Tyre inflation device

A technology for inflating equipment and tires, applied in tire installation, tire parts, vehicle parts, etc., can solve problems such as unfavorable space requirements, and achieve the effect of low cost and small space requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

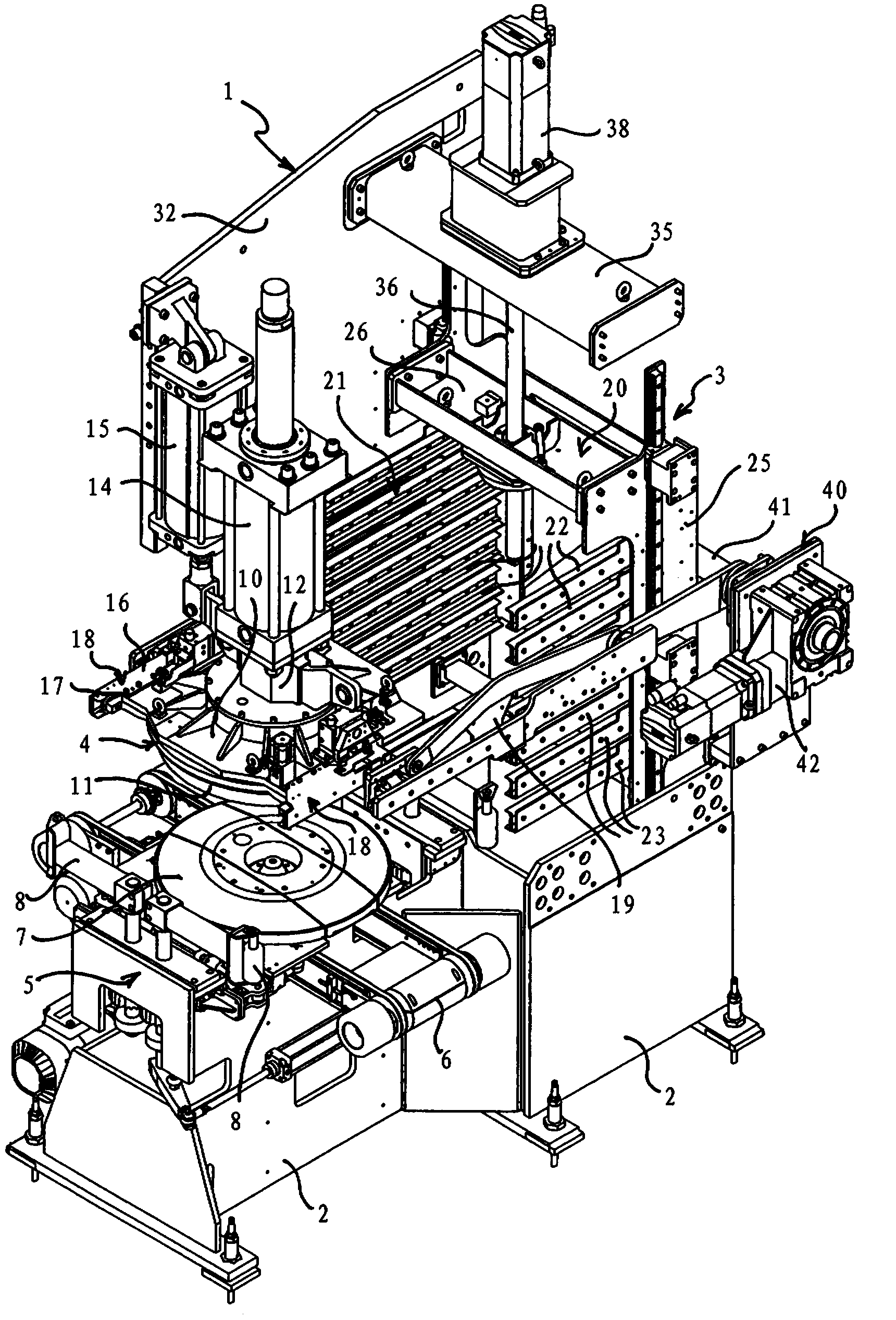

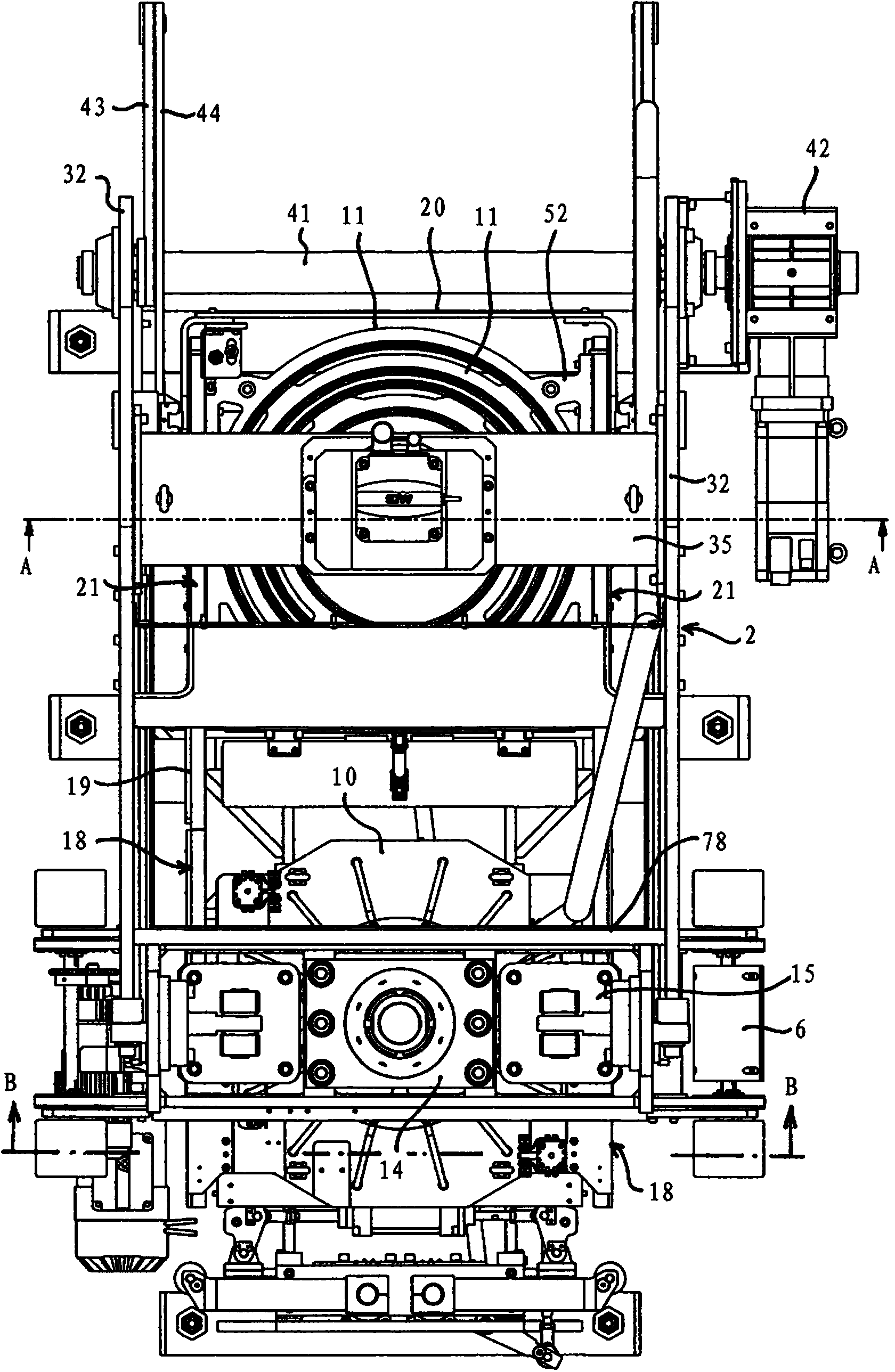

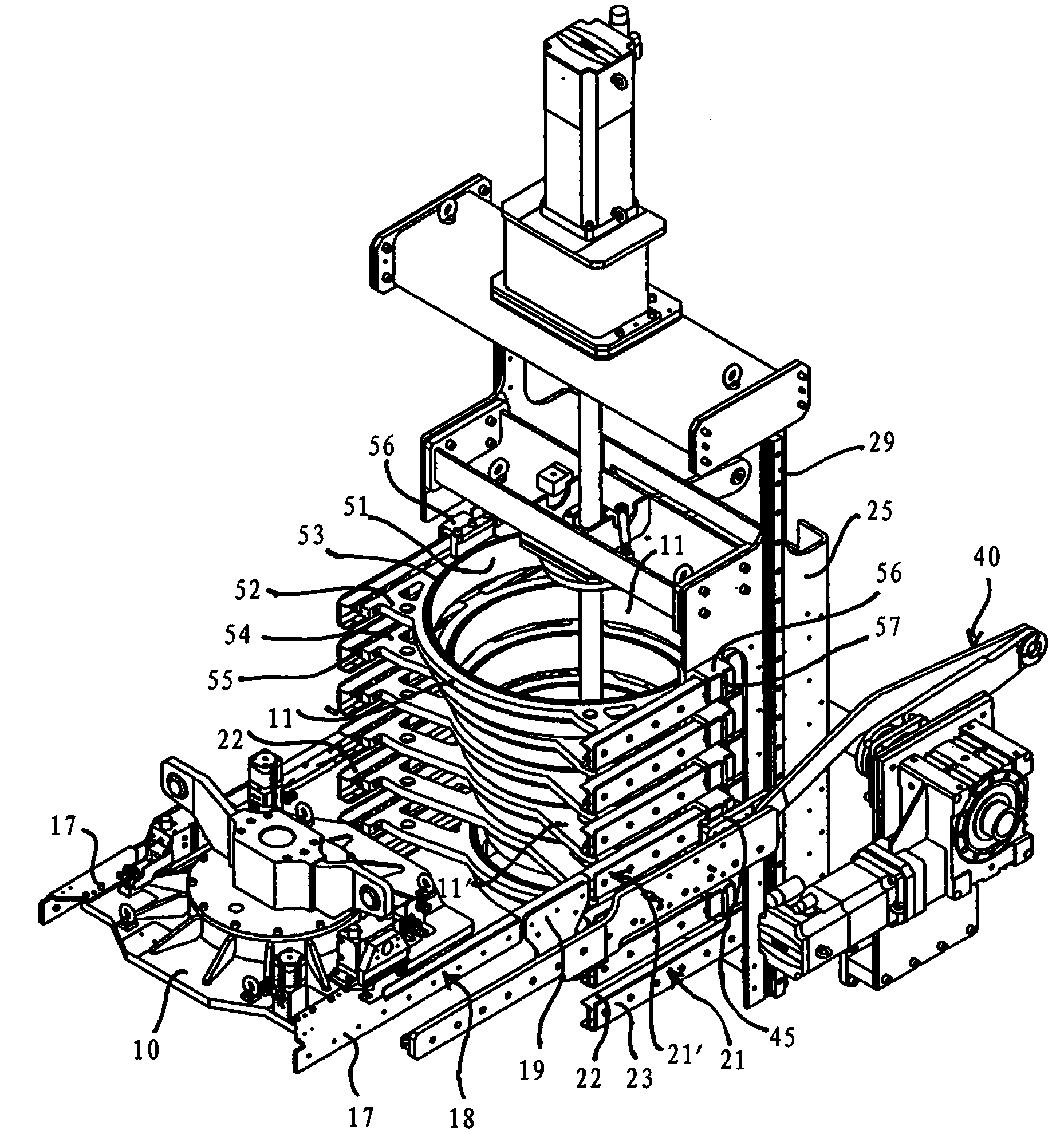

[0035] figure 1 A tire inflation device 1 is shown with a frame 2 , whose front side wall has been cut away in the direction of the view, in order to be able to clearly show details of the storage chamber 3 located behind. The tire inflation device 1 comprises a tire inflation cap 4 as well as a supporting and sealing device 5 which transports a wheel with pre-assembled tires by means of a transport device 6 and rests against the supporting and sealing device 5 by means of one side. On the plate-like platform 7 of. A tire fitting station, in which tires are mounted on wheel rims, is usually connected upstream of the tire inflation system 1 .

[0036] The bearing and sealing device 5 as well as the conveying device 6 are already known from EP1125772B1, the relevant contents are therefore incorporated here. The bearing and sealing device 5 consists of several parts. The plate-shaped platform 7 is divided into several parts and is supported on the machine frame 2 . The diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com