Patents

Literature

158results about How to "Small pressure change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

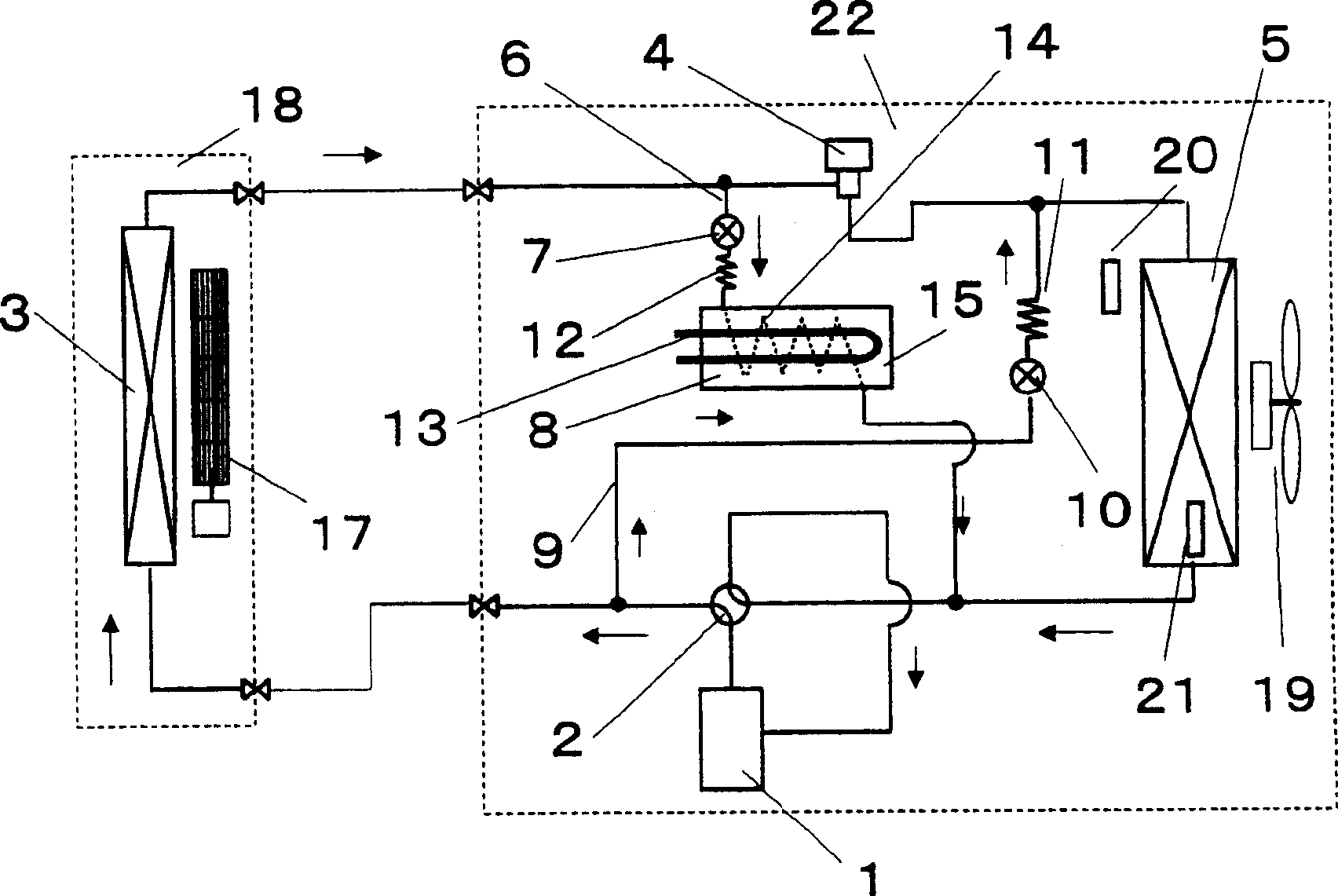

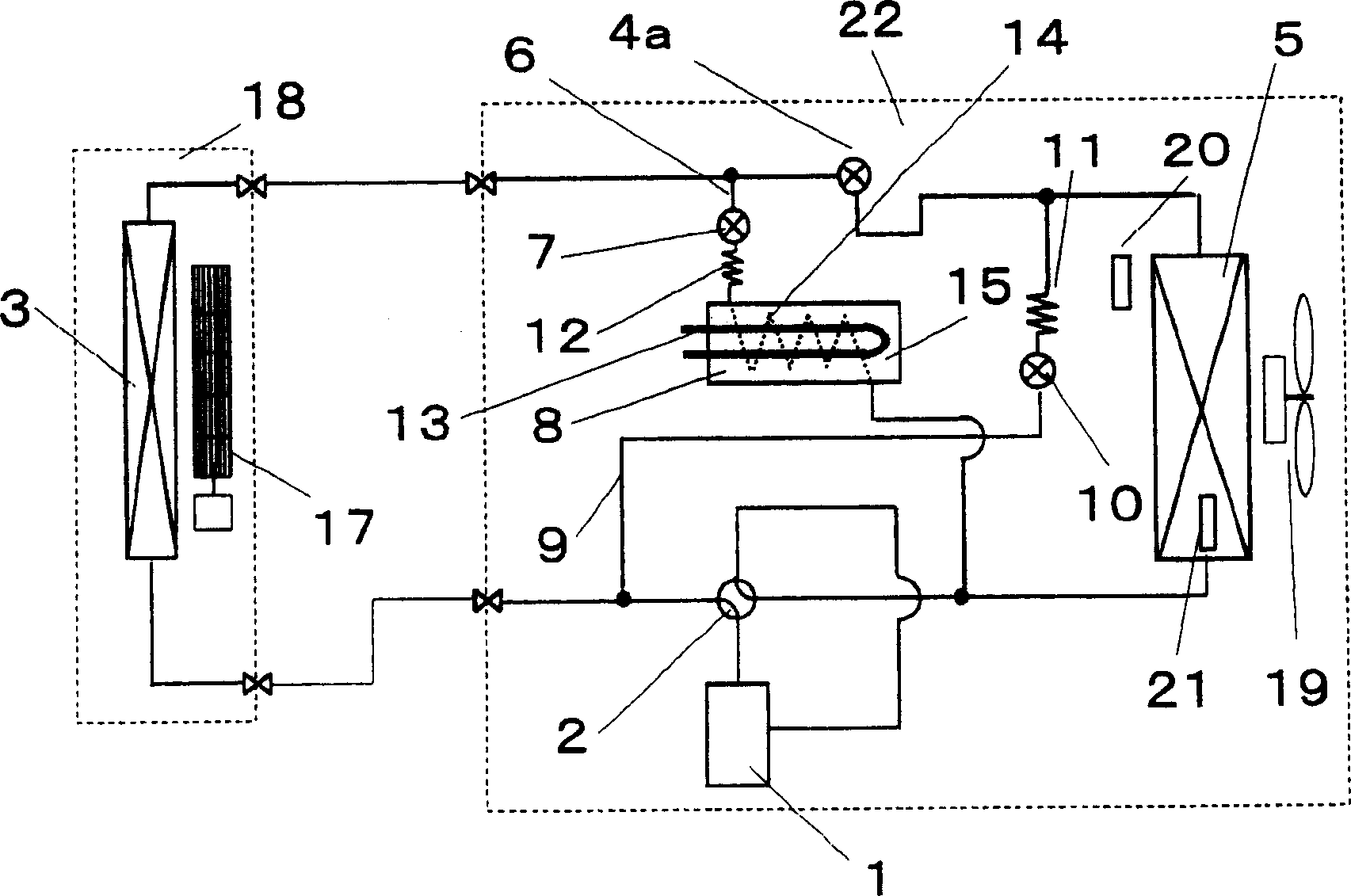

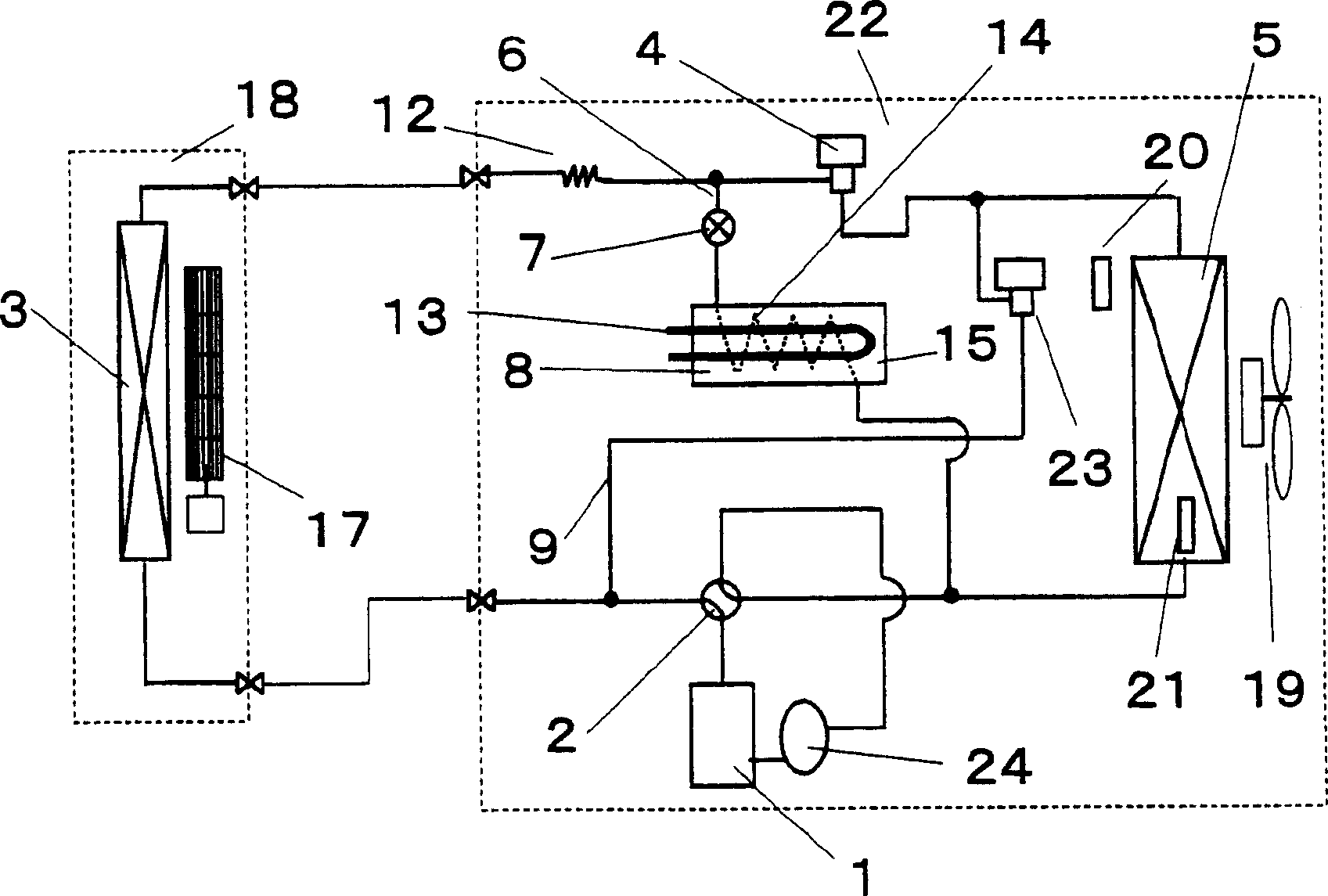

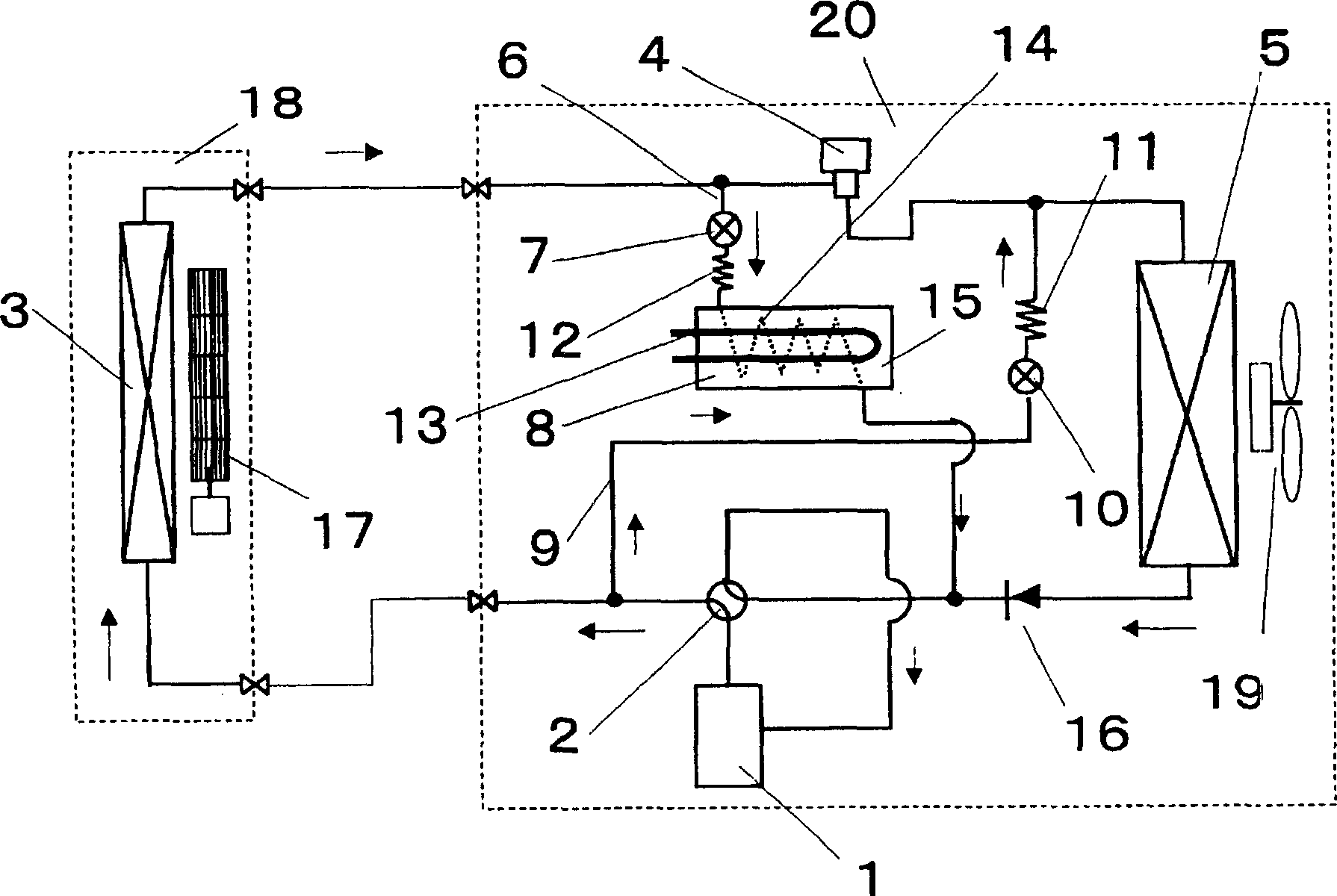

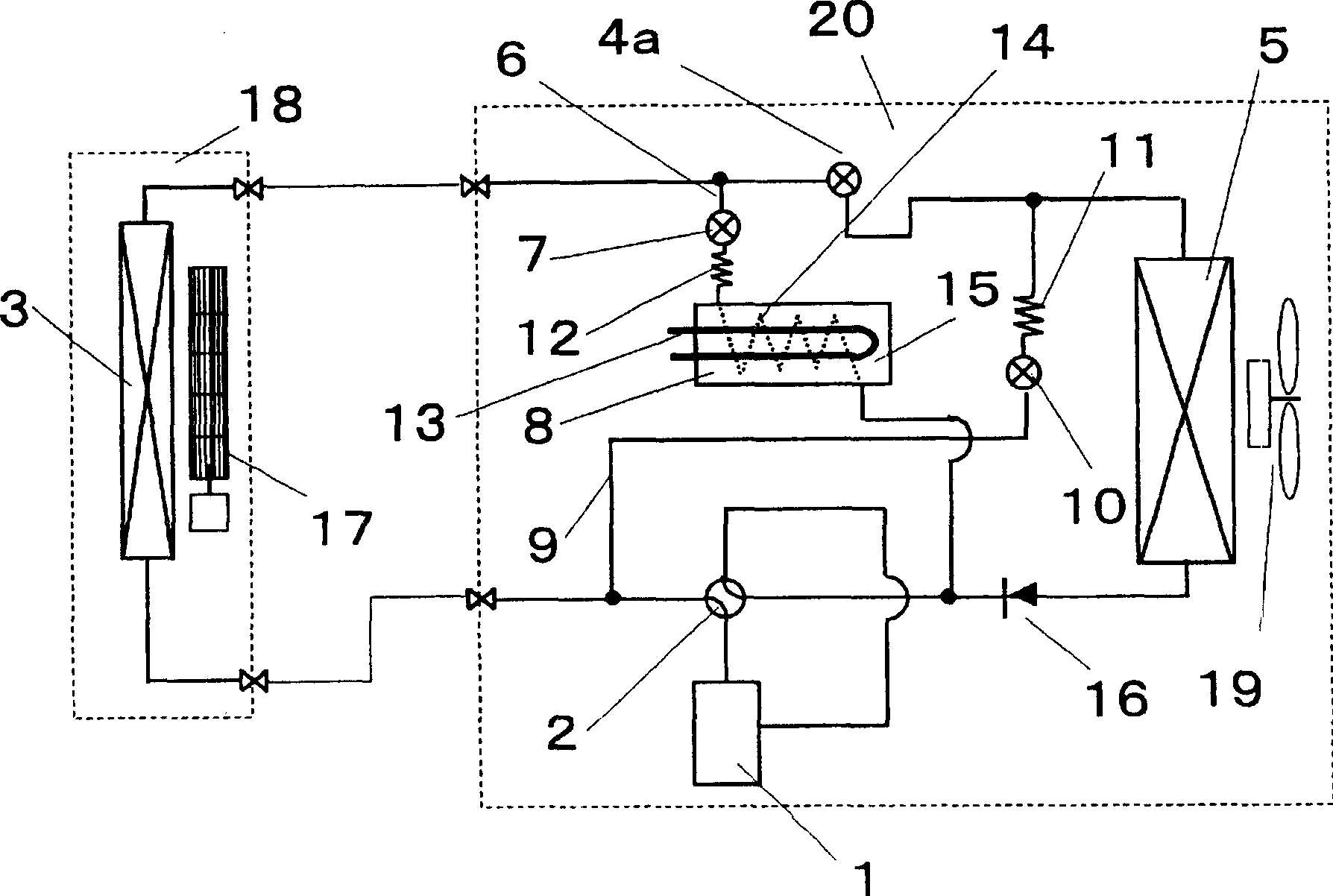

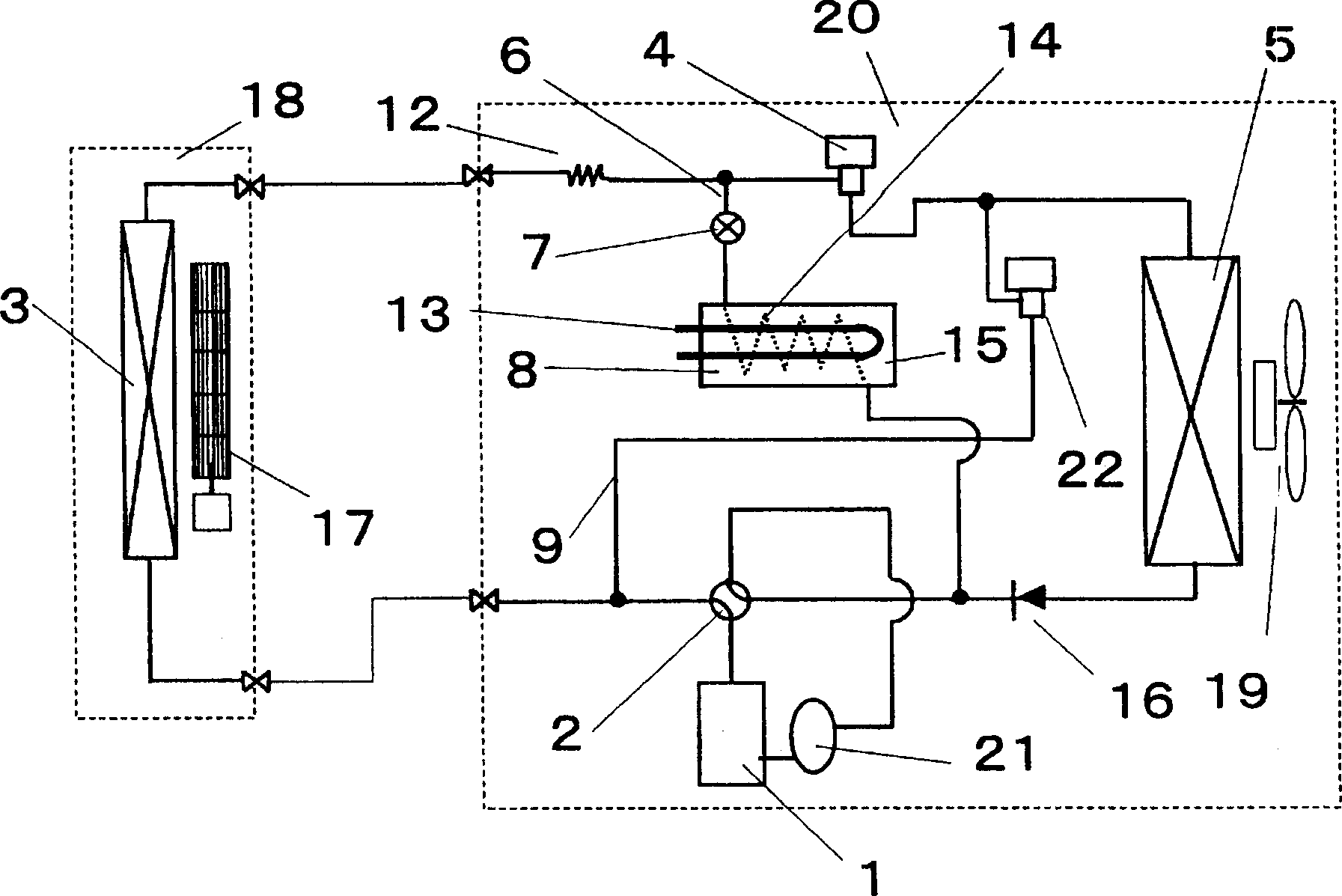

Air conditioner device

InactiveCN1916538ANo noiseSmall oil changeCorrosion preventionCompression machines with reversible cycleFour-way valveEngineering

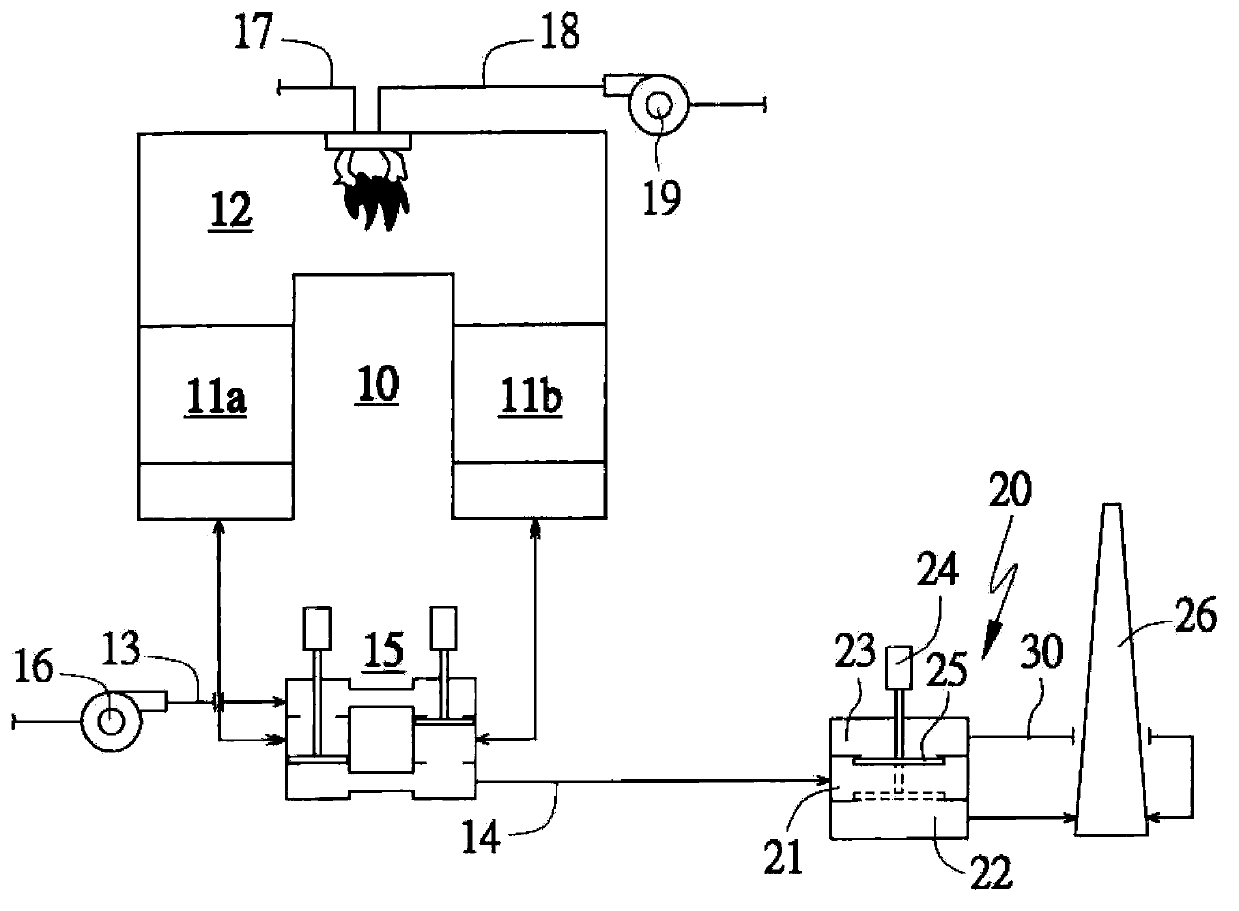

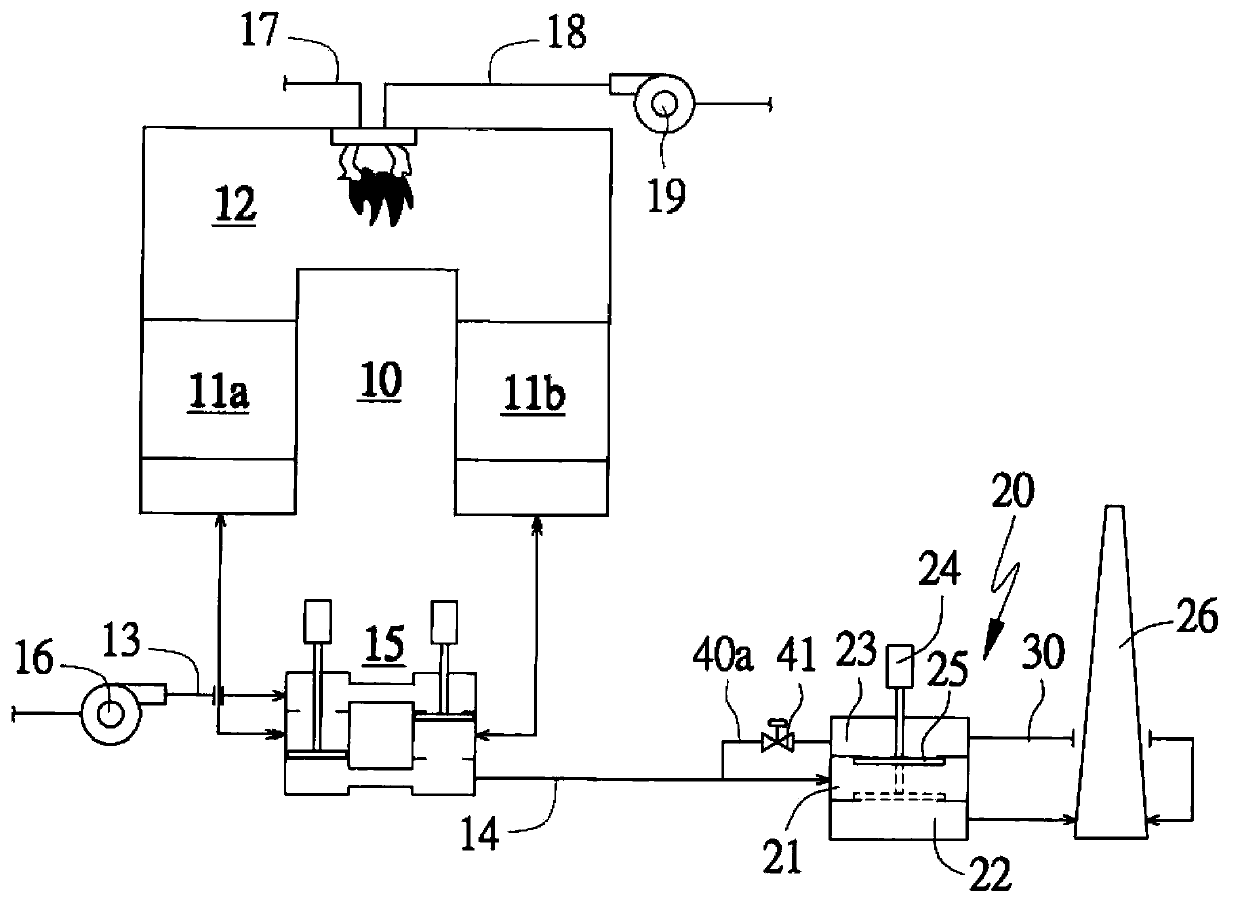

This invention provides an air-conditioner that continues a heating operation while performing a defrosting operation. A first bypass circuit 6 is provided for connecting the portion of a heat-pump-type refrigerating cycle between an indoor heat exchanger 3 and a decompressor 4 to the suction side of a compressor 1. The first bypass valve 6 is provided with a two-way valve 7 and a refrigerant heater 8. Further, a second bypass circuit 9 is provided for connecting the portion between a four-way valve 2 and the indoor heat exchanger 3 to the portion between the decompressor 4 and an outdoor heat exchanger 5. The second bypass circuit 9 is provided with a defrosting two-way valve 10. To defrost the outdoor heat exchanger 5, the decompressor 4 and the defrosting two-way valve 10 are closed according to outside air temperature and a fan 19 is rotated to perform a first defrosting operation. When the temperature detected by the temperature means of the outdoor heat exchanger is less than a predetermined value while the first defrosting operation is within a preset period of time, the two-way valve of the second bypass circuit is opened and an outdoor fan is stopped to perform a second defrosting operation.

Owner:PANASONIC CORP

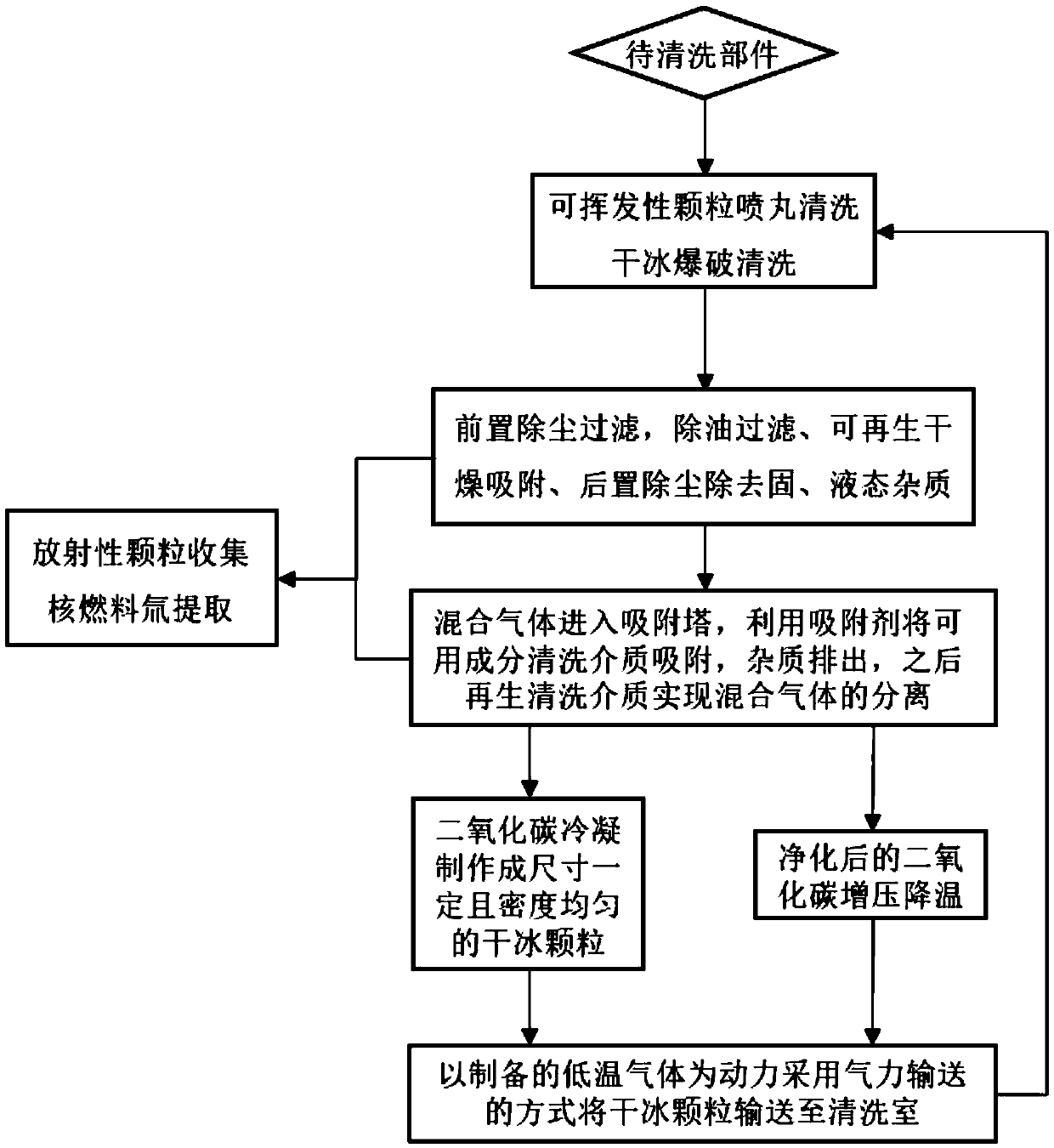

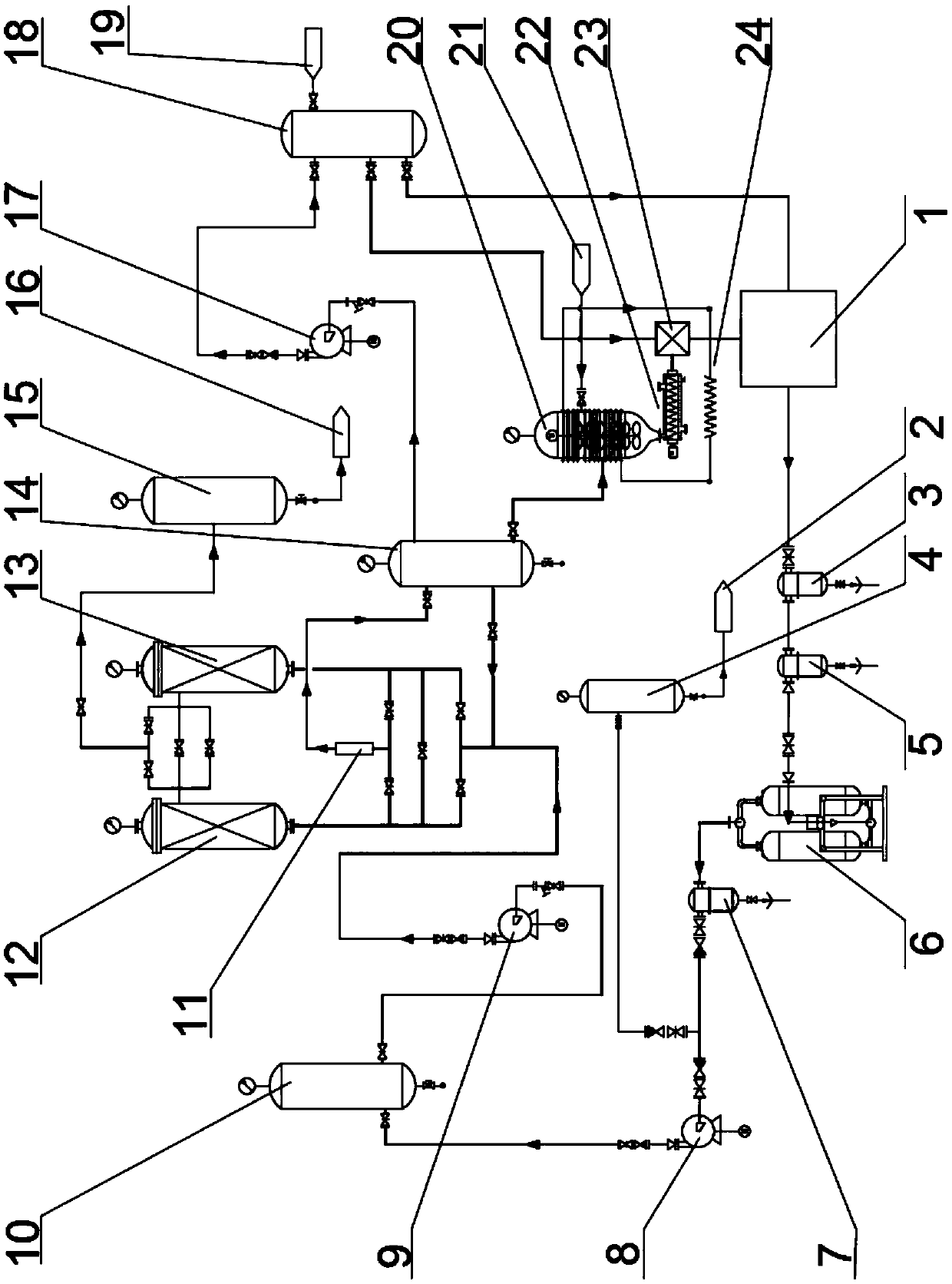

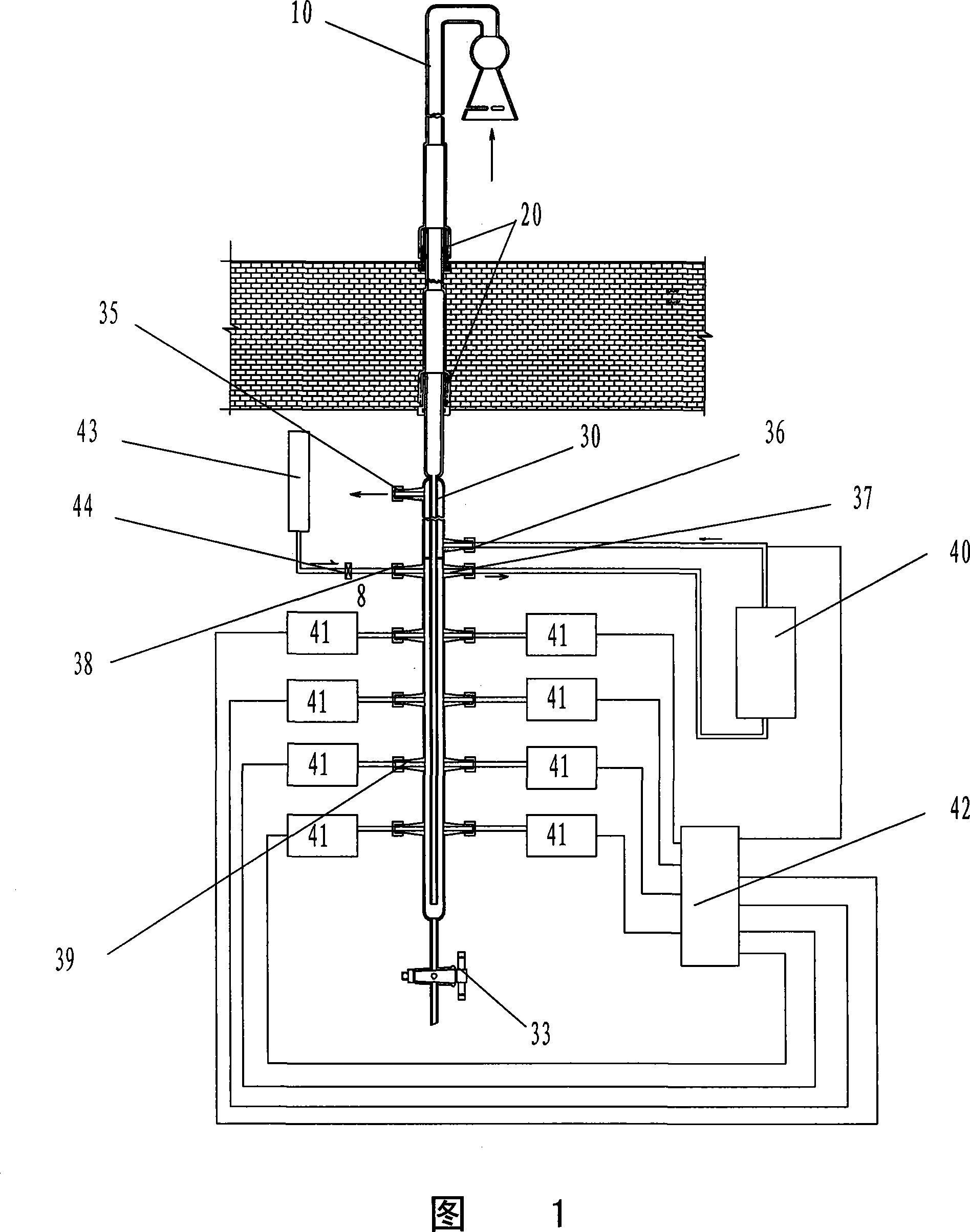

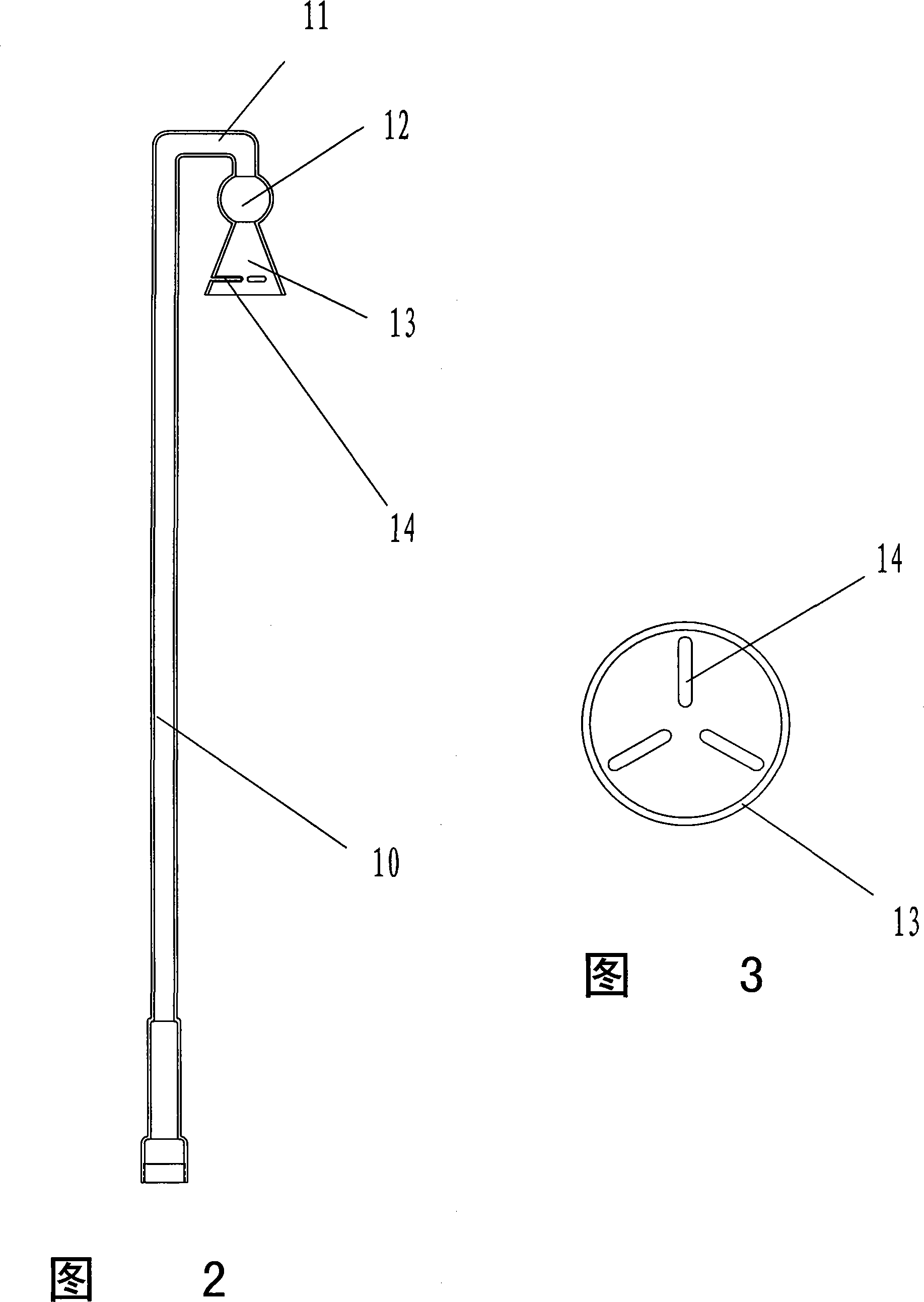

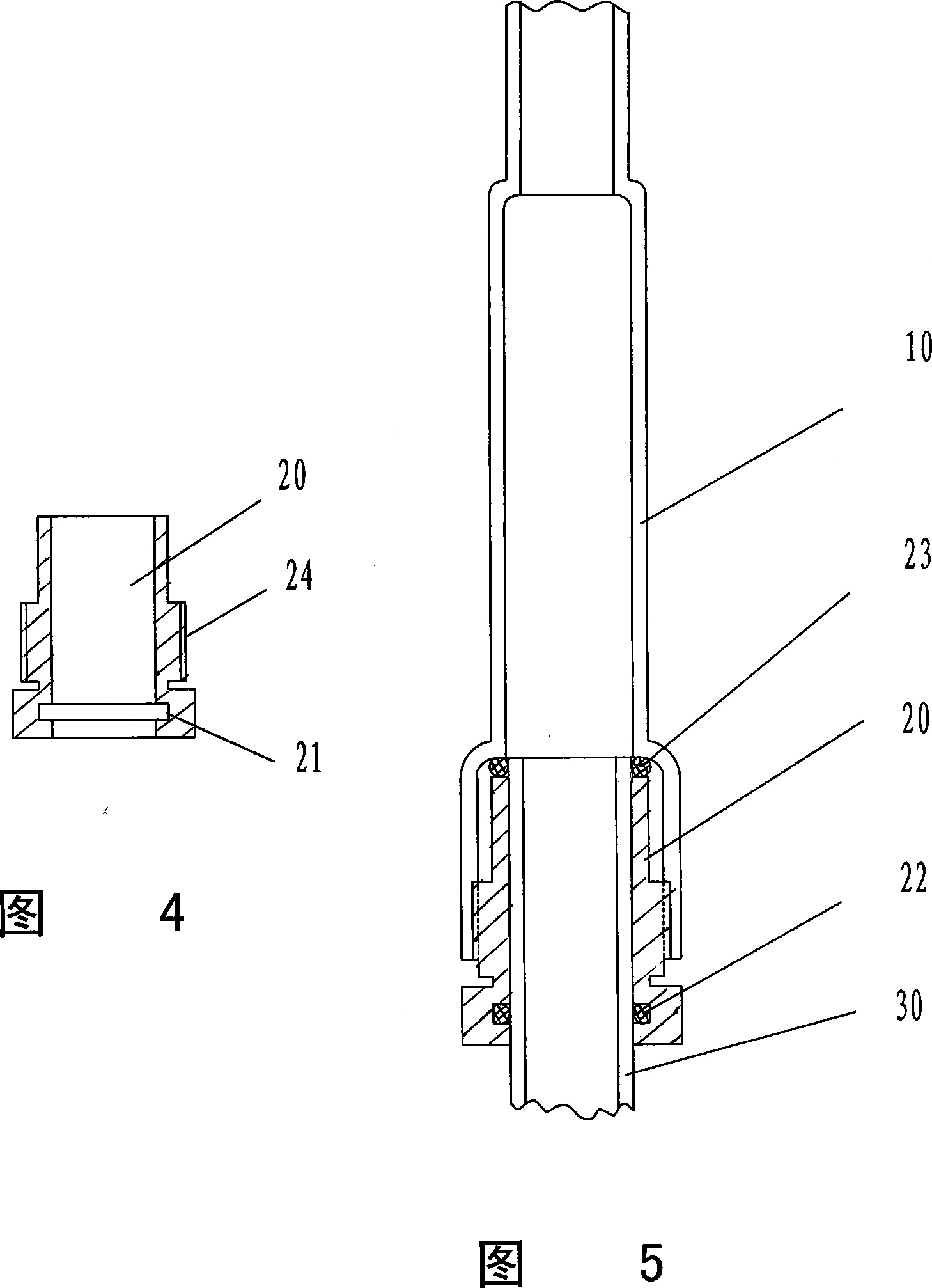

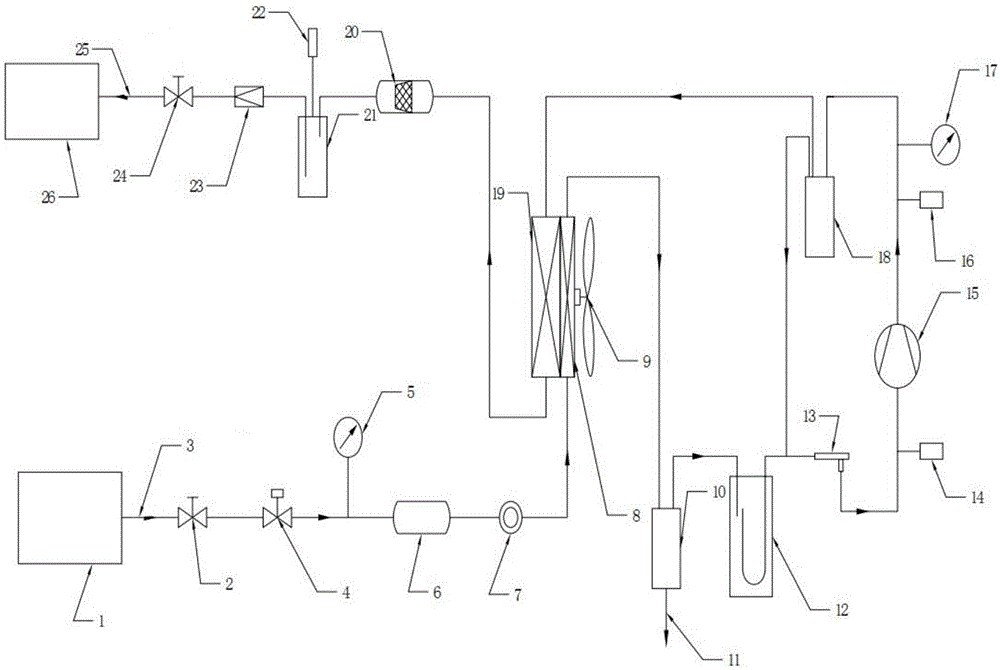

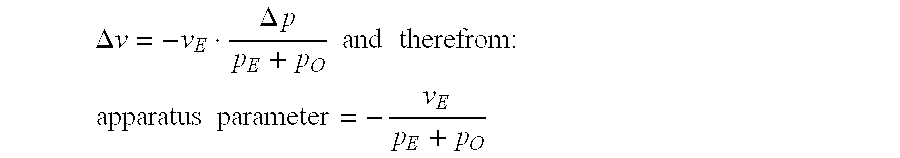

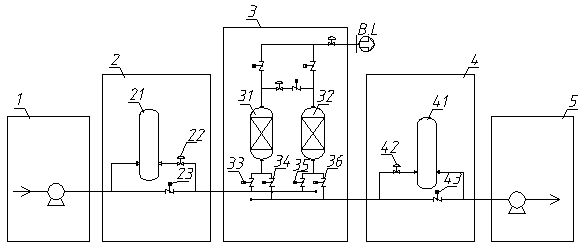

Cleaning waste gas pressure swing adsorption purification and recycling method and device for fusion reactor hot room

ActiveCN105513661AMinimize wasteAchieving classification of by-productsGas treatmentDispersed particle filtrationRadioactive gasCarbon dioxide

The invention relates to a cleaning waste gas pressure swing adsorption purification and recycling method and device for a fusion reactor hot room. The method includes the technological process of cleaning and contaminating, solid and liquid impurity filtration and purification, cleaning medium adsorption separation and regeneration, low-temperature power gas preparation, volatilizable particle regeneration and volatilizable particle remote-distance pneumatic transport. Fusion reactor hot room cleaning waste gas containing radioactive particles and radioactive gas is processed in a low-risk mode through a multiple filtration and pressure swing adsorption method, and separation, classified collection and recycling of radioactive particles, radioactive gas tritium and a cleaning medium carbon dioxide gas are achieved. The purity of regenerated products is high, no external heat source heating is needed, the gas temperature change range is small, the device is more economical and saves more energy, the service life of adsorbent is long, the device maintenance is easy and convenient, automatic production can be completely achieved, and the method and the device are suitable for the hot room environment remotely controlled and operated.

Owner:UNIV OF SCI & TECH OF CHINA

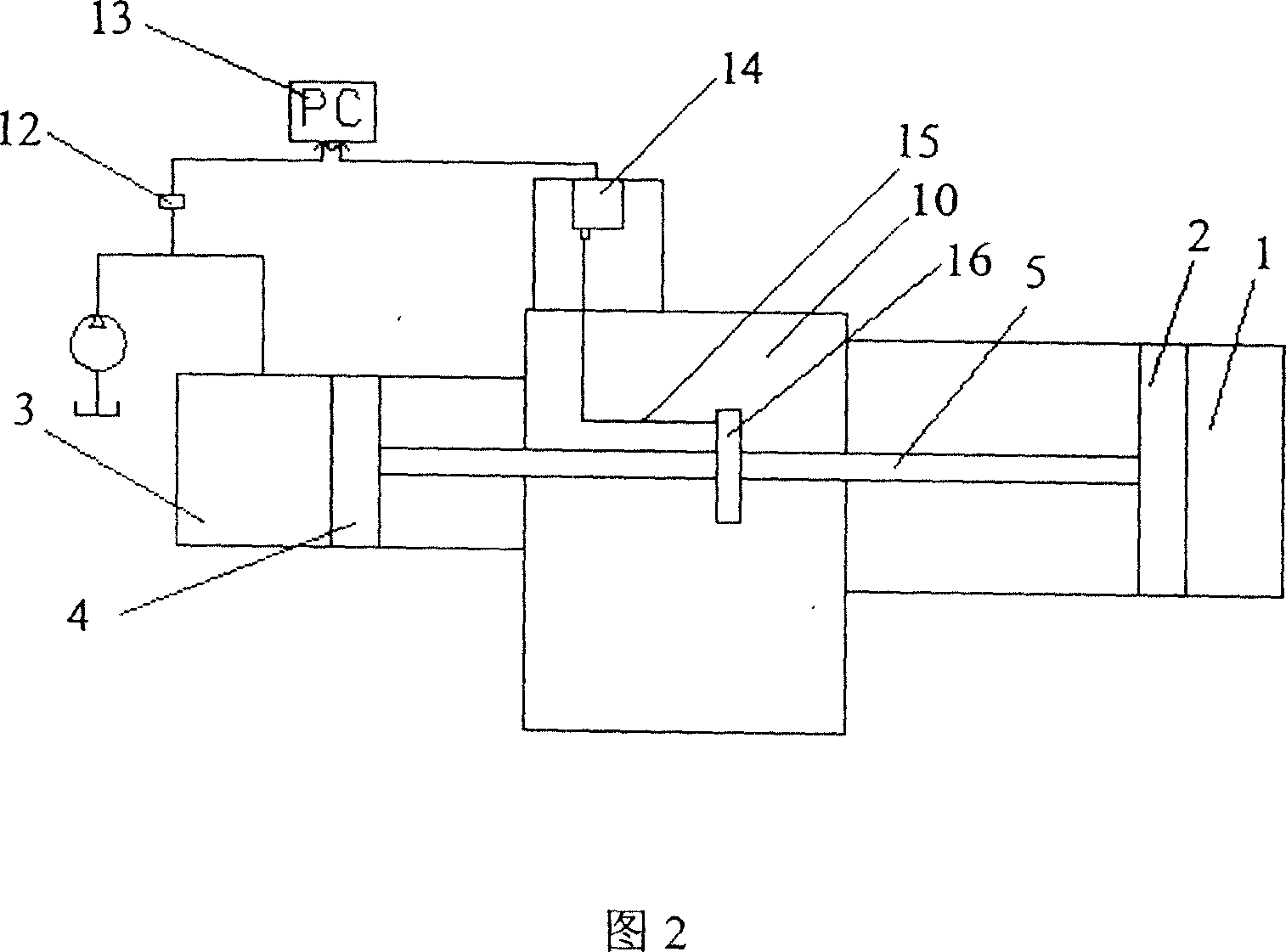

Concrete pump displacement measuring method and apparatus thereof

InactiveCN1975165ARealize acquisitionReal-timePump testingPositive-displacement liquid enginesEngineeringAnalog signal

The present invention discloses a method for measuring concrete pump output and its equipment. Said method includes the following steps: making one end of pressure sensor be mounted on the oil-feeding oil circuit of hydraulic oil cylinder; fixing and mounting the displacement sensor on the water tank by means of supporting frame; making one end of displacement sensor be fixed on the end surface of piston rod connection flange of concrete pump piston rod, another one ends of pressure sensor and displacement sensor are respectively connected with signal collecting card; then inputting the measurement analogue signal into computer software by means of signal collecting card; utilizing pressure sensor and displacement sensor to simultaneously measure pressure of concrete pump hydraulic oil cylinder and concrete cylinder piston stroke; utilizing pressure signal to trigger concrete pump piston displacement signal removing concrete pump piston idle stroke so as to obtain concrete pump effective displacement and can obtain the actual output of concrete pump.

Owner:ZHEJIANG UNIV

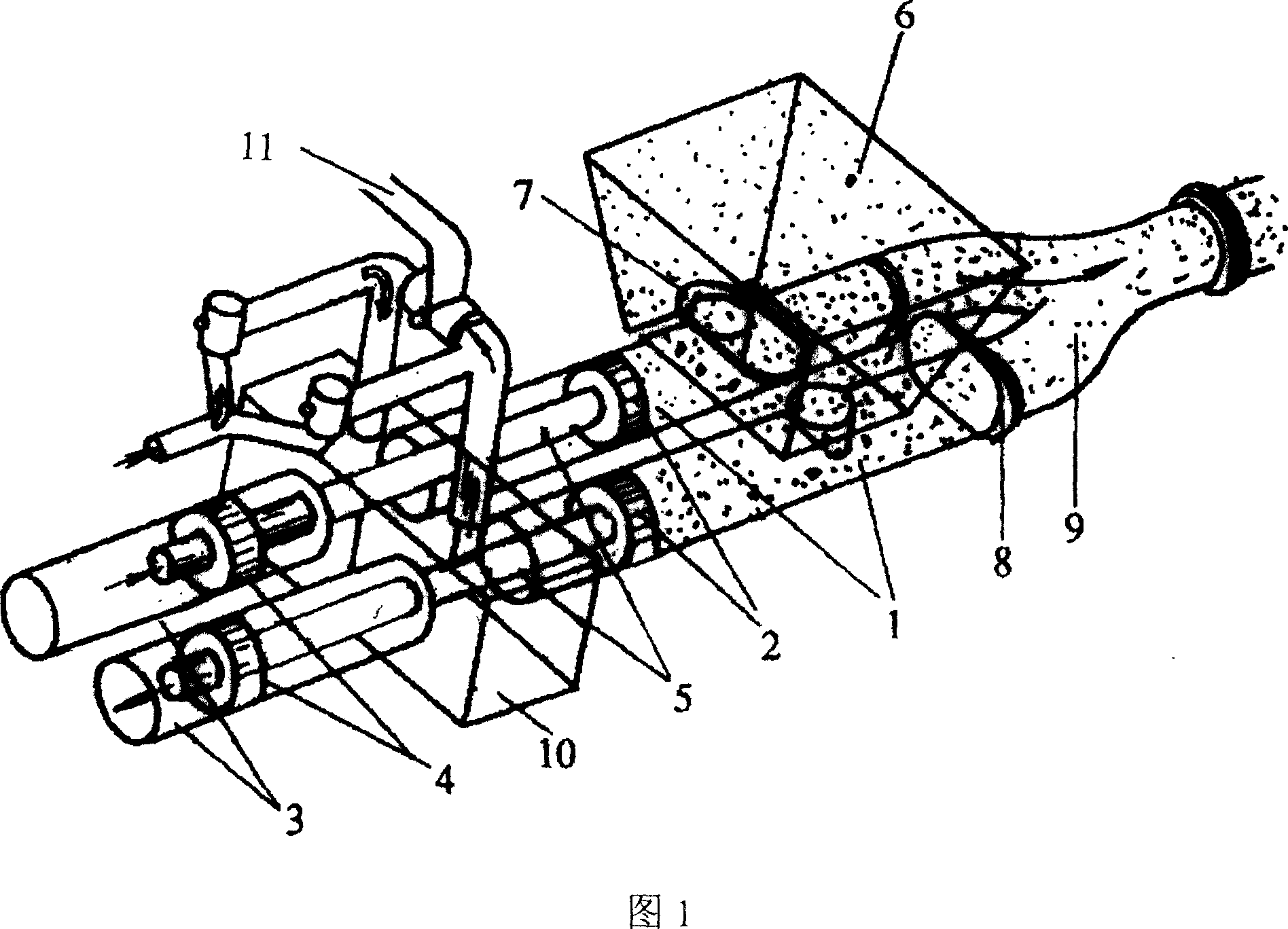

Multi-branch gas sampling pipe

An air sampling tube with multiple branch is prepared as using tube fittings to connect master sampling tube to front end sampling tube, arranging an internal tube and an external tube on said master sampling tube, setting block plate at middle between said internal and external tubes, arranging an air vent and a hot air inlet at external tube above block plate, arranging a flow guide opening and a standard air inlet as well as multiple sample collection opening on external tube below block plate and connecting flow guide opening and standard air inlet as well as various sample collection openings separately to regulation port on a gate valve connected with flow guide pump.

Owner:PEKING UNIV

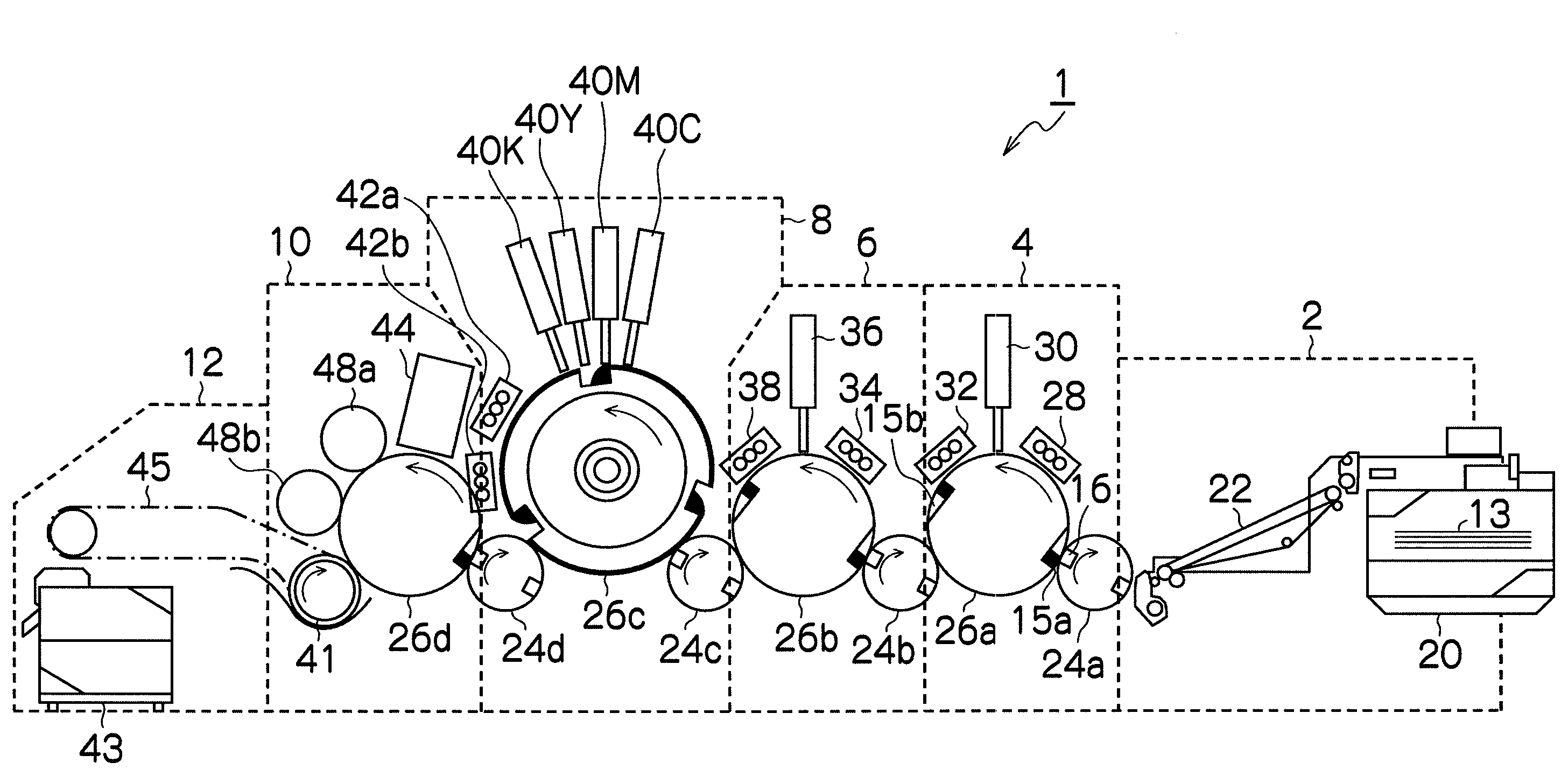

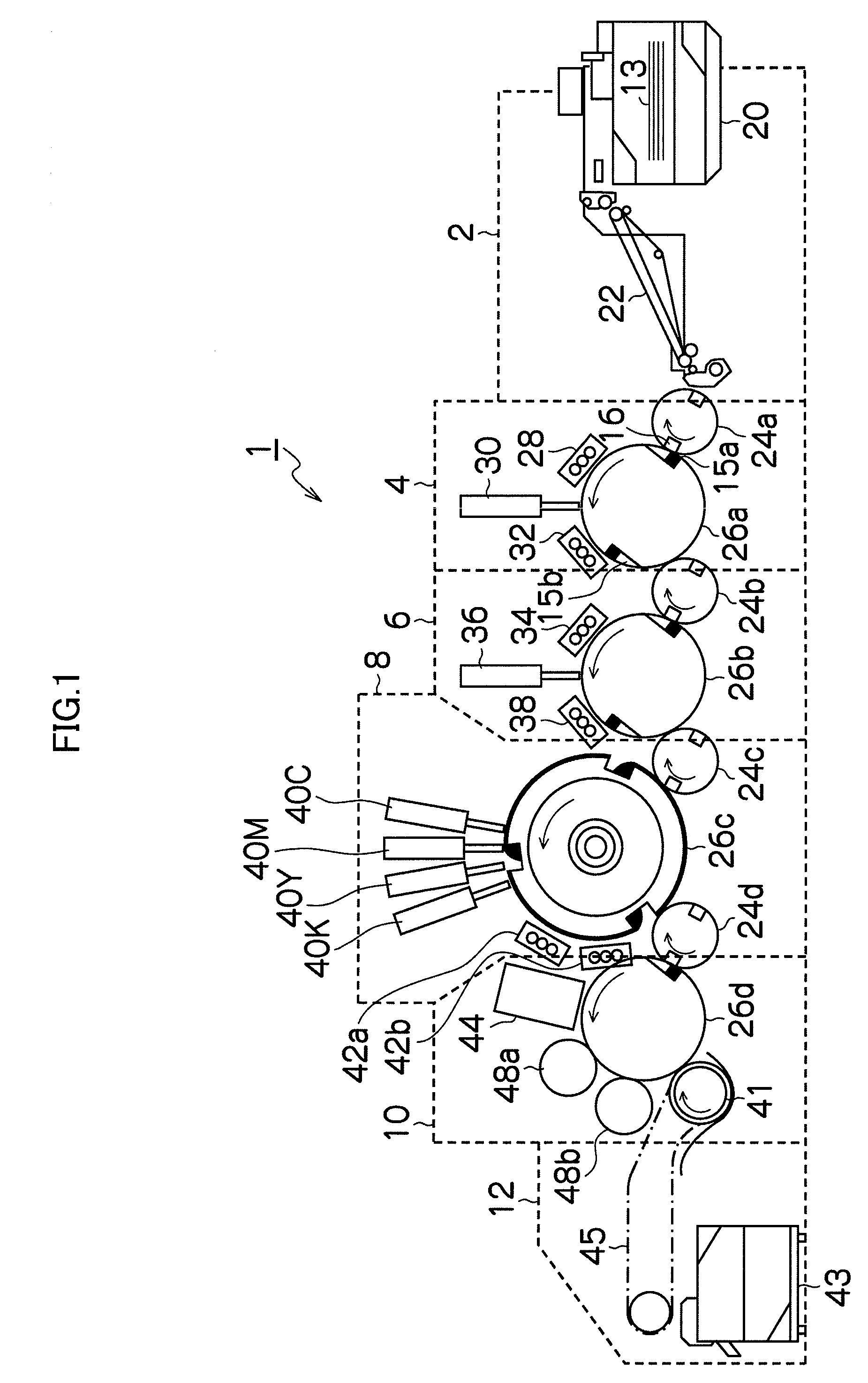

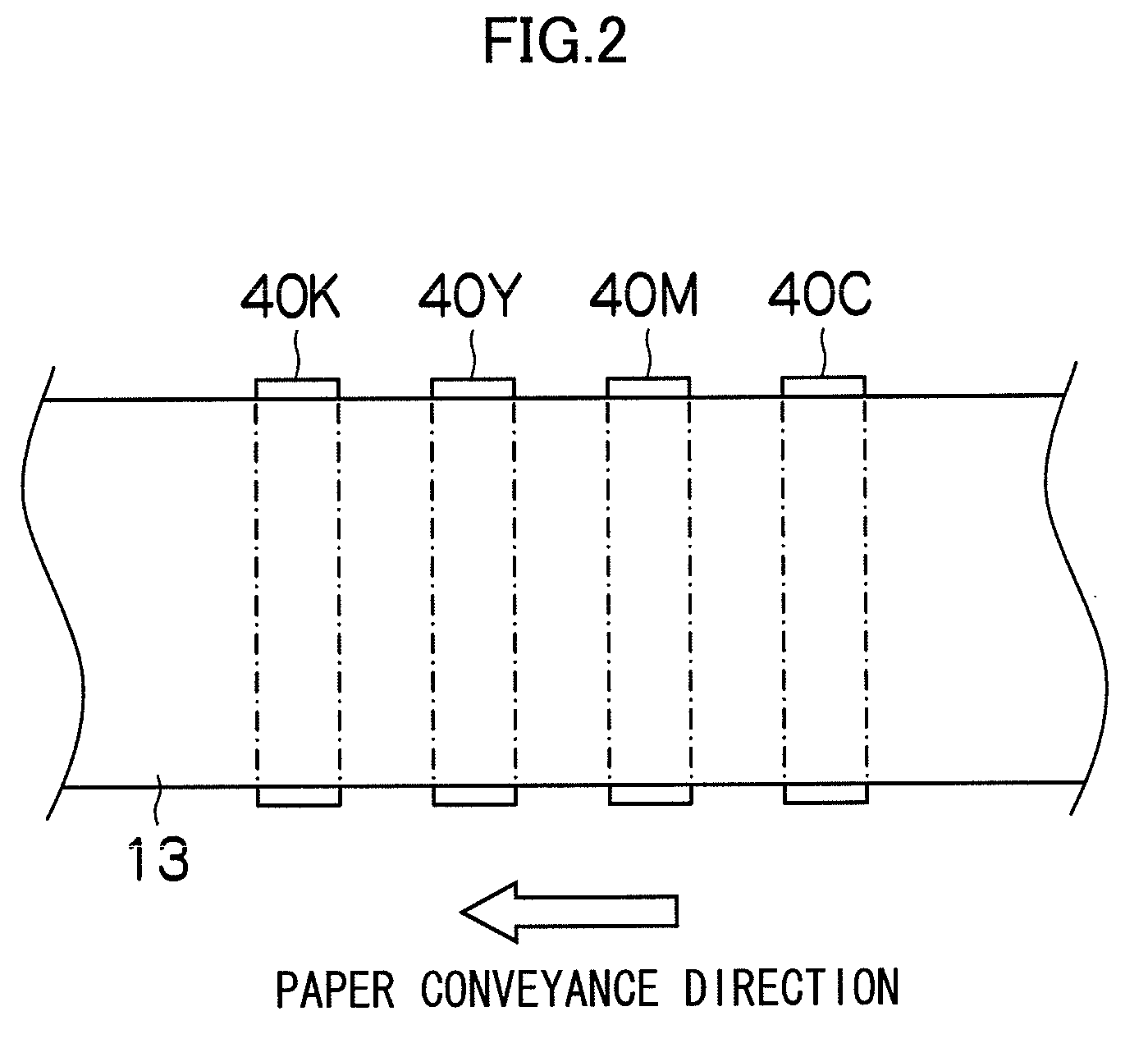

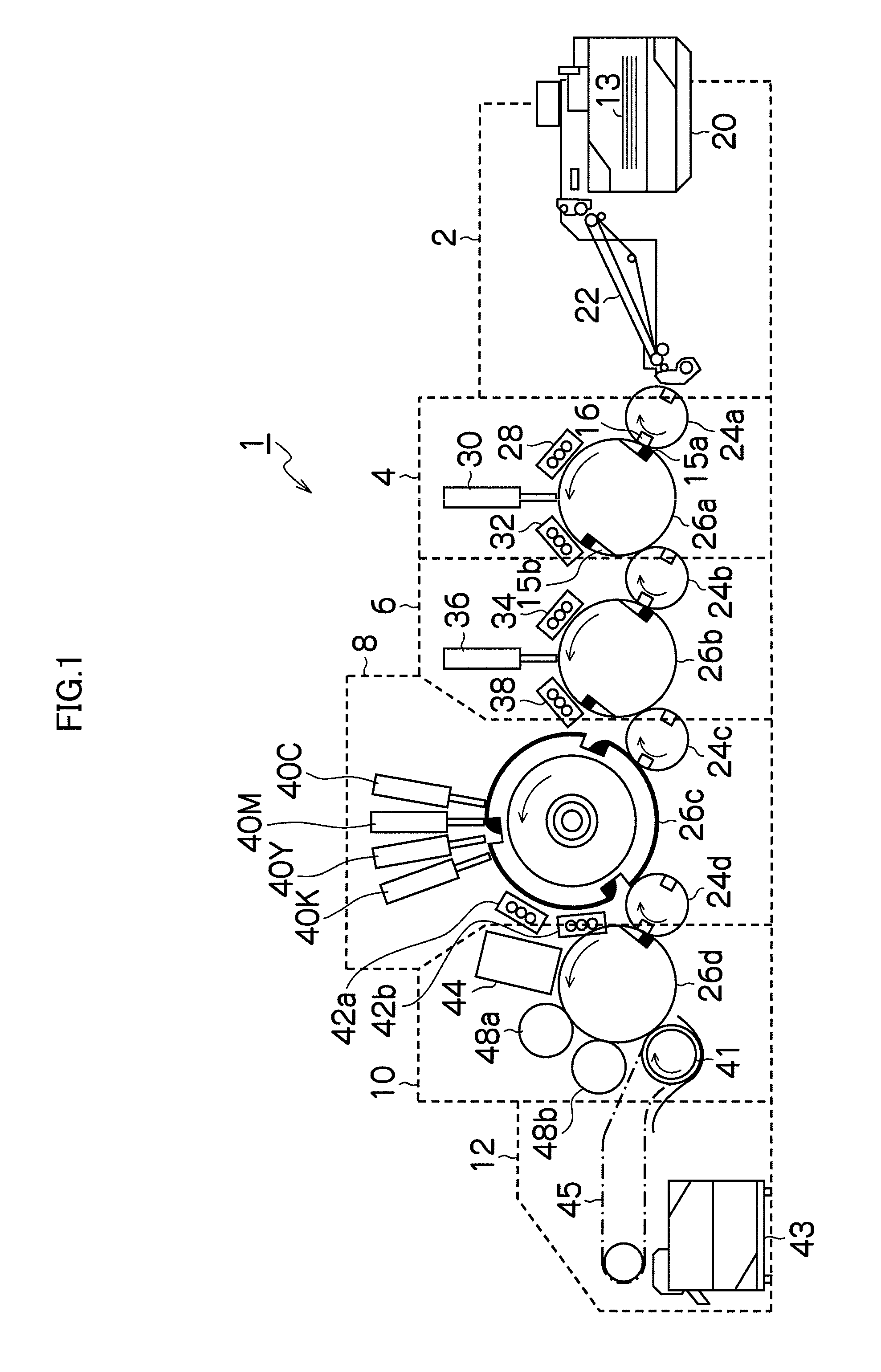

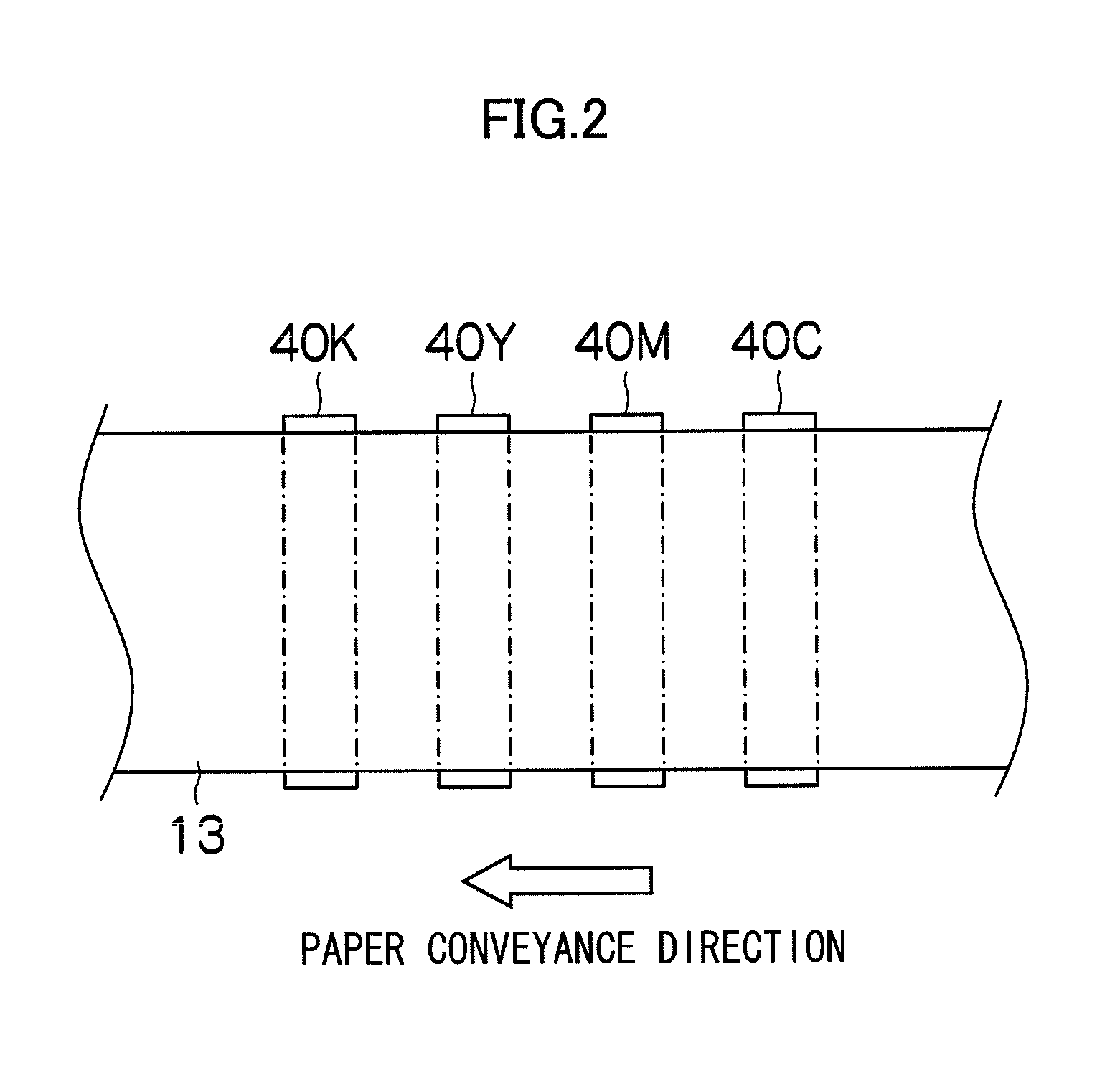

Inkjet recording apparatus and method

ActiveUS20090244131A1Carry-out stablyStable pressure controlInking apparatusOther printing apparatusPositive pressureEngineering

The inkjet recording apparatus includes: an inkjet recording head which includes a nozzle through which liquid is ejected; a pressure regulating unit which includes a liquid chamber that communicates with the nozzle and a gas chamber that is partitioned from the liquid chamber by a flexible film; and a liquid chamber pressure controlling device which controls a pressure of the liquid chamber to a predetermined negative pressure when carrying out back pressure control in which back pressure is applied to the liquid inside the nozzle, wherein: the flexible film causes change in the pressure of the liquid chamber when the liquid is supplied for at least a predetermined supply amount to the liquid chamber in a state where the gas chamber is open to air; and the liquid chamber pressure controlling device carries out the back pressure control after controlling the pressure of the liquid chamber to a predetermined value of positive pressure by supplying the liquid of at least the predetermined supply amount to the liquid chamber.

Owner:FUJIFILM CORP

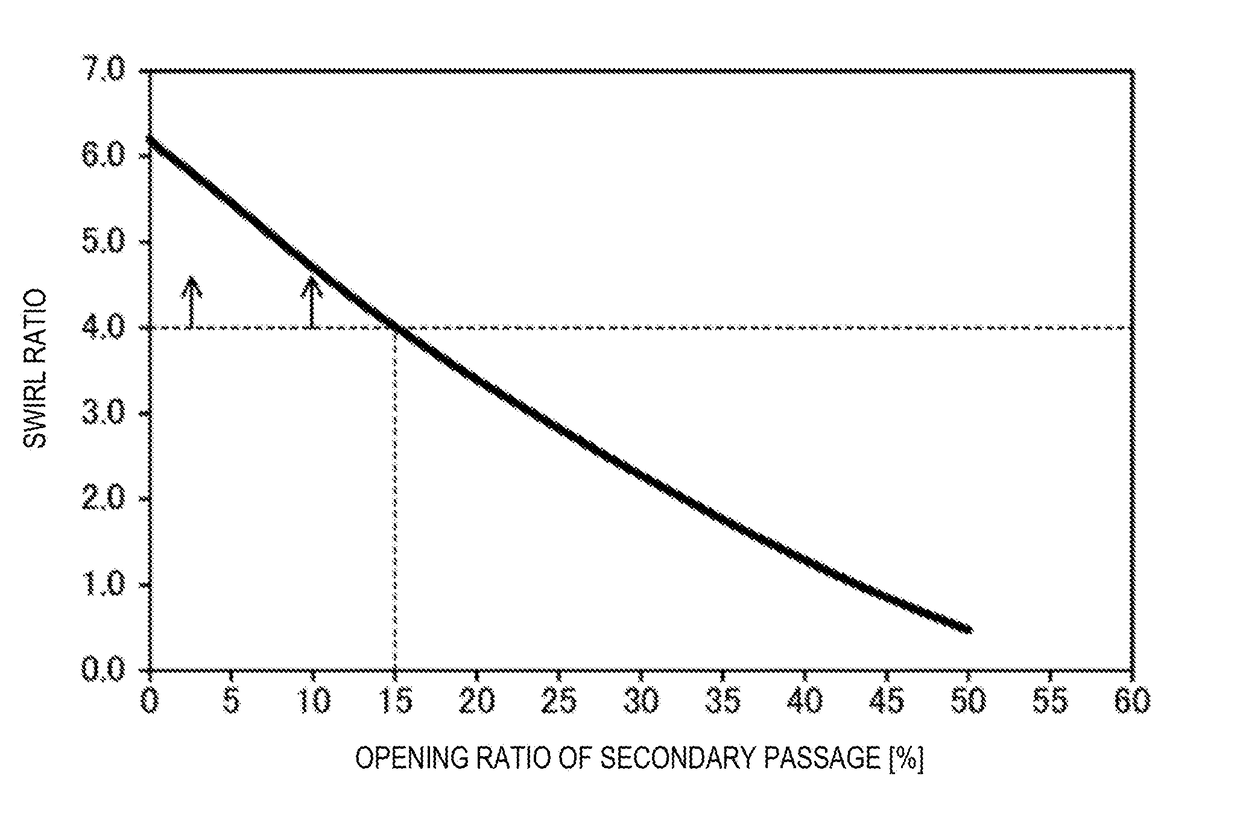

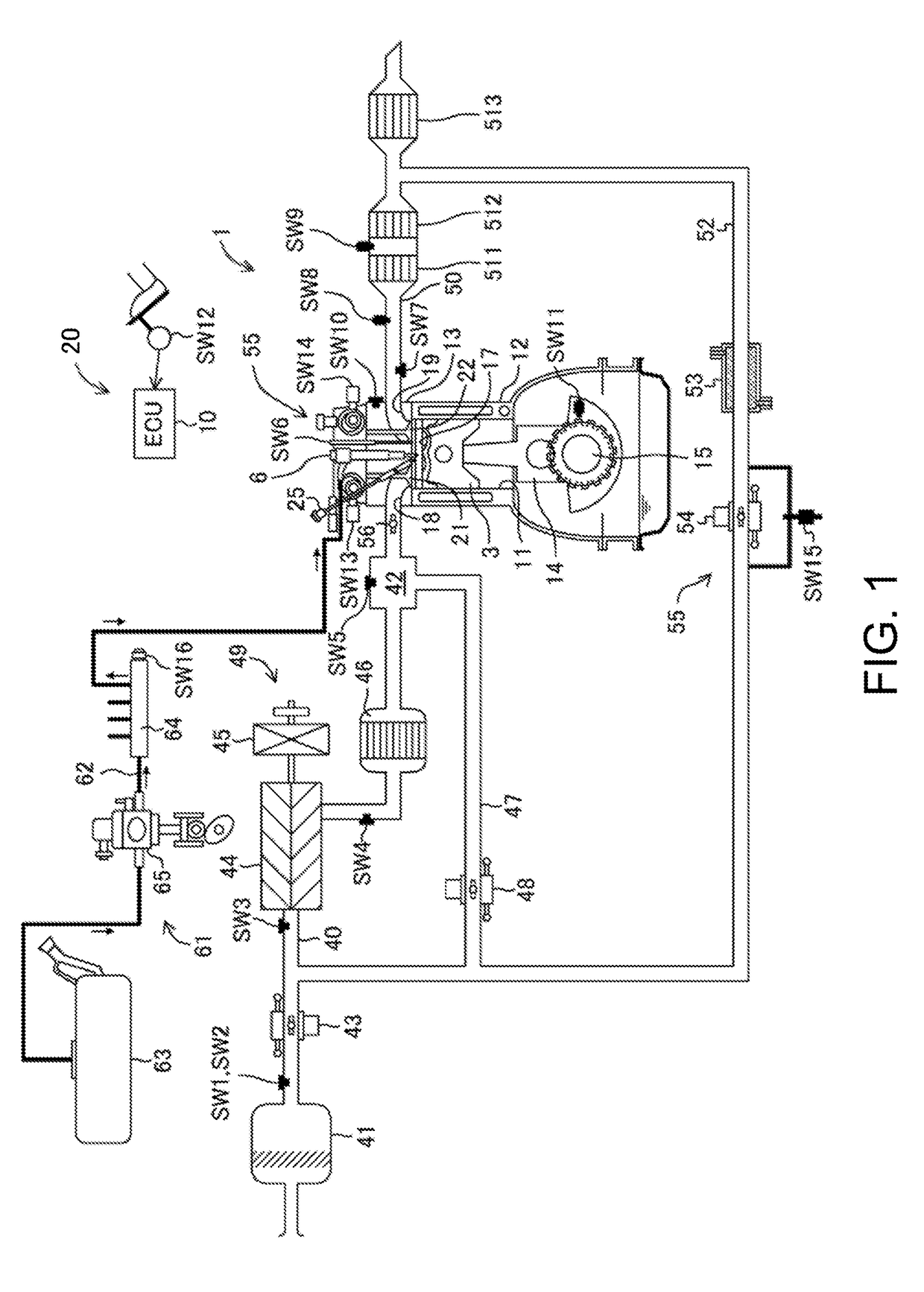

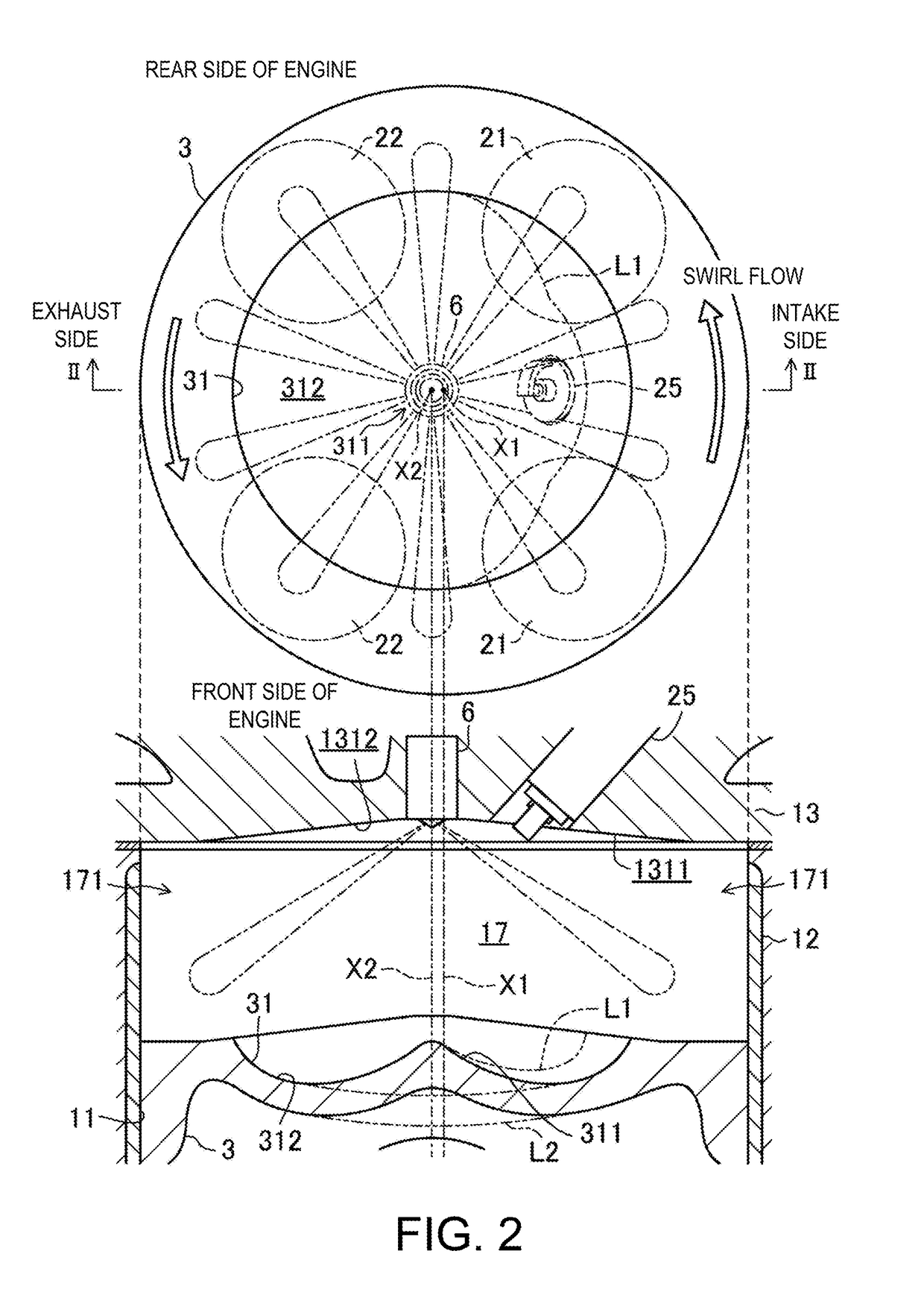

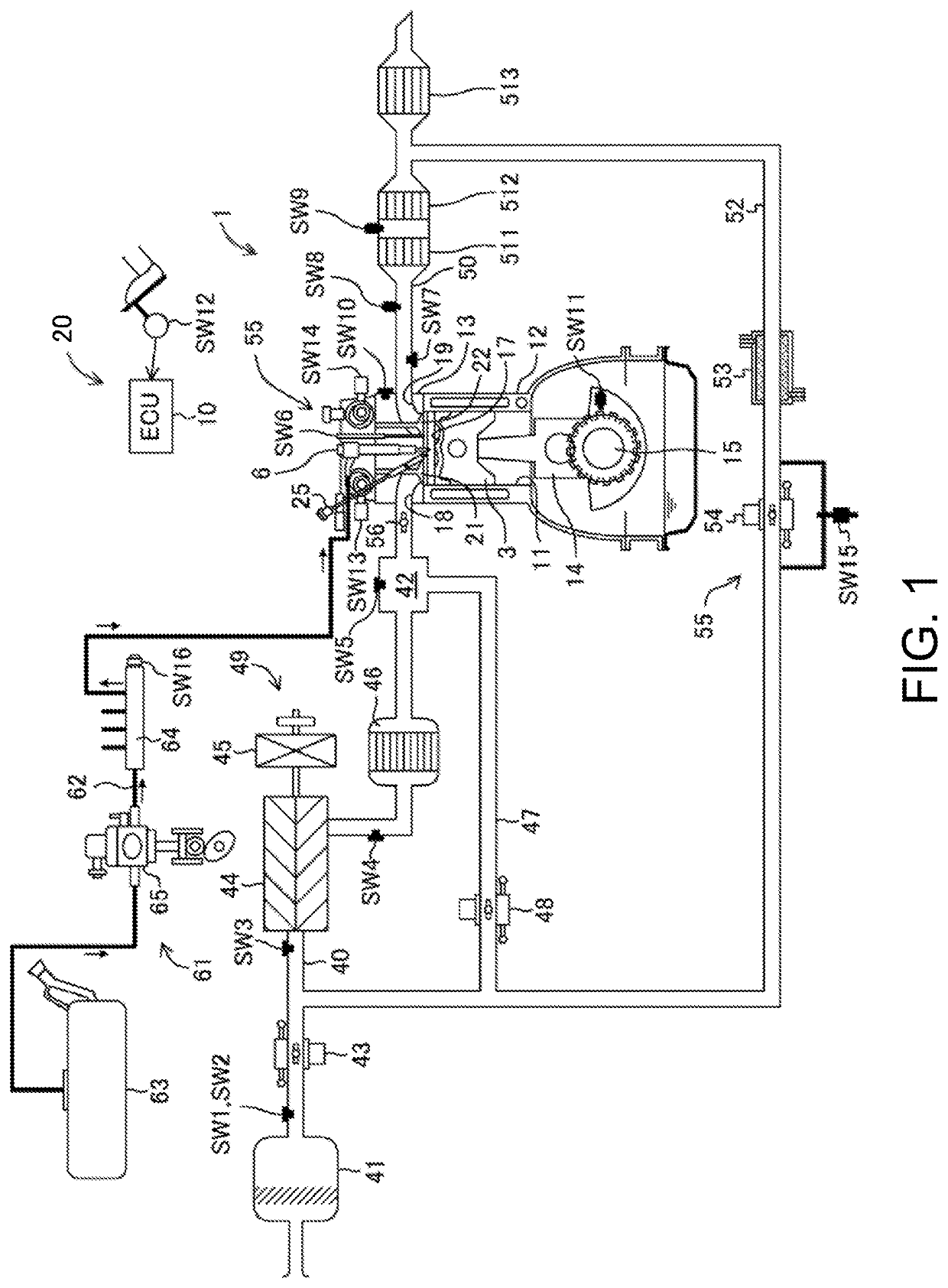

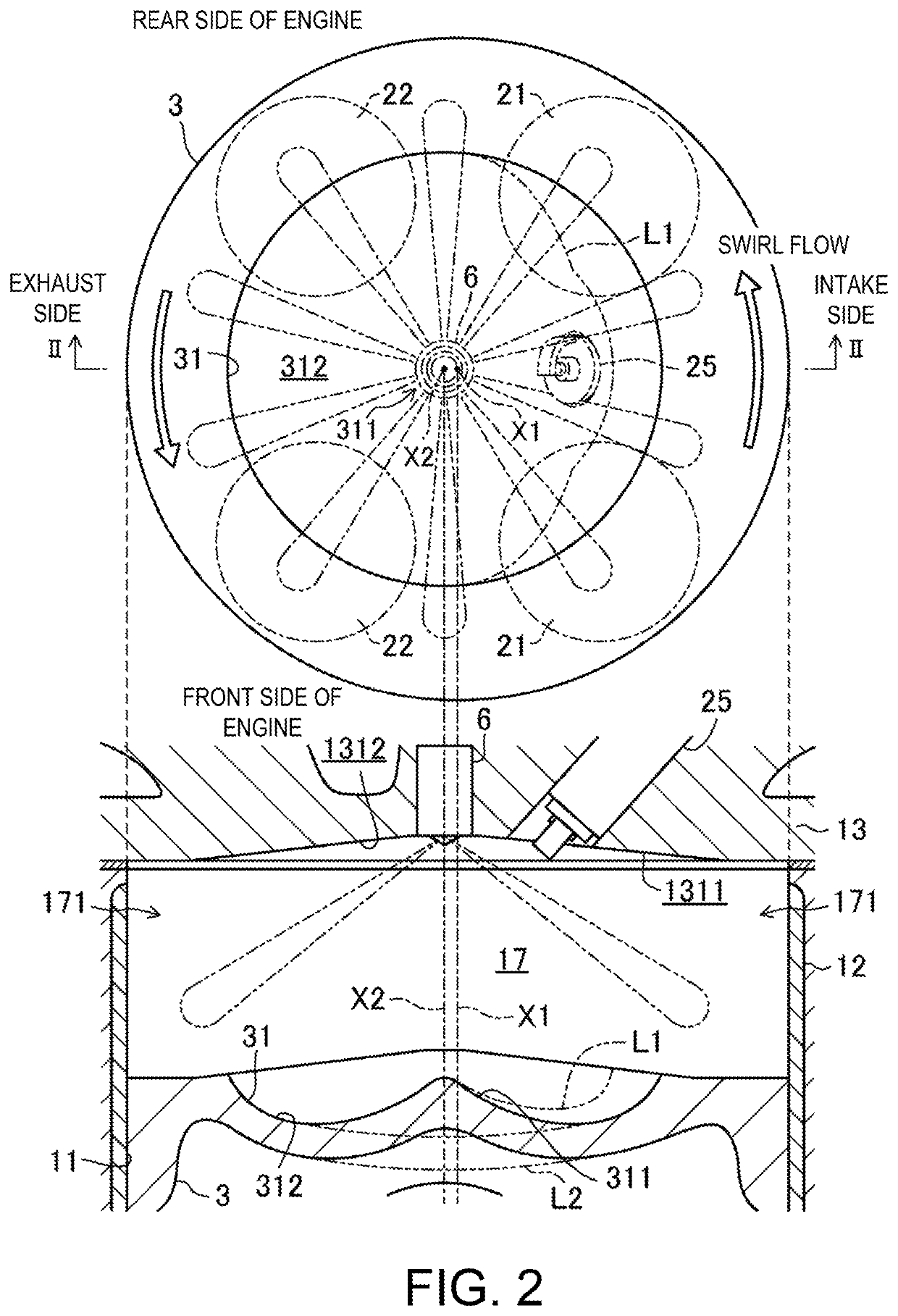

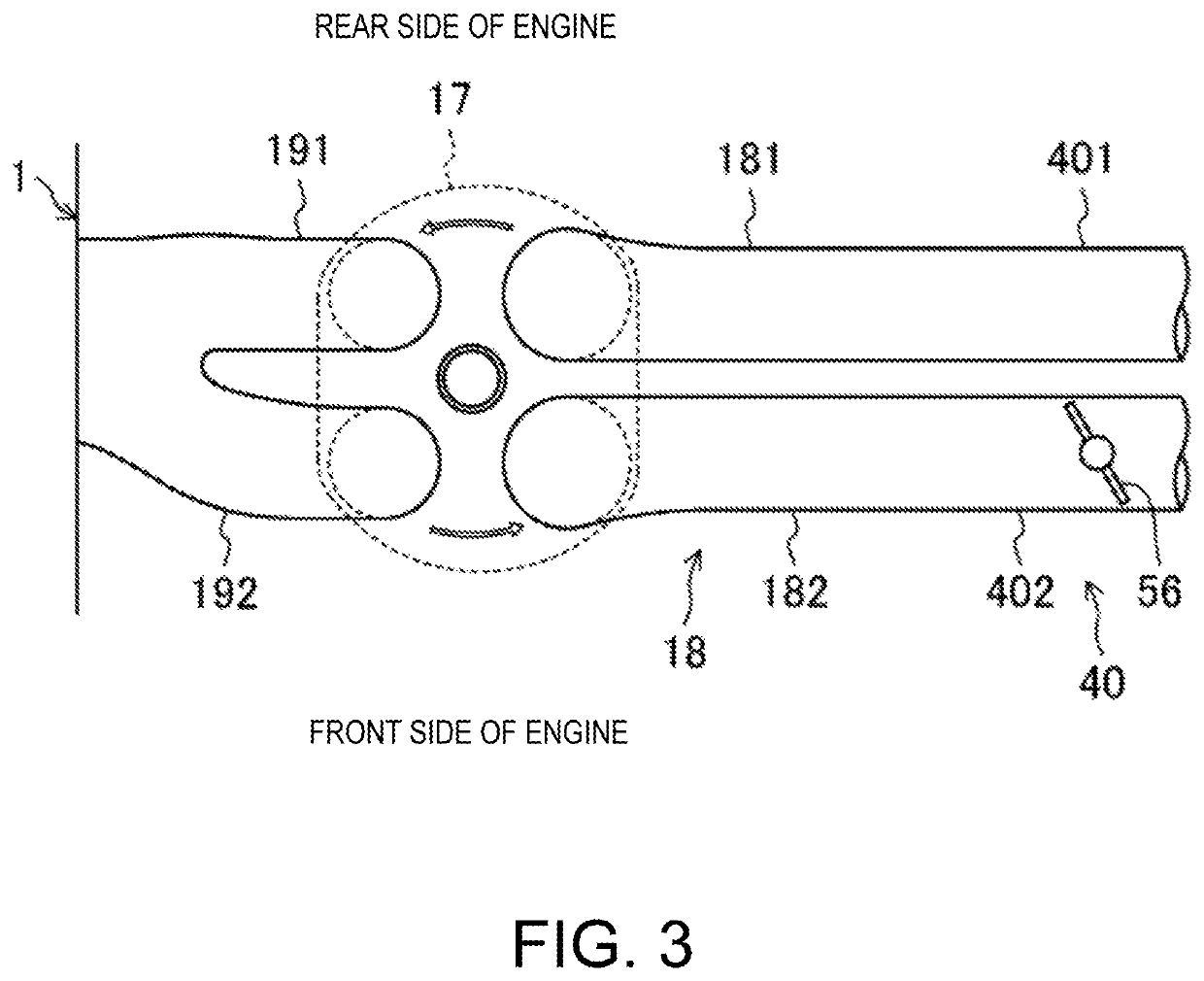

Control system of compression-ignition engine

ActiveUS20180334989A1Improve liquidityImprove performanceElectrical controlInternal combustion piston enginesCombustion chamberControl system

A control system of a compression-ignition engine is provided, which includes an engine configured to cause combustion of a mixture gas inside the combustion chamber, an injector attached to the engine and configured to inject fuel into the combustion chamber, a spark plug disposed to be oriented into the combustion chamber and configured to ignite the mixture gas inside the combustion chamber, and a controller connected to the injector and the spark plug and configured to operate the engine by outputting a control signal to the injector and the spark plug, respectively. After the spark plug ignites the mixture gas to start combustion, unburned mixture gas combusts by self-ignition. The controller outputs the control signal to the injector so that a fuel injection timing is advanced when the engine operates at a high speed than at a low speed.

Owner:MAZDA MOTOR CORP

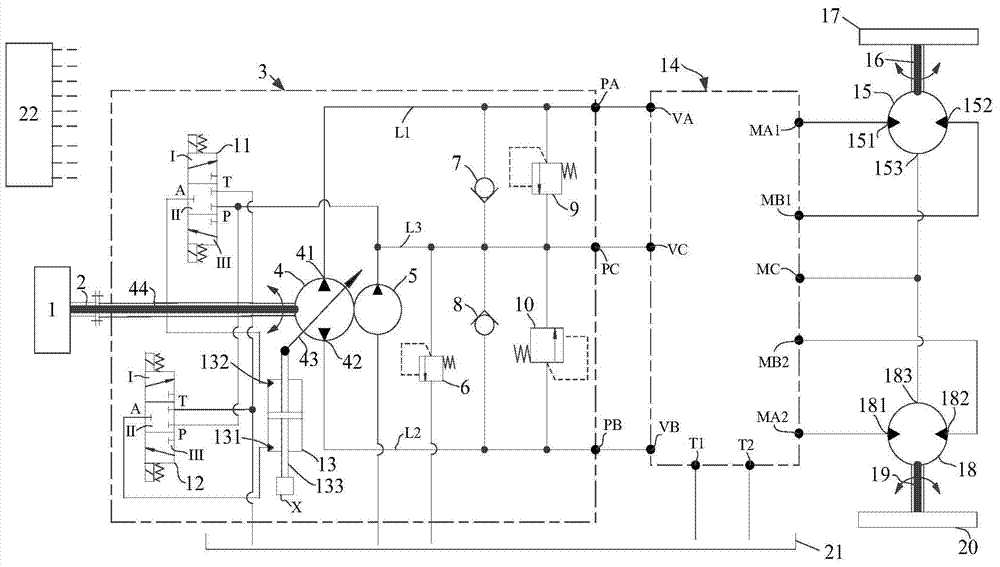

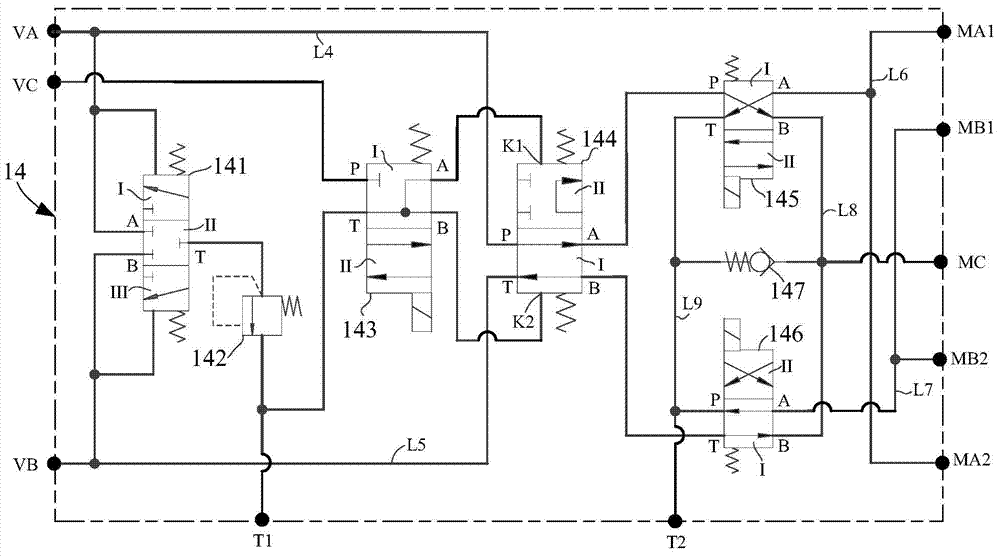

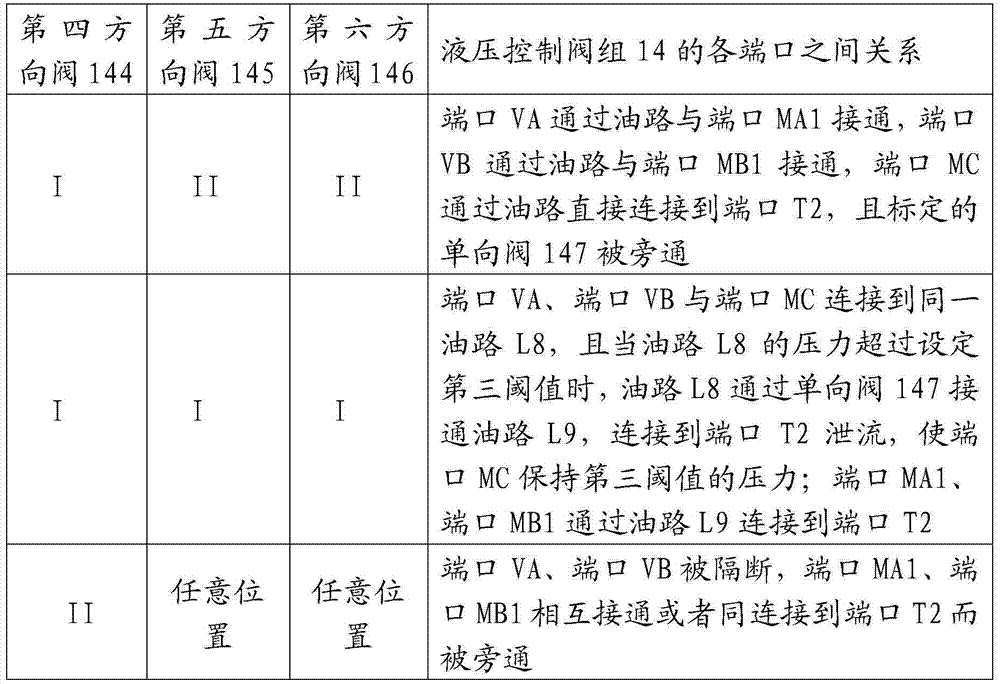

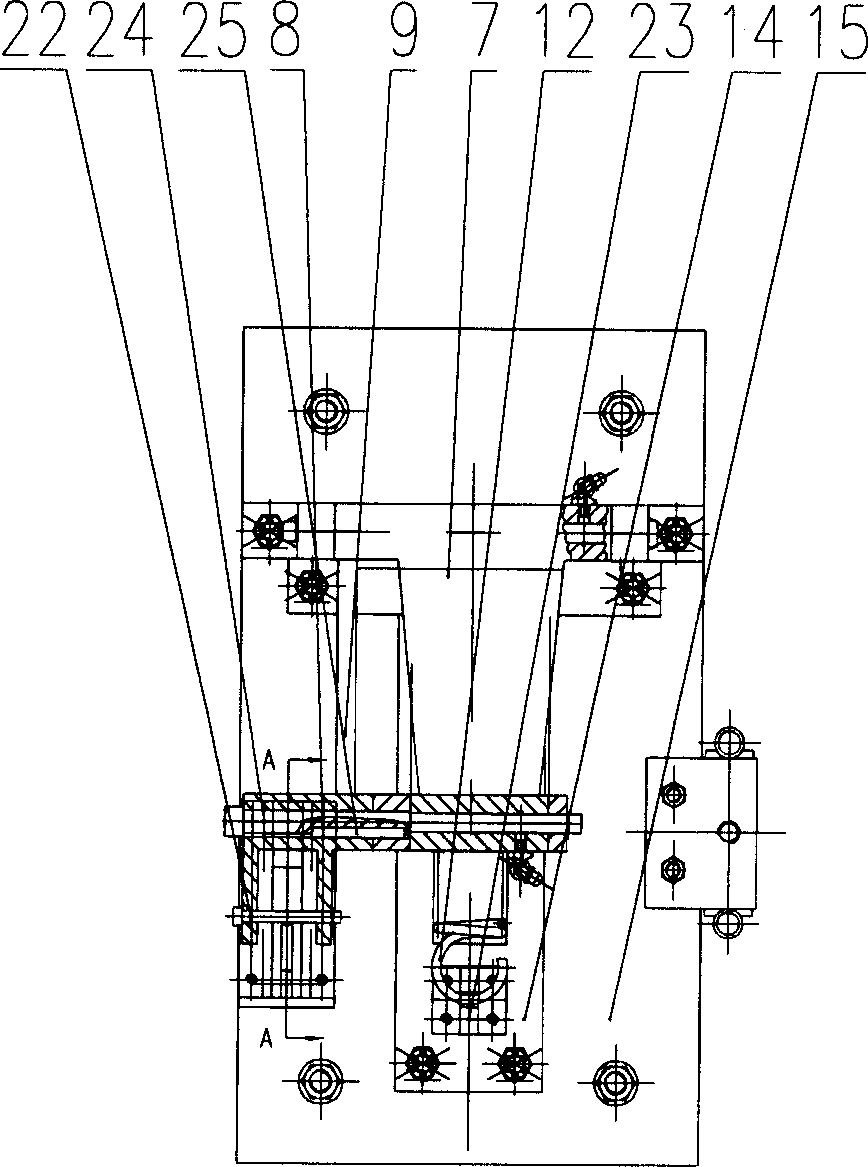

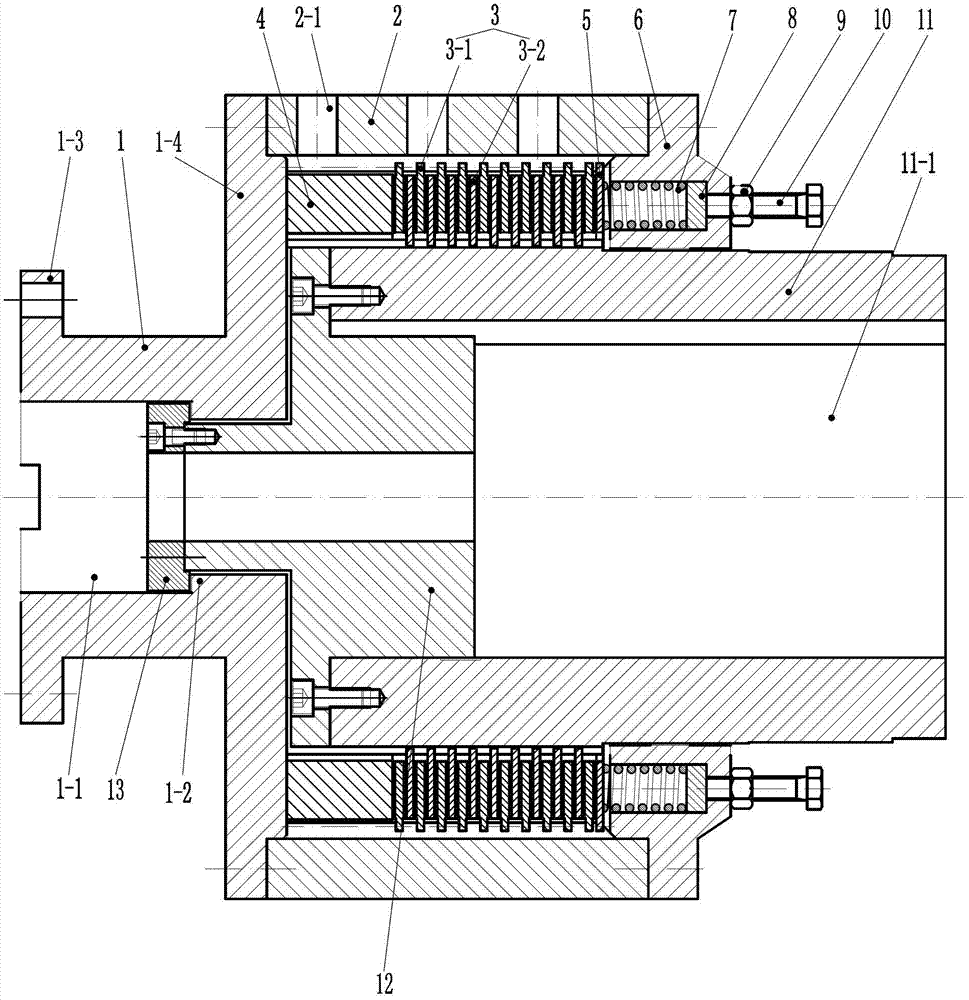

Closed type hydraulic transmission system

InactiveCN103790876AHigh delivery pressureQuick responseServomotor componentsServomotorsHydraulic pumpControl valves

The invention discloses a closed type hydraulic transmission system which solves the problem that impact pressure on a motor shell caused by high-pressure oil during status switching and a certain amount of pressure existing in a loop when a hydraulic motor does not work produce resistance on vehicle running. The closed type hydraulic transmission system comprises a power input mechanism, a hydraulic pump assembly, a hydraulic control valve set, a first hydraulic motor, a second hydraulic motor, a non-pressurization oil tank and a control unit. The power input mechanism is in mechanical connection with the hydraulic pump assembly which is in pipeline connection with the hydraulic control valve set, the hydraulic control valve set is in pipeline connection with the first hydraulic motor and the second hydraulic motor respectively, the first hydraulic motor is in mechanical connection with a load mass body of the first hydraulic motor, the second hydraulic motor is in mechanical connection with a load mass body of the second hydraulic motor, both the hydraulic pump assembly and the hydraulic control valve set are in pipeline connection with the non-pressurization oil tank, and the control unit is connected with the hydraulic pump assembly and the hydraulic control valve set through signal wires.

Owner:JILIN UNIV

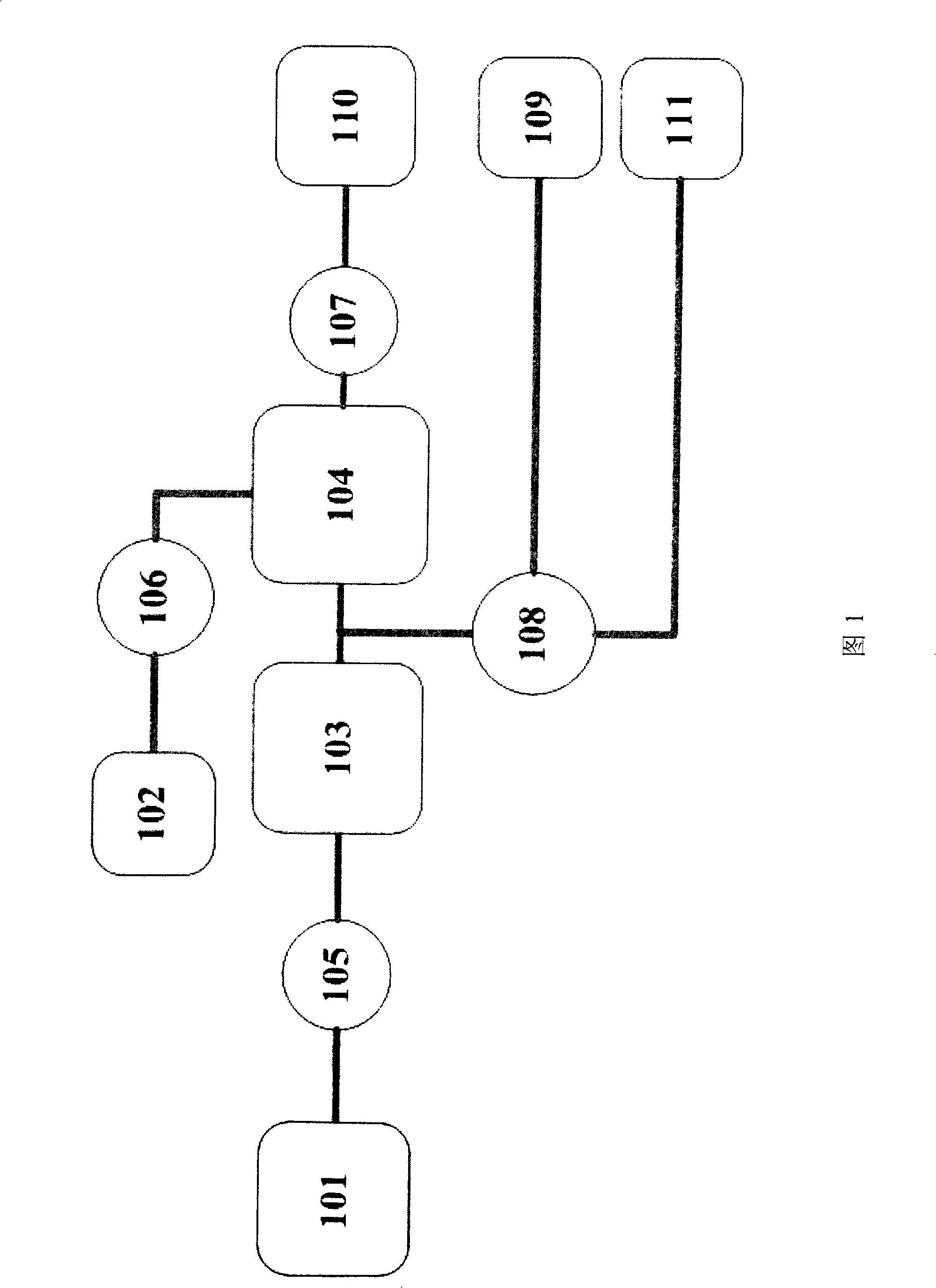

Pipe gas pressure stabilizing regulation system

The invention provides a pipeline gas pressure stabilization regulating system including a pressure monitoring system and a pressure regulating system, the pressure regulating system includes a fuel tank, a first pressure release valve and solenoid switch connected in turn, the solenoid switch connects to a first buffer vessel set, the other end of the first buffer vessel set connects to a regulating valve set by a second buffer vessel set, then connected to a combustor on the one hand; on the other hand the other end of the first buffer vessel set separately connects a secure boot flame and an igniter by a general pressure reducer; a gas pressure sensor in the pressure monitoring system is arranged on the top of the first buffer vessel set and the second buffer vessel set. The inventive system can reduce gas pressure wave motion for maintaining stabilization of the pipeline gas pressure.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

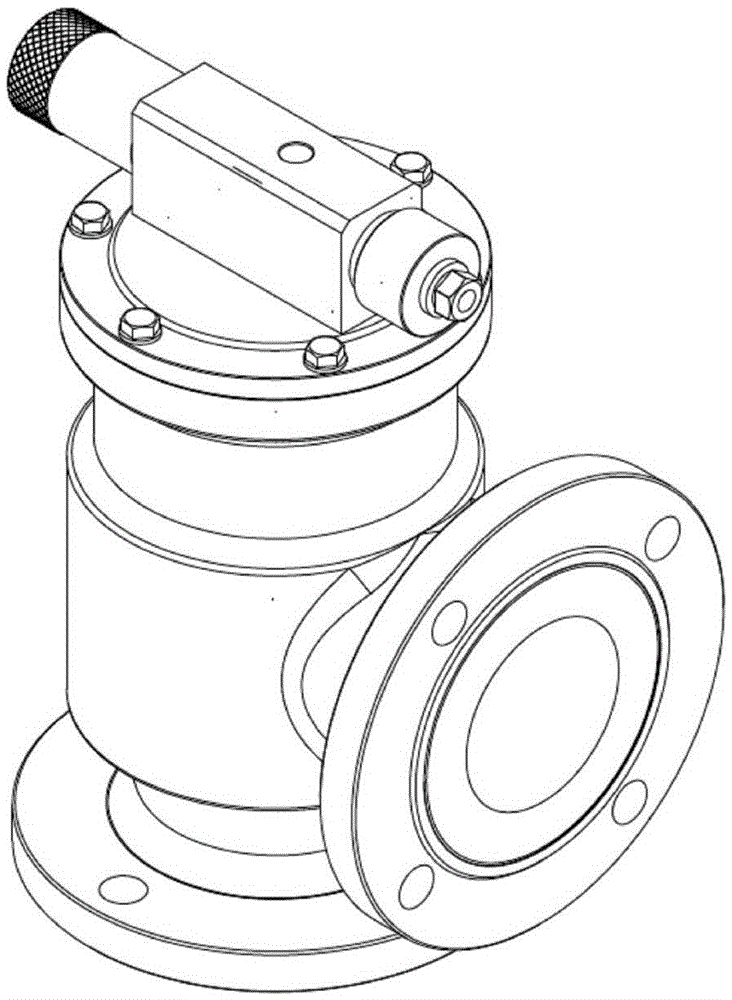

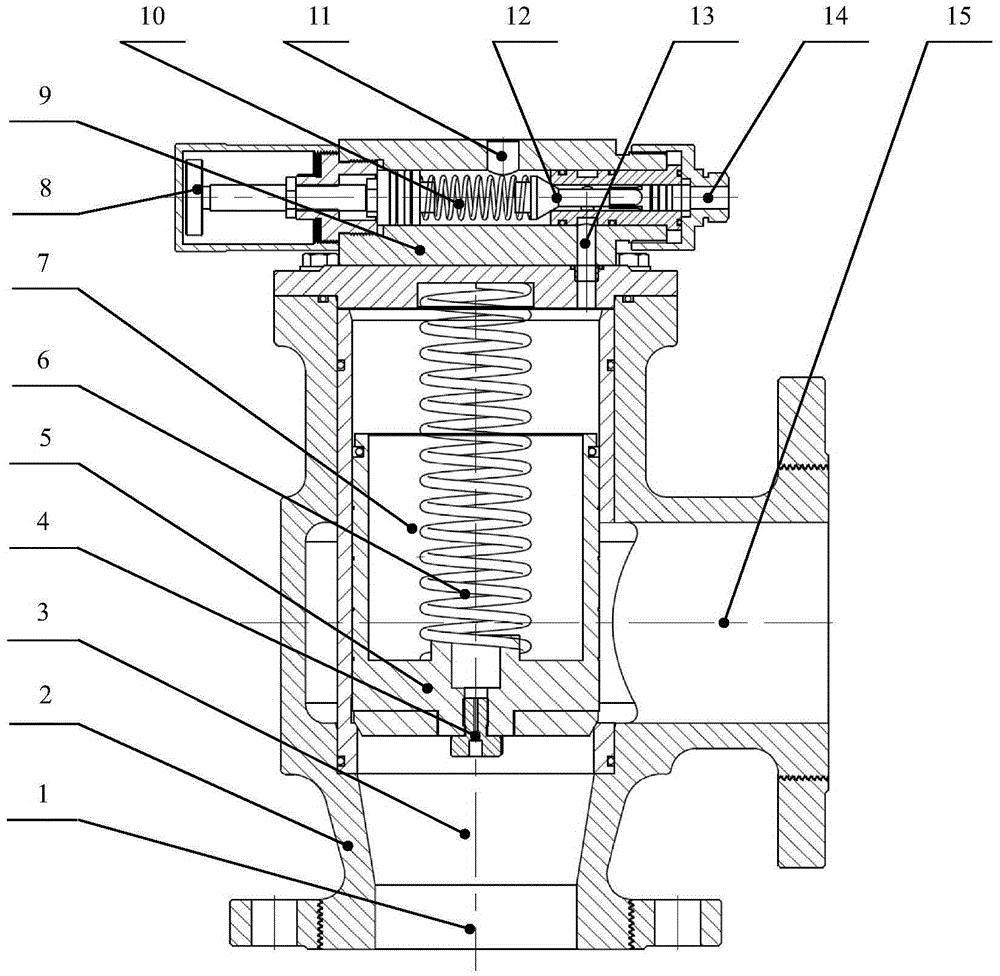

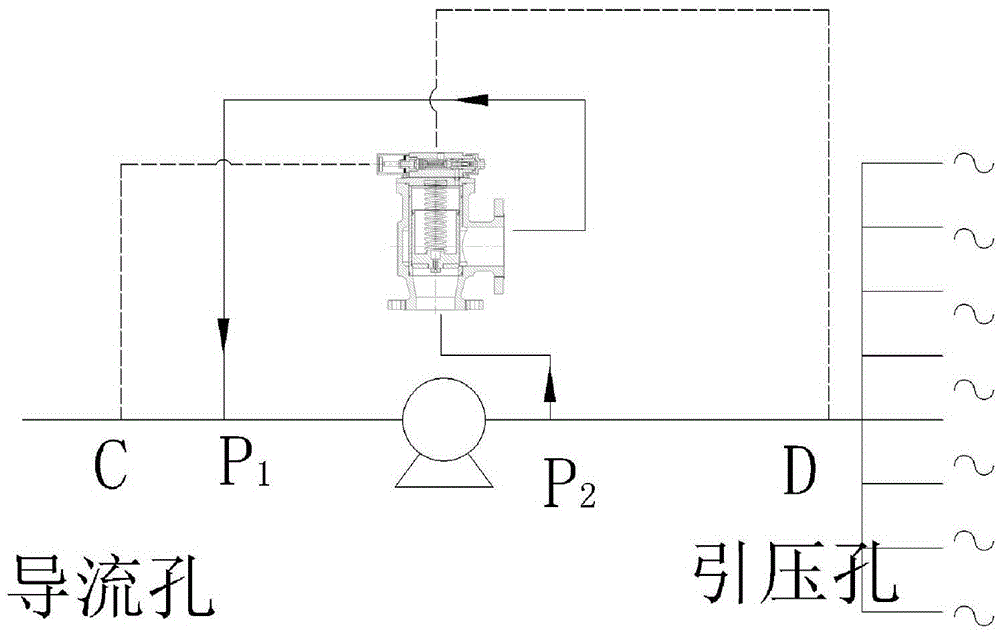

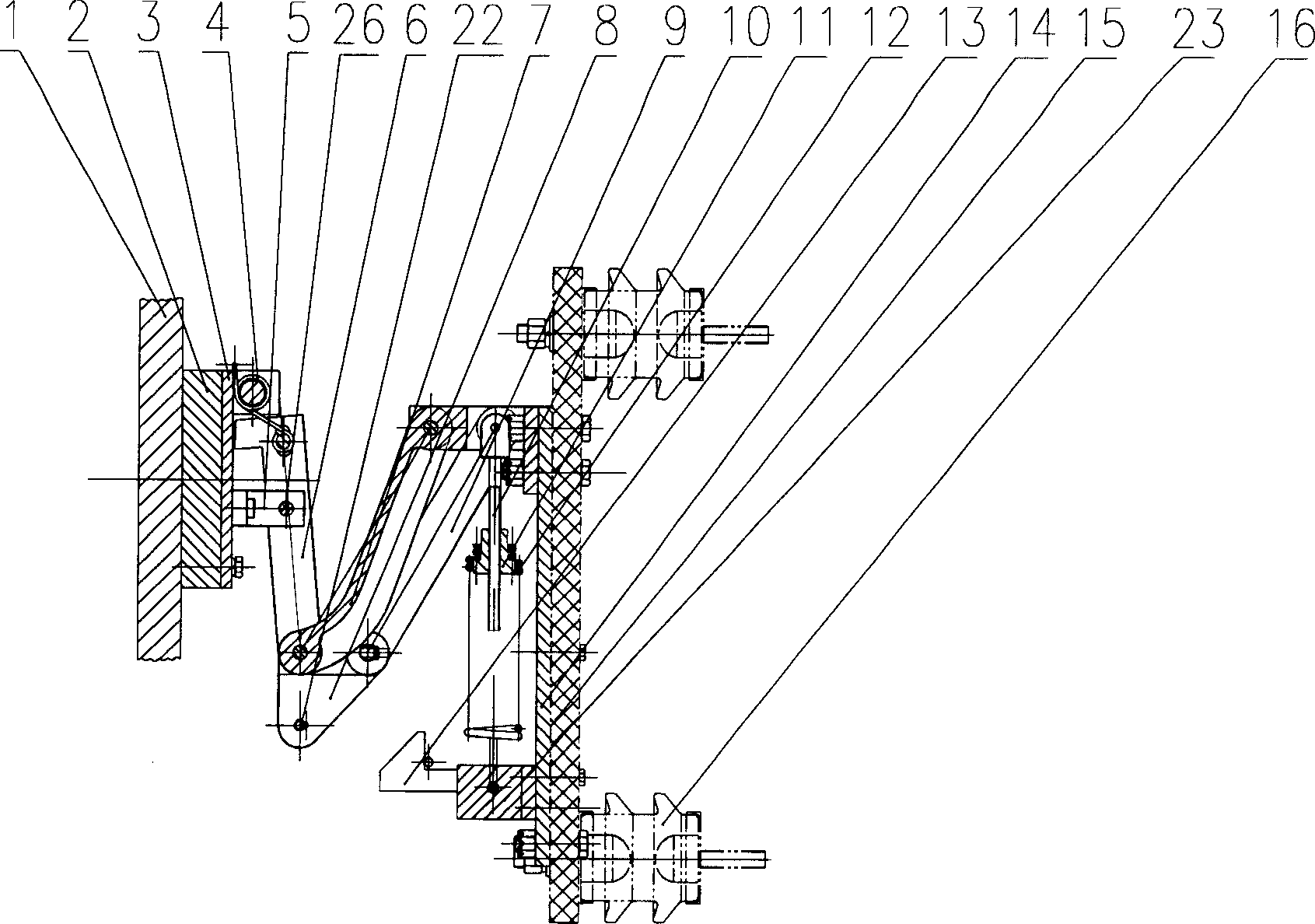

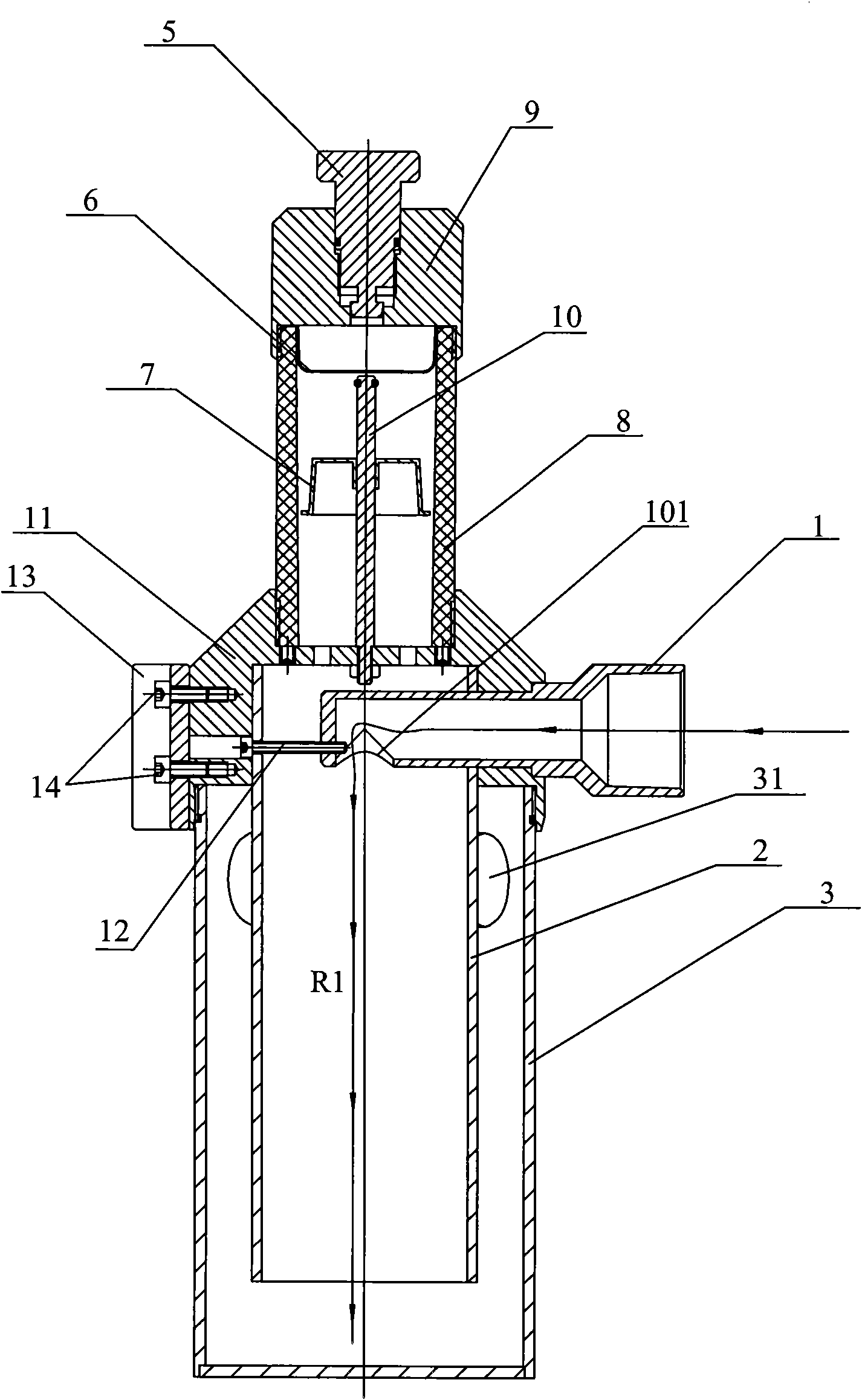

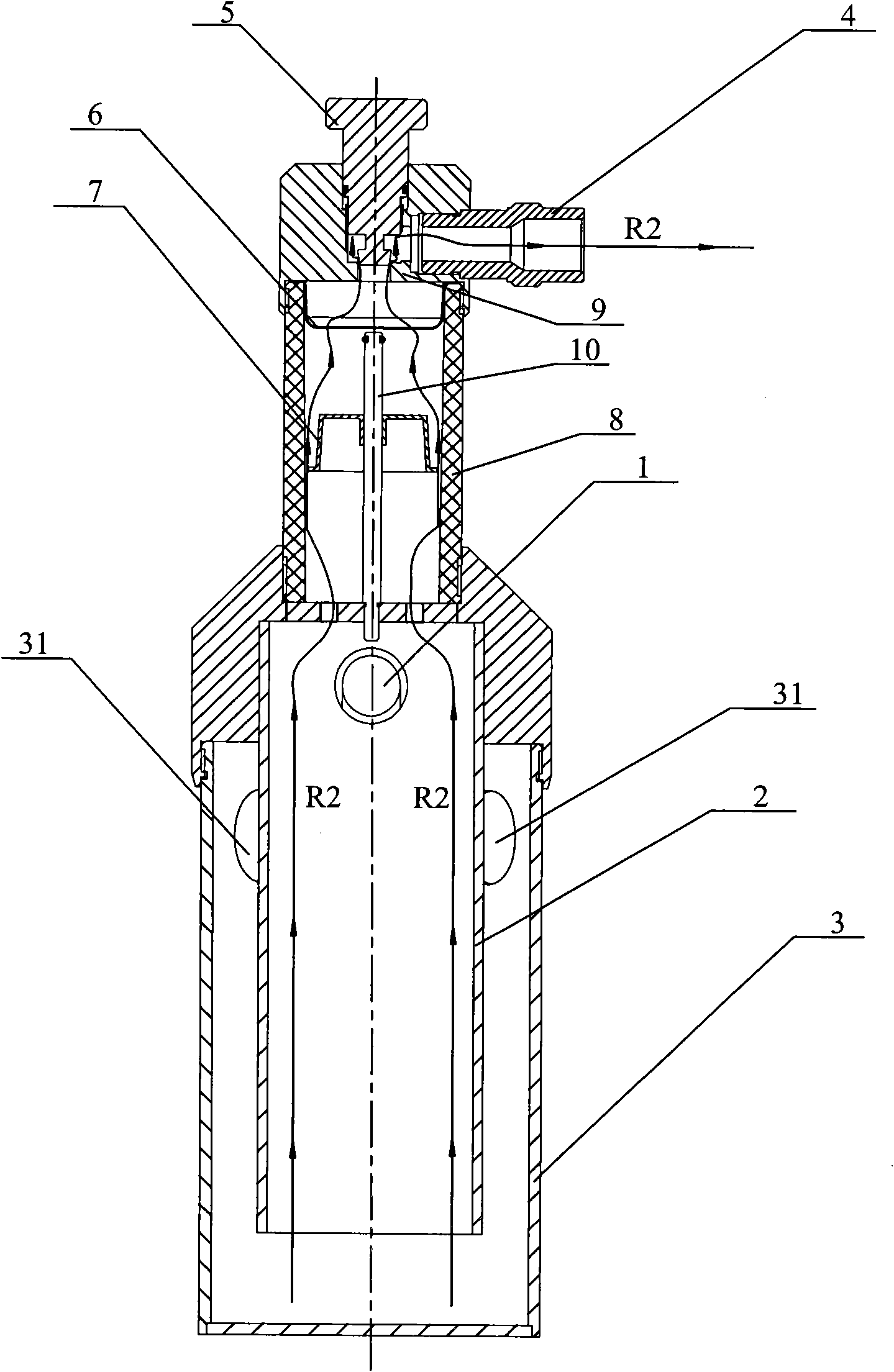

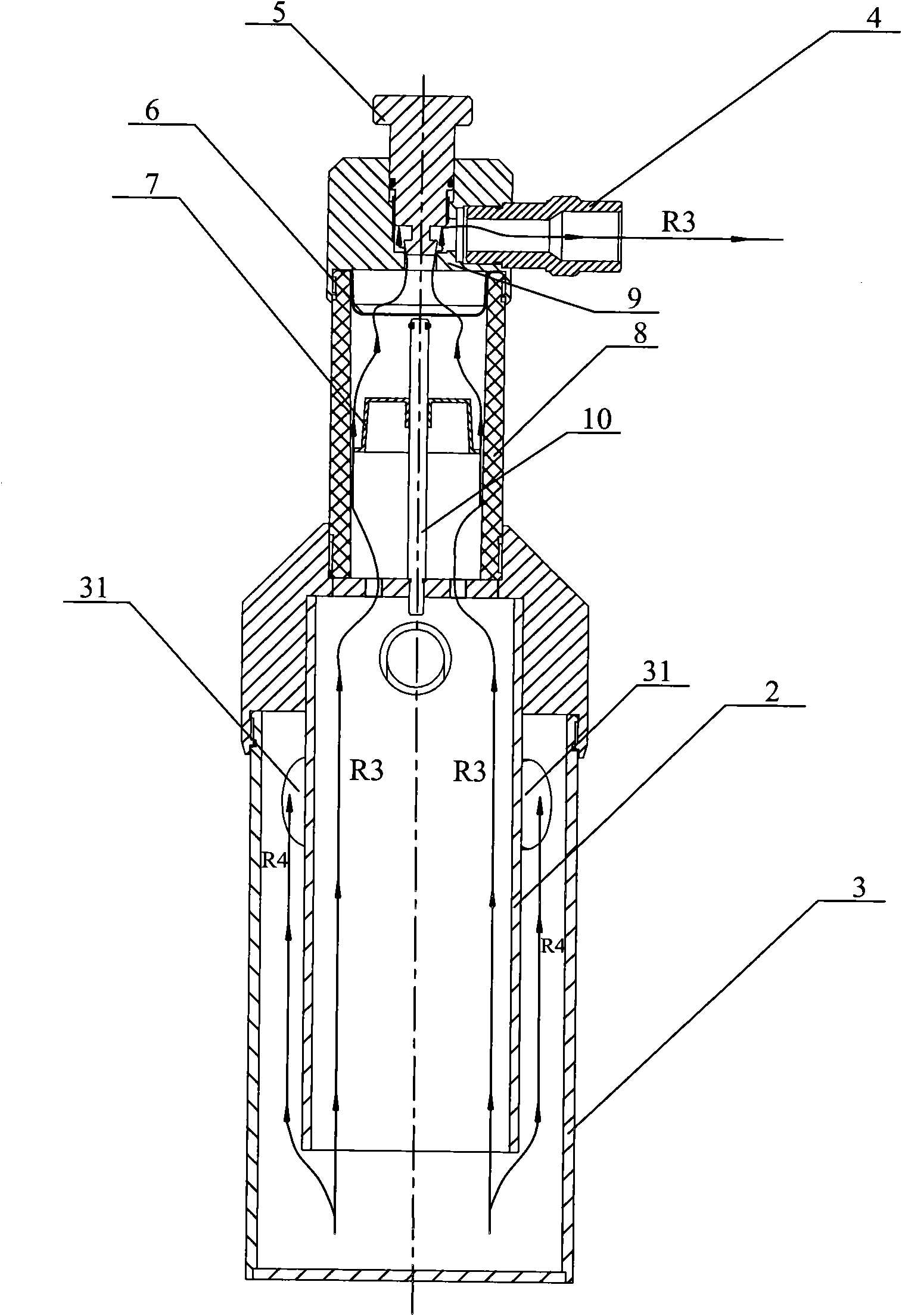

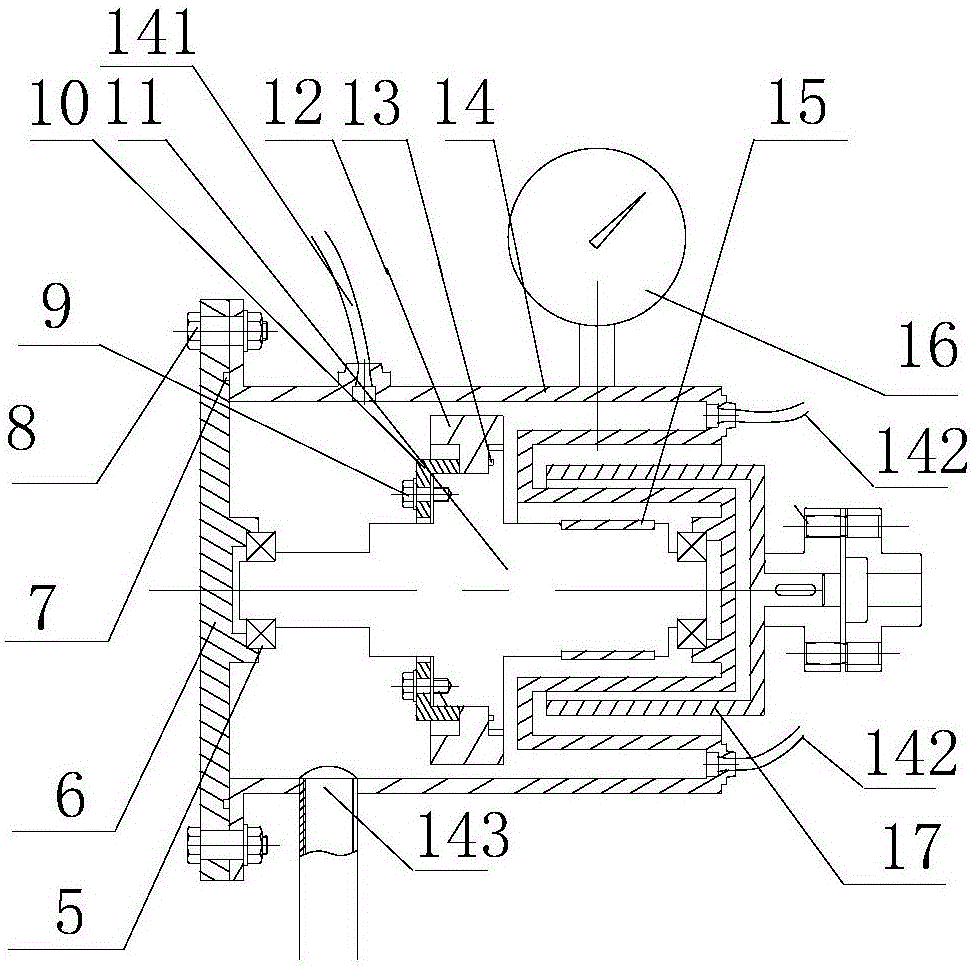

Pilot control branch pipeline flow stabilization regulation apparatus

InactiveCN105605263AGood opening and closing characteristicsSmall pressure changeEqualizing valvesSafety valvesEngineeringPiston

The invention claims to protect a pilot control branch pipeline flow stabilization regulation apparatus which comprises a main valve and a pilot valve. The main valve comprises a main valve body, a main valve inlet positioned in the lower part of the main valve body and a main valve element lower cavity; a main valve element is mounted inside the main valve body; the main valve element is communicated with the main valve element lower cavity by a main valve element damping hole; the main valve element is connected with a main valve element upper cavity; a main valve spring is arranged at the middle position of the main valve element upper cavity; one end of the main valve spring is fixed on the main valve element, and the other end of the main valve spring is positioned at the upper part of the main valve element upper cavity; the pilot valve comprises a pilot valve body and a regulation handle arranged in the pilot valve body; the regulation handle is provided with a pilot valve spring along the axial end; a pilot valve element is arranged in the pilot valve body; an inner cavity of the pilot valve body is communicated with the main valve element lower cavity by a buffer hole; by a piston, the pilot valve element interacts with a pressure medium at a pressure acquisition point, which is introduced by a pressure introduction hole. The apparatus balances and regulates pressure in a refueling pipeline.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

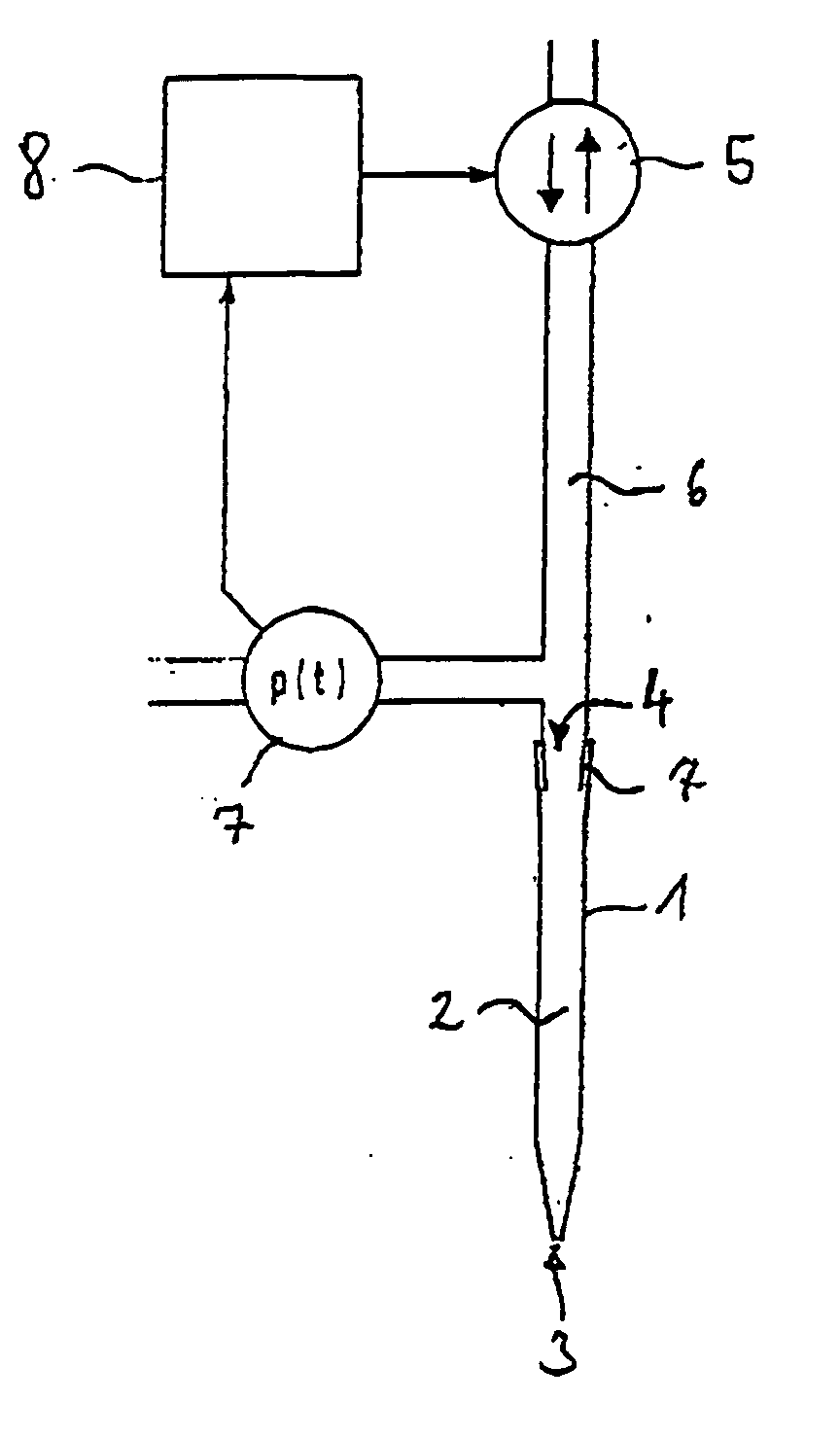

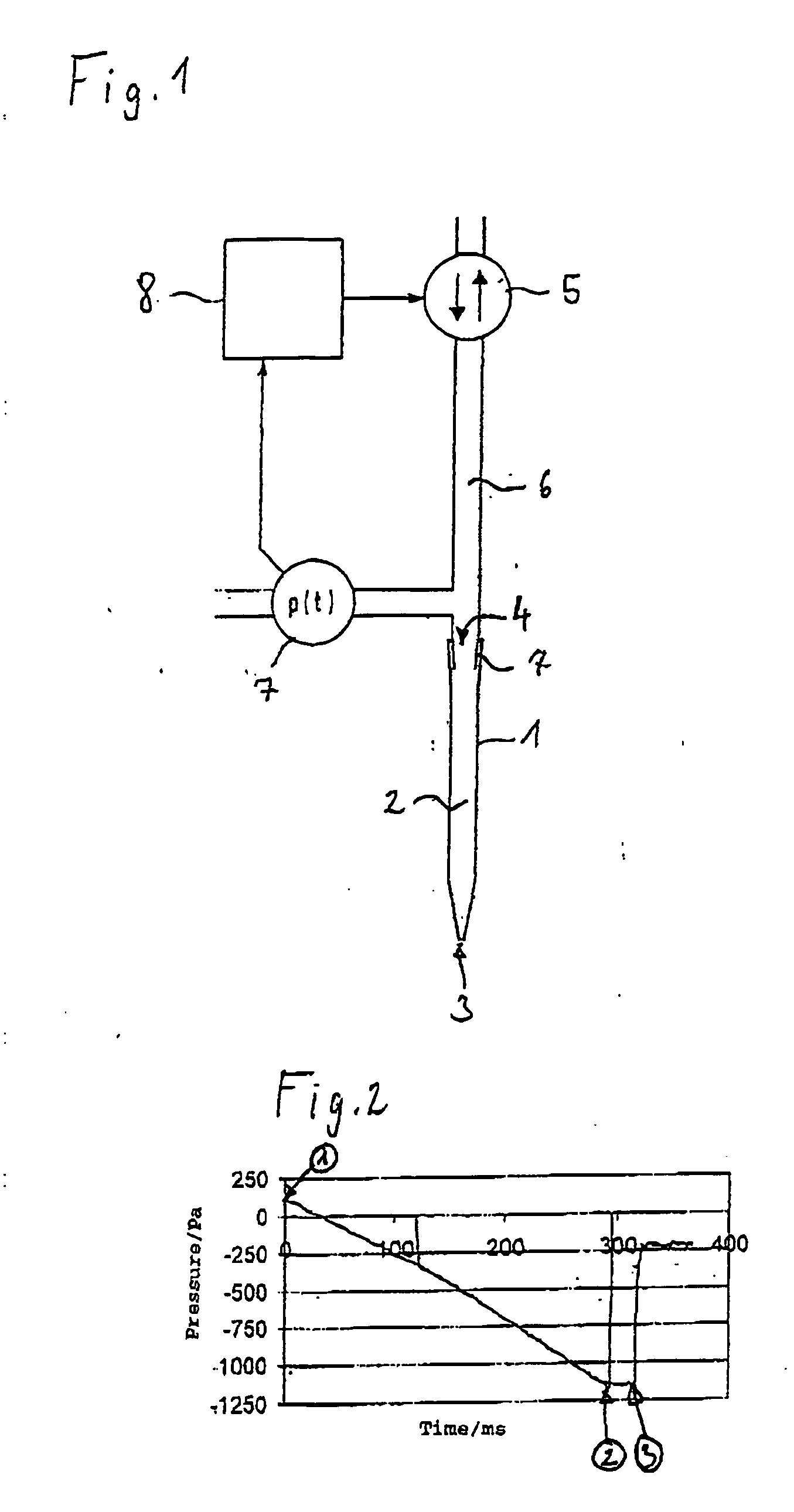

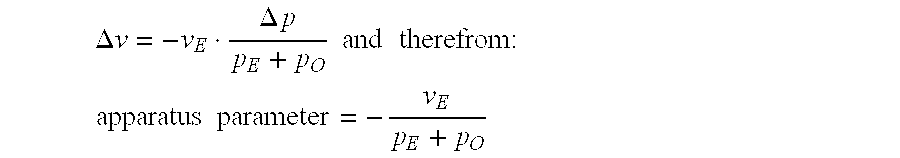

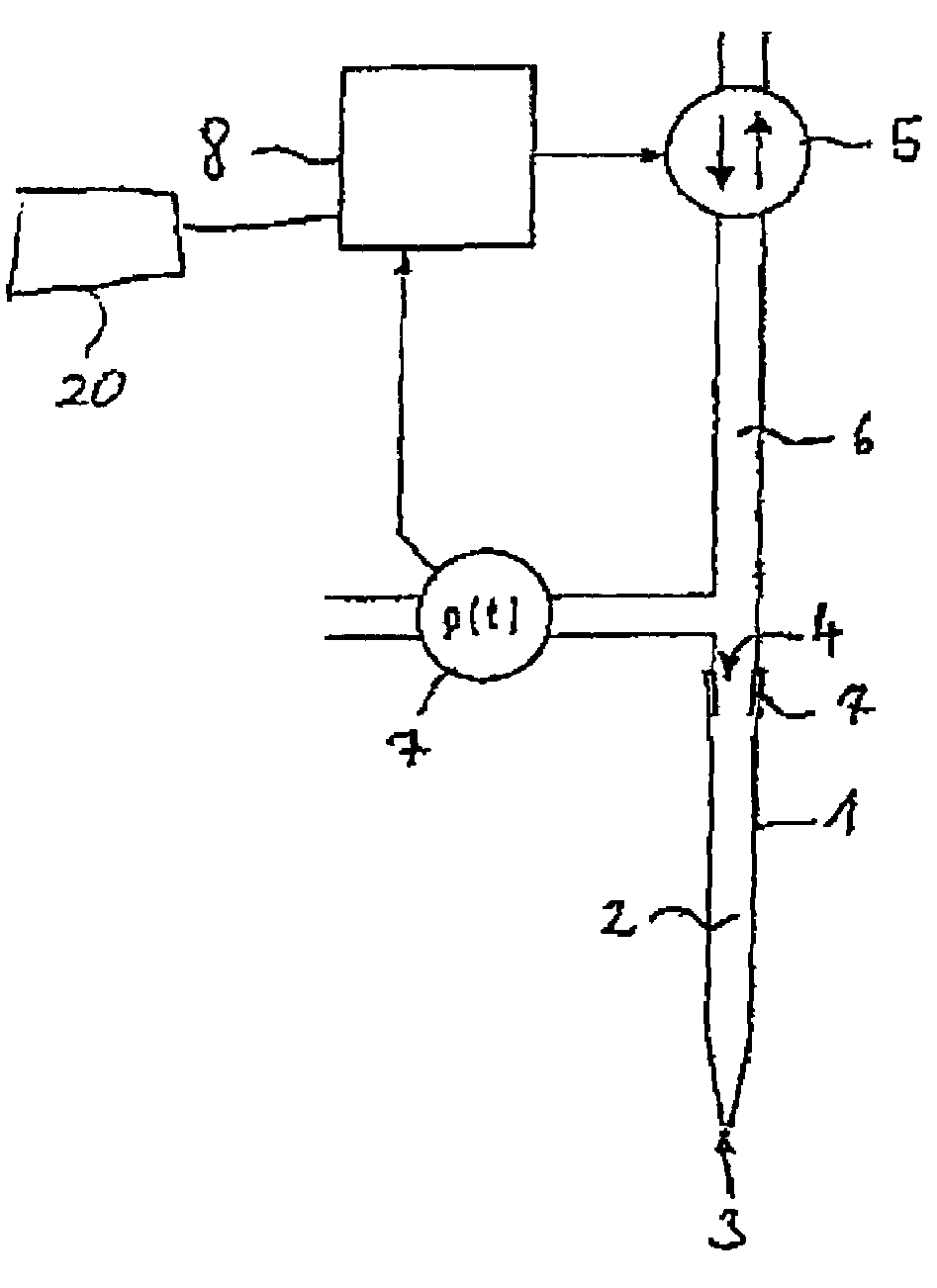

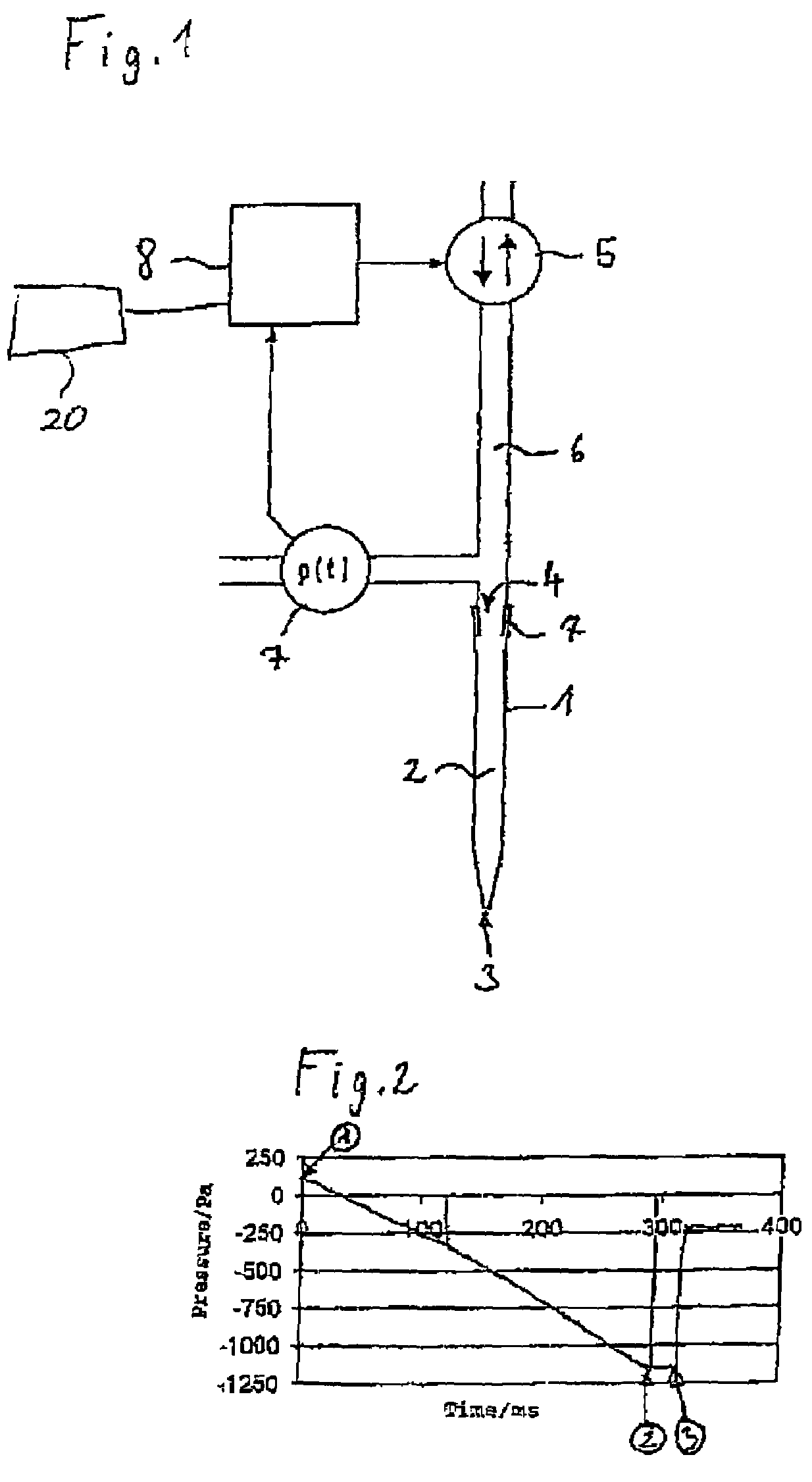

Method of dosing liquid volumes and apparatus for the execution of the method

ActiveUS20060090576A1Small pressure changeAccurately knowBurettes/pipettesMaterial analysisWorking pressureSample volume

Method for dosing liquid volumes, wherein a sample pickup portion with a pickup volume, the boundary of which is perforated with a liquid passage guiding to the outside and a gas passage, is dipped into a liquid with the liquid passage, a negative pressure is suddenly applied to the gas passage, which is generated by a gas displacement system, a drive of the gas displacement system is readjusted such that a constant negative working pressure exists in the sample pickup portion, the taken sample volume is detected with the aid of the readjusted driving path of the drive, the detected taken volume is compared with a predetermined value of the volume that is to be taken, when the predetermined value is reached by the taken volume, the negative pressure applied on the sample pickup portion is suddenly abated, the sample pickup portion with the liquid passage is pulled out of the liquid the sample pickup portion with the liquid passage is directed towards a releasing location, one ore more flow parameters is / are determined from the values of the taken volume, the negative working pressure and the time period required to take up the volume, an overpressure is applied to the gas passage of the sample pickup portion, the moment at which a volume that is to be released is released is determined with the aid of the flow parameter(s) and the overpressure, and when the moment is reached, the overpressure applied to the sample pickup portion is suddenly abated.

Owner:EPPENDORF SE

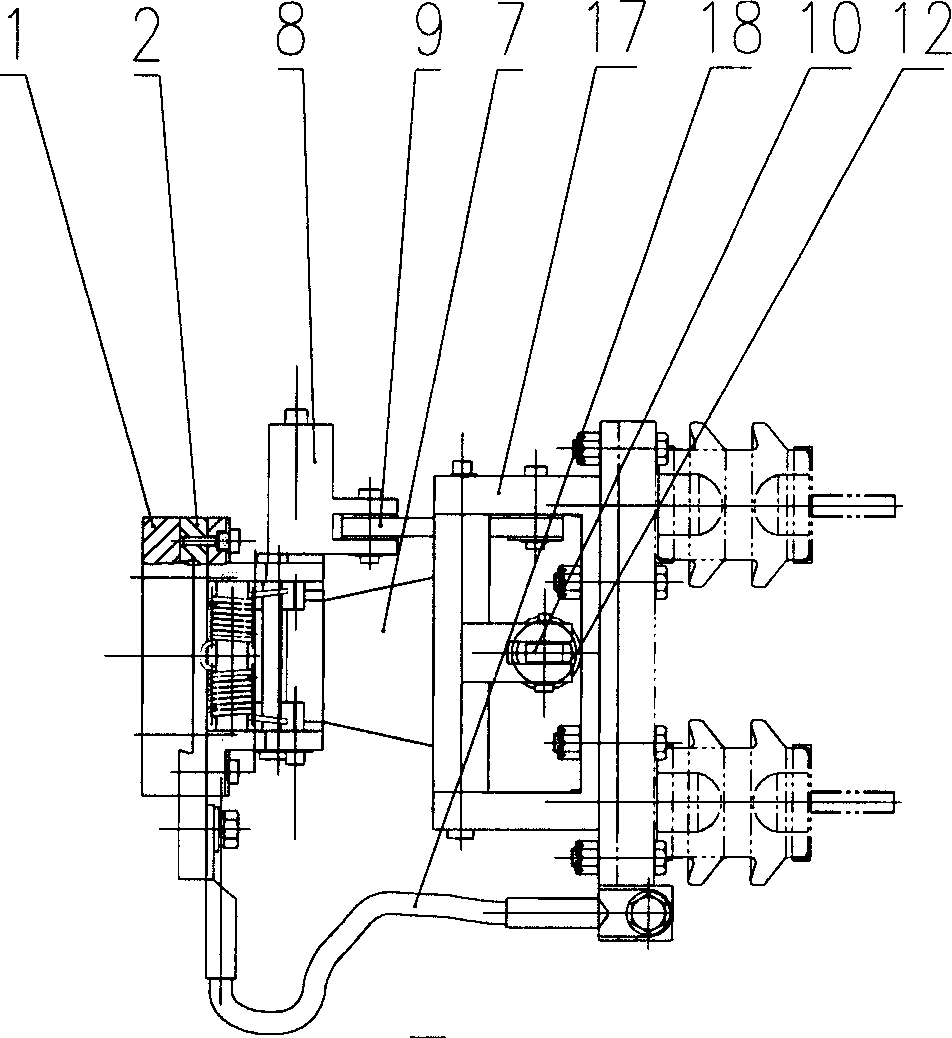

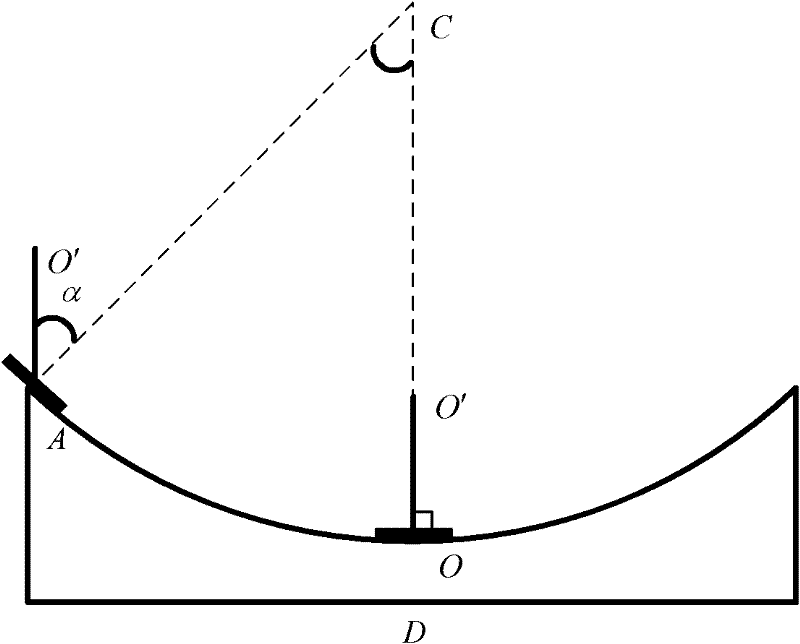

Lateral current collector

InactiveCN1760059AZoom inAchieving Parallel ScalingPower current collectorsEngineeringTorsion spring

A lateral current collector is composed of a current collecting slide block, a swing mechanism, and a base plate. Said swing mechanism connected between said slide block and base plate consists of a 4-connecting-rod unit comprising primary swinging bar, secondary swinging bar, swinging fork bar and the supporter of primary swinging bar, a final swinging bar, and a tensional spring connected between primary swinging bar and base plate.

Owner:NAT UNIV OF DEFENSE TECH

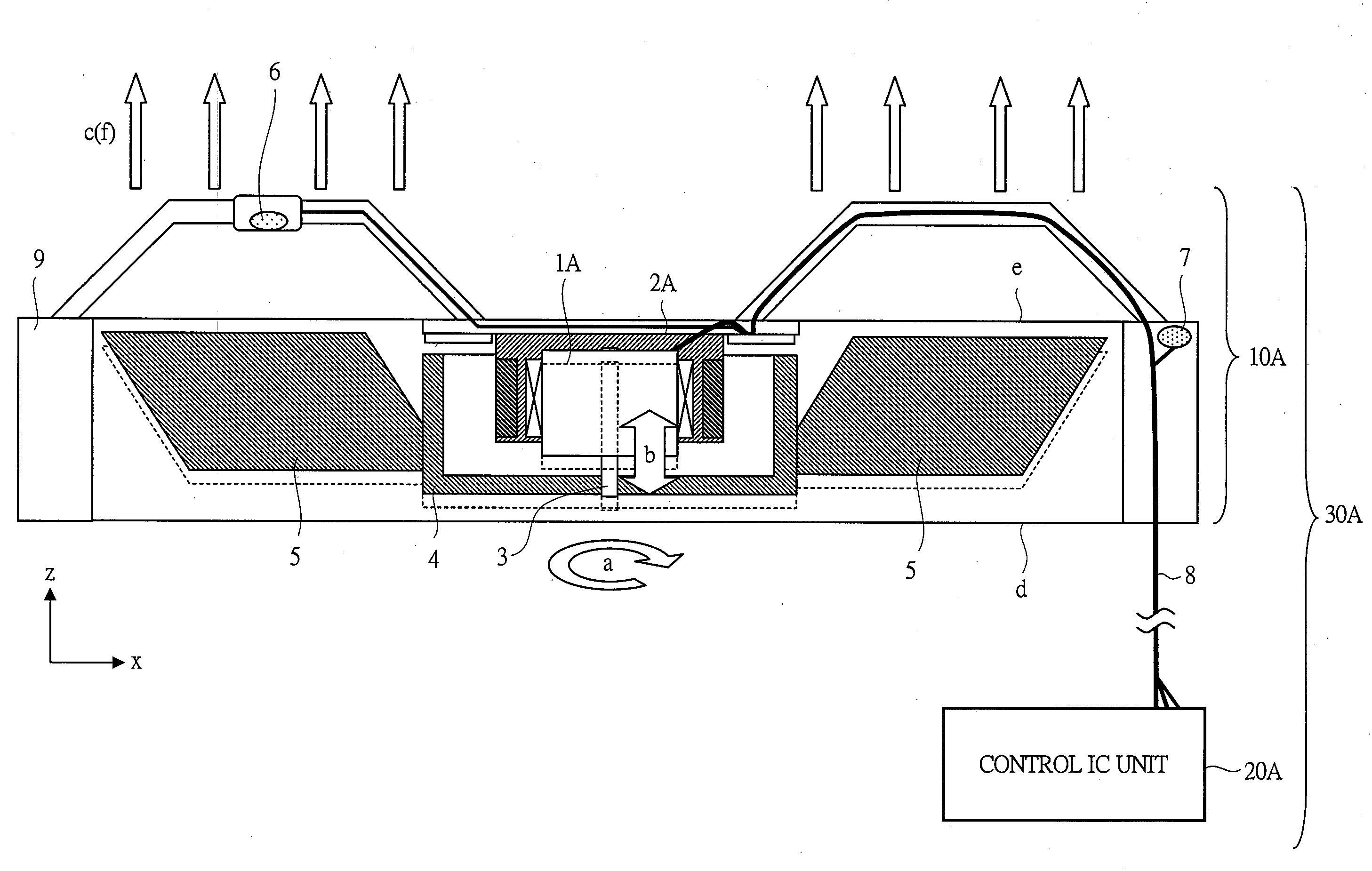

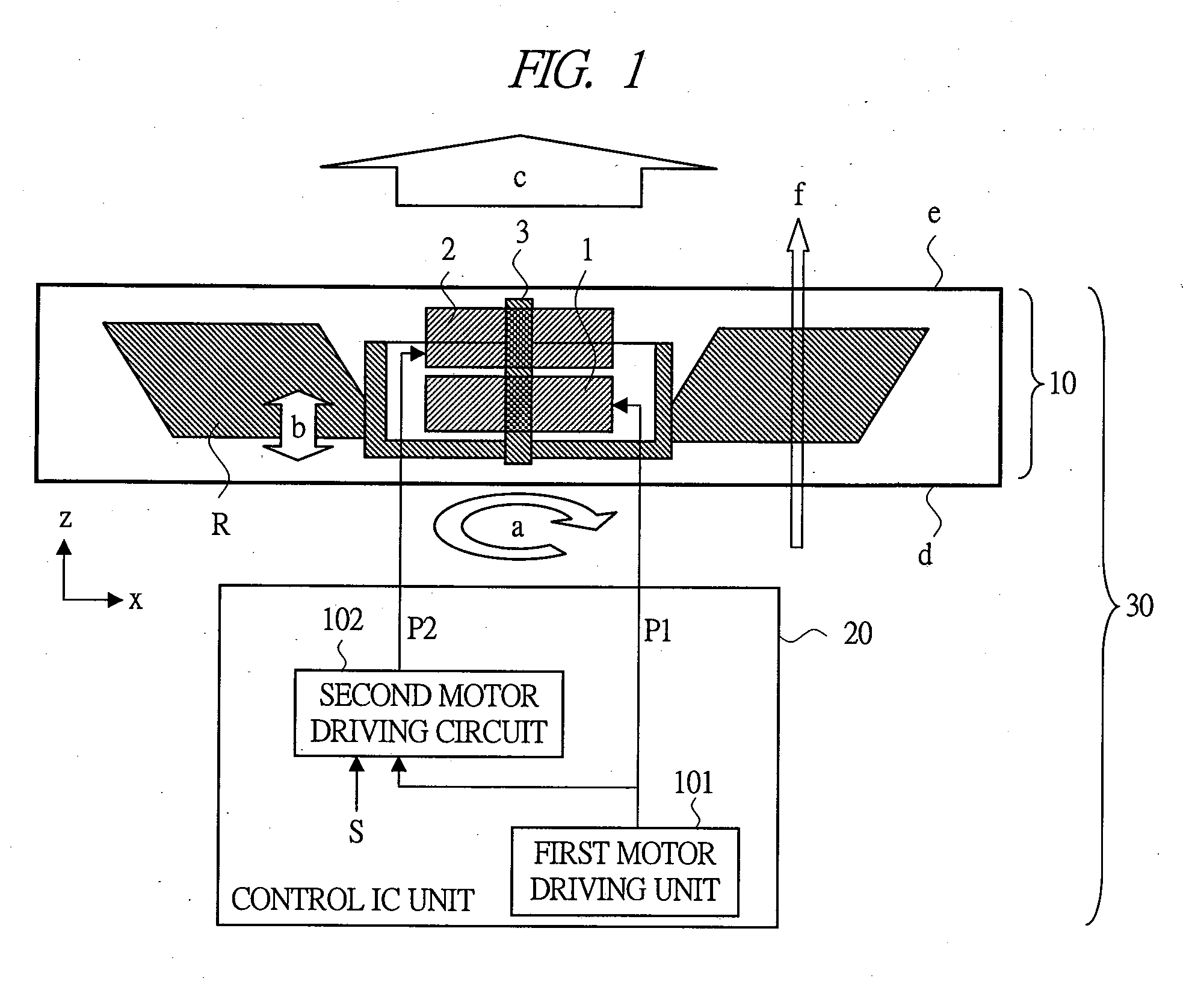

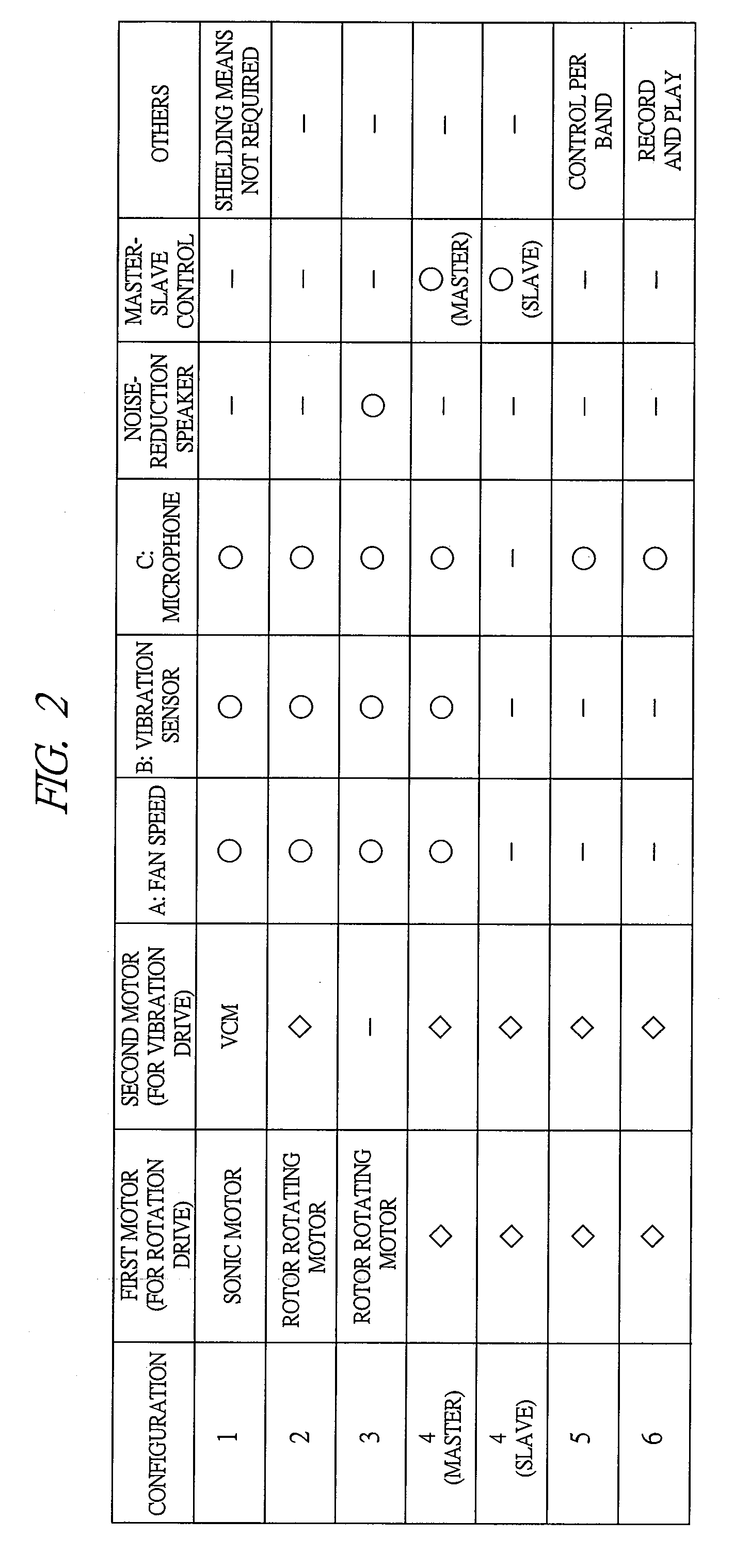

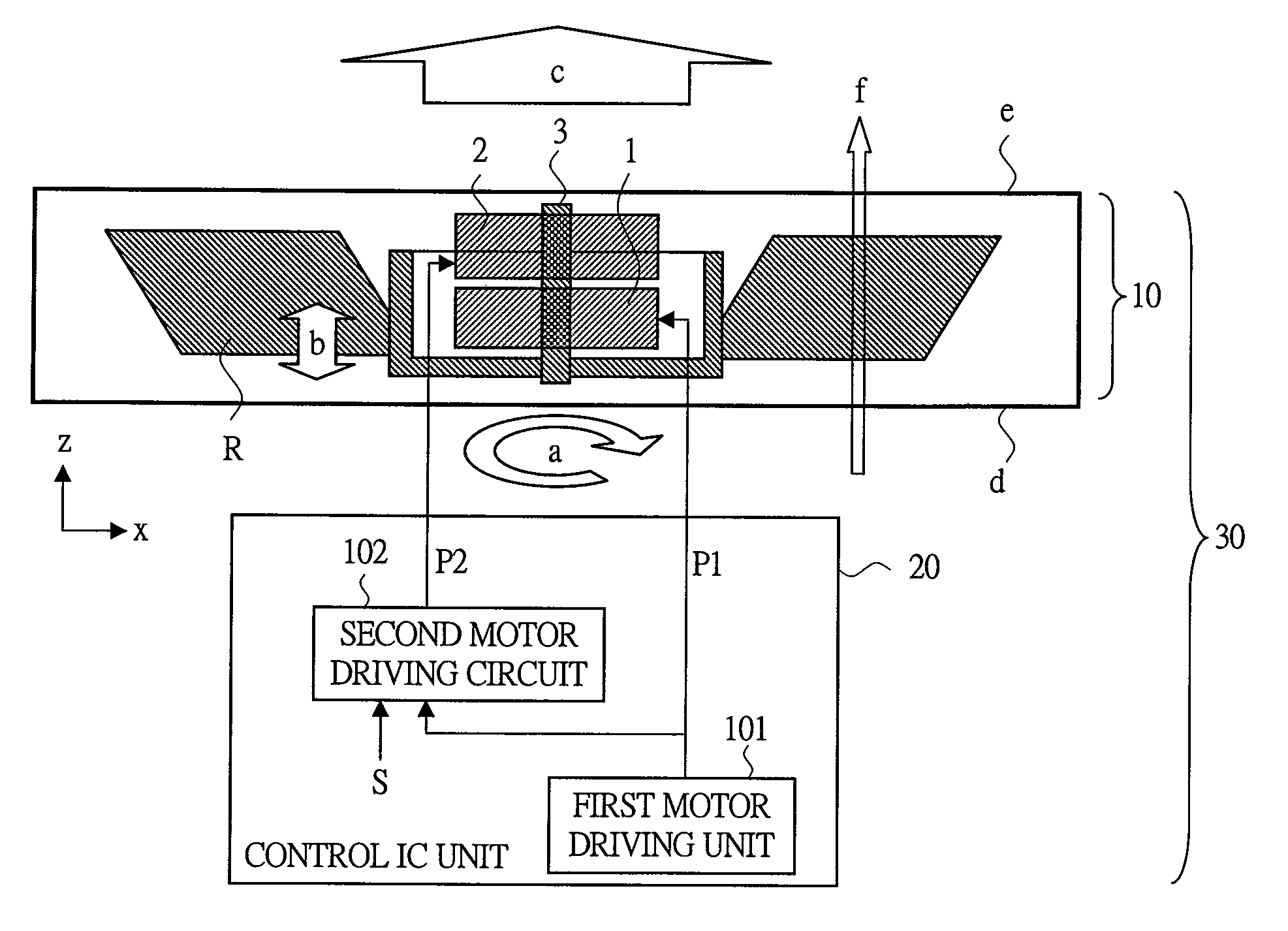

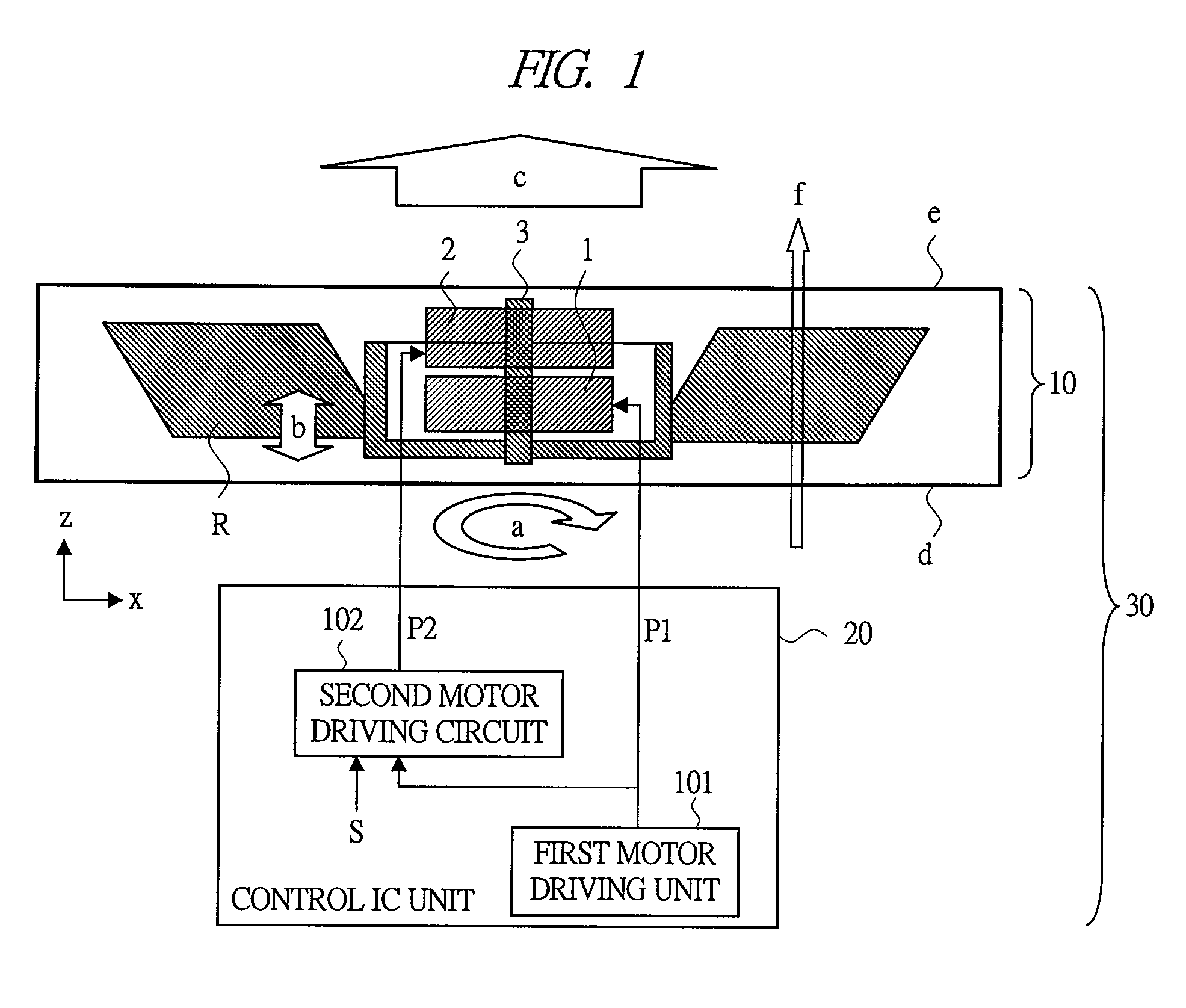

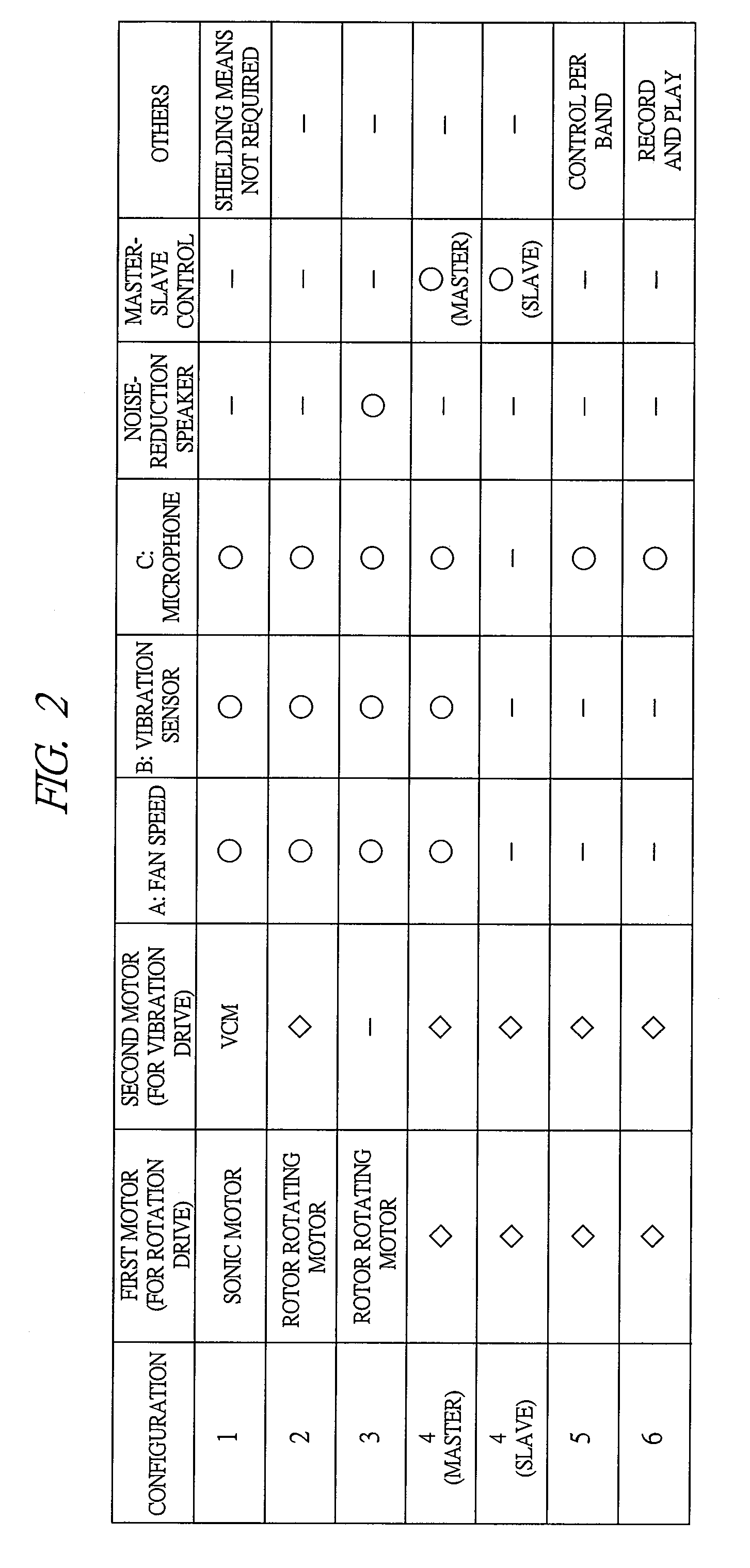

Electronic device having blower

InactiveUS20090129936A1Reduce noiseNoise (emitted sound)Ear treatmentPump componentsWave shapeControl theory

An electronic device having a first motor which rotates a rotating body (for example, blades) about a rotation axis and a second motor which vibrates a vibrator including the rotating body in the axial direction is provided. A control IC unit has a first circuit which subjects the rotation to control drive by a first waveform, and a second circuit which subjects the vibration to control drive by a second waveform. Rotation and vibration of a rotating and vibrating unit driven by the first and second motors generates an airflow and output sound by a synthesized output of a first output corresponding to the rotation and a second output corresponding to the vibration. The control IC unit generates a second waveform by using a reversed-phase waveform with respect to the first waveform or the like and suppresses the output sound by control of the first and second waveforms.

Owner:HITACHI LTD

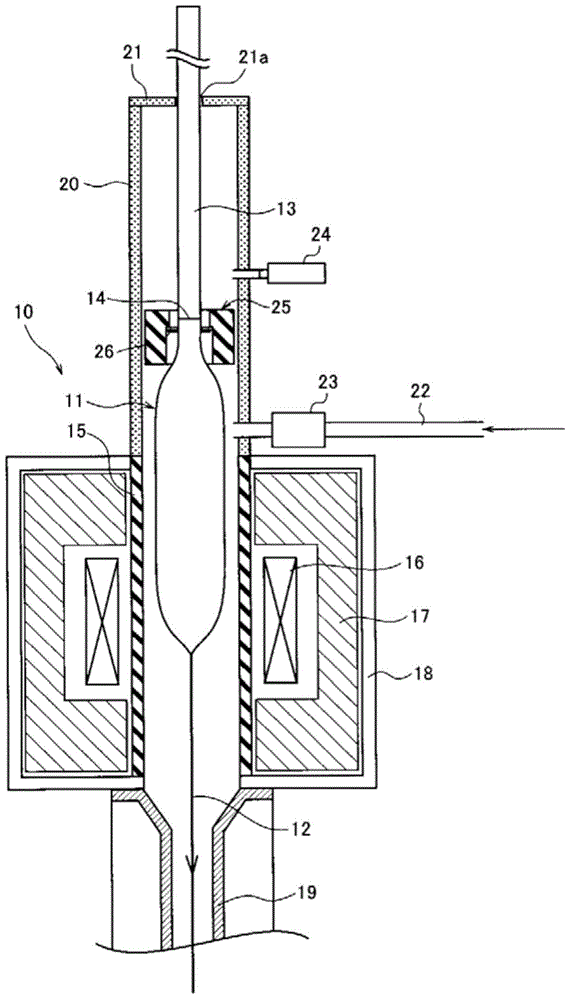

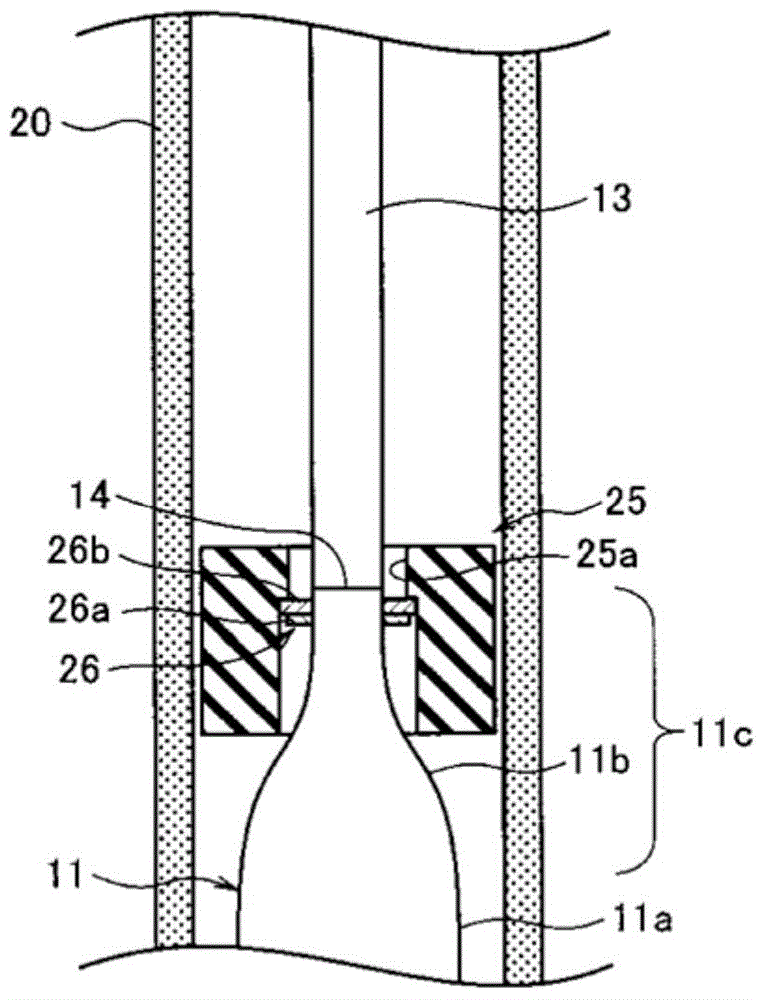

Manufacturing method of fiber

InactiveCN104556677AAvoid convectionSuppression of fluctuations in outer diameterGlass making apparatusFiber drawingWire drawing

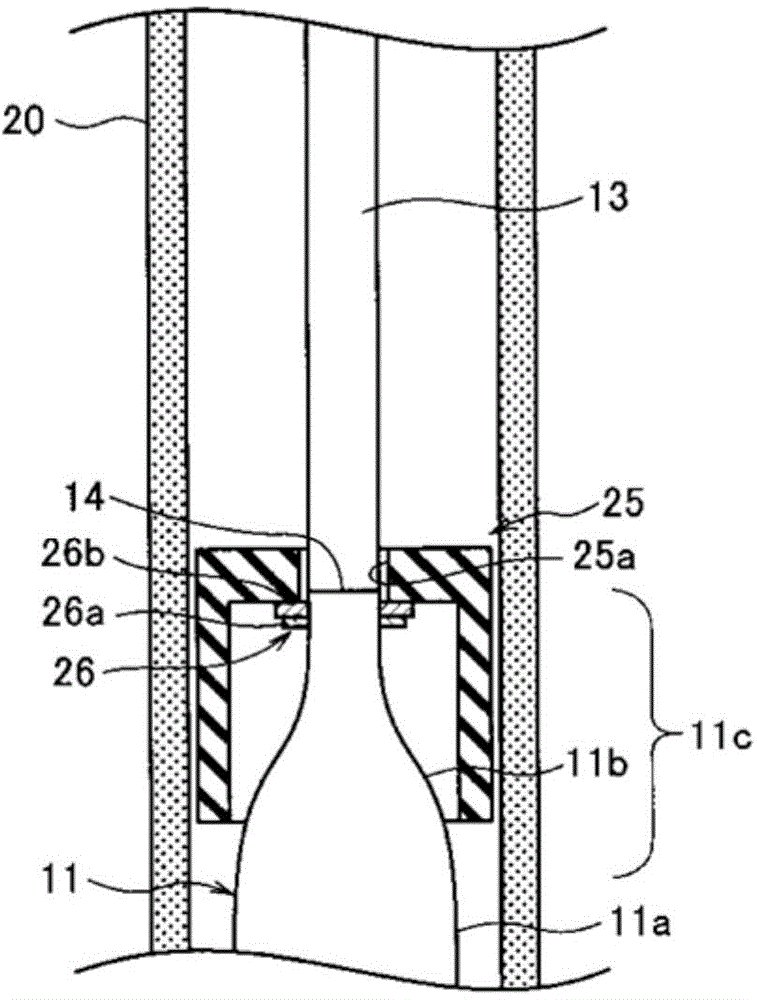

The invention provides a manufacturing method of a fiber. By reducing pressure variation and gas flow variation of a fiber drawing furnace resulting from fiber drawing operation of glass base material so that a variation in the external diameter of the fiber is inhibited to be smaller. The manufacturing method is described in that the upper end of the glass base material (11) for the fiber with a necking portion (11c) at the upper portion is connected with a support rod (13); the fiber is formed by being drawn out through heating and melting of the glass base material for the fiber in the fiber drawing furnace; and the position where the necking portion of the glass base material for the fiber is provided with a part (25), the size of which is larger than or equal to 50% of space between the necking portion and a fuel core pipe so that the fiber is drawn out.

Owner:SUMITOMO ELECTRIC IND LTD

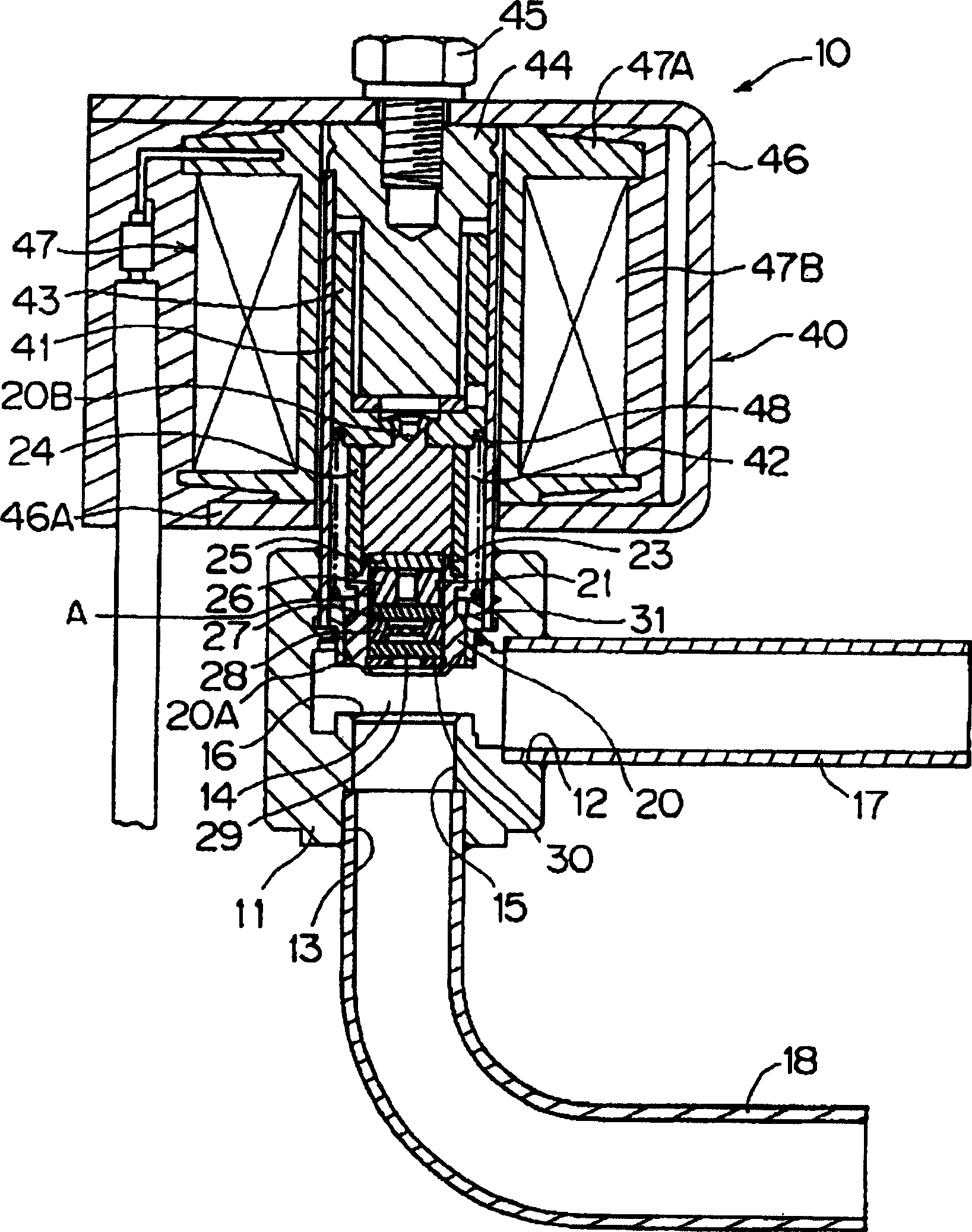

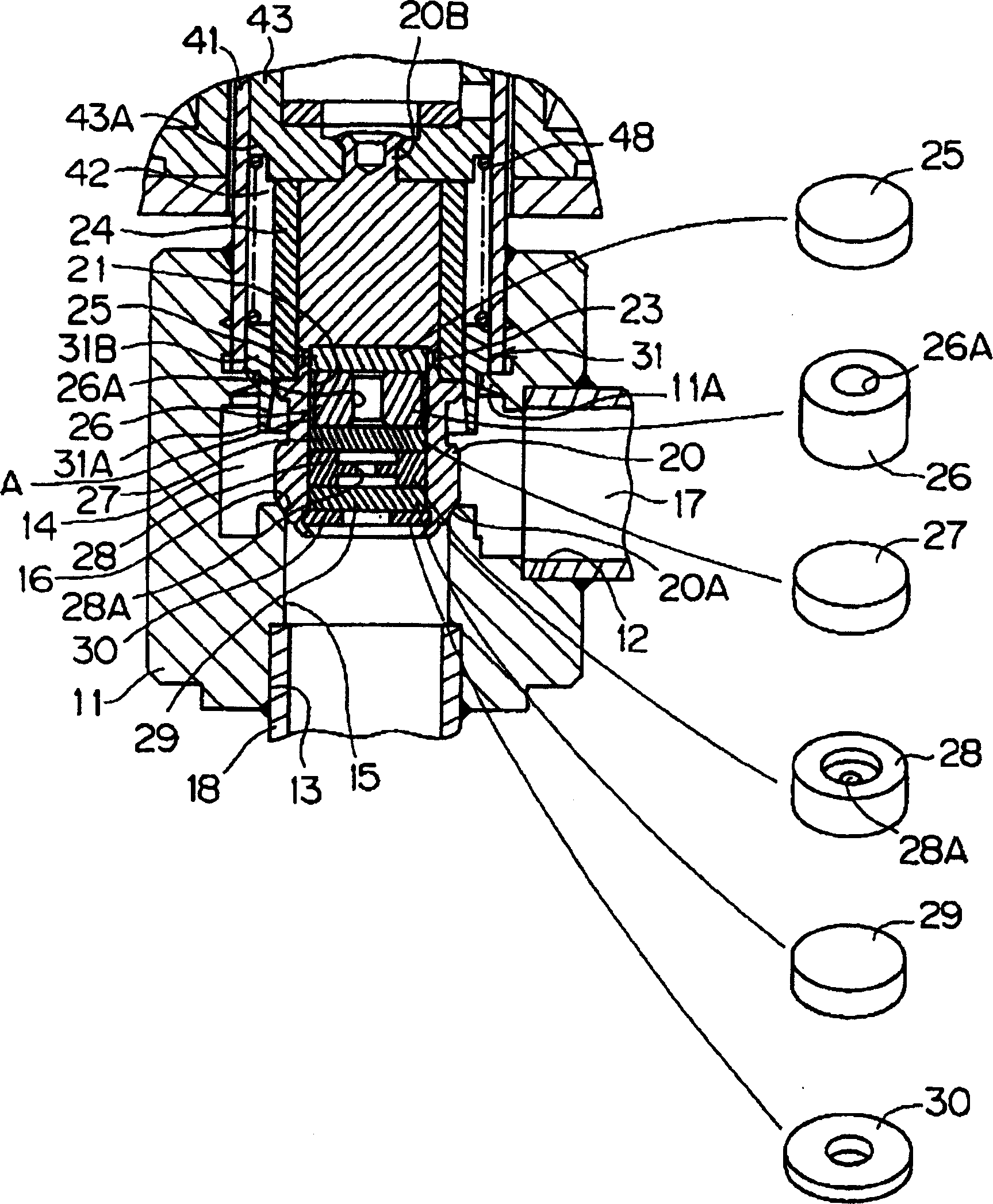

Throttle valve device and air conditioner

ActiveCN1699803ASmall pressure changeReduce noiseOperating means/releasing devices for valvesValve members for absorbing fluid energyEngineeringAir conditioning

The purpose of this invention is to effectively reduce noise, by reducing vibration itself generated in a throttle part in a throttle valve device. A shock absorbing member 26 and a throttle member 28 are arranged in series when viewing a fluid flow flowing in a passage, in the passage for communicating and connecting a first inlet-outlet port 12 with a second inlet-outlet port 13 in a state of closing a valve element 20.

Owner:SAGINOMIYA SEISAKUSHO INC

Control system of compression-ignition engine

ActiveUS10697391B2Small pressure changeReduce combustion noiseElectrical controlInternal combustion piston enginesCombustion chamberLow speed

A control system of a compression-ignition engine is provided, which includes an engine configured to cause combustion of a mixture gas inside the combustion chamber, an injector attached to the engine and configured to inject fuel into the combustion chamber, a spark plug disposed to be oriented into the combustion chamber and configured to ignite the mixture gas inside the combustion chamber, and a controller connected to the injector and the spark plug and configured to operate the engine by outputting a control signal to the injector and the spark plug, respectively. After the spark plug ignites the mixture gas to start combustion, unburned mixture gas combusts by self-ignition. The controller outputs the control signal to the injector so that a fuel injection timing is advanced when the engine operates at a high speed than at a low speed.

Owner:MAZDA MOTOR CORP

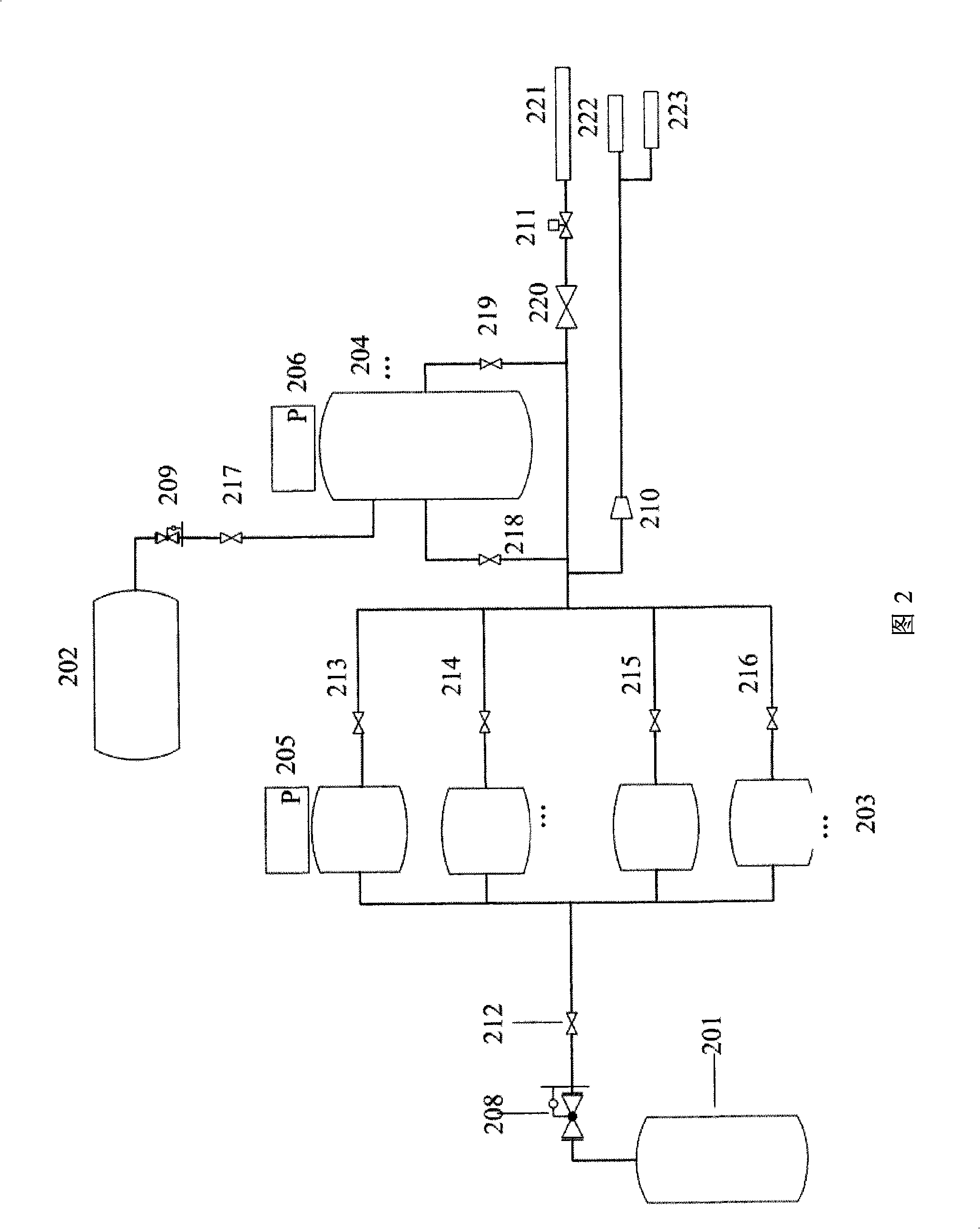

Refrigerant recycling and charging device

The invention provides a refrigerant recycling and charging device. The refrigerant recycling and charging device comprises input pipe fittings, an evaporator, a first oil-gas separator, a compressor, a second oil-gas separator, a condenser and output pipe fittings, which are sequentially communicated, wherein a second oil discharging pipeline of the second oil-gas separator is communicated with a pipeline between the compressor and the first oil-gas separator. According to the design of the refrigerant recycling and charging device, the first oil-gas separator separates refrigeration oil in the refrigerant first, so that the situation that the refrigeration oil enters the compressor to cause damage to the compressor is effectively prevented. The second oil-gas separator separates compressor lubricating oil in the refrigerant flowing from the compressor, so that pollution to the refrigerant is prevented. Besides, the oil discharging pipeline of the second oil-gas separator leads the compressor lubricating oil in the entry end of the compressor, so that the compressor lubricating oil can be recycled, and the service efficiency is improved.

Owner:GUANGDONG HIWAVE TECH

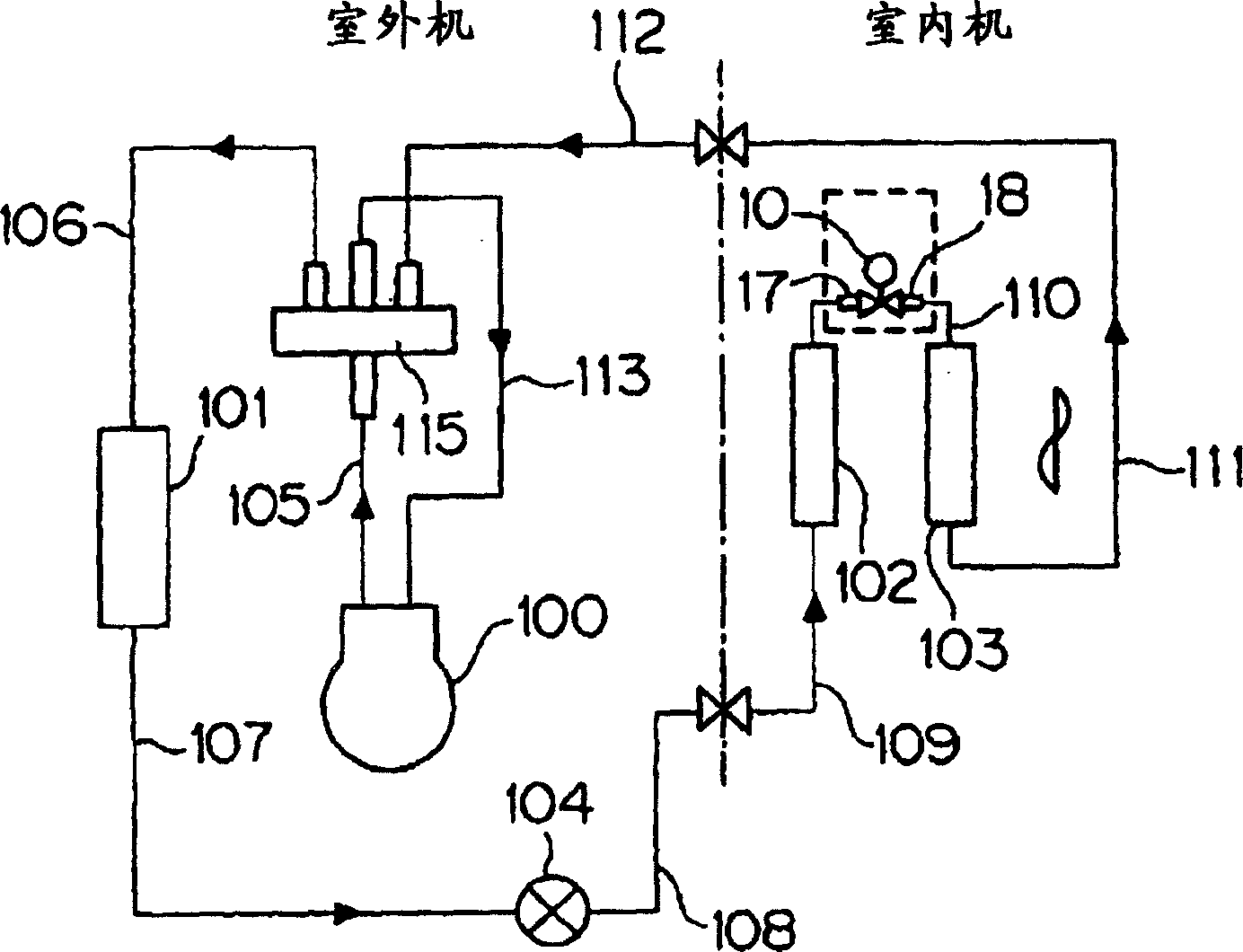

Air conditioner

InactiveCN1769819ALittle changeImprove operational reliabilityMechanical apparatusCorrosion preventionFour-way valveEngineering

The invention provides an air conditioner that continues heating operation and defrost operation at the same time, which is provided with: an indoor heat exchanger (3) and a pressure reducer (4) in a heat pump refrigeration loop. A first bypass circuit (6) is connected between the pipe and the suction side of the compressor (1). The first bypass circuit is provided with a two-way valve (7) and a refrigerant heater (8). In addition, the present invention is also provided with a pipeline and a pressure reducer (4) between the four-way valve (2) connected to the refrigeration loop and the indoor heat exchanger (3) and the outdoor heat exchanger (5). There is a second bypass circuit (9) connected by pipelines therebetween, and a two-way valve (10) is provided on the second bypass circuit. When defrosting the outdoor heat exchanger (5), open the two-way valve (7) on the first bypass circuit (6) and the two-way valve (10) on the second bypass circuit (9), and execute Heating and defrosting operations.

Owner:PANASONIC CORP

Method of dosing liquid volumes and apparatus for the execution of the method

ActiveUS7197948B2Small pressure changeAccurately knowWithdrawing sample devicesWorking pressureStreamflow

Method for dosing liquid volumes, wherein a sample pickup portion with a pickup volume, the boundary of which is perforated with a liquid passage guiding to the outside and a gas passage, is dipped into a liquid with the liquid passage, a negative pressure is suddenly applied to the gas passage, which is generated by a gas displacement system, a drive of the gas displacement system is readjusted such that a constant negative working pressure exists in the sample pickup portion, the taken sample volume is detected with the aid of the readjusted driving path of the drive, the detected taken volume is compared with a predetermined value of the volume that is to be taken, when the predetermined value is reached by the taken volume, the negative pressure applied on the sample pickup portion is suddenly abated, the sample pickup portion with the liquid passage is pulled out of the liquid the sample pickup portion with the liquid passage is directed towards a releasing location, one ore more flow parameters is / are determined from the values of the taken volume, the negative working pressure and the time period required to take up the volume, an overpressure is applied to the gas passage of the sample pickup portion, the moment at which a volume that is to be released is released is determined with the aid of the flow parameter(s) and the overpressure, and when the moment is reached, the overpressure applied to the sample pickup portion is suddenly abated.

Owner:EPPENDORF SE

System and method for preparing oxygen by vacuum pressure swing adsorption

PendingCN108939820AIncrease pressureKeep the pressure constantProductsReagentsVacuum pressureTime delays

The invention relates to a system and method for preparing oxygen by vacuum pressure swing adsorption. The system comprises a velocity type fan, an adsorptive separation unit and a velocity type vacuum pump, wherein a fan work condition control unit is connected between the air inlet of the adsorptive separation unit and the velocity type fan; a vacuum pump work condition control unit is connectedbetween the exhaust of the adsorptive unit and the velocity type vacuum pump; prediction and adjustment can be carried out in advance by regulating the openness of a control valve A when pressure fluctuates, so that the influence caused by time delay of valve action can be eliminated; the inlet flow rate of the fan work condition control unit is equal to the outlet flow rate of the velocity typefan, the pressure of a buffer tank B is kept constant by controlling the flow rate of a valve B to be equal to the inlet flow rate of the vacuum pump, and the inlet flow rate and pressure of the velocity vacuum pump can be kept constant, so that the inlet pressure and outlet pressure are ensured to be smooth.

Owner:CHENGDU HUAXITANG ENVIRONMENTAL PROTECTION TECH CO LTD

Gas absorption system

The invention provides a gas absorption system. The absorption system comprises a gas inlet pipe, a gas capacitor part and a negative pressure exhaust pipe, wherein gas enters the gas capacitor part through the gas inlet pipe; the negative pressure exhaust pipe exhausts the gas in the gas capacitor part to an external device by using negative pressure; and the gas capacitor part comprises a firstchamber, and the side wall of the first chamber is provided with gas holes used for exhausting the gas in the gas capacitor part or allowing external gas to enter the gas capacitor part. The gas absorption system can effectively prevent the gas inside the system from being directly exhausted to the air to harm patients and medical workers, and also can reduce pressure change in the system during accidents so as to furthest prevent influencing the safety of the patients.

Owner:BEIJING AEONMED

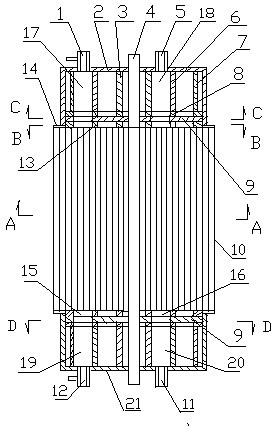

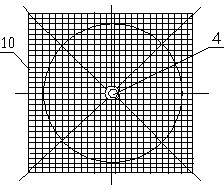

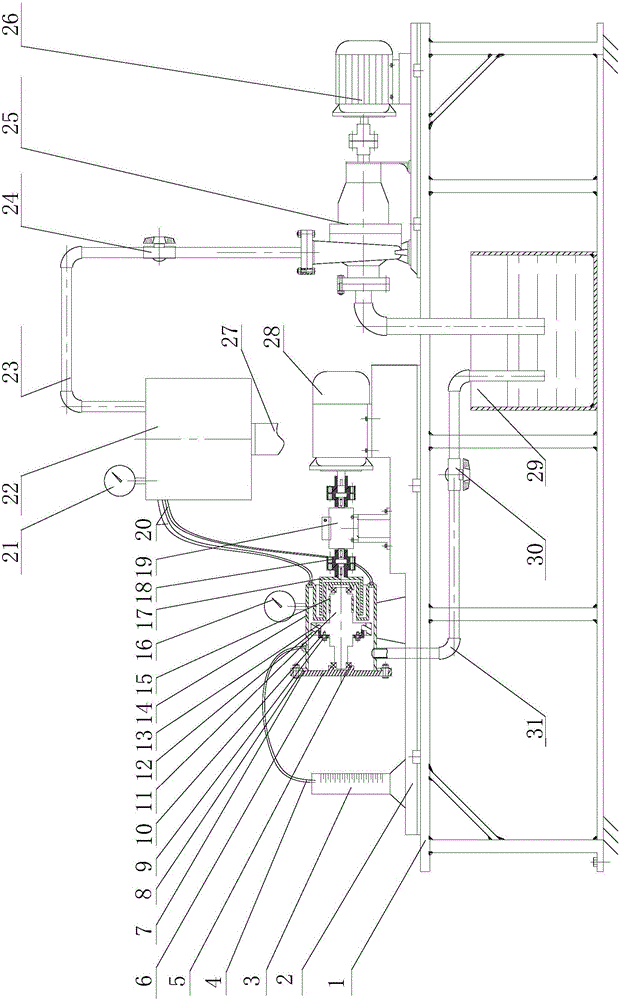

Rotary heat accumulating type heat exchanger

InactiveCN102330994AImprove work performanceEndothermicCombustion processHeat storage plantsEngineeringVALVE PORT

The invention discloses a rotary heat accumulating type heat exchanger, which comprises a heat accumulating body (10), a rotating shaft (4) and disk rotary valves, wherein the rotating shaft movably penetrates through the heat accumulating body, two ends of the heat accumulating body are respectively provided with a cold air box (2) and a hot air box (21), the cold air box is provided with a cold air waste chamber (17) and a combustion air chamber (18), the hot air box is provided with a hot air waste chamber (19) and a high-temperature air chamber (20), the cold air box and the hot air box are internally provided with the disk rotary valves, each disk rotary valve comprises a radial current divider (8) provided with inner current division holes (16) and outer current division holes (15) at intervals, and a circumferential current divider (13); and a valve seat is fixedly arranged on the rotating shaft between the radial current divider and the circumferential current divider. According to the invention, the heat efficiency can be improved to above 90 percent, fuel consumption can be reduced, operation cost of an industrial furnace is reduced, and the quality of combustion air is improved. The rotary heat accumulating type heat exchanger has the advantages of compact structure, stable and reliable use, convenience for installation and maintenance, and long service life.

Owner:林杰 +1

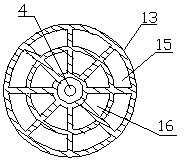

Friction type torque limiting clutch

The invention discloses a friction type torque limiting clutch which comprises a driven shaft interface, a shell, a driving shaft interface and a friction sheet combination, wherein the friction sheet combination is composed of an outer friction sheet and an inner friction sheet; the driven shaft interface is connected at the front end of the shell; the driven shaft interface is arranged inside the shell; the rear end of the shell is connected with a spring base which is sleeved on the driving shaft interface; spring holes are uniformly distributed on the spring base along the circumference; a spiral spring and a cushion block are arranged in each spring hole; one end of the spiral spring props against the cushion block; the other end of the spiral spring stretches outside the spring hole to prop against a pressing ring; a screw hole corresponding to each spring hole is arranged on the rear side plane of the spring base; an adjusting screw is arranged in the screw hole; the adjusting screw props against the cushion block; a locking nut is arranged on the adjusting screw; the front end of the driving shaft interface is connected with an end shaft; the front end of the end shaft is inserted into the hole of the driven shaft interface; and the end shaft is in clearance fit with the hole of the driven shaft interface. The adjusting screw can be adjusted by only using an ordinary small torque winch, so that the on-line adjustment is carried out on a production line conveniently.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

Electronic device having a blower with noise control

InactiveUS7925028B2Noise (emitted sound)Generated as a fan group has to be reducedEar treatmentPump componentsNoise controlElectric machine

An electronic device having a first motor which rotates a rotating body (for example, blades) about a rotation axis and a second motor which vibrates a vibrator including the rotating body in the axial direction is provided. A control IC unit has a first circuit which subjects the rotation to control drive by a first waveform, and a second circuit which subjects the vibration to control drive by a second waveform. Rotation and vibration of a rotating and vibrating unit driven by the first and second motors generates an airflow and output sound by a synthesized output of a first output corresponding to the rotation and a second output corresponding to the vibration. The control IC unit generates a second waveform by using a reversed-phase waveform with respect to the first waveform or the like and suppresses the output sound by control of the first and second waveforms.

Owner:HITACHI LTD

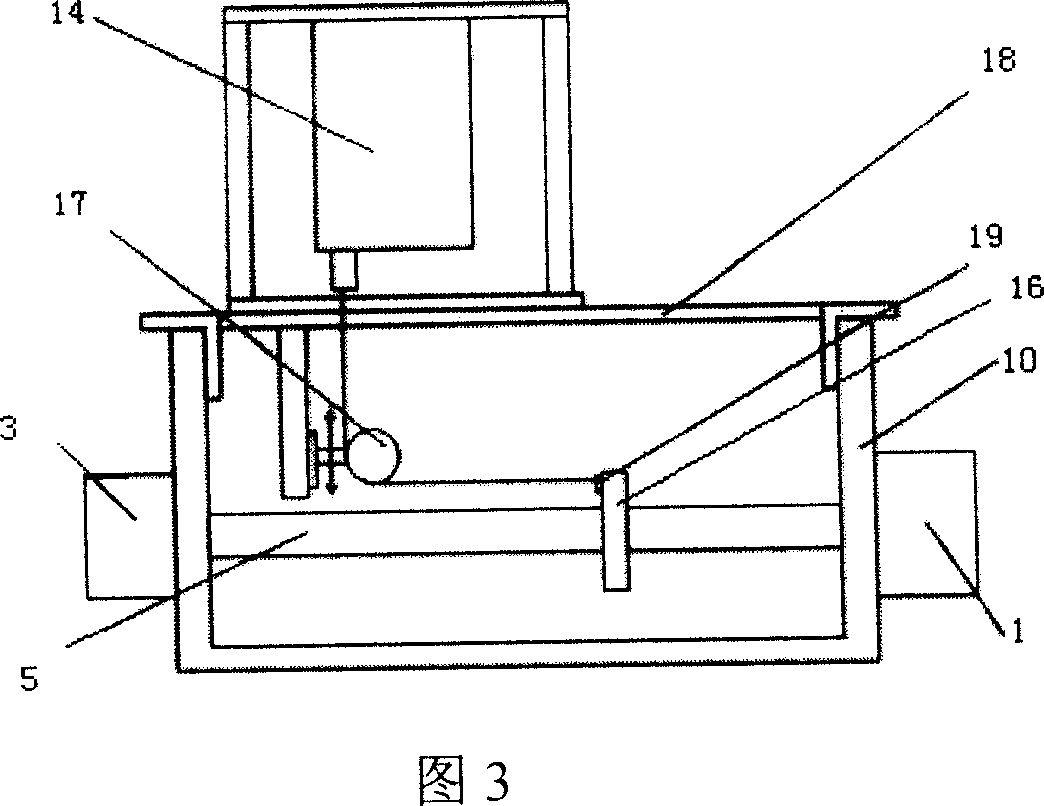

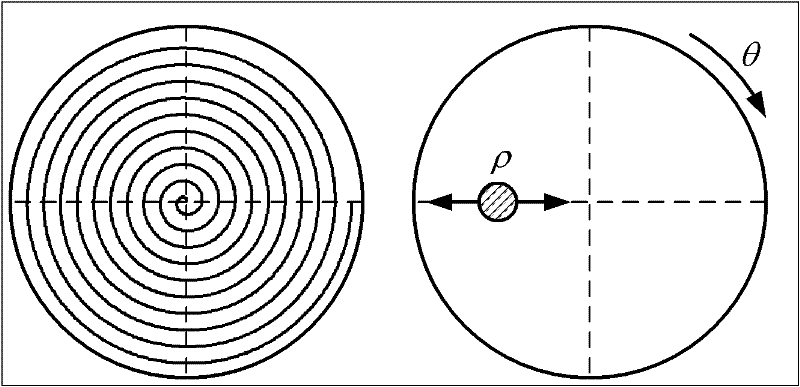

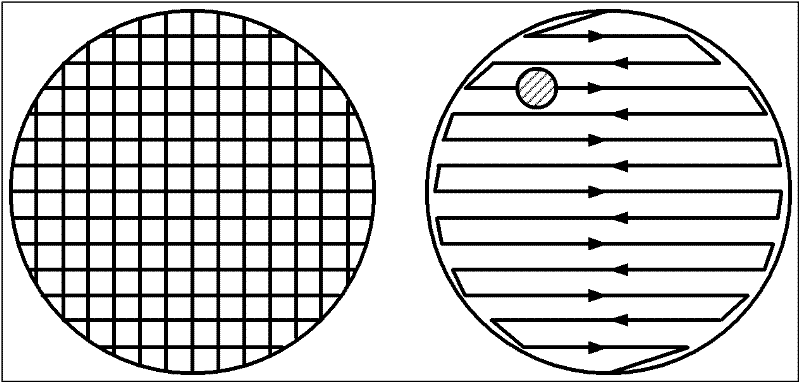

Modification processing method of optical element surface and numerical control machine used thereby

ActiveCN101898325BUniform movement speedDwell time calculation is simpleOptical surface grinding machinesNumerical controlCoupling

The invention discloses a modification processing method of an optical element surface, comprises the following steps: planning a processing and scanning route, converting coordinates, calculating processing dwell time, modifying and processing, converging step by step and the like, is combined with the advantages of an X-Y scanning mode and a rho-theta scanning mode, has the advantages of good stability, strong controllability, simple processing operation and high processing precision, and is especially suitable for the modification processing of the optical element surface of a high gradient workpiece. The invention also discloses a numerical control machine used in the modification processing method, an abrasive disk thereof and a rotation axis thereof are connected with a universal coupling, the rotation axis of a removal function generator is aslant arranged on an engine base in a mode of having an included angle beta with the optical axis of a workpiece to be processed, and the numerical control machine has the advantages of simple structure, low cost and the like.

Owner:NAT UNIV OF DEFENSE TECH

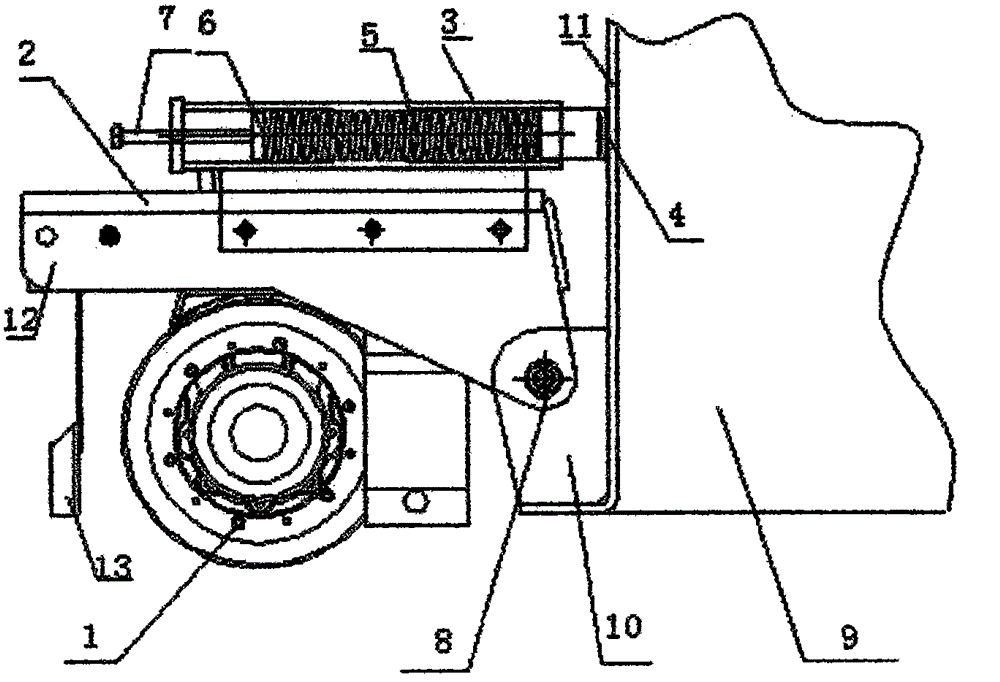

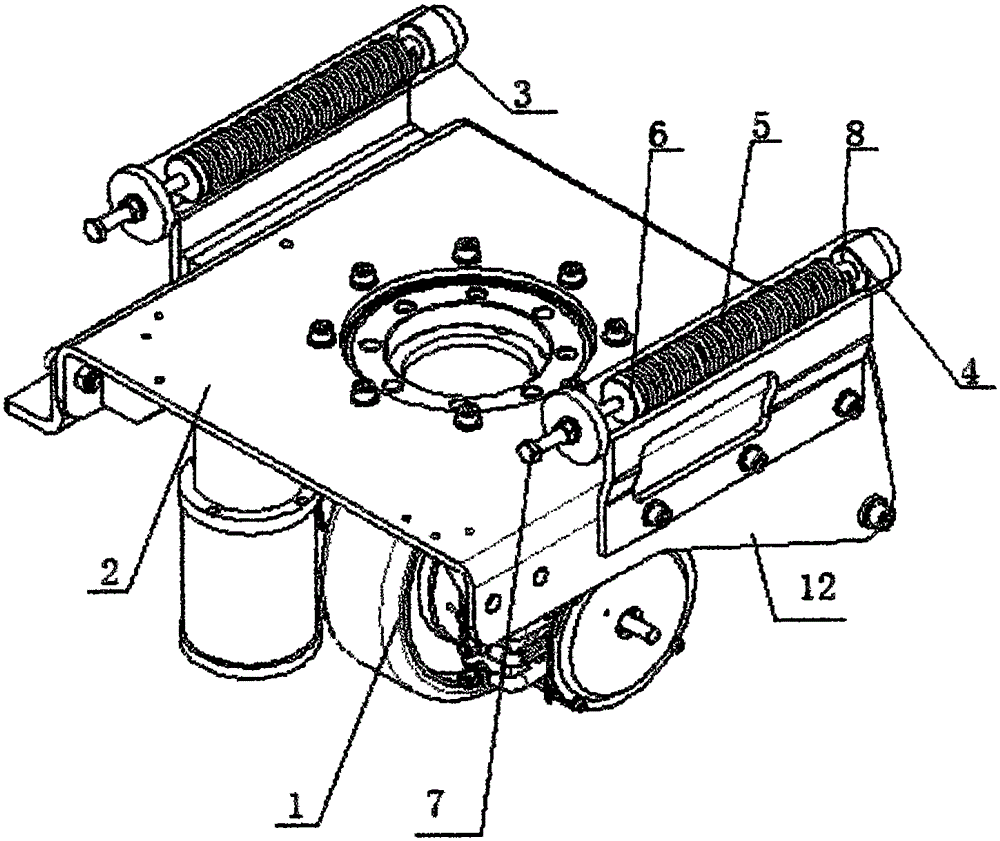

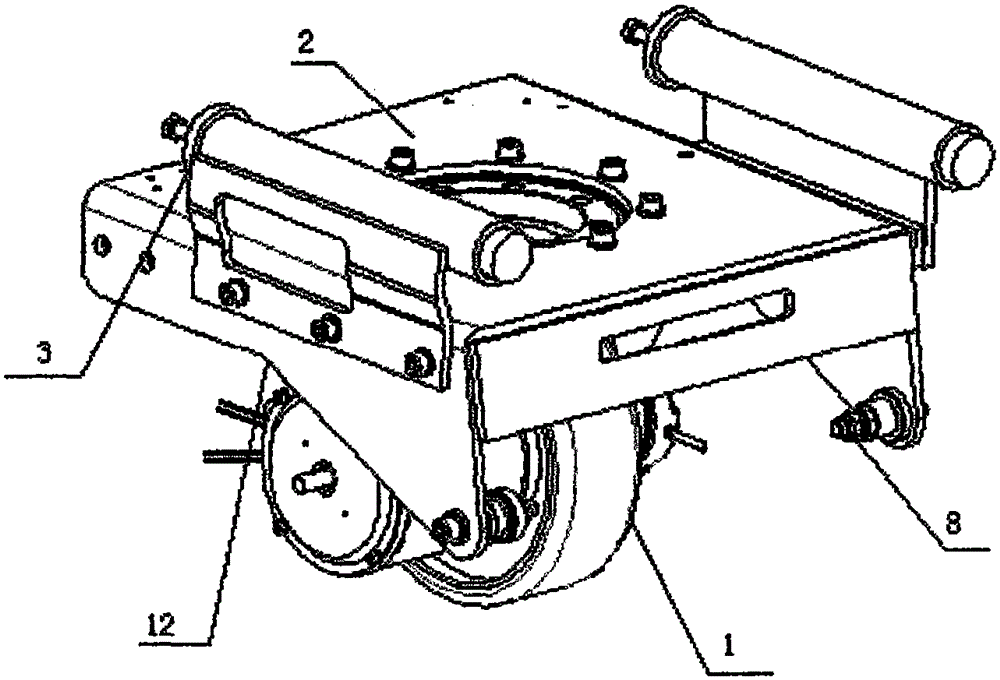

Automatic guided vehicle drive suspension device and automatic guided vehicle

ActiveCN106494257ACompact sizeLarge adjustable rangeSpeed controllerElectric vehicle charging technologyVehicle framePressure regulator

The invention discloses an automatic guided vehicle drive suspension device suspended below a vehicle frame; the automatic guided vehicle drive suspension device comprises a drive wheel set and a mount plate; the drive wheel set is fixed below the mount plate; two side edges of the mount plate are respectively fixedly provided with a side guard plate; the lower side angle of the side guard plate is hinged to the vehicle frame; a pressure regulator is transversely fixed on the mount plate, and can adjust the pressure applied to the vehicle frame. The invention also discloses an automatic guided vehicle having the drive suspension device; the pressure of the drive wheel set can be adjusted, thus effectively utilizing the vehicle frame chassis space.

Owner:GUANGZHOU JINGYUAN MECHANO ELECTRIC EQUIP

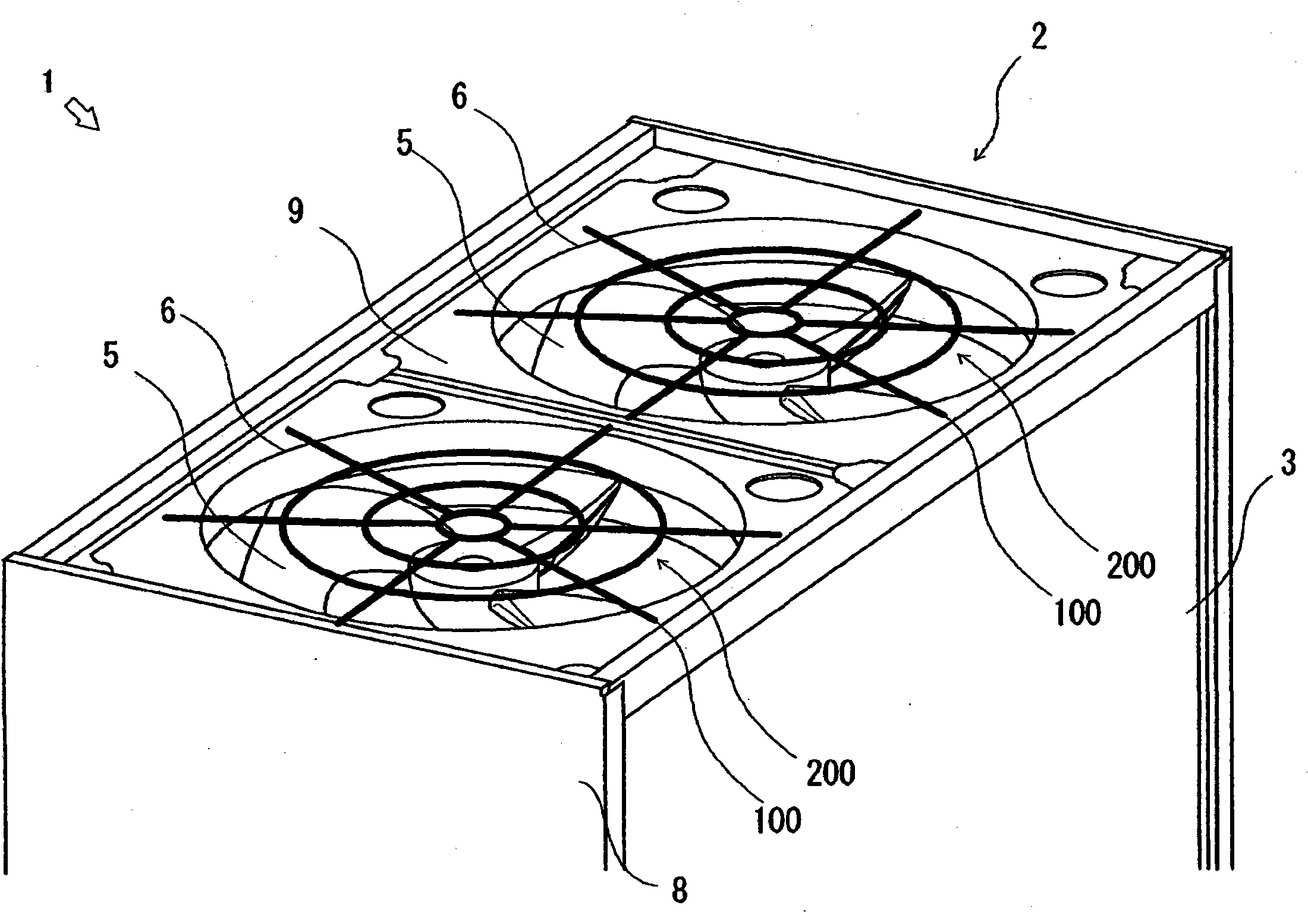

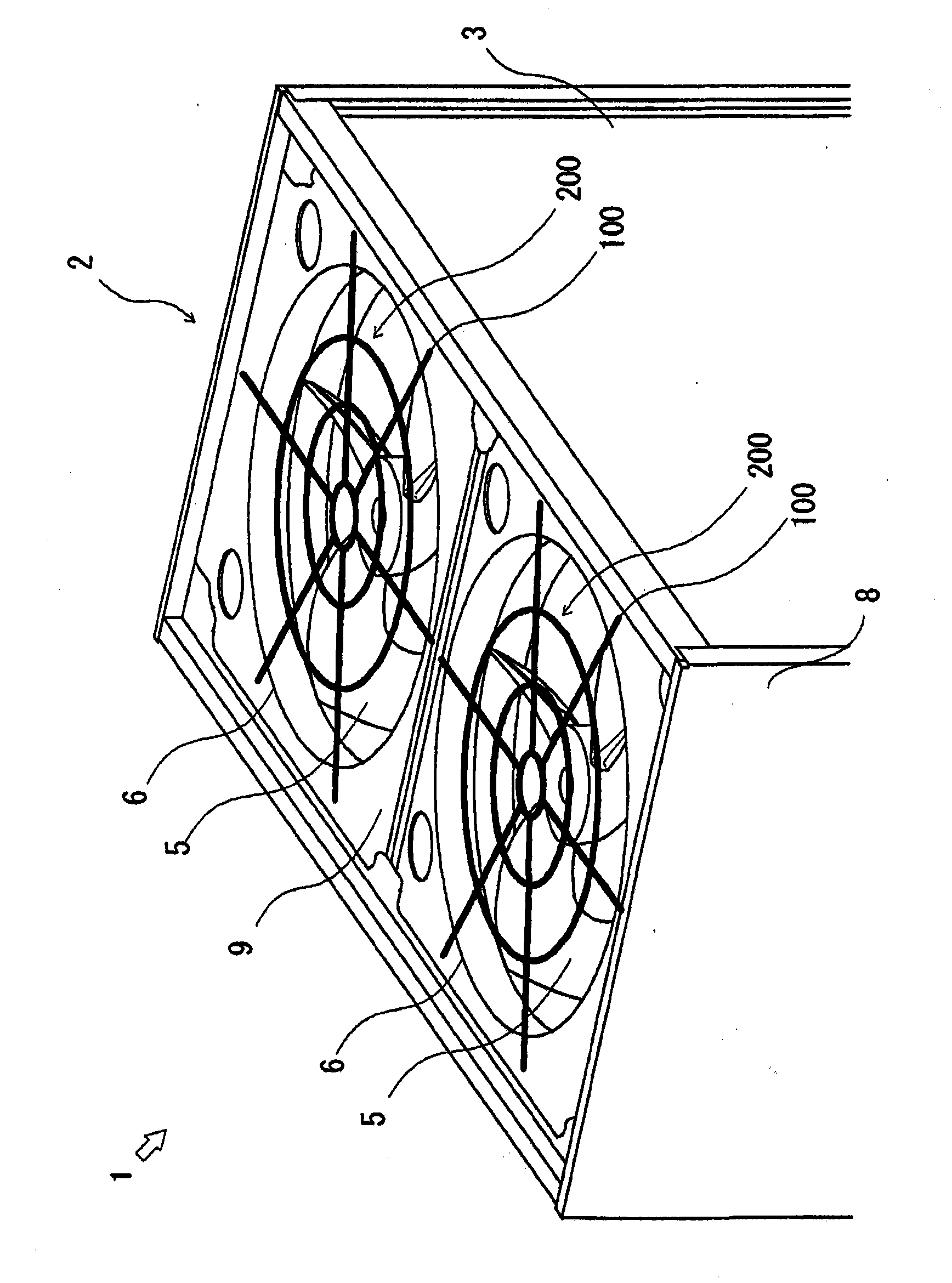

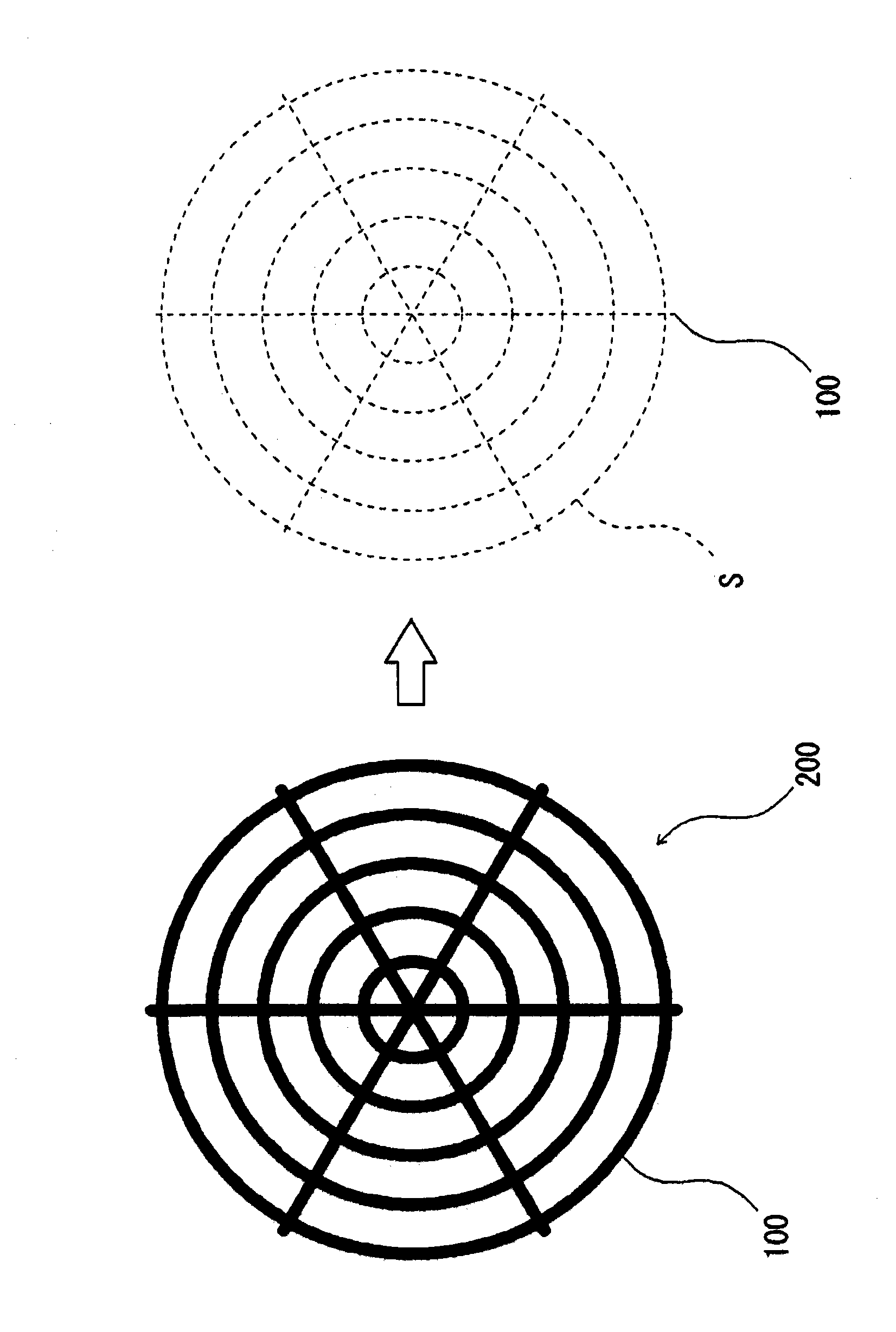

Fan guard

InactiveCN101815907ASmall pressure changeReduce fluid noisePump componentsLighting and heating apparatusForeign matterEngineering

A fan guard which reduces fluid noise while holding the conventional function for blocking intrusion of a hand of a person or a foreign matter. In a fan guard (200) constituted of a plurality of crosspieces (110) and arranged at an outlet (6) of an engine driven heat pump (1) having a fan (5), the crosspieces (110) are formed by continuing unit shapes (110a) bending or curving relative to the reference line (S) for constituting the crosspieces (110) on the fan guard (200). The unit shape (110a) is formed to have a wavy shape, for example.

Owner:YANMAR CO LTD

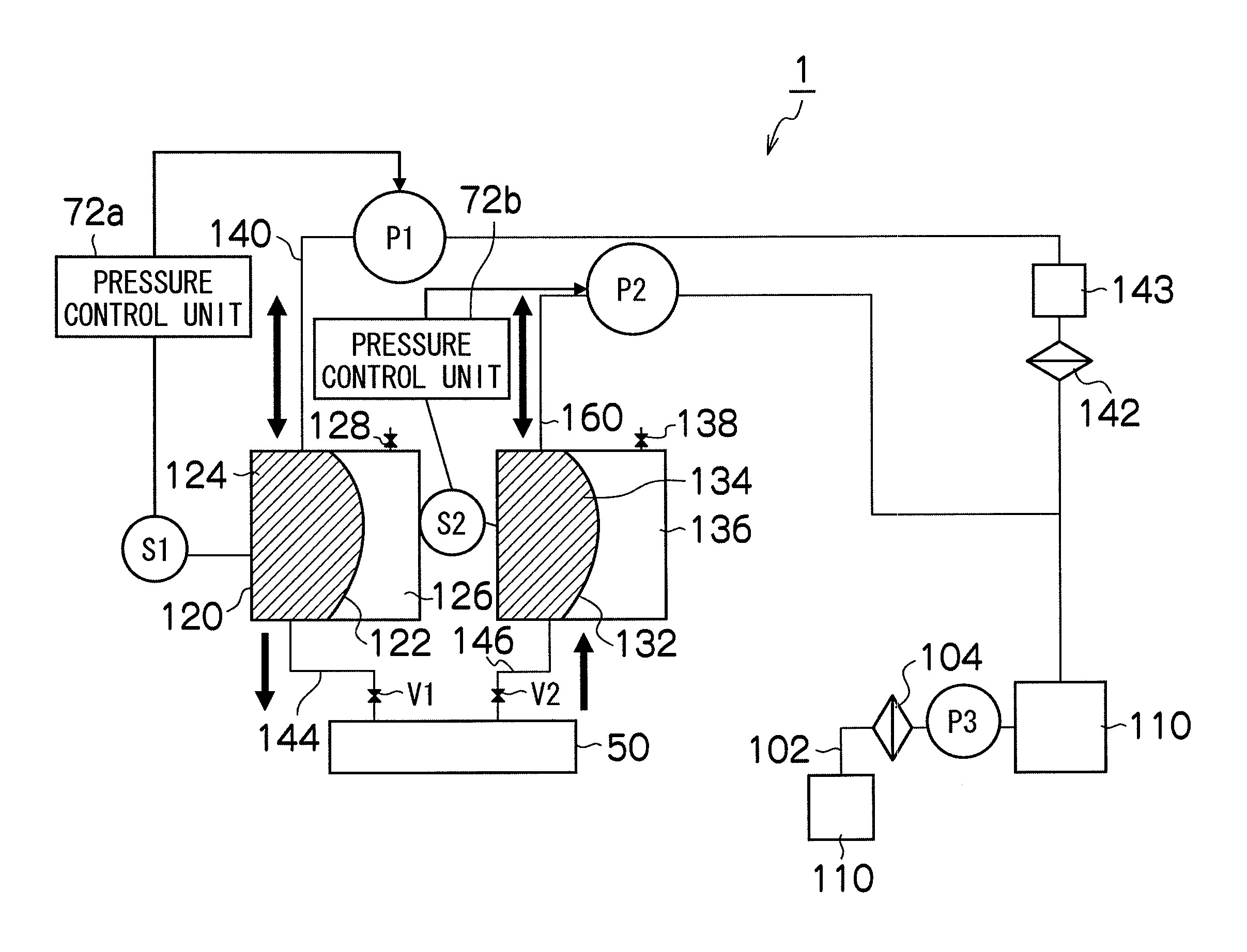

Inkjet recording apparatus and method

ActiveUS8042898B2Stable pressure controlReduce pressure changesInking apparatusOther printing apparatusPositive pressureEngineering

The inkjet recording apparatus includes: an inkjet recording head which includes a nozzle through which liquid is ejected; a pressure regulating unit which includes a liquid chamber that communicates with the nozzle and a gas chamber that is partitioned from the liquid chamber by a flexible film; and a liquid chamber pressure controlling device which controls a pressure of the liquid chamber to a predetermined negative pressure when carrying out back pressure control in which back pressure is applied to the liquid inside the nozzle, wherein: the flexible film causes change in the pressure of the liquid chamber when the liquid is supplied for at least a predetermined supply amount to the liquid chamber in a state where the gas chamber is open to air; and the liquid chamber pressure controlling device carries out the back pressure control after controlling the pressure of the liquid chamber to a predetermined value of positive pressure by supplying the liquid of at least the predetermined supply amount to the liquid chamber.

Owner:FUJIFILM CORP

Ink circulation method and system thereof

ActiveCN109130523AFlow fastShort cycle pathPrintingElectrical and Electronics engineeringEngineering

The invention discloses an ink circulation method. An ink storage device, and a first cartridge, a circular printing head and a second cartridge which are connected circularly are arranged; the ink storage device is connected with the first cartridge; in a main ink path, the ink is conveyed to the first cartridge from the ink storage device; in a first circular ink path, the ink flows through thefirst cartridge, the circular printing head and the second cartridge sequentially through negative pressure; and in a second circular ink path, the ink in the second cartridge is conveyed to the firstcartridge through negative pressure. In comparison with the existing large circulation, the ink can be kept to flow quickly, the circulation path is short, and precipitation is not formed easily. Anink stick is also added on the basis of small circulation as buffer, the pressure changes of the second cartridge are reduced, and the flow speed of the ink flowing through the printing head can thusbe stabilized.

Owner:GUANGZHOU KINGTAU MACHINERY & ELECTRONICS EQUIP CO LTD

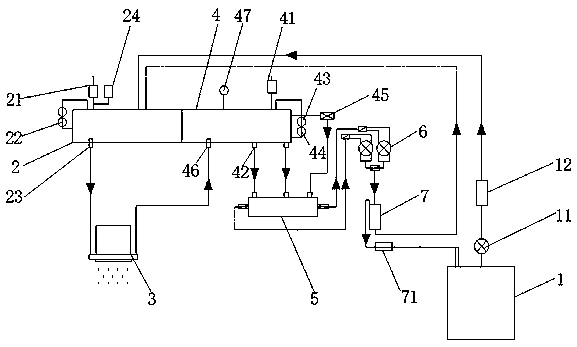

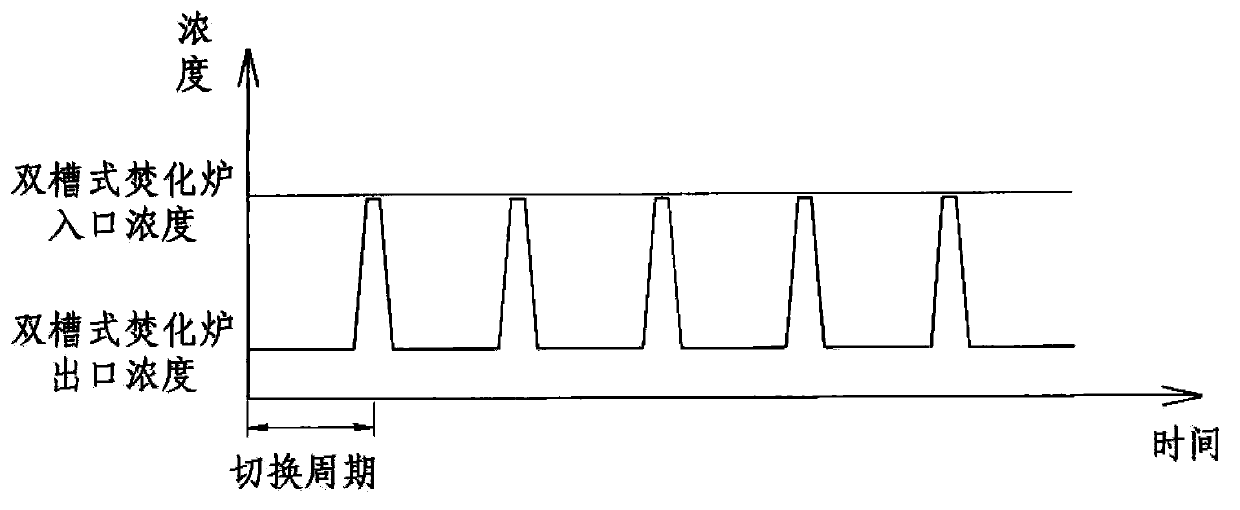

Tail gas switching peak value purification device with heat accumulating type incinerator

ActiveCN103968392ASmall pressure changeReduce odorIncinerator apparatusCombustion chamberExhaust fumes

The invention relates to a tail gas switching peak value purification device with a heat accumulating type incinerator, which comprises the heat accumulating type incinerator and a poppet valve, wherein the inside of the heat accumulating type incinerator is partitioned into a first heat accumulating chamber, a second heat accumulating chamber and a combustion chamber at least, the outside of the heat accumulating type incinerator is connected with a waste gas inlet pipe and an exhaust pipe, and both the inlet pipe and the exhaust pipe are provided with flow control valves; the poppet valve is partitioned into a gas inlet layer connected with the exhaust pipe, a purified gas outlet layer connected with an exhaust chimney and an unpurified gas outlet layer connected with a buffering pipe body, and the lifting of an internal disc is controlled by a drive part to switch airflow to flow out from the purified gas outlet layer or the unpurified gas outlet layer; the other end of the buffering pipe body is connected with the exhaust chimney; the total volume of the buffering pipe body and the unpurified gas outlet layer cannot be smaller than the volume of unpurified gas retained in the heat accumulating chambers and the flow control valve. The tail gas switching peak value purification device has the efficacies of small pressure variation, stable system, less odor, simple structure and space saving.

Owner:JG ENVIRONMENTAL TECH

Universal centrifugal pump wear ring test bed

ActiveCN106678056ASmooth inflowAvoid interferencePump controlNon-positive displacement fluid enginesEngineeringCentrifugal pump

The invention discloses a universal centrifugal pump wear ring test bed comprising a wear ring test unit, a fluid medium supply unit, a leaking liquid collection unit and a test table. The fluid medium supply unit, the wear ring test unit and the leaking liquid collection unit are installed on the test table. The fluid medium supply unit communicates with an inlet of a seal cavity of the wear ring test unit. An outlet of the seal cavity of the wear ring test unit communicates with the leaking liquid collection unit through a pipeline. The universal centrifugal pump wear ring test bed has the beneficial effects that the universal centrifugal pump wear ring test bed can be suitable for measuring leaking amounts of wear rings of different wear ring gaps, different wear ring lengths and different wear ring types; and operation is quite convenient, only the test wear rings need to be replaced when experiments are done on different samples, and most structures do not need to be detached. Measurement results are accurate, the medium leakage amounts are accurately measured through complete sealing of a rotor part and the difference method, the experiment precision is greatly improved, and reliability of the results is ensured.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com