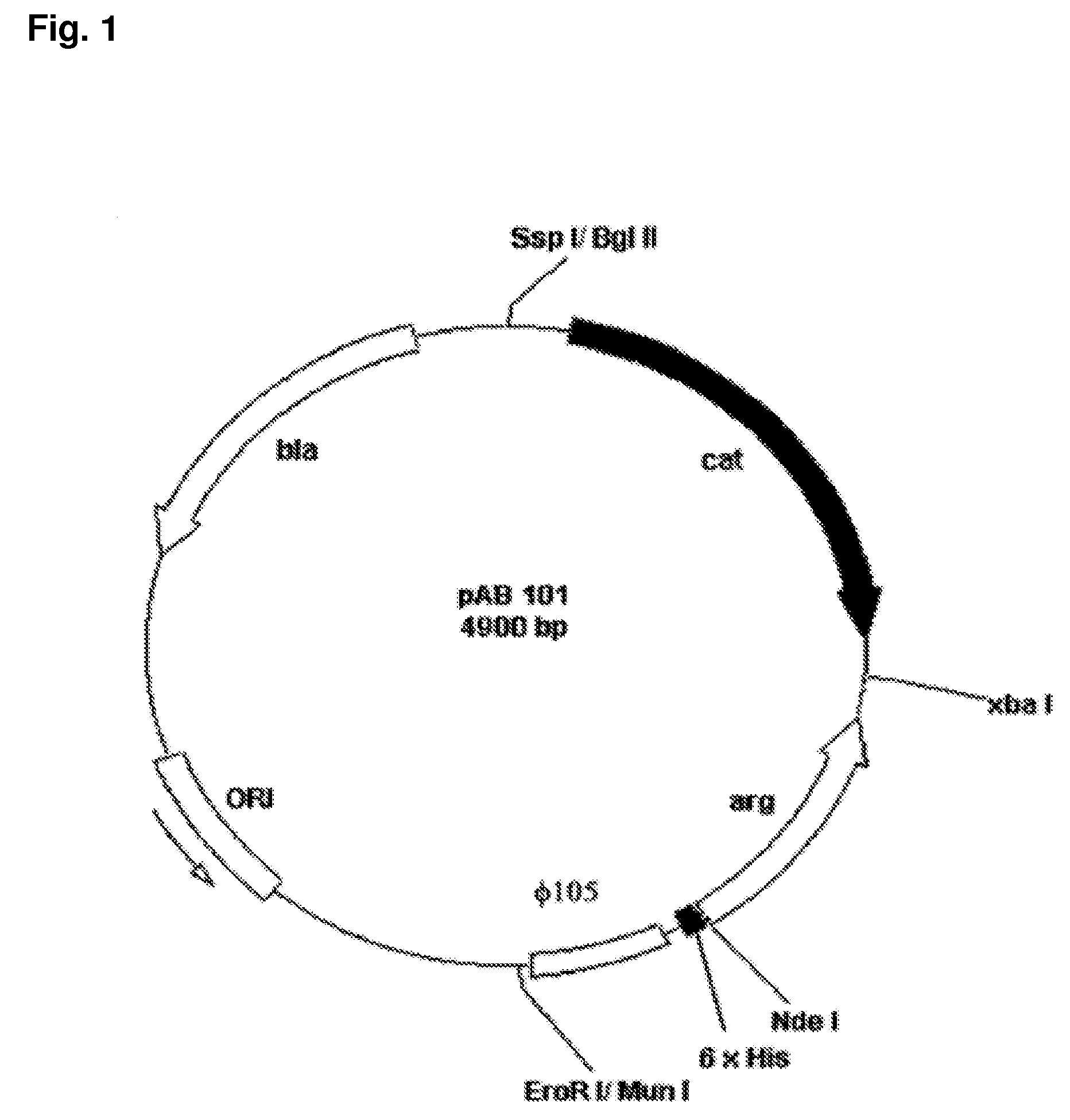

Pharmaceutical preparation and method of treatment of human malignancies with arginine deprivation

ActiveUS20050244398A1Improve enzymatic activityImprove stabilityBacteriaHydrolasesMalignancyArginase

The present invention provides an isolated and substantially purified recombinant human arginase having sufficiently high enzymatic activity and stability to maintain Adequate Arginine Depletion in a patient. The present invention also provides a pharmaceutical composition comprising the modified invention enzyme and method for treatment of diseases using the pharmaceutical composition.

Owner:BIO CANCER TREATMENT INT

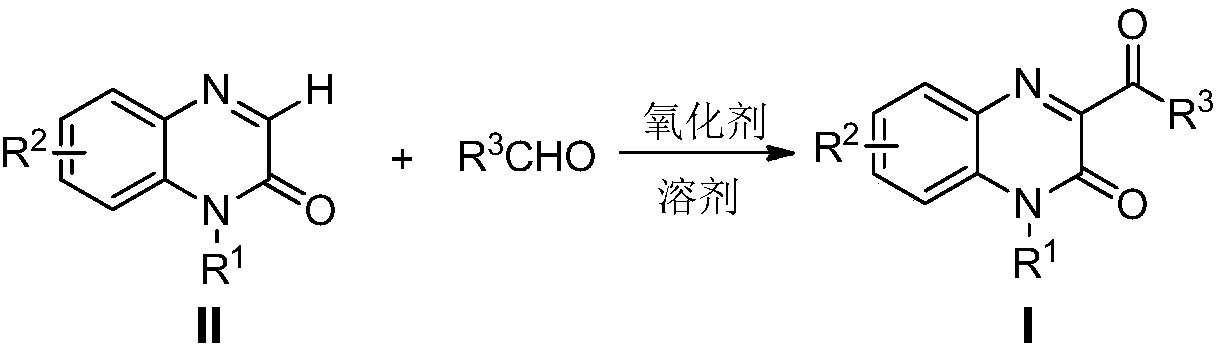

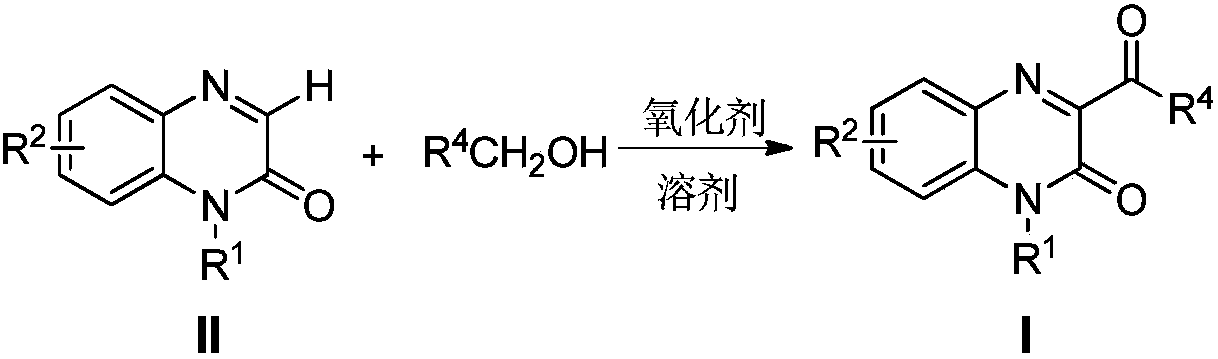

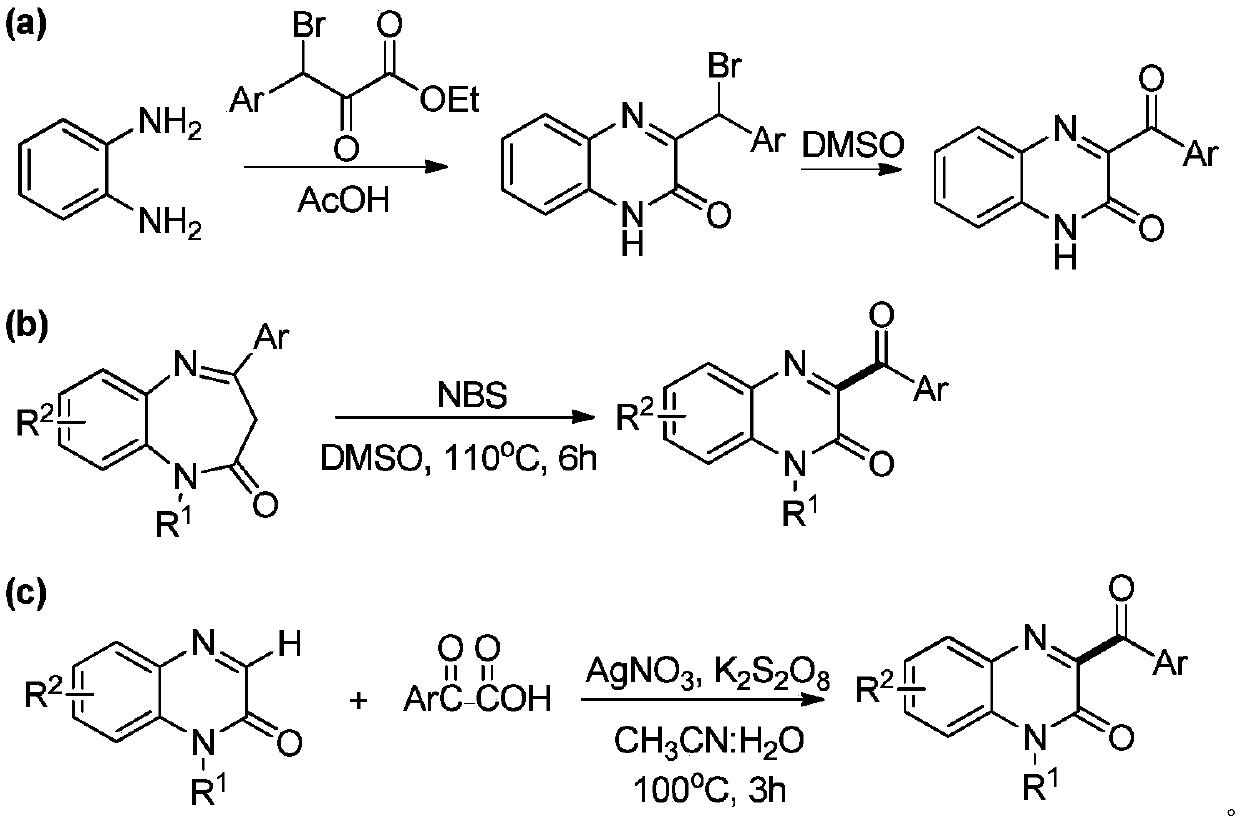

Method for preparing 3-acyl quinoxaline ketone derivative

The invention discloses a method for preparing a 3-acyl quinoxaline ketone derivative (I) and belongs to the field of organic chemistry The method comprises the following steps: by taking a substituted quinoxaline-2-ketone derivative and aldehyde or benzyl alcohol as raw materials, and a 70% tert-butyl hydroperoxide (TBHP) solution as an oxidant, performing a heating reaction in a solvent withoutmetal catalysis, thereby synthesizing the 3-acyl quinoxaline ketone derivative. Compared with a conventional synthesis method, the method has the advantages that firstly, the raw materials are cheap and easy to obtain, the 3-acyl quinoxaline ketone derivative is synthesized at one step, the cost is low, and good application prospects can be achieved; secondly, the method is gentle in reaction condition, high in yield, convenient to operate, beneficial to industrial production and the like, and the reactions are carried out under an air condition. The derivative has potential application in fields such as medicines, chemical engineering and materials, and the invention provides a novel way for synthesis of 3-acyl quinoxaline ketone derivatives. (Refer to Specification).

Owner:HENAN UNIVERSITY OF TECHNOLOGY

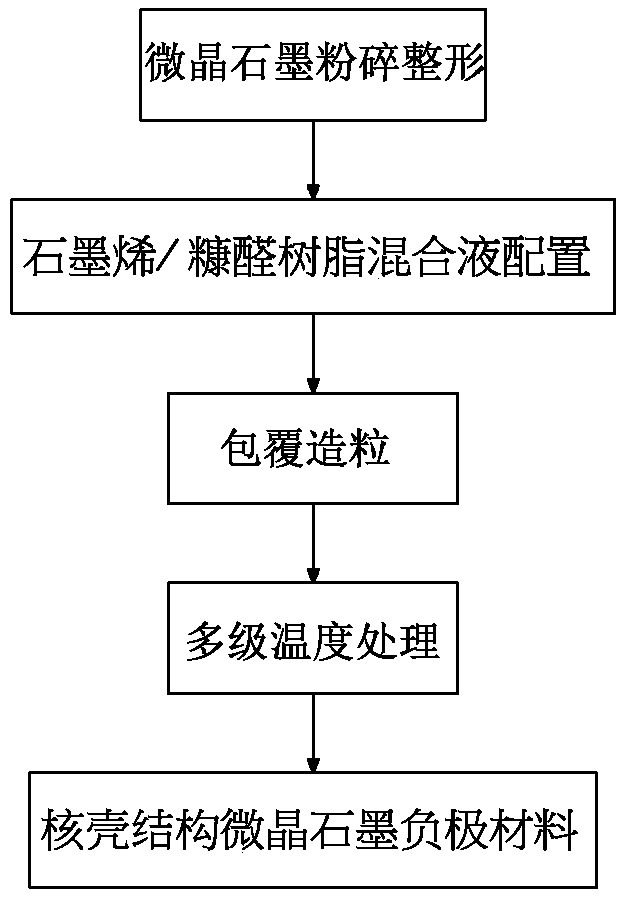

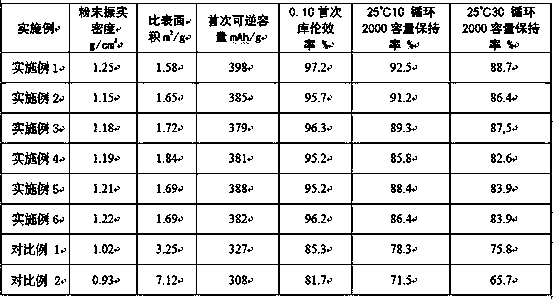

High-performance amorphous graphite negative electrode material and low-cost preparation method thereof

ActiveCN109824047AHigh carbon residue rateHigh densityCarbon compoundsCell electrodesHigh carbonPliability

The invention discloses a high-performance amorphous graphite negative electrode material and a low-cost preparation method thereof. The method includes the steps: (1) crushing and shaping; (2) graphene / furfural resin mixed liquid preparation; (3) coating and granulating; (4) treatment at multistage temperatures. An asphalt / furfural resin composite coating material has high carbon yield, densityand graphitization degree, graphene is doped into the material, and the material is used for enhancing high conductivity and toughness of electrons / ions and improving structure stability. By the aid of a multistage temperature treatment mode, carbonization, graphitization and amorphous graphite purification are combined and implemented, complicated purification of high-purity amorphous graphite isavoided, the method is green and environmentally friendly, processes are simplified, and cost is reduced.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

Process for the direct amination of secondary alcohols with ammonia to give primary amines

InactiveUS8927773B2Isolation and purification of intermediatesAvoid isolationOrganic compound preparationAmino compound preparationAlcoholGas phase

The invention relates to a process for preparing primary amines which comprises the process stepsA) provision of a solution of a secondary alcohol in a fluid, nongaseous phase,B) contacting of the phase with free ammonia and / or at least one ammonia-releasing compound and a homogeneous catalyst and optionallyC) isolation of the primary amine formed in process step B),characterized in that the volume ratio of the volume of the liquid phase to the volume of the gas phase in process step B is greater than or equal to 0.25, and / or in that the ammonia is used in process step B) in a molar ratio based on the hydroxyl groups in the secondary alcohol of at least 5:1.

Owner:EVONIK DEGUSSA GMBH

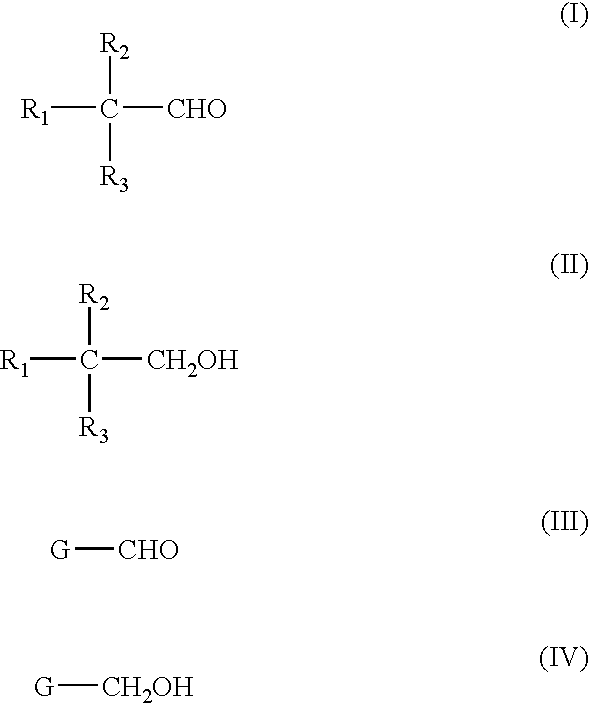

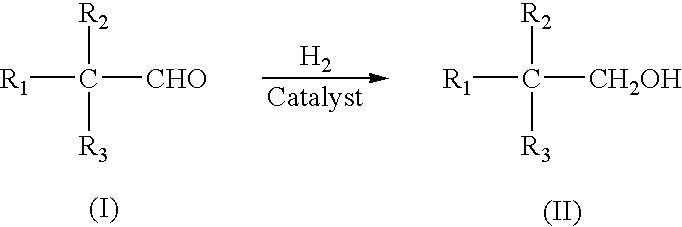

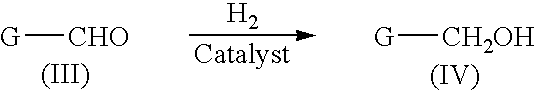

Liquid phase catalytic hydrogenation process to convert aldehydes to the corresponding alcohols

InactiveUS6600078B1Easy to prepareEasy to handleOrganic compound preparationOrganic chemistry methodsChemistryAldehyde

A heterogeneous liquid-phase process for the hydrogenation of aldehydes of Formula (I) and (III) to the corresponding alcohols of Formula (II) and (IV) which process comprises contacting alcoholic or aqueous-alcoholic solution of aldehydes and hydrogen gas with a catalyst comprising a reduced mixture of CuO and ZnO in presence of a metal of group IIIA of the Periodic Table, such as aluminium, as a promoter at a temperature of between about 110° and 180° C. and a pressure of between about 20 and 500 psig.

Owner:SAUDI BASIC IND CORP SA

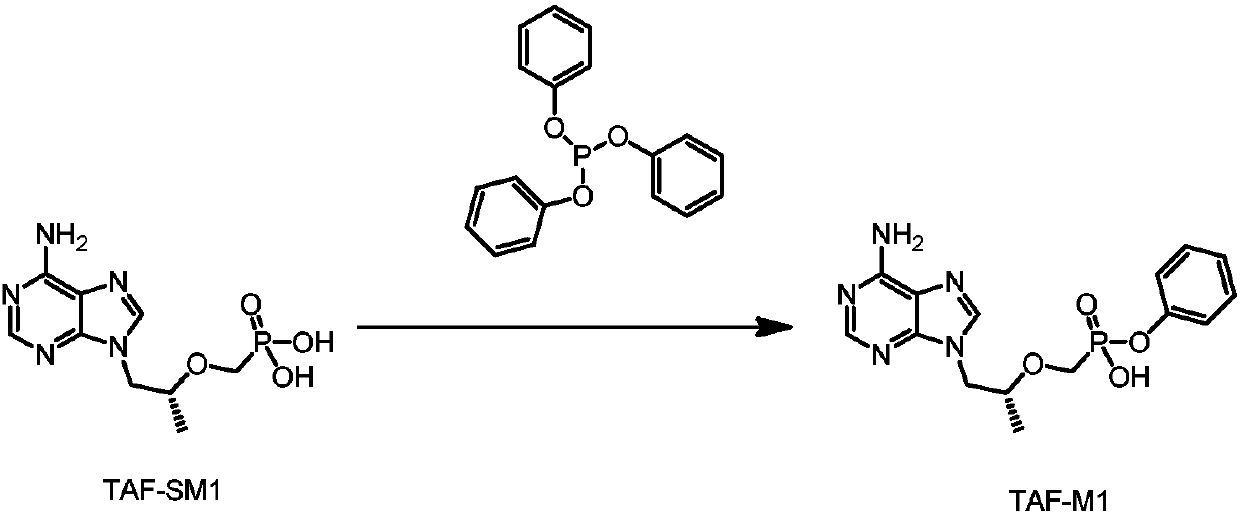

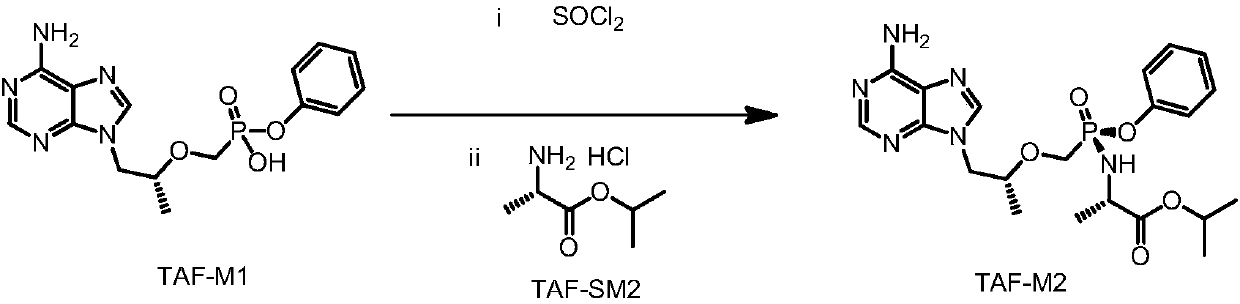

Preparation method of tenofovir alafenamide hemifumarate

InactiveCN107793452AAddressing StereoselectivitySolve control problemsOrganic compound preparationGroup 5/15 element organic compoundsTenofovir alafenamidePhenol

The invention discloses a preparation method of tenofovir alafenamide hemifumarate. The preparation method comprises the following steps of: reacting tenofovir with triphenyl phosphite under the condition of alkali catalysis to prepare tenofovir phenol ester; preparing tenofovir alafenamide through acylating chlorination and a reaction with L-alanine isopropyl ester; preparing tenofovir alafenamide hemifumarate by a special salt-forming process with fumaric acid. The tenofovir alafenamide hemifumarate prepared by the process is accurate in control of a salt type ratio, and simple in process operation, and avoids complex process operation and purification means such as chiral resolution, the total purity can reach 99% or more, and indexes of related substances are qualified.

Owner:YANGTZE RIVER PHARM GRP CO LTD

Smelting method of high-nitrogen sulfur-containing free-cutting steel

InactiveCN111876688AImprove purityQuality improvementManufacturing convertersProcess efficiency improvementSlagIngot

The invention discloses a smelting method of high-nitrogen sulfur-containing free-cutting steel. The smelting method mainly comprises the following steps of converter smelting tapping, LF refining furnace treatment, RH vacuum furnace treatment and continuous casting; an aluminum ingot is added in the tapping process for pre-deoxidation, low-alkalinity slag is made by an LF refining furnace, a small amount of aluminum particles are added in the slag surface, the diffusion deoxidation efficiency is improved, and molten steel is greatly purified; and an RH vacuum furnace adopts nitrogen drive, limit vacuum is kept for a certain time, a first-stage pump is retreated to a fourth-stage pump after vacuum breaking, a nitrogen-containing alloy is added, and circulation is conducted for 5 min, so that the S content and the N content in the steel can be accurately controlled, narrow-range accurate control over molten steel components is guaranteed, meanwhile, the refining period is stabilized, operation is easy, and the method is suitable for mass production. The method is simple, effective, easy to operate, capable of accurately controlling refining time and refining components, improving molten steel quality and guaranteeing the production rhythm and suitable for wide popularization.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

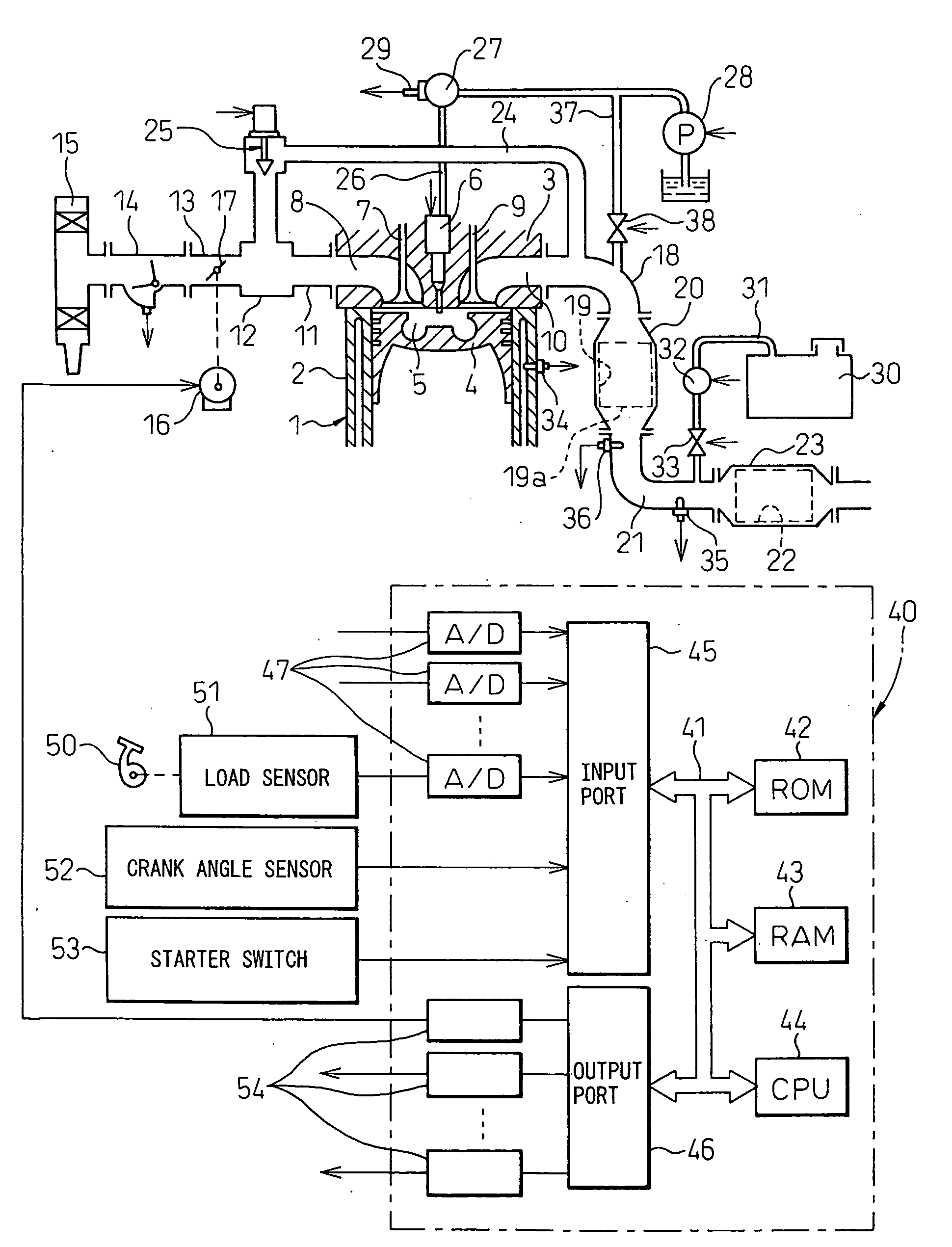

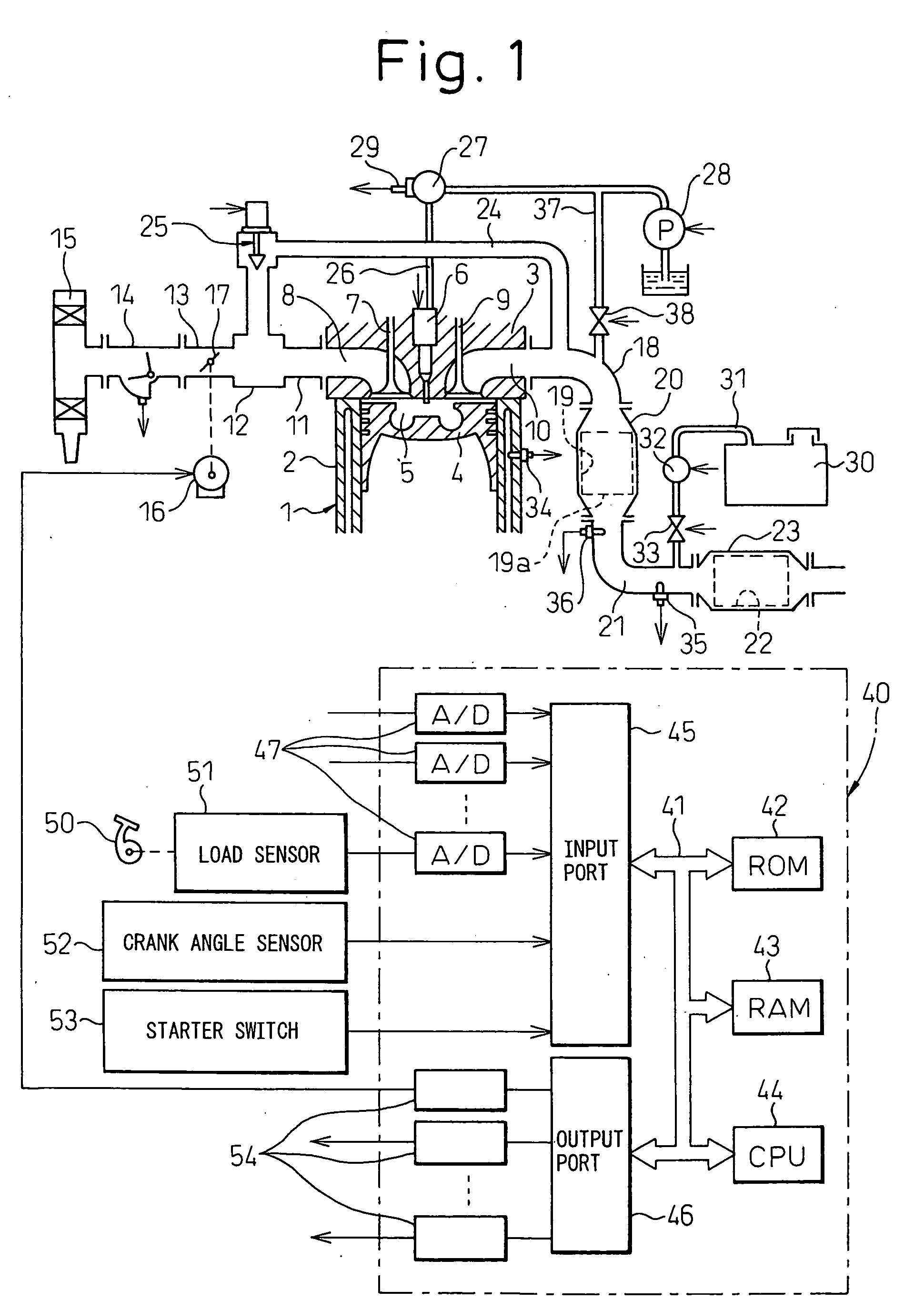

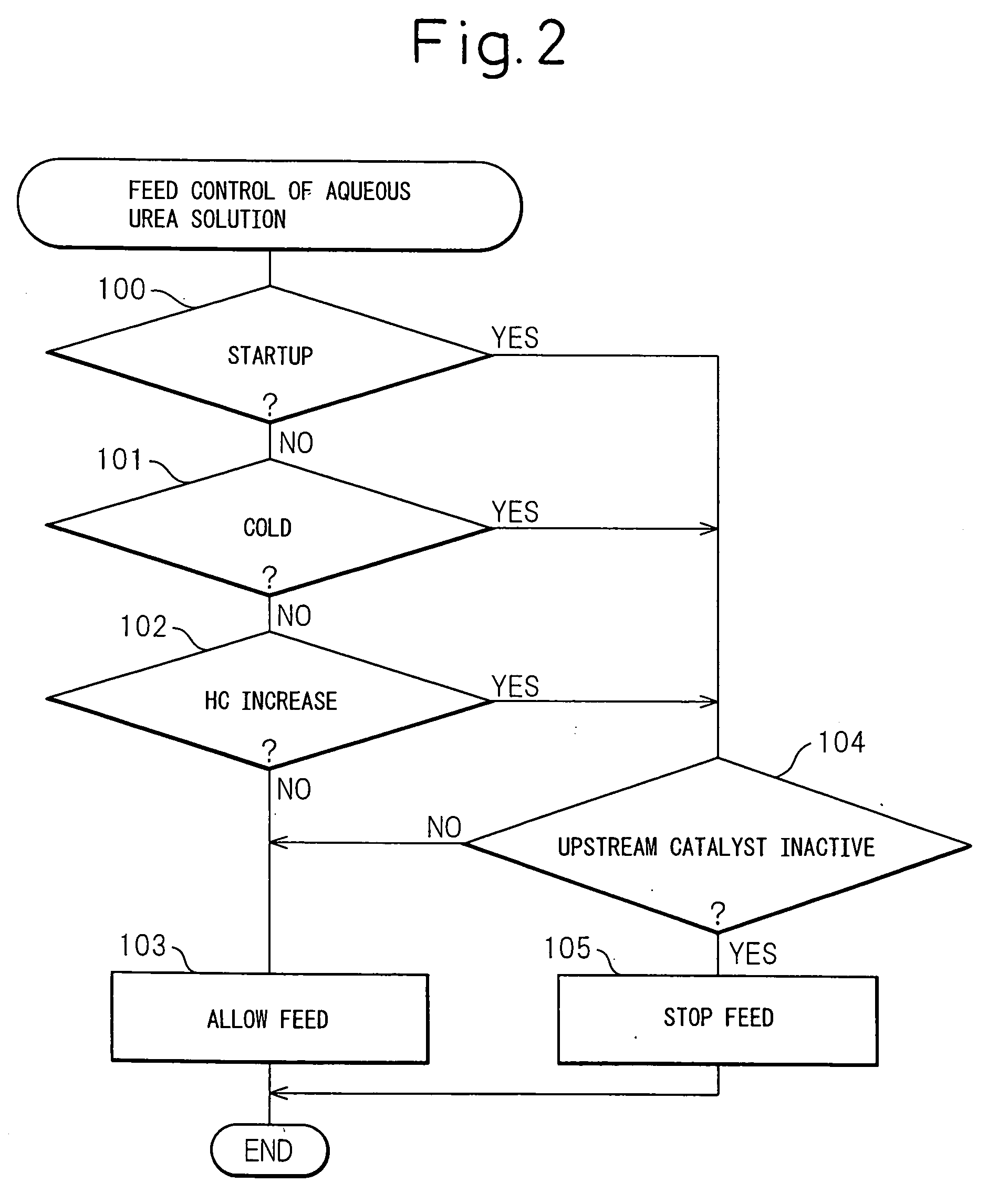

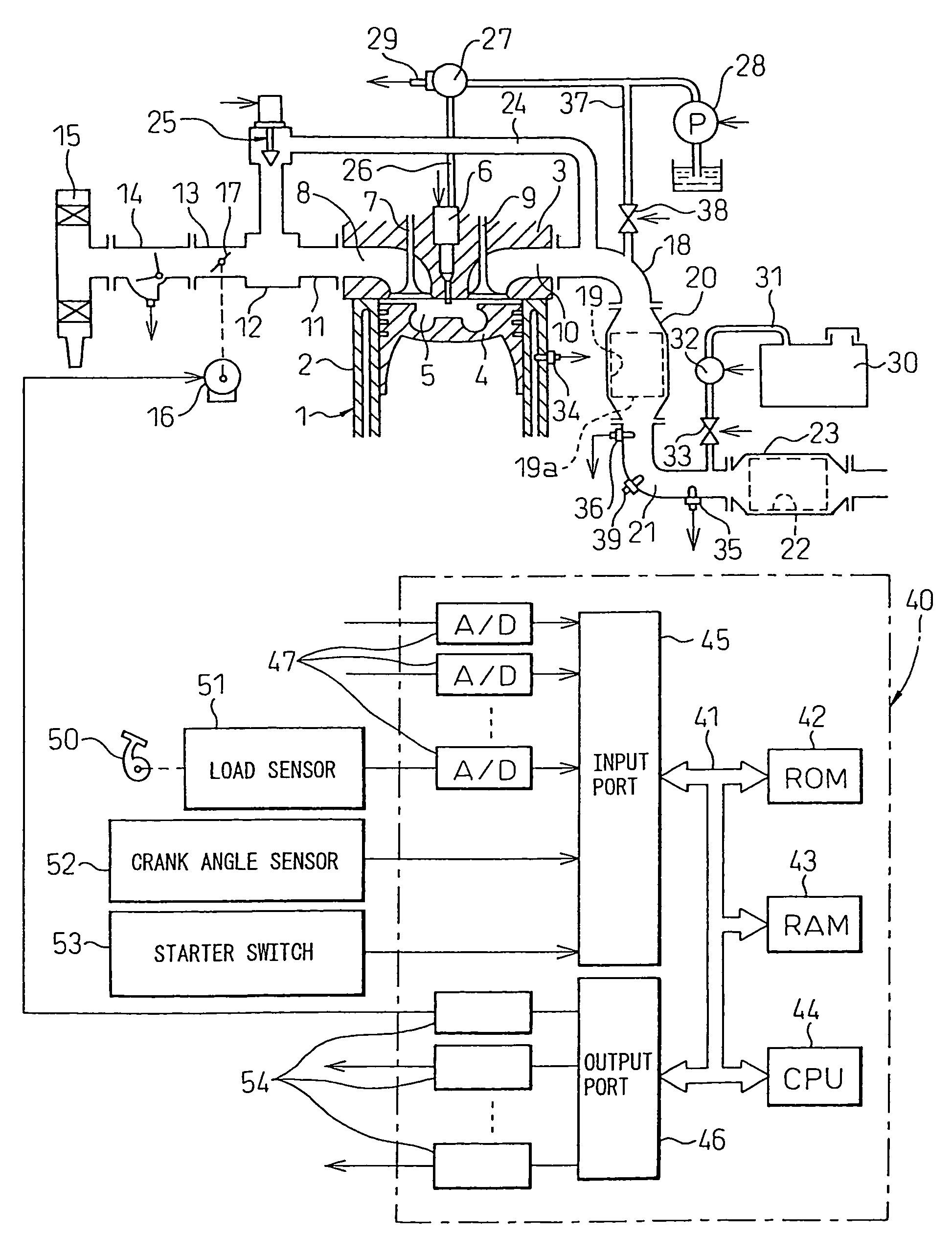

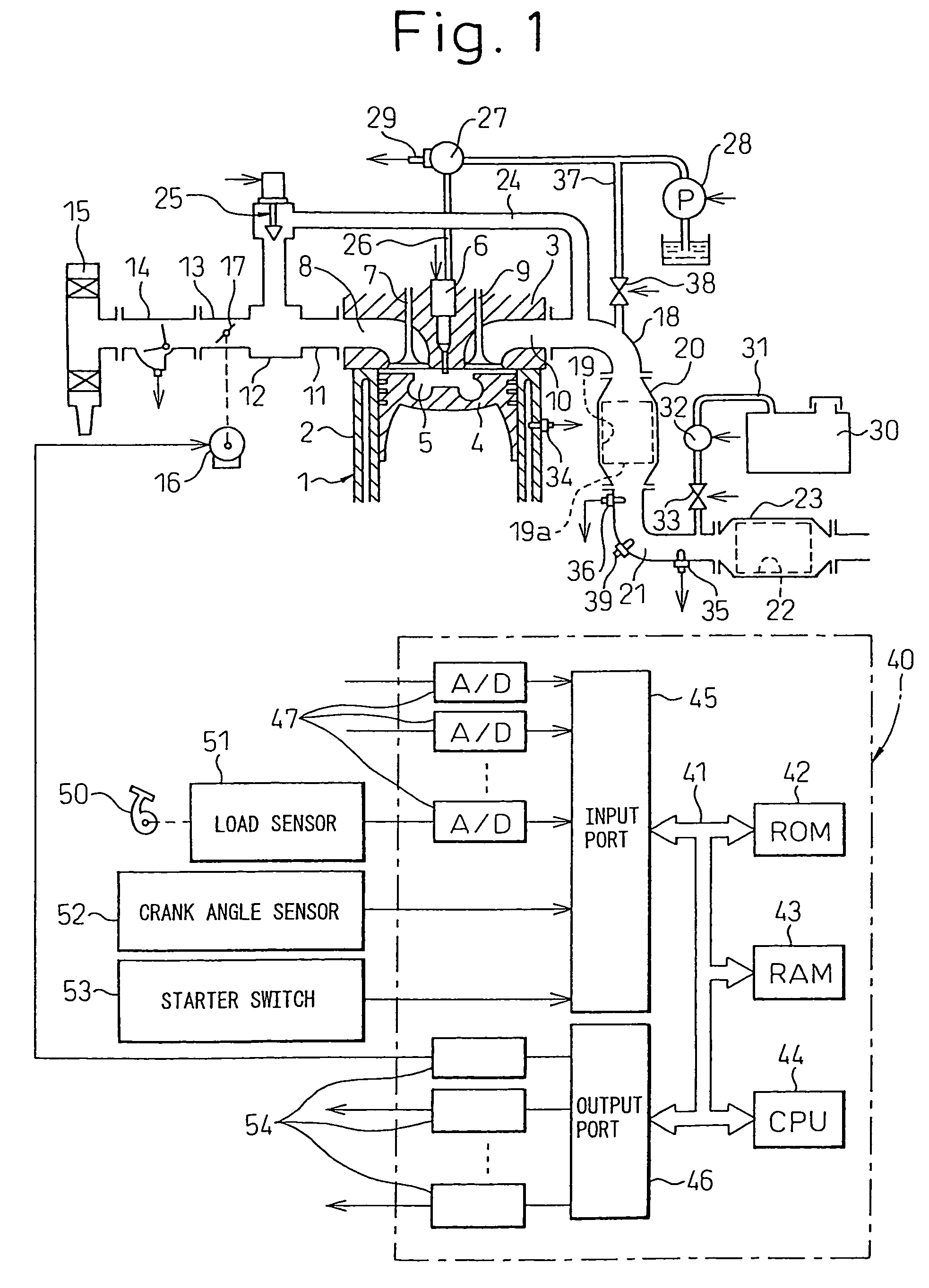

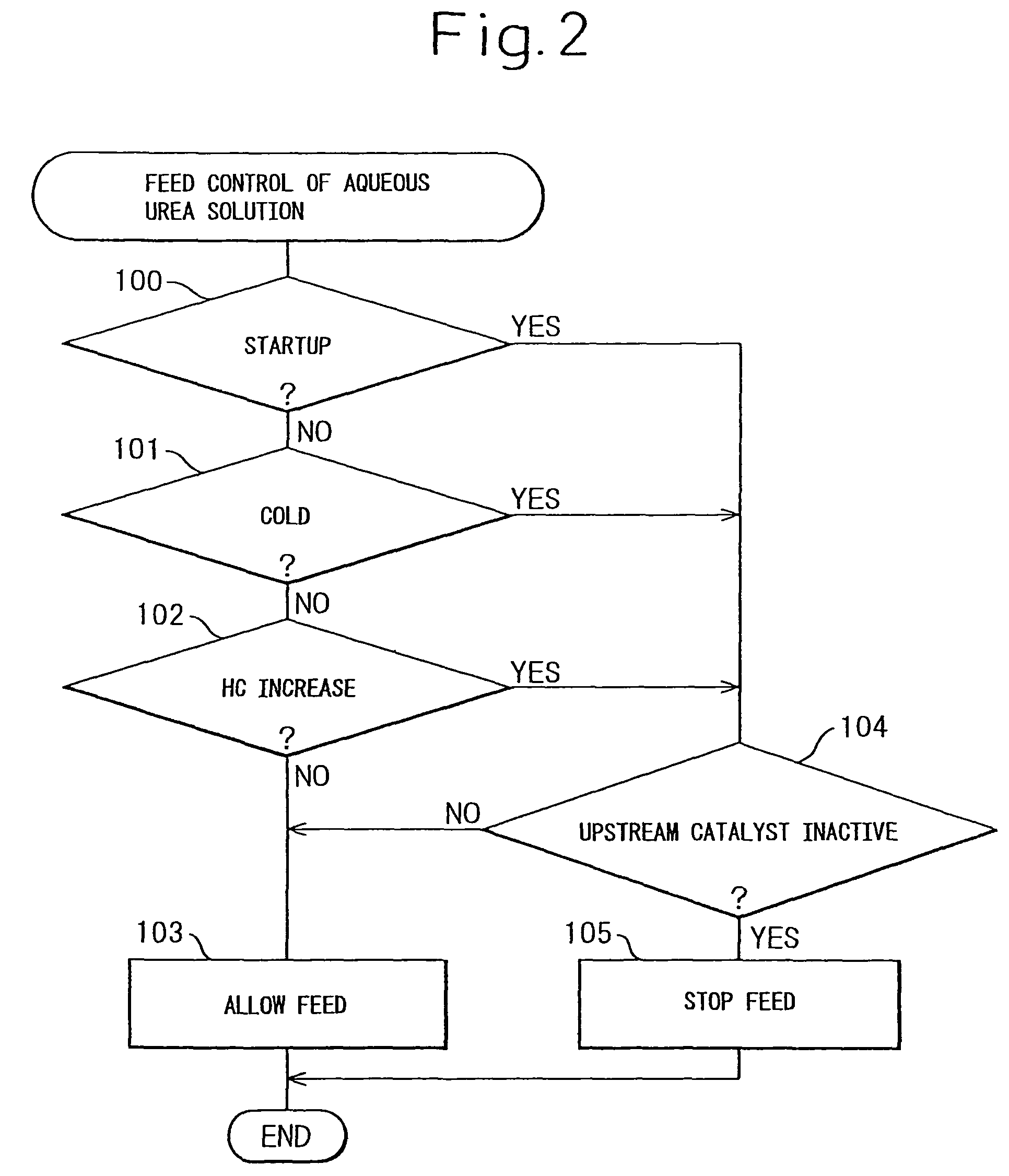

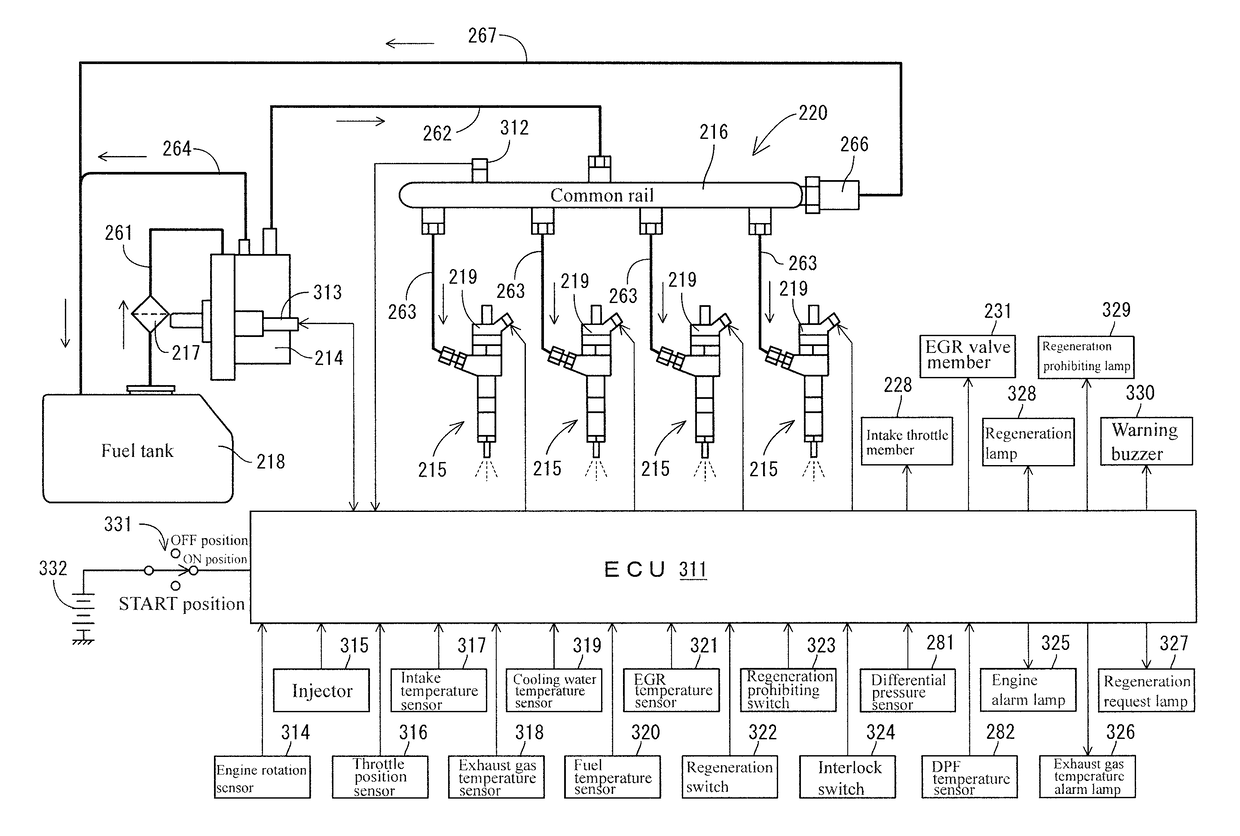

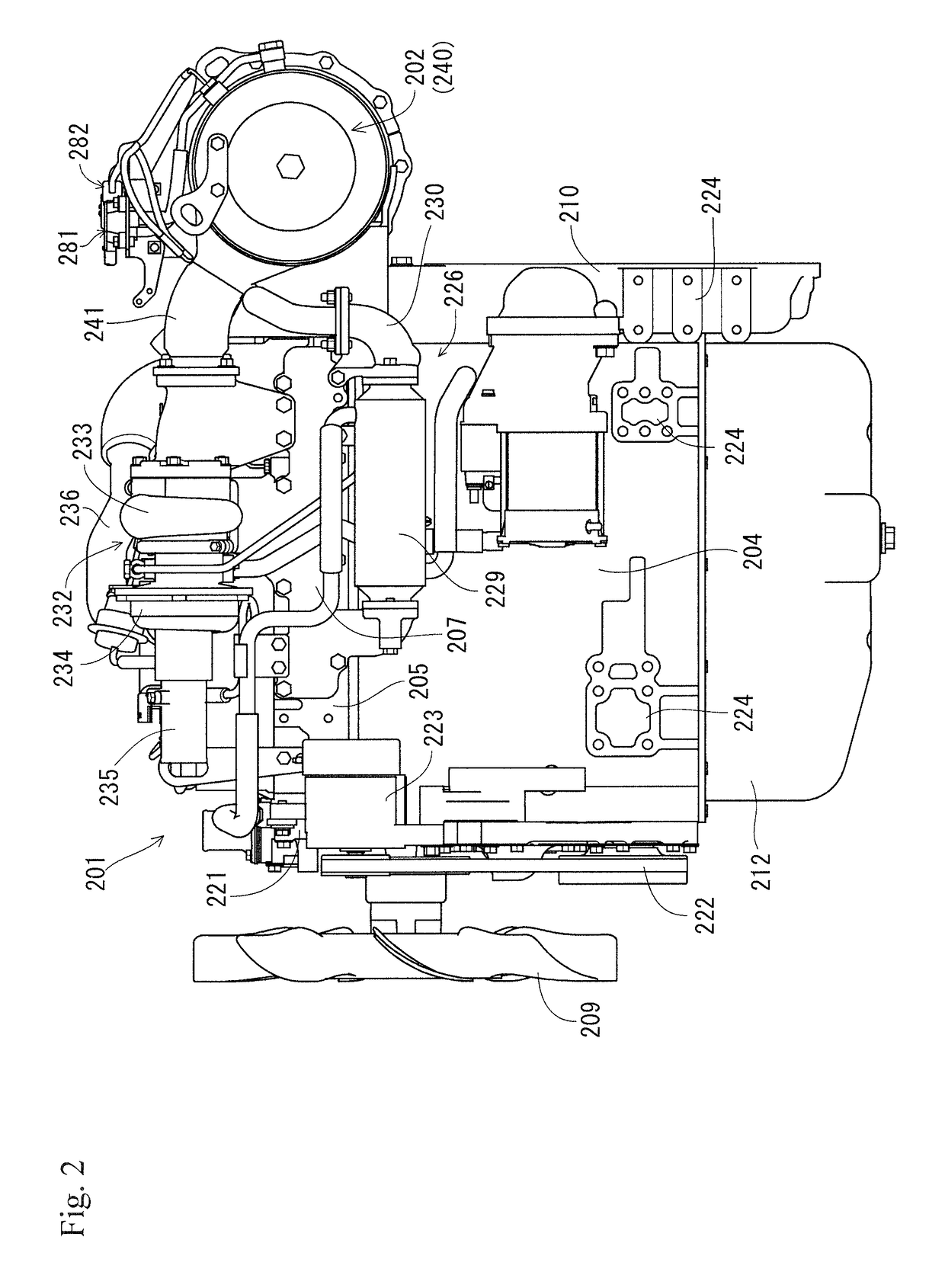

Exhaust Gas Purification System of Internal Combustion Engine

InactiveUS20090007548A1Avoid PurificationInternal combustion piston enginesExhaust apparatusExcess oxygenExhaust fumes

A catalyst suited for reducing NOx in an exhaust gas by ammonia in the presence of excess oxygen is arranged in an engine exhaust passage. An aqueous urea solution is fed from a flow addition valve onto a catalyst, part of the urea fed to the catalyst is stored in the catalyst, and the ammonia generated from the urea stored in the catalyst is used to reduce the NOx in the exhaust gas. At the time of engine startup, at the time of cold operation, and at the time of increase of the HC amount, it is determined that the amount of formaldehyde in the exhaust gas flowing into the catalyst exceeds the allowable amount, and, at this time, the feed of urea to the catalyst is prohibited.

Owner:TOYOTA JIDOSHA KK

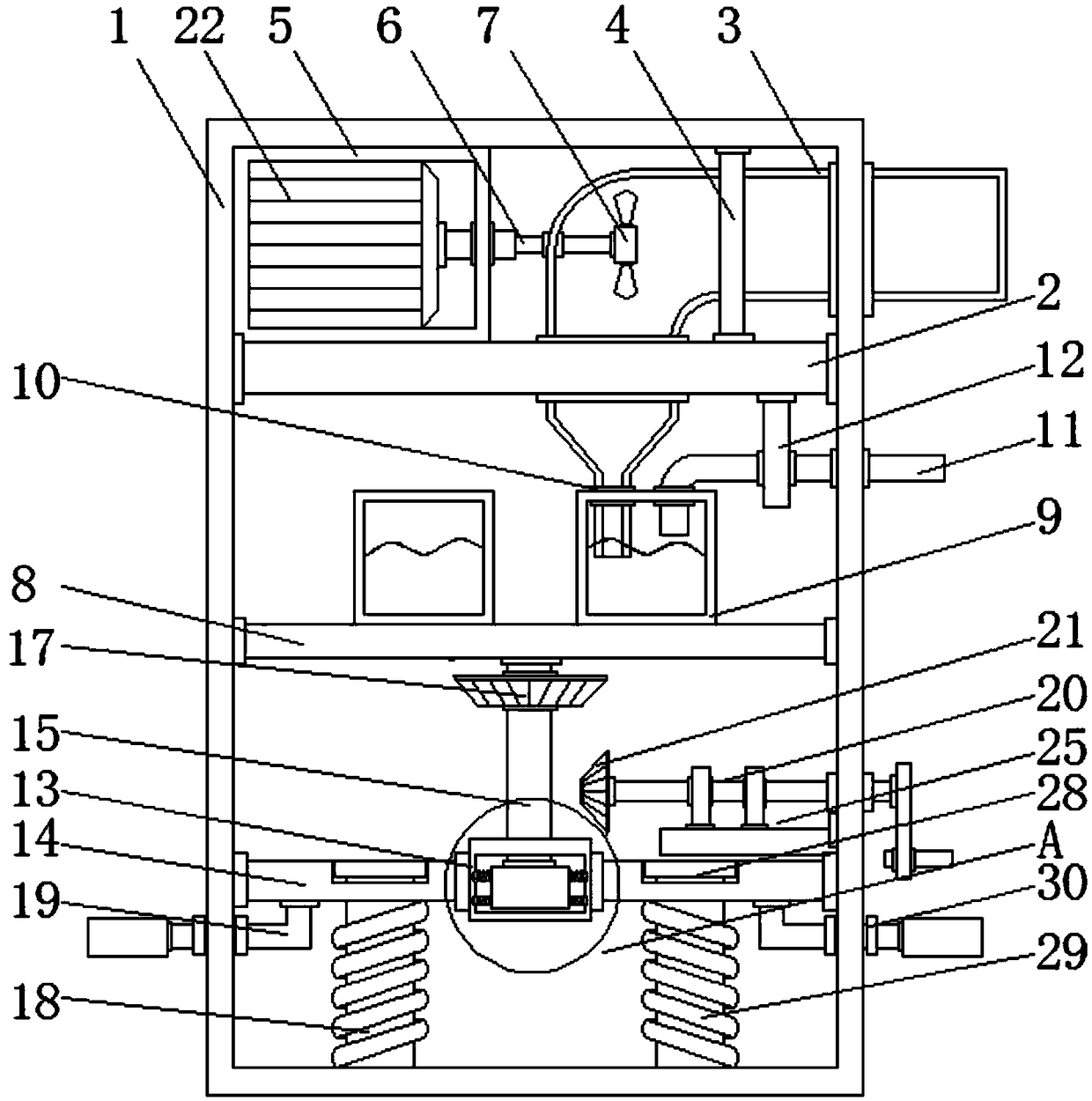

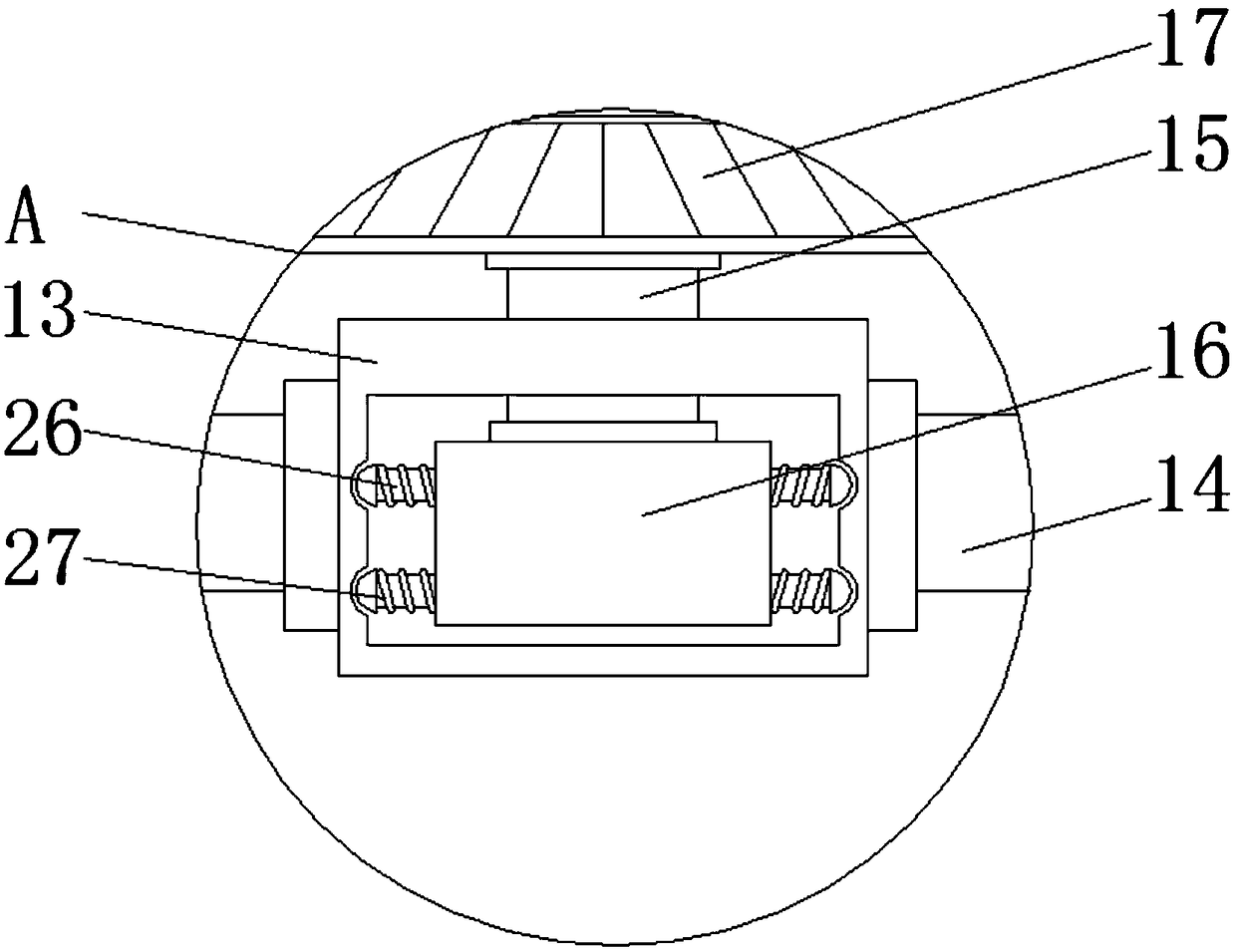

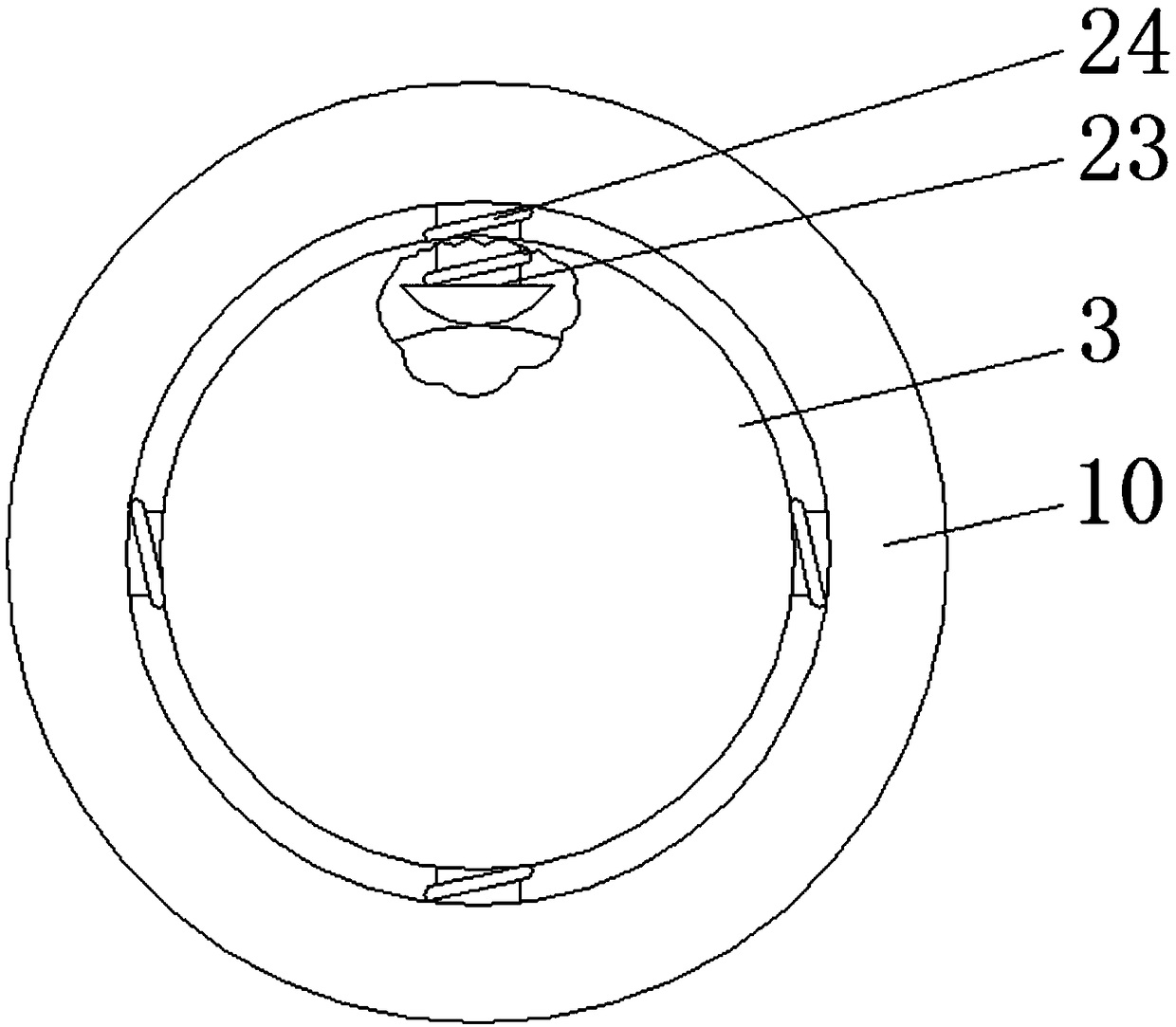

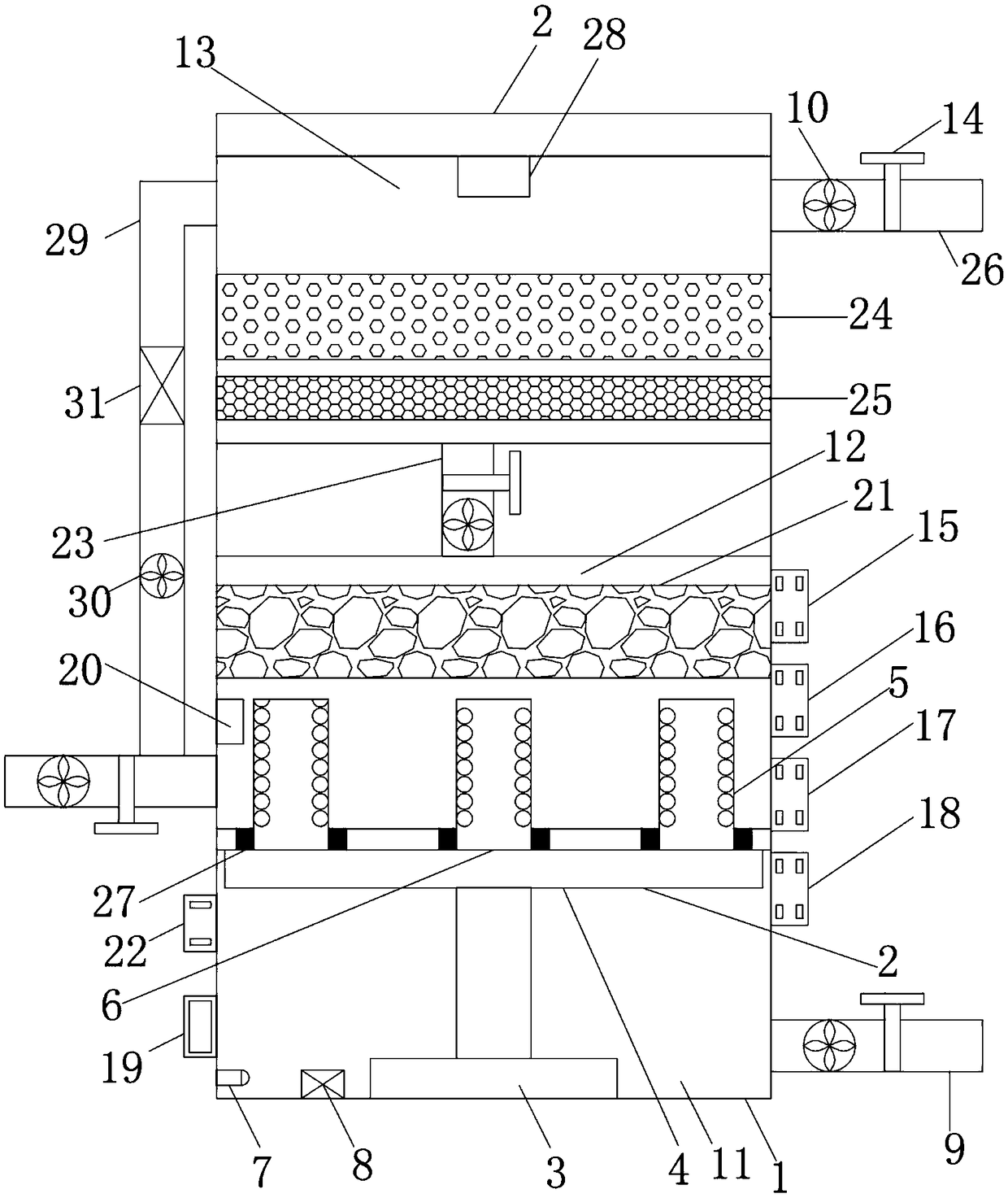

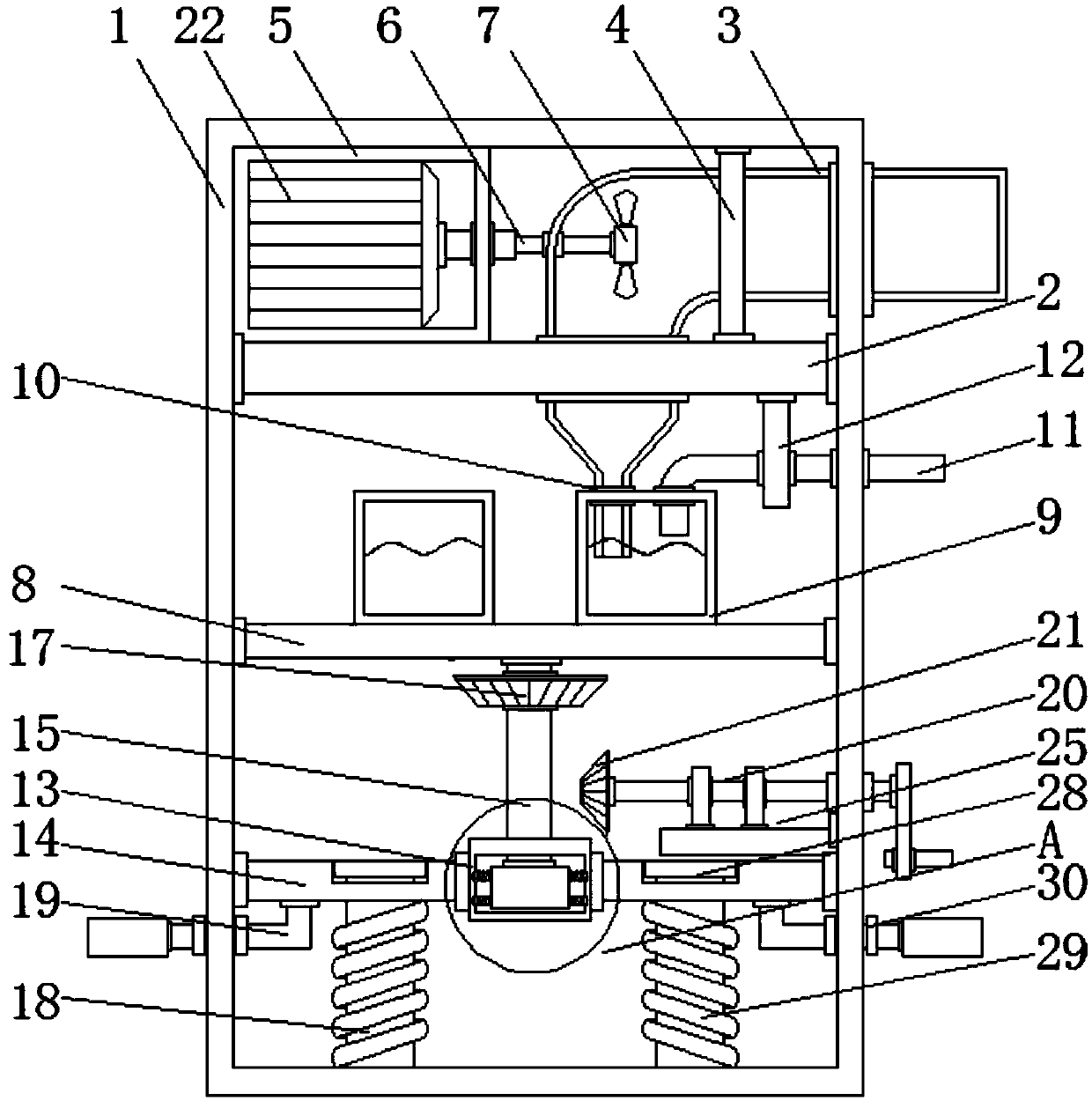

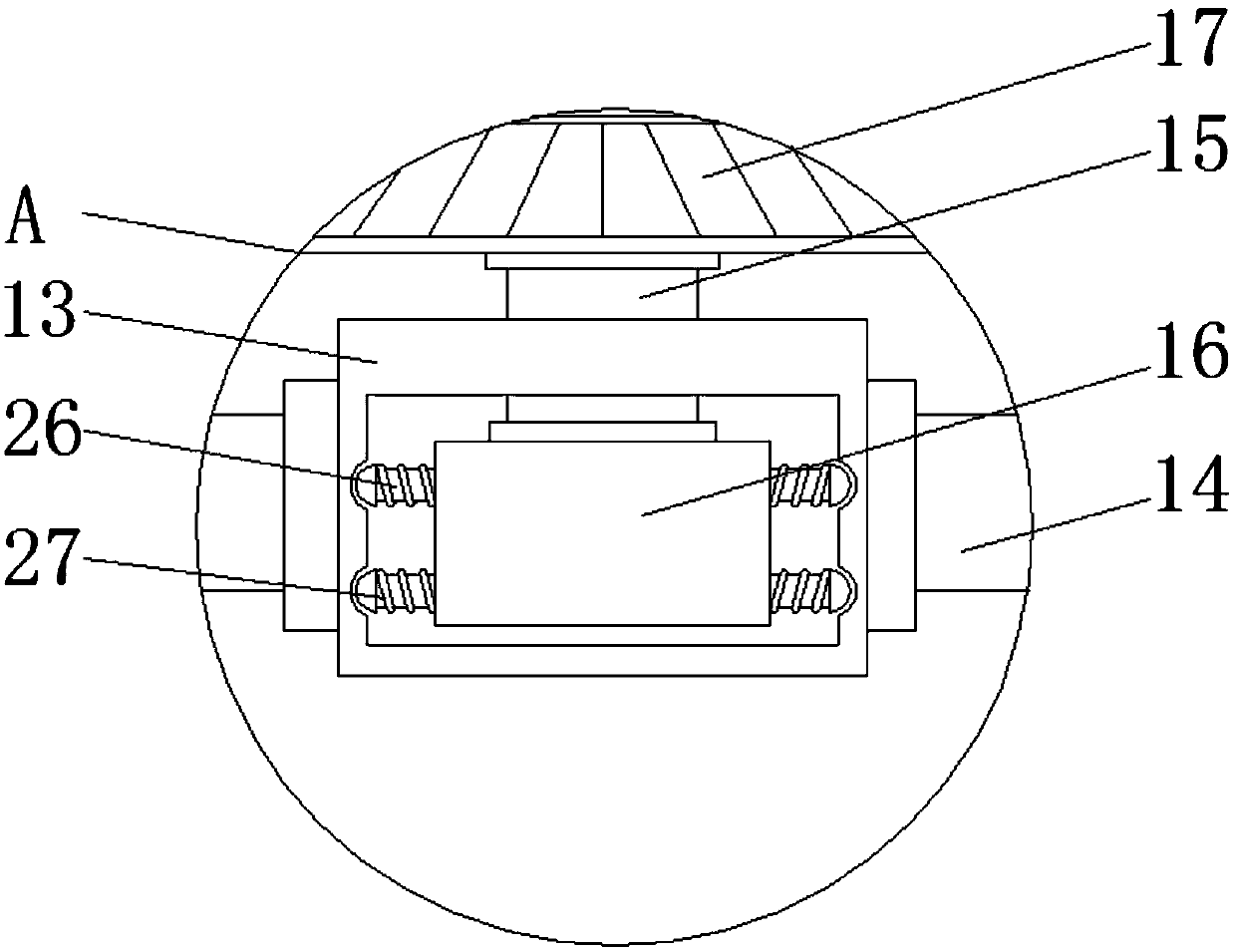

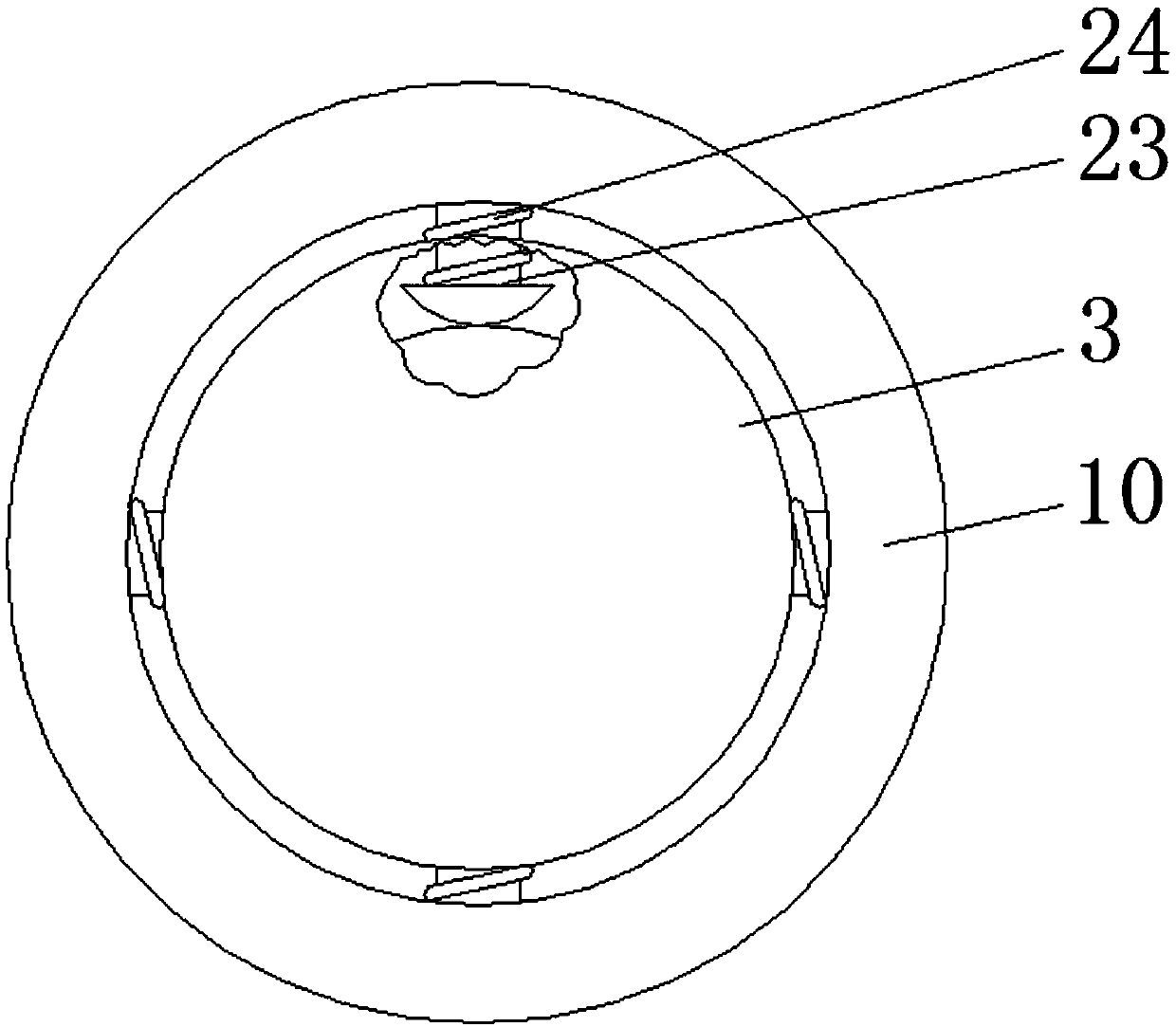

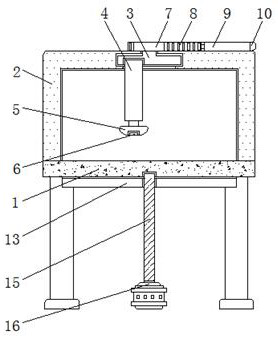

Household air purification device

ActiveCN108816025AImprove practicalitySimple structureGas treatmentUsing liquid separation agentEngineeringAir purification

The invention relates to the technical field of air purification, and discloses a household air purification device. The household air purification device comprises an operation box, a supporting board is arranged in the operation box, the two ends of the supporting board are fixedly connected with the inner walls of the operation box respectively, an air inlet pipe is fixedly sleeved with the topof the right side of the operation box, and one end of the air inlet pipe penetrates through the operation box and extends to the bottom of the supporting board. According to the household air purification device, a rotary disc drives different purification boxes to enable the purification boxes to be clamped to the air inlet pipe and an air outlet pipe, the condition is achieved that the different purification boxes are switched for purifying different harmful substances, the practicability of the purification device is improved, the purification performance is more comprehensive, and the problems that an ordinary household air purification device is single in function and simple in structure, only certain harmful substance in air can be subjected to purification in a general way, and when other harmful substances need to be purified, corresponding purification equipment needs to be changed to, so that not only is change tedious, but also unnecessary economic expenditure is improvedare solved.

Owner:南京蓝宇过滤器材有限公司

Exhaust gas purification system of internal combustion engine

InactiveUS8371106B2Avoid PurificationInternal combustion piston enginesExhaust apparatusPtru catalystExhaust fumes

A catalyst suited for reducing NOx in an exhaust gas by ammonia in the presence of excess oxygen is arranged in an engine exhaust passage. An aqueous urea solution is fed from a flow addition valve onto a catalyst, part of the urea fed to the catalyst is stored in the catalyst, and the ammonia generated from the urea stored in the catalyst is used to reduce the NOx in the exhaust gas. At the time of engine startup, at the time of cold operation, and at the time of increase of the HC amount, it is determined that the amount of formaldehyde in the exhaust gas flowing into the catalyst exceeds the allowable amount, and, at this time, the feed of urea to the catalyst is prohibited.

Owner:TOYOTA JIDOSHA KK

Method for purifying polysulfide silane coupling agent by-product brine

ActiveCN103787373BReduce processingHigh puritySulfate/bisulfate preparationAlkali metal halide purificationSulfate radicalsSilanes

The invention aims at providing a method for purifying a polysulfide silane coupling agent byproduct salt. The method comprises the following steps: A, oxidizing sulfur ions, namely, feeding the byproduct saline of a polysulfide silane coupling agent into a reaction device, and adding a hydrogen peroxide solution in the stirring state to completely convert sulfur ions in the byproduct silane into sulfate radicals; and B, performing a hot saltpeter removal method, namely, filtering to remove impurities in the treated silane, performing multiple-effect evaporation on the obtained clear liquid so as to obtain byproducts sodium chloride and sodium sulfate. Whether the oxidation desulphuration ions are completely reacted can be detected by using a lead acetate test paper detection method or a copper chloride color change method. By adopting the method, sulfur ions can be completely converted into sulfate radicals, a sulfate product can be separated from sodium chloride by using the hot saltpeter removal method, and sodium chloride with high purity can be obtained. The problems of environment friendliness and purification treatment on the byproduct salt sodium chloride are solved.

Owner:南京曙光新材料有限公司

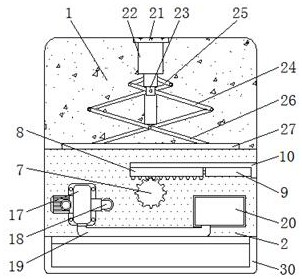

Molecular sieve adsorption apparatus for high-humidity organic waste gas

PendingCN108654326AImprove purification effectAvoid purificationGas treatmentDispersed particle filtrationMolecular sieveHigh humidity

The invention provides a molecular sieve adsorption apparatus for high-humidity organic waste gas, which belongs to the technical field of molecular sieves. The molecular sieve adsorption apparatus comprises a waste gas purifying barrel, wherein the top surface of the waste gas purifying barrel is provided with a sealing cover, the left lower end of the waste gas purifying barrel is provided withan air inlet, the right upper end of the waste gas purifying barrel is provided with an air outlet, and a dehydration chamber, a dehumidifying chamber and a purifying chamber are successively arrangedin the waste gas purifying barrel from bottom to top. The molecular sieve adsorption apparatus for the high-humidity organic waste gas has the advantages of good purifying effect and high working efficiency in the aspect of treating the high-humidity organic waste gas.

Owner:南京博酝化工科技有限公司

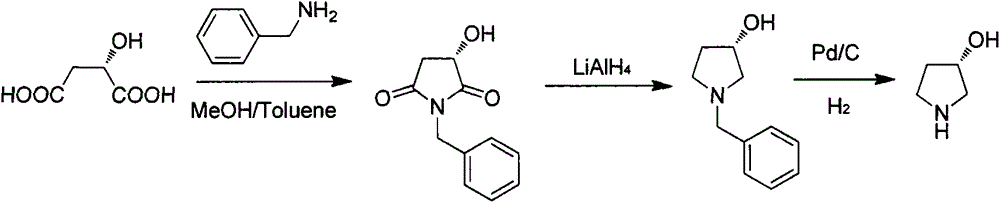

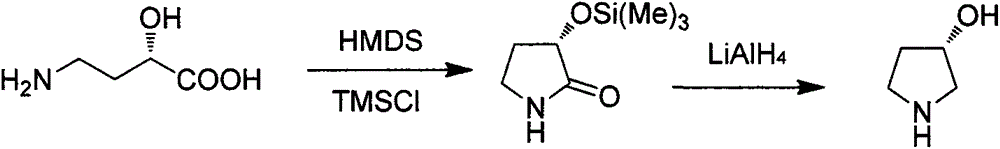

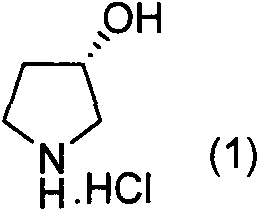

Preparation method of (S)-3-hydroxypyrrolidine hydrochloride

InactiveCN105646321AConvenient sourceLow costOrganic chemistry methodsBulk chemical productionTert-Butyloxycarbonyl protecting groupMitsunobu reaction

The invention relates to the field of chemistry, particularly a preparation method of a key intermediate (S)-3-hydroxypyrrolidine hydrochloride of darifenacin for treating overactive bladder syndrome and an antihypertensive drug barnidipine. The preparation method comprises the following steps: carrying out Mitsunobu reaction on (R)-1-N-tert-butyloxycarbonyl-3-hydroxypyrrolidine so as to be condensed with acid to obtain an upturned-structure ester, hydrolyzing ester bond under alkaline conditions to obtain (S)-1-N-tert-butyloxycarbonyl-3-hydroxypyrrolidine, and removing Boc protecting groups under acidic conditions, thereby finally obtaining the key intermediate. The method is simple and easy to implement, has the advantages of cheap and accessible raw materials, lower cost and high yield, and has potential production value.

Owner:CHINA PHARM UNIV

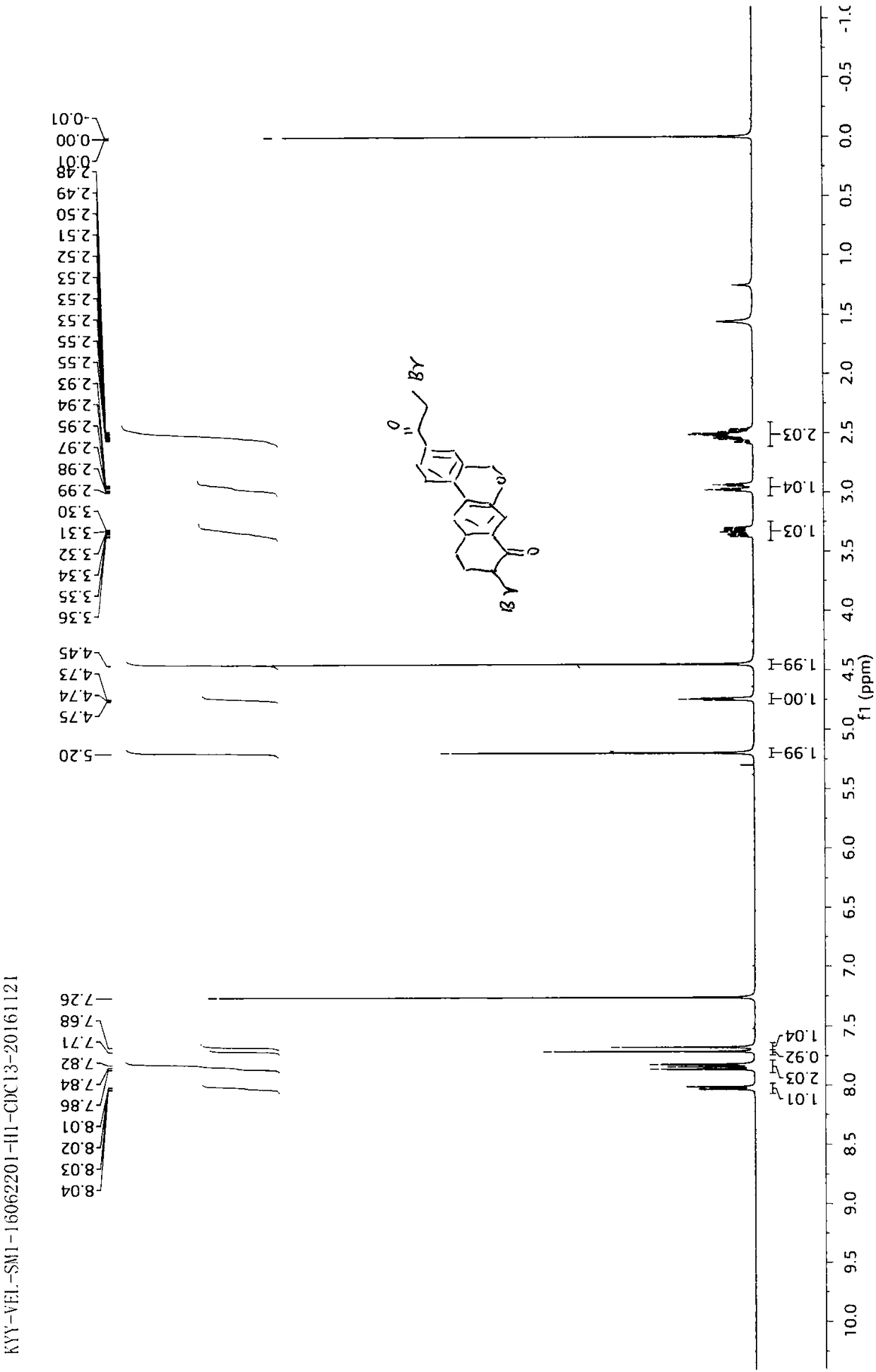

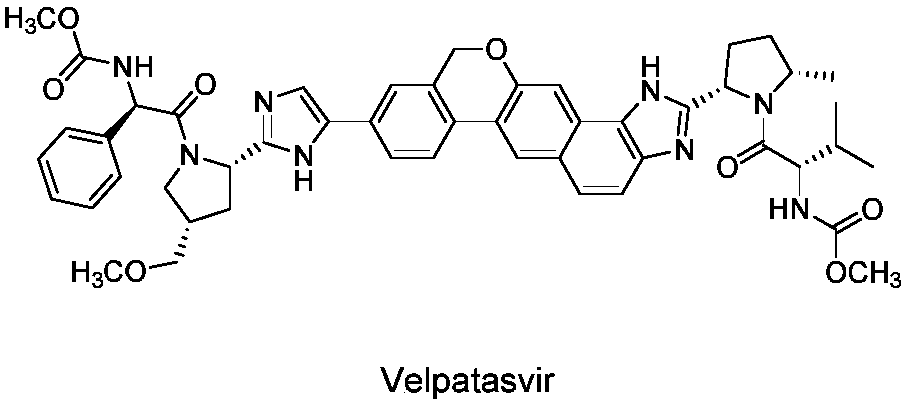

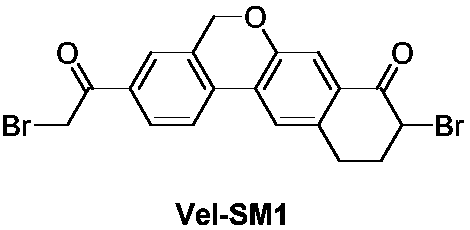

Preparation method of velpatasvir intermediate and analogue thereof

ActiveCN108147972AAvoid PurificationEasy to operateOrganic compound preparationCarboxylic acid amides preparationCombinatorial chemistryColumn chromatography

The invention discloses a preparation method of a compound shown by formula (E), a velpatasvir intermediate shown by formula (K) and an analogue thereof. Materials adopted in the method disclosed by the invention are low-cost and easily obtained; the technological operation is simple; the intermediate and the product need not be subject to column chromatography separation; and the preparation method is suitable for industrialized mass production.

Owner:XILING LAB CO LTD

Process for hydrolysed reforming of liquous cellulose biomass to produce bio-gasoline

ActiveUS8562697B2Sufficient supplyReduce acidityLiquid carbonaceous fuelsBio-feedstockAlkaneCellulose

The invention discloses a process for hydrolyzed reforming of the ligneous cellulose biomass to produce bio-gasoline, which directly transfers the hydrolyzed-material liquid obtained from ligneous cellulose biomass through hydrolyzing into aqueous catalytic reforming system, the feed subjects to aqueous catalytic reforming reaction in low-temperature reforming reactor filled with catalyst Ni / SiO2—Al2O3 and in high-temperature reforming reactor filled with catalyst Ni / HZSM-5 in turn, the reactant is condensed and phase-separated: uncondensed bio-gasoline is absorbed by absorption liquid-C6 alkane, condensed liquid is phase-separated through phase-separator, bio-gasoline is obtained in the upper layer of the phase-separator. The invention creates a new process for producing high-quality liquid fuel oil using biomass as feedstock, which can automatically layer and separate, omitting the step of rectifying and purifying product. The feedstock is cheap and broadly available. The product can directly used in the present vehicle-carried engine system, and have prosperous market prospect.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Pharmaceutical Preparation and Method of Treatment of Human Malignancies with Arginine Deprivation

The present invention provides an isolated and substantially purified recombinant human arginase having sufficiently high enzymatic activity and stability to maintain Adequate Arginine Depletion in a patient. The present invention also provides a pharmaceutical composition comprising the modified invention enzyme and method for treatment of diseases using the pharmaceutical composition.

Owner:BIO CANCER TREATMENT INT

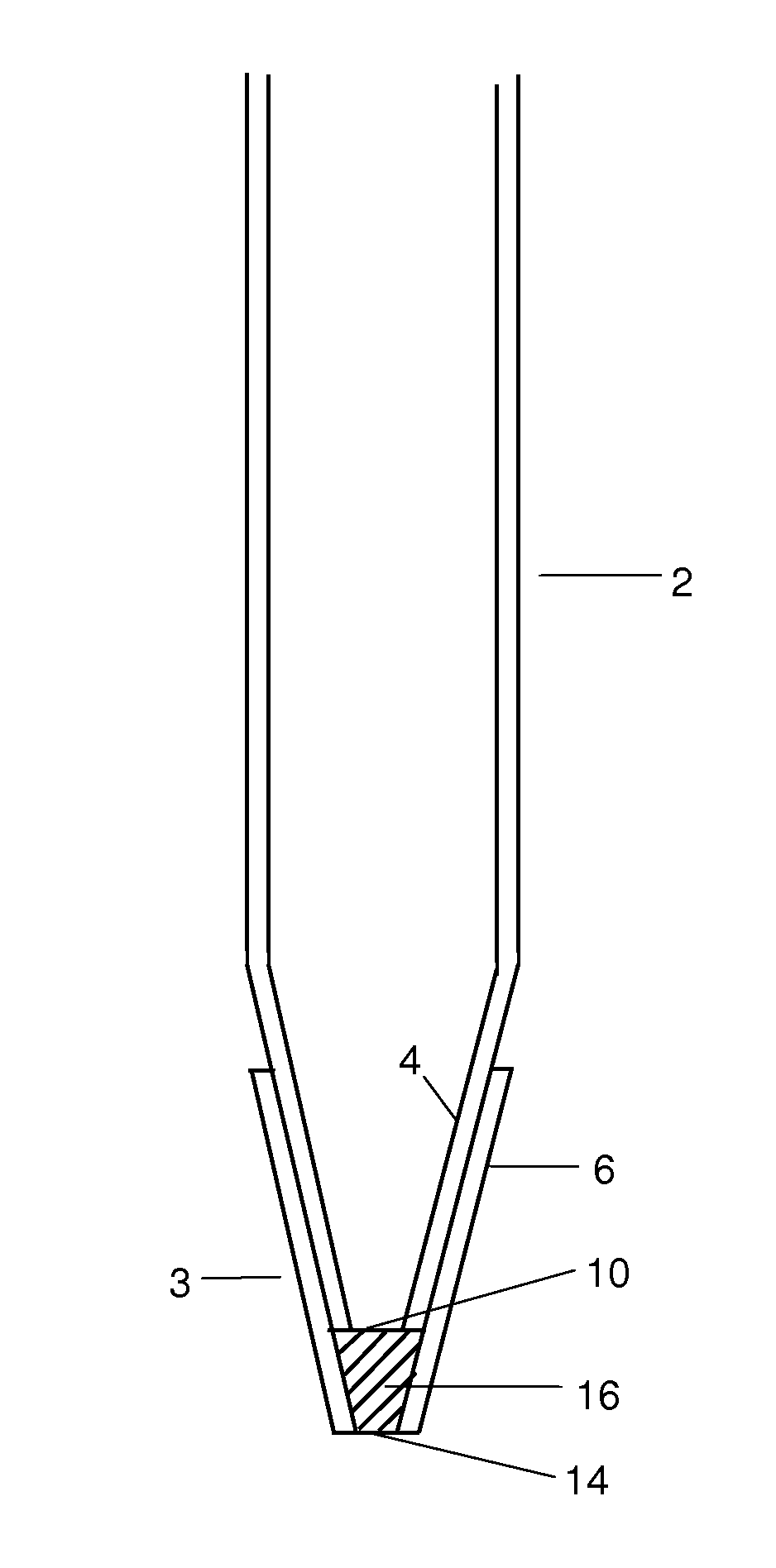

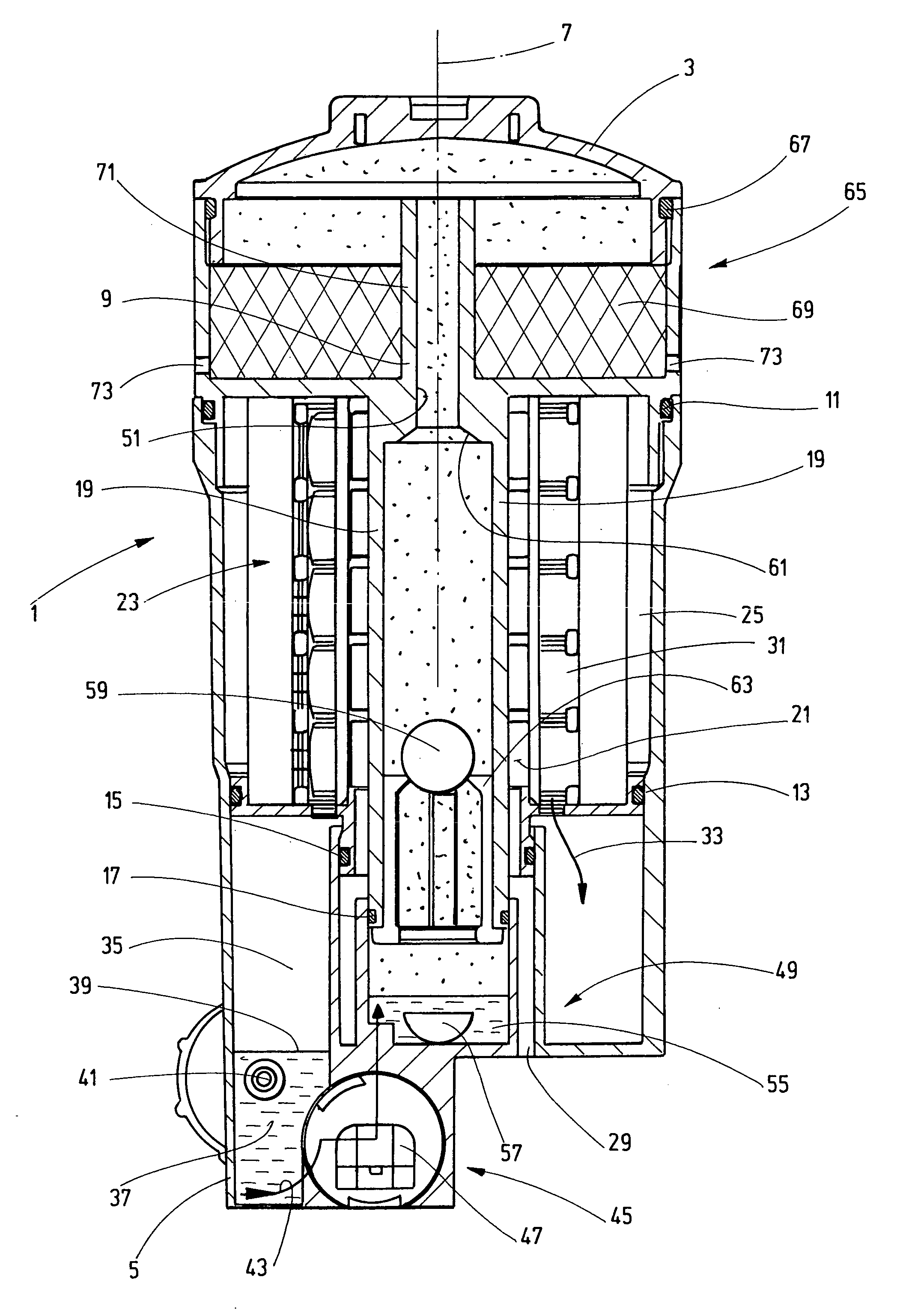

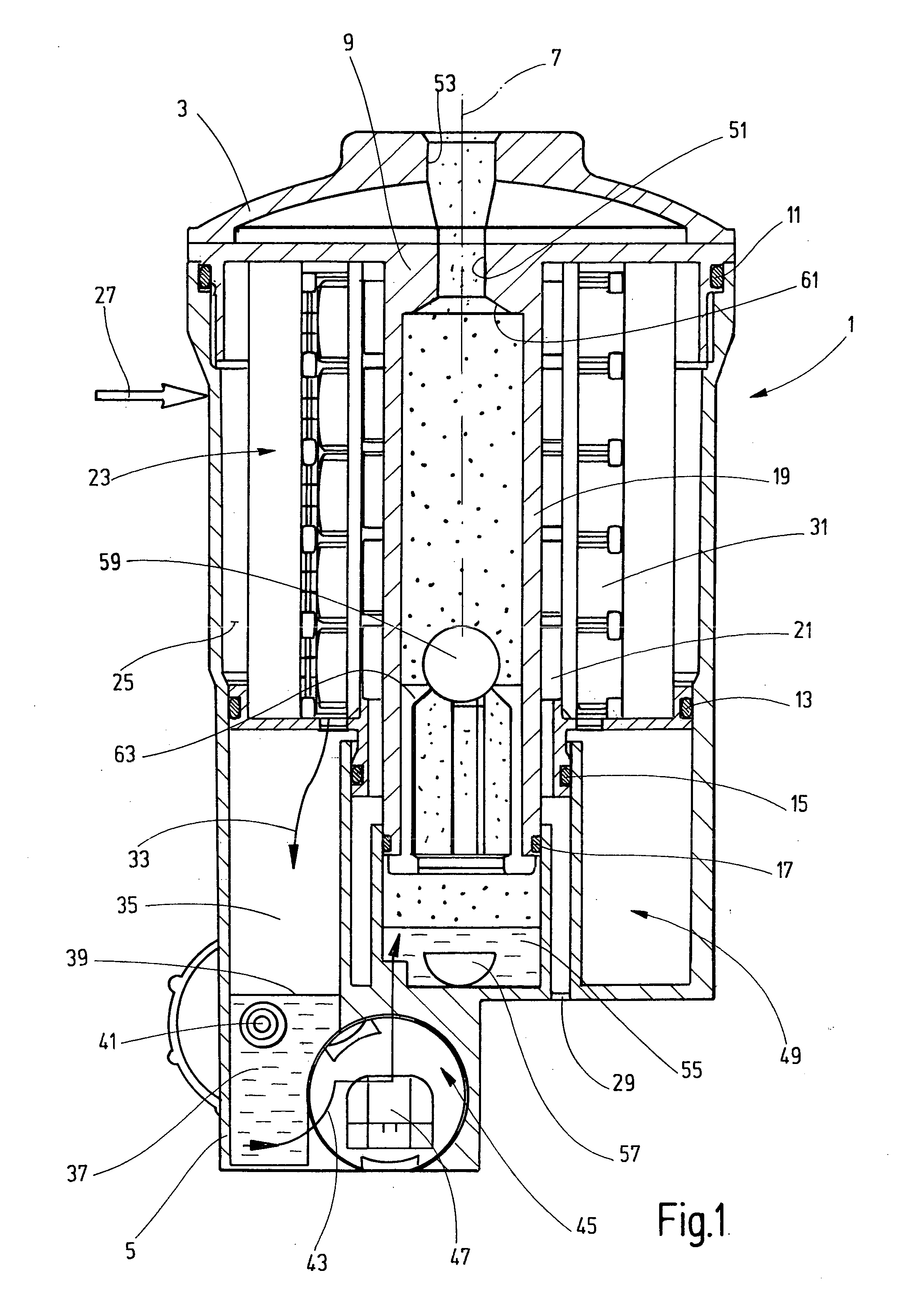

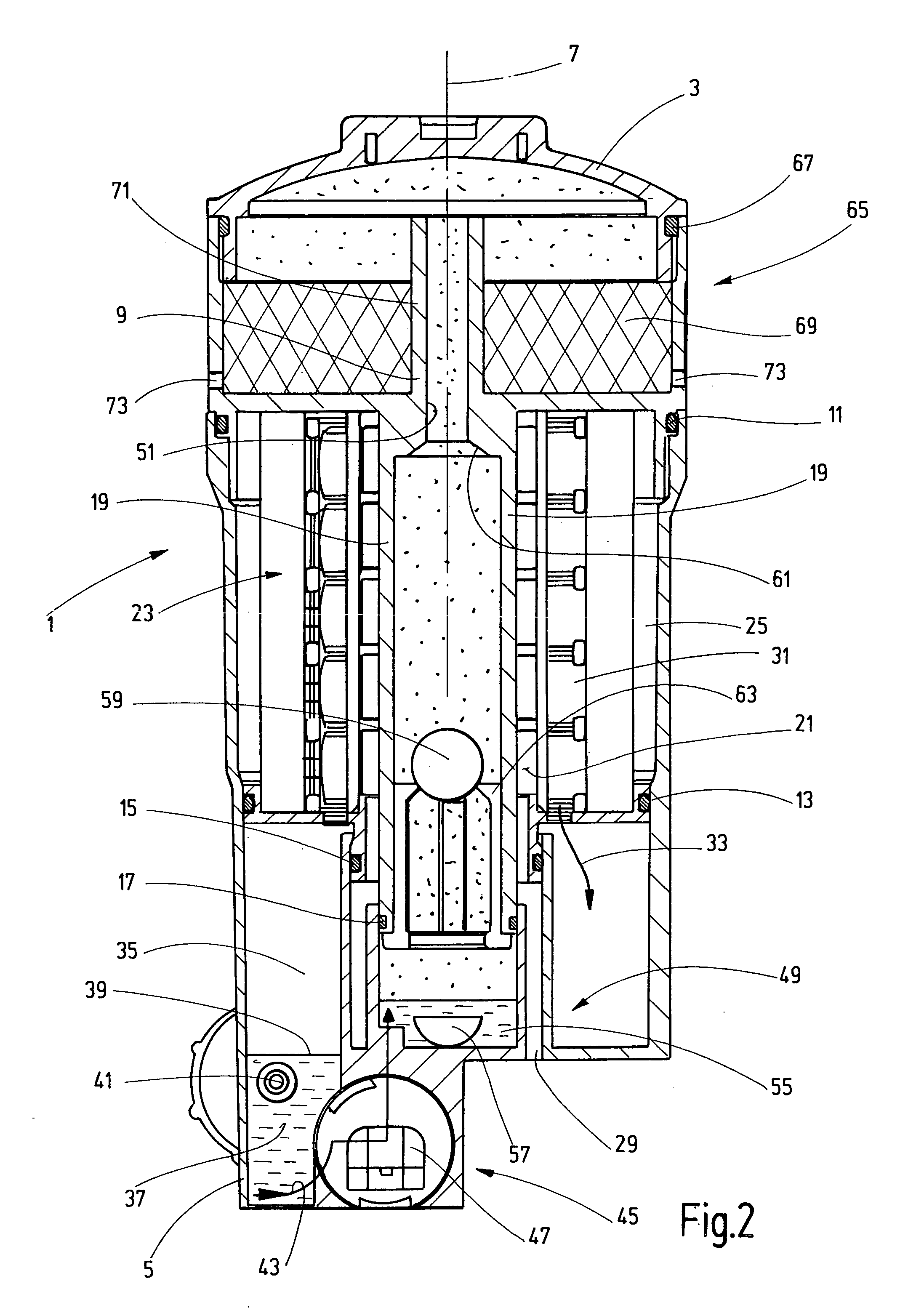

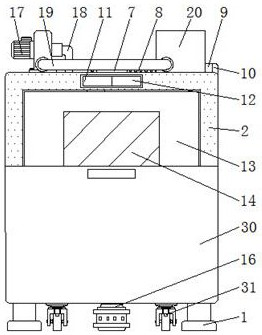

Fuel filter system, especially for diesel engines

ActiveUS8613853B2Improve operational reliabilityEfficient purificationSettling tanks feed/dischargeCombustion enginesWater trapFilter media

A fuel filter system, especially for Diesel engines includes filter housing (1) having a fuel inlet (27) and a fuel outlet (29) and a dehydrating filter medium (23) between the inlet and the outlet for the fuel to pass through. The filter housing (1) has a collection chamber (35) for the water trapped by the filter medium from which collection chamber the water can be supplied to a water absorbing and evaporating device (49) via a controlled dispenser (45). The components of the evaporating steam are releasable into the environment through the evaporating steam outlet (51). The water absorbing and evaporating device (49) has a valve arrangement (59, 61) by which the evaporating water outlet (51) can be closed depending on an inadmissible amount of non-evaporated water (55) collected in the evaporating device (49).

Owner:HYDAC FILTERTECHNIK GMBH

Method for purifying byproduct saline water of polysulfide silane coupling agent

ActiveCN108467050AGood removal effectStable and continuous productionAlkali metal halide purificationSaline waterDistillation

The invention provides a method for purifying byproduct saline water of a polysulfide silane coupling agent. The method comprises steps as follows: a, sulfur ion removal: the byproduct saline water ofthe polysulfide silane coupling agent is added to a reaction device, and a hydrogen peroxide water solution is dropwise added in a stirring state until complete reaction is completed; b, hydrolysis of the polysulfide silane coupling agent: hydrochloric acid is dropwise added to the solution completing complete reaction until the pH of the solution is not larger than 2, and the polysulfide silanecoupling agent is turned into granular solids; c, neutralization: liquid caustic soda is added to the solution reacting in the step b for neutralization until the pH of the solution ranges from 7 to 9; d, solid removal: solids are removed from a product obtained after a neutralization reaction in the step c through an over-press filter, and filtrate enters the next procedure; e, distillation: thefiltrate formed in the step d enters a multi-effect evaporation system and salt and water are separated; f, water recycling: water separated from the step e is prepared into 31% byproduct hydrochloricacid and 30% liquid caustic soda. The continuity for saline water treatment and the production efficiency are improved.

Owner:南京曙光新材料有限公司

Method for preparing sullage fertilizer

InactiveCN101270002AGood characterImprove fertilityBio-organic fraction processingClimate change adaptationEcological environmentSludge

The present invention relates to a production method of a sludge fertilizer. In the method, the collected sludge, straw of crops and wormwood are covered and piled together orderly, repeatedly and uniformly; the sludge is used for covering for 21 days until the inner temperature reaches to 25 to 40 DEG C; the mixture is naturally fermented; after being mixed well, the mixture is piled again and is enclosed by the sludge for 21 days for sedimentation and slaking; and the sludge fertilizer can be prepared after the mixture is turned over. In the method, the harmful sludge is adopted to product helpful fertilizer, thus changing the waste into valuable materials and solving the problem of environmental pollution caused by the sludge. The application of the straw of crops in the field facilitates the improvement of the ecological environment of the crops and the realization of development of sustainable and renewable energy. The wormwood, which is used as the fertilizer, has excellent quality of the fertilizer and is high-quality raw material that is used for preparing fertilizers in the northern part of China. The application of the wormwood is in particular suitable for the field that has been fertilized for a plurality of years. The method requires no power equipment or capital investment, and has the advantages of low cost and no pollution. Thus the method is a production method that can be used for preparing fertilizers of original ecology in the natural ecological environment, according to the lunar solar terms and the difference in various areas.

Owner:TAIYUAN UNIV OF TECH

Preparation method of polyolefin-based composite material

The invention discloses a preparation method of a polyolefin-based composite material. The preparation method comprises the following steps: dissolving polyolefin in an excessive solvent in a stirringstate at 120-250 DEG C; adding a modifying material, and carrying out stirring and mixing; transferring the mixture into a separator to separate solid from liquid; putting the separated solid into melting equipment; adding an additive into the melting equipment, and carrying out melting and preforming at 110-260 DEG C; and carrying out processing and forming, wherein the solvent is at least one of a liquid silane coupling agent, a liquid titanate coupling agent, a liquid aluminate coupling agent, a liquid phthalic acid ester, a liquid terephthalic acid ester, a liquid trimellitic acid ester,a liquid citric acid ester, salicylic acid, white oil, p-phenylenediamine, fatty acid and maleic anhydride. The prepared composite material is more stable in performance, and the volume resistivity, the thermal deformation temperature and the elongation at break are improved.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

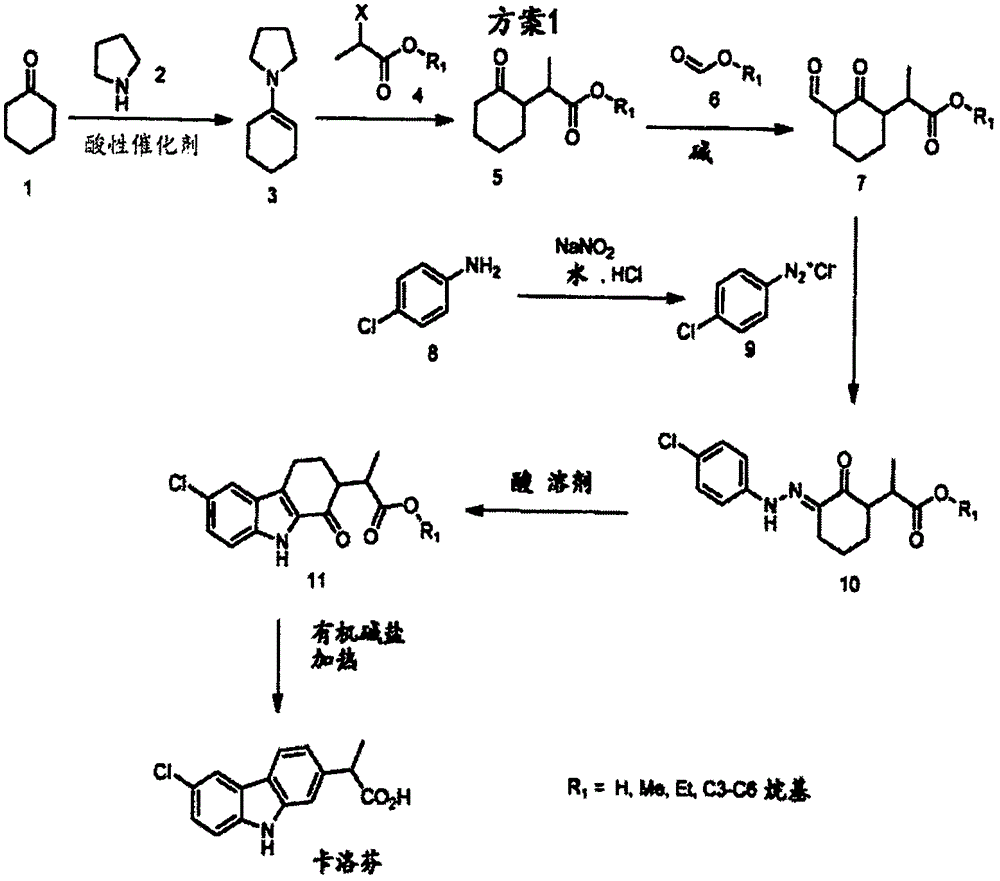

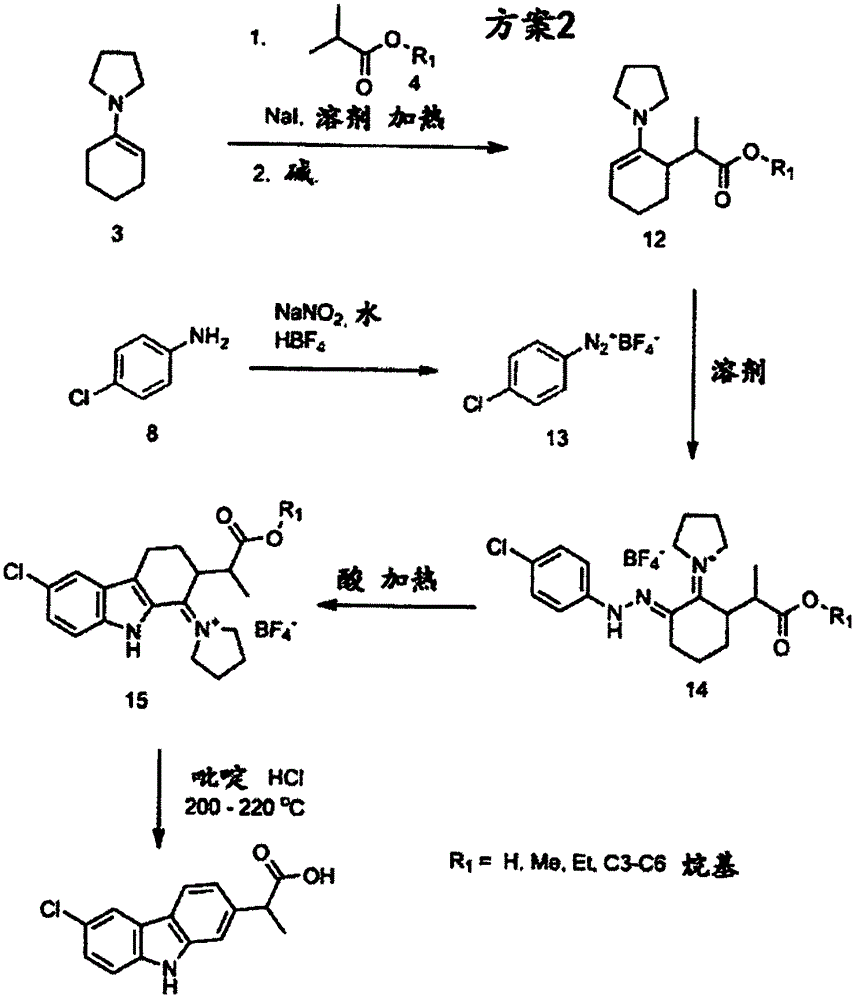

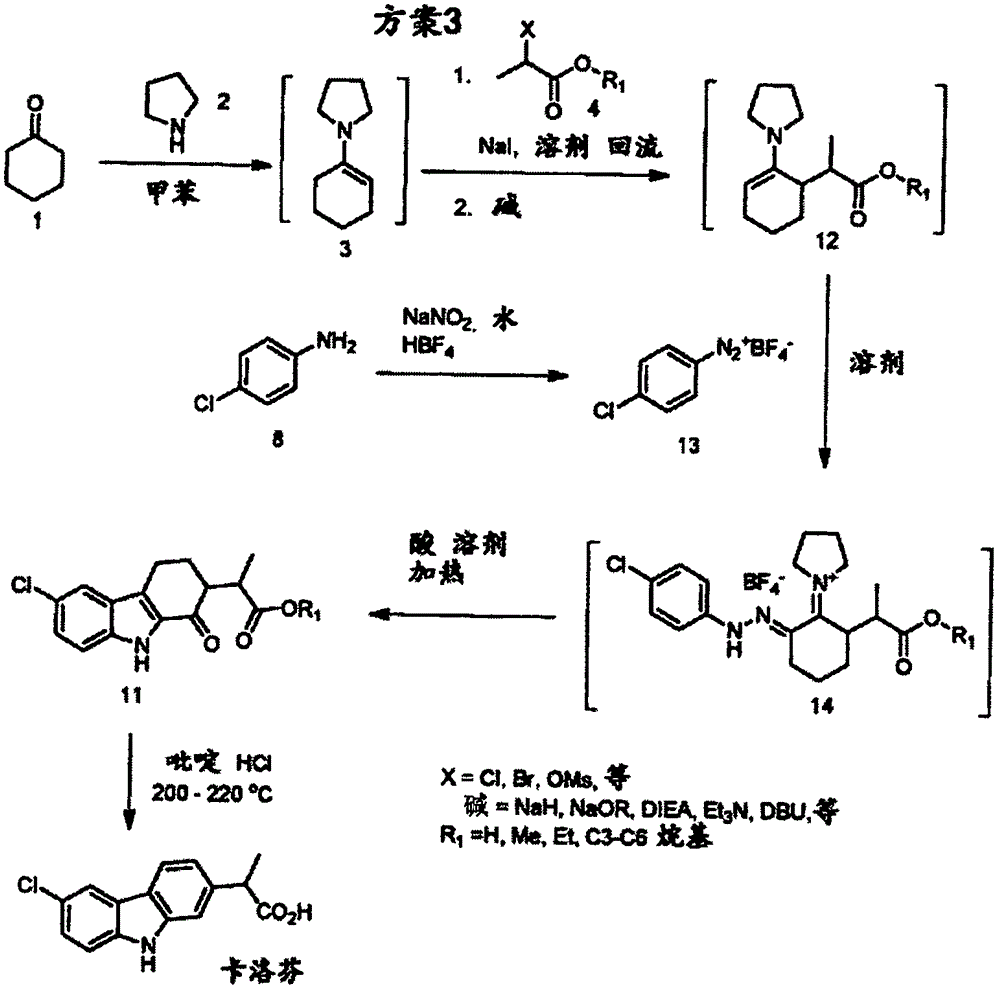

Synthesis method of carprofen

The invention discloses a method and intermediate for synthesizing carprofen and derivatives thereof from cyclohexanone.

Owner:凯默斯股份有限公司

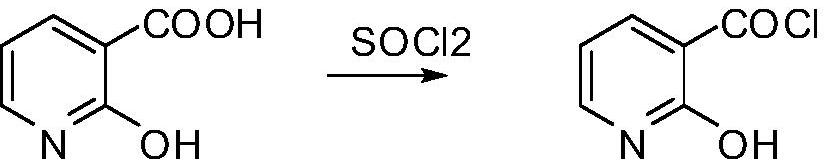

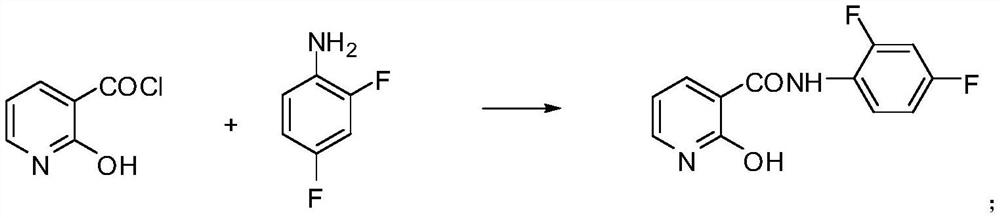

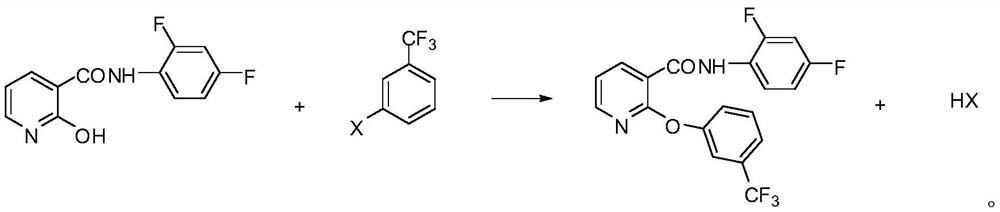

Diflufenican synthesis method

PendingCN113831279AHigh product yieldIncrease production costOrganic chemistryNicotinuric acidSide reaction

The invention provides a diflufenican synthesis method, which comprises the following steps of taking 2-hydroxy nicotinic acid as a raw material, carrying out chlorination reaction on the raw material and thionyl chloride to obtain 2-hydroxy nicotinoyl chloride, carrying out amination reaction on the 2-hydroxy nicotinoyl chloride and 2, 4-difluoroaniline to obtain N-(2, 4-difluorophenyl)-2-hydroxy-nicotinamide, and carrying out etherification reaction onN-(2, 4-difluorophenyl)-2-hydroxy-nicotinamide andm-trifluoromethyl benzene halide. Compared with the prior art, the synthesis method has the advantages that the raw material used in the etherification reaction is the m-trifluoromethyl benzene halide, the raw material used in the etherification reaction in the prior art is the m-trifluoromethyl phenol, the m-trifluoromethyl benzene halide is easier to obtain than the m-trifluoromethyl phenol, and the cost is low; according to the method, the production input cost is reduced while high yield and high content of diflufenican are kept; the synthesis method provided by the invention avoids main side reactions in diflufenican synthesis in the prior art.

Owner:江苏禾裕泰化学有限公司

A household air purification device

ActiveCN108816025BImprove practicalitySimple structureGas treatmentUsing liquid separation agentHazardous substanceEngineering

The invention relates to the technical field of air purification, and discloses a household air purification device. The household air purification device comprises an operation box, a supporting board is arranged in the operation box, the two ends of the supporting board are fixedly connected with the inner walls of the operation box respectively, an air inlet pipe is fixedly sleeved with the topof the right side of the operation box, and one end of the air inlet pipe penetrates through the operation box and extends to the bottom of the supporting board. According to the household air purification device, a rotary disc drives different purification boxes to enable the purification boxes to be clamped to the air inlet pipe and an air outlet pipe, the condition is achieved that the different purification boxes are switched for purifying different harmful substances, the practicability of the purification device is improved, the purification performance is more comprehensive, and the problems that an ordinary household air purification device is single in function and simple in structure, only certain harmful substance in air can be subjected to purification in a general way, and when other harmful substances need to be purified, corresponding purification equipment needs to be changed to, so that not only is change tedious, but also unnecessary economic expenditure is improvedare solved.

Owner:南京蓝宇过滤器材有限公司

Building material compressive strength detection device capable of cleaning disintegrating slag

PendingCN112649300AEasy to cleanEasy to handleMaterial strength using tensile/compressive forcesDirt cleaningPhysical healthSlag

The invention discloses a building material compressive strength detection device capable of cleaning disintegrating slag. The device comprises a base, a first air cylinder, a pressure sensor, a display, a controller, a motor, a suction pump and a purifier; a supporting plate is fixedly connected to the upper surface of the rear end of the base, and the first air cylinder is installed on the inner side of the left end of a limiting plate; a gear is fixedly connected to the upper surface of the limiting plate, a second air cylinder is fixedly connected to the right side of a rack, and the displayer and the controller are both located on the inner side of the middle of the rear end of the supporting plate. The building material compressive strength detection device capable of cleaning the disintegrating slag is high in detection accuracy, splashing of the building material in the detection process can be avoided conveniently, dust generated by detecting the building material can be purified conveniently, the physical health of operators is prevented from being affected, the disintegrating slag on the base can be cleaned conveniently. And the cleaned waste residues can be further treated conveniently.

Owner:THE THIRD ENG CO LTD OF CCCC SECOND HIGHWAY ENG BUREAU

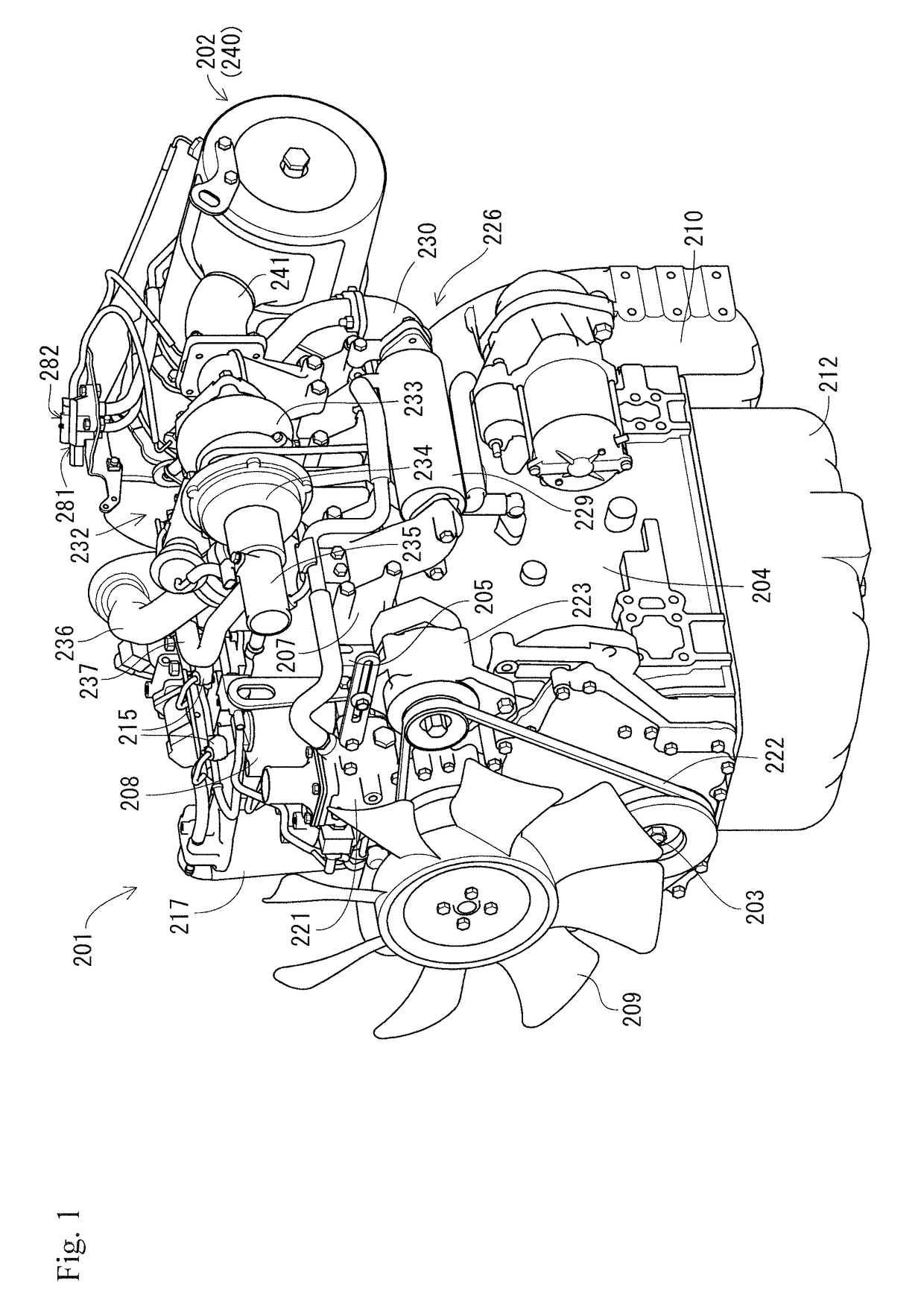

Exhaust gas purification system

ActiveUS9890683B2Excessive dischargeAccumulate moreElectrical controlInternal combustion piston enginesAutomotive engineeringPost injection

It is an object to make it possible to burn and remove particulate matter without generating runaway even if the particulate matter is excessively accumulated at the time of regeneration of an exhaust gas purification device. A common rail engine and the exhaust gas purification device placed in an exhaust gas path of the engine are provided. A plurality of regeneration controls for burning and removing the particulate matter accumulated in the exhaust gas purification device can be executed. The plurality of regeneration controls include at least non-operation regeneration control for raising exhaust gas temperature by combining post injection (E) and predetermined high speed rotation speed, and recovery regeneration control which can be executed when the non-operation regeneration control fails. In the non-operation regeneration control and the recovery regeneration control, the engine is driven exclusively for burning and removing the particulate matter. The recovery regeneration control is carried out at exhaust gas temperature lower than that of the non-operation regeneration control while taking time longer than that of the non-operation regeneration control.

Owner:YANMAR POWER TECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com