Heavy reduction withdrawal and straightening machine of billet caster, and withdrawal and straightening machine hydraulic control system and control method

A hydraulic control system and billet continuous casting technology, which is applied in the field of metallurgical equipment, can solve the problems of large hydraulic cylinder specifications of the tension leveler, increase in the size of the tension leveler equipment, and large pressing force of the tension leveler, so as to improve reliability. Performance and service life, prevention of side force, precise control of roll gap position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

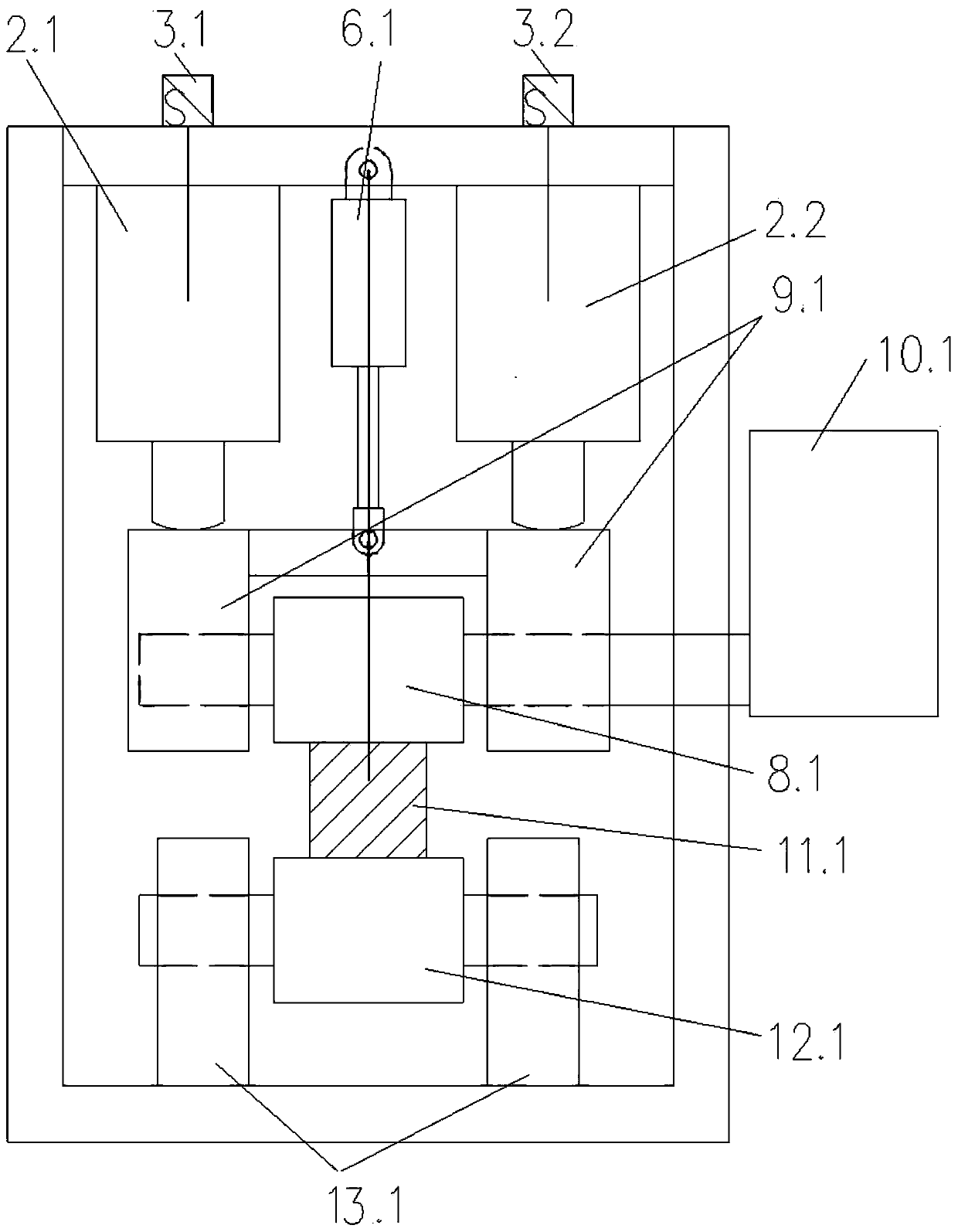

[0024] refer to figure 1 , is a structural schematic diagram of Embodiment 1 of the present invention, a billet continuous casting machine heavy-pressure pull-down leveler, at least including a pull-leveler frame, and the top of the inner side of the pull-leveler frame is connected to the billet continuous caster heavy-pressure pull-down leveler Machine hydraulic control system, the bottom of the inner side of the tension leveler frame is connected with two tension leveler lower roll bearing housings 13.1, the tension leveler lower roll bearing housings 13.1 are connected with the tension leveler lower roll 12.1, the tension leveler lower roll 12.1 is connected The top of the roll 12.1 is connected with the upper roll 8.1 of the tension leveler through the cast slab 11.1, the upper roll 8.1 of the tension leveler is connected by two bearing housings 9.1 of the upper roll of the tension leveler and is located in the middle of the frame of the tension leveler, and the upper roll ...

Embodiment 2

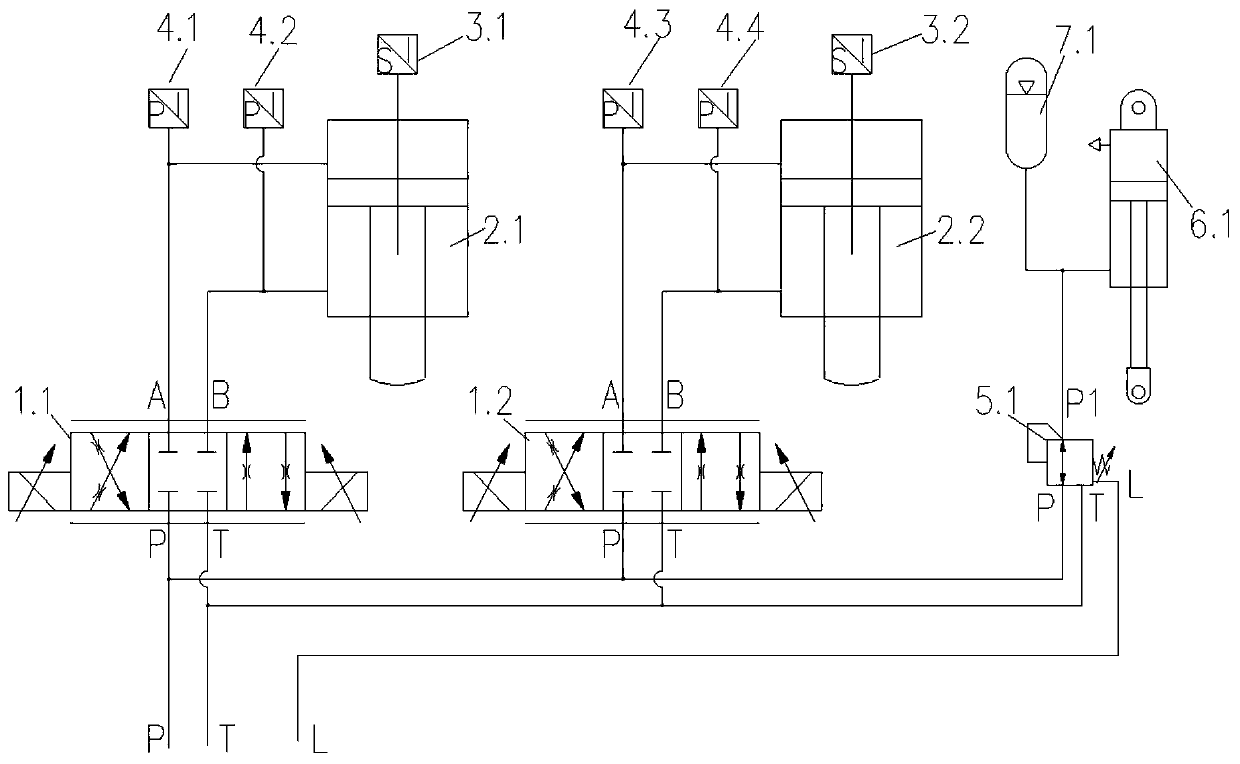

[0028] refer to figure 2, compared with Embodiment 1, the difference of this embodiment is that: a billet continuous casting machine heavy pressure pull-down straightening machine hydraulic control system, including proportional directional valve, stretching straightening machine servo hydraulic cylinder, three-way pressure reducing valve 5.1, balance cylinder 6.1, bladder type accumulator 7.1 and PLC control unit, the tail of the servo hydraulic cylinder of the tension leveler is connected to the top of the inner side of the tension leveler frame through a flange, and the end of the piston rod of the tension leveler servo hydraulic cylinder is Mushroom head type, the piston rod end of the servo hydraulic cylinder of the tension leveler contacts with the top of the upper roller bearing seat 9.1 of the tension leveler through the mushroom head, one end of the balance cylinder 6.1 is hinged with the top of the inner frame of the tension leveler, and the balance cylinder 6.1 The...

Embodiment 3

[0035] A hydraulic control method for a heavy-pressure pull-down straightener of a billet continuous caster includes the hydraulic control system for a heavy-pressure pull-down straightener of a billet continuous caster described in Embodiment 2, including the following steps:

[0036] Step 1: The transmission device 10.1 of the straightening machine drives the upper roll 8.1 of the straightening machine to rotate between the bearing seats 9.1 of the two upper rolls of the straightening machine. Rotate between the bearing housings 13.1 of the lower rollers of a tension leveling machine;

[0037] Step 2: The upper roll 8.1 of the tension leveler controls the servo hydraulic cylinder 2.1 of the first tension leveler, the servo hydraulic cylinder 2.2 of the second tension leveler and the balance cylinder through the PLC control unit in the hydraulic control system of the billet continuous casting machine. 6.1 Further control the roll gap position composed of the upper roll 8.1 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com