New method for preparing isosorbide through cellulose

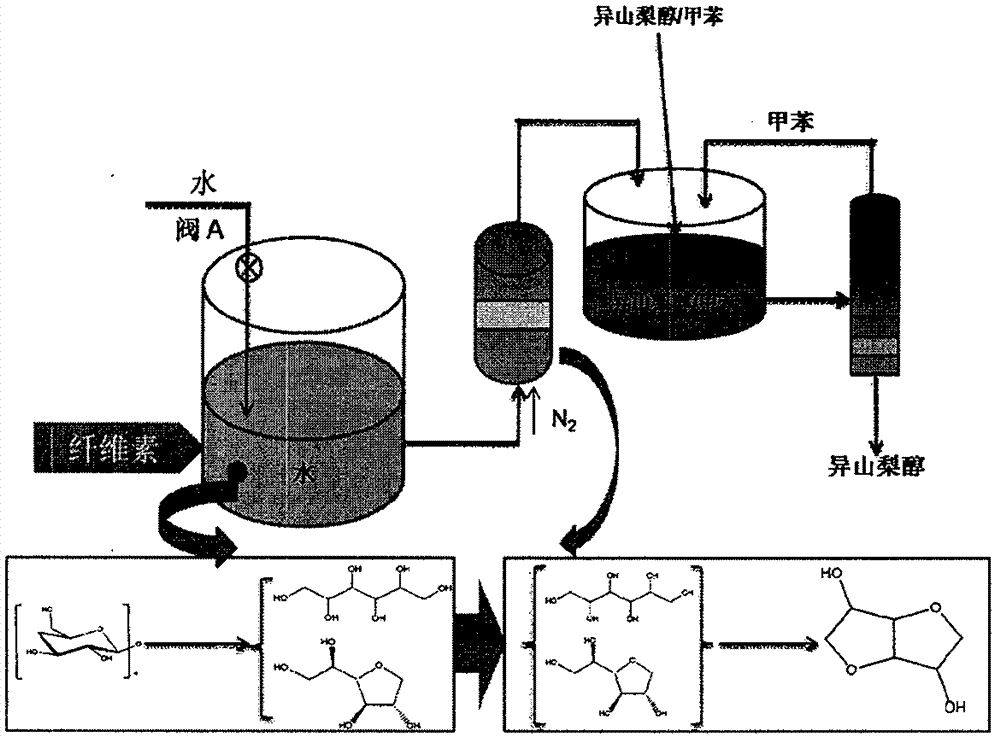

A technology for isosorbide and cellulose is applied in the field of reaction technology for catalyzing cellulose to prepare isosorbide, which can solve the problems of difficult industrialized production, high equipment requirements and high added value, and achieves a simplified purification process and reduced costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

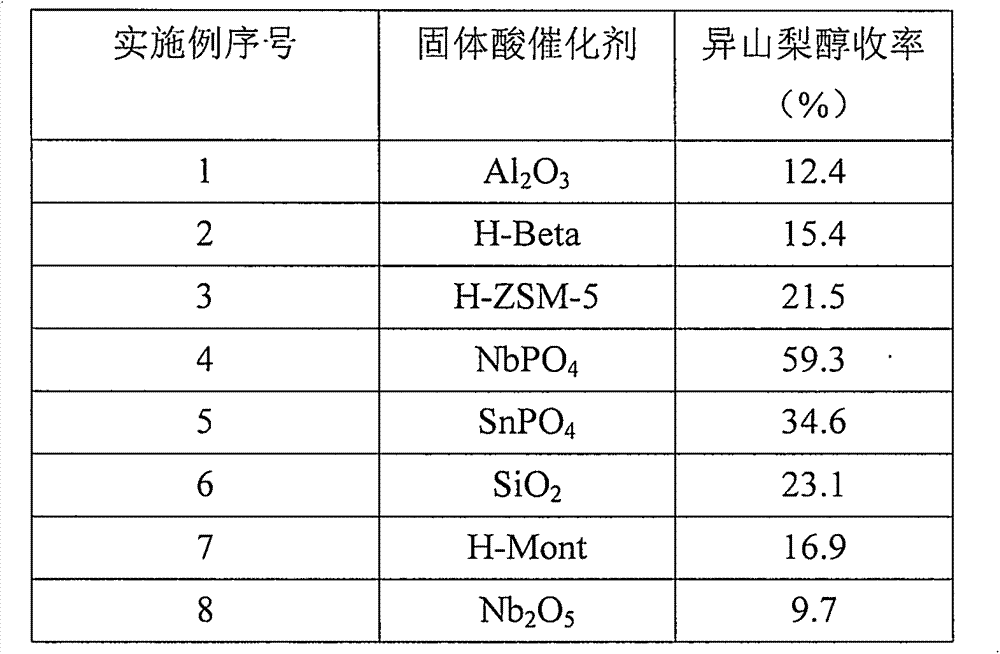

[0031] In eight different reactors, 150g of pure water was added, then 10g of cellulose was added, and catalyst Ru / ZrPO was added separately 41g each, tighten the screw of the reactor, fill with hydrogen 4MPa, place in eight different heating mantles respectively, raise the heating mantles to 170°C respectively, keep the temperature constant, stir, and stop the reaction after 24 hours of reaction. Cool the reaction system to room temperature, separate the reaction liquid through a liquid phase pump and introduce it into a fixed-bed reactor equipped with solid acid. The catalyst contained in the bed is 2g, and nitrogen is used as the balance gas, and the temperature is raised to 210°C , The collected reaction solution was quantitatively analyzed by high performance liquid chromatography and differential detector, and the results obtained by reacting with different solid acid catalysts are shown in Table 1.

[0032] Table 1 Different solid acid catalysts catalyze the yield of ge...

Embodiment 9-14

[0035] Add 150g of pure water into six different reactors, then add 10g of cellulose, add the catalyst Ru / ZrPO respectively 4 1g each, tighten the screw of the reactor, fill with hydrogen 4MPa, place in six different heating mantles respectively, raise the heating mantles to 170°C, keep the temperature constant, stir, and stop the reaction after 24 hours of reaction. The reaction system is cooled to room temperature, and the reaction liquid is separated and introduced into a fixed-bed reactor equipped with a solid acid through a liquid-phase pump. The catalyst contained in the bed is 2 g, and nitrogen is used as the balance gas. The bed temperature is respectively Rising to 190°C, 200°C, 210°C, 220°C, 230°C, 240°C, the collected reaction solution was quantitatively analyzed by high-performance liquid chromatography and differential detector, and the results of the reaction at different reaction temperatures are shown in Table 3 Show.

[0036] The yield of isosorbide under tab...

Embodiment 15-20

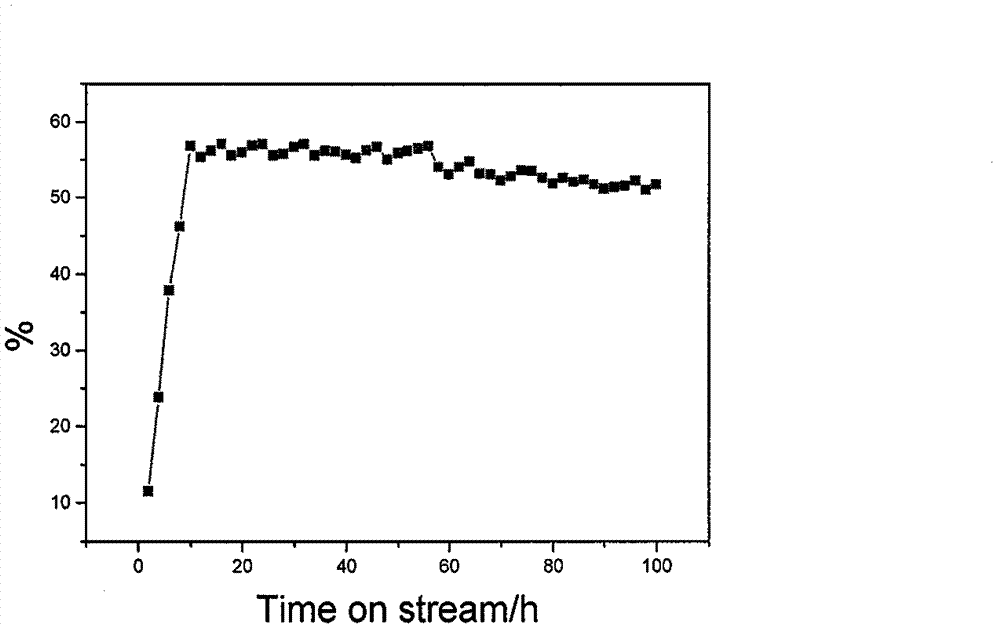

[0040] Add 150g of pure water to the reactor, then add 10g of cellulose, add the catalyst Ru / ZrPO respectively 4 1g each, tighten the screw of the reactor, fill with hydrogen 4MPa, place in the heating mantle, raise the heating mantle to 170°C, keep the temperature constant, stir, and stop the reaction after 24 hours of reaction. Cool the reaction system to room temperature, separate the reaction solution and introduce it into a fixed-bed reactor equipped with solid acid through a liquid-phase pump. The catalyst contained in the bed is 2g, and nitrogen is used as the balance gas, and the temperature is raised to 230°C . The reaction solution was collected regularly, and quantitatively analyzed by high performance liquid chromatography and differential detector. The results obtained under different reaction times are shown in Table 4.

[0041] The yield of isosorbide under the different reaction times of table 4

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com