Hydraulic elevator system of improvement running performance by accumulator

A technology for operating performance and elevator systems, applied in the field of hydraulic elevator systems, can solve problems such as oil leakage, motor elevator actual speed out of sync, motor rotation instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

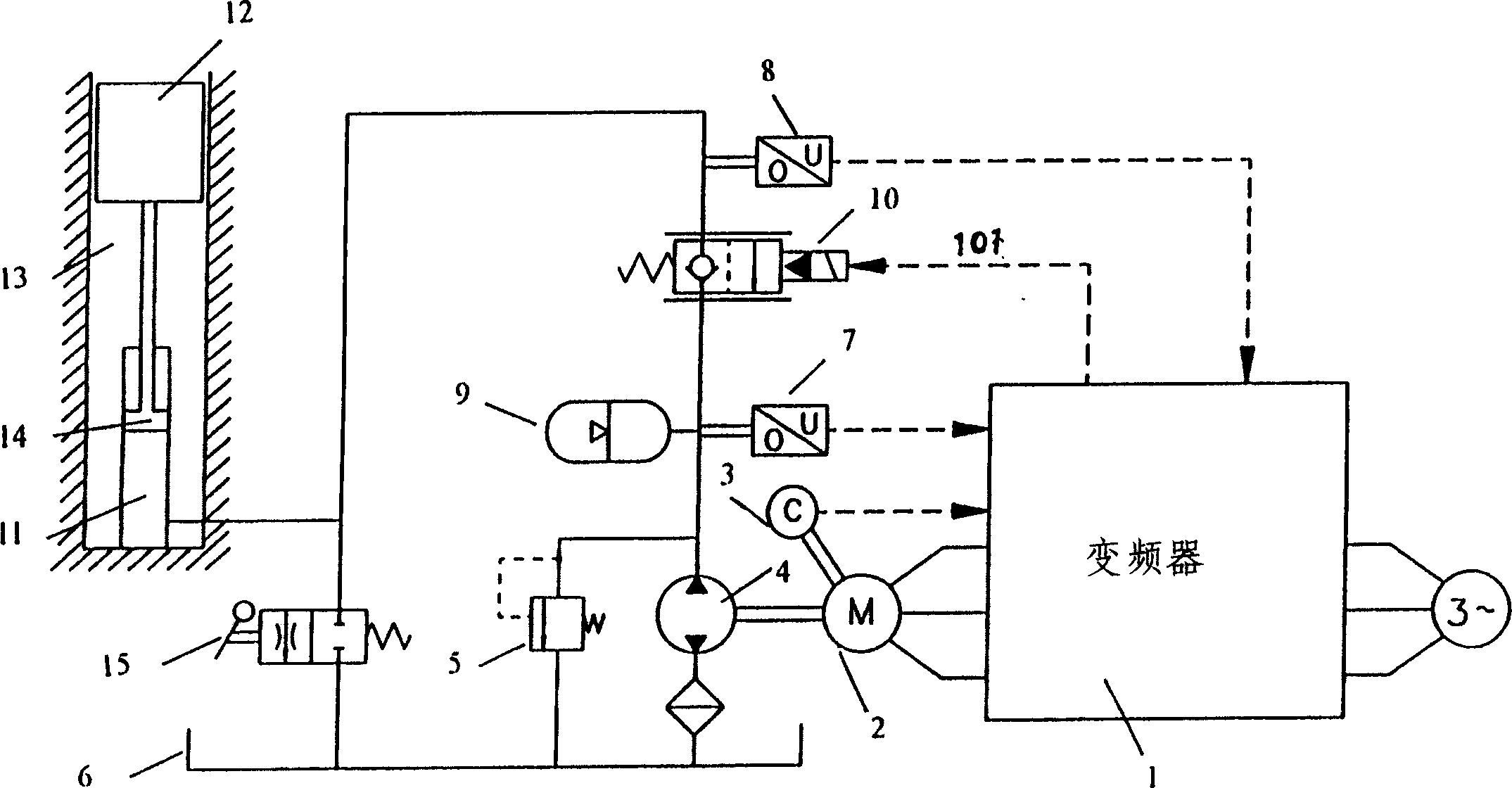

[0015] figure 1 It is a schematic diagram of the hydraulic elevator system and its control device using an accumulator to improve the running performance of the present invention. As shown in the figure, the hydraulic elevator system using an accumulator to improve running performance in the present invention includes an elevator shaft 13, an oil cylinder 11 buried in the bottom pit of the elevator shaft 13, pressure oil injected into the oil cylinder 11, and a piston 14 supported by the pressure oil , the car 12 fixed on the upper end of the piston 14, the motor 2, the hydraulic pump 4, the elevator control and management connected with the motor 2, the driver 1 and the rotary encoder 3, the solenoid valve 10 connected with the hydraulic pump 4 and the oil cylinder 11, The pressure transmitter A7 for detecting the oil pressure at the inlet of the solenoid valve 10 and the outlet of the hydraulic pump 4, the pressure transmitter B8 for detecting the oil pressure at the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com