Patents

Literature

46results about How to "Avoid lateral forces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

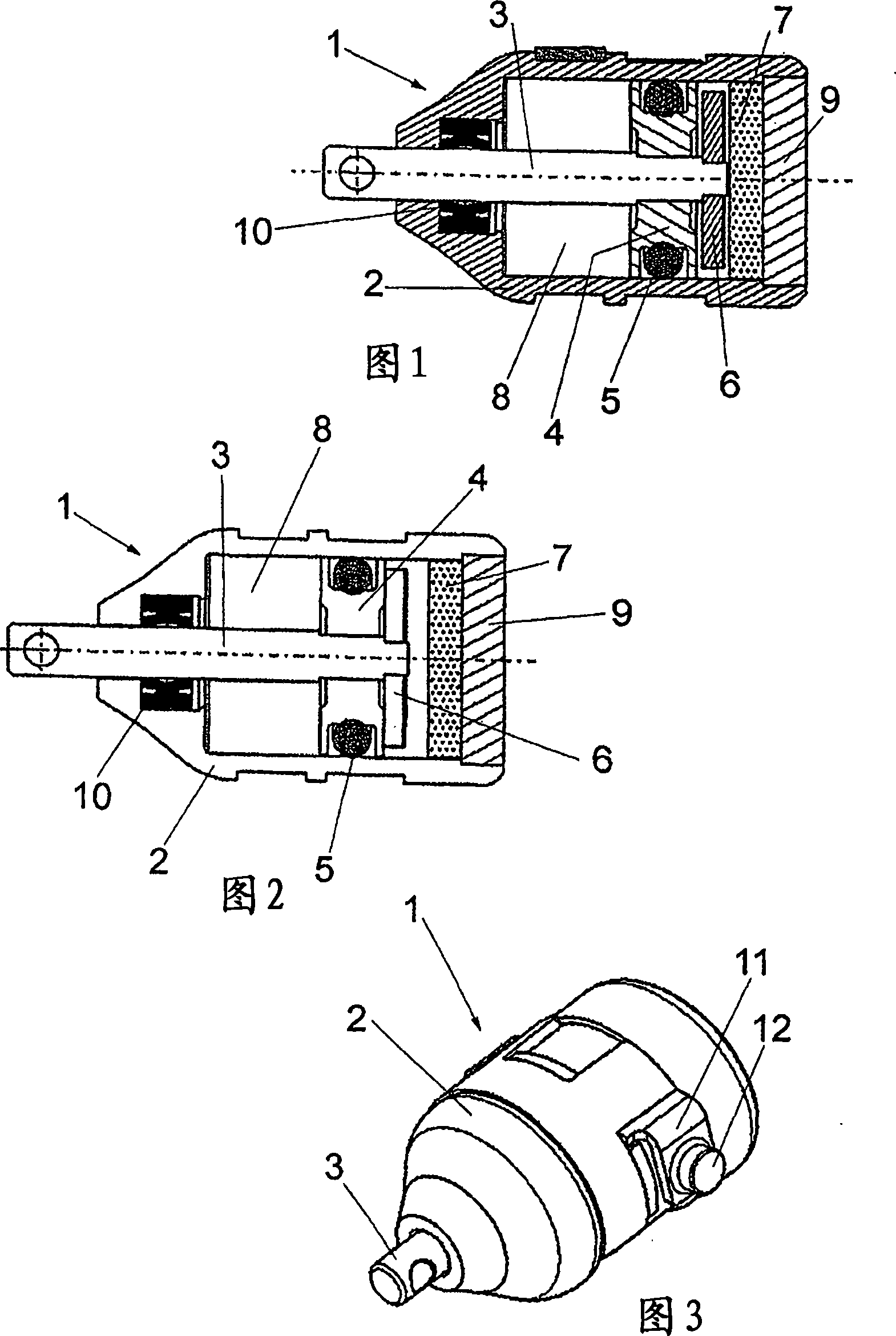

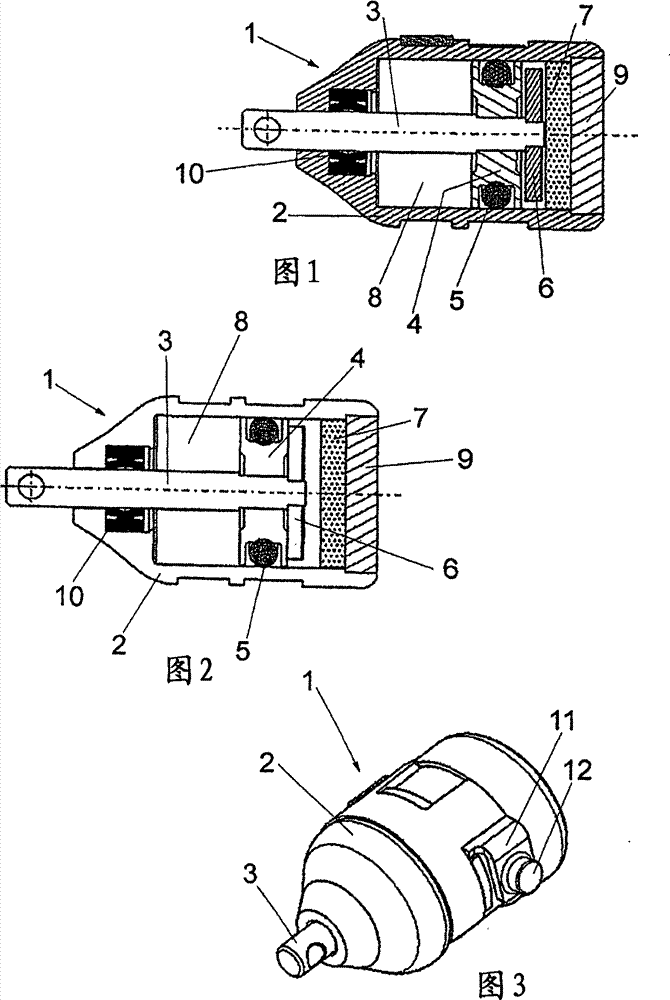

Damper for furniture

ActiveCN101395333AEasy to manufactureSimple clamping processSpringsBuilding braking devicesEngineeringMechanical engineering

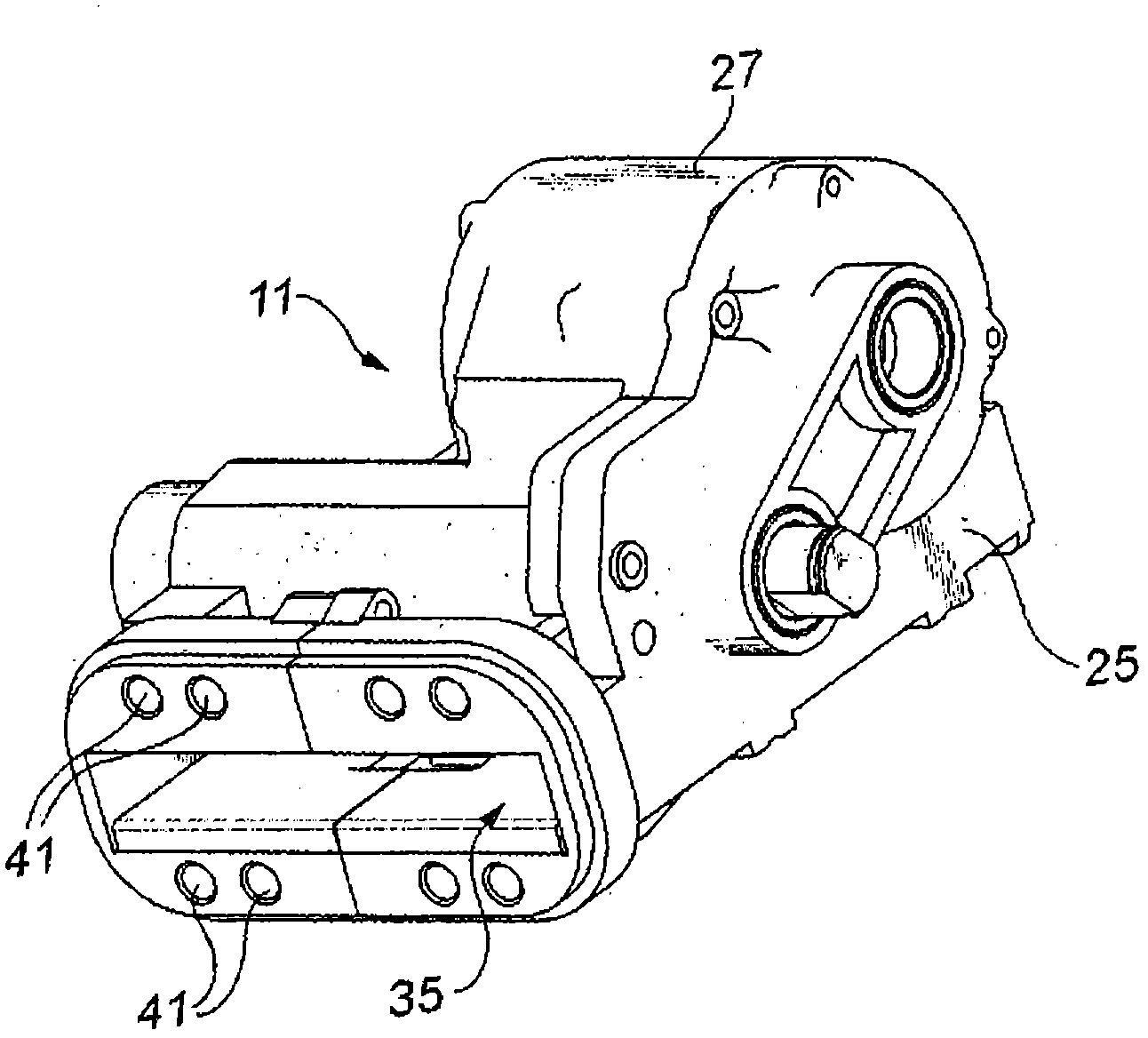

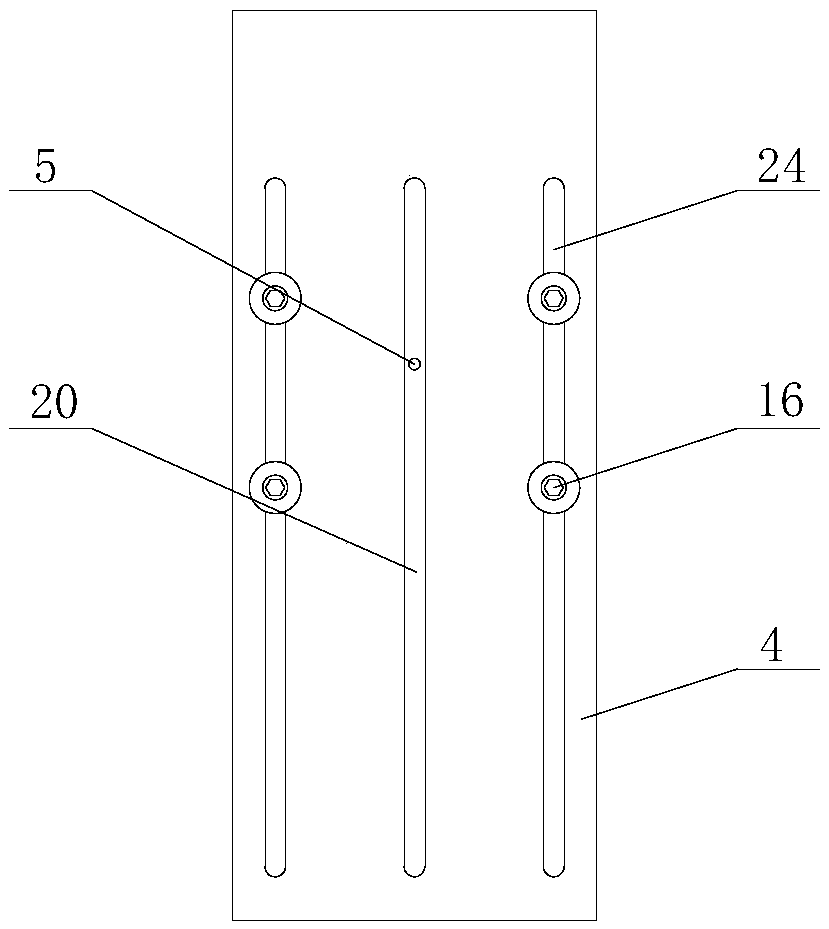

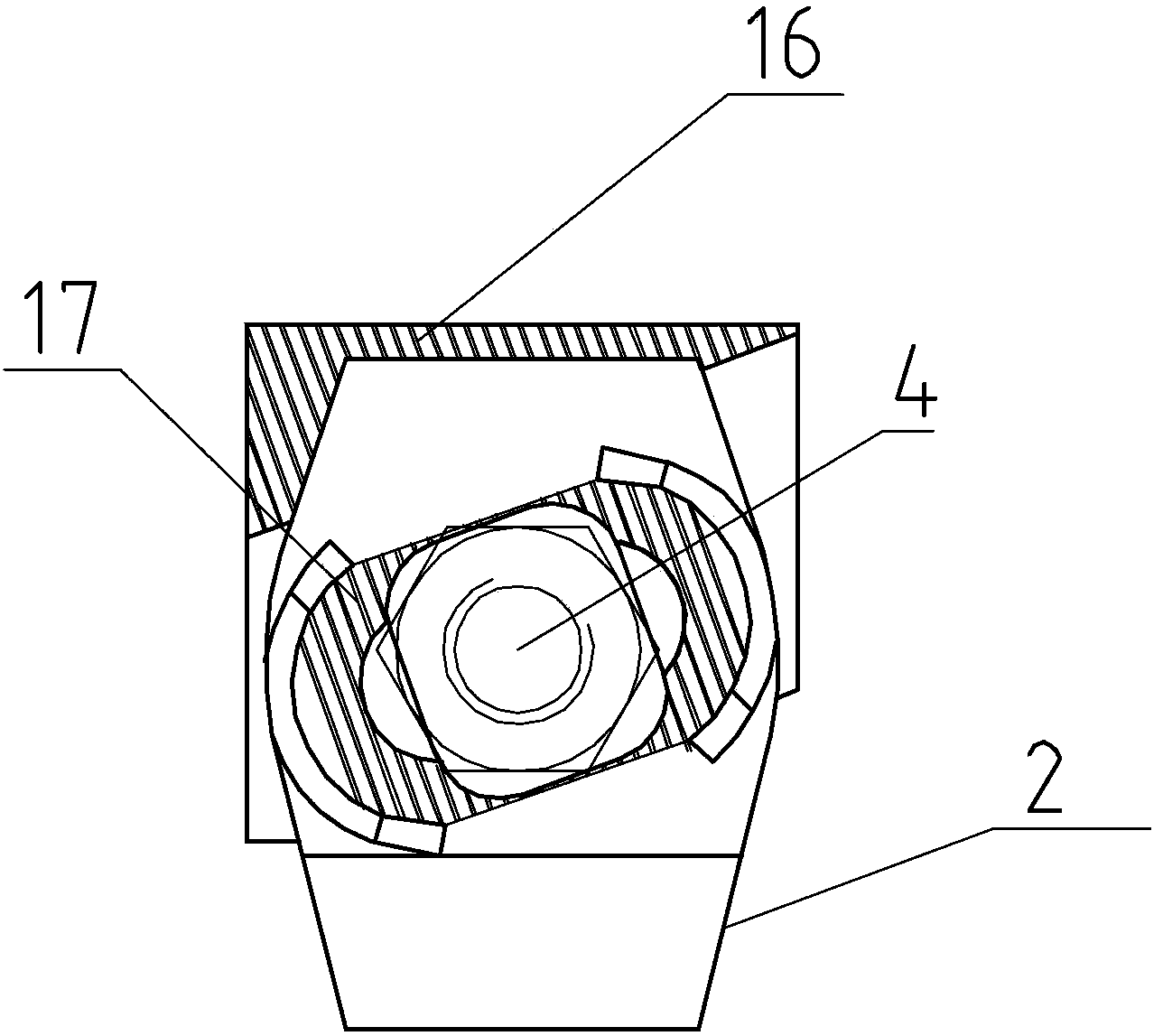

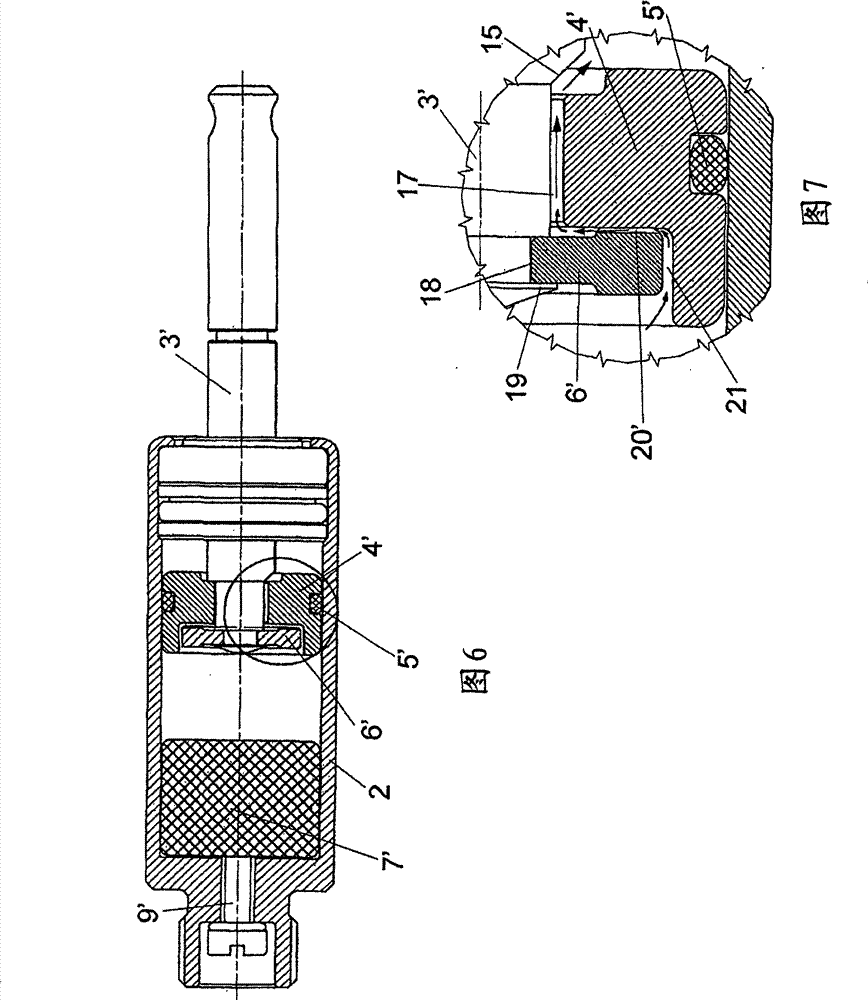

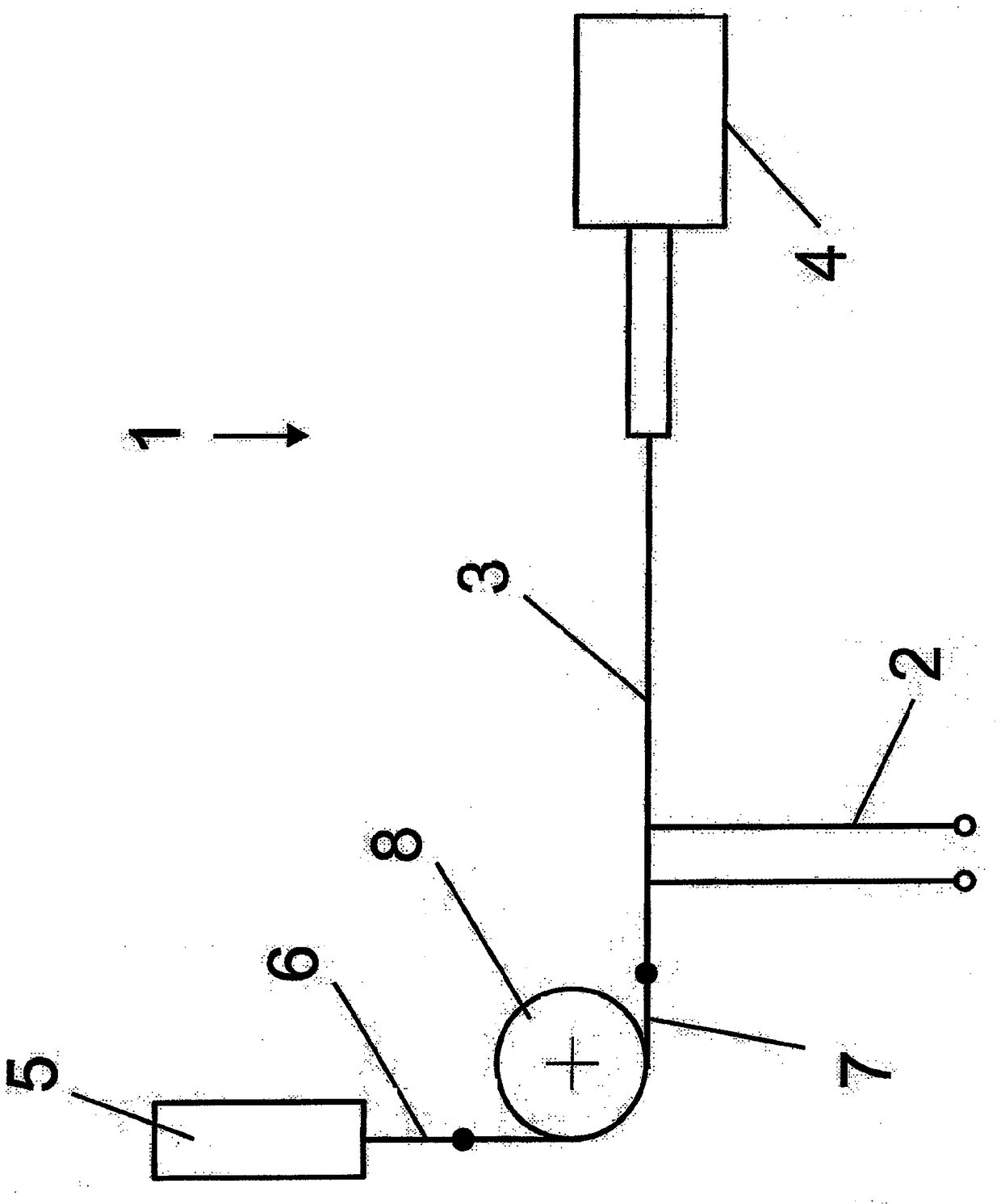

The invention relates to a damper (1) for furniture, especially for hinges, comprising a housing (2) in which a piston (4) connected to a piston rod (3) is received in a mobile manner. When the piston (4) is displaced, a fluid flows inside the housing (2) through a flow channel (20) arranged on or in the piston (4), a different damping force being generated when the piston (4) is displaced in different directions. Parts of the cross-section of the flow channel (20) can be modified by displacing the piston (4) in relation to a plate (6), the plate (6) and / or the piston (4) comprising radially extending grooves forming at least part of the flow channel (20).

Owner:HETTICH ONI

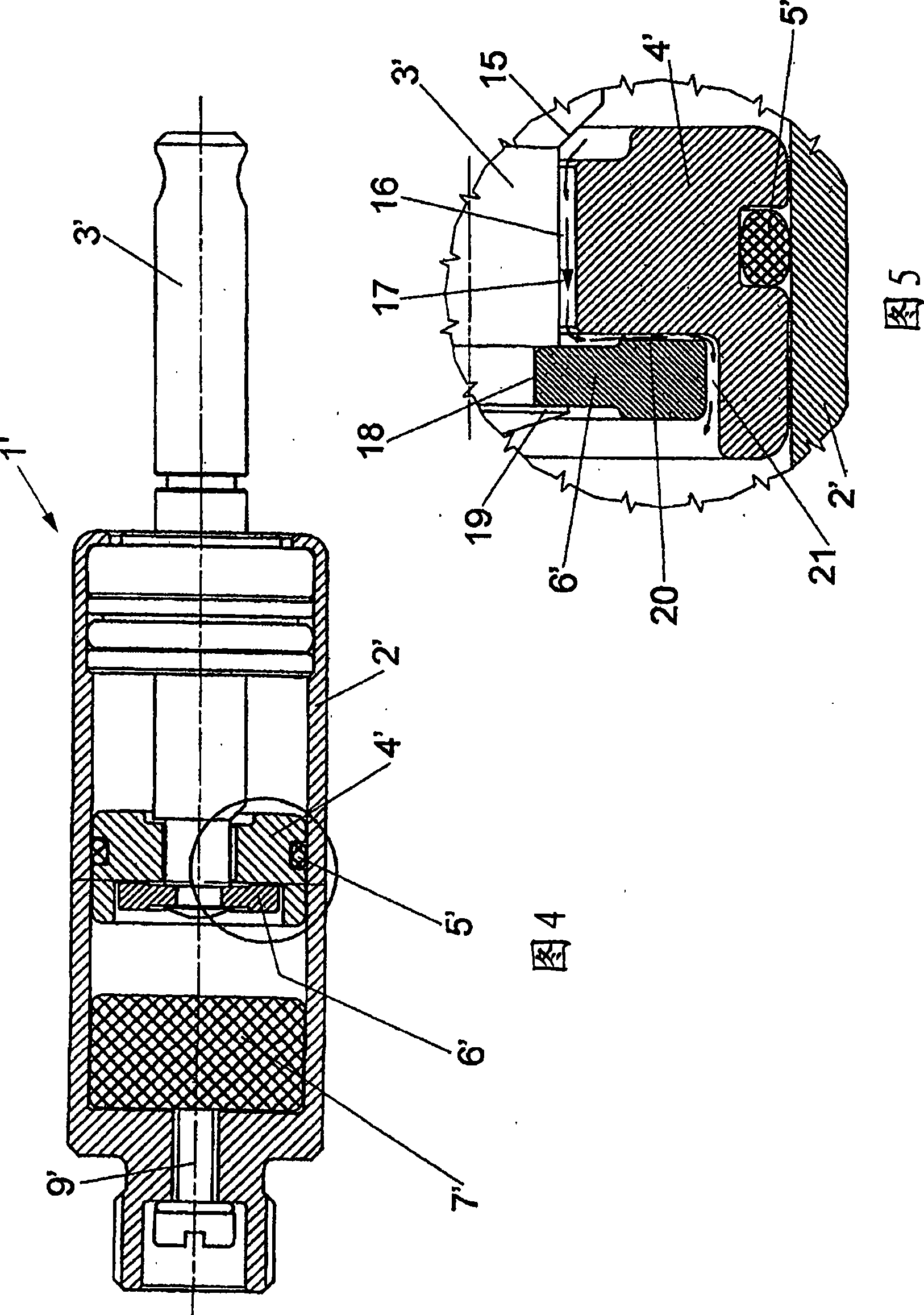

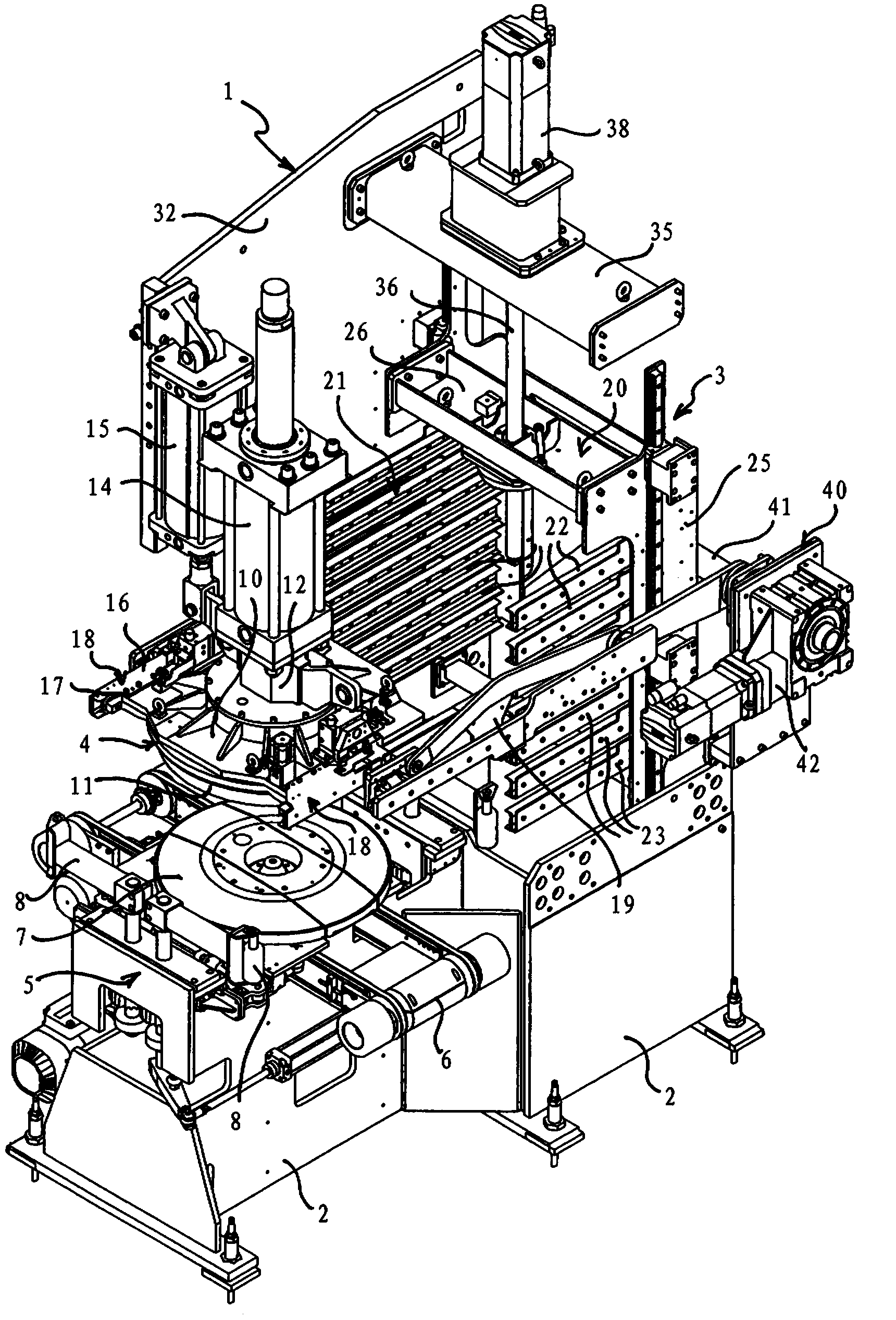

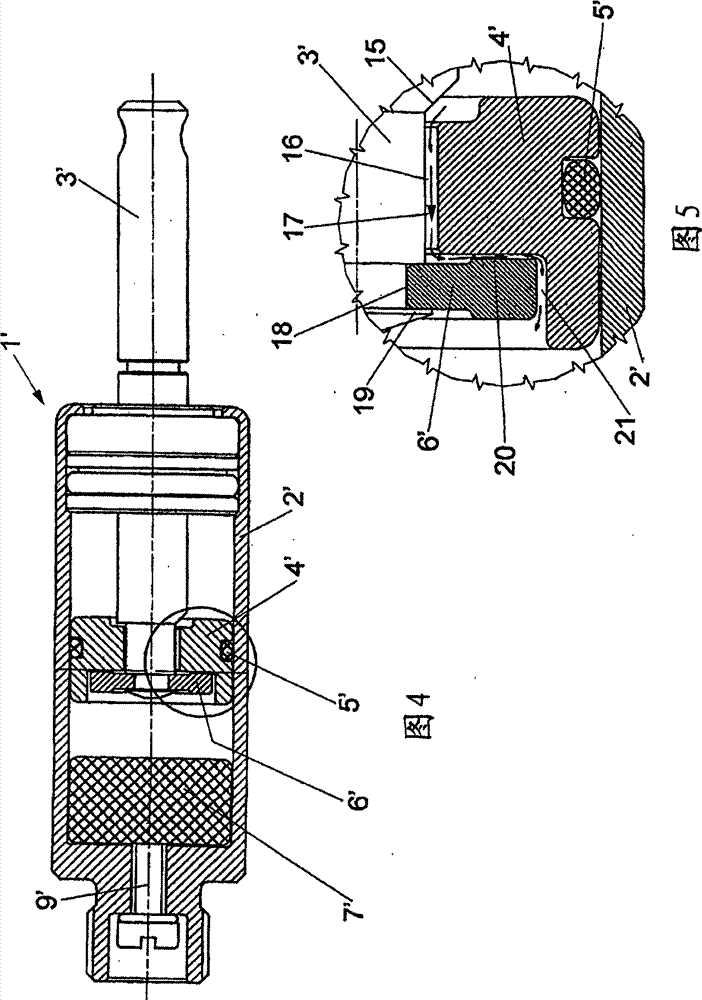

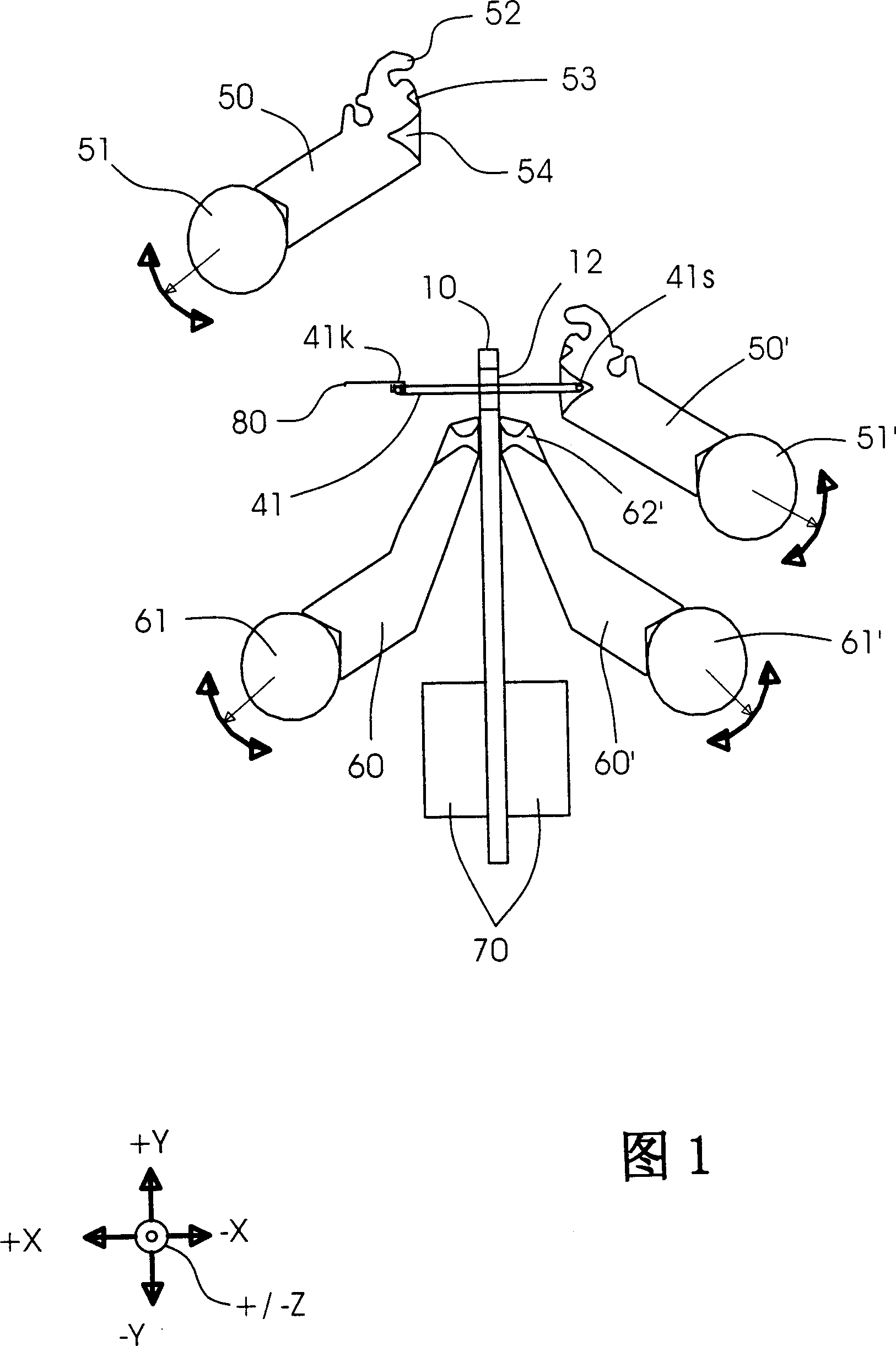

Tyre inflation device

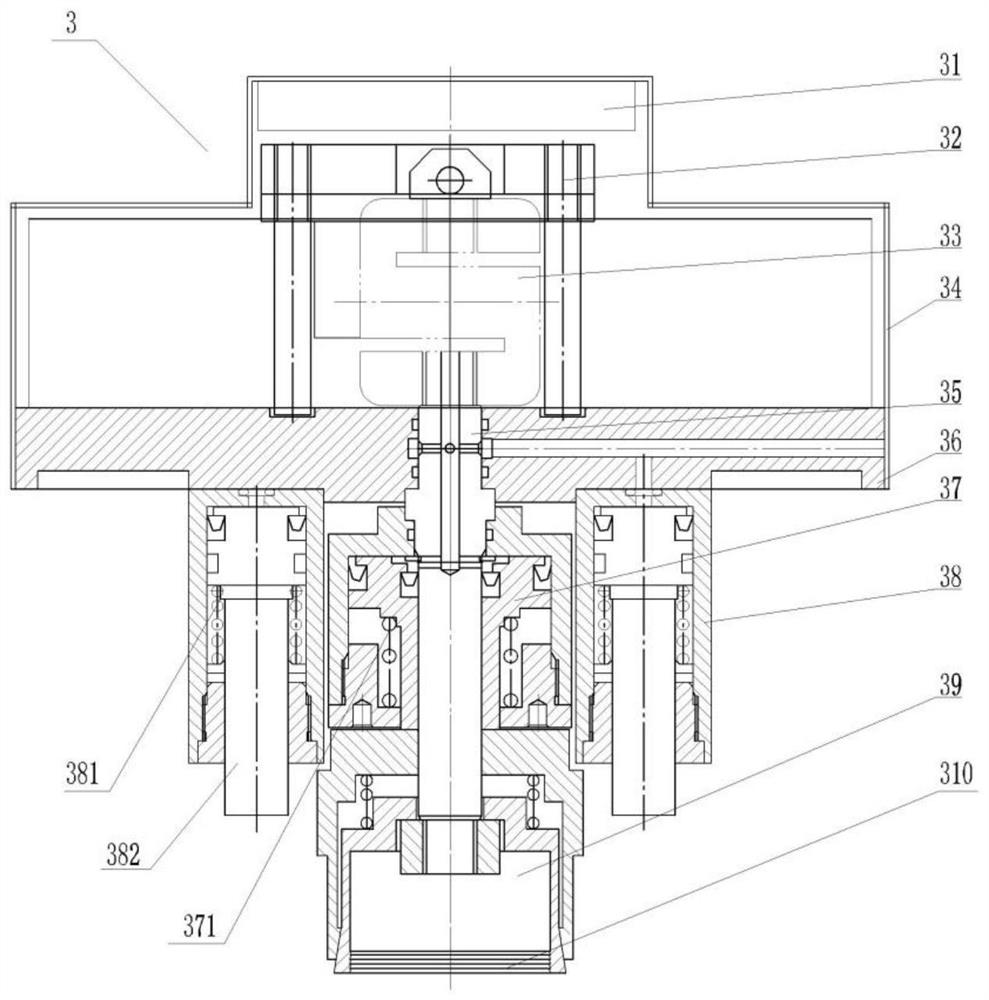

ActiveCN104108381AReduced Tolerance RequirementsAutomatic decouplingVehicle servicing/repairingTyre repairingMechanical engineeringParallel plane

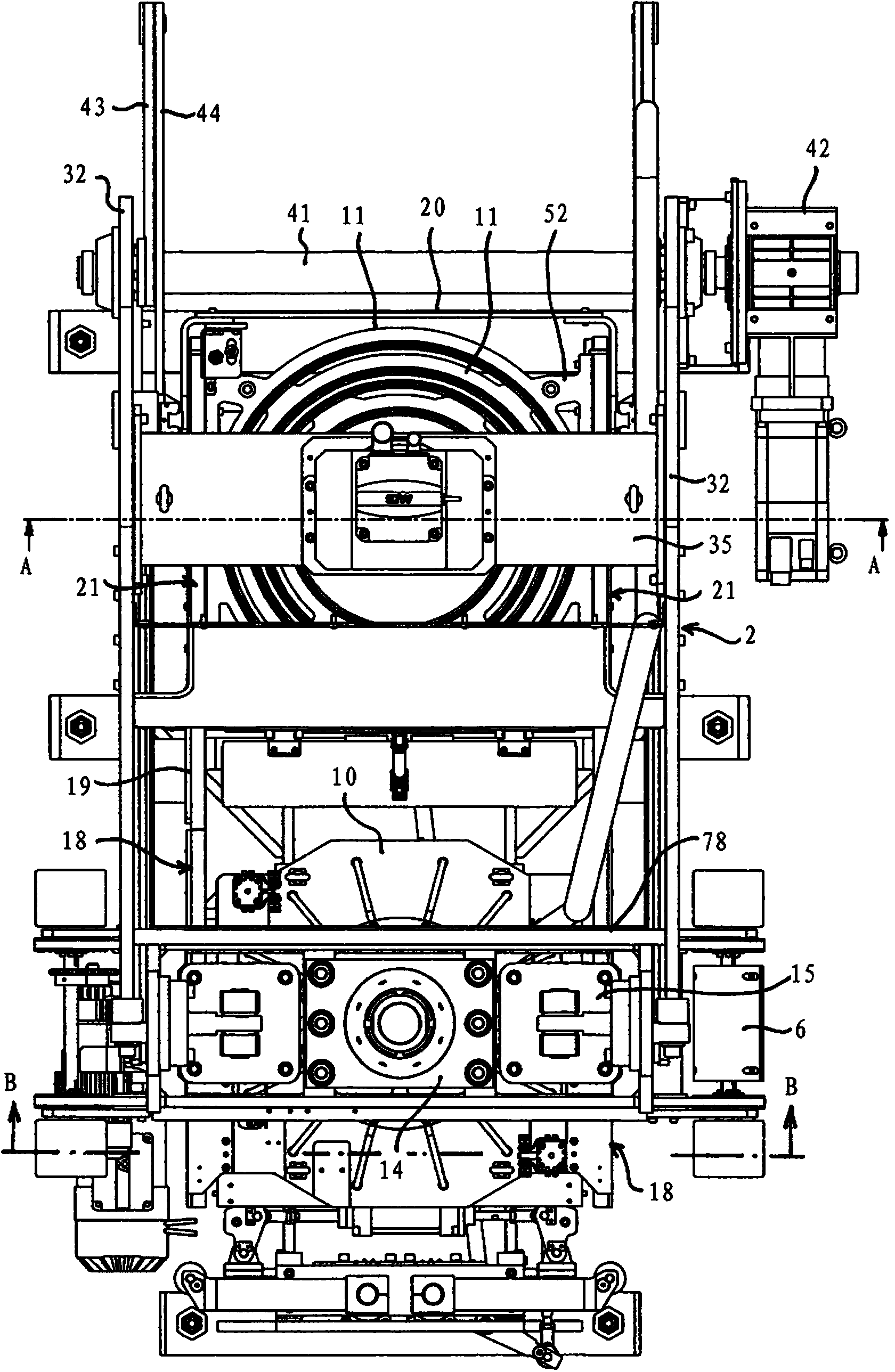

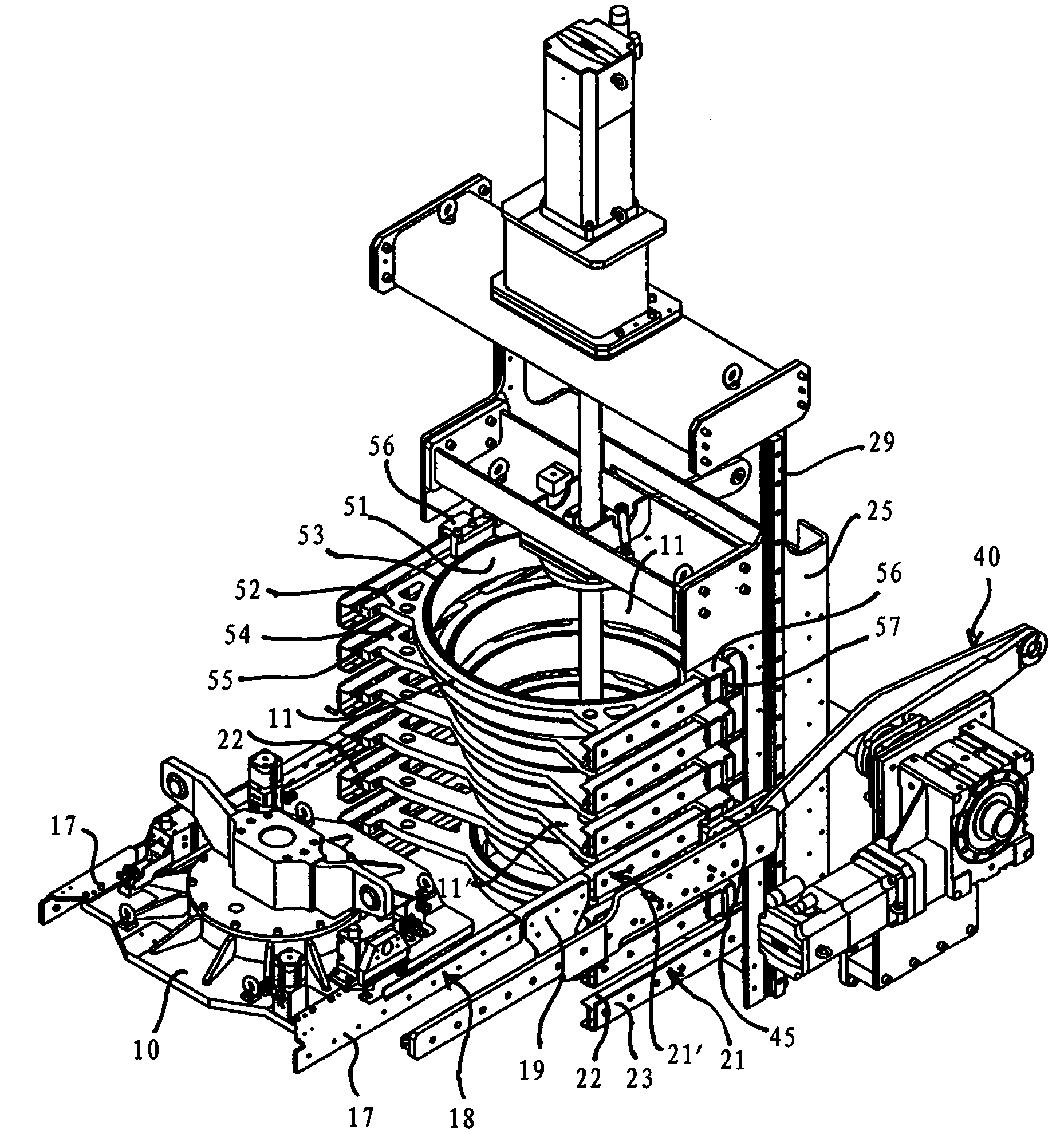

In a tire inflating device having a machine frame (2), a tire filling bell (4) arranged on the machine frame (2) and a supporting and sealing device (5) for sealing a filling chamber. The tire filling bell (4) is comprised of a filling plate (10) and a separate filling ring (11). A magazine (3) has a magazine rack (20) and magazine guides (21) lying in a plurality of parallel planes, each of said guides being able to hold a filling ring (11, 11′) mounted so that it can move. The magazine rack (20) and the filling plate (10) can be moved with respect to each other into a plurality of transfer positions in the direction of the axis of rotation. The magazine guide (21) in each case is connected to a filling plate guide (18) arranged on the filling plate (10) in said transfer positions. A filling ring (11) which is located in the magazine guide (21) arranged in the transfer position can be conveyed by a conveying device (40) into a filling plate guide and a centered position on the filling plate (10).

Owner:SCHENCK ROTEC GMBH

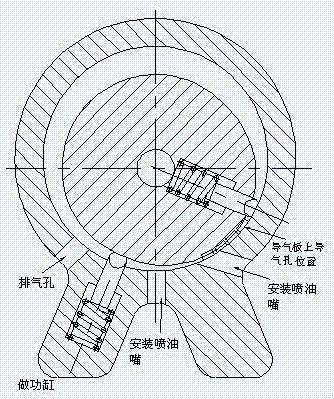

Side-by-side type rotary piston internal combustion engine

InactiveCN107084042AImprove fuel efficiencyReduce volumeInternal combustion piston enginesPistonEngineering

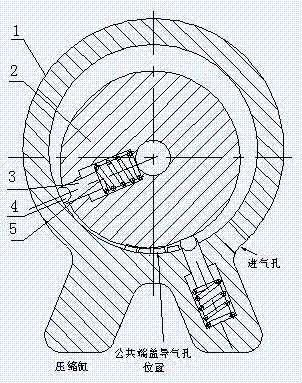

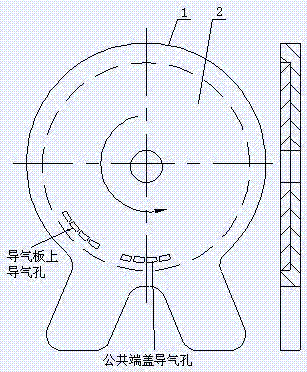

The invention provides a side-by-side type rotary piston internal combustion engine and belongs to the technical field of reciprocating piston type internal combustion engines. Referring to a figure (4), the side-by-side type rotary piston internal combustion engine comprises a main shaft 1, a clamping plate 2, a right end cover 3, an air guide plate 4, a public end cover 5, a nut 6, a bolt 7, a compression cylinder 8, an acting cylinder 9 and a left end cover 10. The main technical characteristics of the side-by-side type rotary piston internal combustion engine are that one cylinder completes air intake and compression, the other cylinder completes acting and exhausting, the two cylinders are connected side by side, and the well compressed air is conveyed to the acting cylinder in time through the rotating air guide plate between the two cylinders so that acting and exhausting can be completed. The side-by-side type rotary piston internal combustion engine has the advantages that during acting, high-pressure air can directly push the main shaft to rotate, the fuel efficiency is greatly improved, and the size is reduced; under the condition of the same output torque or the same power, the cylinder capacity can be reduced by 30% or over, and the size can be reduced by 50% or over; and an intake hole and an exhaust hole are normally open, additional arrangement of an air distributing mechanism is not needed any more, and other performances are all superior to those of the reciprocating piston type internal combustion engine.

Owner:俞启元

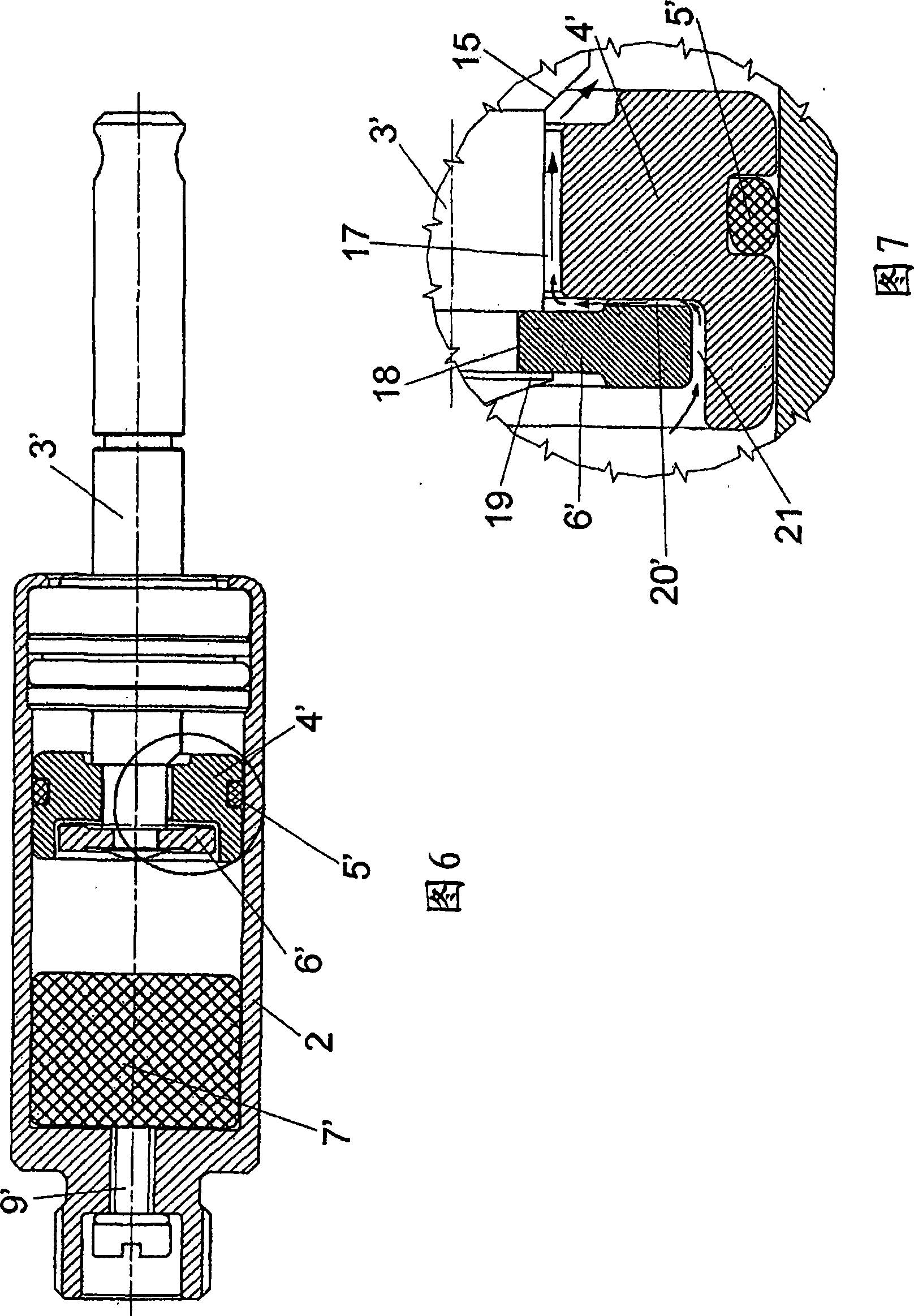

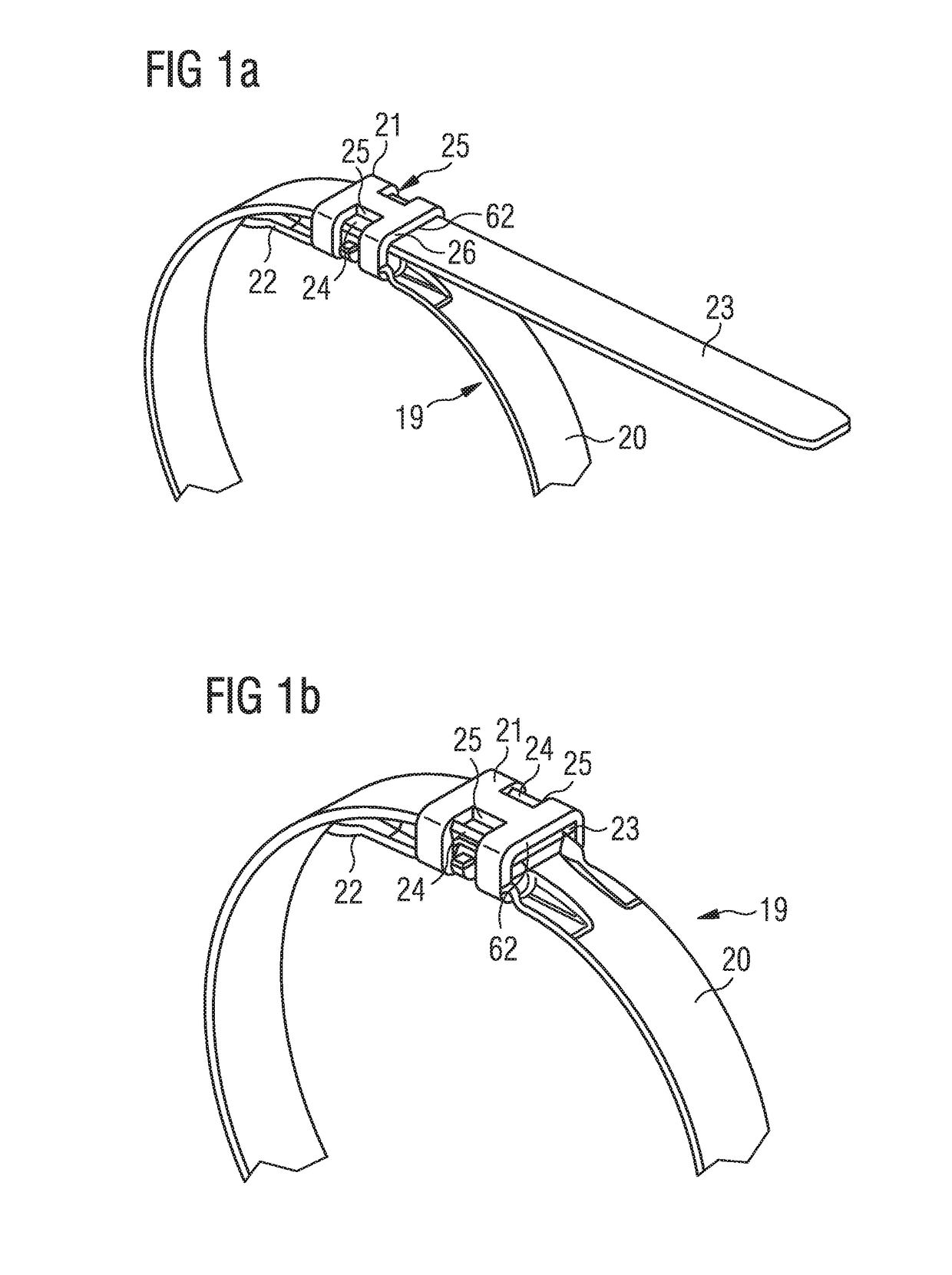

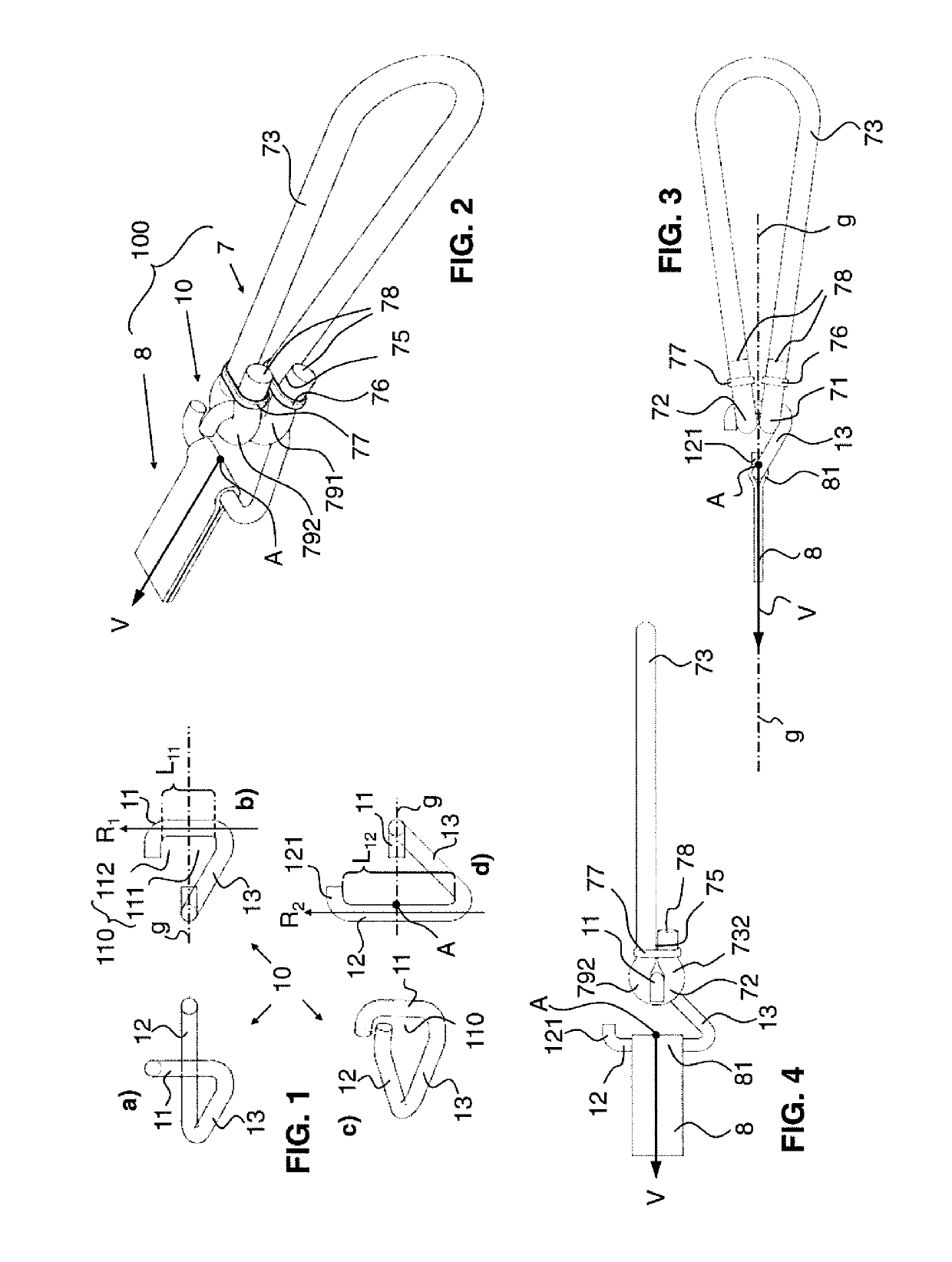

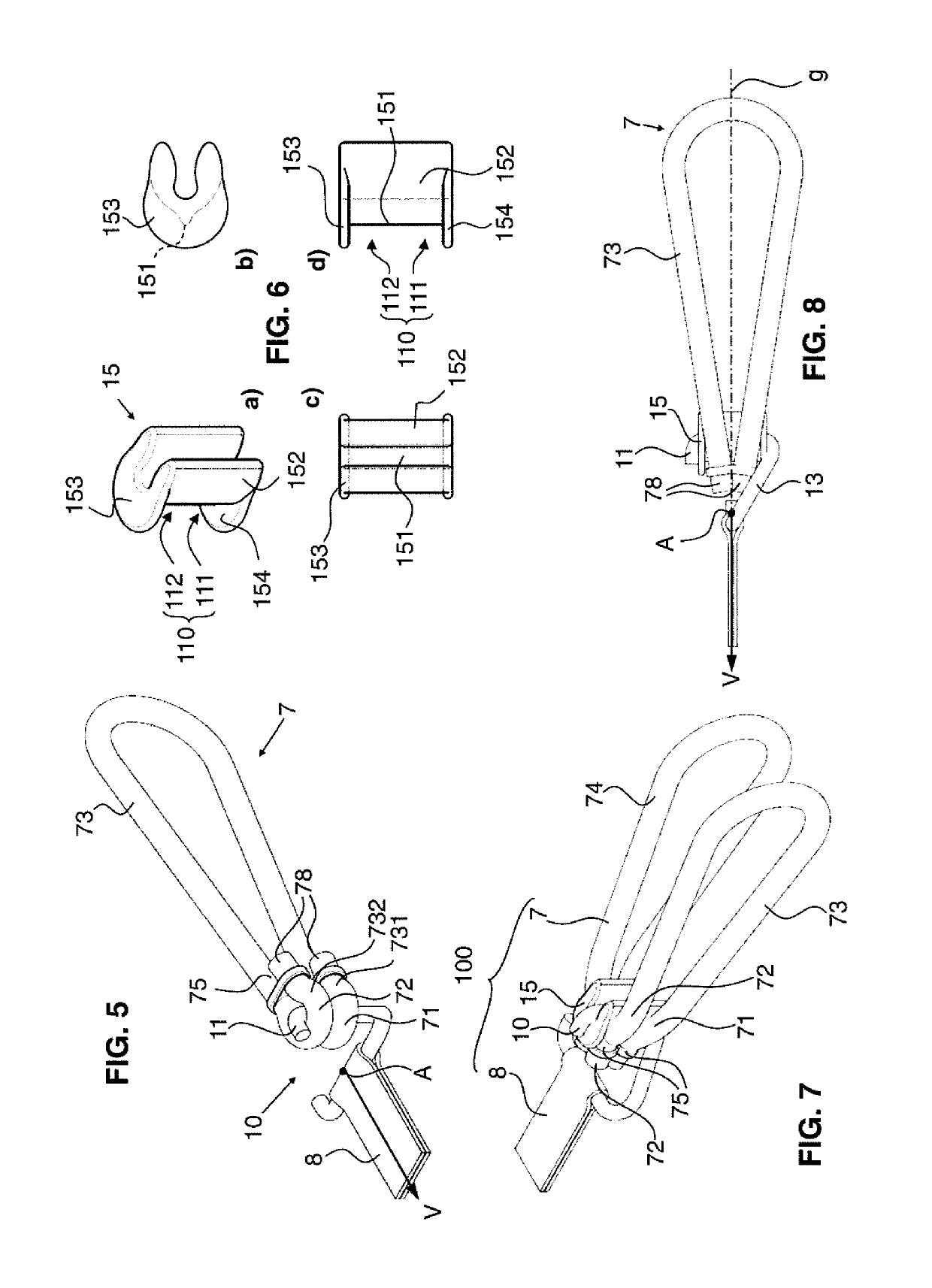

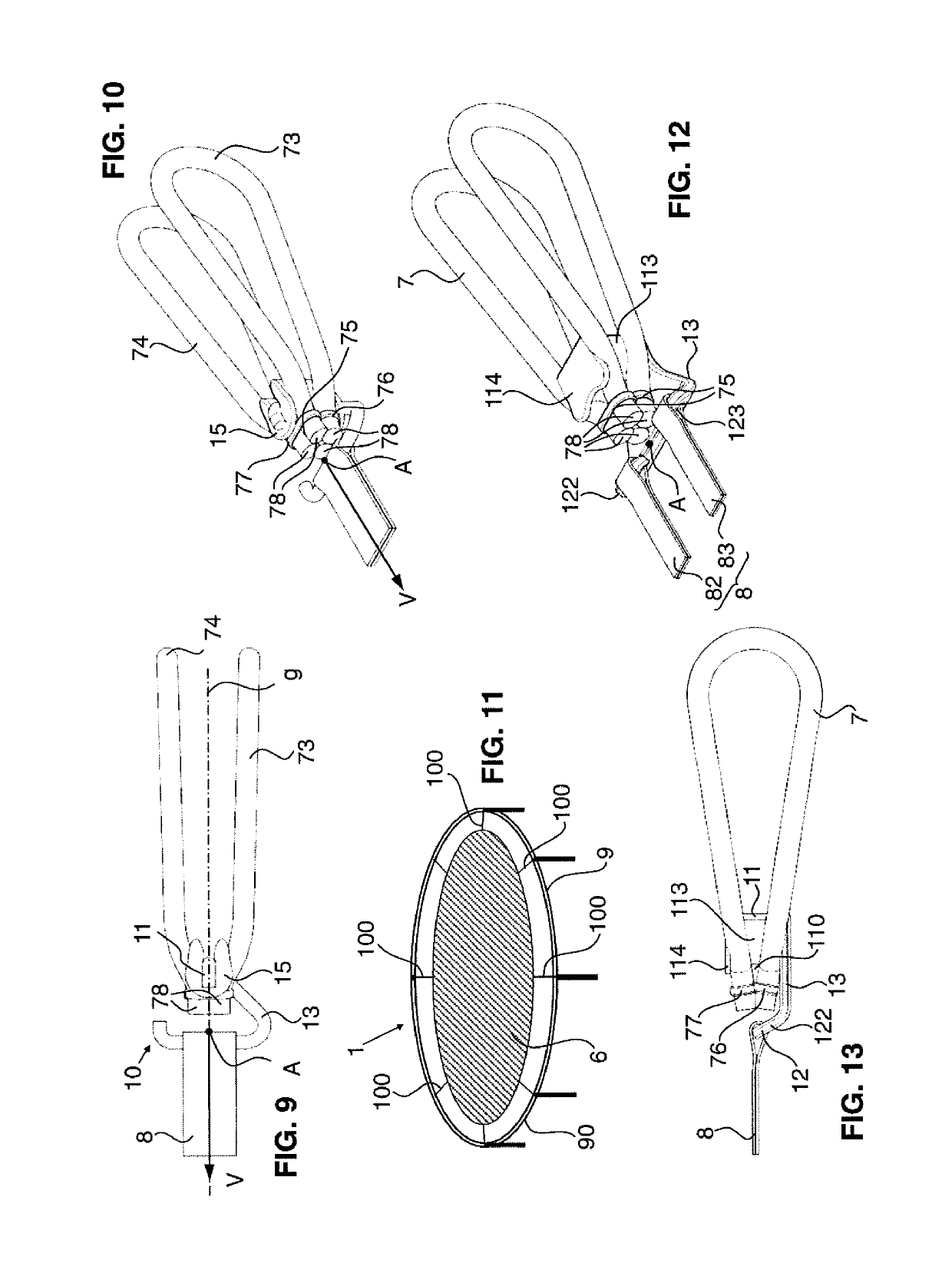

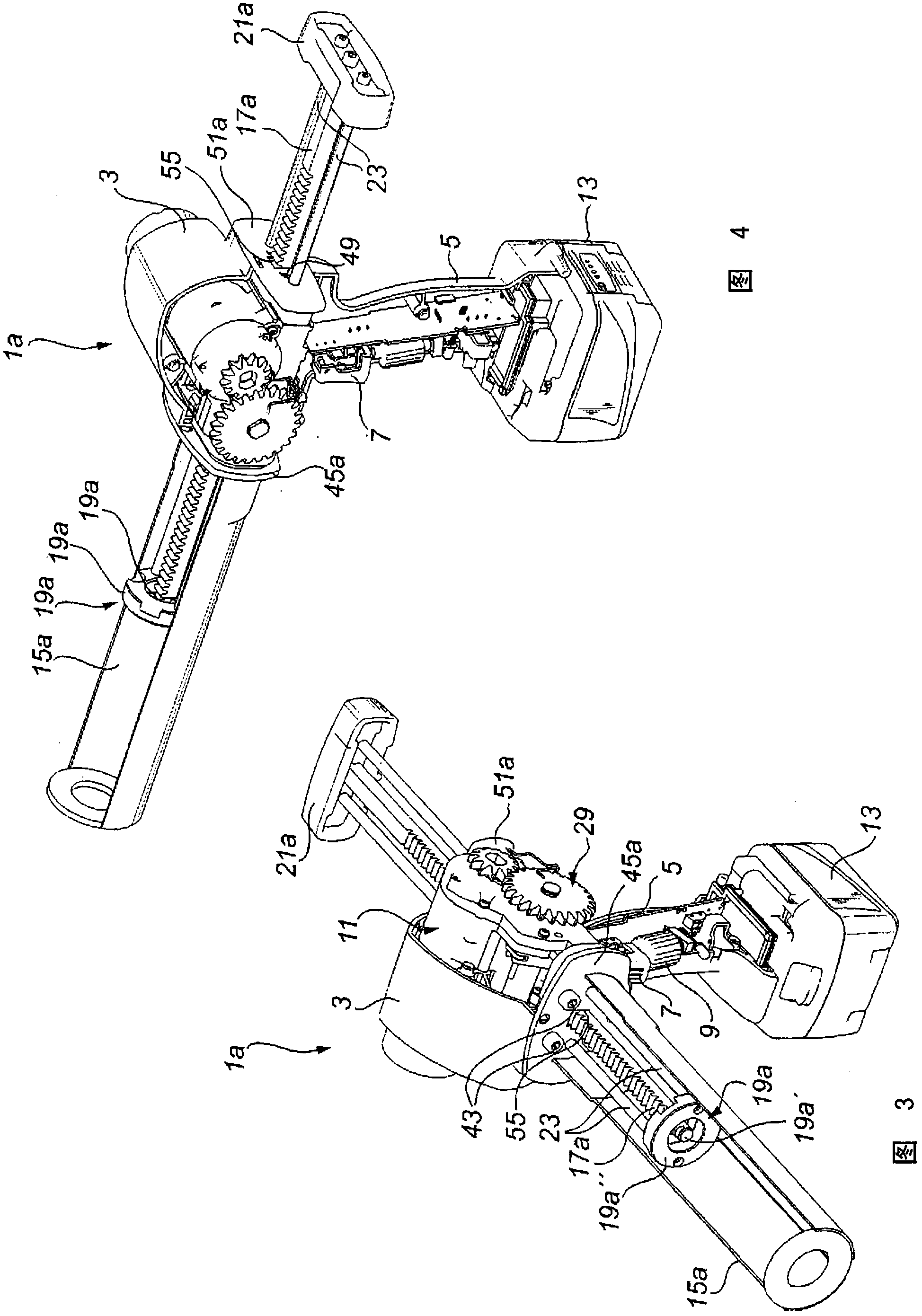

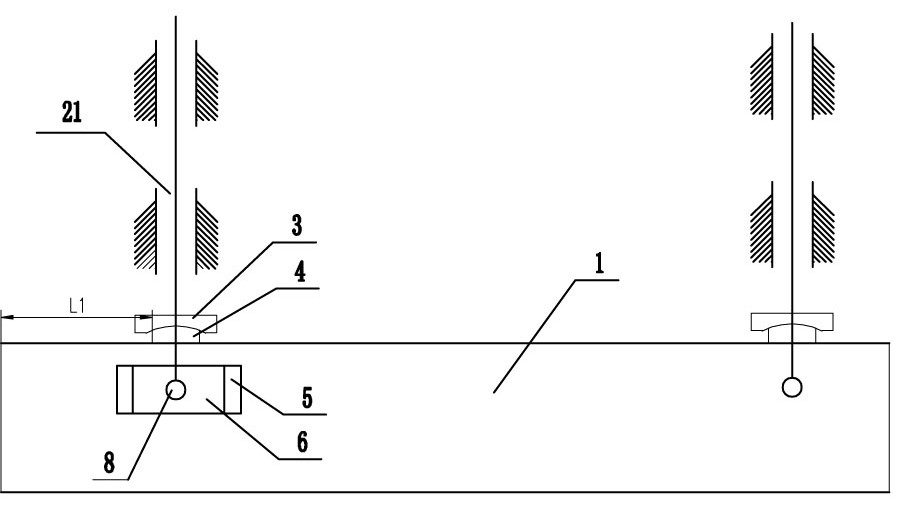

Tool for Mounting a Tension Clamp

ActiveUS20170349307A1Avoid scratchesAvoid lateral forcesFlexible elementsBinding material applicationEngineeringClassical mechanics

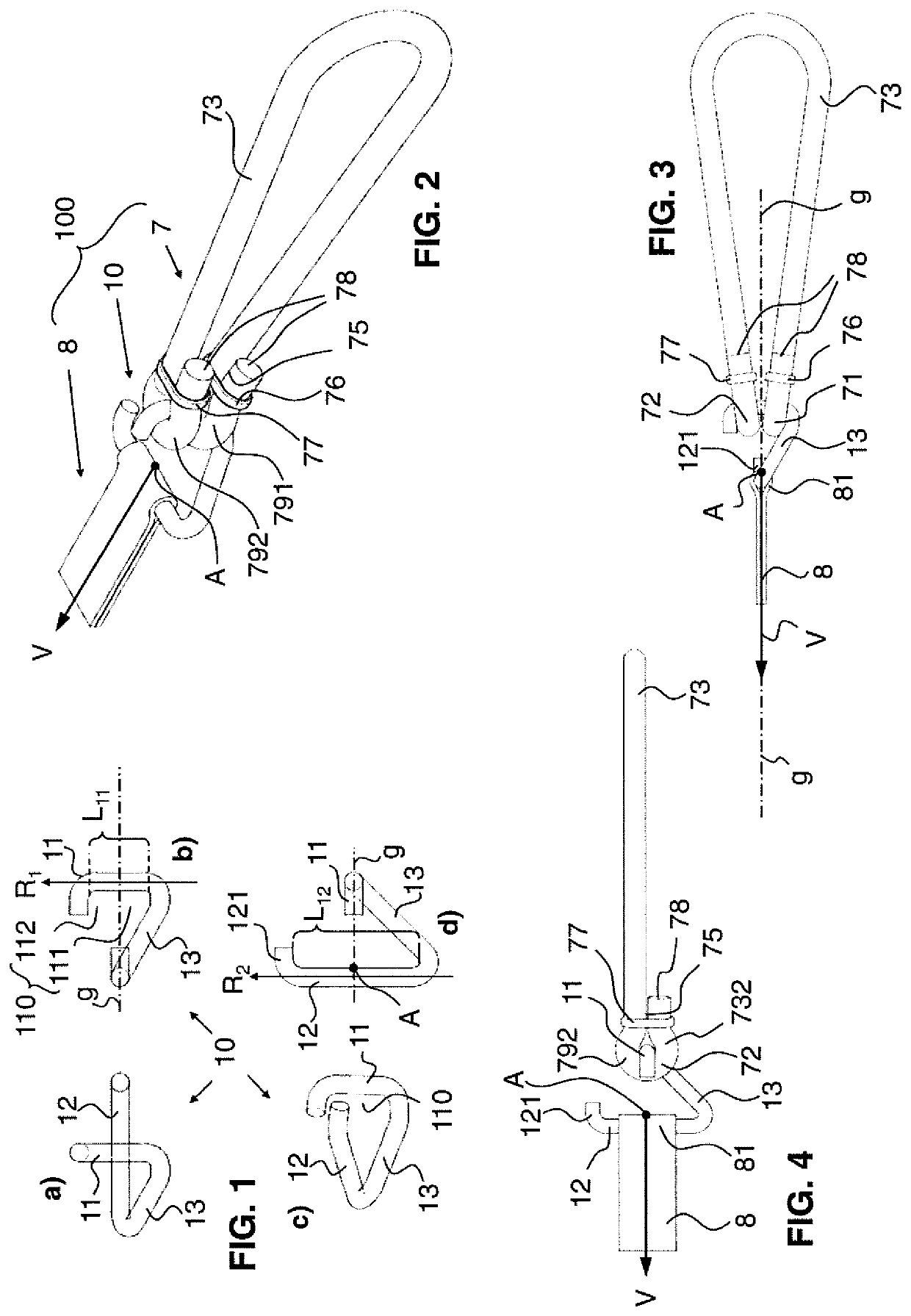

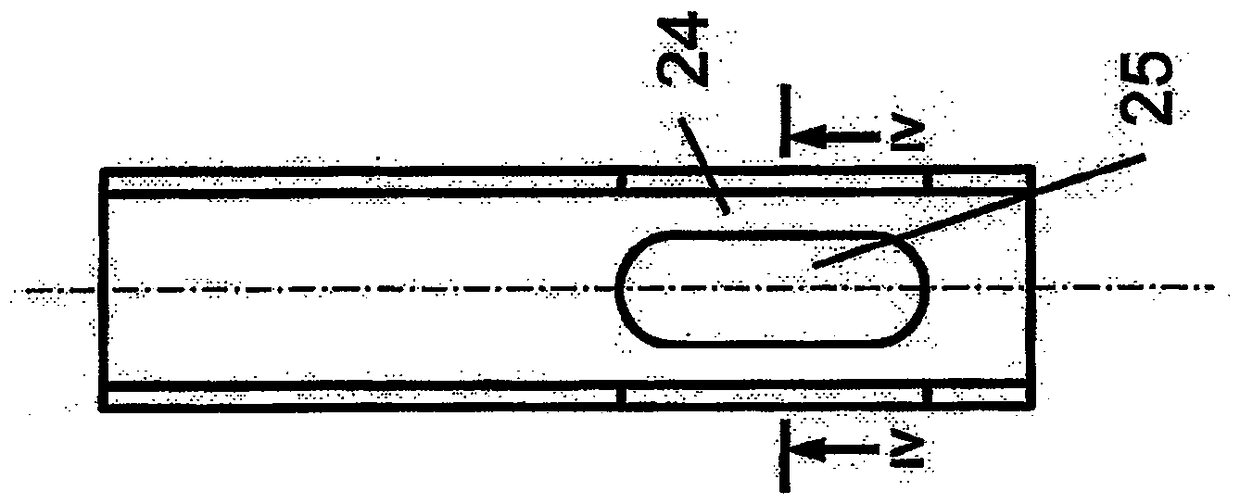

A tension clamp (19) includes a band (20) surrounding an object to be fastened and a buckle (21) arranged on the inner band end portion (22) and surrounding the band (20), with the outer band end portion (23) extending through the buckle (21). A tool for mounting the tension clamp includes a holding device for holding the buckle (21) along with the band (20) surrounding the object to be fastened, a tensioning device for tensioning the band (20) round the object to be fastened by applying tension to the outer band end portion (23), a locking device (50) for locking the buckle (21) on dem band (20), and a severing device for cutting off excessive band length. The locking device (50) has plier jaws (54) adapted to be inserted into lateral windows (25) of the buckle (21) for deforming side edge portions (24) of the other band end portion (23).

Owner:OETIKER SCHWEIZ AG

Fastening device for a trampoline

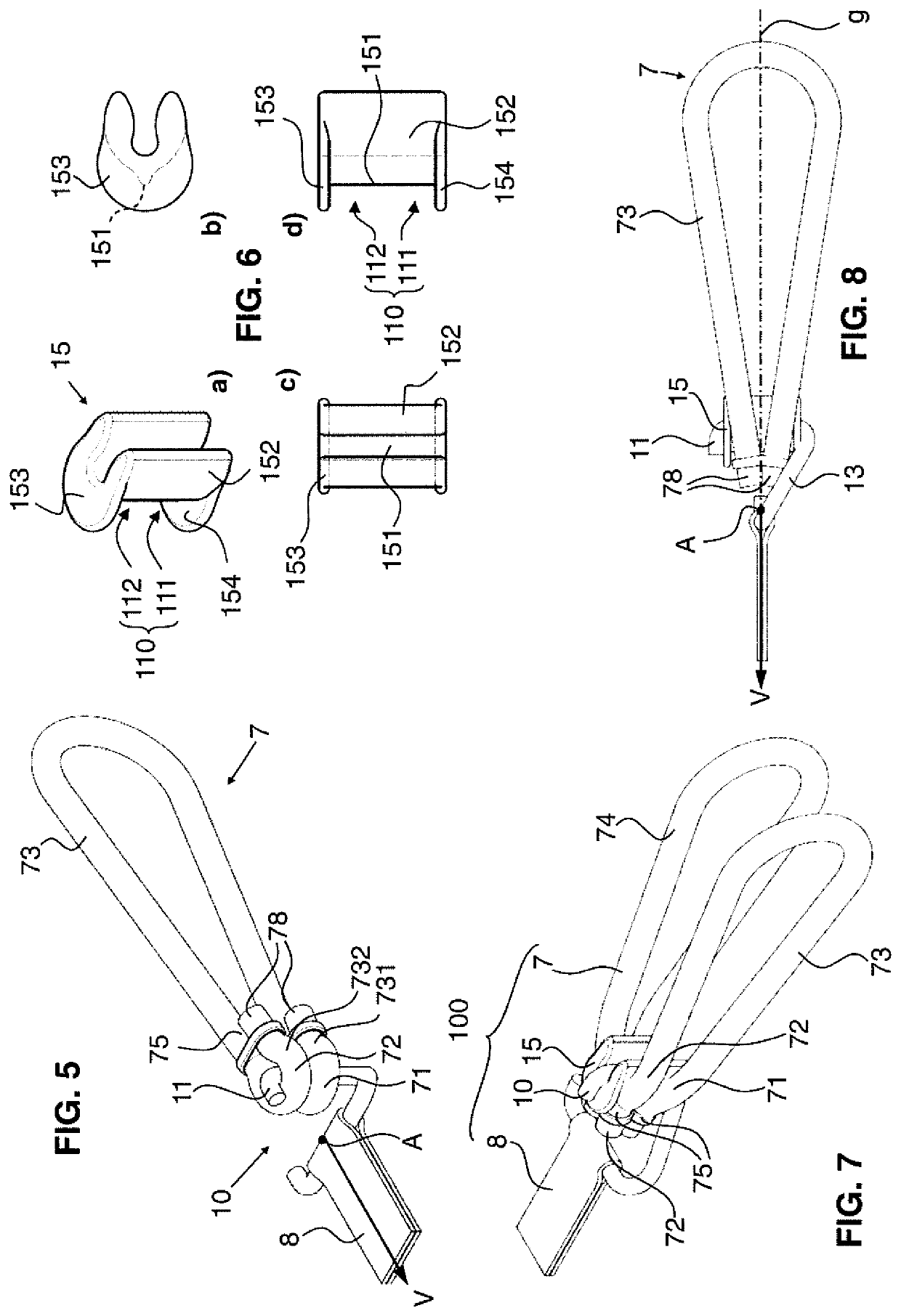

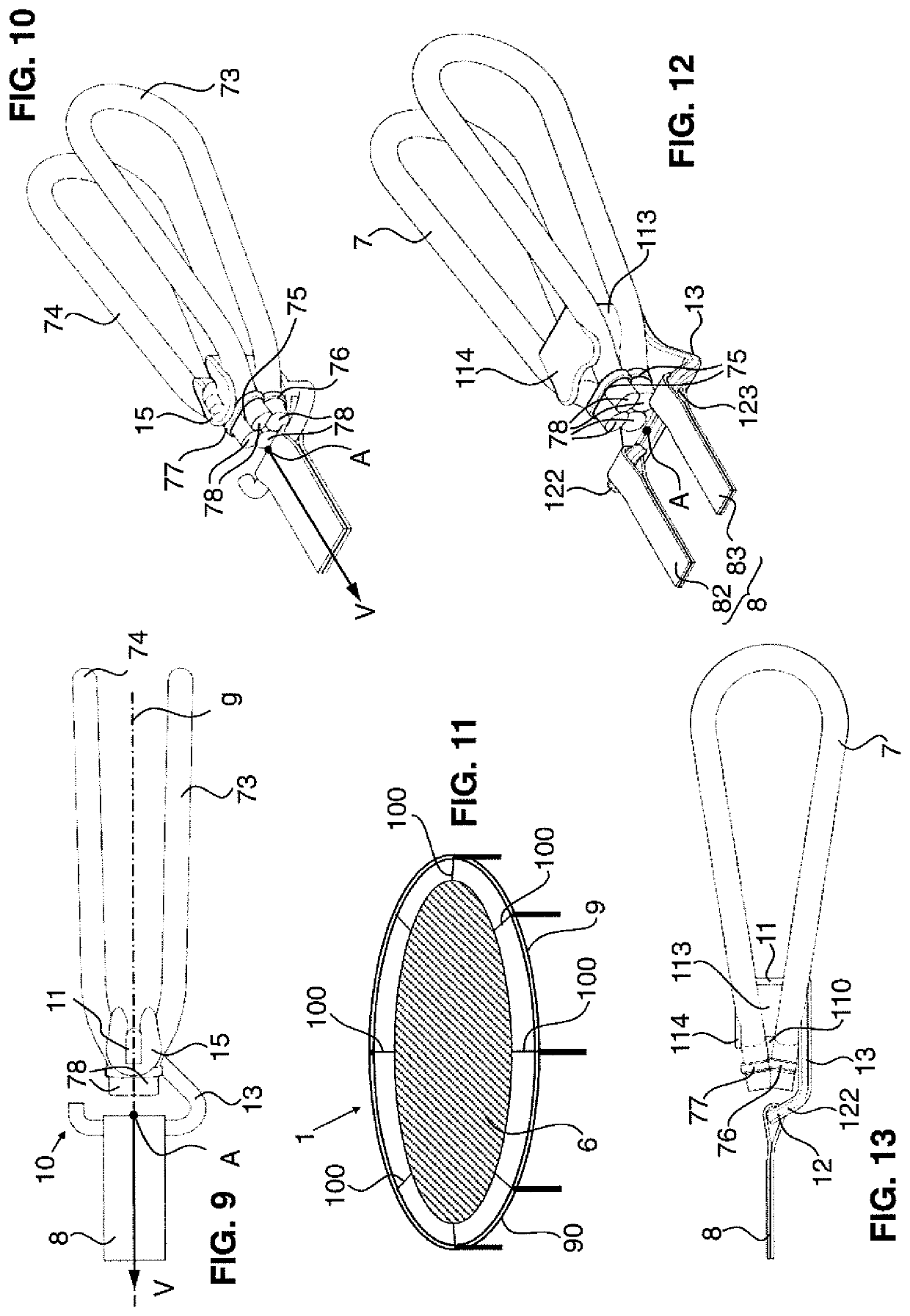

ActiveUS20190143164A1Simple designAvoid lateral forcesSpring boardsTrampolinesEngineeringMechanical engineering

Owner:ANGEHRN AG UMFORMTECHN

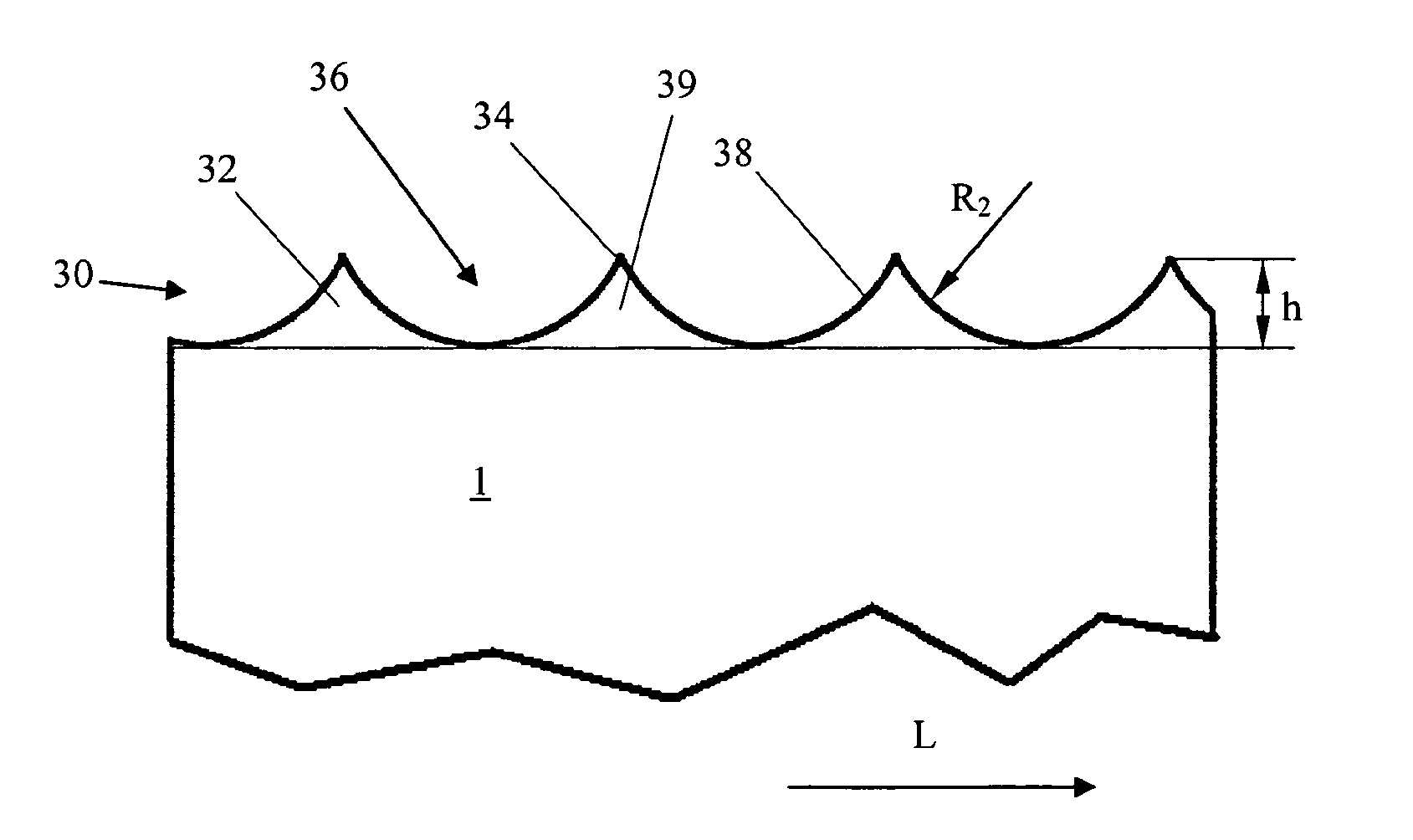

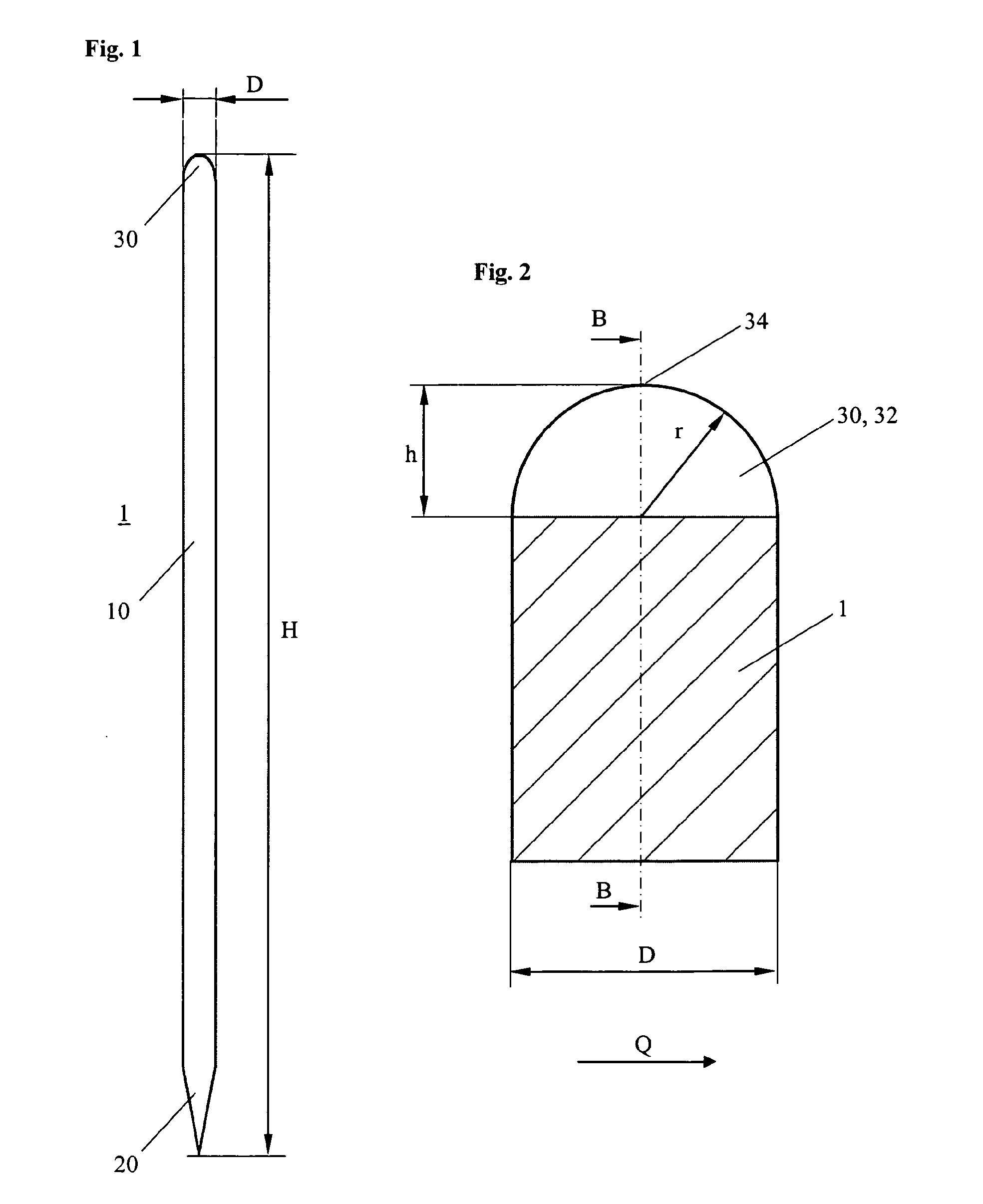

Cutting rules for cutting of flat materials

InactiveUS20110100186A1Improve plastic deformationConvenient introductionMetal working apparatusSaw chainsStructural engineering

The present invention relates to a cutting rule 1, comprising a steel band 10 with a cutting edge 20, a back 30 of the steel band 10 opposite to the cutting edge 20, wherein the back 30 comprises protrusions 32 which during the first use of the cutting rule 1 can be plastically deformed and wherein the protrusions 32 essentially comprise a height h of 30%-70% of the thickness D of the steel band 10. Further, the present invention relates to a cutting rule 1, comprising a steel band 10 with a cutting edge 20, a back 30 of the steel band 10 opposite to the cutting edge 20, wherein the back comprises protrusions 32 that can be plastically deformed during the use of the cutting rule 1 and wherein the protrusions 32 have been produced by grinding or milling of recesses 36 in transverse direction Q of the steel band into the back 30; as well as a cutting rule 1 whose back 30 is surface decarburized such that it can plastically deform during the first use of the cutting rule 1.

Owner:BOEHLER UDDEHOLM PRECISION STRIP GMBH

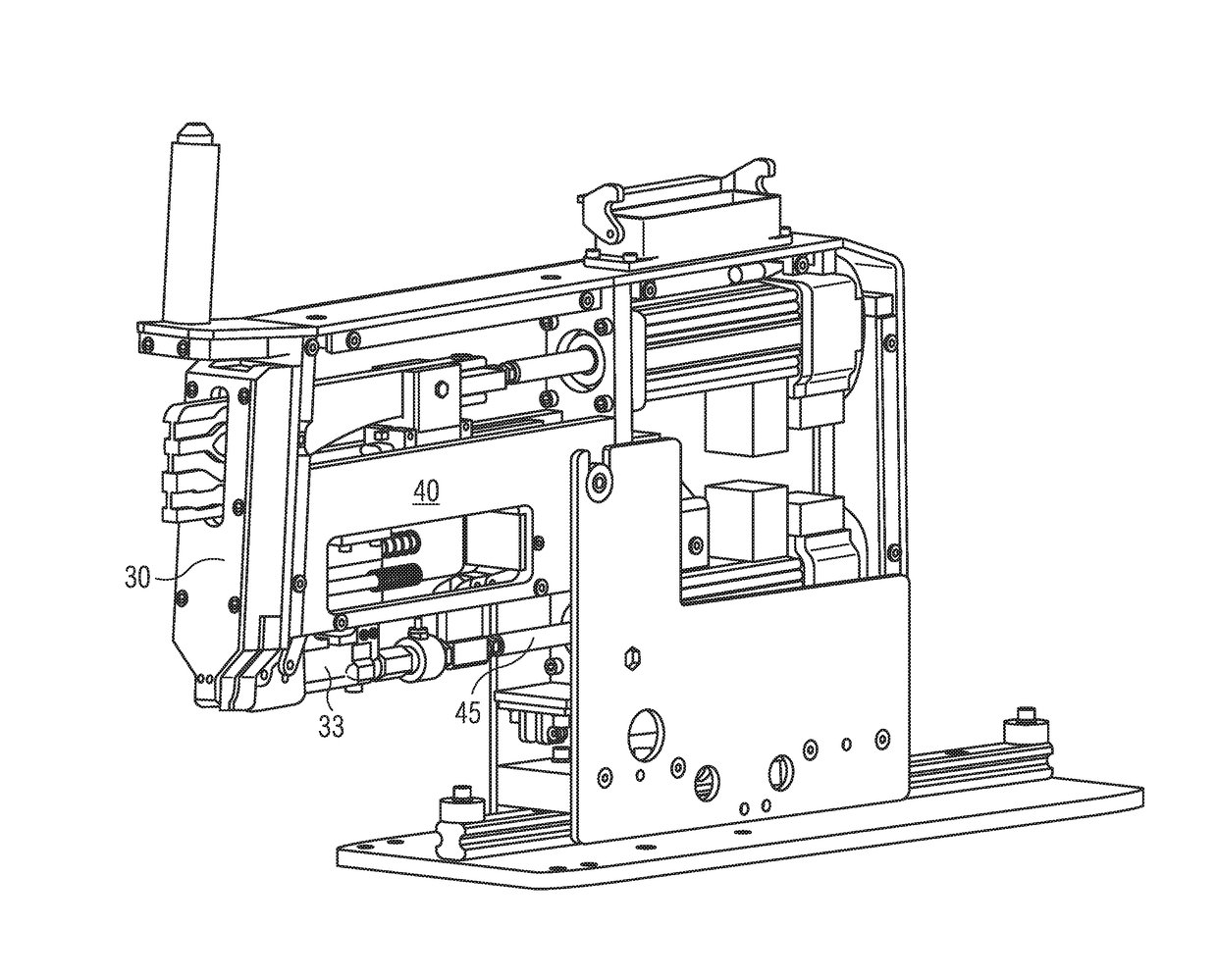

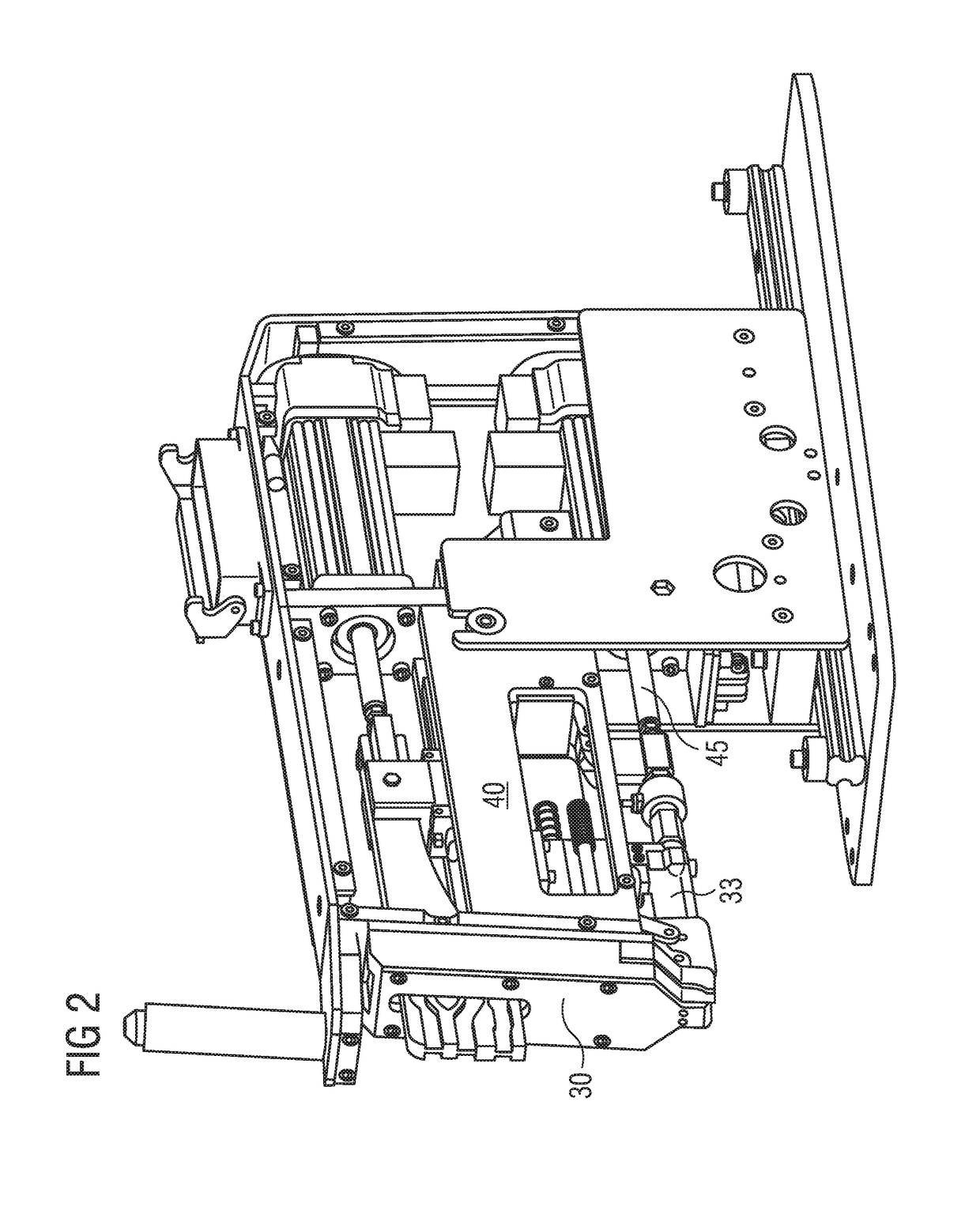

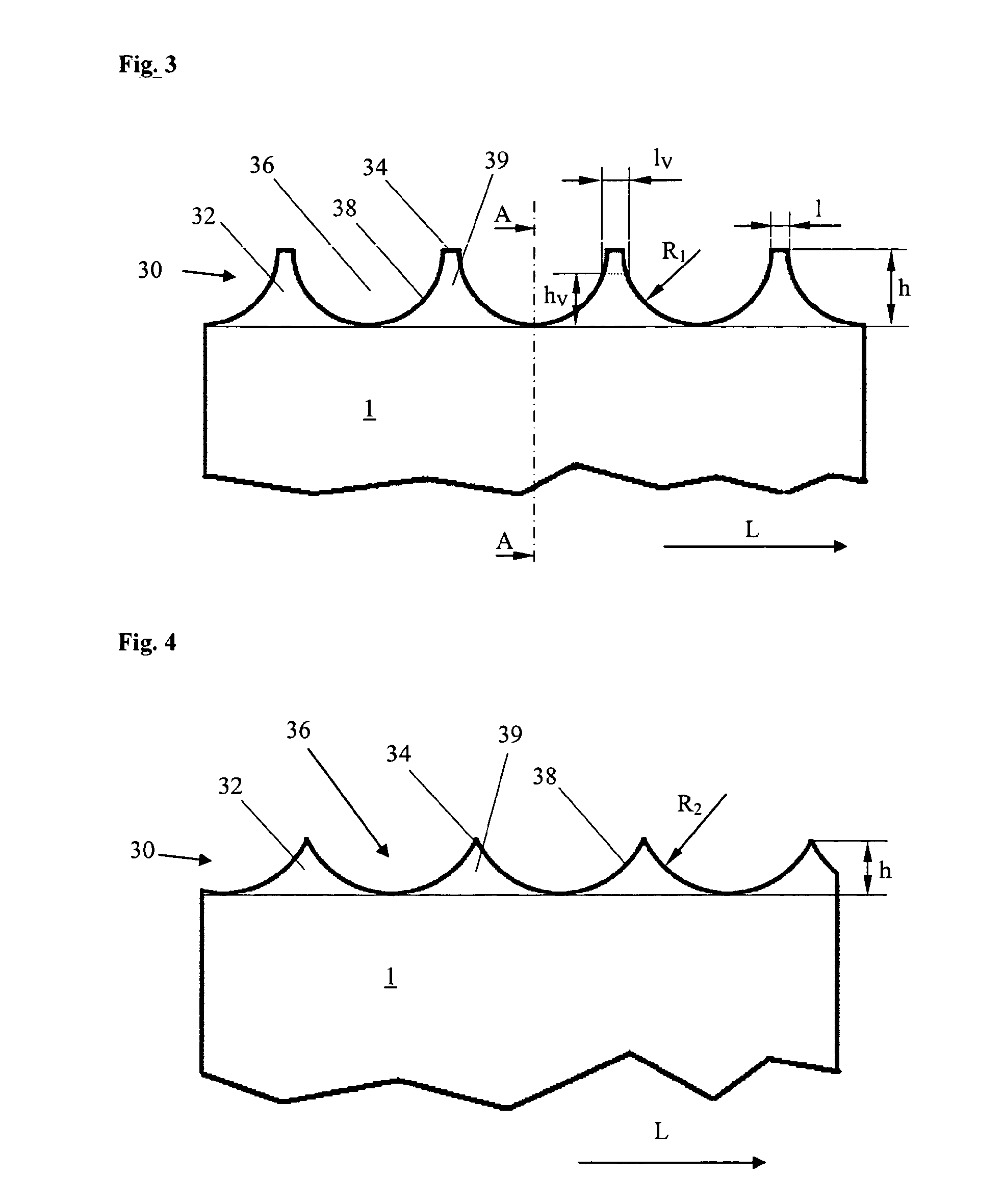

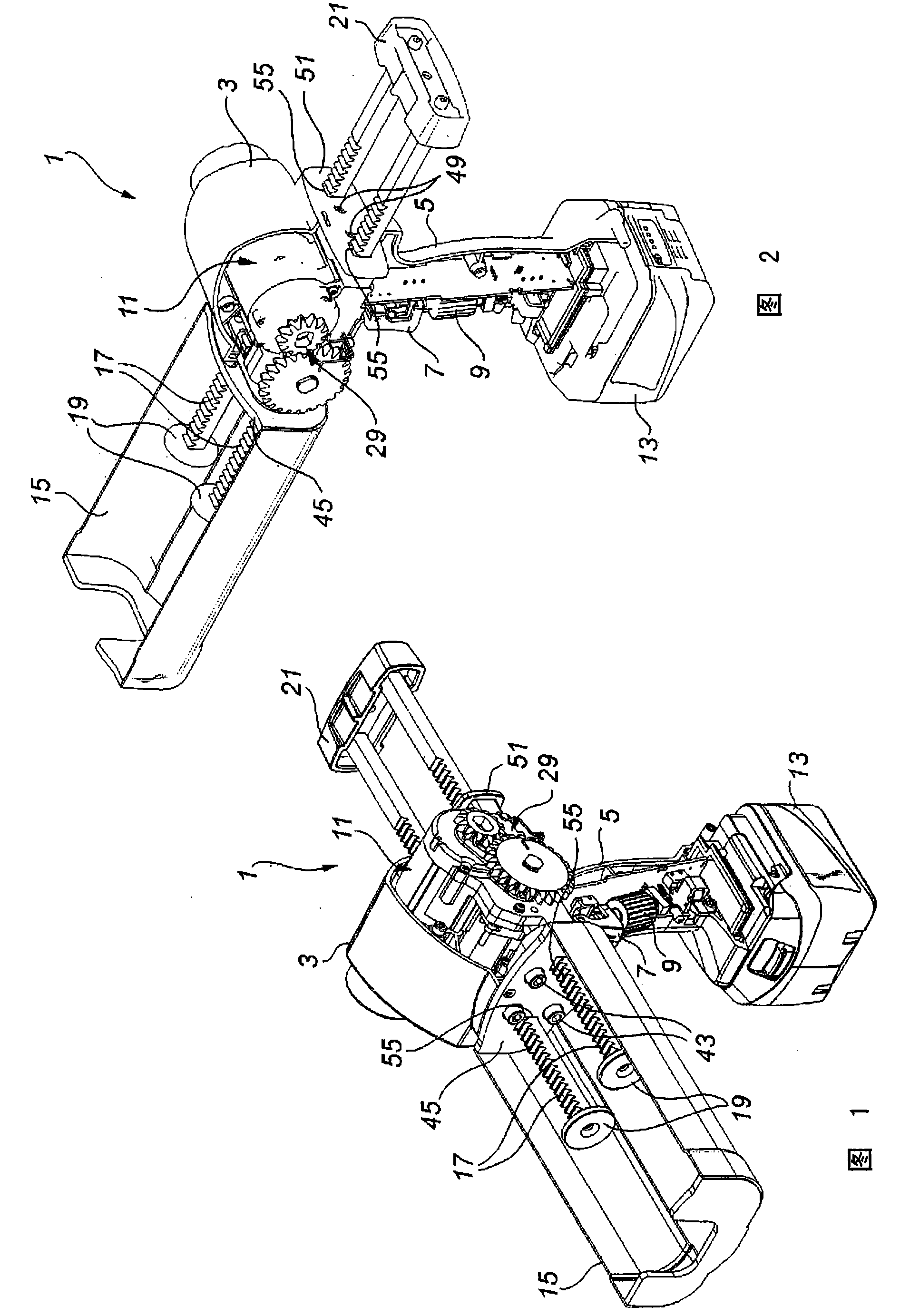

A motorized viscous material dispenser

ActiveCN104349847AConvenient lateral displacementEasy to assembleLiquid surface applicatorsCoatingsPinionPiston

A motorized viscous material dispenser (1), especially a caulking gun, comprises a drive unit (11) with a cylindrical pinion gear, a holder (15) attachable to a front side of the drive unit (11) for receiving at least one container containing viscous material, at least one piston (19), and at least one rack (17) meshing with the cylindrical pinion gear to drive said piston (19). A rear piece (51) attachable to a rear side of the drive unit (11) opposite the front side and a guide piece (45) attachable to the front side of the drive unit (11) comprises guiding apertures (55) through which the rack (17) is extending, whereby the guiding apertures (55) determine the position of the rack (17) relative to the cylindrical pinion gear, when the motorized viscous material dispenser (1) is assembled.

Owner:MEDMIX SWITZERLAND AG

Paper box die-cutting process

InactiveCN104802448APrevent cardboard from sticking to knivesSimple processBox making operationsPaper-makingGraph drawingPulp and paper industry

The invention discloses a paper box die-cutting process and relates to the field of packaging. A die-cutting plate is manufactured by virtue of 7 process steps, namely die-cutting graph drawing, template cutting, cutter line and indentation line loading, checking, die-cutting rubber strip gluing, trial base plate cutting and putting into operation; the paper box die-cutting process is simple in process and high in preparation rate; the die-cutting plate manufactured is good in quality; the production efficiency is improved and the production cost is reduced.

Owner:ANHUI JIAXIN PACKAGING & PRINTING

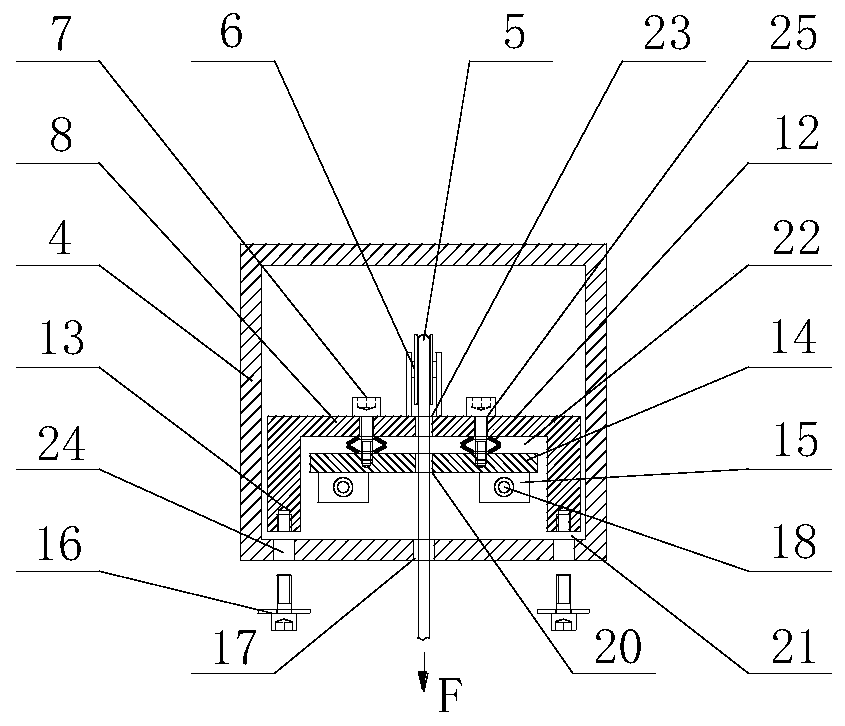

Device for detecting concrete strength by common bearing platform hoop method and detection method thereof

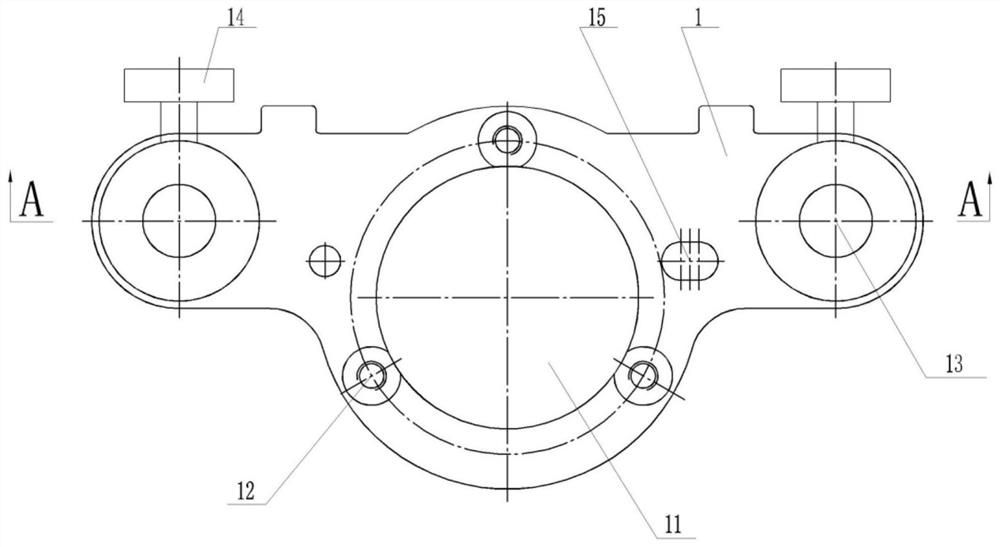

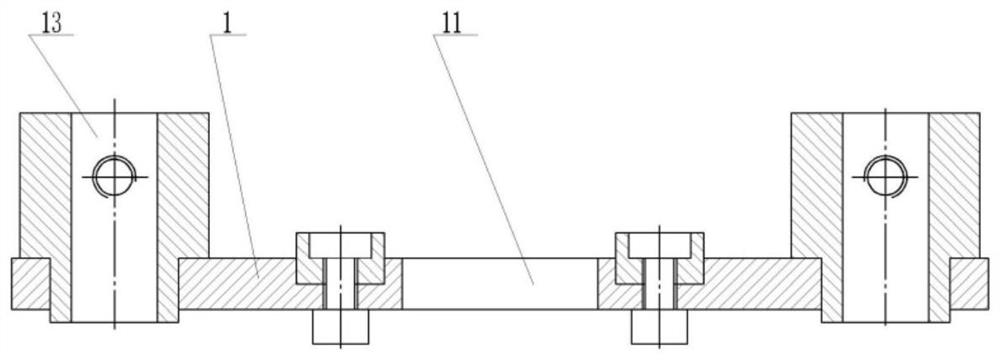

PendingCN112666000AConsistent section diameterConsistent sizePreparing sample for investigationMaterial strength using tensile/compressive forcesArchitectural engineeringStructural engineering

The invention relates to a device for detecting concrete strength by a common bearing platform hoop method and a detection method thereof, the device for detecting the concrete strength by the common bearing platform hoop method comprises a bearing platform in-situ hoop device, and the bearing platform in-situ hoop device comprises a datum plate (bearing platform), an automatic drilling and grinding machine and an automatic in-situ hoop instrument. According to the detection method for detecting the concrete strength by the hoop method, firstly, a hole is drilled in a to-be-detected concrete member, the datum plate is fixed to the to-be-detected member through an expansion pipe bolt hole by using an expansion pipe bolt, then a test piece is prepared, and finally, a detection result is automatically calculated. The equipment and the detection method have the advantages that the detected concrete test piece is prevented from bearing lateral force in the test process, it is guaranteed that the end face of the concrete test piece is perpendicular to the axis, it is guaranteed that the side face of the concrete test piece is straight and smooth, the purpose of manufacturing a standard concrete test piece on site is achieved, and the detection precision is remarkably improved.

Owner:LANGFANG CITY SUNSHINE CONSTR QUALITY INSPECTION CO LTD +1

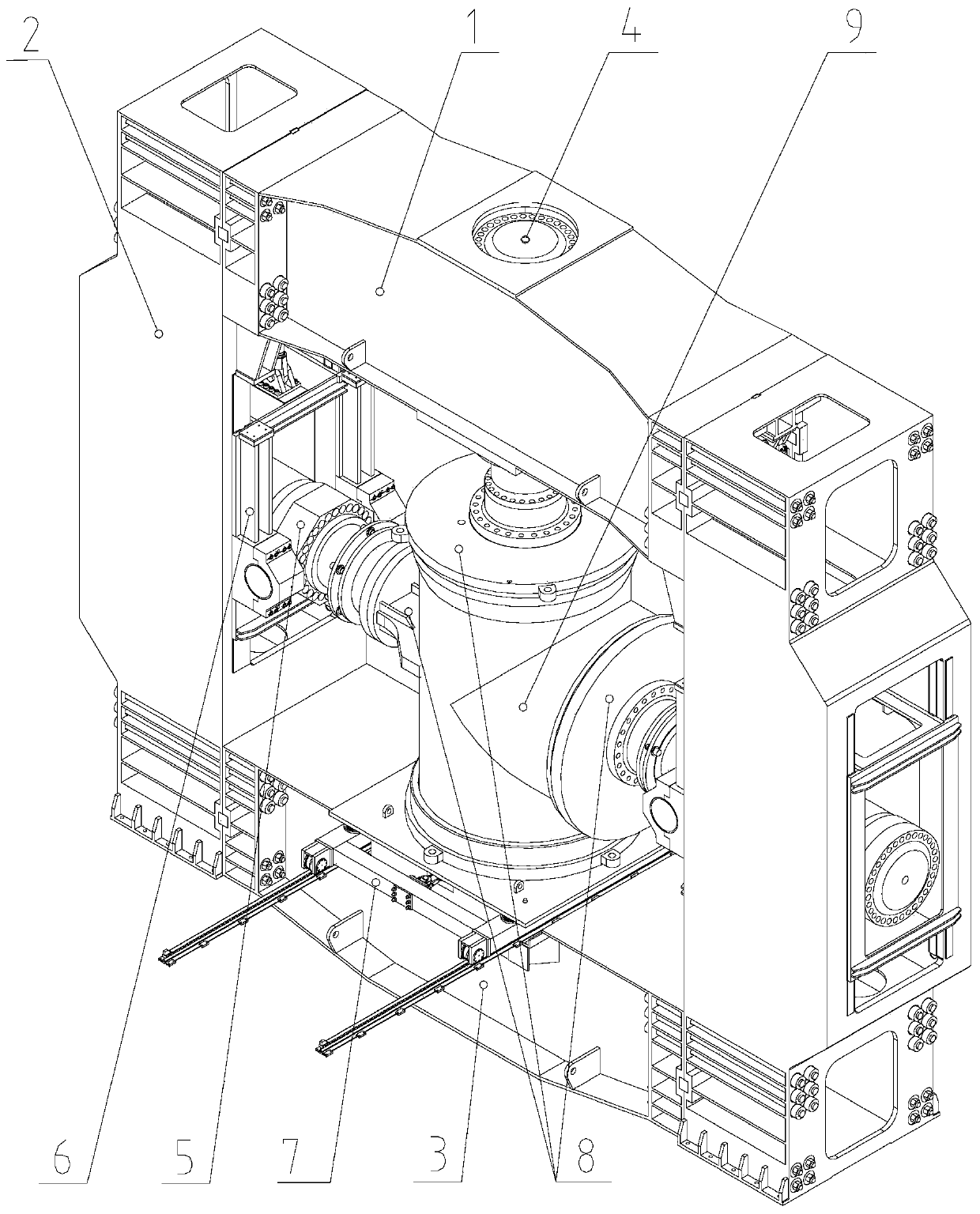

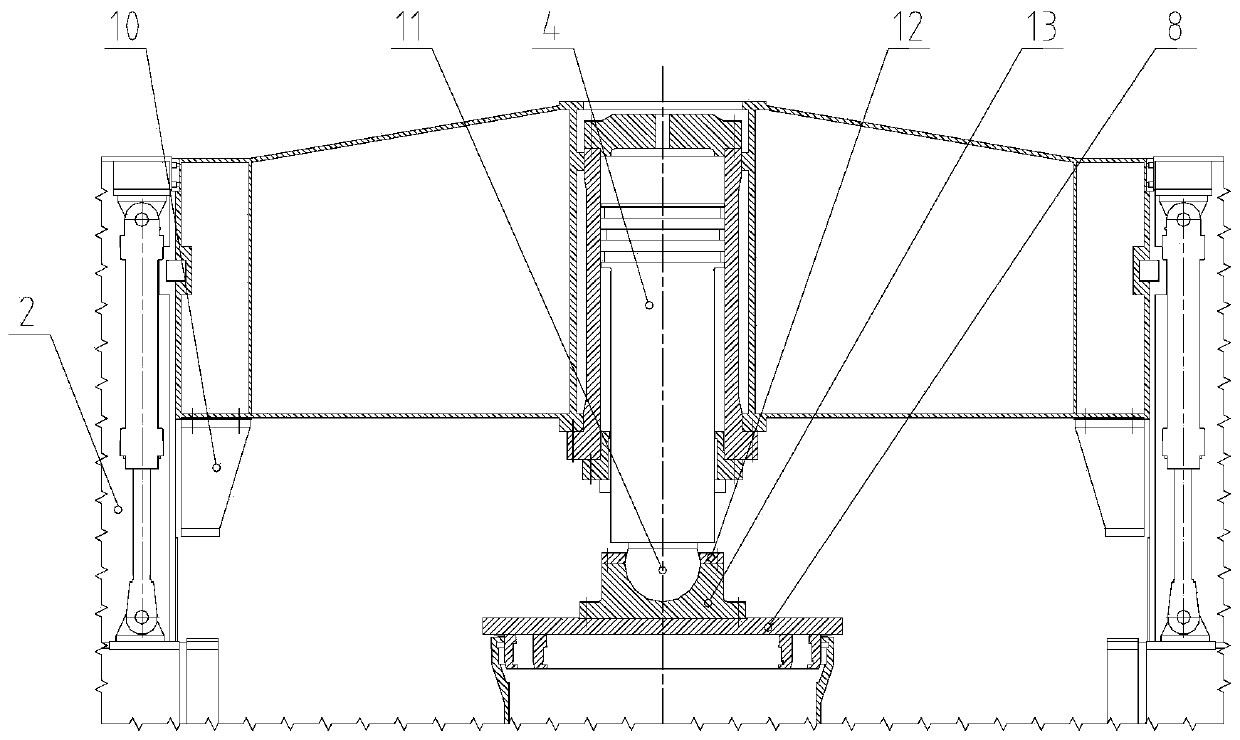

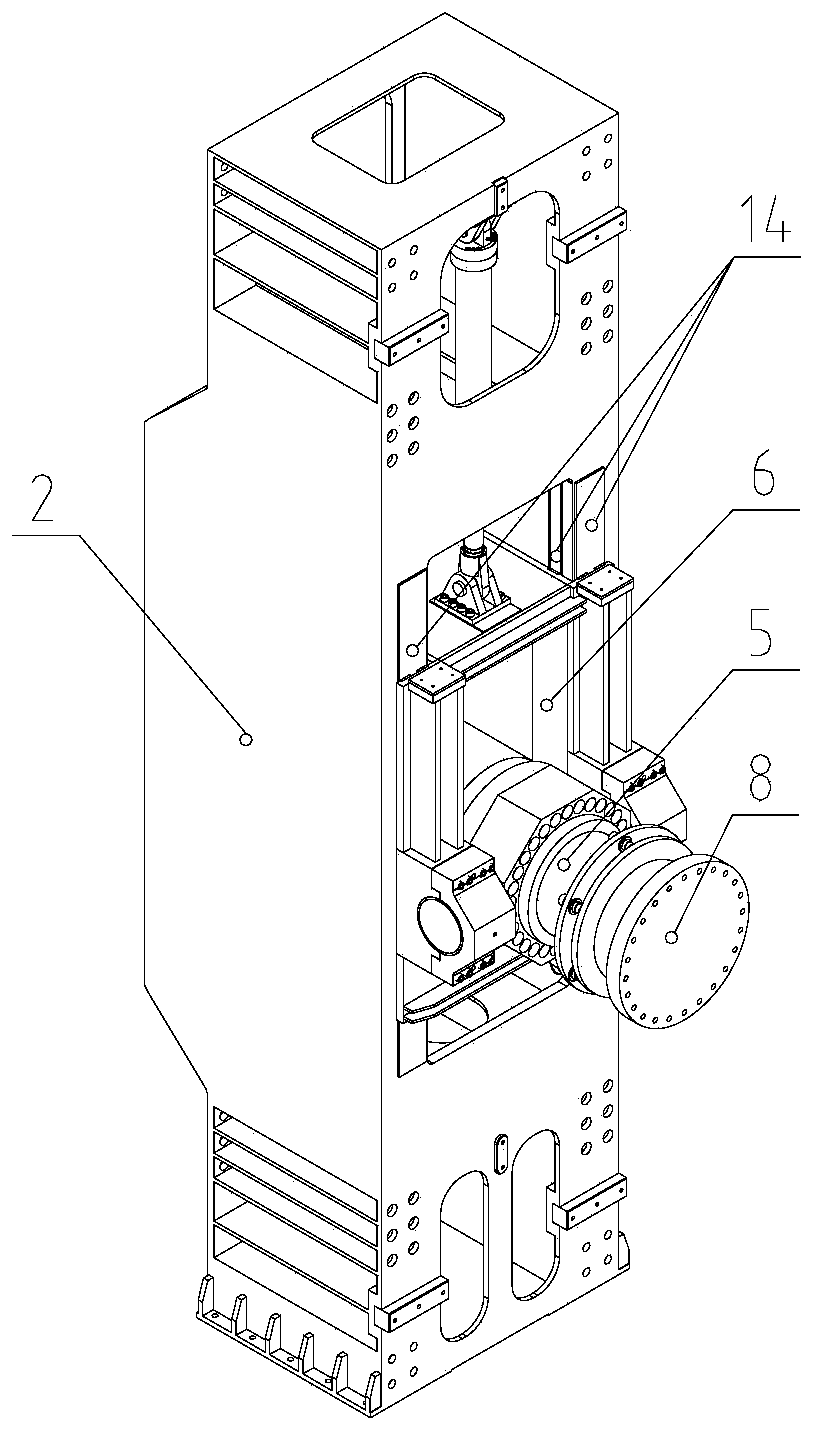

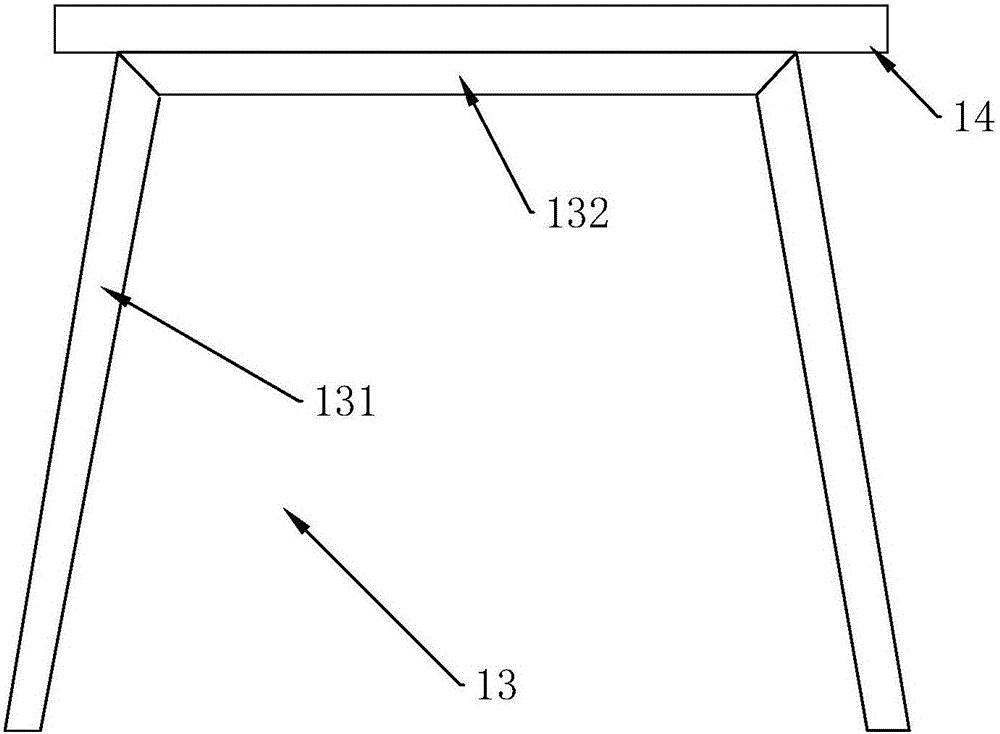

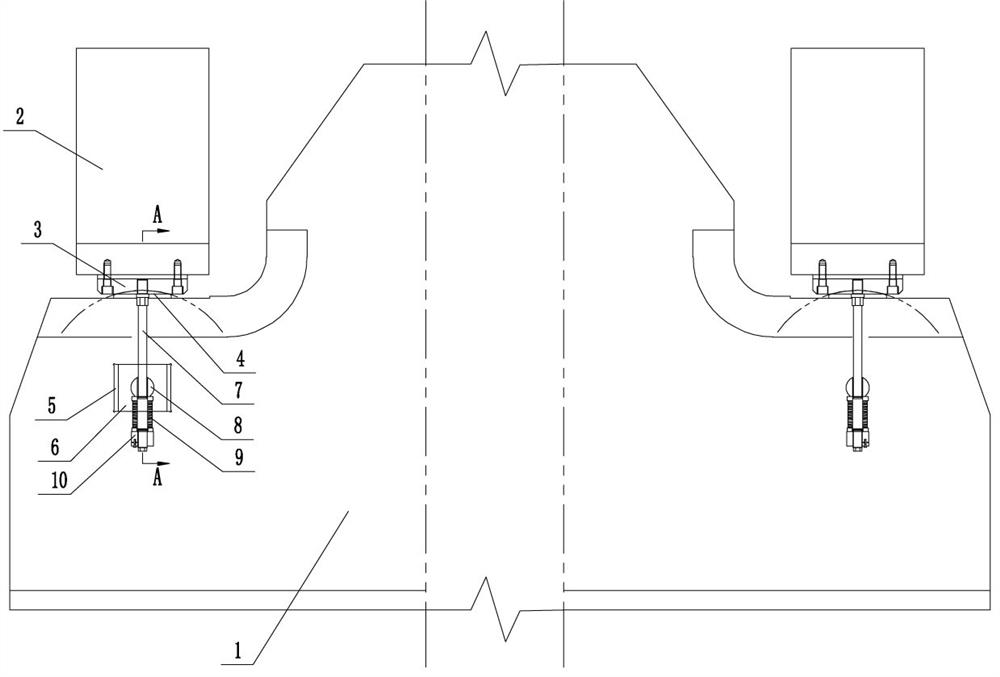

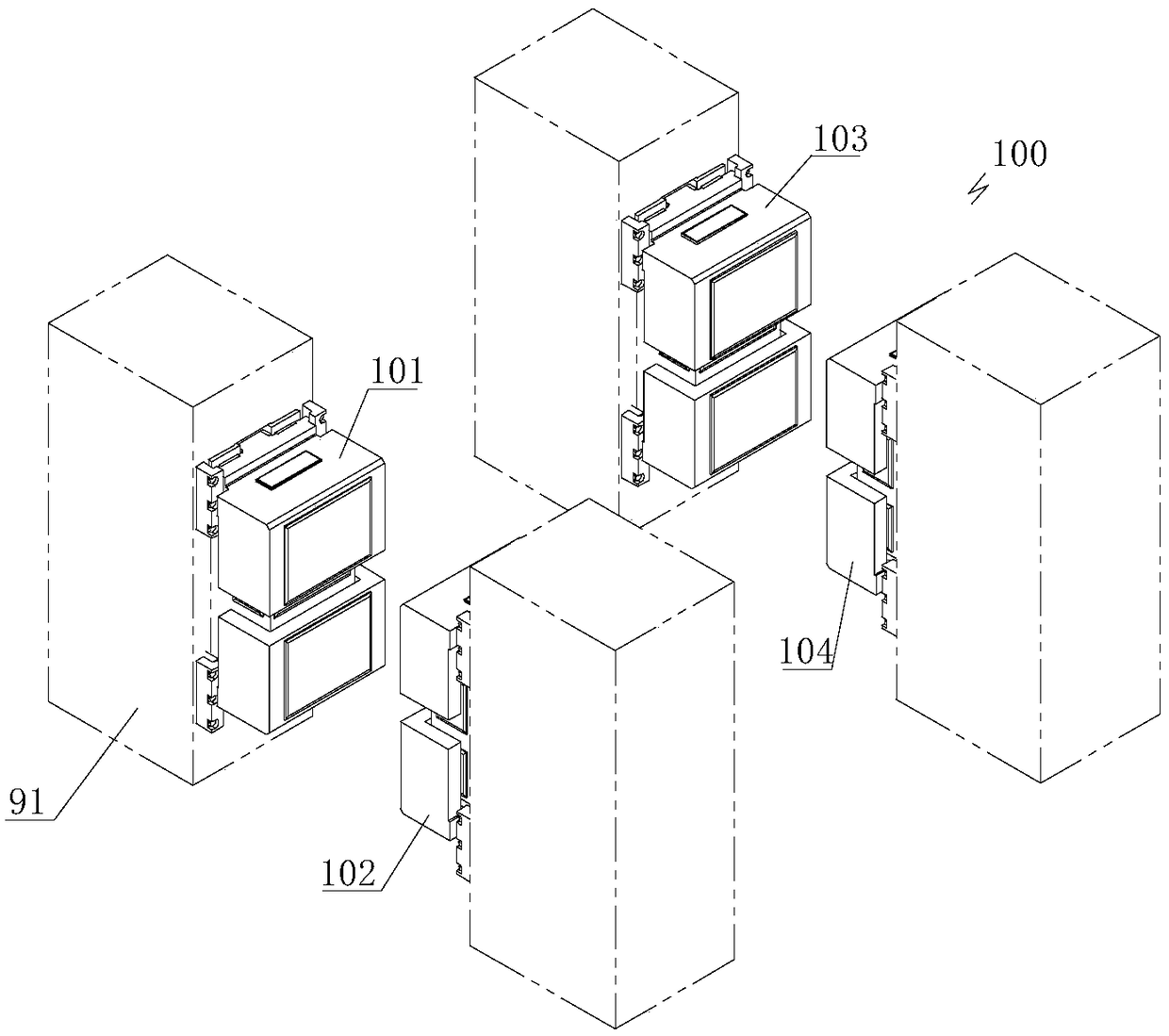

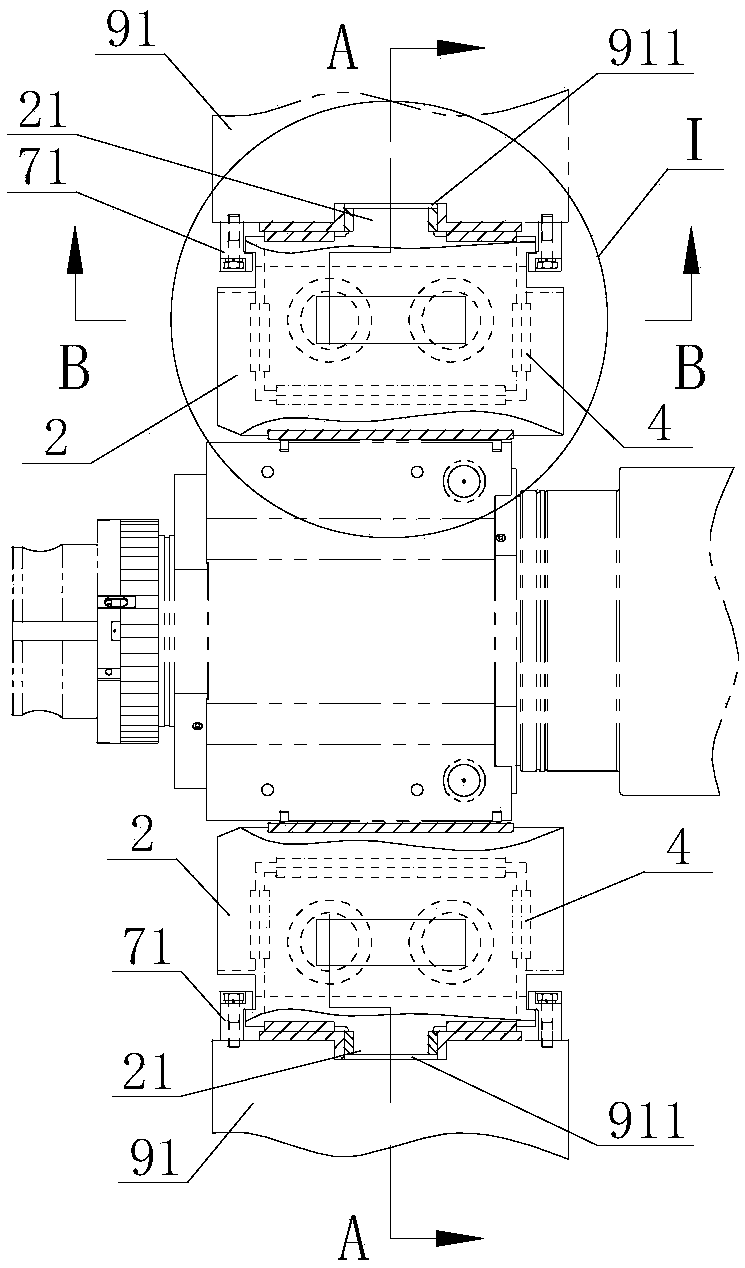

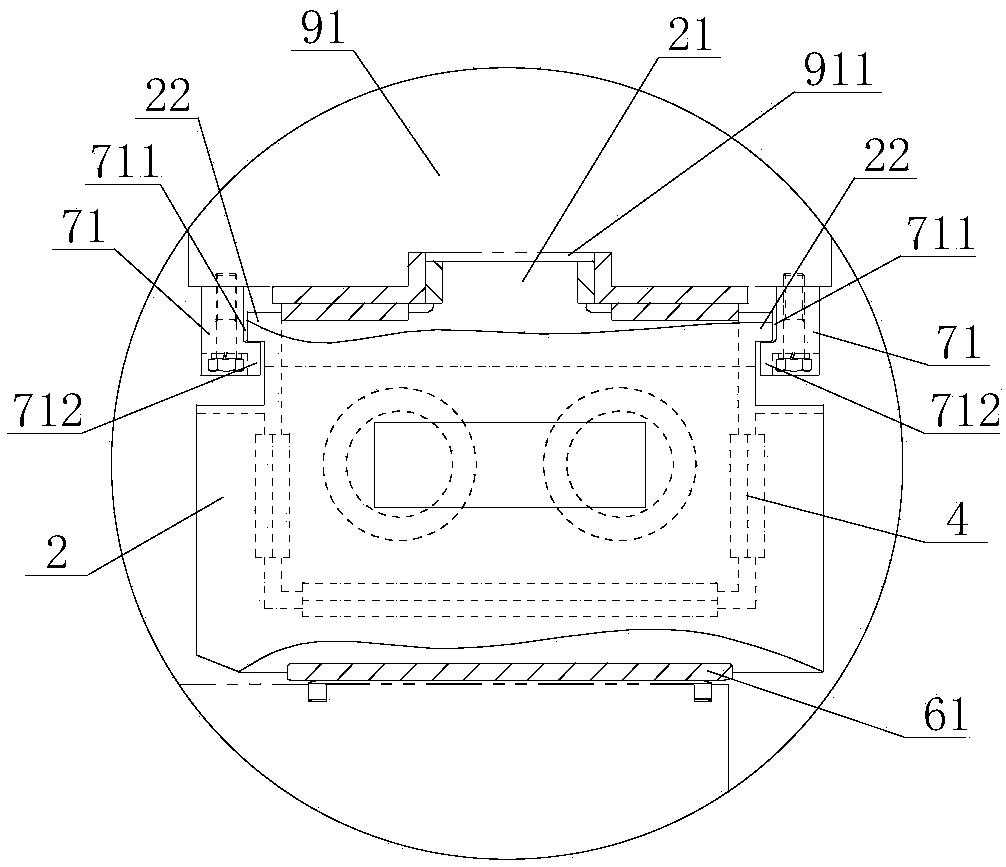

Hydrostatic testing machine for ultra-large drift diameter cast pipe

PendingCN109855980AAvoid lateral forcesExtended service lifeMaterial strength using tensile/compressive forcesMaster cylinderPipe fitting

The invention relates to the technical field of the hydrostatic test device of the cast pipe, specifically hydrostatic testing equipment for an ultra-large drift diameter cast pipe, and relates to hydrostatic test devices in different structural forms and with drift diameters at DN1600-2200 pipe fitting. The hydrostatic testing equipment comprises a mounting support frame, a main cylinder, side cylinders, side cylinder driving mechanisms, a moving trolley and tools, wherein the mounting support frame is a hollow-square shaped frame structure; the main cylinder is arranged at a middle locationof an upper part of the mounting support frame; the side cylinder is arranged at a side cylinder driving mechanism; the side cylinder driving mechanism can move along an upright under the driving of alifting cylinder; the moving trolley is arranged at a lower part of the mounting support frame; a tee pipe fitting is arranged on the moving trolley and moved to the center of the mounting support frame; an upper part port of the tee pipe fitting is blocked by the tool on the main cylinder, the middle port is blocked by the tool on the side cylinder at the left side (or right side), and the otherside cylinder provides support force balance, and the lower part is blocked by the tool on the moving trolley.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

Dismounting device

InactiveCN105822335AAchieve supportPrevent fallingMine roof supportsEngineeringMechanical engineering

Owner:SHANDONG MINING MASCH GRP CO LTD

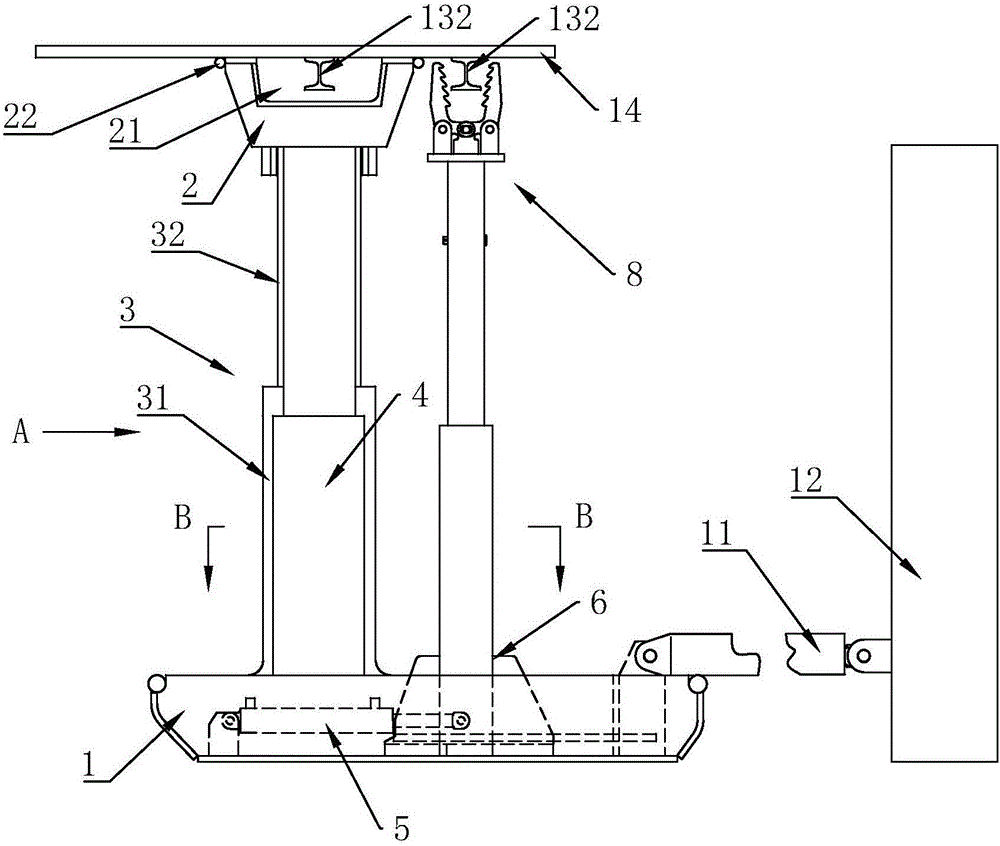

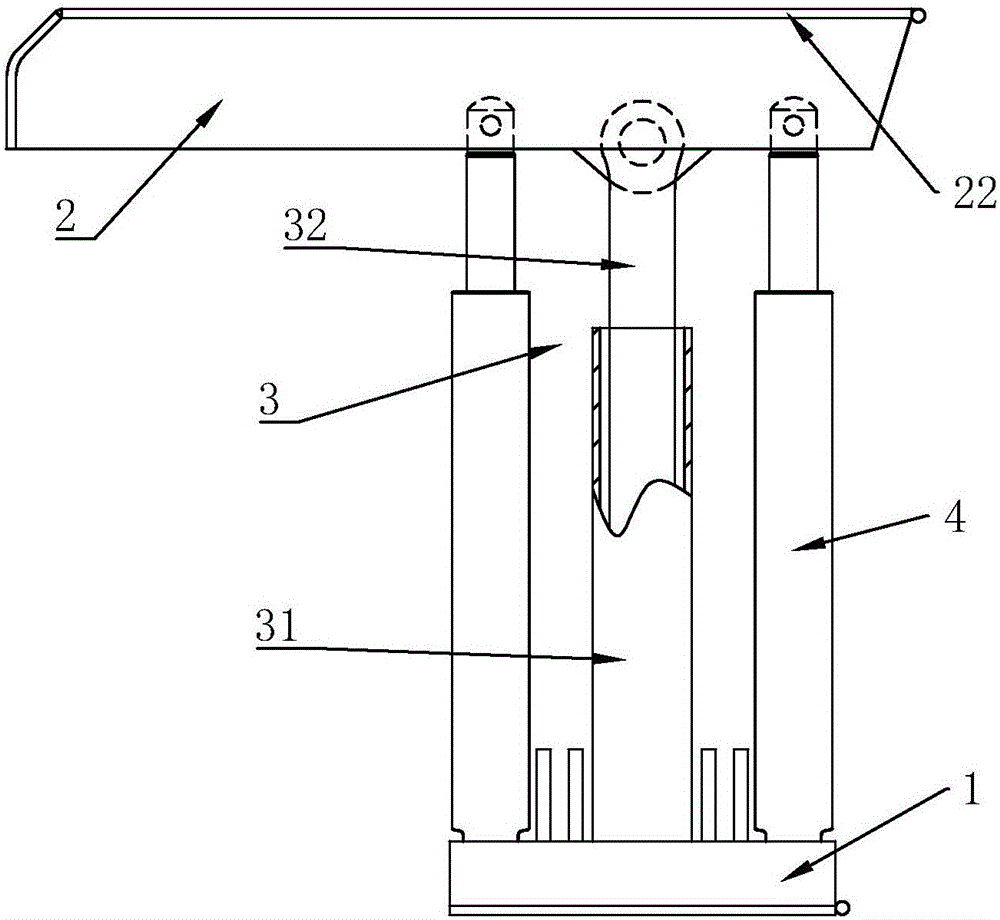

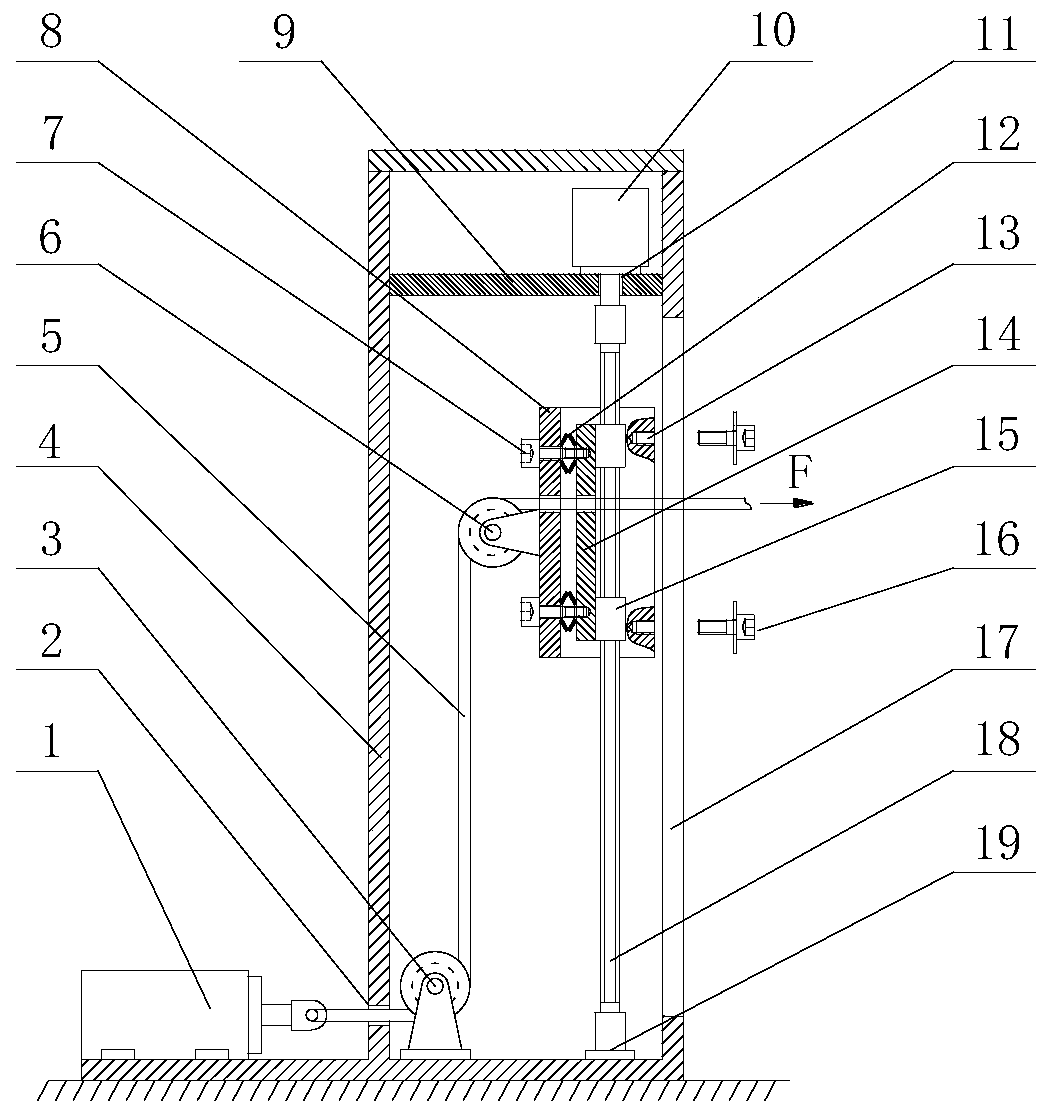

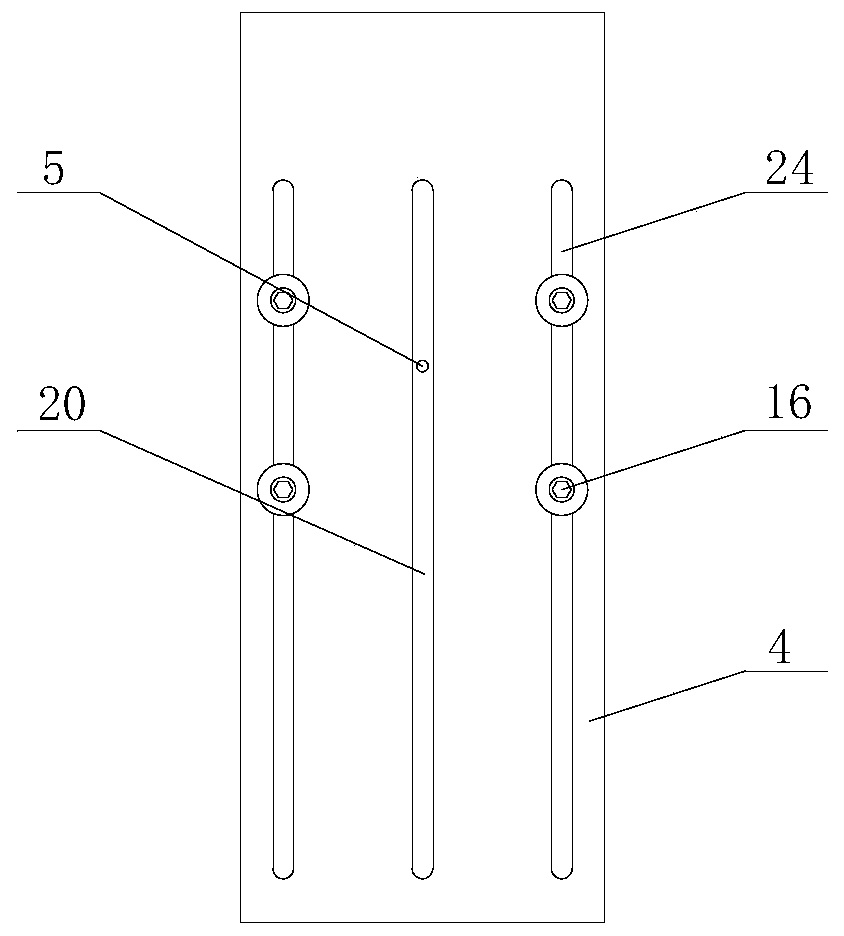

Vertical movement platform with horizontal bearing capacity

ActiveCN109081255AProtect screwAvoid lateral forcesMeasurement devicesPortable liftingEngineeringSlide plate

The invention discloses a vertical movement platform with the horizontal bearing capacity. The vertical movement platform comprises an actuator, a bearing frame, a steel wire rope, a leading-in pulley, a leading-out pulley, a motor, a motor support, a lead screw, a sliding block, a sliding plate, a spring, a bearing bolt, a leading-in hole, a guide bolt, a pulley seat, a support hole, a bearing bolt positioning hole, a sliding plate, a leading-out hole, a lead screw support, a sliding plate guide hole, a passive clearance, an active clearance, a pulley seat guide hole, a positioning guide holeand a guide bolt positioning hole. According to the vertical movement platform, automatic space positioning of the stretching position of the steel wire rope is achieved. Through fastening of the bearing bolt, the pulley seat and the bearing frame are fixedly connected, the borne large load is transmitted to the bearing frame through the pulleys and the pulley seat, and the horizontal force borneby the lead screw can be adjusted through the rigidity of the spring. According to the vertical movement platform, the space adjustment of the output position of loading force is achieved, the loading force totally acts on the bearing frame, and the lead screw is prevented from bearing large horizontal loads.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Fastening device for a trampoline

ActiveUS10898748B2Simple designAvoid lateral forcesSpring boardsTrampolinesStructural engineeringMechanical engineering

Owner:ANGEHRN AG UMFORMTECHN

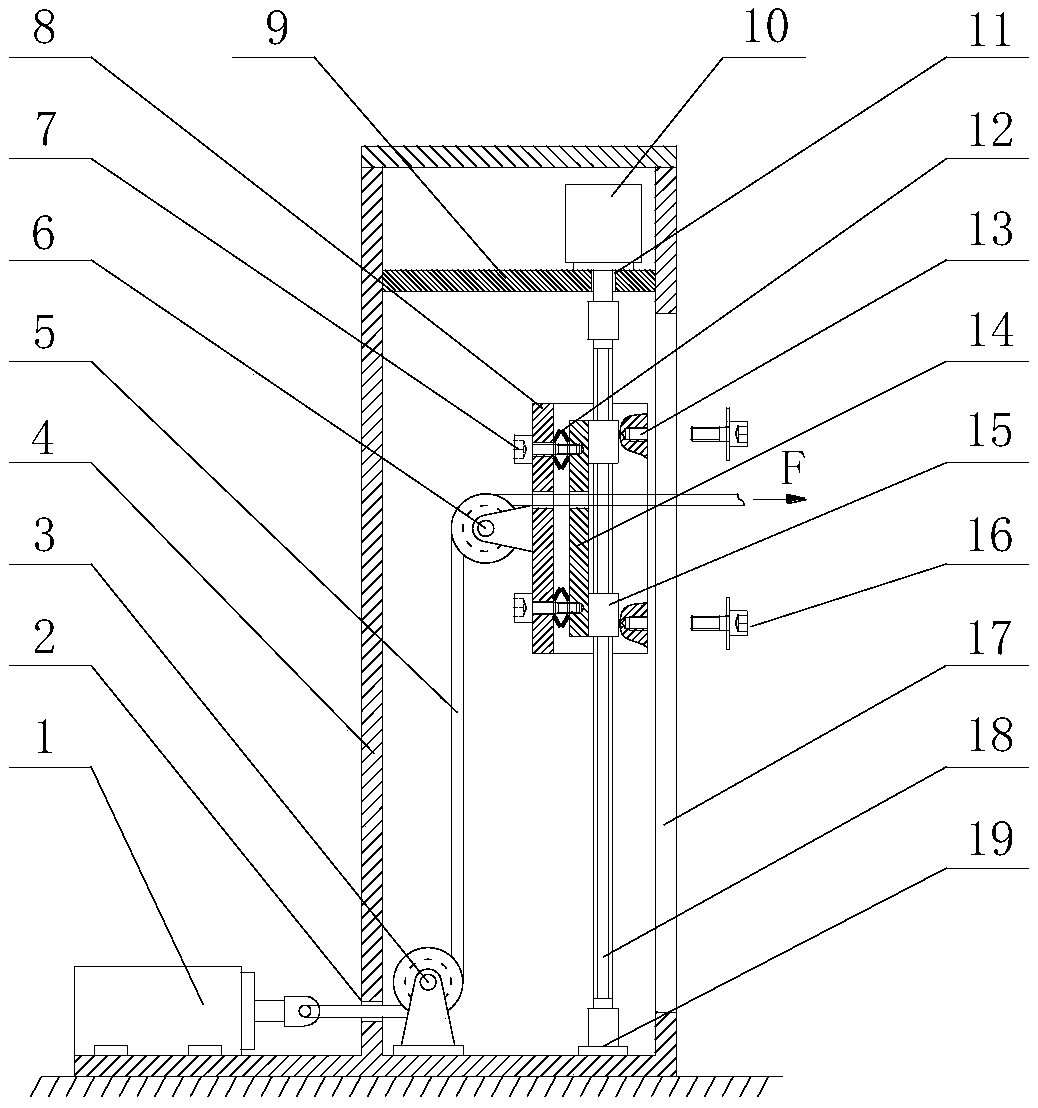

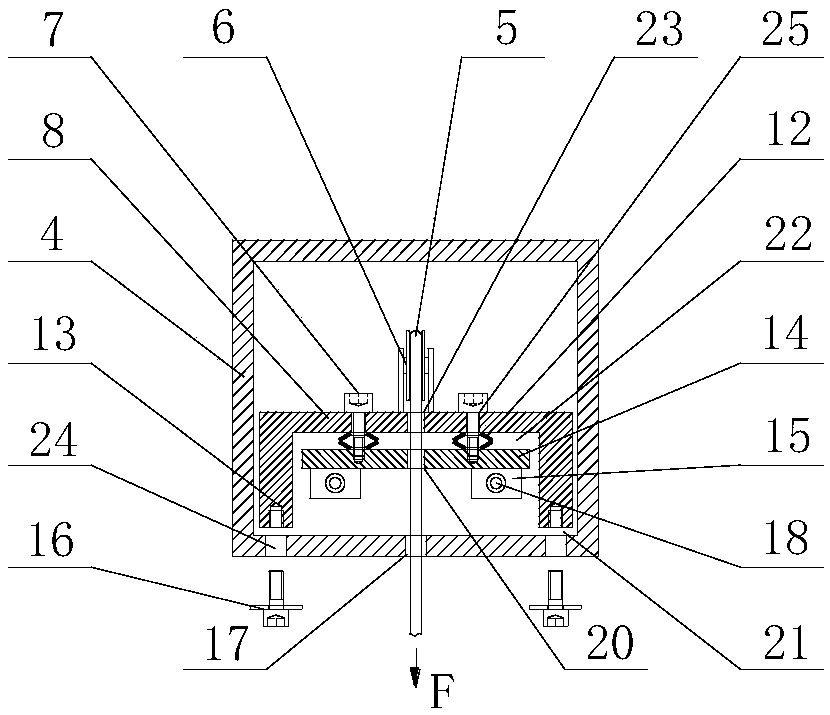

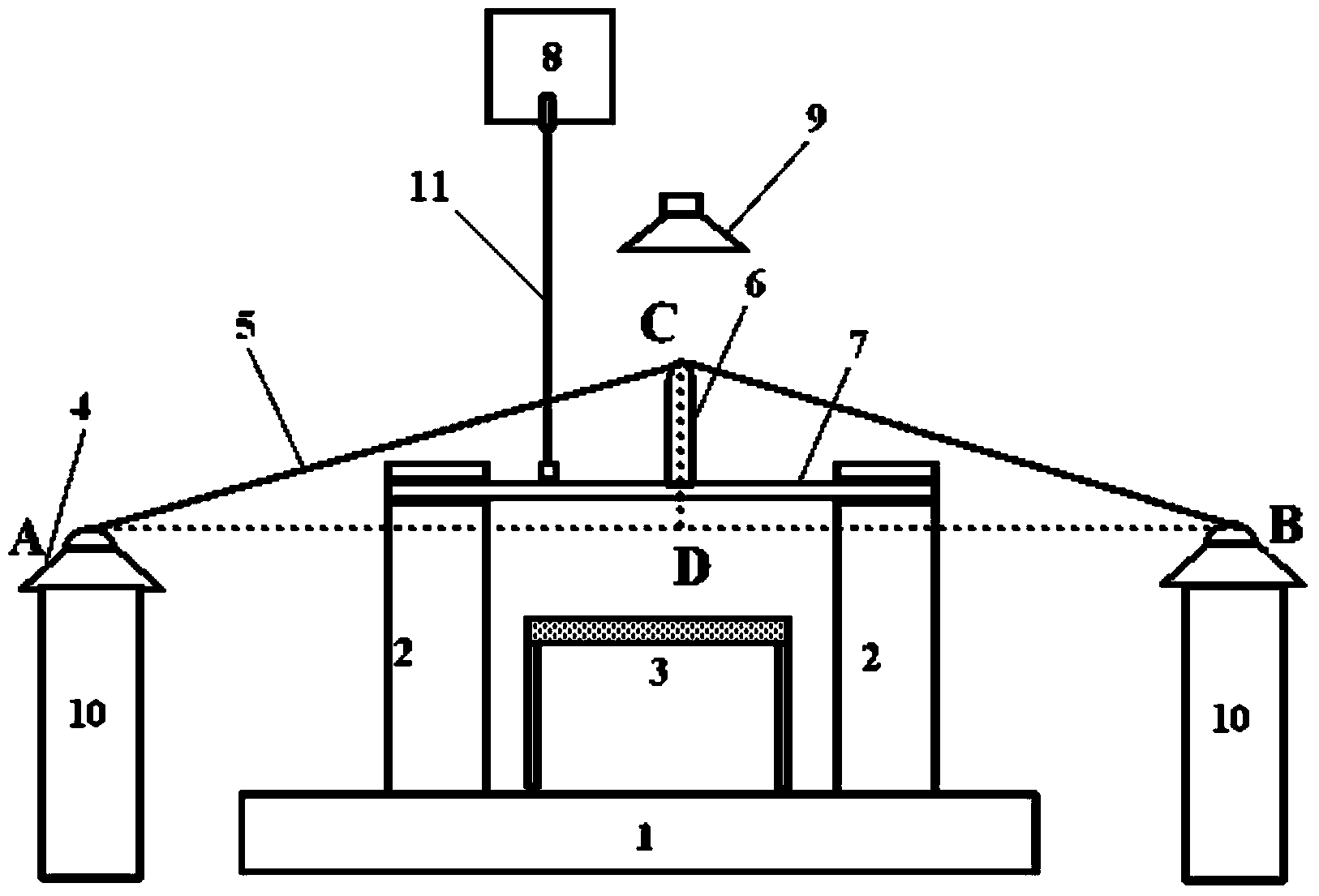

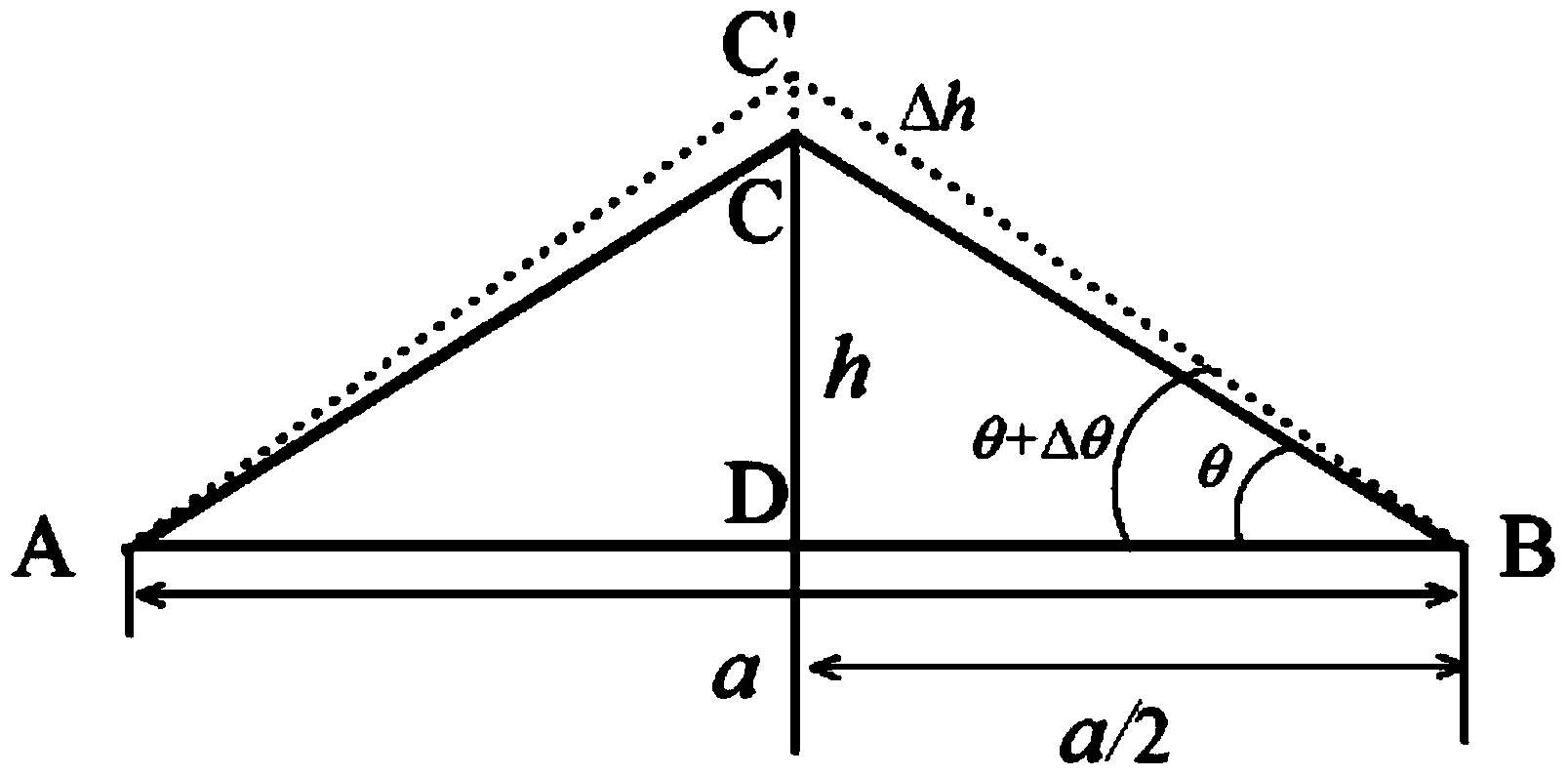

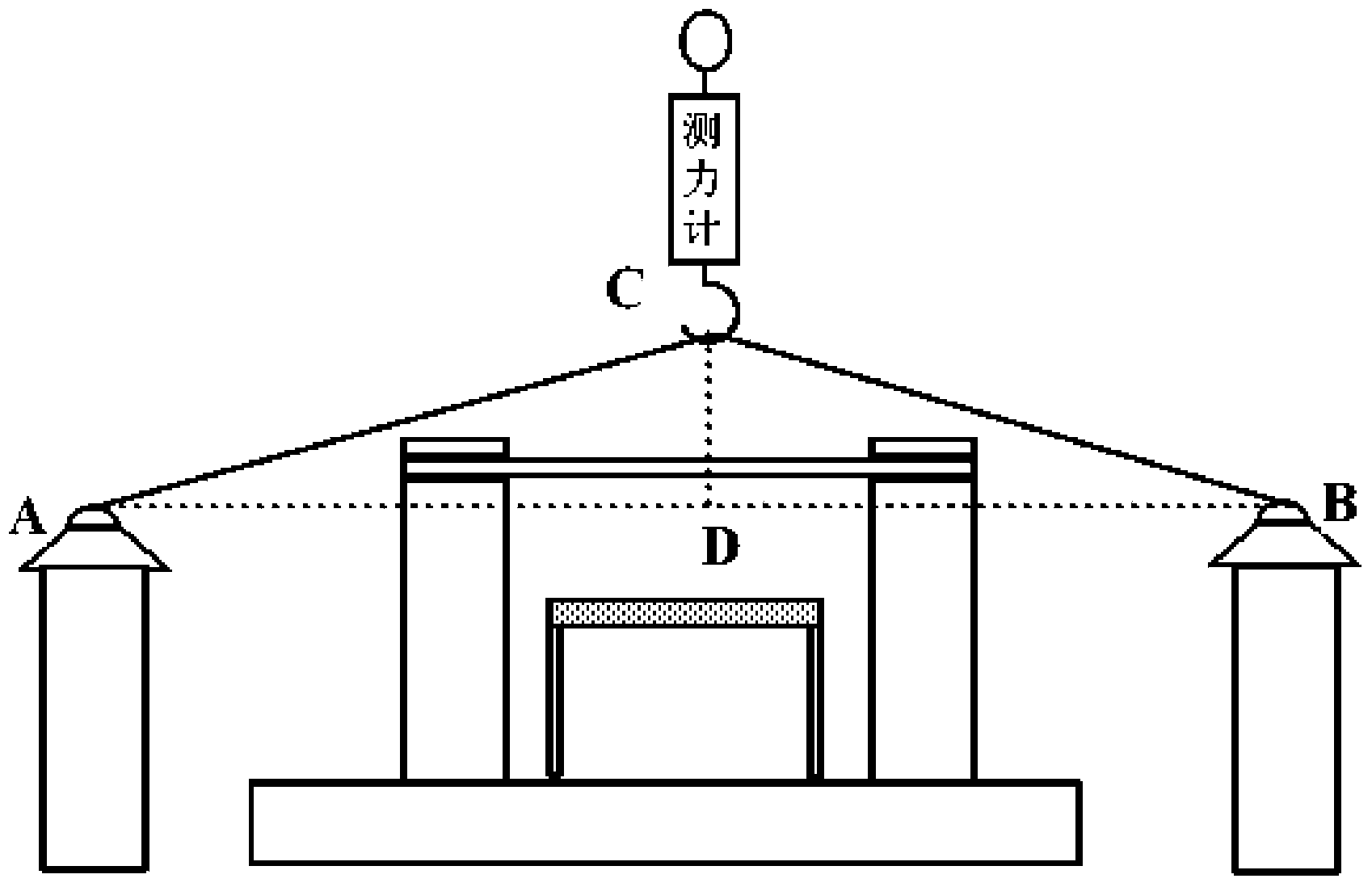

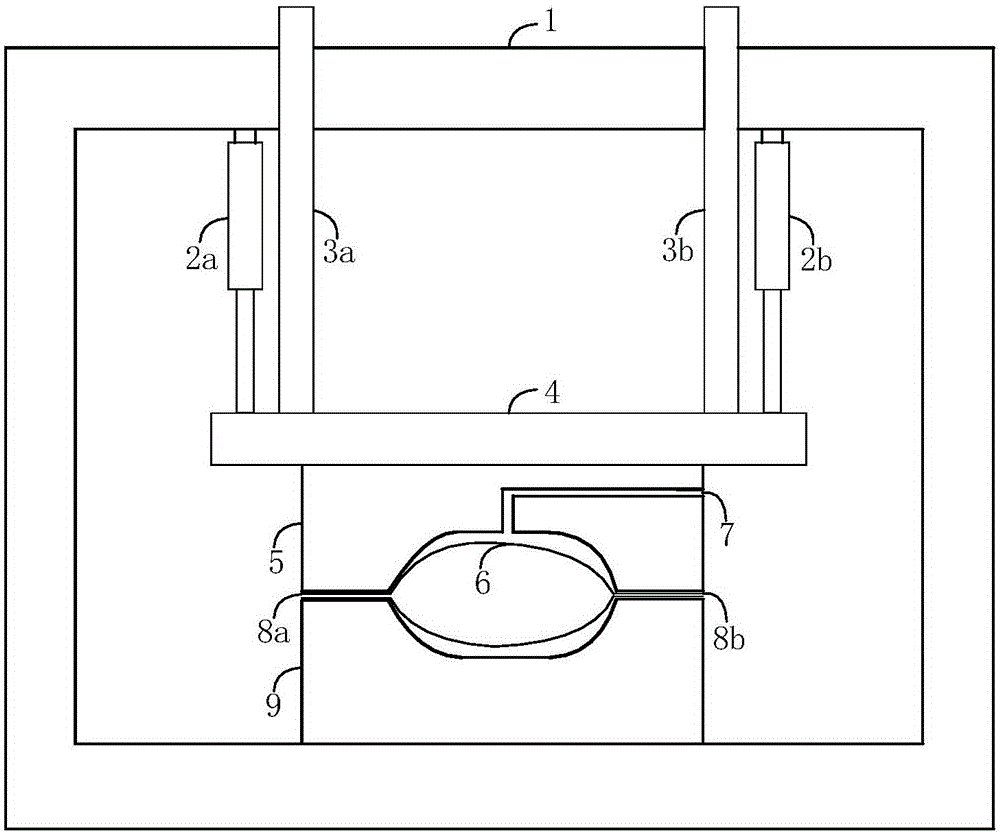

Basic structure element dynamic experiment device for heat and vibration environments and loading method of static load thereof

ActiveCN104251774AAvoid lateral forcesSmall sound fieldMachine part testingStructural dynamicsEngineering

The invention discloses a basic structure element dynamic experiment device for heat and vibration environments and a loading method of a static load thereof, and belongs to the technical field of structure dynamic experiment. The device has the advantage that the boundary condition of the surrounding of a testing object is realized by a clamp and a base, and the tension force of an elastic rope is converted into the pressure of the tested structure member by the highly elastic rope and a force transfer rod which is made of light-weight and high-rigidity material. The static loading method has the advantages that the implementation is feasible, the static load and the error in the vibration process can be accurately predicted and measured, the heat effect is little, the influence by additional mass is little, the stability in the vibration environment is good, and the influence on sound fields is little.

Owner:XI AN JIAOTONG UNIV

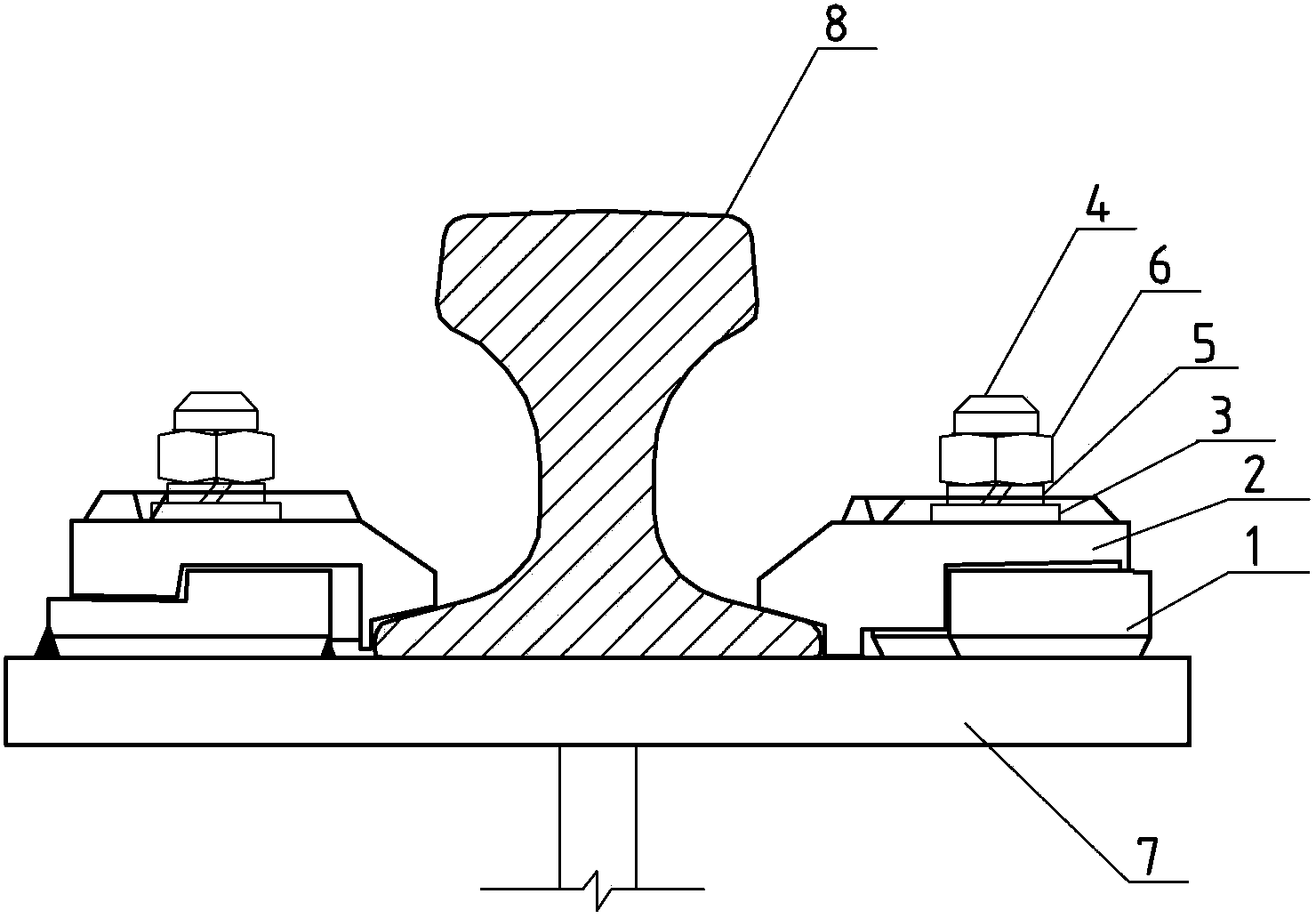

Dual-body track fixing device

The invention belongs to the field of fixing devices, and discloses a dual-body track fixing device. The dual-body track fixing device comprises a fixing base; the middle part of the fixing base is provided with two T-shaped openings; each T-shaped opening is provided with a hopper-shaped bolt; the upper part of the fixing base is also connected with an upper cover; the middle part of the upper cover is provided with two bolt openings; the other ends of the hopper-shaped bolts pass through the bolt openings; the upper part of the upper cover is also provided with two tooth-shaped cushion plates. The invention aims to provide the dual-body track fixing device which is solid, durable, is unique in structure, is safe and convenient, is wide in application, and the overhauling expense is reduced greatly.

Owner:纪军付

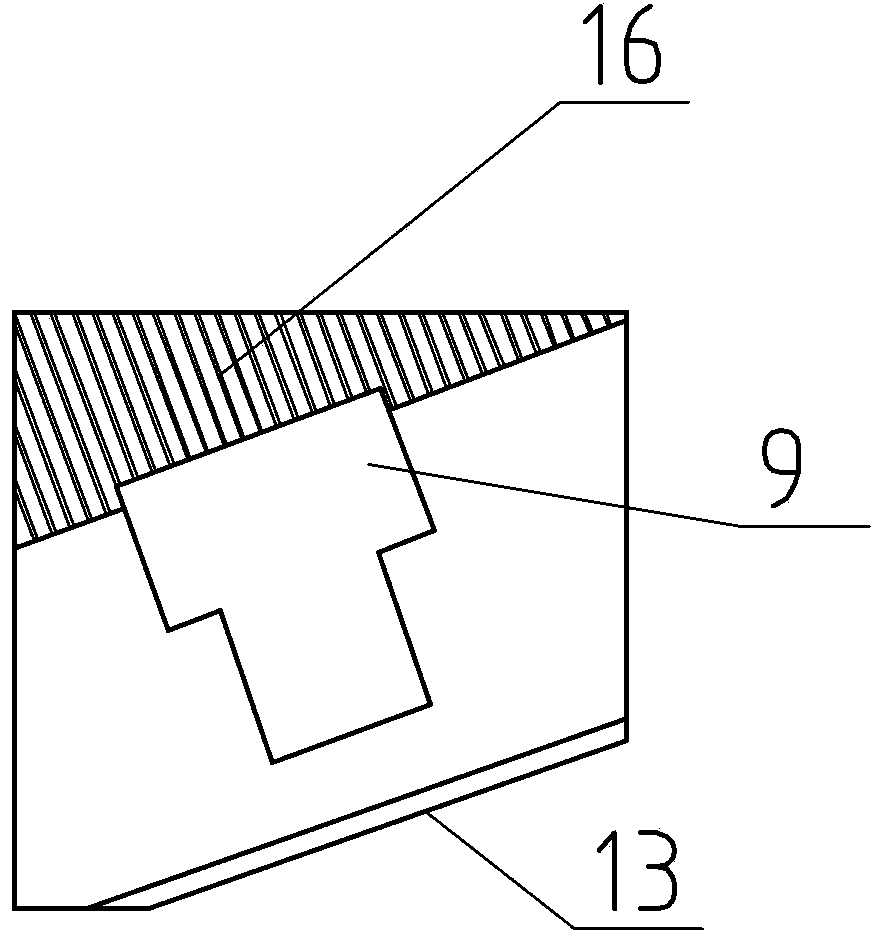

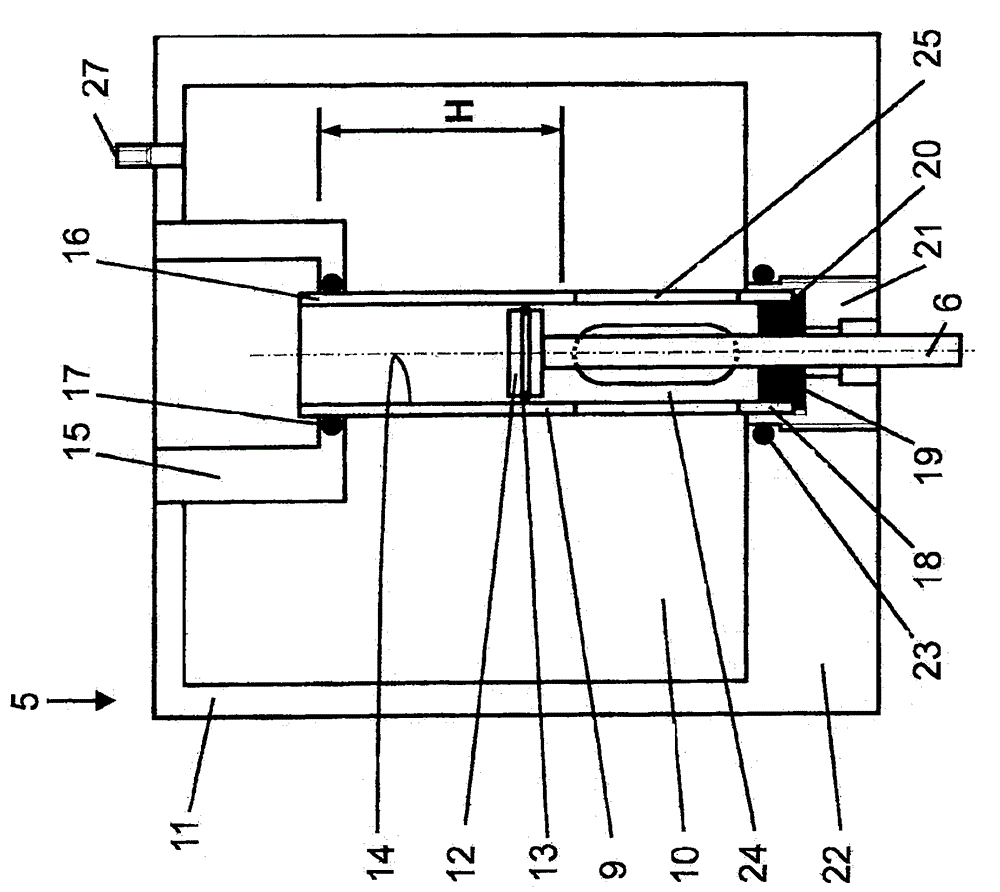

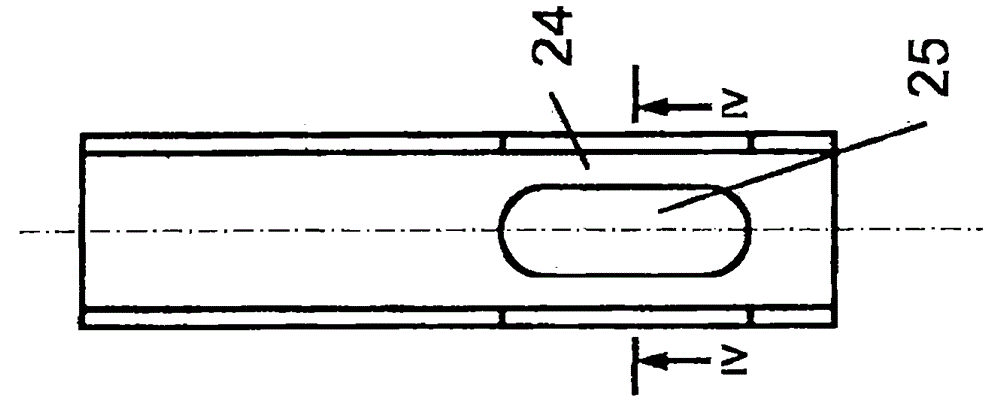

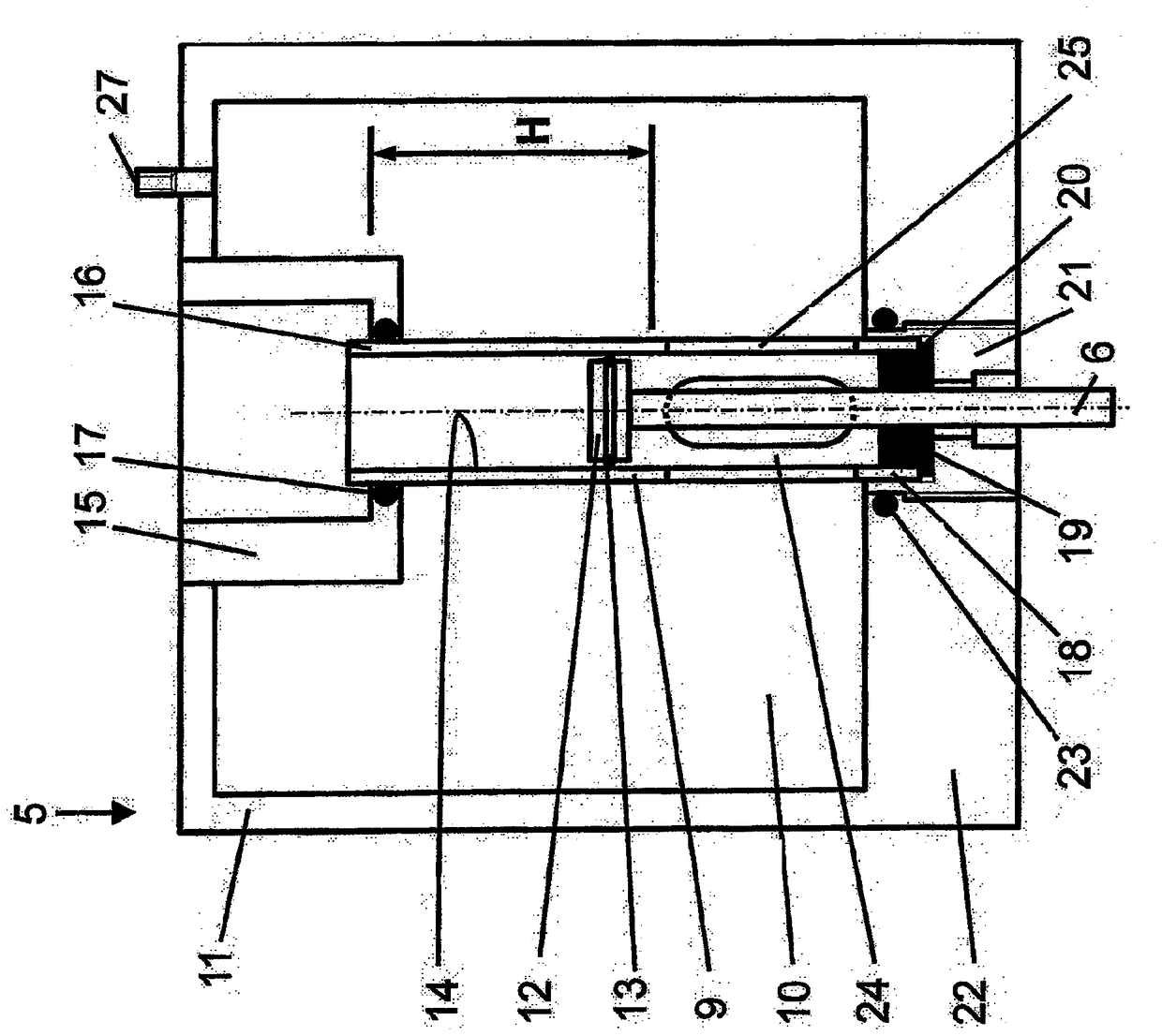

Lay bar of a warp knitting machine

InactiveCN105821576AOrientation is accurateSmall pressure changeWarp knittingFluid-pressure actuatorsPiston-cylinder apparatusInterior space

The invention relates to a lay bar of a warp knitting machine which has at least a guide bar device arranged on a driving element. The driving element and a driving mechanism as well as at least a counter force element (5) are arranged in connection, wherein the counter force element (5) has a piston-cylinder-device. For the piston-cylinder-device, a piston connected to the driving element through a piston rod (6) can move in a cylinder (9) with a certain cylinder cross section in a stroke length (H) region and can be loaded through a pressure medium. People intend to keep the stress change in the driving element little. Therefore the cylinder (9) is arranged in a cavity (10) of a vessel (11) filled by the pressure medium. The cavity (10) has the capacity larger than the external capacity of the cylinder (9) and is in connection with an internal space of the cylinder (9) on a side surface of the piston (12) provided with a piston rod (6). The cylinder (9) is connected to the vessel (11) at at least two positions in a direction parallel to the stroke length (H). The two positions have an interval.

Owner:KARL MAYER R&D GMBH

Automated large outside diameter preform tipping process and obtained glass preform

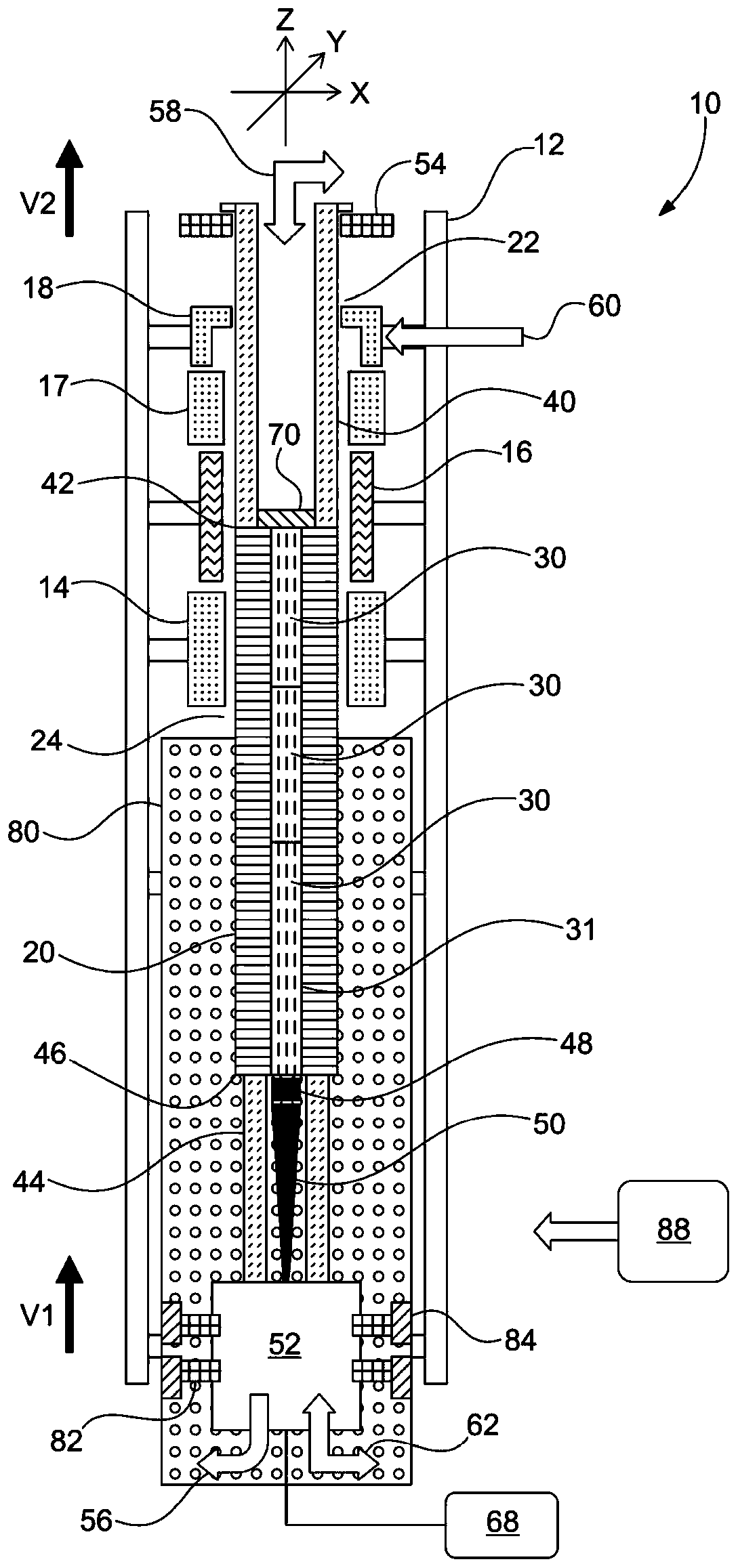

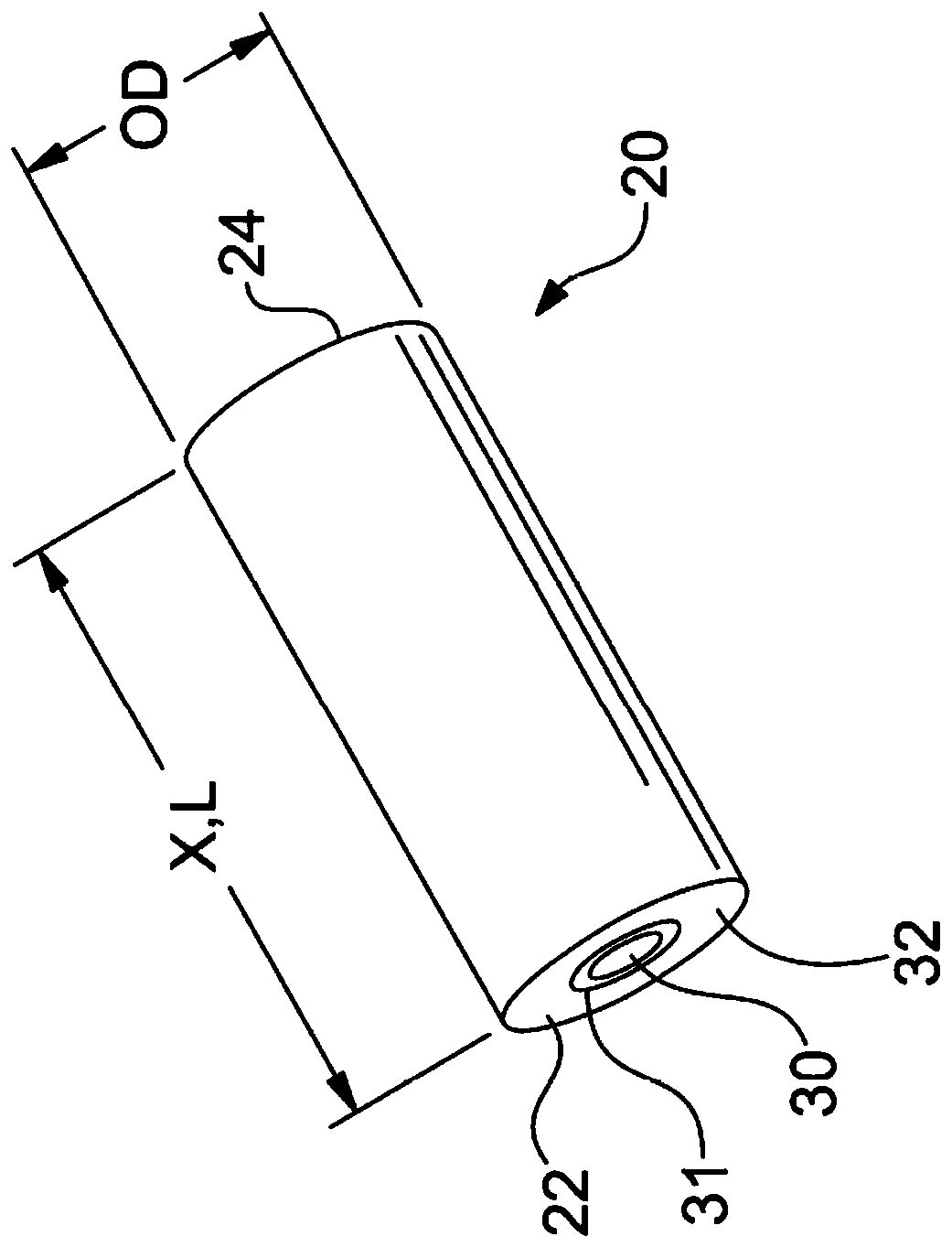

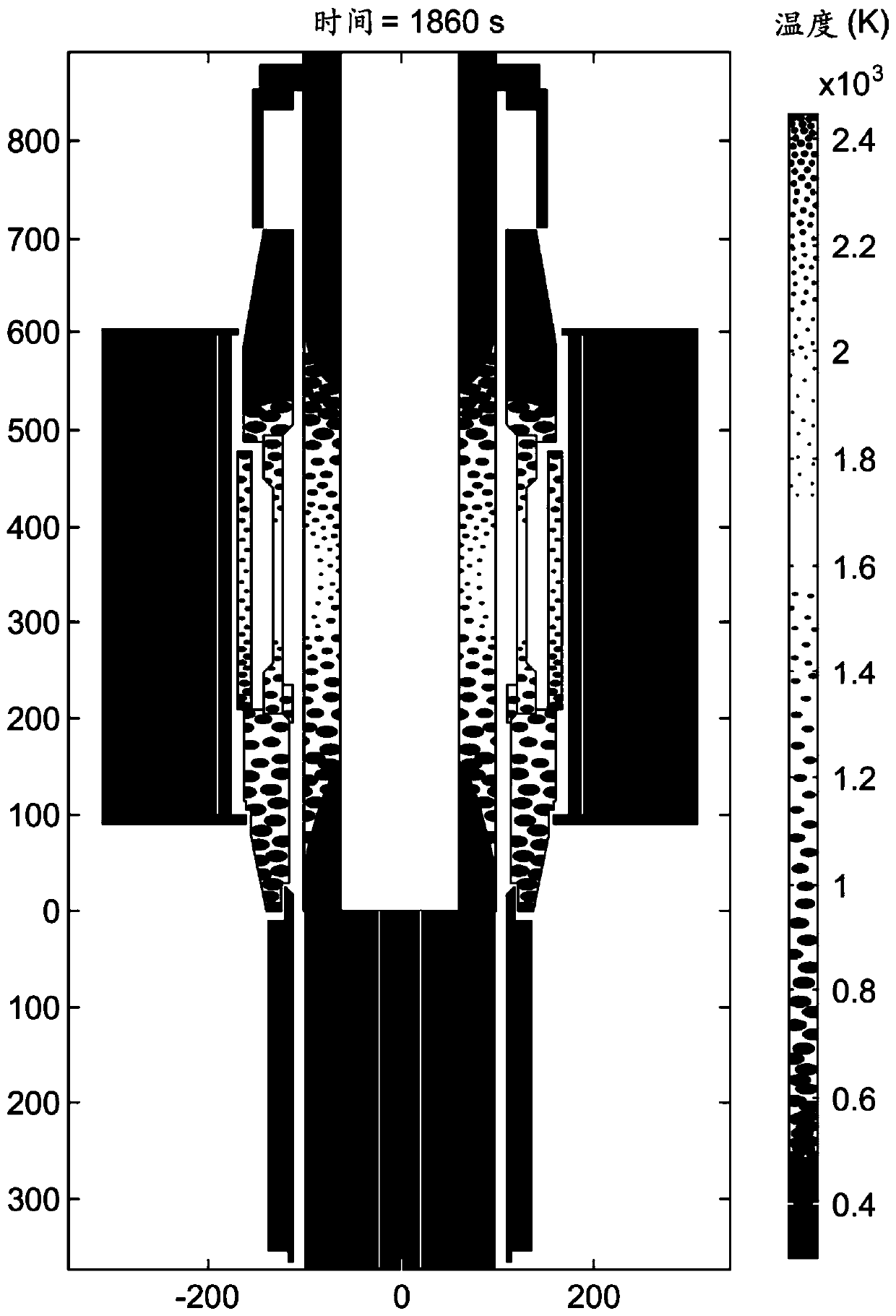

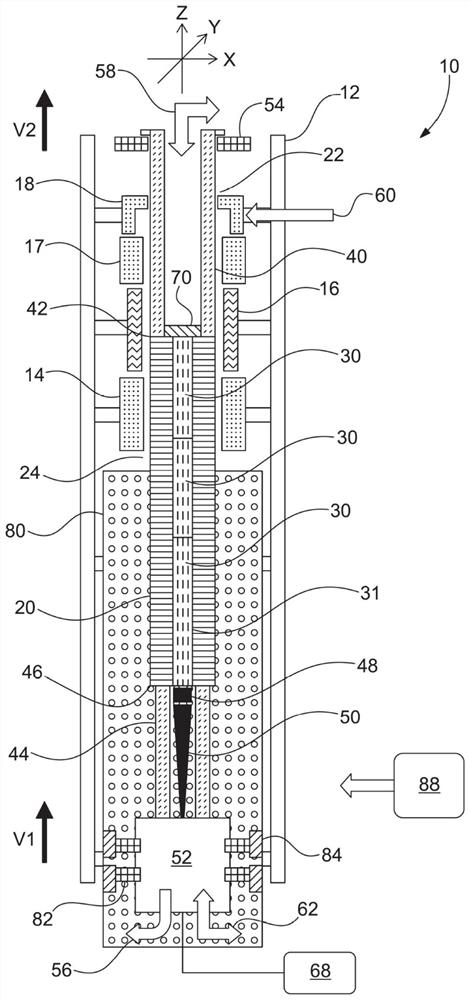

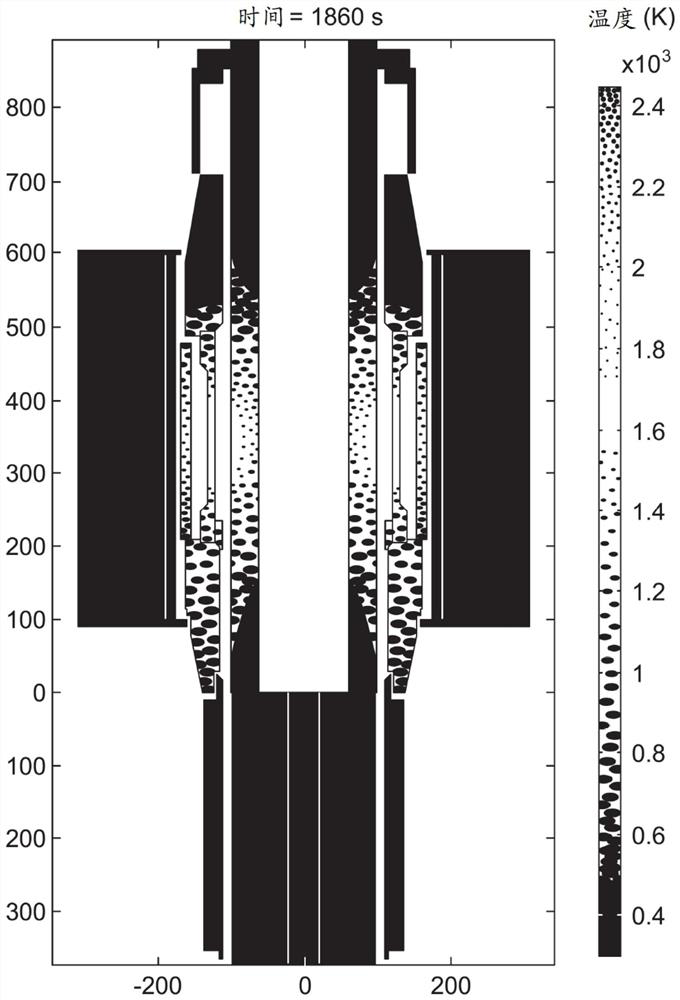

ActiveCN111434633AElimination of waveguide (cladding-core) distortion effectsQuality improvementGlass fibre drawing apparatusGlass reforming apparatusFiberViscosity

An automated large outside diameter preform tipping process. A zone of the preform is heated inside a furnace and softened. The preform tip is shaped and the process is controlled by the movement of the glass above and below the heating zone and by sensing the weight of the lower part of the preform, which in effect is a measure of the viscosity of the softened material. Once the correct viscosityis reached, the bottom holder is moved away from the top holder with a non-linear, accelerated velocity profile (derived from the FEM simulation of glass flow) which is precisely programmed and controlled so that the preform tip is optimally shaped (usually short and sharp tipped) with minimum waste and waveguide distortion when drawn into a fiber. The same concept of the non-linear, acceleratedvelocity profile can also be applied to other tipping processes such as horizontal preform tipping processes.

Owner:HERAEUS QUARTZ NORTH AMERICA LLC

Self-adaptive connecting mechanism for sliding block of bending machine and mounting method

The invention relates to a self-adaptive connecting mechanism for a sliding block of a bending machine, which comprises a rack and the sliding block, an oil cylinder is arranged on each of two sides of the rack, a concave ball pad is fixedly arranged at the bottom end of a piston rod of each oil cylinder, a convex ball pad is arranged on the top surface of the sliding block and corresponds to the concave ball pad, the convex ball pad is matched with the concave ball pad, a pin shaft is arranged on the sliding block and is positioned under the two oil cylinders, and the pin shaft is matched with the concave ball pad. Each pin shaft penetrates through the sliding block, the two sides of each pin shaft are each provided with a double-thread screw, the upper ends of the double-thread screws penetrate through the pin shafts and are connected with the corresponding concave ball pads, the bottom faces of the convex ball pads are in sliding connection with the top faces of the sliding blocks, a sliding groove is formed in the position, located on one pin shaft, of each sliding block, a sliding base is installed in each sliding groove, and the sliding bases horizontally move along the sliding grooves. A pin shaft at the sliding chute penetrates through the sliding seat and is rotationally connected with the sliding seat; a vertical linear track is arranged on each of the positions, corresponding to the pin shafts on the two sides, of the rack, a guide wheel is installed at the end, facing the rack, of each pin shaft, and the guide wheels move along the corresponding linear tracks; the oil cylinder is prevented from being damaged, and installation is more convenient.

Owner:湖北工程职业学院(湖北省机械工业学校黄石高级技工学校) +1

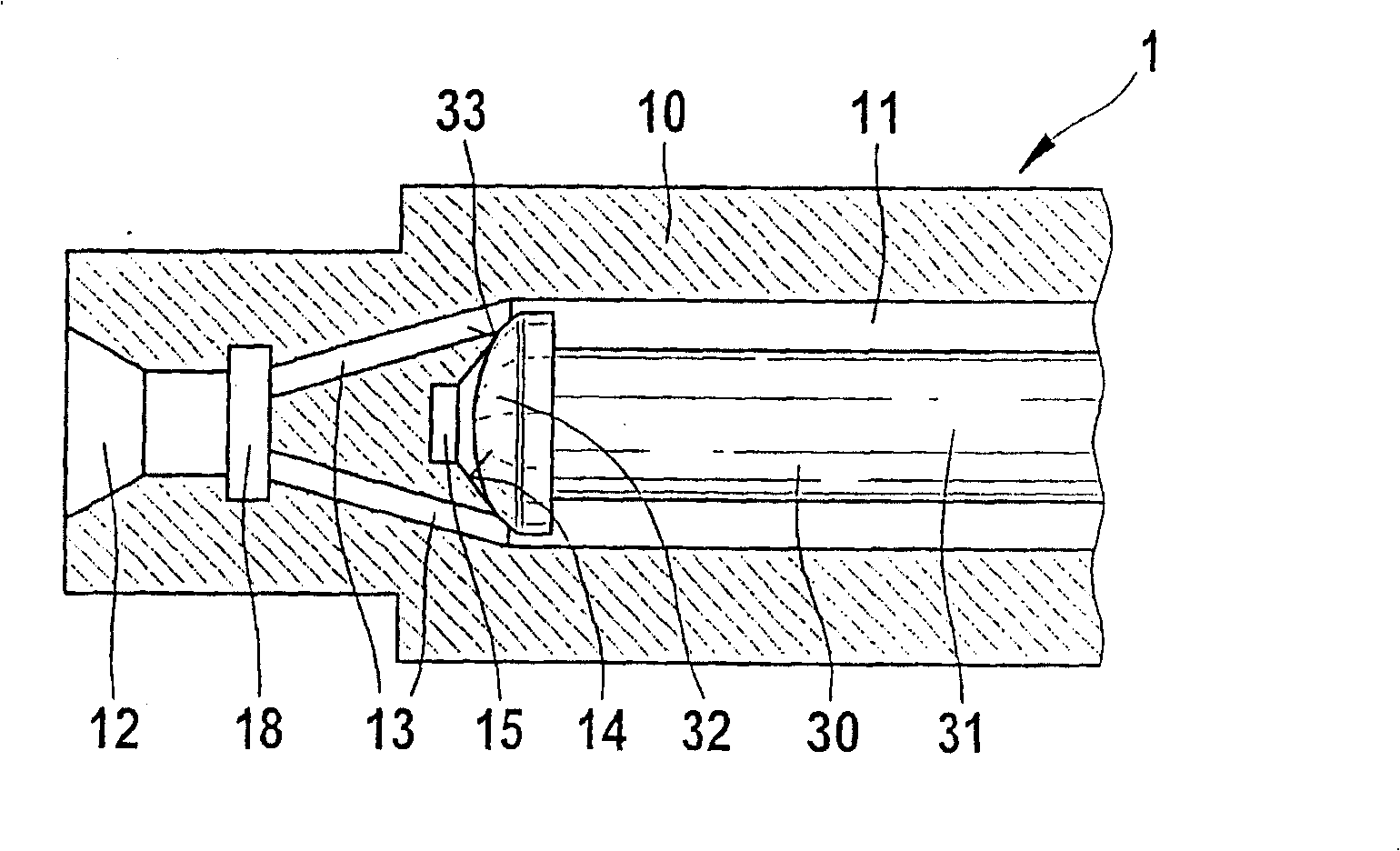

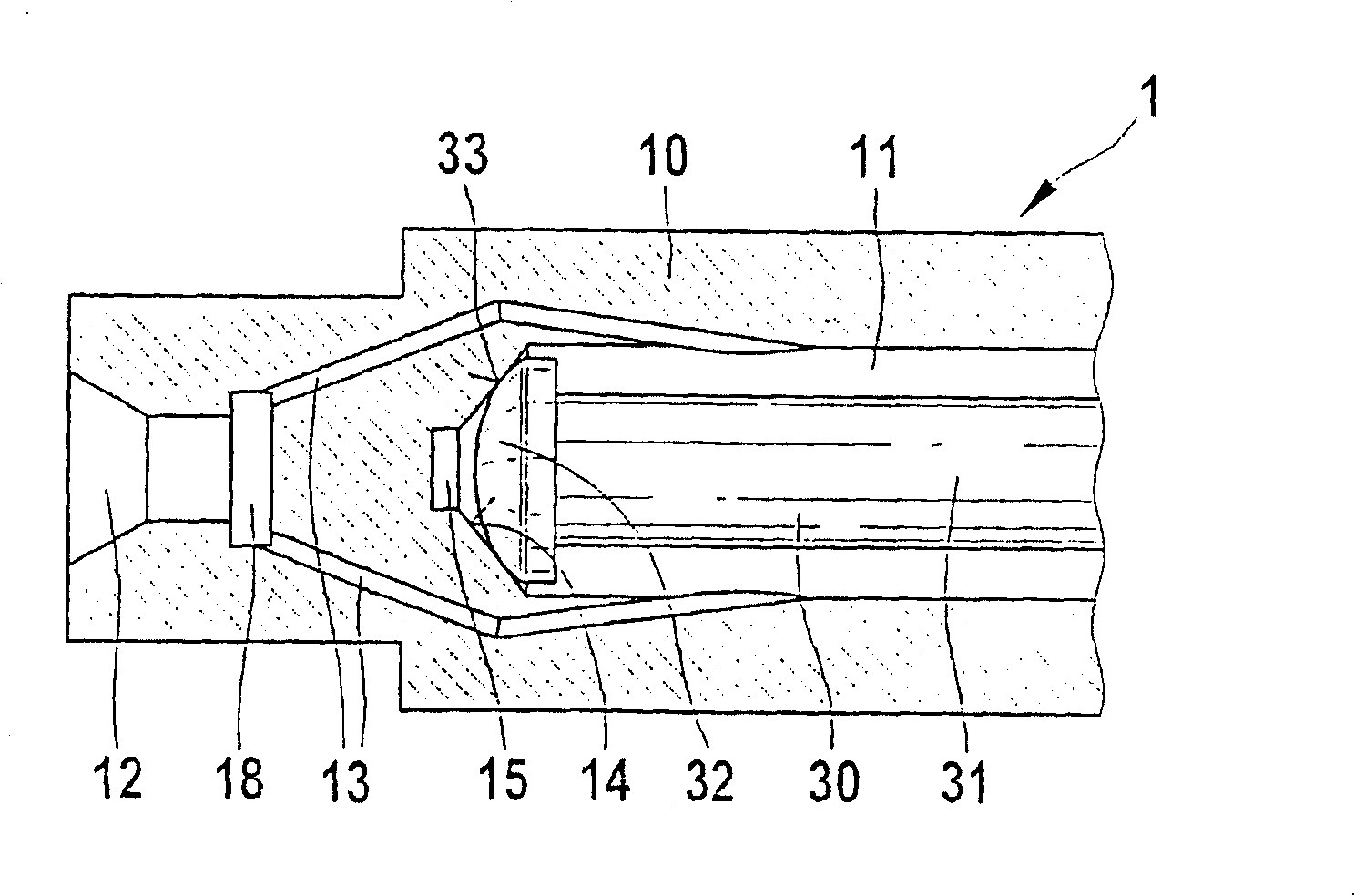

Valve for controlling fluid

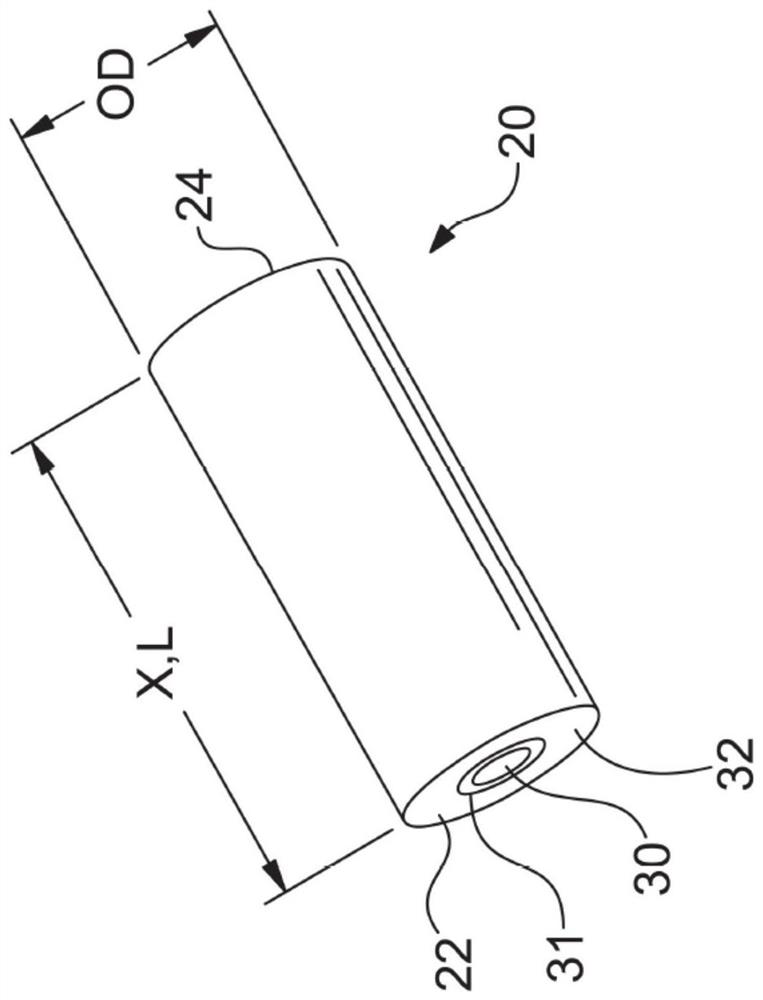

InactiveCN100476193CAvoid lateral forcesEasy machinabilityFuel injection with piezoelectric/magnetostrictive elementsMachines/enginesEngineeringHigh pressure

The invention relates to a valve (1) for controlling liquids, comprising a valve housing (10) having an actuator chamber (11) and a laterally arranged inlet hole (13) that is connected to a high pressure inlet (12), wherein the actuator chamber (11) has an actuator (30) with a plunger (31) and a round end (32), wherein the actuator chamber (11) has a taper gasket that is configured by means of a conical surface (14) on the end of the actuator chamber (11) and a matching annular sealing surface (33) on the round end (32) of the actuator, wherein a cable outlet (17) can be sealed off with the taper gasket. The actuator chamber (11) has at least another inlet hole (13). This makes it possible to achieve a more even power distribution to the actuator (30).

Owner:ROBERT BOSCH GMBH

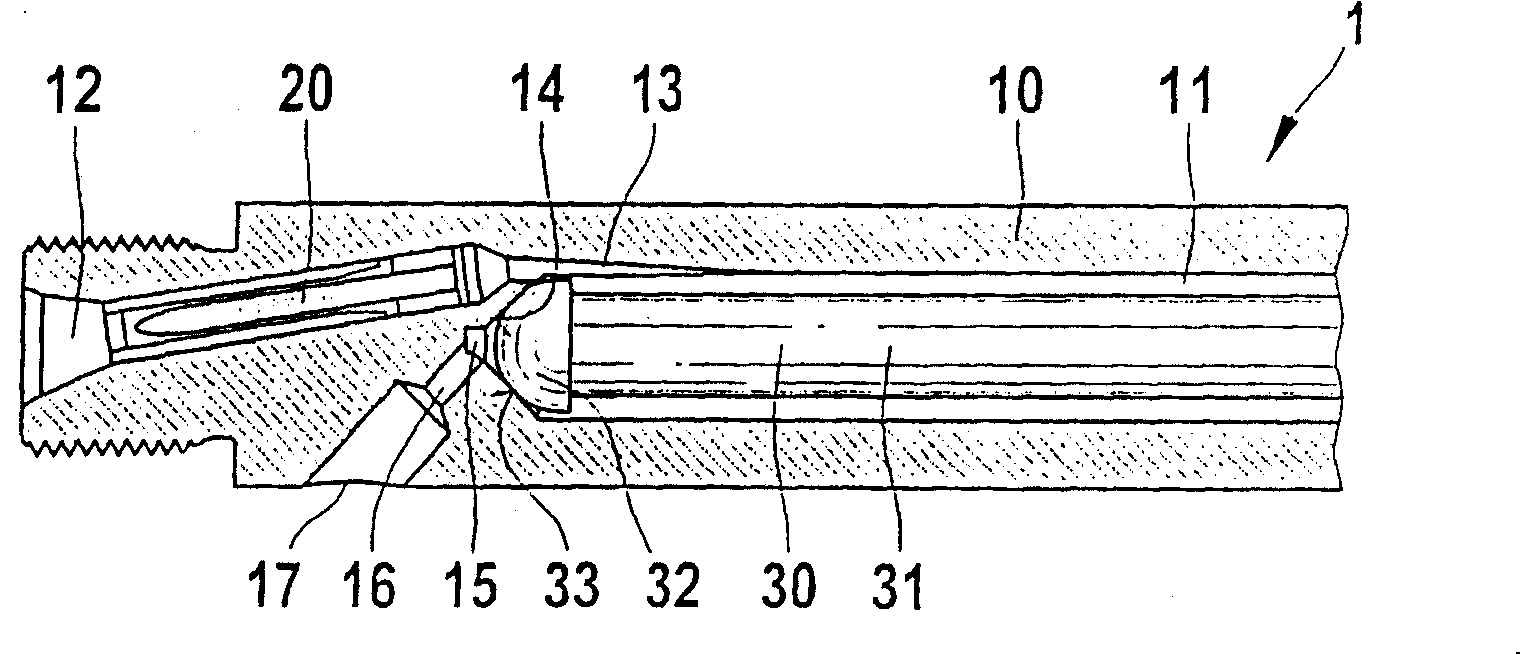

Damper for furniture

ActiveCN101395333BEasy to manufactureLess prone to cloggingSpringsBuilding braking devicesEngineeringDamper

The invention relates to a damper (1) for furniture, which comprises a housing (2) in which a piston (4) connected with a piston rod (3) is received in a mobile manner. When the piston (4) is displaced in the housing (2), a fluid flows through a flow channel (20) arranged on or in the piston (4). Meanwhile, different damping forces are generated when the piston (4) is displaced in different directions. Thus, parts of the cross section of the flow channel (20) can be modified by displacing the piston (4) relative to a plate (6). The plate and / or the piston is provided with radially extending grooves for forming at least one part of the flow channel (20). One side of the housing is provided with a movable balance piston. The balance piston is hermetically guided on the housing and the piston rod. The balance piston is provided with a sealing member. The sealing member abuts against the housing through an outer sealing lip and abuts against the piston rod through an inner sealing lip.

Owner:HETTICH ONI

Automated large outer diameter preform tipping process and resulting glass preform

ActiveCN111434633BElimination of waveguide (cladding-core) distortion effectsQuality improvementGlass fibre drawing apparatusGlass reforming apparatusFiberWaste material

An automated tipping process for large outer diameter preforms. The regions of the preform are heated and softened in a furnace. Shape the preform tip and control the process by moving the glass above and below the heating zone and by sensing the weight of the lower part of the preform, which is actually the viscosity of the softened material metric. After reaching the correct viscosity, the bottom holder is moved away from the top holder according to a nonlinear acceleration rate profile (derived from FEM simulation of glass flow) that is precisely programmed and controlled such that the preform tip Optimally shaped (usually with short and sharp tips) with minimal waste and waveguide distortion when drawn into fibers. The same concept of the non-linear acceleration rate profile can also be applied to other tipping processes, such as horizontal preform tipping processes.

Owner:HERAEUS QUARTZ NORTH AMERICA LLC

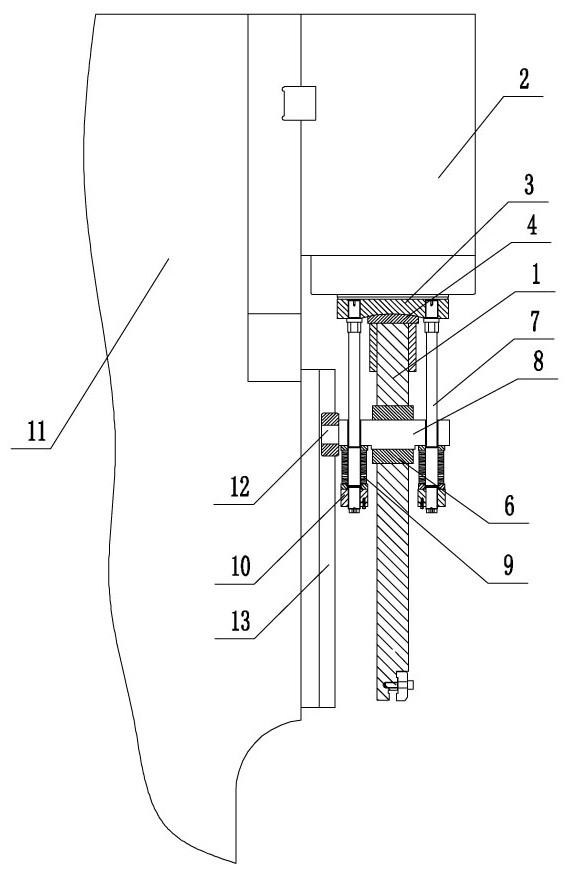

Double-guided work roll bending and balancing device for strip mill

ActiveCN106670236BAvoid lateral forcesProtective tightnessRoll force/gap control deviceRolling equipment maintainenceWork rollStrip mill

The invention provides a dual-guiding work roll bending and balancing device of a plate and strip rolling mill. The dual-guiding work roll bending and balancing device of the plate and strip rolling mill comprises a bending and balancing cylinder. A cylinder block of the bending and balancing cylinder is fixedly arranged on the inner side wall of a mill housing. An upper piston rod is arranged on the top of the cylinder block in sealing, penetrating and sliding manners. A lower piston rod is arranged at the bottom of the cylinder block in sealing, penetrating and sliding manners. The free end of the upper piston rod is connected with an upper guide cover, wherein the upper guide cover abuts against the upper portion of the outer wall of the cylinder block in a sliding manner and can move up and down along the mill housing. The top of the upper guide cover abuts against an upper work roll assembly bearing seat. The free end of the lower piston rod is connected with a lower guide cover, wherein the lower guide cover abuts against the lower portion of the outer wall of the cylinder block and can move up and down along the mill housing. The dual-guiding work roll bending and balancing device of the plate and strip rolling mill overcomes the defects that in the prior art, a guide ring and a seal ring are prone to damage, oil leakage is severe, and the use stability is poor. Full-travel dual guide protection is conducted on the upper piston rod and the lower piston rod, and the work stability of the work roll bending and balancing device is effectively improved.

Owner:CERI TECH +1

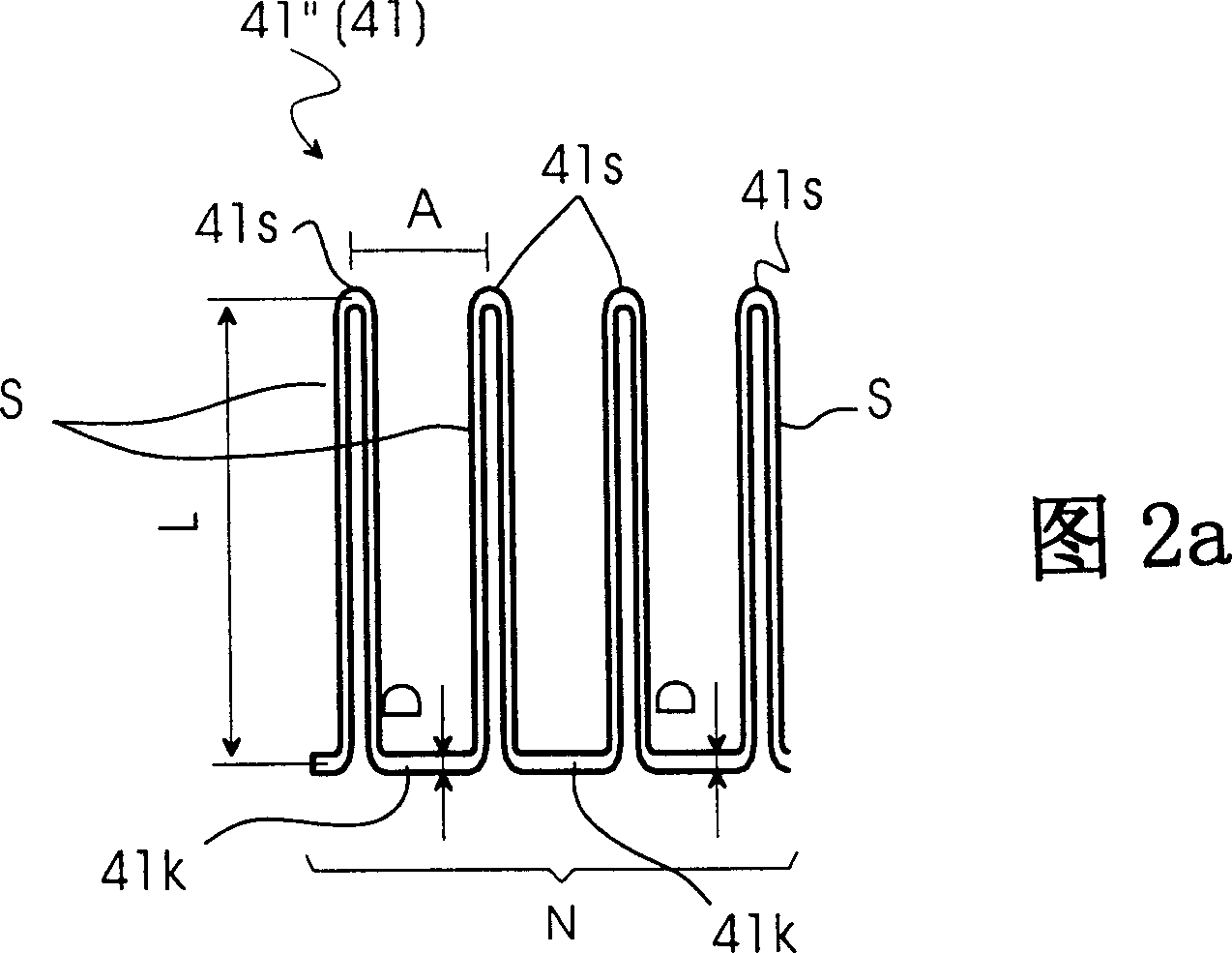

Method for bending metal wire comb-like form binding element

InactiveCN1461706APrecise positioningAvoid lateral forcesWire articlesFiling appliancesEngineeringMetal

Owner:HEIDELBERGER DRUCKMASCHINEN AG

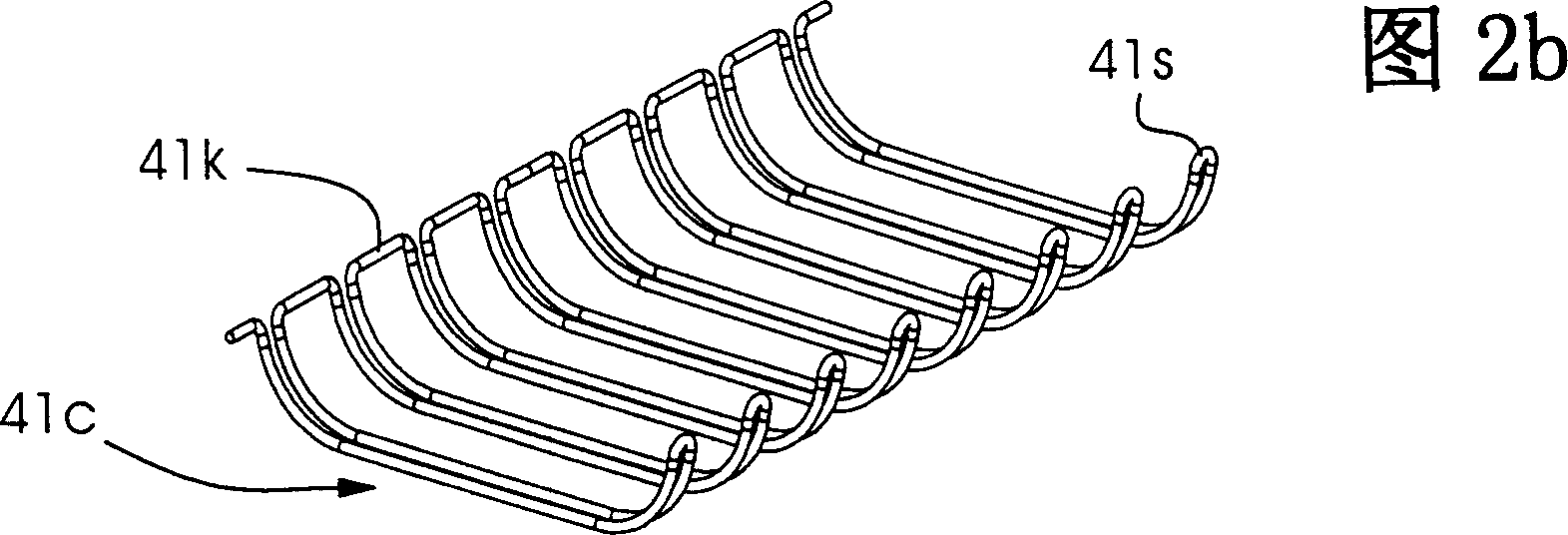

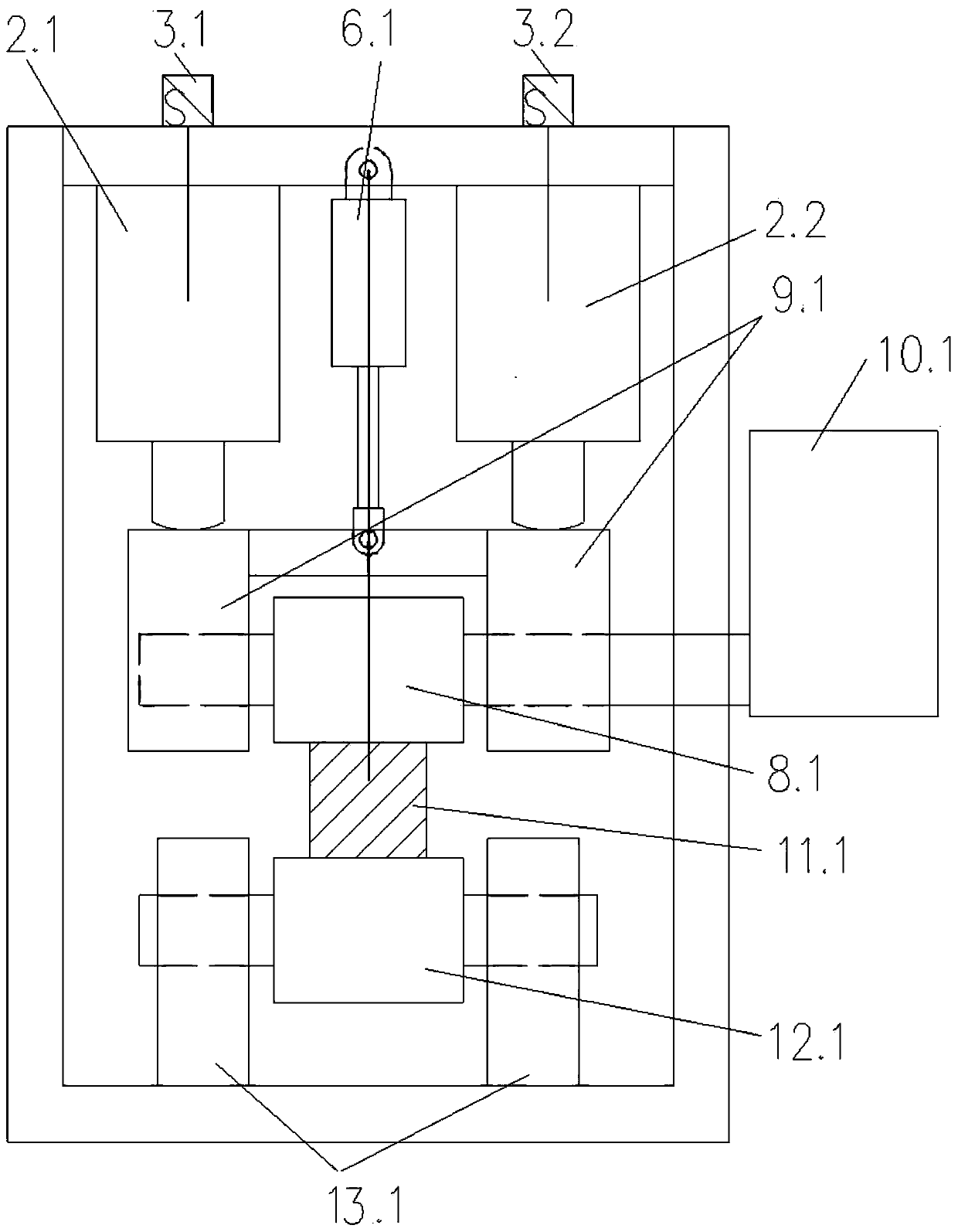

Heavy reduction withdrawal and straightening machine of billet caster, and withdrawal and straightening machine hydraulic control system and control method

PendingCN111570743AAvoid lateral forcesPrecise control of roll gap positionHydraulic cylinderControl system

The invention relates to the field of metallurgical equipment, in particular to a heavy reduction withdrawal and straightening machine of a billet caster, and a withdrawal and straightening machine hydraulic control system and control method. A displacement sensor is arranged in each withdrawal-and-straightening-machine servo hydraulic cylinder, and hydraulic loops of a piston cavity and a rod cavity of each servo hydraulic cylinder are connected with pressure sensors respectively. The two withdrawal-and-straightening-machine servo hydraulic cylinders are used for controlling the lifting and down pressing of an upper roller of the heavy reduction withdrawal and straightening machine, a heavy reduction balance cylinder is used for lifting the upper roller of the withdrawal and straighteningmachine, the heavy reduction balance cylinder adopts the pressure reduced by connecting the rod cavity with a three-way pressure reducing valve, the pressure of the three-way pressure reducing valveis set, it is guaranteed that the upper roller of the heavy reduction withdrawal and straightening machine makes tight contact with the piston rod ends of the two withdrawal-and-straightening-machineservo hydraulic cylinders all the time, the pressure sensors are used for compensating for equipment gaps and equipment deformation in the working process of the heavy reduction withdrawal and straightening machine, and the needed equipment control precision is achieved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

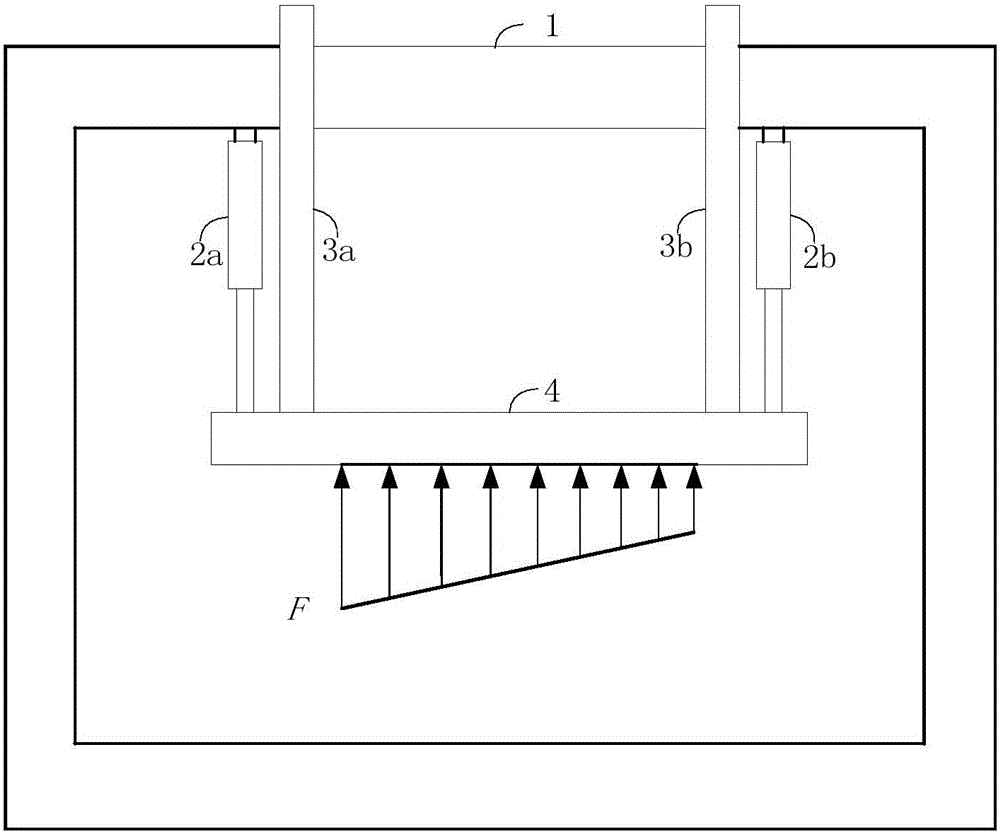

Hydraulic loading system

The application relates to a hydraulic loading system. The hydraulic loading system comprises a loading platform and at least two hydraulic loading components used for exerting pressure onto the loading platform, as well as a control component, wherein the control component adjusts the pressure output by each hydraulic loading component based on the corresponding relationship between the pressure output by the hydraulic loading components and displacement of the position, at which the hydraulic loading components on the loading platform exert pressure on the loading platform and a predetermined point. By adoption of the hydraulic loading system, the hydraulic loading components are prevented from action of a lateral force, and accordingly, abrasion of the hydraulic loading components is avoided.

Owner:BEIHANG UNIV

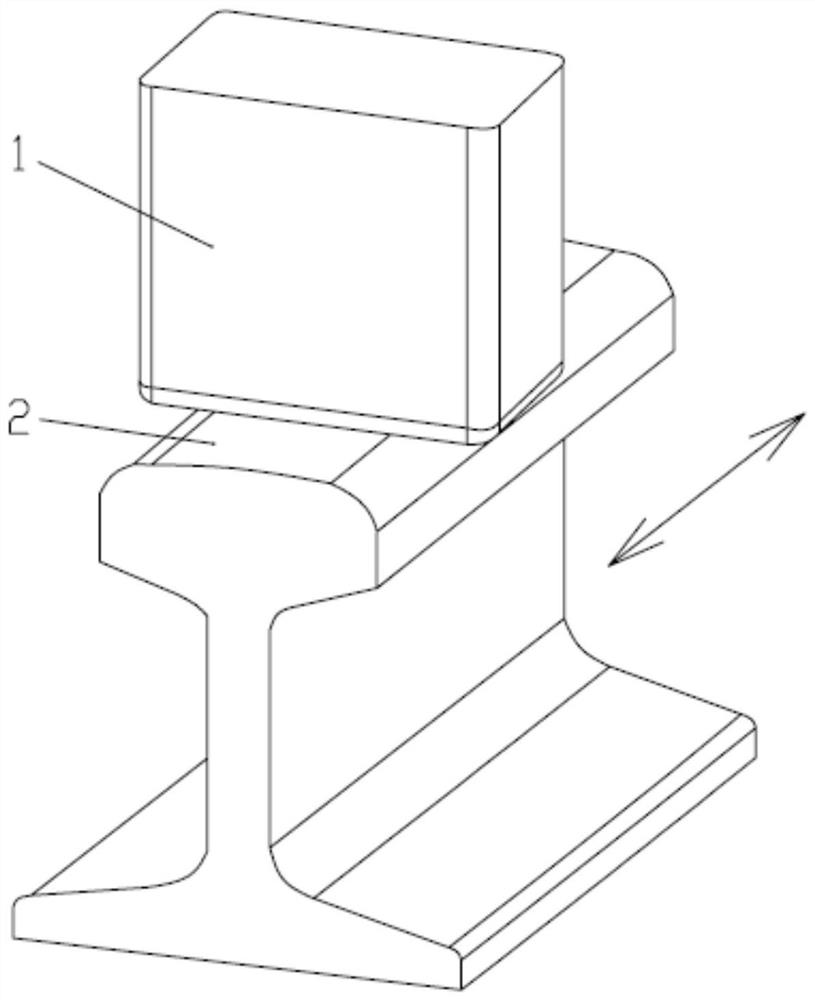

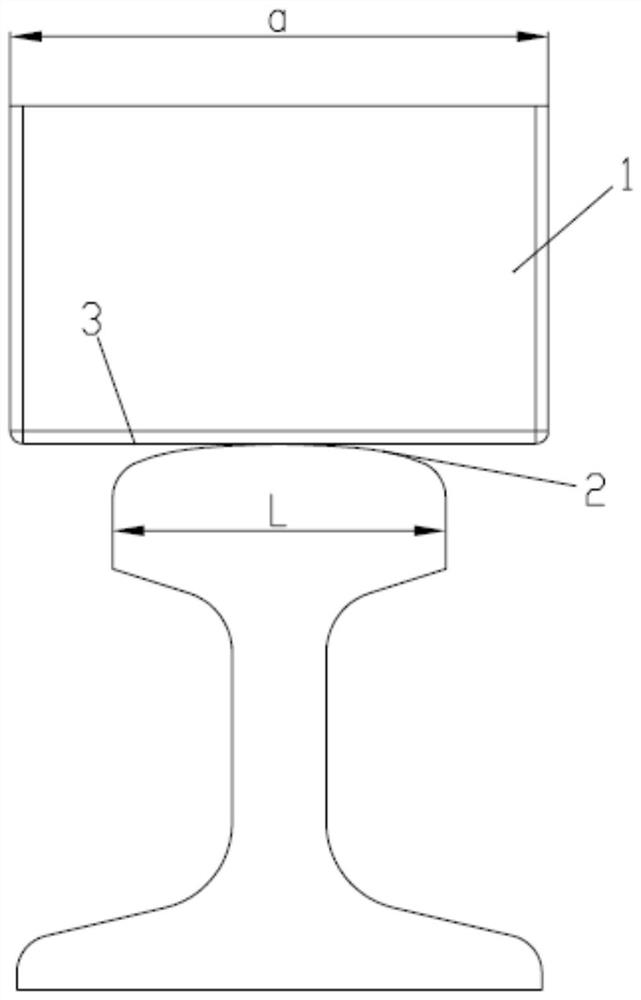

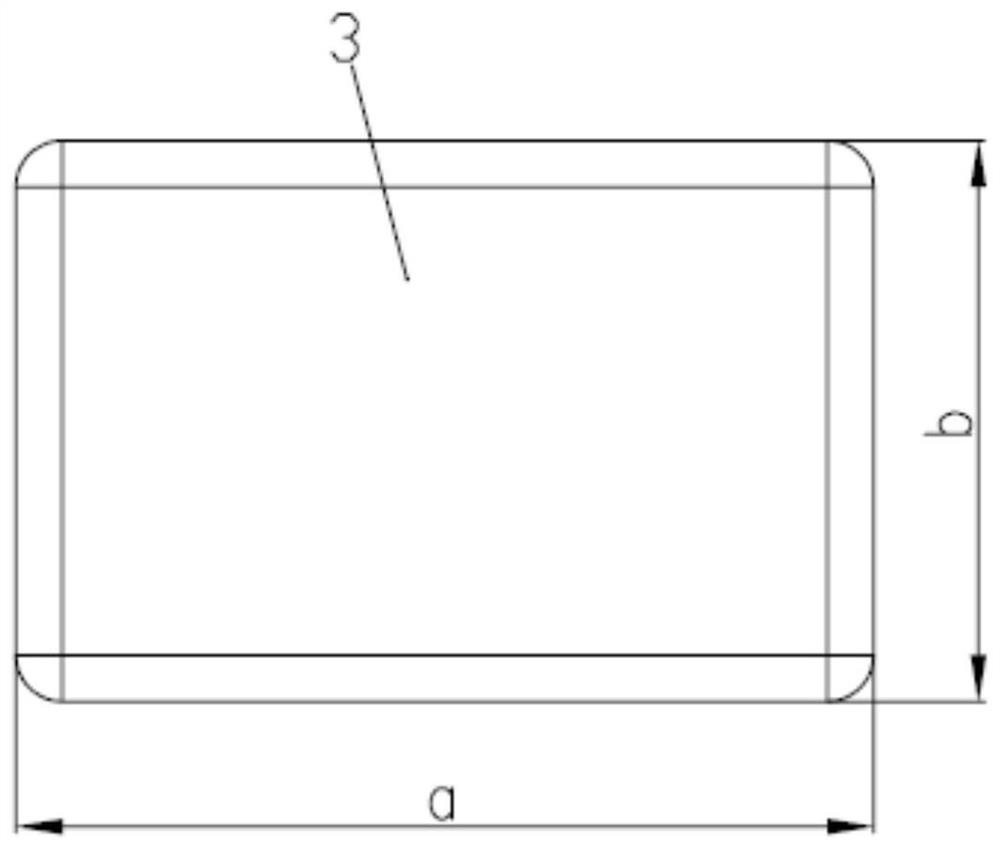

Pressure head capable of reducing lateral bending risk for upward bending supplement straightening of end part of steel rail

PendingCN112620407AAvoid lateral forcesReduced risk of side bendingStructural engineeringLateral bending

The invention discloses a pressure head capable of reducing the lateral bending risk for upward bending supplement straightening of an end part of a steel rail, and belongs to the technical field of metallurgy. The pressure head capable of reducing the lateral bending risk for upward bending supplement straightening of the end part of the steel rail comprises a pressure head body and is characterized in that the pressure head body is of a cuboid structure, and the downward pressing surface, used for being in downward pressing contact fit with the arc-shaped tread of a head part of the steel rail, of the pressing head body is of a plane structure. According to the pressure head capable of reducing the lateral bending risk for upward bending supplement straightening of the end part of the steel rail, by analyzing the problem that a traditional cambered surface pressure head structure easily causes the lateral bending of the steel rail in the process of the upward bending supplement straightening operation on the end part of the steel rail and a mechanism thereof, the invention provides a pressure head form for improving the cambered surface pressure head into the plane structure, in this way, the downward pressure applied to the arc-shaped tread of the head part of the steel rail by the pressure head is always at the highest point of the arc-shaped tread in the upward bending supplement straightening operation process, the generation of lateral component force on the steel rail can be effectively avoided, and then the lateral bending risk in the straightening process can be effectively reduced.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

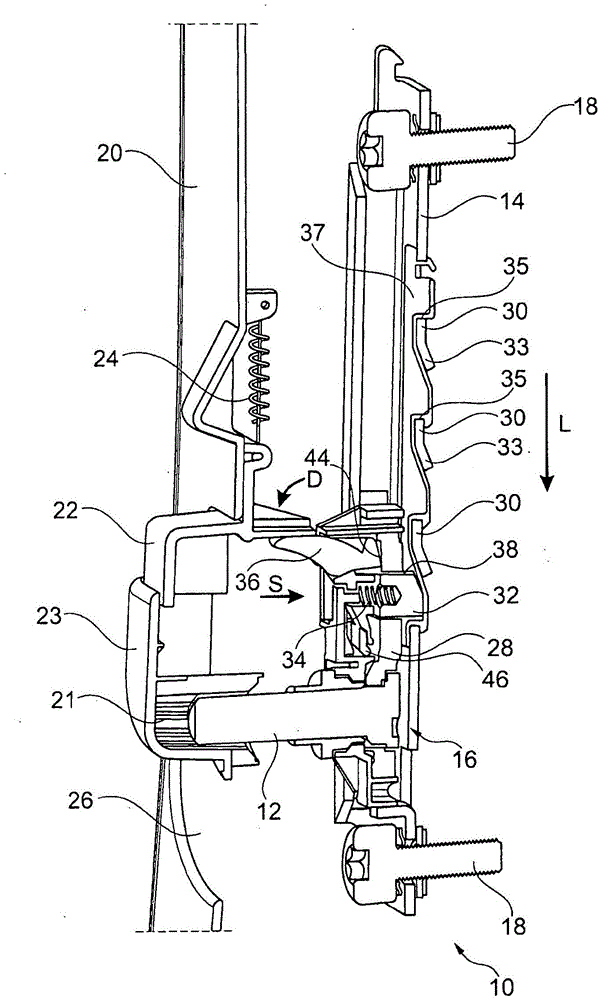

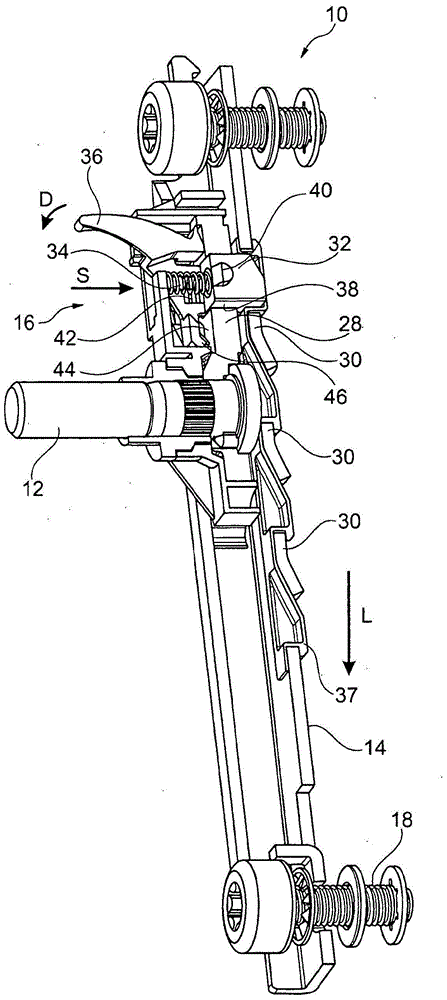

Height adjuster

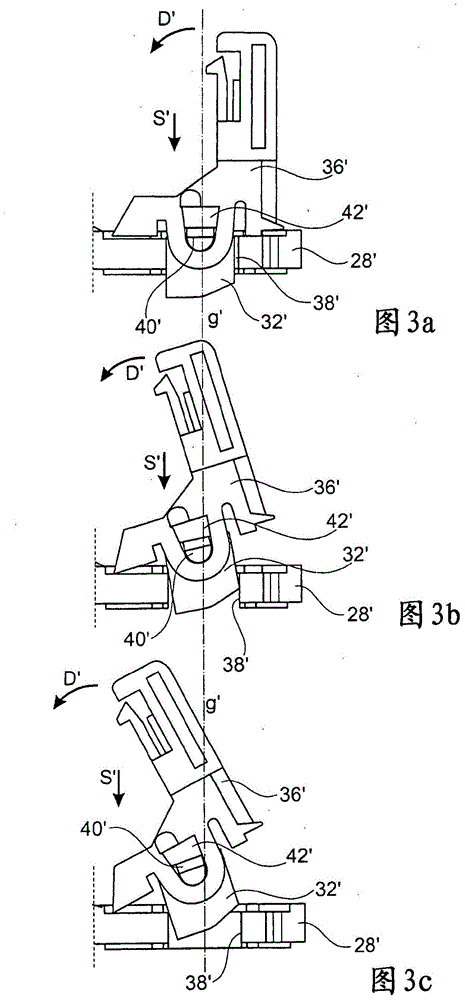

ActiveCN104703847AAvoid lateral forcesSecurity OrientationBelt anchoring devicesEngineeringFixed position

In the case of a height adjuster (10) for a retaining part (12) of a seat belt in a vehicle, with a vehicle-mounted guide rail (14), in which a retaining device (16) for the retaining part (12) of the seat belt is mounted displaceably in the longitudinal direction (L) of the guide rail (14), and with a locking device (28) which can fix the retaining device (16) in the guide rail (14), wherein the locking device (28) has a bolt (32) which is displaceable in a displacement direction (S) between a fixing position, in which the bolt (32) fixes the retaining device (16) to the guide rail (14), and a release position, and also a lever (36) which can actuate the bolt (32), provision is made for the lever (36) to move the bolt (32) on a rectilinear path between the fixing position and the release position.

Owner:TRW AUTOMOTIVE GMBH

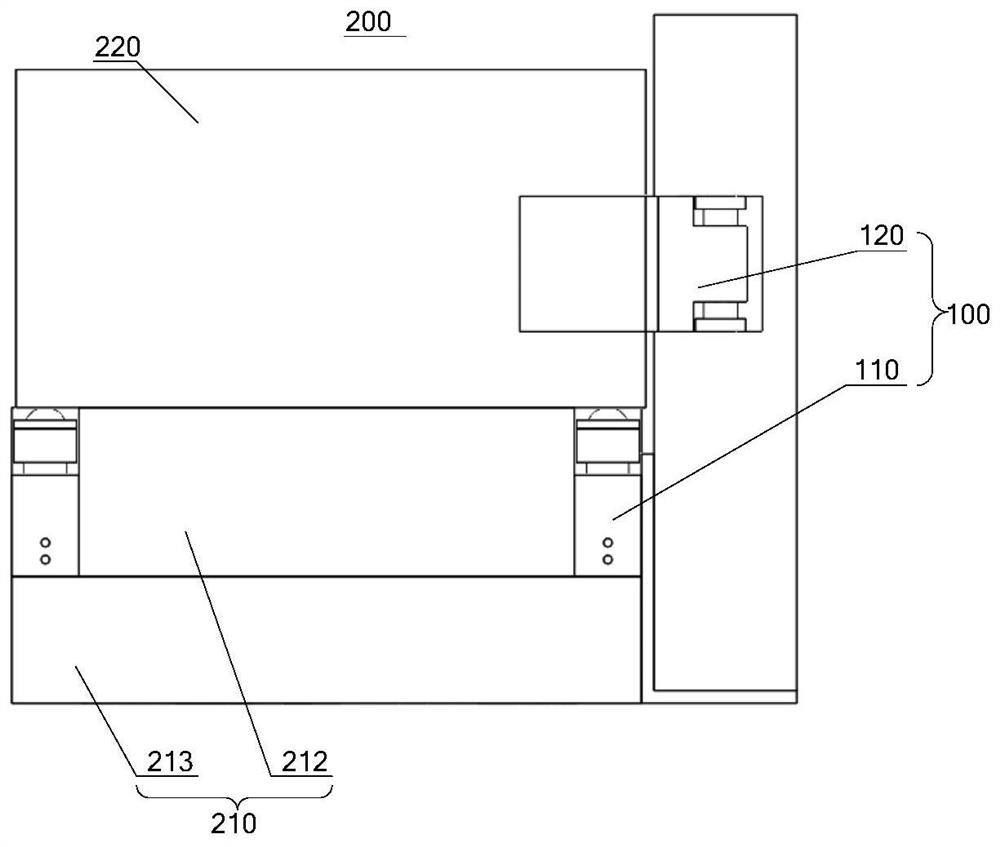

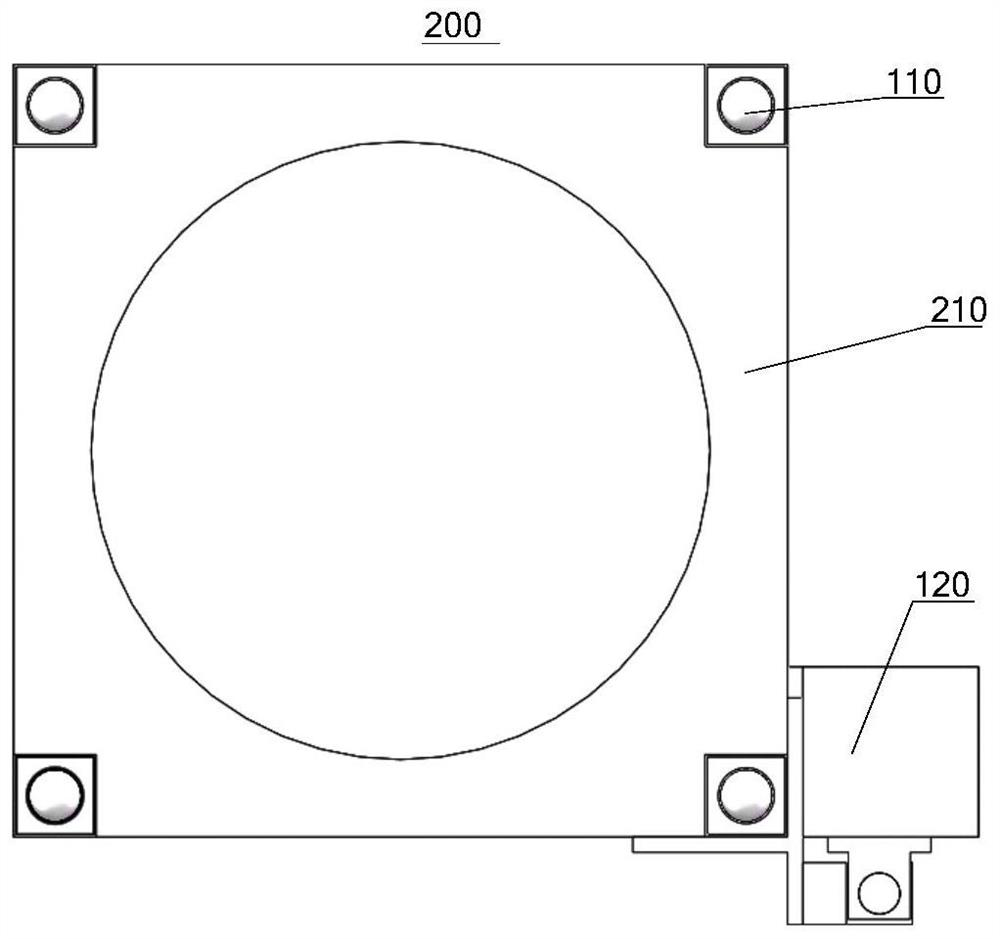

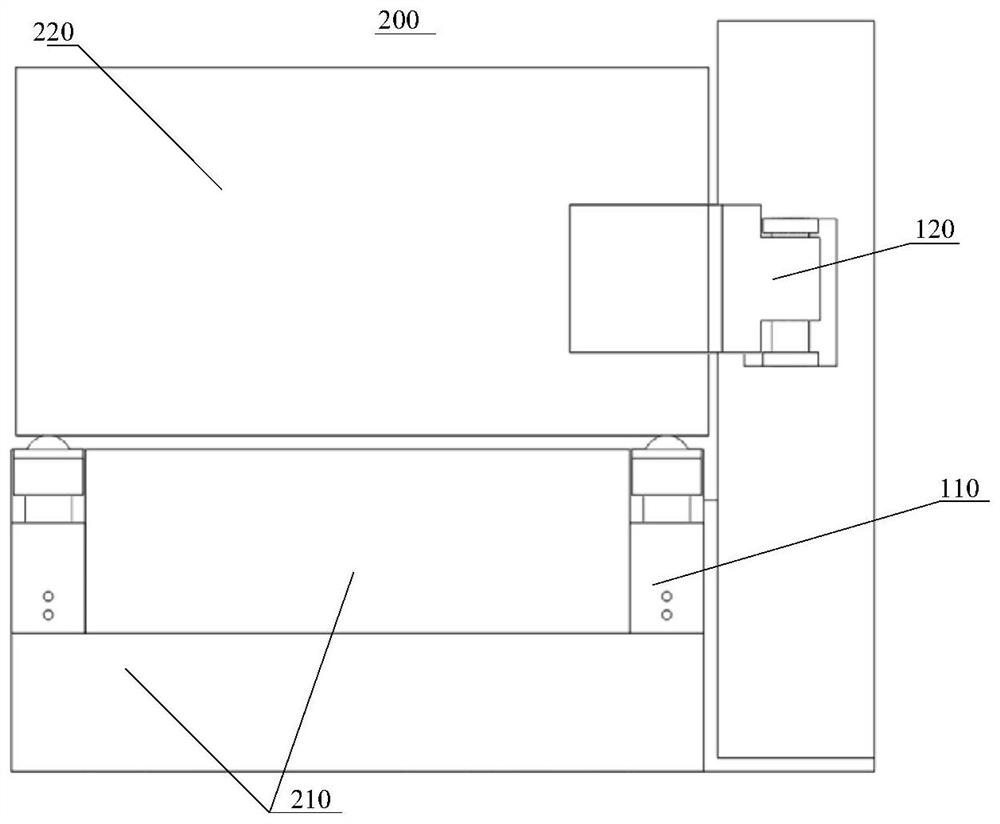

Upper electrode uncovering structure and semiconductor processing equipment

ActiveCN111640690AAvoid lateral forcesGood electrical conductivityFinal product manufactureSemiconductor/solid-state device manufacturingRadio frequencyMechanical engineering

The invention discloses an upper electrode uncovering structure and semiconductor processing equipment. The uncovering structure comprises a first lifting mechanism located below the upper electrode,wherein the first lifting mechanism can independently drive the upper electrode to ascend and descend in the vertical direction in a preset first lifting stage and keep the whole upper electrode in ahorizontal state, so that the upper electrode is switched between a process position and an initial cover opening position; a second lifting mechanism which is located on the side of the upper electrode and connected with the upper electrode, wherein the second lifting mechanism can independently drive the upper electrode to ascend and descend in the vertical direction in a preset second lifting stage, so that the upper electrode is switched between the initial uncovering position and the target uncovering position, and the initial uncovering position is located between the process position and the target uncovering position. The conductive function of the induced coil can be remarkably improved, good electrical conduction between the upper electrode and the cavity is effectively guaranteed, meanwhile, radio frequency leakage can be avoided, and the process result is improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

A vertical motion platform with lateral bearing capacity

ActiveCN109081255BAvoid lateral forcesTo achieve a fixed connectionMeasurement devicesPortable liftingHorizontal forcePilot hole

The invention discloses a vertical movement platform with the horizontal bearing capacity. The vertical movement platform comprises an actuator, a bearing frame, a steel wire rope, a leading-in pulley, a leading-out pulley, a motor, a motor support, a lead screw, a sliding block, a sliding plate, a spring, a bearing bolt, a leading-in hole, a guide bolt, a pulley seat, a support hole, a bearing bolt positioning hole, a sliding plate, a leading-out hole, a lead screw support, a sliding plate guide hole, a passive clearance, an active clearance, a pulley seat guide hole, a positioning guide holeand a guide bolt positioning hole. According to the vertical movement platform, automatic space positioning of the stretching position of the steel wire rope is achieved. Through fastening of the bearing bolt, the pulley seat and the bearing frame are fixedly connected, the borne large load is transmitted to the bearing frame through the pulleys and the pulley seat, and the horizontal force borneby the lead screw can be adjusted through the rigidity of the spring. According to the vertical movement platform, the space adjustment of the output position of loading force is achieved, the loading force totally acts on the bearing frame, and the lead screw is prevented from bearing large horizontal loads.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Bar device for warp knitting machine

InactiveCN105821576BOrientation is accurateSmall pressure changeWarp knittingFluid-pressure actuatorsEngineeringMechanical engineering

The invention relates to a lay bar of a warp knitting machine which has at least a guide bar device arranged on a driving element. The driving element and a driving mechanism as well as at least a counter force element (5) are arranged in connection, wherein the counter force element (5) has a piston-cylinder-device. For the piston-cylinder-device, a piston connected to the driving element through a piston rod (6) can move in a cylinder (9) with a certain cylinder cross section in a stroke length (H) region and can be loaded through a pressure medium. People intend to keep the stress change in the driving element little. Therefore the cylinder (9) is arranged in a cavity (10) of a vessel (11) filled by the pressure medium. The cavity (10) has the capacity larger than the external capacity of the cylinder (9) and is in connection with an internal space of the cylinder (9) on a side surface of the piston (12) provided with a piston rod (6). The cylinder (9) is connected to the vessel (11) at at least two positions in a direction parallel to the stroke length (H). The two positions have an interval.

Owner:KARL MAYER R&D GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com