Method of using alpha-glucosidase for preparing isomaltooligosaccharide

A technology of isomaltooligosaccharide and glucosidase, which is applied in the direction of immobilization on/in the organic carrier, fermentation, etc., can solve the problems of many impurities, unsuitable for industrial production, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

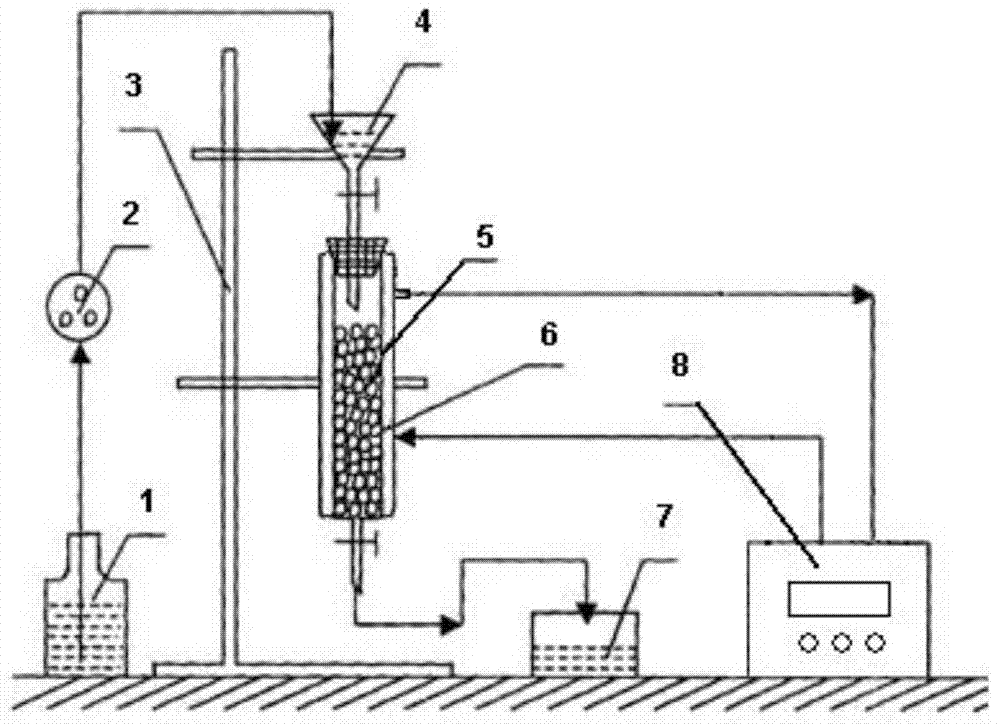

Method used

Image

Examples

Embodiment 1

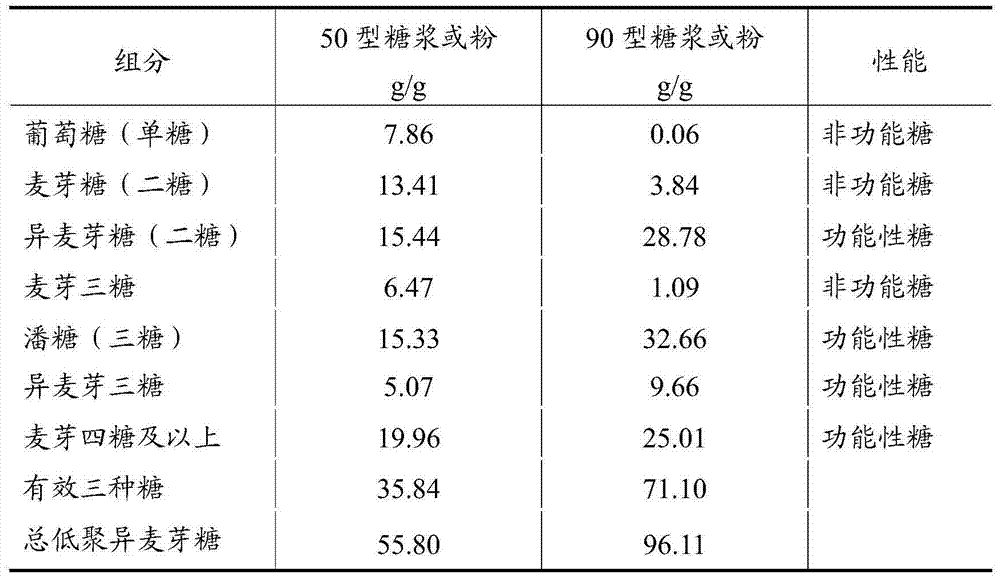

[0093] Example 1: Preparation of Type 50 Isomaltooligosaccharide Syrup Using Sodium Alginate

[0094] The implementation steps of this embodiment are as follows:

[0095] A. Immobilization of α-glucosidase

[0096] 6 parts by weight of the sodium alginate carrier provided by Qingdao Nanshan Ocean Co., Ltd. was dissolved with 12 parts by weight of water, and the obtained solution was vacuum degassed, and then according to 180000IU / 6 grams of sodium alginate, it was added to the degassed solution by Japan Amano Pharmaceutical Co., Ltd. The α-glucosidase sold by the company is mixed with 4 parts by weight of 0.12mol / LpH5.2 phosphate buffer solution, and then added dropwise with 0.6% CaCl by weight 2 Coagulate the liquid to obtain the immobilized α-glucosidase coagulated into a spherical shape, then let it stand, and centrifuge to obtain the supernatant and the precipitate, the supernatant is discarded, and the precipitate is treated with 0.12mol / LpH5.2 Washing with phosphate bu...

Embodiment 2

[0102] Embodiment 2: Use sodium alginate to prepare 50 type isomaltooligosaccharide powder

[0103] The implementation steps of this embodiment are as follows:

[0104] A. Immobilization of α-glucosidase

[0105] 9 parts by weight of the sodium alginate carrier produced by Shanghai Chemical Reagent Co., Ltd. was dissolved in 10 parts by weight of water, and the obtained solution was vacuum degassed, and then according to 150000IU / 9 grams of sodium alginate, was added to the degassed solution by Japan Amano Pharmaceutical Co., Ltd. Co., Ltd. sales of α-glucosidase and 1 weight part of 0.05mol / LpH4.8 phosphate buffer, mix well, and then drop in 0.4% by weight of CaCl 2 Coagulate the liquid to obtain the immobilized α-glucosidase condensed into a spherical shape, then let it stand, and centrifuge to obtain the supernatant and the precipitate, the supernatant is discarded, and the precipitate is treated with 0.05mol / LpH4.8 Washing with phosphate buffer until there is no protein ...

Embodiment 3

[0111] Example 3: Preparation of Type 90 Isomaltooligosaccharide Syrup Using Sodium Alginate

[0112] The implementation steps of this embodiment are as follows:

[0113] A. Immobilization of α-glucosidase

[0114] 8 parts by weight of the food-grade sodium alginate carrier produced by Lianyungang Huanyu Seaweed Co., Ltd. are dissolved in 14 parts by weight of water, and the solution obtained is vacuum degassed, and then according to 120000IU / 8 grams of sodium alginate, add the Alpha-glucosidase and 5 parts by weight of 0.14mol / LpH4.8 phosphate buffer saline sold by Amano Pharmaceutical Co., Ltd. of Japan are mixed uniformly, and then 0.4% CaCl by weight is added dropwise 2 Coagulate the liquid to obtain the immobilized α-glucosidase coagulated into a spherical shape, then let it stand, and centrifuge to obtain the supernatant and the precipitate, the supernatant is discarded, and the precipitate is treated with 0.14mol / LpH4.8 Washing with phosphate buffer until there is no ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com