Heat accumulation type thermal oxidation reactor and purification process technique for low concentration organic waste gas

A thermal oxidation and reactor technology, applied in the field of regenerative thermal oxidation reactors, can solve problems such as non-continuous reaction, large footprint of two-bed thermal storage oxidation processors, large system pressure fluctuations, etc. Low cost, small footprint and compact equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

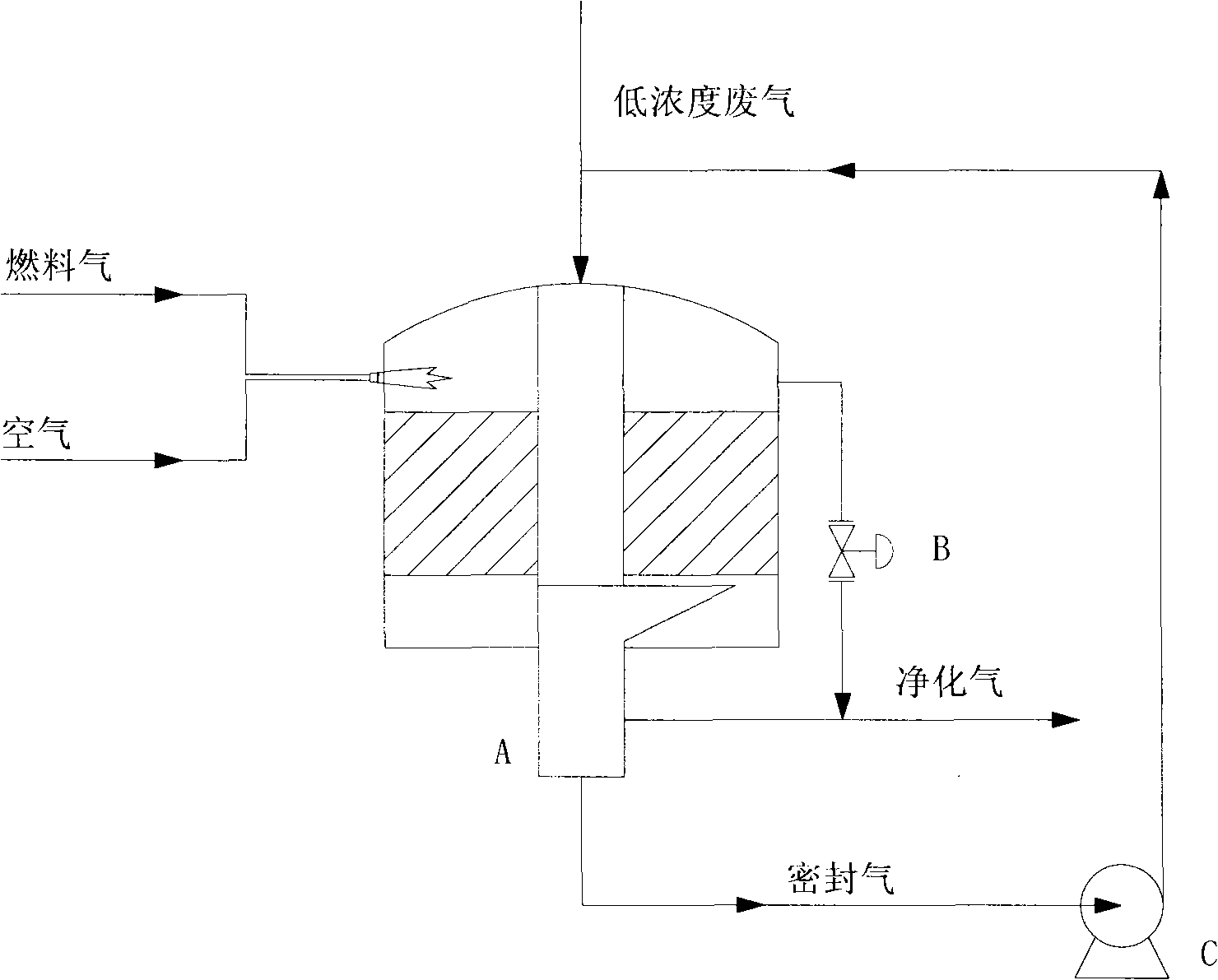

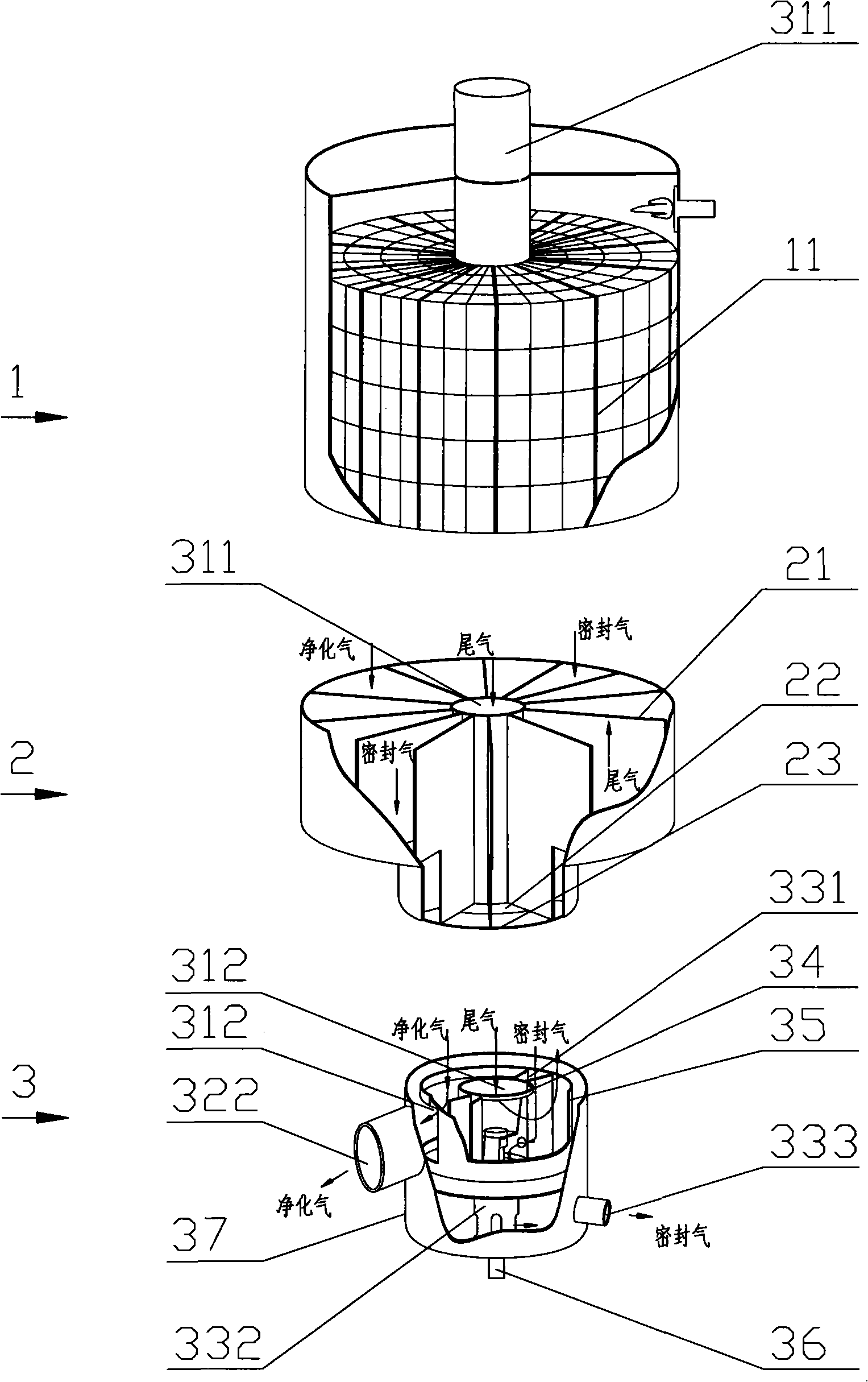

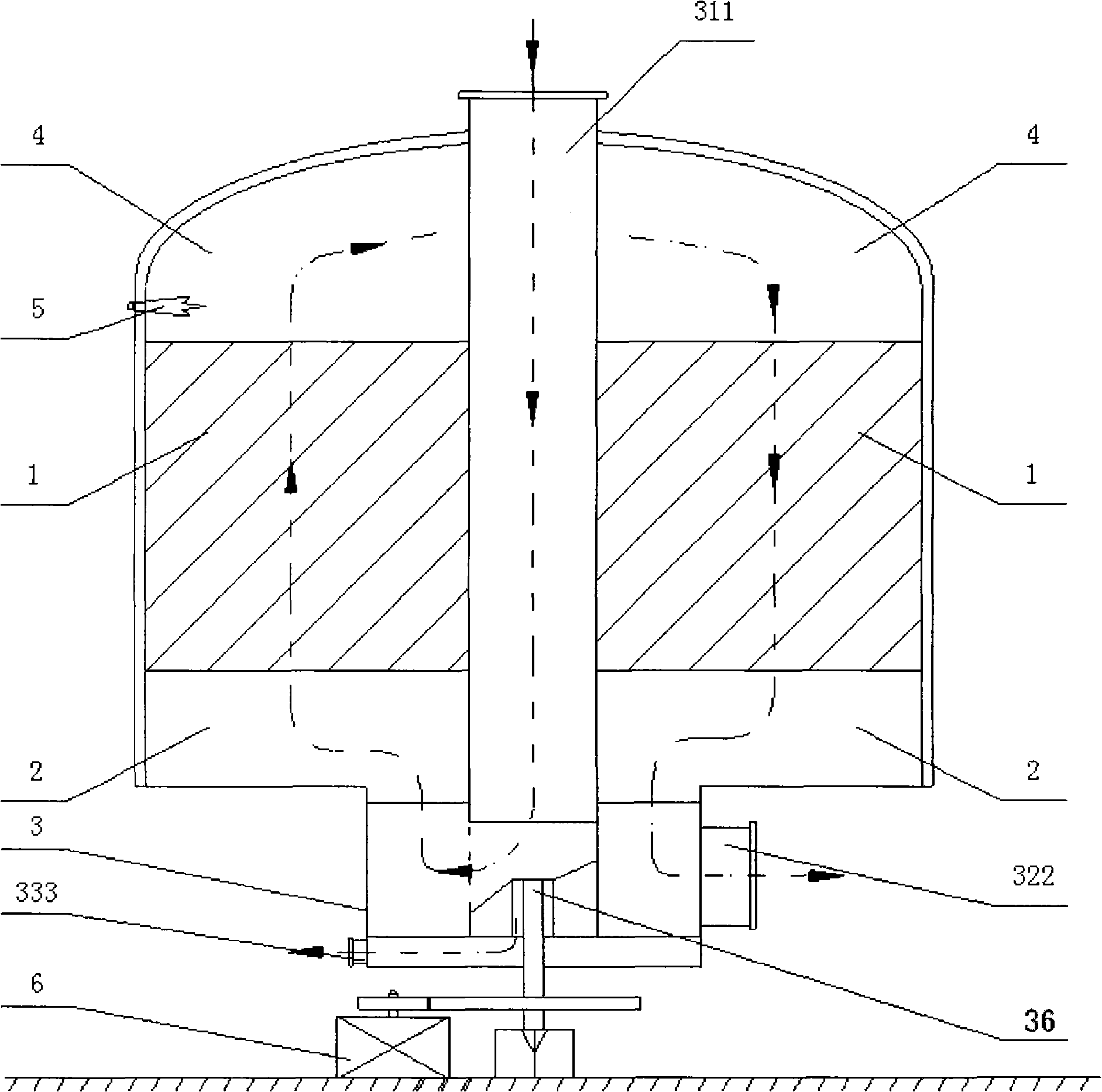

[0033] Such as figure 1 , 2 As shown in and 3, the low-concentration organic waste gas rotary regenerative thermal oxidation processor A provided by the first embodiment of the present invention is used to treat low-concentration organic waste gas from a petrochemical company. The regenerative thermal oxidation processor A has an external purification gas channel The purified gas bypass valve B is used to adjust and control the temperature in the incineration chamber 4; a fan C is connected before the inlet of the sealed gas channel to introduce the sealed gas into the rotary valve 3 and the heat storage ceramic layer 1 to seal the gas channel.

[0034] The working conditions of the petrochemical company's low-concentration organic waste gas are shown in Table 1.

[0035] Table 1. Working condition table of low-concentration organic waste gas of a petrochemical company

[0036]

[0037] First, use the heat generated by the combustor 5 to burn the mixed gas of fuel gas and air t...

Embodiment 2

[0042] In the second embodiment of the present invention, the operating pressure of the low-concentration organic waste gas is 120KPa(A), the operating temperature is 36°C, and the flow rate is 30000Nm3 / h. The low-concentration organic waste gas is heated to 820°C by the high-temperature ceramics that have been thermally stored, and then enters the incineration chamber 4 for thermal oxidation reaction. The temperature rises to about 880°C, and then releases heat to the low-temperature ceramics. After testing, the temperature of the purified gas finally discharged from the thermal thermal oxidation reactor A is 80-90℃, the pressure is 114KPa(A), the average conversion rate of organic matter is 97.5%-98.5%, and the thermal efficiency of the regenerative thermal oxidation reactor It is about 96.6%.

no. 8 example

[0054] In the eighth embodiment of the present invention, the operating pressure of the low-concentration organic waste gas is 110KPa(A), the operating temperature is 30°C, and the flow rate is 96000Nm3 / h. The low-concentration organic waste gas is heated to 810°C by the high-temperature ceramic that has been thermally stored, and then enters the incineration chamber 4 for thermal oxidation reaction. The temperature is increased to about 860°C, and then the low-temperature ceramic is released. After testing, the temperature of the purified gas finally discharged from the regenerative thermal oxidation reactor A is 70~80℃, the pressure is 103KPa(A), and the average conversion rate of organic matter is 97.8%~98.7%. The thermal efficiency is about 97.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com