Patents

Literature

994results about How to "Simple purification process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for effectively reducing metal content in polyetheretherketone

ActiveCN101486784ASimple purification processNo need for heat and pressureCentrifugationDistilled water

The invention relates to a method for effectively reducing the metal content in a polyetheretherketone at normal temperature and pressure. The method mainly comprises purification, centrifugation, washing, and drying. The invention uses hydrochloric acid as purification agent and adds the polyetheretherketone particles into hydrochloric acid solution with certain concentration; after the purification treatment is finished and the centrifugation hydrochloric acid removal is carried out, and then the distilled water is washed to neutral and dried; and polyetheretherketone particles of high quality can be obtained. The method not only can effectively reduce the metal content in the polyetheretherketone and does not change the physical and chemical properties of the polyetheretherketone, but also has the advantages of simple process, easily-fetched raw material, no need of temperature and pressure increase, and low cost.

Owner:JILIN ZHONGYAN HIGH PERFORMANCE PLASTIC

Process fof hydrogenating carboxylic acid and its ester to prepare alcohol

InactiveCN1974510AHigh activityHigh selectivityOrganic compound preparationHydroxy compound preparationPolymer scienceAlcohol

The present invention discloses process of preparing alcohol with carboxylic acid and its ester, and features that C2-C20 carboxylic acid and its ester in 21-92 weight portions, catalyst in 1-21 weight portions and solvent in 5-73 weight portions are added into reactor and reacted with high purity hydrogen at the temperature of 100-200 deg.c, preferably 100-150 deg.c and pressure not lower than 1.0 MPa, preferably 3.0-7.0MP a while stirring at 500-1000 rpm for 6-24 hr to produce alcohol, with the alcohol being taken out after cooling. The carboxylic acid and its ester may have straight chain or branched chain, and the catalyst is solid in the carrier of zirconia in precipitation process sol or marketable product. Gas chromatographic analysis shows the present invention has the conversion rate of carboxylic acid and its ester in 75.0-99.5 % and selectivity of 68.2-99.5 %.

Owner:SICHUAN UNIV

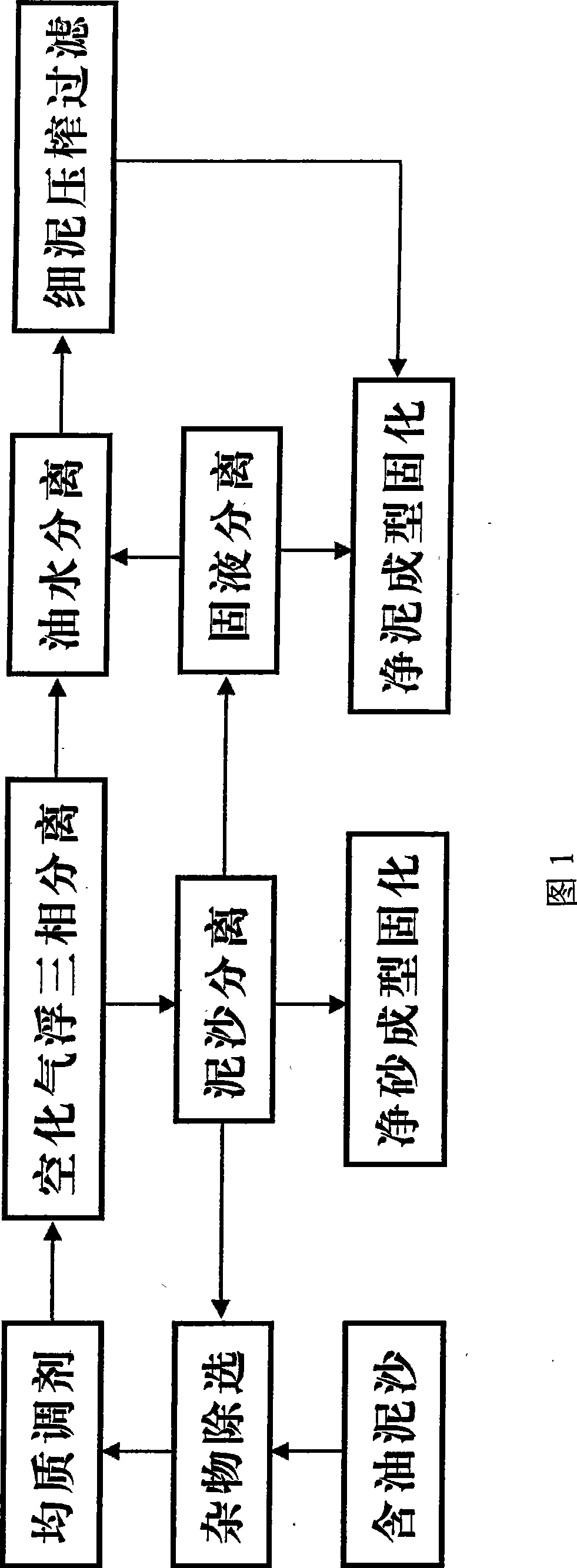

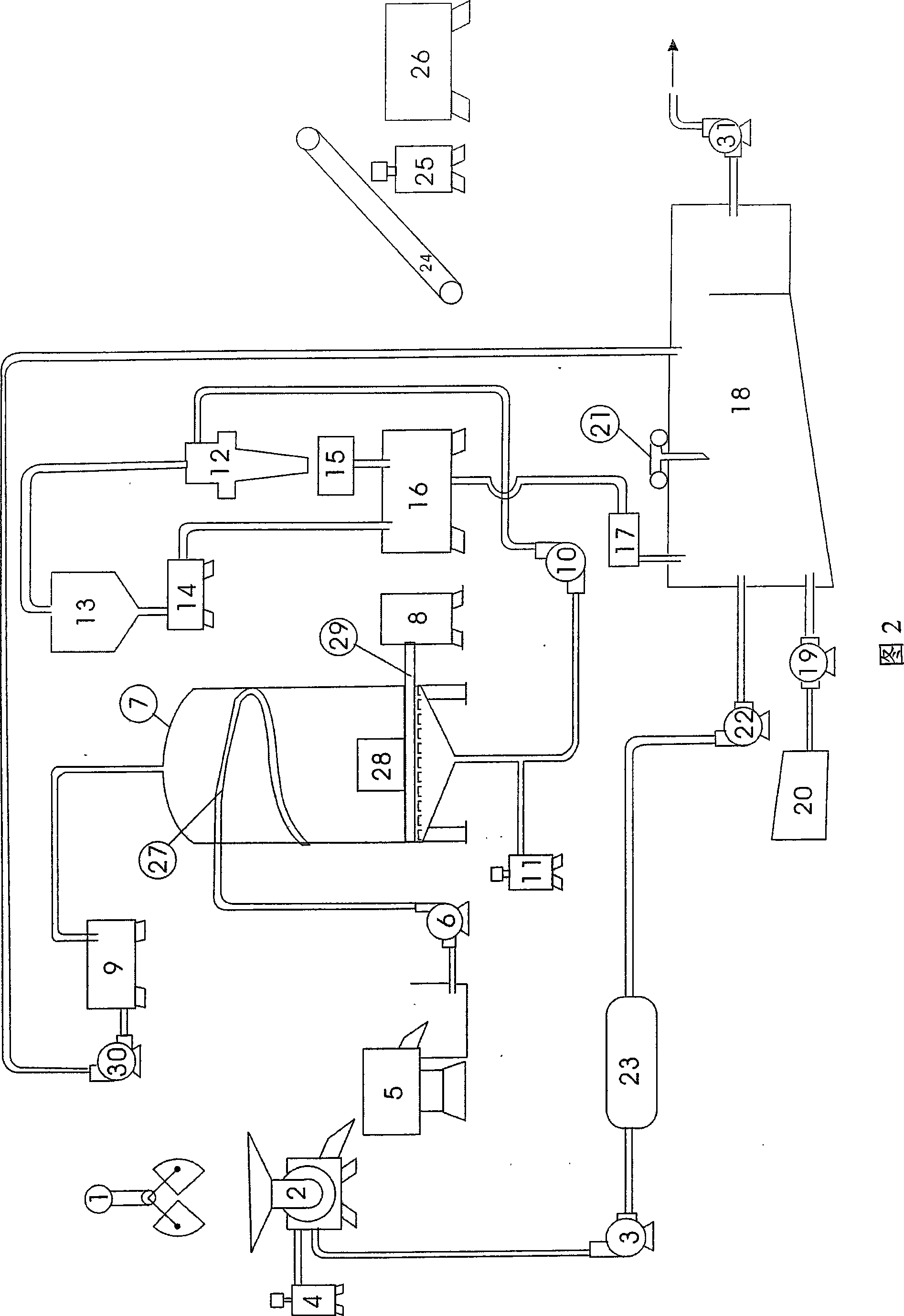

Pollution-free oil-containing mud cleaning treatment method and treatment system thereof

InactiveCN101428247ASolve the problem of secondary pollutionSimple purification processWet separationResource recoverySlurry

The invention relates to a pollution-free oily sediment purification treatment method and a treatment system, and the implementation steps are as follows: adopting a mechanical feeding device for conveying oily sediment to a miscellany removing and sorting device, filtering out and removing the miscellanies therein, perfusing hot water and a reagent into the oily sediment; evenly regulating the oily sediment through mechanical rolling; treating oil, water and sediment in an input tank through a cavitation and air flotation three-phase separator, so as to realize the three-phase separation of the oil, the water and the sediment, and discharging most of the separated oil; separating the sediment through a cyclone separator, and discharging net sand; separating slurry through a centrifuge, discharging net mud; separating fine mud from the water through a pressing filter, discharging net fine mud; separating the oil-water through natural ascending and descending, outputting the oil, and continuously heating water for the cyclic utilization; and curling and molding the discharged net sand and net mud according to routine. The invention realizes the resource recovery of crude oil in oily sediment and reduces the cost for purifying and treating oily sediment effectively, and the purified sediment is made into cured resin used for building materials.

Owner:TIANJIN TAIXING ENG TECH CO LTD

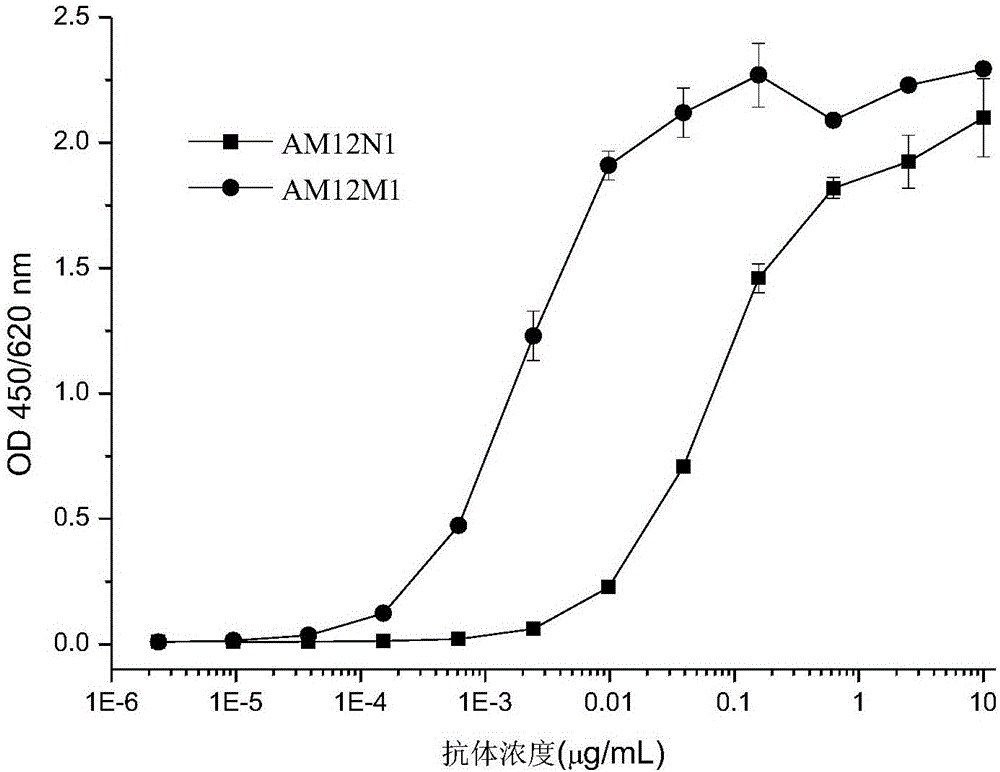

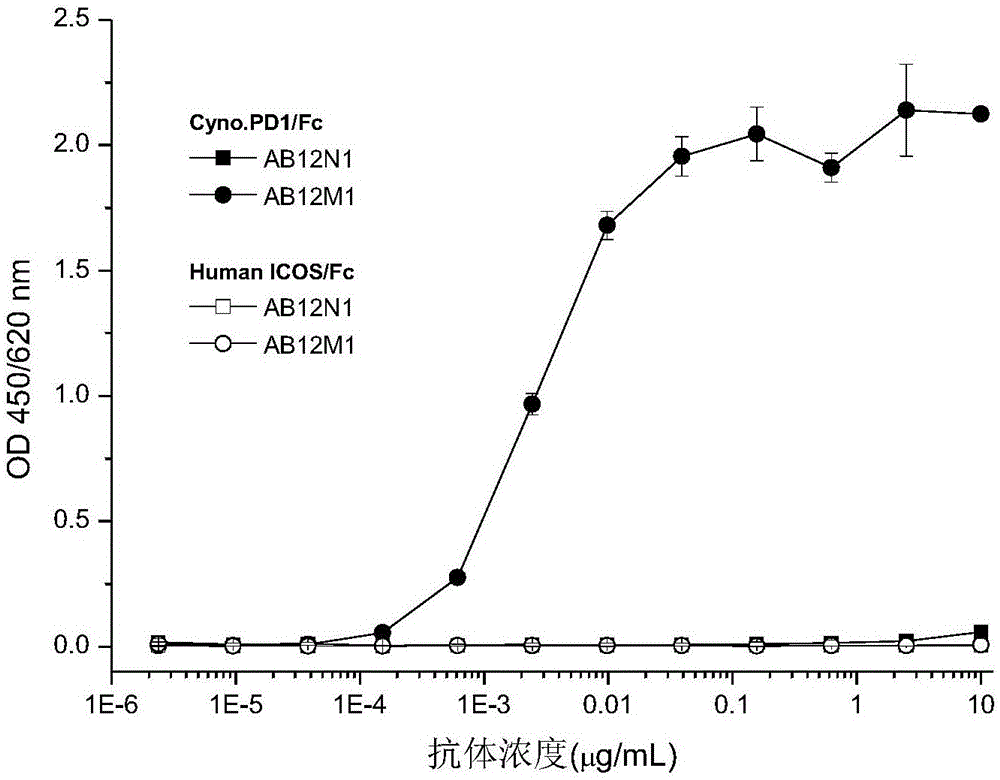

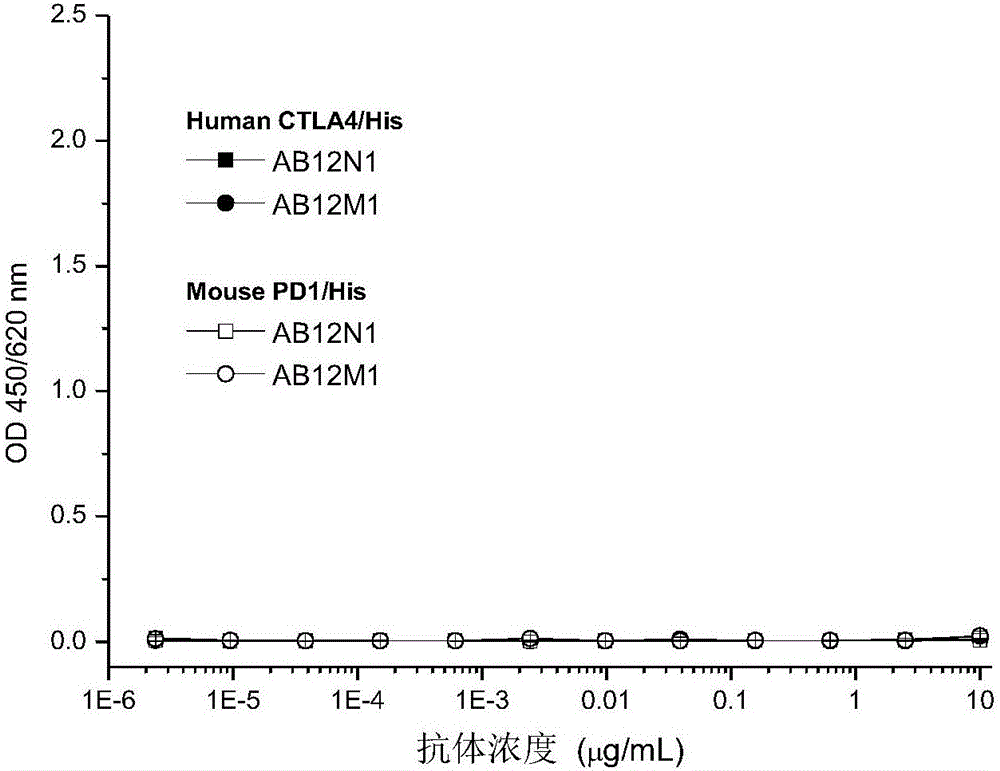

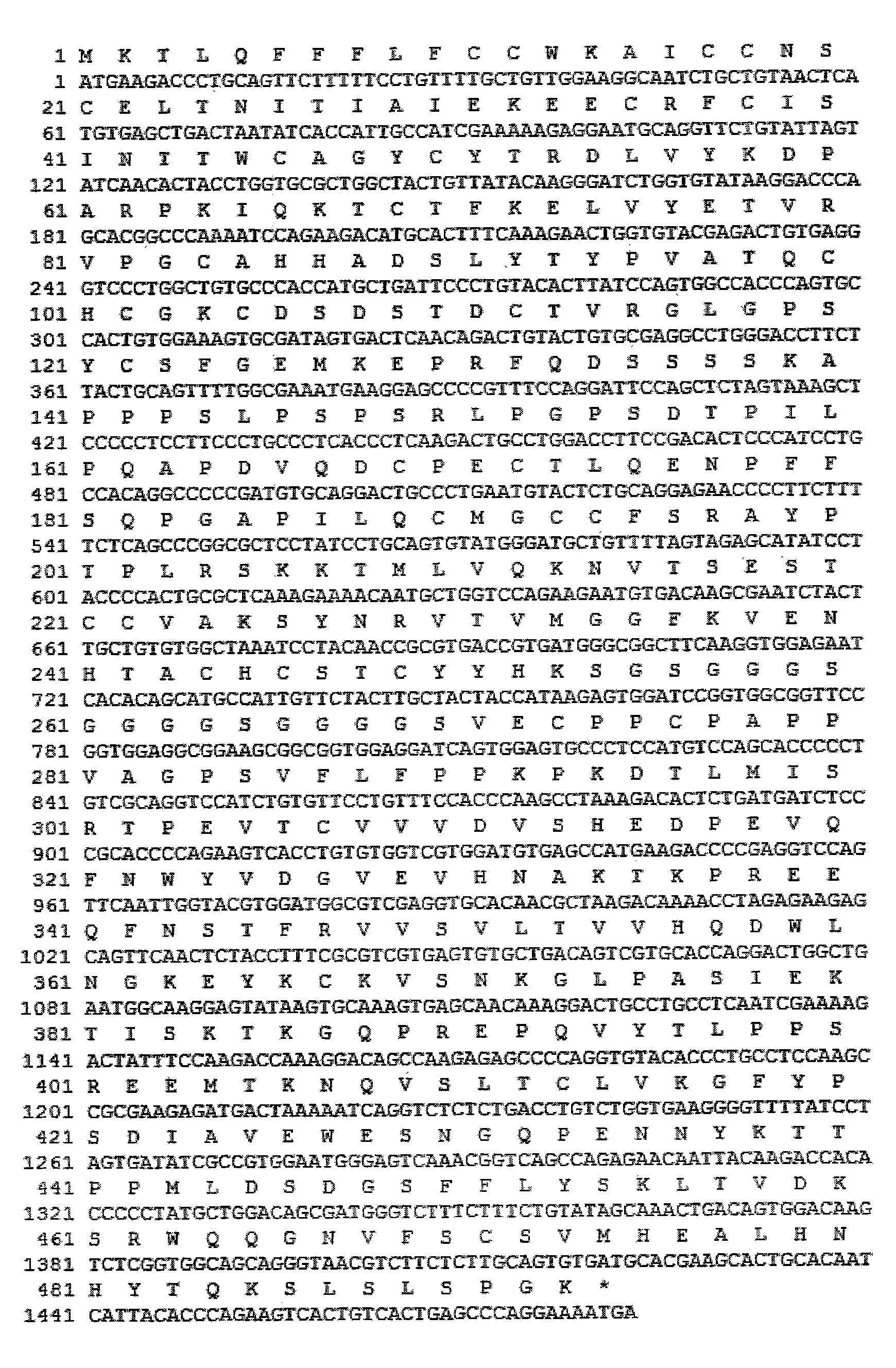

Anti-PD-1 (Programmed Death-1) antibody and application thereof

ActiveCN106519034AHigh binding affinityIncrease productionAntibacterial agentsAntipyreticInfective disorderAntibody

The invention provides an antibody specifically combined with PD-1 (Programmed Death-1) with high affinity, and also provides a nucleic acid molecule for coding the antibody, an expression vector and a host cell for expressing the antibody, and a production method of the antibody. In addition, the invention also provides an immune conjugate and a medicinal composition containing the antibody, and application of the antibody to the preparation of a medicine for treating multiple diseases (including a cancer, an infectious disease and an inflammatory disease).

Owner:LUNAN PHARMA GROUP CORPORATION

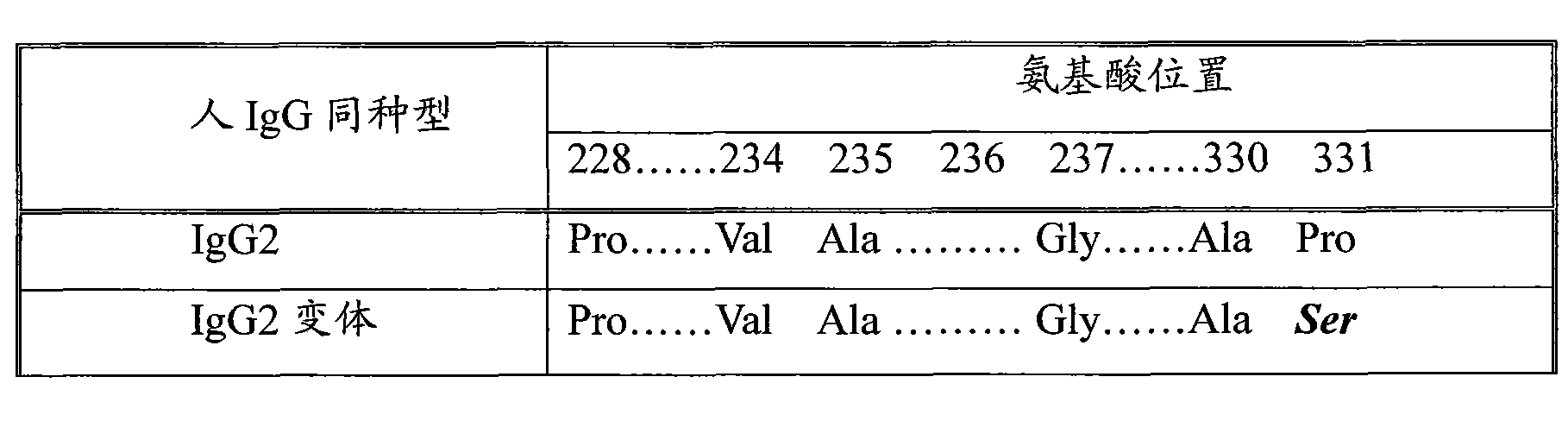

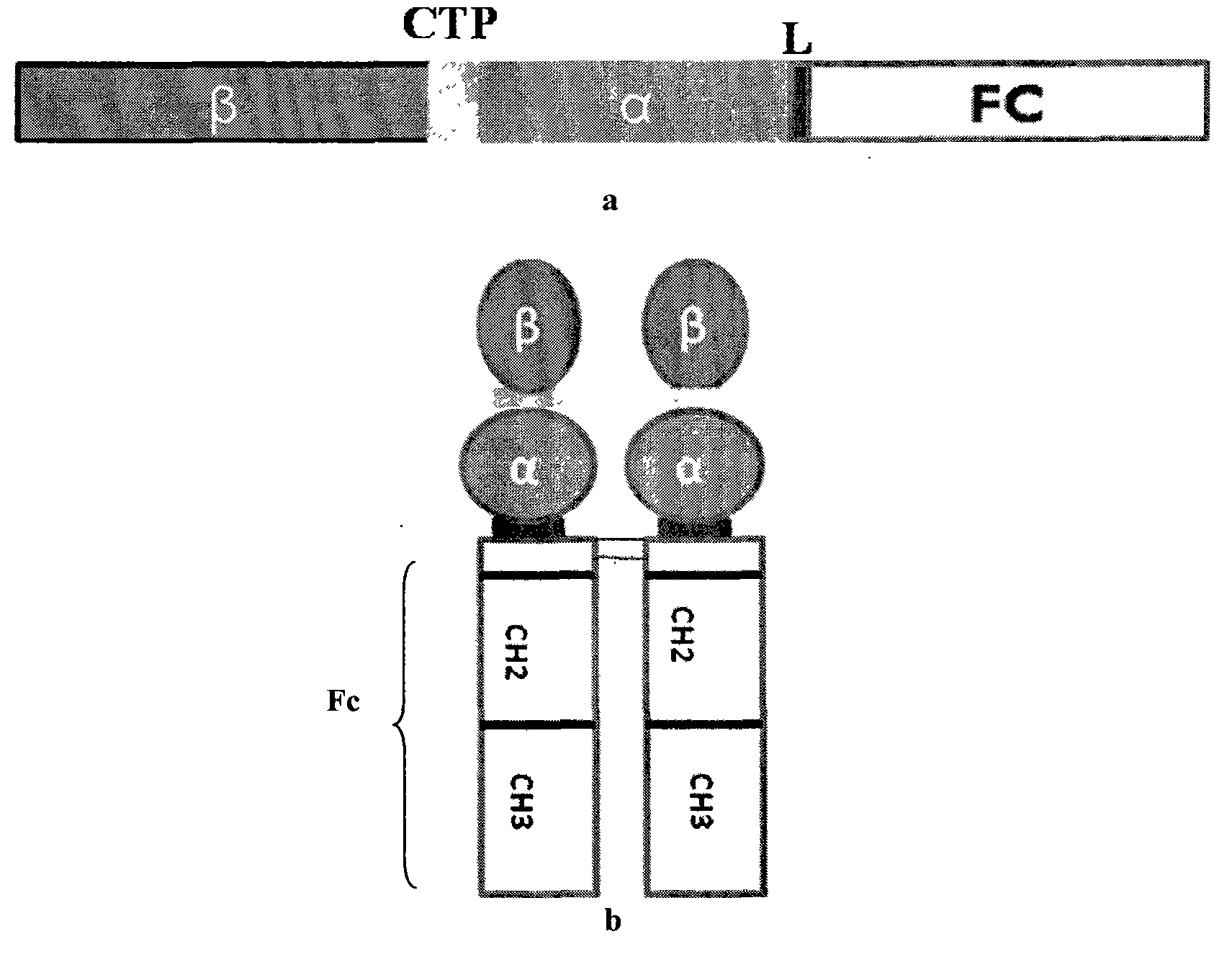

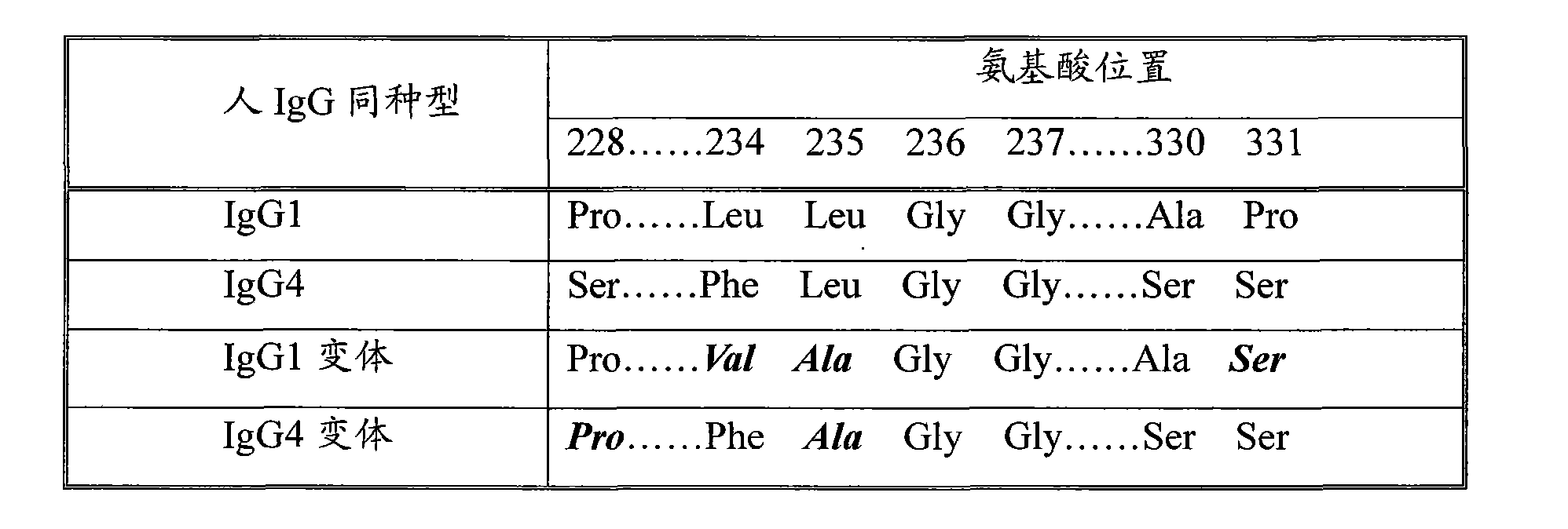

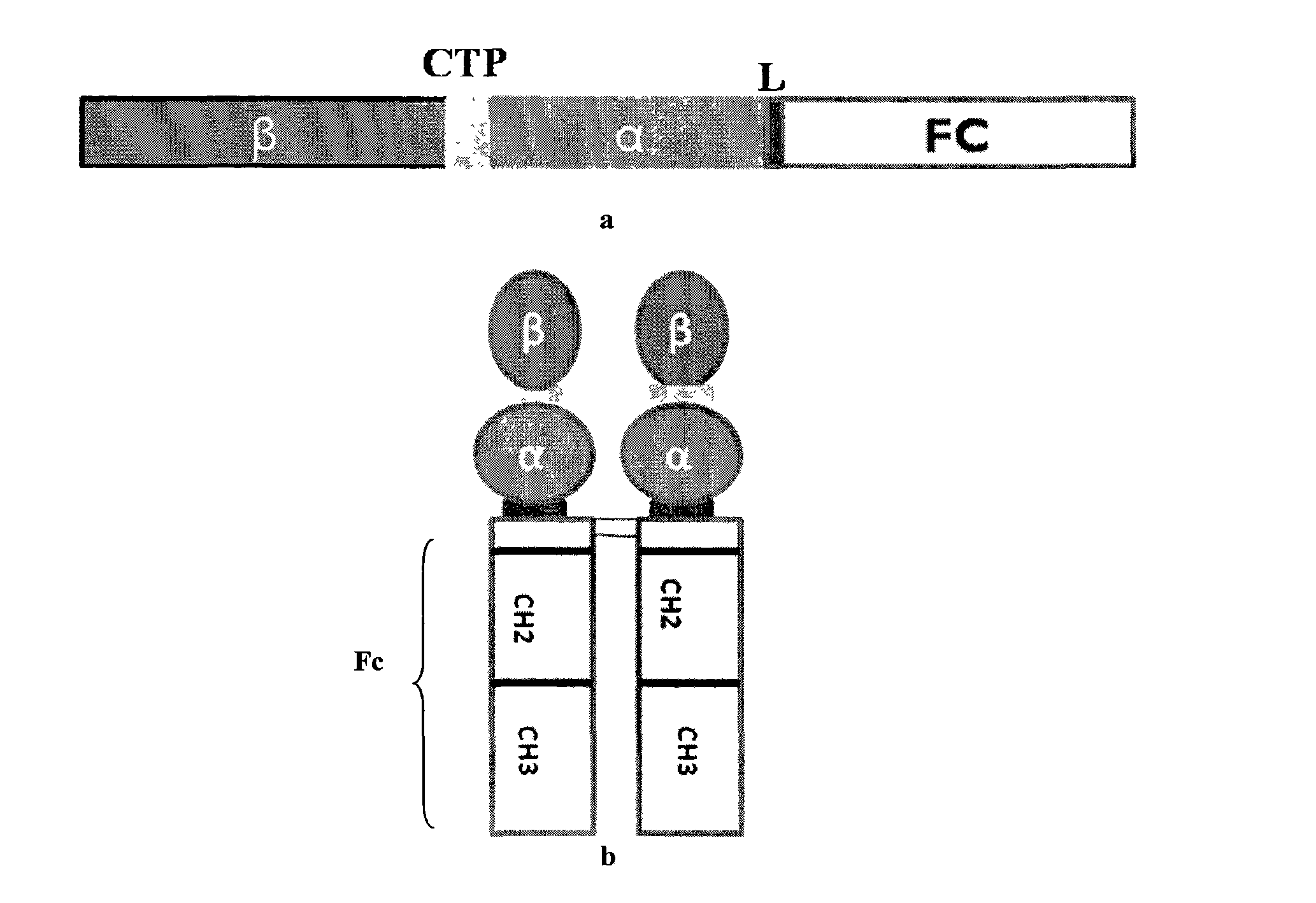

Long-acting recombinant human follicle-stimulating hormone-Fc fusion protein (hFSH-Fc)

ActiveCN103539860AImprove biological activitySmall toxicityPeptide/protein ingredientsAntibody mimetics/scaffoldsRecombinant human follicle stimulating hormoneSide effect

The invention discloses a long-acting recombinant human follicle-stimulating hormone-Fc fusion protein (hFSH-Fc) and a preparation method thereof. The recombinant hFSH-Fc is a dimerization fusion protein. An amino acid sequence of the hFSH-Fc comprises an hFSHbeta subunit, CTP (carboxy-terminal peptide), an hFSHalpha subunit, a flexible peptide linker and a human IgG (immunoglobulin G)2 Fc variant from the N terminal to the C terminal in sequence. The hFSH-Fc has longer half-life in vivo and smaller side effects than existing hFSH. The invention also relates to an application of a recombinant hFSH-Fc composition to preparation of drugs for treating and / or preventing infertility.

Owner:UNICOHEALTH CO LTD

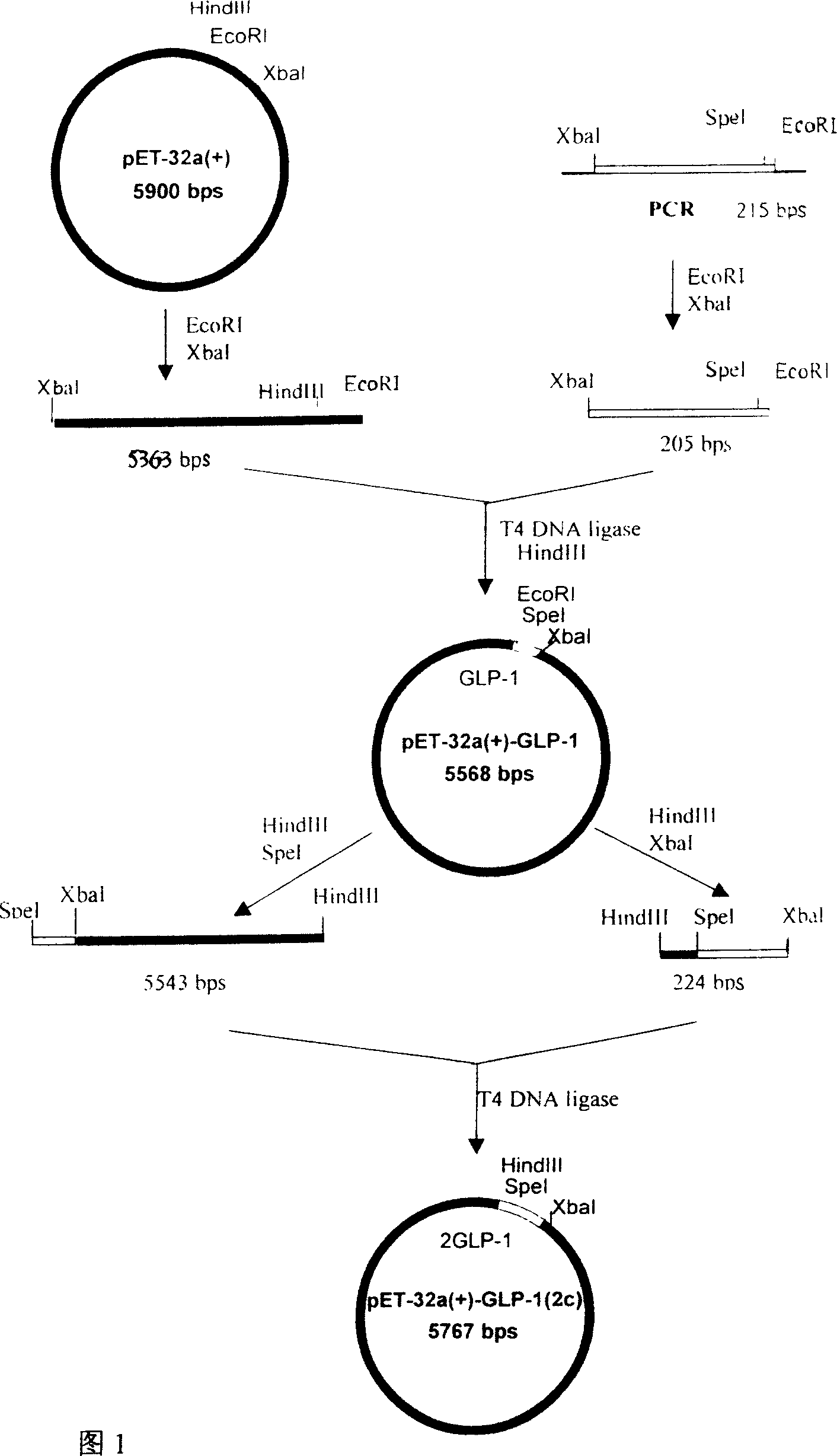

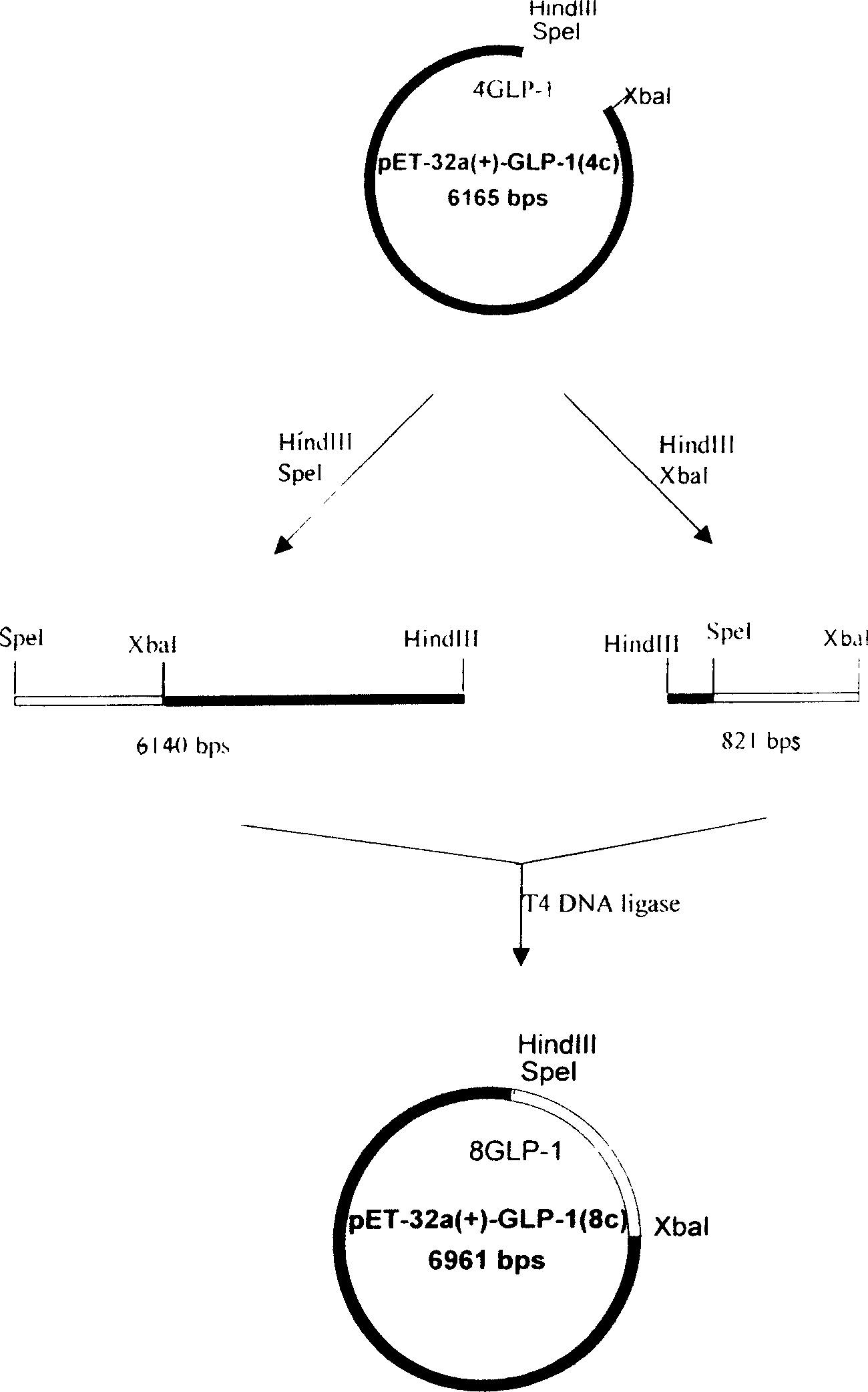

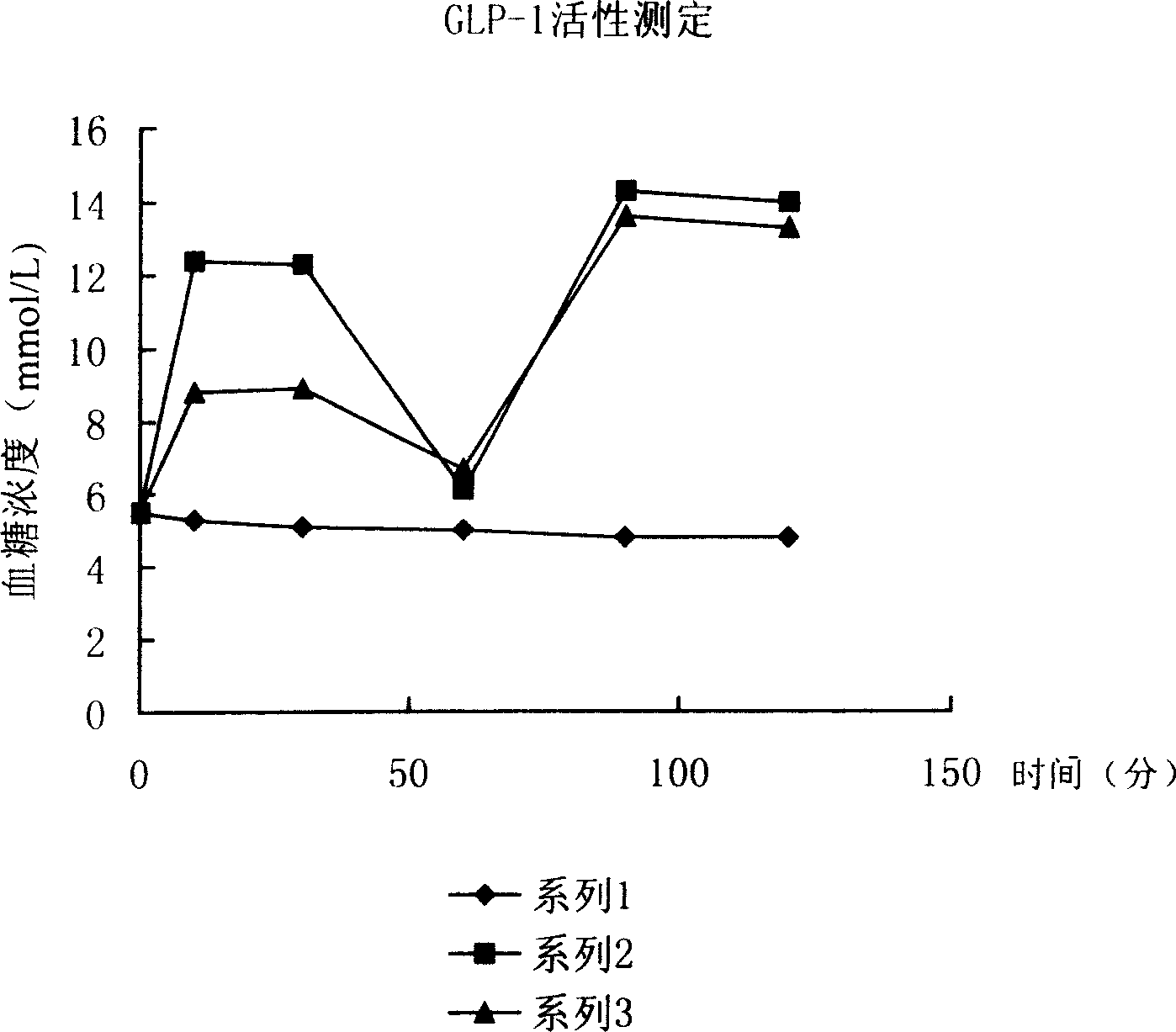

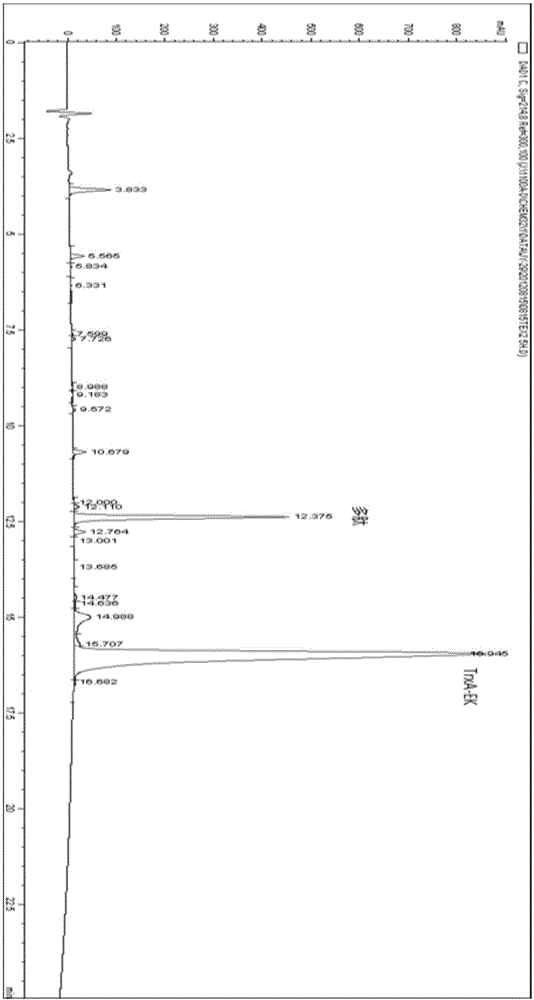

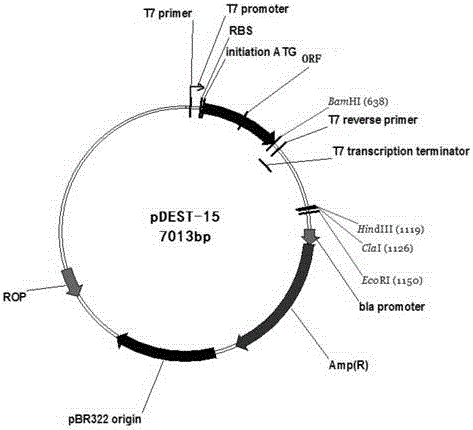

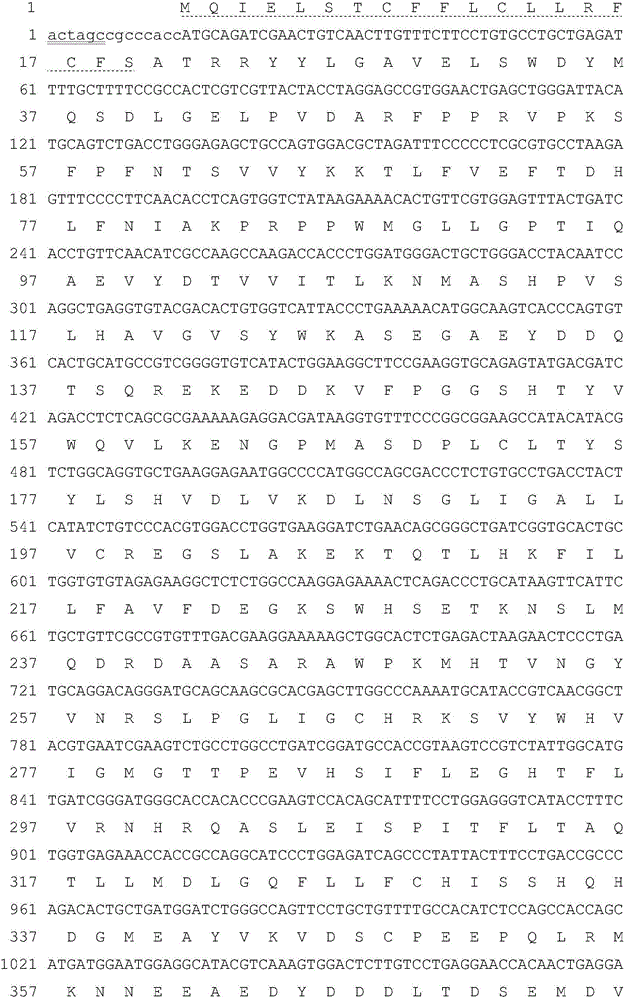

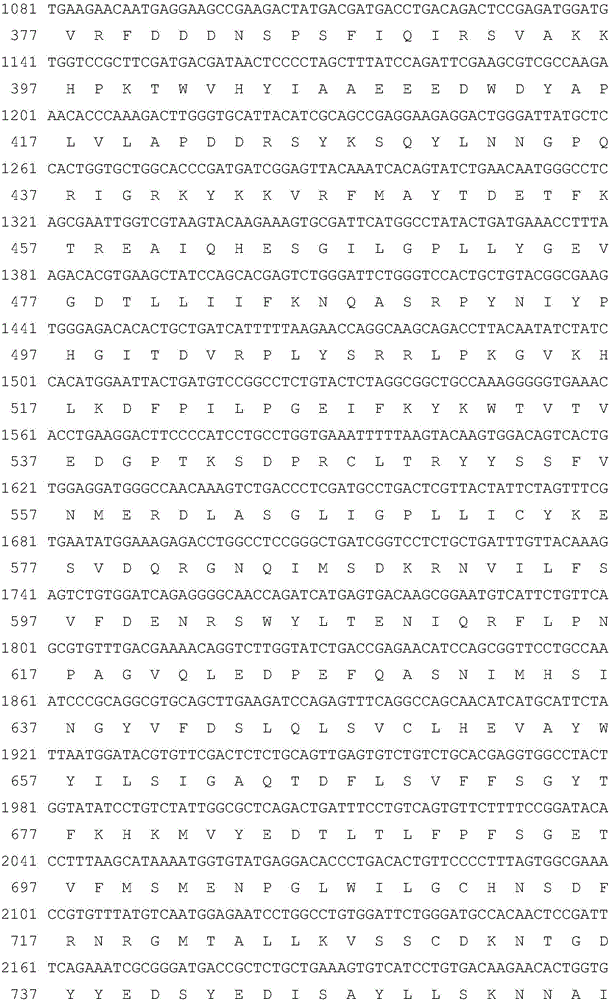

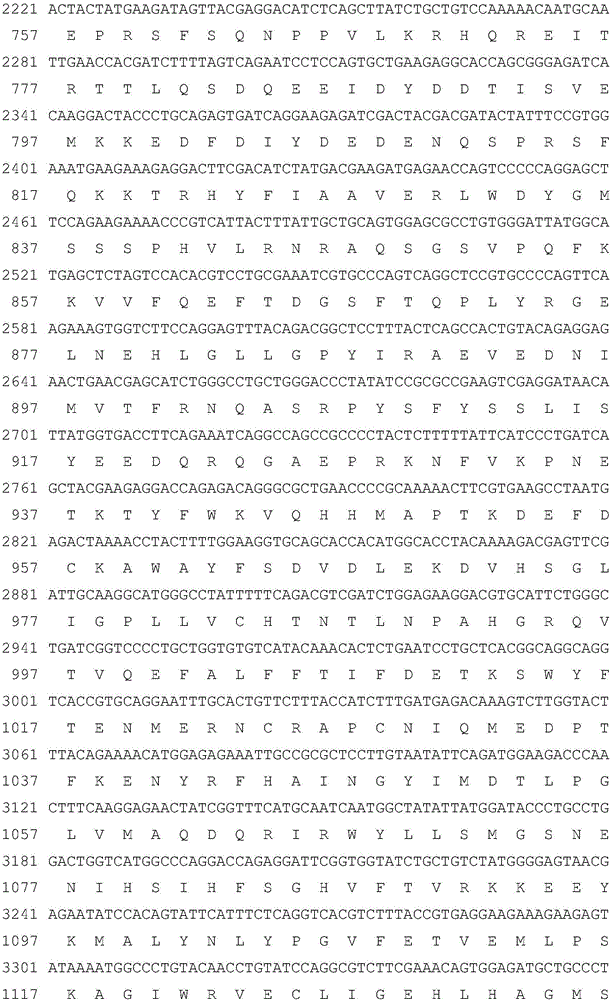

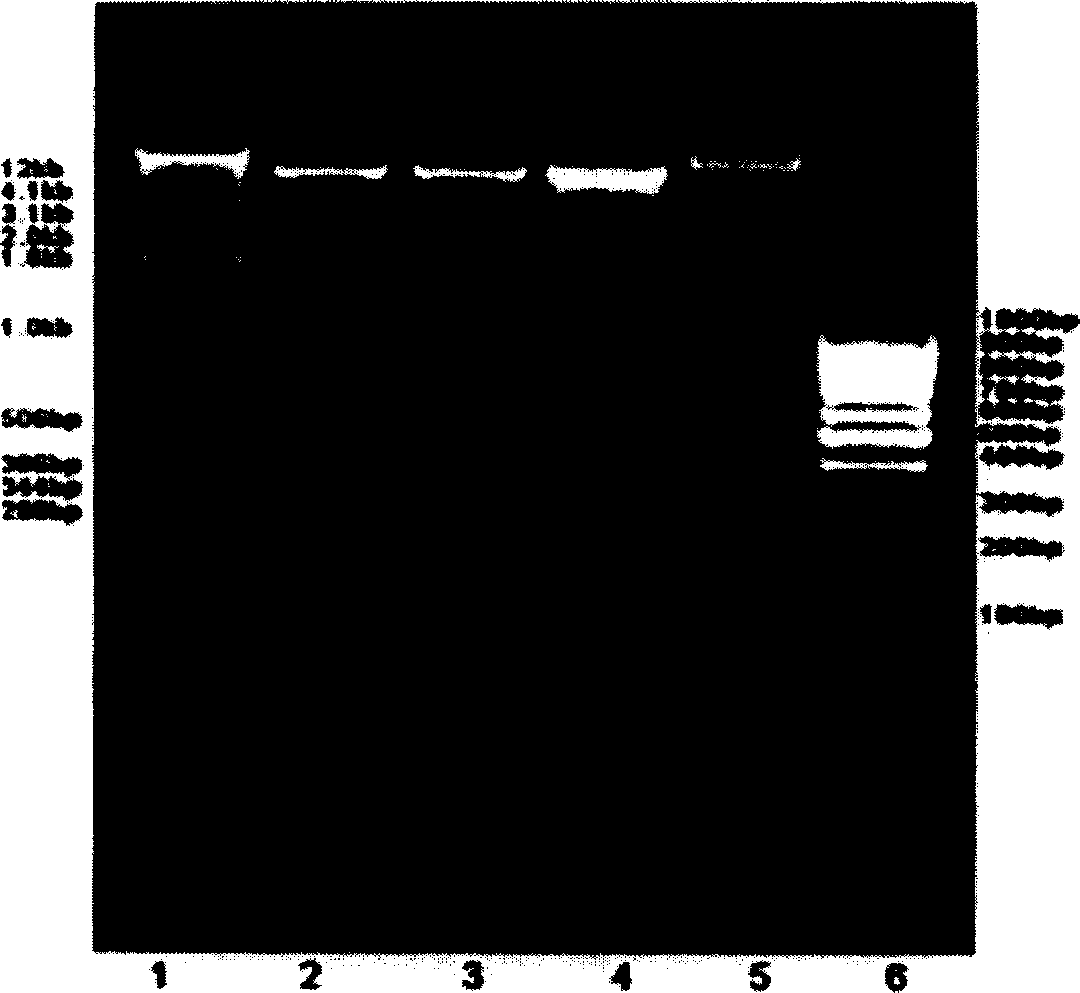

High efficiency experssino human glicentin-1 gene engineering bacteria and its construction method and use

The present invention belongs to the field of biological engineering technology. The gene engineering bacteria is colibacillus DH5-alpha, BL21(DE3) or BLR(DE3) carrying the recombinant plasmid of human glicentin-1 gene, i. e., GLP-1 gene. The construction process of the gene engineering bacteria includes connecting serially DNA sequence containing human glicentin-1 gene to form polymer, constituting expression vector and converting to colibacillus to obtain efficiently expressing human glicentin-1 gene engineering bacteria. With the gene engineering bacteria and through a three-step process of liquid culture, purification to produce human glicentin-1 fusion protein and preparation of human glicentin-1, human glicentin-1 product may be produced. The present invention has the advantages of high expression amount, less purification steps, high yield and low production cost.

Owner:EAST CHINA NORMAL UNIVERSITY

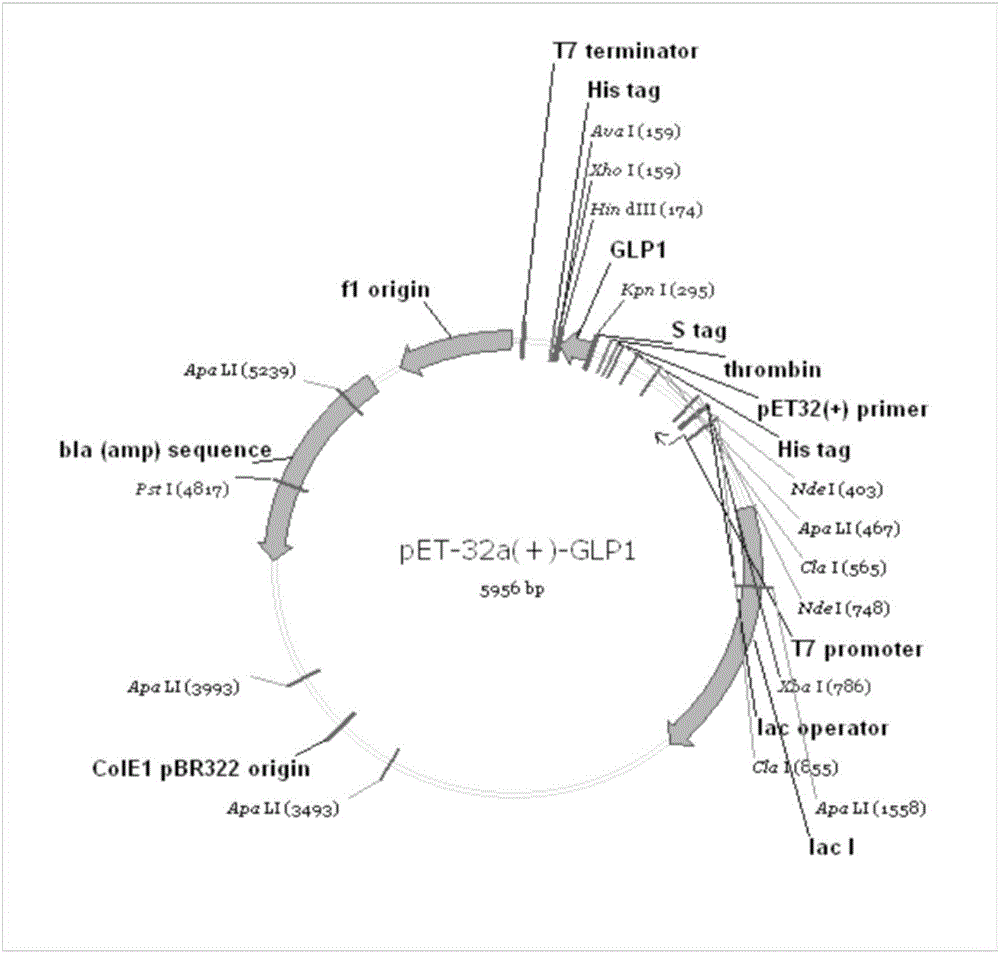

Method for biosynthesis preparation of human GLP-1 polypeptide or analogue thereof

InactiveCN106434717AEasy to separateHigh expressionNucleic acid vectorFusion with protease siteEscherichia coliEnzyme digestion

The invention relates to a method for biosynthesis preparation of human glucagon-like peptide-1 (GLP-1) and an analogue thereof. With adopting of a gene engineering technology, a recombinant escherichia coli expressed GLP-1 fusion protein is constructed, and a protein enzyme digestion site is designed in the fusion protein; a fusion gene has a gene sequence with a form of A-B-C structure, wherein A is a chaperonin gene, B is a nucleotide sequence encoding a connection peptide containing the enzyme digestion site, and C is a gene encoding the GLP-1 or the analogue thereof. After recombinant engineering bacteria is subjected to induced expression, the fusion protein is purified and subjected to enzyme digestion, and then the GLP-1 and the analogue thereof are obtained and are detected to have biological activity. The preparation method of the GLP-1 and the analogue thereof provided by the invention is simple and quick, the production conditions are mild, the product is convenient to separate and extract, the process is simple, and the industrialization prospect is good.

Owner:HANGZHOU JIUYUAN GENE ENG +1

Long-acting recombinant human follicle-stimulating hormone-Fc fusion protein (hFSH-Fc)

ActiveCN103539861AImprove biological activityHigh activityPeptide/protein ingredientsPeptide preparation methodsSide effectRecombinant human follicle stimulating hormone

The invention discloses a long-acting recombinant human follicle-stimulating hormone-Fc fusion protein (hFSH-Fc) and a preparation method thereof. The hFSH-Fc is a dimerization fusion protein. An amino acid sequence of the hFSH-Fc comprises an hFSHbeta subunit, CTP (carboxy-terminal peptide), an hFSHalpha subunit, a flexible peptide linker and a human IgG (immunoglobulin G) Fc variant from the N terminal to the C terminal in sequence. The hFSH-Fc has longer half-life in vivo and smaller side effects than existing hFSH. The invention also relates to an application of a recombinant hFSH-Fc composition to preparation of drugs for treating and / or preventing infertility.

Owner:UNICOHEALTH CO LTD

Genetic engineering strain capable of effectively secreting D-psicose 3-epimerase and construction method and application thereof

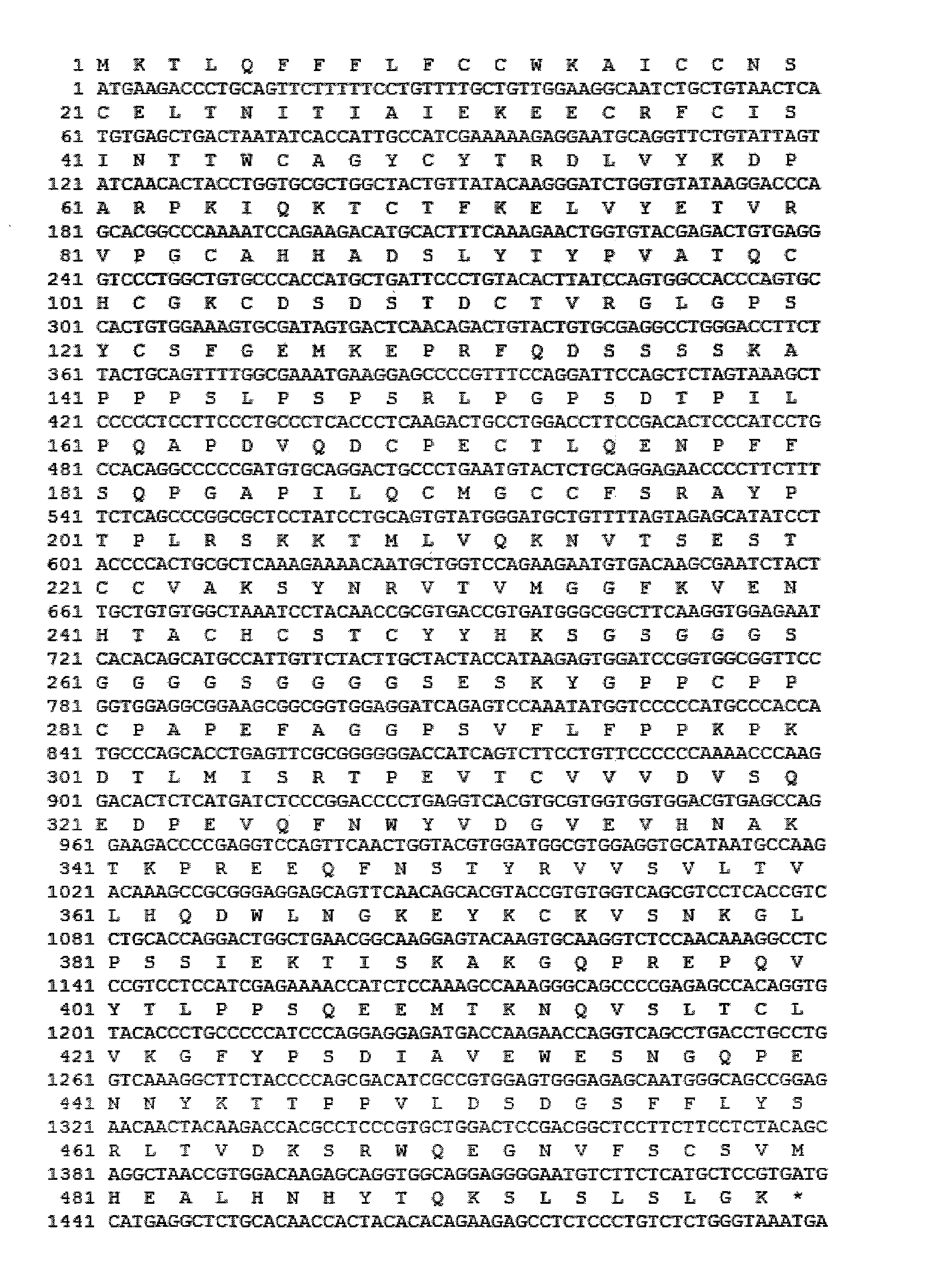

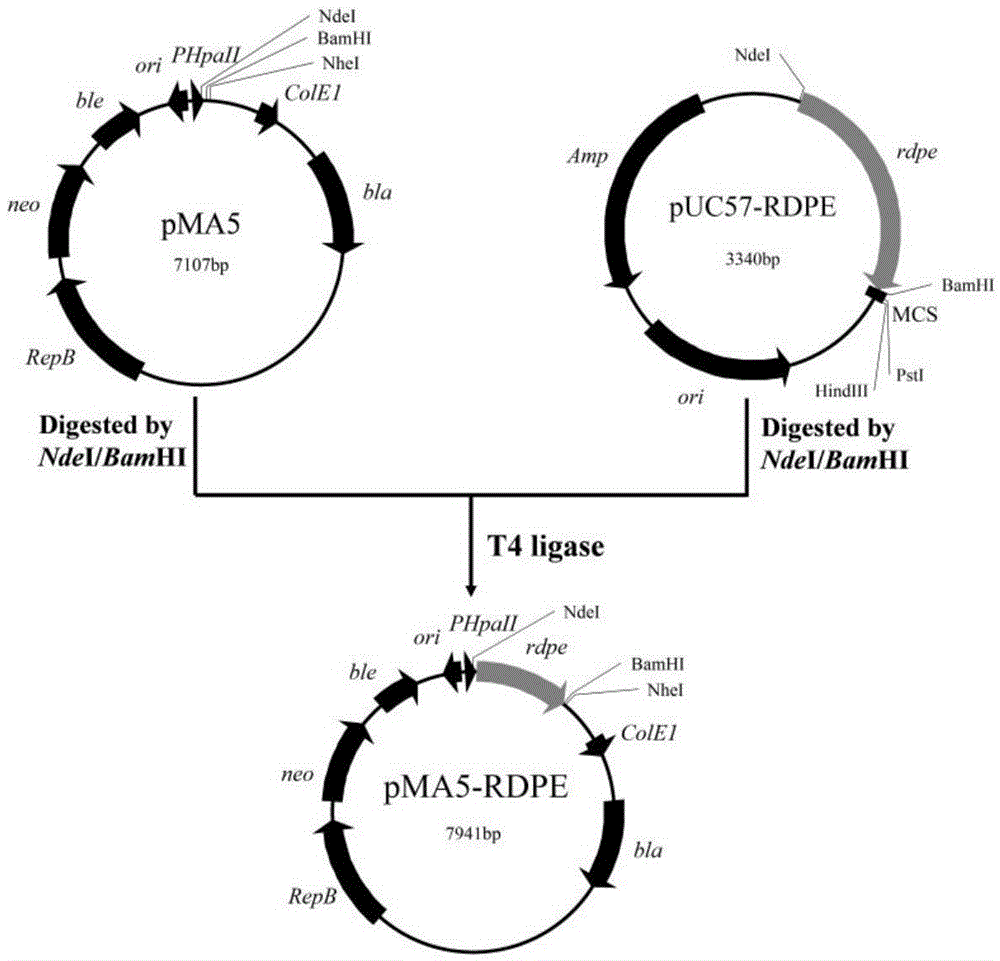

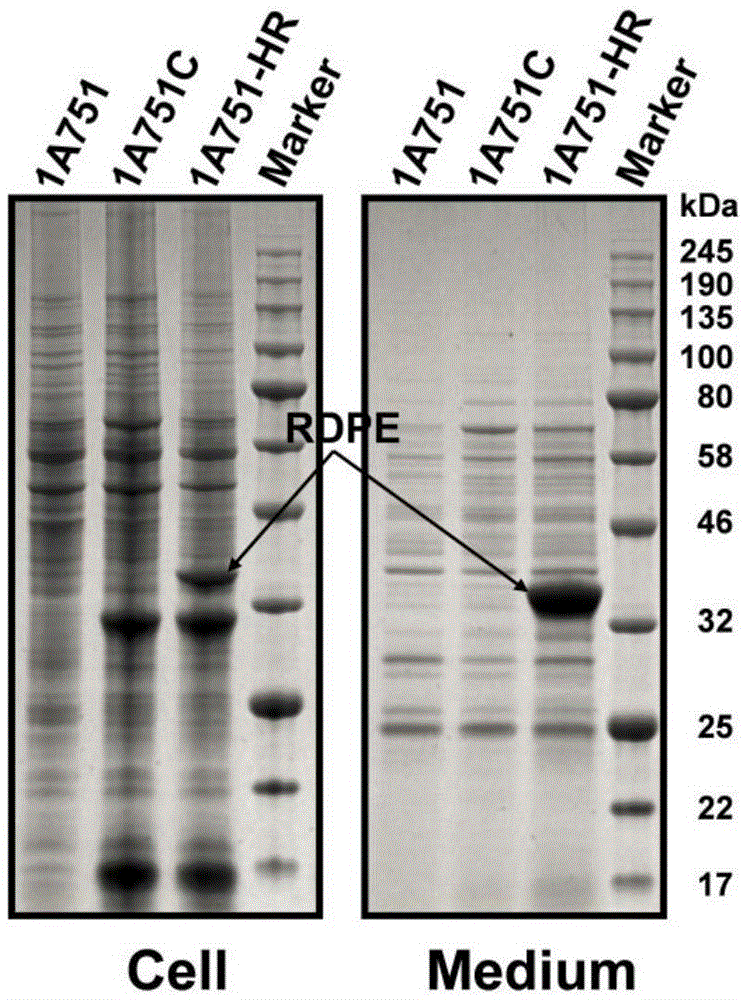

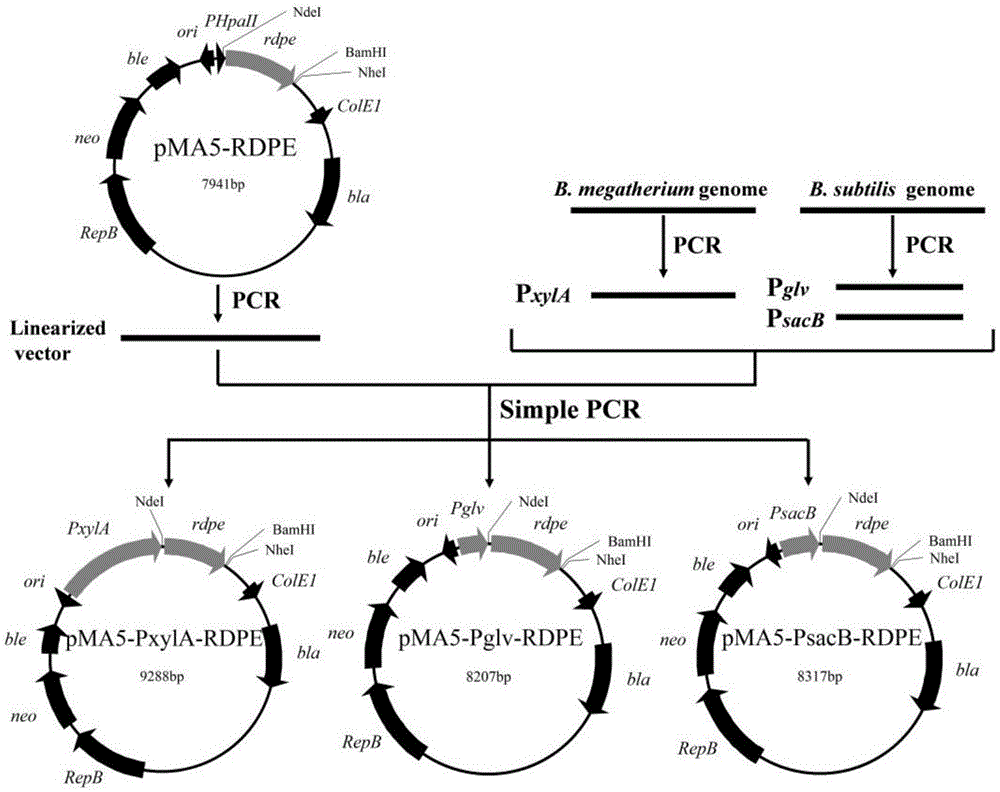

ActiveCN105602879ASimple purification processLow production costBacteriaMicroorganism based processesPsicoseRumen

The invention belongs to the technical field of bioengineering, and particularly relates to a genetic engineering strain capable of effectively secreting D-psicose 3-epimerase and a construction method thereof. A D-psicose 3-epimerase gene rdpe from rumen bacterium Ruminococcus sp. 5_1_39B_FAA is obtained firstly, recombinant plasmid pMA5-RDPE construction and bacillus subtilis conversion are conducted, and then constitutive and secretive expression of RDPE in bacillus subtilis is achieved. By comparing three glucose-induced promoters, the optimal inducible promoter P[xylA] is obtained, and the RDPE secretion level is increased remarkably. By knocking out the xylose utilization gene xylAB (xylA and xylB), the xylose metabolism pathway of bacillus subtilis is blocked, the secretion amount of RDPE is further increased, and the optimal induced concentration of the inducer xylose is reduced to 0.5% from 4.0%. Finally, the engineered strain 1A751SD-XR is evaluated in a 7.5 L fermentation tank, and the RDPE secretion level can be as high as 95 U / mL and 2.6 g / L.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Hyperglycosylatedhuman coagulation factor VIII fusion protein and preparation method and application thereof

ActiveCN106279437AIncrease productionExtended half-life of activity in vivoFactor VIIPeptide/protein ingredientsHuman Chorionic Gonadotropin Beta SubunitHalf-life

The invention discloses a hyperglycosylated human coagulation factor VIII (FVIII) fusion protein and a preparation method and application thereof. The fusion protein successively contains human FVIII, a soft peptide connector, at least one human chorionic gonadotropin betasubunitcarboxyl terminal peptide rigid unit and prolonged half-life period portion (preferably ahumanIgG Fc variant) from an end N to an end C. The fusion protein has biological activity similar to that of recombinant FVIII and prolonged in-vivo activity half-life period, thereby improving the pharmacokinetics and drug efficacy.

Owner:AMPSOURCE BIOPHARMA (SHANGHAI) INC +3

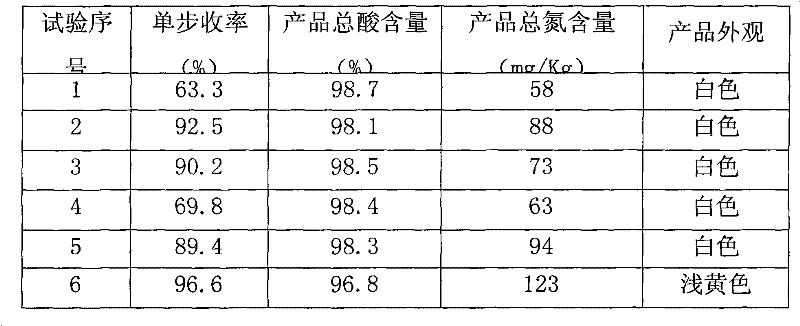

Method for extracting and refining long-chain dicarboxylic acid crude product

InactiveCN102476990AShort processSimple purification processCarboxylic compound separation/purificationSolventChemistry

The invention relates to a method for extracting and refining a long-chain dicarboxylic acid crude product. The method comprises the following steps that: the filtrate and an extracting agent are mixed and heated, and an acid is added to carry out acidifying; a liquid-liquid separation treatment is performed after the extracting agent and the filtrate are subjected to complete mixing and standing under a certain pH value and a certain temperature; the extraction phase is cooled and crystallized; the solvent is removed, and a drying treatment is performed to obtain the purified product. According to the present invention, the adsorbent is not used, such that the process for separation of the adsorbent and the fermentation liquid is saved so as to substantially reduce the purification process; the method has characteristics of simple purification process, high purification yield, and easy control of the purification process.

Owner:CHINA PETROLEUM & CHEM CORP +1

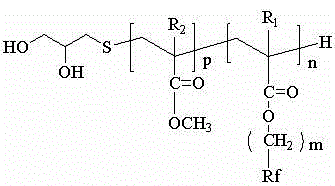

UV-curing side-chain fluorine-containing water-based polyurethane paint and preparation method thereof

ActiveCN103333285AFast curingComply with protectionPolyurea/polyurethane coatingsPolymer scienceWeather resistance

The invention relates to the technical field of paints, particularly to a UV-curing side-chain fluorine-containing water-based polyurethane paint and a preparation method thereof. The preparation method comprises the following steps: by using handy fluorine-containing acrylate monomer and / or fluorine-free acrylic monomer and chain transfer diol as raw materials, carrying out free-radical polymerization to obtain fluorine-containing alkyl diol; polymerizing side-chain fluorine-containing alkyl diol monomer to a water-based polyurethane hard section, and meanwhile, introducing photosensitive reactive group to the tail end of the polyurethane chain to prepare a UV-curing side-chain fluorine-containing water-based polyurethane resin; and blending with assistants to obtain the UV-curing water-based paint. The water-based paint provided by the invention has the characteristics of environmental protection and UV quick curing, has the advantages of excellent solvent property, excellent weatherability, high glossiness, excellent anti-staining property, excellent self-cleaning property and the like, can be used as a waterproof anticorrosive paint for building external walls, automobiles, ships and the like.

Owner:GUANGDONG UNIV OF TECH

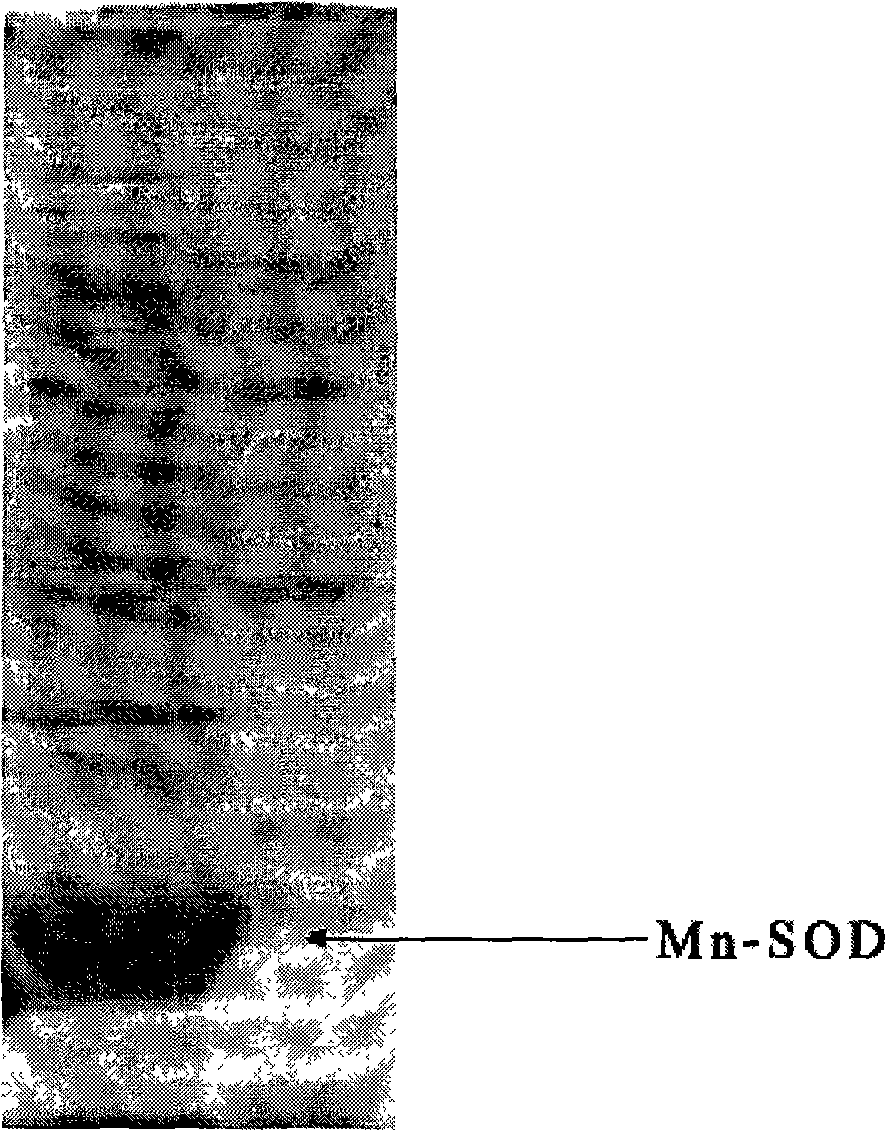

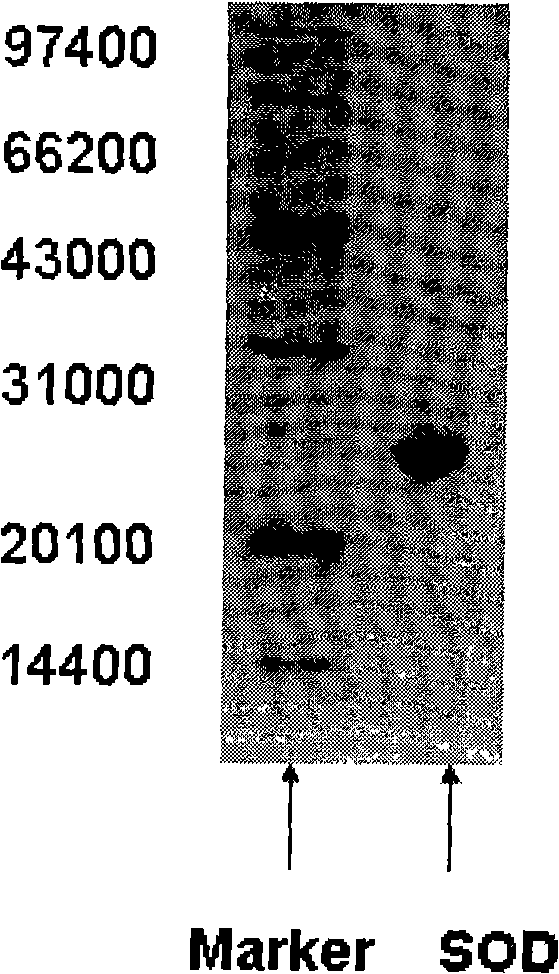

High-density fermentation and purification process for recombination high temperature-resistant hyperoxide dismutase

InactiveCN101275144AAvoid pollutionSimple purification processBacteriaMicroorganism based processesEscherichia coliDismutase

The present invention provides a high density fermentation and a purification process of a recombination high temperature resistance superoxide dismutase, the construction method of the invention includes: using gene coded for SOD in a thermophilic bacteria as a template, designing specific primer amplification target gene having restriction enzyme sites, after double digestion, connecting to plasmid vector pET28a after the same double digestion, constructing a recombinant plasmid, named for pSOD, transforming plasmid pSOD to competence escherichia coli BL21(DE3) by chemical transformation method, obtaining strain having high SOD yield after screening, completing the construction of SOD engineering bacteria; the fermentation process includes four steps of first order seed culture, secondary order feed culture, batch fermentation and induced expression, fermentation product SOD is finally obtained; the fermentation process realizes high level expression of SOD, the expression of the target protein is more than 60% of the bacterial protein total; SOD has excellent thermal stability and heat resistance, the expression product accounts for more than 60% of the whole proteins, and fully soluble protein, avoiding any trouble in the course of inclusion body renaturation; the purification process is simple, having high yield, lower cost, the final product SOD has high purification, high activity and strength stability.

Owner:YANGTZE DELTA REGION INST OF TSINGHUA UNIV ZHEJIANG +1

Method for preparing 1, 6-hexanediol by hydrogenating 1, 6-dimethyl adipate

InactiveCN102372604AHigh activityMild reaction conditionsOrganic compound preparationHydroxy compound preparationPolymer scienceHydrogen

The invention discloses a method for preparing 1, 6-hexanediol by hydrogenating 1, 6-dimethyl adipate, which is characterized by comprising the following steps and metering in parts by weight: 1000 to 10000 parts of oxide is as a carrier, 100 to 200 parts of heavy metal and 40 to 400 parts of co-catalyst metal salt are immersed for 12h at a room temperature to be pumped, filtered, vacuum dried and calcined to obtain a loaded heavy metal catalyst; 1 to 30 parts of the catalyst and 20 to 400 parts of solvent are filled into a reaction kettle, high-pure hydrogen is used for replacing oxygen in the reaction kettle for 3 to 5 times, the catalyst is activated for 2 to 8h under the temperature of 100 to 200 DEG C, pressure of 1.0 to 3.0 MPa and the blending speed of 200 to 1000 rpm, 50 to 200 parts of 1, 6-dimethyl adipate is filled into the reaction kettle after the reaction kettle is opened, the high-pure hydrogen is again used for replacing the oxygen inside the reaction kettle for 3 to 5 times to be reacted for 5 to 12h under the temperature of 150 to 220 DEG C, the pressure of 3.0 to 5.0 MPa and the blending speed of 500 to 1000rpm, and reaction solution is taken out to analyze; and the conversion rate is 60.0 to 99.9 percent, and the selectivity is 70.0 to 99.9 percent.

Owner:SICHUAN UNIV

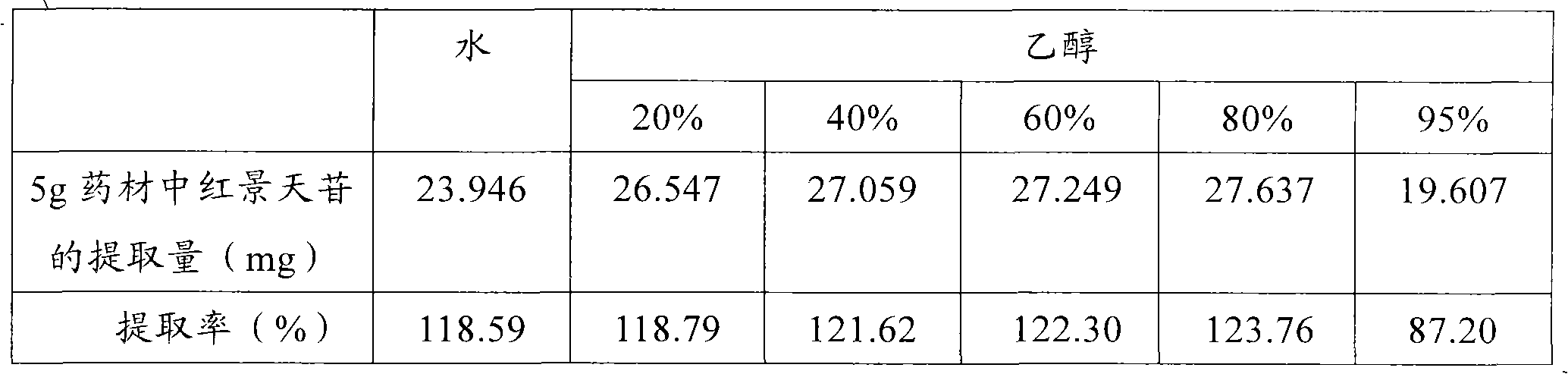

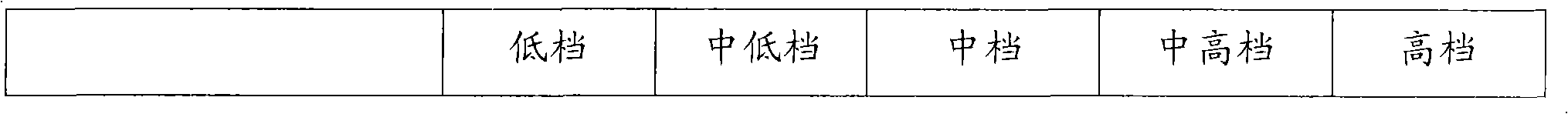

Method for preparing salidroside

ActiveCN101974045AImprove extraction efficiencySimple processSugar derivativesSugar derivatives preparationSalidrosideMicrowave

The invention provides a method for preparing salidroside, which comprises the following steps: 1) extraction: adding water into a Rhodiola crenulata (Hook. f. et Thoms.) H. Ohba medicinal material, performing microwave extraction, filtering, concentrating and obtaining concentrate; 2) purification: performing secondary alcohol precipitation of the concentrate obtained by the step 1) and obtaining filtrate; and 3) refining: loading the filtrate obtained by the step 2) on a macroporous resin, eluting, concentrating, drying and obtaining the salidroside. The preparation method of the invention has the advantages of high extraction efficiency, simple process, capability for industrial production and the like.

Owner:KANGMEI PHARMA

Method for continuously preparing 1,3-propanediol by one-step glycerol conversion

ActiveCN101407448AReduce mass transfer resistanceThe purification process is simple and easyPreparation by OH group eliminationMetal/metal-oxides/metal-hydroxide catalystsSide productGlycerol

The invention relates to a method for continuously preparing 1, 3-propylene glycol by glycerin through one step of conversion. With the presence of metal / solid acid bifunctional catalyst, glycerin water solution and hydrogen are simultaneously and continuously led into a fixed bed reactor and have a catalytic reaction at the temperature of 100-150 DEG C, and a pressure of 2-8MPa, wherein, the volume ratio of hydrogen and glycerin water solution is 600-1200; volume air speed of glycerin water solution is 0.15-1h<-1>; the reaction product is collected and has a gas liquid separation to remove gas hydrogen; the liquid phase is distilled and separated to remove the side product to obtain the 1, 3-propylene glycol product; the metal / solid acid bifunctional catalyst is functioned by zirconia / tungsten oxide complex oxide with attachment of platinum; and weight ratio of each metallic element in the catalyst is: Pt: W: Zr=1-5:5-20:69-55. The process of the reaction is simple; the production can be continuous; high concentration glycerin can be converted under a relatively moderate reaction condition; content of 1, 3-propylene glycol is high, while content of side product is low; and 1, 3-propylene glycol separation and purification cost is low.

Owner:ZHANGJIAGANG GLORY CHEM IND CO LTD

Method for purifying nicotine by using subcritical extraction-molecular distillation coupling technique

The invention discloses a method for purifying nicotine by using a subcritical extraction-molecular distillation coupling technique, belonging to the technical field of extraction separation of natural plants. The method mainly comprises three steps of operation: pretreatment of raw materials, subcritical extraction and molecular distillation; in the pretreatment phase of raw materials, an alkaline water solution is sprayed in tobacco leaves, so the existence form of nicotine is changed from a combination form to a free form; nicotine dissolution is accelerated by solvent-less microwave treatment; and combined with the subcritical extraction-molecular distillation coupling technique, the extraction rate and purity of nicotine can be obviously improved. Butane and dimethyl ether are used as extraction agents in subcritical extraction, so the hazard brought about by organic solvents such as ethyl acetate and petroleum ether to operators and environment can be avoided, the safety is good, and the butane and dimethyl ether can be recycled for saving cost. Molecular distillation adopts a low-temperature one-grade distillation technique, and has few processes and small energy consumption. The nicotine purifying process disclosed by the invention is simple, convenient in operation and suitable for large-scale production and application.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

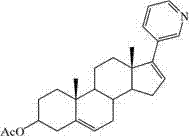

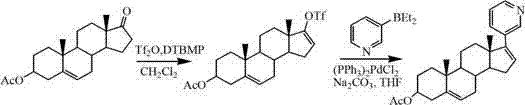

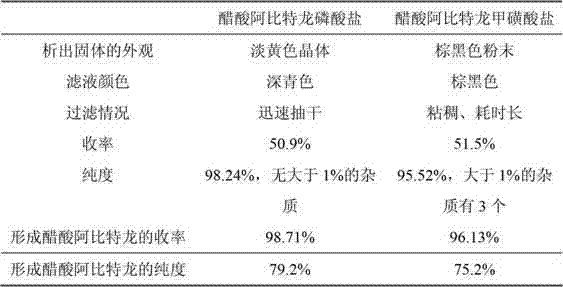

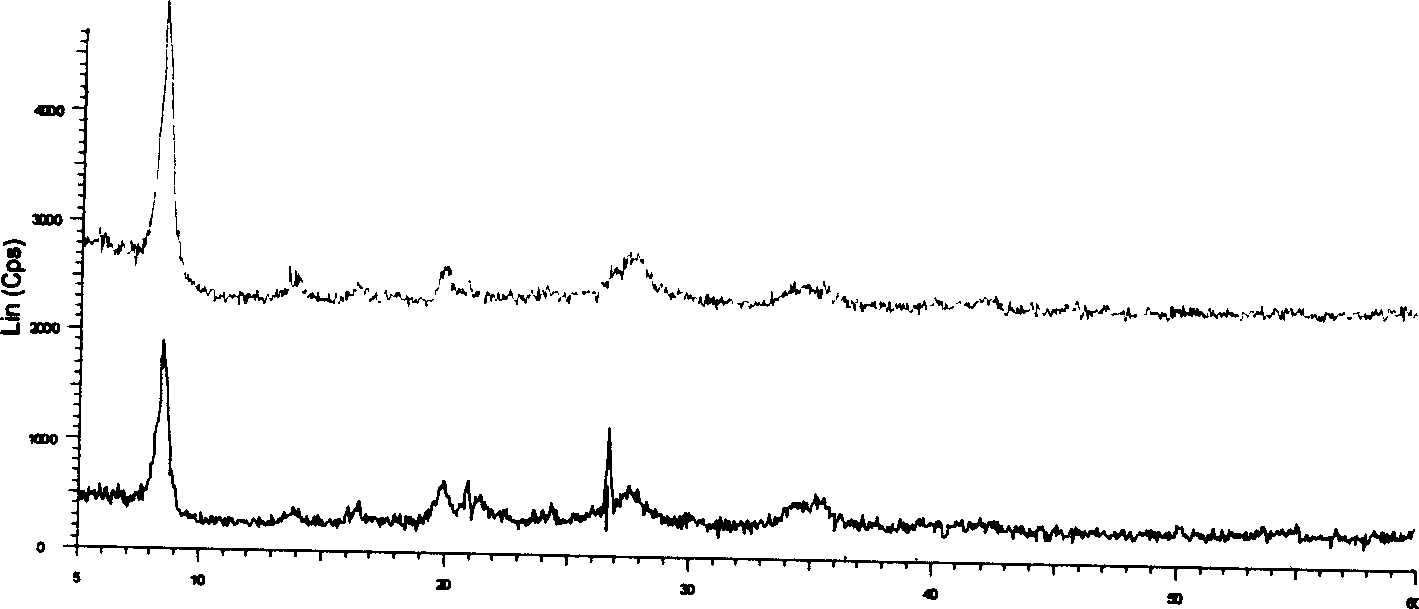

Purifying method for abiraterone acetate

Owner:LUNAN PHARMA GROUP CORPORATION

High pure attapulgite clay and preparation method

InactiveCN1562865ASimple purification processRaw materials are easy to getClaywaresCalciteAqueous solution

The method is preparing high-purity concave soil by physicochemical process to do edulcorating and purifying to natural concave-convex rod clay mine. It is suitable for concave clay mine containing dolomite, quartz sand, calcite or opal. A kind of chemical regent is used as purifying dispersing agent to prepare water solution with proper density which is added concave clay will be processed by machinical forcing and in proper tem., after being fully dispersed and reacted, concave soil with good crystalline form, white color and more than 99 percent of purity is produced by separating and drying.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Method for controlling leaching of silicon impurity during vanadium extraction smelting of vanadium ore

ActiveCN101157981ADoes not affect the leaching rateLeaching ControlProcess efficiency improvementPregnant leach solutionSmelting process

The invention of controlling a lixiviation of silicon impurity during the process of extracting vanadium from navajoite belonging to the technical field of metallurgy, relates to an extraction method of vanadium from navajoite. The method is to add concentrated acid (vitriol, etc.), concentration of which is greater than 5 mol / L, before the lixiviation of siliceous vanadium; then lixiviates are carried out after an aging in normal temperature. When in the process of the lixiviation of the concentrated acid after the aging, the silicon contained the vanadium forms a solid of undissolving SiO2, which retains within the slag instead of dissolved in the lixiviation solution lixiviating with vanadium. The invention is characterized in that the invention effectively controls the lixiviation of the silicon impurity without affecting the lixiviation rate of vanadium or increasing the consumption of chemical raw material, simplifies the subsequent purification process of the silicon during the extraction and smelting of navajoite, lowers production cost, leads the process of extraction and smelting process to be fluent and reliable. The invention reduces the lixiviation of silicon by no less than 95%, which is suitable for the vanadium extraction and a smelting process for the siliceous navajoite such as a stone coal mine, a coal gangue, the navajoite (including vanadium clay mine), a vanadium titanium magnetite, the SiO2 content of which is greater than 2%, or the baked ore and suitable for the extraction and smelting process for the siliceous navajoite the SiO2 content of which is greater than or equal to 2% during the smelting process.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Method for extracting luteolin from peanut roots, stems, leaves and shells

The invention relates to a method for extracting luteolin from peanut roots, stems, leaves and shells, comprising the following steps: washing materials comprising peanut roots, stems, leaves and shells, removing impurities in the peanut roots, stems, leaves and shells, and grinding the peanut roots, stems, leaves and shells subject to impurity removal; extracting by using 75% ethanol, filtering, decoloring, and concentrating at reduced pressure; precipitating by using hot water, filtering, heating filtrate, and concentrating at reduced pressure; absorbing by using KLFC-150 macroporous resin, and eluting by using 75% ethanol; concentrating elution solution at reduced pressureto obtain crude luteolin; dissolving the crude luteolin in ethanol, adding water to dilute the crude luteolin, recovering the ethanol, concentrating, crystallizing, and recrystallizing to obtain the high-purity luteolin product. The operation process is mainly characterized in that the peanut roots, stems, leaves and shells are used as extraction raw materials and are low-cost sustainable resources, the 75% ethanol is used as extraction solvent and eluent, and the product contains no toxic solvent and other residue, is safe and environmentally friendly and is low in production cost and high in yield.

Owner:彭国平

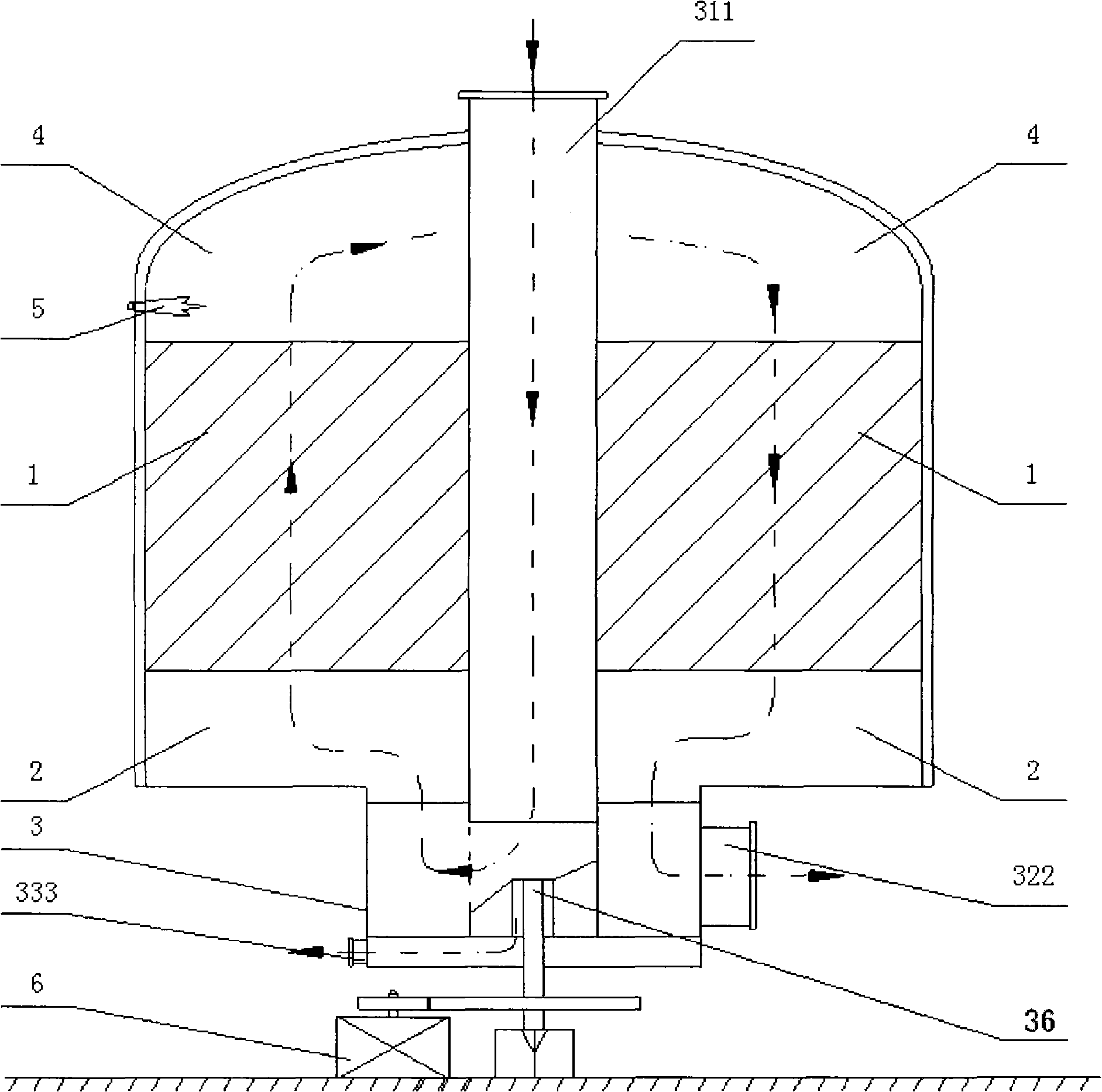

High-temperature water vapor pyrolysis-cracking-gasification device and method for solid fuel

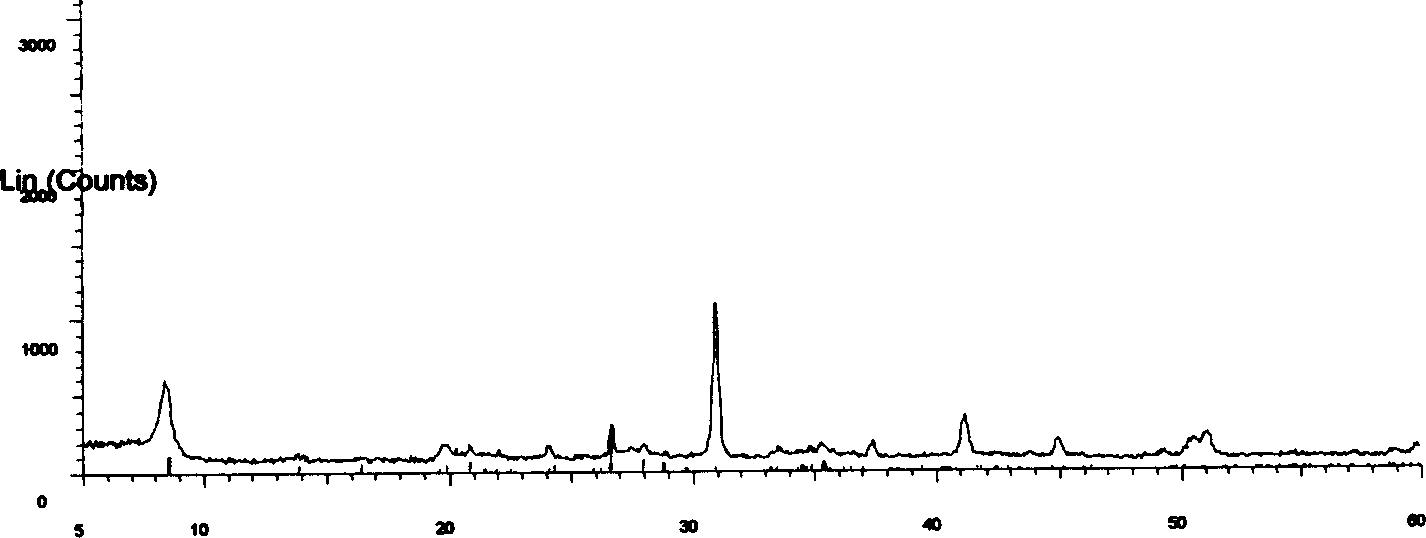

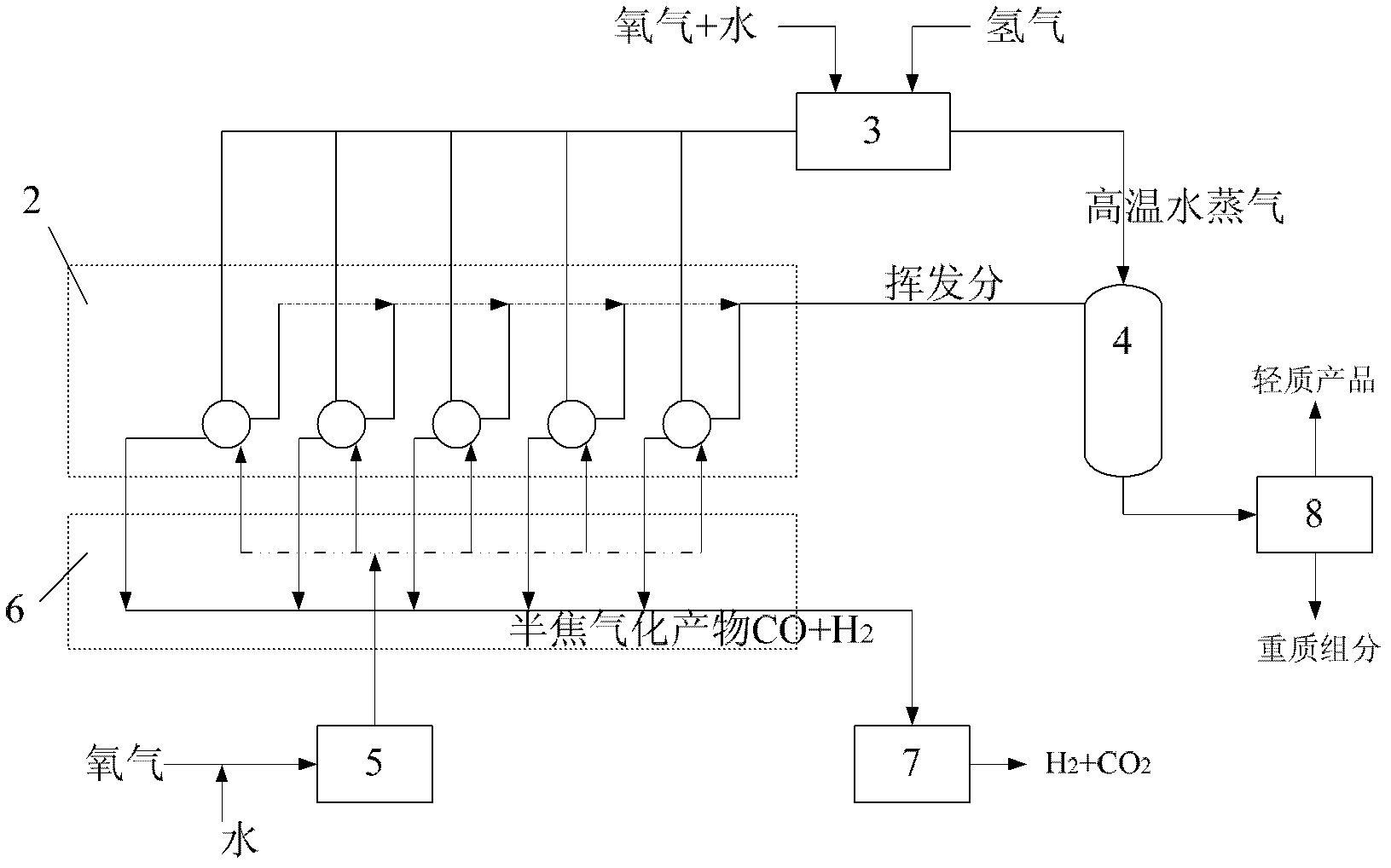

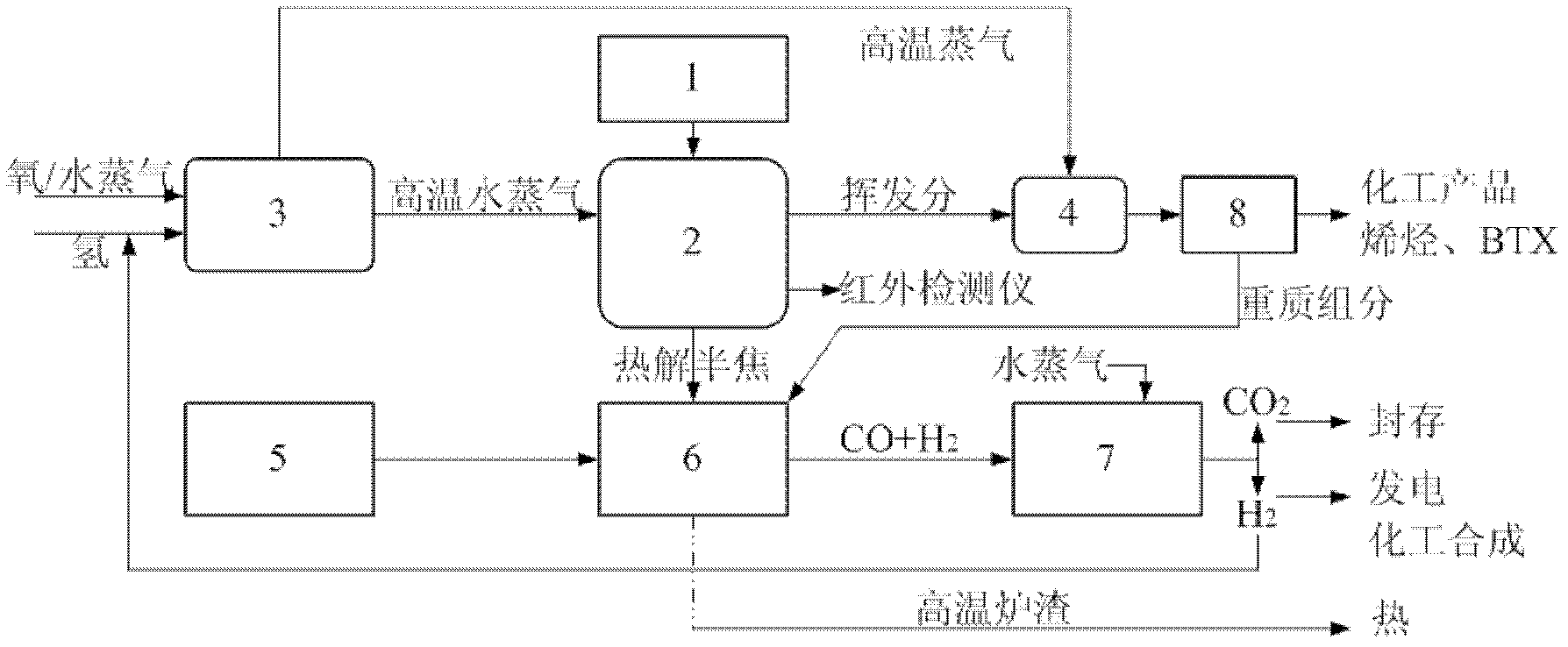

ActiveCN102849676AReduce energy consumptionReduce hydrogen consumptionCarbon compoundsDirect heating destructive distillationHydrogenWater vapor

The invention relates to the comprehensive utilization field of a solid fuel, specifically to high-temperature water vapor pyrolysis-cracking-gasification device and method for the solid fuel. The method includes introducing the high-temperature water vapor generated by the combustion of O2 and H2 into the solid fuel for low-temperature pyrolysis, to separate out the volatile matter and obtain an oil gas product and pyrolysis semi-coke; performing thermal cracking to the oil gas product in hot state under the action of the high-temperature water vapor, and separating to obtain a lightweight product and a heavyweight component; gasifying the pyrolysis semi-coke and the heavyweight component under the action of oxygen-carrying high-temperature water vapor, to obtain water gas; and allowing the reaction between the water gas and water vapor, to obtain CO2 and H2, separating, storing the CO2, and using the H2 in power generation. The invention is characterized in that the high-temperature water vapor generated by hydrogen-oxygen combustion is used to provide heat; the oil gas product generated by the pyrolysis directly enters the thermal cracking reactor in hot state; higher-added value products, such as lightweight olefins and BTX, are obtained via the thermal cracking; and the clean and high-efficiency comprehensive utilization of the solid fuel is realized through fractional extraction.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

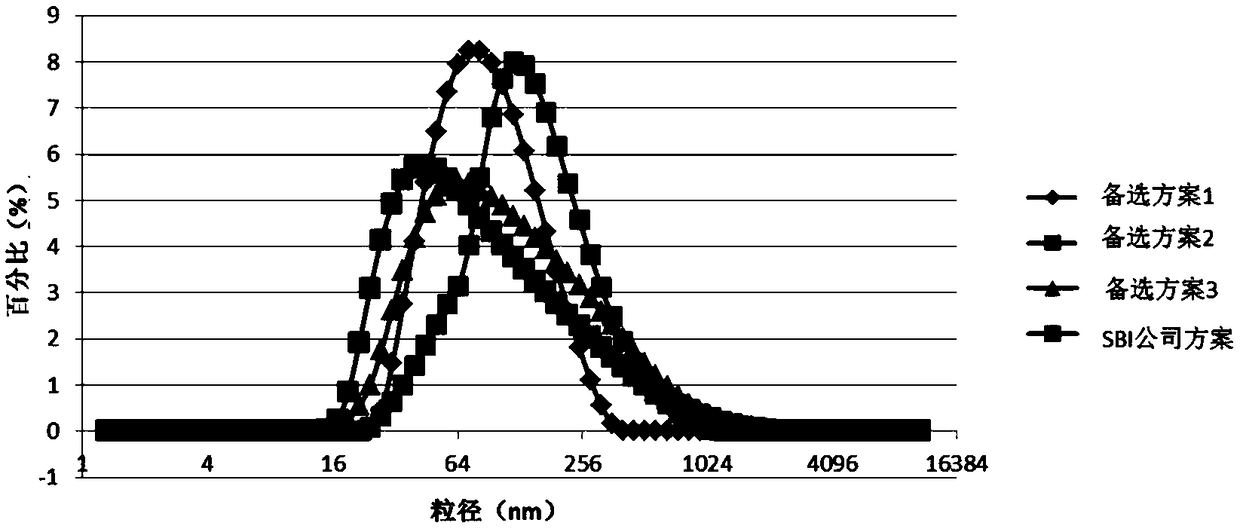

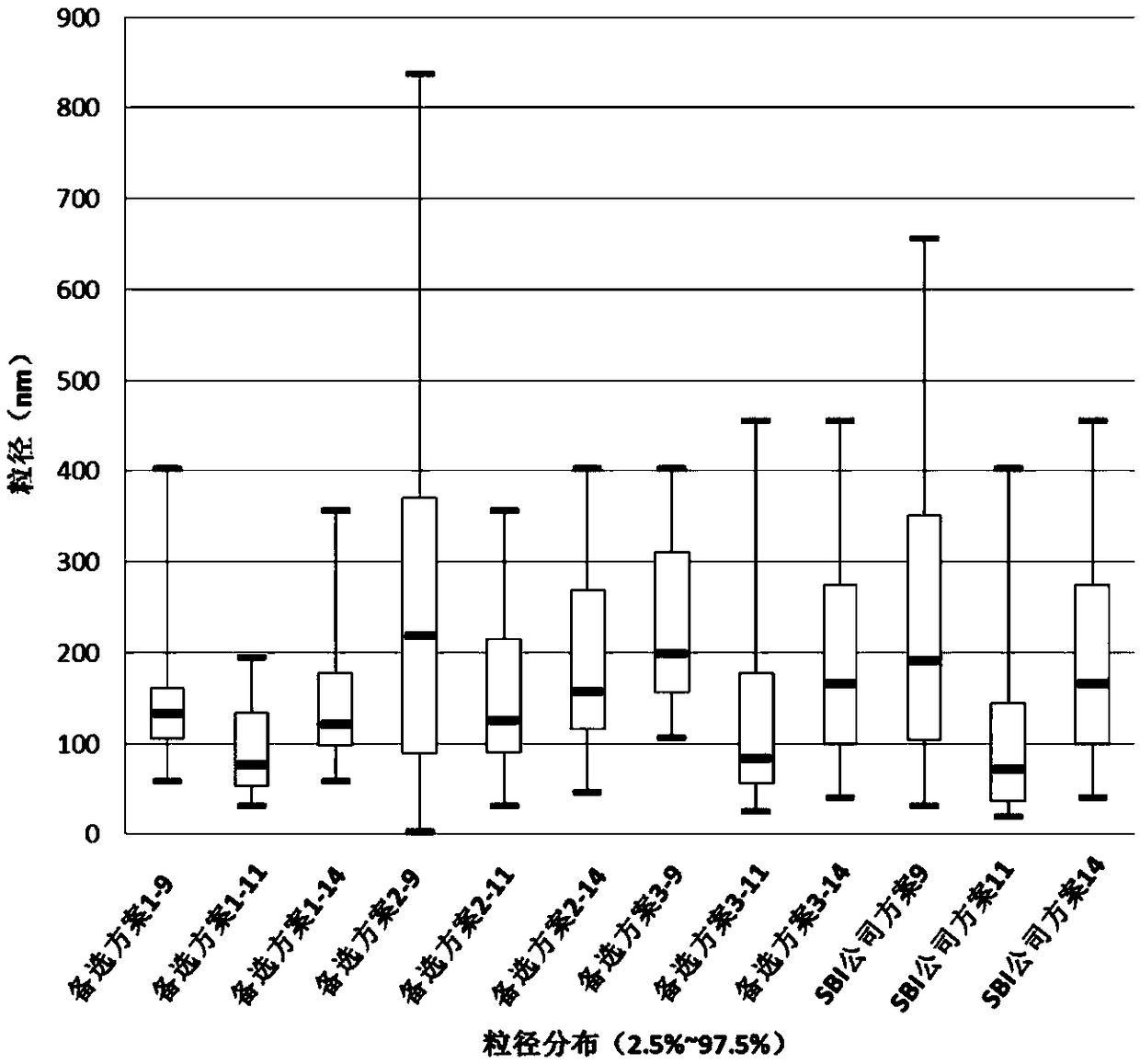

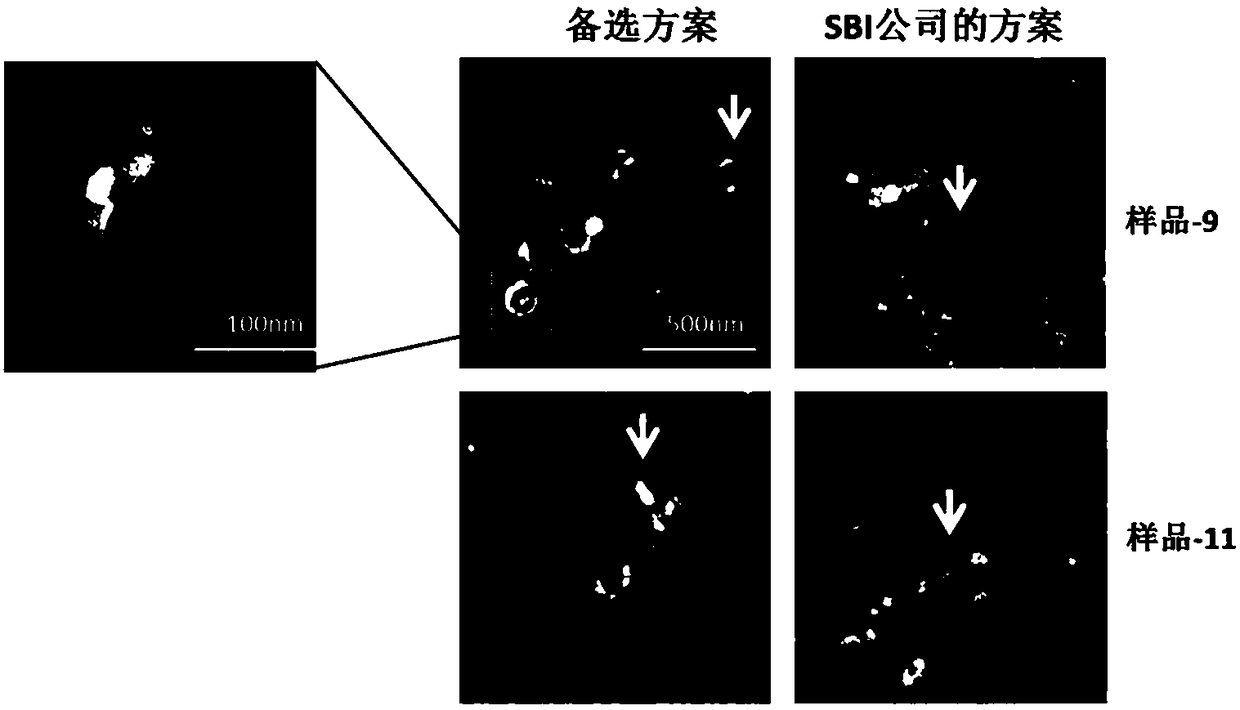

Kit and method for preparing exosomes in serum or plasma

ActiveCN108918228AConcentrated particle size distributionSimple purification processPreparing sample for investigationHydrophilic polymersPolyethylene glycol

The invention discloses a kit and method for preparing exosomes in serum or plasma. The kit comprises an exosome extracting reagent, wherein the exosome extracting reagent is a hydrophilic polymer ora solution of the hydrophilic polymer; the hydrophilic polymer comprises one or a combination of PEG (Poly Ethylene Glycol), dextran sulfate and PVP (Poly Vinyl Pyrrolidone); the molecular weight of the PEG is 20000-1200000 Daltons; the molecular weight of the dextran sulfate is 5000 to 20000 Daltons; and the molecular weight of the PVP is 10000 or 40000-700000 Daltons. The particle size distribution of the exosomes obtained by utilizing the kit is more concentrated; and according to the method for preparing the exosomes, which is provided by the invention, the step of purifying the exosomes is also optimized, so that the exosomes have less impurities and higher purity.

Owner:BEIJING TRANSGEN BIOTECH CO LTD

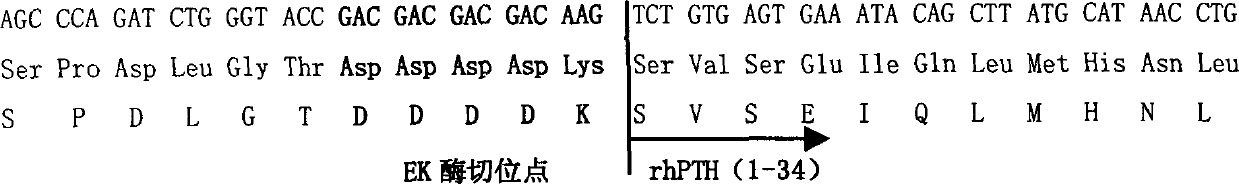

Recombinant human parathormone PTH1-34 preparation method

ActiveCN1807456AHigh expressionEasy to purifyParathyroid hormonesHybrid peptidesGenetic engineeringDNA

The invention provides the method of merged protein which contains recombined human parathormone, coding the merged protein's DNA sequence, the carrier which contains the DNA sequence, the host cell which contains the carrier, using genetic engineering to prepare the merged protein and then produce PTH1-34. Enzyme cutting the merged protein by enterokinase can produce the recombined human parathormone PTH (1-34) has high physiologically active. The expression product is high, purity technology is simple and the cost is depressed, it can be used to the production of recombined human parathormone in force.

Owner:SHANGHAI CELGEN BIO PHARMA CO LTD

Method for quick preparing glycosyl transferred beta-galactosidase

The invention discloses a method for rapid preparation of transgalactosylation beta-galactosidase, which comprises the steps of (1) bacterial strain selection, (2) bacterial activating, (3) bacterial culturing and enzyme producing, (4) gathering bacterial cell, (5) washing, (6) making crude enzyme liquid of beta-galactosidase, (7) making galacto-oligosaccharides from the crude enzyme liquid, (8) carrying out quantitative analysis to the galacto-oligosaccharides.

Owner:SHANDONG UNIV

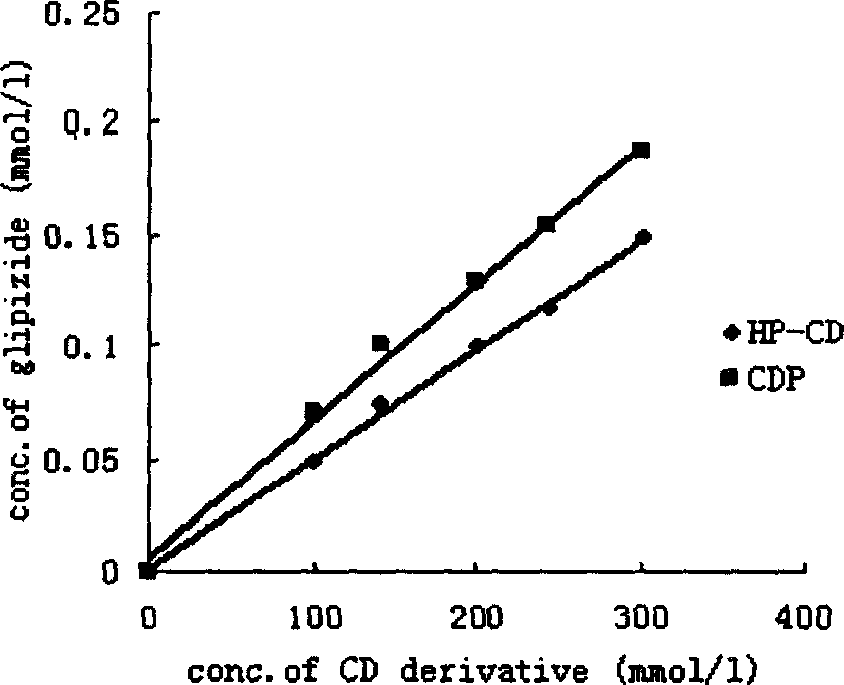

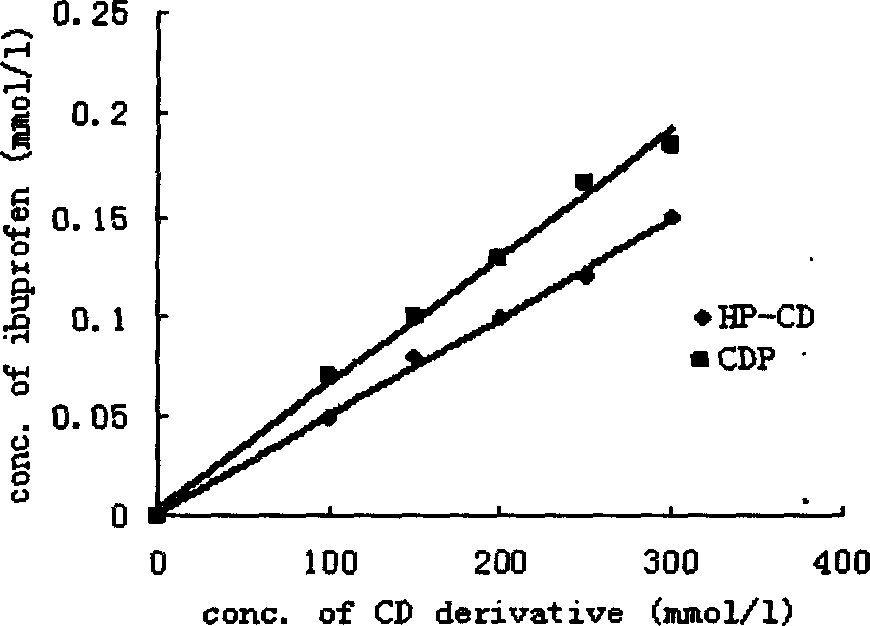

Insoluble drug delivery system based on water-soluble cyclodextrin

InactiveCN1879887AMild reaction conditionsThe purification process is simplePill deliveryCapsule deliveryChemistryWater soluble

The invention relates to an insoluble medicine feeding system based on soluble cyclodextrin polymer, with high yield and the application in batch production, wherein said medicine compound is formed by insoluble medicine and cyclodextrin derivant, whose mass ratio is 0.1-100:1; and said insoluble medicine is the one whose solubility is less than 1% in room temperature; the soluble cyclodextrin polymer uses cyclodextrin as crosslink agent to be concentrated with cyclodextrin monomer. The inventive product is not shaped powder, whose average molecular weight can reach 10000.

Owner:SHENYANG PHARMA UNIVERSITY

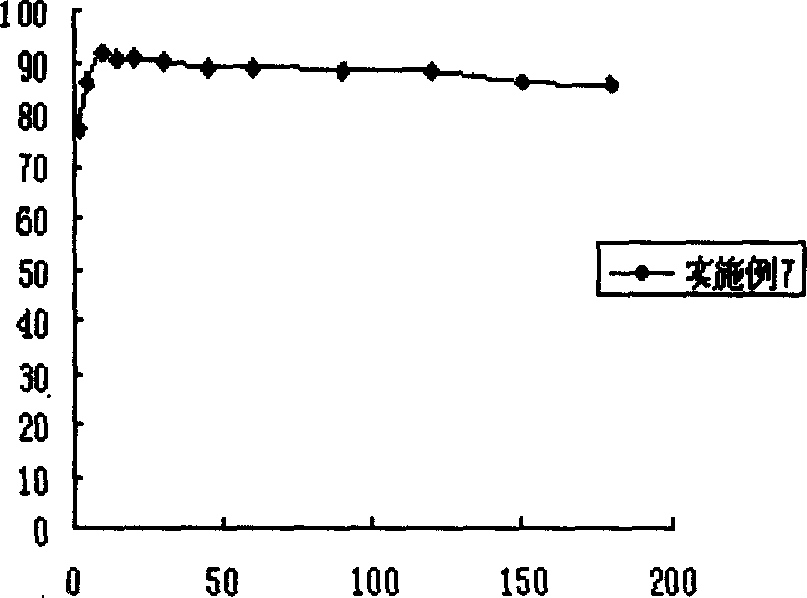

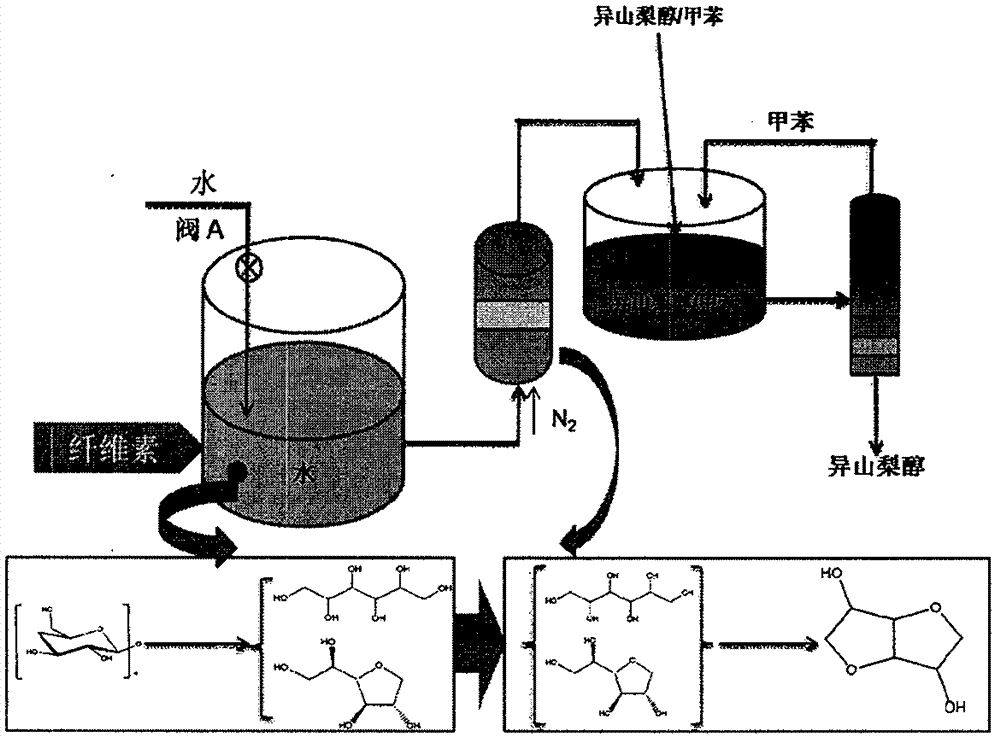

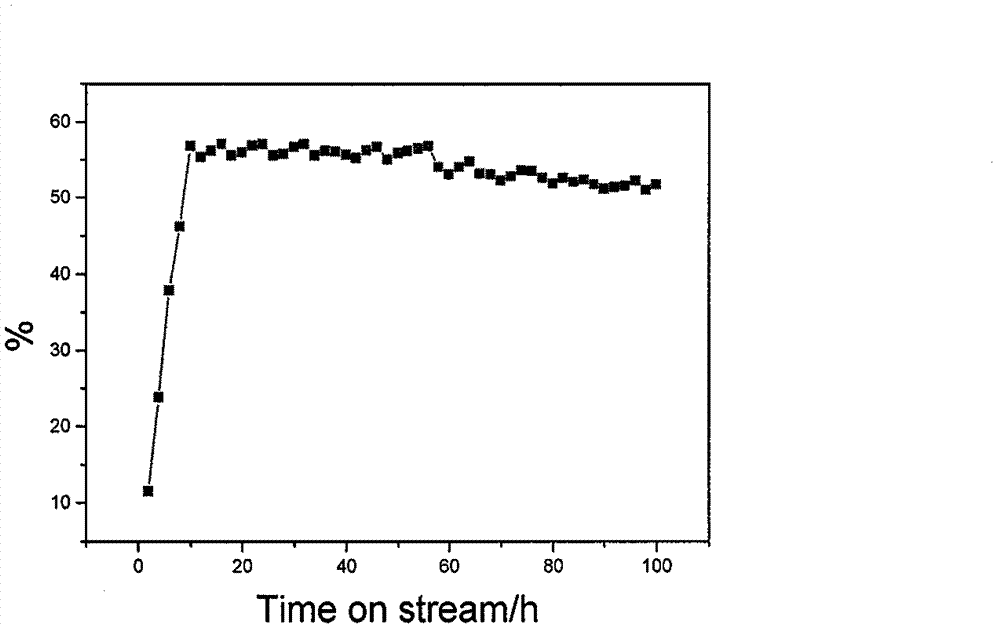

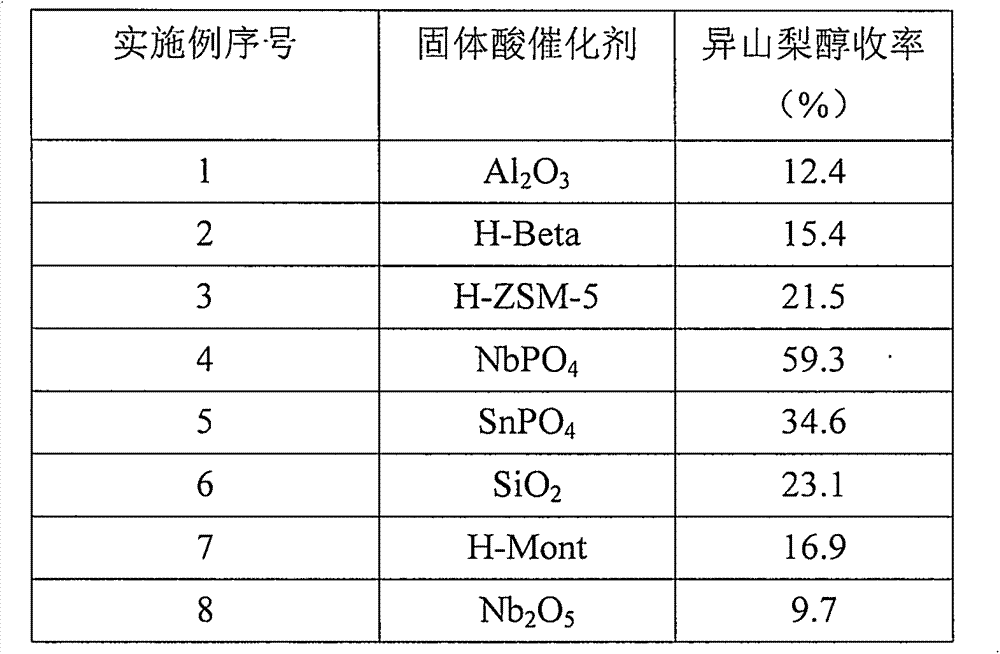

New method for preparing isosorbide through cellulose

InactiveCN103159775APrevent oxidationSimple purification processOrganic chemistryCellulosePtru catalyst

The invention relates to a method for preparing isosorbide through cellulose, and belongs to the preparation field of synthesizing renewable energy sources and chemicals by utilizing of biomasses. The method comprises a step of hydrolyzing the cellulose under a dual-function catalyst of metal-solid acid and adding hydrogen to obtain reaction liquid containing sorbitol, and a step of catalyzing and dehydrating the reaction liquid containing the sorbitol through the solid acid to obtain the isosorbide. According to the method, liquid acid does not need to be added, the reaction liquid containing the sorbitol does not need to be separated and purified, wherein the reaction liquid is obtained by hydrolyzing the cellulose and adding the hydrogen. The method has the advantages that raw material is the cellulose which is abundant, low in cost and environment-friendly, the yield of the isosorbide reaches up to 56.3%, the catalyst is easy to separate and recycle, a very valuable new channel is provided for transferring the cellulose into high value-added chemicals, and the method has a good industrialization application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

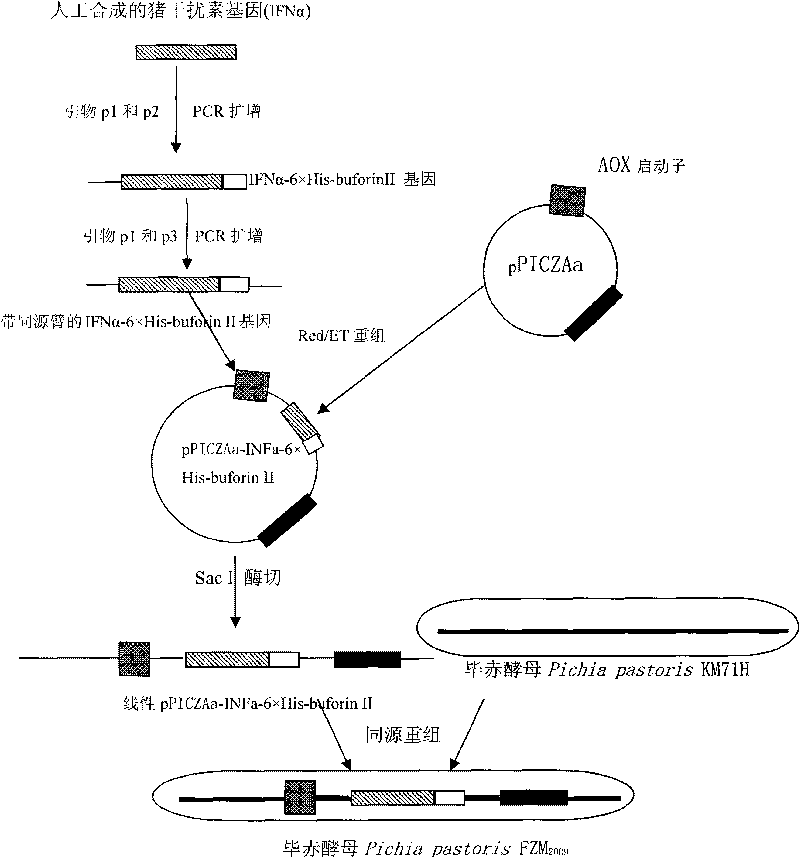

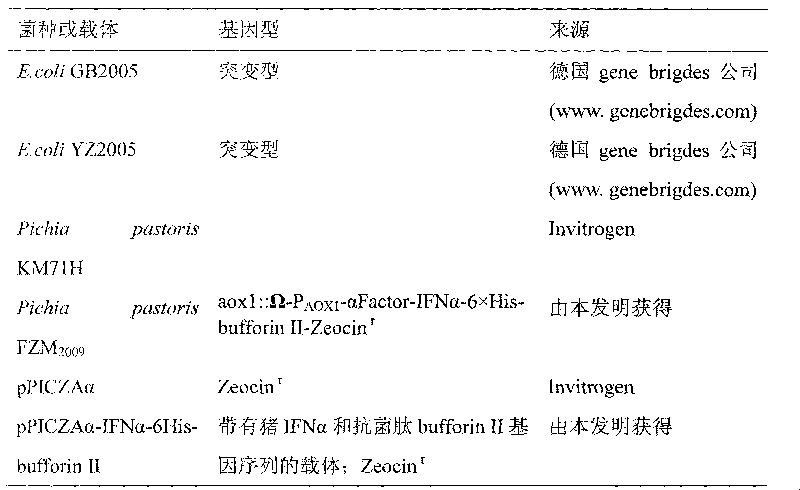

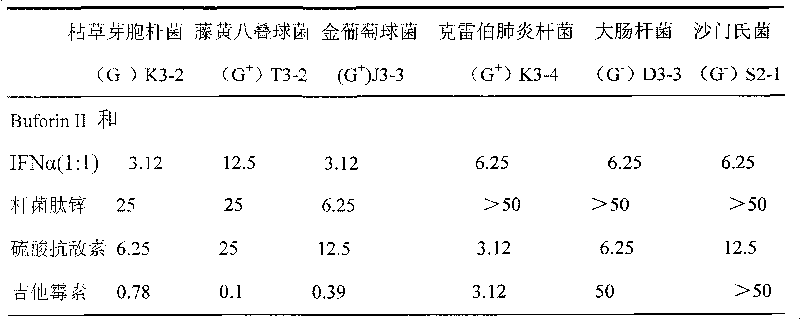

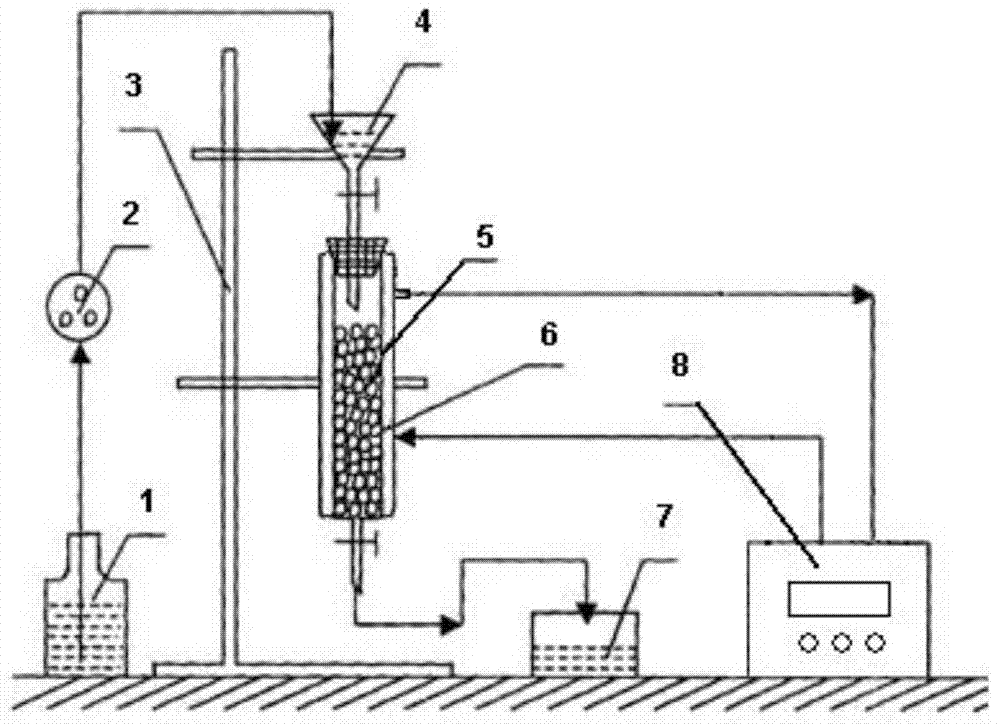

Antibiotic peptide buforin II and porcine INF-alpha fusion expression pichia pastoris, and preparation method and applications thereof

ActiveCN101717737ASolve the difficulty of strong suicidal effectHigh expressionFungiAnimal feeding stuffEnzyme digestionFermentation

The invention discloses an antibiotic peptide buforin II and porcine INF-alpha fusion expression pichia pastoris (Pichia pastoris FZM2009, CCTCC NO:M209259), and a preparation method and applications thereof. The method comprises the steps: A, the construction of expression cassette PAOX1-alpha Factor-IFN alpha-6xHis-bufforin II-Zeocinr; B the construction of expression engineering bacteria Pichia pastoris FZM 2009, wherein the engineering bacteria is resulted from the screening of antibiotics Zeocin and PCR identification; C, the preparation of fusion protein, which comprises the steps: 1) the recovery is implemented on a YPD plate containing 100mug / ml of Zeocin; 2) single clone is inoculated to a YPD-containing culture medium for vibration and culture; 3) 1 volume of culture is inoculated into 10 volumes of a fermentation culture medium for culture; 4) supernatant is obtained by centrifugation; 5) loading buffer with double volume is added into the supernatant, and electrophoresis detection is performed; 6) the supernatant is subject to a molecular sieve gel column to collect components; 7) the collected components are lyophilized to result in fusion protein; 8) buforin II and IFN alpha are obtained by the enzyme digestion of enterokinase on the fusion protein. The fusion protein buforin II and IFN alpha in fusion expression are applied to pig feeds. The method has great feasibility, simple and convenient operation, high expression, low cost and strong bioactivity.

Owner:GUANGDONG HINAPHARM PHARMA CO LTD

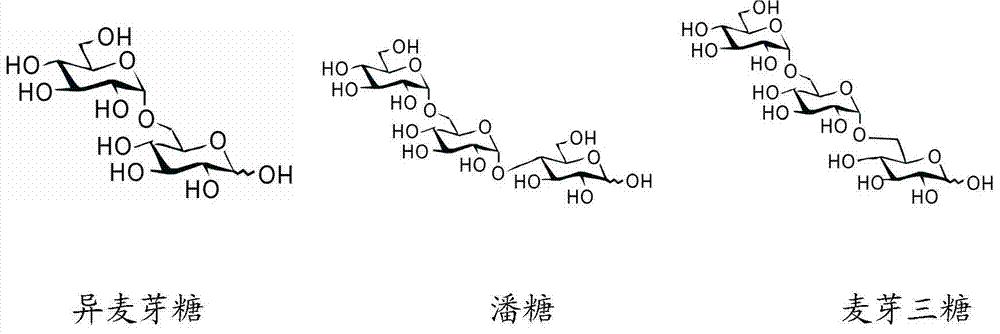

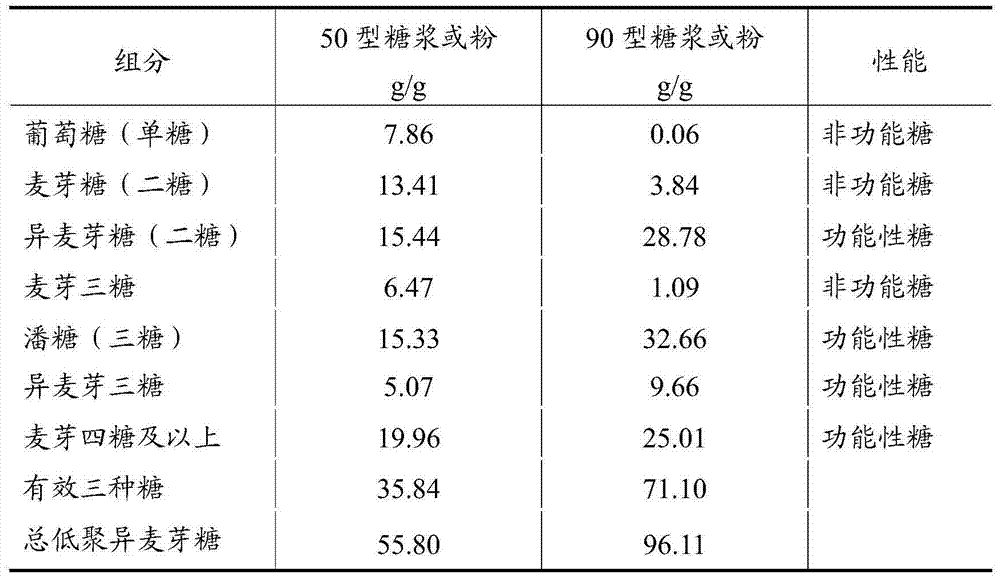

Method of using alpha-glucosidase for preparing isomaltooligosaccharide

ActiveCN103497983AHigh yieldImprove stabilityOn/in organic carrierFermentationAlgluceraseIsomaltooligosaccharide

The invention relates to a method of using alpha-glucosidase for preparing isomaltooligosaccharide. The method includes alpha-glucosidase immobilization, continuous reaction and isomaltooligosaccharide preparation. The alpha-glucosidase is immobilized through alginate, carrageenan and chitosan to implement continuous reaction, converting rate of raw material is 75%, and production cost is reduced by 1 / 3. By the aid of the method, isomaltooligosaccharide 50 or total isomaltooligosaccharide content of the isomaltooligosaccharide 50 is 55%, and the total content of isomalt, panose and isomaltotriose is 35%; isomaltooligosaccharide 90 or total isomaltooligosaccharide content of the isomaltooligosaccharide 90 is 95%, and the the total content of isomalt, panose and isomaltotriose is 70%.

Owner:WUXI JIANTE PHARM CO LTD

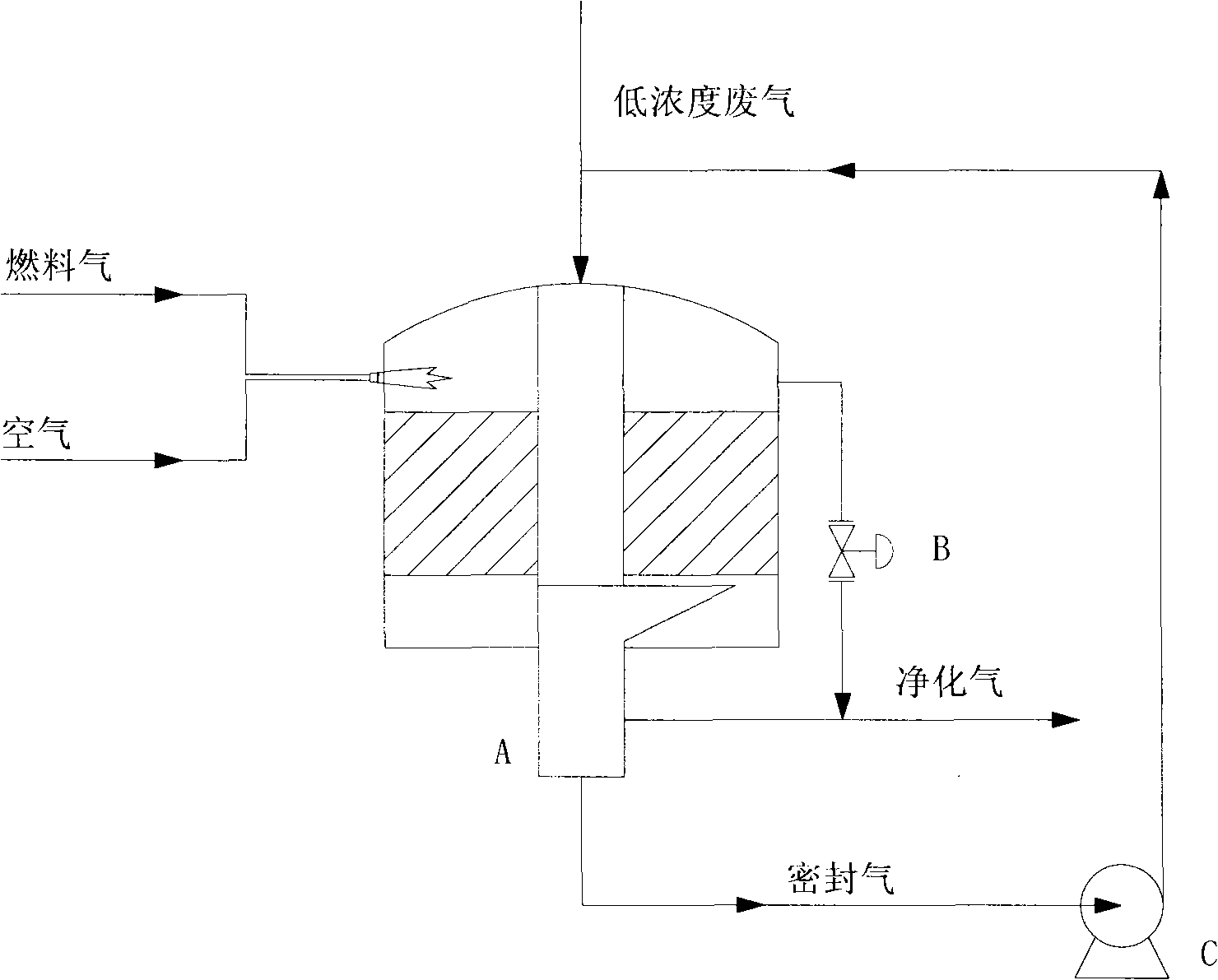

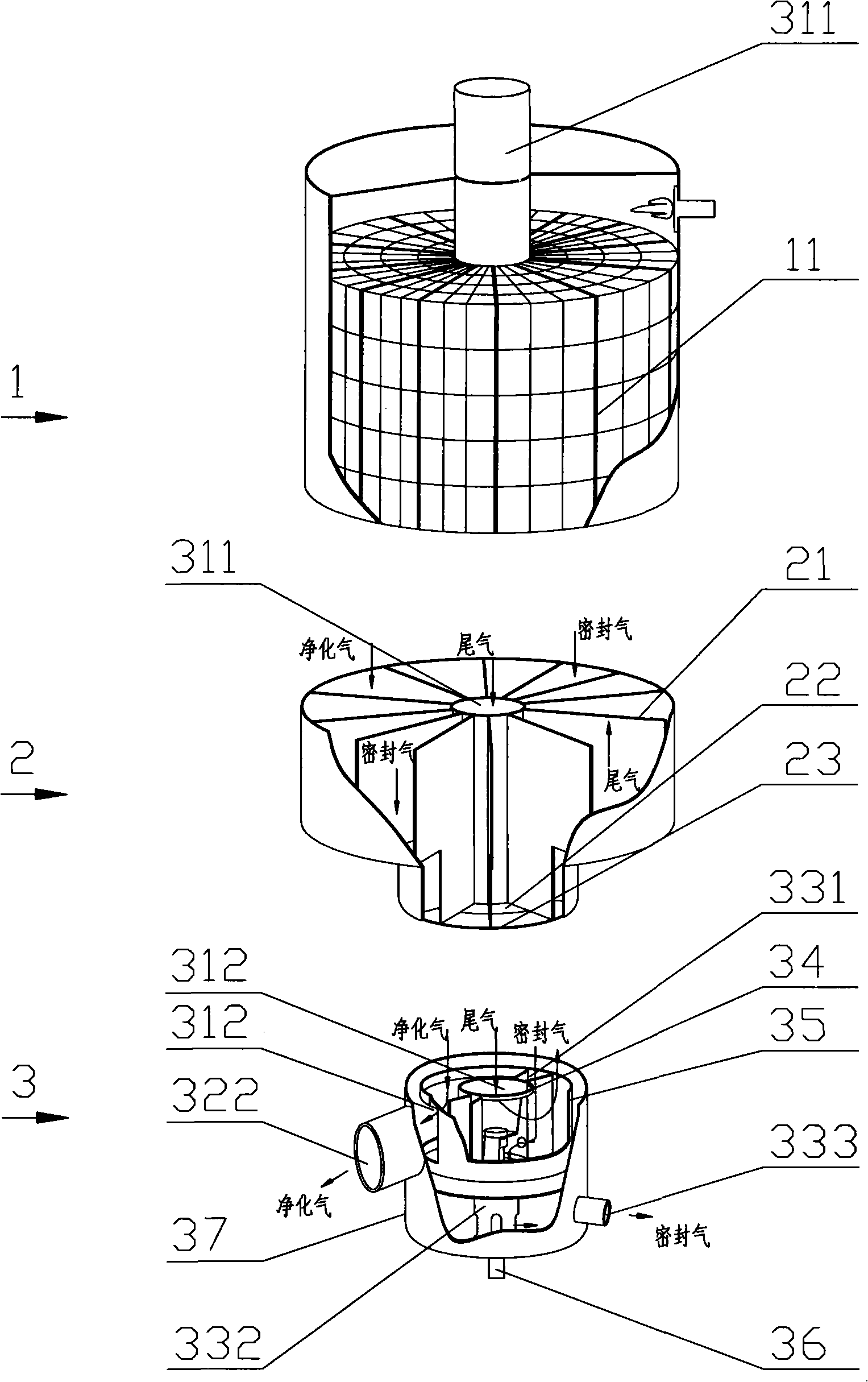

Heat accumulation type thermal oxidation reactor and purification process technique for low concentration organic waste gas

InactiveCN101294709ASmall footprintReduce energy consumptionIncinerator apparatusRotary valveExhaust fumes

The invention discloses a heat accumulating type thermal oxidation reactor. The reactor is mainly composed of an incineration chamber, a heat accumulating ceramic layer, a gas distribution chamber and a rotary valve. Through the distributional effect of the rotary valve, the incineration chamber can carry out rotary aeration, and the reactor carries out heat accumulation, heat emission and cleaning synchronously without intermission; the reaction is continuous without undulation; finally, the organic substances in the exhaust gas with low concentration can be transformed into harmless CO2 and H2O. The thermal oxidation reactor is suitable for processing the exhaust gas of low concentration. In addition, the invention further discloses the process for purifying the exhaust gas of low concentration.

Owner:SHANGHAI DONGHUA ENVIRONMENT ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com