Patents

Literature

196 results about "Thermal oxidizer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A thermal oxidizer (also known as thermal oxidiser, or thermal incinerator) is a process unit for air pollution control in many chemical plants that decomposes hazardous gases at a high temperature and releases them into the atmosphere.

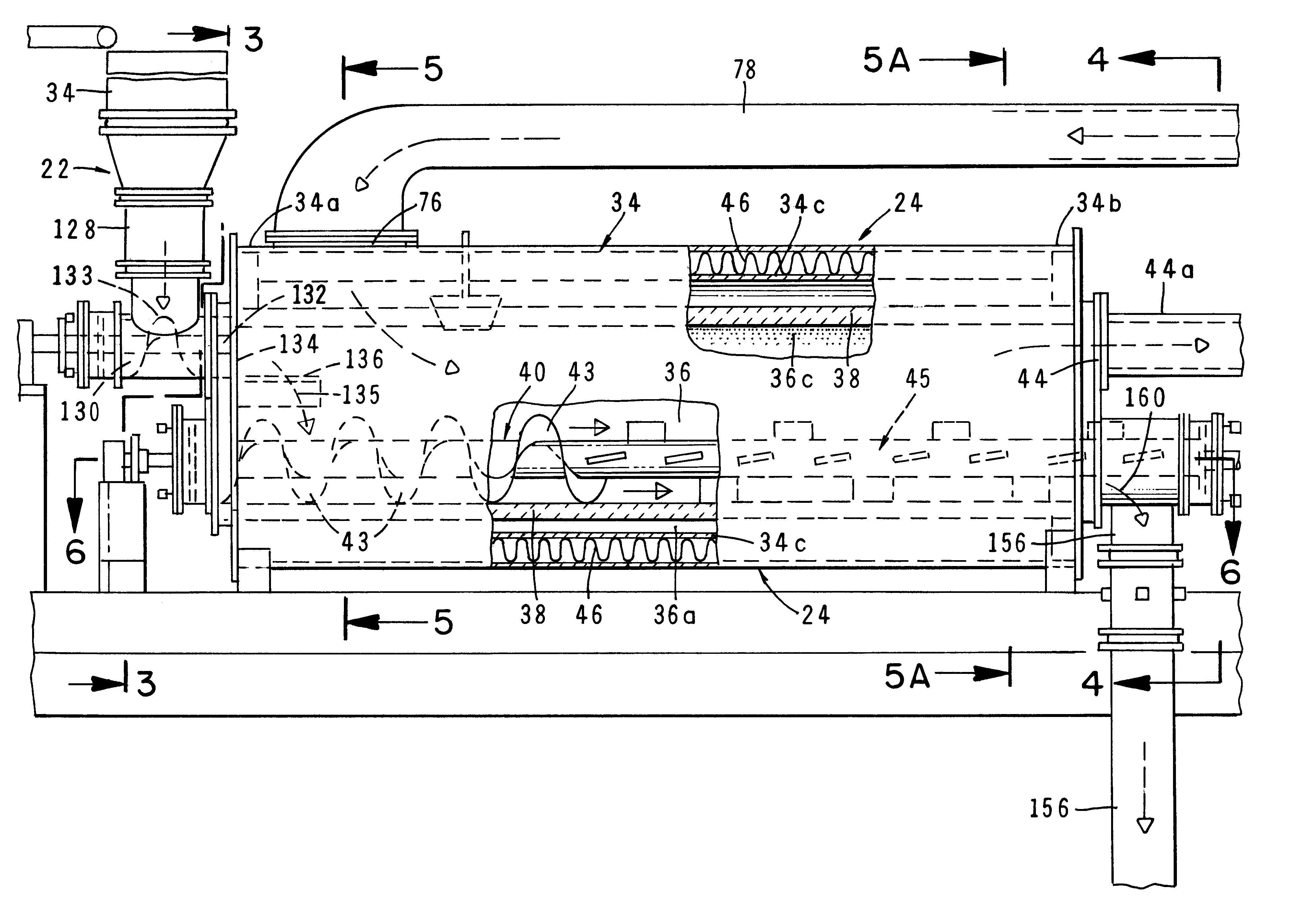

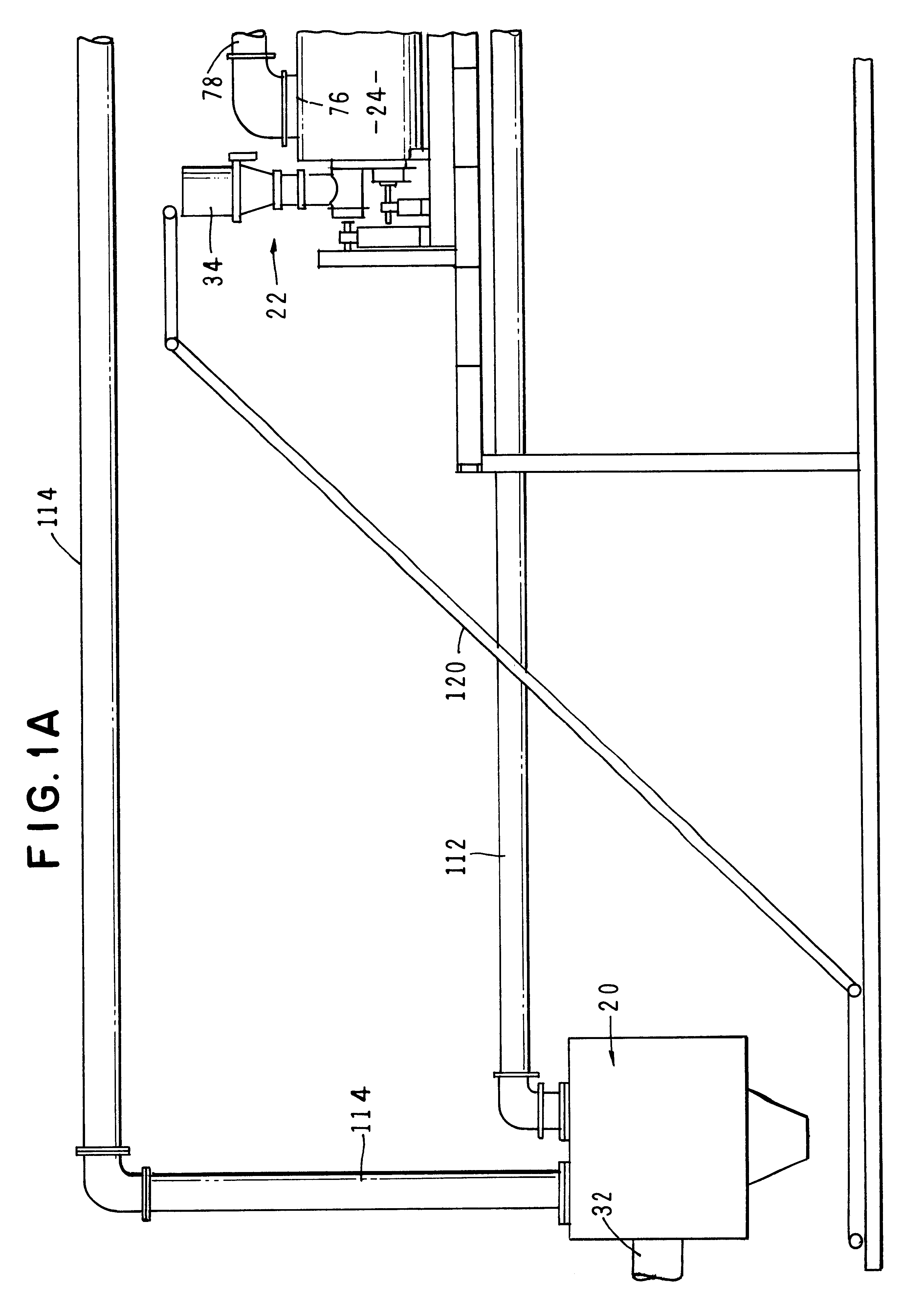

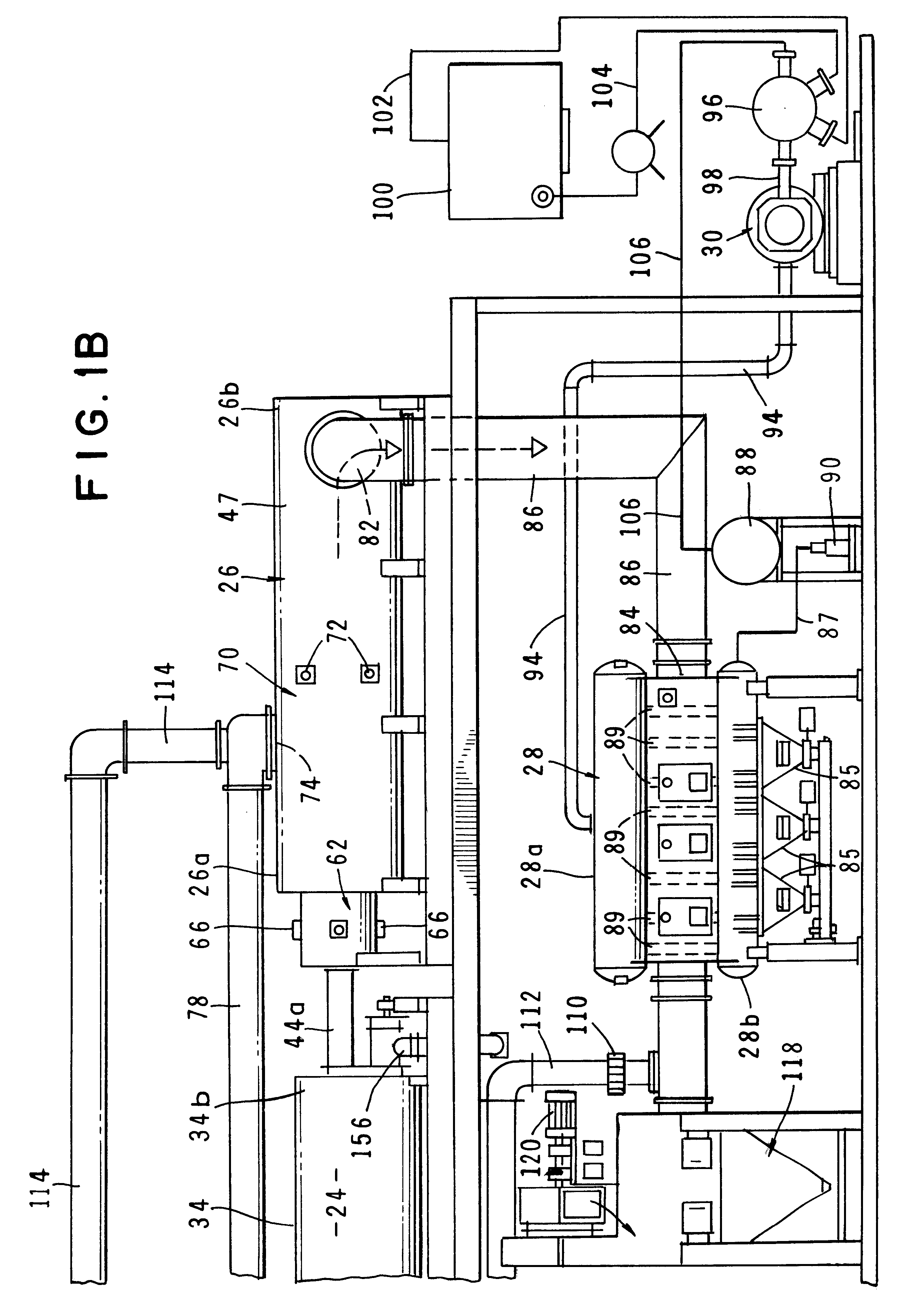

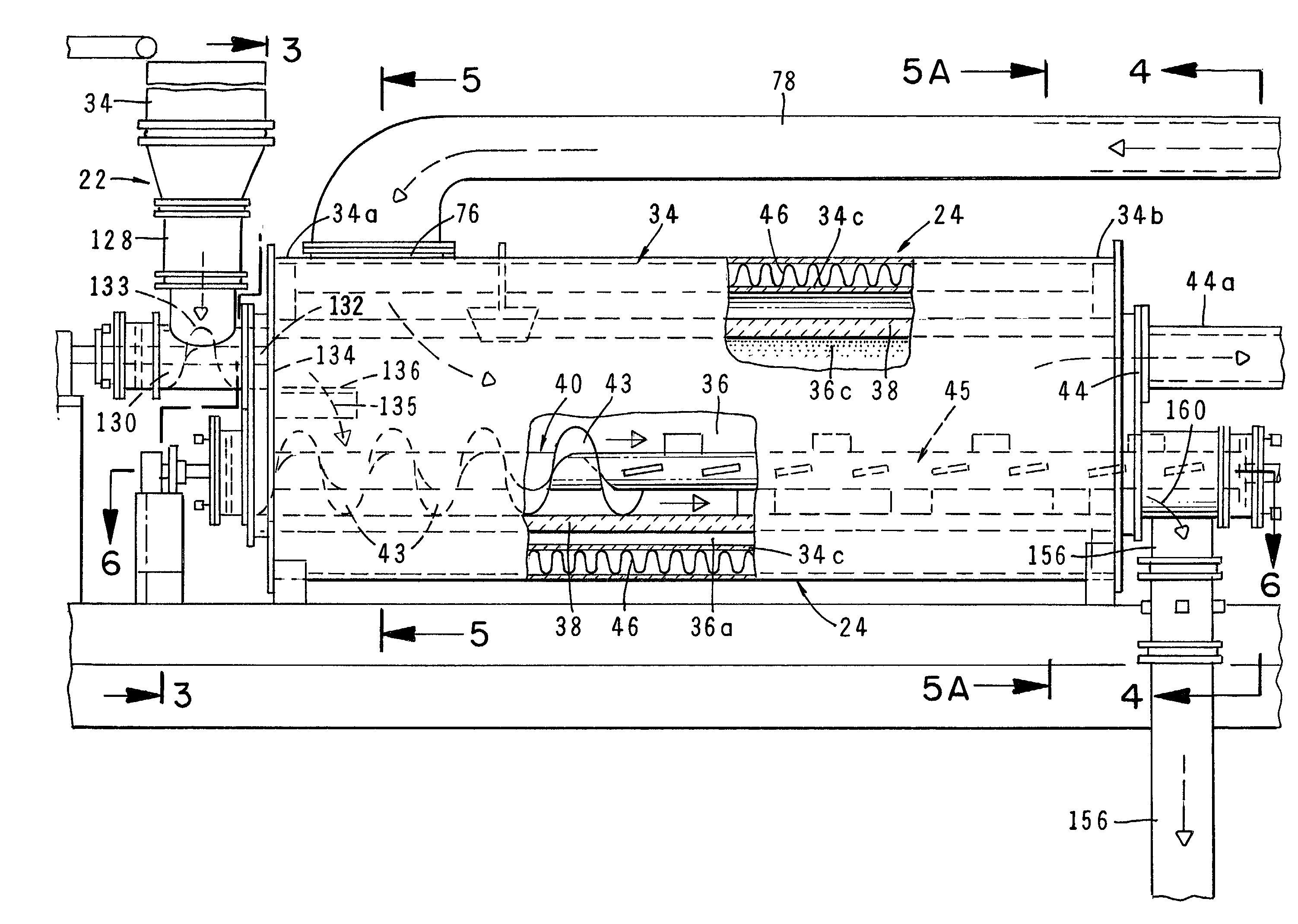

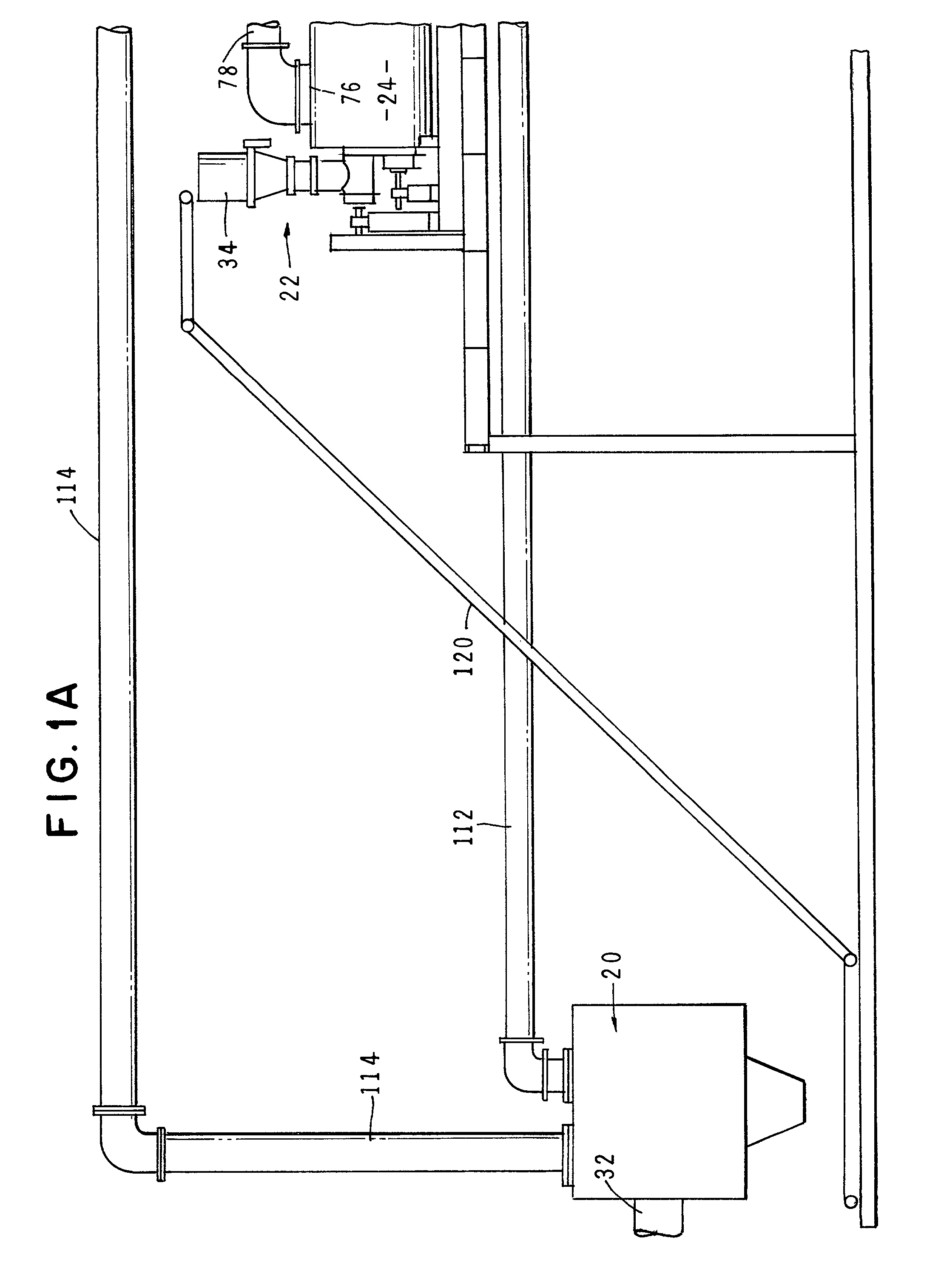

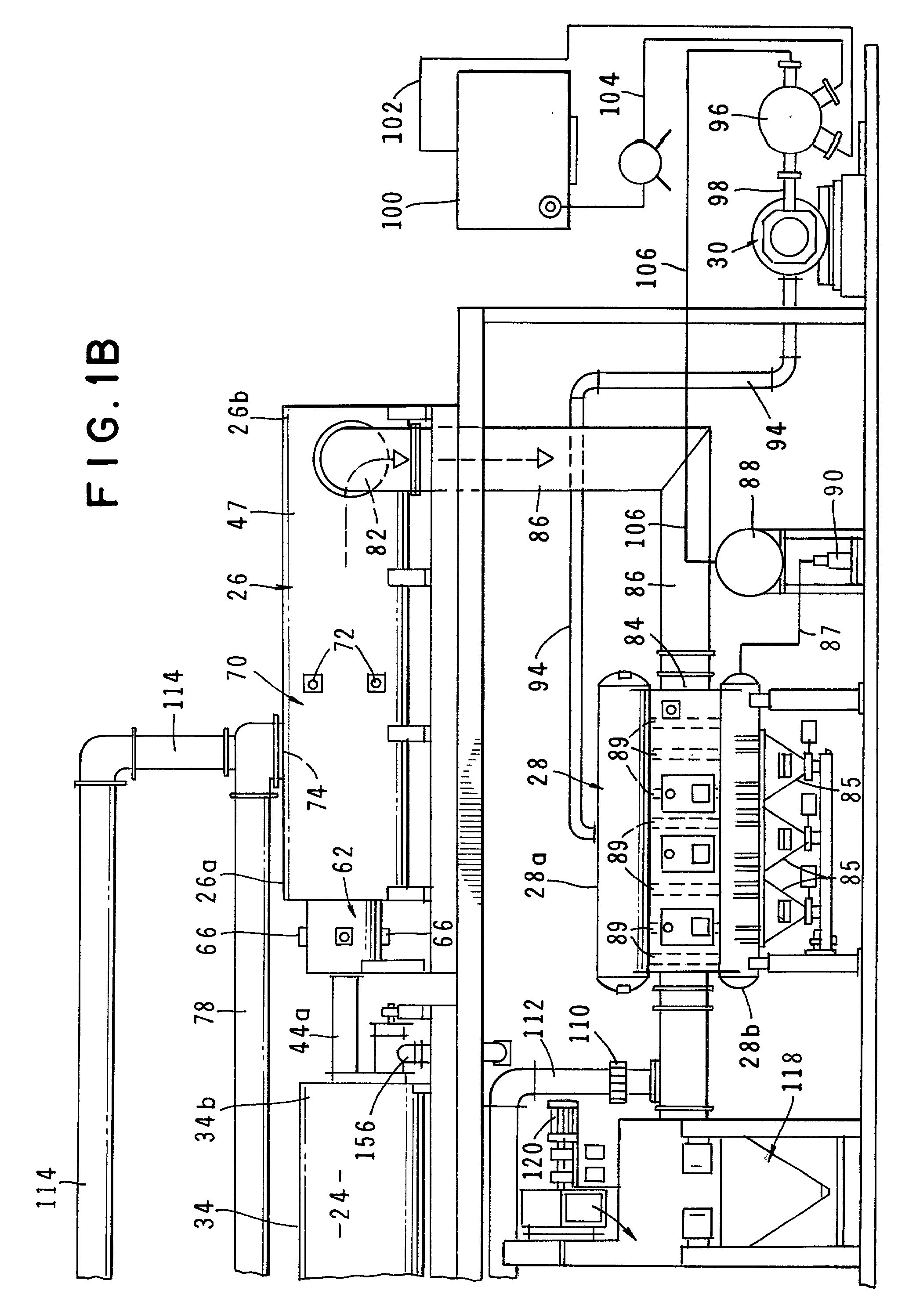

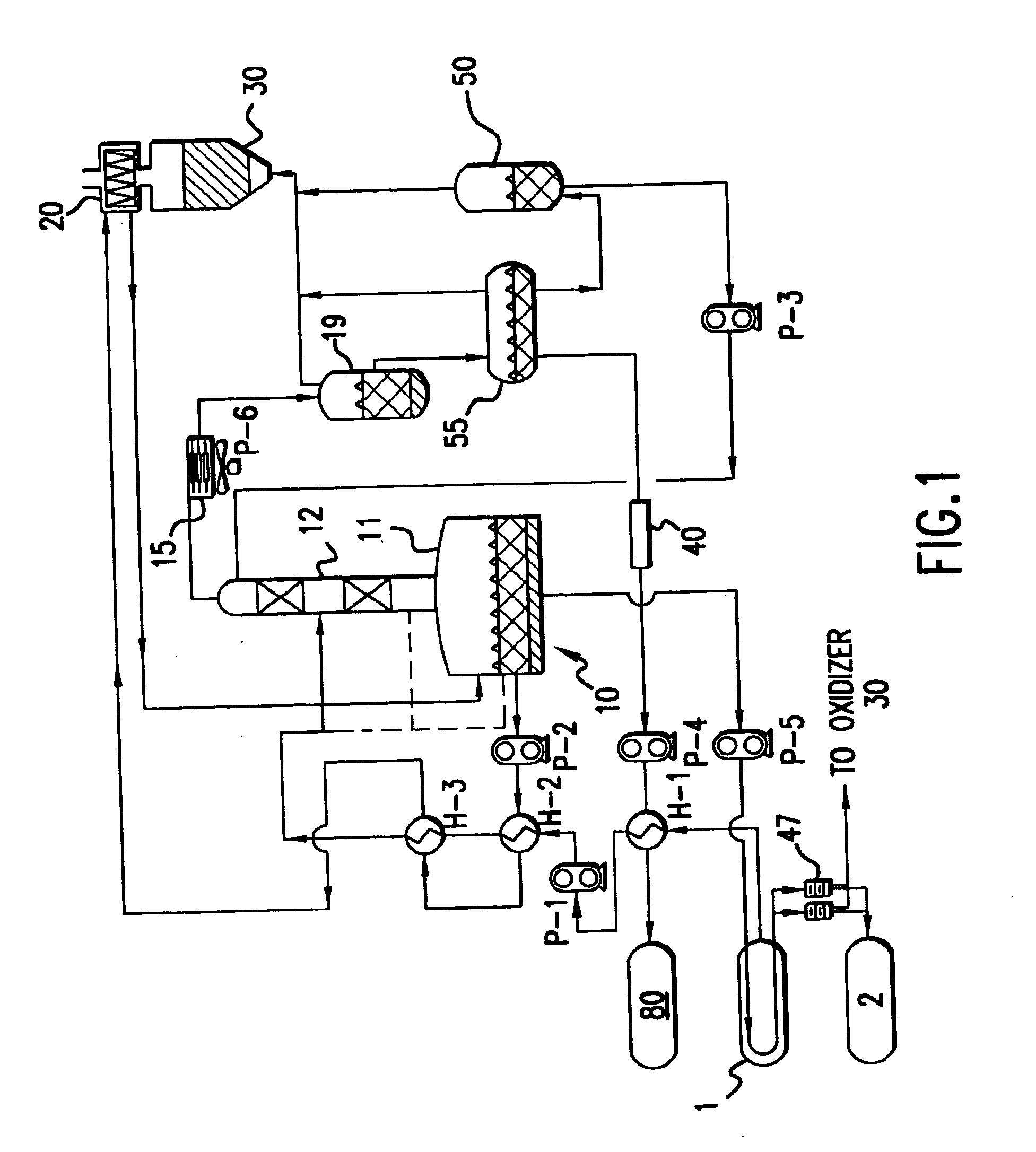

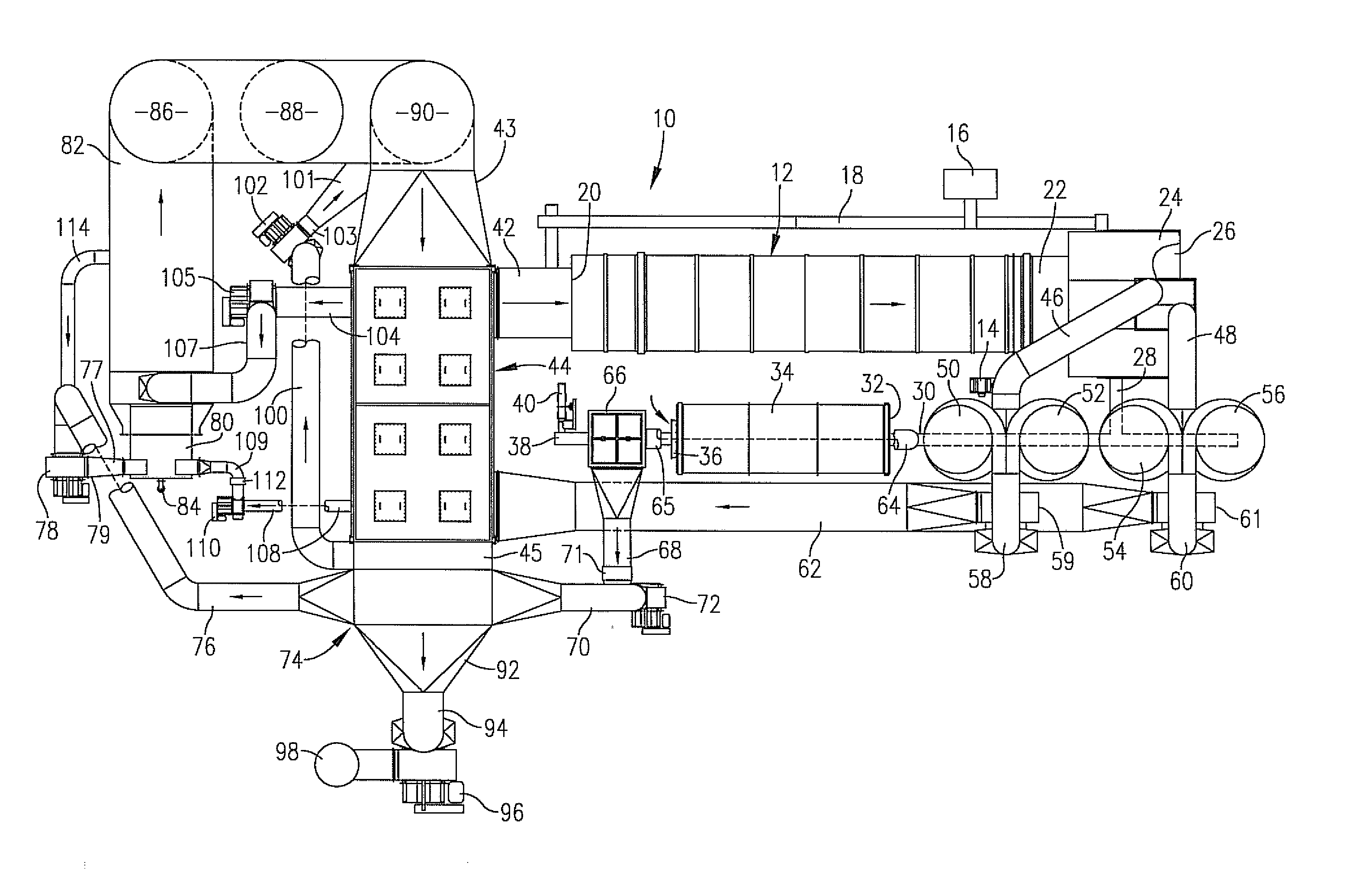

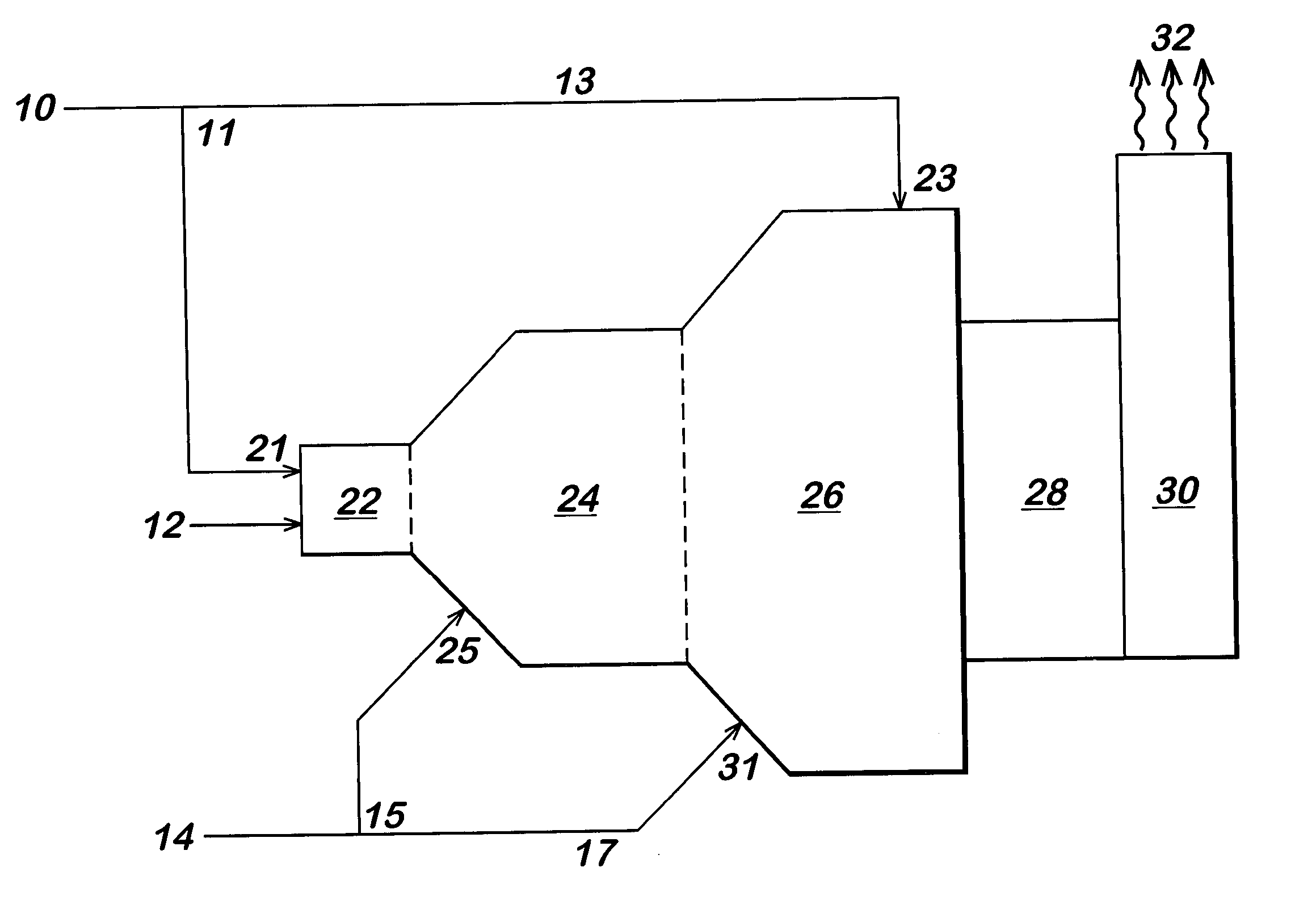

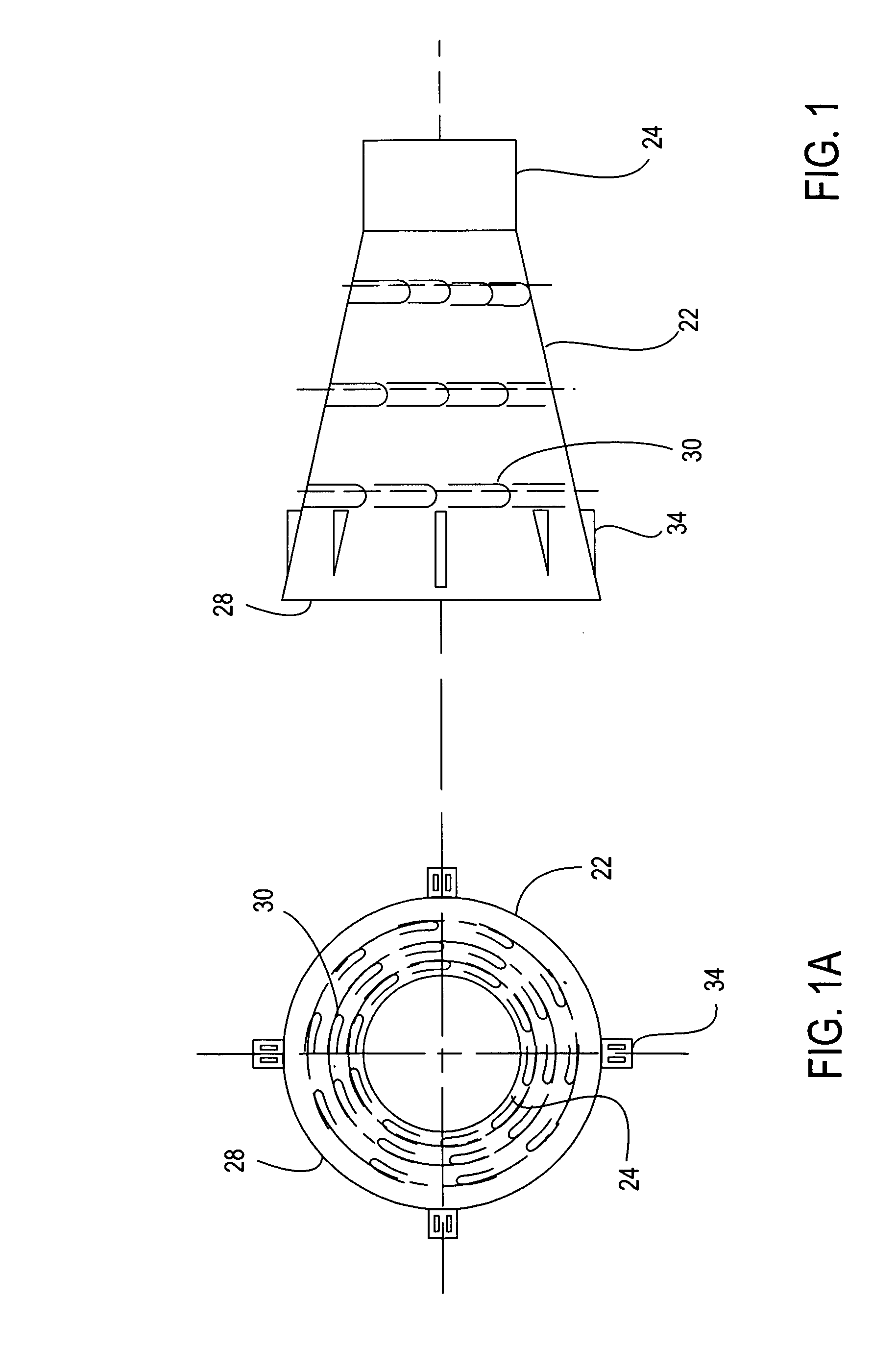

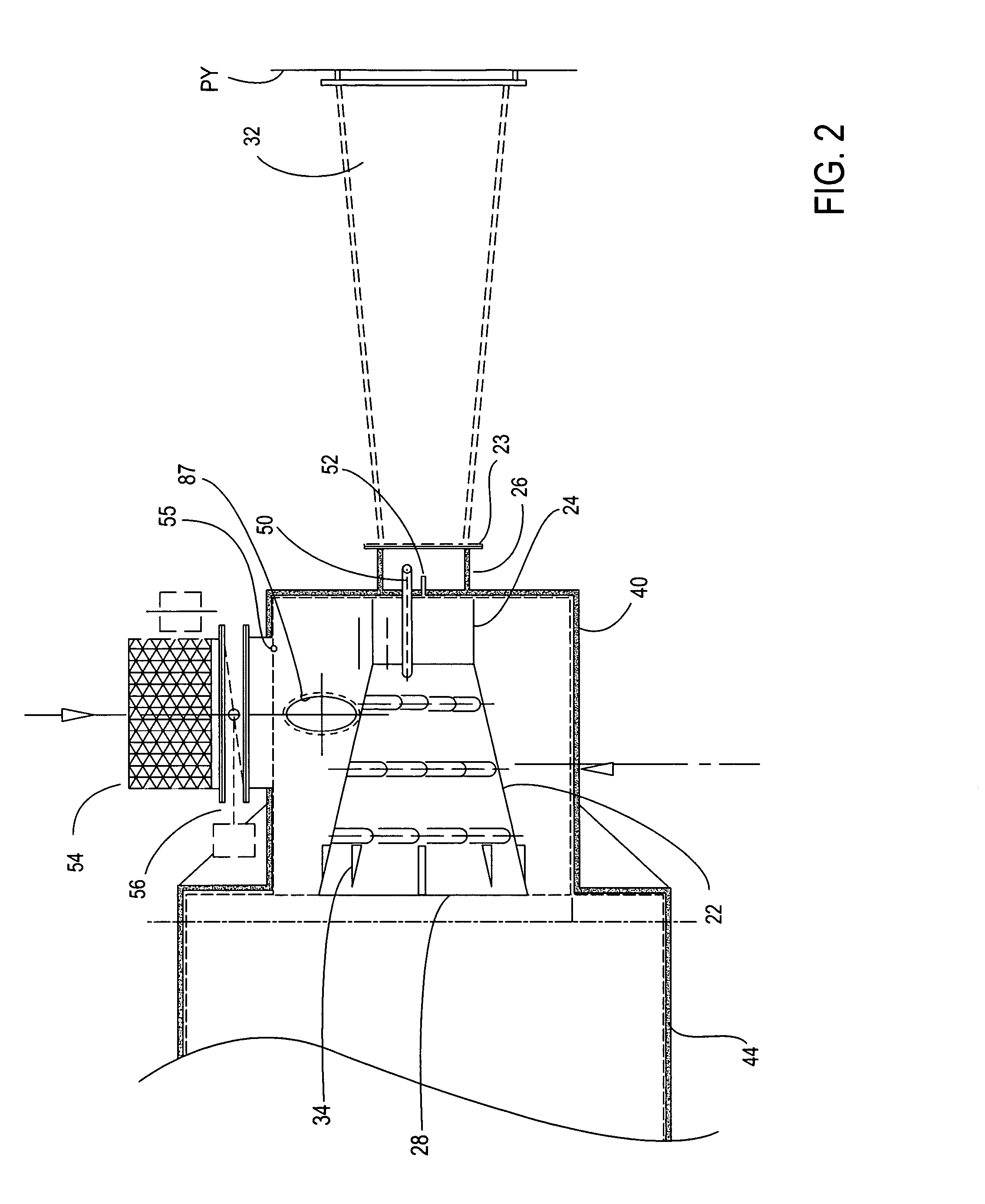

Method and apparatus for treatment of waste

InactiveUS6619214B2Efficient and reliable in operationEasy maintenanceSolid fuel combustionIncinerator apparatusEngineeringTransfer mechanism

An apparatus for treating waste material that comprises four major cooperating subsystems, namely a pyrolytic converter, a two-stage thermal oxidizer, a steam generator and a steam turbine driven by steam generated by the steam generator. In operation, the pyrolytic converter is uniquely heated without any flame impinging on the reactor component and the waste material to be pyrolyzed is transported through the reaction chamber of the pyrolytic converter by a pair of longitudinally extending, side-by-side material transfer mechanisms. Each of the transfer mechanisms includes a first screw conveyor section made up of a plurality of helical flights for conveying the heavier waste and a second paddle conveyor section interconnected with the first section for conveying the partially pyrolyzed waste, the second section comprising a plurality of paddle flights. Once operating, the apparatus is substantially self-sustaining and requires a minimum use of outside energy sources for pyrolyzing the waste materials.

Owner:APS IP HLDG

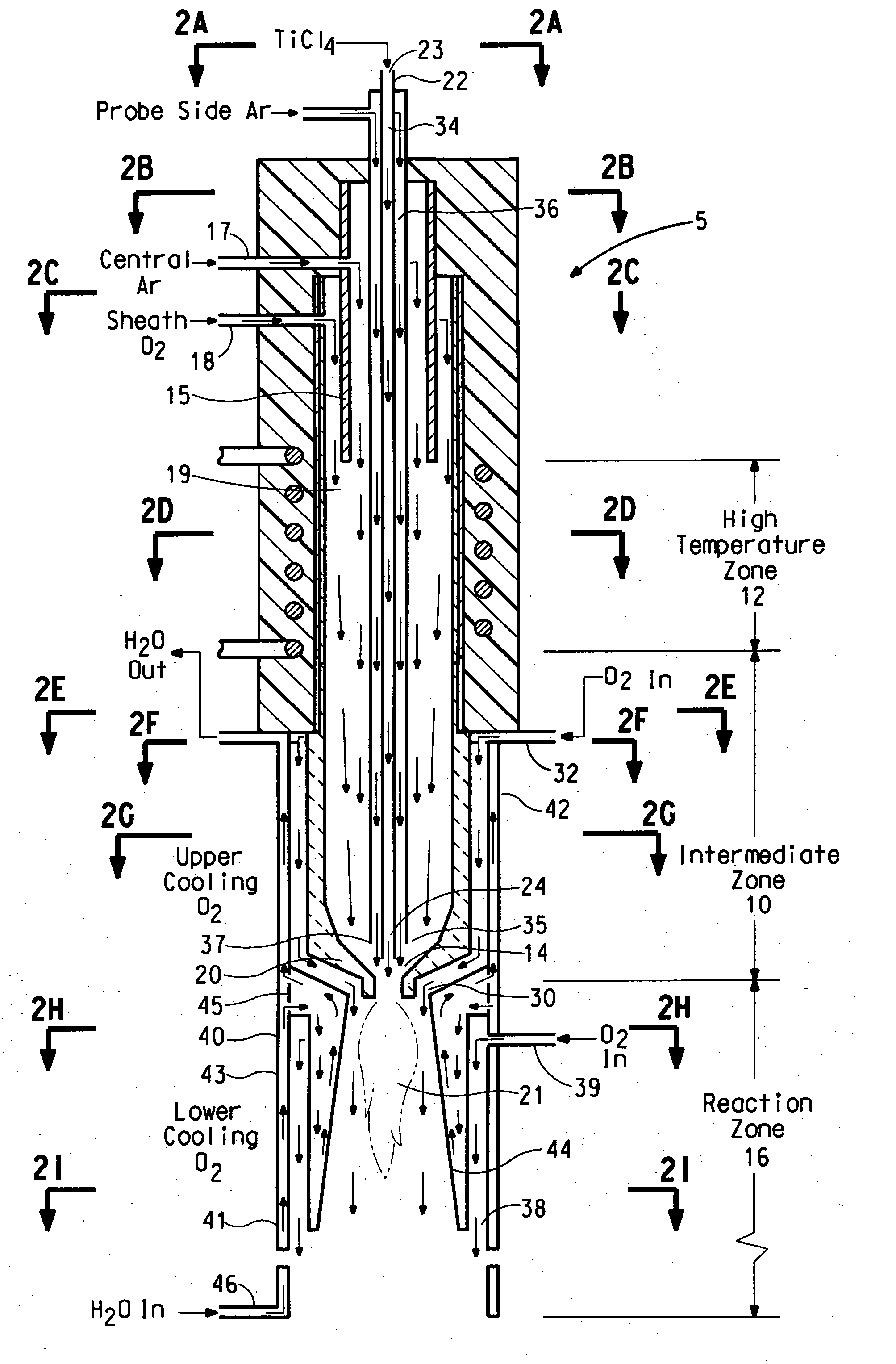

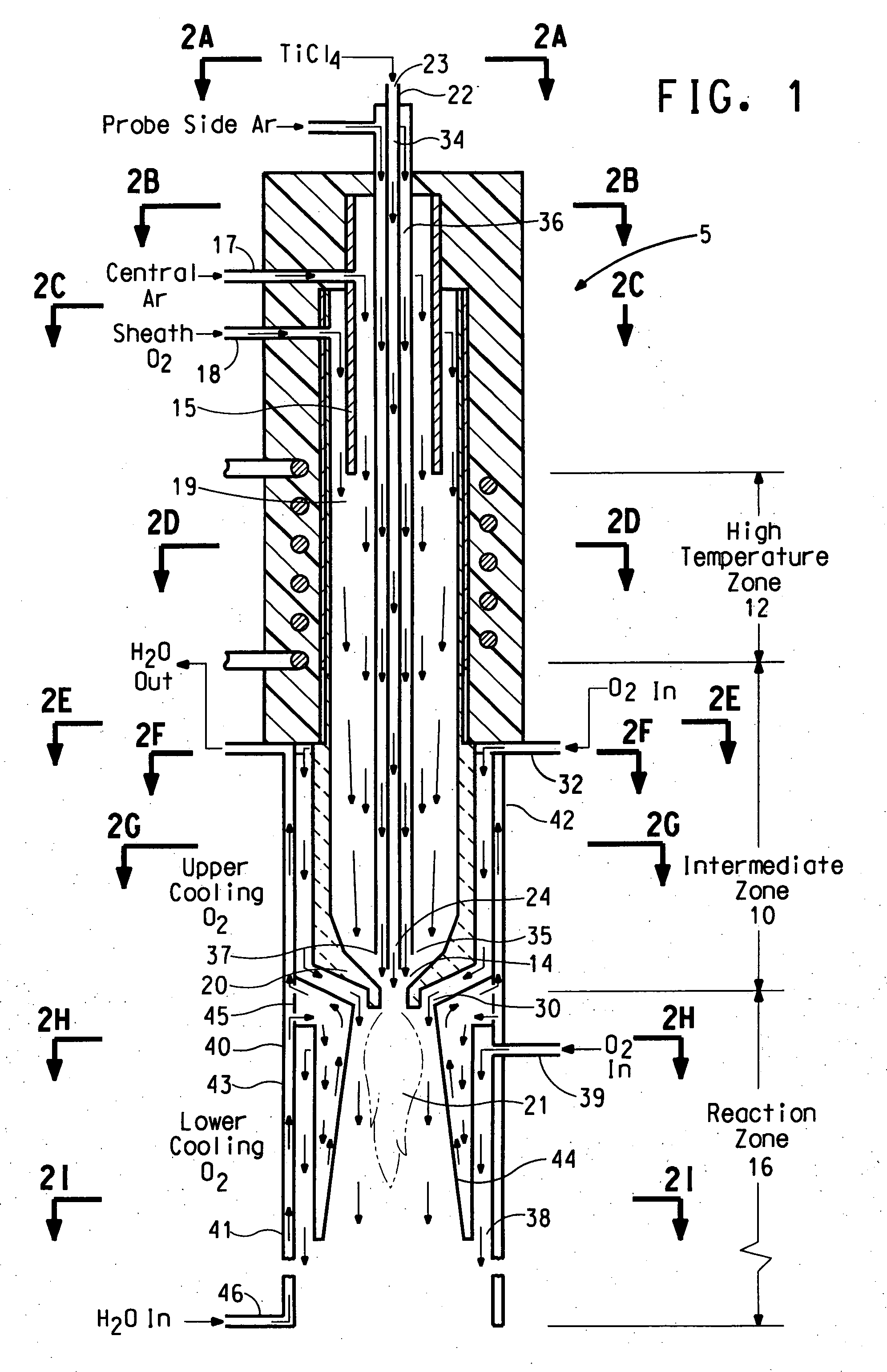

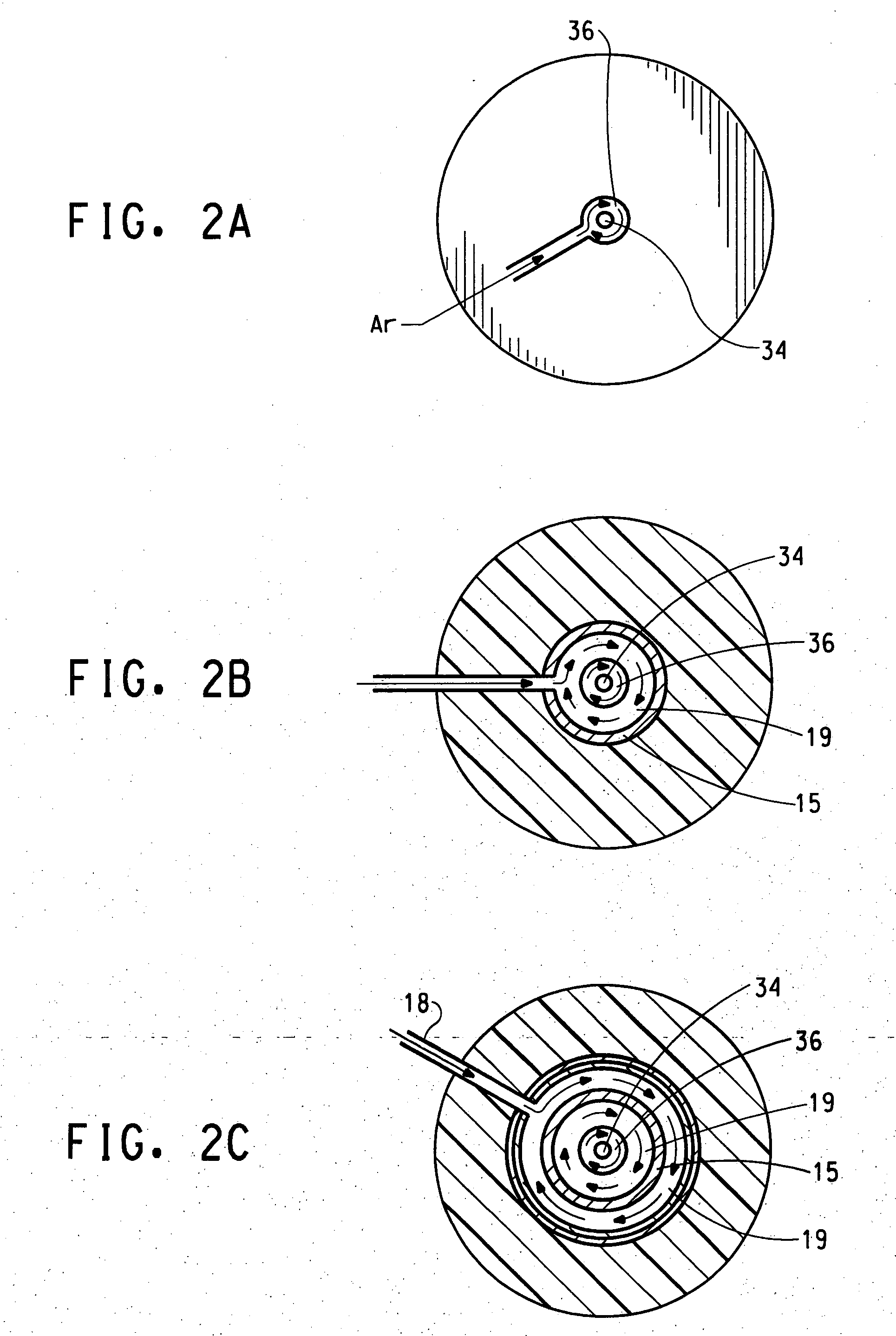

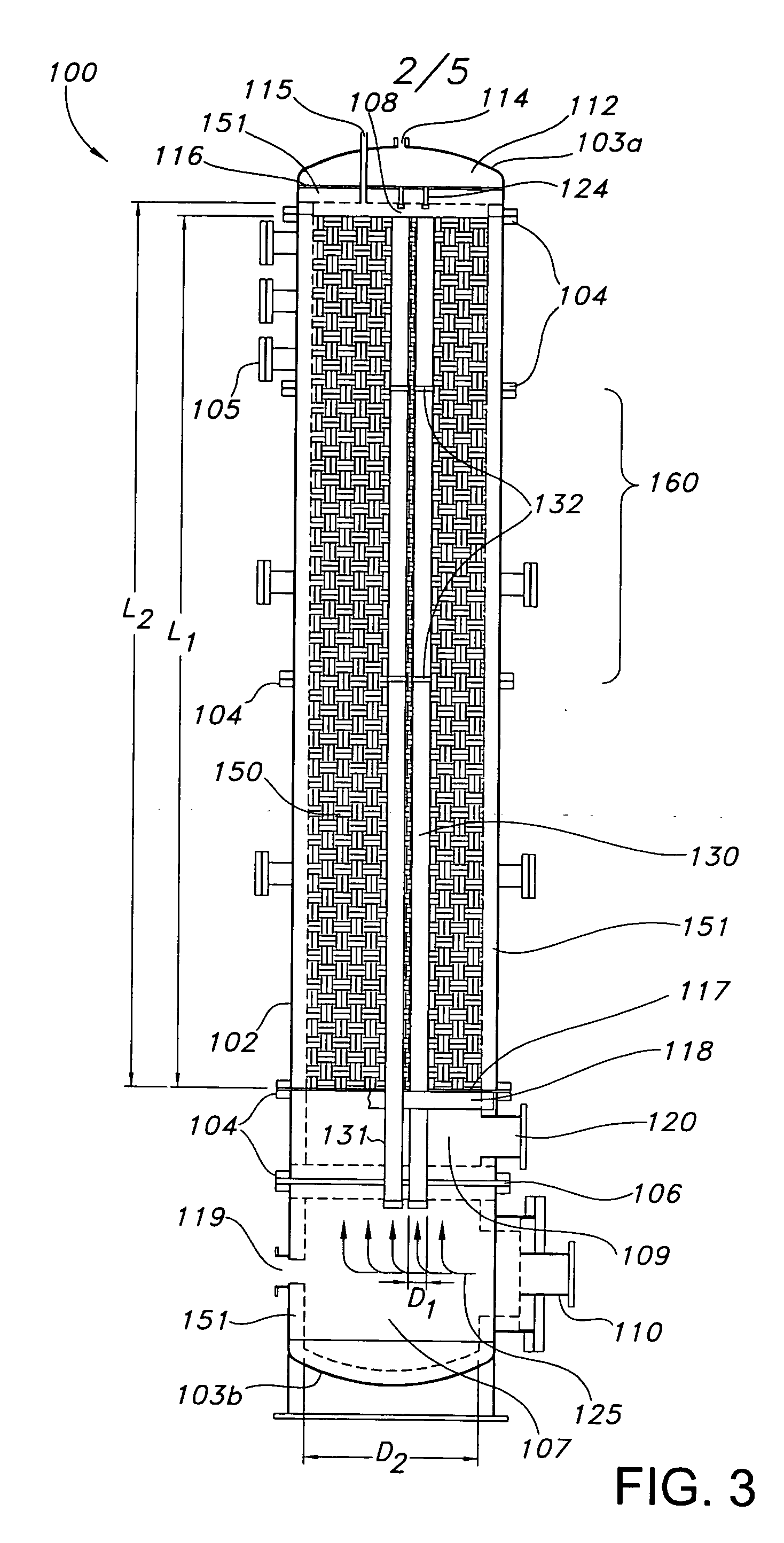

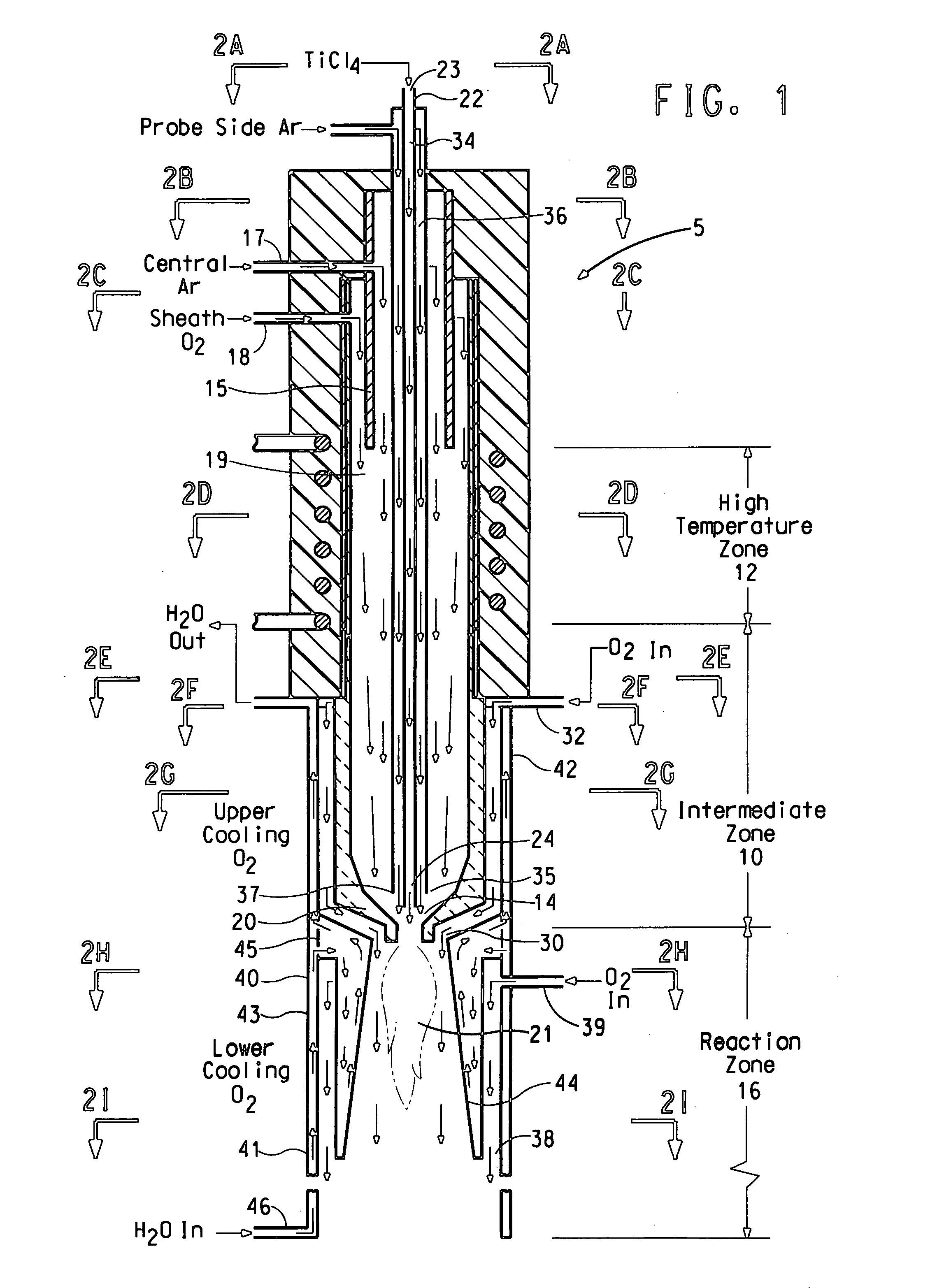

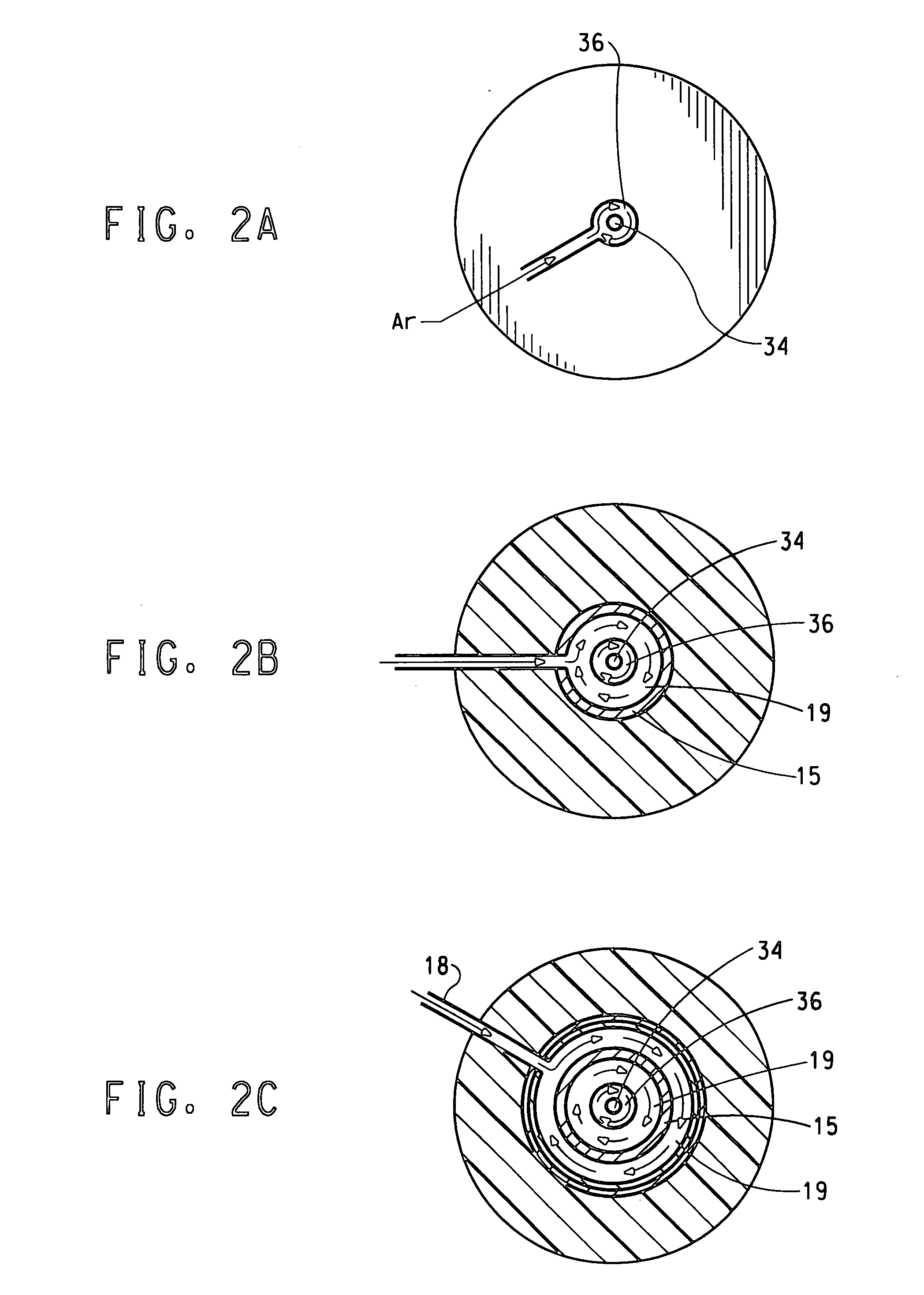

Apparatus for making metal oxide nanopowder

InactiveUS20070292321A1Reduce decreaseEliminate coarse tailMaterial nanotechnologyOxygen/ozone/oxide/hydroxideReaction zoneCooling fluid

There is described an apparatus for making metal oxide particles which are substantially free of coarse tail from an oxidizing agent and a metal reactant in a flow reactor. The apparatus can be a concentric tubular flow reactor comprising a substantially funnel-shaped reactant contacting region located adjacent to a reaction zone which is able to direct a flow of a hot oxidizing agent towards a flow of the metal reactant to form a reaction stream which flows downstream into a reaction zone, whereby the hot oxidizing agent of the reaction stream is able to surround the flow of metal reactant sufficient to prevent the metal reactant from contacting the wall of the reactant contacting region and forming scale on the wall. A cooling fluid conduit being able to direct a flow of a cooling fluid into the reaction zone to flow coaxially with the reaction stream and to form a fluid curtain between the reaction stream and a baffle, which defines at least a portion of the reaction zone, while the metal reactant and hot oxidizing agent within the reaction stream react to form the metal oxide nanopowder prevents scale from forming on the baffle.

Owner:EI DU PONT DE NEMOURS & CO

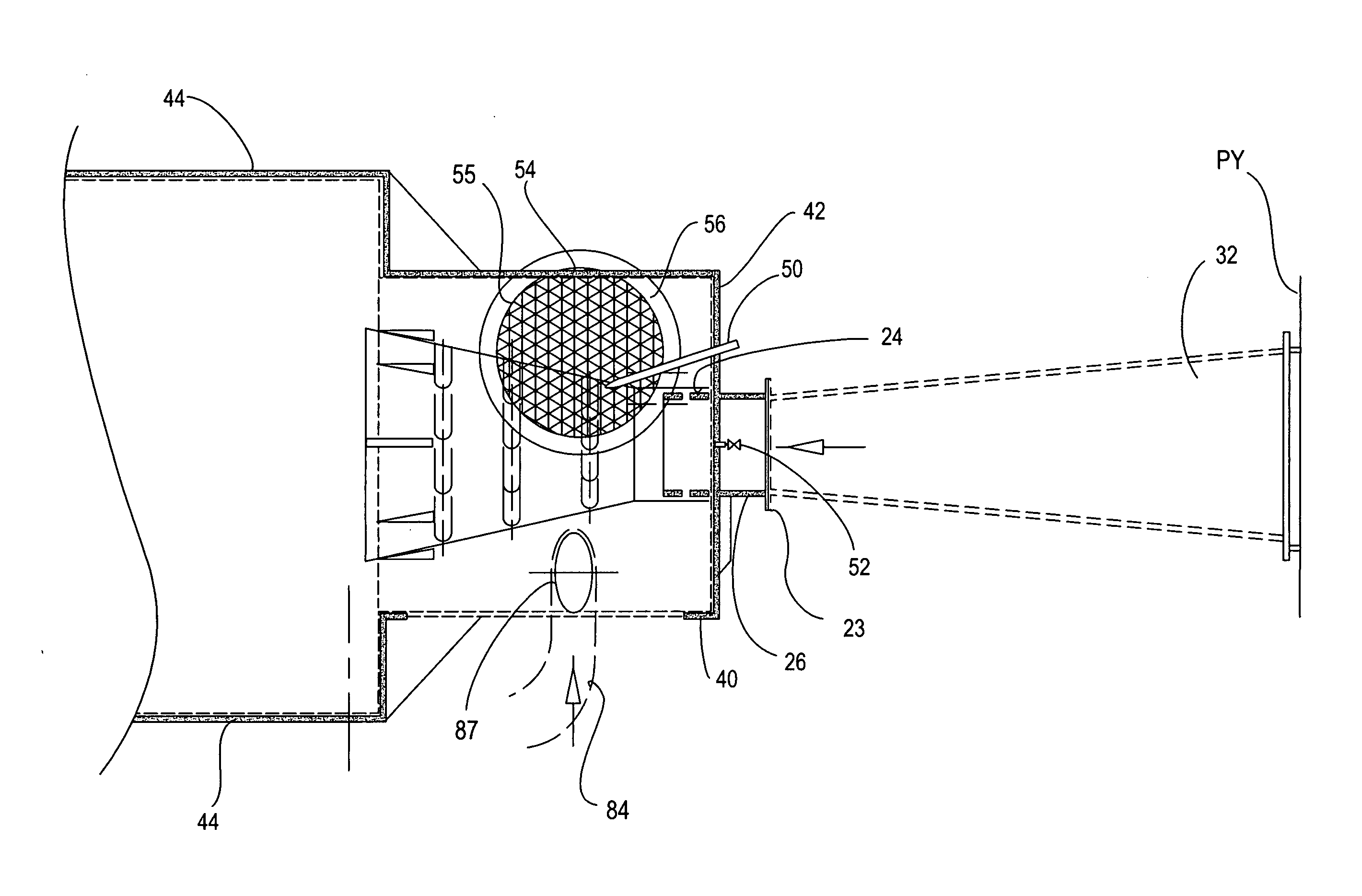

Method and apparatus for treatment of waste

InactiveUS20020195031A1Efficient and reliable in operationEasy maintenanceSolid fuel combustionIncinerator apparatusEngineeringTransfer mechanism

An apparatus for treating waste material that comprises four major cooperating subsystems, namely a pyrolytic converter, a two-stage thermal oxidizer, a steam generator and a steam turbine driven by steam generated by the steam generator. In operation, the pyrolytic converter is uniquely heated without any flame impinging on the reactor component and the waste material to be pyrolyzed is transported through the reaction chamber of the pyrolytic converter by a pair of longitudinally extending, side-by-side material transfer mechanisms. Each of the transfer mechanisms includes a first screw conveyor section made up of a plurality of helical flights for conveying the heavier waste and a second paddle conveyor section interconnected with the first section for conveying the partially pyrolyzed waste, the second section comprising a plurality of paddle flights. Once operating, the apparatus is substantially self-sustaining and requires a minimum use of outside energy sources for pyrolyzing the waste materials.

Owner:APS IP HLDG

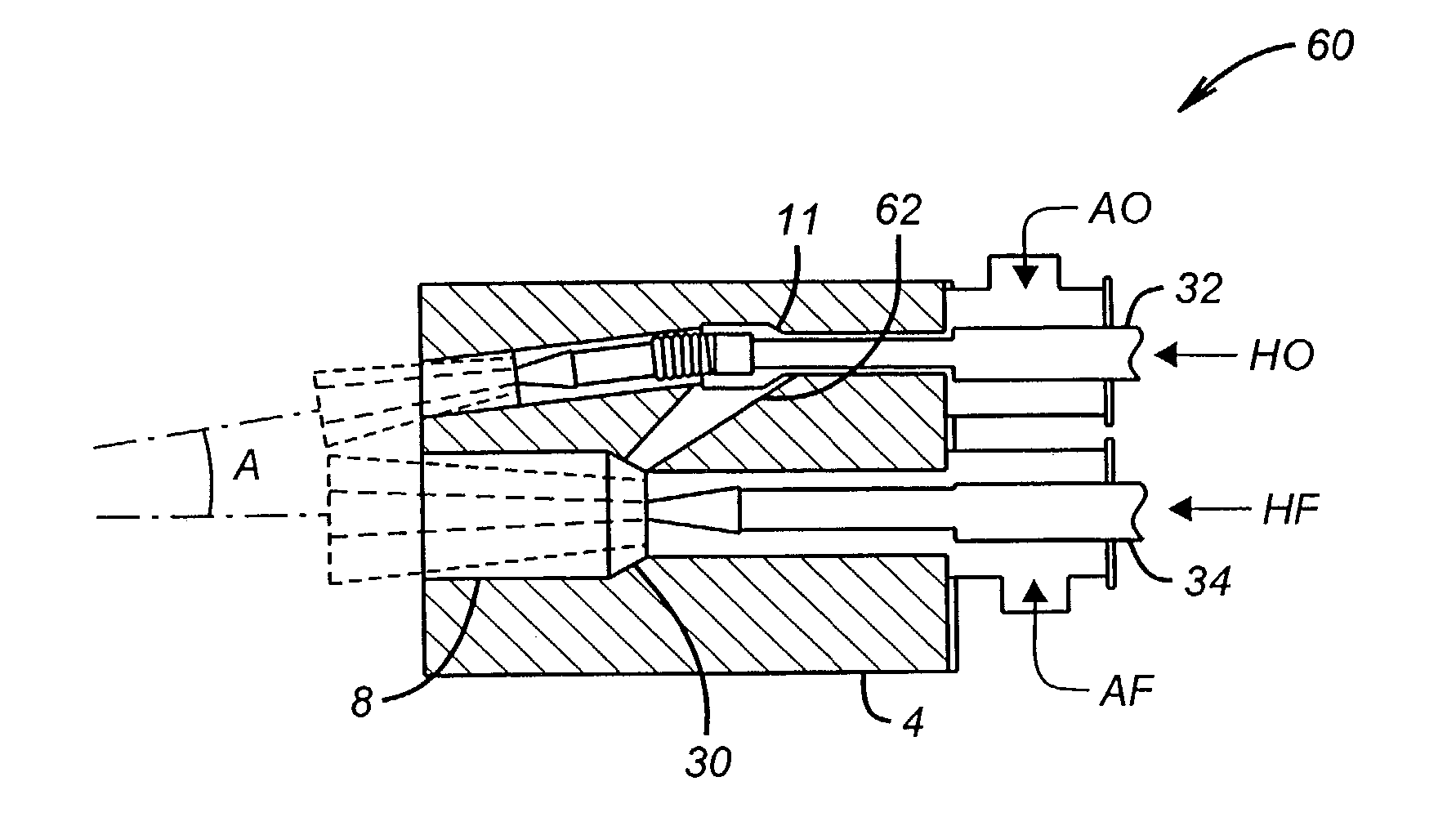

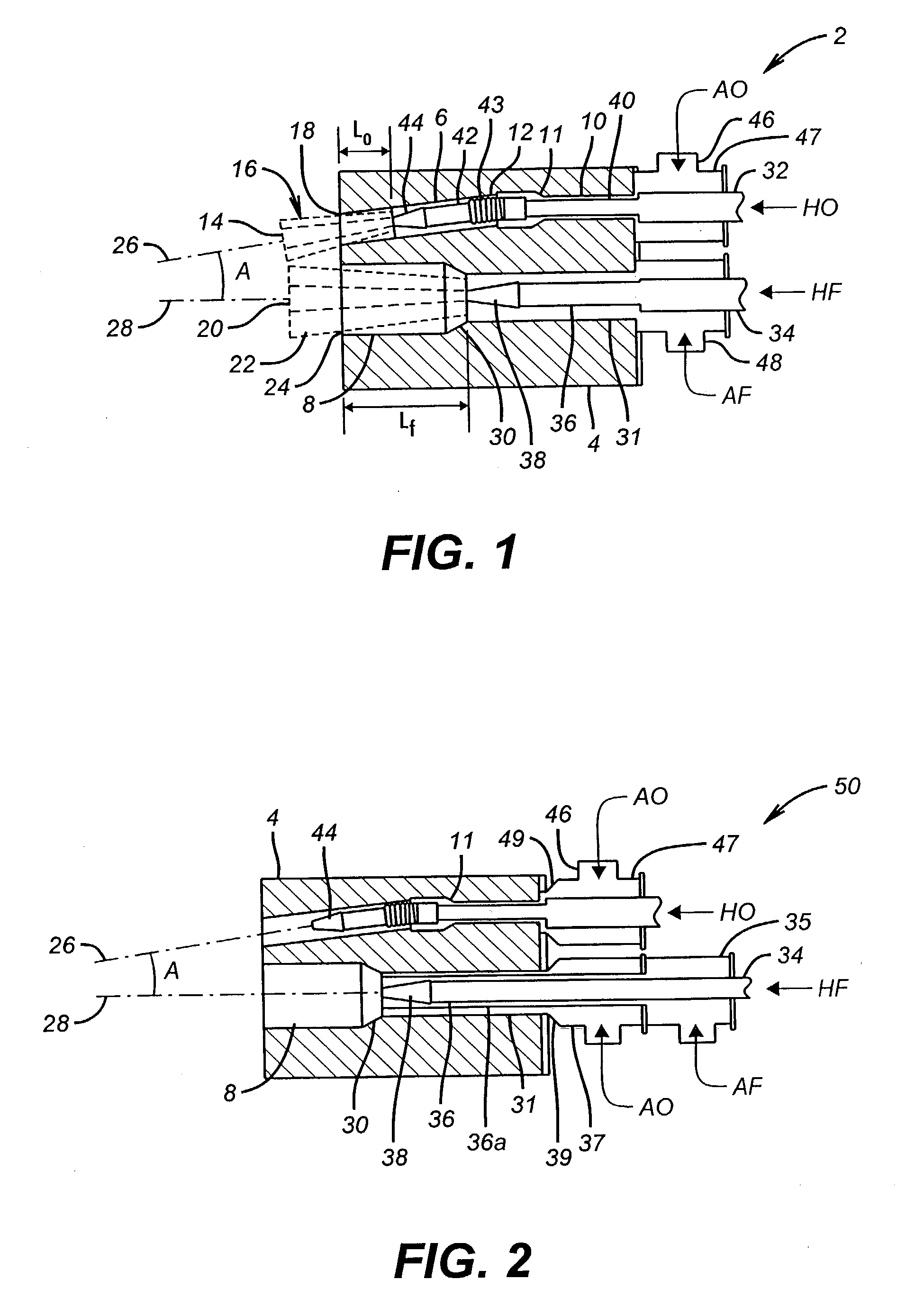

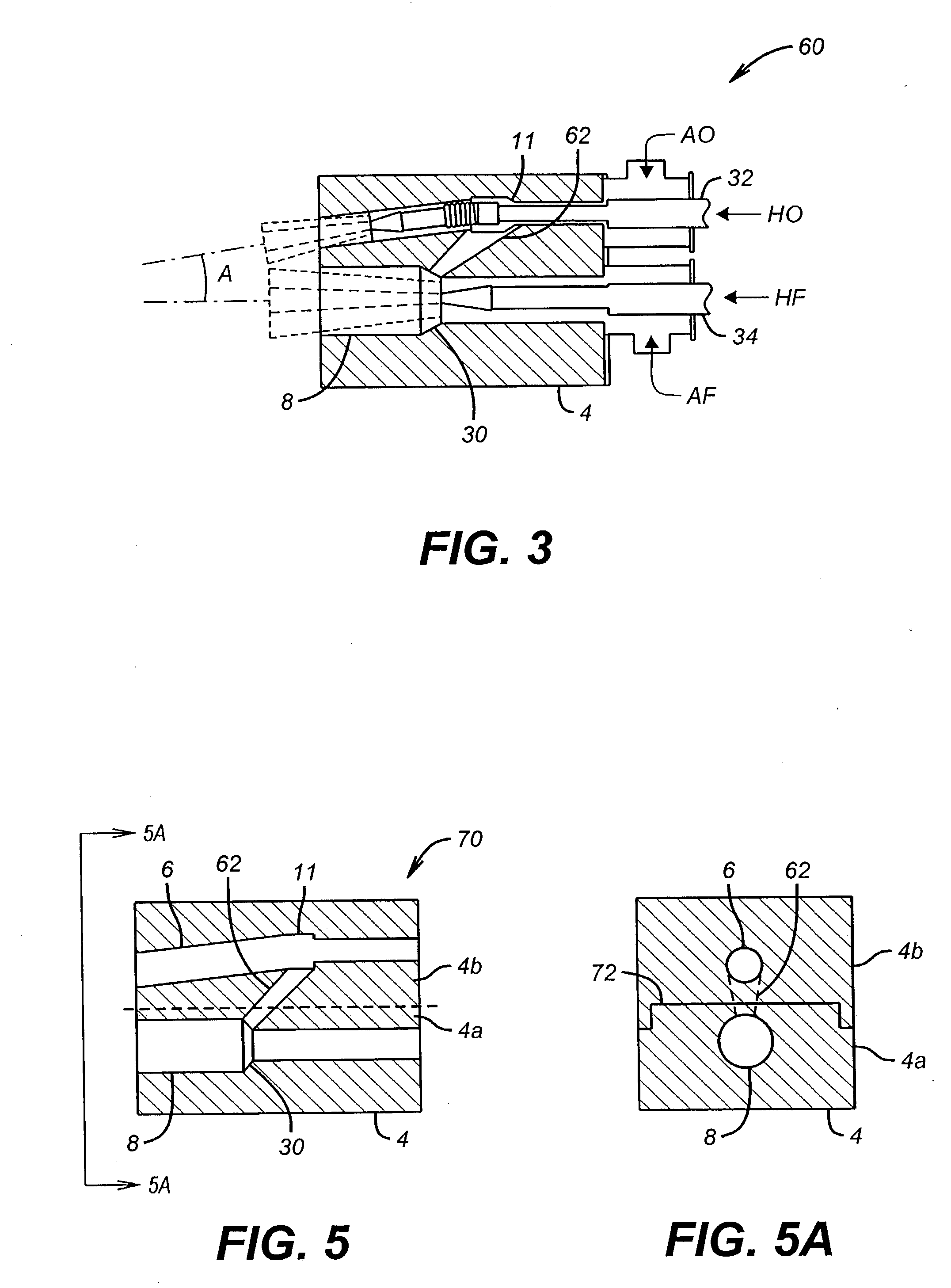

Preheated fuel and oxidant combustion burner

InactiveUS20030157450A1Burner material specificationsIndirect carbon-dioxide mitigationCombustorEngineering

A burner apparatus comprises a conduit adapted to convey preheated oxidant and having outlet and inlet ends, and a conduit adapted to convey preheated fuel and having outlet and inlet ends. The conduit adapted to convey preheated fuel is substantially parallel to the conduit adapted to convey preheated oxidant. The conduit adapted to convey preheated oxidant is positioned substantially vertically above the conduit adapted to convey preheated fuel. The conduit adapted to convey preheated oxidant and the conduit adapted to convey preheated fuel each are positioned within its own respective elongate cavity in a refractory burner block. Each of the conduits are positioned in their respective cavity such that a substantially annular region is present between an outer surface of each conduit and its respective cavity. Each conduit inlet end extends through a respective plenum for receiving an ambient temperature fluid, the plenums adapted to pass the ambient temperature fluid into the respective annular regions.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE +1

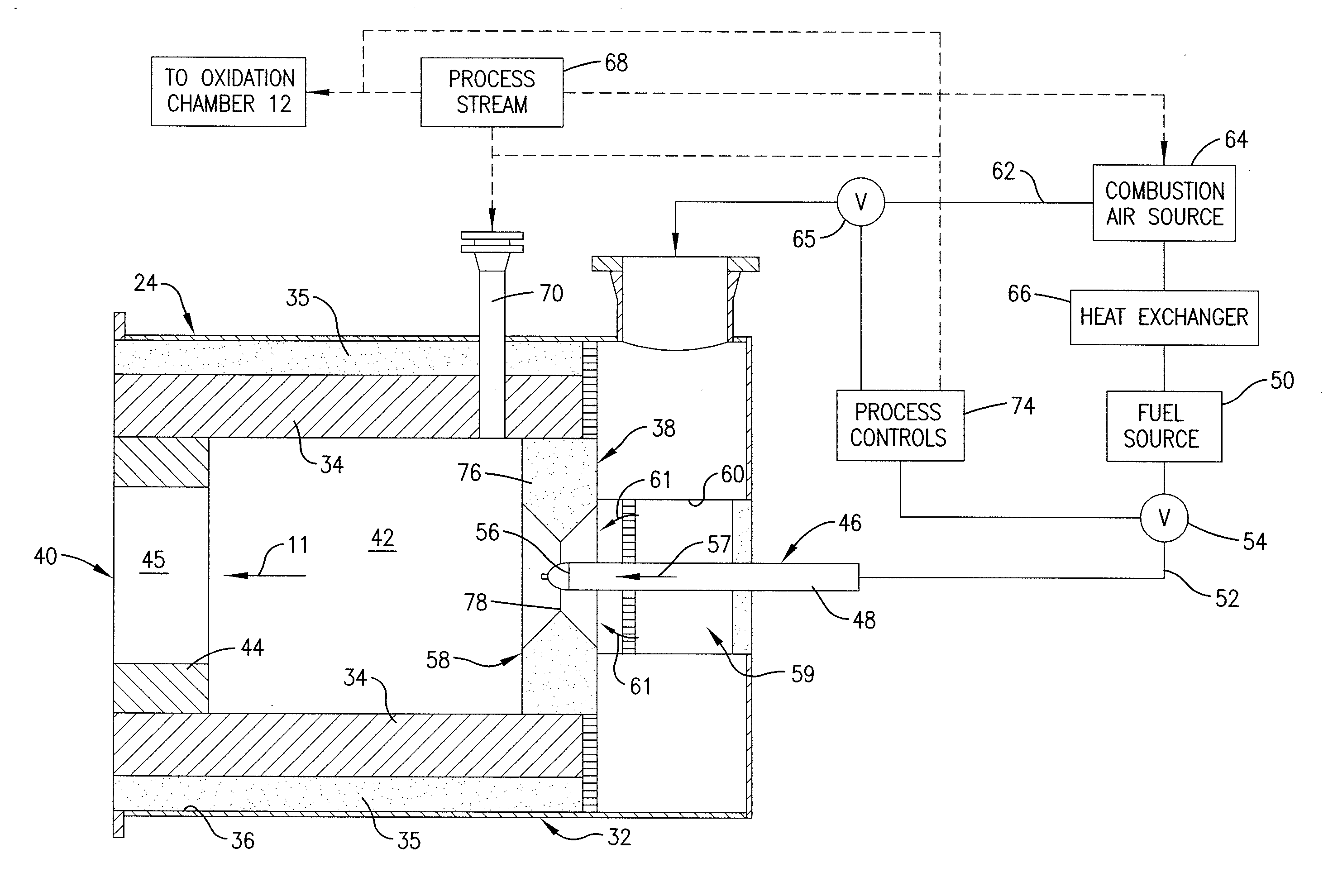

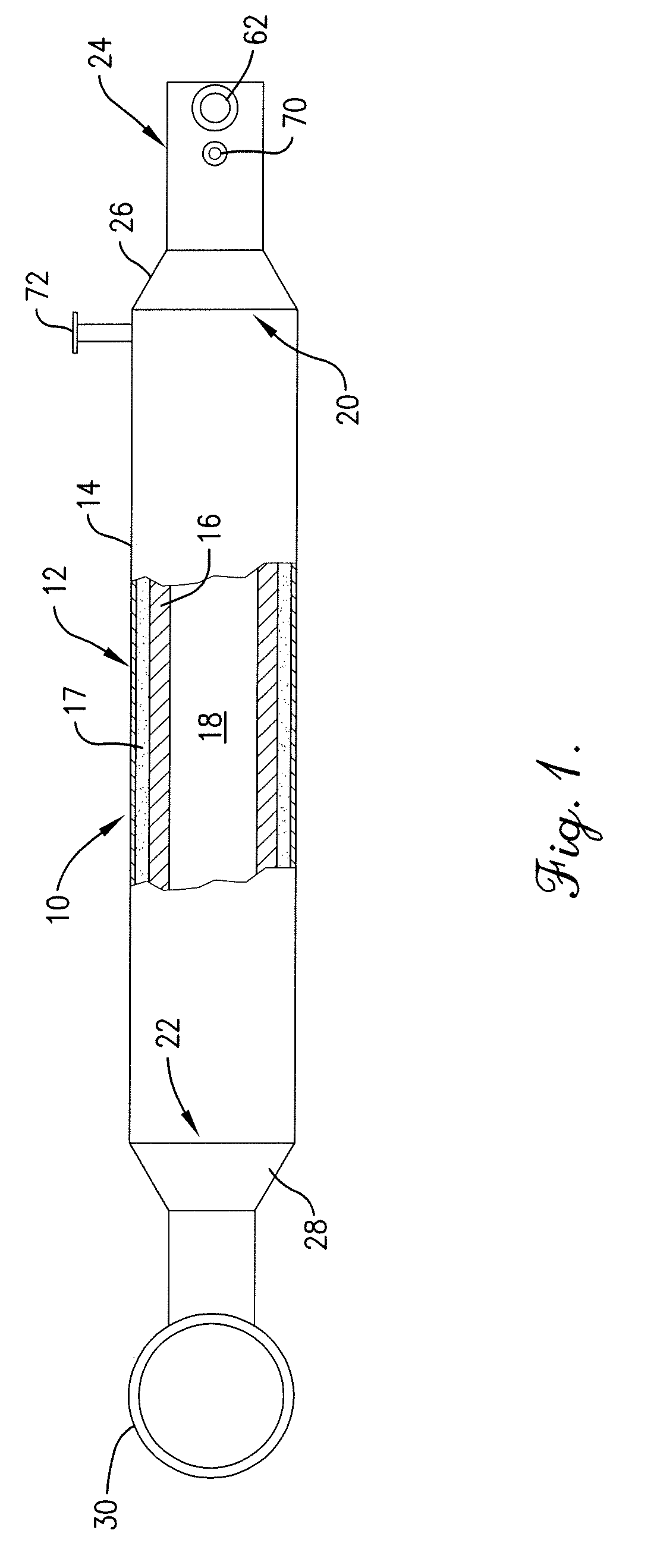

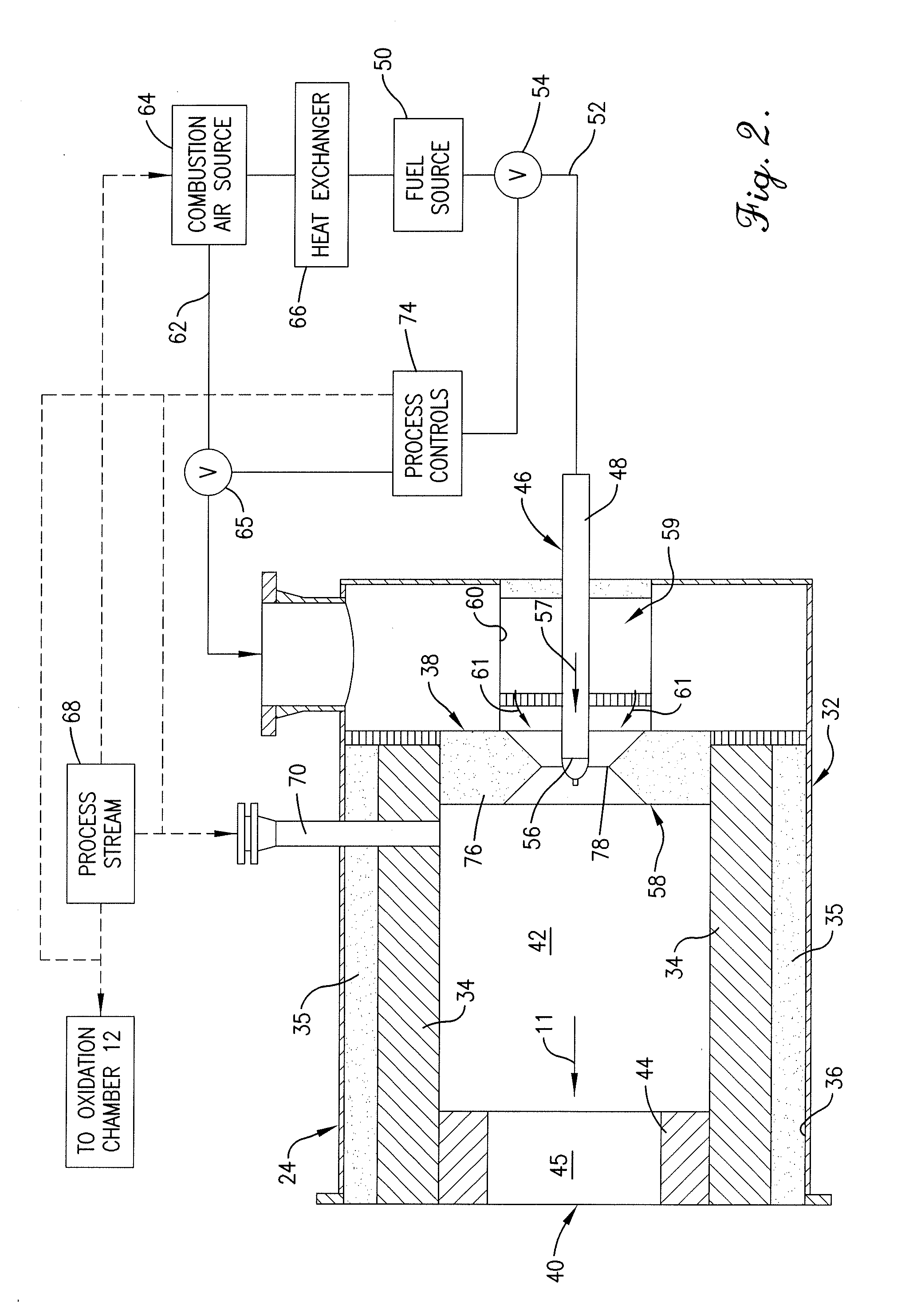

Flameless thermal oxidation method

A thermal oxidizer is provided in which off-gases in a process stream are thermally oxidized within substantially the entire interior volume of an oxidation chamber. The thermal oxidation is conducted without the presence of a flame or with only a minor portion of the fuel being combusted in a flame.

Owner:JOHN ZINK CO LLC

Process for converting tallow to diesel fuel

A process for thermally cracking virgin or waste animal oils (tallow) into a diesel fuel product is provided. The thermal cracking process uses low cracking temperatures from 625 to 725° F. with ambient pressure and no catalyst to generate a column distilled fraction of diesel fuel mixed with light ends, the light ends being flashed off to produce a high quality #2 diesel fuel suitable for road use. The oils to be distilled are exposed to a heat exchanger with a skin temperature of 1750° F. generated by hot air produced by a thermal oxidizer. This results in the processed product going from a liquid to a liguid / gas during the pump around residence time of 3 to 5 seconds before moving up a distillation column as a gas to the desired finished product.

Owner:G O E ENTERPRISES

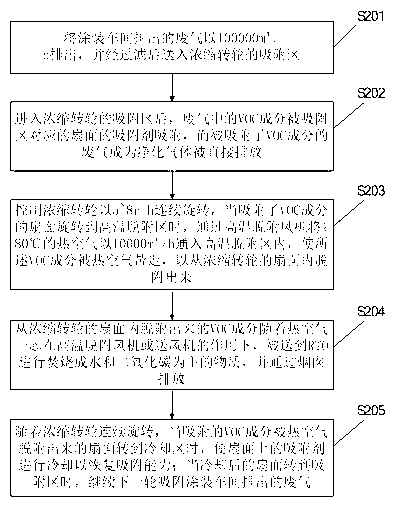

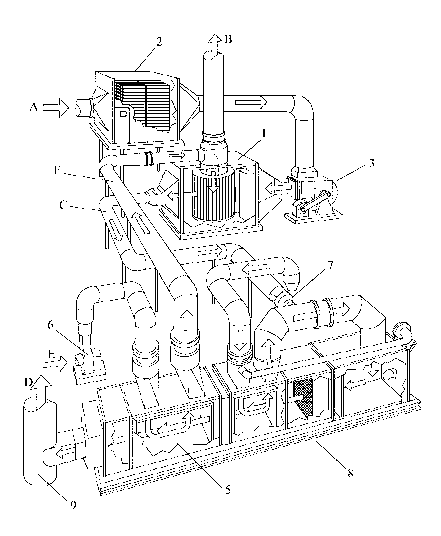

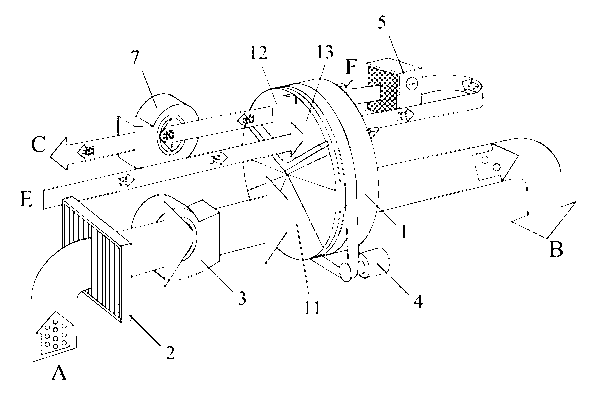

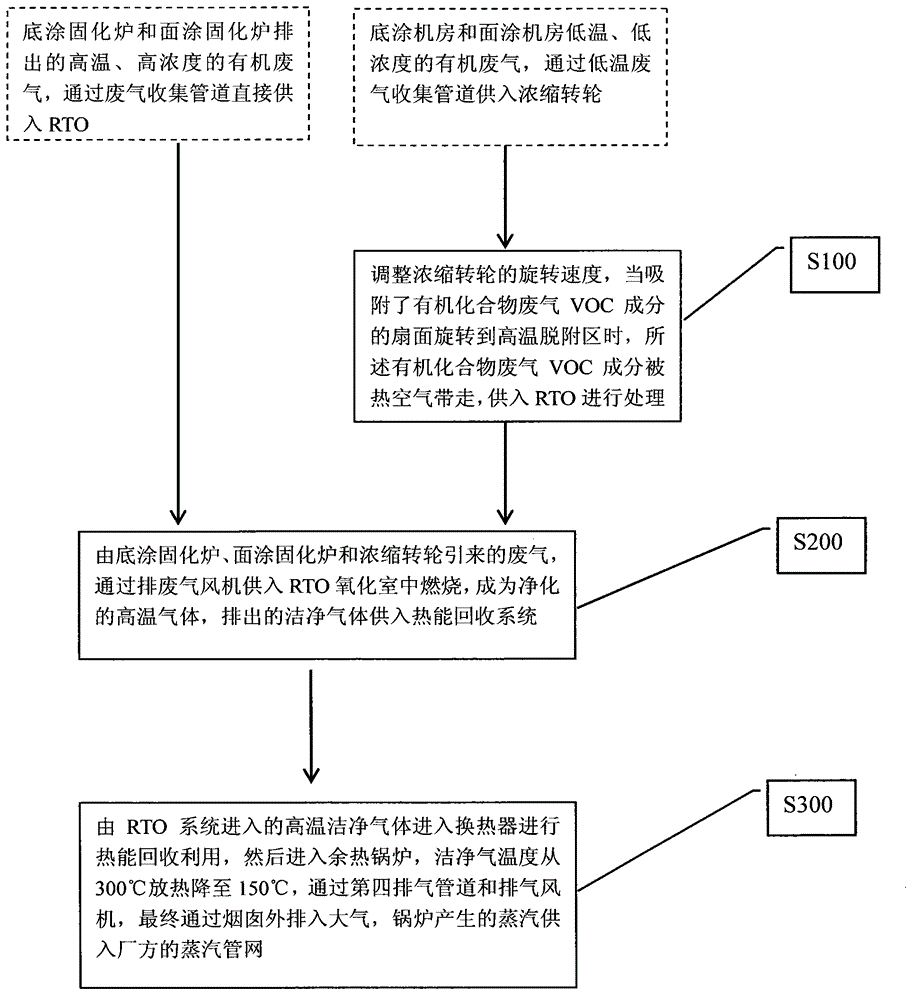

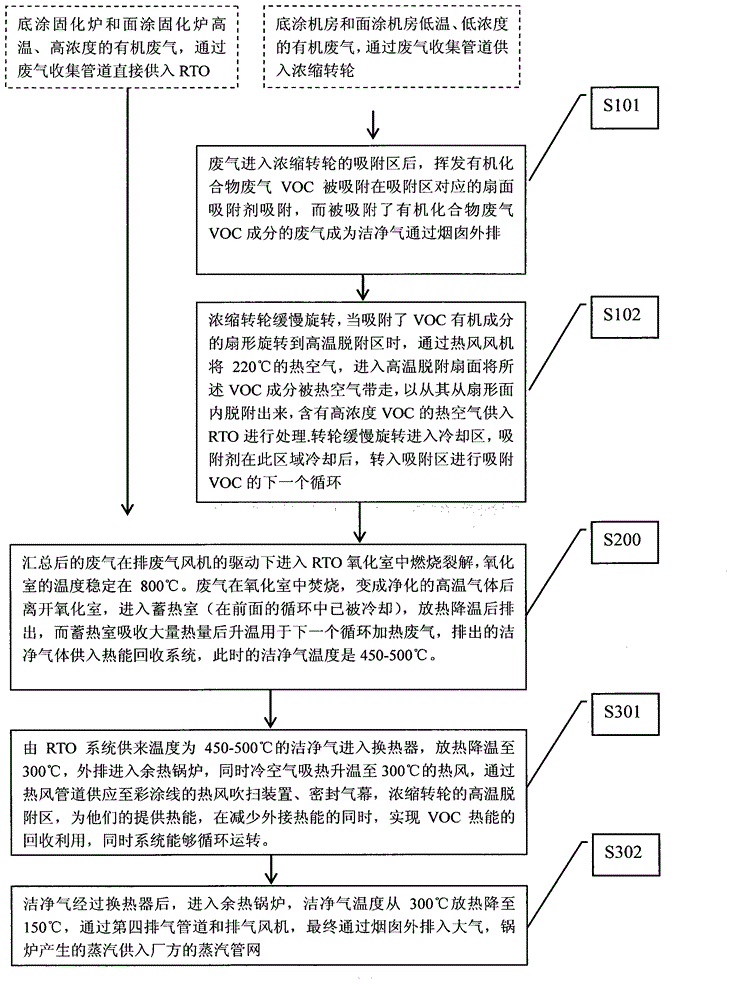

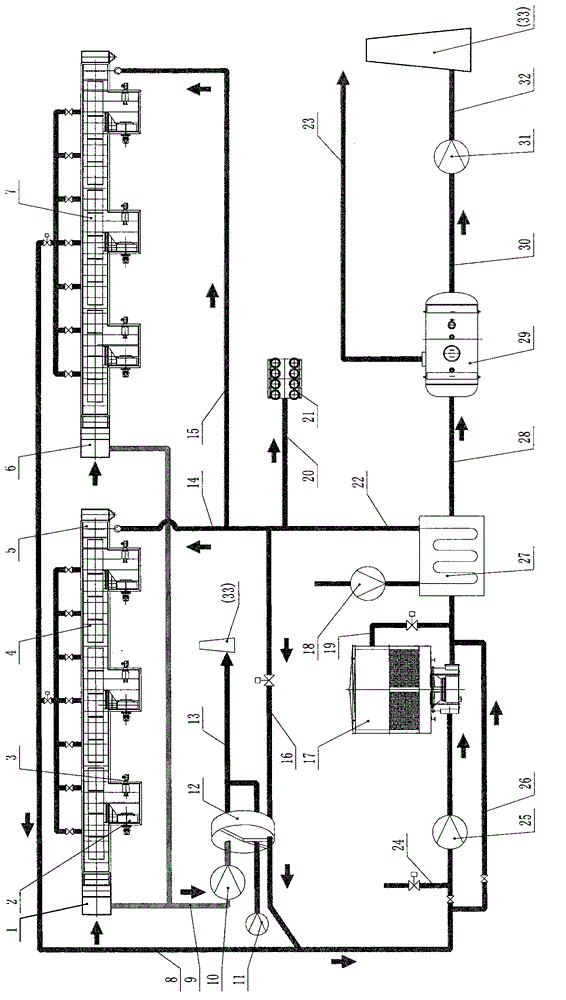

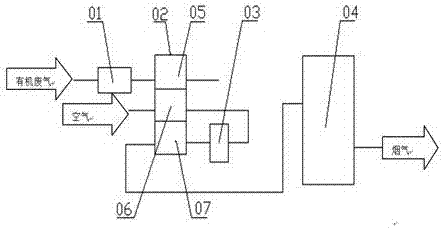

Waste gas treatment method and system of coating workshop based on concentrated runner and RTO (regenerative thermal oxidizer)

InactiveCN103007682AImprove processing efficiencyReduce the processing air volumeDispersed particle separationIncinerator apparatusOrganic solventSorbent

The invention discloses a waste gas treatment method of a coating workshop based on a concentrated runner and an RTO (regenerative thermal oxidizer), wherein the concentrated runner comprises at least one adsorption zone and a high-temperature desorption zone. The waste gas treatment method comprises the steps of feeding waste gas discharged from the coating workshop into the adsorption zone of the concentrated runner after filtering, adsorbing a VOC (volatile organic compound) ingredient in the waste gas by an adsorbent of a sector corresponding to the adsorption zone; controlling the concentrated runner to continuously rotate; when the sector with the adsorbed VOC ingredient rotates to the high-temperature desorption zone, desorbing the VOC ingredient by hot air inside the high-temperature desorption zone, and feeding to the RTO to burn and discharge along with the hot air. With the adoption of the waste gas treatment method and system, the processed air volume of organic waste gas entering the RTO can be effectively reduced; and the concentration of the organic solvent in the RTO organic waste gas is increased. Thus, the RTO treatment efficiency is improved and the operation cost is reduced. The invention further discloses a waste gas treatment system of the coating workshop based on the concentrated runner and the RTO.

Owner:北汽(广州)汽车有限公司

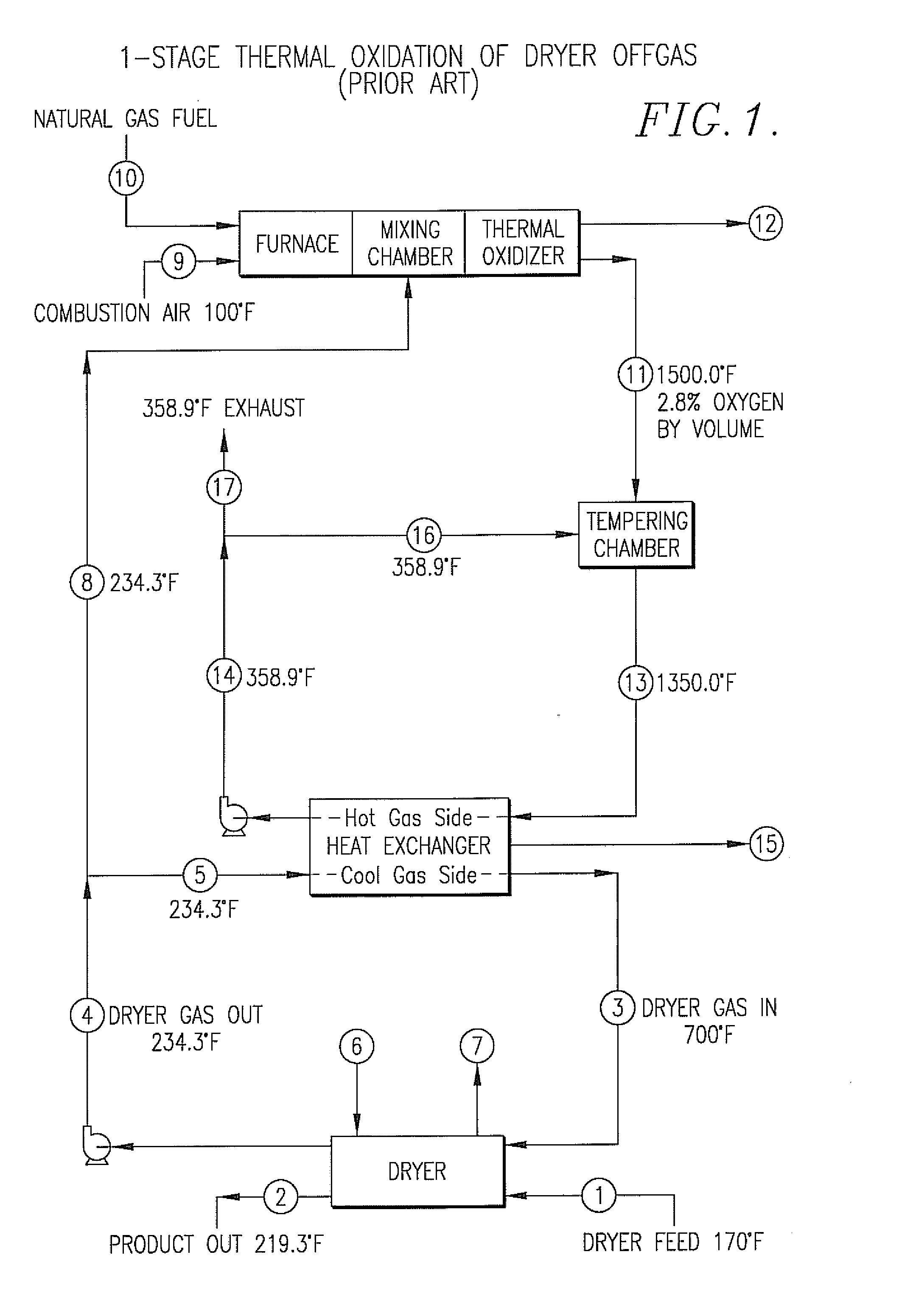

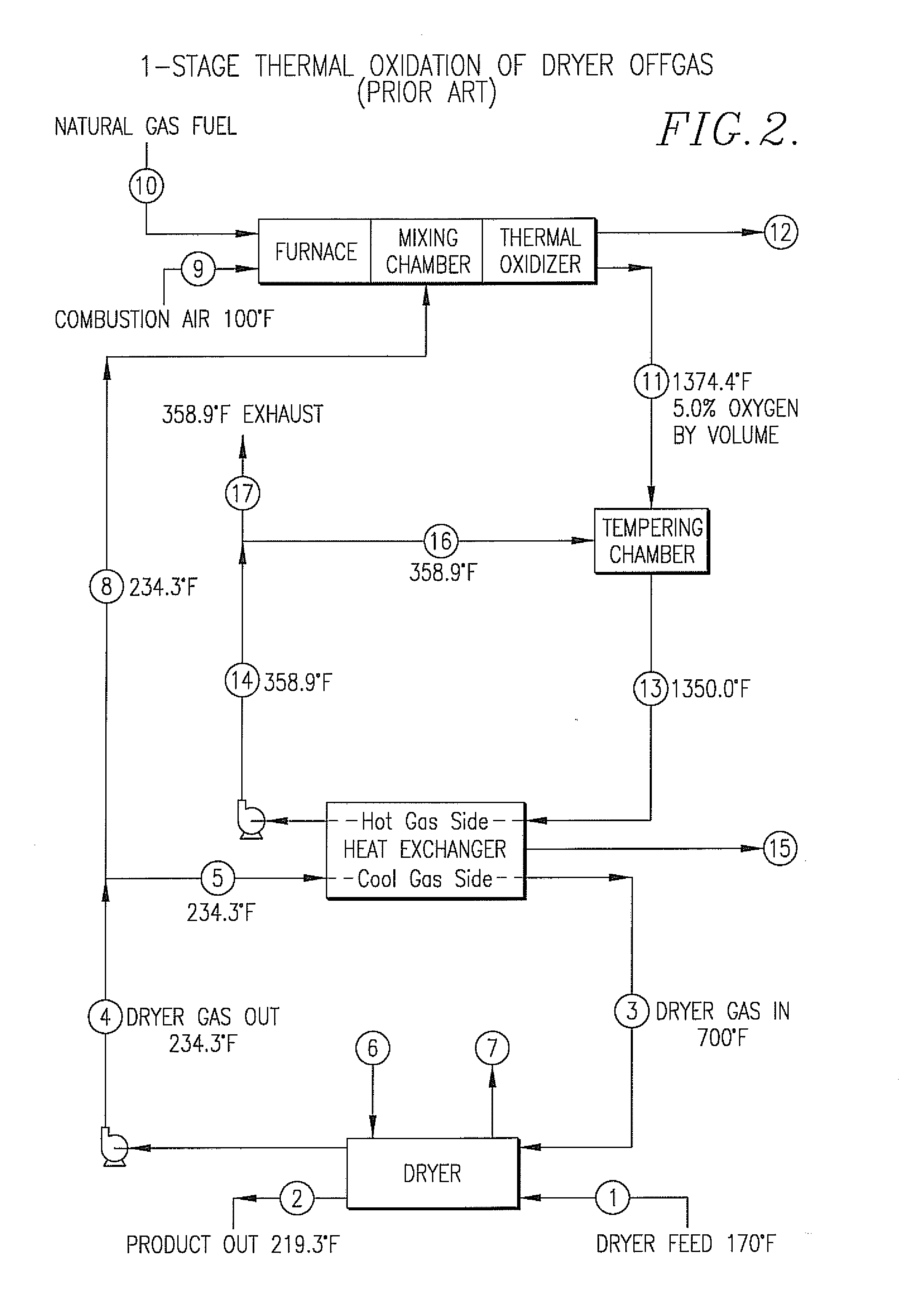

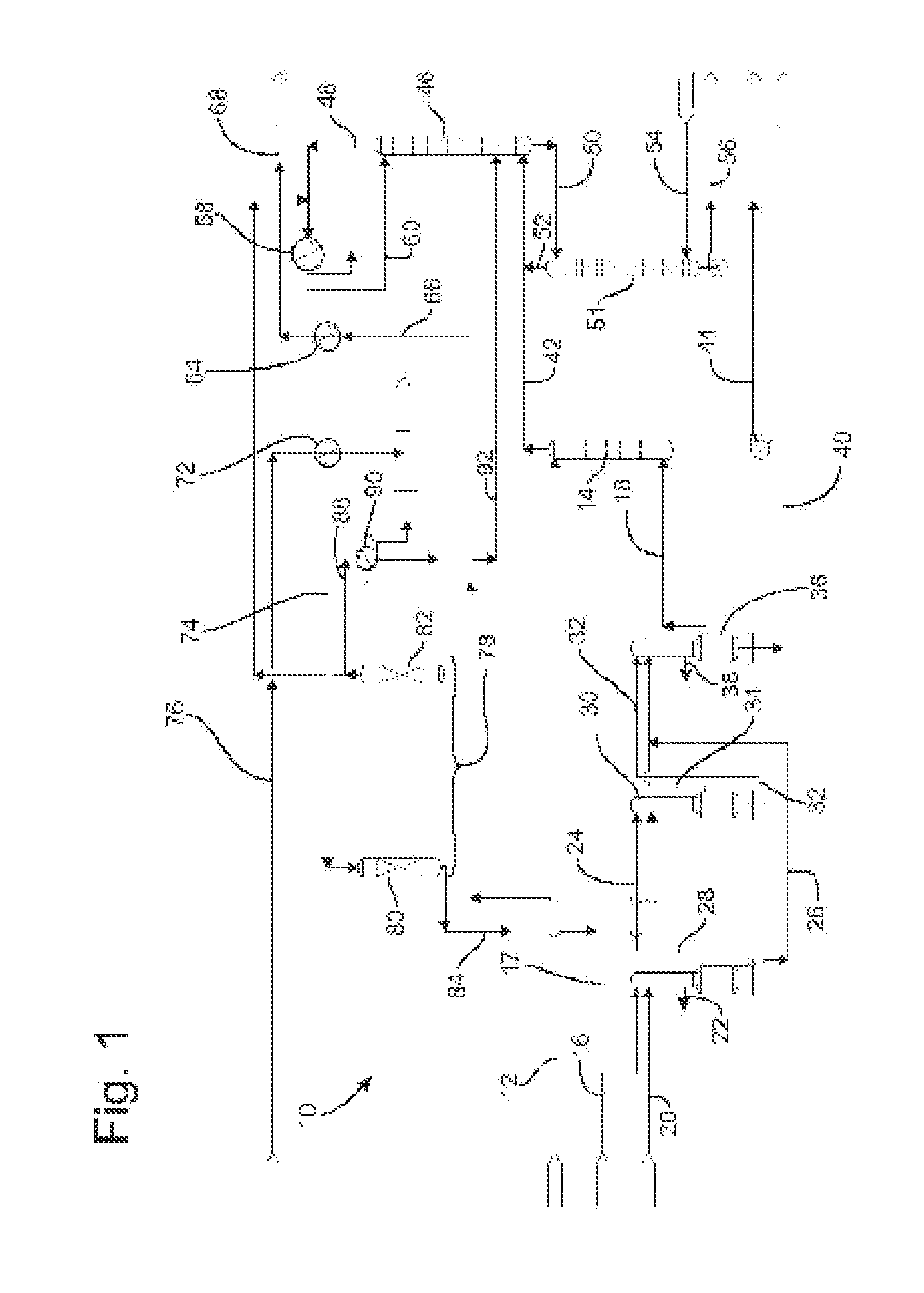

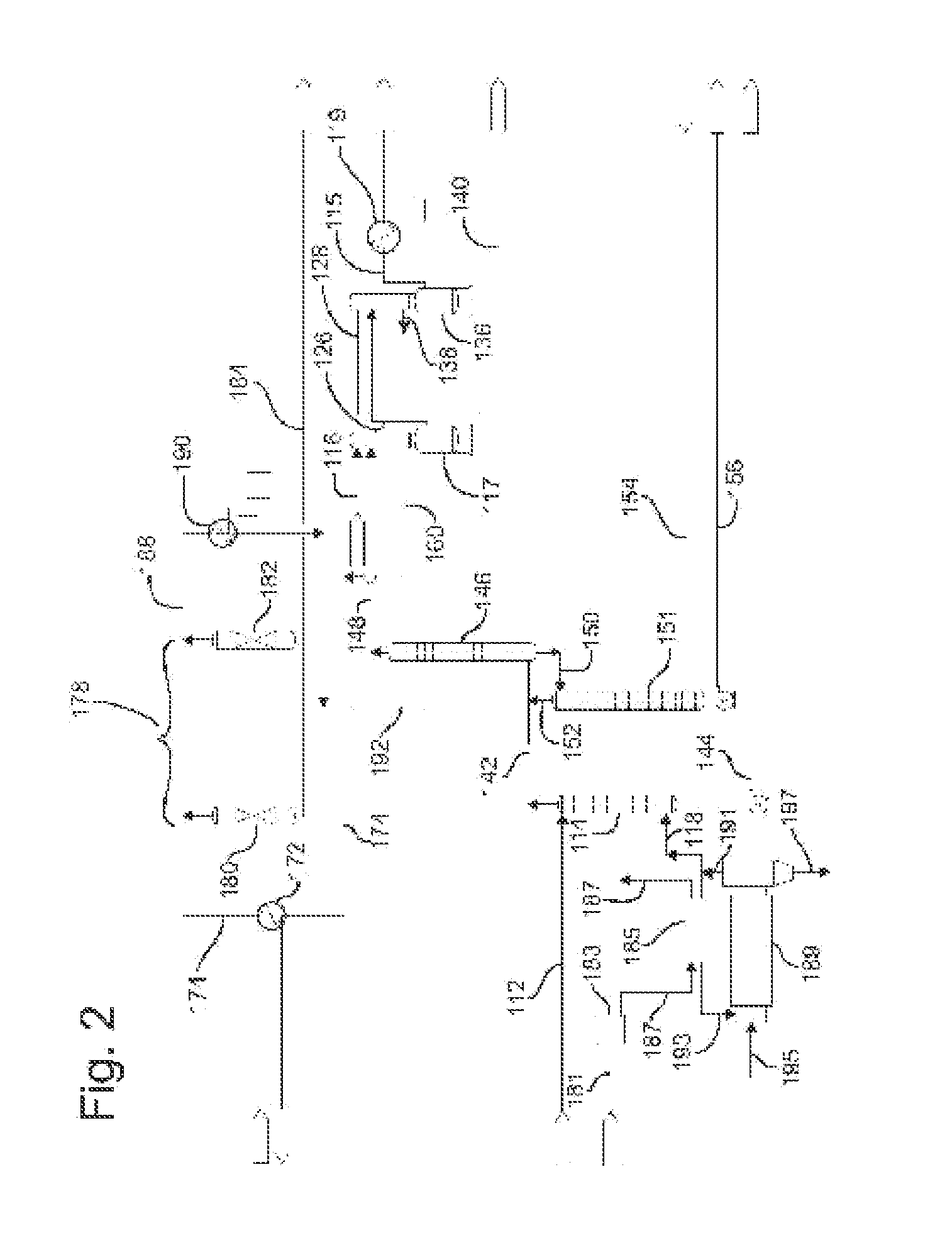

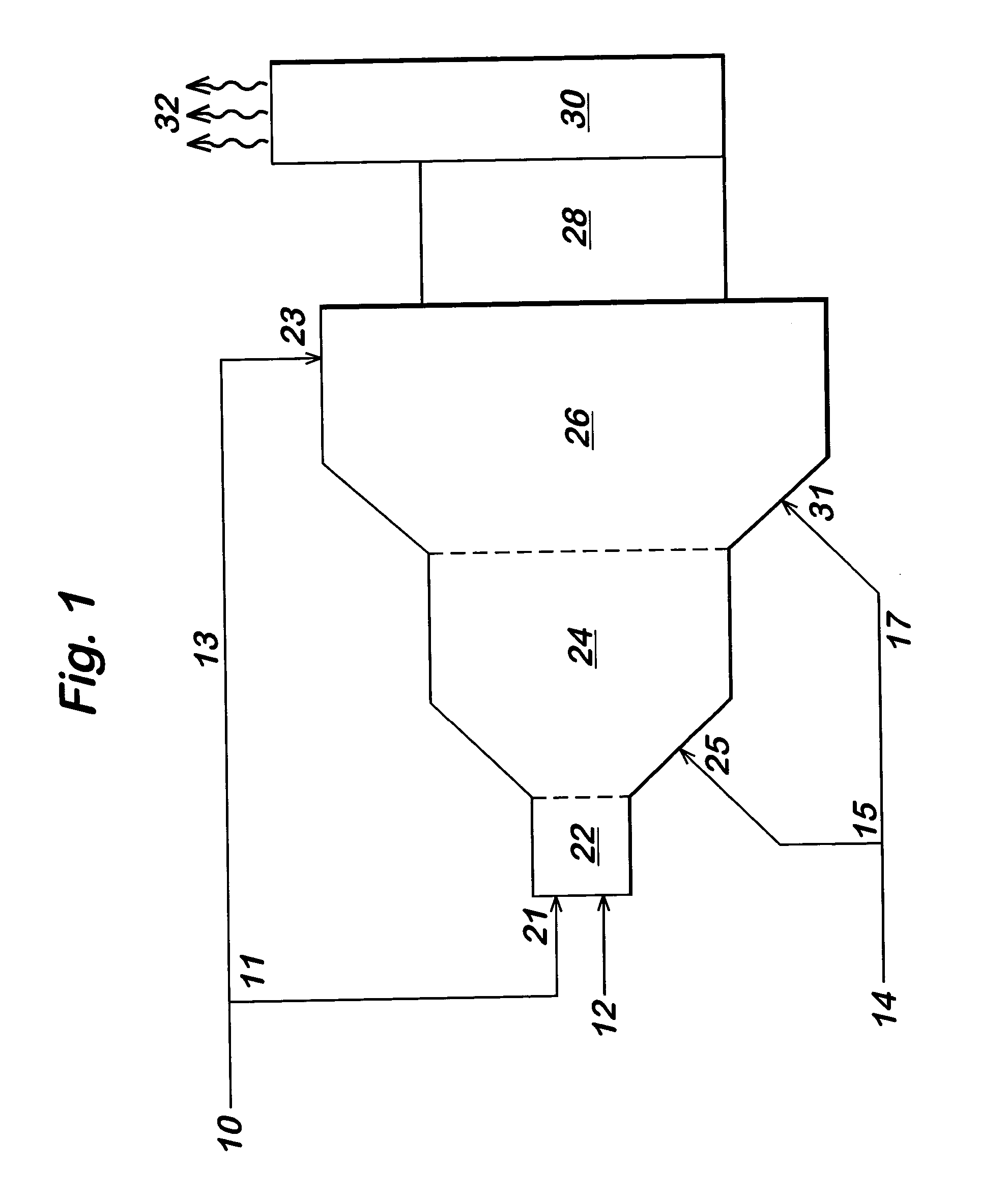

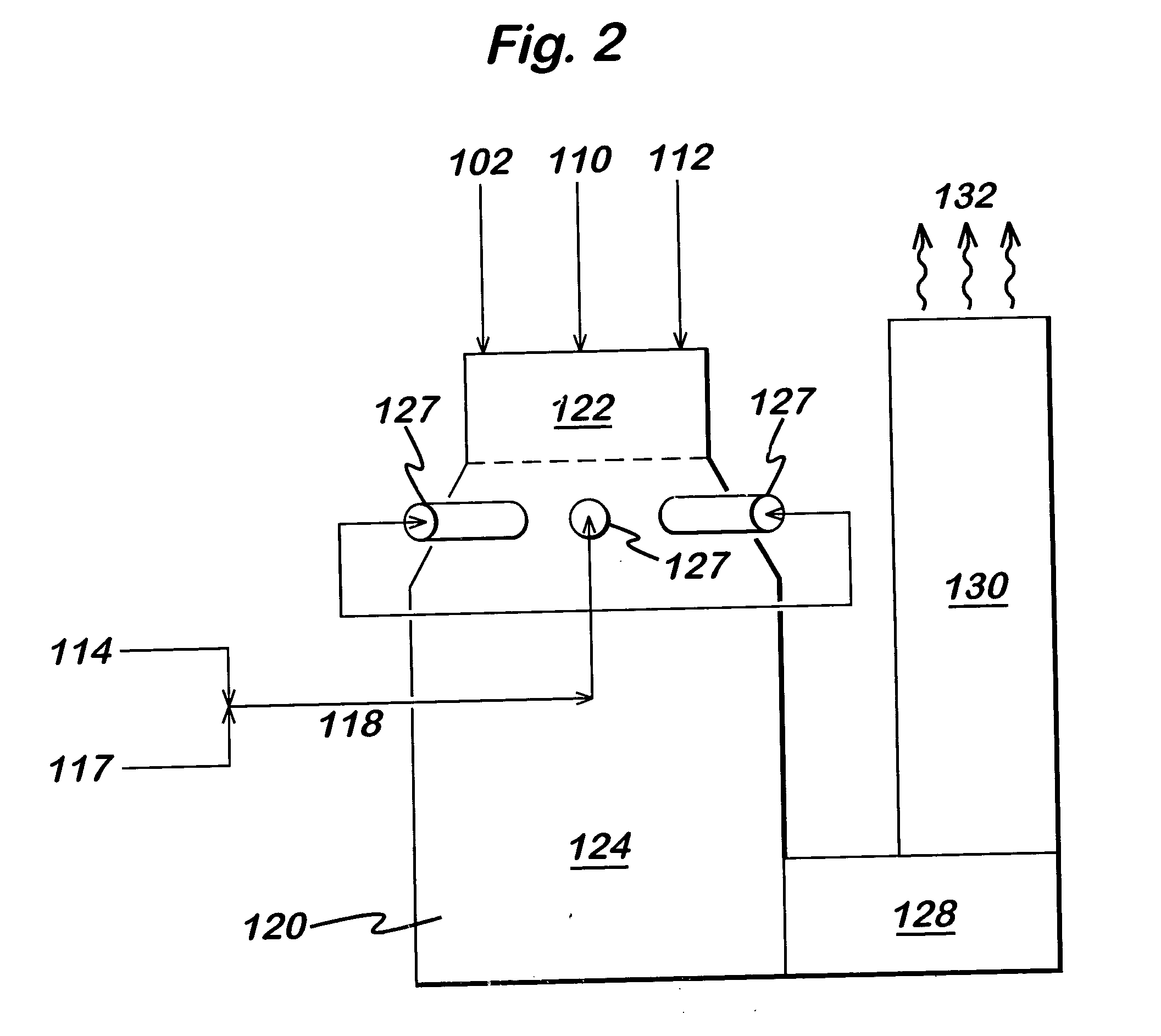

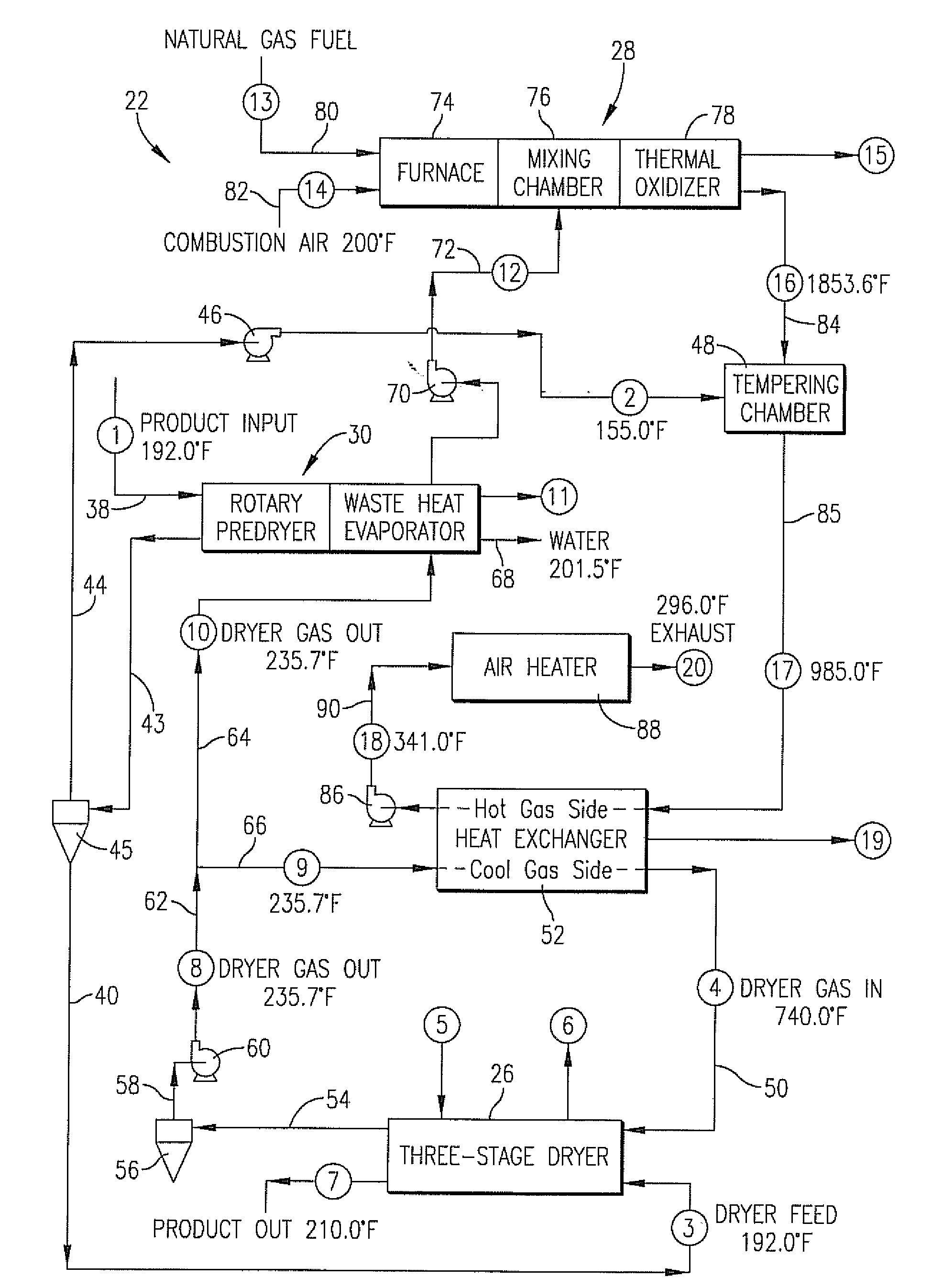

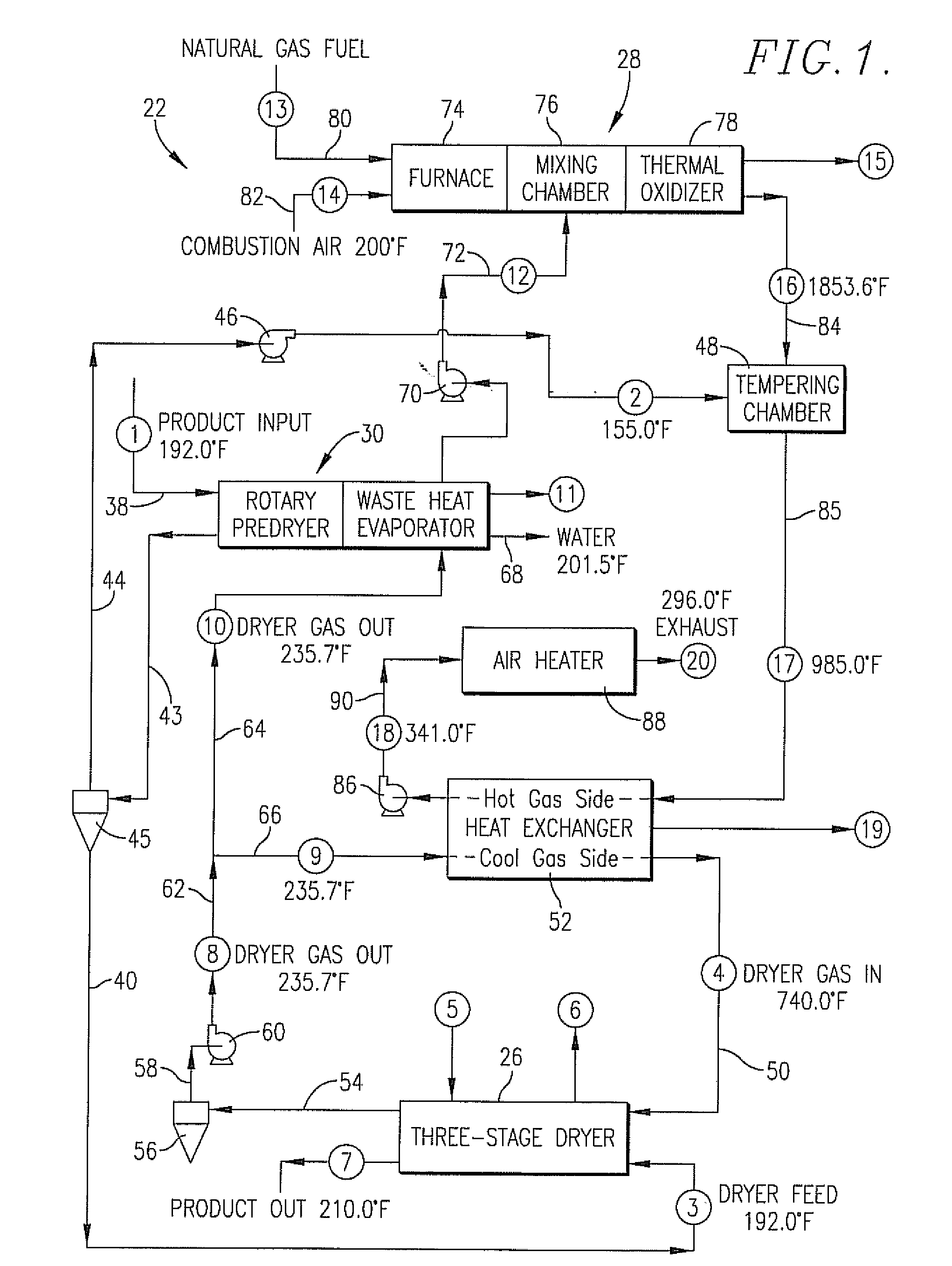

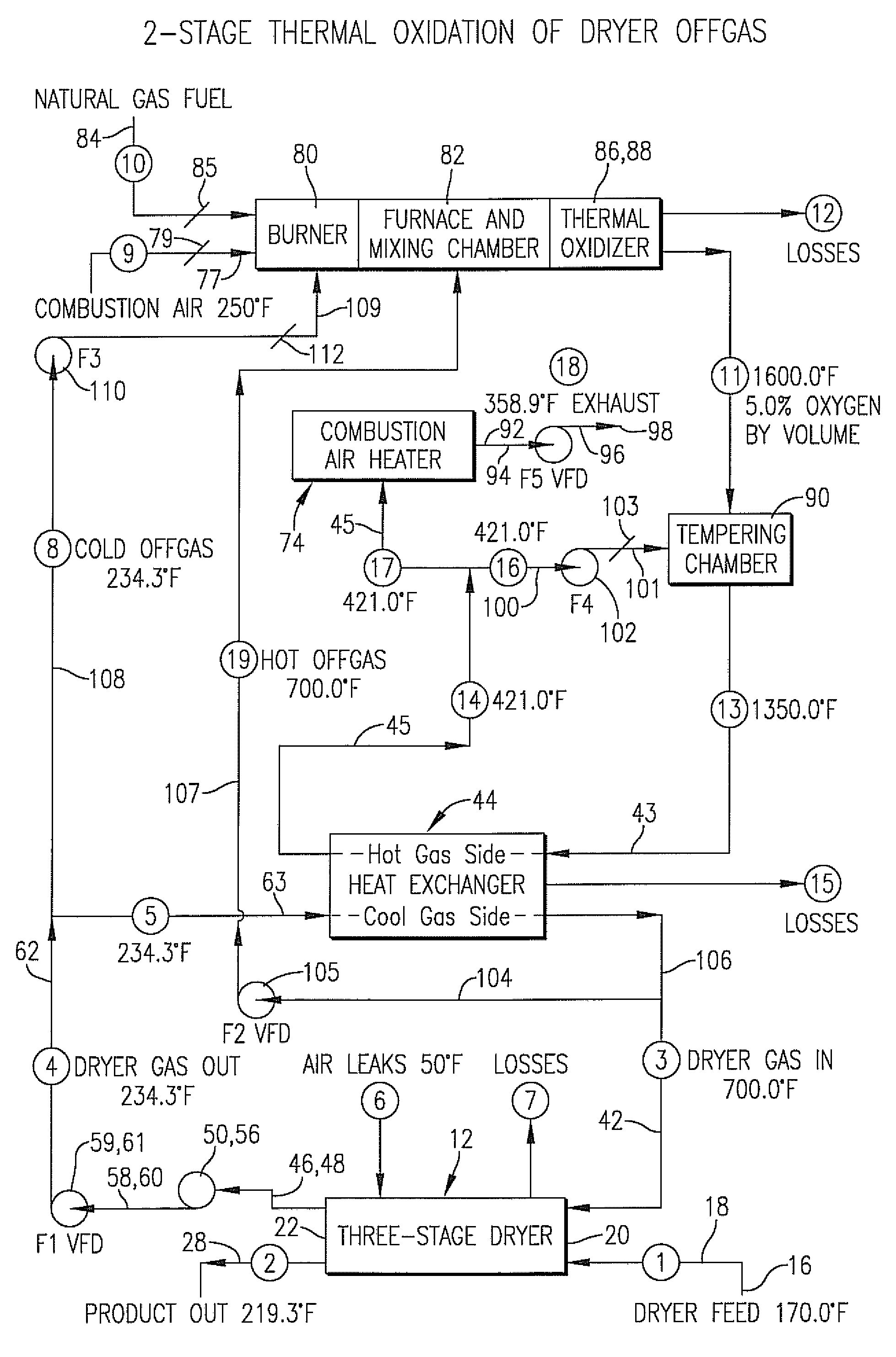

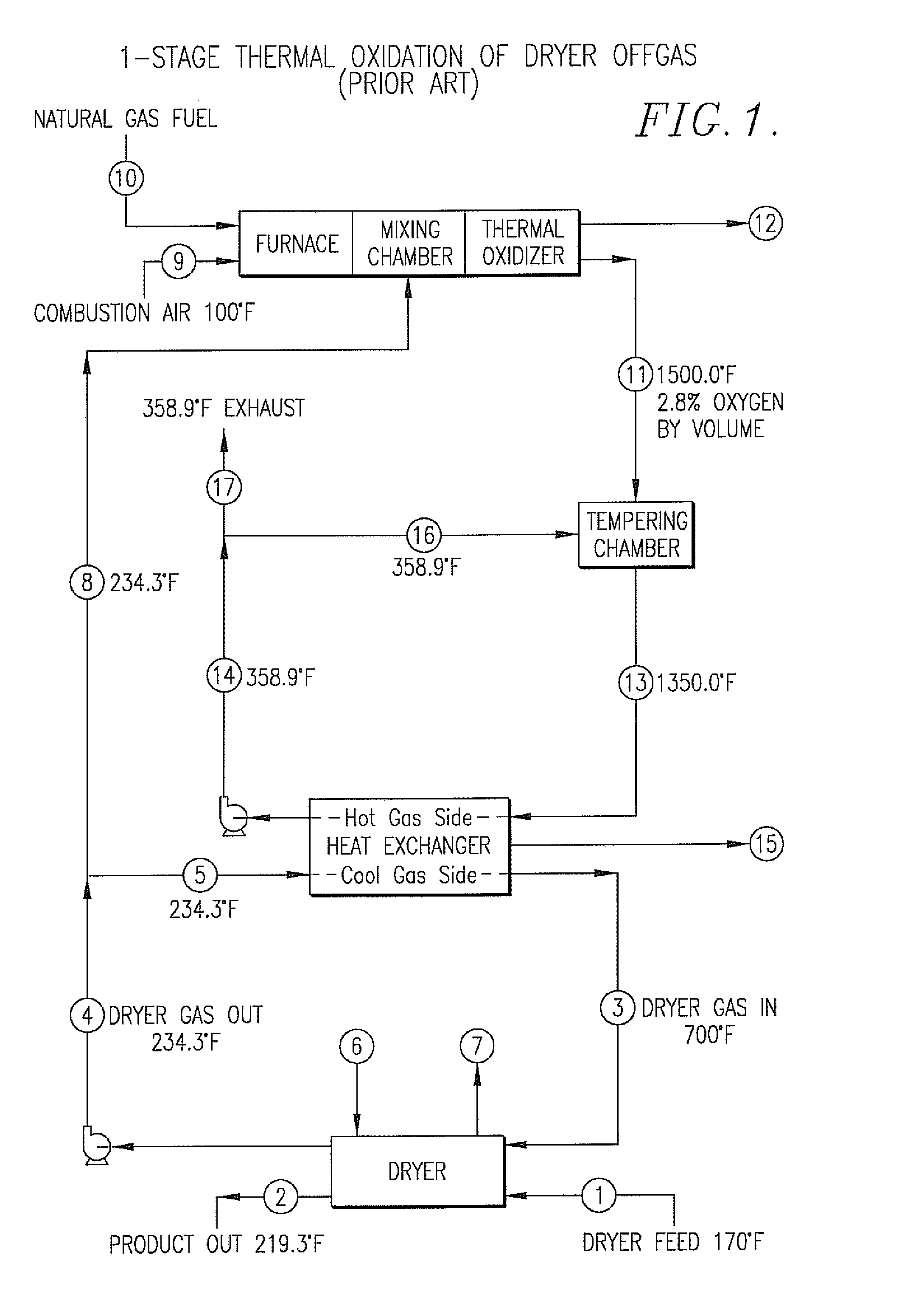

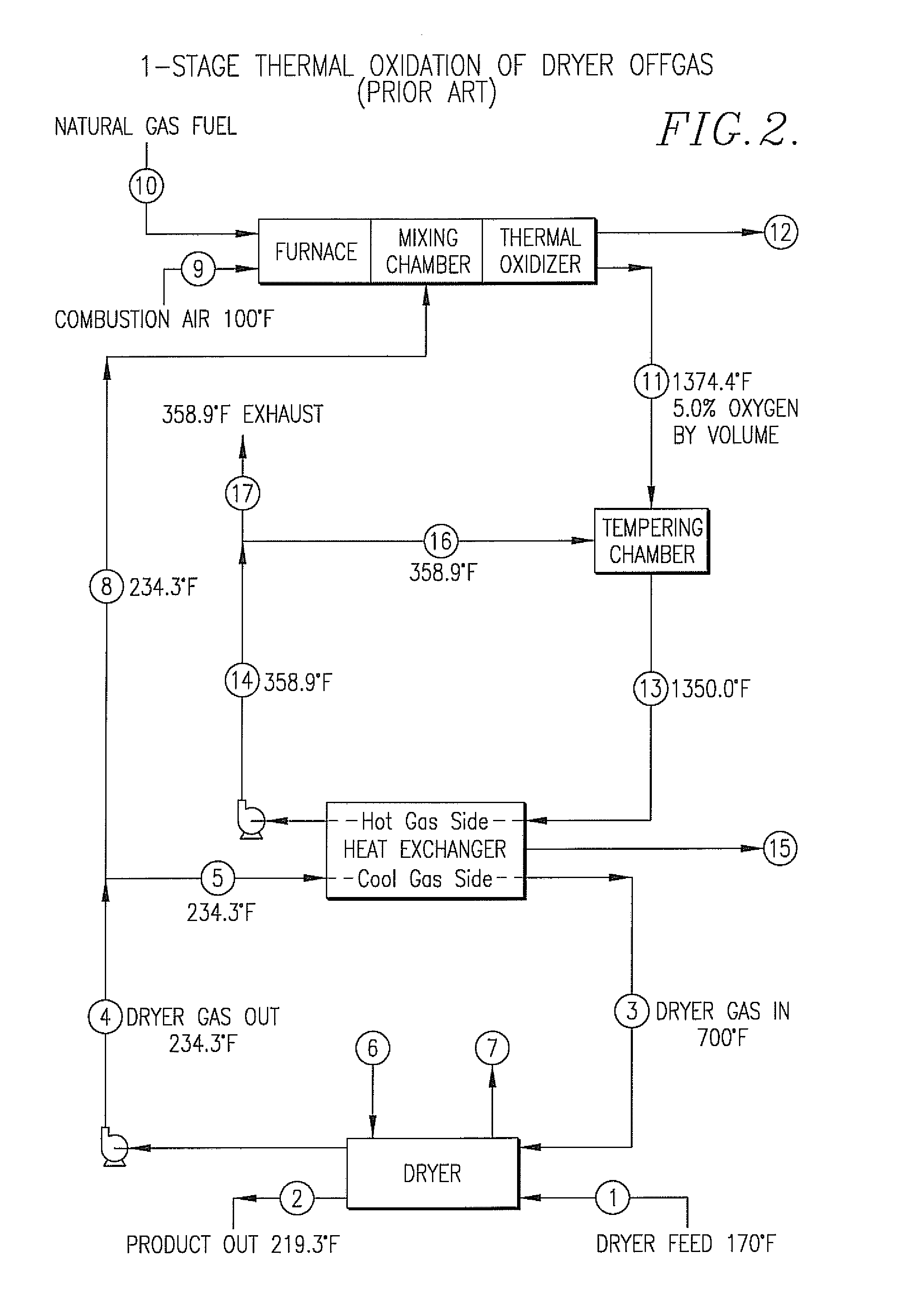

Two-stage thermal oxidation of dryer offgas

ActiveUS20080222913A1Increase temperatureReduce the temperatureDrying solid materials with heatDrying gas arrangementsAtmospheric airOxygen

A method and apparatus are provided for reducing the VOC, CO, and, alternatively, the NOx content of dryer offgas that is discharged into the atmosphere from a moist organic product drying process using thermal oxidizing apparatus that includes a burner, furnace, mixing chamber, thermal oxidizer, tempering chamber, and an indirect gas-to-gas heat exchanger. The dryer offgas is separated into two portions, with a larger portion being preheated by indirect heat exchange with the hot gaseous output from the thermal oxidizer. The non-preheated portion is directed to the burner in the function of flue gas recycle for NOx control. The preheated portion is separated into two portions, with one portion being directed to the furnace / mixing chamber of the thermal oxidizing apparatus. The other portion of the preheated offgas is recycled to the hot gas inlet of the dryer and serves the function of dryer heat transfer media. Ultimately, all the dryer offgas enters the thermal oxidizer, and comprises a smaller non-preheated portion directed to the burner and a larger preheated portion directed to the furnace / mixing chamber. By preheating a large proportion of the offgas directed to the thermal oxidizing apparatus, simultaneous achievement of an adequate thermal oxidizer temperature, 1600° F., and an adequate oxygen concentration of 5% by volume is achieved for optimized thermal oxidation of carbon monoxide and volatile organic compounds.

Owner:AEROGLIDE

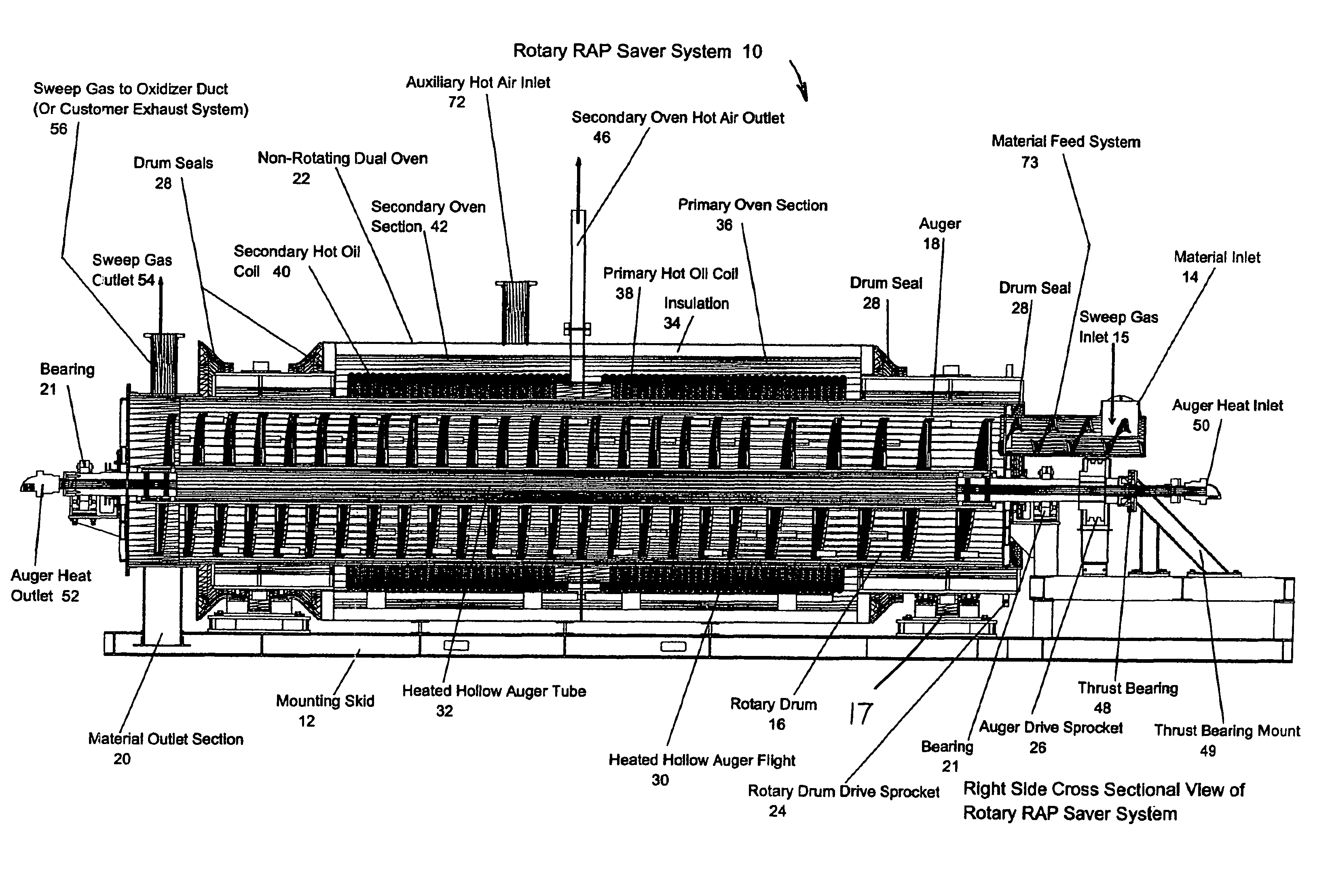

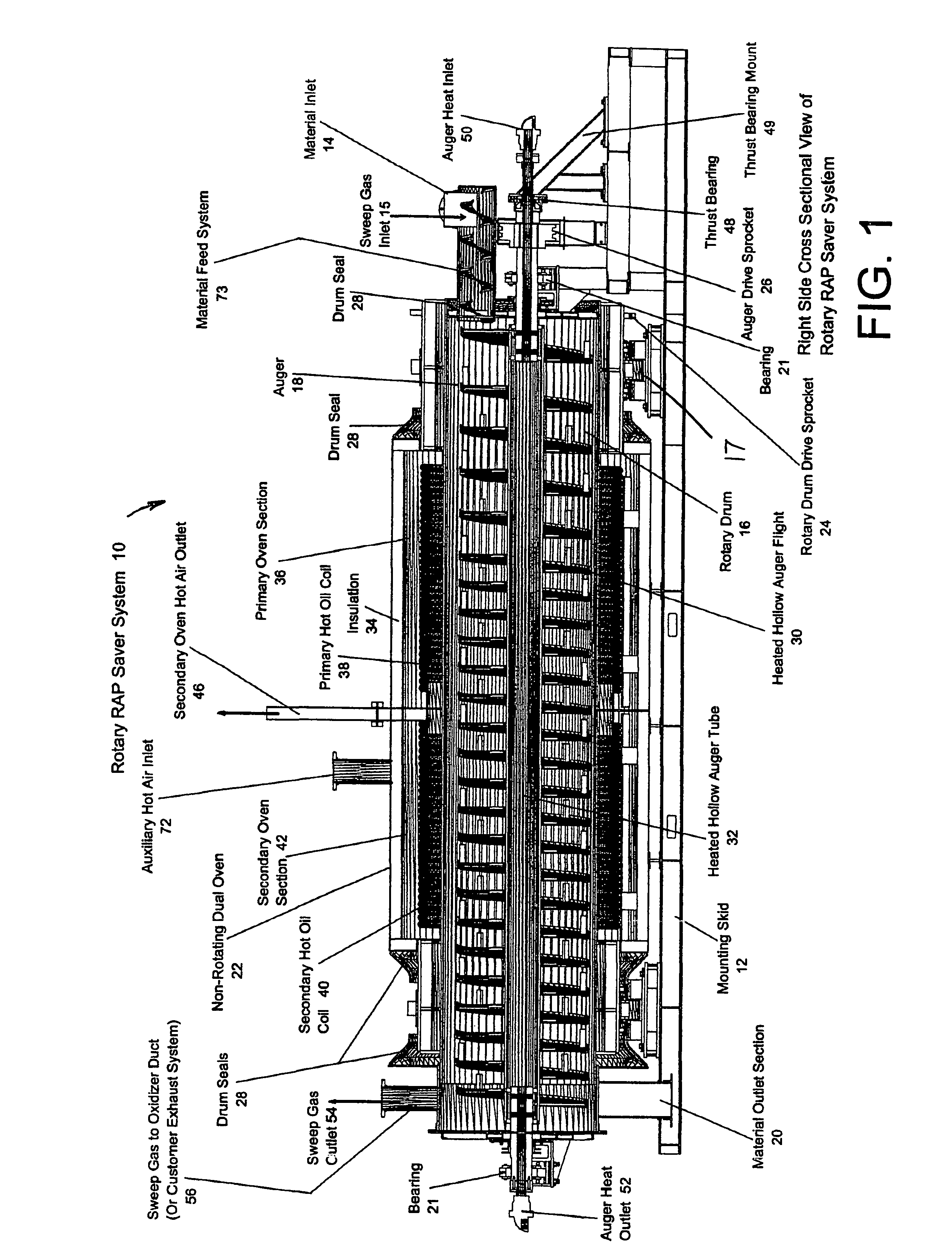

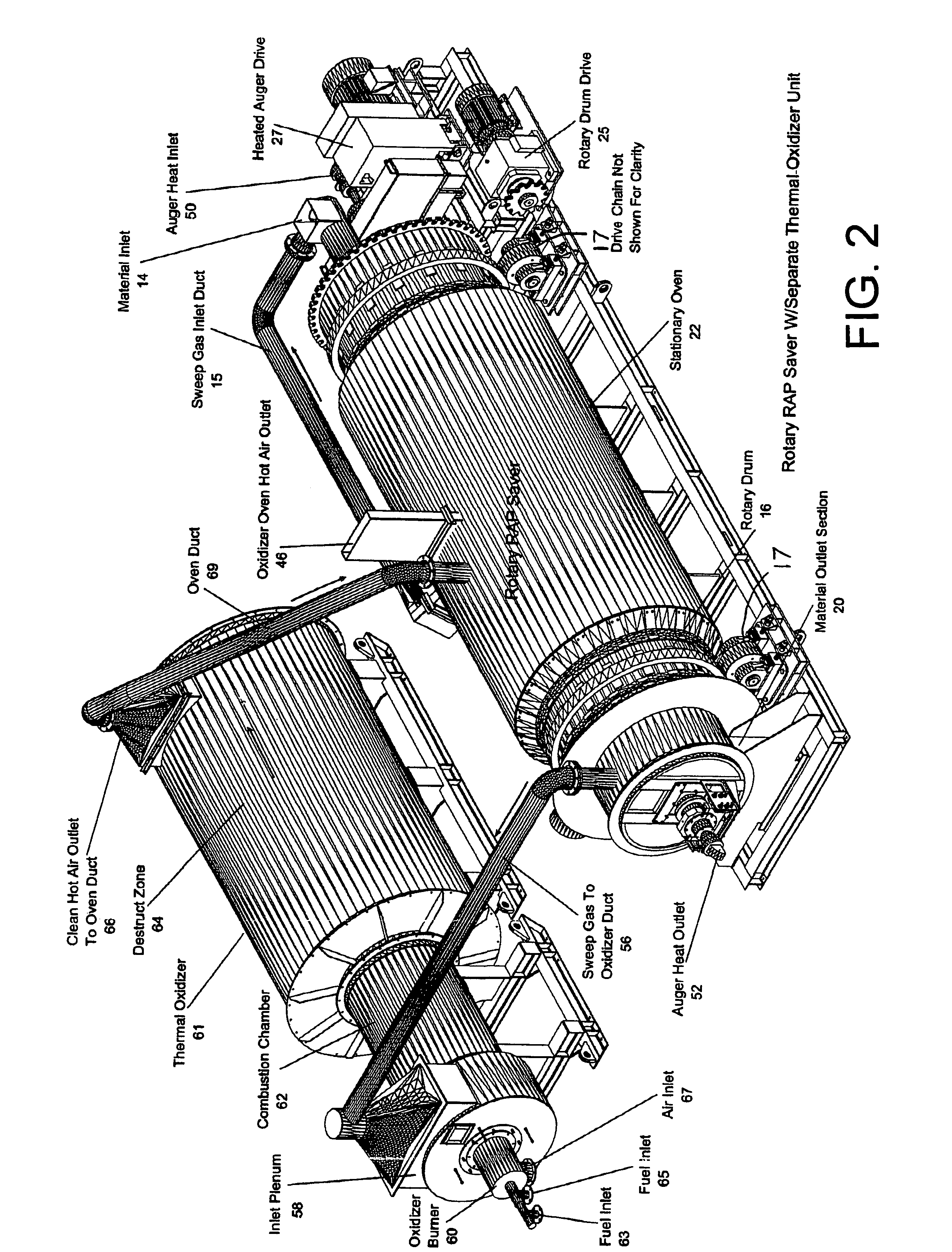

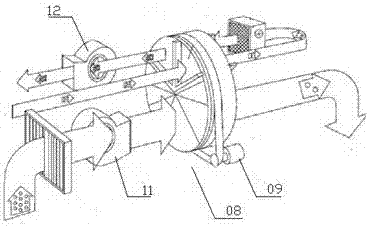

Rotary thermal recycling system

InactiveUS7993048B1Slow gradual elevationRotary drum furnacesCharge manipulationEngineeringMechanical engineering

A Rotary thermal processor for particulate materials has a rotating drum and a rotating hollow auger. A stationary cylindrical oven with stationary coils surrounds the rotating drum. Hot gas heats a first part of the oven, coil and drum. A rotating hollow auger is heated with hot fluid from the coils. Oven exhaust sweeps evaporated and volatized components of the treated materials to separators and a thermal oxidizer. Cleaned gas from the thermal oxidizer heats a second part of the oven coil and drum and exits a stack. The rotating drum and auger lifts and turns the treated material as it is advanced by the auger.

Owner:COLLETTE JERRY R +1

Use of superheated steam dryers in an alcohol distillation plant

InactiveUS20110108409A1Efficient use of energyLow costFermented solutions distillation/rectificationUsing liquid separation agentAlcohol productionFractionating column

The present invention is for the production of fuel grade alcohol, specifically ethanol. A steam dryer is used to dry the solid byproduct into usable animal feed. The steam dryer typically contains less than 6% air in its exhaust stream is directed to the bottoms of one or more distillation columns to heat the distillation column and scrub the exhaust stream simultaneously. The elimination of a thermal oxidizer and the efficient use of the energy in the exhaust stream provide considerable cost savings for an alcohol production plant.

Owner:BROWN CHRISTOPHER J

Method for preparing environment-friendly honeycomb ceramic heat accumulator by use of waste slag

InactiveCN103992099AImprove microstructureSolve the problem of high brittlenessBreaking strengthProcess equipment

The invention discloses a method for preparing an environment-friendly honeycomb ceramic heat accumulator by use of waste slag. On the basis of introducing a great quantity of waste slag and optimizing the traditional process, the new sintering method and technology are applied to the traditional ceramic product, the dry-process equipment is adopted, and one-time formation and two-time laser short-time sintering are realized. The environment-friendly honeycomb ceramic heat accumulator provided by the invention is produced in a clean and pollution-free manner, and the product has the production advantages of high strength, good thermal shock resistance, low processing energy consumption, short production period and cleanness and no pollution. The breaking strength of the honeycomb ceramic heat accumulator is 35-42MPa, the true density is 2.2-2.4g / cm<3>, the water absorption is 0.2-0.9%, the operating temperature is 1,000-1,250 DEG C, and the requirements for the performance of a heat accumulation material in a regenerative thermal oxidizer (RTO) device can be met.

Owner:SHAANXI UNIV OF SCI & TECH

Method for reducing waste oxide gas emissions in industrial processes

InactiveUS20040093860A1Maximizes residence timeImprove destruction efficiencyExhaust apparatusDispersed particle separationEnvironmental engineeringGas emissions

The method of the present invention reduces the emissions of waste oxide gas produced within a thermal oxidizer by the use of a multizone waste thermal oxidizer, comprising at least one primary combustion zone and at least one downstream waste destruction zone. By performing the primary combustion of fuel prior to the destruction of at least a portion of the waste, it has been discovered that NOx emissions from the waste destruction process can be reduced economically and without significant loss of overall waste destruction efficiency.

Owner:DECOURCY MICHAEL STANLEY +2

Color-coating line waste gas treatment and heat recovery method and system based on concentration rotating wheels and RTO (regenerative thermal oxidizer)

InactiveCN104474844ASave energyReduce spendingDispersed particle separationIncinerator apparatusThermal energyHigh concentration

The invention relates to a color-coating line waste gas treatment and heat recovery method and system based on concentration rotating wheels and RTO (regenerative thermal oxidizer). The method comprises the following steps: low-temperature low concentration volatile organic compound waste gas discharged from a base coating machine room and top coating machine room is sent into an adsorption zone of the concentration rotating wheels through a low-temperature waste gas collection pipeline, so that the volatile organic compound waste gas is adsorbed by the adsorbent in the adsorption zone; high-temperature high-concentration volatile organic compound waste gas discharged by a base coating curing oven and a top coating curing oven is sent into a heat storage incinerator through a high-temperature waste gas collection pipeline; hot air mixed gas desorbed from the high-temperature waste gas collection pipeline and the high-temperature desorption zone of the concentration rotating wheels is sent into a heat storage incinerator oxidizing chamber to be combusted; and the discharged high-temperature clean gas is sent into a heat recovery system. Due to the adoption of the heat recovery system, the reheating of the concentration rotating wheels only needs to consume the heat quantity of the heat recovery system without additional heating, thereby saving abundant energy and making contribution to energy saving and emission reduction for the country. The invention also relates to a color-coating line waste gas treatment and heat recovery system based on concentration rotating wheels and RTO.

Owner:北京邦信天硕工程技术有限公司

High-temp alkali-resistant material and use therreof in ceramic filler

A high-temp. alkali-resistant material mainly contains MgO, SiO2 and Al2O3. Its primary crystal phase is forsterite and spinel. Its features are high resistance to alkali corrosion at high temp and use for preparing ceramic filler of heat-accumulating thermal oxidizer to treat organic waste gas in wood industry.

Owner:兰州瑞玛化机有限公司 +1

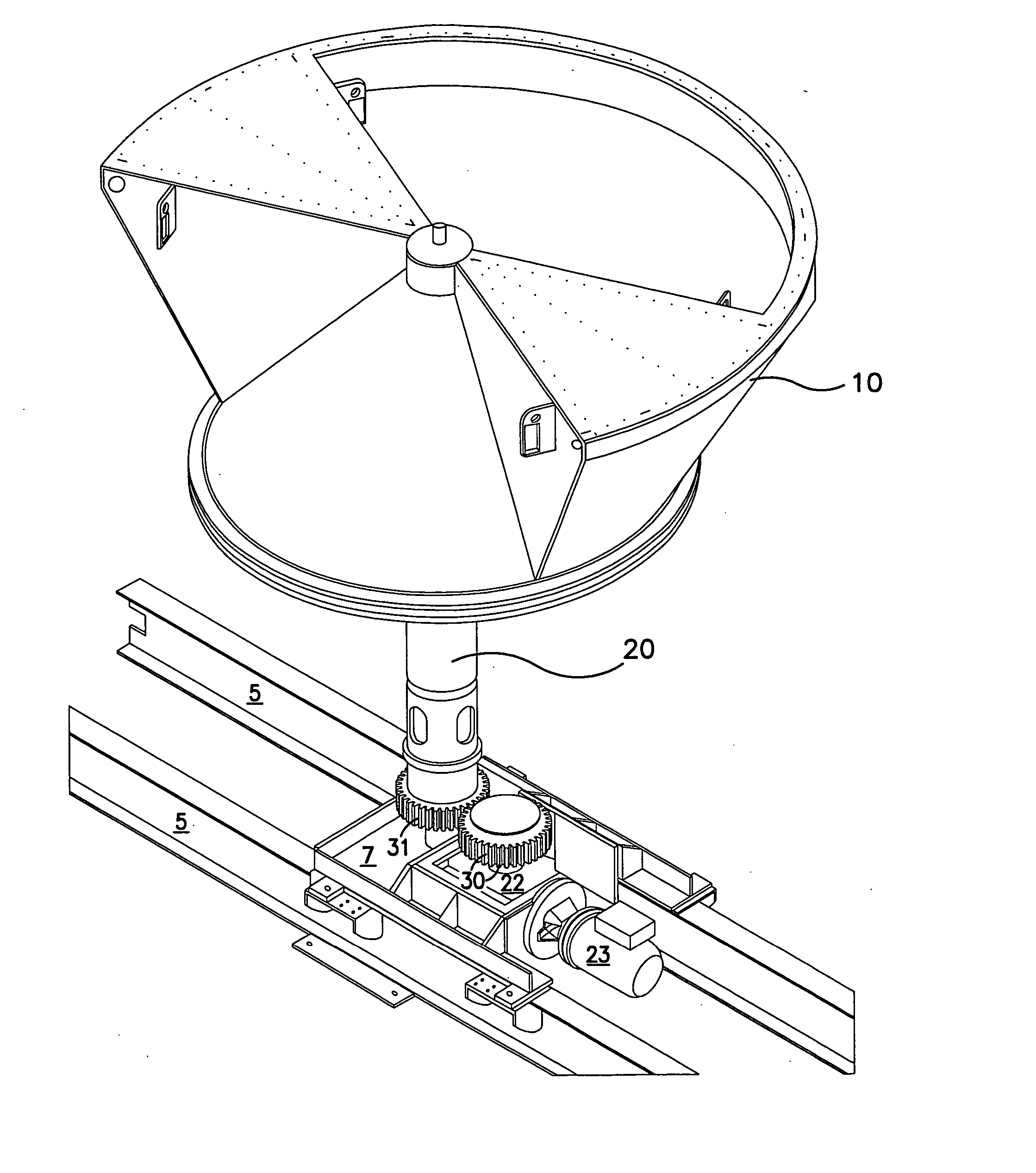

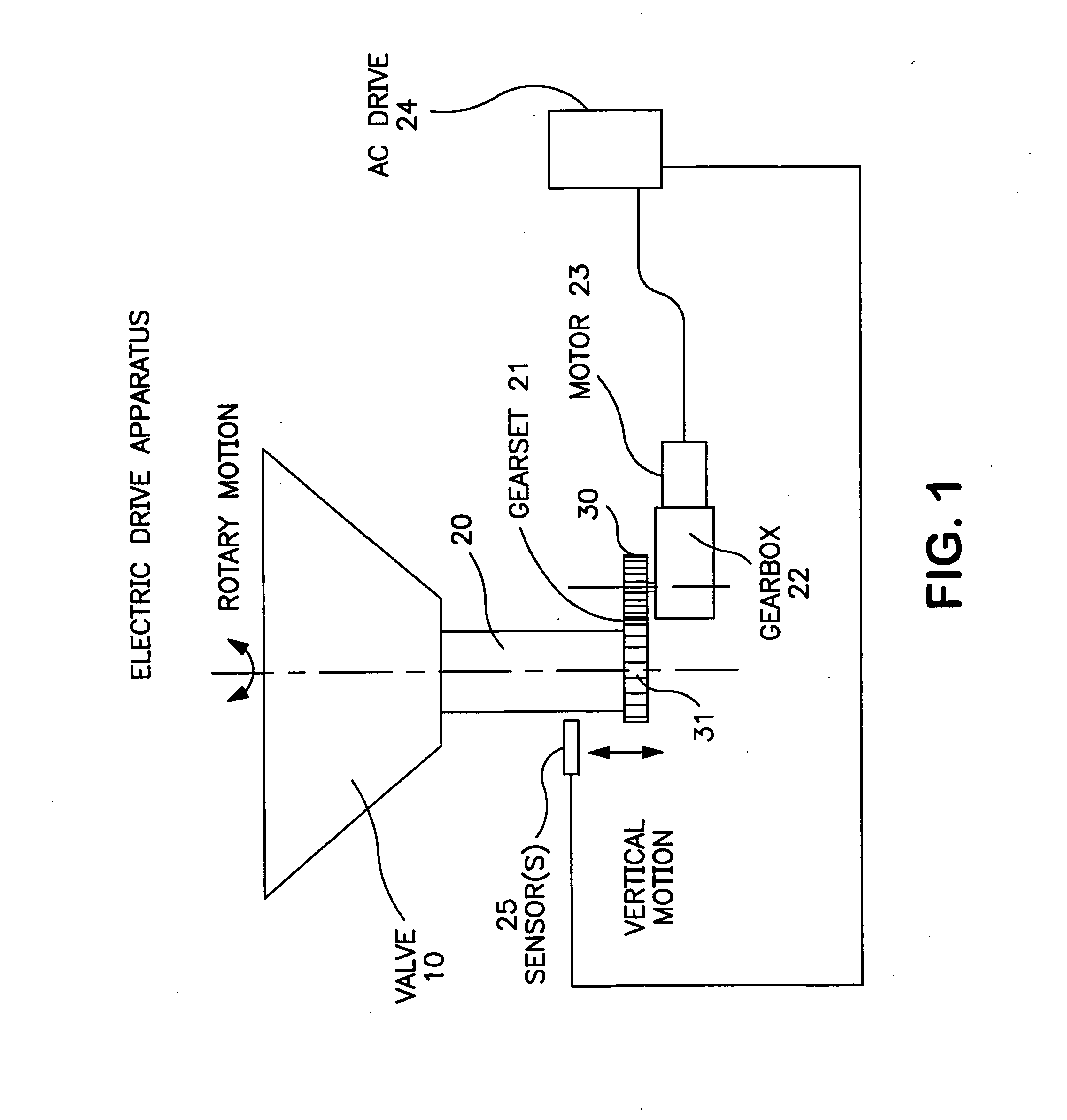

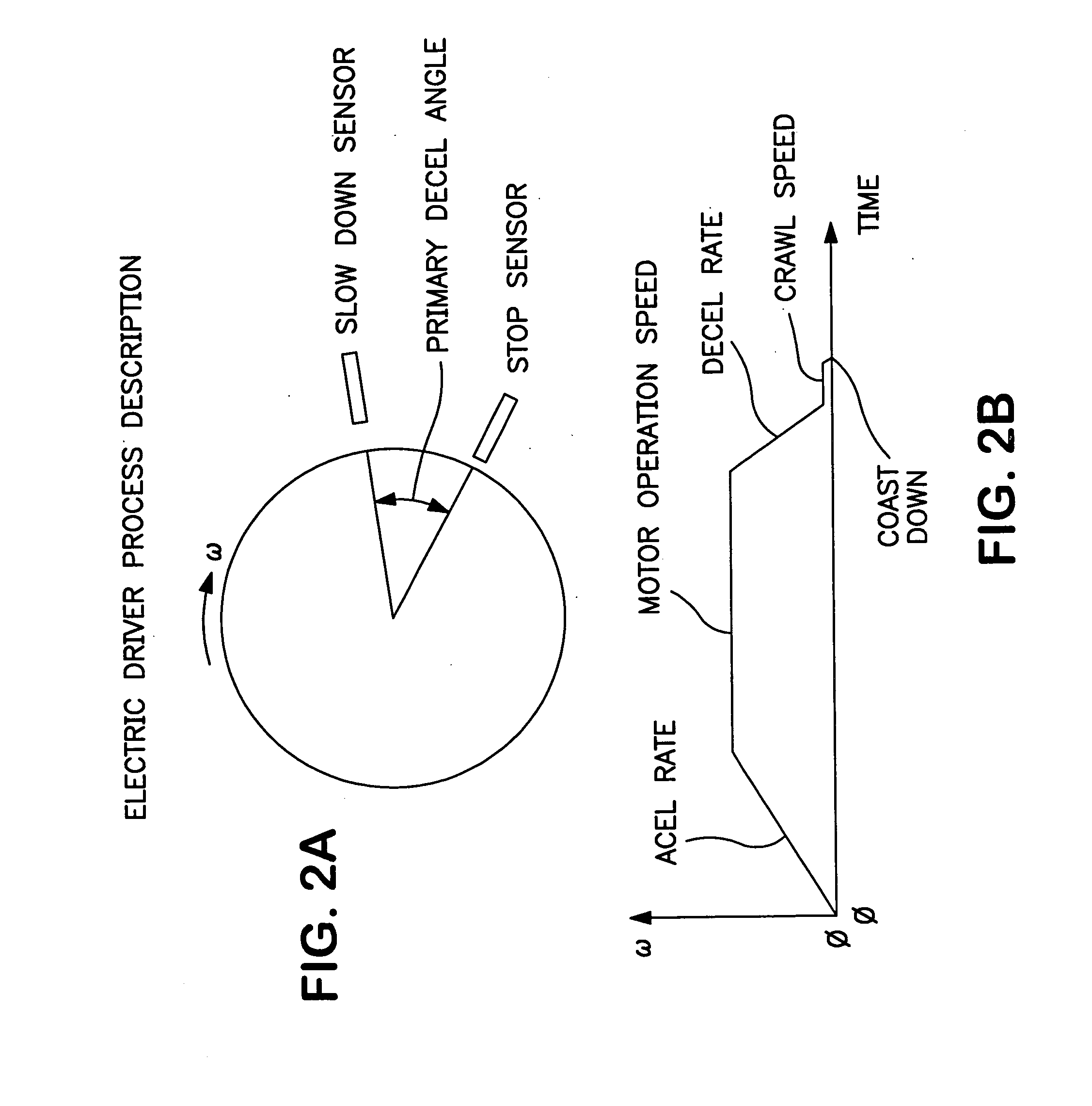

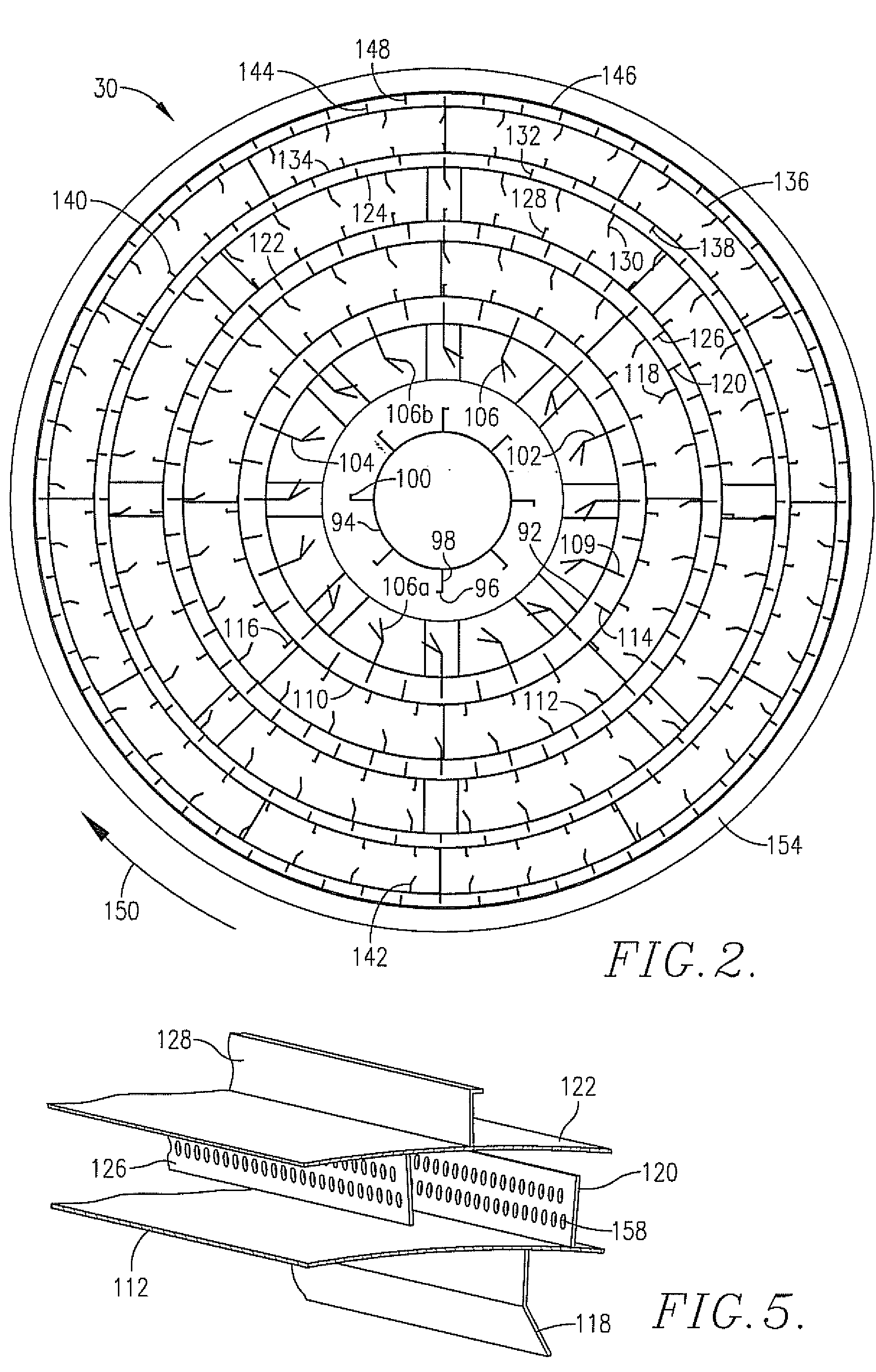

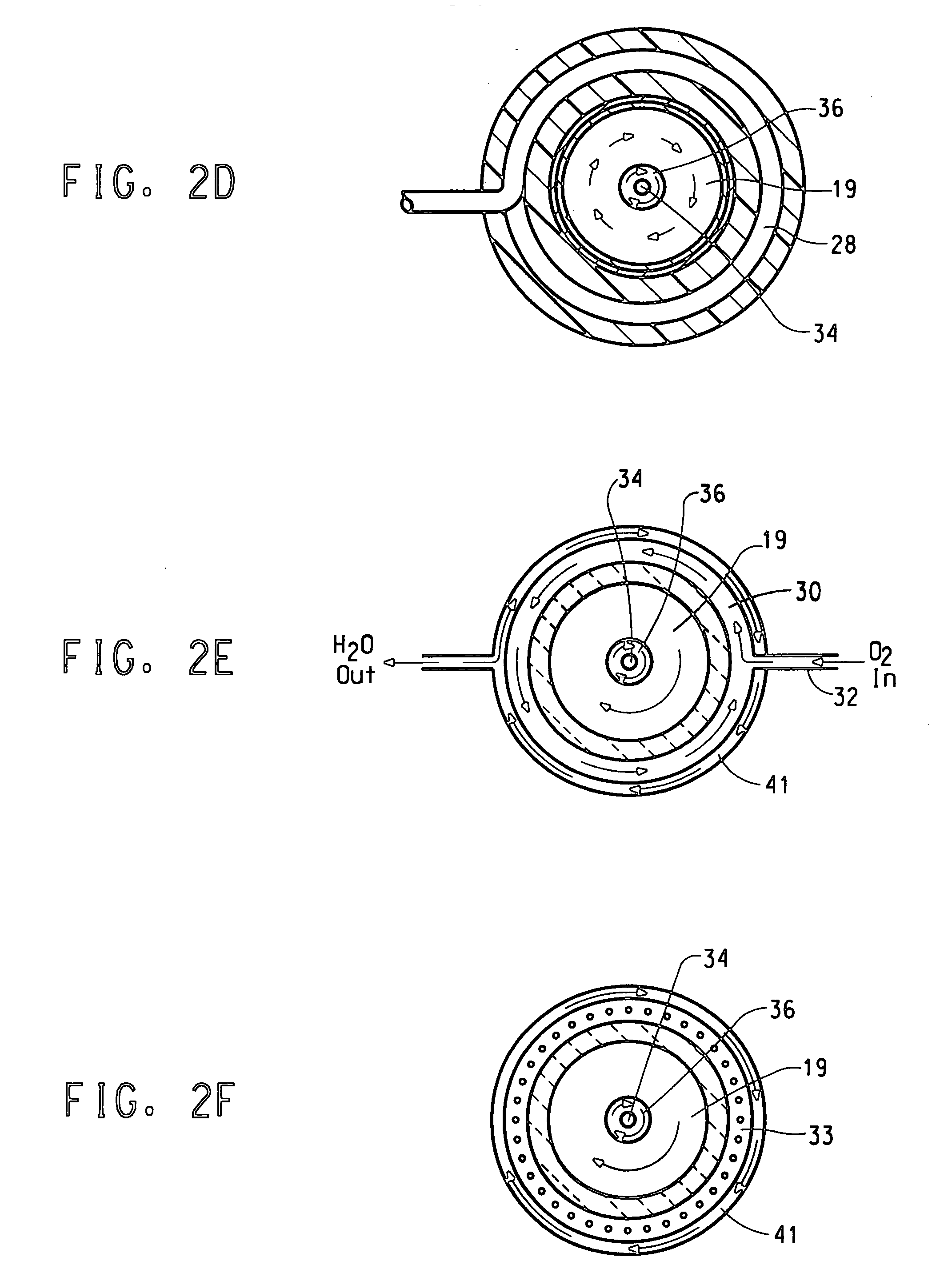

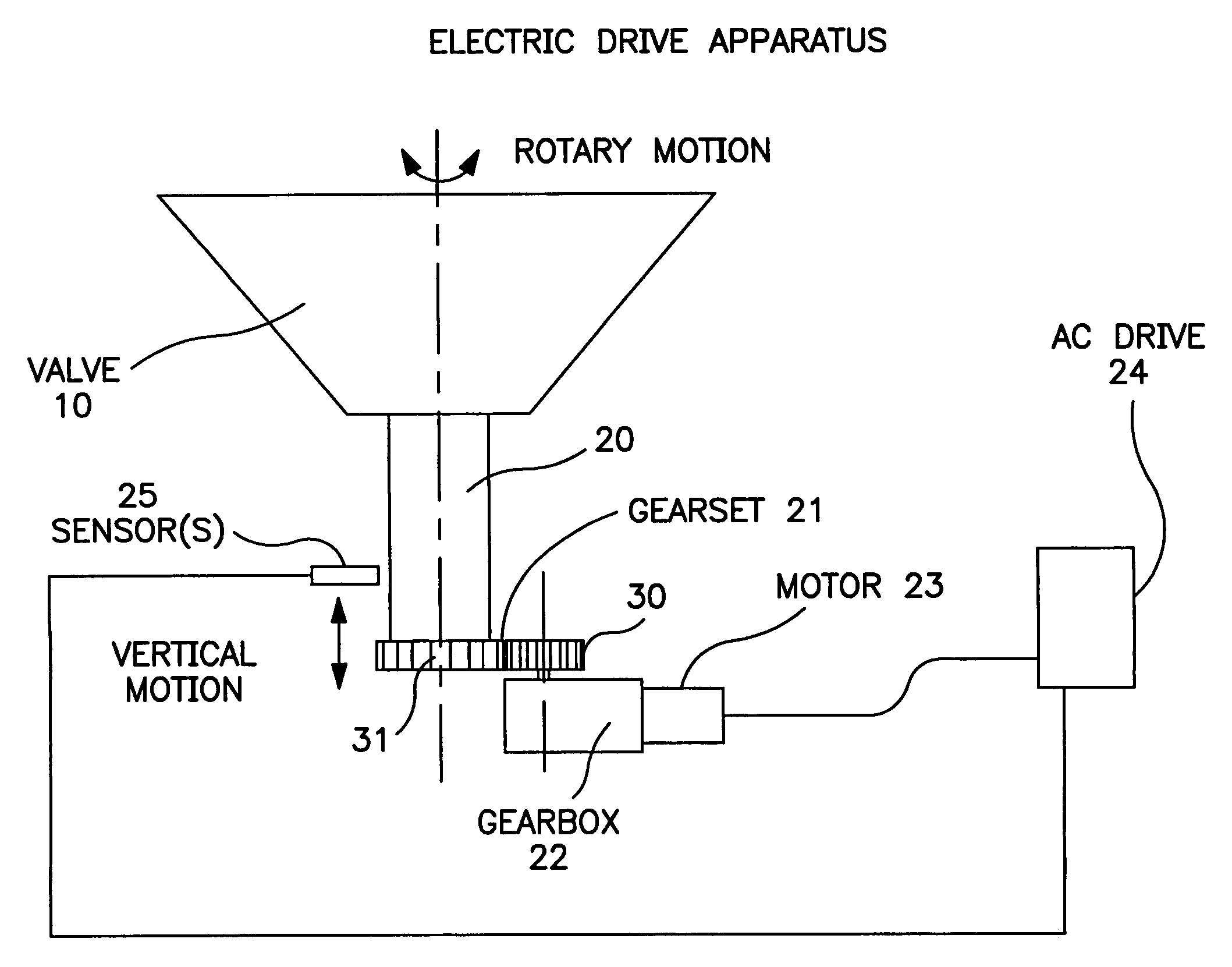

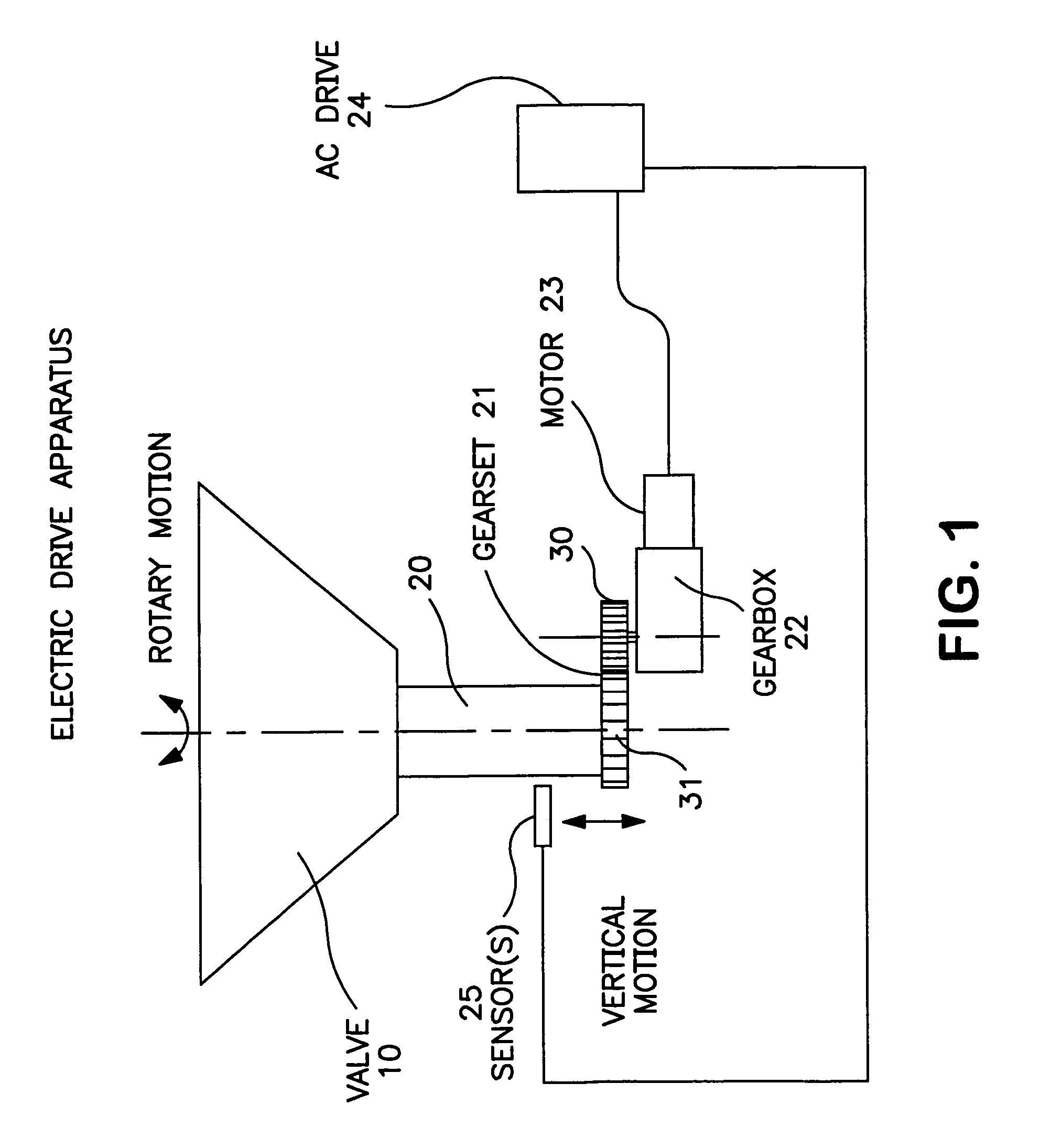

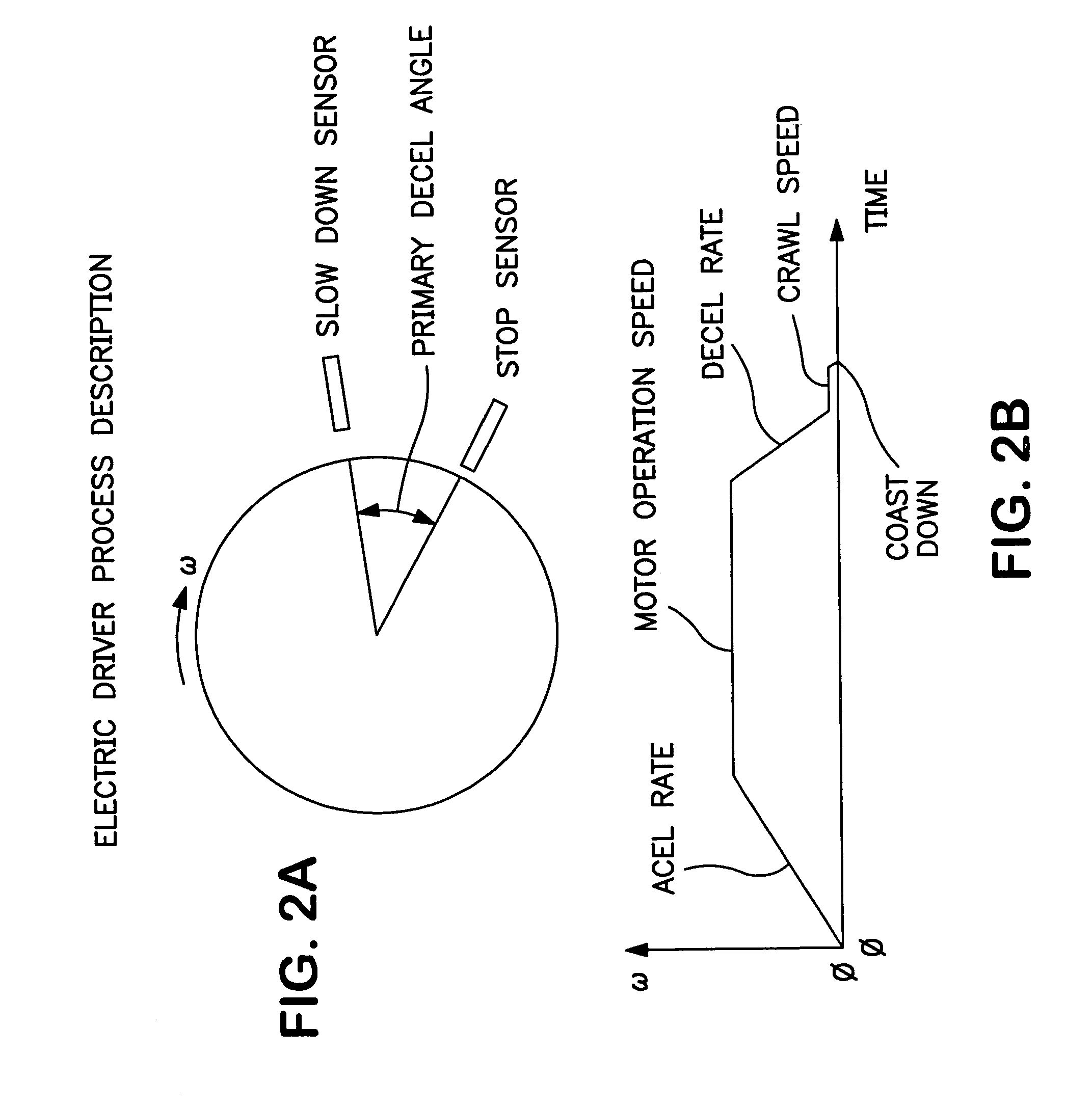

Electric gear motor drive for switching valve

ActiveUS20060102864A1Precise positioningDissipate energyOperating means/releasing devices for valvesValve members for heating/coolingMotor driveGear wheel

Electric drive for a switching valve, the switching valve having such a drive, and a regenerative thermal oxidizer including the switching valve and drive system. The electric drive system allows for the starting and stopping of the rotation of a rotary valve with accurate positioning. The stopping of the valve includes dissipation of the kinetic energy of the valve by electric means. The valve is allowed to move vertically and oscillating rotary motion is possible. The drive system preferably includes a gear, gearbox, variable speed drive and at least one positioning sensor. Valve acceleration and deceleration can be carried out in a controlled fashion and with repeatability, so that the final end position of the valve is consistent. The accommodation of vertical movement of the valve is also within the scope of the present invention.

Owner:DURR SYST INC

Gas recuperative flameless thermal oxidizer

InactiveUS20060084017A1Increase and decrease sizeFurnace componentsCapillary burnersEngineeringThermal oxidizer

The invention provides a gas recuperative flameless thermal oxidizer. The oxidizer includes a matrix bed and at least one feed passage extending at least partially within the matrix bed. The feed passage has an inlet configured to receive combustible vapor or an air-combustible vapor mixture and an outlet configured to deliver the combustible vapor or the air-combustible vapor mixture into the matrix bed. The feed passage has a cross-sectional area and a length within the matrix bed, wherein a ratio of the length (ft) to the cross-sectional area (in2) is at least about 0.5:1.

Owner:SELAS FLUID PROCESSING CORP

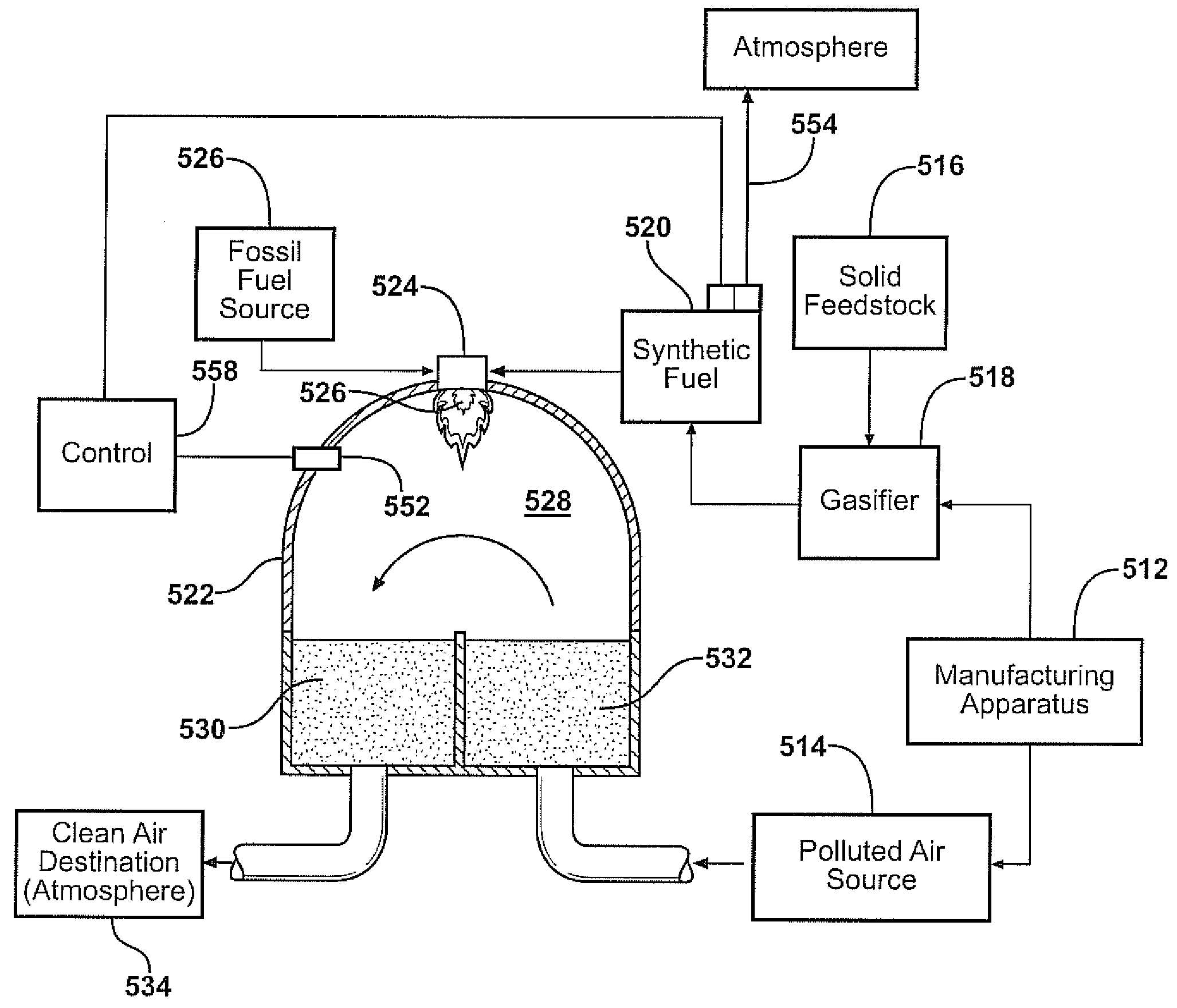

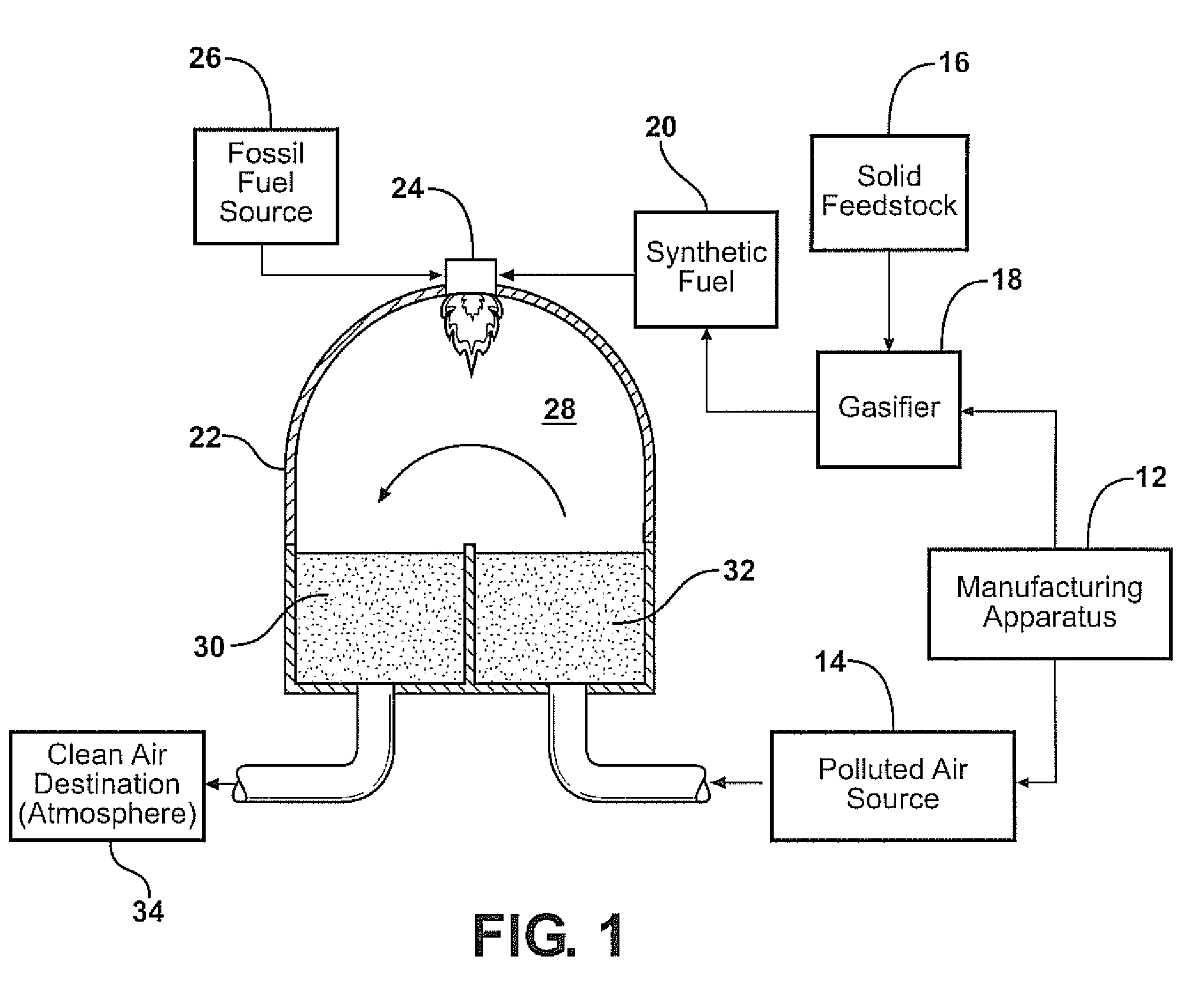

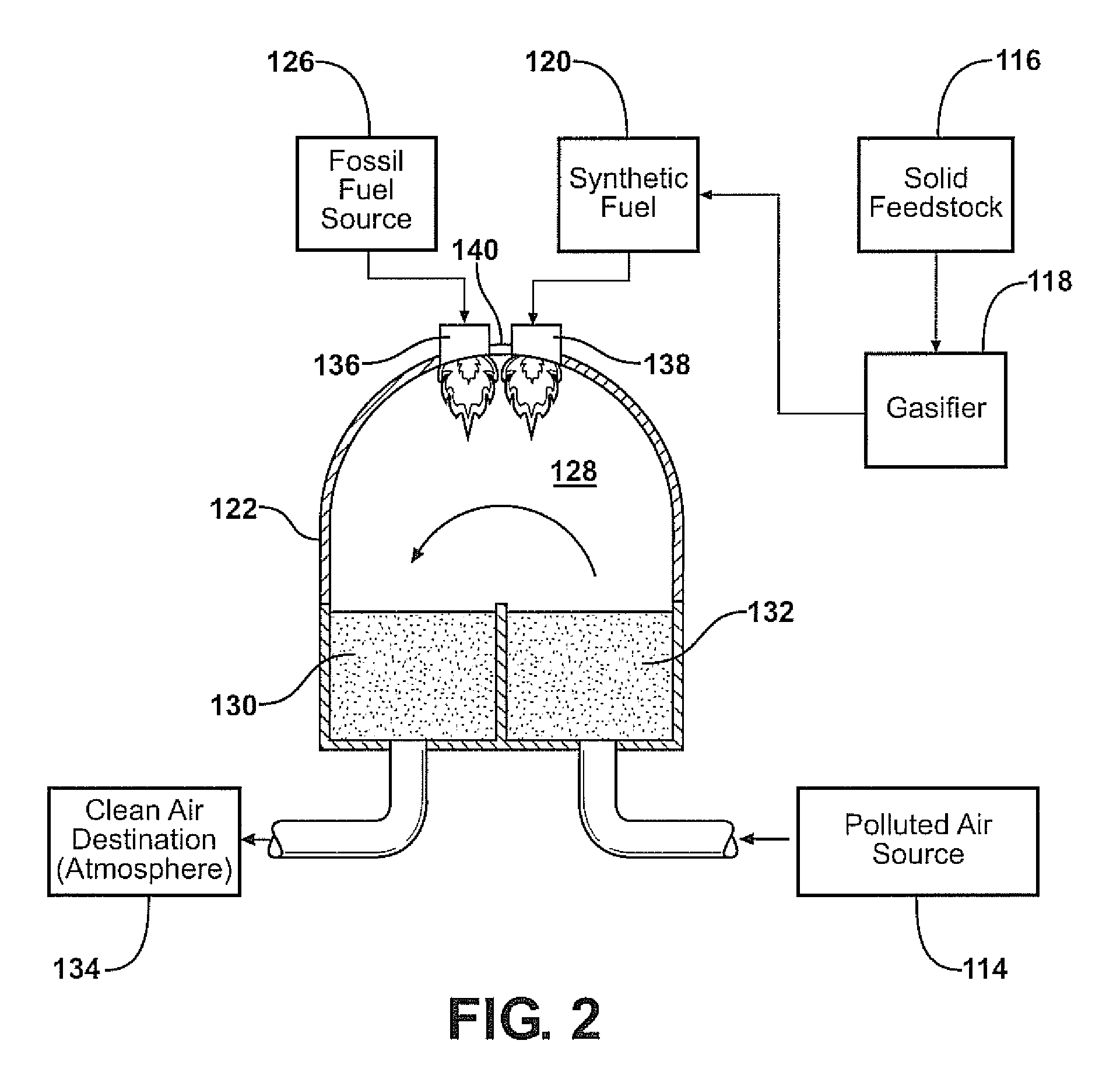

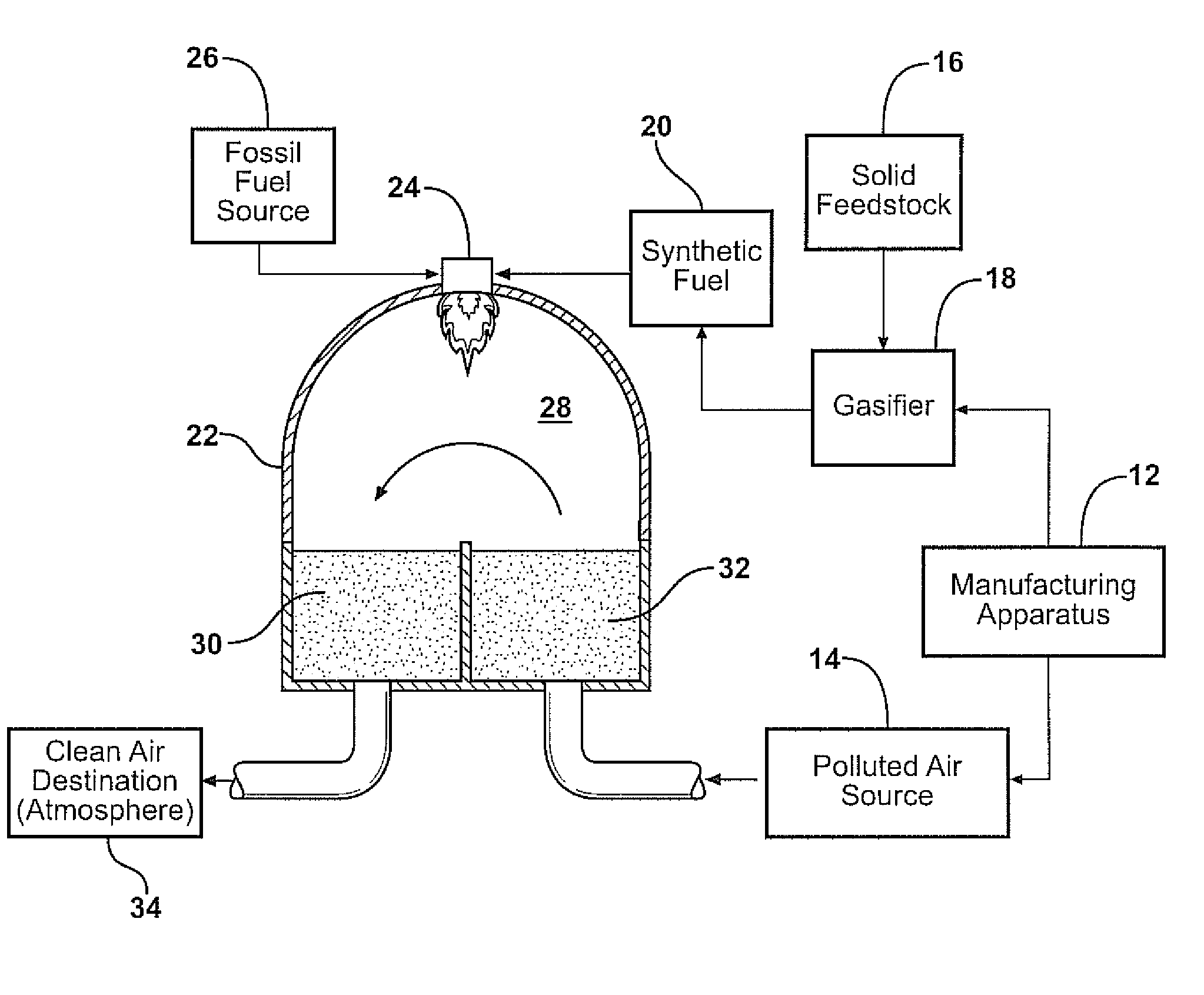

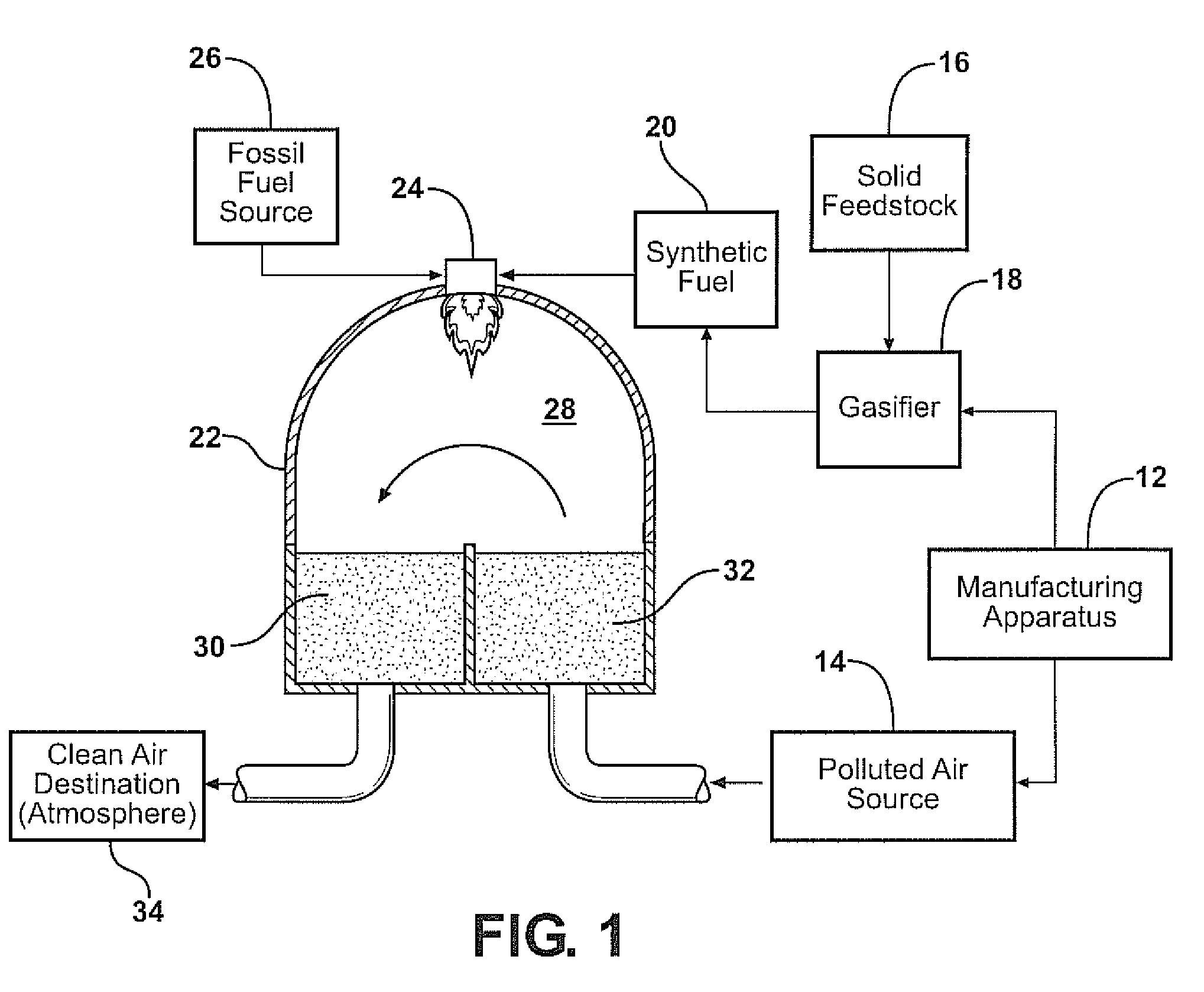

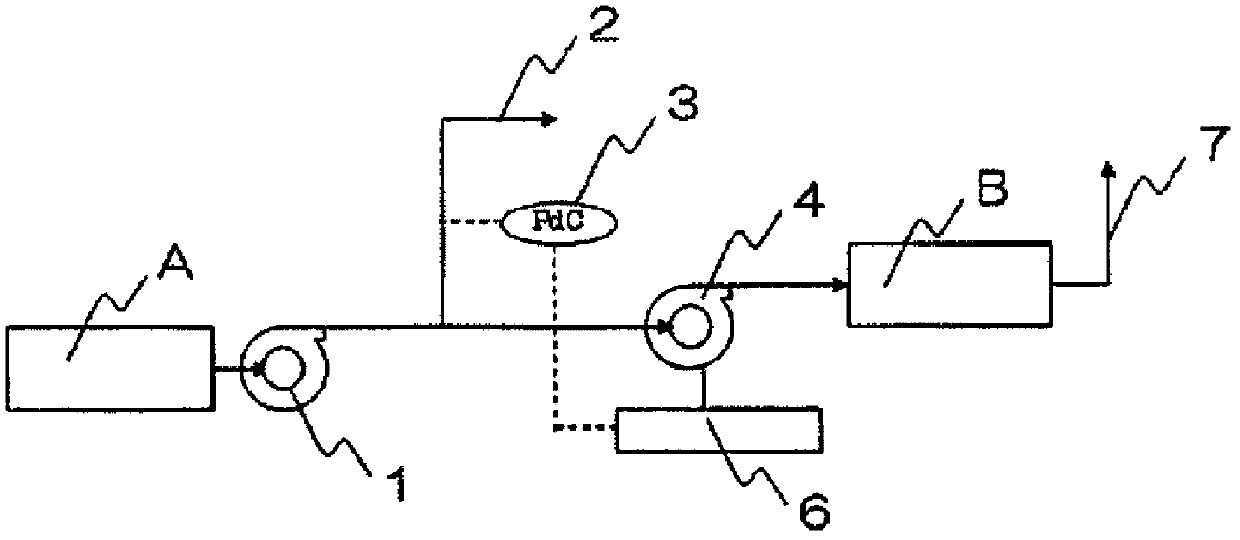

Thermal oxidizer with gasifier

InactiveUS20090221866A1Reduce the amount requiredReduced organic wasteCarbon compoundsExhaust apparatusThermal energyForming gas

A manufacturing apparatus for producing products results in solid waste and organic waste disposed in an air stream. The organic waste is subject to oxidation by a thermal oxidizer receiving the air stream from the manufacturing apparatus for oxidizing the organic waste. The thermal oxidizer includes a clean air outlet for venting the oxidized air stream to the atmosphere. A gasifier receives solid waste from the manufacturing apparatus for gasifying the solid waste and producing synthetic gas. The synthetic gas is introduced to the thermal oxidizer for providing additional thermal energy to the thermal oxidizer reducing the amount of fossil fuel required to provide thermal energy to the thermal oxidizer that is necessary for oxidizing the organic waste disposed in said air stream.

Owner:DURR SYST INC

Moist organic product drying system having a rotary waste heat evaporator

ActiveUS20080229610A1Reduce contentDrying solid materials with heatDrying gas arrangementsEngineeringOxygen

Owner:AEROGLIDE

Process for making metal oxide nanoparticles

InactiveUS20070292340A1Reduce and even eliminateTransparent highMaterial nanotechnologyOxygen/ozone/oxide/hydroxideMetal oxide nanoparticlesReaction zone

There is described a process for preparing metal oxide particles which are substantially free of coarse tail from an oxidizing agent and a vaporous metal reactant in a flow reactor; comprising, (a) directing a flow of the metal reactant into a contacting region of the flow reactor; comprising (a) passing a flow of oxidizing agent through a high temperature zone of the flow reactor to form a flow of hot oxidizing agent and directing the flow of the hot oxidizing agent onto the contacting region of the flow reactor at a flow condition sufficient to form a reaction stream comprising a flow of hot oxidizing agent, a flow of metal reactant and a diffusive flow of the hot oxidizing agent and the metal reactant, the temperature of the hot oxidizing agent being at least sufficient to initiate oxidation of the metal reactant in the diffusive flow; (c) passing the reaction stream into a reaction zone of the flow reactor, while simultaneously introducing a flow of an upper cooling fluid substantially coaxially with the reaction stream to form a fluid curtain which surrounds the reaction stream; (d) maintaining the fluid curtain while the metal oxide particles form within the diffusive flow of the reaction stream and until at least a major portion of the reaction stream is cooled to a temperature below the temperature at which metal oxide particles coalesce; and (e) separating the metal oxide particles from the reaction stream.

Owner:EI DU PONT DE NEMOURS & CO

Electric gear motor drive for switching valve

ActiveUS7308904B2Precise positioningDissipate energyOperating means/releasing devices for valvesValve members for heating/coolingMotor driveGear wheel

Electric drive for a switching valve, the switching valve having such a drive, and a regenerative thermal oxidizer including the switching valve and drive system. The electric drive system allows for the starting and stopping of the rotation of a rotary valve with accurate positioning. The stopping of the valve includes dissipation of the kinetic energy of the valve by electric means. The valve is allowed to move vertically and oscillating rotary motion is possible. The drive system preferably includes a gear, gearbox, variable speed drive and at least one positioning sensor. Valve acceleration and deceleration can be carried out in a controlled fashion and with repeatability, so that the final end position of the valve is consistent. The accommodation of vertical movement of the valve is also within the scope of the present invention.

Owner:DURR SYST INC

Thermal oxidizer with gasifier

InactiveUS8237006B2Reduce the amount requiredReduce wasteCarbon compoundsExhaust apparatusThermal energyAtmosphere

A manufacturing apparatus for producing products results in solid waste and organic waste disposed in an air stream. The organic waste is subject to oxidation by a thermal oxidizer receiving the air stream from the manufacturing apparatus for oxidizing the organic waste. The thermal oxidizer includes a clean air outlet for venting the oxidized air stream to the atmosphere. A gasifier receives solid waste from the manufacturing apparatus for gasifying the solid waste and producing synthetic gas. The synthetic gas is introduced to the thermal oxidizer for providing additional thermal energy to the thermal oxidizer reducing the amount of fossil fuel required to provide thermal energy to the thermal oxidizer that is necessary for oxidizing the organic waste disposed in said air stream.

Owner:DURR SYST INC

Preparation method of high-weathering-resistance and high-wear-resistance polyurethane surface layer resin for vehicle interior decoration leathers

The present invention relates to the technical field of polyurethane resin preparation, and provides a preparation method of a high-weathering-resistance and high-wear-resistance polyurethane surface layer resin for vehicle interior decoration leathers. The preparation method comprises the following treatment steps: adding a solvent, polycarbonate diol, organosilicon polyol, a heat resistance oxidizer and a chain extender into a reaction kettle, heating to a temperature of 48-52 DEG C, stirring, adding non-yellowing isocyanate after the polycarbonate diol is dissolved, uniformly stirring, slowly heating to a temperature of 90-130 DEG C, carrying out a reaction for 110-120 min, adding a catalyst, carrying out a reaction for 120-125 min to prepare a prepolymer, detecting the NCO value of the reaction system, adding a solvent to dissolve the prepolymer when the NCO value is less than the theoretical value, cooling to a temperature of less than or equal to 50 DEG C, carrying out chain extending tackifying on the diluted amine chain extender by using the dropwise adding way, adding isopropanol to carry out end capping when achieving the process viscosity, heating, carrying out stirring mixing, cooling to a temperature of less than or equal to 50 DEG C, and discharging the material.

Owner:FUJIAN XINGYU RESIN

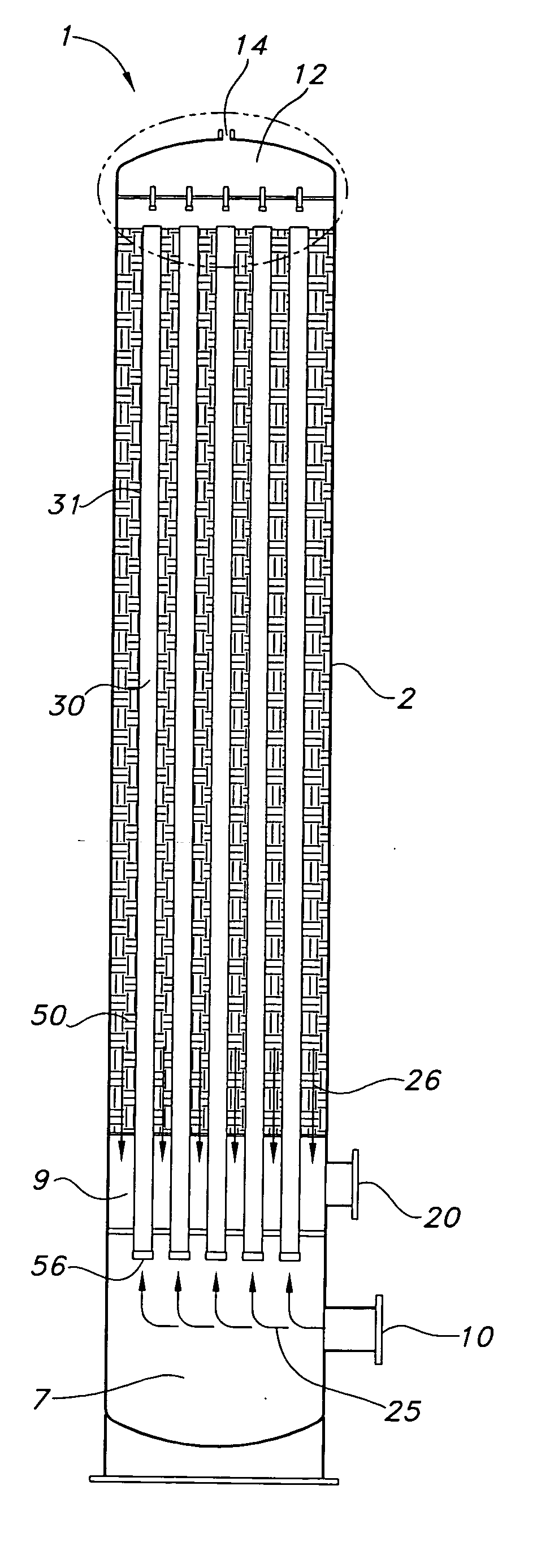

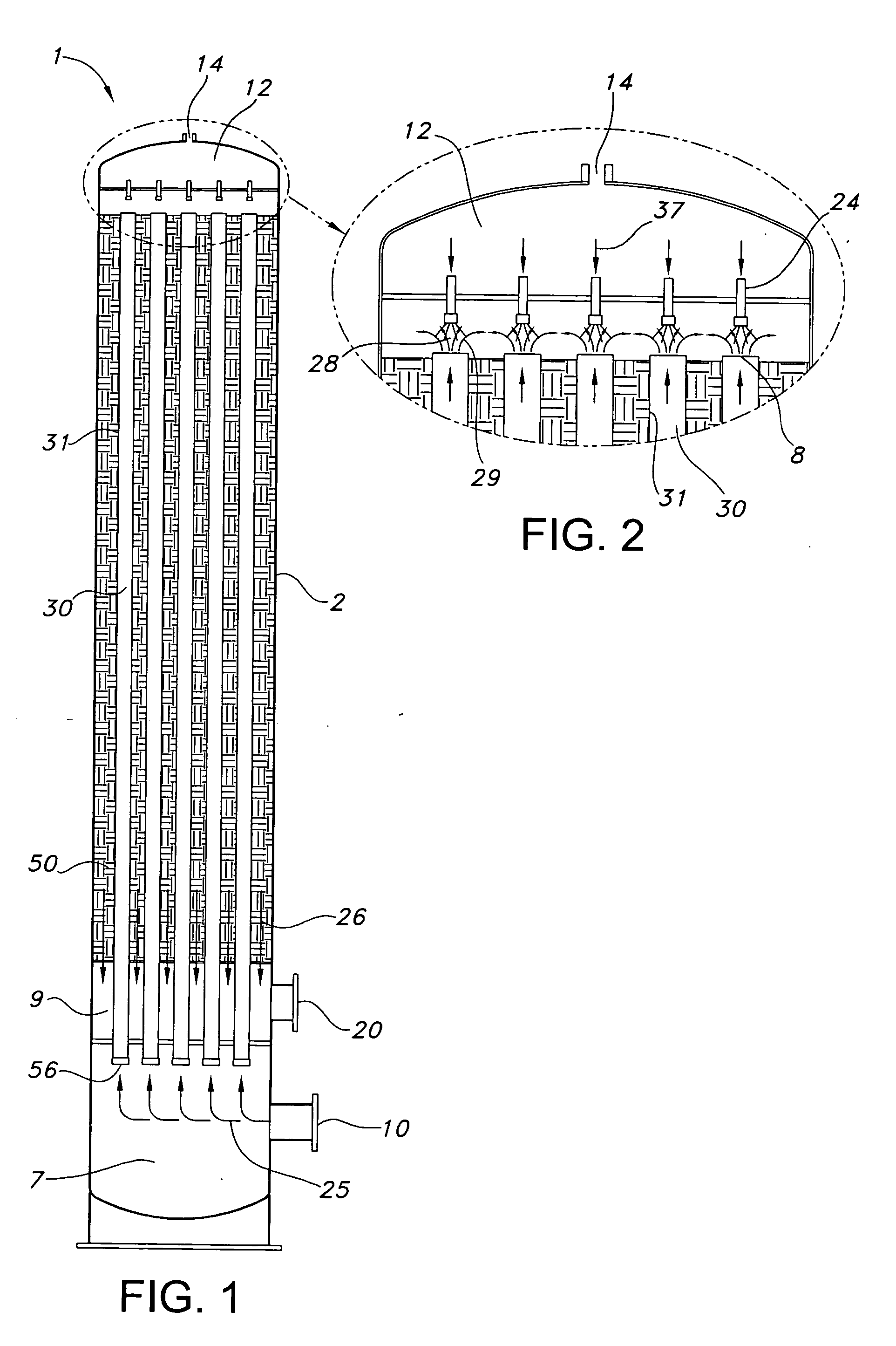

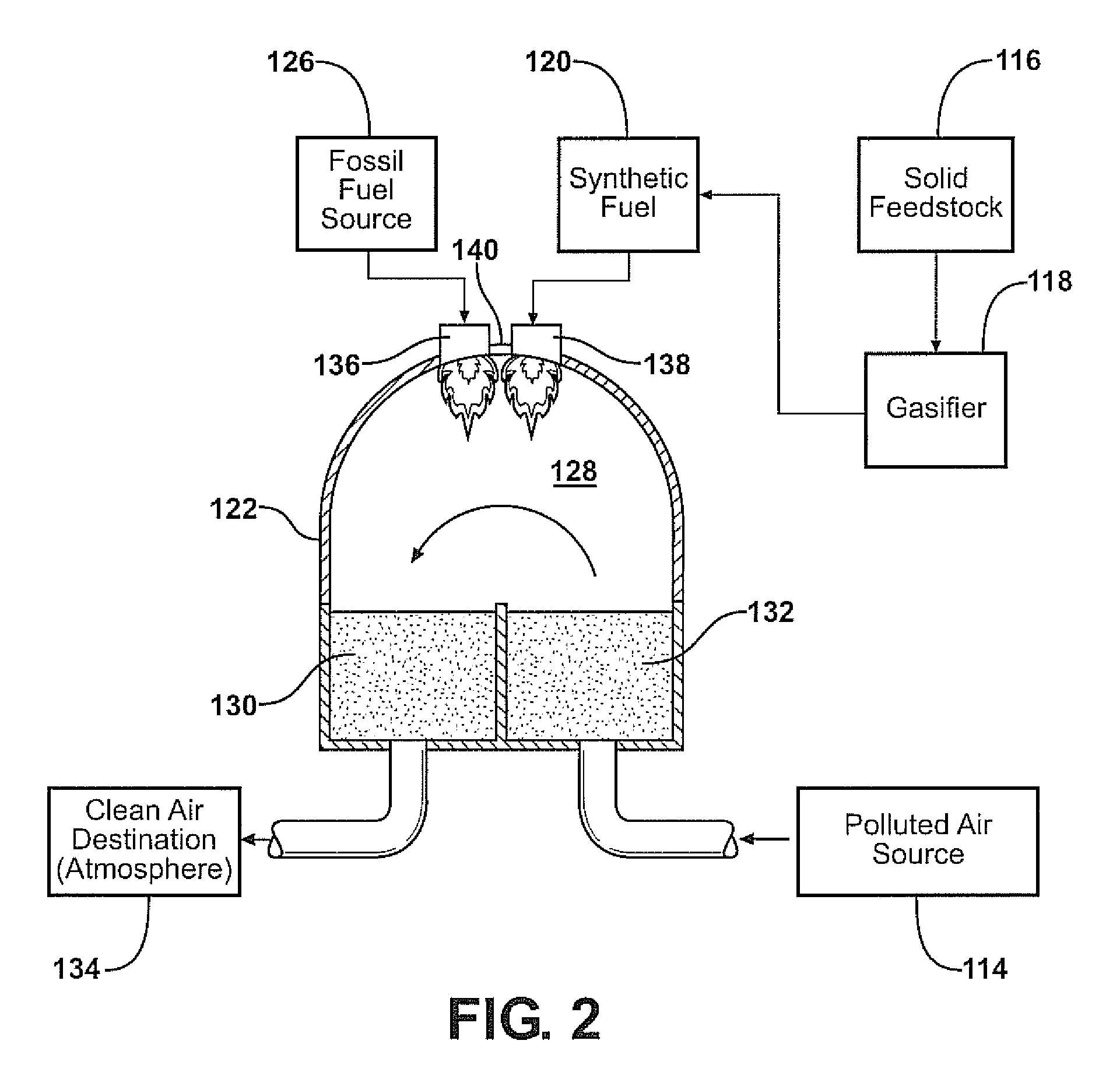

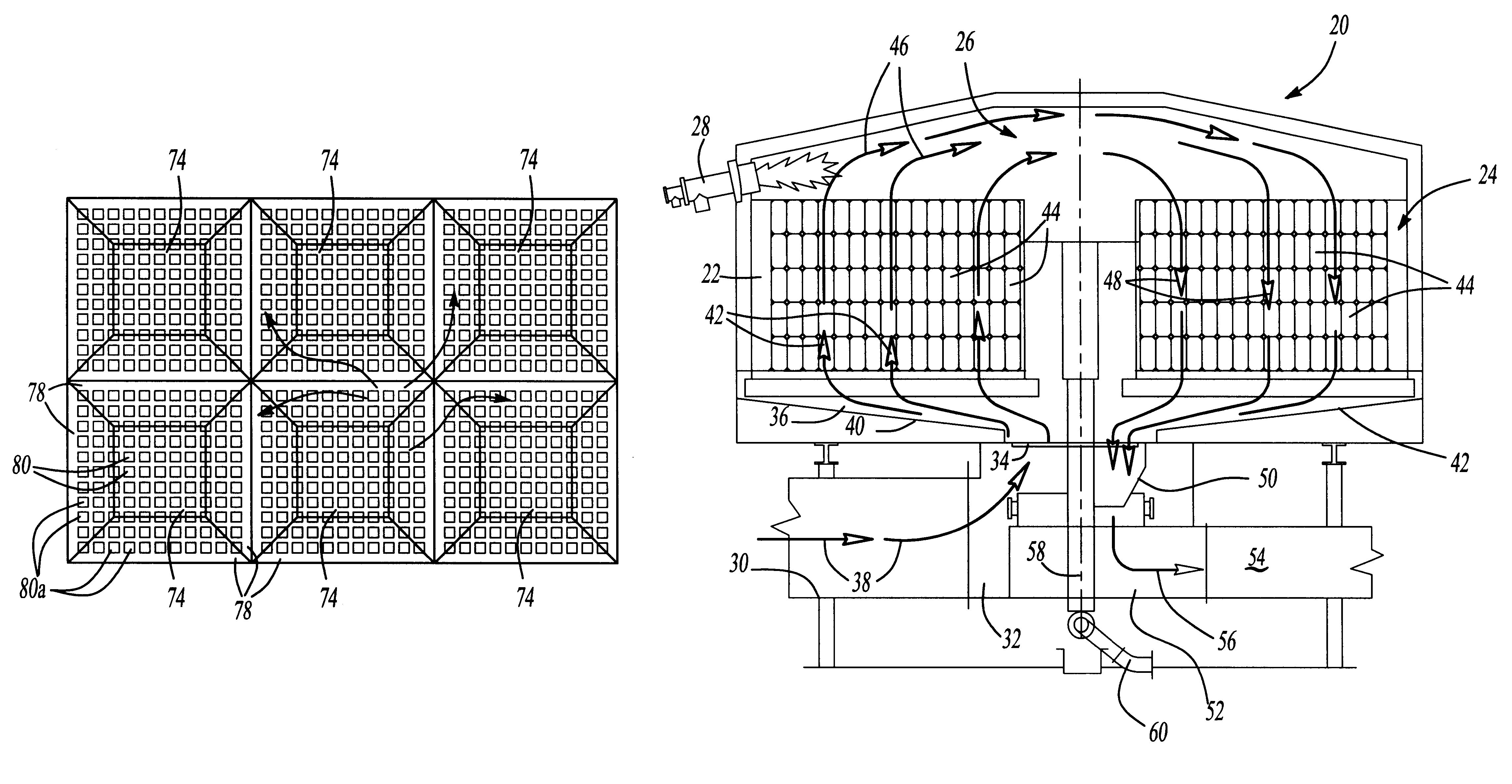

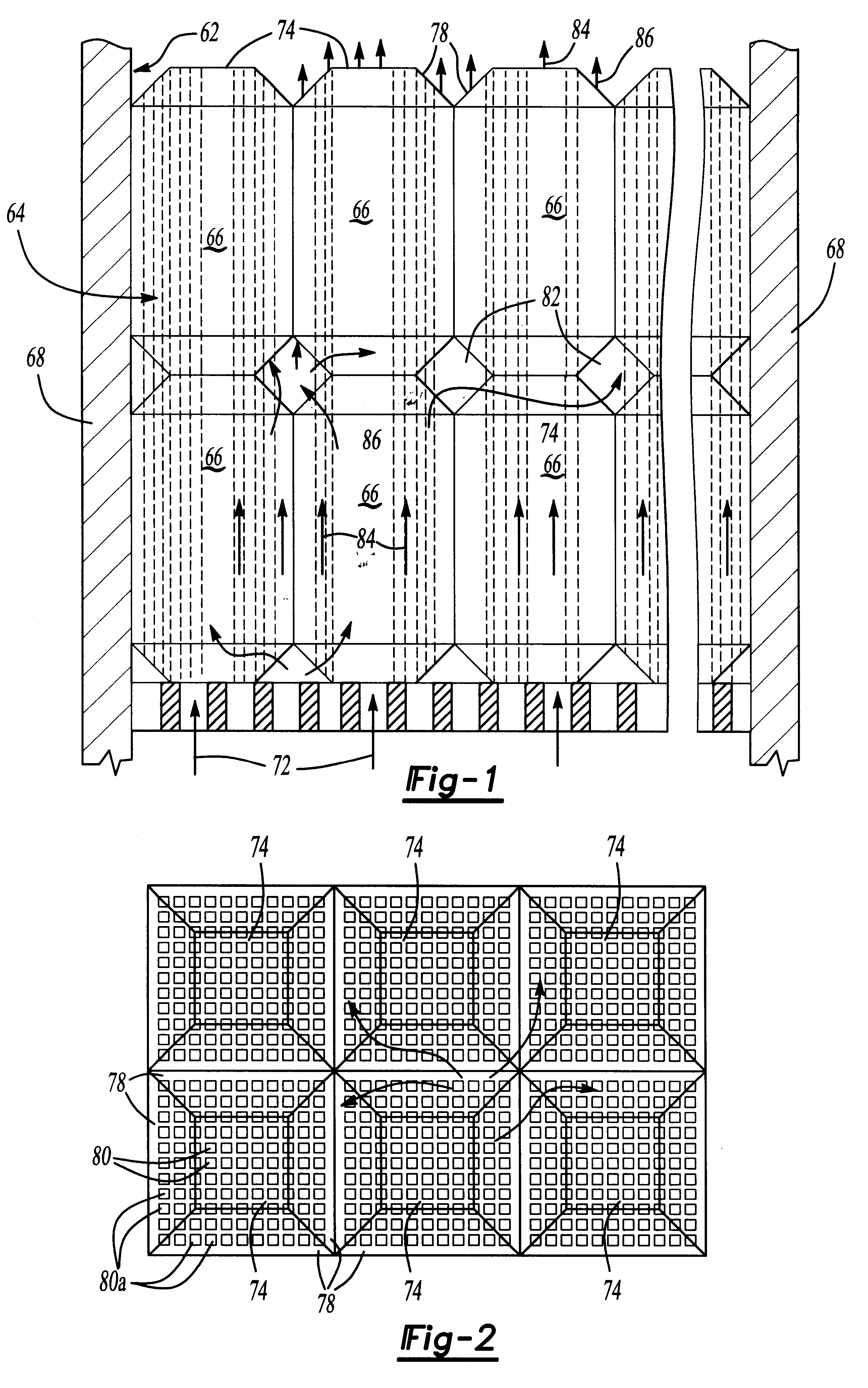

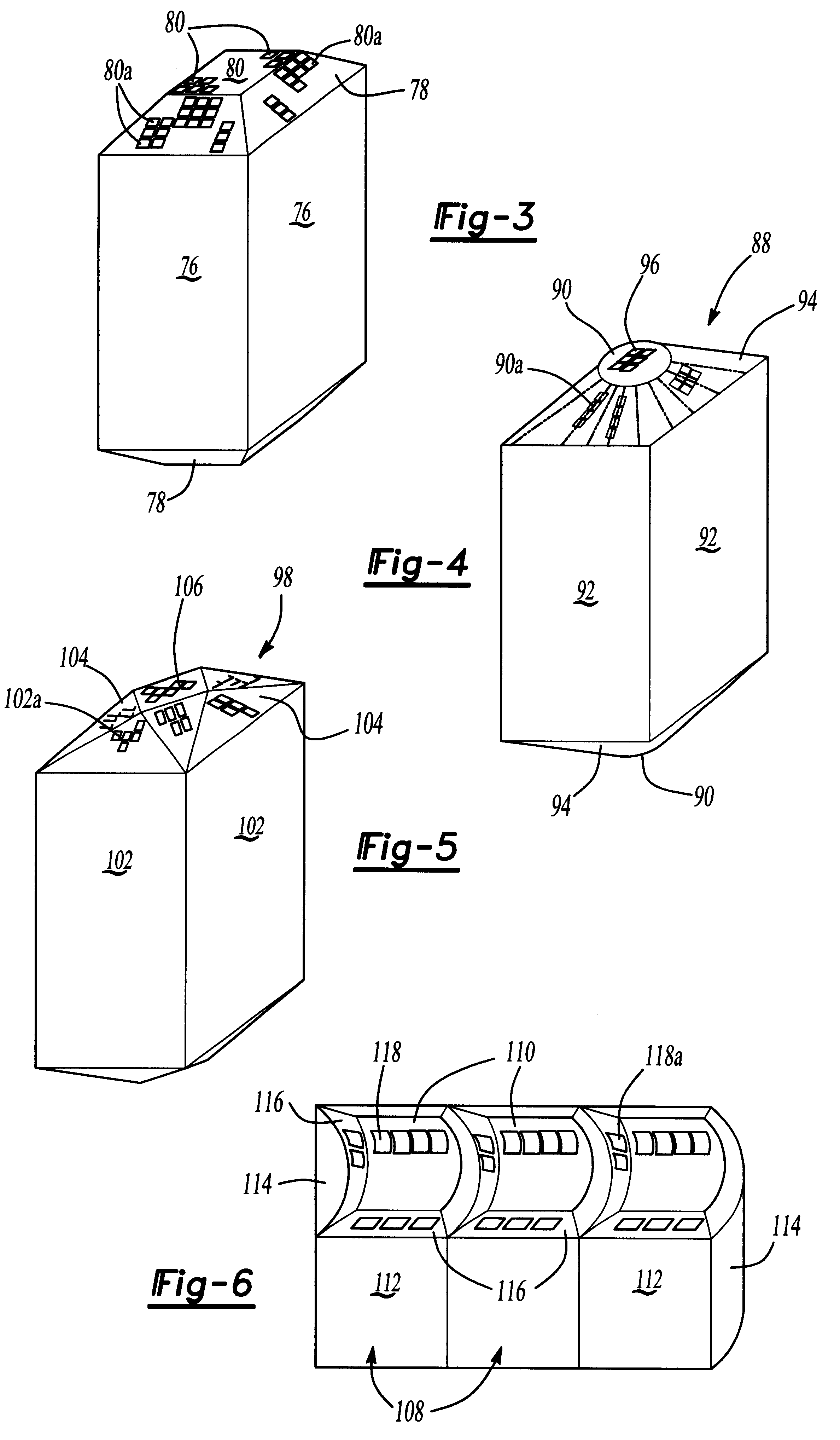

Pollution abatement reactor system having nonprismatic structured media

An apparatus for treating gaseous pollutants in an air stream such as a regenerative thermal oxidizer or a selective catalytic reduction system, including a reaction chamber wherein the reaction media bed within the chamber comprises a plurality of nonprismatic ceramic blocks each having end faces, side faces and a chamfered face extending at an angle relative to the side faces of the blocks. The ceramic blocks are stacked in end-to-end and side-to-side relation within the reaction chamber and the ceramic blocks each include spaced parallel passages extending through the end and chamfered faces. The chamfered faces of adjacent blocks form voids between the blocks promoting turbulent gas flow through the voids and equalizing the pressure within the reaction chamber. The ceramic blocks may be symmetrical, wherein only a portion of the gas flows into the voids between the blocks and the remainder flows through the channels through the end faces or the ceramic blocks may be nonsymmetrical, wherein the chamfered faces are located vertically opposite an end face, such that all of the gas flowing through the reaction chamber flows through the gas passages into the voids between the blocks at alternative levels.

Owner:DURR SYST INC

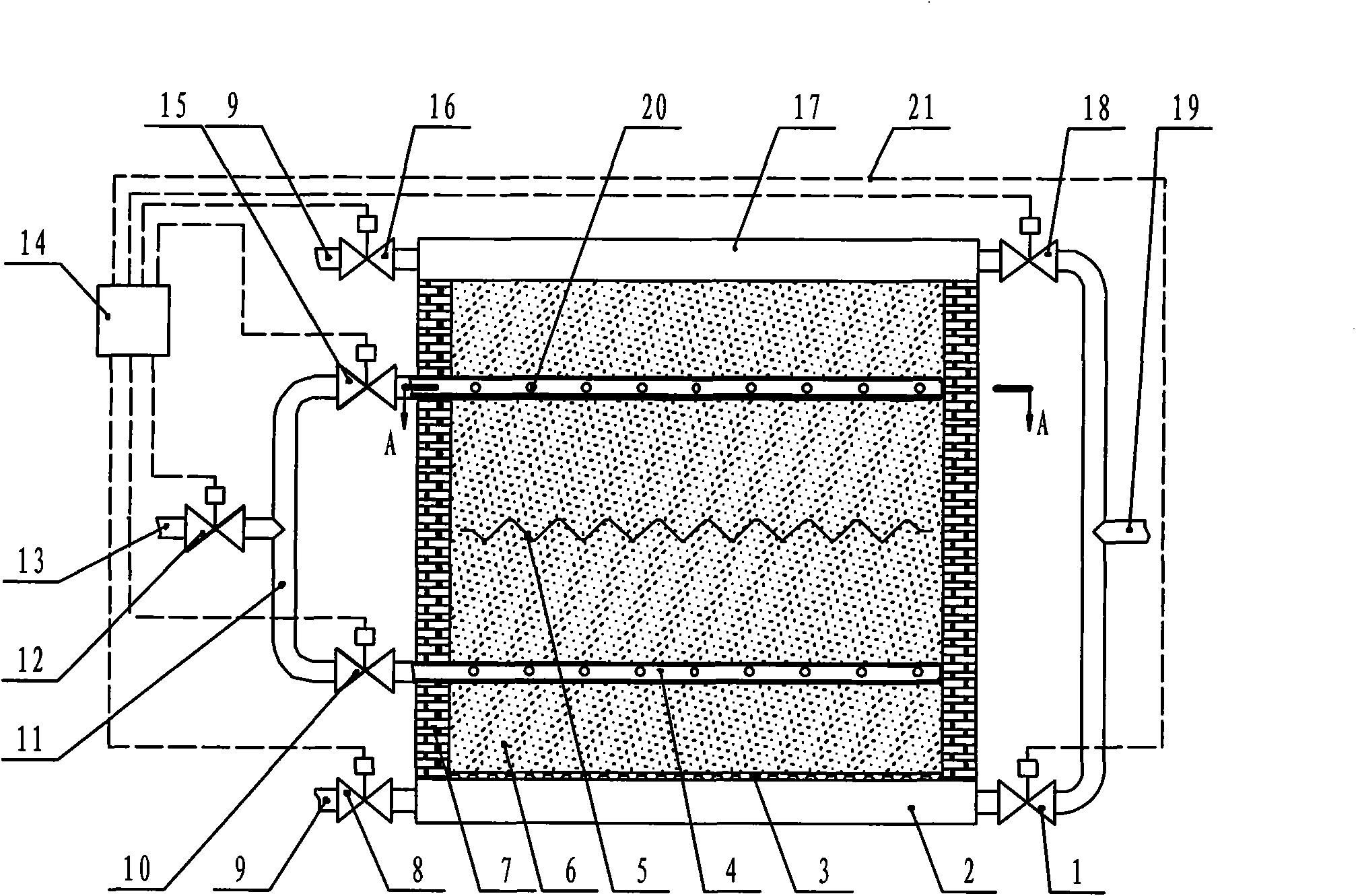

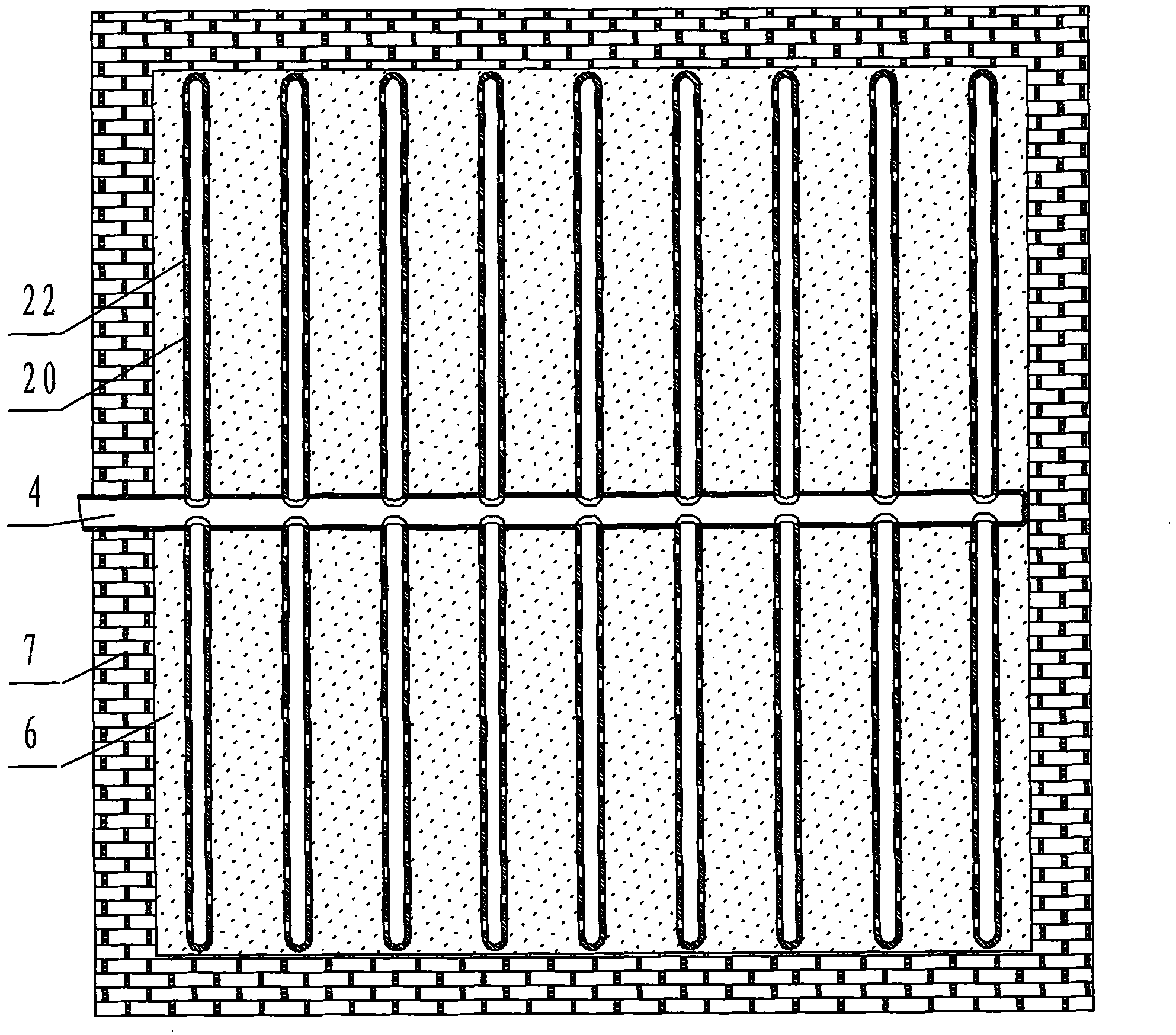

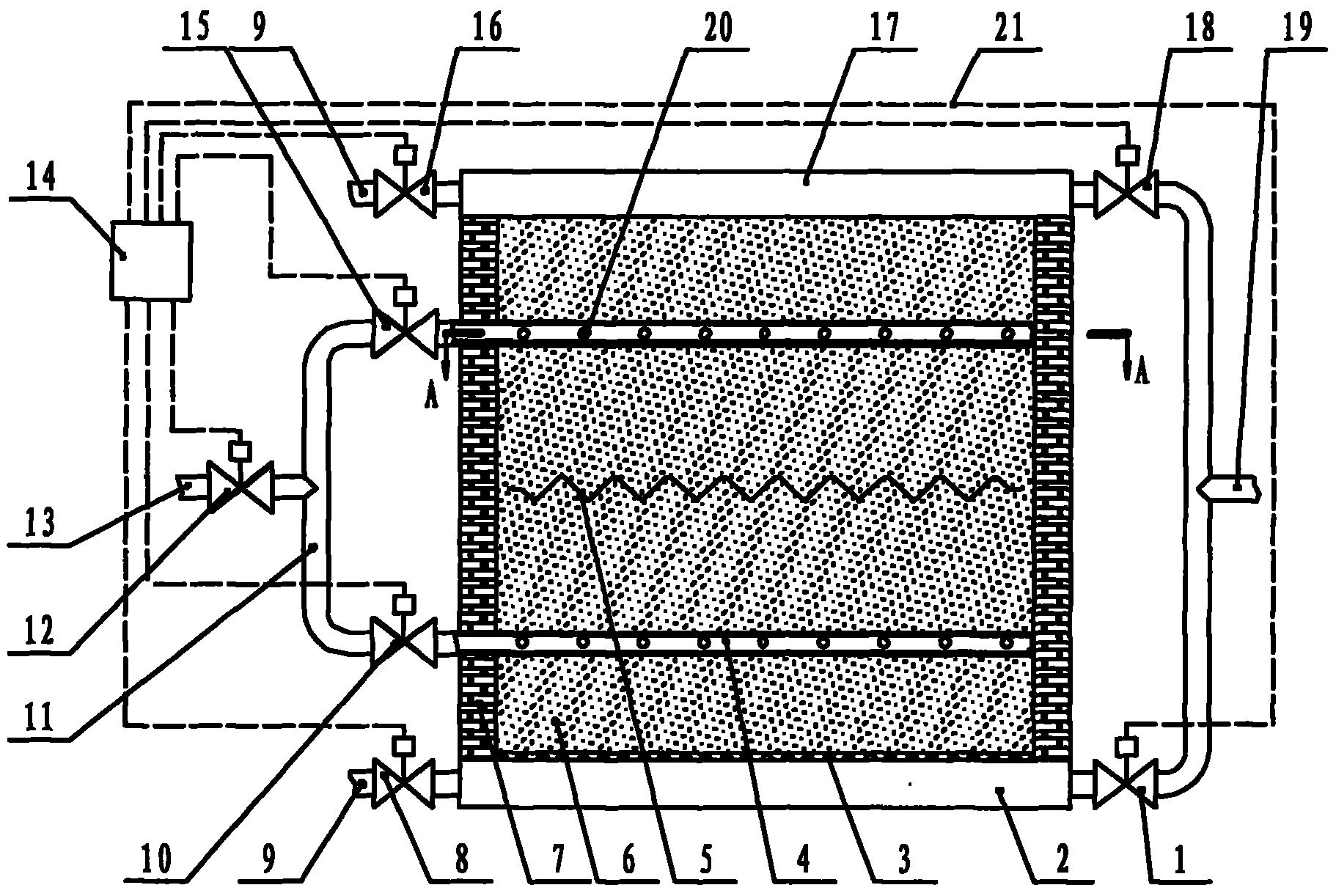

Air extracting and heating coal mine ventilating gas thermal oxidizer unit

The invention relates to an air extracting and heating coal mine ventilating gas thermal oxidizer unit which belongs to the technical field of ultralow-concentration methane flow reversal oxidization and low-density energy recycling. The air extracting and heating coal mine ventilating gas thermal oxidizer unit comprises an oxidizing bed, a support mesh, a heater, a ventilating gas inlet pipe, an upper air collecting box, a lower air collecting box, four reversing valves, a waste gas outlet pipe, an air extracting and heating system and an electric control unit, wherein the air extracting and heating system comprises air extracting main pipes, air extracting branch pipes, two air extracting valves, a hot air collecting pipe, a flow regulating valve and a hot air outlet pipe; and two groups of air extracting main pipes and air extracting branch pipes are symmetrically arranged at the upper side and the lower side of a central area in the oxidizing bed respectively. Coal mine ventilating gas enters the oxidizing bed by controlling the opening and closing of the reversing valves and the air extracting valves under the control of the electric control unit, fully oxidizes methane in the oxidizing bed and extracts partially oxidized hot gas parts for carrying out heat utilization. The invention has the advantages of high methane oxidization rate, easy regulation of extracted heat, stable running of the oxidizer unit, low manufacture cost, and the like.

Owner:SHANDONG UNIV OF TECH

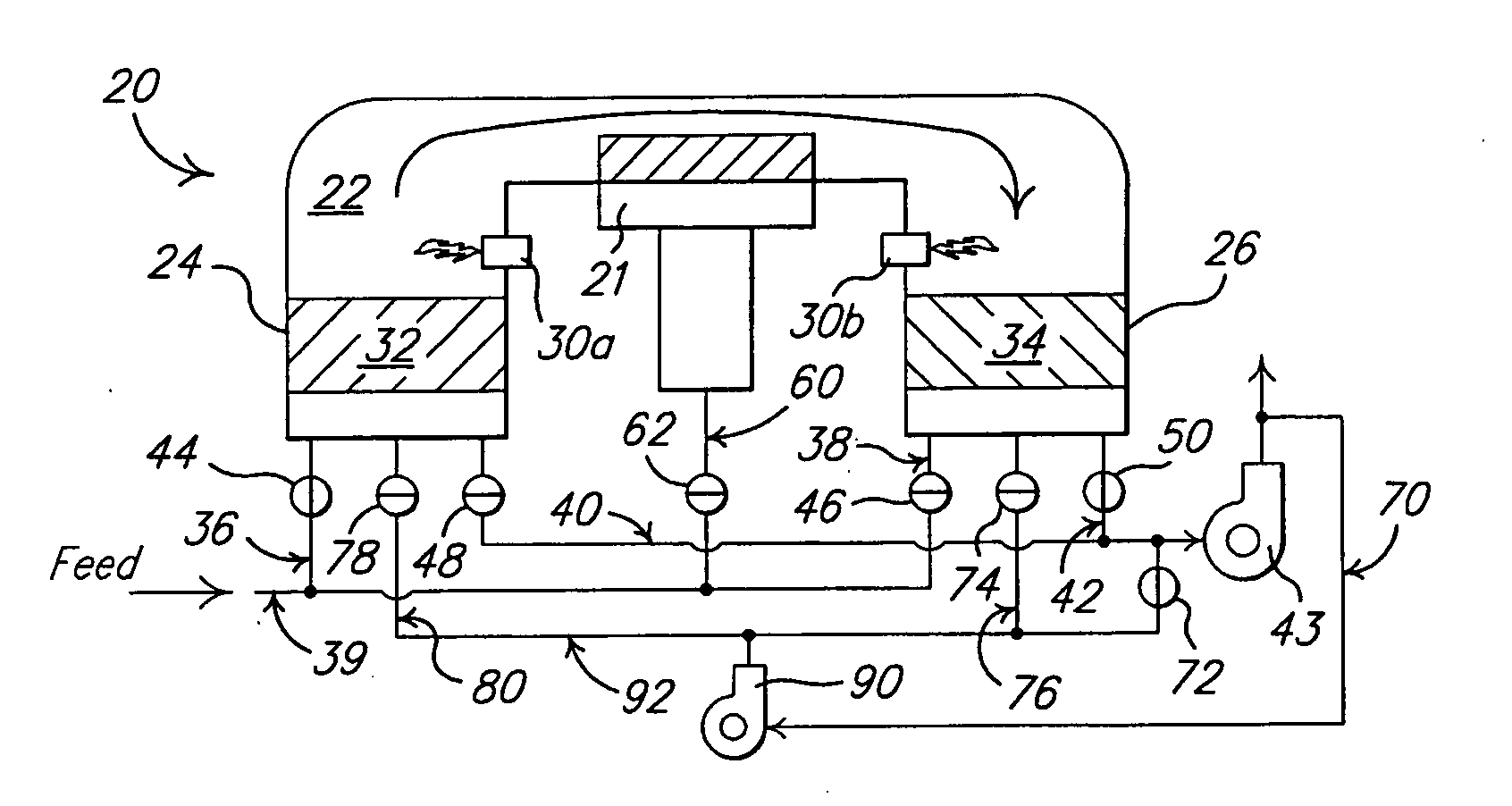

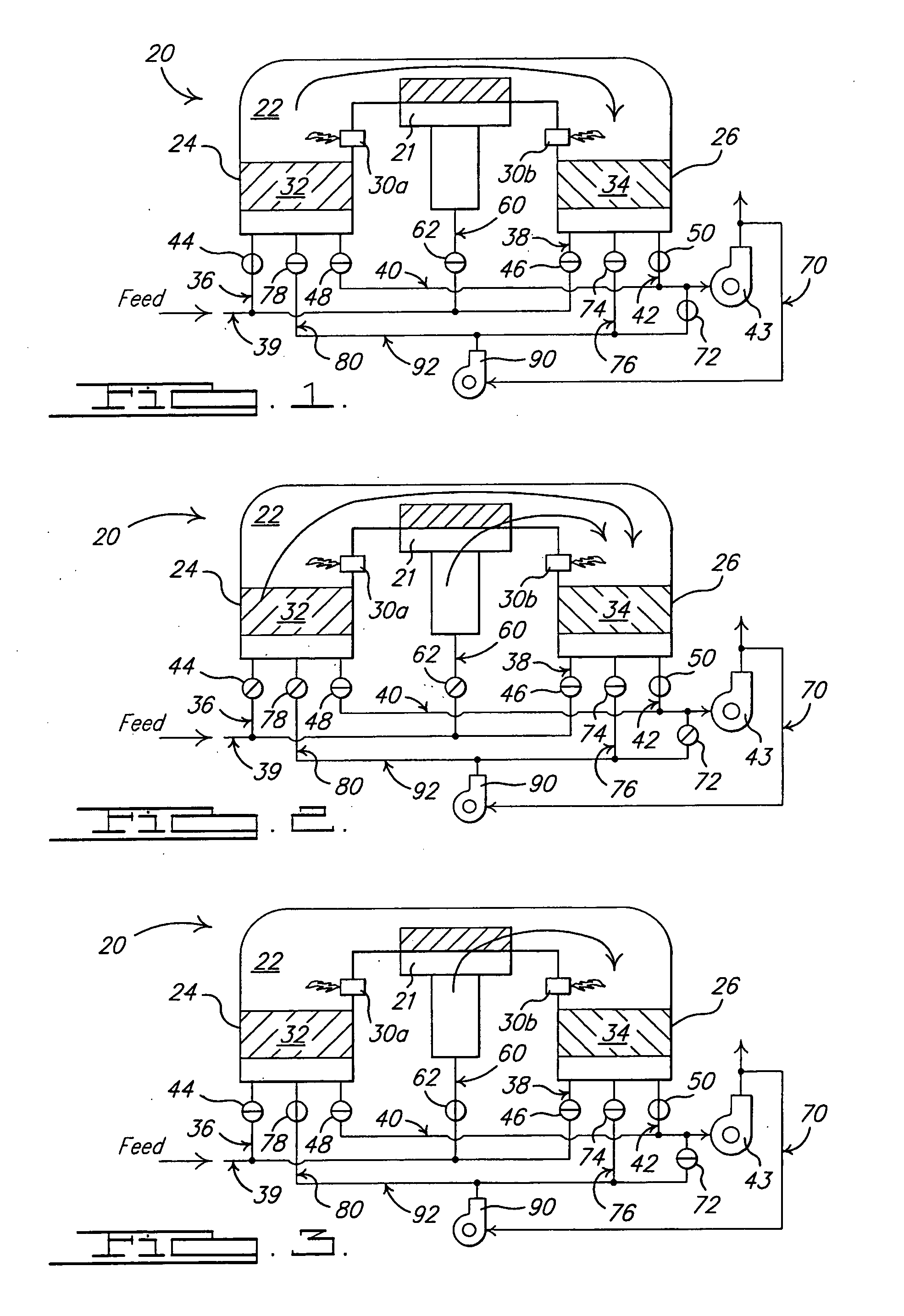

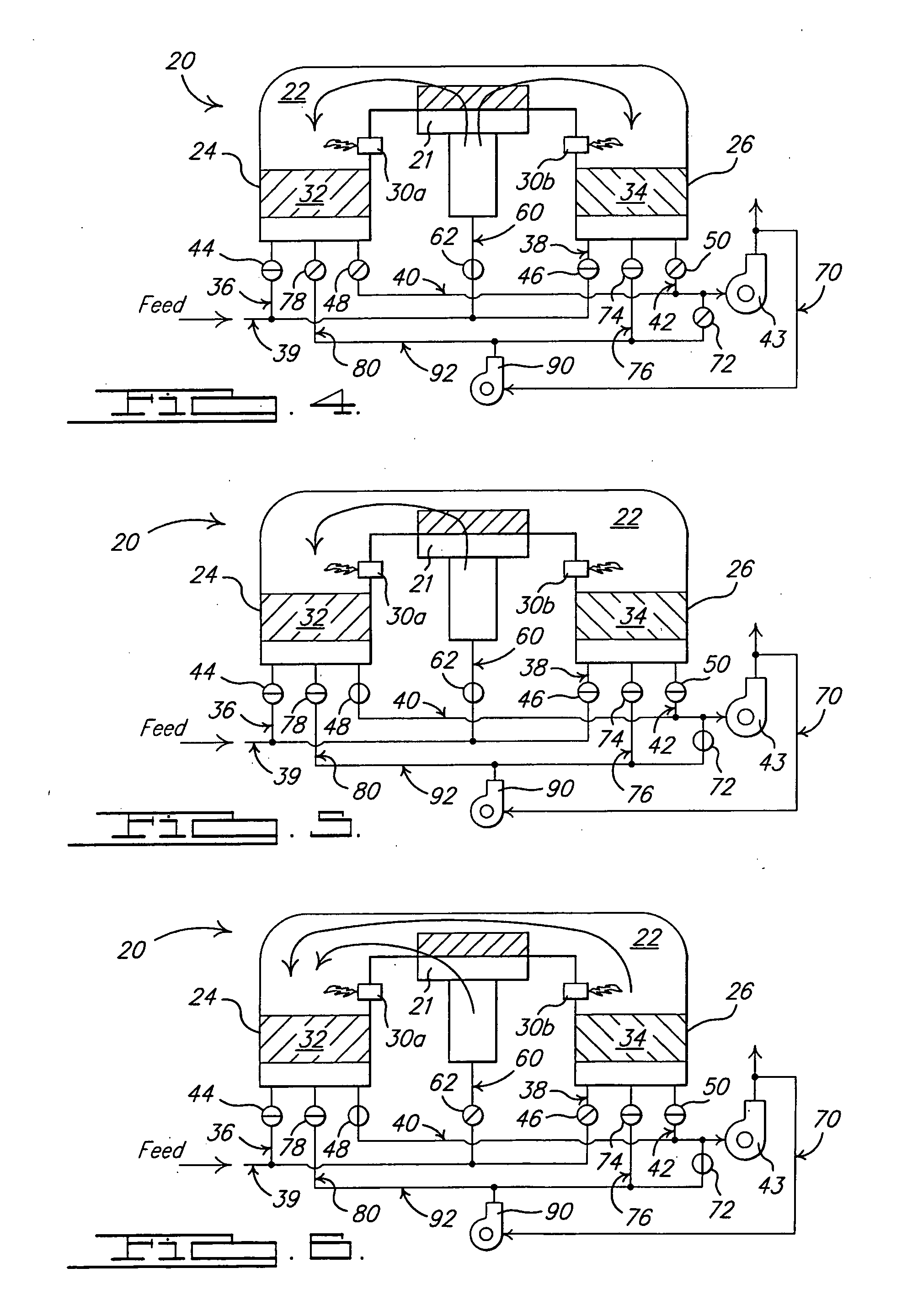

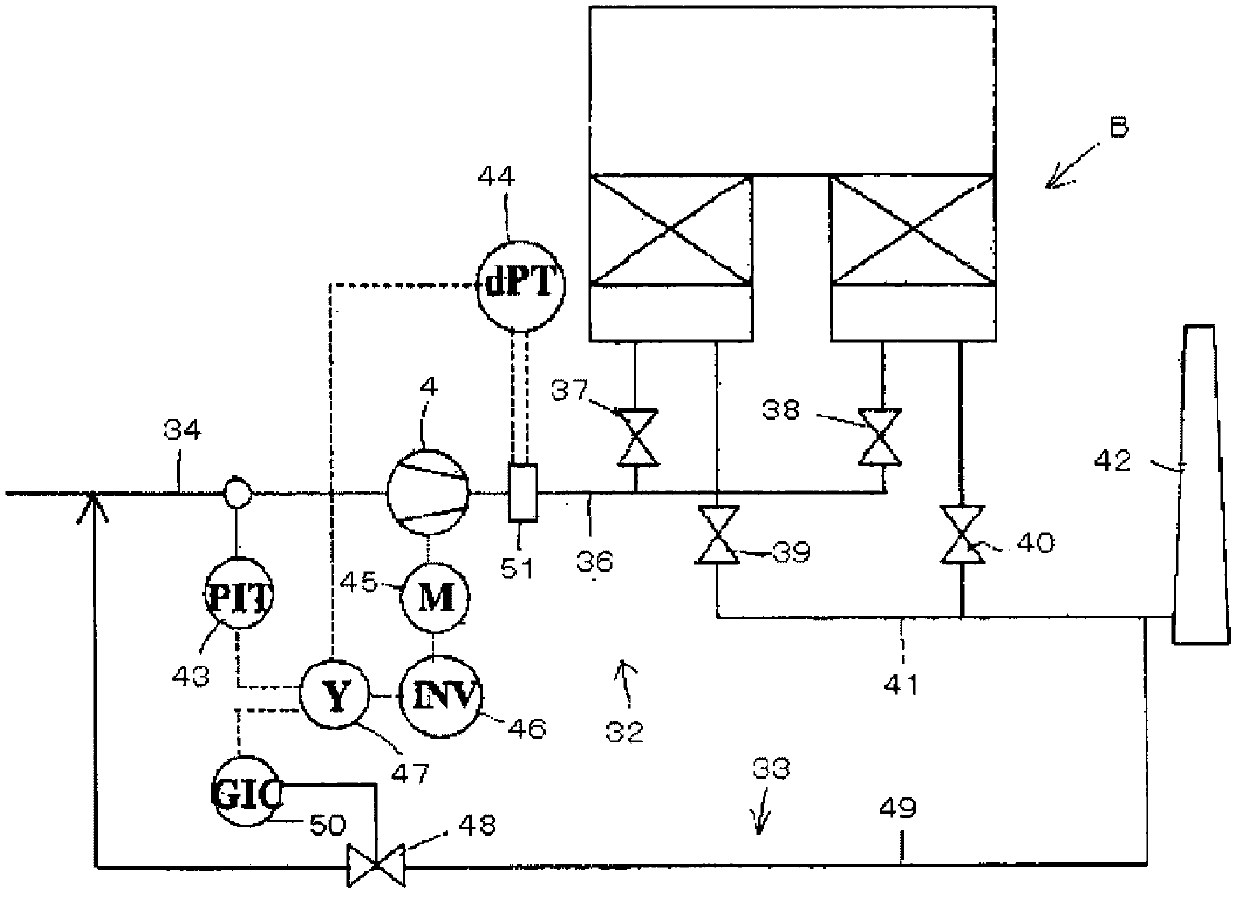

Regenerative thermal oxidizer

InactiveUS20060121403A1Constant fluid pressureKeep the pressureDomestic stoves or rangesStoves/ranges topsCombustion chamberControl system

A regenerative thermal oxidizer system (20) for use in processing a contaminated fluid. The system includes a combustion chamber (22), a contaminated fluid feed duct (39), and at least a first (24) and a second (26) regenerator chambers in fluid communication with the combustion chamber (22). A regenerator half-chamber (21) is provided in fluid and thermal communication with the combustion chamber (22). A first flow control element (44) is provided for controlling a flow of fluid from the system fluid feed duct (39) to the first regenerator chamber (24), and a second flow control element (46) is provided for controlling a flow of fluid from the system fluid feed duct (39) to the second regenerator chamber (26). An intermittent supply duct (60) connects the system fluid feed duct (39) to the regenerator half-chamber (21). A third flow control element (62) controls flow of system feed fluid through the intermittent supply duct (60). Feed fluid is directed either to one of the first (24) and second (26) regenerator chambers or to the half-chamber (21) prior to flowing into the combustion chamber (22) so that the fluid is are pre-heated prior to entering the combustion chamber (21).

Owner:THORNTON LYMAN L

Conical cyclonic oxidizing burner

InactiveUS20070254254A1Extended retention timeCost efficientFurnace componentsSolid fuel combustionCycloneCombustor

A method and device for improved efficiency in thermal oxidation is presented which uses a cyclonic flame to combust a stream of hydrocarbons drawn to the flame source by a pressure differential. The improved burner and method are particularly suited for combusting volatile organic compounds that are a derivative result of another waste management process mechanically attached to a thermal oxidizer. The improved burner is formed by configuring a burner basket into a conical shape with openings that allow a combustible gas to travel along the interior of the basket frame. The gas travels spirally within the basket frame as it is assisted by forced air and when ignited, creates a cyclonic flame effectively combusting material such as volatile organic compounds that are manipulated into contacting the flame.

Owner:SIMEKEN

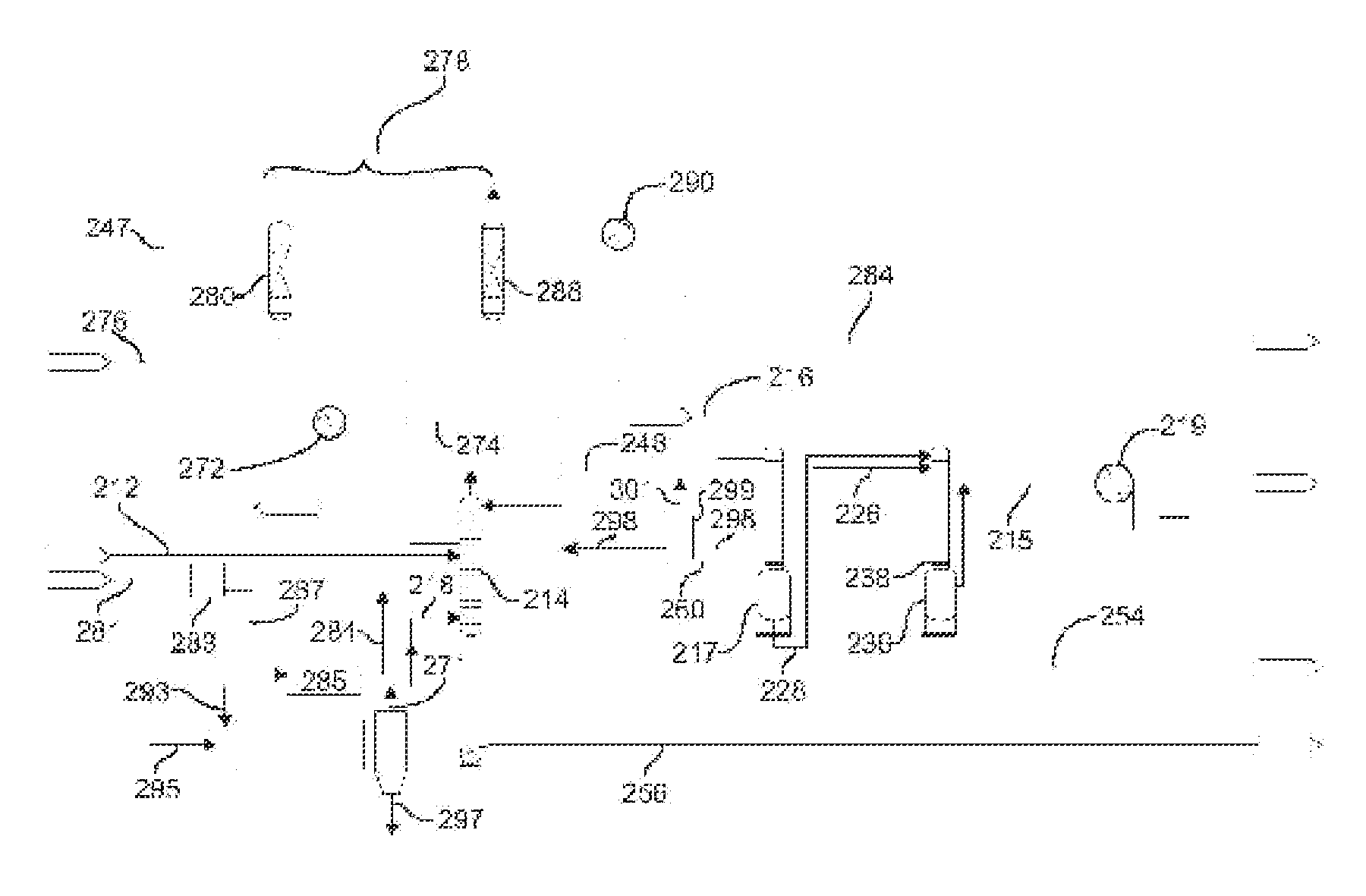

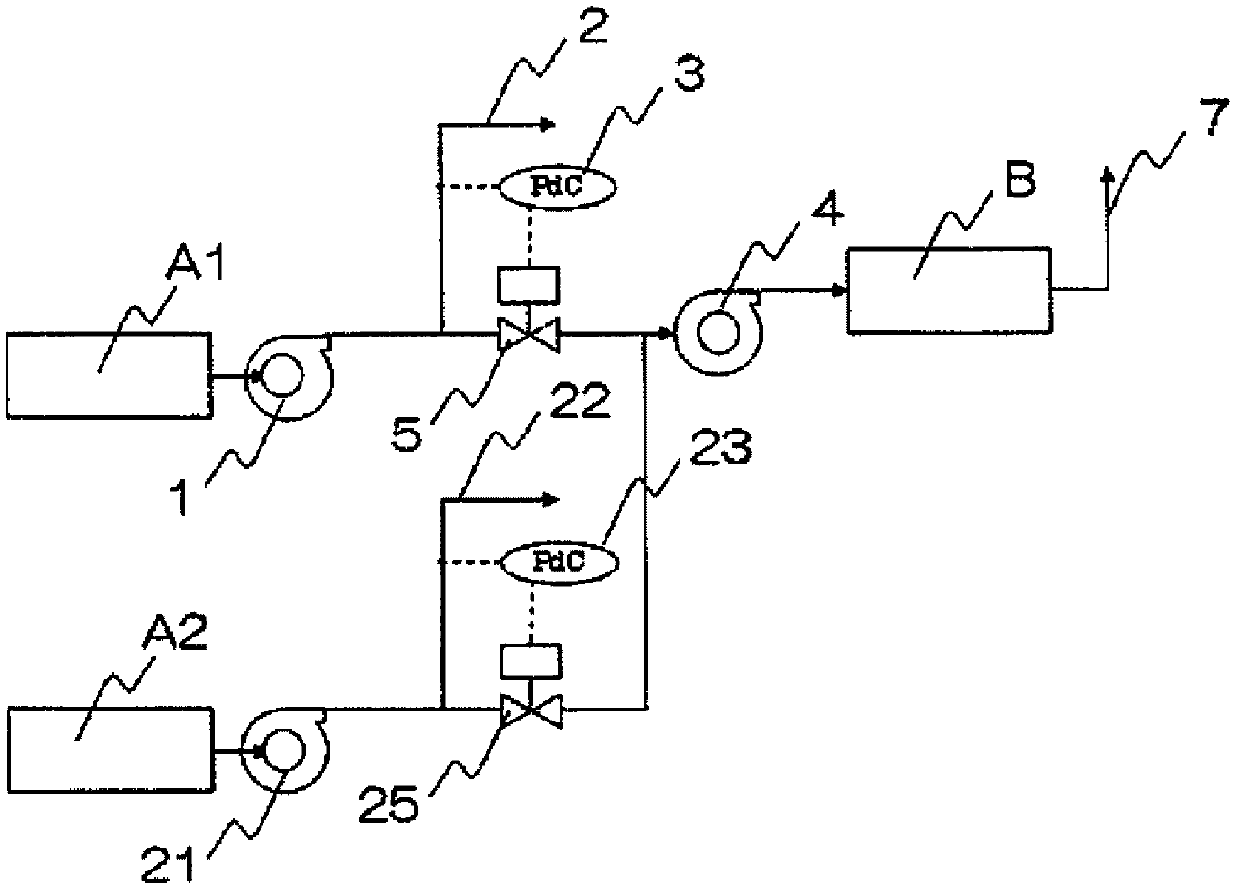

Regenerative thermal oxidization system and method for operating same

ActiveCN102498345AReduce the impactReduce dilutionIncinerator apparatusDraught inductionDifferential pressureAtmospheric air

Provided is a regenerative thermal oxidization system which solves the problem that a regenerative thermal oxidizer (RTO) is completely connected to production equipment by a duct when a damper open to the atmosphere is closed and, accordingly, a static pressure fluctuation generated when an inlet or outlet damper of the RTO is switched is transmitted to the production equipment via the duct, as well as the problem that there is a possibility that a duct open to the atmosphere, which is installed instead of the damper open to the atmosphere, functions as an atmospheric buffer and, accordingly, the amount of exhaust gas from the production equipment varies depending on the amount of production, and the leakage of the exhaust gas from the duct open to the atmosphere and the suction of atmospheric air occur. The regenerative thermal oxidization system is provided with a differential pressure transmitter whereby a duct open to the atmosphere, which is installed in an intake duct that connects the blower of the regenerative thermal oxidizer (RTO) and the exhaust blower of production equipment that generates exhaust gas, is connected to the control damper or the air blower operation inverter of the RTO, said damper or inverter being disposed between the differential pressure transmitter and the blower of the RTO.

Owner:SINTOKOGIO LTD

Waste gas treatment system based on runner concentration and regenerative combustion

PendingCN107469567AIncreased VOC concentrationReduce the processing air volumeGas treatmentDispersed particle separationOrganic solventCombustion chamber

The invention relates to a waste gas treatment system based on runner concentration and regenerative combustion. The waste gas treatment system comprises a filter, a runner concentration device and an RTO (regenerative thermal oxidizer), wherein the runner concentration device comprises a concentration runner and a drive motor, the concentration runner comprises an adsorption zone, a cooling zone and a desorption zone, and an adsorbent is arranged on the sector of the concentration runner; an outlet of the filter is connected with an inlet of the adsorption zone of the concentration runner through a fan; the RTO comprises a combustion chamber, a regeneration chamber, a regenerative body and a reversing valve. The waste gas treatment system has the advantages that the runner concentration device is added, the treatment air volume of organic waste gas entering the RTO can be effectively reduced, the concentration of organic solvent in organic waste gas entering the RTO can be increased, thus, the treatment efficiency of the RTO can be improved and the operation cost can be reduced.

Owner:首控环保设备(上海)有限公司

Two-stage thermal oxidation of dryer offgas

ActiveUS7654011B2Reducing VOC and CO contentLimit production of NOxDrying solid materials with heatDrying gas arrangementsAtmospheric airOxygen

A method and apparatus are provided for reducing the VOC, CO, and, alternatively, the NOx content of dryer offgas that is discharged into the atmosphere from a moist organic product drying process using thermal oxidizing apparatus that includes a burner, furnace, mixing chamber, thermal oxidizer, tempering chamber, and an indirect gas-to-gas heat exchanger. The dryer offgas is separated into two portions, with a larger portion being preheated by indirect heat exchange with the hot gaseous output from the thermal oxidizer. The non-preheated portion is directed to the burner in the function of flue gas recycle for NOx control. The preheated portion is separated into two portions, with one portion being directed to the furnace / mixing chamber of the thermal oxidizing apparatus. The other portion of the preheated offgas is recycled to the hot gas inlet of the dryer and serves the function of dryer heat transfer media. Ultimately, all the dryer offgas enters the thermal oxidizer, and comprises a smaller non-preheated portion directed to the burner and a larger preheated portion directed to the furnace / mixing chamber. By preheating a large proportion of the offgas directed to the thermal oxidizing apparatus, simultaneous achievement of an adequate thermal oxidizer temperature, 1600° F., and an adequate oxygen concentration of 5% by volume is achieved for optimized thermal oxidation of carbon monoxide and volatile organic compounds.

Owner:AEROGLIDE

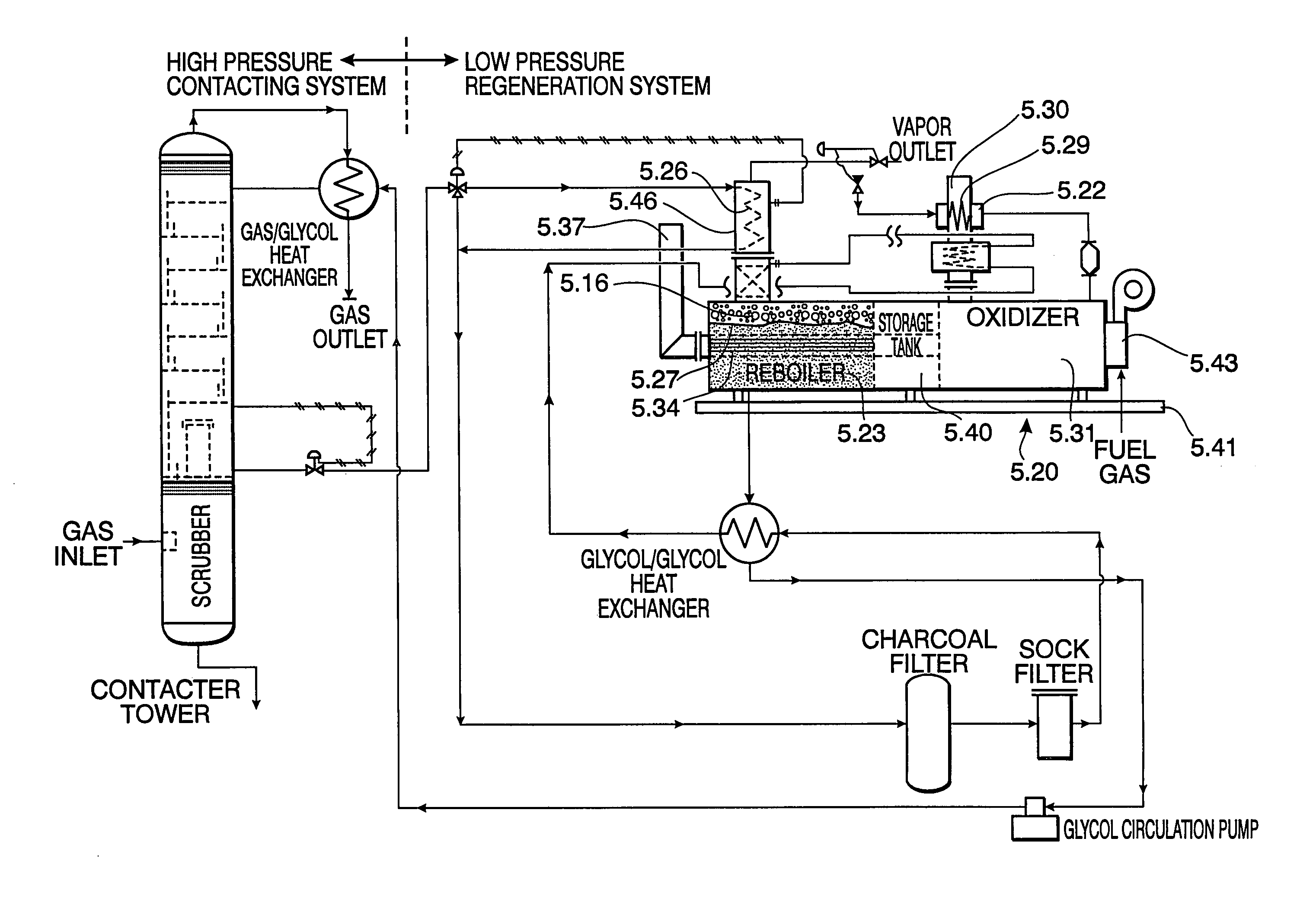

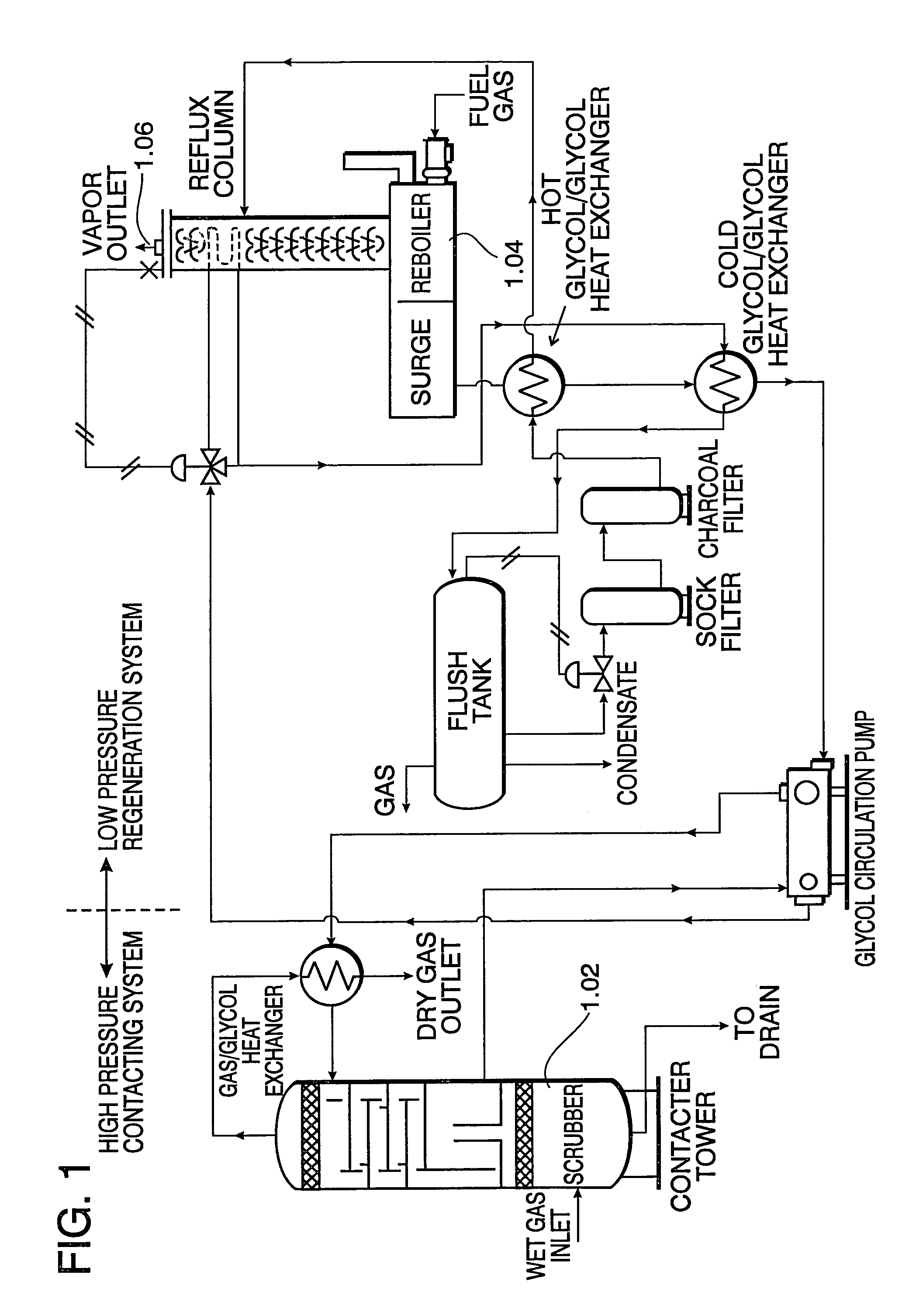

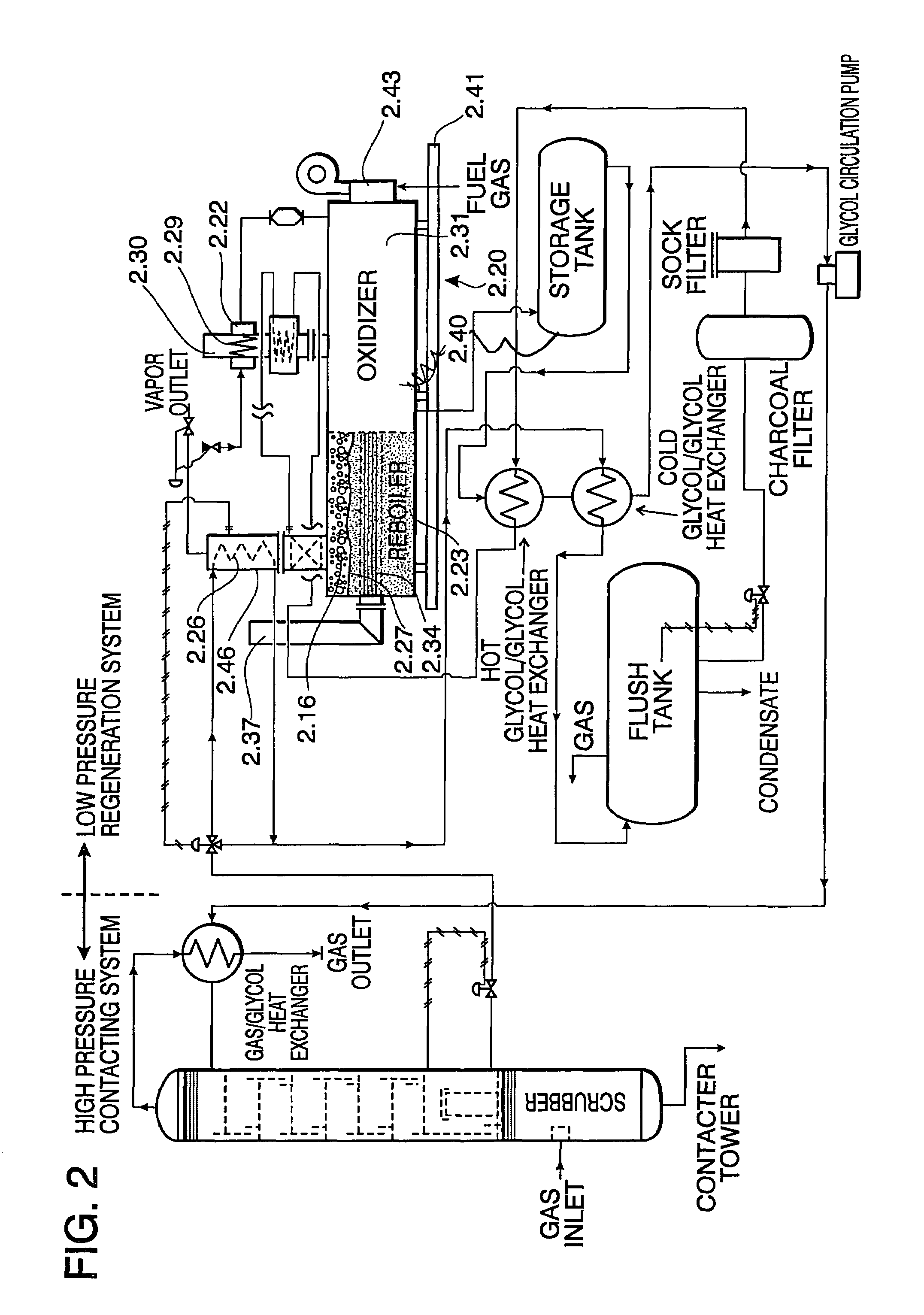

Oxidizing undesired compounds resident within liquid absorbent compounds, reducing atmospheric pollution, regenerating a liquid absorbent and conserving fuel usage associated with reboiler utilization

InactiveUS6964729B1Promote oxidationRetain heatLiquid degasificationOrganic compound preparationCombustion chamberReboiler

An improved method and apparatus for oxidizing undesired compounds residing within a liquid glycol based absorbent wherein the compounds are heated within a reboiler chamber to their boiling point to effectuate production of vaporized effluents. The absorbent's vaporized effluents rise upwardly exiting the reboiler chamber and enter a reflux tower wherein they are partially condensed via a condenser embodied within the interior of the tower. The residual uncondensed effluents are then transported to and first heated via a vaporizer / heat exchanger, thus effectuating the vaporization of any ambient condensed liquids contained within the effluents. The revaporized effluents then enter the invention's thermal oxidizer combustion chamber where they are second heated to a temperature necessary to effectuate destruction of undesirable compounds, such as but not limited to benzene, toluene and xylene. A temperature control throttling mechanism throttles the introduction of supplemental gas as necessary to maintain the temperature necessary to effectuate and maintain destruction of undesirable compounds. The combustion chamber is in fluid communication with a plurality of tubes which pass through the reboiler. The tube bundle generates external tube surface temperatures sufficient to raise a liquid glycol based absorbent in contact therewith to its boiling point. The second heated effluents are then introduced to and through a thermal oxidizer vent stack allowing for the exiting of said effluents. Venting mechanisms located in the invention's still / reflux tower and oxidizer vent stack are controlled in a coordinated manner to ensure temperature consistency of effluents traversing the invention's internal combustion chamber and tube bundle.

Owner:KHOSROWYAR PARVIZ

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com