Substrate processing apparatus

A substrate processing device and substrate technology, which are applied to devices, optics, instruments, etc. for coating liquid on the surface, to achieve the effect of suppressing the amount of calculation processing and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

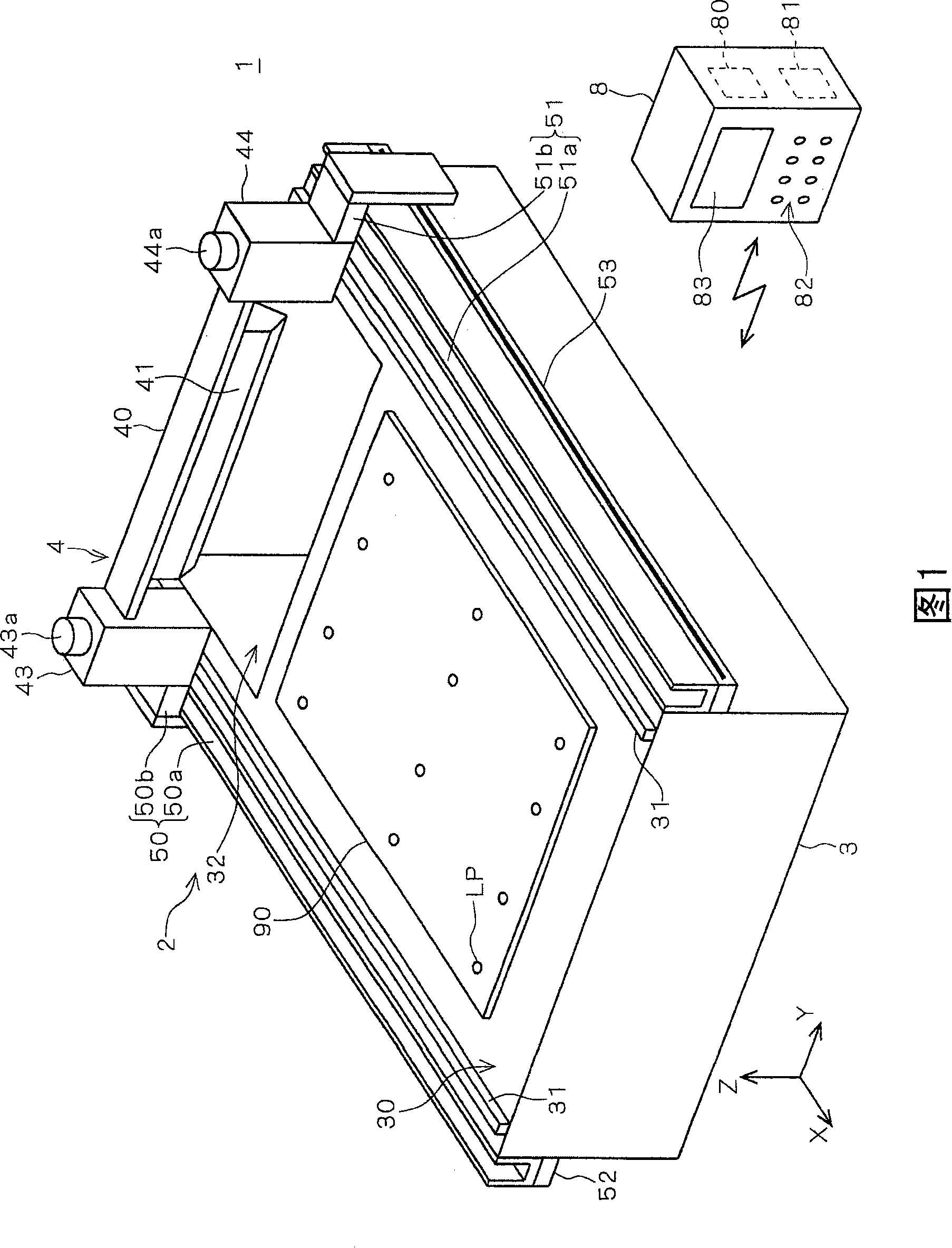

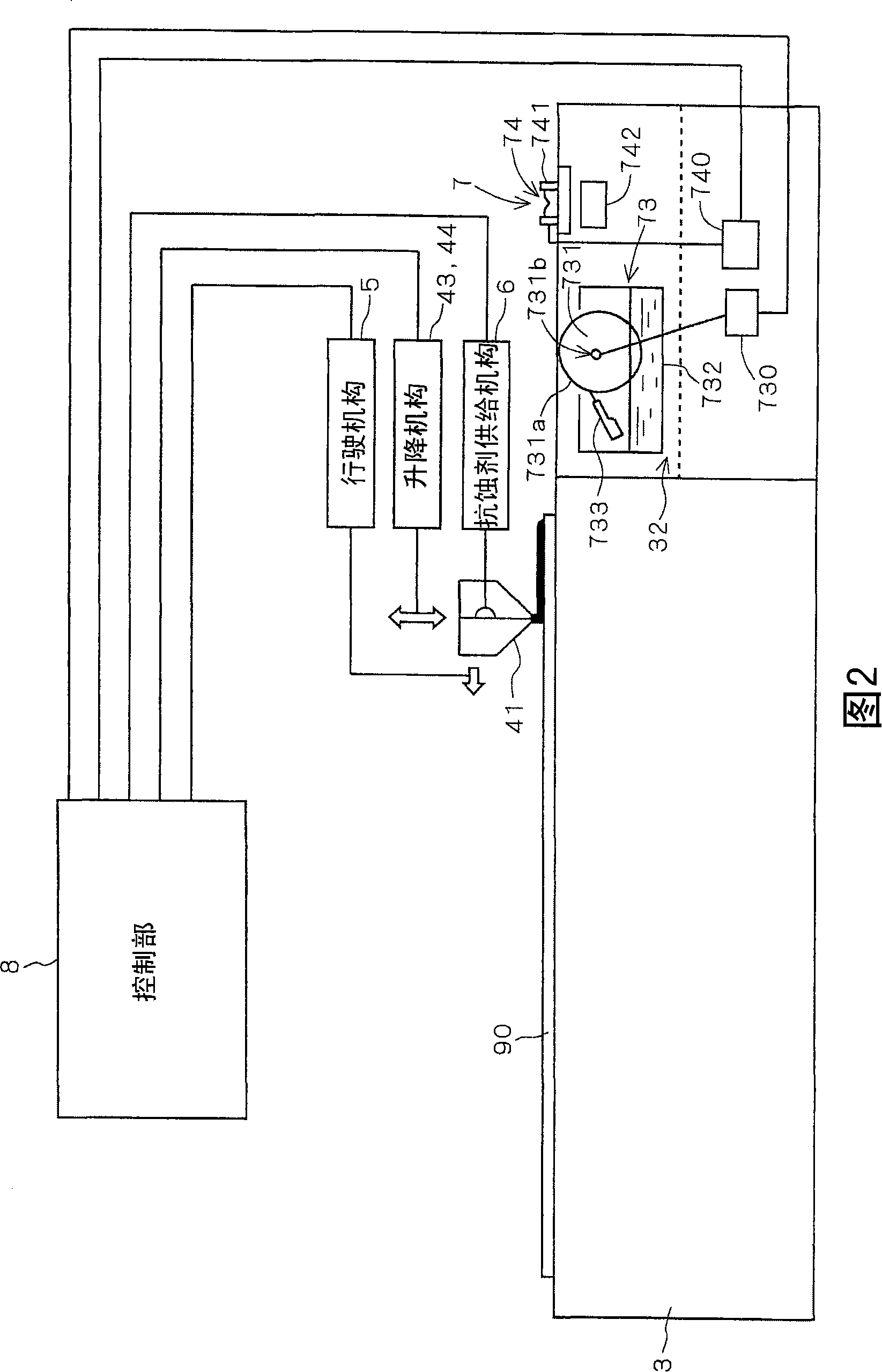

[0032] 1 is a perspective view schematically showing a substrate processing apparatus 1 of the present invention, and FIG. 2 is a side cross-sectional view showing a main body 2 of the substrate processing apparatus 1 and showing main components related to a resist liquid coating operation.

[0033] In FIG. 1 , for ease of illustration and description, it is defined that the Z-axis direction represents the vertical direction, and the XY plane represents the horizontal plane. However, these are defined for the convenience of grasping the positional relationship, and are not limited to the directions described below. The same applies to the following drawings.

[0034] The substrate processing apparatus 1 is roughly divided into a main body 2 and a control section 8, and a square glass substrate used for manufacturing a screen panel of a liquid crystal display device is used as a substrate to be processed (hereinafter simply referred to as "substrate") 90, which is formed on the ...

no. 2 approach

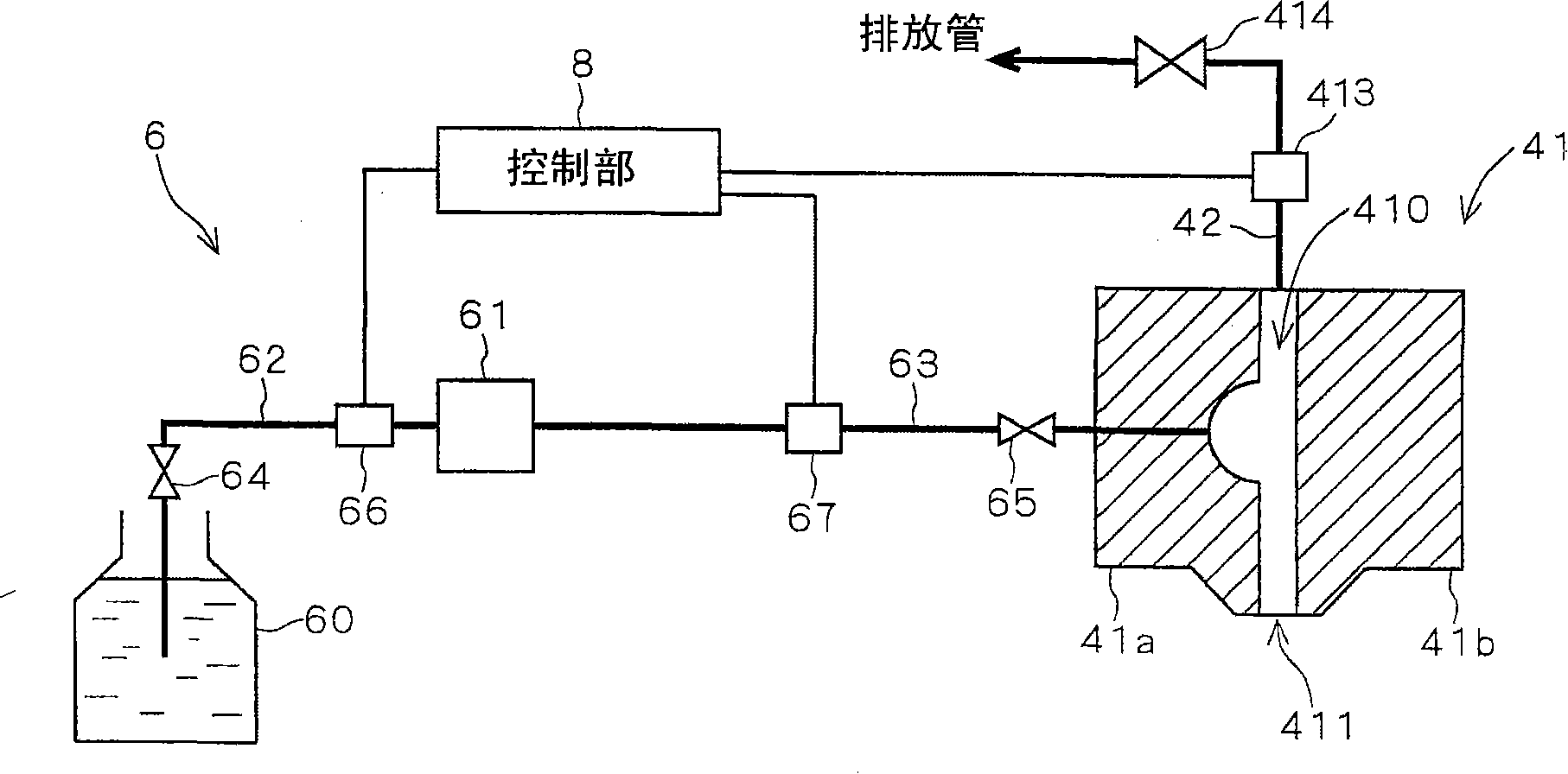

[0120] In the first embodiment, in the control value acquisition step (step S11 ), not only the control value of the pump 61 but also the control value of the traveling mechanism 5 is set. That is, the control value of the traveling mechanism 5 is also preset before the coating process.

[0121] However, in the coating process (step S13 ), the pressure sensor 413 may always measure and control the traveling mechanism 5 so as to follow the measured value when coating starts. That is, the traveling mechanism 5 may be controlled based on the measurement result of the pressure sensor 413 every time the coating process is performed.

[0122] Even with such a configuration, the same effect as that of the first embodiment can be obtained.

[0123]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com