Purification system for flue gas generated by burning wastes and purification process thereof

A technology of incineration flue gas and purification system, applied in chemical instruments and methods, separation of dispersed particles, combined devices, etc., can solve the problems of occupying land resources, high cost of stabilizers, easy precipitation of heavy metals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

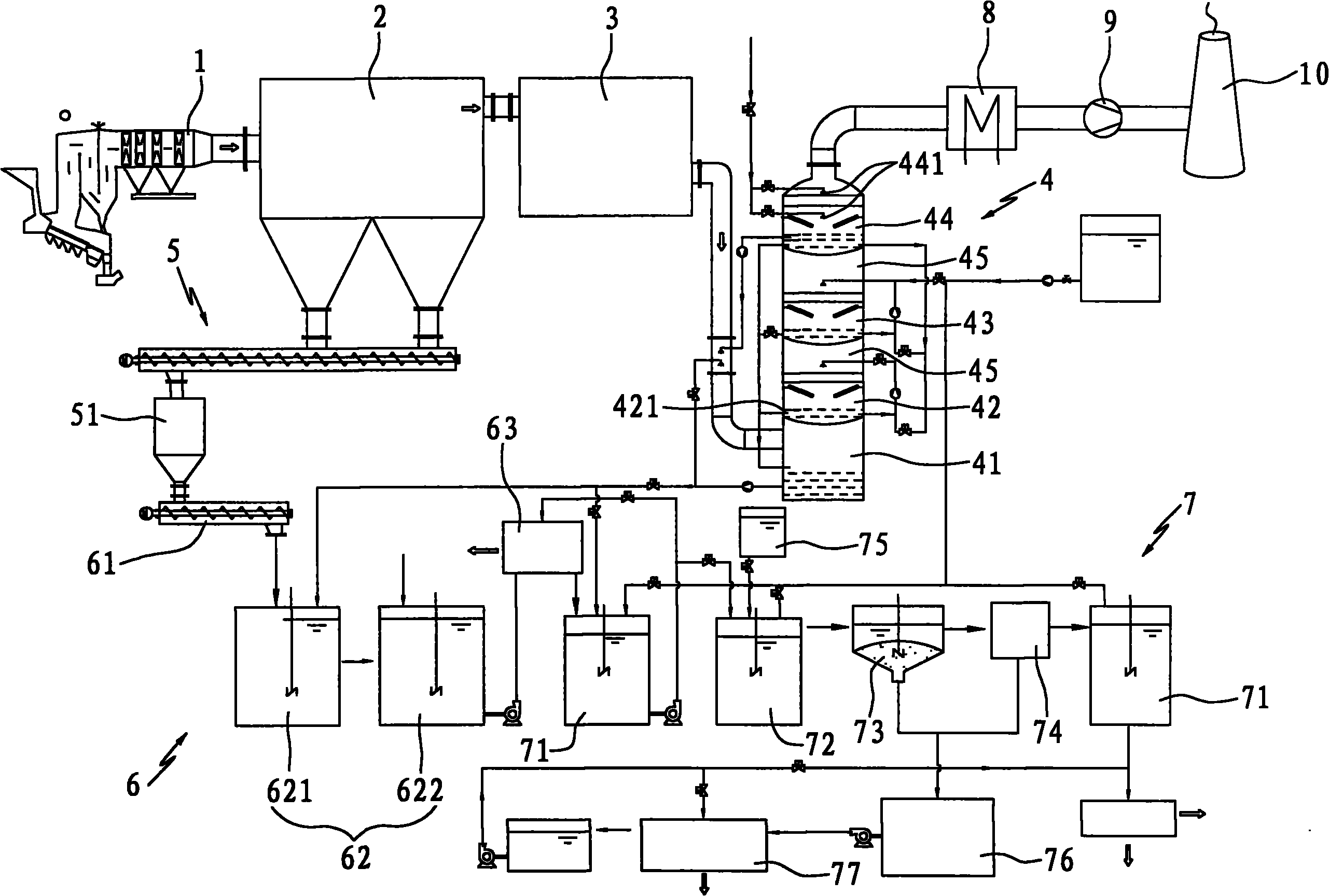

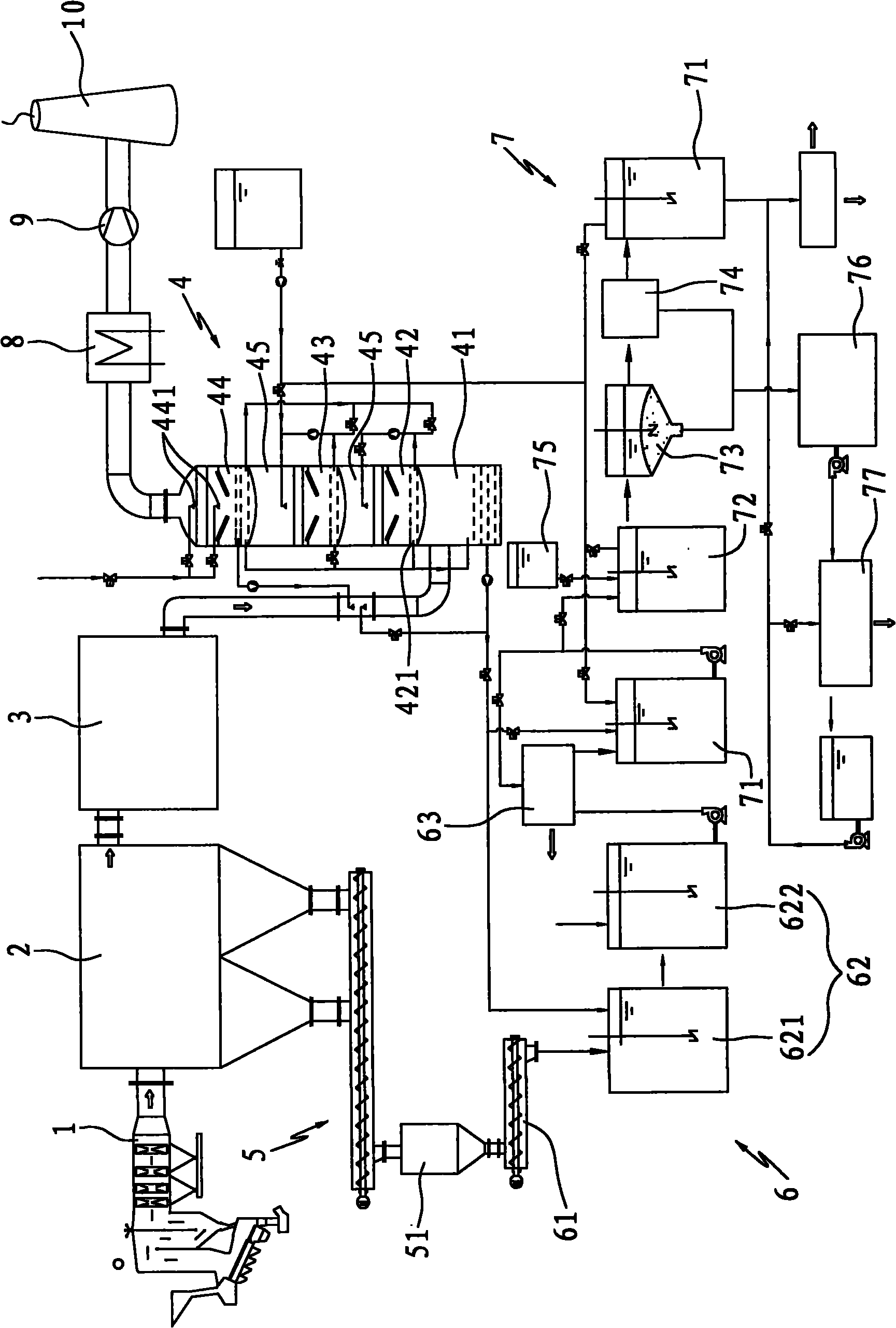

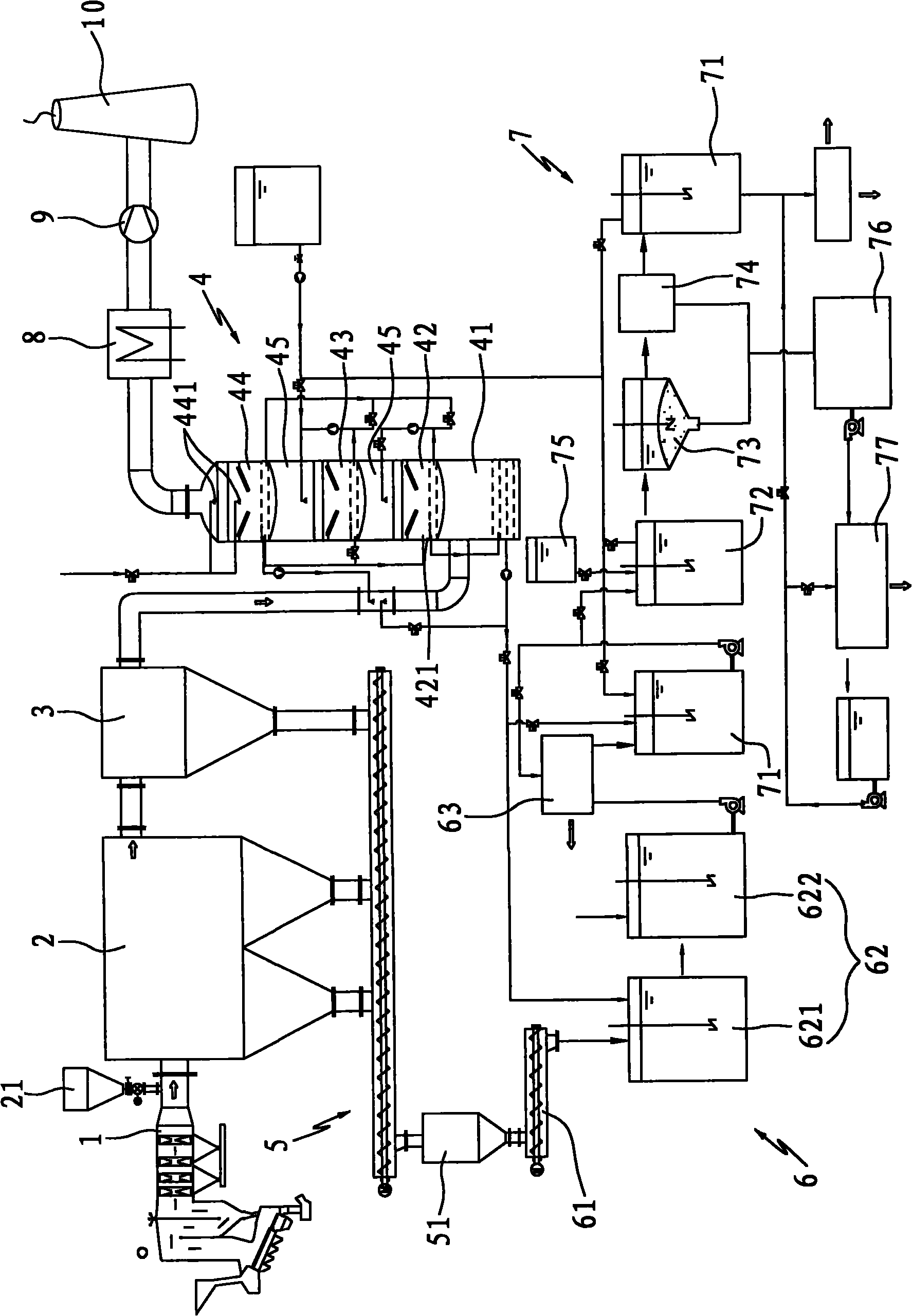

[0053] As shown in Figures 1 and 2, a waste incineration flue gas purification system disclosed by the present invention is arranged between the outlet of the waste incineration (waste heat) boiler and the chimney 10, including the flue 1 of the waste incinerator and the dust collector 2 , Independent dioxin removal device 3, flue gas scrubber 4, fly ash collection device 5, fly ash washing and dehydration system 6, sewage treatment system 7, flue gas heating device 8 and induced draft fan 9.

[0054] One side of the upper part of the dust collector 2 is connected to the flue 1, the other side is connected to the dioxin decomposition and removal device 3, and the bottom of the dust collector 2 is connected to the fly ash collection device 5; the fly ash collection device 5 is connected to the fly ash washing and dehydration system 6, and the The sump at the bottom of the gas scrubber is connected to the fly ash washing and dehydration system; the dioxin decomposition and remova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com