Patents

Literature

47results about How to "Stable pressure control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

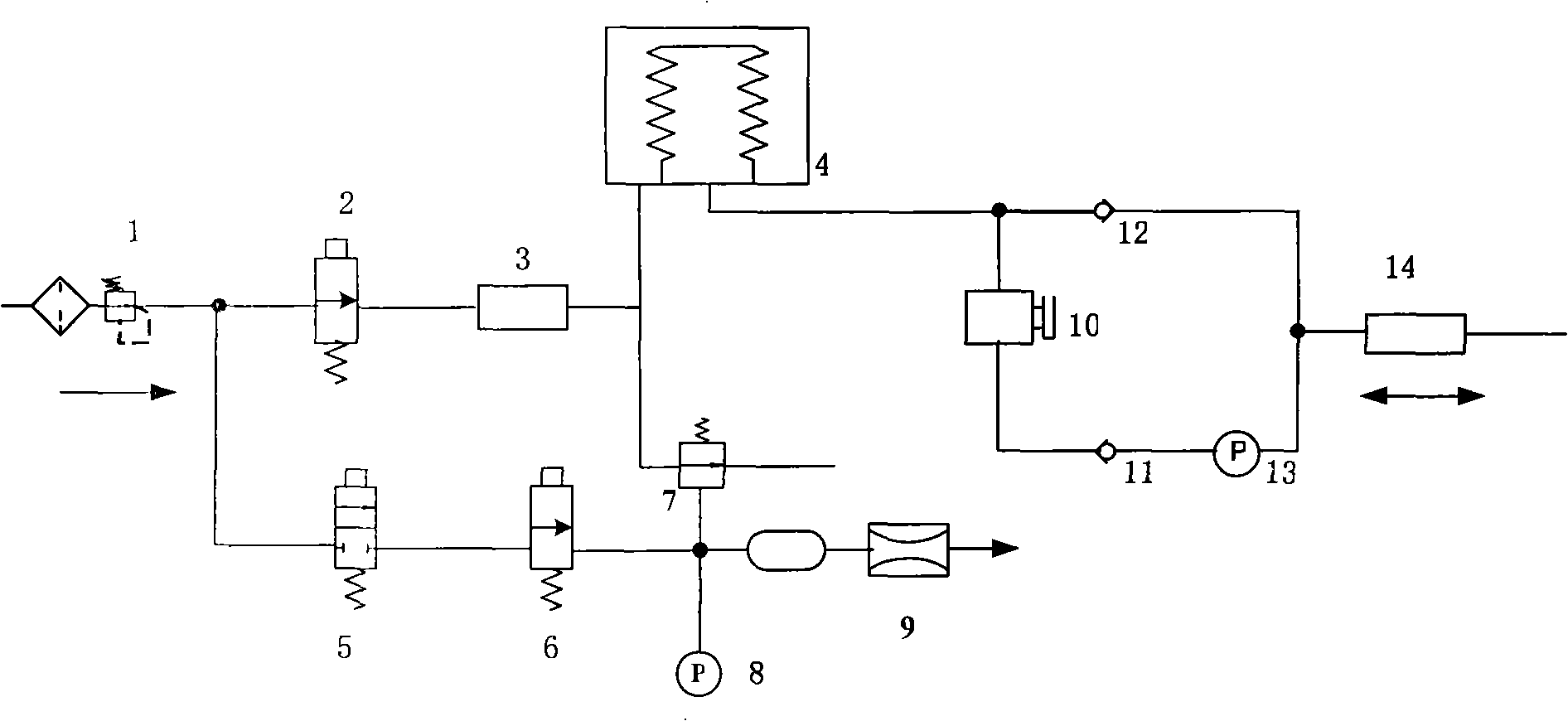

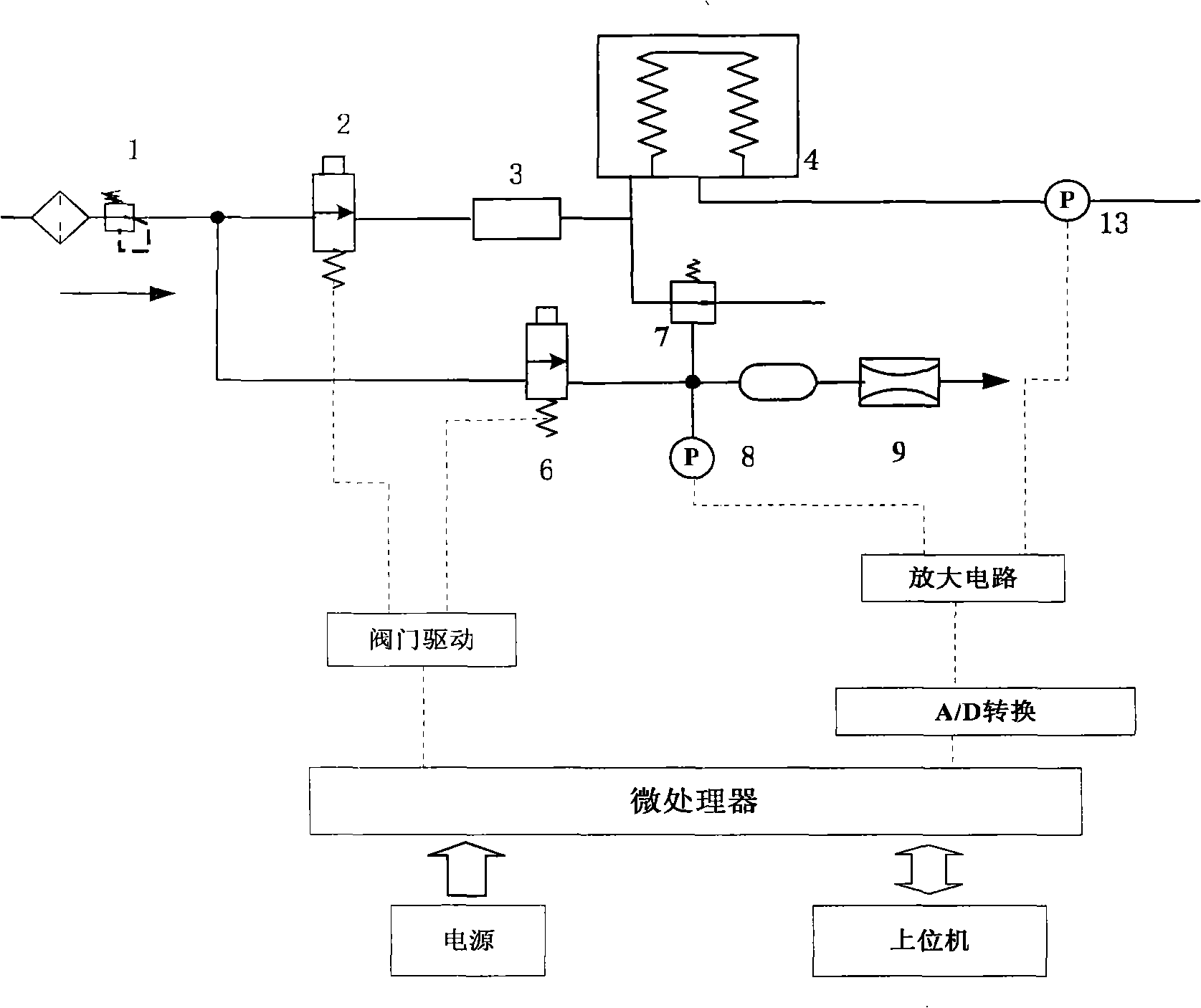

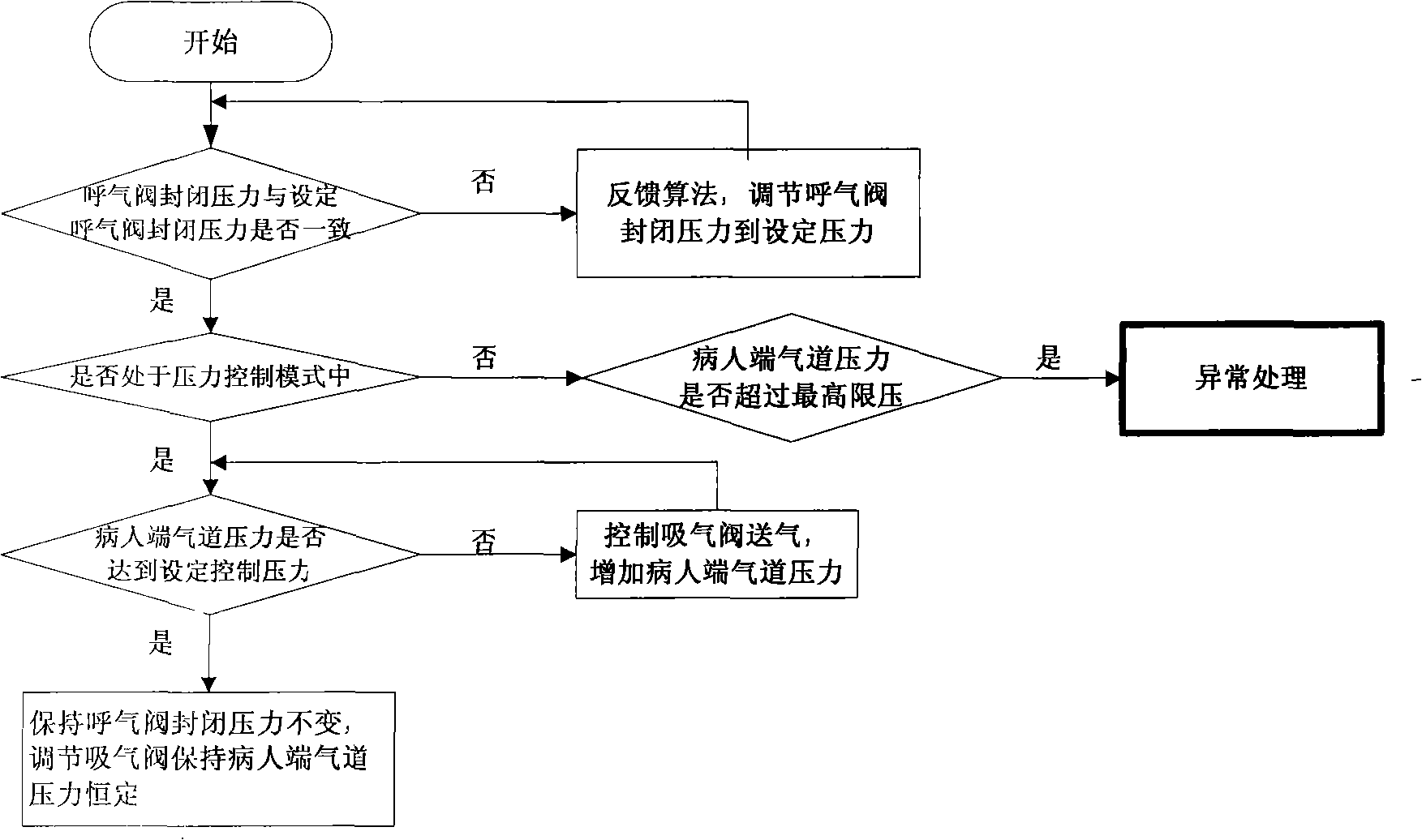

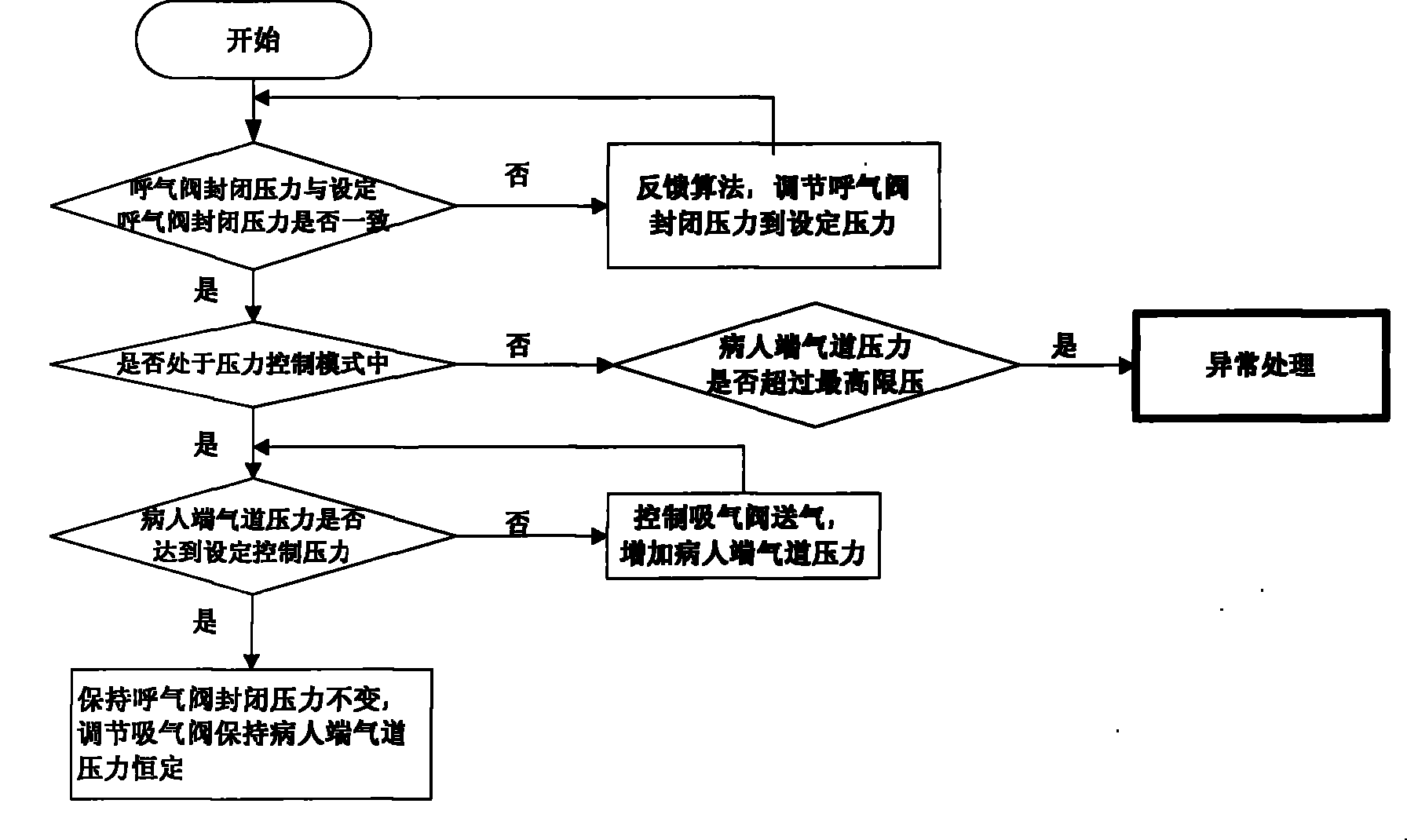

Aerating system of anesthesia apparatus and respirator and pressure monitoring method

ActiveCN101337101AAvoid interferenceStable and reliable pressure monitoringRespiratorsFluid pressure controlEmergency medicineFeedback control

The invention discloses a pressure monitoring and controlling method used in an aerating system of a medical device. The pressure monitoring and controlling method comprises monitoring the confining pressure of an expiratory valve on a real-time basis, and regulating and maintaining the pressure and the set confining pressure of the expiratory valve at the same value; and monitoring the pressure of a patient terminal gas channel on a real-time basis, and regulating and maintaining the pressure to reach a set control pressure. The aerating system used in the medical facility comprises a gas path system and a pressure monitoring and controlling device. The pressure monitoring and controlling device comprises a parameter monitoring and controlling unit, a valve control unit and a master controller, wherein the parameter monitoring and controlling unit includes a first pressure detecting device placed in to the patient terminal gas channel in the gas path system, and a second pressure detecting device for monitoring and controlling the confining pressure of the expiratory valve in the gas path system. A breathing machine and an anaesthetic machine using the aerating system in the technical proposal monitor the pressure of a control branch of the expiratory valve therein and employ the pressure as the basis of the feedback control to effectively avoid the external disturbance, thereby realizing stable and reliable pressure control.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

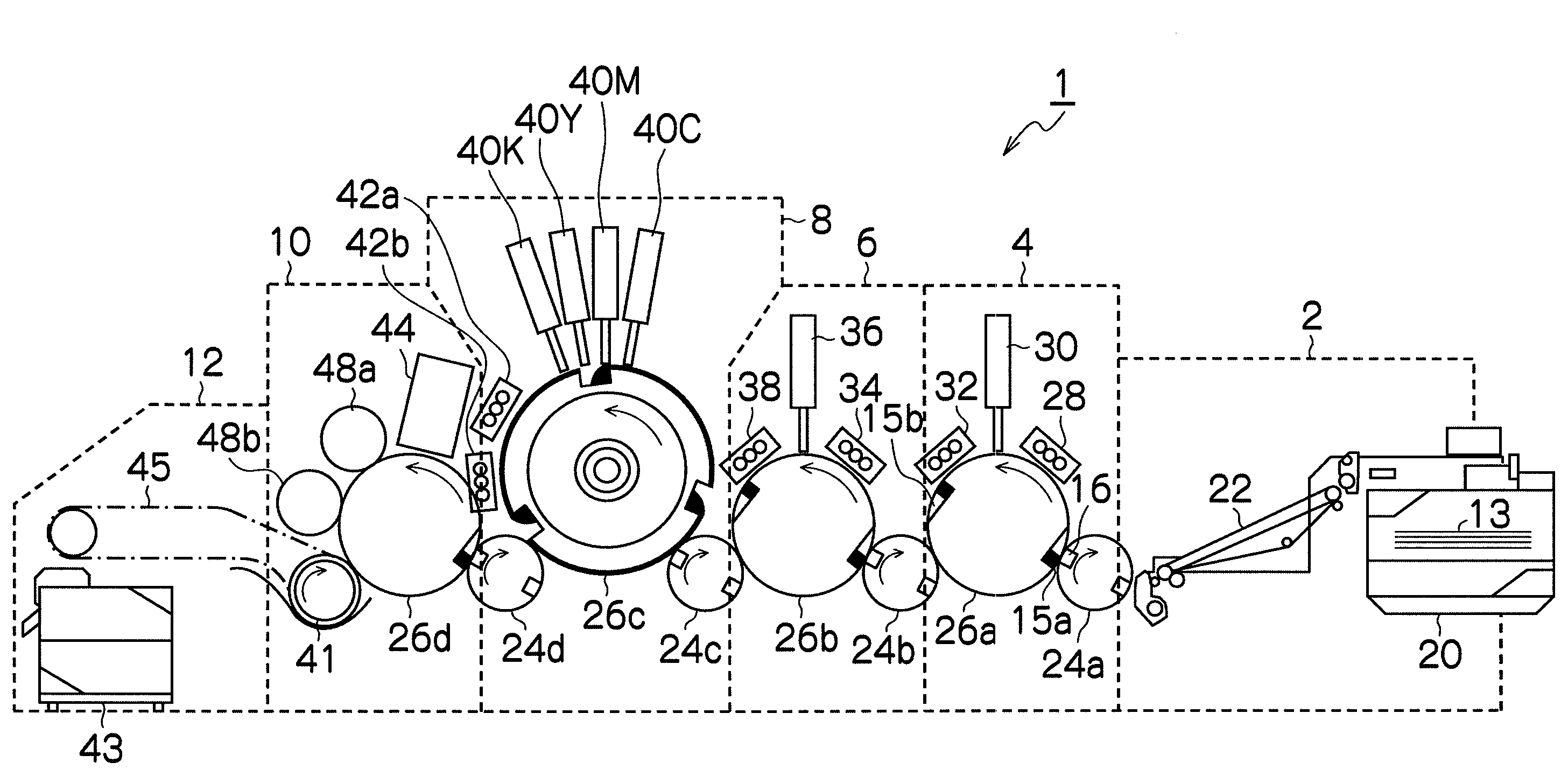

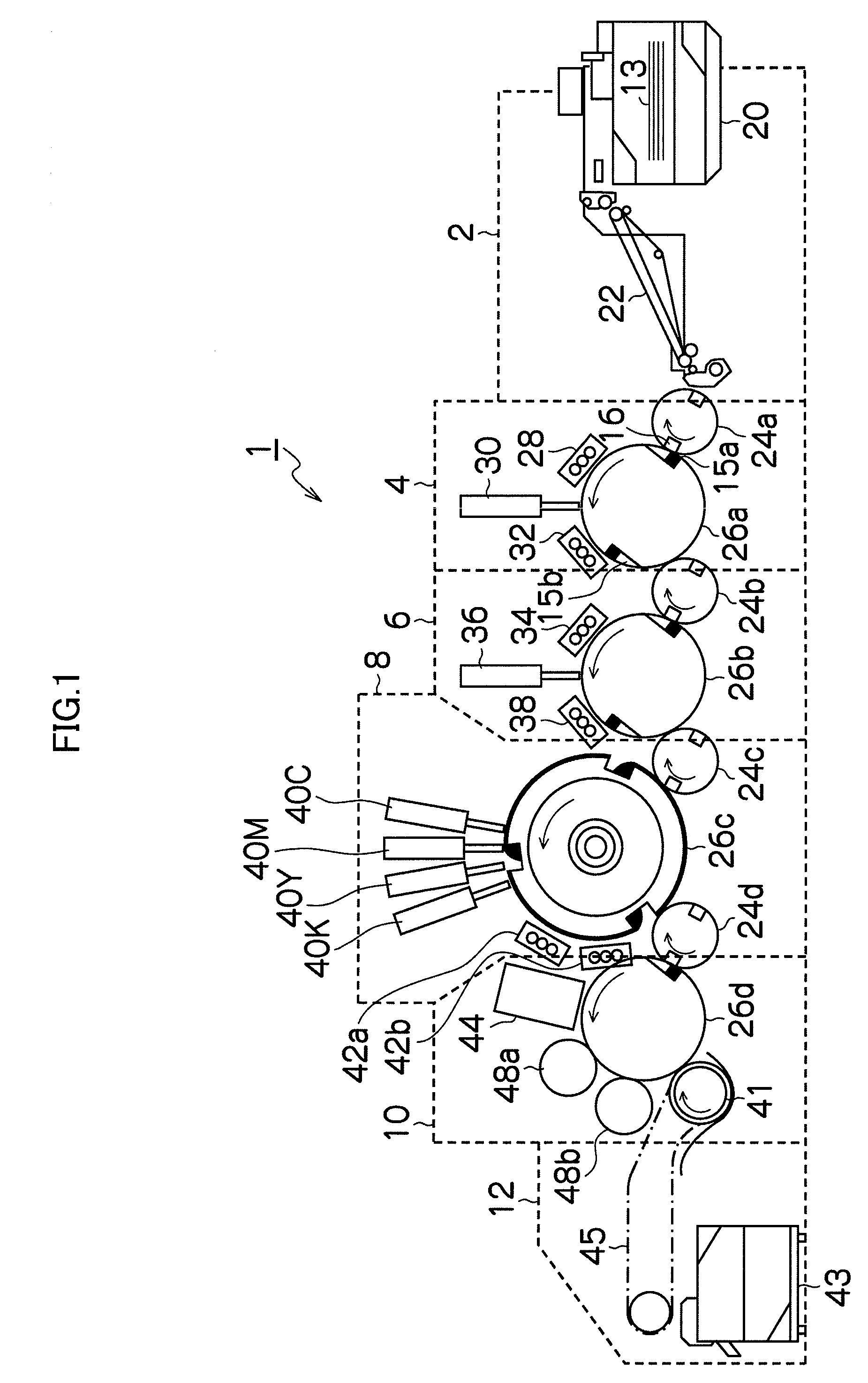

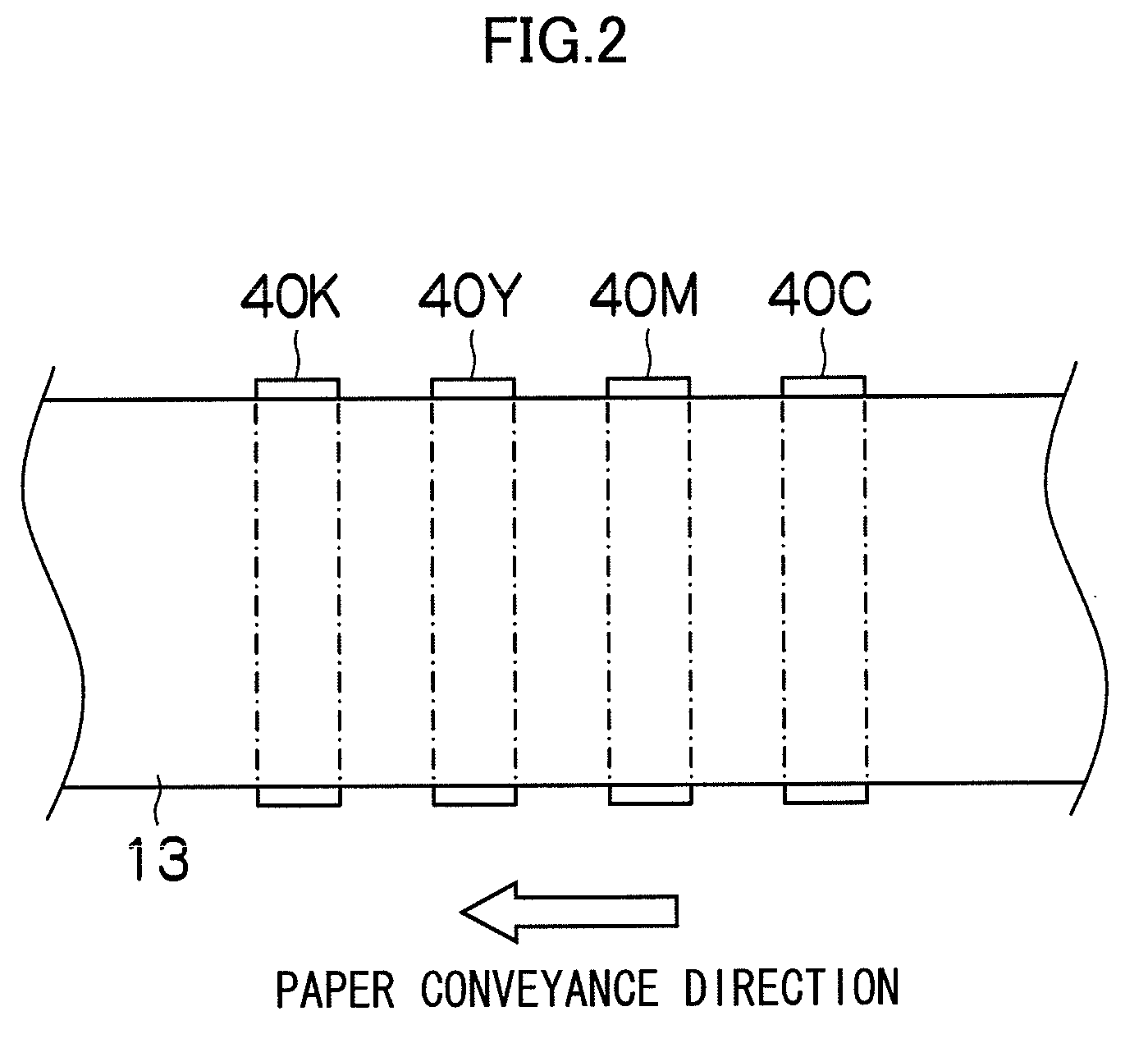

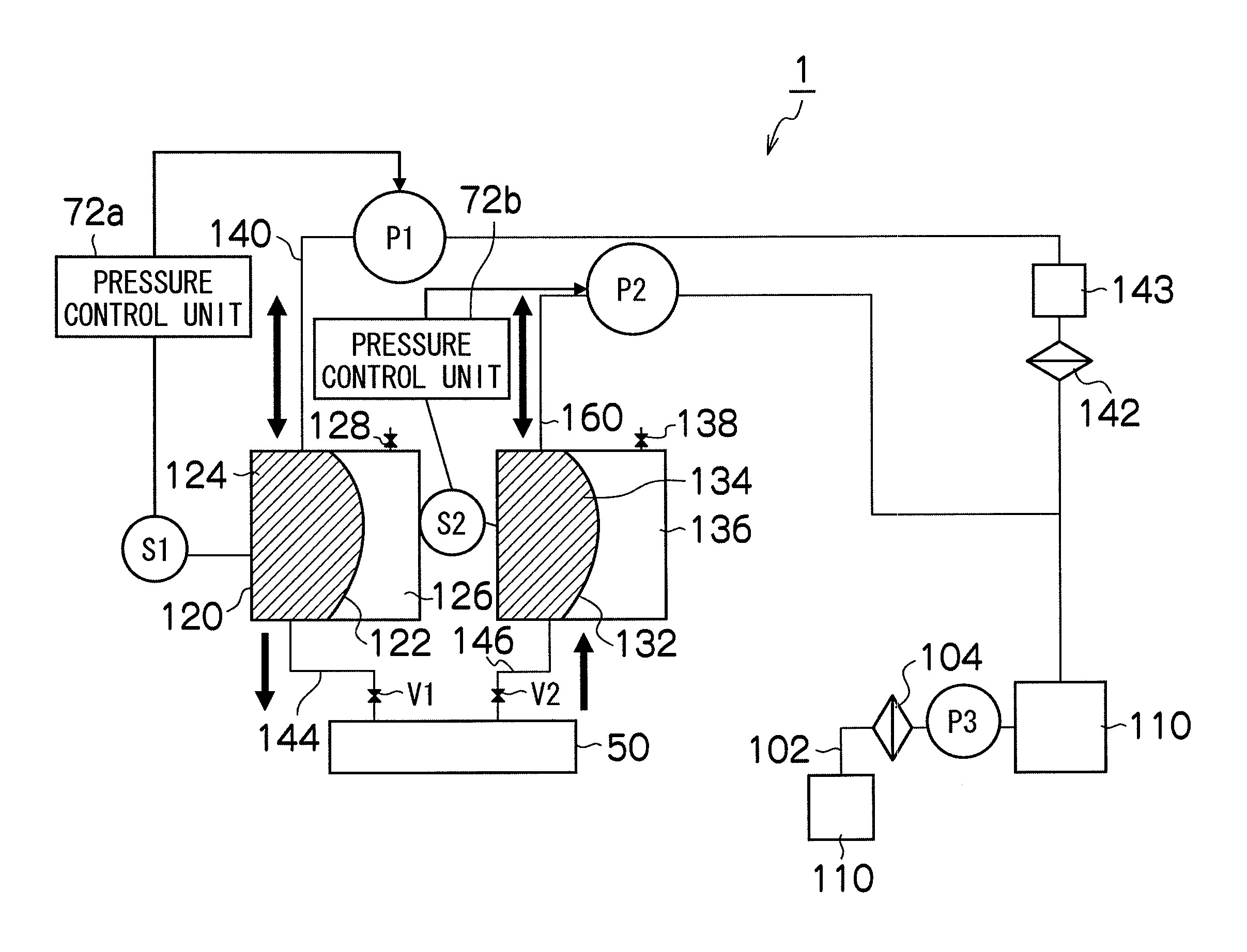

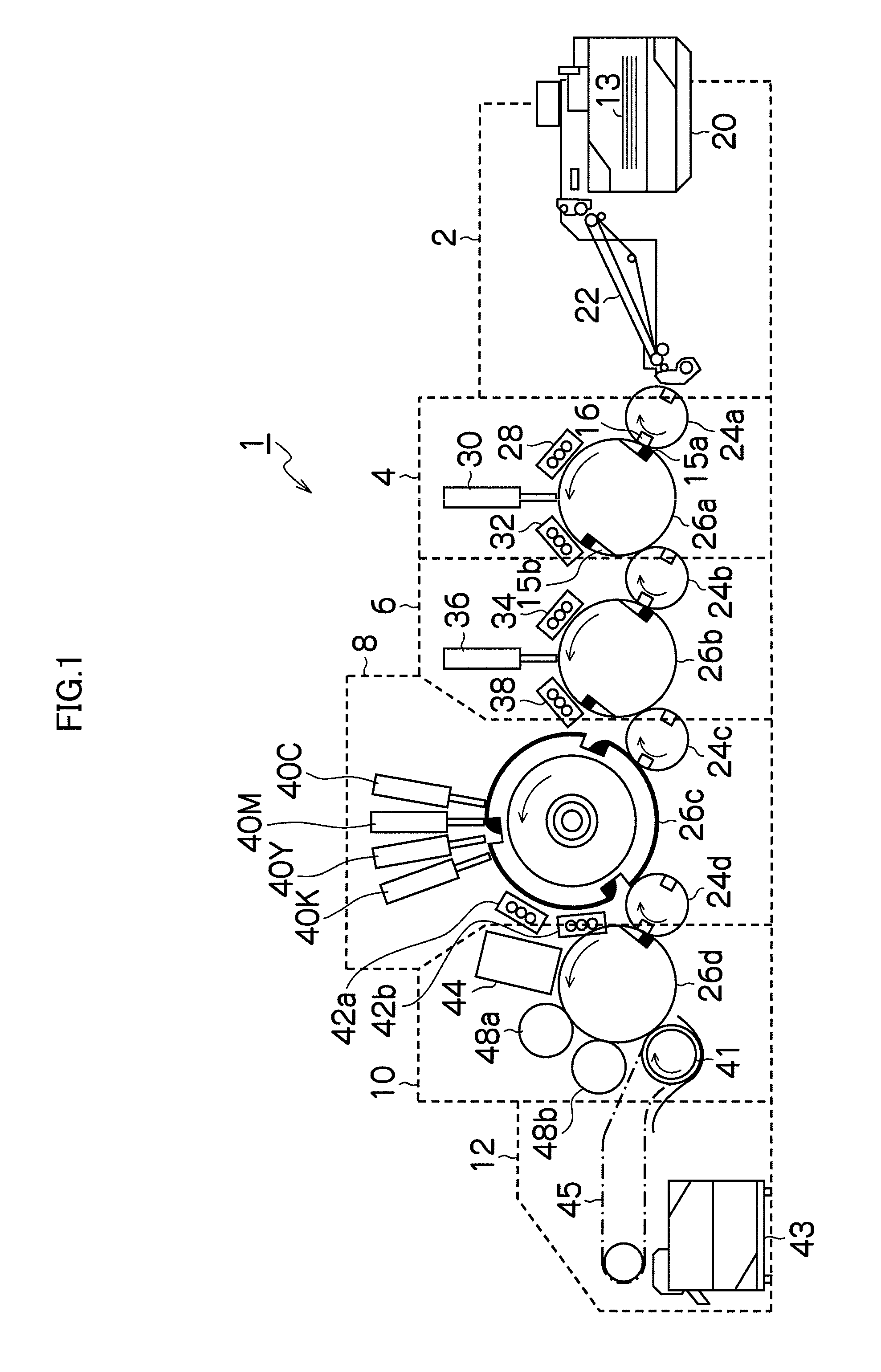

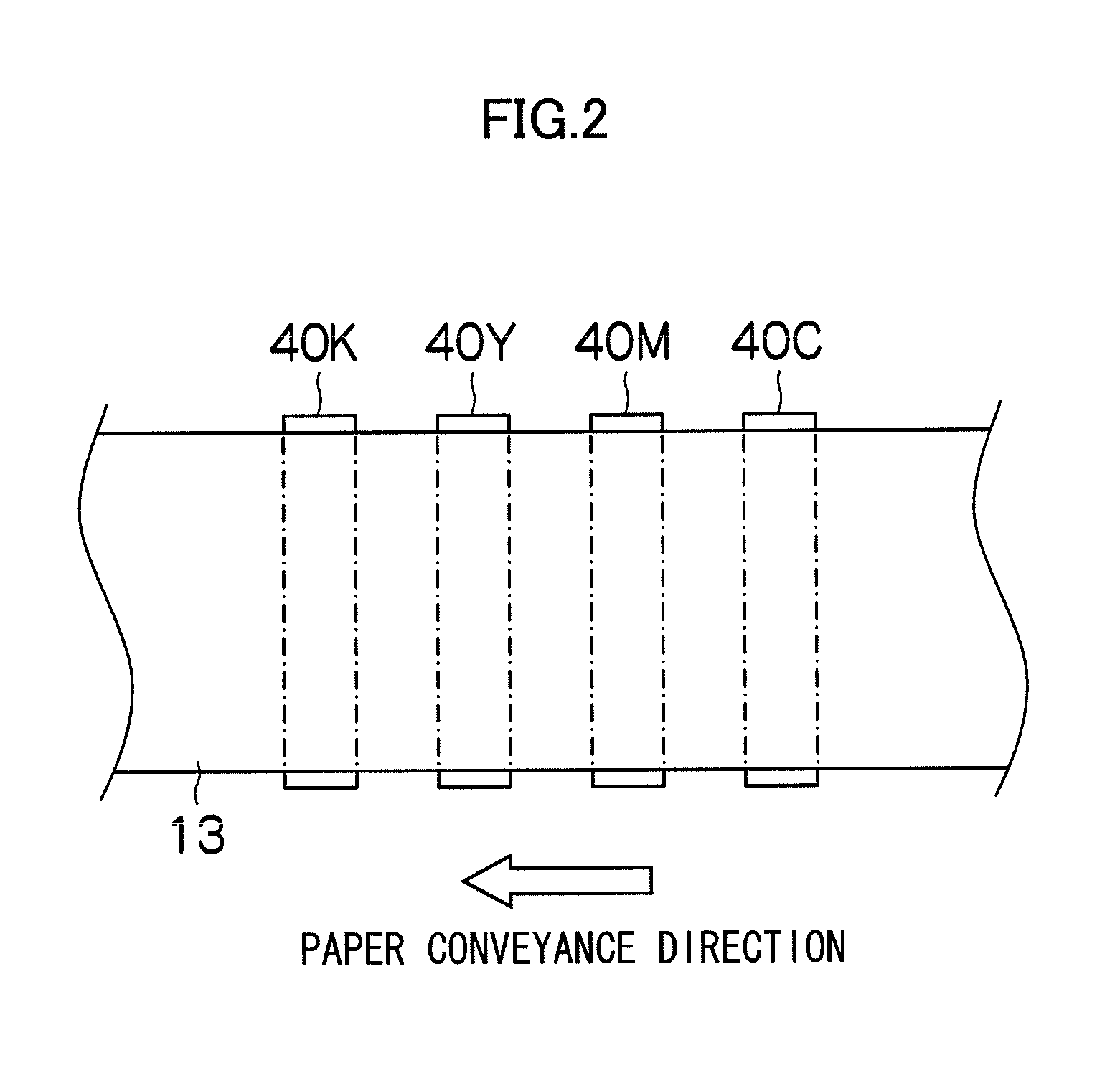

Inkjet recording apparatus and method

ActiveUS20090244131A1Carry-out stablyStable pressure controlInking apparatusOther printing apparatusPositive pressureEngineering

The inkjet recording apparatus includes: an inkjet recording head which includes a nozzle through which liquid is ejected; a pressure regulating unit which includes a liquid chamber that communicates with the nozzle and a gas chamber that is partitioned from the liquid chamber by a flexible film; and a liquid chamber pressure controlling device which controls a pressure of the liquid chamber to a predetermined negative pressure when carrying out back pressure control in which back pressure is applied to the liquid inside the nozzle, wherein: the flexible film causes change in the pressure of the liquid chamber when the liquid is supplied for at least a predetermined supply amount to the liquid chamber in a state where the gas chamber is open to air; and the liquid chamber pressure controlling device carries out the back pressure control after controlling the pressure of the liquid chamber to a predetermined value of positive pressure by supplying the liquid of at least the predetermined supply amount to the liquid chamber.

Owner:FUJIFILM CORP

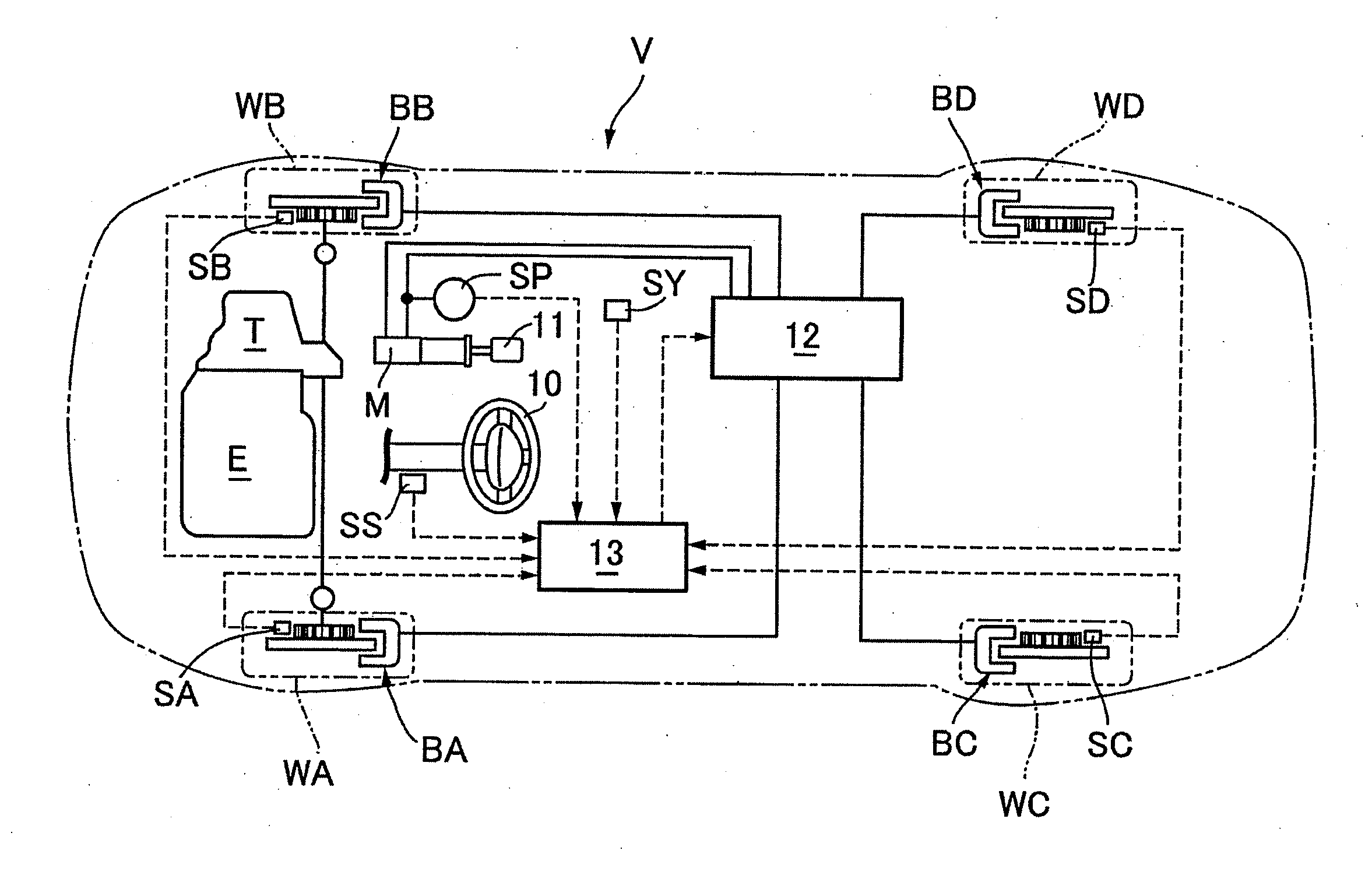

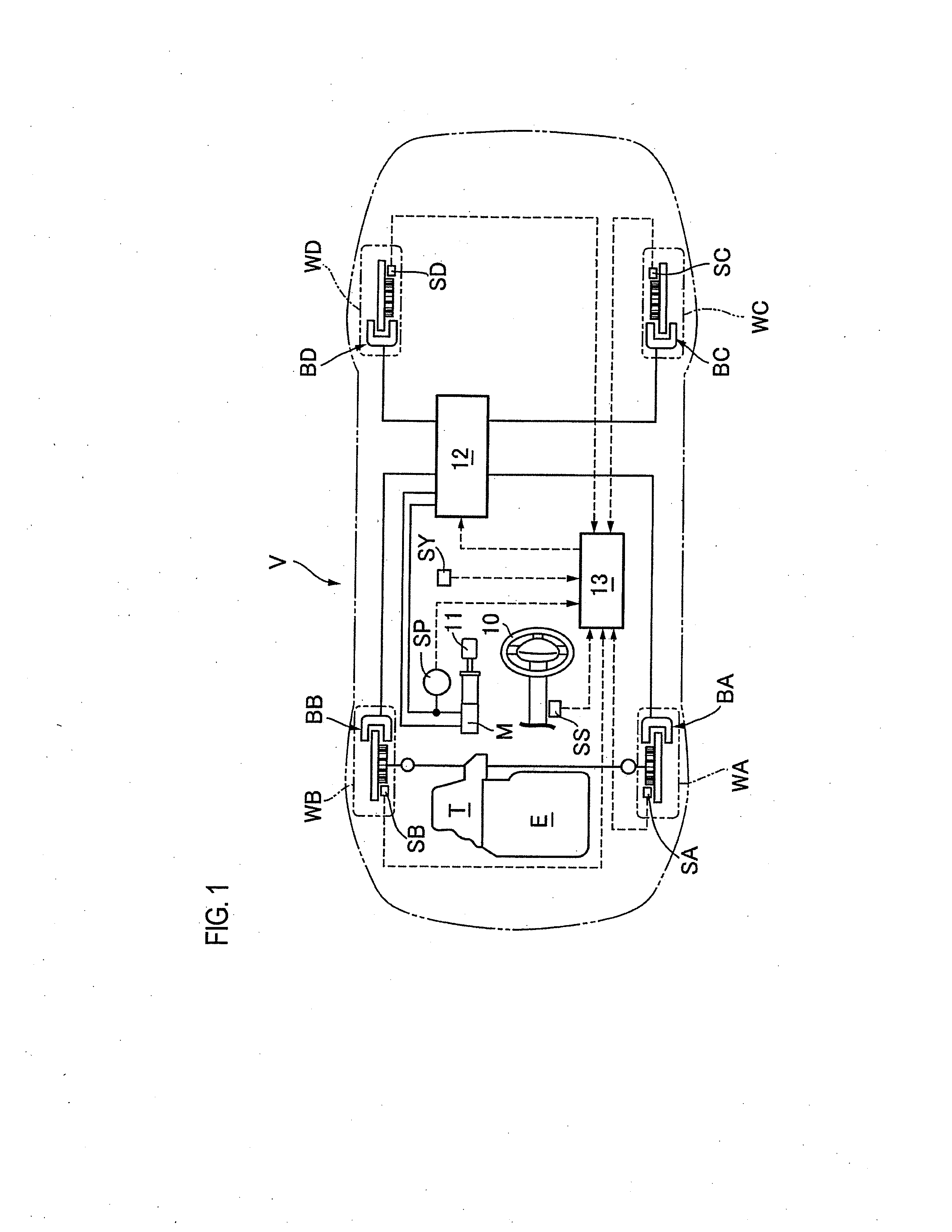

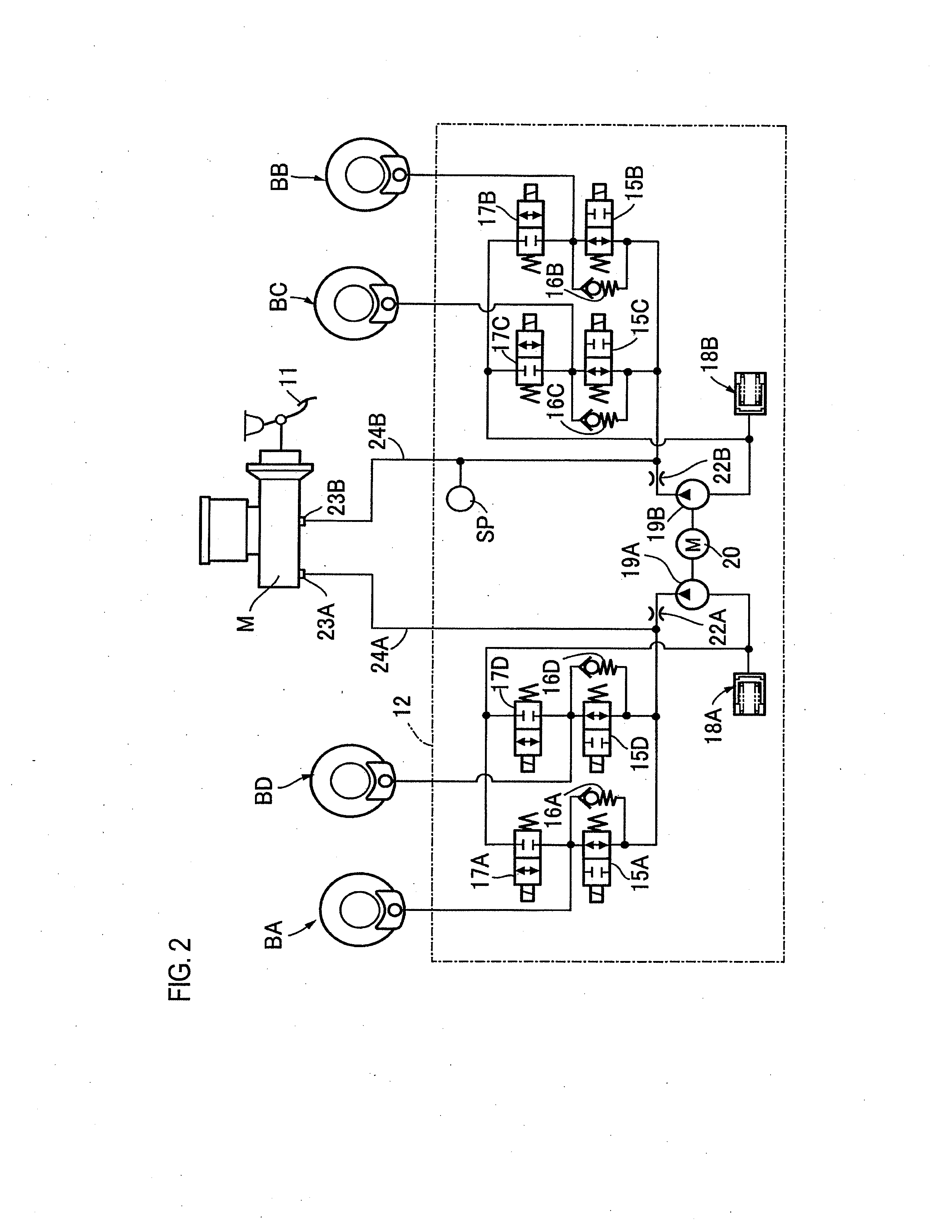

Vehicle brake hydraulic pressure control apparatus

ActiveUS20130184955A1Easy to set upImprove stabilityHand manipulated computer devicesDigital data processing detailsDifferential pressureRoad surface

A vehicle brake hydraulic pressure control apparatus includes a hydraulic pressure adjusting unit, a split road determining section, a differential pressure control section, and a hydraulic pressure adjusting and driving section. The hydraulic pressure adjusting unit individually adjusts brake fluid pressures acting on wheel brakes for wheels. The split road determining section determines whether road surfaces which the wheels are in contact with constitute a split road. In a state where the split road determining section determines during execution of antilock braking control that the road surfaces constitute the split road, the differential pressure control section determines command pressures for the wheel brakes so that differential pressures between the brake fluid pressures of the right and left wheel brakes are equal to or less than a permissible differential pressure. The hydraulic pressure adjusting and driving section controls the hydraulic pressure adjusting unit based on the determined command pressures.

Owner:AUTOLIV NISSIN BRAKE SYST JAPAN CO LTD

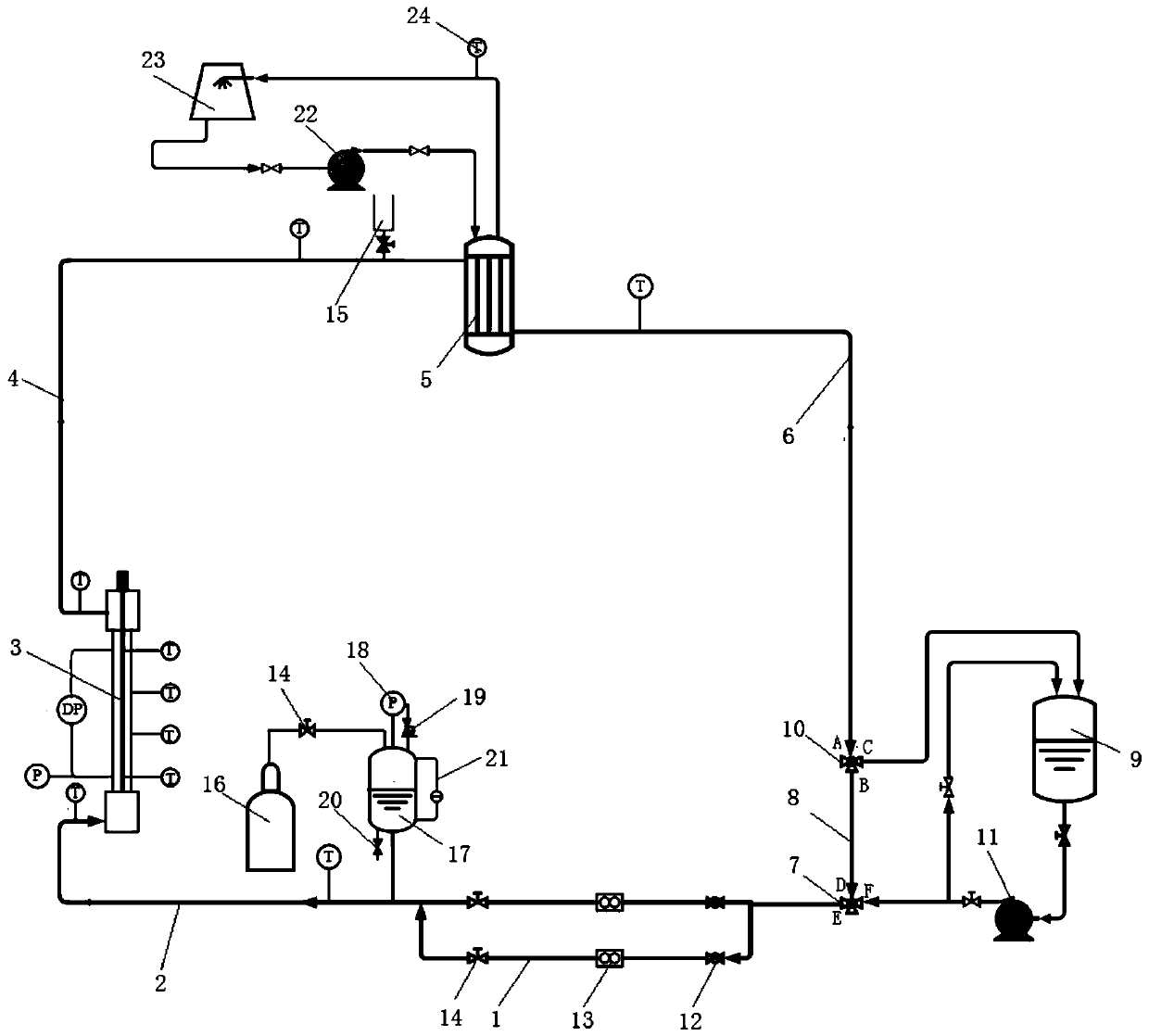

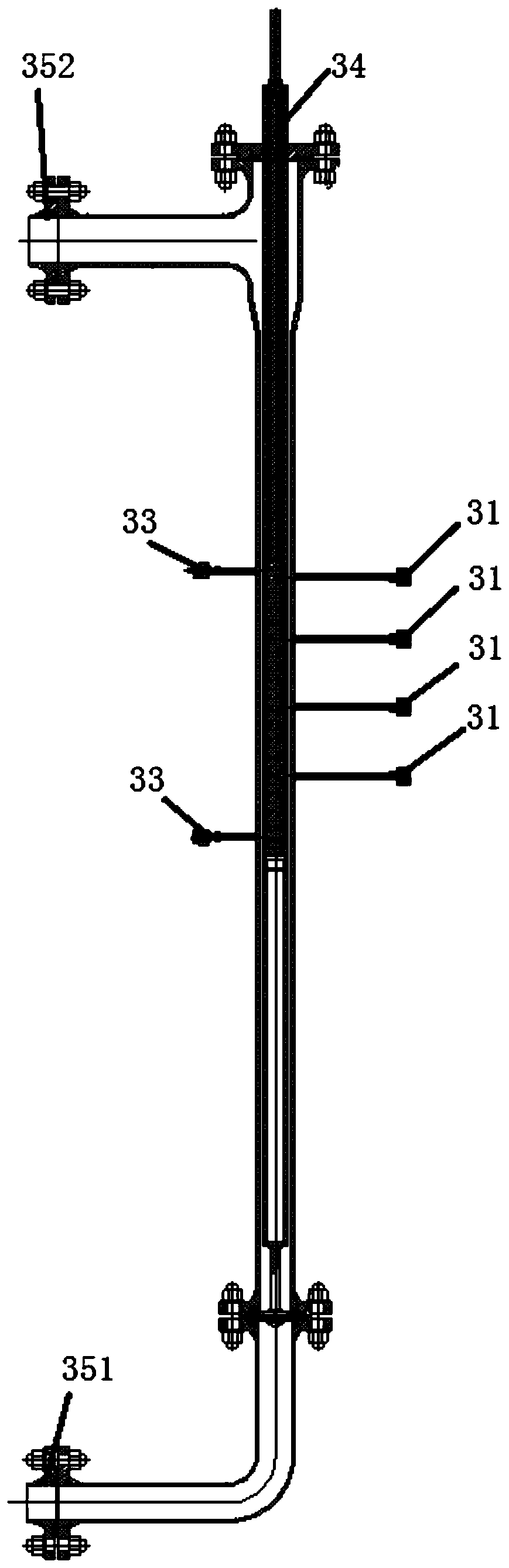

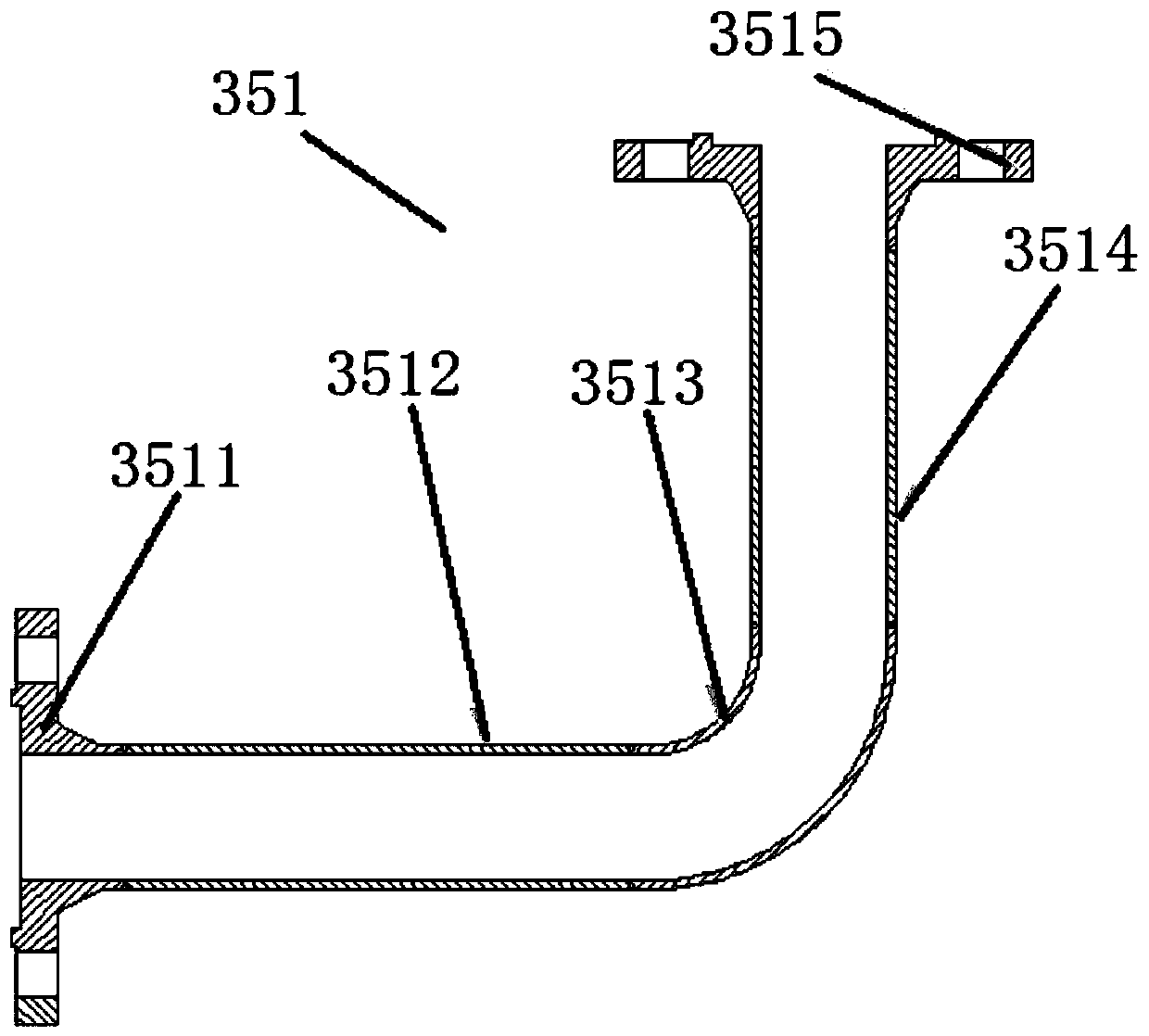

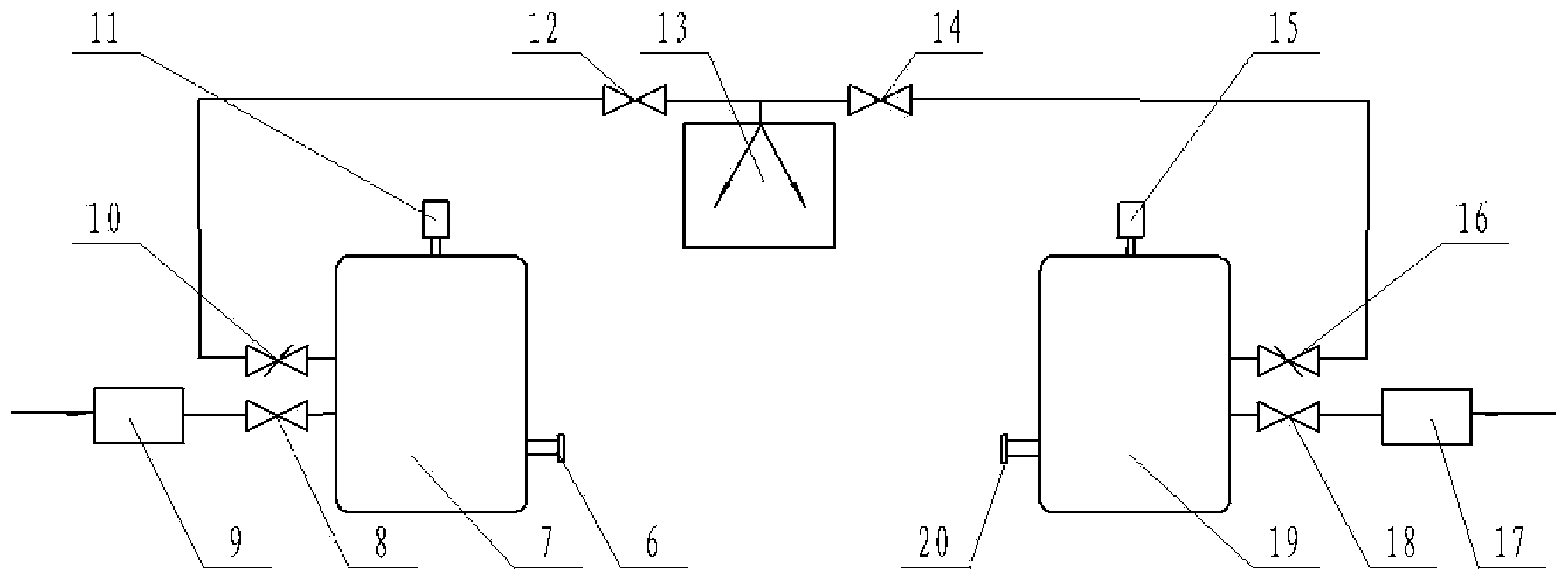

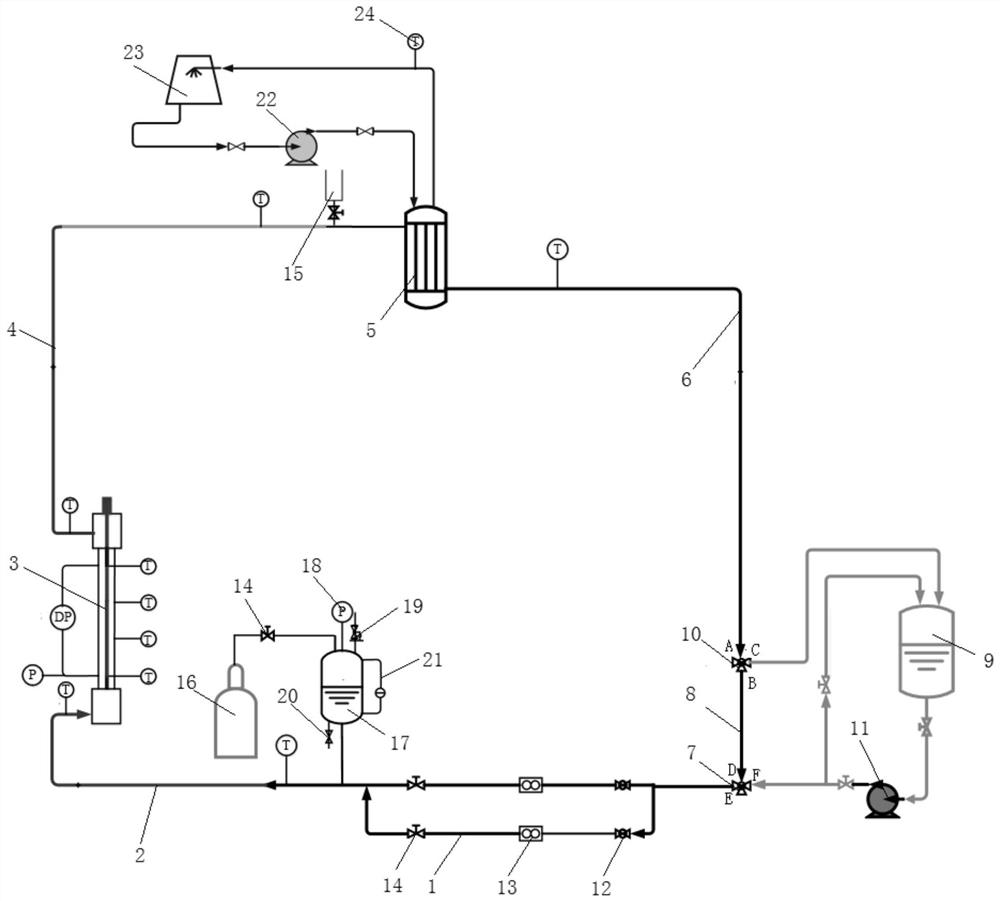

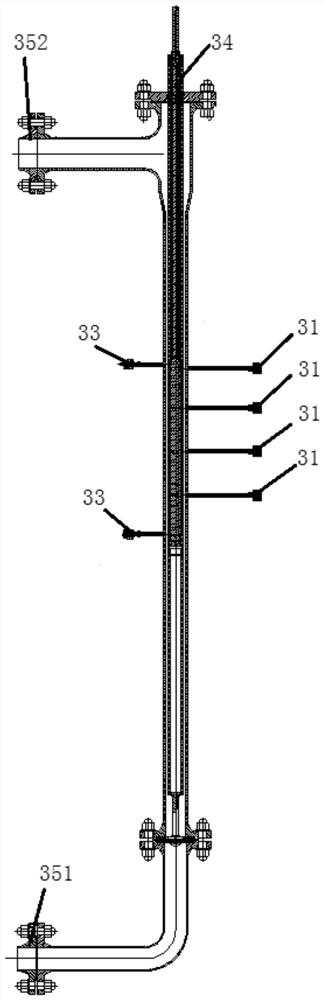

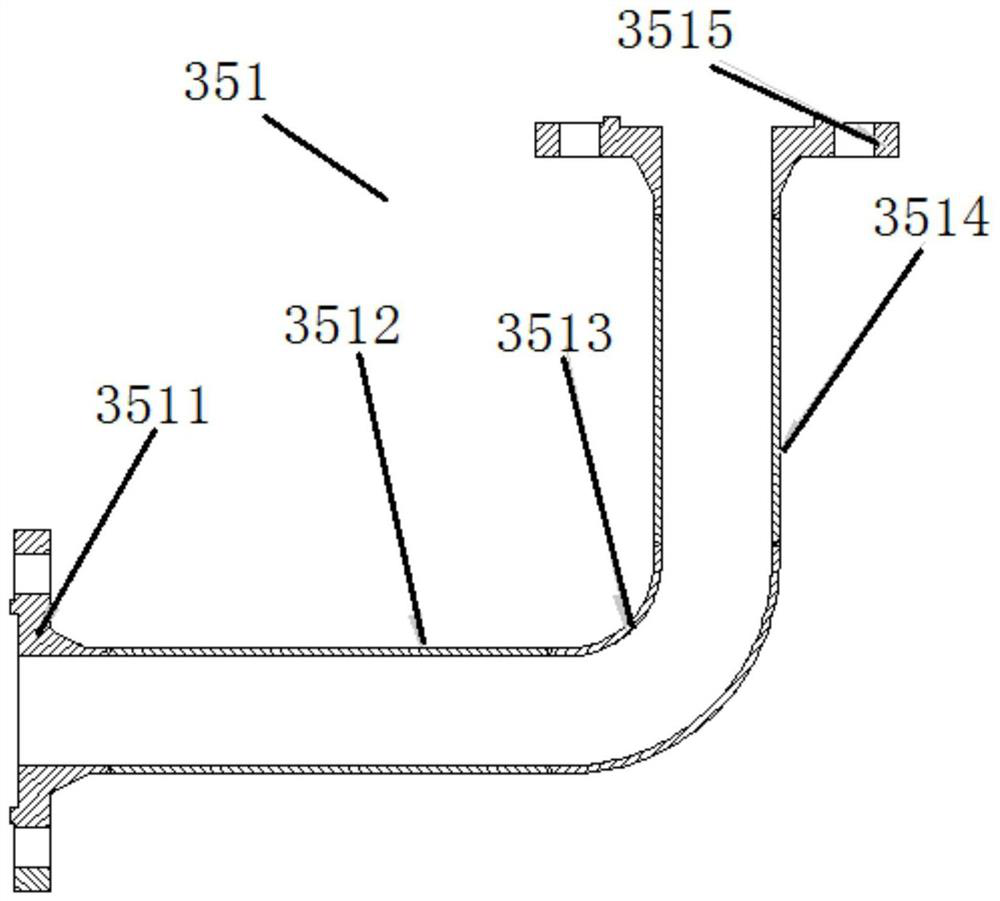

Low-pressure critical heat flux density experiment system and method

ActiveCN111157221AEasy to adjustAvoid being burnedMaterial heat developmentHydrodynamic testingThermodynamicsHeat flow

The invention relates to a low-pressure critical heat flux density experiment system and an experiment method. The system comprises a medium flow measuring pipe section, a preheating pipe section, anexperiment heating pipe section, a medium ascending pipe section, a condenser, a medium descending pipe section, a first three-way valve, a connecting pipeline, a second three-way valve and a water supply unit, a water outlet of the first three-way valve, the medium flow measuring pipe section, the preheating pipe section, the experiment heating pipe section, the medium ascending pipe section, thecondenser, the medium descending pipe section, the second three-way valve, the connecting pipeline and one water inlet of the first three-way valve are sequentially communicated in the flowing direction of a medium, and therefore a circulation loop is formed. The water supply unit is communicated with the other water inlet of the first three-way valve and is used for supplying a circulating medium to the circulating loop. Accurate and reliable data are provided for research on the circulating flow heat exchange characteristic and the critical heat flux density under the working condition of the pulse reactor.

Owner:NORTHWEST INST OF NUCLEAR TECH

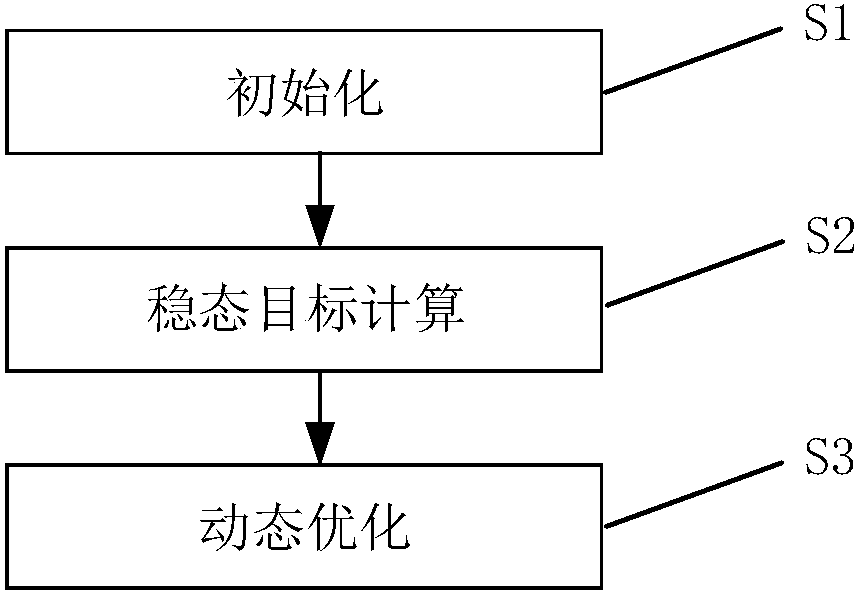

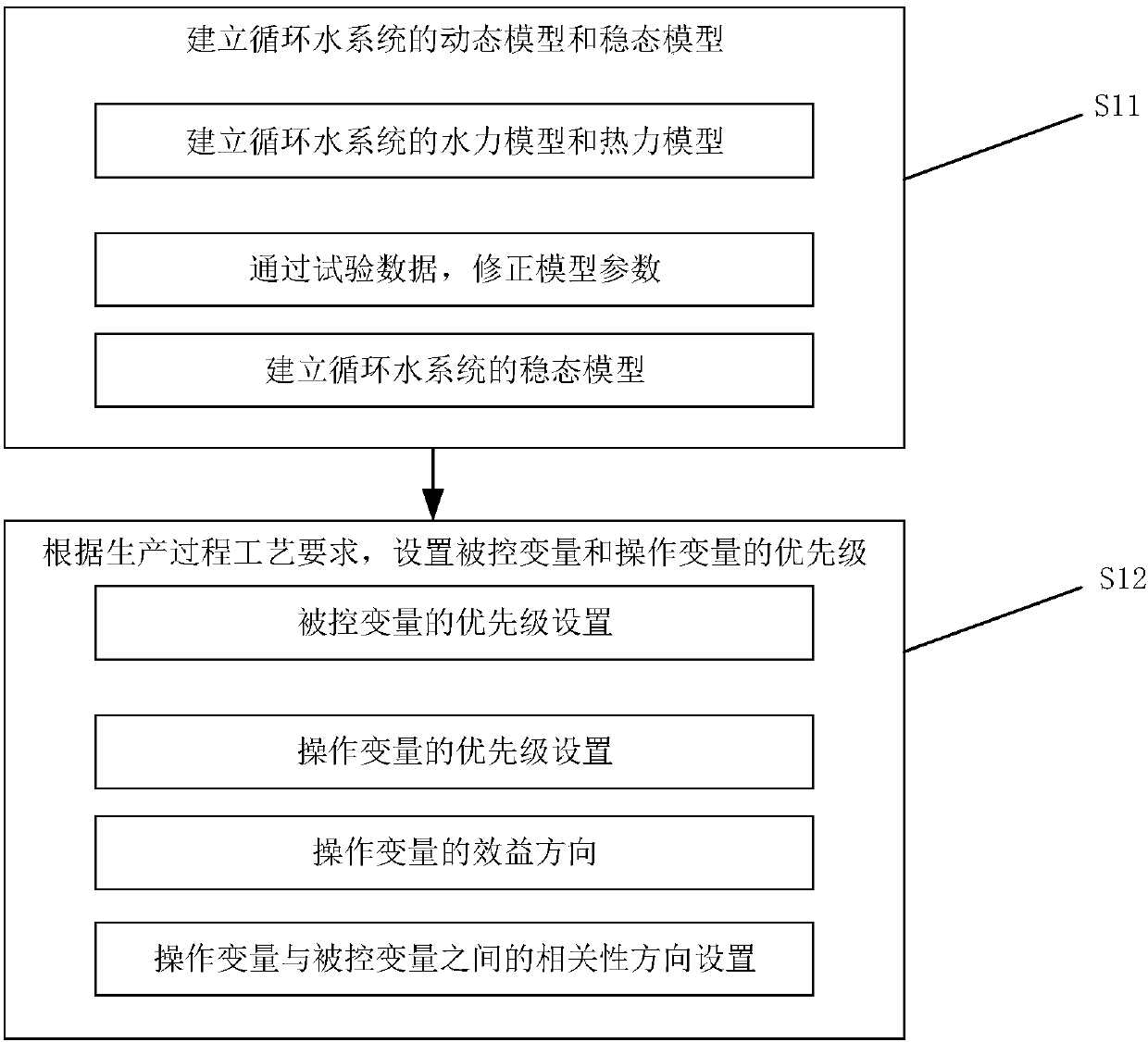

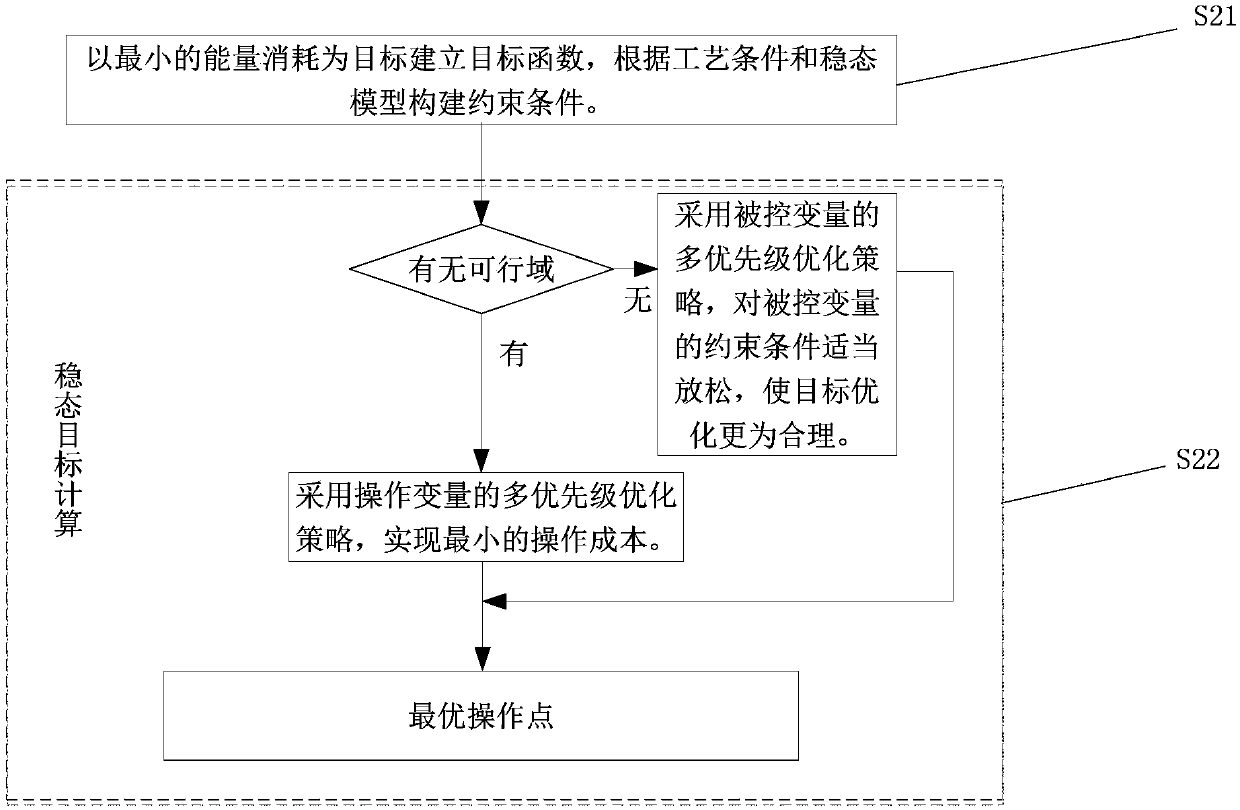

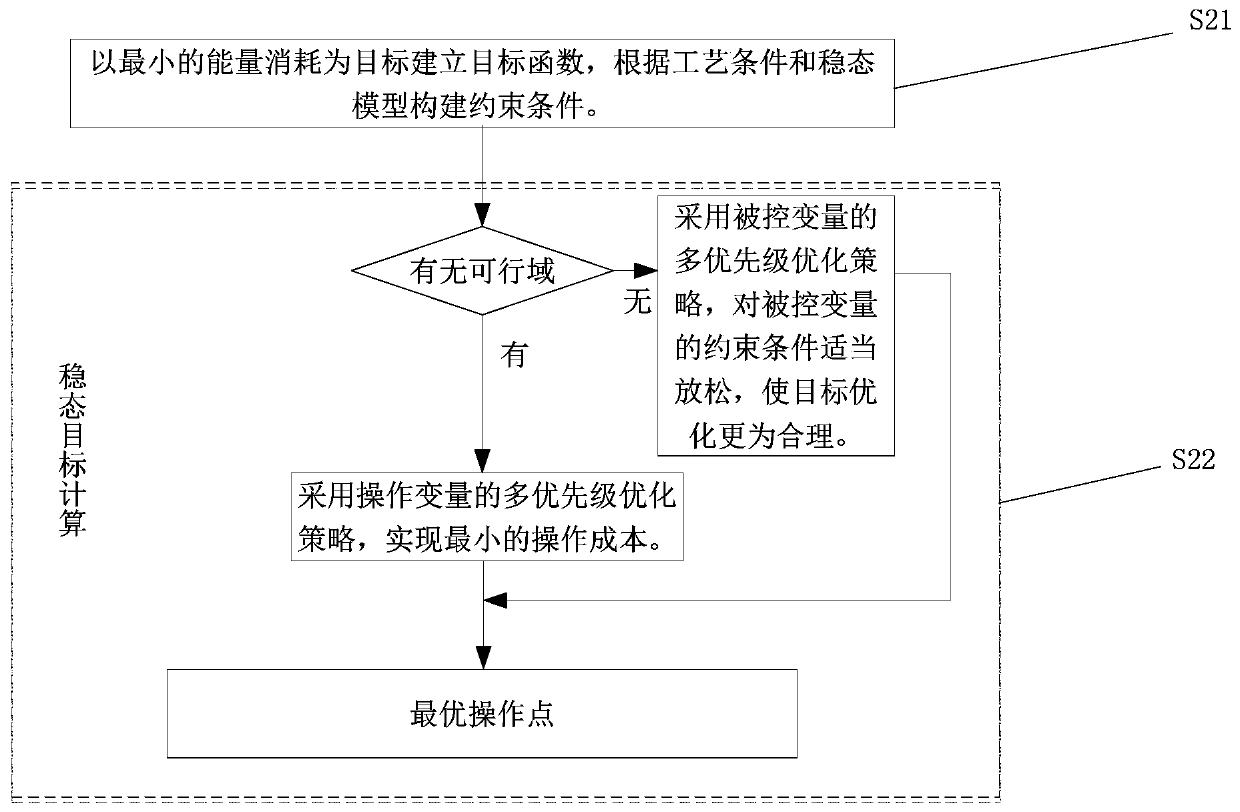

Energy-saving optimization control method for industrial circulating water based on double-layer structure predictive control

ActiveCN108021024AThe output flow of the pipe network is reducedRelieve pressureAdaptive controlControl variableOperating variables

The invention relates to an energy-saving optimization control method for industrial circulating water based on double-layer structure predictive control, which comprises the steps of building a dynamic model and steady-state model of a circulating water system; setting the priority of a controlled variable, the priority of an operating variable, the benefit direction of the operating variable andthe correlation direction between the operating variable and the controlled variable; establishing an objective function, and constructing constraint conditions according to technological conditionsand the steady-state model; if there is a feasible region, acquiring an optimal operating point; otherwise, properly loosening the constraint conditions for the controlled variable to obtain the optimal operating point; enabling the obtained optimal operating point to serve as a set value, building a model prediction controller, and implementing a control action. The energy-saving optimization control method realizes that each production unit of the circulating water system operates with the return water temperature being always below the highest allowable temperature. Meanwhile, the pipe network output flow of the circulating water system is enabled to be reduced, and the pressure is reduced. Therefore, the energy-saving optimization control method realizes the effects that the operationcost is reduced, and the system is energy-saving.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

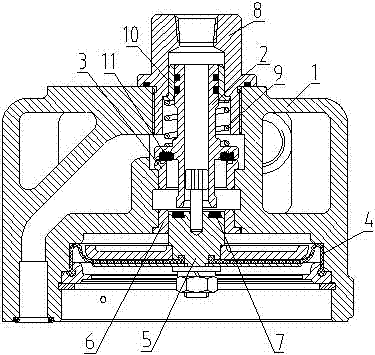

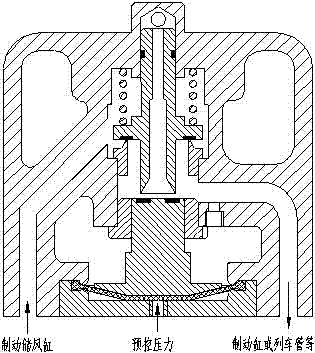

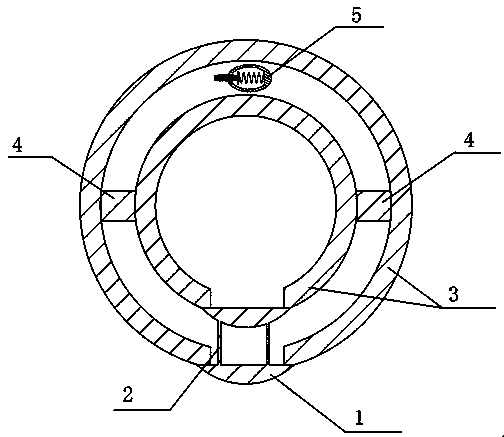

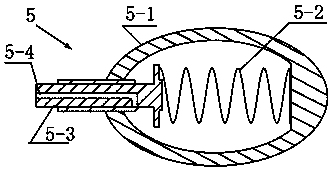

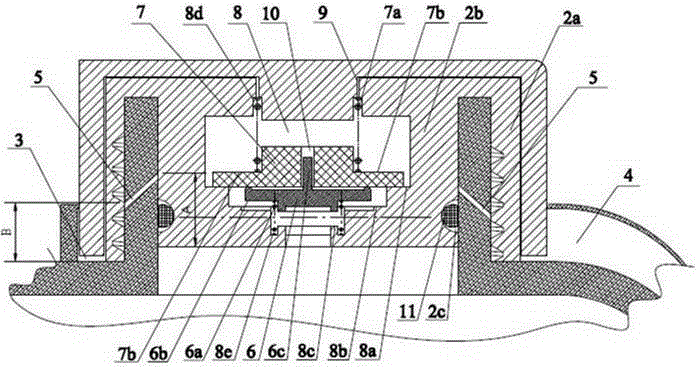

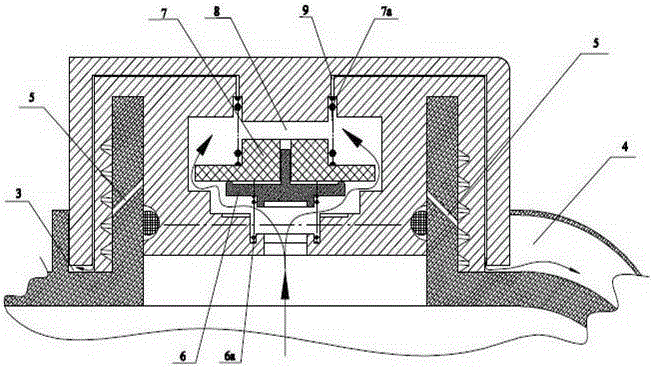

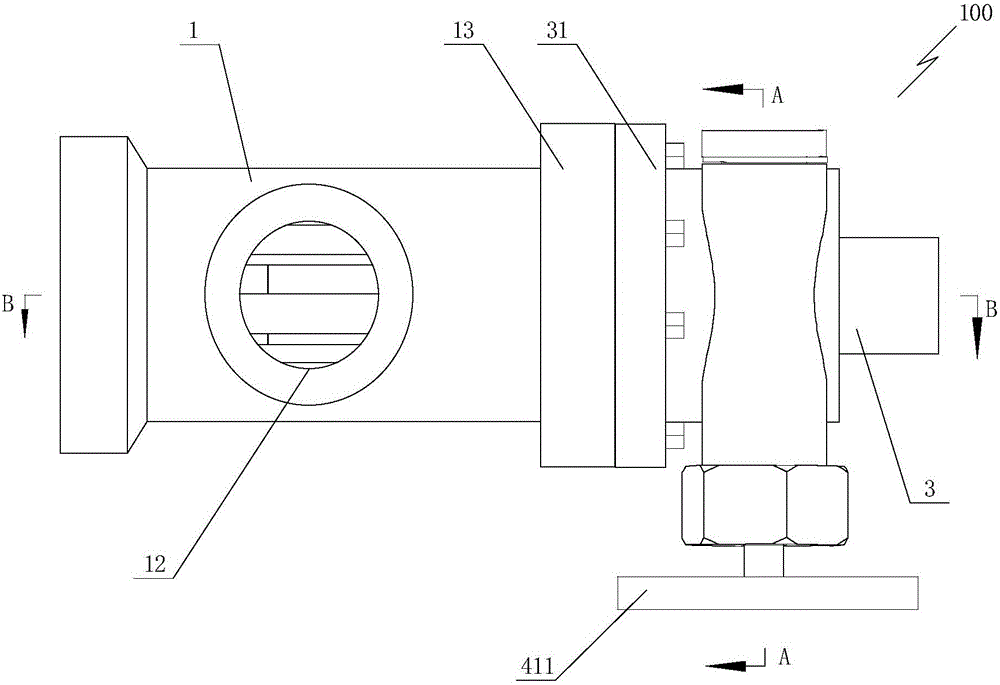

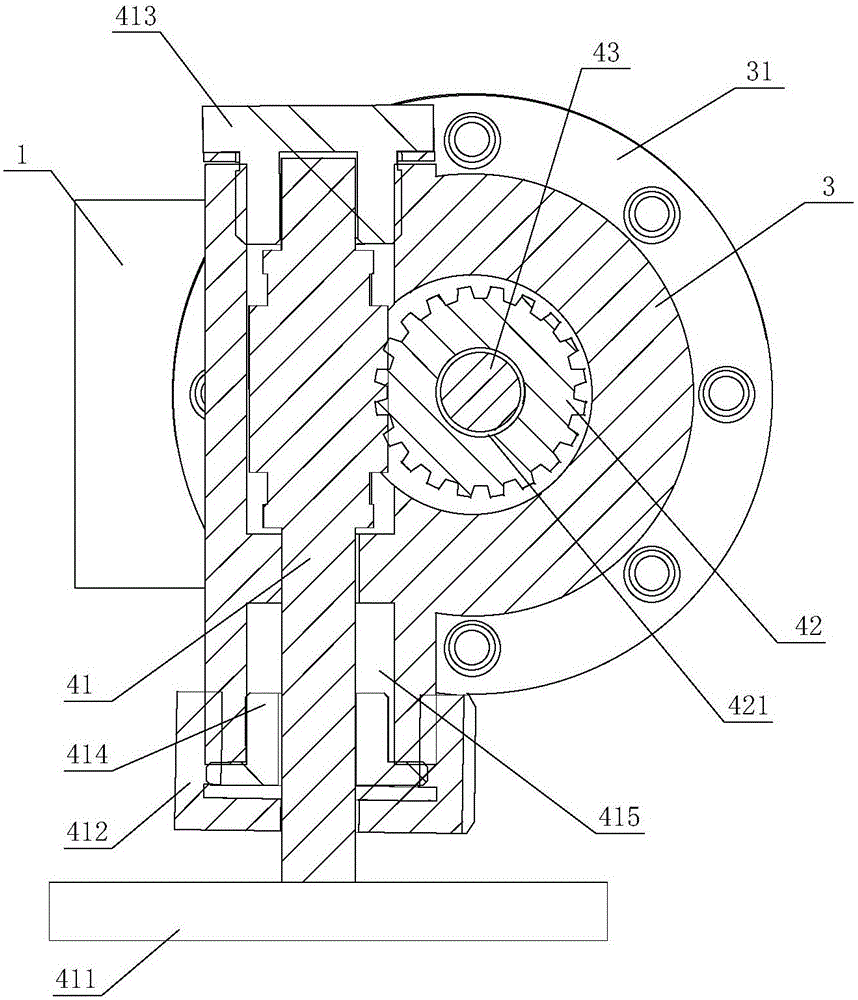

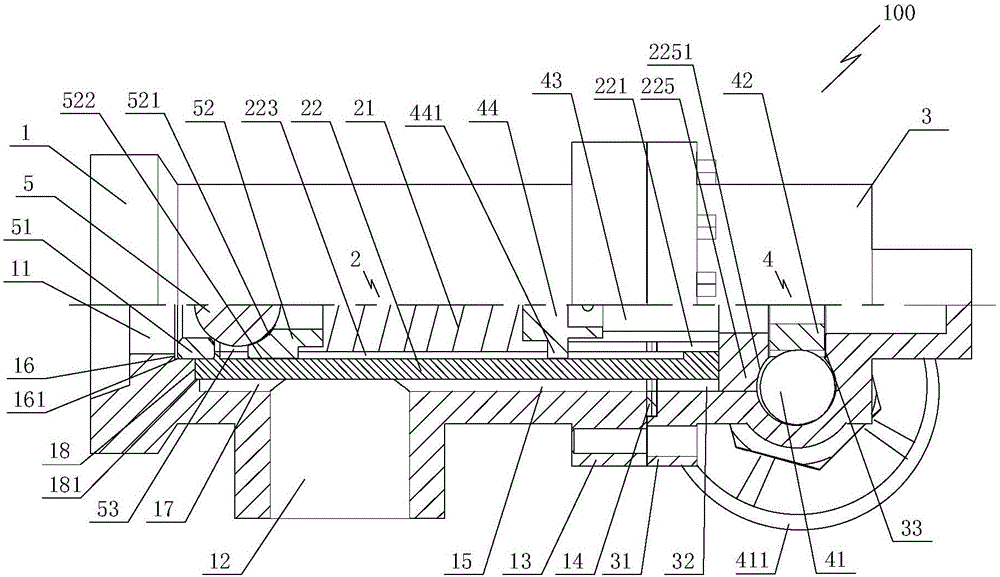

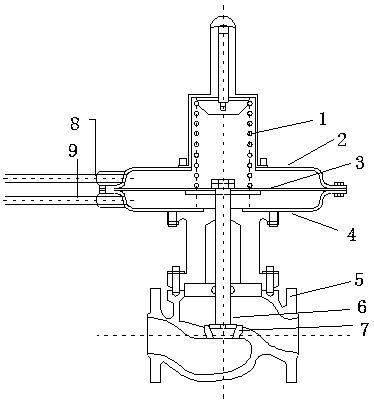

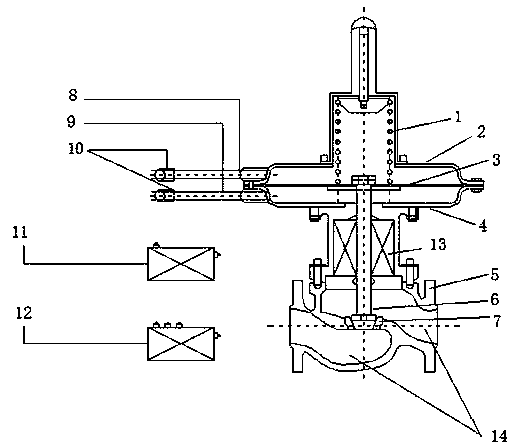

Relay valve for brake system of railway vehicle

The invention relates to a relay valve for a brake system of a railway vehicle. The relay valve comprises a valve body and a valve stem arranged inside a cavity of the valve body; three air channel connectors communicated with the internal cavity of the valve body are arranged on the valve body, two of the air channel connectors are air inlet connectors which are respectively connected with a brake air storage cylinder and controlled pressure, and the other air channel connector is an air outlet connector and is connected with a brake cylinder or a train pipe; an elastic recovery assembly is sleeved on the upper portion of the valve stem, the lower end of the valve stem is in contact connection with a valve port, and a central through hole communicated with the external atmosphere is arranged inside the valve stem; and a pressure regulating assembly placed below the valve stem is further arranged inside the valve body and is used for controlling break-make between the brake cylinder or the train pipe and the atmosphere or the brake air storage cylinder. The relay valve is simple in structure, low in cost and fast in response, and has fast air charging and exhausting properties, outputted pressure can be stably and linearly changed along with change of the controlled pressure, and can be controlled stably, the air flow can be increased or decreased according to the change of the controlled pressure, and functions of air charging, air exhausting or pressure maintaining are realized, so that braking force of the vehicle or a train is controlled.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

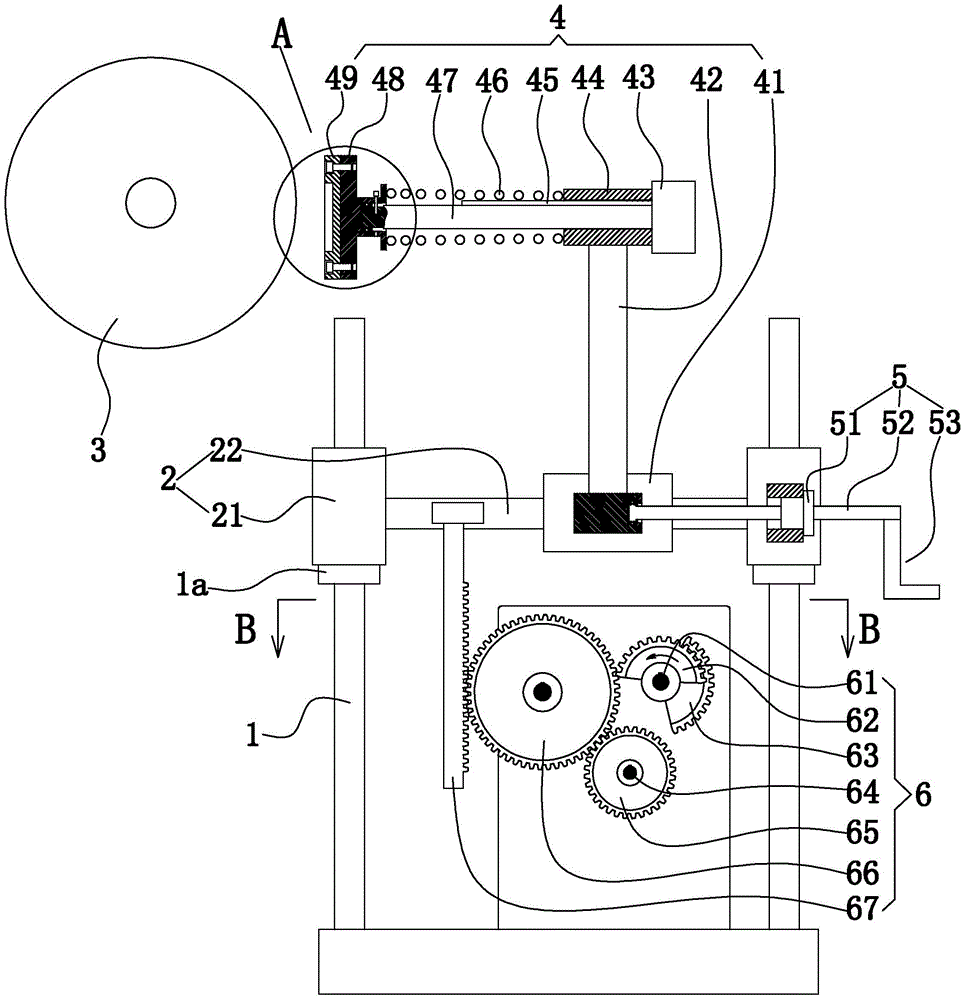

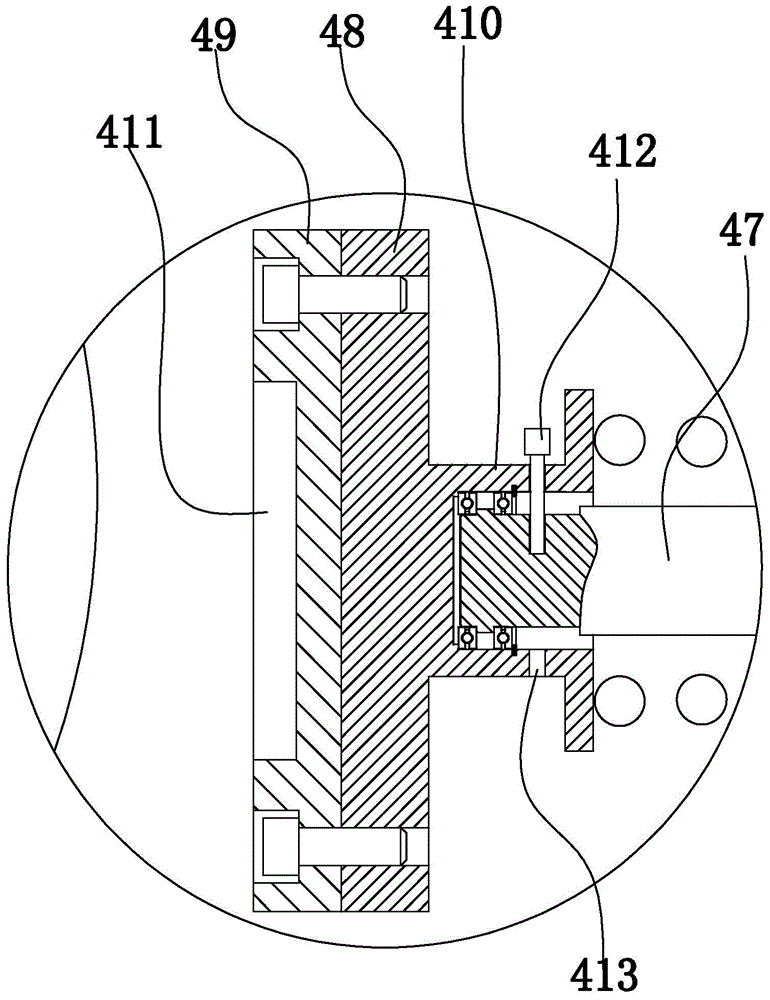

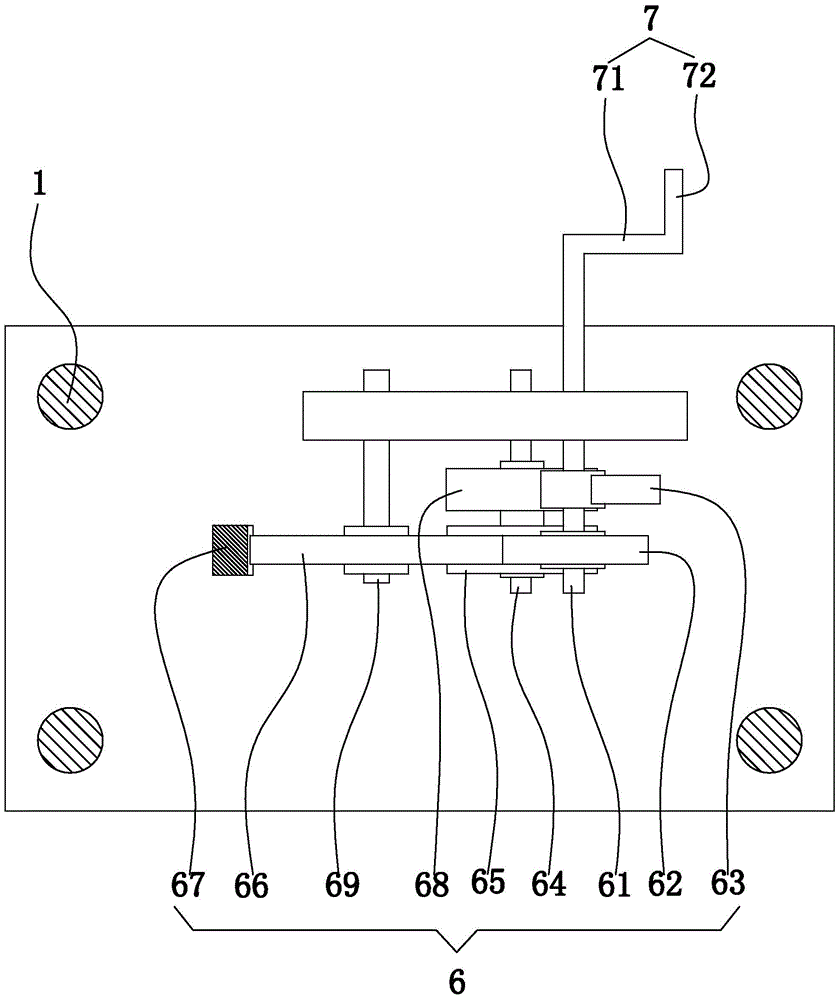

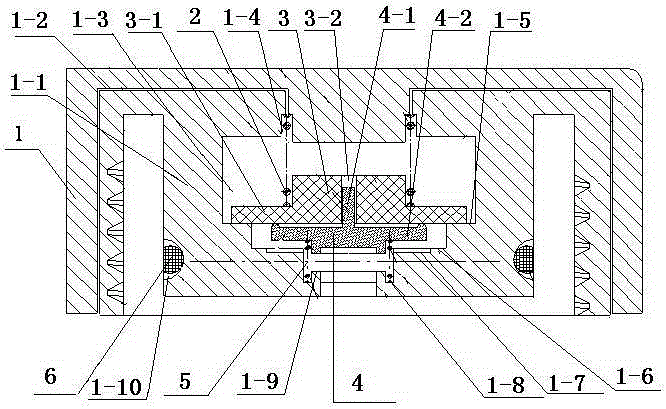

Metallographic grinder and method for polishing metallographic sample of corrosion layer of battery electrode plate

ActiveCN104458368AReduce labor intensityImprove grinding efficiencyPreparing sample for investigationEngineeringDrive motor

The invention discloses a metallographic grinder and a method for polishing a metallographic sample of a corrosion layer of a battery electrode plate, which can effectively reduce the labor intensity of a grinding operation and improve the grinding efficiency, and is beneficial of obtaining clearly displayed metallographic structures. The metallographic grinder comprises a rotatably arranged grinding wheel, a driving motor, a vertical guide post, a lifting platform, a manual lifting executor, a horizontal guide rod, an electrode plate mounting plate and a translation device, wherein the driving motor is used for driving the grinding wheel to rotate, the vertical guide post is arranged on a rack, the lifting platform can lift up and down along the vertical guide post, the manual lifting executor is used for driving the lifting platform to move up and down in a reciprocating manner, the horizontal guide rod is arranged on the lifting platform, the electrode plate mounting device can move along the horizontal guide rod, and the translation device is arranged on the lifting platform and is used for driving the electrode plate mounting device to move along the horizontal guide rod.

Owner:CHAOWEI POWER CO LTD

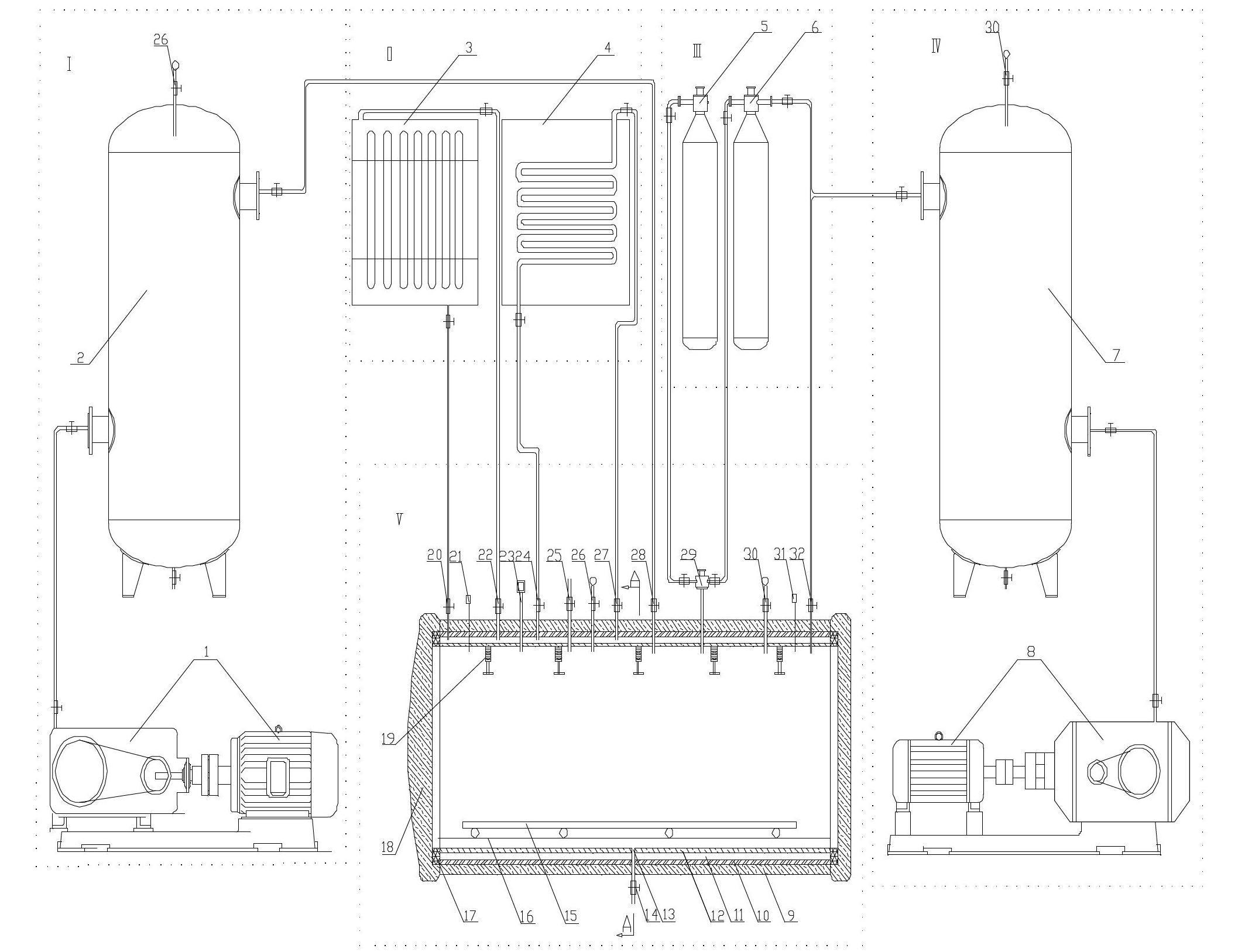

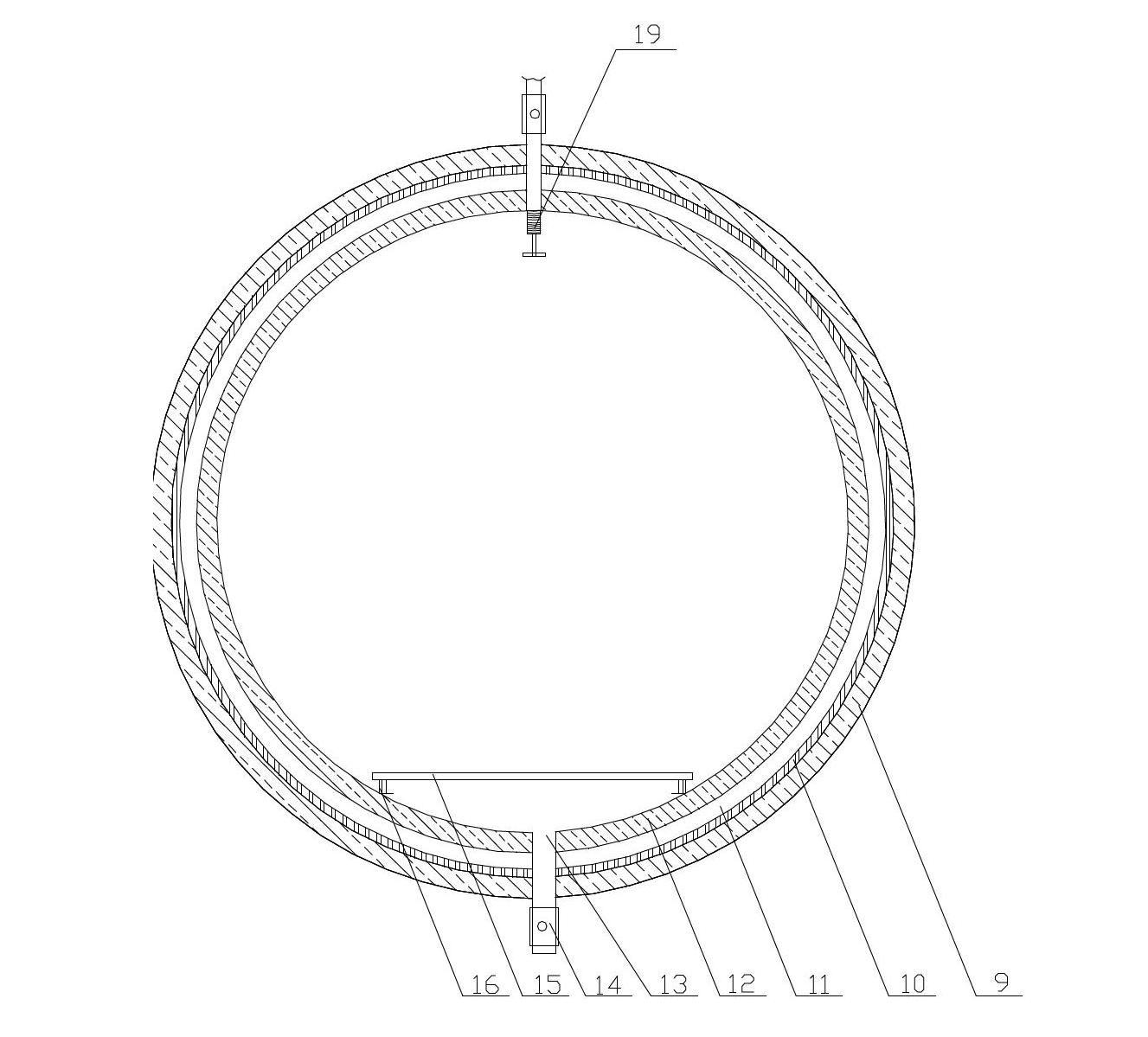

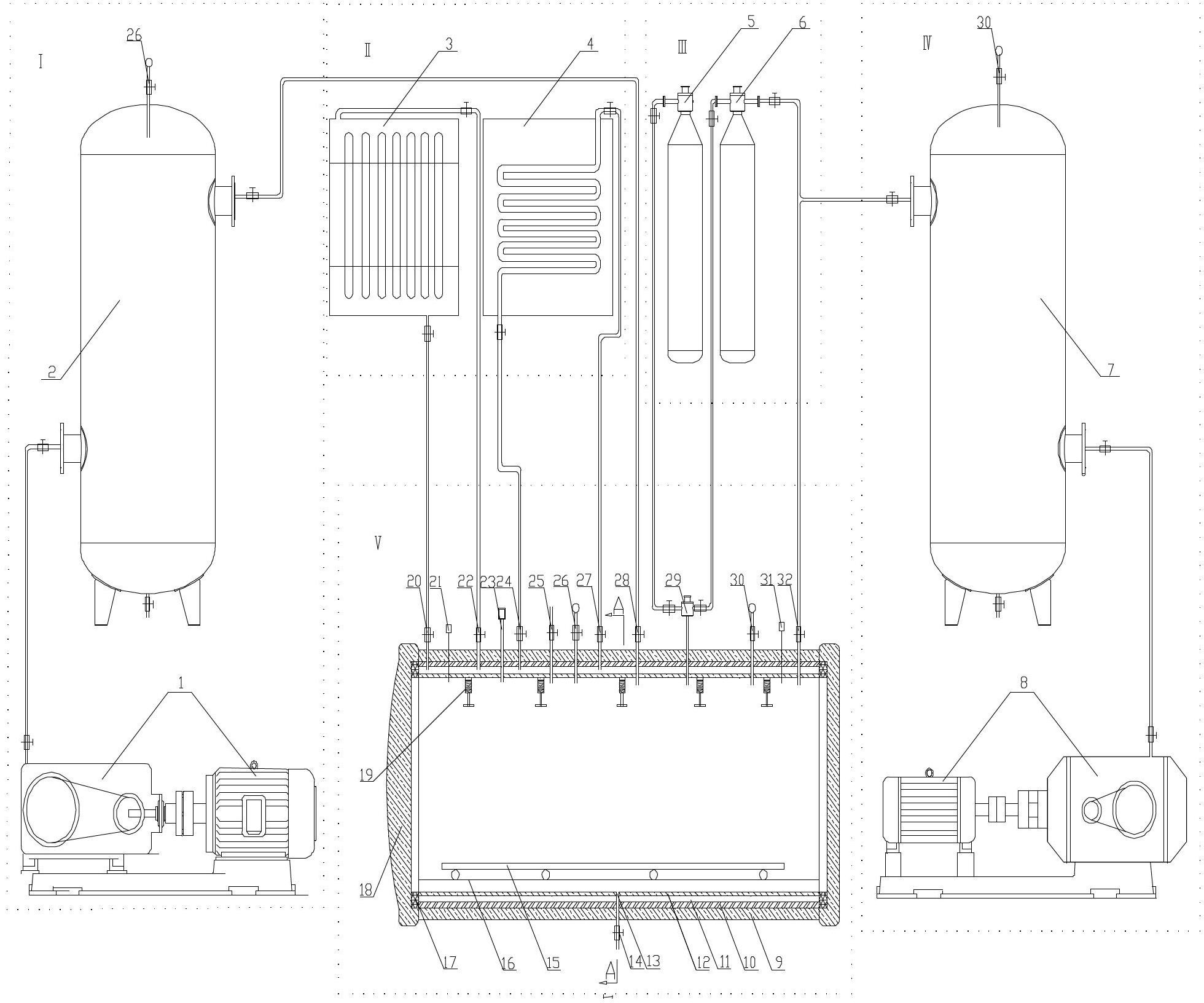

Vacuum pressurizing and dipping equipment for producing wood plastic composite

InactiveCN102626938AEasy to operateEnergy saving pollutionPressure impregnationAutomatic controlProcess engineering

The invention relates to vacuum pressurizing and dipping equipment for producing wood plastic composite. The vacuum pressurizing and dipping equipment mainly comprises the following five parts: a pressure control system I, a temperature control system II, a protection system III, a vacuum system IV and a dipping system V. In a wood plastic composite production process, the pressure control system I, the vacuum system IV and the temperature control system II can be conveniently used for automatically compensating pressure, automatically regulating the vacuum degree and automatically controlling the temperature for producing according to a specified production process; inert gas can be used as protective gas by the protection system III, and the protective gas is collected by a gas collection bottle (6) after production; the dipping system is equipment integrating the functions of wood dipping and heating into a whole, and a slide way (16) and a slide wheel (15) are arranged in the dipping equipment and are convenient for putting wood before dipping and taking out the wood after dipping; and a floating prevention piece (19) can be used for preventing wood from floating above dipping liquid in a dipping process. The vacuum pressurizing and dipping equipment has the characteristics of energy saving, environmental protection, convenience in operation and practicability.

Owner:NORTHEAST FORESTRY UNIVERSITY

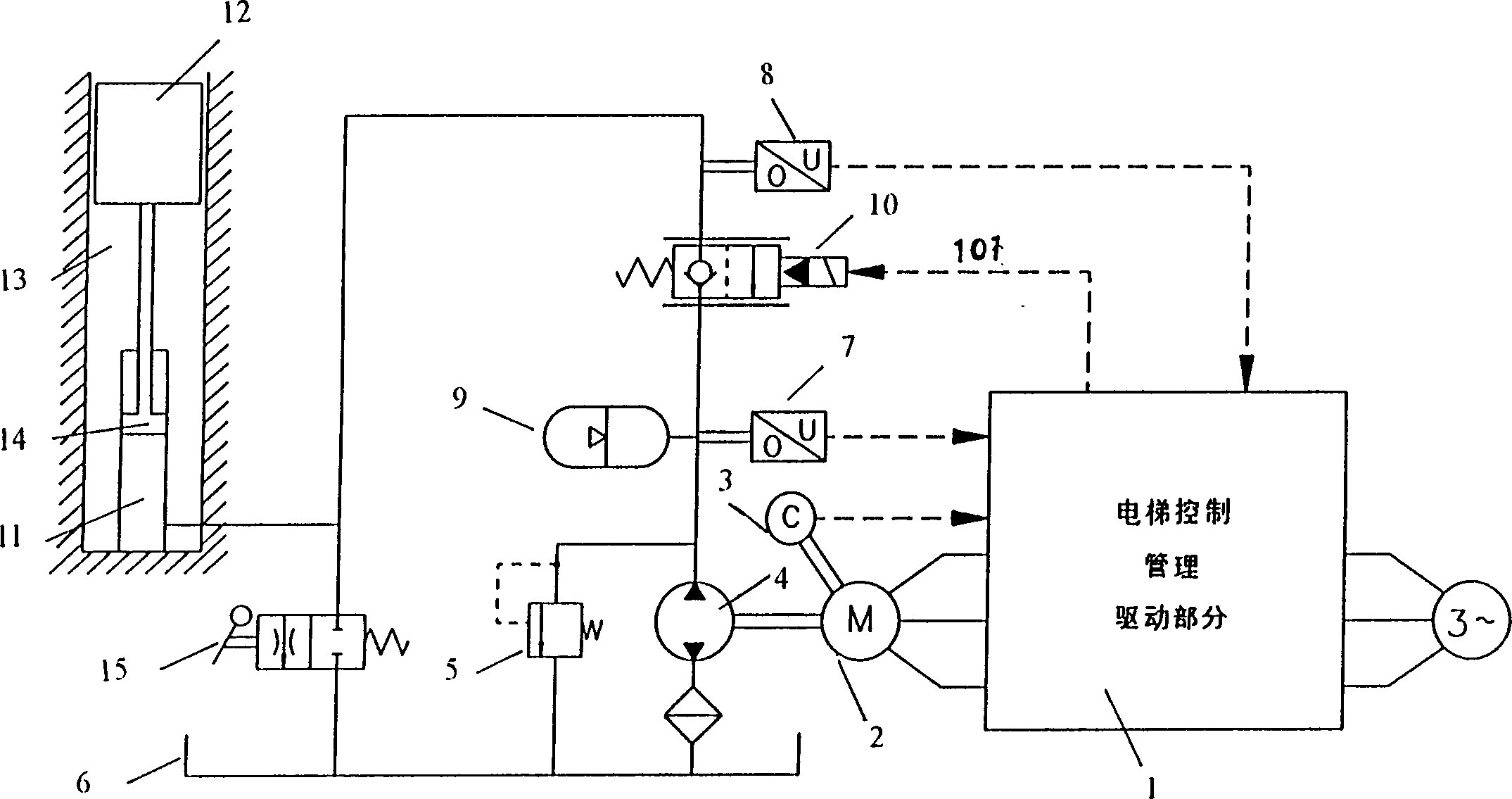

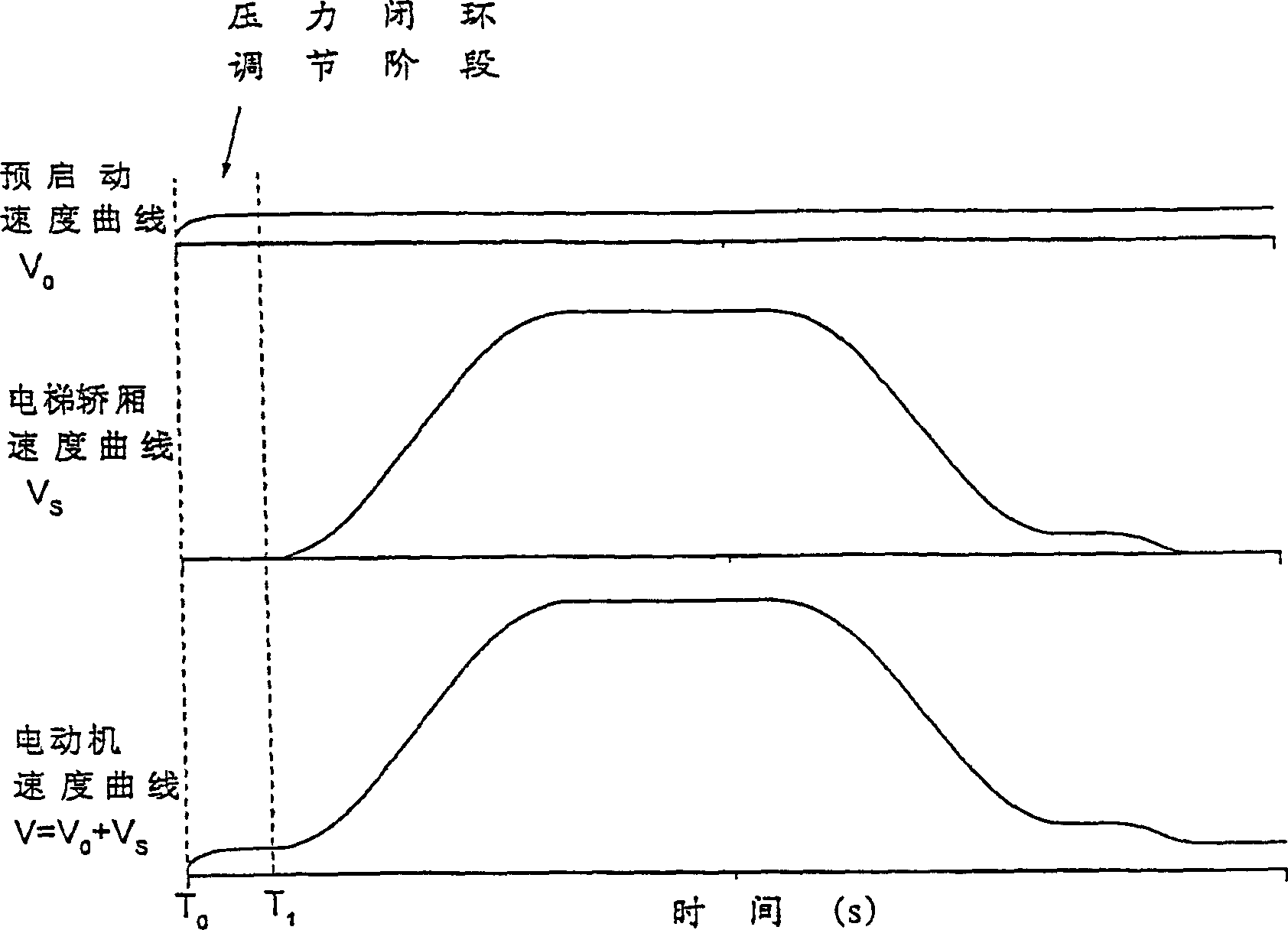

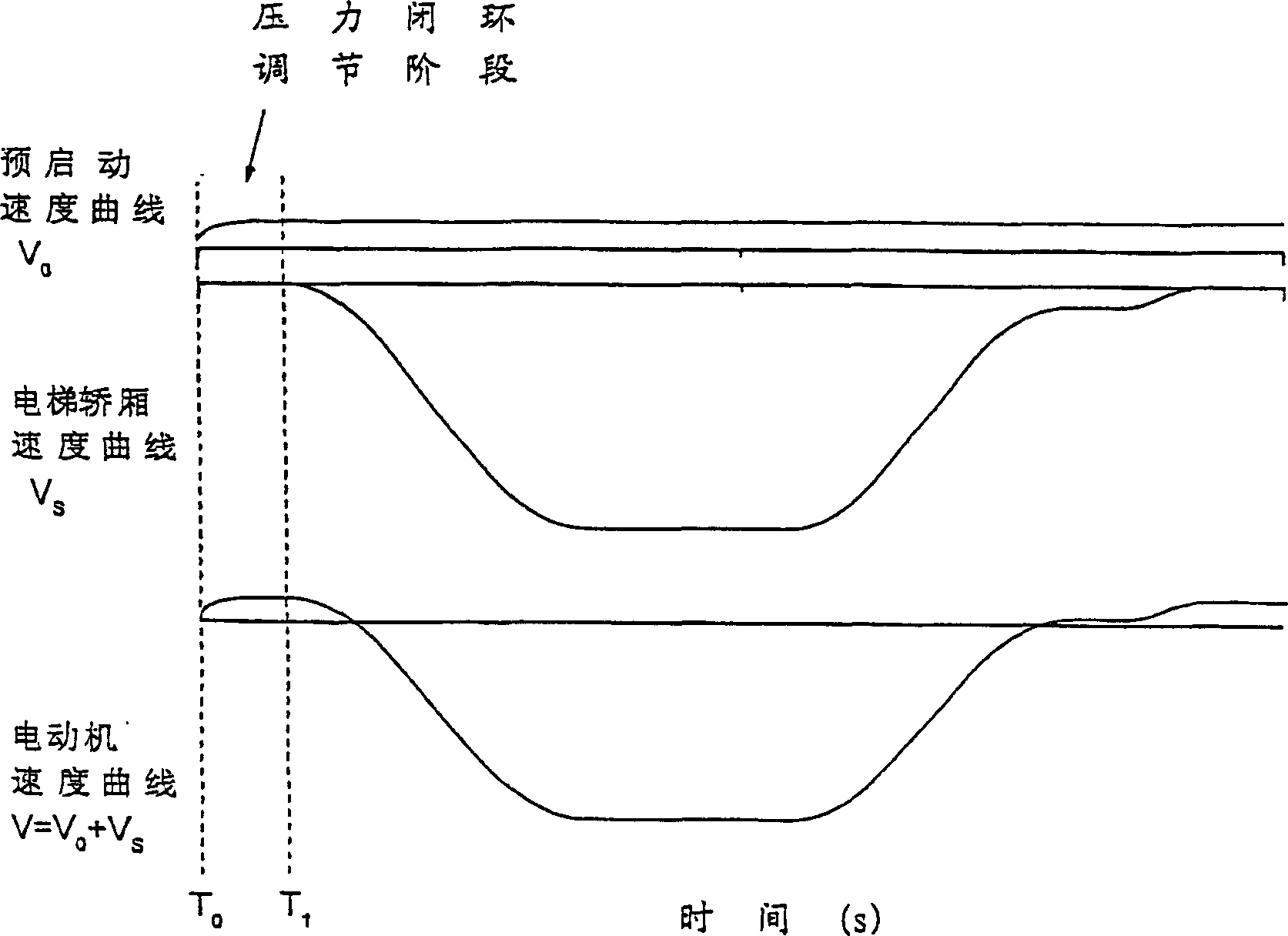

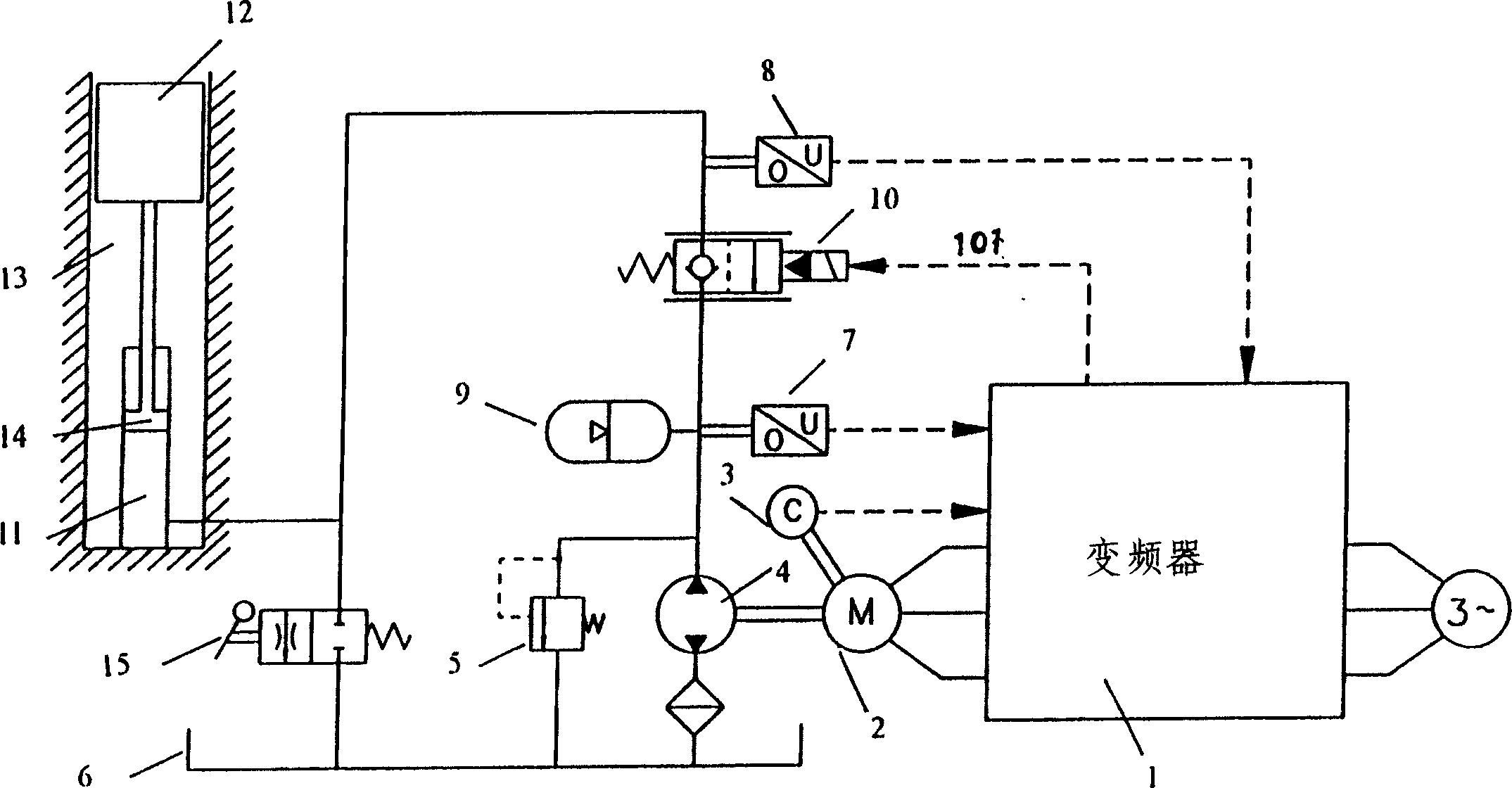

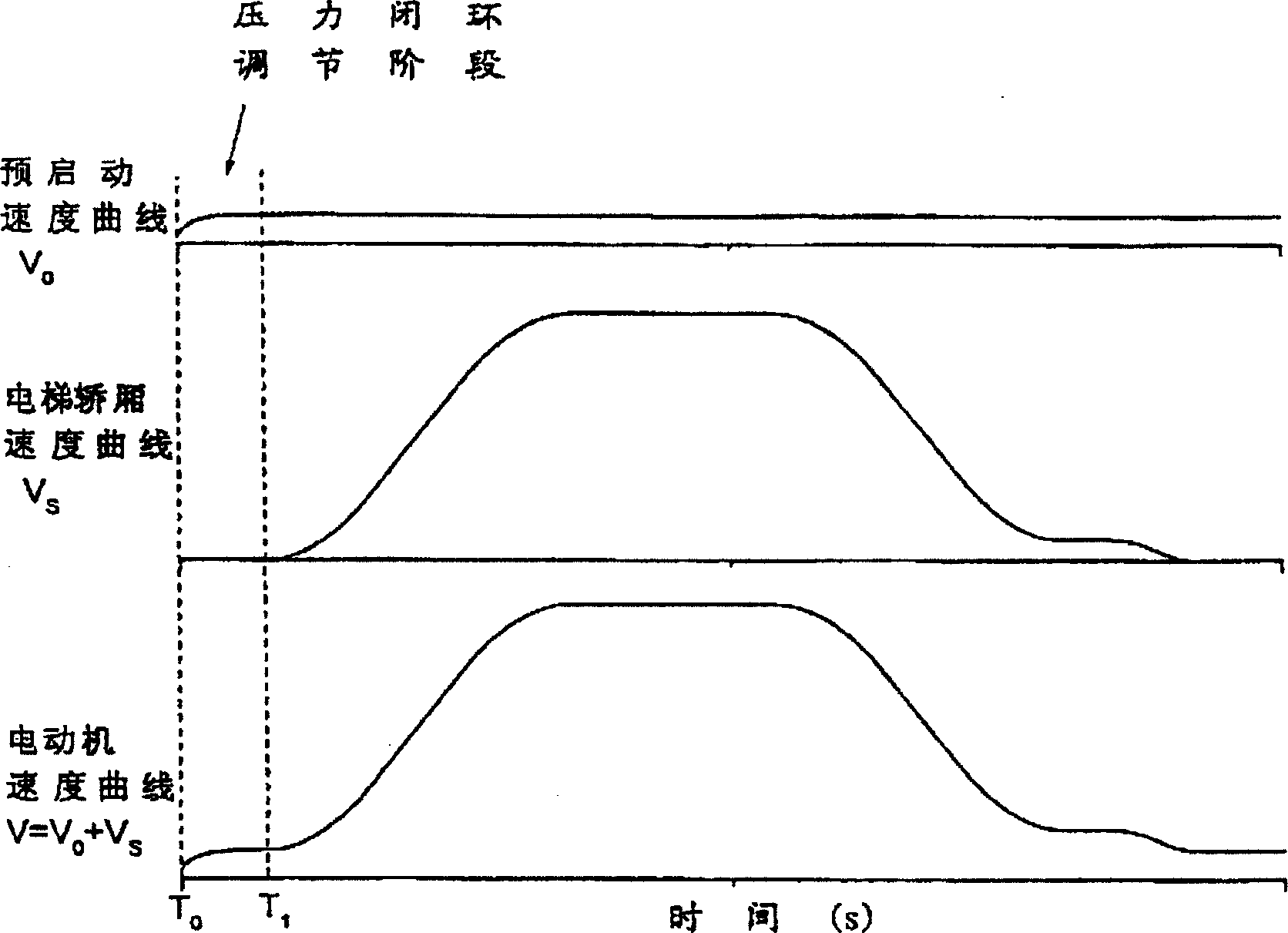

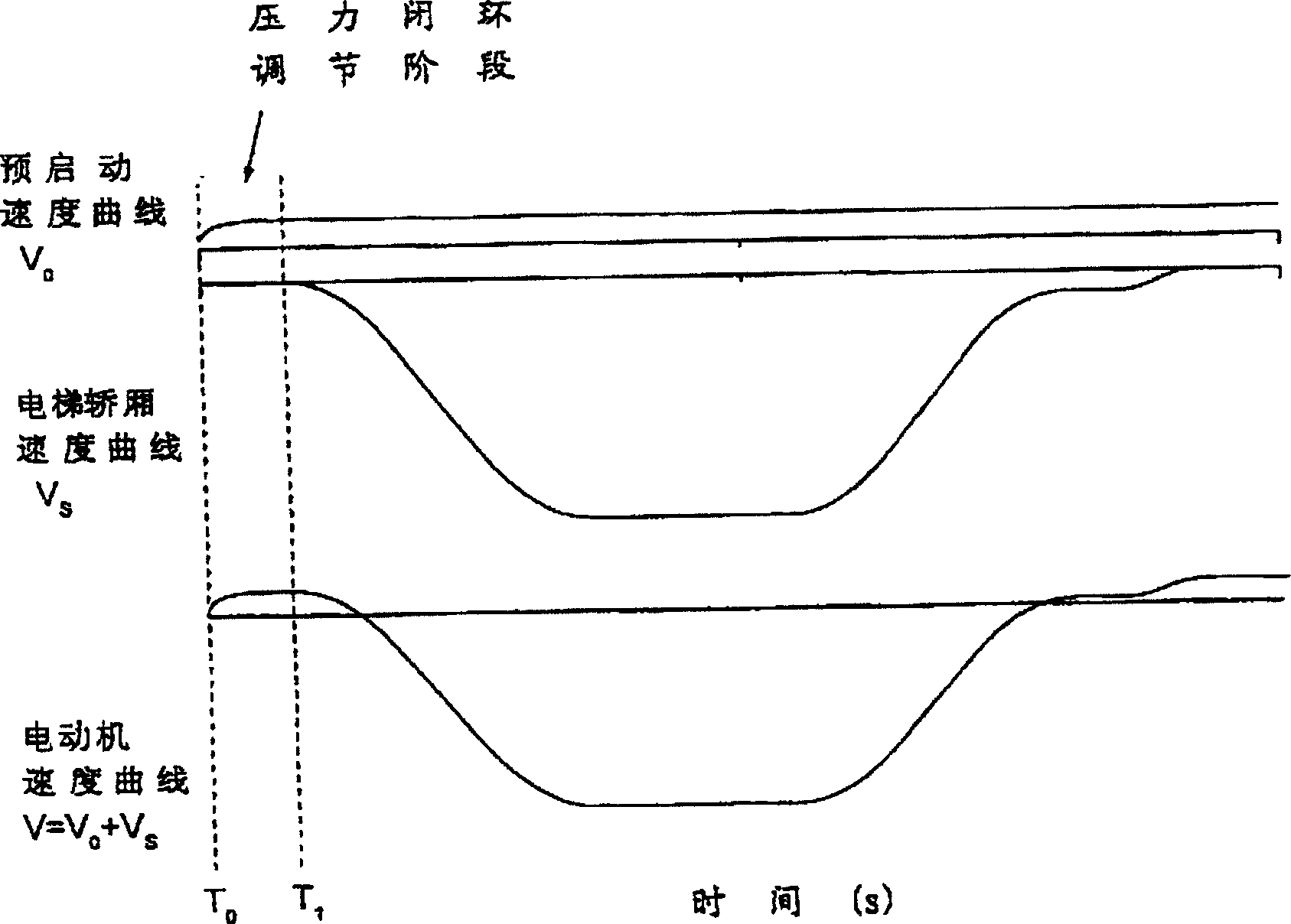

Hydraulic elevator system of improvement running performance by accumulator

InactiveCN1413900AImprove Mathematical ModelAvoid starting shockElevatorsEnergy efficiency in elevatorsElevator systemMathematical model

A hydraulic elevator system using energy accumulator to improve its running performance features that a drive motor whose speed is regulated by changing voltage and frequency is used to change the flow of hydraulic pump. It is composed of cage, asynchronous motor, hydraulic pump electromagnetic valve, oil cylinder, hydraulic energy accumulator and two pressure transducers, which can measure and feed back the pressure of hydraulic pump and oil cylinder to form a pressure closed-loop system for conpensating leakage.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

Cabin of underwater detecting instrument

The invention provides a cabin of an underwater detecting instrument. The cabin of the underwater detecting instrument has certain anti-pressure ability at a great depth underwater and cannot be deformed obviously. The cabin is formed by at least two high strength spherical cabin bodies in a nested mode, the cabin bodies are connected through elastic buffer devices, and the interlayer formed between the cabin bodies is filled with liquid state substances. By the adoption of the structure, the problem that a cabin of the underwater detecting instrument can be damaged due to deepwater pressure in the prior art is solved, and thus the safety of important instrument equipment and personnel in the cabin can be guaranteed.

Owner:冯建金

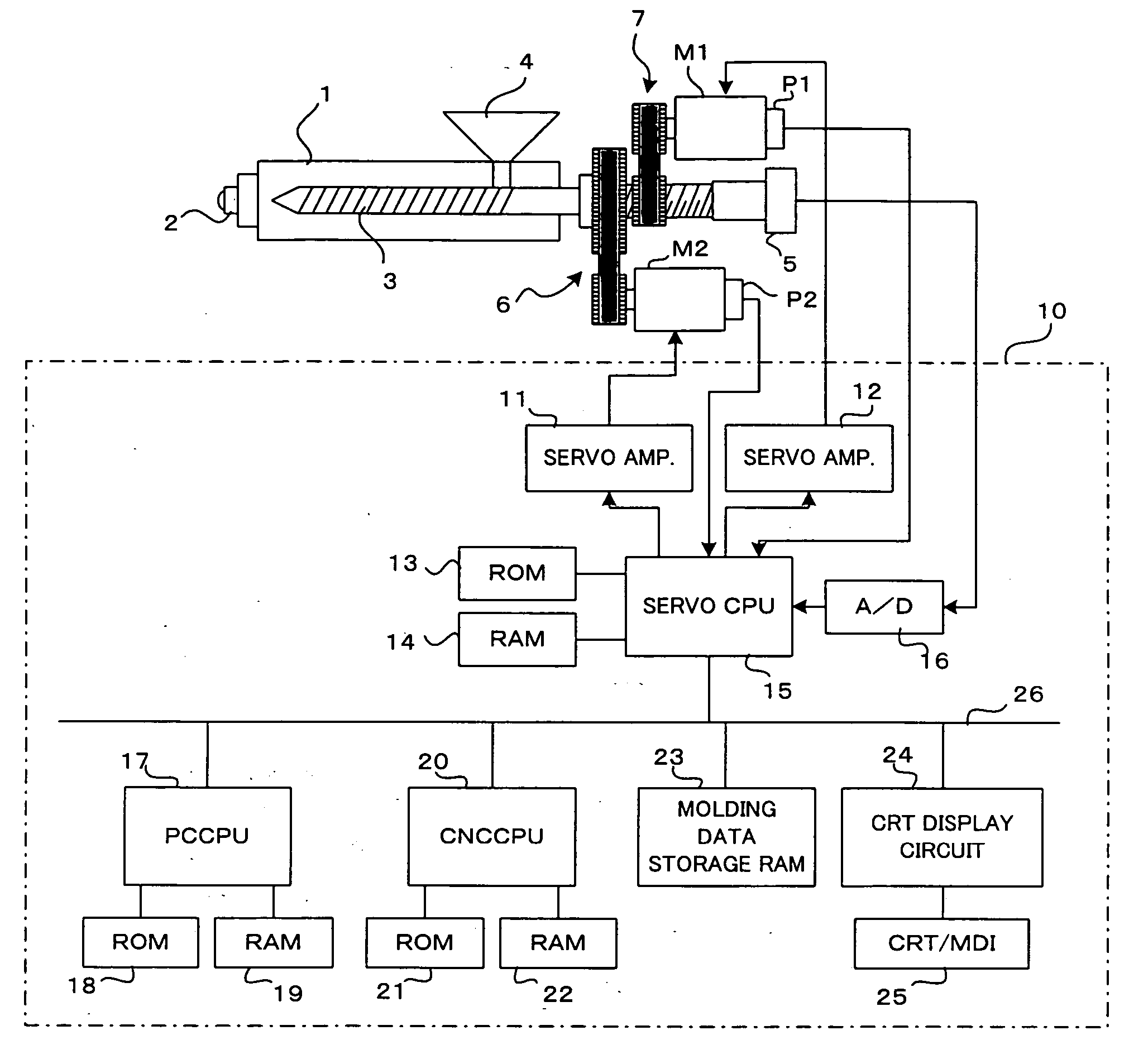

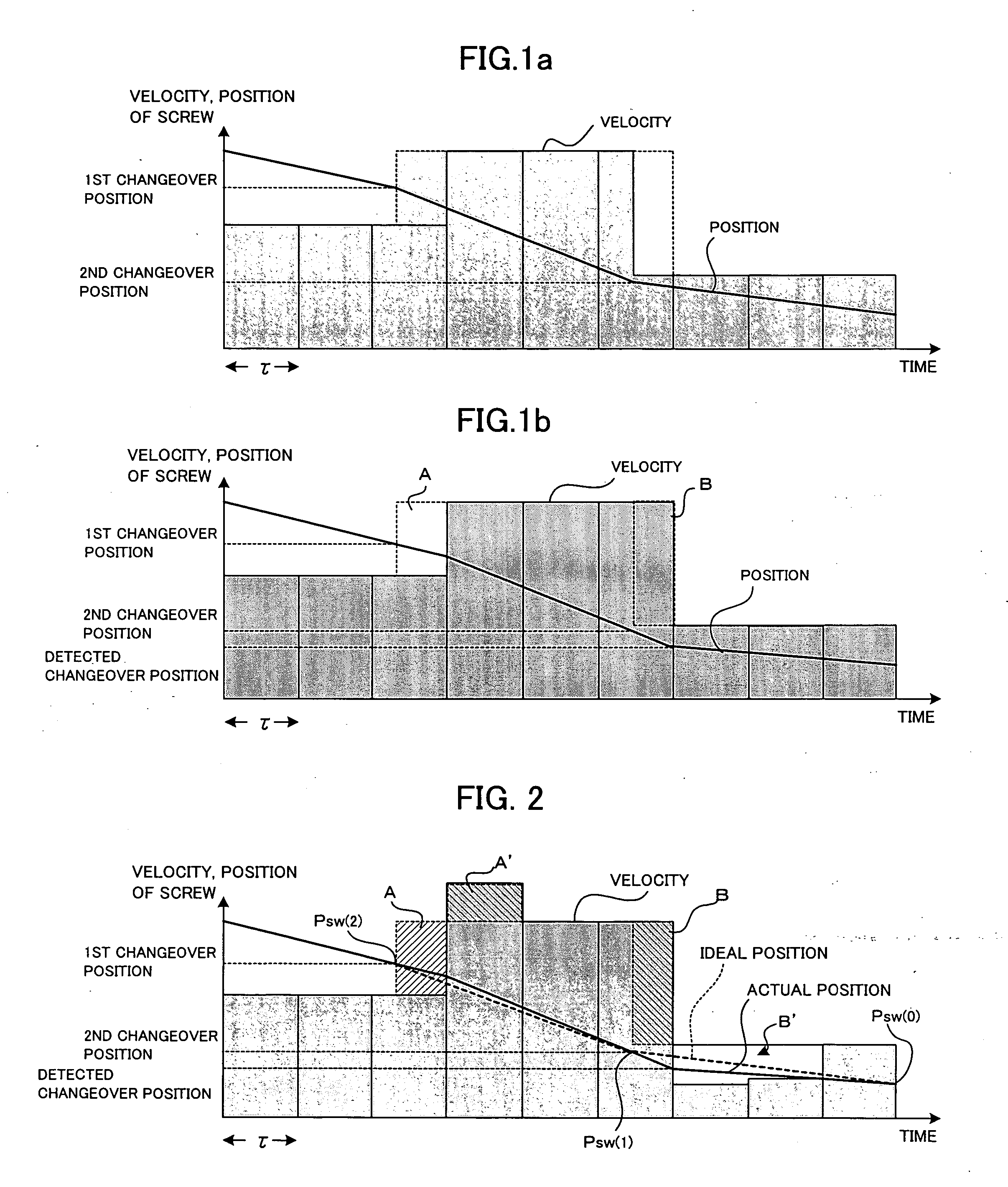

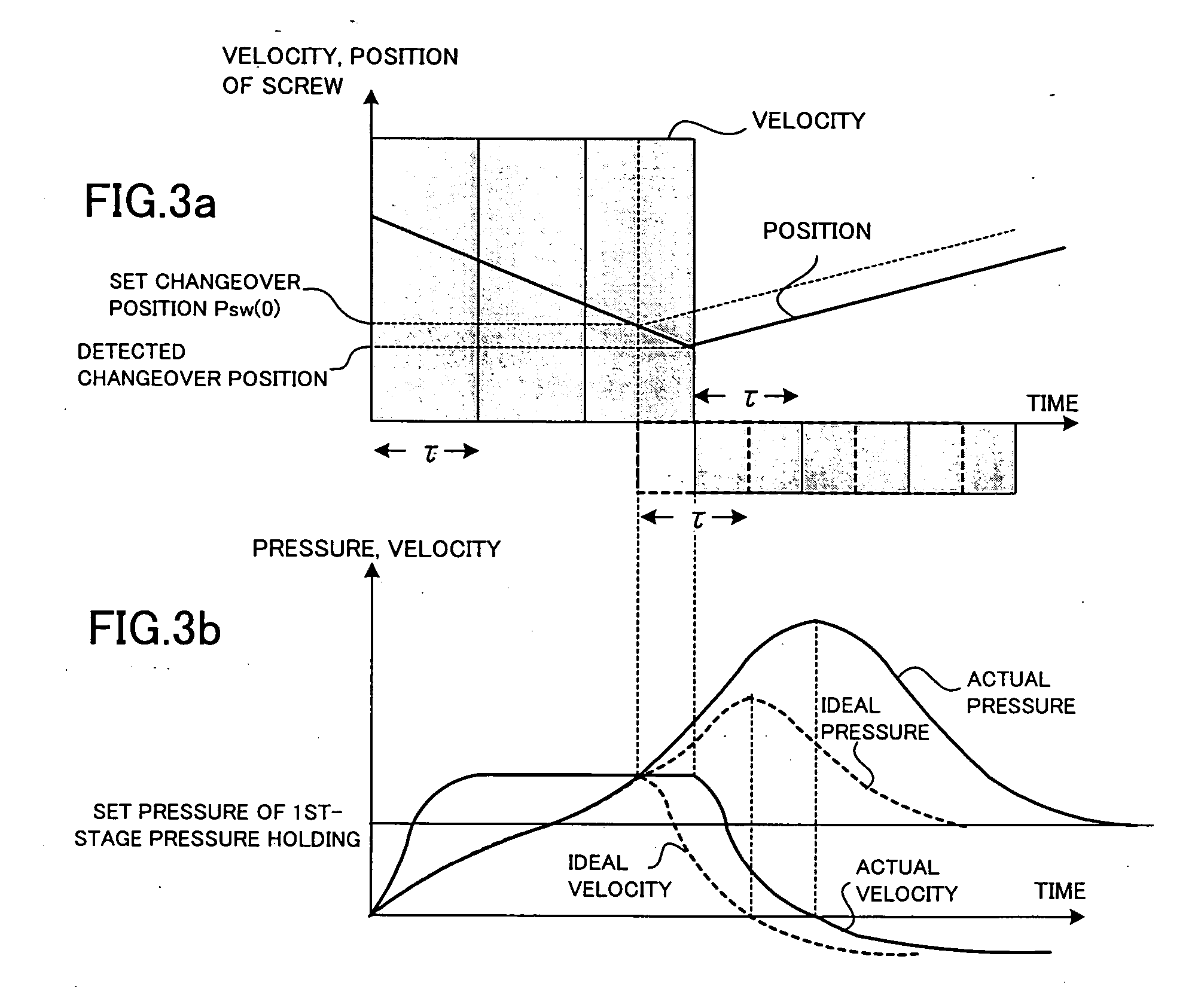

Controller for injection molding machine

ActiveUS20060216370A1Accurate and stable changeoverDispersion suppressionAuxillary shaping apparatusNumerical controlScrew positionTime lag

A controller of an injection molding machine which compensates a delay in an injection velocity changeover and a delay at the time of changeover to the pressure-holding process, and is capable of more accurate and stable injection velocity control and changing control from the injection velocity control to pressure control. In the injection process, a motion command is outputted in every sampling period τ according to the command injection velocity. When a screw position overshoots the set velocity changeover positions Psw(2) and Psw(1), a motion command based on a velocity command of the next interval is outputted from the next period. However, there is time lag between the point when the set changeover position is reached and the point when the motion command is changed after detection thereof. There generates a motion deficiency in a motion amount shown by mark A and overshoot shown by B. Motion commands of the next period or the next and subsequent several periods are compensated with errors in the motion amount caused by the time lag used as compensation amounts A′ and B′. The generated error motion amount is immediately compensated, which enables accurate velocity changing control. By performing the compensation in the same manner when the injection velocity control is switched to the holding pressure control, it is possible to suppress the peak pressure and the dispersion.

Owner:FANUC LTD

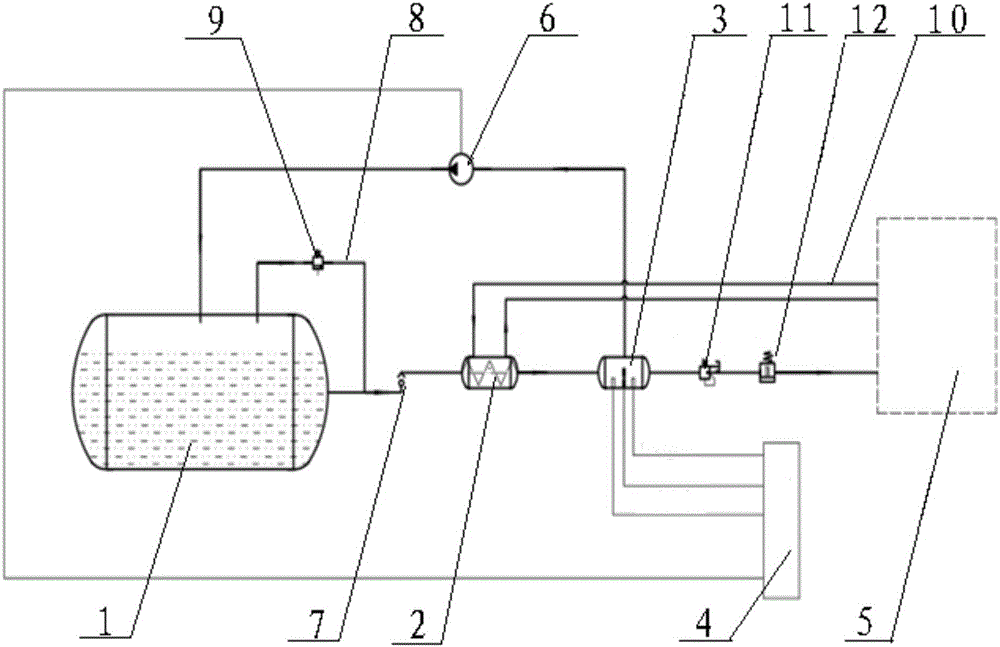

LNG (Liquefied Natural Gas) vehicle-mounted gas cylinder supercharging system

InactiveCN105673258AImprove the safety of useStable jobInternal combustion piston enginesFuel supply apparatusElectricityGas cylinder

The invention discloses an LNG (Liquefied Natural Gas) vehicle-mounted gas cylinder supercharging system. The LNG vehicle-mounted gas cylinder supercharging system comprises a gas cylinder, a vaporizer, a buffer tank and a controller. The LNG vehicle-mounted gas cylinder supercharging system is characterized in that one end of the vaporizer is connected to the gas cylinder via a pipeline; the mounting height of the vaporizer is lower than the lowest liquid level of the gas cylinder; the other end of the vaporizer is connected to the buffer tank; one output of the buffer tank is connected to an engine and the other output of the buffer tank is connected to the gas cylinder via a circulating pump; a temperature sensor, an electric heater and a pressure sensor are arranged in the buffer tank and are connected with the controller via a circuit; meanwhile the controller is connected with the circulating pump to control the working state of the circulating pump. The LNG vehicle-mounted gas cylinder supercharging system disclosed by the invention is not affected by any use condition and environment temperature, the pressure is stably controlled, the stable working of the engine is guaranteed, meanwhile the fuel waste is reduced, the environmental protection is improved and the use safety is enhanced.

Owner:任焕轩

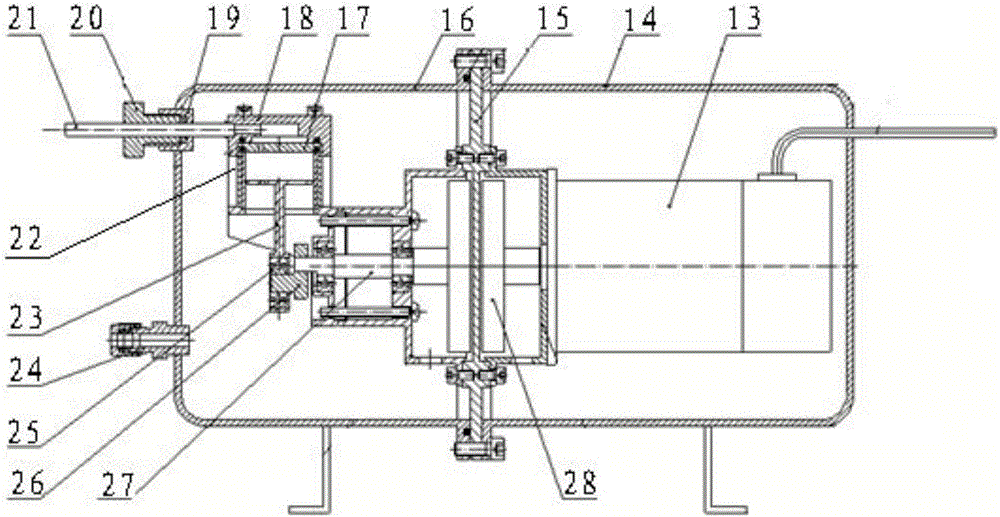

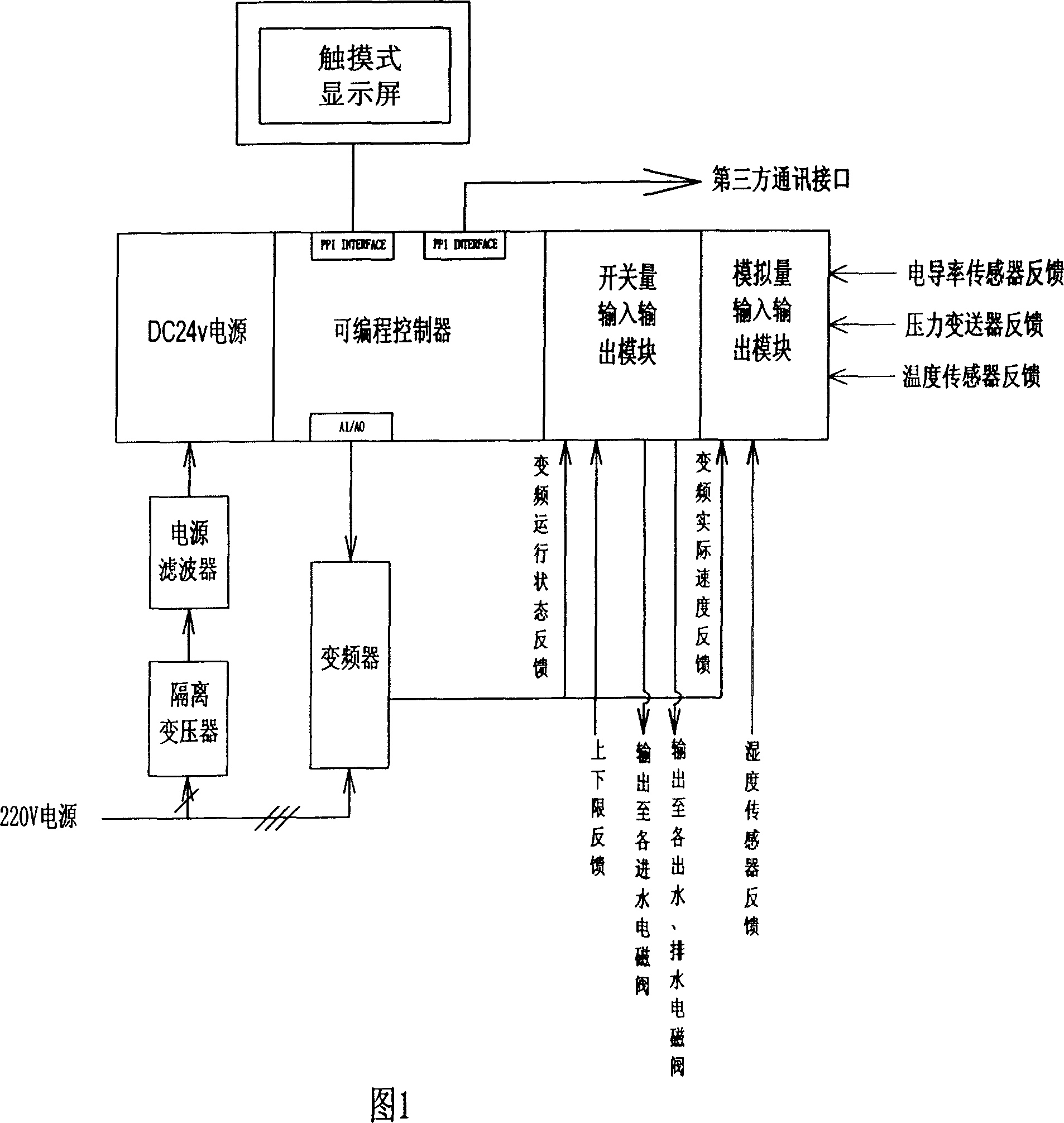

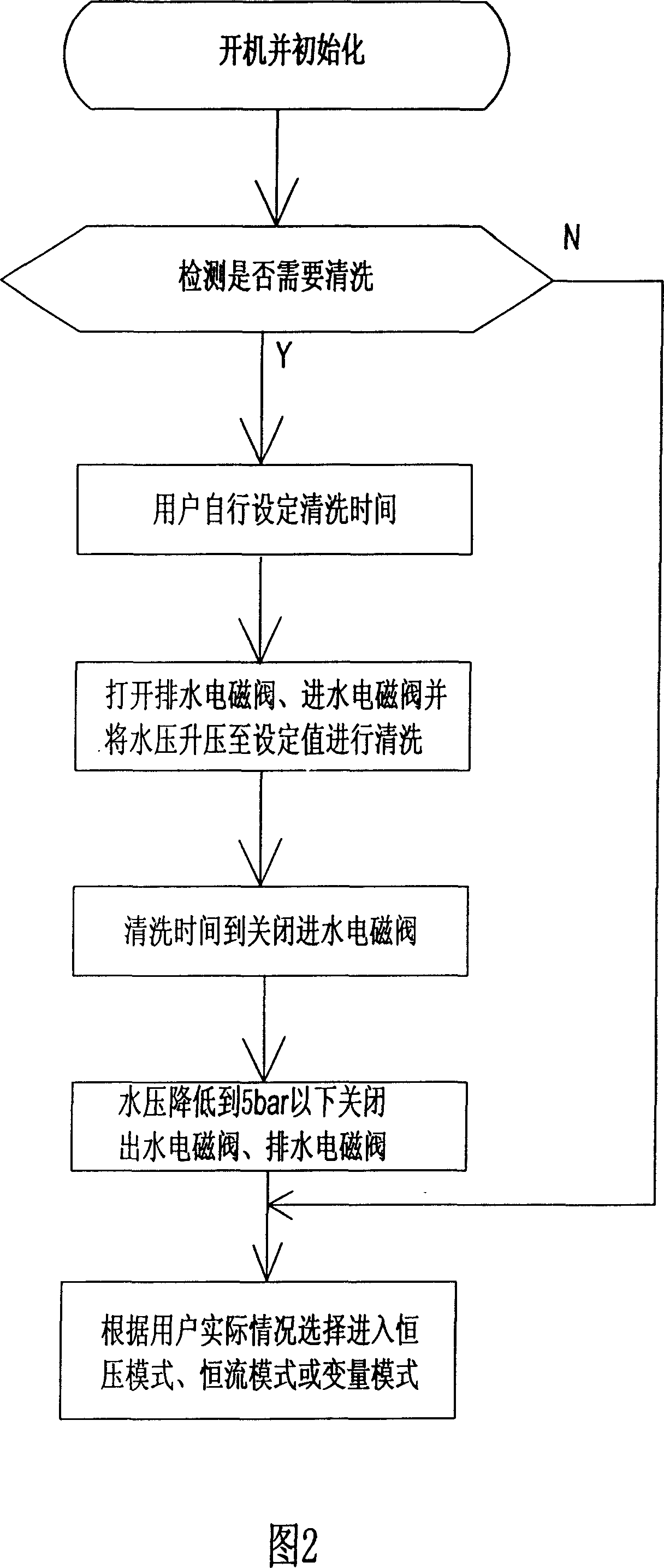

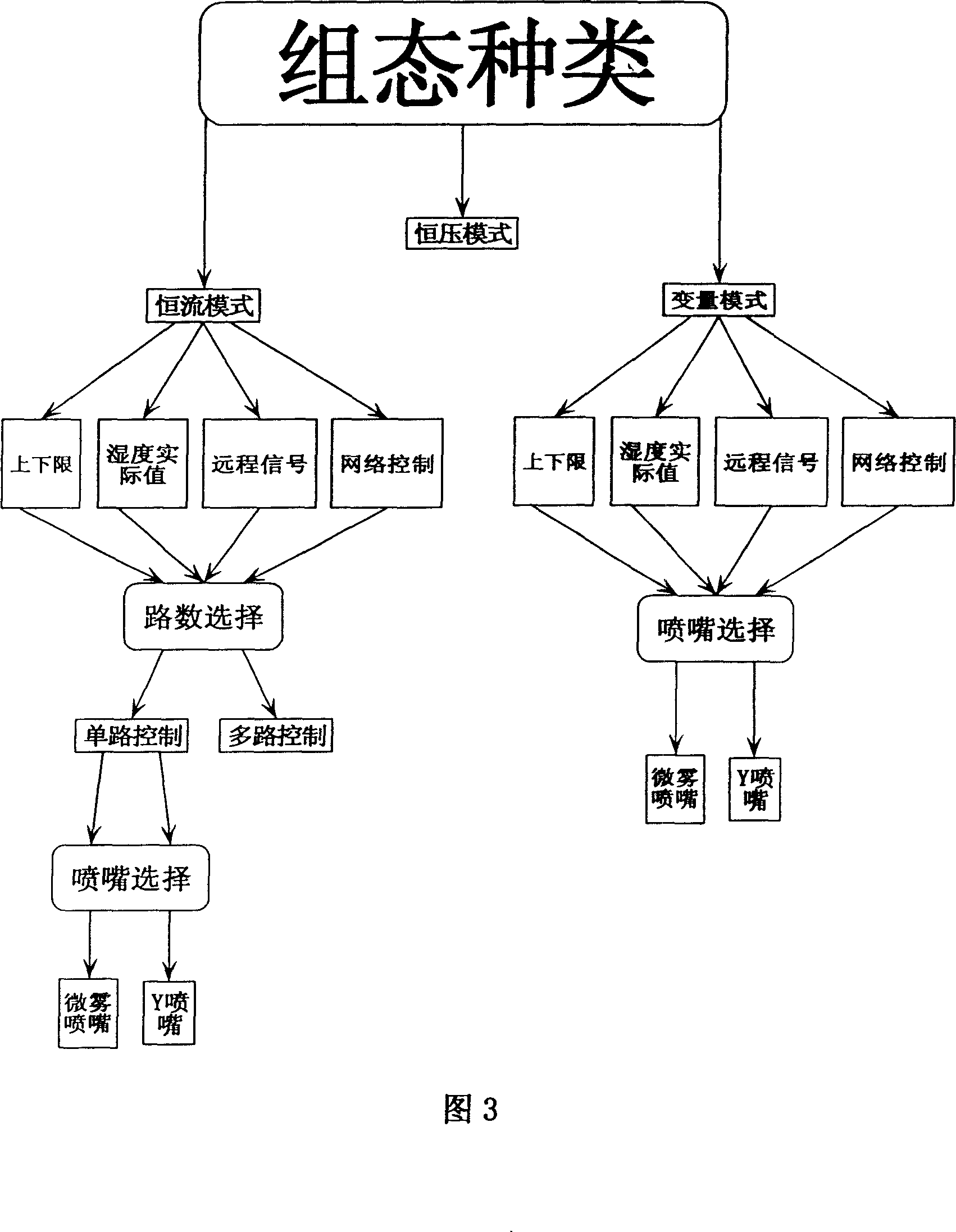

Humidifier control system and method therefor

InactiveCN1920713AExtended service lifeStable pressure controlLighting and heating apparatusAir humidification systemsFrequency changerControl system

The invention relates to a control system of humidifier and relative control method, wherein said system comprises a programmable controller, a touch display, a switch valve input / output module, an analogue valve input / output module, a frequency changer, a separated transformer, a power filter, and a DC24V power source. The control system via the analogue value input / output module obtains the on-site signal of humidifier; and the control system via the switch valve input / output module controls the water inlet, outlet and discharge of humidifier; said control method comprises: selective washing process and needed humidifying process; in the washing process, user can set the washing time; in the humidifying process, user can select pressure-constant mode, current-constant mode or variable mode; and the control system, via selected limits, humidity real valve, remote signal control, or network control, controls the humidification. The invention has stable pressure.

Owner:朱洪杰

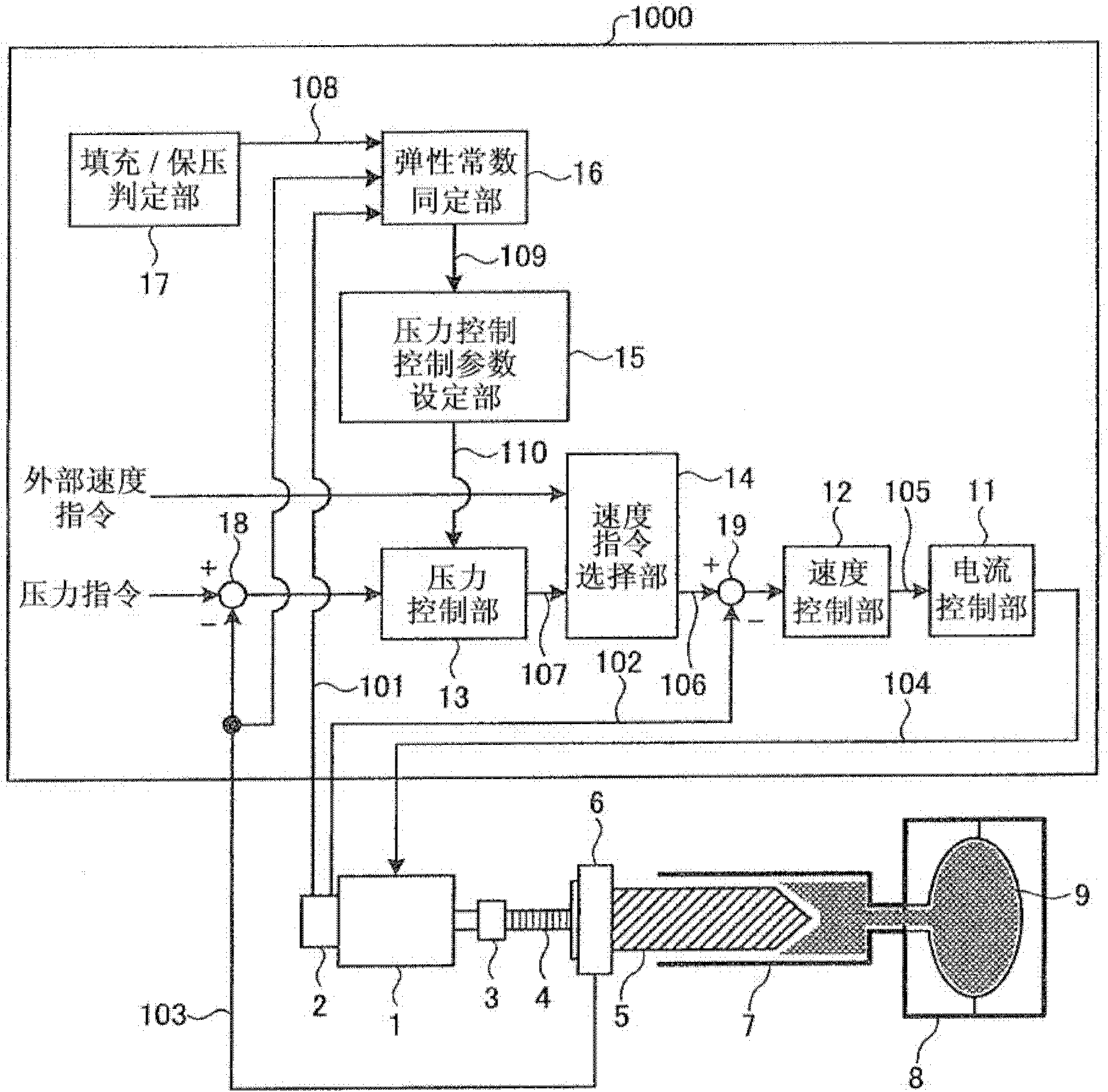

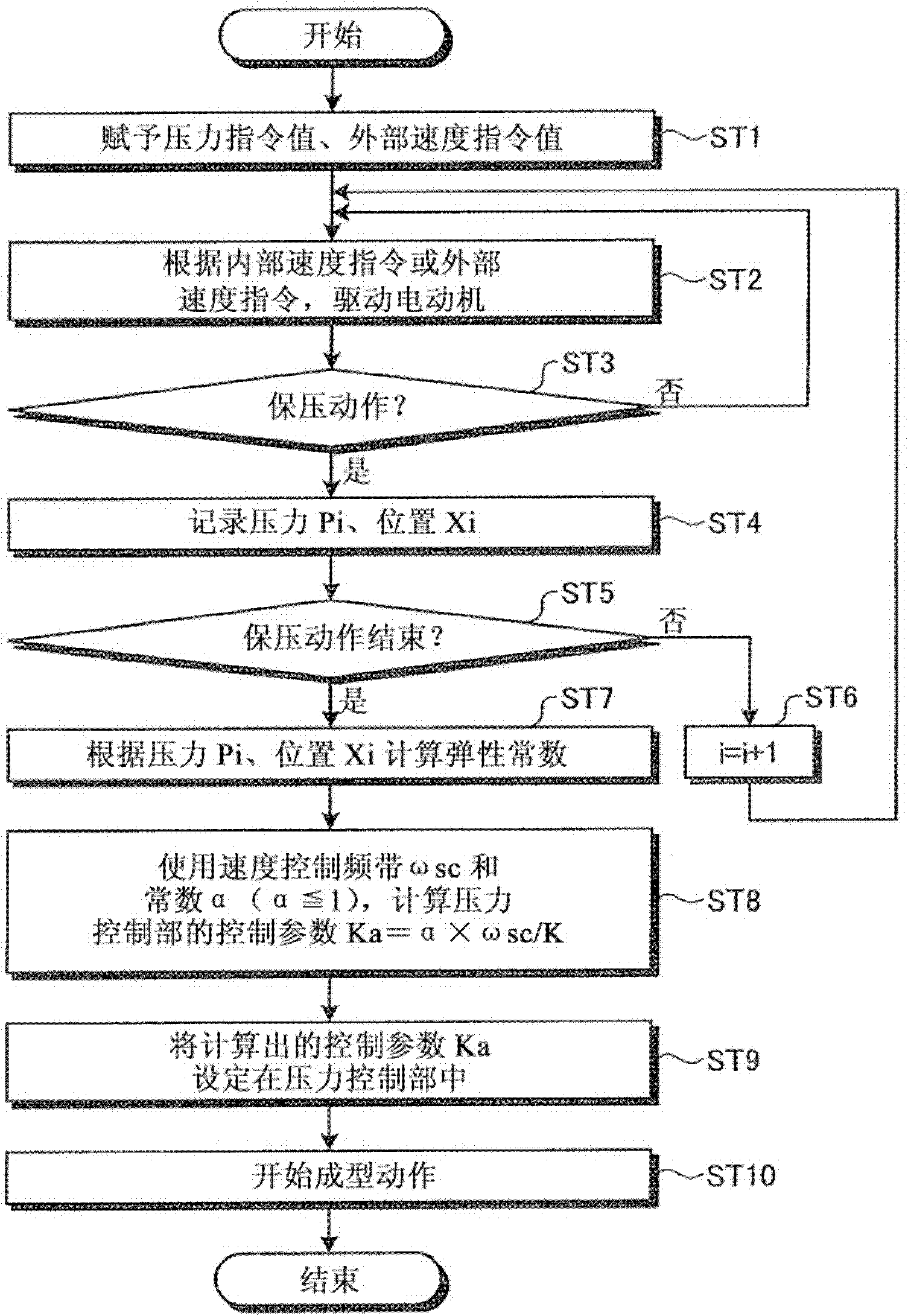

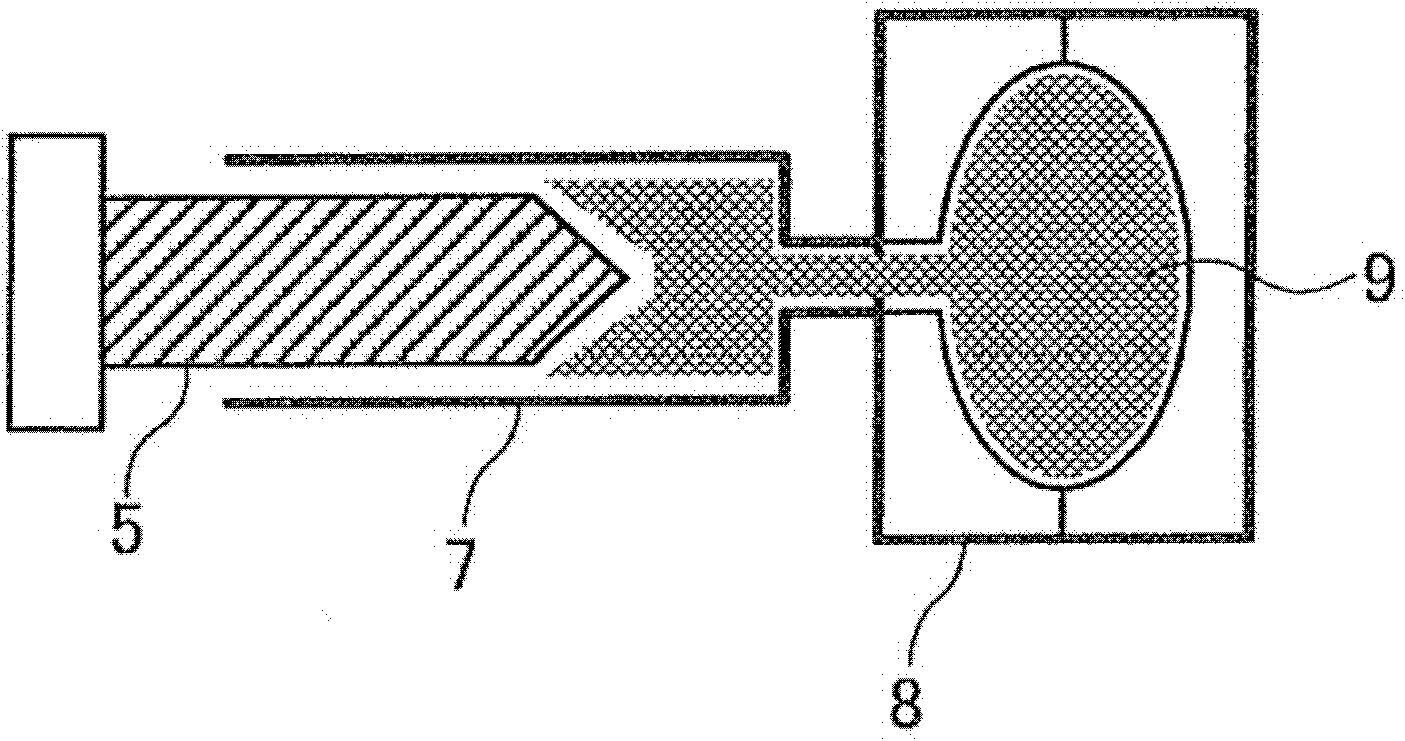

Control device and control method for injection molding machine

ActiveCN103038048AFollow the speed command with sufficient precisionStable pressure controlInjection molding machineInjection moulding

In order to perform stable pressure control, provided is a control device for an injection molding machine which comprises: a filling / pressure keeping assessment unit which assesses whether or not the injection molding machine is performing a pressure keeping operation (Step ST3); an elastic constant identification unit which, when the filling / pressure keeping assessment unit assesses that the pressure keeping operation is performed (Yes in Step ST3), acquires a pressure detection value and a position detection value as motor operation information (Step ST4), and identifies an elastic constant K on the basis of the acquired pressure detection value and position detection value (Step ST7); and a pressure control parameter setting unit which calculates a proportional gain Ka of a pressure control unit so that a product of the proportional gain Ka of the pressure control unit and the elastic constant K is smaller than a velocity control band Omegasc of a velocity control unit (Step ST8), and sets the pressure control unit to the calculated proportional gain Ka(Step ST9).

Owner:MITSUBISHI ELECTRIC CORP

Hydraulic elevator system of improvement running performance by accumulator

InactiveCN1228229CImprove Mathematical ModelAvoid starting shockElevatorsEnergy efficiency in elevatorsElevator systemMathematical model

A hydraulic elevator system using energy accumulator to improve its running performance features that a drive motor whose speed is regulated by changing voltage and frequency is used to change the flow of hydraulic pump. It is composed of cage, asynchronous motor, hydraulic pump electromagnetic valve, oil cylinder, hydraulic energy accumulator and two pressure transducers, which can measure and feed back the pressure of hydraulic pump and oil cylinder to form a pressure closed-loop system for conpensating leakage.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

Inkjet recording apparatus and method

ActiveUS8042898B2Stable pressure controlReduce pressure changesInking apparatusOther printing apparatusPositive pressureEngineering

The inkjet recording apparatus includes: an inkjet recording head which includes a nozzle through which liquid is ejected; a pressure regulating unit which includes a liquid chamber that communicates with the nozzle and a gas chamber that is partitioned from the liquid chamber by a flexible film; and a liquid chamber pressure controlling device which controls a pressure of the liquid chamber to a predetermined negative pressure when carrying out back pressure control in which back pressure is applied to the liquid inside the nozzle, wherein: the flexible film causes change in the pressure of the liquid chamber when the liquid is supplied for at least a predetermined supply amount to the liquid chamber in a state where the gas chamber is open to air; and the liquid chamber pressure controlling device carries out the back pressure control after controlling the pressure of the liquid chamber to a predetermined value of positive pressure by supplying the liquid of at least the predetermined supply amount to the liquid chamber.

Owner:FUJIFILM CORP

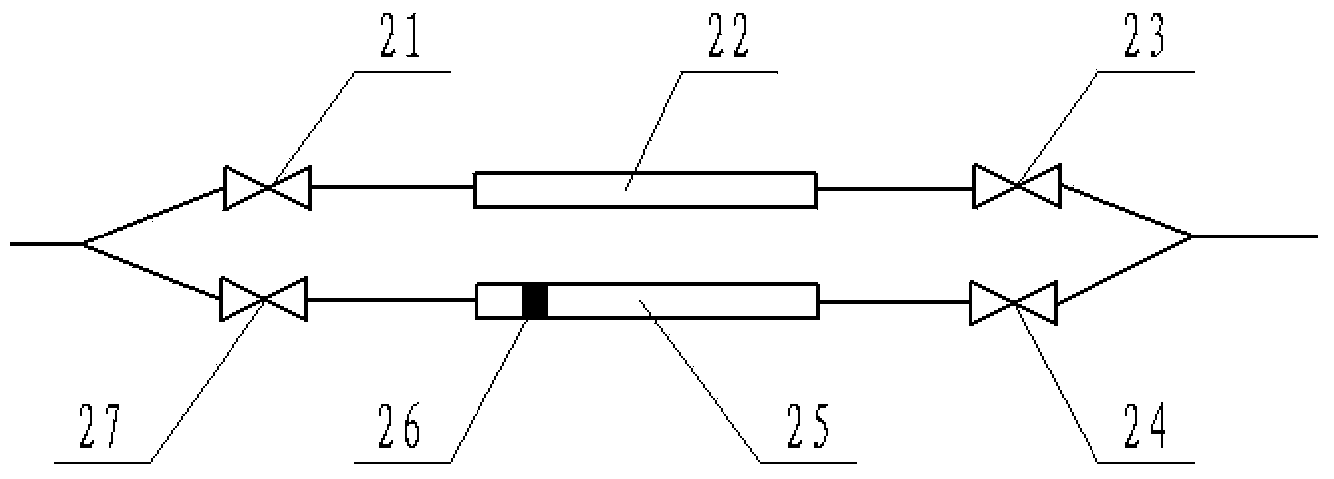

Gas micro-flow measuring device

ActiveCN103644947AEasy to pick up and more accurateEliminate the effects ofVolume/mass flow measurementMicro nanoMeasurement device

The invention discloses a gas micro-flow measuring device. The device comprises an inlet pressure-stabilizing container, a to-be-measured micro-nano channel or device, a two-channel volume indication unit, an outlet pressure-stabilizing container and an image type position recording unit, wherein the pressure in the pressure-stabilizing containers is matched with a gas supply flowmeter through throttle valves for continuous high-resolution regulation; then one channel of the two-channel volume indication unit is used for building stable flow in the to-be-measured micro-nano channel or device with the inlet pressure-stabilizing container and the outlet pressure-stabilizing container; and the other channel for presetting liquid drops is switched on, and the image type position recording unit consisting of a microscope objective and a CCD (charge coupled device) camera is used for tracking the movement of the liquid drops. The measuring device has the advantages of high measuring accuracy and resolution and proneness to implementation.

Owner:NORTHEASTERN UNIV

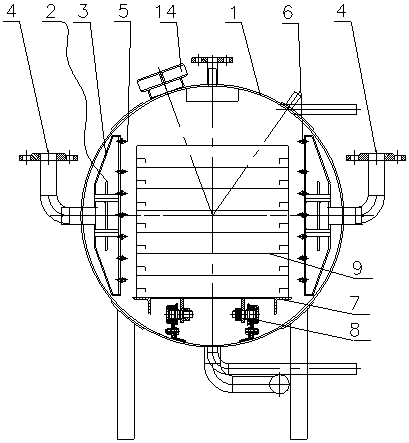

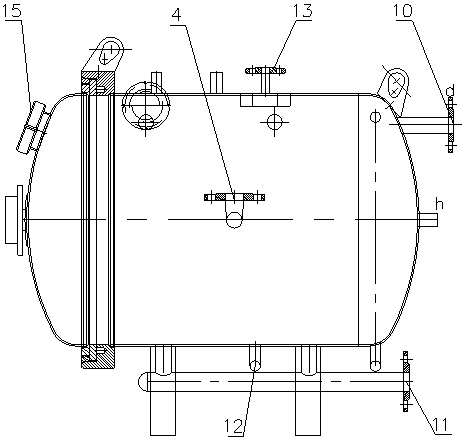

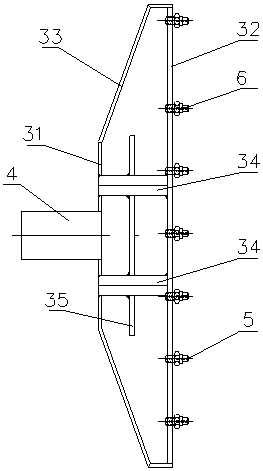

Fully automatic side spraying type stewing and boiling sterilization pot

PendingCN107684003AUniform pressureAvoid stress-reducing situationsFood processingFood preservationProgrammable logic controllerEngineering

The invention discloses a fully automatic side spraying type stewing and boiling sterilization pot, which comprises a sterilization pot and spraying devices arranged inside the sterilization pot, wherein the spraying devices are symmetrically arranged at the two sides inside the sterilization pot; each spraying device comprises a spraying support frame, a spraying water inlet and a spraying wateroutlet; the spraying water inlet and the spraying water outlet are formed in the two sides of the spraying support frame; the spraying support frame is a fan-shaped hollow sealing body formed by a water inlet plate, a water outlet plate and a connecting plate; the spraying water inlet is formed in the water inlet plate; the spraying water outlet consists of a plurality of water outlet spray headsin parallel arrangement; a water inlet is formed in the upper part of the sterilization pot; a water outlet is formed in the lower part of the sterilization pot; a steam inlet is formed in the bottom;an exhaust opening is formed in the top; the upper part of the sterilization pot is also provided with an observation window used for observing the inside condition of the sterilization pot. The temperature, the pressure and the sterilization time inside the sterilization pot can be controlled through a PLC (programmable logic controller). The fully automatic side spraying type stewing and boiling sterilization pot has the advantages that the energy consumption is low; the cost is low; the sterilization pressure, temperature and time can be easily controlled; no sterilization dead corner exists; the sterilization time is short; the temperature is low; the original mouthfeel, visual appearance and nutrition of cubilose can be remained; the fully automatic side spraying type stewing and boiling sterilization pot is suitable for countrywide physical distribution.

Owner:上海银盏食品有限公司

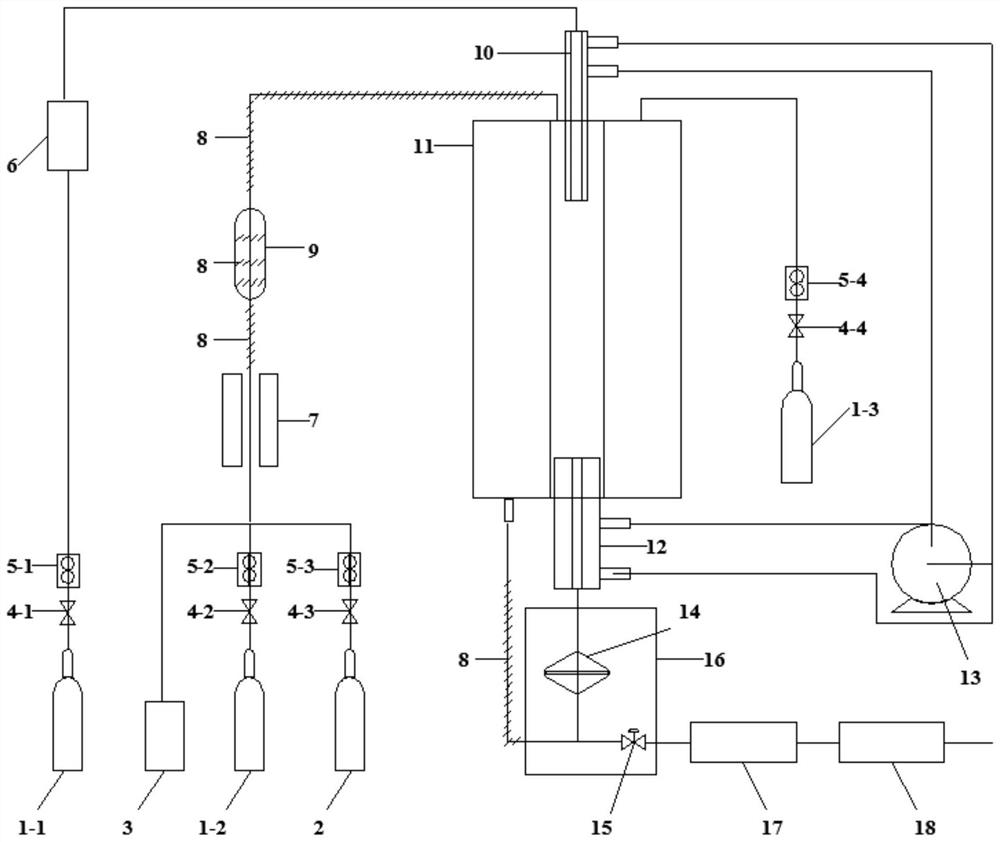

Gasification/combustion performance testing device for solid fuel under pressurized oxygen-water vapor condition and use method of gasification/combustion performance testing device

ActiveCN113406297AImprove combustion efficiencyStable pressure controlFuel testingOxygen tankFlue gas

The invention relates to a gasification / combustion performance testing device and a use method thereof, in particular to a gasification / combustion performance testing device for solid fuel under a pressurized oxygen-water vapor condition and a use method of the gasification / combustion performance testing device, aims to solve the problem that an experimental research system and method for pressurized oxygen-water vapor combustion mode performance evaluation are unavailable at present. The device consists of an inert gas tank, an oxygen tank, a high-pressure constant-flow water injection pump, a powder feeder, a preheating furnace, a heating belt, a premixing tank, a sample injection gun, a one-dimensional furnace, a sampling gun, a gas-solid separator, a high-temperature-resistant back pressure valve, a constant-temperature box, a water-vapor separator and a flue gas analyzer. The method comprises the steps that: solid fuel particles are placed in the powder feeder, the inert gas tank is opened, the one-dimensional furnace is heated, the inert gas tank and the oxygen tank are opened, the high-pressure constant-flow water injection pump is started,the high-temperature-resistant back pressure valve is adjusted,the powder feeder is started for thermochemical conversion, and meanwhile gas phase detection is conducted; and the water injection pump, the inert gas tank and the oxygen tank are closed, the high-temperature-resistant back pressure valve is adjusted, heating and residual particle sample and condensate water detection are turned off, and operation is repeated.

Owner:HARBIN INST OF TECH

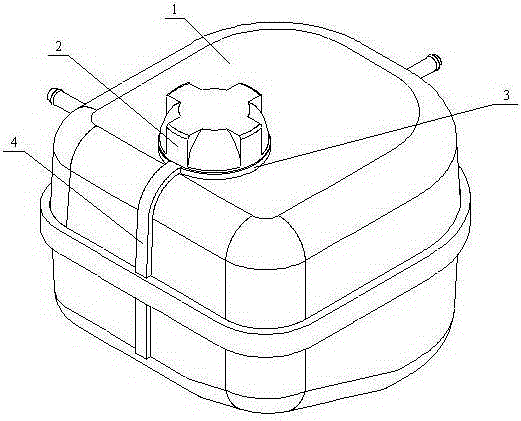

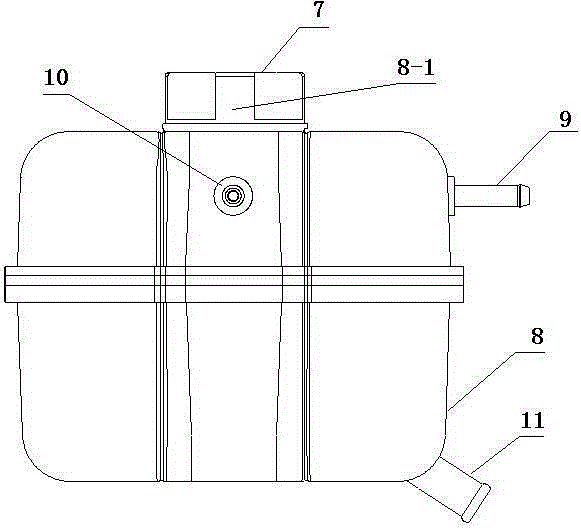

Pressure relief and diversion structure of water storage bottle for automobile

ActiveCN102654077BIncrease in sizeHigh control precisionMachines/enginesEngine cooling apparatusWater storageExhaust valve

The invention provides a decompression and stream guidance structure of an automobile water storage bottle. The decompression and stream guidance structure comprises a bottle body and a bottle cover, and is characterized by further comprising an annular groove around the lower end of a neck of a bottle body. The bottle cover is divided into an outer cover and a cover plug; a bottle cover inner cavity is arranged at the center of the cover plug, and an air inlet-outlet valve is mounted in the bottle cover inner cavity; a driving air leakage channel is arranged inside the outer cover; one end of the driving air leakage channel is connected with the bottle cover inner cavity, and the other end of the driving air leakage channel extends into the annular groove; and a manual air leakage hole is formed in the middle section of the neck of the bottle body. According to the decompression and stream guidance structure provided by the invention, on the one hand, the design of the annular groove and a stream guidance groove is used, so that a high-pressure gas-liquid mixture does not splash outside the bottle to cause pollution; and on the other hand, the manual decompression hole is arranged, so that a high-pressure cooling liquid in the bottle is rapidly decompressed when the water storage bottle is opened, and the personal injury is avoided.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

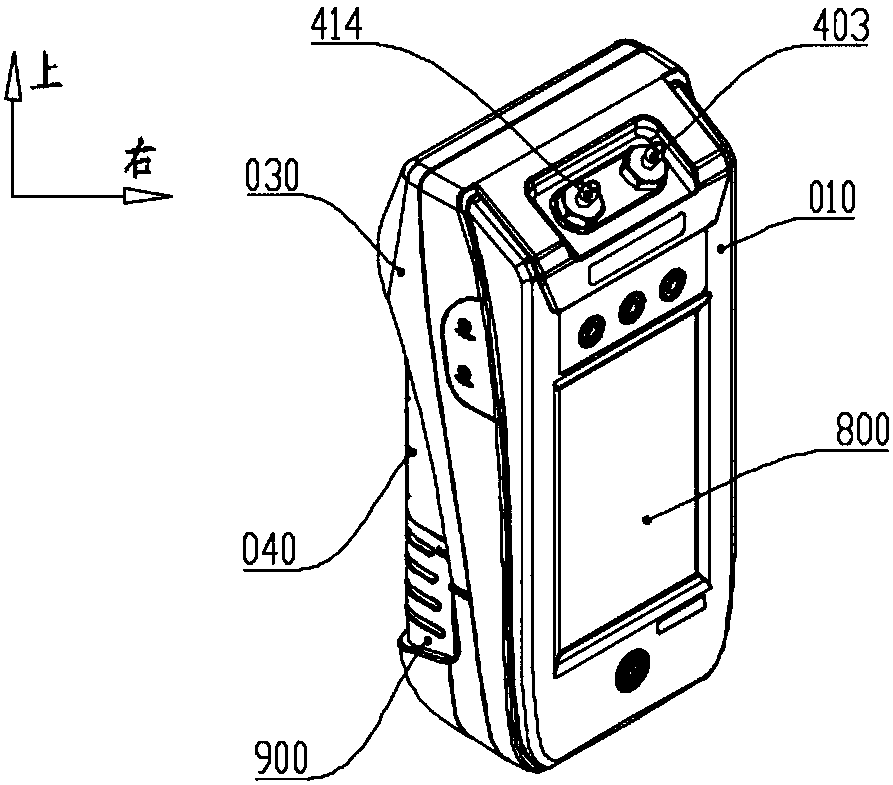

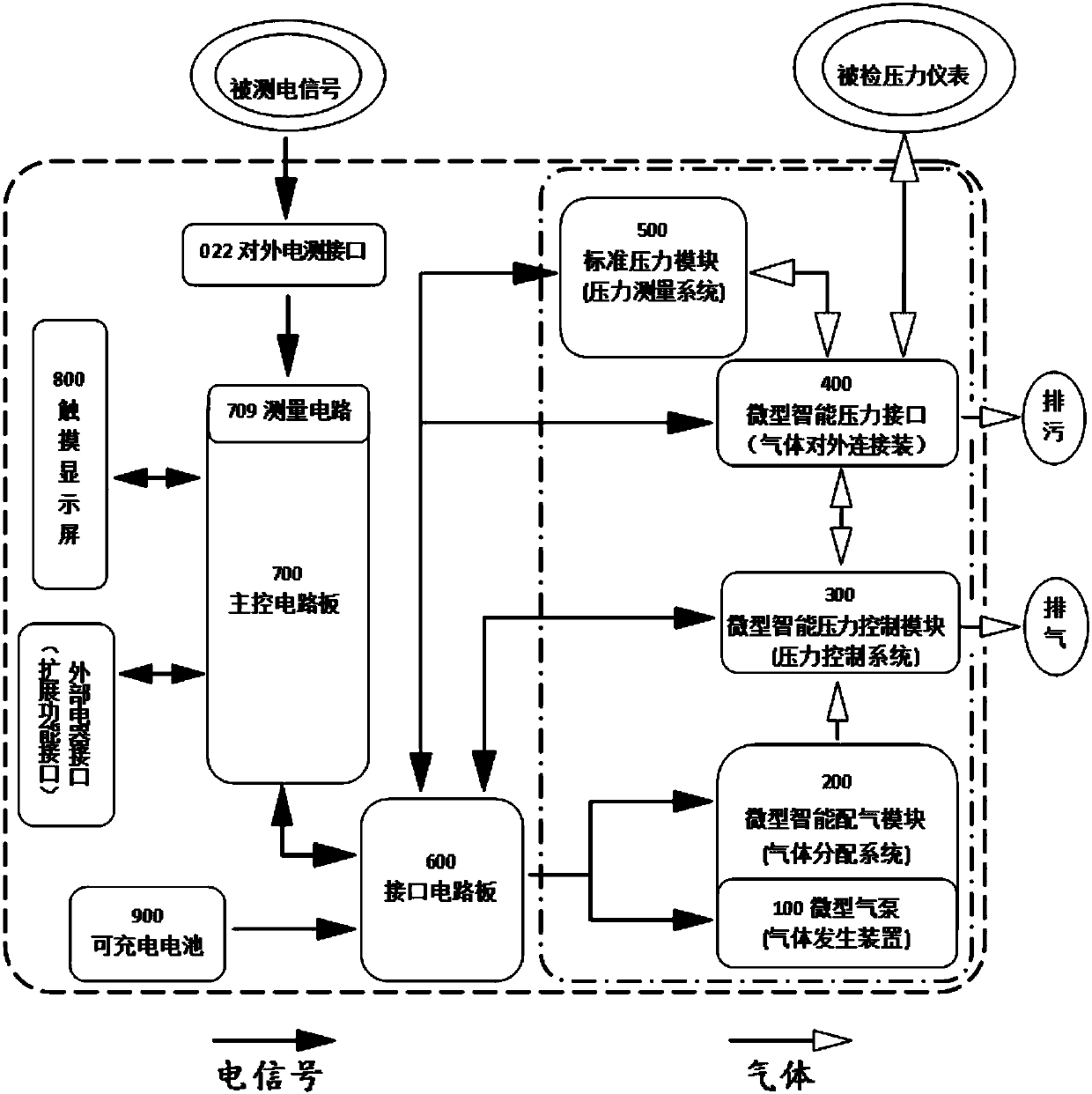

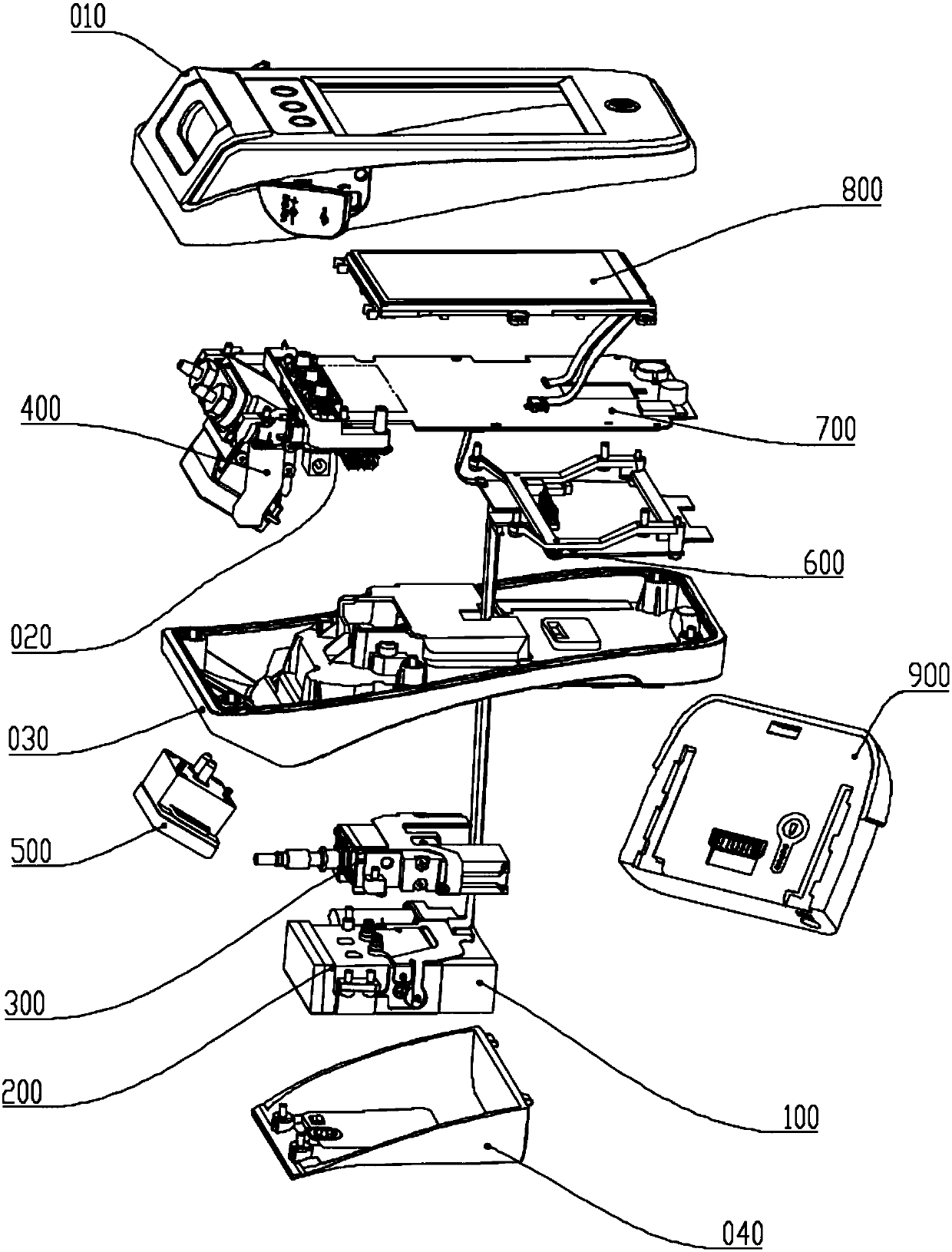

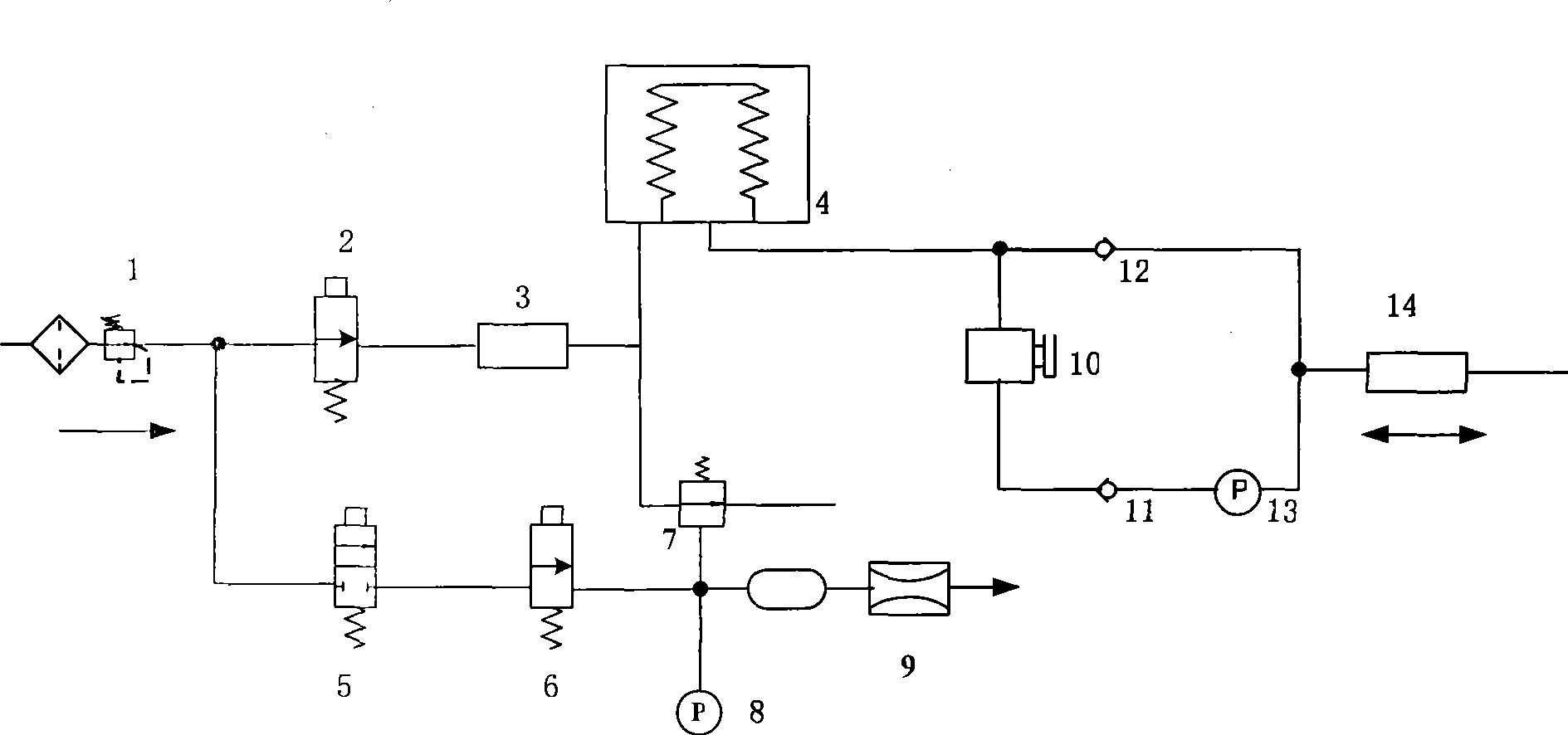

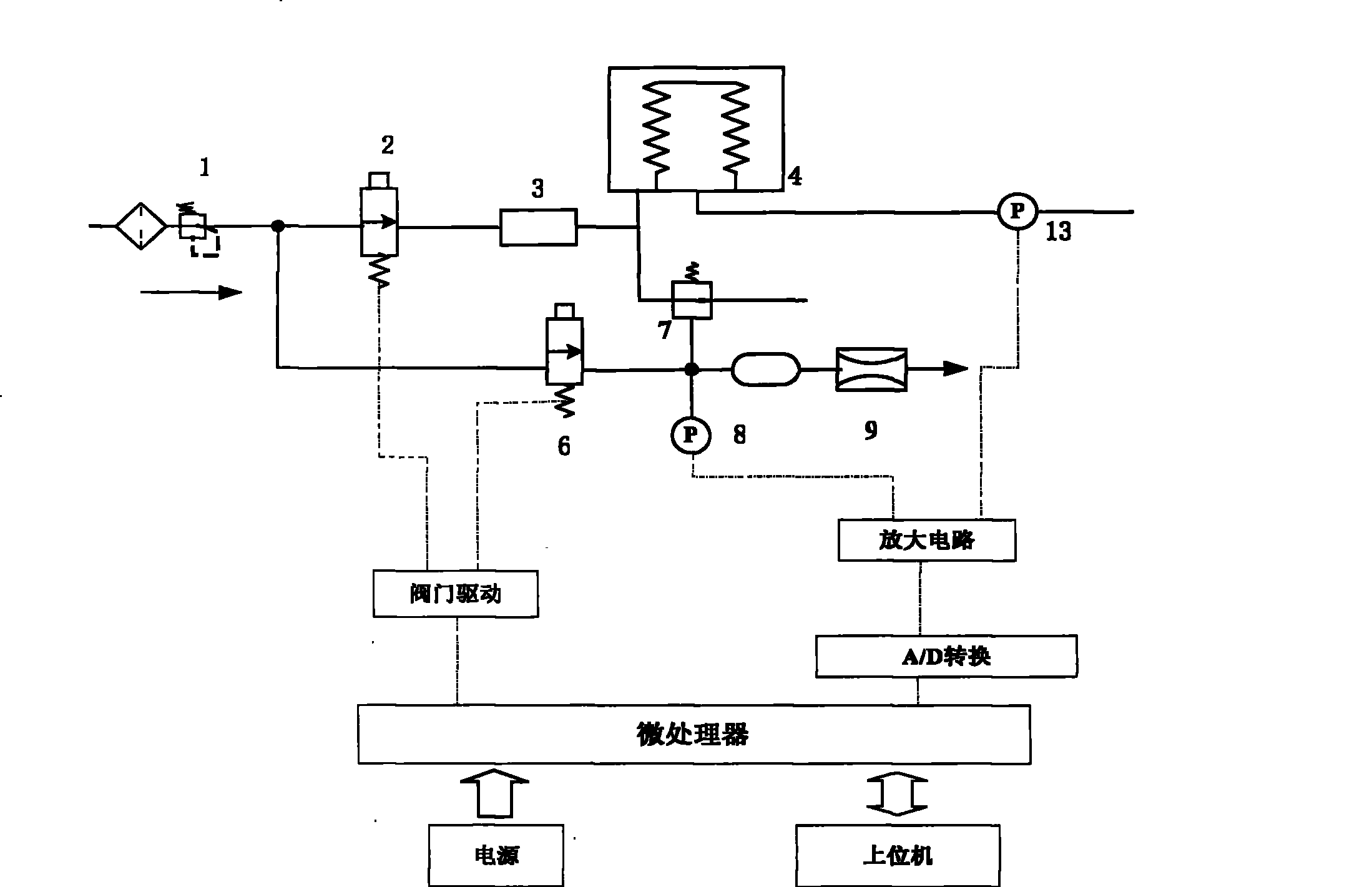

Handheld automatic pressure calibrator

PendingCN107643146AReduce volumeLight in massFluid pressure measurementPressure generationEngineering

The present invention provides a handheld automatic pressure calibrator. The calibrator comprises a housing and an air passage member and a circuit member which are arranged in the housing, the air passage member includes a pressure source capable of supplying pressure gas, and the air passage member, the circuit member and the pressure source are integrally assembled in the housing and are integrally assembled into a shape suitable for holding by hands. The handheld automatic pressure calibrator can fully realize all the functions of pressure generation, pressure control, pressure meter connection, pressure calibration process record, operation result and report output, and is suitable for checking on-site online pressure meters.

Owner:BEIJING CONST INSTR TECH INC

Aerating system of anesthesia apparatus and respirator and pressure monitoring method

ActiveCN101337101BAvoid interferenceStable and reliable pressure monitoringRespiratorsFluid pressure controlMedical equipmentSystem pressure

The invention discloses a pressure monitoring and controlling method used in an aerating system of a medical device. The pressure monitoring and controlling method comprises monitoring the confining pressure of an expiratory valve on a real-time basis, and regulating and maintaining the pressure and the set confining pressure of the expiratory valve at the same value; and monitoring the pressure of a patient terminal gas channel on a real-time basis, and regulating and maintaining the pressure to reach a set control pressure. The aerating system used in the medical facility comprises a gas path system and a pressure monitoring and controlling device. The pressure monitoring and controlling device comprises a parameter monitoring and controlling unit, a valve control unit and a master controller, wherein the parameter monitoring and controlling unit includes a first pressure detecting device placed in to the patient terminal gas channel in the gas path system, and a second pressure detecting device for monitoring and controlling the confining pressure of the expiratory valve in the gas path system. A breathing machine and an anaesthetic machine using the aerating system in the technical proposal monitor the pressure of a control branch of the expiratory valve therein and employ the pressure as the basis of the feedback control to effectively avoid the external disturbance, thereby realizing stable and reliable pressure control.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

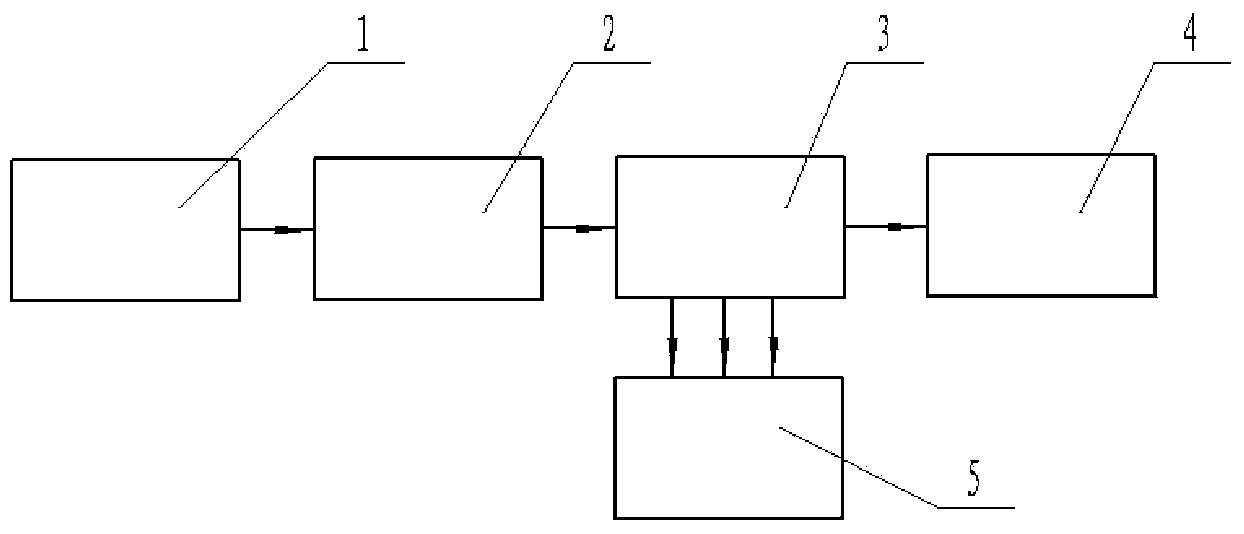

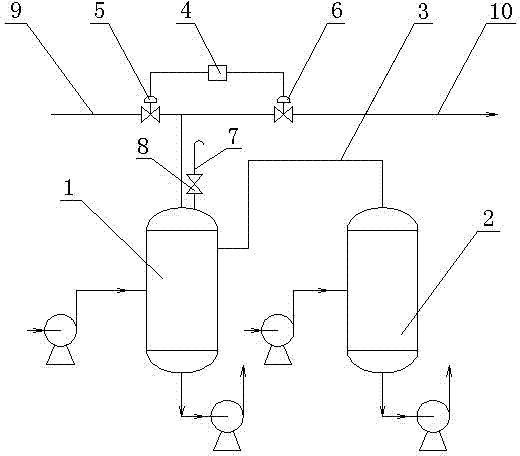

Automatic nitrogen pressure regulating control device of refining and cracking buffer tanks

ActiveCN103566829AReasonable structural designGuaranteed uptimeFluid pressure control using electric meansChemical/physical/physico-chemical processesAutomatic controlBuffer tank

The invention relates to a pressure regulating device, and particularly relates to an automatic nitrogen pressure regulating control device of refining and cracking buffer tanks. The automatic nitrogen pressure regulating control device and is composed of the cracking buffer tank, the refining buffer tank and a nitrogen charging pipeline; the device is characterized in that a top pipeline of the refining buffer tank is connected to the upper part of the cracking buffer tank, and the top of the cracking buffer tank is connected with the nitrogen charging pipeline through a nitrogen control valve; a blow-down pipeline connected by an air release valve, is arranged between the top of the cracking buffer tank and the nitrogen control valve, and the nitrogen control valve and the air release valve are connected with a pressure balance switch controller through a circuit. The automatic nitrogen pressure regulating control device of the refining and cracking buffer tanks, provided by the invention, has the advantages that the structure is reasonable, the operation is smooth and stable, and the pressure control is stable; a condition that the pressures in the refining buffer tank and the cracking buffer tank are stable is guaranteed through practical verification, the normal operation of a feeding pump of the refining and cracking buffer tanks is guaranteed, and the safe and stable production purpose is achieved.

Owner:七台河宝泰隆新能源有限公司

Pressure regulating type pressure control valve

ActiveCN105090580AStable pressure controlControl pressure range is stableEqualizing valvesSafety valvesPressure controlled ventilationSmall range

The invention relates to a pressure regulating type pressure control valve. The pressure regulating type pressure control valve comprises a first shell. A pipe fluid inlet is formed in one end of the first shell, a pipe fluid outlet is formed in the side wall of the first shell, and a thrust spring component is sleeved with the first shell. The other end of the first shell is connected with a second shell, and a thrust spring pushing unit abutting against the thrust spring component is arranged in the second shell. One end of the inside of the first shell is sleeved with a first ball seat, one end of the first ball seat abuts against the inside of the first shell, and the other end of the first ball seat abuts against a sealed ball. The other side of the sealed ball abuts against a second ball seat, an axial interval annular space between the first ball seat and the second ball seat forms an annular fluid channel which is communicated with the pipe fluid outlet, and the other end of the second ball seat abuts against one end of the thrust spring component. By means of the pressure regulating type pressure control valve, the problems of pressure holding, equipment damage and leakage of fluid caused by small-range fluctuation of flow can be effectively solved, the pressure control is stable during working, the structure is simple, and the usage is convenient.

Owner:PETROCHINA CO LTD

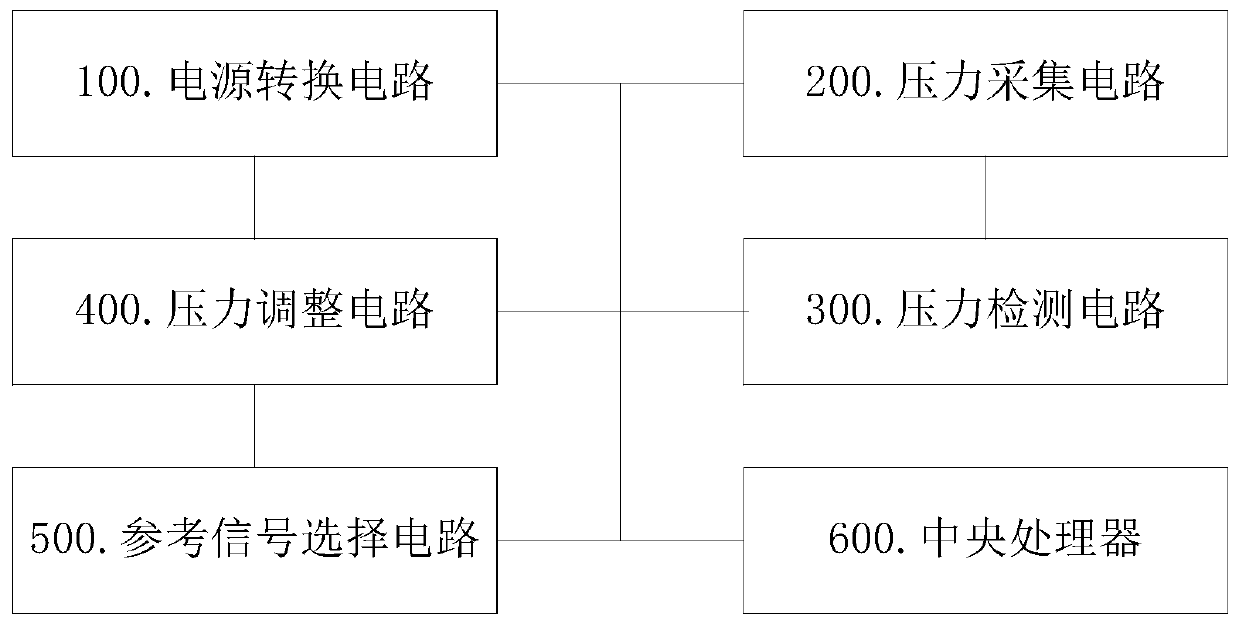

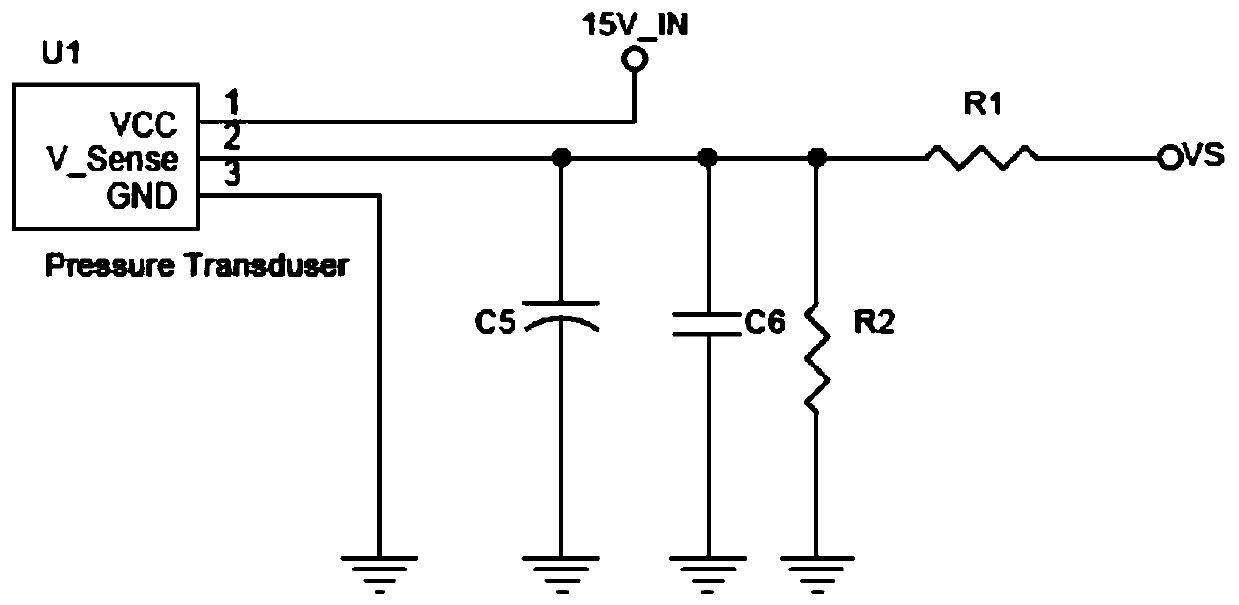

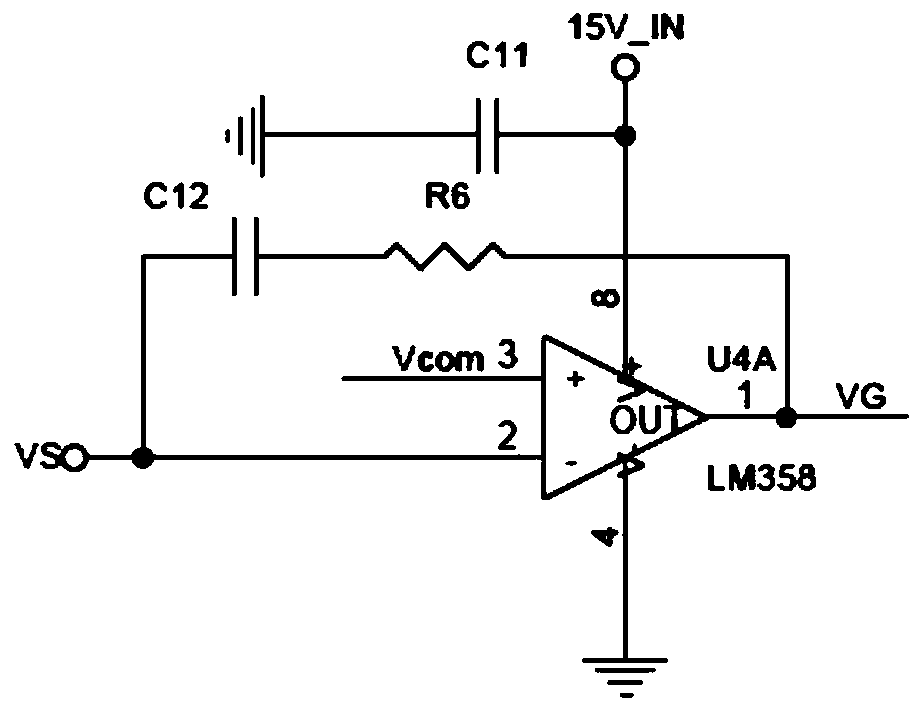

Fluid module pressure control circuit based on flow cytometer

PendingCN109916805AStable pressure controlCost-effectiveFluid pressure control using electric meansIndividual particle analysisComputer moduleEngineering

The invention discloses a fluid module pressure control circuit based on a flow cytometer. The pressure control circuit includes a power conversion circuit, a pressure collecting circuit, a pressure detecting circuit, a pressure adjusting circuit and a reference signal selecting circuit, wherein the pressure collecting circuit and the pressure adjusting circuit are in communication connection withan input end of the pressure detecting circuit, an output end of the pressure detecting circuit is in communication connection with the pressure adjusting circuit, after the pressure control circuitis powered by the power conversion circuit, a pressure signal of the sheath liquid flow collected by the pressure collecting circuit is inputted to the pressure detecting circuit and compared with a reference pressure signal provided by the reference signal selecting circuit, generated pressure difference is further outputted, the pressure difference outputted by the pressure detecting circuit isinputted to the pressure adjusting circuit, and the flow of the sheath liquid flowing through a pressure control valve is adjusted by the pressure adjusting circuit according to the magnitude of the pressure difference, and thereby control of the flow pressure of the sheath liquid is realized.

Owner:无锡厦泰生物科技有限公司

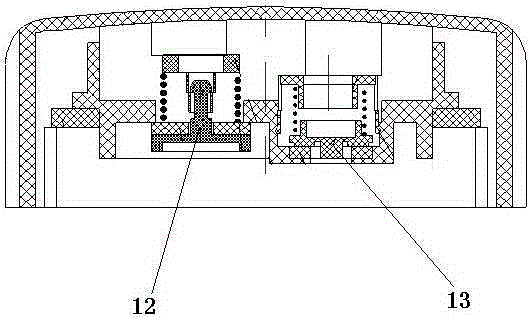

Water storage bottle cap for engine cooling system

ActiveCN102619612BIncrease in sizeStable pressure controlMachines/enginesEngine cooling apparatusWater storageExhaust valve

The invention discloses a water storage bottle cap of an engine cooling system. The water storage bottle cap comprises an outer cap and a cap plug, wherein a stepped hole downwardly communicated with a bottle body is formed in the centre of the cap plug; an exhaust valve spring, an exhaust valve, an air inlet valve and an air inlet valve spring are installed in the stepped hole from top to bottom in sequence; at least one first ventilation hole is formed in the outer cap; the stepped hole is communicated with outside through the first ventilation hole; the stepped hole has at least three stages; the stepped hole has first, second and third steps from top to bottom in sequence; the upper end of the exhaust valve spring is in contact with the inner side of the top surface of the outer cap; the lower end of the exhaust valve spring is supported on the exhaust valve; the exhaust valve is matched with the first step under the elastic action of the exhaust valve spring; the upper end of the air inlet valve spring is in contact fit with the air inlet valve; the lower end of the air inlet valve spring is supported on the third step; the air inlet valve is in contact fit with the second step under the elastic action of the air inlet valve spring; and a second ventilation hole is formed in the exhaust valve. The water storage bottle cap disclosed by the invention has the advantages of simple structure, easy manufacture and low cost; furthermore, the control precision is easy to ensure.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

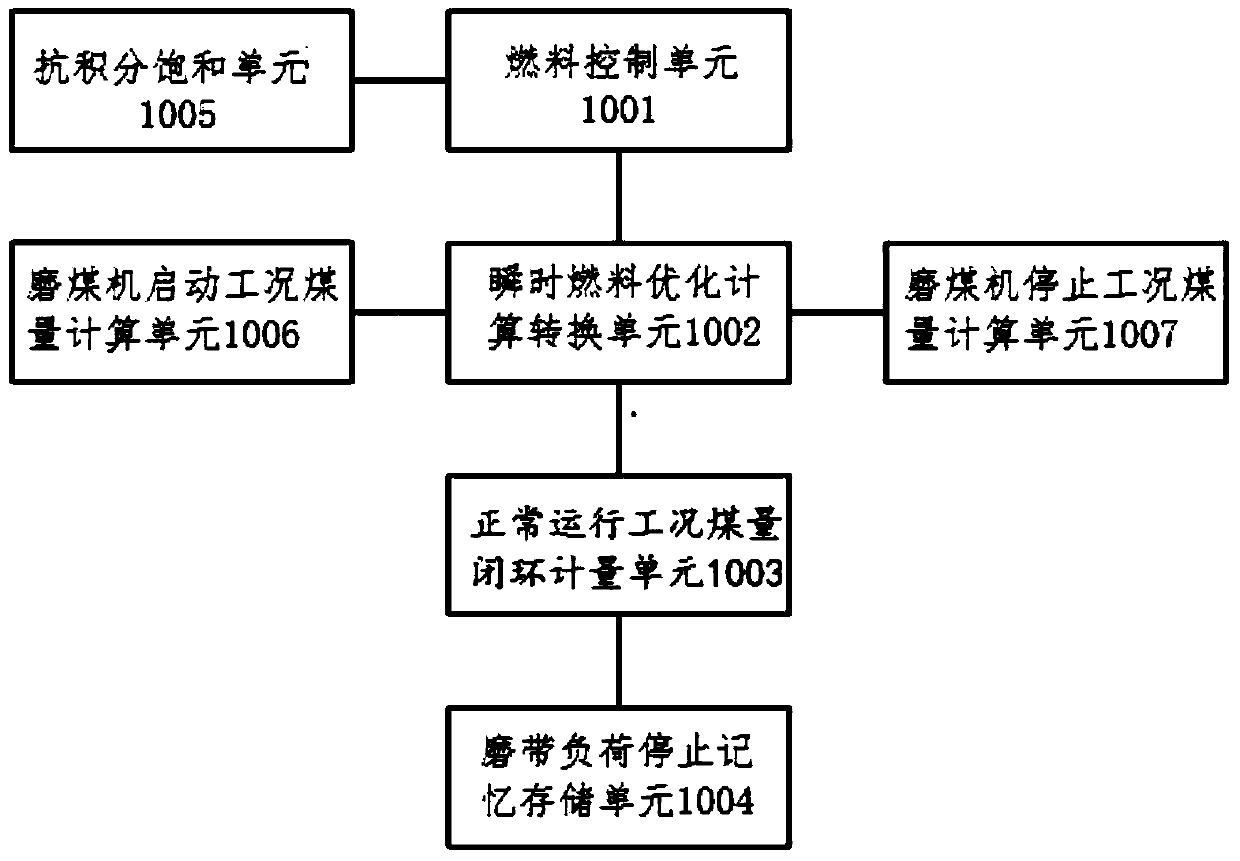

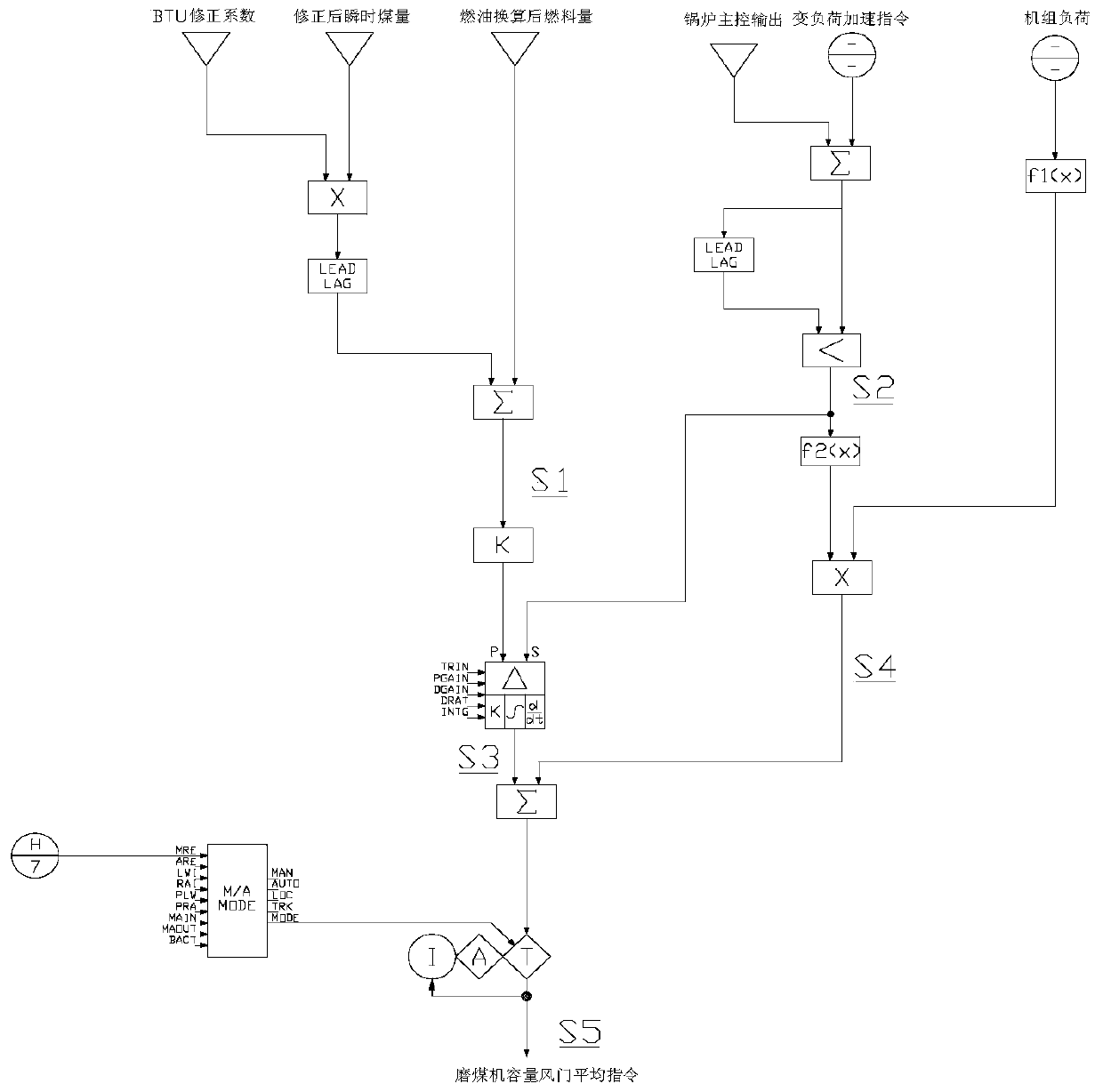

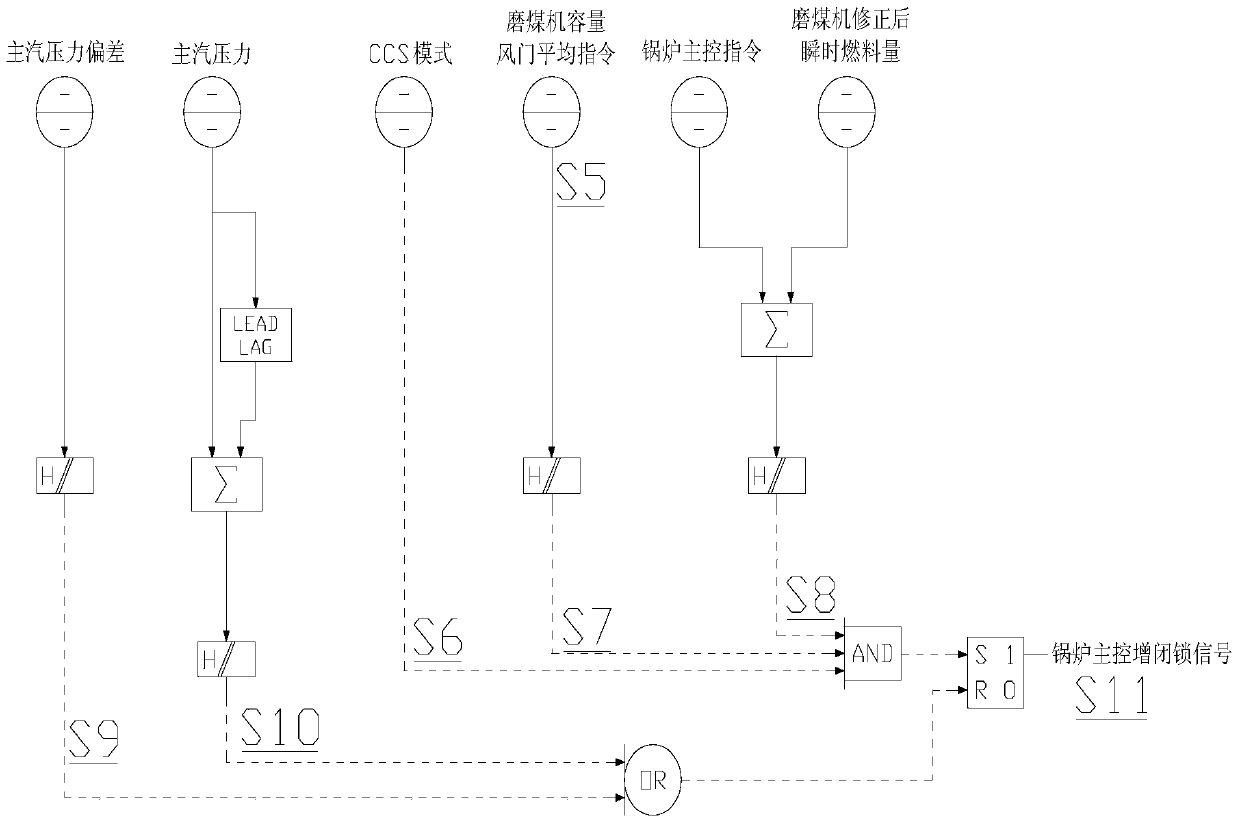

A system and method for instantaneous fuel optimization of thermal power units with double-inlet and double-outlet coal mills

ActiveCN104941783BStable pressure controlImprove adjustment qualityGrain treatmentsThermodynamicsControl signal

The invention discloses a double-in and double-out coal mill thermal power generating unit instantaneous fuel optimization system and method. The system comprises a fuel control unit, an instantaneous fuel optimization calculation and conversion unit, a normal operation working condition coal quantity closed loop measuring unit and an abrasive belt load stopping memory storage unit, wherein the fuel control unit is used for receiving a control instruction sent by a boiler and an acceleration signal of a variable load, calculating a control signal of a coal mill capacity air door, and sending a result to the instantaneous fuel optimization calculation and conversion unit; the instantaneous fuel optimization calculation and conversion unit is used for judging a conversion condition through operation states of a corresponding coal mill and coal feeder, and transmitting a result to the fuel control unit; the normal operation working condition coal quantity closed loop measuring unit is used for forming an instantaneous fuel quantity correction factor through a theoretical coal quantity which is linearly determined by the capacity air door and a coal feeder instantaneous coal quantity and according to a difference between the quantities, and sending a result to the instantaneous fuel optimization calculation and conversion unit; and the abrasive belt load stopping memory storage unit is used for receiving a result of the normal operation working condition coal quantity closed loop measuring unit.

Owner:STATE GRID CORP OF CHINA +3

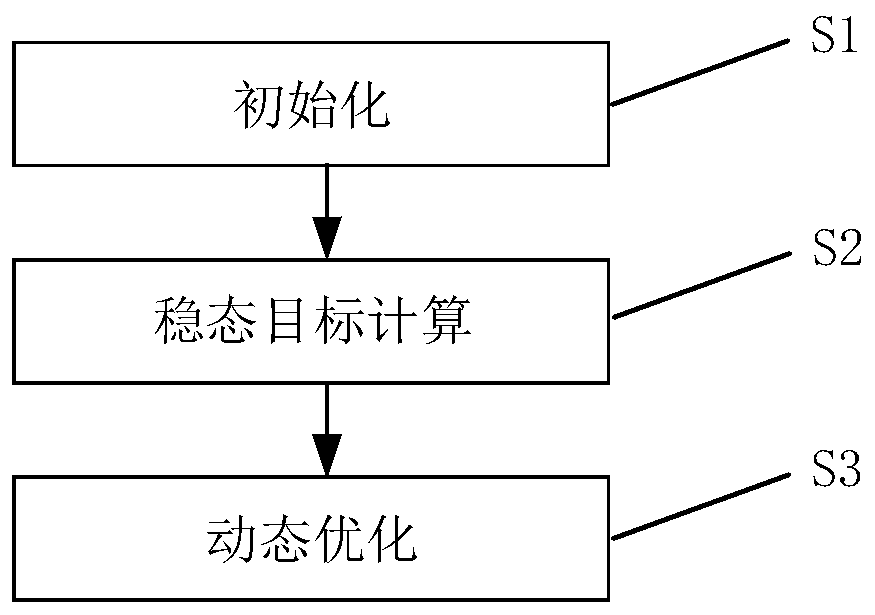

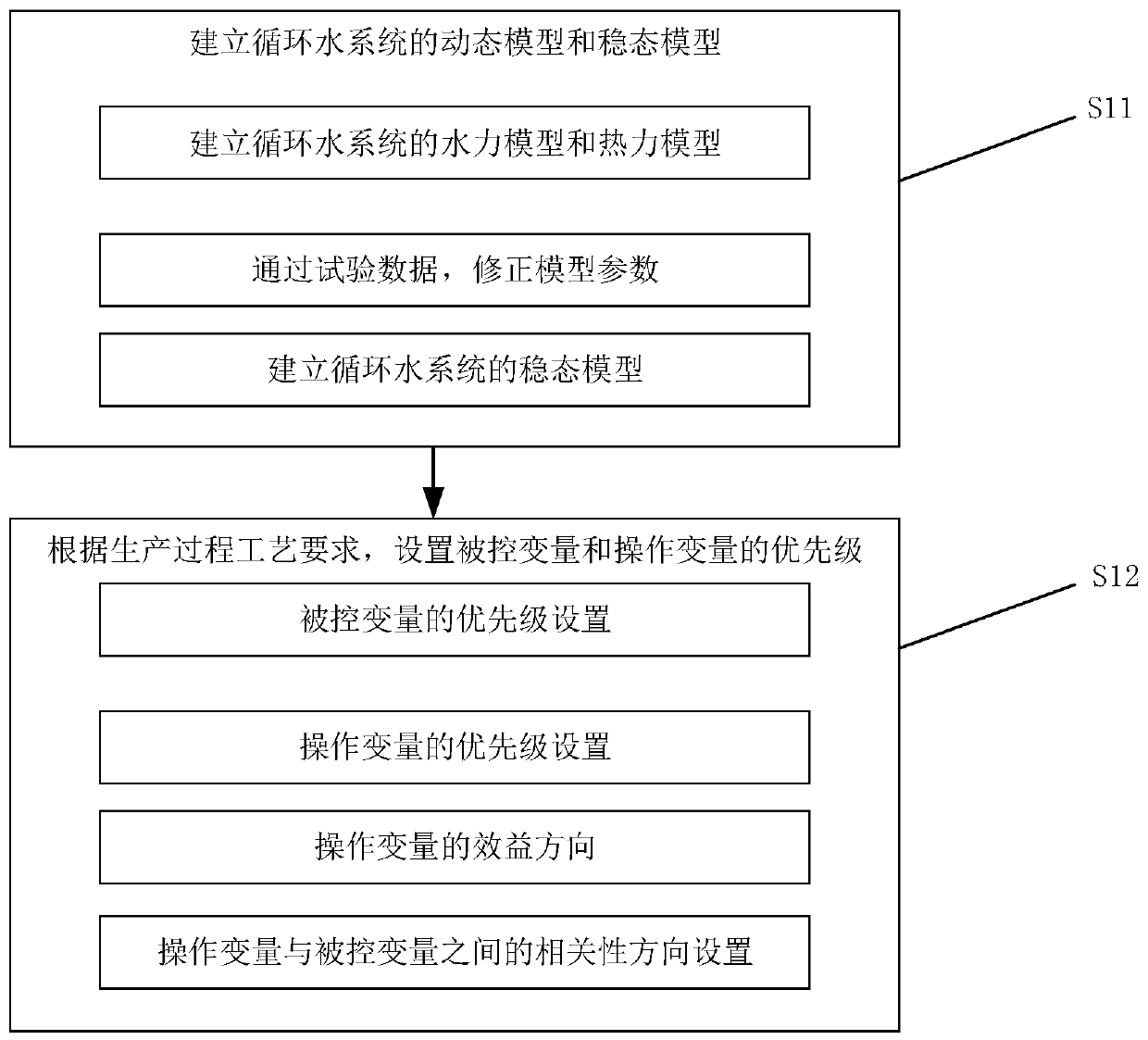

Optimal control method for energy saving of industrial circulating water based on double-layer structure predictive control

ActiveCN108021024BPrecise temperature controlStable pressure controlAdaptive controlWater basedOperating point

The invention relates to an energy-saving optimization control method for industrial circulating water based on double-layer structure predictive control, which comprises the steps of building a dynamic model and steady-state model of a circulating water system; setting the priority of a controlled variable, the priority of an operating variable, the benefit direction of the operating variable andthe correlation direction between the operating variable and the controlled variable; establishing an objective function, and constructing constraint conditions according to technological conditionsand the steady-state model; if there is a feasible region, acquiring an optimal operating point; otherwise, properly loosening the constraint conditions for the controlled variable to obtain the optimal operating point; enabling the obtained optimal operating point to serve as a set value, building a model prediction controller, and implementing a control action. The energy-saving optimization control method realizes that each production unit of the circulating water system operates with the return water temperature being always below the highest allowable temperature. Meanwhile, the pipe network output flow of the circulating water system is enabled to be reduced, and the pressure is reduced. Therefore, the energy-saving optimization control method realizes the effects that the operationcost is reduced, and the system is energy-saving.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Self-operated regulating valve for boiler gas pipeline

PendingCN111120717AStable pressure controlQuick responseOperating means/releasing devices for valvesLift valveThermodynamicsCombustor

The invention relates to a self-operated regulating valve for a boiler gas pipeline. The self-operated regulating valve comprises a main body, an electromagnetic induction module, a piezoelectric transmitter, a controller and a pulse current generator, and is characterized in that an electromagnetic induction coil, the piezoelectric transmitter, the pulse current generator and the controller are additionally arranged on the existing self-operated regulating valve; and when a boiler combustor is closed or the upstream / downstream pipeline pressure of the self-operated regulating valve fluctuates, axial pulse electromagnetic force is applied to a valve element through the electromagnetic induction coil, and the response speed and the regulating stability of the regulating valve are improved.

Owner:GUANGDONG INSPECTION & RES INST OF SPECIAL EQUIP ZHUHAI INSPECTION INST

A low-pressure critical heat flux experimental system and experimental method

ActiveCN111157221BEasy to adjustAvoid being burnedHydrodynamic testingMaterial heat developmentHeat flowCondenser (heat transfer)

The invention relates to a low-pressure critical heat flux experimental system and an experimental method. The system includes a medium flow measurement pipe section, a preheating pipe section, an experimental heating pipe section, a medium ascending pipe section, a condenser, a medium descending pipe section, a first three-way valve, a connecting pipeline, a second three-way valve and a water supply unit; the first three-way The water outlet of the valve, the medium flow measurement pipe section, the preheating pipe section, the experimental heating pipe section, the medium ascending pipe section, the condenser, the medium descending pipe section, the second three-way valve, the connecting pipeline, and a water inlet of the first three-way valve along the The flow direction of the medium is communicated in sequence to form a circulation loop; the water supply unit communicates with the other water inlet of the first three-way valve for supplying circulation medium to the circulation loop. The proposal of the invention provides accurate and reliable data for the research on the heat transfer characteristics of the circulating flow and the critical heat flux density under the condition of the pulsed reactor.

Owner:NORTHWEST INST OF NUCLEAR TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com