Patents

Literature

589 results about "Sand-paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing recuperated yarn tube base paper by using waste slag and product thereof

ActiveCN101435171ASave resourcesAvoid churnWater-repelling agents additionPaper recyclingYarnProcess engineering

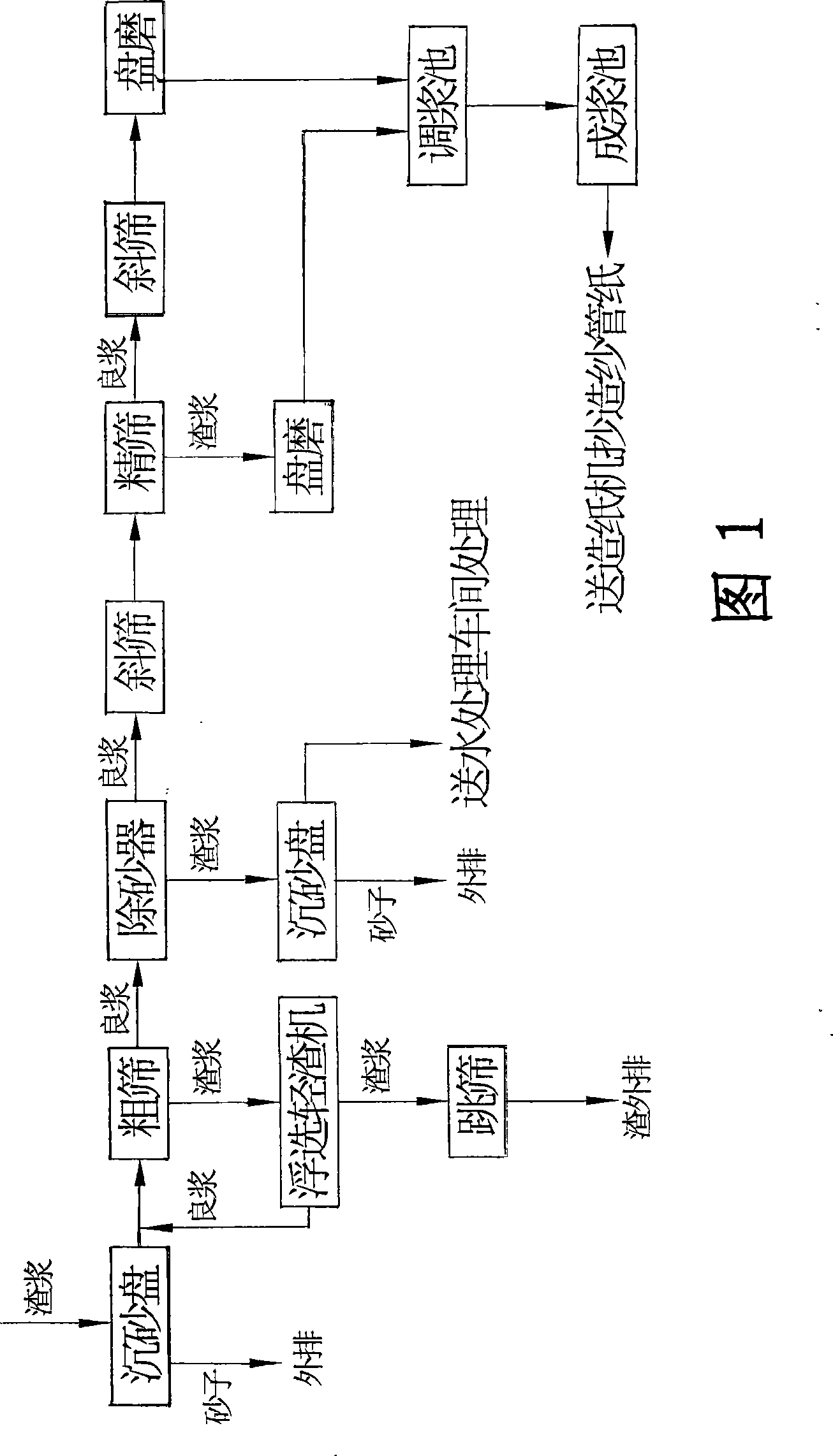

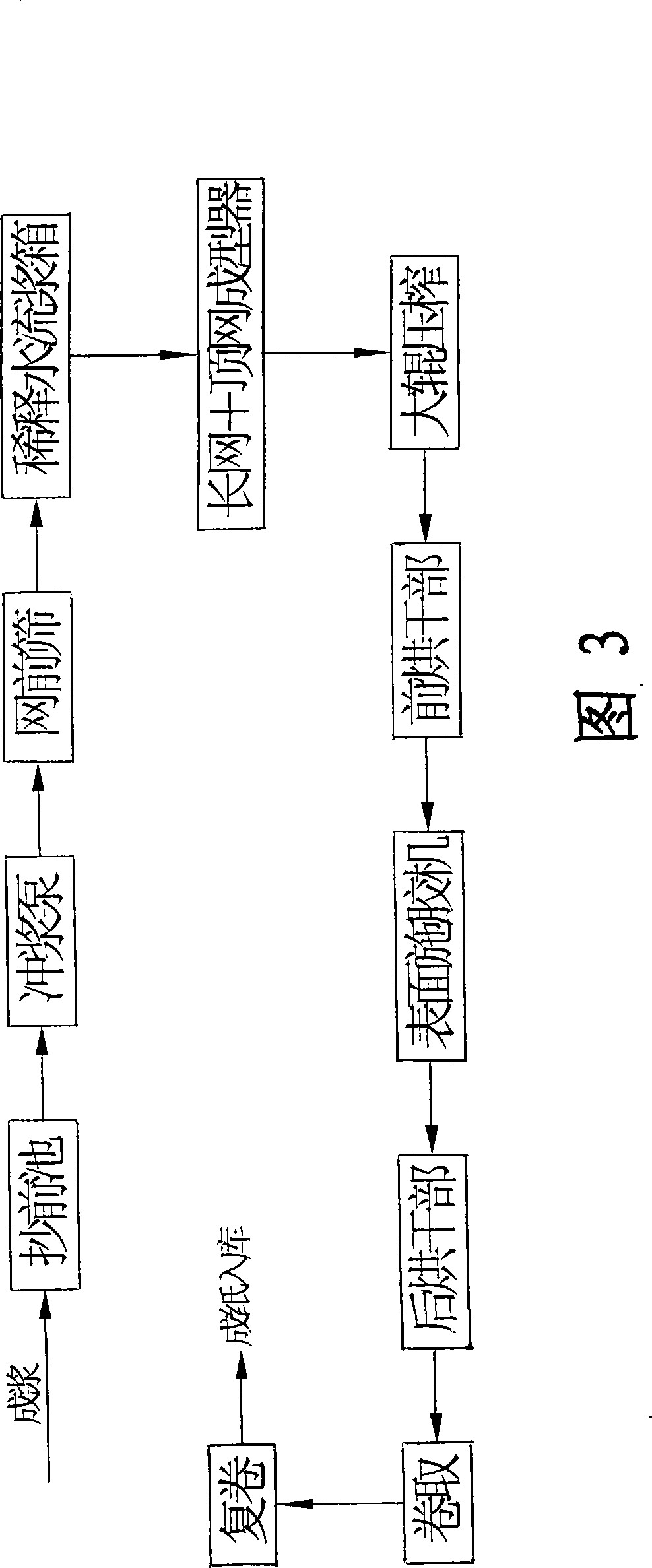

The invention relates to a manufacturing method which utilizes waste residue to produce regenerated yarn cop base paper and an obtained product thereof. The method comprises the following steps: the full stuff of processed waste slurry residue and the full stuff of processed waste paper are mixed according to proportion to carry out sand paper tube forming and then the regenerated yarn cop base paper is obtained. By adopting the method, waste paper resources can be saved, waste water treatment can be reduced, and the obtained regenerated yarn cop base paper has the advantages of low ration, good quality and the like.

Owner:JIAN GRP

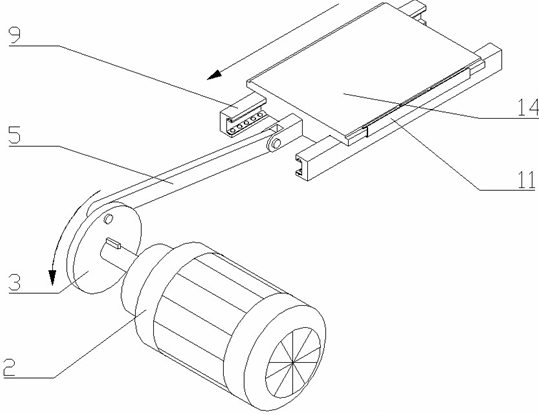

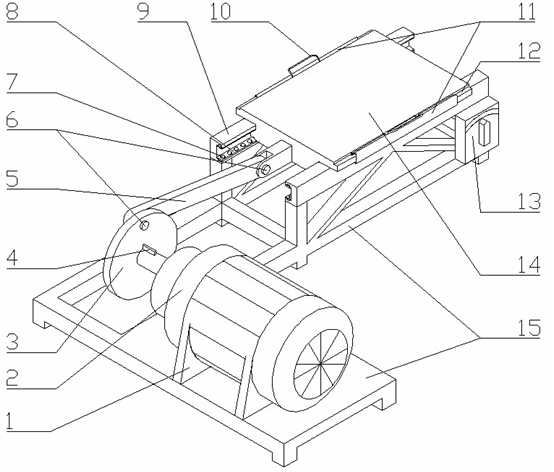

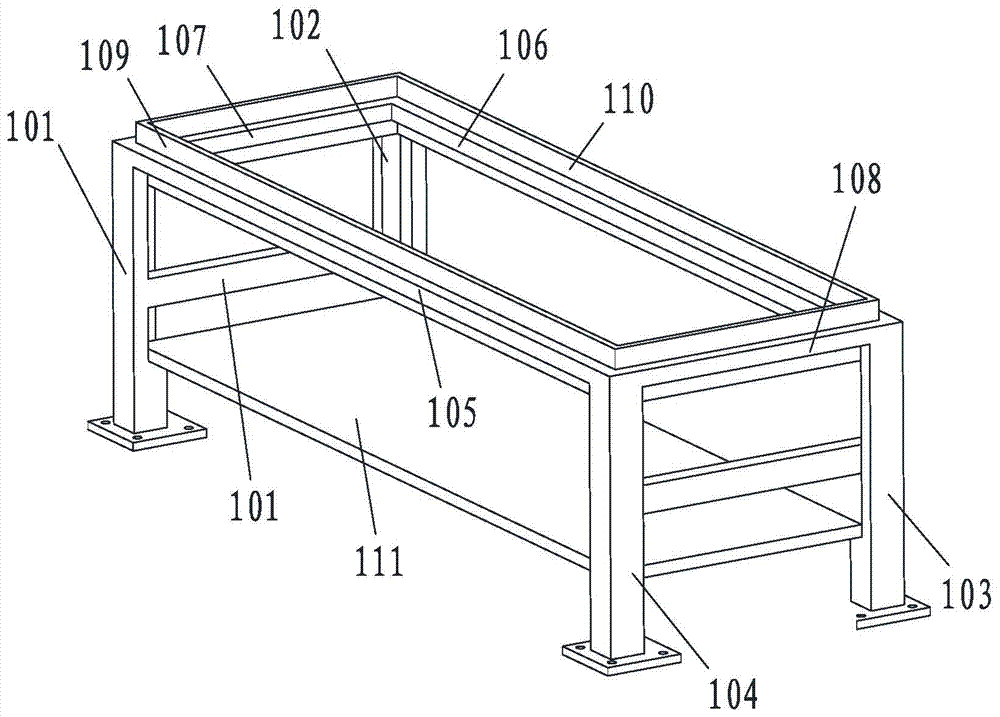

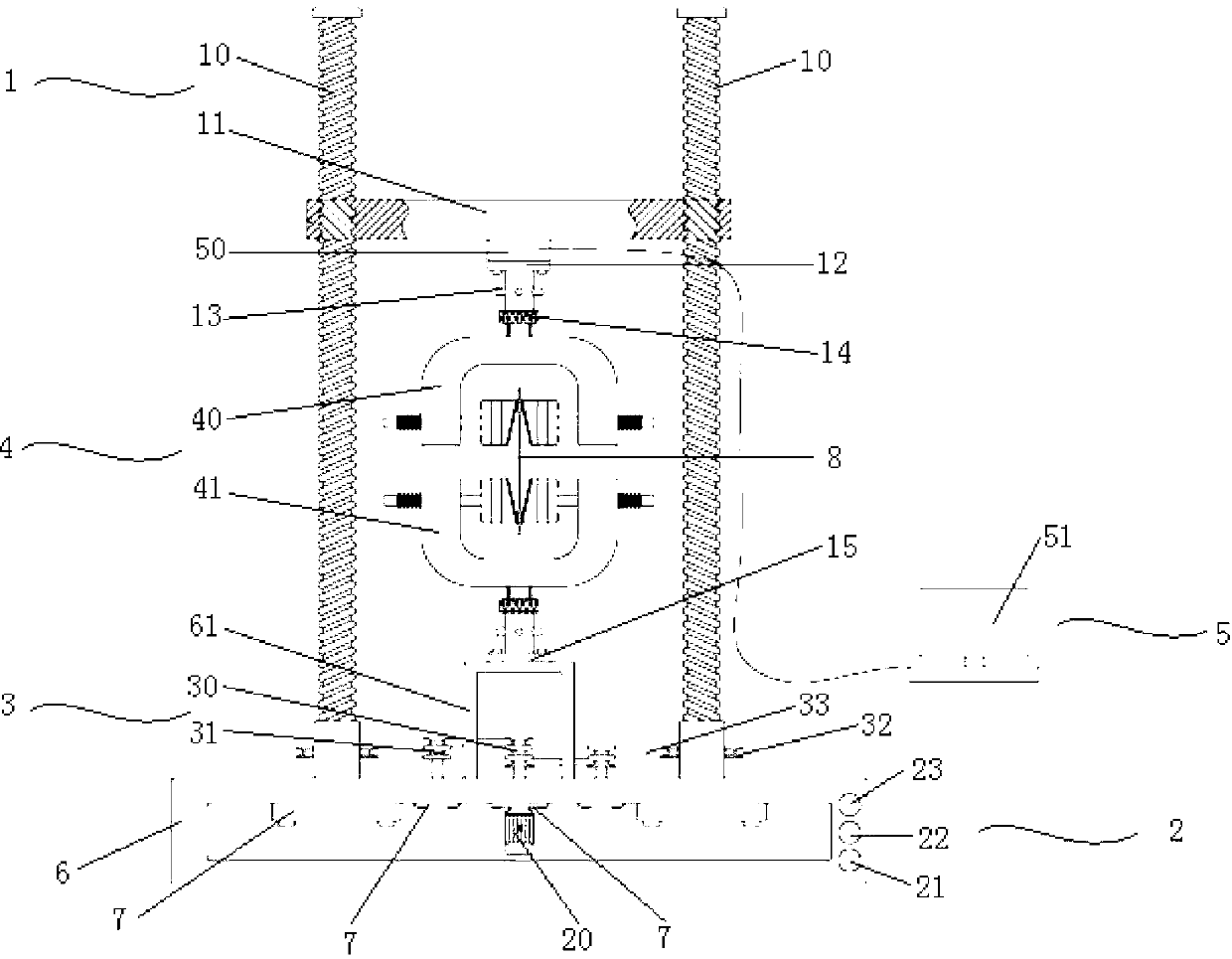

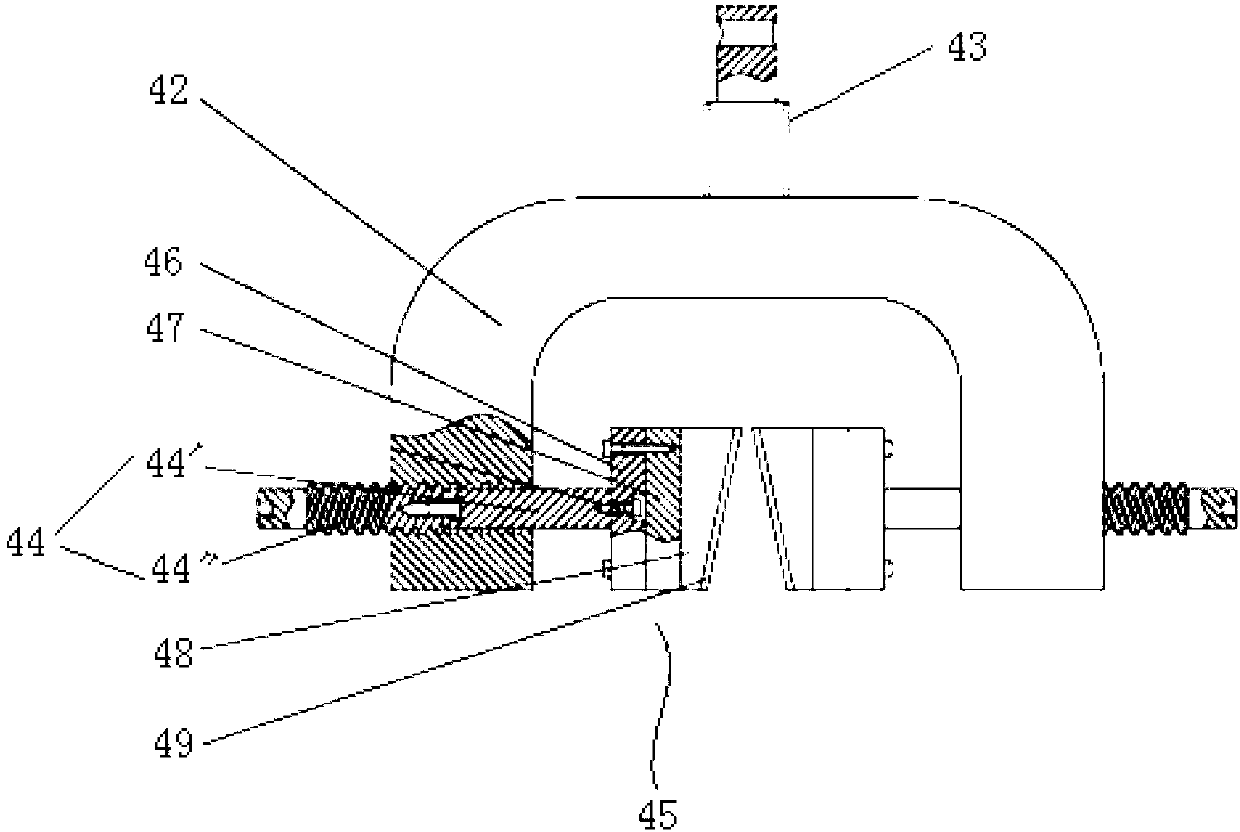

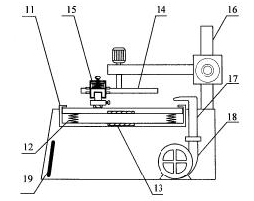

Linear reciprocating type pre-milling machine

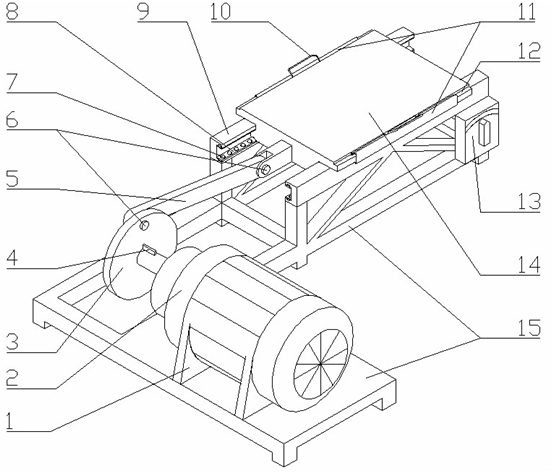

InactiveCN102528612AMeet the polishing requirementsHigh polishing precisionPreparing sample for investigationGrinding machinesReciprocating motionSand-paper

The invention relates to a device for pre-milling before a metallic phase of metal is observed and a stress test sample is polished, in particular to a linear reciprocating type pre-milling machine which comprises a milling platform, a reciprocating link mechanism, a motor and a supporting base, wherein the milling platform comprises a linear guide rail, a plane milling plate and a sand paper fixing clamp; the reciprocating link mechanism comprises a cam and a connecting rod; a small-size alternated current motor with a speed-regulating device is served as the motor; a frame type simple supporting base is served as the supporting base; and a speed-regulating switch is placed on one side of the supporting base. The linear reciprocating type pre-milling machine can be used for keeping straight and homonymous scratches of a metal test piece all the time during a milling process and increasing the milling precision; the milling reciprocating speed can be adjusted according to the requirement during the milling process, so that the polishing and milling efficiency is increased. The linear reciprocating type pre-milling machine has the advantages of convenience in operation, simple and compact structure, space-saving property, cost-lowering property, wide application scope and capability of meeting the polishing and milling demands of various test pieces.

Owner:JIANGSU UNIV

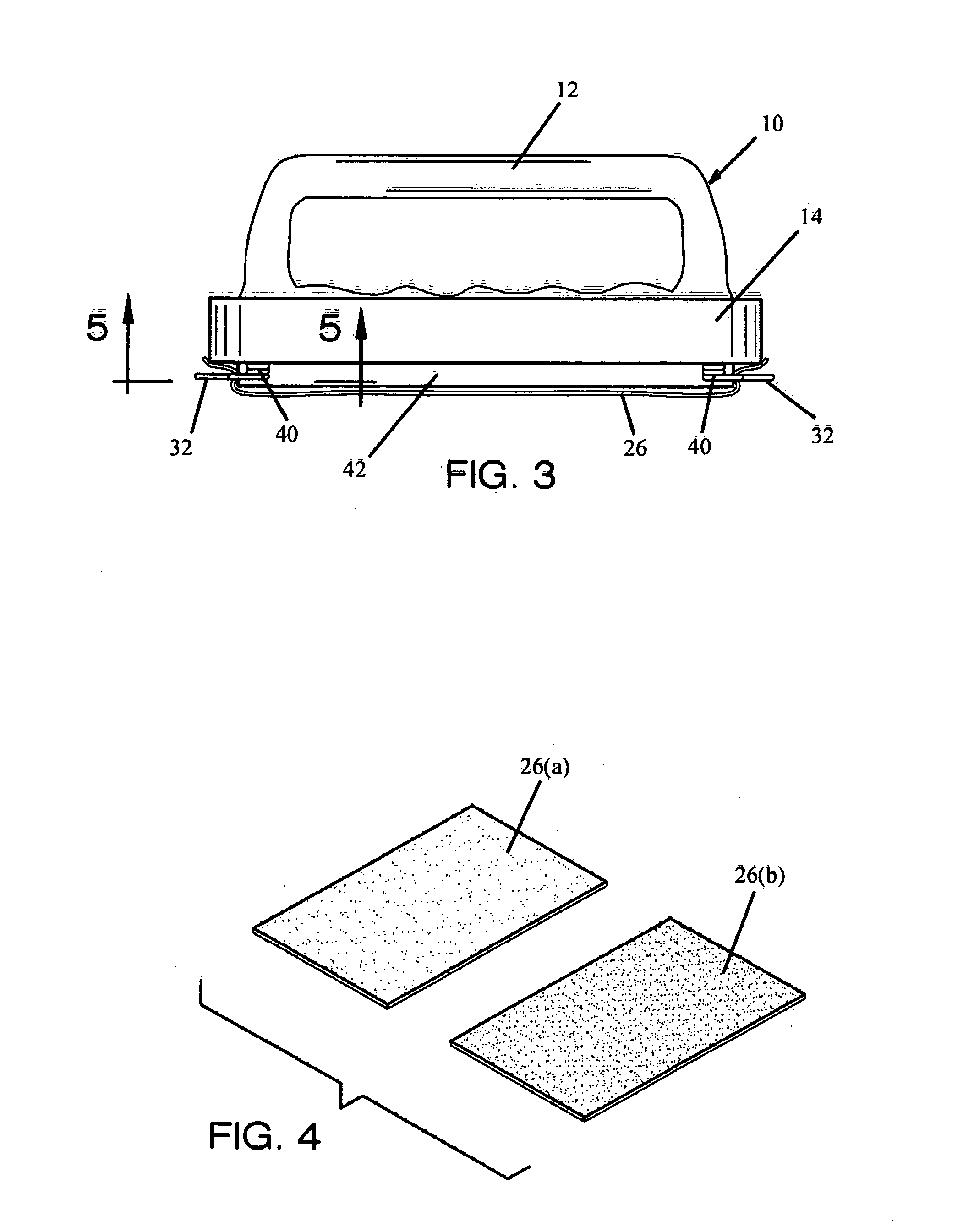

Skin treatment device and method for exfoliation and cellulite reduction

A novel device and method for use in providing multiple cosmetic treatments is disclosed, where a sanding tool is provided with sanding surfaces for use in imparting exfoliation, depilation, and cellulite treatments on the skin of a person. Select sanding surfaces are use for each of the exfoliation, depilation and cellulite treatments with the sanding action being generated by the orbital sanding effects of a palm sander. Specifically, a 100 grit (CAMI) sanding paper is used for exfoliation, a 180 grit (AMI) sanding paper is used for depilation, and the sander pad of the sanding tool of the present invention is used directly on the skin for cellulite reduction.

Owner:FERRARA JOELLA ANN

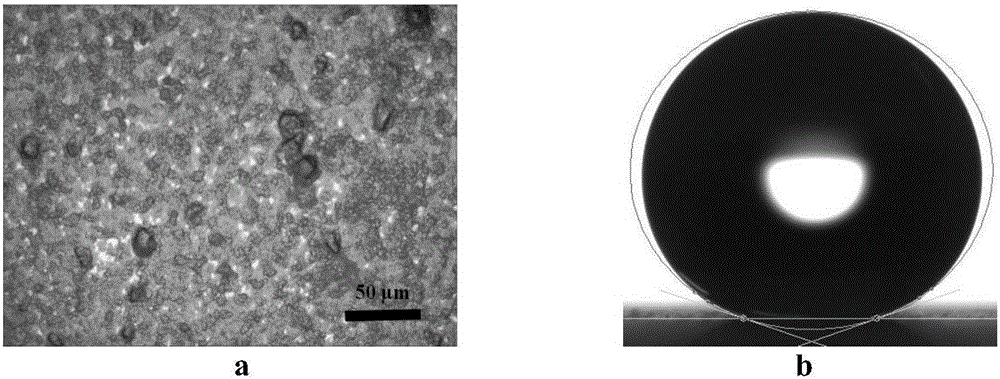

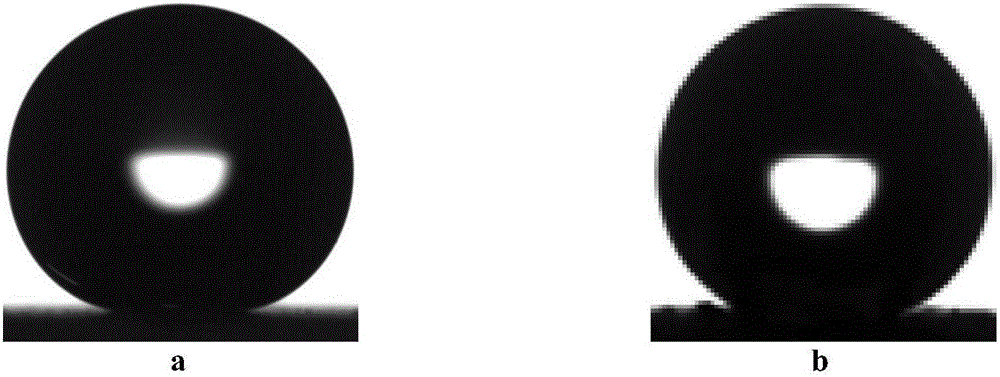

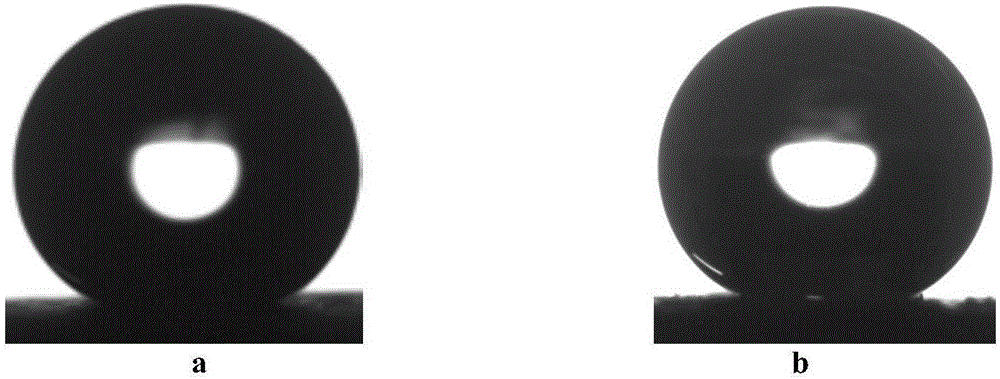

Transferable wearing-resistant flexible super-hydrophobic film and preparation method thereof

ActiveCN106366912AReduce the binding forceIntegrity guaranteedPretreated surfacesPolyurea/polyurethane coatingsWear resistantRoom temperature

The invention discloses a transferable wearing-resistant flexible super-hydrophobic film and a preparation method thereof. The preparation method comprises the following steps: by using a two-step coating method, coating the surface of a smooth substrate which is subjected to degreasing and decontamination treatment or is coated with a resin film releasing agent with soft and hard compounded resin, further coating the surface of the half-cured compounded resin with a super-hydrophobic nano coating, performing room-temperature or high-temperature curing, and separating from the substrate, or coating the surface of a base film, and curing, thereby obtaining the transferable wearing-resistant flexible super-hydrophobic film directly. The transferable wearing-resistant flexible super-hydrophobic film has the advantages of being simple in process, simple and easy to operate, low in cost and the like, and has industrial on-scale production prospects. The transferable wearing-resistant flexible super-hydrophobic film disclosed by the invention is relatively good in wearing resistance, good in resistance on external force such as finger friction and sand paper grinding and good in flexibility, and can be adhered to complex substrate surfaces along with shapes after being cut.

Owner:SOUTHEAST UNIV

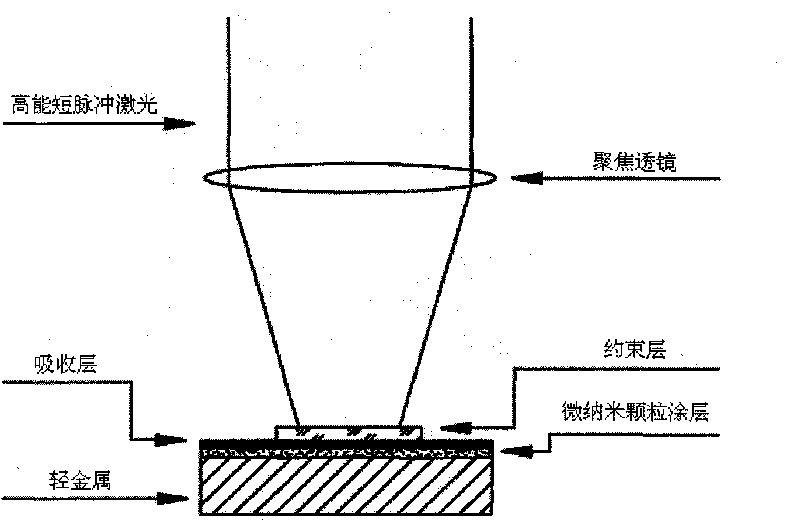

Light metal surface laser impact micronano particle injection reinforcing method

The invention relates to a light metal surface laser impact micronano particles injection reinforcing method, comprising the following steps: 1) removing the oxide layer probably existing on the surface of the light metal by a mechanical polishing or chemical corrosion method, then grinding and polishing with sand paper, and finally cleaning the surface of the light metal alloy with acetone or alcohol; 2) precoating the micronano particles on the surface of the light metal with inorganic bonding agent, recoating a layer of black paint on the surface of the micronano particle coating layer to serve as the absorption layer of laser impact after drying, and drying naturally; 3) impacting the absorption layer and the micronano particle layer with high-energy short pulse laser, and utilizing K9 glass or running water as a restriction layer during laser impact; and 4) soaking the micronano particle coating layer processed by acetone, and then removing the absorption layer through washing with running water or ultrasonic washing to obtain the micronano particle injection reinforcing layer. The invention integrates the actions of laser impact reinforcement, nano particle reinforcement and nano particle reinforcement, can dramatically improve hardness, abrasion resistance and fatigue resistance property of light metal surface layer, and has wide application prospect.

Owner:TSINGHUA UNIV

Corrosion sample inlaying method

InactiveCN103543060ATightly boundSample preparation is beautiful and generousPreparing sample for investigationEpoxyRoom temperature

The invention discloses a corrosion sample inlaying method. The method comprises the following steps of: based on an epoxy resin inlay, which is composed of 60-80% of matrix resin, 10-25% of conductive powder, 2-10% of dispersing agent and 7-15% of curing agent by weight, orderly arranging the sample to be inlaid, namely the corrosion sample, completely covering the sample with a die, and then, pouring the epoxy resin inlay into the die until submerging the corrosion sample; curing 3-12h at room temperature, uncovering flat surface paper, taking out the sample from the die, respectively sanding the sample with 120#, 240#, 400#, 600#, 800# and 1000# sand paper stage by stage, and then, polishing the sample. With the method disclosed by the invention, the processed corrosion sample can be used for metallomicroscopy observation or electron microscopy scanning observation, so that organization, structure and form of the cross section of the corrosion sample are shown integrally and really.

Owner:CHINA PETROCHEMICAL CORP +1

Epoxy resin binding agent for sand paper and its preparation method

InactiveCN1651542ALong shelf lifeExtended service lifeAbrasion apparatusEpoxy resin adhesivesEpoxyDiluent

An epoxy resin adhesive for abrasive paper is prepared from the component A composed of epoxy resin and diluent, the component B consisting of solidifying agent and toughening agent and the component C which is solvent through proportionally mixing component A with B, stirring, proportionally adding component C and stirring.

Owner:WUHAN UNIV OF TECH

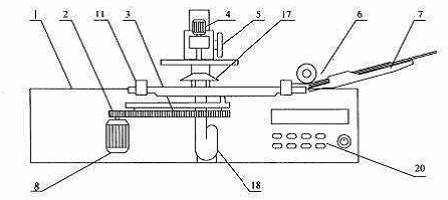

Metallographic test sample preparation instrument

InactiveCN104330294AAvoid manufacturing defectsAchieve recyclingPolishing machinesPreparing sample for investigationLow noiseTest sample

The invention discloses a metallographic test sample preparation instrument which comprises a stander, a metallographic test sample clamping mechanism, a five-degree-of-freedom driving mechanism, a grinding mechanism, a polishing mechanism and a test sample corrosion structural block. The five-degree-of-freedom driving mechanism is matched with the metallographic test sample clamping mechanism, so that a moving trace of a metallographic test sample in a preparation process can be precisely controlled, and high-quality preparation of the metallographic test sample can be finished by assisting of the grinding mechanism, the polishing mechanism and the test sample corrosion structural block; the polishing, grinding and corrosion processes of the test sample can be automatically controlled; the labor and the time are greatly saved; meanwhile, the test sample preparation defects caused by mistakes or insufficient experience of a technician are avoided. Furthermore, the metallographic test sample preparation instrument has the advantages of small occupation space, high equipment utilization rate, low noise, no pollution, convenience in metallographic sand paper replacement, recycling of polishing liquid, compact structure, low manufacturing cost, convenience in mounting and maintenance and the like.

Owner:SHANDONG UNIV OF SCI & TECH

Straw stretching property test device

InactiveCN103344494AIncrease tightnessImprove compactnessMaterial strength using tensile/compressive forcesSand-paperMechanical engineering

The invention relates to a straw stretching property test device. The test device comprises a stretching mechanism, a power mechanism, a transmission mechanism, a clamping mechanism, a data information acquisition and transmission control platform and a machine frame base, wherein the clamping mechanism comprises an upper clamp unit tightly connected to the stretching mechanism and a lower clamp unit tightly connected to the machine frame base; the upper clamp unit and the lower clamp unit form a symmetrical structure; each clamp unit comprises a clamp main body; a connecting member tightly connected with the stretching mechanism / the machine frame base is arranged in the center at one end of each clamp main body; a threaded through hole is radially formed in each side at the other end of the clamp main body; an adjusting member capable of being screwed inwards / outwards is inserted into each threaded through hole; the inner end of each adjusting member is tightly connected with a clamping head member; the two clamping head members also form a symmetrical structure; each clamping head member comprises a pushing plate, a resin cushion layer, a rubber cushion layer and a sand paper cushion layer which are tightly connected to each adjusting member in sequence. The test device adapts to a stretching property test of different types of straws.

Owner:CHINA AGRI UNIV

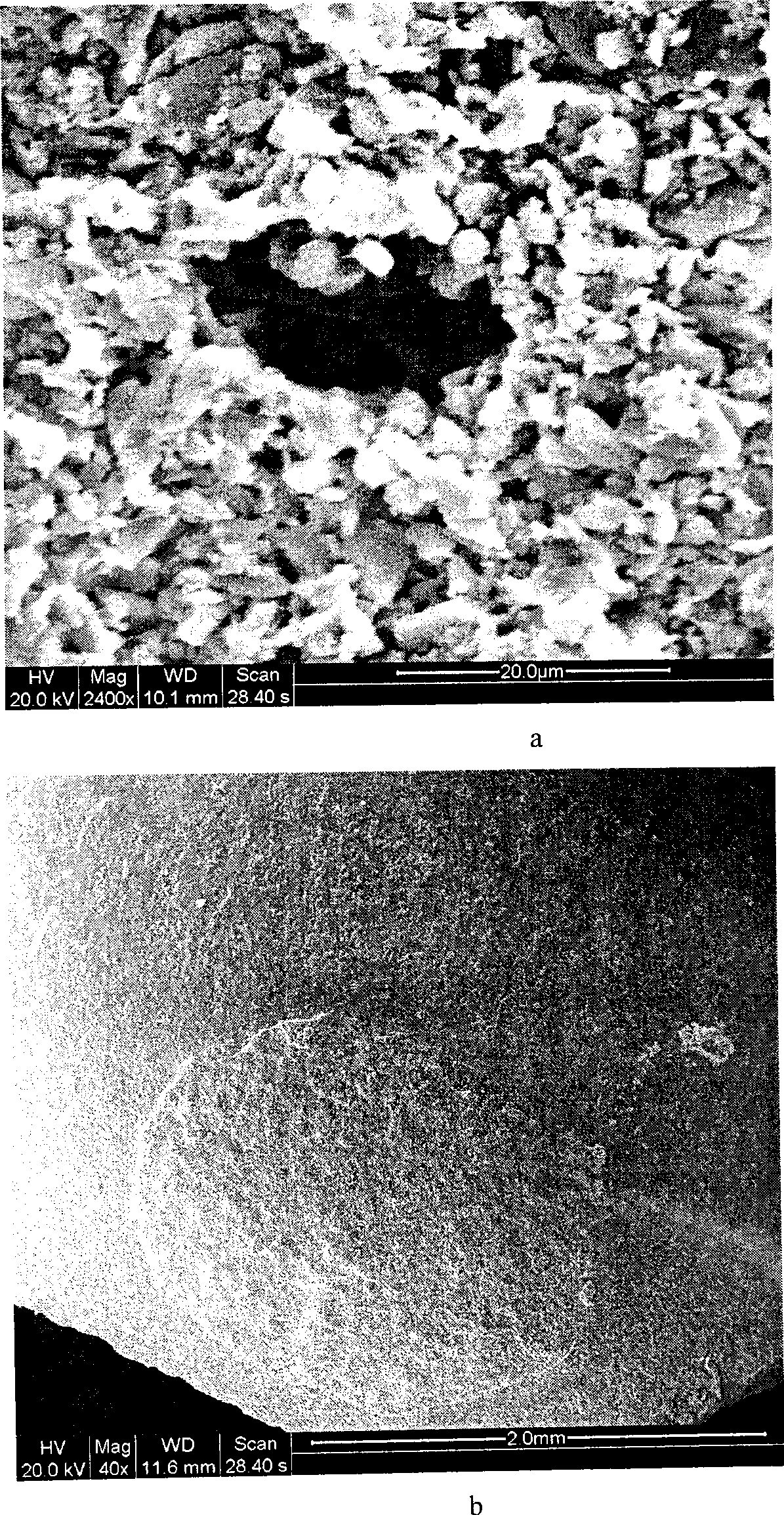

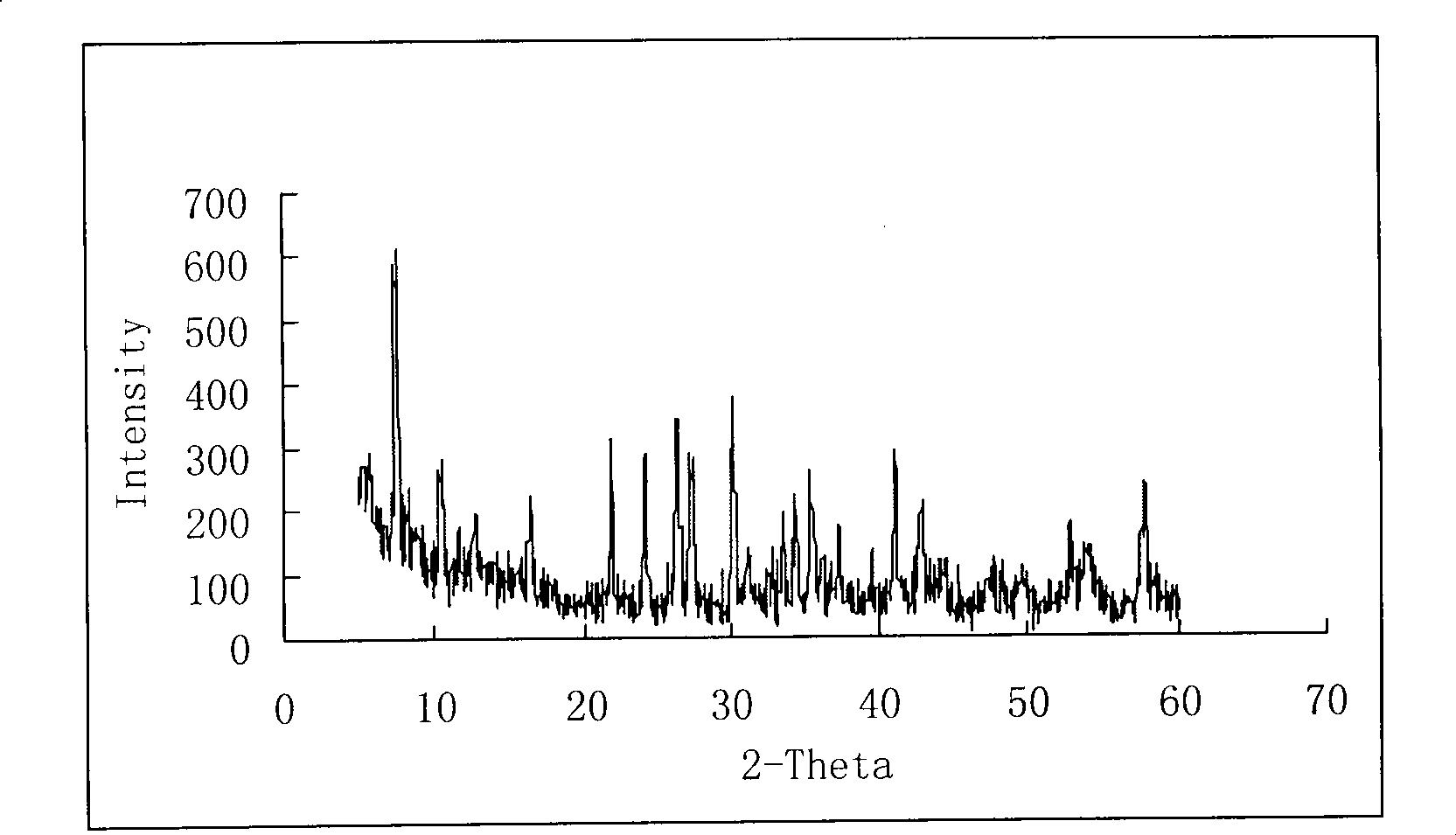

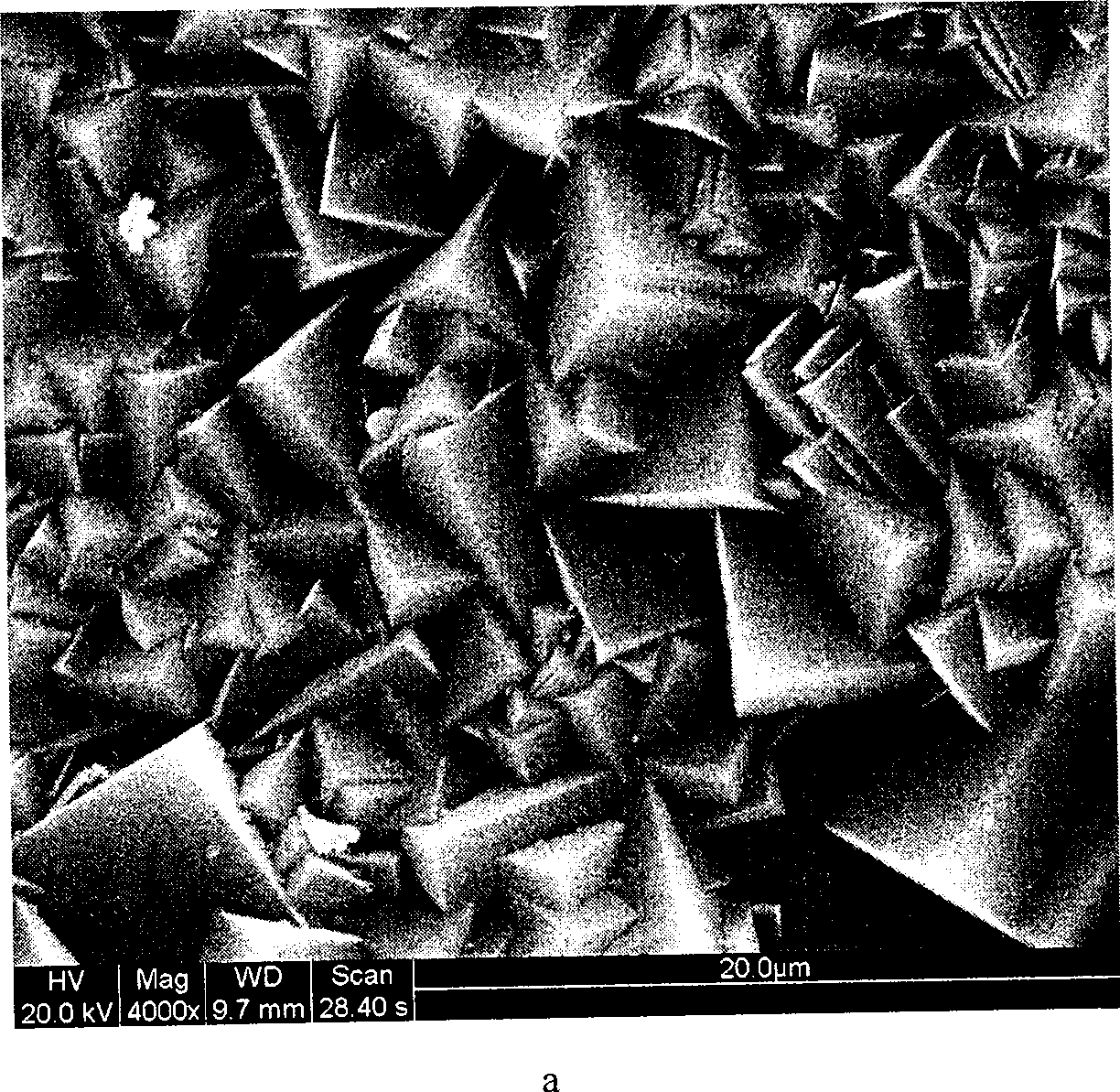

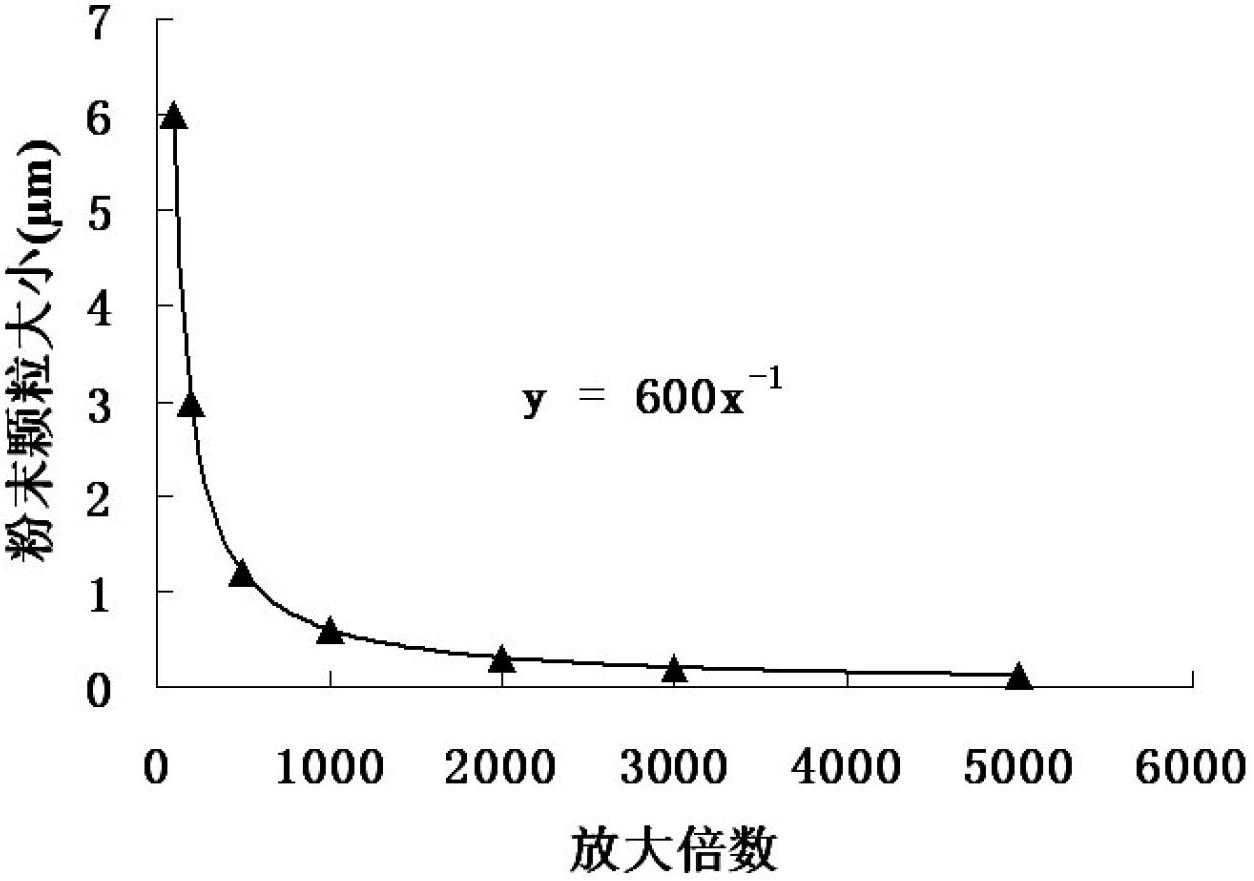

Method for synthesizing NaA zeolite membrane

ActiveCN101381087AHigh selectivityImprove permeabilitySemi-permeable membranesAluminosilicate zeolite type-AMolecular sieveHydrothermal synthesis

The invention relates to a method for synthesizing a NaA molecular sieve membrane. A seed crystal coating mode of combining the coating and the dipping of seed crystal is used for the synthesis of the molecular sieve membrane. Firstly, a supporting body is polished by sand paper and is dried; a seed crystal paste is coated on the surface of the supporting body to remove the possible defects on the surface of the supporting body; secondly, the seed crystal is precoated by a lifting and dipping method; and finally the NaA molecular sieve membrane is synthesized by a hydrothermal synthesis method. The NaA molecular sieve membrane synthesized by the method has continuous and compact surface, excellent separation performance and good repeatability and is suitable for scale preparation.

Owner:JIANGSU NINE HEAVEN HIGH TECH

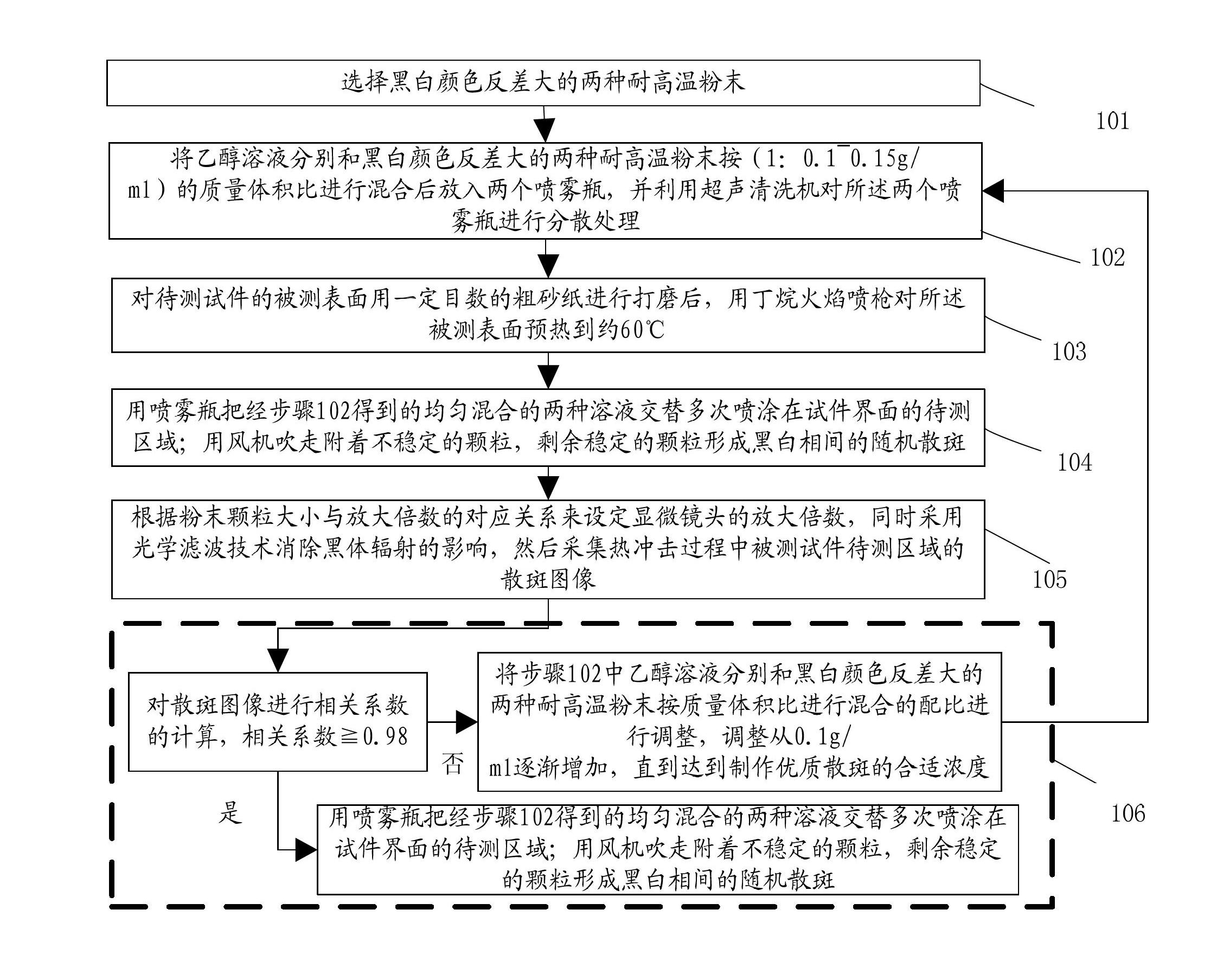

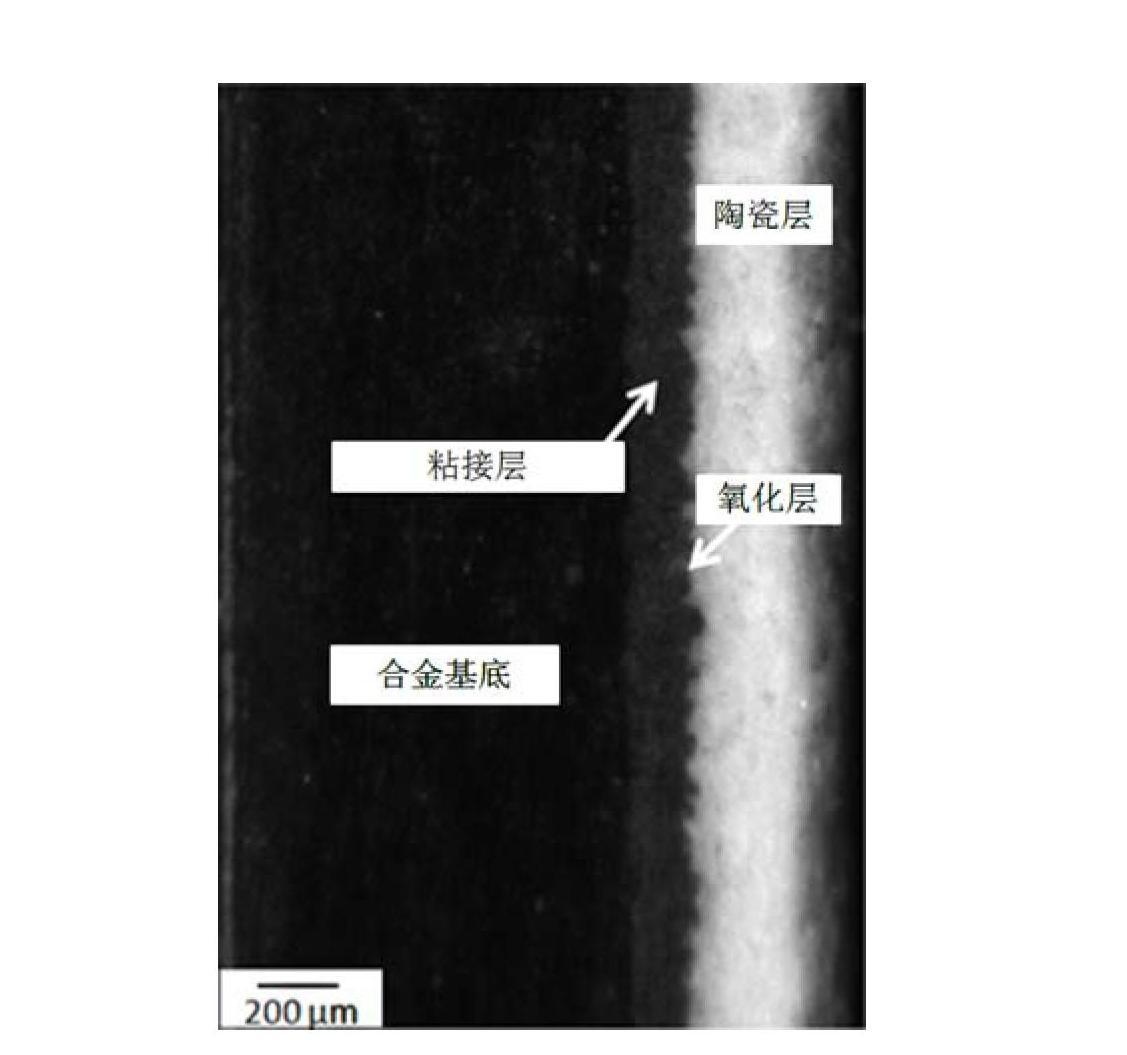

Micro-scale speckle manufacturing method for interface high-temperature deformation measurement

InactiveCN102679899AMeet the high temperature thermal shock deformation measurementMeet thermal shock deformation measurementUsing optical meansBlack-body radiationThermal deformation

The invention discloses a micro-scale speckle manufacturing method for interface high-temperature deformation measurement, comprising the following steps of: selecting two types of high-temperature-resisting powder with a great black and white color difference; respectively mixing an ethanol solution with the two types of the high-temperature-resisting powder according to a mass / volume ratio of 1: (0.1-0.15) (g / ml) and putting into two spraying bottles; utilizing an ultrasonic washing machine to carry out dispersion treatment on the solutions in the spraying bottles; polishing a surface to be detected by sand paper; utilizing a butane flame spraying gun to heat to be about 60 DEG C; utilizing the spraying bottles to alternately spray the two types of the uniformly-mixed solutions on the surface to be detected; utilizing a draught fan to blow off unstable grains attached in the solutions to form random speckles; utilizing a microscope lens and matching an optical filtering technology capable of eliminating black body radiation influences to collect speckle images at a room temperature and a high temperature; and carrying out related coefficient calculation on the speckle images and finishing the manufacturing of the speckle images when the related coefficient is more than or equal to 0.98. The micro-scale speckle manufacturing method for the interface high-temperature deformation measurement can improve the precision and can measure a thermal deformation field of high-temperature-resisting composite materials of an interface region under thermal shock.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

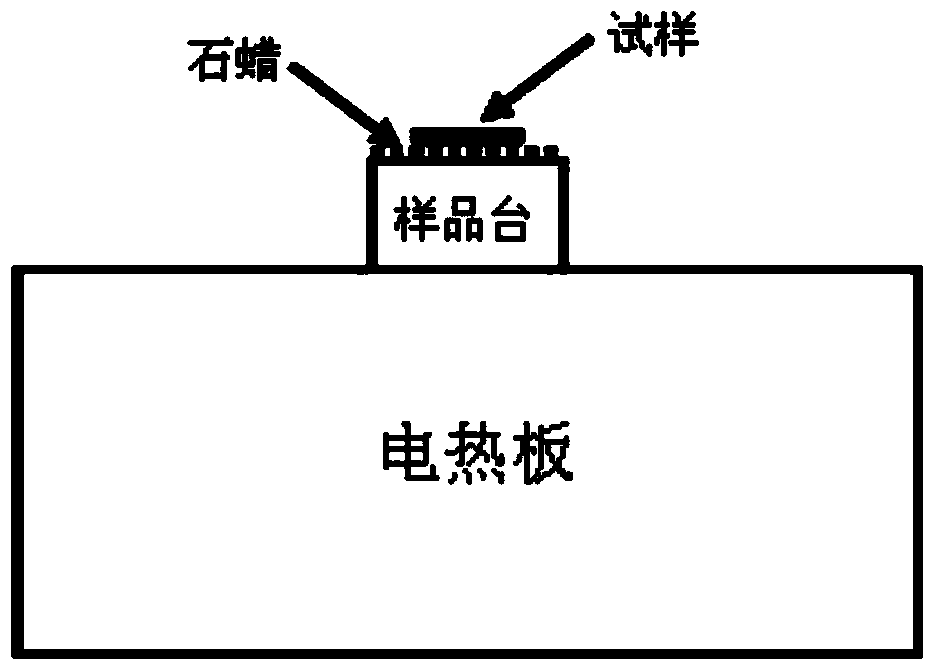

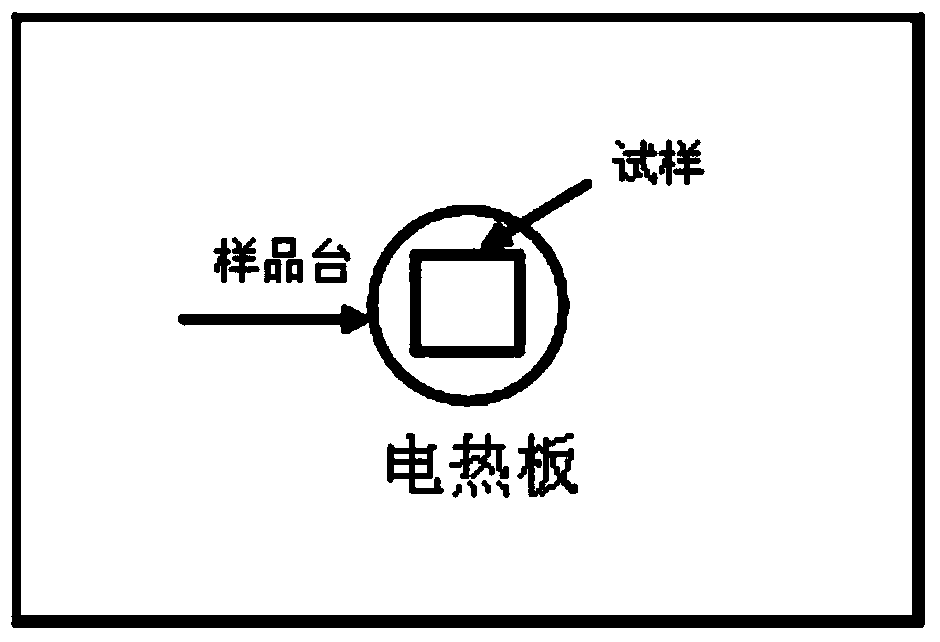

Sample preparation method for electron back scattering diffraction analysis of thin steel and iron material

InactiveCN103913364AQuality improvementImprove observation effectMaterial analysis using wave/particle radiationPreparing sample for investigationParaffin oilsSand-paper

The invention discloses a sample preparation method for electron back scattering diffraction analysis of a thin steel and iron material. The sample preparation method comprises the following steps: (1) taking a small plate surface of the thin steel and iron material as a sample, grinding one surface of the sample to be flat by using sand paper, and taking the flatly ground surface as a surface A; (2) selecting a cylindrical body as a sample table, uniformly melting a proper amount of paraffin on the sample table, and sticking the sample onto the molten paraffin until the paraffin is solidified and the sample is fixed to the sample table; (3) grinding and polishing the surface A of the sample fixed on the sample table; corroding the polished sample in natal for 3-15 seconds; and (4) observing and analyzing the sample processed through the steps (1) to (3) in electron back scattering diffraction equipment. The method is used for preparing a high-quality EBSD analysis sample without residual stress; the observation effect and quality are relatively high, so that the method is very suitable for preparing the EBSD analysis sample of the thin steel and iron material with the thickness not exceeding 0.5mm.

Owner:武钢集团有限公司

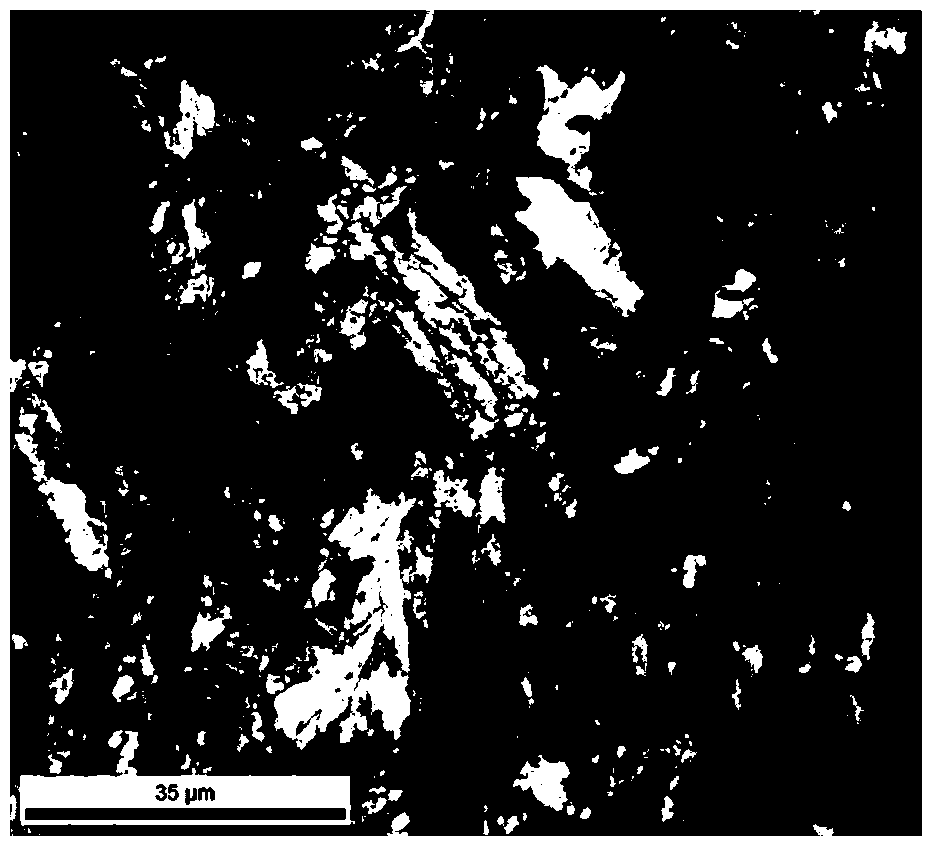

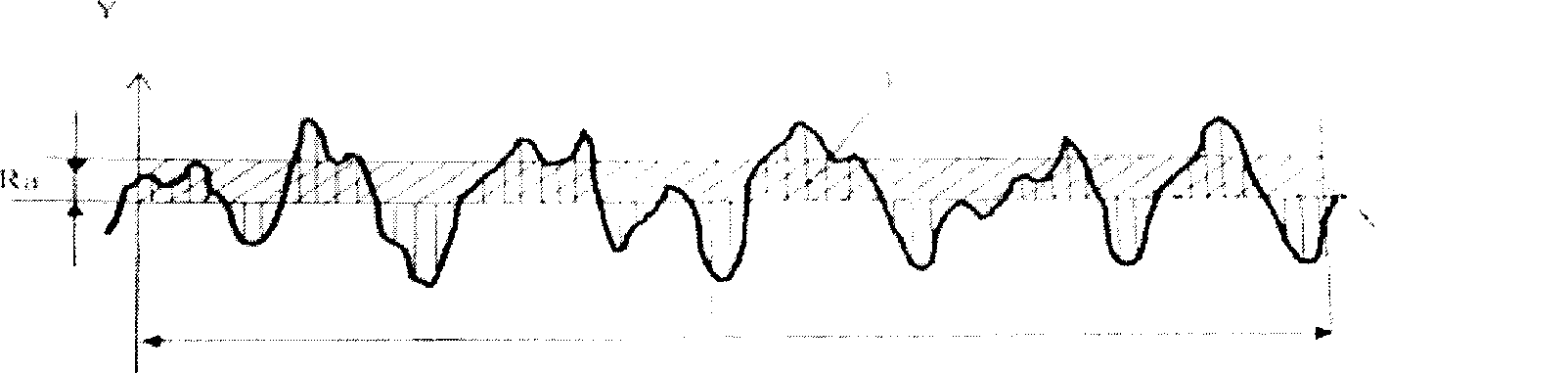

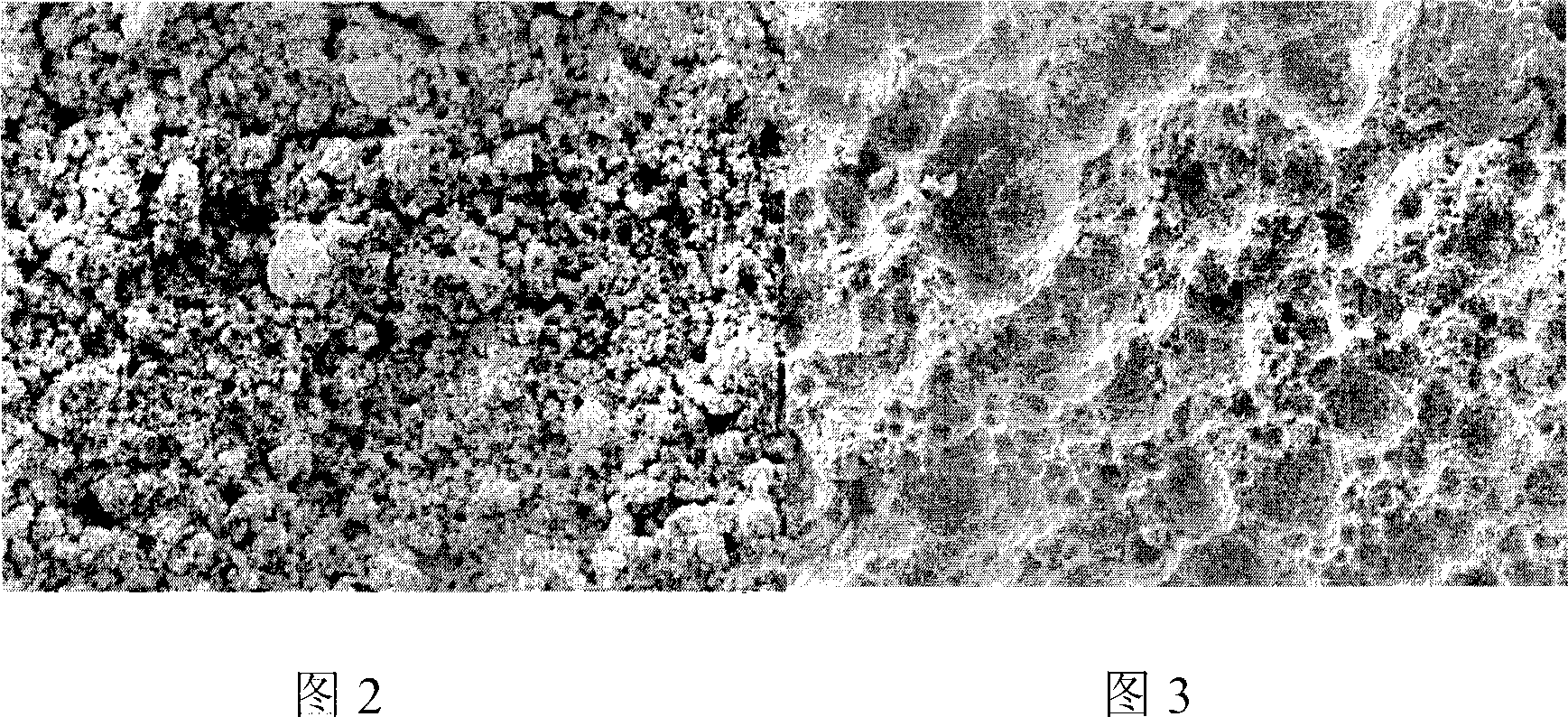

Treatment method of metal printing plate surface for offset-printing plate-making

ActiveCN101422992AHas the ability to absorb inkAvoid AnodizingPrinting pre-treatmentElectrochemical anodizationPolymer coatings

The invention belongs to the field of printing plate materials, relates to a metal plate base without electrochemistry anodic oxidation treatment, in particular to a treatment method of the surface of the metal plate base used for offset printing plate-making. The metal plate base used for offset printing is not treated by anodic oxidation and directly uses sand paper of different sand meshes for evenly sanding the surface thereof in transverse direction and longitudinal direction, so as to lead the surface of the metal plate base to have even roughness (Ra equals to 0.6-3Mum), the sanded metal plate base is washed and dried and the surface thereof is coated by hydrophilic polymer coating and then dried to obtain the metal plate base used for offset printing plate-making. The contact angle between the obtained metal plate base used for offset printing plate-making and the water is 2.0-76.2 degrees.

Owner:INST OF CHEM CHINESE ACAD OF SCI

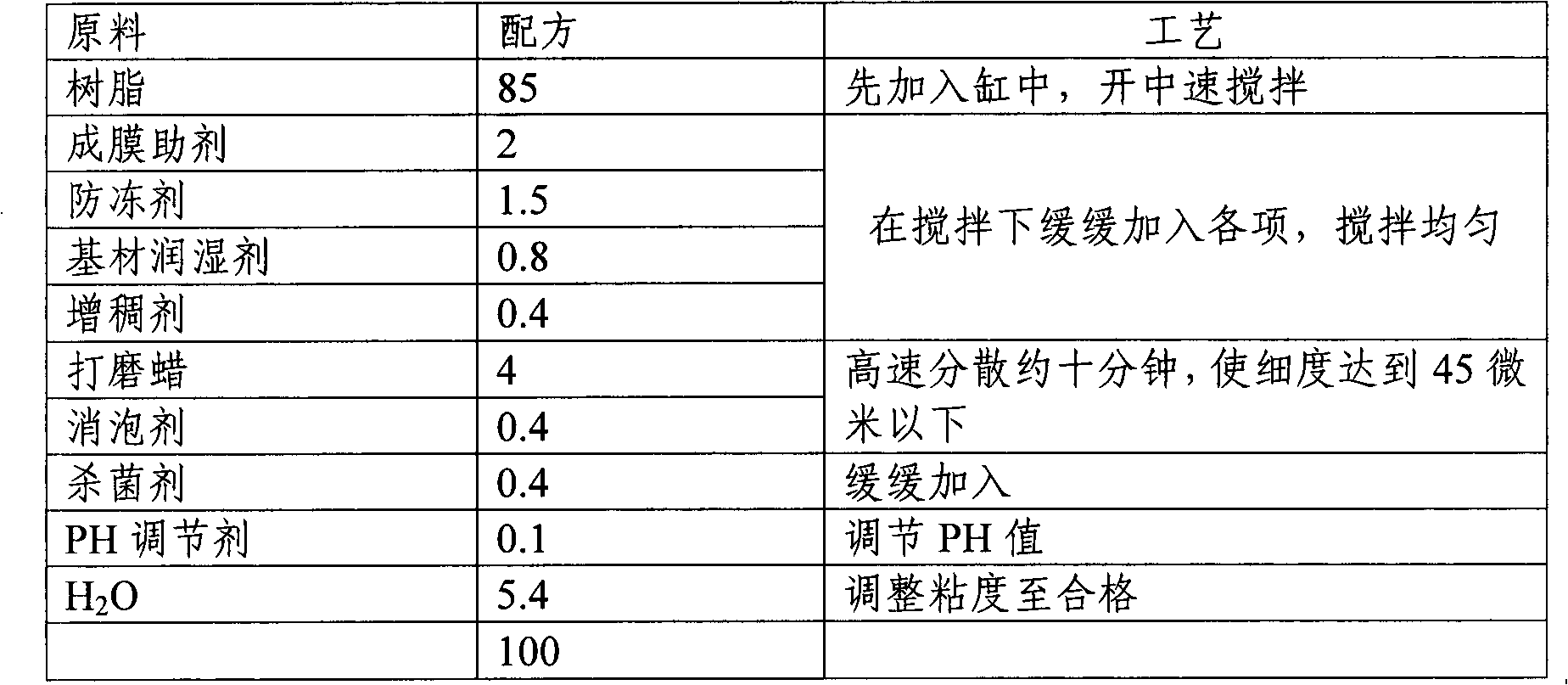

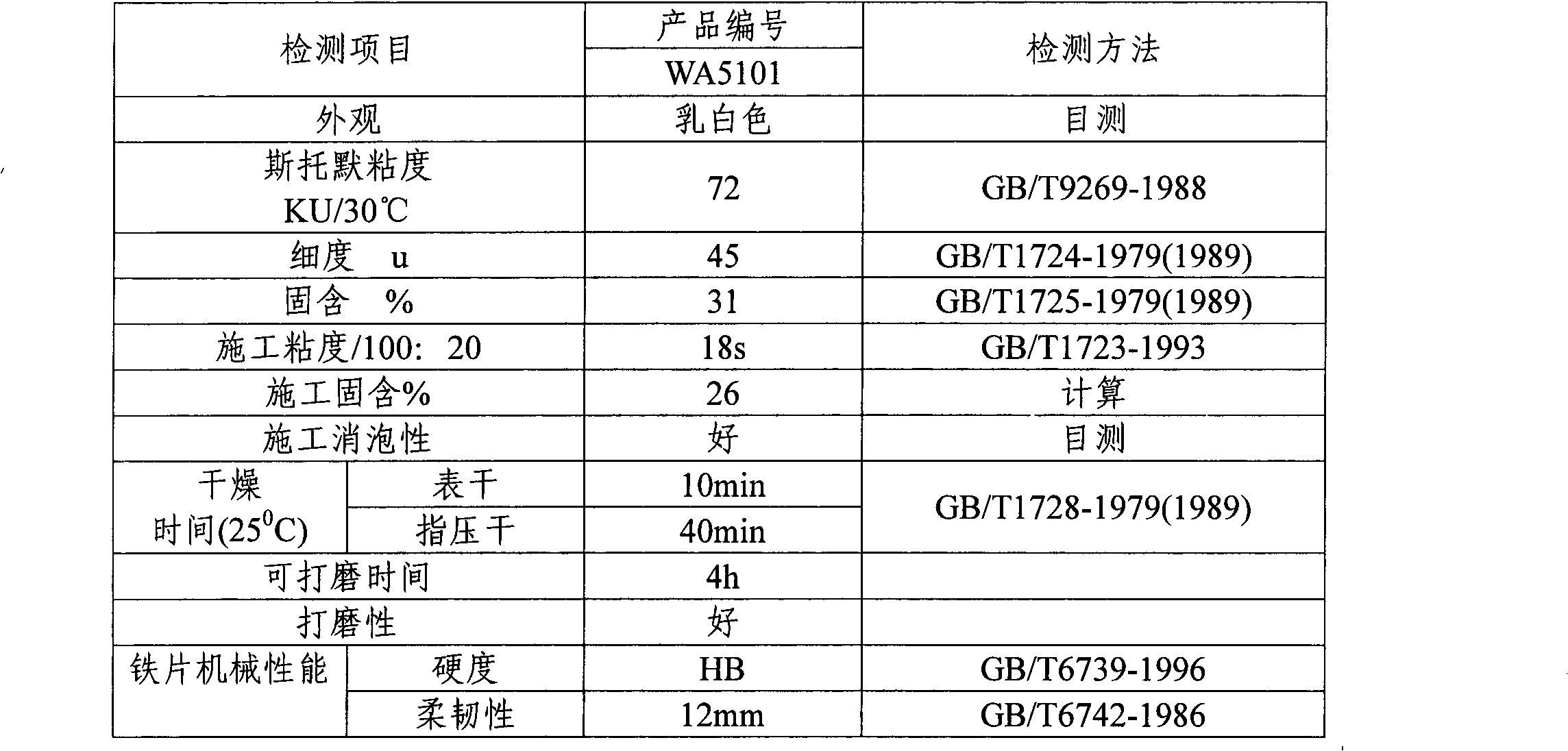

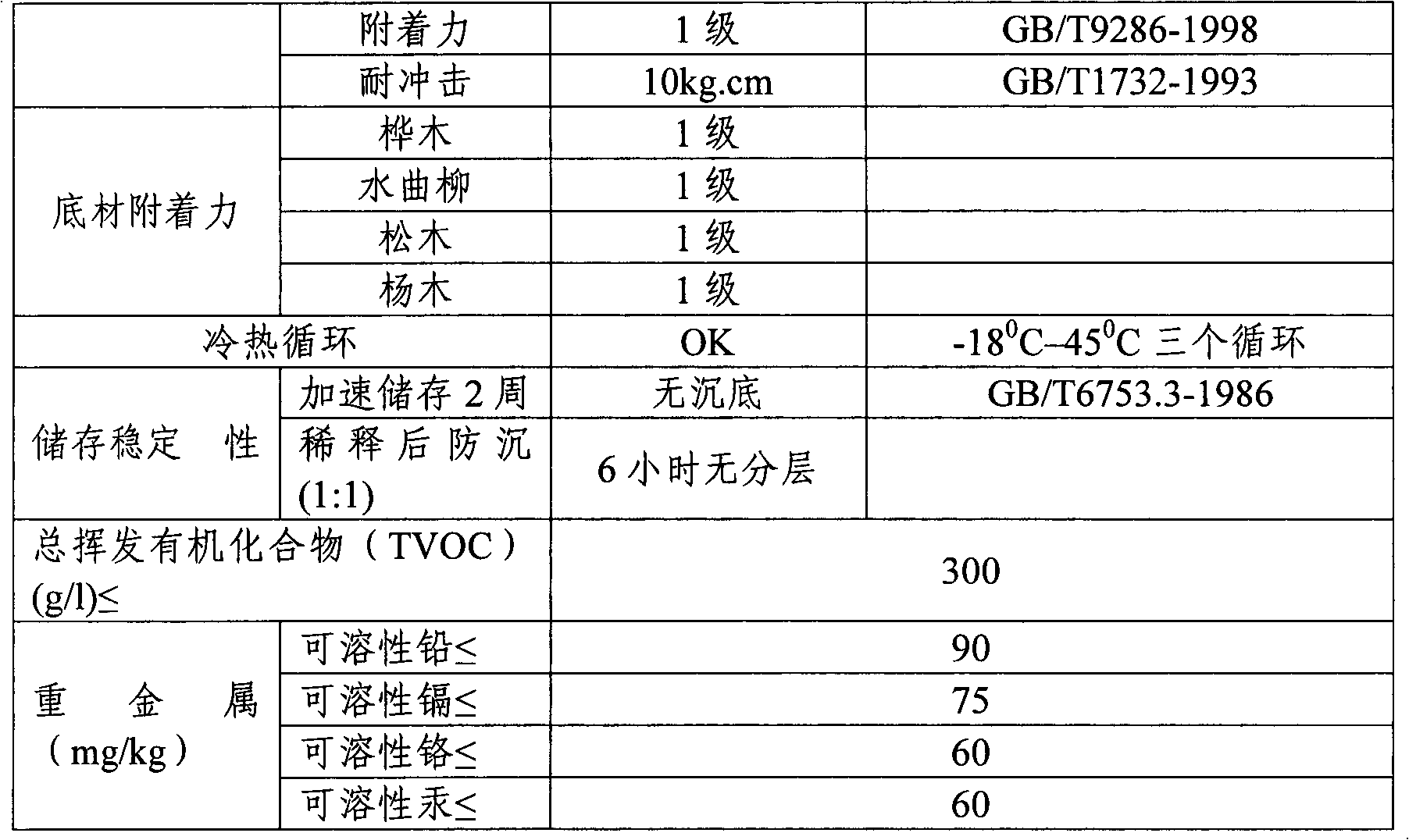

Water -emulsifiable nitrolacquer and preparation method thereof

The invention provides a water-emulsifiable nitrolacquer and a preparation method thereof. The water emulsion nitrolacquer comprises the following components in percentage by weight: 70%-90% of water-base nitro resin, 0.2%-0.5% of defoaming agent, 0.1%-0.5% of preservative, 2.5%-1% of substrate wetting agent, 3%-5% of sanding wax, 0.2%-0.6% of thickening agent, 1%-2% of antifreeze, 0%-0.2% of pH adjusting agent, 1%-3.5% of film forming auxiliary agent and 4%-20% of water. The water emulsion nitrolacquer has the advantages of good penetration property, quick drying, good sanding property, no adhesion to sand paper, little odor and no toxicity, and can be used as American water-base full-open spray after being produced. The product conforms to national standards and law regulations when exported to American and European Union, and has little odor; and the nitrolacquer film has the advantages of good sanding and adhesion property, quick drying and the like, thereby being suitable for flowline production.

Owner:珠海展辰新材料股份有限公司

Method for preparing transmission electron microscope sample of soft brittle phototransistor

InactiveCN102023111AProtection from being brokenAvoid breakingPreparing sample for investigationAdhesiveProtection layer

The invention belongs to the technical field of the preparation of transmission electron microscope samples of soft brittle phototransistors, and relates to a method for preparing a transmission electron microscope sample of a soft brittle phototransistor, in particular to a method for preparing a transmission electron microscope sample of a soft brittle photo semiconducting transistor. The method is characterized in that a hard brittle semiconductor with micro Vickers hardness of over 8 GPa is used as a protective layer of the soft brittle phototransistor, wherein the roughness Ra of the ultra-smooth surface of the protective layer is below 1 nanometer, and the thickness is below 650 micrometers; sand paper of 120 to 800 meshes is adopted in the coarse grinding stage, and a membrane is ground by adopting diamond of between 0.1 and 30 micrometers in the accurate grinding stage; the protective layer is bonded with the sample by adopting a hot setting adhesive which is insoluble in an organic solvent, and a first surface of the ground transmission electron microscope sample is bonded with a substrate by adopting a hot setting adhesive which is soluble in the organic solvent; and in the final stage of accurate grinding, the transmission sample and a thin area of the protective layer are obtained by a stress-free grinding method. The method has the advantages that the preparation of the transmission electron microscope sample of the soft brittle phototransistor is realized, and high-resolution transmission electron microscope atomic images are obtained.

Owner:DALIAN UNIV OF TECH

Fiber web reinforced vulcanized paper and reinforced sand paper

InactiveCN102094365AHigh strengthImprove toughnessSpecial paperAbrasion apparatusSand-paperPulp and paper industry

The invention relates to paper added with fibers. The fiber web reinforced vulcanized paper comprises a paper fiber layer and a fiber web framework; a fiber web woven by fiber strings is used as the fiber web framework; the fiber strings are made of fibers; and the fiber web framework is buried inside the paper fiber layer. Based on the characteristics of the adopted fiber web, after the fiber web is used as the fiber web framework, the fiber web reinforced vulcanized paper has higher flexibility and strength, and is hardly decomposed. A flexible grinding apparatus made of the vulcanized paper manufactured by the technical scheme has higher strength and toughness. Reinforced sand paper comprises the vulcanized paper and an abrasive layer attached to the vulcanized paper; the vulcanized paper is the fiber web reinforced vulcanized paper. By the fiber web reinforced vulcanized paper, the performance of the reinforced sand paper can be enhanced effectively; and the reinforced sand paper has the characteristics of degradability, low cost and high flexibility and the like.

Owner:上海奉贤久安工具厂

Laser hardening ossifying technique of railway high speed heavy rail

The invention relates to a railway high-speed heavy rail laser quenching hardening process, which comprises that: first, gasoline or alcohol decontamination solvents are used to remove the oil and rust on a steel rail surface, and the sand paper polishing on steel surface is carried out in order to evenly spray an absorbing light coating; second, an absorbing light coating SiO2 mixed with a bonding agent is uniformly coated on the steel surface with a spray gun or a brush , in order to increase the absorption rate of metal surface to CO2 Laser. The proportion between the coating and adhesivs is of 80g to 100g of SiO2 and 500ml to 600ml of alcohol and 15 ml of paint flakes. The pre-coated thickness is of 0.02mm to 0.05 mm; third, an integral-round spot is changed to a rectangular spot through a broadband integral mirror technology, and the bandwidth sizes for length and width are of 30 mm is multiplied by 1mm; fourth, a DL-HL-10000 type CO2 laser is used to fast scan the steel rail surface to realize rapid heating and cooling on the surface of the steel rail. By adoption the laser quenching strength method, the invention is capable of replacing the high-alloy material with the common railway steel rail material, thereby reducing the steel rail cost; the invention is capable of repairing the failure rail, thus reducing the material waste, and bringing greater economic benefits.

Owner:鞍山大陆激光技术有限公司

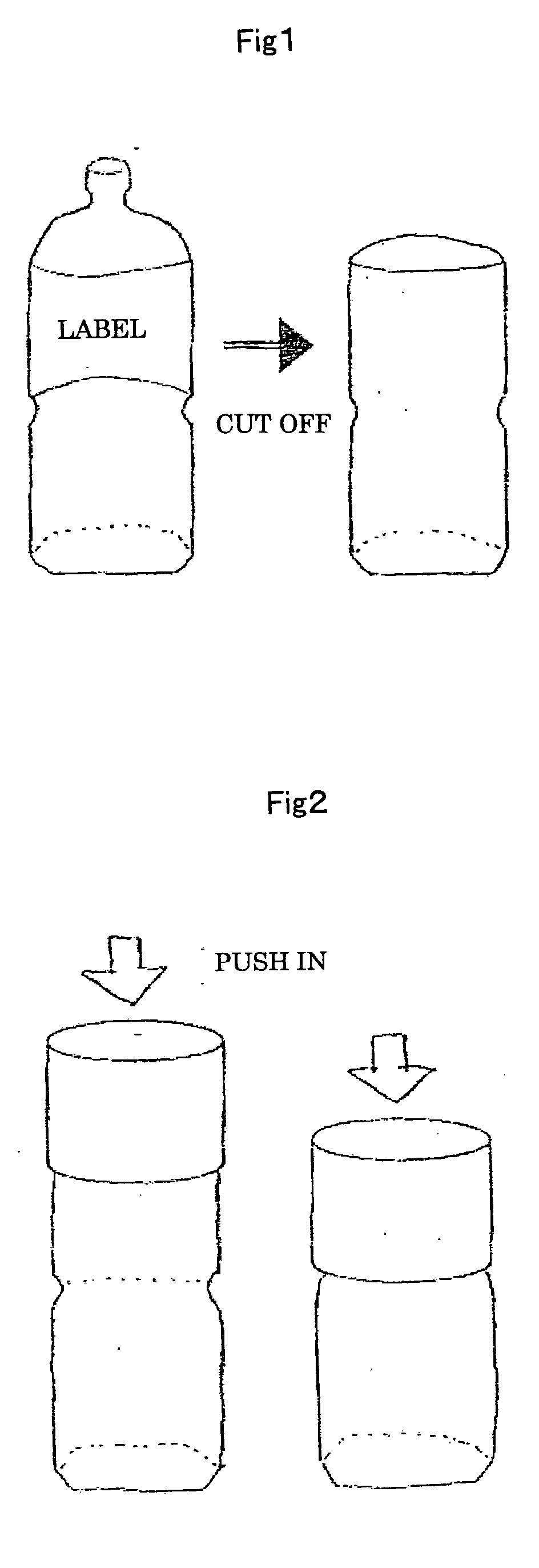

Bobbin body paper made of waste paper pulp and production process thereof

InactiveCN103147343AImprove flex resistanceImprove toughnessSpecial paperPaper recyclingAdhesiveSand-paper

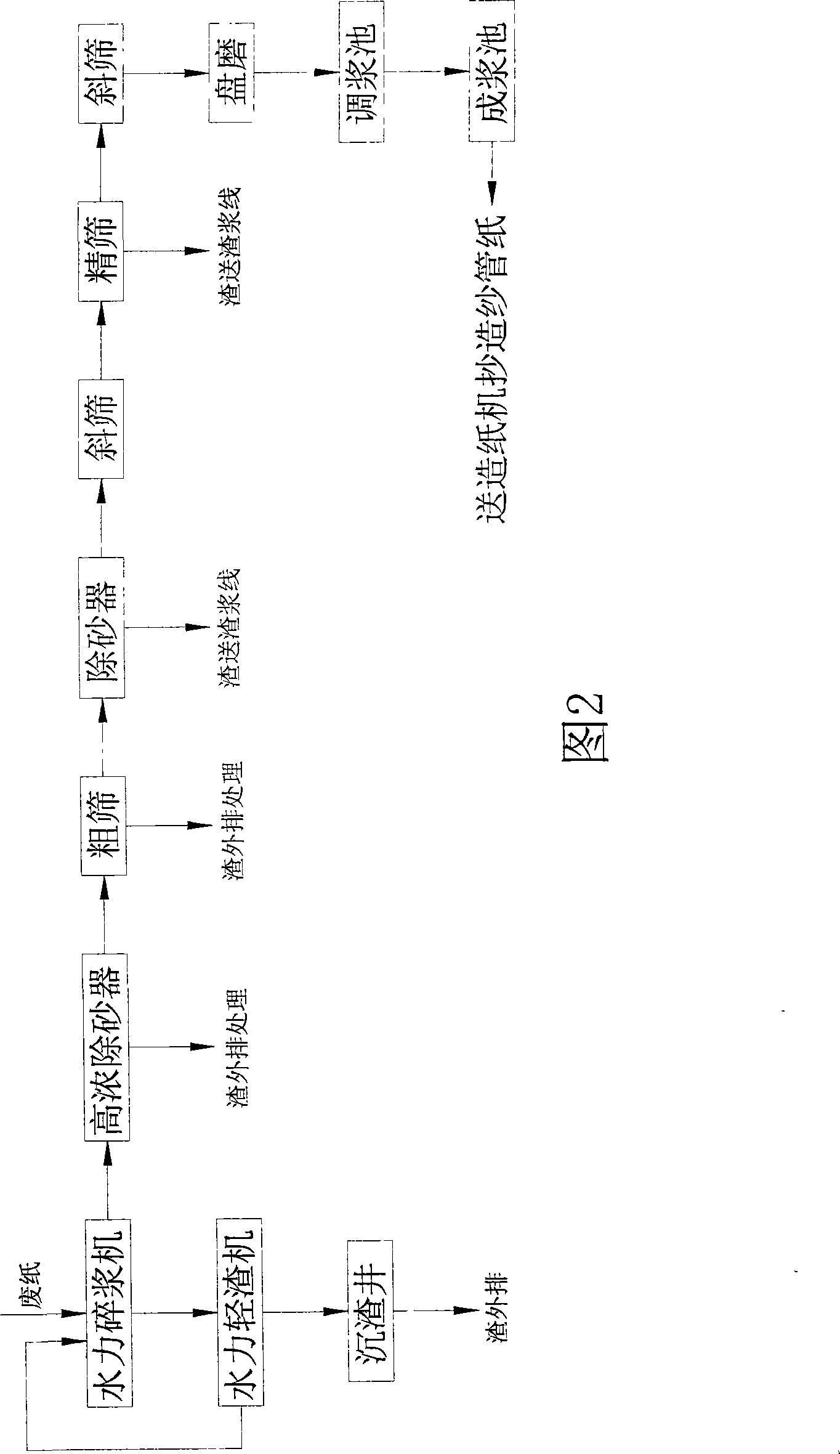

The invention relates to a manufacturing process of bobbin body paper, and in particular relates to bobbin body paper made of waste paper pulp and a production process thereof. The production process comprises the following steps of: 1, pulping of waste paper pulp; 2, preparing wear-resisting ingredients which comprises the components in parts by weight as follows: 100 parts of organic macromolecular material, 0.1-0.5 parts of stabilizer, 0-1 parts of lubricant, 0.5-1.5 parts of antioxidant, 1-1.5 parts of adhesive and 1-1.5 parts of mountain flour; 3, doping 1-2.5% of wear-resisting ingredients to the pulp of the waste paper pulp obtained by the step 1 and uniformly mixing through a high speed stirrer to obtain wear-resisting pulp; and 4, mixing the wear-resisting pulp with waste paper pulp treated according to proportion, and manufacturing a sand paper pipe to obtain regenerated bobbin body paper, wherein the proportion of the wear-resisting pulp and the waste paper pulp is (40-60):(60-40). The invention is applied to preparing bobbin body paper by using waste paper pulp, and the wear-resistance is improved.

Owner:FUJIAN YIYUAN WASTE UTILIZATION

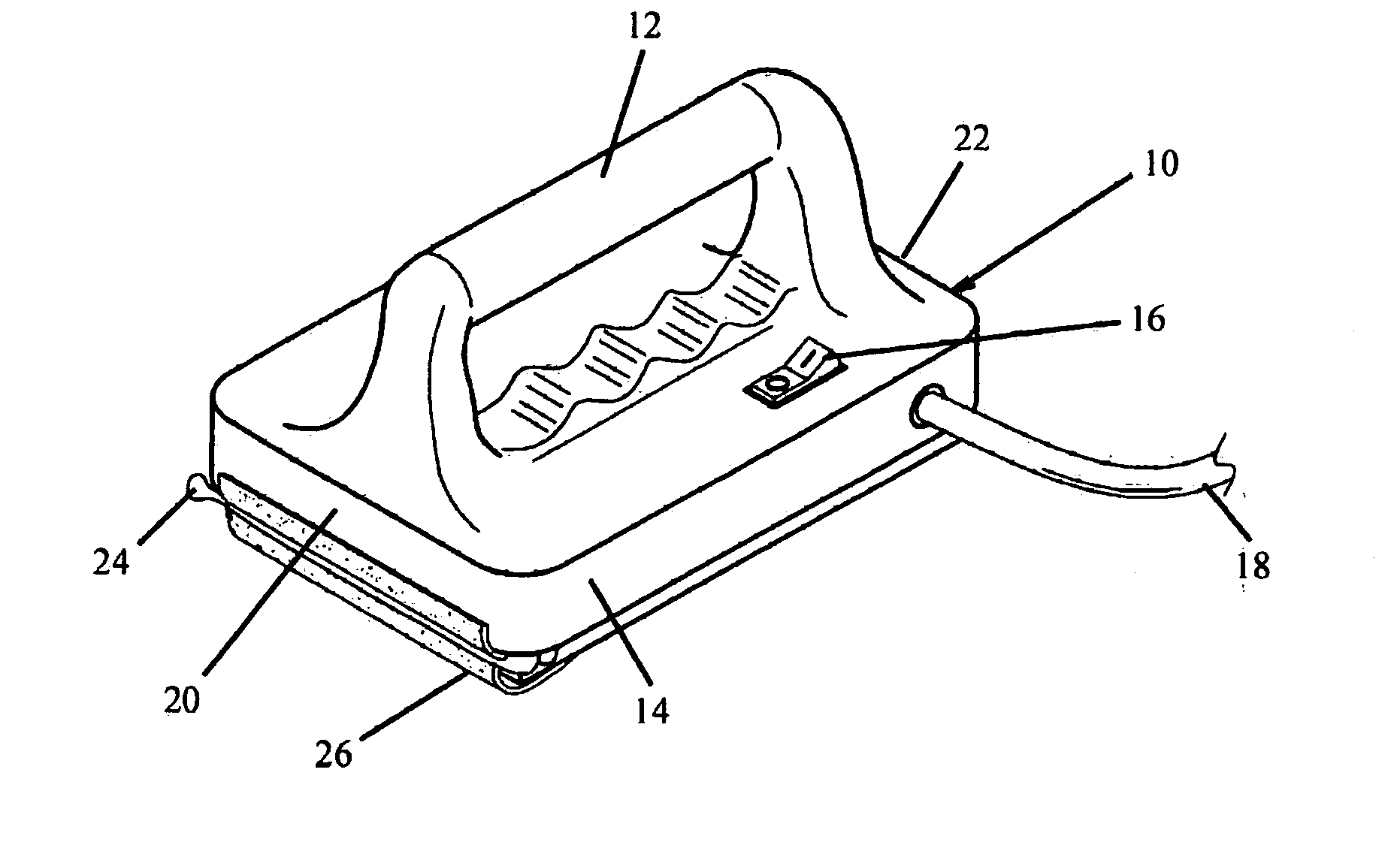

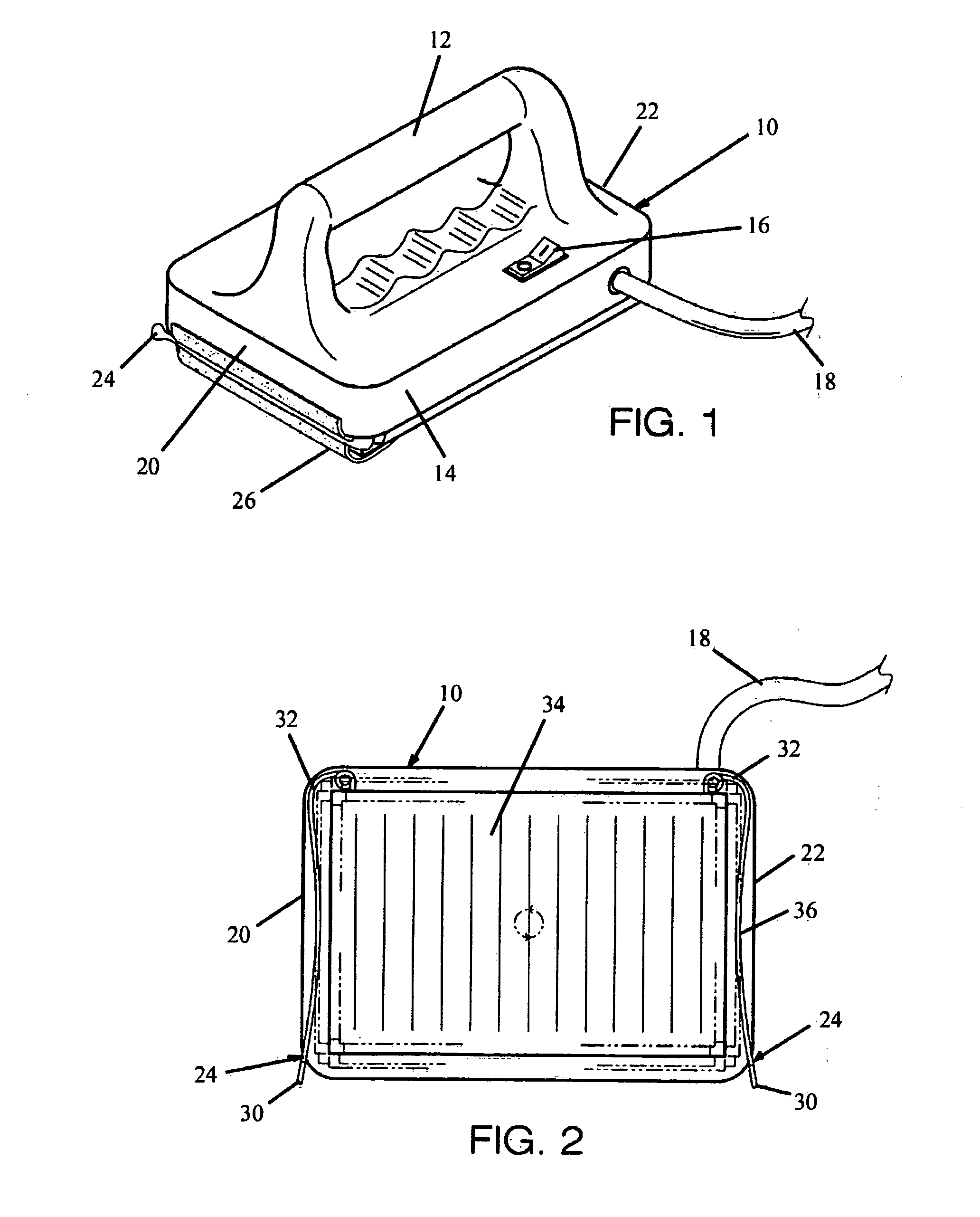

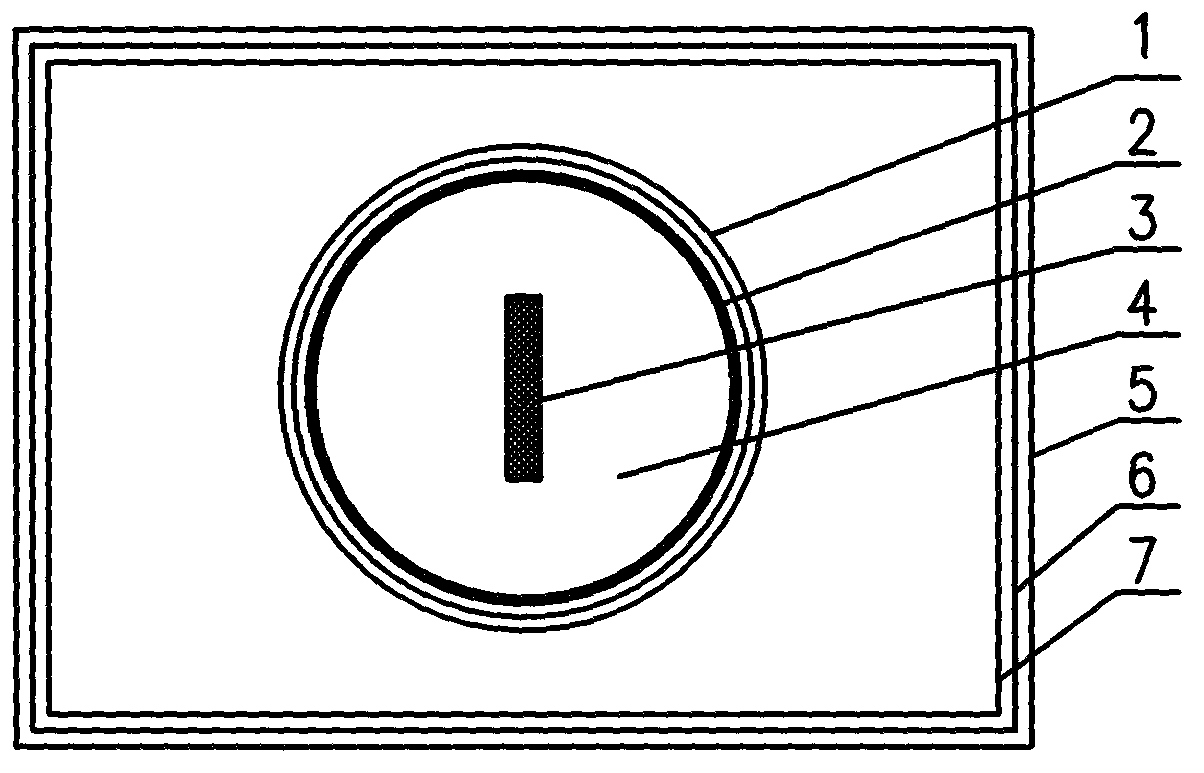

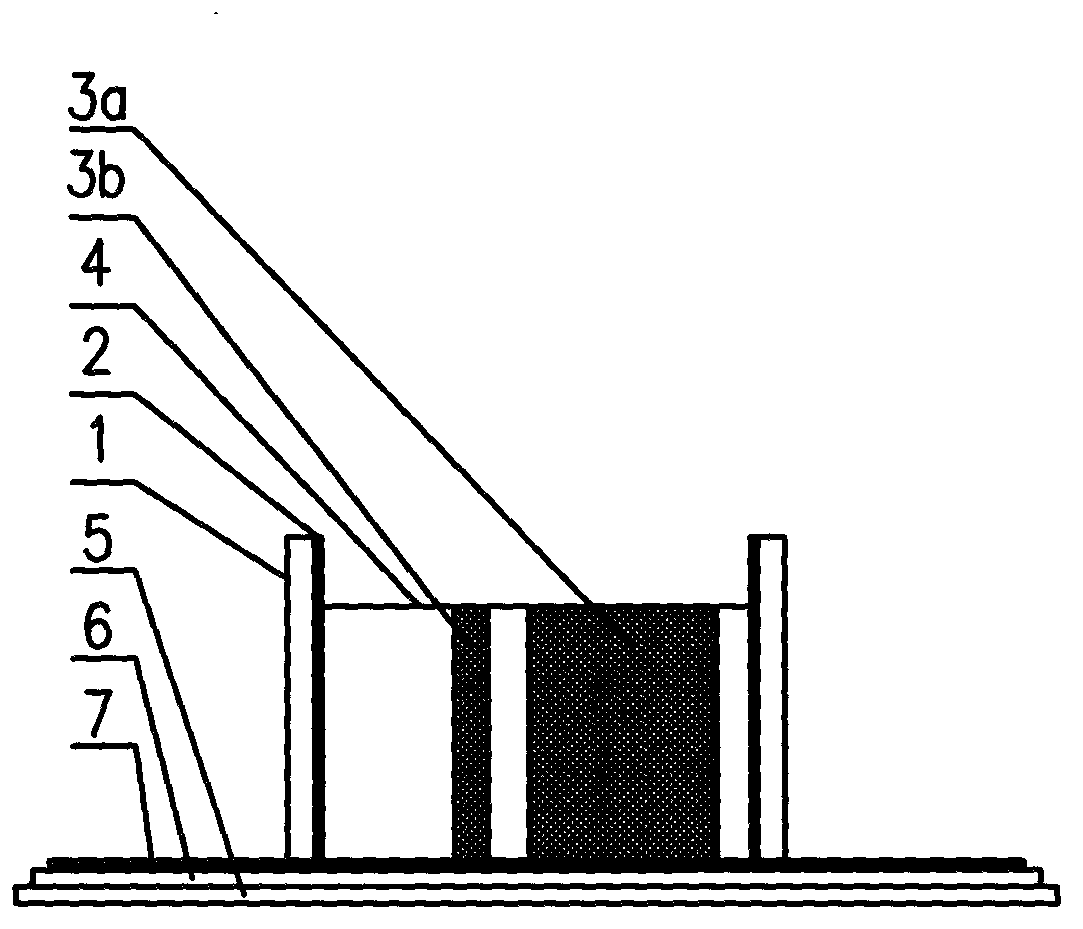

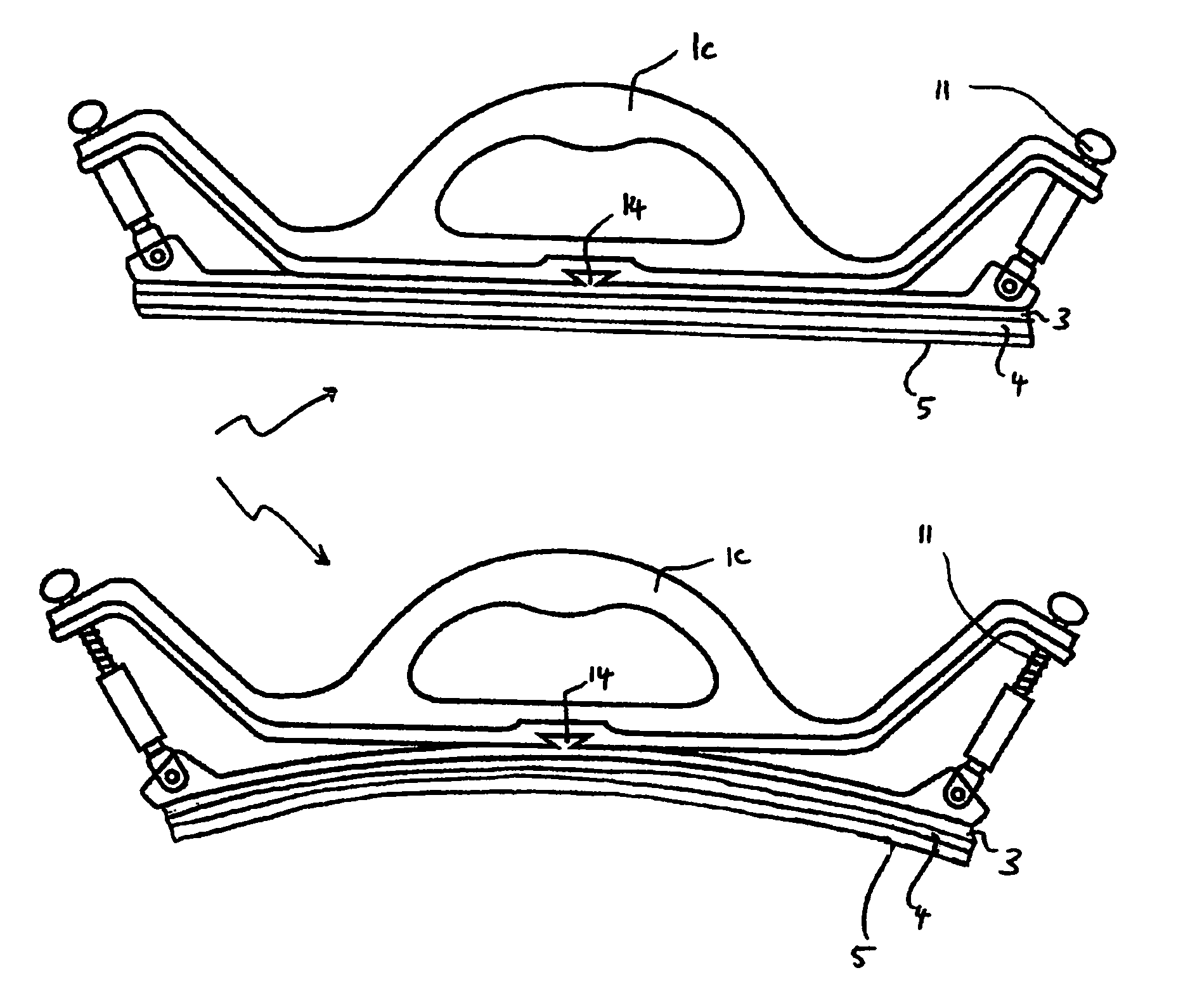

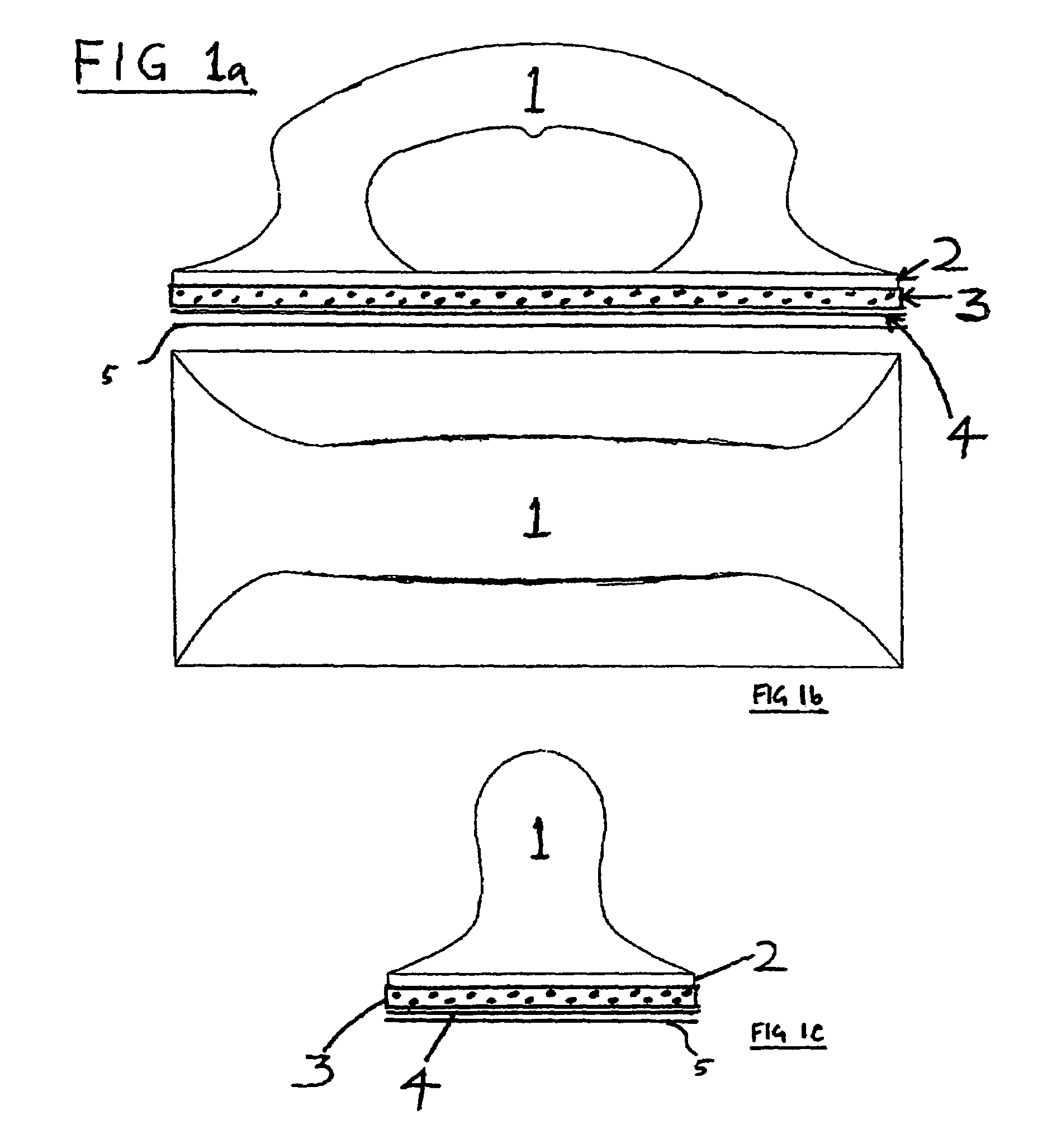

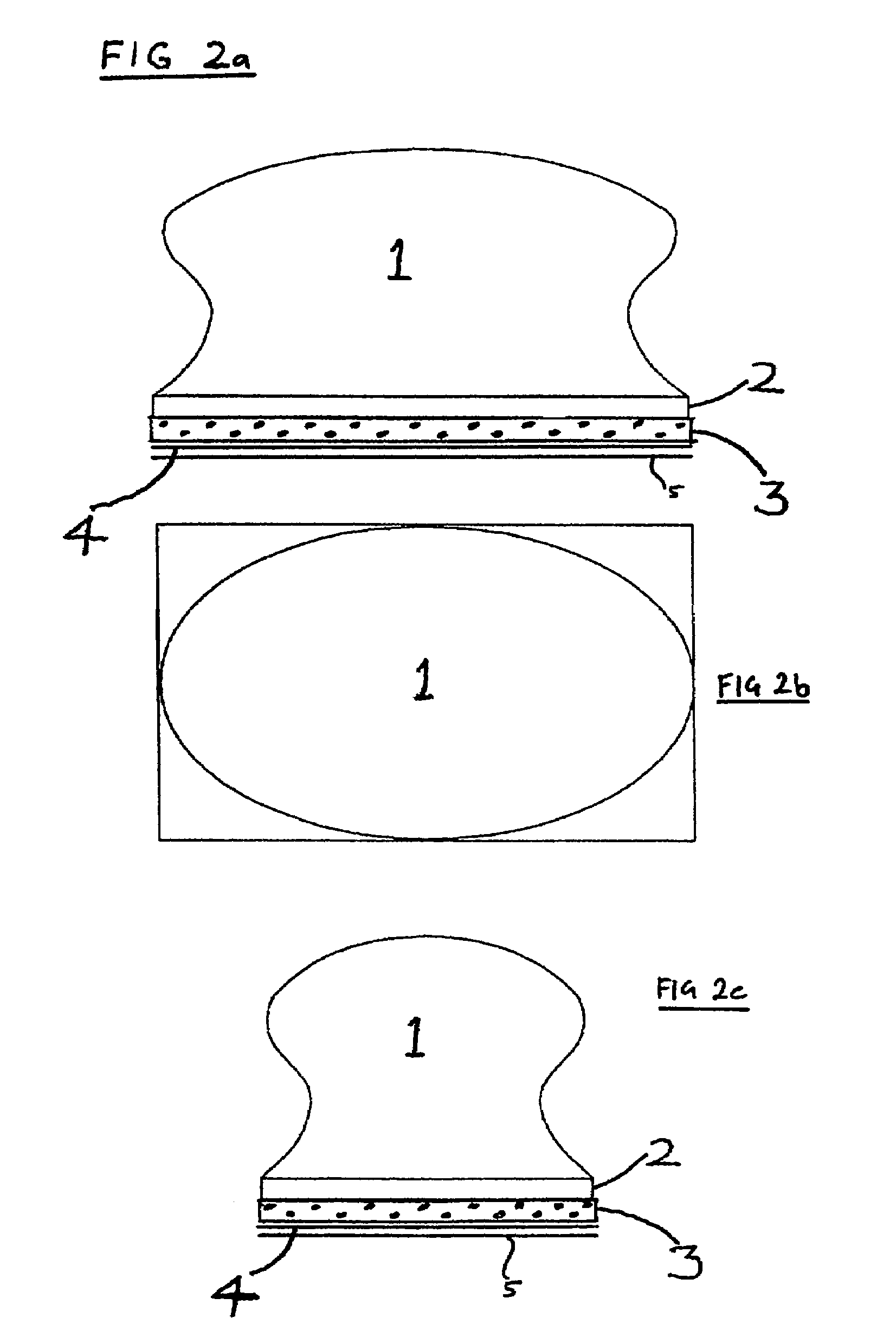

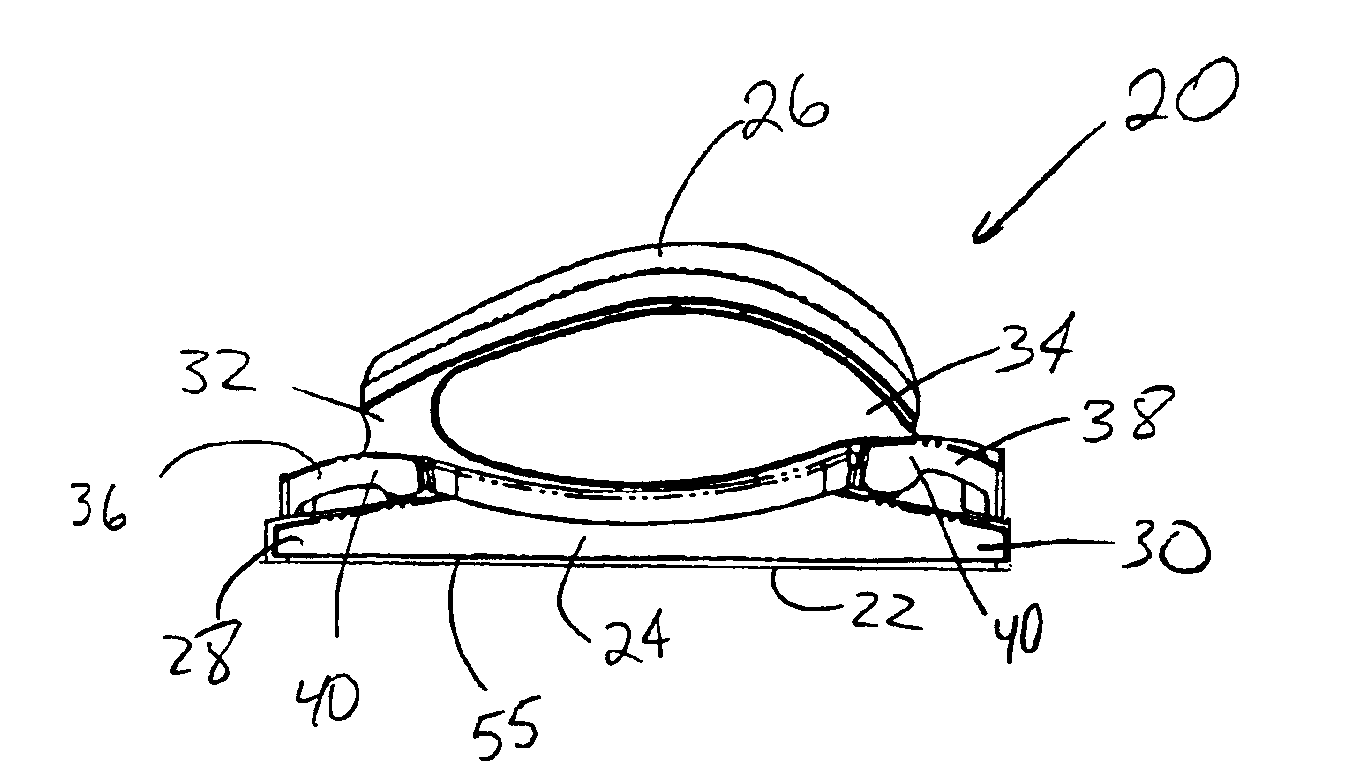

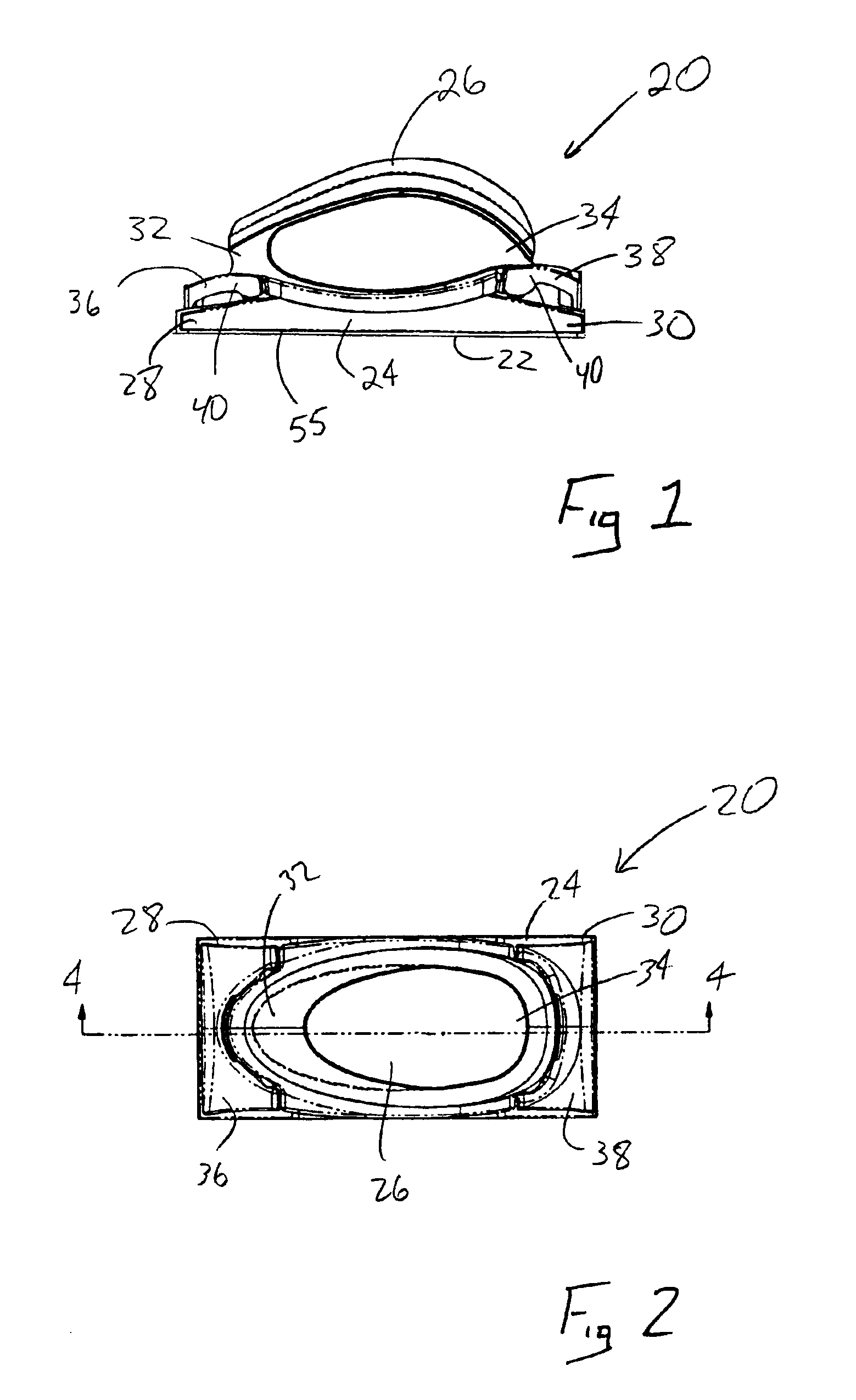

Abrasive holder

An abrasive tool comprising of a base portion (2), having a foam layer (3) affixed to the abrasive tool base portion, and a plastic film layer (4) affixed, bonded or glued to the foam layer. This tool is adapted to receive an abrasive material layer (5) or sand paper or other abrasive material having a pressure sensitive adhesive applied to one side of the abrasive material, to allow said abrasive material to be stuck and affixed to the abrasive tool. The abrasive tool may be hand operated, or operated by electric power, air power, or other motive power.

Owner:RED DEVIL SANDFAST

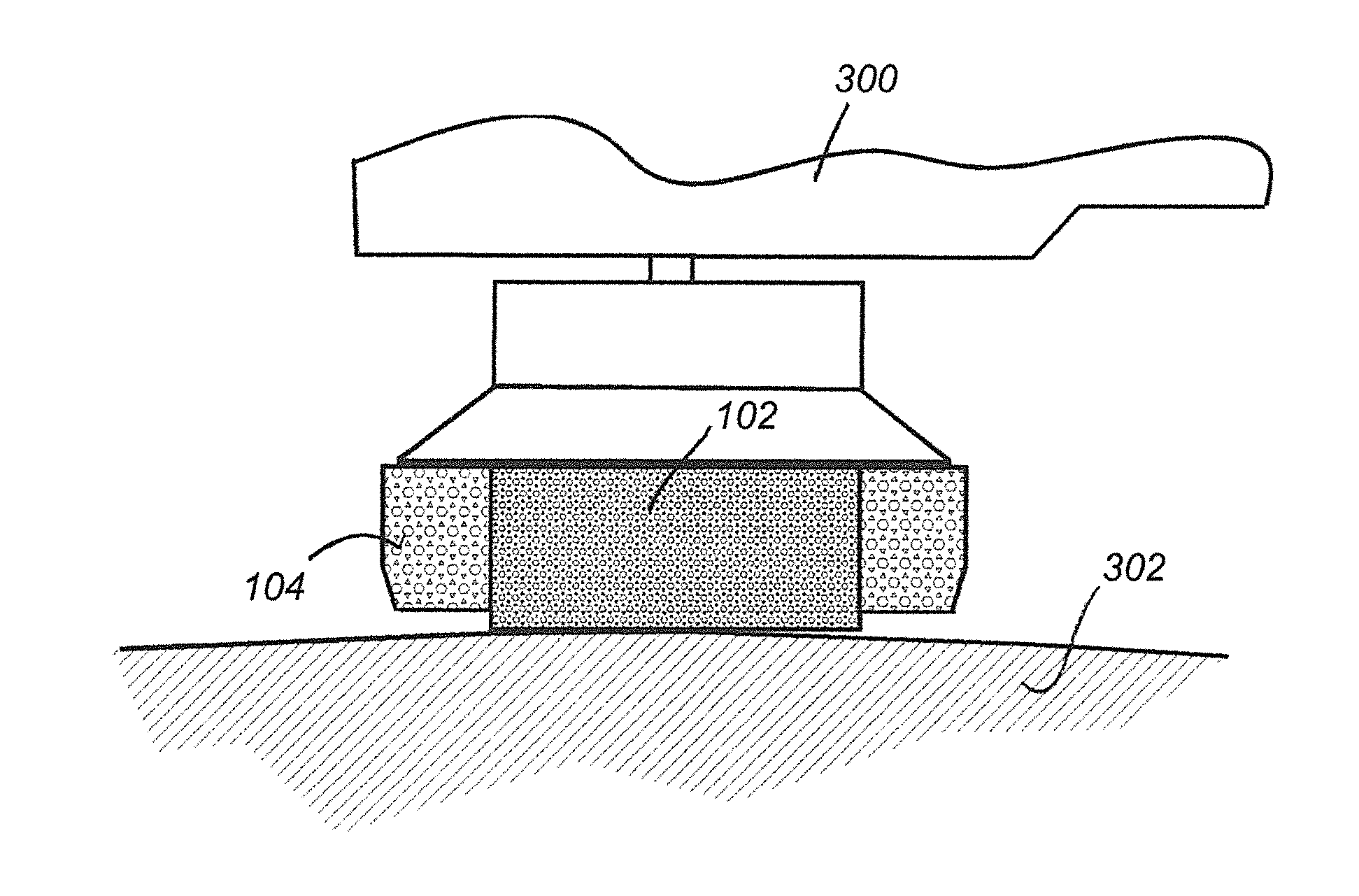

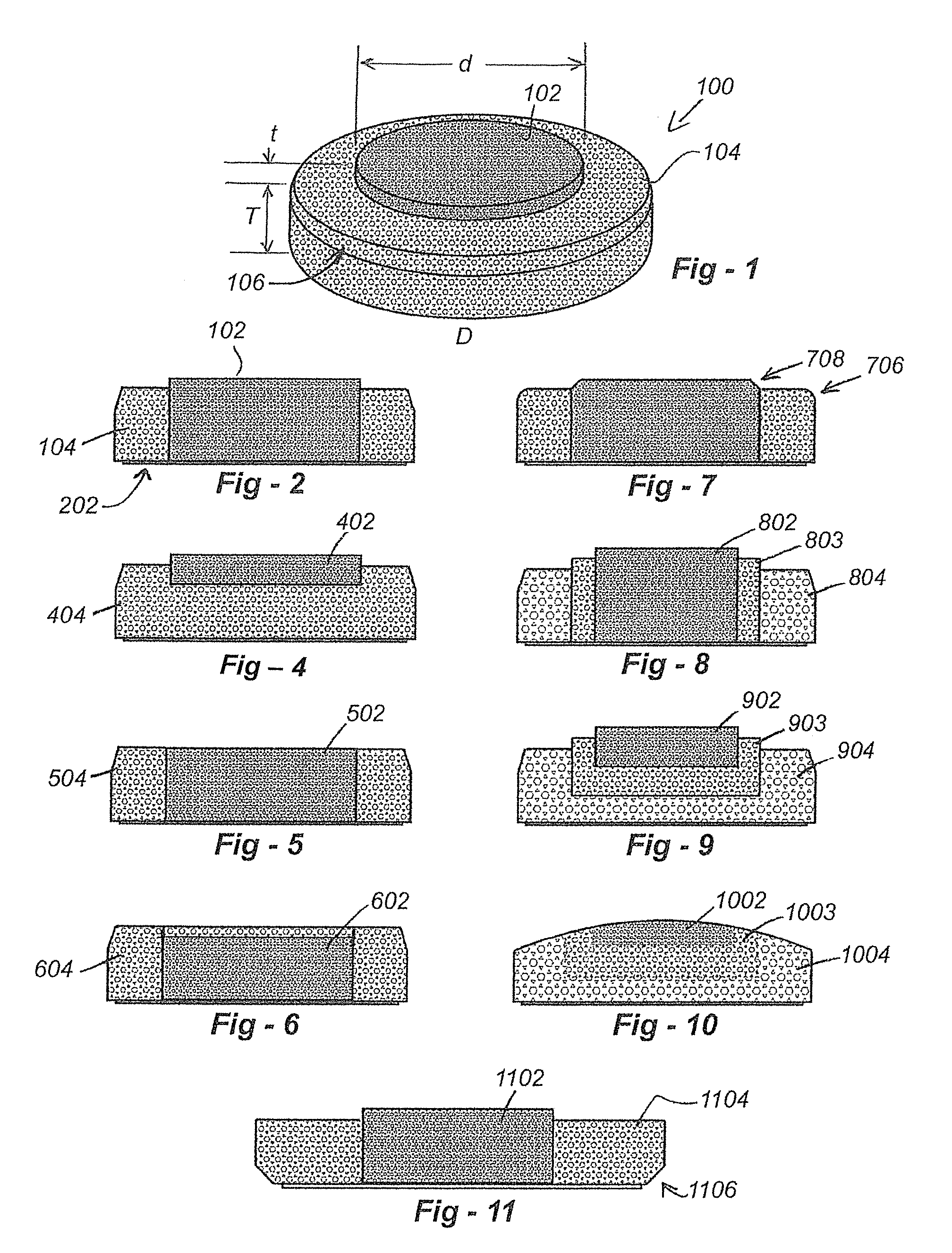

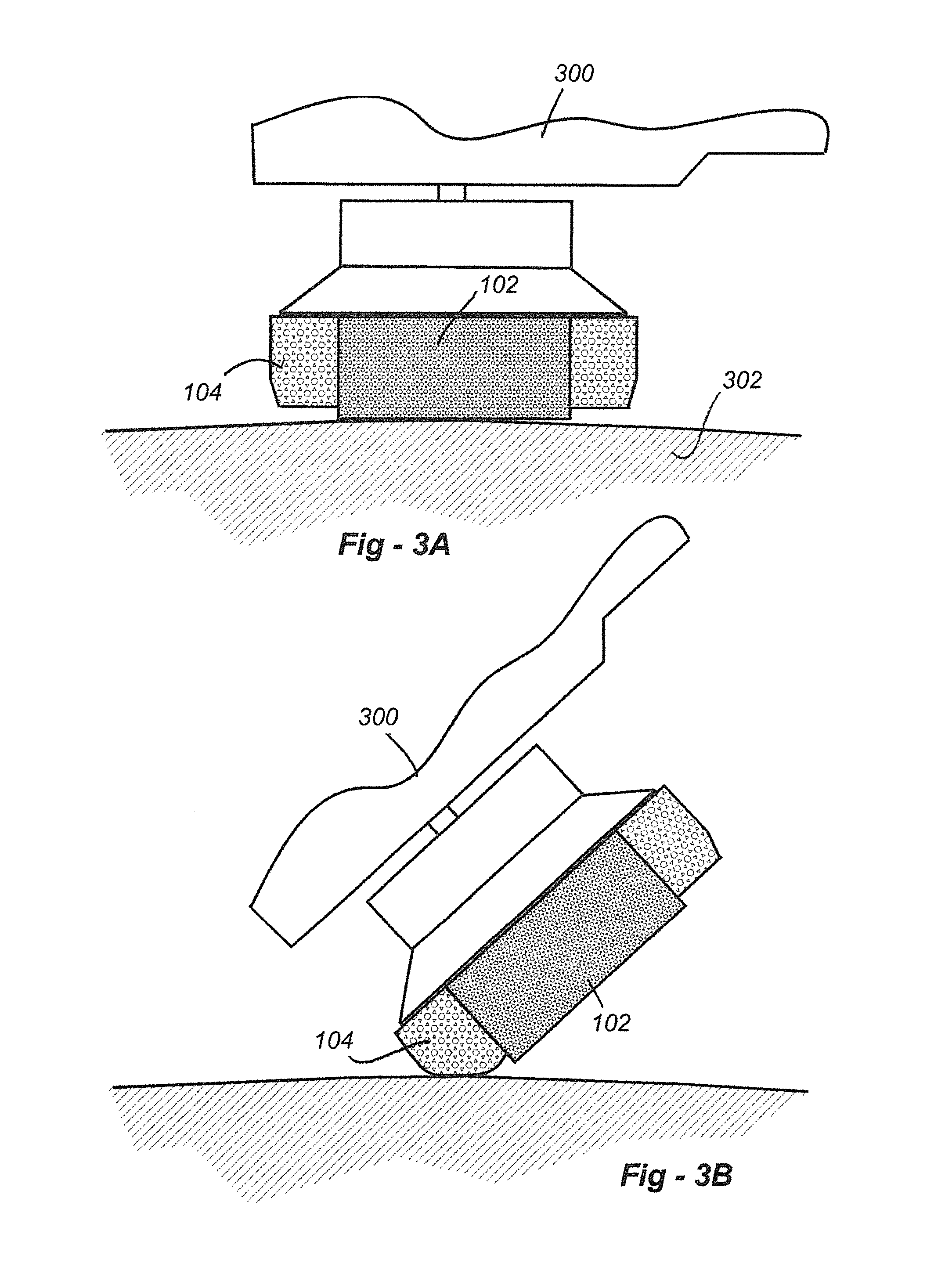

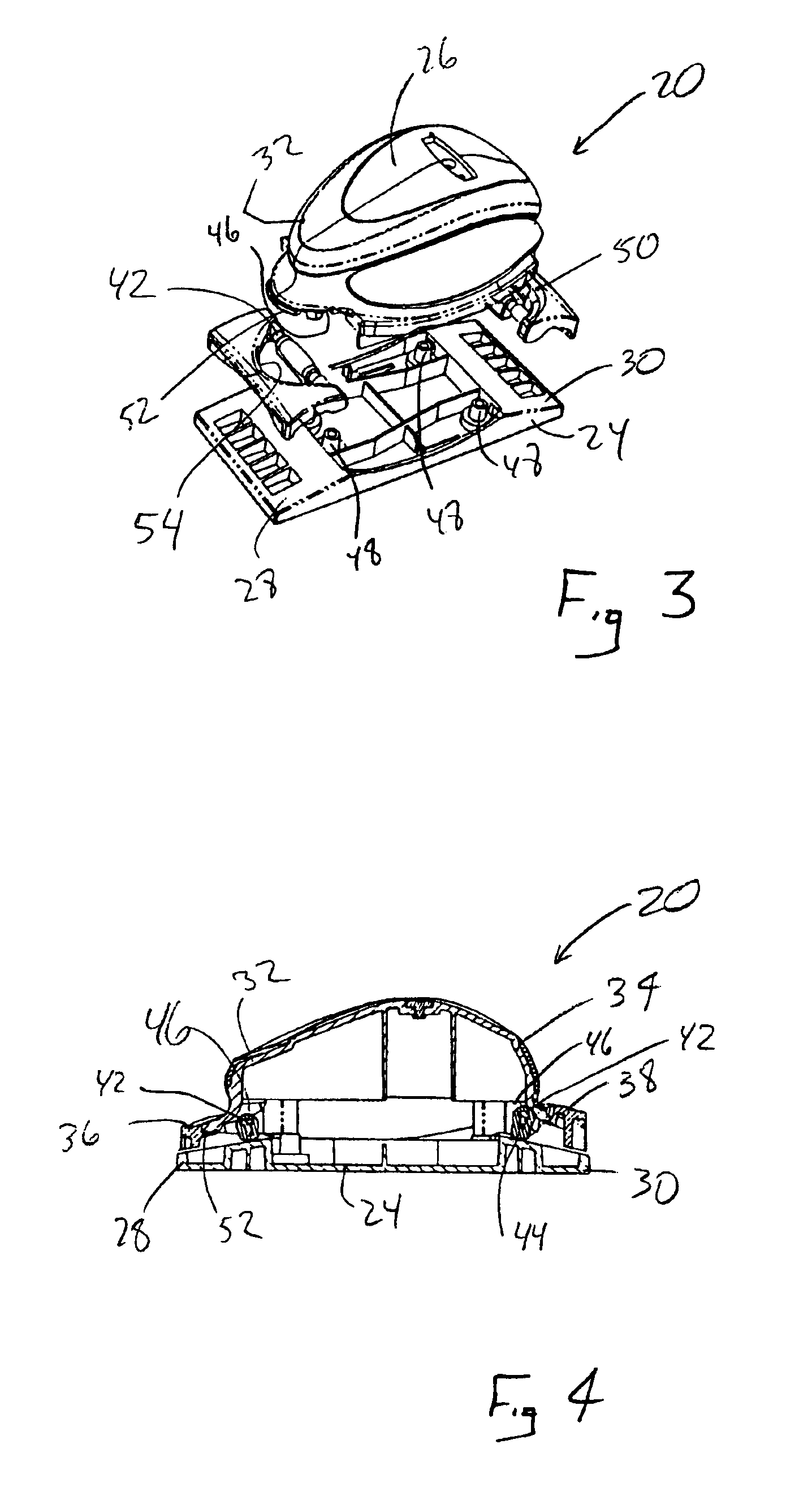

Composite pads for buffing and polishing painted vehicle body surfaces and other applications

A composite pad includes an outer pad portion having a surface with a firmness, stiffness or abrasiveness, and an inner pad portion disposed on or in the outer pad portion, the inner pad portion having a surface with a firmness, stiffness or abrasiveness which is greater than that of the outer pad surface. The backside of the composite pad preferably includes a hook-and-loop or other mechanism for attachment to a tool such as an orbital polisher. The inner portion may used to remove larger scratches left from sand paper (or other abrasives) then, without removing the pad, the polisher tool may be tilted relative to the surface enabling the outer portion to buff the area and remove any swirl marks. The surface of the inner pad may be raised relative to the surface of the outer pad, flush or recessed. In the preferred embodiments the various pad portions are made of foam material such as polyurethane.

Owner:R B L PROD LLC

Heat shrinking polyester film

InactiveUS20060063008A1Good printabilityHigh transparencySynthetic resin layered productsFlat articlesPolyesterEngineering

A heat-shrinkable polyester type film has a dynamic friction coefficient of at least one face with one face of another film of μd≦0.27 and range R≦0.05 and a weight loss of less than 0.24 g / m2 after 10 reciprocation times with 400 g load using a color fastness rubbing tester comprising a friction element bearing a sand paper with #1000 particle diameter.

Owner:TOYOBO CO LTD

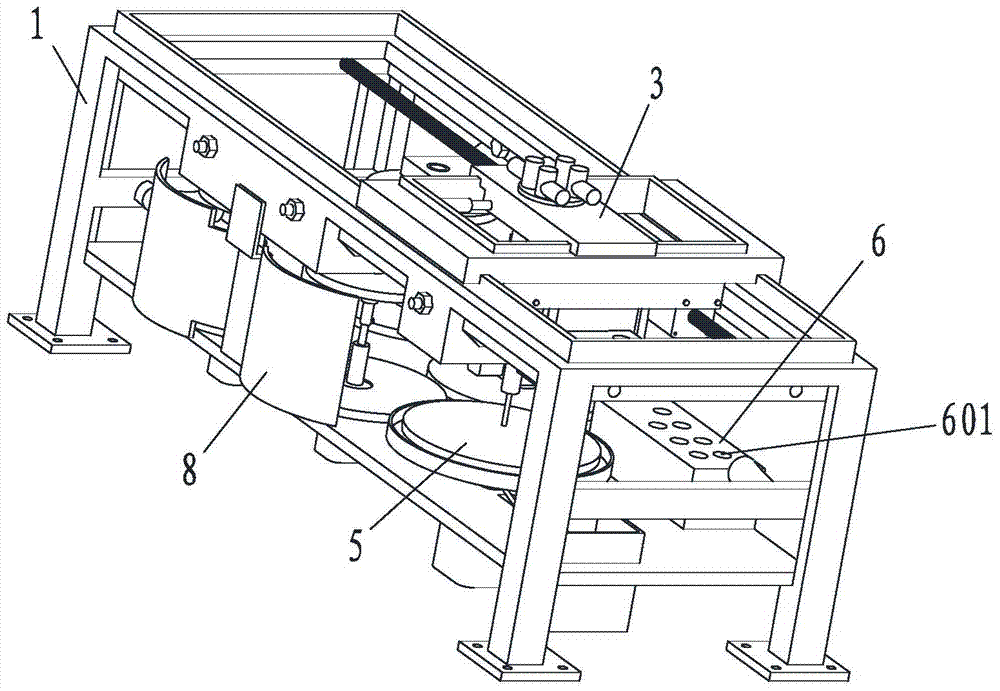

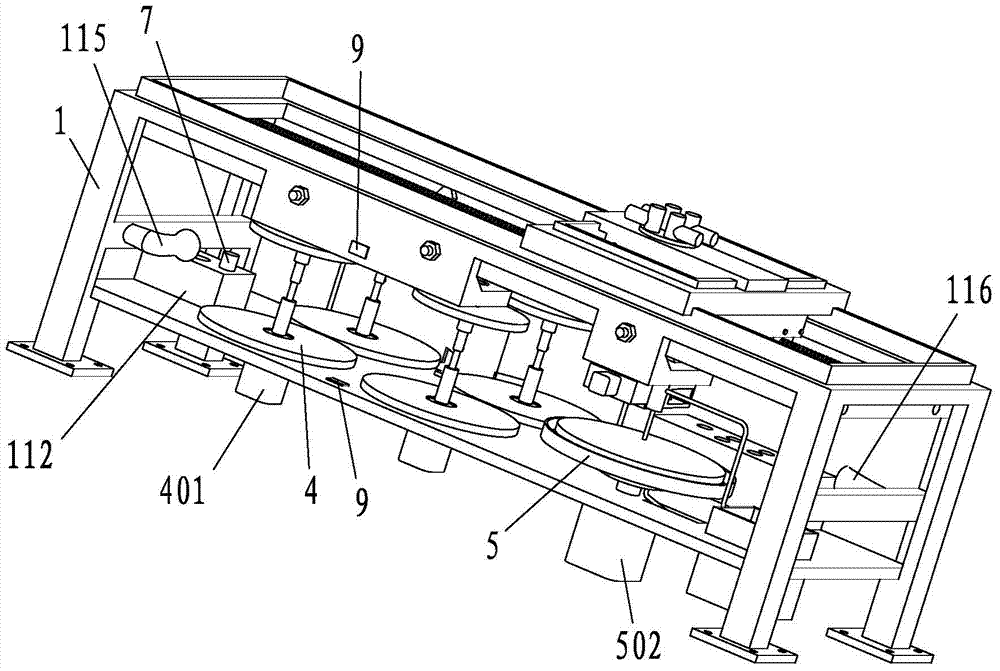

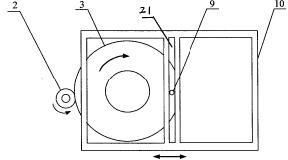

Automatic metallographic specimen polishing device

ActiveCN102607922AConvenient continuous batch preparationImprove work efficiencyPreparing sample for investigationMicrocontrollerElectric machinery

The invention discloses an automatic metallographic specimen polishing device which solves the problems of large labor intensity and low working efficiency of the traditional device. The automatic metallographic specimen polishing device comprises a sand paper clamp box (11), a sand paper grinding wheel (6) and a sand paper tray (7) which are arranged on the surface of a chassis (1), wherein a sliding chute (21) and a pin roll (9) are arranged on a rectangular sand paper disk (10), the pin roll (9) is fixedly arranged on a big gear (3) which is connected with an output shaft of a drive motor (8) through a small gear (2), the drive motor (8) is arranged in the chassis (1), an electric magnet (13) is arranged on a bottom plate of the sand paper clamp box (11), a spring (12) is arranged between the bottom plate of the sand paper clamp box (11) and the rectangular sand paper disk (10), and a steering motor (4), the drive motor (8) and the electric magnet (13) are electrically connected with a singlechip (19) arranged in the chassis (1). The automatic metallographic specimen polishing device can be used for conveniently and continuously preparing metallographic specimens in batch, and has high efficiency and operation safety.

Owner:ELECTRIC POWER RES INST STATE GRID SHANXI ELECTRIC POWER +1

High-strength paper backing sand paper and manufacturing method thereof

InactiveCN101318314AUniform density distributionGuaranteed thicknessAbrasion apparatusGrinding devicesAdhesiveUltra fine

The invention discloses high-strength paper-based sand paper, which consists of base paper, an impregnating agent, a coating reagent and an under adhesive. The manufacturing method of the sand paper includes the following steps of unwinding, impregnating, coating, calendaring setting, winding, identification marking, under adhesive coating, high pressure electrostatic sand planting, pre-drying, glue coating, main drying, rolling, solidifying, unrolling and warehousing. The high-strength paper-based sand paper and the manufacturing method thereof have the advantages that the base paper which adopts the high-density material of 250g / m2 is high in tensile strength and the produced finished abrasive belt products can replace the similar abrasive cloth products; the sand paper is high in smoothness and can be used for manufacturing sand paper with ultra-fine particle sizes and the thinnest size can reach 1200 model; a new radiating wave type electrostatic sand planting technology is adopted with the voltage of 36 kv and frequency of 60Hz, and the gaps between compression rollers are kept between 1 and 6cm (micro adjustment can be made according to the particle sizes of the abrasive fillers that go through the compression rollers) so as to ensure the uniform distribution of the sand planting density; the cryolite is adopted as a filling agent in the under adhesive coating in order to ensure the thickness of the under adhesive and the bond force and to prevent adhesive penetration; the upper sands are evenly distributed, and the sand particles and work pieces are kept on the same plane and are attached closely in the grinding, and the consumption of the sand particles is synchronous and the ground wood work pieces have smooth surfaces; the antistatic function is provided.

Owner:张刚

Abrading mechanisms

Hand held abrading tools are disclosed. The abrading tools include clamping mechanisms to quickly and reliably secure sanding paper, bristled sheets, polishing cloths, and the like, to the tool, while at the same time providing the operator with increased agility and ability to reach relatively hard to reach or oddly shaped surfaces.

Owner:NEWELL OPERATING COMPANY

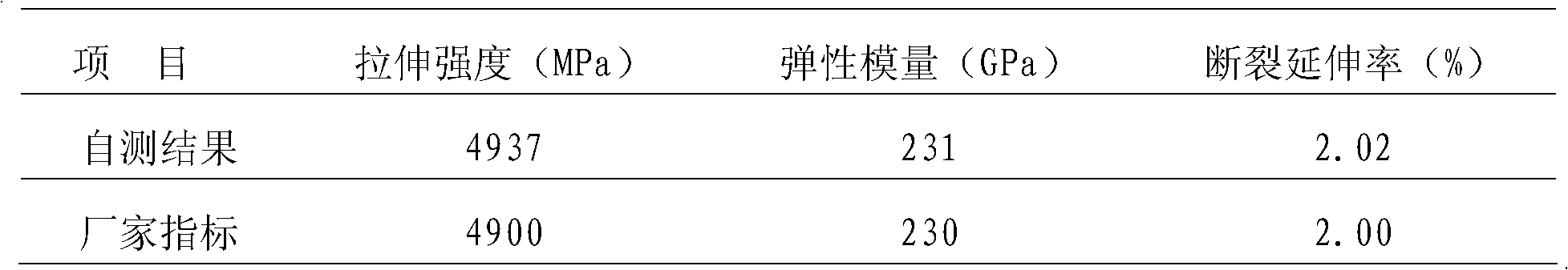

Method for preparing 12k multifilament sample and testing stretching performance of sample

ActiveCN102507283AOvercome the instability of manual sample preparationGuaranteed performancePreparing sample for investigationMaterial strength using tensile/compressive forcesFiberSand-paper

The invention relates to a method for preparing a 12k multifilament sample and testing the stretching performance of the sample. The carbon fiber multifilament sample is obtained by preparing a gum from TDE-85, powdery DDM and acetone, impregnating and curing. When the carbon fiber multifilament sample is tested, the carbon fiber multifilament sample to be tested is wrapped by 80 or 100 mesh carborundum cloth and W28A metallographical sand paper. The method which adopts mechanical impregnation sample preparation allows a defect of the unstableness of manual sample preparation to be effectively overcome, no reinforcements to be needed by the cured sample, and the good exertion of performances of the whole multifilament to be guaranteed and makes test results be rapidly and stably obtained,and the sample can satisfy production requirements and technological indexes provided by manufacturers.

Owner:XIAN KANGBEN MATERIAL

Full-resin water-resistant sand paper

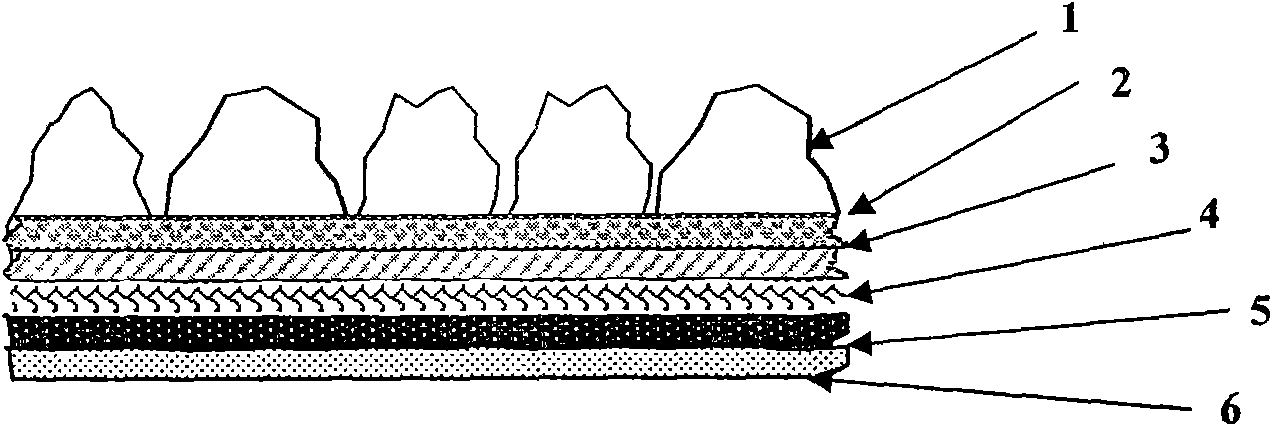

ActiveCN101623853ANo pollution in the processTransportation safetyAbrasion apparatusAcrylic resinWater resistant

The invention relates to full-resin water-resistant paper, which is composed of six layers including an abrasive material layer, an adhesive layer, a basic adhesive layer, a sand surface processing layer, a sand paper base paper layer and a waterproof processing layer from top to bottom, wherein the adhesive layer is the mixture of a urea-formaldehyde resin, iron red and ammonium chloride; the basic adhesive layer is the mixture of a water-soluble acrylic resin, an amine resin, flour and iron red; the sand surface processing layer is the mixture of nanometer-sized styrene-butadiene latex, modified starch solution, water and a penetrating agent JFS; the waterproof processing layer is the mixture of the nanometer-sized styrene-butadiene latex and the penetrating agent JFS. The invention abandons a solvent alkyd resin and uses the water-soluble resin adhesive with environmental performance, such as the urea-formaldehyde resin, the water-soluble acrylic resin, the amine resin, the nanometer-sized styrene-butadiene latex and the like. As the invention completely uses the water-soluble resins, the environmental pollution is nearly zero. The full-resin water-resistant paper has no environmental pollution and has safe transport and use.

Owner:HUBEI YULI ABRASIVE BELTS GRP +2

Filter element for filtration and manufacturing method thereof

InactiveCN101766989AWide variety of sourcesDoes not change physical and chemical propertiesOther chemical processesWater/sewage treatment by sorptionAdhesiveFiltration

The invention relates to a filter element, in particular to a filter element for filtration and a manufacturing method thereof. In the preparation process of the filter element, various raw materials are weighed according to percentage by weight in a formula, adding materials according to specified steps and then mixing and stirring evenly, extruding or punching for shaping in a preset mould, drying the water in the model at a certain temperature for sizing, namely forming the porous filter element with specified shape. The filter element of the invention utilizes various non-toxic and harmless raw materials with absorption characteristics, is formed by bonding water-borne adhesive, has the characteristics that the usage of a filter material in unit volume is large, the adsorption efficiency is high, the finished filter element after adsorption and saturation can regenerate under the condition of high temperature while the original physicochemical property of the filter element is not changed, the surface of the filter element after being jammed by absorbing and stopping sundries can be polished by sand paper and reused, and the like; in addition, the cost for manufacturing the water-borne adhesive is low and the raw materials are safe and environmental friendly.

Owner:张顺

Braze welding method for hard alloy and low-alloy and high-strength steel

ActiveCN103071878AImprove mechanical propertiesUniform tissueWelding/cutting media/materialsSoldering mediaAlloyFiller metal

The invention discloses a braze welding process for a hard alloy and low-alloy and high-strength steel, which belongs to a braze welding method for high-strength base steel. The method comprises the following steps of: preparing the low-alloy and high-strength steel, the hard alloy and a manganese brass flaky brazing filler metal qualified in raw material inspection; removing oxide layers on the surfaces of the low-alloy and high-strength steel, the hard alloy and the manganese brass flaky brazing filler metal with sand paper; coating a soldering flux QJ-302 on the two faces of the brazing filler metal; placing the brazing filler metal between the low-alloy and high-strength steel and the hard alloy; fixing by using a clamp; placing into a KSL-1100X box type furnace; setting the heating speed at 10 DEG C per minute; heating till the solidus temperature of the brazing filler metal is 909 DEG C, and preserving heat for 30 minutes; setting a heating speed at 9 DEG C per minute; heating to 960 DEG C, and preserving heat for 10 minutes; cooling to 300 DEG C, and preserving heat for 30 minutes; and performing furnace cooling to the room temperature to obtain a weldment. The hard alloy is welded on the surface of the low-alloy and high-strength steel, so that the surface hardness and wear resistance of the low-alloy and high-strength steel can be enhanced, the mechanical property and mechanical performance are improved, and the application fields of the low-alloy and high-strength steel and the hard alloy are expanded.

Owner:CHINA UNIV OF MINING & TECH

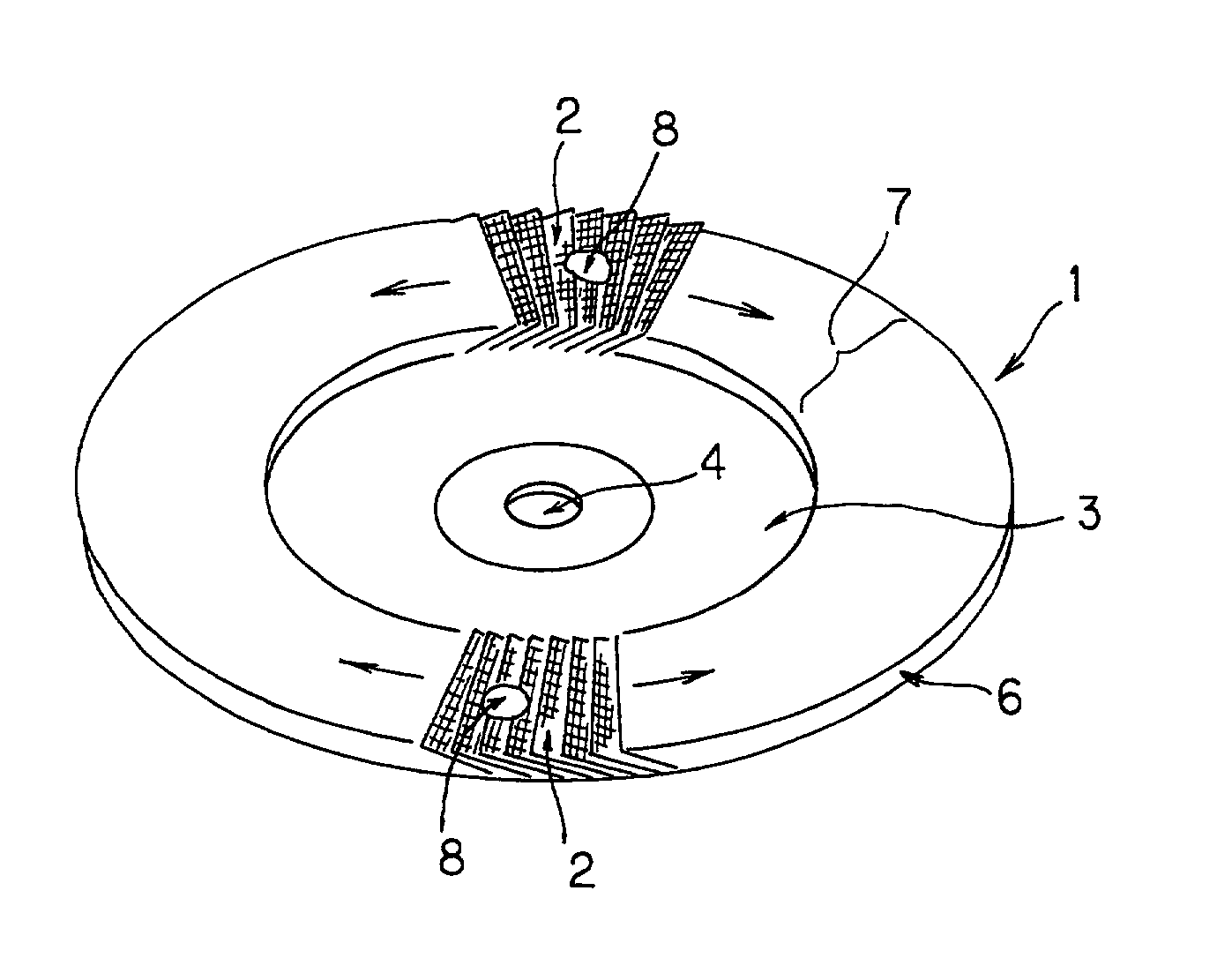

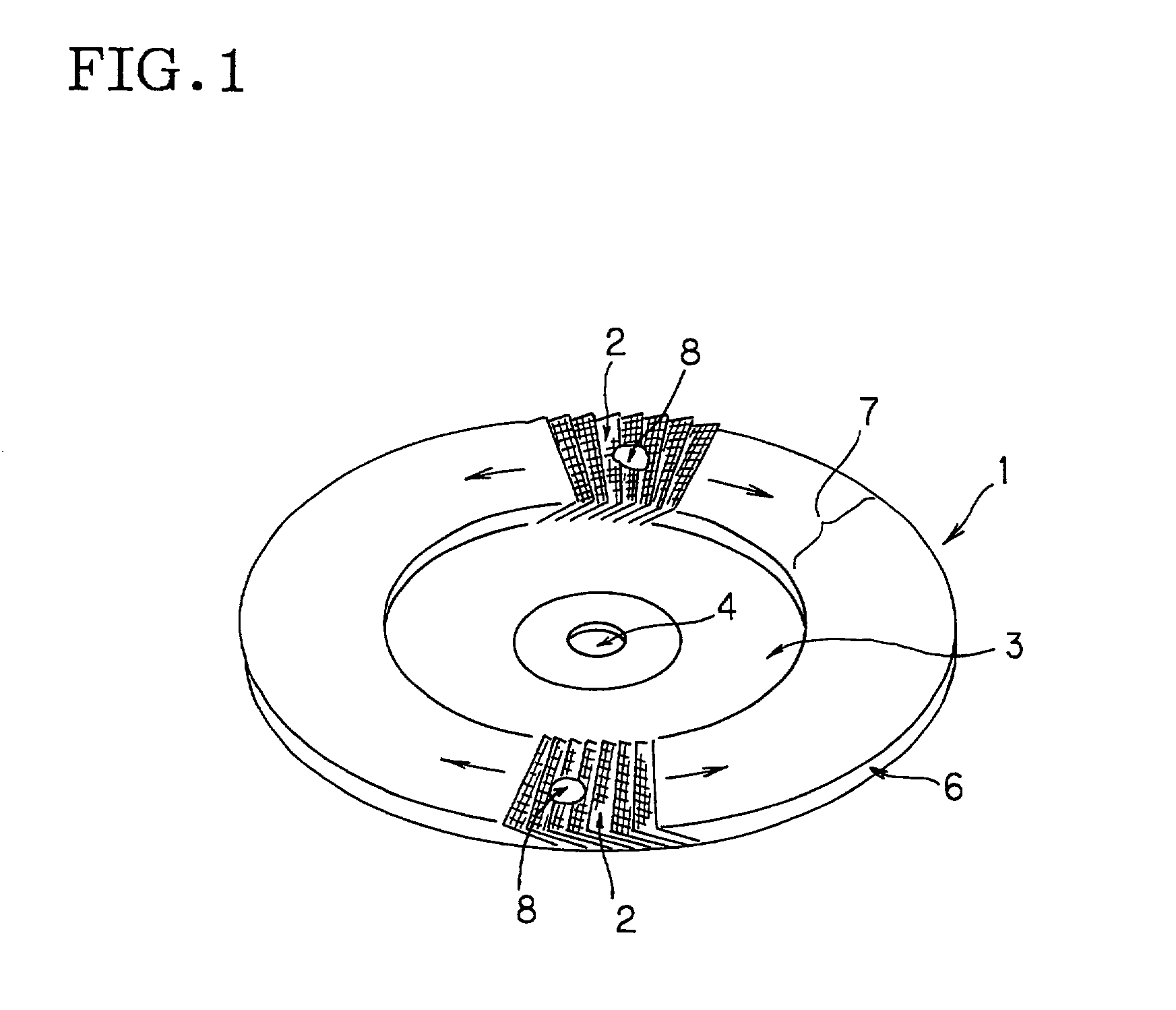

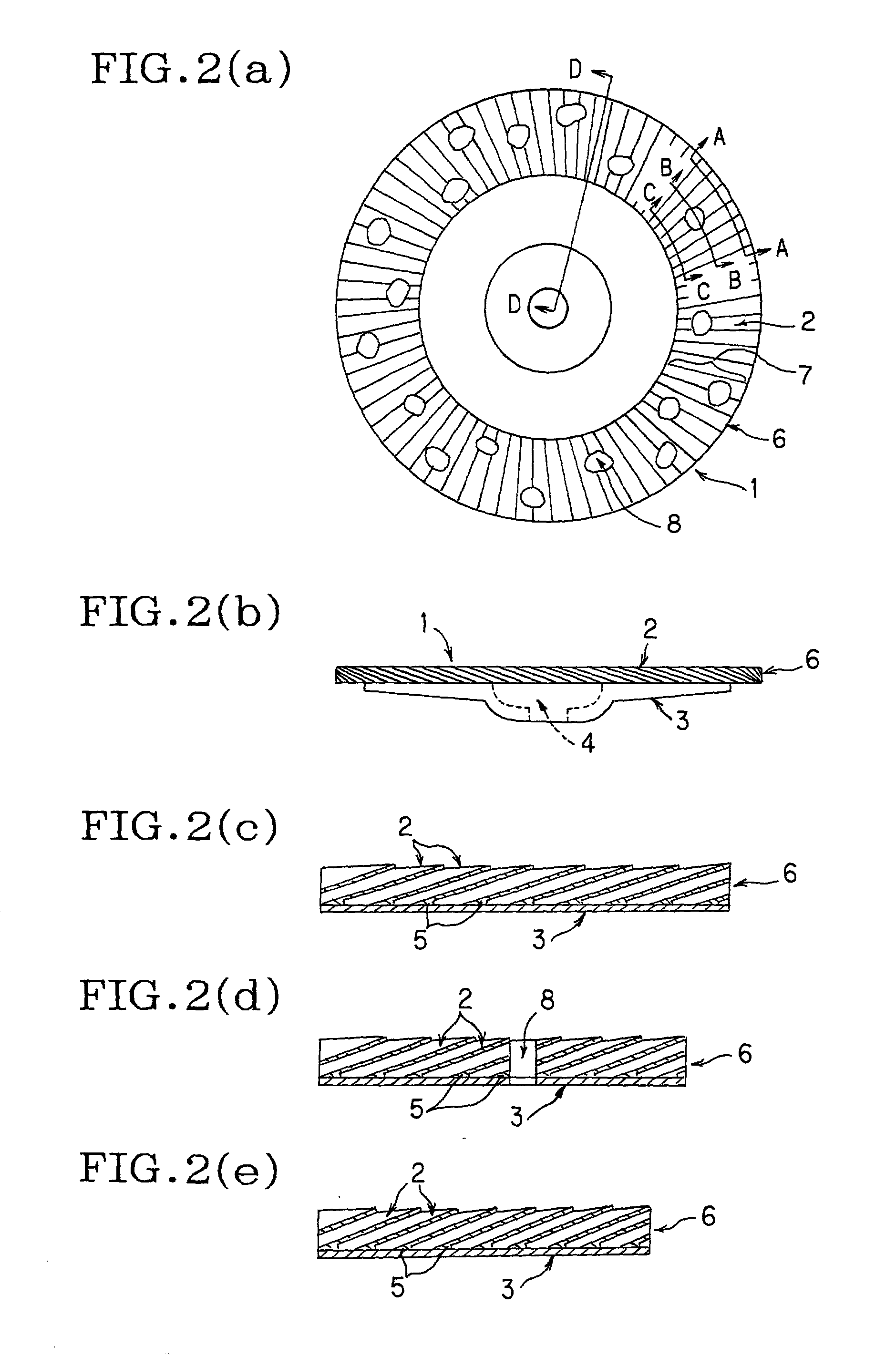

Soft polishing disc with holes and method of manufacturing the same

A soft polishing disc with holes is composed of an abrasive member, which is obtained by radially disposing abrasive pieces each composed of a sand paper having abrasive grains coated on a soft base cloth while partially stacking the abrasive pieces and by coupling them with each other by a thermosetting resin, and ventilation holes are formed through the disc. The soft polishing disc with holes can stably grind and polish a workpiece even if it is soft or hard and has a good air ventilation property, maintains an air cooling effect for a long period of time, is difficult to be loaded with chips, increases the heat radiation property of an abrasive surface and makes it to difficult for a workpiece to be burnt.

Owner:KANTOSEITO

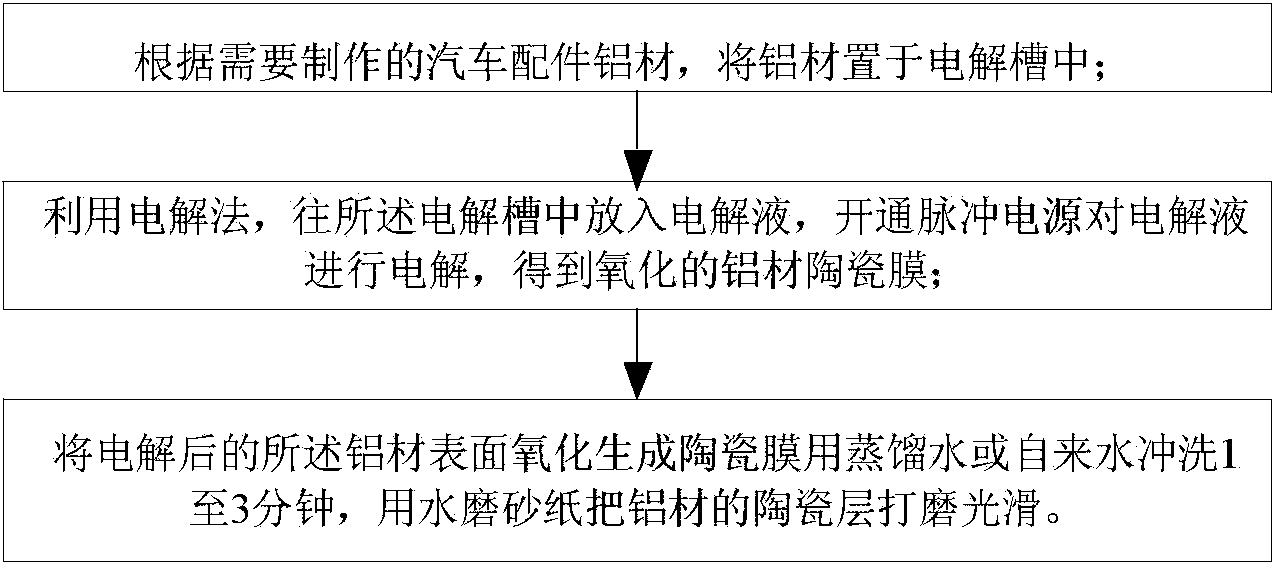

Micro-arc oxidation method of car part aluminum material

InactiveCN103643278ASimple compositionEasy to operate and controlAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention relates to a micro-arc oxidation method, and particularly relates to a micro-arc oxidation method of a car part aluminum material, the micro-arc oxidation method of the car part aluminum material comprises the following steps: taking the car part aluminum material according to the needs, putting the car part aluminum material into an electrolyzer; using an electrolytic process, putting an electrolyte into the electrolyzer, opening a pulsed power supply to electrolyze the electrolyte to obtain an aluminum material ceramic membrane; washing the ceramic membrane generated on the surface of the electrolyzed aluminum material with distilled water or tap water for 1 to 3 minutes, and using water sand paper for polishing smoothly a ceramic layer of the aluminum material. The provided micro-arc oxidation ceramic membrane of the car part aluminum material is firmly combined with a substrate, is compact in structure, the electrolyte composition of the micro-arc oxidation method is simple, the micro-arc oxidation method is easy to operate and control, the produced micro-arc oxidation ceramic membrane has good wear resistance, corrosion resistance, high temperature impact resistance and electrical insulation property, and the process has no pollution to the environment, so that the durability of the car part aluminum material is greatly improved.

Owner:重庆普穗汽车零部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com