Air extracting and heating coal mine ventilating gas thermal oxidizer unit

A technology of wind gas and thermal oxidation, which is used in gas emission, safety devices, mining equipment, etc., can solve the problems of high temperature resistance performance of the extraction system, affecting the operation stability of the oxidation device, and increasing the manufacturing cost of the oxidation device. To achieve the effect of shortening the heating and starting process, improving operation stability and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

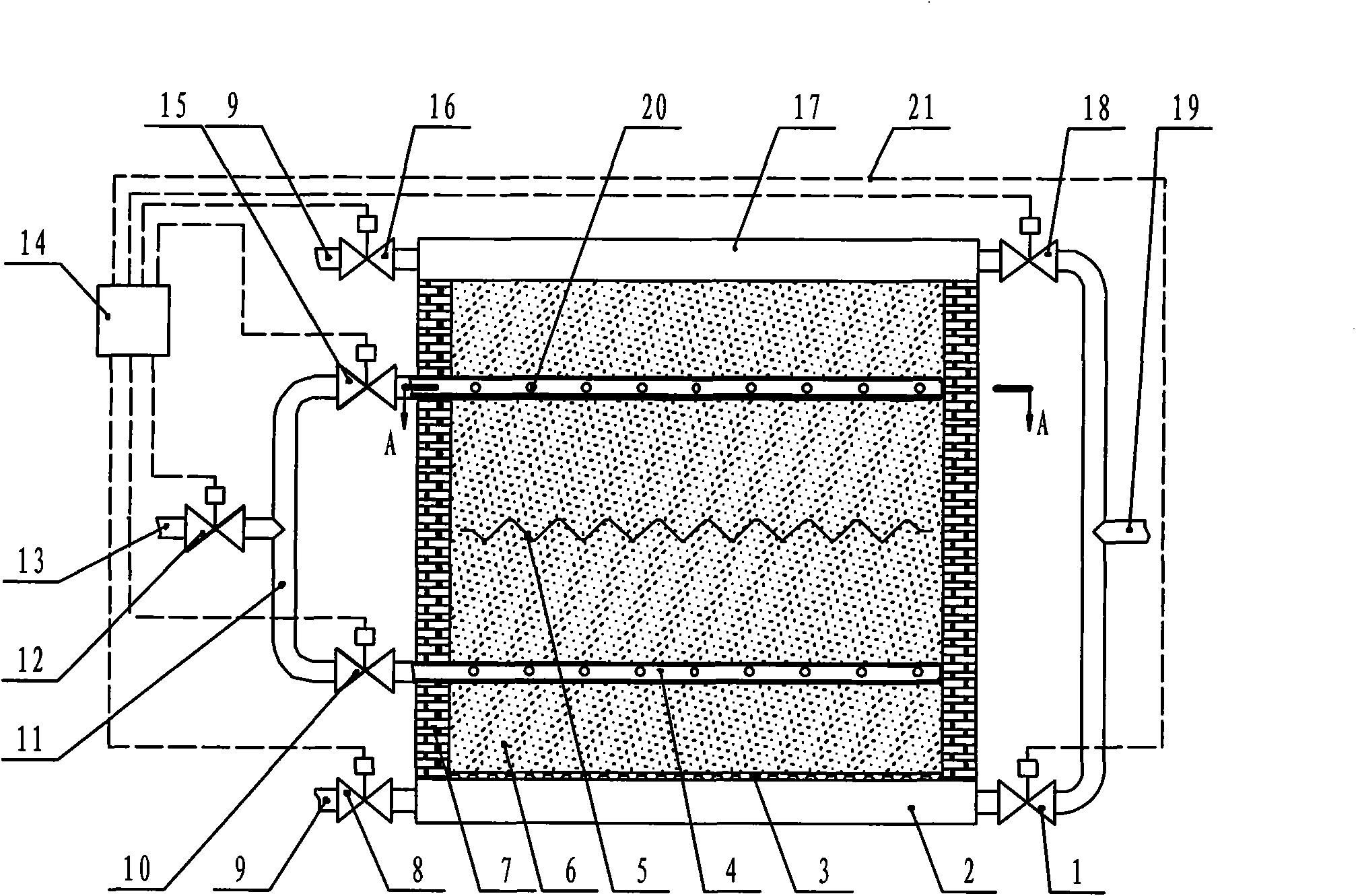

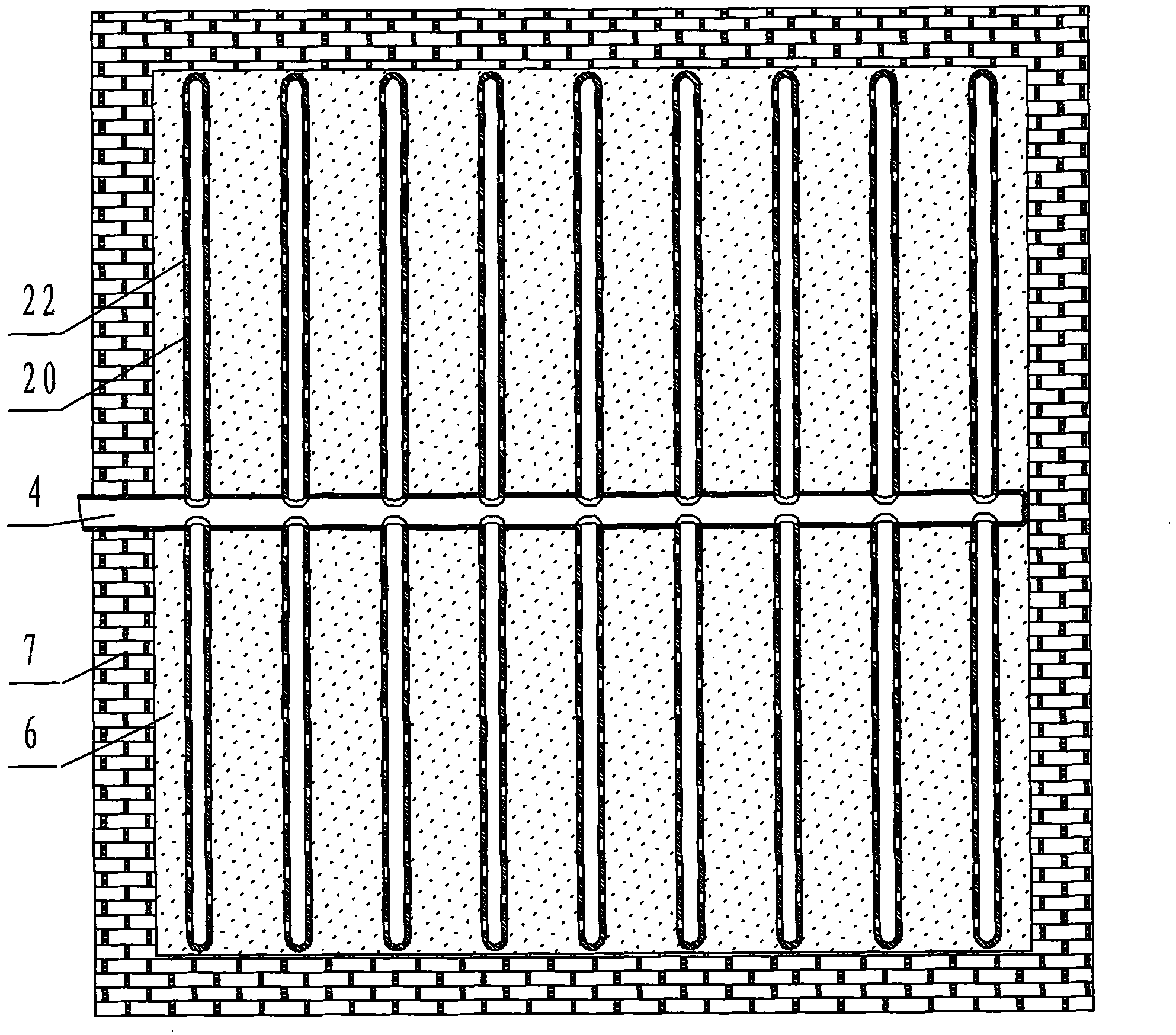

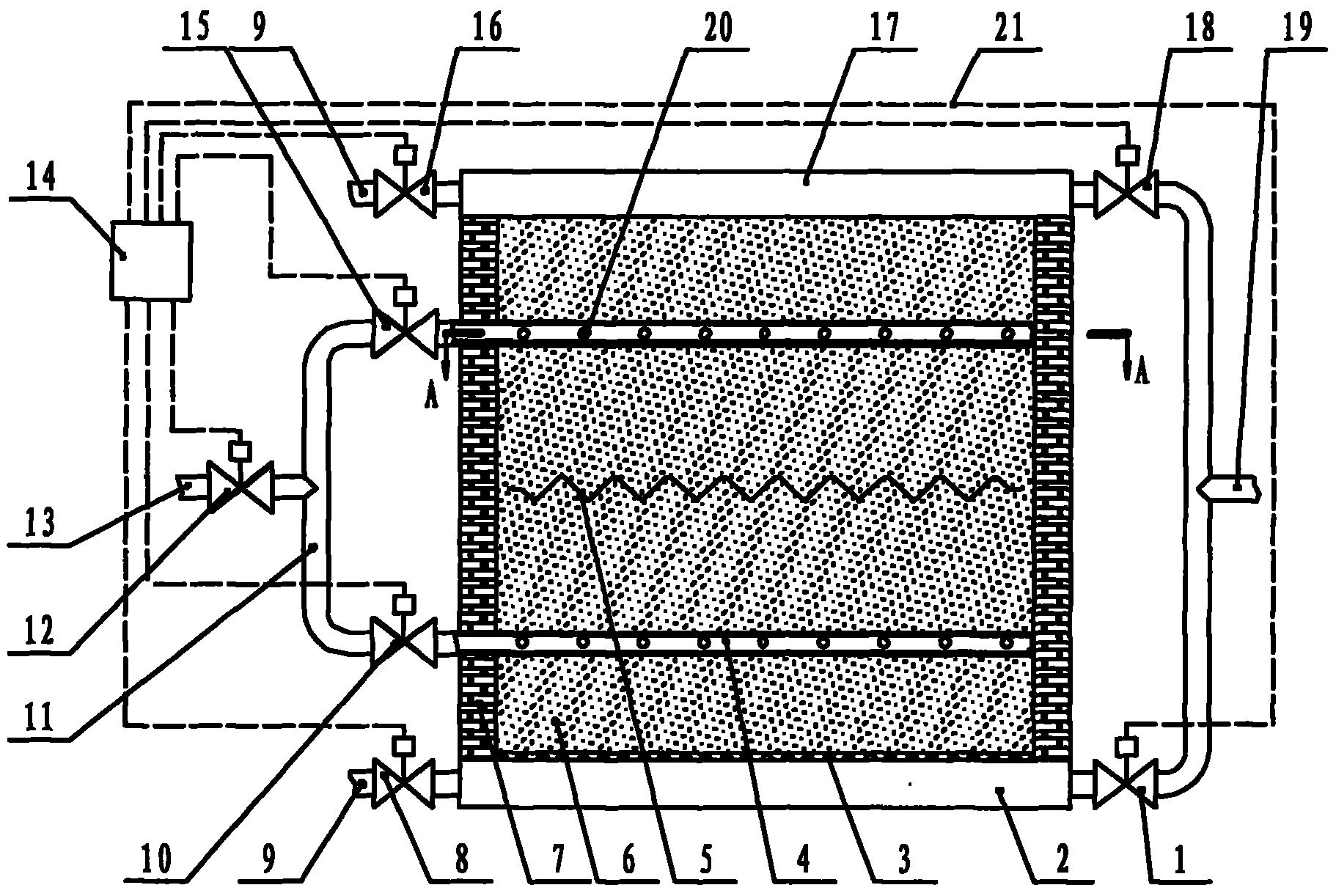

[0021] in figure 1 with figure 2 In the illustrated embodiment: the oxidation bed 6 of the coal mine exhaust air gas thermal oxidation device is a vertical structure, surrounded by heat preservation and refractory materials 7, the bottom is provided with a supporting net 3, and the inner center is provided with a heater 5; The box 17 is arranged in the upper part of the oxidation bed 6, one end is connected to the exhaust air inlet pipe 19 through the fourth reversing valve 18, and the other end is connected to the exhaust gas outlet pipe 9 through the third reversing valve 16; the lower gas collecting box 2 is provided In the lower part of the oxidation bed 6, one end is connected to the exhaust air inlet pipe 19 through the first reversing valve 1, and the other end is connected to the exhaust gas outlet pipe 9 through the second reversing valve 8; two in the air extraction and heat extraction system The exhaust manifold 4 is symmetrically arranged on the upper and lower sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com