Patents

Literature

84results about How to "Precise movement control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

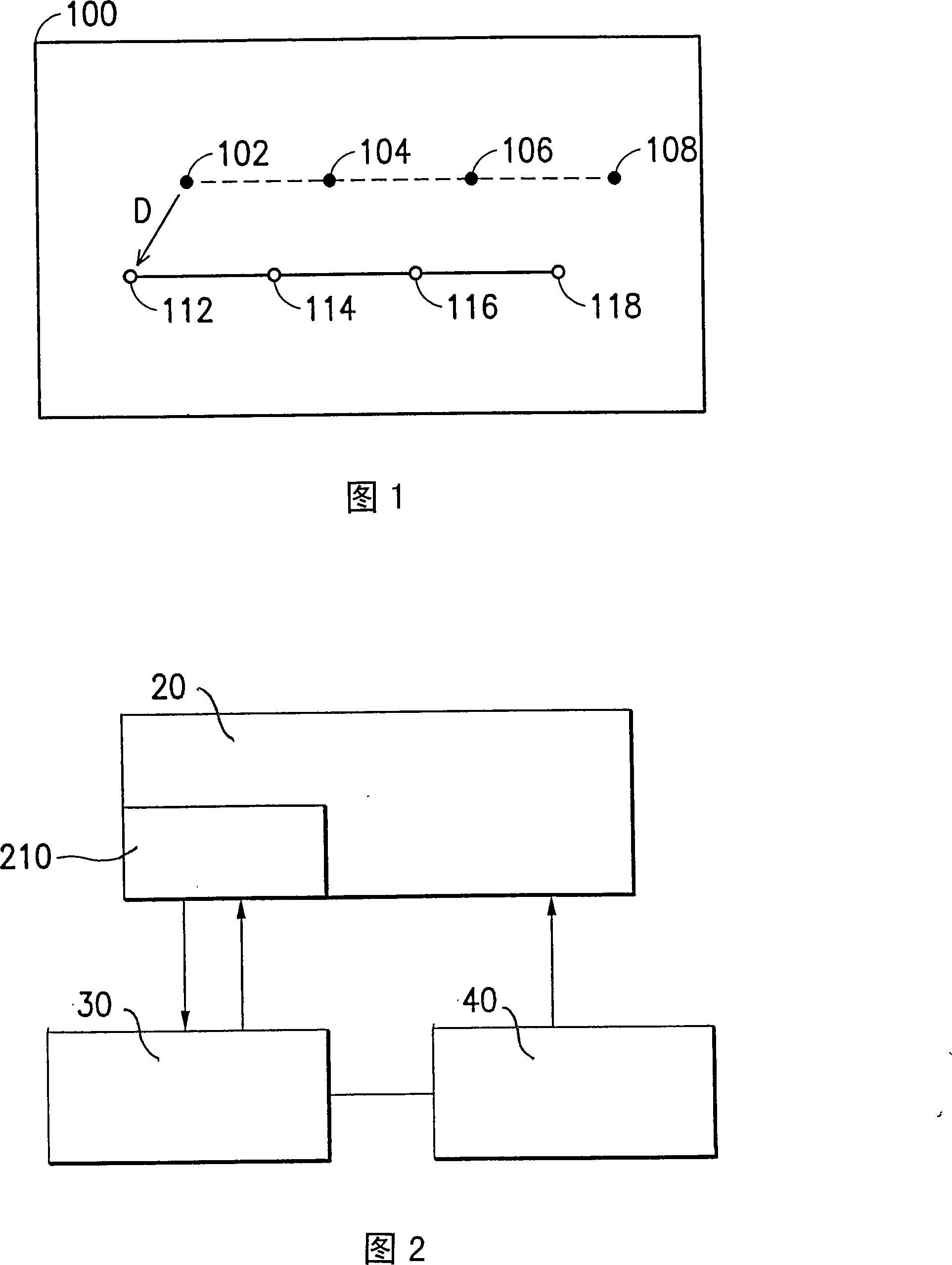

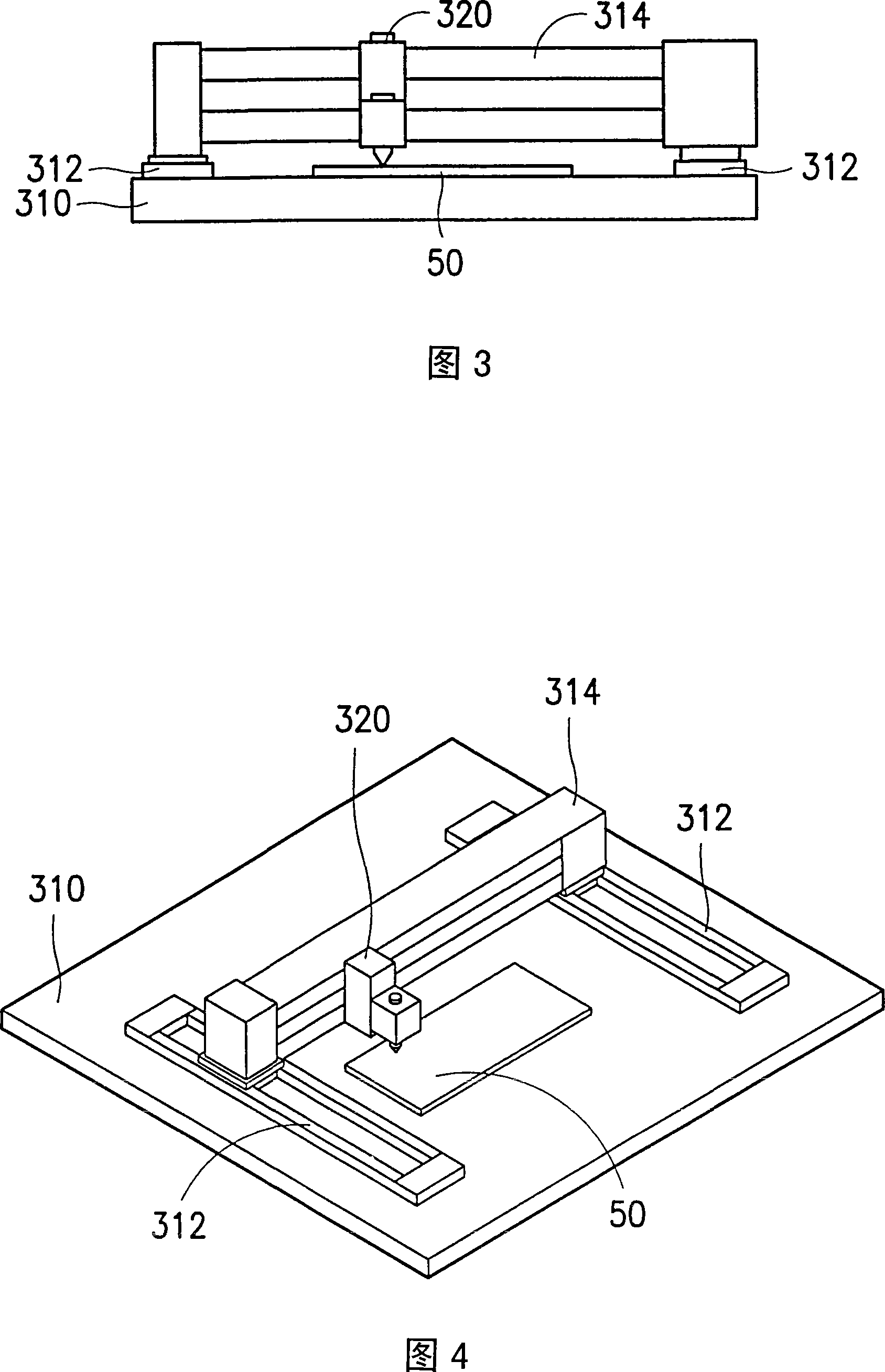

Touch panel test device and method

InactiveCN101187685AEliminate the disadvantages of misjudgmentPrecise movement controlDigital circuit testingError detection/correctionComputer hardwareTouchscreen

The invention discloses a device for testing toughing screens, which is characterized in that the invention comprises computer equipment, a point pressure testing machine, and a measuring control adapting card. The invention also discloses a method for testing the touching screens, which comprises arranging a standard screen whose testing results have been known into the point pressure testing machine, inputting testing parameters into the computer equipment, testing the standard screen according to a test of a testing standard point, obtaining a testing standard value, storing the testing standard value into the computer equipment, arranging a testing touching screen into the point pressure testing machine, deciding and correcting the testing point of the testing screen, and testing the testing point, obtaining the testing results after comparing the testing value with the testing standard value, and storing and outputting the testing results. The invention can be used to eliminate the defects of testing results erroneous judgments due to machine positional errors of the point pressure testing machine, tests aren't limited into moving speeds; quality can be decided through only one test according to the touching screens in different types and dimension specifications.

Owner:张福尧

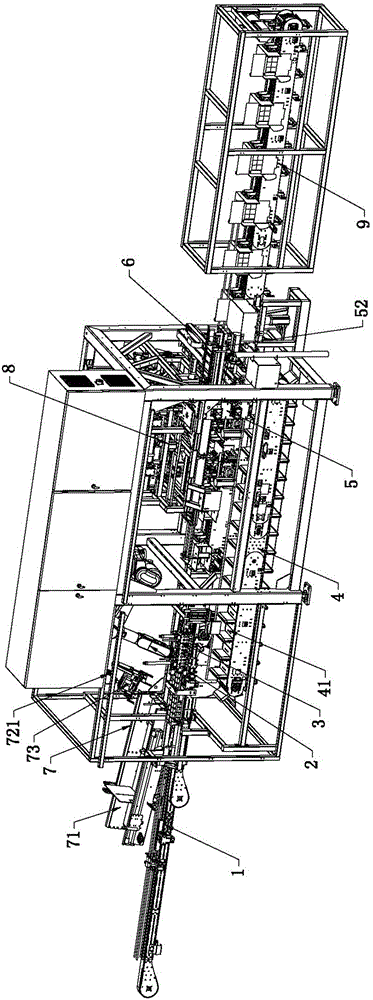

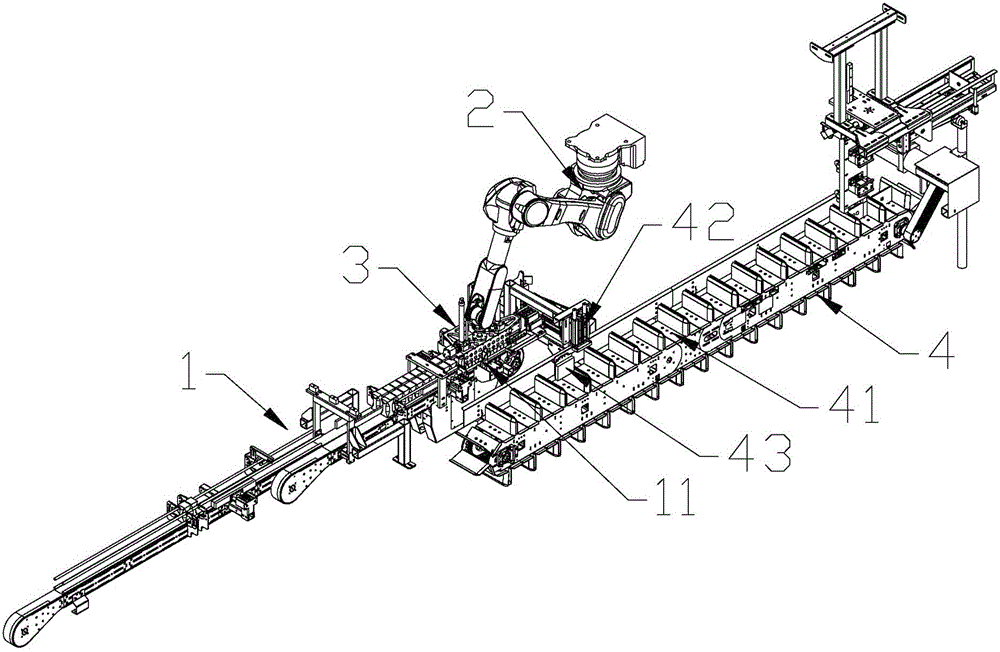

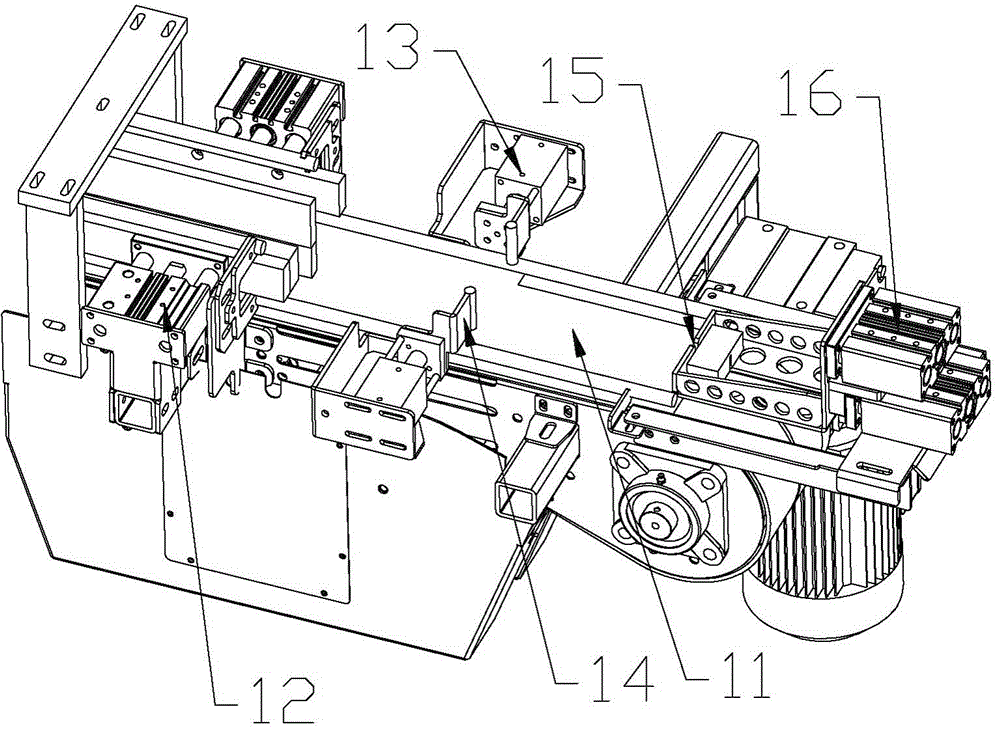

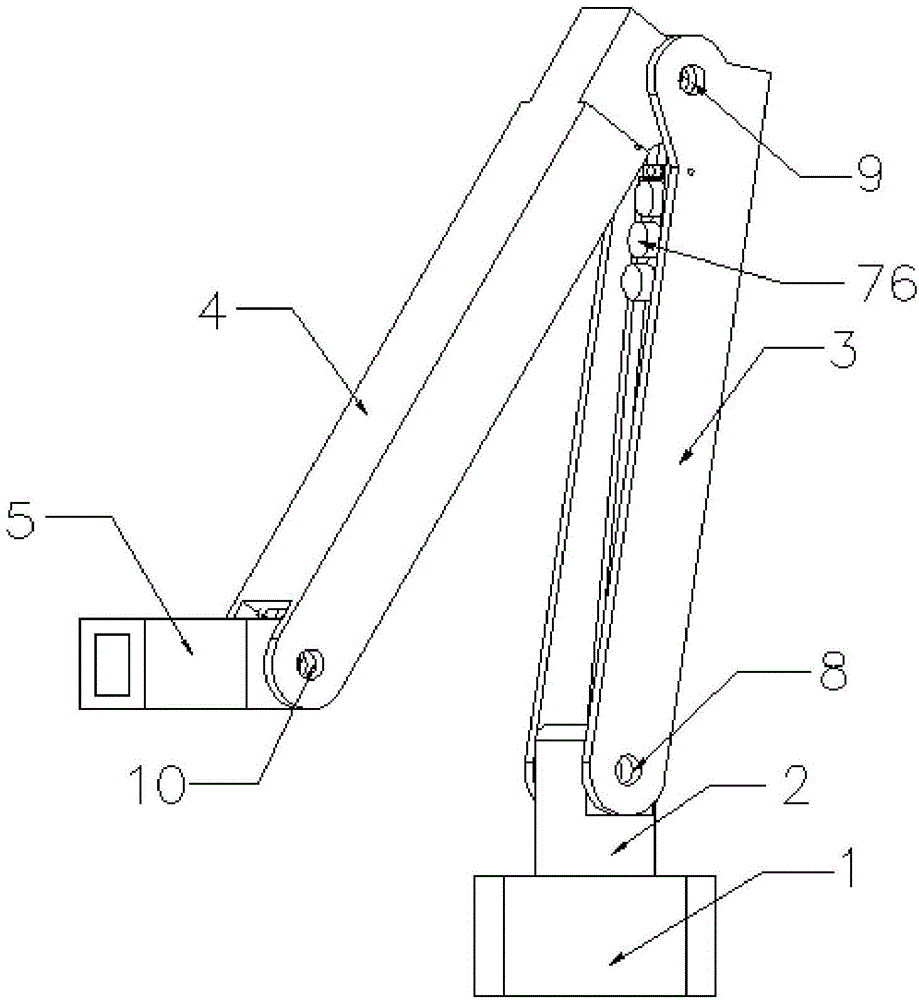

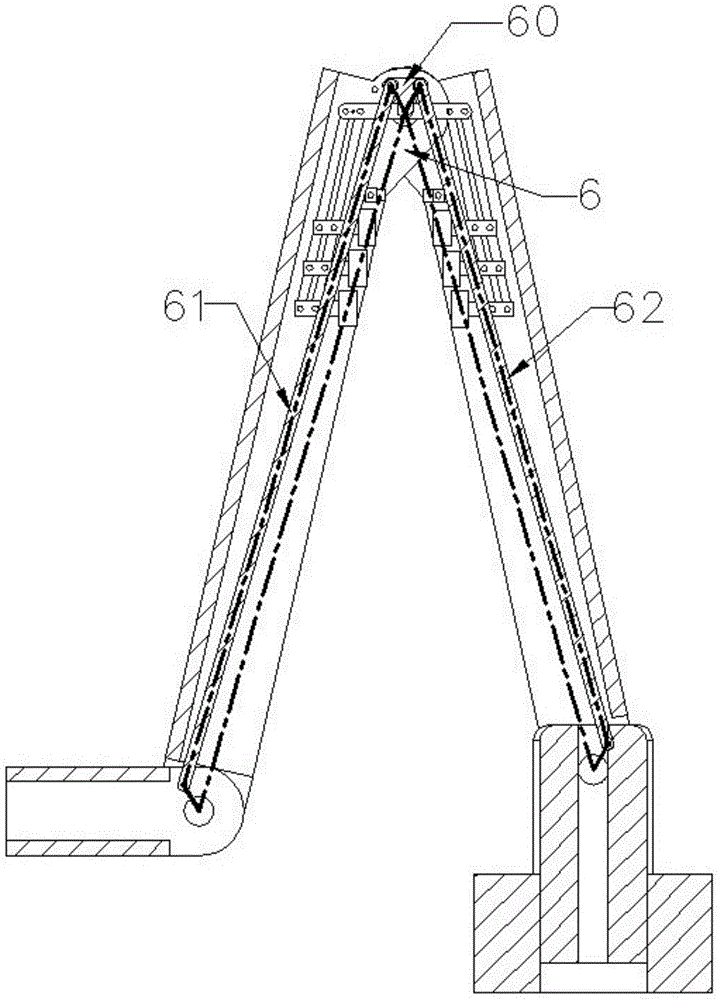

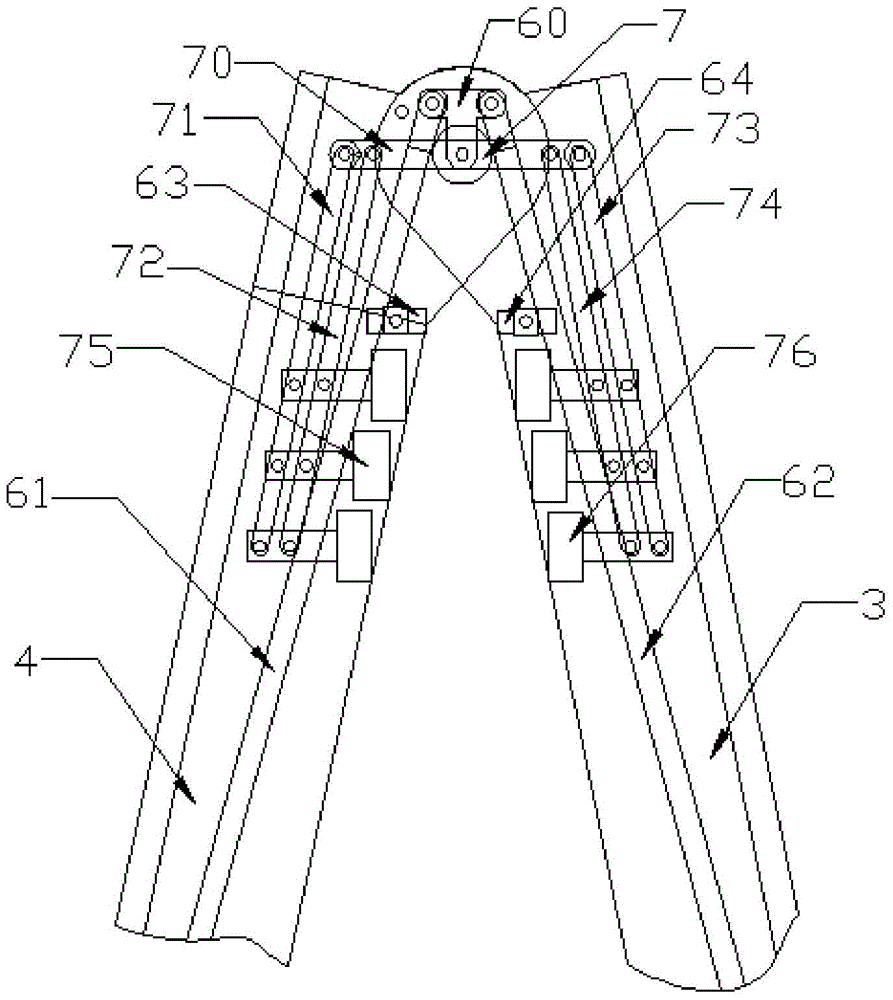

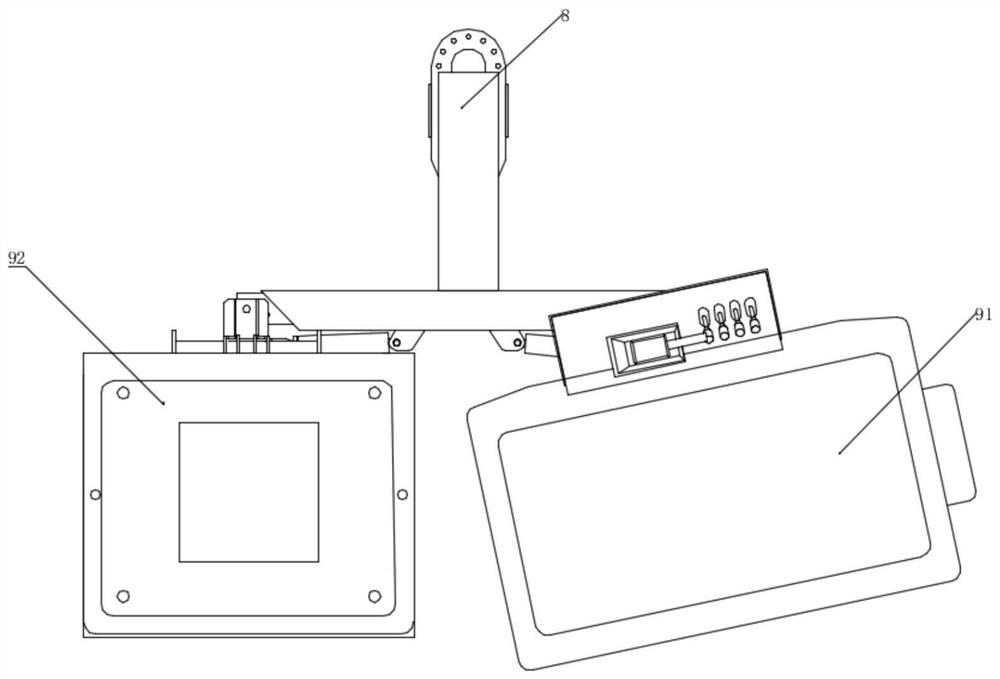

Automatic encasement system for Lilezuan milk bag gift boxes

ActiveCN104828288ASolve the problem that it is difficult to vertically transport automatic packingPrecise movement controlIndividual articlesEngineeringWorkload

The invention discloses an automatic encasement system for Lilezuan milk bag gift boxes. The automatic encasement system comprises a milk bag integration conveying line (1), a milk bag robot (2) and a milk bag unit conveying line (4), wherein a milk bag clamp (3) at the lower end of a manipulator of the milk bag robot (2) catches a milk bag unit on the milk bag integration conveying line (1) and pushes the milk bag unit into a corresponding milk bag unit separation slot (41) under the condition that the milk bag unit is in a horizontal state; then a small baffle plate insertion machine (5) inserts a small baffle plate into a middle clearance of the milk bag unit, and a horizontal pushing mechanism (6) is used for horizontally pushing the milk bag unit with the inserted small baffle plate into a packaging case already provided with a large lining plate on a packaging case conveying line (9); finally the packaging case already provided with the large lining plate, the small baffle plate and the milk bag unit is covered and encased to finish the whole automatic encasement process. According to the automatic encasement system for the Lilezuan milk bag gift boxes, the milk bag encasement operation is creatively changed from vertical encasement into horizontal encasement, so that the production operation is more stable, the maintenance is easy and convenient, and the workload can be reduced to the maximum extent.

Owner:苏州澳昆智能机器人技术有限公司

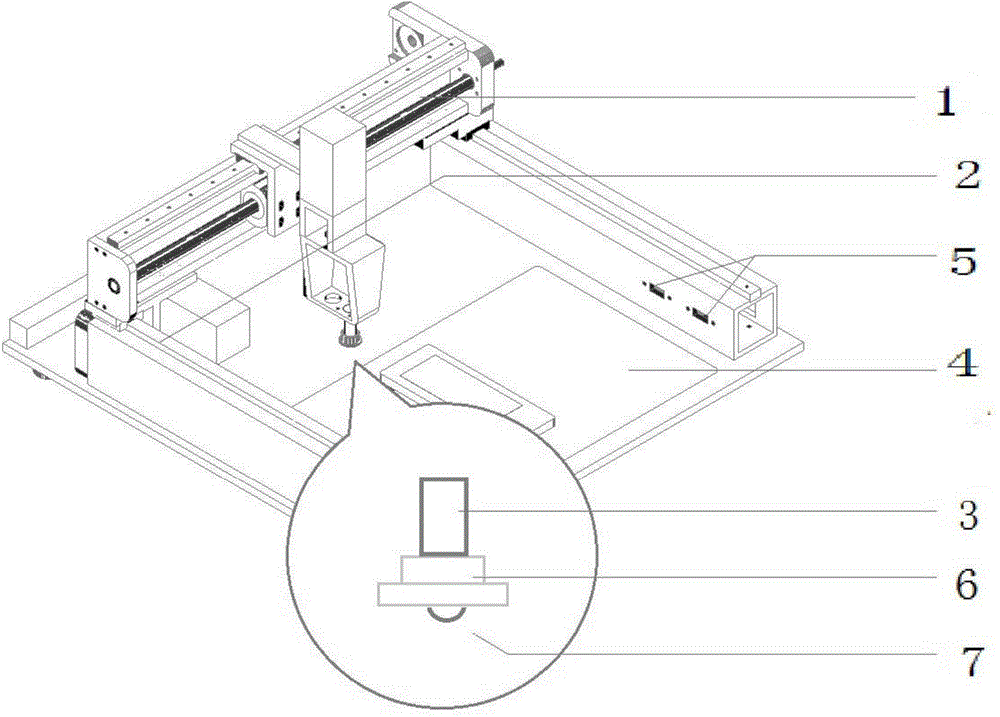

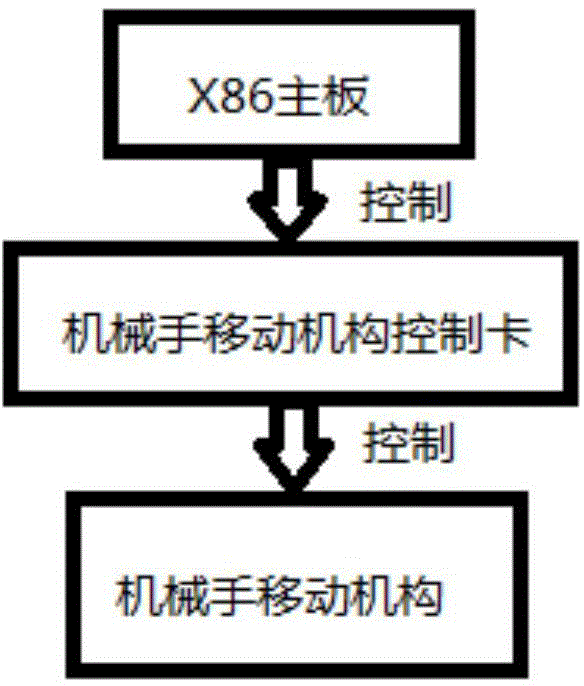

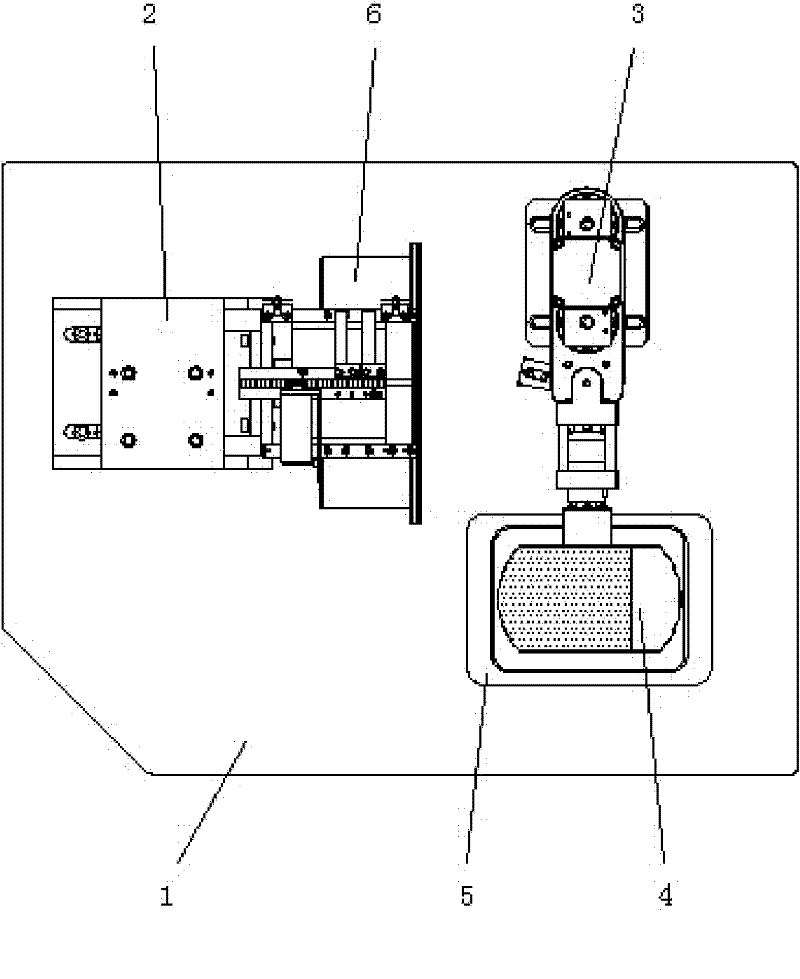

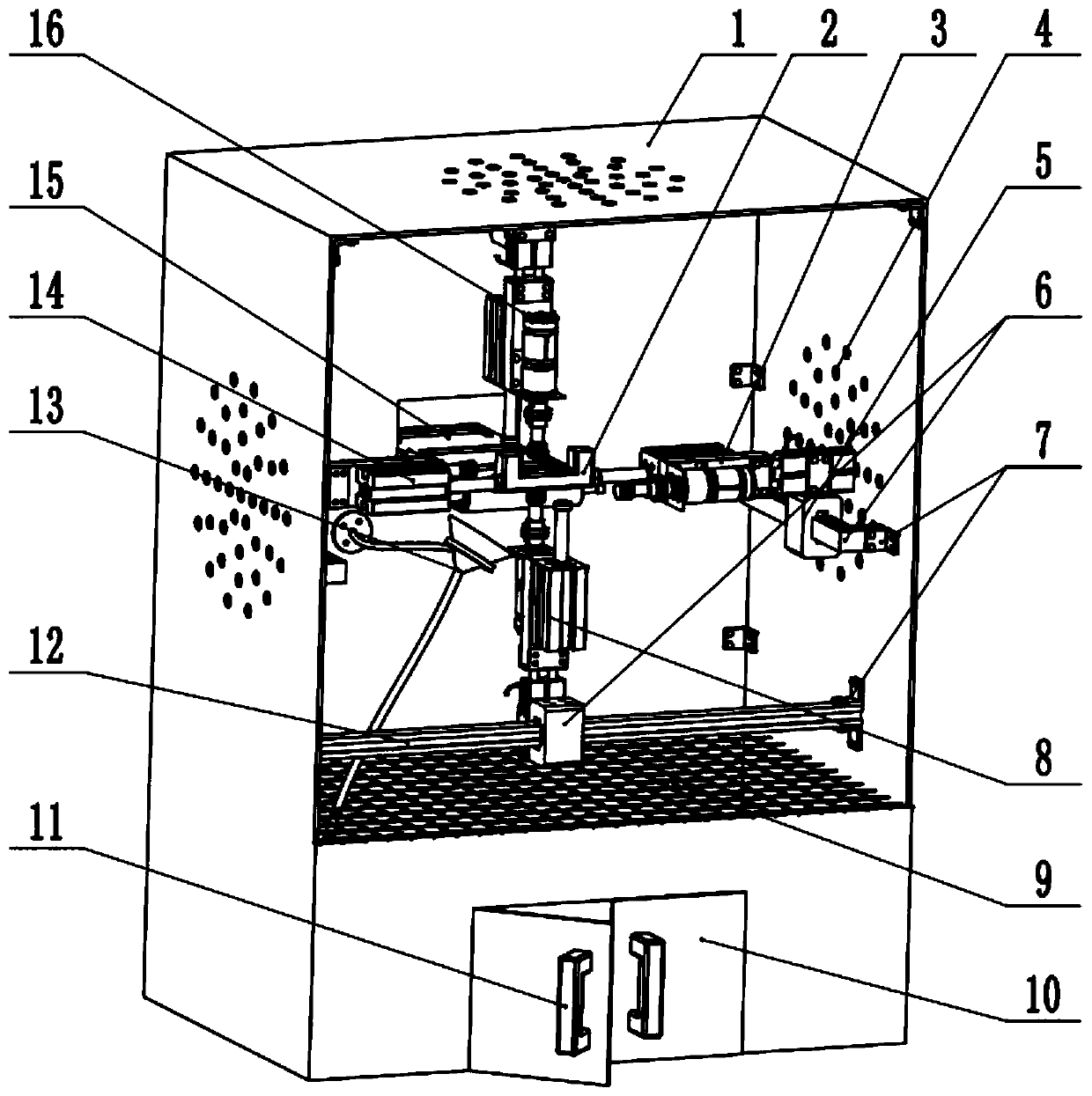

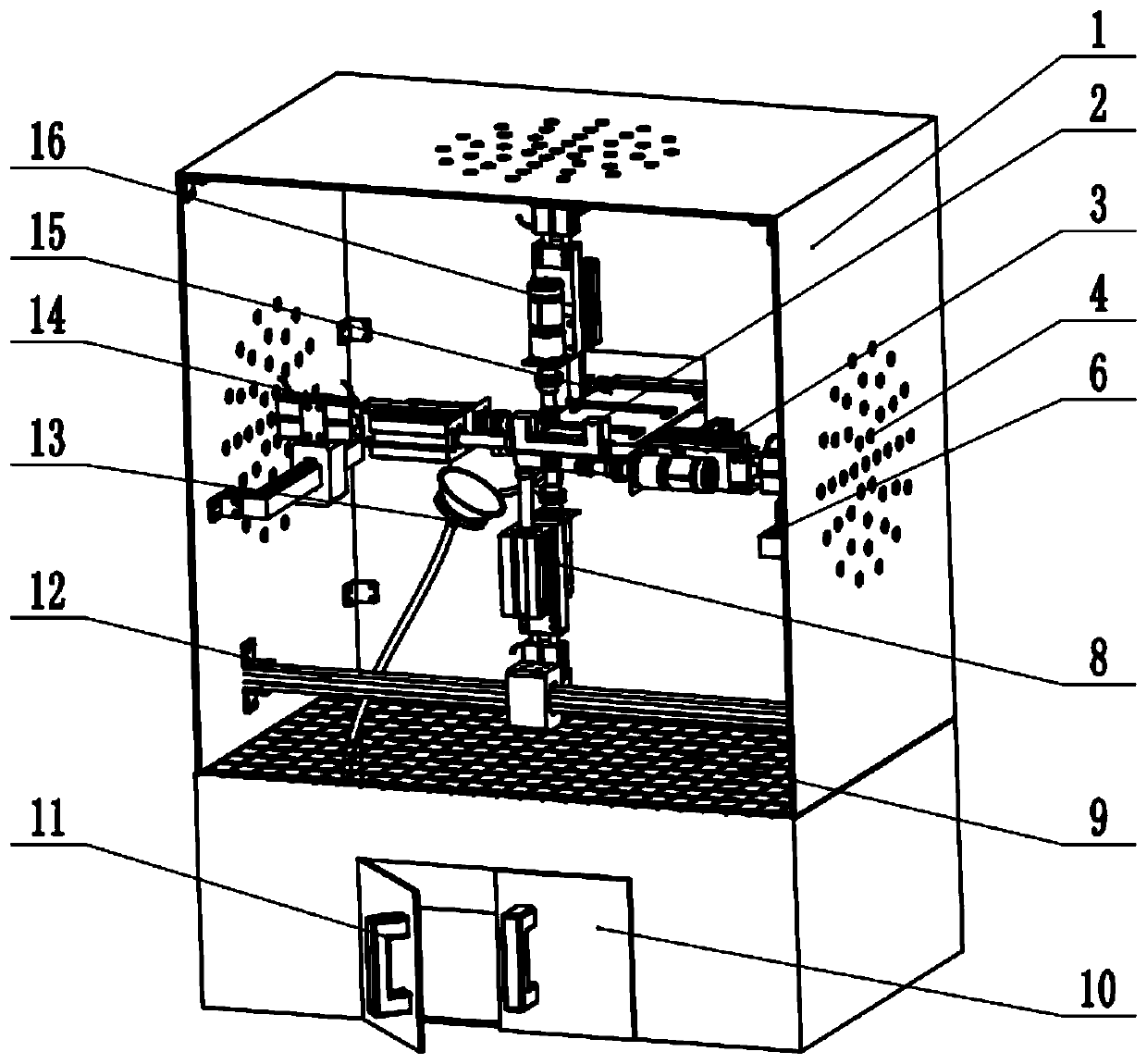

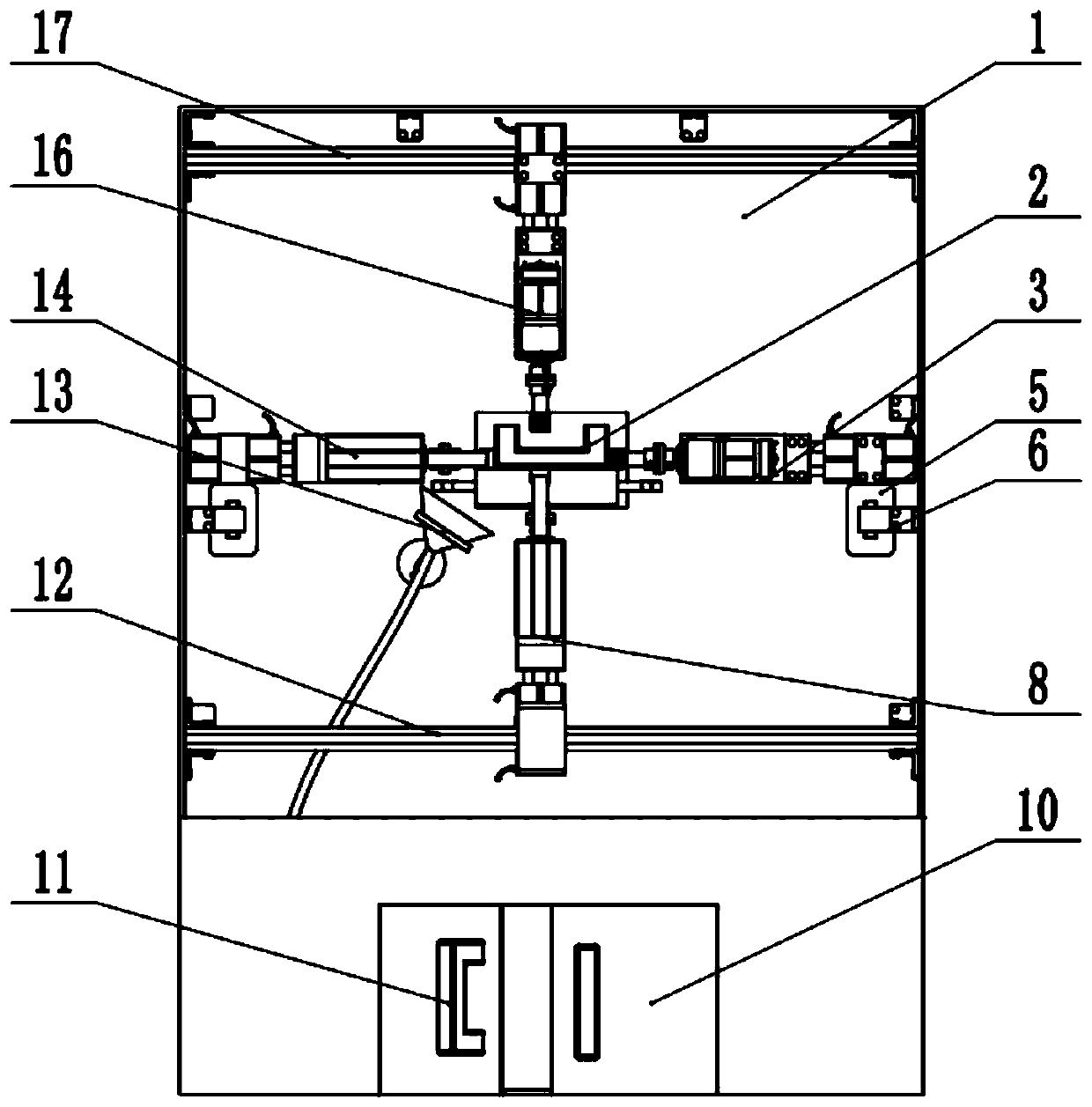

Manipulator device for automatic testing of mobile phone and use method

ActiveCN104608120APrecise movement controlGuaranteed progressProgramme-controlled manipulatorSubstation equipmentThree-dimensional spaceEngineering

The invention provides a manipulator device for automatic testing of a mobile phone. The manipulator device comprises a box, an X86 mainboard, a manipulator moving mechanism control card, a manipulator moving mechanism, a manipulator, a camera and a tray. The X86 mainboard, the manipulator moving mechanism control card, the manipulator moving mechanism, the manipulator, the camera and the tray are located in the box, the X86 mainboard is connected with the manipulator moving mechanism control card, the manipulator moving mechanism control card drives the manipulator moving mechanism, the manipulator is arranged on the manipulator moving mechanism which is of a three-dimensional space moving structure, the camera is connected with the X86 mainboard through a network and located over the tray, and the tray is located below the manipulator. The manipulator device can be used for replacing manual operation, assists in completing automatic testing of the mobile phone and guarantees the schedule and quality of testing work.

Owner:天津市康凯特软件科技有限公司

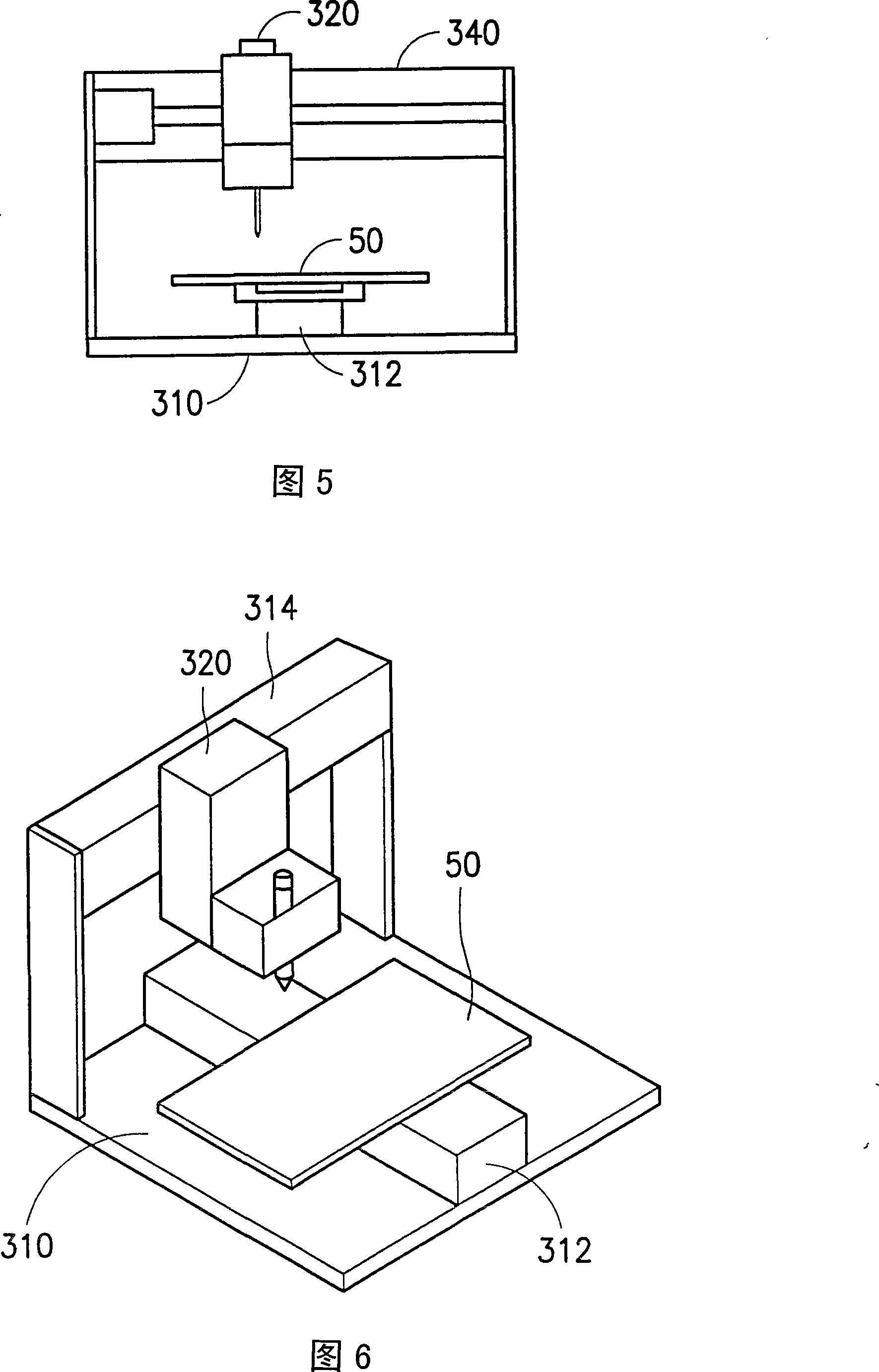

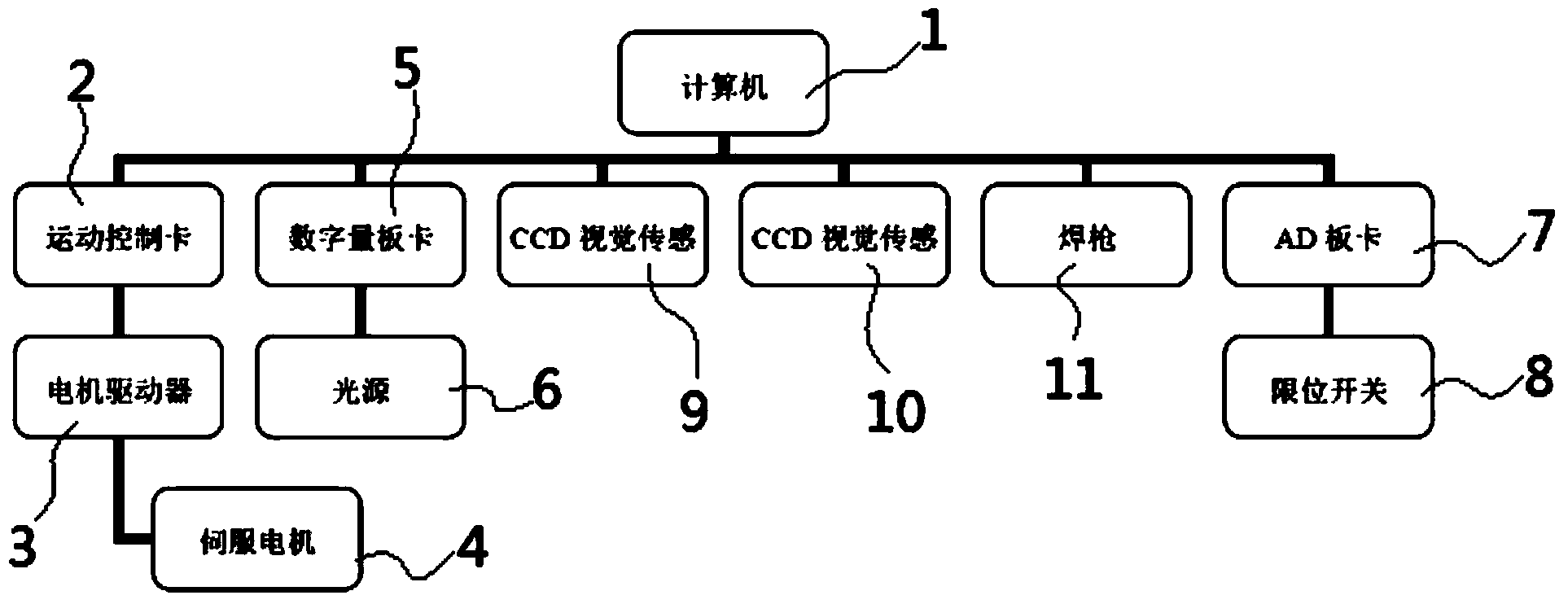

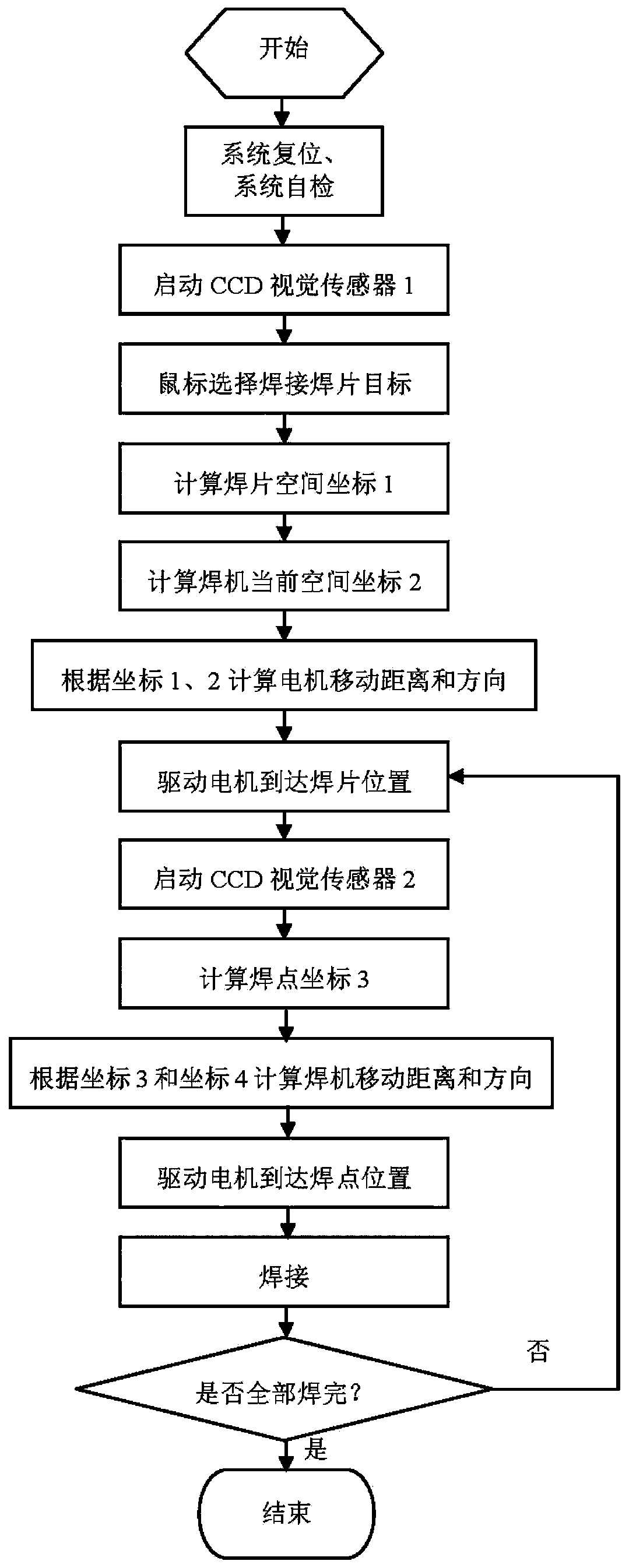

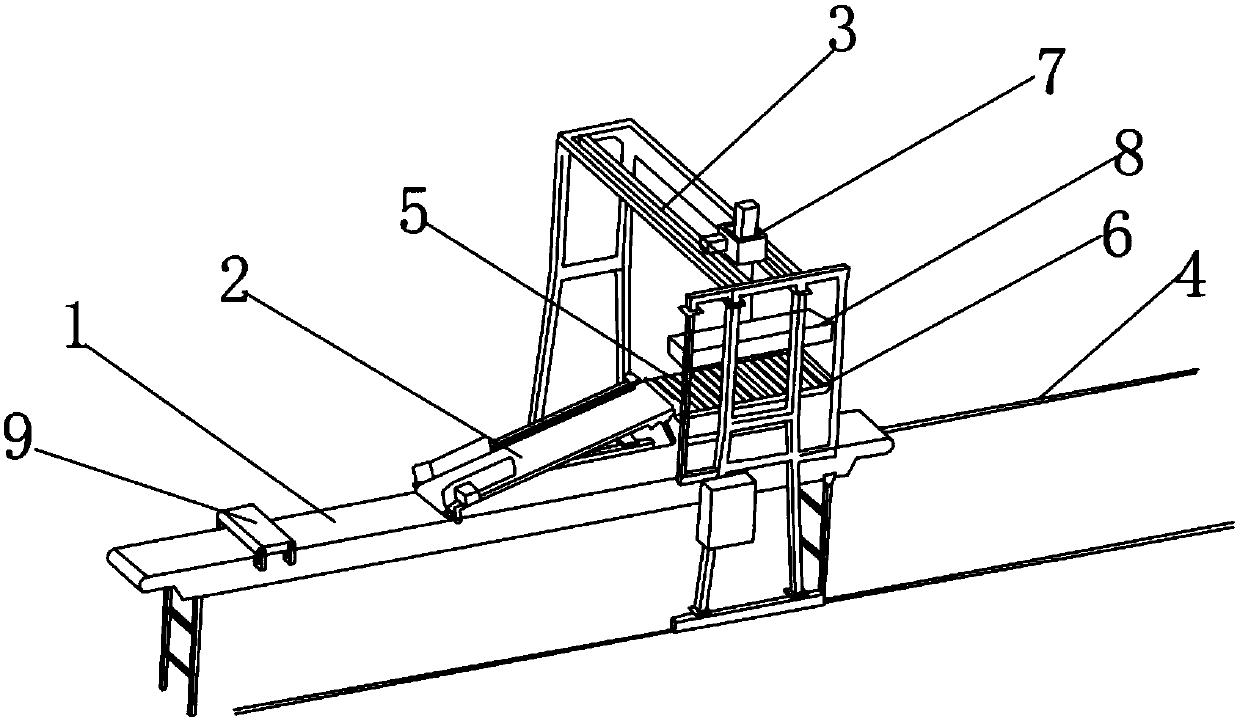

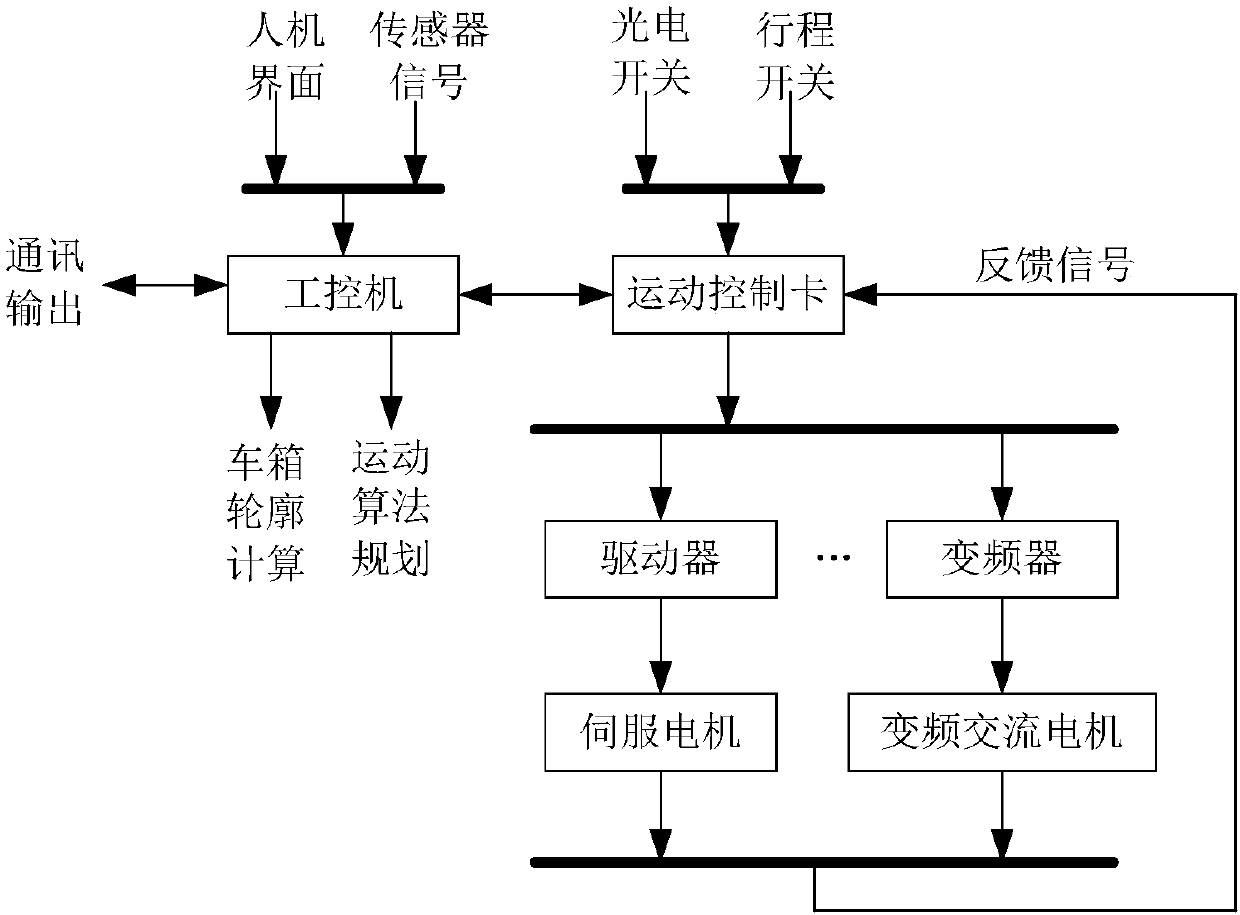

Control system and control method for movement of welding machine

ActiveCN104384762APrecise movement controlSimple and fast operationWelding/cutting auxillary devicesAuxillary welding devicesSolar batteryVision sensor

The invention discloses a control system and a control method for movement of a welding machine. The control system is composed of a control host machine, a movement control card, a digital quantity board card, CCD vision sensors, a servo motor, a driver, a guide rail, a light source, an AD board card and a limiting switch; a man-machine operation interface is adopted by the system for receiving a user instruction; the position and the operation area of the welding machine are monitored by the system through the remote CCD vision sensor in real time; a user can control the quick movement of the welding machine by clicking the position of a target welding slice with a mouse; after the welding machine reaches the position of the welding slice, a close-range CCD vision sensor for identifying a welding spot works; the secondary movement positioning is performed according to a space coordinate given by a welding spot image identifying algorithm, the welding spot is accurately positioned, and the subsequent welding operation is performed. According to the scheme, the accurate movement control within 6*4.5m wide scope is realized, the control precision reaches 0.1mm, and the control system can be applied to the movement control for a solar battery array resistance welding machine as well as the other industry fields requiring wide-scope quick accurate positioning.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

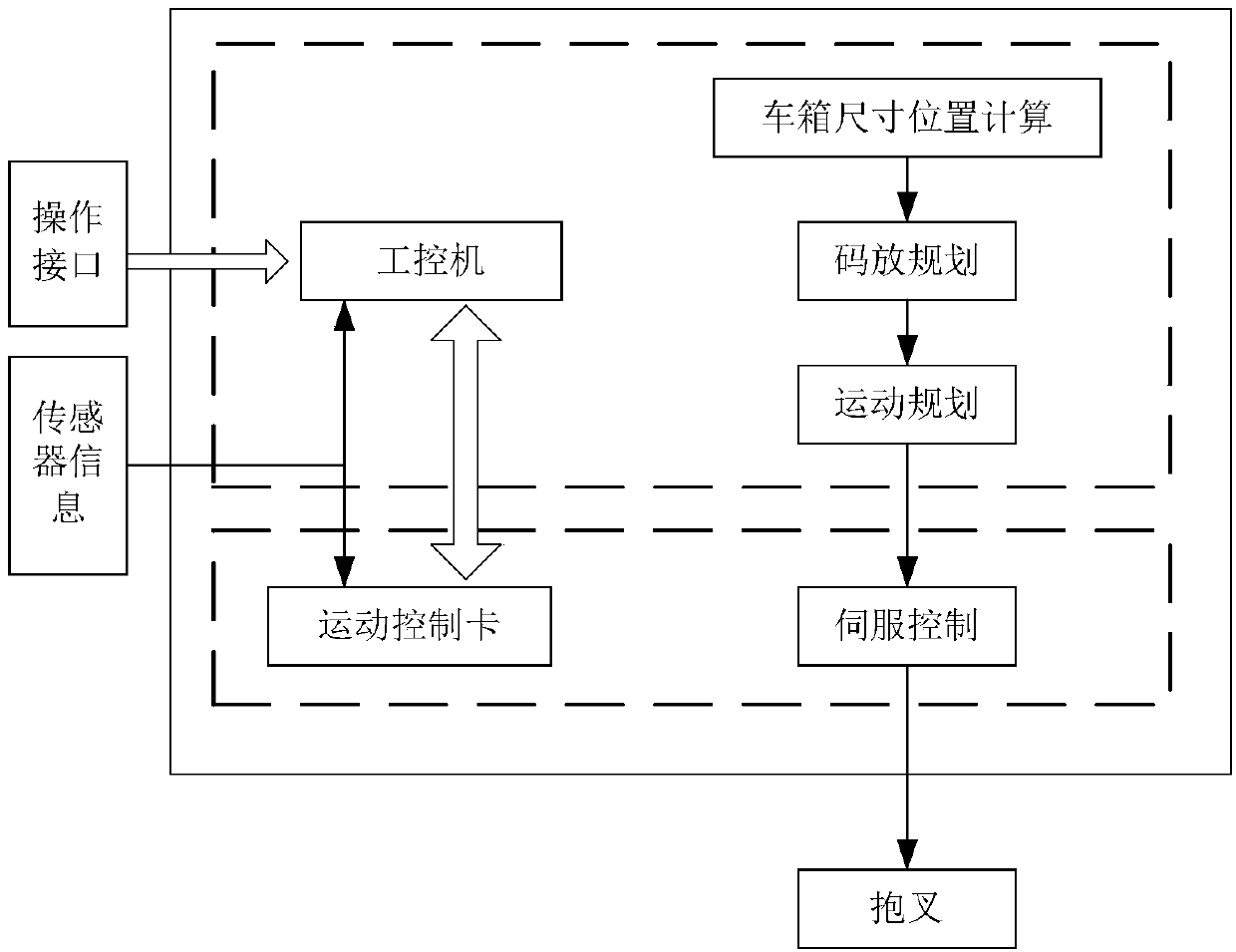

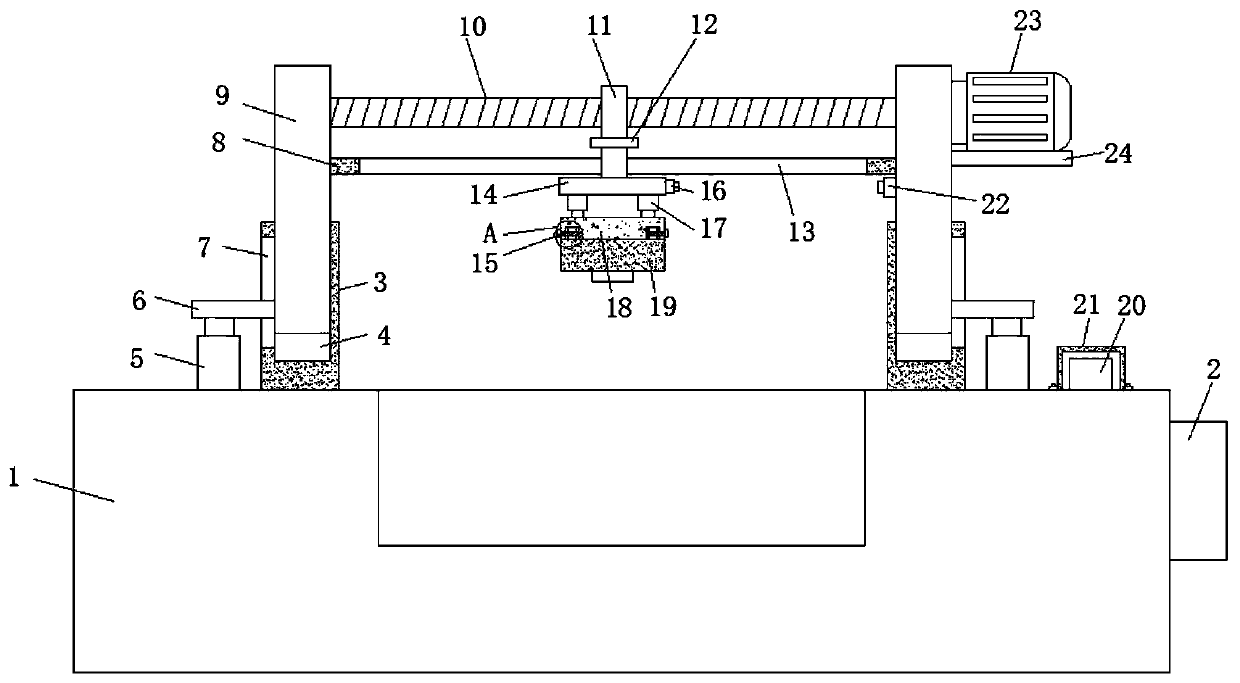

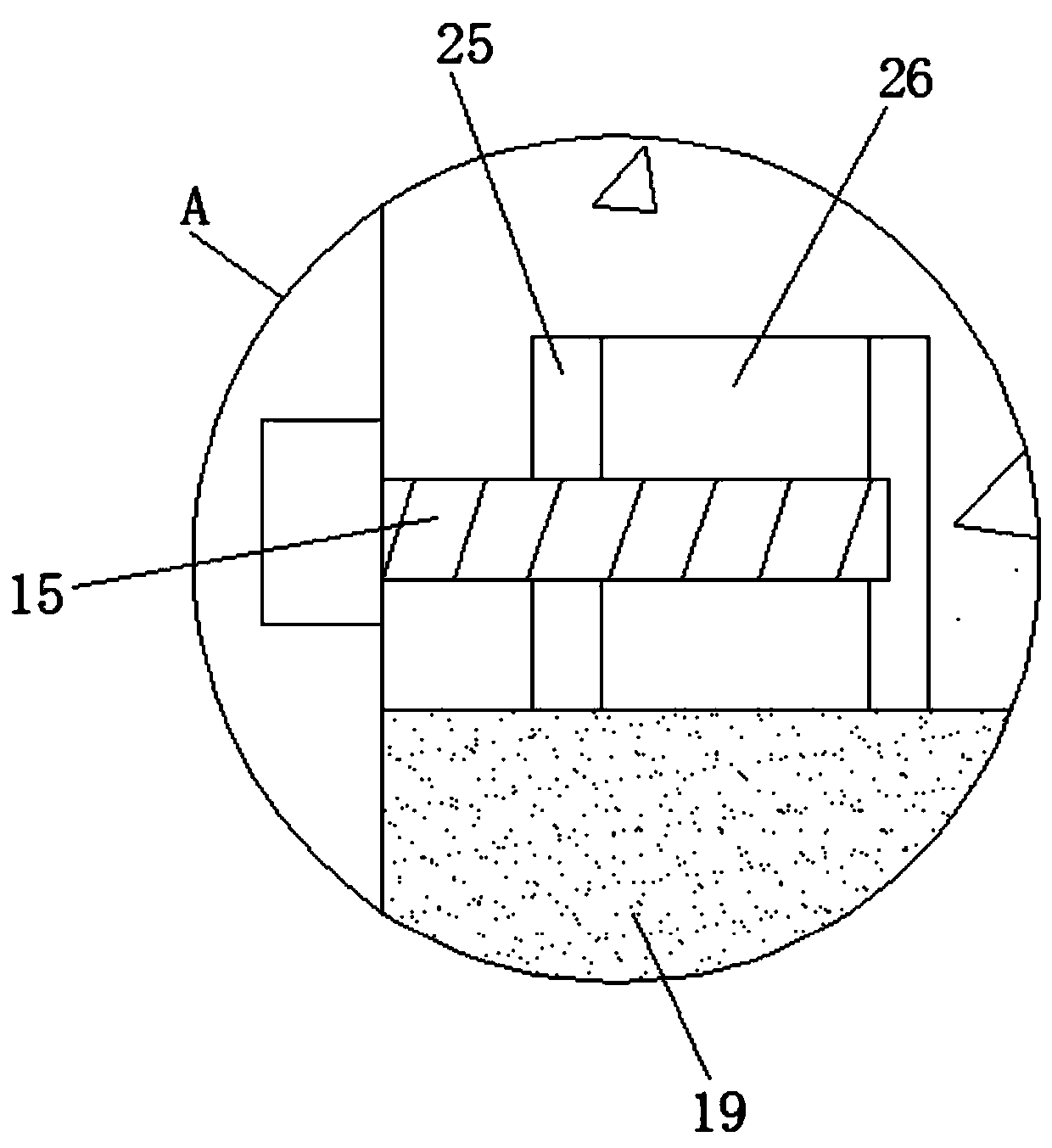

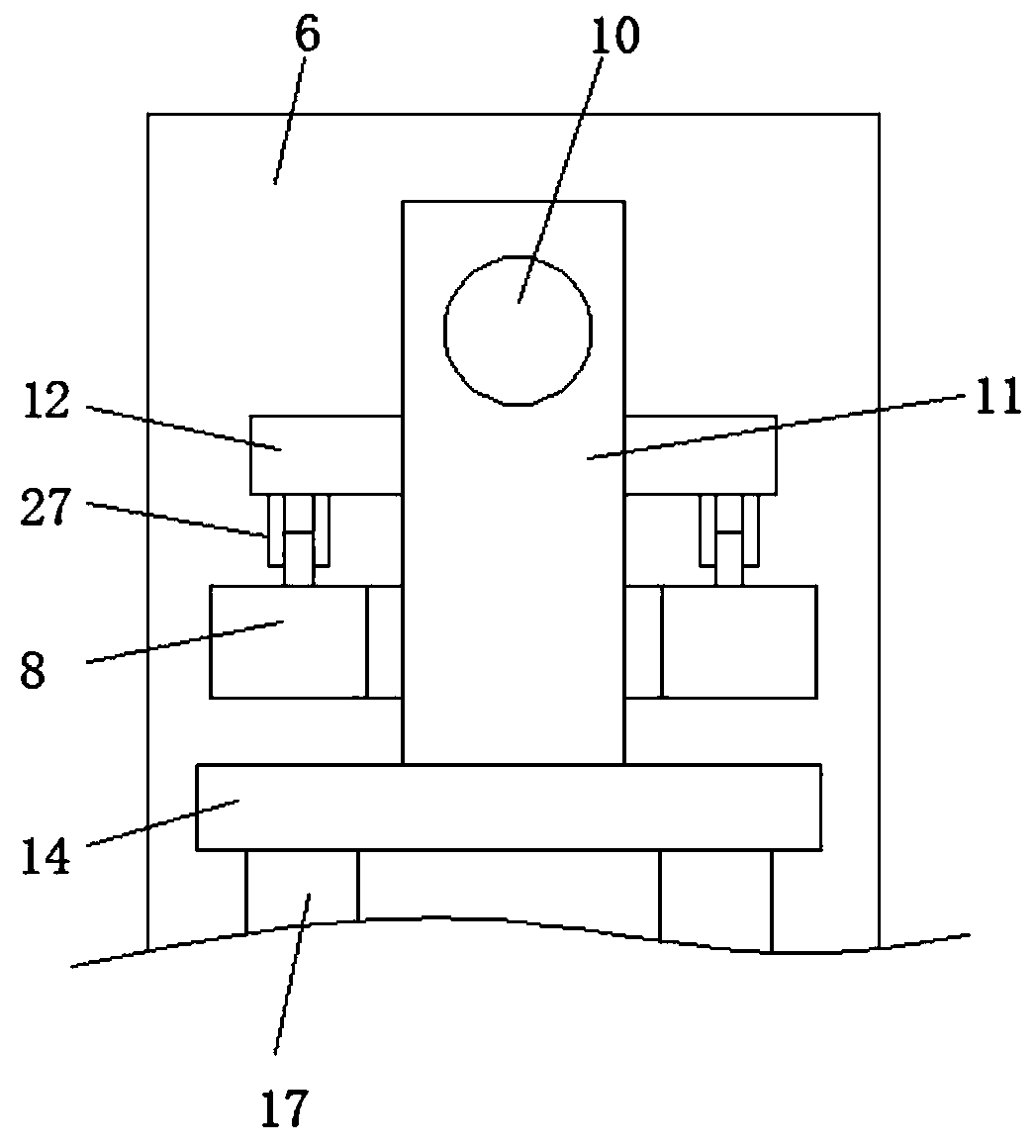

Gantry type bagged material intelligent car loader capable of rising and lowering goods supply platform

ActiveCN107738930APrecise movement controlMaximize utilizationConveyorsControl devices for conveyorsControl systemOutput device

The invention discloses a gantry type bagged material intelligent car loader capable of rising and lowering a goods supply platform. The gantry type bagged material intelligent car loader is mainly composed of a movable portal frame, a conveyer belt, a slope conveyer belt, the lifting type goods supply platform, a vacuum chuck mechanical hand and a car recognition device. According to the gantry type bagged material intelligent car loader, unloading positions of different vehicles like flat cars and engineering vehicles are distinguished, material positions are reasonably arranged, a limited space is utilized to the greatest extent, and the defects that the space is unreasonably utilized due to the fact that material arrangement is unreasonable due to manual operation, and materials fall off due to road conditions are effectively avoided; and a bag outputting device is arranged between the conveyer belt and the goods supply platform, motion of material bags after bag outputting is accurately controlled, the bag outputting takt and the car loading takt are consistent, a control system accurately controls walking motion of the portal frame, lifting motion of the goods supply platform, and lifting motion, translation goods taking, and stacking of the vacuum chuck mechanical hand, and a high-efficiency automatic car loading effect is achieved.

Owner:滁州潍铭扬智能科技有限公司

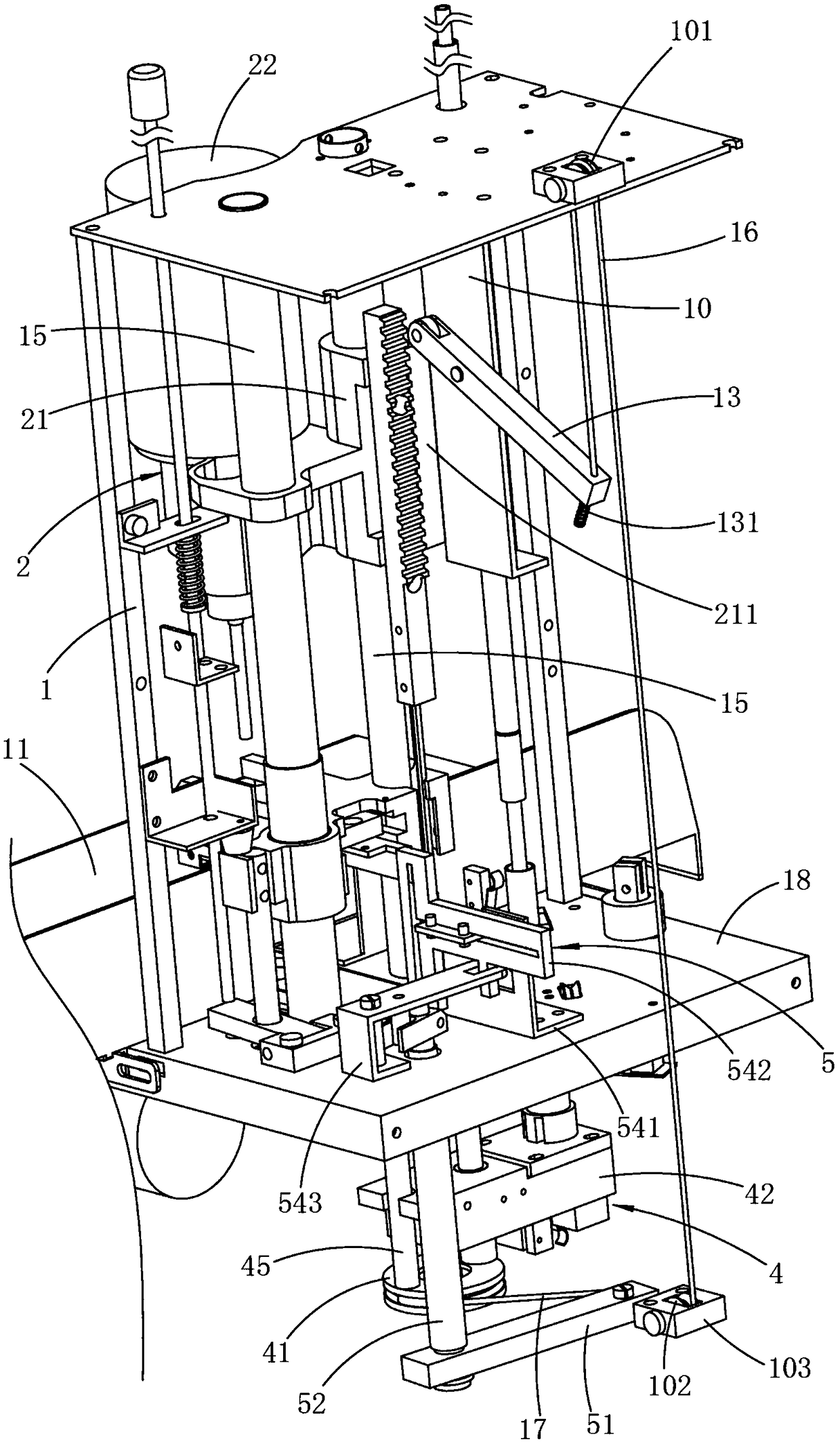

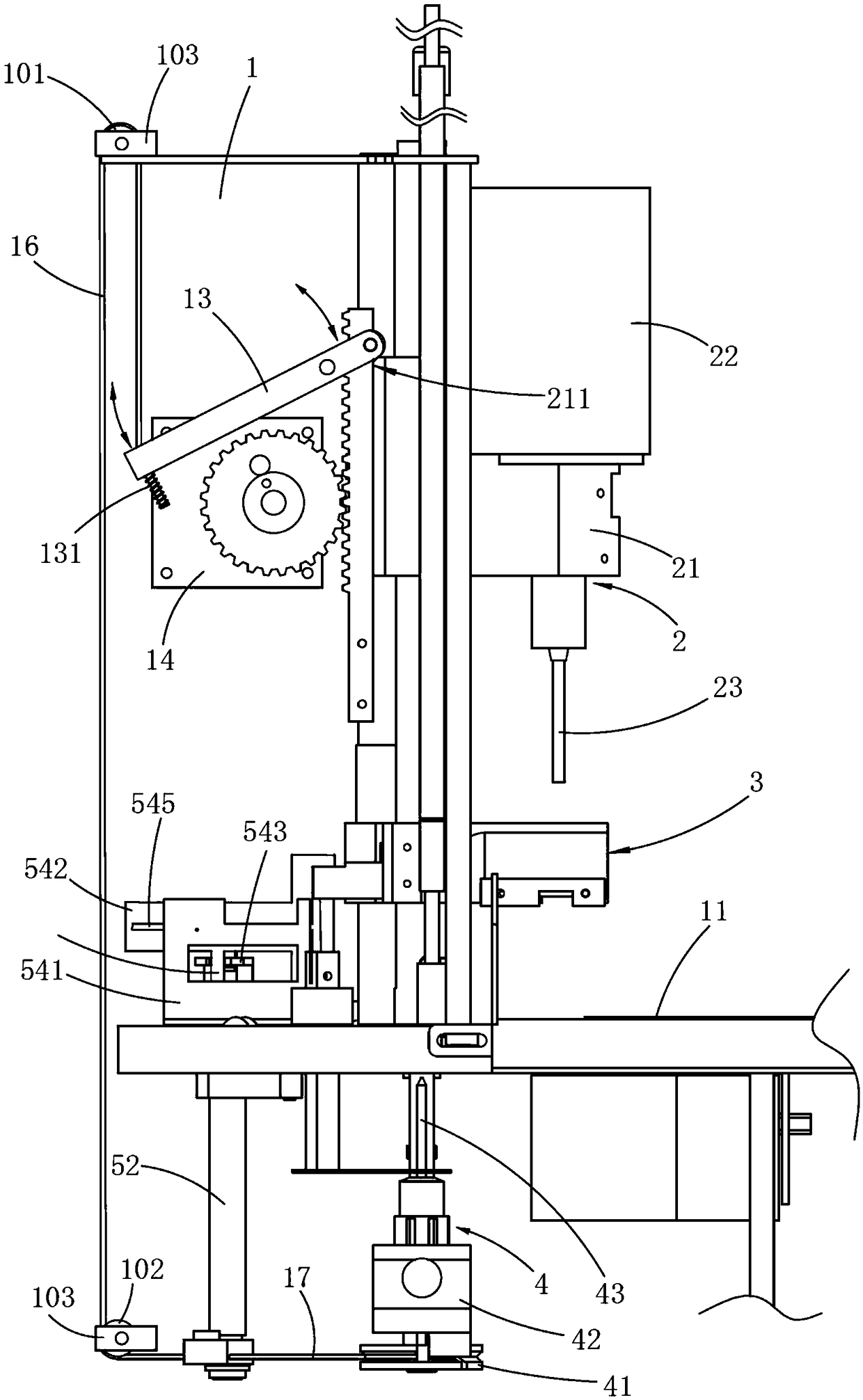

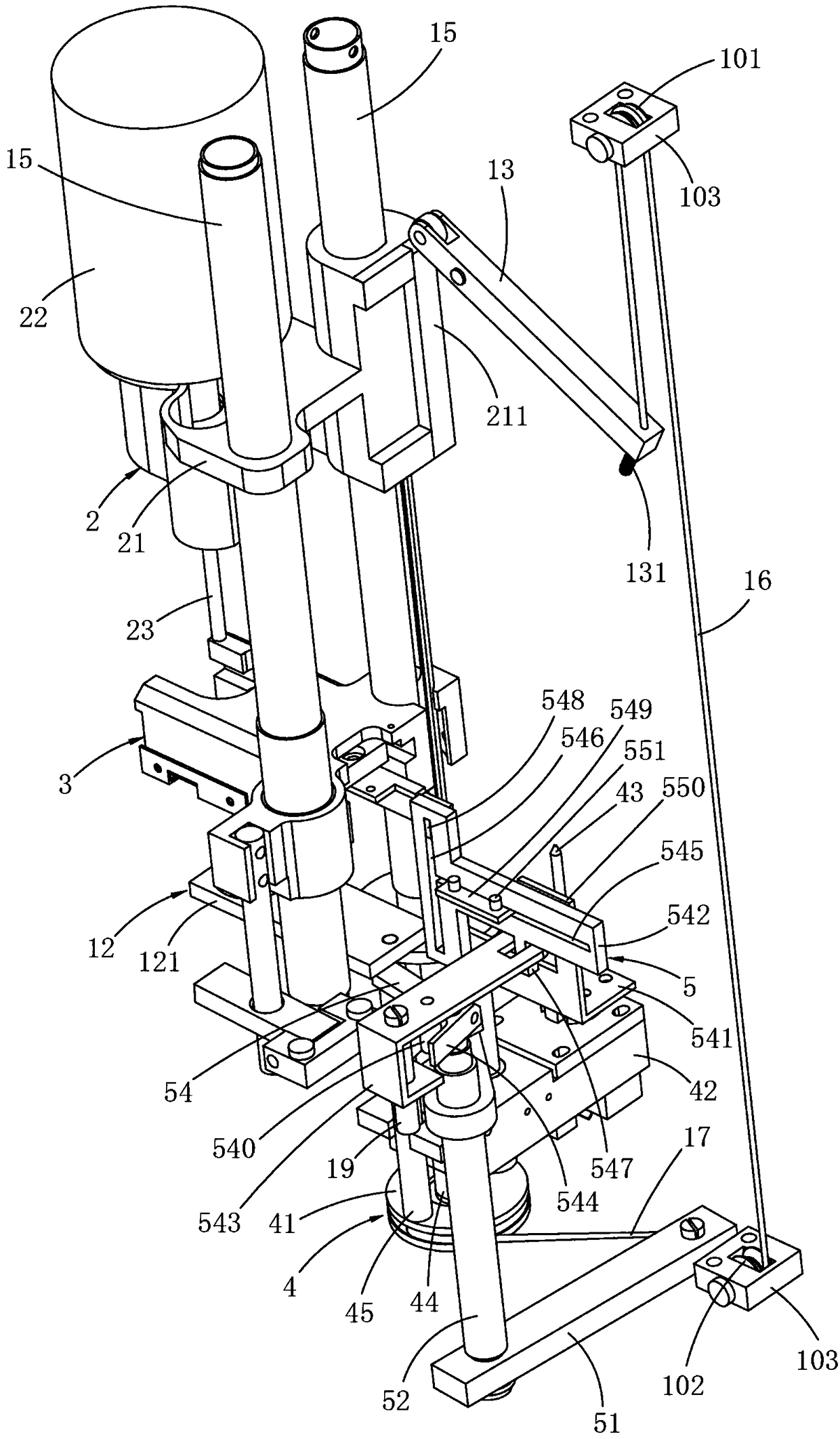

Mechanism simplifying full-automatic drilling and pressure riveting stapling machine

The invention discloses a mechanism simplifying full-automatic drilling and pressure riveting stapling machine. A rubber pad mechanism is arranged at the middle portion of a rack in a sliding manner,and a position switching mechanism is arranged between an upper rivet head and the rubber pad mechanism and connected with the upper rivet head and the rubber pad mechanism. The rack is in pivot jointwith a transmission lever, and the transmission lever is provided with a drive end and a transmission end. In the drilling device lifting process, a drilling device abuts against the drive end of thetransmission lever, and accordingly the transmission lever is driven to move. The rack is provided with a transmission mechanism, the first end of the transmission mechanism is connected with the transmission end of the transmission lever, and the second end of the transmission mechanism is connected with the upper rivet head, the rubber pad mechanism or the position switching mechanism. The mechanism simplifying full-automatic drilling and pressure riveting stapling machine is simple in structure, independent-drive motors do not need to be installed, and a plurality of complex drive actionsare finished.

Owner:东莞市银友机电科技有限公司

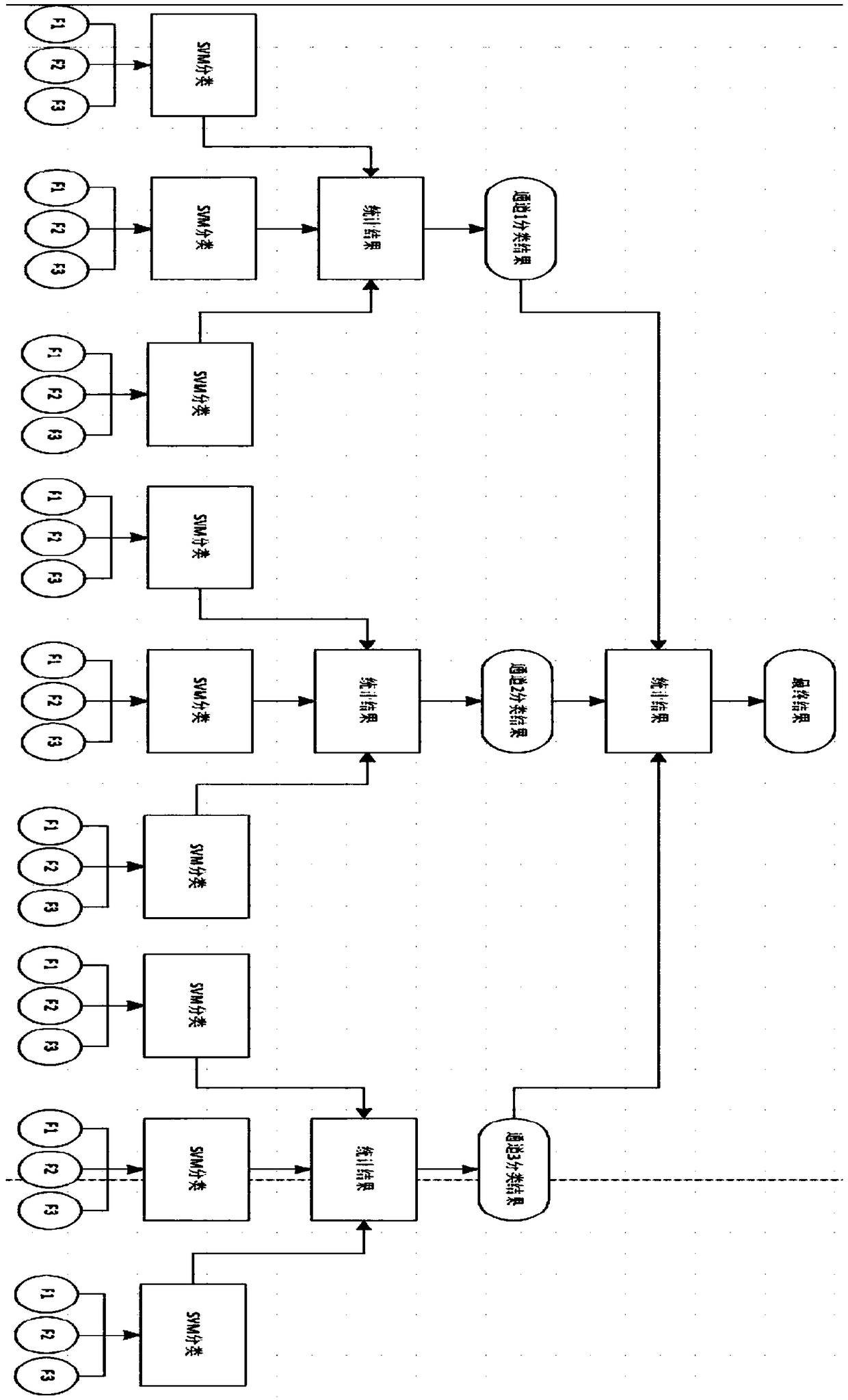

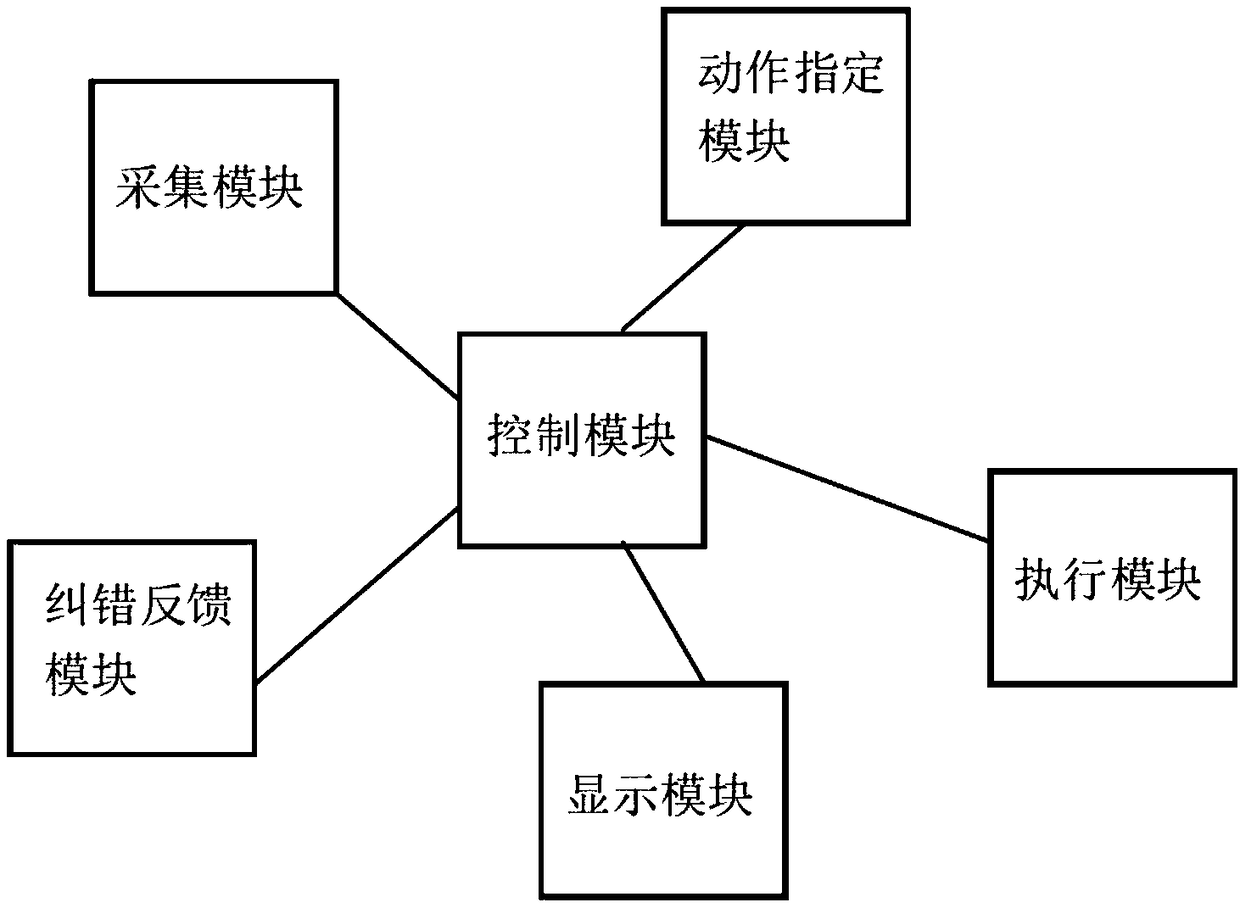

Bionic hand control system and control method based on myoelectric bracelet

ActiveCN108703824AReduce complexityImprove experienceArtificial handsProgramming complexityGyroscope

The invention provides a bionic hand control system and control method based on a myoelectric bracelet. The bionic hand control system comprises an acquisition module, a control module and an execution module, wherein the acquisition module is used for collecting myoelectric signals of a user and the direction, speed, accelerated speed of a built-in gyroscope and other information and sending thecollected information to the control module through a wireless mode; the control module is used for receiving the signals sent by the acquisition module, processing the signals, extracting feature values, performing feature dimension reduction, classifying and recognizing the signals according to a pre-trained classifier, and sending a corresponding execution instruction to the execution module and a display module according to a classified result; and the execution module is used for receiving and executing an instruction issued by the control module, mapping the instruction to the motion state of each motor and controlling the action of a bionic hand. The bionic hand control system and control method based on the myoelectric bracelet have the advantages that the recognition rate of the system is improved, the program complexity is reduced, the real-time performance of the system is improved, accurate motion control can be made on artificial limbs for different users through a self-learning error-correcting mechanism, and the user experience is improved.

Owner:安徽哈工标致医疗健康产业有限公司

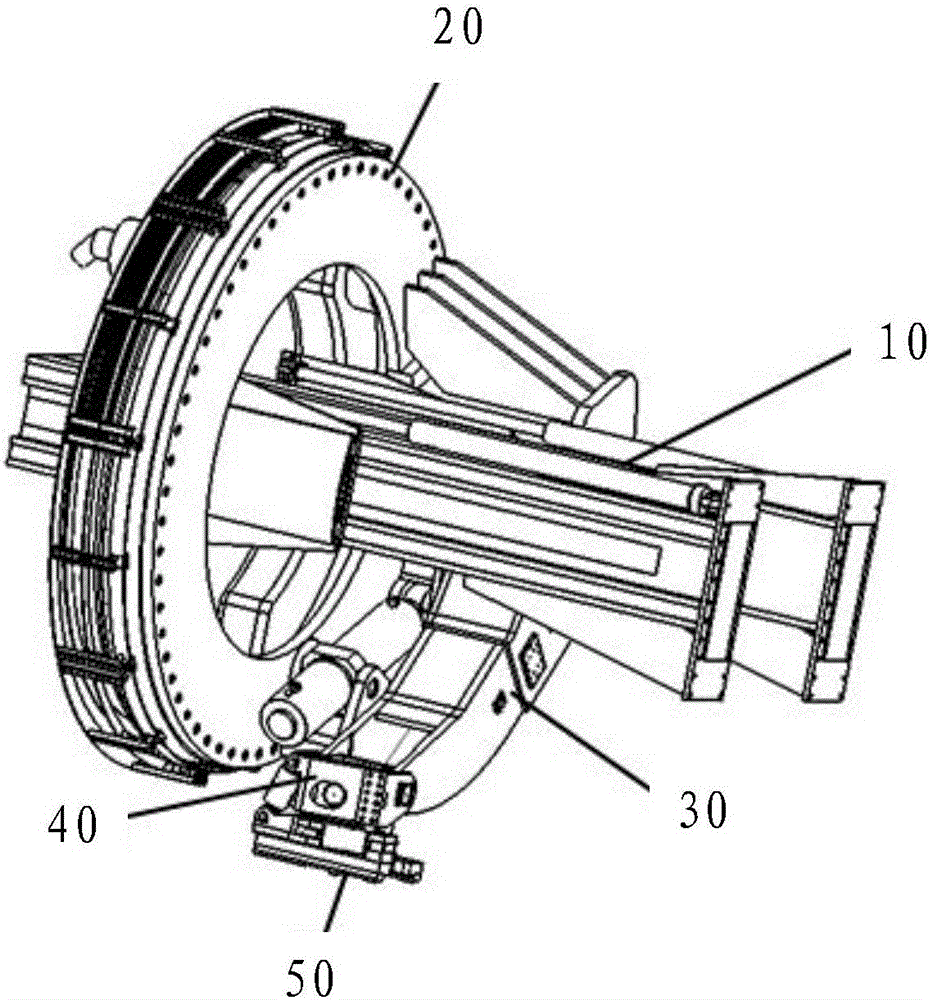

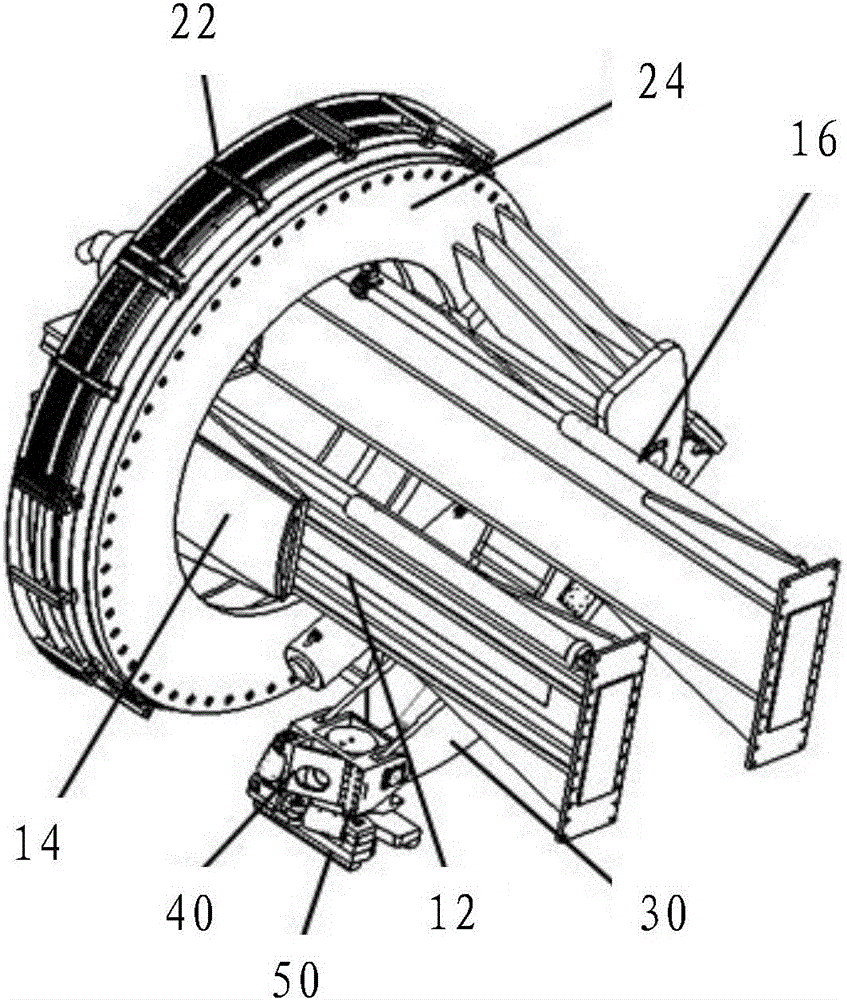

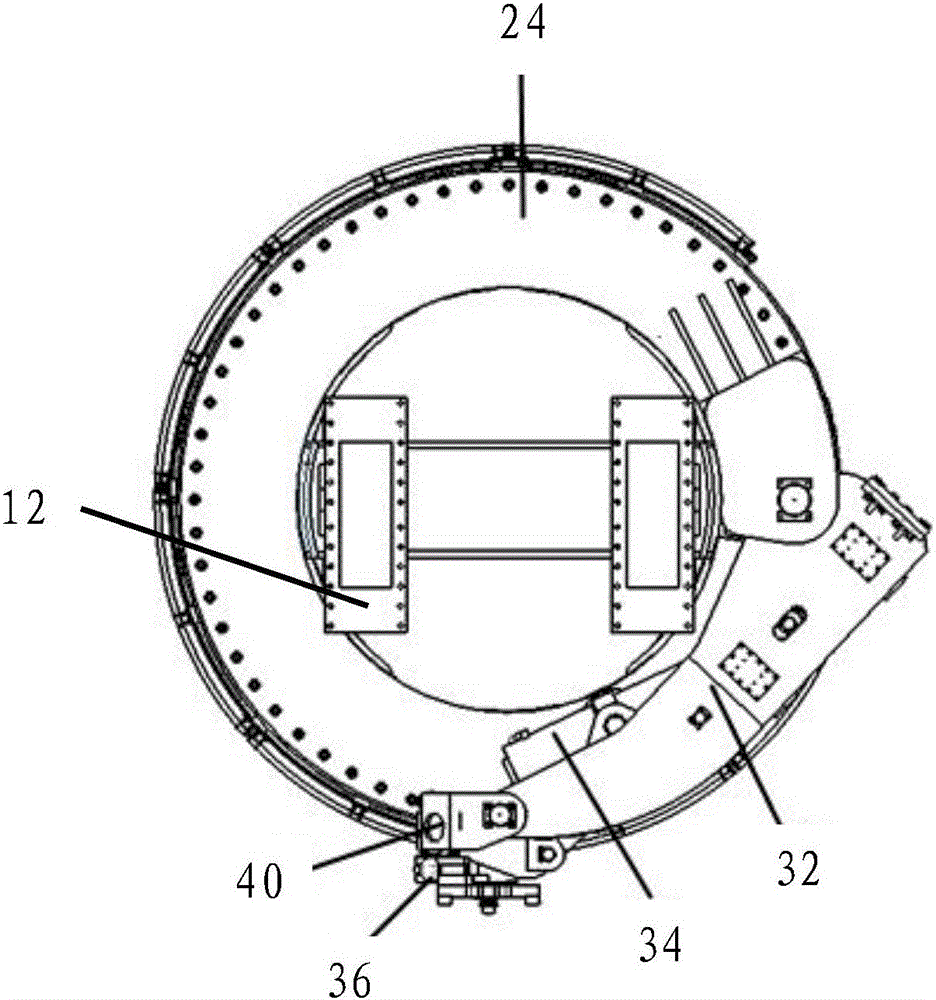

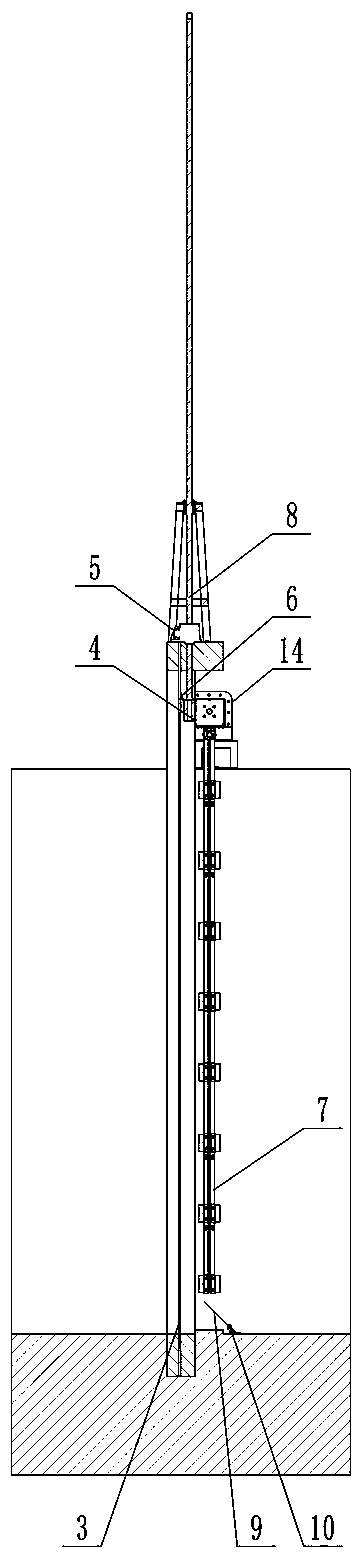

Telescopic single mechanical arm duct piece splicing machine for rectangular shield

InactiveCN106522987AQuality improvementPrecise movement controlUnderground chambersTunnel liningControl systemMotion control

The invention discloses a telescopic single mechanical arm duct piece splicing machine for a rectangular shield. The telescopic single mechanical arm duct piece splicing machine comprises a horizontal moving system, a rotation system, a telescopic mechanical arm system, a manipulator system, a duct piece clamping device and a motion control system. The horizontal moving system is fixed to a shield machine body and arranged in the axial direction of a duct piece of the rectangular shield. The rotation system is connected to the horizontal moving system and moves on the horizontal moving system. The telescopic mechanical arm system is connected to the rotation system and makes telescopic motion, and the telescopic mechanical arm system can rotate along the axis of the duct piece of the rectangular shield and swing around the rotation system. The manipulator system is connected to the telescopic mechanical arm system and rotates and swings around the telescopic mechanical arm system, so that the duct piece clamping device is connected to the end of the manipulator system and clamps the duct piece. The motion control system is connected to the telescopic mechanical arm system and controls the motion track of the telescopic mechanical arm system.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

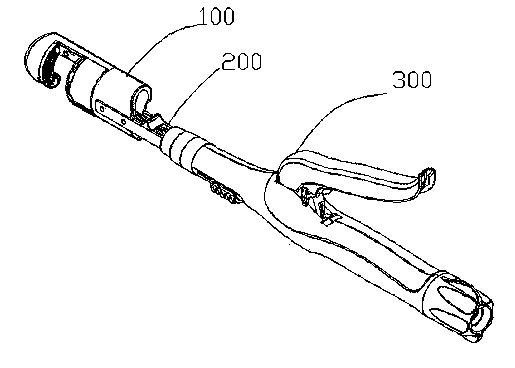

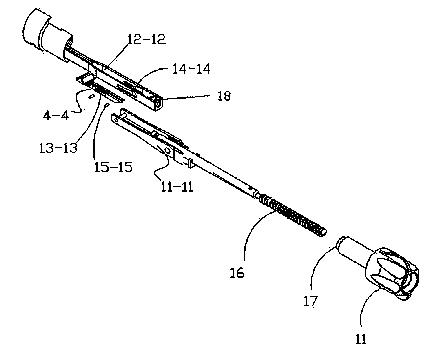

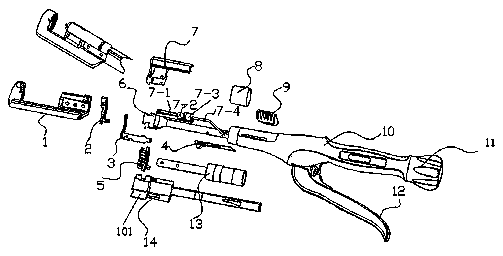

Disposable internal opening cutting and enclosing anastomat

ActiveCN104224259AResolve the bleedingReduce stenosisDiagnosticsSurgical staplesEngineeringBiomedical engineering

The invention relates to the technical field of disposable anastomats, in particular to a disposable internal opening cutting and enclosing anastomat. The disposable internal opening cutting and closing anastomat comprises a cutting molding assembly, a transmission assembly and a gun body provided with a triggering assembly, wherein the cutting molding assembly comprises a nail cabin bracket, a scalpel support ring, a nail pressing seat, a nail pushing device, a nail cabin support and a nail cabin; the nail cabin is clamped in a clamping groove of the nail cabin support through a buckle; the nail cabin support is directly connected with the gun body through the transmission assembly; the head of the nail cabin is circular-arc-shaped or parabolic; nail grooves of the nail cabin are of asymmetrical mode; the transmission assembly comprises a transmission lead screw; the lead screw is a large-screw-pitch left-handed lead screw; the tail end of the lead screw is connected with a corresponding lengthened nut assembly; the lengthened nut assembly and a knob positioned at the tail end of the gun body are molded together by injecting or embedded together; the gun body is a lever type or connecting-rod-type gun body. The disposable internal opening cutting and enclosing anastomat is skillful in design, and has a good application prospect; by adopting the disposable internal opening cutting and enclosing anastomat, a plurality of use problems in the prior art can be solved effectively.

Owner:JIANGSU QIANJING MEDICAL EQUIP

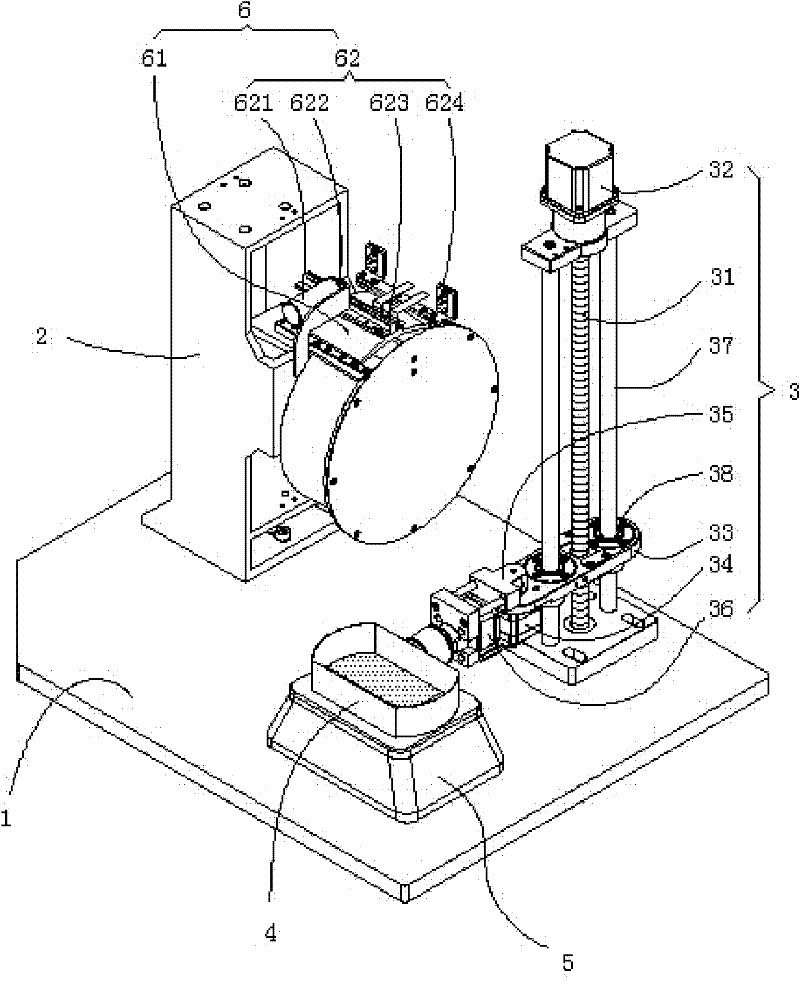

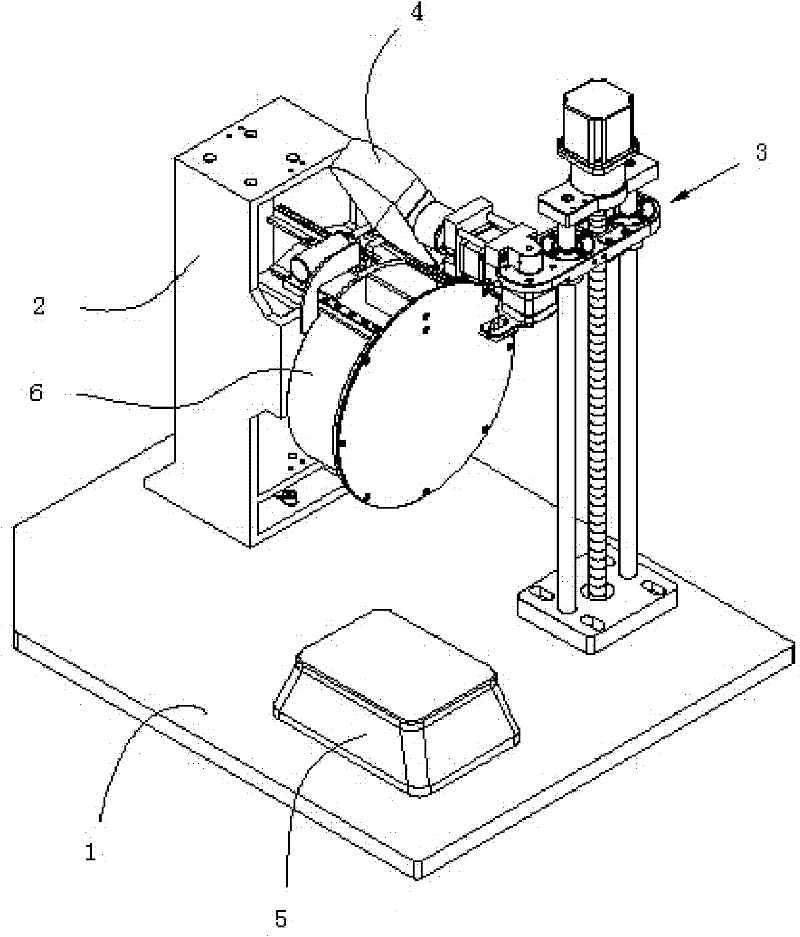

Automatic measuring instrument for bituminous coal caking index

The invention relates to an automatic measuring instrument for bituminous coal caking index, comprising a base, wherein a rotary drum rack, a manipulator component and a balance are arranged on the base; a rotary drum is rotatably arranged on the rotary drum rack; the manipulator component is connected with a sample weighing screen; the rotary drum is provided with a movable door arranged on the circumferential surface and a movable door control component that can control the movable door to open and close; the internal wall of the movable door is coincident to the internal round surface of the rotary drum; when the movable door is closed, the movable door is one part of the internal wall of the rotary drum; and the sample weighing screen can be controlled by the manipulator component to be rotated to the weighing position on the balance, the sample dumping position above the rotary drum and the sample containing position below the rotary drum. In the invention, by whole layout arrangement, the working procedure of manually determining the bituminous coal caking index can be integrated into automatic operation; the defect of manual determination can be overcome; and the automatic measuring instrument can be used conveniently and quickly, can be controlled flexibly, is accurate in measurement, and has smart and reasonable design and high practicability.

Owner:常州市方嘉电子仪器有限公司

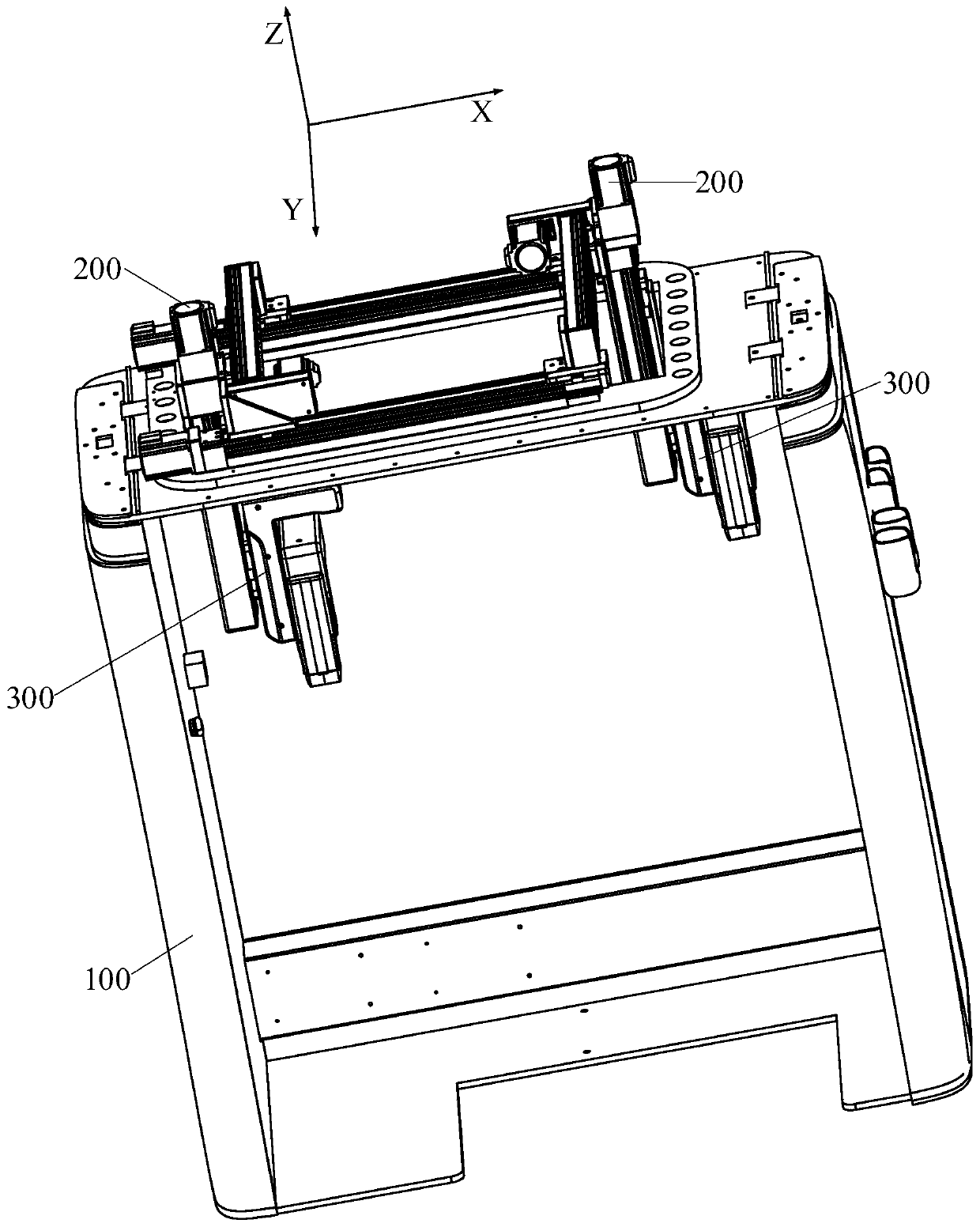

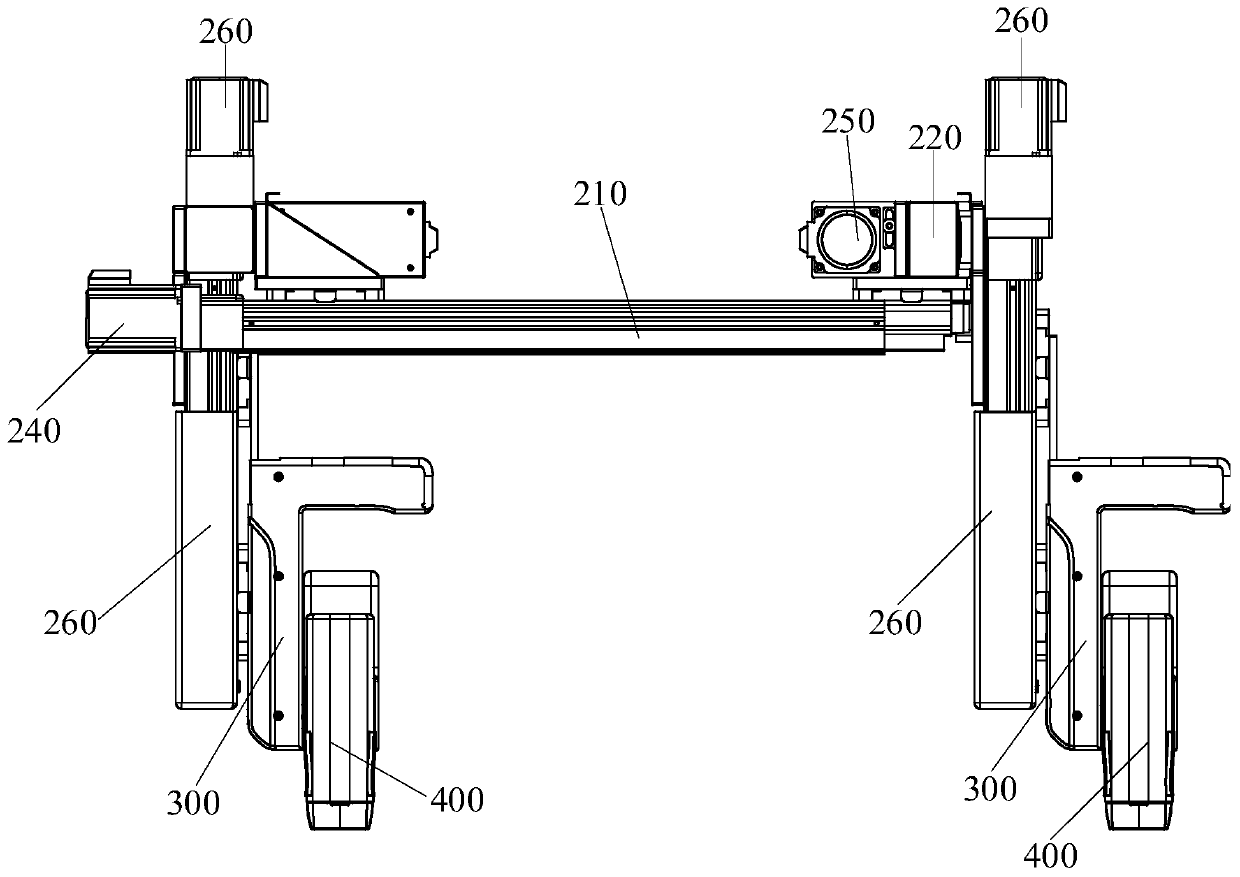

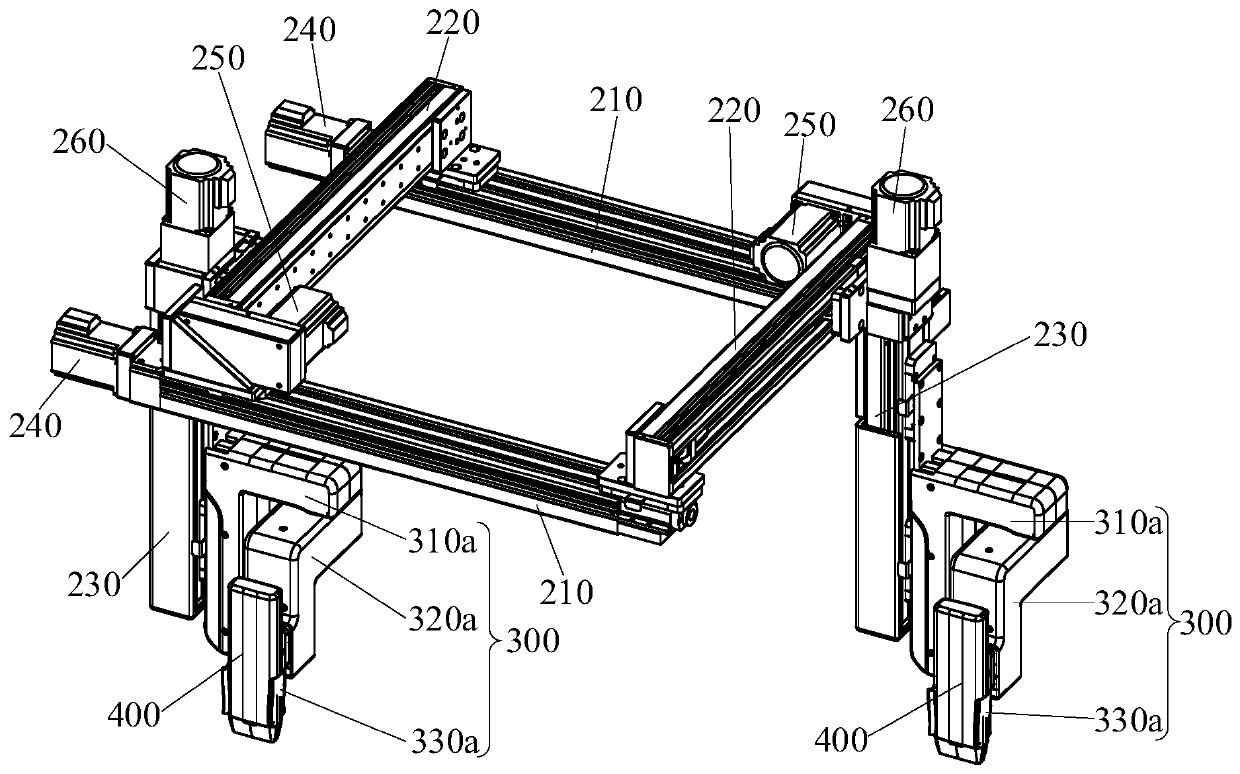

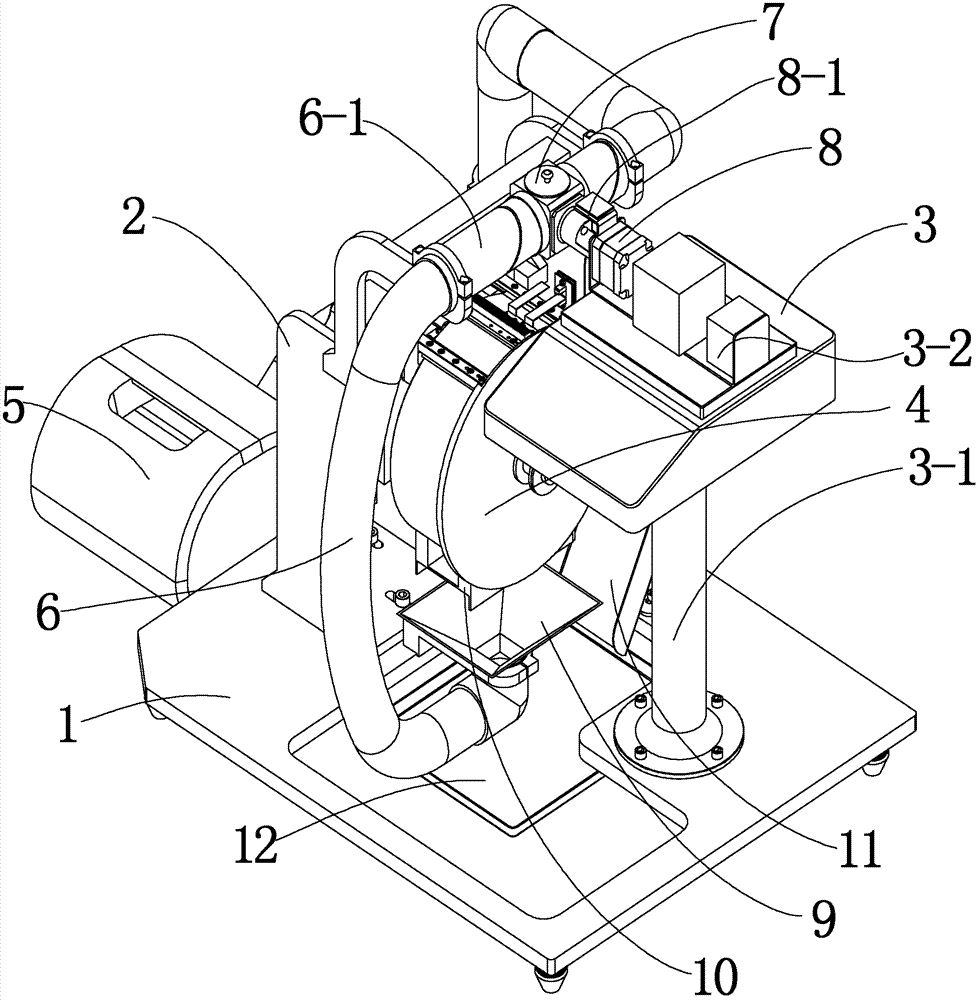

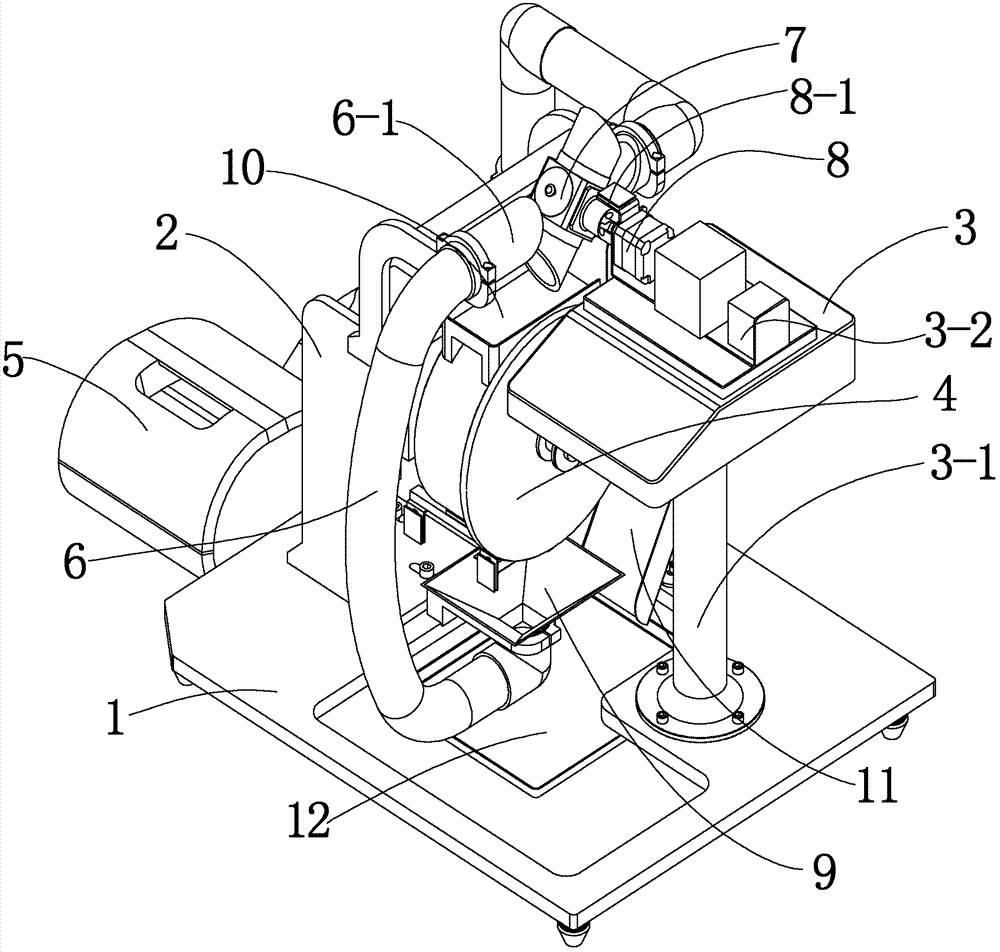

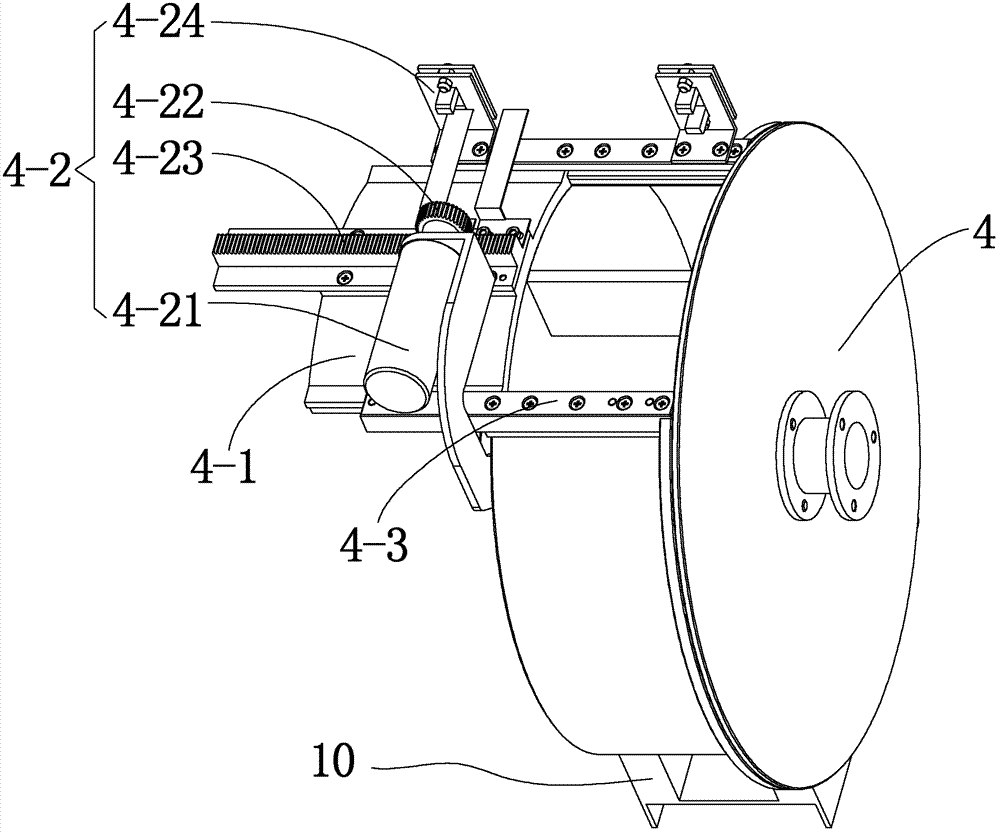

Automatic ultrasonic breast scanning equipment

PendingCN110664437APrecise movement controlAdjust the fit in timeOrgan movement/changes detectionUltrasonic/sonic/infrasonic dianostic techniquesLinear motionEngineering

The invention discloses automatic ultrasonic breast scanning equipment. The automatic ultrasonic breast scanning equipment comprises a supporting frame and one or more mechanical arms arranged at thetop of the supporting frame through a linear motion mechanism, the linear motion mechanism comprises first linear guide rails arranged in the X-axis direction, second linear guide rails arranged on the first linear guide rails in the Y-axis direction and third linear guide rails arranged on the second linear guide rails in the Z-axis direction, the mechanical arms are located on the third linear guide rails, and the execution ends of the mechanical arms are used for installing ultrasonic scanning probes. By accurately controlling motion of the two mechanical arms, the attaching degree of the ultrasonic scanning probes and the breasts is adjusted in time, and detection errors caused by factors such as shaking of the ultrasonic scanning probes are avoided, so that breast detection is accurately completed, and standardized scanning data are obtained to assist diagnosis and treatment.

Owner:SHENZHEN AISONO INTELLIGENT MEDICAL TECH CO LTD

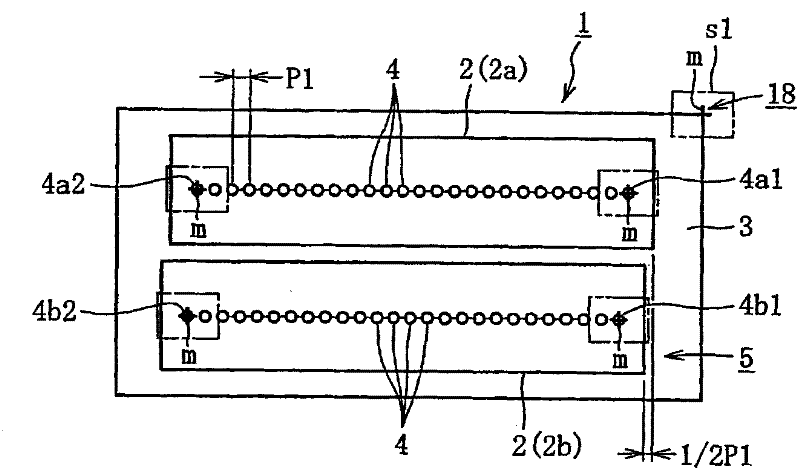

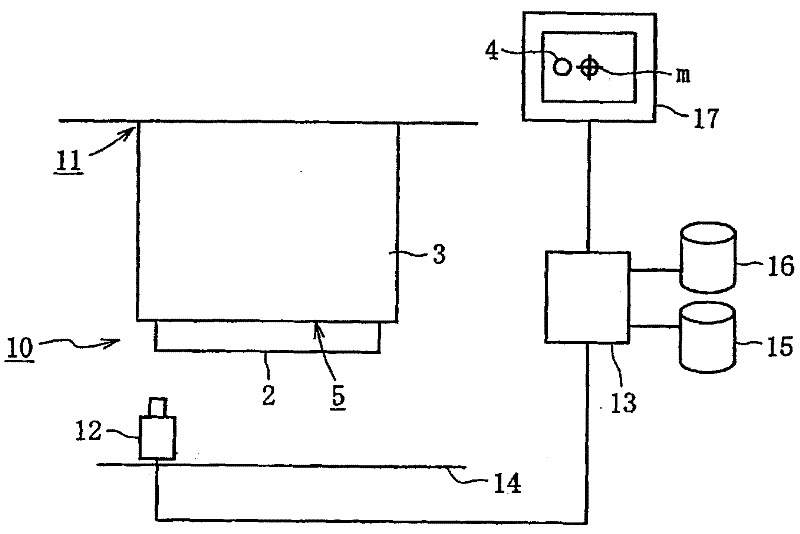

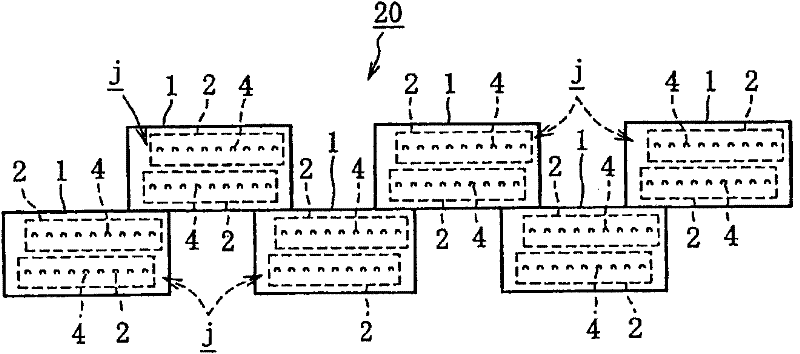

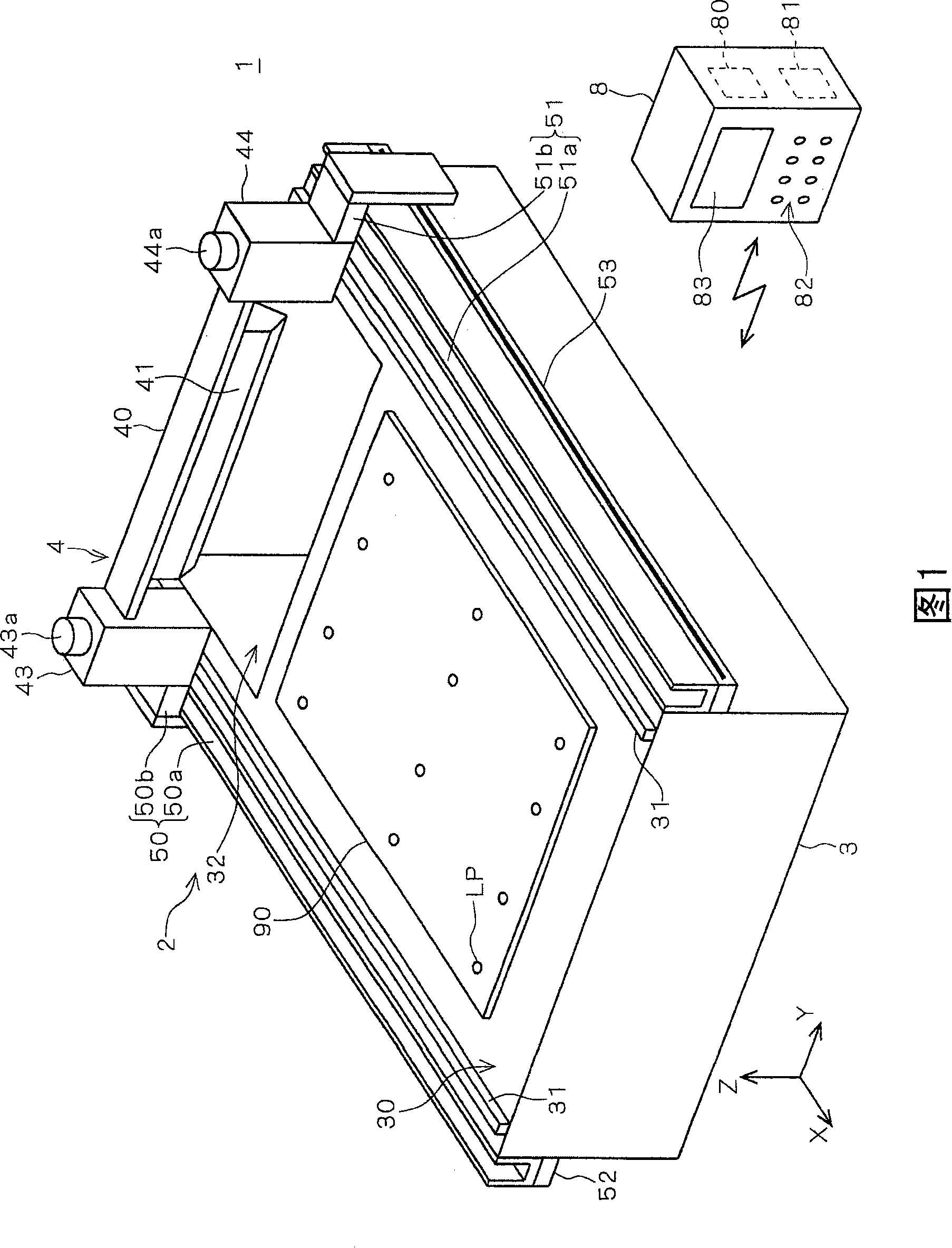

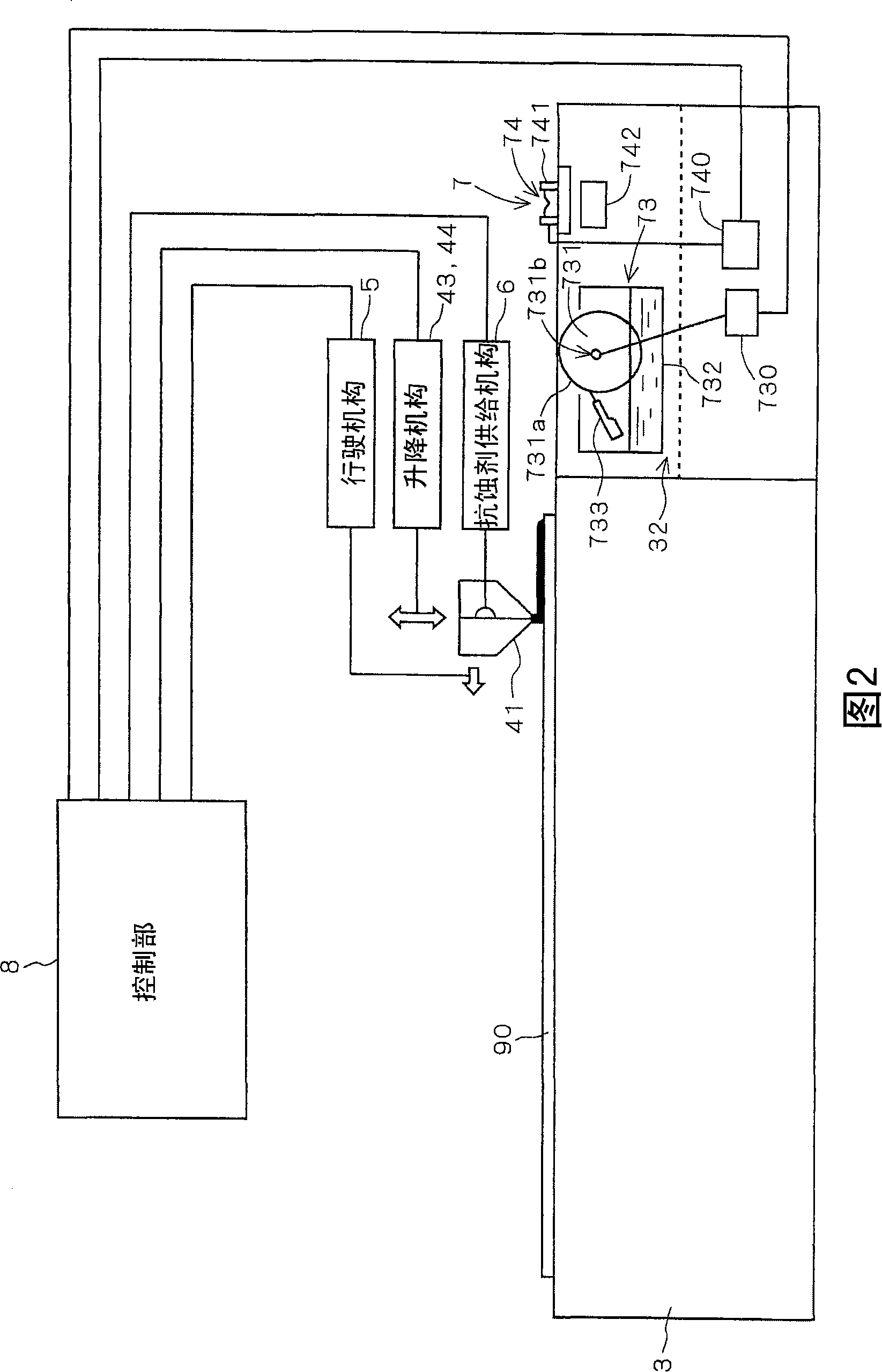

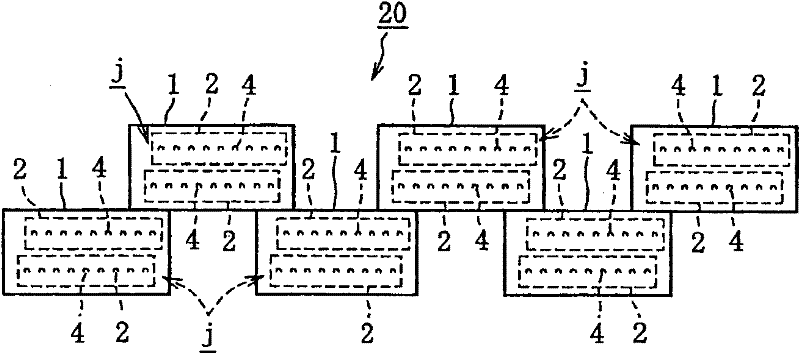

Film coating device and film coating method

The present invention relates to a film coating device and a film coating method. The film coating device utilizes an ink-jet printer to form films on the surfaces of objects to be coated with coating liquid. The film coating device is provided with a print head unit capable of moving on the surfaces of objects to be coated along the first direction. For the print head unit, a plurality of print heads are successively arranged in a direction perpendicular to the first direction across the whole coating width.

Owner:ISHII HYOKI

Full automatic caking index determinator

ActiveCN103091195AOvercome the shortcomings of manual determinationAccurate measurementWeighing by removing componentEngineeringMechanical engineering

The invention relates to a full automatic caking index determinator which comprises a pedestal; a rotary drum shelf and a balance are disposed on the pedestal; a rotary drum is disposed on the rotary drum shelf; the rotary drum is provided with a sliding door on a circumferential surface, and a sliding door control assembly for controlling the opening and closing of the sliding door; the determinator also comprises a dust collector, a pipeline connected with an air inlet of the dust collector, a sample container and a rotation mechanism for driving the rotation of the sample container; the rotation mechanism is disposed at a weighing position of the balance; the sample container is disposed at a sample inversion position above the rotary drum, is disposed at the middle part of the pipeline and is communicated with the pipeline; gaps are left between the pipeline and the two ends of the sample container communicated with the pipeline; an air outlet of the sample container is provided with a screen mesh; a sample receiving container is disposed at a sample receiving position below the rotary drum, and is communicated with the air inlet at the end of the pipeline. The invention provides the full automatic caking index determinator which can complete the determination work automatically, and can combine three procedures of sampling, screening, and weighing into one.

Owner:常州市方嘉电子仪器有限公司

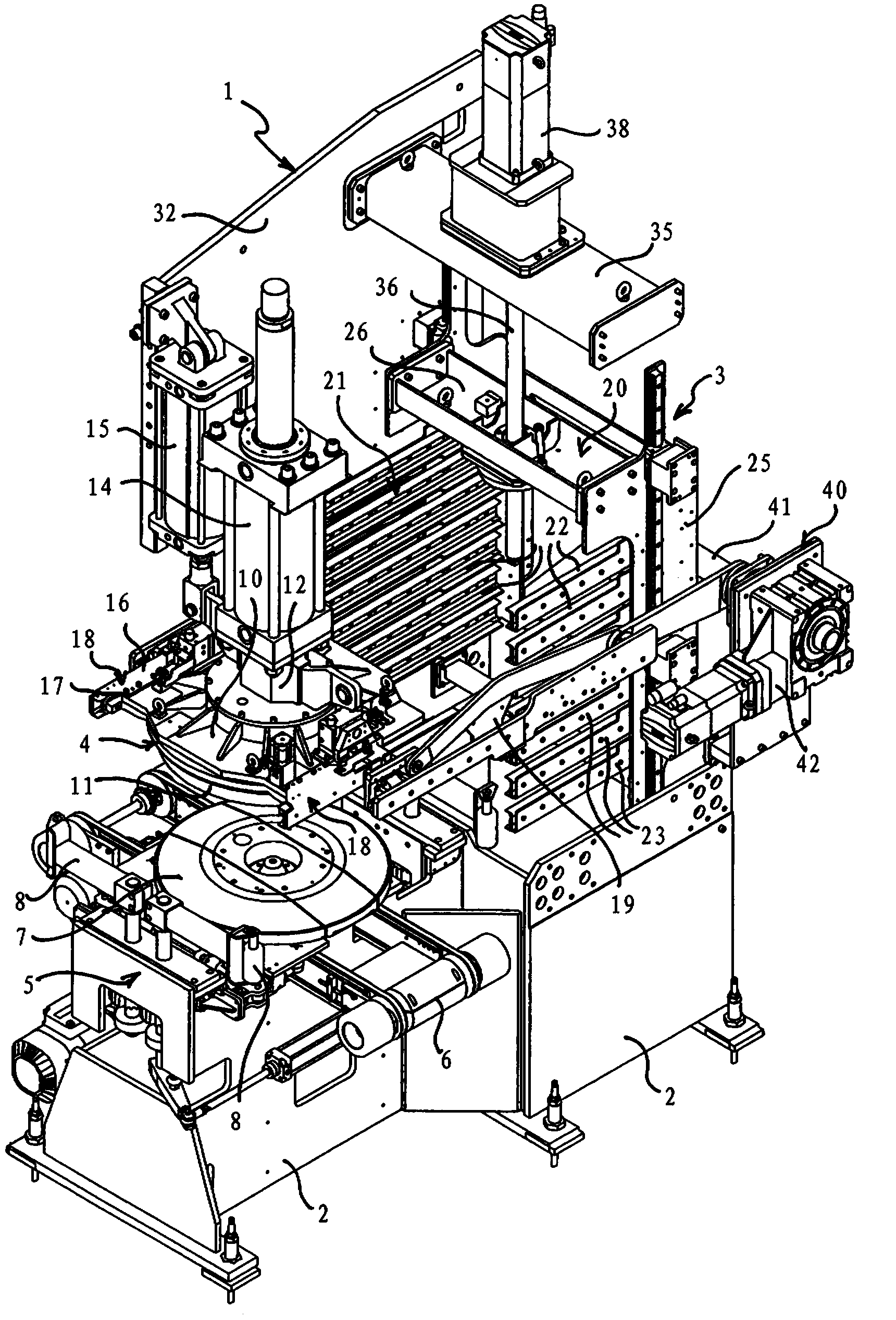

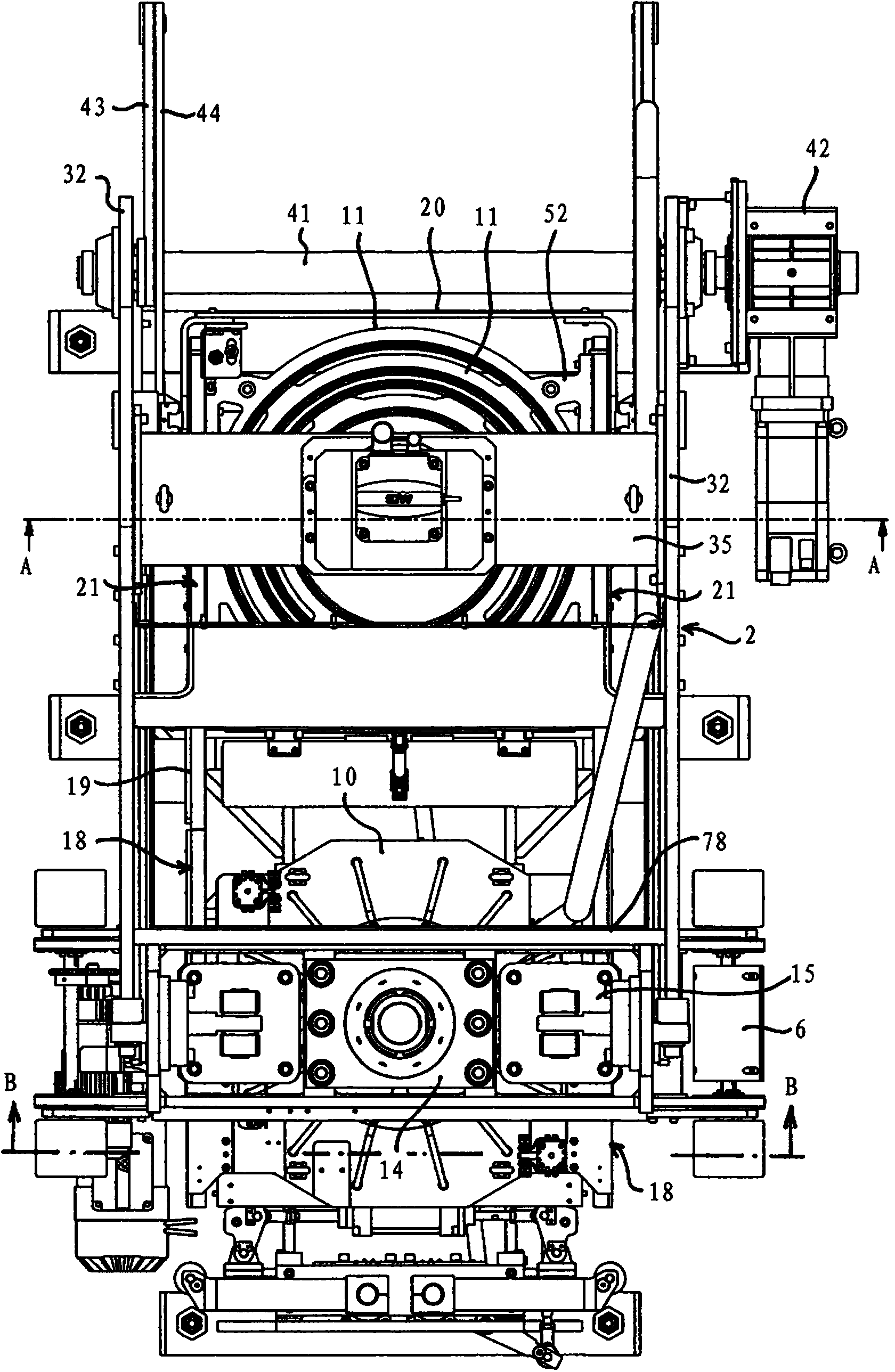

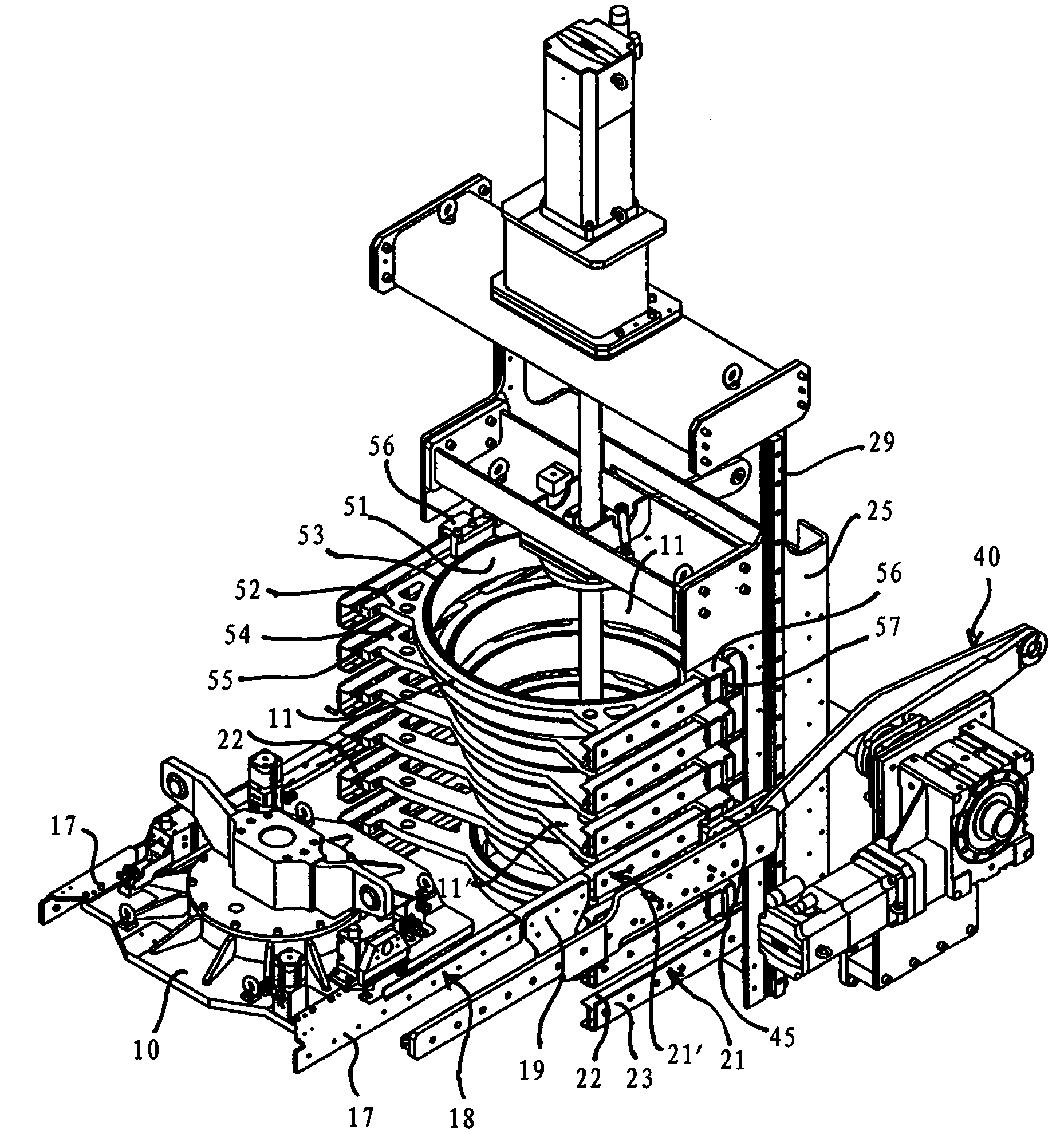

Tyre inflation device

ActiveCN104108381AReduced Tolerance RequirementsAutomatic decouplingVehicle servicing/repairingTyre repairingMechanical engineeringParallel plane

In a tire inflating device having a machine frame (2), a tire filling bell (4) arranged on the machine frame (2) and a supporting and sealing device (5) for sealing a filling chamber. The tire filling bell (4) is comprised of a filling plate (10) and a separate filling ring (11). A magazine (3) has a magazine rack (20) and magazine guides (21) lying in a plurality of parallel planes, each of said guides being able to hold a filling ring (11, 11′) mounted so that it can move. The magazine rack (20) and the filling plate (10) can be moved with respect to each other into a plurality of transfer positions in the direction of the axis of rotation. The magazine guide (21) in each case is connected to a filling plate guide (18) arranged on the filling plate (10) in said transfer positions. A filling ring (11) which is located in the magazine guide (21) arranged in the transfer position can be conveyed by a conveying device (40) into a filling plate guide and a centered position on the filling plate (10).

Owner:SCHENCK ROTEC GMBH

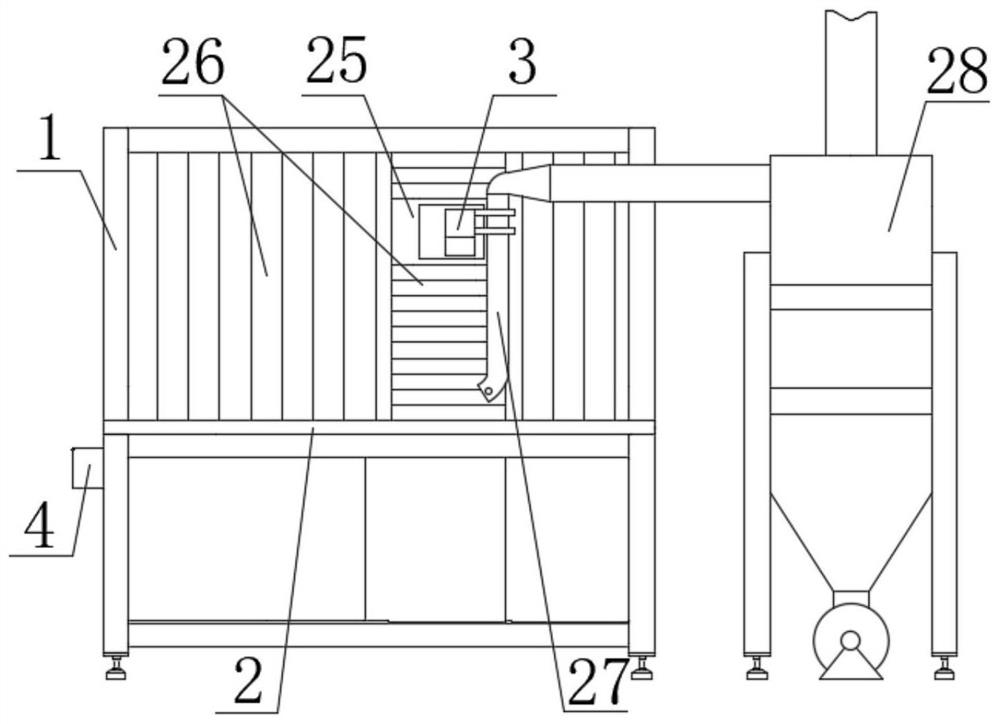

Automatic polishing workroom suitable for combined cabinet handles

PendingCN110181367ASwipe does not generatePrevent fallingGrinding drivesGrinding machinesEngineeringMachining

The invention discloses an automatic polishing workroom suitable for combined cabinet handles, and belongs to the field of machining equipment. The automatic polishing workroom consists of a workroomseparation plate, a first machining device, a slide mechanism, a guide mechanism, a bottom machining device, a dustproof net, a dust collecting room door sheet, a dust collecting room door sheet handle, a bottom slide rail, a dust sucking device, a second machining device, a loading device, a top machining device and a top slide rail; the first machining device and the second machining device aremounted on two sides of the workroom separation plate; the bottom machining device and the top machining device are mounted at the bottom and the top of the workroom separation plate; the loading device is mounted behind the workroom separation plate; and the dust sucking device is mounted on the inclined lower side of a polishing piece. The automatic polishing workroom has the following beneficial effects: during polishing of handles, the first machining device, the second machining device, the top machining device and the bottom machining device can synchronously polish multiple surfaces ofthe handles through cooperation between respective guide mechanisms and double-shaft double-rod cylinders, so that both manpower and time are saved.

Owner:孙浩翔

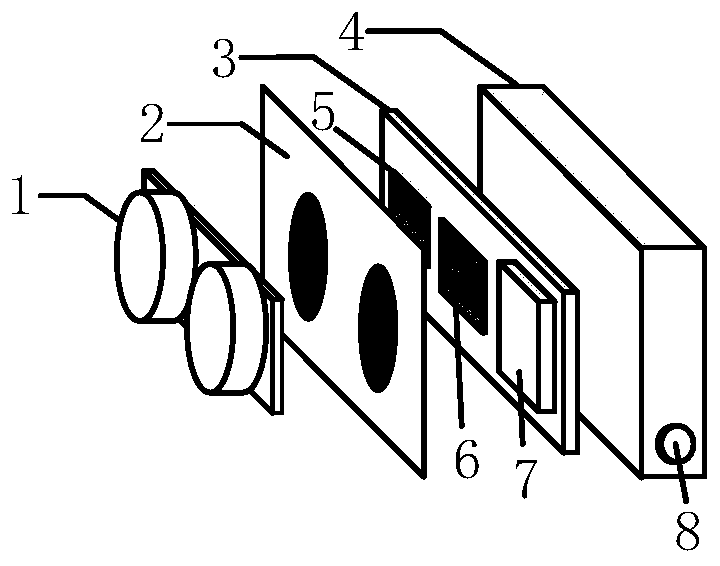

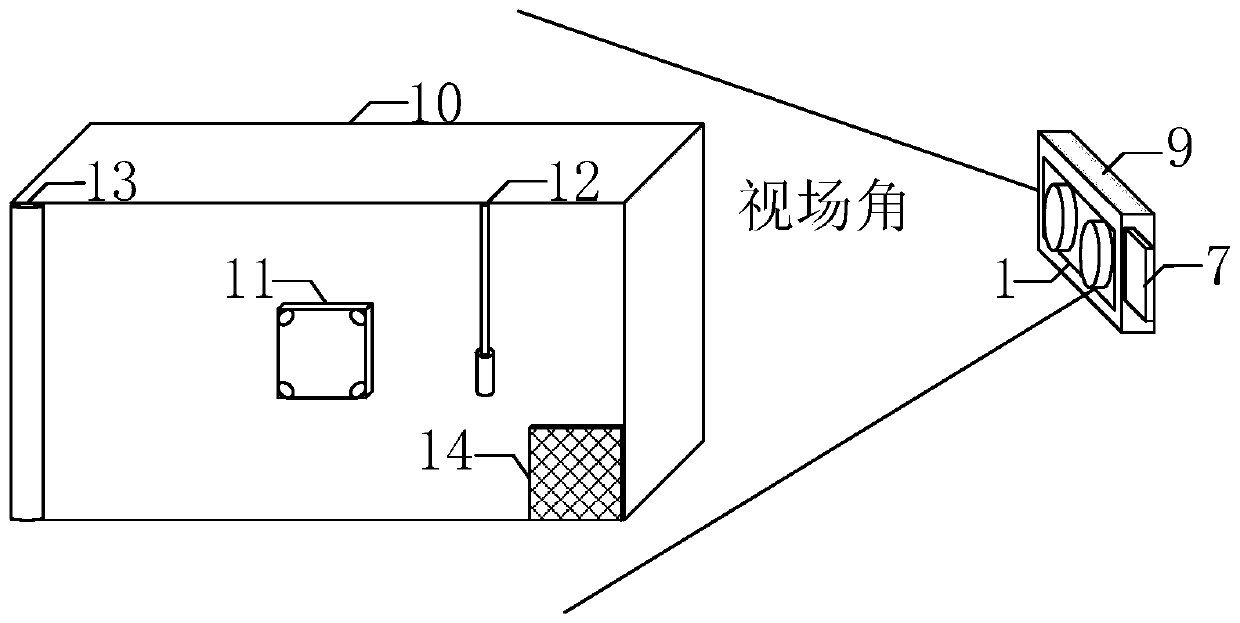

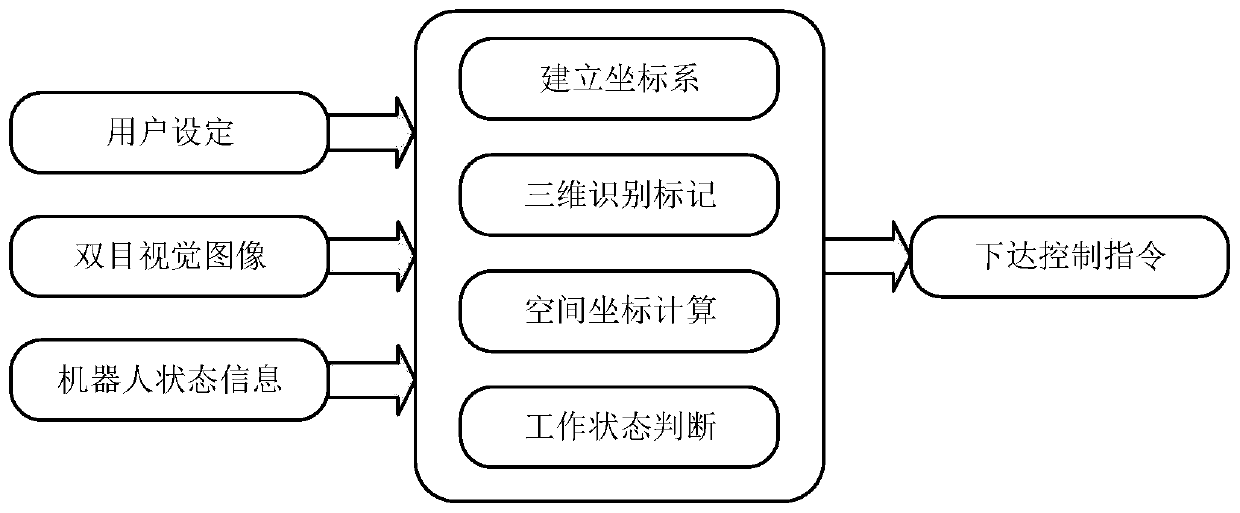

Three-dimensional vision-based fish tank cleaning robot motion control device and control method

PendingCN110587602AReduce in quantityImprove experienceImage enhancementProgramme-controlled manipulatorSimulationVisual perception

The invention discloses a three-dimensional vision-based fish tank cleaning robot motion control device and a control method. The control device comprises a front panel and a rear panel, wherein the front panel and the rear panel can be assembled together to form a shell of the control device, a binocular vision module is arranged in the shell, a lens of the binocular vision module extends out ofthe front panel, a circuit board is arranged in the shell, a central processing unit, a graphics processing unit and a communication module are arranged on the circuit board, the binocular vision module, the graphics processing unit and the communication module are electrically connected with the central processing unit and are controlled by the central processing unit, and a power supply port forsupplying power to components in the control device is arranged on the rear panel. According to the control device, the computer binocular vision technology and the digital image processing algorithmare combined and applied to the motion control of a fish tank cleaning robot, and when the fish tank cleaning robot is in a fish tank, the precise position of the robot and the distance between the robot and an obstacle can be calibrated and the motion state of the robot can be judged.

Owner:青岛森科特智能仪器有限公司

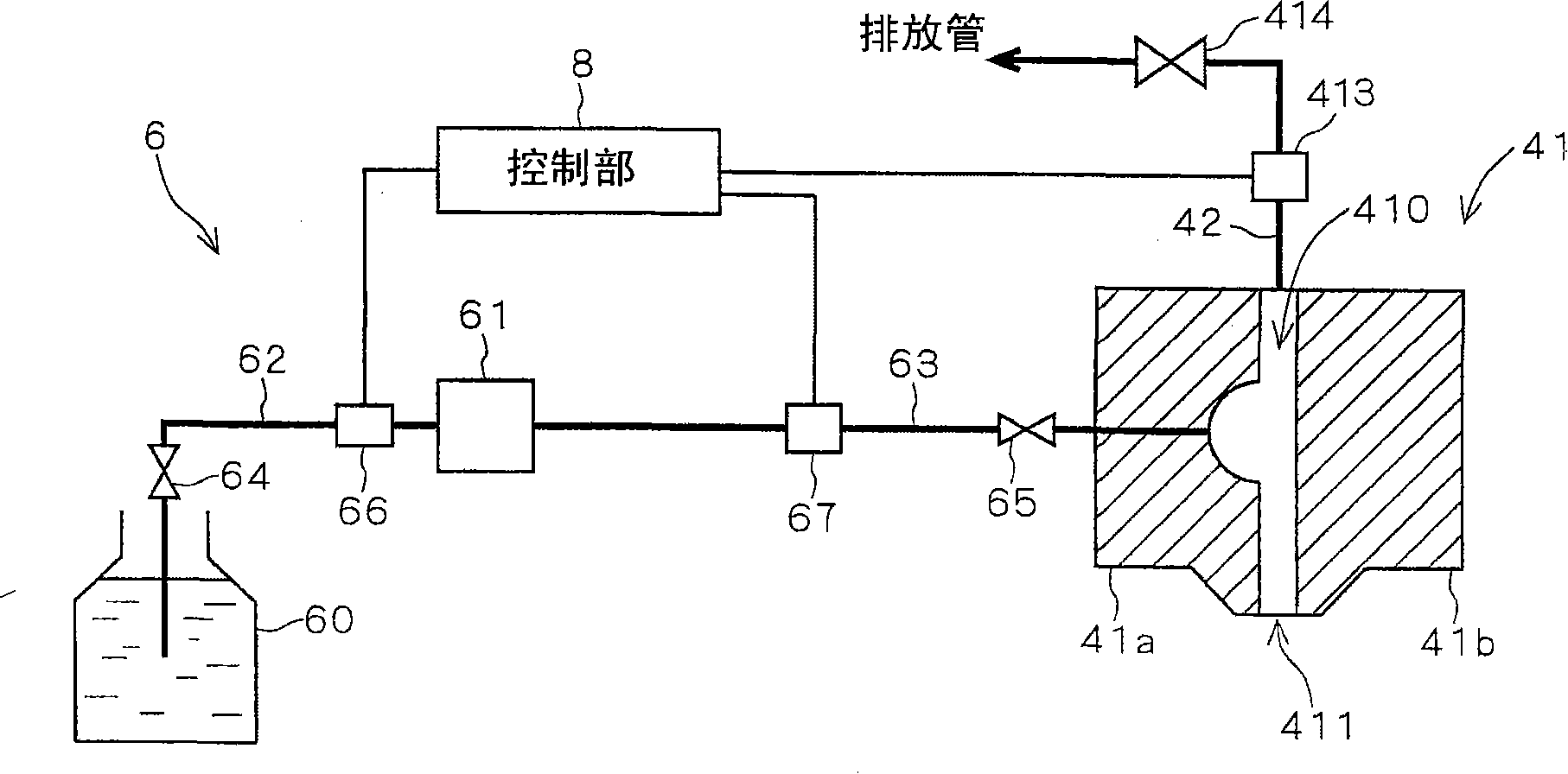

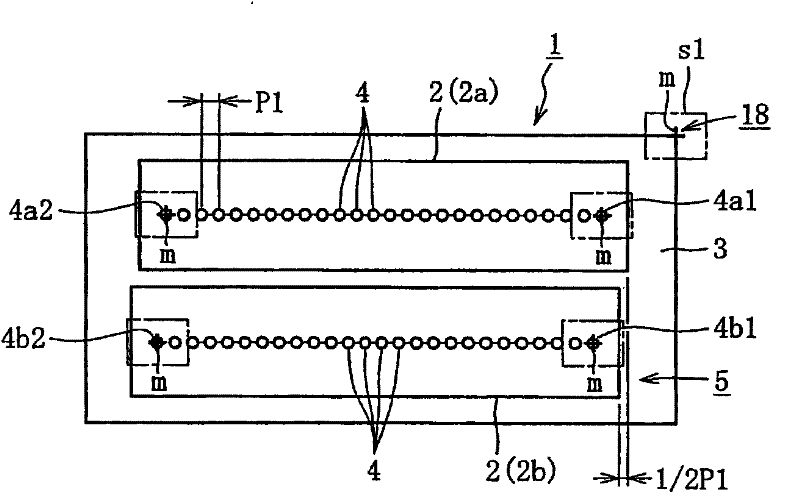

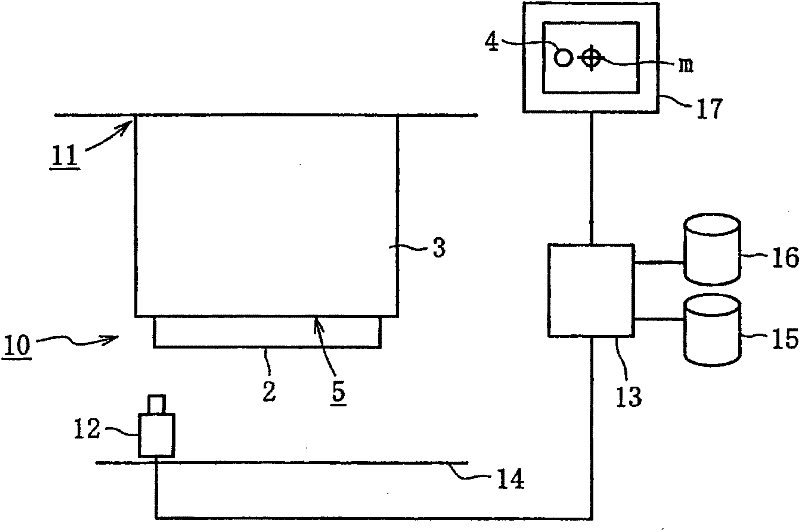

Substrate processing apparatus

ActiveCN101181706AMeasure the ejection stateAccurate measurementLiquid surface applicatorsSemiconductor/solid-state device manufacturingEngineeringSecondary side

The invention relates to a substrate processing device which can measure the state of the processing liquid sprayed from a slit nozzle accurately. The invention is provided with a pipe (42) for extracting air at the secondary side of the slit nozzle (41). The pipe (42) is independent instead of directly communicating with the pipe (63) positioned at the first side of the slit nozzle (41). Besides, the pipe (42) is directly communicated with a stream (410) inside the slit nozzle (41). The pipe (42) is provided with a pressure sensor (413) so as to transfer the measure value to a control part (8). The corrosion resistance liquid is supplied to the slit nozzle (41) through a pump (61) and the pressure inside the pipe (42) at this time is measured through the pressure sensor (413).

Owner:DAINIPPON SCREEN MTG CO LTD

Abnormal jet detecting device of ink jet head and detecting method

ActiveCN101746130AReduce adverse effectsImprove responsivenessPower drive mechanismsEngineeringNozzle

The present invention provides an abnormal jet detecting device of an ink jet head and a detecting method. The position or liquid width of a liquid material is calculated in at least two positions in the jet direction of a nozzle, based on an image taken after the liquid material is ejected out from the nozzle of an ink jet head, so the abnormal jet of the nozzle is detected.

Owner:ISHII HYOKI

Efficient laser marking method and device for multi-style small-batch articles

The invention discloses an efficient laser marking method and device for multi-style small-batch articles. The laser marking method comprises the steps that a drawing is prepared and typeset on a computer, the thickness of marks in the drawing is set, a contour is marked on a working platform according to the drawing, the marked articles are placed on the contour, the focusing height is set according to the thickness, and then laser marking is carried out. The laser marking device comprises a rack, and the working platform and a three-axis linkage mechanism which are distributed front and back are connected to the rack. The three-axis linkage mechanism is connected with a laser marking head located above the working platform, the three-axis linkage mechanism is electrically connected with a control box, and the laser marking head is also electrically connected with the control box. The efficient laser marking method and device for the multi-style small-batch articles can be suitable for laser marking operation of multiple types of small-batch articles, and further has the advantages of being high in machining efficiency, convenient to operate, high in safety, capable of conveniently removing pollutants, high in machining precision, stable in control and good in dust removal and environmental protection performance.

Owner:张振宇

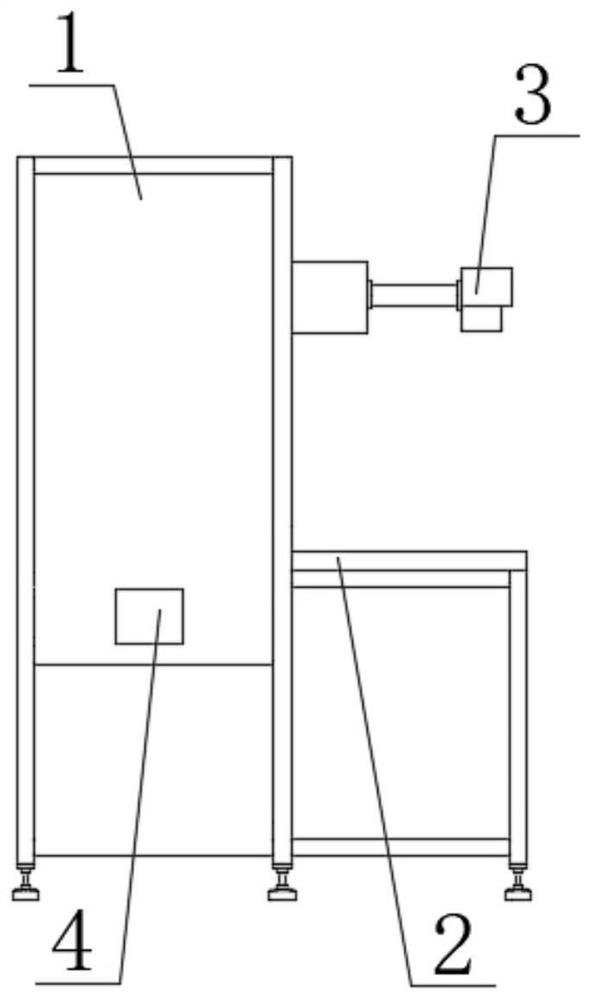

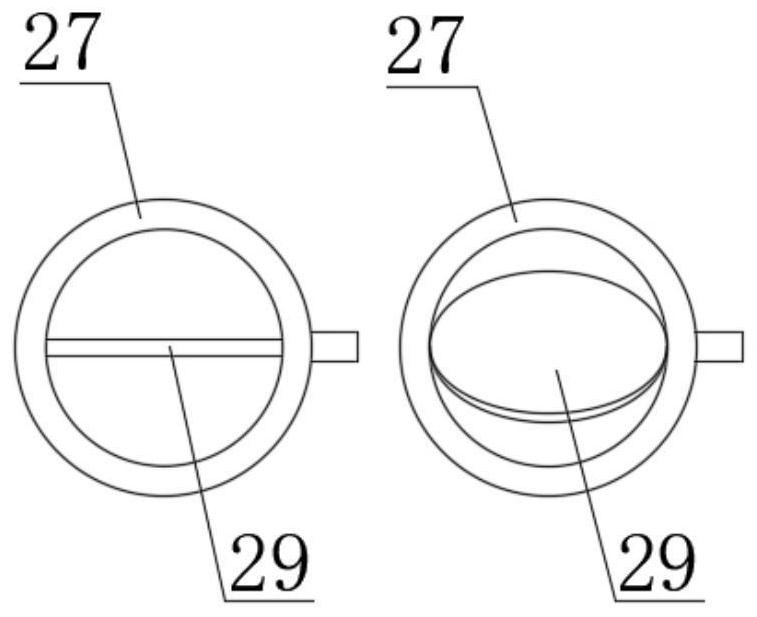

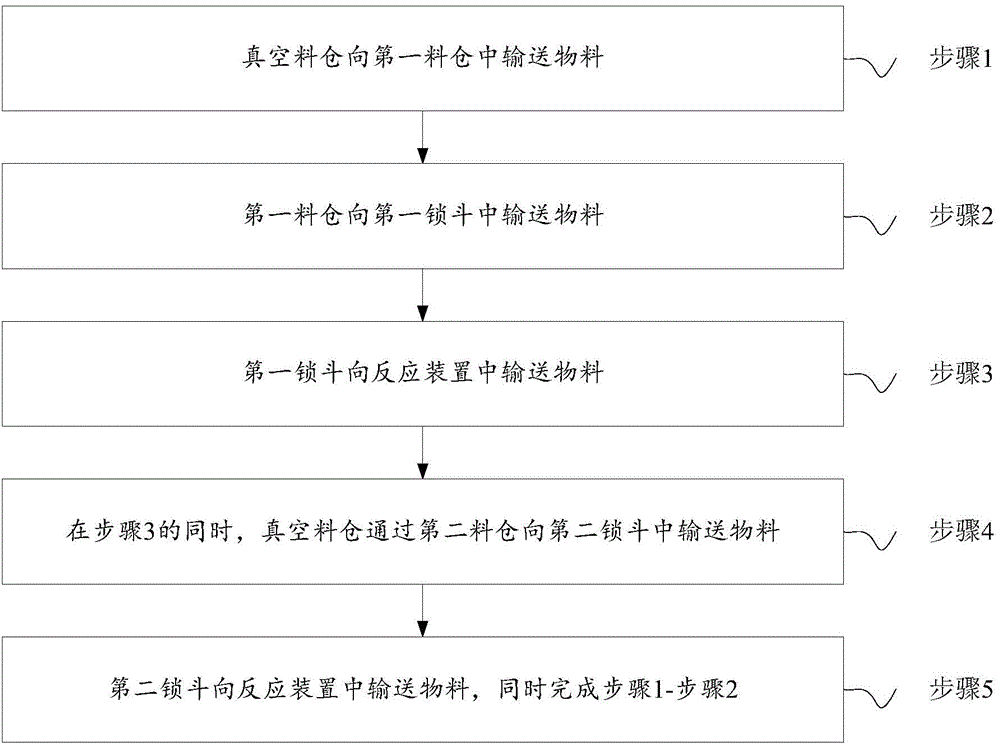

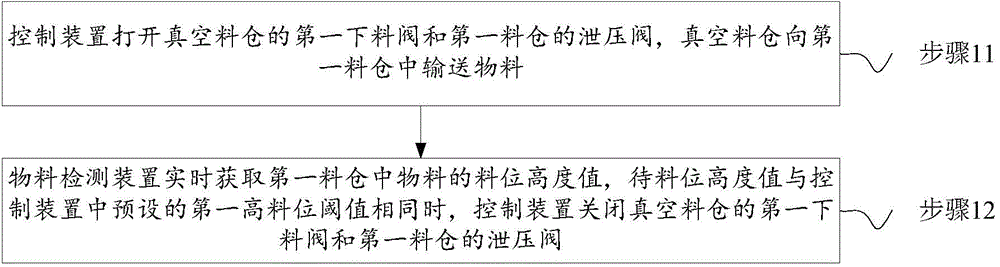

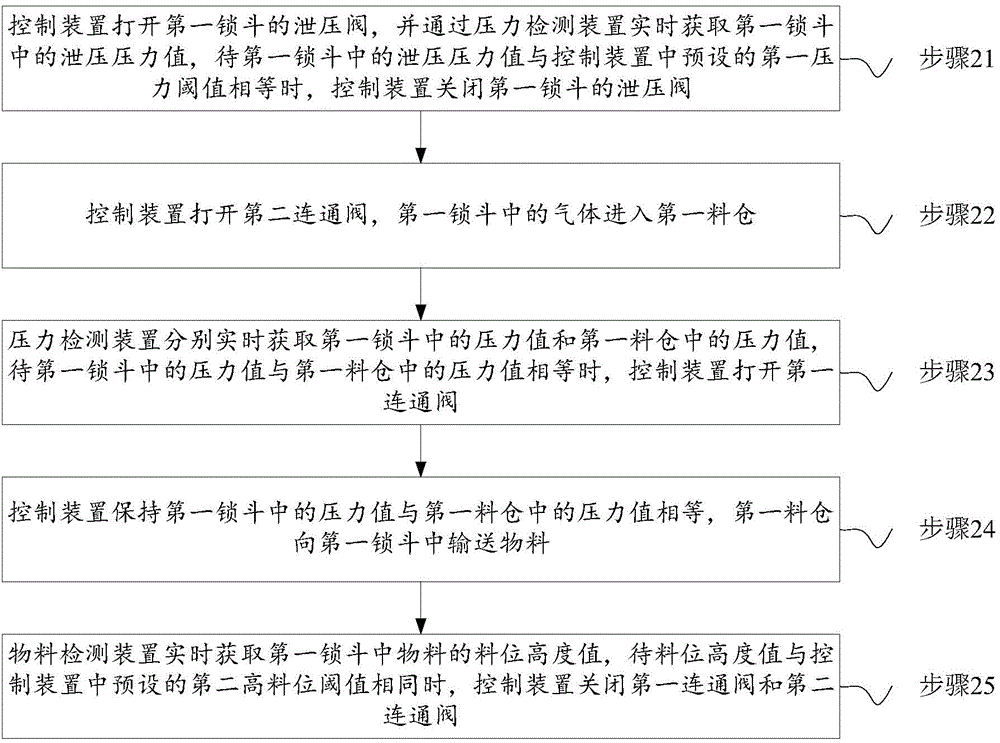

Dense-phase conveying control method and system

ActiveCN104692127APrecise movement controlPrecise loading and unloadingBulk conveyorsTransfer procedureEngineering

The invention discloses a dense-phase conveying control method and system, relates to the technical field of pneumatic conveying, and solves the problems that switching continuity among conveying systems and material conveying stability are affected easily due to manual control for a parallel conveying mode, the safety is poorer and the efficiency is lower. According to the dense-phase conveying control method, a material detection device and a pressure detection device acquire the material level height values and pressure values of bins and lock hoppers of the conveying systems in real time respectively, and feed the material level height values and the pressure values back to a control device; the control device compares the material level height values and the pressure values with preset high and low material level threshold values and pressure threshold values respectively, and controls opening and closing of valves according to comparison results; and the control device controls a vacuum bin to convey materials automatically to a reaction device alternately through the conveying systems according to the material level height values and the pressure values of the conveying systems. The dense-phase conveying control method and system are mainly applied to a material conveying process.

Owner:ENN SCI & TECH DEV

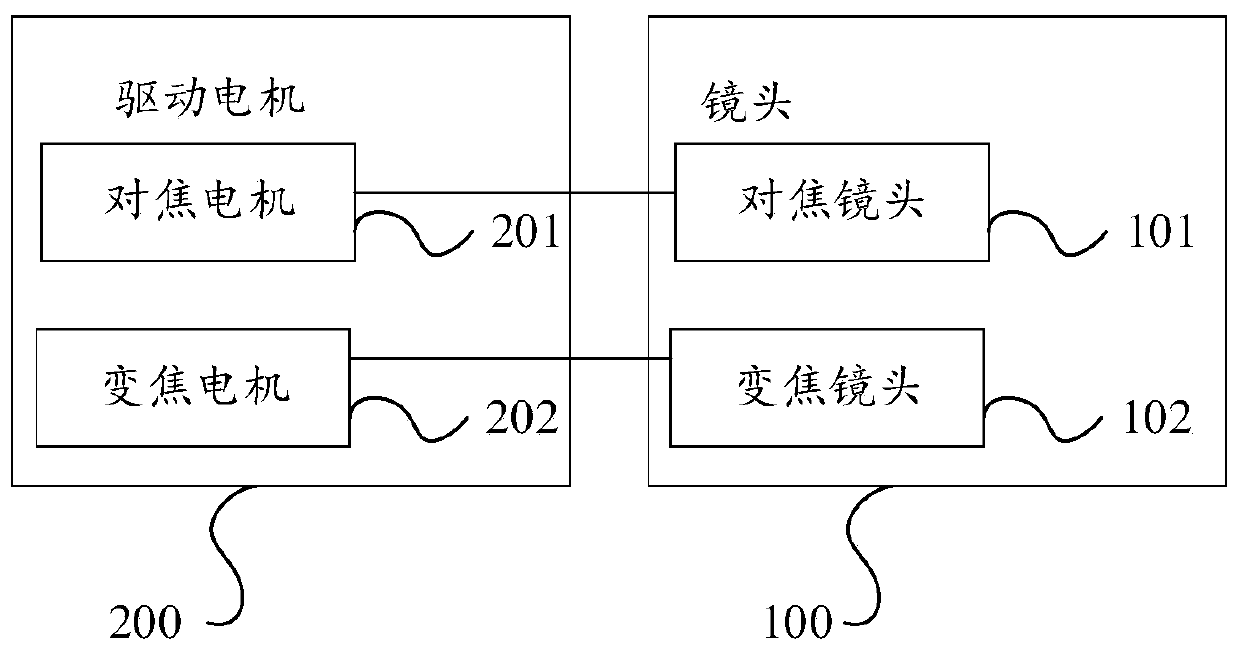

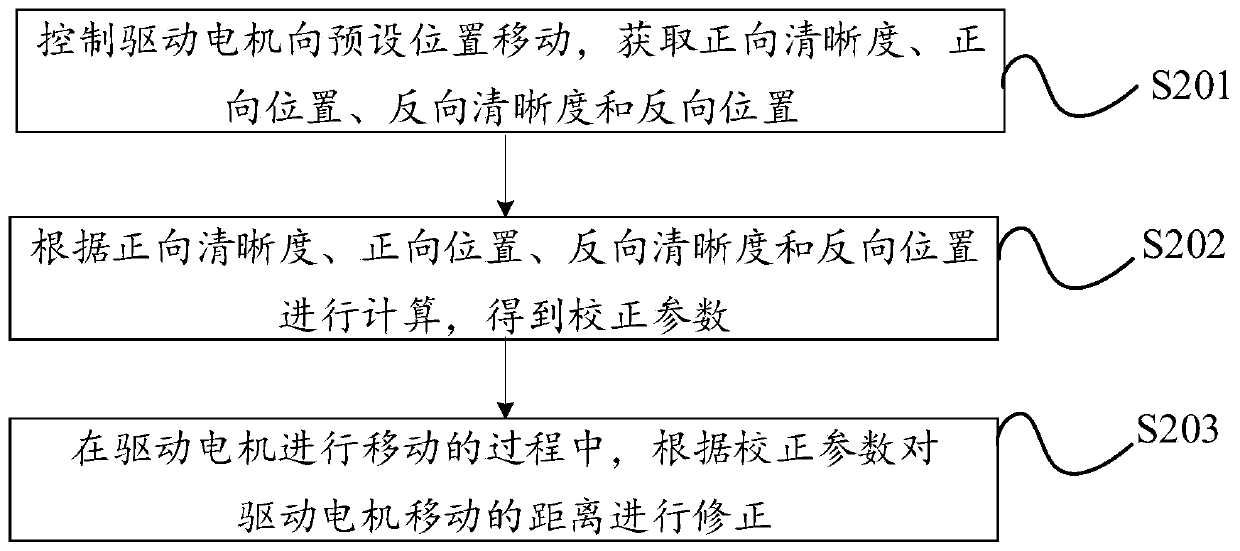

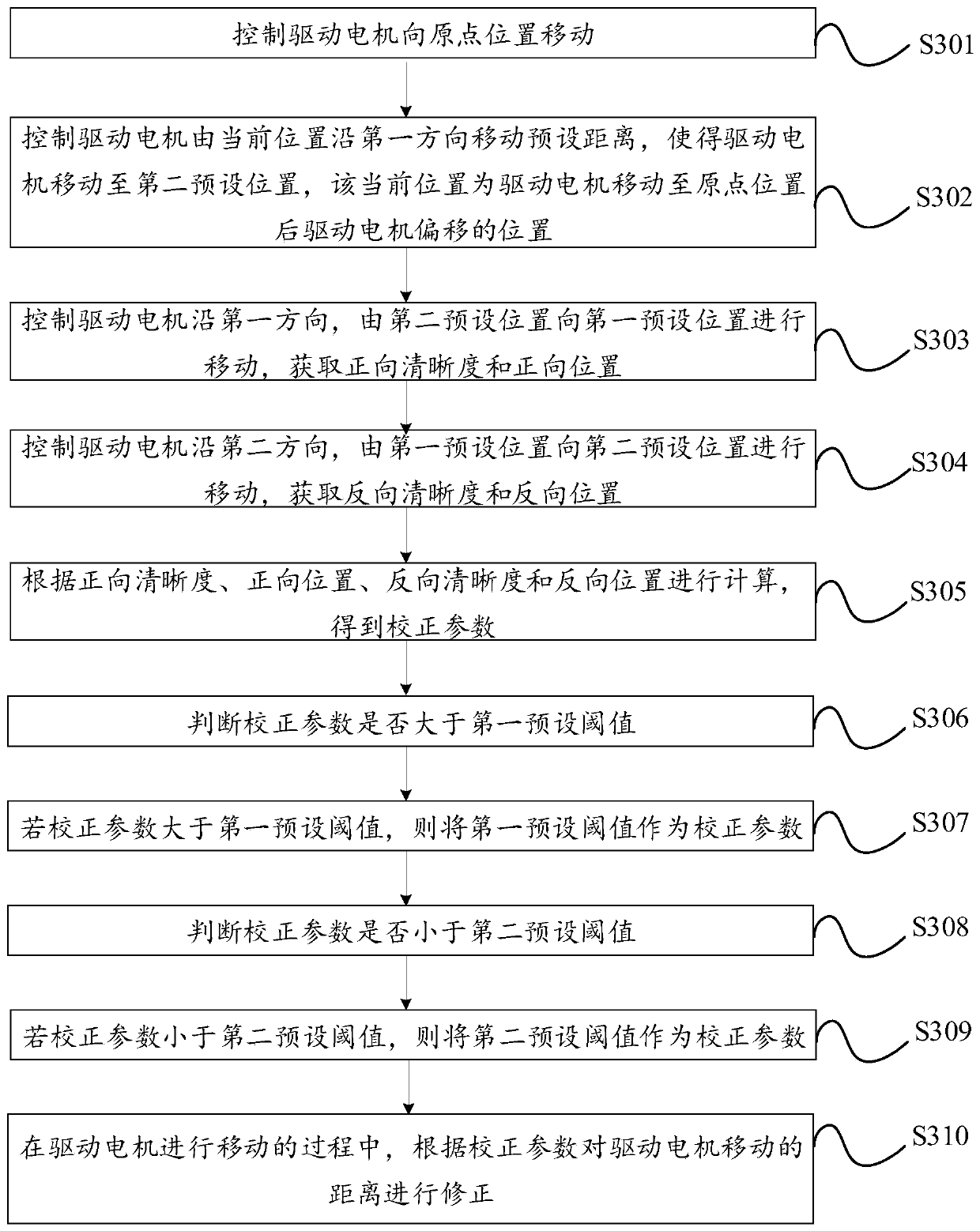

Focusing correction method and device

ActiveCN109996005AReduce mistakesAccurate focusTelevision system detailsColor television detailsDrive motorComputer science

The invention provides a focusing correction method and device, and relates to the technical field of lens control. The focusing correction method comprises the steps that by controlling a driving motor to move towards a preset position, the forward definition, the forward position, the reverse definition and the reverse position are obtained, calculation is conducted according to the forward definition, the forward position, the reverse definition and the reverse position, and correction parameters are obtained; and finally, during the moving process of the driving motor, the moving distanceof the driving motor is corrected according to the correction parameters; through acquiring correction parameters, the moving distance of the driving motor is corrected according to the correction parameters; accurate focusing of a lens and accurate synchronous focusing can be realized in the zoom process of the lens; the problem that a shot scene is unclear due to the fact that a lens cannot be accurately focused in the prior art is avoided, errors generated when a driving motor moves are reduced, the driving motor can accurately control movement of a terminal, the lens focusing accuracy is improved, and therefore the shot scene is clearer.

Owner:重庆紫光华山智安科技有限公司

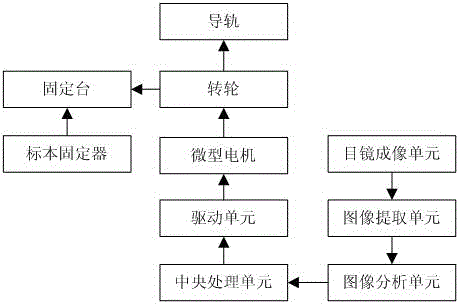

Microscope object stage specimen fixator automatic control system

InactiveCN105005140AAutomatic control automatic realizationFast movement controlMicroscopesEyepieceAutomatic control

The invention discloses a microscope object stage specimen fixator automatic control system comprising a transmission mechanism, a micro-motor, a driving unit, a central processing unit, an eye lens imaging unit, an image extraction unit and an image analysis unit. The eye lens imaging unit is arranged on an eye lens and used for generating an image of a specimen on the eye lens. The image extraction unit is used for extracting images in real time. The image analysis unit is used for analyzing the extracted images and judging cover area of the specimen in the images so as to acquire a cover value. The central processing unit is used for judgment according to the cover value. When the cover value is lower than the preset cover value, a control signal is generated. The driving unit is used for converting the control signal into a driving signal to be outputted. The micro-motor is used for generating driving force. The transmission mechanism is used for driving a specimen fixator to linearly move. Movement of the specimen fixator can be rapidly and accurately realized without artificial adjustment.

Owner:苏州南光电子科技有限公司

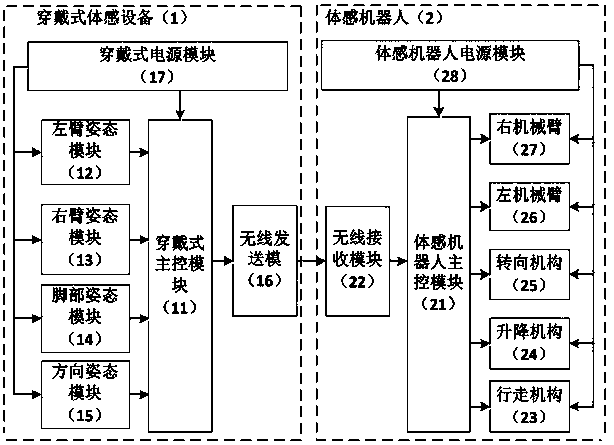

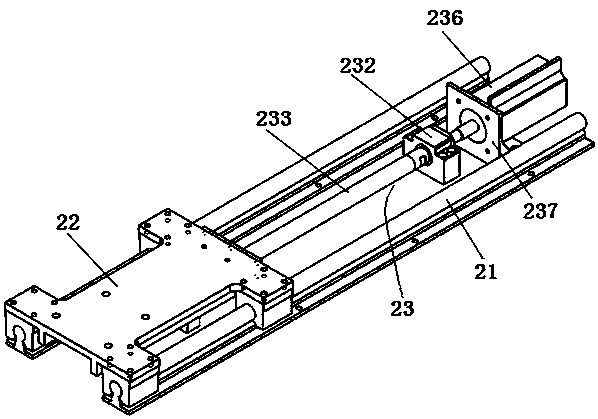

Wearable somatosensory robot

PendingCN108044608AFast motion controlPrecise movement controlProgramme-controlled manipulatorEngineeringSomatosensory system

The invention discloses a wearable somatosensory robot which comprises wearable somatosensory equipment (1) and a somatosensory robot (2) and is also characterized by a wearable main control module (11), a left arm posture module (12), a right arm posture module (13), a foot posture module (14), a direction posture module (15), a wireless transmitting module (16) and a wearable power module (17) included in the wearable somatosensory equipment (1) as well as a somatosensory robot main control module (21), a wireless receiving module (22), a walking mechanism (23), a lifting mechanism (24), a steering mechanism (25), a left mechanical arm (26), a right mechanical arm (27) and a somatosensory robot power module (28) included in the somatosensory robot (2). The wearable somatosensory robot disclosed by the invention can effectively solve the problems that an operator cannot carry out a task normally due to the influence of high temperature, nuclear radiation and other environmental conditions in the field of industrial measurement and control, and also can realize quicker and more accurate motion control of more dimensions.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

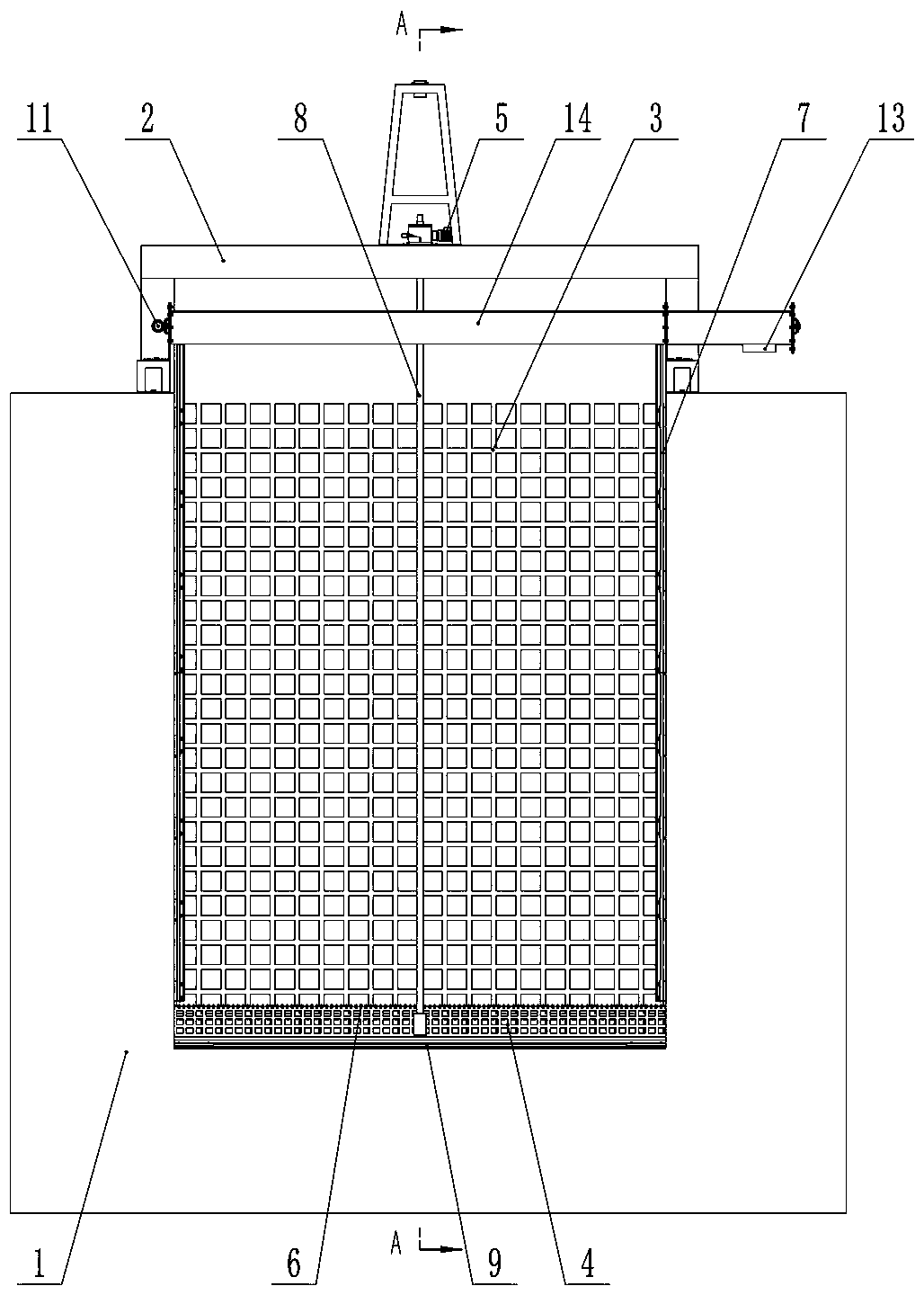

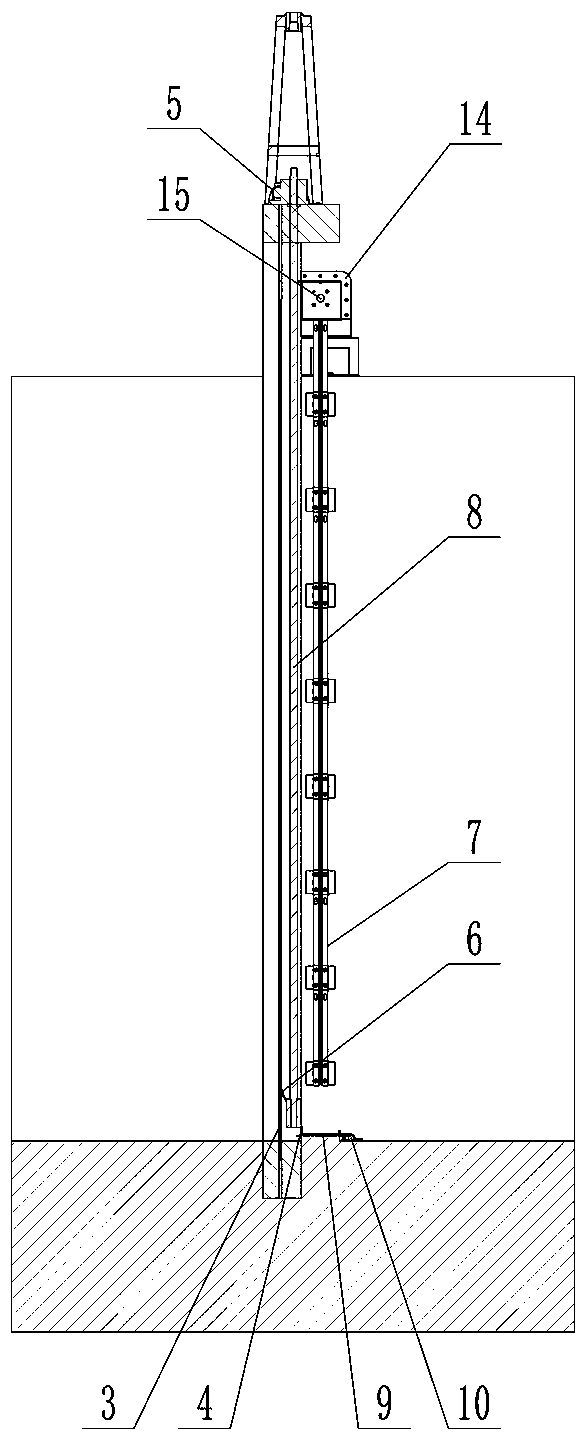

Device for automatically cleaning flat filter screen in forebay

PendingCN111097211AClean up in timeWon't hurtStationary filtering element filtersMotor driveElectric machinery

The invention provides a device for automatically cleaning a flat plate filter screen in a forebay. The device comprises a fixing frame, a flat plate filter screen mounted on the fixing frame, a temporary storage hopper arranged on the outer side of the flat plate filter screen, and a lifting motor. A scraping and brushing mechanism is arranged on the outer side face, right opposite to the flat plate filter screen, of the temporary storage hopper, the gap between the scraping and brushing mechanism and the flat plate filter screen ranges from 3mm to 6mm, the lifting motor drives the temporarystorage hopper to ascend and descend in the direction parallel to the flat plate filter screen, and in the initial state, the temporary storage hopper is located at the bottom end of the outer side ofthe flat plate filter screen. The device for automatically cleaning a flat plate filter screen of a forebay has the advantages of scientific design, good cleaning effect, no damage to the filter screen, intelligence and high efficiency.

Owner:郑州赛为机电设备有限公司

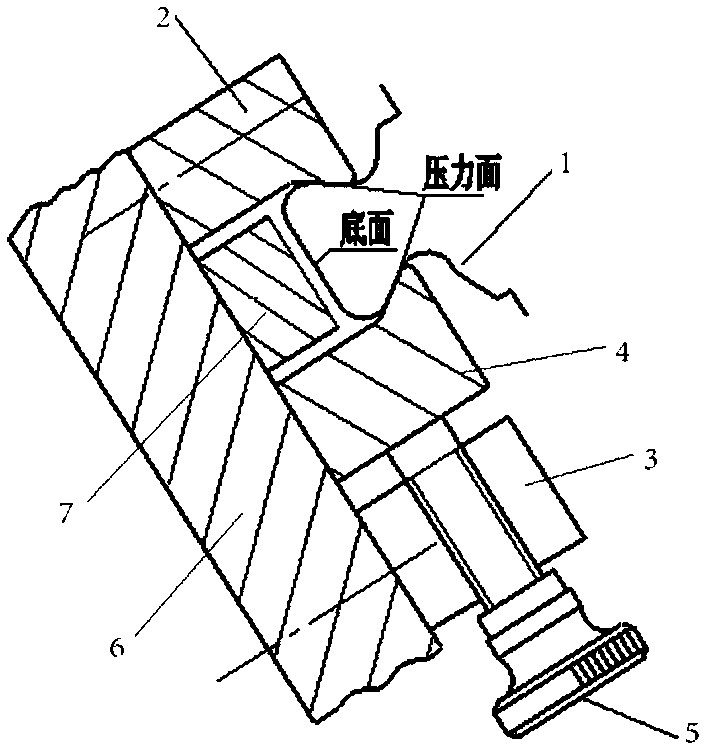

Engine blade measuring device

InactiveCN108981629AAchieving pressure surface positioningCompact structureMechanical measuring arrangementsButt jointEngineering

The invention discloses an engine blade measuring device. The device comprises a blade tenon clamping mechanism, the blade tenon clamping mechanism comprises a pedestal and a positioning block and a compressing block, opposite to the positioning block, arranged on the pedestal, the positioning block is fixedly connected to the pedestal, the compressing block can translate on the pedestal, and theside, opposite to the compressing block, of the positioning block is provided with a force application side corresponding to the pressure surface of a blade tenon; and the compressing block moves towards the positioning block to clamp the blade tenon. Via reasonable structural design, force application to the blade tenon can be controlled more accurately and easier, it is ensured that the bottom of the tenon is butt joint in an aligned way, the blade is avoided for swinging in the height direction, the measuring stability is improved, positions in air inlet and exhaust sides of the blade are measured accurately stably, and the consistency in repeated measurement is higher.

Owner:AECC AVIATION POWER CO LTD

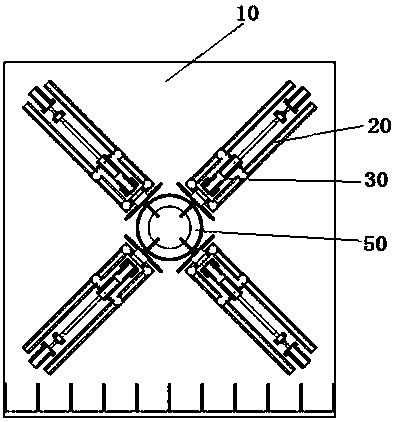

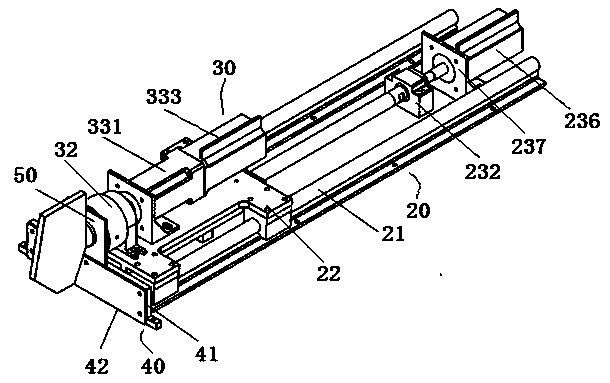

Gas rudder testing device

ActiveCN110987399AQuick responsePrecise movement controlMachine part testingStructural engineeringControl theory

The invention provides a gas rudder testing device. The gas rudder testing device comprises a base and deflection / withdrawal control assemblies installed on the base along the same circumference. Eachdeflection / withdrawal control assembly comprises a withdrawal control assembly, including a slide rail, a sliding block and a first driving device, wherein the slide rail is installed on the base; the sliding block can be slidably installed on the slide rail. The first driving device is in driving connection with the corresponding sliding block. The device also comprises a deflection control assembly, which comprises a supporting base, a switching device and a second driving device. The supporting base is installed on the sliding block; the switching device is installed on the supporting base; and the second driving device is in driving connection with the switching device. According to the invention, multiple or one deflection / withdrawal control assembly can be used for testing a gas rudder according to actual test requirements, and each deflection / withdrawal control assembly can select synchronization or respective control according to requirements, so that the deflection performance or the withdrawal performance or the deflection performance and the withdrawal performance of the gas rudder can be cooperatively tested.

Owner:武汉天拓宇航智能装备有限公司

Three-axis hybrid-driven mechanical arm

ActiveCN104608123AReduce volumeSimple structureProgramme-controlled manipulatorMechanical engineeringPosition sensor

A three-axis hybrid-driven mechanical arm comprises a base, a support, a rear arm, a front arm and a palm. The palm is connected with the support through a first connecting rod mechanism formed by two parallelogram mechanisms, and a first infrared distance meter which is arranged on a connecting rod of the front arm is aligned with a second infrared distance meter which is arranged on a connecting rod of the rear arm; an electromagnetic coil drive mechanism used for driving the front arm and the rear arm to open and close relatively is arranged in the front arm and the rear arm, and the electromagnetic coil drive mechanism comprises a second connecting rod mechanism and electromagnetic coils; a worm gear type direct-current servo motor which is used for driving the support to rotate around the base and driving the rear arm to rotate around the support is arranged in the support; the support and the rear arm are both provided a position sensor, and the output ends of the position sensors, and the output end of the first infrared distance meter and the output end of the second first infrared distance meter are all connected with the input end of a controller; the controlling end of the worm gear type direct-current servo motor, the controlling end of the first electromagnetic coil and the controlling end of the second electromagnetic coil are all connected with the output end of the controller.

Owner:HUZHOU ZHILI CHILDRENS CLOTHING DEV

Moving code spraying device for food packaging machine

InactiveCN111038796APrecise movement controlConvenient codingPackagingStructural engineeringFood packaging

The invention relates to the technical field of food packaging, in particular to a moving code spraying device for a food packaging machine. Specific to the problems that in the prior art, the heightof a moving code spraying device cannot be adjusted conveniently, and demounting and mounting of a code spraying machine are not convenient, the following scheme is now put forwards. According to thefollowing scheme, the moving code spraying device comprises a base and a code spraying machine, two supporting plates and two first electric telescopic rods are fixed to the top of the base, containing grooves are formed in the tops of the two supporting plates, lifting plates are arranged in the two containing grooves, and the tops of the two lifting plates extend to the outer portions of the containing grooves. Connecting grooves are formed in the sides, away from each other, of the two supporting plates, and connecting plates are fixed to one sides of the two lifting plates. The moving codespraying device is reasonable in structure, ingenious in design and easy to operate, the height of the code spraying machine can be adjusted conveniently, and therefore the moving code spraying device can adapt to code spraying of objects with different heights; and in addition, the code spraying machine can be demounted and mounted conveniently, and therefore the purpose of conveniently overhauling the code spraying machine is achieved.

Owner:安徽采林间食品有限公司

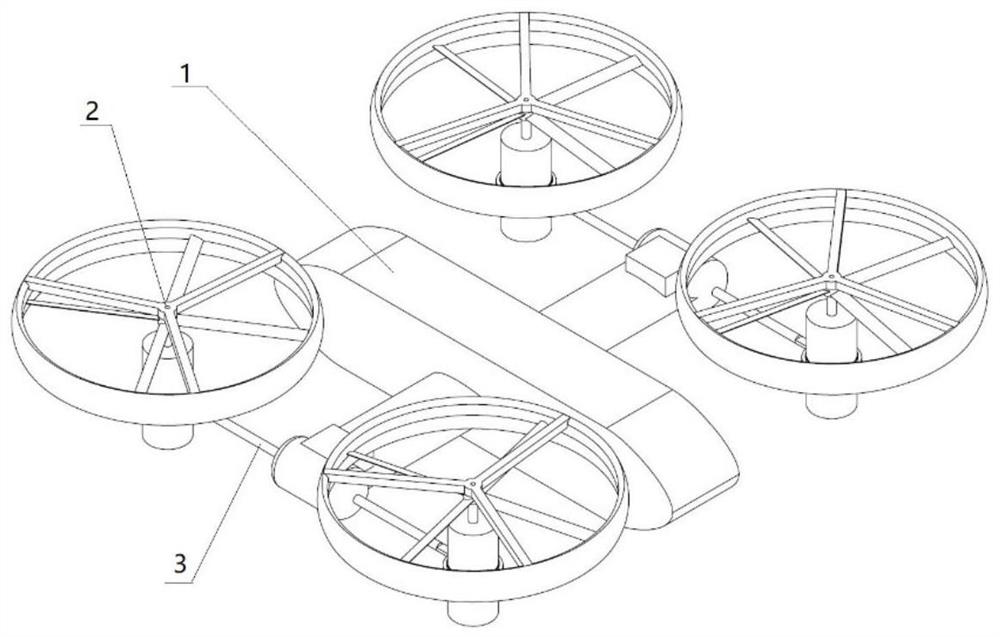

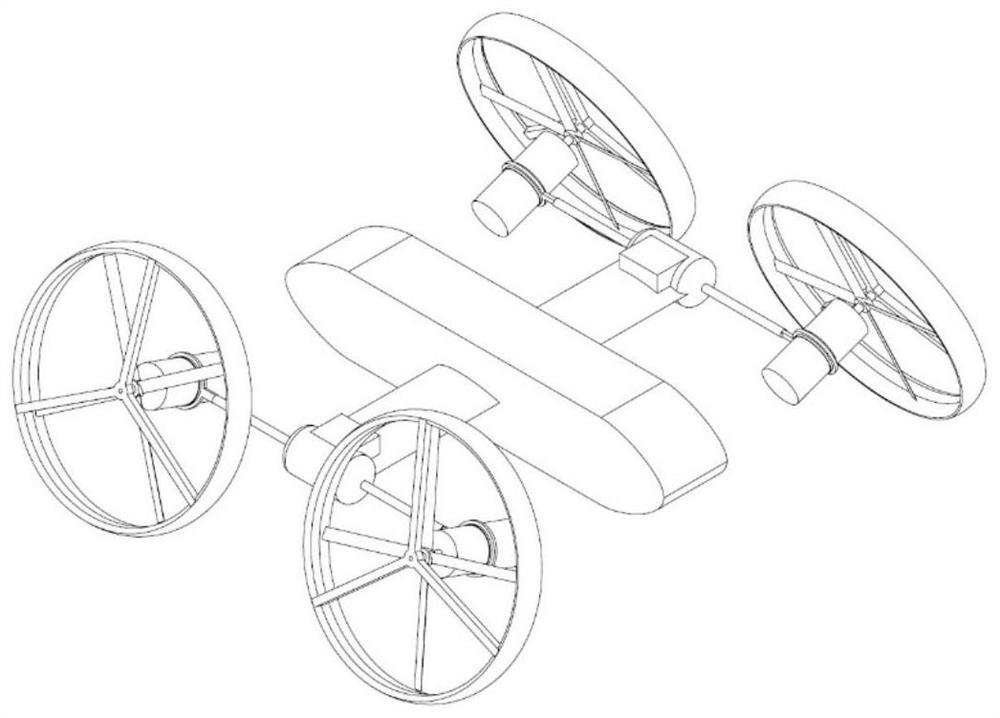

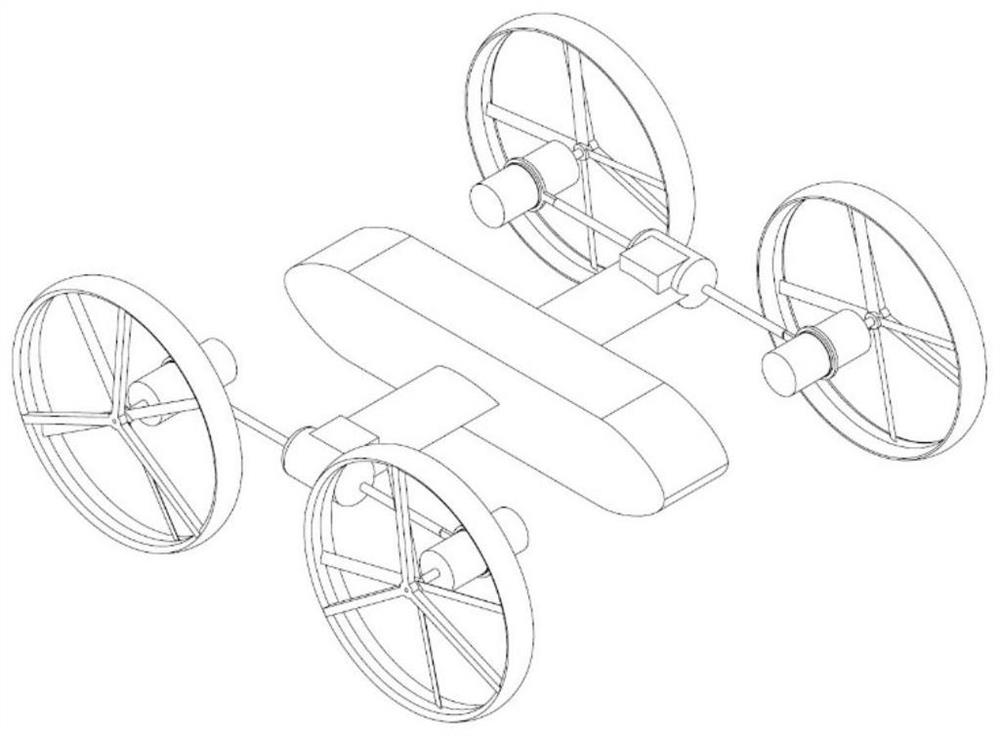

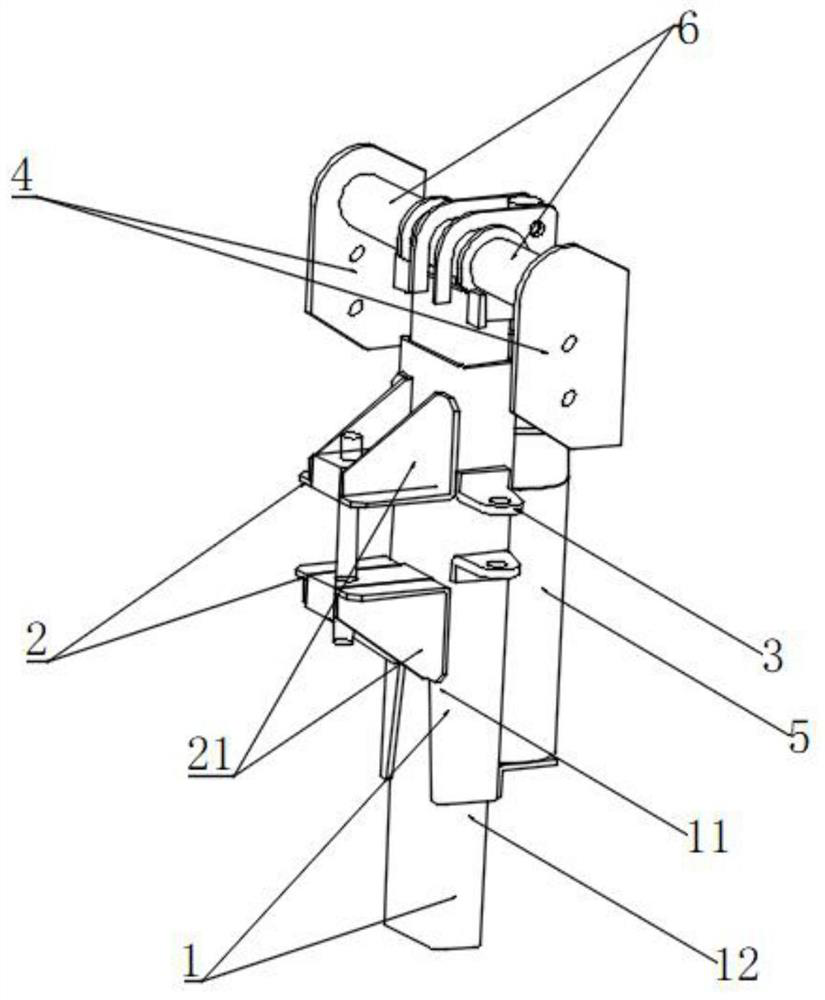

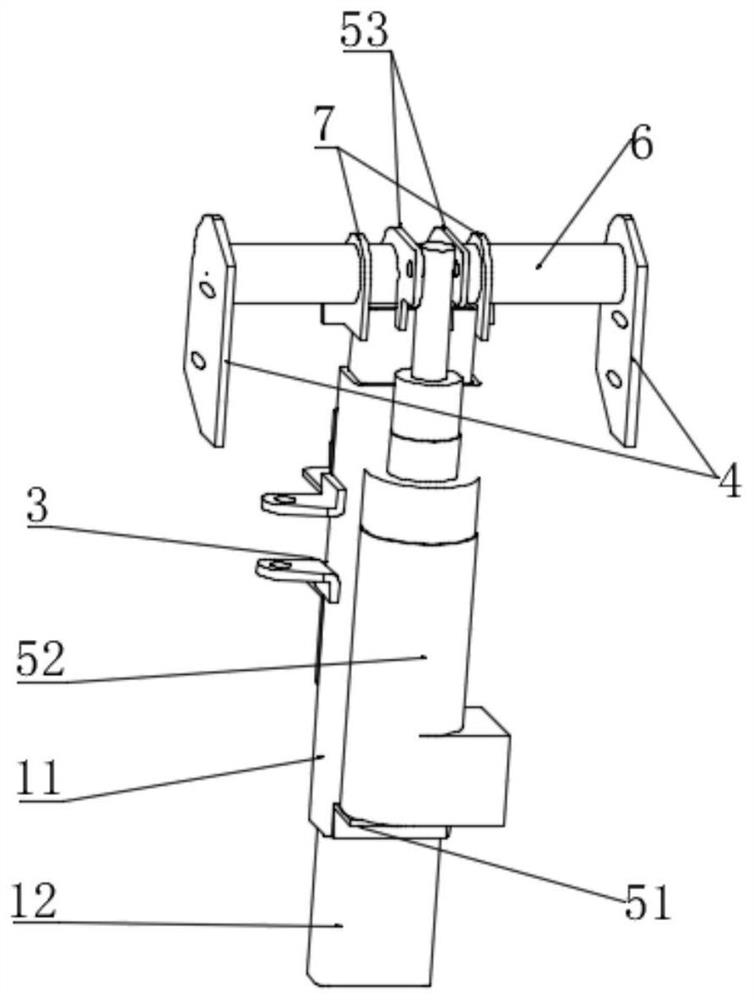

Variable-configuration air-ground unmanned platform capable of realizing air-ground joint debugging

InactiveCN113276613AChange sizeImprove obstacle performanceConvertible aircraftsAircraft convertible vehiclesMachineControl theory

The invention discloses a variable-configuration air-ground unmanned platform capable of realizing land-air joint debugging. The variable-configuration land-air unmanned platform comprises a vehicle body, machine arms, extension arms, a deflection mechanism and a power assembly, extension arms are symmetrically arranged on the two sides of the vehicle body and rotationally connected with the machine arms through deflection mechanisms, and the length direction of the machine arms is parallel to the length direction of the vehicle body. Power assemblies are arranged at two ends of the arms; the deflection mechanism drives the machine arm and the power assembly to deflect around the axis of the machine arm; in the land walking mode, the power assembly serves as a walking wheel; in the flight mode, the power assembly provides lift force. According to the invention, dynamic switching between a flight mode and a land walking mode can be realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +1

Working bucket connecting device, insulating bucket arm vehicle cooperative working bucket and insulating bucket arm vehicle

PendingCN113998632AReduce construction difficultyImprove work efficiencySafety devices for lifting equipmentsApparatus for overhead lines/cablesMovement controlStructural engineering

The invention discloses a working bucket connecting device, an insulating bucket arm vehicle cooperative working bucket and an insulating bucket arm vehicle. The working bucket connecting device comprises a sliding assembly, a connecting device fixing base, a rotating oil cylinder base, a working bucket connecting plate, a lifting oil cylinder assembly and a connecting device main shaft. The sliding assembly comprises a sliding assembly fixing piece and a sliding assembly sliding piece, and the sliding assembly fixing piece is arranged on the outer side of the sliding assembly sliding piece in a sleeving mode. The connecting device fixing base is arranged on the side wall of the sliding assembly fixing piece. The rotating oil cylinder base is arranged on the side wall adjacent to the connecting position of the sliding assembly fixing piece and the connecting device fixing base. The connecting device main shaft is fixedly connected with the top end of the sliding assembly fixing piece, and two ends are respectively provided with a working bucket connecting plate. Accurate movement control over the double buckets is achieved through the working bucket connecting device, so that constructors can conveniently control the two working buckets respectively, the actual requirements in the construction process are met, the construction difficulty is lowered, and safety accidents are avoided.

Owner:STATE GRID TIANJIN ELECTRIC POWER +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com