Metallographic grinder and method for polishing metallographic sample of corrosion layer of battery electrode plate

A battery plate and metallographic grinding technology, which is applied in the preparation of test samples, etc., can solve the problems of battery plate samples being scratched, abrasive particles easily embedded in the surface of the plate, and easily embedded in the surface of the plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

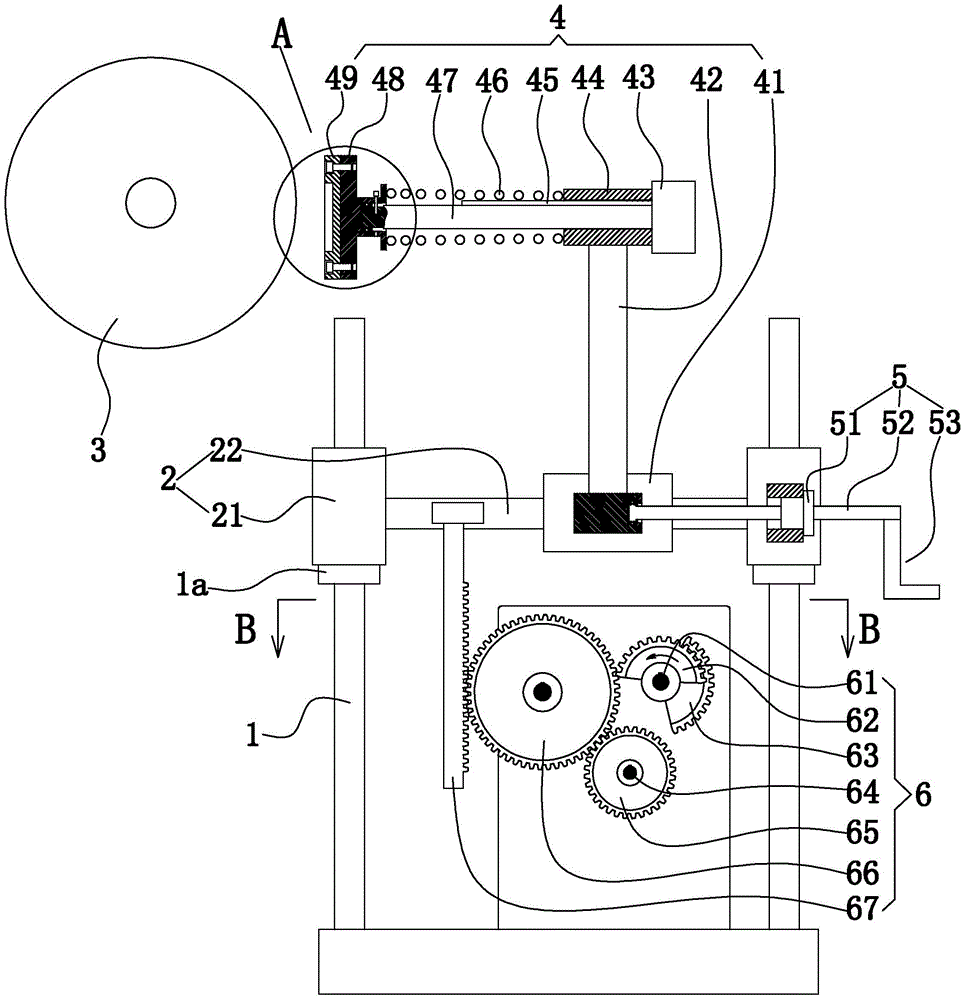

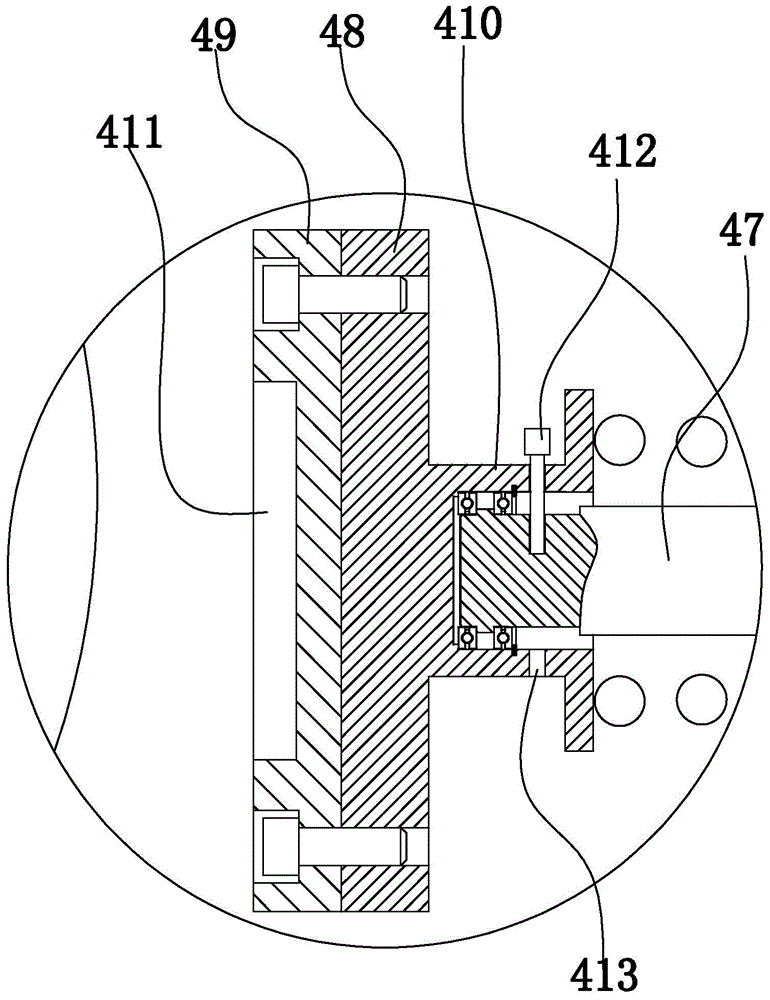

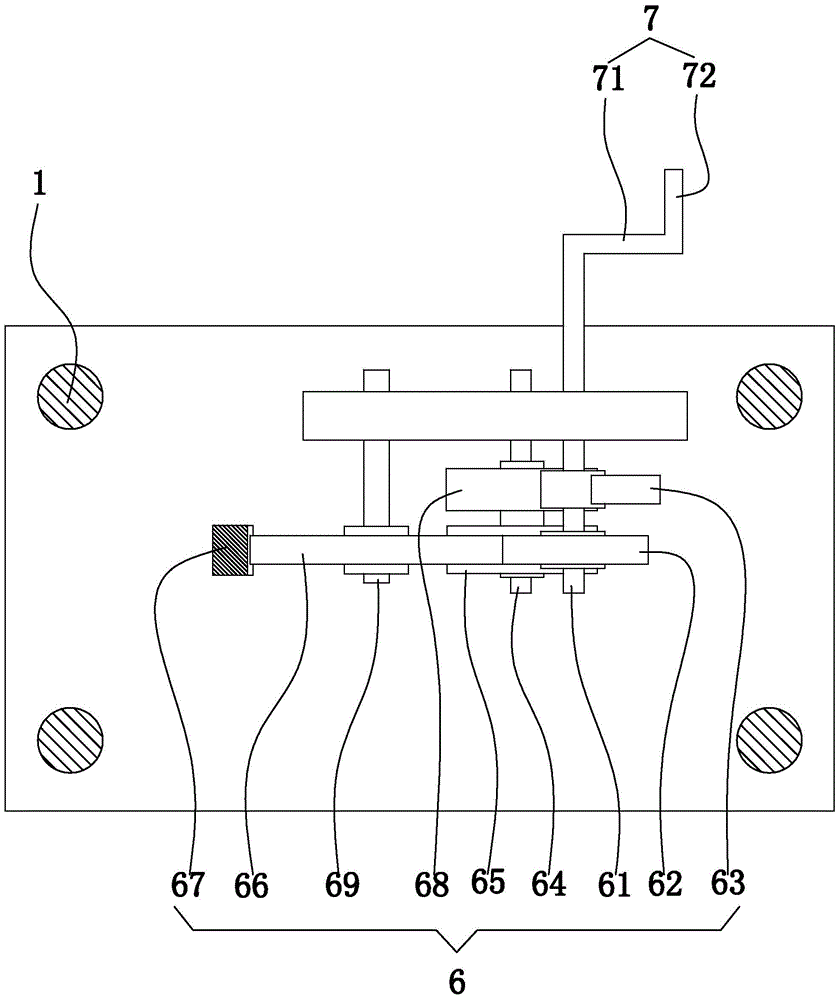

[0061] Example 1: Such as figure 1 As shown, a metallographic grinding device includes a frame, a grinding wheel 3 rotatably arranged on it, a driving motor for driving the grinding wheel to rotate, and a vertical guide post 1 arranged on the frame that can be guided vertically. The column lifting platform 2 is used to drive the manual lifting actuator 6 for reciprocating up and down the lifting platform, the horizontal guide rod 22 arranged on the lifting platform, the pole plate mounting device 4 which can move along the horizontal guide rod and the On the lifting platform, a translation device 5 for driving the pole plate mounting device to move along the horizontal guide rod. A vertical guide sleeve 21 adapted to the vertical guide post is provided on the lifting platform, and the vertical guide sleeve is slidably sleeved on the vertical guide post. A ring-shaped limiting protrusion 1a is provided on the vertical guide post and below the vertical guide sleeve.

[0062] Such ...

Embodiment 2

[0094] Embodiment 2: A method for polishing a metallographic sample of a corrosion layer of a battery electrode plate of a metallographic grinding device, which sequentially includes the following steps:

[0095] (1) Water sandpaper pretreatment: First, attach a layer of paraffin wax on the surface of the water sandpaper; then, use a lead alloy block for grinding, and use distilled water as a lubricant during the grinding process.

[0096] (2) The battery electrode plate samples are sequentially ground with 200# water sandpaper → 400# water sand paper → 800# water sand paper → 1500# water sand paper → 2000# water sandpaper. The water sandpapers of the above models are respectively subjected to step (1) Water sandpaper pretreatment process; distilled water is used as lubricant during grinding process; every time the water sandpaper is changed during grinding process, the battery electrode plate sample should be rotated 90 degrees in the same direction, and the surface of the battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com